Dremel 1671 Owner's Manual

DR

M

L:

SCROL

a er s manual

WARNING

For your own safety

read your

Owner s Manual

before operating

your

MODEL 1671 T

PE

2 SC

Dremel

Scroll Saw

assembly • operation • safet instruc ions

DREM

L:

49

15

- 21 st

Street IRacine. Wisco

nsin 53406, U.S.A.

For

m

No

. 5296678 4/

91

PAINTE

D

IN

U.S

A.

For Your Safety

...

•

READ

ALL

INSTRUCTION S Failure

to

follow the safety rules listed

below

and other

AWARNING

basic safety pre

ca

utions may result

In

serious personal injury.

W

ork

Area

• KEEP W

ORK

AREAS CLEA N. Cluttered areas and

benches invite accidents.

• MA

KE

WORKSHOP

CH I LD·PROOF -

wlth

padlocks,

aster switches. or by remov ing starter keys.

Perso na I Safe

ty

• STAY ALER

T.

Watch what

you are

doin

g.

Use

common sense.

Do

not operate tool when you are

ti red.

• KEEP GUARDS

IN

PLACE,

in

working

order, and

in

proper adjustment and alignment.

•

DON'T

OVERREACH. Keep proper footing and

balance at all Imes.

•

DISCONNECT

TOOLS.

When

not in use; before

servicing; when

c langmg blades. bits, cutters,

etc.

•

REMOVE

ADJUSTIN

G KEYS

AND

WRENC

HES.

For

m habit

of

chee to

see

that keys and adjusting

wrench

es

are removed

~rom

tool before turning it on.

• NEVER STA

ND

ON TOOL. Seriousinjurycouldoccur

If the tool

IS

tipped

or

If th e cutting tool

is

acci-

dent

ally contacted.

•

AVOID

ACCIDENTAL STARTING. Don't carry

plugg

- n

001

'h

finger on switch.

Be

sure

s

ch

IS

OFF

en plugg

ed

Tn.

• USE

RECOMMENDEDACC

ESSORIE

S.

Consultthe

owner's

manual for recom

mended accessor

ies.

Follow [he instructions that accompany the accessOries. The use

of

improper accessories may

cause hazards.

• DRESS PROPERL

Y.

Do

not wear

loo

se

clothing or

j

ew

elry. Th

ey

can

be cau

ght in moving parts. Rubber

gloves and non-skid footwear are

re

commended

when working

outdoors. Wear protective hair

covering to contain long hair.

•

ALWA

YS USE SAFETY GLAS SES. Also use face or

dust mask

if

cutting operation is dusty. Everyday

eyeglasses only have impact resistant l

enses;

they are

not

safety glasses.

All repairs. electric al or mechanical.

AWARNING

should be attempted

only

by trained

repairm en. Contact the nearest Dr mel Service Center,

or

AuthOrized Dremel Serv ice Station or other com-

petent repair service. U

se

only

Dremel replacement

parts; any other may create

a hazard.

•

CHECK

DAMAGED

PARTS. Before further use

of

e

001.

a guard or other part that is damaged should

care ully checked to determine that it

will

operate

proper and perform its

int

ended function . Check f

or

alg

e

of

moving parts, binding of moving parts,

ea

ge

0 parts, mounting, and any other conditions

- a ec s operation. Aguard or other part that

ed s

00

d be properly repair

ed

or replaced.

SWitches replace

d.

Do not ljse tool if

urn

It

on or off.

Tool

Use

CE TOOL. It

will

do the job

bett

er and

_

or

which

it was designed.

TOOL

Don't force sma

ll

tool

or

Job

of

a heavy-dUty tool. Don't

OOfDC>se

no

Intended-

for

exa

mple; don't

c mg tree limbs or l

og

s.

• SECURE

se lamps or a vise to hold work.

It's

safe

~

hand and it fm

es both

hands

OFFEED. Feedworkm

oabladeorcu

tter

against

tn

of

ro allan

of

the blade or cutter

only.

• NEVER

LEAVE

TOOL

RUNNING

UNATTENDED.

Turn

pOVlier

• lea e too until it comes

to

a

co

mplete s OP

• DO

NOT

ALTER 0

preciSion

bLJ

specified

IS

condition.

• AVOID GASEOUS

tools in gaseo

s

the

se

tools

no

ig

nit

e fumes.

