Page 1

Foreword

This service manual is the result of the

dedication of The

Dometic

its engineers in giving service people the

necessary instruction for making accurate

analyses of certain conditions. Provided is

a diagnostic chart leading a qualified

mechanic into the service manual pages to

locate and solve symptoms which may

Corporation and

occur.

Dometic

has continued its

commitment in providing service people

with this, the most up-to-date information

about servicing

Dometic

RV accessories.

Form No. 3 106930.005

2/96

(Replaces 05

1409 1/93)

Page 2

CONTENTS

PAGE NO.

RM2604 & 2804

STD DIAGNOSTIC FLOW CHART . . . . . . 1

SECTION 1

ACVOLTAGE

REQUIREMENTS

SECTION 2

AC COMPONENTS

2.1 Heating Element . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2

Thermostat

SECTION 3

DC

VOLTAGE

REQUIREMENTS

SECTION 4

DC COMPONENTS

4.1

Switch . .

4.2

I

4.3

4.4

4.5

4.6

4.7

niter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I!

lectrodee

HighVolta

Door

Relay

Heating Element . . . . . . . . . .

SECTION 5

LP

REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

GAS

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.._.............._........................_......................_......_..............

. ... . . . . . . . . . . . . .. . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . .

e Cable . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

\

Switcc

.._...................._.._._....................._._.........._................._.........

.._..................._..........................................

..__._._...........

.._......_.........._....._.......___...........................

. . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .

.._.............................................

.._...._.._..........................................

..__......._._.........__..._...___...........___........

3

.

3

3

3

4

:

5

5

5

SECTION 6

LP GAS COMPONENTS

Shut-Off Valve..

:::

Filter..

Thermostat..

iii::

By-pass

SafetyValve...............................................................................

i::

Thermocouple

Burner.........................................................................................

:.z

6:9

6.10

6.11

Orifice.........................................................................................

..........................................................................................

Screw

FlueBaffle

Flue

Cap.....................................................................................

Flue Tube....................................................................................

SECTION 7

WIRING

7.1 External Wiring . . . . . . . . . . . . . . . . . .

7.2

Internal

Wiring

SECTION 8

OTHER

Leveling.......................................................................................

Ventilation

AirLeaks...................................................................................

DoorPosition..

Ambient Temperature..

Coolin

Food

High Humi

Interior Liner Seal to Frame

2

Unit..

tora

d

...........................................................................

................................................................................

............................................................................

.............................................................................

...................................................................................

.._....___..._............._..._._._.._._._......_........

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

...................................................................................

...........................................................................

.............................................................................

e

............................................................................

ityy

............................................................................

..............................................................

.......................................................

