Page 1

Contour Sander

Owner’s Manual

Model 6000

HONESTLY NOW … Have you read

this OWNER’S MANUAL?

Parlez-vous français?

Voir page 12

¿Habla español?

Vea página 23

Safety

•

Assembly

•

Operation

•

Maintenance

•

Accessory Information

•

Warranty

•

• Service Parts

P.O. Box 1468

Racine, Wisconsin 53401

Robert Bosch Tool

1-800-437-3635

http://www.dremel.com

Dremel brand products are manufactured and sold by the

Dremel Division of Robert Bosch Tool Corporation

2610919361 4/03 Printed in U.S.A.

all rights reserved

©

Corporation

1997

Page 2

Power Tool Safety Rules

!

injury.

WARNING

Read and understand all instructions. Failure to follow all instructions

listed below, may result in electric shock, fire and/or serious personal

SAVE THESE INSTRUCTIONS

Work Area

Keep your work area clean and well lit.

Cluttered benches and dark areas invite

accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power

tools create sparks which may ignite the

dust or fumes.

Keep by-standers, children, and visitors

away while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

Double Insulated tools are equipped with

a polarized plug (one blade is wider than

the other.) This plug will fit in a polarized

outlet only one way. If the plug does not

fit fully in the outlet, reverse the plug. If it

still does not fit, contact a qualified

electrician to install a polarized outlet. Do

not change the plug in any way. Double

Insulation eliminates the need for the

three wire grounded power cord and

grounded power supply system. Before

plugging in the tool, be certain the outlet

voltage supplied is within the voltage marked

on the nameplate. Do not use “AC only”

rated tools with a DC power supply.

Avoid body contact with grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased

risk of electric shock if your body is

grounded. If operating the power tool in

damp locations is unavoidable, a Ground

Fault Circuit Interrupter must be used to

supply the power to your tool. Electrician’s

rubber gloves and footwear will further

enhance your personal safety.

Don't expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the

cord to carry the tools or pull the plug

from an outlet. Keep cord away from

heat, oil, sharp edges or moving parts.

Replace damaged cords immediately.

Damaged cords increase the risk of electric

shock.

When operating a power tool outside, use

an outdoor extension cord marked "W-A"

or "W." These cords are rated for outdoor

use and reduce the risk of electric shock.

Refer to “Recommended sizes of Extension

Cords” in the Accessory section of this

manual.

Personal Safety

Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

Dress properly. Do not wear loose

clothing or jewelry. Contain long hair.

Keep your hair, clothing, and gloves away

from moving parts. Loose clothes, jewelry,

or long hair can be caught in moving parts.

Keep handles dry, clean and free from oil

and grease.

Avoid accidental starting. Be sure switch

is “OFF” before plugging in. Carrying tools

with your finger on the switch or plugging in

tools that have the switch “ON” invites

accidents.

Remove adjusting keys or wrenches

before turning the tool “ON”. A wrench or

a key that is left attached to a rotating part of

the tool may result in personal injury.

Do not overreach. Keep proper footing

and balance at all times. Proper footing

and balance enables better control of the

tool in unexpected situations.

Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must

be used for appropriate conditions.

Tool Use and Care

Use clamps or other practical way to

secure and support the workpiece to a

stable platform. Holding the work by hand

-2-

Page 3

or against your body is unstable and may

lead to loss of control.

Do not force tool. Use the correct tool for

your application. The correct tool will do

the job better and safer at the rate for which

it is designed.

Do not use tool if switch does not turn it

“ON” or “OFF”. Any tool that cannot be

controlled with the switch is dangerous and

must be repaired.

Disconnect the plug from the power

source before making any adjustments,

changing accessories, or storing the tool.

Such preventive safety measures reduce the

risk of starting the tool accidentally. Store

idle tools out of reach of children and

other untrained persons. Tools are

dangerous in the hands of untrained users.

Maintain tools with care. Keep cutting

tools sharp and clean. Properly maintained

tools, with sharp cutting edges are less likely

to bind and are easier to control. Any

alteration or modification is a misuse and

may result in a dangerous condition.

Check for misalignment or binding of

moving parts, breakage of parts, and any

other condition that may affect the tools

operation. If damaged, have the tool

serviced before using. Many accidents are

caused by poorly maintained tools. Develop

a periodic maintenance schedule for your

tool.

Use only accessories that are

recommended by the manufacturer for

your model. Accessories that may be

suitable for one tool,

when used on another tool.

may become hazardous

Service

Tool service must be performed only by

qualified repair personnel. Service or

maintenance performed by unqualified

personnel could result in a risk of injury. For

example: internal wires may be misplaced or

pinched, safety guard return springs may be

improperly mounted.

When servicing a tool, use only identical

replacement parts. Follow instructions in the

Maintenance section of this manual. Use of

unauthorized parts or failure to follow

Maintenance Instructions may create a risk of

electric shock or injury. Certain cleaning agents

such as gasoline, carbon tetrachloride,

ammonia, etc. may damage plastic parts.

Contour Sander Safety Rules

Unplug the sander before changing

accessories. Accidental start-ups may

occur if sander is plugged in while changing

an accessory.

If your tool is equipped with a dust bag,

empty it frequently and after completion

of sanding. Be extremely careful of dust

disposal, materials in fine particle form may

be explosive. Do not throw sanding dust on

an open fire. Spontaneous combustion, may

in time, result from mixture of oil or water

with dust particles.

Always wear eye protection and a dust

mask for dusty applications and when

sanding overhead. Sanding particles can

be absorbed by your eyes and inhaled easily

and may cause health complications.

Use special precautions when sanding

chemically pressure treated lumber, paint

that may be lead based, or any other

materials that may contain carcinogens. A

suitable breathing respirator and protective

clothing must be worn by all persons

entering the work area. Work area should be

sealed by plastic sheeting and persons not

protected should be kept out until work area

is thoroughly cleaned.

Do not wet sand with this sander. Liquids

entering the motor housing is an electrical

shock hazard.

Do not use sandpaper intended for larger

sanding pads. Larger sandpaper will extend

beyond the sanding pad causing snagging,

tearing of the paper or kick-back. Extra

paper extending beyond the sanding pad

can also cause serious lacerations.

Clamp or secure workpiece when

sanding. Clamping the workpiece prevents

it from being ejected from under the sander

and leaves both hands free to control the

tool.

Keep the cord away from the accessory.

The cord can become entangled with the

pad or contour.

-3-

Page 4

WARNING

!

grinding, drilling, and other construction

activities contains chemicals known to

cause cancer, birth defects or other

reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement

and other masonry products, and

Some dust created by

power sanding, sawing,

• Arsenic and chromium from chemicallytreated lumber.

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area,

and work with approved safety equipment,

such as those dust masks that are specially

designed to filter out microscopic particles.

-4-

Page 5

Symbols

0

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Diameter Size of drill bits, grinding wheels, etc.

n

0

.../min Revolutions or reciprocation per minute Revolutions, strokes, surface speed,

0 Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque or position settings.

I, II, III, Higher number means greater speed

No load speed Rotational speed, at no load

orbits etc. per minute

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated

Construction tools.

Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Ni-Cad RBRC seal Designates Ni-Cad battery recycling

program

This symbol designates

that this tool is listed by

Underwriters Laboratories.

This symbol designates

that this tool is listed to

Canadian Standards by

Underwriters Laboratories.

This symbol

designates

that

this tool

complies

to NOM

Mexican

Standards.

This symbol designates

that this tool is listed by

the Canadian Standards

Association.

This symbol designates

that this tool is listed by

Underwriters Laboratories,

and listed to Canadian

Standards by Underwriters

Laboratories.

-5-

Page 6

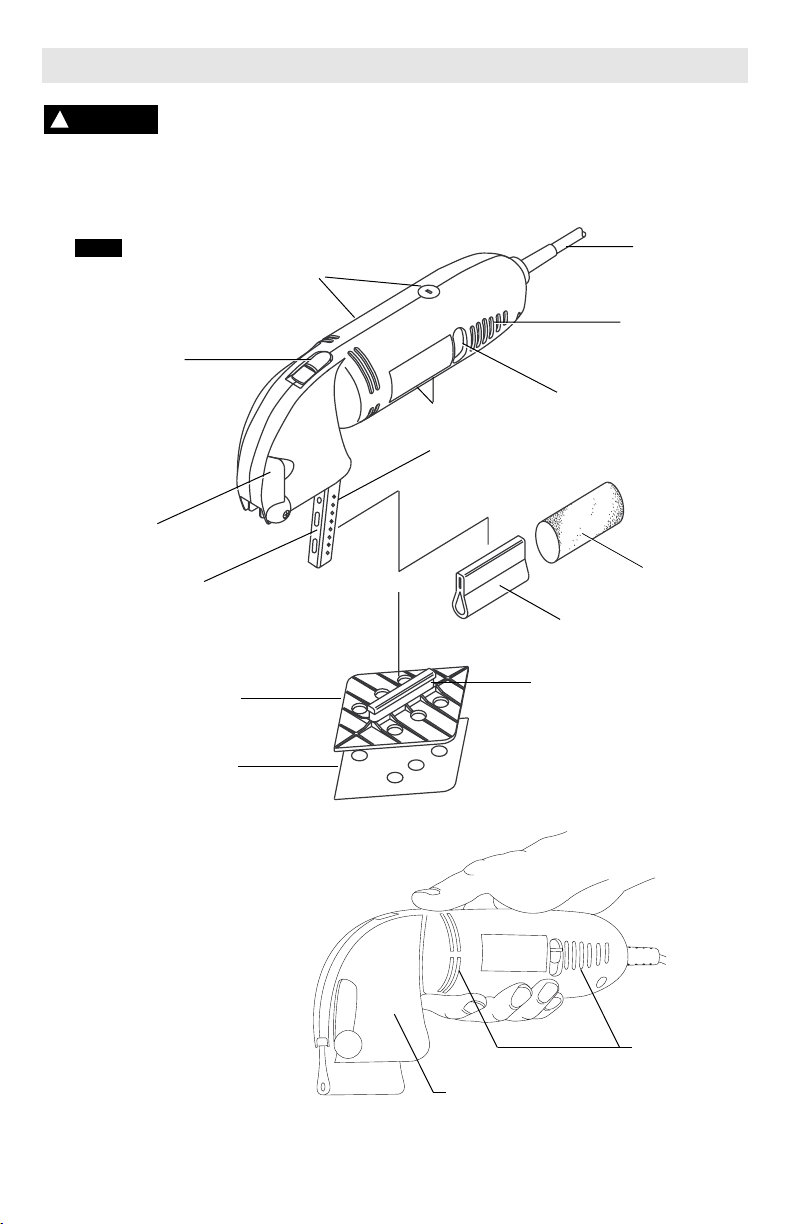

Functional Description and Specifications

WARNING

!

