Page 1

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Technical

Service

Manual

Part Number: 4114846-001

Date: 20 May 2002

© 2002 Draeger Medical, Inc.

Rev: R

Narkomed 6000

Anesthesia System

Page 2

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Page 3

RETURN TO CD-ROM TABLE OF CONTENTS

Narkomed 6000 Service Manual Table of Contents

Summary of What's New in Rev. R

DESCRIPTION

SECTION 1:

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

SECTION 2:

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Accessing the Service Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2 Advanced Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3 Service Monitors Notebook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.4 Service Configuration Notebook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.5 Service Dump Notebook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.6 Service Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.6A Service Log Entry Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18B

2.7 NM6000 Event Log Transfer Using Service Laptop with Windows 95 or 98 . . . . . . . . 2-19

2.7A NM6000 Event Log Transfer Using Service Laptop with Windows NT . . . . . . . . . . . 2-23A

2.7B Event Log Transfer: Alternate Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23H

2.8 Divan Ventilator Power-up Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2.9 Divan Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

SECTION 3:

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 Power Supply and Voltage Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4A

3.3 Troubleshooting Guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4B

PAG E

SECTION 4:

Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Cylinder Yoke Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2 Cylinder Pressure Regulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.3 Cylinder and Pipeline Pressure Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.4 Flowmeters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.5 Flow Control Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4.6 Minimum O2 Flow Cutoff Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4.7 Auxiliary Oxygen Flowmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4.8 Oxygen Supply Failure Protection Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

4.9 Oxygen Supply Pressure Alarm Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

4.10 Oxygen Ratio Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

4.11 O2 Flush Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

4.12 Ventilator Piston-Cylinder Diaphragm Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

4.13 Divan Ventilator PCB Assemblies, Battery and EPROM Replacement . . . . . . . . . . . . 4-39

4.14 Breathing System and Diaphragm Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

4.15 Breathing System and Ventilator Lip Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

4.16 Ventilator Replacement - Complete Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-49

4.17 Caster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

4.18 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55

4.19 Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-57

Rev. R

i

Page 4

CONTENTS (continued)

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

DESCRIPTION

4.20 Workstation Processor Assembly (WPU). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-60

4.21 VPO Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-63

4.22 Vitalbus Hub PCB Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-66

4.23 Agent Analyzer Assembly; Lithium Battery (TK-RAM IRIA) Replacement. . . . . . . . . 4-68

4.23A GAP Pump Assembly Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-71A

4.23B IRIA Sensor Head Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-71C

4.23C GAP Personality PCB & Common Processor PCB Replacement . . . . . . . . . . . . . . . . . 4-71E

4.23D IRIA Controller PCB Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-71H

4.23E Water Trap, Solenoid, Variable Restrictor Replacement & Retubing Procedure . . . . 4-71K

4.24 CRT Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-72

4.24A Flat Panel Display Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-75A

4.25 Table Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-76

4.25A Strip Chart Recorder Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-77A

4.26 Flow Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-78

4.27 Oxygen Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-80

4.28 Lower Frame Cover (skirt) Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-82

4.29 Divan Safety Plate Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-84

4.30 WPU Mother Board Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-87

4.31 Vaporizer Mounting and Exclusion System Replacement . . . . . . . . . . . . . . . . . . . . . . . 4-96

4.32 Main Pneumatic Valve Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-98

4.33 Divan Ventilator Front Bezel and Related Components Replacement . . . . . . . . . . . . 4-100

4.34 Integrated Patient Monitor Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 4-108

4.35 Divan Motor Drive Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-111

4.36 Divan PEEP Valve Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-113

4.37 Divan Pressure Sensors Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-118

PAG E

SECTION 5:

Adjustment and Calibration Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 Cylinder Pressure Regulator Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2 Oxygen Supply Pressure Alarm Switch Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.3 Oxygen Ratio Controller (ORC) Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.4 Oxygen Sensor Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.5 Breathing Pressure Monitor Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.6 Agent Monitor Sample Flow Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5.7 CRT Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.7A Flat Panel Brightness, Contrast, Phase and Video Position Adjustments . . . . . . . . . 5-17A

5.8 Touch Screen Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.8A Advanced Touch Screen Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19A

5.9 Ventilator Supply Pressure Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5.10 Ventilator Supply Flow Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5.11 Ventilator Control Pressure Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

5.12 Breathing System Leveling Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

5.13 Bag Pole Friction Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

5.14 Right Vaporizer Vertical Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

5.15 System Electrical Switch Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

5.16 Local Time Zone Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

5.17 Narkomed 6000 Alarm Volume Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

SECTION 6:

PMS Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Materials Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

ii

Rev. R

Page 5

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

CONTENTS (continued)

DESCRIPTION PAG E

Periodic Manufacturers Certification General Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

PM Certification Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.1 Service Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6.2 Battery Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

6.3 Open Reservoir Scavenger - if applicable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

6.4 Scavenger Interface, A/C - if applicable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6.5 Suction Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6.6 Suction Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6.7 High Pressure Leak . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6.8 Regulator and Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

6.9 Oxygen Supply Failure Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

6.10 Flowmeters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

6.11 Oxygen Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

6.12 Oxygen Concentration Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

6.13 Oxygen Ratio Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

6.14 Fresh Gas Leak Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

6.15 Minimum O2 Control Solenoid Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

6.16 Divan Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

6.17 Divan Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-35

6.18 Divan Operating Mode Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-39

6.19 Respiratory Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-45

6.20 Pressure Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-47

6.21 Agent Analyzer Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-49

6.22 O2 Flush Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-52

6.23 Reset Logbook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-53

6.24 Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-54

6.25 Vapor Exclusion System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-55

6.26 Table Top Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-55

6.27 Flowmeter Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-55

6.28 CRT Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-55

6.29 Operator’s Instruction Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-56

6.30 Final Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-56

SECTION 6A:

PMS Procedure: Integrated Patient Monitoring Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A-1

6A.1 Electrical Safety Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A-3

6A.2 ECG Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A-5

6A.3 Battery Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A-7

6A.4 Defibrilator Synchronization Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A-8

6A.5 ST Segment Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A-9

6A.6 Invasive Blood Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A-10

6A.7 Temperature Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A-16

6A.8 Cardiac Output Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A-17

6A.9 SPO2/Pulse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A-19

6A.10 NIBPStrip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A-21

6A.11 Chart Recorder Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A-23

6A.12 Final IPMM and Strip Chart Recorder Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A-24

SECTION 7:

System Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1 Exclusion System Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 deleted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Rev. P

iii

Page 6

CONTENTS (continued)

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

DESCRIPTION

7.3 deleted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7.4 deleted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

7.5 deleted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

7.6 Gas Analyzer Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

7.7 Installation of Flow Sensor Anti-rotation Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

7.8 Installation of Bag Arm O-ring, Locking Knob, and Friction Screw Adjustment. . . . . 7-14

7.9 Lubrication of Ventilator Piston Rod. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

7.10 deleted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

7.11 Vitalbus Hub Conversion to Single Com Port Configuration. . . . . . . . . . . . . . . . . . . . . 7-18

7.12 Divan Motor Drive Belt Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

PAG E

iv

Rev. P

Page 7

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

CONTENTS (continued)

DESCRIPTION PAG E

SECTION 8:

Spare and Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Monitor and touchscreen assembly, related parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2, 8-3

Flat panel display and related parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3A, 8-3B

Table lamp assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4, 8-5

Strip Chart Recorder Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5A, 8-5B

Gas analyzer assembly and components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6, 8-7

Gas analyzer tubing and related items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7A, 8-7B

Integrated Patient Monitoring Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7C, 8-7D

Divan piston-cylinder unit, lip seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8, 8-9

Divan electronics assemblies, batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10, 8-11

Absorber canister and diffuser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11A, 8-11B

Divan motor drive assembly, pressure sensors, PEEP valve . . . . . . . . . . . . . . . . 8-11C, 8-11D

Divan breathing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12, 8-13

Ultrasonic flow sensor, oxygen sensor, hose assemblies. . . . . . . . . . . . . . . . . . . . . . . 8-14, 8-15

Pipeline inlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16, 8-17

Failsafe assemblies, ORC, O

supply pressure switch, min. flow O2 solenoid . . . . 8-18, 8-19

2

Flowmeter shield, knobs, gauges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20, 8-21

Auxiliary O

flowmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22, 8-23

2

Suction switch, vacuum valve asm, cockpit sub-asm, main switch. . . . . . . . . . . 8-23A, 8-23B

Flow tubes, flow control valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24, 8-25

Cylinder pressure regulators, O2 flush valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26, 8-27

Bag arm assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-27A, 8-27B

Cylinder yokes and related parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28, 8-29

VPO assembly, interface assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-30, 8-31

Vitalbus assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-32, 8-33

Power supply, casters, processor and related items, cord retainer hardware. . . . . . 8-34, 8-35

Internal cables and wire harness assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-36, 8-37

Open Reservoir Scavenger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-38, 8-39

Scavenger, A/C, Vent Grill Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-40, 8-41

Vapor mounting and exclusion system; paint, Loctite, Molykote, silicon adhesive . 8-42, 8-43

Boom Arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-44, 8-45

Rev. R

v

Page 8

NARKOMED 6000 ANESTHESIA SYSTEM

GAS

INSTRUMENTATION

PANEL

AUXILIARY O2

FLOWMETER

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

MONITOR

SCREEN

ABSORBER

STRIP CHART

RECORDER

DIVAN

VENTILATOR

SV00285

1-0

Rev. H

Page 9

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

INTRODUCTION

1.0 RECOMMENDATIONS

Because of the sophisticated nature of Draeger Medical, Inc. anesthesia equipment and its

critical importance in the operating room setting, it is highly recommended that only

appropriately trained and experienced professionals be permitted to service and maintain

this equipment. Please contact DrägerService

equipment.

