Page 1

JA-3, JA3MC, JA3MC3

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

DANGER

TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK,

CAREFULLY FOLLOW THESE INSTRUCTIONS

TABLE OF CONTENTS

DESCRIPTION PAGE

Installation and maintenance manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A1

Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A2

Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A3

Distances to respect & installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A4

Operation / instruction for oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before calling for service - Answers to most frequent questions . . . . . . . A8

Oven maintenance and cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A10

For more information, please call our office: . . . . . . . . . . . . . . . . . . . . . . . A11

SECTION « B » DIMENSIONS

JA-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B1

A6

JA3MC et JA3MC3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B4

SECTION « E » COMPONENT PARTS

JA-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E1

JA3MC et JA3MC3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E4

SECTION « G » ELECTRIC SCHEMATIC

JA-3 120V/208V/1PH & 120V/240V/1PH (5000 WATTS). . . . . . .. . G1

JA-3 220V/1PH/50HZ (5000 WATTS) . . . . . . . . . . . . . . . . . . . . . . . . . G2

JA3MC 120V/1PH (2000 WATTS). . . . . . . . . . . . . . . . . . . . . . . . . . . . G3

JA3MC 120/208V/1PH (2000 WATTS) . . . . . . . . . . . . . . . . . . . . . . . . G4

JA3MC 120/240V/1PH (2000 WATTS) . . . . . . . . . . . . . . . . . . . . . . . . G5

JA3MC 220V/1PH/50HZ (2000 WATTS) . . . . . . . . . . . . . . . . . . . . . . . G6

JA3MC3 120/208V/1PH & 120/240V/1PH (3000 WATTS) . . . . . . . . G7

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FAMJA3.DOC

Rev. 2000/10/27

Page 2

A1

INSTALLATION AND MAINTENANCE MANUAL

The manufacturer suggests to read this manual carefully and to keep it for future reference.

This Jet Air oven is manufactured with first quality material by experienced technicians. Proper

installation and maintenance will guarantee a reliable service for years to come.

A nameplate fixed to the front or the right side of the oven specifies the serial number, model

number, number of phase, amperage, voltage and frequency.

Drawings, electrical diagram, and replacement part numbers are included in this manual. The

electrical diagram is affixed in the control panel at the back of the oven.

WARNING

DOYON is not responsible for damages to the property or the equipment caused

by personnel who is not certified by known organizations. The customer is

responsible for finding qualified technicians in gas, electricity and plumbing for

the installation of the oven.

Page 3

A2

C O N S T R U C T I O N

You just bought the most advanced electric oven in the world, the "DOYON" technology at its best.

This oven is manufactured using the highest quality components and material.

This oven gives a perfect uniform baking with its unique Jet Air convection system. The DOYON

ovens are designed with parts that are easy to find.

S H I P P I N G

For your safety, this equipment is verified by qualified technicians and carefully crated before

shipment. The freight company assumes full responsibility concerning the delivery in good condition

of the equipment in accepting to transport it.

IMPORTANT

RECEPTION OF THE MERCHANDISE

Make sure to verify that the received equipment is not damaged before signing the delivery receipt.

If a damage or a lost part is noticed, write it clearly on the receipt. If it is noticed after carrier left,

contact immediately the freight company in order that they do their inspection.

We do not assume the responsibility for damages or losses that may occur during transportation.

Page 4

A3

W A R N I N G S

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY APPLIANCE

POWER FAILURE WARNING

WHEN YOU HAVE A POWER FAILURE, SHUT OFF THE OVEN POWER SWITCH TO

PROTECT THE ELECTRONIC COMPONENT WHEN THE POWER RETURNS.

IMPORTANT

INSTALLATION AND SERVICE

Installation and service must be done by specialized technicians. Contact a certified electrician and

plumber for set up.

The oven must be connected to the utility and electrically grounded in conformity to the effective

local regulations. If these are not established, the oven must be connected according to the Canadian

Electrical Code (CSA-C22.1- XX) or National Electrical Code (NFPA 70-XX). Refer to last

edition year for XX.

Page 5

A4

DISTANCES TO RESPECT

A) Back of the oven: 4 inches

B) Top of the oven: a clearance of 36 inches to the ceiling must exist to allow adequate venting

of hot parts.

C) Floor: 4 inches minimum

D) Sides of oven: Do not install other than easily removable equipment for service and

maintenance (not closer than 4 inches).

E) It is recommended to have a certain length (48") of electric cable between oven and wall to

help gain access for service.

Page 6

A5

I N S T A L L A T I O N

IN GENERAL

Take off the packaging material with care. Take off all the material used for packing and

accessories.

1. To the electrician.

Electrical supply installation must be in accordance with the electrical rating on the nameplate.

WARNING

The electrician must make sure that the supply cable does not come in contact with the

oven top which becomes hot.

