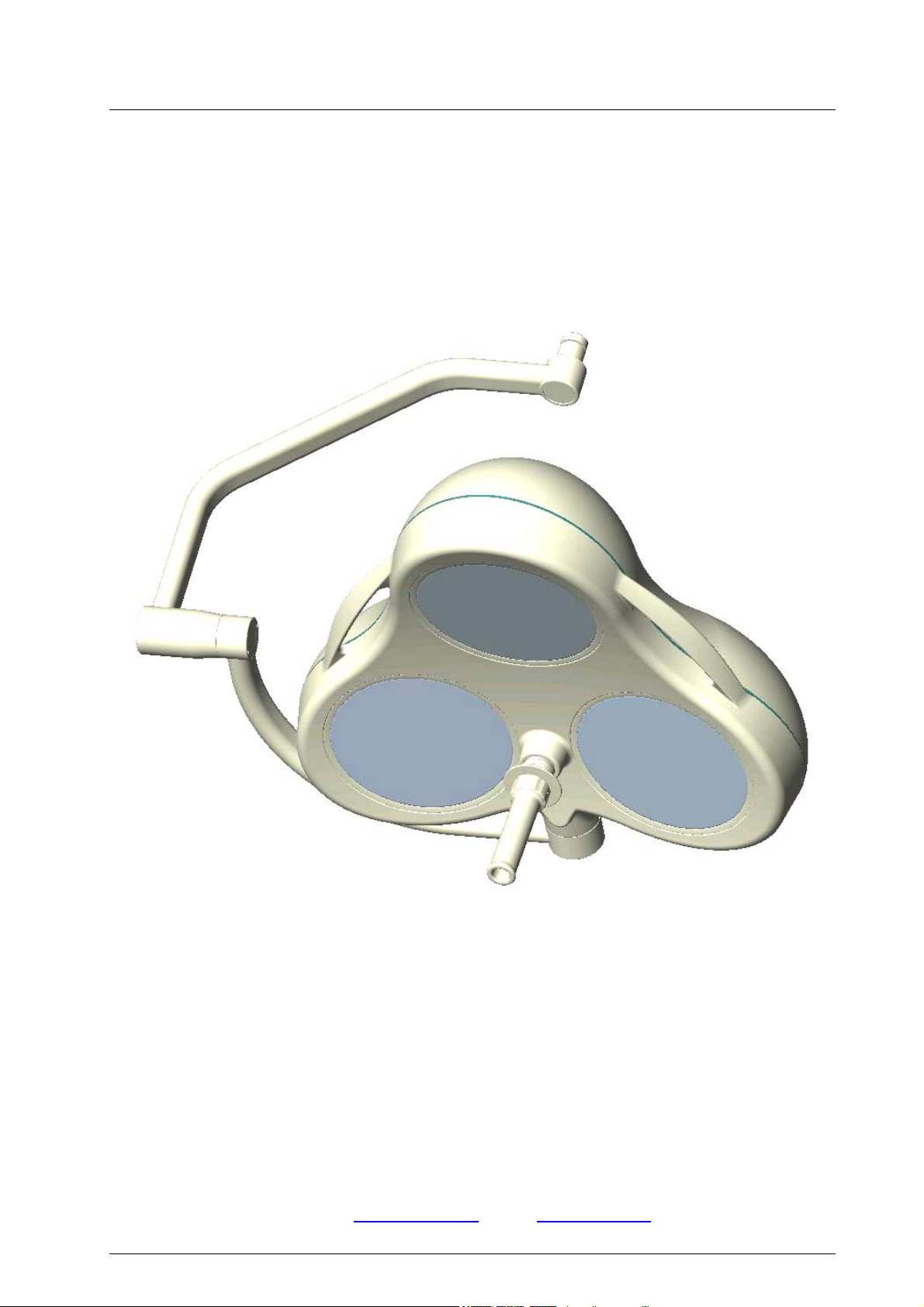

Mach M3

Dr. Mach

Lamps and Engineering

Operating instructions

MACH M3

Mach M3 stand lamp, F- / F/H / DF- / DF/H-model

Mach M3 emergency stand lamp, F- / F/H /DF- / DF/H-model

Mach M3, wall lamp, F- / F/H / DF- / DF/H-model

Mach M3 ceiling lamp for room heights up to 2,8m, F- / F/H / DF- / DF/H-model

Mach M3 ceiling lamp for room heights between 2,8m – 3m, F- / F/H / DF- / DF/H-model

Dr. Mach GmbH u. Co., Floßmannstrasse 28, D-85560 Ebersberg

Tel.: +49 (0)8092 2093 0, Fax +49 (0)8092 2093 50

Internet: www.dr-mach.com, E-mail: info@dr-mach.de

59200001 Edition 06 28.11.2002 / Bak page 1/22

Mach M3

Dr. Mach

Lamps and Engineering

List of contents

1. Safety instructions ....................................................................................page 4

2. Operating the lamp MACH M3..................................................................page 5

2.1 Brief description of the lamp...............................................................page 5

2.1.1 Merging of light fields (F-model)..................................................page 5

2.1.2 Focusing (DF-model) ..................................................................page 5

2.1.3 Light intensity control (/H-model).................................................page 5

2.2 Adjusting the illuminated area by........................................................page 6

merging of light fields (for F and F/H-models)

2.3 Adjusting the illuminated area by........................................................page 6

merging of light fields and focusing –

Duo Focus system (for DF and DF/H-models)

2.4 Overview of the lamp functions ..........................................................page 7

2.5 Adjusting the light intensity.................................................................page 8

2.6 Positioning..........................................................................................page 9

3. Cleaning ...................................................................................................page 10

3.1 Sterilisable handle ..............................................................................page 10

3.2 Lamp housing, dispersing lens and support system...........................page 12

4. Maintenance .............................................................................................page 12

4.1 Adjustments at the lamp head............................................................page 12

4.2 Removing the upper housing part ......................................................page 13

4.3 Changing of spare parts .....................................................................page 14

4.3.1 Changing the halogen bulbs........................................................page 14

4.3.2 Changing the dispersing lens ......................................................page 15

5. Data..........................................................................................................page 16

5.1 Electrical data.....................................................................................page 16

5.2 Environmental conditions ...................................................................page 16

6. CE-mark ...................................................................................................page 16

7. Disposal....................................................................................................page 16

8. Spare parts...............................................................................................page 17

9. Spare parts list..........................................................................................page 19

10. Appendix: Setting the primary voltage at the block transformer

300VA (extra) ........................................................................page 20

59200001 Edition 06 28.11.2002 / Bak page 2/22

Mach M3

Dear customer!

Congratulations for achieving our new OT-lamp MACH M3.

The MachVISION optical system provides an illuminated field with improved contrast and

excellent homogeneity. Combined with the Duo-Focus feature this offers a unique possibility

for adaptation to the wound area.

With this lighting system you profit from a whole range of new developments, based on 50

years of experience in the production of operating and doctor’s lights.

The lighting system is characterised by a previously inconceivable general colour rendition

value of Ra = 96. In other words, the colours are reproduced naturally and in high

contrast. The wound area is shown in a comfortable light.

The different reds of a wound area can now be recognised very precisely. For the doctor or

surgeon this means a considerable improvement in the recognition of details in the wound

area.