Draeger Medical, Inc. also recommends that its anesthesia equipment be serviced at threemonth intervals. Periodic Manufacturer’s Service Agreements are available for equipment

manufactured by Draeger Medical, Inc. For further information concerning these

agreements, please contact us at (800) 543-5047.

®

at (800) 543-5047 for service of this

Draeger Medical, Inc.

HOW TO USE THIS MANUAL

products/material in need of factory repair shall be sent to:

DrägerService

3124 Commerce Drive

Telford, PA 18969 U.S.A.

(Include RMA Number)

The manual is divided into several sections. The DIAGNOSTICS section describes self-test

and service diagnostics for checking the system functions. An understanding of the on-board

service capabilities is necessary before any attempt is made to troubleshoot the unit. The

TROUBLESHOOTING section lists error codes and provides troubleshooting guides to

assist the Technical Service Representative in locating the source of a problem. The

REPLACEMENT PROCEDURES section contains instructions for removal and replacement

of assemblies that are considered field-replaceable. The ADJUSTMENT AND

CALIBRATION PROCEDURES section contains the field procedures needed to restore

original system specifications. The Periodic Manufacturer’s Service (PMS) PROCEDURE

section outlines the steps required to verify the electrical, mechanical and pneumatic safety

of the unit and also identifies components requiring periodic replacement.

GENERAL TROUBLESHOOTING GUIDELINES

Troubleshooting the Narkomed 6000 should always begin by communicating with those who

observed or experienced a problem with the unit. This may eliminate unnecessary

troubleshooting steps. Once a general problem is identified, refer to the troubleshooting flow

charts in Section 3 to determine the proper corrective action to be taken.

After any component is replaced, verify that the unit is operating properly by running the

appropriate diagnostic procedure. The PMS PROCEDURE in Section 6 must also be

performed after any component is replaced.

The general arrangement of the Narkomed 6000 anesthesia system is shown on the opposite

page.

1-1

Page 10

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000INTRODUCTION (continued)

WARNINGS

Warnings are used in this manual before procedures which if not performed correctly could

result in personal injury.

CAUTIONS

Cautions are used in this manual to alert service personnel to the possibility of damage to

the equipment if a procedure is not performed correctly.

Copyright

Copyright© 2001 by Draeger Medical, Inc. All rights reserved. No part of this publication

may be reproduced, transmitted, transcribed, or stored in a retrieval system in any form or

by any means, electronic or mechanical, including photocopying and recording, without

written permission of Draeger Medical, Inc.

Trademark Notices

Narkomed, Narkomed GS, Vigilance Audit, Vitalert and Vitalink are registered trademarks

of Draeger Medical, Inc. All other products or name brands are trademarks of their

respective owners.

Disclaimer

The content of this manual is furnished for informational use only and is subject to change

without notice. Draeger Medical, Inc. assumes no responsibility or liability for any errors or

inaccuracies that may appear in this manual.

1-2

Page 11

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000 DIAGNOSTICS

2.0 DIAGNOSTICS

The Narkomed 6000 contains a diagnostic system that monitors certain system functions

and records their operational status. A series of tests is performed when the system is

powered up and the results are displayed on the monitor screen. At the completion of the

diagnostics, one of three screens will appear as shown in the following examples:

SYSTEM 1 PASS

VPO Pod PASS

GAP Pod PASS

VENTILATOR PASS

SYSTEM FUNCTIONAL

SYSTEM 1 PASS

VPO Pod PASS

GAP NVRAM failure FAIL

VENTILATOR PASS

SYSTEM CONDITIONALLY FUNCTIONAL

press key to continue

SYSTEM 1 PASS

VPO Pod Firmware FAIL

GAP Pod PASS

VENTILATOR FAIL

SYSTEM NON-FUNCTIONAL

Continue

Continue

Continue

The screen labeled SYSTEM FUNCTIONAL indicates that all tests have passed. This screen

will be displayed for approximately five seconds, and the system will then proceed to the

monitor screen. (Touching the Continue key will bring up the monitor screen immediately.)

The screen labeled SYSTEM CONDITIONALLY FUNCTIONAL indicates that a problem

has been detected but the system is still usable. This screen will remain displayed until the

Continue key is touched.

The SYSTEM NON-FUNCTIONAL screen indicates that a serious problem has been

detected. The system will not proceed any further.

Further diagnostic functions are available through service screens that can be accessed at

the monitor. The following pages provide a description of the service screens. If no display is

present upon system power-up, refer to Section 3 of this manual for troubleshooting

assistance.

2-1

Page 12

DIAGNOSTICS (continued)

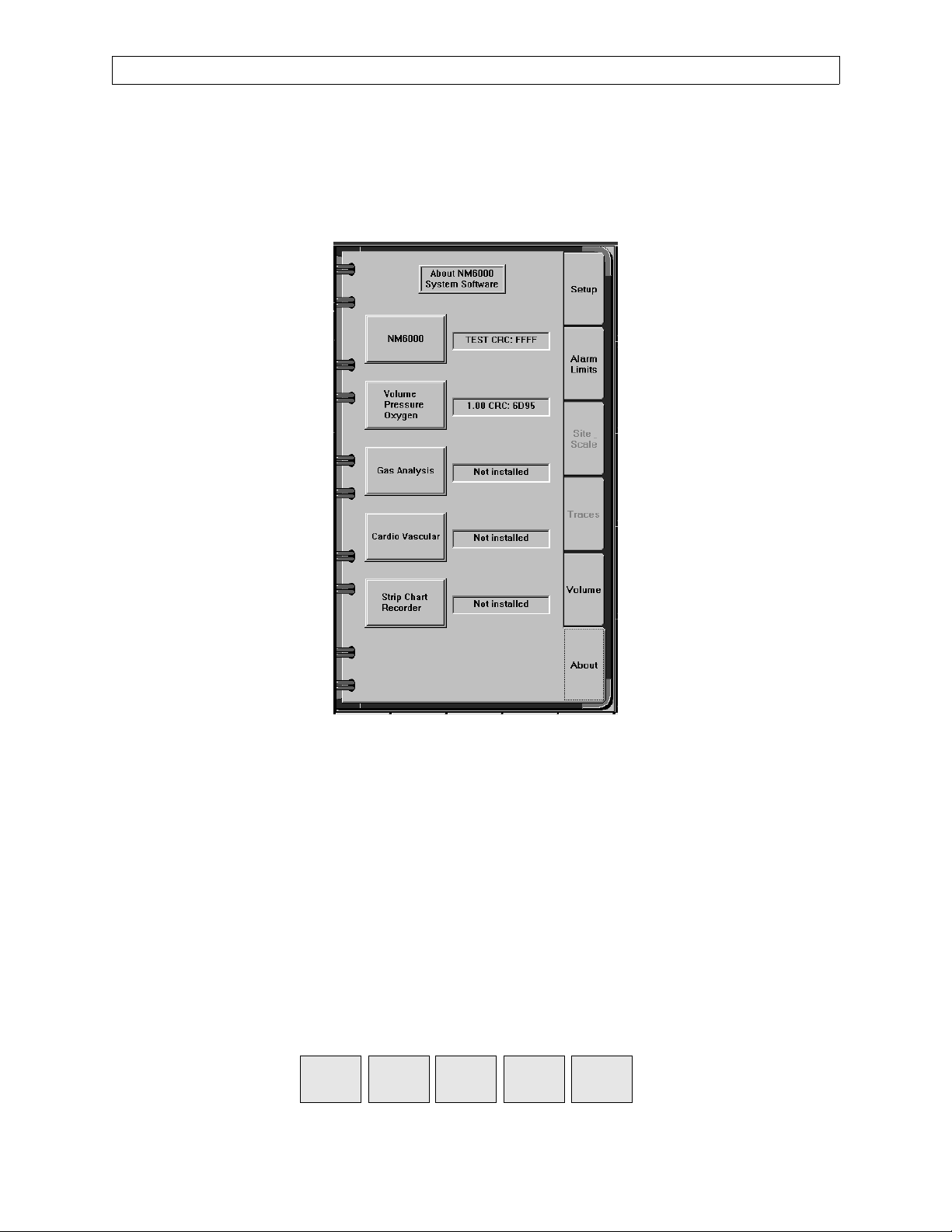

2.1 Accessing the Service Screens

To access the service screens you must first touch the Setup key at the bottom of

the screen to display the setup notebook, then touch the About tab to display the

About page of the setup notebook as shown in Figure 2-1.

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

Figure 2-1. Setup Notebook About Page

On the About page, touch the following keys in this order:

1. Volume, Pressure, Oxygen

2. Gas Analysis

3. NM6000

4. Strip Chart Recorder

In the service mode, the following keys are added at the bottom of the screen:

Exit

Service

Service

Monitors

Service

Config

2-2

Service

Dump

Service

Log

Rev. B

Page 13

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000 DIAGNOSTICS (continued)

2.2 Advanced Service Mode

The Advanced service mode allows the service technician to change the NM6000

serial number via the NM6K Configuration Page (described later), to install or

remove software options, update Pod based software and also allows the Pod

Logs and Service Log (described later) to be cleared.

