Page 1

NORTH

AMERICAN

DRÄGER

RETURN TO CD-ROM TABLE OF CONTENTS

OPERATOR’SINSTRUCTIONMANUAL

NARKOMED 3

ANESTHESIA SYSTEM

Page 2

RETURN TO CD-ROM TABLE OF CONTENTS

Page 3

RETURN TO CD-ROM TABLE OF CONTENTS

NARKOMED 3

OPERATOR’S INSTRUCTION MANUAL

TABLE OF CONTENTS

FOREWORD ....................................................i

GENERAL DESCRIPTION ......................................... 1

MOVING THE NARKOMED 3 ....................................... 3

GAS DELIVERY SYSTEM .......................................... 4

AV-E ANESTHESIA VENTILATOR .................................. 20

POWER SUPPLY SYSTEM ........................................ 23

MAIN SWITCH PANEL ........................................... 26

MONITORING SYSTEM .......................................... 28

NARKOMED 3 SETUP & INSTALLATION ............................. 53

PRE-USE CHECKOUT PROCEDURE ................................ 62

CLEANING AND STERILIZATION ................................... 69

PRECAUTIONS (MAINTENANCE & USE) ............................. 71

SPARE AND REPLACEMENT PARTS ................................ 74

APPENDIX 1: NARKOMED 3 SPECIFICATIONS ........................ 76

APPENDIX 2: NARKOMED 3 ALARM MESSAGES ....................... 84

APPENDIX 3: NARKOMED 3 TROUBLESHOOTING GUIDE ................ 90

APPENDIX 4: VISUAL SYMBOLS ................................... 91

INDEX ....................................................... 92

Page 4

RETURN TO CD-ROM TABLE OF CONTENTS

Page 5

RETURN TO CD-ROM TABLE OF CONTENTS

FOREWORD

OPERATOR’S RESPONSIBILITY FOR PATIENT SAFETY

North American Dräger anesthesia products

are designed to provide the greatest degree of

patient safety that is practically and

technologically feasible. The design of the

equipment, the accompanying literature, and

the labeling on the equipment take into

consideration that the purchase and use of

the equipment are restricted to trained

professionals, and that certain inherent

characteristics of the equipment are known to

the trained operator. Instructions, warnings,

and caution statements are limited, therefore,

to the specifics of the North American Dräger

design.Thispublicationexcludes references to

hazards which are obvious to a medical

professional, to the consequences of product

misuse, and to potentially adverse effects in

patients with abnormal conditions. Product

modification or misuse can be dangerous.

North American Dräger disclaims all liability

for the consequences of product alterations or

modifications, as well as for the consequences

which might result from the combination of

North American Dräger products with

products supplied by other manufacturers if

such a combination is not endorsed by North

American Dräger.

The operator of the anesthesia system must

recognize that the means of monitoring and

discovering hazardous conditions are specific

to the composition of the system and the

various components of the system. It is the

operator, and not the various manufacturers

or suppliers of components, who has control

overthe final compositionand arrangement of

the anesthesia system used in the operating

room. Therefore, the responsibility for

choosing the appropriate safety monitoring

devices rests with the operator and user of

the equipment.

Patient safety may be achieved through a

variety of different means depending on the

institutional procedures, the preference of the

operator, and the application of the system.

These means range from electronic

surveillance of equipment performance and

patient condition to simple, direct contact

between operator and patient (direct observation of clinical signs). The responsibility for

the selection of the best level of patient

monitoring belongs solely to the equipment

operator. To this extent, the manufacturer,

North American Dräger, disclaims responsibility for the adequacy of the monitoring

package selected for use with the anesthesia

system. However, North American Dräger is

available for consultation to discuss

monitoring options for different applications.

NorthAmericanDräger’s liability, whether

arisingoutoforrelatedto manufacture and

sale of the goods, their installation,

demonstration, sales representation, use,

performance, or otherwise, including any

liability based upon North American

Dräger’s Product Warranty, is subject to

and limited to the exclusive terms and

conditionsas set forth,whether based upon

breach of warranty or any other cause of

action whatsoever, regardless of any fault

attributabletoNorth American Dräger and

regardless of the form of action (including,

without limitation, breach of warranty,

negligence, strict liability, or otherwise).

LIMITATION OF LIABILITY

THESTATED EXPRESSED WARRANTIES ARE

IN LIEU OF ALL OTHER WARRANTIES, EXPRESSEDORIMPLIED,INCLUDING,WITHOUT

LIMITATION, WARRANTIES OF MERCHANTABILITY, FITNESS FOR ANY PARTICULAR

PURPOSE, OR NON-INFRINGEMENT.

North American Dräger shall not be liable

for, nor shall buyer be entitled to recover

any special incidental, or consequential

damages or for any liability incurred by

buyer to any third party in anyway arising

out of or relating to the goods. North

American Dräger disclaims any liability

arising from a degraded system due to an

improperly designed or malfunctioning

third party interfaced product.

i

Page 6

WARRANTY

RETURN TO CD-ROM TABLE OF CONTENTS

All North American Dräger products are

guaranteed to be free of defects of

workmanshipormaterialforaperiodofone

year from date of delivery. The following

are exceptions to this warranty:

1. Defects caused by misuse,

mishandling, tampering, or by

modifications not authorized by

North American Dräger or its

representatives are not covered.

2. Rubber and plastic components and

materialsarewarrantedtobefreeof

defects at time of delivery.

3. Respiratoryvolumesensors, fuel-cell

oxygen sensors, and the MINUTE

VOLUMETER have a six-month

limited warranty. Fuel-cell oxygen

sensor capsules have an

eight-month limited warranty from

the date of delivery.

®

4. Warranty for Durasensors

is

limited to a period of six months

from the date of delivery.

Oxisensors

™

are warranted to be

free of defects at time of delivery.

Any product whichproves tobe defectivein

workmanship or material will be replaced,

credited, or repaired with North American

Drägerholding the option.North American

Dräger is not responsible for deterioration,

wear, or abuse. In any case, North

American Dräger will not be liable beyond

the original selling price.

Goodsare subjectto the termsof applicable

warranty. Defective products will be

accepted for return at North American

Dräger’s discretion, and only during the

warranty period.

Application of this warranty is subject to

the following conditions:

1. North American Dräger or its

authorized representative must be

promptly notified, in writing, upon

detectionof thedefectivematerialor

equipment.

2. Defective material or equipment

mustbe returned, shippingprepaid,

to North American Dräger or its

authorized representative.

3. Examination by North American

Dräger or its authorized representative must confirm that the defect

is covered by the terms of this

warranty.

4. Notification in writing, of defective

material or equipment must be

received by North American Dräger

or its authorized representative no

later than two (2) weeks following

expiration of this warranty.

In order to assure complete protection

under this warranty, the

Warranty-Registrationcardand/orPeriodic

Manufacturer’s Service record (if

applicable) must be returned to North

American Dräger within ten (10) days of

receipt of the equipment.

The above is the sole warranty provided by

NorthAmerican Dräger.Nootherwarranty

expressed or implied is intended.

Representatives of NorthAmerican Dräger

are not authorized to modify the terms of

this warranty.

DURASENSOR and OXISENSOR are Trademarks of Nellcor Incorporated.

ii

Page 7

RETURN TO CD-ROM TABLE OF CONTENTS

TERMS AND CONDITIONS

All merchandise to be returned must have

prior written authorization by North

American Dräger, and a valid Return

Material Authorization (RMA) Number

shall appearon the shipping label, packing

slip, purchase order and any other related

documents.

When requesting authorization to return

material, the following information should

be provided:

1. Customer purchase order and date.

2. NAD order number, shipping date,

and method of shipment (available

from packing slip).

3. Invoice date and number.

4. Quantity,NADproduct number, and

description of merchandise to be

returned.

5. Reason for return.

The following are accepted reasons for

return of merchandise:

1. Materialfailurewithinthewarranty

period.

2. Repairs.

3. Customer order in error.

4. Sales/Service order entry error.

5. Shipping Errors.

Material is subject to the terms of any

applicable warranty. Premature failure of

products shall be accepted for return at

North American Dräger’s discretion, and

only during the warranty period.

Material to be returned which is not under

warranty should have been purchased

withinthirtydaysofrequestforreturn,and

returned within thirty days after request.

Material shall be returned unused, and in

NADshippingcontainers.Materialshallbe

subjecttoa20%restockingcharge,withthe

exception of material failure within the

warranty period or NAD error.

The following merchandise is not eligible

for return, unless proven defective:

1. Sterile material, unless shipped in

error by NAD.

2. Rubberandplastic components that

have been used.

3. Speciallyordered orproduceditems.

5. Material which has been altered or

abused.

All items to be returned should be shipped

to:

North American Dräger

Technical Service Department

24 Commerce Drive

Telford, PA 18969

Attn: Customer Service Department

(Include RMA Number)

Any shortages or errors in shipment of

goods must be reported to North American

Dräger within two (2) weeks of receipt.

iii

Page 8

REPAIR AND SERVICE

RETURN TO CD-ROM TABLE OF CONTENTS

Repair of this equipment must be

performed by an authorized North

American Dräger Technical Service

North American Dräger recommends that

anesthesia machines be serviced at three

month intervals.

Representative.

Periodic Manufacturer’s Service Contracts

North American Dräger products/material

in need of factory repair shall be sent to:

areavailable forproducts manufactured by

NorthAmericanDräger.These agreements

are available from the NAD Inc. Technical

North American Dräger

Technical Service Department

Service Department or our Factory

Authorized Technical Service Centers.

24 Commerce Drive

Telford, PA 18969

(Include RMA Number)

RESTRICTION

Federal law restricts this device to sale by, or on the order of, a physician.

iv

Page 9

DISPLAY SCREENS

SENSOR/CORD

LINE WRAPS

PATIENT

INTERFACE

PANEL

MANUAL

SPHYGMOMANOMETER

GAUGE (OPTIONAL)

VENTILATOR

BELLOWS

BREATHING SYSTEM

SENSOR INTERFACE

PANEL

MAIN SWITCH

PANEL

BOOM ARM

(OPTIONAL)

SYSTEM CONTROL

KEYPAD

MONITOR

RACK

AV-E VENTILATOR

THREE-GAS OR

FOUR-GAS SELECTOR

SWITCH (OPTIONAL)

FLOWMETER

BANK

VAPORIZERS

(OPTIONAL)

FRESHGAS

COMMON

OUTLET

O

2

FLUSH

BUTTON

OP30001

AUXILIARY OXYGEN

FLOWMETER (OPTIONAL)

RETURN TO CD-ROM TABLE OF CONTENTS

GENERAL DESCRIPTION

The NARKOMED

anesthesia system. All NARKOMED 3

machines are equipped with pneumatic

circuitry, for mixing gases and liquid

agent vapor, and a comprehensive

monitoring system.

The pneumatic system is capable of

delivering up to four gases simultaneously

and one liquid anesthetic agent from a

selection of up to three. Oxygen (O

nitrous oxide (N

NARKOMED 3 machines. Optional gases

are air, carbon dioxide (CO

Helium (O

-He).

2

®

3 is a continuous flow

) and

O) are standard on all

2

), and Oxygen-

2

2

Up to three optional vaporizers may be

mounted on the vaporizer exclusion

system. The optional vaporizers are

Halothane, Enflurane and Isoflurane.