The R96 lighting system uses computer-optimised cold-light filters that reduce both the

unwanted build-up of heat in the head area and the heat radiated on the illuminated

wound area to a minimum.

Pay attention to the special mounting instructions for ceiling and wall lamps.

All information quoted here relates only to the illuminants. Details of ceiling or wall installation

can be found in the mounting instructions.

Dr. Mach

Lamps and Engineering

59200001 Edition 06 28.11.2002 / Bak page 3/22

Mach M3

Dr. Mach

Lamps and Engineering

1. Safety instructions

Pay attention to the instructions for use when handling the lamp.

WARNING:

This device has not been designed for use in potentially explosive areas.

According to the Medical Device Regulation the lamp is classified under class I.

Store the OT-lamp in its package for at least 24 hours in the respective room before

mounting, in order to equal temperature differences.

Please read the instructions for use carefully to make the most of your lighting

system and to avoid any damages to the device.

The lamps may only be repaired and special assembly work may only be carried

out on the reflector or sockets by ourselves or a company that has been expressly

authorised by us.

The manufacturer can only be made responsible for the safety of the lamp if

repairs and alterations are carried out by the manufacturer himself or a company

that guarantees to observe the safety regulations.

The manufacturer cannot be made liable for personal or material damages if the

lamp is operated inexpediently or incorrectly or used for purposes other than

those for which it is intended.

The lamp is to be dismantled from the spring arm in reverse order to its assembly.

This may only be carried out after the assembly-locking device has been inserted

and secured since the arm is under spring tension.

Make sure that the lamp is in perfect working order before every use.

Attention, external transformer!

The lamp works only with an external transformer 300VA.

The external transformer (Order No. 6701 0208) must be tested and validated

according to IEC 60601-1.

If the external transformer is not tested and validated according to IEC 60601-1, it

is not allowed to use it with Dr. Mach OT-lamps.

59200001 Edition 06 28.11.2002 / Bak page 4/22

Mach M3

2. Operating the lamp MACH M3

2.1 Brief description of the lamp

The OT-lamp MACH M3 is available in following versions:

- Standard OT-lamp (F) with merging of light fields

- Duo-Focus OT-lamp (DF) with merging of light fields and focusing

- F- or DF- lamps with light intensity control (/H)

