MACH 130F/130 Ceiling, Wall, Stand model

Directions for use

MACH 130F/130

MACH 130F 22,8V UL

UNIFLEX R96 120V UL

Dr. Mach

Lamps and Engineering

Mach 130F;130 / Uniflex R96 120V UL stand-lamp - one-handed height adjustment

Mach 130F;130 stand-lamp – new type stand

Mach 130F;130F 22,8V UL;130 / Uniflex R96 120V UL wall lamp

Mach 130F;130F 22,8V UL;130 / Uniflex R96 120V UL single ceiling-lamp

Mach 130F;130F 22,8V UL;130 / Uniflex R96 120V UL combined ceiling-lamp

Dr. Mach GmbH u. Co., Flossmannstrasse 28, D-85560 Ebersberg

Tel.: +49 (0)8092 2093 0, Fax +49 (0)8092 2093 50

Internet: www.dr-mach.com, E-mail: info@dr-mach.de

59100001 Edition 12 07.02.2005 / Bak Page 1/28

MACH 130F/130 Ceiling, Wall, Stand model

Dr. Mach

Lamps and Engineering

List of contents

1. Safety instructions ............................................................................................... Page 3

2. Operating the lamp Mach 130/Uniflex R96 120V UL .......................................... Page 4

2.1 ON/OFF switch, light intensity control........................................................... Page 4

2.2 Positioning .................................................................................................... Page 5

2.3 Light field adjustment (focusing)................................................................... Page 5

3. Cleaning .............................................................................................................. Page 6

3.1 Sterilizable handle ........................................................................................ Page 6

3.2 Lamp head, protective disk........................................................................... Page 8

4.Maintenance......................................................................................................... Page 9

4.1 Adjustments at the ceiling/ wall attachment.................................................. Page 9

4.2 Adjustments at the stand model ................................................................... Page 10

4.3 Adjustments at the lamp head ...................................................................... Page 11

4.4 Changing of spare parts ............................................................................... Page 12

4.4.1 Changing the halogen bulbs ................................................................. Page 12

4.4.2 Changing the fuses (230V; 120V)......................................................... Page 13

4.4.3 Changing the ON/OFF switch (potentiometer) (before 10.2002) .......... Page 14

4.4.4 Changing the ON/OFF switch (potentiometer) (after 10.2002) ............. Page 15

4.4.5 Changing the filter disk ......................................................................... Page 16

4.4.6 Changing the protective disk................................................................. Page 17

4.4.7 Conversion to sterilizable handle .......................................................... Page 18

5. Data..................................................................................................................... Page 19

5.1 Technical data .............................................................................................. Page 19

5.2 Wiring............................................................................................................ Page 20

5.3 Environmental conditions.............................................................................. Page 21

6. Characteristics..................................................................................................... Page 21

6.1 Specification of bulb...................................................................................... Page 22

6.2 Specification of fuse...................................................................................... Page 22

6.3 CE-mark........................................................................................................ Page 22

7. Disposal............................................................................................................... Page 22

8. Spare parts.......................................................................................................... Page 23

8.1 Mach 130F 230V ceiling/wall/stand model - short arm................................ Page 23

8.2 Mach 130 230V ceiling/wall/stand model - short arm .................................. Page 24

8.3 Mach 130F/130 120V ceiling/wall/stand model - short arm ......................... Page 25

8.4 Uniflex R96 UL 120V* ceiling/wall/stand model - short arm ........................ Page 25

8.5 Mach 130F 22,8V ceiling/wall model ........................................................... Page 26

8.6 Mach 130F UL 22,8V ceiling/wall model* ................................................... Page 26

8.7 Short arm (stand model) ............................................................................... Page 26

8.8 SWING (stand model)................................................................................... Page 26

8.9 Spare parts list.............................................................................................. Page 27

* For spare parts of the ceiling and wall attachment see separate instructions for the UL- recog-

nised products.

59100001 Edition 12 07.02.2005 / Bak Page 2/28

MACH 130F/130 Ceiling, Wall, Stand model

Dr. Mach

Lamps and Engineering

1. Safety instructions

Please pay attention to the directions for use when handling the lamp.

Attention:

This device is not suitable for use in hazardous locations. The lamp is classified

as a Group 1 device according to the Regulations for EEMP.

Repairs to the lamp and special installation work on the reflector or plug-in socket should

only be carried out by ourselves or a company expressly authorised by ourselves.

The manufacturer is only responsible for the safety of the lamp if repairs and alterations

have been carried out by themselves or a company who can guarantee that the safety

regulations have been observed.

The manufacturer is not liable for personal or material damages if the lamp is misappropriately or incorrectly operated or misused.

Make sure that the lamp is in perfect working order before every use.

The lamps Mach 130F/130F 22,8V UL and Uniflex R96 120V UL may not be used

without the dielectric filter disk.

The dielectric filter disk between reflector and protective disk prevents a damaging heating

of the illuminated area.

The lamps Mach 130 may not be used without the conversion filter.

The lamp body may only be dismantled from swivel arm the (in reverse order to its assembly) after the arm has been secured since the arm is under spring tension.

Installation of Mach 130/130F with electronic transformer 230V

Installing the lamp connect the phase to the ON/OFF switch. The voltage of the neutral line

has to be less than low voltage.

59100001 Edition 12 07.02.2005 / Bak Page 3/28

MACH 130F/130 Ceiling, Wall, Stand model

Dr. Mach

Lamps and Engineering

2. Operating the lamp Mach 130/Uniflex R96 120V UL

20,21

or 67,68

Features of of Mach 130 / Uniflex lamps:

• Mach 130F with focusable light field size and

integrated dielectric filter disk

The reflector is adapted to the dielectric filter

disk.

• Mach 130 with fix-focus and integrated conversion filter

The reflector is adapted to the conversion filter.

• Mach 130F 22,8V UL with focusable light field

size and integrated dielectric filter disk.

The reflector is adapted to the dielectric filter

disk.

• Uniflex R96 120V UL with focusable light field

size and integrated dielectric filter disk.

The reflector is adapted to the dielectric filter

disk.

The lamp-types mentioned above are available as:

• Mach 130F/130 22,8V / external transformer

• Mach 130F/130 120V / integrated toroid trans-

former

• Mach 130F/130 230V / integrated electronic

transformer and light intensity control

• Uniflex R96 UL 120V / integrated toroid transformer

• Mach 130F UL 22,8V / external transformer

2.1 ON/OFF switch,

light intensity control

The push button switch 20/67 switches the lamp on

and off.

The lamps with integrated electronic transformer/

230V offer as an additional facility the function of

light intensity control.

To activate the function of light intensity control

turn the push-button switch 21/68.

At lamps with external transformer, in addition to

the push-button switch 20/67 a two-pole switch

ON/OFF must be provided by the customer.