Disconnect the plug from the power source before making any

assembly, adjustments or changing accessories. Such preventive safety

measures reduce the risk of starting the tool accidentally.

Contour Sander

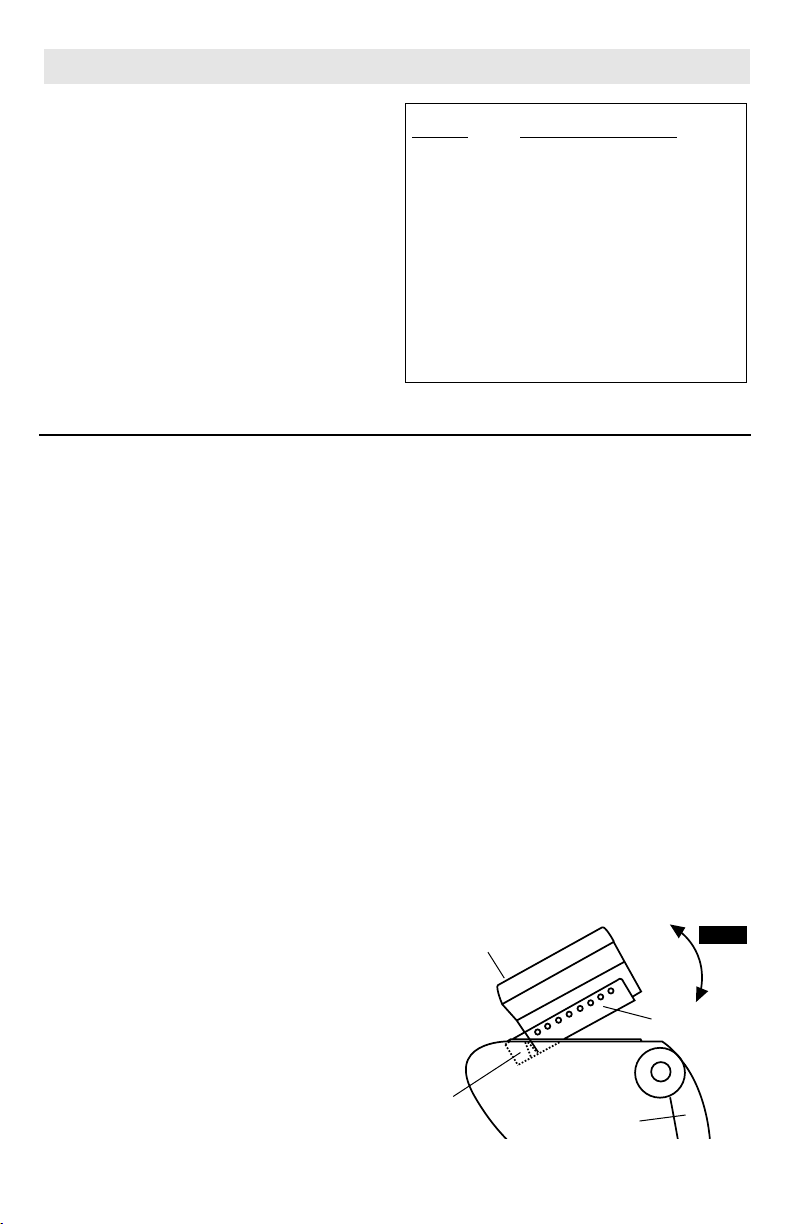

FIG. 1

ON/OFF

SWITCH

RELEASE

LEVER

CLAMP

HOLDER

DETAIL

MOTOR

BRUSHES

GRIP

DIMPLES

PAD

POWER CORD

VENTILATION

OPENINGS

VARIABLE

SPEED SWITCH

SANDING

TUBE

CONTOUR

RUBBER

GRIP RING

HOOK & LOOP

PAPER

See diagram for proper way to

hold tool. The head of sander

will get warm as it is being

used. Please use care to make

sure ventilation openings are

not covered during use.

NOTE: For tool specifications refer to the nameplate on your tool.

VENTILATION

OPENINGS

WARM AREA

-6-

Page 7

Operating Instructions

ON/OFF AND VARIABLE

SPEED SWITCHES

Your Sander is equipped with a variable

speed switch and a separate on/off switch.

The speed can be controlled from minimum

to maximum speed by moving the switch

lever to desired setting.

TO TURN TOOL “ON”: Slide switch to the

“ON”position (I) on symbol.

TO TURN TOOL “OFF” Slide switch to the

“OFF” position (0) off symbol.

TO INCREASE SPEED: Move variable speed

control lever toward the + sign.

TO DECREASE SPEED: Move variable speed

control lever toward the – sign.

Setting

Material/Application

Low Delicate surfaces, veneers,

or light surface finishing &

polishing

Low Plastics or other soft surfaces

Medium Solid wood, fast stock

removal, paint removal

High General use, metal sanding &

finishing, chipboard, coarse

sanding on rough surfaces,

& polishing

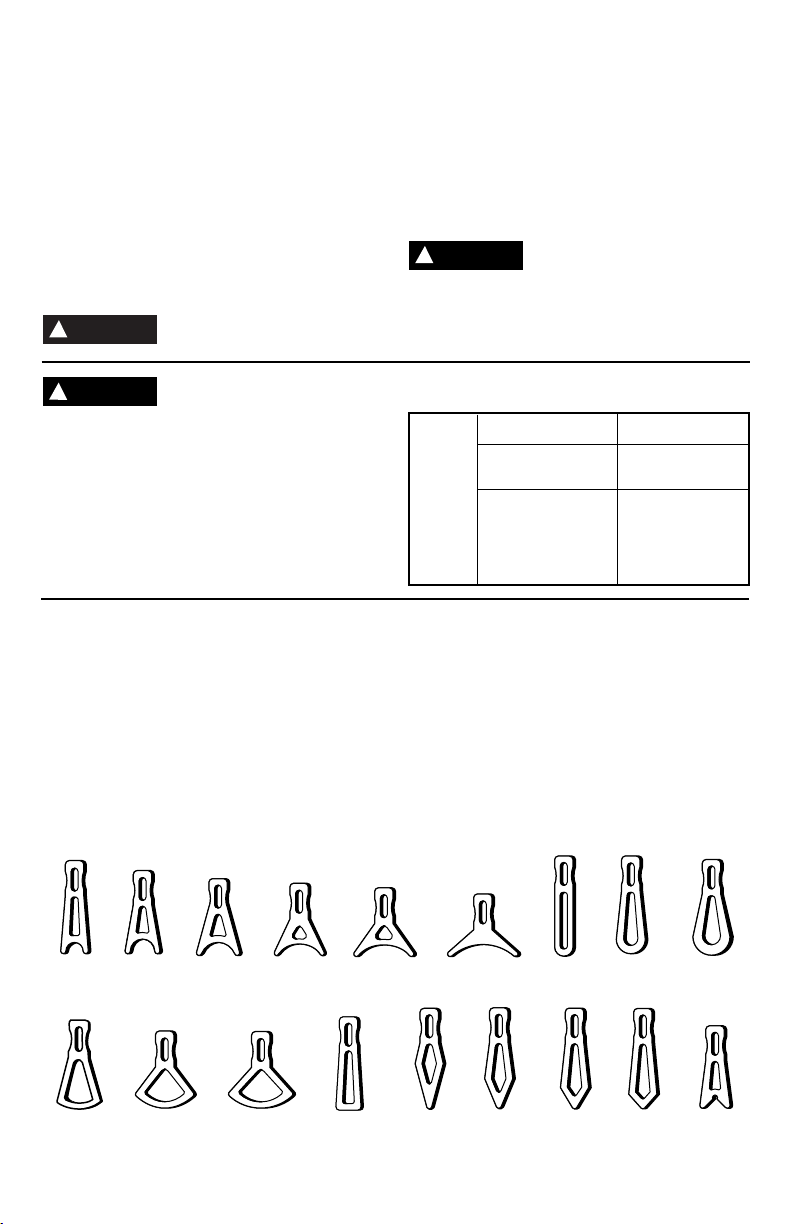

SELECTING A CONTOUR SHAPE

Individual contour shapes are available in three

basic styles. A variety of radiuses are available

in each style:

Convex shapes: 1/8", 3/16", 1/4", 3/8", 1/2",

5/8"

Concave shapes: 1/8", 3/16", 1/4", 3/8", 1/2",

5/8"

Angled shapes: Flat, 30°, 60°, 45°, 90°, -90°

The contour shapes are available in a variety of

different radiuses to match common

configurations. Additionally, each contour can

be modified or customized by trimming or

shaping the material to the desired form.

INSTALLING AND REMOVING DETAIL

PAD & OPTIONAL SHUTTER PAD

Your sander is equipped with a quick change

clamping mechanism that allows you to easily

change accessories without additional tools.

To attach detail pad or optional shutter pad to

the sander:

1. Disconnect sander from power source.

2. Rotate red release lever to lower the

accessory clamp holder.

3. Apply hook and loop backed sandpaper to

pad.

4. Insert pad completely into the top and

back of the holder until it reaches the rear

"stop".

HINT: Make sure the small grip dimples have

firmly secured the rubber grip ring (Fig. 1).

5. Press holder firmly back up into place

until the pad "snaps" into position.

To remove pad, rotate lever to release and

lower the clamp holder. Remove the pad

from the holder. You are now ready to install

another pad or contour shape.

When using detail sanding pads, regularly

rotate the pad 180 degrees to maximize all

surfaces for longer, more efficient use.

INSTALLING AND REMOVING

CONTOURS

To attach a contour shape to the sander:

1. Disconnect sander from power source.

2. Rotate red release lever to lower the

accessory clamp holder.

3. Apply either a sanding tube or pressure

sensitive adhesive directly to contour shape.

4. Insert contour completely into the top and

back of the holder until it reaches the rear

"stop" (Fig. 2).

