Page 1

Operation &

Maintenance

Manual

EXCAVATOR

DX225LC-5

Serial Number 1001 and Up

950106-01108FNA

December 2019

Page 2

Page 3

Operation and Maintenance Manual

DX225LC-5 Excavator

Serial Number 1001 and Up

DOOSAN and the DOOSAN logo are registered

trademarks of DOOSAN Corporation in the United

States and various other countries around the

world.

950106-01108FNA

December 2019

Original Instructions Copyright DOOSAN 2019©

Page 4

Page 5

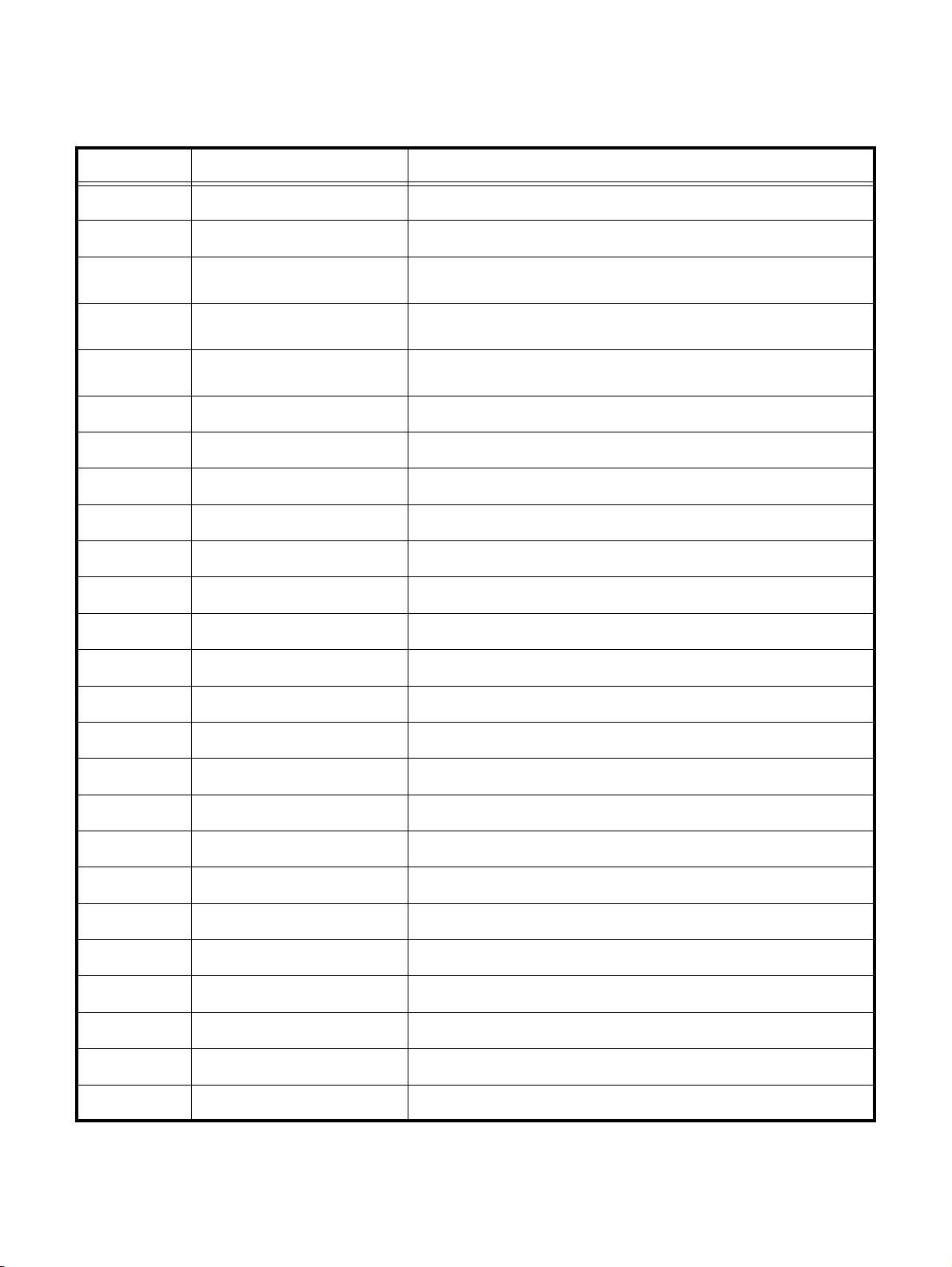

1REVISION

Date ltems Location

Oct. 2018 Revised text & figures Operating Controls - User Menu - Machine Configuration

Oct. 2018 Revised text Operation - Engine Start

Oct. 2018 Revised text & figures

Feb. 2019 Revised text

Aug. 2019 Revised text

Dec. 2019 Revised text & figures Operation - Quick Coupler Operation

Inspection, Maintenance and Adjustment - Fluid Capacities,

Change Pilot Filter, Track Tension

Inspection, Maintenance and Adjustment - Service data

comment add.

Inspection, Maintenance and Adjustment - Maintenance

Intervals.

Page 6

Page 7

Table of Contents

Foreword ....................................................................................0-1

AEM Safety Manual (North America Only) ........................................ 0-6

Federal and California Emission Control Systems............................. 0-7

Safety..........................................................................................1-1

Safety Decals..................................................................................... 1-2

General ............................................................................................ 1-18

Transportation.................................................................................. 1-31

Operation ......................................................................................... 1-33

Maintenance .................................................................................... 1-53

Environment and Circumstances ..................................................... 1-69

Operating Controls....................................................................2-1

Component Locations ........................................................................ 2-2

Operator's Area.................................................................................. 2-6

Operational Controls and Panels ....................................................... 2-8

Display Monitor ................................................................................ 2-26

User Menu ....................................................................................... 2-54

Heater and Air Conditioner Control Panel........................................ 2-96

Stereo ............................................................................................ 2-102

Miscellaneous Electrical Devices................................................... 2-103

Seat Adjustment............................................................................. 2-105

Engine Emergency Stop Switch..................................................... 2-108

Emergency Exit Glass Breaking Tool ............................................ 2-109

Miscellaneous Convenience Devices ............................................ 2-110

Miscellaneous Access Covers and Doors...................................... 2-117

DX225LC-5

Air Gun and Compressor (Optional) .............................................. 2-119

Table of Contents

I

Page 8

Operation....................................................................................3-1

To Operate a New Excavator............................................................. 3-1

Starting and Stopping Engine ............................................................ 3-2

Safety Lever..................................................................................... 3-17

Travel ............................................................................................... 3-18

Operating Instructions...................................................................... 3-24

Operating Precautions ..................................................................... 3-40

Parking Excavator............................................................................ 3-47

Towing Procedure............................................................................ 3-48

Attachments ..................................................................................... 3-49

Hydraulic Attachments (Optional) .................................................... 3-52

Lifting Objects .................................................................................. 3-70

Lifting Objects with Quick Coupler ................................................... 3-72

Operation Under Abnormal Conditions ............................................ 3-74

Long Term Storage .......................................................................... 3-82

Inspection, Maintenance and Adjustment...............................4-1

Maintenance Information ................................................................... 4-1

Machine Setup Position for Maintenance .......................................... 4-5

Maintenance Handling Access........................................................... 4-7

Handling Oil, Fuel, DEF (AdBlue), Coolant........................................ 4-8

Electrical System Maintenance........................................................ 4-14

Recommend Fuel, Coolant, and Lubricant ...................................... 4-15

Fluid Capacities ............................................................................... 4-21

Table of Recommended Lubricants ................................................. 4-22

Maintenance Intervals...................................................................... 4-24

10 Hour / Daily Service .................................................................... 4-27

50 Hour / Weekly Service ................................................................ 4-41

250 Hour / Monthly Service.............................................................. 4-45

500 Hour / 3 Month Service ............................................................. 4-50

1,000 Hour / 6 Month Service .......................................................... 4-61

DX225LC-5Table of Contents

II

Page 9

2,000 Hour / Yearly Service ............................................................. 4-71

4,000 Hour / Biennial Service .......................................................... 4-78

4,500 Hour / Biennial Service .......................................................... 4-79

12,000 Hour / 6 Year Service........................................................... 4-82

Air-conditioning System ................................................................... 4-83

Bucket .............................................................................................. 4-84

Electrical System ............................................................................. 4-86

Engine Cooling System.................................................................... 4-90

Fuel Transfer Pump (Optional) ........................................................ 4-94

Handling of Accumulator.................................................................. 4-97

Track Tension .................................................................................. 4-98

Venting and Priming Hydraulic System.......................................... 4-100

Maintenance in Special Conditions................................................ 4-102

Transportation ...........................................................................5-1

Loading and Unloading ...................................................................... 5-2

Lifting Machine................................................................................... 5-8

Specification ..............................................................................6-1

Standard Specification ....................................................................... 6-1

Overall Dimensions............................................................................ 6-2

Disassembled Parts, Dimension and Weight..................................... 6-4

Ground Pressure................................................................................ 6-6

Digging Force..................................................................................... 6-7

Working Range .................................................................................. 6-8

Excavator Rated Lift Capacity Tables.............................................. 6-12

Approximate Weight of Workload Materials..................................... 6-59

Index ...........................................................................................7-1

DX225LC-5

Table of Contents

III

Page 10

IV

DX225LC-5Table of Contents

Page 11

This Operation & Maintenance Manual was written to give owner

or operator instructions on safe operation and maintenance of

DOOSAN equipment. READ AND UNDERSTAND THIS

OPERATION AND MAINTENANCE MANUAL BEFORE

OPERATING YOUR DOOSAN EQUIPMENT. Keep this manual

in the cabin so it is always available. If it is lost, order another

one from your DOOSAN distributor.

If there are any questions, contact your DOOSAN distributor.

This manual may illustrate options and accessories not installed

on your equipment.

Any modification made without written authorization or approval

from DOOSAN can create a safety hazard.

Always replace parts with genuine DOOSAN parts or DOOSAN

authorized replacement parts.

Intended Use

The machine is intended to be used under normal conditions for

applications described in this manual. If it is used for other

purposes, or in potentially hazardous environments, special

precautions must be followed and the machine must be

equipped for such use. Examples include, but are not limited to,

are: falling object guards, work lights, etc. Do not engage in

prohibited uses as described in this manual. Contact your

DOOSAN distributor for further information.

Foreword

Engine and Emission Control System

Maintenance

Proper inspection, maintenance and repair is essential to

keeping engine and machine systems properly operating. This

includes proper inspection and maintenance of the machine's

emission control system. This could include machine and engine

components, such as an EGR (Exhaust Gas Recirculation)

system, fuel system, turbocharger, electrical system, air intake

system and/or cooling system.

As a heavy-duty off-road diesel engine owner, you are

responsible for performing required maintenance. The required

maintenance procedures are outlined in this Operation &

Maintenance Manual, or Shop Manual. Do not remove, alter, or

render inoperative, any emission control system.

DX225LC-5

Foreword

0-1

Page 12

Machine Capacity

Do not exceed machine capacity by modifying machine or using

unapproved attachments.

Exceeding machine capacity can adversely affect machine

performance characteristics such as: stability, system

certifications such as brakes and steering, the Roll-over

Protective Structure (ROPS) and can result in death or serious

injury. Contact your DOOSAN distributor for further information.

Attachments

These and other attachments are approved for use on this

machine. Do not use unapproved attachments. Attachments not

manufactured by DOOSAN may not be approved. See your

DOOSAN distributor for information about approved

attachments and attachment manuals.

•Buckets

• Hydraulic Breakers

• Grapples

• Plate Compactors

• Quick Couplers

California Proposition 65

Breathing diesel engine exhaust exposes you to chemicals

known to the State of California to cause cancer and birth

defects or other reproductive harm.

• Always start and operate the engine in a wall-ventilated

area.

• If in an enclosed area, vent the exhaust to the outside.

• Do not modify or tamper with the exhaust system.

• Do not idle the engine except as necessary.

This product can expose you to chemicals including lead, which

is known to the State of California to cause cancer and birth

defects or other reproductive harm.

For more information go to www.P65Warning.ca.gov.

0-2

DX225LC-5Foreword

Page 13

Product Identification Number (PIN)

EX1403864

Figure 1

EX1301247

Figure 2

Figure 3

EX1301248

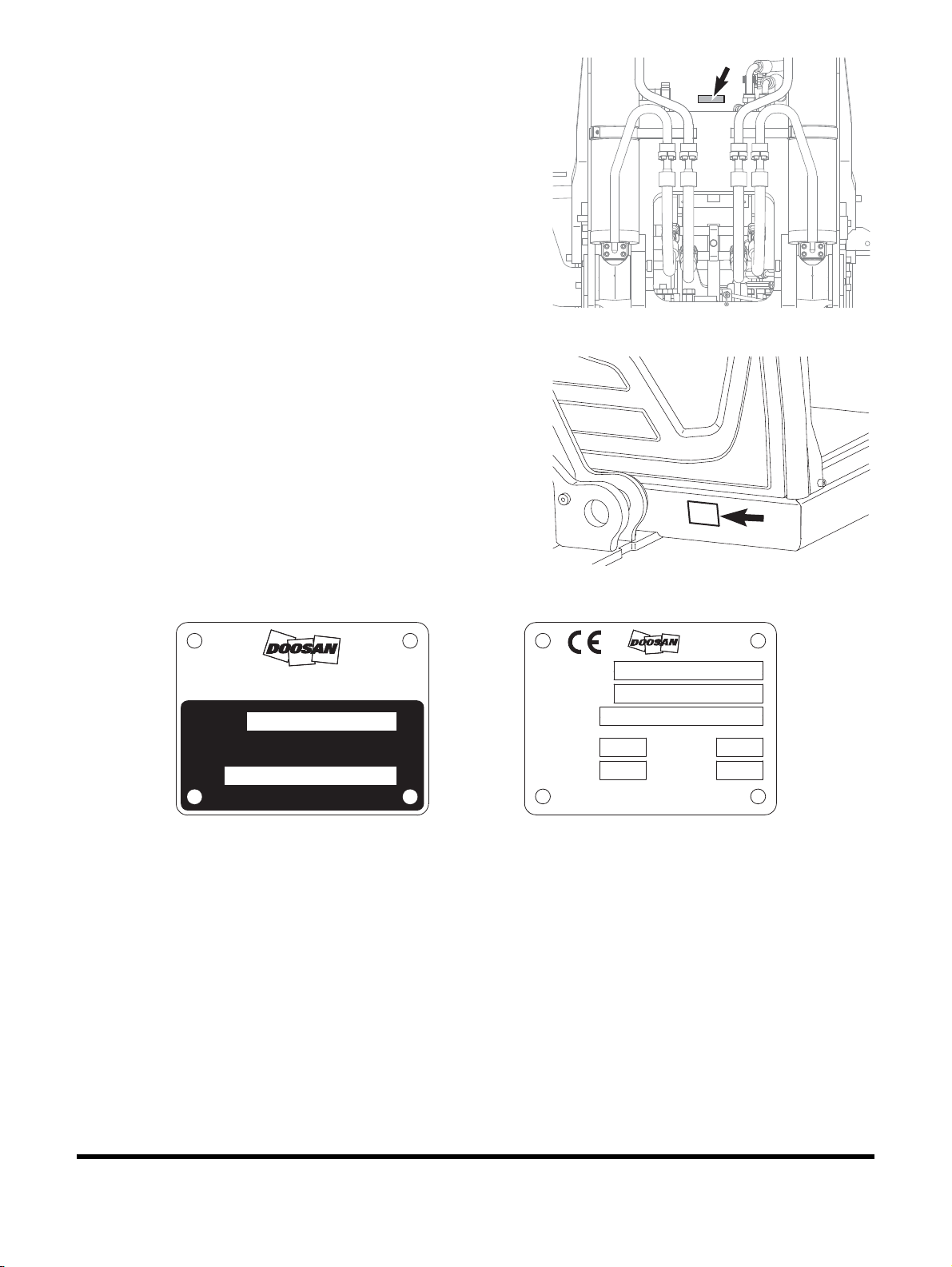

Doosan Infracore Co., Ltd.