59100001 Edition 12 07.02.2005 / Bak Page 4/28

MACH 130F/130 Ceiling, Wall, Stand model

GL

58,59

40 44

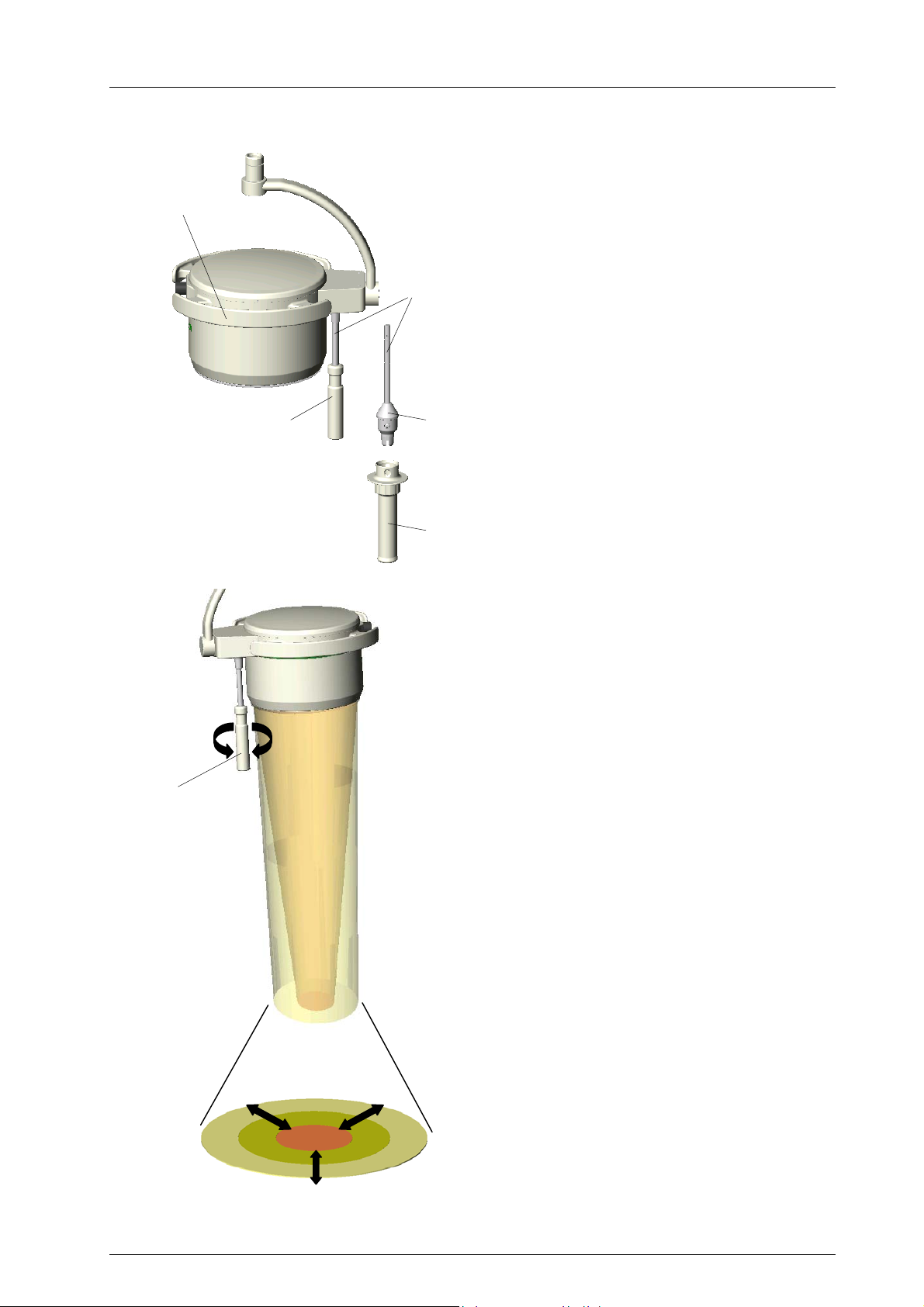

2.2 Positioning

Use the handle 40/45 or the handle rail GL to position the lamp.

There are two handle-types available:

• Standard handle 40

• Sterilizable handle 45

Dr. Mach

Lamps and Engineering

The standard handle is fixed to the handle bar

58/59 and can be removed.

The sterilizable handle can be removed for sterilisation. It is fixed by the couple 44 to the handle

bar 58/59.

40,45

45

2.3 Light field adjustment (focusing)

Mach 130F/130F 22,8V UL/

Uniflex R96 120V UL

The lamp-models Mach 130F/130F 22,8V UL and

Uniflex R96 120V UL have a focusing function. That

means, you can either enlarge the diameter of the

light field or bundle the light to a smaller area, depending on the circumstances.

To activate the function of focusing turn the handle

40/45 (see figure).

59100001 Edition 12 07.02.2005 / Bak Page 5/28

MACH 130F/130 Ceiling, Wall, Stand model

Dr. Mach

Lamps and Engineering

3. Cleaning

V

45

Cleaning / disinfection and sterilisation

Basics

Efficient cleaning / disinfection is an essential requirement for effective sterilisation of the handle.

Within the scope of responsibility for the sterility of the products it should be noted that only sufficiently

validated equipment and product specific processes are used for cleaning / disinfection and that the validated parameters are complied with in every cycle.

In addition, the hospital / clinic hygiene regulations must be observed.

Cleaning / disinfection

Cleaning and disinfection must be carried out immediately after use.

A mechanised process (disinfector) should be used for cleaning / disinfection. The efficiency of the process used must be recognised and validated in principle (e.g. listed under disinfectants and disinfection

procedures tested and recognised by Robert-Koch-Institute / DGHM).

When using other procedures (e.g. a manual procedure), proof and process efficiency in principle must

be provided within the scope of validation.

Proof in principle of the suitability of the handles for efficient cleaning / disinfection was provided using a

cyclic cleaning system (Netsch-Bellmed T-600-IUDT/AN, programme 2 for small parts; code B).

It is not allowed to use agents / disinfectants, which contain the following substances, as these may

cause changes in the material:

- High-concentration organic and inorganic acids

- Chlorinated hydrocarbons

- 2-ethoxyethanol

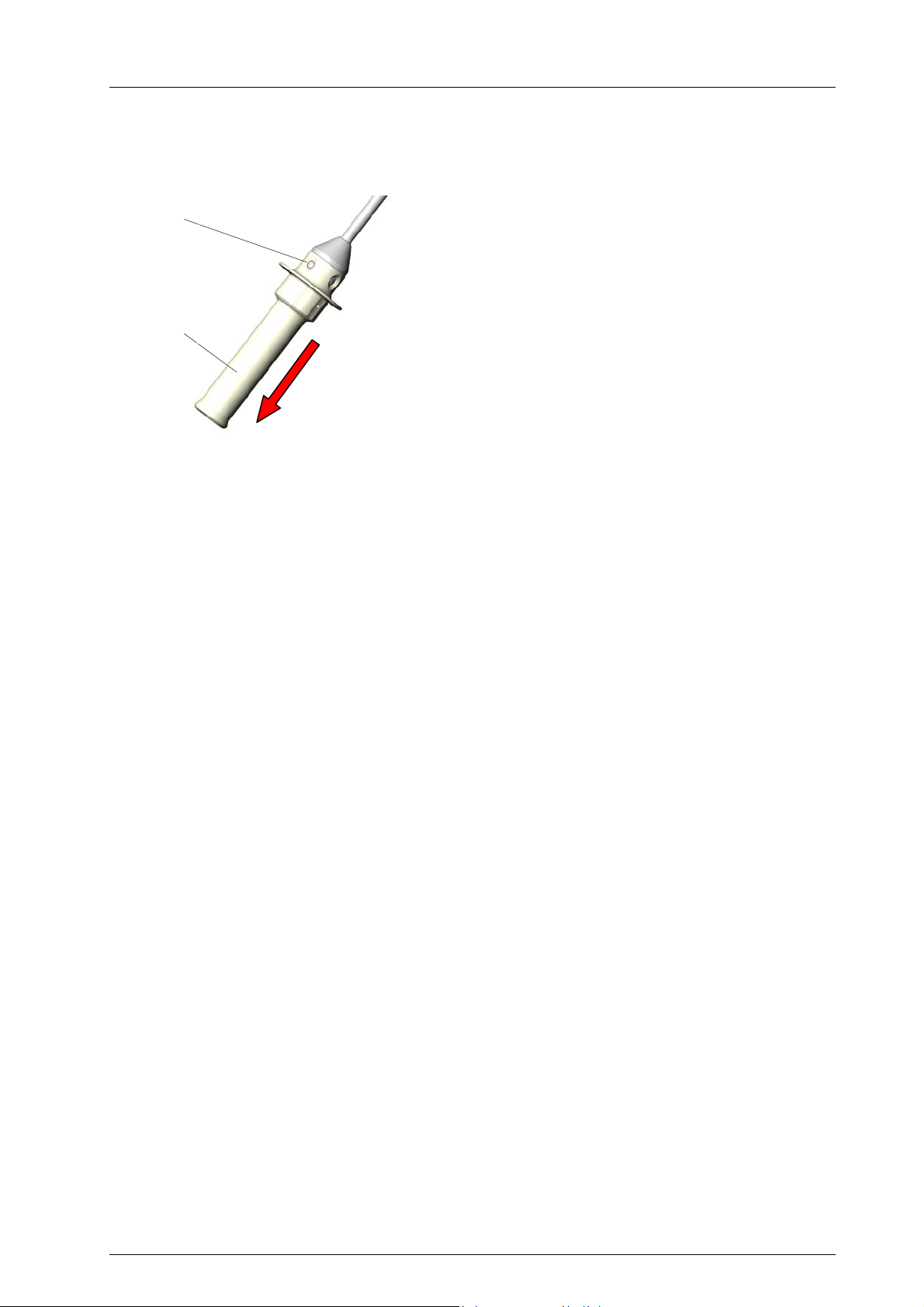

3.1 Sterilizable handle

The lamps Mach 130/Mach 130F 22,8V UL/Uniflex

R96 120V UL can be equipped as an option with a

sterilizable handle 45.

