Page 1

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

For English Version Version française Versión en español

See page 2 Voir page 22 Ver la página 43

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

1-800-4-DREMEL (1-800-437-3635) www.dremel.com

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informations

et les adresses de nos centres

de service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

P.O. Box 081126 Racine, WI 53408-1126

2050

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:38 AM Page 1

Page 2

2

Work area safety

Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

Electrical safety

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

us e a ny adapt e r plugs wi t h earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric

shock.

Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is earthed or

grounded.

Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

If operating a power tool in a damp location

is unavoidable, use a Ground Fault Circuit

Interrupter (GFCI) protected supply. Use of

an GFCI reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and

us e c o mmon sen se w hen ope r atin g a

power tool. Do not use a power tool while

you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention

while operating power tools may result in

serious personal injury.

Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

Read all safety warnings and all instructions. Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

General Power Tool Safety Warnings

Safety Symbols

The definitions below describe the level of severity for each signal word. Please read the manual

and pay attention to these symbols.

!

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a hazardous

situation which, if not avoided, will result in minor or moderate injury.

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:38 AM Page 2

Page 3

3

Prevent unintentional starting. Ensure the

s

wi tch is in the off-p ositi on bef ore

connecting to power source and / or battery

pa ck, pic king up or ca rryi ng the too l.

Carrying power tools with your finger on the

switch or energizing power tools that have the

switch on invites accidents.

Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key

left attached to a rotating part of the power

tool may result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. This enables better

co n trol of the powe r too l in unex p ected

situations.

Dress properly. Do not wear loose clothing

or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewelry or long hair can be caught in

moving parts.

If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce dust-

related hazards.

Power tool use and care

Do not for ce th e pow er to o l. Use the

correct power tool for your application. The

correct power tool will do the job better and

safer at the rate for which it was designed.

Do not use the power tool if the switch does

not turn it on and off. Any power tool that

ca n n o t be control l e d with the swit c h is

dangerous and must be repaired.

Disconnect the plug from the power source

a

nd/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment

or binding of moving parts, breakage of

parts and any other condition that may

affect the power tool’s operation. If damaged,

have the power tool repaired before use.

Ma n y a c c i dents are caused by po o r l y

maintained power tools.

Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

Use the power tool, accessories and tool

bits etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

Service

Have your power tool serviced by a qualified

re p a i r p e r s on u s i ng o n ly i d e ntical

replacement parts. This will ensure that the

safety of the power tool is maintained.

Safety warnings common for

grinding, sanding, wire brushing,

polishing, carving or abrasive

cutting-off operations:

This power tool is intended to function as a

gr inde r, san der, wi re br ush, pol ishe r,

carving or cut-of f tool. Read all safety

warnings, instructions, illustrations and

specifications provided with this power

tool. Failure to follow all instructions listed

below may result in electric shock, fire and/or

serious injury.

Do not us e acc ess ories which a re not

specifically designed and recommended by

the tool manufacturer. Just because the

accessory can be attached to your power tool,

it does not assure safe operation.

The RATED SPEE D of the acce ssories

must be at least equal to the operating

speed setting marked on the power tool.

Accessories running faster than their RATED

SPEED can break and fly apart.

The outside diameter and the thickness of

your accessory must be within the capacity

rating of your power tool. Incorrectly sized

accessories cannot be adequately controlled.

The arbor size of wheels, sanding drums or

any other accessory must properly fit the

sp i ndle or col l et o f t h e p o wer tool.

Accessories that do not match the mounting

hardware of the power tool will run out of

balance, vibrate excessively and may cause

loss of control.

Safety Rules for Rotary Tools

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:38 AM Page 3

Page 4

4

M

andrel mounted wheels, sanding drums,

cutters or other accessories must be fully

inserted into the collet or chuc k. If the

ma ndre l is ins uff icien tly held a nd/or the

overhang of the wheel is too long, the mounted

wheel may become loose and be ejected at

high velocity.

Do not use a damaged accessory. Before

each use inspect the accessory such as

abra sive wheels for chips and cracks,

sanding drum for cracks, tear or excess

wear, wire brush for loose or cracked wires.

If power tool or accessory is dropp ed,

inspect for damage or install an undamaged

accessory. After inspecting and installing

an ac cess o ry, posi tion you rsel f an d

bystanders away from the plane of the

rotating accessory and run the power tool

at maximum no-load speed for one minute.

Damaged accessories will normally break apart

during this test time.

Wear pe rsona l prot ectiv e equi pment .

Depending on application, use face shield,

sa fety goggl es or safety glass es. As

ap prop riat e, wear dus t m ask, he aring

protectors, gloves and workshop apron

capable of stopping sma ll ab ras ive or

workpiece fragments. The eye protection

must be capable of stopping flying debris

generated by various operations. The dust

mask or respirator must be capable of filtrating

pa rtic les gen erat e d b y your oper atio n .

Prolonged exposure to high intensity noise may

cause hearing loss.

Keep bystanders a safe distance away from

work area. Anyone entering the work area

must wear personal protective equipment.

Fr agme nts of wor kpie ce or of a bro ken

accessory may fly away and cause injury

beyond immediate area of operation.

Hold the power tool by insulated gripping

su rfac es onl y, whe n perf ormi ng an

operation where the cutting accessory may

contact hidden wiring or its own cord.

Cutting accessory contacting a “live” wire may

make exposed metal parts of the power tool

“live” and could give the operator an electric

shock.

Always hold the tool firmly in your hand(s)

during the start-up. The reaction torque of the

motor, as it accelerates to full speed, can cause

the tool to twist.

Use clamps to support workpiece whenever

practical. Never hold a small workpiece in

o

ne hand and the tool in the other hand

while in use. Clamping a small workpiece

allows you to use your hand(s) to control the

tool. Round material such as dowel rods, pipes

or tubing have a tendency to roll while being

cut, and may cause the bit to bind or jump

toward you.

Position the cord clear of the spinning

accessory. If you lose control, the cord may be

cut or snagged and your hand or arm may be

pulled into the spinning accessory.

Never lay the power tool down until the

accessory has come to a complete stop.

The spinning accessory may grab the surface

and pull the power tool out of your control.

After chang ing the bits or mak ing any

adjustments, make sure t he collet nut,

chuck or any other adjustment devices are

securely tightened. Loose adjustment devices

can unexpectedly shift, causing loss of control,

loose rotating components will be violently

thrown.

Do not run the power tool while carrying it

at your side. Accidental contact with the

spinning accessory could snag your clothing,

pulling the accessory into your body.

Regularly clean the power tool’s air vents.

The motor’s fan will draw the dust inside the

ho usin g and exce ssiv e acc umul atio n of

powdered metal may cause electrical hazards.

Do n ot o pera te the pow er tool ne ar

flammable materials. Sparks could ignite

these materials.

Do not use accessories that require liquid

coolants. Using water or other liquid coolants

may result in electrocution or shock.

Use only in well-ventilated area. Working in a

safe environment reduces risk of injury.

Allo w for suff icient space, at least 6”,

between your hand and the spinning bit. Do

not reach in the area of the spinning bit. The

proximity of the spinning bit to your hand may

not always be obvious.

Do not touch the bit or collet after use. After

use the bit and collet are too hot to be touched

by bare hands.

Do not alter or misuse tool. Any alteration or

modification is a misuse and may result in

serious personal injury.

This product is not intended for use as a

dental drill, in human or veterinary medical

applications. Serious injury may result.

Safety Rules for Rotary Tools - (cont.)

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:38 AM Page 4

Page 5

5

Safety Rules for Rotary Tools - (cont.)

Kickback and Related Warnings

K

ickback is a sudden reaction to a pinched or

snagged rotating wheel, backing pad, brush or

any other accessory. Pinching or snagging

causes rapid stalling of the rotating accessory

which in turn causes the uncontrolled power

tool to be forced in the direction opposite of the

accessory’s rotation.

For example, if an abrasive wheel is snagged

or pinched by the workpiece, the edge of the

wheel that is entering into the pinch point can

dig into the surface of the material causing the

wheel to climb out or kickout. The wheel may

either jump toward or away from the operator,

de pend ing on d irect ion of t he wheel’s

movement at the point of pinching. Abrasive

wheels may also break under these conditions.

Kickback is the result of power tool misuse

and/ or in cor rect ope rating procedures or

conditions and can be avoided by taking proper

precautions as given below.

Maintain a firm grip on the power tool and

position your body and arm to allow you to

resist kickback forces. The operator can

control kickback forces, if proper precautions

are taken.

Use special care when working corners,

sh arp edg es etc. Avoi d b ounci ng and

snagging the accessory. Corners, sharp

edges or bouncing have a tendency to snag the

rotating accessory and cause loss of control or

kickback.

Do not attach a toothed saw blade. Such

blades create frequent kickback and loss of

control.

Always feed the bit into the material in the

same direction as the cutting edge is exiting

fr om the mat eria l (which is the sa me

direction as the chips are thrown). Feeding

the tool in the wrong direction causes the

cutting edge of the bit to climb out of the work

and pull the tool in the direction of this feed.

When using rotary files, cut-off wheels,

high-speed cutters or tungsten carbide

cutters, always have the work securely

clamped. The se wheels w ill grab if they

become slightly canted in the groove, and can

kickback. When a cut-off wheel grabs, the

wheel itself usually breaks. When a rotary file,

high-speed cutter or tungsten carbide cutter

grabs, it may jump from the groove and you

could lose control of the tool.

Safety warnings specific for

grinding and abrasive

cutting-off operations:

Us e on ly wheel typ es that are

recommended for your power tool and only

fo r re comm ende d ap plic ation s. F o r

example: do not grind with the side of a cutoff wheel. Abrasive cut-off wheels are intended

for peripheral grinding, side forces applied to

these wheels may cause them to shatter.

For threaded abrasive cones and plugs use

only undamaged wheel mandrels with an

unrelie ved shoulder flange th at ar e of

correct size and length. Proper mandrels will

reduce the possibility of breakage.

Do not ja m a cut- off w heel or apply

excessive pressure. Do not attempt to make

an excessive depth of cut. Overstressing the

wheel increases the loading and susceptibility

to twisting or snagging of the wheel in the cut

an d th e po ssib ility of kickba c k or whe el

breakage.

Do not position your hand in line with and

behind the rotating wheel. When the wheel,

at the point of operation, is moving away from

your hand, the possible kickback may propel

the spinning wheel and the power tool directly

at you.

When wheel is pinched, snagged or when

interrupting a cut for any reason, switch off

the power tool and hold the power tool

motion less until the w heel comes to a

complete stop. Never attempt to remove the

cut-off wheel from the cut while the wheel is

in motion otherwise kickback may occur.

Investigate a nd tak e corrective a ction to

eliminate the cause of wheel pinching or

snagging.

Do not restart the cutting operation in the

workpiece. Let the wheel reach full speed

and carefully re-enter the cut. The wheel may

bind, walk up or kickback if the power tool is

restarted in the workpiece.

Support panels or any oversized workpiece

to minimize the risk of wheel pinching and

kickback. Large workpieces tend to sag under

their own weight. Supports must be placed

under the workpiece near the line of cut and

near the edge of the workpiece on both sides of

the wheel.

Use extra caution when making a pocket

cut into existing walls or other blind areas.

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:38 AM Page 5

Page 6

6

Additional Safety Warnings

The protruding wheel may cut gas or water

pipes, electrical wiring or objects that can

cause kickback.

Safety warnings specific for wire

brushing operations:

Be aware that wire bristles are thrown by

the brush even during ordinary operation.

Do not overstress the wires by applying

excessive load to the brush. The wire bristles

can easily penetrate light clothing and/or skin.

Allow brushes to run at operating speed for

at least one minute before using them.

During this time no one is to stand in front

or in line with the brush. Loose bristles or

wires will be discharged during the run-in time.

Direct the discharge of the spinning wire

brush away from you. Small particles and tiny

wire fragments may be discharged at high

velocity during the use of these brushes and

may become imbedded in your skin.

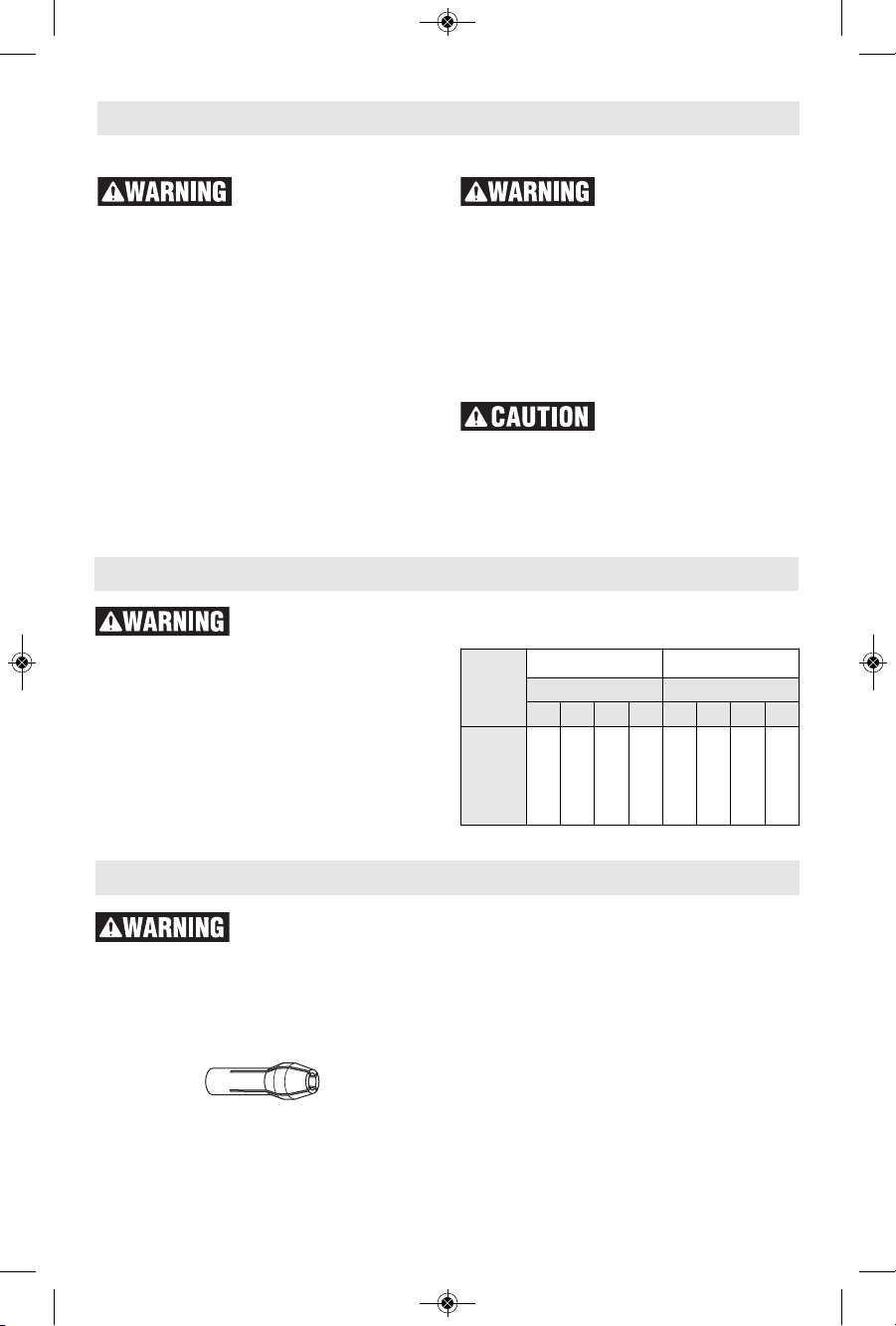

Do not use rou t er bit

with the Dremel chuck.