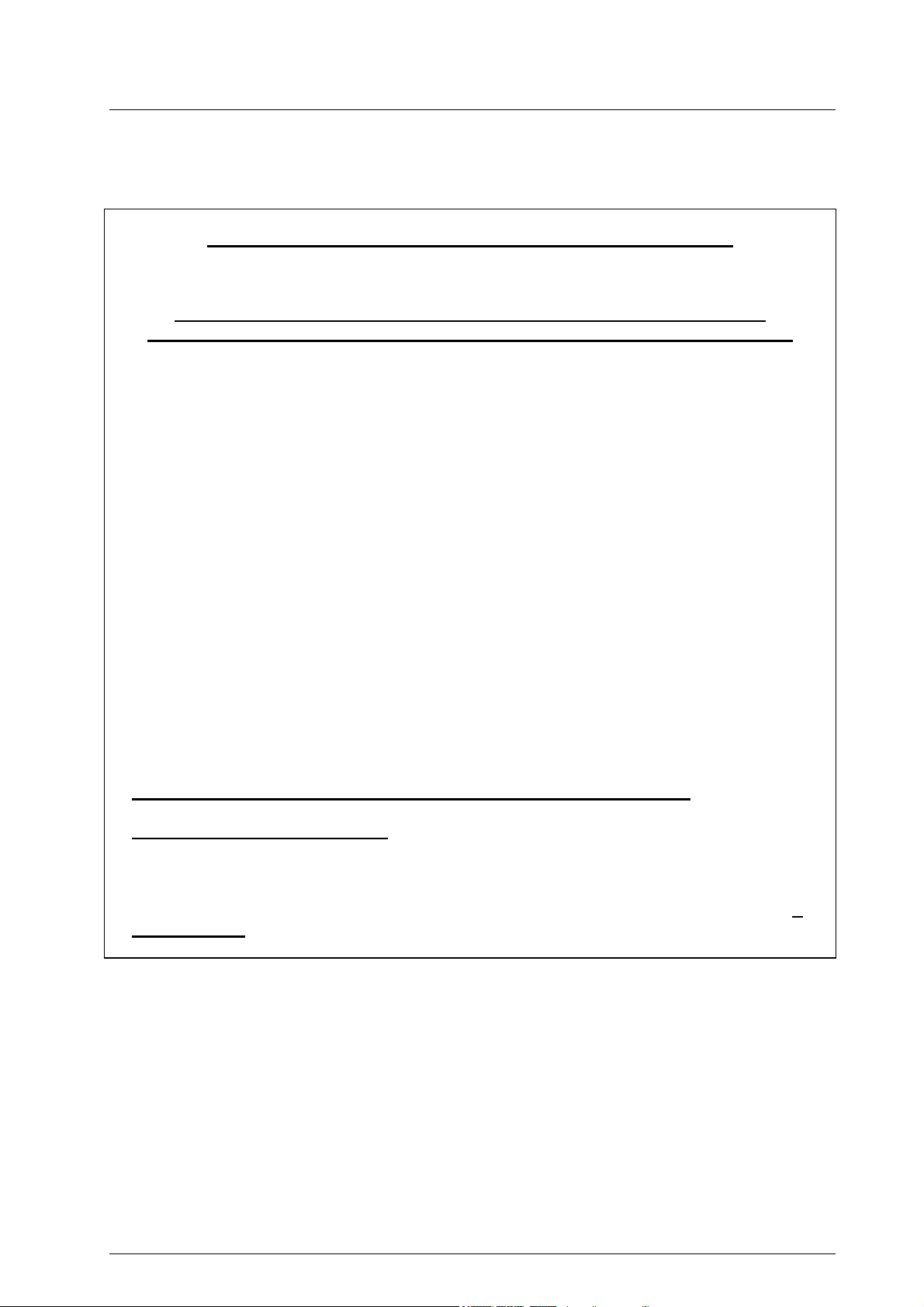

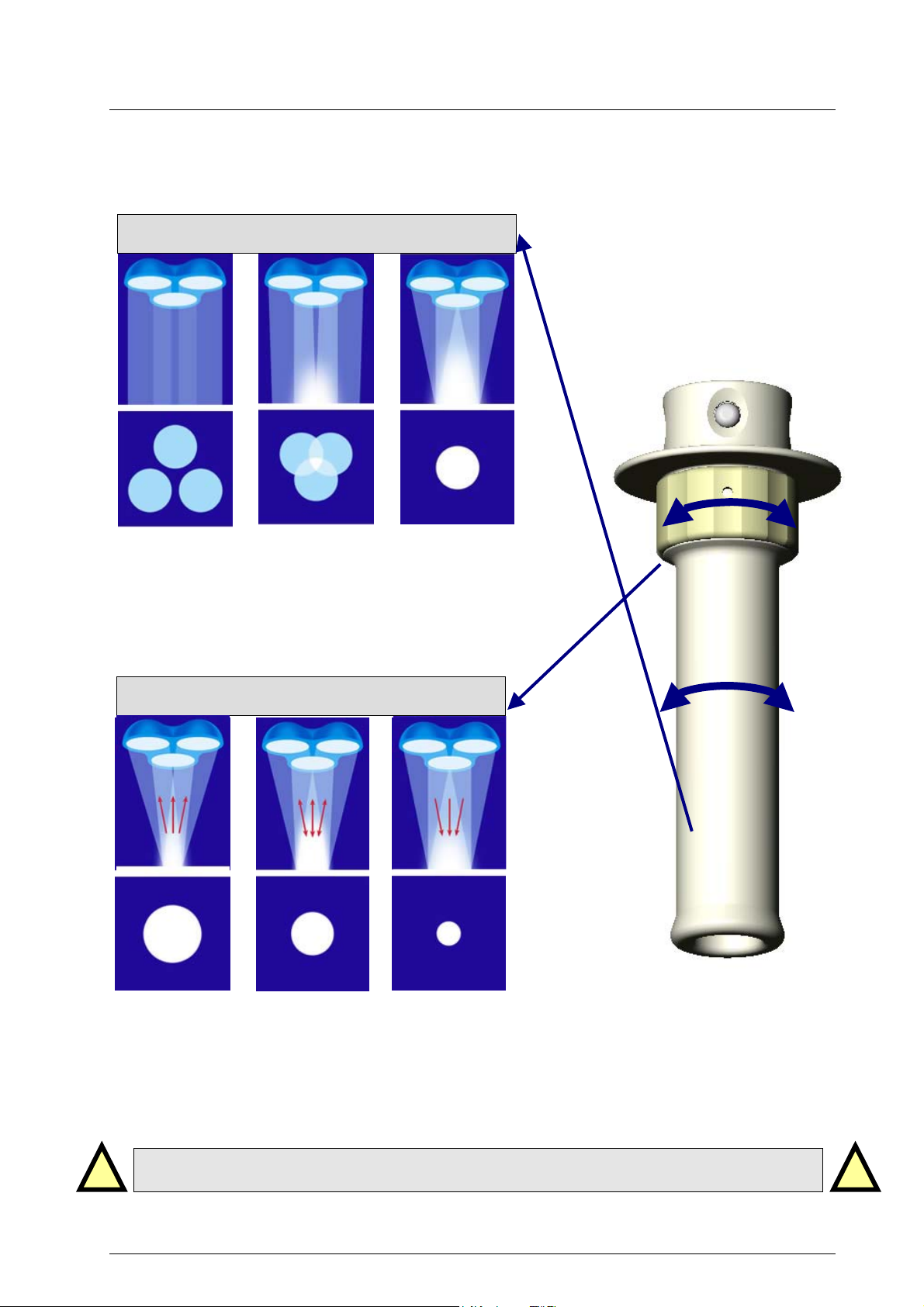

2.1.1 Merging of light fields

(F- model)

The F-model offers light field adjustment by

merging the individual light fields of each

reflector by swivelling them.

NOTE: This feature is activated by turning the

sterilisable handle.

Dr. Mach

Lamps and Engineering

2.1.2 Focusing (DF- model)

The DF-model offers a second additional

facility to further adjust the illuminated field to

an extra small or extra large size, depending

on the specific requirements, by focusing

through moving the bulbs up or down.

NOTE: This feature is activated by turning the

ring at the top of the sterilisable handle.

2.1.3 Light intensity control (/H- model)

The OT-lamp models offer an optional feature, the light intensity control.

You can adjust the light intensity between 50% and 100%, according to your requirements.

59200001 Edition 06 28.11.2002 / Bak page 5/22

Mach M3

Dr. Mach

Lamps and Engineering

2

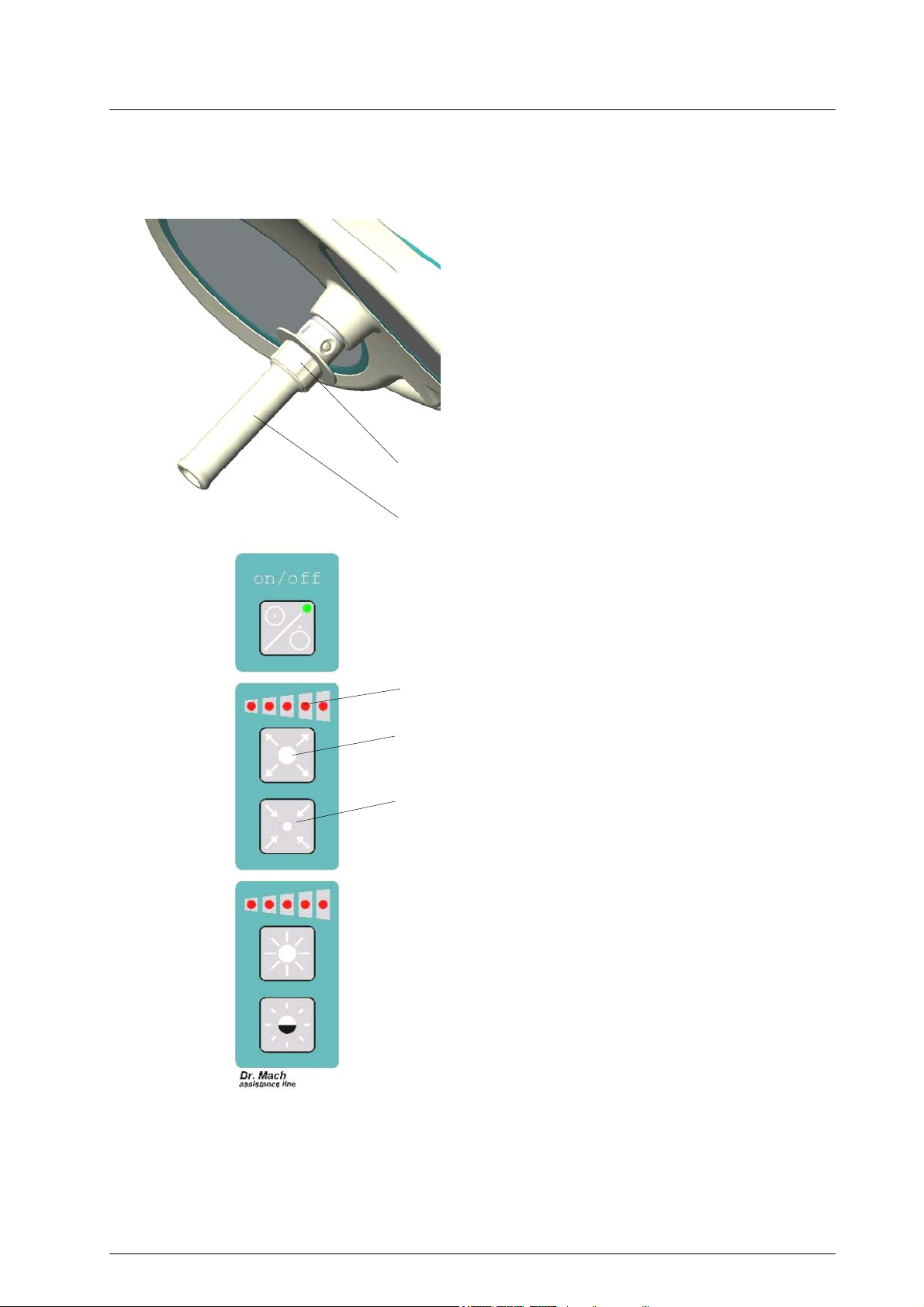

2.2 Adjusting the illuminated area by

merging the light fields

(for F and F/H-models)

All F and F/H lamp models offer the feature of

“merging the light fields”. This feature is activated by

turning the sterilisable handle 1.

