Page 1

825125800

©2006 Dometic Corporation

LaGrange, IN 46761

MO-M 0606

CANADA

Service Offi ce 2320 Industrial Parkway Elkhart, IN 46515 Dometic Corporation

Dometic Corporation

48 Zatonski, Unit 3

2320 Industrial Pkwy. Brantford, ON N3T 5L8

Elkhart, IN 46516

CANADA

Phone: 574-294-2511 Call: 800-544-4881 Phone: 519-720-9578

®

®

2. Don’t touch electrical switches.

3. Extinguish any open fl ame.

4. Immediately call your gas supplier.

Si vous sentez une odeur de gaz:

2. Ne touchez à aucun interrupteur.

3. Éteignez toute fl amme nue.

4. Avertissez immédiatement votre

fournisseur de gaz.

fl ammable vapors and liquids in the

vicinity of this or any other appliance.

autre appareil.

tion, service or maintenance can cause

fourni avec l’appareil. Pour obtenir de

taires, consultez un installateur ou un

service d’entretien qualifi é ou le fournis-

seur de gaz.

!

AVERTISSEMENT

WARNING

!

Page 2

- 2 -

____________________

9

eversing

the door swing

9

ounting

the door panel(s)

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

____________________

0

APPENDIX A - REARVIEW EQUIPMENT

__________

APPENDIX B - WIRING DIAGRAMS

______________

3

This manual describes the installation procedure of the following refrigerator models: RM2351, RM2354, RM2451, RM2454,

RM2551, RM2554, RM2652, RM2662, RM2663, RM2852, RM2862, RM3862 and NDR1062. For information about mainte-

nance and operating instructions, refer to the

USER MANUAL (825 12 57-00)

The unit must be installed by qualifi ed personnel only. This manual should be read and understood before installation. Follow the

instructions and comply with installation specifi cations and dimensions to ensure that the refrigerator is installed safely and runs

effi ciently. Be aware of possible safety hazards when seeing alert symbols on the refrigerator as well as in this manual. Modifi ca-

tion of this product can be hazardous and could result in personal injury or property damage.

CERTIFICATION AND CODE REQUIREMENTS

______

3

VENTILATION REQUIREMENTS

__________________

3

3

V

enti

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

Clearances

Overall and recess d

. . . . . . . . . . . . . . . . . . . . . . . . .

5

__________________

6

6

Securing the refrigerator

6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

Connections

SYMBOLS

The following symbols are used throughout the manual:

Indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate injury.

Used without the safety alert symbol indicates, a potentially hazardous situation which, if not avoided

may result in property damage.

Information

Step-by-step instructions

CAUTION

!

WARNING

!

CAUTION

Page 3

- 3 -

This appliance is certifi ed under the latest edition of ANSI Z21.19•CSA 1.4 Refrigerators using gas fuel. The installation

must conform with local codes, or in absence of local codes, the following standards as applicable.

In the U.S. the installation must conform with:

National Fuel Gas Code, ANSI Z223.1/NFPA 54

(latest edition).

Recreational Vehicles Code, ANSI A119.2 (latest edition).

Manufactured Home Construction and Safety Standard, Title

24 CFR, Part 3280.

If an external electrical source is utilized, the refrigerator, when

installed, must be electrically grounded in accordance with

local codes or, in the absence of local codes, the National Elec-

trical Code, ANSI/NFPA 70 - (latest edition).

In CANADA, the installation must conform with:

Natural Gas and Propane Installation Code, CSA B149.1

CSA Z240 RV Series, Recreational Vehicles.

Current CSA Z240.4, Gas-equipped Recreational Vehicles

and Mobile Housing.

If an external electrical source is utilized, the refrigerator,

when installed, must be electrically grounded in accordance

with local codes or, in the absence of local codes, the Canadian

Electrical Code, CSA C22.1, Parts I and II - (latest edition).