• M

AINTAIN

TOOLS

WITH

CARE. Keep tools sharp

an

d clean for

be

e and safer performance. Follow

instru tions

for ng and changing accessories.

Inspect tool cords

per odically and jf damaged, have

re

paired

by

aut

eel

Service

facility. I nspect exten-

si

on cords per

00

cally and replace

if

damaged. Keep

ha

ndles dry. clean and free

from

oil and grease.

Before connecting the tool to

B

AWARNING

power source (receptacle, outlet.

etc.), be sure voltage supplied is the same

as

tha t

specified on the nameplate

of

the tool. A

power

sou rce

With voltage greater than that specified

for

the tool can

result in SERIOUS INJURY to the user,

as

well

as

damage to the tool.

If

in doubt.

DO

NOT PLUG IN THE

TOOL.

USing a

power

source

with

voltage less than

the nameplate rating

is

harmf

ul to the motor.

"SAV E THESE INSTRUCTIONS"

Page

2

Tool Safety Rules

• For your w n saf ety,

do

not

attempt

AWARNING

to operate y

our

scroll saw u

nlll

it is

com pletely assembled and ins

talled

accordIng to the

instr

uct

ions

..

. and until you read and understand

the

following:

• GENERAL SAF

ETY

RULES

.......

.......

See

Pa

ge

2

• TOOL RULES

................

........

..

See

Page

3

• GEm NG

TO

KNOW YOUR S

AW

... . ....

See

Page

5

• OPERATIONS

........

..

..

.. ..

..

See Page 0

• ADJUST

MENTS .......

..

...

....

. See Pages 6 7 8

• M

AIN

TENANCE

............

..

. . ...

..

See

Pag

Stabi I

ity

of

Saw

• Your scroll saw mu st be bolted securely to a stand 0

workbench . In addi tion, if there is any tendency

for'

e

scroll s

aw

t tip over or move

during

certain operat ons

such

as

cut

ting long, heavy boards. bolt your scro

ll

Sil

stand or

workbenc

h to the floor.

L

ocation

• This scroll saw

IS

intended for Indoor use only.

Protec

tion

: Eyes ,

Hands, Face, Ears, Body

• Wear safety goggl

es

and

a face shield if operation is

dusty. Wear ear plugs or

muffs during extended

periods

of operation . Do

not wear gloves .

..

roll long

sleeves above the elbow.

• Do

not

cut p,ec

es

of

material too small to hold by

hand.

HINT:

When

makin g a very small cutout.

always secure the workpiece to a scrap piece of

plywood

WI

h

doub

le-faced tape. This w

ay,

the

wor

k is

supported and your fingers are away from the blade.

•

AVOid

awkward

hand positions

where

a sudden slip

could cause a hand to move into the blade.

• Never turn

your

scroll saw on before clearing the table

of all objects (tools, scraps of wood. etc.) except for the

workpiece and related feed or support devices for the

operation planned.

• ALWAYS adjust the

drop

foot and blade guard to just

clear the

workpiece

to

protect the operator. keep blade

breakage

to

a mi

nimum

and provide

maximum

support

for

blade.

• Always

adjust

blade tension correctly.

•

Make

sure blade teeth run

downward

toward

table.

Page 3

:ike su

re

it

IS

• Hold the

work

fl

Only

feed the matenal fast

e

cut.

Keep fingers away fro

• Do not feed the ma e

•

Use caution w hen

cutting

(

In

cross sec tion

- It co Id p

cut

is complet d. A ple .. e

of

must

lay flat on the table and not

mIle being

Cll

t.

• Use caution when

cutting

oft

round materta

a Nel rods or

tub

ing . They have a tendenc

5 -

de

being cut. causin g the blade to bite

• e

esaw

OFF

, make sur

_

00

r leave the scr " saw runnm g unatten

ed

. T

rn

the saw h

as

come

toa

camp

ete

and th

en

remove plug fr

om

power

suppl

efore

tile

work

area.

•

no

perform layout. assembly or setup work on

lhe

Ie

the cutti ng tool IS operating.

off

and remove plug from

power

supply

outlet

5tal mg or removing

an

accessory attachment

•

•

av,

_ Iy

par! of this

sc

roll saw

be

missing. bend or

or any e

le

ctri c

al

compo

nen t fatl to

shut

off

power switch

and remove

r supply outl

et. .Replace dam

aged

, missi

ng.

