Page 1

ÉQUIPEMENT DOYON INC.

1255, rue Principale

Linière, Qc, Canada G0M 1J0

Tel.: 1 (418) 685-3431

Canada: 1 (800) 463-1636

US: 1 (800) 463-4273

FAX: 1 (418) 685-3948

Internet: http://www.doyon.qc.ca

e-mail: doyon@doyon.qc.ca

SM200, SM201, SM300, SM401, SM402NA

Product / Produit:

Serial number / Numéro de série:

Page 2

PLANETARY DOUGH MIXER

SM200, 201, 300, 401, 402NA

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

DANGER

TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK,

CAREFULLY FOLLOW THESE INSTRUCTIONS

TABLE OF CONTENTS

SECTION « A » DESCRIPTION PAGE

Installation and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A1

Construction and shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A3

SM mixers chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A4

Installation and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A5

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A6

Mixer cleaning and maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A7

Planetary dough mixer description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A8

Installation of vegetable or meat cutter attachment . . . . . . . . . . . . . . . . . A9

For more information, please call our office . . . . . . . . . . . . . . . . . . . . . . . A13

SECTION « B » DIMENSIONS

SM200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B1

SM201 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B2

SM300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B3

SM401 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B4

SM402NA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B5

SECTION « E » COMPONENT PARTS

SM200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E1

SM201 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E4

SM300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E8

SM401 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E12

SM402NA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E15

SECTION « G ». ELECTRIC SCHEMATICS

SM200 & SM201 120 Volts 60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . G1

SM300 120 Volts 60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G2

SM401 120 Volts 60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G3

Page 3

SM201 & 401 220 Volts 50/60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G4

SM402NA 220 Volts 50/60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G5

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FAMMIX-A.DOC

REV. 2008/07/22

Page 4

A1

INSTALLATION AND MAINTENANCE MANUAL

The manufacturer suggests reading this manual carefully.

The planetary dough mixer is manufactured with first quality materials by experienced technicians.

Normal use and adequate maintenance will guarantee a reliable service for years to come.

The planetary dough mixer is available in five different models: SM200, 20 quart with hub

attachment. SM201, 20 quart without hub attachment. SM300, 30 quart with hub attachment.

SM401, 40 quart without hub attachment. SM402NA, 40 quart with hub attachment.

A nameplate fixed to the side of the mixer specifies the serial number, model number, amperage,

voltage and frequency.

Drawings, electrical diagrams, and replacement part numbers are included in this manual.

ATTENTION

ÉQUIPMENT DOYON INC. is not responsible for damages to the property or

the equipment caused by non-certified personnel. The customer is responsible

for finding a qualified electrician for the installation of the slicer.

Page 5

A2

C O N S T R U C T I O N

You now have the most performant planetary dough mixer on the market in its category. This

planetary mixer is manufactured using the highest quality components and materials.

S H I P P I N G

For your safety, this equipment has been verified by qualified technicians and carefully crated before

shipment. The freight company takes full responsibility for the delivery of this equipment in good

condition, by accepting to transport it.

IMPORTANT

RECEPTION OF THE MERCHANDISE

Make sure to verify that the received equipment is not damaged before signing the delivery receipt. If

damage or loss is noticed, write it clearly on the receipt and have the carrier sign it. If the damage is

noticed after the carrier left, contact the freight company immediately so that they may inspect it.

We do not take responsibility for damages or losses that may occur during transportation.

Page 6

A3

W A R N I N G

FOR YOUR SAFETY

BEFORE CLEANING OR ANY MAINTENANCE PROCEDURE

MAKE SURE THE MAIN POWER IS OFF.

IMPORTANT

INSTALLATION AND SERVICE

A qualified technician must do servicing.

The mixer must be connected to the utility and electrically grounded in conformity to the effective

local regulations. If these are not established, the oven must be connected according to the Canadian

Electrical Code (CSA-C22.1-XX) or National Electrical Code (NFPA 70-XX). Refer to last

edition year for XX.

Page 7

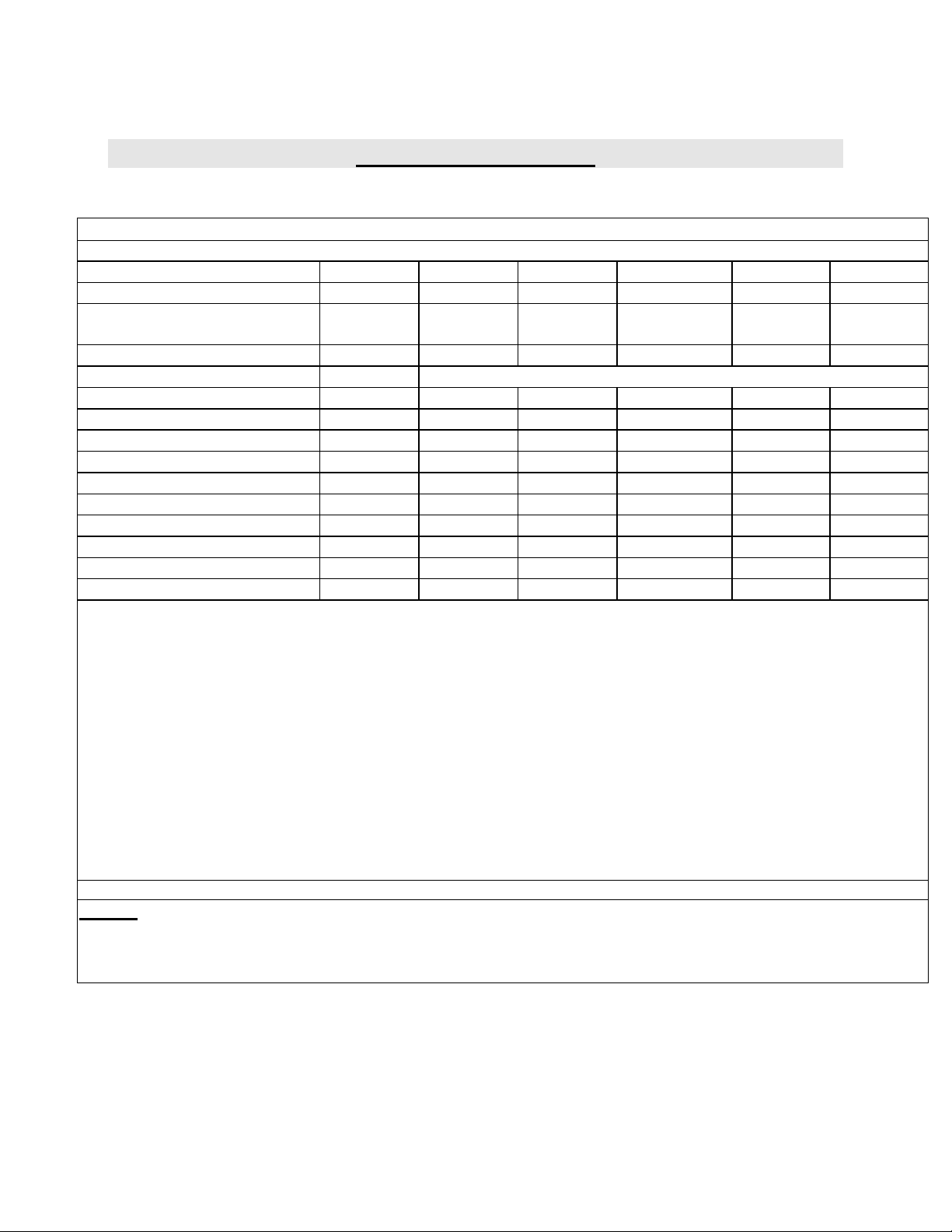

A4

SM MIXERS CHART

Tool SM402NA SM401 SM300 SM201 SM200

Bowl capacity (qts or liters) 40 40 30 20 20

Standard #12 attachment

hub

Transmission driven by Belt Belt Gear Belt Gear

Cake Falt beater 45 lb/20kg 30lb/13.5kg 25lb/11.3kg 20lb/9kg 20lb/9kg

Sponge cake Whip 30lb/13.5kg 20lb/9kg 18lb/8kg 12lb/5.4kg 12lb/5.4kg

Bread dough 60%AR Hook 35lb/15.5kg 30lb/13.5kg 25lb/11.3kg 18lb/8kg 18lb/8kg

Whole wheat dough 50%AR Hook 35lb/15.5kg 20lb/9kg 15lb/6.8kg 10lb/4.5kg 10lb/4.5kg