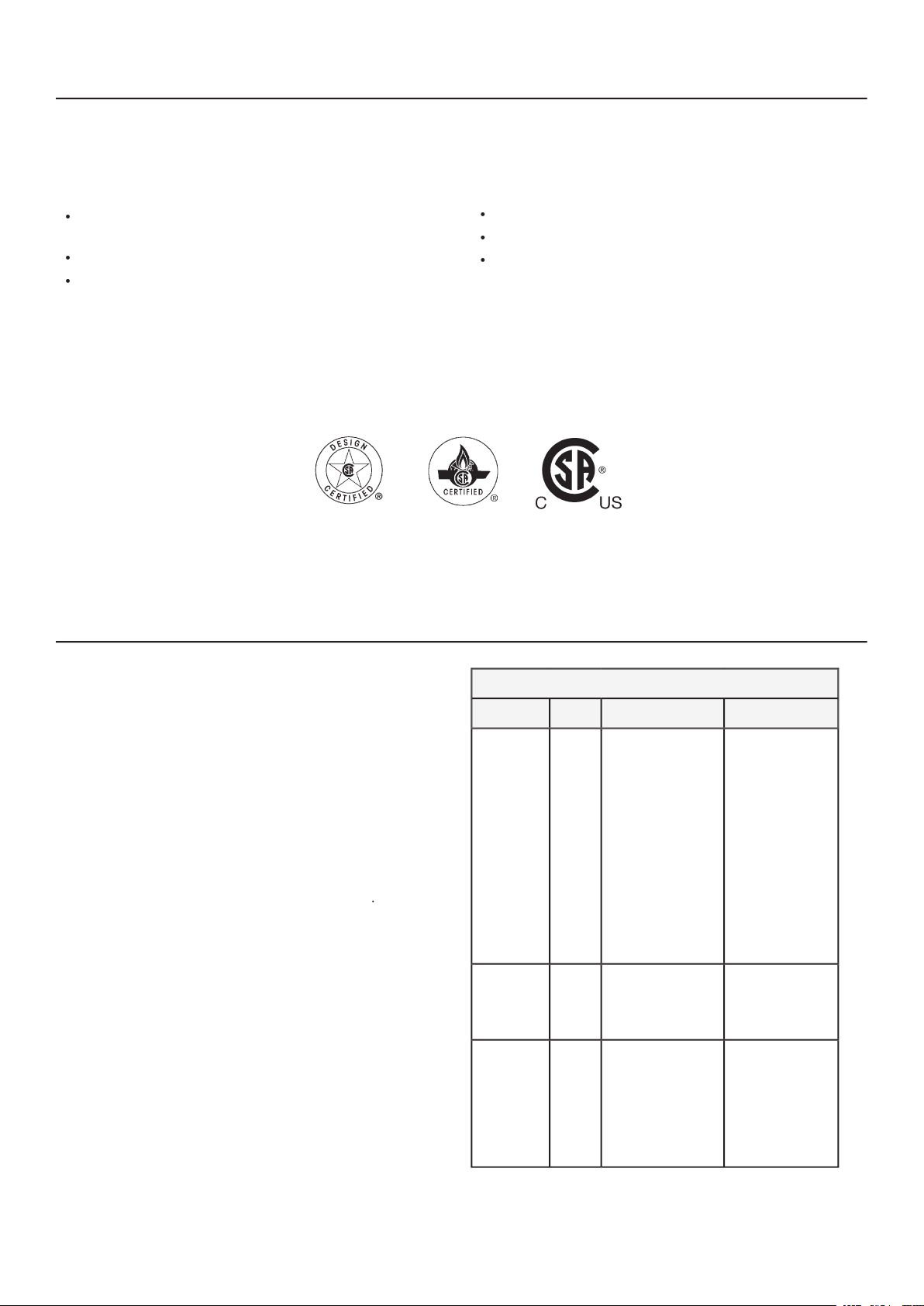

VENTILATION REQUIREMENTS

Certifi ed Vent System Kits

Components

RM2351

RM2354

3A

Roof Base

Roof Cover

Lower Side Vent

Lower Side Vent

Upper Side Vent

Lower Side Vent

Power Vent Asm.