To enter the Advanced service mode, touch the following keys on the About page

of the Setup Notebook in this order:

1. Strip Chart Recorder

2. NM6000

3. Gas Analysis

4. Volume, Pressure, Oxygen

2.3 Service Monitors Notebook

Touch the Service Monitors key at the bottom of the screen to display the

Service Monitors Notebook.

Touching each tab of the service monitors notebook will bring up the

corresponding service screen page, as described in the following paragraphs.

If desired, touch the Exit Service key to return to the monitoring screen.

Rev. L

2-3

Page 14

DIAGNOSTICS (continued)

2.3.1 Oxygen Monitor Service Screen

The Oxygen page of the service monitors notebook is shown on the left

side of Figure 2-2. This page displays current and stored A/D values for

the oxygen cells, date and time of the last O

instructions for performing a zero calibration.

If the O2 zero calibration values stored in the VPO pod are invalid upon

startup, a SERVICE O2 MON advisory is posted, the Service Monitors

Oxygen page will show a blank Last O2 Calibration date, and the

message ZERO CALIBRATION INVALID is displayed on the Service

Monitors Oxygen page as shown on the right side of Figure 2-2. These

three things also occur if a zero calibration is attempted with a current

cell value of less than 230 or greater than 260.

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

zero calibration, and

2

Refer to Section 5 for details on both zero and 21% O

calibrations.

2

Figure 2-2. Service Monitors Notebook, Oxygen Page

2-4

Rev. F

Page 15

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000 DIAGNOSTICS (continued)

2.3.2 Pressure Monitor Service Screen

Touch the Pressure tab of the Service Monitors Notebook to display the

pressure monitor service screen shown in Figure 2-3.

This page displays current pressure value, stored zero and span values,

and procedures for performing zero and span calibrations.

Test equipment connections are given in Section 5.

Rev. B

Figure 2-3. Service Monitors Notebook, Pressure Page

2-5

Page 16

DIAGNOSTICS (continued)

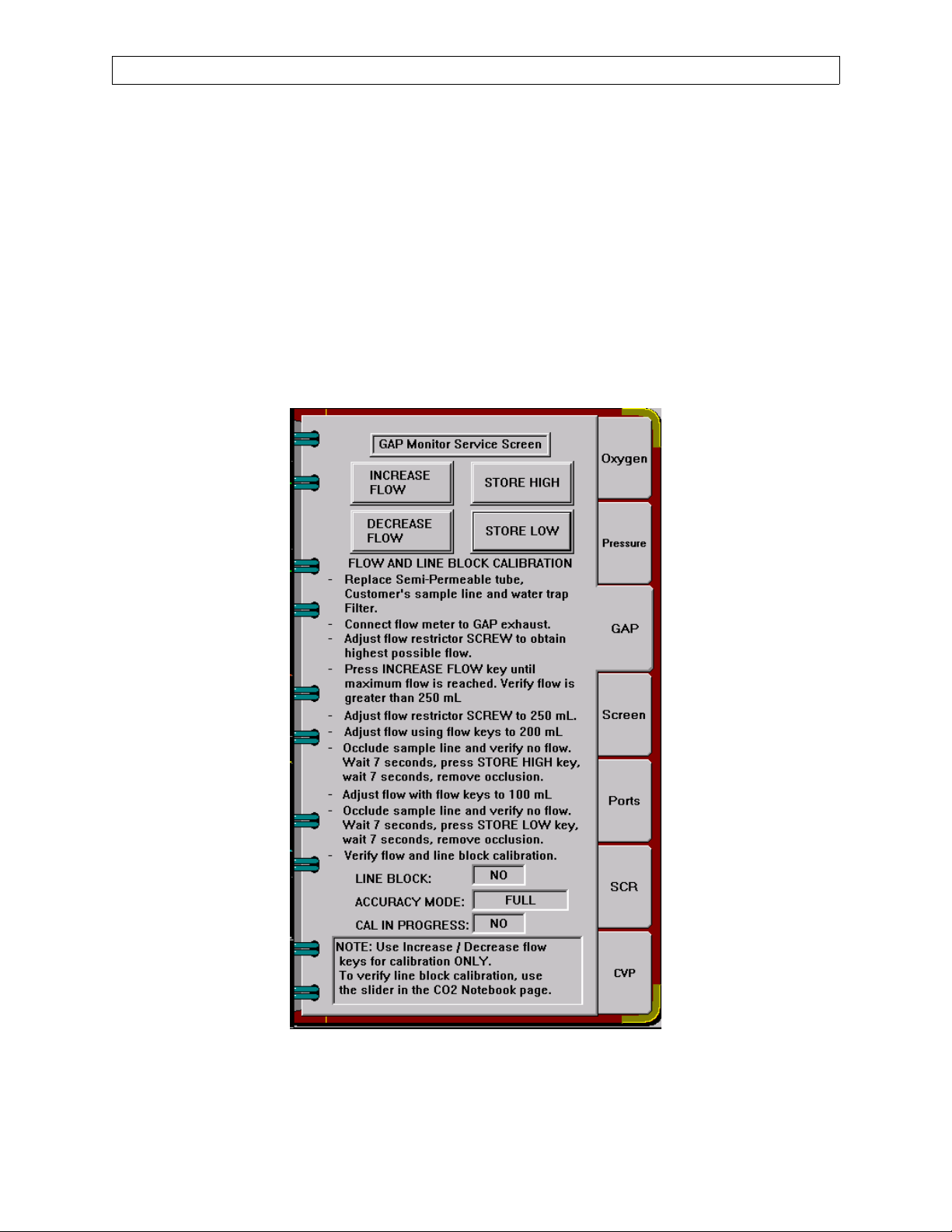

2.3.3 Gas Analyzer Sample Flow Service Screen

Touch the GAP tab of the Service Monitors Notebook to display the flow

monitor service screen shown in Figure 2-4.

This page provides touch keys and procedures for adjusting and storing

the high (200 mL/min.) and low (100 mL/min.) sample line flow rates.

Line block, accuracy mode, and calibration in progress indications are

also provided on this page.

Location of the adjustable flow restrictor for initial flow rate setting, and

test equipment connections are given in Section 5.

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

Figure 2-4. Service Monitors Notebook, GAP Page

2-6

Rev. R

Page 17

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000 DIAGNOSTICS (continued)

2.3.4 Screen Functions

Touch the Screen tab of the Service Monitors Notebook to display the

service screen shown in Figure 2-5.

Touch screen calibration is needed whenever a monitor is replaced, or

when picture size or centering is adjusted. This ensures correct

registration of the touch screen coordinates with the picture.

NOTE: An advanced touch screen calibration procedure is needed when

calibration is not possible under the usual procedure.

The Brightness/Contrast and Phase buttons are used to display test

patterns for adjustments on machines with a flat panel display.

Refer to Section 5 for the complete procedures.

Rev. B

Figure 2-5. Service Monitors Notebook, Screen Page

2-7

Page 18

DIAGNOSTICS (continued)

2.3.5 Port Configuration

Touch the Ports tab of the Service Monitors Notebook to display the port

configuration service screen shown in Figure 2-6. On machines with

only one com port (com 2), the screen shown in Figure 2-6A applies.

This page allows com ports 5, 6, 7, and 8 on the machine to be configured

for communication with external devices. Touching each parameter

displayed allows you to cycle through the available settings for the

corresponding port. The selections are:

Baud: 9600, 19200, 38400

Parity: EVEN, ODD, NONE

Stop Bits: 1, 2

Data Bits: 7, 8

Protocol: Vitalink

When the desired settings are displayed, touch the APPLY key to store

the settings.

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

Figure 2-6. Service Monitors Notebook,

Port Configuration Page

2-8

Figure 2-6A. Service Monitors Notebook,

Port Configuration Page,

One Com Port

Rev. B

Page 19

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000 DIAGNOSTICS (continued)

