Page 1

TRX II

TRX II

Portable documenting calibrator

! Simulates and Reads RTD’s

and thermocouples

! Sources and reads Millivolts, Volts,

Milliamps, Ohms and frequency

! Measures pressure -14.7 to 10,000 psi

! Dual readout: measure and source

! Data storage for field calibrations

! Data transfer via RS 232 or PCMCIA card

Page 2

Portable documenting calibrator

TRX II

A new standard for portable multifunction calibrators

The Druck TRX II portable documenting calibrator is the

culmination of many years of combined field experience with the

Druck and Unomat series of calibrators.

This one self-contained, battery powered package simulates and

measures RTD’s,thermocouples and resistance, as well as

sourcing and reading milliamps, millivolts, volts and frequency.

The rugged design includes an impact resistant enclosure which

is fastened to the carrying case for convenience and safety.

Dedicated alphanumeric and documenting keypads surround a

large LCD panel with dual readout and backlight. Connectors for

source and measure are kept separate and a 24V output is

provided for loop power.

The TRX II’s extensive measurement capabilities can include

pressure measurement by connecting Druck pressure sensors

which have been digitally characterized to give high accuracy.

This highly accurate and easy to use documenting calibrator

provides improved data quality and quicker calibration time since

data can be uploaded and downloaded via the PCMCIA card or

the RS232 interface.

High performance and multi-functional

Typical accuracies: 0.01% reading ±0.01% FS for mA

measurement.

0.05% FS for pressure measurement

Measure: mA, mV, volts, T/C’s, RTD’s, pressure,

ohms, frequency and switch state.

Source: mA, mV, volts, T/C’s, RTD’s, ohms and

frequency

Remote pressure sensors: 1 to 10,000 psi including gauge, absolute

and differential

Loop power: 24 Vdc

Data storage: 1 Mbyte and 2 Mbyte PCMCIA cards

Data transfer: RS 232 or PCMCIA card

Simple to operate

The combined Druck and Unomat knowledge of customer needs, and

innovative design, results in a high performance, yet easy to operate,

multi-function documenting calibrator.

The key to the simple operation of the TRX II is the structured menu.

Input and output readings are displayed simultaneously for test modes

such as T-I and P-I, allowing quick comparison of the values. Used in

conjunction with Linkpak-W calibration software, or Intecal-W database

software, the TRX II will perform automatic calibrations from predefined procedures, calculating and reporting errors to the operator

and storing the results on a PCMCIA card. This intuitive approach,

whether used manually or automatically, ensures correct set up for the

job at hand and improves working efficiency and data accuracy.

The TRX II provides simple and flexible data transfer to fit in with most

working practices. Information can be reviewed on screen or

transferred to and from the TRX II using the RS 232 interface.

Alternatively, without docking the instrument to a PC, data can be

transferred by exchanging PCMCIA cards.

The operating system works in several languages and provides scaling,

step and ramp features for calibration and maintenance. The TRX II,

which includes extensive self-test routines, can be relied upon time

and time again for field calibration in extreme conditions.