Upper Side Vent

Upper Side Vent

Lower Side Vent

Lower Side Vent

3103633.XXX*

3103634.XXX*

3109350.XXX*

RM183

RM123A

RM183

3108705.751**

RM123A

3109492.003

RM183

3109492.003

RM2451

RM2454

RM2551

RM2554

3A

Roof Base

Roof Cover

Lower Side Vent

3103633.XXX*

3103634.XXX*

3109350.XXX*

RM2652

RM2662

RM2663

RM2852

RM2862

RM3862

NDR1062

4A

Roof Base

Roof Cover

Lower Side Vent

3103633.XXX*

3103634.XXX*

3109350.XXX*

Ventilation is one of the requirements for proper cooling

unit operation. The installation should be made in such a man-

ner as to separate the combustion system from the living space

of the mobile home or recreational vehicle. Openings for air

minimum dimension of not less than 1/4 inch.

Proper installation requires one

lower fresh air intake

and one

upper exhaust vent

roof vent

and one

lower side vent.

The ventilation kits shown in this

manual have been certifi ed for use with the different models as

displayed in the “Certifi ed Vent System Kits” table

The ventilation kits must be installed and used without

modifi cation! An opening toward the outside at fl oor level

in the refrigerator compartment has be provided for ventila-

tion of heavier-than-air fuel gases. The lower vent of the

recommended kits is provided with proper size openings.

The fl ow of combustion and ventilating air must not be

obstructed.

The lower side vent is fi tted with a panel, which provides

an adequate access opening for ready serviceability of the

burner and control manifold of the refrigerator. This should

be centered on the back of the refrigerator.

contact your supplier.

For further information, contact your dealer or distributor.

Page 4

- 4 -

Minimum clearances (in inches) to combustible materials:

Top (

G

) 0

K

) 0

Bottom (

) 0

Rear (

) 0 / 1

(

RM2351 & RM2354

)

M: The distance b

etween the rearmost part of the refrigerator and the

wall behind it.

VENTILATION HEIGHTS

It is essential that all maximum or minimum dimensions are

pendent on adequate fl ow of air over the rear of the refrigerator.

side vent

RM2351

RM2354

inches

mm

inches

mm

31

787

34

RM2451

RM2454

37-3/4

960

RM2551

RM2554

44-1/2

RM2652

RM2662

RM2663

RM2852

RM2862

RM3862

NDR1062

63-3/4

A

B

B

Minimum

ventilation

height

Condenser

A

Condenser

The upper vent

should be centered

over the condenser

coil at the back of

the refrigerator.

