Page 1

DIAGNOSTIC SERVICE MANUAL

AMERICANA & AMERICANA PLUS

RM 2351, RM 2354, RM 2451, RM 2454

RM 2551, RM 2554, RM 2652, RM 2662

RM 2663, RM2852, RM2862 & NDR1062

USA

SERVICE OFFICE

Dometic Corporation

2320 Industrial Parkway

Elkhart, IN 46516

574-294-2511

CANADA

Dometic Distribution

46 Zatonski Unit 3

Brantford, Ontario

CANADA N3T 5L8

519-720-9578

For Service Center

Assistance Call:

800-544-4881

Form No. 3311143.000 02/07

©2007 Dometic Corporation

LaGrange, IN 46761

Page 2

Foreword

This service manual is the result of the dedication of The Dometic Corporation Technical staff

and its engineers in giving service people the

necessary instruction for making accurate analyses of certain conditions. Provided is a diagnos-

tic chart leading a qualied mechanic into the

service manual pages to locate and solve symptoms which may occur. Dometic has continued

its commitment in providing service people with

this, the most up-to-date information about servicing Dometic RV accessories.

SAFETY INSTRUCTIONS

This manual has safety information and instructions to help users eliminate or reduce the risk

of accidents and injuries.

RECOGNIZE SAFETY INFORMATION

This is the safety-alert symbol. When you see this

symbol in this manual, be alert to the potential

for personal injury.

Follow recommended precautions and safe operating instructions.

UNDERSTAND SIGNAL WORDS

A signal word , WARNING OR CAUTION is used

with the safety-alert symbol. They give the level

of risk for potential injury.

Indicates a potentially hazard-

ous situation which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazard-

ous situation which, if not avoided may result in

minor or moderate injury.

When used without the safety

alert symbol indicates, a potentially hazardous

situation which, if not avoided may result in property damage.

Read and follow all safety information and instructions.

1

Page 3

CONTENTS

DIAGNOSTIC FLOW CHART............................................................................. 4

PAGE NO.

SECTION 1

OPERATION

Refrigerator Operation ........... ........................................................................6

SECTION 2

AC VOLTAGE

AC Voltage Requirements................ ...........................................................9

SECTION 3

AC COMPONENTS

Heating Element ....................... ...............................................................10

SECTION 4

DC VOLTAGE

DC Voltage Requirements ............... ........................................................10

SECTION 5

DC COMPONENTS

5.1 DC heating Element ................................ ..................................11

5.2 Thermistor ............................ .....................................................11

5.3 Solenoid Valve.................................... .......................................11

5.4 Igniter ........................ ................................................................11

5.5 High Voltage Cable ................................. ..................................12

5.6 Electrode ....................................................................................12

5.7 DC Relay ....................................................................................12

5.8 Upper Circuit Board ....................... ............................................13

5.9 Lower Circuit Board ....................... ............................................13

5.10 Door Switch ......................... ......................................................18

5.11 Climate Control Heater & Switch ................................ ...............18

5.12 Low Ambient Switch ............... ...................................................18

5.13 Fuses .........................................................................................18

5.14 Thermofuse ................................................................................18

SECTION 6

LP GAS

LP Gas Requirements ................... ......................................................19

SECTION 7

LP GAS COMPONENTS

7.1 Manual Gas Shut-Off Valve .................. .....................................19

7.2 Orice ................................... .....................................................19

7.3 Thermocouple .............................. .............................................20

7.4 Burner .................................... ...................................................20

2

Page 4

CONTENTS

PAGE NO.

SECTION 7

7.5 Flue Bafe.............................................................................................20

7.6 Flue Cap ..............................................................................................20

7.7 Flue Tube .............................................................................................20

SECTION 8

COOLING UNIT

8.1 Leveling......................... ........................................................................21

8.2 Ventilation ..............................................................................................21

8.3 Air Leaks......................... .......................................................................23

8.4 Interior Liner Seal to Frame ...................................................................23

8.5 Door Position .........................................................................................24

8.6 Ambient Temperature ............................................................................24

8.7 Cooling Unit ...........................................................................................25

8.8 Food Storage .........................................................................................26

8.9 High Humidity ........................................................................................26

SECTION 9

WIRING

9.1 Internal Wiring.............................. ........................................................26

9.2 External Wiring........................... ..........................................................26

9.3 Wiring Schematics.............................. ..................................................26

SECTION 10

ICE MAKER

10.1 Operation.............................. ..............................................................26

10.2 Mold Heater........................... .............................................................27

10.3 Ice Ejector.............................. .............................................................27

10.4 Mold Thermostat......................... ........................................................27

10.5 Shut Off Arm................... ....................................................................27

10.6 Mold Switches........................... .........................................................27

10.7 Timing Motor........................... ............................................................28

10.8 Water Valve ........................................................................................28

10.9 Ice Maker Replacement... ...................................................................28

10.10 Water Fill Adjustment.................... ......................................................28

10.11 Water Supply.................. .....................................................................29

10.12 Wiring Schematics..............................................................................29

3

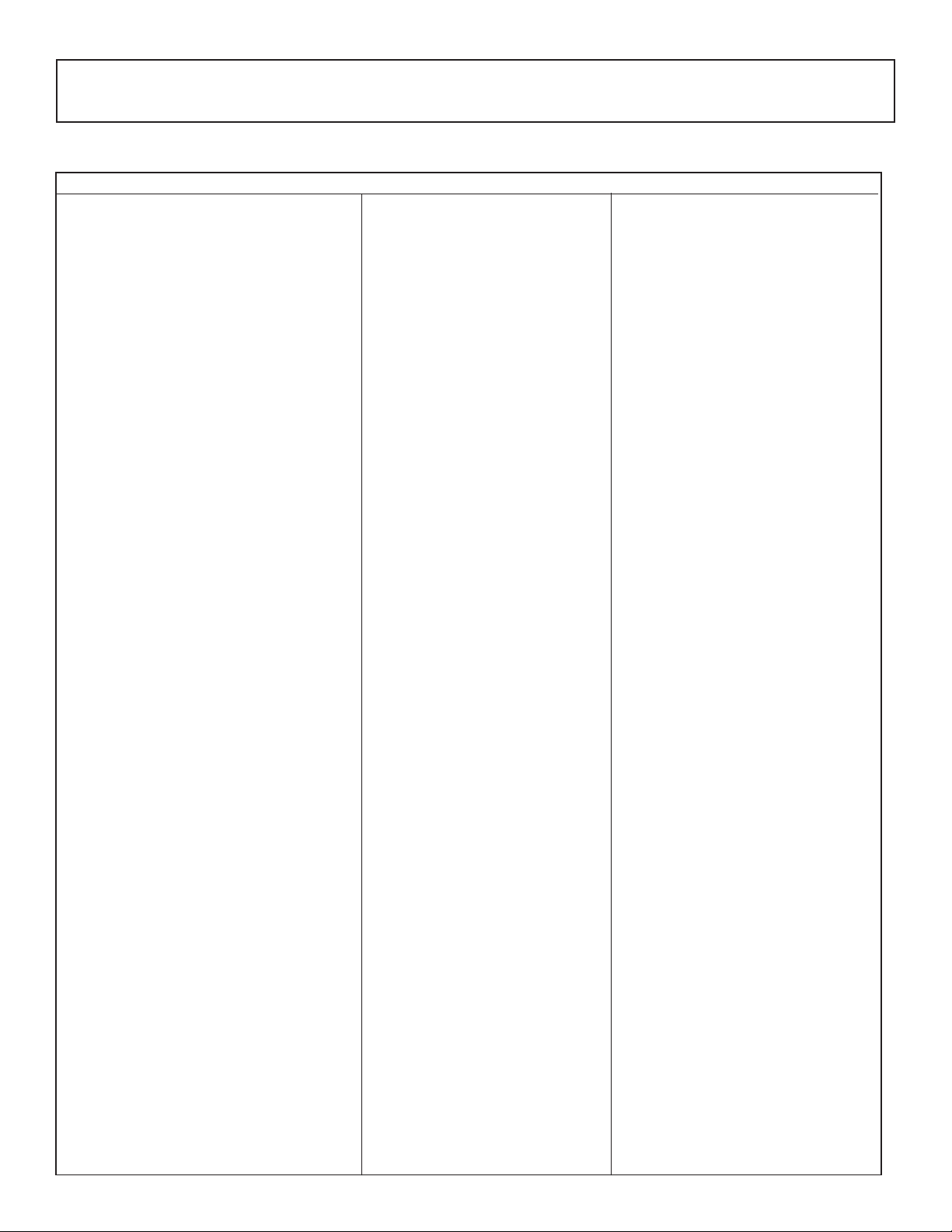

Page 5

This program will address the most common system problems associated with the RM2351, RM2354, RM2451, RM2454,

RM2551, RM2554, RM2652 ,RM2662,RM2663,RM2852and RM2862 refrigerators supplied by The Dometic Corporation.

Our intent is to provide you with a guideline of checks to make, should you encounter one of the following symptoms.

SYMPTOM

1. No operation - no panel lights

2. No operation - has panel lights

3. No AC operation - operates on gas mode

4. No Gas operation - operates on AC mode

CAUSE

Operation

DC Volts

Fuse

Wiring

Upper Circuit Board

Lower Circuit Board

Operation

DC Volts

Thermistor

Wiring

Lower Circuit Board

Operation

AC Volts

Fuse

Heating Element

Wiring

Lower Circuit Board

Operation

LP Gas

Manual Gas Valve

Igniter

High Voltage Cable

Electrode

Solenoid

Wiring

Lower Circuit Board

SECTION & PAGE

1, page 06

4, page 10

5, page 18

9, page 26

5, page 13

5, page 13

1, page 06

4, page 10

5, page 11

9, page 26

5, page 14

1, page 07

2, page 09

5, page 19

3, page 11

9, page 24

5, page 13

1, page 06

6, page 19

7, page 19

5, page 11

5, page 12

5, page 12

5, page 11

9, page 24

5, page 13

5. Insufcient cooling on all modes.

6. Insufcient cooling on AC - cools properly

on gas mode.