Bit may become a projectile and cause serious

injury.

GFCI and personal protection devices like

electrician’s rubber gloves and footwear will

further enhance your personal safety.

Use only power supply number 2610Z09738

provided with the tool.

Keep handles dry, clean and free from oil

and grease. Slippery hands cannot safely

control the power tool.

Use clamps or other practical way to secure

and supp ort the w orkpiece to a stab le

platform. Holding the work by hand or against

your body is unstable and may lead to loss of

control.

Develop a periodic maintenance schedule

for your tool. When cleaning a tool be

careful not to disassemble any portion of

th e tool si nce int ernal wires ma y be

misplaced or pinched or safety guard return

sp ring s may be impr oper ly mou nted .

Certain cleaning agents such as gasoline,

carb on te trachloride , ammoni a, et c. ma y

damage plastic parts.

Risk of injury to user. The power cord must only

be serviced by a Dremel Service Facility..

Some dust cr eated by

power sanding, sawing,

grinding, drilling, and other construction

activities contains chemicals known to

ca use ca ncer, b i r t h de f ects or ot her

reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and

other masonry products, and

• Arsen ic and ch romium from chemically-

treated lumber.

You r risk from t h e s e expos u r e s varie s ,

depending on how often you do this type of

work. To redu ce your ex pos ure to these

chemicals: work in a well ventilated area, and

work with approved safety equipment, such as

those dust masks that are specially designed

to filter out microscopic particles.

Safety Rules for Rotary Tools - (cont.)

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:38 AM Page 6

Page 7

7

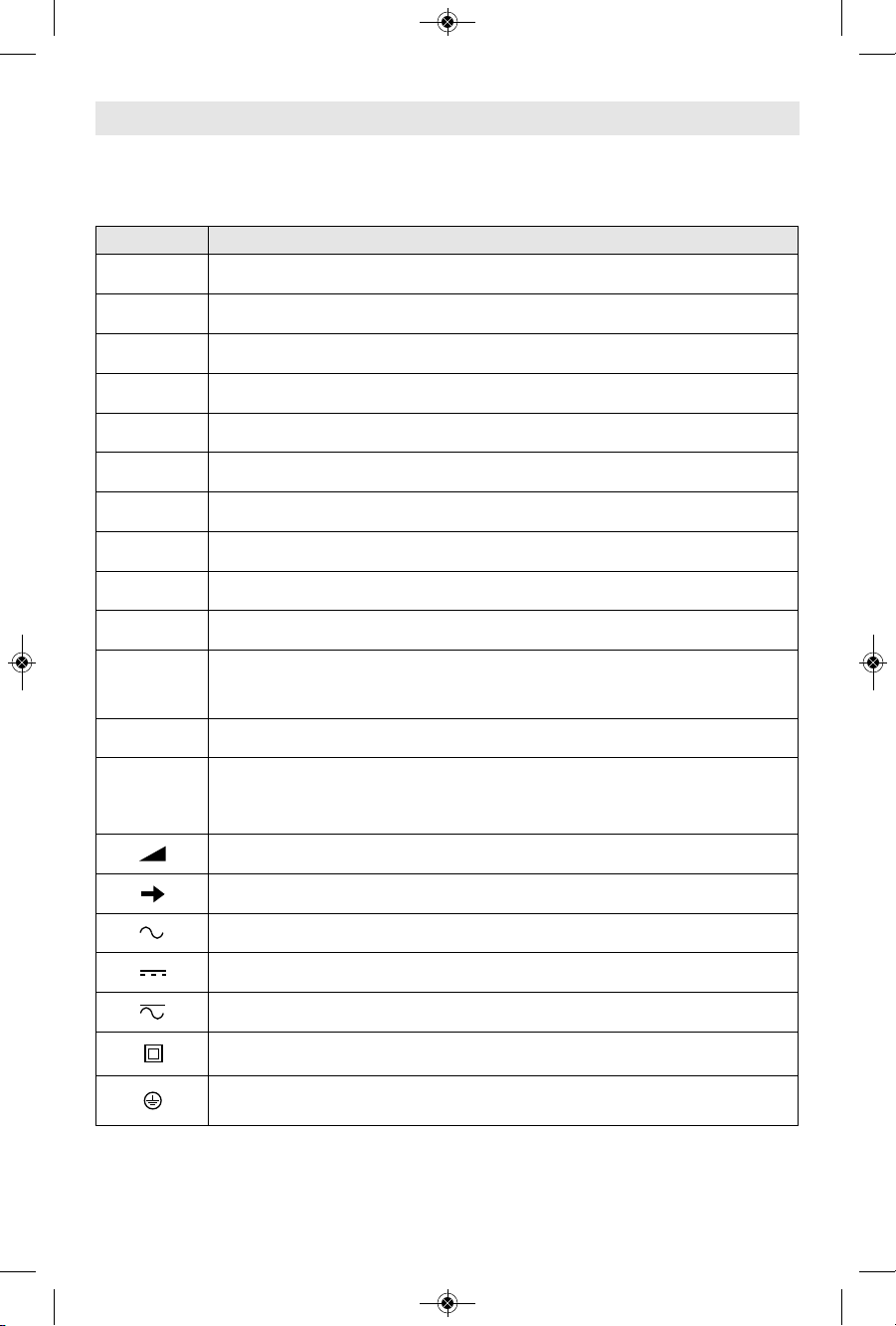

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbols

Symbol Designation / Explanation

V Volts (voltage)

A Amperes (current)

Hz Hertz (frequency, cycles per second)

W Watt (power)

kg Kilograms (weight)

min Minutes (time)

s Seconds (time)

⌀

Diameter (size of drill bits, grinding wheels, etc.)

n

0

No load speed (rotational speed at no load)

n Rated speed (maximum attainable speed)

.../min

Revolutions or reciprocation per minute (revolutions, strokes, surface speed,

orbits etc. per minute)

0 Off position (zero speed, zero torque...)

1, 2, 3, ...

I, II, III,

Selector settings (speed, torque or position settings. Higher number means

greater speed)

0

Infinitely variable selector with off (speed is increasing from 0 setting)

Arrow (action in the direction of arrow)

Alternating current (type or a characteristic of current)

Direct current (type or a characteristic of current)

Alternating or direct current (type or a characteristic of current)

Class II construction (designates double insulated construction tools)

Earthing terminal (grounding terminal)

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:38 AM Page 7

Page 8

8

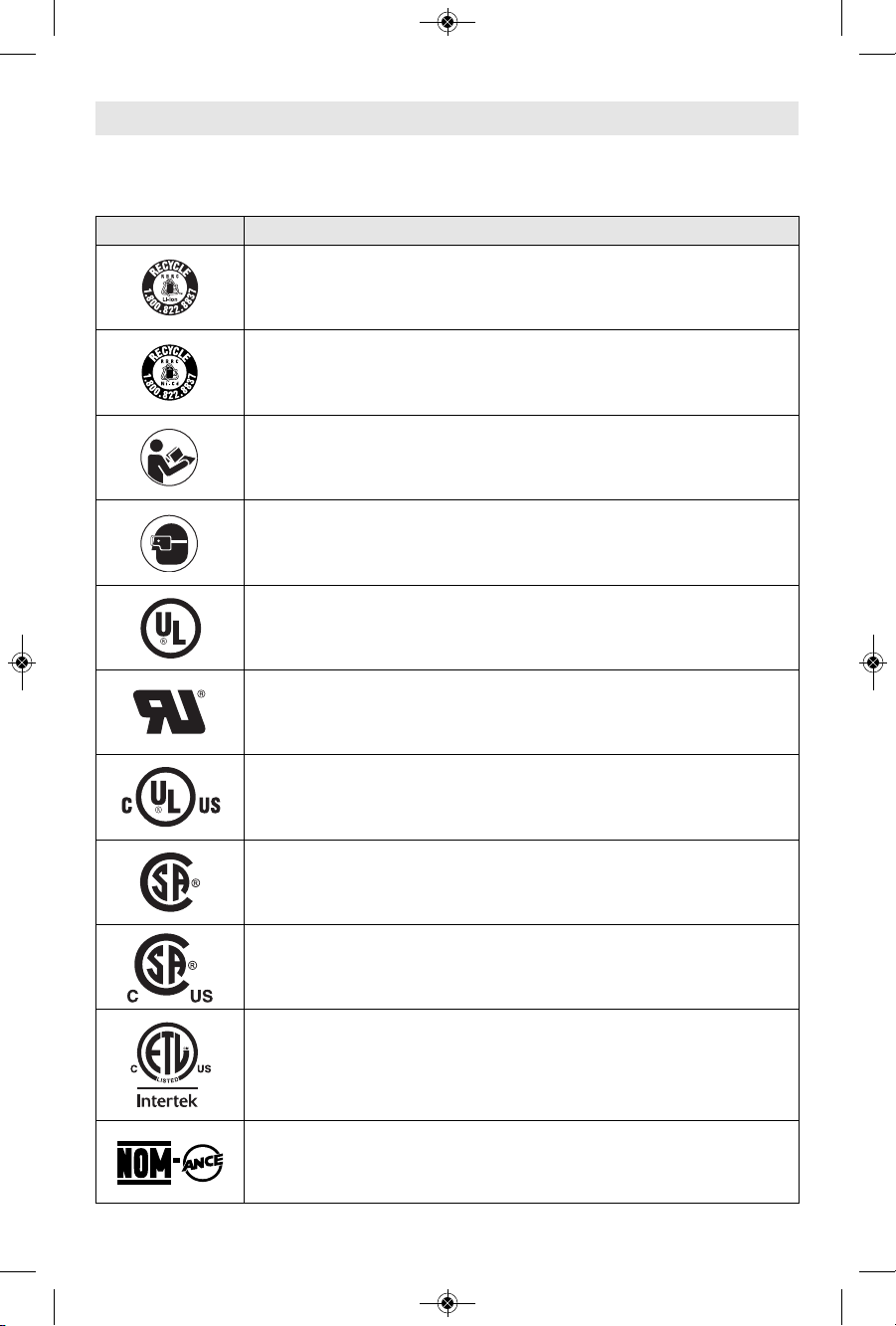

Symbols (continued)

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Designation / Explanation

Designates Li-ion battery recycling program

Designates Ni-Cad battery recycling program

Alerts user to read manual

Alerts user to wear eye protection

This symbol designates that this tool is listed by Underwriters Laboratories.

This symbol designates that this component is recognized by Underwriters

Laboratories.

This symbol designates that this tool is listed by Underwriters Laboratories,

to United States and Canadian Standards.

This symbol designates that this tool is listed by the Canadian Standards

Association.

This symbol designates that this tool is listed by the Canadian Standards

Association, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Intertek Testing

Services, to United States and Canadian Standards.

This symbol designates that this tool complies to NOM Mexican Standards.

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:38 AM Page 8

Page 9

9

Disconnect the plug f rom t he po wer source before maki ng an y

assembly, adjustments or changing accessories. Such preventive

safety measures reduce the risk of starting the tool accidentally.