The sterilizable handle 45 is removable and sterilizable. Before using the first time and before every

use the handle sleeve must be cleaned, disinfected

and sterilised.

The handle sleeve must be removed for sterilisation:

• To remove press the lock V and pull off the

sterilisable handle sleeve 45 while keeping the

lock pressed.

• To attach, push on and slightly twist the handle

until the lock V engages securely.

Handles often become unsterile during an OP;

therefore always keep additional handles available

for exchange.

59100001 Edition 12 07.02.2005 / Bak Page 6/28

MACH 130F/130 Ceiling, Wall, Stand model

Dr. Mach

Lamps and Engineering

When cleaning / disinfecting, the following procedures must be followed:

Process Time (sec.)

Zone 1 Pre-rinse, external, cold, 10 – 15°C 45 Washing, acidic, external 35°C 120 Draining time 10 Re-rinse, external approx. 80°C *10 Draining time *15 Re-rinse, external approx. 80°C *15 Draining time 15

Zone 2 Washing, alkaline, external, 93°C 135 Draining time 10 Re-rinse, external, acidic, 90°C 10 Draining time 15 Re-rinse, external 90°C 15 Draining time 15

Zone 3 Drying, external 100 – 120°C 200

Zone 4 Drying, external 100 – 120°C 200

Door open / close & transport 60 (sluice discharge)

Cycle time overall ca. 290

* When occupying the disinfection zone (washing zone 2), the re-rinse and draining times will depend on

the respective objects being washed therein!

≈ 5 minutes

Sterilisation

Only previously cleaned and disinfected handles may be sterilised.

The handles are placed in a suitable sterilisation pack (one-way sterilisation pack, e.g. foil / paper sterilisation bags, single or double pack) in accordance with DIN EN 868 / ISO 11607 for steam sterilisation

and then sterilised.

Use only the sterilisation procedure listed below for sterilisation. Other sterilisation procedures (e.g. ethylene oxide, formaldehyde and low-temperature plasma sterilisation) are not permissible.

Steam sterilisation procedure

Validated in accordance with DIN EN 554/ISO 11134

Maximum sterilisation temperature 134°C

Proof in principle of the handles’ suitability for effective sterilisation was provided using a fractional vacuum process (Euroselectomat 666 by MMM Münchner Medizin Mechanik GmbH, sterilising temperature

134°C, holding time 7 min.)

Inspection / durability

The handles should be inspected for damage and changed before re-use, if required.

The handles may be cleaned / disinfected, sterilised and re-used for a maximum of 1000 times. If the

handles are re-used more than 1000 times, then this will be the responsibility of the hospital / clinic.

59100001 Edition 12 07.02.2005 / Bak Page 7/28

MACH 130F/130 Ceiling, Wall, Stand model

15

3.2 Lamp head, protective disk

The lamp has a high-quality surface, which can be

cleaned with conventional cleaning agents.

The protective disk 15 is made of an high-quality

plastic. Pay attention to the following during cleaning:

- Wipe over the disk 15 with a wet cloth (never

- Only use disinfectant with less then 20% alco-

Dr. Mach

Lamps and Engineering

use a dry cloth!).

hol.

Wipe the disk 15 after cleaning with an antistatic,

non-fluffy cloth.

Alc. ≤ 20 %

59100001 Edition 12 07.02.2005 / Bak Page 8/28

MACH 130F/130 Ceiling, Wall, Stand model

Dr. Mach

Lamps and Engineering

4. Maintenance

The lamp has been designed and built so that regular maintenance intervals are not necessary.

In order to keep the system easy running throughout its life span we recommend that the hinges be

greased once a year with an acid-free grease.

X

+

Width 5

Hole 1

2

10°

1

-

4.1 Adjustments at the ceiling /

wall attachment

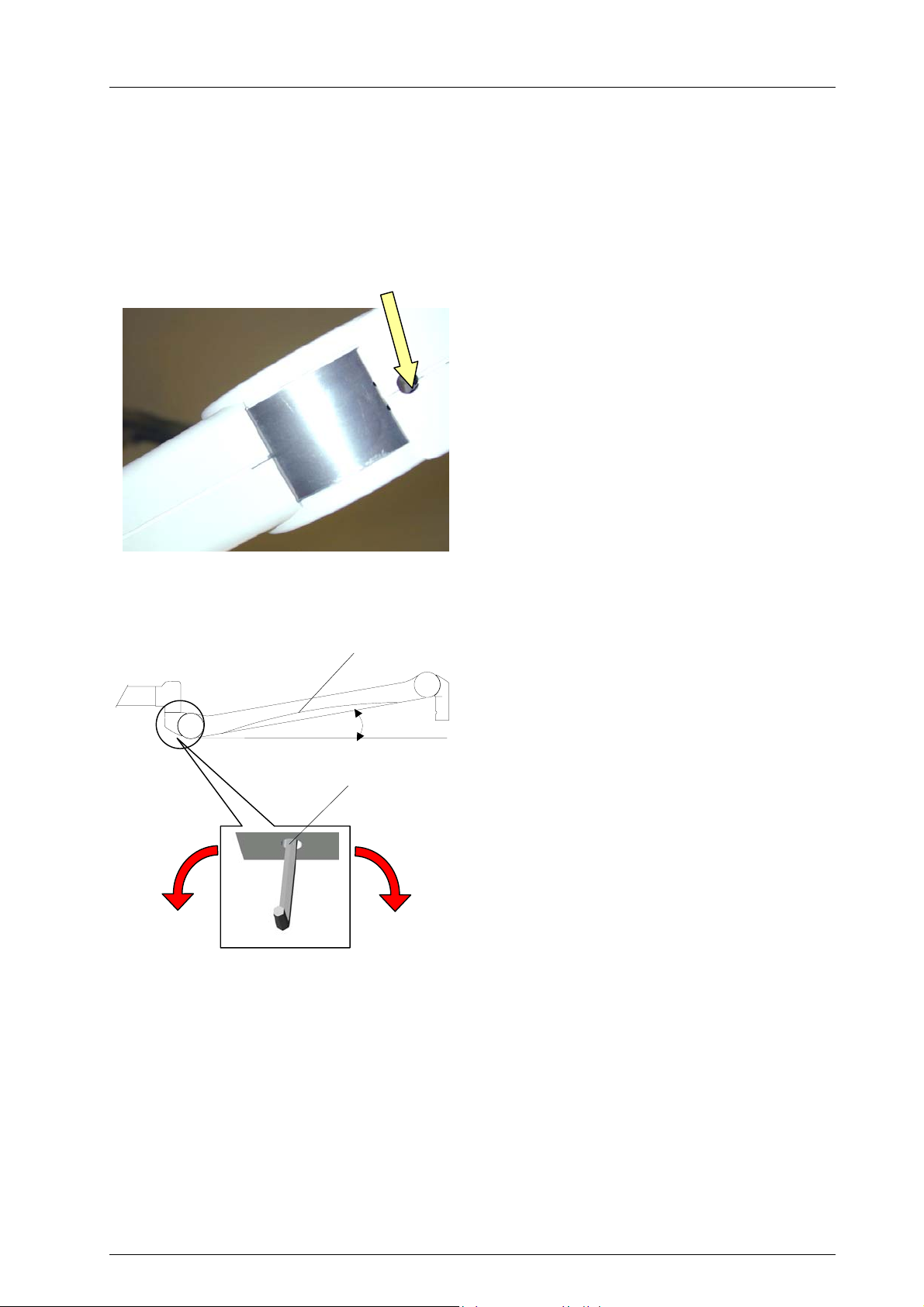

♦ Adjusting the spring arm

Note:

Maximum additional load at spring arms: Spring

arms are equipped with different springs to compensate the lamp / device weight.

To adjust the spring force make sure that the spring

arm with the lamp / device can come to rest in any

desired position.

• A hole 1 is located at the position marked by

detail X.

• Position the spring arm 2 with the lamp / device

approximately 10° above horizontal.

• Insert Allan key (width 5, included in the scope of

supply) into the hole 1.

If the spring arm drops, the spring force is too low:

- Rotate the adjustment screw to the left (counter

clockwise) in the + direction.

If the spring arm rises, the spring force is too high:

- Rotate the adjustment screw to the right (clock-

wise) in the - direction.

If the spring arm with the lamp / device cannot

come to rest in any desired position after the

spring force has been adjusted, the springs must

be replaced by a service technician.