The vaporizers are mechanically

interlocked so that only one vaporizer may

be used at a time.

The anesthesia machine’s monitoring

system integrates the functions of the

electronic monitors and organizes

information from these monitors on two

screens.

Figure 1 NARKOMED 3 Anesthesia System, Front View

1

Page 10

GENERAL DESCRIPTION (continued)

RETURN TO CD-ROM TABLE OF CONTENTS

The monitoring package includes an

oxygen analyzer, breathing pressure

monitor, respiratory volume monitor,

respiratory gas analyzer, pulse oximeter,

andnoninvasiveblood pressure monitor.In

addition, the anesthesia machine monitors

all key anesthesia system functions (e.g.,

oxygen supply pressure, O

O flow ratio,

2/N2

backup battery status).

The monitoring system organizes alarm

messages into Warnings, Cautions, and

Advisories, presenting them on the central

alarm display.

Audible alarms are organized into three

distinct sound patterns and are delivered

by a central audio annunciator. A second

display screen can present real-time trace,

trend, bargraph and data displays.

The NARKOMED 3 can be optionally

equipped with an absorber system and/or

a Bain circuit adapter. Two different

scavenger systems are available,

permitting the best match with the

hospital’s waste gas disposal system. An

adjustable Positive End Expiratory

Pressure (PEEP) valve is available on the

ventilator or absorber assembly.

FIVE PORT

SERIAL INTERFACE

(OPTIONAL)

PIPELINE

SUPPLY

FITTINGS

CIRCUIT

BREAKERS

OP30002

Figure 2 NARKOMED 3 Anesthesia System, Back View

AC CONVENIENCE

RECEPTACLES

(117 VAC OPTION)

VACUUM FITTINGS

FOR SUCTION

ASSEMBLY

(OPTIONAL)

AC POWER

CABLE

2

Page 11

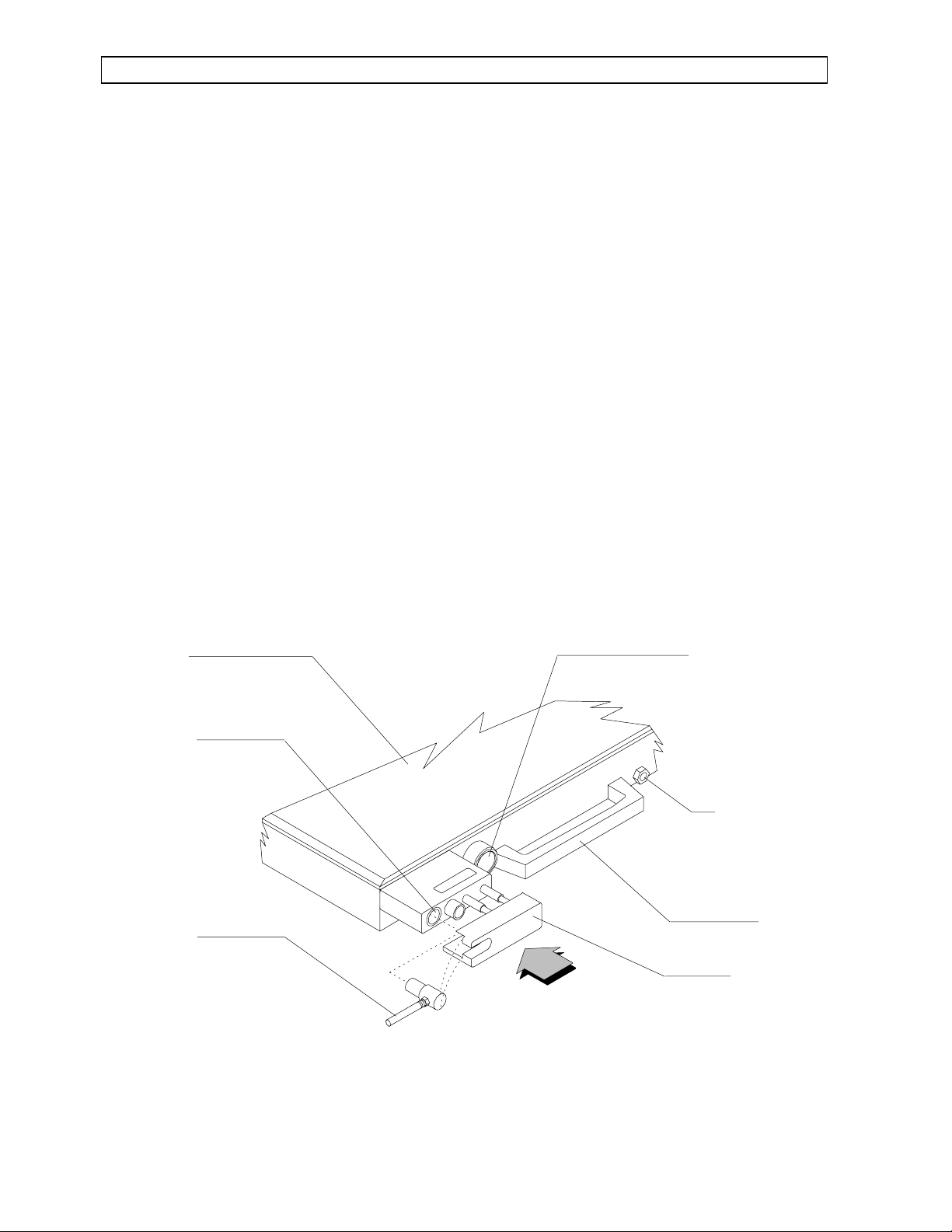

HANDLE

PUSH/PULL BAR

(FRAME MOUNT)

(OPTIONAL)

PUSH/PULL BAR

(VENTILATOR MOUNT)

(OPTIONAL)

OP30003

RETURN TO CD-ROM TABLE OF CONTENTS

MOVING THE NARKOMED 3

When movingthe NARKOMED 3, use only

the handles shown in Figure 3. DO NOT

push or pull the anesthesia machine using

the Absorber System, Vaporizers,

Ventilator Bellows, or Boom Arm.

Remove the Absorber System, along with

anyexternal monitors orequipment,before

moving the anesthesia machine.

Retract the boom arm, before moving the

anesthesia machine.

The NARKOMED 3 is equipped with two

locking casterson the front of the machine.

These castersmay be unlockedby stepping

on the lock mechanism on top of the caster.

DO NOT attempt to move the anesthesia

machine while the casters are locked.

Exercise caution when moving the

anesthesia machine on ramps, or over

thresholds.

It is recommended that two people be used

when moving the machine.

Figure 3 Acceptable Handles for Transportation

3

Page 12

GAS DELIVERY SYSTEM

RETURN TO CD-ROM TABLE OF CONTENTS

Standard Gases

The NARKOMED 3 is equipped with

pneumatic circuitry for the delivery of

oxygen (O

) and nitrous oxide (N2O). It

2

has at least one oxygen and one nitrous

oxide yoke for attachment of gas cylinders.

Optional Gases

In addition to oxygen and nitrous oxide,

the NARKOMED 3 may be equipped with

up to two additional gases. The additional

gases may be air, oxygen-helium (O

mixture (25% O

dioxide (CO

, 75% He) or carbon

2

). The additional gas is

2

-He)

2

supplied to the anesthesia system by

means of pin-indexed cylinders and yokes,

diameter-indexed safety system (DISS)

pipeline connections, or both (if so

selected).

Color Coding

Pipeline Connections

The DISS gas fittings for oxygen, nitrous

oxide, and an optional third gas arelocated

on the right side of the flowmeter housing.

The DISS fittings prevent improper

connection of supply hoses. The inlets

include check valves to prevent back flow

leakage into the atmosphere when supply

hoses are not connected, or into the

attached supply hoses when reserve

cylinders are in use.

Each pipeline connection is equipped with

a filter to prevent foreign material from

entering the internal gas piping of the

NARKOMED 3. Pipeline gases should be

supplied at 50-55 psi.

Each connection, valve, gauge, and

flowmeter is labeled andcolor coded for the

appropriate gas, as shown in the table

below.

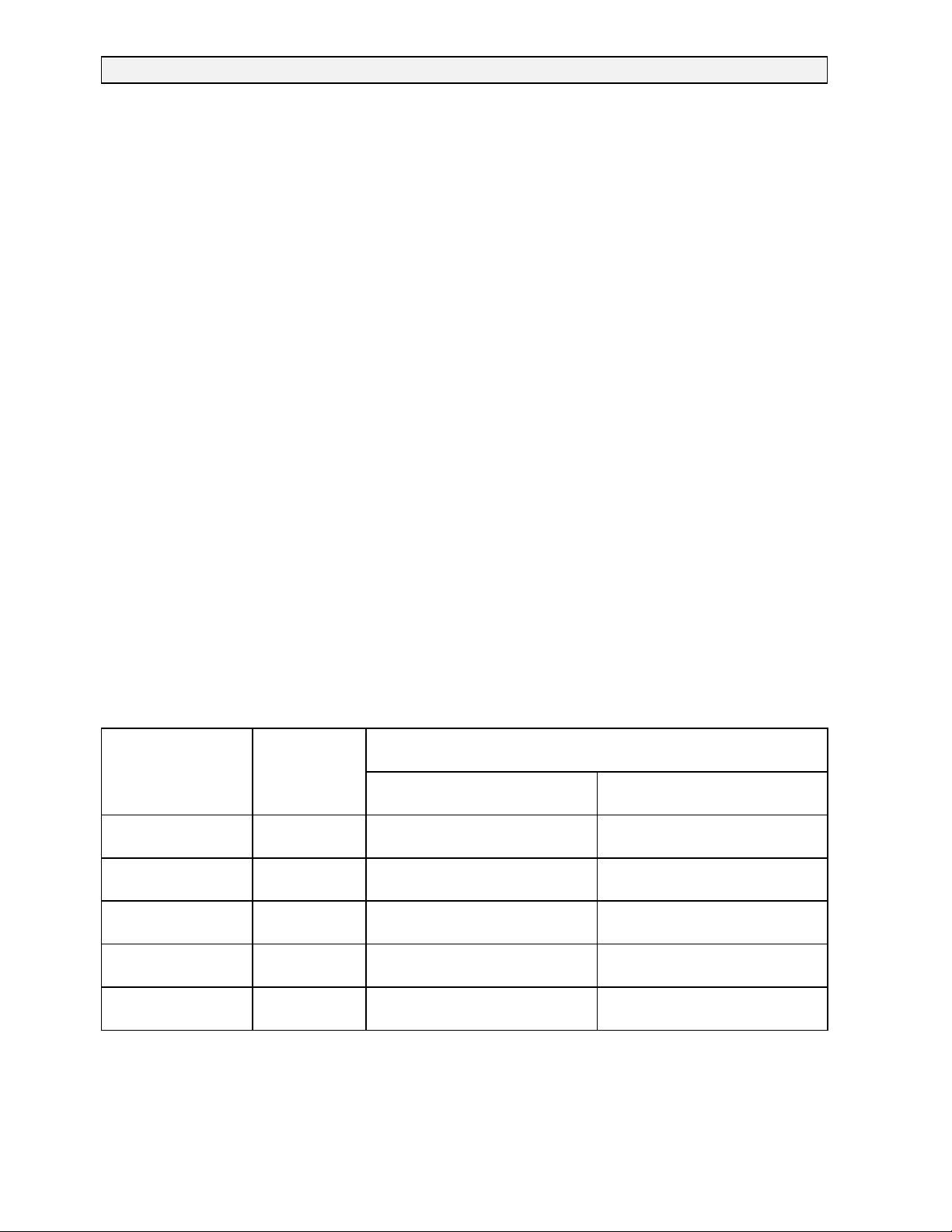

COLOR CODE

GAS MARKING

U.S. CANADA (CSA)

Air AIR Yellow Black/White checkered

Carbon Dioxide CO

2

Gray Gray

Oxygen-Helium O2-He Green/Brown Diag. Stripes White/Brown Diag. Stripes

Nitrous Oxide N2O Blue Blue

Oxygen O

2

Green White

4

Page 13

Gas Cylinder Yokes

O2 YOKE

O

2

YOKE

(OPTIONAL)

N

2

O YOKE

(OPTIONAL)

N

2

O YOKE

AIR ,CO2,

OR O

2

-He YOKE

(OPTIONAL)

OP30004

RETURN TO CD-ROM TABLE OF CONTENTS

GAS DELIVERY SYSTEM (continued)

The NARKOMED 3 can be equipped with

a maximum of two oxygen and two nitrous

oxide cylinder hanger yokes (Figure 4). An

additional yoke for an optional third gas is

also available. The cylinder is the primary

supply for carbon dioxide and oxygenhelium.