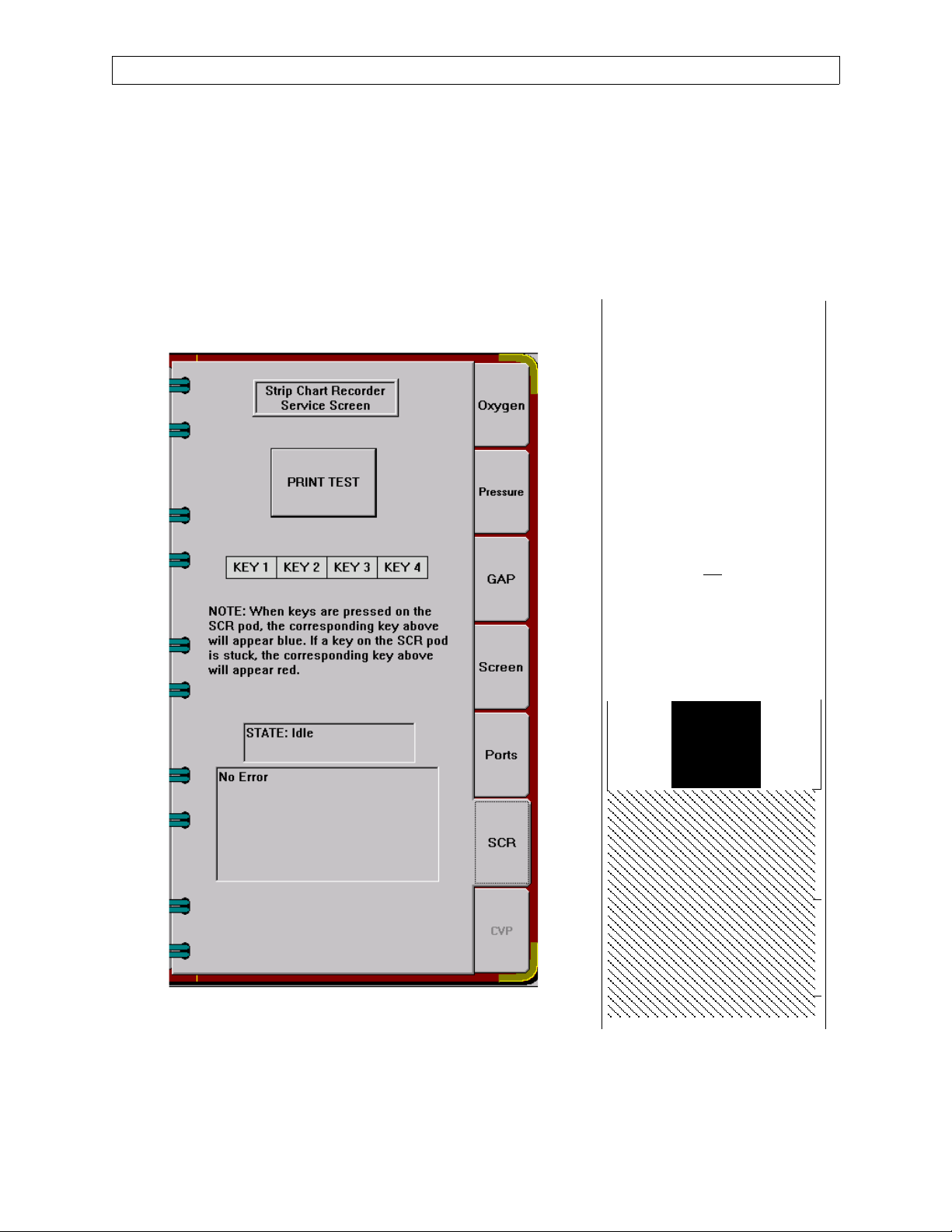

2.3.6 SCR Print Test

Touch the SCR tab on the Service Monitors Notebook to display the Strip

Chart Recorder Service Screen as shown in Figure 2-6B.

Diagnostic functions are provided for keys on the strip chart recorder.

Touching the PRINT TEST button will produce the printer output shown

in Figure 2-6C.

^^^^^^^^^^^^^^^^^^^^^^^^

*** AR42 Ver. 2.05 **

sn ØØØØ429792

ØØ: ↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓

1Ø: ↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓

2Ø: !”#$%&’()*+,-./

3Ш: Ш123456789:;<=>?

4Ш: @ABCDEFGHIJKLMNO

5Ш: PQRSTUVWXYZ[\]^6Ш: ‘abcdefghijklmno

7Ш: pqrstuvwxyz{|}¯

8Ш: ЗьйвдаезклипомДЕ

9Ш: ЙжЖфцтыъяЦЬ¢£¥.ƒ

AШ: бнуъсСao

BШ: ↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓

CØ: ↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓

DØ: ↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓

EØ: ↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓

FØ: ↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓

¿↓↓↓↓¡↓↓

Figure 2-6B. Service Monitors Notebook,

SCR Page

Rev. H

2-8A

^^^^^^^^^^^^^^^^^^^^^^^^

Figure 2-6C. Test Print

Page 20

DIAGNOSTICS (continued)

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

This page intentionally left blank

2-8B

Rev. H

Page 21

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000 DIAGNOSTICS (continued)

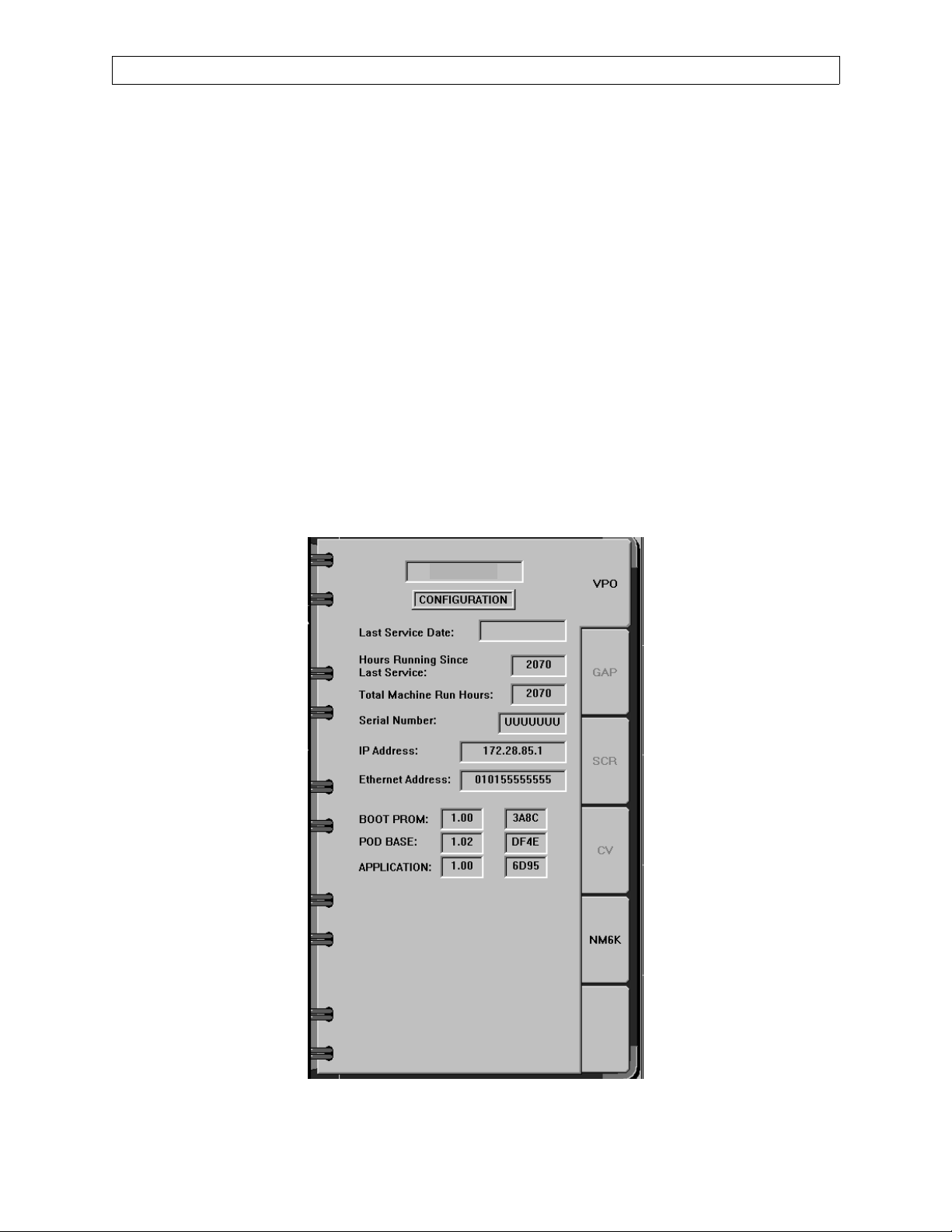

2.4 Service Configuration Notebook

Touch the Service Config key at the bottom of the screen to display the Service

Configuration Notebook shown in Figure 2-7. Tabs are displayed for each pod,

and for the Narkomed 6000. Touching each tab of the service configuration

notebook will bring up the corresponding configuration page, as described in the

following paragraphs. (An Options page is enabled when you are in the

Restricted Service Mode. See Paragraph 2.2A.)

2.4.1 Pod Configuration Pages

The VPO, GAP, SCR and CV pages display the following information for

each pod:

Last Service Date

Hours Running Since Last Service

Total Machine Run Hours

Serial Number

IP Address

Ethernet Address

Identification for Boot Prom, Pod Base Software and Application

VPO

Rev. F

Figure 2-7. Service Configuration Notebook, VPO Page

2-9

Page 22

DIAGNOSTICS (continued)

2.4.2 UPDATE Page

Touching the UPDATE tab of the Service Configuration Notebook will

display the page shown in Figure 2-8.

This page allows the service technician to download images to the pods.

If the information on the update page does not match the image on the

host, this information on the update page appears in red when in the

Advanced service mode. When in Advanced mode, pressing the

appropriate box initiates a download, and the information in the boxes

reflects the state of the download. NOTE: When the key is pressed, the

notebook disappears. Press the Service Config key to refresh the Service

Config Notebook. If not in Advanced mode, pressing the boxes will

display the message: “Enter Advanced Access Mode in order to

download.”

