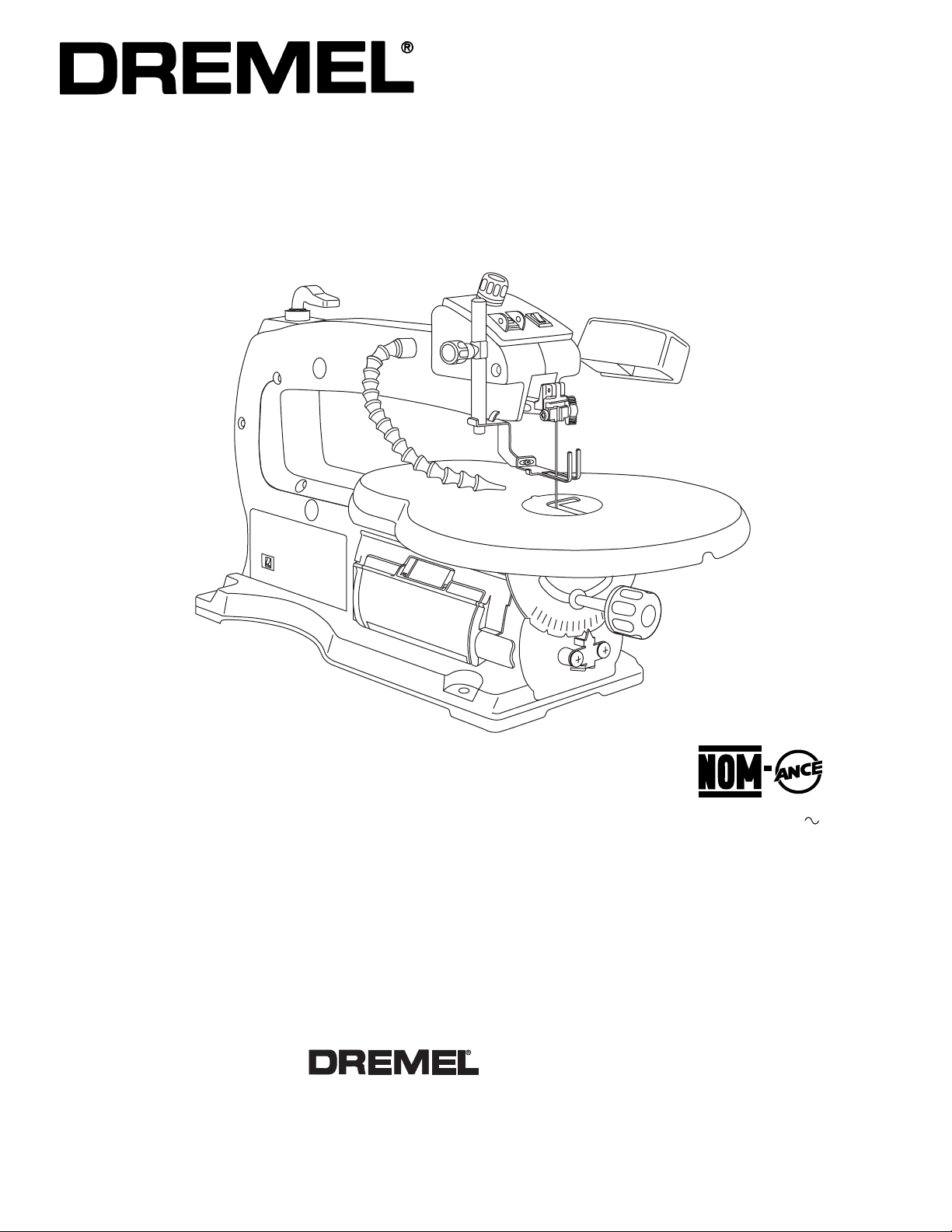

Page 1

owner’s manual

MODEL 1680, VARIABLE SPEED

16” SCROLL SAW

Form No. 2610914195 7/01 Printed in Taiwan

Parlez-vous français? Voir page 21

¿Habla español? Ver página 41

P.O. Box 1468

Racine, Wisconsin

1-800-437-3635

http://www.dremel.com

Voltage rating 120 V 50 - 60Hz

Amperage rating 1.4 A

No load speed n0 500-1,600/min

Throat 16”

Blade 5” Plain and pin-end

Blade stroke 3/4”

Cutting capacity 2” at 0º; 1” at 45º

assembly • operation • safety instructions

Page 2

2.

Work Area

KEEP CHILDREN AWAY

Do not let visitors contact tool or extension cord. All visitors should be kept away from work area.

KEEP WORK AREAS CLEAN

Cluttered areas and benches invite accidents.

MAKE WORKSHOP CHILD-PROOF

With padlocks, master switches.

AVOID DANGEROUS ENVIRONMENTS

Don’t use power tools in damp or wet locations. Keep

work area well lit. Do not expose power tools to rain. Do

not use the tool in the presence of flammable liquids or

gases.

Personal Safety

KNOW YOUR POWER TOOL

Read and understand the owner’s manual and labels

affixed to the tool. Learn its application and limitations as

well as the specific potential hazards peculiar to this tool.

DON’T OVERREACH

Keep proper footing and balance at all times.

STAY ALERT

Watch what you are doing. Use common sense. Do not

operate tool when you are tired. Do not operate while

under medication or while using alcohol or other drugs.

DRESS PROPERLY

Do not wear loose clothing or jewelry. They can be caught

in moving parts. Rubber gloves and non-skid footwear are

recommended when working outdoors. Wear protective

hair covering to contain long hair.

USE SAFETY GLASSES

Also face or dust mask if cutting operation is dusty, and ear

plugs during extended periods of operation.

Everyday eyeglasses have only impact resistant lenses,

they are NOT safety glasses.

GUARD AGAINST ELECTRIC SHOCK

Prevent body contact with grounded surfaces. For example: pipes, radiators, ranges, refrigerator enclosures.

DISCONNECT TOOLS FROM POWER SOURCE

When not in use, before servicing, when changing

blades, bits, cutters, etc.

KEEP GUARDS IN PLACE

In working order, and in proper adjustment and

alignment.

REMOVE ADJUSTING KEYS AND WRENCHES

Form the habit of checking to see that keys and adjusting

wrenches are removed from tool before turning it on.

AVOID ACCIDENTAL STARTING

Make sure the switch is in the “OFF” position before plugging in tool.

GROUND ALL TOOLS

This tool is equipped with an approved 3-conductor cord

and a 3 prong grounding type plug to fit the proper

grounding type receptacle. The green conductor in the

cord is the grounding wire. Never connect the green wire

to a live terminal.

NEVER STAND ON TOOL OR ITS STAND

Serious injury could occur if the tool is tipped or if the cutting tool is accidentally contacted. Do not store materials

on or near the tool such that it is necessary to stand on the

tool or its stand to reach them.

CHECK DAMAGED PARTS

Before further use of the tool, a guard or other part that is

damaged should be carefully checked to ensure that it will

operate properly and perform its intended function. Check

for alignment of moving parts, mounting, and any other

conditions that may affect its operation. A guard or other

part that is damaged should be properly replaced.

All repairs, electrical or mechanical, should

be attempted only by trained repairmen.

Contact the nearest Dremel Service Center, Authorized

Dremel Service Station or other competent repair service.

Use only Dremel replacement parts; any

others may create a hazard.

The use of any other accessories not spec-

ified in the current Dremel catalog, may create a hazard.

General Safety Rules

“READ ALL INSTRUCTIONS” Failure to follow the safety rules listed below

and other basic safety precautions may result in serious personal injury.

“SAVE THESE INSTRUCTIONS”

WARNING

!

WARNING

!

WARNING

!

WARNING

!

Page 3

3.

Tool Use

DON’T FORCE TOOL

It will do the job better and safer at the rate for which it was

designed.

USE THE RIGHT TOOL

Don’t force a small tool or attachment to do the job of a

heavy duty tool. Don’t used tool for purpose not intended—for example, don’t use a circular saw for cutting tree

limbs or logs.

SECURE WORK

Use clamps or a vise to hold work when practical. It’s safer

than using your hand and it frees both hands to operate

the tool.

NEVER LEAVE TOOL RUNNING UNATTENDED

Turn power off. Don’t leave tool until it comes to a complete stop.

Tool Care

DO NOT ALTER OR MISUSE TOOL

These tools are precision built. Any alteration or modification not specified is misuse and may result in dangerous

conditions.

AVOID GASEOUS AREAS

Do not operate electric tools in a gaseous or explosive

atmosphere. Motors in these tools normally spark, and

may result in a dangerous condition.

MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for better and safer performance. Follow instructions for lubricating and changing

accessories. Inspect tool cords periodically and if damaged, have repaired by authorized service facility. Inspect

extension cords periodically and replace if damaged. Keep

handles dry, clean and free from oil and grease.

Before connecting the tool to a power

source (receptacle, outlet, etc.), be sure

voltage supplied is the same as that specified on the nameplate of the tool. A power source with a voltage greater than

that specified for the tool can result in serious injury to the

user, as well as damage to the tool. If in doubt, DO NOT

PLUG IN THE TOOL. Using a power source with a voltage

less than the nameplate rating is harmful to the motor

.

Additional Safety Rules

For your own safety, do not operate your

Scroll Saw until it is completely assembled

and installed according to the instructions...and until you

have read and understood the following:

1. General Safety Rules..............................................2-4

2. Motor Specifications and Electrical ..........................

Requirements ............................................................5

3. Getting to Know Your Scroll Saw ........................8-9

4. Operating Adjustments ..........................................10

5. Basic Scroll Saw Operations ............................11-14

6. Mounting the Scroll Saw....................................15-16

7. Maintaining Your Scroll Saw ..................................17

8. STABILITY OF SAW

Your Scroll Saw must be bolted securely to a stand or

workbench. In addition, if there is any tendency for the

Scroll Saw to tip over or move during certain operations,

such as cutting long, heavy boards, bolt your Scroll Saw

stand or workbench to the floor.

9. LOCATION

This Scroll Saw is intended for indoor use only.

10. PROTECTION: Eyes, hands, face, ears and body.

TO AVOID BEING PULLED INTO THE

BLADE—

DO NOT WEAR: Loose Fitting Gloves

Necktie

Loose Clothing

Jewelry

DO: TIE BACK LONG HAIR

ROLL LONG SLEEVES ABOVE ELBOWS

a. If any part of your saw is missing, malfunctioning, has

been damaged or broken . . . such as the motor switch, or

other operating control, a safety device or the power

cord...cease operating immediately until the particular part

is properly repaired or replaced.

b. Do not cut piece too small to hold by hand.

HINT: When making a very small cut out, always secure

the workpiece to a scrap piece of plywood with doublefaced tape. This way, the work is supported and your fingers are away from the blade.

c. Never turn your Scroll Saw on before clearing the table

of all objects (tools, scraps of wood, etc.) except for the

workpiece and related feed or support devices for the

operation planned.

WARNING

!

WARNING

!

WARNING

!

Page 4

4.

Additional Safety Rules

d. Avoid awkward hand positions where a sudden slip

could cause a hand to move into the blade.

• ALWAYS adjust the drop foot to just clear the workpiece to protect the operator, keep blade breakage to a

minimum and provide maximum support for blade.

• Always adjust blade tension correctly.

• The Scroll Saw should cut on the down stroke. Always

make sure blade teeth are oriented downward toward

table.

• When cutting a large piece of material, make sure it is

supported at table height.

• Hold the work firmly against the table.

• Do not feed the material too fast while cutting. Only

feed the material fast enough so that the blade will cut.

Keep fingers away from the blade.

• Use caution when cutting off material which is irregular

in cross section‚ it could pinch the blade before the cut

is completed. A piece of molding, for example, must lay

flat on the table and not be permitted to rock while

being cut.

• Use caution when cutting off round material such as

dowel rods or tubing. They have a tendency to roll while

being cut, causing the blade to “bite”.

e. Never leave the Scroll Saw running unattended. Turn

the saw OFF, make sure the saw has come to a complete

stop, and then remove plug from power supply before

leaving the work area.

f. Do not perform layout, assembly or setup work on the

table while the cutting tool is operating.

g. Turn saw off and remove plug from power supply outlet

before installing or removing an accessory attachment.

h. Access Door must be closed before operation.

i. Quick Release Tension Lever should be in down position

before operating.

11. THINK SAFETY

SAFETY IS A COMBINATION OF OPERATOR COMMON

SENSE AND ALERTNESS AT ALL TIMES WHEN THE

SCROLL SAW IS BEING USED.

Do not allow familiarity (gained from fre-

quent use of your Scroll Saw) to become

commonplace. Always remember that a careless fraction

of a second is sufficient to inflict severe injury.

The operation of any power tool

can result in foreign objects

being thrown into the eyes,

which can result in severe eye

damage. Always wear safety

goggles that comply with ANSI

Z87.1 before commencing

power tool operation.

Some dust created by power sanding,

sawing, grinding, drilling, and other

construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and other

masonry products, and

• Arsenic and chromium from chemically treated lumber.

Your risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work

with approved safety equipment, such as those dust masks

that are specially designed to filter out microscopic

particles.

WARNING

Wear Eye Protection

NOTE AND FOLLOW THE SAFETY WARNINGS AND INSTRUCTIONS

THAT APPEAR ON THE PANEL ON SCROLL SAW HOUSING:

WARNING

!

WARNING

!

