REFRIGERATOR FOR LP-GAS AND ELECTRIC OPERATION

RM2300

RM2400

RM2600

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don’t touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity of this or any other appliance.

RM2500

RM2800

Installation

Instructions for use

Gas equipment

Electric equipment

Maintenance

Fault tracing

Door panel

Page

5-8

9-10

10

10-11

11

11

12

DSC

#308

mD

1

emetic

quality leisure line products

SERVICE OFFICE

DOMETIC SALES CORP.

509 South Poplar

LaGrange, IN 46761

I

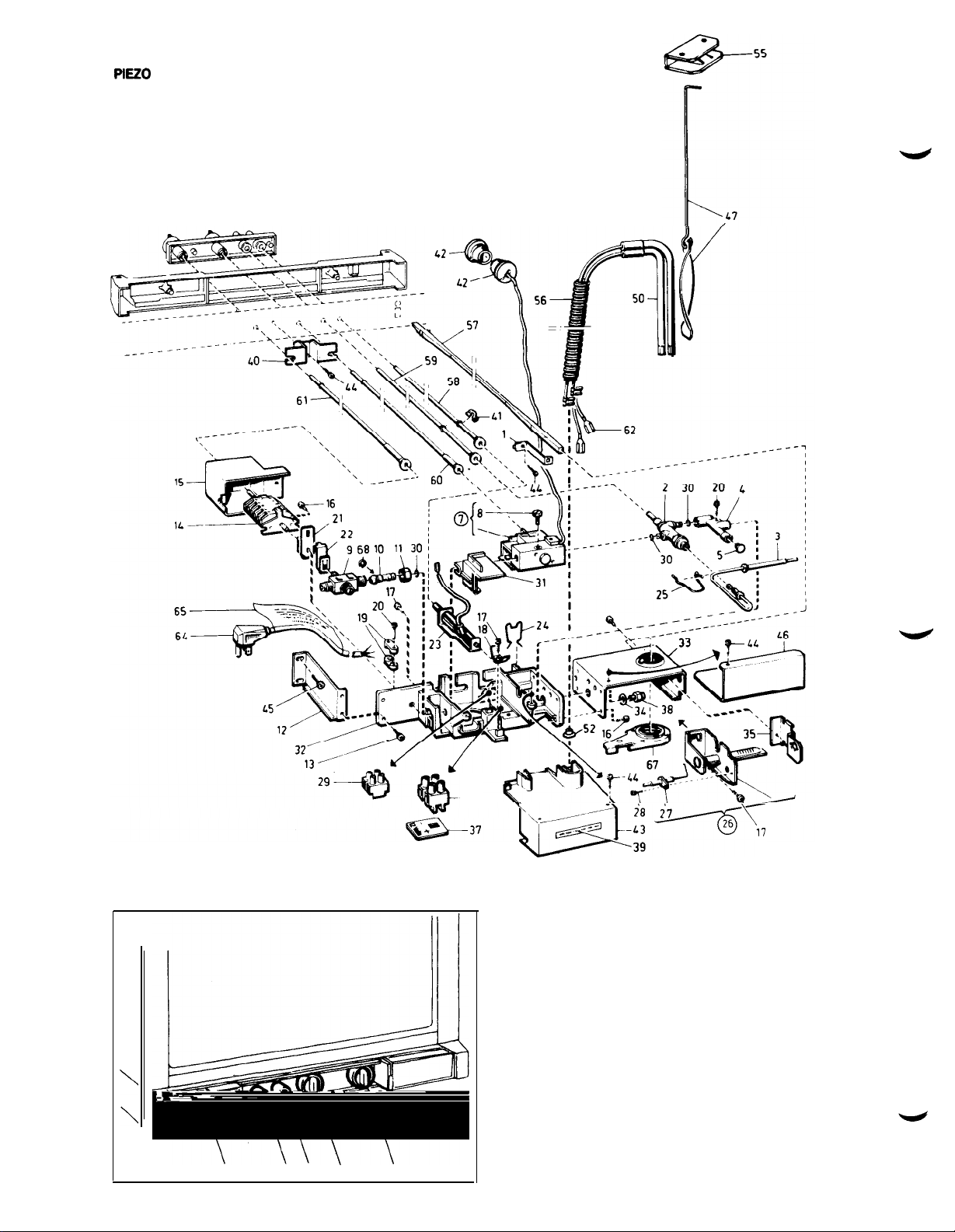

REFRIGERATORS WITH

PIE20 IGNITER

RM

2300/2400

E

DCB A

-36

@;:aq\

Item Description

No.