2 To the plumber

This equipment is to be installed to comply with the applicable federal, state, or local plumbing

codes.

Connect the steam system (1/4 NPT) to the cold water distribution network. We highly

recommend a water softener to eliminate minerals in the water. We suggest to use CUNO #

CFS6135 (Doyon part number PLF240).

Page 7

A6

O P E R A T I O N

1. Turn the switch to the " ON " position .

° The light of the oven must lite.

3 Adjust the thermostat at the desired setting.

4 Heat the unit until you reach the baking temperature

When the desired temperature is reached, the red light goes out and the green turns on.

If the light is still "ON" and the oven does not produce heat, call for service.

5 Load the oven as fast as possible to avoid letting out too much heat.

6 Set the timer to the desired value and start it. (see "TIMER" adjustment on next page).

NOTE: The timer does not shut the oven off at the end of its cycle. It simply activates the buzzer.

7 Wait until the product is ready. Do not open the doors until the product is done.

Page 8

A7

O V E N I N S T R U C T I O N S

BAKING

350oF (Croissants, Sweet Doughs, Small rolls)

375oF (Baguette bread, round loaf, 16 oz. bread and more)

o

F (If the oven is filled to its capacity)

375

DOORS OPENING

Open the doors as little as possible. This will affect the baking.

TIMER

The oven is provided with a portable digital timer. The timer can also be installed ont the bracket

located under the main switch.

POWER FAILURE

When the power comes back the oven will start automatically. It is recommanded to turn off the oven

to avoid that it starts without supervision.

Page 9

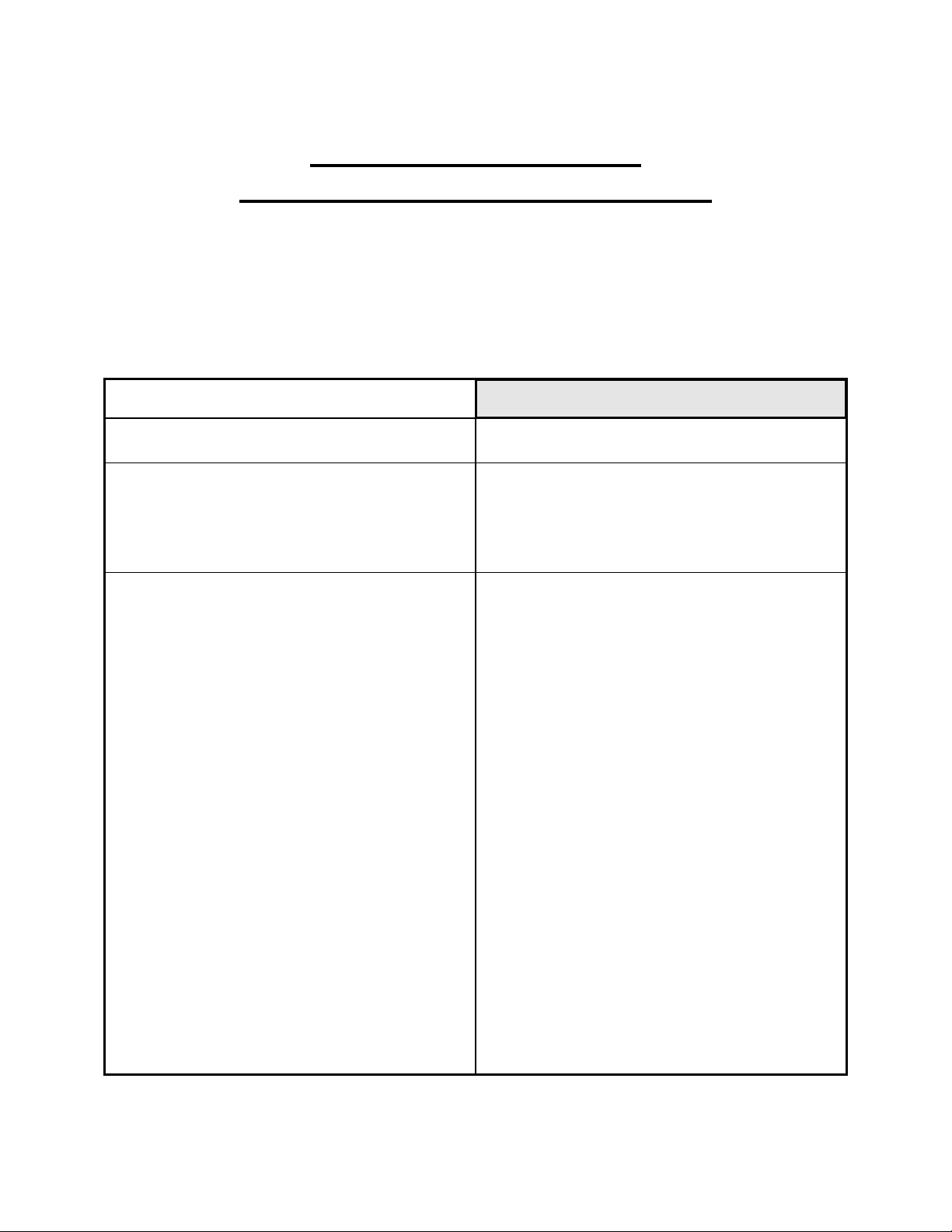

A8

Before calling for service

Answers to most frequent questions

Always cut off the main power before replacing any parts. Take care of water piping and