Whole wheat dough 70%AR Hook 40lb/18kg 30lb/13.5kg 25lb/11.3kg 15lb/6.8kg 15lb/6.8kg

Donut dough 65%AR Hook 35lb/15.5kg 20lb/9kg 15lb/6.8kg 7 lb/3.2kg 7 lb/3.2kg

Pizza dough (thin) 40% AR Hook 25lb/11.3kg 15lb/6.8kg 10lb/4.5kg 5 lb/2.3kg 5 lb/2.3kg

Pizza dough 45% AR Hook 27lb/12.2kg 18lb/8kg 12lb/5.4kg 7 lb/3.2kg 7 lb/3.2kg

Pizza dough (med) 50% AR Hook 30lb/13.6kg 20lb/9kg 15lb/6.8kg 10lb/4.5kg 10lb/4.5kg

Pizza dough (thick) 60% AR Hook 35lb/15.8kg 25lb/11.3kg 20lb/9kg 15lb/6.8kg 15lb/6.8kg

% AR(ABSORPTION RATIO) =WATER WEIGHT (lbs) DIVIDED BY FLOUR WEIGHT(lbs)

CAPACITY DEPENDS ON MOISTURE CONTENT OF DOUGH .

ABOVE CAPACITIES ARE BASED ON 12 % FLOUR MOISTURE AT 70°F (21°C) WATER

TEMPERATURE.

yes no yes no yes

Dough weight

1 US GALLON OF WATER = 8.33 lbs (3.8kg)

1 CANADIAN GALLON OF WATER =10 lbs (4.5kg)

DROP THE ABOVE CHART BY 10% WHEN YOU USE HIGH GLUTEN FLOUR

FOR EXAMPLE: YOU ARE USING 1/2 WATER US GALLON & 12lbs FLOUR

8.33lbs ÷ 2 = 4.17lbs, 4.17lbs WATER ÷ 12lbs FLOUR = 0.35

THAT MEANS YOU WILL HAVE A 35% DOUGH (AR)

NOTE:

• HUB ATTACHMENT SHOULD NOT BE IN PLACE WHILE MIXING.

• MUST MIX PIZZA DOUGH ON FIRST GEAR ONLY.

• 2ND SPEED SHOULD NEVER BE USED ON 50% AR OR LOWER PRODUCTS

Page 8

A5

I N S T A L L A T I O N

IN GENERAL

Open the crate and remove all materials used for packing as well as the accessories.

Put the mixer on a straight floor and make sure the mixer is level.

For a optimal stability and security use the hole on each leg to fix the mixer on the floor or the table

Each unit is set up to be used with the electrical supply specified on the nameplate fixed on the side

of the mixer.

To the electrician

The electrical supply installation must be in accordance with the electrical rating on the nameplate.

PLANETARY DOUGH MIXER OPERATION

1. Put your dough recipe in the bowl.

2. Put the bowl in place on the mixer.

3. Install the proper agitators.

4. Pull up the lift bowl handle.

5. Close the bowl guard.

6. Set the proper speed.

7. Pull the stop switch.

8. Push the start switch to start the mixer.

9. To change speed, turn the motor off. Allow the planetary to stop rotating, move speed

selector handle at the desired speed and restart the mixer. If you can not change the speed, put

the speed selector handle at neutral position (between two speeds), start and stop the mixer

and change speed before the mixer is almost stop.

10. NEVER CHANGE THE SPEED WHEN THE MIXER WORKS.

11. IF YOU OPEN THE BOWL GUARD OR PUSH DOWN THE BOWL, THE MIXER

WILL AUTOMATICALLY STOP.

WARNING

NEVER TRY TO PUT YOUR HAND IN THE BOWL WHEN THE MIXER IS ON.

ALWAYS DISCONNECT THE ELECTRICAL CORD OR MAIN POWER BRAKER.

POWER FAILURE

With security bowl guard .When you have a power failure you don’t have to switch off the mixer. It

will not start working when the power comes back on.

Without security bowl guard. When the power comes back on, the mixer will start automatically if it

was on before the power failure. It is necessary to put the switch to « OFF » so that the mixer does

not start without supervision.

Page 9

A6

TROUBLESHOOTING

BEFORE CALLING FOR SERVICE

ANSWERS TO MOST FREQUENT QUESTIONS

Always cut the main power off before replacing any parts.

Questions Solutions

The mixer does not turn on when powered.

The breaker comes off.

Check if the electric cord is connected.

Check the breaker of the building.

Check the breaker on the back of the mixer.

Check if the stop switch is pulled out.

Check if the bowl guards are closed properly.

Check if the bowl lift is up.

If the mixer is still not working, call a

technician or call us.

Check your dough recipe, you might have put

too much dough for the mixer.

If the breaker still come off, call a technician.

Page 10

A7

f

MIXER CLEANING AND MAINTENANCE

LUBRICATION

The motor has grease-packed ball bearings and requires little attention. The transmission gearing

is packed with special grease that will last for several years. When grease is needed for

replacement, it should be ordered from our factory.

The bowl lift are to be cleaned and lubricated with vegetable grease.

CLEANING

We recommend cleaning the mixer and agitators every time you finish the production.

TO CLEAN ONCE PER W EEK

1- Remove (scrape OFF) the

floor residue from the

bowl guide.

2- If needed, clean the bowl

guide with water and soap.

Then, dry (wipe OFF) the

guide while raising and

lowering the bowl.

3- Apply a light film o

vegetable grease.