Remark:

The ring 2 has no function here.

1

2.3 Adjusting the illuminated area by

merging the light fields and

focusing – Duo-Focus system

(for DF and DF/H models)

DF- and DF/H-models also have a “focusing”

function (Duo-Focus).

4

5

6

The combination of merging of light fields and

focusing (Duo-Focus-system) enables the ideal

adjustment of the light field to the wound area in a

range from 8 cm to 35 cm diameter. Such a large

range of adjustment is not possible with conventional

technique.

To activate the focusing function turn the adjusting

ring 2 on the handle or, -if the lamp is equipped with

a keypad at the cardan bow (for DF/H-models) –

press touch buttons 5,6.

Press touch button 5 to expand the focus and touch

button 6 to bundle the light on a minimum area. The

current focused diameter is shown in the LED-display

4.

59200001 Edition 06 28.11.2002 / Bak page 6/22

Mach M3

MERGING OF LIGHT FIELDS

2.4 Overview of the lamp functions

Merging of light fields and focusing

Dr. Mach

Lamps and Engineering

Merging the individual light fields of each reflector

is done by swivelling the reflectors. The light fields

overlap.

This feature is activated by turning the sterilisable

handle (1).

FOCUSING

Ring (2)

Handle (1)

Focusing is done by moving the bulbs inside the

reflectors up or down. In this way you can further

adjust the illuminated field to an extra small or extra

large size, depending on the specific requirements.

This feature is activated by turning the ring (2) at the

top of the sterilisable handle.

Always activate merging of light fields first by turning the handle (1), then activate

focusing when necessary by turning the ring (2)

59200001 Edition 06 28.11.2002 / Bak page 7/22

!!

Mach M3

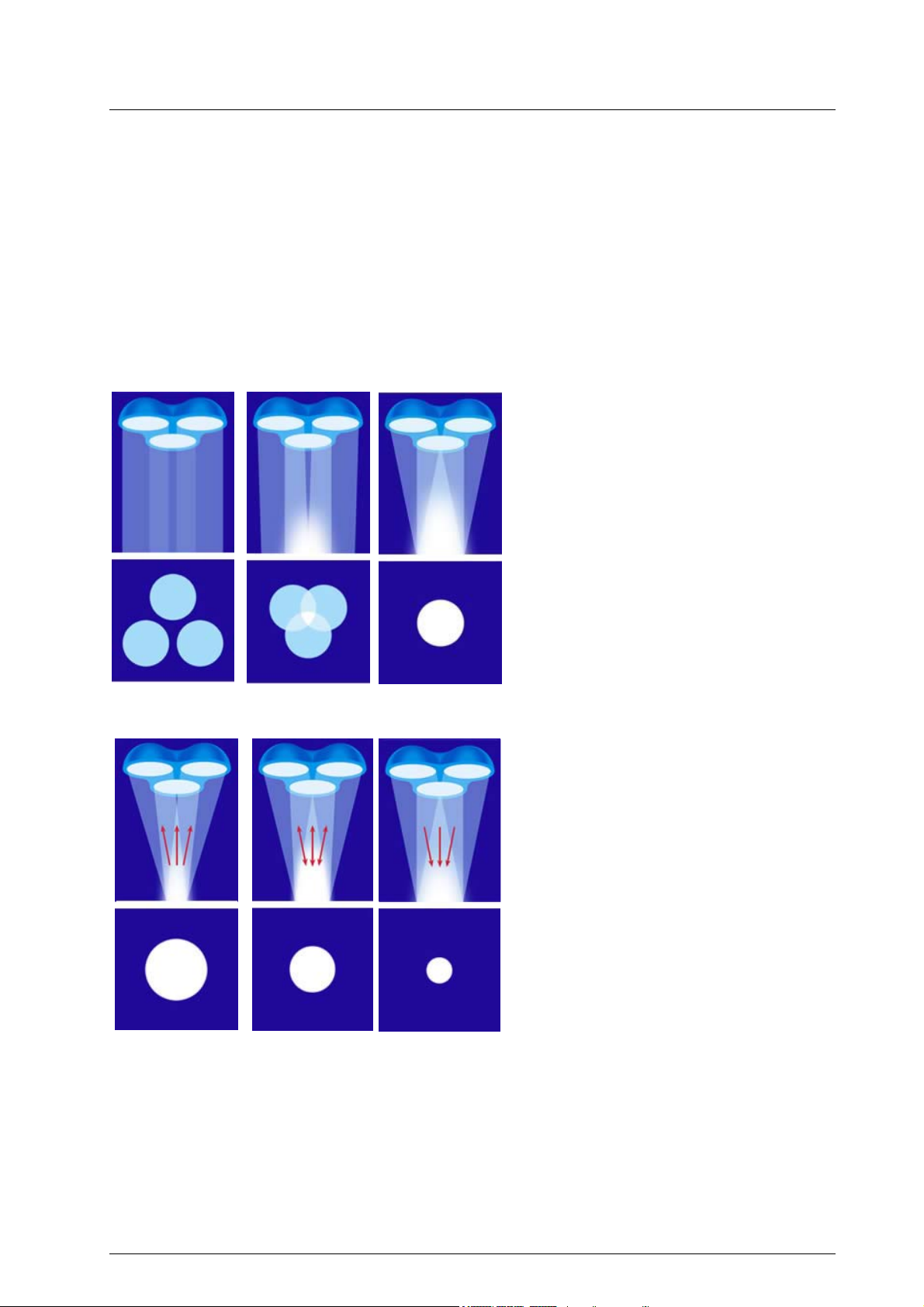

Key pad

1

2

3

Dr. Mach

Lamps and Engineering

2.5 Adjusting the light intensity

(for F/H and DF/H models only)

Select the desired light intensity before the

operation.

At these models the adjustment is done by the

keypad at the cardan bow. The intensity can be

infinitely adjusted between 50% and 100%.

Press push button 2 to increase the light intensity

and press push button 3 to reduce the light intensity.

The light intensity set is shown by LED-display 1.

For other light models we recommend a dimmer in

the supply line.

59200001 Edition 06 28.11.2002 / Bak page 8/22

Mach M3

2.6 Positioning

1

Dr. Mach

Lamps and Engineering

1

Use the sterile handle 2 or the handle rails 1 to

position the lamps.

Use the handle rail to position the lights before the

operation.

Use the sterile handle for positioning during the

operation. This handle can be removed for

sterilization.

2

1,4m

(1,5m)

1m

0,7m

(0,6m)

0

The working distance of the F-lamps is 0,7m to

1,4m.

The working distance of the DF-lamps is 0,6m to

1,5m.

The handle is supplied with a detectable mechanical

catching. When the handle catches in this position,

the lamp is optimally set for a working distance of 1

meter.

Two or more lamps can be used for an intensive

illumination of large operation fields.

It is also possible to illuminate two operation fields

simultaneously.

59200001 Edition 06 28.11.2002 / Bak page 9/22

Mach M3

Dr. Mach

Lamps and Engineering

3. Cleaning

V

1

Cleaning / disinfection and sterilisation

Basics

Efficient cleaning / disinfection is an essential requirement for effective sterilisation of the handle.