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

Figure 2-8. System Update Download Screen

2-10

Rev. M

Page 23

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000 DIAGNOSTICS (continued)

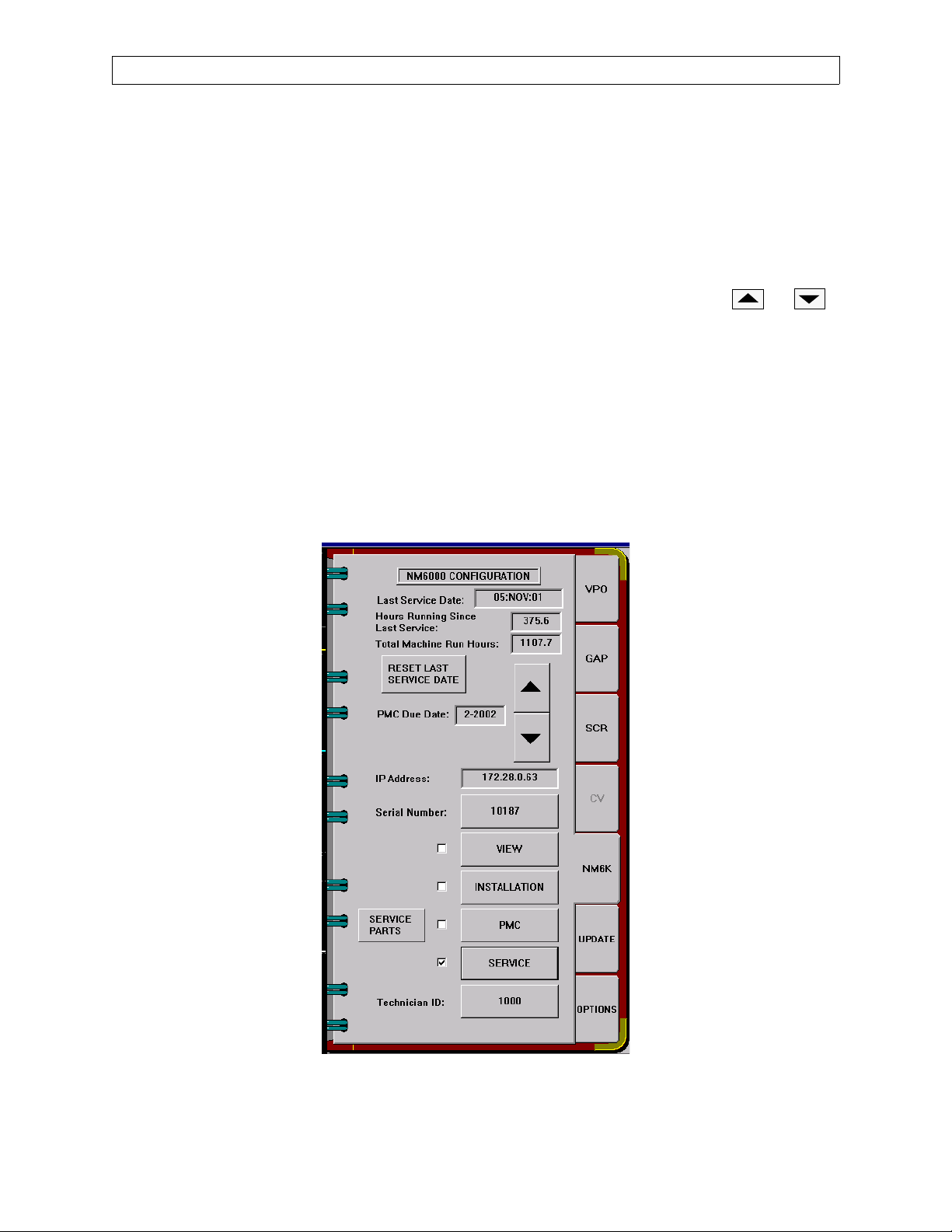

2.4.3 NM6K Configuration Page

Touching the NM6K tab of the Service Configuration Notebook will

display the NM6000 configuration page shown in Figure 2-9. This page

displays the Last Service Date, Hours Running Since Last Service, and

Total Machine Run Hours. Touching the RESET LAST SERVICE DATE

key will reset the displayed last service date to the current date for the

machine and for all connected pods.

This page also displays the next PMS Due Date. Touch the or

keys to set the desired date.

A Service Parts listing (described later) is also accessed through this

screen.

Should the machine’s processor be replaced, the machine serial number

needs to be entered. You can only do this while in the Advanced service

mode: Press the Serial Number button, and type the new number with

the touch keys that appear on the page. Press the Serial Number button

again to enter the number. This event will be recorded in the Service

Log.

Rev. R

Figure 2-9. Service Configuration Notebook, NM6K Page

2-11

Page 24

DIAGNOSTICS (continued)

2.4.4 Service Parts Screens

Press the SERVICE PARTS button on the NM6K Configuration Page to

view the service parts list as shown in Figure 2-10. If you are in the

PMS mode (press the Preventive Maintenance button and enter a valid

technician ID), you will be able to modify the list. If you are not in the

PMS mode and attempt to modify the list, you will be prompted to “Enter

Preventive Maintenance in order to change part information.”

In the user access mode Several keys appear on the Service Parts screen;

their function are as follows:

PREVIOUS: Move to the entry above the current selection.

NEXT: Move to the entry below the current selection

REPLACE: Brings up a dialog box asking if the selected part

SERIAL NUMBER: Brings up a keyboard for the user to enter a serial

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

was replaced.

number

OK: Saves all information, and returns display to the

NM6K configuration page. Any changes made are

recorded in the service log.

CANCEL: Any changes made to the list are not saved, and

display returns to the NM6K configuration page.

In the Advanced access mode, the following additional keys are

displayed:

FACTORY DEFAULTS: Changes the list to factory defaults for part

numbers, descriptions, quantity and schedule.

SET DATES: Brings up dialog box that allows user to set

dates for the selected part, or to clear all dates.

PART NUMBER: Brings up a keyboard that allows user to

change a part number.

When the Service Parts screen is entered for the first time, all dates and

serial numbers are blank except for pod serial numbers. You can select a

part by using the Previous or Next keys, or by pressing the desired row

on the screen under one of the date columns.

When you press the Replace key, the screen appears as shown in Figure

2-11.

2-12

Rev. B

Page 25

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000 DIAGNOSTICS (continued)

Figure 2-10. Service Parts Screen

Figure 2-11. Service Parts Replacement Query

Rev. B

If you press the No button, the dates are not modified.

If you press the Yes button the current date will be entered under Last

Date for the item selected, and the Next Date will be calculated using the

schedule. If there is no replacement schedule, the Next Date will remain

blank.

2-13

Page 26

DIAGNOSTICS (continued)

If you press any row under the Schedule column, a dialog box will appear

asking if you replaced all parts with the same schedule. If you answer

No, the dates are not modified. If you answer Yes, all dates for parts with

the same schedule can be updated. All blank Next Dates will be modified

assuming that this is the first replacement. If the current date is in the

same month or later than the Next Date, that row will appear in red.

If you press any row in red under the Description or Quantity column, a

dialog box will appear asking if you replaced all parts that are due. If you

answer Yes, the Last Date and Next Date will be updated for all parts

that are due to be replaced.

Pressing the Set Dates key will bring up the screen shown in Figure 2-

12.

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

4115864

Figure 2-12. Service Parts Set Dates Screen

If you press the Clear Selected Date key, the Last Date and Next Date for

the selected part will be cleared.

If you press the Clear All Dates key, all information in the Last Date and

Next Date columns will be cleared.

If you press the Set Selected Last Date key, The Last Date for the

selected part will be changed to the month and year shown on this

window.

2-14

Rev. E

Page 27

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000 DIAGNOSTICS (continued)

If you press the Set All Next Dates Based on Selected Date and Schedule

key, all the information in the Next Date column will be calculated based

on the selected month and year. The selected month and year can be

changed using the arrow keys.

If you press the Set Selected Next Date key, the Next Date for the

selected part will be changed to the month and year selected.

Pressing the SAVE key will update the parts list display. If you press the

QUIT key, none of the changes made using this window will be saved.

Rev. B

2-15

Page 28

DIAGNOSTICS (continued)

2.4.5 NM6000 Software Options Screen

Touching the Options tab in the Service Configuration Notebook will

display the page shown in Figure 2-8A.

This page allows the service technician to enable or disable software

controlled options when in advanced service menu. This page can not be

selected in User Access Service Mode.

NOTE: ‘Air Only Mode’ and Templates & Sounds options also require

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

keyloks to enable these features. If application software is

version 2.06, Low Flow Wizard also requires a Keylok to enable

this feature.