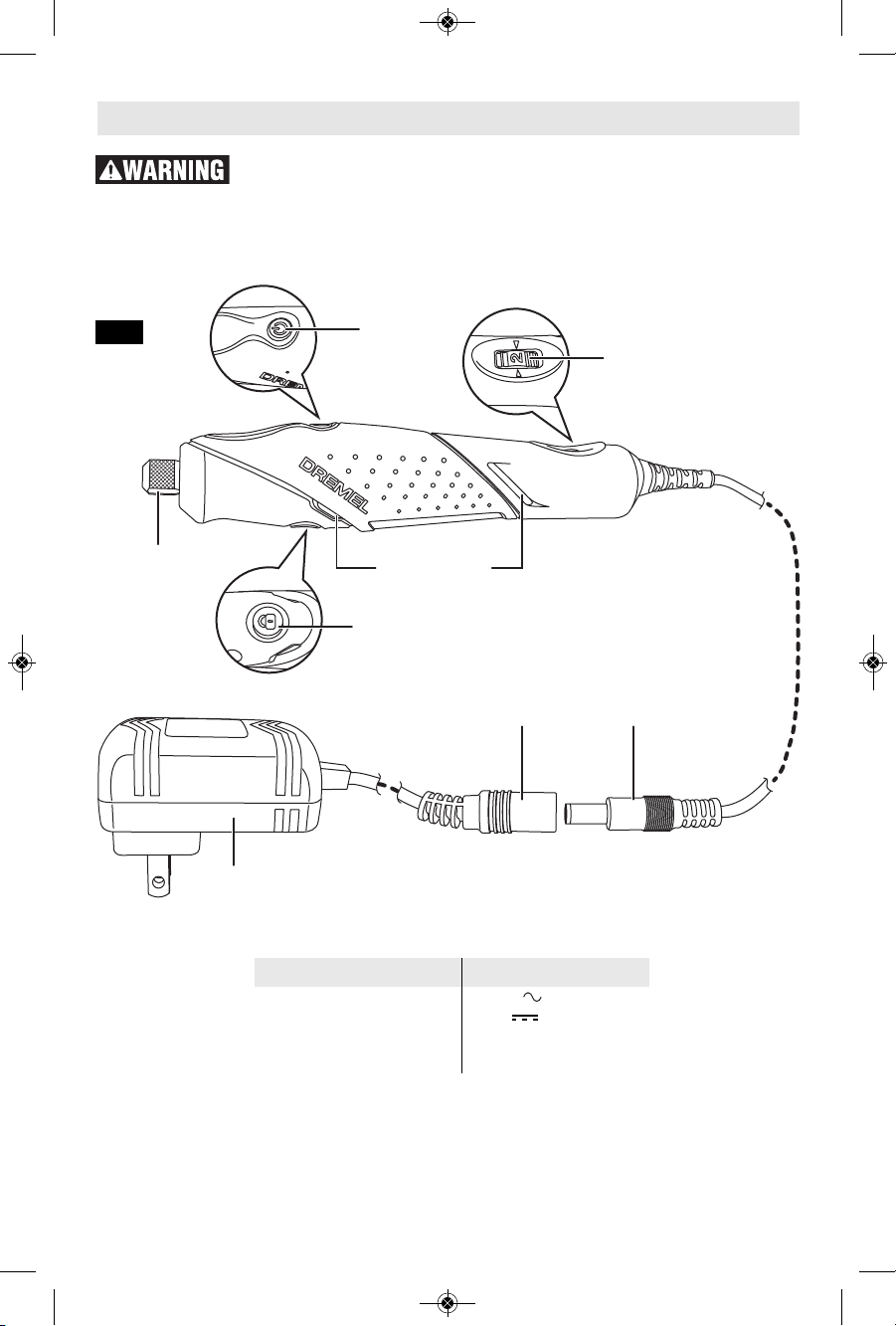

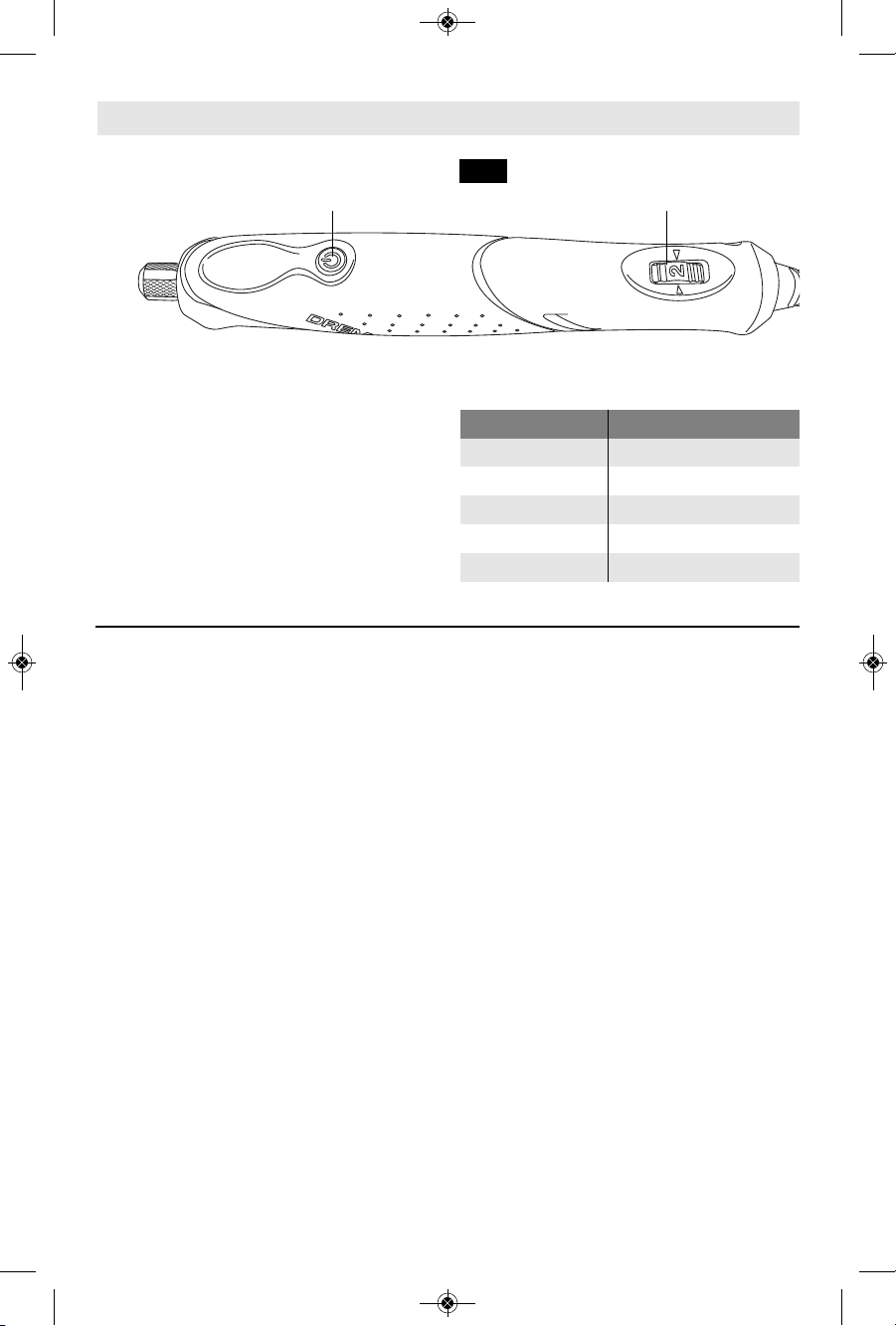

Functional Description and Specifications

Model 2050 High Speed Rotary Tool

ON/OFF

BUTTON

SHAFT LOCK

BUTTON

POWER

SUPPLY

DC

SOCKET

DC

JACK

VENTILATION

OPENINGS

COLLET

NUT

Model number 2050

Power Input rating 120V 60Hz

Power Output rating

18V 0.5A

Rated speed n 5,000—22,000 /min

Nut capacity 1/32"—1/8"

FIG. 1

VARIABLE

SPEED DIAL

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:38 AM Page 9

Page 10

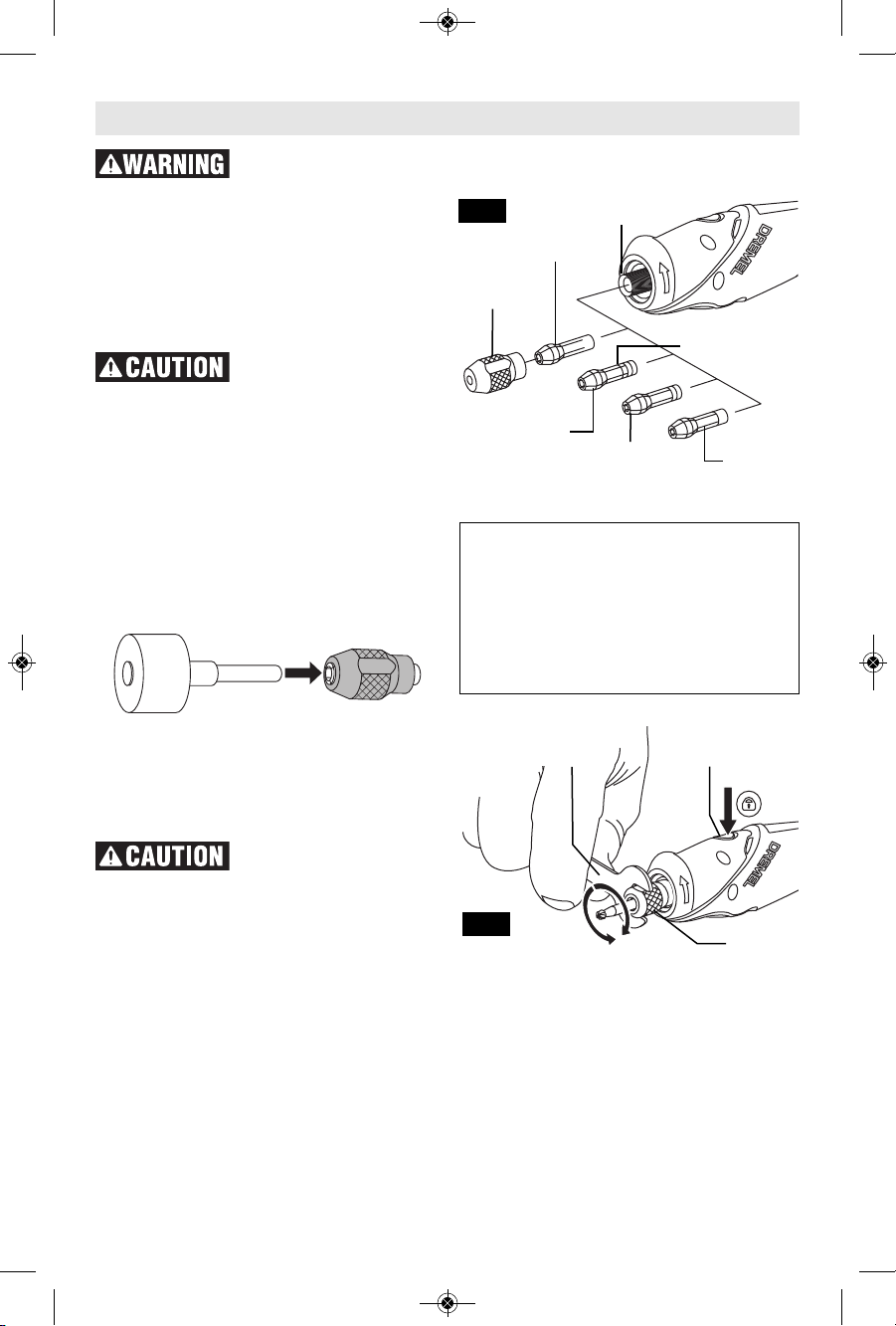

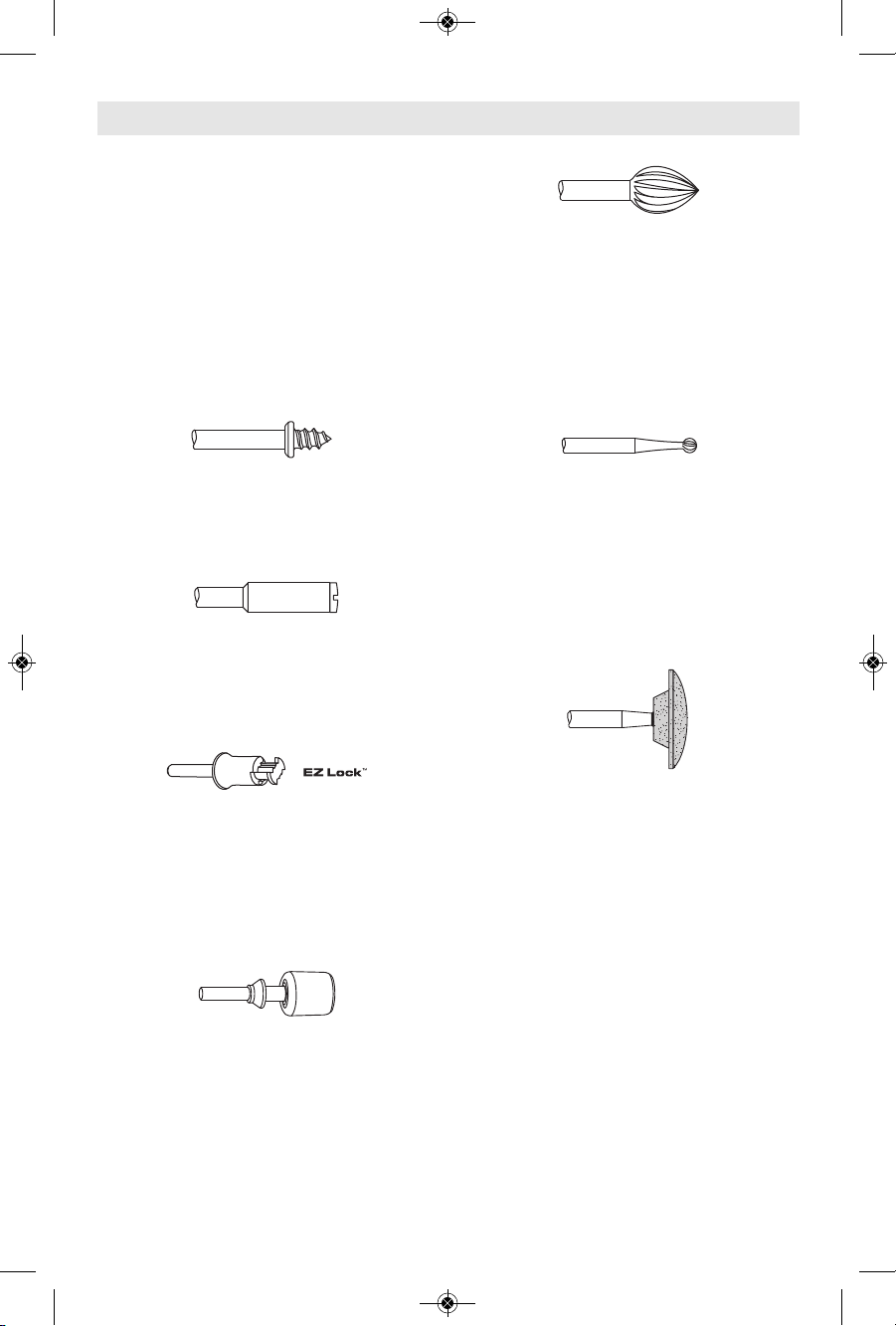

C

OLLETS

Four different size collets (see illus tration), to

accommodate different shank sizes, are avail able for your Rotary Tool. To install a different

collet, remove the collet nut and remove the old

collet. Insert the unslotted end of the collet in

the hole in the end of the tool shaft. Replace

collet nut on the shaft.