7-11, Hwasu-dong, Dong-gu,

Incheon, Korea

PRODUCT IDENTIFICATION NUMBER

⣆㔲#⎇ᵮ#ᴲ㛢

MADE IN KOREA

⣆㔲ᬯ

MODEL

950209-02977

Operating

Identification

Construction

Year of

Number

Product

Power

Engine

7-11, Hwasu-dong, Dong-gu,

Doosan Infracore Co., Ltd.

Incheon, Korea

kW

Mass

Model Name

Machine Type

Made in Korea

kg

First Year

of Service

950205-01325A

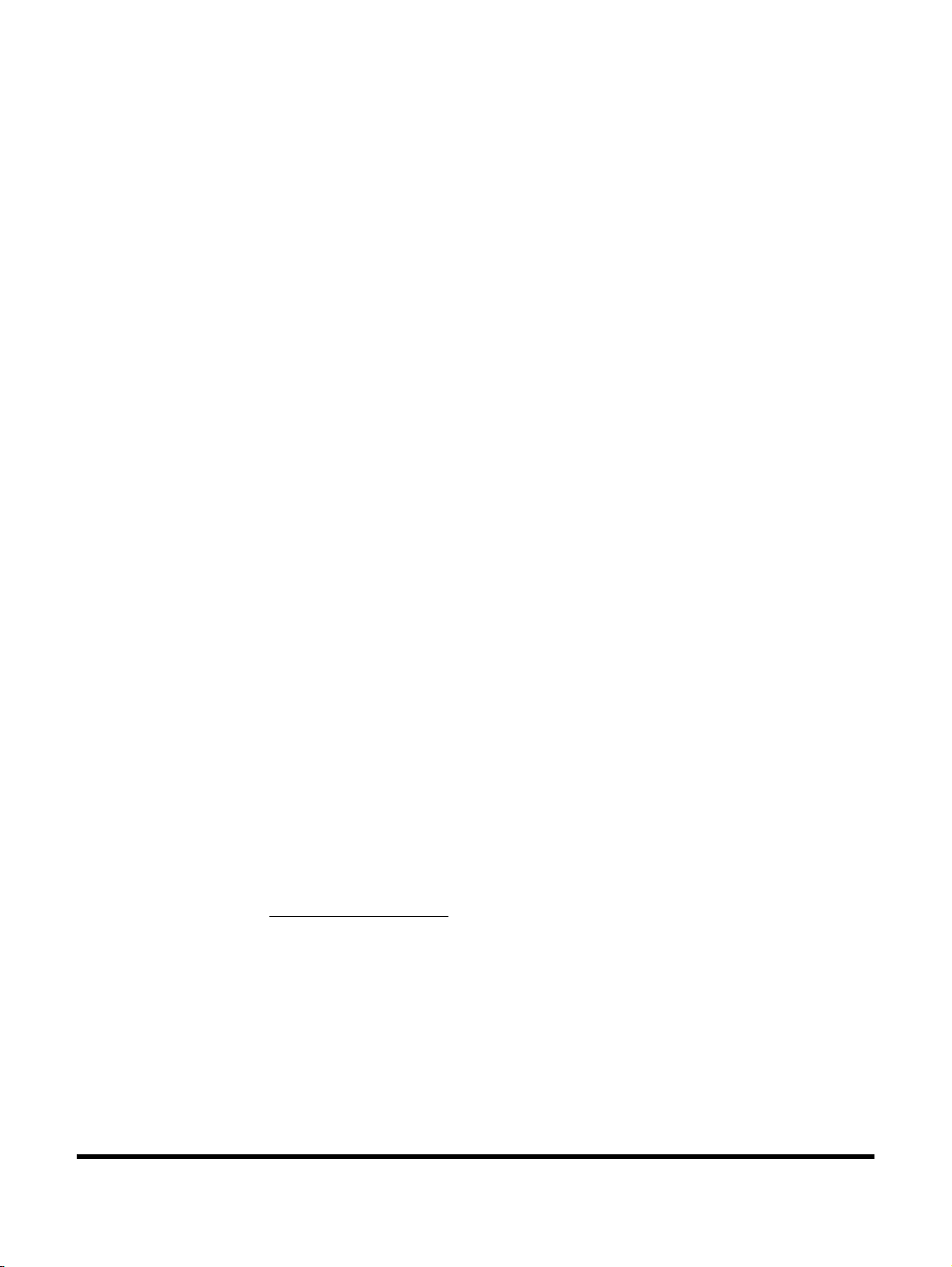

A PIN number is stamped on upper frame under boom foot

(

Figure 1). It is also stamped on a product identification plate

(Figure 2) on outside of cabin on right-hand side.

NOTE: Record these numbers and their locations. These will

be required whenever warranty or service work is

requested. Keep these numbers on file in case

machine is stolen.

Component Serial Numbers

There are many serial numbers on each traceable component of

the machine. Record these numbers and their locations. These

will be required whenever warranty service work is requested.

DX225LC-5

Foreword

0-3

Page 14

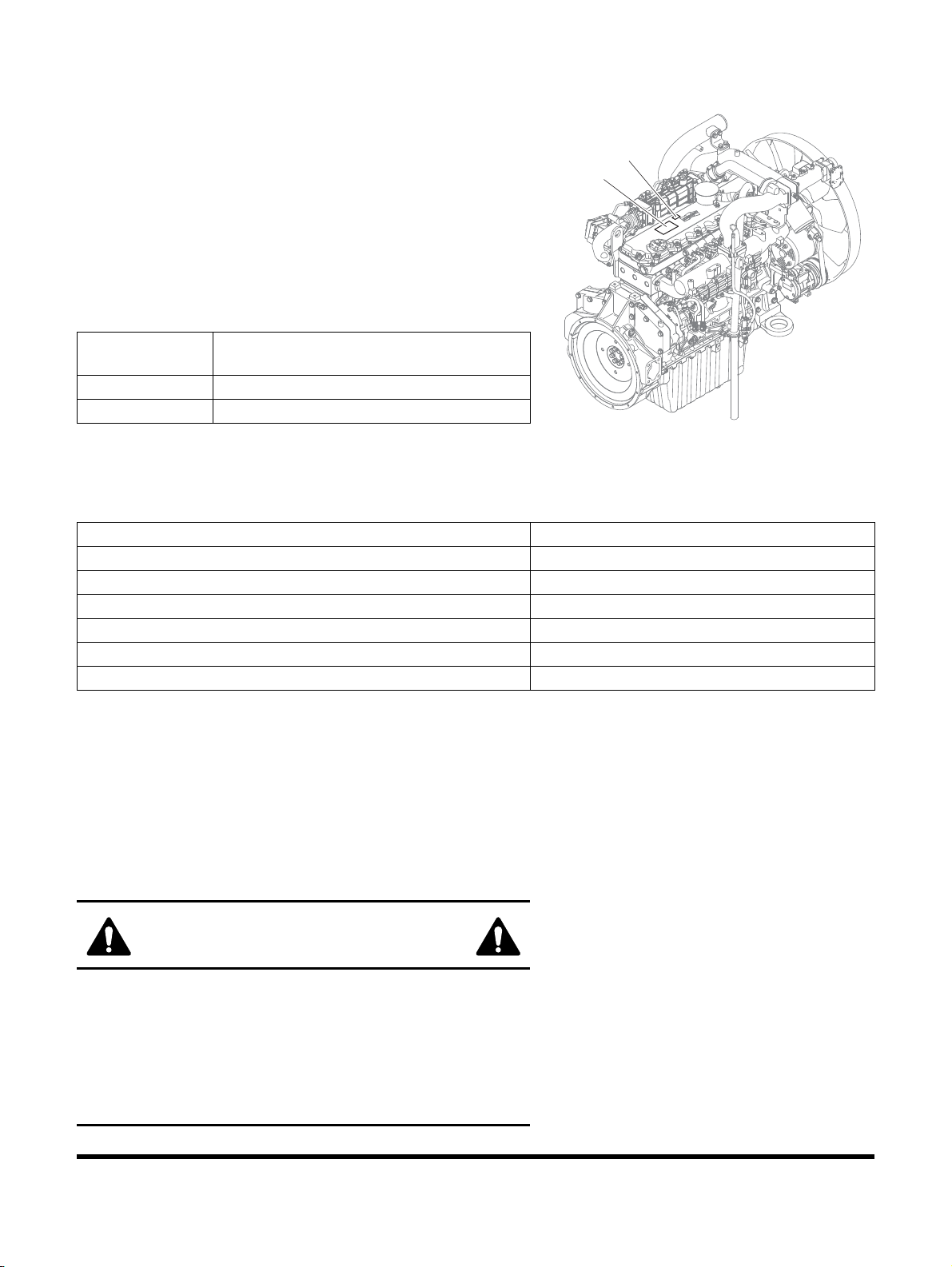

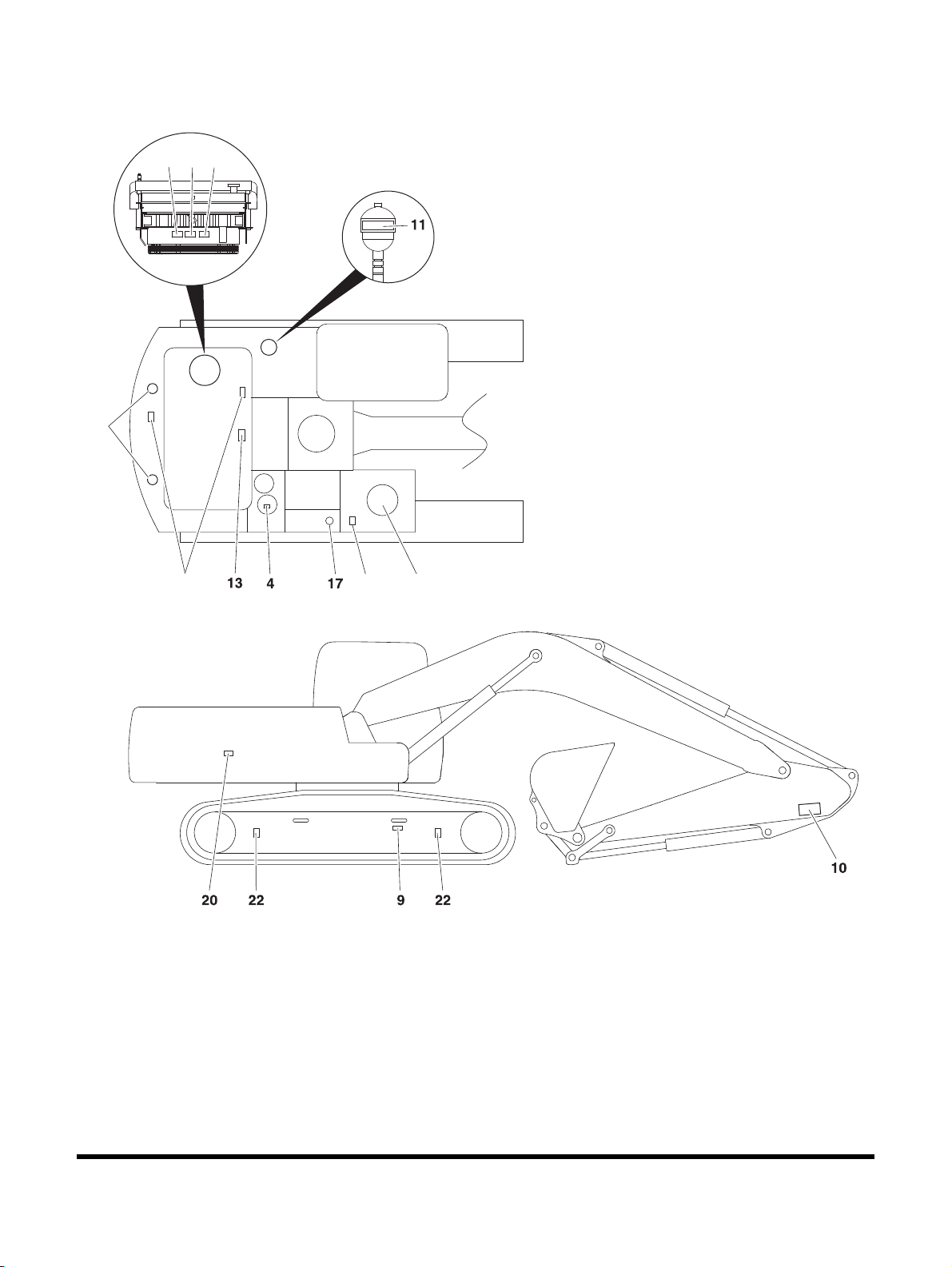

Engine Identification

1

2

EX1403746

Figure 4

Engine Data Plate

The engine data plate provides important facts about the engine.

The engine serial number (ESN) and control parts list (CPL)

provide information for service and ordering parts. The engine

data plate must not be changed unless approved by DOOSAN.

The engine data plate and engine serial number are located on

the head cover. Have the following engine data available when

communicating with a DOOSAN Authorized Repair Location.

The following information on data plate is mandatory when

sourcing service parts:

Reference

Number

1 Engine Data Plate

2 Engine Serial Number

Description

Your Machine Serial Numbers

Product Identification Number (PIN)

Machine Serial No.

Engine Serial No.

Main Pump

Swing Motor

Travel Motor

Main Control Valve

Safety Messages

Safety messages and safety decals included in this manual and

on the machine provide instructions how to operate, service and

maintain the machine. Safety messages and safety decals

indicate potential hazards and describe safety precautions

required to avoid hazards. Operator and maintenance personnel

should read and understand these safety messages and decals

before beginning operation or maintenance.

SAFETY ALERT SYMBOL

Be Prepared - Get to Know All Operating and Safety

Instructions.

This is a Safety Alert Symbol. Wherever it appears in this

manual or on safety decals on the machine, you must be

alert to the potential for personal injury or accidents.

Always observe safety precautions and follow

recommended procedures.

0-4

DX225LC-5Foreword

Page 15

Signal Words

The signal words "DANGER", "WARNING", "CAUTION" are

used throughout safety messages and safety decals in this

manual or on the machine. They indicate an existence of, and

the relative seriousness of, a hazard. All three indicate that a

safety risk is involved. Observe the precautions indicated

whenever a Safety Alert Symbol is present, no matter which

signal word appears next to it.

