Page 1

DM 2610934164 05-06 10/6/06 8:41 AM Page 1

400 Series Digital

High Speed Rotary Tool

Operating/Safety Instructions

Model 398-49

HONESTLY NOW … Have you read

this OWNER’S MANUAL?

• Safety

• Assembly

• Operation

• Maintenance

• Accessory Information

• Warranty

• Service Parts

03-5415317

http://www.dremel.com

Dremel brand products are manufactured and sold by the

Dremel Division of Robert Bosch T

2610934164 10/06 Printed in Mexico

ool Corporation

This symbol refers to

the EMC requirements

of the Australian

Standards

Page 2

DM 2610934164 05-06 10/6/06 8:41 AM Page 2

Power Tool Safety Rules

WARNING

!

Read and understand all instructions. Failure to follow all instructions listed below, may

result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases, or dust.

which may ignite the dust or fumes.

Keep by-standers, children, and visitors away while

operating a power tool. Distractions can cause you

to lose control.

Power tools create sparks

Electrical Safety

Double Insulated tools are equipped with a polarized

plug (one blade is wider than the other.) This plug

will fit in a polarized outlet only one way. If the plug

does not fit fully in the outlet, reverse the plug. If it

still does not fit, contact a qualified electrician to

install a polarized outlet. Do not change the plug in

any way.

the three wire grounded power cord and grounded

power supply system. Before plugging in the tool, be

certain the outlet voltage supplied is within the voltage

marked on the nameplate. Do not use “AC only” rated

tools with a DC power supply.

Avoid body contact with grounded surfaces such as

pipes, radiators, ranges and refrigerators. There is

an increased risk of electric shock if your body is

grounded. If operating the power tool in damp

locations is unavoidable, a Ground Fault Circuit

Interrupter must be used to supply the power to your

tool. Electrician’s rubber gloves and footwear will

further enhance your personal safety.

Don't expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

Do not abuse the cord. Never use the cord to carr

the tools or pull the plug from an outlet. Keep cord

away from heat, oil, sharp edges or moving parts.

Replace damaged cords immediately.

cords increase the risk of electric shock.

When operating a power tool outside, use an

outdoor extension cord marked "W

cords are rated for outdoor use and reduce the risk of

electric shock. Refer to “Recommended sizes of

Extension Cords” in the Accessory section of this

manual.

Double Insulation eliminates the need for

Damaged

."

-A" or "W

These

Personal Safety

Stay alert, watch what you are doing and use

common sense when operating a power tool. Do not

use tool while tired or under the influence of drugs,

alcohol, or medication.

while operating power tools may result in serious

personal injury.

Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair, clothing,

and gloves away from moving parts. Loose clothes,

jewelry, or long hair can be caught in moving parts.

Keep handles dry, clean and free from oil and grease.

Avoid accidental starting. Be sure switch is “OFF”

before plugging in. Carrying tools with your finger on

the switch or plugging in tools that have the switch

“ON” invites accidents.

Remove adjusting keys or wrenches before turning

the tool “ON”. A wrench or a key that is left attached

to a rotating part of the tool may result in personal

injury.

Do not overreach. Keep proper footing and balance

at all times. Proper footing and balance enables

better control of the tool in unexpected situations.

Use safety equipment. Always wear eye protection.

Dust mask, non-skid safety shoes, hard hat, or

hearing protection must be used for appropriate

conditions.

A moment of inattention

Tool Use and Care

Use clamps or other practical way to secure and

support the workpiece to a stable platform. Holding

the work by hand or against your body is unstable

and may lead to loss of control.

Do not force tool. Use the correct tool for your

application.

y

safer at the rate for which it is designed.

Do not use tool if switch does not turn it “ON” or

“OFF”.

switch is dangerous and must be repaired.

Disconnect the plug from the power source before

making any adjustments, changing accessories, or

storing the tool.

reduce the risk of starting the tool accidentally.

Store idle tools out of reach of children and other

untrained persons. Tools are dangerous in the hands

of untrained users.

Page 2

The correct tool will do the job better and

Any tool that cannot be controlled with the

Such preventive safety measures

Page 3

DM 2610934164 05-06 10/6/06 8:41 AM Page 3

Maintain tools with care. Keep cutting tools sharp

and clean. Properly maintained tools, with sharp

utting edges are less likely to bind and are easier to

c

control. Any alteration or modification is a misuse and

may result in a dangerous condition.

Check for misalignment or binding of moving parts,

breakage of parts, and any other condition that may

affect the tools operation. If damaged, have the tool

serviced before using.

poorly maintained tools. Develop a periodic

maintenance schedule for your tool.

Use only accessories that are recommended by the

manufacturer for your model. Accessories that may

be suitable for one tool, may become hazardous when

used on another tool.

Many accidents are caused by

Safety Rules for Rotary Tools

Accessories must be rated for at least the speed

recommended on the tool warning label.

and other accessories running over rated speed can

fly apart and cause injury.

Hold tool by insulated gripping surfaces when

performing an operation where the cutting tool may

contact hidden wiring or its own cord. Contact with

a "live" wire will make exposed metal parts of the tool

"live" and shock the operator. If cutting into existing

walls or other blind areas where electrical wiring may

exist is unavoidable, disconnect all fuses or circuit

breakers feeding this worksite.

Do not operate the flexible shaft with a sharp bend.

Over bending the shaft can generate excessive heat

on the jacket or hand piece. The recommended

minimum is 13cm radius.

Always disconnect the power cord from the power

source before making any adjustments or attaching

any accessories. You may unexpectedly cause the

tool to start leading to serious personal injury.

Be aware of the switch location, when placing the

tool down or when picking the tool up.

accidentally activate the switch.

Always hold the hand piece firmly in your hands

during the start-up. The reaction torque of the motor,

as it accelerates to full speed, can cause the shaft to

twist.

Always wear safety goggles and dust mask. Use

only in well ventilated area.

devices and working in safe environment reduces risk

of injury.

Using personal safety

Wheels

You may

Service

Tool service must be performed only by qualified

repair personnel.

by unqualified personnel could result in a risk of

injury. For example: internal wires may be misplaced

or pinched, safety guard return springs may be

improperly mounted.

When servicing a tool, use only identical

replacement parts. Follow instructions in the

Maintenance section of this manual. Use of

unauthorized parts or failure to follow Maintenance

Instructions may create a risk of electric shock or

injury. Certain cleaning agents such as gasoline,

carbon tetrachloride, ammonia, etc. may damage

plastic parts.

After changing the bits or making any adjustments,

make sure the collet nut and any other adjustment

devices are securely tightened. Loose adjustment

device can unexpectedly shift, causing loss of control,

loose rotating components will be violently thrown.

Do not reach in the area of the spinning bit. The

proximity of the spinning bit to your hand may not

always be obvious.

Allow brushes to run at operating speed for at least

one minute before using wheel. During this time no

one is to stand in front or in line with the brush.

Loose bristles or wires will be discharged during the

run-in time.

Wire and bristle brushes must never be operated at

speeds greater than 15.000/min. Direct the

discharge of the spinning wire brush away from

you. Small particles and tiny wire fragments may be

discharged at high velocity during the “cleaning”

action with these brushes and may become imbedded

in your skin. Bristles or wires will be discharged from

the brush at high speeds.

Wear protective gloves and face shield with wire or

bristle brushes. Apply wire or bristle brushes lightly

to the work as only the tips of the wire/bristles do

the work. “Heavy” pressure on bristles will cause the

wire or bristle to become overstressed, resulting in a

wiping action and will cause the bristles/wire to be

discharged.

Carefully handle both the tool and individual

grinding wheels to avoid chipping or cracking.

Install a new wheel if tool is dropped while

Service or maintenance performed

Page 3

Page 4

DM 2610934164 05-06 10/6/06 8:41 AM Page 4

Safety Rules for Rotary Tools - (cont.)

grinding. Do not use a wheel that may be damaged.

Fragments from a wheel that bursts during operation

will fly away at great velocity possibly striking you or

bystanders.

Never use dull or damaged bits. Sharp bits must be

handled with care. Damaged bits can snap during

use. Dull bits require more force to push the tool,

possibly causing the bit to break.

Use clamps to support workpiece whenever

practical. Never hold a small workpiece in one hand

and the tool in the other hand while in use. Allow

for sufficient space, at least 15,2cm, between your

hand and the spinning bit. Round material such as

dowel rods, pipes or tubing have a tendency to roll

while being cut, and may cause the bit to “bite” or

jump toward you. Clamping a small workpiece allows

you to use both hands to control the tool.