Al ways use the col let

which matches the shank

size of the accessory you plan to use. Never

force a larger diameter shank into a collet.

Note: Most rotary tool kits do not include all

four collets sizes.

FIXING STUCK COLLETS

It is possible for a collet to get stuck within the

collet nut especially if a collet nut is tightened

on to t he t ool witho ut a bi t in pl a ce. If t his

happens, the collet can be removed from the

collet nut by pushing the shank of an accessory

into the hole in the collet nut. This should cause

the collet to pop out of the collet nut.

COLLET NUT

To loosen, first press shaft lock button and

rotate the shaft by hand until the lock engages

the shaft preventing further rotation. Your

Dremel 2050 is equipped with a quick shaft lock

mechanism.

Do not engage lock while

the Rotary Tool is running.

With the shaft lock engaged use the collet

wrench to loosen the collet nut if necessary. The

collet nut must be loosely threaded on when

inserting an accessory. Change accessories by

inserting the new one into the collet as far as

possible to minimize runout and unbalance.

With the shaft lock engaged, use collet wrench

to securely tighten the collet nut (Fig. 3). Avoid

excessive tightening of the collet nut when

there is no bit inserted.

COLLET

NUT

TO

LOOSENTOTIGHTEN

SHAFT LOCK

BUTTON

FIG. 3

10

Always unplug Rotary Tool before changing accessories, changing

collets or servicing your Rotary Tool.

Assembly

COLLET IDENTIFICATION CHART

Collet sizes can be identified by the rings

on the back end of collet.

1/32" Collet has one (1) ring.

1/16" Collet has two (2) rings.

3/32" Collet has three (3) rings.

1/8" Collet has no rings. (Included in

most tool kits on the tool)

COLLET

NUT

IDENTIFICATION

RINGS

480

1/8"

COLLET

SHAFT

481

3/32"

COLLET

482

1/16"

COLLET

483

1/32"

COLLET

FIG. 2

COLLET

WRENCH

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:38 AM Page 10

Page 11

11

Operating Instructions

Observe all warnings and

safety instructions when

us ing the rot ary tool. Fai lure to fol low

recommended procedures could re sult in

personal injury or property damage.

Dremel 2050

Thank you for purchasing the Dremel 2050.

Th is pro duct wa s d esig ned by th e m any

Dremel users who passionately use their rotary

tools daily. This tool was designed to give you

the ultimate performance when working on

versatile detailed projects.

The Dremel 2050 is a versatile craft rotary tool,

which provides the best results for versatile

detailed projects. The slim size of the tool

allows for maximum control and allows you

closer to your work piece. The lightweight

design and soft grip on the tool mean the tool

can be held comfortably for extended periods of

use. You will appreciate the many applications

that the Dremel 2050 can easily tackle.

Rotary Tool Introduction

The Rotary Tool is comfortable in the hand, and

is made to accept a variety of accessories

in clud ing engr avin g point s an d cutter s,

polishing wheels and brushes and sanding

bands . Accesso ries c ome in a varie ty of

shapes and permit you to do a number of

different jobs. As you be come familiar with the

range of accessories and their uses, you will

learn just how versatile the Rotary Tool is. You’ll

see dozens of uses you hadn’t thought of

before.

The real secret of the Rotary Tool is its speed.

To understand the advantages of its high

speed, you have to know that the standard

portable electric drill runs at speeds up to 2,800

re volu tion s pe r m inut e. T he R otar y Tool

operates at speeds up to 22,000 revolutions

per minute. The typical electric drill is a lowspeed, high torque tool; the Rotary Tool is just

the opposite – a high-speed, low torque tool.

The major difference to the user is that in the

high speed tools, the speed combined with the

acces sory mounted in the collet does the work.

You don’t apply pressure to the tool, but simply

hold and guide it. In the low speed tools, you

not only guide the tool, but also apply pressure

to it, as you do, for example, when drilling a hole.

It is this high speed, along with its compact size

and wide variety of special accessories, that

makes the Rotary Tool differ ent from other

tools. The speed enables it to do jobs low

speed tools cannot do, such as engraving glass

and sanding rough wooden edges.

Getting the most out of your Rotary Tool is a

matter of learning how to let this speed work for

yo u. To lea rn abo ut mor e use s and the

ve rsat ilit y of Dr emel acce ssori es an d

attachments refer to this Owner's Manual or

check our website at www.Dremel.com or join

the conversation at facebook.com/dremel.

Turning tool on and off

Insert DC jack of the rotary tool into DC socket

of the power supply (Fig. 1). Insert power

supply into power outlet.

Assembly

BALANCING ACCESSORIES

For precision work, it is important that all

accessories be in good balance (much the

same as the tires on your automobile). To true

up or balance an accessory, slightly loosen

collet nut and give the accessory or collet a 1/4

turn. Re tighten the collet nut and run the Rotary

Tool. You should be able to tell by the sound

and feel if your accessory is running in balance.

Continue adjusting in this fashion until best

balance is achieved. To maintain balance on

abrasive wheel points, before each use, with

the wheel point secured in the collet, turn on

the Rotary Tool and run the 415 Dressing

Stone lightly against the revolving wheel point.

This removes high spots and trues up the

wheel point for good balance.

IMPORTANT SAFETY INSTRUCTIONS - SAVE THESE INSTRUCTIONS

DANGER - TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, CAREFULLY

FOLLOW THESE INSTRUCTIONS

For connection to a supply not in the U.S.A., use an attachment plug adapter of the proper

configuration for the power outlet, if needed.

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:38 AM Page 11

Page 12

12

The tool is turned “ON” by the on/off button

(Fig. 1 and 9).

TO TURN TH E TOOL “ON” pr e s s and

release the on/off blue button.

TO TURN T H E TOO L “OFF” p r e ss and

release the on/off button.

Adjust the tool speed using the speed dial.

See “Operating Speeds” Section.

Stall Protection

This tool has a stall protection feature built

into it to protect the motor in the event of a

stall. If you stall the tool for too long, or bind

the bit in a work piece, especially at high

speeds, it will automatically turn itself off.

Simply take the tool out of the material you

we re s tall ed i n, t urn it bac k on aga in t o

continue using it.

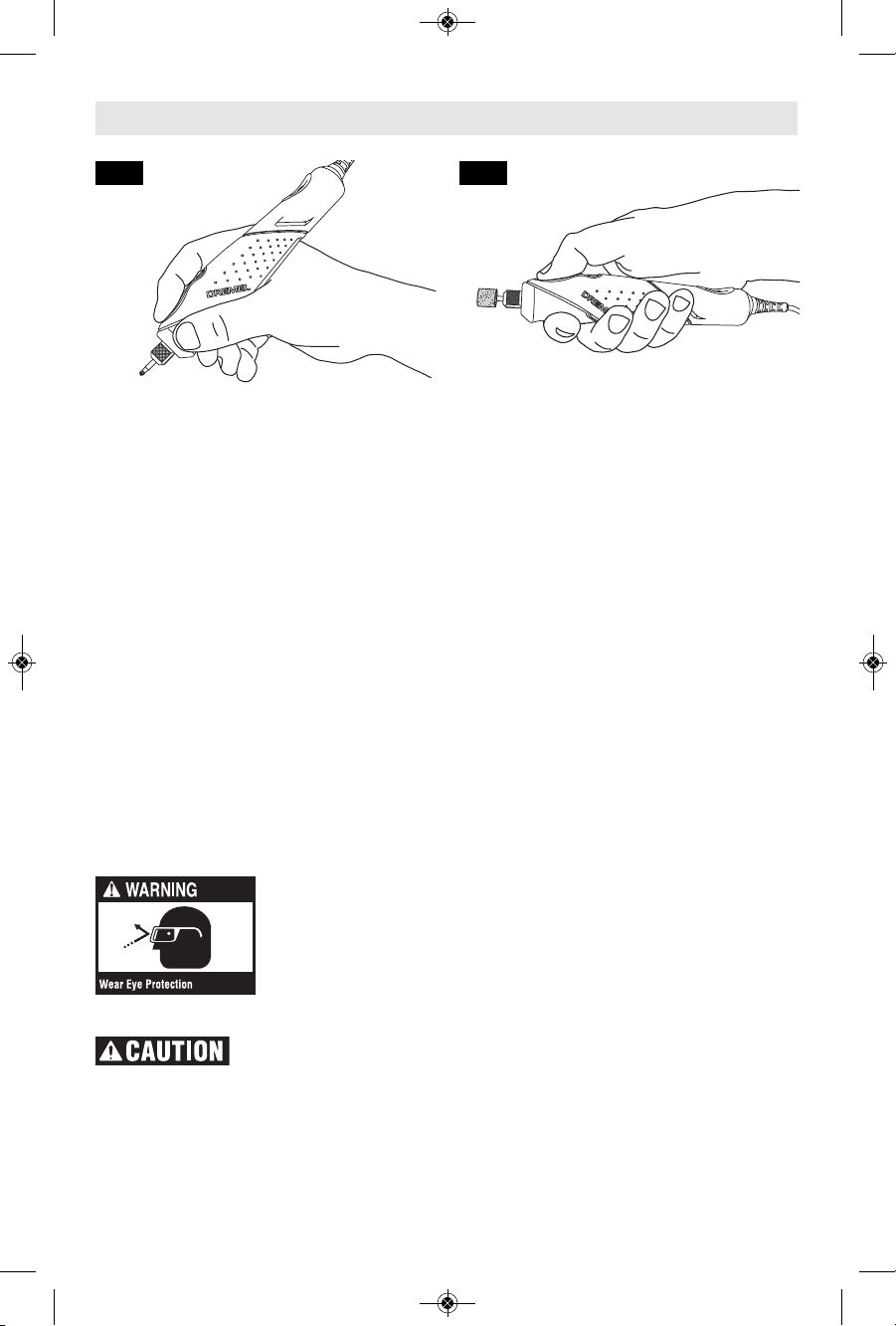

Using the Rotary Tool

The first step in learning to use the Rotary Tool

is to get the “feel” of it. Hold it in your hand and

feel its weight and balance. Feel the taper of

the housing. This taper permits the Rotary Tool

to be grasped much like a pen or pencil (Fig. 4).

Always hold the tool

away from your face.

Ac cess orie s can be

da mage d durin g

handling, and can fly

apart as they come up

to speed. This is not

common, but it does happen.

Whenever you hold the

tool, be ca refu l n ot to

cover the air vents with your hand. This

blocks the air flow and causes the motor to

overheat.

Practice on scrap materials first to see how the

Rotary Tool's high speed action performs. Keep

in mind that the work is done by the speed of

the tool and by the accessory in the collet. You

should not lean on or push the tool during use.

Instead, lower the spinning accessory lightly to

the work and allow it to touch the point at which

you want sanding or etching to begin. Con centrate on guiding the tool over the work using

very little pressure from your hand. Allow the

accessory to do the work.

For best control in close or detailed work, grip

the Rotary Tool like a pencil between your

thumb and forefinger (Fig. 4).

The “Golf Grip” method of holding the tool is

used for more aggressive operations such as

sanding or grinding a flat surface (Fig. 5).

Usually, it is best to make a series of passes with

the tool rather than attempt to do all the work in

on e pass. To san d a w o o den s u r face, f o r

example, pass the tool back and forth over the

work, much as you would a small paint brush.

Sand a little material on each pass until you

reach the desired depth. For most work, the

gentle touch is best. With it, you have the best

control, are less likely to make errors, and will

get the most effi cient work out of the accessory.

To select the right speed for each job, use a

practice piece of material.

VARIABLE SPEED DIAL

Your tool is equipped with a variable speed

dial. Th e sp eed may be adjust ed duri ng

operation by presetting th e dial on or

between any one of the settings.

FIG. 5FIG. 4

Operating Instructions

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:38 AM Page 12

Page 13

You can refer to the charts on page 14 to

determine the proper speed, based on the

material being wor k e d and the type of

accessory being used. These charts enable

you to select both the correct acces sory and

the optimum speed at a glance.

The speed of Rotary Tool is controlled by

setting this dial on the housing (Fig. 6).

13

Needs for Slower Speeds

Certain materials, however, (some plastics

and precious metals, for ex ample) require a

relatively slow speed because at high speed

the friction of the accessory generates heat

and may cause damage to the material.

Slow speeds (15,000 RPM or less) usually

are best for polishing operations employing

the felt polishing ac ces sories. They may also

be best for working on deli cate projects as

“eggery” work, delicate wood carving and

fragile model parts. (All brushing applications

require lower speeds to avoid wire discharge

from the holder.)

Higher speeds are better for carving and

shaping wood.

Hardwoods, metals and glass require high

speed operation, and drilling should also be

done at high speeds.

The p o i n t t o reme m b e r i s this: M a n y

applications and accessories in our line will

provide the best performance at full speed,

but for certain materials, applications, and

accessories, you need slower speeds, which

is the reason our variable speed models are

available.