To prevent a cylinder from being

improperly connected, the yokes are

labeled, color-coded, and keyed for gasspecific cylinders using the Pin Index

Safety System.

Figure 4 Gas Cylinder Yokes (Right, Rear View)

5

Page 14

GAS DELIVERY SYSTEM (continued)

RETURN TO CD-ROM TABLE OF CONTENTS

A sintered bronze filter within each yoke

prevents foreign material from entering

the internal gas piping of the NARKOMED

3. A check valve in each yoke prevents

back flow into the cylinder or leakage into

the atmosphere if the cylinder is not

mounted on the yoke.

When the machine is configured with two

yokes for the same gas, the check valve

prevents migration of gas from one

cylinder to another. If a cylinder is not

mounted to a yoke, the attached yoke plug

shouldbe placedbetween the yokehandle’s

threaded bolt and the yoke’s gas inlet.

When attaching acylinder, ensure onlyone

washer is installed between the cylinder

and the yoke gas inlet. The use of

multiple washers may compromise the Pin

Index Safety System. The integrity of both

index pins must be verified whenever a

new cylinder is installed. Cylinders

attached to the hanger yokes must contain

gasatthe recommended pressures outlined

in the table below.

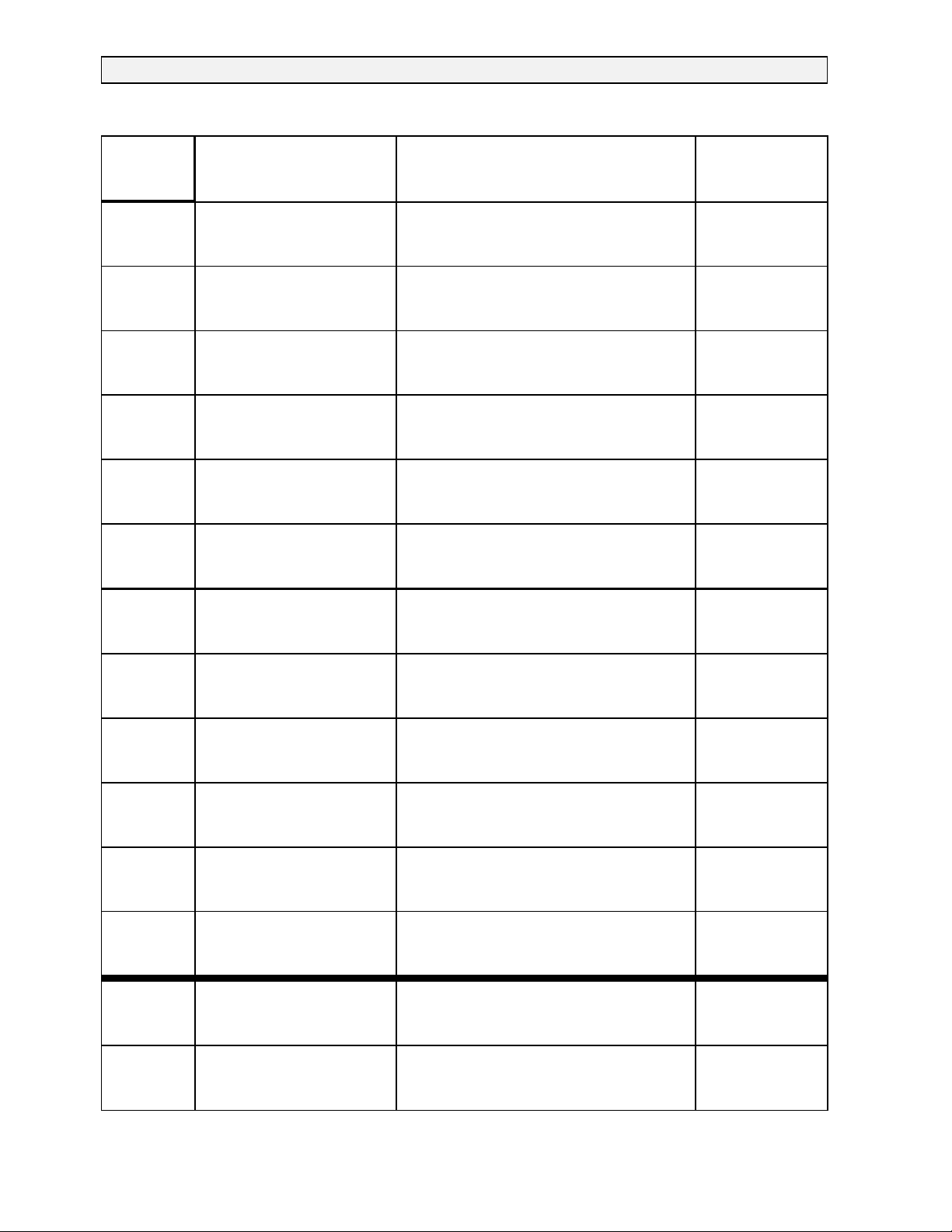

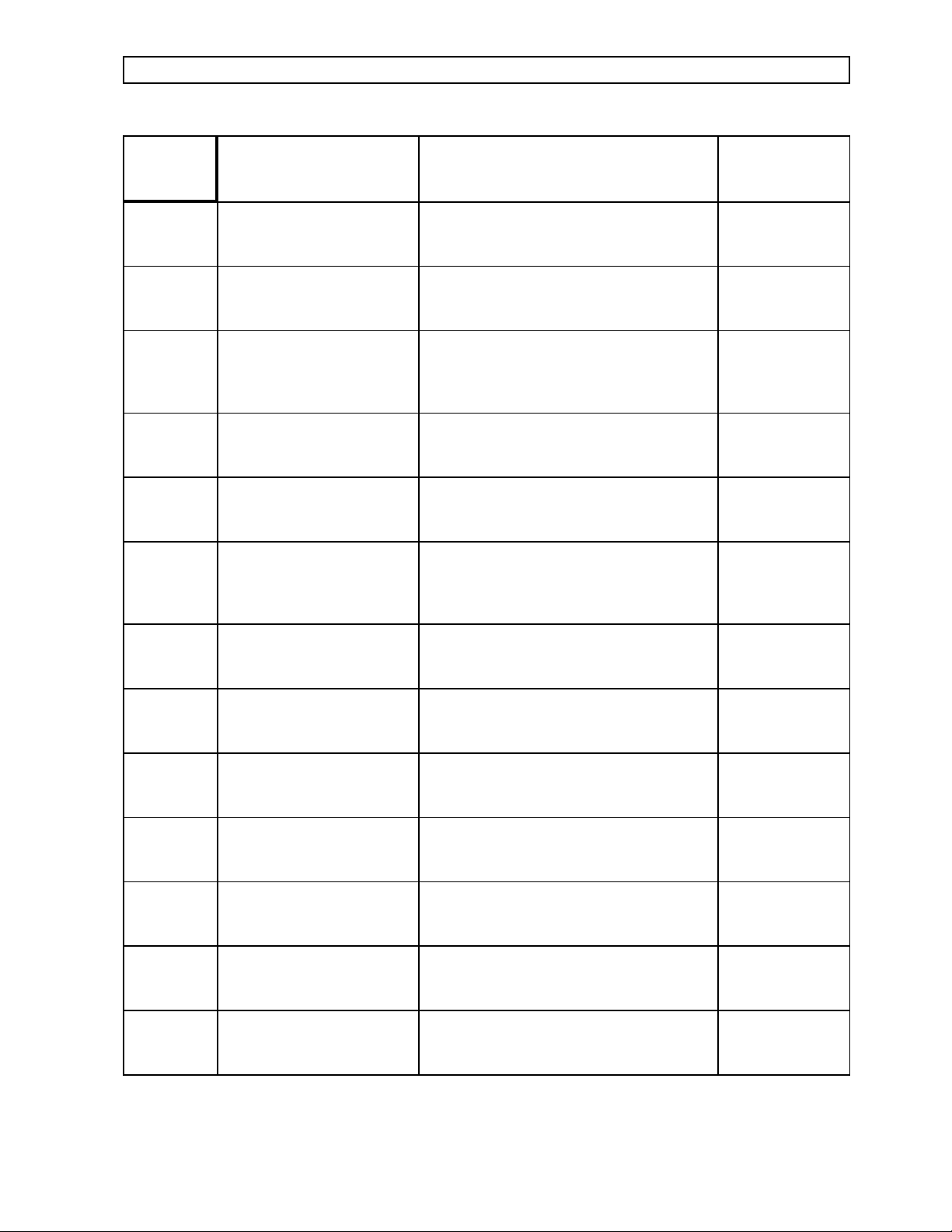

RECOMMENDED RESERVE CYLINDER

MAXIMUM PRESSURES

GAS MAX PSI

Pressure Regulators

Each cylinder gas circuit incorporates a

pressure regulator that reduces the gas

pressure. These regulators are preset

below the commonly used hospital pipeline

pressure of 50-55 psi to ensure that gas

will be supplied from the pipeline and not

the cylinder if both sources of supply are

open. Pressure relief valves, integral to the

regulator, prevent excessive pressure in

case of regulator failure or excessive

pipeline pressure.

NOTE: Canadian machines are equipped

with an additional pipeline overpressure

relief valve that is set to open at 75 psi

(520 kPa).

Cylinder Pressure Gauges

Each cylinder gas circuit on the

NARKOMED 3 is provided with a cylinder

pressure gauge, located at the bottom of

the flowmeter panel on the front of the

machine (Figures 5, 6, & 7). Each gauge is

labeled and color-coded for its respective

gas.

When a cylinder’s valve is open, its

pressure gauge indicates the gas pressure

in the cylinder. The dial is marked with

concentric scales in psi and kPa.