DANGER

DANGER - This signal word is used on safety messages and

safety labels and indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING

WARNING - This signal word is used on safety messages and

safety labels and indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION

CAUTION - This signal word is used on safety messages

and safety labels and indicates a potentially hazardous

situation which, if not avoided, could result in minor or

moderate injury.

Other Signal Words

In addition to safety signal words, the following signal words are

used to indicate proper and effective use of machine.

IMPORTANT

This signal word identifies procedures which must be

followed to avoid damage to machine.

NOTE: The word "NOTE" identifies information for effective

use.

DX225LC-5

Foreword

0-5

Page 16

AEM SAFETY MANUAL

Figure 5

(NORTH AMERICA ONLY)

The AEM Safety Manual delivered with the machine gives

general safety information.

The AEM Safety Manual must be read and understood before

beginning operation or maintenance and is not intended to

replace the Operation & Maintenance Manual delivered with the

machine.

DX225LC-5Foreword

0-6

Page 17

FEDERAL AND CALIFORNIA EMISSION CONTROL SYSTEMS

Limited Warranty for Non-road Engines (CI) (FDICL05.8LEA (DL06P))

Owner’s Warranty Rights and Obligations

The U.S. Environmental Protection Agency (EPA), the California Air Resources Board (ARB), and DOOSAN

INFRACORE are pleased to explain the Federal and California Emission Control System Warranty on your

2015MY to 2017MY non-road engine. DOOSAN INFRACORE has designed, built and equipped the engine so as

to conform at the time of sale with all applicable regulations of the EPA and of the California ARB. In California,

new heavy-duty off-road engines must be designed, built and equipped to meet the State’s stringent anti-smog

standards.

DOOSAN INFRACORE must warrant to the initial owner, and each subsequent owner, the emission control

system on your engine for the periods of time listed below provided there has been no abuse, neglect, improper

maintenance or unapproved modifications of your engine. Your emission control system may include those parts

listed below:

1. Fuel Metering System

Fuel Supply Pump (HP Pump), Injector, Common Rail, Glow Plug

2. Air-Induction System

Intake Manifold, Turbocharger System

3. Exhaust Gas Recirculation (EGR) System

EGR Valve, EGR Cooler

4. Catalyst or Thermal Reactor System

Diesel Oxidation Catalyst (DOC), Exhaust Manifold, SCR System, Catalyst, NOx Sensor

5. Positive Crankcase Ventilation (PCV) System

Right Head Cover

6. Electronic Control System

ECU, Cam/ Crank Sensor, Coolant Temperature Sensor, MAF Sensor, MAP Sensor (Manifold Pressure

Sensor), Inlet Boost Temperature Sensor, Fuel Temperature Sensor, Common Rail Pressure Sensor

7. Miscellaneous Items Used In Above Systems

Temperature and time sensitive valve and switches

Solenoids and wiring harnesses

Hoses, clamps, fittings and tubing, sealing gasket

Pulleys, belts and idlers

Emission control information labels

Where a warrantable condition exists, DOOSAN INFRACORE CONSTRUCTION EQUIPMENT AMERICA

(hereafter "DICEA") will repair your heavy-duty off-road engine at no cost to you including diagnosis, parts, and

labor.

DX225LC-5

Foreword

0-7

Page 18

Manufacturer's Warranty Coverage

The 2015MY to 2017MY heavy-duty off-road engines are warranted for five years or 3,000 hours of operation,

whichever occurs first. If any emission-related part on your engine is defective, the part will be repaired or

replaced by DICEA.

The warranty period shall begin on the date the machine is delivered to the first retail customer.

Owner’s Warranty Responsibilities

As the heavy-duty off-road engine owner, you are responsible for the performance of the required maintenance

listed in the Operation and Maintenance Manual. DOOSAN INFRACORE and DICEA recommends that you

retain all receipts covering maintenance on your heavy-duty off-road engine, but DOOSAN INFRACORE and

DICEA cannot deny warranty solely for the lack of receipts or for your failure to ensure the performance of all

scheduled maintenance.

As the heavy-duty off-road engine owner, you should however be aware that DOOSAN INFRACORE and DICEA

may deny you warranty coverage if your heavy-duty off-road engine or a part has failed due to abuse, neglect,

improper maintenance or unapproved modifications.

Your engine is designed to operate on Ultra Low Sulfur Diesel Fuel Only. Use of any other fuel may result in

your engine no longer operating in compliance with the EPA’s emissions requirements.

You are responsible for initiating the warranty process. The EPA and California ARB suggest that you present

your heavy-duty off-road engine to a DICEA dealer as soon as a problem exists. The warranty repairs should be

completed by the dealer as expeditiously as possible.

If you have any questions regarding your warranty rights and responsibilities, you should contact your nearest

authorized DICEA dealer or contact DICEA at

Doosan Infracore Construction Equipment North America

2905 Shawnee Industrial Way

Suwanee, GA 30024

USA

1-800-743-4340

0-8

DX225LC-5Foreword

Page 19

1Safety

DX225LC-5

Safety

1-1

Page 20

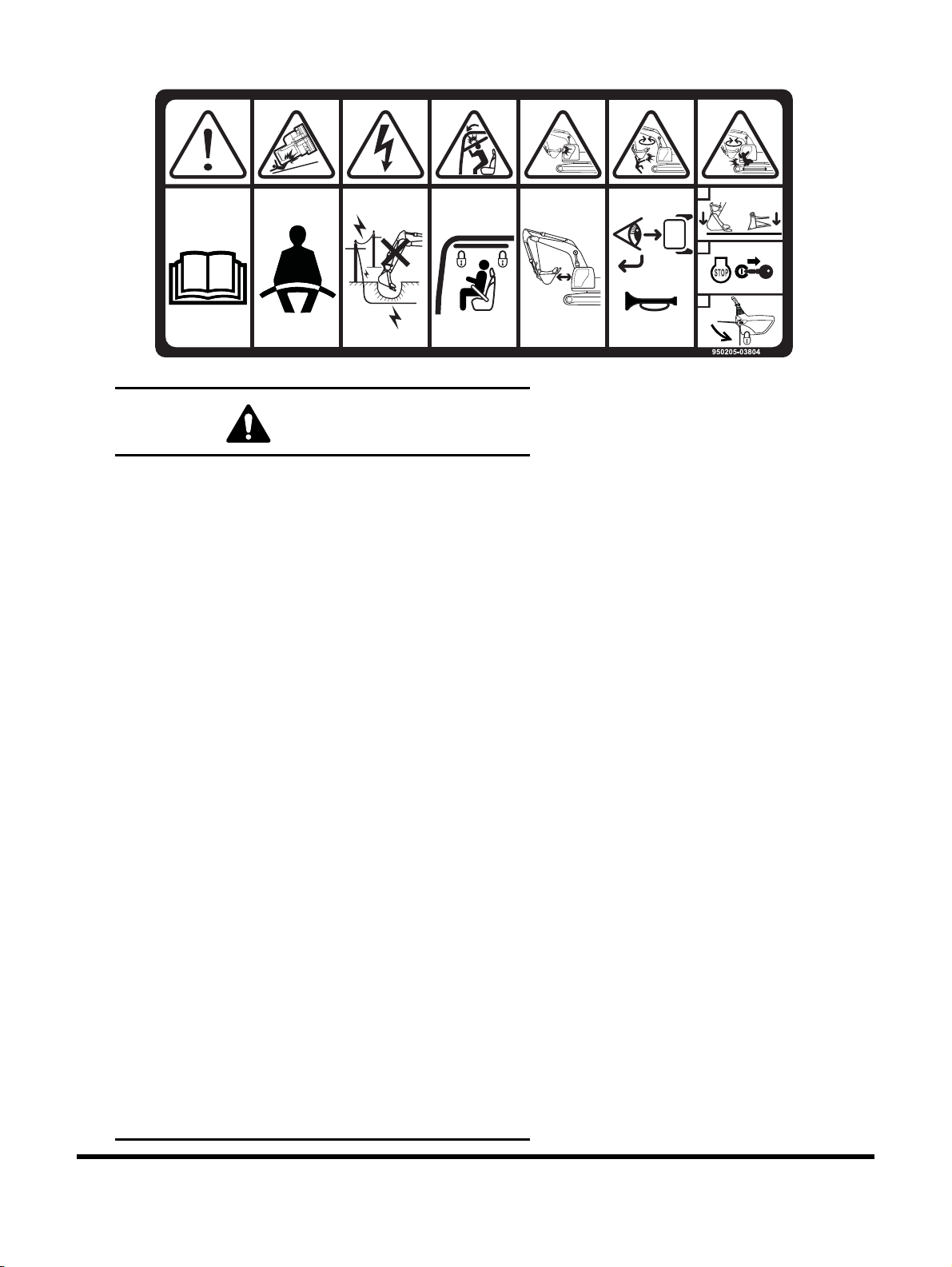

SAFETY DECALS

Safety decals are attached to the machine to alert the operator

or maintenance person about potential hazards, the

consequences of potential injury, and instructions and/or actions

required to avoid the hazard. The location of the safety decals

and the description of the decals are reviewed in the following

section. Please become familiarized with all safety decals and

their messages.

Make sure that all the safety decals are in their correct location

and legible. Clean or replace the safety decals if they are

damaged, missing, or the texts and pictorials are not legible.

When you clean the safety decals, use a soft cloth, water, and

soap. Do not use solvent, gasoline, or other harsh chemicals to

clean the safety decals because this could loosen the adhesive

that secures the decals to the machine. Remember, if a safety

decal is attached to a part that is replaced, install a new safety

decal on the replacement part.

This machine uses safety decals with and without text. The type

and number of safety decals can vary depending upon

geographical regions and machine models.

Safety Decals With Text

Safety decals with text consist of a signal word, pictorial and a

text message panel. In some cases, a pictorial panel may not be

part of the safety decal.

1-2

DX225LC-5Safety

Page 21

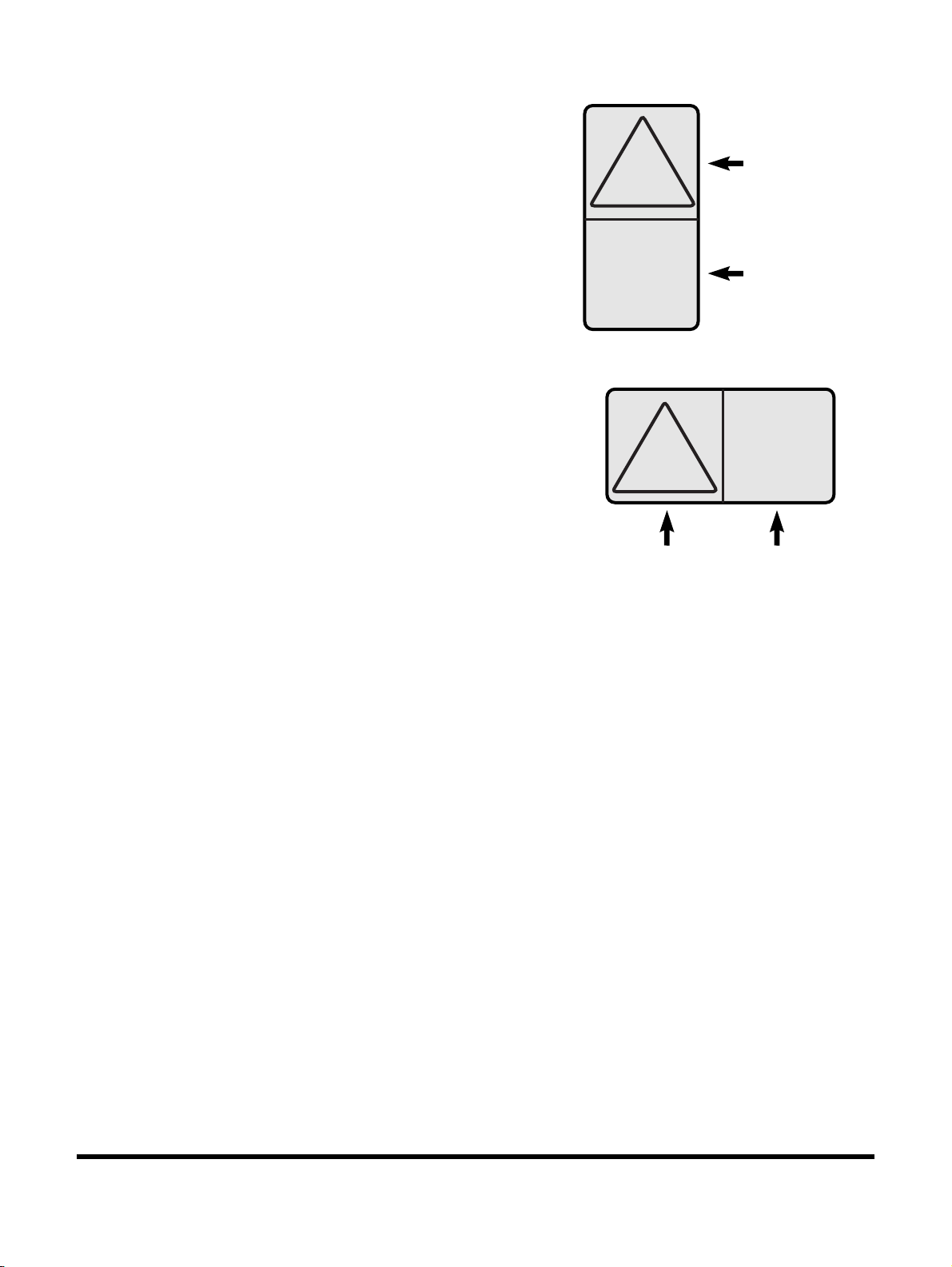

Safety Decals Without Text (No-Text)

Horizontal Configuration

Vertical Configuration

Hazard

Panel

Avoidance

Panel

Hazard

Panel

Avoidance

Panel

FG018723

Figure 1

Safety decals without text consist of a hazard panel(s) and

avoidance panel(s). Hazard panels are located at the top or left

side and the avoidance panels are located at the bottom or right

side of the decal depending on its configuration. The hazard

panels use a black triangular band and a pictorial to identify the

hazard and the potential consequences of failure to follow the

instructions. Avoidance panels use pictorials and/or prohibition

signs to identify the actions necessary to avoid the hazard.

A safety decal may contain more than one hazard panel and

more than one avoidance panel.