G:\ACAD10\MELANGE\SM300\SM300.dft

Page 11

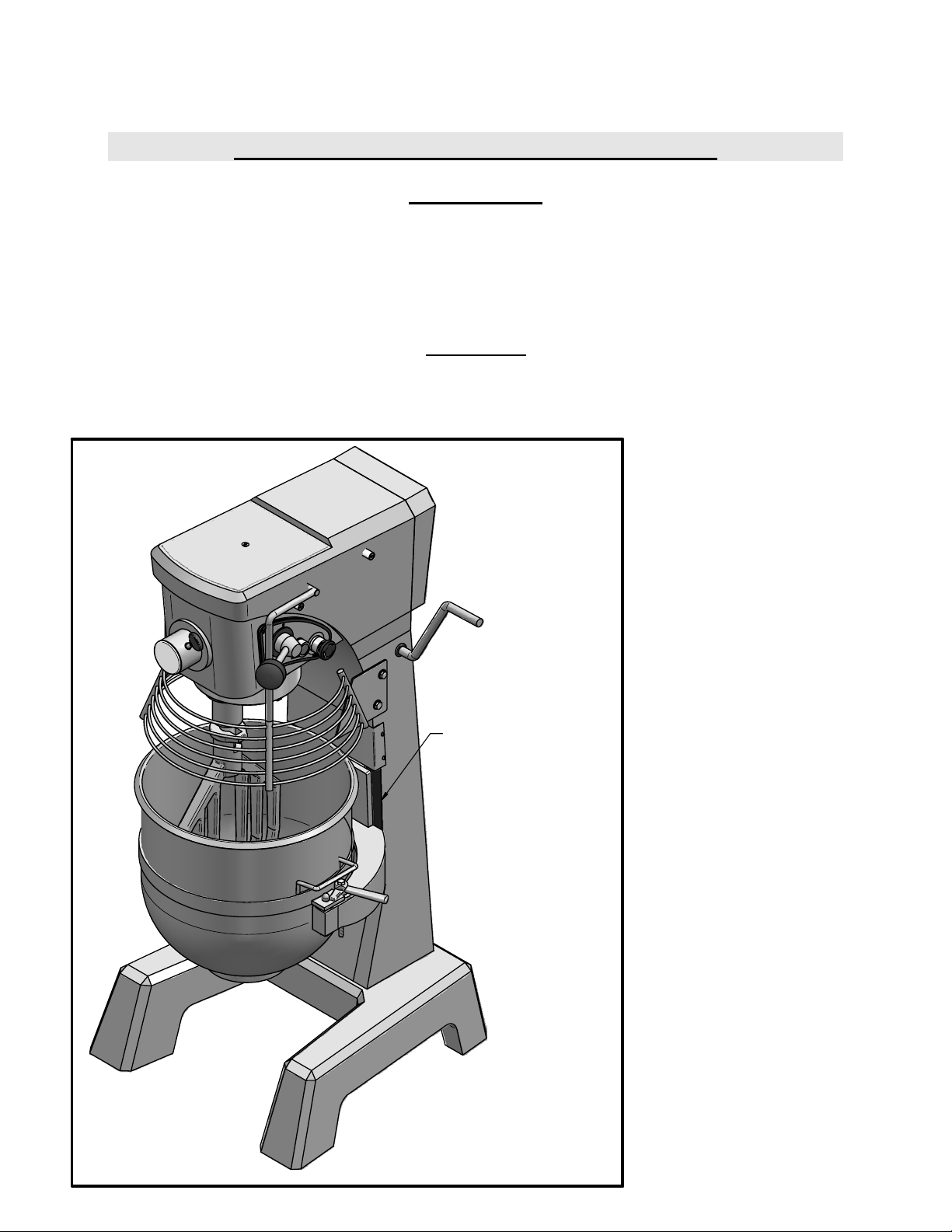

A8

PLANETARY DOUGH MIXER DESCRIPTION

SM200

20-quart mixer with stainless steel bowl, hook, beater and whip

Security bowl guard with Hub attachment for meat grinder and vegetable cutter.

Motor: 1/2 HP.120 Volts 12 Amp. 60 Hz NEMA 5-15P.

Transmission engages by gear.

Weight: 250 pounds.

Finish dough capacity: 4.5 kilo (10 pounds).

SM201

20-quart mixer with stainless steel bowl, hook, beater and whip

Security bowl guard without Hub attachment for meat grinder and vegetable cutter.

Motor: 1/2 HP.120 Volts 8 Amp. 60 Hz NEMA 5-15P.

Transmission engages by timing belt.

Weight: 250 pounds.

Finish dough capacity: 4.5 kilo (10 pounds).

SM300

30-quart mixer with stainless steel bowl, hook, beater and whip

Security bowl guard with Hub attachment for meat grinder and vegetable cutter.

Motor: 1 HP.120 Volts 16 Amp. 60 Hz NEMA 5-20P.

Transmission engages by gear.

Weight: 350 pounds.

Finish dough capacity: 6.8 kilo (15 pounds).

SM401

40-quart mixer with stainless steel bowl, hook, beater and whip

Security bowl guard without Hub attachment for meat grinder and vegetable cutter.

Motor: 1 HP.120 Volts 14 Amp. 60 Hz NEMA 5-20P.

Transmission engages by timing belt.

Weight: 465 pounds.

Finish dough capacity: 9 kilo (20 pounds).

SM402NA

40-quart mixers with stainless steel bowl, hook, beater and whip

Security bowl guard with Hub attachment for meat grinder and vegetable cutter.

Motor: 1 1/2 HP. 208-240 Volts 14 Amp. 60 Hz NEMA 6-20P.

Transmission engages by timing belt.

Weight: 525 pounds.

Finish dough capacity: 13.6 kilo (30 pounds).

NOTE : The finish dough capacity is calculated at 50% A.R. water temperature of 70°F.

Speed # 1 used for heavy mixture such as pizza dough and bread dough.

Speed # 2 used for light dough which must rise quickly or for whipping.

Speed # 3 used for light work like whipping cream, beating eggs and mixing thin batters.

Beater is commonly used for thin batters, cakes, and mashing patties.

Whip is best for whipping cream and beating eggs.

Dough arm is for pizza and bread dough.