electric cable when pulling the oven.

Control parts on the front:

Control and motor system on the back of

oven:

OVEN

Remove the front or side panel by removing

the screws.

Remove the back panel by removing the

screws.

Questions

The oven does not turn on when installed.

The blower does not run and the oven does

not produce heat (lights are on).

Uneven baking

Solutions

Check the breakers on the front panel.

Check the breaker of the building.

If the oven has already functioned, check if the

doors are tightly closed.

Check the overload relays located in the control

compartment. If anyone of these is disengaged,

call for a qualified technician.

Make sure that the grills do not obstruct the

airflow. Do not use foil on grills.

The oven temperature is too high.

For best result, cooking temperature should be

around 3500 F to 3750 F.

To put in or take out bread pans, open the door

2"(5 cm) and wait 5 secondes before opening

the door completely.

Check the oven temperature by using an oven

thermometer and make sure that it is even to the

thermostat setting.

Check if the baking time is longer than usual

and if the oven is baking much more on the

bottom. If it is the case, one element may be

burned.

If the oven is baking too much on the sides, it is

possible that the fan is not cycling properly.

(Check if the motor turns 2.5 minutes in a

direction, stops 30 seconds and starts for 2.5

minutes in the opposite direction).

The doors should not be opened unnecessarily to

conserve the heat.

Find out leak of heat and correct it.

Page 10

A9

The steam works in the oven but the light

inside the steam button does not lite.

If steam device does not work properly.

Replace the light bulb inside the push button.

The oven must have been heating for at least

half an hour before you use steam system. If

not, water will appear at the bottom of the oven.

Check if the water supply valve (of the

building) is open.

Check if the water needle valve (of the oven) is

open one-eighth of a turn. Just close it and open

it one-eighth of a turn, maximum.

Check the solenoid valve.

Check the preset steam timer in the back

control box.

Be sure to inject steam while the fan is running.

The steam button light should lite during the

steam injection.

Page 11

A10

Oven maintenance and cleaning

MAINTENANCE OF THE OVEN

• It is recommended to use a water filter and to clean or replace it regularly to avoid

accumulation of minerals inside the unit.

• Once a year or as needed, clean the small float switch reservoir of the proofer (see parts

description for localisation).

CLEANING

Step by step Recommendations

Clean the inside of the oven with water and

soap.

After cleaning the inside of the oven, apply a

silicone base oven protector. It avoids food

from sticking to the metal.

Clean the oven windows with products like

Brasso or equivalents. They are copper

cleaners but good for this use.

Clean the oven exterior with a stainless steel

polish.

We recommend and sell:

Dirt Buster III : Action foam cleaner.

CHEMCO

Part number : NEB201

Warning: Never use cleaners such as EasyOff or equivalents in the oven.

We recommend and sell:

316 Silicone base protector and lubricant for

oven

Dow Corning

Part number : EXS400

We recommend and sell:

Wright's: Cream copper cleaner

J.A. Wright & Co.

Part number : EXC300

We recommend and sell:

Stainless steel cleaner.

SANY or CURTIS (commestible)

Part number : NES201

Page 12

A11

For more information, please contact our office :

DOYON EQUIPMENT INC.