1

2 Thermo

3 Thermo

4 Coupling

7

9

10

11

14

23 Lighter

26 Burner

27

29 Terminal

30 Sealing ring

31

33 Burner housing

Fig.1

Retainer

electric safety valve

couple element

Thermostat

Cut-off valve

Nipple

Nut

Switch

Electrode

Snap catch

39

35

Burner retainer

36

Terminal

38

Burner jet

42

Plug

43

Cover

46

Cover

47

Flue baffle

50

Heater

52

Bushing

53 Retaining ring

30

12/120V

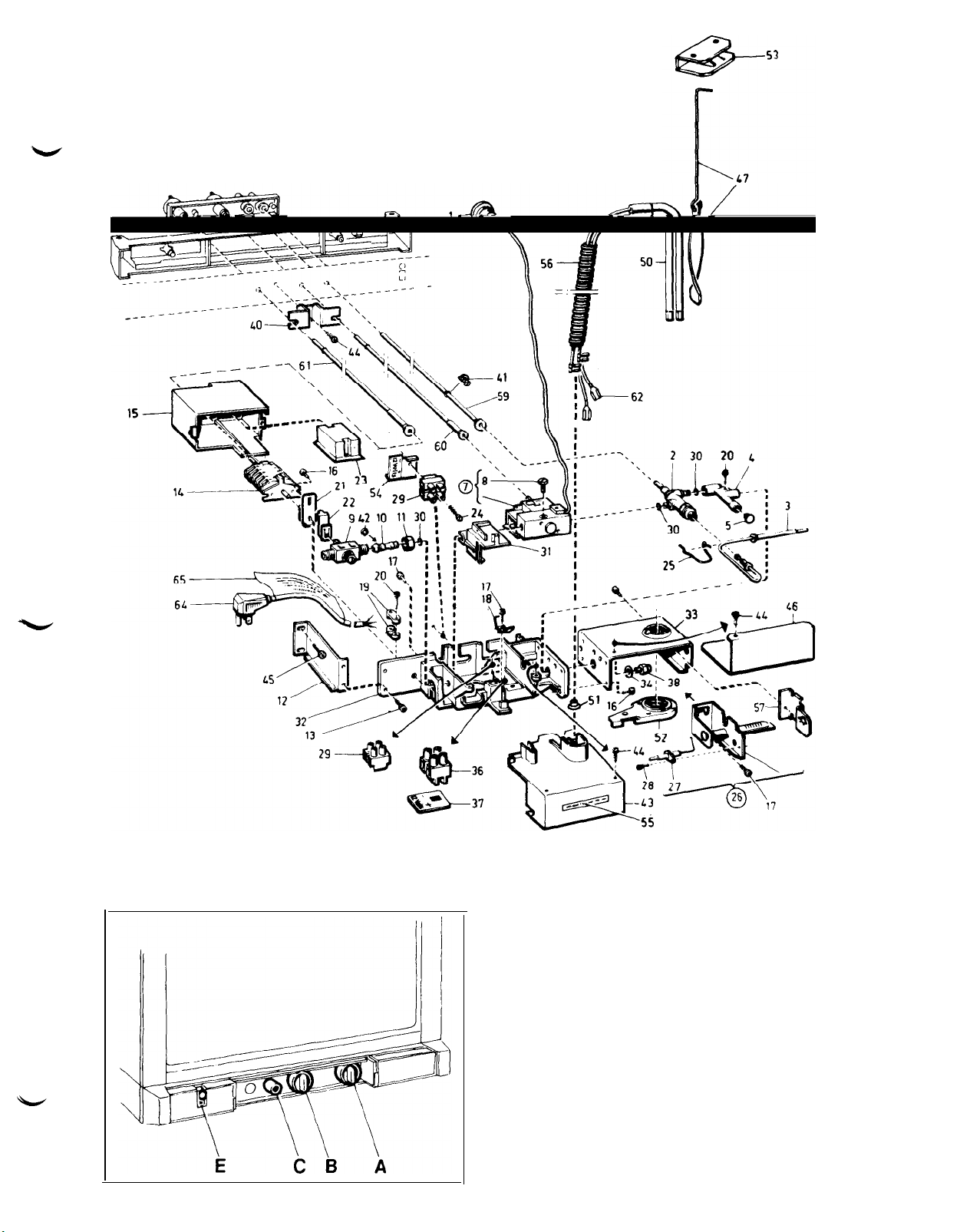

REFRIGERATORS WITH

AUTOMATIC IGNITION

RM

2500

Fig.2

Item

Description

No.