Page 12

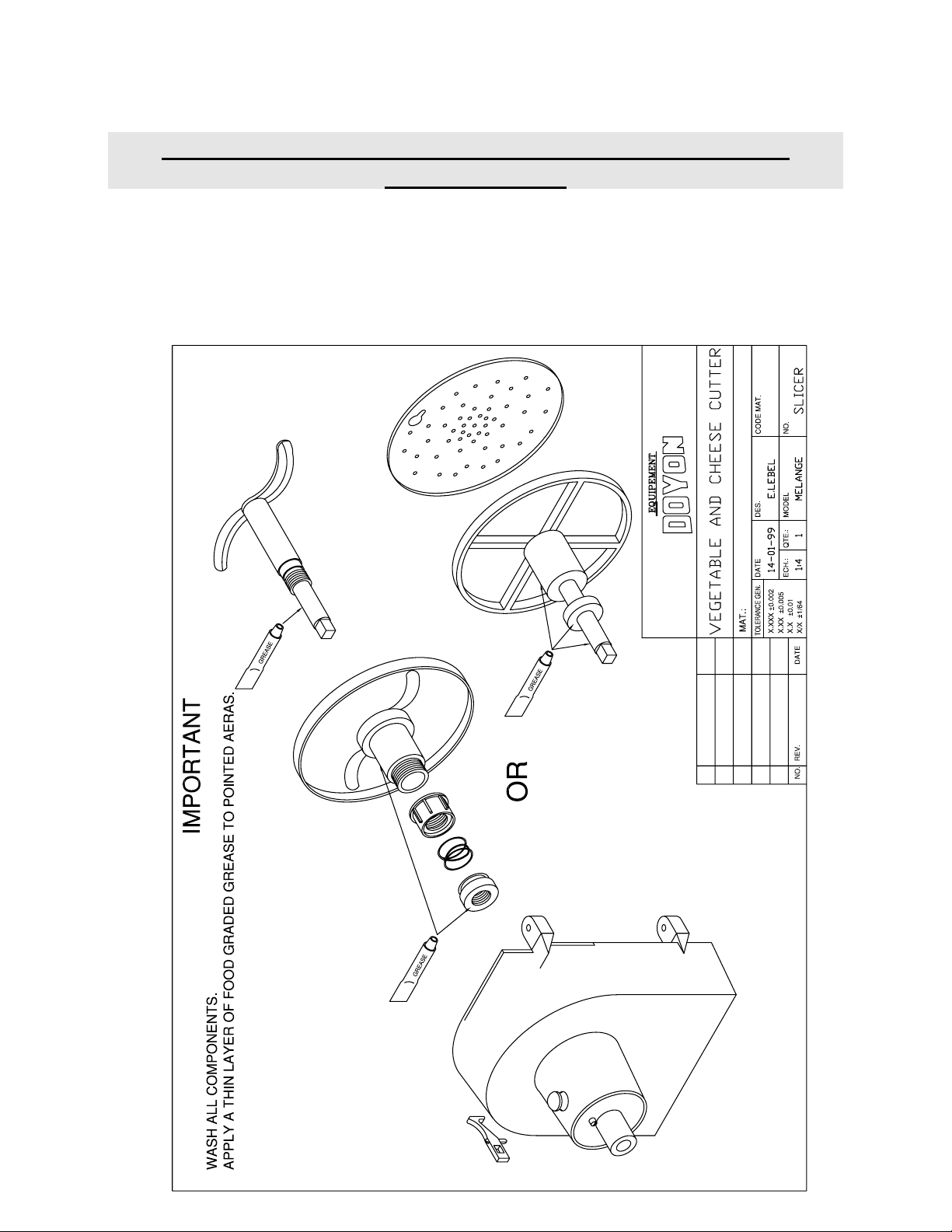

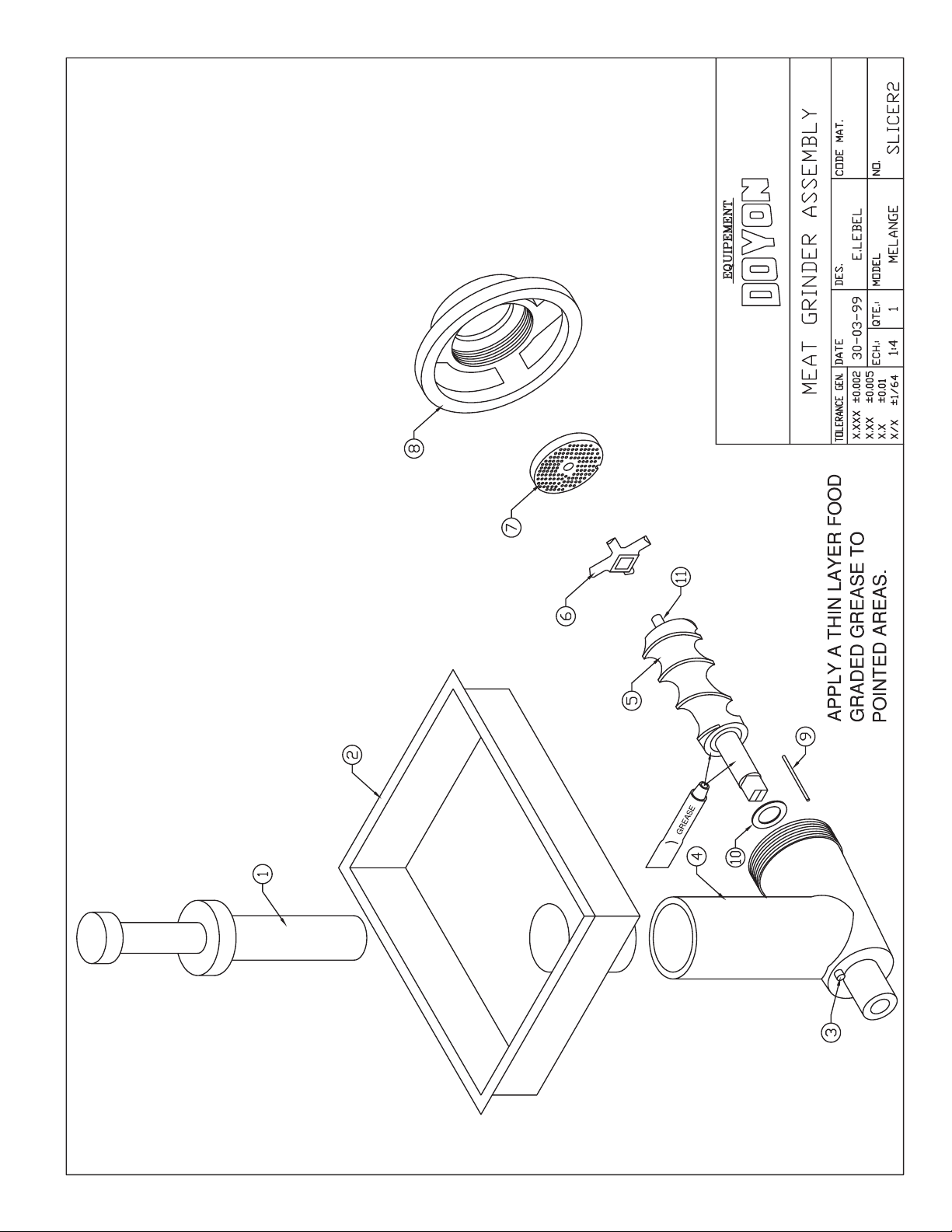

A9

INSTALLATION OF VEGETABLE OR MEAT CUTTER

ATTACHMENT

Insert the attachment with a slight twist to the left so that the stop stud of the attachment is tight

against the side of the hole in the mixer. The attachment speed is selected by the speed selector

handle. Use the first speed for meat and cheese. Speed #2 and #3 for cutting vegetables.