6

6

6

6

7

7

7

7

7

7

7

7

9

9

10

10

10

11

11

11

11

Page 3

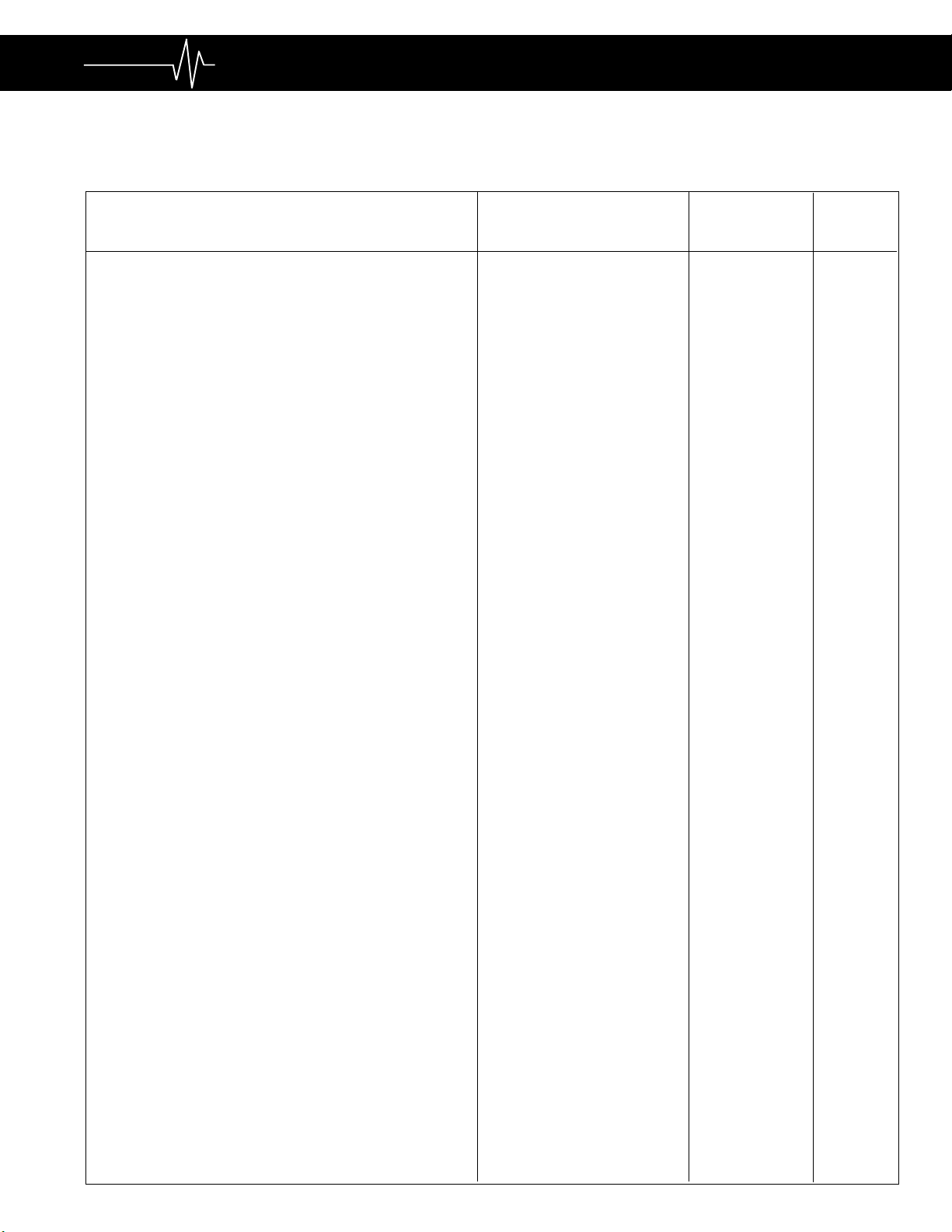

DIAGNOSTIC SERVICE MANUAL

Diagnostic Service Manuals

Dometic

®

RM2604/2804

Refrigerators

This program will address the most common system problems associated with the RM2604/2804 Manual Refrigerators supplied by The Dometic Corporation. Our intent is to provide you with a guideline of checks to make, should

you encounter one of the following symptoms.

REFERREFER

REFER

REFERREFER

TOTO

TO

SYMPTOMSYMPTOM

SYMPTOM

SYMPTOMSYMPTOM

CAUSECAUSE

CAUSE

CAUSECAUSE

TOTO

SECTIONSECTION

SECTION

SECTIONSECTION

STEPSTEP

STEP

STEPSTEP

1. No operation.

2. No electric operation.

3. No gas operation — no spark.

4. No gas operation — sparks but no flame.

5. No cooling on any mode.

DC Volts 3

Wiring 7

Switch 4.1

AC Volts 1

Heating Element 2.1

Thermostat 2.2

Switch 4.1

Wiring 7.2

DC Volts 3

Igniter 4.2

Electrode 4.3

High Voltage Cable 4.4

Switch 4.1

Wiring 7.2

LP gas 5

Filter 6.2

Orifice 6.11

Burner 6.7

Shut-off Valve 6.1

Safety Valve 6.5

Thermocouple 6.6

Level 8.1

Ambient Temperature 8.5

Cooling Unit 8.6

6. No cooling on gas — cools properly on electric.

7. No cooling on electric — cools properly on gas.

8. Insufficient cooling on all modes.

9. Insufficient cooling on electric — cools properly

on gas.