7. Insufcient cooling on Gas - cools properly

on AC mode.

8. Freezes.

Ventilation

Leveling

Ambient Temperature

Air Leaks

Thermistor

Cooling Unit

AC Volts

Heating Element

Lower Circuit Board

LP Gas

Orice

Flue Bafe

Flue Tube

Burner

Lower Circuit Board

Operation

Thermistor

Lower Circuit Board

4

8, page 21

8, page 21

8, page 24

8, page 23

5, page 11

8, page 25

2, page 09

3, page 10

5, page 13

6, page 19

7, page 19

7, page 20

7, page 20

7, page 20

5, page 13

1, page 06

5, page 12

5, page 14

Page 6

SYMPTOM

CAUSE

SECTION & PAGE

9. Check light on

10. Interior light on when door is closed

11. Rapid formation of frost

12. Water on frame

DC Volts

Wiring

LP Gas

Manual Gas Valve

Solenoid

Orice

Burner

Thermocouple

Lower Circuit Board

Wiring

Low Ambient Switch

Door Switch

Door Position

Food Storage

Interior Liner to Frame

High Humidity

Air Leaks

Interior Liner to Frame

High Humidity

Air Leaks

Climate Control Heater

4, page 10

9, page 26

6, page 19

7, page 19

5. page 11

7. page 19

7. page 20

7. page 20

5. page 13

9. page 26

5. page 18

5. page 18

8. page 24

8. page 26

8. page 23

8. page 26

8. page 23

8. page 23

8. page 26

8. page 23

5. page 18

5

Page 7

SECTION 1

REFRIGERATOR OPERATION

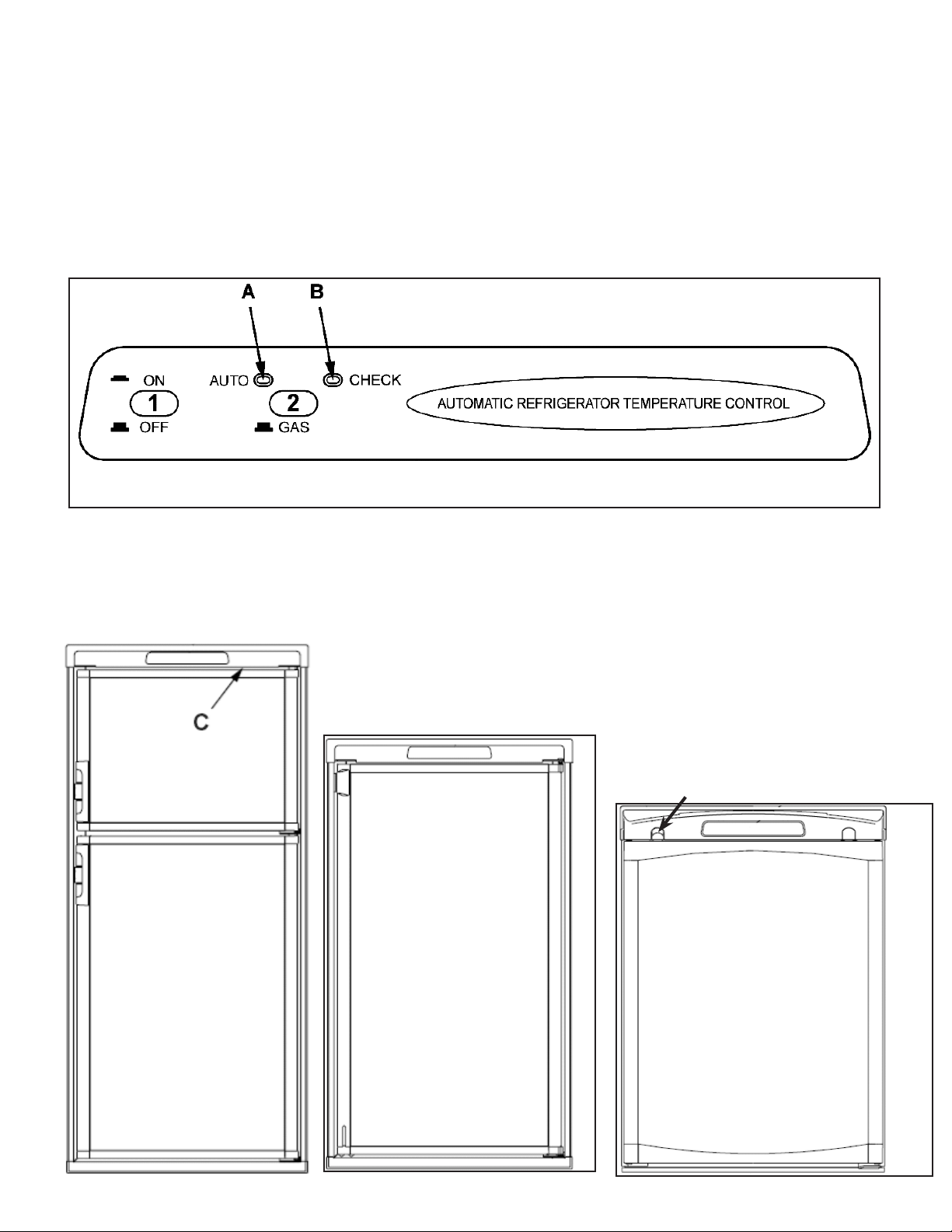

DISPLAY PANEL RM2351, RM2451, RM2551, RM2652, RM2852

AUTO TEMPERATURE CONTROL

Refrigerator Control Panel

RM2652 & RM2852

RM2662 & RM2862

RM2451 & RM2551

AMERICANA 2-WAY MODEL

1. Main Power Button ON/OFF

2. AUTO/GAS Mode Selector Button

A. AUTO Mode indicator lamp

B. CHECK indicator lamp (Gas Mode

Only)

C. Climate control switch only on

RM2652 & RM2862

Travel Latch

RM2351

6

Page 8

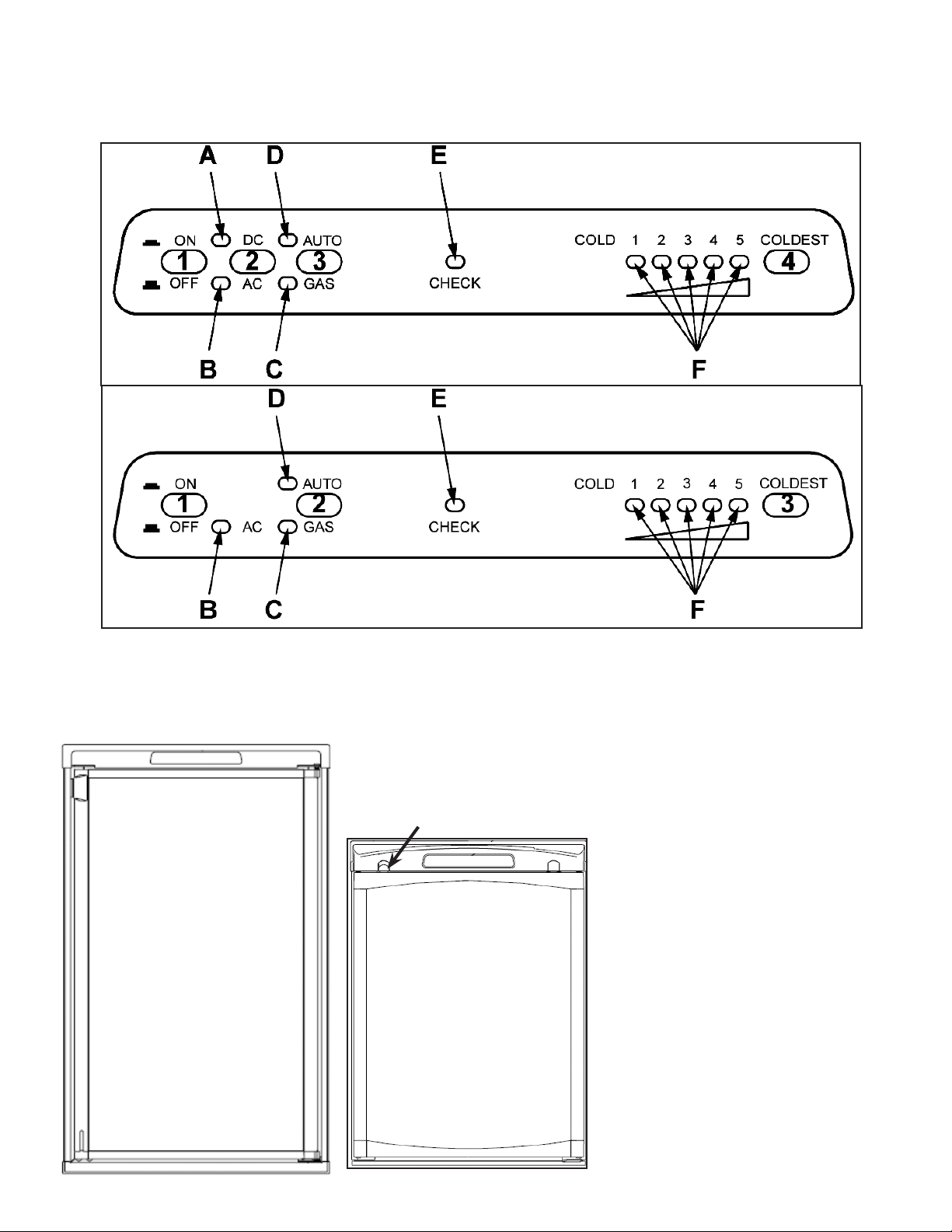

DISPLAY PANEL RM2354, RM2454, RM2554 RM2663 3-way

DISPLAY PANEL RM2662, RM2862 2-WAY

Refrigerator Control Panels

3-WAY

2-WAY

RM2454 & RM2554

Travel Latch

RM2354

3-WAY

1. Main Power Button ON/OFF

2. DC Mode Selector Button

3. AUTO/GAS Mode Selector Button

4. Temperature Selector Button

A. DC Mode Indicator Lamp

B. AC Mode Indicator Lamp

C. GAS Mode Indicator Lamp

D. AUTO Mode Indicator Lamp

E. CHECK Indicator Lamp

(Gas Operation Only)