59100001 Edition 12 07.02.2005 / Bak Page 9/28

MACH 130F/130 Ceiling, Wall, Stand model

20°

B

Dr. Mach

Lamps and Engineering

♦ Adjusting the spring force

(new type ceiling/wall attachment)

To adjust the spring force proceed as follows:

a) The spring arm moves down on its own:

• Pull the lamp head approx. 20° downwards until

drilled hole B lies on the upper side of the joint

between spring arm and horizontal arm and a

screw is visible in the hole.

• Insert a slotted screw driver into drilled hole B.

• Turn adjusting screw to the left (anticlockwise),

the spring force increases.

b) The spring arm moves up on its own:

• Pull the lamp head approx. 20° downwards until

drilled hole B lies on the upper side of the joint

between spring arm and horizontal arm and a

screw is visible in the hole.

• Insert a slotted screw driver into drilled hole B.

Turn adjusting screw to the right (clockwise),

the spring force decreases.

4.2 Adjustments at the stand model

♦ One handed height adjustment

It is usually not necessary to adjust the spring force

at stands with one-handed height adjustment.

Stand for Mach 120 / 120F, Mach 115 and

Makrolux (∅ 13,8mm)

An adjustment of the spring force is not possible.

II

Stand for Mach 130 / 130F and Soloflex –

design with short arm (∅ 22,8mm)

AR

I

SR

• Push the extension tube AR into the stand tube

SR to the stop (I).

• Insert a screwdriver into the extension tube AR

(II).

• Turn the screw inside the extension tube AR very

carefully.

A slight turn of the screw may change the height

adjustment.

♦ Adjusting the spring arm

(new type stand)

For adjusting the spring force proceed as described

at the ceiling and wall attachment.

59100001 Edition 12 07.02.2005 / Bak Page 10/28

MACH 130F/130 Ceiling, Wall, Stand model

X

Screwdriver

4 JS

Dr. Mach

Lamps and Engineering

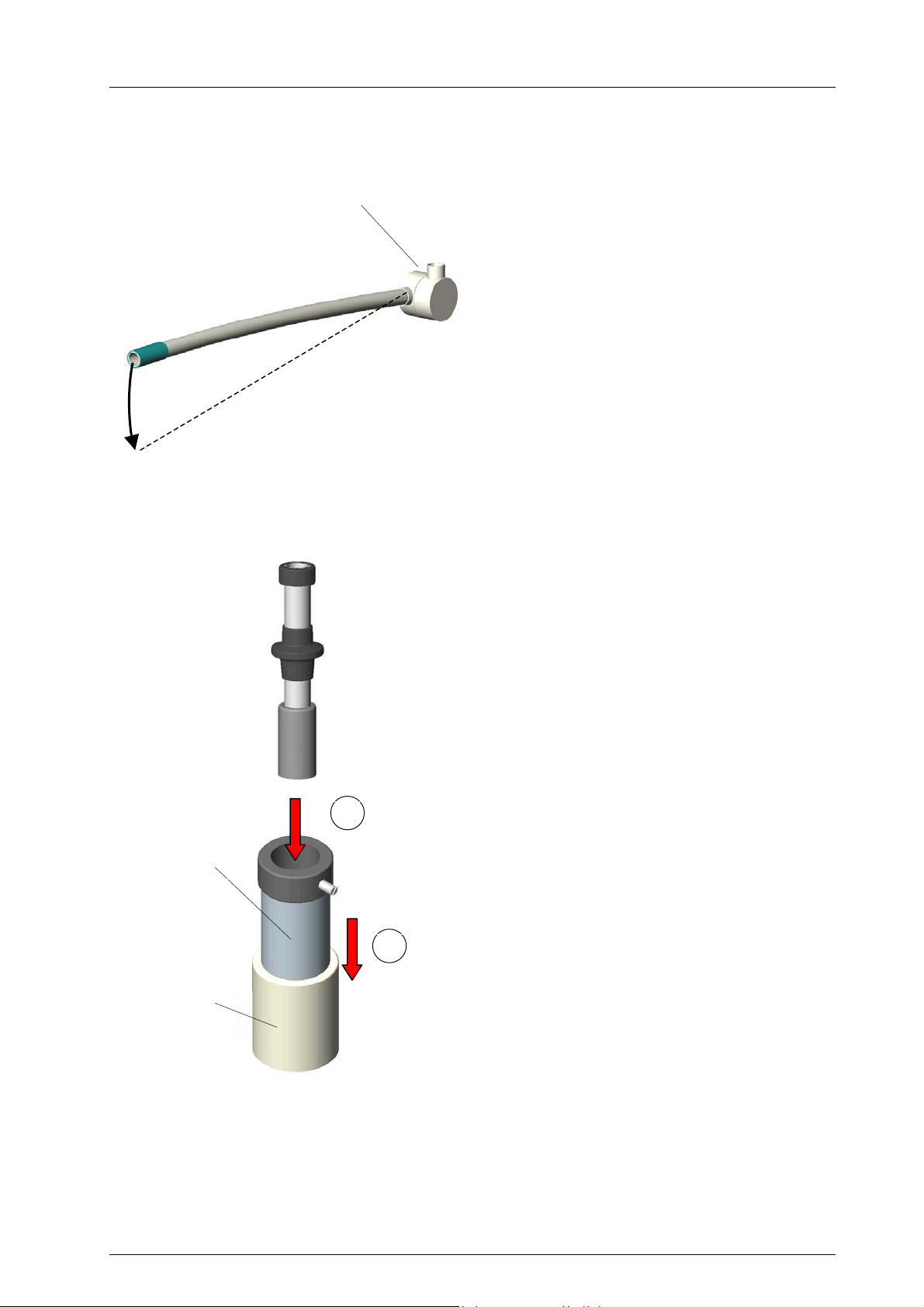

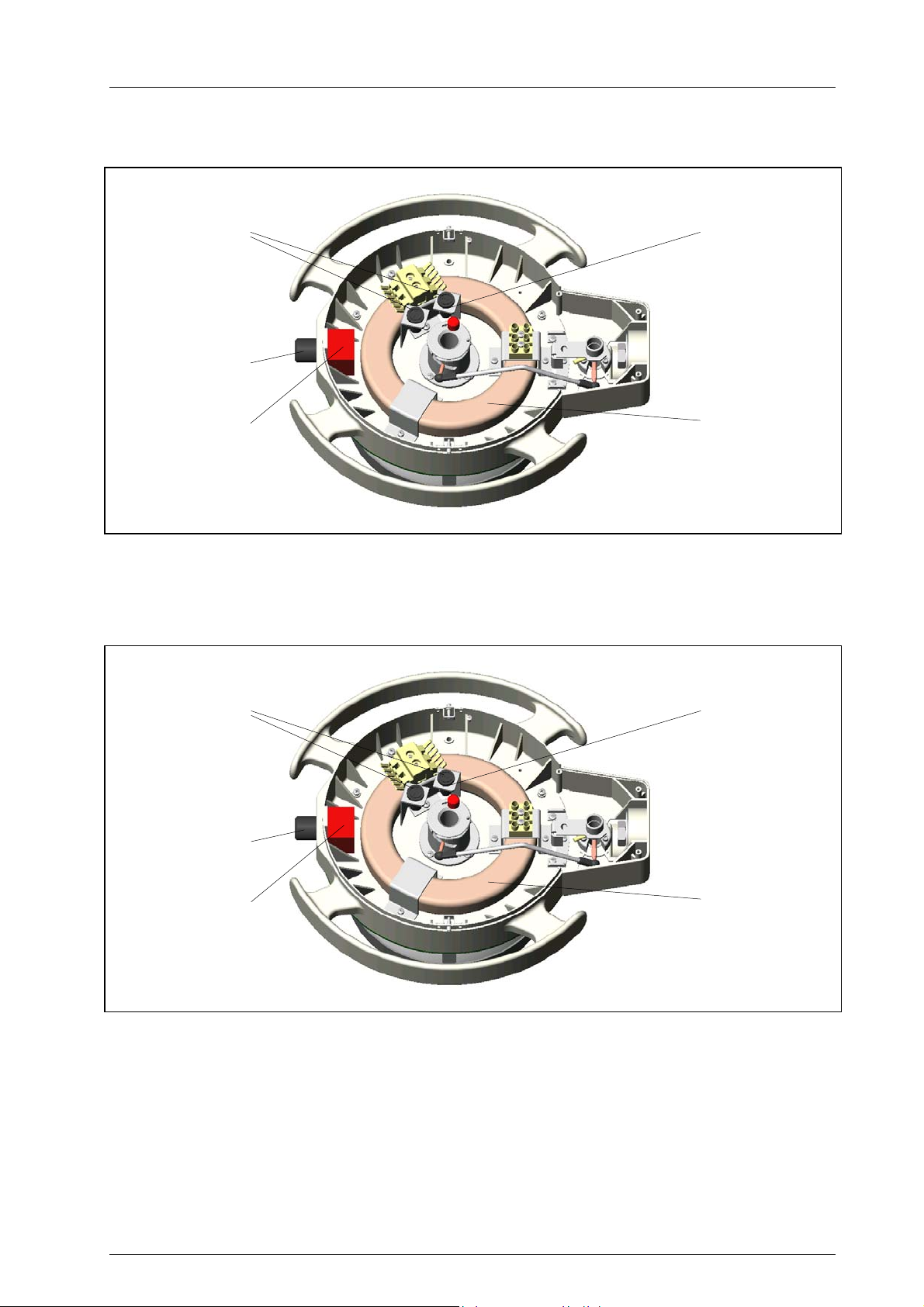

4.3 Adjustments at the lamp head

♦ Adjusting the movability of the handle for

focusing (Mach 130F/130F 22,8V UL/

Uniflex R96 120V UL)

In case you notice that the handle moves to easily or

to heavily, it may be necessary to adjust its movability.