LP Gas 5

Thermostat 6.3

Filter 6.2

Orifice 6.11

Burner 6.7

Flue Baffle 6.8

Flue Tube 6.10

AC Volts 1

Heating Element 2.1

Thermostat 2.2

Switch 4.1

Wiring 7.2

Level 8.1

Ventilation 8.2

Ambient Temperature 8.5

Air Leaks 8.3

Thermostats 2.2 & 6.3

Cooling Unit 8.6

AC Volts 1

Heating Elements 2.1

Thermostat 2.2

1

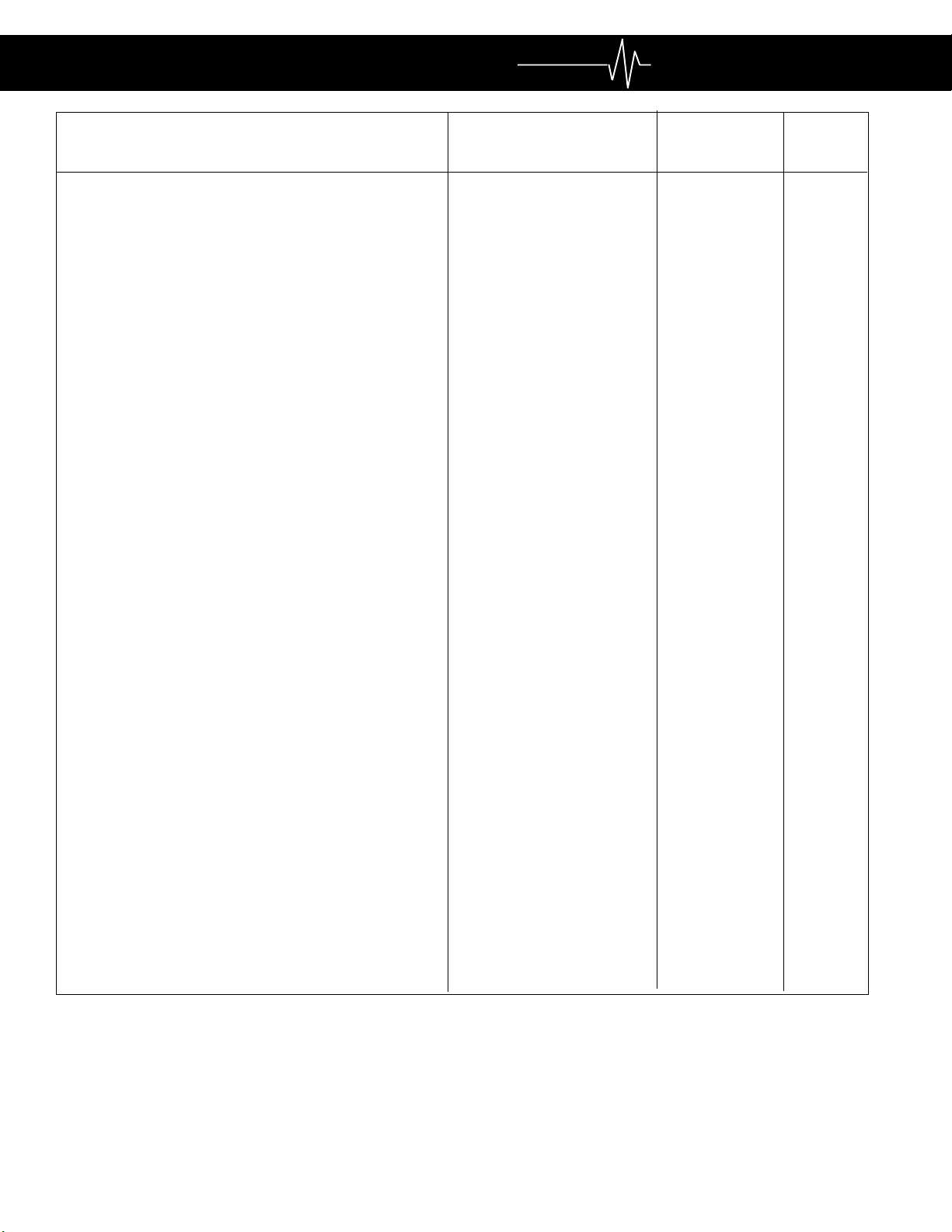

Page 4

Dometic

®

RM2604/2804

Refrigerators

SYMPTOMSYMPTOM

SYMPTOM

SYMPTOMSYMPTOM

CAUSECAUSE

CAUSE

CAUSECAUSE

DIAGNOSTIC SERVICE MANUAL

REFERREFER

REFER

REFERREFER

TOTO

TO

TOTO

STEPSTEP

STEP

SECTIONSECTION

SECTION

SECTIONSECTION

STEPSTEP

10. Insufficient cooling on gas.

Cools properly on electric.

11. Freezes on electric – cools properly on gas.

12. Freezes on gas – cools properly on electric.

13. On gas mode, sparks while flame is lit.

14. Won't stay lit on gas.

LP Gas Pressure 5

Thermostat 6.3

Filter 6.2

Orifice 6.11

Burner 6.7

Flue Baffle 6.8

Flue Tube 6.10

Thermostat 2.2

Wiring 7.2

Bypass Screw 6.4

Thermostat 6.3

Electrode 4.3

LP Gas 5

Bypass Screw 6.4

Filter 6.2

LP Gas 5

Safety Valve 6.5

Thermocouple 6.6

Flue Baffle 6.8

Flue Cap 6.9

Orifice 6.11

Burner 6.7

15. Rapid formation of frost.

16. Interior light on when door is closed.

17. No DC operation – cools properly on AC and

gas.

18. Insufficient cooling on DC– cools properly on

AC and gas.

Food Storage 8.7

Air Leaks 8.3

Interior Liner Seal to Frame 8.9

High Humidity 8.8

Wiring 7.2

Door Switch 4.5

Door Position 8.4

DC Volts 3

Heating Element 4.7

Switch 4.1

Wiring 7.2

Relay 4.6

DC Volts 3

Heating Element 4.7

Relay 4.6

2

Page 5

DIAGNOSTIC SERVICE MANUAL

Dometic

®

RM2604/2804

Refrigerators

SECTION 1

AC V OL T A GE REQUIREMENTS

The refrigerator is a 120-volt AC, 60 Hz appliance. The

proper operating range is 100 to 132 volts. Check the

AC volts at the receptacle where the refrigerator is

attached. Voltage is outside of the proper operating

range, correct the power source problem.

SECTION 2

AC COMPONENTS

2.1 HEATING ELEMENT

The heating element is

designed to deliver a

predetermined amount of

heat to the cooling unit.

To check a heating

element, remove the

heater leads from the

terminal block and

measure for proper

resistance across the

two leads with a properly

calibrated ohm meter. This check is to be done with the

heating element at room temperature. The proper ohms

for RM2604 is 48 and RM2804 is 44 with a tolerance of

ten percent. If the resistance is outside the tolerance

range, replace the heating element.

the refrigerator. The operational range is 10.5 to 15 volts

DC. Connecting the refrigerator to an unregulated

converter can result in improper operation of the refrigerator. Check for proper voltage at the terminal block or

blocks at the back of the refrigerator. If power is outside

the operational range, correct the power supply problem.

The power supply to the refrigerator must be fused. The

interior light and igniter must be on a separate circuit and

will draw about 1 amp at 12 volts DC. The DC heating

element (on 3-way models only) will draw 18 amps at 12

volts DC. The maximum fuse size is 25 amps for the

RM2604 and RM2804.

COVER

MANUAL GA S

SHUTOFF VA LVE

3 P RONG P LUG

FOR 120V A C

3-WAY ONLY

ALL UNIT S

TERMINAL BL OCKS

12 Volts

DC

Heater

12 Volts

DC

Reigniter

Lamp

2.2 THERMOSTAT

It is an electric only thermostat. On 2-way models it

controls the AC heating element. On 3-way models it

controls the DC heating element as well as the AC

heating element. The thermostat regulates the cabinet

temperature by making and breaking the heat source

circuit. The internal mechanism breaks contact (continuity) when adequate cabinet temperature has been

reached. Check the thermostat for continuity or use a

jumper wire with insulated clips and bypass the thermostat.