F. Temperature Indicator Lamps

2-WAY

1. Main Power Button ON/OFF

2. AUTO/GAS Mode Selector Button

3. Temperature Selector Button

B. AC Mode Indicator Lamp

C. GAS Mode Indicator Lamp

D. AUTO Mode Indicator Lamp

E. CHECK Indicator Lamp

( GAS Mode Only)

F. Temperature Indicator Lamps

7

Page 9

OPERATION INSTRUCTIONS

IMPORTANCE OF LEVELING A

REFRIGERATOR

In an absorption refrigerator system, ammonia is liqueed

in the nned condenser coil at the top rear of the refrigerator. The liquid ammonia then ows into the evaporator

(inside the freezer section) and is exposed to a circulat-

ing ow of hydrogen gas, which causes the ammonia to

evaporate, creating a cold condition in the freezer. When

starting this refrigerator for the very rst time, the cooling

cycle may require up to four hours of running time before the cooling unit is fully operational. The tubing in the

evaporator section is specically sloped to provide a continuous movement of liquid ammonia, owing downward

by gravity through this section. If the refrigerator is operated when it is not level and the vehicle is not moving, liquid ammonia will accumulate in sections of the evaporator

tubing. This will slow the circulation of hydrogen and ammonia gas, or in severe cases, completely block it, resulting in a loss of cooling. Any time the vehicle is parked for

several hours with the refrigerator operating, the vehicle

should be leveled to prevent this loss of cooling. The vehicle needs to be leveled only so it is comfortable to live in

(no noticeable sloping of oor or walls). When the vehicle

is moving, the leveling is not critical, as the rolling and

pitching movement of the vehicle will pass to either side

of level, keeping the liquid ammonia from accumulating in

the evaporator tubing.

OPERATION

Before starting the refrigerator, check that all the manual

gas valves are in the ON position. DO NOT forget the

manual shutoff valve on the rear of the refrigerator. This

refrigerator is equipped with a control system which can

be set to automatically select either 120 volt AC or LP gas

operation (AUTO mode), or if desired LP gas only (GAS

mode) or DC volts (DC Heater) where applicable.

Auto Thermostat

In both AUTO mode and GAS mode operation, the temperature is controlled by a factory preset temperature setting. The refrigerator controls will work down to 9.6 volt

DC.

Most LP gas appliances used in recreational vehicles are vented to the outside of the

vehicle. When parked close to a gasoline

pump, it is possible that the gasoline fumes

could enter this type of appliance and ignite

from the burner ame, CAUSING A FIRE OR

AN EXPLOSION.

FOR YOUR SAFETY, when refueling, shut

off all LP gas appliances which are vented

to the outside.

OPERATION

Auto Thermostat

A.

A continuous 12 volt DC supply must be available for

the electronic control to function.

B.

Press the main power ON/OFF button (1) to

the DOWN position.

C.

In AUTO mode, the AUTO lamp A will be illuminated.

The control system will automatically select between

AC and GAS operation with AC having priority. The

temperature is controlled by a factory preset temperature setting.

D.

In GAS mode operation, no lamps will be illuminated

and the temperature is controlled by a factory preset

temperature setting.

OPERATION

Adjustable Thermostat

A.

A continuous 12 volt DC supply must be available for

the electronic control to function.

B.

Press the main power ON/OFF button (1) to the DOWN

position.

C.

In AUTO mode, the AUTO lamp D will be illuminated.

The control system will automatically select between

AC and GAS operation with AC having priority. Temperature is selected by the user.

D.

In GAS mode operation, the GAS lamp C will be illuminated and only operate on LP only. Temperature is

selected by user.

E.

In DC mode, the DC lamp A will be illuminated and the

unit will only operate on DC until DC volts drops below

9.6 VDC.

Auto Mode

Press the AUTO/GAS button 2 (Auto Thermostat) or button 3 (Adjustable Thermostat) to the DOWN position. The

AUTO mode indicator lamp (A auto or D adjustable thermostat) will illuminate. If 120 volts AC is available, the

control system will select AC operation. If 120 volts AC is

not available, the control system will automatically switch

to GAS operation. Within 45 seconds the burner should

be ignited and operating normally. If the CHECK indicator

lamp (B auto or E adjustable thermostat) illuminates, the

control has failed to ignite the burner on GAS. To reset

when the CHECK indicator lamp, press the main power

ON/OFF button (1) to the OFF then ON position. Systems with the new lower control board are a three (3) try

system on gas. On the initial refrigerator start-up on gas

(120 volts AC is not available), it may take longer than 45

seconds to allow air to be purged from the gas line. If the

refrigerator has not been used for a long time or the LP

tanks have just been relled, air may be trapped in the

supply lines. To purge the air from the lines may require

resetting the main power ON/OFF button (1) three or four

times. If repeated attempts fail to start the LP gas operation, check to make sure that the LP gas supply tanks are

not empty and all manual shutoff valves in the lines are

open.

8

Page 10

Note: Do not continue to reset GAS operation if the

CHECK indicator lamp continues to be illuminated after

several tries.

GAS Mode

Move the AUTO/GAS button 2 (Auto Thermostat) or button

3 (Adjustable Thermostat) to the UP position. The AUTO

mode indicator lamp (A) will go off. Within 45 seconds the

burner should be ignited and operating normally.

DC Mode 3 Way Units Only

Press the DC mode indicator button (2) to the DOWN

position. (Lamp [A] will light). Press the TEMPERATURE

SELECTOR button (4) until the lamp (F) at the desired

position is illuminated. The refrigerator will continue to operate in the DC mode until switch (2) is moved to the UP

position or control voltage falls below 9.6 VDC. The DC

mode overrides all the other operating modes. Discharging of the battery will occur if the vehicle engine is not

running.

Note: The DC mode is a holding mode not a full cooling mode. DC should be used once the unit is cooled

down and constant supply of DC available (driving

down the road).

To Shut Off The Refrigerator

The refrigerator may be shut off while in any mode of

operation by pressing the main power ON/OFF button to

the UP (OFF) position. This shuts off all DC power to the

control system.

Description Of Operating Modes

Auto Mode

When operating in the AUTO mode, the AUTO mode indicator lamp (A) will illuminate. The control system will

automatically select between AC and GAS operation with

AC having priority over GAS. If the control system is operating with AC energy and it then becomes unavailable,

the system will automatically switch to GAS. As soon as

AC becomes available again the control will switch back

to AC operation. Gas operation (120 volts AC is not avail-

able). The control system will activate the ignition system and will make three attempts to light the burner for

a period of approximately 45 seconds with two minutes

rest (purge) interval. If unsuccessful, the CHECK indicator lamp (B) will illuminate. To restart an ignition attempt

with the CHECK lamp illuminated or to clear (turn off) the

CHECK lamp, press the main power ON/OFF button to

the OFF position and wait a few seconds, then return to

the ON position. The control system will attempt a new ignition sequence. If 120 volts AC becomes available while

the CHECK indicator lamp is on, the CHECK lamp will not

turn off until the main power ON/OFF button is pressed

to the OFF then ON position but the unit will operate on

AC.

Gas Mode

When operating in the GAS mode, the AUTO mode indicator lamp (A) will be off. This mode provides LP gas operation only. The control system will activate the ignition

system and will make three attempts to light the burner for

a period of approximately 45 seconds with two minutes

a period of approximately 45 seconds with two minutes (purge) interval after each trial. If unsuccessful, the

CHECK indicator lamp (B) will illuminate. To restart GAS

operation, press the main power ON/OFF button (1) to

the OFF and then ON position. The control system will

attempt a new ignition sequence. If the refrigerator has

not been used for a long time or the LP tanks have just

been relled, air may be trapped in the supply lines. To

purge the air from the lines may require resetting the main

power ON/OFF button (1) three or four times. If repeated

attempts fail to start the LP gas operation, check to make

sure that the LP gas supply tanks are not empty and all

manual shutoff valves in the lines are turned on.

DC Mode 3 Way Units Only

Press the DC mode indicator button (2) to the DOWN

position. (Lamp [A] will light). Press the TEMPERATURE

SELECTOR button (4) until the lamp (F) at the desired

position is illuminated. The refrigerator will continue to operate in the DC mode until switch (2) is moved to the UP

position or control voltage falls below 9.6 VDC.

The DC mode overrides all the other operating modes.

Discharging of the battery will occur if the vehicle engine

is not running.

Note: The DC mode is a holding mode not a full cooling mode. DC should be used once the unit is cooled

down and constant supply of DC available (driving

down the road).

To Shut Off The Refrigerator

The refrigerator may be shut off while in any mode of

operation by pressing the main power ON/OFF button to

the UP (OFF) position. This shuts off all DC power to the

control system.

Limp Mode

This control system contains a feature where it will continue to operate the cooling system in event of a failure of

a major operating component. If the control cannot read

the temperature sensor and control to the preset temperature, then the control will run the cooling unit continuously at the energy source available. The refrigerator will

continue to operate in this mode indenitely or until a new

sensor is installed and the system is reset.