Within the scope of responsibility for the sterility of the products it should be noted that only sufficiently

validated equipment and product specific processes are used for cleaning / disinfection and that the

validated parameters are complied with in every cycle.

In addition, the hospital / clinic hygiene regulations must be observed.

Cleaning / disinfection

Cleaning and disinfection must be carried out immediately after use.

A mechanised process (disinfector) should be used for cleaning / disinfection. The efficiency of the

process used must be recognised and validated in principle (e.g. listed under disinfectants and

disinfection procedures tested and recognised by Robert-Koch-Institute / DGHM).

When using other procedures (e.g. a manual procedure), proof and process efficiency in principle must

be provided within the scope of validation.

Proof in principle of the suitability of the handles for efficient cleaning / disinfection was provided using a

cyclic cleaning system (Netsch-Bellmed T-600-IUDT/AN, programme 2 for small parts; code B).

It is not allowed to use agents / disinfectants, which contain the following substances, as these may

cause changes in the material:

- High-concentration organic and inorganic acids

- Chlorinated hydrocarbons

- 2-ethoxyethanol

3.1 Sterilisable handle

At delivery the lamp is equipped with the handle

sleeve 1. The handle sleeve is removable and

sterilisable. Before using the first time and before

every use the handle sleeve must be cleaned,

disinfected and sterilised.

The handle sleeve must be removed for sterilisation:

• To remove press the lock V and pull off the

sterilisable handle sleeve 1 while keeping the

lock pressed.

• To attach, push on and slightly twist the handle

until the lock V engages securely.

Handles often become unsterile during an OP;

therefore always keep additional handles available

for exchange.

59200001 Edition 06 28.11.2002 / Bak page 10/22

Mach M3

Dr. Mach

Lamps and Engineering

When cleaning / disinfecting, the following procedures must be followed:

Process Time (sec.)

Zone 1 Pre-rinse, external, cold, 10 – 15°C 45 Washing, acidic, external 35°C 120 Draining time 10 Re-rinse, external approx. 80°C *10 Draining time *15 Re-rinse, external approx. 80°C *15 Draining time 15

Zone 2 Washing, alkaline, external, 93°C 135 Draining time 10 Re-rinse, external, acidic, 90°C 10 Draining time 15 Re-rinse, external 90°C 15 Draining time 15

Zone 3 Drying, external 100 – 120°C 200

Zone 4 Drying, external 100 – 120°C 200

Door open / close & transport 60 (sluice discharge)

Cycle time overall ca. 290

* When occupying the disinfection zone (washing zone 2), the re-rinse and draining times will depend on

the respective objects being washed therein!

≈ 5 minutes

Sterilisation

Only previously cleaned and disinfected handles may be sterilised.

The handles are placed in a suitable sterilisation pack (one-way sterilisation pack, e.g. foil / paper

sterilisation bags, single or double pack) in accordance with DIN EN 868 / ISO 11607 for steam

sterilisation and then sterilised.

Use only the sterilisation procedure listed below for sterilisation. Other sterilisation procedures (e.g.

ethylene oxide, formaldehyde and low-temperature plasma sterilisation) are not permissible.

Steam sterilisation procedure

Validated in accordance with DIN EN 554/ISO 11134

Maximum sterilisation temperature 134°C

Proof in principle of the handles’ suitability for effective sterilisation was provided using a fractional

vacuum process (Euroselectomat 666 by MMM Münchner Medizin Mechanik GmbH, sterilising

temperature 134°C, holding time 7 min.)

Inspection / durability

The handles should be inspected for damage and changed before re-use, if required.

The handles may be cleaned / disinfected, sterilised and re-used for a maximum of 1000 times. If the

handles are re-used more than 1000 times, then this will be the responsibility of the hospital / clinic.

59200001 Edition 06 28.11.2002 / Bak page 11/22

Mach M3

Alc. ≤ 20 %

2

Dr. Mach

Lamps and Engineering

3.2 Lamp housing, dispersing lens

and support system

The OT-lamp MACH M3 has a high-quality surface,

which can be cleaned with conventional cleaning

agents.

The lens system 2 is made of a high-quality plastic.

Pay attention to the following during cleaning:

- Never wipe over the lens system 2 with a dry

cloth (always clean with a wet cloth).

- Only use disinfectants with less than 20%

alcohol.

Wipe the lens system 2 after cleaning with an

antistatic, non-fluffy cloth.

4. Maintenance

MACH lamps are supplied with brakes on the suspension fixture and on the lamp housing. Adjust these

brakes as necessary after installation.

If the lamp is difficult to move or if it does not stay in position, the brake forces should be adjusted.

The lamps and suspension fixtures have been designed and built, so that regular maintenance intervals

are not necessary.

In order to keep the system easy running throughout its life span, we recommend that the hinges should

be greased once a year with acid-free grease.

When adjusting the brakes or the hinges at the ceiling attachment please consult the mounting

instructions “Ceiling attachment with heavy central axis” or “Ceiling / wall attachment”.

Upper housing part

3

4

4.1 Adjustments at the lamp head

The fine adjustment for handling the lamps can be

carried out at points 2 and 3.

To adjust the brakes use a screw driver with

appropriate size.

If you cannot adjust the brakes at points 2 and 3

anymore as tight as necessary, you will have to

replace them.

Remark:

In order to adjust brake 2, the upper housing

part must be removed.

59200001 Edition 06 28.11.2002 / Bak page 12/22

Mach M3

Dr. Mach

Lamps and Engineering

5

4.2 Removing the upper housing part

6

The upper housing part can be removed by turning

the turn-lock fastener 8.

7

The upper housing part has two markings, 6

(Lock) and 5 (Up). The notch 7 at the turn-lock

fastener 8 shows the open or close status of the

8

upper housing part.

5

Turn the turn-lock fastener 8 to the left over the

marking 5 until stop and hold it in this position.

8

Lift the upper housing part with the other hand at

the cardanic suspension 9 and remove it uniformly.

Be careful when removing the upper housing

part, do not damage the sealing profile 10!

9

Mount the upper housing part in reverse order:

Turn the turn-lock fastener 8 again to the left over

the marking 5 until stop and hold it in this position.

Put the upper housing part flush on the bottom

10

housing part.

Be careful when mounting the upper housing

part, do not damage the sealing profile 10!

Turn the turn-lock fastener 8 under slight pressure

on the upper housing part to the right until the

marking 6 (Lock).

Check by eye-control, if the upper housing part is

mounted uniformly on the bottom housing part of

9

the lamp.

59200001 Edition 06 28.11.2002 / Bak page 13/22

Mach M3

4.3 Changing of spare parts

1

3

2

4

Dr. Mach

Lamps and Engineering

4.3.1 Changing the halogen bulbs

Dr. Mach uses special halogen bulbs as illuminants.

Only original Dr. Mach replacement bulbs may

be used.

The use of other bulbs can lead to a considerable

reduction of the light power and increase in the

thermal load.

The halogen bulbs have a service life of approx.

1200 hours. We recommend changing all halogen

bulbs in a lamp at the same time to keep

maintenance work to a minimum.

• Turn off the lamp.

• Remove the upper housing part of the lamp as

described in chapter 4.2.

ATTENTION: Parts of the housing and the

halogen bulb may be very hot immediately

after use.

• Loosen the red knurled screw 1 and remove the

lamp socket 2 without removing the electrical

connection 3.

• Remove the faulty halogen bulb 4 from the

socket.

