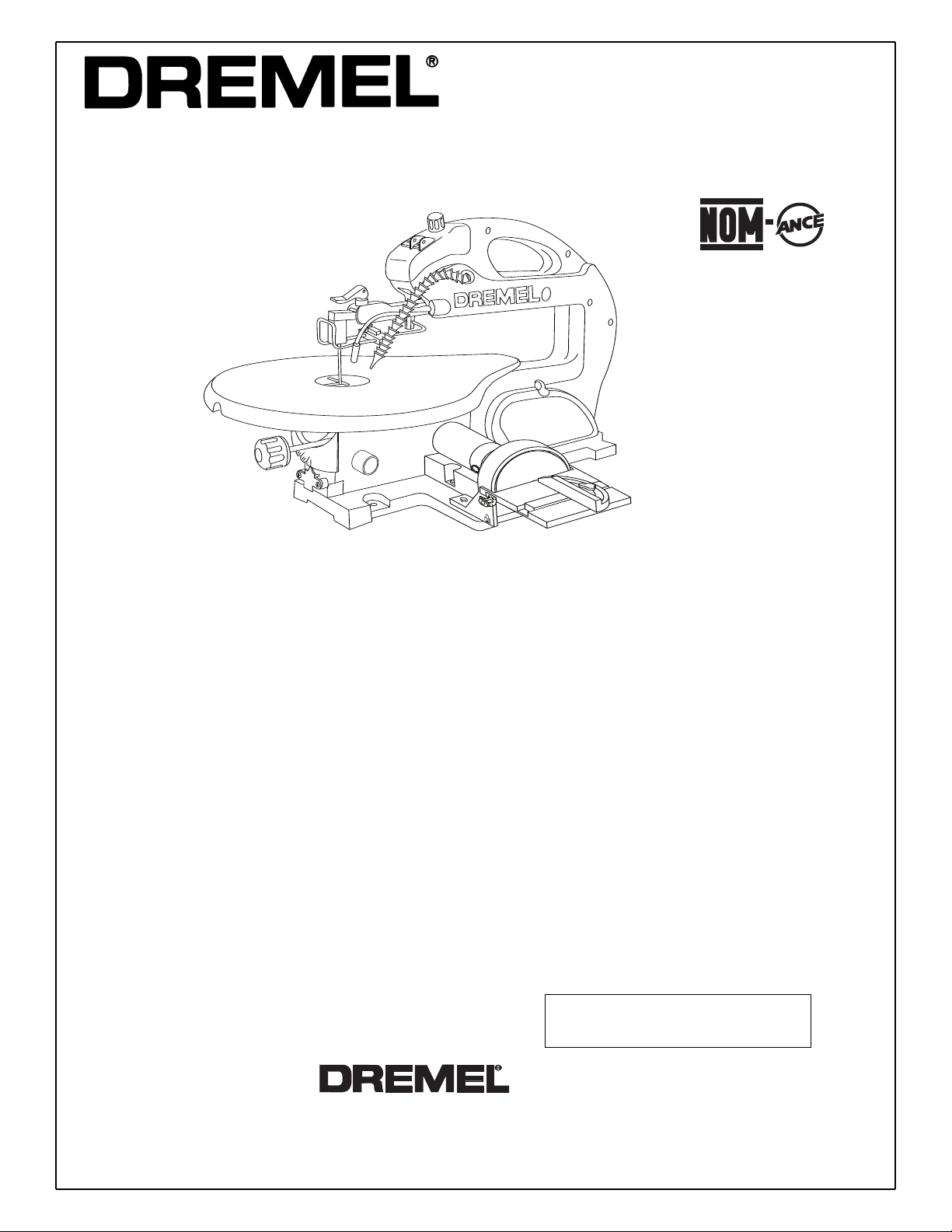

Page 1

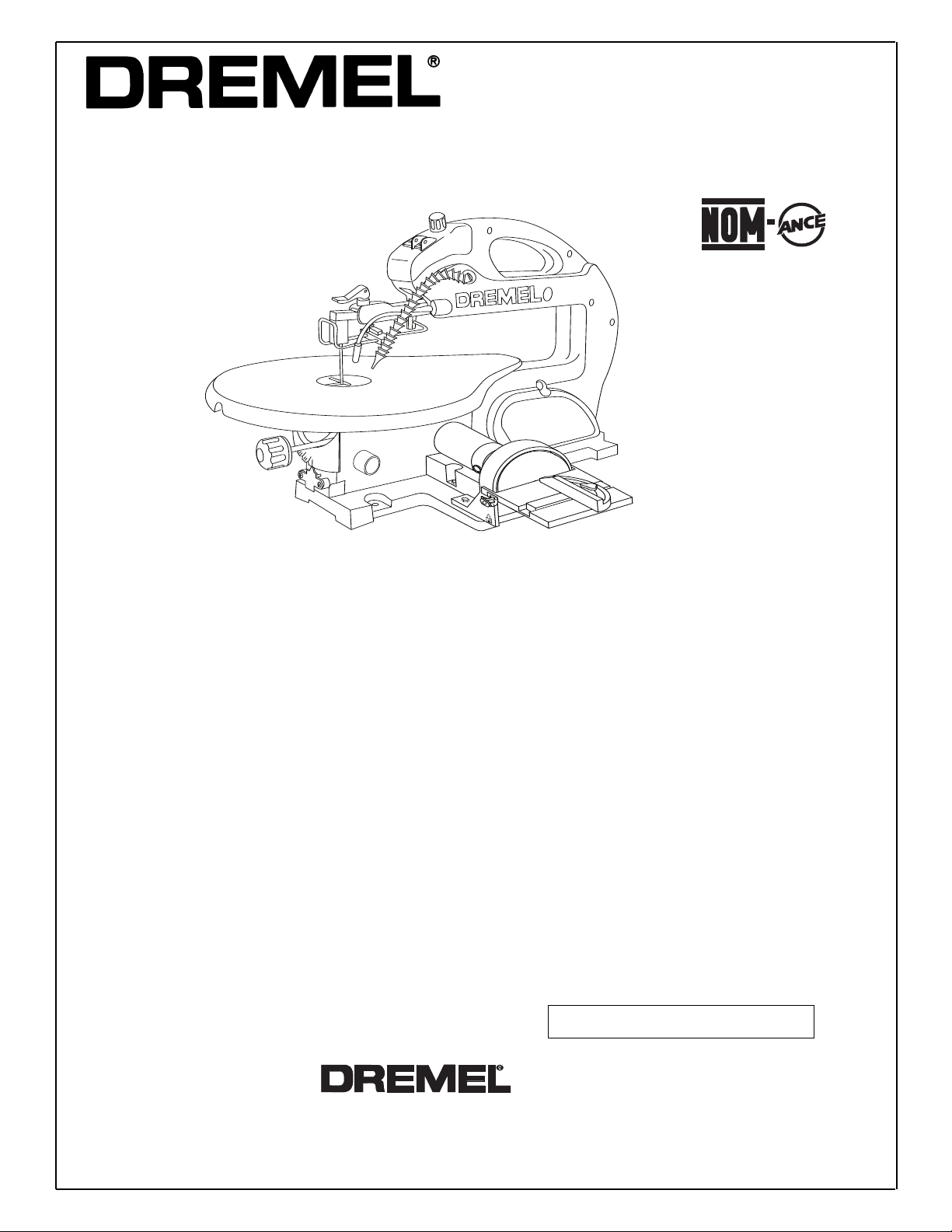

MODEL 1800

VARIABLE SPEED

Owner’s Manual

Manual Contents

General Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Specific Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 5

Additional Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 6

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Motor Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Connection to a Power Source . . . . . . . . . . . . . . . . . . . . .7

Unpacking & Checking Contents . . . . . . . . . . . . . . . . . . . . .8

Getting to Know Your Scroll Station . . . . . . . . . . . . . . .9 - 10

Glossary of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Installing the Disc Table . . . . . . . . . . . . . . . . . . . . . . . . .11

Installing the Flex Shaft (optional accessory) . . . . . . . .11

Mounting the Scroll Station to a Bench . . . . . . . . . . . . .12

Mounting the Scroll Station to Plywood . . . . . . . . . . . . .13

Operation

Basic Scroll Station Operations . . . . . . . . . . . . . . . . . . .

Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Removing and Installing Pin-End Blades . . . . . . . . . . . .

Removing and Installing Plain-End Blades . . . . . . . . . .15

Blade Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

10

14

14

18” Scroll Station

Making Interior Scroll Cuts . . . . . . . . . . . . . . . . . . . . . . .16

Adjusting the Table for Horizontal or Bevel Cutting . . . .16

Operating Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Aligning the Degree Scale Pointer . . . . . . . . . . . . . . . . .17

Removing and Installing Abrasive Discs . . . . . . . . . . . .17

Power ON/OFF Switch . . . . . . . . . . . . . . . . . . . . . . . . . .17

Adjusting the Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Adjusting the Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Variable Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . .18

Adjusting Side Table . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Squaring Side Table . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Maintaining Your Scroll Station . . . . . . . . . . . . . . . . . . . . . .19

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Carbon Brushes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Troubleshooting

Recommended Accessories

Dremel Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . .22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

. . . . . . . . . . . . . . . . . . . . . . . .

Parlez-vous français? Voir page 23

¿Habla español? Ver página 50

18

21

Form No. 2610922039 0504

4915 21st Street

Racine, WI 53406

1-800-437-3635

http://www.dremel.com

Page 2

General Safety Rules

WARNING

!

READ ALL INSTRUCTIONS! Failure to follow the safety rules listed below and other basic safety precautions

may result in serious personal injury

.

Work Area

KEEP CHILDREN AWAY

Do not let visitors contact tool or extension cord. All visitors

should be kept away from work area.

KEEP WORK AREAS CLEAN

Cluttered areas and benches invite accidents.

MAKE WORKSHOP CHILD-PROOF

Use padlocks, master switches.

AVOID DANGEROUS ENVIRONMENTS

Don’t use power tools in damp or wet locations. Keep work

area well lit. Do not expose power tools to rain. Do not use

the tool in the presence of flammable liquids or gases.

Personal Safety

KNOW YOUR POWER TOOL

Read and understand the owner’s manual and labels affixed

to the tool. Learn its application and limitations as well as the

specific potential hazards peculiar to this tool.

DON’T OVERREACH

Keep proper footing and balance at all times.

STAY ALERT

Watch what you are doing. Use common sense. Do not operate tool when you are tired. Do not operate while under medication or while using alcohol or other drugs.

DRESS PROPERLY

Do not wear loose clothing or jewelry. They can be caught in

moving parts. Rubber gloves and non-skid footwear are recommended when working outdoors. Wear protective hair covering to contain long hair.

USE SAFETY GLASSES

Also wear face or dust mask if cutting operation is dusty, and

ear plugs during extended periods of operation.

Everyday eyeglasses have only impact resistant lenses, they

are NOT safety glasses.

GUARD AGAINST ELECTRIC SHOCK

Prevent body contact with grounded surfaces. For example:

pipes, radiators, ranges, refrigerator enclosures.

DISCONNECT TOOLS FROM POWER SOURCE

When not in use, before servicing, when changing blades,

bits, cutters, etc.

KEEP GUARDS IN PLACE

In working order, and in proper adjustment and alignment.

REMOVE ADJUSTING KEYS AND WRENCHES

Form the habit of checking to see that keys and adjusting

wrenches are removed from tool before turning it on.

AVOID ACCIDENTAL STARTING

Make sure the switch is in the “OFF” position before plugging

in tool.

GROUND ALL TOOLS

This tool is equipped with an approved 3-conductor cord and

a 3 prong grounding type plug to fit the proper grounding type

receptacle. The green conductor in the cord is the grounding

wire. Never connect the green wire to a live terminal.

NEVER STAND ON TOOL OR ITS STAND

Serious injury could occur if the tool is tipped or if the cutting

tool is accidentally contacted. Do not store materials on or

near the tool such that it is necessary to stand on the tool or

its stand to reach them.

CHECK DAMAGED PARTS

Before further use of the tool, a guard or other part that is

damaged should be carefully checked to ensure that it will

operate properly and perform its intended function. Check for

alignment of moving parts, mounting, and any other conditions that may affect its operation. A guard or other part that

is damaged should be properly replaced.

WARNING

!

the nearest Dremel Service Center, Authorized Dremel

Service Station.

WARNING

!

WARNING

!

a hazard.

WARNING

!

ities contains chemicals known to cause cancer, birth defects

or other reproductive harm. Some examples of these chem

icals are:

• Lead from lead-based paints,

Crystalline silica from bricks and cement and other mason

•

ry products, and

Arsenic and chromium from chemically treated lumber.

•

Your risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that

are specially designed to filter out microscopic particles.

All repairs, electrical or mechanical, should be

attempted only by trained repairmen. Contact

Use only Dremel replacement parts; any others may create a hazard.

The use of any other accessories not specified in the current Dremel catalog, may create

Some dust created by power sanding, sawing,

grinding, drilling, and other construction activ-

-

-

SAVE THESE INSTRUCTIONS

2

Page 3

Specific Safety Rules

Scroll Station Station

Always disconnect the power cord from the power

source before making any adjustments or attaching any

accessories. Always turn off saw before disconnecting it

to avoid accidental starting when reconnecting to a

power source.

leading to serious personal injury.

Never leave tool running unattended. Turn power off.

Don't leave tool until it comes to a complete stop.

Never leave the switches in "ON" position. Before plugging the tool in, check that the switches are "OFF".

Accidental start-ups could cause injury.

Do not use tool if switch does not turn it on and off. Have

broken switches replaced by an authorized service center.

Use only Dremel Scroll Station blades. Use the right blade

size, style and cutting speed for the material and the type of

cut. Sharp blades minimize stalling and kickbacks. Blade

teeth should point down toward the table.

Avoid awkward operations and hand positions and

always make sure you have good balance.

could cause your hand to move into the blade.

Firmly clamp or bolt your saw station to a stable, level

workbench or table.

approximately waist height.

Never stand on tool. Serious injury could occur if the tool is

tipped or if the blade is unintentionally contacted.

Before making a cut, be sure all adjustments are secure.

Loose table or guards could shift in use and cause you to

loose control of the workpiece.

Always adjust drop foot to just clear the workpiece.

Proper adjustment of the drop foot will help protect your fin

gers and keep blade breakage to a minimum.

Always support large workpieces while cutting to mini

mize risk of blade pinching and kickback.

piece may cause the table to slip, walk or slide while cutting.

Be sure the blade path is free of nails. Inspect for and

remove nails from lumber or workpiece before cutting or

sanding.

Keep hands away from cutting area. Do not hand hold

pieces so small that your fingers go under the blade guard.

Do not reach underneath work or in blade cutting path with

your hands and fingers for any reason.

Never start the tool when the blade is in contact with the

workpiece. Allow the motor to come up to full speed

before starting a cut.

on start up will cause it to jump.

You may unexpectedly cause the tool to start

A sudden slip

The most comfortable table height is

Heavy work-

Blade in contact with the workpiece

Observe and follow correct direction of feed and do not

feed the material too quickly. Hold the work firmly

against the table.

of the blade. Feeding material too forcefully may cause blade

to snap.