DX225LC-5

Safety

1-3

Page 22

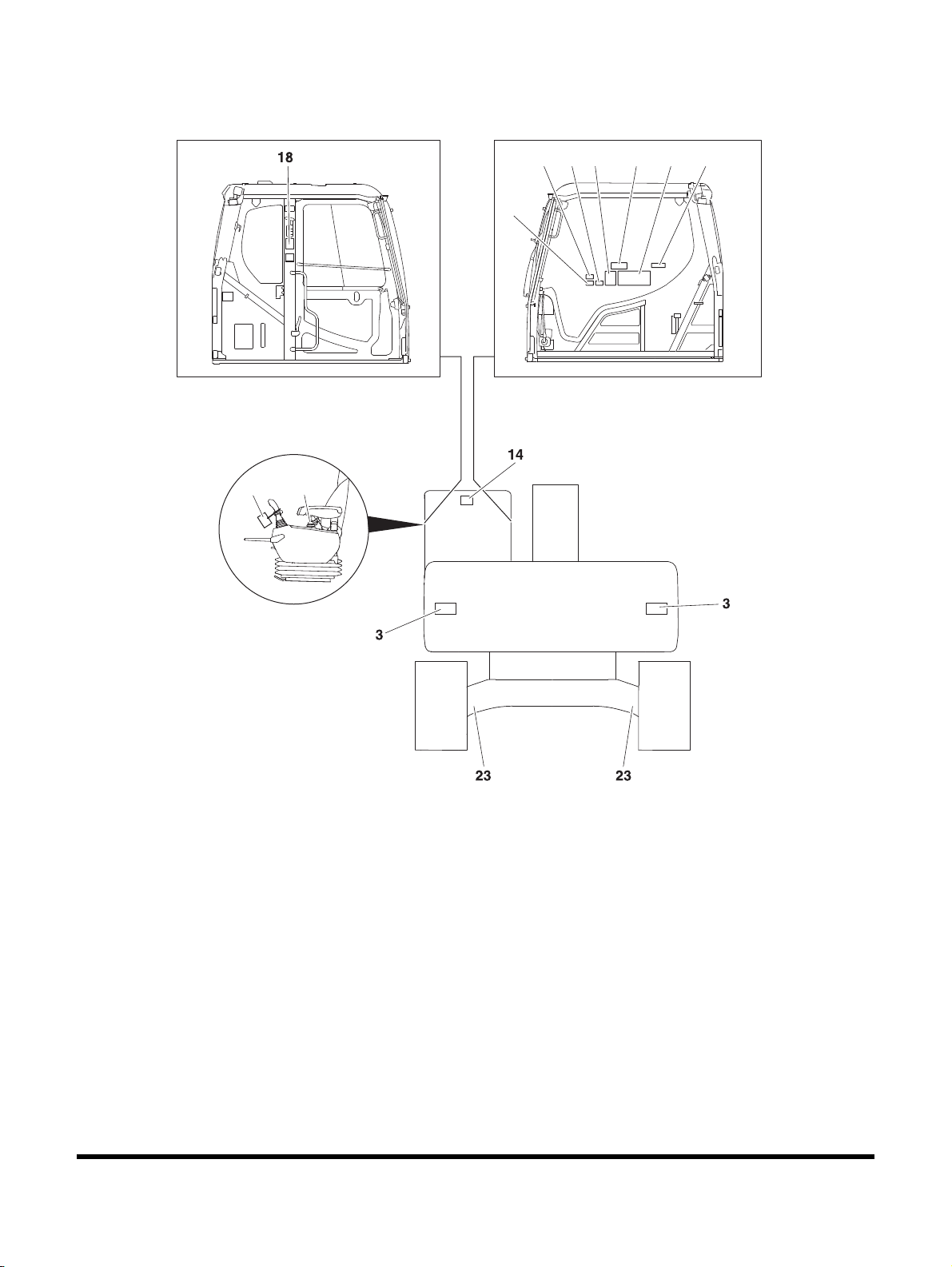

Information and Location for Safety Decals

227

DS1801352

2928 21 15 16 1

24

Figure 2

DX225LC-5Safety

1-4

Page 23

Information and Location for Safety Decals (Continued)

Figure 3

465

25

12

26

19, 7, 8

EX1403849

DX225LC-5

Safety

1-5

Page 24

1. General Hazard (950205-03804)

EX1301176

1

2

3

WARNING

AVOID DEATH OR SERIOUS INJURY

• Never use excavator without instructions.

• Read Operation & Maintenance Manual before

operation.

• Sound the horn to alert bystanders before

operating.

• Always fasten your seat belt.

• Explosion or electrocution can occur if machine

contacts utility lines or pipes. Check for overhead

or underground lines before operating.

• Secure and lock front window when it is in raised

position.

• Attachment interference can cause death, serious

injury or machine damage. Check attachment to

machine clearance through full working cycle

before operation.

• Keep bystanders out of swing area and travel

path and always look in the travel direction.

• Ensure mirrors and rear view camera are clean

and working properly.

• Never operate machine from outside the

operator's position.

• TO LEAVE THE EXCAVATOR:

1) Lower the attachment and dozer blade (if

equipped) to the ground and make sure all

controls are in neutral.

2) Stop engine and remove key.

3) Lower safety lever to LOCK position.

1-6

DX225LC-5Safety

Page 25

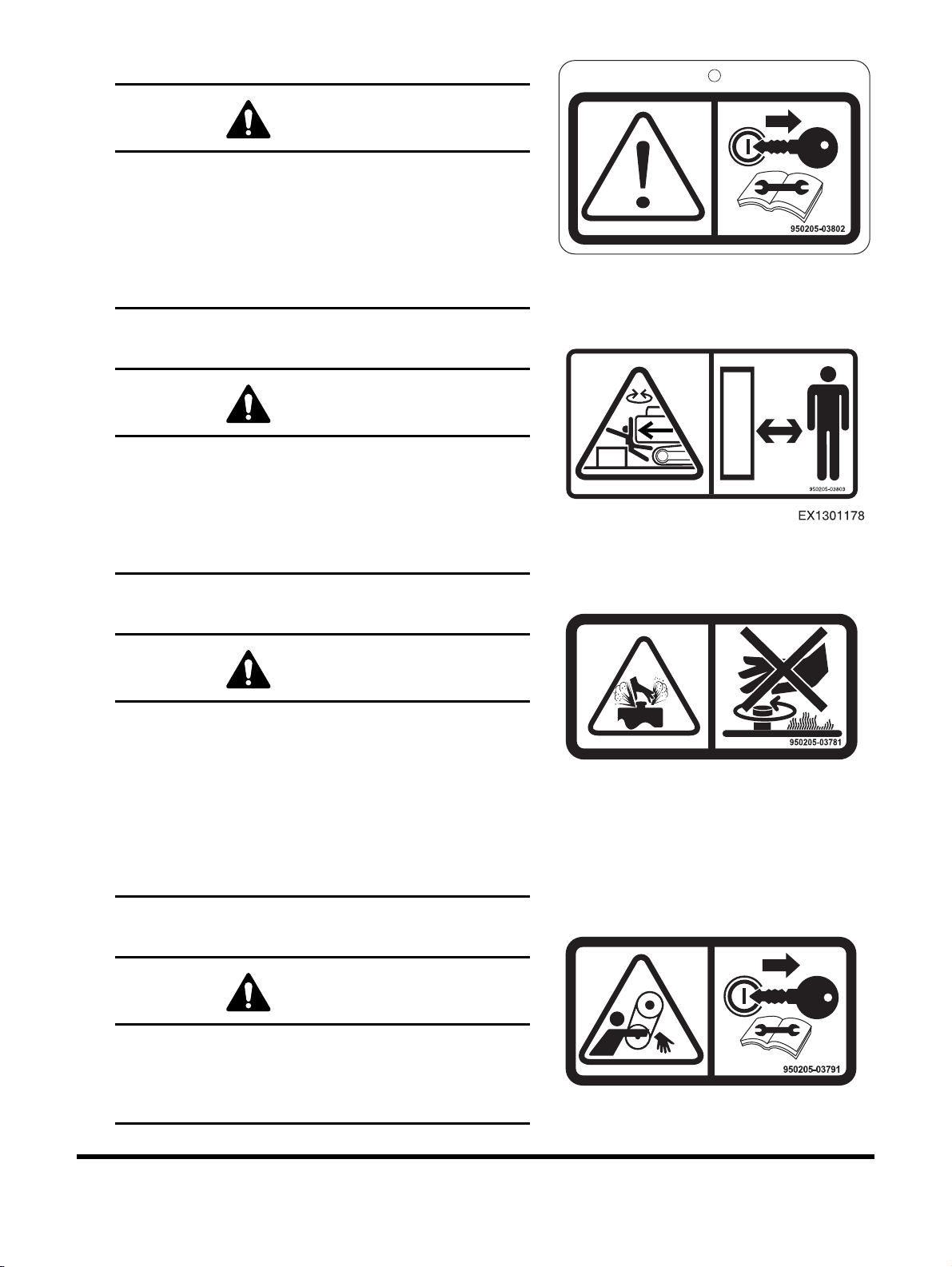

2. Warning Tag - "Do Not Operate" (950205-03802)

EX1301180

EX1301181

WARNING

AVOID DEATH OR SERIOUS INJURY

• Stop engine and remove key.

• Attach "DO NOT OPERATE" warning tag to the

controls before servicing the machine.

• Do not operate when performing inspection or

maintenance.

3. Keep Bystanders Away (950205-03803)

WARNING

AVOID DEATH OR SERIOUS INJURY

• Keep out of swing area and travel path.

• Always look in the travel direction.

EX1301177

• Make sure swing area is clear of bystanders and

objects.

4. Hot Pressurized Fluid (950205-03781)

WARNING

HOT PRESSURIZED FLUID CAN CAUSE

SERIOUS BURNS

• Do not loosen or open cap when hot.

• Before opening:

1) Turn engine off.

2) Allow machine to cool.

3) Tip cap and open slowly to relieve pressure.

5. Entanglement in Rotating Parts (950205-03791)

WARNING

ROTATING PARTS CAN CAUSE DEATH OR

SERIOUS INJURY

Keep away from belt and rotating parts. Stop engine

before servicing.

DX225LC-5

Safety

1-7

Page 26

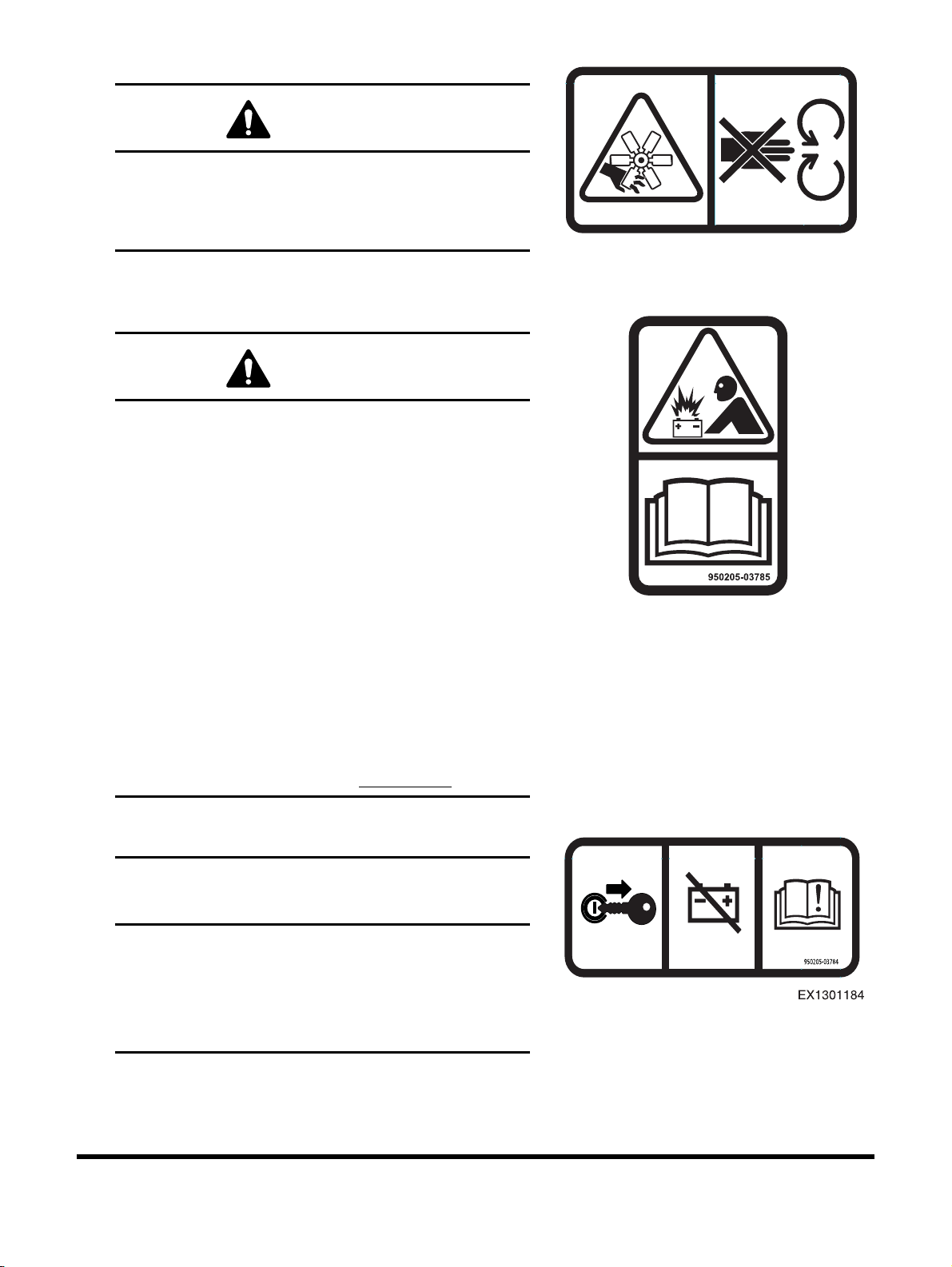

6. Rotating Fan (950205-03788)

WARNING

CONTACT WITH ROTATING FAN CAN CAUSE

DEATH OR SERIOUS INJURY

Keep away from fan and rotating parts. Stop engine

before servicing.

7. Battery Explosion (950205-03785)

WARNING

AVOID DEATH OR SERIOUS INJURY

• Read and follow instructions in Operation &

Maintenance Manual for battery maintenance.

• Keep arcs, sparks, flames, and lighted tobacco

away.

• Do not store metal tools or flammable materials

on or around batteries.

• Wear safety goggles and rubber gloves when

working with batteries.

• If battery acid contact occurs:

1) Flush your skin with water immediately and

apply baking soda or lime to neutralize the

acid.

950205-03788

EX1301182

EX1301183

2) Flush your eyes with water for 10 - 15

minutes.

3) Get medical attention immediately.

8. Battery Disconnection (950205-03784)

IMPORTANT

AVOID ELECTRICAL COMPONENT DAMAGE

Disconnecting the battery while the engine is running

can cause damage to electrical components.

Disconnect battery only when the engine is turned

OFF.