Air 2200

Carbon Dioxide 830

Oxygen-Helium 2400

Nitrous Oxide 745

Oxygen 2200

6

Page 15

10

9

8

7

6

5

4

3

2

11

2

3

4

5

6

7

8

9

10 1000

900

800

700

600

500

400

300

200

100100

200

300

400

500

600

700

800

900

1000

N2O

O

2CYLINDERCYLINDER

PIPELINEPIPELINE

COLOR-CODED

GAS LABEL

OP10005

CYLINDER

PRESSURE

GAUGE, O

2

PIPELINE

PRESSURE

GAUGE, O

2

PRECISION FLOW

CONTROL KNOB, O2

FLOWMETER KNOB

GUARD

INDICATOR

FLOATS, O

2

COARSE FLOW TUBE

(l/min), O

2

FINE FLOW TUBE

(ml/min), O2

N

2O

O

2

RETURN TO CD-ROM TABLE OF CONTENTS

GAS DELIVERY SYSTEM (continued)

Figure 5 Standard Flowmeter Bank

7

Page 16

GAS DELIVERY SYSTEM (continued)

COARSE FLOW TUBE

(l/min), N

20

RETURN TO CD-ROM TABLE OF CONTENTS

1000

1000

10 1000

10

10

FINE FLOW TUBE

(ml/min), N2O

INDICATOR

FLOATS, N2O

FLOWMETER KNOB

GUARD

PRECISION FLOW

CONTROL VALVE, N

PIPELINE PRESSURE

GAUGE, N

O

2

2O

900

800

700

600

500

400

300

200

100

N2O

900

9

800

8

700

7

600

6

500

5

400

4

300

3

200

2

100

1

AIR

9

900

8

800

7

700

6

600

5

500

4

400

3

300

2

200

1

100

0

9

8

7

6

5

4

3

2

1

2

PIPELINEPIPELINEPIPELINE

CYLINDER PRESSURE

GAUGE, N

2O

OP10006

Figure 6 Three-Gas Flowmeter Bank (Air Option)

8

N2O

AIR

2

CYLINDERCYLINDERCYLINDER

0

Page 17

RETURN TO CD-ROM TABLE OF CONTENTS

GAS DELIVERY SYSTEM (continued)

10

1000 10

900

800

700

600

500

400

300

200

10

9

8

7

6

5

4

3

2

9

8

7

6

5

4

3

2

1.0

.8

.6

.4

.2

10

1000

9

8

7

6

5

4

3

2

900

800

700

600

500

400

300

200

O2-He

100

N

2OO2

1

AIR

PIPELINE PIPELINE PIPELINE

100

AIR

FINE FLOW TUBE

(ml/min), O

9

COARSE FLOW TUBE

2

(l/min), O2

8

7

6

INDICATOR

5

4

FLOATS, O

2

FLOWMETER KNOB

3

2

GUARD

PRECISION FLOW

1

CONTROL KNOB, O2

PIPELINE

PRESSURE

GAUGE, O2

2

CYLINDER CYLINDER CYLINDER

-HeN2O

O

2

O

OP10007

Figure 7 Four-Gas Flowmeter Bank (Air & Oxygen-Helium Option)

CYLINDER

PRESSURE

GAUGE, O2

9

Page 18

GAS DELIVERY SYSTEM (continued)

RETURN TO CD-ROM TABLE OF CONTENTS

For non-liquefied gases (O

, Air, O2-He) the

2

indicated pressure is proportional to the

gas content of the cylinder. For liquefied

gases (N

O, CO2) the gauge indicates the

2

vapor pressure of the liquefied gas in the

cylinder. This pressure remains constant

until all of the liquid in the cylinder has

vaporized. When the liquid has vaporized,

the cylinder pressure decreases

proportionally with further removal of gas

from the cylinder.

NOTE: If two reserve cylindersof the same

gas are open at the same time, the cylinder

pressure gauge will indicate the pressure

in the cylinder having the higher pressure.

Pipeline Pressure Gauges

Pipeline pressure gauges for oxygen and

nitrous oxide are standard (Figures 5, 6, &

7). If the anesthesia machine is equipped

with air, a pipeline pressure gauge for air

is also included.

These gauges are located directly below

their corresponding flowmeters and flow

control valves, and are labeled and colorcoded for theirrespective gases.Concentric

scales in psi and kPa indicate thedelivered

pipeline supply pressure. When the

machine is connected to a functioning

pipelinesupply,each gauge shouldindicate

50-55 psi. A deviation from within this

range indicates an improperly adjusted

pipeline gas supply system and may

adversely affect the operation of the

NARKOMED 3.

A fluctuating pipeline supply pressure, for

example, would cause a corresponding

fluctuation of the delivered flow of that

gas. An excessively low pipeline pressure

may activate the corresponding reserve

cylinder and deplete its contents (if the

reserve cylinder valve was left in the open

position).

Carbon dioxide and oxygen-heliummixture

supplies for NARKOMED 3 machines are

provided exclusively from cylinders. Thus,

these gases do not require pipeline

pressure gauges.

10

Page 19

RETURN TO CD-ROM TABLE OF CONTENTS

GAS DELIVERY SYSTEM (continued)

Oxygen Supply Pressure Failure

Protection Device (OFPD)

The oxygen failure protection device

(OFPD) is a pneumatically operated valve

located in the anesthesia machine’s

internal supply lines for all machine gas

circuits except oxygen. The OFPD valve is

controlled by the gas pressure in the

oxygensupply line. Properoxygenpressure

keeps the valve open. A failure or

reduction of pressure in the oxygen supply

line will proportionally reduce and

eventually shut off the supply of all other

gases.

When the OFPD is activated, the

flowmeters indicate a reduced gas flow,

proportional to the reduction of oxygen

supply pressure. When the oxygen supply

pressure (from either pipeline or reserve

cylinders) drops below approximately 37

psi, an "LO O

SUPPLY" alarm message

2

appears on the central alarm display. The

red "O

SUPPLY PRESSURE" indicator

2

light on the main switch panel lights, and

an intermittent audible alarm sounds.

Flow Control Valves

A needle valve is located below the fine

flowmeter tube for each specific gas. This

valve is used to adjust the flow of gas

(Figures 5, 6, & 7). Counterclockwise

rotation of the valve knob increases flow,

while clockwise rotation decreases flow.

A zero stop prevents damage to the flow

control valve seats. If necessary, an

authorized service representative of North

American Dräger can readjust the stop.

Each flow control knob is identified by its

color code and chemical symbol. Also, the

oxygen flow control valve is touch-coded

with a deeply fluted knob.

Unless the anesthesia machine has been

specifically modified to eliminate the

minimum oxygen flow feature (see

"Minimum Oxygen Flow"), the flow of

oxygen cannot be totally shut off. DO NOT

force the oxygen flow control knob over its

end stop in an effort to shut off the flow.

Forcing the knob could damage the valve

seat.

If only one source of oxygen supply

pressure (either reserve cylinders or

pipeline) fails, while the other maintains

proper supply pressure within the

machine’s oxygen supply lines, the OFPD

and "LO O

SUPPLY" alarm will not

2

activate.

11

Page 20

GAS DELIVERY SYSTEM (continued)

Flowmeters

RETURN TO CD-ROM TABLE OF CONTENTS

Flowmeters, located immediately above

their corresponding flow control valves

(Figures 5, 6 & 7), display the flow rate of

each gas delivered for the fresh gas

mixture. Dual (fine and coarse) flowmeter

tubes are used in tandem for oxygen,

nitrous oxide, and air (if provided). Single

flowmeter tubes are used for other gases

when supplied.

Oxygen, nitrous oxide and air flowmeters

are equipped with floats, half chromeplated and half colored red, to indicate free

movement through rotation. Single tube

flowmeters are equipped with stainless

steel or black glass floats. Regardless of

the float type, the position of the center of

the ball along the flowmeter scale should

be used as an indication of the flow rate.

All flowmeters are labeled and color-coded

Oxygen, nitrous oxide, and air flowmeters

at each end of the flowtube.

are certified to be within ±2.5% of full

scale at 20° C and 760 mm Hg. Single

flowtubes are certified to be within ±5% of

full scale. Flowmeter ranges and

accuracies are outlined in the table below.

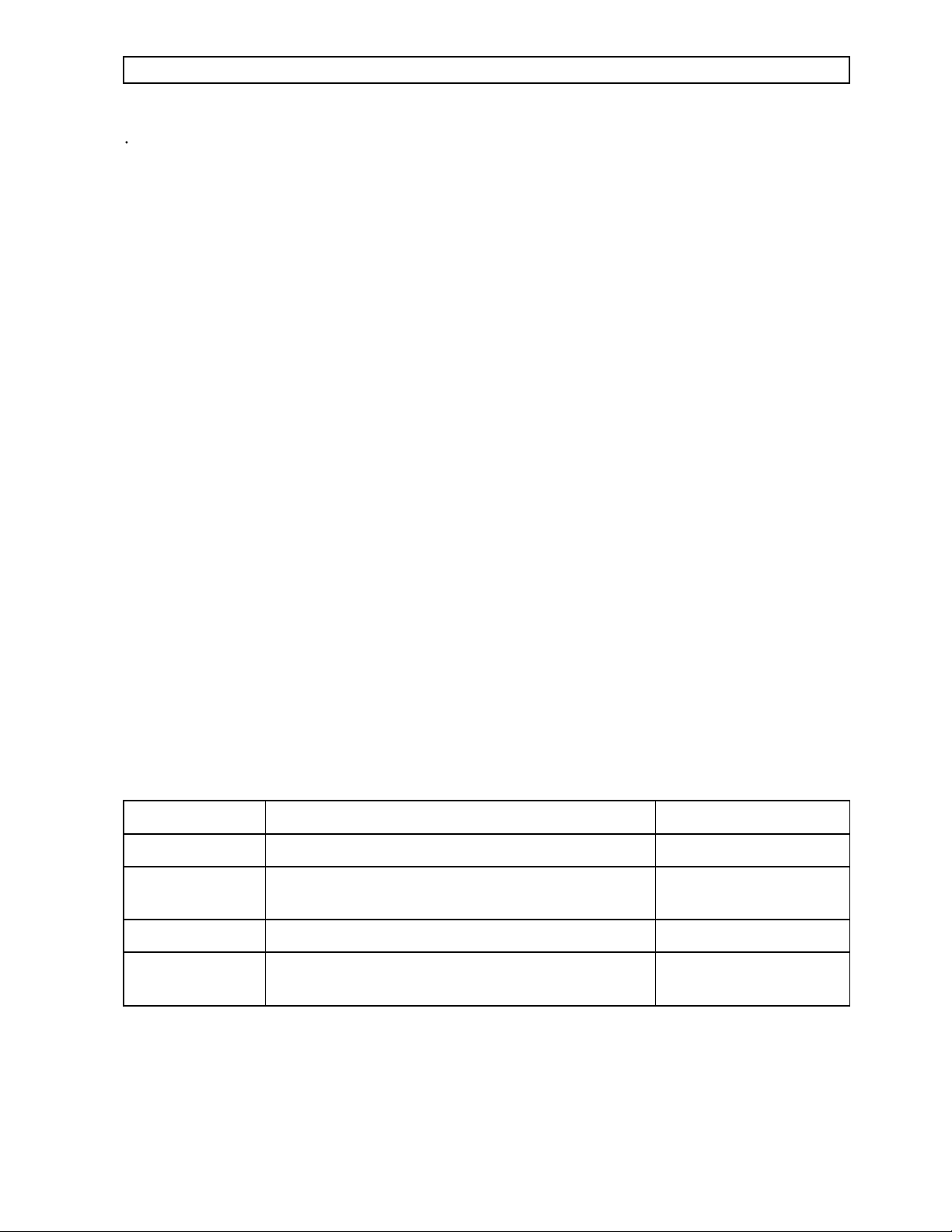

FLOWTUBE RANGES & ACCURACIES

GAS TUBE RANGE (l/min) ACCURACY (%FS)

Oxygen Fine 0-1 ±2.5

Oxygen Coarse 0-10 ±2.5

Nitrous Oxide Fine 0-1 ±2.5

Nitrous Oxide Coarse 0-10 ±2.5

Air Fine 0-1 ±2.5

Air Course 0 -10 ±2.5

0-1 ± 50 cc of range

Air Dual Tapered

0-10 ±5

Oxygen-Helium Single 0-10 ±5

Carbon Dioxide Single 0- 1.0 ±5

12

Page 21

RETURN TO CD-ROM TABLE OF CONTENTS

GAS DELIVERY SYSTEM (continued)

Low-Flow Flowmeters (Optional)

For low-flow anesthesia, the NARKOMED

3 can be configured with low-flow, dualtube flowmeters for oxygen and nitrous

oxide. These flowmeters function in the

same manner as the standard dual-tube

flowmeters, but are calibrated to provide

greater resolution for low-flow anesthesia.