To aid yo u in d e t e r m i n i n g the o p t i m u m

operational speed for differ ent materials and

different accessories, we have constructed a

series of tables that appear on page 14. By

referring to these tables, you can discover

the recommended speeds for each type of

acc e s s o r y. Look t h e s e tables ov e r and

become familiar with them.

Ultimately, the best way to determine the

correct speed for work on any material is to

prac tic e f or a few minutes on a piece of

scrap, even after referring to the chart. You

can quic kly le arn that a sl owe r or faster

speed is more effective just by observing

what hap pens as you make a pass or two at

different speeds.

Some rules of thumb in regard to speed:

- Polishing, buffing and cleaning with any

type of bri stle br ush must be d one at

speeds not greater than 15,000 RPM to

prevent damage to the brush.

- Increasing the pressure on the tool is not

the answer when it is not performing as

you think it should. Perhaps you should be

using a different accessory, and perhaps

an adjustment in speed would solve the

problem. Leaning on the tool does not

help.

Let speed do the work!

Operating Speeds

F

IG. 6

ON/OFF

BUTTON

VARIABLE

SPEED DIAL

Settings for Approximate Revolutions

Dial Setting Speed Range

1 5,000-7,000 RPM

2 8,000-10,000 RPM

*3 11,000-14,000 RPM

4 15,000-18,000 RPM

5 19,000-22,000 RPM

* Maximum Setting for Wire Brush.

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:38 AM Page 13

Page 14

14

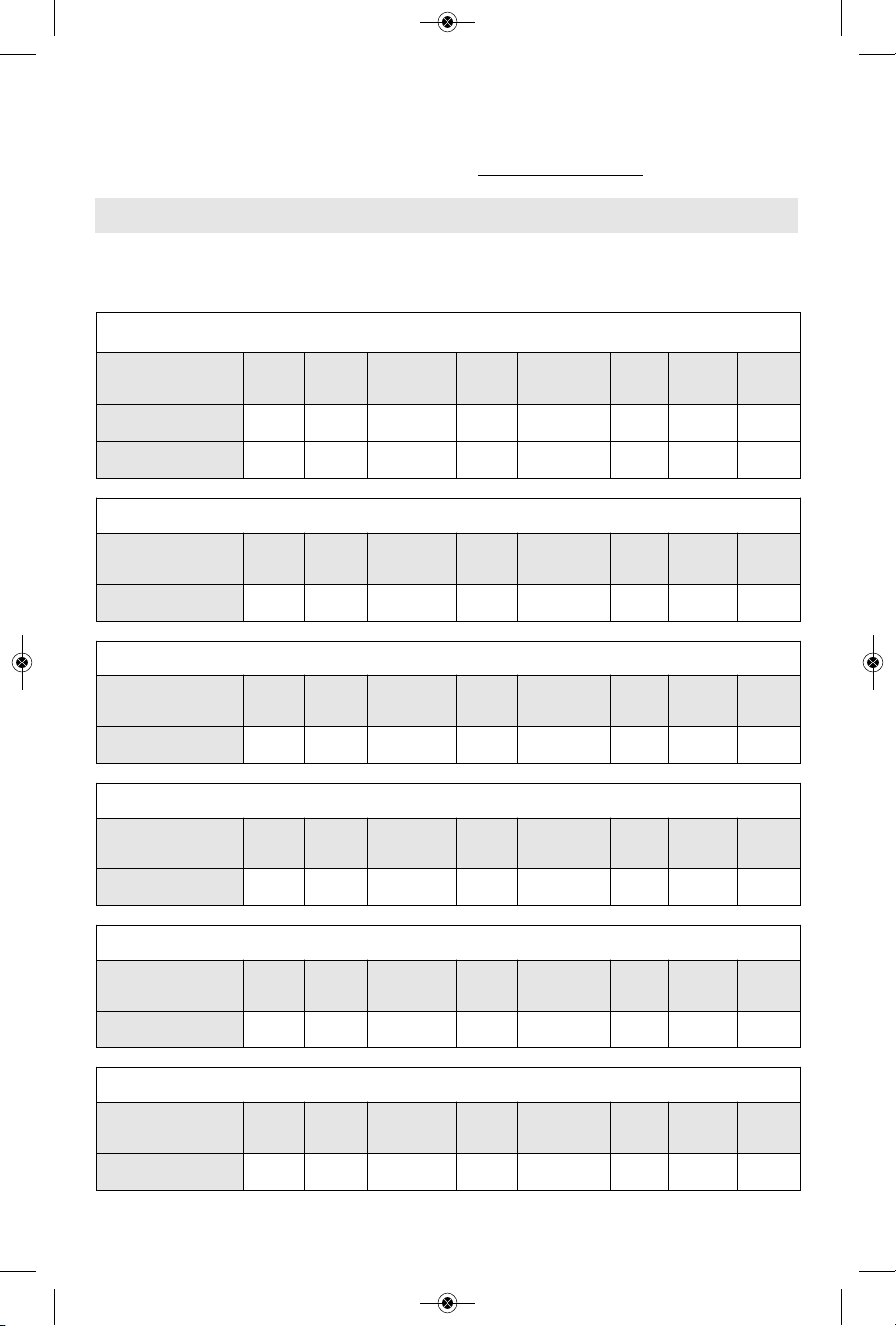

Set speed dial to the setting recommended for the material being worked and the catalog

number of accessory being used. For speed range for each setting please refer to “Operating

Speeds” on page 13.

Speed Dial Settings

High Speed Cutters

Catalog

Number

Soft

Wood

Hard

Wood

Laminates

/Plastics

Steel

Aluminum,

Brass, etc.

Shell/

Stone

Ceramic Glass

191 5 5 2 3-4 5 - - -

125 5 3-4 2 3-4 3-4 - - -

Engraving Cutters

Catalog

Number

Soft

Wood

Hard

Wood

Laminates

/Plastics

Steel

Aluminum,

Brass, etc.

Shell/

Stone

Ceramic Glass

105 5 5 5 2 3-4 - - -

Diamond Wheel Points

Catalog

Number

Soft

Wood

Hard

Wood

Laminates

/Plastics

Steel

Aluminum,

Brass, etc.

Shell/

Stone

Ceramic Glass

7103 5 5 - - - 5 5 5

Polishing Accessories

Catalog

Number

Soft

Wood

Hard

Wood

Laminates

/Plastics

Steel

Aluminum,

Brass, etc.

Shell/

Stone

Ceramic Glass

414, 429 - - - 3-4 3-4 3-4 3-4 3-4

Wire Brushes

Catalog

Number

Soft

Wood

Hard

Wood

Laminates

/Plastics

Steel

Aluminum,

Brass, etc.

Shell/

Stone

Ceramic Glass

428 2-3 2-3 1 2-3 2-3 - - -

Sanding Bands and Discs

Catalog

Number

Soft

Wood

Hard

Wood

Laminates

/Plastics

Steel

Aluminum,

Brass, etc.

Shell/

Stone

Ceramic Glass

430, 431, 438 1-5 1-5 1-4 5 5 1-5 1-5 -

Use only Dremel®, high-performance accessories.

Questions or Problems? Call 1-800-437-3635

or check our website at www.Dremel.com

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:38 AM Page 14

Page 15

15

COLLETS

If you expect to use a variety of accessories,

we recommend that in the beginning you

purchase a complete set of four collets. Store

these so that you will have the proper size of

collet for any accessory or drill bit you want

to use. Currently, the 1/8", 3/32",1/32" and

1/16" collets accommodate all of the avail able Dremel accessories. 1/8" collets are

included in most rotary tool kits.

Dremel Accessories

Use only Dremel®, high-performance accessories. Other accessories are

not designed for this tool and may lead to personal injury or property damage.

Store accessories in a dry and temperate environment to avoid corrosion and deterioration.

The number and variety of accessories for the Rotary Tool are almost limitless. There is a category

suited to almost any job you might have to do and a variety of sizes and shapes within each

category which en ables you to get the perfect accessory for every need.

Extension Cords

If an extension cord is

necessary, a cord with

adequate size conductors that is capable

of carrying the current necessary for your

to o l m u s t be used. Th i s w i l l prevent

excessive v oltag e dro p, loss of power or

overheating. Grounded tools must use 3-wire

extension cords that have 3-prong plugs and

receptacles.

NOTE: The smaller the gauge number, the

higher the cord capacity.

RECOMMENDED SIZES OF EXTENSION CORDS

120 VOLT ALTERNATING CURRENT TOOLS

Tool’s

Ampere

Rating

Cord Size in A.W.G. Wire Sizes in mm

2

Cord Length in Feet Cord Length in Meters

25 50 100 150

15 30 60 120

3-6

6-8

8-10

10-12

12-16

18

18

18

16

14

16

16

16

16

12

16

14

14

14

–

14

12

12

12

–

0.75

0.75

0.75

1.0

–

0.75

1.0

1.0

2.5

–

1.5

2.5

2.5

4.0

–

2.5

4.0

4.0

–

–

Service

NO USER SE R V I C E -

AB L E PARTS INSIDE .

Preventive maintenance performed by un au thor i z e d personn e l may result i n

mi s p l a c i n g of internal wires and

components which could cause serious

hazard. We recom mend that all tool service

be performed by a Dremel Service Center.

SE RVIC E MEN: Disco n nect tool an d /or

charger from power source before servicing.

D.C. MOTORS

The motor in your tool has been engineered

for many hours of dependable service. To

maintain peak efficiency of the motor, we

recommend it be examined every six months.

Only a genuine Dremel replacement motor

specially designed for your tool should be

used.

Cleaning

To avoid accidents,

always be sure the tool

is turned “OFF” before cleaning. The tool

may be cleaned most effectively with com pr e s s e d dry air. A l w a y s w e a r s a f e t y

go g g l e s when cleaning tools w i t h

compressed air.

Ventilation openings and switch levers must

be kept clean and free of foreign matter. Do

not attempt to clean by inserting pointe d

objects through opening.

Certain cleaning agents

an d solve n t s dam a g e

plastic parts. Some of these are: gasoline,

car bon tetrachloride, chlorinated cleaning

solvents, ammonia and household detergents

that contain ammonia.

Maintenance

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:39 AM Page 15

Page 16

16

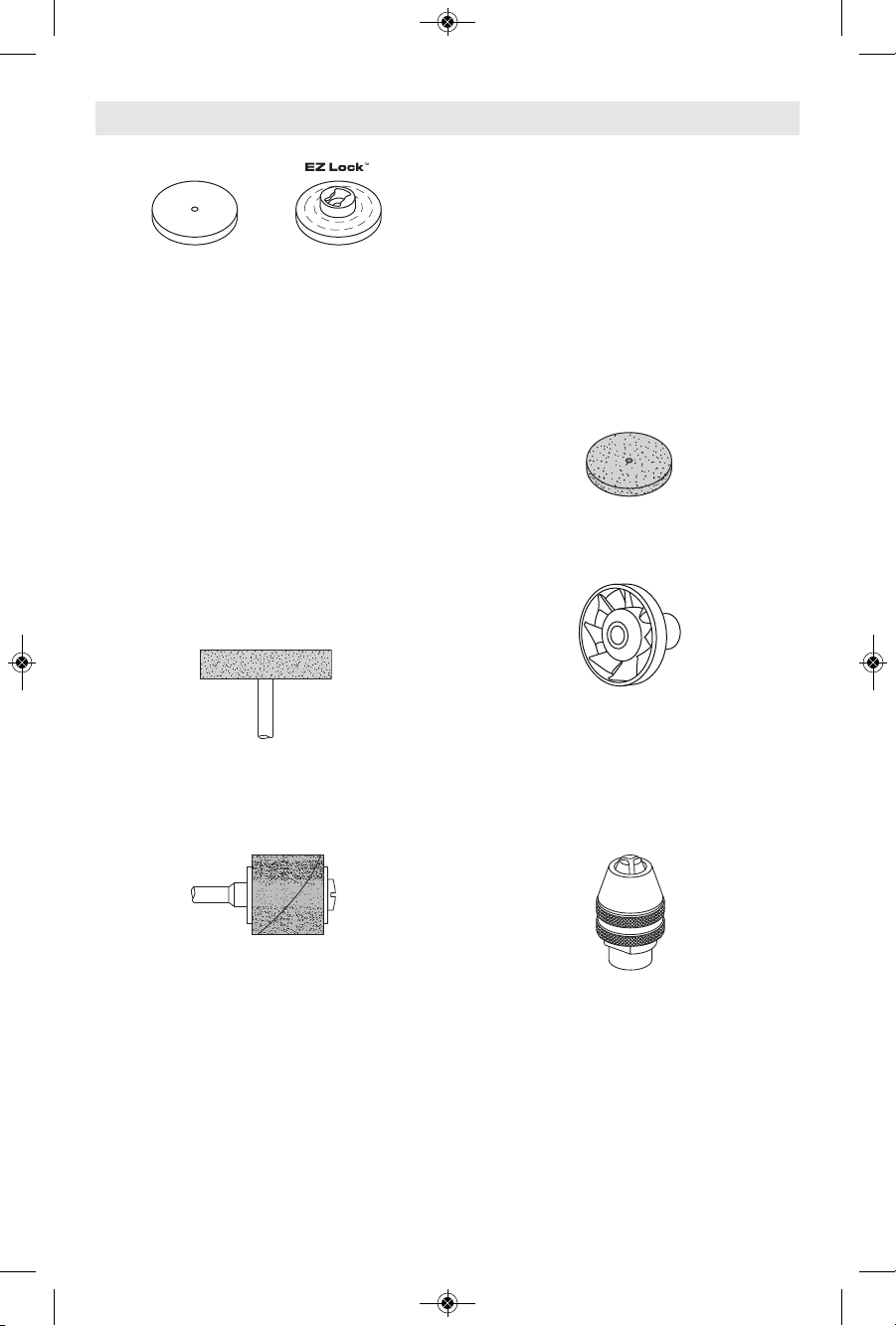

MANDRELS

A mandrel is a shank with a threaded or screw

he ad, which are requ i red when y ou u se

polishing accessories, cutting wheels, sanding

di scs, and p ol ish ing point s . Th e re ason

mandrels are us ed is t hat san ding di scs,

cutting wheels and similar accesso ries must

be replaced frequently. The mandrel is a per manent shank, allowing you to replace only

the worn head when necessary, thus saving

the expense of replacing the shaft each time.