Minimum

ventilation

height

VENTILATION REQUIREMENTS

Page 5

- 5 -

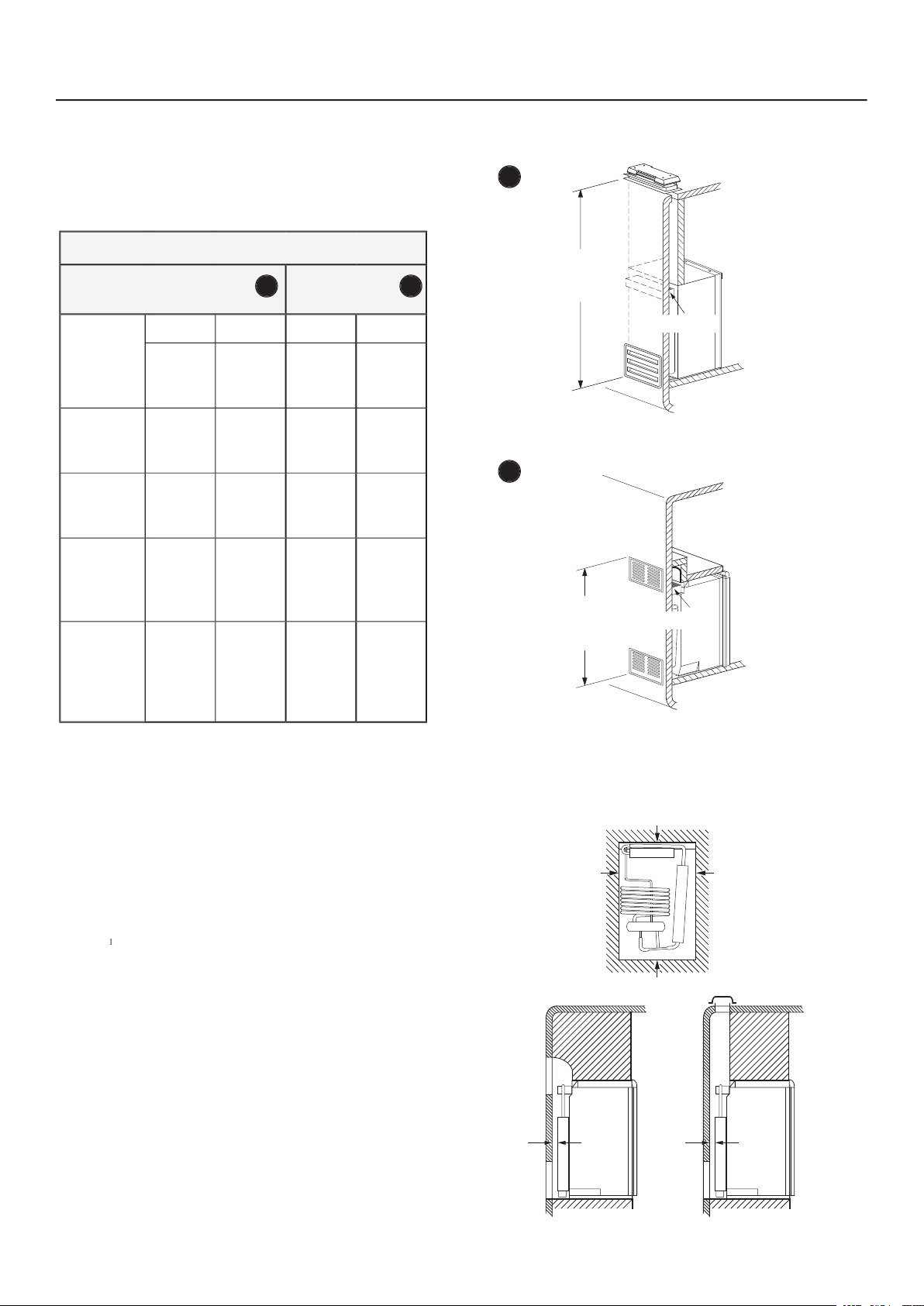

VENTILATION REQUIREMENTS

Dimensions

Overall

Height A

Width B

Depth C

Height H

Width W

Depth D

RM2351

RM2354

inches

30-5/32

21-7/8

22-22/32

29-3/4

20-1/2

21-3/8

766

756

RM2451

RM2454

inches

37-3/8

24-7/8

24-11/16

39-9/16

23-11/16

24

mm

948

632

627

928

602

610

RM2551

RM2554

inches

43-1/2

24-7/8

24-11/16

42-5/8

23-11/16

mm

632

627

602

610

RM2652

RM2662

RM2663

inches

24-7/8

26-1/32

23-11/16

24

632

661

602

610

RM2852

RM2862

RM3862

inches

60-51/64

24-7/8

26-1/32

23-11/16

632

661

602

610

NDR1062

inches

60-54/64

24-7/8

26-5/8

23-11/16

24

mm

632

676

602

610

Side view

View from above

Page 6

- 6 -

Be careful when installing the refrigerator model

NDR1062

insulated panel technology. These insulating panels

are located on the top, back, bottom, sides and doors.

If the surface is punctured, loss of insulation will oc-

cur, resulting in poor refrigerator performance.

For a proper installation, follow these instructions:

Make sure the fl oor is solid and level.

The refrigerator must be level and installed in a substantial

enclosure.

Do not install the appliance directly on carpeting. Carpet-

ing must be removed or protected by a metal or wood panel

beneath the appliance, which extends at least full width and

depth of the appliance.

RM2451-2454-2551-2554-2652-2662-2663-2852-28623862 & NDR1062

A

wood strip

must be in place across the

upper opening of the enclosure. The top

frame of the refrigerator will be anchored to

the wood strip with screws.