ATTENTION: Never touch new halogen bulbs

with your fingers. Always use the original

packaging or a clean cloth.

• Carefully insert the new halogen bulb

(22.8V/50W).

• Re-assemble the lamp in reverse order

59200001 Edition 06 28.11.2002 / Bak page 14/22

Mach M3

1

2

1

2

3

Dr. Mach

Lamps and Engineering

1

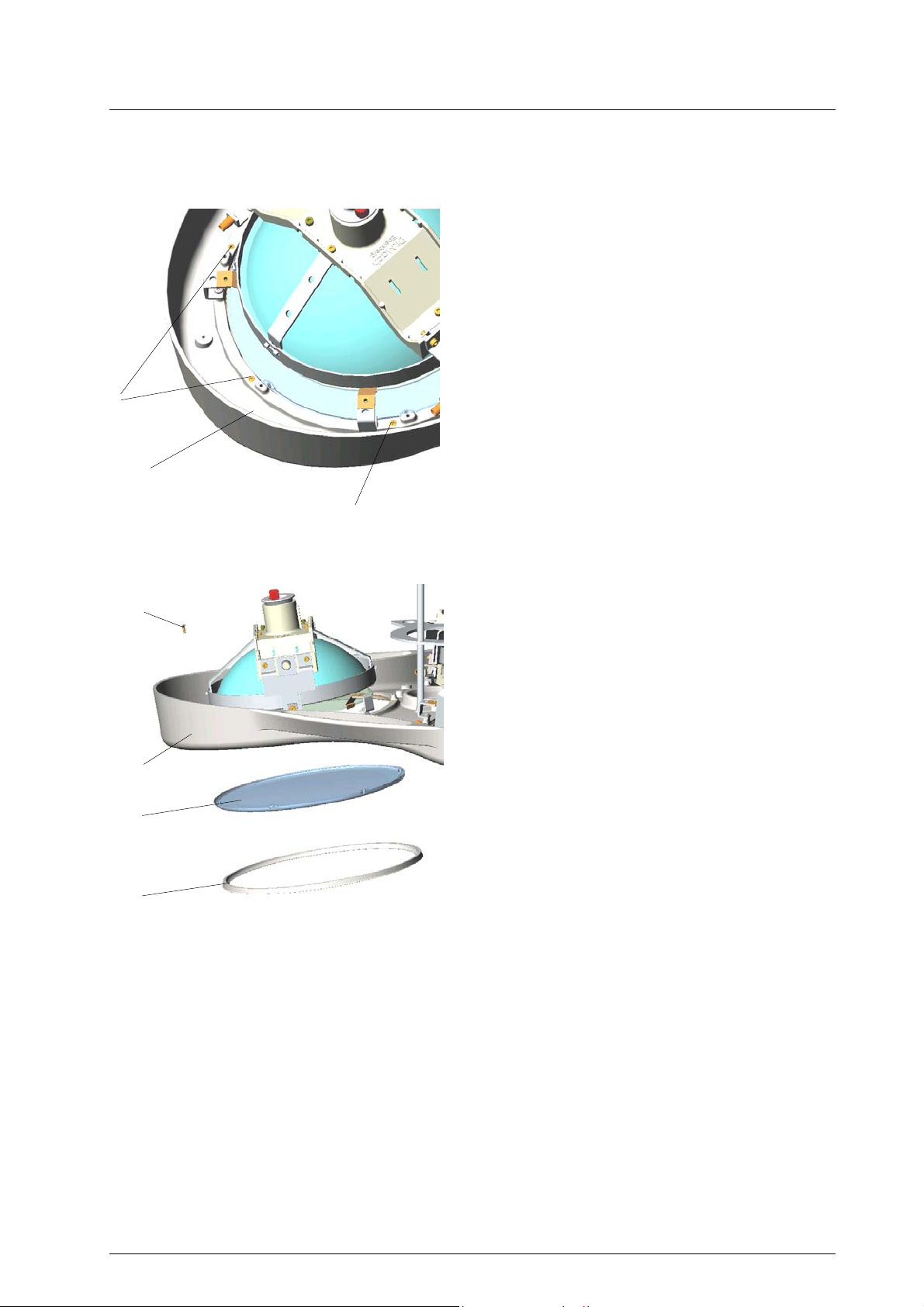

4.3.2 Changing the dispersing lens

The dispersing lens is made of a high-quality plastic.

In case the dispersing lens looses its optical

characteristics, this can reduce the luminous

intensity and the light quality, which can be provided.

It may be necessary to exchange the dispersing

lens.

To change the dispersion lens proceed as follows:

Always place the dispersing lens on a soft, nonscratching base to preserve its surface.

• Turn off the lamp.

• Remove the upper housing part of the lamp as

described in chapter 4.2.

ATTENTION: Parts of the housing may be

very hot immediately after use.

• Loosen the six screws 1 at the bottom housing

part 2 with a cross screw driver.

ATTENTION: Hold the dispersing lens 3 and

the retaining ring 4 while loosening the

screws 1, so the lens and the ring cannot fall

down.

• Remove the dispersing lens 3 and the retaining

ring 4 downwards.

• Replace the dispersing lens.

• Fix the dispersing lens and the retaining ring at

the bottom part of the lamp housing.

ATTENTION: Secure the screws 1 against

loosening with safety lake and adhesive at the

screw head.