To adjust the movability of the handle proceed as

follows:

• Turn off the lamp.

• Loosen the housing cap arrest by pushing the

arrest pin X (e.g. with a ball pen).

• Remove the cover 4 of the lamp.

• You can adjust the movability of the handle by

turning the levelling screw JS with a screwdriver.

Clockwise - stronger

Anticlockwise - easier

10

A

♦ Manipulating the lamp

The lamp bow 10 enables a perfect movability and

positioning of the lamps Mach 130F/130F 22,8V UL/

130 and Uniflex R96 120V UL.

The brake force in the axis A is set. It is usually not

necessary to adjust it.

3

In case it is necessary to adjust the brake force proceed as follows:

• Remove the upper housing part 3 of the lamp.

4

• Remove the trapezoid cover 4.

• Tighten the nut 5 with a fork wrench (size across

flats 19) as much as necessary.

SW 19

5

59100001 Edition 12 07.02.2005 / Bak Page 11/28

MACH 130F/130 Ceiling, Wall, Stand model

3

47

11,61

12

electrical

connection

X

30

4.4 Changing of spare parts

4.4.1 Changing the halogen bulbs

Dr. Mach uses special halogen bulbs as illuminants.

Only original Dr. Mach replacement bulbs may

be used.

The use of other bulbs can lead to a considerable

reduction of the light power and increase in the

thermal load.

To change the bulbs proceed as follows:

• Turn off the lamp.

• Loosen the housing cap arrest by pushing the

• Tilt up the cap 3 and lift off from the facing arrest

• Loosen holding screw 47 of lamp head.

Attention! If the bulb is changed immediately

after operating the lamp, this screw may be hot.

• Pull out the lamp base 11/61 of its guide, without

Do not touch the halogen bulb with naked hands.

• Draw halogen bulb 12 (22,8-24V/50W) carefully

• Put in the new halogen bulb.

• Mounting of the lamp base 11/61 and lamp hous-

Remark:

The halogen bulbs have a service life of approx.

1000 hours without any deterioration in their

luminosity.

Dr. Mach

Lamps and Engineering

arrest pin X (e.g. with a ball pen).

pin.

loosing the electrical connection.

from its socket.

ing cap in reverse order.

59100001 Edition 12 07.02.2005 / Bak Page 12/28

MACH 130F/130 Ceiling, Wall, Stand model

26,27,28

or 26,65

4.4.2 Changing the fuses

The fuses in the lamp housing (models with built-in

transformer only) prevent the transformer burning

through in the event of a short circuit. The fuses are

situated beneath the housing cap.

Visible type 5x20/0,63A/250V/T for 230 V

Visible type 5x20/1,25A/250V/T for 120/127 V

Visible type UR 5x20/1,25A/250V/T for

Uniflex R96 UL120V

If the bulb is no longer on, check the bulb first, then

the fuses.

To change the fuses, proceed as follows:

• Turn off the lamp.

• Loosing the housing cap arrest by pushing the

• Tilt up the cap 3 and lift off from the facing arrest

• Turn the black fuse holder 26 ¼ of a rotation anti-

• Replace the cap 3 in the same way as taking off,

In the case of designs where the transformer is in the

ceiling flange, external, or the lamp is connected to

the 24V network, the necessary fuses are provided

by the customer.

Pay attention to the instructions from the local installer.

Dr. Mach

Lamps and Engineering

(Mach 130/130F 230V/120V and Uniflex

R96 UL 120V)

arrest pin X (e.g. with a ball pen).

pin.

clockwise with a screwdriver, change fuses 27/28,

65, insert fuse holder under slight pressure and

rotate in a clockwise direction (bayonet catch).

so that the arrest pins click into position.

59100001 Edition 12 07.02.2005 / Bak Page 13/28

MACH 130F/130 Ceiling, Wall, Stand model

21,68 22 AD

BM 20,67

black brown

yellow

yellow

electromechanical

component BT

potentiometer

4.4.3 Changing the ON/OFF switch

(potentiometer)- Mach 130F/130,

date of construction before oct. 2002

Exchange only by

skilled electrician!!

You can turn the lamps Mach 130F/130 on and off

using the push button switch 21/68.

At designs with 230V and built-in electronic transformer, the push button switch 21/68 also features

the function of light intensity control.

To change the ON/OFF switch (potentiometer) proceed as follows:

• Turn off the lamp.

• Loosen the push button 21/68.

• Loosen the fixing nut BM and pull the potenti-

ometer 20/67 and the metal disc 22 out of the

lamp housing.

• Solder the cables off the potentiometer.

Mount the new ON/OFF switch 20/67:

• Push the cables through and nick them.

• Solder the cables on the potentiometer as

shown below.

• Insert the potentiometer in the cover AD. The

lateral cover plates remain open.

• Mount the potentiometer including the cover AD

in the lamp housing, so that the electromechanical component points to the lamp housing.

• Place the metal disc 22 on the lag area of the

potentiometer, so that the stop pin is in the upper position.

• Fix the nut BM for approx. 2 thread lengths.

• Push the lateral cover plates of the cover AD

between the lamp housing and the potentiometer.

The potentiometer must be completely covered (protection against electric shock).

The cables are on the downside of the cover.

• Fix the nut BM.

Attention! Do not overturn the thread!

• Turn the axis of the potentiometer clockwise to

the endpoint (by hand).

• Mount the push button 21/68 and turn it clock-

wise to the endpoint (by hand).

• Push the button 21/68 to stop and fix the socket

head cap screw.

Check the function of the lamp.

Dr. Mach

Lamps and Engineering

59100001 Edition 12 07.02.2005 / Bak Page 14/28

MACH 130F/130 Ceiling, Wall, Stand model

AD

4.4.4 Changing the ON/OFF switch

Dr. Mach

Lamps and Engineering

(potentiometer)- Mach 130F/130,

date of construction after oct. 2002

Figure 1

axis

21,68 22

BM

Figure 2

recess

Figure 3

black

yellow

Potentiometer

20,67

for cable

brown

yellow

Exchange only by

skilled electrician!!

You can turn the lamps Mach 130F/130 on and off

using the push button switch 21/68.

At designs with 230V and built-in electronic transformer, the push button switch 21/68 also features

the function of light intensity control.

To change the ON/OFF switch (potentiometer) proceed as follows:

• Turn off the lamp.

• Loosen the push button 21/68.

• Loosen the fixing nut BM, and pull the potenti-

ometer 20/67 and the metal disc 22 out of the

lamp housing.

• Solder the cables off the potentiometer.

• Solder the cables on the new ON/OFF switch

(potentiometer) (see figure 3).

• Loosen the fixing nut BM from the new ON/OFF

switch (potentiometer).

• Insert the new ON/OFF switch (potentiometer).

Attention! Do not pinch the cables!

• Place the metal disc 22 on the lag area of the

potentiometer, so that the stop pin is in the upper position.

• Fix the nut BM for approx. 1/2 thread lengths.

• Press the switch 20/67 to the inside of the lamp,

until the cover AD can be mounted from above

between lamp housing and switch (see figure

1).

• Lead the cables through the recess on the bot-

tom side of the cover (see figure 2).

The ON/OFF switch is completely covered (protection against electric shock).

• Fix the nut BM.

Attention! Do not overturn the thread!

• Turn the axis of the potentiometer clockwise to

the endpoint (by hand).