Use caution when cutting materials with an irregular

cross-section or rounds like dowel rods. If possible lay

the material on its "flat" side when cutting. For round

stock use a "Vee" block to support the material.

material like molding will tend to rock and may bind while cutting. Rounds will tend to roll while being cut and the blade

may "bite" and grab it from your control.

Do not remove jammed cutoff pieces until blade has

stopped. Never touch blade or other moving parts during use. Contacting the blade or other moving mechanism

may cause injury.

Feed work into a blade against the teeth

Wavy

Power Take Off Safety Rules

The use of attachments and accessories not recommended by Dremel may result in risk of injuries.

Remove the Scroll Station blade and replace it with the

Scroll Station blank in the blade holder before operating

any attachment from the power take off. Avoid the possibility of contacting the reciprocating blade while sanding.

Inadvertent contact with a blade could cause serious

lacerations.

Unplug the tool before changing accessories or attachments.

in while changing an accessory.

Keep the cord to the side away from sanding pad or other

attachments.

become entangled with the pad or other moving components.

Accidental start-ups may occur if sander is plugged

The cord can be dragged into housing and

Disc Sander Safety Rules

-

-

Use only 5" diameter adhesive backed sandpaper discs.

Do not use sandpaper intended for larger sanding pads.

Larger sandpaper will extend beyond the sanding pad causing snagging, tearing of the paper or kickback.

Make sure the sandpaper disc is not torn or loose before

turning tool on.

Properly adjust sanding disc to avoid it overhanging the

Spinning sanding disc overhanging its pad can cause

pad.

severe lacerations.

Always position your workpiece on the downward side of

the direction of rotation arrow while sanding.

work firmly against the table. Sanding on the upward side of

the rotation could cause the workpiece to lift up or kickback.

Refer to rotation arrow on your sander guard.

Avoid awkward hand positions while sanding. A sudden

slip could cause a hand to move into abrasive disc.

The disc could fly away unexpectedly.

Hold the

3

Page 4

Specific Safety Rules

Keep your fingers and clothing away from the sanding

disc. Do not sand pieces that are so small that your fingers touch the sanding disc while sanding. Don't use a

rag to hold workpiece while sanding.

or wedged between the pad and the table.

Do not sand pieces of material that cannot be supported

by the table. When sanding larger workpieces provide

additional support at the sanding table height.

workpiece may cause the table to shift and you could lose

control.

Use miter fence when sanding. Supporting the workpiece

prevents it from being ejected from the sander and leaves

both hands to control the work.

Do not wet sand with this sander. A liquid entering the

motor housing is an electrical shock hazard.

Use special precautions when sanding chemically pressure treated lumber, paint that may be lead based, or any

other materials that may contain carcinogens.

sons entering the work area must wear a suitable breathing

respirator and protective clothing. Plastic sheeting should

seal Work area and persons not protected should be kept out

until work area is thoroughly cleaned.

They could get cut

Oversized

All per-

wheels to avoid chipping or cracking. Install a new wheel

if tool is dropped while grinding. Do not use a wheel that

may be damaged.

ing operation will fly away at great velocity possibly striking

you or bystanders.

Never use dull or damaged bits. Sharp bits must be handled with care.

require more force to push the tool, possibly causing the bit

to break.

Use clamps to support workpiece whenever practical.

Never hold a small workpiece in one hand and the tool in

the other hand while in use. Allow for sufficient space, at

least 6", between your hand and the spinning bit.

material such as dowel rods, pipes or tubing have a tendency to roll while being cut, and may cause the bit to "bite" or

jump toward you. Clamping a small workpiece allows you to

use both hands to control the tool.

Inspect your workpiece before cutting. When cutting

irregularly shaped workpieces, plan your work so it will

not slip and pinch the bit and be torn from your hand. For

example, if carving wood, make sure there are no nails or

foreign objects in the workpiece.

can cause the bit to jump.

Fragments from a wheel that bursts dur

Damaged bits can snap during use. Dull bits

Round

Nails or foreign objects

-

Flex Shaft Safety Rules

Do not operate the flexible shaft with a sharp bend. Over

bending the shaft can generate excessive heat on the jacket

or hand piece. The recommended minimum is 6" radius.

Be aware of the switch location, when placing the flex

shaft down or when picking the tool up.

dentally activate the switch.

Always hold the hand piece firmly in your hands during

the start-up.

ates to full speed, can cause the shaft to twist.

After changing the bits or making any adjustments, make

sure the collet nut and any other adjustment devices are

securely tightened. Loose adjustment device can unex-

pectedly shift, causing loss of control; loose rotating components will be violently thrown.

Do not reach in the area of the spinning bit. The proximi

ty of the spinning bit to your hand may not always be obvious.

Allow brushes to run at operating speed for at least one

minute before using wheel. During this time no one is to

stand in front or in line with the brush.

wires will be discharged during the run-in time.

Wear protective gloves and face shield with wire or bristle brushes. Apply wire or bristle brushes lightly to the

work as only the tips of the wire/bristles do the work.

"Heavy" pressure on bristles will cause the wire or bristle to

become overstressed, resulting in a wiping action and will

cause the bristles/wire to be discharged.

Carefully handle both the tool and individual grinding

The reaction torque of the motor, as it acceler-

You may acci-

Loose bristles or

Never start the tool when the bit is engaged in the material. Let the bit reach its full set speed before contacting

the workpiece.

causing loss of control of the cutter.

Avoid bouncing and snagging the wheel, especially

when working corners, sharp edges etc.

loss of control and kickback.

The direction of feed with the bit into the material when

carving, routing or cutting is very important. Always feed

the bit into the material in the same direction as the cutting edge is exiting from the material (which is the same

direction as the chips are thrown).

wrong direction causes the cutting edge of the bit to climb out

of the work and pull the tool in the direction of this feed.

If the workpiece or bit becomes jammed or bogged down,

turn the tool "OFF" by the switch. Wait for all moving

-

parts to stop and unplug the tool, then work to free the

jammed material.

could restart unexpectedly causing serious personal injury.

Do not leave a running tool unattended, turn power off.

Only when tool comes to a complete stop it is safe to put it

down.

Do not grind or sand near flammable materials. Sparks

from the wheel could ignite these materials.

Do not touch the bit or collet after use. After use the bit

and collet are too hot to be touched by bare hands.

Do not allow familiarity gained from frequent use of your

rotary tool to become commonplace.

The bit cutting edge may grab the material

This can cause

Feeding the tool in the

If the switch to the tool is left "ON" the tool

Always remember

4

Page 5

that a careless fraction of a second is sufficient to inflict

severe injury.

Do not alter or misuse tool. Any alteration or modification is

a misuse and may result in serious personal injury.

When using the steel saws, cutoff wheels, high-speed

cutters or tungsten carbide cutters, always have the

work securely clamped. Never attempt to hold the work

Additional Safety Rules

Tool Use

DON’T FORCE TOOL

It will do the job better and safer at the rate for which it was

designed.

USE THE RIGHT TOOL

Don’t force a small tool or attachment to do the job of a heavy

duty tool. Don’t use tool for purpose not intended—for example, don’t use a circular saw for cutting tree limbs or logs.

SECURE WORK

Use clamps or a vise to hold work when practical. It’s safer

than using your hand and it frees both hands to operate the

tool.

NEVER LEAVE TOOL RUNNING UNATTENDED

Turn power off. Don’t leave tool until it comes to a complete

stop.

Tool Care

DO NOT ALTER OR MISUSE TOOL

These tools are precision built. Any alteration or modification

not specified is misuse and may result in dangerous conditions.

AVOID GASEOUS AREAS

Do not operate electric tools in a gaseous or explosive atmosphere. Motors in these tools normally spark, and may result

in a dangerous condition.

with one hand while using any of these accessories.

reason is that these wheels will grab if they become slightly

canted in the groove, and can kickback, causing loss of control resulting in serious injury. Your second hand should be

used to steady and guide the hand holding the tool. When a

cutoff wheel grabs, the wheel itself usually breaks. When the

steel saw, high-speed cutters or tungsten carbide cutter grab,

it may jump from the groove and you could lose control of the

tool.

For your own safety, do not operate your Scroll Station until

it is completely assembled and installed according to the

instructions...and until you have read and understood the fol

lowing:

1. General Safety Rules ........................................................2

2. Motor Specifications and

Electrical Requirements ..................................................7

3. Getting to Know Your Scroll Station ......................9 - 10

4. Operation ..................................................................14 - 16

5. Maintaining Your Scroll Station ....................................19

STABILITY OF SAW

Your Scroll Station must be bolted securely to a stand or

workbench. In addition, if there is any tendency for the Scroll

Station to tip over or move during certain operations, such as

cutting long, heavy boards, bolt your Scroll Station stand or

workbench to the floor.

The

LOCATION

This Scroll Station is intended for indoor use only.

PROTECTION: Eyes, hands, face, ears and body.

WARNING

!

DO NOT WEAR:

• Loose Fitting Gloves

• Necktie

• Loose Clothing

• Jewelry

TO AVOID BEING PULLED INTO THE

BLADE—

-

MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for better and safer performance.

Follow instructions for lubricating and changing accessories.

Inspect tool cords periodically and if damaged, have repaired

by authorized service facility. Inspect extension cords periodically and replace if damaged. Keep handles dry, clean and

free from oil and grease.

Before connecting the tool to a power source (receptacle, outlet, etc.), be sure voltage supplied is the same as that speci

fied on the nameplate of the tool. A power source with a voltage greater than that specified for the tool can result in serious

injury to the user, as well as damage to the tool. If in doubt, DO

NOT PLUG IN THE TOOL. Using a power source with a voltage less than the nameplate rating is harmful to the motor

-

.

DO:

• Tie Back Long Hair

• Roll Long Sleeves Above Elbow

If any part of your saw is missing, malfunctioning, has

a.

been damaged or broken . . . such as the motor switch, or

other operating control, a safety device or the power

cord...cease operating immediately until the particular part

is properly repaired or replaced.

b. Do not cut piece too small to hold by hand.

HINT: When making a very small cut out, always secure

the workpiece to a scrap piece of plywood with doublefaced tape. This way, the work is supported and your fingers are away from the blade.

c. Never turn your Scroll Station on before clearing the table

of all objects (tools, scraps of wood, etc.) except for the

workpiece and related feed or support devices for the

operation planned.

5

Page 6

Additional Safety Rules

d. Avoid awkward hand positions where a sudden slip could

cause a hand to move into the blade.

ALWAYS adjust the drop foot to just clear the workpiece to

•

protect the operator, keep blade breakage to a minimum

and provide maximum support for blade.

• Always adjust blade tension correctly.

The Scroll Station should cut on the down stroke. Always

•

make sure blade teeth are oriented downward toward

table.

• When cutting a large piece of material, make sure it is supported at table height.

• Hold the work firmly against the table.

• Do not feed the material too fast while cutting. Only feed

the material fast enough so that the blade will cut. Keep

fingers away from the blade.

• Use caution when cutting off material which is irregular in

cross section‚ it could pinch the blade before the cut is

completed. A piece of molding, for example, must lay flat

on the table and not be permitted to rock while being cut.

• Use caution when cutting off round material such as dowel

rods or tubing. They have a tendency to roll while being

cut, causing the blade to “bite”.

e. Never leave the Scroll Station running unattended. Turn

the saw OFF, make sure the saw has come to a complete

stop, and then remove plug from power supply before

leaving the work area.

f. Do not perform layout, assembly or setup work on the

table while the cutting tool is operating.

g. Turn saw off and remove plug from power supply outlet

before installing or removing an accessory attachment.

h. Access Door must be closed before operation.

i. Quick Release Tension Lever should be in down position

before operating.

THINK SAFETY

SAFETY IS A COMBINATION OF OPERATOR COMMON

SENSE AND ALERTNESS AT ALL TIMES WHEN THE Scroll

Station IS BEING USED.

WARNING

!

monplace. Always remember that a careless fraction of a

second is sufficient to inflict severe injury.

WARNING

!

ties contains chemicals known to cause cancer, birth defects

or other reproductive harm. Some examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and other

masonry products, and

• Arsenic and chromium from chemically treated lumber.

Your risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work

with approved safety equipment, such as those dust

masks that are specially designed to filter out microscopic

particles.

Do not allow familiarity (gained from frequent

use of your Scroll Station) to become com-

The operation of any power tool

can result in foreign objects being

thrown into the eyes, which can

result in severe eye damage.

Always wear safety goggles that

comply with ANSI Z87.1 before

commencing power tool operation.

Some dust created by power sanding, sawing,

grinding, drilling,and other construction activi-

NOTE AND FOLLOW THE SAFETY WARNINGS AND INSTRUCTIONS

THAT APPEAR ON THE PANEL ON SCROLL STATION HOUSING:

6

Page 7

Specifications

General Specifications

Voltage Rating . . . . . . . . . . . . . . . . . . . . . . . . .120 V, 60 Hz

Amperage Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.6 A

No Load Speed . . . . . . . . . . . . . . .No500-1,700/min (SPM)

Throat

Blade . . . . . . . . . . . . . . . . . . . . . . . . . .5” plain and pin-end

Blade Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3/4"

Cutting Capacity . . . . . . . . . . . . . . . . . . .1fl" at 0°, 1" at 45°

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce

the risk of electric shock.