Page 5

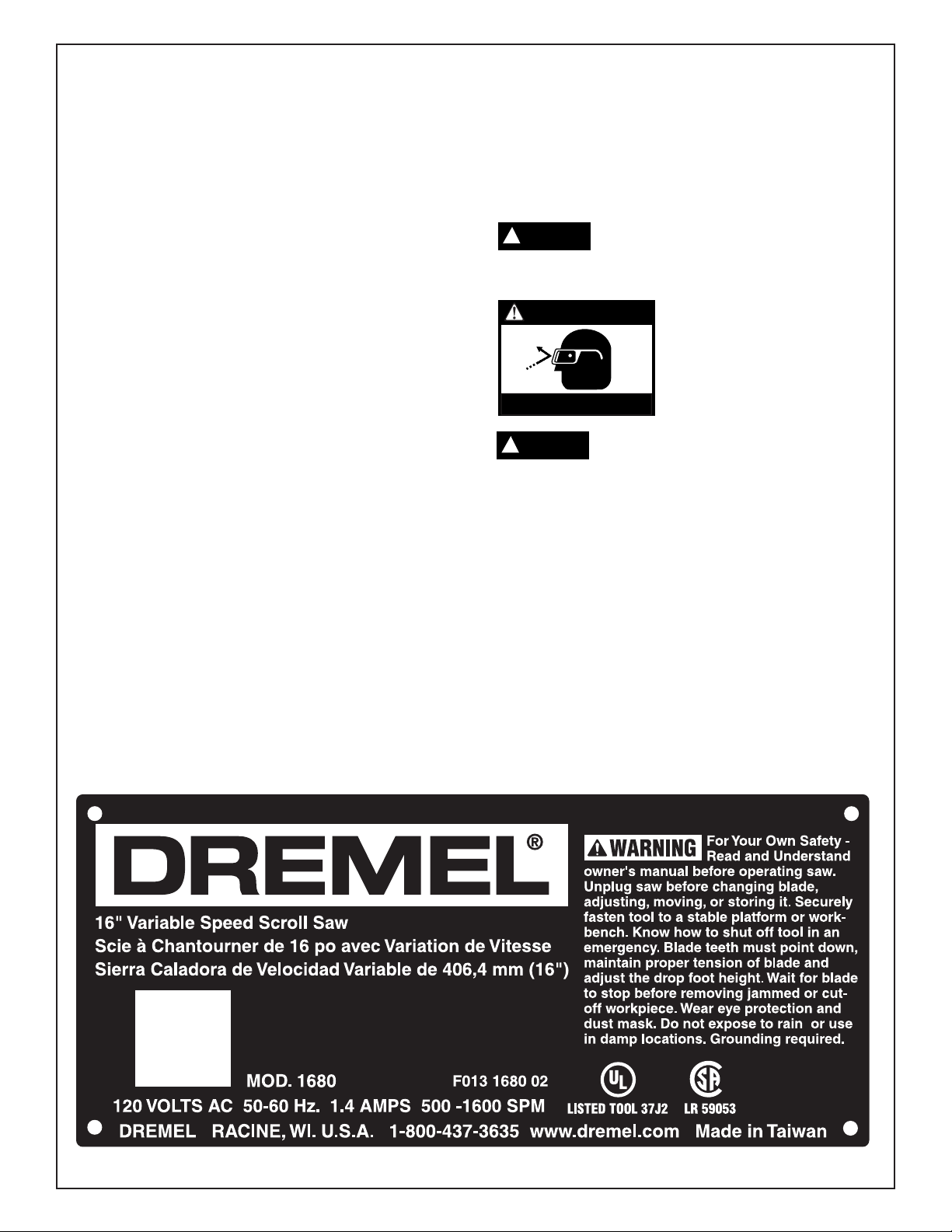

Motor Specifications

In the event of a malfunction or breakdown, grounding provides

a path of least resistance for electric current to reduce the risk of

electric shock.

This Scroll Saw is designed to use a Variable Speed RPM motor.

It is wired for operation on 110-120 volts, 60 Hz. alternating current. Before connecting the motor cord to power source, make

certain the switch is in the “OFF” position and be sure the electric current is of the same characteristics as stamped on the

nameplate.

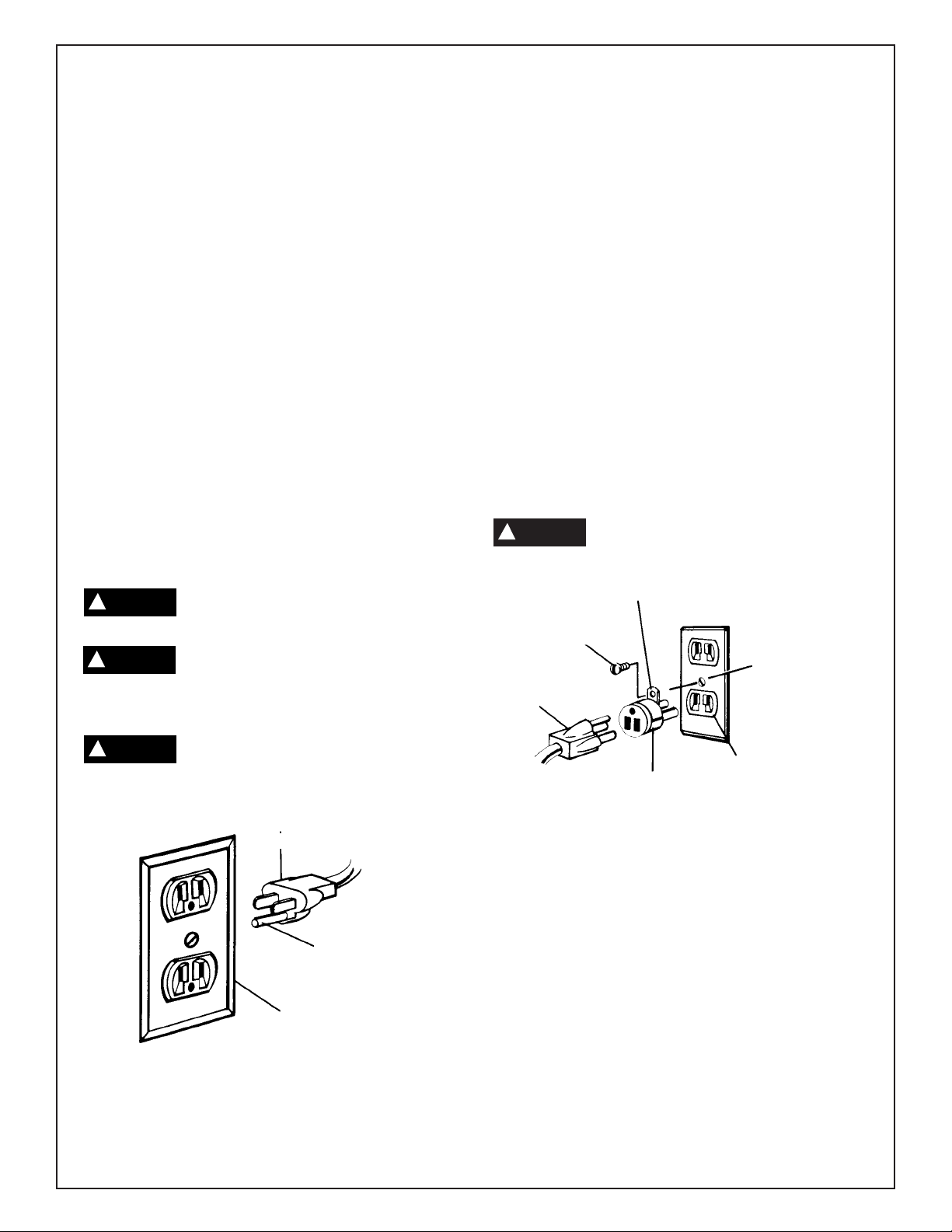

Connection To A Power

Source

This machine must be grounded while in use to protect the operator from electric shock.

Plug power cord into a 110-120V properly grounded type outlet

protected by a 15-amp dual element time delay fuse or circuit

breaker.

Not all outlets are properly grounded. If you are not sure that

your outlet, as pictured below, is properly grounded; have it

checked by a qualified electrician.

To avoid electric shock, do not touch the

metal prongs on the plug when installing or

removing the plug to or from the outlet.

Failure to properly ground this power tool can

cause electrocution or serious shock, particularly when used near metal plumbing or other metal objects.

If shocked, your reaction could cause your hands to hit the

tool.

If power cord is worn, cut or damaged in any

way, have it replaced immediately to avoid

shock or fire hazard.

Your unit is for use on 120 volts; it has a plug that looks like

the one below.

This power tool is equipped with a 3-conductor cord and

grounding type plug, approved by Underwriters Laboratories

and the Canadian Standards Association. The ground conductor has a green jacket with or without yellow stripes and is

attached to the tool housing at one end and to the ground

prong in the attachment plug at the other end.

This plug requires a mating 3-conductor grounded type outlet

as shown. It must be grounded in accordance with all local

codes and ordinances.

If the outlet you are planning to use for this power tool is of the

two-prong type, DO NOT REMOVE OR ALTER THE

GROUNDING PRONG IN ANY MANNER. Have a qualified

electrician replace the TWO-prong outlet with a properly

grounded THREE prong outlet.

Improper connection of the equipment-grounding conductor

can result in a risk of electric shock. If repair or replacement of

the electric cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the

grounding instructions are not completely understood, or if in

doubt as to whether the tool is properly grounded.

The temporary adapter should be used only until a properly

grounded outlet can be installed by a qualified electrician.

The green grounding lug extending from the

adapter must be connected to a permanent

ground such as a properly grounded outlet box.

NOTE: The adapter illustrated is for use only if you already

have a properly grounded 2-prong receptacle. Adapter is not

allowed in Canada by the Canadian Electrical Code. Always

use proper extension cord.

The use of any extension cord will cause some loss of power.

To keep this to a minimum and to prevent overheating and

motor burn-out, use the table below to determine the minimum wire size (A.W.G.) extension cord. Use only 3-wire extension cords which have 3-prong grounding type plugs and 3pole receptacles which accept the tool’s plug. Make sure your

extension cord is in good condition.

Extension Cord Length Wire Size A.W.G.

0-25 Feet 18

26-50 Feet 16

51-100 Feet 16

5.

Motor Specifications and

Electrical Requirements

WARNING

!

“SAVE THESE INSTRUCTIONS”

3-PRONG PLUG

GROUNDING PRONG

ALWAYS USE A

GROUNDED

OUTLET

DANGER

!

DANGER

!

WARNING

!

SCREW

GROUNDING LUG

3-PRONG

PLUG

ADAPTER

2-PRONG

RECEPTACLE

MAKE SURE THIS

IS CONNECTED TO

A KNOWN

GROUND

Page 6

6.

Table of Contents

General Safety Rules......................................................2

Additional Safety Rules ................................................3-4

Motor Specifications and Electrical

Requirements ..................................................................5

Connection to a Power Source..........................................5

Unpacking and Checking Contents ..............................7

Table of Loose Parts..........................................................7

Glossary of Terms............................................................8

Getting to Know Your Scroll Saw ..............................8-9

Operating Adjustments ................................................10

Setting the Table for Horizontal or Bevel Cutting............10

Aligning the Degree Scale Pointer ..................................10

Basic Scroll Saw Operations ..................................11-14

Removing and Installing Pin-End Blades ........................12

Removing and Installing Plain-End Blades ....................12

Adjusting the Lamp..........................................................13

Replacing the Bulb ..........................................................13

On/Off Switch ..................................................................13

Variable Speed Switch ....................................................13

Reset Button ....................................................................13

Making Interior Scroll Cuts Pin-End Blades and

Plain-End Blades..............................................................14

Mounting the Scroll Saw..........................................15-16

Mounting the Scroll Saw to a Bench ..............................15

Mounting the Scroll Saw to Plywood ..............................16

Attaching Scroll Saw to Leg Set......................................16

Maintaining Your Scroll Saw ........................................17

Lubrication ......................................................................17

Recommended Accessories ........................................18

Trouble Shooting............................................................19

Dremel Limited Warranty ..............................................22

Service Parts List......................................................61-64

Page 7

7.

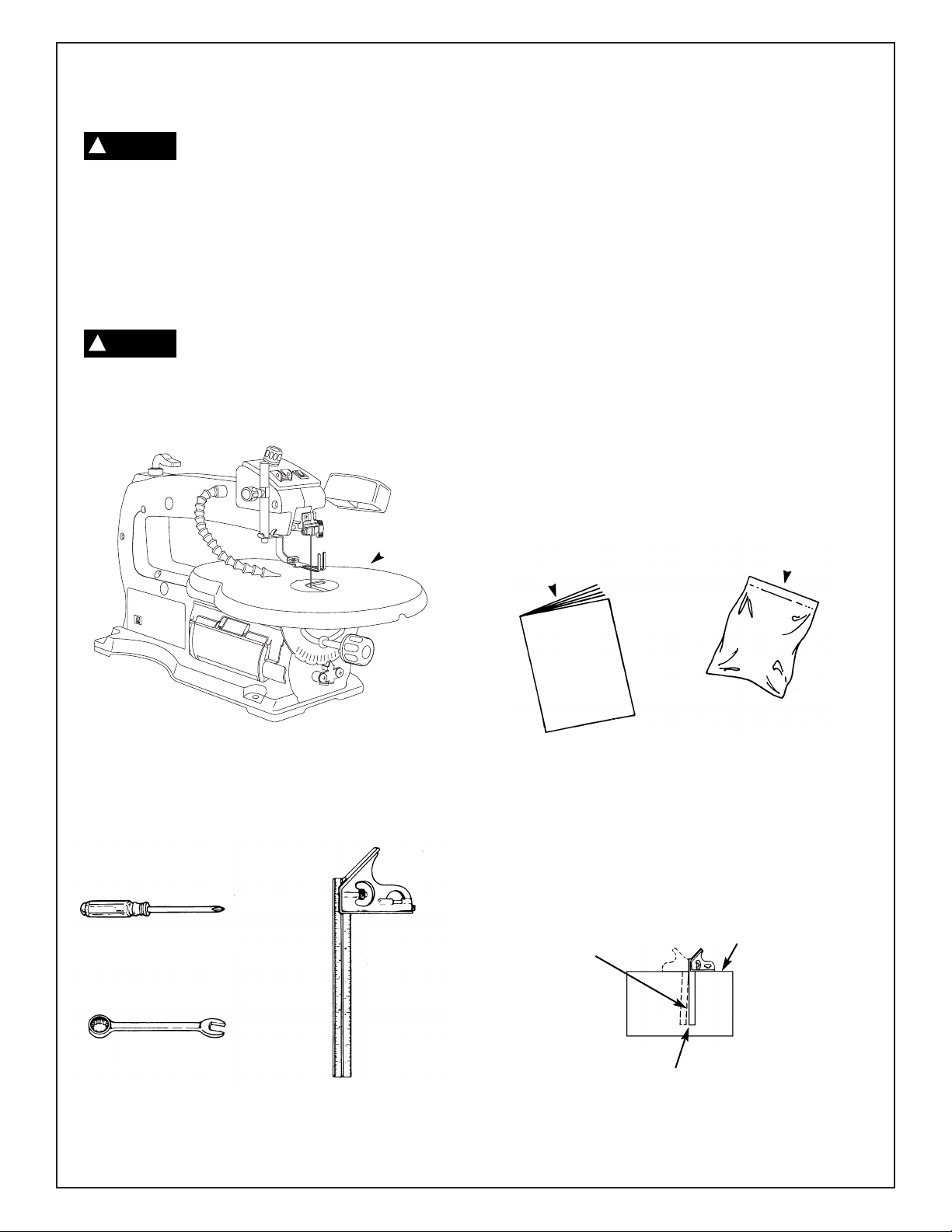

To avoid injury from unexpected starting or

electrical shock, always remove plug from

power source when tool is not in use.