Page 13

A10

Page 14

A11

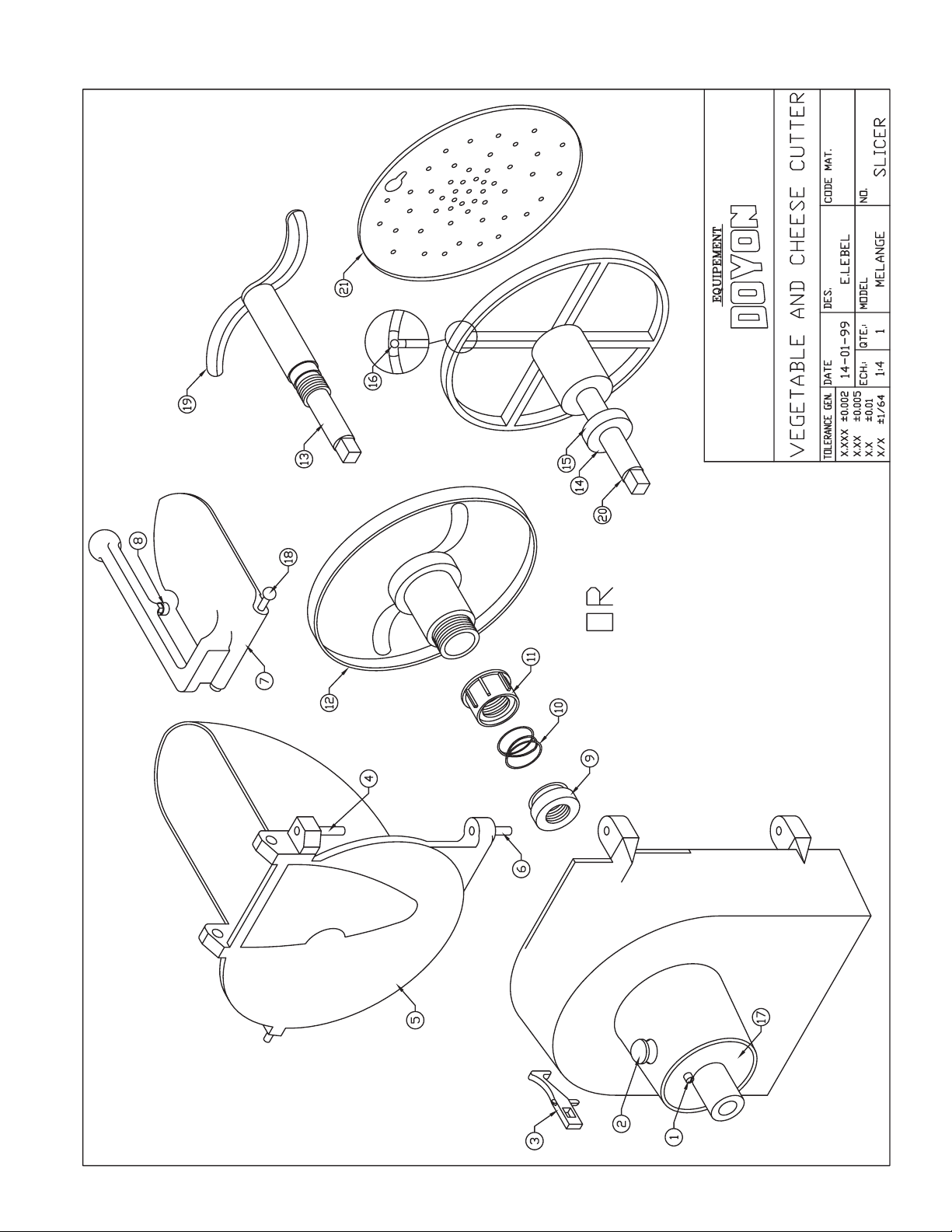

Item Part Number Description Quantity

1 CL1010 LOCK SCREW 1

2 CL1007 KNIFE DISC LOCK ON 1

3 CL1005 DOOR LATCH 1

4 CL1012 UPPER HINGE PIN 1

5 CL1002 DOOR 1

6 CL1013 LOWER HINGE PIN 1

7 CL1003 PUSHER DOOR AND HANDLE 1

8 CL1018 ADJUSTEMENT SCREW FOR DOOR 1

9 CL1024 LOCK NUT 1

10 CL1023 TENSION SPRING 1

11 CL1022 KNIFE ADJUSTINGNUT FOR DISC 1

13 CL1571 HOLDER FOR CL6101K 1

14 CL1026 COLLER FOR DISC HOLDER 1

15 CL1026A SET SCREW FOR CL1026 1

16 CL1030 STUDS FOR DISC HOLDER 8

17 CL1008 NOSE FOR HOUSING HUB 1

18 CL1036 ROUND PIN 1

19 CL12K KNIFE 1

14,15,16,20 6107 DISC SUPPORT #12 ASSEMBLY 1

9,10,11,12,13,19 6101 DISC ASSEMBLY #12 1

21 6102 SHREDDER 3/32’’ 1

OR 6105 SHREDDER 3/16’’ 1

OR 6103 SHREDDER 1/4’’ 1

Model : VEGETABLE SLICER View : EXPLODE

Page 15

A12

Page 16

A13

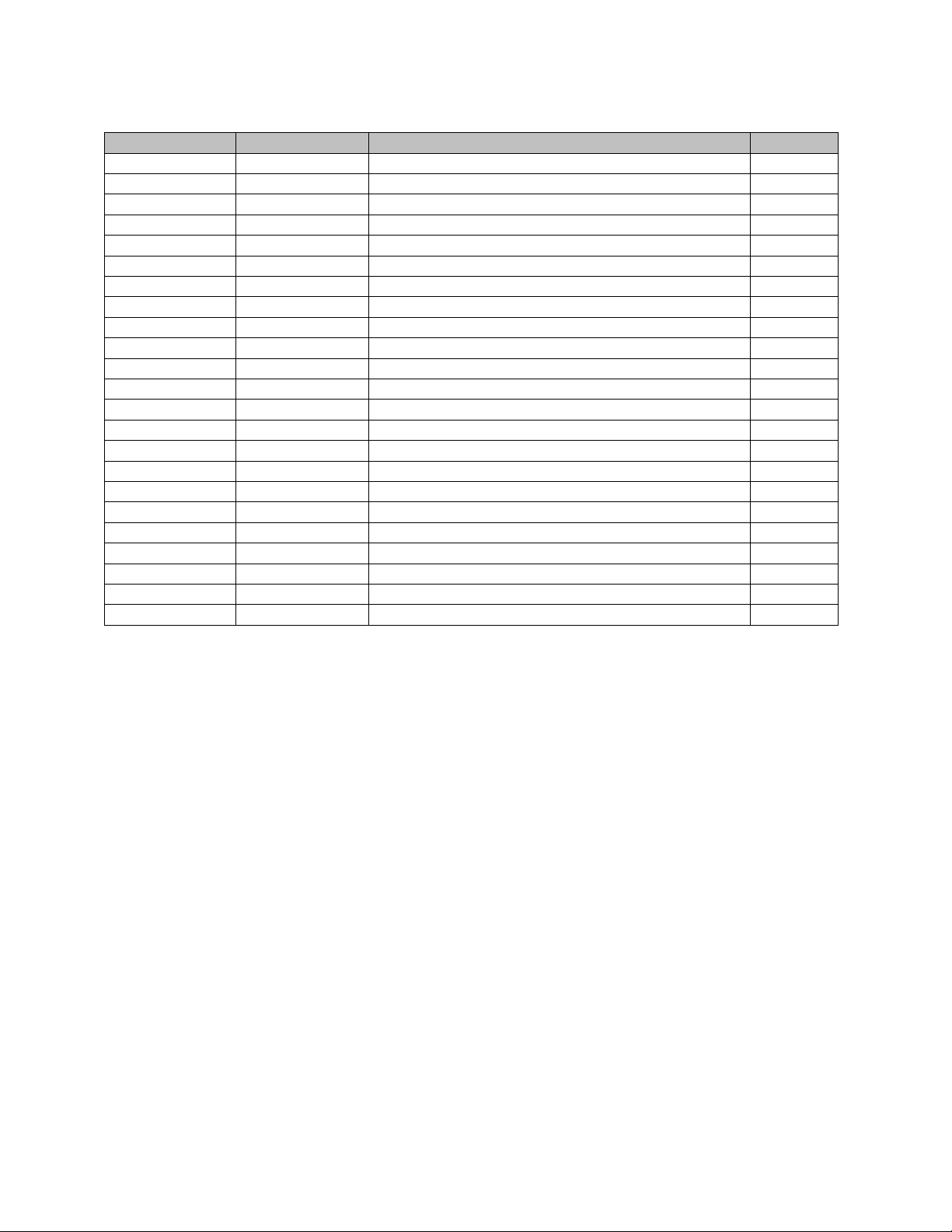

Item Numéro Pièce Description Quantité

1 MGHST6 PUSHER 6’’ 1

2 MG12PAN PAN 1

3 ---- 1

4 MG12CYL CYLINDER (LOOKS LIKE A ELBOW) 1

5 MG12HW WORN GEAR (LIKE A SCREW) 1

6 MG012KN(KNH) KNIFE (CROSS) 1

7 MG12-XXX CHOPPER DISC 1

8 MG12HR RING 1

9 MG12PIN PIN THE AVOID THE CHOPPER DISC TO TURN 1

10 MG12FW FIBER WASHER 1

11 MG12STD CHOPPER FEED SCREWS STUD 1

Modèle : MEAT GRINDER Vue : EXPLODE

MG12-125 1/8’’

MG12-187 3/16’’

MG12-250 1/4’’ (STANDARD)

MG12-312 5/16’’

Page 17

A14

FOR MORE INFORMATION,

PLEASE CONTACT OUR OFFICE :

DOYON EQUIPMENT INC.