Screw Mandrel No 401

This is a screw mandrel used with the felt

polishing tip and felt polishing wheels. 1/8"

shank.

Small Screw Mandrel No 402

This is a mandrel with a small screw at its tip,

and is used with emery and fiberglass cutting

wheels, sanding discs and polishing wheels.

1/8" shank.

EZ Lock Mandrel No 402

The D r e m e l EZ L o c k makes a c c e s s o r y

changes easy as PULL - TWIST - RELEASE.

The one-piece mandrel design simplifies the

process of changing cutting wheels, buffs

and d e t ai l a b r a s i v e b r u s h e s ( EZ L o c k

compatible accessories).

EZ Drum™ Mandrel No EZ407SA

Th e Dre m e l EZ Dru m mak e s acc e ssory

changes easy as PULL - INSERT - PRESS

DOWN. T h e one-piece m a n d r e l design

simplifies the process of changing sanding

bands.

High Speed Cutters

Available in many shapes, high speed cutters

are used in carving, cutting and slotting in

wo o d , pla s t i cs an d soft meta l s such as

aluminum, copper and brass. These are the

accessories to use for freehand routing or

carving in wood or plastic, and for precision

cu ttin g . Ma de o f hi gh qu alit y st e el. 1/8 "

shank.

Engraving Cutters

This group has a wide variety of sizes and

shapes, and are made for intricate work on

ceramics (greenwa r e ) , wo o d ca r v i n g s ,

jewelry and scrimshaw. They often are used

in making complicat ed printed circuit boards.

They should not be used on steel and other

very hard mate ria ls but a re excel len t o n

wood, plastic and soft metals. 1/8" shank.

Aluminum Oxide Grinding Stones

(red/brown)

Round, pointed, flat — you name the shape

and there is one available in this category.

These are made of aluminum oxide and cover

vi r tuall y ev e ry p o ssibl e kin d of gri nding

application. Use them for sharpening lawn

mo wer b lade s , sc rewd r iver tips , kn ives,

scissors, chisels and other cutting tools. Use

to r e m o v e flash f r o m metal cast i n g s ,

deburring any metal after cutting, smoothing

welded joints, grinding off rivets and re mov ing

ru s t . These g r i n d i n g stones can b e

re s h a r p e n e d wi t h a dr e s s i n g st o n e . In

machine shops, high speed drills and cut ters

normally are ground with aluminum oxide

wheels. 1/8" shank.

Dremel Accessories (Continued)

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:39 AM Page 16

Page 17

17

Silicon Carbide Grinding Stones

(blue/green)

Tougher than aluminum oxide points, these

are m a d e es p e c i a l l y for u s e on h a rd

materials s u c h a s glass and ce ramics.

Typical uses might be the removal of stilt

marks and excess glaze on ceramics and

engraving on glass. 1/8" shank.

Diamond Wheel Points

Excellent for fine detail work on wood, jade,

ceramic, glass and other hard material. Bits

are cove red with diamond particl es. 1/8"

shanks. (Not re c ommended for

drilling)

Wire Brushes

Maximum oper a t i n g

speed 15,000/min. Allow

brush to run at 15,000/min for one minute

before us e. Refer to Operating Sp eeds

section for proper tool speed setting.

Three different shapes of wire brushes are

available. The three shapes come in three

different materials: stainless steel, brass and

carbon wire. The stainless steel perform well

on pewter, aluminum, stainless steel, and

other metals, witho ut leaving "after-rust".

Brass brushes are non sparking, and softer

than steel; making them good for use on soft

me t a l like g o l d , cooper and b r a s s. The

carbon wire brushes are good for general

purpose cleaning.

Bristle Brushes

These are ex c e l l e n t cleaning too l s on

silverware, jew elry and antiques. The three

shapes make it poss ible to get in to tight

corners and othe r diffi cult places . Bristle

brushes can be u s e d w i t h po l i s h i n g

compound for faster cleaning or polishing.

Brushing Pressure

1. Remember, the tips of a wire brush do the

work. Operate the brush with the lightest

pressure so only the tips of the wire come

in contact with the work.

2. If heavier pressures are used, the wires

will be overstressed, resulting in a wiping

action; and if this is continued, the life of

the brush will be shortened due to wire

fatigue.

3. Apply the brush to the work in such a way

that as much of the brush face as possible

is in full contact with the work. Applying the

side or edge of the brush to the work will

resu lt in wi re breakage and shortened

brush life.

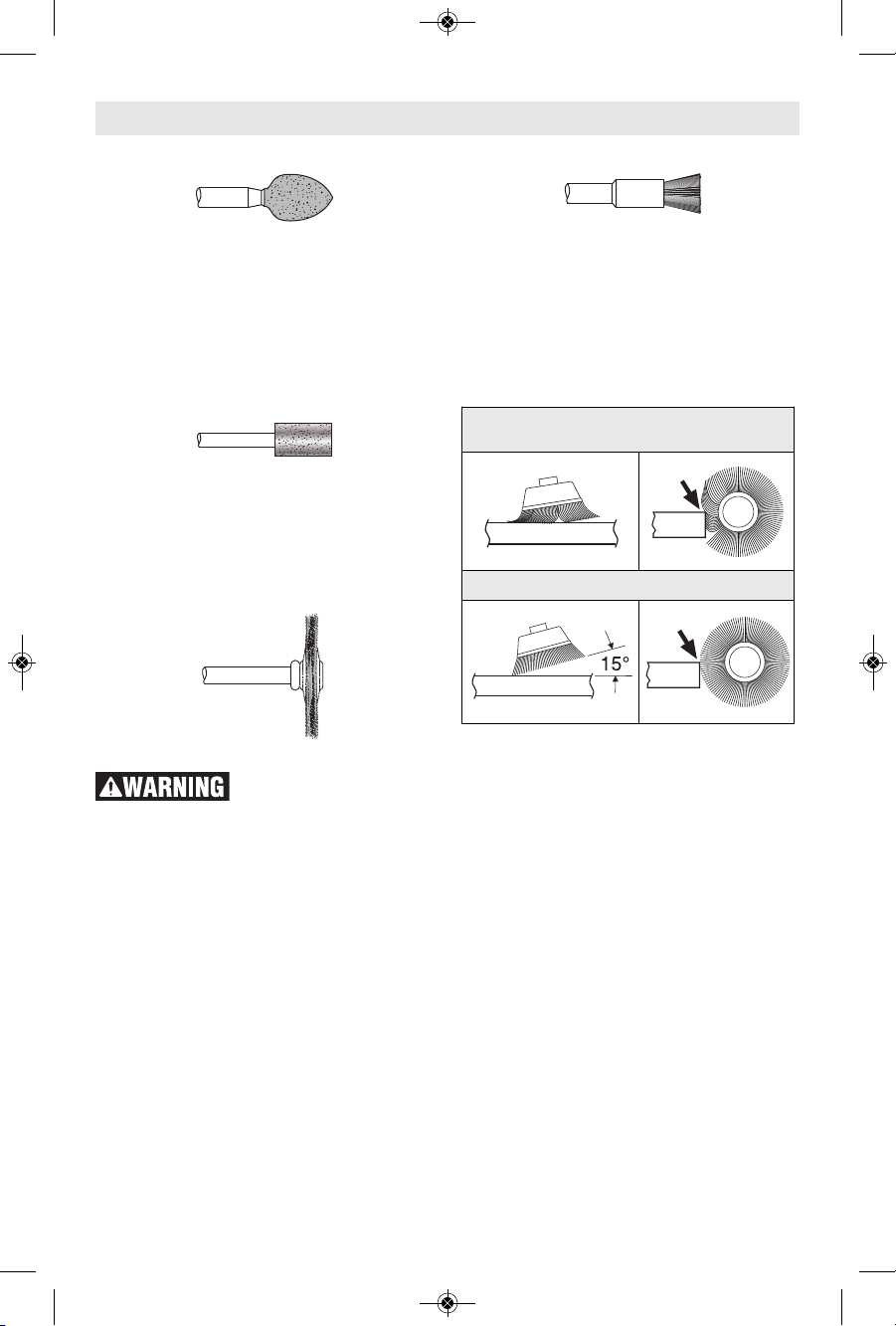

INCORRECT:

Excessive pressure can cause wire breakage.

CORRECT: Wire tips doing the work.

Dremel Accessories (Continued)

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:39 AM Page 17

Page 18

18

Dremel Accessories (Continued)

Polishing Accessories

These in clud e an impre gnated polishing

point and an impregnated polishing wheel for

bringing metal sur faces to smooth finish; a

felt polishing tip and felt polish ing wheel, and

cloth polishing wheel, all used for polishing

plastics, metals, jewelry and small parts. Also

included in this group is a p o l i s h ing

compound (No. 421) for use with the felt and

cloth polishers.

Polishing po i n t s m a k e a v ery smooth

surface, but a high luster is obtained using

felt or cloth wheels and polishing compound.

For best results polishing accessories

should be used at speeds not greater than

15,000 RPM.

No po lis hing co mpo und is ne ede d when

using the 425 Polishing Wheel.

Aluminum Oxide Abrasive Wheels

Use to remove paint, deburr metal, polish

stainless steel and other metals. Available in

medium grit. 1/8" shank.

Sanding Accessories

Sanding discs in fine, medium and coarse

grades are made to fit mandrel No. 402 and

EZ407. They can be used for nearly any

sm all san ding job you mig h t ha ve, fro m

model making to fine furniture finish ing. In

addition, there is the drum sander, a tiny

drum wh ich fits into the Rotary Tool and

makes it possible to shape wood, smooth

fiberglass, sand inside curves and other diffi cult places, and other sanding jobs. You

replace the sanding bands on the drum as

they become worn and lose their grit. Bands

come in fine medium and coarse grades.

Flapwheels grind and polish flat or contoured

surfaces. They are used most effectively as a

finishing sander af t e r h e a v i e r sur f a c e

sanding and material removal is completed.

Flapwheels come in fine and coarse grades.

Buffs are a great finishi ng accesso ry for

cleaning and lig h t sanding. Th e y work

effectively on metal, glass, wood, aluminum

and plastics. Coarse and medium buffs are

sold together. All buffs are sold individually.

Do not exceed 15,000 RPM in speed. 1/8"

shank.

Grinding Wheel

Use for deburring, removing rust, and general

purpose grinding. Use with Mandrel #402.

Collet Fan

Blows dust away for greater visibility to work

piece . G reat fo r sanding, en graving and

carving. Do not use dust blower to stop or

slow down the tool. Do no t conta ct dust

blower with fingers or workpiece during use.

Dremel Chuck

This chuck allows you to quickly and easily

change accessories on Dremel Rotary Tools

without c h a n g i n g col l e t s . Accepts

accessories with 1/32” - 1/8” shank. Read

in s t ruction man u a l . Ins e r t and sec u r e ly

tighten the shank of the accessory well within

the jaws of the chuck.

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:39 AM Page 18

Page 19

19

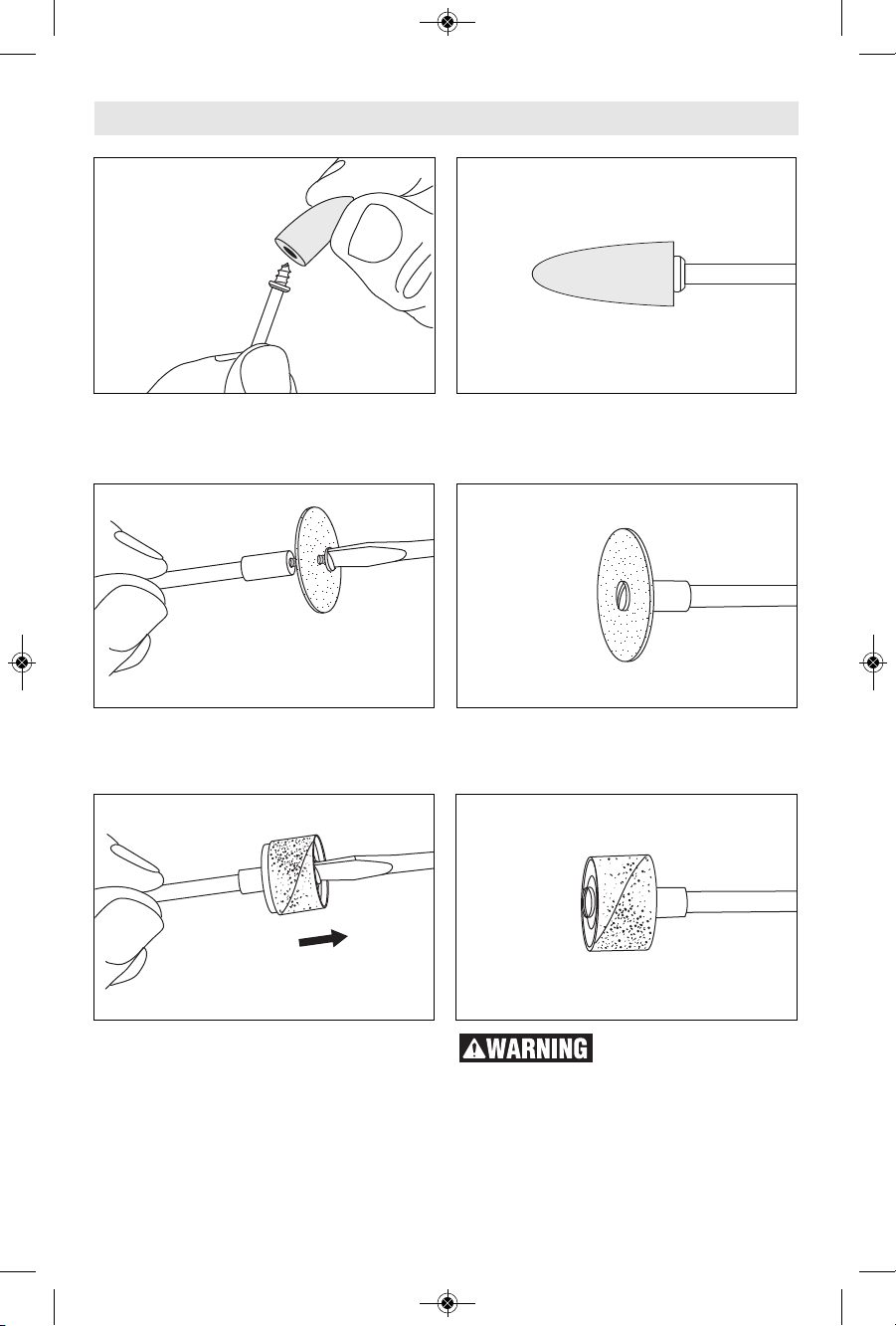

Mandrel N° 402 has a small screw at its tip, and is used with sanding discs.