1

Plug

2

Thermo

3

Thermo

4

Coupling

7

Thermostat

Cut-off valve

9

Nipple

10

11

Nut

14

Switch

Reigniter

23

26

Burner

27

Electrode

Terminal block

29

30

Sealing ring

31

Snap catch

33

Burner housing

electric safety valve

couple element

36

Terminal block

36

Burner jet

43

Cover

46

Cover

47

Flue baffle

50

Heater

51

Bushing

52

Clamping plate

53

Flue top

55

Label for 12V

57

Burner

59

Push rod

60

Shaft, thermostat

61

Shaft, switch

62

Lead for

64

Flexible cord

retainer

12/120V

3

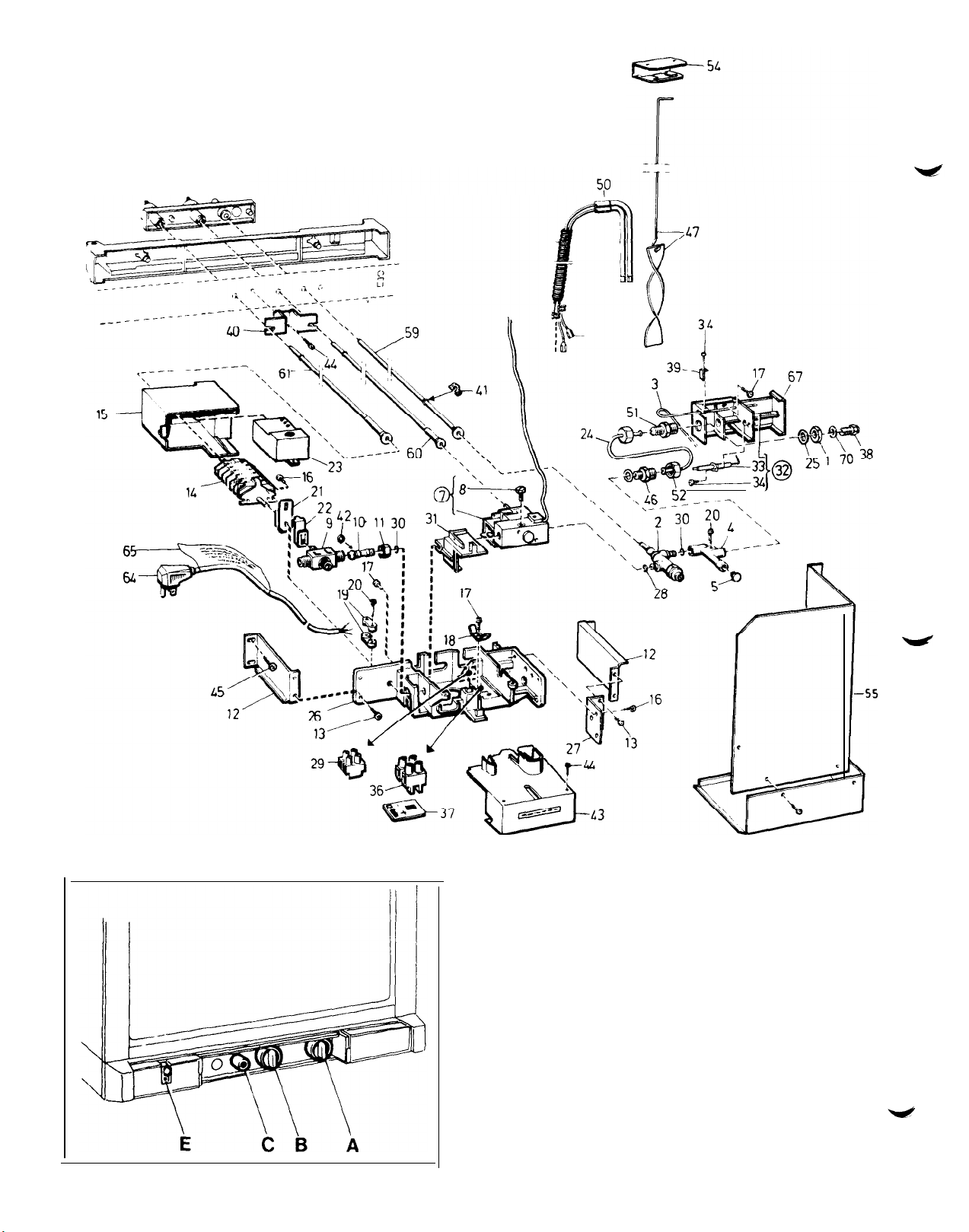

REFRIQERATORS WITH

AUTOMATIC IQNITION

RM2600

RM2800

Fig.3

Item

No.

2

3

4

7

9

10

11

14

23

24

29

31

Snap catch

32

Burner

33

Electrode

36

Terminal block

36

Burner jet

Description

Thermo

electric safety valve

Thermo

couple element

Coupling

Thermostat

Cut-off valve

Nipple

Nut

Switch

Reigniter

Gas

tube

Terminal block

43

Cover

46

Nipple

47

Flue baffle

50

Heater

51

Nipple

54

Flue cap

55

Protection plate

59

Push rod

60

Shaft, thermostat

61

Shaft, switch

64

Flexible cord

67

Burner housing

INSTALLATION

GENERAL INSTRUCTIONS

This

appliance is designed for storage of foods and storage

of frozen foods and maklng ice.

The refrigerators outlined hereon have been design certified

under ANS 221.19 -- 1983. Refrigerators by the American Gas

Association for installation in a mobile home or recreational vehicle and are

The certifications are, however, contingent on the

being made in accordance with the following instructions as applicable.