All areas within the recess have to be sealed. The sealing

ance’s combustion system from the vehicle interior.

Make sure there is a complete seal between the front frame

of the refrigerator and the top, sides and bottom of the enclo-

the front frame for this purpose.

RM2351

and

RM2354

the foremost fl oor of the enclosure.

Be careful not to damage the sealing strip when the

refrigerator is put in place!

•

SECURING THE REFRIGERATOR

When installing the refrigerator, make sure the heat can not be

trapped in the space between the refrigerator and storage area.

This would make the top of the refrigerator hot and reduces the

effi ciency of the refrigerator. Any space between the counter,

After the refrigerator has been installed (ensuring a combustion

cause leakage between the frame and cabinet!

RM2351-2354

Install the fi ve screws in the following order:

Four screws installed through the front frame.

(To cover the screw heads, use the plugs in the parts

bag.)

One screw installed in the rear base.

RM2451-2454-2551-2554-2652-2662-2663-28522862-3862 & NDR1062

Install the six screws in the following order:

Two screws installed through the front base.

(Installation of the lower front strip.)

The refrigerator is provided with a lower front

to be attached after the

refrigerator is set into

the cutout opening.

Install the lower front

under the bottom

hinge plate.

The hinge plate can be

on the right or left side

depending on the door swing.

Once the lower front strip is slipped under the

hinge, the part is possible to swing into place.

2.

a)

RM2351-2354RM2451-2454-2551-25542652-2662-2663-28522862-3862 &NDR1062

2

1

Page 7

- 7 -

with two screws: One screw through the hinge

and on the opposite side and then, one screw

through the lower front strip.

Two screws installed in the top frame.

Remove the top decoration panel.

Open the door.

Gently push the tabs out

of the hole in the hinge

with a fl at blade screw-

driver (both sides).

Carefully tilt the top

decoration panel and

lift to remove from top

frame. Be careful not to

damage the circuit board and wires.

Install the two screws in the top frame, the holes

are accessible from underneath.

tape.

Replace the top decoration panel. Be careful not

to pinch the wires behind the panel. Make sure

the tabs snap back into the holes in the hinge

plate.

Two screws installed in the rear base.

b)

2.

a)

b)

c)

d)

e)

f)

3.

2

1

A hole must be drilled through fl ooring and the installer needs

to make sure the hose does not kink when run through the fl oor.

longer hose than supplied is required to get the water to drain

outside of the vehicle, the installer will have to supply the extra

length of hose.

Hook up to the gas supply line is accomplished at the manual

gas valve, which is furnished with a 3/8” SAE (UNF 5/8” -18)

male fl are connection. All completed connections should be ex-

amined for leaks using a solution of liquid detergent and water.

Be very careful when working on or near the gas sys-

tem. Do not use an open fl ame to check for gas leaks!

The gas supply system must incorporate a pressure regulator

to maintain a supply pressure of not more than 11 inches water

column. When testing the gas supply system at test pressures:

> 1/2 psi

- the refrigerator and its individual shutoff valve

must be disconnected from the gas supply piping system.

≤ 1/2 psi

- the appliance must be isolated from the gas

off valve.

If detailed instructions on the installation and connection to

the gas supply are required, please contact your dealer or

distributor.

WARNING

!

Hole for drain water hose

RM2351-2354

Hole for drain water hose

RM2451-2454-2551-25542652-2662-2663-28522862-3862 & NDR1062

Page 8

- 8 -

Testing LP gas safety shut off

The gas safety shut off must be tested after the refrigerator is

connected to LP gas supply.

RM2354-2454-2554-2662-2663-2862-3862 &NDR1062

To test the gas safety shut off, follow these steps:

Check that the gas fl ame is lit and the GAS mode

indicator lamp is on.

Close the manual gas shutoff valve at the back of the

refrigerator.

Wait for approx. 6 minutes. The CHECK indicator

lamp should be lit and the GAS mode indicator lamp

Remove the protection cover.

Open the manual gas shutoff valve. Do not change

any button positions on the control panel.