Figure 2-12 A. Software Options Screen

2-15A

Rev. R

Page 29

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000 DIAGNOSTICS (continued)

This page intentionally left blank

Rev. L

2-15B

Page 30

DIAGNOSTICS (continued)

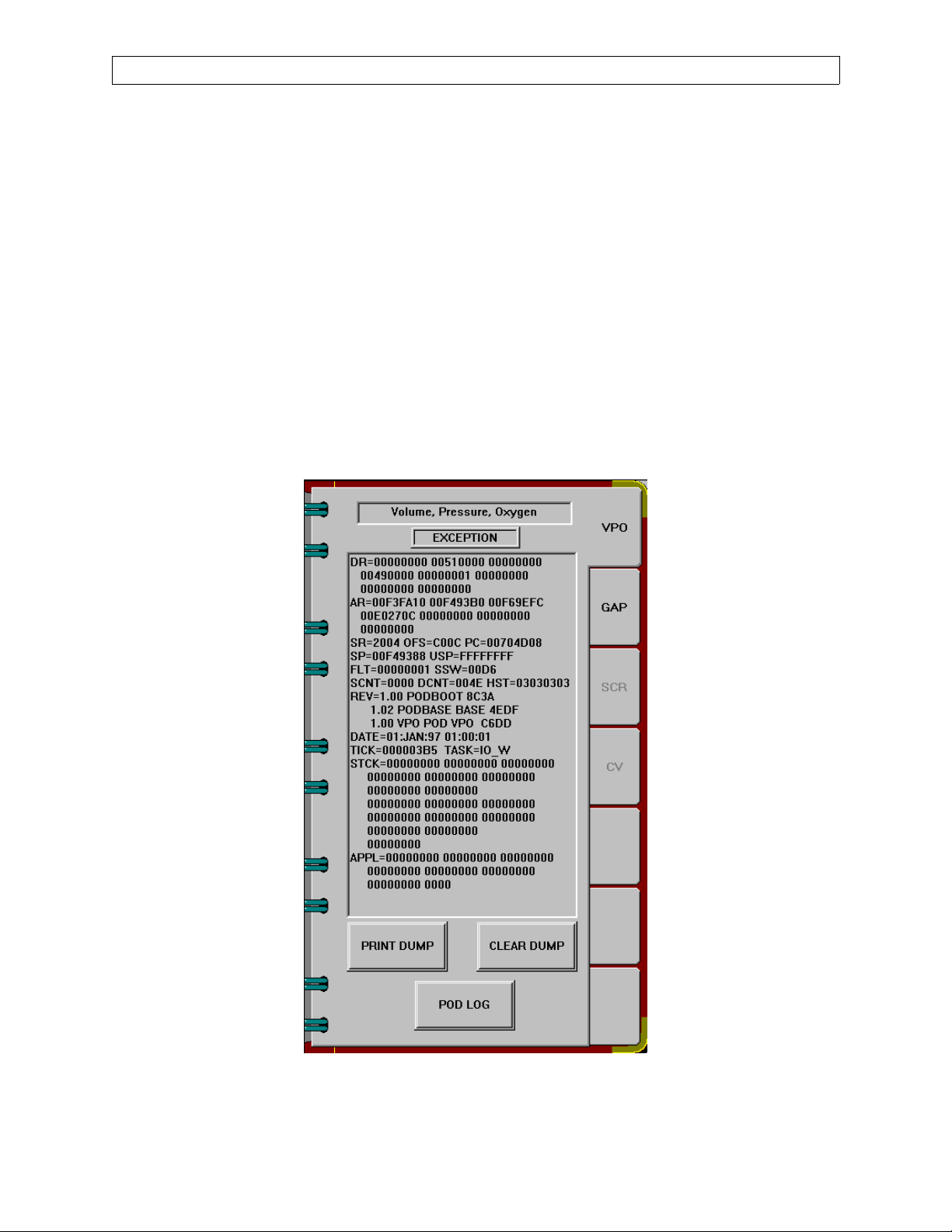

2.5 Service Dump Notebook

Touch the Service Dump key at the bottom of the screen to display the Service

Dump Notebook shown in Figure 2-13. Tabs are displayed for each pod, and for

the Narkomed 6000. Touching each tab of the service dump notebook will

display dump data for the corresponding page.

Touch the PRINT DUMP key to print out the data on the strip chart recorder. If

there is no strip chart recorder on the machine, then touching the PRINT

DUMP key will write the data to a file on the hard drive of the NM6000.

To clear the service dump, enter the advanced service menu, then touch the

CLEAR DUMP key to clear the service dump data for that page.

Touching the POD LOG button causes the pod log screen to be displayed in the

same area as the service log. See next page.

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

Figure 2-13. Service Dump Notebook

2-16

Rev. L

Page 31

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000 DIAGNOSTICS (continued)

2.5.1 Pod Log Screens

While the NM6000 is obtaining the service log, a progress bar is displayed

and an ABORT REFRESH button is enabled. Pressing this button will

cause the NM6000 to stop acquiring the service log from the pod.

Figure 2-13A. Pod log download screen

When all entries are obtained (or refresh is aborted), the ABORT

REFRESH button becomes the REFRESH BUTTON, and the SAVE,

PRINT, CLEAR and OK buttons appear.

Rev. F

Figure 2-13B. Pod log screen

2-16A

Page 32

DIAGNOSTICS (continued)

Pressing the REFRESH button will cause the NM6000 to obtain the log from

the pod again. When the SAVE button is pressed, the pod service log is saved to

a file according to pod type:

GAP: c:\nad\datfiles\podlog_gap.txt VPO: c:\nad\datfiles\podlog_vpo.txt

The pod service log is saved as an ASCII file with a header followed by service

log entries each on a separate line. The header contains the type of pod, date

and time log was saved, pod serial number, version and CRC for the BOOT

PROM, PBS and application, NM6000 serial number, version and CRC. Each

log entry contains the date and time, parameter value, and text:

SERVICE POD LOG FOR THE VPO POD

DATE: 9-22-1999 TIME: 10:48:23

POD SERIAL NUMBER: NNNNNNNN

BOOT PROM VERSION: 1.01 CRC: 7295

POD BASE VERSION: 1.02 CRC: 4EDF

APPLICATION VERSION: DEV1 CRC: 8D00

NM6000 SERIAL NUMBER: 145

NM6000 VERSION: 0.0 CRC: FFFF

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

--------------------------------------------------

09-22-99 10:36 007C8D4C PB01 System time set

09-22-99 10:14 00F00104 VP42 O2 CAL zero

09-22-99 10:14 08BD09E9 VP42 O2 CAL gain

09-22-99 10:07 00000000 VP44 Sensor Disconnect

The CLEAR button is enabled when you are in the Advanced Access mode.

Pressing this button clears the pod log. Pressing the OK button removes the pod

service log screen. While the pod service log is displayed, the soft keys and

numeric boxes are disabled. If an entry under the ID column is pressed, the

following dialog box is displayed:

Do you want to display events with ID VPXX?

The VPxx in the title corresponds to the ID of the entry that was pressed. If YES

is pressed, the displayed service log contains only entries with the selected ID. If

an entry is pressed under any column other than ID, that entry is displayed in

blue. The entry is then marked with * in the saved text.

2-16B

Rev. F

Page 33

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000 DIAGNOSTICS (continued)

2.6 Service Log

Press the Service Log key at the bottom of the screen to display the service log.

Initially, a blank page appears as shown in Figure 2-14.

Figure 2-14. Service Log Initial Screen

Press the Refresh button to bring up the service log as shown in Figure 2-15.

Rev. R

Figure 2-15. Service Log

2-17

Page 34

DIAGNOSTICS (continued)

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

Figure 2-15A. Data Log Screen

Figure 2-15B. Alarm Log Screen

2-18

Rev. R

Page 35

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000 DIAGNOSTICS (continued)

Error events are displayed in red, warning events appear in yellow, and

information events are in white. Pressing the Save button will save the service

log to the hard drive for later retrieval.

Several Filter keys are displayed with the service log. When the Filter Date key

is pressed, a filter date window appears which allows you to select only the

events by date that you want to display. Press the OK button to display those

events.

Pressing the Filter Source and Category button brings up a window that allows

you to select the source (SysOneMgr, etc.) and display any or all categories of

error, warnings or information events. Press the OK button to display those

events. If you press the RESET button on this window, all sources and

categories are displayed.

Pressing the Filter ID button brings up a window that allows you to display

events by ID number. Press the ALL button; it then becomes blank. Enter the

desired ID using the number buttons. That number will then appear on the

blank button. Press the OK button to display those selected events.

NOTE: the Clear key is active only if you are in the Advanced service mode.

When you press this key, a dialog box “Do you really want to clear the service

log?” appears. If you press the Yes button, the service log will be cleared.

Information contained in each type log may be viewed using various filters:

Selecting a Date filter allows the log to be sorted by first or last event, or to be

filtered by specified date ranges. See Figure 2-15C.

Figure 2-15C. Alarm - Filter Date

Rev. R

2-18A

Page 36

DIAGNOSTICS (continued)

Selecting Filter Event ID and entering a specific event ID will display only the

entries that match the selected ID. See Figure 15D.

Figure 2-15D. Alarm - Filter Event ID

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

Selecting Filter Source, Category and Type provides numerous filters allowing

for customized views of entries that meet several filtering criteria.

See Figure 2-15E.

Figure 2-15E. Alarm - Filter Source

2-18B

Rev. R

Page 37

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000 DIAGNOSTICS (continued)

2.6.1 Save Service Log window

When the LOCAL SAVE button is pressed, all logs are saved to the file

c:\nad\datfiles\slog.txt. All buttons on this window are disabled while

the service log is being saved.

Figure 2-15F. Save Service Log window

When the Computer button is pressed, a software keyboard is displayed

that allows you to change the computer name. You can also select from

the last five computer names entered. The default computer name is

SRVLAP.

When the Folder button is pressed, a software keyboard is displayed that

allows you to change the folder name. You can also select from the last

five folder names entered. The default folder name is NAD Software.

CAUTION: Before connecting an external computer to the Narkomed

6000, verify the computer is running a virus protection application set to

scan all files and is enabled. You must also verify that the definition files

and scan engines are of current vintage.