NOTE: Care should be used. Do not short to thermostat

casing. Also remove the jumper after testing is completed.

If the above test allows the refrigerator to operate,

replace the thermostat.

SECTION 3

DC VO L T AGE REQUIREMENTS

For the refrigerator to operate the interior light, igniter

(gas mode) and DC volt operation (3-way models only),

DC voltage must be supplied to the terminal block or

blocks (2 terminal blocks on 3-way models) at the rear of

SECTION 4

DC COMPONENTS

4.1 SWITCH

This is the switch that selects the mode of operation

(120 volt AC, gas and 12 volt DC). It is also a circuit

interrupter for each mode of operation on the refrigerator. When the customer selects either AC, gas or DC (3way models only) operation, the selector switch directs

electricity first to the interior light and the thermostat and

on to the heating element or the igniter for gas mode.

When this switch is turned off, the AC or DC circuit is

interrupted. To check the switch in the AC mode,

continuity should exist between these terminals: 1 to 1A,

2 to 2A and 7 to 7A. To check the switch in the gas

mode, continuity should exist between these terminals: 4

to 4A and 7 to 7A.

To check the switch in the DC mode (on 3-way models

only), continuity should exist between these terminals: 5

to 5A, 6 to 6A and 7 to 7A.

NOTE: To do a continuity check, first be sure all power

is disconnected or off to the refrigerator. Second,

remove all wires from the switch. After the check, be

3

Page 6

Dometic

®

RM2604/2804

Refrigerators

DIAGNOSTIC SERVICE MANUAL

sure switch is wired properly per the wiring diagram (See

Sec. 7.2).

When the switch is in the off position a continuity reading

SHOULD NOT be indicated on any terminals. If the

above test results are correct, DO NOT REPLACE the

switch. If any one of the above tests are not correct

REPLACE the switch.

Interior Light

Circuit

DC Mode

7654 21

7a6a5a

Interior Light Circuit

Gas Mode

4a2a1a

Gas Mode

DC Mode

+Term.Ign.Lamp Term. Block

AC Mode

AC Mode

Thermostat

Thermostat

+Term. on Igniter

AC line

41265

7

6a7a 5a 4a 2a 1a

Thermo-

+Reigniter-Lamp Term.

stat

#30 Term.on Relay (+

#86 Term. on

Door Switch

AC Neutral

AC Heater

4.2 IGNITER

The igniter is an electronic device that produces high

voltage to create a spark at the burner, only on gas

mode. It also produces an increased DC voltage at the L

terminal which is directed to the indication lamp each

time a spark is produced. First, check that the switch is

in the gas mode and is completing the circuit (See Sec.

4.1). Next, verify proper voltage at the positive (+) and

ground (-) terminals of the igniter. The reading should be

within one volt of incoming voltage at the igniter and

lamp terminal block. A voltage drop of more than one

volt would indicate a loose connection (See Sec. 7.2).

No voltage would indicate an open circuit, check switch

(See Sec. 4.1), wiring (See Sec. 7.2) and DC voltage

requirements (See Sec. 3).

sound. If not, replace the igniter. Next, with the igniter

producing spark, set the meter on 20 volts DC or lower

scale, connect meter leads to L and ground terminals on

the igniter. The meter should read a pulsating voltage. If

not, replace the igniter.

If all of the previous checks are correct, the igniter is

HIGH VOLTAGE

good, DO NOT REPLACE. The pulsating voltage allows

a lamp to illuminate on the front of the refrigerator to

advise the customer spark has been produced. To check

the lamp, first, verify it is wired correctly. Next, verify the

lamp receptacle is receiving the signal, if so, and lamp is

not illuminating (flashing), replace the lamp.

NOTE: Do not supply DC power to the lamp. It will not

illuminate with normal DC power. For the lamp to

illuminate it must receive an increased DC signal.

4.3 ELECTRODE

To check the electrode, first do a visual inspection for

cracks or breaks on the ceramic insulator. Also, verify

the mounting bracket is attached properly to the electrode. If either of the above conditions are found, replace

the electrode. Next, check the spark gap. It must be set

at three sixteenths (3/16) of an inch and the tip of

electrode above the slots in the burner.

HIGH VOLTAGE

Next, disconnect DC power at the igniter, lamp terminal

block. Remove high voltage cable from igniter. Reconnect DC power, the igniter should produce a sparking

4

ELECTRODE

TIP

3/16"

BURNER

NOTE: If igniter (See Sec. 4.2) and high voltage cable

(See Sec. 4.4) are good and there is no spark at the tip

of the electrode, REPLACE THE ELECTRODE.

4.4 HIGH VOLTAGE CABLE

NOTE: Be sure switch (See Sec. 4.1) and igniter (See

Sec. 4.2) are good before checking the high voltage

cable and the switch is in the gas mode.

Page 7

DIAGNOSTIC SERVICE MANUAL

Dometic

®

RM2604/2804

Refrigerators

To check the high voltage cable, first disconnect DC

power at the igniter, lamp terminal block. Next, disconnect high voltage cable from electrode. Then reconnect

DC power to the terminal block. If sparking starts, cable

is good, DO NOT REPLACE, check the electrode (See

Sec 4.3). If no sparking, disconnect DC power at the

igniter, lamp terminal block and then disconnect high

voltage cable at the igniter. Reconnect DC power to the

terminal block. If sparking sound from igniter, replace the

high voltage cable.

