Dremel 03-5415317 User Manual

DM 2610938876 03-06.qxd 3/17/06 9:21 AM Page 1

300 Series

Instructional Safety

Manual

High Speed Rotary Tool

03-5415317

http://www

Dremel brand products are manufactured and sold by the

Dremel Division of Robert Bosch

Form No. 2610938876 03/06 Robert Bosch Tool Corporation © 2004

.dremel.com

ool Corporation

T

All Rights Reserved

DM 2610938876 03-06.qxd 3/17/06 9:21 AM Page 2

GENERAL SAFETY RULES

!

WARNING

tool” in all of the warnings listed below refers to your mains-operated (corded) power tool

or battery-operated (cordless) power tool.

Read all instructions. Failure to follow all instructions listed below

may result in electric shock, fire and/or serious injury.

The term “power

SAVE THESE INSTRUCTIONS

Work area safety

Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust.

tools create sparks which may ignite the

dust or fumes.

Keep children and bystanders away

while operating a power tool.

can cause you to lose control.

Power

Distractions

Electrical safety

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any adapter plugs with earthed

(grounded) power tools.

and matching outlets will reduce risk of electric shock.

Avoid body contact with earthed or

grounded surfaces such as pipes, radiators, ranges and refrigerators.

increased risk of electric shock if your body

is earthed or grounded.

Do not expose power tools to rain or wet

conditions.

increase the risk of electric shock.

Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the

risk of electric shock.

When operating a power tool outdoors,

use an extension cord suitable for outdoor use.

use reduces the risk of electric shock.

Do not use AC only rated tools with a DC

power supply.

to work, the electrical components of the AC

rated tool are likely to fail and create a haz

ard to the operator.

If operating the power tool in damp locations is unavoidable a Ground Fault

Water entering a power tool will

Use of a cord suitable for outdoor

While the tool may appear

Unmodified plugs

There is an

Circuit Interrupter (GFCI) must be used

to supply the power to your tool.

and personal protection devices like electrician’s rubber gloves and footwear will further enhance your personal safety.

Personal safety

Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool

while you are tired or under the influence

of drugs, alcohol or medication.

moment of inattention while operating

power tools may result in serious personal

injury.

Use safety equipment. Always wear eye

protection.

mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions will reduce personal injuries.

Avoid accidental starting. Ensure the

switch is in the off-position before plugging in.

ger on the switch or plugging in power tools

that have the switch on invites accidents.

Remove any adjusting key or wrench

before turning the power tool on.

wrench or a key left attached to a rotating

part of the power tool may result in personal injury.

Do not overreach. Keep proper footing

and balance at all times.

ter control of the power tool in unexpected

situations.

Dress properly

ing or jewelry. Keep your hair, clothing

and gloves away from moving parts.

Loose clothes, jewelry or long hair can be

caught in moving parts.

If devices are provided for the connection of dust extraction and collection

-

facilities, ensure these are connected

and properly used.

can reduce dust-related hazards.

Safety equipment such as dust

Carrying power tools with your fin-

This enables bet-

. Do not wear loose cloth-

Use of these devices

GFCI

A

A

2

DM 2610938876 03-06.qxd 3/17/06 9:21 AM Page 3

Keep handles dry, clean and free from oil

and grease.

control the power tool.

Slippery hands cannot safely

Power tool use and care

Do not force the power tool. Use the correct power tool for your application.

correct power tool will do the job better and

safer at the rate for which it was designed.

Do not use the power tool if the switch

does not turn it on and off.

that cannot be controlled with the switch is

dangerous and must be repaired.

Disconnect the plug from the power

source and/or the battery pack from the

power tool before making any adjustments, changing accessories, or storing

power tools.

ures reduce the risk of starting the power

tool accidentally.

Store idle power tools out of the reach of

children and do not allow persons unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tools operation. If damaged, have the power tool

repaired before use.

caused by poorly maintained power tools.

Such preventive safety meas-

Any power tool

Many accidents are

The

SAVE THESE INSTRUCTIONS

Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

Use the power tool, accessories and tool

bits etc., in accordance with these

instructions and in the manner intended

for the particular type of power tool, taking into account the working conditions

and the work to be performed.

power tool for operations different from

those intended could result in a hazardous

situation.

Use clamps or other practical way to

secure and support the workpiece to a

stable platform.

or against your body is unstable and may

lead to loss of control.

Holding the work by hand

Use of the

Service

Have your power tool serviced by a qualified repair person using only identical

replacement parts.

safety of the power tool is maintained.

Develop a periodic maintenance schedule for your tool. When cleaning a tool be

careful not to disassemble any portion of

the tool since internal wires may be misplaced or pinched or safety guard return

springs may be improperly mounted.

Certain cleaning agents such as gasoline,

carbon tetrachloride, ammonia, etc. may

damage plastic parts.

This will ensure that the

SAFETY RULES FOR ROTARY TOOL

Hold tool by insulated gripping surfaces

when performing an operation where the

cutting tool may contact hidden wiring or

its own cord.

make exposed metal parts of the tool "live"

and shock the operator.

Use clamps or other practical way to

secure and support the workpiece to a

stable platform.

or against your body is unstable and may

lead to loss of control.

Accessories must be rated for at least the

speed recommended on the tool warning

label.

Contact with a "live" wire will

Holding the work by hand

Wheels and other accessories run

ning over rated speed can fly apart and

cause injury.

If cutting into existing walls or other blind

areas where electrical wiring may exist is

unavoidable, disconnect all fuses or circuit

breakers feeding this worksite.

Do not operate the flexible shaft with a

sharp bend.

generate excessive heat on the jacket or

hand piece. The recommended minimum is

6" radius.

Always disconnect the power cord from

the power source before making any

-

adjustments or attaching any acces-

3

Over bending the shaft can

DM 2610938876 03-06.qxd 3/17/06 9:21 AM Page 4

SAFETY RULES FOR ROTARY TOOL (CONTINUED)

sories. You may unexpectedly cause the tool

to start leading to serious personal injury.

Be aware of the switch location, when

placing the tool down or when picking the

tool up.

switch.

Always hold the hand piece firmly in your

hands during the start-up.

torque of the motor, as it accelerates to full

speed, can cause the shaft to twist.

Always wear safety goggles and dust

mask. Use only in well ventilated area.

Using personal safety devices and working in

safe environment reduces risk of injury.

After changing the bits or making any

adjustments, make sure the collet nut and

any other adjustment devices are securely tightened.

unexpectedly shift, causing loss of control,

loose rotating components will be violently

thrown.

Do not reach in the area of the spinning

bit.

hand may not always be obvious.

Allow brushes to run at operating speed

for at least one minute before using

wheel. During this time no one is to stand

in front or in line with the brush.

bristles or wires will be discharged during the

run-in time.

Wire and bristle brushes must never be

operated at speeds greater than

15,000/min. Direct the discharge of the

spinning wire brush away from you.

Small particles and tiny wire fragments may

be discharged at high velocity during the

“cleaning” action with these brushes and may

become imbedded in your skin. Bristles or

wires will be discharged from the brush at

high speeds.

Carefully handle both the tool and individual grinding wheels to avoid chipping or

cracking. Install a new wheel if tool is

dropped while grinding. Do not use a

wheel that may be damaged.

from a wheel that bursts during operation will

fly away at great velocity possibly striking you

or bystanders.

Never use dull or damaged bits. Sharp

bits must be handled with care.

bits can snap during use. Dull bits require

more force to push the tool, possibly causing

the bit to break.

Use clamps to support workpiece whenever practical. Never hold a small work

You may accidentally activate the

The reaction

Loose adjustment device can

The proximity of the spinning bit to your

Loose

Fragments

Damaged

piece in one hand and the tool in the other

h

and while in use. Allow for sufficient

space, at least 6", between your hand and

the spinning bit.

dowel rods, pipes or tubing have a tendency

to roll while being cut, and may cause the bit

to “bite” or jump toward you. Clamping a

small workpiece allows you to use both

hands to control the tool.

Inspect your workpiece before cutting.

When cutting irregularly shaped workpieces, plan your work so it will not slip

and pinch the bit and be torn from your

hand.

For example, if carving wood, make

sure there are no nails or foreign objects in

the workpiece. Nails or foreign objects can

cause the bit to jump.

Never start the tool when the bit is

engaged in the material.

edge may grab the material causing loss of

control of the cutter.

Avoid bouncing and snagging the wheel,

especially when working corners, sharp

edges etc.

and kick-back.

The direction of feed with the bit into the

material when carving, routing or cutting

is very important. Always feed the bit into

the material in the same direction as the

cutting edge is exiting from the material

(which is the same direction as the chips

are thrown).

direction, causes the cutting edge of the bit to

climb out of the work and pull the tool in the

direction of this feed.

If the workpiece or bit becomes jammed

or bogged down, turn the tool “OFF” by

the switch. Wait for all moving parts to

stop and unplug the tool, then work to

free the jammed material.

the tool is left “ON” the tool could restart

unexpectedly causing serious personal

injury.

Do not leave a running tool unattended,

turn power off.

complete stop it is safe to put it down.

Do not grind or sand near flammable

materials.

ignite these materials.

Do not touch the bit or collet after use.

After use the bit and collet are too hot to be

touched by bare hands.

Regularly clean the tool's air vents with

compressed air.

powdered metal inside the motor housing

-

may cause electrical failures.

Round material such as

The bit cutting

This can cause loss of control

Feeding the tool in the wrong

If the switch to

Only when tool comes to a

Sparks from the wheel could

Excessive accumulation of

4

DM 2610938876 03-06.qxd 3/17/06 9:21 AM Page 5

SAFETY RULES FOR ROTARY TOOL (CONTINUED)

Do not allow familiarity gained from frequent use of your rotary tool to become

commonplace.

c

areless fraction of a second is sufficient to

inflict severe injury.

Do not alter or misuse tool. Any alteration

or modification is a misuse and may result in

serious personal injury.

This product is not intended for use as a

dental drill, in human or veterinary medical applications.

When using the steel saws, cutoff wheels,

high speed cutters or tungsten carbide

cutters, always have the work securely

clamped. Never attempt to hold the work

with one hand while using any of these

accessories.

wheels will grab if they become slightly canted in the groove, and can kickback causing

loss of control resulting in serious injury. Your

second hand should be used to steady and

guide the hand holding the tool. When a cutoff wheel grabs, the wheel itself usually

Always remember that a

Serious injury may result.

The reason is that these

breaks. When the steel saw, high speed cutt

ers or tungsten carbide cutter grab, it may

jump from the groove and you could lose

control of the tool.

WARNING

!

construction activities, contains chemicals known to cause cancer, birth defects

or other reproductive harm. Some examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement

and other masonry products, and

• Arsenic and chromium from chemically

treated lumber.

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals, work in a well ventilated area, and

work with approved safety equipment, such

as those dust masks that are specially

designed to filter out microscopic particles.

Some dust created by

power drilling and other

5

DM 2610938876 03-06.qxd 3/17/06 9:21 AM Page 6

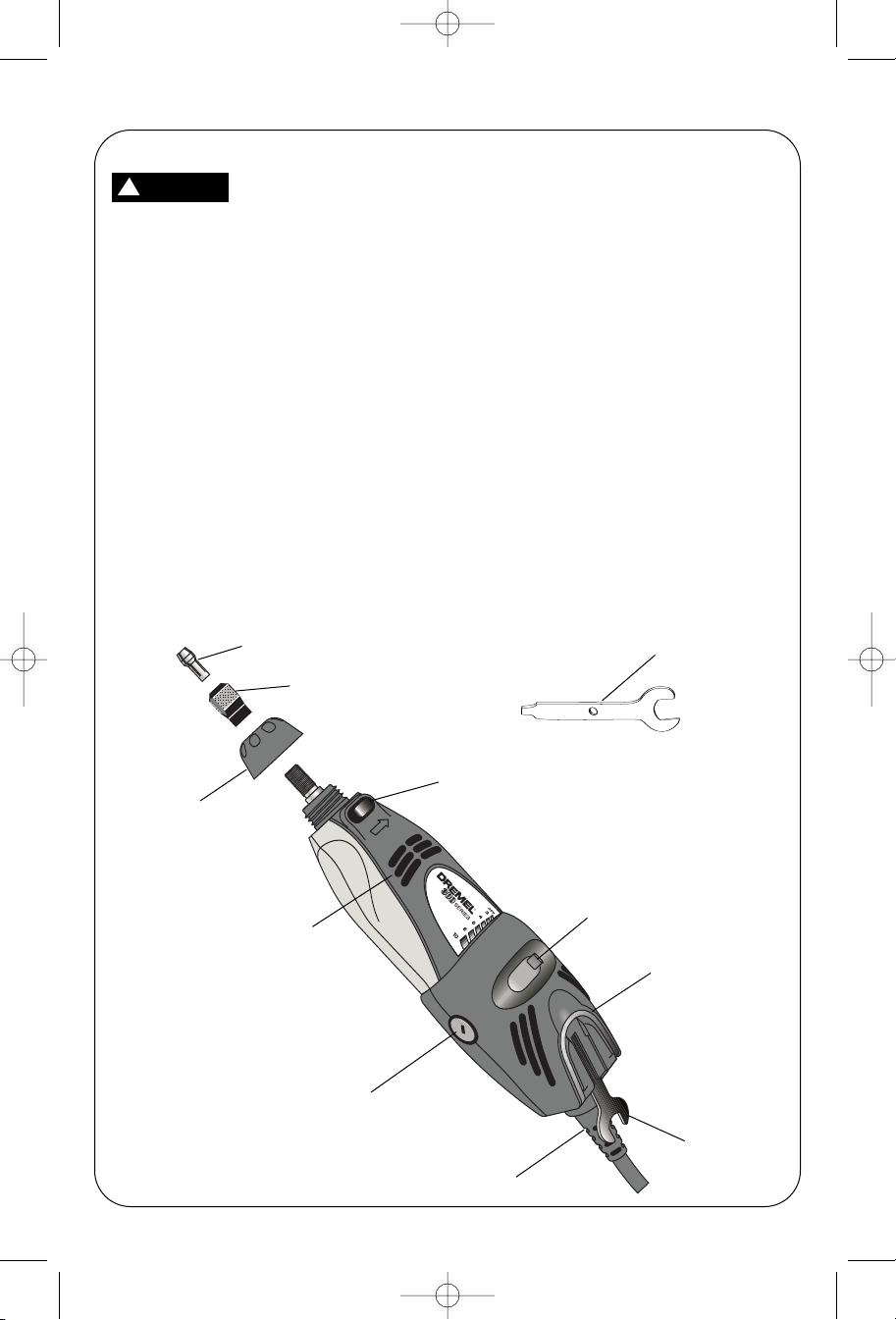

GETTING TO KNOW YOUR ROTARY TOOL

Unpacking & Checking Contents

WARNING

!

cal shock, always remove plug from wall

outlet when tool is not in use.

Separate all loose parts from packing materials and check each item with the contents

listed on the carton to make sure all items are

accounted for before discarding any packing

material.

To avoid injury from unexpected starting or electri-

Description

The 300 Series rotary tool consists of a small,

but effective AC universal motor construction

that incorporates high speed to complete

cutting, drilling, carving, sharpening, etching,

grinding, sanding, shaping, polishing, cleaning

and much more.

The 300 Series rotary tool has high speeds of

10,000 – 37,000 rpms, while a typical drill only

has a top speed of 2,500 rpms. The high

speeds allows your Dremel rotary tool to

Collet

Collet Nut

perform with high performing results. There is

n

o need to apply pressure to your tool, it is the

speed of rotary tool that will complete even

the toughest task.

Your Dremel’s rotary tool performance does

depend upon the accessories that you use.

Due to the high speeds of your rotary tool, we

highly recommend that you always use

Dremel accessories and attachments for the

best results. Dremel’s accessories and

attachments go through very controlled and

extensive testing and must meet very high

standards before being approved. From drill

bits to router bits, felt wheels to wire and nylon

brushes, cut-off wheels to sanding bands,

engravers to cutting bits and more.

Thus, the success you will experience with

your Dremel rotary tool system – rotary tool,

accessories and attachments; unlimited

versatility for you and your projects no matter

where you are.

Collet Wrench

Housing Cap

Ventilation Openings

Brush Cover

(one each side)

Shaft Lock Button

Power Cord

6

On/Off Switch

Hanger

rench

W

Storage

DM 2610938876 03-06.qxd 3/17/06 9:21 AM Page 7

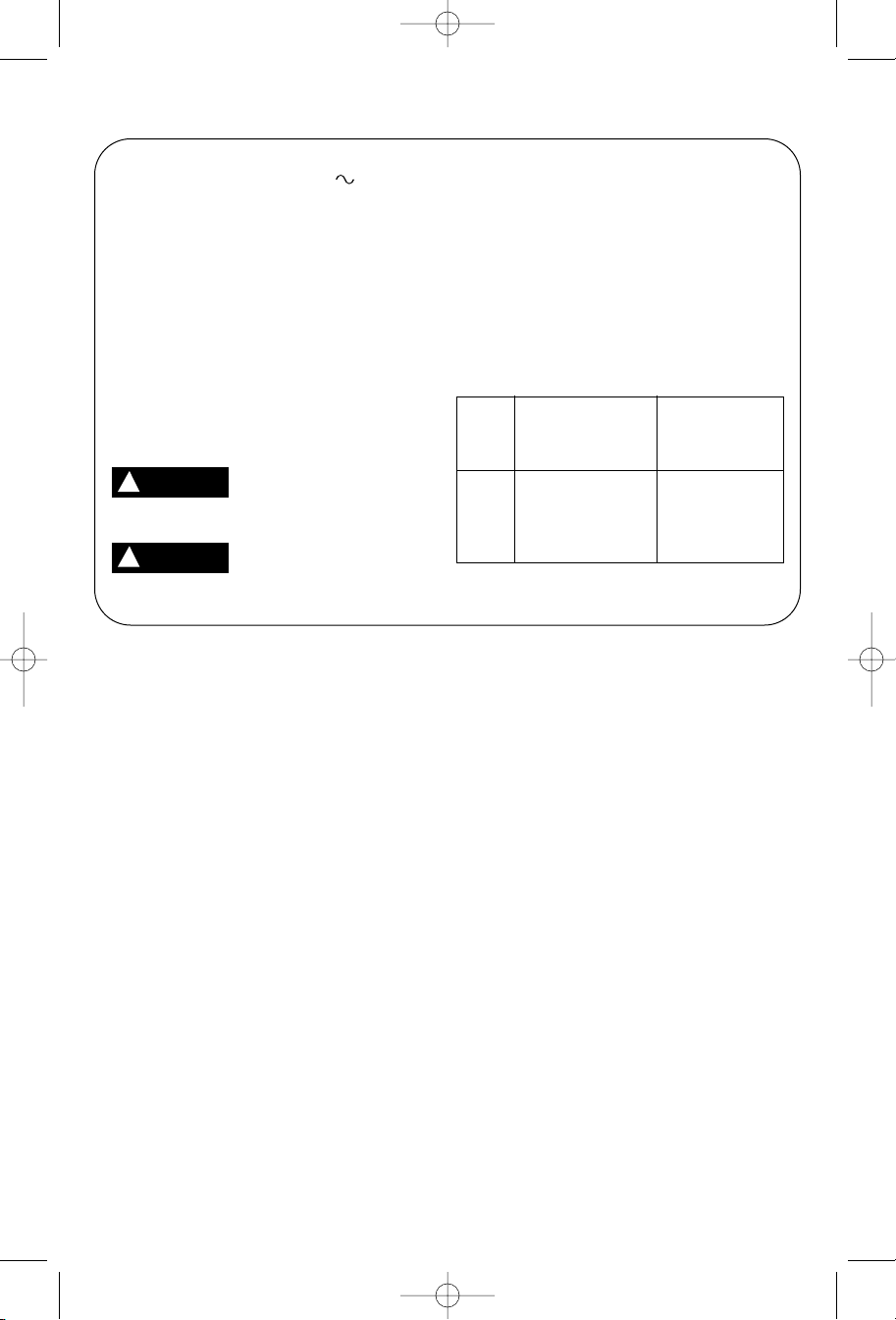

SPECIFICATIONS

General Specifications

Voltage Rating . . . .230-240 V , 50-60 Hz

Amperage Rating . . . . . . . . . . . . . . . .1.15 A

No Load Speed . . . .No10,000-37,000/min

Collet Capacity . . . .1/32", 1/16", 3/32", 1/8"

Motor Specifications

This Rotary Tool utilizes a variable highspeed RPM motor. It is wired for operation on

230-240 volts, 50-60 Hz. alternating current.

Before connecting the motor cord to wall outlet, make certain the power switch is in the

OFF position and be sure the electric current

is of the same characteristics as stamped on

the Rotary Tool nameplate.

Connection To A Power Source

DANGER

!

prongs on the plug when installing or

removing the plug to or from the outlet.

DANGER

!

have it replaced immediately to avoid

shock or fire hazard.

To avoid electric shock,

do not touch the metal

If power cord is worn, cut

or damaged in any way,

Extension Cords

If an extension cord is necessary, a cord

with adequate size conductors that is

capable of carrying the current necessary

for your tool must be used.

vent excessive voltage drop, loss of power or

overheating.

RECOMMENDED SIZES

OF EXTENSION CORDS

40 VOLT ALTERNATING CURRENT TOOLS

2

NOTE: The smaller the gauge number, the

heavier the cord.

C

Tool’s

Ampere

R

ating

1-6

6

-8

8-10

10-12

12-16

ord Size in A.W.G.

Cord Length in Feet Cord Length in Meters

25 50 100 150 15 30 60 120

1

8 16 16 14 .75 .75 1.5 2.5

18 16 14 12 .75 1.0 2.5 4.0

18 16 14 12 .75 1.0 2.5 4.0

16 16 14 12 1.0 2.5 4.0 —

14 12 — — — — — —

This will pre-

Wire Sizes in mm

2

7

0

DM 2610938876 03-06.qxd 3/17/06 9:21 AM Page 8

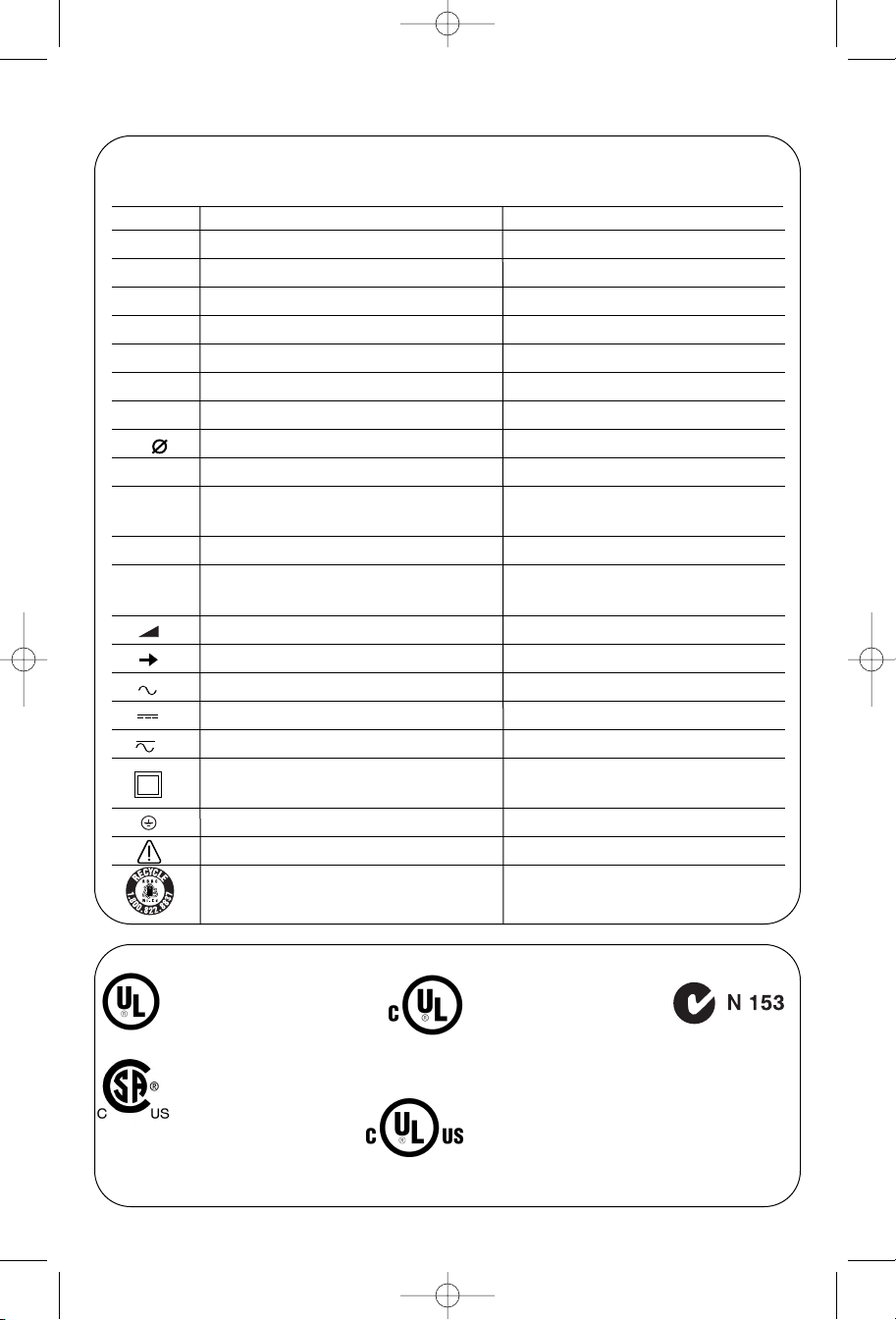

SYMBOLS

IMPORTANT! S

ome of the following symbols may be used on your tool. Please study

them and learn their meaning. Proper interpretation of these symbols will allow you to

operate the tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Diameter Size of drill bits, grinding wheels,etc.

n

0

No load speed Rotational speed, at no load

.../min Revolutions or reciprocation Revolutions, strokes, surface speed,

per minute orbits etc. per minute

0 Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque or position settings.

I, II, III, Higher number means greater speed

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated

Construction tools.

Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Ni-Cad RBRC seal

Designates Ni-Cad battery recycling

program

This symbol designates

that this tool is listed by

Underwriters Laboratories.

This symbol designates

that this tool is listed by

the Canadian Standards

Association, and is listed

to US Standards by CSA.

This symbol designates

that this tool is listed to

Canadian Standards by

Underwriters

Laboratories.

This symbol designates

that this tool is listed by

Underwriters Laboratories,

and listed to Canadian

Standards by Underwriters

This symbol

designates

that

this tool com

plies

Australian

to

Standards.

-

Laboratories.

8