1255, rue Principale

Linière, QC, Canada G0M 1J0

Tel. : (418) 685-3431

Canada : 1-800-463-1636

U.S. : 1-800-463-4273

FAX : (418) 685-3948

Internet: http://www.doyon.qc.ca

E-mail : doyon@doyon.qc.ca

Page 18

SECTION

B

DIMENSIONS

Page 19

B1B2B3B4B5

Page 20

Page 21

Page 22

Page 23

Page 24

SECTION

E

COMPONENT PARTS

Page 25

E 1

SM200

Page 26

E 2

Item Part Number Description Quantity

1 200001 BOLT 1

2 200002 COVER 1

3 200003 NUT 1

4 200004 BEARING COVER 1

5 200005 RETAINING TWIN BEARING 1

6 200006 TRANSMISSION COVER 1

7 200007 SPACER 1

8 200008 CLUTCH ASSEMBLY 1

11 200011 46 TEETH BEVEL GEAR 1

12 200012 29 TEETH GEAR 1

13 200013 BRASS OR METAL BUSHING 1

14 200014 2 TO 3 SPEED BUSHING 1

15 200015 METAL BUSHING 1

16 200016 38 TEETH GEAR 1

17 200017 SPACER 1

18 200018 MAIN SHAFT 1

19 200019 BEARING (#6205) QURB30 1

20 200020 SEAL 35-52-10 (#13989) 1

21 200021 METAL BUSHING 1

22 200022 NUT 1

23 200023 5 TEETH WORM GEAR FOR MOTOR 1

24 200024 SPACER 1

25 200025 MOTOR SHAFT 1

26 200026 MOTOR COIL 1

27 200027 START CAPACITOR 1

28 200028 MOTOR COVER 1

29 200029 MECHANICAL CENTRIFUGAL SWITCH 1

30 200030 SPACER METAL STARTER 1

31 200031 COVER 1

32 200032 FORK 1

33 200033 SHAFT 1

34 200034 PLUNGER 1

35 200035 SPRING 1

36 200036 BOLT 1

37 200037 NUT 1

38 200038 WASHER 1

39 200039 BEARING (#6201) QURB07 1

40 200040 15 TEETH GEAR SHAFT 1

41 200041 29 TEETH BRASS WORM GEAR 1

42 200042 SNAP RING 1

43 200043 BEARING (#6201) QURB07 1

44 200044 NUT 1

45 200045 BEARING (#6201) QURB07 1

46 200046 15 TEETH GEAR SHAFT 1

47 200047 32 TEETH GEAR 1

48 200048 SPACER 1

49 200049 23 TEETH GEAR 1

50 200050 SNAP RING 1

51 200051 BEARING (#6201) QURB07 1

52 200052 TRANSMISSION CASTING 1

53 200053 SHIFTER ASSEMBLY 1

56 200056 NUT 1

Page 27

E 3

57 200057 19 TEETH GEAR 1

58 200058 BEARING (#6203) QURB09 1

59 200059 35 TEETH BEVEL GEAR 1

60 200060 SPACER 1

61 200061 THUMB SCREW 1

62 200062 HUB ATTACHMENT 1

63 200063 COVER 1

64 200064 63 TEETH RING GEAR 1

65 200065 PLANETARY CASTING 1

66 200066 CUP DRIP 1

67 200067 BEARING (#6204) QURB10 1

68 200068 SEAL 27-45-10 (#9748) 1

69 200069 BOWL CLIPS 1

70 200070 BOWL SUPPORT 1

71 200071 PEDESTAL 1

72 200072 ROD BOWL LIFT 1

73 200073 ARM BOWL LIFT 1

74 200074 BOWL LIFT HANDLE 1

75 200075 CUTTER PIN 1

76 200076 NUT 1

77 200077 BASE 1

82 200082 PLANETARY SHAFT 1

83 200083 BARREL SWITCH 1

84 200084 ROCKER SWITCH 1

85 200085 START SWITCH (ELI555 & ELP994) 1

86 200086 STOP SWITCH (ELI555 & ELP991) 1

87 200087 BOWL LIMIT SWITCH 1

88 200088 BOWL SUPPORT GUARD SWITCH 1

89 200089 BREAKER (ELB099) 1

Model : SM200 View : Explode

Page 28

E 4

SM201

Page 29

E 5

Page 30

E 6

Page 31

E 7

Item Part Number Description Quantity

1 201001 COVER 1

2 201002 BELT 255L 1

3 201003 CASTING TRANSMISSION 1

4 201004 SPEED CHANGING SHAFT 1

5 201005 SPINDLE CASE 1

6 201006 BOWL SUPPORT 1

7 201007 BASE 1

8 201008 HEX-SCREW 1

9 201009 SPEED INDICATOR 1

10 201010 PEDESTAL 1

11 201011 BELT 60 TEETH GEAR 1

12 201012 MOTOR BELT GEAR 1

13 201013 TRANSMISSION COVER 1

14 201014 MOTOR 1

15 201015 25-32-40 TEETH TRIPLE GEAR 1

16 201016 MAIN SHAFT 1

17 201017 29 TEETH GEAR 1

18 201018 21 TEETH GEAR 1

19 201019 12 TEETH GEAR SHAFT 1

20 201020 12 TEETH GEAR SHAFT 1

21 201021 59 TEETH RING GEAR 1

22 201022 18 TEETH GEAR 1

23 201023 PLANETARY SHAFT 1

24 201024 BOWL LIFT HANDLE 1

25 201025 ARM BOWL LIFT 1

26 201026 ROD 1

27 201027 BOLT 1

28 201028 FORK 1

29 201029 SPEED CHANGING SHAFT 1

30 201030 SHAFT FOR GUIDE FORK 1

35 201035 GUIDE ROD FOR BOWL 1

36A 201036A CLIPS SCREW 1

36B 201036B RIGHT SIDE CLIPS 1

36C 201036C LEFT SIDE CLIPS 1

37 201037 TOGGLE SWITCH 1

38 201038 SEAL 25-47-8 (#9748) 1

39 201039 BEARING (#6203) QURB09 1

40 201040 BEARING (#6005) QUR010 1

42 201042 SEAL 28-47-7 (#10959) 1

43 201043 BEARING (QURB30) 1

44 201044 BOWL AND GARD SWITCH 1

45 201045 BEARING (QURB09) 2

47 201047 START SWITCH 1

48A 201048A CONTACTOR 110 VOLTS (ELC912) OR 220 VOLTS (ELC913) 1

48B 201048B CONTACTOR NEW MODEL 1

49 201049 BRAKER 13 AMPS. 1

50 201050 STOP SWITCH 1

54 201045 BEARING (QURB09) 1

55 201055 ELECTRIC BOX 1

56 201056 BOWL GUARD MICRO SWITCH (NEW MODEL) 1

Page 32

E 8

Model : SM201 View:Explode

Page 33

E 9

SM300

Page 34

E 10

Page 35

E 11

Page 36

E 12

Page 37

E 13

Item Part Number Description Quantity

1 300002 BEARING COVER 1

3 300003 3/4-16 NUT 1

4 300004 BEARING (#6204) QURB10 1

7 300007 TRANSMISSION COVER 1

8 300008 CLUTCH SPACER 1

9 300009 37 TEETH CLUTCH 1

12 300012 46 TEETH BEVEL GEAR 1

13 300013 24 TEETH GEAR 1

14 300014 BRASS BUSHING 1

15 300015 2ND AND 3RD SPEED CLUTCH 1

16 300016 MAIN SHAFT 1

17 300017 KEY 1/4 x 1/4 1

18 300018 KEY 3/16 x 3/16 1

19 300019 KEY 1/4 x 1/4 1