SECTION 2 AC VOLTAGE

AC VOLTAGE REQUIREMENTS

This is an energized circuit. Shock can occur

if not tested properly. Testing is to be done

by a qualied service technician.

The proper operating range is 100 to 132 volts. If voltage

drops below 100 volts, cooling efciency will decrease

with voltage decrease.

9

Page 11

The refrigerator will not switch to another mode of operation until all AC power is lost. The refrigerator is equipped

with a three-prong (grounded) plug for protection against

shock hazards, and should be plugged directly into a

properly grounded three-prong receptacle.

SECTION 3 AC COMPONENTS

Heating Element

The heating element is designed to deliver a predetermined amount of heat to the cooling unit. To check a heating element, remove the heater leads from the printed

circuit board and measure for proper resistance across

the two leads with a properly calibrated ohm meter. This

check is to be done with the heating element at room

temperature. You should obtain the following readings ±

10%:

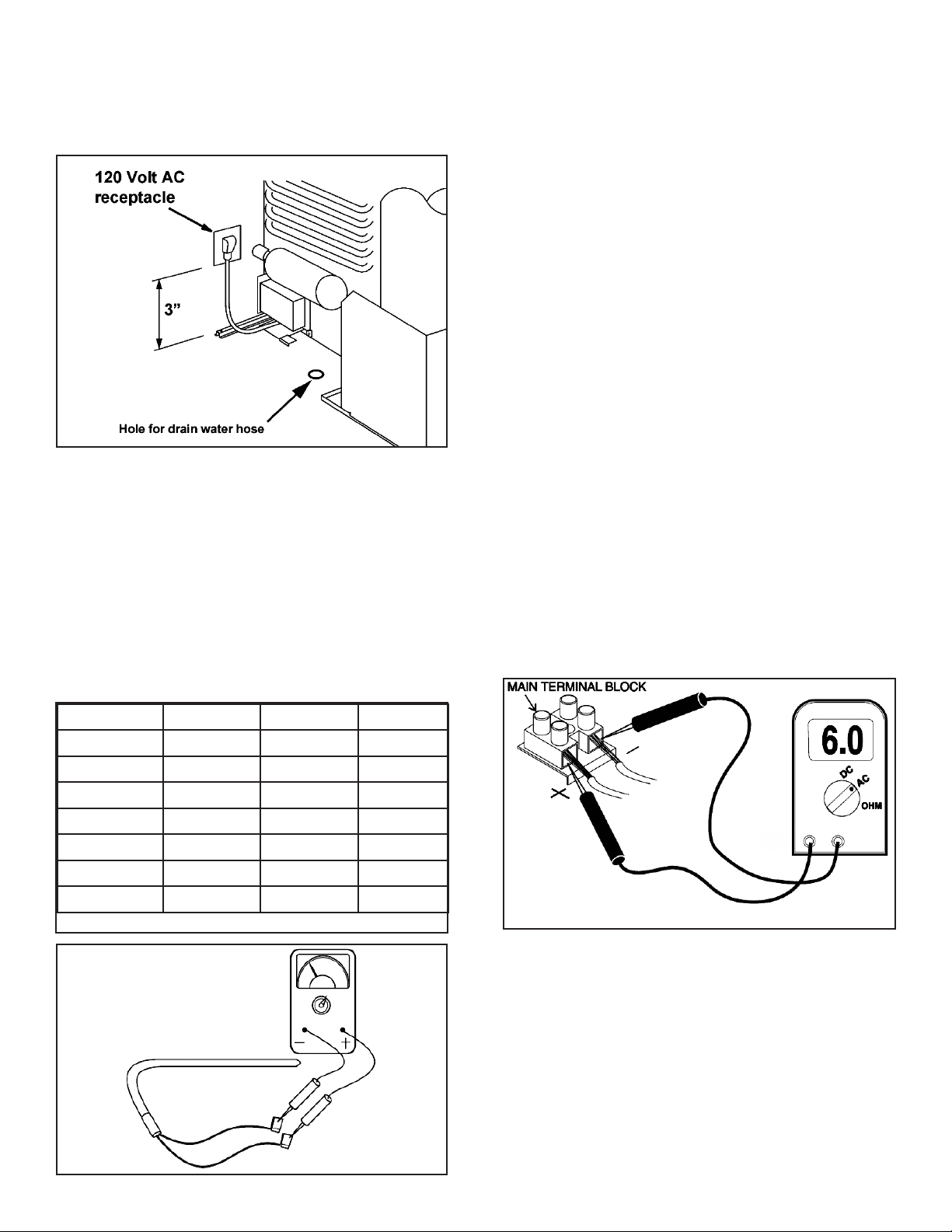

SECTION 4 DC VOLTAGE

DC Voltage Requirements

Clean Direct Current (DC) power is mandatory for hightech circuits to operate as designed. A battery will provide

straight line DC power. The converter and alternator produce DC power by a series of diodes that rectify alternating current to DC. The Dometic control system will only

tolerate up to 6 AC volts on the DC line. AC ripple can be

measured by a digital voltmeter set on the AC scale at the

main DC terminal block connections at the refer. Six volts

AC or less is acceptable. If AC volts exceed 6 on the DC

incoming line the power source should be cleaned up. AC

voltage in excess of 6 volts will affect the processor and

create erratic operation. When testing for AC ripple on the

DC line put a load on the converter. The operational range

of the unit is a minimum of 9.6V DC to a maximum of

22V DC. The unit will automatically shut down until voltage has decreased to 18V DC. The refrigerator requires

at least 9.6V DC for proper operation; however the panel

lights will continue to illuminate until voltage has dropped

to 4V DC or below. Do not use the body or chassis of

the RV as a substitute for either of the two conductors.

The refrigerator must be connected to the battery circuit

with two wires of adequate capacity to avoid voltage drop.

Proper polarity is crucial for refrigerator operation.

No other electrical equipment or lighting should be

connected to the refrigerator circuit. Just because you

can read volts does not mean you have the amps to operate the control system. If relays buzz, lights go dim or out

during operation, this could indicate there is a loose connection somewhere.

Main Terminal Block

Model WATTS OHMS AMPS

RM2351-4 175 80 1.5

RM2451-4 175 80 1.5

RM2551-4 175 80 1.5

RM2652 325 44 2.7

RM2662-3 325 44 2.7

RM2852 325 44 2.7

RM2862 325 44 2.7

Never over or under size the AC heater.

Grounds

The operation of the Dometic refrigerator is also dependent on good, clean ground connections. Loose or corroded ground terminals create an unknown resistance factor

that can affect the voltage detected by the Power Module.

A loose negative DC wire will create a negative millivolt

signal that the control board will pick up and create erratic

operation. Check the integrity of the grounds from the refrigerator all the way to the power source/battery. Clean or

tighten any suspicious looking connections.

Note: The DC terminal block below the control board

should be cleaned and tightened at the 4 wires.

10

Page 12

SECTION 5 DC COMPONENTS

5.1 DC Heating Element

Remove the heater leads from the lower circuit board or

relay and measure for proper resistance across the two

leads. You should obtain the following readings ± 10%:

Model Watts Amps Volts Ohms

RM2354 150 12.5 12 .96

RM2454 175 15.0 12 .80

RM2554 175 15.0 12 .80

RM2663 215 18.0 12 .67

NOTE: The DC mode is a holding mode not a full cooling

mode. DC should be used once the unit is cooled down on

gas or AC and driving (constant supply of DC) down the

road. A continuity reading will indicate an open or com-

plete circuit. Never over or under size the DC heater.

5.2 Thermistor

Disconnect the thermistor harness from the P2, 2-pin terminal on the lower circuit board. Place the thermistor in

a glass of ice water (more ice than water), approximately

33° F to 35° F. Wait 8 to 10 minutes. You should get a

reading of approximately 8,000 to 10,000 ohms. Always

test from the wire side as shown with the meter as not to

create a connection problem at the P2 connector.

5.3 Solenoid Valve

Check the solenoid coil with a properly calibrated ohm

meter. Remove the connectors from the solenoid and

measure the resistance across the terminals. The proper

reading would be 49 ohms with tolerance range of ten

percent. Failure of the solenoid is very unlikely. Next,

hook up a manometer at the test port. Then check for DC

volts at gas valve terminals (Yellow + White -) while the

unit is in trial-for-ignition. If DC volts are present and pressure is low, replace the valve. If DC volts are not present

at the valve while the unit is in trial-for-ignition, verify that

the wire at Plug 3, Terminal 2 on lower circuit board has

DC volts (9 or more).

5.4 Igniter

The igniter used on Dometic model refrigerators operates

on 12 volt DC. On gas operation the igniter senses the

resistance through the ame between the electrode and

burner. When there is no ame at the burner, the resis-

tance is high and the igniter begins sparking to light the

burner. As soon as the ame is lit, the resistance between

the electrode and burner drops and the igniter stops

sparking. The resistance is monitored by the igniter, and,

if for any reason the ame goes out, the igniter begins

sparking until the burner is lit. The resistance between the

electrode and burner drops and the igniter stops sparking.

11

Page 13

This is an energized circuit. Shock can occur

if not tested properly. Testing is to be done

by a qualied service technician.

This insures that the ame will always be lit when desired. First verify proper voltage at the positive (Yellow

+) and ground (Black –) terminals of the igniter. The reading should be within 1.5 volt of incoming voltage at the

main terminal block during trial-for-ignition. Next, remove

the high voltage cable from the igniter. The igniter should

produce a sparking sound during trial-for-ignition. If not,

replace the igniter. While operation is in the gas mode, the

power module and igniter are constantly monitoring the

presence of ame. If the ame is blown out, the reignitor

will immediately start sparking. When the power module

senses the loss of ame (thermocouple voltage below 13

MVDC) the 45 seconds trial for ignition period is started. The igniter installed on the refrigerators as original

equipment is part number 2931132019 (RV Gas Model

679). This igniter is rated 50 MA. This igniter may also be

used on any other model. When replacing the igniter always provide the product number for proper replacement.