Inspect your workpiece before cutting. When cutting

irregularly shaped workpieces, plan your work so it

will not slip and pinch the bit and be torn from your

hand. For example, if carving wood, make sure there

are no nails or foreign objects in the workpiece. Nails

or foreign objects can cause the bit to jump.

Never start the tool when the bit is engaged in the

material. The bit cutting edge may grab the material

causing loss of control of the cutter.

Avoid bouncing and snagging the wheel, especially

when working corners, sharp edges etc.

cause loss of control and kick-back.

The direction of feed with the bit into the material

when carving, routing or cutting is very important.

Always feed the bit into the material in the same

direction as the cutting edge is exiting from the

material (which is the same direction as the chips

are thrown). Feeding the tool in the wrong direction,

causes the cutting edge of the bit to climb out of the

work and pull the tool in the direction of this feed.

If the workpiece or bit becomes jammed or bogged

down, turn the tool “OFF” by the switch. Wait for

all moving parts to stop and unplug the tool, then

work to free the jammed material. If the switch to

the tool is left “ON” the tool could restart

unexpectedly causing serious personal injury.

Do not leave a running tool unattended, turn power

off. Only when tool comes to a complete stop it is

safe to put it down.

Do not grind or sand near flammable materials.

Sparks from the wheel could ignite these materials.

This can

Do not touch the bit or collet after use. After use the

bit and collet are too hot to be touched by bare hands.

Regularly clean the tool's air vents by compressed

air. Excessive accumulation of powdered metal inside

the motor housing may cause electrical failures.

Do not allow familiarity gained from frequent use of

your rotary tool to become commonplace. Always

remember that a careless fraction of a second is

sufficient to inflict severe injury.

Do not alter or misuse tool. Any alteration or

modification is a misuse and may result in serious

personal injury.

This product is not intended for use as a dental

drill, in human or veterinary medical applications.

Serious personal injury may result.

When using the steel saws, cutoff wheels, high

speed cutters or tungsten carbide cutters, always

have the work securely clamped. Never attempt to

hold the work with one hand while using any of

these accessories. The reason is that these wheels

will grab if they become slightly canted in the groove,

and can kickback causing loss of control resulting in

serious injury. Your second hand should be used to

steady and guide the hand holding the tool. When a

cutoff wheel grabs, the wheel itself usually breaks.

When the steel saw, high speed cutters or tungsten

carbide cutter grab, it may jump from the groove and

you could lose control of the tool.

WARNING

!

drilling, and other construction activities contains

chemicals known to cause cancer, birth defects or

other reproductive harm. Some examples of these

chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and other

masonry products, and

• Arsenic and chromium from chemically treated

lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such

as those dust masks that are specially designed to

filter out microscopic particles.

Some dust created by power

sanding, sawing, grinding,

Page 4

Page 5

DM 2610934164 05-06 10/6/06 8:41 AM Page 5

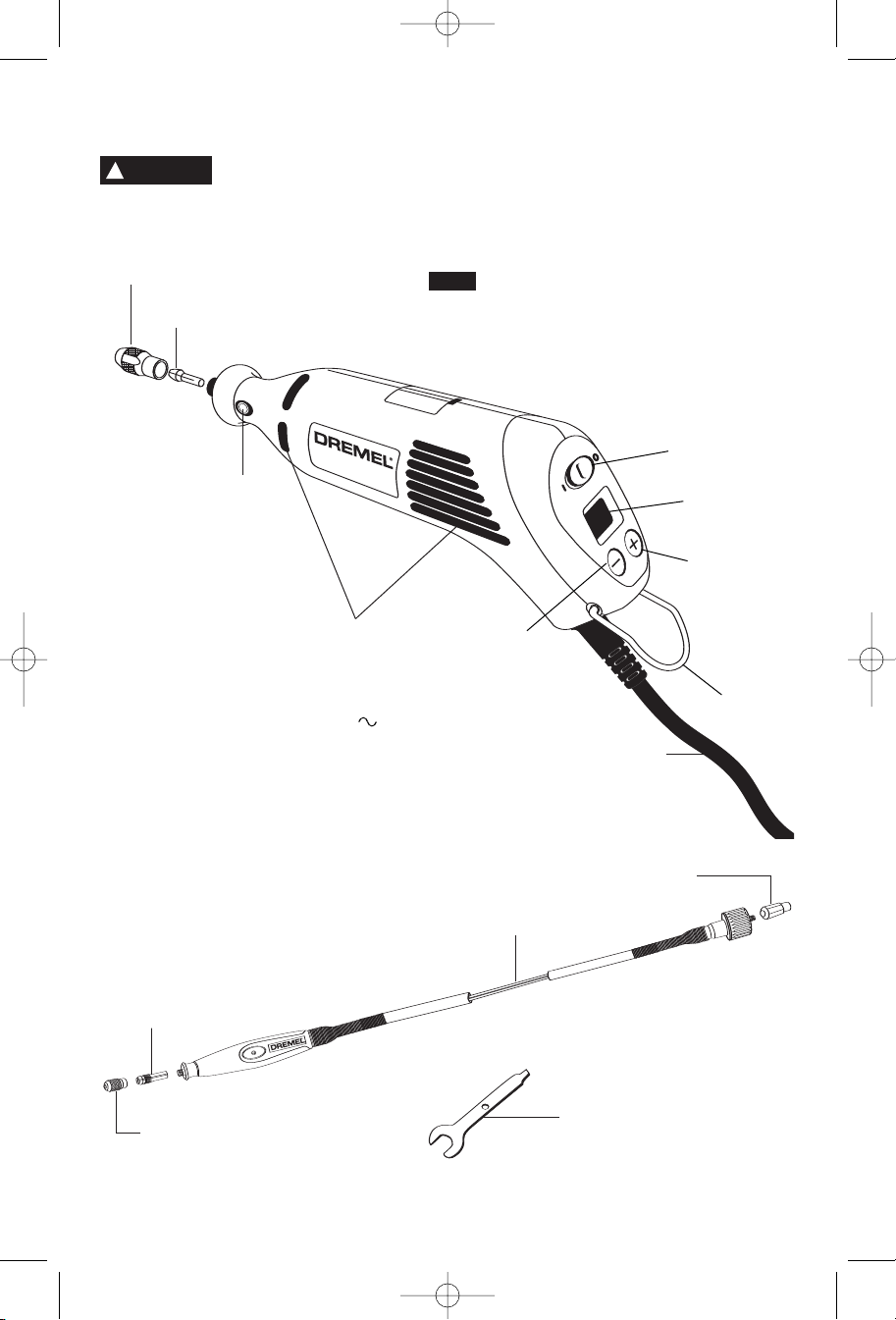

Functional Description and Specifications

WARNING

!

tool accidentally.

COLLET NUT

COLLET

Disconnect the plug from the power source before making any assembly, adjustments

or changing accessories. Such preventive safety measures reduce the risk of starting the

Rotary Tool

FIG. 1

SWITCH

SHAFT LOCK

BUTTON

VENTILATION

OPENINGS

Model number 398-49

Voltage rating 230-240 V , 50-60 Hz

Power rating 140W

No load speed n05.000-33.000/min

Collet capacities 0,8mm, 1,6mm, 2,4mm, 3,2mm

COLLET

SPEED

DOWN

BUTTON

FLEXIBLE

SHAFT

CORE

L.C.D.

DISPLAY

SPEED UP

BUTTON

HANGER

CORD

DRIVER

CAP

COLLET NUT

(NOT INCLUDED)

WRENCH

Page 5

Page 6

DM 2610934164 05-06 10/6/06 8:41 AM Page 6

Assembly

!

WARNING

collets or servicing your Rotary Tool.