4.5 DOOR SWITCH

The door switch is an open switch when the switch arm

is depressed (interior light should be off). When the

refrigerator door is open, the switch is closed (interior

light should be on). Check that the switch assembly is

properly aligned and that it is not broken. Check the

switch assembly for continuity. When the switch arm is

depressed there should not be continuity. When the

switch arm is NOT depressed there should be continuity.

If any of the checks are incorrect, replace the switch.

4.6 RELAY (3-WAY MODELS ONLY)

The relay controls the circuit to the DC heating element.

The load (amps) of the DC heating element goes

through the relay.

To check the relay, first verify the

selector switch is on DC mode

(See Sec. 4.1) and the

thermostat (See Sec. 2.2) is

NOT completing the circuit.

Next, verify voltage is present

between terminals 85 and 30. If

voltage is not present, check

wiring to both terminals. (See

Sec. 7.2)

Next, check for voltage

between terminals 85 and 87.

If voltage is present, the relay

is defective and needs to be

replaced.

Second, verify the selector switch is

on DC mode (See Sec. 4.1) and the

thermostat (See Sec. 2.2) is completing the circuit.

Next, verify voltage is present

between terminals 85 and 86.

If no voltage is present, check

wiring and connections (See

Sec. 7.2).

85

30

87

85

85

86

between terminals 85 and 87. If no voltage is present,

the relay is defective, replace it.

87

85

4.7 HEATING ELEMENT

(3-WAY MODELS ONLY)

The heating element is designed to deliver a predetermined amount of heat to the cooling unit. Check the

heating element with ohms resistance using a properly

calibrated ohm meter. This check is to be done with the

element at room temperature. The proper ohms for

RM2604 and RM2804 DC heating element is .67 with a

tolerance range of ten (10) percent. If the heating

element is outside the

tolerance range, replace it.

NOTE: It will take a very

precise ohm meter to

accurately read this

measurement. If a precise

ohm meter is not available,

a continuity reading will

indicate an open or complete circuit. If an open

circuit is the test result,

replace the element.

SECTION 5

LP GAS REQUIREMENTS

The LP gas pressure to the refrigerator should be 11

inches water column with half of all BTU’s of the RV

turned on. With all other appliances turned off, the

pressure to the refrigerator should not exceed 12 inches

water column. To check the gas pressure when the

refrigerator is operating, there is a pressure test housing

located just prior to the orifice.

Next, if voltage is present,

between 85 and 86 terminals,

then voltage should be present

PRESSURE T EST HOUSING

5

Page 8

Dometic

®

RM2604/2804

Refrigerators

DIAGNOSTIC SERVICE MANUAL

SECTION 6

LP GAS COMPONENTS

6.1 SHUT-OFF VALVE

It is the valve where the incoming LP gas supply is

attached. This valve is direct coupled to the selector

switch. When the selector switch is turned to the electric

mode, the shut-off valve is automatically closed. When

this same switch is turned to the LP gas mode, the valve

opens and allows gas flow and the electric circuit to the

heating elements is also automatically interrupted. To

check the shut-off valve, remove and inspect for any

obstructions.

COVER

MANUAL GA S

SHUTOFF VA LVE

3-WAY ONLY

3 P RONG P LUG

FOR 120V A C

ALL UNIT S

6.2 FILTER

A filter is located in the inlet fitting to the gas thermostat.

It protects the internal valve portion of the thermostat by

collecting any particles and/or oil that could get into the

LP gas line. The filter can become saturated and cause

a restriction to gas flow. This could cause a lack of

cooling on gas mode. If you suspect a restriction, first

verify the thermostat (See Sec. 6.3) and by-pass screw

(See Sec. 6.4) are good. If these components are good,

remove the filter and replace with a new one if proper

gas pressure is supplied to the refrigerator and you

cannot get proper gas pressure at the pressure test

housing.

LINE

TERMINAL BL OCKS

12 Volts

DC

Heater

12 Volts

DC

Reigniter

Lamp

SHUTOFF VA LVE

FILTER

COUPLING

6.3 THERMOSTAT

On the LP gas mode, full line pressure is directed

through the thermostat to the burner until the thermostat

senses that the refrigerator cabinet has reached proper

cooling temperature. At that time an internal valve closes

and redirects the gas flow through the by-pass screw.

This reduces the amount of LP gas going to the burner

assembly. The gas flow remains in this “by-pass” mode

until the thermostat senses that the refrigerator cabinet

needs more cooling. Again, the thermostat directs LP

gas flow through the thermostat at full line pressure until

the cabinet temperature is sufficient. The thermostat is

calibrated by the manufacturer so that at mid-range the

cabinet temperature should be approximately 40 degrees Fahrenheit. To check the calibration of the

thermostat, place a container of water in the cabinet of

the refrigerator and operate at mid-range setting until the

thermostat is satisfied. Then, check the temperature of

the water. It should be approximately 40 degrees. We do

not recommend any calibration in the field. If calibration

is not correct, replace the thermostat. To check the

thermostat for proper gas flow, set the thermostat to

maximum and check the gas pressure at the pressure

test port. It should be line pressure, between 11 to 12

inches water column. If you have less than 11 inches of

water column pressure, the next step would be to shut

off the gas supply and remove the by-pass screw. Then

install a by-pass screw that does not have the small oring on it. Next, turn on the gas supply and take a

reading. If the manometer now reads 11 inches of water

column, the thermostat is defective and must be replaced. If the by-pass screw test shows no change in

pressure, the problem lies in the filter (See Sec. 6.2), the

shut-off valve (See Sec. 6.1) or the gas supply (See

Sec. 5). Shut off the gas supply, remove the by-pass

screw, replace it with a proper one that has an o-ring

and turn the gas on.