They are calibrated as shown in the table

below.

Auxiliary Oxygen Flowmeter (Optional)

For the delivery of a metered flow of pure

oxygen (such as for the delivery of oxygen

through a nasal cannula), an optional

auxiliary oxygen flowmeter can be

mounted on the left side of the flowmeter

bank. It is calibrated from 0 to 10 l/min at

an accuracy of ±5% of full scale. This

flowmeter can be used with the machine

turned off.

Minimum Oxygen Flow

The oxygen dispensing system incorporates

a calibrated bypass flow of 150 ±50 ml/min

(at 50 psi pipeline pressure), to ensure the

delivery of some oxygen even if the flow

control valve is fully closed.

If required for low-flow anesthesia, the

NARKOMED 3 can be optionally modified

to eliminate the minimum oxygen flow

feature. A label above the oxygen

flowmeter indicates that the anesthesia

machine has been modified to eliminate

minimum oxygen flow.

If air is an additional gas, when the gas

selector switch is set to the "ALL GASES"

position, the minimum oxygen flow is

automatically disabled.

NOTE: The flow control valve for the

auxiliary oxygen flowmeter does not

include a zero stop. Do not over tighten.

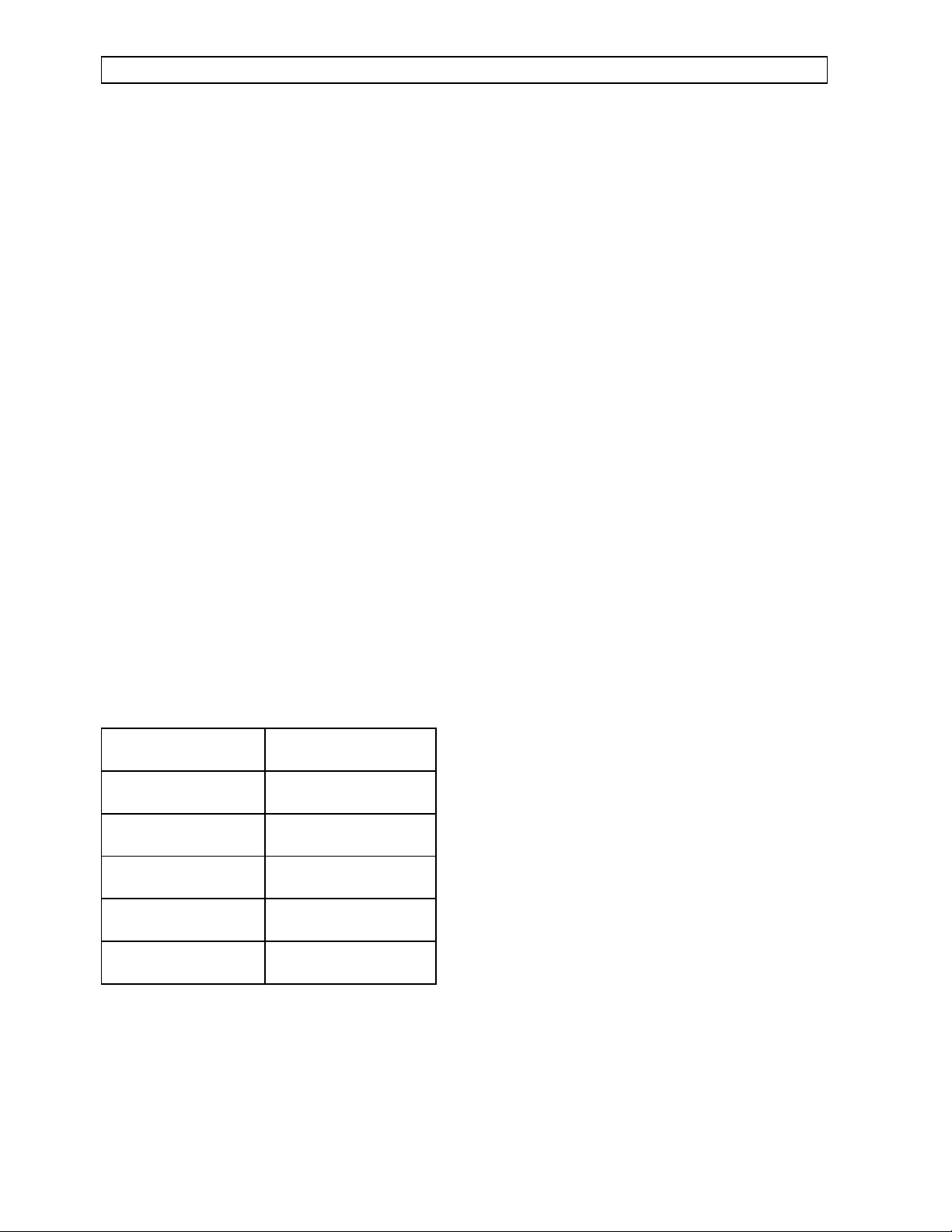

LOW-FLOW FLOWTUBE RANGES & ACCURACIES

GAS TUBE RANGE ACCURACY

Oxygen Fine 0 - 500 ml/min ±2.5% (FS)

Oxygen Coarse 0 - 10 l/min ±2.5% (> 1 l/min)

±15% Rate (< 1 l/min)

Nitrous Oxide Fine 0 - 500 ml/min ±2.5% (FS)

Nitrous Oxide Coarse 0 - 10 l/min ±2.5% (> 1 l/min)

±15% Rate (< 1 l/min)

13

Page 22

GAS DELIVERY SYSTEM (continued)

Oxygen Ratio Monitor/Controller (ORMC)

RETURN TO CD-ROM TABLE OF CONTENTS

The ORMC is a pneumatic O

2/N2

O

interlock system designed to maintain a

fresh gas oxygen concentration of at least

25 ±4 %. It permits independent control of

the oxygen and nitrous oxide flows, but by

proportionally limiting the nitrous oxide

flow, the ORMC prevents a flow ratio that

could result in a hypoxic fresh gasmixture.

The ORMC works by limiting the nitrous

oxide flow whenever the operator selects

oxygen and nitrous oxideflow control valve

settings that would otherwise result in a

hypoxic fresh gas mixture. For example, if

the operator opens the nitrous oxide flow

control valve excessively without making a

corresponding increase in the oxygen flow

control valve setting, the flow of nitrous

oxide will not increase, even though its

flow control valve setting has been greatly

increased. Similarly, if the operator

decreases the oxygen flow without also

decreasing the nitrous oxide flow, the

nitrous oxide flow will automatically drop

in proportion to the oxygen flow.

Due to rebreathing of previously exhaled

gas in a circle system, lower fresh gas

flows require a higher oxygen

concentration to maintain a sufficient

inspiratory oxygen concentration. For that

reason, the ORMC is designed to maintain

higher levels of oxygen in the fresh gas at

lower flow rates. Figure 8 illustrates the

ORMC’s response curve.

NOTE: At lower fresh gas flow rates, the

ORMC maintains fresh gas oxygen

concentrations well above 25% of the

combined oxygen and nitrous oxide flow.

The ORMC interlocks only the flows of

oxygen and nitrous oxide. Hypoxic fresh

gas concentrations are possible if an

additional gas other than air is used.

14

Page 23

Gas Selector Switch (Optional)

)

RETURN TO CD-ROM TABLE OF CONTENTS

GAS DELIVERY SYSTEM (continued)

Setting the gas selector switch to the "O

O" position permits oxygen and nitrous

N

2

&

2

oxide flows to the appropriate flowmeter

controls. This position also enables the

minimum oxygen flow.

100

90

80

70

60

The "ALL GASES" position of the gas

selector switch permits the additional

gases to flow to their respective flowmeter

controls, allowing a mixture of all gases.

However, setting the switch to the "ALL

GASES" position automatically disables

the minimum O

flow.

2

OP10008

50

CONCENT RA TION (%)

2

DELIVERABLE OXYGEN CONCENTRATIONS

40

30

FRESHGAS O

20

10

UNDELIVERABLE OXYGEN CONCENTRATIONS

0 24 68101214161820

FRESH GAS FL OW RA TE (L/min

Figure 8 ORMC Response

15

Page 24

GAS DELIVERY SYSTEM (continued)

HANDWHEEL

ADJUSTMENT

FILLER

VALVE

DRAIN

VALVE

SIGHT

GLASS

FILLER

FUNNEL

OP20051

Vaporizers (Optional)

RETURN TO CD-ROM TABLE OF CONTENTS

The NARKOMED 3 can be equipped with

up to three Vapor 19.1 vaporizers for the

administration of liquid anesthetics. The

vaporizers (Figures 9 & 10) are located to

the right of the flowmeters.

Vaporizers may be equipped with either an

open-funnel filler or a pin-indexed filler.

(Only pin-indexed fillers are permitted in

Canada).

A calibrated concentration of vaporized

anesthetic is produced by adjusting the

top-mounted handwheel of the selected

vaporizer to the desired concentration

indicated on the dial. Clockwise rotation

decreases the anestheticconcentration and

counterclockwise rotation increases the

concentration.

Figure 9 Vaporizers (with Standard Filler/Drain Mechanisms)

16

Page 25

RETURN TO CD-ROM TABLE OF CONTENTS

GAS DELIVERY SYSTEM (continued)

A cam and lever interlock system,

incorporated into the vaporizer bank,

prevents more than one vaporizer from

being activated and requires all unused

vaporizers to be locked in their zero

volume percent positions.

Detailed operating instructions for the

vaporizers are in a separate manual

supplied with the vaporizer.