CONTOUR

REAR

STOP

RELEASE LEVER

FIG. 2

CLAMP

HOLDER

-7-

Page 8

Operating Instructions (cont.)

Hint: make sure the small grip dimples have

firmly secured the sandpaper surface.

5. Press holder firmly back up into place

until the contour "snaps" in place.

To remove contour, rotate lever to release

and lower the clamp holder. You are now

ready to install another contour shape or

detail pad.

When using sanding tubes, rotate them

regularly to maximize all surfaces for longer,

more efficient use.

“Accessory Tips”

Contours: Use sanding tubes that are long

lasting, reusable and easy to install. To

install, slide tube completely over desired

contour, and shape paper to contour.

Contour abrasive tubes can also be rotated

on the contour, to maximize the use of the

abrasive surface.

PSA Rolls: Rolls with pressure sensitive

adhesive can also be used with individual

contours. Unroll a strip of abrasive to fit the

particular contour, and cut to length with

scissors. When using pressure sensitive

adhesive, optimal clamping can be obtained

if the entire contour surface is wrapped with

paper. Firmly press the abrasive in place on

the contour. To remove abrasive, lift a

corner of the sheet with your fingernail and

peel it off. Dispose of the used abrasives,

they are not reusable.

HINT: When using 1/8" and 3/16" concave

contours with sanding tubes, it will be easier to

conform the abrasive to the workpiece if a finer

grit paper is used.

HINT: When reaching into extremely tight

places, the contour can be extended beyond

the front of the tool.

NOTE: DO NOT APPLY EXCESSIVE

PRESSURE TO THE TOOL WHILE IN USE.

ALLOW THE SPEED OF THE TOOL AND THE

ACCESSORY TO DO THE WORK. APPLYING

UNNECESSARY PRESSURE WILL CAUSE

THE ACCESSORY TO WEAR UNEVENLY - IT

WILL NOT SERVE TO PERFORM THE WORK

MORE QUICKLY.

NOTE: The contour shapes have been

extruded to the dimension indicated on the

shape. When doing exacting work, it will be

necessary to provide an allowance for the

sandpaper being used. Heavier/coarser grit

papers require a greater allowance.

PSA Adhesives work best at temperatures

above 25 degrees F. If PSA abrasives and

pads are stored at lower temperatures, it may

be necessary to allow them to come to room

temperature before use.

PSA Rolls must be stored in a dust-free

environment to prevent contamination of

adhesive.

After considerable use, the detail pad backing

surface may become worn. The backing pad

must be replaced when it no longer offers a

firm grip. If you are experiencing premature

wearout of the backing pad facing, decrease

the amount of pressure you are applying

during operation of the tool.

“Tool Tips”

This machine is particularly suitable for access

to corners and edges that are otherwise

difficult to reach or require hand sanding.

Profiles and grooves may be finished using the

tip or edge of the selected accessory, which

should occasionally be rotated during use to

distribute the wear on the accessory or

backing pad surface.

Always be certain that smaller workpieces are

securely fastened to a bench or other support.

Larger panels may be held in place by hand on

a bench or sawhorse.

SANDING: Open-coat aluminum oxide sanding

sheets are recommended for most wood or

metal sanding applications, as this synthetic

material cuts quickly and wears well.

-8-

Page 9

The following suggestions may be used as a

SELECTING ABRASIVES

general guide for abrasive selection, but the

best results will be obtained by sanding a test

sample of the workpiece first.

Grit

Application

Coarse For rough wood, metal sanding,

80 grit rust, paint, or old material removal.

Medium For general wood or metal sanding.

120 grit

Extra fine For final sanding of bare wood,

220 grit smoothing old paint, or preparing a

finished surface for recoating.

With the workpiece firmly secured, turn tool

“ON”. Contact the work with the tool after the

sander has reached the selected speed, and

remove it from the work before switching the

tool “OFF”. Operating your sander in this

manner will prolong switch and motor life, and

greatly increase the quality of your work.

Your contour sander uses an in-line sanding

motion. The best surface finish will be

Maintenance

achieved while operating the sander in-line

with the wood grain. Faster stock removal can

be achieved by operating the sander across

the grain when working out rough areas, then

finishing by sanding with the grain.

DO NOT APPLY EXCESSIVE PRESSURE —

LET THE TOOL DO THE WORK. EXCESSIVE

PRESSURE WILL RESULT IN POOR

HANDLING, VIBRATION, AND UNWANTED

SANDING MARKS.

If the surface is rough, begin with coarser grits

and then complete the surfacing with medium

and fine abrasives. To avoid uneven results, do

not skip more than one grit size when going

from coarser to finer, and do not sand in one

area for too long. When the job is completed,

gently lift the tool from the work surface and

slide switch to the "OFF" position.

To ensure longer life and even wear, lightly

brush any residue or clogged materials from

sandpaper surface prior to each use.

!

WARNING

Do not wet sand with this

sander.

Service

!

WARNING

personnel may result in misplacing of

internal wires and components which could

cause serious hazard. We recommend that

all tool service be performed by a Dremel

Service Facility.

The brushes and commutator in your tool have

been engineered for many hours of

dependable service. To maintain peak

efficiency of the motor, we recommend every

two to six months the brushes be examined.

Only genuine Dremel replacement brushes

specially designed for your tool should be

used.

The brushes should be inspected frequently

when tools are used continuously. If your tool

runs sporadically, loses power, makes

unusual noises or runs at a reduced speed,

check the brushes. To continue using the tool

in this condition will permanently damage

your tool.

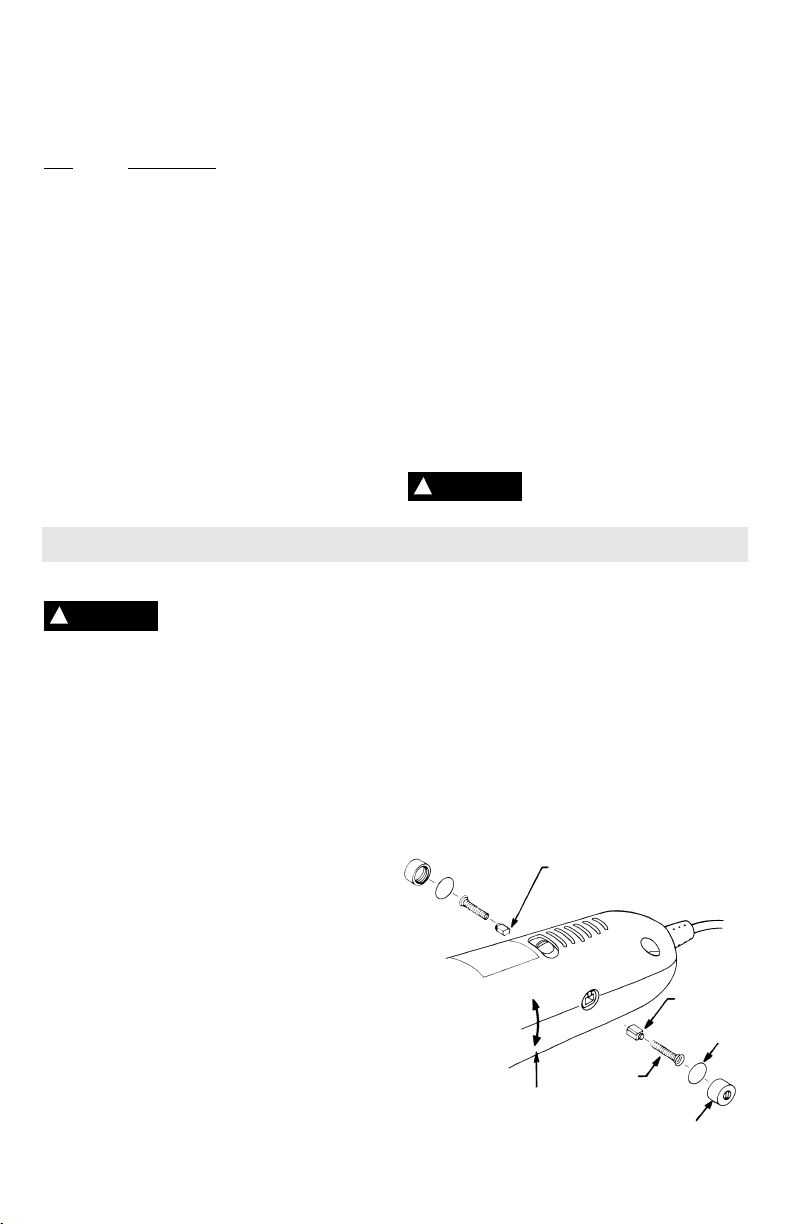

With the cord unplugged, remove the brush

Preventive maintenance

performed by unauthorized

CARBON BRUSHES

MAINTENANCE OF

REPLACEABLE BRUSHES

#5090930

caps one at a time with a small screwdriver

by rotating cap counter-clockwise and check

each brush.

If the brush is less than 1/8" long and the end

surface of the brush that contacts the

commutator is rough and/or pitted, they

should be replaced. Check both brushes.

Usually the brushes will not wear out simultaneously. If one brush is worn out, replace

both brushes. Make sure the brushes are

installed as illustrated. The curved surface of

the brush must match the curvature of the

commutator.

CURVED END OF BRUSH

MUST MATCH CURVATURE

OF HOUSING

BRUSH

BRUSH

CURVATURE

OF HOUSING

SPRING

BRUSH CAP

-9-

WASHER

Page 10

After replacing brushes the tool should be run

at no-load; place on a clean surface and run

freely for 5 minutes before loading (or using)

the tool. This will allow the brushes to “seat”

properly and will give you more hours of life

from each set of brushes. This will also

extend the total life of your tool since the

commutator surface will “wear” longer.

TOOL LUBRICATION

Your Dremel tool has been properly

lubricated and is ready to use. Under normal

use no additional lubrication is required.

Cleaning

!

WARNING

To avoid accidents always

disconnect the tool from the

power supply before cleaning or performing

any maintenance. The tool may be cleaned

most effectively with compressed dry air.

Always wear safety goggles when cleaning

tools with compressed air.

Ventilation openings and switch levers must be

kept clean and free of foreign matter. Do not

attempt to clean by inserting pointed objects

through openings.

!