The

1. National Fuel Gas Code ANSI Z223.1-1

2. Manufactured Home Construction and Safety Standard, Title

24 CFR, Pan

3. Recreational Vehicles

The unit must be electrically grounded in accordance with the

National Electric Code

an external alternating current electrical source is utilized.

4. Any applicable local code

The installation must in Canada conform with

1. Current CGA B 149 Gas Installation Codes

2. Current CSA Standard Z 240.4 GAS - EQUIPPED

RECREATIONAL VEHICLES AND MOBIL HOUSING

3. Any applicable local code

The unit must be electrically grounded in

current CANADIAN ELECTRICAL CODE C 22 Parts 1 and 2.

appproved

installation must in the USA conform with:

by the Canadian Gas Association.

984

32-80,

ANSI/NFPA

ANSI/NFPA

No. 501 C-1977

No. 70-1984 when installed if

accordence

installation

with the

ELECTRICAL CONNECTION

120VoltsAC

The refrigerator is equipped with a three prong (grounded) plug

for protection against shock hazards and should be plugged

directly into a properly grounded three prong receptacle. Do not

cut or remove the grounding prong from this plug. The cord

should be routed to avoid coming in contact with the burner cover

flue cover or other hot components.

Refrigerator models requiring 12 V DC

supply

On units provided with interior light or automatic reigniter or both

there is one additional terminal block marked “12

Power” units with interior light or automatic reigniter or both there

are two additional blocks.

The refrigerator must be connected to the battery

wires of adequate capacity to avoid voltage drop. The wire gage

should be chosen with consideration to the wire length in accordance with table below. The 12 V circuit must be fused. Maximum

circuit fuse size: 15 Amps. for the models RM2300 and

RM2400, 20 Amps. for RM2500, 30

Amps. for

Do not use the body or chassis of the vehicle as a substitute for

either of the two conductors. No other electrical equipment or

lighting should be connected to the refrigerator circuit. The

refrigerator will draw from 10 to 23 Amps at 12 Volt depending on

model.

The interior light and the reigniter must be connected to a separate battery circuit and will draw about 1 Amp.

Maximum two conductor wire length in feet and meter.

RM

2800.

V”.

circuit

Amps.

for RM2600 and 40

On “Three

with two

Ventilation

The installation shall be made in such a manner as to separate

the combustion system from the living space of the mobile home

or recreational vehicle. Openings for air supply or for venting of

combustion products shall have a minimum dimension of not

1/4

less than

Proper installation requires one lower fresh air intake and one

upper exhaust vent. The ventilation kits shown in this instruction

booklet have been certified for use with the refrigerator models

listed in the tables. Certified

list. The ventilation kits must be installed and used without

modification. An opening towards the outside at floor level in the

refrigerator compartment must be provided for ventilation of

heavier-than-air fuel gases. The lower vent of the recommended

kits is provided with proper size openings. The flow of combustion and ventilating air must not be obstructed.

For ready serviceability of the burner and control manifold parts

of the refrigerator the lower side vent is fitted with a

which provides an adequate access opening.

inch.

vent system kits, see separate

liftout

panel

CAUTION

Do

parked.

If possible the installation of a 12 Volt operated refrigerator

should be completed with a relay mounted either in the car or

in the recreational vehicle (see below). This relay will

automatically

stopped.

GAS CONNECTION

Hook-up to the gas supply line is accomplished at the manual

gas valve, which is furnished with a

flare connection. All completed connections should be checked

for leaks with soapy water.

The gas supply system must incorporate a pressure regulator to

maintain a supply pressure of not more than 11 inches water

column.

When testing the gas supply system at test pressures in excess

of

1/2

psig

the refrigerator and its individual shutoff valve must be

disconnected from the gas supply piping system.

When testing the gas supply system at pressures less or equal

psig the appliance must be isolated from the gas supply piping

system by closing its individual manual shutoff

In case detailed instructions on the installation and connection to

the gas supply are required, contact your dealer or distributor.

3/8"

SAE (UNF 5/8- 18) male

valve.

1/2

6 ft.

69 64 49 34 31

4 ft. 110

not

Operate the refrigerator on 12 Volt when the vehicle is

YOU

102 79

will run out of battery in a rather short time.

cut out the refrigerator when the car engine is

55

50

135

220

5

SPECIAL HINTS

Note. Do not install the appliance directly on carpeting.

Carpeting must be protected by a metal or wood panel

beneath the appliance which extends at least full width and

depth of the appliance.

The refrigerator must be installed in a substantial

enclosure and must be level. A spirit level is supplied

with each refrigerator and by placing it in the freezer compartment one can level the refrigerator both ways front to

back and side to side. When installing the refrigerator in

the enclosure care should be taken to ensure a complete

sealing between the front frame of the refrigerator and

the top, sides and bottom of the enclosure. For this

purpose a length of sealing strip is applied to rear surfaces of the front frame. A sealing strip should also be

applied to the foremost floor of the enclosure as shown

in fig 8. The sealing strip should provide a complete isolation of the appliance combustion system from the vehicle

interior.