DO NOT install the Channel Mark 6, Model 12 E igniter

(shown below) as a service replacement part. Installation

of the Channel Products, Inc., Gasliter Mark 6, Model 12

E, will VOID the Warranty on the refrigerator. To acquire

the proper igniter always provide the product number.

5.5 High Voltage Cable

If sparking starts during trial-for-ignition, the cable is good.

If there is no sparking during trial-for-ignition, disconnect

DC power at the refrigerator terminal block or switch unit

off. Disconnect high voltage cable from electrode. Reconnect DC power. If there is a sparking sound from the

igniter during trial-for-ignition, then replace high voltage

cable or electrode. On newer units the electrode and high

voltage cable are integrated into one component.

5.6 Electrode

Do a visual check for cracks or breaks on the ceramic insulator. A hair line crack can be hard to see at the electrode.

The spark gap must be set at three-sixteenths (3/16”) of

an inch and tip of electrode above the slots in the burner.

When adjusting always loosen the screw and move into

place, never try to move without loosing the screw. On

newer units the electrode and high voltage cable are integrated into one component. To acquire the proper part

always provide the product number.

5.7 DC Relay

The relay controls the circuit to the DC heating element. The load (amps) of the DC heating element goes

through the relay. Only used on newer 3 way units or

units that have the UNIVERSAL POWER MODULE KIT

(3308742.000) installed.

P3 Harness

Blue Wire

85

(+) 12 VDC

Heater Element Wire

Verify that the following components are good: upper circuit board, thermistor, 5 or 6 wire harness and 30/3-amp

fuses. In the DC mode Plug 3, Terminal 4 (positive 86)

and Terminal 3 (negative 85) should have voltage to close

the relay. If no voltage in the DC mode change the lower

board.

12

87

86

P3 Harness

Blue Wire

30

Red Battery

Wire

Page 14

Wires from control board P3 harness to relay.

Terminal 85 P3-3 harness blue negative.

Terminal 86 P3-4 harness blue positive.

Wires to relay from DC source and DC heater.

Terminal 87 to DC heater positive.

Terminal 30 positive from DC power source.

If DC voltage to terminals 85 & 86, but no continuity between 30 & 87 the relay will need to be changed. Refer to

wiring diagram on the back of the product or check parts

list for proper diagram. To acquire the proper wiring dia-

gram always use the product number.

5.8 Upper Circuit Board

With main ON/OFF switch on display panel in OFF

position: Check for DC voltage at Plug 1, Terminal 4

(orange wire +) positive and terminal 5 (red wire -)

negative DC on the lower circuit board. If no voltage,

then check fuse condition. Check for DC voltage between J4 positive and J10 negative terminals on the

lower circuit board (rst generation) or J1 positive and

J10 negative on the current board (3850415013). If

no voltage on orange wire, fuse test OK and voltage

into lower control, replace the lower board. Next,

with main ON/OFF switch on check for DC voltage at

the upper circuit board between terminal 4 (orange

wire) and terminal 3 (red wire) which is negative (–)

DC. If no voltage and your previous check veried

voltage at the lower circuit board between the wires,

test and/or replace the cable assembly between the

upper and lower controls.

5.9 Lower Circuit Board

WIRING Original style control 3 way & 2 way

Note: 2 Way will not have a J1 for DC heater

P1 To upper control board

P2 Thermistor

P3 To gas valve, igniter

J1 To DC heater

J2 To interior light and climate control

J3 Negative lead from thermocouple

J4 Positive 12V DC from terminal block

J5 AC line voltage (Black)

J6 AC neutral line (White)

J7 AC neutral out to AC heater

J8 AC line out to AC heater Switched side

J10 Positive lead from thermocouple

Thermocouple positive lead may be on the ground strip

on early units. Reference full wiring diagram next page.

WIRING: Current style control 3/2 way, 2 way

will not have wires from P3 to external DC relay

Board part number 3850415013

P1 To upper control board

P2 Thermistor

P3 To gas valve, igniter and DC heater relay if 3 way

J1 Positive 12V DC from terminal block

J2 To interior light and climate control.

J3 To auxiliary fan (S.) and/or ice maker heat tape

J4 Negative lead from thermocouple

J5 AC line voltage (Black)

J6 AC neutral line (White)

J7 AC neutral out to AC heater

J8 AC line out to AC heater Switched side

J9 Positive wire from thermocouple

J10 Negative to Chassis ground

Note: Terminals 9 and 10 could be reversed as both terminals are ground on control board.

Upper Board Pin Connector Wire Location

WIRING: Current style with integrated igniter

Board part number 3850712013

P1 To upper control board

P2 Thermistor

P3 To gas valve

J2 To interior light / climate control.

J4 Positive 12V DC from terminal block

J5 AC line voltage (black)

J6 AC neutral line (white)

J7 AC neutral out to AC heater

J8 AC line out to AC heater Switched side

J10 Negative to Chassis ground

Note: Units that have integrated igniter do not use a

thermocouple.

13

Page 15

WIRING ORIGINAL STYLE CONTROL 3 / 2 WAY, 2 WAY WILL NOT HAVE A J1 TO DC HEATER

14

Page 16

J1

J2

J3

J4

J5

J6

J7

J8

J9

J10

B

BLACK

BROWN

RED

ORANGE

GREEN

C

WHITE

WHITE

T

7

6

7

6

1

2 3

N

L

+

-

12V DC

L

4

2

1

2

2

A

CIRCUIT BOARD POWER MODULE

CIRCUIT BOARD DISPLAY

B

C

THERMISTOR

GAS VALVE

D

E

REIGNITER

THERMOCOUPLE

F

G

ELECTRODE

RETAINER FOR BURNER

H

I

TERMINAL BLOCK

GROUND TERMINAL STRIP

J

K

ABSORPTION UNIT

HEATER 120V AC

L

M

HEATER 12V DC

LIGHT

N

O

SWITCH

FUSE 3A

P

Q

FUSE 5A

DC HEATER RELAY

R

S

HEATING CABLE

SWITCH

T

U

TERMINAL BLOCK

1

WHITE

BLACK

2

3

GREEN

GREEN/YELLOW

4

5

GREY

BROWN

6

7

BLUE

YELLOW

8

BLUE

BLUE

WHITE

12V DC

120V AC

ML

2

9

2

2

D

7

1

K

U

9

2

J

7

E

R

5

F

G

8

A

N

O

I

H

P3

YELLOW

P Q

S

P2

P1

GND

2

9

RED

A---CIRCUIT BOARD POWER MODULE

B---CURCUIT BOARD DISPLAY

C---THERMISTOR

D---REIGNITER

F---THERMOCOUPLE

G---ELECTRODE

H---RETAINER FOR BURNER

I--- TERMINAL BLOCK

J--- GROUND TERMINAL STRIP

K--- ABSORPTION UNIT

L--- HEATER 120V AC

M-- HEATER 12V DC

N-- LIGHT

O-- SWITCH

P-- FUSE 3 AMP

Q-- FUSE 5 AMP

R-- DC HEATER RELAY

S-- HEATING CABLE

T-- SWITCH

U-- TERIMAL BLOCK

1-- WHITE

2-- BLACK

3-- GREEN

4-- GREEN/YELLOW

5-- GRAY

6-- BROWN

7-- BLUE

8-- YELLOW

9-- RED

CURRENT CONTROL SYSTEM WIRING 2 WAY WILL NOT HAVE DC RELAY & HEATER

Part number 3850415013

15

Page 17

WIRING INTERGRATED IGNITER CONTROL

Part number 3850712013

16

Page 18

Lower Board Testing

ALL TESTS ARE TO BE DONE WITH THE RE-

FRIGERATOR IN THE COOLING MODE.

Unplug the thermistor from the control board during

lower board testing to assure unit is calling for cooling.

The millivolts meter should read between 25 to 35 milli-

volts with the gas ame burning. When the power module

senses the loss of ame (thermocouple voltage below 13

MVDC) the 45 seconds trial for ignition period is started.

Turning the refrigerator OFF–ON while operating in the

gas mode may cause a check light.

DC Volts

Measure volts between terminal J4 positive (early control)

and the ground and integrated igniter board. Current control board J1 positive and ground. Voltage should be the

same as at the positive (+) and negative (–) on DC input

terminal block. 9.6 min to 22 max would be the operating

range. Refer to wiring diagram on the product number unit

you are currently working on. If voltage outside the 9.6 to

22 range, check power supply, terminal block and correct

power source before going on with the test.

AC Mode

This is an energized circuit. Shock can occur

if not tested properly. Testing is to be done

by a qualied service technician.

Test upper control board and harness between upper

and lower before testing lower for proper AC operation.

Check that incoming AC voltage is present at terminals

J5 (black) and J6 (white) on the circuit board. With unit on

AC operation, check for voltage at the heating element

connection terminals J7 and J8 on the circuit board. If no

voltage is present, check the 5 amp AC, 3 amp DC fuses,

wiring harness and upper control. If AC volts are present

at J5 and J6 and no voltage on J7 and J8 the AC voltage

detection circuit is damaged and the control board will

need to be changed.

Note: A loose ground will create erratic or no

gas operation on all systems.

Gas Mode Integrated Igniter

Verify that the following components are good: upper circuit board, electrode with cable, wire harness and 3-amp

fuse. Units that have integrated igniter do not have a ther-

mocouple. The igniter senses the ame thru the electrode

and communicates with the lower main control. The integrated igniter used on certain Dometic model refrigerators

operates on 12 volt DC thru the control board. On gas

operation the igniter senses the resistance through the

ame between the electrode and burner. When there is no

ame at the burner, the resistance is high and the igniter

begins sparking to light the burner. As soon as the ame

is lit, the resistance between the electrode and burner

drops and the igniter stops sparking. The resistance is

monitored by the igniter, and, if for any reason the ame

goes out, the igniter begins sparking until the burner is lit.