CAUTION

Certain cleaning agents and

solvents damage plastic

parts. Some of these are: gasoline, carbon

tetrachloride, chlorinated cleaning solvents,

ammonia and household detergents that

contain ammonia.

!

WARNING

If an extension cord is

necessary, a cord with

adequate size conductors that is capable

of carrying the current necessary for your

tool must be used. This will prevent

excessive voltage drop, loss of power or

overheating. Grounded tools must use 3-wire

extension cords that have 3-prong plugs and

receptacles.

NOTE: The smaller the gauge number, the

heavier the cord.

Your Contour Sander can be equipped with

an optional dust collection wand. This device

is effective in sanding pad dust collection

when used with a shop vacuum with hose

dimensions of ID 1-1/2” or OD 1-3/8” or an

appropriate adapter to fit (see diagram on

page 31). When using the wand, be sure to

align the sanding sheet holes with the holes

in the sanding pad to allow the dust wand to

function properly.

The detail pad (and optional shutter pad) can

be used with hook/loop sandpaper with or

without holes for dust collection. If you’ve

RECOMMENDED SIZES OF EXTENSION CORDS

120 VOLT ALTERNATING CURRENT TOOLS

Tool’s

Ampere

Rating

3-6

6-8

8-10

10-12

12-16

Cord Size in A.W.G.

Cord Length in Feet Cord Length in Meters

25 50 100 150 15 30 60 120

18 16 16 14 .75 .75 1.5 2.5

18 16 14 12 .75 1.0 2.5 4.0

18 16 14 12 .75 1.0 2.5 4.0

16 16 14 12 1.0 2.5 4.0 —

14 12 — — — — — —

Wire Sizes in mm

2

purchased sandpaper without holes, holes

can be punched manually for use with the

dust wand.

Using sandpaper with holes - while not using

the dust wand - will not harm or damage

your work. This sander will operate

effectively with or without the dust collection

system.

To order individual contours (below), or for

additional information about the dust

collection feature, call Dremel Customer

Service @ 1-800-437-3635.

#6017 #6018 #6019 #6020 #6021 #6022 #6023 #6024 #6025

1/8" 3/16" 1/4" 3/8" 1/2" 5/8" 1/8" 3/16" 1/4"

Radius

#6026 #6027 #6028 #6029 #6030 #6031 #6032 #6033 #6034

3/8" 1/2" 5/8" Flat 30º 45º 60º 90º 90º

-10-

Page 11

Dremel Limited Warranty

Your Dremel product is warranted against defective material or workmanship for a period of two

years from date of purchase. In the event of a failure of a product to conform to this written warranty,

please take the following action:

1. DO NOT return your product to the place of purchase.

2. Carefully package the product by itself, with no other items, and return it, freight prepaid, along

with:

A. A copy of your dated proof of purchase (please keep a copy for yourself).

B. A written statement about the nature of the problem.

C. Your name, address and phone number to:

UNITED STATES

Dremel Service Center Dremel Service Center

4915 Twenty-First Street OR 4631 E. Sunny Dunes

Racine, Wisconsin 53406 Palm Springs, CA 92264

CANADA OUTSIDE

Giles Tool Agency CONTINENTAL UNITED STATES

6520 Lawrence Av. East See your local distributor or write

Scarborough, Ont. to Dremel, 4915 Twenty-First St.

Canada M1C 4A7 Racine, Wisconsin 53406

We recommend that the package be insured against loss or in transit damage for which we cannot be

responsible.

This warranty applies only to the original registered purchaser. DAMAGE TO THE PRODUCT

RESULTING FROM TAMPERING, ACCIDENT, ABUSE, NEGLIGENCE, UNAUTHORIZED REPAIRS OR

ALTERATIONS, UNAPPROVED ATTACHMENTS OR OTHER CAUSES UNRELATED TO PROBLEMS

WITH MATERIAL OR WORKMANSHIP ARE NOT COVERED BY THIS WARRANTY.

No employee, agent, dealer or other person is authorized to give any warranties on behalf of Dremel.

If Dremel inspection shows that the problem was caused by problems with material or workmanship

within the limitations of the warranty, Dremel will repair or replace the product free of charge and

return product prepaid. Repairs made necessary by normal wear or abuse, or repair for product

outside the warranty period, if they can be made, will be charged at regular factory prices.

DREMEL MAKES NO OTHER WARRANTY OF ANY KIND WHATEVER, EXPRESSED OR IMPLIED, AND

ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

WHICH EXCEED THE ABOVE MENTIONED OBLIGATION ARE HEREBY DISCLAIMED BY DREMEL AND

EXCLUDED FROM THIS LIMITED WARRANTY.

This warranty gives you specific legal rights and you may also have other rights which vary from state to

state. The obligation of the warrantor is solely to repair or replace the product. The warrantor is not liable

for any incidental or consequential damages due to any such alleged defect. Some states do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitations or exclusion may

not apply to you.

For prices and warranty fulfillment in the continental United States, contact your local Dremel distributor.

Exportado por: Robert Bosch Tool Corporation Mt. Prospect, IL 60056 -2230, E.U.A.

Importado en México por: Robert Bosch, S.A. de C.V., Calle Robert Bosch No. 405, Zona Industrial,

Toluca, Edo. de México, C.P. 50070, Tel. (722) 2792300

-11-

Page 12

Ponceuse à contours

Manuel de l’utilisateur

Modèle 6000

SOYEZ FRANC … Avez-vous lu

ce MANUEL ?

• Sécurité

• Assemblage

• Fonctionnement

• Maintenance

• Informations sur les accessoires

• Garantie

• Pièces de service

P.O. Box 1468

Racine, Wisconsin 53401

Robert Bosch Tool

1-800-437-3635

http://www.dremel.com

Les produits de marque Dremel sont fabriqués et commercialisés par la

Division Dremel de Robert Bosch Tool Corporation

-12-

tous droits réservés

©

Corporation

1997

Page 13

Règles de Sécurité Générales

!

AVERTISSEMENT

et/ou de blessures graves.

Vous devez lire et comprendre toutes les instructions. Lenon-respect, même

partiel, des instructions ci-après entraîne un risque de choc életrique, d'incendie

CONSERVEZ CES INSTRUCTIONS

Aire de travail

Veillez à ce que l'aire de travail soit propre et bien

éclairée. Le désordre et le manque de lumière

favorisent les accidents.

N'utilisez pas d'outils électriques dans une

atmosphère explosive, par exemple enprésence de

liquides, de gaz ou de poussières inflammables. Les

outils électriques créent des étincelles qui pourraient

enflammer les poussières ou les vapeurs.

Tenez à distance les curieux, les enfants et les

visiteurs pendant que vous travaillezavec un outil

électrique. Ils pourraient vous distraire et vous faire

faire une fausse manoeuvre.

Sécurité électrique

Les outils à double isolation sont équipés d'une fiche

polarisée (une des lames est pluslarge que l'autre),

qui ne peut se brancher que d'une seule façon dans

une prise polarisée. Si la fiche n'entre pas

parfaitement dans la prise, inversez sa position ; si

elle n'entre toujours pasbien, demandez à un

électricien qualifié d'installer une prise de courant

polarisée. Ne modifiez pas la fiche de l'outil. La

double isolation élimine le besoin d'un cordon

d'alimentationà trois fils avec mise à la terre ainsi que

d'une prise de courant mise à la terre. Avant de

brancher l'outil, assurez-vous que la tension de la prise

correspond, à celle indiquée sur la plaque signalétique.

N'utilisez pas d'outils prévus pour courant alternatif

seulement avec une source de courant continu.

Évitez tout contact corporel avec des surfaces mises à

la terre (tuyauterie, radiateurs, cuisinières,

réfrigérateurs, etc.). Le risque de choc électrique est

plus grand si votre corps est encontact avec la terre.Si

l'utilisation de l'outil électrique dans un endroit humide

est inévitable, un disjoncteur de fuite à la terre doit être

utilisé pour alimenter votre outil. Des chaussures et des

gants en caoutchouc d'électricien contribueront à

accroître davantage votre sécurité personnelle.

N'exposez pas les outils électriques à la pluie ou à

l'eau. La présence d'eau dans un outil électrique

augmente le risque de choc électrique.

Ne maltraitez pas le cordon. Ne transportez pas l'outil

par son cordon et ne débranchez pas la fiche en tirant

sur le cordon. N'exposez pas le cordon à la chaleur, à

des huiles, à des arêtes vives ou à des pièces en

mouvement. Remplacez immédiatement un cordon

endommagé. Un cordon endommagé augmente le

risque de choc électrique.

Lorsque vous utilisez un outil électrique à l'extérieur,

employez un prolongateur pour l'extérieur marqué «

W-A » ou « W ». Ces cordons sont faits pour être

utilisés à l'extérieur et réduisent le risque de choc

électrique. Reportez-vous aux « Dimensions

recommandées des cordons de rallonge » dans la

section Accessoires de ce manuel.

Sécurité des personnes

Restez alerte, concentrez-vous sur votre travail et

faites preuve de jugement. N'utilisez pas un outil

électrique si vous êtes fatigué ou sous l'influence de

drogues, d'alcool ou de médicaments. Un instant

d'inattention suffit pour entraîner des blessures graves.

Habillez-vous convenablement. Ne portez ni

vêtements flottants ni bijoux. Confinez les cheveux

longs. N'approchez jamais les cheveux, les

vêtements ou les gants des pièces en mouvement.

Des vêtements flottants, des bijoux ou des cheveux

longs risquent d'être happés par des pièces en

mouvement. Gardez les poignées sèches, propres et

exemptes d'huile et de graisse.

Méfiez-vous d'un démarrage accidentel. Avant de

brancher l'outil, assurez-vous que son interrupteur est

sur ARRÈT. Le fait de transporter un outil avec le doigt

sur la détente ou de brancher un outil dont l'interrupteur

est en position MARCHE peut mener tout droit à un

accident.

Enlevez les clés de réglage ou de serrage avant de

démarrer l'outil. Une clé laissée dans une pièce

tournante de l'outil peut provoquer des blessures.

Ne vous penchez pas trop en avant. Maintenez un bon

appui et restez en équilibre entout temps. Un bonne

stabilité vous permet de mieux réagir à une situation

inattendue.

Utilisez des accessoires de sécurité. Portez toujours

des lunettes ou une visière. Selon les conditions,

portez aussi un masque antipoussière, des bottes de

sécurité antidérapantes, un casque protecteur et/ou un

appareil antibruit.