NOTE: Check for leaks with an approved LP gas leak

solution whenever any part of the gas system has been

worked on.

6.4 BY-PASS SCREW

The by-pass screw is a small brass screw located on

any Dometic gas thermostat that regulates gas flow in

the low flame mode. There are three common sizes of

this screw: S-17 (350 BTU), S-14 (325 BTU) and S-11

(300 BTU). To check the by-pass screw, connect a

manometer at the pressure test housing. The pressure

on low flame mode should be 3 to 5 inches water

column. Above 5 inches water column on low flame

mode could cause an over-cooling situation. The bypass screw used on the RM2604 and the RM2804 is S-

14.

GAS

THERMOSTAT

6

Page 9

DIAGNOSTIC SERVICE MANUAL

Dometic

®

RM2604/2804

Refrigerators

6.5 SAFETY VALVE

The safety valve is an assembly that shuts off the supply

of LP gas to the burner if the flame goes out for any

reason. This is to ensure that a concentration of unburned gas does not accumulate in the refrigerator vent

area. To check the safety valve, use a known good

thermocouple (See Sec. 6.6) and install into the safety

valve. Next, supply flame to the tip of the thermocouple

for 2 to 3 minutes while holding in on the safety valve

stem. Next, remove flame from thermocouple tip and

release safety valve stem. The safety valve should hold

in for at least 30 seconds. If it releases earlier than 30

seconds, replace the safety valve.

6.6 THERMOCOUPLE

The thermocouple is a component extending above the

burner assembly so the tip is in the path of the flame. It

will produce 14 to 30 millivolts DC in normal operation.

To check the thermocouple, use a known good safety

valve (See Sec. 6.5) and attach to the thermocouple.

Next, supply flame to the tip of the thermocouple for 2 to

3 minutes while depressing the safety valve. Remove

the flame and release the safety valve. The valve should

hold for at least 30 seconds. If it does not hold the safety

valve open for 30 seconds, replace the thermocouple. If

it does hold for 30 seconds or more, the thermocouple is

good, do not replace it.

NOTE: Be sure the tip on the thermocouple is clean.

6.7 BURNER

The burner is a slotted metal tube located below the flue

tube on the cooling unit. It should be level and the slots,

in the burner, should be directly below the flue tube. The

burner should be cleaned periodically, at least once a

year. To clean the burner, remove from the refrigerator

and check for any foreign residue that could cause a

deflection of the gas flow or the flame. Next, soak the

burner in an alcohol based solvent and allow to air dry.

After cleaning, reinstall in the refrigerator.

6.8 FLUE BAFFLE

The flue baffle is designed to concentrate the heat, from

the gas flame, at a certain area of the flue tube. It should

be cleaned periodically, at least once a year. To clean,

remove from the flue tube and check for any damage,

then clean thoroughly. The length of the flue baffle

assembly (flue baffle and wire) for the RM2604 is 31-9/

16 inches and for the RM2804 is 37-1/8 inches. The flue

baffle itself for the RM2604 is 3/4 inch wide and 5-1/4

inches long, for the RM2804 is 3/4 inch wide and 6

inches long. The proper baffle position for the RM2604 is

1-5/8 inches from the burner to the bottom of the baffle;

for the RM2804 is 1-3/4 inches from the burner to the

bottom of the baffle.

6.9 FLUE CAP

The flue cap is located at the top

of the flue tube and is attached

with a screw. It must be properly

attached or flame outage could

occur.

6.10 FLUE TUBE

The flue tube is a component of

the cooling unit. It must be

cleaned periodically, at least

once a year. To clean, remove

flue cap and flue baffle, then cover the burner and

clean by using a flue brush. Dometic Part Number

0151404001. If the flue tube becomes coated with scale

or residue from combustion of LP gas, the efficiency of

gas operation decreases.

NOTE: After cleaning be sure to reinstall the flue baffle

and flue cap.

6.11 ORIFICE

The orifice is a small brass fitting that has a ruby membrane that is laser beam drilled and is mounted on the

gas line just prior to the burner. The orifice should be

cleaned periodically, at least once a year, by using an

alcohol based solvent and allowing to air dry. Never use

a drill bit or jet tip cleaner to clean any orifice as these

devices will damage the factory machined part and

create a potentially dangerous condition. The correct

orifice for the RM2604 is number 53 jet, for the RM2804

is number 58 jet.

NOTE: Always use the proper orifice. Never use a larger

orifice as this could cause a lack of cooling problem.

SECTION 7

WIRING

7.1 EXTERNAL WIRING

1. 120 volts AC connection: The refrigerator is

equipped with a three prong (grounded) plug for

protection against shock hazards and should be

plugged directly into a properly grounded three prong

receptacle. Do not cut or remove the grounding prong

from this plug.