When the REMOTE SAVE button is pressed, all buttons on the SAVE

SERVICE LOG window are disabled. If the NM6000 is unable to find the

remote computer, an error message is displayed, the buttons are enabled,

and no further processing occurs. If the remote computer is found, the

NM6000 attempts to create a directory in the format \\computer

name\folder name\nm6k\SNXXXXXXXX. The NM6000 will then copy

all the files from the c:\nad\datfiles directory and the NT event file

APPEVENT.EVT to the remote location. The NM6000 will then save the

current service log to the remote location using the name

slog_date_time.txt where the date and time will be replaced with the

current date and time. If the NM6000 is unable to copy the files, an error

message is displayed and the buttons are enabled.If the service log is

successfully saved, a message that contains the path and name of the

saved service log will be displayed and the buttons will be enabled.

Rev. R

The saved service log is an ASCII text file in the line format

date time~source name of event~category~event ID~event

type~description~data.

Each line is a separate event log entry. Most entries will contain no data.

2-18C

Page 38

DIAGNOSTICS (continued)

2.6A Service Log Entry Detail

Software Version 1.05 adds the following Service Log Entry Detail window. If a

service log entry is pressed while the log keys are enabled, this window is

displayed, showing detailed information about the currently selected event. The

selected event will be highlighted in blue in the event log. A box on this window

displays the following:

ERROR in red for error events

WARNING in yellow for warning events

INFORMATION in white for informational events

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

Figure 2-15G. Service Log Entry Detail window

Pressing the Previous button causes the previous event to be higlighted in blue

on the service log, and the information for the previous event is displayed in the

Service Log Entry Detail window. The last selected entry returns to its

appropriate color. Pressing the Previous button for the most recent entry causes

no changes.

Pressing the Next button causes the next event to be highlighted in blue on the

service log, and the information for the next event is displayed in the Service

Log Entry Detail window. The last selected entry returns to its appropriate

color. Pressing the Next button for the oldest entry causes no changes.

Pressing the Close button removes the Service Log Entry Detail window, and

the last selected entry in the service log returns to its appropriate color.

2-18D

Rev. R

Page 39

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000 DIAGNOSTICS (continued)

2.7 NM6000 Event Log Transfer Using Service Laptop with Windows 95, 98 or Me

The following procedure allows the Narkomed 6000’s event log and POD logs to be

downloaded to a service laptop using either Windows 95 or 98 operating system. The

logs are saved to the laptop’s hard drive NM6K folder for subsequent analysis. (Refer to

Section 2.7A if using a service laptop with Windows NT operating system.) The

following items are needed:

--Service laptop computer, IBM PC or compatible

with: Type II or larger PCMCIA slots

500 MB hard drive minimum

Windows 95 or 98

Etherlink card configured to share files

--Vitalan cable P/N 4113989-001

CAUTION: Before connecting an external computer to the Narkomed 6000, verify the

computer is running a virus protection application set to scan all files and is enabled.

You must also verify that the definition files and scan engines are of current vintage.

2.7.1 Configure the laptop as shown in Figure 2-16.

2.7.2 With the Narkomed 6000 System Power switch at STANDBY and the laptop

computer Off, connect the laptop’s etherlink cable to any Vitalbus port on the

Hub. See Figure 2-17.

2.7.3 Power up the laptop computer and the NM6000. Press the Divan Standby key to

cancel the ventilator self-test, and wait for the power up diagnostics to finish.

Verify the green LED on the Lancard cable is illuminated. (If the laptop

computer prompts for a password, select Cancel.)

2.7.4 Press the Setup key and select the About tab on the About System Software

notebook. Enter the primary service menu code and select OK on the Service

Mode screen to enter the USER ACCESS service mode.

2.7.5 Under the Service Mode screen select the NM6000 tab and enter the advanced

service code to enter the ADVANCED ACCESS mode.

2.7.6 Press the Service Config key and select the SERVICE key. Using the NM6000

on-screen keyboard, enter your service ID number then press OK.

2.7.7 Press the Service Log key to call up the service event log.

2.7.8 Press the Refresh key to refresh the logs. During this activity the Save key text

will turn gray. When the Save key turns black again, press the Save key to bring

up the SAVE SERVICE LOG dialog.

2.7.9 If the laptop computer name is not SRVLAP or the desired folder is not NAD

Software, touch these keys to make the required edits.

Rev. N

2.7.10 Press the REMOTE SAVE button. If the NM6000 is unable to find the remote

computer, an error message is displayed. If the remote computer is found, the

NM6000 attempts to create a directory in the format \\computer name

‘SRVLAP’\folder name ‘NAD Software’\nm6k\SNXXXXXXXX.

2-19

Page 40

DIAGNOSTICS (continued)

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

1. Turn on the laptop if necessary

Install the Drivers

2. Ensure that the Ethernet card and driver are

installed.

Set the Computer Name and IP Address

3. Select “Start->Programs->Windows Explorer”

from the task bar.

4. Right click “Network Neighborhood” or My

Network Places” if using Windows Me. If there

is not a selection for “Network Neighborhood” or

“My Network Places”, select StartàSettingsà

Control PanelàNetwork. Launch the install

wizard to load “Client for Microsoft Networks.”

5. Select the PROPERTIES button.

6. Select the “Identification” tab.

7. Enter the following data (as necessary):

Computer Name: srvlap

Work Group: Service

8. Select the “Configuration” tab.

9. Select the “TCP/IP” item (looks like an electrical

plug).

10. Press the “Properties” button.

11. Select the “IP Address” tab.

21. Ensure that the directory “NAD

Software”\NM6K exists on the C:\ drive.

22. Right click the “NAD Software” directory.

23. Select the “Sharing” menu item.

24. Select the “Sharing” tab.

25. Select the “Share As...” radio button.

26. Ensure that “NAD Software appears as the

share name.

27. Select the “Full” Access type radio button.

28. Press APPLY, then OK.

Turn off the Dial-Up modem (if applicable)

29. Right click “My Computer:”

30. Select the Properties menu item.

31. Select the “Device Manager” tab.

32. Expand “Network Adapters” by clicking the “+”

box on the line.

33. Select the Dial-up adapter.

34. Select the PROPERTIES button.

35. Ensure that “Disable in this hardware profile”

is checked.

12. Select the “Specify an IP address” radio button.

13. Set the following fields:

IP Address: 172.28.0.130

Subnet Mask: 255.255.0.0

14. Press OK.

Share the directories

15. Select the “Access Control” tab.

16. Select the “Share-level access control” radio

button.

17. Select the “Configuration” tab.

18. Click on “File and Print Sharing” button.

19. Select the “I want to be able to give o thers access

to my files” item.

20. Press OK, and press OK again to exit the

Network dialog box.

Figure 2-16. Configuring the Windows 95, 98 Laptop

36. Press OK.

Clean up and Reboot

37. Close all open windows.

38. Select “Start->Shut Down” from the task bar.

39. In the “Shut Down Windows” dialog box, select

“Restart the Computer?”

40. Press “Y

system to reboot.

es”; allow several minutes for the

2-20

Rev. N

Page 41

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000 DIAGNOSTICS (continued)

SV00368

Rev. K

Figure 2-17. Connections for Windows 95, 98 Event Log Transfer

2-21

Page 42

DIAGNOSTICS (continued)

2.7.11 After successful completion of an Event Log transfer, the file will be

located on the laptop computer as shown in Figure 2-18.

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

Figure 2-18. Laptop Computer File Example

2.7.12 Verify the fourteen files transferred properly to the laptopo and forward

the files to DMI’s Technical Support Department for further analysis.

NOTE: The Appevent.evt, Slog.txt, and Slog_xxxxxxxx_xxxxxx.txt files

must each contain at least 100KB of data.

2-22

Rev. K

Page 43

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000 DIAGNOSTICS (continued)

Figure 2-19. Deleted

Figure 2-20. Deleted

Figure 2-21. Deleted

Rev. K

2-23

Page 44

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued)

2.7A NM6000 Event Log Transfer Using Service Laptop with Windows NT

The following procedure allows the Narkomed 6000’s event log and POD logs to be

downloaded to a service laptop using Windows NT operating system. The logs are saved

to the laptop’s hard drive NM6K folder for subsequent analysis. (Refer to Section 2.7 if

using a service laptop with Windows 95 or 98 operating system.) The following items are

needed:

--Service laptop computer, IBM PC or compatible

with: Type II or larger PCMCIA slots

500 MB hard drive minimum

Windows NT

Etherlink card configured to share files

--Vitalan cable P/N 4113989-002

CAUTION: Before connecting an external computer to the Narkomed 6000, verify the

computer is running a virus protection application set to scan all files and is enabled.

You must also verify that the definition files and scan engines are of current vintage.

NM6000

2.7A.1 With the Narkomed 6000 System Power switch set to STANDBY and the laptop

computer Off, connect the laptop’s etherlink cable to any Vitalbus port on the

Hub as shown in Figure 2-21A.

SV00368

Figure 2-21A. Connections for Windows NT Event Log Transfer

2-23A

Rev. N

Page 45

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000 DIAGNOSTICS (continued)

2.7A.2 Power up the laptop computer and the NM6000. Press the Divan

Standby key to cancel the ventilator self test. When prompted for a

network password, enter “password” and wait for the power up

diagnostics to finish.