• Mount the push button 21/68 until stop and fix

the socket head cap screw.

Check the function of the lamp.

59100001 Edition 12 07.02.2005 / Bak Page 15/28

MACH 130F/130 Ceiling, Wall, Stand model

3

S

X

2

4.4.5 Changing the filter disk / conversion

The filter disk between reflector and protective disk

4

(Mach 130F and Uniflex R96 UL only) prevents a

damaging heating of the illuminated area.

ATTENTION!

The lamps may not be used without this filter.

S

To change the filter disk 14 / conversion filter 72

proceed as follows:

• Turn off the lamp.

• Loosen the housing cap arrest by pushing the

• Tilt up the cover 3 and lift off from the facing

• Remove cover 4.

• Loosen the three screws S (position of the

• Remove the bottom part 2 of the lamp housing.

Dr. Mach

Lamps and Engineering

filter

arrest pin X (e.g. with a ball pen).

arrest pin.

screws see topview below).

Attention: Hold the bottom part of the lamp

housing carefully, it is loosen now.

16

14, 72

S

You can see the filter disk 14 / the conversion filter

72 in front of you. It is kept by the four springs 16.

X

S

S

59100001 Edition 12 07.02.2005 / Bak Page 16/28

MACH 130F/130 Ceiling, Wall, Stand model

Dr. Mach

Lamps and Engineering

II II

16b

14

16b

III

I

III III

16a

I

marking

2

15

52,53

15

• Press the filter disk 14 / the conversion filter 72

carefully against two springs 16a (I).

Attention: Touch the filter disk only with a

non-fluffy cloth.

• Press the springs 16b to the edge (II) and lift

the filter disk (III).

• Insert the new filter disk in reverse order. Make

sure that the marking points to the upper side of

the lamp housing as shown in the figure. The

reverse side of the disk is steam finished.

Only use filter disks / conversion filters, that

have been cleaned properly.

• Fix the bottom part 2 of the lamp housing with

the three screws S.

• Fix the cover 3, so that the two arrest pins snap

in.

4.4.6 Changing the protective disk

In case you notice a impediment of the light quality

because of a dull protective disk, it may be necessary to change the disk.

To change the protective disk proceed as follows:

• Turn off the lamp.

• Remove the bottom part 2 of the lamp housing

as described at point 4.4.4.

• Loosen the six screws 52 and remove them

including the washers 53.

Attention: Hold the protective disk carefully,

it is loosen now.

• Remove the protective disk 15.

• Insert the new dispersion lens, so that it is

placed even to the bottom part of the lamp

housing.

• Fix the dispersion lens with the six screws 52

and the washers 53.

Attention: Only use dispersion lenses, that

have been cleaned accordingly.

• Fix the bottom part 2 of the lamp housing.

• Fix the cover 3, so that the arrest pins snap in.

59100001 Edition 12 07.02.2005 / Bak Page 17/28

MACH 130F/130 Ceiling, Wall, Stand model

58,59

S, ZS

40

4.4.7 Conversion to sterilizable handle

Extent of supply:

− sterilizable handle sleeve

− couple

− 1 screw M4x35 DIN 912:A2 with with safety

• Turn off the lamp.

• Remove the standard handle 40:

Dr. Mach

Lamps and Engineering

lake

Remove the cover AD using a screwdriver.

Loosen the screw S M4x6 DIN 7985 with a

cross screwdriver.

Remove the screw S M4x35 DIN 912:A2 and

the lock washer ZS ∅4,3 DIN 6797.

Hold the handle 40, while removing the screw

and the lock washer, to ensure no damaging in

the lamp housing.

Remove the handle 40.

AD

58,59

• Put couple 44 on the handle bar 58,59.

• Fix the couple 44 with the screw S1 M4x35 DIN

912:A2 with safety lake to the handle bar.

• Push the sterilizable handle sleeve on the cou-

ple 44, so that it is secured by push-button DK.

44

DK

S1

59100001 Edition 12 07.02.2005 / Bak Page 18/28

MACH 130F/130 Ceiling, Wall, Stand model

Dr. Mach

Lamps and Engineering

5. Data

5.1 Technical data

Design with 230 Volt

~ Wechselstrom Alternating current

Pr Primärseitig 230V / 0,29A Primary side

Sek Sekundärseitig 22,8V / 2,19A Secondary side

Leistungsaufnahme 50VA Power consumption

Hz Hertz-Frequenz 50 / 60Hz Frequency Hertz

Sicherung 5x20/0,63A/250V AC/t Fuse

Schutzgrad Type „B“ Class of protection

Design with 120 Volt

~ Wechselstrom Alternating current

Pr Primärseitig 230V / 0,58A Primary side

Sek Sekundärseitig 22,8V / 2,19A Secondary side

Leistungsaufnahme 50VA Power consumption

Hz Hertz-Frequenz 50 / 60Hz Frequency Hertz

Sicherung 5x20/1,25A/250V AC/t Fuse

Schutzgrad Type „B“ Class of protection

Design with 120 Volt UL

~ Wechselstrom Alternating current

Pr Primärseitig 230V / 0,58A Primary side

Sek Sekundärseitig 22,8V / 2,19A Secondary side

Leistungsaufnahme 50VA Power consumption

Hz Hertz-Frequenz 50 / 60Hz Frequency Hertz

Sicherung UR 5x20/1,25A/250V AC/t Fuse

Schutzgrad Type „B“ Class of protection

Design with 22,8 Volt (external transformer)

~ Wechselstrom Alternating current

Nennspannung 22,8V Rated voltage

Nennstrom 2,19A Rated current

Hz Hertz-Frequenz 50 / 60Hz Frequency Hertz

Schutzgrad Typ „B“ Class of protection

59100001 Edition 12 07.02.2005 / Bak Page 19/28

r

MACH 130F/130 Ceiling, Wall, Stand model

5.2 Wiring

Mach 130F /130 design with 230V

Built in electronic transformer

Transformer

Halogen bulb

Switch

Dr. Mach

Lamps and Engineering

L

230V

N

P

Mach 130F /130 and Uniflex R96 UL design with 120V

Built in toroid transformer

1

Switch

2

3

Toroid

transforme

N

L

P

Halogen bulb

59100001 Edition 12 07.02.2005 / Bak Page 20/28

MACH 130F/130 Ceiling, Wall, Stand model

Mach 130F / 130F UL / 130 design with 22,8V

External transformer

Dr. Mach

Lamps and Engineering

22,8V

Switch

Halogen bulb

P

5.3 Environmental conditions

Operation

Temperature +10°C +40°C

Relative atmospheric humidity 30% 75%

Air pressure 700 hPa 1060 hPa

Transport / Storage

Temperature -10°C +50°C

Relative atmospheric humidity 20% 90%

Air pressure 700 hPa 1060 hPa

Min. Max.

Min. Max.

6. Characteristics

59100001 Edition 12 07.02.2005 / Bak Page 21/28

Protective conductor

Switch „ON / OFF“

MACH 130F/130 Ceiling, Wall, Stand model

6.1 Specification of bulb

Dr. Mach

Lamps and Engineering

22,8V 50W

G 6,35

HALOGEN

Voltage, power

Socket

Mode of operation

6.2 Specification of fuse

Design with 230 Volt

5x20

Visible fuse 5x20

Delay action 0,63A

T0,63A

Design with 120 Volt

5x20

Visible fuse 5x20

Delay action 1,25A

T1,25A

Design with 22,8 Volt

The lamps Mach 130F/ 130F 22,8V UL / 130 with external transformer do not have any fuses in the lamp

housing.

6.3 CE-mark

The products Mach 130F/130 comply to the standards 93/42/EEC for medical products of

the European Community’s Council.

7. Disposal

The lamp does not contain any danger goods.

The components of the lamp should be properly disposed at the end of its shelf-life.

Make sure, that the materials are carefully separated.

For disposal proceed as follows:

• The electrical conducting boards should be submitted to an appropriate recycling proceeding.

• The lamp housing should be submitted to thermal disposal.

• The rest of the components should be disposed according to the contained materials.