4

59200001 Edition 06 28.11.2002 / Bak page 15/22

Mach M3

5.1 Electrical data

Dr. Mach

Lamps and Engineering

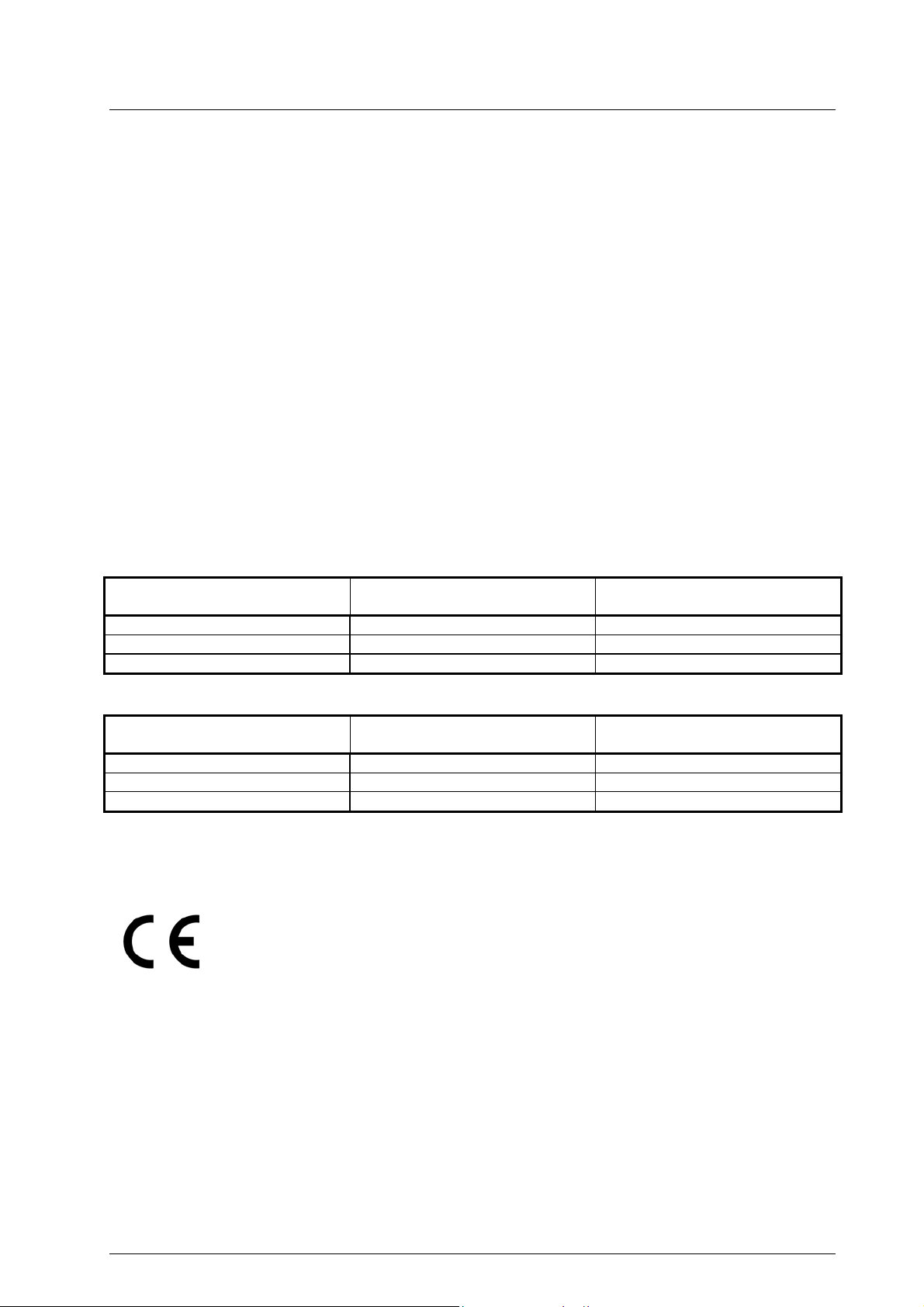

5. Data

Power consumption

Voltage AC/DC

Current

Frequency

Degree of protection

Class of protection

Mach M3

150 W to max. 162 W, depending on design

22,8 V

6,5 A to max. 7,1 A

50 / 60 Hz

Type B

I.

Standards IEC 601-1

5.2 Environmental conditions

Operation

Temperature +10°C +40°C

Relative atmospheric humidity 30 % 75 %

Air pressure 700 hPa 1060 hPa

Transport / storage

Temperature -10°C +50°C

Relative atmospheric humidity 20 % 90 %

Air pressure 700 hPa 1060 hPa

Min. Max.

Min. Max.

6. CE-mark

The products Mach M3 comply with the standards 93/42/EEC for medical products of the

European Community’s Council.

Dr. Mach GmbH is certified according to DIN EN 46001:1996 and DIN EN ISO 9001:1994

by TÜV München.

7. Disposal

The OT-lamp doesn’t contain any danger goods.

The components of the OT-lamp should be properly disposed at the end of its shelf-life.

Make sure, that the materials are carefully separated.

The electrical conducting boards should be submitted to an appropriate recycling proceeding.

The rest of the components should be disposed according to the contained materials.