2. 12-volt connection for igniter and interior light:

The connection is made to the terminal block marked

12 volts DC REIGNITER-LAMP. The interior light and

the igniter must be connected to a separate battery

circuit and will draw about 1 amp at 12 volts DC.

3. 12-volt DC connection for heater (3 -way models

only): This connection is made to the terminal block

marked DC VOLT HEATER. The refrigerator must be

connected to the battery circuit with two wires of

7

Page 10

Dometic

(ENGINE)

®

RM2604/2804

Refrigerators

adequate capacity to avoid voltage drop. The wire

gauge should be chosen with consideration to the

wire length in accordance with the following table.

MAXIMUM TOTAL CONDUCTOR WIRE LENGTH IN FEET

AWG RM2604 RM2804 Int. Light Only

10 17 17 55

8272785

BREAKER

POINT

IGNITION

COIL

DIAGNOSTIC SERVICE MANUAL

SWITCH KEY

12V DC

(RV)

HEATER

REIGNTER AND

INTERIOR LIGHT

RELAY

BATTERY

Do not use the body or chassis of the vehicle as a

substitute for either of the two conductors. No other

electrical equipment or lighting should be connected to

the refrigerator circuit. The refrigerator will draw 18 amps

at 12 volts DC.

DO NOT OPERATE THE REFRIGERATOR ON 12VOLT WHEN THE VEHICLE IS PARKED. THE CUSTOMER WILL RUN OUT OF BATTERY IN A RATHER

SHORT TIME. IF POSSIBLE, THE INSTALLATION OF

A 12-VOLT OPERATED REFRIGERATOR SHOULD

BE COMPLETED WITH A RELAY MOUNTED EITHER

IN THE TOW VEHICLE OR IN THE RECREATIONAL

VEHICLE. THIS RELAY WILL AUTOMATICALLY CUT

OUT THE REFRIGERATOR WHEN THE MOTOR IS

STOPPED.

RM2604 & RM2804 2-WAY 120 V O LTS

GH

1

2

2

4

7

1

B

A

120 VOLTS AC

E

BATTERY

7.2 INTERNAL WIRING

Check all wires and the connectors to ensure a proper

and tight connection. Also verify the refrigerator is wired

per the wiring diagram for the model you are working on.

(See wiring diagram below and on the next page.)

12 VOLTS DC

G

H

74

A

7a

L

4

22

12 VOLTS DC

REIGNITER

LAMP

120 VOLTS AC

WHITE

1

2

BLACK

GREEN

3

4

GREEN/YELLOW

8

4a

2a

1a

4

N

L

2

C

7a 4a

K4

1

1

2

1

1

C

3

1

2

D

1

J

F

4

1

2

I

120 VOLTS AC

1

2

A

2a 1a

E

C

B

D

N

L

F

I

A

SWITCH

B

THERMOSTAT

TERMINAL BL OCK

C

D

TERMINAL BL OCK

HEATER

E

F

REIGNITER

LAMP

G

H

DOOR SW ITCH

INDICATION L AMP

I

TERMINAL ST RIP

J

ABSORPTION UNIT

K

L

BRACKET

Page 11

DIAGNOSTIC SERVICE MANUAL

RM2604 & RM2804 3-W AY 12/120 VO LTS

Dometic

®

RM2604/2804

Refrigerators

647

5

7a 6a

5a

D

4

2

1

2

3

4

12 VOLTS

2

DC

HEATER

12 VOLTS DC

REIGNITER

LAMP

120 VOLTS AC

WHITE

BLACK

GREEN

GREEN/YELLOW

JK

12VOLTS

AC

2

2

1

2

1

A

4a

2a

1a

1

2

4

N

L

1

B

4

86

85

3

1

2

2

87

H

30

2

4

C

1

D

E

1

I

H

1

1

2

1

L

I

120 VOLTS

DC

4

4

12 VOLTS DC MODE

6

5

6a 5a

A

G

B

H

2a

12 VOLTS DC MODE

J

K

74

1

7a 4a

A

I

L

120 VOLTS AC MODE

2

1

A

1a

N

L

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

F

B

E

SWITCH

THERMOSTAT

TERMINAL BL OCK

TERMINAL BL OCK

TERMINAL BL OCK

HEATER

HEATER

RELAY

REIGNITER

LAMP

DOOR SW ITCH

INDICATION L AMP

TERMINAL ST RIP

ABSORPTION UNIT

BRACKET

SECTION 8

OTHER

8.1 LEVELING

Leveling is one of the requirements for proper operation

with absorption refrigerators. The absorption design

utilizes no mechanical pumps or compressors to circulate the refrigerant within the system, so proper leveling

must be maintained to provide the correct refrigerant

flow. Without proper leveling, refrigerant within the

cooling unit will collect and stagnate at certain areas.

Without proper refrigerant flow, the cooling process will

stop. The RM2604 and RM2804 has a type of cooling

unit that utilizes an enclosed pump tube surrounded by a

solution to protect the assembly. To insure proper

leveling with these models, the vehicle needs to be

leveled so it is comfortable to live in. (No noticeable

sloping of floor or walls). When the vehicle is moving,

leveling is not critical as the rolling and pitching movement of the vehicle will pass to either side of level,

keeping the refrigerant from accumulating in the piping.