59100001 Edition 12 07.02.2005 / Bak Page 22/28

MACH 130F/130 Ceiling, Wall, Stand model

8. Spare parts

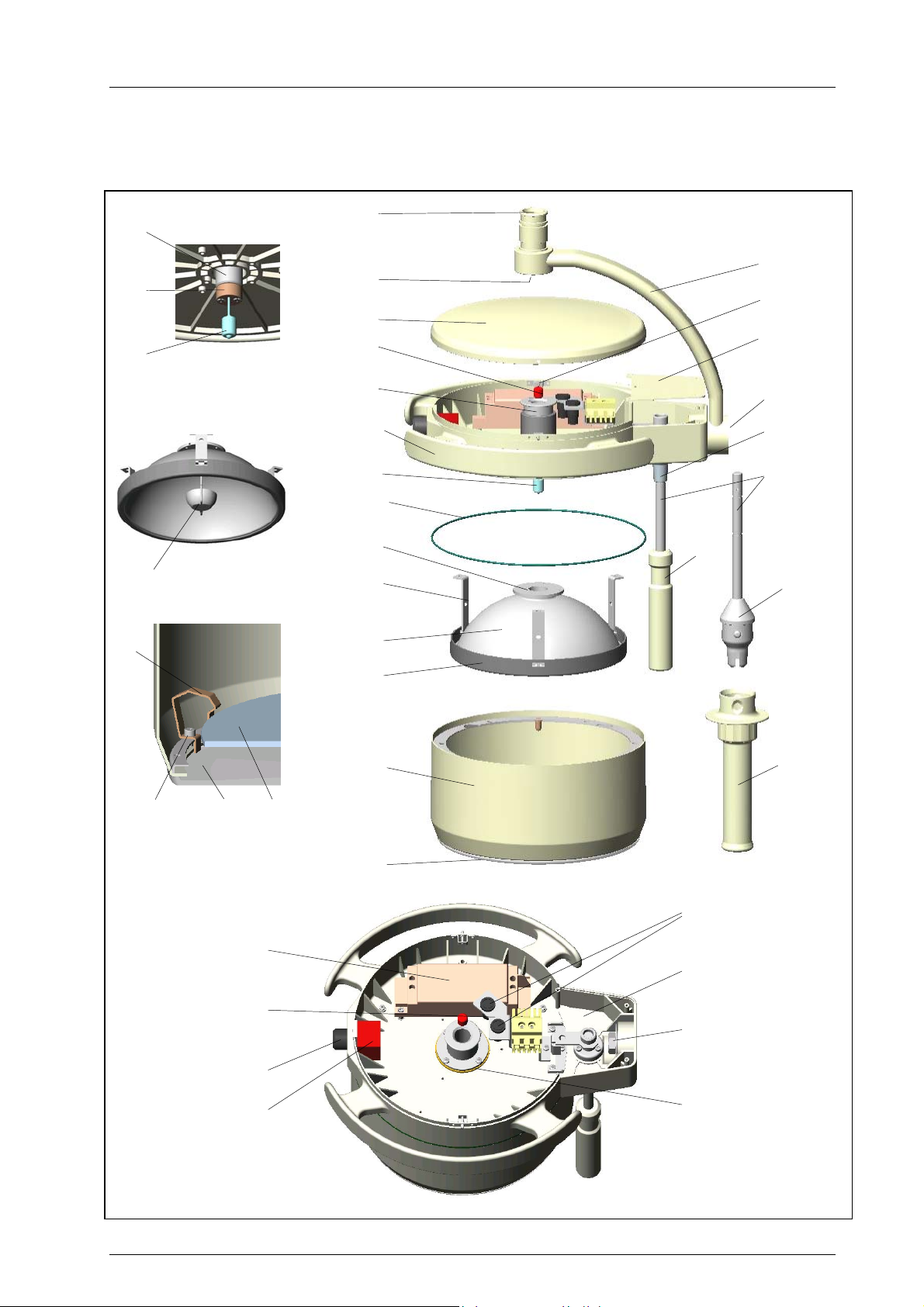

8.1 Mach 130F design with 230 Volt

built in electronic transformer

11

13

12

31

48

03

47

08

01

12

41

Dr. Mach

Lamps and Engineering

10

17,18

04,35

30

48

39

58

16

19

52,53

23

25

07

06

40

44

50

05

45

02

14 15

15

26,27

04

32,33,34

21,22

20

57

59100001 Edition 12 07.02.2005 / Bak Page 23/28

38

30

MACH 130F/130 Ceiling, Wall, Stand model

8.2 Mach 130 design with 230 Volt

built in electronic transformer

61

31

Dr. Mach

Lamps and Engineering

16

13

12

19

48

10

17,18

03

47

04,35

09

48

01

12

39

58

41

07

06

40

44

51

05

52,53

15 72

23

25

21,22

20

02

15

45

26,27

04

32,33,34

57

59100001 Edition 12 07.02.2005 / Bak Page 24/28

MACH 130F/130 Ceiling, Wall, Stand model

8.3 Mach 130F/130 design with 120 Volt -built in toroid transformer

Dr. Mach

Lamps and Engineering

26,28

21

20,67

Remark: For the rest of spare parts see lamp Mach 130F/130 –design with 230 Volt

8.4 Uniflex R96 UL 120 Volt -built in toroid transformer

64

24

26,65

68

67

Remark: For the rest of spare parts see lamp Mach 130F/130 –design with 230 Volt

64

66

59100001 Edition 12 07.02.2005 / Bak Page 25/28

MACH 130F/130 Ceiling, Wall, Stand model

Dr. Mach

Lamps and Engineering

8.5 Mach 130F/130 design with 22,8 Volt -external transformer

Remark: For spare parts see lamp 130F/130 (design with 230V), excepting the electronic transformer,

the fuses and the fuse holders.

8.6 Mach 130F UL design with 22,8 Volt -external transformer

Remark: For spare parts see lamp Uniflex R96 UL (design with 22,8V), excepting the toroid transformer,

the fuses and the fuse holders.

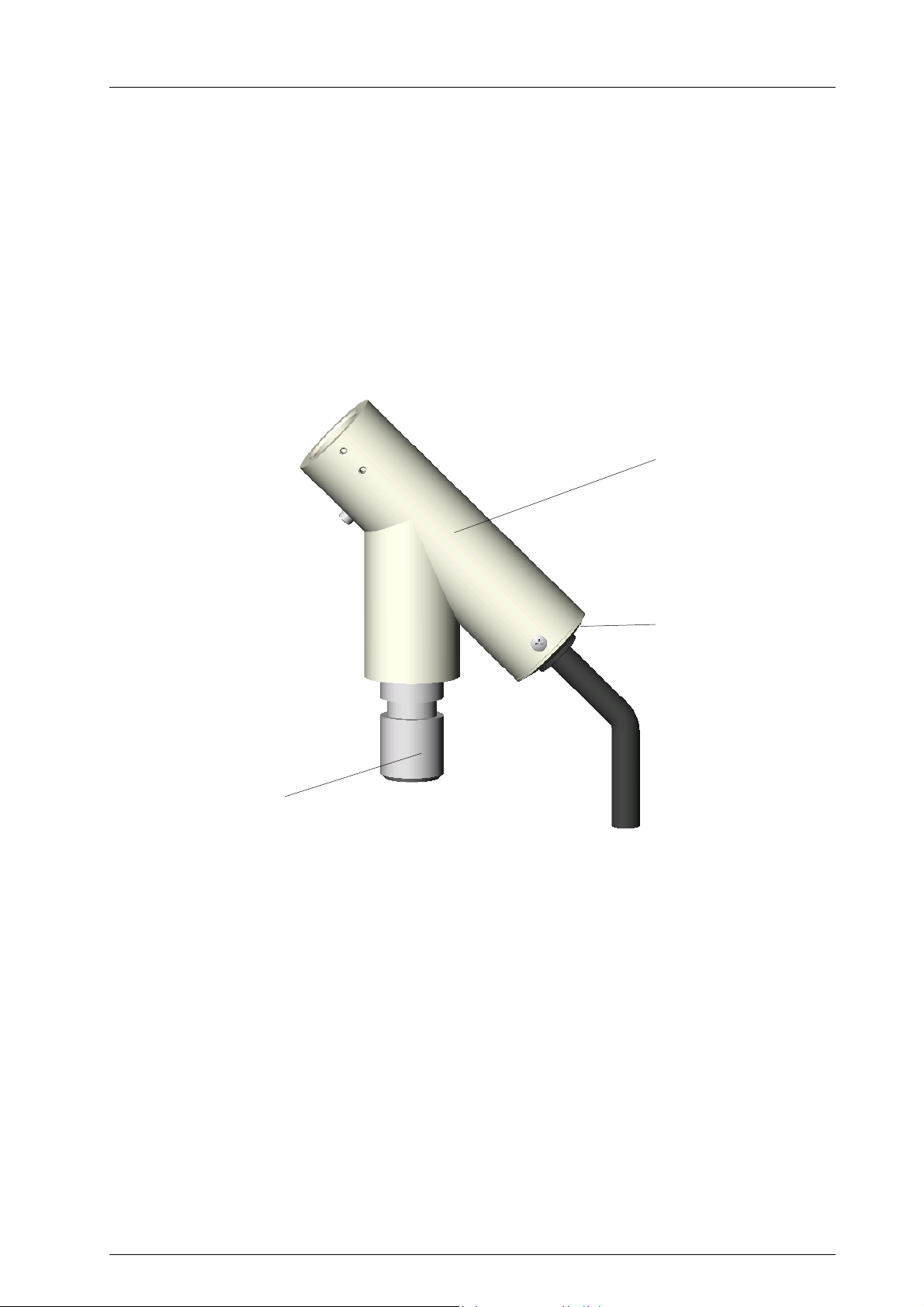

8.7 Short arm (stand model)

71

70

8.8 New type stand

Remark: For spare parts see mounting instructions for new type stands.