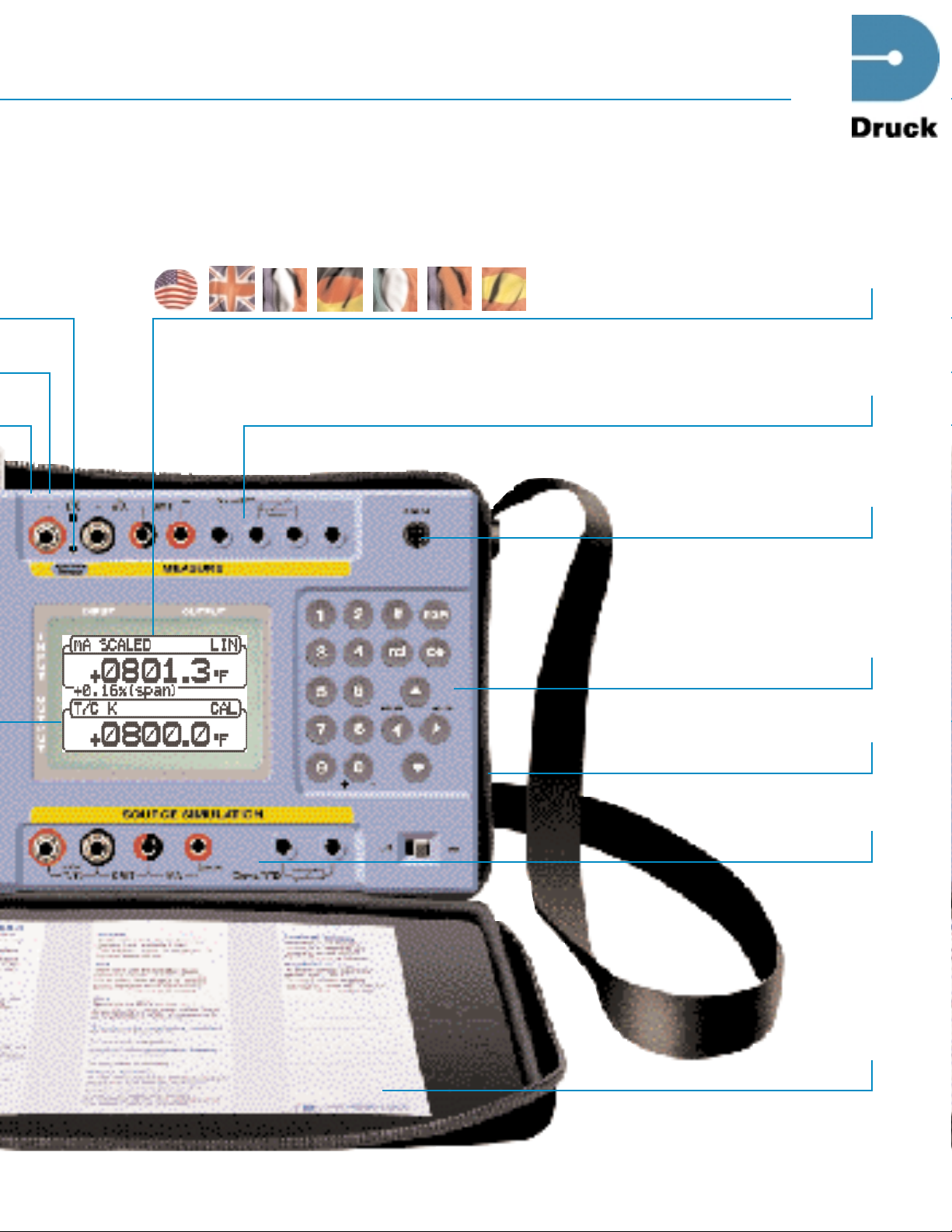

Direct connection for T/C

compensation wires

Connectors for external

pressure sensor

LCD screen protected by a scratch

resistant anti-reflection window

Cold junction compensation

at point of contact

PCMCIA slot for

card types 1 or 2

Backlight key

Shoulder strap

Page 3

Multilingual firmware supported by Linkpak-W

calibration software.

User guide for quick

reference in the field

Output connectors

Carrying case

secured to TRX II

Numerical keys for

entering values

RS 232 for

Data transfer

Input connectors

Page 4

The TRX II has been designed for ease of use while meeting a wide range of

application needs including calibration, maintenance and commissioning. The

dual parameter display shows the measured and sourced values in large

clear digits with all applicable information such as the units of measurement

and range. With safety in mind, construction of the shoulder strap allows

hands free operation while maintaining display visibility.

Some of the capabilities

! Measure/source mA

! Measure/simulate 12 types of T/C

! Measure/simulate 9 types of RTD

! Measure/source frequency and pulses

! Simulate transmitter input and measure transmitter output

! Measure/source mV/V

! Measure/source resistance

! Measure pressure: -14.7 to 10,0 00 psi

! Test switches: captures values on contact change

Easy to operate

The easy to operate menu driven software enables the calibrator to be set

up very quickly. Simply scroll through the menus and select the

appropriate parameters.

Operating and connection errors such as loop resistance mismatch and

cold junction temperature sensor absence are reported. The

KEYSTR OKING

memory enables instant recall of previously stored user tests.

TRX II

Applications

MULTIFUNCTION PORTABLE CALIBRATOR

TEMPERATURE SENSOR SIMULATION AND LOOP CHECKING

The auto step and ramp modes enable a single technician to test and

commission control loops. The calibrator is left to generate a pre-programmed

output, while the technician checks the signal further down the loop.

End to end control loop performance can be checked with one instrument by

simulating a temperature signal at the start of the loop.

When troubleshooting apply a three step approach.

Step one:

Measure the sensor output to confirm correct connection

and operation.

Step two:

Check and calibrate the transmitter by simulating temperature

signals and measuring the corresponding mA outputs.

Step three:

Feed the loop with a mA signal and check wiring and

instrumentation further down the line.

Page 5

CALIBRATION FOR ISO 9000

Direct connection of thermocouple compensation wires eliminates the

need for special connectors and reduces additional cold junction errors.