20 300020 31 TEETH GEAR 1

21 300021 SPACER 1

22 300022 BEARING (#6206) QURB011 1

23 300023 BUSHING 1

24 300024 SEAL 40-62-8 (#15845) 1

25 300025 3/4 WASHER 1

26 300026 NUT 1

27 300027 HUB ATTACHMENT 1

28 300028 1/4 x 1 SCREW 1

29 300029 HUB ATTACHMENT 1

30 300030 THUMB SCREW 1

31 300031 35 TEETH BEVEL GEAR 1

32 300032 BEARING (#6203) QURB09 1

33 300033 12-25-26-18 TEETH QUADRUPLE GEAR SHAFT 1

34 300034 BEARING (#6203) QURB09 1

35 300035 BEARING (#6202) QURB08 1

36 300036 KEY 1/4 x 1/4 1

37 300037 12 TEETH GEAR SHAFT 1

38 300038 17 TEETH BRASS WORM GEAR 1

39 300039 COVER 1

40 300040 BEARING (#6202) QURB08 1

41 300041 SNAP RING 1

42 300042 FORK 1

43 300043 ROD SHIFTER GUIDE 1

44 300044 SEE 300046 1

46 300046 SPEED INDICATOR ASSEMBLY WITH #300044 1

50 300050A START SWITCH (ELI555 & ELP994) 1

51 300051 STOP SWITCH (ELI575 & ELP991) 1

52 300052 SPEED INDICATOR HANDLE 1

53 300053 "O" RING 1

55 300055 59 TEETH RING GEAR 1

56 300056 SNAP RING 1

58 300058 18 TEETH GEAR 1

59 300059 BEARING (#6204) QURB10 1

61 300061 KEY 1/4 X 1/4 1

62 300062 SPINDLE SHAFT 1

63 300063 PIN 1

64 300064 BEARING (#6205) QURB30 1

Page 38

E 14

65 300065 SEAL 30-52-8 (#11640) 1

66 300066 CUP DRIP 1

71 300071 BOWL GUARD 1

77 300077 LEFT SIDE BOWL HANDLE 1

80 300080 NUT 1

81 300081 MOTOR WORM GEAR 1

83 300083 BEARING (#6203) QURB09 1

84 300084 KEY 1

85 300085 MOTOR ROTOR 1

86 300086 CENTRIFUGAL SWITCH 1

88 300088 PLATE 1

89 300089 BEARING (#6203) QURB09 1

90 300090 FLANGE 1

92 300092 COVER 1

94 300094 BOWL GUIDE ROD 1

95 300095 RIGHT SIDE BOWL HANDLE 1

97 300097 SPRING 1

107 300107 CAPACITOR 1

108 300108 COVER 1

110 300110 BOWL GUARD SWITCH 1

114 300114 COVER 1

117 300117 CONTACTOR 1

118 300118 COVER 1

120 300120 ROD ASSEMBLY 1

130 300130 BOWL SUPPORT SWITCH 1

131 300131 15 AMPS BREAKER (ELB099) 1

Model : SM300 View : Explode

Page 39

E 15

SM401

Page 40

E 16

Page 41

E 17

Item Part Number Description Quantity

1 401001 COVER 1

2 401002 BELT 300L 1

3 401003 TRANSMISSION CASE 1

4 401004 SEE 401029 1

5 401005 SPINDLE CASE 1

6 401006 ARCH 1

7 401007 BASE 1

8 401008 BOLT 1

9 401009 SPEED INDICATOR 1

10 401010 PEDESTAL 1

11 401011 70 TEETH GEAR BELT 1

12 401012 13 TEETH MOTOR GEAR BELT 1

13 401013 TRANSMISSION COVER 1

14 401014 MOTOR 1

15 401015 27-37 TEETH DOUBLE GEAR 1

16 401016 CENTRAL SHAFT 1

17 401017 34 TEETH GEAR 1

18 401018 24 TEETH GEAR 1

19 401019 15 TEETH GEAR SHAFT 1

20 401020 13 TEETH GEAR SHAFT 1

21 401021 69 TEETH RING GEAR 1

22 401022 22 TEETH GEAR 1

23 401023 SPINDLE SHAFT 1

24 401024 BOWL LIFT HANDLE 1

25 401025 ARM BOWL LIFT 1

26 401026 PIN 1

27 401027 SPRING 1

28 401028 FORK 1

29 401029 SPEED CHANGING SHAFT 14 TEETH 1

30 401030 GUIDE FORK SHAFT 1

35 401035 GUIDE ROD FOR BOWL 1

36A 401036A CLIPS SCREW 1

36B 401036B RIGHT SIDE CLIPS 1

36C 401036C LEFT SIDE CLIPS 1

37 401037 TOGGLE SWITCH 1

38 401038 SEAL 1

39 401039 BEARING (#6205) QURB30 1

40 401040 BEARING #(6006) QURB012 1

42 401042 SEAL 32-55-18 (#12755) 1

43 401043 BEARING (#6204LLU) QURB10 2

44 401044 BOWL AND GUARD SWITCH 1

45 401045 BEARING (QURB011) 1

46 401046 46 TEETH GEAR 1

47 401047 START SWITCH A (GREEN) 1

48A 401048A CONTACTOR 110 VOLTS (ELC912) OR 220 VOLTS (ELC913) 2

48B 401048B CONTACTOR NEW MODEL 1

49 401049 BRAKER 20 AMPS. 1

50 401050 STOP SWITCH 1

56 401056 BOWL GUARD MICRO SWITCH 1

Model : SM401 View : Explode

Page 42

E 18

SM402NA

Page 43

E 19

Page 44

E 20

Page 45

E 21

Page 46

E 22

Item Part Number Description Quantity

1 402N001 COVER SCREW 1

2 402N002 COVER SCREW 1

3 402N003 TRANSMISSION COVER 1

4 402N004 ON / OFF MAIN SWITCH 1

5 402N005 BOWL GUARD MICRO SWITCH 1

6 402N006 THUM SCREW 1

7 402N007 HUB ATTACHMENT 1

8 402N008 ATTACHMENT CAP 1

9 402N009 THRUST WASHER 1

10 402N010 BEVEL GEAR 35 TEETH 1

11 402N011 KNEADER 1

12 402N012 BEARING (6206Z) QURB011 1

13 402N013 SEAL 62-35-10 1

14 402N014 PADDLE 1

15 402N015 PLANETARY SHAFT 1

16 402N016 WHIP 1

17 402N017 BOWL 1

18 402N018 BOWL LOCK HANDLE 2

19 402N019 BOWL SUPPORT 1

20 402N020 SCREW 1

21 402N021 NUT STOP 1

22 402N022 BOLT 1

23 402N023 HOLDER ARCH 1

24 402N024 BASE 1

25 402N025 SCREW 1

26 402N026 NET 1

27 402N027 TREADED ROD FOR BOWL SUPPORT 1

28 402N028 GLISSIERE DU SUPPORT DU BAS 1

29 402N029 BEARING (6005ZZ) QURB010 1

30 402N030 O-RING 1

31 402N031 30 TEETH OBLIQUE GEAR 1

32 402N032 O-RING 1

33 402N033 SHAFT 1

34 402N034 30 TEETH OBLIQUE GEAR 1

35 402N035 O-RING 1

36 402N036 OIL LESS BEARING 1

37 402N037 BOWL SUPPORT MICROSWITCH 1

38 402N038 O-RING 1

39 402N039 BOWL LIFT HANDLE 1

40 402N040 O-RING 1

41 402N041 BACK COVER 1

42 402N042 SCREW 1

43 402N043 CHROME RING 1

44 402N044 PLANETARY 1

45 402N045 67 TEETH RING GEAR 1

46 402N046 BEARING (#6204) QURB10 1