69

59100001 Edition 12 07.02.2005 / Bak Page 26/28

MACH 130F/130 Ceiling, Wall, Stand model

Dr. Mach

Lamps and Engineering

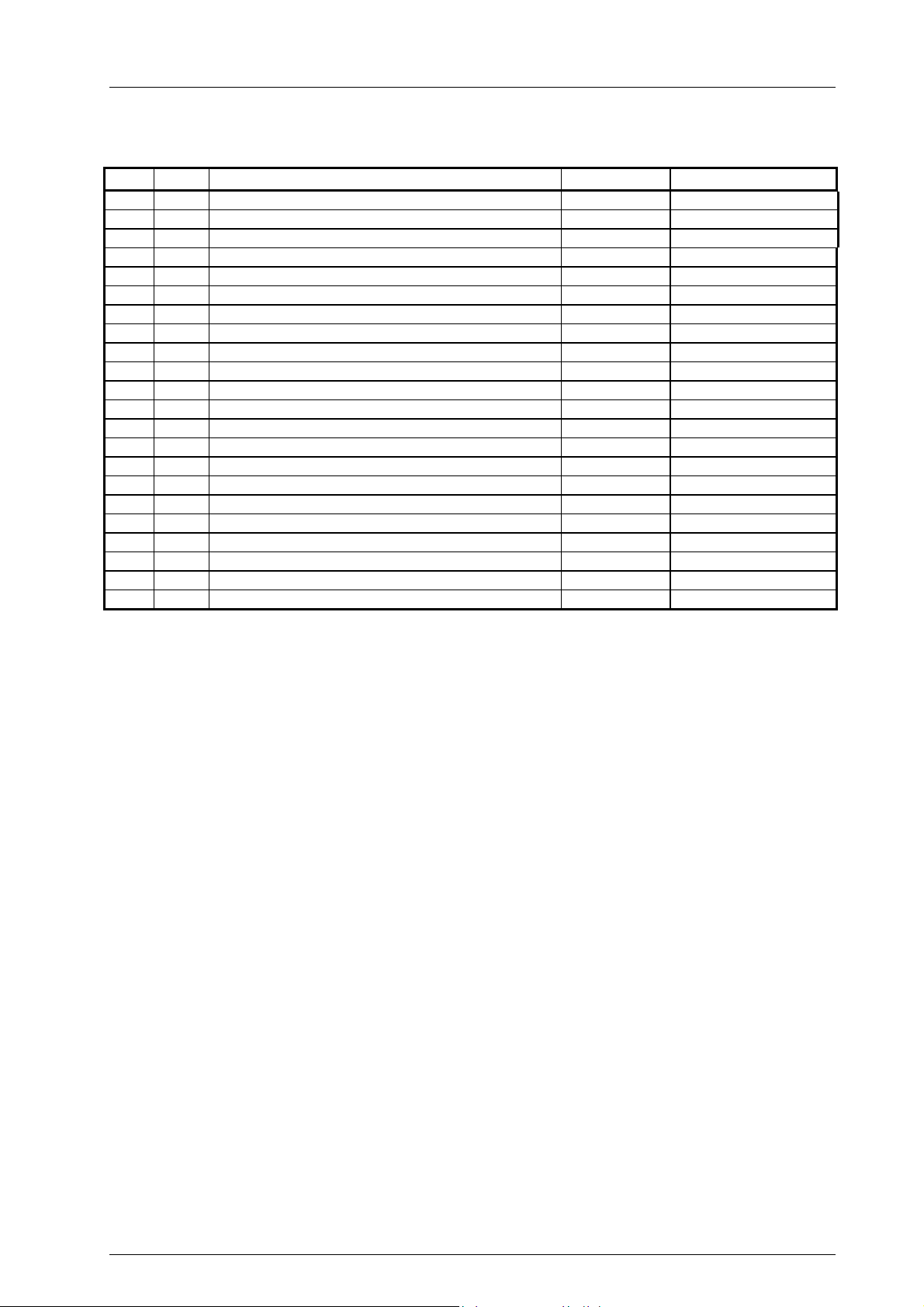

8.9 Spare parts list

Item Qty. Name EDVNO Remarks

01 1 Base frame 10030201

10012005 no serigraph, ECO

02 1 Housing lower part

03 1 Cover of lamp housing 10011001

04 1 Covering plate 10030216

05 1 Retaining ring for reflector 10060202

06 3 Clamping angle, complete 10061002

07 1 Center sleeve for reflector 10061202

08 1 Guiding tube for focus 10030202

09 1 Guiding tube for fix-focus 10050210

10 1 Lamp bow, complete 10100001

11 1 Lamp holder focus 10050002

12 1 Halogen bulb 22,8V/50W 67100201

13 1 Lamp socket with cable 67320001 No. 32560

14 1 Dielectric filter disk 23250201

15 1 Dispersion lens 21200201

16 3 Retaining spring 10012202

17 2 Arrest pin 10030205

18 2 Pressure spring 10030212

19 1 Shadower 10061003

20 1 Switch (dimmer) with fixing nut 67340003

21 1 Push button 10160201

22 1 Stop pin for dimmer 10160204

23 1 TRONIC transformer

50VA /prim. 230V AC /24V AC

24 1

25 1 Fuse base (TRONIC –transformer) 10030215

26 2 Fuse holder 67370001

27 2 Visible fuse 5x20/0,63A/250V/t 67370003 230V nom. V

28 2 Visible fuse 5x20/1,25A/250V/t 67370004 120/127V nom. V

29

30 1 Adjusting lever for focusing 10050202

31 1 Sliding contact (plug) 07102004

32 1 Plate spring 65982006

33 1 Washer 10030210

34 1 Nut 67900002

35

36

37

38 1 Adjusting screw 65212010

39 1 Insertion of handle 10030204

40 1 Handle, standard 08030305

41 1 Sealing ring turquoise, RAL 5018 21080206

42

43

44 1 Couple for sterilizable handle sleeve 10152001

45 1 Sterilizable handle sleeve 22150002

46

47 1 Arrest screw (red) 10050206

48 2 Cover 07100201

49

50 1 Glass-reflector (Mach 130F) 28060235

Toroid transformer 55VA /prim. 120V AC /24V AC

10012008 no serigraph, R96

10012009 with serigraph, R96

10012011 with serigraph, ECO

67010401

67010112 For Philips

59100001 Edition 12 07.02.2005 / Bak Page 27/28

MACH 130F/130 Ceiling, Wall, Stand model

Dr. Mach

Lamps and Engineering

Spare parts list

Item Qty. Name EDVNO Remarks

51 1 Glass reflector (Mach 130) 67380101

52 6 Head cap screw M2,5x8-A2, DIN912 65052077

53 6 Washer A3,2 DIN125-A2 65512017

54 6 Head cap screw M2,5x6-A2, DIN912 65052077

55 6 Plate 21012203

56

57 1 Heat protector 10030218

58 1 Handle bar focus 10013204

59

60

61 1 Lamp holder fix-focus 10050004

62

63

64 1 Fuse base (toroid transformer) 10030222

65 2 Visible fuse UR 5x20/1,25A/250V AC/t 67370008 FSD 0034,3999

66 1 Toroid transformer (Uniflex R96 UL) 67010107 BV 385424

67 1 Switch with fixing nut (UR) 67340008

68 1 Push button UR 67340010

69 1 Cover 07103001

70 1 Handle coupling 10160203

71 1 Housing 07102005

72 1 Conversion filter D175 Calflex Eco 67390203

59100001 Edition 12 07.02.2005 / Bak Page 28/28

Loading...

Loading...