Be careful not to damage the sealing strip applied to the floor of

the enclosure when the refrigerator is put in

In the front frame and in the base at the rear of the refrigerator

there are holes for screws for fixing the refrigerator in the enclosure. See fig. 9.

Any space between counter or storage area and the top of the

refrigerator greater than 1

duced at the rear of the refrigerator will otherwise become trap-

ped in this space making the top of the refrigerator hot and

reducing the

efficiency

1/2"

should be blocked. The heat pro-

of the refrigerator.

place.

Fig.8

TO REMOVE AND REPAIR

THE REFRIGERATOR

Before working on the refrigerator, make sure that

and optional 12 V DC. Leads are disconnected. Close the gas

valve. Unscrew the hexagon nut (#11 Fig. 2) and move the

Valve

on the gas line out of the bracket. Check that the valve

slips out of the clip connection with the switch shaft.

Loosen the screws fixing the refrigerator to the enclosure and

remove the refrigerator.

When replacing the refrigerator make sure that the sealing strips

are properly positioned. After reassembly the gas connection

should be checked for leaks.

120

V A.C.

TEST OF THE GAS SAFETY SHUTOFF

The gas safety shutoff device must be tested after the refrigerator is placed in operation.

Refrigerator wlth piezo ignitor. (Figure 1)

1.

Start the

for gas operation with piezo igniter.

2.

Check that the gas flame is lit. This can be observed through the reflector (E).

Close the gas valve by turning the knob (A) back to

3.

position “OFF”.

Wait 1 minute.

4.

5.

Remove cover plate, see (46) in fig 1. Open the gas

valve by turning the knob (A) to position “GAS”

without pushing the button (C) and (D). Test that no

gas comes through the jet, (item 38.) Use soap

water solution. Be careful not to damage the jet.

After test, rinse the jet with water. Once more be

6.

careful no to damage the jet. Assemble the cover

plate. Start the refrigerator by following the instruction for gas operation with piezo igniter. Normal

gas operation should now return. Operate for at

least 5 minutes.

refrigerato;according

to the instruction

Refrigerator with automatic reigniter. (Fig 2 & 3)

6.

Fig.9

Start the refrigerator according to the instruction

for gas operation with automatic reigniter.

Check that the gas flame is lit. The lamp (E) is out.

Close the gas valve by turning the knob (A) back to

position “OFF”.

Wait 1 minute, disconnect 12 V D.C.

Remove cover plate, see (46) fig. 2 for

(55) fig. 3 for

turning knob (A) to position “GAS” without pushing

the button (C). The igniter will not spark. Test that

no gas comes through the jet, (item 38). Use soapy

water. Be careful not to damage the jet.

After the test rinse the jet with water. Once more

be careful not to damage the jet. Assemble the

cover plate. Connect the 12 V D.C. again. Start the

refrigerator by following the instruction for gas

operation with automatic reigniter. Normal gas

operation should now return. Operate for at least 5

minutes.

RM

2600/2800.

Open the gas valve by

RM

2500 and

CERTIFIED INSTALLATION

Certified installations require one roof vent and one lower side

vent or as optional one upper vent and one lower side vent.

The two alternatives are provided for by using the different kits

listed in the Appendix.

For further information contact your dealer or distributor.