1-8

DX225LC-5Safety

Page 27

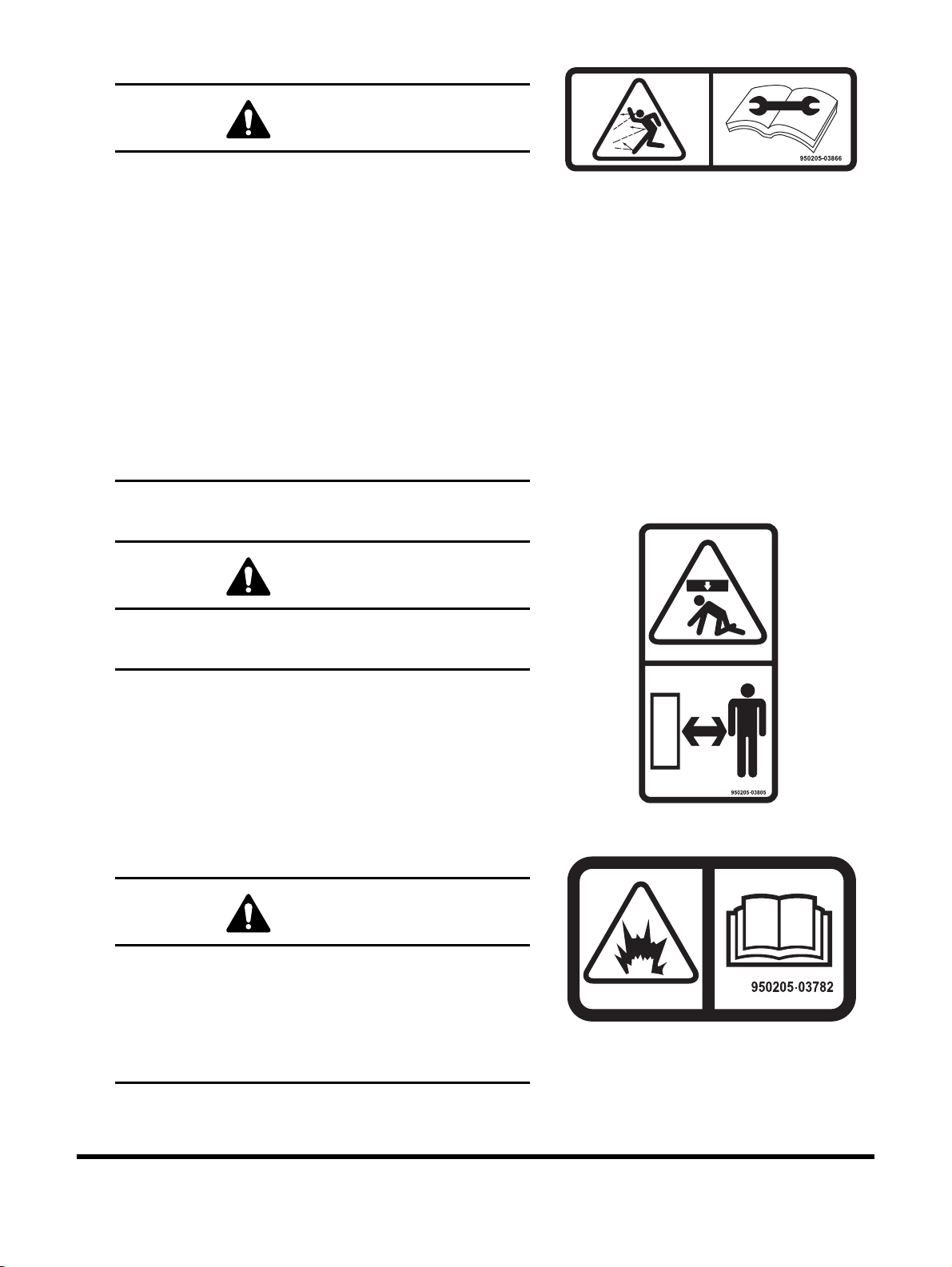

9. Flying Debris or Objects (950205-03866)

EX1301185

EX1301186

EX1301187

WARNING

HIGH-PRESSURE GREASE CAN CAUSE

DEATH OR SERIOUS INJURY

• Track adjusting systems use grease under highpressure which can penetrate body if improperly

serviced.

• NEVER LOOSEN track tension grease valve more

than one complete turn from the fully tightened

position.

• Bleed off pressure slowly and keep body away

from grease valve.

• Wear eye protection.

• Read and follow instructions in Operation &

Maintenance Manual for more information on

track adjustment.

10. Crush Hazard (950205-03805)

WARNING

AVOID DEATH OR SERIOUS INJURY

Stay clear of the boom, arm, and attachment.

11. Pressurized Gas and Fluid (950205-03782)

WARNING

AVOID DEATH OR SERIOUS INJURY

• Heat or impact can cause the accumulator to

explode.

• Keep away from flame.

• Do not weld on or drill into accumulator.

DX225LC-5

Safety

1-9

Page 28

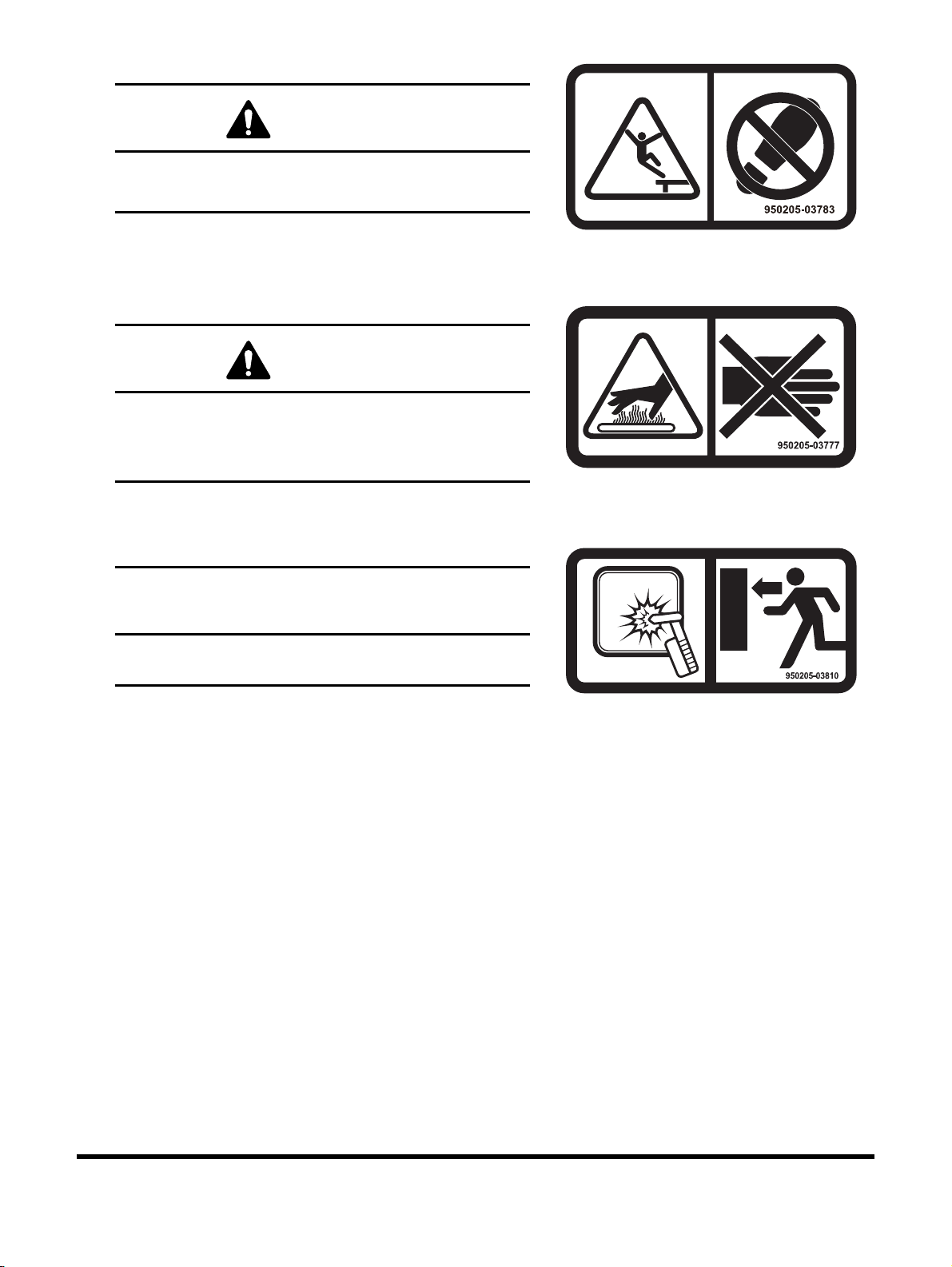

12. Fall Hazard (950205-03783)

WARNING

AVOID DEATH OR SERIOUS INJURY

Do not step in this area.

13. Hot Surface (950205-03777)

WARNING

HOT SURFACE CAN CAUSE SERIOUS BURNS

• Do not touch hot surface.

• Allow to cool before servicing.

EX1301188

EX1301189

14. Emergency Exit (950205-03810)

IMPORTANT

If primary exit is blocked, use glass breaking tool to

break glass for secondary exit.

EX1301190

1-10

DX225LC-5Safety

Page 29

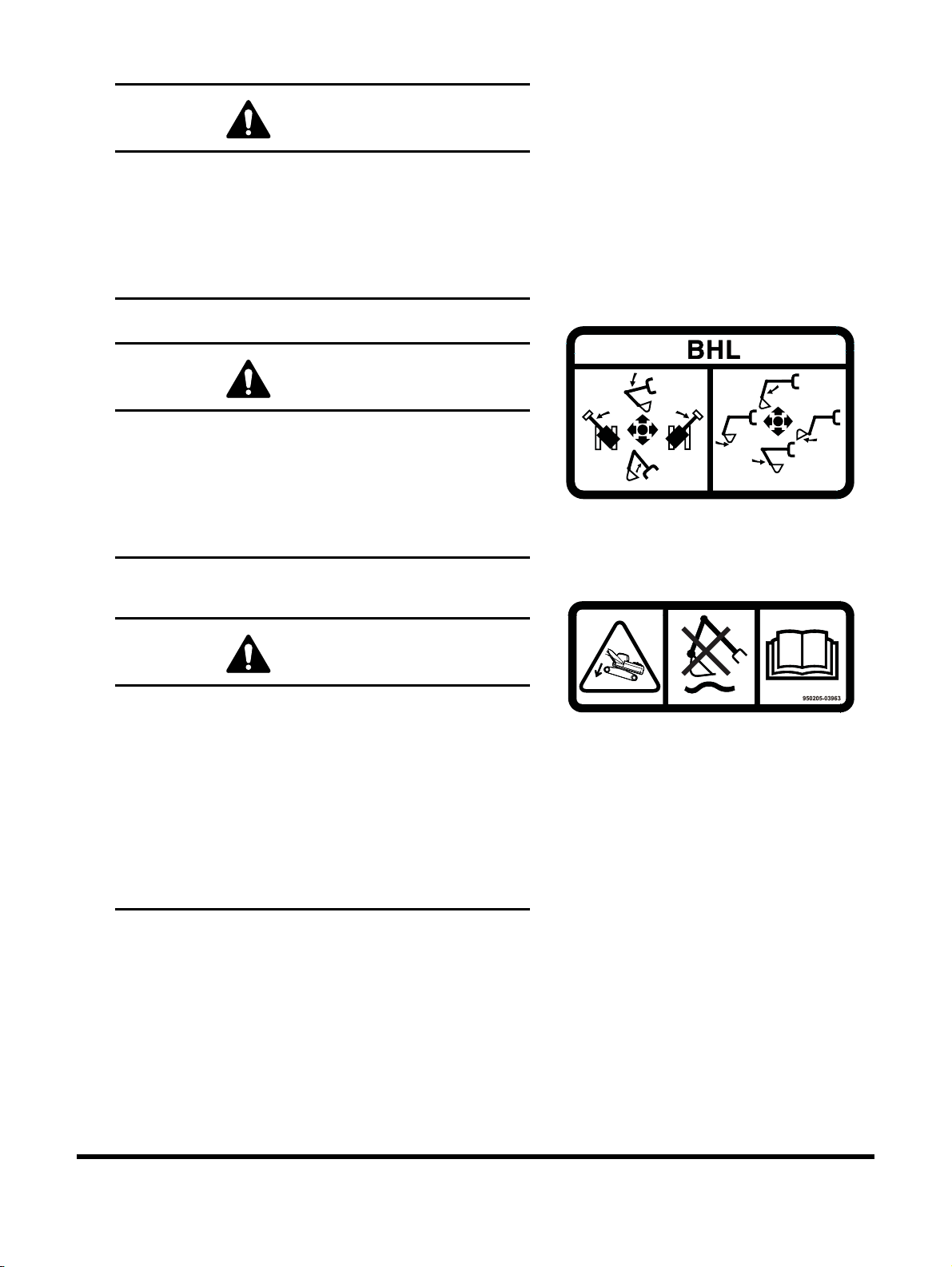

15. ISO Control Pattern (950205-03860)

WARNING

AVOID INJURY OR DEATH

Read and understand the Operation & Maintenance

Manual for more information.

Refer to "Operating Instructions" section of this

manual for details regarding the work levers

(joysticks) control functions.

BHL Control Pattern (US Only) (950205-03868)

WARNING

AVOID INJURY OR DEATH

Read and understand the Operation & Maintenance

Manual for more information.

Refer to "Operating Instructions" section of this

manual for details regarding the work levers

(joysticks) control functions.

16. Impact Hazard (Optional) (950205-03963)

WARNING

AVOID DEATH OR SERIOUS INJURY

• Activating the Intelligent Floating Boom Control

with the tracks raised up can cause the machine

to drop suddenly.

• Do not activate Intelligent Floating Boom Control

when tracks are raised.

• Do not raise tracks when control is activated.

Refer to "Intelligent Floating Boom Control (Optional)"

section of this manual for more information.

EX1301192

EX1301193

DX225LC-5

Safety

1-11

Page 30

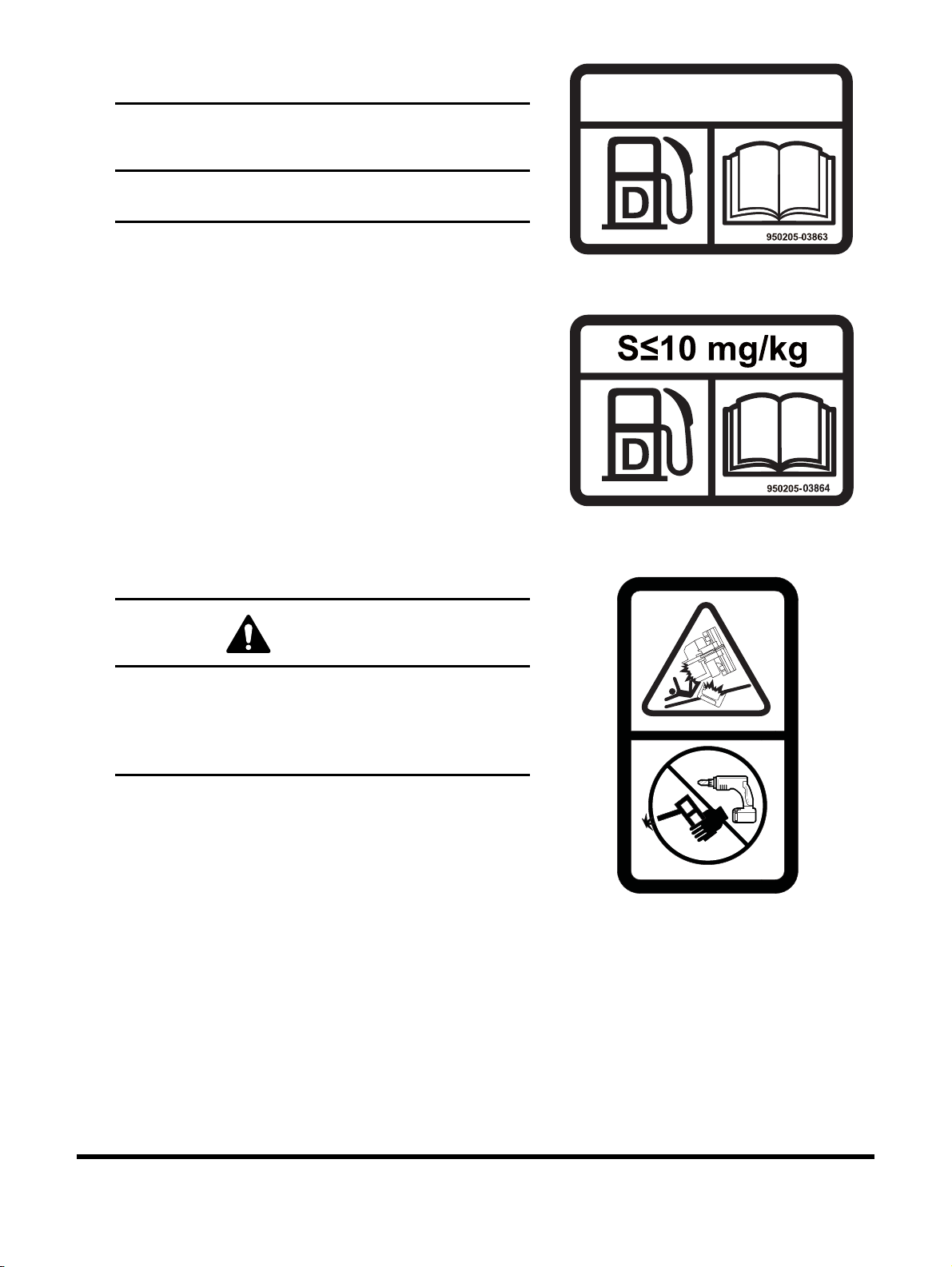

17. Ultra Low Sulfur Diesel Fuel (Optional)

950205-03861

(950205-03863, 950205-03864)

IMPORTANT

Only use Ultra Low Sulfur Diesel (ULSD) fuel with this

machine.