Apply a non corrosive commercial bubble solution

to the burner jet orifi ce. No bubbles should appear at

the opening of the burner jet orifi ce. The presence of

bubbles indicates a defective gas safety shutoff, and

If no bubbles are present at the burner jet orifi ce,

rinse it with fresh water. Be careful not to damage

the burner jet orifi ce.

Put back the cover.

Press the ON/OFF button once to turn the refrigera-

tor off and then press it again to turn the it back on.

Normal operation of the burner should return.

Allow the burner to operate for a minimum of fi ve

minutes.

RM2351-2451-2551-2652-2852

To test the gas safety shut off, follow these steps:

Check that the gas fl ame is lit. In AUTO mode the

AUTO mode indicator lamp is on.

Then, follow steps 3-11 in instruction above.

2.

3.

4.

6.

7.

9.

2.

3.

The refrigerator is equipped with a grounded three-prong plug

for protection against shock hazards. It should be plugged di-

rectly into a properly grounded three-prong receptacle. Do not

cut or remove the grounding prong from this plug!

The free length of the cord is 2 feet. It should be routed to

avoid direct contact with the burner cover, fl ue cover or any

other components that could damage the cord insulation.

To allow easy access through the vent door, it is recommended

that the receptacle is placed:

To the left of the refrigerator. (On the opposite side of the

refrigerator burner assembly.)

3”

above the refrigerator mounting fl oor

(

RM2662-2663- 2862-3862 & NDR1062

).

4-6”

above the refrigerator mounting fl oor

(

RM2351-2354

)

6”

above the refrigerator mounting fl oor

(

RM2451-2454- 2551-2554-2652-2852

).

120 Volt AC

receptacle

3” / 6” from the bottom

of the plastic receptacle

above the fl oor

receptacle

Page 9

- 9 -

RM2451-2551-2652-2852

designed for 12 V DC operation of the cooling system. How-

ever, 12 V DC must be supplied to operate the controls.

RM2354-2454-2554-2662-2663-2862-3862 & NDR1062

These refrigerator models require a continuous 12 V DC sup-

ply to maintain the automatic energy system.

The connection is made to the positive (+) and negative (-)

terminals of the terminal block on back of the refrigerator, see

APPENDIX A - REARVIEW EQUIPMENT

be observed when connecting to the DC supply. Do not use the

chassis or vehicle frame as one of the conductors. Connect two

wires at the refrigerator and route to the DC supply. Ensure the

connections are clean, tight and free from corrosion.

The distance the current must travel from the battery to the

refrigerator dictates the AWG wire size to be used. Should the

wire be too small for the distance, a voltage drop will result

causing a decreased cooling capacity.