47 402N047 21 TEETH PIGNON GEAR 1

48 402N048 COOLING FAN 1

49 402N049 SPEED HANDLE ASSEMBLY 1

50 402N050 MECHANICAL CENTRIFUGAL SWITCH 1

51 402N051 SHIFTER BLACK HANDLE 1

52 402N052 PLATINUM SWITCH 1

Page 47

E 23

53 402N053 SPEED HANDLE ASSEMBLY 1

54 402N054 SPEED HANDLE ASSEMBLY 1

55 402N055 OPERATE PLATE 1

56 402N056 1 1/2 HP MOTOR 1

57 402N057 CASE TRANSMISSION 1

58 402N058 CAPACITOR 1

59 402N059 WHEEL BELT 18 TEETH 1

60 402N060 TRANSMISSION BELT 1

61 402N061 TRANSMISSION COVER 1

62 402N062 BEARING (#6204) QURB10 1

63 402N063 BEARING (#6204) QURB10 1

64 402N064 BEARING (#6206) QURB11 1

65 402N065 TRANSMISSION WHEEL BELT 85 TEETH 1

66 402N066 LEVEL KEY 1

67 402N067 STOP NUT 1

68 402N068 GREASE PLUG 1

69 402N069 FRONT GUARD SLAB 1

70 402N070 NUT FOR # 47 1

71 402N071 O-RING 1

72 402N072 LEAD-IN GREASE PAD 1

73 402N073 CLUTCH GEAR ASSEMBLY 1

74 402N074 CLUTCH GEAR ASSEMBLY 1

75 402N075 BEVEL GEAR 52 TEETH 1

76 402N076 CLUTCH GEAR ASSEMBLY 1

77 402N077 CLUTCH GEAR ASSEMBLY 1

78 402N078A 36 TEETH GEAR FOR OLD MODEL 1

OR 402N078B 35 TEETH GEAR FOR NEW MODEL 1

79 402N079 BRASS BUSHING 1

80 402N080 8 MM x 40 MM KEY 1

81 402N081 BRASS BUSHING 1

82 402N082 45 TEETH GEAR 1

83 402N083 SPACER 1

84 402N084 BEARING #6207 1

85 402N085 C CLIP 1

86 402N086 STEEL BUSHING 1

87 402N087 SEAL 72-45-12 1

88 402N088 STOP NUT 1

89 402N089 DRIVEN SHAFT 1

90 402N090 10 MM x 55 MM KEY 1

91 402N091 10 MM x 40 MM KEY 1

92 402N092 SLEEVE CLUTCH 1

93 402N093 FORK ASSEMBLY 1

94 402N094 FORK ASSEMBLY 1

95 402N095 FORK ASSEMBLY 1

96 402N096 FORK ASSEMBLY 1

97 402N097 FORK ASSEMBLY 1

98 402N098 BEARING (#6204) QURB11 1

99 402N099 C CLIP 1

100 402N100 BEARING (#6204) QURB11 1

101 402N101 20 TEETH GEAR 1

102 402N102 STEEL SPACER 1

103 402N103A 15 TEETH MAIN SHAFT (OLD MODELE) 1

OR 402N103B 14 TEETH MAIN SHAFT (NEW MODELE) 1

104 402N104 C CLIP 1

Page 48

E 24

105 402N105 STOP NUT 1

106 402N106A 29 TEETH GEAR (OLD MODEL) 1

OR 402N106B 30 TEETH GEAR (OLD MODEL) 1

107 402N107 13 TEETH TRANSMISSION SHAFT 1

108 402N108 C CLIP 1

109 402N109 STOP NUT 1

110 402N110 STOP NUT 1

111 402N111 KEY 1

112 402N112 KEY 1

113 402N113 SLEEVE BEARING #TA 45 35 FOR 402N007 1

114 402N114 OIL SEAL #TA 45 35 FOR 402N007 1

115 402N115 OIL SEAL (36 X 30 X 3) 1

116 402N116 WASHER FOR # 117 1

117 402N117 BOWL GUARD SCREW 1

118 402N118 BOWL GUARD 1

119 402N119 ELECTRIC BOX 1

120 402N120 OVERLOAD RELAY 1

121 402N121 CONTACTOR 1

122 402N122 START SWITCH 1

123 402N123 STOP SWITCH 1

Model : SM402NA View : Explode

Page 49

SECTION

G

ELECTRIC SCHEMATIC

Page 50

G1G2G3G4G5

Page 51

Page 52

Page 53

Page 54

Page 55

G5

LIMITED WARRANTY

(Continental United States Of America And

Canada Only)

Doyon Equipment Inc. guarantees to the original purchaser only that

its product are free of defects in material and workmanship, under

normal use.

This warranty does not cover any light bulbs, thermostat calibration or

defects due to or resulting from handling, abuse, misuse, nor shall it

extend to any unit from which the serial number has been removed or

altered, or modifications made by unauthorized service personnel or

damage by flood, fire or other acts of God. Nor will this warranty

apply as regards to the immersion element damaged by hard water.

The extent of the manufacturer’s obligation under this warranty shall

be limited to the replacement or repair of defective parts within the

warranty period. The decision of the acceptance of the warranty will

be made by Doyon Equipment service department, which decision

will be final.

The purchaser is responsible for having the equipment properly

installed, operated under normal conditions with proper supervision

and to perform periodic preventive maintenance.

If any parts are proven defective during the period of one year from

date of purchase, Doyon Equipment Inc. hereby guarantees to replace,

without charge, F.O.B. Linière, Quebec, Canada, such part or parts.

Doyon Equipment Inc will pay the reasonable labor charges in

connection with the replacement parts occurring within one year from

purchase date. Travel over 50 miles, holiday or overtime charges are

not covered. After one year from purchase date, all labor and

transportation charges in connection with replacement parts will be the

purchaser’s responsibility.

Doyon Equipment Inc. does hereby exclude and shall not be liable to

purchaser for any consequential or incidental damages including, but

not limited to, damages to property, damages for loss of use, loss of

time, loss of profits or income, resulting from any breach or warranty.

In no case, shall this warranty apply outside Canada and continental

United States unless the purchaser has a written agreement from

Doyon Equipment Inc.

Loading...

Loading...