Verify the network workgroup. If unknown, this information can be

found as follows: From the Windows NT desktop: right click on Network

Neighborhood; select Priorities, select the Identification tab. The

workgroup will be listed in one of the text boxes displayed. If the

workgroup is not “Goldisk”, use procedure 2.7B. It is also highly

recommended that you contact your information systems admistrator to

make the necessary changes to the laptop. (To work correctly, workgroup

must be “Goldisk”, administrator password must be “NAD123NAD123”)

2.7A.3 Verify the computer name for the laptop; ie: SRVLAP028. See Figure 2-

21B. If unknown, this information can be found as follows:

From the Windows NT Desktop:

-- Right-click on Network Neighborhood

-- Select Properties

-- Select the Identification tab

-- The computer name will be listed in one of the text boxes displayed

Rev. L

Figure 2-21B. Computer Name Identification Screen

2-23B

Page 46

DIAGNOSTICS (continued)

2.7A.4 Verify the laptop TCP/IP address is updated to communicate with the

NM6000. If unknown, this information can be found as follows:

-- From the Network dialog in Figure 2-21B, click on the Protocols tab.

--A dialog window shall appear as in Figure 2-21C

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

Figure 2-21C. Protocols Tab

-- Click once on the TCP/IP Protocol entry in the list of Network

Protocols.

-- Click the P

roperties button

-- A dialog shall appear as in Figure 2-21D.

--Using the drop down arrow, select the correct Ethernet adapter.

2-23C

Rev. L

Page 47

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000 DIAGNOSTICS (continued)

Rev. K

Figure 2-21D. TCP/IP Properties

-- Select S

pecify an IP address radio button

-- Enter the above shown I

address numbers, use the space bar to advance to the third and fourth

sets.)

-- Enter the above shown Su

-- Select OK to close the TCP/IP Properties dialog window

NOTE: If the MS loop adapter interferes with the proper operation of

the TCP/IP adapter, contact your IS administrator.

-- Select OK to close the Network dialog window

-- Shut down and restart the laptop computer for the new Network

settings to take effect. (When prompted for a password, enter

“password”)

2-23D

P Address (after entering the second set of IP

bnet Mask

Page 48

DIAGNOSTICS (continued)

2.7A.5 Verify the laptop file folders are configured to share with the NM6000. If

unknown, this information can be found as follows:

-- Right-click the Start key

-- Select Explorer

-- At the (C:) select the NAD Software folder (with a hand under it). If

none is present, create it:

F

ile...New...Folder, name it NAD Software

-- If a hand was not under the NAD Software folder, modify it:

Right-click (ALT + ENTER) Sharing, select Shared As,

Permission, Type, Full Control, OK, Apply, OK

You should now see a hand under the NAD Software folder as shown in Figure

2-21E

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

Figure 2-21E. NAD Software Folder

-- Select NM6K folder. If none is present, create it:

Select NAD Software, File...New...Folder, name it NM6K

2-23E

Rev. K

Page 49

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000 DIAGNOSTICS (continued)

2.7A.6 On the NM6000, press the Setup key and select the About tab on the

About SystemSoftware notebook. Enter the primary service menu code

and select OK on the Service Mode screen to enter the USER ACCESS

service mode.

2.7A.7 Under the Service Mode screen select the NM6000 tab and enter the

advanced service code to enter the ADVANCED ACCESS mode.

2.7A.8 Press the Service Config key and select the SERVICE key. Using the

NM6000 on-screen keyboard, enter your service ID number, then press

OK.

2.7A.9 Press the Service Log key to call up the service event log.

2.7A.10Press the Refresh key to refresh the logs. During this activity the Save

key text will turn gray. When the Save key text turns black again, press

the Save key to call up the SAVE SERVICE LOG dialog.

2.7A.11 If the Laptop computer name is not SRVLAP028 or the desired folder is

not NAD Software, touch these keys and make the required edits.

2.7A.12Press the REMOTE SAVE button. If the NM6000 is unable to find the

remote computer, an error message is displayed. If the remote computer

is found, the NM6000 attempts to create a directory in the format

\\computer name’SRVLAP’\folder name ‘NAD

Software’\nm6k\SNXXXXXXXX. (The S/N listing is derived from the

NM6000 CONFIGURATION page.)

Rev. K

2-23F

Page 50

DIAGNOSTICS (continued)

2.7A.13After successful completion of an Event Log transfer, the file will be

located on the laptop computer as shown in Figure 2-18.

.

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

Figure 2-21F. Laptop Computer File Example

2.7A.14Verify the fourteen files transferred properly to the laptopo and forward

the files to DMI’s Technical Support Department for further analysis.

NOTE: The Appevent.evt, Slog.txt, and Slog_xxxxxxxx_xxxxxx.txt files

must each contain at least 100KB of data.

2-23G

Rev. K

Page 51

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000 DIAGNOSTICS (continued)

2.7B. Event Log Transfer: Alternate Procedure

2.7B.1 Verify the computer name of the laptop, ie: SRVLAP028. See Figure 2-

21G. If unknown, this information can be found as follows:

From the Windows NT Desktop:

-- Right-click on Network Neighborhood

-- Select Properties

-- Select the Identification tab

-- The computer name will be listed in one of the text boxes displayed

Rev. L

Figure 2-21G. Computer Name Identification Screen

2.7B.2 Update the TCP/IP address to communicate with the NM6000.

-- From the Network dialog in Figure 2-21G, click on the Protocols tab.

-- A dialog window shall appear as in Figure 2-21H.

2-23H

Page 52

DIAGNOSTICS (continued)

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

Figure 2-21H. Protocols Tab

-- Click once on the TCP/IP Protocol entry in the list of Network

Protocols.

-- Click the P

roperties button

-- A dialog shall appear as in Figure 2-21J.

2-23J

Rev. L

Page 53

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000 DIAGNOSTICS (continued)

Rev. L

Figure 2-21J. TCP/IP Properties

-- Select S

pecify an IP address radio button

-- Enter the above shown I

address numbers, use the space bar to advance to the third and fourth

sets.)

-- Enter the above shown Su

-- Select OK to close the TCP/IP Properties dialog window

-- Select OK to close the Network dialog window

-- Shut down and restart the laptop computer for the new Network

settings to take effect.

2-23K

P Address (after entering the second set of IP

bnet Mask

Page 54

DIAGNOSTICS (continued)

2.7B.3 Configuring the Laptop:

On the Laptop computer:

-- Right-click the Start key

-- Select Explorer

-- At the (C:) select NAD Software folder (with a hand under it). If none is

present, create it:

ile...New...Folder, name it NAD Software

F

-- If a hand was not under the NAD Software folder, modify it:

Right-click (ALT + ENTER) Sharing, select Shared As,

Permission, Type, Full Control, Apply, OK

-- Select NM6K folder. If none is present, create it:

File...New...Folder, name it NM6K

-- Select the Event Log folder. If none is present, create it:

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

File...New...Folder, name it Event Log

You should now see a hand under the NAD Software folder as shown in Figure

2-21K.

Figure 2-21K. Shared Event Folder

2-23L

Rev. L

Page 55

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000 DIAGNOSTICS (continued)

2.7B.4 Turn the Narkomed 6000 System Power switch to ON. Allow the system

to complete its power up self diagnostic tests, then press Ctrl+F9,

Alt+F9, and Ctrl-ESC on the NM6K keyboard to call up the Start menu.

NOTE: Use the Arrow and Tab keys to navigate through the selections.

-- Select Start...F

-- L

ook in: My Computer

ind File or Folders

-- In the Named list: select AppEvent.evt. If the dropdown window is

empty, type in AppEvent.evt. See Figure 2-21L.

-- Select Find Now

-- Verify that the file is highlighted and press Ctrl+C to copy the file.

-- Click on the X at the top right to close the Find window.

Figure 2-21L. Find AppEvent.evt Screen

-- Press the Window key or Ctrl+Esc to bring up the task bar.

-- Type R for R

-- In the O

dropdown window is empty, type in \\SRVLAP

un

pen list: select \\SRVLAP028, then select OK. If the

028.

NOTE: If the computer name is not SRVLAP028, type in \\ followed by

the appropriate name as previously identified.

-- Select OK

Figure 2-21M. Run Box

Rev. L

2-23M

Page 56

DIAGNOSTICS (continued)

2.7B.5 A Network Password window should soon appear indicating an

incorrect user name or password. This is normal. Enter the computer’s

name (SRVLAP028) in the C

portion of this listed field and enter the word “password” in the

assword field. Press the Enter key.

P

NOTE: If the host NM6000 cannot locate the networked laptop computer,

recheck the laptop’s configuration setting.

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM6000

onnect As: field by removing the “\\”

Figure 2-21N. Network Password

2.7B.6 A window should appear on the NM6000 showing all shared folders on

the laptop, as identified with a hand under the folder. If no shared

folders appear, recheck the selections made in the Configuring the

Laptop section.

-- Open the EventLog Folder (SRVLAP028\NAD

Software\NM6K\Eventlog)

-- Press CTRL+V to paste the file to the laptop.

-- Verify that the AppEvent.evt file appears on the NM6000 screen.

-- Select the AppEvent.evt file.

-- Select F

ile, Rename, move the cursor to the left of the file name and