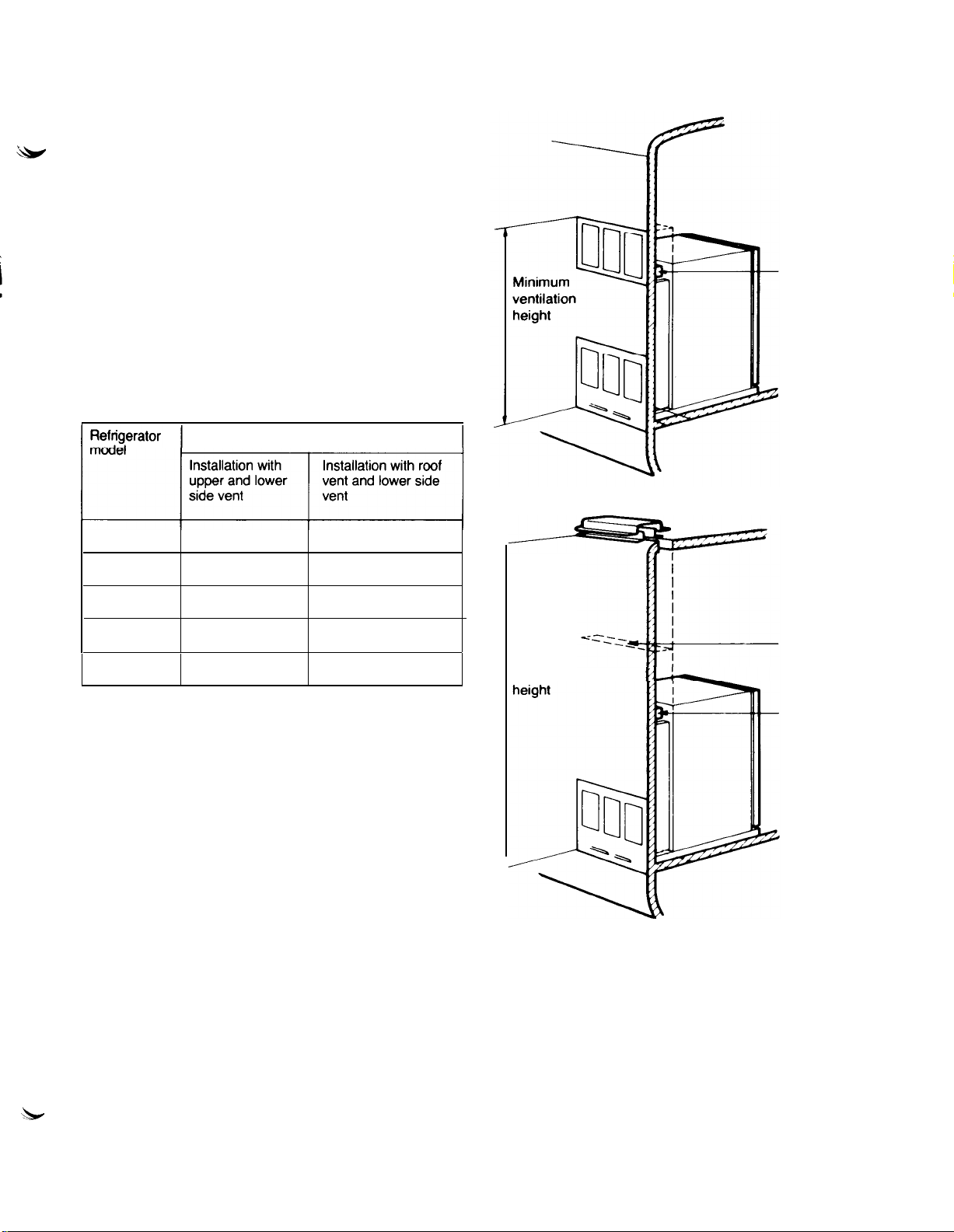

METHODS OF INSTALLATION

The methods of installation are shown in figures 10 a and 10 b.

It is essential that all maxlmum or minimum dimensions are

strictly maintained as the performance of the refrigerator is

dependent on an adequate flow of air over the rear of the

refrigerator.

VENTILATION -HEIGHTS

Minimum ventilation heights in inches and mm

RM2300 in.

RM2400

RM2500

RM2600

RM2800

in. 34

in.

in.

in.

37 31

42

56

62

Ventilation

Fig. 10

Condenser

a

Duct cross

section

area 5"x18"

Condenser

Fig. 10 b

7

CLEARANCES

Minimum

G. Top 0

K.

L: Bottom 0

M: Rear 1

N: See example below

Clearance

the wall behind the refrigerator

Clearance N on top of the condenser is related to the minimum

ventilation height

See Fig 11 and examples below

clearances in

Side

0

M

between the

inches

to combustible materials are

rearmost

part of the refrigerator and

L

Fig.1 1

Refrigerator Overall product Installation product

model

0

RM2400inch

RM2500inch

RM26000

RM28000

This method of installation and these

dimensions dimensions

Height

A

inch

30 3/8 21 11/16 22

32 15/16 23 24 11/16 32 1/8 21 9/16 22 15/16 32 5/16 21 13/16 23 15/16 1 1/4

40 13/16 23 24 11/16 40

inch

52 23 24 11/16 51 3/16 21 9/16 22 15/16 51 3/8 21 13/16 23 15/16 1 1/8

inch

57 15/16 24 15/16 24 11/16 57

Width Depth

B

C

Height

h

1/16

clearences

d

Width

W

20 1/4 20 3/8 29 3/4 20 1/2 21 3/8 1 1/4

21

1/8 23 7/16 22 15/16 57 1/2 23 13/166 23 15/16 1 1/8

will give you adequate space for servicing and proper installation.

Depth

d

9/16 22 15/16 40 3/16 21 13/16 23 15/16 1 1/4

e

Recess

dimensions top of condenser

Height

H

Width

W

Depth

D

View from above

Distance between

and top of

refrigerator

e

h

T

EXAMPLES

The clearance N for the RM 2300 model is derived at in the

following way.

Installation with upper and lower side vents

N= Minimum ventilation height 37 minus installation height

29 9/16 plus distance between condenser top and

tor top 1 114

in:

N=37-29 9/16+1 1/4=8

mm:

N=940-751+32=221

Installation with roof vent and lower side vent

N=Minimum ventilation height 31 minus installation height

29 9116 plus distance between condenser top and refrigerator top 1 114 plus distance between roof surface and

cap 5 114

in: N=31 -29 9/16+1 1/4+5 1/4=7 15/16 inches

N=787-751+32+134=202

mm:

11/16 inches

mm

mm

refringera-

roof

vent

Fig.1 2

INSTRUCTIONS FOR USE

HOW TO START THE REFRIGERATOR

Leveling

In the boiler, ammonia vapor is distilled from an

ammonia-water mixture and carried to the finned condenser, where it liquifies. The liquid flows to the

evaporator, where it creates cold by evaporating into a

circulating flow of hydrogen gas. If the evaporator coil is

not level the liquid readily accumulates, forming pockets

which can impair the gas

which case, of course, the cooling will stop.