ULTRA LOW SULFUR

DIESEL FUEL ONLY

EX1301196

EX1301194

18. ROPS Warning (Optional) (950205-03861)

WARNING

AVOID DEATH OR SERIOUS INJURY

• Do not weld on or drill holes in the protective

structure.

• Replace ROPS, if damaged or modified.

950205-03861

EX1301197

1-12

DX225LC-5Safety

Page 31

19. Falling Object (Optional) (950205-03786)

WARNING

UNSUPPORTED DOOR CAN FALL CAUSING

DEATH OR SERIOUS INJURY

• To open door:

1) Hold door firmly.

2) Lift door slowly until locking device

engages.

• To close door:

1) Hold door firmly.

2) Press locking device to disengage.

3) Lower door slowly.

EX1301198

DX225LC-5

Safety

1-13

Page 32

20. Hydraulic Oil Check (Optional) (950205-06281, 950205-03965, 950205-06282)

IMPORTANT

INCORRECT OIL LEVEL OR INCORRECT FLUID CAN

CAUSE HYDRAULIC SYSTEM DAMAGE

Place the excavator with the boom and arm fully

extended with the attachment on the ground before

checking hydraulic fluid level.

Use hydraulic oil which is suitable for machine.

32

950205-06281

EX1505097

1-14

EX1505098

68

950205-06282

EX1505099

DX225LC-5Safety

Page 33

21. Hydraulic Breaker (Optional) (950205-03964)

EX1402396

950212-02440

IMPORTANT

AVOID HYDRAULIC SYSTEM DAMAGE

To adjust breaker impact, see Operation &

Maintenance Manual for additional instructions.

22. Lift/Tie down (Optional) (950205-03815)

Identifies lift point and tie down point location.

EX1301200

23. Tie down (Optional) (950205-03816)

Identifies tie down point location.

24. Electric Welding Attention (950212-02440)

IMPORTANT

950205-03815

EX1301201

EX1301203

Electrical welding on the frame can damage the

engine's electronic control unit (ECU).

DX225LC-5

Safety

1-15

Page 34

25. Do Not Lift (950205-03570)

EX1402619

WL1300370

ISO 22241 DIN 70070

950205-01489A

WARNING

AVOID DEATH OR SERIOUS INJURY

Not a lift point for machine.

Refer to the "Lifting Machine" section of this manual

for detailed information regarding the lifting point.

26. DEF (AdBlue) (950205-01489A)

IMPORTANT

• Use only the specified diesel exhaust fluid.

• See the Operation & Maintenance Manual for

more information.

1-16

DX225LC-5Safety

Page 35

27. Dozer (950205-03881)

WE1500865

950205-05450

WARNING

AVOID DEATH OR SERIOUS INJURY

• Check the dozer blade location before traveling.

When the blade is to the rear, operate the steering

levers/foot pedal in the opposite direction to

when the blade is in the front.

• Before moving, make sure there are no persons

or property in the way. Never allow riders.

Sound the horn to alert workers and bystanders

that you are about to move the machine.

• Always make sure the path is clear during travel.

• Use extreme caution when reversing travel.

Be sure there is a clear path behind the machine.

• Operate the travel control levers smoothly to

avoid sudden starts or stops.

• Before leaving the operator's seat, make sure to

lock out all control systems and stop engine to

avoid accidental activation of the controls.

950205-03881

EX1402247

28. Lifting Capacity (950205-05450)

WARNING

AVOID DEATH OR SERIOUS INJURY

Whenever you handling and lifting objects, ensure

operator manual available on the station and refer

lifting chart.

29. California Proposition 65 (950205-07650)

WARNING: Breathing diesel engine exhaust exposes

you to chemicals known to the State of California to cause

cancer and birth defects or other reproductive harm.

• Always start and operate the engine in a wall-ventilated area.

• If in an enclosed area, vent the exhaust to the outside.

• Do not modify or tamper with the exhaust system.

• Do not idle the engine except as necessary.

For more information go to www.P65warning.ca.gov.

WARNING: This product can expose

you to chemicals including lead,

which is known to the state of

California to cause cancer and birth

defects or other reproductive harm

For more information go to

www.P65warning.ca.gov/diesel

950205-07650

DS1801347

DX225LC-5

Safety

1-17

Page 36

GENERAL

Safe Operation is Operator's

Responsibility

Only trained and authorized personnel should operate and

maintain the machine.

Follow all safety rules, regulations and instructions when

operating or performing maintenance on machine.

• Do not operate machine if you are under the influence of

drugs or alcohol. An operator who is taking prescription

drugs must get medical advice to determine if he or she

can safely operate a machine.

• When working with other personnel on a work site, be sure

that all personnel know nature of work and understand all

hand signals that are to be used.

• Be sure that all guards and shields are installed in their

proper location. Have guards and shields repaired or

replaced immediately if damaged.

• Be sure that you understand the use and maintenance of

all safety features such as safety lever and seat belt. Use

them properly.

• Never remove, modify or disable any safety features.

Always keep them in good operating condition.

• Always check for and know the location of underground

and overhead utility lines before excavating.

• Failure to use and maintain safety features according to

instructions in this manual, Safety Manual and Shop

Manual can result in death or serious injury.

Know Your Machine

Know how to operate your machine. Know the purpose of all

controls, gauges, signals, indicators and monitor displays. Know

the rated load capacity, speed range, braking and steering

characteristics, turning radius and operating clearances. Keep in

mind that rain, snow, ice, loose gravel, soft ground, slopes etc.,

can change operating capabilities of your machine.

1-18

DX225LC-5Safety

Page 37

Proper Work Tools and Attachments

FG018457

Figure 4

Only use work tools and attachments that are recommended by

DOOSAN for use on DOOSAN machines. When installing and

using optional attachments, read instruction manual for

attachment, and general information related to attachments in this

manual. Because DOOSAN cannot anticipate, identify or test all

attachments that owners may want to install on their machines,

contact DOOSAN for written authorization and approval of

attachments, and their compatibility with optional kits.

Attachments and attachment control systems that are

compatible with the machine are required for safe and reliable

machine operation. Do not exceed maximum operating weight

(machine weight plus attachment) that is listed on ROPS

certification plate.

Make sure that all guards and shields are in place on machine

and on work tool. Depending on type or combination of work

equipment, there is a potential that work equipment could

interfere with the cabin or other parts of machine. Before using

unfamiliar work equipment, check if there is any potential of

interference, and operate with caution.

While you are performing any maintenance, testing, or

adjustments to attachments, stay clear of the following areas:

cutting edges, pinch points, and crushing surfaces.

Never use attachment as a work platform or manlift.

Contact your DOOSAN distributor about auxiliary hydraulic kits

for attachments installation. If you are in doubt about

compatibility of a particular attachment with a machine, consult

your DOOSAN distributor.

Pressurized Fluids

Pressurized air or fluids can cause debris and/or fluids to be

blown out. This could result in death or serious injury.

Immediately after operations are stopped, coolant, engine oil,

and hydraulic oil are at their highest temperatures and the

radiator and hydraulic tank are still under pressure. Always wait

for temperature to cool down. Follow specified procedures when

attempting to remove caps, drain oil or coolant, or replacing

filters. Always wait for temperature to cool down, and follow

specified procedures when performing these operations. Failure

to do so can result in death or serious injury.

When pressurized air and/or pressurized water is used for

cleaning, wear protective clothing, protective shoes, and eye

protection. Eye protection includes goggles or a protective face

shield.

Pressure can be trapped in a hydraulic system and must be

relieved before maintenance is started.

Releasing trapped pressure can cause sudden machine

movement or attachment movement. Use caution if you

disconnect hydraulic lines or fittings.

DX225LC-5

Safety

1-19

Page 38

High-pressure oil that is released can cause a hose to whip or oil

HAOA110L

Figure 5

HAOA100L

Figure 6

to spray. Fluid penetration can result in death or serious injury. If

fluid enters skin or eyes, get immediate medical attention from a

physician familiar with this injury.

Obey all local laws and regulations for disposal of liquids.

To prevent hot coolant from spraying out, stop engine and wait

for coolant to cool. Using gloves, slowly loosen cap to relieve

pressure.

Flying or Falling Objects

On work sites where there is a potential hazard that flying or

falling objects can hit operator's cabin, select and use a guard to

match operating conditions for additional operator protection.

Working in mines, tunnels, deep pits, and loose or wet surfaces,

could produce hazard of falling rocks or flying objects. Additional

protection for operator's cabin could be required such as an

Operator Protection Guard (OPG) or window guards. Contact

your DOOSAN distributor for information on available protective

guards.

To prevent personnel from being struck by flying objects, keep

personnel out of work area.

1-20

DX225LC-5Safety

Page 39

Personal Protective Equipment (PPE)

HAOA020L

Figure 7

Do not wear loose clothing and accessories. Secure long hair.

These items can snag on controls or on other parts of

equipment.

Do not wear oily clothes. They are highly flammable.

Do not forget that some risks to your health may not be

immediately apparent. Exhaust gases and noise pollution may

not be visible, but these hazards can cause disabling or

permanent injuries. Breathing masks and/or ear protection may

be required.

Wear a hard hat, safety shoes, safety goggles, mask, leather

gloves, earplugs and other protective equipment, as required.

While working on machine, never use inadequate tools. They

could break or slip, or they may not adequately perform intended

functions.

Correction of Machine Problems

If any machine problems are found during operation and

maintenance (noise, vibration, smell, incorrect gauges, smoke,

oil leakage, etc.), or if any abnormal warning alerts are displayed

on display monitor, stop the machine and take the necessary

corrective actions. Do not operate machine until problem has

been corrected.

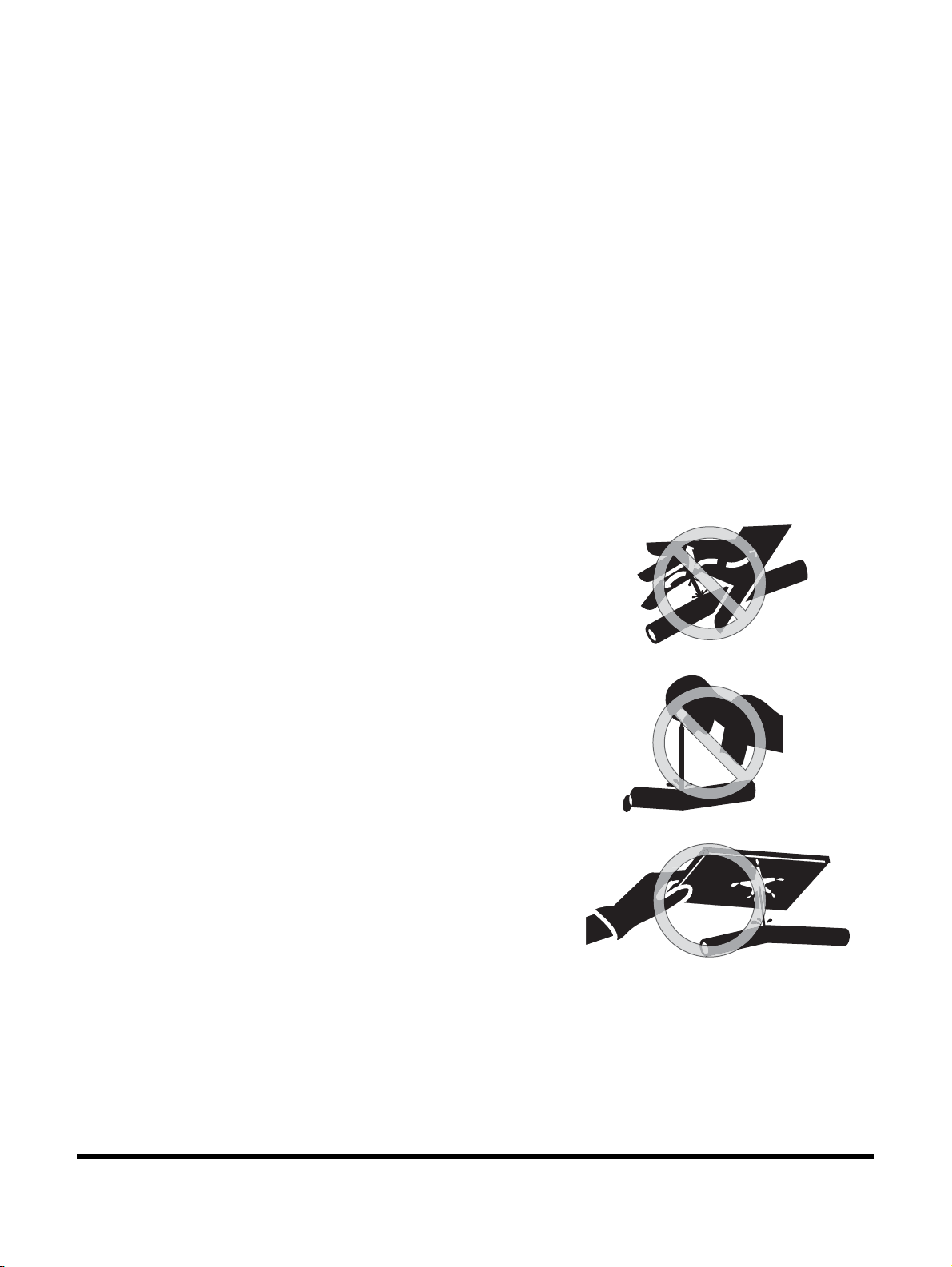

Crushing and Cutting

Keep objects away from moving fan blades. Fan blades can

throw and cut objects.