This Scroll Station is designed to use a variable speed RPM

motor. It is wired for operation on 110-120 volts, 60 Hz. alternating current. Before connecting the motor cord to wall outlet, make certain the power switch is in the OFF position and

be sure the electric current is of the same characteristics as

stamped on the Scroll Station nameplate.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18"

Motor Specifications

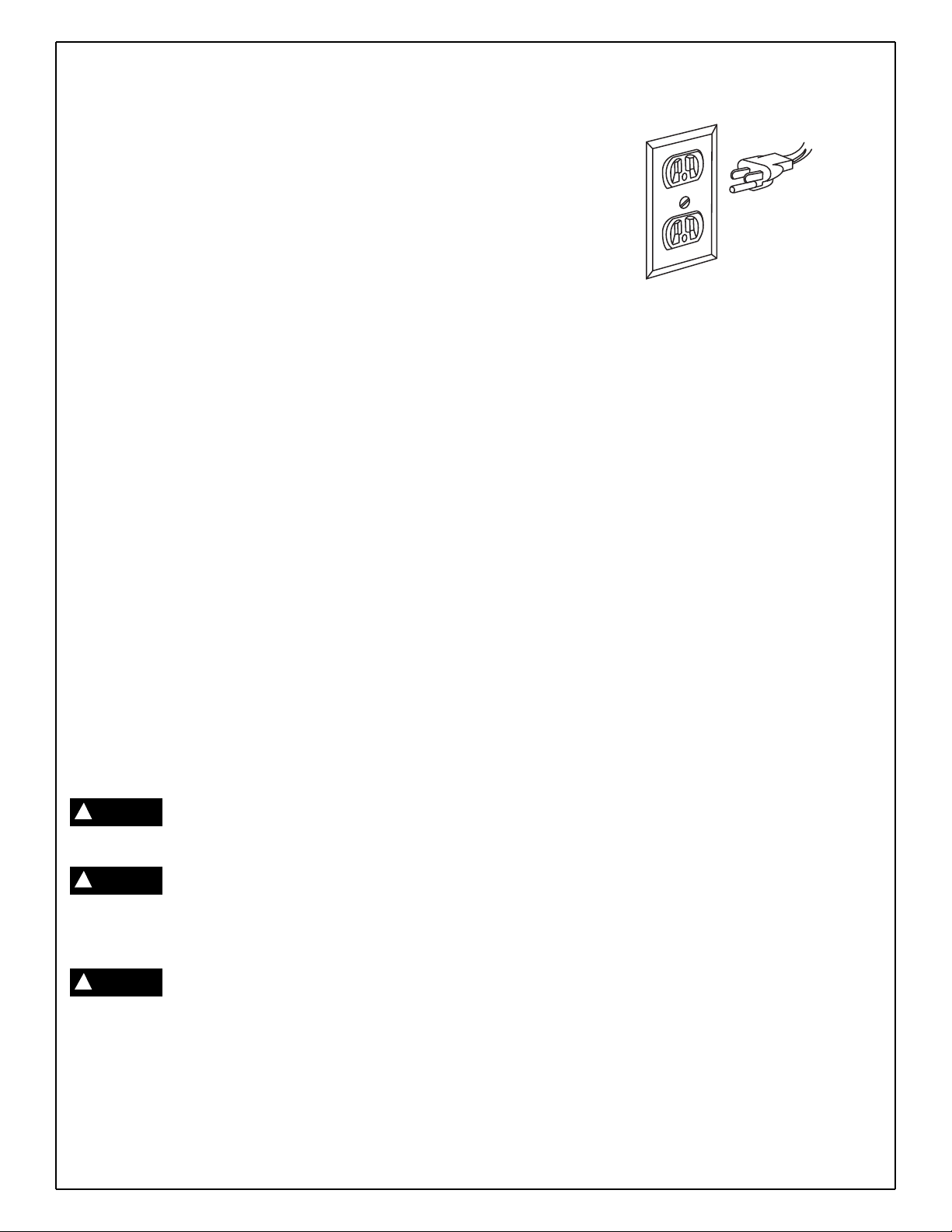

Figure 1. Grounded Wall Outlet

Your unit is for use on 120 volts; it has a plug that looks like

the one in Figure 1.

This power tool is equipped with a 3-conductor cord and this

plug requires a mating 3-conductor grounded type outlet as

shown. It must be grounded in accordance with all local codes

and ordinances.

If the outlet you are planning to use for this power tool is of the

two-prong type, DO NOT REMOVE OR ALTER THE GROUNDING PRONG IN ANY MANNER. Have a qualified electrician

replace the TWO-prong outlet with a properly grounded

THREE-prong outlet.

Connection To A Power Source

This machine must be grounded while in use to protect the

operator from electric shock.

Plug power cord into a 110-120V properly grounded type outlet protected by a 15-amp dual element time delay fuse or circuit breaker.

Not all outlets are properly grounded. If you are not sure that

your outlet, as pictured on this page, is properly grounded;

have it checked by a qualified electrician.

DANGER

!

removing the plug to or from the outlet.

DANGER

!

larly when used near metal plumbing or other metal objects.

If shocked, your reaction could cause your hands to hit the

tool.

DANGER

!

shock or fire hazard.

To avoid electric shock, do not touch the

metal prongs on the plug when installing or

Failure to properly ground this power tool can

cause electrocution or serious shock, particu-

If power cord is worn, cut or damaged in any

way, have it replaced immediately to avoid

Improper connection of the equipment-grounding conductor can

result in a risk of electric shock. If repair or replacement of the

electric cord or plug is necessary, do not connect the equipmentgrounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the

grounding instructions are not completely understood, or if in

doubt as to whether the tool is properly grounded.

Always use proper extension cord. The use of any extension

cord will cause some loss of power. To keep this to a minimum

and to prevent overheating and motor burn-out, use the table

below to determine the minimum wire size (A.W.G.) extension

cord. Use only 3-wire extension cords which have 3-prong

grounding type plugs and 3-pole receptacles which accept the

tool’s plug. Make sure your extension cord is in good condition.

Extension Cord Length

0-25 feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

26-50 feet

51-100 feet

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wire Size A.W.G.

16

16

SAVE THESE INSTRUCTIONS

7

Page 8

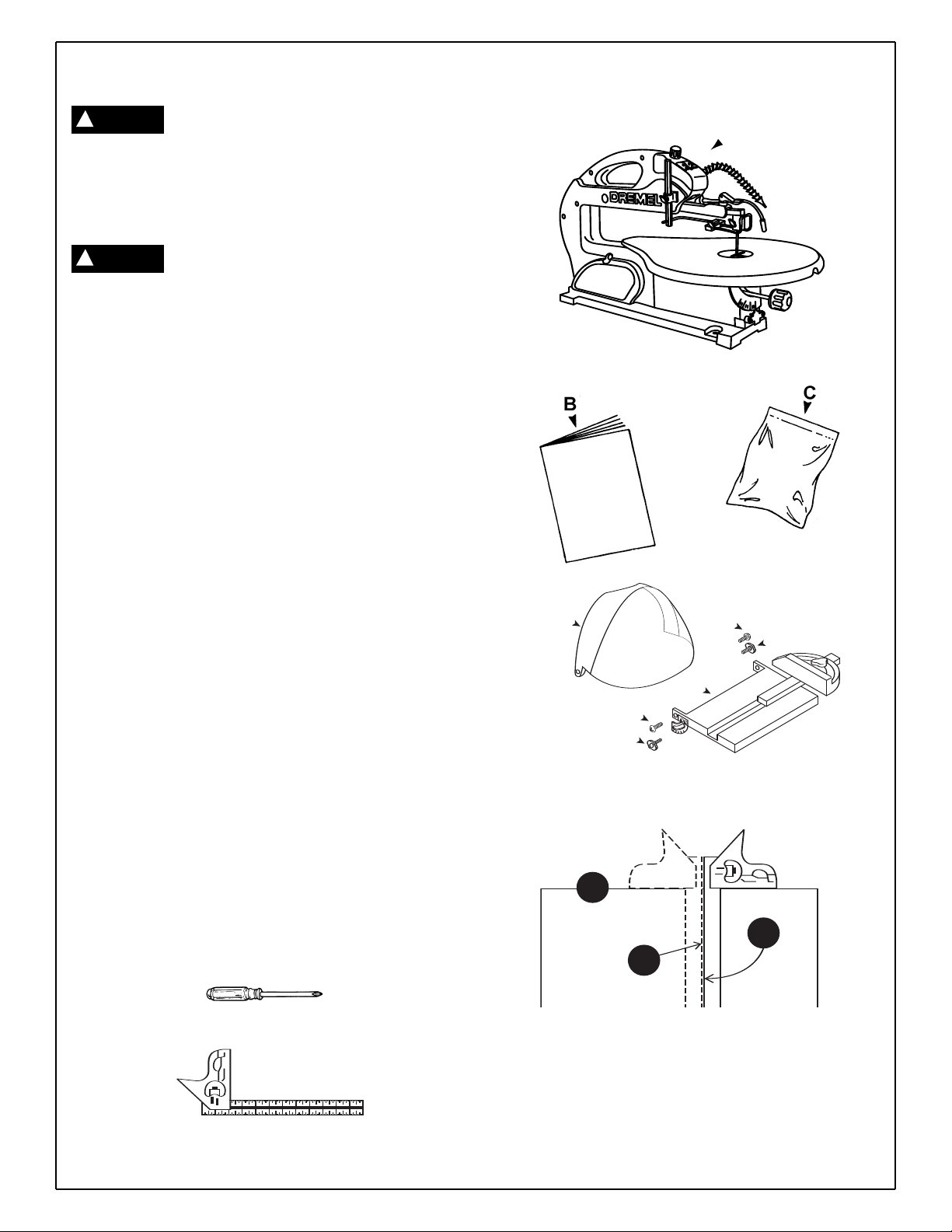

Unpacking & Checking Contents

A

D

E

E

F

F

G

1

2

3

WARNING

!

wall outlet when tool is not in use.

Model 1800 Scroll Station is shipped complete in one carton.

Separate all “loose parts” from packing materials and check

each item with the “Packing List” to make sure all items are

accounted for before discarding any packing material.

WARNING

!

or turn the switch on until the missing parts are obtained and

are installed correctly.

Item Description Qty.

A 18” Scroll Station ......................................................1

B Owner’s Manual ........................................................1

C Parts Bag (containing) ..............................................1

D Side Table with Side Miter ......................................1

E Flat Head Screws....................................................2

F Wing Knobs ............................................................2

G. Flip-up Guard ..........................................................1

Allen Wrench (2 mm, 2.5 mm & 4 mm) ..................1

Drive Screw for Flex Shaft Attachment ..................1

Adaptor for future additions ....................................1

Spacer ....................................................................2

O Ring ....................................................................2

Drive Nut ................................................................1

Blades ............................................................................12

To avoid injury from unexpected starting or

electrical shock, always remove plug from

If any parts are missing, do not attempt to

operate Scroll Station, plug in the power cord

Packing List

To remove protective coating from the table surface, moisten

a soft cloth with kerosene or WD-40 and wipe off coating. Do

not use acetone, gasoline or lacquer thinner for this purpose.

After removing protective coating, If you wish, you may apply

a coat of paste wax to the table to allow the workpiece to slide

easily across the table surface and deter rust. Wipe the table

thoroughly with a clean dry cloth.

NOTE: Hardware to mount this Scroll Station to a bench or

leg set is NOT supplied. See ASSEMBLY-MOUNTING THE

SCROLL STATION, P

size.

IMPORTANT! If you require any assistance with these

instructions, please contact the Dremel Service Department

at:

age 8, for recommended hardware

1-800-437-3635

Figure 2. Packing List Parts

Tools Needed

Phillips Screwdriver (not included)

1. Use the straight edge of a 3/4" thick board (this edge

Combination Square (not included)

2. Draw a line on the board along this edge.

3. There should be no gap or overlap when the square is

Combination Square Must be True

must be perfectly straight).

flipped over in dotted position.

8

Page 9

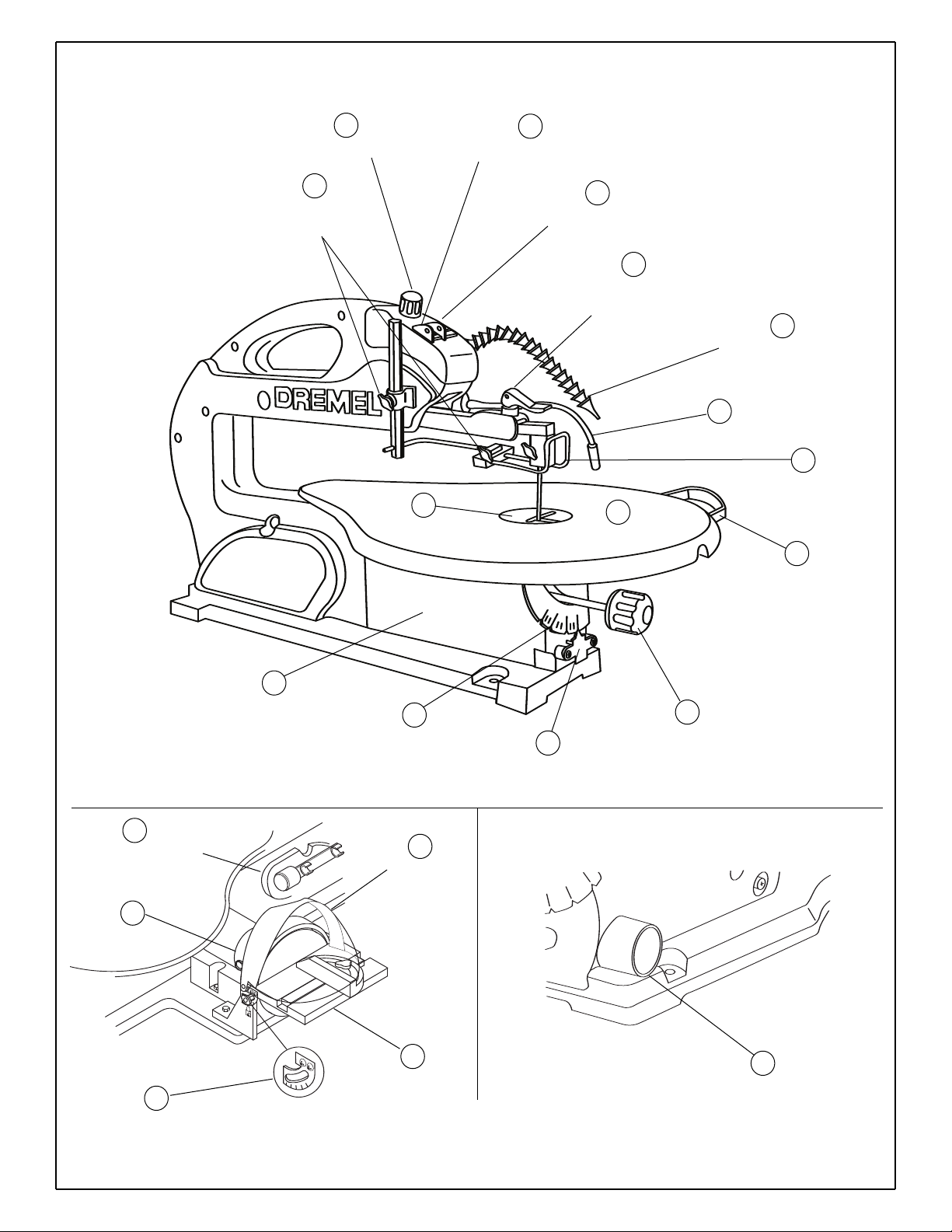

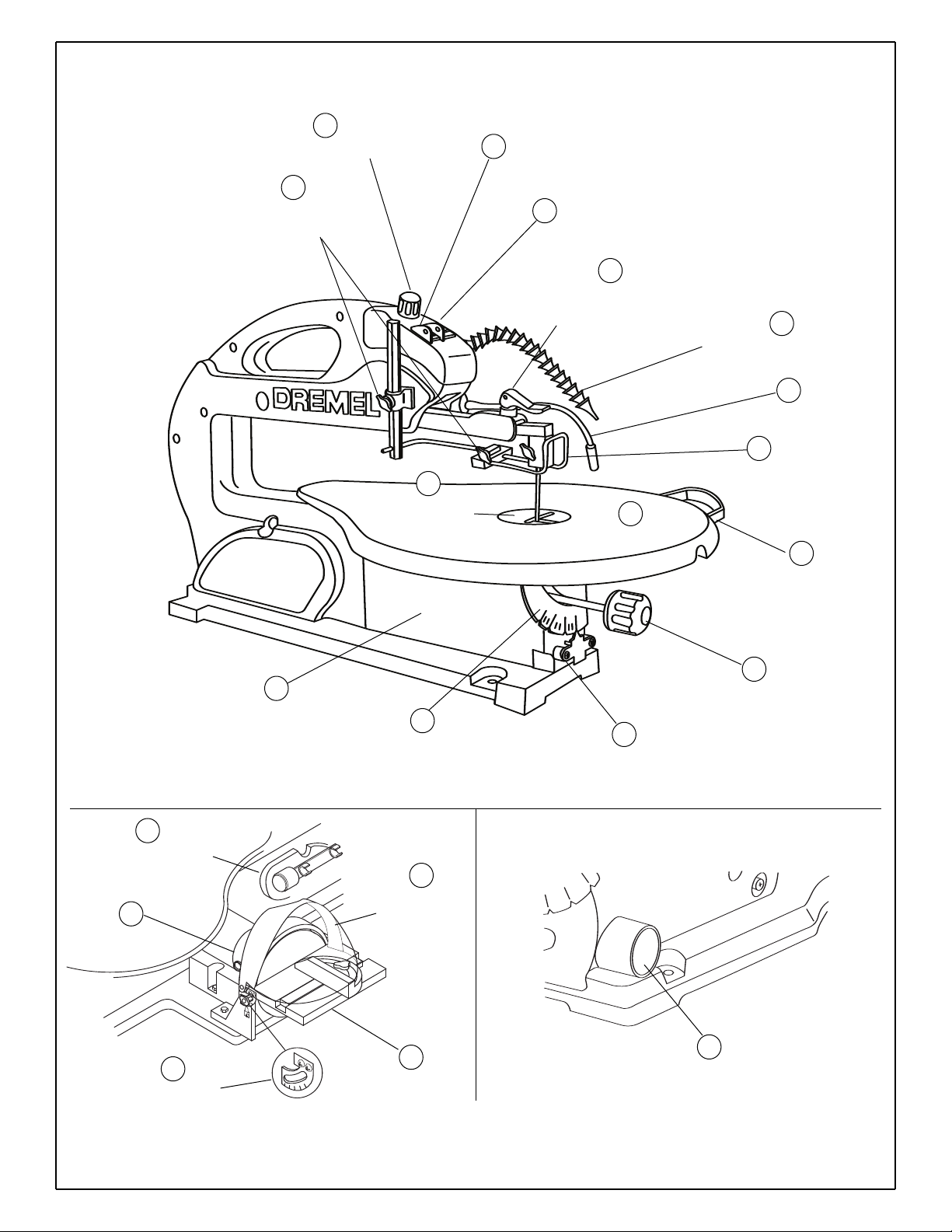

Getting to Know Your Scroll Station

8

Variable Speed Dial

4

Drop Foot

Wing Knob (2)

Table Insert

9

Power ON/OFF Switch

Light ON/OFF Switch

12

10

5

Quick Release

Tension Lever

2

Sawdust Blower

13

Light

3

Drop Foot

11

Table

1

Blade Storage

Drawer

20

Flex Shaft Holder

18

Motor

17

Side Table Scale

14

Easy Access Door

15

Table Tilt Detents

19

Flip-up

Guard

16

Side Table &

Disc Sander

Figure 3. Scroll Station Components

7

Degree Scale

6

Table Lock Knob

21

Vacuum Hook-up

9

Page 10

Getting to Know Your Scroll Station

This versatile Scroll Station is great for making toys, puzzles,

games, fretwork, and jewelry. Because of its cutting capacity,

it is a handy do-it-yourself tool. It cuts wood up to 1fl" thick as

well as plastics and non-ferrous metals.

1. BLADE STORAGE DRAWER

Your Scroll Station is equipped with a blade storage area

located under the right side of the saw table (when facing

table). The blade storage area conveniently stores both Pinand Plain-end blades.

2. SAWDUST BLOWER

Keeps workpiece clean for better visibility. For best results,

always direct air flow from blower tube at blade and workpiece. To adjust, simply bend to desired position.

3. DROP FOOT

The drop foot should always be lowered until it just rests on

top of the workpiece to prevent workpiece from lifting, but not

so much that the workpiece drags.

4. DROP FOOT WING KNOBS

Allows you to adjust the height and rotation of the drop foot

and lock it into the desired position.

5. QUICK RELEASE TENSION LEVER

Allows you to quickly loosen, or tighten the blade to its proper tension with lever action.

10. LIGHT SWITCH

To turn light on, push light switch to the ON (I) position; to

turn light off, push light switch to the OFF (O) position.

11. TABLE

Provide working surface to support workpiece.

12. TABLE INSERT

Insert may be removed for ease of changing blades. Insert

should always be in place and flush with table during cutting

operation.

13. LIGHT

Illuminates the workpiece.

14. EASY ACCESS DOOR

Allows easy access to lower blade holder when changing

blades.

15. TABLE TILT DETENTS

Automatically stops the table to the left at 0°, 15°, 30°, and

45° increments, and to the right up to 5°.

16. SIDE TABLE & DISC SANDER

Allows multiple positIons for sanding work piece.

17. SIDE TABLE TILT SCALE

Displays adjustments at 0°, 15°, 30°, and 45° increments.

6. TABLE LOCK KNOB

Allows you to tilt the table and lock it at desired angle up to

45° to the left or 5° to the right.

7. DEGREE SCALE

Shows the degree the table is tilted.

8. VARIABLE SPEED DIAL

Your Scroll Station is equipped with a variable speed dial for

greater versatility.

9. POWER ON/OFF SWITCH

Has holes provided by the switch for a lock (not included).

THIS FEATURE IS INTENDED TO PREVENT UNAUTHOURIZED AND POSSIBLY HAZARDOUS USE BY CHILDREN AND OTHERS.

the ON (I) position; to turn saw off, push power switch to the

OFF (O) position.

To turn saw on, push power switch to

Glossary of Terms

KERF The slot cut by the blade.

LEADING EDGE

The edge of the workpiece which is pushed into the blade

first.

SAWBLADE PATH

The area of the workpiece directly in line with and moving

toward the sawblade edge.

18. MOTOR

Provides power to the disc sander and optional flex shaft tool.

19. FLIP-UP GUARD

Protects disc sander when saw is in operation.

20. FLEX SHAFT HOLDER

Protects flex shaft (if attached) when saw is in operation. Flex

shaft should be disconnected before sawing is performed.

21. VACUUM HOOK-UP

Your Scroll Station is equipped with a vacuum hook-up. This

feature will allow you to attach any 1-1/4" vacuum hose into

the hole provided for convenient sawdust removal.

BLADE TOOTH SET

The distance that the edge of the sawblade tooth is bent

(onset) outward from the side of the blade.

TRAILING EDGE

The workpiece edge last cut by the sawblade.

WORKPIECE

The item on which the cutting operation is being performed.

10

Page 11

AAsssseem

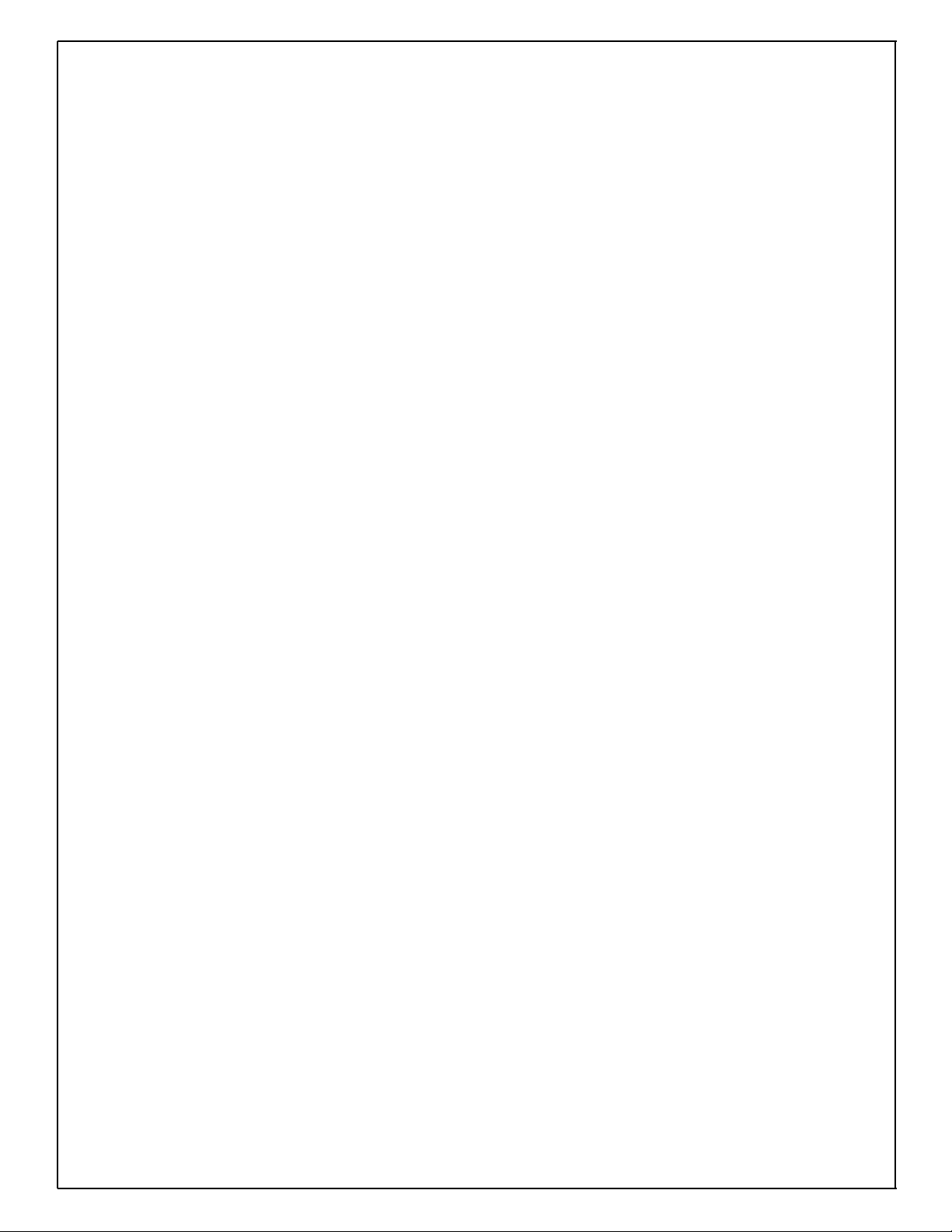

Installing the Disc Table & Guard

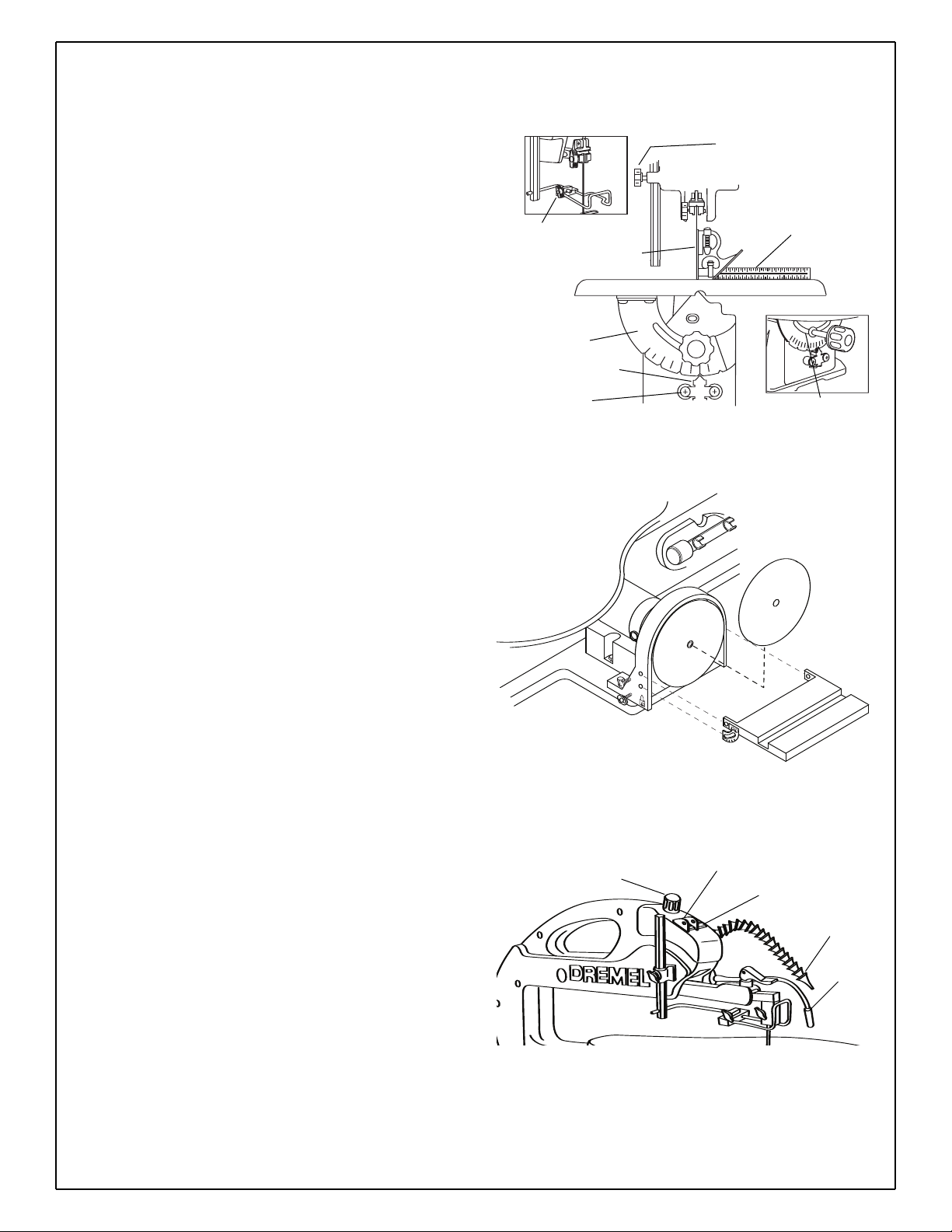

Refer to Figure 4.

Assemble the side table and guard, using two wing knobs,

large spacers, flat head screws, and o-rings. Put spacers on

wing knobs, then insert through sliding scales on sides of table

and screw into bottom holes in base. Next, insert flat head

screws through clear plastic guard, then though o-rings and

tighten into top holes on table and base. Adjust table to

desired angle and tighten wing knobs.