When the recreational vehicle is stationary it must be

leveled to be comfortable to live in. If the refrigerator is

properly installed, the freezer shelf parallel to the floor,

the refrigerator will then also perform properly. A bubble

level should be placed on the freezer shelf. When the

vehicle is in tow, the continuous rolling and pitching

movement will not affect the refrigerator as long as the

movement passes either side of level, but when the trailer

is temporarily parked this sensitivity of the refrigerator

should be remembered. So

the refrigerator make sure the recreational vehicle is

leveled to be comfortable to live in.

Gas Operation

1.

To start the refrigerator turn the knob (A) to position “GAS”.

2.

Turn the thermostat knob (B) a quarter of a turn

from position “OFF”.

3.

Push the button (C) to stop and push the button (D)

of the piezo igniter. The pushing has to be repeated

until the gas is lit at the burner. This can be

ed through the reflector(E).

4.

After the gas is lit keep the button (C) pushed for

10 seconds. Release the button and check through

the reflector that the burner flame stays burning. If

not, repeat the lighting procedure. To shut off the

refrigerator turn the knob (A) to off position.

Gas Operation

with automatic reigniter (Fig. 2 & 3)

1.

To start the refrigerator turn the knob (A) to position “GAS”. Lamp (E) comes on.

2.

Turn the gas thermostat knob (B) a quarter of a

turn from position “OFF”.

3.

Press the button (C) to stop and keep it depressed.

When lamp (E) goes out, wait 15 sec. and release

button (C). If the lamp comes on again, repeat the

procedure. If flame blows out, reignition will take

place automatically. To shut off the refrigerator

turn the knob (A) to off position.

curculation

or even block it, in

once more, before you start

with piezo igniter (Fig. 1)

observ-

Electric Operation (Fig.

Check that the 120 Volt plug is correctly connected

1.

to the main supply. When the refrigerator is equipped for 12 Volt D.C. operation the low voltage connection is made at the terminals marked at the rear

of the refrigerator.

2.

Turn the knob (A) to desired position for electric

operation.

3.

Turn the thermostat knob (B) a quarter of a turn

from position “OFF”.

To shut off the refrigerator turn the knob (A) to

position.

1,2,3)

off-

HOW TO USE THE REFRIGERATOR

Food Storage Compartment

The food storage compartment is completely closed and

unventilated, which is necessary to maintain the required

low temperature for food storage. Consequently foods

having a strong odor or those liable to absorb odors

should be covered. Vegetables, salads, etc. should be

covered to retain their crispness. The coldest positions in

the refrigerator are underneath the cooling evaporator

and at the bottom of the refrigerator, and the least cold

positions are on the upper door shelves. This should be

considered when different types of food are placed in the

refrigerator.

Defrosting

Shut off the refrigerator.

Empty the refrigerator, leaving the drip tray under the fin-

ned evaporator and the cabinet and freezer doors open. If

desired, defrosting may be speeded up by filling the ice

tray with hot water and placing it in the freezer.

When the frost on the finned evaporator section has

melted water will be collected in the drip tray. The drip

tray should be emptied at regular intervals.

When all frost is melted, empty the drip tray and dry the

interior of the refrigerator with a clean cloth.

Replace the drip tray and ice tray, replace all food stuffs

and set the thermostat knob to its normal position.

NOTE: After a replacement of the LP Gas bot-

tles or a Ion period with refrigerator

off, the gas

with air. In such a case the lighting

procedure has to be repeated until the

air is pushed out of the line and the

gas has reached the burner.

Pme is likely to be filled

Frozen Food Storage Compartment

The ice trays should be placed in direct contact with the freezer

shelf for fastest ice making. Quick frozen soft fruits and ice cream

should be placed in the coldest part of the compartment which is

at the bottom of the aluminium liner or, in models with a shelf, on

this or just below it. Frozen vegetables, on the other hand, may

be stored in any part of the compartment.

The compartment is not designed for the deep or quick

freezing of foodstuffs. Meat or fish foods, whether raw or

prepared, and provided they are pre-cooled in the

refrigerator, can however, also be stored in the frozen

food storage compartment. They can then be stored

about three times as long as in the fresh food storage

compartment. To prevent drying out, keep food in covered

dishes, in plastic bags or wrapped in aluminum foil.

Ice Making

Ice cubes can be made in the ice trays which should be

filled with water to within

ice cubes seize the tray with both hands and twist the

tray. Cubes not required should be replaced in the tray.

Refill the tray with water and replace the tray on the

freezer shelf.