1255, rue Principale

Linière, Qc, Canada G0M 1J0

Tel. : 1 (418) 685-3431

Canada : 1 (800) 463-1636

U.S. : 1 (800) 463-4273

FAX : 1 (418) 685-3948

Internet: www.doyon.qc.ca

E-Mail : doyon@doyon.qc.ca

Page 13

SECTION

B

DIMENSIONS

Page 14

B1B2B3B4B5

Page 15

Page 16

Page 17

Page 18

Page 19

B6

Page 20

SECTION

E

COMPONENT PARTS

Page 21

E1

Page 22

E2

Item Part Number Description Quantity

1 P1710F OVEN DOOR 17 1/4" X 10 1/4" 1

2 QUP540 BLACK HANDLE 1

3 QUA400 DOOR MAGNET 2

4 ELL650 PILOT LIGHT 1

5 ELT544B THERMOSTAT RANCO 480 °F 1

AND ELT552 THERMOSTAT KNOB 550F 1

AND ELT620 THERMOSTAT BEZEL 1

6 ELI635 SWITCH 20A/130V - 15A/240 V P. LIGHT 1

7 PAP400 AJUSTABLE LEG 1/2-13 NC 4

8 ELB096 5A BREAKER 1

OR ELB098 2A BREAKER (220V ONLY) 1

Model : JA-3 View : FRONT

Page 23

E3

Page 24

E4

Item Part Number Description Quantity

1 ELE110 STRAIGHT ELEMENT 208V 2500W 2

OR ELE120 STRAIGHT ELEMENT 240V 2500W 2

2 ELM934 MOTOR 240 VOLTS FOR FC16 (JA3 ONLY) 1

3 ELC908 HEATING CONTACTOR 1

4 ELT680 THERMOSTAT 700°F 1

Model : JA-3 View : BACK

Page 25

E5

Page 26

E6

Item Part Number Description Quantity

(ON 220V 1PH 50Hz)

1 ELE120 STRAIGHT ELEMENT 240V 2500W 2

2 ELM934 MOTOR 240 VOLTS FOR FC16 (JA3 ONLY) 1

3 ELC908 HEATING CONTACTOR 1

4 ELT715 TRANSFORMER 240>120 100VA 1

5 ELT680 THERMOSTAT 700°F 1

Model : JA-3 View : BACK 220V

Page 27

E7

Page 28

E8

Item Part Number Description Quantity

1 P1710F OVEN DOOR 17 1/4" X 10 1/4" 1

2 QUP540 BLACK HANDLE 1

3 QUA400 DOOR MAGNET 2

4 ELL650 PILOT LIGHT 1

5 ELT544B THERMOSTAT RANCO 480 °F 1

AND ELT552 THERMOSTAT KNOB 550F 1

AND ELT620 THERMOSTAT BEZEL 1

6 ELI635 SWITCH 20A/130V - 15A/240 V P. LIGHT 1

7 PAP400 AJUSTABLE LEG 1/2-13 NC 4

Model : JA3MC View : FRONT

Page 29

E9

Page 30

E10

Item Part Number Description Quantity

1 ELE125 STRAIGHT ELEMENT 120V 1000W 2,

OR ELE300 STRAIGHT ELEMENT 3000W 208 VOLTS (FOR MODEL 3000 WATTS

ONLY)

OR ELE305 STRAIGHT ELEMENT 3000W 230 VOLTS (FOR MODEL 3000 WATTS

ONLY)

OR ELE121 STRAIGHT ELEMENT 120V 1500W (FOR MODEL 1500 WATTS ONLY) 1

2 ELM957 MOTOR 1/70HP 115V 60 OR 50Hz 1

3 ELT715 TRANSFORMER 240>120 100VA (220V 1PH 50Hz ONLY) 1

1

1

Model : JA3MC View : BACK

Page 31

SECTION

G

ELECTRIC SCHEMATIC

Page 32

G1G2G3G4G5G6G7

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

39

LIMITED WARRANTY

(Continental United States Of America And Canada Only)

Doyon Equipment Inc. guarantees to the original purchaser only that

its product are free of defects in material and workmanship, under

normal use.

This warranty does not cover any light bulbs, thermostat calibration or

defects due to or resulting from handling, abuse, misuse, nor shall it

extend to any unit from which the serial number has been removed or

altered, or modifications made by unauthorized service personnel or

damage by flood, fire or other acts of God. Nor will this warranty

apply as regards to the immersion element damaged by hard water.

The extent of the manufacturer’s obligation under this warranty shall

be limited to the replacement or repair of defective parts within the

warranty period. The decision of the acceptance of the warranty will

be made by Doyon Equipment service department, which decision

will be final.

The purchaser is responsible for having the equipment properly

installed, operated under normal conditions with proper supervision

and to perform periodic preventive maintenance.

If any parts are proven defective during the period of one year from

date of purchase, Doyon Equipment Inc. hereby guarantees to replace,

without charge, F.O.B. Linière, Quebec, Canada, such part or parts.

Doyon Equipment Inc will pay the reasonable labor charges in

connection with the replacement parts occurring within one year from

purchase date. Travel over 50 miles, holiday or overtime charges are

not covered. After one year from purchase date, all labor and

transportation charges in connection with replacement parts will be the

purchaser’s responsibility.

Doyon Equipment Inc. does hereby exclude and shall not be liable to

purchaser for any consequential or incidental damages including, but

not limited to, damages to property, damages for loss of use, loss of

time, loss of profits or income, resulting from any breach or warranty.

In no case, shall this warranty apply outside Canada and continental

United States unless the purchaser has a written agreement from

Doyon Equipment Inc.

Loading...

Loading...