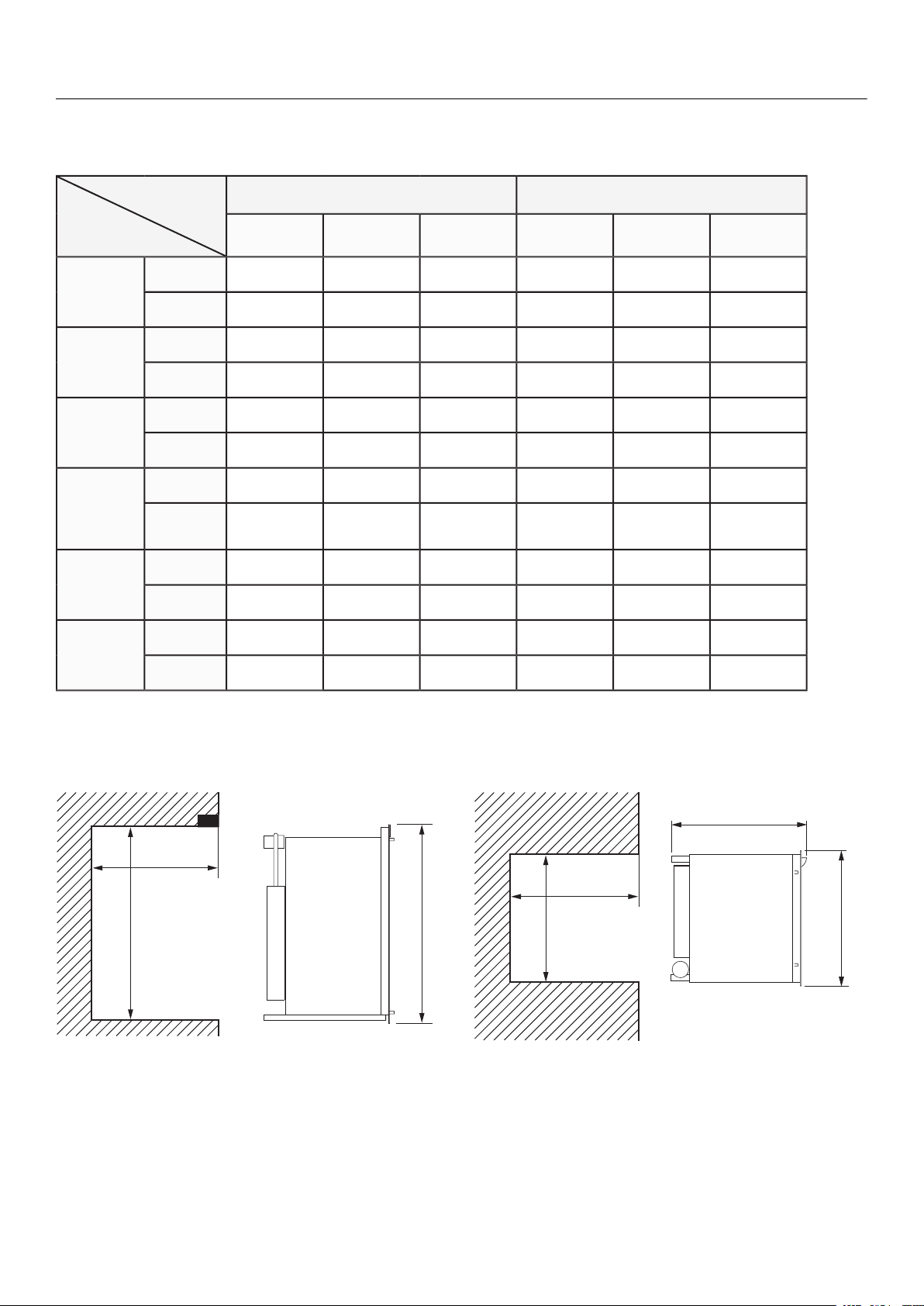

CONDUCTOR WIRE SIZE AND LENGTH

WIRE

MODEL

Length

AWG

ft

m

RM2351

RM2451

RM2551

RM2652

RM2662

RM2852

RM2862

RM3862

NDR1062

27

RM2354

RM2454

RM2554

RM2663

27

For 3-way models, the voltage drop affects the wattage output

of the 12V cartridge heater and the refrigerator performance.

The 12V DC heater is fused with a 30 amp. in-line blade fuse.

Recommended wire sizes are displayed in the following table:

The refrigerator is equipped with hinges that makes it possible

to change the direction the door opens by moving the hinges to

the opposite side. A special hinge kit must be used in order to

change the door swing. For conversion kit number, refer to the

USER MANUAL (825125700), APPENDIX B - SPARE PARTS

Optional door insert panels are available for

RM2351-2354-2451-2454-2551-2554-2652-26622663-2852-2862 & NDR1062

normally delivered without door panel(s).

Before starting the mounting work, read this instruction thor-

oughly and check that the panel dimensions are in compliance

with those given in the “Panel dimensions” table

max

min

Width

max

min

UPPER

mm

403

401

inch

20-3/4

20-5/8

LOWER /

DOOR

RM2351

RM2354

642

640

498

496

inch

25-9/32

25-3/16

RM2451

RM2454

RM2652

RM2662

RM2663

inch

32-9/16

32-1/2

20-3/4

20-5/8

RM2551

RM2554

RM2852

RM2862

NDR1062

983

981

inch

38-11/16

38-5/8

20-3/4

20-5/8

Page 10

- 10 -

Snap in

To mount the panel, follow these steps:

Open the door 90 degrees.