HANDWHEEL

ADJUSTMENT

WARNING: Only one vaporizer can be

activated at a time. If the exclusion system

permits simultaneous activation of more

than one vaporizer, DO NOT use the

anesthesia machine. Contact anauthorized

NAD service representative for repairs.

OP20052

FILLER

VALVE

SIGHT

GLASS

FILLER

PORT

PORT

DRAIN

DRAIN

VALVE

WING

SCREWS

Figure 10 Vaporizers (with Optional Pin-Indexed Filler/Drain Mechanisms)

17

Page 26

GAS DELIVERY SYSTEM (continued)

TABLETOP

FRESH GAS

OUTLET

FRESH GAS

LOCKING BAR

(EXTENDED POSITION)

HANDLE

LUER-FITTING

FOR MANUAL

SPHYGMOMANOMETER

(OPTIONAL)

RELEASE TO

LOCK

FRESH GAS

HOSE

OP10011

O2 FLUSH CONTROL

RETURN TO CD-ROM TABLE OF CONTENTS

Oxygen Flush

A manually operated, self-closing, oxygen

flush valve (Figure 11) is located on the

left front corner of the machine’s frame. A

bezel is mounted around the push button

in order to prevent accidental engagement.

The valve, when actuated, delivers an

unmetered oxygen flow of approximately

55 l/min directly to the NARKOMED 3’s

fresh gas common outlet. The oxygen flush

may be used without the SYSTEM

POWER switch being in the "ON" position.

Fresh Gas Common Outlet

The fresh gas common outlet (Figure 11)

delivers the fresh gas mixture (consisting

of oxygen, nitrous oxide, optional gases,

and vapors of a liquid anesthetic) to the

patient breathing system. It is located to

the left of the oxygen flush button on the

front of the anesthesia machine.

The outlet’s 15 mm cylindrical female

fitting is designed to accept a 15 mm male

fitting on the absorber fresh gas hose. The

male fitting slides into a retaining slot in

the spring-loaded safety locking bar

(Figure 11) to prevent inadvertent

disconnection of the fresh gas hose.

The 15 mm male fitting on the fresh gas

hose is unique to North American Dräger

design and cannot be replaced by that of

any other manufacturer.

Fresh Gas Adapter (Optional)

The optional fresh gas adapter allows the

NARKOMED 3 to monitor the fresh gas

oxygen concentration when using a nonrebreathing circuit. The fresh gas adapter

is designed to fit securely into the fresh

gas common outlet of the anesthesia

machine. A detailed description and

operating instructions can be found in the

Fresh Gas Adapter Operator’s Instruction

Manual.

Figure 11 Oxygen Flush Control & Freshgas Common Outlet

18

Page 27

RETURN TO CD-ROM TABLE OF CONTENTS

GAS DELIVERY SYSTEM (continued)

Fresh Gas Common Outlet (Canada)

The fresh gas common outlet (Figure 12)

delivers the fresh gas mixture (consisting

of oxygen, nitrous oxide, optional gases,

and vapors of a liquid anesthetic) to the

patient breathing system. It is located to

the left of the oxygen flush button on the

front of the anesthesia machine. The outlet

incorporates a dual fitting that allows use

of either a 15 mm male fresh gas hose

fitting (such as supplied with North

American Dräger Absorbers and Bain

Circuit Adapters) or a 22 mm female

fitting with a load-bearing threaded mount

(such as for Magill circuits meant to be

threaded onto the fresh gas common

outlet).

When using the 15 mm male and female

fittings, make sure that the spring-loaded

locking bar fits over the male fresh gas

hose fitting, securing it in the female

fitting.

When using the Magill circuit fitting,

swing the spring-loaded locking bar to the

side to gain access to the threaded load

bearing fitting.

Suction System (Optional)

The NARKOMED3 can be configured with

internal vacuum piping for a suction

drainage assembly. A DISS vacuum fitting

on the rear of the machine connects, via a

hose, to a wall vacuum outlet. The suction

drainage assembly mounts on a DISS

fitting on the machine’s right front corner.

The suction drainage assembly consists of

a 700 cc clear glass bottle, vacuum on/off

valve, vacuum control knob, and vacuum

gauge. A ball float at the top of the bottle’s

inlet pipe automatically prevents overfill.

Consultthe operatinginstructions supplied

with this device before use.

TABLETOP

OP10012

FRESH GAS

HOSE

SPHYGMOMANOMETER

RELEASE TO

LOCK

O

Figure 12 Oxygen Flush Control & Freshgas Common Outlet for Canada

2

FLUSH CONTROL

LUER-FITTING

FOR MANUAL

(OPTIONAL)

HANDLE

FRESH GAS

LOCKING BAR

19

Page 28

AV-E ANESTHESIA VENTILATOR

FREQUENCY

CONTROL

I.E.

RATIO

CONTROL

FLOW

GAUGE

FLOW

CONTROL

VENTILATOR

POWER

SWITCH

TIDAL VOLUME

ADJUSTMENT

KNOB

SETTING POINTER

TIDAL VOLUME

VENTIL ATO R RE LI EF

VALVE (W /1 9M M

SCAVEN GE R

HOSE TE RM IN AL )

22MM BREATHING

HOSE T ERM INAL

OP30014

RETURN TO CD-ROM TABLE OF CONTENTS

The anesthesia ventilator (Figure 13) is

volume-preset and time-cycled. It has a

solid-state timer andindependent controls.

Thepneumatic powerto the ventilatormay

be supplied through the pipeline supply or,

if the pipeline supply either fails or is

disconnected, through cylinders. The

pressure of the supply gas must be

between 40 and 60 psi. The ventilator will

not function if thispressure drops below 32

psi.

The monitoring system’s breathing

pressure and expiratory flow waveform

displays can be used as an aid in adjusting

the ventilator. For further details, see the

MONITORING SYSTEM section of this

manual.

Figure 13 AV-E Ventilator

20

Page 29

RETURN TO CD-ROM TABLE OF CONTENTS

AV-E ANESTHESIA VENTILATOR (continued)

NOTE: The anesthesia ventilator is

designed for use with an NAD absorber

system, which incorporates a

Manual/Automatic selector valve. This

valve allows the operator to bring into the

breathing system either the breathing bag

and pop-off valve for manual ventilation,

or the ventilator bellows for automatic

ventilation. Breathing system hose

connections to this valve are described in

the SETUP & INSTALLATION section of

this manual.

Ventilator Power Switch

The ventilator power switch controls both

pneumatic and electrical power to the

ventilator. In the "OFF" position the

ventilatoris notoperable, and theAdvisory

message "VENT OFF" appears on the

anesthesia machine’s central alarm

display. Inthe "ON" position the ventilator

is activated and cycles according to the

settings of the other controls.

The ventilator power switch also

automatically enables the monitoring

system’s volume-related alarms and apnea

pressure alarm.

Smaller tidal volumes can be adjusted by

setting the pointer below the 200 ml

marking on the bellows chamber. Larger

tidal volumes can be selected by choosing

settings above the 1400 ml calibration. As

in any volume-presetanesthesia ventilator,

the actual tidal volume delivered to the

patient’s lungs may differ from the preset

volume at the bellows due to the

compliance of the breathing system and

fresh gas flow. To accurately set the tidal

volume, the operator should refer to tidal

and minute volume measurements.

The position of the tidal volume indicator

can be calibrated by an NAD authorized

service representative for a specific

combination of fresh gas flow and

equipment compliance.

Frequency Control

The respiratory frequency can be set

between 1 and 99 BPM (in 1 BPM

increments) using the two-digit thumb

wheel switch labeled "FREQUENCY"

(Figure 13). A setting of "00" will cause the

ventilator to remain in the expiratory

phase indefinitely.

Tidal Volume Adjustment

The tidal volume may be adjusted between

50 and 1500 ml. A self-locking knob,

located above the bellows assembly (Figure

13), adjusts a bellows stop within the

canister. To adjust the tidal volume,

depress the self-locking knob to allow

rotation. Set the tidal volume, as indicated

by the pointer on the bellows chamber

scale (marked 200 to 1400 ml), to the

desired set point.

Inspiratory/Expiratory (I:E) Phase Time

Ratio Control

The operator can vary the

inspiratory/expiratory phase time ratio in

calibrated steps from 1:1 through 1:4.5.

Calibrations are marked on the I:E

controller-indicator thumb wheel in 0.5

increments. The thumb-wheel is located to

the right of the frequency thumb wheel

and is labeled "I:E RATIO" (Figure 13).

21

Page 30

AV-E ANESTHESIA VENTILATOR (continued)

RETURN TO CD-ROM TABLE OF CONTENTS

Inspiratory Flow Control

The rotary knob marked "INSPIRATORY

FLOW" controls the flow rate of gas into

the bellows chamber, and the inspiratory

flow rate of gas into the patient’s lungs.

However, due to such variables as total

lung compliance, equipment compliance,

and airwayresistance, the inspiratory flow

control cannot be calibrated with

numerical values. Instead,the gaugeto the

left of the control knob is labeled with

three zones, "LOW," "MEDIUM," and

"HIGH" (Figure 13).

The flow setting is to be adjusted so that

the bellows is fully compressed at the end

of the inspiratory phase. In order to deliver

the desired, preset tidal volume, adjust the

inspiratory flow control so that the bellows

corrugations make contact with each other

but are not deformed at the end of the

inspiratory phase.

The inspiratory flow control can be used to

create an inspiratory plateau at the end of

the inspiratory cycle. It also affects the

peak inspiratory pressure that can be

developed within the patient breathing

system. Always check the pressure

indicatedby the breathingsystem pressure

gauge and waveform when adjusting the

inspiratory flow control.

Ventilator Relief Valve

During automatic ventilation, the

manual/automatic selector valve isolates

the absorber’s APL (adjustable pressure

limiting) valve from the breathing system.

To compensate for the continuous

introduction of fresh gasinto the breathing

system, the ventilator incorporates a relief

valve mounted behind the bellows

chamber.

The ventilator relief valve remains closed

until the end of expiration so that the

ascending bellows can expand upward and

refill. When the bellows is completely

filled, any excess gas in the system is

released by the ventilator relief valve to

the scavenging system. As in any

ascending bellows, the force needed to

overcome gravity acting on the bellows

causes a PEEP within the breathing

system, in this case approximately 2 cm

O.

H

2

Bellows PEEP Valve (Optional)

An optional ventilator PEEP valve mounts

beneaththebellows.(An optional absorbermounted PEEP valve is also available.)

The operator can set a PEEP of

approximately 2 to 15 cm H

O with the

2

PEEP valve control knob. Clockwise

rotation of the knob increases PEEP and

counterclockwiserotation decreases PEEP.

The breathing system pressure gauge and

the breathing pressure monitor indicate

the amount of PEEP at the end of

exhalation. For details, see the Bellows

PEEP Valve Instruction Manual.

22

Page 31

Power Supply

RETURN TO CD-ROM TABLE OF CONTENTS

POWER SUPPLY

The NARKOMED 3 is equipped with a

central power supply for the ventilator,

alarm system, and monitoring system. The

power of each monitor is individually

regulatedto prevent voltagefluctuationsin

one monitor from influencing the

performance of the other monitors.

The NARKOMED 3 must be plugged into

an AC outlet when in use.