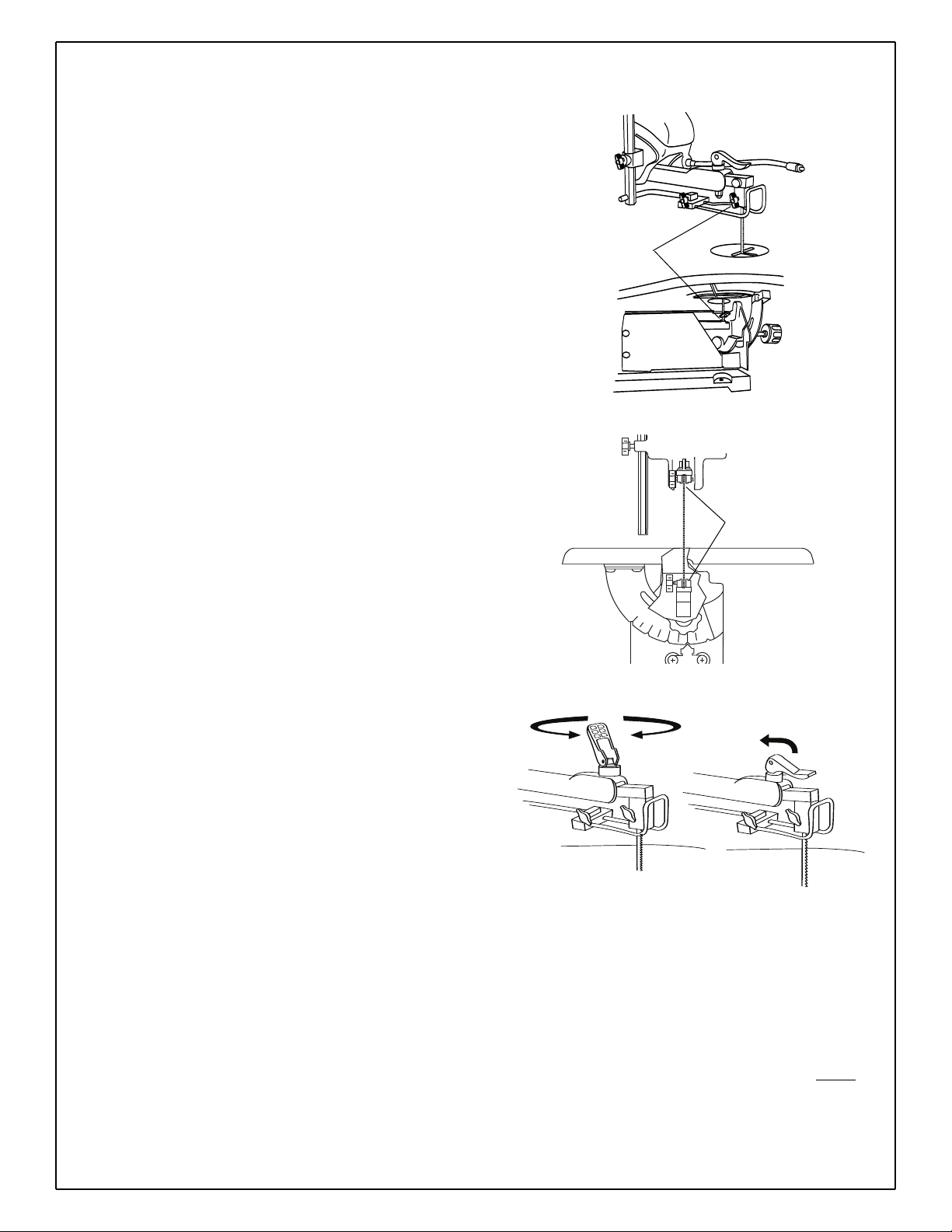

Installing the Flex Shaft

(Optional Accessory - Model 225)

The optional flex shaft is used mainly for drilling pilot holes

when making interior scroll cuts (see

sanding. Also refer to the manual supplied with the Flex

Shaft.

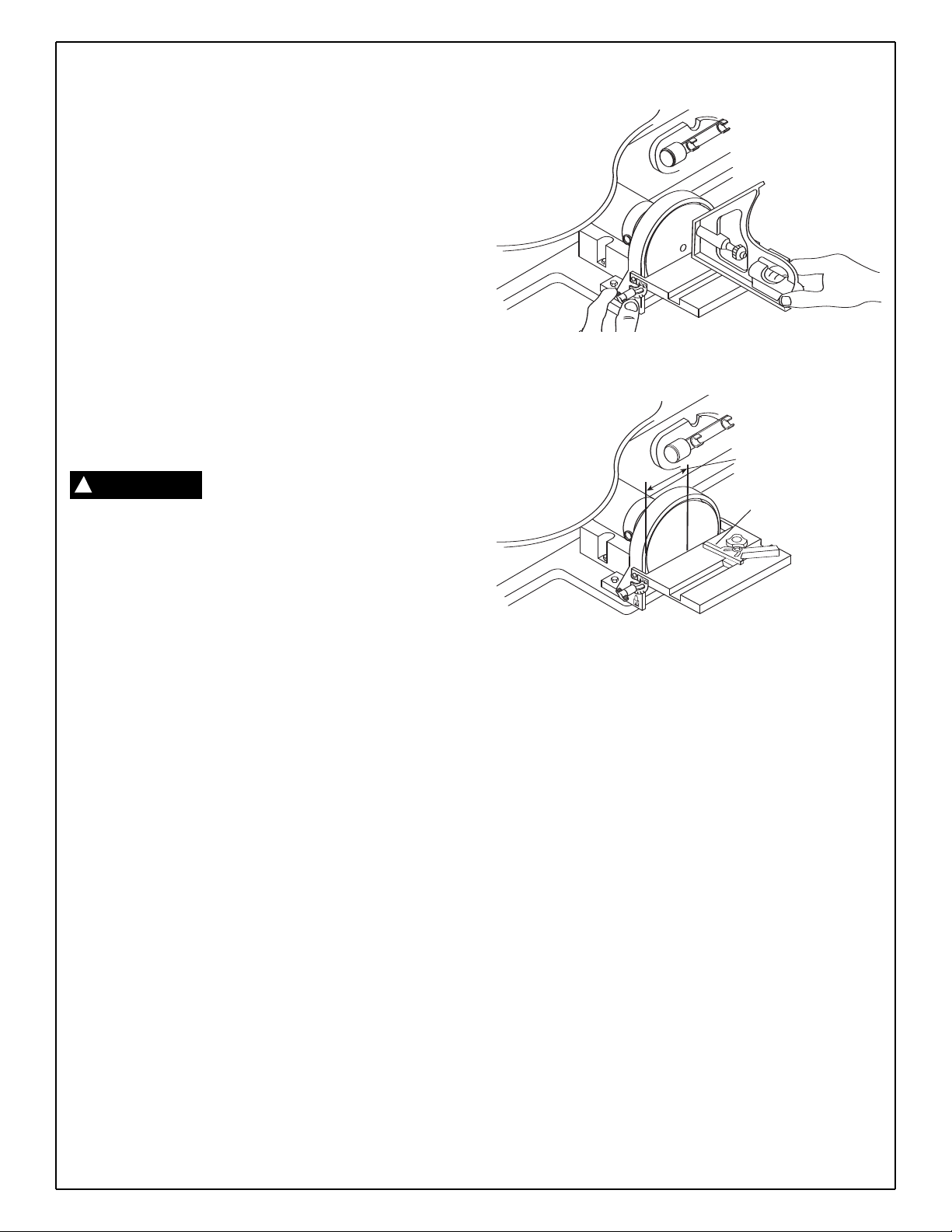

Refer to Figure 5.

OPERATION) or for

mbbllyy

Figure 4. Installing the Side Table

Flex Shaft Holder

1. Remove the two Phillips head mounting screws and

wing knobs securing the side table to the guard.

2. Remove the Phillips head screw securing the disc to the

motor and remove the disc.

3. Insert the drive screw (supplied with the Scroll Station)

into the end of the motor shaft and tighten securely.

4. Insert square cable through the square hole in the drive

screw and fully into the motor shaft.

5. Secure the flex shaft to the motor shaft and tighten

securely.

6. Flex shaft should be disconnected from the motor shaft

before sawing is performed.

WARNING

!

WARNING

!

Flex shaft must be stored in holder when

attached and not in use.

Do not engage shaft lock on handpiece while

motor is running.

Drive Nut

Figure 5. Installing the Flex Shaft

(optional accessory)

11

Page 12

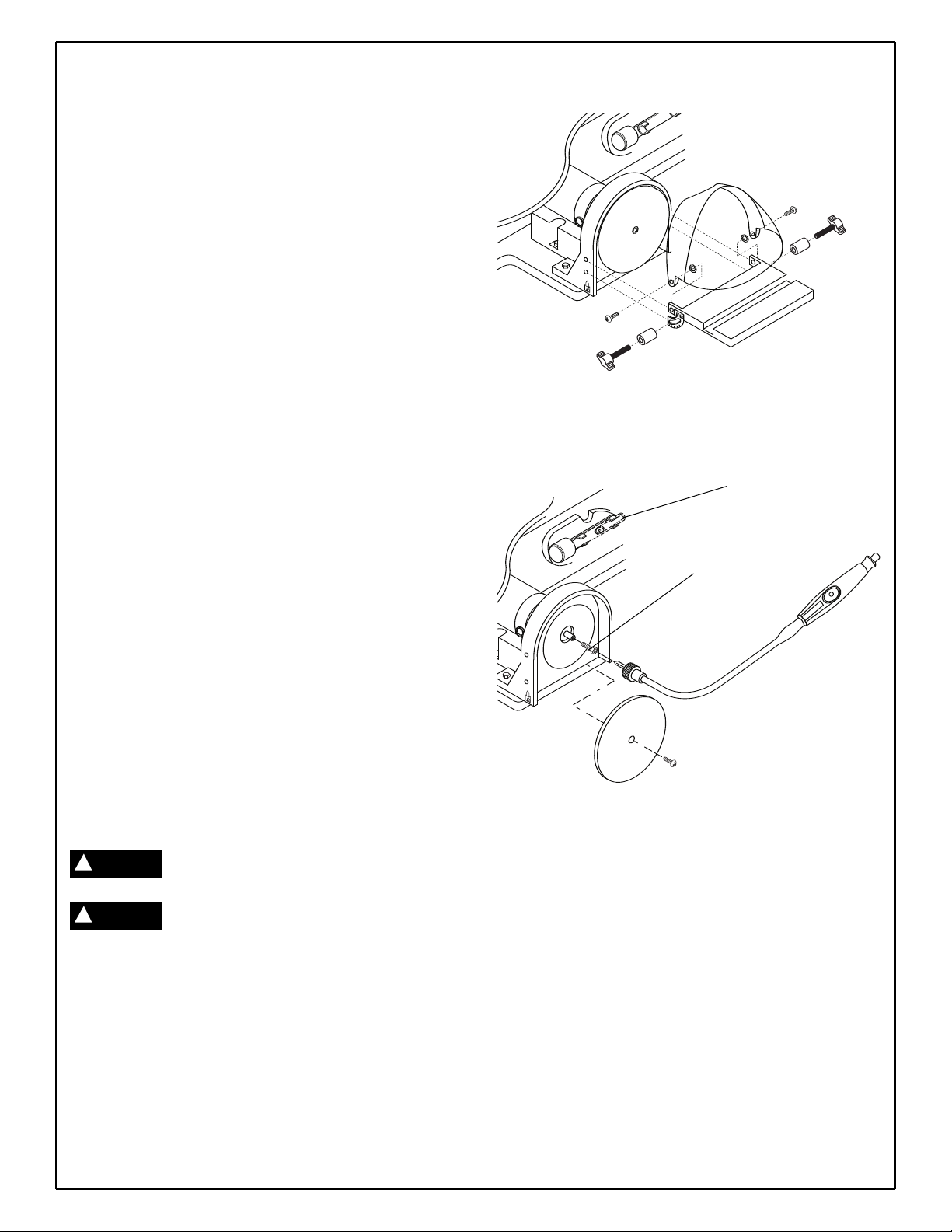

Assembly

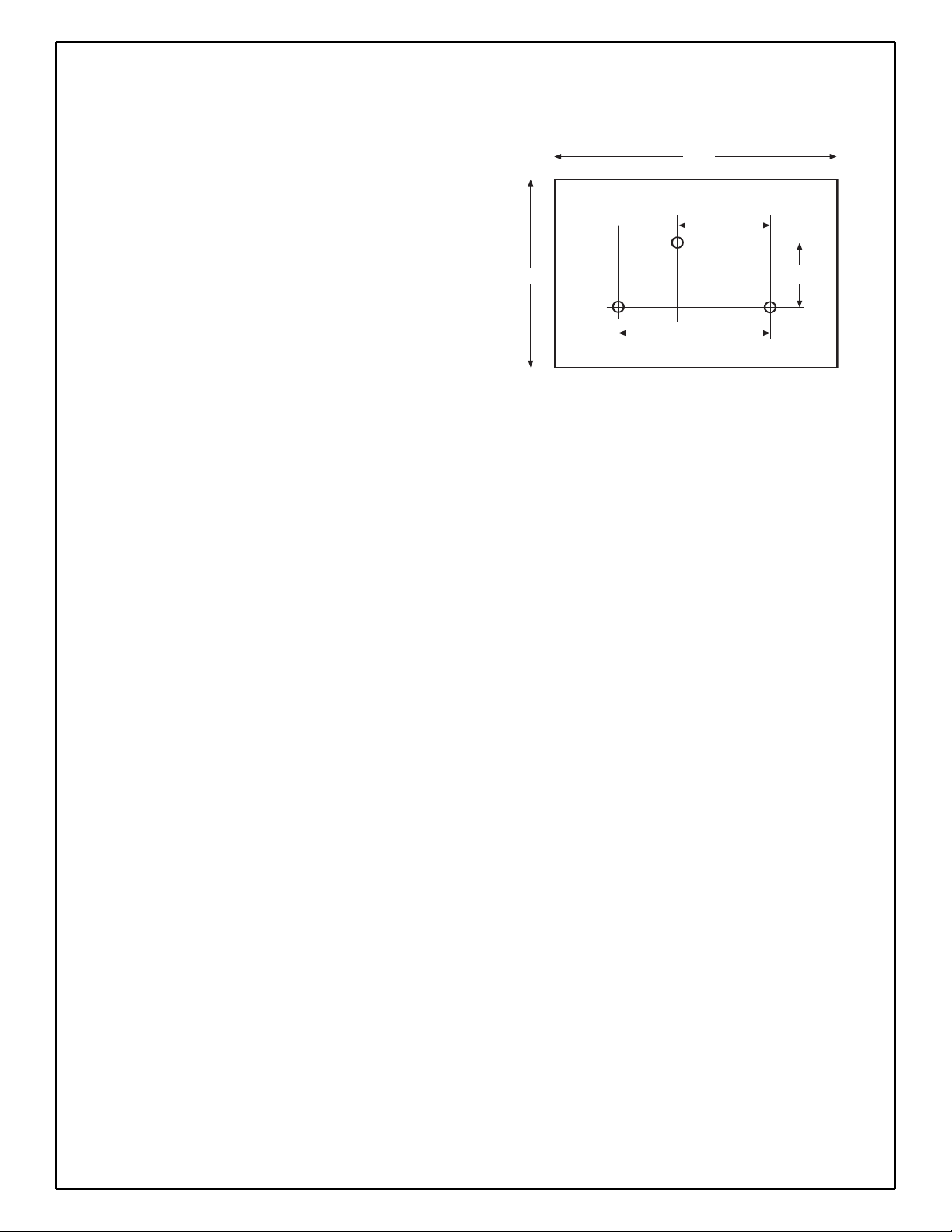

11-7/8"

19-13/16""

7-7/8"

Mounting the Scroll Station

to a Bench

The Scroll Station should be fastened securely to a firm supporting surface such as a stand or workbench, using the three

mounting holes.

NOTE: When mounting this saw to a workbench, a solid

bench is preferable to a plywood bench where noise and

vibration will be more noticeable.

We recommend to reduce noise and vibration, that a soft

foam pad be placed between your Scroll Station and workbench (not included).

Quantity Description

1 Soft foam pad, such as carpet padding,

24”x12”x1/2”

When mounting the Scroll Station to a workbench, holes

should be drilled through the foam pad or carpet and mounting surface of the workbench using the dimensions illustrated

in Figure 6.

Each of the three mounting holes should be bolted securely

using no less than 1/4" hex bolts, flat washers, lockwashers,

and nuts (not included). We recommend:

Quantity Description

4 Hex Head Bolts,

1/4"-20 x 1/4"-20 x Length Required

4 Flat Washers, 9/32" I.D.

4 Lockwasher, 9/32" I.D.

8 Hex Nuts, 1/4"-20

(Hardware not included)

Refer to Figures 6 and 7.

1. Locate and mark where the Scroll Station is to be mounted.

2. Drill the three (3) 5/16" holes through the workbench.

3. Place the Scroll Station on the workbench aligning holes

in the base with the holes drilled in the workbench. Insert

all three (3) bolts and secure using washers, lockwash

ers and nuts.

Figure 6. Bench Mounting Template

-

NOTE: Do NOT overtighten mounting bolts. If using recom

mended foam pad, leave some cushion in the foam pad for

absorbing noise and vibration.

-

Figure 7. Table Mounting Hardware (not included)

12

Page 13

Assembly

24"

11-7/8"

19-13/16"

7-7/8"

15"

Mounting the Scroll Station

to Plywood

An alternative method of securing your Scroll Station is to

fasten the Scroll Station base to a mounting board 18" x 24".

Any good grade of plywood with a 3/4" minimum thickness is

recommended. Follow the instructions for

SCROLL STATION TO A BENCH

board for the workbench and using 1/4"-20 flat head screws

for the hex head bolts (Figure 7). Screws must be mounted

from underneath the plywood with washers and nuts on top.

NOTE: For proper stability, holes must be countersunk so

screw heads are flush with the bottom surface of the supporting board.

Securely clamp board to workbench using two or more “C”

clamps.

, substituting the 18" x 24"

MOUNTING THE

Figure 8. Plywood Mounting Template

13

Page 14

Operation

Basic Scroll Station Operations

Follow these instructions for operating your Scroll Station to

get the best results and to minimize the likelihood of personal injury.

WARNING

!

Protection: Eyes, Hands, Face, Ears and Body

WARNING

!

DO NOT WEAR:

• Loose Fitting Gloves

• Necktie

• Loose Clothing

• Jewelry

DO:

• Tie Back Long Hair

• Roll Long Sleeves Above Elbows

• The saw does not cut wood by itself. You allow the saw to

cut wood by guiding the wood into the blade as it moves.

• The blade teeth cut ONLY on the down stroke.

• The drop foot should always be lowered until it just rests

on top of the workpiece.

• You must feed the wood into the blade slowly because the

teeth of the blade are very small and they can only remove

wood when they are on the down stroke. The blade will flex

backwards when applying feed pressure. Too much feed

pressure will cause blade breakage. Let the blade do the

work.

• There is a learning curve for each person who wants to

use this saw. During that period of time it is expected that

some blades will break until you learn how to use the saw

and receive the greatest benefit from the blades.

• Best results are achieved when cutting wood less than

1" thick.

• When cutting wood thicker than 1", the user must feed the

wood very slowly into the blade, increase blade tension

and take extra care not to bend or twist the blade while cutting in order to maximize blade life.

Teeth on Scroll Station blades wear out and blades must

•

be replaced frequently for best cutting results. Scroll

Station blades generally stay sharp for 1/2 hour to 2 hours

of cutting.

• To get accurate cuts, be prepared to compensate for the

blade’s tendency to follow the wood grain as you are cutting.

When choosing a blade to use with your Scroll Station

consider the following carefully:

• Choose a blade that allows at least three (3) teeth to be in

contact with the workpiece at all times.

• Very fine, narrow blades should be used to scroll cut in thin

wood (1/4" thick or less).

Always observe the safety precautions here

and on pages 2 - 6.

To avoid being pulled into the saw blade –

• To cut thicker wood, use wider blades with fewer teeth per inch.

• Most blade packages state the size or thickness of wood

which that blade is intended to cut, and the radius (size of

curve) which can be cut with that blade.

• Wider blades can’t cut curves as tight or small as thinner

blades.

• This saw uses 5" long, Pin- or Plain-End type blades only

(See

RECOMMENDED

Blades wear faster when (1) cutting plywood, which is very

•

abrasive, (2) when sawing wood which is thicker than the

3/4" blade stroke, (3) when sawing hardwood or (4) when

side pressure is placed on the blade.

ACCESSORIES

on page 21).

Blades

Your new Scroll Station accepts 5" Pin-End blades or 5"

Plain-End blades (See

page 21).

The blades can be used in either 0° (forward facing) or 90° (to

the left) position.

1. Remove hex bolt from upper and lower blade holders.

2. Remove blade holders and rotate 90° so the blade slot

faces the left side of the saw.

3. Re-install hex bolts and tighten securely.

WARNING

!

blades or making adjustments.

To prevent personal injury always disconnect

the plug from power source before changing

RECOMMENDED ACCESSORIES on

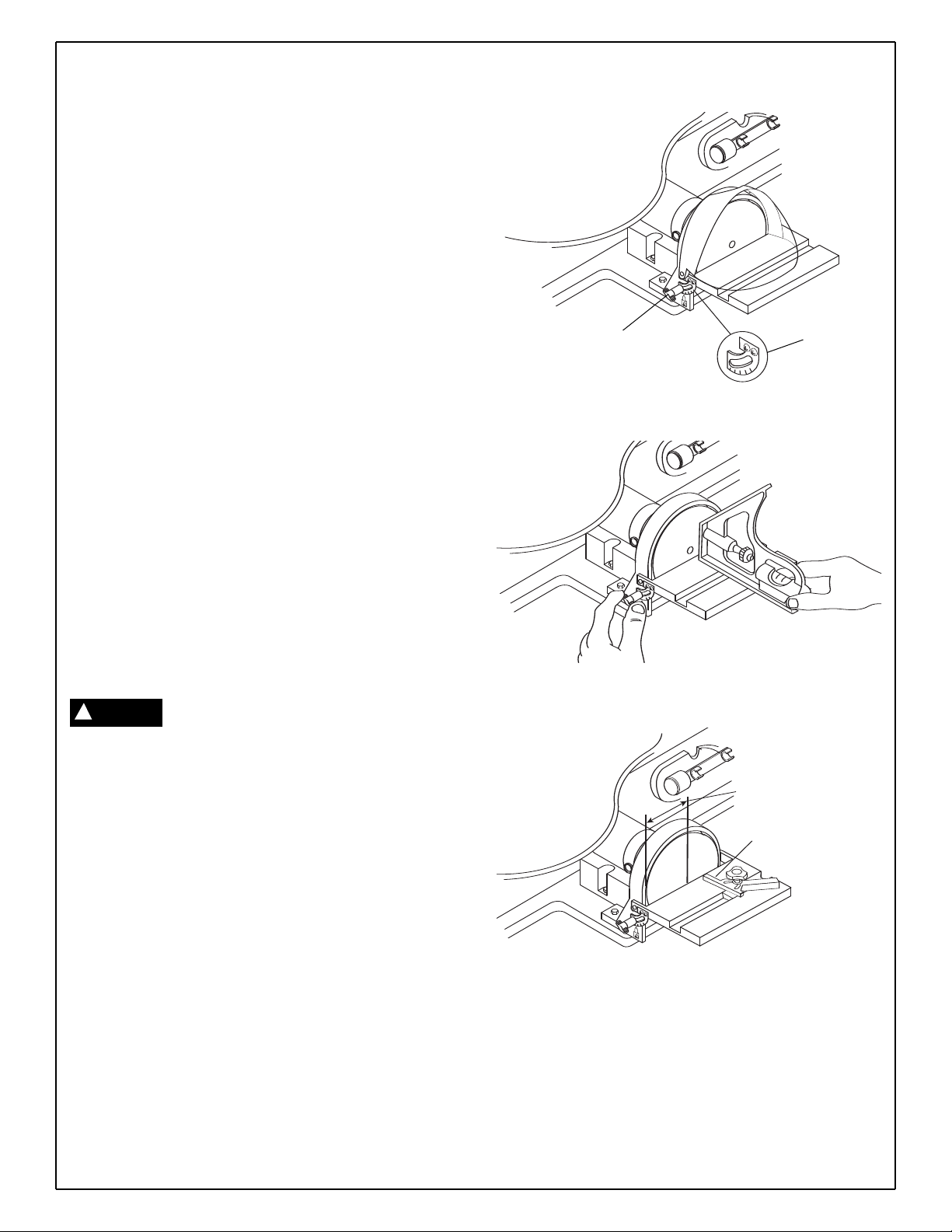

Removing and Installing

Pin-End Blades

Release blade tension by lifting up the Quick Release

1.

Tension Lever and turning counterclockwise (Figure 11).

2. Open easy access door and loosen the blade clamping

knobs on the upper and lower blade holders. Remove

blade from the upper and lower blade holders by pulling

forward on blade and then lifting the blade through the

access hole in the table. Slight downward pressure

against the upper holder may be helpful when removing

blade from upper holder.

NOTE: Table insert may be removed for better access. Table

insert must be replaced before operating the saw.

3. Look at the blade holders closely and notice the blade

slots and pin recesses in the blade holder

NOTE: In order to cut, and avoid uncontrollable lifting of the

workpiece, the teeth of the blade used on the Scroll Station

should always point downward as shown in (Figure 11) when

installed.

s.

14

Page 15

Operation

4. Install the blade by inserting one end of the blade

through the access hole in the table and hook the blade

pin in the pin recess in the lower blade holder. Slide the

top blade pin into the pin recess of the upper blade holder. You may need to press down lightly on the upper

blade holder to install the blade.

5. Check to see that the pins are properly located in the

blade holders.

6. To properly secure the blade securely tighten the wing

knob on the upper and lower holders.

7. Tension blade (see

BLADE TENSION below).

Removing and Installing

Plain-End Blades

1. Release blade tension by lifting up the Quick Release

Tension Lever (Figure 11) and turn counterclockwise.

2. Open easy access door and loosen the blade wing knob

on the upper and lower blade holders (Figure 9). Remove

blade from the upper and lower blade holders by pulling

forward on blade and then lifting the blade through the

access hole in the table. Slight downward pressure may be

necessary on the upper arm.

NOTE: Table insert may be removed for better access. Table

insert must be replaced before operating the saw.

3. Install the blade by inserting one end of the blade through

the access hole in the table and centering the blade in the

blade slot in the upper and lower blade holders (Figure 10).

Wing

Knobs

Figure 9. Changing Blades

Blades Properly Seated

in Holders

Figure 10. Installing Blades

4. To properly secure the blade securely tighten the wing

knob on the upper and lower holders.

5. Tension blade (see

NOTE: In order to cut, and avoid uncontrollable lifting of the

workpiece, the teeth of the blade used on the Scroll Station

should always point downward as shown in (Figure 9) when

installed.

BLADE TENSION below).

Blade Tension

To tension blade, move Quick Release Tension Lever to

“down” position. As the lever is lowered, tension will be

applied to the blade (Figure 11).

ATTENTION: Moving the lever downward should require

moderate, steady pressure only. If heavy pressure is needed,

the blade is too tight. Loosen tension by rotating the Quick

Release Tension Lever counterclockwise 1-2 turns, then

reset the tension lever to the “down” position. If the tension

lever is in the “down” position and the blade is too loose, you

can increase tension by leaving the tension lever “down” and

rotating it clockwise just until you feel the slack in the blade

Figure 11. Quick Release Tension Lever

removed. Then turn the tension lever ONE full turn clockwise.

This amount of blade pressure should do well for most cutting

operations and blades.

When the blade tension has been properly adjusted, you

should be able to lift up the Quick Release Tension Lever,

remove and install the blade, lower the lever and return the

original blade tension. The life of the tension lever will be

extended if you back the tension off one-half turn

ing the lever.

NOTE: It may be necessary to re-adjust the tension lever

when using different types of blades.

15

before lift

-

Page 16

Operation

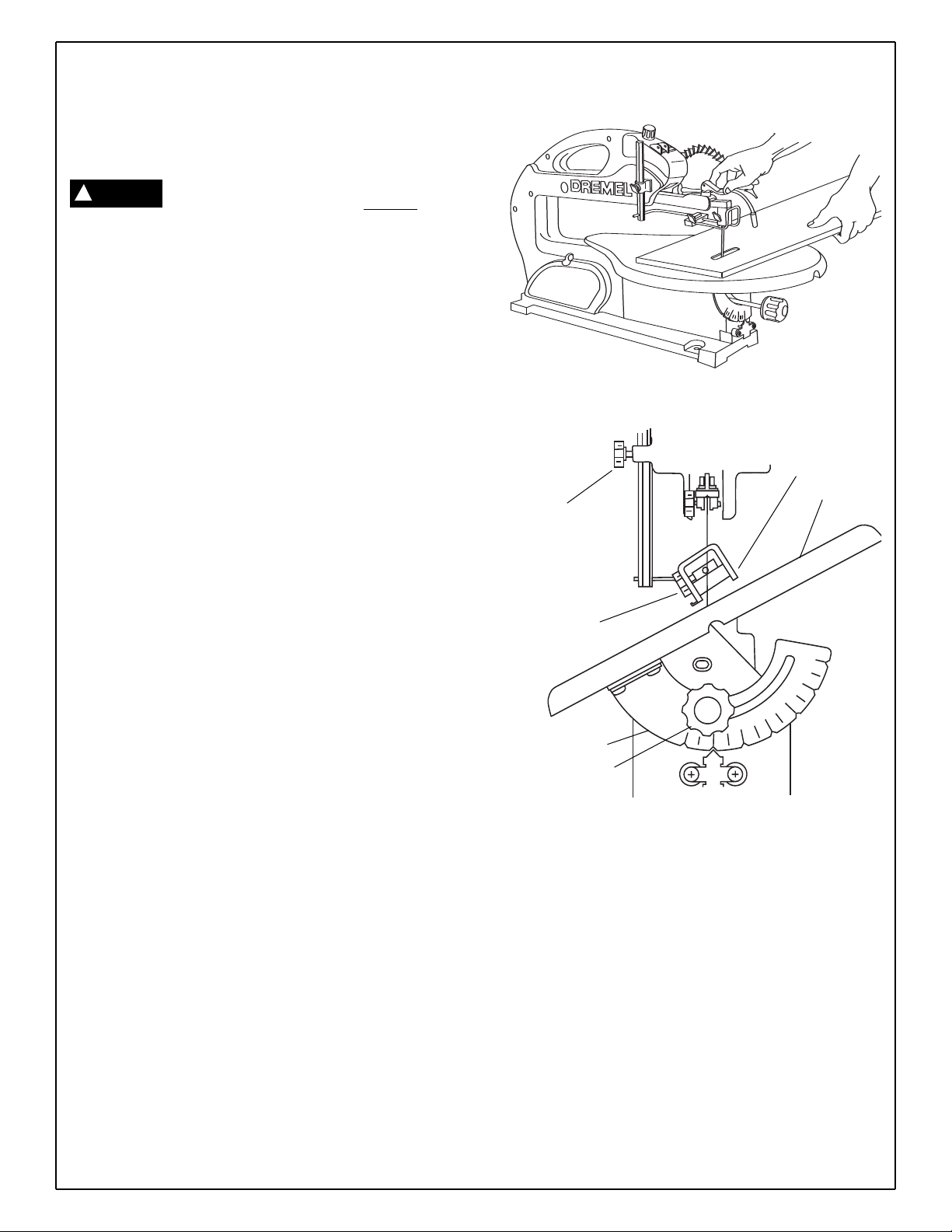

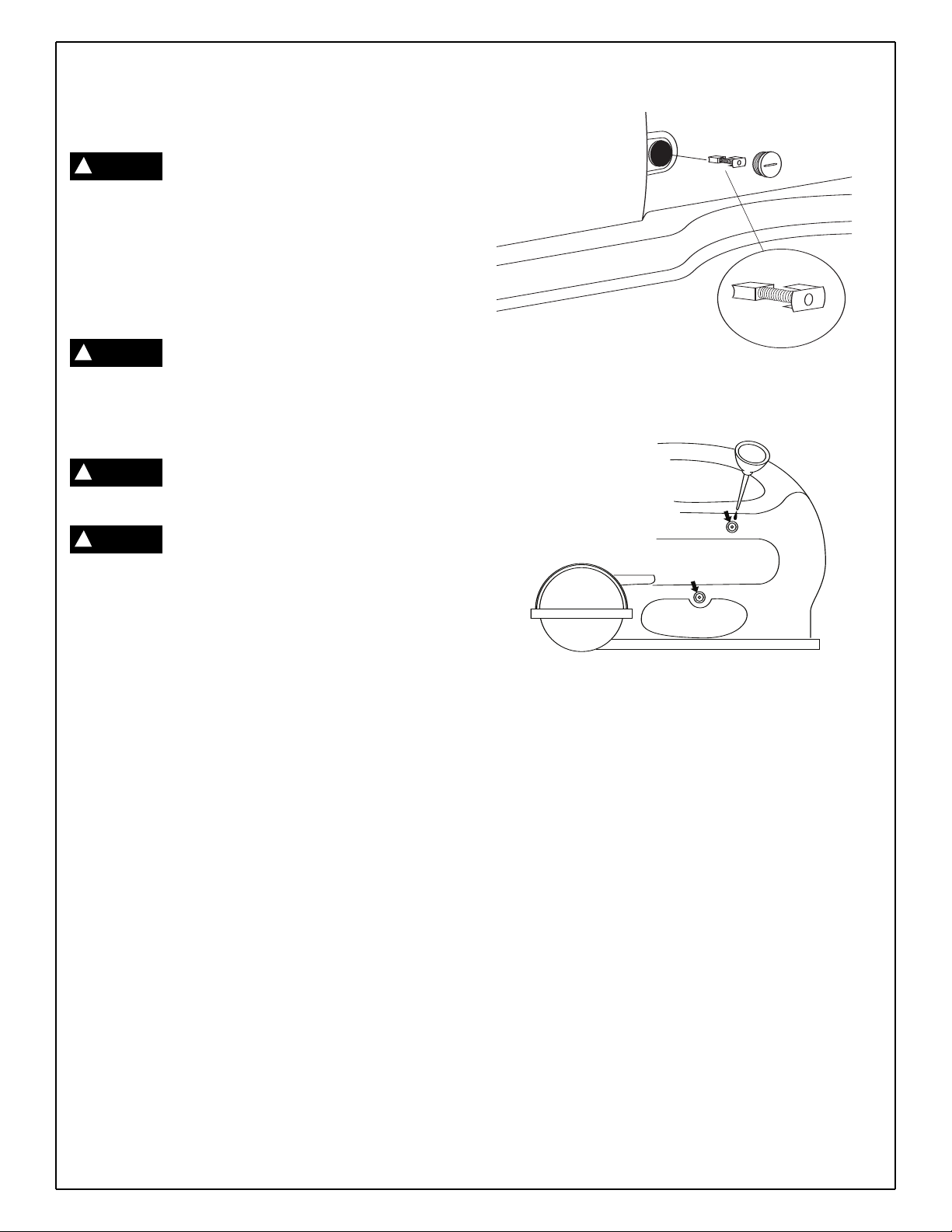

Making Interior Scroll Cuts

(Pin-End Blades & Plain-End Blades)

WARNING

!

REMOVE PLUG FROM POWER SOURCE BEFORE

REMOVING OR REPLACING THE BLADE.

A main benefit of this saw is the ability to perform intricate

interior cuts quickly and easily. This is best accomplished

using the Quick Release Tension Lever. Simply follow these

steps (Figure 12):

1. Drill appropriate sized pilot hole in work piece.

2. Release Quick Release Tension Lever.

3. Remove the blade from the upper blade holder as

explained on page 14 or 15,

INSTALLING BLADES

4. Thread blade through pilot hole from underneath the

workpiece. If needed, remove the table insert. This will

allow the blade to angle forward for more clearance

between the workpiece and the upper arm housing.

Reinstall the blade in the upper blade holder. Replace

table insert.

5. Re-tension blade by pulling tension lever down.

6. Lower drop foot until it just rests on top of the workpiece

and you’re ready to begin cutting.

TO AVOID ACCIDENTAL STARTING,

ALWAYS TURN SWITCH TO

REMOVING AND

.

OFF (O)

AND

Figure 12. Making Interior Scroll Cuts

Drop Foot

Table

Drop Foot

Wing Knob

(Height

Adjustment)

Drop Foot

Wing Knob

(Angle

Adjustment)

7. When finished making the interior scroll cuts simply remove

the blade from the upper blade holder, as described on page

14 & 15,

remove the board from the table.

REMOVING AND INSTALLING BLADES, then

Adjusting the Table for

Horizontal or Bevel Cutting

1. Loosen the table lock knob, and the saw table can be tilted to the left and locked at any angle from 0° horizontal

cutting position up to 45° for bevel cutting (Figure 15).

Your tool also features table tilt detents which audibly

click into place to the left every 15°. The table may be

tilted to the right up to 5°.

A degree scale is provided under the work table as a

2.

convenient reference for setting the approximate table

angle for bevel cutting. When greater precision is

required, make practice cuts and adjust the table as necessary for your requirements.

3. Loosen the drop foot wing knob and lower by hand until

it just rests above the workpiece surface, then securely

tighten the drop foot wing knob. The drop foot should

always rest just above the workpiece to help prevent the

workpiece from lifting off the table.

Degree Scale

Table Lock Knob

Figure 13. Adjusting Table for Horizontal

or Bevel Cutting

When cutting with the table angled, adjust drop foot so

4.

it’s parallel to the table. To adjust, loosen the wing knob,

turn drop foot to correct angle, tighten wing knob (Figure

13).

Always make sure the blade does not contact either side of

the drop foot, table opening or insert.

NOTE: When cutting at extreme angles, the drop foot should

be lifted off the workpiece, as it will impede cutting. Hold the

workpiece against the table.

16

Page 17

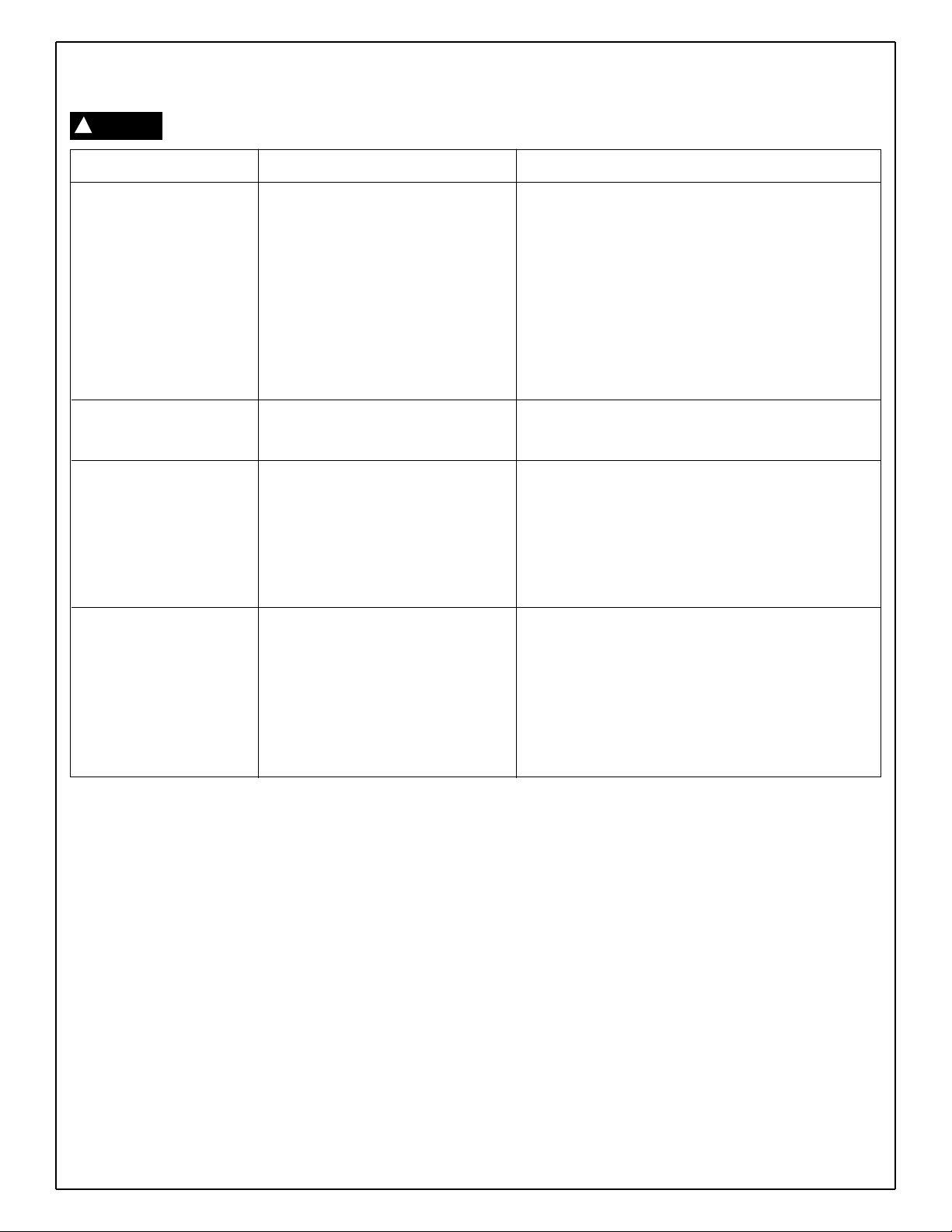

Operating Adjustments

Aligning the

Degree Scale Pointer

The table is factory set to 0º. If further adjustments are nec

essary, please follow the instructions below:

1. Loosen the table lock knob and move the table until it is

90° to the blade.

2. Remove the blade, remove the drop foot assembly, then

reinstall the blade (see

BLADES

table next to the blade as shown in (Figure 14) to check

if the table is 90º to the blade. If no adjustment is

required, re-install the drop foot assembly.

If adjustment is necessary. Loosen, but don’t remove the

two screws holding the pointer. With the steel ball cen

tered in the 0º detent, slide the pointer left or right until

the blade is parallel to the square.

3. Tighten the table lock knob, both screws, and reinstall

the drop foot. Remember, the degree scale is a convenient guide but should not be relied upon for precision.

Make practice cuts in scrap wood to determine if your

angle setting is correct.

, page 14 or 15). Place a small square on the

REMOVING AND INSTALLING

Removing and Installing

Drop Foot Wing Knob

(Height Adjustment)

-

Drop Foot

Wing Knob

(Angle

Adjustment)

Degree Scale

-

Pointer

Adjustment Screw

Figure 14. Aligning the Degree Scale Pointer

Blade

Pointer

Square

Steel Ball

Abrasive Discs

The disc furnished with the sander is self-adhesive type.

Refer to Figure 15.

1. Remove the the disc table adjustment wing knobs and

Phillips hd. screws, then remove the disc table.

2. To remove the abrasive disc, work the edge of disc back

then peel it away from the backing plate.

Rotate the disc and continue peeling until it is removed.

3.

4. Remove the protective backing from the new disc.

Carefully center disc on backing plate and apply pres

sure to disc.

Install disc table using Phillips hd. screws and lock

5.

knobs.

Power ON/OFF Switch

Turn the power on or off using the Power ON (I) / OFF (O) switch

(Figure 16).

Your saw features an overload switch that protects the motor

from overheating and damage. If the switch is tripped, the motor

will automatically stop. When this occurs, turn the ON/OFF

switch to the OFF (O) position. The tool will automatically reset.

Turn the power switch to the ON (I) position.

-

Figure 15. Removing and Installing Abrasive Discs

Power ON/OFF Switch

Variable Speed Control

Light ON/OFF Switch

Blower

Light

Adjusting the Lamp

Turn the lamp switch to ON (I). Position the lamp as needed to

illuminate the workpiece (Figure 16).

Figure 16. Adjusting the Lamp or Blower

17

Page 18

Operating Adjustments

Sand on this half

of disc only

Miter Gauge

Adjusting the Blower

Position the blower as needed to blow-off sawdust from the

workpiece (Figure 16).

Variable Speed Control

Turn the control to vary the speed of the saw, disc sander and

other optional attachments (Figure 16).

Adjusting Side Table

Loosen the side table lock knobs and move the side

1.

table to the desired angle. A scale is located under the

left side lock knob (Figure 17).

Wing Knob

(1 each side)

Scale

2. Tighten the wing knobs.

Squaring Side Table

For most projects, the table should be square with the sanding disc. Check using a combination square (Figure 18).

1. Place a square on the table with the other end against

the sanding disc. Check that the table is 90° to the disc.

2. If the table is not 90° to the disc, loosen the adjustment

wing knobs and move the table to the desired position.

Tighten adjustment knobs and check again for squareness.

NOTE: Any desired angle can be checked the same way

using a protractor instead of a square.

WARNING

!

workpiece supported by the table. If the back half of the

disc is used, dust and grit will be thrown up in your face

and the workpiece can be pulled out of your hands

resulting in painfully abraded fingers.

The miter gauge (Figure 19) is used for making most angle cuts,

such as the corners of a frame. The angle setting on the table

should be used only for rough work. To make perfect joints,

such as required for picture framing, a protractor should be

used to make settings. Adjustments are made by loosening

wing knobs, moving gauge to desired angle, then tightening

wing knobs.

Sanding is done only on the forward half of

the disc as shown in Figure 19, with the

Figure 17. Adjusting the Side Table Angle

Figure 18. Checking Side Table Squareness

Figure 19. Disc Sanding Surface

18

Page 19

Maintaining Your Scroll Station

General

WARNING

!

let before maintaining or lubricating your Scroll Station.

Frequently blow out any dust that may accumulate inside the

motor.

An occasional coat of paste wax on the work table will allow

materials being cut to glide smoothly across the work surface

and deters rust.

CAUTION

!

chloride, chlorinated cleaning solvents, ammonia and household detergents that contain ammonia. Avoiding use of these

and other types of cleaning agents minimizes the probability

of damage.

WARNING

!

have it replaced immediately.

WARNING

!

the nearest Dremel Factory Service Center. Use only Dremel

replacement parts, any others may create a hazard.

For your own safety, turn power switch to OFF

and remove plug from the power source out-

Certain cleaning agents and solvents damage

plastic parts. Including: gasoline, carbon tetra-

To avoid shock or fire hazard, if the power

cord is worn or cut, or damaged in any way,

All repairs, electrical or mechanical, should be

attempted only by trained repairmen. Contact

Figure 20. Checking Motor Carbon Brushes

Carbon Brushes

The brushes and commutator in your tool have been engineered for many hours of dependable service. To maintain

peak efficiency of the motor, we recommend the brushes be

examined every two to six months. Only genuine Dremel

replacement brushes specially designed for your tool should

be used.

The brushes should be inspected frequently when tools are

used continuously. If your tool runs sporadically, loses power,

makes unusual noises or runs at a reduced speed, check the

brushes. To continue using the tool in this condition will permanently damage your tool.

With the cord unplugged, remove the brush caps one at a

time with a small screwdriver by rotating cap counter-clock

wise and check each brush (Figure 20).

If the brush is less than 1/8" long and the end surface of the

brush that contacts the commutator is rough and/or pitted,

replace the brush. Check both brushes. Usually the brushes

will not wear out simultaneously. If one brush is worn out,

replace both brushes. Make sure the brushes are installed as

illustrated. The curved surface of the brush must match the

curvature of the commutator.

Figure 21. Lubrication

each set of brushes. This will also extend the total life of your

tool since the commutator surface will wear longer.

Lubrication

ARM BEARINGS

Lubricate the arm bearings with oil after 10 hours of use. Reoil after every 50 hours of use or whenever there is a squeak

coming from the bearings.

-

TO LUBRICATE

1. Remove rubber plug to expose bronze bearing.

Squirt a generous amount of SAE 20 oil around the shaft

2.

end and bronze bearing.

3. Replace rubber plug.

Let the oil soak in overnight in this condition.

4.

After replacing brushes the tool should be run at no-load;

place it on a clean surface and run it freely for 5 minutes

before loading (or using) the tool. This will allow the brushes

to “seat” properly and will give you more hours of life from

19

Page 20

Troubleshooting

WARNING

!

TROUBLE

Breaking blades.

Jammed disc sander

Motor will not run.

Turn power switch to “OFF” (O) and always remove plug from the wall outlet before troubleshooting.

PROBLEM

Wrong tension.

1.

Over working blade.

2.

3. Wrong blade application.

4. Twisting blade in wood.

5. Incorrect teeth per inch.

1. Material jammed in disc.

1. Defective cord or plug.

2. Defective motor.

3. Defective wire connections.

4. Brushes worn.

REMEDY

Adjust blade tension, see

1.

INSTALLING BLADES

(Pin End) or (Plain End).

Reduce feed rate, see

2.

TION

, Page 14.

3. Use narrow blades for cutting thin wood, wide blades

for thicker wood.

4. Avoid side pressure on blade - avoid over-tensioning

pin-end blade.

5. Blade should have minimum 3 teeth in contact with

workpiece.

1. Turn off and unplug saw.

Remove material.

1. Replace defective parts before using saw

again.

2. & 3. Consult Dremel Service. Any attempt to

repair this motor may create a HAZARD

unless repair is done by a qualified service

technician.

4. Replace both brushes.

REMOVING AND

, Pages 14 & 15.

BASIC Scroll Station OPERA

-

Vibration

NOTE: There will always be

some vibration present when

the saw is running because of

motor operation.

1. Improper mounting of saw.

2. Unsuitable mounting surface.

3. Loose table or table resting

against motor.

1. See

2. The heavier your work bench is, the less vibration will

3. Tighten table wing knob.

MOUNTING YOUR Scroll Station,

Pages 12 & 13.

occur. A plywood workbench will not be as good a

work surface as the same size solid lumber. Use

common sense in choosing a mounting surface.

20

Page 21

Recommended Accessories

Use only Dremel accessories. Follow instructions that accompany accessories. Use of improper accessories may cause hazards.

LEG SET Magnifier

Cat. No.

2615018500 2615018505

Cat. No. Suggested Usage Width Thick TPI Speed

16412 For cutting wood 3/8" to 2" thick .110" x .018" x 10 Any

16411 For cutting wood 3/16" to 1" thick .110" x .018" x 15 Any

16413 For cutting wood thinner than 1/4" thick .070" x .010" x 18.5 Any

The Pin-End blades, while somewhat easier to put in and take out of the machine, do not always produce the same controlled cutting action provided with the Plain-End blade. These narrow Plain-End blades allow the user to cut more detailed, intricate patterns

and smaller inside cuts.

Cat.No. Suggested Usage Width Thick TPI Speed

16453 For cutting hard and soft woods 1/4" to 2" thick .062" x .020" x 9.5 High

16446 For close radius cutting in materials 1/8" or thicker .038" x .016" x 12.5 High

16440 .022" x .010" x 28 High

Cat. No.

Dremel offers both Pin- and Plain-End 5 inch blades.

PIN-END SAW BLADES

Pin-End blades permit relatively tight radius cutting in hard and soft wood.

PLAIN-END

SPIRAL

Saws in all directions without turning the workpiece.

Cat. No. Suggested Usage Kerf TPI Speed

16463 For wood, plastic and abrasive materials .034" - .036" x 41

METAL PIERCING

For cutting precious and non-ferrous metals; these must be used at very slow speeds.

They perform well on machines that have variable speed capability and

should be lubricated with beeswax, or a light machine oil.

Cat. No. Suggested Usage Kerf TPI Speed

16483 Metals and other hardwood materials. .033" x .016" x 36 Low

REVERSE TOOTH

Provides a smooth, splinter free finish. Eliminates the need for excessive finish sanding,

and leaves a clean sharp edge on both the top and bottom of your workpiece.

Cat. No.

16431

16432 For cutting hard or soft woods 1/8" or thicker .038" x .016" x 12.5 Any

Suggested Usage Kerf TPI Speed

For cutting hard or soft woods up to 1/8" thick.

.029" x .012" x 20

Any

21

Page 22

Dremel Limited Warranty

Your Dremel product is warranted against defective material or workmanship for a period of two years from date of purchase. In the event of a failure of a product to conform to this written warranty, please take the following action:

1. DO NOT return your product to the place of purchase.

2. Carefully package the product by itself, with no other items, and return it, freight prepaid, along with:

A. A copy of your dated proof of purchase (please keep a copy for yourself).

B. A written statement about the nature of the problem.

C. Your name, address and phone number to:

UNITED STATES

Dremel Service Center

4915 21st Street OR 4631 E. Sunny Dune

Racine, WI 53406 Palm Springs, CA 92264

CANADA OUTSIDE

Giles Tool Agency CONTINENTAL UNITED STATES

6520 Lawrence Av. East See your local distributor or write

Scarborough, Ont. to Dremel, 4915 21st Street

Canada M1C 4A7 Racine, WI 53406

We recommend that the package be insured against loss or in transit damage for which we cannot be responsible.

This warranty applies only to the original registered purchaser. DAMAGE TO THE PRODUCT RESULTING FROM TAMPERING, ACCIDENT,

ABUSE, NEGLIGENCE, UNAUTHORIZED REPAIRS OR ALTERATIONS, UNAPPROVED ATTACHMENTS OR OTHER CAUSES UNRELATED

TO PROBLEMS WITH MATERIAL OR WORKMANSHIP ARE NOT COVERED BY THIS WARRANTY.

No employee, agent, dealer or other person is authorized to give any warranties on behalf of Dremel. If Dremel inspection shows that the problem

was caused by problems with material or workmanship within the limitations of the warranty, Dremel will repair or replace the product free of charge

and return product prepaid. Repairs made necessary by normal wear or abuse, or repair for product outside the warranty period, if they can be

made, will be charged at regular factory prices.

DREMEL MAKES NO OTHER WARRANTY OF ANY KIND WHATEVER, EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE ABOVE MENTIONED OBLIGATION ARE HEREBY DISCLAIMED BY DREMEL AND EXCLUDED FROM THIS LIMITED WARRANTY.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state. The obligation of the warrantor is solely

to repair or replace the product. The warrantor is not liable for any incidental or consequential damages due to any such alleged defect. Some states do

not allow the exclusion or limitation of incidental or consequential damages, so the above limitations or exclusion may not apply to you.

For prices and warranty fulfillment in the continental United States, contact your local Dremel distributor.

Dremel Service Center

22

Page 23

Poste à chantourner de 18 po

AVEC VARIATION DE VITESSE

Mode d'emploi

Table des Matières

Consignes de Sécurité Générales . . . . . . . . . . . . . . . .24-25

Consignes de Sécurité Spécifiques . . . . . . . . . . . . . . .25-27

Consignes de Sécurité Supplémentaires . . . . . . . . . . .28-30

Caractéristiques Techniques . . . . . . . . . . . . . . . . . . . . . . .31

Caractéristiques Générales . . . . . . . . . . . . . . . . . . . . . . .31

Caractéristiques du Moteur . . . . . . . . . . . . . . . . . . . . . . .31

Raccordement à une Source d'alimentation . . . . . . . . .31

Déballage et Vérification du Contenu . . . . . . . . . . . . . .32-33

Apprenez à Connaître Votre Scie à Chantourner . . . .34-35

Glossaire des Termes . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assemblage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35-37

Installation de la Table de Ponçage . . . . . . . . . . . . . . . .35

Installation de l'arbre Flexible (accessoire en option) . .35

Montage du poste à chantourner sur un établi . . . . . . .36

Montage du Poste à Chantourner sur un Contreplaqué37

Utilisation

Utilisation élémentaire de la scie à Chantourner . . . . . .

Lames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Montage et démontage des lames à bouts à Goujons .

Montage et démontage des lames à bouts lisses . . . . .39

Tension de la lame . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38-41

35

38

39

Modèle 1800

Réalisation de découpes Internes . . . . . . . . . . . . . . . . .40

Réglage de la Table pour Scier à l'horizontal . . . . . . . .40

ou en Biseau . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Utilisation des Réglages . . . . . . . . . . . . . . . . . . . . . . . .42-44

Alignement de l'index de l'échelle en Degrés . . . . . . . .42

Montage et démontage des Disques Abrasifs . . . . . . . .42

Interrupteur Marche / Arrêt . . . . . . . . . . . . . . . . . . . . . . .43

Réglage de la Lampe . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Réglage de la Soufflette . . . . . . . . . . . . . . . . . . . . . . . . .43

Commande de Variation de Vitesse . . . . . . . . . . . . . . . .

Réglage de la Table Latérale . . . . . . . . . . . . . . . . . . . . .43

Mise à l'équerre de la Table latérale . . . . . . . . . . . . . . .43

Entretien de Votre scie à Chantourner . . . . . . . . . . . . .45-46

Généralités . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Charbons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Lubrification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dépannage

Accessoires Conseillés . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Garantie limitée de Dremel

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

¿Habla español? Ver página 50

43

46

47

49

4915 21st Street

Racine, WI 53406

1-800-437-3635

http://www.dremel.com

Page 24

Consignes de Sécurité Générales

AVERTISSEMENT

!

corporelle grave.

VEUILLEZ LIRE TOUTES LES INSTRUCTIONS ! Si on ne suit pas les consignes de sécurité

se trouvant ci-dessous ainsi que d'autres précautions élémentaires de sécurité, il y a risque de blessure

Lieu de Travail

NE LAISSEZ PAS LES ENFANTS S'APPROCHER

Ne laissez pas les tiers toucher à l'outil ou au cordon. Ne

laissez pas les tiers s'approcher de la zone de travail.

GARDEZ LE LIEU DE TRAVAIL PROPRE

Les lieux ainsi que les établis encombrés invitent

les accidents.

PENSEZ À LA SÉCURITÉ DES ENFANTS DANS VOTRE

ATELIER

Utilisez des cadenas ou des interrupteurs généraux.

ÉVITEZ LES MILIEUX DANGEREUX

N'utilisez pas d'outils électriques dans des lieux humides ou

mouillés. Éclairez convenablement le lieu de travail.

N'exposez pas les outils électriques à la pluie. N'utilisez pas

l'outil en présence de gaz ou de liquides inflammables.

Sécurité Personnelle

CONNAISSEZ VOTRE OUTIL ÉLECTRIQUE

Lisez et comprenez le mode d'emploi ainsi que les étiquettes

fixées sur l'outil. Apprenez ses usages et ses limites aussi

bien que les dangers potentiels qui lui sont spécifiques.

NE VOUS PENCHEZ PAS

Conservez toujours une bonne assise et un bon équilibre.

RESTEZ VIGILANT

Faites attention à ce que vous faites. Utilisez votre bon sens.

N'utilisez pas l'outil quand vous êtes fatigué, quand vous êtes

sous l'emprise de médicaments, d'alcool ou d'autres

drogues.

PORTEZ DES VÊTEMENTS APPROPRIÉS

Pas de vêtements amples ou de bijoux qui risquent d'être

happés par les pièces en mouvement. Il est conseillé de

porter des gants en caoutchouc et des chaussures antidérapantes quand on travaille dehors. Si vous avez les cheveux

longs, portez une coiffe de protection.

PORTEZ DES LUNETTES DE SÉCURITÉ.

Portez également un masque facial ou un masque à pous

sière si l'usinage produit de la poussière, mettez-vous aussi

des bouchons dans les oreilles si vous utilisez l'outil pendant

une longue période.

-

DÉBRANCHEZ VOS OUTILS

Quand vous ne vous en servez pas, avant un entretien, lors

d'un changement de lame, de foret, de fer, etc.…

LAISSEZ TOUS LES CAPOTS EN PLACE

En bon état de fonctionnement et réglés et alignés correctement.

ENLEVEZ TOUTES LES CLÉS ET CLÉS DE RÉGLAGE.

Prenez l'habitude de contrôler que toutes les clés et clés de

réglage ont été enlevées de l'outil avant de le mettre en route.

ÉVITEZ LES DÉMARRAGES INTEMPESTIFS

Assurez-vous que l'interrupteur est en position Arrêt (OFF)

avant de brancher le cordon.

RELIEZ TOUS VOS OUTILS À LA TERRE

Cet outil est muni d'un cordon homologué à 3 conducteurs et

d'une fiche mâle à 3 broches avec terre prévue pour

s'adapter à une prise de terre approprié. Le conducteur vert

du cordon est le fil de terre. Ne raccordez jamais le conducteur de terre sur une borne de phase.

NE GRIMPEZ JAMAIS SUR L'OUTIL OU SUR SON

PIED.

Il y a risque de blessures graves si l'outil bascule ou si vous

touchez l'outil de coupe accidentellement. Ne rangez pas de

matériaux sur ou près de l'outil de telle sorte qu'il est nécessaire de grimper sur l'outil ou sur son pied pour les atteindre.

VÉRIFIEZ L'ÉTAT DES PIÈCES.

Avant de continuer à utiliser l'outil, tout capot ou autre pièce

abîmée doit être contrôlé soigneusement pour s'assurer qu'il

fonctionne correctement et qu'il peut remplir la fonction pour

laquelle il a été conçu. Vérifiez que les pièces mobiles sont

alignées. Vérifiez que l'assemblage est correct et que rien

d'autre ne risque d'affecter le fonctionnement. Tout capot (ou