Model 1680 Motorized Scroll Saw is shipped complete in

one carton.

1. Unpacking and Checking Contents. Separate all “loose

parts” from packing materials and check each item with

the “Table of Loose Parts” to make sure all items are

accounted for before discarding any packing material.

If any parts are missing, do not attempt to

operate Scroll Saw, plug in the power

cord or turn the switch on until the missing parts are

obtained and are installed correctly.

Table of Loose Parts

Item Description Qty.

A 16” Scroll Saw ..........................................................1

B Owner’s Manual ........................................................1

C Loose Parts Bag (containing)....................................1

Allen Wrench (3 mm) ................................................1

Allen Wrench (5 mm) ................................................1

Blades ....................................................................11

NOTE: Hardware to mount this Scroll Saw to a bench or

leg set is NOT supplied. See mounting instructions on

Page 15-16 for recommended hardware size.

To remove protective coating from the table surface,

moisten a soft cloth with kerosene and wipe off coating.

Do not use acetone, gasoline or lacquer thinner for this

purpose.

After removing protective coating, If you wish, you may

apply a coat of paste wax to the table to allow the workpiece to slide easily across the table surface and deter

rust. Wipe the table thoroughly with a clean dry cloth.

COMBINATION SQUARE MUST BE TRUE

Check its accuracy as illustrated below.

Unpacking and Checking Contents

Tools Needed

WARNING

!

WARNING

!

COMBINATION

SQUARE

SHOULD BE NO GAP OR OVERLAP WHEN

SQUARE IS FLIPPED OVER IN DOTTED POSITION

DRAW LIGHT LINE

ON BOARD ALONG

THIS EDGE

STRAIGHT EDGE OF

BOARD 3/4” THICK-

THIS EDGE MUST BE

PERFECTLY STRAIGHT

B

C

A

PHILLIPS SCREWDRIVER

WRENCHES

7/16 in.

Page 8

8.

This versatile Scroll Saw is great for making toys, puzzles,

games, fretwork, and jewelry. Because of its cutting capacity, it is a handy do-it-yourself tool. It cuts wood up to 2

inches thick as well as plastics and non-ferrous metals.

1. BLADE & WRENCH STORAGE CASE

Your Scroll Saw is equipped with a blade storage area

located on the easy access door of the saw. The blade

storage area conveniently stores your allen wrenches, and

both Pin and Plain end blades.

2. SAWDUST BLOWER

Keeps workpiece clean for more accurate scroll cuts. For

best results, always direct air flow from blower tube at

blade and workpiece. To adjust, simply bend to desired

position.

3. VACUUM HOOK-UP

Your Scroll Saw is equipped with a vacuum hook-up. This

feature will allow you to attach any 1-1/4" vacuum hose

into the hole provided for convenient sawdust removal.

4. DROP FOOT

The foot should always be lowered until it just rests on top

of the workpiece to prevent workpiece from lifting, but not

so much that the workpiece drags.

5. DROP FOOT LOCK KNOB

Allows you to raise or lower the foot and lock it at desired

heights.

6. QUICK RELEASE TENSION LEVER

Allows you to quickly loosen, or tighten the blade to it’s

original tension with lever action.

7. TABLE LOCK KNOB

Allows you to tilt the table and lock it at desired angle up

to 45 degrees to the right or left.

8. DEGREE SCALE

Shows the degree the table is tilted.

9. VARIABLE SPEED DIAL

Your Scroll Saw is equipped with a variable speed dial for

greater versatility.

10. POWER ON/OFF SWITCH

Has holes provided by the switch for a lock (not included).

THIS FEATURE IS INTENDED TO PREVENT UNAUTHOURIZED AND POSSIBLY HAZARDOUS USE BY

CHILDREN AND OTHERS. To turn saw on, push power

switch to the “on” position; to turn saw off, push power

switch to the “off” position.

11. LIGHT SWITCH

To turn light on, push light switch to the “on” position; to

turn light off, push light switch to the “off” position.

12. TABLE

Provide working surface to support workpiece.

12.a TABLE INSERT

Should always be in place and flush with table during cutting operation.

13. LIGHT

Illuminates the workpiece.

14. EASY ACCESS DOOR

Allows easy access to lower blade holder when changing

blades.

15. CIRCUIT BREAKER

Protects motor from from overheating and damage.

16. TABLE TILT DETENTS

Automatically stops the table to the right or left at 0, 15,

30, and 45 degree increments.

17. ALLEN WRENCHES

Convenient wrenches, assists in making blade changes

and adjustments if desired.

Getting to Know Your Scroll Saw

Glossary of Terms

KERF The slot cut by the blade.

LEADING EDGE

The edge of the workpiece which is pushed into the

blade first.

SAWBLADE PATH

The area of the workpiece directly in line with and moving

toward the sawblade edge.

BLADE TOOTH SET

The distance that the edge of the sawblade tooth is bent

(onset) outward from the side of the blade.

TRAILING EDGE

The workpiece edge last cut by the sawblade.

WORKPIECE

The item on which the cutting operation is being performed.

Page 9

9.

Getting to Know Your Scroll Saw

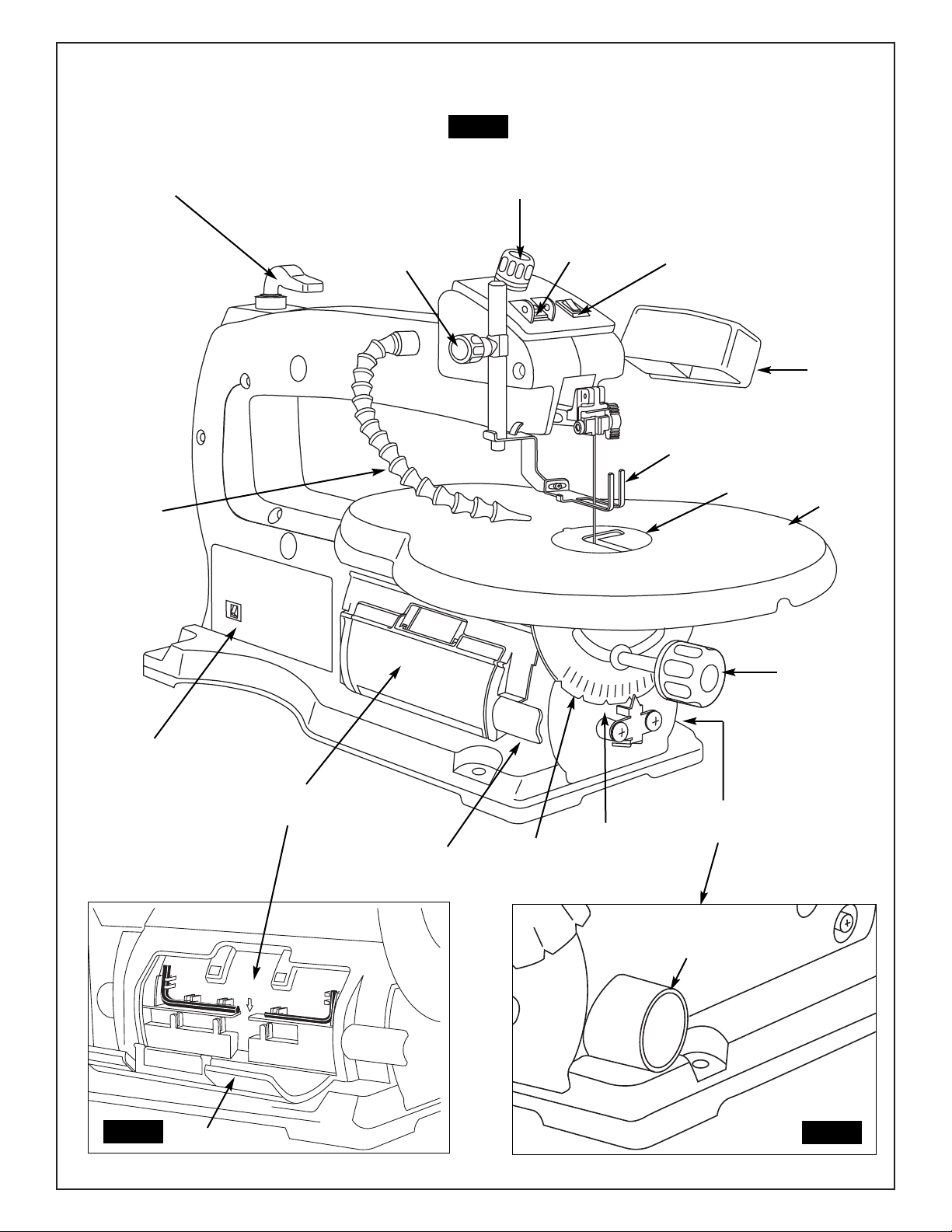

6

QUICK RELEASE

TENSION LEVER

5

DROP FOOT

LOCK KNOB

2

SAWDUST

BLOWER

4

DROP FOOT

12

TABLE

9

VARIABLE SPEED

DIAL

7

TABLE

LOCK KNOB

8

DEGREE

SCALE

FIG. 1

3

VACUUM

HOOK-UP

14

EASY ACCESS

DOOR

10

POWER

ON/OFF

SWITCH

13

LIGHT

11

LIGHT

SWITCH

15

CIRCUIT

BREAKER

1

BLADE & WRENCH

STORAGE CASE

16

TABLE

TILT

DETENTS

FIG. 2

FIG. 3

DOOR

VACUUM HOOK-UP

12a

TABLE INSERT

Page 10

NOTE: When cutting at extreme angles, the drop foot

should be lifted off the workpiece, as it will impede cutting.

Hold the workpiece against the table. The drop foot may

be disassembled when thick materials are cut at extreme

angles.

10.

Operating Adjustments

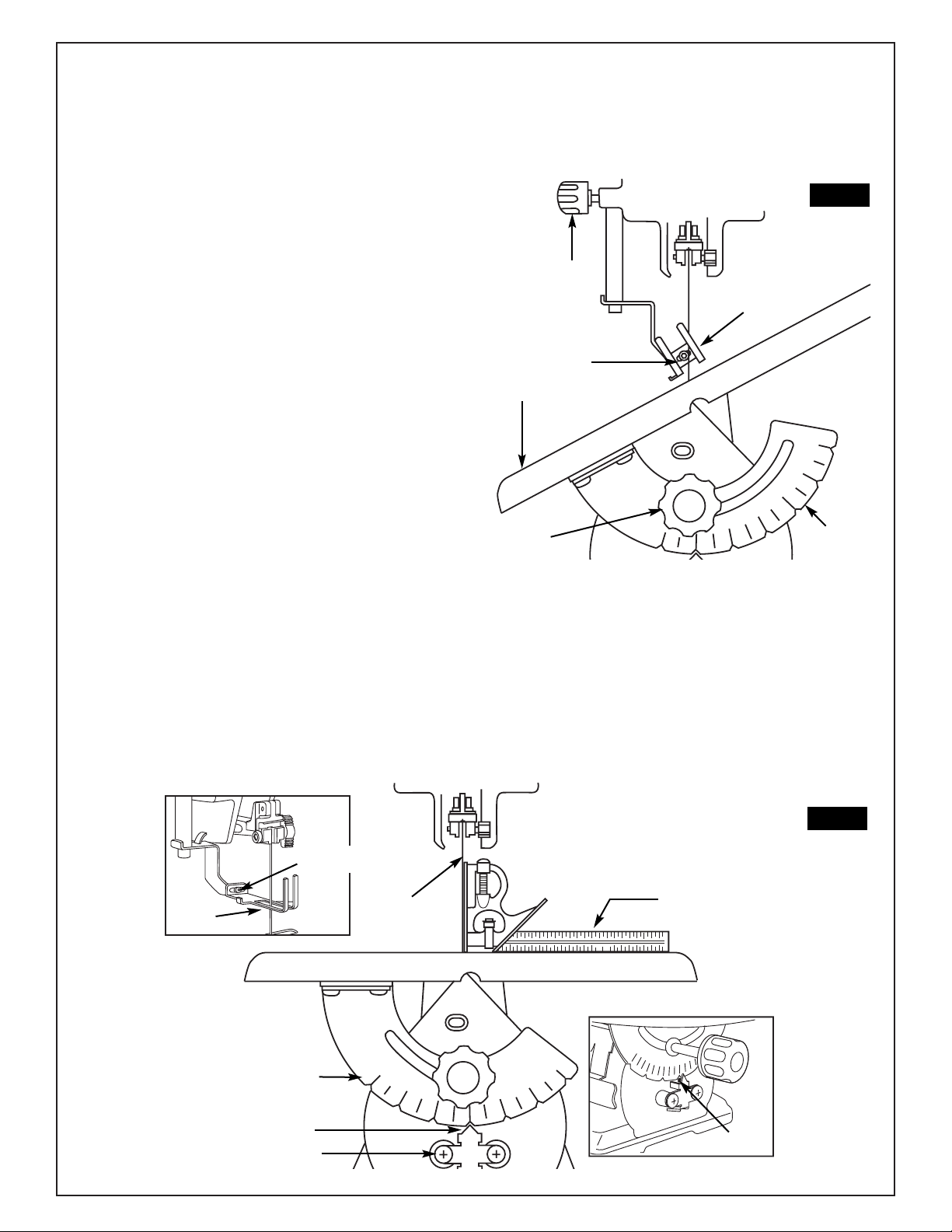

Setting the Table for

Horizontal or Bevel Cutting

1. Loosen the table lock knob, and the saw table can be

tilted to the right or left and locked at any angle from 0

degree horizontal cutting position up to 45 degrees for

bevel cutting (Fig. 4). Your tool also features table tilt dentents which automaticlly stops the table to the right or left

every 15 degrees.

2. A degree scale is also provided under the work table as

a convenient reference for setting the approximate table

angle for bevel cutting. When greater precision is required,

make practice cuts and adjust the table as necessary for

your requirements.

Adjusting the hold down clamp

The hold down clamp should always rest just above the

workpiece to help prevent the workpiece from lifting from

the table.

1. Hold the drop foot, loosen the drop foot lock knob and

lower by hand until it just rests above the workpiece surface, and securely tighten the drop foot lock knob.

2. When cutting with the table angled, adjust drop foot so

it’s parallel to the table. To adjust, loosen screw with the

allen wrench provided, turn foot to correct angle, tighten

screw.

Always make sure the blade does not contact either side

of the drop foot, or the table opening.