Do not use a wire rope that is kinked or frayed, or a wire rope

with any loss of diameter. Wear leather gloves when handling a

wire rope.

When striking a loose retainer pin, it can fly out and can cause a

serious injury. Make sure that area is clear of personnel when

striking a retainer pin. To avoid injury to your eyes, wear safety

goggles when striking a retainer pin.

Do not put your hand, arm or any other part of your body

between movable parts. If going between movable parts is

necessary, always position and secure work equipment so it

cannot move. Properly support equipment before performing

any work or maintenance under raised equipment.

If control levers are operated, clearance between machine and

work equipment will change and this may lead to serious

damage or can result in death or serious injury. Stay clear of

areas that may have a sudden change in clearance with

machine movement or equipment movement. Stay clear of all

rotating and moving parts. Unless instructed, never attempt

adjustments while machine is moving or while engine is running.

DX225LC-5

Safety

1-21

Page 40

Do not depend on hydraulic cylinders to support raised

HDO1010L

Figure 8

FG019095

Figure 9

FG019096

Figure 10

equipment. Equipment can fall if a control is moved, or if a

hydraulic line breaks, is loosened or disconnected.

If it is necessary to remove guards to perform maintenance,

always install guards after maintenance is completed.

Hot Coolant and Oils - Burn Prevention

Do not touch any part of an operating engine. Immediately after

operations are stopped, coolant, engine oil, and hydraulic oil are

at their highest temperatures. The radiator and hydraulic tank

are still under pressure. Always wait for temperature to cool

down. Attempting to remove caps, drain oil or coolant, or

replacing filters may lead to serious burns, if done when hot.

Relieve all pressure in air system, hydraulic oil system,

lubrication system, fuel system, and cooling system, before any

lines, fittings or related items are disconnected.

To prevent hot oil or coolant from spraying out, stop engine, wait

for oil and coolant to cool. Using gloves, slowly loosen cap to

relieve pressure.

1-22

DX225LC-5Safety

Page 41

Fire and Explosion Prevention

Figure 11

Figure 12

FG018458

All fuels, most lubricants and some coolant mixtures are

flammable and can cause a fire resulting in death or serious

injury, and property damage. Flammable fluids that are leaking

or spilled onto hot surfaces or onto electrical components can

cause fire.

Inspect for and remove all flammable materials such as spilled

fuel and oil, and debris from machine. Do not allow any

flammable materials to accumulate on machine.

Always observe the following:

• Add fuel, oil, antifreeze and hydraulic fluid to machine only

in a well ventilated area. Machine must be parked with

controls, lights and switches turned "OFF". Engine must be

"OFF" and any flames, glowing embers, auxiliary heating

units or spark causing equipment must be extinguished, or

turned "OFF" and kept well clear of machine.

• Dust that is generated from repairing or grinding

nonmetallic hoods or nonmetallic fenders can be toxic,

flammable and explosive. Repair these components in a

well ventilated area away from flames or sparks and wear

dust mask when grinding painted parts.

HDO1015I

Maintenance

The machine and some attachments have components that are

at high temperatures under normal operating conditions. The

primary source of high temperatures are the engine and exhaust

system. If damaged or incorrectly maintained, the electrical

system can be a source of arcs or sparks.

Flammable debris (leaves, straw, etc.) must be removed

regularly. If flammable debris is allowed to accumulate, it can

cause a fire hazard. Clean machine often to avoid this

accumulation. Flammable debris in an engine compartment is a

potential fire hazard.

The operator's area, engine compartment and engine cooling

system must be inspected every day and cleaned. This is

necessary to prevent fire hazards and overheating.

Operation

Do not use machine where exhaust, arcs, sparks or hot

components can contact flammable material, explosive dust or

gases.

Do not operate machine near any flame.

Exhaust shields (if equipped) protect hot exhaust components

from oil spray or fuel spray in case of a break in a line, hose, or

seal. Exhaust shields must be correctly installed.

DX225LC-5

Safety

1-23

Page 42

Electrical

EX1400129

Figure 13

Check all electrical wiring and connections for damage daily.

Keep battery terminals clean and tight. Repair or replace any

damaged part or wires that are loose or frayed. Clean all

electrical connections and tighten all electrical connections.

Never check battery charge by placing a metal object across

terminal posts. Use a voltmeter or a hydrometer.

Battery gas can explode and can result in death or serious

injury. Follow procedures in this manual for connecting battery

and for jump-starting. Do not jump-start or charge a frozen or

damaged battery. Keep any flames or sparks away from

batteries. Do not smoke in battery charging area.

Improper jumper cable connections can cause an explosion that

can result in death or serious injury. Refer to

"Starting Engine

with a Booster Cable" on page 3-12, for proper procedure in this

manual.

Do not charge a frozen battery. This can cause an explosion.

After market radios or other electric operated equipment in cabin

must have a fuse in the electrical circuit.

Hydraulic System

Check hydraulic tubes, hoses and fittings for damage, wear or

for leaks. Hydraulic lines and hoses must be properly routed and

have adequate support and secure clamps. Leaks can cause

fires. Never use a flame or bare skin to check for leaks.

Tighten or replace any parts that show leakage.

Check that all hose and tube clamps, guards, and cushions are

securely attached. If they are loose, they can vibrate during

operation and rub against other parts. This can cause damage

to hoses and cause high-pressure oil to spray on hot surfaces,

causing a fire and death or serious injury.

Always clean fluid spills. Do not use gasoline or diesel fuel for

cleaning parts. Use commercial nonflammable solvents.

DX225LC-5Safety

1-24

Page 43

Fueling

EX1400130

Figure 14

Figure 15

FG018458

Use caution when you are refueling a machine.

Fuel is flammable and can catch fire if it is brought close to a

flame.

Stop engine and let it cool before adding fuel. Do not smoke

while you are refueling a machine. Do not refuel a machine near

flames or sparks. Fill fuel tank outdoors.

Keep fuel and other fluid reservoir caps tight and do not start

engine until caps have been secured.

Store fuels and lubricants in properly marked containers away

from unauthorized personnel. Store oily rags and any flammable

materials in protective containers.

Static electricity can produce dangerous sparks at fuel filling

nozzle. In very cold, dry weather or other conditions that could

produce a static discharge, keep tip of fuel nozzle in constant

contact with neck of fuel filling nozzle, to provide a ground.

Always place plastic fuel containers on the ground before filling.

Never Use Ether Starting Aids

Do not use ether or starting fluids on any engine that has glow

plugs, or an electric grid type manifold heater. These starting

aids can cause an explosion and result in death or serious

injury.

Use procedures in this manual for connecting battery and for

jump-starting.

Welding and Grinding

Always clean machine and attachment, set battery disconnect

switch to "OFF" position, and disconnect wiring from electronic

controllers before welding. Cover rubber hoses, battery and all

other flammable parts. Keep a fire extinguisher near machine

when welding.

Toxic dust or gas can be produced when grinding or welding

painted parts. Grinding or welding painted parts must be done in

a well ventilated area. Wear dust mask when grinding painted

parts.

Dust generated from repairing nonmetallic parts such as hoods,

fenders or covers can be flammable or explosive.

Repair such components in a well ventilated area away from

flames or sparks.

Do not weld on lines or on tanks that contain flammable fluids.

Do not flame cut lines or tanks that contain flammable fluid.

Clean any such lines or tanks thoroughly with a nonflammable

solvent before welding or flame cutting.

DX225LC-5

Safety

1-25

Page 44

If a Fire Occurs

FG018459

Figure 16

HDO1009L

Figure 17

Figure 18

If a fire occurs:

• Do not attempt to move machine or continue operations.

• Turn starter switch to "O" (OFF) position to stop engine.

• Use handrails, guardrails and steps to get off machine.

• Immediately call for help or fire station.

• When using a fire extinguisher, always aim extinguisher at

base of fire.

• If an optional fire extinguishing system is in place, be

familiar with its operating procedures.

NOTE: Depending on job conditions, other procedures could

be necessary if a fire occurs.

Fire Extinguisher and First-aid Kit

(Emergency Medical Kit)

To be prepared in the event of a fire:

• Be sure that fire extinguishers have been provided and

read labels to ensure that you know how to use them. It is

recommended that an appropriately sized (2.27

larger) multipurpose A/B/C fire extinguisher be mounted in

cabin. Check and service fire extinguisher at regular

intervals and make sure that all work site crew members

are adequately trained in its use.

kg [5 lb] or

• Inspect fire extinguisher and service fire extinguisher

regularly.

• Follow instructions on extinguisher instruction plate.

• Keep a first aid kit in storage compartment (Figure 18) and

keep another kit at work site. Check kit periodically and

keep it properly supplied.

• Keep emergency numbers for doctor, ambulance service,

hospital and fire department readily available.

EX1403736

1-26

DX225LC-5Safety

Page 45

Electrical System and Electrical Shock

Never short across starter terminals or across batteries.

Shorting could damage electrical system and engine neutral

start system.

When engine is running or immediately after it has stopped, high

voltage is generated at injector terminal and inside engine

controller, so there is a potential for an electrical shock. Never

touch injector terminal or inside of engine controller.

NOTE: If it is necessary to touch injector terminal or inside

engine controller, contact your DOOSAN distributor.

Roll-over Protective Structure (ROPS)

The operator's cabin is a ROPS certified structure for protecting

the seat-belted operator. It absorbs the impact energy of a rollover impact. Do not allow machine weight (mass) to exceed

certified value on certification plate. If weight is exceeded, the

ROPS structure will not be able to fulfill its safety function.

Do not increase machine weight beyond certified value by

modifying machine or by installing attachments on machine. If

weight limit of protective equipment is exceeded, protective

equipment will not be able to protect operator, and this can

result in death or serious injury. Always observe the following:

• This machine is equipped with a protective structure. Do

not remove protective structure and perform operations

without it.

• Never modify the operator's cabin by welding, grinding,

drilling holes or adding attachments unless instructed by

DOOSAN in writing. Changes to the cabin can cause loss

of operator protection from roll-over and falling objects, and

result in death or serious injury.

• When protective structure is damaged or deformed by

falling objects or by rolling over, its strength will be reduced

and it will not be able to adequately protect the operator.

Contact your DOOSAN distributor if you have any

questions about the ROPS. Never repair a damaged

ROPS cabin.

• Always wear your seat belt when operating machine.

DX225LC-5

Safety

1-27

Page 46

ROPS Certification

Figure 19

This DOOSAN excavator has an operator's cabin that meets

ROPS requirements. The seat belt must be worn for roll-over

protection.

The ROPS certification plate (Figure 19) is found on the left side

of the cabin on most models. It may vary slightly in its location

on some models.

Check the ROPS cabin, mounting, and hardware for damage.

Never modify the ROPS cabin. Replace the cabin and hardware

if damaged. See your DOOSAN distributor for parts.

ROPS − Roll-over Protective Structure complies with

12117-2:2008, EN13531:2001.

ISO

WARNING

AVOID DEATH OR SERIOUS INJURY

Never modify the operator cabin by welding, grinding,

drilling holes or adding attachments unless instructed in

writing by DOOSAN. Changes to the cabin can cause loss

of operator protection from roll-over and falling objects,

and can result in death or serious injury.

EX1300529

DX225LC-5Safety

1-28

Page 47

Protecting Cabin from Flying or Falling Objects (Optional)

1

FG020947

Figure 20

2

FG018595

Figure 21

In a work site where additional operator protection is necessary

from falling or flying objects, install adequate protective guards

on the cabin.

For breaker operation, install a front guard (1, Figure 20) and

apply a laminated coating sheet to front glass. Contact your

DOOSAN distributor for recommendations.

When performing demolition or cutting operation, install a front

guard and top guard.

Apply a protective laminated coating sheet to outside of front

window. This will prevent glass from being scratched by dust

when cleaning it or running wipers.

When working in mines, quarries or other work sites where there

is a hazard of falling rocks, install Operator Protection Guard

(OPG) (2,

Figure 21) and apply a laminated coating sheet to

front glass.

When OPG is installed, and front window needs to be cleaned,

loosen bolts marked with arrows (

Figure 21). Be sure to tighten

bolts when done.

Never attempt to alter or modify any protective structure

reinforcement system, by drilling holes, welding, remounting or

relocating fasteners. Any serious impact or damage to system

requires a complete inspection of the structure. Reinstallation,

recertification and/or replacement of system may be necessary.

Contact your DOOSAN distributor for available safety guards

and/or recommendations to protect against objects that could

strike operator's cabin. Make sure that all other work site crew

members are kept away from excavator when operating.

If any glass on machine is broken, replace it with new glass

immediately.

NOTE: The preceding instructions assume that conditions

are for standard operations, but it may be necessary

to add additional guards depending on operating

conditions or local rules or regulations for the work

site. Always contact your DOOSAN distributor for

advice.

DX225LC-5

Safety

1-29

Page 48

Emergency Exit from Operator's Station

Figure 22

This machine is equipped with a glass breaking tool. It is found

on left pillar of cabin. This tool can be used to break the glass to

exit from cabin in an emergency. Grip handle firmly and use

sharp point to break glass.

• Be careful also not to slip on broken pieces of glass on

ground.

WARNING

AVOID DEATH OR SERIOUS INJURY

Protect your eyes when breaking the glass.

EX1300679

DX225LC-5Safety

1-30

Page 49

TRANSPORTATION

Obey State and Local Over-the-Road

Regulations

Check federal, state and local laws and regulations regarding

weight, width and length of a load before making preparations

for transporting on public roads or highways.

The hauling vehicle, trailer and load must be in compliance with

applicable regulations for the shipping route.

Partial disassembly of excavator may be necessary to meet

travel restrictions or particular conditions at work site. See Shop

Manual for information on partial disassembly.

Refer to "Transportation" on page 5-1, for information on

loading, unloading and towing.

The machine can be disassembled into parts for transporting.

Contact your DOOSAN distributor for assistance with

disassembly.

Loading and Unloading

To prevent machine tipping or roll-over when loading or

unloading machine, always do the following:

• Perform loading and unloading only on firm and level

ground. Maintain a safe distance from edge of road or

drop-off.

• Never use work equipment to load or unload machine. The

machine may fall or tip over.

• Always use loading ramps of adequate strength and

capacity. Be sure that ramps are wide, and long enough to

provide a safe loading slope. Take steps to prevent ramps

from moving out of position or coming off.

• Clean ramp surfaces so they are free of grease, oil, ice and

loose materials. Remove dirt from machine tracks and

undercarriage. On a rainy day, be careful since ramp

surfaces can be slippery.

• Turn auto idle switch "OFF".

• Run engine at low speed and travel slowly.

• When on ramps, do not operate any control lever except

for travel lever.

• Never correct your steering on ramps. If necessary, drive

off ramps, correct machine direction, then drive back onto

ramps.