IS before

re

suming

operation.

Think

Safety

n of operator

comm

on sense and

sc

ro

ll s

aw

is

in

operation.

•

AWARNING

o

allow

familiarity (gained from

uent

use

of

your scroll saw)

to

I a s remember

ha

a care-

become carefe

s _

less fraction

0'

a

~p.(~nid

mJU ry.

WEA

The

operation

of

any

power

tool can result

in

foreign

objects being

thrown

into

the

eyes. which can result in

seve

re

eye damage.

Always

wear safety glasses or eye

shie lds before commencing

power

tool

oper

ation.

We

recom

mend Wide

Vision

Safety

Mask

for

use

over

specta cles or standard safety glasses.

•

Grounding Instructions

Grounded Too

ls

With

Three-Prong Plugs

I mproper grounding ca s oc

AWARNING

or electroc

e

Grounding of this tool is necessa

tect you from electric

shoc a

is equ ipped

with

an appro '

!h,·,.:H>-JVO,ftn

three-prong ground n9grounding-type rece

'3_

'==

pro 9 from the ree pr e

green (or green and e C a

elOf

In

the cord s the

grounding

wire

e e onnect

he

green (or green and

yellow) wire

to

a e termmal. Your unIt

is

for use

on

less than 1

50

volts and it has plug

that

looks like

Fig. "A".

FIG. A

FIG. C

A,'ap"

"

FIG. B

~

CU!

err

G

ruundlnQ

G·

oun

dlrlll

Cover 0' Grou

nded

Means

-

P·onq

QUI

II't

Bo)(

An ada

pt

.r, Fig.

8" and '

C"

is

availa ble for connecting

Fig A plugs to

two

-prong receptacl

es.

The green

colored

ngld

ear. ug etc

.,

e tending from the adapter

must

be connected 0 a perman ent grou nd such

as

a

properl

gra

ded

au

Ie

box

o ernel

OTE The grounding adapter. Fig. "C"

is

prohib it

ed

in

C=

a b Canadian Electrical Code-Part 1. Therefore

ons for

Its

u

se

are not applicable

In

Canada.

Extension Cords

se

of

damaged cords can shock,

burn

Dr electrocute.

o

worn

cords immediately. The

c size

to

u e, depending on cord

'e amperag e rating

of

tool.

If

in

t:3Vler gauge. An undersized cord

hne voltag

e,

resulting in loss

of

. NOTE: The smaller the gauge

e cord.

ension cor s with

three-ho

le

he tool plug and ha

ve

three-

pugs. Thr

ee-wi

re

extension

A

eCOlmn:lelxl

um

Gauge

for

Cord

Extensions

e

Electri

c Tools

9

Chart

A.W

.G.

-

-----

--1

Cord

Length

in

Feet

50

100

'50

, 6

14

14 12

4

12

"4

12

Not

Recommended

Your

Dremel product

IS

'/arranted against defective material

Of

!"

U HORIZEO REPAIRS OR

workmanst1ip f

or

a period of ooe year f

rom

date of purchase, In

Ih~

J}tIIm:::O\~

TTACHMENTS OR OTHE

R

even! of a failur of a produCl

to

conform

to

this written

WaIT

an

LEMS

WITH MATER

IAL

OR

please take the following actioo:

BEe

BY THIS WARRAN

TY,

•

1, DO NOT return your produ

ct

to

the place of purchase,

e.' person IS authorized to ive any

Dremal inspection shows that the

2. Carefully package the product by itself. with no other item

s,

PI' S

With

material or workmanship

retu

rn

it

freight prepaid. along with:

arran y Dremel wi

ll

repair or replace the

A.

A copy of your dated proof of purchase (please

kee

p a

~

elum product prepai

d.

Repal

rs

made

for yourself).

€a

abuse.

or repair for product outside the

'" ca

be

made. will be charged

at regular

B A written statement about

th

e nature of the problem.

C

Your

nam

e.

address and phone number

to:

AE

E...

ES

NO OTH

ER

WARRA

NTY

OF

ANY

KIND

TEVER.

EXPRESSED

OR IMPLIED. A

ND

ALL I

MPl

iED

UNITED STATES

"'

... "-"' ..",,'

ES

OF ERCHANTABI

LITY

AND F

ITN

ESS

FOR A

PAR

-

Dremel

Service Cen

ter

Dremel Service

Cente1'

C PURPOSE WHICH EXCEED THE ABO

VE

MENTIONED

4915

Twenty-F

irst Street

OR

4631

E.

Su

nny

[)t

BUGATlON

AR

E HEREBY DISCLAIMED

BY DRE

MEL

AND

Racine. Wlsconsin

53406

Palm

Spnngs,

CA

2264

EXCLUDED FROM T

HI LIMITED WARR

ANTY

.

EASTERN CANADA

WESTE

RN

CANADA

ThIs arranty gives you specific legal rights and you may also have

Giles

Tool

Agency otem Tools

olher rights

wt1

ich vary from state to state. The obligation of the

6520 Lawrence a

.... east,

OR

3851 Main

51.

warrantor

is

solely to repair or replace!h product. The warrantor Is

Scarborough,

Onl.

Va

ncou

...

er,

ac

.

not liable torany inCidental orconsequenti

al

damages due to any such

Canada

M1C 4A7

Canada

V5V

3P1

alleged defect Some states do not allow the excl sicn or limltalionsof

We recommend that the package be insured against lossordamage

in

incidental or r.onseQuenlial damages, so the above Iimita1ions

or

transit,

for

which we cannot be

res

ponsi

Ie.

exclusion may not apply to you.

This

warranty applies only

to

the original registered purchaser.

For pri

ces and warranty fulfillment

in

the continental United Sates,

DAMAGE TO THE P

ROD

UCT

RES

ULTI

NG

F OM TAMPERING,

cootac! your local Dremel dislnbutor.

Pa

ge4

_ __

\

~~~~~

~~

TABLE INSERT

POSITIONED

FOR

PLAIN END BLADES

DEGR

EE

SCALE

TAB

LE

INS

ERT

ON/

OFf

SWITCH

Getting to know your scr

DEGREE SCALE

I e

liM'

BLADE

STORAGE \

BOX

-:1

WRENCH~

BLADE

ADAPTER

FRONT

VIEW

OF

BLADE

AND

TABLE INSERT

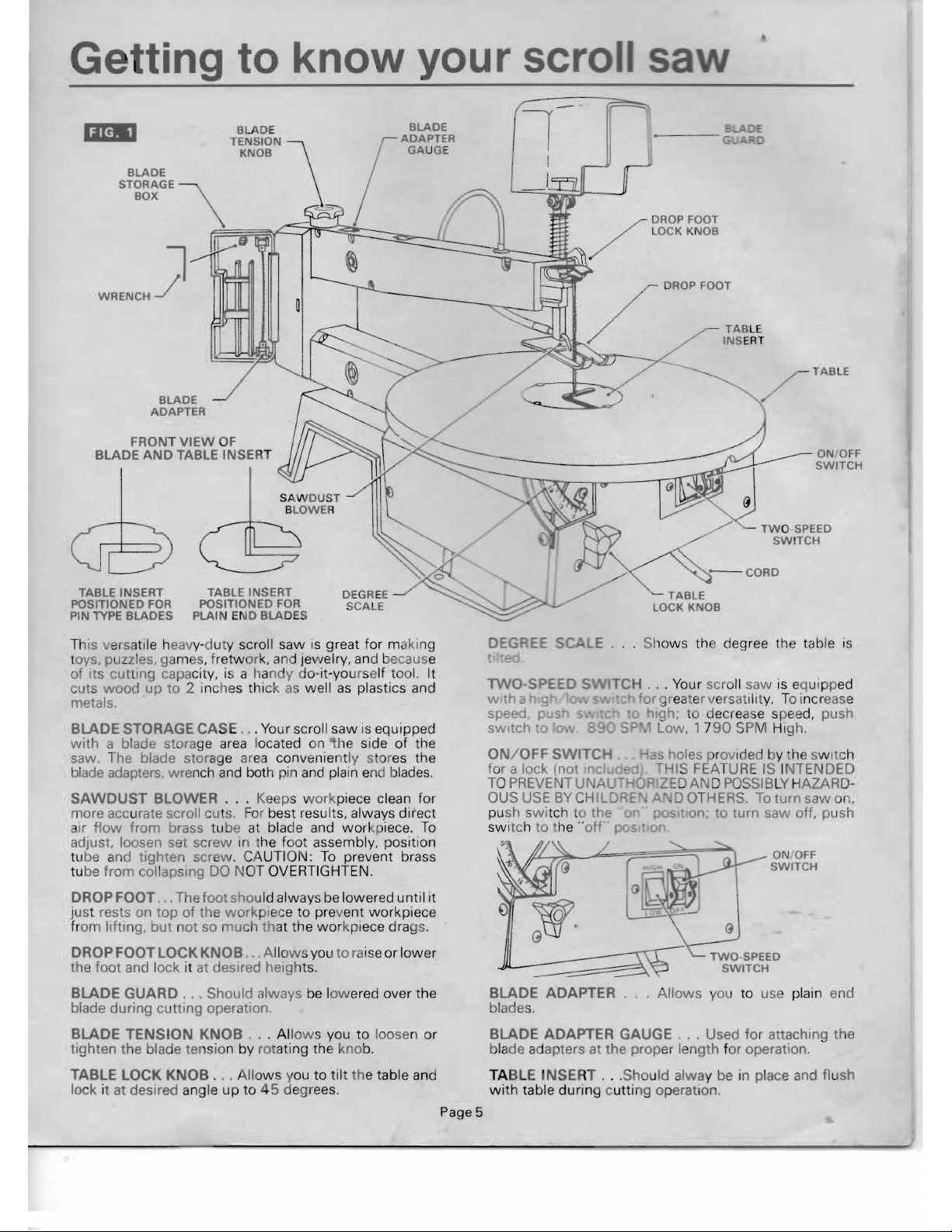

Th

is

versatile heavy-duty scroll saw

is

great for making

toys, puzzles, games, fretwork,

and Jewelry, and because

of its cutting capa

ci

ty, is a han y do-it-yourself too

l.

It

cuts

wood

up

to

2 inches thick

as

well

as

plastics and

metals.

BLADE STORAGE CASE

..

. Your scroll

saw

is

equipped

with

a blade storage

area

located on he side of the

saw. The blade stor

ag

e ar

ea

convenie

ntly stor

es

the

blade adapters, wrench

and

both pin

and

plain e

nd blades

.

SAWDUST BLOWER

...

Keeps workpiece clean for

more accurate scroll cu

s. For best resu lt

s,

always direct

air

flow

from brass tube at blade and

wor

kp iece.

To

adjust. loosen set screw in the foot assembly, position

tube and tighten screw.

CA

UTION:

To

prevent brass

tu be from collapsmg

DO

NOT OVERTIGHTEN.

DROP FOOT,. The foot should always be lowered until it

just rests on

top

of

the

workpiece to

prevent workpiece

from lifting,

but

not so much that the workpiece drags.

DROP FOOT LOCK KNOB .. A

llows

you to raise or lower

the foot and lock it at desired heigh ts.

BLADE GUARD

...

Should always

be low

ered over the

blade during cutting operation

BLADE TENSION KNOB .

..

All

ows

you to loosen or

tig hten the blade tension by rotating the kno

b.

TABLE LOCK KNOB .

..

All

ows

you to

tilt

th e table and

lock it at desired angle

up

to

45

degrees.

TABLE INSERT

POSITIONED

FOR

PIN

lYPE

BLADES

Page5

Fr

-

'~

1

~

Shows the degree the table

is

TCH . . . Your scroll saw

is

equipp

ed

ch or greater versat ility. To incr

eas

e

a

1'1Igh

, t decrea e speed, push

SLow

, 17

90

SPM High.

ON/OFF

SWITCH . as holes pr

OV

ided by he SWitch

for a lock (not

dud

'HIS

FEATURE

IS

INTENDED

TOPREVENTUNAU O IZEOANOPOSSIBLY HAZARDOUS USE

BY

CHILD E D OT

HERS.

To

turn saw on,

pu

sh

swi

tch

to

the 0

po

_It on; a turn

saw

off, push

switch to t

he "off

.

ON/

OFF

SWITCH

BLADE ADAPTER . . .

Allows

you to us plain end

blades.

BLADE ADAPTER

GAUGE.

, , Used for attaching the

bl

ade ad

apters at the proper length for operation.

TABLE INSERT .

..

Should alway be in place and flus h

with

table during cutting operat ion

I

Loading...

Loading...