Power Cord

A fifteen foot cord with a 3-prong hospital

grade plug is supplied with the

NARKOMED 3. The allowable input

voltage range is from 90 to 130 VAC at 50

or 60 Hz. Excess cable is to be stored on

the cord wrap at the rear of the

NARKOMED 3. When unplugging the

power cord be sure to pull the plug, not the

cord.

Hospital Grade Convenience Receptacles

The NARKOMED 3 is equipped with four

convenience receptacles. The receptacles

are "active" whenever the NARKOMED 3

is plugged into an outlet, regardless if the

machine is turned on. They are mounted

on the upper rear of the anesthesia

machine (see Figure 2). The total current

for devices plugged into the receptacles

must not exceed 5 amps. A 5 amp circuit

breakerprotects the conveniencereceptacle

circuit. This circuit also incorporates an

EMIfilter, which minimizesinterferenceto

the anesthesia machine from devices

plugged into the convenience receptacles.

NOTE: Devices plugged into the

convenience receptacles contribute to the

anesthesia system’s total leakage current.

This total leakage current must not exceed

100 micro amps.

240 Volt Power Supply (Optional)

The NARKOMED 3 can be equipped with

an optional 240 VAC power supply. A 4.5

meter cable supplies the AC power. The

allowable input voltage range is from 200

to 260 VAC at 50 or 60 Hz. The 240 VAC

power supply does not include convenience

receptacles. A pilot light replaces the

circuit breaker for the convenience

receptacles; it illuminates when AC power

is supplied to the NARKOMED 3.

Backup Battery System

The backup battery system consists of a

rechargeable 12 volt battery (13 amp-hour,

sealed lead-acid) and a built-in battery

charging system. The batteryand charging

system are not user-serviceable and are

located in the bottom of the machine’s

frame.

Although most hospitals have emergency

generators to provide AC power when line

power fails, delays may be encountered

before generator power comes on line. The

backup battery system automatically

providespower duringthe interim between

line power failure and the activation of the

hospital’s emergency generator. The

backup battery would also provide power if

the anesthesia machine’s power cord is accidentally unplugged during a case.

When the hospital’s emergency generator

comes on line (or when a disconnected

power cord is reconnected), the

NARKOMED 3 automatically switches

back to AC power and recharges its

battery. The battery charging system will

charge thebattery any timethat the power

cord is connected to an active AC power

source. The charger can recharge a fully

discharged battery in approximately 16

hours.

23

Page 32

POWER SUPPLY (continued)

Backup Battery Operating Instructions

RETURN TO CD-ROM TABLE OF CONTENTS

To prevent premature battery failure,

backup battery power must be used only

during interruption of primary AC power.

No anesthetic procedure shall be started

using an anesthesia machine if the yellow

"AC POWER FAIL" indicator light or the

yellow "BATTERY LOW" indicator light is

illuminated.

The operator must test the backup battery

system daily. To test the battery ensure

that the SYSTEM POWER switch on the

main switch panel is in the "ON" position.

Then press and hold the "BATTERY

TEST" button on the main switch panel

(Figure 14).A green BATTERY TEST light

indicates thatpower is available to operate

the electrical components of the anesthesia

machine, but it does not indicate how long

this power will be provided. This depends

on the duration ofprevious batteryuse and

recharging.

Machine Functions While on Backup

Battery Power

2. In the second stage, to preserve the

battery for vital machine functions,

power to the display screens and

SPHYGMOMED is discontinued, and

power is supplied only to the following

machine functions: O

BAROMED, O

SATMED, SPIROMED,

2

MED,

2

the main switch panel, and the AV-E

ventilator. The battery will power the

machine in this state for at least 10

additional minutes.

The "AC POWER FAIL" alarm panel

indicator continuesto alert theoperator

of the AC failure condition, but since

power to the display screens has been

discontinued, noalarm messages canbe

displayed. At the beginning of the

second stage, the yellow "BATTERY

LOW" main switch panel indicator

illuminates, and remains illuminated

until the third stage. Also, the Error

Code "E07" appears in the

SPHYGMOMED front panel display

window.

If the hospital’s primary AC power fails,

the backup battery system works in three

stages:

1. For approximately thefirstfive minutes

of battery activation, the battery

powers all machinefunctions (including

the two display screens), except the AC

convenience receptacles and the

MULTISPEC.The operator isalerted to

this condition with the following:

The yellow "AC POWER FAIL"

indicator on the anesthesia

machine’s alarm panel illuminates.

The alarm message "AC PWR

FAIL" appears in the central alarm

display.

A single-tone audible alarm sounds.

The Error Code "E07" appears in

the MULTISPEC front panel

display window.

3. In the third stage (when the battery

voltage drops to 10 volts), all electrical

power to the anesthesia machine is

automatically cut off to prevent deep

discharge of the battery. (Deep

discharge damages lead-acid batteries.)

At this point, all gas supply systems

remain operative. However, since

battery power has been cut off, the AVE ventilator is inoperative, and manual

ventilation by bag squeezing must be

performed. In this final stage, the

anesthesia machine cannot provide

monitoring or alarm functions until it is

reconnected to an active AC power

source.

NOTE: If the NARKOMED 3 is left

with its power cable not plugged into an

active AC wall outlet for a period of

seven days or more, the backup battery

may become depleted. In this instance,

the power cable must be plugged into

an active AC outlet and the battery

must be allowed to charge for at least

16 hours.

24

Page 33

RETURN TO CD-ROM TABLE OF CONTENTS

POWER SUPPLY (continued)

Circuit Breakers

The electrical system includes three

magnetic circuit breakers to protect the

various machine functions (primary AC

power input, convenience receptacles, and

backup battery power).

The circuit breakers are located on the

lower right side of the machine. When the

plunger of a circuit breaker is flush with

the surface of its base, the circuit breaker

is in its normal, closed position. A circuit

breaker is open (tripped) when its plunger

extends beyond its base. The cause of an

open breaker must be investigated and the

appropriate corrective action must be

taken before the anesthesia system is

returned to service.

EMI Filtering

All power for the NARKOMED 3 is filtered

for conducted electromagnetic interference

by a low pass filter in the primary AC line.

This filter also prevents noise generated

within the NARKOMED3 fromleaving the

device through the AC line.

25

Page 34

MAIN SWITCH PANEL

T

RETURN TO CD-ROM TABLE OF CONTENTS

The main switch panel, located between

the ventilatorbellows and flowmeter bank,

incorporates alarms to communicate the

status of the gas delivery and power

supply systems.

These alarms are annunciated and

simultaneously displayed on the central

alarm display. Refer to Figure 14 for the

location of the indicators and controls on

the main switch panel.

RED O2 SUPPLY

PRESSURE

LOW INDICATOR

YELLOW AC POWER

LOW INDICATOR

Oxygen Supply Pressure Alarm

The oxygen supply pressure alarm

activates if the oxygen supply pressure

(from both the pipeline supply and reserve

cylinders) in the system decreases below

approximately 37 psi. The LED indicator

marked "O

continuously red, the alarm message "LO

O

display, and an intermittent audible alarm

sounds.

O SUP PLY PRESSURE

2

POWER F AILAC

LOWBATTERY

BATTE RY TEST

SUPPLY PRESSURE" lights

2

SUPPLY" appears on the central alarm

2

BATTERY TES

PUSH BUTTON

YELLOW BATTERY

LOW INDICATOR

GREEN BATTERY

TEST INDICATOR

Figure 14 Main Switch Panel

26

ON

STANDBY

SYSTEM POWER

SYSTEM POWER

SWITCH

OP20050

Page 35

RETURN TO CD-ROM TABLE OF CONTENTS

MAIN SWITCH PANEL (continued)

NOTE: If only one source of oxygen supply

pressure (either cylinders or pipeline) fails

while the other maintains proper supply

pressure within themachine’s oxygensupply

lines, the oxygen supply pressure alarm will

not activate.

Battery Test

The operator must test the backup battery

system daily. To testthe battery ensure that

the SYSTEM POWER switch on the main

switch panel is in the "ON" position. Then

press and hold the "BATTERY TEST"

button on the main switch panel. If the

battery has been charged to normal

operatingpotential, thegreen indicator light

comes on when the BATTERY TEST button

is pressed. Any time that the battery

potential drops below the normal operating

threshold, the yellow "BATTERY LOW"

indicator comes on, whether the "BATTERY

TEST" button has been pressed or not.

NOTE: Do not rely only on the "BATTERY

LOW" indicator for anassessment ofbattery

capacity. If the backup battery becomes

completely depleted and the machine does

not have AC power, the "BATTERY LOW"

indicator will have no source of power and

will not function. Therefore, always

remember to perform the daily battery test.

AC Power Failure Indicator

The yellow "AC POWER FAIL" LED signals

AC power disruption. The LED illuminates

whenever the battery supplies power to the

monitoring system and the electronic

ventilator. A single tone also sounds when

AC power is first disrupted. If the

anesthesia machine’s backup battery is

completely discharged, the AC power failure

indicator will not be supplied with thepower

and will not function.

System Power Switch

The SYSTEM POWER switch of the

NARKOMED 3 has two positions:

"STANDBY"and "ON". Inthe"ON" position,

the SYSTEM POWER switch actuates all

gas and electric power. In the "STANDBY"

position, the switch shuts down the alarm

system and the gas supplies.

The SYSTEM POWER switch must be

depressed when turning to prevent

inadvertent disengagement. A green LED

indicator adjacent to the switch remains lit

when the switch is in "ON" position and

supplying power to the machine. Also, a

single brief tone sounds when the switch is

turned to the "ON" position.

Regardless of the switch setting, the battery

chargingcircuit andconvenience receptacles

are activated whenever the power cable is

attached to an active wall receptacle. To

prevent drainage of the backup battery and

waste or depletion of the oxygen supply

through the minimum oxygen flow, the

SYSTEM POWER switch must be turned to

the "STANDBY" position whenever the

machine is not in use.

System Power Switch Failure Alarm

A steady, high-pitched audible alarm

activates if the NARKOMED 3 pneumatic

circuitry is pressurized by the SYSTEM

POWER switch, but a malfunction in the

switch prevents activation of the monitoring

system. The alarm is produced by a speaker

located on the power supply controller.

There is no visual indicator associated with

the SYSTEM POWER switch failure alarm.

Flowmeter Lights

The SYSTEM POWER switch controls the

lights for the flowmeter panel. When the

switch is turned to the "ON" position, the

flowmeter lights come on.

27

Page 36

MONITORING SYSTEM

RETURN TO CD-ROM TABLE OF CONTENTS

GENERAL DESCRIPTION

The NARKOMED 3 incorporates six

standard, integral monitors:

BAROMED breathing pressure monitor

O2MED oxygen analyzer

O2SATMED pulse oximeter

SPIROMED respiratory volume

monitor

MULTISPEC respiratory gas analyzer

SPHYGMOMED noninvasive blood

pressure monitor

Figure 15 illustrates the front panels of the

monitors. Each monitor consists of a modular

chassis that mounts in a monitoring rack to

the right of the monitoring system display

screens.

MED Oxygen Analyzer

O

2

The O

MED uses a dual redundant galvanic

2

cell sensor tomonitor and digitallydisplay the

oxygen concentration in thepatient breathing

system. The operator can set low and high

oxygen concentration alarm limits, calibrate

the monitor to 21% oxygen with a single

keystroke, and view oxygen concentration

data on a trend graph display. An O

Sensor

2

alarm warns of sensor cable disconnection,

sensor malfunction, and sensor degradation.