• When driving up or down ramps, the center of gravity of

machine will change suddenly causing the tracks to drop

down to the ramps or trailer. This will occur at the joint

between the ramps and trailer. Travel slowly over this point.

DX225LC-5

Safety

1-31

Page 50

• For machines equipped with a cabin, always lock door

after loading machine to prevent door from suddenly

opening during transportation.

Transporting Machine

When transporting machine on a trailer or truck, do the following:

• The weight, transportation height, and overall length of

machine may change depending on work equipment

attached to it. Always check the machine dimensions and

work equipment's dimensions before transporting.

• When passing over bridges or structures on private land,

check that structure is strong enough to support weight of

machine. Before traveling on public roads, check with

appropriate authorities and follow their instructions.

1-32

DX225LC-5Safety

Page 51

OPERATION

Always make sure that the machine is properly maintained.

Before Engine Starting

Machine Condition

Every day before starting engine for first time, perform the

following checks and repair machine before operating, as

necessary. If these checks are not properly done death or

serious injury could result.

• Check coolant, fuel, and hydraulic tank oil levels, and

check for clogged air cleaner and damage to electrical

wiring.

• Check operation of gauges, cameras (if equipped) and

angle of mirrors, and check that safety lever is in LOCKED

position.

• Check that work equipment and travel controls move

freely, and work controls return to "NEUTRAL" when

released.

• Check that attachment is properly attached and locked.

Make sure that the machine is equipped with a lighting system

that is adequate for job conditions and lights are working

properly.

Before moving machine, check position of undercarriage. The

normal travel position is with idler wheels to front under cabin

and drive sprockets to rear. When undercarriage is rotated in

reversed position, directional or travel controls must be operated

in opposite directions.

Before performing checks, move machine to an area where

there are no obstructions, and operate slowly. Do not allow

personnel near machine.

Know maximum operating dimensions of your machine.

DX225LC-5

Safety

1-33

Page 52

Work Site

EX1300680

DANGER

No Entry

Figure 23

Before starting operations, thoroughly check work area for any

hazards, such as underground utility lines, overhead electrical

lines, unstable ground, excessive slopes, etc.

Before starting engine and moving machine, make sure that no

one is underneath machine, around machine, or on machine.

Know width and length of your machine and work equipment to

maintain proper clearance when you operate machine or work

equipment near fences or near boundary obstacles.

Know appropriate work site hand signals and personnel that are

authorized to give hand signals. Follow hand signals from only

one person.

If you need to operate on a street, protect pedestrians and cars

by designating a person for work site traffic duty or by erecting

fences and posting "No Entry" signs around work site.

Erect barricades or fences, post "No Entry" signs, and take other

steps to prevent people from coming close to or entering work

site. If people come too close to a moving machine, they may be

struck or caught by machine, and this can result in death or

serious injury.

1-34

DX225LC-5Safety

Page 53

Mounting/Dismounting

Figure 24

EX1301112

Figure 25

Figure 26

Before getting on or off machine, if there is any oil, grease, or

mud on handrails, guardrails, steps, or track shoes, wipe it off

immediately. Always keep these parts clean. Repair any

damage and tighten any loose bolts.

Never jump on or off machine. In particular, never get on or off a

moving machine. These actions can result in death or serious

injury.

When getting on or off machine, always face machine. Maintain

three-point contact (both feet and one hand or one foot and both

hands) with handrails, guardrails, steps, and track shoes to

ensure that you support yourself securely.

Never hold onto any control levers when getting on or off

machine.

Securely latch door. If you grip handrail inside door when

moving on top of track shoes, and door latch is not securely

engaged, door may move and cause you to fall.

Use points marked by arrows in diagram when getting on or off

machine.

Do not carry tools or supplies when you mount or dismount the

machine.

EX1301111

DX225LC-5

EX1301113

Safety

1-35

Page 54

Cleaning

Remove all straw, wood chips, leaves, grass, paper and other

flammable debris accumulated in engine compartment, mufflers

and around battery. Remove any dirt from window glass,

mirrors, handrails, and steps.

Do not leave tools or spare parts in operator's cabin. Vibration of

machine during operation can cause tools or spare parts to fall

and damage or break control levers or switches. Tools and

spare parts can also get caught in spaces between control

levers and cause accidental movement of work equipment

causing death or serious injury.

When entering operator's cabin, always remove all mud and oil

from your shoes. If you operate travel pedal with mud or oil stuck

to your shoes, your foot could slip off the control, or dirt and

debris may interfere with proper operation of control levers.

After using ashtray, make sure that any matches or cigarettes

are properly extinguished, and be sure to close ashtray.

Clean window glass and working lights for good visibility.

Do not stick suction pads to window glass. Suction pads act as a

lens and can cause fire.

Never bring flammable or explosive items into operator's cabin.

Do not leave cigarette lighters laying around operator's cabin. If

temperature inside operator's cabin becomes too high, there is a

potential hazard that lighter could explode.

Secure all loose items such as lunch boxes, and other items that

are not a part of equipment.

Operator Station

Inspect condition of seat belt and mounting hardware. Replace

any parts that are worn or damaged. Do not use a seat belt

extension on a retractable seat belt.

Adjust seat so full pedal travel can be achieved with operator's

back against back of seat.

Keep all windows and doors closed on machine.

Adjust operator's seat to a position where it is easy to perform

operations, and check that there is no damage or excessive

wear to seat belt or mounting clamps.

Adjust and clean mirrors so area to rear of machine can be seen

clearly from operator's seat.

When standing up from operator's seat, always place safety lever

securely in "LOCK" position. If you accidentally move work

equipment levers when they are not locked, the machine could

suddenly move and cause damage, death or serious injury.

1-36

DX225LC-5Safety

Page 55

Seat Belt

Check seat belt daily for correct function.

Inspect seat belt system more often if machine is exposed to

severe environmental conditions or applications. Conduct the

following inspections and replace seat belt system as

necessary:

1. Check webbing. If system is equipped with a retractor, pull

webbing completely out and inspect full length of webbing.

Look for cuts, wear, fraying, dirt and stiffness.

2. Check buckle and latch for correct operation.

3. Make sure latch plate is not excessively worn, deformed or

buckle is not damaged or casing is broken.

4. Check retractor web storage device (if equipped) by

extending webbing and checking that it spools out and

retracts correctly.

5. Check webbing in areas exposed to ultraviolet (UV) rays

from sun or extreme dust or dirt. If original color of webbing

in these areas is extremely faded and/or webbing is

packed with dirt, webbing strength may be reduced.

NOTE: Contact your DOOSAN distributor for seat belt

system replacement parts.

WARNING

AVOID DEATH OR SERIOUS INJURY

Failure to properly inspect and maintain seat belt and

seat belt system can cause lack of operator restraint

and can result in death or serious injury.

Before fastening seat belt, check that there is no

problem in belt mounting bracket. If it is worn or

damaged, replace seat belt. Fasten seat belt so it is not

twisted.

Always wear seat belt when operating machine.

DX225LC-5

Safety

1-37

Page 56

Visibility Information

Figure 27

A rear view camera (if equipped) and mirrors provide the

operator with additional means to see the work area.

NOTE: These devices may vary from one region to another,

depending upon local and regional regulations. If a

machine is moved or sold into another region or

marketplace, it is the owner's responsibility to make

sure it complies with all applicable regulations.

NOTE: Your machine may be equipped with additional visual

aids other than the

4

Figure 27 shown.

12

3

WARNING

AVOID DEATH OR SERIOUS INJURY

Failure to check for and clear people from the surrounding

area of a machine can result in death or serious injury. The

operator should make sure that visual aids (mirrors and

camera(s)) are in proper working condition.

Your machine may be equipped with visual aids such as mirrors

or a side and rear view camera. Even with these aids, there still

may be areas around the machine which cannot be seen from

the operator's seat. Always keep personnel and bystanders out

of the work area. Be careful when operating and always look in

direction of travel.

1. Front Mirror on the Cabin (1)

2. Front Mirror on the Cabin (2)

3. Side Camera

4. Rear View Camera

DS1801379

Adjust visual aids for best visibility around machine.

When swinging work equipment or backing up, press camera

button (if equipped) to change display mode on display monitor

so you can check rear and side of machine.

DX225LC-5Safety

1-38

Page 57

Before moving machine, look around work site and use mirrors

12 m (

4

72 in)

F

W

D

DS1801381

Figure 28

12 m (

4

72 in)

F

W

D

DS1801382

Figure 29

and display monitor to confirm that no one is in the work area.

While operating or traveling in places with poor visibility it may

be impossible to confirm condition of work site. Inspect and

remove any obstacles around the machine that could be

damaged and keep other personnel out of the work area.

Inspect equipment and repair immediately if there are problems

with visual aids. If machine cannot be fixed immediately, DO

NOT use the machine. Contact your DOOSAN distributor and

arrange for repairs.

Restricted Visibility

Some areas may not be seen from the operator's position.

Get aid from proper job site organization and minimize visibility

masking hazard.

Refer to "Visibility Information" in the Operation and

Maintenance Manual for more information regarding job site

organization.

Figure 28 ~ Figure 30 provide an approximate visual indication

of the areas at ground level inside a radius of 12 m (39' 4") from

the operator of significant restricted visibility for various machine

configurations.

Figure 31 provides the position of the attachment and equipment

in the Travel position.

• Visible areas without visual aids at the ground level

• Visible areas with rear CCTV and mirrors

DX225LC-5

Safety

1-39

Page 58

• Visible areas with side/rear CCTV and mirrors

12 m (

4

72 in)

F

W

D

DS1801383

Figure 30

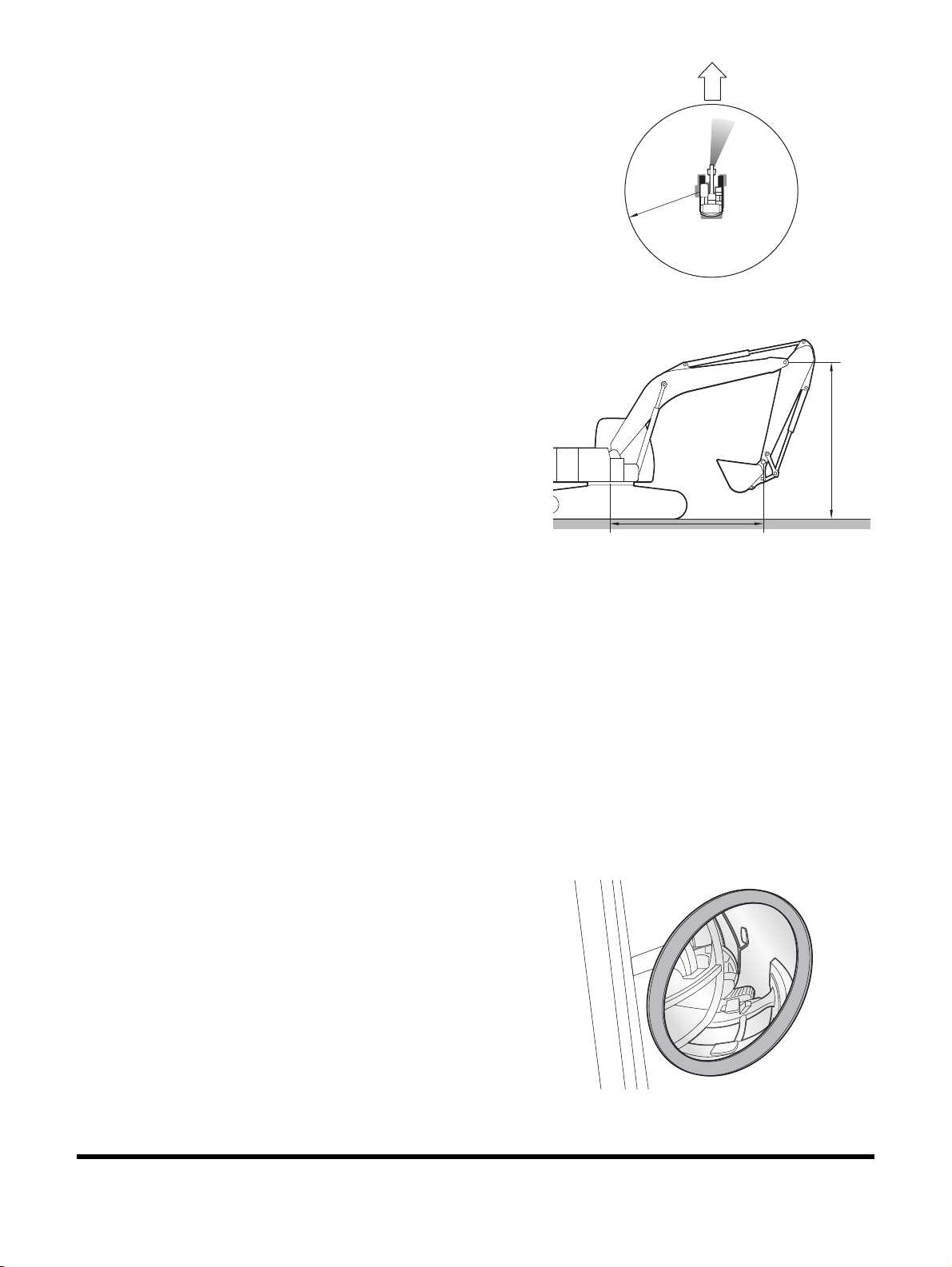

Figure 31

DS1801222

Figure 32

• Machine travel position

–A is 5.3 m (17' 5") from swing center to bucket pin

–B is 4.2 m (13' 9") from ground to arm pin

B

Mirror Adjustment

Frequently ensure the mirrors are directed properly.

• Park the machine on a level surface.

• Lower the attachment to the ground.

• Lower the safety lever to the LOCK position.

• Stop the engine.

• Use the machine access system.

NOTE: You may need hand tools to adjust certain types of

mirrors.

1. Front mirror on the cabin (1)

If equipped, adjust the front mirror on the cabin (1, Figure

27) so the front of the right track can be seen from the

operator seat.

A

DS1801218

1-40

DX225LC-5Safety

Page 59

2. Front mirror on the cabin (2)

DS1801380

Figure 33

If equipped, adjust the front mirror on the cabin (2, Figure

27) so the front of the left side can be seen from the

operator seat.

3. Additional mirrors other than Figure 27

If equipped, adjust the mirrors whenever you change

operators and ensure the mirrors are in proper working

conditions.

Work Site Rules

• If visibility cannot be sufficiently assured, use a flagman.

The operator should pay careful attention to signals and

follow instructions from flagman.

• Signals should only be given by one flagman.

• When working in dark places, turn "ON" work lights and

front lights on the machine. Set up additional lighting in

area.

• Stop operations if there is poor visibility, such as fog, snow,

rain, or sandstorms.

• Check mirrors and rear view camera (if equipped) on

machine before starting operations. Clean off any dirt and

adjust view for good visibility.

When operating or traveling during poor visibility conditions,

follow the preceding work site rules.

It may not be possible to adjust all visual aids to see all the way

around the machine. Therefore, additional precautions such as

flagman, barricades, etc., must be taken to keep other personnel

out of the work area.

DX225LC-5

Safety

1-41

Page 60

Boost Starting or Charging Engine

Batteries

Follow these instructions to prevent an explosion or fire when

connecting booster cables to batteries: