Page 1

Owner’s and Safety Manual (pages 2-25)

Manuel d’emploi et de sécurité (pages 26-49)

Manual de empleo y de seguridad (página 50-73)

Warning:

Read and understand this Owner’s and Safety Manual. Always follow safety precautions in the Owner’s and

Safety Manual. Improper use can cause serious injury! The engine exhaust from this product contains chemicals known

to the State of California to cause cancer, birth defects or other reproductive harm. Keep this Owner’s and Safety Manual!

Attention:

Suivez toujours les conseils de sécurité du présent manuel d’emploi et de sécurité. Une utilisation incorrecte de la

débroussailleuse peut entraîner des blessures graves! Conservez avec soin ce manuel. Les gaz d’échappement émis

par ce produit contiennent des produits chimiques connus par l’Etat de Californie pour provoquer le cancer, des défauts

de naissance ou autres dommages de reproduction. Lisez et comprenez ce manuel.

Advertencia:

Observe siempre las instrucciones de seguridad contenidas en el manual. Lea y compenétrese con el contenido

del manual. El uso inadecuado de la desbrozadoras puede causar lesiones de gravedad. Los gases de escape del motor

de este producto contienen sustancias químicas conocidas en el Estado de California como causantes de cáncer,

defectos genéticos y otros problemas relacionados con la reproducción. Conserve este manual cuidadosamente.

MS-3310

MS-4010

MS-4510

1

Page 2

Thank you for choosing a DOLMAR product!

We trust that you will be a satisfied customer. By choosing a DOLMAR you have chosen one of the most advanced brushcutters. We are the world´s oldest manufacturer of gasoline powered saws (1927), giving us

almost 7 decades of experience with two-stroke-engine

powered tools.

The MS-3310, MS-4010 and MS-4510 brushcutters combine the benefits of state-of-the-art technology with ergonomic design, and are professional machines intended

for all types of use.

The high-efficiency engine is the heart of the brushcutter,

and has been completely redesigned. Special cylinder

geometry, computerized control times, and

maintenance-free electronic ignition give high performance with low fuel consumption.

The drive shaft is designed for continuous heavy-duty

use, with 9 bearings and a tough centrifugal clutch. The

fuel tank is positioned forward, for the right c to make long

jobs easier and less fatiguing.

Some of the other technical features of your DOLMAR

brushcutter are:

- Precision-tuned vibration damping

Four conical hollow absorption elements, between

the engine and the main tube and between the engine

and the tank unit with handles, reduce felt vibration to

a minimum, for comfortable, untiring long-term working.

- Multi-function handle

All important controls are located on the right handle

for ease of operation.

- Easy cutting-tool change

A new locking system developed by DOLMAR allows

you to lock the cutting tool for simple, safe blade

changing.

- High-efficiency noise reduction

The completely encapsulated engine and the

resonator-chamber intake muffler make this brushcutter remarkably quiet.

The following industrial property rights apply: US 512606,

EP 0438611, EP 0696414, GBM 9106194, GBM

9412925.

To ensure your own safety and to get the maximum

performance out of your DOLMAR brushcutter, we urge

you to

read this instruction manual carefully before putting

the brushcutter into operation and strictly observe

all of the safety regulations! Failure to do so can

result in serious injury to the operator and/or

bystanders!

Packing

Your DOLMAR brushcutter comes in a cardboard box to

protect it from shipping damage.

Cardboard is a raw material. We encourage you to re-use

the box or recycle it (waste paper).

RE Y

Table of contents Page

Packing ......................................................................2

Delivery inventory.....................................................3

Explanation of symbols ........................................... 3

SAFETY PRECAUTIONS

General precautions .............................................. 4

Personal protective equipment.............................. 4

Handling fuels / Refuelling..................................... 5

Putting into operation..........................................5-6

Kickback.................................................................6

Working behavior / Method of working .................. 7

Applications for cutting tools.................................. 7

Transport ...............................................................7

Storage .................................................................. 7

Maintenance ..........................................................8

First Aid.................................................................. 8

Technical data ...........................................................9

Components .............................................................. 9

PUTTING INTO OPERATION

Mounting the tube handle .................................... 10

Installing the cutter guard ...............................10-11

Installing the steel bush cutter,

8-tooth eddy blade or star blade.....................11-12

Installing the trimmer head ..................................12

Installing the line cutter........................................ 12

Installing the metal cutter guard and

chisel type saw blade ..........................................13

The gear box........................................................13

Fuel mixture ......................................................... 14

Storage of fuel ..................................................... 14

Refuelling.............................................................14

Putting on the harness.........................................15

Balancing the brushcutter.................................... 15

Starting the engine...............................................16

Carburetor adjustment.........................................17

REPAIR AND MAINTENANCE WORK

Sharpening of cutting tools .................................. 18

Trimmer head ...................................................... 19

Starter cable replacement ..............................19-20

Cleaning the air filter............................................20

Replacing/cleaning the spark arrestor screen..... 21

Inspecting and replacing the spark plug.............. 21

Checking the muffler bolts ................................... 21

Suction head in the fuel tank ............................... 22

Muffler guard (for USA only)................................ 22

Information about the gear box............................22

Shutting down procedure and storage ................ 22

Service, spare parts and guarantee.................23-24

Troubleshooting......................................................24

Extract from the spare part list ............................. 25

Notes ........................................................................ 25

Service centres (see enclosure)

2

Page 3

Delivery inventory

max.

10.000 1/min

max.

11.500 1/min

3

1

4

1. Brushcutter

2. Shoulder Strap*

3. Cutter*

4. Guard*

5. Tool Protection* (not shown)

6. Servicing Tool (not shown)

7. Owner’s and Safety Manual (not shown)

* The parts as shown differ from model to model, and may look different from this illustration.

If one of these parts is missing when you unpack the brushcutter, contact your dealer!

2

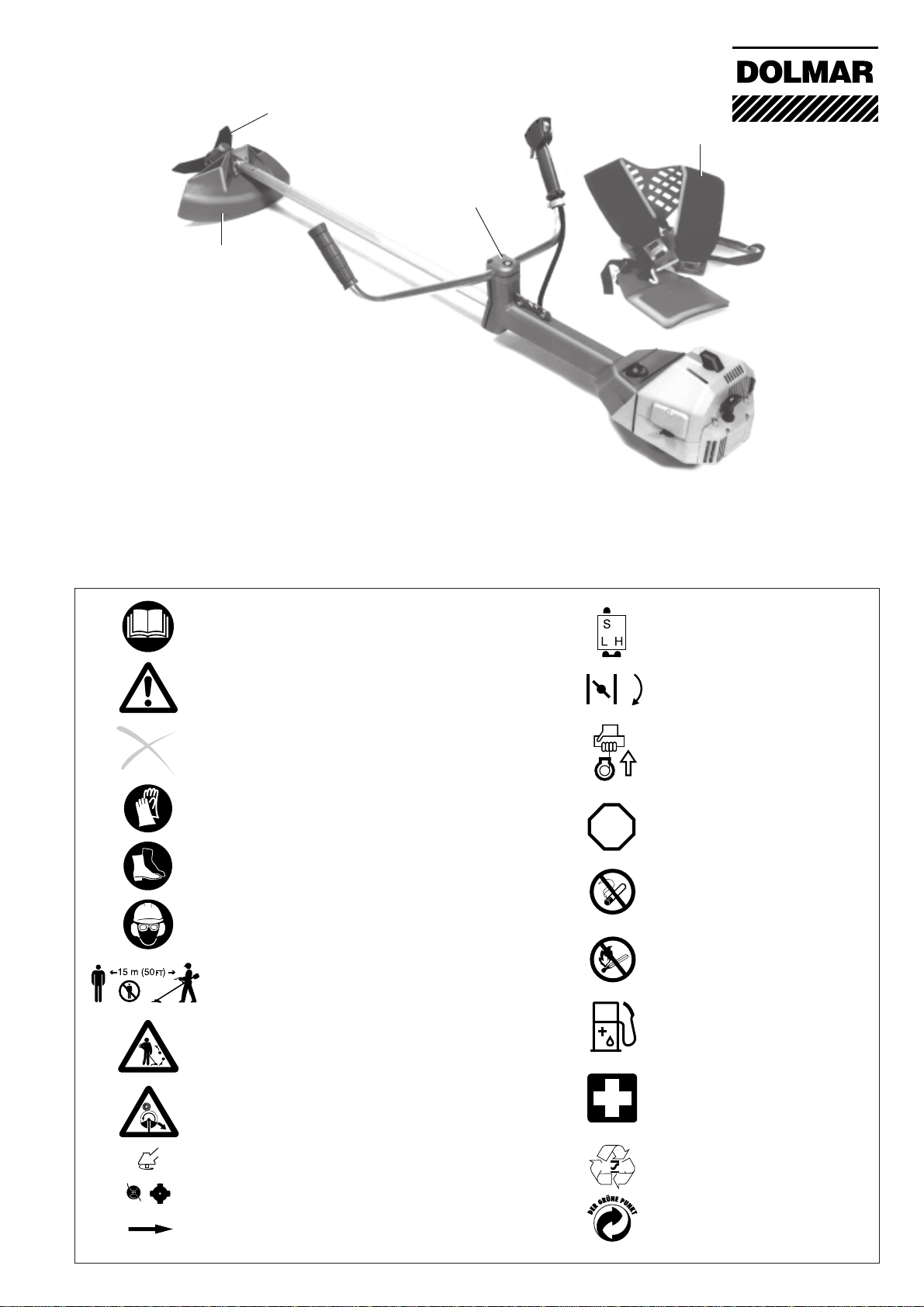

Explanation of symbols

You will notice the following symbols on the brushcutter and in the Owner’s and Safety Manual.

Read the Owner’s and Safety manual and

follow all warnings and safety instructions!

Particular care and caution!

Forbidden!

Wear protective gloves!

STOP

Wear safety shoes!

Wear protective helmet, face, eye and

hearing protection (eye protection must

comply with ANSI Z87-1)!

The distance between the machine and

bystanders shall be at least 50 feet!

Carburetor adjustment

Choke

Start engine

Stop engine!

No smoking!

No open flame!

DANGER:

Beware of thrown objects!

CAUTION: Kickback!

(blade thrust)

Maximum tool rpm

Direction of blade rotation

Fuel and oil mixture

First aid

RE Y

Recycling

3

Page 4

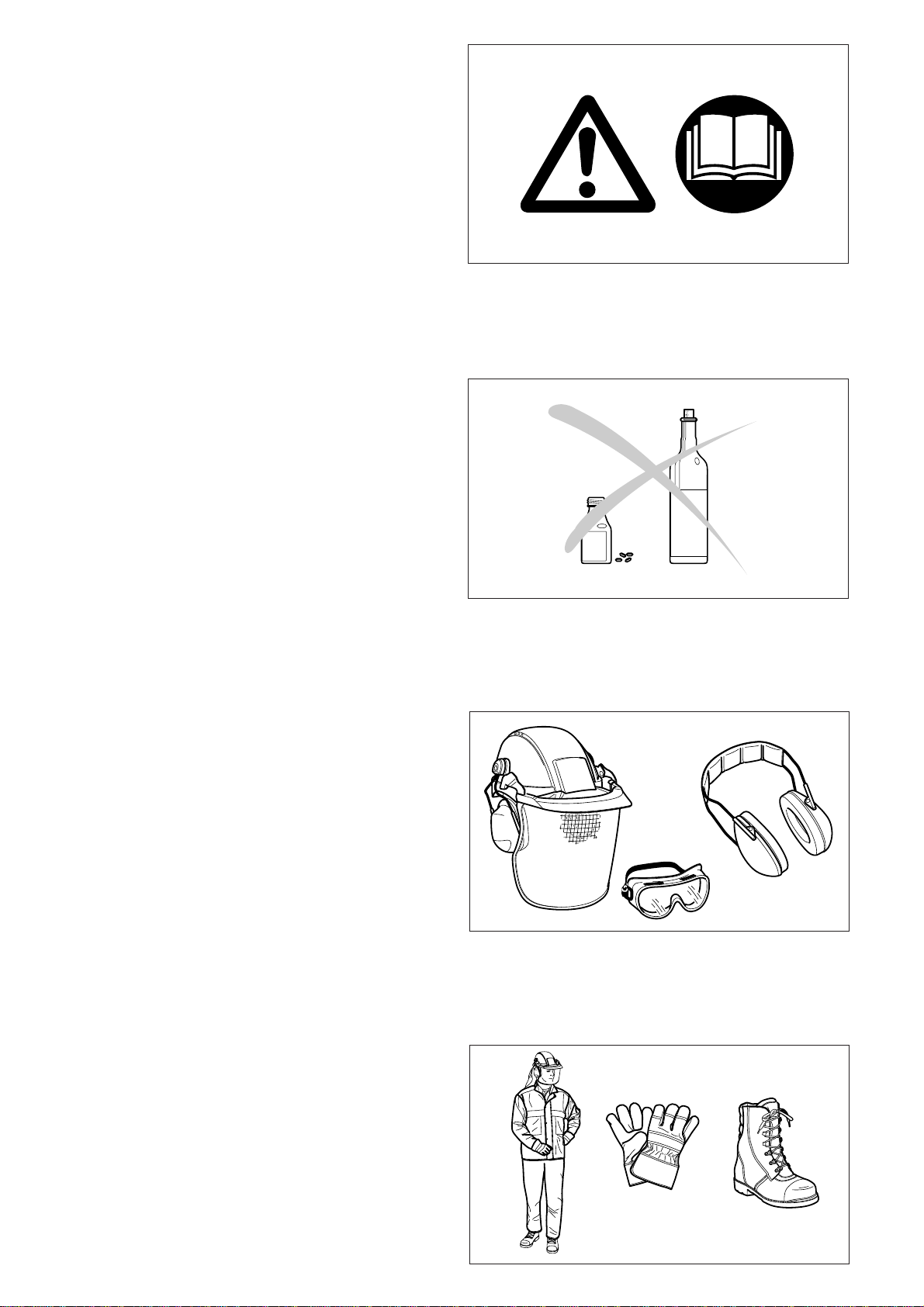

SAFETY PRECAUTIONS

1

2

3

General precautions

To ensure correct operation, the user has to read this

instruction manual to make himself familiar with the

handling of the brushcutter. Insufficiently informed

users will risk danger to themselves as well as others

due to improper handling (1).

- It is recommended only to lend the brushcutter to

people who have experience with brushcutters. When

lending the brushcutter to someone else, give him this

Instruction Manual as well.

- First-time users should ask their dealer for basic

instructions, or contact a forestry school. To familiarize yourself with the basic handling of

gasoline-powered brushcutting, start out with trimming jobs before moving up to sawing.

- Children and persons under 18 years must not be

allowed to operate the brushcutter with metal cutting

tools (such as saw blades, steel bush cutter, star

blades etc.). Exceptions may be made for persons

over 16 for training purposes under the supervision of

a qualified trainer.

- Always use brushcutters with the utmost care and

attention.

- Operate the brushcutter only if you are in good physical condition. Perform all work calmly and carefully.

The user must accept liability for others.

- Never use the brushcutter after consumption of alcohol, drugs or medication (2).

Personal protective equipment

- The clothing worn should be functional and appropriate, i.e. it should be tight-fitting but not cause hindrance. Do not wear either jewellery or clothing which

could become entangled with bushes or shrubs.

- In order to avoid head-, eye-, hand- or foot injuries

as well as to protect your hearing, the following

protective equipment and protective clothing must

be used during operation of the brushcutter:

- It is recommended to wear a protective helmet; it is

imperative when working in forests. The protective

helmet (1) should be checked at regular intervals for

damage and must be replaced after 5 years at the

latest. Use only approved protective helmets. If you

have long hair, always wear a hairnet!

- The face shield (2) of the protective helmut protects

against flying sawdust, wood chips or stone chippings. During operation of the brushcutter always

wear goggles or a visor to prevent eye injuries.

- Wear adequate noise protection equipment to avoid

hearing impairement ( ear muffs (3), ear plugs etc.).

Octave brand analysis upon request.

- The forestry safety jacket (4) is equipped with spe-

cial red coloured shoulder parts. The arms and neck

should always be protected by clothing.

- The protective trousers (5) are made from a nylon

fabric with 22 layers and protects against cuts. We

strongly recommend its use. In any case, it is essential that a long pair of trousers made of tough material

be worn during operation of the brushcutter. Do not

wear short pants.

- Protective gloves (6) made of thick leather are part

of the prescribed equipment and must always be worn

during operation of the brushcutter.

- Safety shoes or boots (7) fitted with anti-skid sole,

steel toe caps and leg protection must always be

used. Safety shoes equipped with a protective layer

give protection against cuts and ensure a secure

footing. Do not wear sandals or go barefoot.

4

1

2

3

4

7

5

4

6

Page 5

Handling fuels / Refuelling

- Stop the engine before refuelling.

- Keep away from open flame or sparks and do not smoke

while refuelling or mixing fuel (5).

- Let the engine cool down before refuelling.

- Fuel may contain substances similar to solvents. Eyes

and skin should not come in contact with mineral oil

products. Always wear protective gloves when refuelling

(5). Frequently clean and change protective clothes. Do

not breathe in fuel vapors. Inhalation of fuel vapours can

be hazardous to your health.

- Before refuelling the brushcutter make sure it is in a

stabile position.

- Do not spill fuel or oil. When you have spilt fuel or oil

immediately clean the brushcutter. Fuel should not

come in contact with clothes. If your clothes come in

contact with fuel, change them at once.

- Ensure that no fuel ooze into the soil (environmental

protection). Use an appropriate base.

- Refuelling is not allowed in closed rooms. Fuel vapors

will accumulate near the floor (explosion hazard).

- Carefully tighten the locking screw of the fuel tank and

inspect the fuel cap at regular intervals.

- Change the place before starting the engine at least 10

feet (3 meters) from the place of refuelling (6).

- Fuel cannot be stored for an unlimited period of time.

Buy only as much as will be consumed in the near future.

- Use only approved and marked containers for the transport and storage of fuel. Ensure children have no access

to fuel.

5

10 feet

(3 meters)

6

Putting into operation

- Do not work alone. Another person must be nearby

in case of emergencies (within shouting distance).

- Children and other persons must remain more than 50

feet (15 meters) from the working area. Keep an eye out

for animals as well (7).

- Before use always check that the brushcutter is safe

for operation:

Make sure the cutting tool is securely installed. The

throttle must automatically return to the off position

when released, and the throttle lever lock must work

properly. The cutting tool must not turn during idling. The

handles should be clean and dry. The on/off switch must

function properly. The guard must be undamaged and

securely installed in the correct position. Otherwise

you are in danger of injury!

- Start the brushcutter only in accordance with the instructions. Do not use any other methods for starting the

engine (8)!

- Use this brushcutter and its cutting tools only for the

uses they are intended for as specified in the documentation.

- Never use, for example, wire or wire-rope which can

break off and become a dangerous projectile. Use only

flexible, non-metallic line recommended in this manual.

- Start the brushcutter only after complete assembly

and inspection. Operation of the device is only

permitted after all the appropriate accessories are

attached!

- The cutting tool must be equipped with its appropriate guard. Never run the cutter without this guard!

- The cutting tool must not turn during idling. If necessary

adjust the idling speed.

o

360

50 feet

(15 meters)

7

8

5

Page 6

- Before starting, make sure that the cutting tool has no

contact with hard objects such as branches, stones etc.

- The engine must be switched off immediately if there are

any noticeable changes in the behaviour of the equipment.

- Should the cutting tool hit stones or other hard objects,

immediately switch off the engine and inspect the cutting tool.

- Inspect the cutting tool at freqvent intervals for damage

(detect hairline cracks by means of tapping - noise test).

Hairline cracks can occur in the region of the base of the

teeth (9) after long use. Damaged cutting tools and

cutting tools with hairline cracks must not be used

any longer under any circumstances.

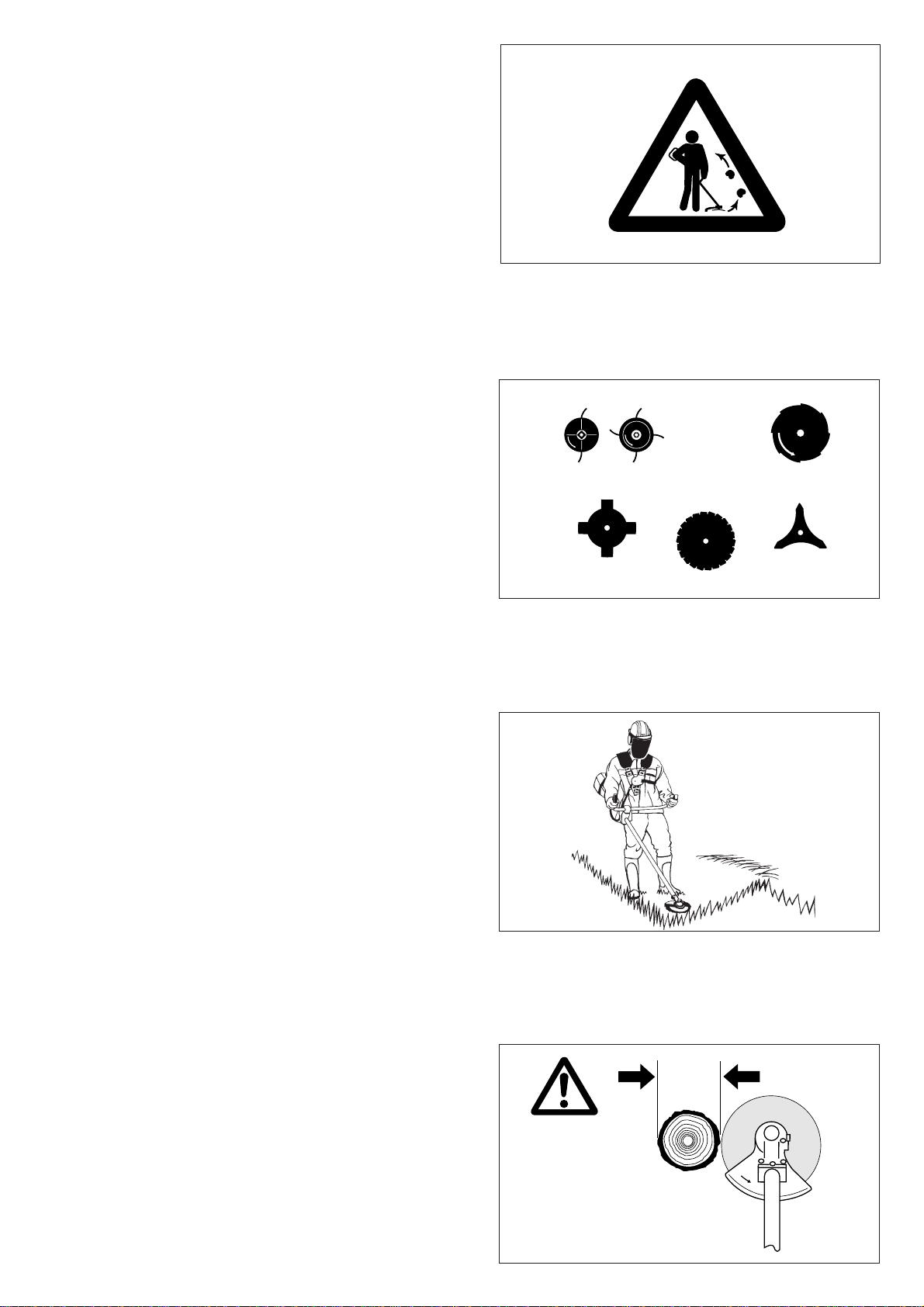

- Operate the brushcutter only with the shoulder strap

attached, which is to be suitably adjusted before putting

the brushcutter into operation (10). It is essential to

adjust the shoulder strap according to the user’s size to

prevent fatigue during use. Never hold the cutter with

one hand during use.

- When working with the brushcutter always hold it with

both hands (10). Keep cutting attachment below waist

level. Keep proper footing and balance at all times.

- Operate the brushcutter in such a manner as to avoid

inhalation of the exhaust gases. Do not start or operate

the brushcutter in closed rooms (risk of gas poisoning).

Carbon monoxide is an odorless gas; breathing exhaust

fumes can kill. Work only in well-ventilated places.

- When taking a break or leaving the brushcutter unattended, turn off the engine (11), make sure the cutting

attachment has stopped and set the brushcutter down in

such a way that there is no risk of injury to yourself or

others.

- Never put the hot brushcutter onto dry grass or onto any

combustible materials.

- Shut off the engine during transport or when moving on

to a new location (11).

- Never operate the engine with a faulty exhaust muffler.

If the spark arrestor screen is damaged, replace it

immediately. The use of the brushcutter with a damaged

spark arrestor can cause bushfires!

9

10

11

STOP

STOP

● Breaks

● Transport

● Refuelling

● Maintenance

● Tool Replacement

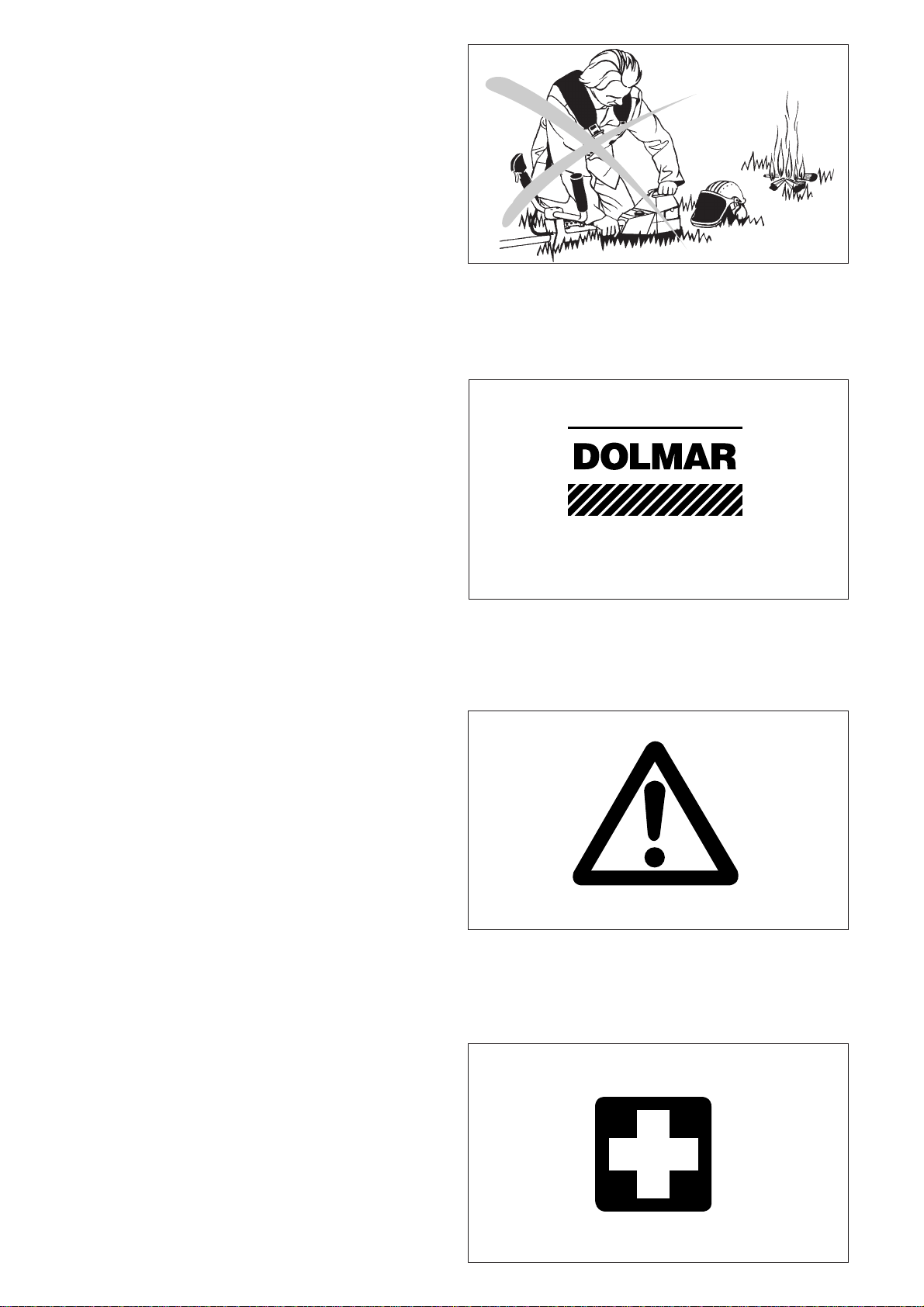

Kickback (Blade Thrust)

When operating the brushcutter, uncontrolled kickback

may occur.

This particularly the case when cutting in the area between

12 and 2 (12).

Never start a cut in this area when cutting hard objects such as brush, bushes etc.

If you do this, the brushcutter will be thrown to one side at

high speed and with great force. High risk of injury!

Never start a cut in the area between 12 and 2 (Fig. 12).

Kickback prevention (13):

- To avoid kickbacks, observe the following:

- Always watch what you´re doing! Be careful when

continuing cuts started previously.

- The cutting tool must be turning at full speed before

starting cuts.

- There is a high risk of injury in the area between 12 and

2, especially when using metal cutting blades.

- Cuts in the areas between 11 and 12 and between 2

and 5 should be performed only by trained operators

and at their own risk.

- Easy, low-kickback cutting is possible in the area between 8 and 11.

6

CAUTION:

Kickback!

12

CAUTION:

Kickback!

13

9

12

3

6

Page 7

Working behavior / Method of working

- Use the brushcutter only in good light and visibility.

During the winter season beware of slippery or wet

areas, ice and snow (risk of slipping). Always ensure a

safe footing.

- Never cut above your shoulder height.

- Never stand on a ladder and run the brushcutter.

- Never climb up into trees to perform cutting operations

with the brushcutter.

- Never work on unstable surfaces.

- Make sure the cutting area is free of foreign objects such

as stones and metal items. Foreign particles can rebound (danger of injury, 14), damage the cutting tool

and cause dangerous kickbacks.

- Before commencing cutting, the cutting tool must have

reached full working speed.

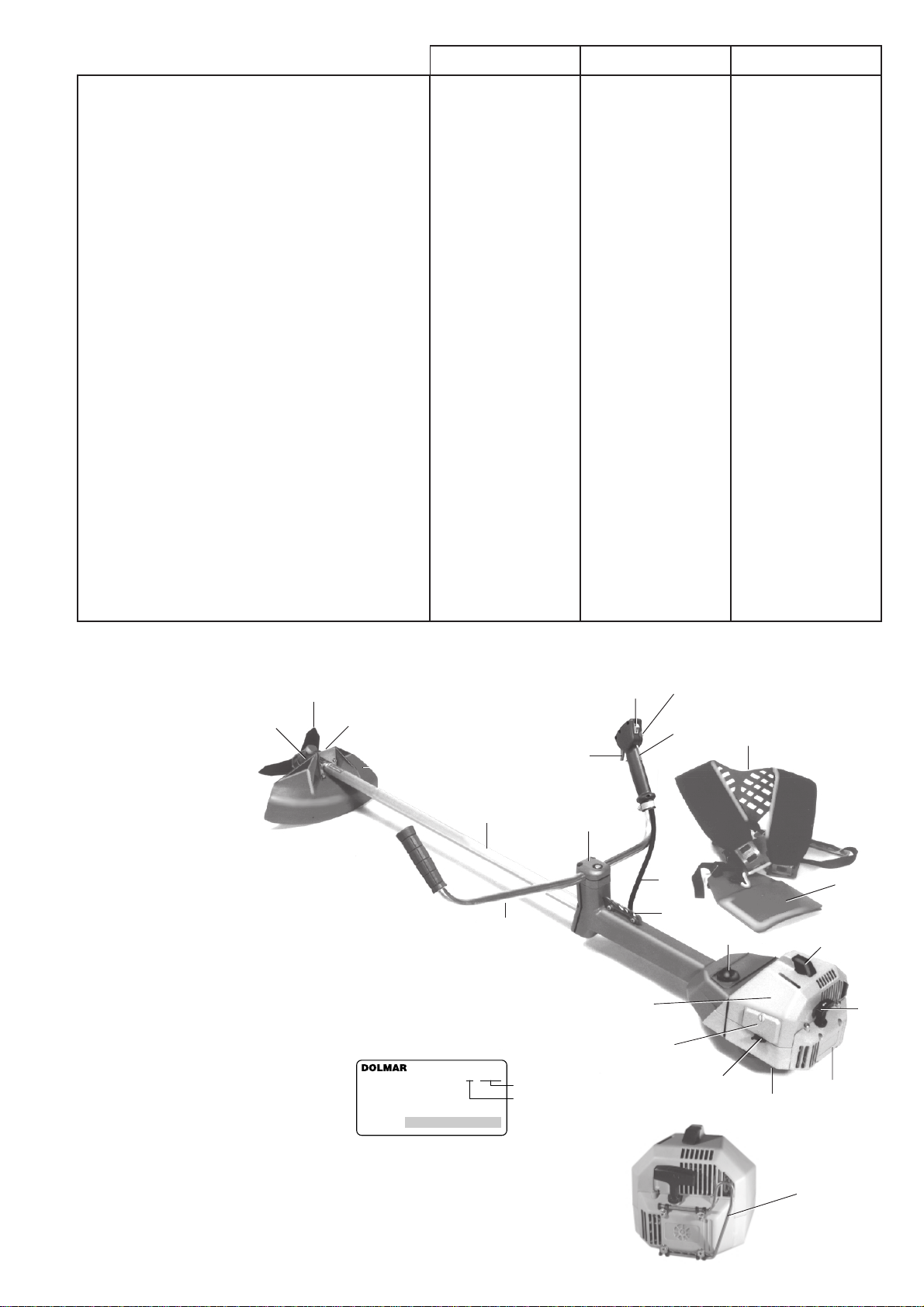

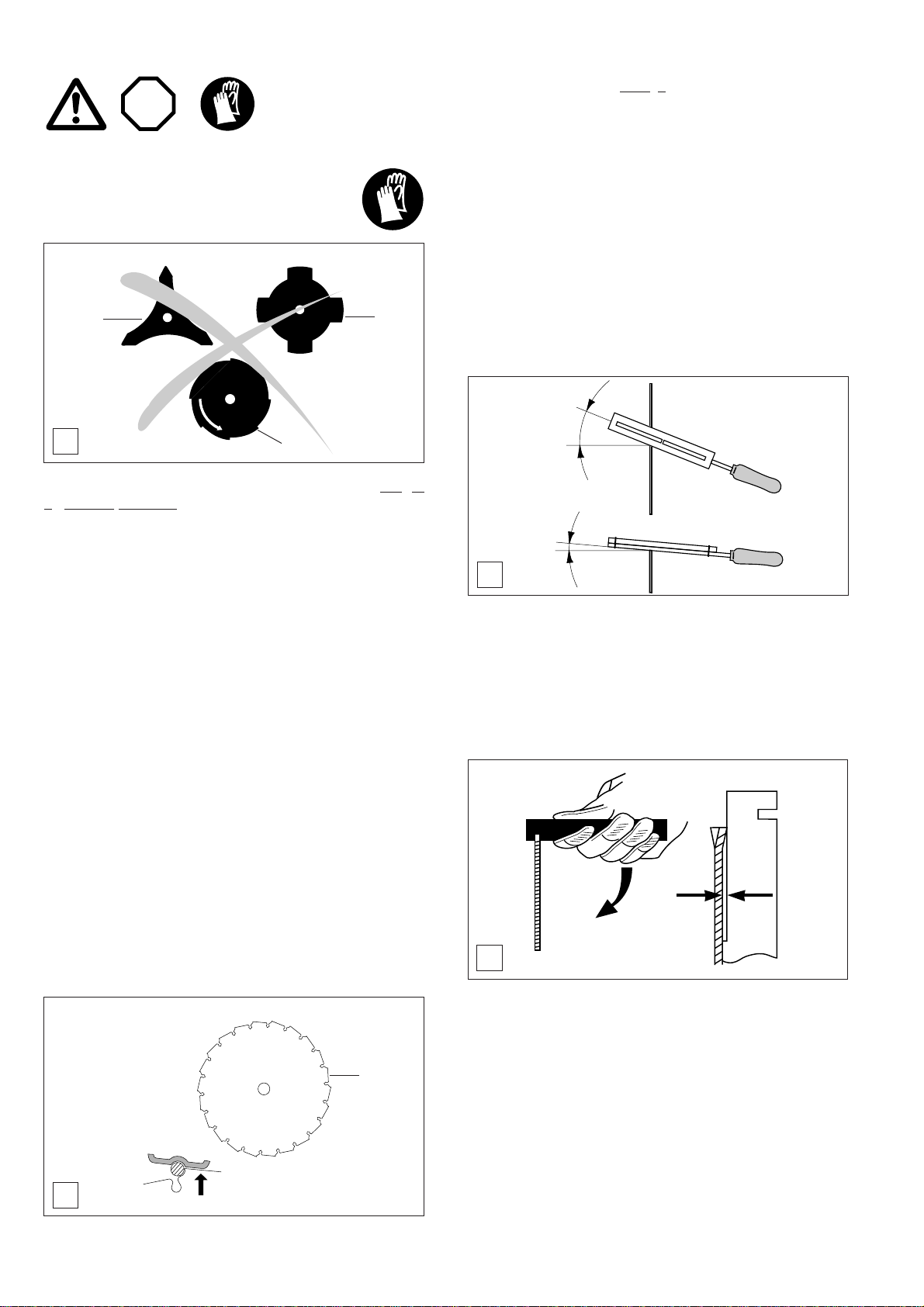

Applications for cutting tools

Employ only the correct cutting tool for the job in hand (15)!

Do not use tools for jobs they are not designed for.

2-line -/ 4-line trimmer head:

Exclusively for cutting along walls, fences, grass edges,

trees, posts etc. (supplementing the lawn mower).

8-tooth eddy blade, 4-tooth star blade, steel bush cutter:

For cutting thicker materials like weeds, tall grass, bushes,

shrubs, mixed growth, thickets, etc. with stems up to 2 cm

(3/4") thick. Perform this cutting work by swinging the brush

cutter evenly in half-circles from left to right (similar to a

scythe) (16).

Chisel type saw blade:

For forestry cleanup work and for harvesting small trees

with trunks up to 6" (15 cm) thick (17). Apply even pressure

when cutting.

DANGER:

Beware

thrown objects!

14

2-line -/ 4-line trimmer head 8-tooth eddy blade

4-tooth star blade steel bush cutter

15

chisel type saw blade

Transport

- When transporting the equipment or moving to

another working location, the brushcutter must be

switched off in order to avoid unintentionally starting

the cutting tool.

- Never carry and transport the brushcutter when the

cutting tool is in operation!

- The tool protection included with the equipment must

always be used if the brushcutter is transported over

longer distances.

- Ensure that the brushcutter is safely secured so that no

fuel can run out before transporting it in a vehicle. Empty

the fuel tank before transporting the brushcutter.

- Before shipping the brushcutter, completely empty the

fuel tank.

Storage

- The brushcutter must be safely stored in a dry room. Use

the tool protection for metal cutting tools. Keep the

brushcutter out of reach of children.

- If the brushcutter is stored for a long period of time, it

should be given a thorough maintenance check and a

complete inspection at an authorized DOLMAR service

centre.

- If the brushcutter is stored for a long period of time, the

fuel tank should be completely emptied and the carburetor

run dry. Fuels may only be stored for a limited period of

time and could cause deposits to form in the tank or in

the carburetor.

- Fuel remains in reserve canisters should be used for

other engines or disposed of.

16

Max

ø 6"

(15 cm)

17

7

Page 8

Maintenance

- Always make sure the brushcutter is in good working

order before using it. This includes in particular the

cutting tool, guard, harness and fuel system (check for

leaks). Particular attention must be paid to the cutting

blades, which must be correctly sharpened.

CAUTION: Metal cutting tools must be sharpened only

at an authorized service centre!

A tool which has been improperly sharpened can cause

unbalance and thus considerable danger of injury.

Apart from this, the equipment may be damaged due to

vibrations.

- When changing the cutting tool, cleaning the brushcutter

and the cutting tool etc., it is essential to switch off the

engine and pull the spark plug cap.

- Replace cracked, bent, warped, damaged or dull cutting

tools immediately. Never straighten or weld damaged

cutting tools.

- Operate the brushcutter with as little noise and pollution

as possible. In particular check the correct setting of the

carburetor.

- Clean the brushcutter at regular intervals and check that

all screws and nuts are well tightened.

- Never service or store the brushcutter near open flames

(18)!

- Always store the brushcutter in a locked storage area,

with the fuel tank completely empty and the carburetor

run dry. Keep the brushcutter out of reach of children.

Observe the accident pre- vention instructions issued

by the relevant trade associations and insurance companies. Do not make any modifications to the brushcutter - you will only be putting your own safety at risk!

The performance of maintenance or repair work by the user

is limited to those activities described in this instruction

manual. All other work must be done by the DOLMAR

customer service (19).

Use only original DOLMAR spares and accessories.

The use of non-DOLMAR spares, accessories, or cutting

tools increases the risk of accident. DOLMAR will not

accept any liability for accidents or damage caused by the

use of non-approved cutting tools and fixing devices of

cutting tools, or accessories.

18

SERVICE

19

First Aid

A first-aid kit should always be nearby as a precaution in the

event of an accident.

Immediately replace any items taken from the first aid kit.

When calling for help, give the following information:

- Place of accident

- What happened

- Number of persons injured

- Nature of injuries

- Your name

NOTE

Individuals with poor circulation who are exposed to excessive vibration may experience injury to blood vessels or the

nervous system.

Vibration may cause the following symptoms to occur in the

fingers, hands or wrists: ”Falling asleep” (numbness), tingling, pain, stabbing sensation, alteration of skin colour or of

the skin. If any of these symptoms occur, see a physici-

an!

8

20

21

Page 9

Technical Data

MS-3310 MS-4010 MS-4510

Displacement cu. in 2.0 (33 cm3) 2.4 (39 cm3) 2.7 (45 cm3)

Bore inch 1.46 (37 mm) 1.57 (40 mm) 1.69 (43 mm)

Stroke inch 1.22 (31 mm) 1.22 (31 mm) 1.22 (31 mm)

Rated capacity per ISO 8893 kW 1.6 1.8 2.3

Operating speed rpm 9,000 9,000 9,000

Max. engine speed with

one-part metal cutting tool

1)

rpm 13,500 13,500 13,500

Maximum speed of the tool spindle with

one-part metal cutting tool

1)

rpm 10,400 10,400 10,400

Idling speed rpm 2,500 2,500 2,500

Clutch engagement speed rpm 3,500 3,500 3,500

Sound pressure level at the operators ear 3)dB (A) 98

Sound pressure level at the bystander’s position (50 ft) 3)dB (A) 75

Carburetor (diaphragm-carburetor) Type

WALBRO WT-225 A WALBRO WT-225 A WALBRO WT-225 A

a) /

a)

/ 77

101

b)

b)

98

76

a)

/ 102

a) / 78 b)

b)

99

76

a) /

102

a) / 78 b)

Ignition system Type Transistor ignition Transistor ignition Transistor ignition

Spark plug Type

Electrode gap inch

Fuel consumption per ISO 8893

Specific consumption per ISO 8893

2)

kg/h 0.72 0.81 1.03

2)

g/kWh 450 450 450

CHAMPION RCJ6Y CHAMPION RCJ6Y CHAMPION RCJ6Y

.

020-.030 (0.5-0.8 mm) .020-.030 (0.5-0.8 mm) .020-.030 (0.5-0.8 mm)

Fuel tank capacity oz. 31.7 (0.9 l) 31.7 (0.9 l) 31.7 (0.9 l)

Mixture ratio (Fuel/2-stroke oil)

- when using DOLMAR oil 50 : 1 50 : 1 50 : 1

- when using DOLMAR HP 100-oil 100 : 1 100 : 1 100 : 1

- when using other oils 40 : 1 40 : 1 40 : 1

Gear ratio 1 : 1.3 1 : 1.3 1 : 1.3

Dimensions, assembled,

length / width / height inch 71.1 / 26.8 / 8.9 71.1 / 26.8 / 8.9 71.1 / 26.8 / 8.9

Total weight with plastic guard

(without cutting tool) lbs 17.42 (7.9 kg) 17.42 (7.9 kg) 17.42 (7.9 kg)

1)

The maximum rated speed of the trimmer head is not exceeded when using a DOLMAR trimmer head.

2)

At max. power. 3) According to ANSI B 175.3. a) With one-part metal cutting tool. b) With 2-line nylon cutting head.

b)

1

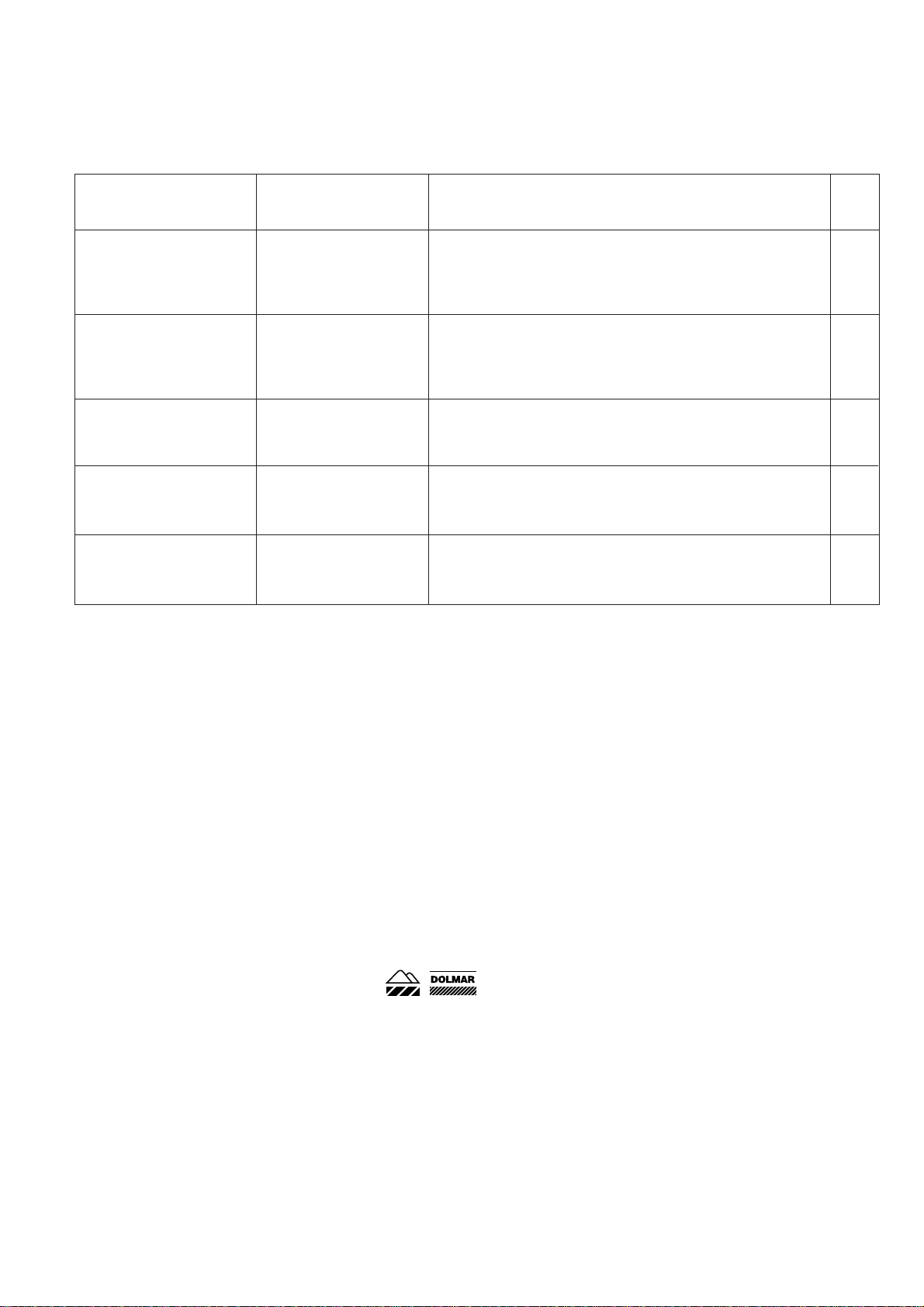

Components

1 Cutting tool

2 Gear box

3 Locking bolt

4 Guard (Cutter guard)

5 Main tube

6 Handle tube

7 Throttle (throttle trigger)

8 Short-circuit switch (Start/Stop)

9 Stop knob for halfway throttle

10 Safety locking button (throttle trigger lockout)

11 Bowden cable guide

12 Tube handle holder

13 Hole bar

14 Tank cap

15 Spark plug

16 Starter grip

17 Fan housing

18 Type plate

19 Choke lever

20 Air filter (behind air filter cover)

21 Cover

22 Harness

23 Hip protection pad

24 Muffler guard (for USA only)

2

3

Type plate (MS-4510 shown)

DOLMAR GmbH

22045 Hamburg

Germany

Indicate when ordering spare parts!

4

5

MS-4510

9806 123456

Spark Arrester 385 174 301

386.000.000

7

12

6

Serial number

Year of manufacture

8

21

11

20

13

9

10

14

19

22

23

15

16

17

18

24

9

Page 10

PUTTING INTO OPERATION

STOP

CAUTION: When working on the brushcutter always be absolutely certain to switch off the engine, pull the

spark plug cap and wear protective gloves!

IMPORTANT: Do not start the brushcutter until fully assembled and inspected!

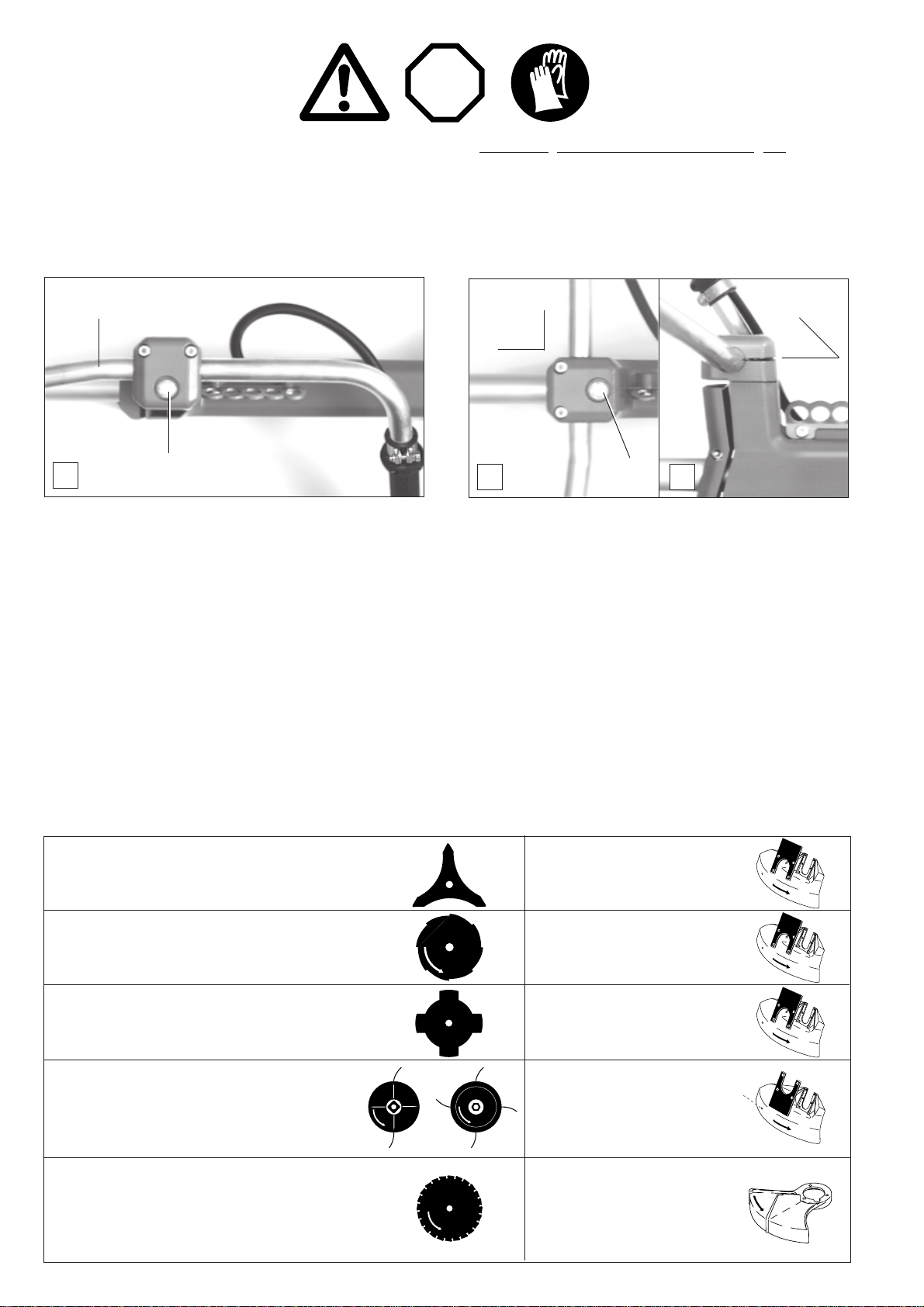

Mounting the tube handle

The handle tube (A/1) comes fixed parallel to the main tube.

1

0

90

45

0

A

- Use the universal wrench to loosen the locking screw

(A/2) (counter-clockwise) until it is possible to turn the tube

handle through 900.

2

B

- After the tube handle has engaged in the 90° position,

tighten the locking screw (B/2) a little, while still leaving it

loose enough to allow further adjustment of the tube handle

according to your size (See "Balancing the brushcutter").

- Move the handle tube into a position approximately 45°

with respect to the main tube (C).

2

C

Installing the cutter guard

IMPORTANT: Safety regulations and your own safety make it imperative to use the right cutter guard with a

given cutting tool! Use only the combinations shown here, and when switching to a different

cutting tool always change the cutter guard as well!

WARNING: Use only the cutting tools shown here! It is not permitted to use other cutting tools as this can

increase danger of accidents and cause damage to the equipment!

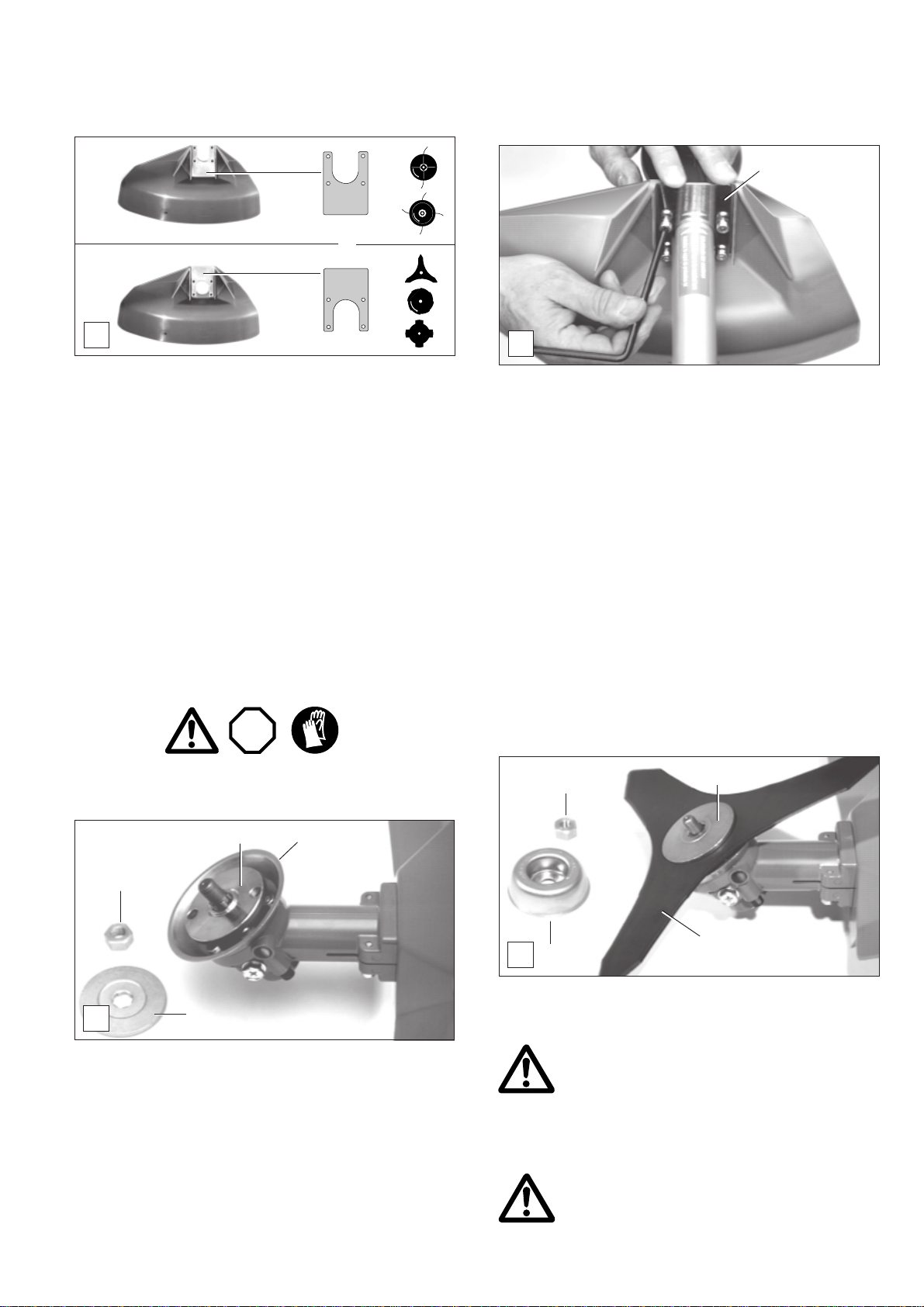

Tool/guard combinations for the MS-3310, MS-4010 and MS-4510

Cutting tool Cutter guard

Steel bush cutter, part no. 385 224 130

Outside diameter 300 mm (12"), arbour 20 mm Part no. 010 341 612

8-tooth eddy blade, part no. 385 224 180

Outside diameter 255 mm (10"), arbour 20 mm Part no. 010 341 612

Star blade, part no. 385 224 140

Outside diameter 255 mm (10"), arbour 20 mm Part no. 010 341 612

2-line trimmer head, part no. 385 224 501

4-line trimmer head, part no. 385 224 541

Cutting range 400 mm (16"). Use only 2.4 mm (.095") replacement cutting line. part no. 010 341 612

15 m part no. 369 224 070

120 m part no. 369 224 072 part no. 957 341 010!

Chisel type saw blade, part no. 385 224 160 part no. 010 341 100 (for 225 mm)

Outside diameter 225 mm (9"), arbour 20 mm

Chisel type saw blade, part no. 385 224 170 part no. 010 341 030 (for 200 mm)

Outside diameter 200 mm (8"), arbour 20 mm Impressed: 385 341 030

10

* Install line cutter (knife),

Impressed: 385 341 045

*

Page 11

CAUTION:

The cutter guard supplied must always be fitted in the right position, to ensure your personal safety and to meet legal

accident prevention regulations.

Never use the brushcutter without a cutter guard installed!

A

1

B

C

The position of the mounting plate (C/1) will depend on the

type of cutting tool in use (trimmer head or metal blade).

The position of the mounting plate determines whether the

guard will be positioned higher or lower.

When using a trimmer (line) head apply the mounting position

as shown in fig. A.

The mounting position as shown in fig. B is required for use

with the following tools:

• Star blade

• 8-tooth eddy blade

• Steel bush cutter

Always fix the metal cutter guard if a chisel type saw blade

is used (refer to page 13).

2

D

- To install, lay the guard on the holder on the gear box.

Place the mounting plate (D/2) on the guard in the

appropriate position (A or B) for the type of cutting tool in

use and tighten the installing screws with the Allen key as

shown.

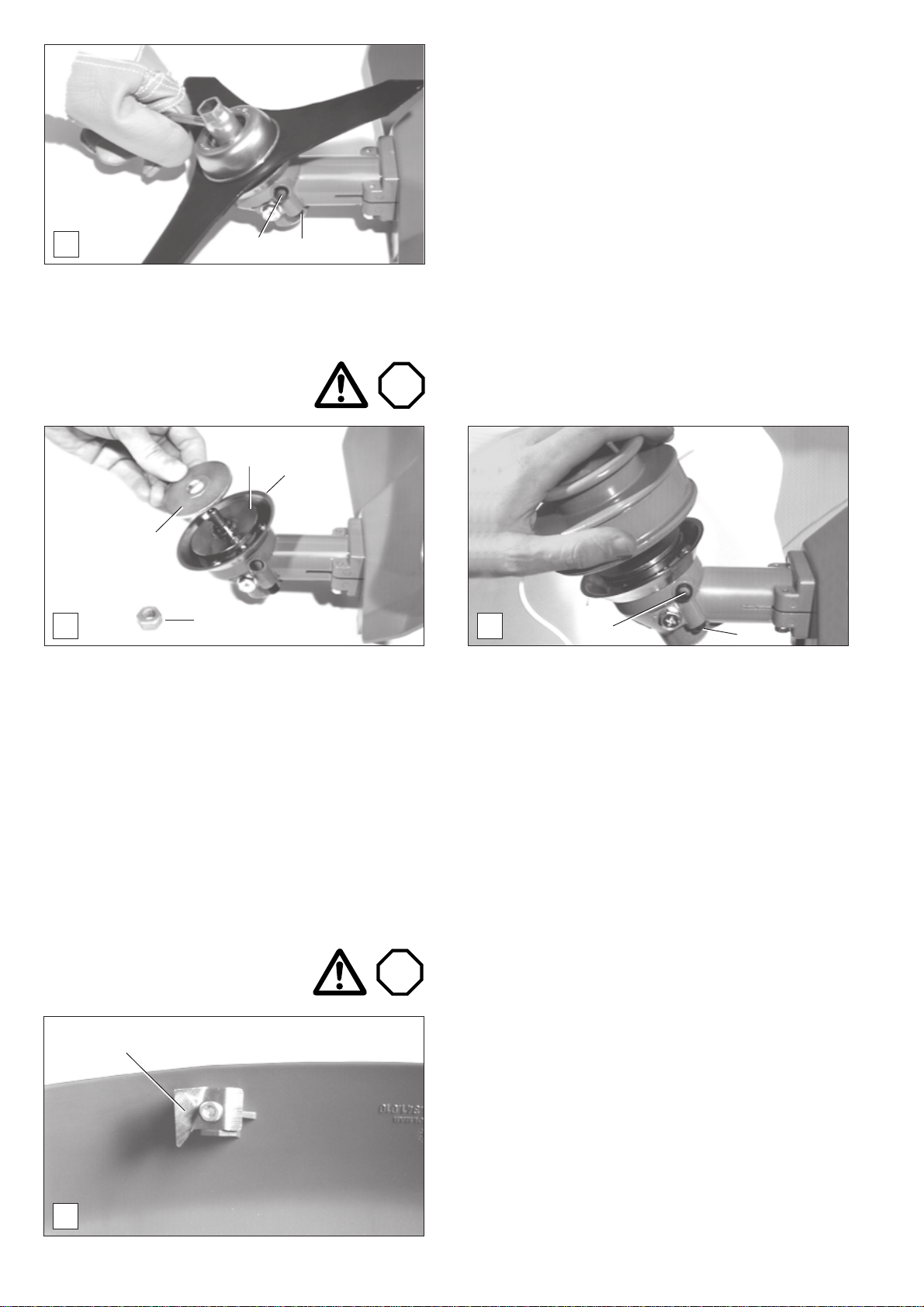

Installing the steel bush cutter, 8-tooth eddy

blade or star blade

STOP

Always switch off the engine and disconnect the spark

plug cap before mounting cutting tools! Wear protective

gloves!

5

6

3

E

When using the blade cutting tools mentioned on the preceding page, install the cutter guard with the mounting plate in

position B (see “Installing the cutter guard”).

- Unscrew the locknut (E/3) from the shaft by turning it

clockwise.

Note: The locknut is provided with a left-hand thread!

- Remove the pressure disk (E/4) and the locking disk (E/5).

- Tighten the winding guard (E/6) with the three screws

provided.

- Put the locking disk (E/5) back on (make sure it is in the

right position).

4

3

F

7

- Put on the cutting tool (F/8) and finally the pressure disk

(F/4) as shown in the picture.

Important! The picture shows the steel bush

cutter. When installing the 8-tooth eddy blade

make sure to observe the direction of rotation

arrows on blade and on cutter guard!

- Put on the sliding cup (F/7) and screw the lock nut (F/3)

manually onto the shaft.

The sliding cup is included in the accessories!

Important! The locknut (F/3) has a plastic insert

protection. For safety reasons, this nut must be

replaced immediately if it becomes loose. It must be

replaced in any event after 10 tool changes at the

latest. (Order no. 385 228 041)

4

8

11

Page 12

G

10

Installing the trimmer head

Always switch off the engine and

disconnect the spark plug cap

before mounting the trimmer head!

- Press the locking button (G/9) and hold it down, while using

the combination wrench to turn the shaft counter-clockwise

until the locking button engages and locks the shaft.

- Now tighten the locknut counter-clockwise using the

combination wrench.

- To unlock the locked shaft press the release button (G/

10). The locking button (G/9) will trip (if necessary turn the

cutting tool slightly).

- Check to make sure the cutting tool can turn freely.

Use the shaft lock in the same way when dismounting the cutting tool.

9

STOP

5

6

4

H

When using the trimmer head install the cutter guard with the

mounting plate in position A (see “Installing the cutter guard”).

Always install the line cutter (see below, “Installing the line

cutter”)!

- Unscrew the locknut (H/1) from the shaft by turning it

clockwise.

Note: The locknut has a left-hand thread!

- Place the pressure disk (H/4) on the shaft as shown.

1

2-line trimmer

head shown

I

- If necessary, install the winding guard (H/6) (three screws).

T o do so, first remove the locking disk (H/5) (note its position

as installed).

- Screw the trimmer head onto the shaft by turning it

counter-clockwise.

- Press the locking button (I/9) and hold it down while turning

the trimmer head counter-clockwise until the locking button

engages, locking the shaft.

- Now tighten the trimmer head by hand.

- Press the release button (I/10) to unlock the shaft. The

locking button (I/9) will jump out (it may be necessary to

turn the trimmer head slightly).

- Check to make sure the trimmer head can turn freely.

10

9

Installing the line cutter

11

J

12

STOP

The line cutter and its mounting screw are included in the

accessory pack.

- The picture shows the line cutter (J/11) mounted on the

cutter guard with the mounting screw.

Note:

If you adjust the length of the trimmer line (see page 19),

the line cutter will automatically cut the lines to identical

length during operation.

Caution:

Always turn off the engine before adjusting the line

length!

Page 13

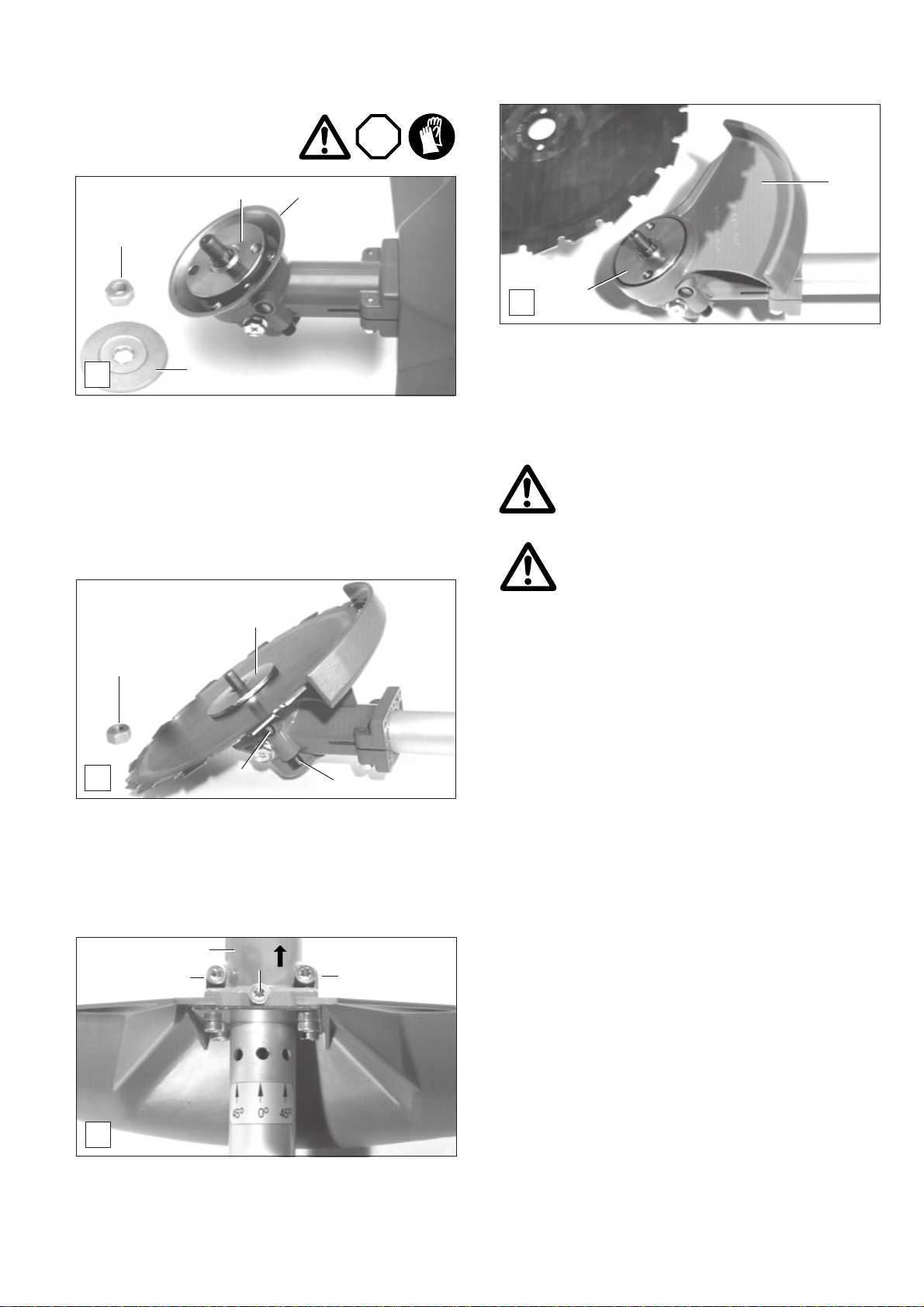

Installing the metal cutter guard and chisel type

saw blade

Always switch off the engine and

disconnect the spark plug cap

before mounting cutting tools!

Wear protective gloves!

STOP

5

6

3

K

Always install the metal cutter guard when installing the chisel

type saw blade!

- Unscrew the locknut (K/3) from the shaft by turning it

clockwise.

Note:The locknut has left-hand thread!

- Remove the pressure disk (K/4) and the locking disk (K/5).

4

4

3

M

10

9

12

L

- If the winding guard is on, remove it (K/6) by unscrewing

the three screws.

- Screw the steel cutter guard (L/12) on tightly.

- Put the locking disk (L/5) on.

- Put on the cutting tool and finally the pressure disk (M/4)

as shown in the picture.

- Screw the locknut (M/3) onto the shaft by hand.

- Press the locking button (M/9) and hold it down while using

the combination wrench to turn the shaft counter-clockwise

until the locking button engages and locks the shaft.

- Now tighten the locknut counter-clockwise using the

combination wrench.

- Press the release button (M/10) to unlock the shaft. The

locking button (M/9) will jump out (if necessary turn the

saw blade slightly).

- Check to make sure the saw blade can turn freely.

5

Important! When installing the chisel type saw

blade make sure that the direction of rotation

arrows on saw blade and on cutter guard are

pointing in the same direction!

Important: The locknut (K/3) has a plastic insert

protection. For safety reasons, this nut must be

replaced immediately if it becomes loose. It must be

replaced in any event after 10 tool changes at the

latest (order no. 385 228 041)!

The gear box

14

N

13

15

14

In order to achieve easier operation along slopes and fitches,

it is possible to swivel the gear box (N/13) from the normal

position to either side by approximately 45 degrees.

Adjustment:

- Loosen the two screws (N/14).

- Loosen screw (N/15) enough to turn the gear box in the

direction indicated by the arrow until the three boreholes

are visible at the main tube.

- Turn the gear box in the direction indicated until the position

of the screw (N/15) matches up with the borehole.

- Move the gear box back again and tighten the first screw

(N/15) and subsequently the remaining two screws (N/14)

by the same amount.

13

Page 14

Fuel mixture

Gasoline

1.0 Us-gal. (3.7 l)

2.5 Us-gal. (9.4 l)

5.0 Us-gal. (18.9 l)

The brushcutter is powered by a high-performance two-stroke

engine. The engine runs on a mixture of gasoline and two-stroke

engine oil.

The engine was designed for regular lead-free gasoline with an

octane number of at least 91 ROZ. If this is not available,

higher-octane gasoline may be used. This will not damage the

engine, but may impair engine performance.

A similar situation will arise from the use of leaded fuel. To

obtain optimum engine operation and to protect your

health and the environment, only unleaded fuel should be

used! Gasoline which contens alcohol should not used in

DOLMAR products.

For lubricating the engine use a two-stroke engine oil (quality

grade: API-TC), which is added to the fuel. The engine has

been designed for use of DOLMAR HP 100 high-performance

two-stroke engine oil and a mixture ratio of only 100:1 to protect

the environment. In addition, a long service life and reliable

operation with a minimum emission of exhaust gases are

ensured.

DOLMAR HP 100 high-performance two-stroke engine oil is

available in the following sizes:

0.5 l part no. 980 008 109

DOLMAR high-performance two-stroke engine oil is available

in two different sizes:

1 l part no. 980 008 107

100 ml part no. 980 008 106

In case DOLMAR high-performance two-stroke engine oil is

not available, it is urgently recommended to use a mixture ratio

of 40:1 with other two-stroke engine oils, as otherwise optimum

operation of the engine cannot be guaranteed.

Preparation of the correct mixture ratio:

50:1 When using DOLMAR high-performance two-stroke oil,

i.e. 50 parts gasoline /1 part oil.

100:1 when using DOLMAR HP 100 high-performance two-

stroke engine oil, i. e. mix 100 parts gasoline with 1 part

oil.

40:1 When using other brands, i.e. 40 parts gasoline / 1 part

oil.

Note:

When preparing the fuel mixture, always first mix the entire oil

quantity with half of the gasoline, and then add the rest of the

gasoline. Shake the mixture well before putting in the fuel tank.

It is not wise to add more oil to the mixture than specified, even

if this may seem safer for the engine. More oil only leads to

increased combustion residues, which not only pollute the

environment, but are also bad for the cylinder exhaust

channel, muffler and the spark arrester screen. Furthermore

fuel consumption will increase and performance will fall.

14

40:1

other oil DOLMAR oil DOLMAR oil

OIL

+

3.2 floz.(94 cm3) 2.5 floz.(75 cm3) 1.3 floz.(38 cm3)

8.0 floz.(236 cm3) 6.4 floz.(189 cm3) 3.2 floz.(94 cm3)

16.0 floz.(473 cm3) 12.8 floz.(378 cm3) 6.4 floz.(189 cm3)

50:1

OIL

50:1

DOLMAR

100:1

HP 100

AVOID SKIN AND EYE CONTACT!

Utmost care is required when handling fuel. Fuel may contain

substances similar to solvents. Refuel either in a well ventilated

room or outdoors. Do not inhale fuel vapours. Fuel vapours are

poisonous and can be hazardous to your health. Avoid eye and

skin contact with fuels and mineral oils. Mineral oil products

degrease your skin. If your skin comes in contact with these

substances repeatedly and for an extended period of time, it will

desiccate. Various skin deseases may result. In addition, allergic reactions are known to occur. Eyes can be irritated by

contact with oil. If oil comes into your eyes, immediately wash

them with clear water.

If your eyes are still irritated, see a doctor immediately!

Storage of Fuel

Fuels have a limited storage life. Fuel and fuel mixtures age.

Therefore fuel and fuel mixtures, which have been stored for

too long, can cause starting problems. Purchase only that

amount of fuel, which will be consumed over the next few

months.

Store fuel safely in a dry place in approved containers

only.

Refuelling

STOP

FOLLOW THE SAFETY PRECAUTIONS!

Be careful and cautious when handling fuels.

The engine must be switched off!

2

1

B

- Thoroughly clean around the tank cap (B/1) so that no dirt

can enter the fuel tank.

- Before refuelling the brushcutter make sure it is in a

le position.

- Unscrew the tank cap (B/2) and carefully fill in the fuel

mixture up to the lower edge of the filler neck. Fill the tank

carefully, making sure not to spill any fuel.

- Tightly screw on the plug.

Clean screw plug and tank after refuelling.

stabi-

Page 15

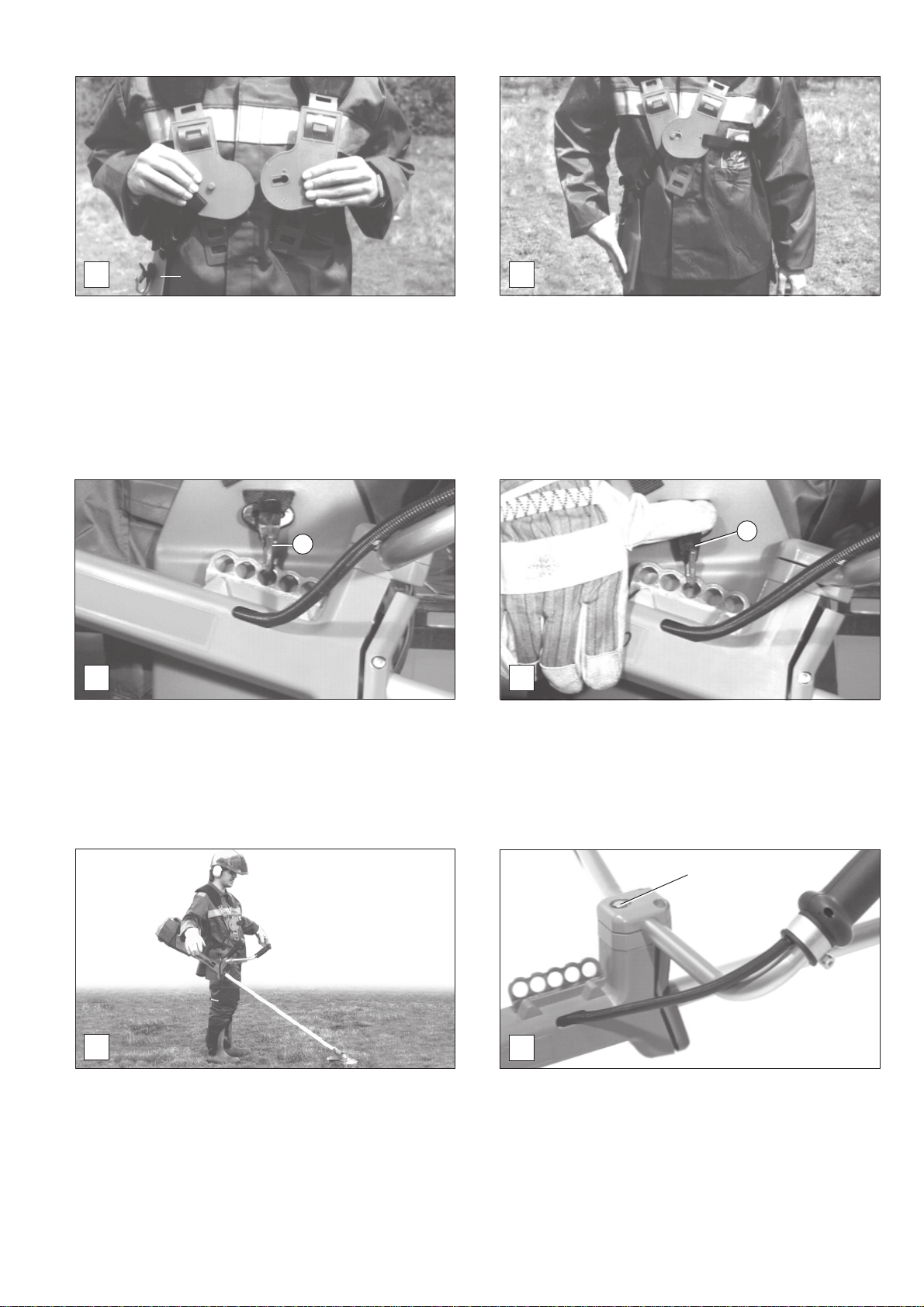

Putting on the harness

2

A

- Place the harness over both shoulders so that the hip pad

(A/1) is located on your right hand side.

- Adjust the harness until the chest plate (A/2) fits across

your chest.

1

Balancing the brushcutter

3

C

- Fill the fuel tank.

- Attach the brushcutter to the fixing hook (C/3) located on

the waist pad.

- 5 boreholes are provided for the correct personal balancing

of the brushcutter .

B

- Adjust the height of the hip pad means by of the chest

strap until the fixing hook is located about one hand’s width

above the hip bone.

- To open the harness detach the chest plates.

The harness and the brushcutter can then easily and

quickly be removed.

4

D

- To remove the brushcutter, first depress the lock (D/4) and

then detatchthe brushcutter from the fixing hook.

E

- The ground clearance will depend on the kind of cutting

tool selected.

- When using the trimmer head or steel bush cutter, the

trimmer head or sliding cup should touch the ground lightly

without the user having to hold the unit.

- In difficult terrain or when using the steel bush cutter or 8tooth eddy blades the brushcutter should balance about

12" (30 cm) above the ground without the user having to

hold the unit.

5

F

- Adjust the handles according to the working condition and

then always retighten the locking screw (F/5).

15

Page 16

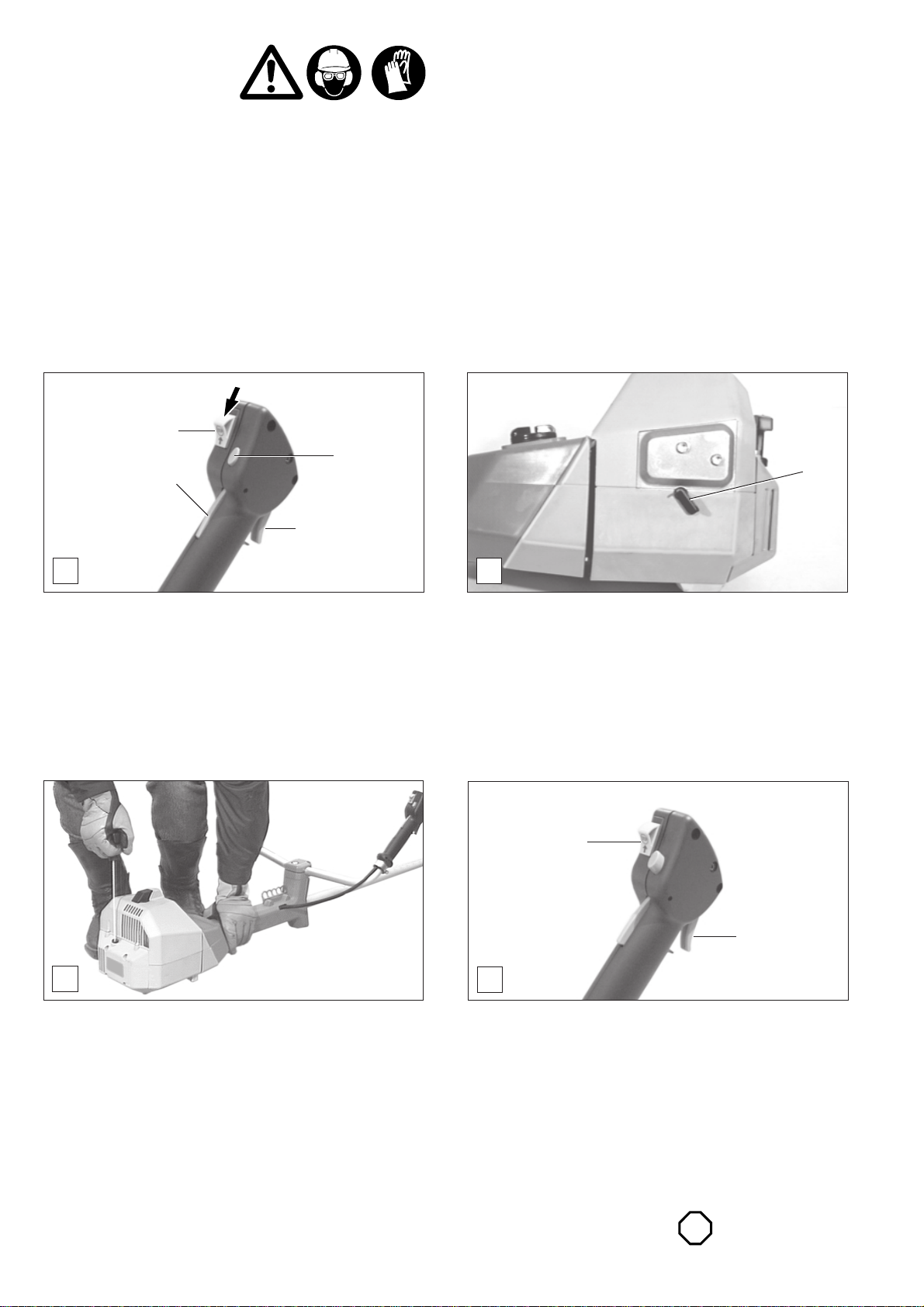

Putting into operation

Observe accident-prevention regulations!

Do not start the brushcutter until fully assembled and

inspected!

Starting the engine

- Move at least 10 feet (3 meters) away from where you filled

the fuel tank.

- Make sure you have a good footing, and lay the brushcutter

on the ground in such a way that the cutting tool is not

touching the ground or anything else.

Cold start

6

10

7

9

8

G

- Move the switch (G/6) in the direction of the arrow.

- To set the half-throttle catch, press the throttle (G/8) with

the throttle trigger lockout (G/7) pressed and then press

the catch (G/10). Release the throttle (G/8) and then the

throttle trigger lockout (G/7).

I

H

- Turn the choke lever (H/9) downwards to choke the engine.

6

8

J

- Hold the brushcutter frimly down with one hand, as

illustrated above.

- Pull the starter handle out slowly until resistance is noticed,

then pull the starter handle out fully with a quick and forceful

movement.

- Do not pull out the whole starter cable to its full extent and

do not let the starter handle jump back, but let it slowly

automatically rewind itself.

- Repeat starting procedure until ignition is achieved.

- Turn the choke lever (H/9) back up and pull the starter

cable again until the engine starts.

16

- After the engine has started, press the throttle (J/8) all the

way in and release immediately. This will disengage the

half-throttle position.

- Run the engine for approximately 1 minute at a moderate

speed before commencing work.

Warm start

Similar to a cold start but without the choke.

Turning off the engine

Move switch (J/6) to the position .

STOP

Page 17

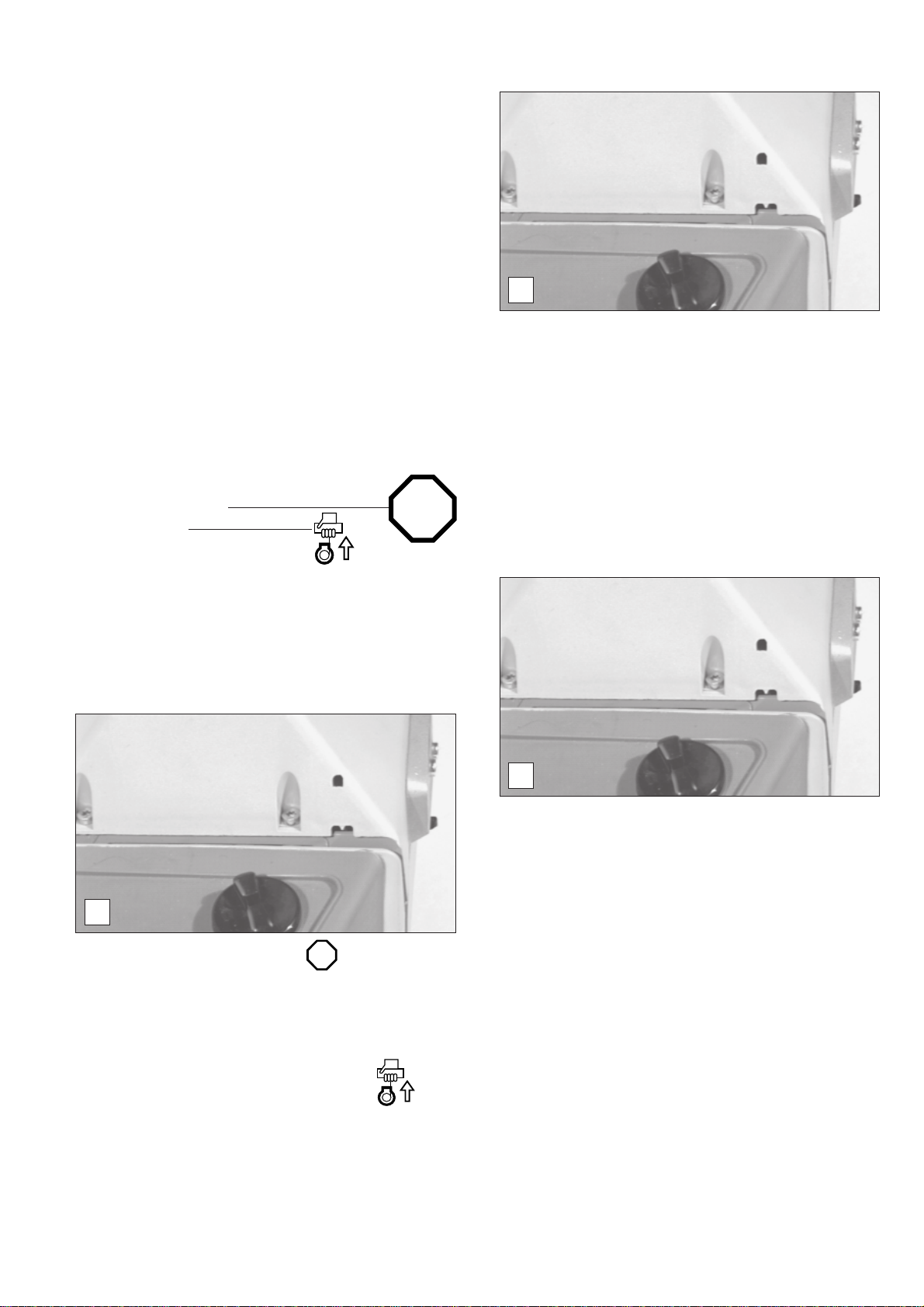

Carburetor adjustment

Important information:

The carburetor of this tool is fitted with limiter caps which restrict

the range of adjustment and prevents over-rich mixture

settings. This ensures providing good engine power and

efficient fuel consumption.

Before installing the limiter caps, the manufacturer performs

the „Basic Adjustment” procedure.

Maximum power is achieved throughcarburetor adjustment. It requires a warm engine and a clean air filter and

should preferably be performed by an expert.

The carburetor comes factory-set for the atmospheric pressure at sea-level. At other elevations and during the run-in

phase with a new engine it may be necessary to adjust the

carburetor.

A tachometer (order no. 950 233 210) is a must for accurate

carburetor adjustment.

Before adjusting the carburetor, install the cutting tool you are

going to use and warm up the engine by running it 3-5 minutes.

S

H

B

Set idling speed (step 3)

- If the cutting tool turns when the engine is idling, screw the

throttle-valve stop screw (S) until the cutting tool stops

turning. The idling speed should be now 2,300-2,500 rpm/

min.

For a precise adjustment the following steps are to be

performed:

1. Check adjustment

2. Start engine

3. Set idling speed

4. Adjust speed

5. Check idling speed

6. Check acceleration

7. Check max. speed or output

8. Repeat adjustment procedure starting with step 3, until

idling speed, max. speed and acceleration are reached

with the adjustment made.

STOP

L H

A

Adjustment instructions (step 1)

- Before initial operation make sure that the adjusting screws

(H and L) have not been set in all the way. Limiter caps do

not protect the engine from leaning.

- Turn the two adjusting screws (H and L) counter-clockwise as far as they will go.

- Start the engine and let it warm up (step 2).

STOP

Adjust speed (step 4)

- Set the engine speed to 13,000-13,500 RPM by adjusting

the main jet screw (H). Screwing it in makes the fuel/air

mixture leaner (less fuel, more air) and increases the engine

speed.

Caution:

Engine speeds above 13,500 RPM reduce engine life!

L

C

Check idling speed (step 5)

- Now check the idle speed. It should be 2,300-2,500 RPM

(the cutting tool should not turn). If necessary, adjust the

idle speed with the idle jet screw (L). Turning it in increases

the speed, and turning it out decreases it.

Check acceleration (step 6)

- This is the time it takes for the engine to go from idle speed

to maximum speed when you press the throttle hard.

- If acceleration is too slow, turn the idle screw (L) out about

1/8 turn.

17

Page 18

REPAIR AND MAINTENANCE WORK

CAUTION: Before doing any work on the brushcutter, always switch off the motor and pull

STOP

CAUTION: Start the brushcutter only after complete assembly and inspection!

the plug cap off the spark plug. Always wear protective gloves!

Sharpening of cutting tools

Caution: Wear always gloves during

sharpening!

1

After it has been sharpened and resharpened several times

the chisel type saw blade must be sharpened and balanced

at a qualified workshop.

2

Caution:

For to safety reasons, never try to straighten or weld a

damaged cutting tool!

D

Note: The cutting tools below should be sharpened only at

a qualified workshop! Manual resharpening will result in

an imbalance of the cutting tool, causing vibrations and

engine damage.

• Steel bush cutter (D/1)

• Star blade (D/2)

• 8-tooth eddy blade (D/3)

Expert sharpening can be obtained from a DOLMAR service

station.

Note: To increase the working life the steel bush cutter and

the star blade may be turned over once until their second cutting sides are blunt.

3

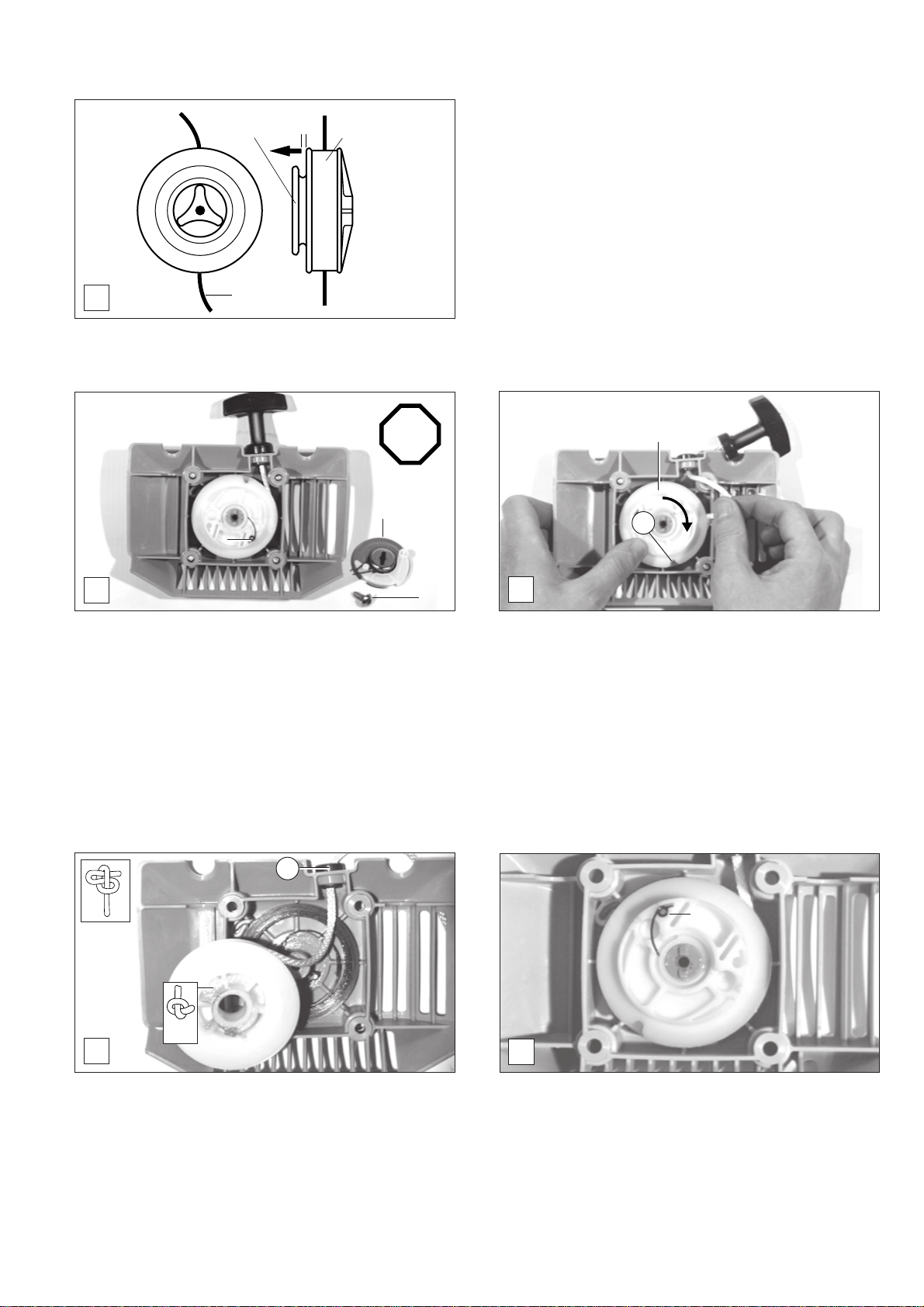

Chisel type saw blade

When sharpening the chisel type saw blade (E/4) with a round

file take care to sharpen all tooth recesses evenly.

The damage of only one tooth requires equal sharpening or

refiling of all other teeth.

If teeth have broken off the chisel type saw blade, it has to be

replaced.

Uneven sharpening will result in strong vibration due to an

imbalance which will cause damage to the cutter as well as

generating vibration in the handles.

Use only a special 5.5 mm dia. round file for saw blades with

support (part no. 953 009 000) to sharpen the chisel type saw

blade. Other round files are not suitable.

When hand-sharpening a mounted saw blade, make sure the

brushcutter is properly supported.

4

E

20o-25

o

F

Always maintain a sharpening angle of 20-25 degrees (F).

For this purpose please observe that the markings on the top

surface of the file should follow in a parallel direction to the

saw blade.

The inclination should be approximately 5 degrees (F).

5

o

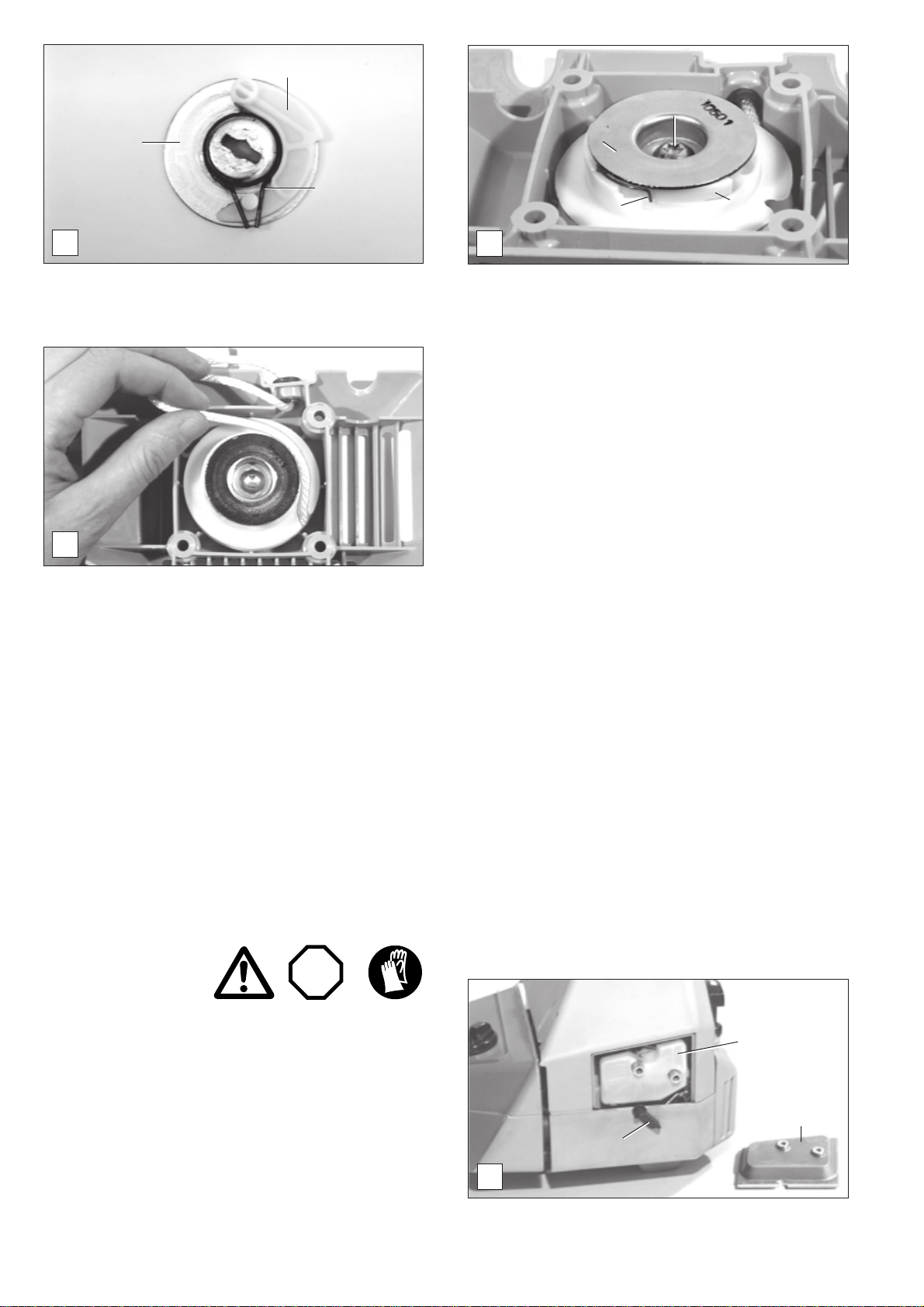

Setting the teeth

A

.040"

(1mm)

B

G

Should the saw blade jam during cutting, inspect the tooth

setting.

The setting should be .040" (1 mm).

T o correct the setting of the saw blade teeth use the saw blade

adjusting tool which is available as an accessory

(Part no. 953 385 010).

The existing tooth setting of the saw blade must be strictly

maintained!

Push down on the adjusting tool as shown (A).

T o inspect the tooth setting, hold the adjusting tool against the

saw blade. The tooth should touch against the offset part of

the adjusting tool (B).

File only the tooth face. The file support should rest on the

back of the tooth as illustrated above (arrow).

18

Page 19

Trimmer head

Lengthening the line

A

3

Starter cable replacement

- Hold the housing (A/1) firmly and pull the housing cover

12

Schematic

(A/2) out against the spring pressure in the direction of the

arrow (figure) until it is possible to turn the cover (A/2)

counter-clockwise.

- Stop pulling out on the cover (A/2) and turn it

counter-clockwise until it snaps back in.

- Pull the line ends (A/3) out as far as they will go. Repeat

this procedure until you have about 6" (15 cm) of line

available.

A detailed description of this adjustment is included with the

trimmer head.

STOP

5

6

B

- Unscrew the ventilator housing.

- Screw out the center screw (B/4).

- Remove the guide disk (B/5) complete with the starter

ratchet and the brake spring.

- Remove the pawl spring (B/6).

4

9

8

7

C

- Pull out the starter handle and starter cable to length of

about 12" (30 cm).

- Hold the starter cable drum and pull out the starter cable

using a screw driver or similar tool.

- Let the drum slowly turn backwards (in the direction of the

arrow) with the starter cable in the appropriate slot (C/7)

until the tension in the spring has been released.

- Remove the drum (C/8).

- If starter cable has split or frayed, remove it from the drum.

- Lubricate the center shaft of the starter cable drum with a

multipurpose grease (Part no. 944 360 000) before

commencing re-assembly.

11

10

D

- Push the starter cable through the guide hole (D/9) and

then feed the cable through the opening in the drum and

tie a knot as shown above.

- Press the knotted end of the starter cable (D/10) into the

appropriate slot in the drum.

- Feed the other cable end through the handle and secure

with the knot shown in (D/11).

- Wind the cable onto the drum for about 3 1/4 turns. Pay

attention to the correct direction of rotation (counterclockwise when assembled).

12

E

- Put the starter cable drum into the housing and check to

make sure the return spring is hooked in the correct position

by turning it slightly counter-clockwise.

- Insert the pawl spring (E/12) into the starter cable drum as

shown.

19

Page 20

13

STOP

4

5

14

F

- Lubricate the guide disk (F/5) with a mulitpurpose grease

and install the pawl (F/13) and the brake spring (F/14) as

illustrated above.

H

5

6

13

G

- Install the guide disk (G/5) along with the pawl and brake

spring into the starter cable drum in such a manner that

the pawl spring (G/6) is pressed against the pawl (G/13).

- Turn the guide disk (G/5) so that the shaft guide is located

in the slot of the guide disk.

- Screw down the center screw (G/4) to hold the assembly

in place.

- Pull the starter cable out of the drum, then insert it into the

appropriate slot in the drum and turn the drum, together

with the starter cable counter-clockwise for 1 turn. Release

the drum and let the spring tension wind up the cable.

- Repeat the above procedure until the starter handle has

reached its correct starting location on the ventilator

housing assembly.

- Reassemble the ventilator housing.

Instructions for maintenance

Do not do any maintenance or servicing work not described in this Instruction Manual. All such work may be done only by a DOLMAR

service station.

After refuelling the brushcutter 50 times, it should be given a thorough maintenance check and a complete inspection at a DOLMAR

service centre.

Daily maintenance

Perfom the following work daily after use:

- Clean the outside of the brushcutter and inspect for damage.

- Clean the air filter (see below). Under dusty working conditions the air filter must be cleaned more often.

- Check the cutting tool for damage and make sure it is tight.

- Check to make sure that there is sufficient difference between the idle and engagement speed so that the cutting tool does not

turn when the engine is idling. If necessary, reduce the idle speed (see page 17). If the cutting tool still turns during idling, take

the brushcutter to a service center.

- Check the function of the safetylocking button, the short-circuiting switch and of the throttle lever (see page 16).

Cleaning the air filter

- Remove the air filter cover (I/15). Close the choke lever

(I/16) to prevent the entry of dust particles into the

carburetor.

- Remove the air filter (I/17) and clean it with a soft brush.

Caution:

To prevent eye injuries, do not blow out dirt particles.

- Very dirty filters can be cleaned out using regular

dishwashing liquid in lukewarm water.

- In case of strong pollution clean more often (several times

a day) because only a clean filter ensures full engine power.

- Before reinstalling the air filter check the choke valve for

dirt particles, and if necessary clean it out with a brush.

- Carefully dry the air filter and reinstall it.

20

16

I

Important: If the air filter is damaged replace it immediate-

ly! Torn-off fabric pieces and large dirt particles can

destroy the engine.

17

15

Page 21

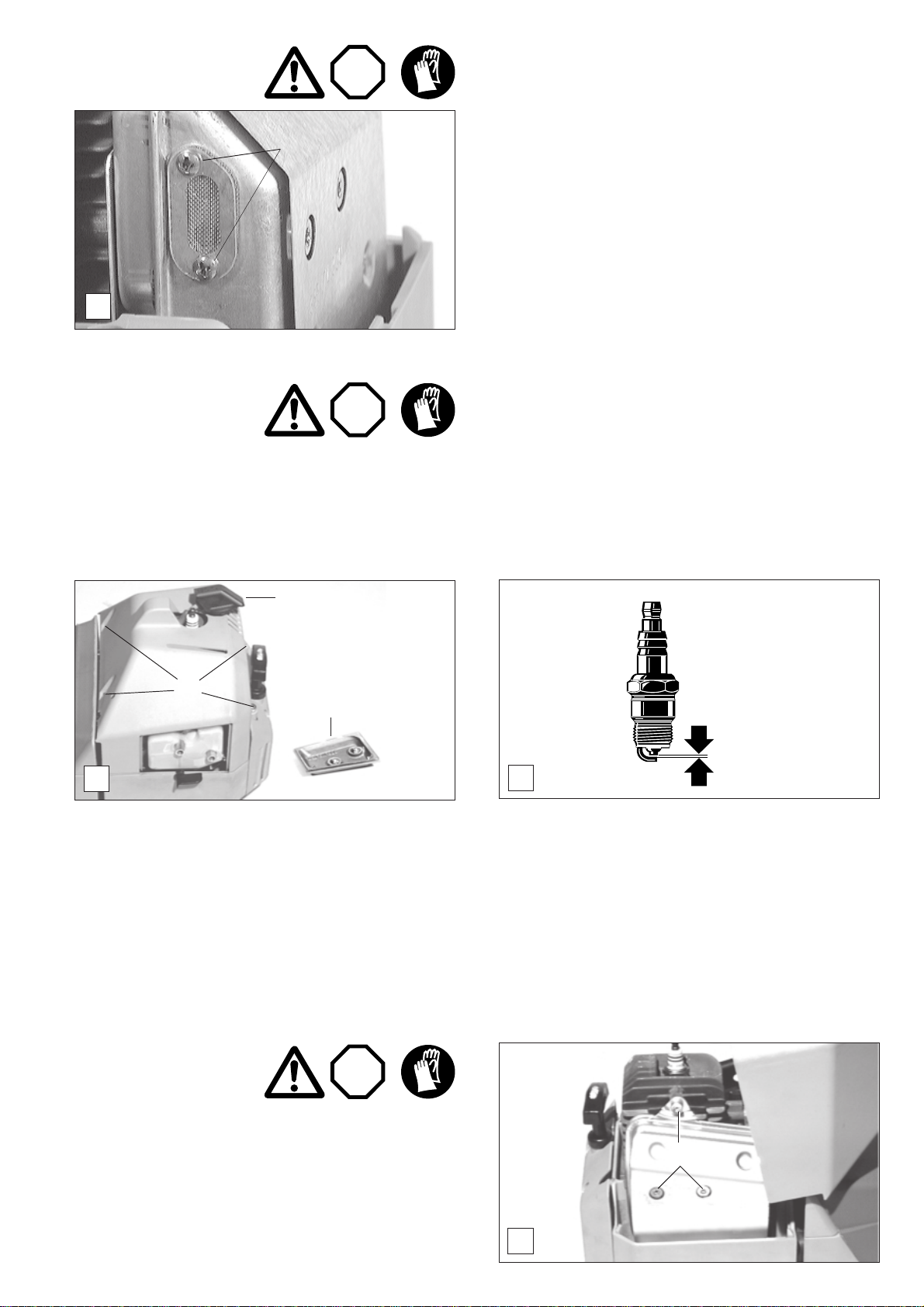

Replacing/cleaning the

spark arrestor screen

J

Weekly maintenance

STOP

The spark arrestor screen should be checked and cleaned

5

regularly.

- Remove the filter cover (see "Checking the muffler bolts").

- Loosen the 2 screws (J/5) and remove the spark arrestor

screen.

- Clean the spark arrestor screen with a soft brush.

NOTE: Do not use sharp or pointed objects for screen cleaning. Damaged or misformed screen wires may result.

IMPORTANT: If the spark arrestor screen is damaged

replace it immediately!

- Reassembly the spark arrestor screen and tighten the

screws.

Inspecting and replacing

the spark plug

CAUTION:

NEVER touch the spark plug or spark plug cap while the

engine is running (high voltage).

Never do maintenance work with the engine running!

A hot engine can cause severe burns. Wear protective

gloves!

STOP

18

19

15

K

The spark plug must be replaced if the insulator is damaged

or if the electrodes are severely eroded or dirty or oily.

- Pull the spark plug cap (K/18) off the plug. Use only the

combination wrench supplied with the brushcutter to

remove the spark plug.

Note: Replace only with CHAMPION RCJ-6Y, BOSCH WSR

6F or NGK BPMR 7A spark plugs!

.020" - .030"

(0.5 - 0.8 mm)

L

Electrode gap

The electrode gap must be .020" - .030" (0.5 - 0.8 mm).

Checking the ignition spark

- Remove the spark plug. With the spark plug cable on, hold

the plug against the cylinder (but not near the spark plug

hole!) using insulated pliers.

- Turn the on/off switch to “I” (on).

- Pull the starter cable hard.

A spark should be visible at the electrode gap.

Checking the muffler

bolts

Caution:

Do not tighten the muffler bolts while the engine is hot!

- Remove plug connector (K/18) and unscrew and remove

the filter cover (K/15).

- Loosen the four fixing bolts (K/19) of the cover and remove

it.

- Check the muffler bolts (M/20) for tightness using the Allen

key. If loose, tighten manually. Do not over-tighten.

STOP

20

M

21

Page 22

Periodic maintenance

STOP

Suction head in the fuel tank

STOP

21

N

Muffler guard

The felt filter (N/21) of the suction head is used to filter the fuel

taken in by the carburetor.

A periodical visual inspection of the felt filter should be conducted. For this purpose open the tank cap, and use a wire

hook to pull out the suction head through the tank opening. If

the filter has hardened or is dirty or clogged, replace it (see

"Excerpt from the spare-parts list").

Insufficient fuel supply can result in the admissible maximum

speed being exceeded. It is therefore important to replace the

felt filter at least every three months to ensure a good fuel

supply to the carburetor.

O

Information about the gear box

24

P

23

22

Check if the muffler guard (O/22) is in good condition. A bent,

broken or missing muffler guard can cause bush fires especially during dry weather conditions.

Replace a non-functional muffler immediately!

Also check the four clamp rings (O/23) before using the

brushcutter. Replace damaged clamp rings immediately! The

correct mounting and positioning of the muffler is essential to

guarantee protection against a possible fire hazard from the

engine exhaust.

The gear box (P/24) is provided with a permanant lubrication

and consequently does not need any maintenance.

However, if large quantities of grease are leaking from the

gear box, consult a DOLMAR service station.

Servicing and maintenance

We recommend that a comprehensive maintenance and inspection be performed at regular intervals.

Any maintenance or adjustment work not described in this

manual may be performed

tion.

only by a DOLMAR service sta-

Shutting down procedure and storage

If you are not planning to use the brushcutter for a period in excess of 6 weeks, it is recommended to observe the following

instructions:

• Perform the servicing operations as described on pages 18 to 24.

• Empty the fuel tank and run the engine until the carburetor is dry. Fuels have only a short storage life and can cause sedimentary

deposits in the fuel tank or carburetor.

• Remaining fuel in canisters should be used for other engines, or properly disposed of.

• Clean and lightly lubricate metallic cutting tools.

• Store the brushcutter in a dry place only.

• The next time you use the brushcutter, purchase new fuel and prepare the two-stroke mixture as specified.

22

Page 23

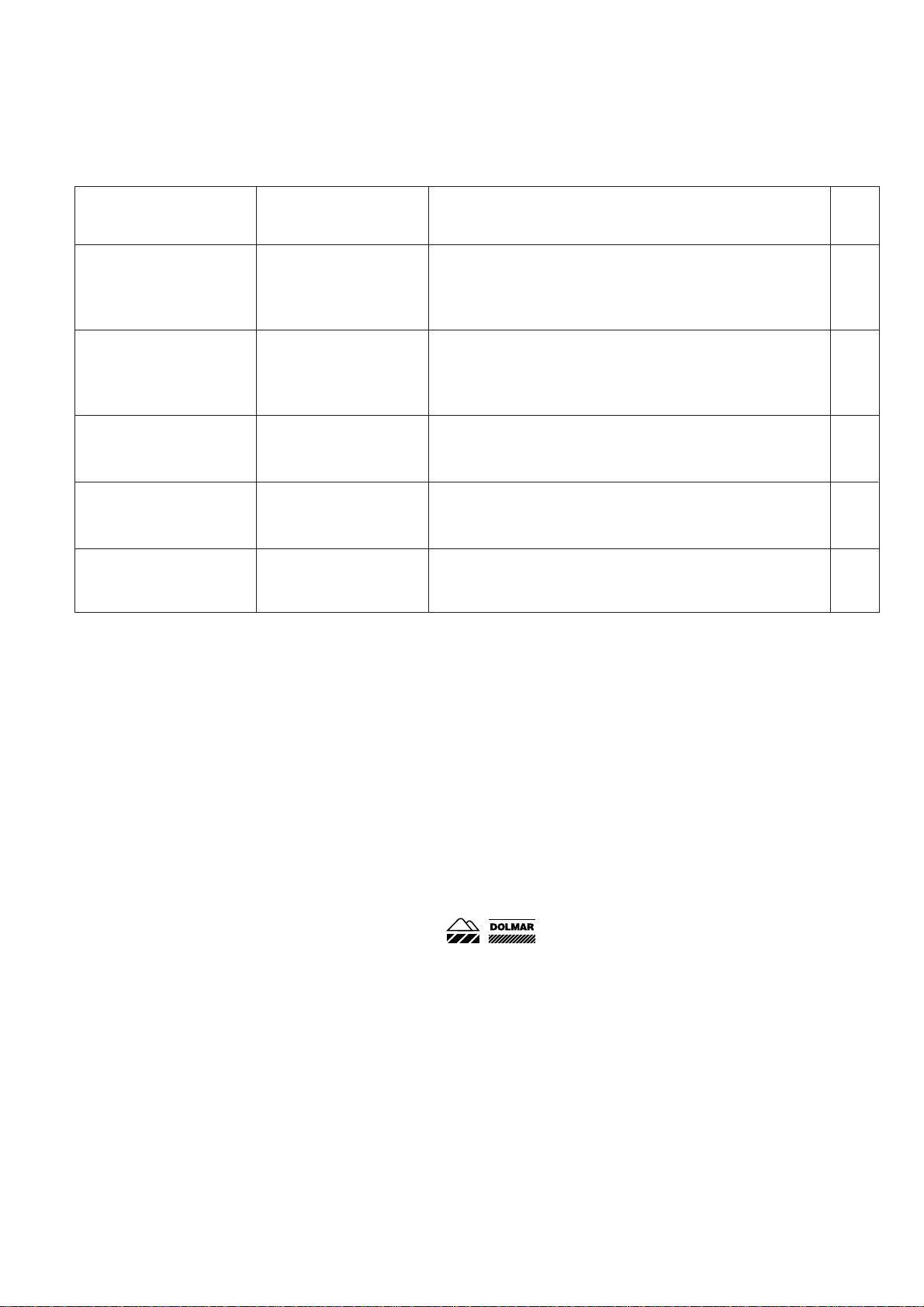

Instructions for periodic maintenance

To ensure long life, prevent damage and ensure the full functioning of the safety features the following maintenance must be

performed regularly. Guarantee claims can be recognized only if this work is performed regularly and properly. Failure to perform

the prescribed maintenance work can lead to accidents!

Page

General Engine assembly Visual inspection for damage, loose attachment

and fuel tank sealing

After each refuelling Throttle lever Functional check

Safety lock button Functional check

STOP-switch Functional check

Daily Air filter Clean

Cutting tool Check for damage and sharpness

Idle speed Check (cutting tool must not move)

Weekly Spark plug Inspection, replace if necessary

Muffler Clean and tighten bolts

Quarterly Suction head Replace

Fuel tank Clean

Shutting down Fuel tank Empty

procedure Carburetor Run empty

20-22

16

16

16

20

18

17

21

21

22

Service, spare parts and guarantee

Maintenance and repair

The maintenance and repair modern brushcutters and safety-related components and assemblies requires qualified technical

training and a workshop equipped with special tools and testing devices.

We therefore recommend that you consult a DOLMAR service centre for all work not described in this instruction manual.

The DOLMAR service centres have all the necessary equipment and skilled and experienced personnel, who can work out cost-

effective solutions and advise you in all matters.

Please contact your nearest service centre (list enclosed).

Spare parts

Reliable long-term operation, as well as the safety of your brushcutter, depend among other things on the quality of the spare parts

used. Use only original DOLMAR parts, marked

Only original spare parts and accessories guarantee the highest quality in material, dimensions, functioning and safety.

Original spare parts and accessories can be obtained from your local dealer. He will also have the spare part lists to determine the

required spare part numbers, and will be constantly informed about the latest improvements and spare part innovations.

Please bear in mind that if parts other than original DOLMAR spare parts are used, this will automatically invalidate the DOLMAR

product guarantee.

We will furthermore not accept any liability damages arising from the use of non-DOLMAR spare parts.

23

Page 24

Guarantee

DOLMAR guarantees the highest quality and will therefore reimburse all costs for repair by replacement of damaged parts resulting from material or production faults occurring within the guarantee period after purchase. Please note that in some countries

particular guarantee conditions may exist. If you have any questions, please contact your salesman, who is responsible for the

guarantee of the product.

Please note that we cannot accept any responsibility for damage caused by:

• Disregard of the instruction manual.

• Non-performance of the required maintenance and cleaning.

• Exceeding of the maximum admissible speed due to incorrect carburetor adjustment.

• Incorrect carburetor adjustment.

• Normal wear and tear.

• Obvious overloading due to permanent exceeding of the upper performance limits.

• Use of force, improper use, misuse or accidents.

• Overheating due to dirt in the coolant-air intake system including air filter.

• Work on the chain saw by unskilled persons or inappropriate repairs.

• Use of unsuitable spare parts or parts which are not original DOLMAR parts, insofar as they have caused the damage.

• Use of unsuitable or old oil.

• Damage related to conditions arising from lease or rent contracts.

• Damages caused by disregarding loose outer bolted connections.

Cleaning, servicing and adjustment work is not covered by the guarantee. All repairs covered by the guarantee must be performed

by a DOLMAR service centre.

Troubleshooting

Fault System Observation Cause

Engine will not start or Ignition system Ignition spark OK Fault in fuel supply or compression system,

starts only with difficulty mechanical defect

No ignition spark STOP switch is depressed, wiring fault or short

circuit, spark plug or connector defective,

ignition module faulty

Fuel supply Fuel tank full Incorrect choke position, carburetor defective,

suction head dirty, fuel supply line bent or

interrupted

Compression Inside of engine Cylinder bottom gasket defective, crankshaft

system seals damaged, cylinder or piston rings

defective or worn

Outside of engine Poor sealing of spark plug

Mechanical fault Starter not engaging Broken starter spring, broken parts inside engine

Warm start problems Tank filled Incorrect carburetor setting

ignition spark OK vent operation

Engine starts but Fuel supply Tank full Incorrect idle speed, suction head or

dies immediately carburetor dirty

Fuel tank vent defective, fuel supply line

interrupted,cable or STOP switch faulty

Insufficient power Several systems Engine idling Air filter dirty, carburetor adjustment

may be affected incorrect, muffler clogged, exhaust duct in

simultaneously the cylinder clogged

24

Page 25

Extract from the spare parts list

Use only original DOLMAR spare parts. For repairs and

replacement of other parts see your DOLMAR service station.

MS-3310

MS-4010

MS-4510

Pos. DOLMAR-No. Qty. Description

12

8

9

7

1 385 160 103 1 Starter housing

2 387 164 010 1 Starter cable, dia. 3 mm (1/8")

3 908 605 205 4 ✪ Fillister head screw M5x10x20

4 385 173 100 1 Air filter

5 385 118 060 1 Cover

6 908 605 145 2 ✪ Fillister head screw M5x7x14

7 965 603 021 1 Spark plug

8 010 114 045 1 Tank cap

9 963 601 150 1 Suction head

10 385 228 041 1 Locknut

11 965 527 060 1 Air filter gasket

12 385 174 080 1 Spark arrestor screen assy.

2

11

4

5

6

1

3

10

Notes

25

Page 26

Nous vous remercions pour votre confiance!

Nous désirons que vous soyez un client satisfait de DOLMAR.

Vous avez choisi une des débroussailleuses DOLMAR les plus

modernes. DOLMAR est dans le monde le plus ancien

constructeur de tronçonneuses (1927) et possède ainsi une

expérience de plusieurs dizaines d'années dans le domaine

des appareils entraînés par moteur à 2 temps.

Les débroussailleuses MS-3310, MS-4010 et MS-4510

réunissent les avantages d'une technique moderne avec

construction ergonomique et sont par là des débroussailleuses

professionnelles pour utilisation multiple.

Le moteur à haute puissance - cœur de la débroussailleuse a été complètement réétudié. Le moteur avec construction

optimale du cylindre, temps de commande calculés par

ordinateur et allumage électronique nécessitant aucun entretien

permet d'obtenir une haute puissance avec une consommation

minime de carburant.

L'arbre d'entraînement est à 9 paliers et équipé d'un embrayage

centrifuge solide pour utilisation de longue durée dans des

conditions difficiles. Le réservoir de carburant placé devant

permet un bon emplacement du centre de gravité et ainsi un

bon équilibre de la machine pendant le travail.

Les avantages techniques particuliers de cette débroussailleuse

DOLMAR sont entre autres:

- Amortissement optimal des vibrations

4 éléments amortisseurs creux coniques, d'une part entre

moteur et tube principal, et d'autre part entre réservoir et

poignée, permettent d'amoindrir le plus possible les

vibrations pour l'utilisateur, de telle sorte que celuici puisse

travailler confortablement en économisant ses

forces,même en utilisation de longue durée

- La poignée à fonctions multiples

Tous les éléments de commande principaux sont

rassemblés de façon ergonomique sur la poignée droite.

- Changement facile d'outil

Le tout nouveau dispositif de blocage étudié par DOLMAR

permet, par pression sur bouton, de bloquer l'outil pour un

changement simple et sûr.

- Amortissement du bruit très efficace Ladébro

ussailleuse travaille silencieusement grâce à son moteur

entièrement fermé et l'amortissement des bruits à

l'aspiration par une chambre de résonance.

Dans l’appareil ont été observés les droits de protection

suivants: US 512606, EP 0438611, EP 0696414, GBM

9106194, GBM 9412925.

De façon à garantir votre sécurité personnelle et un

fonctionnement optimal de la débroussailleuse ainsi que la

puissance désirée, nous vous demandons:

Avant la première mise en service, lisez attentivement les

instructions d'emploi et observez strictement les consignes

de sécurité. La non-observation de ces instructions risque

d’entraîner des blessures mortelles!

Emballage

Votre débroussailleuse DOLMAR est emballée dans un carton

et donc à l’abri de toute détérioration pendant le transport.

Les cartons sont des matières premières recyclables, ils peuvent donc être remis dans le cycle de la matière première

(réutilisation des viuex papiers).

RE Y

26

Sommaire Page

Emballage ................................................................ 26

Etendue de la fourniture ........................................ 27

Explication des symboles...................................... 27

CONSIGNES DE SECURITE

Consignes de sécurité générales ........................28

Equipement de protection personnel................... 28

Carburants / Remplissage du réservoir...............29

Mise en service...............................................29-30

Choc-retour (kickback) ........................................ 30

Comportement et technique de travail ................ 31

Outils de coupe.................................................... 31

Transport .............................................................31

Entreposage ........................................................31

Maintenance ........................................................ 32

Premiers secours................................................. 32

Caractéristiques techniques .................................33

Description des pièces...........................................33

MISE EN SERVICE

Montage de la poignée tubulaire .........................34

Montage du capot de protection .....................34-35

Montage du couteau à 3 dents,

du disque de coupe à 8 dents et

du couteau à 4 dents ......................................35-36

Montage du dispositif de coupe à fils ..................36

Montage du couteau de fil ...................................36

Montage du capot de protection

métallique et de la scie circulaire à gouge .......... 37

Le réducteur angulaire......................................... 37

Mélange carburant............................................... 38

Stockage du carburant ........................................ 38

Remplissage du réservoir....................................38

Mise en place du harnais.....................................39

Equilibrage de la débroussailleuse...................... 39

Démarrage ........................................................... 40

Réglage du carburateur ....................................... 41

TRAVAUX DE MAINTENANCE

Affûtage des outils de coupe ...............................42

Dispositif de coupe à fils......................................43

Changement du câble de lancement..............43-44

Nettoyage du filtre à air ....................................... 44

Changement / nettoyage du pare-étincelles........45

Vérification / remplacement de la bougie ............45

Contrôle des vis du silencieux ............................. 45

Tête d'aspiration dans réservoir de carburant..... 46

Protège-silencieux (pour Etats-Unis)................... 46

Réducteur angulaire ............................................ 46

Service après-vente et entretien .........................46

Service atelier, pièces de rechange

et garantie...........................................................47-48

Recherche des causes de panne .......................... 48

Extrait de la liste des pièces détachées ...............49

Notes ........................................................................ 49

Liste d'ateliers spécialisé (voir annexe)

Page 27

Etendue de la fourniture

max.

10.000 1/min

max.

11.500 1/min

3

2

1

4

1. Débroussailleuse

2. Harnais*

3. Outil de coupe*

4. Capot de protection*

5. Protecteur d'outil* (non illustré)

6. Outil pour entretien (non illustré)

7. Manuel d’emploi et de sécurité (non illustré)

* Les pièces marquées d'un * peuvent être de version différente suivant le modèle.

L'illustration ne représente donc pas absolument les pièces livrées.