On new refrigerators,

the decoration strip are

taped inside the door;

if installed on the door,

remove the door decora-

tion strip (2) by gently

pushing the four tabs

away with a fl at blade

Insert the vertical edges

into the grooves of the

door frame (3).

Push the panel down-

wards so that the lower

horizontal edge of the

panel (4) is fi tted into

the bottom grove (5).

2.

3.

4.

RM2351-2354

We recommend to mount the panel on the door before the

refrigerator is installed in the enclosure.

To mount the panel, follow these steps:

grooves on the vertical edges of the door .

Push the panel upwards.

Put the two plastic panel stops (from the parts bag)

in the two holes at the lower door frame.

Put the decoration strip across the door and fasten it

with three screws (from the parts bag).

RM2451-2454-2551-2554-2652-2662- 2663-28522862 & NDR1062

With screws

To mount the panel, follow these steps:

Open the door 90 de-

grees.

On new refrigerators,

the decoration strip is

taped inside the door; if

installed on the door, re-

move the door decoration

three screws (1).

Insert the vertical edges

into the grooves of the

door frame (3).

Push the panel down-

wards so that the lower

horizontal edge of the

panel (4) is fi tted into the

bottom grove (5).

Put the decoration strip

across the door so that

the gap is covered. Se-

cure the decoration strip

with the three screws

removed in step 2.

2.

3.

4.

2.

3.

4.

1

1

1

2

1

1

1

3

3

4

5

1

2

2

To remove the refrigerator, follow these steps:

Cap the gas supply line.

Loosen the screws anchoring the refrigerator to the

enclosure.

Replacement is the reverse of removal. When reinstalling the

refrigerator, make sure the sealing strips are properly posi-

tioned. Check all connections for gas leaks.

2.

3.

Before removing the refrigerator:

Verify that the AC and DC voltage leads are disconnected.

Disconnect the gas supply line at the rear of the refrigerator.

Always use a back up wrench when loosening and tighten-

ing connections.

Page 11

- 11 -

APPENDIX A - REARVIEW EQUIPMENT

RM2351

RM2354

Power module

cove

r

Flexible

cord

12

V DC

Terminal block

Inlet fitting

Manual

gas shutoff valve

Burner jet

Screw for protection cover

Protection

cover

Drain

water hose

Flue baffle

Heate

r

Power module

cove

r

Flexible

cord

12

V DC

Terminal block

Inlet fitting

Manual

gas shutoff valve

Burner jet

Screw

for protection cover

Protection

cover

Drain

water hose

Flue baffle

Hea

ters

Rela

y

Page 12

- 12 -

APPENDIX A - REARVIEW EQUIPMENT

12V DC

Relay,

3-

Way only

Power

module

cover

Flexible cord

12

volt DC

Terminal block

Drain

water hose

Inlet

fitting

Manual

gas

shu

toff valve

Burner

jet

Screw

for protection cover

Protectio

n

cover

Flue

baffle

Hea

ter(s)

Thermofuse

Flexible cord

Power

module

cove

r

Relay,

3-way only

12

volt

Terminal block

Drain

water hose

Inlet fitting

Manual gas shutoff valve

Burner

jet

Screw

for protection cover

Heate

r

Flue baffle

Protection cover

12V DC

RM2451-2454-2551-2554

RM2652-2662-2663-2852-2862-3862-NDR1062

Page 13

- 13 -

APPENDIX B - WIRING DIAGRAMS

RM2351-2451-2551

RM2354-2454-2554

Page 14

- 14 -

APPENDIX B - WIRING DIAGRAMS

RM2652-2662-2852-2862

RM2663

Page 15

- 15 -

APPENDIX B - WIRING DIAGRAMS

RM3862 - NDR1062 (BS, SS)*

steel doors

SS = Stainless

steel doors

B = Door insert

panels

NDR1062 (B)*

Page 16

PLEASE AFFIX THESE INSTRUCTIONS

TO THE REFRIGERATOR

PLEASE RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

Loading...

Loading...