TABLE

TABLE

LOCK KNOB

SQUARE

BLADE

DEGREE

SCALE

POINTER

POINTER

ADJUSTMENT SCREW

FIG. 5

FIG. 4

DROP

FOOT

DROP

FOOT

LOCK

KNOB

DEGREE

SCALE

Aligning the Degree Scale Pointer

STEEL

BALL

DROP

FOOT

MOUNTING

SCREW

The table is factory set to 0º. If further adjustments are

necessary, please follow the instructions below:

1. Loosen the table lock knob and move the table until it is

90 degree to the blade.

2. With the wrench provided remove the drop foot assembly, mounting screw, and washer, and move it out of the

way. Place a small square on the table next to the blade as

shown in (Fig. 5) to check if the table is 90º to the blade. If

no adjustment is required, replace the drop foot assembly,

washer and screw.

If adjustment is necessary. Loosen, but don’t remove the

two screws holding the pointer. With the steel ball centered in the 0º detent, slide the pointer left or right until the

blade is parrallel to the square.

4. Tighten the table lock knob, both screws, and replace

drop foot, washers and screw. Remember, the degree

scale is a convenient guide but should not be relied upon

for precision. Make practice cuts in scrap wood to determine if your angle setting is correct.

MOUNTING

SCREW

Page 11

11.

Basic Scroll Saw Operations

Follow these instructions for operating your Scroll Saw to

get the best results and to minimize the likelihood of personal injury.

ALWAYS OBSERVE THE SAFETY PRECAUTIONS HERE AND ON PAGES 2, 3, 4,

AND 5.

1. Protection: Eyes, Hands, Face, Ears and Body

TO AVOID BEING PULLED INTO THE

BLADE—

DO NOT WEAR: Loose Fitting Gloves

Necktie

Loose Clothing

Jewelry

DO: TIE BACK LONG HAIR

ROLL LONG SLEEVES ABOVE

ELBOWS

• The saw does not cut wood by itself. You allow the saw

to cut wood by guiding the wood into the blade as it

moves.

• The blade teeth cut ONLY on the down stroke.

• The drop foot should always be lowered until it just rests

on top of the workpiece.

• You must feed the wood into the blade slowly because

the teeth of the blade are very small and they can only

remove wood when they are on the down stroke. The

blade will flex backwards when applying feed pressure.

Too much feed pressure will cause blade breakage.

• There is a learning curve for each person who wants to

use this saw. During that period of time it is expected that

some blades will break until you learn how to use the saw

and receive the greatest benefit from the blades.

• Best results are achieved when cutting wood less than

one inch thick.

• When cutting wood thicker than one inch the user must

feed the wood very slowly into the blade, increase blade

tension and take extra care not to bend or twist the blade

while cutting in order to maximize blade life.

• Teeth on Scroll Saw blades wear out and as such must be

replaced frequently for best cutting results. Scroll Saw

blades generally stay sharp for 1/2 hour to 2 hours of cutting.

• To get accurate cuts be prepared to compensate for the

blade’s tendency to follow the wood grain as you are cutting.

• When choosing a blade to use with your Scroll Saw

consider the following carefully:

• Choose a blade that allows at least three (3) teeth to be in

contact with the workpiece at all times.

• Very fine, narrow blades should be used to scroll cut in thin

wood (1/4 inch thick or less).

• To cut thicker wood, use wider blades with fewer teeth per

inch.

• Most blade packages state the size or thickness of wood

which that blade is intended to cut, and the radius (size of

curve) which can be cut with that blade.

• Wider blades can’t cut curves as tight or small as thinner blades.

• This saw uses 5 inch long, Pin or Plain-End type blades

only (See Accessories on page 18).

• Blades wear faster when (1) cutting plywood, which is

very abrasive, (2) when sawing wood which is thicker

than the 3/4 inch blade stroke, and (3) when sawing

hardwood, or when side pressure is placed on the

blade.

WARNING

!

WARNING

!

Page 12

12.

Basic Scroll Saw Operations

Blades

Your new Scroll Saw accepts 5 inch Pin-End blades or 5 inch

Plain-End blades (See Accessories on page 18).

To prevent personal injury always disconnect

the plug from power source before changing

blades or making adjustments.

Removing and Installing

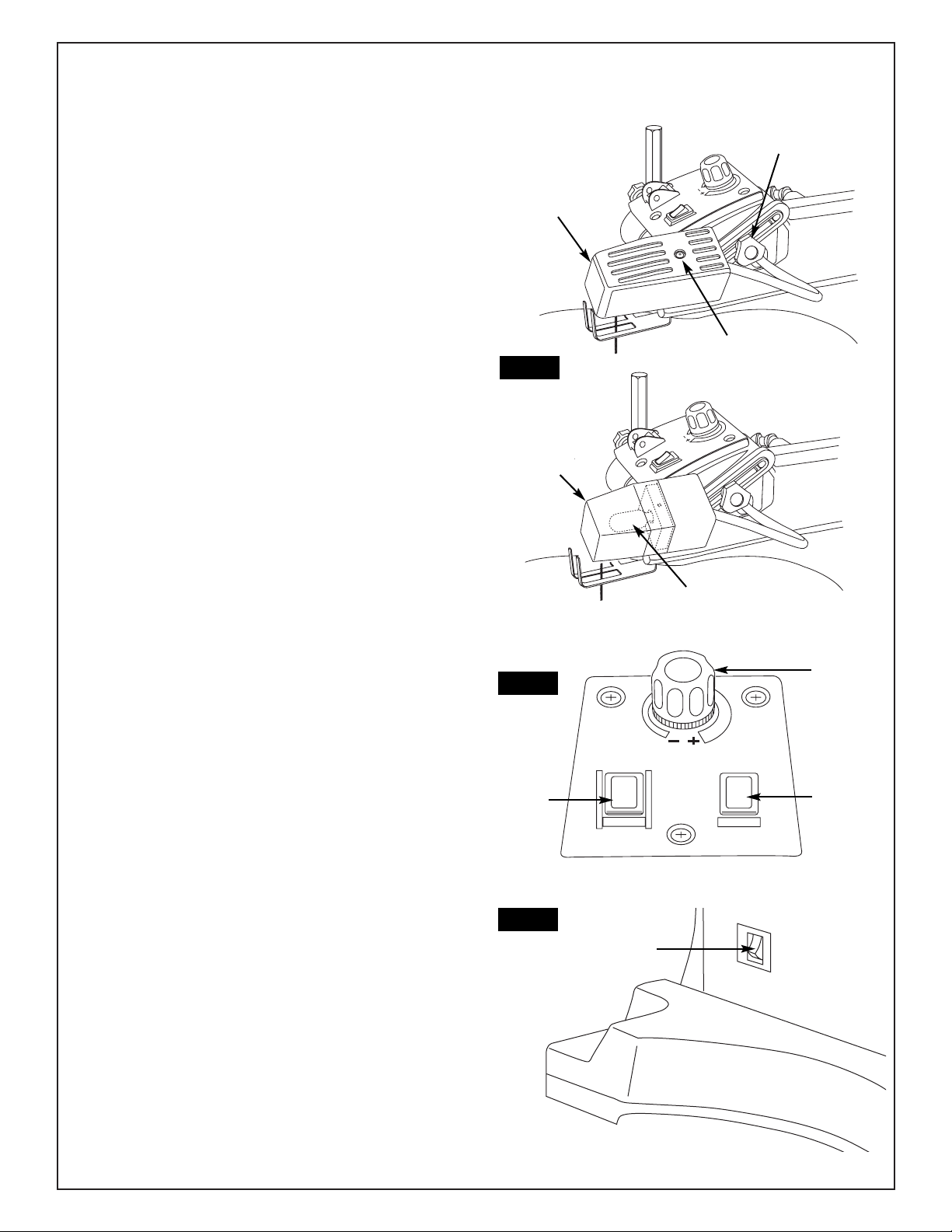

Pin-End Blades

1. Release blade tension by lifting up the Quick Release

Tension Lever (Fig. 7).

2. Open easy access door and loosen the blade clamping

knob on the upper and lower blade holders. Remove blade

from the upper and lower blade holders by pulling forward on

blade and then lifting the blade through the access hole in

the table. Slight downward pressure against the upper holder may be helpful when removing blade from upper holder.

3. Look at the blade holders closely and notice the blade

slots and pin recesses in the blade holders.

NOTE: In order to cut, and avoid uncontrollable lifting of the

workpiece, the teeth of the blade used on the Scroll Saw

should always point downward as shown in (Fig. 6) when

installed.

4. Install the blade by inserting one end of the blade through

the access hole in the table and hook the blade pin in the pin

recess in the lower blade holder. Slide the top blade pin into

the pin recess of the upper blade holder. You may need to

press down lightly on the upper blade holder to install the

blade.

5. Check to see that the pins are properly located in the blade

holders.

Removing and Installing

Plain-End Blades

1. Release blade tension by lifting up the Quick Release

Tension Lever (Fig. 7).

2. Open easy access door and loosen the blade clamping

knob on the upper and lower blade holders. Remove blade

from the upper and lower blade holders by pulling forward

on blade and then lifting the blade through the access hole

in the table.

3. Install the blade by inserting one end of the blade through

the access hole in the table and centering the blade in the

blade slot in the upper and lower blade holders. To secure

the blade securely tighten the clamping knob on the upper

and lower holders. If desired, the allen wrench provided can

assist in securely tightening the blade into the upper and

lower blade holders (Fig. 6).

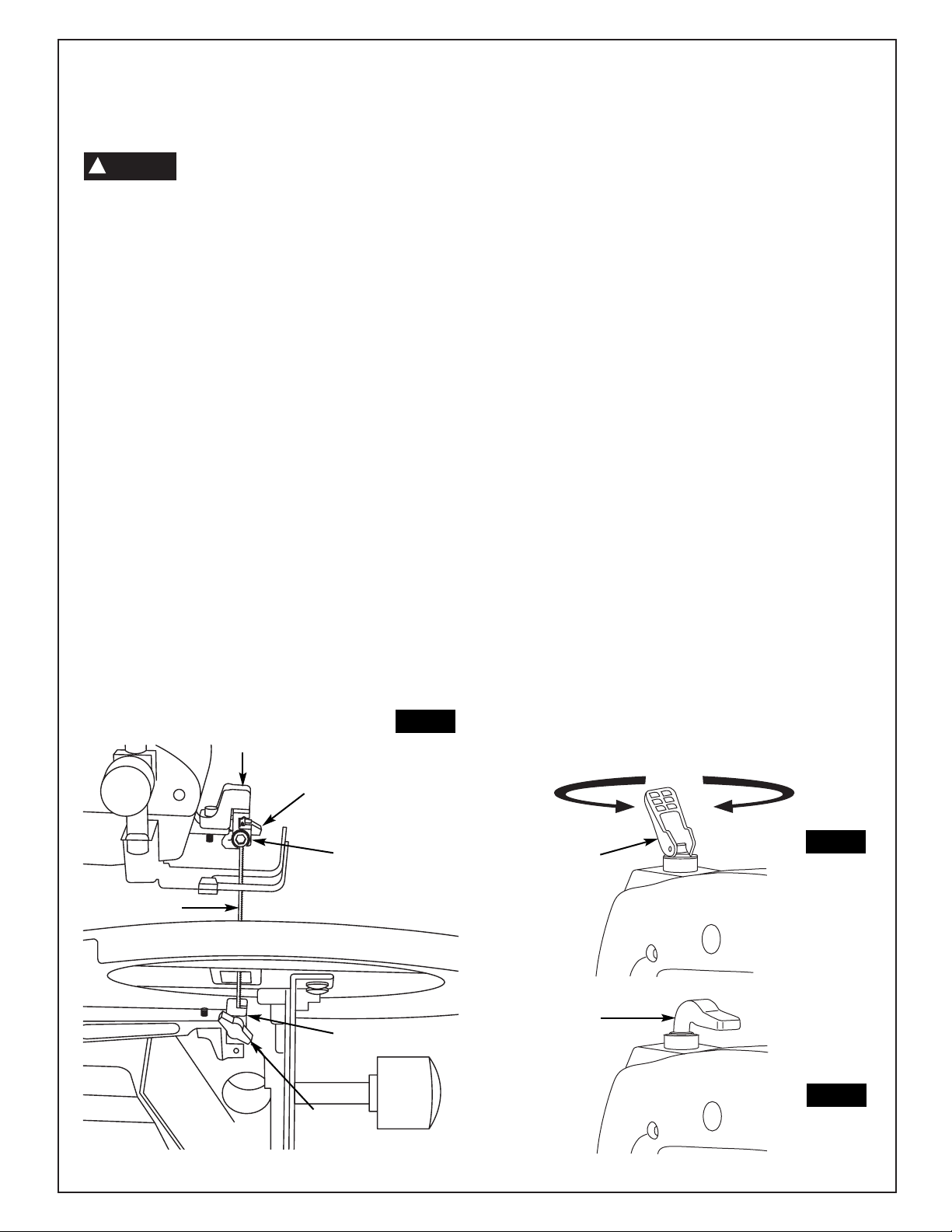

Blade Tension

To tension blade, move Quick Release Tension Lever to “down”

position. As the lever is lowered, tension will be applied to the

blade (Fig. 8).

ATTENTION: Moving the lever downward should require moderate, steady pressure only. If heavy pressure is needed, the

blade is too tight. Loosen tension by rotating the Quick Release

Tension Lever counterclockwise 1-2 turns, then reset the tension lever to the “down” position. If the tension lever is in the

“down” position and the blade is too loose, you can increase

tension by leaving the tension lever “down” and rotating it

clockwise just until you feel the slack in the blade removed.

Then turn the tension lever ONE full turn clockwise. This amount

of blade pressure should do well for most cutting operations

and blades (Fig. 7).

When the blade tension has been properly adjusted, you should

be able to lift up the Quick Release Tension Lever, remove and

install the blade, lower the lever and return the original blade

tension.

NOTE: It may be necessary to re-adjust the tension lever when

using different types of blades.

WARNING

!

UPPER BLADE

HOLDER

TABLE TILTED FOR PICTURE CLARITY

SLIGHT

PRESSURE

HERE

FIG. 6

LOWER BLADE

HOLDER

CLAMP

KNOB

CLAMP

KNOB

BLADE

FIG. 7

FIG. 8

QUICK RELEASE

TENSION LEVER

LOOSEN

TIGHTEN

QUICK RELEASE

TENSION LEVER

Page 13

13.

Basic Scroll Saw Operations

Adjusting the Lamp

1. Position the lamp as needed to illiminate the workpiece.

2. Loosen lock knob, slide lamp to desired position and

tighten lock knob (Fig. 9).