Mandrel No. 401 is used with the felt polishing tip and wheels. Thread the tip on to the screw

carefully. The felt tip must thread down straight on the screw Mandrel, and be turned all the

way to the collar.

To replace a band on the Drum Sander, loosen

the screw without removing it to contract the

drum then slide the old band off. Slide the new

sanding band on and then expand the drum by

tightening the screw once again.

Before each use, check

to make certain that all

components are assembled to accessory

shank and that the drum is sufficiently

expanded to secure the band during use. If

sanding band is loose on the drum during

operation it may “fly” off and strike you or

bystanders.

Replacing Screw Mandrel Accessories

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:39 AM Page 19

Page 20

20

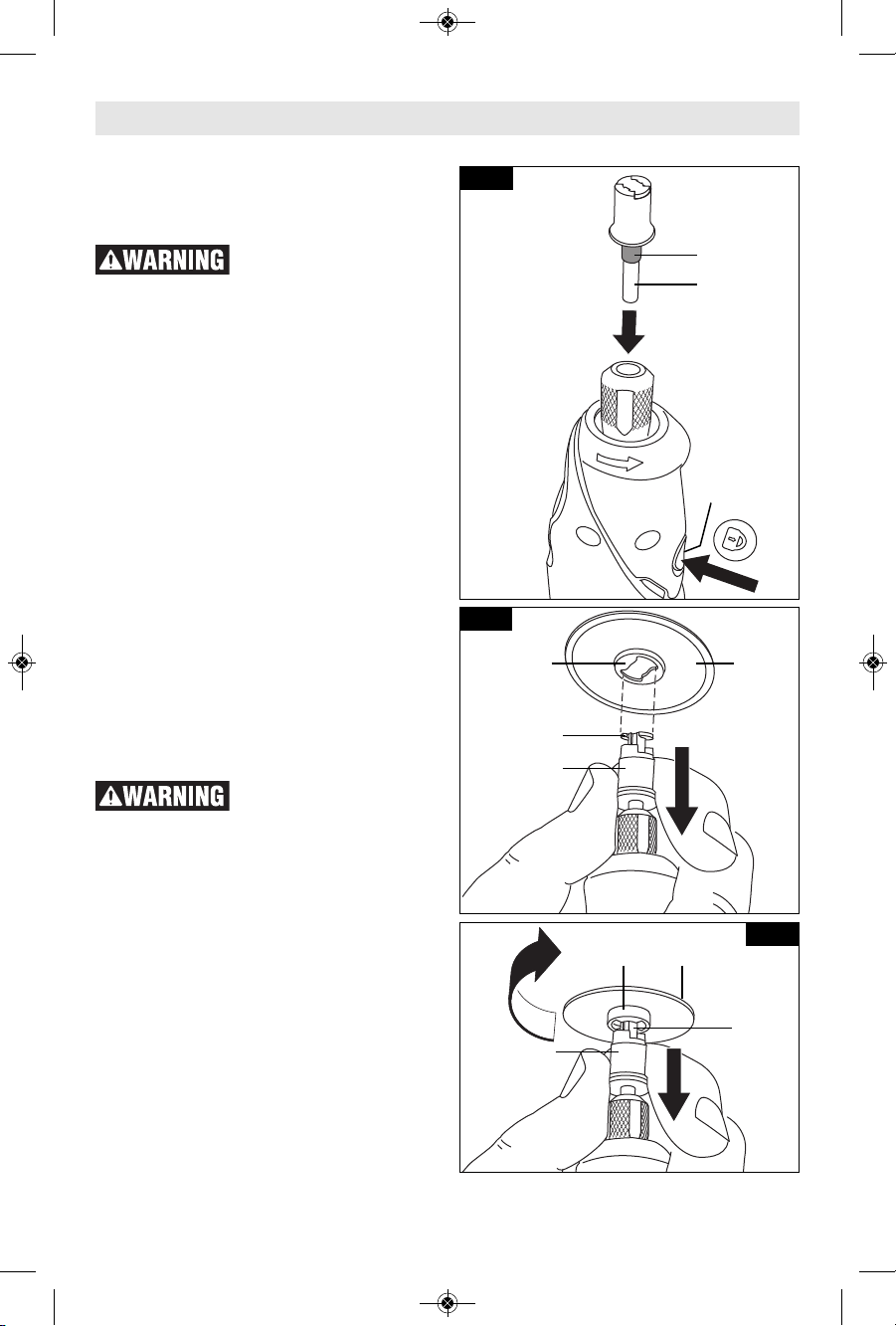

EZ Lock™ Mandre l No . EZ 4 0 2 h a s a

spring-loade d sleeve and is used wit h

s

anding disks, abrasive buffs and polishing

cloth.

Alwa ys make sure the

rotary tool is “OFF” and

disconnect the plug fr o m the powe r

source or the battery pack from the tool

before changing ac c e s s o r i e s . S u c h

preventative safety measures reduce the risk

of starting the power tool accidentally.

To load accessory:

1. Insert EZ Lock™ mandrel 1 into collet as

deep as possible and tighten Dremel collet

nut (Fig. A1).

Note: There is a blue spacer 2 that will

bottom out on the collet nut, setting the

mandrel to the correct depth.

2. Pull spring-lo a d e d slee v e 3 D O W N

towards tool with one hand and hold. You

can b r a ce t h e to o l on t he b o d y o r

workbench for extra leverage (Fig. A2).

3. With the other hand, align bow tie interface

4 on mandrel with metal bow tie interface 5

on bottom of accessory 6 (Fig. A2).

4. Place accessory on the mandrel to a point

just below the bow tie on the mandrel 4

and twis t 9 0 degrees until the b ow tie

interface 5 on the accessory 6 aligns with

the sleeve 3. Release sleeve 3. Accessory

6 should lock in place (Fig. A3).

Incorrect s e a t i n g of

acce sso ry on mandrel

may lead to personal injury or property

damage. To check for proper seating, hold

shaft lock button 7 and twist the accessory 6.

The accessory 6 will not be able to rotate on

mandrel.

To unload accessory:

1. Pull spring-loaded sleeve 3 DOWN toward

tool with one hand (Fig. A3).

2. Hold s l e e v e 3 do wn while t w i s t i n g

accessory 6 90 degrees (Fig. A3).

3. Remove accessory 6 (Fig. A3).

During use

Avoid damage to EZ lock™ mandrel by not

letting it contact the workpiece.

EZ Lock™Operating Instructions

FIG. A2

90°

FIG. A3

FIG. A1

1

7

2

3

4

56

3

4

56

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:39 AM Page 20

Page 21

21

EZ Drum™ Mandrel No. EZ407SA has a

spring loaded sleeve an d is used with

sanding bands.

Alwa ys make sure the

rotary tool is “OFF” and

disconnect the plug fr o m the powe r

source or the battery pack from the tool

before changing ac c e s s o r i e s . S u c h

preventative safety measures reduce the risk

of starting the power tool accidentally.

Always make sure accessory is properly

seated on mandrel before use. Incorrect

seating of accessory on mandrel may lead to

personal injury or property damage.

To load accessory:

1. As indicated, place two fingers underneath

the mandrel and pull firmly up. This will

place the EZ Drum™ in the "unlocked"

position (Fig. B1).

2. Keeping two fingers beneath the mandrel,

slide the sandin g ba nd d own until the

entire blue mandrel is covered (Fig. B2).

3. To return to "locked" position, press firmly

down on the top of the mandrel (Fig. B3).

Removing the sanding band on

the mandrel:

1. Place two fingers underneath the mandrel

and pull firmly up. This will place the EZ

Drum™ in the "unlocked" position (Fig.

B1).

2. Sandin g b and will now e asily s lid e off

mandrel ( F i g . B2). D o n ot squ e e z e

sand ing ba nd when removin g from EZ

Drum™ mandrel. This can lead to rubber

band pulling off mandrel and becoming

inoperable.

FIG. B1

FIG. B2

FIG. B3

EZ Drum™Operating Instructions

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:39 AM Page 21

Page 22

22

Veuillez lire tous les avertissements et toutes les consignes de sécurité. Si

l'on n'observe pas ces avertissements et ces consignes de sécurité, il existe un

risque de choc électrique, d'incendie et/ou de blessures corporelles graves.

CONSERVEZ TOUS LES AVERTISSEMENTS ET TOUTES LES CONSIGNES

DE SÉCURITÉ POUR RÉFÉRENCE FUTURE.

Dans les avertissements, le terme « outil électroportatif » se rapporte à votre outil branché sur le secteur (avec fil) ou

à votre outil alimenté par piles (sans fil).

Avertissements généraux concernant la sécurité des outils électroportatifs

Sécurité du lieu de travail

Maintenez le lieu de travail propre et bien éclairé.

Les risques d’accident sont plus élevés quand on

travaille dans un endroit encombré ou sombre.

N’utilisez pas d’outils électroportatifs dans des

atmosphères explosives, comme par exemple en

présence de gaz, de poussières ou de liquides

inflammables. Les outils électroportatifs produisent

des étincelles qui risquent d’enflammer les poussières

ou les vapeurs.

Éloignez les enfants et les visiteurs quand vous vous

servez d’un outil électroportatif. Vous risquez une

perte de contrôle si on vous distrait.

Sécurité électrique

Les fiches des outils électroportatifs doivent

correspondre à la prise. Il ne faut absolument jamais

modifier la fiche. N’utilisez pas d’adaptateur de prise

avec des outils électroportatifs munis d’une fiche de

terre. Le risque de choc électrique est moindre si on

utilise une fiche non modifiée sur une prise qui lui

correspond.

Évitez tout contact du corps avec des surfaces reliées

à la terre tels que tuyaux, radiateurs, gazinières ou

réfrigérateurs. Le risque de choc électrique augmente

si votre corps est relié à la terre.

N’exposez pas les outils électroportatifs à la pluie ou

à l’humidité. Si de l’eau pénètre dans un outil

électroportatif, le risque de choc électrique augmente.

Ne maltraitez pas le cordon. Ne vous en servez

jamais pour transporter l’outil électroportatif, pour le

tirer ou pour le débrancher. Éloignez le cordon de la

chaleur, des huiles, des arêtes coupantes ou des

pièces mobiles. Les cordons abîmés ou emmêlés

augmentent les risques de choc électrique.

Si vous utilisez un outil électroportatif à l’extérieur,

employez une rallonge conçue pour l’extérieur. Ces

rallonges sont faites pour l’extérieur et réduisent le

risque de choc électrique.

S'il est absolument nécessaire d'utiliser l'outil

électroportatif dans un endroit humide, utilisez une

alimentation protégée par un disjoncteur de fuite de

terre (GFCI). L'utilisation d'un disjoncteur GFCI réduit

les risques de choc électrique.

Sécurité personnelle

Restez concentré, faites attention à ce que vous

faites, et servez-vous de votre bon sens lorsque vous

utilisez un outil électroportatif. N'employez pas

d’outils électroportatifs quand vous êtes fatigué ou

sous l’emprise de drogues, d’alcool ou de

médicaments. Quand on utilise des outils

Symboles relatifs à la sécurité

Les définitions ci-dessous décrivent le niveau de gravité pour chaque terme signalant un danger. Veuillez lire le

mode d’emploi et lire la signification de ces symboles.

!

C’est le symbole d’alerte relatif à la sécurité. Il est utilisé pour vous

avertir de l’existence possible d’un danger de lésion corporelle.

Obéissez à tous les messages relatifs à la sécurité qui suivent ce

symbole pour éviter tout risque de blessure ou même de mort.

DANGER indique une situation dangereuse qui, si elle n’est pas

évitée, causera la mort d’une personne ou une blessure grave.

AVERTISSEMENT indique une situation dangereuse qui, si elle

n’est pas évitée, pourrait causer la mort d’une personne ou une

blessure grave.

MISE EN GARDE, conjointement avec le symbole d’alerte en

liaison avec la sécurité, indique une situation dangereuse qui, si

elle n'est pas évitée, causera une blessure légère ou modérée.

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:39 AM Page 22

Page 23

23

Avertissements relatifs à la sécurité communs aux

opérations de meulage, de ponçage, de passage à

la brosse métallique, de polissage, de ciselage et

de tronçonnage abrasif :

Cet outil électroportatif est conçu pour fonctionner

comme outil adapté aux opérations de meulage, de pon çage, de passage à la brosse métallique, de polis sage,

de ciselage ou de tronçonnage. Lisez l’en sem ble des

avertissements relatifs à la sécurité, des instruc tions,

des illustrations et des spécifications accom pagnant cet

outil électroportatif. Le non-respect de toutes les

instructions figurant ci-dessous pourrait causer un choc

électrique, un incendie et/ou une blessure grave.

N’utilisez pas d’accessoires qui ne sont pas conçus et

recommandés spécifiquement par le fabricant de l’outil.

Le simple fait que l’accessoire puisse être connecté à votre

outil électroportatif ne suffit pas à garantir un

fonctionnement sans danger.

La VITESSE NOMINALE des accessoires doit être au

moins égale à la vitesse de fonctionnement indiquée

sur l’outil électrique. Si des accessoires fonctionnent à

une vitesse supérieure à leur VITESSE NOMINALE, ils

risquent de se casser et d’être projetés dans l’air.

Le diamètre extérieur et l’épaisseur de votre acces soire

électroportatifs, il suffit d’un moment d’inattention pour

causer des blessures corporelles graves.

Utilisez des équipements de sécurité personnelle.

Portez toujours une protection oculaire. Le port

d'équipements de sécurité tels que des masques

antipoussières, des chaussures de sécurité

antidérapantes, des casques de chantier et des

protecteurs d'oreilles dans des conditions appropriées

réduira le risque de blessure corporelle.

Évitez les démarrages intempestifs. Assurez-vous que

l'interrupteur est dans la position arrêt (Off) avant de

brancher l'outil dans une prise de courant et/ou un

bloc-piles, de le ramasser ou de le transporter. Le

transport d'un outil électroportatif avec le doigt sur la

gâchette ou le branchement de cet outil quand

l'interrupteur est en position de marche (ON) est une

invite aux accidents.

Enlevez toutes les clés de réglage avant de mettre

l’outil électroportatif en marche. Si on laisse une clé

sur une pièce tournante de l’outil électroportatif, il y a

risque de blessure corporelle.

Ne vous penchez pas. Conservez toujours une bonne

assise et un bon équilibre. Ceci vous permettra de

mieux maîtriser l’outil électroportatif dans des situations

inattendues.

Habillez-vous de manière appropriée. Ne portez pas

de vêtements amples ou de bijoux. Attachez les

cheveux longs. N’approchez pas les cheveux, les

vêtements ou les gants des pièces en mouvement.

Les vêtements amples, les bijoux ou les cheveux longs

risquent d’être happés par les pièces en mouvement.

Si l’outil est muni de dispositifs permettant le

raccordement d’un système d’aspiration et de

collecte des poussières, assurez-vous que ces

dispositifs sont raccordés et utilisés correctement.

L'utilisation d'un dépoussiéreur peut réduire les dangers

associés à l'accumulation de poussière.

Utilisation et entretien des outils

électroportatifs

Ne forcez pas sur l’outil électroportatif. Utilisez l’outil

électroportatif qui convient à la tâche à effectuer.

L’outil qui convient à la tâche fait un meilleur travail et

est plus sûr à la vitesse pour lequel il a été conçu.

Ne vous servez pas de l’outil électroportatif si son

interrupteur ne parvient pas à le mettre en marche ou

à l’arrêter. Tout outil électroportatif qui ne peut pas

être commandé par son interrupteur est dangereux et

doit être réparé.

Débranchez la fiche de la prise ou enlevez le bloc-pile

de l’outil électroportatif avant tout réglage,

changement d’accessoires ou avant de ranger l’outil

électroportatif. De telles mesures de sécurité

préventive réduisent le risque de démarrage intempestif

de l’outil électroportatif.

Rangez les outils électroportatifs dont vous ne vous

servez pas hors de portée des enfants et ne permettez

pas à des personnes qui ne connaissent pas l’outil

électroportatif ou qui ignorent ces consignes de s’en

servir. Les outils électroportatifs sont dangereux dans

les mains d’utilisateurs inexpérimentés.

Entretenez les outils électroportatifs. Vérifiez que les

pièces mobiles sont alignées correctement et ne

coincent pas. Vérifiez qu’il n’y a pas de pièces

cassées ou d’autre circonstance qui risquent

d’affecter le fonctionnement de l’outil électroportatif.

Si l’outil est abîmé, faites-le réparer avant de

l’utiliser. De nombreux accidents sont causés par des

outils électroportatifs mal entretenus.

Maintenez les outils coupants affûtés et propres. Les

outils coupants entretenus correctement et dotés de

bords tranchants affûtés sont moins susceptibles de

coincer et sont plus faciles à maîtriser.

Utilisez l'outil électroportatif, les accessoires et les

embouts d'outil, etc. conformément à ces

instructions, en tenant compte des conditions de

travail et des travaux à réaliser. L'emploi d’outils

électroportatifs pour des tâches différentes de celles

pour lesquelles ils ont été prévus peut résulter en une

situation dangereuse.

Entretien

Faites réparer votre outil électroportatif par un agent

de service qualifié n’utilisant que des pièces de

rechange identiques. Ceci assure que la sécurité de

l’outil électroportatif est préservée.

Consignes de sécurité pour outils rotatifs

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:39 AM Page 23

Page 24

24

Consignes de sécurité pour outils rotatifs - (suite)

doivent être compris dans la capacité nominale de votre

outil électromécanique. Des accessoires de taille

incorrecte ne peuvent pas être contrôlés de façon

adéquate.

La taille de l’axe de rotation des meules, des tambours

de ponçage ou de tous autres accessoires doit corres pondre exactement à celle de l’axe de rotation ou à la

douille de l’outil électroportatif. Les accessoires qui ne

correspondent pas à la taille du matériel de montage de

l’outil électroportatif fonctionneront de manière désé qui librée, avec des vibrations excessives, et ils risqueraient de

causer une perte de contrôle.

Les MEULES MONTÉES à mandrin, ainsi que les

cylindres de contact, les outils de coupe ou autres

accessoires doivent être totalement insérés dans la

douille ou le mandrin. Si le mandrin n’est pas

suffisamment maintenu et/ou si le porte-à-faux de la

meuleuse est trop long, la MEULE MONTÉE risque de se

détacher et d’être éjectée violemment.

N’utilisez pas un accessoire endommagé. Avant chaque

utilisation, inspectez l’accessoire (p. ex., une meule

abrasive pour vous assurer qu’il n’y a pas de fissures ou

d’éclats, un tambour de ponçage pour vous assurer qu’il

n’est pas fissuré ou excessivement usé, ou une brosse

métallique pour vous assurer qu’elle ne comporte pas de

fils desserrés ou fissurés). Si vous avez laissé tomber

l’outil ou l’accessoire, inspectez-le pour vous assurer

qu’il n’est pas endommagé ou installez un accessoire

qui n’est pas endommagé. Après avoir inspecté et

installé un accessoire, placez-vous (et toutes autres

personnes présentes) hors de la trajectoire prévisible de

l’accessoire en rotation, et faites fonctionner l’outil

électroportatif à la vitesse maximum à vide pendant une

minute. Des accessoires endommagés se briseraient

normalement avant la fin de la durée de ce test.

Portez des équipements de protection personnelle.

Selon l’application, utilisez un écran de protection du

visage, des lunettes de protection ou des lunettes de

sécurité. Suivant les besoins, portez également un

masque de protection contre la poussière, des protec teurs d’oreilles, des gants et un tablier d’atelier capable

d’intercepter des petits objets ou fragments d’ouvrage

abrasifs. Le dispositif de protection des yeux doit être

capable d’intercepter des débris volants projetés par

diverses opérations. L’appareil respiratoire ou le masque

de protection doit être capable de filtrer les particules

produites par votre opération. Une exposition prolongée à

un bruit de haute intensité peut causer une perte auditive.

Veillez à ce que toutes les personnes présentes soient à

une distance de sécurité de la zone de travail. Toute

personne entrant dans la zone de travail doit porter des

équipements de protection personnelle. Des fragments

d’ouvrage ou d’un accessoire cassé pourraient être

projetés violemment et causer des blessures au-delà de la

zone d’opération immédiate.

Tenez seulement l’outil électroportatif par ses surfaces

de préhension isolées lorsque vous effectuez une

opération lors de laquelle l’accessoire de coupe peut

entrer en contact avec des câbles cachés ou son propre

cordon d’alimentation. L’entrée en contact d’un accessoire

de coupe avec un fil sous tension pourrait rendre

conductrices des parties en métal exposées de l’outil

électroportatif et causer un choc électrique à l’opérateur.

Tenez toujours l’outil fermement à la main (ou avec les

deux mains) lors de la mise en marche. Le couple de

réaction du moteur, lorsqu’il passe à la vitesse maximale,

risque de causer une rotation accidentelle de l’outil.

Utilisez des brides de fixation pour soutenir l’ouvrage

chaque fois que cela est possible. Ne tenez jamais un

ouvrage de petites dimensions d’une main et l’outil de

l’autre main lorsque ce dernier est en marche.

L’assujettissement d’un ouvrage de petites dimensions

vous permet d’utiliser votre main ou vos deux mains pour

mieux contrôler l’outil. Des objets ronds tels que des tiges,

des tuyaux ou des tubes ont tendance à rouler lorsqu’ils

sont coupés, ce qui peut coincer l’embout ou le faire sauter

dans votre direction.

Positionnez le cordon à une distance suffisante de

l’accessoire en rotation. En cas de perte de contrôle, le

cordon risquerait d’être coupé ou coincé, et votre main ou

votre bras pourrait être attiré dans l’accessoire en rotation.

Ne posez jamais l’outil électroportatif avant que l’ac ces soire se soit totalement arrêté. L’accessoire en rotation

risquerait d’accrocher la surface et de tirer sur l’outil, vous

faisant perdre le contrôle de l’outil électroportatif.

Après avoir changé un embout ou effectué un réglage,

veillez à ce que l’écrou de fixation de la douille ou tout

autre dispositif de fixation soit solidement attaché. Des

dispositifs de fixation mal serrés pourraient changer

de position de manière imprévisible et causer une perte de

contrôle, auquel cas les composants en rotation

mal assujettis se détacheraient et seraient projetés

violemment.

Ne laissez pas l’outil électroportatif en marche pendant

que vous le transportez. Un contact accidentel avec

l’accessoire pourrait lui faire accrocher vos vêtements,

attirant ainsi l’accessoire vers votre corps et risquant de

vous blesser.

Nettoyez régulièrement les évents d’aération de l’outil

électroportatif. Le ventilateur du moteur attirera de la

poussière à l’intérieur du carter, et une accumulation

excessive de métal en poudre pourrait causer des dangers

électriques.

N’utilisez pas l’outil électroportatif à proximité de

matériaux inflammables. Des étincelles risqueraient de

mettre le feu à ces matériaux.

N’utilisez pas d’accessoires qui nécessitent des liquides

de refroidissement. L’utilisation d’eau ou d’autres liquides

de refroidissement pourrait causer une électrocution ou un

choc électrique.

Utilisez seulement dans un endroit bien ventilé. Travailler

dans un environnement sécurisé réduit les risques de

blessures.

Prévoyez suffisamment d’espace, au moins 15 cm, entre

votre main et la mèche en train de tourner. Maintenez

2610Z09741 12-17 2050.qxp_2050 12/19/17 10:39 AM Page 24

Page 25

25

Consignes de sécurité pour outils rotatifs - (suite)

toutes les parties de votre corps à une distance

suffisante de la mèche en rotation. La proximité de la

mèche en rotation par rapport à votre main n’est pas

toujours évidente.

Ne touchez pas la mèche ou la douille tout de suite

après avoir utilisé l’outil. Après l’emploi, la mèche et la

douille sont trop chaudes pour que l’on puisse les toucher

avec les mains nues.

Ne modifiez pas l’outil et ne le soumettez pas à un usage

abusif. Toute altération ou modification est considérée

comme une utilisation inappropriée et pourrait entraîner

des blessures graves.

Ce produit n’a pas été conçu pour une utilisation comme

foret dentaire ou pour d’autres applications médicales

ou vétérinaires. Cela risquerait de causer des blessures

graves.

Avertissements concernant l’effet de rebond

et avertissements associés

L’effet de rebond est une réaction soudaine à un pince ment

ou à l’accrochage d’une meule, d’un plateau porte-disque,

d’une brosse ou de tout autre accessoire en rotation. Le

pincement ou l’accrochage cause un blocage rapide de

l’accessoire en rotation, ce qui, à son tour, cause la

projection de l’outil électroportatif qui n’est plus contrôlé

dans le sens opposé à celui de la rotation de l’accessoire.

Par exemple, si une meule abrasive est accrochée ou

pincée par l’ouvrage, le bord de la meule qui entre dans le

point de pincement peut s’enfoncer dans la surface du

matériau et causer un choc en retour, étant éjectée

violemment du matériau. La meule peut alors être projetée

vers l’opérateur, ou dans le sens contraire, en fonction du

sens du mouvement de la meule au point de pincement.

Les meules abrasives risquent également de se casser

dans de telles circonstances.

L’effet de rebond est la conséquence d’une utilisation

incorrecte de l’outil électroportatif et/ou de conditions ou

de procédures d’utilisation incorrectes ; il peut être évité si

l’on prend les précautions appropriées, comme indiqué cidessous.

Maintenez une prise ferme sur l’outil électroportatif et

positionnez votre corps et vos bras de façon à vous

permettre de résister à la force d’un tel effet de rebond

éventuel. L’opérateur peut contrôler les forces des effets

de rebond s’il prend les précautions nécessaires.

Faites particulièrement attention lorsque vous travaillez

dans des coins, sur des bords tranchants, etc. Évitez de

faire rebondir l’accessoire ou de le laisser s’accrocher.

Les coins, les bords tranchants et les rebondissements ont

tendance à accrocher un accessoire en rotation et de

causer une perte de contrôle ou un choc en retour.

N’attachez pas une lame de scie dentelée. De telles