Ice making is accelerated if the thermostat knob is turned to

setting “MAX”. It is a good idea to do this a few hours before an

anticipated need for ice but be sure to turn the knob back to

normal setting when the ice is formed or the foodstuffs in the

cabinet may become frozen hard.

1/4"

from the top. To release the

desired controlled cabinet temperature.

At OFF

The Flame Failure Safety Device

The tip of the thermo-couple must reach in over two

slots of the burner. To replace the thermocouple proceed as follows:

1.

Remove the cover

Unscrew plug and pull thermocouple straight out.

2.

Remove spring.

3.

4.

Pull out thermocouple sideways from burner housing.

5.

Bend the new thermocouple to the same shape as

the old one.

6.

Reassemble in reverse order. Check that the tip has

been correctly refitted in relation to burner.

7.

Mount plug, taking care not to damage the threaded

hole in the aluminum cap of the housing. The plug

must be properly tightened to the valve housing to

ensure good contact between the thermocouple and

the magnetic coil within the housing.

The Thermostat

The refrigerator is equipped with a thermostat which is regulated

by turning the knob to different settings in order to obtain the

Under normal operating conditions the thermostat

valve remains closed and the burner is running continuously at the by-pass rate, just enough to keep the

burner lit.

To Shut Off the Refrigerator

To shut off the refrigerator turn the knob (A) to off position. If the cabinet is not in operation over a period of

weeks, it should be emptied and cleaned and the door left

ajar. Some models are provided with interior light, which

comes on when the door is opened. To avoid discharging

the battery, the light should be shut off. Use tape to close

the switch or remove the lamp. The ice trays should also

be dried and kept outside the cabinet.

Cleaning

To clean the interior lining of the refrigerator use lukewarm weak

soda solution. The evaporator, ice trays and shelves must,

however, be cleaned with warm water only. Never use strong

chemicals or abrasives to clean these parts or the protective

surface will be spoiled. It is important always to keep the

refrigerator clean.

Do not store explosive substances in the refrigerator

such as cigarette lighter fluid, gasoline, ether or the

I”“““”

I

FLAME FAILURE

SAFI

c--T

At MAX

The thermostat valve remains open and the burner is

running continuously at full gas rate. Lowest cabinet

and freezer temperatures are obtained at this setting.

Between these two extremes of the dial various controlled temperatures can be obtained, by turning the

thermostat knob to a suitable position. The closer to

MAX the lower the temperature. As soon as the required cold temperature inside the cabinet is reached,

the thermostat cuts the burner main flame leaving the

by-pass flame to keep the safety valve open.

The Igniter

The refrigerator is fitted either with a piezo igniter (see fig. 1) or an

automatic reigniter (fig. 2 and 3) which does not normally need

any maintenance. If the igniter does not work properly contact an

authorized service center.

ELECTRIC EQUIPMENT

Cartridge heater

The refrigerator is equipped also for electric operation. Many

models are equipped for both 120 Volts A C and 12 Volts D C

operation.

The heat necessary for the operation of an absorption

type cooling unit is supplied by an electric heater

mounted in a pocket of the boiler system.

10

To replace the heater, first of course check that the wall

plug is disconnected. If the refrigerator is equipped for 12

Volts D.C. operation, make sure that the 12 V leads are

disconnected. Then proceed as follows:

GAS EQUIPMENT

1. Remove the cover of the main control structure by loosening

Flue Top and Baffle

The flue baffle is suspended from the top and must be in position

in the central tube of the cooling unit.

2. Disconnect the heater leads

3. Pull off the metal hose

the two screws

INSTRUCTIONS FOR MOUNTING THE DOOR PANEL

The refrigerator is normally delivered without door panel(s).

Before starting the mounting work check that the panel dimen-

sions are in compliance with those given in the table and read the

instructions through. When mounting the panel, proceed as

follows.

A.

Remove the door decoration list (2) with its two screws (1).

The upper corners of the upper panel

the lower comers of the lower panel has to be cut according

to the sketch.

B.

Insert one of the vertical edges of the panel into the groove

of the door frame (3).

C.

Rend the panel gently so that the free side of the panel can

be slipped into the corresponding groove of the door frame

(4).

D.

Push the panel downwards so that the lower horizontal

edge of the panel is fitted into the bottom groove (5).

Between the upper edge of the panel and the door frame

E.

there is now a gap which should be covered by the decoration strip.

F.

Put the strip across the door so that the gap is covered and

push it upwards (6).

The tabs on the inside of the strip should fit in behind the

flange of the door frame. Secure the decoration strip by

means of the two screws (1).

(2door

models) and

Panel dimensions

Thickness max. 4 mm

REFRIG.

MODELS

RM

2366

RM

2400

RM

2500

RM2600

HEIGHT

+ 1-

1/32

25 1/2

28 1/16

35

15/16

5/32

inch

inches

WIDTH

+1- 1/32

21

1/16

22

13/32

22

13/32

inch

Loading...

Loading...