Note: Lamp shade angle is fixed and cannot be adjusted.

Replacing the Bulb

1. Use only a (25 watt maximum), candelabra base bulb.

Turn the light switch off and unplug the saw.

2. Remove the shade screw and the outer shade cover.

3. Slide the inner shade off the bulb socket.

4. Replace bulb and reassemble the shades (Fig. 9).

Note: Additional bulbs are available through Customer

Service.

ON/OFF Switch

1. To turn power ON or OFF push the power switch

(Fig. 10).

Variable Speed Switch

1.Your saw is equipped with a variable speed dial.

The blade stroke rate may be adjusted by simply rotating

the dial (Fig. 10).

To increase speed, rotate dial clockwise.

To reduce speed, rotate dial counterclockwise.

Reset Button

Your saw features a reset button that protects the motor

from overheating and damage (Fig. 11).

1. If the switch pops, turn the power ON/Off switch to the

off position.

2. Unplug the cord from the power source and allow the

saw to cool down.

3. Return reset button to its original position.

FIG. 9

FIG. 10

LOCK KNOB

SHADE SCREW

OUTER

SHADE

COVER

INNER

SHADE

BULB

VARIABLE

SPEED DIAL

LIGHT

SWITCH

POWER

ON/OFF

SWITCH

RESET

BUTTON

FIG. 11

POWER

SPEED

ON

I

OFF

OFF

O

ON

I

O

LIGHT

3

A

M

P

Page 14

14.

Basic Scroll Saw Operations

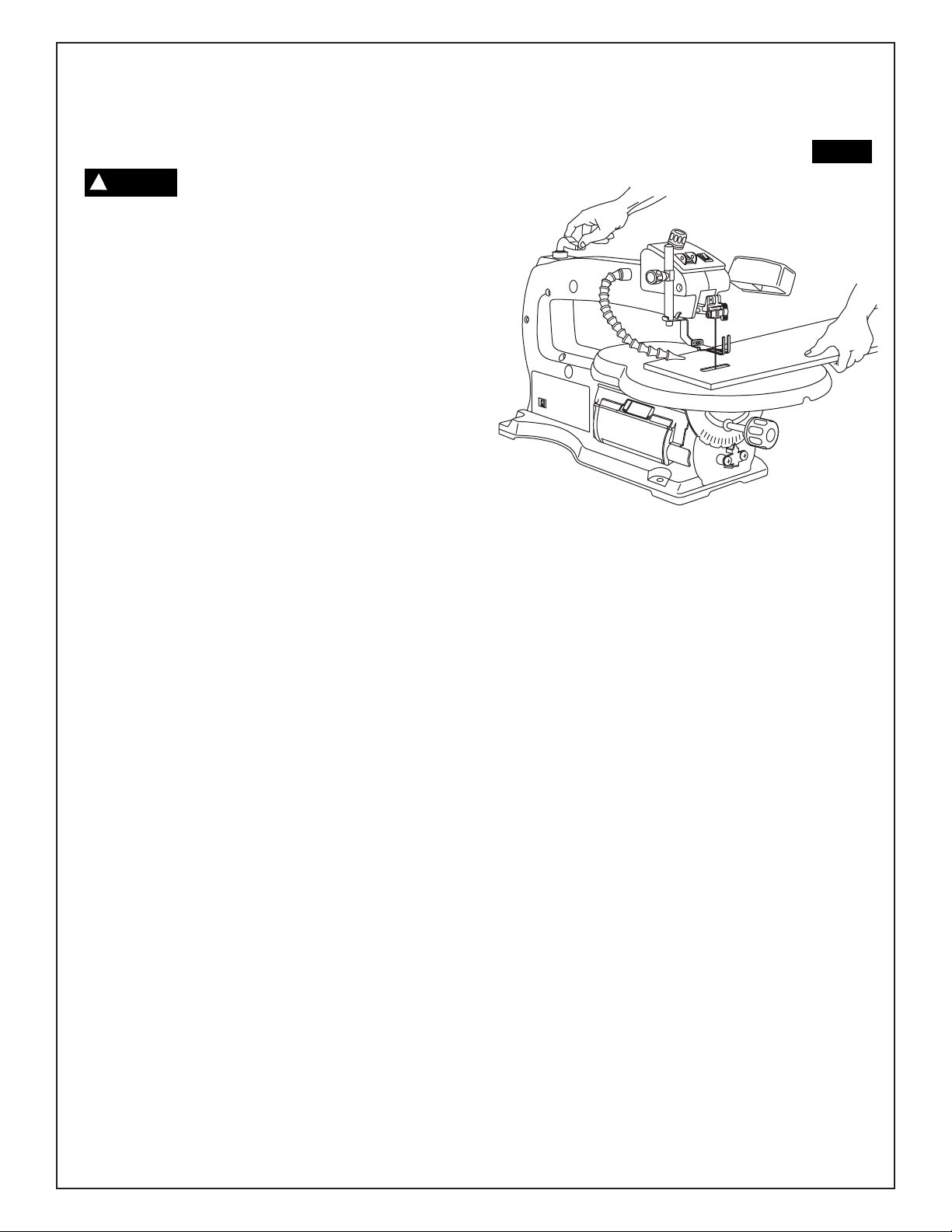

Making Interior Scroll Cuts

(Pin-End Blades and Plain-End Blades)

TO AVOID ACCIDENTAL STARTING,

ALWAYS TURN SWITCH “OFF” AND

REMOVE PLUG FROM POWER SOURCE BEFORE

REMOVING OR REPLACING THE BLADE.

A main benefit of this saw is the ability to perform intricate

interior cuts quickly and easily. This is best accomplished

using the Quick Release Tension Lever. Simply follow these

steps (Fig. 12):

1. Drill appropriate sized pilot hole in work piece.

2. Release Quick Release Tension Lever.

3 Remove the blade from the upper blade holder as explained

on page 12 Removing and Installing (Pin-End) or (Plain-End)

blades.

4. Thread blade through pilot hole from underneath the workpiece. If needed, remove the table insert. This will allow the

blade to fall forward for more clearance between the workpiece

and the upper arm housing. Reinstall the blade in the upper

blade holder.

5. Retension blade by pulling tension lever down.

6. Lower drop foot until it just rests on top of the workpiece and

you’re ready to begin cutting.

7. When finished making the interior scroll cuts simply remove

the blade from the blade holders, as described on page 12

Removing and Installing (Pin-End) or (Plain-End) blades, and

remove the board from the table.

WARNING

!

FIG. 12

Page 15

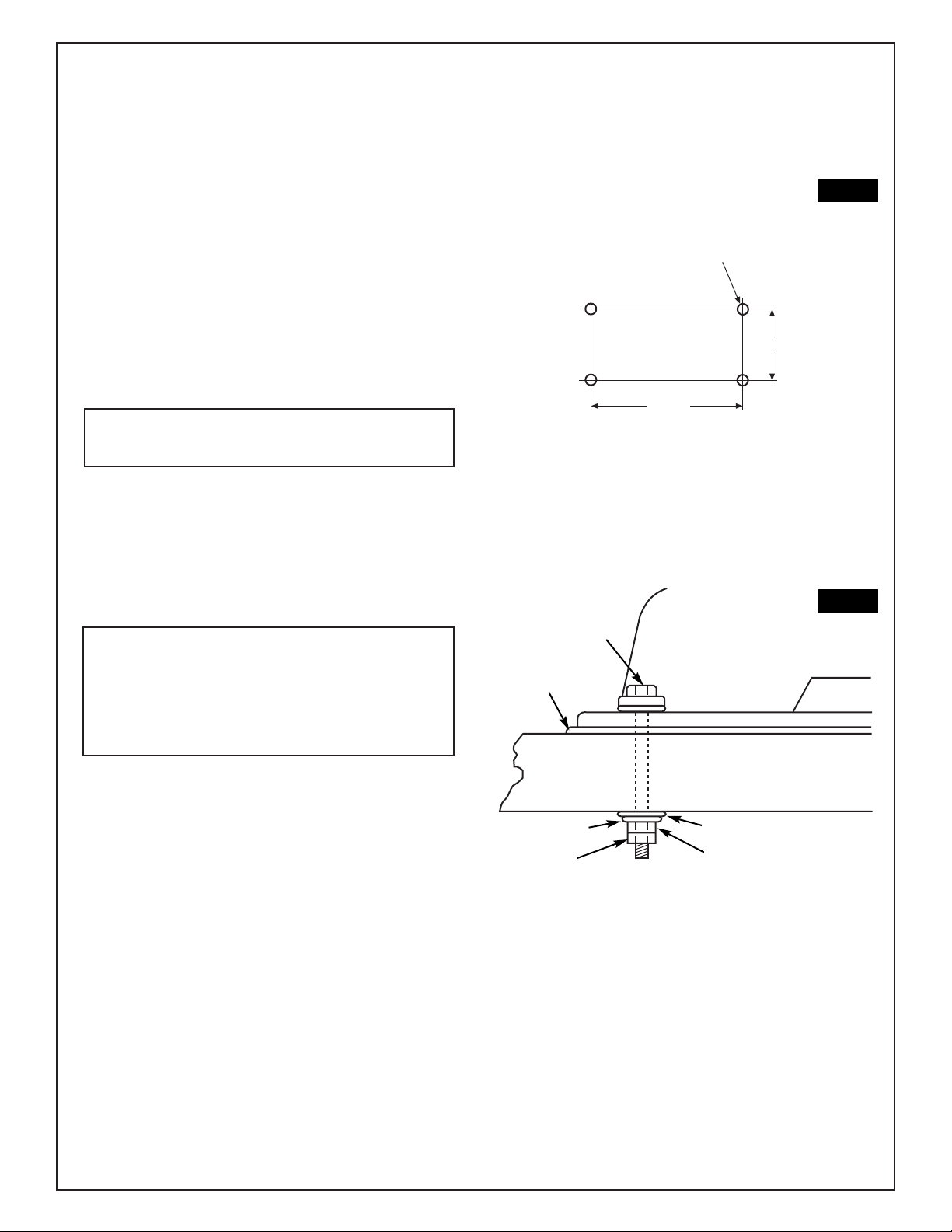

15.

Mounting the Scroll Saw

SCROLL SAW BASE

1/2” Foam Pad or

Carpet (optional)

WORKBENCH

HEX HEAD

BOLT

FIG. 14

FIG. 13

5/16”

Dia.

6 1/4

”

FLATWASHER

LOCKWASHER

HEX NUT

JAM NUT

16 3/4”

Mounting the Scroll Saw

to a Bench

1. The Scroll Saw should be fastened securely to a firm

supporting surface such as a stand or workbench, using

the four mounting holes.

Note: When mounting this saw to a workbench, a solid

bench is preferable to a plywood bench where noise and

vibration will be more noticeable.

We recommend to reduce noise and vibration, that a soft

foam pad be placed between your Scroll Saw and workbench. (Not Supplied)

Quantity Description

1 Soft foam pad, such as carpet padding,

24”x12”x1/2”

2. When mounting the Scroll Saw to a workbench, holes

should be drilled through the foam pad or carpet and

mounting surface of the workbench using the dimensions

illustrated in Figure 13.

Each of the four mounting holes should be bolted securely using no less than 1/4” hex bolts, flat washers, lock

washers, and nuts. We recommend:

Quantity Description

4 Hex Head Bolts,

1/4”-20 x 1/4”-20 x Length Required

4 Flat Washers, 9/32” I.D.

4 Lockwasher, 9/32” I.D.

8 Hex Nuts, 1/4”-20

(Hardware not supplied)

A. Locate and mark where the Scroll Saw is to be mounted.

B. Drill the four 5/16” holes through the workbench.

C. Place the Scroll Saw on the workbench aligning holes

in the base with the holes drilled in the workbench. Insert

all four (4) screws and tighten.

Note: Do NOT overtighten mounting bolts - leave some

cushion in the foam pad for absorbing noise and vibration.

ATTENTION: When inserting the front right hex head bolt,

it will be necessary to insert the hex head bolt from the

bottom side of the workbench, and secure with hex nut

from the top side of Scroll Saw Base.

Example of mounting this Scroll Saw to workbench (Fig.

14).

Page 16

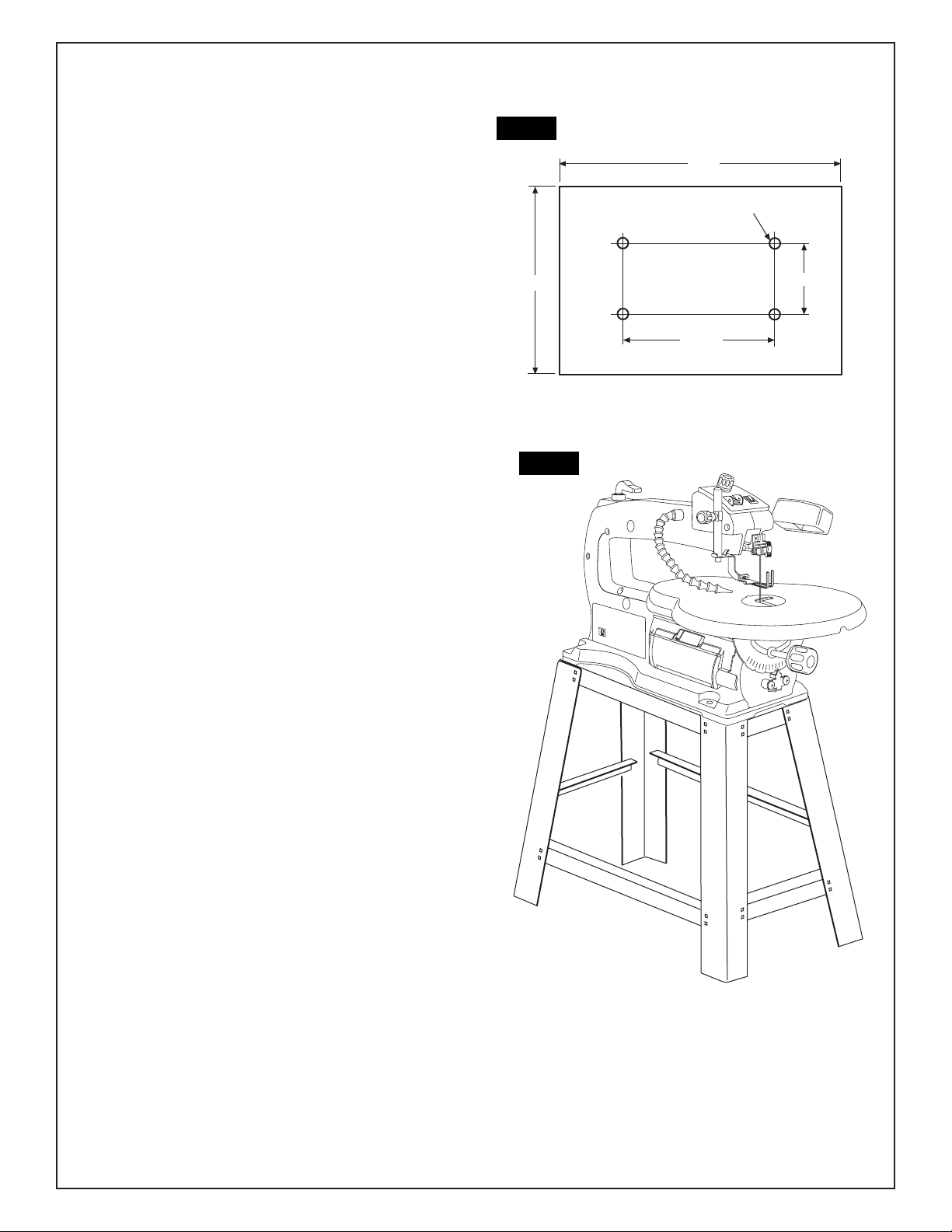

16.