This is the most reliable and accurate method of monitoring cold junction

temperatures in a portable field calibrator.

In calibration mode the display shows all the required information. Both

mV and mA values are displayed in °F for easy comparison, along with

the calculated error expressed as % of span or reading.

The TRX II will simulate the temperature signal to the transmitter to be

calibrated and will simultaneously measure and display the output. A 24

volt power supply is provided for stand alone operation.

TEMPERA TURE TRANSMIT TER SIMULATION AND CALIBRA TION

The connection of 2, 3 and 4 wire RTD‘s is detected automatically, a

feature unique to Druck portable field calibrators.

Dedicated keys for documenting field calibrations eliminate human errors

and are available as standard. The ’AS FND’ (as found) and ‘AS LEFT’ keys

start the respective procedures for storing calibration data which can be

recalled using the ‘VIEW’ key.

Optional PCMCIA cards represent the most efficient data transfer media.

Docking of the calibrator with the PC is unnecessary as a card

containing calibration data can be exchanged for another containing new

procedures/work orders, enabling technicians and calibrators to spend

more time in the field.

Data is transferred to the PC from the PCMCIA card or the RS 232

interface for analysis, certificate printing and archiving. Exporting facilities

are provided for wordprocessor and spreadsheet applications or in-house

maintenance systems.

Page 6

Remote pressure sensors offer a cost effective means

of expanding the capabilities of the TRX II, for example:

n Calibration of pressure transmitters

n Testing pressure switches

n For differential pressure applications

n For flow measurement calibrations

The capability of the TRX II can be extended by adding

up to 8 external pressure sensors (connected one at a

time). With ranges from 1 to 10,0 00 psi and all welded

stainless steel and Hastelloy construction, sensors can

be chosen to suit many applications. Remote pressure

sensors require a mating cable approximately 4.5 feet

in length. One end connection interfaces with the

remote pressure sensor electrical input and one end

mates with the TRX II remote pressure sensor electrical

input (please refer to Option B2). Druck has applied the

latest technology and production techniques to develop

these sensors which are digitally corrected for nonlinearity and temperature effects.

Specifications

Over 50 sensor ranges are available including gauge,

absolute and differential versions and with accuracy

better than 0.05% FS, even the most up to date

pressure instrumentation can be maintained and

calibrated.

REMOTE PRESSURE SENSORS

Pressure ranges

(optional)

APPLICATION: Pressure transmitter Pressure switch

Note 1: Absolute up to 1000 psi.

Note 2: All ranges shown in bold are in stock.

Pressure connection:1/4NPT female.

Comments

Maximum line pressure 500 psi

Differential ranges uni-directional use only

Absolute

5 psi

10 psi

15 psi

20 psi

30 psi

50 psi

75 psi

100 psi

150 psi

200 psi

300 psi

450 psi

500 psi

600 psi

1000 psi

Dif

ferential

5 psi

10 psi

15 psi

30 psi

50 psi

75 psi

100 psi

150 psi

200 psi

300 psi

500 psi

Gauge

1 psi

2.5 psi

3 psi

5 psi

10 psi

15 psi

20 psi

30 psi

50 psi

75 psi

100 psi

150 psi

200 psi

300 psi

450 psi

500 psi

600 psi

1000 psi

1500 psi

2000 psi

2500 psi

3000 psi

5000 psi

6000 psi

10000 psi

Page 7

Input

mV

V

mA

Ohms

Frequency

Counts/minute

Counts/hour

Totalizing

counter

Remarks

R - input > 20 M Ohm

R - input > 1 M Ohm

R - input 2.5 Ohm fused

at 0.9 mA excitation

at 0.9 mA excitation

R - input > 300 k Ohm

R - input > 300 k Ohm

R - input > 300 k Ohm

R - input > 300 k Ohm

R - input > 300 k Ohm

R - input > 300 k Ohm

Resolution

0.001

0.01

0.0001

0.001

0.001

0.01

0.1

0.01

0.1

1

1

1

infinite

Accuracy

0.02% + 0.01%

0.025% + 0.005%

0.025% + 0.0 05%

0.05% + 0.005%

0.01% + 0.01%

0.005% + 0.02%

0.02% + 0.015%

0.006%

0.1 Hz

1 Hz

2 c/min.