This insures that the ame will always be lit when desired.

The integrated ignition system is also a three try control.

Turning the refrigerator OFF–ON while operating in the

gas mode may cause a check light. If you have voltage to

the gas valve during trial-for-ignition but no spark and

the electrode with cable checks good, change the lower

control board.

Note: Never engage the gas mode with the electrode cable unplugged from control board. This will

damage the igniter on the board.

Gas Mode

Note: All current Dometic control boards are 3

try systems in the gas mode. There is a 2 minute purge cycle between each trial for ignition.

Flame failure will take 6 to 7 minutes.

Verify that the following components are good: upper circuit board, thermistor, wire harness and 3-amp fuse. First,

check for voltage during trial-for-ignition at Plug 3, Terminals 1 (white Wire -) and 2 (yellow wire +) to the igniter

and solenoid. If no voltage is present change the circuit

board. If voltage is present, check for voltage at the igniter

and solenoid. If no voltage is present, check the wires. To

check the ame sense circuit of the lower circuit board,

operate the refrigerator on GAS and measure the millivolts between J3 (NEGATIVE) terminal original control or

J4 current control and the other wire (POSITIVE) connection from the thermocouple.

DC Mode 3-Way Units

Verify that the following components are good: upper circuit board, wire harness, DC heater and 3/30 amp DC fuse

and relay. With the DC mode selected on the upper control, v erify voltage between terminals J4 positive and the

ground strip early control or J1 positive current control and

J10 negative is above 9.6 min. When the DC heater is activated it will draw approximately 12 to 18 amps and if the

power source is weak the control voltage will drop below

proper operating range and shut down. Check for DC volts

from J1 (positive) early control to DC heater, if no DC volts

change the control board. On late controls (3850415013

& 3850712013 [integrated igniter]) the DC heater load

(amps) goes through a stand alone relay. In the DC mode

Plug 3, Terminal 4 (positive) and Terminal 3 (negative)

should have voltage to close the relay. If you have voltage coming in with unit in DC mode but nothing out to

DC heater or relay, change the control board. Refer to wiring diagram on the back of the product or check parts list

for proper diagram. To acquire the proper wiring diagram

always use the product number.

17

Page 19

5.10 Door Switch

The door switch is an open switch when the switch arm

is depressed (interior light should be off). When the refrigerator door is open the switch is closed (interior light

should be on). Check that the switch assembly is properly

aligned and that it is not broken. Check the switch as-

sembly for continuity. To do a continuity check, rst be

sure all power is disconnected or OFF to the refrigerator.

Second, remove all wires from the switch assembly, then

check the switch.

After the check, be sure the switch assembly is wired

properly per the wiring diagram. When the switch is depressed, there should not be continuity. When the switch

is NOT depressed, there should be continuity. If any of

these checks are incorrect, replace the switch.

When the low ambient control is turned on it by-passes

the interior light switch and turns on the interior light. The

heat load of the 10 watt light bulb will cause the cooling

unit to cycle approximate every 35 to 55 minutes. This will

help keep the temperature in the freezer in the freezing

zone. In low ambient temperatures the freezer will warm

up because the refer box will not call for much cooling.

When the refer calls for cooling it will cool the freezer rst

and then cool the refer box. When it is cool outside the

refer box won’t call for as much cooling and the freezer

might warm up to normal food storage temperature (34

to 35). The second thing the control will do is keep the

cooling unit from freezing up in low outdoor temperatures.

(20 to 0 F)

5.11 Climate Control Heater & Switch

Not used on all units. Disconnect the wires from the

switch and do a continuity check. In the OFF position,

there should be no continuity. In the ON position, there

should be a continuity reading. To check the heater itself,

perform an ohms resistance reading on the heater wire by

using a properly calibrated ohm meter. From the side of

the switch that only has two wires, with switch off take an

ohms reading to ground. The proper ohms reading will be

24 ohms ± 10%. The approximate amp draw is less than

.5 (1/2) amp.

Function

During the summer months of high temperatures and

humidity, the metal frame between the freezer and fresh

food compartments may have water droplets forming. The

number of water droplets will increase if the vehicle isn’t

air conditioned during these months. Some refrigerators

come standard with a 12 volt (DC) climate control that

will evaporate the water droplets when they form. To have

the climate control on, you position the switch (normally

located beneath the top decoration panel that houses the

control panel) to ON. The approximate amp draw is less

than .5 (1/2) amp.

Note: The climate control will draw 12 volt DC power

continuously when in the ON position on certain models.

It should be turned OFF when a charging source is not

available or unit is in storage.

5.13 Fuses

The 3 amp DC fuse is designed to protect the circuit board

from internal/external DC shorts. The 5 amp AC fuse is

designed to protect the integrity of the AC detection and

heater circuit from shorts. On 3-way models only, the 30

or 35- amp DC fuse is designed to protect the DC heater

circuit integrity. All fuses can be checked for continuity. If

a fuse blows don’t replace it until the problem has been

found. If a fuse blows there is a short or component that

has created the problem.

5.14 Thermofuse

Newer and replacement cooling units have a Thermofuse

located on the boiler. The function of the thermofuse is

to shut down the control system in the event the cooling

unit has a problem. On certain units the fuse can be reset

by pushing the button in the center. The thermofuse is a

non-replaceable component of the cooling unit. When the

fuse pops it is normally an indication the cooling unit has

a problem and the cooling unit will have to be replaced.

The fuse can be checked for continuity .

5.12 Low Ambient Switch

Not used on all units. Disconnect the wires and do a continuity check. In the OFF position, there should be no

continuity. In the ON position, there should be a continuity reading. All RV absorption refrigerators, while similar,

operate a little differently than your home refrigerator. Dometic designers and engineers have equipped your refrigerator with an exclusive feature that allows for troublefree operation in low ambient temperature ( below 50° F)

for extended periods of time. Simply turn on the low ambient switch located beneath the top decoration panel that

houses the control panel. Once the outdoor temperature

is above 50° F, the low ambient switch should be turned

off.

18

Page 20

SECTION 6 LP GAS REQUIREMENTS

DO NOT use a ame to check for gas

The LP gas pressure to the refrigerator should be 11 inches water column with half of all BTU’s of the RV turned

on. With all other appliances off, the pressure to the refrigerator should not exceed 12 inches water column. To

check the gas pressure when the refrigerator is operating,

there is a pressure test port below the solenoid valve assembly.

SECTION 7 LP GAS COMPONENTS

7.1 Manual Gas Shutoff Valve

The manual shutoff valve is a non-serviceable part. The

valve is part of the solenoid valve assembly. It is very rare

to have problems with the manual shutoff or the solenoid

assemblies. If you have checked gas pressure and it is

low, check pressure at input line to refer. If pressure is 11

inches at input and low at the pressure test port, change

solenoid valve assembly. The valve is not opening all the

way.

6. No bubbles should appear at the opening of the burner

jet orice. The presence of bubbles indicates a defective

gas safety shutoff, and service is required.

7. If no bubbles were present at the burner jet orice, it

should be rinsed with fresh water. Be careful not to dam-

age the burner jet orice. Replace cover and press the

main power ON/OFF button (1) OFF and back ON. Normal operation of the burner should return. Allow the burn-

er to operate for a minimum of ve minutes.

7.2 Orice

The Dometic orice is a brass alloy with a man-made ruby

pressed in the center that has been laser-beam drilled in

a spiral pattern. The orice is cleaned by using an alcohol

based solvent. Soak the orice for approximately 1 hour

and allow to air dry. Don’t insert anything in the center of

the orce it will harm the man-made ruby. Don’t use an

air nozzle to blow thru the orice as the ruby could be

moved. Never over or under size the orice on a Dometic

refrigerator. The cooling unit is designed to work with a

predetermined amount of heat and modifying the orice

size will decrease cooling. If there is a lack of cooling on

gas operation, verify the orice is the proper size per the

chart .

TESTING LP GAS SAFETY SHUTOFF

The gas safety shutoff must be tested after the refrigerator is connected to the LP gas supply.

To test the gas safety shutoff, proceed as follows:

1. Start the refrigerator according to the instructions, and

switch to GAS mode.

2. Check that the gas ame is lit and the GAS mode indicator lamp is on.

3. Close the manual gas shutoff valve at the back of the

refrigerator.

4. Wait for one minute for units prior to 2003 and six to

seven for units after 2003 (Three Try Board). The CHECK

indicator lamp should be on and the GAS mode indicator

lamp should be off.

5. Remove protection cover from burner and open the

manual gas shutoff valve. Do not change any button positions on the control panel. Apply a non-corrosive commer-

cial bubble solution to the burner jet orice.

DO NOT use a wire or pin when cleaning the burner

jet as damage can occur to the precision opening.

This can cause damage to the refrigerator or create

a re hazard.

MODEL JET SIZE

RM2351-4 #39

RM2451-4 #43

RM2551-4 #43

RM2652 #58

RM2662-3 #58

RM2852 #58

RM2862 #58

Always check the parts list with the model and product

number to assure the right jet size.

19

Page 21

7.3 Thermocouple

The Thermocouple is a component that extends over

the burner assembly so its tip is in the path of the ame.

During normal gas operation, the thermocouple should

produce 25 to 35 millivolts when connected to the lower

circuit board. Any reading below 18 millivolts could cause

erratic gas operation. Note: A reading of 18 or less could

be caused by low gas pressure, carbon build up or improper thermocouple location. The thermocouple should

be centered over the burner and extend over 3 slots. The

control board reads negative millivolts from the thermocouple and the positive lead goes to the ground terminal

on the control board or ground strip.

Note: A rapid on/off of the switch or a brief interruption of

DC power source does not allow the thermocouple time

to cool. When the power is restored, the thermocouple

has not cooled completely and the check light may come

on. Turning the refrigerator OFF–ON while operating in

the gas mode may cause a check light. The new lower

control has built-in delay when the unit is rst turned on.

If the lower control reads millivolts in excess of 6 MVDC

the control will go into a 30 second gas delay before attempting to light on gas. To test the thermocouple set the

meter to DC millivolts. Put the black lead from the meter

to terminal J3 ( original board ) or J4 ( current board ) and

the red lead from the meter to J10 or other lead from thermocouple. Start the unit on gas and measure the DC millivolts produced by the thermocouple. The thermocouple

should produce 22 to 36 millivolts within 45 seconds. If

the millivolts are 20 or below erratic operation will occur.

Anything below 10 to 13 the control board will not keep

the gas valve energized and turn on the check light after

the 45 second trial-for-ignition.

7.4 Burner

The slots in the burner should be directly below the ue

tube. The burner should be cleaned periodically, at least

once a year. Soak the burner in an alcohol based solvent

and allow to air dry. If the burner does not have a good

ground it can cause erratic gas operation. The electrode

sparks to the burner tube and a erratic ground will cause

erratic gas operation.

7.5 Flue Bafe

The ue bafe ( spiral bafe ) is a twisted piece of metal

that hangs in the ue tube to slow the heat from the ame

to the proper location on the cooling unit. If the ue bafe

is too high or low the heat will not be transferred to the

cooling unit properly.

MODEL ABOVE

SIZE

BURNER

RM2351-4 1-15/32 3-15/16X25/32

RM2451-4 1-15/32 3-15/16X25/32

RM2551-4 1-15/32 3-15/16X25/32

RM2652 1-7/8 5-1/8X13/16

RM2662-3 1-7/8 5-1/8X13/16

RM2852 1-7/8 5-1/8X13/16

RM2862 1-7/8 5-1/8X13/16

Lack of heat transfer to the cooling unit will cause low cooling performance in the gas mode. It should be cleaned

periodically, at least once a year. The proper position of

the bafe above the burner should be as shown in the

chart : Always refer to parts list on the model/product

number unit you are currently working on.

7.6 Flue Cap

The ue cap is located at the top of the ue tube and is

attached with a screw or pushed down over tube. Not all

units will come with a ue cap. The design of the bafe

wire in the ue tube will slow down a down draft.

7.7 Flue Tube

Carbon build up will not allow the heat transfer to the cool-

ing unit and cause lack of cooling on gas. The ue tube is

welded to the boiler of the cooling unit. In a rough riding

coach there have been rare cases where the weld will

crack and create lack of cooling. The ue tube must be

cleaned periodically, at least once a year. Clean by using

a ue brush, Dometic Part No. 0151404001.

Bafe

20

Page 22

SECTION 8 COOLING UNIT

8.1 Leveling

Leveling is one of the requirements for proper operation

of absorption refrigerators. The absorption design utilizes

no mechanical pumps or compressors to circulate the refrigerant within the system, so proper leveling must be

maintained to provide the correct refrigerant ow. Without proper leveling, refrigerant within the cooling unit will

collect and stagnate at certain areas. Without proper re-

frigerant ow, the cooling process will stop. Absorption

refrigerators have a type of cooling unit that utilizes an enclosed pump tube surrounded by a solution to protect the

assembly. To ensure proper leveling, the vehicle needs

to be leveled so it is comfortable to live in. (No noticeable

sloping of oor or walls). When the vehicle is moving, leveling is not critical as the rolling and pitching movement

of the vehicle will pass to either side of level, keeping the

refrigerant from accumulating in the piping

Typical Roof Vent and Side Wall Vent

PERFECTLY LEVEL NOT REQUIRED

MORE LEVEL = BETTER OPERATION

8.2 Ventilation

The installation shall be made in such a manner as to

separate the combustion system from the living space of

the mobile home or recreational vehicle. Openings for air

supply or for venting of combustion products shall have a

minimum dimension of not less than 1/4 inch. Ventilation

is a critical requirement for proper cooling unit operation.

The coach vent system must be able to provide a way to

direct the hot air, produced by the action of the cooling

unit, out away from the installation of the refrigerator. The

refrigerator extracts heat from the interior of the refrigerator cabinet and dissipates the heat out through the vent

system. In a proper installation there should be zero (0”)

clearance surrounding the sides and top of the refrigera-

tor to achieve proper air ow. Clearance from the back of

the refer to the outside wall must be kept less than 1 inch.

All potential dead air pockets should be blocked or bafed

to ensure that heat won’t be trapped in these spaces and

reduce efciency.

Note: Refrigerators should be installed in accordance

with appropriate installation instructions received with the

refrigerator.

FOR MORE UPDATED INFORMATION ON UNIQUE

VENTILATION REQUIREMENTS, refer to Vent Installa-

tion Instructions, Form No. 3308666.XXX.

BAFFLE

Typical Two Side Wall Vents

TUR NI NG

VANE

BAFFLE

21

Page 23

Typical Two Side Wall Vent Application. Always

Refer To Vent Instructions 3308666.xxx

22

Page 24

8.3 Air Leaks

Check the gasket on the doors to be sure of a positive

air seal. A simple method to check gaskets is to close

the door on a dollar bill, then pull the dollar bill out. If no

resistance is felt, the gasket in that place is not sealing

properly. This should be done on all four sides of the door

in several places. If a gasket is not sealing properly, lift

up inside of door gasket and insert 1/4” ball of berglass

insulation at all four corners on both doors. This is especially important to the top corners. Next warm the gasket

material with a hair dryer. Then close the door and the

magnetic strip should pull the gasket to the metal frame.

Leave door closed until the material has cooled. Then

recheck for a positive seal. If a positive seal cannot be

achieved, replace the door gasket. Also check that the

cooling unit is installed properly. The cooling unit’s foam

block, the portion that surrounds the evaporator coils,

must be ush to the cabinet at the back of the refrigerator

and have a positive seal. If the cooling unit is not installed

properly, remove and install properly.

Note: Air leaks will cause insufcient cooling as well as

rapid formation of frost.

8.4 Interior Liner Seal To Frame

There is a seal that is applied to the liner in the area

where the metal frame makes contact with the interior

liner. If this seal is incomplete, cold air can migrate out to

the metal frame. If this happens, condensation could form

on the frame and could promote rapid formation of frost.

If you suspect an improper seal, apply a small bead of

silicone all the way around the perimeter where the frame

meets the interior liner. Next remove all screws securing

the refrigerator into the cabinet and slide the refrigerator

out approximately 2–4 inches. Clean the metal frame and

foil-backed insulation around the refrigerator. Apply a foilbacked adhesive tape to the joint between outer frame

and foil-backed refrigerator insulation. Make sure the

refrigerator is dry and that the surface temperatures are

above 50° F. Use a clear silicon caulking compound and

seal the seam between the refrigerator’s plastic liner and

the metal frame. Apply the silicon in a continuous bead

around both the refrigerator freezer and food compart-

ments.

DO NOT OVERHEAT

AS YOU CAN MELT THE MATERIAL

Another source for an air leaks could be the drain hose.

When units are installed, there is a check valve at the end

of the drain. At install the hose might be shortened and

the check valve must be moved to the end of drain hose.

Any time lack of performance or excessive frost is experienced, look for the check valve at the end of hose.

CAULK SEAM BETWEEN

PLASTIC LINER AND

METAL FRAME

( R e f r i g e r a t o r

shown with doors

removed)

23

APPLY FOIL-BACKED OR ALUMINUM

TAPE TO JOINT BETWEEN OUTER

FRAME AND FOIL-BACKED REFRIGERATOR INSULATION. GO AROUND

THE COMPLETE FRAME.

Page 25

Note: To form a proper seal, it is important not to leave

any gaps.

8.5 Door Position

If the upper or lower door is closing too high or low against

the frame, cold air leakage can occur. Adding or deleting

a at thin washer on top of the lower or middle hinge pin

can raise or lower the door position. To correct the door

alignment, loosen the hinge screws slightly and reorient

the door in the proper position. Hold the door in its new

position and carefully retighten the hinge screws.

8.6 Ambient Temperature

This is the temperature surrounding the recreational vehicle, as well as the temperature of air at the back of the

refrigerator. As the ambient temperature increases, the air

temperature in the area of the cooling unit increases. Improper venting at this point will cause the cooling unit to

have reduced efciency. A refer that chases the out-side

temperature is improperly vented or has a weak cooling

unit.

24

Page 26

25

Page 27

8.7 Cooling Unit

The cooling unit is a self-contained, hermetically sealed

set of coils where the refrigeration process takes place.

The chemicals involved in the cooling process include

hydrogen, ammonia, water and a rust inhibiting agent.

There are no repairs recommended on the cooling unit.

If it is defective, replace with a new cooling unit. To check

the cooling unit, rst verify the AC heating element is

good, proper ohms at room temperature, proper venting

and unit is level. Then place approximately one gallon of

water inside the refrigerator and place a thermometer in

one of the containers of water. Next, unplug the thermistor from the lower control board. This will by-pass the

thermostat control and operate for at least 12 hours. Then

check the temperature on the thermometer. It should be

at 43 degrees or lower depending on test conditions. If so,

the cooling unit is good. If the temperature of the water is

above 43 degrees, replace the cooling unit. The outside

temperature will affect the cooling capacity of the unit.

There is that rare occasion when the cooling unit will work

OK for the rst 12 hours and then start to warm up. If the

customers complaint is “works OK for 2 to 5 days and

then warms up” the unit may have an internal problem. To

test this it would be necessary to operate the cooling unit

for up to 24 to 48 hours in the test mode.