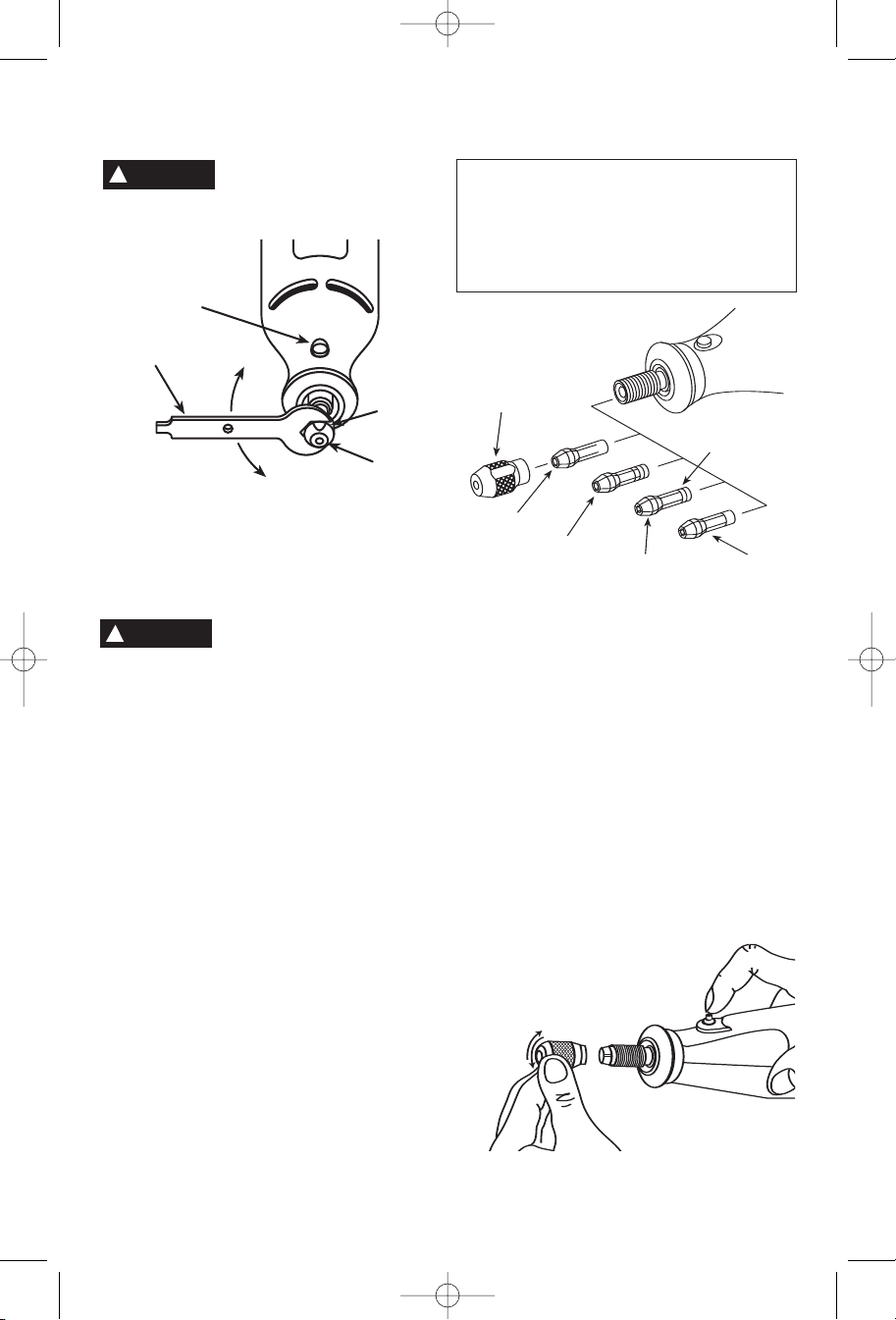

S

COLLET

WRENCH

Always unplug Rotary Tool before

changing accessories, changing

HAFT LOCK

BUTTON

TO TIGHTEN

TO LOOSEN

COLLET

NUT

COLLET

COLLET

To loosen, first press shaft lock button and rotate the

shaft by hand until the lock engages the shaft

preventing further rotation.

!

CAUTION

With the shaft lock engaged use the collet wrench to

loosen the collet nut if necessary. Change accessories

by inserting the new one into the collet as far as

possible to minimize runout and unbalance. With the

shaft lock engaged, finger tighten the collet nut until the

accessory shank is gripped by the collet. Avoid

excessive tightening of the collet nut.

Do not engage lock while the

Rotary Tool is running.

COLLETS

Four different size collets (see illustration), to

accommodate different shank sizes, are available for

your Rotary Tool. To install a different collet, remove the

collet nut and remove the old collet. Insert the unslotted

end of the collet in the hole in the end of the tool shaft.

Replace collet nut on the shaft. Always use the collet

which matches the shank size of the accessory you

plan to use. Never force a larger diameter shank into a

collet.

BALANCING ACCESSORIES

For precision work, it is important that all accessories

be in good balance (much the same as the tires on your

automobile). T

loosen collet nut and give the accessory or collet a 1/4

turn. Retighten collet nut and run the Rotary Tool. You

should be able to tell by the sound and feel if your

accessory is running in balance. Continue adjusting in

this fashion until best balance is achieved. To maintain

balance on abrasive wheel points, before each use, with

o true up or balance an accessor

y, slightly

COLLET IDENTIFICATION CHART — Collet sizes can

be identified by the rings on the back end of collet.

0,8mm Collet has one (1) ring.

1,6mm Collet has two (2) rings.

2,4mm Collet has three (3) rings.

3,2mm Collet has no rings.

COLLET

NUT

IDENTIFICATION

RINGS

480

3,2mm

COLLET

the wheel point secured in the collet, turn on the Rotary

Tool and run the 415 Dressing Stone lightly against the

revolving wheel point. This removes high spots and

trues up the wheel point for good balance.

The hanger is provided for the use of hanging your

tool while using the flex-shaft or for storage. If you do

not use the hanger, remove it from the tool and snap

it back into place underneath the cord so it will be out

of the way while the tool is in use.

481

2,4mm

COLLET

482

1,6mm

COLLET

FLEX-SHAFT TO ROTARY TOOL INSTALLATION

To properly attach the flex-shaft to the rotary tool,

THREE items must be removed from the tool: the

housing cap, collet nut and collet.

Step 1. Press the Shaft lock button, unscrew and

remove the collet nut.

Step 2. Unscrew the housing cap from the tool.

Page 6

483

0,8mm

COLLET

Page 7

DM 2610934164 05-06 10/6/06 8:41 AM Page 7

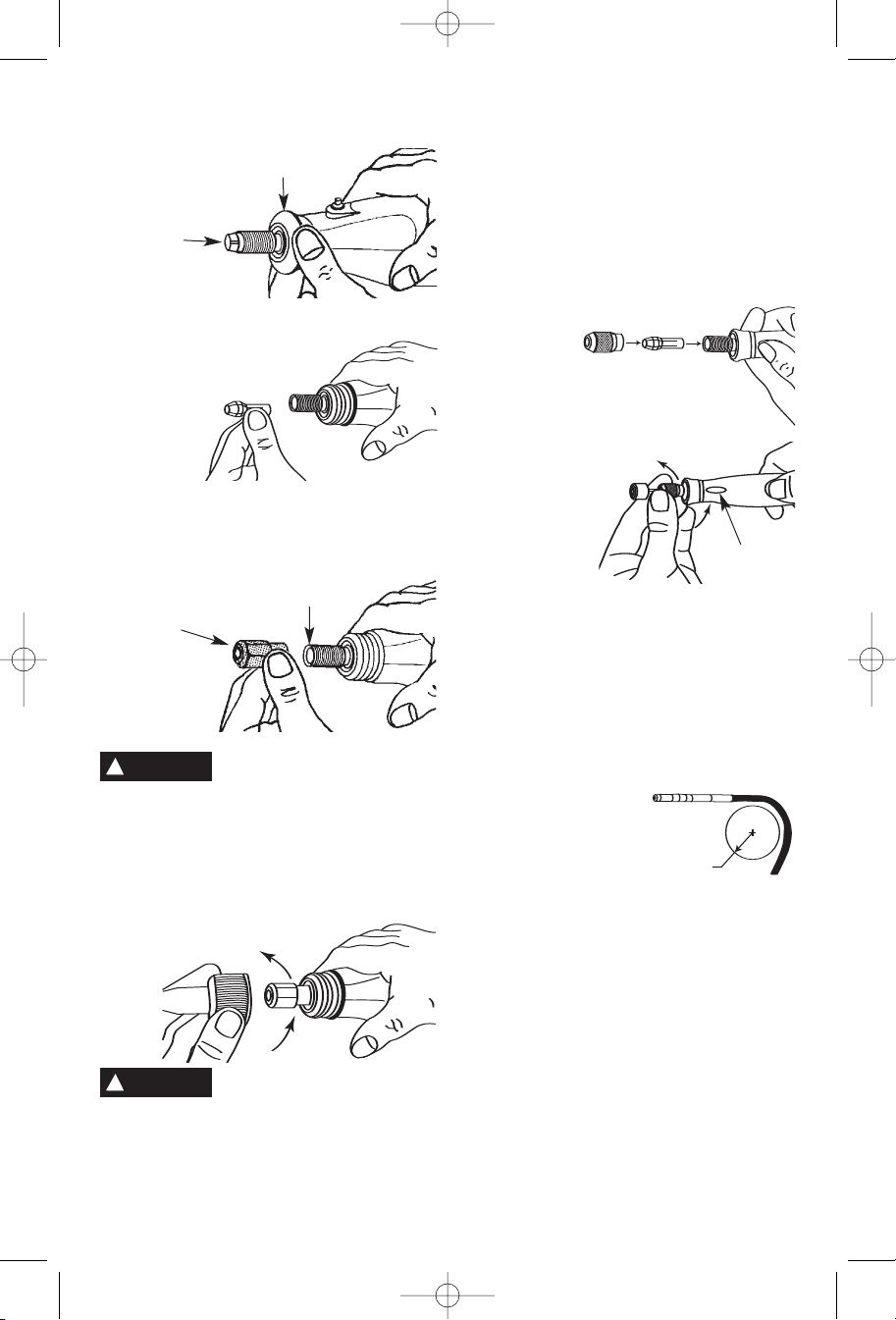

Assembly - (cont.)

OUSING

H

AP

C

OLLET

C

inside)

(

Step 3. Remove the collet.

Note: If the collet nut and collet are not removed from

the motor shaft, the tool will not function properly.

Step 4. Install the driver cap on the motor shaft and

tighten.

MOTOR

SHAFT

DRIVER

CAP

!

CAUTION

the driver cap finger tight and then tighten an

additional 1/3 turn with the wrench. (Wrench included

with your rotary tool kit)

Step 5. Attach by screwing the collar of the flex-shaft

to the rotary tool. Make sure the square end of the

center core engages the square hole socket in the

driver cap.

!

CAUTION

could cause disengagement of center core from

handpiece. If tool stops when shaft is bent, center

core may be lodged in driver cap. Loosen shaft and

remove core from driver cap. Then screw flexible

shaft onto rotary tool housing again.

To prevent damage to tool, do not

overtighten driver cap. Tighten

Do not pull out center core to

engage into driver cap. This

Disengagement of the Flex-Shaft

The flexible shaft may become disengaged if the

motor of your rotary tool is not elevated higher than

the working end of the flex-shaft. The #2222 Rotary

Tool Stand is recommended to hold the rotary tool at

the proper height.

Collet and Accessory Assembly

The collet assembly consists of a collet nut and collet.

Take the collet nut

and collet that

were removed

from your tool in

step 2 and 3 and

insert them into

the tip of the flexshaft handpiece.

Insert an accessory or

bit as deeply as

possible to avoid

wobble during use.

With the shaft lock

button engaged on the

flex-shaft handpiece

retighten the collet nut.

Collet Removal and Replacement

Four different size collets to accommodate different

shank sizes, are sold separately for your flex-shaft. To

install a different collet, remove the collet nut and

remove the old collet. Insert the unslotted end of the

collet in the hole in the end of the flex-shaft. Replace

collet nut on the shaft. Always use the collet which

matches the shank size of the accessory you plan to

use. Never force a larger diameter shank into a

collet.

Do not operate the

flexible shaft with a

sharp or multiple

bends. Over bending

the shaft can generate

excessive heat on the

jacket or hand piece

and may cause the flexible shaft to disengage from

tool. The minimum recommended bend radius is 13cm.

Flexible Shaft Lubrication

The flex-shaft should be lubricated after every 25-30

hours of use. To lubricate, unscrew the flex-shaft

assembly from the motor housing. Pull the center

core out of the flex-shaft assembly. Wipe a very thin

film automotive wheel bearing grease on to the center

core and reinsert it back into the shaft. To prevent

damage to tool do not over grease shaft. Too much

grease will cause the unit to overheat.

Reattach the flex-shaft to the rotary tool.

Contents of 225 Flex-Shaft Attachment

Qty. Description

1 Flex-Shaft Assembly (1,07m long)

1 Driver Cap

Page 7

13CM

RADIUS

SHAFT LOCK

BUTTON

Page 8

3

/4

1

/2

1

/4

0

DM 2610934164 05-06 10/6/06 8:41 AM Page 8

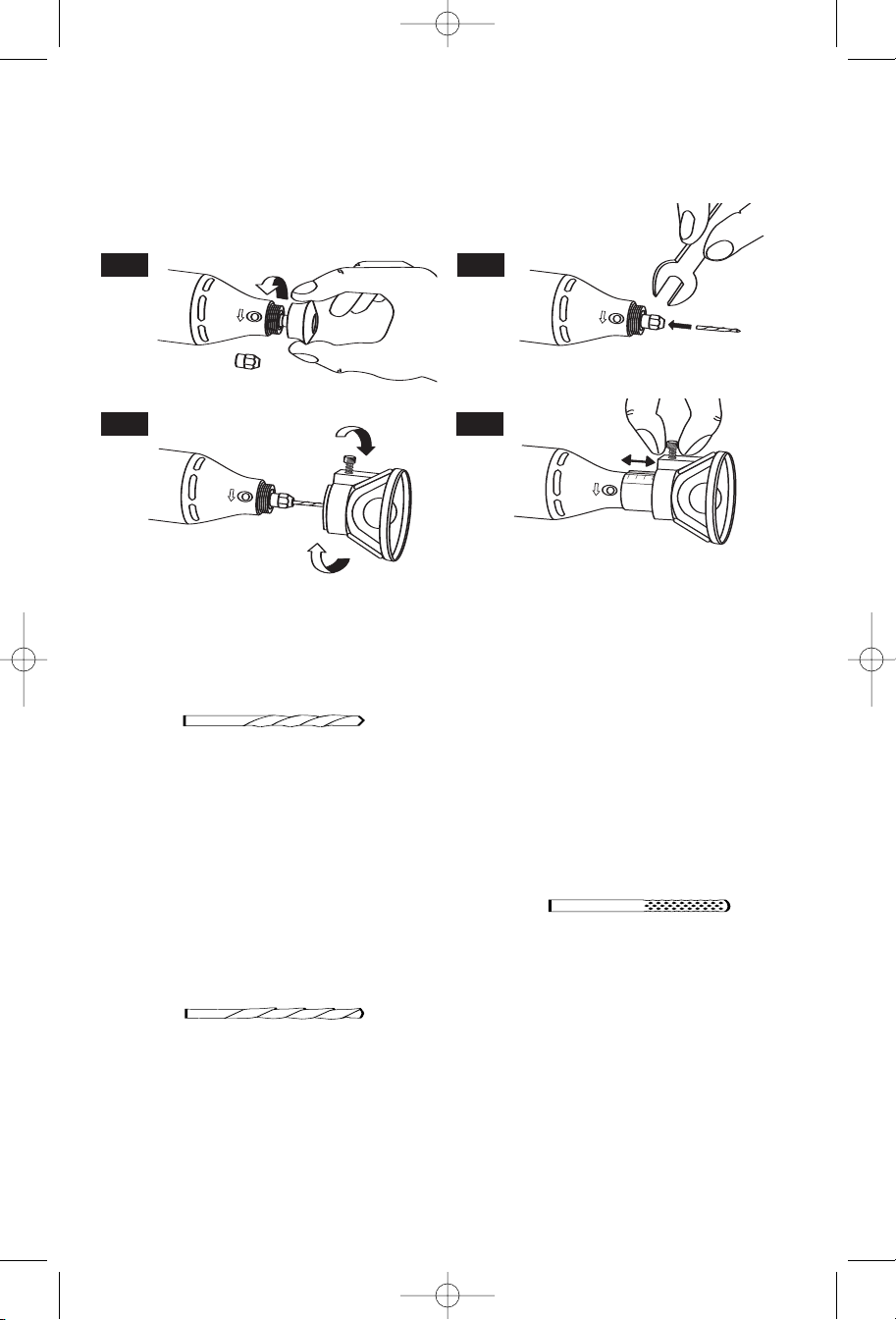

utting Guide Installation

C

The cutting guide 565 (sold separately) comes

completely assembled and ready to use. For use in a

variety of materials up to 19,1mm thick. Match the bit

Important: When viewing the tool from the top, the

bit rotates clockwise. Feed direction of cutting must

be counter-clockwise.

type to material to be cut. Always hold the tool firmly,

using slow steady pressure to make cuts.

To attach, follow the four steps shown below.

FIG. 1 FIG. 2

FIG. 3

Operating Instructions for Cutting Guide

Attachment

#560

Drywall Cutting Bit

For use in drywall.

• When inserting the #560 bit into your MultiPro tool,

make sure that the bit has been inserted as far as

possible.

• When making freehand cuts in drywall, example

repairing a hole in drywall, use the Multipurpose bit

#561, cutting in a clockwise direction. When using a

template (outlet box) behind the drywall, use the

drywall bit #560, cutting in a counter-clockwise

direction.

#561

Multipurpose Cutting Bit

For use in wood, plastics, drywall, fiberglass, vinyl

or aluminum siding, acoustical tile and laminates.

• When inserting the #561 bit into your MultiPro tool,

make sure that the bit has been inserted as far as

possible.

• When making freehand cuts in Drywall, example

repairing a hole in drywall, use the Multipurpose bit

FIG. 4

#561, cutting in a clockwise direction. When using a

template (outlet box) behind the drywall, use the

drywall bit #560, cutting in a counter-clockwise

direction.

• When using #561, Multipurpose Cutting Bit, and

#562, Tile Cutting Bit, start the bit into the material at

a 45 degree angle and then slowly bring it to a 90

degree angle to begin the cut.

#562

Tile Cutting Bit

For use on wall tile, cement board and plaster

• When inserting the #562 bit into your MultiPro tool,

it is very important that 1,6mm-3,2mm of smooth

shank remains visible above the collet.

• When using #561, Multipurpose Cutting Bit, and

#562, Tile Cutting Bit, start the bit into the material at

a 45 degree angle and then slowly bring it to a 90

degree angle to begin the cut.

• NOT FOR USE ON FLOOR TILE

Page 8

Page 9

a

aa

aa

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

DM 2610934164 05-06 10/6/06 8:41 AM Page 9

Operating Instructions for Rotary Tool

and Flex-Shaft Attachment

The following operation applies to the Rotary Tool and Flex-Shaft attachment,

The Rotary Tool is a handful of high-speed power. It

serves as a carver, grinder, polisher, sander, cutter,

power brush, drill and more.

The Rotary Tool has a small, powerful electric motor, is

comfortable in the hand, and is made to accept a large

variety of accessories including abrasive wheels, drill

bits, wire brushes, polishers, engraving cutters, router

bits, and cutting wheels. Accessories come in a variety

of shapes and permit you to do a number of different

jobs. As you become familiar with the range of

accessories and their uses, you will learn just how

versatile the Rotary Tool is. You’ll see dozens of uses

you hadn’t thought of before.

The real secret of the Rotary Tool is its speed. To

understand the advantages of its high speed, you have

to know that the standard portable electric drill runs at

speeds up to 2.800 revolutions per minute. The Rotary

Tool operates at speeds up to 33.000 revolutions per

except the pictures depict the Rotary Tool.

minute. The typical electric drill is a low-speed, high

torque tool; the Rotary Tool is just the opposite – a

high-speed, low torque tool. The chief difference to the

user is that in the high speed tools, the speed

combined with the accessory mounted in the collet

does the work. You don’t apply pressure to the tool, but

simply hold and guide it. In the low speed tools, you

not only guide the tool, but also apply pressure to it, as

you do, for example, when drilling a hole.

It is this high speed, along with its compact size and

wide variety of special accessories, that makes the

Rotary Tool different from other power tools. The speed

enables it to do jobs low speed tools cannot do, such

as cutting hardened steel, engraving glass, etc.

Getting the most out of your Rotary Tool is a matter of

learning how to let this speed work for you.

Sharpen Tools Precise Drilling Shape Wood

Carve Wood

Deburr Metal

Page 9

Cut Metal

Page 10

a

a

WARNING

Wear Eye Protection

DM 2610934164 05-06 10/6/06 8:41 AM Page 10

sing the Rotary Tool

U

The first step in learning to use the Rotary Tool is to

get the “feel” of it. Hold it in your hand and feel its

weight and balance. Feel the taper of the housing. This

taper permits the Rotary Tool to be grasped much like

a pen or pencil.

When you turn on the tool for the first time, hold it

away from your face. Accessories can be damaged

during handling, and can fly apart as they come up to

speed. This is not common, but it does happen.

Practice on scrap materials first to see how the Rotary

Tool cuts. Keep in mind that the work is done by the

speed of the tool and by the accessory in the collet.

You should not lean on or push the tool into the work.

Questions or Problems ? Call 03-5415317

or check our website at www

Instead, lower the spinning accessory lightly to the

work and allow it to touch the point at which you want

cutting (or sanding or etching, etc.) to begin. Concentrate on guiding the tool over the work using very

little pressure from your hand. Allow the accessory to

do the work.

Usually, it is best to make a series of passes with the

tool rather than attempt to do all the work in one pass.

To make a cut, for example, pass the tool back and

forth over the work, much as you would a small paint

brush. Cut a little material on each pass until you reach

the desired depth. For most work, the gentle touch is

best. With it, you have the best control, are less likely

to make errors, and will get the most efficient work out

of the accessory.

.Dremel.com

For best control in close work, grip the Rotary Tool

like a pencil between your thumb and forefinger.

The “handgrip” method of holding the tool is used

for operations such as grinding a flat surface or

using cutoff wheels.

CAUTION

!

with your hand. This blocks the air flow and causes

the motor to overheat.

Page 10

Whenever you hold the tool, be

careful not to cover the air vents

Page 11

DM 2610934164 05-06 10/6/06 8:41 AM Page 11

Operating Speeds for Accessories

Electronic Feedback Circuitry (EFC)

Your tool is equipped with a internal electronic

feedback system that provides a "soft start", which

will reduce the stresses that occur from a high

torque start. The system also helps to keep the

pre-selected rotating speed virtually constant

between no-load and load conditions.

Set the speed indicator to fit the job; to achieve the

best job results when working with different materials, the speed of the Rotary Tool should be

regulated. Model 398-49 Rotary Tool has an

integral speed control.

!

CAUTION

tool.

To select the right speed for each job, use a

practice piece of material. Vary speed to find the

best speed for the accessory you are using and the

job to be done.

NOTE: Speed is affected by voltage changes. A

reduced incoming voltage will slow the RPM of the

tool, especially at the lowest setting. If your tool

appears to be running slowly increase the speed

setting accordingly.

An external speed control

should never be used with this

Digital Speed Selector Switch

Your rotary tool features a digital speed selector

switch which displays an L.C.D. reading of the tool’s

RPM. The speed can be selected from 5.000 RPM to

33.000 RPM in 1.000 RPM increments by simply

depressing the positive or negative buttons on the

switch.

TO TURN TOOL "ON": slide ON/OFF switch to the

"ON" position.

TO TURN TOOL "OFF": slide ON/OFF switch to the

"OFF" position.

TO INCREASE SPEED: depress button with + sign.

TO DECREASE SPEED: depress button with - sign.

Needs for Slower Speeds

Certain materials, however, (some plastics, for example) require a relatively slow speed because at

high speed the friction of the accessory generates

heat and causes the plastic to melt.

Slow speeds (15.000 RPM or less) usually are best

for polishing operations employing the felt polishing

accessories. They may also be best for working on

delicate projects as “egger

carving and fragile model parts. All brushing

applications require lower speeds to avoid wire

discharge from the holder

Higher speeds are better for carving, cutting, routing,

shaping, cutting dadoes or rabbets in wood.

y” work, delicate wood

.

Hardwoods, metals and glass require high speed

operation, and drilling should also be done at high

speeds.

The point to remember is this: You can do the great

majority of work at its regular speed of 33.000 RPM.

But for certain materials and types of work, you need

slower speeds — which is the reason the variable

speed models were developed.

To aid you in determining the optimum operational

speed for different materials and different

accessories, we have constructed a series of tables

that appear on page 13, 14, and 15. By referring to

these tables, you can discover the recommended

speeds for each type of accessory. Look these tables

over and become familiar with them.

Ultimately, the best way to determine the correct

speed for work on any material is to practice for a

few minutes on a piece of scrap, even after referring

to the chart. You can quickly learn that a slower or

faster speed is more effective just by observing what

happens as you make a pass or two at different

speeds. When working with plastic, for example,

start at a slow rate of speed and increase the speed

until you observe that the plastic is melting at the

point of contact. Then reduce the speed slightly to

get the optimum working speed.

Some rules of thumb in regard to speed:

1. Plastic and materials that melt at low

temperatures should be cut at low speeds.

2. Polishing, buffing and cleaning with a wire brush

must be done at speeds below 15.000 RPM to

prevent damage to the brush.

3. Wood should be cut at high speed.

4. Iron or steel should be cut at top speed if using

tungsten carbide accessory, but at slower speeds

if using high speed steel cutters. If a high speed

steel cutter starts to chatter — this normally

means it is running too slow.

5. Aluminum, copper alloys, lead alloys, zinc alloys

and tin may be cut at various speeds, depending

on the type of cutting being done. Use paraffin or

other suitable lubricant on the cutter to prevent

the cut material from adhering to the cutter teeth.

Increasing the pressure on the tool is not the answer

when it is not cutting as you think it should. Perhaps

you should be using a different cutter, and perhaps

an adjustment in speed would solve the problem. But

leaning on the tool seldom helps.

Use only Dremel Tested, High Performance Accessories.

Page 11

Page 12

DM 2610934164 05-06 10/6/06 8:41 AM Page 12

GLASS

CERAMIC

STONE

SHELL/

ALUMINUM,

BRASS, ETC.

STEEL

• Depending on cutting direction relative to grain.

* Speed for light cuts, caution burning on deep grooves.

PLASTIC

LAMINATES

HARD

WOOD

9.000-11.000

18.000-24.000

25.000-33.000

5.000-9.000

9.000-11.000

18.000-24.000

HIGH SPEED CUTTERS

9.000-11.000*

9.000-11.000*

12.000-17.000*

25.000-33.000*

12.000-17.000*

25.000-33.000*

5.000-9.000

9.000-11.000

25.000-33.000

25.000-33.000

5.000-9.000

9.000-11.000

12.000-17.000

12.000-17.000

9.000-11.000

12.000-17.000

12.000-17.000

5.000-8.000

9.000-11.000

9.000-11.000

9.000-11.000

12.000-17.000

12.000-17.000

12.000-17.000

12.000-17.000

18.000-24.000

18.000-24.000

18.000-24.000

18.000-24.000

18.000-24.000

5.000-8.000

9.000-11.000

9,000-11,000

18.000-24.000

ENGRAVING CUTTERS

9.000-11.000*

9.000-11.000*

25.000-33.000*

25.000-33.000*

9.000-11.000*

12.000-17.000*

25.000-33.000*

18.000-24.000*

12.000-17.000*

12.000-17.000*

18.000-24.000*

9.000-11.000*

25.000-33.000*

25.000-33.000*

25.000-33.000*

25.000-33.000*

5.000-11.000*

9.000-11.000*

9.000-11.000*

9.000-11.000*

9.000-11.000*

9.000-11.000*

RUBBER POLISHING POINT

12.000-17.000*

12.000-17.000*

25.000-33.000*

25.000-33.000*

25.000-33.000

25.000-33.000

25.000-33.000

25.000-33.000

25.000-33.000

25.000-33.000

25.000-33.000

25.000-33.000

CUTTING ACCESSORIES

5.000-9.000*

5.000-9.000*

•

Use only Dremel Tested, High Performance Accessories.

9.000-11.000•

12,000-25,000•

9.000-11.000•

12.000-17.000•

25.000-33.000•

HIGH SPEED ROUTER BITS (Use with cutting guide or shaper/router table)

SPEED SETTINGS

SOFT

WOOD

25.000-33.000*

197

198

NUMBER

CATALOG

189, 190

14, 124, 134, 144

1

100, 121, 131, 141

115, 178

192, 194

118, 191, 193

116, 117, 125, 196

199

Page 12

25.000-33.000*

25.000-33.000*

25.000-33.000*

10

107, 1

105, 108

106, 109

25.000-33.000*

25.000-33.000*

25.000-33.000*

111

112

113

425, 427

18.000-24.000*

18.000-24.000*

18.000-24.000*

25.000-33.000*

25.000-33.000*

25.000-33.000*

25.000-33.000*

25.000-33.000*

25.000-33.000*

12.000-25.000

560, 561, 562

409, 420, 426, 540

25.000-33.000*

25.000-33.000*

12.000-17.000*

12.000-17.000*

654

610

650, 652

612, 613, 614, 632, 640

Page 13

DM 2610934164 05-06 10/6/06 8:41 AM Page 13

GLASS

5.000-11.000

12.000-25.000

12.000-25.000

12.000-25.000

12.000-25.000

12.000-25.000

12.000-25.000

18.000-25.000

CERAMIC

SHELL/

ALUMINUM,

STEEL

• Depending on cutting direction relative to grain.

* Speed for light cuts, caution burning on deep grooves.

LAMINATES

18.000-33.000 18.000-33.000

STONE

18.000-24.000

BRASS, ETC.

DIAMOND WHEEL POINTS

PLASTIC

25.000-33.000

5.000-17.000

5.000-11.000

18.000-24.000

5.000-8.000

25.000-33.000

25.000-33.000

5.000-17.000

5.000-17.000

5.000-11.000

5.000-11.000

18.000-24.000

18.000-24.000

5.000-8.000

5.000-8.000

25.000-33.000

25.000-33.000

25.000-33.000

5.000-17.000

5.000-17.000

5.000-17.000

5.000-11.000

5.000-11.000

5.000-11.000

18.000-24.000

18.000-24.000

18.000-24.000

5.000-8.000

5.000-8.000

5.000-8.000

ALUMINUM OXIDE GRINDING STONES

HARD

WOOD

25.000-33.000

25.000-33.000

25.000-33.000

25.000-33.000

25.000-33.000

25.000-33.000

9.000-11.000

25.000-33.000

5.000-17.000

5.000-11.000

18.000-24.000

5.000-8.000

SILICON CARBIDE GRINDING STONES

12.000-25.000

12.000-25.000

5.000-8.000

5.000-8.000

5.000-11.000

5.000-11.000

5.000-11.000 5.000-8.000

25.000-33.000

25.000-33.000

25.000-33.000

12.000-17.000

12.000-17.000

12.000-17.000

12.000-25.000

12.000-25.000

12.000-25.000

12.000-25.000

5.000-8.000

5.000-8.000

5.000-8.000

5.000-8.000

5.000-11.000

5.000-11.000

5.000-11.000

5.000-11.000

25.000-33.000

25.000-33.000

25.000-33.000

25.000-33.000

12.000-17.000

12.000-17.000

TUNGSTEN CARBIDE CUTTERS

12.000-17.000

12.000-17.000

18.000-25.000

18.000-25.000 18.000-25.000

5.000-9.000

5.000-9.000

12.000-17.000

Use only Dremel Tested, High Performance Accessories.

25.000-33.000

SPEED SETTINGS

SOFT

WOOD

911, 921, 962

8173, 8174, 8175

Page 13

25.000-33.000

25.000-33.000

25.000-33.000

25.000-33.000

8215

973, 8184

903, 971, 8193

981, 8200, 8202

83702, 86442

83322, 83642,

85562

85422

84922

83142, 84382

85342, 85602

18.000-24.000 18.000-24.000 5.000-8.000 9.000-11.000

85622

9901, 9902,

9903, 9904,

9909, 9910, 9911

9905, 9906, 9912

25.000-33.000

18.000-24.000 18.000-24.000

NUMBER

CATALOG

7103, 7105, 7117,

7120, 7122, 7123,

25.000-33.000

7134, 7144

945, 997, 8153

541, 915, 923, 924,

913, 914, 943, 953, 954,

25.000-33.000

904, 922, 932

941, 952, 984,

8160, 8162, 8163

963, 964, 974, 992

Page 14

DM 2610934164 05-06 10/6/06 8:41 AM Page 14

GLASS

25.000-33.000

25.000-33.000

CERAMIC

STONE

SHELL/

ALUMINUM,

BRASS, ETC.

STEEL

• Depending on cutting direction relative to grain.

* Speed for light cuts, caution burning on deep grooves.

PLASTIC

LAMINATES

HARD

WOOD

5.000-25.000

5.000-25.000

5.000-25.000

5.000-25.000

5.000-25.000

5.000-25.000

25.000-33.000

25.000-33.000

25.000-33.000

25.000-33.000

25.000-33.000

25.000-33.000

SANDING ACCESSORIES

5.000-12.000

5.000-12.000

5.000-12.000

5.000-25.000

5.000-25.000

5.000-25.000

25.000-33.000

25.000-33.000

25.000-33.000

25.000-33.000

25.000-33.000

25.000-33.000

25.000-33.000

25.000-33.000

POLISHING ACCESSORIES

Use only Dremel Tested, High Performance Accessories.

SPEED SETTINGS

SOFT

WOOD

5.000-25.000

5.000-25.000

5.000-25.000

NUMBER

CATALOG

407, 408, 432

430, 431, 438

439, 440, 444

466, 414,429, 422, 423

461, 462, 463, 464, 465

Page 14

Page 15

DM 2610934164 05-06 10/6/06 8:41 AM Page 15

Maintenance

Service

!

WARNING

personnel may result in misplacing of internal wires

and components which could cause serious hazard.

We recommend that all tool service be performed by a

Dremel Service Facility.

CARBON BRUSHES

The brushes and commutator in your tool have been

engineered for many hours of dependable service. To

maintain peak efficiency of the motor, we recommend

every two to six months the brushes be examined. Only

genuine Dremel replacement brushes specially

designed for your tool should be used.

BRUSH

Preventive maintenance

performed by unauthorized

BRUSH

DOOR

CURVED END OF

BRUSH MUST

MATCH CURVATURE

OF HOUSING

FIG. 1

FIG. 2

BRUSH

SPRING

MAINTENANCE OF REPLACEABLE BRUSHES

MODEL 398-49

The brushes should be inspected frequently when

tools are used continuously. If your tool runs sporadically, loses power, makes unusual noises or runs at a

reduced speed, check the brushes. To continue using

the tool in this condition will permanently damage

your tool.

To Remove Brush Door

Disconnect the tool from the power supply. Each

brush door is held in place by a snap latch. To

disengage latch, place screwdriver end of wrench

(included) in slot at rear of door and pry up as

shown in Figure 1. With latch disengaged, using a

little force, pull up rear of door and lift away brush

door and spring assembly from housing, Figure 2.

Check Both Brushes

Turn tool so the brush falls out of holder and check

each brush. If the brush is less than 3,2mm long and

the end surface of the brush that contacts the

commutator is rough and/or pitted, they should be

replaced. Check both brushes. Usually the brushes will

not wear out simultaneously. If one brush is worn out,

replace both brushes. Make sure the brushes are

installed as illustrated. The curved surface of the

brush must match the curvature of the commutator.

To Replace Brush Door

Rest squared underside of brush door on the

squared cavity openings. Check to be sure the spring

rests on the V groove of the brush, Figure 3. Push

front of door down into the slot, Figure 4, then push

down and snap the rear latch into it’s slot, Figure 5.

After replacing brushes the tool should be run at noload; place it on a clean surface and run it freely for 5

Any Questions Call

03-5415317

FIG. 3

Page 15

Page 16

DM 2610934164 05-06 10/6/06 8:41 AM Page 16

FIG. 4

FIG. 5

minutes before loading (or using) the tool. This will

allow the brushes to “seat” properly and will give you

more hours of life from each set of brushes. This will

also extend the total life of your tool since the

commutator surface will “wear” longer.

BEARINGS

Model 398-49 has ball bearing construction. Under

normal use no additional lubrication is required.

Cleaning

!

WARNING

power supply before cleaning or performing any

maintenance. The tool may be cleaned most effectively

with compressed dry air. Always wear safety goggles

when cleaning tools with compressed air.

Ventilation openings and switch levers must be kept

clean and free of foreign matter. Do not attempt to clean

by inserting pointed objects through openings.

!

CAUTION

Some of these are: gasoline, carbon tetrachloride,

chlorinated cleaning solvents, ammonia and household

detergents that contain ammonia.

To avoid accidents always

disconnect the tool from the

Certain cleaning agents and

solvents damage plastic parts.

Extension Cords

!

WARNING

adequate size conductors that is capable of

carrying the current necessary for your tool must

be used. This will prevent excessive voltage drop,

loss of power or overheating. Grounded tools must

use 3-wire extension cords that have 3-prong plugs

and receptacles.

RECOMMENDED SIZES OF EXTENSION CORDS

240 VOLT ALTERNATING CURRENT TOOLS

Max. Tool

Ampere Rating

10 10 1,0 25

10 15 1,5 32

If an extension cord is

necessary, a cord with

Cord Ampere

Rating

Cord Sizes in

2

mm

Cord Length

in Meters

Page 16

Page 17

DM 2610934164 05-06 10/6/06 8:41 AM Page 17

Dremel Accessories

WARNING

!

The number and variety of accessories for the Rotary

Tool are almost limitless. There is a category suited to

almost any job you might have to do — and a variety

of sizes and shapes within each category which enables you to get the perfect accessory for every need.

Refer to the DREMEL ACCESSORY ORDER FORM for

illustrations of the accessories available. These

accessories may be found at your local hardware,

hobby or home center dealers.

Collets

If you expect to use a variety of accessories, we

recommend that in the beginning you purchase a

complete set of four collets. Store these so that you will

have the proper size of collet for any accessory or drill

bit you want to use.

2,4mm,0,8mm and 1,6mm collets accommodate all

of the available Dremel accessories. 3,2mm collets

are included in most rotary tool kits.

Mandrels

A mandrel is a shank with a threaded or screw head,

which are required when you use polishing

accessories, cutting wheels, sanding discs, and polishing points. The reason mandrels are used is that

sanding discs, cutting wheels and similar accessories

must be replaced frequently. The mandrel is a permanent shank, allowing you to replace only the worn

head when necessary, thus saving the expense of

replacing the shaft each time.

Screw Mandrel No. 401

This is a screw mandrel used with the felt polishing tip

and felt polishing wheels. 3,2mm shank.

Small Screw Mandrel No. 402

This is a mandrel with a small screw at its tip, and is

used with emery and fiberglass cutting wheels, sanding

discs and polishing wheels. 3,2mm shank.

Use only Dremel Tested, High Performance Accessories. Other accessories are not

designed for this tool and may lead to personal injury or property damage.

Tungsten Carbide Cutters

These are tough, long-lived cutters for use on hardened

steel, fired ceramics and other very hard materials.

They can be used for engraving on tools and garden

equipment. 3,2mm shanks.

Engraving Cutters

This group has a wide variety of sizes and shapes, and

are made for intricate work on ceramics (greenware),

wood carvings, jewelry and scrimshaw. They often are

used in making complicated printed circuit boards.

They should not be used on steel and other very hard

materials but are excellent on wood, plastic and soft

metals. 2,4mm shank.

Currently, the 3,2mm,

Fast cutting, needle-sharp teeth for greater material

removal with minimum loading. Use on fiberglass,

wood, plastic, epoxy and rubber. 3,2mm and 6,4mm

shank.

Aluminum Oxide Grinding Stones (red/brown)

Round, pointed, flat — you name the shape and there is

one available in this category. These are made of

aluminum oxide and cover virtually every possible kind

of grinding application. Use them for sharpening lawn

mower blades, screwdriver tips, knives, scissors, chisels

and other cutting tools. Use to remove flash from metal

castings, deburring any metal after cutting, smoothing

welded joints, grinding off rivets and removing rust.

These grinding stones can be resharped with a dressing

stone. In machine shops, high speed drills and cutters

normally are ground with aluminum oxide wheels.

3,2mm shank.

Structured Tooth

Tungsten Carbide Cutters

Threaded Tip Mandrel No. 424

This is a mandrel with a threaded tip which threads into

the polishing point accessor

y No. 427. 3,2mm shank.

High Speed Cutters

Available in many shapes, high speed cutters are used

in carving, cutting and slotting in wood, plastics and

soft metals such as aluminum, copper and brass. These

are the accessories to use for freehand routing or

carving in wood or plastic, and for precision cutting.

Made of high quality steel. 3,2mm shank.

Silicon Carbide Grinding Stones (blue/green)

Tougher than aluminum oxide points, these are made

especially for use on hard materials such as glass and

ceramics. Typical uses might be the removal of stilt

marks and excess glaze on ceramics and engraving on

glass. 3,2mm shank.

Diamond Wheel Points

Excellent for fine detail work on wood, jade, ceramic,

glass and other hard material. Bits are covered with

diamond particles. 2,4mm shanks.

Page 17

Page 18

DM 2610934164 05-06 10/6/06 8:41 AM Page 18

olishing Accessories

Wire Brushes

Three different shapes of wire brushes are available.