2 c/hour

2 counts

Range

0 ... 100 mV

100 ... 600 mV

0 ... 6 V

6 ... 60 V

0 ... 52 mA

0 ... 400 Ohm

400 ... 2000 Ohm

0 ... 655 Hz

655 ... 1310 Hz

1310 ... 20,000 Hz

0 ... 6 x 10

5

0 ... 107-1

0 ... 10

8

-1

MEASURE SPECIAL FEATURES

TRX II

Standard specification

Temperature units

ÞF or ÞC

Temperature scales

IPTS 68 or ITS 90 selectable

Pressure units

15 units

Step

10 programmable, 10%, 20%, 25%. Manual step or adjust able timer

Ramp

Fully programmable travel time (up/down and dwell)

Scaling

5 digits and sign on all electrical ranges

Temperature transmitter calibration

Both input and output readings in temperature units

Calibration feature extended for all output functions

Temperature transmitter simulation

mA output reads in temperature units

Signal converter

Converts any input into any output, fully isolated

Keystroking

Storage for 9 user defined test configurations

Switch test

Display freezes on open and closed with Switch resistance measurement

Data log

1 Mbyte up to 8 Mbyte of data storage

Computer interface

RS 232 and PCMCIA card (RS 232 cable and PCMCIA card are supplied with

Option A or PCMCIA release card kit referenced on price list.)

PCMCIA station

PCMCIA card type 1 or 2

Language

English, French, German, Italian, Portuguese and Spanish

Power management

Auto backlight OFF, battery low indicator and status from menu.

Panel

2.6 x 1.6 inch Graphic LCD with backlight

Readout

Typically 5 readings/ second

Calibration reference

72 °F ±2ÞF, R.H. 45% ±15%

Accuracies

Accuracies true for 60 °F to 80 °F. Outside these limits add 0.0003%/ÞF typically

Temperature

Operation: 15 °F to 120 °F

Humidity:

0 - 90% non condensing

Sealing

Generally to NEMA 12 (IP53)

Conformity

EN50081-1, EN50082-1, CE Marked

Physical

2.65 lb, 8.25 x 4.75 x 2.0 inch

Power supply

4 x 1.5 V alkaline “C” cells or 4 x 1.2 V Ni-Cad “C” cells

Accuracy ( % of reading + % of range)

Output

mV

V

mA

Ohms

Pulse

Frequency

pulses/min

pulses/hour

Remarks

R - output < 0.2 Ohm

R - output < 0.2 Ohm

R - max 900 Ohm

at 1 mA excitation

at 1 mA excitation

R - input > 300 k Ohm

0 ... 24 V/ 34 mA max.

0 ... 24 V/ 34 mA max.

0 ... 24 V/ 34 mA max.

0 ... 24 V/ 34 mA max.

Resolution

0.001

0.0001

0.001

0.01

0.1

1

0.01

1

1

1

Accuracy

0.01% + 0.005%

0.01% + 0.005%

0.01% + 0.02%

0.005% + 0.02%

0.02% + 0.015%

infinite

0.01 Hz

1 Hz

1 p/min

1 p/hour

Range

-10 ... 10 0 mV

0 ... 12 V

0 ... 24 mA

0 ... 400 Ohm

0 ... 2000 Ohm

0 ... 10

8

-1

0 ... 100 Hz

0 ... 20,000 Hz

0 ... 6000

0 ... 99,999

SOURCE

Accuracy ( % of reading + % of range)

RTD

Pt1000 ➀

Pt500 ➀

Pt200 ➀

Pt100 ➀

Pt50 ➀

D-100 ➁

Ni100 ➂

Ni120 ④

Cu10 ⑤

Resolution

0.2 °F

0.2 °F

0.2 °F

0.06 °F

0.11 °F

0.06 °F

0.2 °F

0.2 °F

0.6 °F

Source

0.4 °F

0.7 °F

1.1 °F

0.6 °F

0.9 °F

0.6 °F

0.4 °F

0.4 °F

3.6 °F

Accuracy

Measure

0.4 °F

0.7 °F

1.1 °F

0.6 °F

0.9 °F

0.6 °F

0.4 °F

0.4 °F

3.6 °F

Range

-328/752 °F

-328/1562 °F

-328/1562 °F

-328/1562 °F

-328/1562 °F

-328/1166 °F

-76/482 °F

-112/500 °F

-328/500 °F

TEMPERATURE

➀ = IEC 751,➁ = JIS 1604-1989,➂ = DIN 43760,④ = MINCO 7, ⑤= MINCO 16-9

Best case, Mid Range accuracies

T/C

J ➀

L ➁

K ➀

T ➀

U ➁

B ➀

R ➀

S ➀

E ➀

N ➀

C ➀

D ➀

Resolution

0.2 °F

0.2 °F

0.2 °F

0.2 °F

0.2 °F

0.2 °F

0.2 °F

0.2 °F

0.2 °F

0.2 °F

0.2 °F

0.2 °F

Source

0.6 °F

0.4 °F

0.6 °F

0.4 °F

0.4 °F

1.3 ° F

1.3 ° F

1.3 ° F

0.4 °F

0.6 °F

0.9 °F

0.9 °F

Accuracy

Measure

0.9 °F

0.6 °F

1.3 °F

0.6 °F

0.6 °F

1.8 °F

1.8 °F

2.5 °F

0.7 °F

1.1 °F

1.8 °F

1.8 °F

Range

-346/2192 °F

-328/1652 °F

-418/2498 °F

-418/752 °F

-328/1112 °F

482/3308 °F

-58/3214 °F

-58/3214 °F

-418/1832 °F

-328/2372 °F

32/4208 °F

32/4523 °F

➀ = IEC 584, ➁ = DIN 43710

Best case, Mid Range accuracies

Note: Thermocouple accuracies do not include cold junction compensation errors

DISPLAY

ENVIRONMENTAL

Page 8

(B1) Remote pressure sensors (refer to pressure range table)

Sensors from 1 to 10,000 psi are available for use with the

TRX II. The calibrator has a single remote channel which can be

configured for use with up to 8 sensors (one at a time). At least one

mating cable is required per TRX II when ordering remote pressure

sensors - see Option (B2)

(B2) Mating cable for remote sensors P/N TAS-5-A074

A 4.5 ft. mating cable for connecting remote sensors to the TRX II.

At least one cable per TRX II should be ordered when ordering

Option (B1).

(C) Charger/power supply P/N 13603 state 110 or 220v

This adapter has been designed with two functions.

It can either power the TRX II from line voltage or it can recharge

Ni-cad batteries. The charger and adapter circuits are separate,

allowing the user to recharge and operate the unit simultaneously.

ACCESSORIES

The TRX II is supplied with carr ying case, test leads, user guide, handbook

and calibration certificate as standard.

CALIBRATION STANDARDS

Calibrators manufactured by Druck are calibrated against precision

equipment traceable to the National Institute of Standards and Technology

(NIST). Druck is an ISO 9001 registered company.

TRX II

Options and related products

Druck Incorporated

4 Dunham Drive

New Fairfield, CT 06812

Tel: 203-746-0400

Fax:203-746-2494

E-Mail:sales@druckinc.com

http://www.druckinc.com

Representative

PDS-AO74 4/99

OPTIONS

(A1) Linkpak-W calibration software (P/N LINKW)

Linkpak-W calibration software has been developed to help meet

the growing demand on industry to comply with quality systems

and calibration documentation. Test

procedures are created in a Windows based

application and devices due for calibration

are reported and grouped into work orders

for transfer to one of three calibrators, the

DPI 605, TRX-II and the MCX. Calibration

results, including files from the DPI 610, are uploaded to the PC via

the RS 232 interface or PCMCIA card, for analysis and to print

calibration certificates.

(A2) Intecal-W calibration database software (P/N INTEW)

Intecal-W Windows based soft ware builds on the basic concept of

Linkpak-W supporting both portable field

calibrators and on-line workshop calibrators.

Manual data entry is also a key feature for

recording data. Intecal-W is an easy to learn

and easy to use calibration management

software for process plants, workshops,

contractors, manufacturers and service companies. It offers high

productivity of calibration scheduling, calibration work and

documentation. Device information, calibration procedures and

calibration results are stored in an instrument database and multiple

databases can be created for organizing client accounts, processes

or areas. Extensive management features are provided including a

database search engine, time based calibration due queries and

standard reports.

RELATED PRODUCTS

Intecal calibration management software

Intecal Windows

®

based software builds on the basic concept of

Linkpak W supporting laboratory and field calibrations with extensive

management and analysis features. Intecal interfaces with a range of

instruments and offers a complete solution to calibration management.

Portable field calibrators

Druck manufactures a wide range of portable pressure, temperature and

electrical field calibrators. A selection of these are shown below.

Laboratory and workshop instruments

Druck also manufactures a comprehensive range of pressure indicators

and controllers. Included in this range are the Pressurements industrial

deadweight testers and the Ruska high precision controllers and primary

standard piston gauges.

Pressure transducers and transmitters

Druck instruments complement an extensive range of pressure

transducers and transmitters, utilized in a variety of aerospace,

automotive, depth level and process applications.

Please refer to manufacturer for further information on related products.

ORDERING INFORMATION

Please state the following (where applicable):

1. TRX II type number.

2. Options, including part numbers. For remote pressure sensors please

also state the pressure range required.

Note: Options should be ordered as separate items.

Continuing development sometimes necessitates specification

changes without notice.

Loading...

Loading...