8.8 Food Storage

Proper refrigeration requires free air circulation within the

food storage compartment. Restricted air circulation within

this compartment will cause higher cabinet temperatures.

To remedy this situation, simply rearrange your foodstuffs.

It is also essential that the shelves are not covered with

paper or large storage containers. Always remember to

allow for proper air circulation. Odorous or highly avored

foods should always be stored in covered dishes, plastic

bags or wrapped in foil or waxed paper to prevent food

odors. Vegetables, lettuce, etc., should be covered to re-

tain their crispness.

NEVER PUT HOT FOOD INTO THE REFRIGERATOR.

To reduce frost formation in and on the freezing compartment, cover stored liquids and moist foods and do not

leave the door open longer than necessary. When the

refrigerator is heavily loaded, it takes a longer time for

refrigerator temperatures to lower, also increasing the ice

making time. A very heavy load may also cause defrosting. Defrosting every 7 to 21 days would be normal, depending on the humidity level.

SECTION 9 WIRING

9.1 Internal Wiring

Check all wires and the connectors to ensure a proper

and tight connection. Also verify the refrigerator is wired

per the wiring diagram for the model you are working on.

(See applicable wiring diagrams for your model refrigerator). A loose connection can create erratic operation. Always check the wires at the DC terminal block, two wires

in and two wires out.

9.2 External Wiring

120 Volts AC Connection: The refrigerator is equipped

with a three prong (grounded) plug for protection against

shock hazards and should be plugged directly into a properly grounded three prong receptacle. DO NOT cut or remove the grounding prong from this plug.

12 Volt Connection : The connection is made to the terminal block marked 12 volts DC. The control system is

connected to a battery/converter circuit and could draw

about 3 amps at 12 volts DC. The refrigerator must be

connected to the battery circuit with two wires of adequate

capacity to avoid voltage drop. Proper polarity is crucial

for refrigerator operation. Don’t use the chassis for the

ground circuit. No other electrical equipment or light-

ing should be connected to refrigerator circuit. A loose

connection will create erratic operation.

On three way units the DC heater will draw up to 18

AMPS and size of wires should follow installation instructions for the model unit you are working on.

9.3 Wiring Schematics

To view typical wiring schematics look in the Lower Circuit

board testing section 5, pages 14, 15 and 16. All units

should have a specic schematic on the rear of that unit.

To acquire the proper one always have the product number when you call or e-mail.

SECTION 10 ICE MAKER

10.1 Operation

The refrigerator must be allowed to precool properly before starting the ice maker. The refrigerator has to be connected to 120 volts AC before the ice maker can operate.

The water line manual shutoff valve (not part of Dometic

unit) must be open. To start making ice, move the ice level

bail arm to DOWN position.

8.9 High Humidity

High humidity may cause a small amount of condensation

to form on the frame of the refrigerator. In some cases it

can develop to such a degree that it will run off the frame.

As the humidity is reduced, the sweating will decrease.

High humidity can also be a factor in rapid formation of

frost.

26

Page 28

When the ice maker thermostat senses the preset tem-

perature for ejection of the ice cubes, the ngers will start

to rotate, dumping any ice cubes and lling the mold with

water. When the storage container is full of ice, the ice

level bail arm cannot return to the DOWN position. This

will stop further production of ice until the container is

emptied and the bail arm is returned to the down position.

The absorption system will keep the compartment at the

proper temperature for storage of ice. Ice making is accelerated if the thermostat is set to the coldest position. It

is a good idea to do this a few hours before you anticipate

a need for ice. The rst few cycles may have small cubes

due to air trapped in the water lines. The rst container of

ice cubes should be dumped if the water system has been

winterized or not used for several weeks.

Note: if the ice maker was cleaned and drained, no ice

cubes will be dumped into the storage container during

the rst few cycles.

10.2 Mold Heater

The mold heater uses 165 watts to thaw the ice free from

the mold. It is wired in series with the thermostat which

also acts as a safety device. With power to the appliance off, check for resistance between the two leads to

the heater element. You should obtain a reading of approximately 80 ohms +/- 10%. If the heater is found to be

defective, the manufacturer recommends replacement of

the entire ice making unit for proper operation.

10.4 Mold Thermostat

This is a single-pole, single-throw, bimetal switch. It starts

an ejection cycle by closing at 15º F ± 5º. The reset temperature is 50º F ± 5º. The thermostat is in series with the

mold heater and acts as a safety against overheating in

case of a mechanical failure. If the thermostat is defective, replace it. The mold thermostat starts the ice ejection

cycle. The freezer must be down to proper temperature

for the mold thermostat to start the cycle. The cycle can

be started by turning the large gear clock wise 1/8 to 1/4

of a turn.

10.5 Shut Off Arm

The shutoff arm is cam driven. It operates a switch to control the quantity of ice produced. During the ejection cycle

the arm is raised and lowered during each of the two revolutions of the timing cam. If the shutoff arm comes to rest

on top of the ice in the storage bin during either revolution,

the switch will remain open and stop the ice maker at the

end of that revolution. The arm has a manual shutoff built

into the linkage; by raising the arm as high as possible, it

will lock in that position until forced down. If the arm and

switch do not operate properly, check for damage and repair or replace parts as necessary.

10.3 Ice Ejector

The ice ejector blades sweep the ice from the mold cavities during the ejection cycle. The drive end of the ejector

is “D” shaped for positive coupling. The bearings at both

ends are lubricated with silicone grease. If the ejector

blades are frozen into the ice, defrost the ice maker and

manually cycle the ice making unit, making sure the ejec-

tor stops at the right location.

10.6 Mold Switches

The three switches are single-pole, double-throw style.

They are identical and interchangeable. The holding

switch assures completion of a revolution once a cycle

has started. The water valve switch opens the water

valve during the ll stage of the cycle. NOTE: This is the

only adjustable component of the ice maker. If you use a

double throw switch, DO NOT use the N.O. terminal. The

shutoff switch stops the ice maker’s operation when the

storage bin is full.

27

Page 29

10.9 Ice Maker Replacement

10.7 Timing Motor

This is a low-wattage, stall-type motor which is geared to

the timing cam and ice ejector. It is a one RPM motor. To

check the motor, disconnect power to the appliance and

test for continuity between the two leads. If you DO NOT

have continuity, replace the motor. If you have continuity

and the motor runs, DO NOT replace.

10.8 Water Valve

This valve is solenoid operated. When it is open it releases water from the source to the mold. The amount

of water is proportional to the length of time the water

valve switch is held closed by its timing cam. Disconnect

power to the appliance, remove the wires to the water

valve solenoid coil, and check for continuity between the

two terminals. The ohms should be between 200 to 500.

If you have continuity, the solenoid is good. It takes 10-15

watts to energize the solenoid coil. The mold heater and

coil are in series. When the mold heater is activated, this

causes the voltage to drop to about 105 VAC at the coil.

The valve has a ow washer inside which acts as a pressure regulator. A strainer is installed to prevent dirt, rust,

etc, from entering the valve. Check for any debris which

might obstruct the ow of water, or prevent the valve from

closing completely when the circuit is not energized. Remove any obstructions. If the valve still fails to operate

properly, replace it. If the valve has been cracked from

freezing this would not be a warranty item.

This is an energized circuit. Shock can occur

if not tested properly. Testing is to be done

by a qualied service technician.

It may be necessary to replace the entire ice maker assembly. Disconnect power to the appliance. Disconnect

the 4 pin connector from the ice maker unit. Check each

wire for continuity to make sure the wiring is good before

replacing the ice maker unit. If there is no continuity on

any of these wires, replace or repair them as necessary

and recheck the ice maker unit to determine whether the

problem was in the wiring or the unit itself. Remove the

three screws holding the unit to the plate. Before replacing the ice maker assembly check the temperature in the

freezer. For the unit to cycle it should be 12 degrees or

cooler as the mold thermostat starts the cycle.

10.10 Water Fill Adjustment

The correct water level in the mold is important for the

proper production of ice. The size of the ice cubes depends on the amount of water which enters the mold. The

cubes should be approximately 1/2” wide, 3/4” high and 2-

1/2” long. If the water overows in the mold, rst check to

see if the ice maker unit is level in the appliance. Next ensure that the appliance is installed level in the RV. If there

is still water overow, adjustment of the water ll screw is

necessary. Locate the screw on the ice maker assembly.

Turn the screw as necessary toward the “+” or “—” side.

One full turn of the screw will make an 18 cc change in

the amount of water. DO NOT turn the screw more than

one full turn at a time. If the water level is too high, it can

also cause the ejector blades to become frozen in the ice.

Follow the procedures above to correct the problem.

28

Page 30

10.11 Water Supply

To operate properly, the water pressure in the water supply line must be between 15 lbs. PSI and 125 lbs. PSI.

Lower water pressure, water turned off, or obstructions

or air in the water line can cause low or no ice production. First check to see that the water supply is fully turned

on. Visually check the line for kinks, etc. which might ob-

struct the ow of water. To remove trapped air, loosen the

connection at the water solenoid valve of the appliance.

Ensure that pressurized water is reaching this point, and

bleed off any air in the line. Retighten the connection,

making sure there are no leaks.

10.12 Wiring Schematics

WHITE AC NEUTRAL

TO BOARD J6

12 VDC POSITIVE

J2 OR J3 HEATER

WATER LINE

BLACK AC LINE

TO BOARD J5

This is an energized circuit. Shock can occur

if not tested properly. Testing is to be done

by a qualied service technician.

Refer to the wiring diagram supplied with the unit you

are working on, and make sure all wiring connections are

correct and tight. There are 4 wires coming from the ice

maker.

BLACK: Connected to incoming hot from AC power

source. This could be split wire at the AC BLACK at the