Utilisation et entretien des outils

Immobilisez le matériau sur une surface stable au

moyen de brides ou de toute autre façon adéquate. Le

fait de tenir la pièce avec la main ou contre votre corps

offre une stabilité insuffisante et peut amener un

dérapage de l'outil.

Ne forcez pas l'outil. Utilisez l'outil approprié à la

tâche. L'outil correct fonctionne mieux et de façon plus

sécuritaire. Respectez aussi la vitesse de travail qui lui

est propre.

-13-

Page 14

N'utilisez pas un outil si son interrupteur est bloqué.

Un outil que vous ne pouvez pas commander par son

interrupteur est dangereux et doit être réparé.

Débranchez la fiche de l'outil avant d'effectuer un

réglage, de changer d'accessoire oude ranger l'outil.

De telles mesures préventives de sécurité réduisent le

risque de démarrage accidentel de l'outil. Rangez les

outils hors de la portée des enfants et d'autres

personnes inexpérimentées. Les outils sont dangereux

dans les mains d'utilisateurs novices.

Prenez soin de bien entretenir les outils. Les outils de

coupe doivent être toujours bien affûtés et propres.

Des outils bien entretenus, dont les arêtes sont bien

tranchantes, sont moins susceptibles de coincer et plus

faciles à diriger.Toute altération ou modification

constitue un usage erroné et peut causer un danger.

Soyez attentif à tout désalignement ou coincement

des pièces en mouvement, à tout bris ou à toute autre

condition préjudiciable au bon fonctionnement de

l'outil. Si vous constatez qu'un outil est endommagé,

faites-le réparer avant de vous en servir. De

nombreux accidents sont causés par des outils en

Règles de sécurité pour les ponceuses à contours

mauvais état. Élaborez un calendrier d'entretien

périodique de votre outil.

N'utilisez que des accessoires que le fabricant

recommande pour votre modèle d'outil. Certains

accessoires peuvent convenir à un outil, mais être

dangereux avec un autre.

Réparation

La réparation des outils électriques doit être confiée à

un réparateur qualifié. L'entretien ou la réparation d'un

outil électrique par un amateur peut avoir des

conséquences graves. Ainsi, des fils internes peuvent

être mal placés ou pincés, des ressorts de rappel de

protecteur peuvent être montés erronément.

Pour la réparation d'un outil, n'employez que des

pièces de rechange d'origine. Suivez les directives

données à la section « Réparation » de ce manuel.

L'emploi de pièces non autorisées ou le non-respect des

instructions d'entretien peut créer un risque de choc

électrique ou de blessures. Certains agents nettoyants

tels qu'essence, tétrachlorure de carbone, ammoniac,

etc., peuvent abîmer les pièces en plastique.

Débranchez la ponceuse avant de changer les

accessoires. Une mise en marche accidentelle peut

survenir si la ponceuse est branchée pendant le

changement d'un accessoire.

Si votre outil est équipé d'un sac à poussière,

videz-le souvent et au terme du ponçage. Procédez

extrêmement soigneusement dans l'évacuation de la

poussière, les matières sous forme de particules fines

peuvent être explosives. Ne jetez pas le bran de scie

sur des flammes nues. Une combustion spontanée

peut parfois résulter d'un mélange d'huile ou d'eau

avec des particules de poussière.

Portez toujours des lunettes de protection et un

masque anti-poussières pour les applications

poussiéreuses et lors du ponçage au-dessus de la

tête. Des particules de ponçage peuvent être

absorbées par vos yeux et inhalées facilement et

peuvent causer des problèmes de santé.

Utilisez des précautions spéciales en ponçant le

bois d'oeuvre traité chimiquement par pression, la

peinture pouvant contenir du plomb, ou tout autre

matériau qui peut contenir des agents

cancérigènes. Toutes les personnes pénétrant dans

la zone de travail doivent porter un respirateur et des

vêtements protecteurs adéquats. L'aire de travail doit

être scellée par des feuilles en plastique, et les

personnes non protégées doivent être maintenues à

l'extérieur jusqu'à ce que l'aire de travail soit dûment

nettoyée.

Ne poncez pas par voie humide à l'aide de cette

ponceuse. La pénétration de liquides dans le carter

du moteur constitue un risque de secousses

électriques.

N'utilisez pas du papier de verre destiné à des

blocs de ponçage plus gros. Le papier de verre de

dimensions plus grandes fera saillie au-delà du bloc

de ponçage entraînant ainsi des accrocs, un

déchirement du papier ou un rebond. Le papier

supplémentaire faisant saillie au-delà du bloc de

ponçage peut également causer des lacérations

graves.

Fixez à l'aide de brides ou assujettissez l'ouvrage

en ponçant. La fixation de l'ouvrage à l'aide de brides

l'empêche d'être éjecté depuis le dessous de la

ponceuse et laisse les deux mains libres pour

contrôler l'outil.

Tenez le cordon à l'écart de l'accessoire. Le cordon

peut s'emmêler avec le patin ou le contour.

-14-

Page 15

AVERTISSEMENT

!

meulage, perçage et autres travaux du bâtiment

peuvent créer des poussières contenant des produits

chimiques qui sont des causes reconnues de cancer,

de malformation congénitale ou d’autres problèmes

reproductifs. Ces produits chimiques sont, par

exemple :

• Le plomb provenant des peintures à base de plomb,

• Les cristaux de silices provenant des briques et du

ciment et d’autres produits de maçonnerie, et

Les travaux à la machine

tel que ponçage, sciage,

• L’arsenic et le chrome provenant des bois traités

chimiquement

Le niveau de risque dû à cette exposition varie avec la

fréquence de ces types de travaux. Pour réduire

l’exposition à ces produits chimiques, il faut travailler

dans un lieu bien ventilé et porter un équipement de

sécurité approprié tel que certains masques à poussière

conçus spécialement pour filtrer les particules

microscopiques.

-15-

Page 16

Symboles

0

Important : Certains des symboles suivants peuvent être utilisés sur votre outil. Veuillez les étudier et apprendre

leur signification. Une interprétation appropriée de ces symboles vous permettra d'utiliser l'outil de façon plus

efficace et plus sûre.

Symbole Nom Désignation/Explication

V Volts Tension (potentielle)

A Ampères Courant

Hz Hertz Fréquence (cycles par seconde)

W Watt Puissance

kg Kilogrammes Poids

min Minutes Temps

s Secondes Temps

Diamètre Taille des mèches de perceuse, meules,

etc.

n

0

.../min Tours ou mouvement alternatif par Tours, coups, vitesse en surface, orbites,

0 Position d'arrêt Vitesse zéro, couple zéro ...

1, 2, 3, ... Réglages du sélecteur Réglages de vitesse, de couple ou de

l, ll, lll, ... position. Un nombre plus élevé signifie

Vitesse à vide Vitesse de rotation, à vide

minute etc., par minute,

une vitesse plus grande.

Sélecteur variable à l'infini avec arrêt La vitesse augmente depuis le réglage 0

Flèche Action dans la direction de la flèche

Courant alternatif Type ou caractéristique du courant

Courant continu Type ou caractéristique du courant

Courant alternatif Type ou caractéristique du courant

ou continu

Construction classe II Désigne des outils construits avec double

isolation

Borne de terre borne de mise à la terre

Symbole d'avertissement Alerte l'utilisateur aux messages

d'avertissement.

Sceau Ni-Cad RBRCmc Désigne le programme de recyclage des piles

Ni-Cad.

Ce symbole signifie que cet

outil est approuvé par

Underwriters Laboratories.

Ce symbole signifie que cet

outil est approuvé par

l'Association canadienne de

normalisation.

Ce symbole signifie que

cet outil est approuvé

conformément aux normes

canadiennes par Underwriters

Laboratories.

Ce symbole signifie que cet outil

est approuvé par Underwriters

Laboratories et qu’il a été

homologué selon les normes

canadiennes par Underwriters

Laboratories.

Ce symbole

signifie que

cet outil se

conforme aux

normes

mexicaines

NOM.

-16-

Page 17

Description fonctionnelle et spécifications

!

AVERTISSEMENT

Débranchez la fiche de la prise de courant avant d'effectuer quelque assemblage

ou réglage que ce soit ou de changer les accessoires. Ces mesures de sécurité

préventive réduisent le risque d'une mise en marche accidentelle de l'outil.

Ponceuse à contours

FIG. 1

INTERRUPTEUR

MARCHE/ARRÊT

LEVIER DE

RELÂCHEMENT

SUPPORT DE

SERRAGE

PATIN POUR TRAVAIL

DE PRÉCISION

BALAIS DU

MOTEUR

DÉPRESSIONS

DE PRISE

CORDON

PRISES D'AIR

COMMANDE À

VITESSE

TUBE DE

PONÇAGE

CONTOUR

BAGUE DE SERRAGE

EN CAOUTCHOUC

PAPIER À CROCHETS

ET BOUCLES

Il faut tenir l’outil comme illustré sur le

schéma. La tête de la ponceuse chauffe

pendant l’utilisation. Faites bien

attention de ne pas couvrir les ouïes de

ventilation pendant l’utilisation.

ZONE CHAUDE

REMARQUE : Pour spécifications de l'outil, reportez-vous à la plaque signalétique de votre outil.

-17-

PRISES D'AIR

Page 18

Consignes de fonctionnement

INTERRUPTEUR MARCHE/ARRÊT ET

COMMANDE À VITESSE VARIABLE

Votre ponceuse est pourvue d'une commande à vitesse

variable et d'un interrupteur marche/arrêt distinct. La

vitesse peut être réglée depuis une vitesse minimale à

une vitesse maximale en déplaçant le levier de

l'interrupteur à la position désirée.

POUR METTRE L'OUTIL EN MARCHE : Faites glisser

l'interrupteur au symbole de marche (I) de la position

de marche.

POUR METTRE L'OUTIL À L'ARRÊT : Faites glisser

l'interrupteur au symbole d'arrêt (0) de la position

d'arrêt.

POUR ACCROÎTRE LA VITESSE : Déplacez le levier de la

commande à vitesse variable vers le signe +.

POUR DIMINUER LA VITESSE : Déplacez le levier de la

commande à vitesse variable vers le signe –.