The unit can also (through alarm messages

on the central alarm display) alert the

operator that a calibration is due or that an

internal electronics malfunction hasoccurred.

A detailed description and operating

instructions can be found in the O

MED

2

Operator’s Instruction Manual.

BAROMED Breathing Pressure Monitor

The BAROMED monitors breathing system

pressure ateither the absorberor the Y-piece.

The unit can display mean, peak, or positive

end expiratory (PEEP) pressure in cm H

O.

2

The operator can set alarm limits for high

pressure and threshold pressure with

adjustment keys. Alarms are provided for

highpressure,pressure below thresholdfor15

and 30 seconds, subatmospheric (< -10 cm

O) pressure, excessive PEEP, and

H

2

continuing pressure above the set threshold

for 15 seconds. Also, the unit can alert the

operator of an improperly set threshold

pressure with the alarm message

"THRESHOLD LO" on the central alarm

display. A detailed description and operating

instructions can be found in the BAROMED

Operator’s Instruction Manual.

SPIROMED Respiratory Volume Monitor

TheSPIROMED usesapositive displacement,

rotating-lobe impeller sensor to monitor and

display tidal volume, minute volume, and

respiratory rate. The operator can set a low

alarm limit for minute volume with

adjustment keys. A fixed alarm warns of

reverse flow through the sensor. An apnea

alarm is generated if the sensor does not

sense a breath for 15 and 30 seconds. A

volume sensor alarm activates if the sensor

cord is disconnected or damaged. A detailed

description and operating instructions can be

found in the SPIROMED Operator’s Instruction Manual.

28

Page 37

MULTISPEC Respiratory Gas Analyzer

6

RETURN TO CD-ROM TABLE OF CONTENTS

MONITORING SYSTEM (continued)

The MULTISPEC uses a non-dispersive

infrared analyzer to monitor carbon dioxide,

O and anesthetic concentration in asample

N

2

withdrawn from thepatient breathingsystem

at the Y-piece. The unit displays end-tidal

(in mm Hg), as well as inspiratory and

CO

2

expiratory anesthetic concentrations (in %).

Using front panel adjustment keys, the

operator can set both high and low alarm

limits for end-tidal CO

and anesthetic

2

concentration.

O2MED OXYGEN ANALYZER

VOL %

OXYGEN

OXYGEN LO

OXYGEN HI

O2 SENSOR

OXYGEN ALARMS

HI LO

O2CAL

Apnea alarms are generated if the monitor

does not sense a CO

30 seconds. An inspiratory CO

generated if the inspiratory CO

fluctuation for 15 and

2

high alarm is

2

partial

2

pressure exceeds 5 mm Hg. Alarms are also

providedfor sample-lineblockage and internal

electronic failure. Zero calibration can be

performed with a single soft-touch key. The

unit also performs zero calibrations

automatically. A detailed description and

operating instructions can be found in the

MULTISPEC Operator’sInstruction Manual.

SPHYGMOMED NONINVASIVE

BLOOD PRESSURE MONITOR

SYSTOLIC

/min mmHg

DIASTOLIC

INTERVAL

SYSTOLIC HI

SYSTOLIC LO

STAT

BP ERROR

SYSTOLIC ALARMS

HI LO

STOPSTARTSTAT

O2SATMED PULSE OXIMETER

2

SaO

/min %

PULSE

SaO2 LO

PULSE LO

PULSE HI

SaO2 SENSOR

SaO2/PULSE ALARMS

HI LO

MULTISPEC RESPIRATORY

GAS ANALYZER

ET CO2

ET AGENT

INSP AGENT

mmHg

%

APNEA

ET CO2 HI

ET CO2 LO

AGENT HI

AGENT

SELECT

HI LO

CAL

ALARMS

FigureFigure 1515 NARKOMED 3 Monitors

OXI

ALARMS

DISABLE

CO2/AGT

ALARMS

DISABLE

/min liter

cm H2O

SPIROMED RESPIRATORY

VOLUME MONITOR

MIN VOL

TIDAL VOL

BPM

APNEA

MIN VOL LO

REV FLOW

VOL SENSOR

MINUTE VOLUME ALARMS

LO

BAROMED BREATHING

PRESSURE MONITOR

MEAN

PEAK

PEEP

APNEA

PRES HI

SUB ATM

CTNG PRES

BREATHING PRESSURE ALARMS

HI

VOLUME

ALARMS

DISABLE

APNEA

ALARMS

DISABLE

OP3001

29

Page 38

MONITORING SYSTEM

O

SATMED Pulse Oximeter

2

RETURN TO CD-ROM TABLE OF CONTENTS

The O

SATMED pulse oximeter uses a

2

spectrophotometric infrared transmission

sensor to noninvasively measure arterial

hemoglobin oxygen saturation. The unit

displays either percent SpO

or pulse rate. The

2

operator can set both high and low alarm

limits for SpO

and pulse rate withadjustment

2

keys. Alarms are also provided for an absence

of pulse (no pulse at the sensor for 10 seconds)

and disconnection of the sensor cable. A

detailed descriptionand operating instructions

can be found in the O

SATMED Operator’s

2

Instruction Manual.

SPHYGMOMED Noninvasive Blood Pressure

Monitor

The SPHYGMOMED employs oscillometric

means todetermine the patient’s systolic, diastolic, and mean blood pressure (mean arterial

pressure) and pulse rate. The unit also

displays the interval between measurements,

instantaneous cuff pressure, and sample age.

The operator can sethigh and low alarm limits

for systolic blood pressure with adjustment

keys. Alarms are also provided for several selfdiagnostic conditions, including improper cuff

set-up, cuff disconnection, and internal

malfunction. A detailed description and

operating instructions can be found in the

SPHYGMOMED Operator’s Instruction

Manual.

Manual Sphygmomanometer (Optional)

An aneroid manual sphygmomanometer can

be mountedon the NARKOMED 3 (see Figure

16).

The sphygmomanometer gauge mounts on the

left-handside of theanesthesia machine, above

the ventilator bellows, either on a mount on

the machine itself or on the underside of the

optional boom arm.

To install the gauge, tighten the gauge’s

threaded mounting ring in a clockwise

direction over the gauge mount. Then, attach

the fitting on the free end of the gauge hose to

the fitting labeled "BP GAUGE" on the upper

left side of the anesthesia machine.

To install the blood pressure cuff, first attach

the short hose on the cuff to the longer

extension hose. The two hoses join with Luer

lock fittings. Then, attach the free end of the

extension hose to the fitting labeled "BP

CUFF" on the patient interface panel.

The Manual Sphygmomanometer uses the

same blood pressure cuff as the

SPHYGMOMED noninvasive blood pressure

monitor. Some users mayprefer to use one cuff

for both the SPHYGMOMED and Manual

Sphygmomanometer by switching the cuff

extension hose from the SPHYGMOMED

interface panel fitting to the identical "BP

CUFF" fitting below it on the interface panel.

To install the cuff inflation bulb, insert the

male Luer fitting (slip-fit type) on the bulb

hose into the female Luer fitting (labeled "BP

BULB") to the right of the O2 flush button on

the front of the anesthesia machine.

After installation, check the gauge’s pressure

indication. With zero pressure applied to the

gauge and cuff, the gauge pointer should

remain within the band marked on the face

plate. The gauge accuracy is ±1 % of full scale

within a range of 75-225 mm Hg and ±3% of

full scale outside of this range.

To check the manual sphygmomanometer for

leaks, place the blood pressure cuff around a

rigid cylindrical object of approximately the

same diameter as a human arm. Inflate the

cuff to a pressure of 250 mm Hg, as indicated

on the sphygmomanometer gauge.

30

Page 39

THREADED HOSE

FITTINGS FOR

GAUGE AND CUFF

INTERNAL PIPING

CONNECTS BULB FITTING

TO GAUGE AND CUFF FITTING

SPHYGMOMANOMETER

GAUGE

OP30017

CUFF EXTENSION

HOSE (12 FT. LONG)

GAUGE HOSE

FEMALE LUER FITTING

(SLIP-FIT) FOR CUFF

INFLATION BULB

RETURN TO CD-ROM TABLE OF CONTENTS

MONITORING SYSTEM (continued)

Then, watch the gauge reading for 10

seconds; the gauge indication shall not

decrease more than 10 mm Hg within this

time period.

To isolate a specific source of leaks, eliminate

components from the system and perform the

test described above.

For example, to exclude the cuff inflation

bulb, pinch the cuff inflation hose after

inflating the cuff to 250 mm Hg. To exclude

the cuff itself, remove the extension hosefrom

the interface panel, occlude the "BP CUFF"

fitting, and then pressurize the gauge to a

reading of 250 mm Hg.

FigureFigure 1616 Manual Sphygmomanometer

31

Page 40

MONITORING SYSTEM (continued)

RETURN TO CD-ROM TABLE OF CONTENTS

Breathing System Sensor Interface Panel

A panel of four sensor connections is provided

on the lower left side of the NARKOMED 3

(Figure 17). These connections pertain to the

patient breathing system and thus are

mounted close to the absorber assembly. The

MED sensor cord leads from the O2MED

O

2

sensor (mounted in the inspiratory valve)and

plugs into a pin-type connector on the panel.

The BAROMED breathing pressure pilot line

leads from either the absorber (shorter pilot

line) or the Y-piece (longer pilot line) and

plugs into a quick-connect fitting on the

panel. The SPIROMED sensor cord leads

from the SPIROMED sensor on the absorber

top dome to apin-type connector on the panel.

The MULTISPEC exhaust line leads from a

hose barb fitting on the panel to an adapter

on the scavenger system.

Patient Sensor Interface Panel

A panel of four sensor connections is provided

on the upper left side of the NARKOMED 3

monitoringbank(Figure17).TheO

SATMED

2

incorporates an interface cable/preamplifier

assembly that mounts on the boom arm and

plugs into a pin-type connector on the panel.

The MULTISPEC sample line leads from a

15 mm sample adapter at the Y-piece to a

Luer lock fitting on the semi-permeable

tubing, which then connects to the sample

lineinterfacepanel.TheSPHYGMOMEDcuff

extension hose leads from the blood pressure

cuff to a threaded hose connection on the

panel. The optional manual

sphygmomanometer hose connections occupy

the bottom slot on the interface panel and are

intended for the gauge hose and the cuff

extension hose.

Boom Arm (Optional)

An optional boom arm can be mounted on the

left side of the monitoring bank. Patient

sensor lines(O

SATMED interfacecable, CO

2

sample line, SPHYGMOMED cuff extension

hose) can be routed from the patient to the

anesthesia machine in an organized fashion

with the boom arm. The arm can be adjusted

to the desired position to retain the lines in

the most convenient position.

System Communications

Although designed to operate independently,

each monitor is equipped with data

communications capabilities, allowing it to

become a component of a structured and

organized anesthesia Data Management

System. This system approach allows other

devices in the system to analyze, display, and

record the data and alarm conditions from

any monitor.

Alarm Strategy

The monitoring system has been designed to

support a uniform and structured alarm

strategy.This strategy solvesamajor problem

in the operating room today — the confusion