Never use wire brushes at speeds greater than

15.000 RPM. Refer to Operating Speeds section for

proper tool speed setting. The three shapes come in

three different materials: stainless steel, brass and

carbon wire. The stainless steel perform well on

pewter, aluminum, stainless steel, and other metals,

without leaving "after-rust". Brass brushes are non

sparking, and softer than steel; making them good for

use on soft metal like gold, cooper and brass. The

carbon wire brushes are good for general purpose

cleaning.

P

These include an impregnated polishing point and an

impregnated polishing wheel for bringing metal surfaces to smooth finish; a felt polishing tip and felt

polishing wheel, and cloth polishing wheel, all used for

polishing plastics, metals, jewelry and small parts. Also

included in this group is a polishing compound (No.

421) for use with the felt and cloth polishers.

Polishing points make a very smooth surface, but a

high luster is obtained using felt or cloth wheels and

polishing compound. For best results polishing

accessories should be used at speeds not greater

than 15.000 RPM. Refer to Operating Speeds section

for proper tool speed setting.

No polishing compound is needed when using the

425 Polishing Wheel or 427 Polishing point.

Bristle Brushes

These are excellent cleaning tools on silverware, jewelry and antiques. The three shapes make it possible to

get into tight corners and other difficult places. Bristle

brushes can be used with polishing compound for

faster cleaning or polishing.

Aluminum Oxide Abrasive Wheels

Brushing Pressure

1. Remember, the tips of a wire brush do the work.

Operate the brush with the lightest pressure so only

the tips of the wire come in contact with the work.

2. If heavier pressures are used, the wires will be

overstressed, resulting in a wiping action; and if this

is continued, the life of the brush will be shortened

due to wire fatigue.

3. Apply the brush to the work in such a way that as

much of the brush face as possible is in full contact

with the work. Applying the side or edge of the brush

to the work will result in wire breakage and shortened

brush life.

CORRECT:

Wire tips doing the work.

INCORRECT:

Excessive pressure can cause wire breakage.

Use to remove paint, deburr metal, polish stainless

steel and other metals. Available in fine and medium

grits. 3,2mm shank.

Sanding Accessories

Sanding discs in fine, medium and coarse grades are

made to fit mandrel No. 402. They can be used for

nearly any small sanding job you might have, from

model making to fine furniture finishing. In addition,

there is the drum sander, a tiny drum which fits into the

Rotary Tool and makes it possible to shape wood,

smooth fiberglass, sand inside curves and other difficult places, and other sanding jobs. You replace the

sanding bands on the drum as they become worn and

lose their grit. Bands come in fine and coarse grades.

Flapwheels grind and polish flat or contoured surfaces.

They are used most effectively as a finishing sander

after heavier surface sanding and material removal is

completed. Flapwheels come in fine and coarse grades.

Buffs are a great finishing accessor

light sanding. They work effectively on metal, glass,

wood, aluminum and plastics. Coarse and medium

buffs are sold together

y for cleaning and

. 3,2mm shank.

Grinding Wheel

Use for deburring, removing rust, and general purpose

grinding. Use with Mandrel #402.

Page 18

Page 19

DM 2610934164 05-06 10/6/06 8:41 AM Page 19

Dremel Accessories - (Cont.)

Tile Cutting Bit

Cutting Wheels

These thin discs of emery or fiberglass are used for

slicing, cutting off and similar operations. Use them for

cutting off frozen bolt heads and nuts, or to reslot a

screw head which has become so damaged that the

screwdriver won’t work in it. Fine for cutting BX cable,

small rods, tubing, cable and cutting rectangular holes

in sheet metal.

Cuts ceramic wall tile, cement board, and plaster.

Spiral Cutting Bit

Cuts through all types of wood and wood composites.

Drywall Cutting Bit

Gives you fast, clean cuts in drywall.

Mandrel No. 401 is used with the felt polishing tip and wheels. Thread the tip on to the screw carefully. The felt

tip must thread down straight on the screw Mandrel, and be turned all the way to the collar.

High Speed Router Bits

For routing, inlaying, and mortising in wood and other

soft materials. Use only with Dremel No. 330 Router

attachment or No. 231 Shaper/Router table.

Mandrel No. 402 has a small screw at its tip, and is used with emery cutting wheels and sanding discs. Higher

speeds, usually maximum, are best for most work, including cutting steel. Which is shown here.

Page 19

Page 20

DM 2610934164 05-06 10/6/06 8:41 AM Page 20

The machine-screw threading on Mandrel No. 424 threads into polishing point No. 427. This and other

threaded mandrels must be screwed firmly down to the collar before being used.

To replace a band on the Drum Sander, loosen the screw without removing it to contract the drum then slide

the old band off. Slide the new sanding band on and then expand the drum by tightening the screw once again.

WARNING

!

band is loose on the drum during operation it may “fly” off and strike you or bystanders.

Before each use, check to make certain that all components are assembled to accessory

shank and that the drum is sufficiently expanded to secure the band during use. If sanding

Dremel Attachments

565

Multipurpose Cutting Kit

• Includes 2 drywall cutting bits (560) and 1 spiral

cutting bit (561)

• Cuts fiberglass, wood & drywall easily

566

Tile Cutting Kit

• Includes 1 ceramic tile cutting bit (562)

• Cuts ceramic wall tile to any shape

Questions or Problems? Call 03-5415317

Page 20

Page 21

DM 2610934164 05-06 10/6/06 8:41 AM Page 21

Dremel Attachments

Add these Dremel attachments to your compact workshop and make your Rotary Tool more versatile.

Shapes, edges, chamfers, cuts, rabbets, dadoes, etc.

Adjustable edge guide can be easily removed for

freehand routing. The Model 330 can be used with

Models 270, 275, 280, 285, 380, 395, 398, and 850.

For precision drilling, routing, grooving, 15,2mm

square work surface, 0 to 7,6mm throat depth. T

slotted for guides, hold downs. Holds Models 275,

285, 395, 398, and 850.

Model 330 Router Attachment

Model 212 Drill Press

able

Allows finger-tip control for tight corners and hardto-reach areas. 1,07m long cable attaches to Models

275, 285, 395, 398, and 850. Pencil-like 12,7mm

diameter hand piece is cool-running and ideal for

light duty wood carving and other uses.

Converts the Rotar

shaper

professional quality slotting, edge trimming, grooving

and sanding of irregular shapes accurately and with

ease. Large 20,3cm x 15,2cm worktable. Use with

Models: 270, 275, 280, 285, 370, 380, 395, 398, and

850.

Page 21

Model 225 Flex-Shaft

Model 231 Shaper/Router Table

. Clamp it to a workbench and per

ool into a bench mounted wood

y T

form

Page 22

DM 2610934164 05-06 10/6/06 8:41 AM Page 22

23

810

825

801

4

16

5

824

2

801

22

825

826

3

28

650

30

824

27

MODEL 400 SERIES

Pagina 22

Page 23

DM 2610934164 05-06 10/6/06 8:41 AM Page 23

ORDER BY PART NUMBER, NOT CODE NUMBER

2 2615298792 Field Assembly

3 2610907942 Armature & Bearing Assembly

4 2610928648 Control Panel Assembly

5 2610999103 Cord

23 2615294043 Hanger

27 2615297355 Collet Nut

22 2615302505 Rubber bearing ring

16 2615302530 Brush Holder Assembly

30 2610913684 Housing Cap

28 2615000480 Collet

650 2610930692 Wrench

801 2610928647 Housing Set

810 2610907940 Brush (pair)

826 2615302807 Collet Lock Assembly

824 2615294035 Screws (includes 5)

825 2610928650 Brush Door w/ Spring (pair)

CODE NO. PART NO. DESCRIPTION

Pagina 23

Page 24

DM 2610934164 05-06 10/6/06 8:41 AM Page 24

7

10

6

8

DREMEL CUTTING GUIDE

9

5

4

Driver Cap

Flexible Shaft Core

Overthrow Nut Assembly

Guide

Guide insert

Screw spring & nut

DREMEL FLEX-SHAFT ATTACHMENT

3

2

ORDER BY PART NUMBER, NOT CODE NUMBER

1

Page 24

1 2615297355 Collet Nut (Not included)

CODE NO. PART NO. DESCRIPTION

483 0,8mm Collet available as Accessory (Not included)

482 1,6mm Collet available as Accessory (Not included)

481 2,4mm Collet available as Accessory (Not included)

2615294178

2610914543

2610915085

2615302049

2615302102

2615302103

7

4 90962 Wrench Available as Accessory (Not included)

2 480 3,2mm Collet available as Accessory (Not included)

3 2610914485 Handpiece Cap

8

5

6

9

10

Loading...

Loading...