Réglage Matériau/Application

Bas Surfaces délicates, placages ou

finissage et polissage légers en

surface

Bas Plastiques ou autres surfaces

molles

Moyen Bois massif, enlèvement rapide des

matériaux, décapage de la peinture

Élevé Usage général, ponçage et finition

des métaux, panneaux

d'agglomérés, ponçage grossier

sur les surfaces rudes, et polissage

SÉLECTION D'UNE FORME DE CONTOUR

Les formes individuelles de contour sont offertes en

trois types de base. Différents rayons sont offerts dans

chaque type :

Formes convexes : 1/8 po, 3/16 po, 1/4 po, 3/8 po, 1/2

po, 5/8 po

Formes concaves : 1/8 po, 3/16 po, 1/4 po, 3/8 po, 1/2

po, 5/8 po

Formes à angle : Plat, 30°, 60°, 45°, 90°, -90°

Les formes de contour sont offertes en un éventail de

rayons différents correspondant à des configurations

répandues. En outre, on peut modifier ou adapter

chaque contour en taillant ou en façonnant le matériau

à la forme désirée.

POSE ET DÉPOSE DU PATIN POUR TRAVAIL DE

PRÉCISION ET DU PATIN FACULTATIF POUR VOLETS

Votre ponceuse est pourvue d'un mécanisme de

serrage à changement rapide qui vous permet de

changer facilement les accessoires sans outils

supplémentaires.

Pour fixer le patin pour travail de précision ou le patin

facultatif pour volets à la ponceuse :

1. Débranchez la ponceuse de la prise de courant.

2. Faites tourner le levier rouge de relâchement de

manière à abaisser le support de serrage d'accessoires.

3. Posez le papier de verre avec dos à crochets et

boucles sur le patin.

4. Insérez le patin entièrement dans la partie supérieure

et l'arrière du support jusqu'à ce qu'il atteigne la butée

arrière.

CONSEIL : Assurez-vous que les petites dépressions de

prise ont fixé solidement la bague de serrage en

caoutchouc (Fig. 1).

5. Remettez le support en place en exerçant une

pression ferme jusqu'à ce que le patin « s'enclenche »

en position.

Pour enlever le patin, faites tourner le levier pour

relâcher et abaisser le support serrage d'accessoires.

Retirez le patin du support. Vous êtes maintenant prêt à

poser un autre patin ou forme de contour.

Lorsque vous utilisez des patins de ponçage pour travail

de précision, tournez régulièrement le patin de 180

degrés afin de maximaliser toutes les surfaces en vue

d'une utilisation plus longue et plus efficace.

Pour fixer une forme de contour à la ponceuse :

1. Débranchez la ponceuse de la prise de courant.

2. Faites tourner le levier rouge de relâchement de

manière à abaisser le support de serrage d'accessoires.

3. Posez soit un tube de ponçage ou un auto-adhésif

directement sur la forme de contour.

BUTÉE

ARRIÈRE

POSE ET DÉPOSE DES CONTOURS

CONTOUR

SUPPORT DE

SERRAGE

LEVIER DE

RELÂCHEMENT

-18-

FIG. 2

Page 19

Consignes de fonctionnement (suite)

4. Insérez le contour entièrement dans la partie

supérieure et l'arrière du support jusqu'à ce qu'il

atteigne la butée arrière (Fig. 2).

CONSEIL : Assurez-vous que les petites dépressions de

prise ont fixé solidement la surface du papier de verre.

5. Remettez le support en place en exerçant une

pression ferme jusqu'à ce que le contour « s'enclenche

» en position.

Pour enlever le contour, faites tourner le levier pour

relâcher et abaisser le support de serrage d'accessoires.

Vous êtes maintenant prêt à poser une autre forme de

contour ou un autre patin pour travail de précision.

Conseils relatifs aux accessoires

“

Contours : Utilisez des tubes de ponçage durables,

réutilisables et faciles à poser. Pour poser, faites glisser

le tube entièrement par-dessus le contour désiré et

façonnez le papier au contour. Vous pouvez également

tourner les tubes abrasifs de contour sur le contour afin

de maximaliser l'utilisation de la surface abrasive.

Rouleaux à auto-adhésif : Vous pouvez également

utiliser les rouleaux à auto-adhésif avec les contours

individuels. Déroulez une bande d'abrasif

correspondant au contour particulier, et coupez à la

longueur à l'aide de ciseaux. En utilisant un autoadhésif, vous pouvez obtenir un serrage optimal en

enveloppant de papier toute la surface du contour.

Pressez fermement l'abrasif en place sur le contour.

Pour retirer l'abrasif, soulevez un coin de la feuille avec

votre ongle et détachez-la. Jetez les abrasifs usés, ils ne

sont pas réutilisables.

CONSEIL : Lorsque vous utilisez les contours concaves

de 1/8 po et de 3/16 po avec les tubes de ponçage, il est

plus facile d'adapter l'abrasif à l'ouvrage en utilisant un

papier à grain plus fin.

Lorsque vous utilisez des tubes de ponçage, tournez-les

régulièrement afin de maximaliser toutes les surfaces en

vue d'une utilisation plus longue et plus efficace.

CONSEIL : Lorsque vous atteignez des endroits

extrêmement restreints, vous pouvez étendre le contour

au-delà de la partie avant de l'outil.

REMARQUE : N'EXERCEZ PAS UNE PRESSION

EXCESSIVE SUR L'OUTIL PENDANT QU'IL EST EN

USAGE. LAISSEZ LA VITESSE DE L'OUTIL ET

L'ACCESSOIRE FAIRE LE TRAVAIL. L'EMPLOI D'UNE

PRESSION SUPERFLUE USERA L'ACCESSOIRE DE

FAÇON INÉGALE ET NE PERMETTRA PAS D'EXÉCUTER

LE TRAVAIL PLUS RAPIDEMENT.

”

REMARQUE : Les formes de contour ont été extrudées

à la dimension indiquée sur la forme. En exécutant un

travail exigeant, il faudra prévoir une tolérance en

fonction du papier de verre employé. Les papiers à grain

plus lourd/grossier nécessitent une tolérance plus

grande.

Les auto-adhésifs donnent des prestations optimales à

des températures supérieures à -4°C. Si les patins et les

abrasifs auto-adhésifs sont stockés à des températures

plus basses, il peut être nécessaire de les laisser

atteindre la température ambiante avant de les utiliser.

Les rouleaux à auto-adhésif doivent être stockés dans

un environnement sans poussière afin de prévenir la

contamination de l'adhésif.

Après un usage intensif, il se peut que la surface d'appui

du patin pour travail de précision soit usée. Le coussinet

d'appui doit être remplacé lorsqu'il n'offre plus une

prise ferme. En cas d'usure prématurée de la surface du

coussinet d'appui, réduisez le niveau de pression que

vous exercez durant l'utilisation de l'outil.

Conseils relatifs à l'outil

“

Cette machine est particulièrement adaptée pour l'accès

aux coins et aux bords qui sont par ailleurs difficiles à

atteindre ou qui nécessitent un ponçage manuel. Les

profilés et les rainures peuvent être finis en utilisant

l'extrémité ou le bord de l'accessoire sélectionné qu'on

doit parfois tourner durant l'usage de manière à répartir

l'usure sur la surface de l'accessoire ou du coussinet

d'appui.

Assurez-vous toujours que les ouvrages plus petits sont

fixés solidement à un établi ou autre support. Les

”

panneaux de plus grandes dimensions peuvent être

maintenus en place à la main sur un établi ou un

chevalet de scieur.

PONÇAGE : Les feuilles de ponçage en oxyde

d'aluminium à couche ouverte sont recommandées

pour la plupart des applications de ponçage du bois ou

des métaux, car cette matière synthétique coupe

rapidement et dure longtemps.

-19-

Page 20

Vous pouvez vous reporter aux suggestions ci-après

comme guide général de sélection des abrasifs, mais

vous obtiendrez de meilleurs résultats en procédant

d'abord à un essai de ponçage sur un échantillon du

matériau.

Grain Application

Grain grossier Pour le bois rugueux, le ponçage

80 des métaux, ou l'enlèvement de

Grain moyen 120 Pour le ponçage général du bois

Grain ultra-fin 220 Pour le ponçage de finition du

L'ouvrage étant fixé solidement, mettez l'outil en

marche. Mettez l'ouvrage en contact avec l'outil une fois

que la ponceuse a atteint la vitesse sélectionnée, et

retirez l'outil de l'ouvrage avant de mettre l'outil à

l'arrêt. L'utilisation de votre ponceuse de cette manière

prolongera la durée de l'interrupteur et du moteur, et

accroîtra considérablement la qualité de votre

travail.Votre ponceuse de contour utilise un mouvement

SÉLECTION DES ABRASIFS

la rouille, de la peinture ou des

vieux matériaux

ou des métaux

bois nu, le lissage de la vieille

peinture ou la préparation d'une

surface finie en vue d'une

nouvelle application.

Maintenance

Entretien

!

AVERTISSEMENT

non autorisés peut entraîner un positionnement erroné

des composants et des fils internes, et ainsi causer

des dangers sévères. Il est recommandé que l’entretien

et la réparation de nos outils soient confiés à un centre

de service-usine Dremel ou à un centre de service

après-vente Dremel agréé.

Les balais et le collecteur de votre outil ont été conçus

pour donner plusieurs heures de fonctionnement sans

aléas. Pour maintenir le moteur en forme, nous

recommandons d’examiner les balais tous les deux à six

mois. Vous ne devriez utiliser que les balais de rechange

d’origine Dremel qui conviennent spécialement à votre

outil.

ENTRETIEN DES BALAIS REMPLAÇABLES #5090930

Les balais doivent être inspectés fréquemment lorsque

les outils sont utilisés de façon continue. Si l’outil ne

tourne que sporadiquement, perd de la puissance,

produit des bruits inusités ou tourne à vitesse réduite,

vérifiez les balais. Si vous continuez à utiliser l’outil

dans cet état, vous pourriez l’abîmer de façon

permanente.

Le cordon étant débranché, retirez les capuchons des

BALAIS DE CHARBON

L’entretien préventif

effectué par des employés

de ponçage en ligne. Vous obtiendrez le meilleur fini de

surface en utilisant la ponceuse en ligne avec le grain du

bois. On peut obtenir un enlèvement plus rapide des

matériaux en utilisant la ponceuse à travers le grain

lorsqu'on passe sur des surfaces rugueuses, puis en

finissant en ponçant avec le grain.