FIG. 16

Mounting the Scroll Saw

Mounting the Scroll Saw to

Plywood

An alternative method of securing your Scroll Saw is to

fasten the Scroll Saw base to a mounting board 18” x 24”.

Any good grade of plywood with a 3/4” minimum thickness is recommended. Follow the instructions for

“Mounting the Scroll Saw to a Bench”, substituting the 18”

x 24” board for the workbench and using 1/4”-20 Flat

Head Screws for the Hex Screws (Fig.15).

Note: For proper stability, holes must be counter sunk so

screw heads are flush with the bottom surface of the supporting board.

Securely clamp board to workbench using two or more

“C” Clamps.

Attaching the Scroll Saw to

Leg Set

(Available as Accessory)

If you prefer to mount your Scroll Saw to a leg set we recommend the leg set for benchtop tools which is available

through Dremel. The model number is 16500. This leg set

is an optional accessory and instructions to mount the

Scroll Saw to this leg set are included in the package (Fig.

16).

FIG. 15

5/16” Dia.

6 1/4”

16 3/4”

18”

24”

Page 17

17.

Maintaining Your Scroll Saw

FIG. 18

Maintenance

For your own safety, turn power switch

“OFF” and remove plug from the power

source outlet before maintaining or lubricating your Scroll

Saw.

GENERAL

Frequently blow out any dust that may accumulate inside

the motor.

An occasional coat of paste wax on the work table will

allow materials being cut to glide smoothly across the

work surface and deters rust.

Certain cleaning agents and solvents dam-

age plastic parts. Including: gasoline, carbon tetrachloride, chlorinated cleaning solvents, ammonia

and household detergents that contain ammonia. Avoiding

use of these and other types of cleaning agents minimizes

the probability of damage.

To avoid shock or fire hazard, if the power

cord is worn or cut, or damaged in any way,

have it replaced immediately.

All repairs, electrical or mechanical, should

be attempted only by trained repairmen.

Contact the nearest Dremel Factory Service Center, or

other competent repair service. Use only Dremel replacement parts, any others may create a hazard.

Carbon Brushes

The brushes and commutator in your tool have been engineered for many hours of dependable service. To maintain

peak efficiency of the motor, we recommend every two to six

months the brushes be examined. Only genuine Dremel

replacement brushes specially designed for your tool should

be used.

The brushes should be inspected frequently when tools are

used continuously. If your tool runs sporadically, loses

power, makes unusual noises or runs at a reduced speed,

check the brushes. To continue using the tool in this condition will permanently damage your tool.

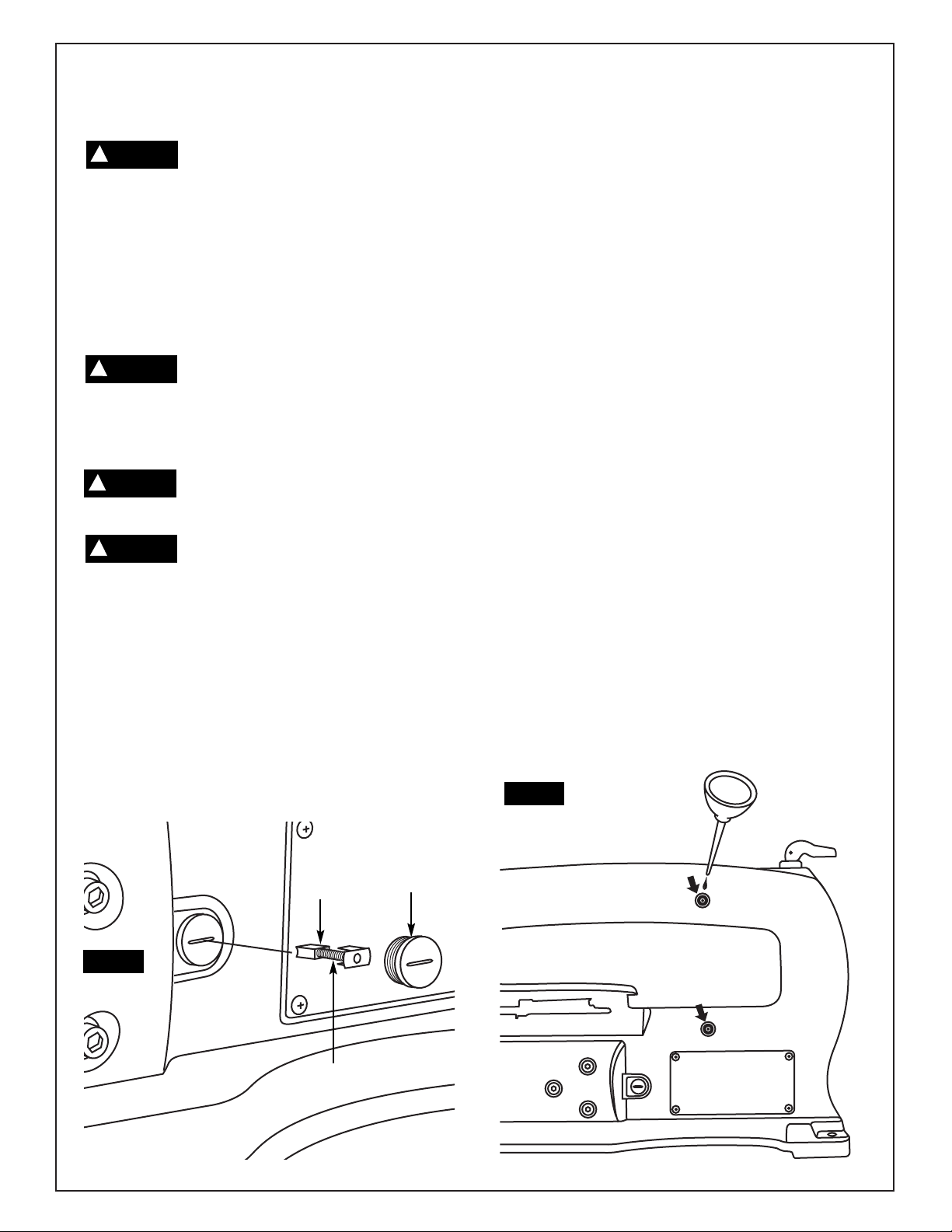

With the cord unplugged, remove the brush caps one at a

time with a small screwdriver by rotating cap counter-clockwise and check each brush (Fig. 17).

If the brush is less than 1/8" long and the end surface of the

brush that contacts the commutator is rough and/or pitted,

they should be replaced. Check both brushes. Usually the

brushes will not wear out simultaneously. If one brush is

worn out, replace both brushes. Make sure the brushes are

installed as illustrated. The curved surface of the brush must

match the curvature of the commutator.

After replacing brushes the tool should be run at no-load;

place it on a clean surface and run it freely for 5 minutes

before loading (or using) the tool. This will allow the brushes

to “seat” properly and will give you more hours of life from

each set of brushes. This will also extend the total life of your

tool since the commutator surface will “wear” longer.

Lubrication

ARM BEARINGS

Lubricate the arm bearings with oil after 10 hours of use.

Re-oil after every 50 hours of use or whenever there is a

squeak coming from the bearings.

TO LUBRICATE

1. Turn saw on its side (Fig. 18).

2. Remove rubber plug to expose bronze bearing.

3. Squirt a generous amount of SAE 20 oil around the shaft

end and bronze bearing.

4. Let the oil soak in overnight in this condition.

5. Next day repeat the above procedure for the opposite

side of the saw.

CAUTION

!

WARNING

!

WARNING

!

FIG. 17

WARNING

!

BRUSH

CAP

BRUSH

SPRING

BRUSH

Page 18

Use only Dremel accessories. Follow instructions that accompany accessories. Use of improper accessories may cause hazards.

LEG SET

Cat. No.

16500 Scroll Saw Stand

Saw Blades

Dremel offers both Plain and Pin-End 5 inch blades.

PIN-END

Pin-End blades permit relatively tight radius cutting in hard and soft wood.

Cat. No. Suggested Usage Width Thick TPI Speed

16412 For cutting wood 3/8” to 2” thick .110” x .018” x 10 Any

16411 For cutting wood 3/16” to 1” thick .110” x .018” x 15 Any

16413 For cutting wood thinner than 1/4” thick .070” x .010” x 18.5 Any

PLAIN-END

The Pin-End blades, while somewhat easier to put in and take out of the machine, do not always produce the same controlled

cutting action provided with the Plain-End blade. These narrow Plain-End blades allow the user to cut more detailed, intricate

patterns and smaller inside cuts.

Cat.No. Suggested Usage Width Thick TPI Speed

16453 For cutting hard and soft woods 1/4” to 2” thick .062” x .020” x 9.5 High

16446 For close radius cutting in materials 1/8” or thicker .038” x .016” x 12.5 High

16443 For very tight radius work in thin materials, up to 1/8” .029” x .012” x 20 High

16440 .022” x .010” x 28 High

16448 .045” x .017” x 11.5 High

SPIRAL

Saws in all directions without turning the workpiece.

Cat. No. Suggested Usage Kerf TPI Speed

16461 For wood, plastic and abrasive materials .028” - .030” x 46 Any

16463 .034” - .036” x 41

METAL PIERCING

For cutting precious and non-ferrous metals; these must be used at very slow speeds. They perform well on machines

that have variable speed capability and should be lubricated with beeswax, or a light machine oil.

Cat. No. Suggested Usage Kerf TPI Speed

16483 Metals and other hardwood materials. .033” x .016” x 36 Low

REVERSE TOOTH

Provides a smooth, splinter free finish. Eliminates the need for excessive finish sanding, and leaves a clean sharp edge on

both the top and bottom of your workpiece.

Cat. No. Suggested Usage Kerf TPI Speed

16431 For cutting hard or soft woods up to 1/8” thick. .029” x .012” x 20 Any

16432 For cutting hard or soft woods 1/8” or thicker .038” x .016” x 12.5 Any

16433 For cutting hard or soft woods 3/8” to 2” thick .047” x .017” x 11.5 Any

PERMA-GRIT TUNGSTEN CARBIDE

Shapes and cuts ceramic tiles cleanly and accurately. Cuts intricate patterns easily in any direction. Also use for thin

wood. Not for use on ceramic floor tile.

Cat. No. Suggested Usage Kerf Grit Speed

16471 For very tight radius work in cearmic tile or thin wood. .031” x .033” 60 Medium

16472 For close radius cutting in ceramic tile or thin wood. .046” x .048” 120 Medium

18.

Recommended Accessories

Page 19

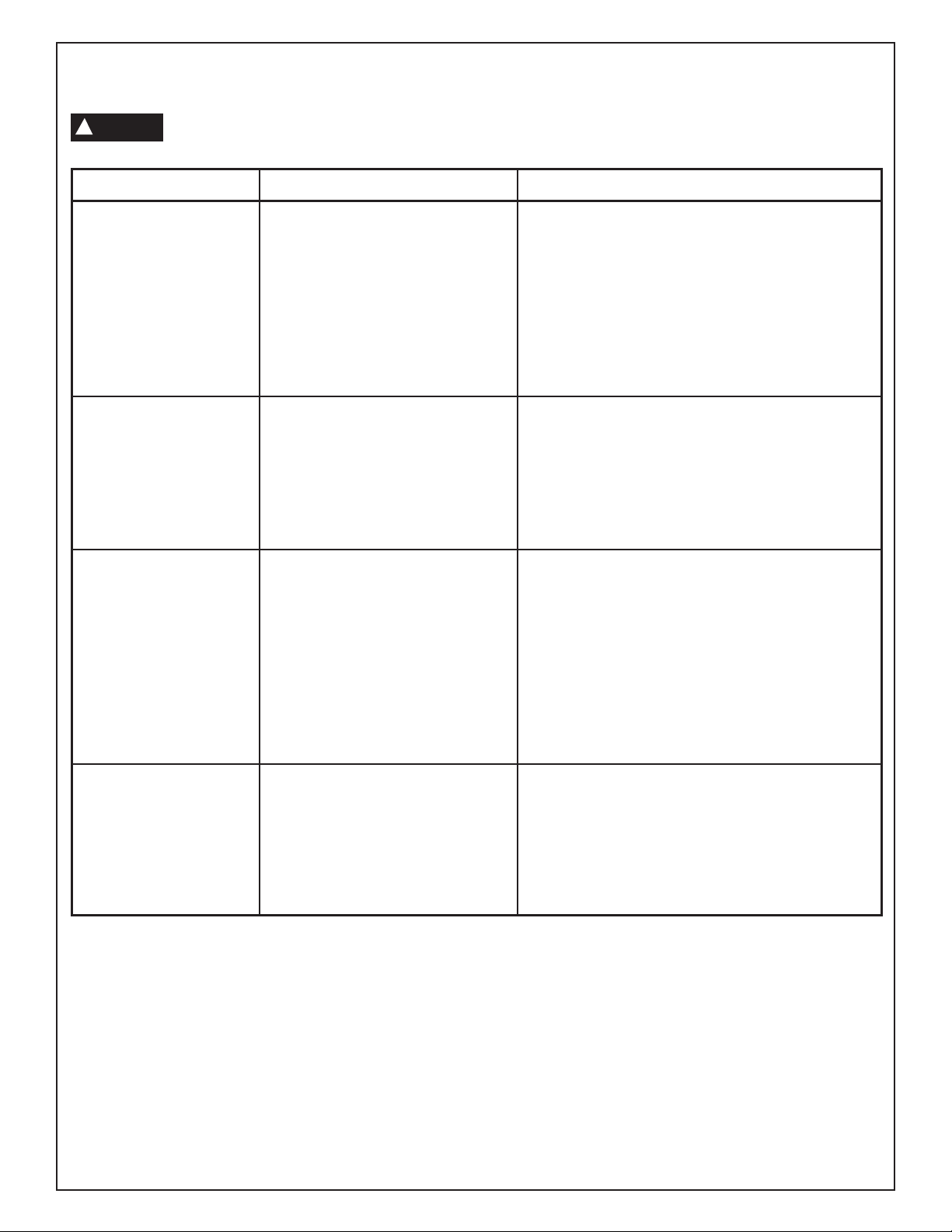

19.

Troubleshooting

Turn switch “OFF” and always remove plug from the power source before troubleshooting.

PROBLEM

1. Wrong tension.

2. Over working blade.

3. Wrong blade application.

4. Twisting blade in wood.

5. Incorrect teeth per inch.

1. Defective cord or plug.

2. Defective motor.

3. Defective wire connections.

4. Brushes worn.

1. Improper mounting of saw.

2. Unsuitable mounting surface.

3. Loose table or table resting

against motor.

REMEDY

1. Adjust blade tension, see “REMOVING AND

INSTALLING BLADES,” Page 12 (Pin End) or (Plain

End).

2. Reduce feed rate, see “BASIC SCROLL SAW

OPERATION,” Page 11.

3. Use narrow blades for cutting thin wood, wide

blades for thicker wood.

4. Avoid side pressure on blade.

5. Blade should have minimum 3 teeth in contact with

workpiece.

1. Replace defective parts before using saw

again.

2. & 3. Consult Dremel Service. Any attempt to

repair this motor may create a HAZARD

unless repair is done by a qualified service

technician.

4. Replace both brushes.

1. See “MOUNTING YOUR SCROLL SAW,” Pages 15

& 16.

2. The heavier your work bench is, the less vibration

will occur. A plywood workbench will not be as good

a work surface as the same size solid lumber. Use

common sense in choosing a mounting surface.

3. Tighten table lock knob.

WARNING

!

TROUBLE

Breaking blades.

Motor will not run.

Vibration

NOTE: There will always

be some vibration present

when the saw is running

because of motor operation.

Page 20

Dremel Limited Warranty

Your Dremel product is warranted against defective material or workmanship for a period of two years from date of purchase. In the

event of a failure of a product to conform to this written warranty, please take the following action:

1. DO NOT return your product to the place of purchase.

2. Carefully package the product by itself, with no other items, and return it, freight prepaid, along with:

A. A copy of your dated proof of purchase (please keep a copy for yourself).

B. A written statement about the nature of the problem.

C. Your name, address and phone number to:

UNITED STATES

Dremel Service Center Dremel Service Center

4915 Twenty-First Street OR 4631 E. Sunny Dune

Racine, Wisconsin 53406 Palm Springs, CA 92264

CANADA OUTSIDE

Giles Tool Agency CONTINENTAL UNITED STATES

6520 Lawrence Av. East See your local distributor or write

Scarborough, Ont. to Dremel, 4915 Twenty-First St.

Canada M1C 4A7 Racine, Wisconsin 53406

We recommend that the package be insured against loss or in transit damage for which we cannot be responsible.

This warranty applies only to the original registered purchaser. DAMAGE TO THE PRODUCT RESULTING FROM TAMPERING, ACCIDENT, ABUSE, NEGLIGENCE, UNAUTHORIZED REPAIRS OR ALTERATIONS, UNAPPROVED ATTACHMENTS

OR OTHER CAUSES UNRELATED TO PROBLEMS WITH MATERIAL OR WORKMANSHIP ARE NOT COVERED BY THIS

WARRANTY.

No employee, agent, dealer or other person is authorized to give any warranties on behalf of Dremel. If Dremel inspection

shows that the problem was caused by problems with material or workmanship within the limitations of the warranty, Dremel

will repair or replace the product free of charge and return product prepaid. Repairs made necessary by normal wear or

abuse, or repair for product outside the warranty period, if they can be made, will be charged at regular factory prices.

DREMEL MAKES NO OTHER WARRANTY OF ANY KIND WHATEVER, EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE ABOVE MENTIONED

OBLIGATION ARE HEREBY DISCLAIMED BY DREMEL AND EXCLUDED FROM THIS LIMITED WARRANTY.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state. The obligation of

the warrantor is solely to repair or replace the product. The warrantor is not liable for any incidental or consequential damages

due to any such alleged defect. Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitations or exclusion may not apply to you.

For prices and warranty fulfillment in the continental United States, contact your local Dremel distributor.

20.

Page 21

Manuel de l’utilisateur

MODÈLE 1680, SCIE À CHANTOURNER DE 406,4 mm

AVEC VARIATION DE VITESSE

P.O. Box 1468

Racine, Wisconsin

1-800-437-3635

http://www.dremel.com

Tension nominale c.a. 120 V 50 - 60Hz

Intensité nominale 1,4 A

Vitesse à vide n0 500-1 600/min

Profondeur 406,4 mm

Lame 127 mm à bouts lisses ou à goujons

Course de la lame 19,5 mm

Capacité de coupe 50,8 mm” à 0º; 25,4 mm à 45º

assemblage • fonctionnement • consignes de sécurité

Page 22

22.

Consignes générales de sécurité

« LIRE TOUTES LES INSTRUCTIONS » L’utilisateur qui négligerait de suivre les consignes de sécurité énoncées

ci-dessous et de prendre d’autres précautions élémentaires risquerait de subir de graves blessures.

Zone de travail

NE LAISSEZ PAS LES ENFANTS S’APPROCHER

Ne laissez aucune personne entrer en contact avec l’outil ou le cordon

de rallonge. Tout visiteur doit se tenir à une distance suffisante de la

zone de travail.

ASSUREZ-VOUS QUE VOTRE ZONE DE TRAVAIL EST BIEN

DÉGAGÉE

Des lieux et des établis encombrés multiplient les risques d’accident.

FAITES EN SORTE QUE VOTRE ATELIER NE PRÉSENTE AUCUN

DANGER POUR LES ENFANTS

en installant des cadenas et des interrupteurs généraux.

NE TRAVAILLEZ PAS DANS UN ENVIRONNEMENT DANGEREUX

Un outil électrique ne doit jamais être employé dans un endroit humide

ou mouillé, ni être exposé à la pluie. Éclairez bien les lieux où vous

travaillez. N’utilisez pas l’outil en présence de liquides ou de gaz

inflammables.

Sécurité de l’utilisateur

FAMILIARISEZ-VOUS AVEC VOTRE OUTIL

Lisez attentivement le manuel de l’utilisateur et les étiquettes collées

sur l’outil, afin de bien les comprendre. Vous devez connaître aussi

bien les possibilités et les limites de l’outil que les dangers éventuels

précis qu’il présente.

GARDEZ TOUJOURS VOTRE ÉQUILIBRE

Assurez-vous que vous ne risquez pas de trébucher ou de perdre

l’équilibre.

RESTEZ SUR VOS GARDES

Gardez toujours les yeux sur votre travail. Faites preuve de bon sens.

N’utilisez pas l’outil quand vous êtes fatigué, ni si vous êtes sous

l’effet d’un médicament, de l’alcool ou d’une autre drogue.

PORTEZ DES VÊTEMENTS APPROPRIÉS

Évitez de porter des vêtements flottants ou des bijoux qui risqueraient

d’être happés par des pièces mobiles. Le port de gants en caoutchouc

et de chaussures à semelle antidérapante est recommandé si vous

travaillez à l’extérieur. Portez une coiffure de protection si vous avez

les cheveux longs.

PORTEZ DES LUNETTES DE SÉCURITÉ

Portez également un masque facial ou un masque antipoussières si

l’opération de coupe produit de la poussière, ainsi que des protègeoreilles lors des travaux de longue durée. Bien que les lunettes

ordinaires aient des verres résistant aux chocs, ce ne sont PAS des

lunettes de sécurité.

PROTÉGEZ-VOUS CONTRE LES CHOCS ÉLECTRIQUES

Évitez d’entrer en contact avec les surfaces mises à la terre, telles que

tuyaux, radiateurs, cuisinières et réfrigérateurs, quand vous utilisez

l’outil.

DÉBRANCHEZ LES OUTILS

Quand ils ne servent pas ; avant l’entretien ; avant de changer les

lames, les forets, les couteaux, etc.

LAISSEZ EN PLACE LES CARTERS DE PROTECTION

Ils doivent être en bon état, bien réglés et bien alignés.

ENLEVEZ LES CLÉS ET LES CLÉS DE RÉGLAGES

Prenez l’habitude de vérifier que toutes les clés et clés de réglage ont

été ôtées de l’outil avant de mettre celui-ci en marche.

ÉVITEZ LES MISES EN MARCHE ACCIDENTELLES

Assurez-vous que l’interrupteur est en position « ARRÊT » quand

vous branchez l’outil.

METTEZ TOUJOURS LES OUTILS À LA TERRE

Cet outil est doté d’un cordon homologué à trois conducteurs et d’une

fiche à trois broches avec mise à la terre adaptée aux prises de

courant correspondantes. Le fil de terre du cordon est de couleur

verte. Ne jamais raccordez ce conducteur vert à une borne sous

tension.

NE MONTEZ JAMAIS SUR L’OUTIL NI SUR SON SOCLE

L’utilisateur s’expose à de graves blessures s’il renverse l’outil ou s’il

entre en contact avec l’outil de coupe. Ne pas entreposer des objets

quelconques, sur l’outil ou près de celui-ci, de façon à ce qu’il faille

monter sur l’outil ou sur son socle pour les atteindre.

EXAMINEZ LES PIÈCES ENDOMMAGÉES

Avant de poursuivre votre travail, examinez soigneusement toute

pièce endommagée afin de vérifier si elle fonctionne toujours

correctement et qu’elle remplit la fonction voulue. Vérifiez que les

pièces mobiles sont correctement alignées et bien assujetties, et

remédiez à tout autre problème qui risquerait d’affecter son

fonctionnement. Un carter de sécurité ou toute autre pièce qui serait

en mauvais état doivent être réparés.

Les réparations électriques ou mécaniques

ne doivent être enterprises que par des

techniciens qualifiés. Adressez-vous à votre Centre de service Dremel

le plus proche, à une Station-service Dremel agréée ou à un autre

service de réparation compétent.

N’utilisez que des pièces de rechange

Dremel ; tout autre type de pièce risquerait

de présenter un danger.

L’emploi de tout accessoire non préconisé

par le catalogue Dremel actuel peut

présenter un danger.

« CONSERVEZ CES INSTRUCTIONS »

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

!

Page 23

23.

Utilisation de l’outil

N’IMPOSEZ PAS DE CONTRAINTES EXCESSIVES À L’OUTIL

Il sera plus efficace et plus sûr si vous le faites fonctionner au régime

pour lequel il a été conçu.

EMPLOYEZ L’OUTIL QUI CONVIENT

N’employez pas un outil ou un accessoire de capacité réduite pour

faire un travail exigeant un outil de grande puissance. N’utilisez

pas l’outil pour des travaux autres que ceux pour lesquels il a été

conçu. Par exemple, n’utilisez pas une scie circulaire pour couper des

branches d’arbre ou des rondins.

ASSUJETTISSEZ BIEN LA PIÈCE SUR LAQUELLE VOUS TRAVAILLEZ

Si possible, utiliser des serre-joints ou un étau pour fixer la pièce.

Vous courrez moins de risques qu’en la tenant à la main, et garderez

ainsi les deux mains libres pour actionner l’outil.

NE VOUS ÉLOIGNEZ JAMAIS DE L’OUTIL SANS L’ARRÊTER

Coupez le contact et ne vous éloignez pas avant que l’outil ait complètement cessé de fonctionner.

Entretien de l’outil

NE MODIFIEZ PAS L’OUTIL ET NE LE SOUMETTEZ PAS À UN

USAGE ABUSIF

Cet outil a été fabriqué selon des critères de haute précision. Toute

modification ou transformation non prévue constitue un usage abusif

et risque de présenter un danger.

ÉVITEZ LES ENDROITS À L’ATMOSPHÈRE CONTAMINÉE PAR

DES GAZ

N’employez pas d’outils électriques dans une atmosphère gazeuse ou

explosive. Les moteurs de ces outils produisent normalement des

étincelles qui risqueraient de présenter un danger.

PRENEZ SOIN DE VOS OUTILS ET ENTRETENEZ-LES BIEN

En les gardant bien affûtés et propres, vous en obtiendrez le rendement maximum dans des conditions optimales de sécurité. Suivez les

instructions pour le graissage ou la pose et le démontage des accessoires. Inspectez les cordons d’alimentation à intervalles réguliers et,

s’ils sont endommagés, faites-les réparer à un centre de service

après-vente autorisé. Inspectez périodiquement les cordons de rallonge et remplacez ceux qui ont été endommagés. Gardez les poignées des outils sèches, propres et exemptes de toute trace d’huile ou

de graisse.

Avant de raccorder votre outil à une

source de courant (prise de courant, etc.),

assurez-vous que la tension est bien la même que celle indiquée sur

la plaque d’identification de l’outil. Le branchement d’un outil sur une

source de courant ayant une tension supérieure à celle prescrite par le

fabricant présente des risques de dommages corporels graves pour

l’utilisateur et peut causer des dégâts à l’outil. En cas de doute,

NE BRANCHEZ PAS L’OUTIL SUR UNE PRISE DE COURANT. L’utilisation d’une source de courant ayant une tension inférieure à celle

indiquée sur la plaque d’identification peut endommager le moteur.

Pour votre sécurité, ne mettez pas en

marche votre ponceuse avant de l’avoir

complètement assemblée et installée conformément aux instructions

et d’avoir lu et compris les chapitres suivants :

1. Consignes générales de sécurité . . . . . . . . . . . . . . . . 22–24

2. Caractéristiques du moteur et besoins électriques . . . . . . 25

3. Faites connaissance avec votre scie à chantourner . . . 28–29

4. Règlages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5. Fonctionnement de base de la scie à chantourner . . . . 31–34

6. Montage de la scie à chantourner . . . . . . . . . . . . . . . 35–36

7. Entretien de la scie à chantourner . . . . . . . . . . . . . . . . . 37

8. STABILITÉ DE LA SCIE

Vous devez boulonner solidement votre scie à un support ou à un

établi. En outre, si votre scie à chantourner a tendance à basculer ou

à bouger pendant certaines opérations, comme la coupe de planches

longues et lourdes, boulonnez au plancher le support ou l'établi de

votre scie.

9. EMPLACEMENT

Cette scie à chantourner n'est destinée qu'à usage intérièur.

10. PROTECTION : Yeux, mains, oreilles et reste du corps.

POUR NE PAS ÊTRE HAPPÉ PAR

LA LAME EN MOUVEMENT —

NE PAS PORTER DE : gants de trop grande taille

cravate

vêtements flottants

bijoux

ATTACHEZ LES CHEVEAUX LONGS

ROULEZ LES MANCHES LONGUES JUSQU’AU-DESSUS

DES COUDES

a. Si une pièce quelconque de la scie manque, ne fonctionne pas, est

endommagée ou cassée (p. ex., interrupteur du moteur, autre

commande, dispositif de sécurité ou câble d’alimentation), cessez

d’utiliser l’outil jusqu’à ce que la pièce en question soit correctement

réparée ou remplacée.

b. Ne coupez pas une pièce trop petite pour pouvoir la tenir à la main.

CONSEIL PRATIQUE : Quand vous coupez une petite pièce, fixez

toujours la pièce avec du ruban adhésif double-face à un morceau de

contreplaqué à jeter. La pièce sera ainsi supportée pendant le travail,

et vos doigts seront à l'écart de la lame.

c. Ne mettez jamais sous tension votre scie à chantourner avant de

débarrasser la table de tous les objets qui s'y trouvent (outils, rebuts

de bois, etc.), à l'exception de la pièce et des objets qui servent à

pousser ou à supporter pour l'opération prévue.

Consignes de sécurité supplémentaires

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

!

Page 24

24.

Consignes de sécurité supplémentaires

d. Ne placez jamais vos doigts de telle manière qu’ils puissent entrer

en contact avec la lame si votre main glissait.

• Ajustez TOUJOURS le dispositif de retenue de manière à dégager

uniquement la pièce, afin de protéger l'opérateur, de maintenir la

bris de lame au minimum et de donner un support maximum à la

lame.

• Ajustez toujours la tension de la lame correctement.

• La scie à chantourner doit couper quand la lame descend. Assurezvous toujours que les dents de la lame sont orientées vers la table.

• Lors de la coupe d'une grosse pièce, assurez-vous que celle-ci est

supportée à la hauteur de la table.

• Tenez fermement la pièce contre la table.

• Ne poussez pas la pièce trop rapidement quand vous coupez. Poussez

juste assez rapidement pour vous assurer que la lame coupe bien.

N'approchez pas vos doigts de la lame.

• Faites attention quand vous coupez des pièces de section transversale

irrégulière. Elles peuvent pincer la lame avant que la coupe ne soit

terminée. Vous devez, par exemple, tenir bien à plat une pièce de

moulure sur la table, et vous ne devez pas la laisser basculer pendant la coupe.

• Faites attention quand vous coupez des matériaux ronds comme

des tiges ou des tuyaux. Ils ont tendance à rouler pendant la coupe,

ce qui cause une « morsure » de lame.

e. Ne laissez jamais la scie à chantourner en marche sans

surveillance. Mettez la scie hors tension, assurez-vous que la scie est

complètement arrêtée, puis enlevez la fiche de la prise de courant

avant de quitter la zone de travail.

f. Ne faites pas de travail d'aménagement, d'assemblage ou de

préparation sur la table pendant que la scie est en marche.

g. Mettez la scie hors tension, et enlevez la fiche de la prise de

courant avant de poser ou d'enlever un accessoire.

h. Assurez-vous que la porte d'accès est fermée avant de mettre la

scie en marche.

i. Le levier de tension à relâchement rapide doit être descendu avant

la mise en marche.

11. LA SÉCURITÉ AVANT TOUT

POUR ASSURER SA SÉCURITÉ, L’UTILISATEUR DOIT FAIRE

PREUVE DE BON SENS ET DE PRUDENCE PENDANT TOUT LE

TEMPS OÙ IL SE SERT DE LA SCIE À chantourner.

Ne laissez pas l’habitude (découlant d’un

usage fréquent de votre scie à chantourner)

endormir votre vigilance. N’oubliez jamais qu’une fraction de seconde

d’inattention peut entraîner de graves blessures.

Les outils électriques peuvent projeter

des corps étrangers dans les yeux de

leur utilisateur et lui infliger de graves

blessures oculaires. Portez toujours

des lunettes de sécurité répondant aux

normes ANSI Z87.1 (cette caractéristique est indiquée sur l’emballage)

avant d’utiliser un outil électrique.

Les travaux à la machine tel que

ponçage, sciage, meulage, perçage et

autres travaux du bâtiment peuvent créer des

poussières contenant des produits chimiques qui sont des causes

reconnues de cancer, de malformation congénitale ou d’autres

problèmes reproductifs. Ces produits chimiques sont, par

exemple :

• Le plomb provenant des peintures à base de plomb,

• Les cristaux de silices provenant des briques et du ciment et

d’autres produits de maçonnerie, et

• L’arsenic et le chrome provenant des bois traités chimiquement

Le niveau de risque dû à cette exposition varie avec la fréquence de

ces types de travaux. Pour réduire l’exposition à ces produits

chimiques, il faut travailler dans un lieu bien ventilé et porter un

équipement de sécurité approprié tel que certains masques à

poussière conçus spécialement pour filtrer les particules

microscopiques.

NOTEZ ET OBSERVEZ LES MISES EN GARDE ET LES CONSIGNES DE SÉCURITÉ

QUI APPARAISSENT SUR LE BOÎTIER DE LA SCIE À CHANTOURNER :

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

Portez Des Lunettes De Protection

AVERTISSEMENT

ADVERTENCIA

120 V~ 50-60 Hz 1,4 A 500 -1 600 carreras por minuto

Page 25

Caractéristiques du moteur

En cas de défaillance ou de panne, la mise à la terre fournit un parcours

de moindre résistance au courant pour réduire le risque de chocs

électriques.

Cette scie à chantourner est conçue pour fonctionner avec un moteur à

vitesse variable. Son câblage est conçu pour un courant alternatif de

110 -120 volts, 60 Hz. Avant de brancher le cordon électrique sur une

prise de courant, assurez vous que l'interrupteur est en position

d'arrêt, et que le courant électrique a les mêmes caractéristiques que

celles apparaissant sur la plaque signalétique de la scie à chantourner.

Alimentation électrique

Cette machine doit être reliée à la terre lorsqu’elle est en marche afin

de protéger l’utilisateur contre les risques de choc électrique.

Brancher le cordon d’alimentation dans une prise de 110-120 volts

correctement mise à la terre et protégée par un fusible ou coupe-circuit

à retard à double élément de 15 ampères.

Toutes les prises de courant ne sont pas correctement reliées à la

terre. Si vous n’êtes pas certain que la prise que vous voulez utiliser

(voir illustration ci-dessous) soit correctement mise à la terre, faites-la

vérifier par un électricien.

Pour éviter les chocs électriques, ne pas toucher les

broches métalliques de la fiche lorsque vous l’intro-

duisez dans la prise de courant ou que vous l’en retirez.

Si cet outil électrique n’est pas correctement mis à

la terre, l’utilisateur risque d’être électrocuté ou de

subir un grave choc électrique, tout particulièrement si l’outil est

installé à proximité de tuyauteries ou d’autres objets métalliques. Sous

l’effet d’un choc électrique éventuel, vos mains pourraient entrer en

contact avec l’outil de coupe.

Si le cordon d’alimentation est usé, en-

taillé ou endommagé de quelque façon

que ce soit, faites-le remplacer immédiatement afin d’eliminer les dangers d’électrocution et d’incendie.

Votre appareil est conçu pour fonctionner à une tension de 120 volts ;

il est doté d’une fiche d’aspect similaire à celle présentée dans

l’illustration ci-dessous.

Cet outil électrique est doté d’un cordon à trois conducteurs et d’une

fiche de type terre approuvés par les Laboratoires des assureurs et

l’Association canadienne de normalisation. Le fil de terre a un isolant

de couleur verte avec ou sans rayures jaunes. Une de ses extrémités

est fixée au boîtier de l’outil et l’autre à la broche de terre de la prise

mâle.

Cette fiche ne peut être branchée que dans une prise de courant à trois

conducteurs avec mise à la terre du type présenté dans l’illustration.

Elle doit être mise à la terre selon les règlements et décrets de votre

localité.

Si la prise que vous voulez utiliser est du type à deux broches, NE

RETIREZ PAS LA BROCHE DE MISE À LA TERRE DE LA FICHE ET NE

LA MODIFIEZ EN AUCUNE FAÇON. Faites appel à un électricien

qualifié pour remplacer la prise à DEUX broches avec une prise à

TROIS broches correctement reliée à la terre.

Un mauvais raccordement du conducteur de mise à la terre de

l'équipement peut produire un risque de chocs électriques. Si la

réparation ou le remplacement du cordon électrique ou de la fiche

s'avère nécessaire, ne branchez pas le conducteur de mise à la terre

de l'équipement sur une prise sous tension.

Vérifiez avec un électricien autorisé ou le personnel de service

après-vente si vous ne comprenez pas parfaitement les instructions de

mise à la terre, ou si vous ne savez pas si la scie est bien mise à la terre.

Un adaptateur peut être utilisé mais uniquement de manière

temporaire en attendant qu’un électricien qualifié ait installé une prise

correctement reliée à la terre.

La borne de mise à la terre de couleur

verte dépassant de l’adaptateur doit être

reliée à une terre permanente telle qu’une prise de courant

correctement mise à la terre.

NOTA : L’adaptateur présenté dans l’illustration ne doit être utilisé que

si vous disposez d’une prise de courant à deux broches correctement

mise à la terre. Le Code canadien de l’électricité interdit l’utilisation de

cet adaptateur au Canada. Toujours utiliser une rallonge appropriée.

L’utilisation d’une rallonge entraîne une légère perte de puissance.

Pour minimiser cette dernière tout en évitant que le moteur ne

surchauffe ou ne grille, servez-vous du tableau ci-dessous pour

déterminer le calibre minimum (A.W.G.) du câble de rallonge.

N’utilisez que des rallonges à trois conducteurs munies de fiches de

type terre à trois broches et des prises de courant à trois broches

adaptées à la fiche de l’outil. Assurez-vous que votre rallonge est en

bon état.

Longueur du câble de rallonge Calibre (A.W.G.)

0-25 pieds 18

26-50 pieds 16

51-100 pieds 16

25.

« CONSERVEZ CES INSTRUCTIONS »

Caractéristiques du moteur et

besoins électriques

FICHE À TROIS BROCHES

BROCHE DE MISE À

LA TERRE

TOUJOURS UTILISER

UNE PRISE DE

COURANT AVEC

PRISE DE TERRE

BORNE DE MISE À LA

VIS

FICHE À TROIS

BROCHES

ADAPTATEUR

PRISE DE COURANT À

DEUX BROCHES

S’ASSURER QUE LE

LOGEMENT DE LA

VIS EST BIEN RELIÉ

À LA TERRE

AVERTISSEMENT

!

DANGER

!

AVERTISSEMENT

!

DANGER

!

Page 26

26.

Table des matières

Consignes générales de sécurité . . . . . . . . . . . . . . . . . . . . . . . . 22

Consignes supplémentaires de sécurité . . . . . . . . . . . . . . . 23–24

Caractéristiques du moteur et besoins électriques . . . . . . . . . . 25

Alimentation d'électricité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Déballage et vérification du contenu . . . . . . . . . . . . . . . . . . . . . 27

Tableau des pièces séparées . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Glossaire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Faites connaissance avec votre scie à chantourner . . . . . . . 28–29

Règlages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Prèparation de la table à une coupe horizontale ou biseautée . . . . 30

Alignement de l'aiguille d'indication d'angle en degrés . . . . . . . . . 30

Fonctionnement de base de la scie à chantourner . . . . . . . 31–34

Dépose et pose des lames à goujons . . . . . . . . . . . . . . . . . . . . . . 32

Dépose et pose des lames baïonnettes . . . . . . . . . . . . . . . . . . . . 32

Réglage de la lampe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Remplacement de l’ampoule . . . . . . . . . . . . . . . . . . . . . . . . . .33

Interrupteur marche/arrêt . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Bouton de variation de vitesse . . . . . . . . . . . . . . . . . . . . . . . .33

Bouton de réarmement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Comment faire des chantournements intérieurs

(lames baïonnettes et lames à goujons) . . . . . . . . . . . . . . . . . . . . 34

Montage de la scie à chantourner . . . . . . . . . . . . . . . . . . . . 35–36

Montage de la scie à chantourner à un établi . . . . . . . . . . . . . . . . 35

Montage de la scie à chantourner à une planche

de contreplaqué . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Fixation de la scie à chantourner à un ensemble de pieds . . . . . . 36

Entretien de votre scie à chantourner . . . . . . . . . . . . . . . . . . . . . 37

Lubrification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Accessoires recommandés . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Dépannage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Garantie limitée Dremel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Liste des pièces de rechange . . . . . . . . . . . . . . . . . . . . . . . . 61-64

Page 27

27.

Pour éviter toute blessure due à une mise

en marche inattendue ou à des chocs

électriques, débranchez toujours la fiche de la prise quand vous

n'utilisez pas l’outil.

La scie à chantourner à moteur modèle 1680 est emballée

entièrement dans une seule boîte en carton.

1. Déballage et vérification du contenu. Séparez toutes les pièces

détachées des matériaux d'emballage et vérifiez chaque article sur le

« Tableau de pièces détachées », afin de vous assurer de bien avoir

tous les articles avant de jeter les matériaux d'emballage.

Si une pièce manque, n'essayez pas de

faire fonctionner la scie à chantourner, de

brancher le cordon d'alimentation ou de mettre l'interrupteur en

position de marche, avant d'avoir obtenu et d'avoir bien installé la

pièce manquante.

Tableau des pièces détachées

Article Description Quantité

A Scie à chantourner 406,4 mm . . . . . . . . . . . . . . . .1

B Guide d'utilisation . . . . . . . . . . . . . . . . . . . . . . . . . .1

C Sac de pièces détachées qui contient . . . . . . . . . . . .1

Clé Allen (3 mm) . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Clé Allen (5 mm) . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Lames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

REMARQUE : Les ferrures nécessaires au montage de cette scie à