8.2 VENTILATION

Ventilation is one of the requirements for proper cooling

unit operation. The coach vent system must be able to

provide a way to direct the hot air, produced by the

action of the cooling unit, out away from the installation

of the refrigerator. The refrigerator extracts heat from

the interior of the refrigerator cabinet and dissipates the

heat out through the vent system. In a proper installation

there should be as little open space as possible surrounding the sides and top of the refrigerator to achieve

proper air flow. All potential dead air pockets should be

blocked or baffled to insure that heat won’t be trapped in

these spaces and reduce efficiency. In addition, the

cooling unit should be at least one half (1/2) inch from

the nearest surface made of combustible material.

NOTE: Refrigerators should be installed in accordance

with appropriate installation instructions received with

the refrigerator.

8.3 AIR LEAKS

0" CLEARANCE

FROM SIDE OF

CABINET

1/2" FROM

COMBUSTIBLE

MATERIALS

PATH OF

AIR FLOW

9

Page 12

Dometic

®

RM2604/2804

Refrigerators

DIAGNOSTIC SERVICE MANUAL

Check the gasket on the doors to be sure of a positive

air seal. A simple method to check gaskets is to close

the door on a dollar bill, then pull the dollar bill out. If no

resistance is felt, the gasket is not sealing properly. This

should be done on all four sides of the door. If a gasket

is not sealing properly, first warm the gasket material

with a hair dryer.

DO NOT OVERHEAT

AS YOU CAN MELT THE MATERIAL.

Then close the door and the magnetic strip should pull

the gasket to the metal frame. Leave door closed until

the material has cooled. Then re-check for a positive

seal. If a positive seal cannot be achieved, replace the

door gasket. Also check that the cooling unit is installed

properly. The cooling unit’s foam block, the portion that

surrounds the evaporator coils, must be flush to the

cabinet at the back of the refrigerator and have a

positive seal. If the cooling unit is not installed properly,

remove and install properly.

NOTE: Air leaks will cause insufficient cooling as well as

rapid formation of frost.

tioned to re-orient the door. Turn the refrigerator on its

side to gain access to the two front base screws. Loosen

both screws slightly. Reposition the base until the door is

re-oriented. Re-tighten the base screws while holding

the base in its new position.

BASE

FRONT

8.4 DOOR POSITION

The door position can be checked by observing any

misalignment of the door in relation to the frame.

To correct an

SMOOTH FIT,

PROPER SEAL

alignment of the door, loosen the hinge screws slightly,

and re-orient the door in the proper position. Hold the

door in its new position and carefully retighten the hinge

screws.

BASE

SCREWS

NOTE: Improper position of the lower door can cause

the interior light to stay on when door is closed.

8.5 AMBIENT TEMPERATURE

This is the temperature surrounding the recreational

vehicle, as well as the temperature of air at the back of

the refrigerator. As the ambient temperature increases,

the air temperature in the area of the cooling unit

increases. Improper venting at this point, will cause the

cooling unit to have reduced efficiency.

If the door needs more adjustment than is available

through the hinge adjustment, the base can be reposi-

10

Page 13

DIAGNOSTIC SERVICE MANUAL

Dometic

®

RM2604/2804

Refrigerators

8.6 COOLING UNIT

The cooling unit is a self-contained, hermetically sealed

set of coils where the refrigeration process takes place.

The chemicals involved in the cooling process include

hydrogen, ammonia, water and a rust inhibiting agent.

There are no repairs recommended on the cooling unit.

If it is defective, replace with a new cooling unit. To

check the cooling unit, first verify the AC heating element is good (See Sec. 2.1). Then place approximately

one gallon of water inside the refrigerator and place a

thermometer in one of the containers of water. Next,

supply 115 volts direct to the AC heating element and

operate for at least 12 hours. Then check the temperature on the thermometer. It should be at 45 degrees or

lower depending on test conditions (See ambient temperature Sec. 8.5). If so, the cooling unit is good. If the

temperature of the water is above 45 degrees, replace

the cooling unit.

8.7 FOOD STORAGE

Proper refrigeration requires free air circulation within the

food storage compartment. Restricted air circulation

within this compartment will cause higher cabinet

temperatures. To remedy this situation, simply rearrange

your foodstuffs. It is also essential that the shelves are

not covered with paper or large storage containers.

Always remember to allow for proper air circulation.

Odorous or highly flavored foods should always be

stored in covered dishes, plastic bags or wrapped in foil

or waxed paper to prevent food odors. Vegetables,

lettuce, etc., should be covered to retain their crispness.

NEVER PUT HOT FOOD INTO THE REFRIGERATOR.

To reduce frost formation in and on the freezing compartment, cover stored liquids and moist foods and do

not leave the door open longer than necessary. When

the refrigerator is heavily loaded, it takes a longer time

for refrigerator temperatures to lower, also increasing

the ice making time. A very heavy load may also cause

defrosting.

8.8 HIGH HUMIDITY

High humidity may cause a small amount of condensation to form on the frame of the refrigerator. In some

cases it can develop to such a degree that it will run off

the frame. As the humidity is reduced, the sweating will

decrease. High humidity can also be a factor in rapid

formation of frost.

8.9 INTERIOR LINER SEAL TO FRAME

There is a seal that is applied to the liner in the area

where the metal frame makes contact with the interior

liner. If this seal is incomplete, cold air can migrate out

to the metal frame. If this happens, condensation could

form on the frame and could promote rapid formation of

frost. If you suspect an improper seal, apply a small

bead of silicone all the way around the perimeter where

the frame meets the interior liner.

11

Loading...

Loading...