N'EXERCEZ PAS UNE PRESSION EXCESSIVE LAISSEZ L'OUTIL FAIRE LE TRAVAIL. UNE PRESSION

EXCESSIVE ENTRAÎNERA UN PIÈTRE MANIEMENT,

DES VIBRATIONS ET DES MARQUES NON DÉSIRÉES

DE PONÇAGE.

Si la surface est rugueuse, commencez par des grains

plus gros, puis terminez le travail de surface avec des

abrasifs moyens et fins. Pour éviter des résultats

inégaux, ne sautez pas plus d'une dimension de grain

en passant du plus grossier au plus fin, et ne poncez

pas trop longtemps à un endroit. Une fois le travail

terminé, levez délicatement l'outil de la surface de

travail et faites glisser l'interrupteur à la position d'arrêt.

Pour prolonger la durée et répartir l'usure

uniformément, brossez délicatement pour enlever tout

résidu ou matériau bloqué sur la surface du papier de

verre avant chaque usage.

!

AVERTISSEMENT

humide.

balais un à la fois, à l’aide d’un petit tournevis, en

tournant le capuchon en sens anti-horaire, et vérifiez

chacun des balais.

Si le balai a moins de 1/8" de long et que le bout du

balai qui vient en contact avec le commutateur est

rugueux et/ou piqué, le balai doit être remplacé. Vérifiez

les deux balais. Habituellement, les balais ne s’usent

pas simultanément mais, si l’un d’eux est usé,

remplacez les deux. Assurez-vous que les balais sont

posés de la manière illustrée. La surface courbée du

balai doit suivre la courbe du commutateur.

COURBURE

Après avoir remplacé les balais, on doit faire tourner

l’outil sans charge ; placez-le sur une surface propre et

N'utilisez pas cette ponceuse

pour le ponçage par voie

L’EXTRÉMITÉ COURBÉE

DU BALAI DOIT SUIVRE

LA COURBE DU BÂTI

RESSORT

DE BALAI

DU BÂTI

BALAI

CAPUCHON DU BALAI

-20-

RONDELLE

Page 21

laissez-le tourner librement pendant cinq minutes sans

charger (ou utiliser) l’outil. Les balais pourront ainsi se

« caler » adéquatement, et chaque jeu de balais durera

plus longtemps. La vie totale de votre outil s’en trouvera

également prolongée car la surface du commutateur

durera plus longtemps.

GRAISSAGE DE L’OUTIL

Votre outil Dremel a été convenablement graissé et

est prêt à utiliser. Aucun graissage supplémentaire

n'est nécessaire dans des conditions normales

d'utilisation.

Nettoyage

!

AVERTISSEMENT

Pour éviter le risque

d’accidents, débranchez

toujours l’outil de la prise de courant avant de

procéder au nettoyage ou à l’entretien. Vous pouvez

très bien le nettoyer à l’air comprimé. Dans ce cas,

portez toujours des lunettes de sécurité.

Gardez les prises d’air et les interrupteurs propres et

libres de débris. N’essayez pas de les nettoyer en

introduisant des objets pointus dans leurs ouvertures.

!

AVERTISSEMENT

Certains produits de

nettoyage et dissolvants

dont la gazoline, le tétrachlorure de carbone, les

nettoyeurs chlorés, l’ammoniaque et les détergents

ménagers contenant de l’ammoniaque peuvent abîmer

les pièces en plastique.

!

AVERTISSEMENT

Si un cordon de rallonge

s'avère nécessaire, vous

devez utiliser un cordon avec conducteurs de

dimension adéquate pouvant porter le courant

nécessaire à votre outil. Ceci préviendra une chute

excessive de tension, une perte de courant ou une

surchauffe. Les outils mis à la terre doivent utiliser des

cordons de rallonge trifilaires pourvus de fiches à trois

broches ainsi que des prises à trois broches.

REMARQUE : Plus le calibre est petit, plus le fil est gros.

Votre ponceuse à contours peut être équipée d'un

tube de collecte de poussière offert en option. Ce

dispositif est efficace lors de la collecte de poussière à

l'aide d'un patin de ponçage lorsqu'il est utilisé avec

un aspirateur d'atelier dont les tuyaux présentent un

diamètre intérieur de 1 1/2 po ou un diamètre

extérieur de 1 3/8 po ou un adaptateur approprié pour

correspondance (reportez-vous au schéma de la page

31). Lorsque vous utilisez le tube, assurez-vous

d'aligner les trous de la feuille de papier de verre sur

les trous du patin de ponçage afin de permettre un

fonctionnement approprié du tube de poussière.

Le patin pour travail de précision (et le patin pour

volets offert en option) peuvent être utilisés avec du

DIMENSIONS DE RALLONGES RECOMMANDÉES

OUTILS 120 VOLTS COURANT ALTERNATIF

Intensité

nominale

de l’outil

3-6

6-8

8-10

10-12

12-16

Longueur en pieds

Calibre A.W.G.

25 50 100 150 15 30 60 120

18 16 16 14 .75 .75 1.5 2.5

18 16 14 12 .75 1.0 2.5 4.0

18 16 14 12 .75 1.0 2.5 4.0

16 16 14 12 1.0 2.5 4.0 —

14 12 — — — — — —

Longueur en mètres

Calibre en mm

2

papier de verre à crochets et boucles avec ou sans

trous pour collecte de poussière. Si vous avez acheté

du papier de verre sans trous, vous pouvez percer des

trous manuellement pour utilisation avec le tube de

poussière.

L'utilisation de papier de verre avec trous - sans

utilisation du tube de poussière - n'abîmera et

n'endommagera pas votre travail. Cette ponceuse

fonctionnera efficacement avec ou sans système de

collecte de poussière.

Pour commander des contours individuels (ci-après)

ou pour plus de renseignements au sujet du dispositif

de collecte de poussière, appelez le Service clientèle

Dremel au 1-800-437-3635.

#6017 #6018 #6019 #6020 #6021 #6022 #6023 #6024 #6025

3.2mm 4.6mm 6.4mm 9.5mm 13.0mm 7.8mm 3.2mm 4.8mm 6.4mm

Rayon

#6026 #6027 #6028 #6029 #6030 #6031 #6032 #6033 #6034

9.5mm 13.0mm 7.8mm Plat 30º 45º 60º 90º 90º

-21-

Page 22

Garantie limitée de Dremel

Votre produit Dremel est garanti contre les vices de matériaux ou d’exécution pendant un délai deux

ans depuis la date d’achat. Dans l’hypothèse où le produit ne se conformerait pas à cette garantie

écrite, veuillez procéder de la façon suivante :

1. NE RAPPORTEZ PAS le produit à l’endroit où vous l’avez acheté.

2. Emballez avec soin le produit seul, sans aucun autre article, et renvoyez-le, port payé,

accompagné :

A. d’une copie de votre preuve d’achat datée (veuillez en garder une copie pour vous-même)

B. d’une déclaration écrite concernant la nature du problème

C. d’une indication de vos nom, adresse et numéro de téléphone, à l’adresse suivante :

ÉTATS-UNIS

Dremel Service Center Dremel Service Center

4915 Twenty-First Street OU 4631 E. Sunny Dunes

Racine, Wisconsin 53406 Palm Springs, California 92264

CANADA À L’EXTÉRIEUR DU TERRITOIRE

Giles Tool Agency CONTINENTAL DES ÉTATS-UNIS

6520 Lawrence Av. East Consultez votre distributeur local ou écrivez à :

Scarborough, Ontario Dremel

Canada M1C 4A7 4915 Twenty-First St.

Nous vous recommandons d’assurer le paquet contre la perte ou les dommages en cours de route

dont nous ne pouvons assumer la responsabilité.

Cette garantie n’est offerte qu’à l’acheteur enregistré d’origine. LES DOMMAGES AU PRODUIT

RÉSULTANT DE MANIPULATIONS, ACCIDENT, USAGE ABUSIF, NÉGLIGENCE, RÉPARATIONS OU

ALTÉRATIONS NON AUTORISÉES, UTILISATION D’ACCESSOIRES NON APPROUVÉS OU AUTRES

CAUSES NON LIÉES À LA DÉFAILLANCE DES MATÉRIAUX OU DE L’EXÉCUTION NE SONT PAS

COUVERTS PAR CETTE GARANTIE.

Aucun employé, mandataire, vendeur ou autre personne n’est autorisé à accorder des garanties au

nom de Dremel. Si l’inspection effectuée par Dremel révèle que le problème a été causé par une

défaillance des matériaux ou de l’exécution dans les limites de la garantie, Dremel réparera ou

remplacera le produit gratuitement et renverra le produit port payé. Si elles peuvent être effectuées,

les réparations rendues nécessaires par l’usure normale ou un usage abusif, ou les réparations du

produit une fois expirée la période de garantie, seront facturées aux tarifs réguliers de l’usine.

DREMEL N’ACCORDE AUCUNE AUTRE GARANTIE DE QUELQUE NATURE QUE CE SOIT, EXPLICITE

OU IMPLICITE, ET TOUTES LES GARANTIES IMPLICITES DE COMMERCIALISATION ET

D’APTITUDE À UN USAGE PARTICULIER EN SUS DE L’OBLIGATION SUSVISÉE SONT DÉNIÉES

PAR LES PRÉSENTES PAR DREMEL ET EXCLUES DE CETTE GARANTIE LIMITÉE.

Cette garantie vous accorde certains droits précis, et vous pouvez également avoir d’autres droits qui

varient d’un endroit à un autre. L’obligation du garant se limite à réparer ou remplacer le produit. Le

garant n’est responsable d’aucun dommage accessoire ou indirect attribuable à cette supposée

défaillance. Certaines juridictions ne permettent pas l’exclusion ou la limitation des dommages

accessoires ou indirects ; il se peut donc que les limitations ou l’exclusion qui précède ne

s’appliquent pas à vous.

En ce qui concerne les prix et la façon de vous prévaloir de la garantie sur le territoire continental des

États-Unis, mettez-vous en contact avec votre distributeur Dremel local.

Exportado por: Robert Bosch Tool Corporation Mt. Prospect, IL 60056 -2230, E.U.A.

Importado en México por: Robert Bosch, S.A. de C.V., Calle Robert Bosch No. 405, Zona

Industrial, Toluca, Edo. de México, C.P. 50070, Tel. (722) 2792300

Racine, Wisconsin 53406

-22-

Page 23

Lijadora de contornear

Manual del usuario

Modelo 6000

Sea sincero … ¿Ha leído este

MANUAL DEL USUARIO?

• Seguridad

• Ensamblaje

• Funcionamiento

• Maintenance

• Información sobre accesorios

• Garantía

• Piezas de repuesto

P.O. Box 1468

Racine, Wisconsin 53401

1-800-437-3635

http://www.dremel.com

Los productos de la marca Dremel son fabricados y vendidos por la

División Dremel de Robert Bosch Tool Corporation

-23-

©

Robert Bosch Tool

Corporation

1997

Todos los derechos

reservados

Page 24

Normas de seguridad para herramientas mecánicas

!

ADVERTENCIA

personales graves.

Lea y entienda todas las instrucciones. El incumplimiento de todas las instrucciones

indicadas a continuación puede dar lugar a sacudidas eléctricas, incendios y/o lesiones

CONSERVE ESTAS INSTRUCCIONES

Area de trabajo

Mantenga el área de trabajo limpia y bien iluminada.

Las mesas desordenadas y las áreas oscuras invitan a

que se produzcan accidentes.

No utilice herramientas mecánicas en atmósferas

explosivas, tales como las existentes en presencia de

líquidos, gases o polvos inflamables. Las

herramientas mecánicas generan chispas y éstas

pueden dar lugar a la ignición del polvo o los vapores.

Mantenga a las personas que se encuentren

presentes, a los niños y a los visitantes alejados al

utilizar una herramienta mecánica. Las distracciones

pueden hacer que usted pierda el control.

Seguridad eléctrica

Las herramientas con aislamiento doble están

equipadas con un enchufe polarizado (un terminal es

más ancho que el otro). Este enchufe entrará en un

tomacorriente polarizado solamente de una manera.

Si el enchufe no entra por completo en el

tomacorriente, déle la vuelta. Si sigue sin entrar,

póngase en contacto con un electricista competente

para instalar un tomacorriente polarizado. No haga

ningún tipo de cambio en el enchufe. El aislamiento

doble elimina la necesidad del sistema de cordón de

energía de tres hilos conectado a tierra y la fuente de

energía conectada a tierra. Antes de enchufar la

herramienta, asegúrese de que la tensión del

tomacorriente suministrada se encuentre dentro del

margen de la tensión especificada en la placa del

fabricante. No utilice herramientas con capacidad

nominal "AC solamente" ("AC only") con una fuente de

energía DC.

Evite el contacto del cuerpo con las superficies

conectadas a tierra tales como tuberías, radiadores,

estufas de cocina y refrigeradores. Hay mayor riesgo

de que se produzcan sacudidas eléctricas si su cuerpo

está conectado a tierra. Si la utilización de la

herramienta mecánica en lugares húmedos es

inevitable, se debe usar un interruptor de circuito para

fallos a tierra para suministrar la energía a la

herramienta. Los guantes de goma para electricista y el

calzado antideslizante aumentarán más la seguridad

personal.

No exponga las herramientas mecánicas a la lluvia ni

a situaciones húmedas. La entrada de agua en una

herramienta mecánica aumentará el riesgo de que se

produzcan sacudidas eléctricas.

No abuse del cordón. Nunca use el cordón para llevar

las herramientas ni para sacar el enchufe de un

tomacorriente. Mantenga el cordón alejado del calor, el

aceite, los bordes afilados o las piezas móviles. Cambie

los cordones dañados inmediatamente. Los cordones

dañados aumentan el riesgo de que se produzcan

sacudidas eléctricas.

Al utilizar una herramienta mecánica a la intemperie,

utilice un cordón de extensión para intemperie

marcado "W-A" o "W". Estos cordones tienen

capacidad nominal para uso a la intemperie y reducen el

riesgo de que se produzcan sacudidas eléctricas.

Consulte "Tamaños recomendados de los cordones de

extensión" en la sección Accesorios de este manual.

Seguridad personal

Manténgase alerta, fíjese en lo que está haciendo y

use el sentido común cuando utilice una herramienta

mecánica. No use la herramienta cuando esté

cansado o se encuentre bajo la influencia de drogas,

alcohol o medicamentos. Un momento de distracción

al utilizar herramientas mecánicas puede dar lugar a

lesiones personales graves.

Vístase adecuadamente. No se ponga ropa holgada ni

joyas. Sujétese el pelo. Mantenga el pelo, la ropa y

los guantes alejados de las piezas móviles. La ropa

holgada, las joyas o el pelo largo pueden quedar

atrapados en las piezas móviles. Mantenga los mangos

secos, limpios y libres de aceite y grasa.

Evite el arranque accidental. Asegúrese de que el

interruptor esté en la posición "OFF" (apagado) antes

de enchufar la herramienta. El llevar las herramientas

con el dedo en el interruptor o el enchufar herramientas

que tengan el interruptor en la posición "ON"

(encendido) invita a que se produzcan accidentes.

Quite las llaves de ajuste o de tuerca antes de

encender la herramienta. Una llave de ajuste o de

tuerca que se deje puesta en una pieza giratoria de la

herramienta puede ocasionar lesiones personales.

No intente alcanzar demasiado lejos. Mantenga un

apoyo de los pies y un equilibrio adecuados en todo

momento. El apoyo de los pies y el equilibrio

adecuados permiten un mejor control de la herramienta

en situaciones inesperadas.

Utilice equipo de seguridad. Use siempre protección

de los ojos. Se debe utilizar una máscara antipolvo,

zapatos de seguridad antideslizantes, casco o

protección de los oídos según lo requieran las

condiciones.

Utilización y cuidado de las herramientas

Utilice abrazaderas u otro modo práctico de fijar y

soportar la pieza de trabajo a una plataforma estable.

La sujeción de la pieza de trabajo con la mano o contra

-24-

Page 25

el cuerpo resulta inestable y puede ocasionar pérdida de

control.

No fuerce la herramienta. Use la herramienta

correcta para la aplicación que desea. La herramienta

correcta hará el trabajo mejor y con más seguridad a la

capacidad nominal para la que está diseñada.

No utilice la herramienta si el interruptor no la

enciende o apaga. Toda herramienta que no se pueda

controlar con el interruptor es peligrosa y debe ser

reparada.

Desconecte el enchufe de la fuente de energía antes

de hacer cualquier ajuste, cambiar accesorios o

guardar la herramienta. Estas medidas de seguridad

preventivas reducen el riesgo de arrancar la herramienta

accidentalmente.

Guarde las herramientas que no esté usando fuera

del alcance de los niños y otras personas no

capacitadas. Las herramientas son peligrosas en las

manos de los usuarios no capacitados.

Mantenga las herramientas con cuidado. Conserve

las herramientas de corte afiladas y limpias. Las

herramientas mantenidas adecuadamente, con bordes

de corte afilados, tienen menos probabilidades de

atascarse y son más fáciles de controlar. Toda

alteración o modificación constituye un uso incorrecto y

puede tener como resultado una situación peligrosa.

Compruebe la desalineación o el atasco de las piezas

móviles, la ruptura de piezas y cualquier otra

situación que pueda afectar el funcionamiento de las

herramientas. Si la herramienta está dañada, haga

que realicen un servicio de ajustes y reparaciones a

la herramienta antes de usarla. Muchos accidentes

son causados por herramientas mantenidas

deficientemente. Establezca un programa de

mantenimiento periódico para la herramienta.

Utilice únicamente accesorios que estén

recomendados por el fabricante de su modelo. Los

accesorios que pueden ser adecuados para una

herramienta pueden volverse peligrosos cuando se

utilizan en otra herramienta.

Servicio

El servicio de ajustes y reparaciones de una

herramienta debe ser realizado únicamente por

personal de reparaciones competente. El servicio o

mantenimiento realizado por personal no competente

podría ocasionar un peligro de que se produzcan

lesiones. Por ejemplo: Los cables internos pueden

colocarse mal o pellizcarse, los resortes de retorno de

los protectores de seguridad pueden montarse

inadecuadamente.

Al realizar servicio de ajustes y reparaciones de una

herramienta, utilice únicamente piezas de repuesto

idénticas. Siga las instrucciones que aparecen en la

sección Mantenimiento de este manual. El uso de

piezas no autorizadas o el incumplimiento de las

instrucciones de Mantenimiento puede ocasionar un

peligro de que se produzcan sacudidas eléctricas o

lesiones. Ciertos agentes de limpieza, tales como

gasolina, tetracloruro de carbono, amoníaco, etc.,

pueden dañar las piezas de plástico.

Normas de seguridad para la lijadora de contornear

Desenchufe la lijadora antes de cambiar

accesorios. Se pueden producir arranques

accidentales si la lijadora está enchufada mientras se

cambia un accesorio.

Si su herramienta está equipada con una bolsa para

polvo, vacíela frecuentemente y después de

terminar de lijar. Sea extremadamente cuidadoso al

eliminar el polvo, ya que los materiales en forma de

partículas finas pueden ser explosivos. No tire el

polvo resultante del lijado a un fuego abierto. Al cabo

del tiempo se puede producir una combustión

espontánea como consecuencia de la mezcla de

aceite o agua con las partículas de polvo.

Use siempre protección para los ojos y una

máscara antipolvo para aplicaciones que generen

polvo y al lijar en alto. Las partículas resultantes del

lijado pueden ser absorbidas por los ojos e inhaladas

fácilmente y pueden causar complicaciones de salud.

Use precauciones especiales al lijar madera

tratada químicamente a presión, pintura que pueda

estar basada en plomo o cualquier otro material

que pueda contener carcinógenos. Todas las

personas que entren en el área de trabajo deben usar

un aparato de respiración adecuado y ropa

protectora. El área de trabajo debe cerrarse con

cubiertas colgantes de plástico y debe mantenerse

fuera a las personas no protegidas hasta que el área

de trabajo haya sido limpiada a fondo.

No lije en mojado con esta lijadora. La entrada de

líquidos en la caja del motor constituye un peligro de

sacudidas eléctricas.

No use papel de lija diseñado para zapatas de lijar

más grandes. El papel de lija más grande sobresaldrá

de la zapata de lijar, causando atasco y rasgado del