59200001 Edition 06 28.11.2002 / Bak page 16/22

Mach M3

Dr. Mach

Lamps and Engineering

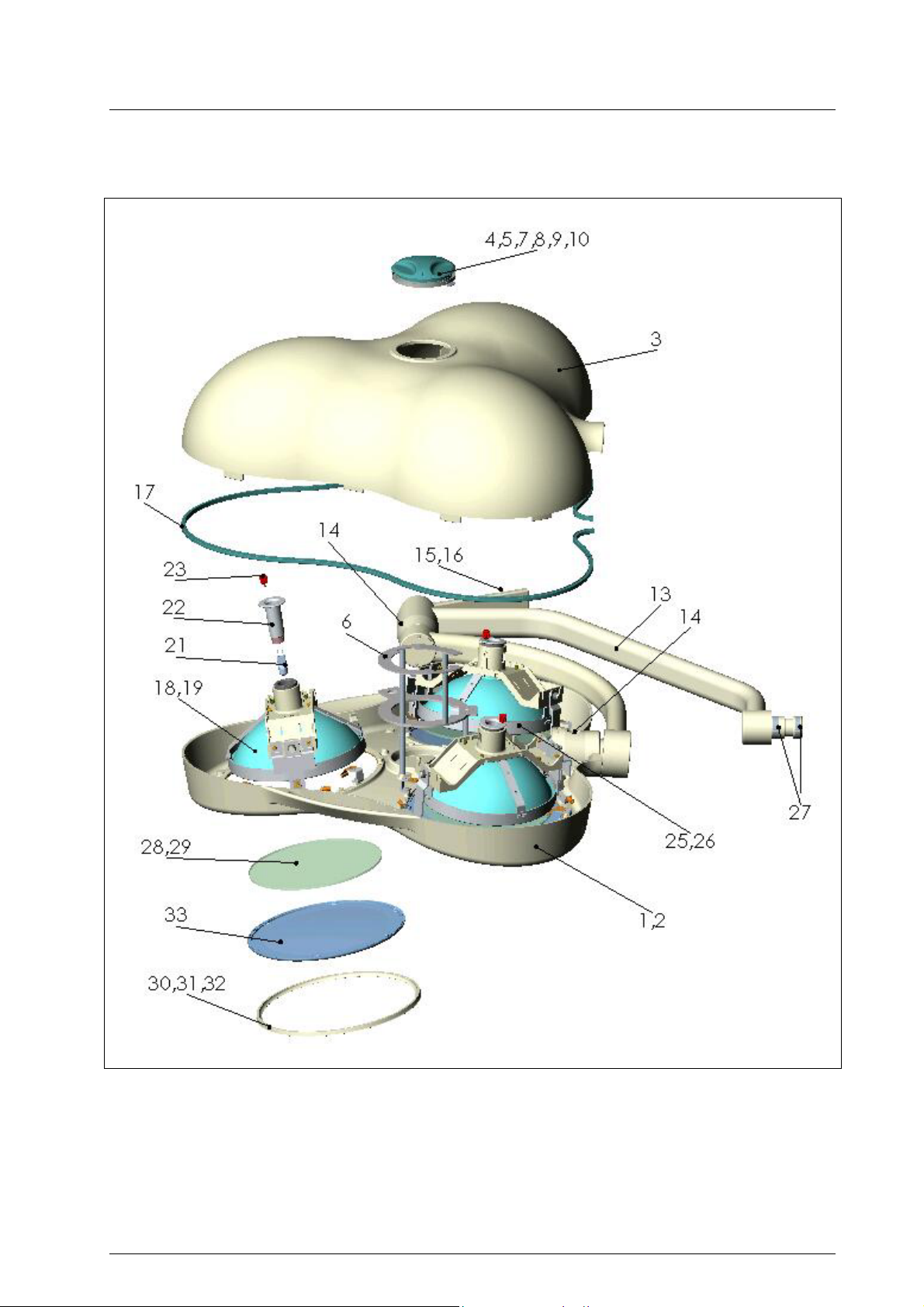

8. Spare parts

59200001 Edition 06 28.11.2002 / Bak page 17/22

Mach M3

Dr. Mach

Lamps and Engineering

8. Spare parts - continuation

11 12 25

Bowden control

Detail A

Detail A

39 38 37 36 35

59200001 Edition 06 28.11.2002 / Bak page 18/22

40

Mach M3

Dr. Mach

Lamps and Engineering

9. Spare parts list

Item Qty. Name EDVNO Remarks

1 1 Lower housing part for lamp without camera 20012204

2 1 Lower housing part for lamp with camera 20012205

3 1 Upper housing part 20011201

4 1 Turn-lock fastener 20088209

5 1 Locking washer 20088201

6 1 Locking sheet metal 20089208

7 1 Adjusting sheet metal 0,5 20088205 alternative

8 1 Adjusting sheet metal 1,0 20088206 alternative

9 1 Adjusting sheet metal 1,5 20088207 alternative

10 1 Adjusting sheet metal 2,0 20088208 alternative

11 1 Sterilisable handle 21150002

1 Coupling DF for sterilisable handle 20220001 DF-model

12

13 1 Cardanic suspension

14 1 Brake screw M12

15 1 Keypad OPLT DF/H-model

16 1 Keypad holder 21115003

17 1 Sealing cord RAL 5018 20088211

18 3 Reflector unit DF 20060001 DF-model

19 3 Reflector unit F 20060002

20 12 Fixing screw M3x16 DIN 912

21 3 Halogen bulb 22,8V 50W 67100201

22 3 Socket for halogen bulb 67320007

23 3 Knurled screw 28060213

24 2 Fuse 0,63 AT 5x20 67370003

25 1 Dimmer module OPDIM V3.0 24080001 Check version and

26 1 PCB board OPDX-M3 V0.10 67250101 Check version and

27 1 Gear motor 67030105

28 3 Filter disk 23250201

29 12 Spring holder 20086001

30 3 Retaining ring

31 18 Fixing screw M3x10 DIN 912

32 18 Washer 65512017

33 3 Dispersing lens 21200201

34 1 Acrylic glass box for transformer 300VA 67610101 Accessory

Bowden control

35 1

36 1

37 1

38 1

39 6

40 1

1 Coupling F for sterilisable handle 20220002 F-model

1 Coupling DF-M for sterilisable handle 20220003 DF-M-model

65052012

with washer

number

number

65052078

with lock washer

Primary shaft 20080201

Screw M3x6:Ni ULF 65052002

Screw M3x6 DIN 912,

turned-to-size head

Tension bolt 20080206

Cable holder 67900006

Round stranded rope 20080202

28082203

59200001 Edition 06 28.11.2002 / Bak page 19/22

Mach M3

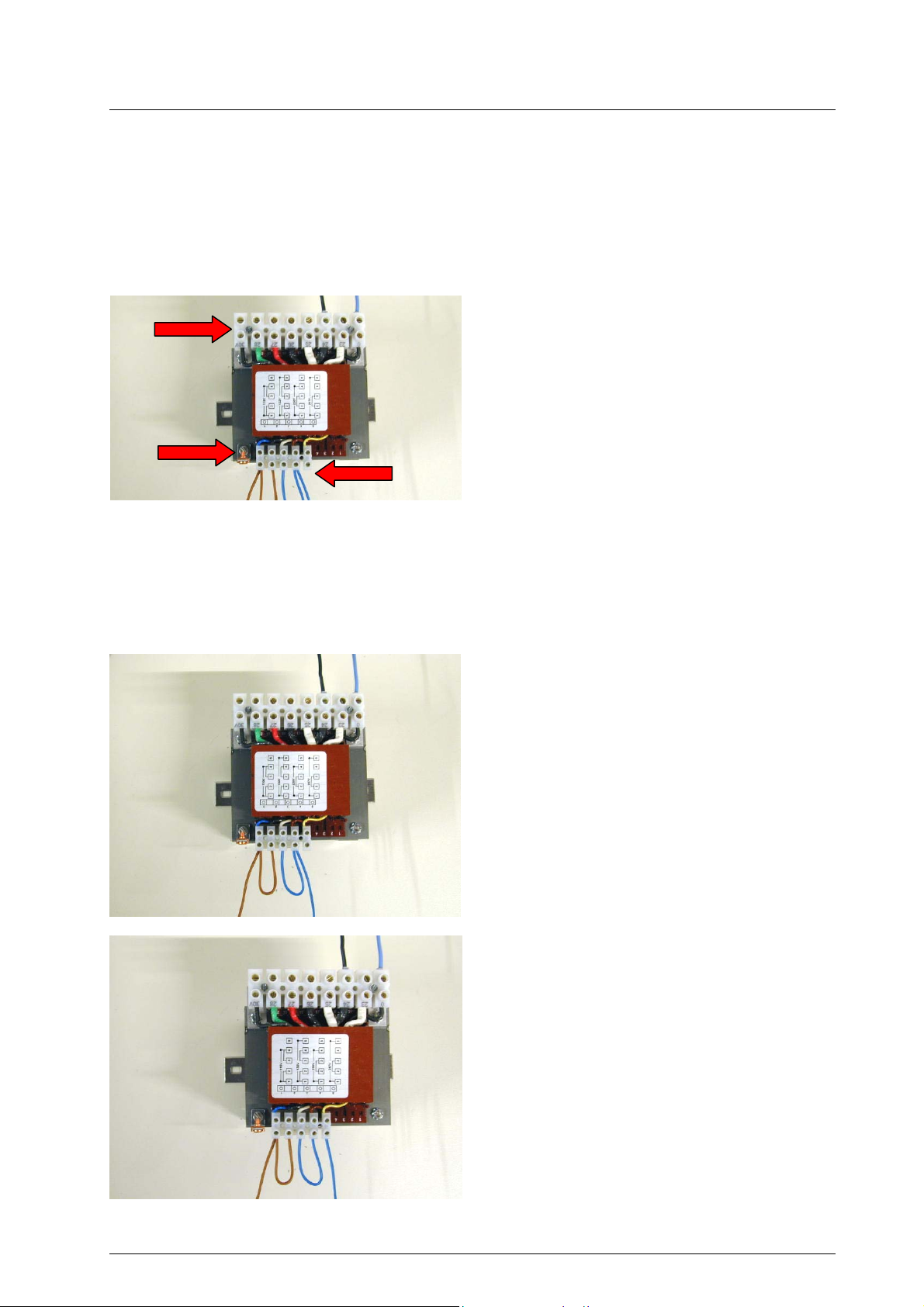

Setting the primary voltage at the

block transformer 300VA (extra)

Clamps on the transformer

Dr. Mach

Lamps and Engineering

10. Appendix

3

Pos.1 earthing connection at the

transformer

Pos.2 primary side

Pos.3 secondary side

1

2

• Connect the transformer to earth. Use the provided clamps pos.1 at the transformer, respectively at

the transformer plate.

See also the explanations on page 19/46 of the mounting instructions “Ceiling and wall

attachment” no. 59500001 / edition 05.

Overview of the possible settings of the primary voltage

Setting for115V

Setting for 132V

59200001 Edition 06 28.11.2002 / Bak page 20/22

Mach M3

Dr. Mach

Lamps and Engineering

Setting for 230V

Setting for 247V

59200001 Edition 06 28.11.2002 / Bak page 21/22

Mach M3

Dr. Mach

Lamps and Engineering

59200001 Edition 06 28.11.2002 / Bak page 22/22

Loading...

Loading...