Page 1

English / Français / Spanish

C

Brush Cutter

Débroussailleuse

Desbrozadora

MS-250.4

ISTRUZIONI D’USO

MANUAL DE INSTRUCCIONES

String Trimmer

Taille-bordures

Cortabordes

MS-251.4

INSTRUCTION MANUAL

MANUEL D’INSTRUCTIONS

MANUAL DE INSTRUCCIONES

MS-250.4

Important:

Read this instruction manual carefully before putting the Brush Cutter/String Trimmer into operation and strictly observe the safety

regulations!

Preserve instruction manual carefully!

Recommandation importante:

Lire soigneusement ce manuel d’instructions avant de mettre la débroussailleuse / taille-bordures en service et observer

rigoureusement les consignes de sécurité!

Conserver soigneusement ce manuel d’instructions.

Importante:

Leer cuidadosamente este manual de instrucciones antes de poner en marcha la máquina y observar estrictamente las normas de

seguridad.

Conservar este manual de instrucciones con cuidado.

MS-251.4

Page 2

Thank you very much for purchasing the DOLMAR Brush Cutter/String

trimmer. We are pleased to recommend to you the DOLMAR Brush Cutter/

String trimmer which is the result of a long development programme and many

years of knowledge and experience.

Please read this booklet which refers in detail to the various points that will

demonstrate its outstanding performance. This will assist you to obtain the

best possible result from your DOLMAR Brush Cutter/String trimmer.

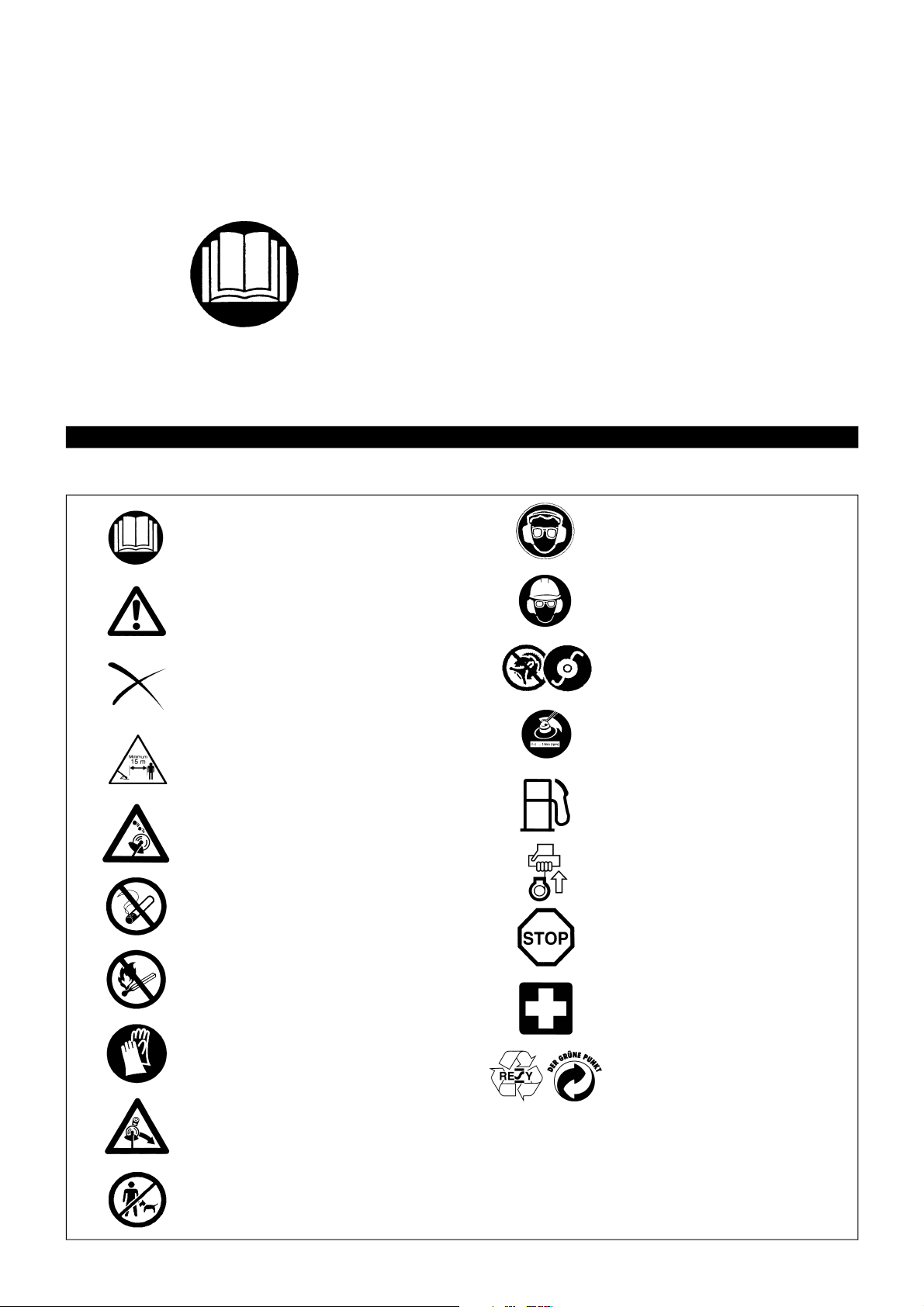

SYMBOLS

You will note the following symbols when reading the instructions manual.

Read instruction Manual

Table of Contents Page

Symbols ...................................................................... 1

Safety instructions ..................................................... 2

Technical data ............................................................ 6

Designation of parts ................................................... 7

Mounting of handle ..................................................... 8

Mounting of protector ................................................. 9

Mounting of cutter blade or nylon cutting head ......... 10

Before start of operation .......................................... 11

Correct handling of machine ..................................... 13

Points in operation and how to stop ......................... 13

Resharpening the cutting tool ................................... 15

Servicing instructions ............................................... 17

Storage ..................................................................... 20

Wear eye and ear protection

(for String trimmer only)

Take Particular care and Attention

Forbidden

Keep distance

Flying object hazard

No Smoking

No open flame

Wear protective helmet, eye and ear

protection (for Brush Cutter only)

Do not use metal blades

(for String trimmer only)

Top permissible tool speed

Fuel (Gasoline)

Engine-Manual start

Emergency stop

First Aid

Protective gloves must be worn

Kickback

Keep the area of operation clear of all

persons and pets

Recycling

ON/START

I

O

1

OFF/STOP

Page 3

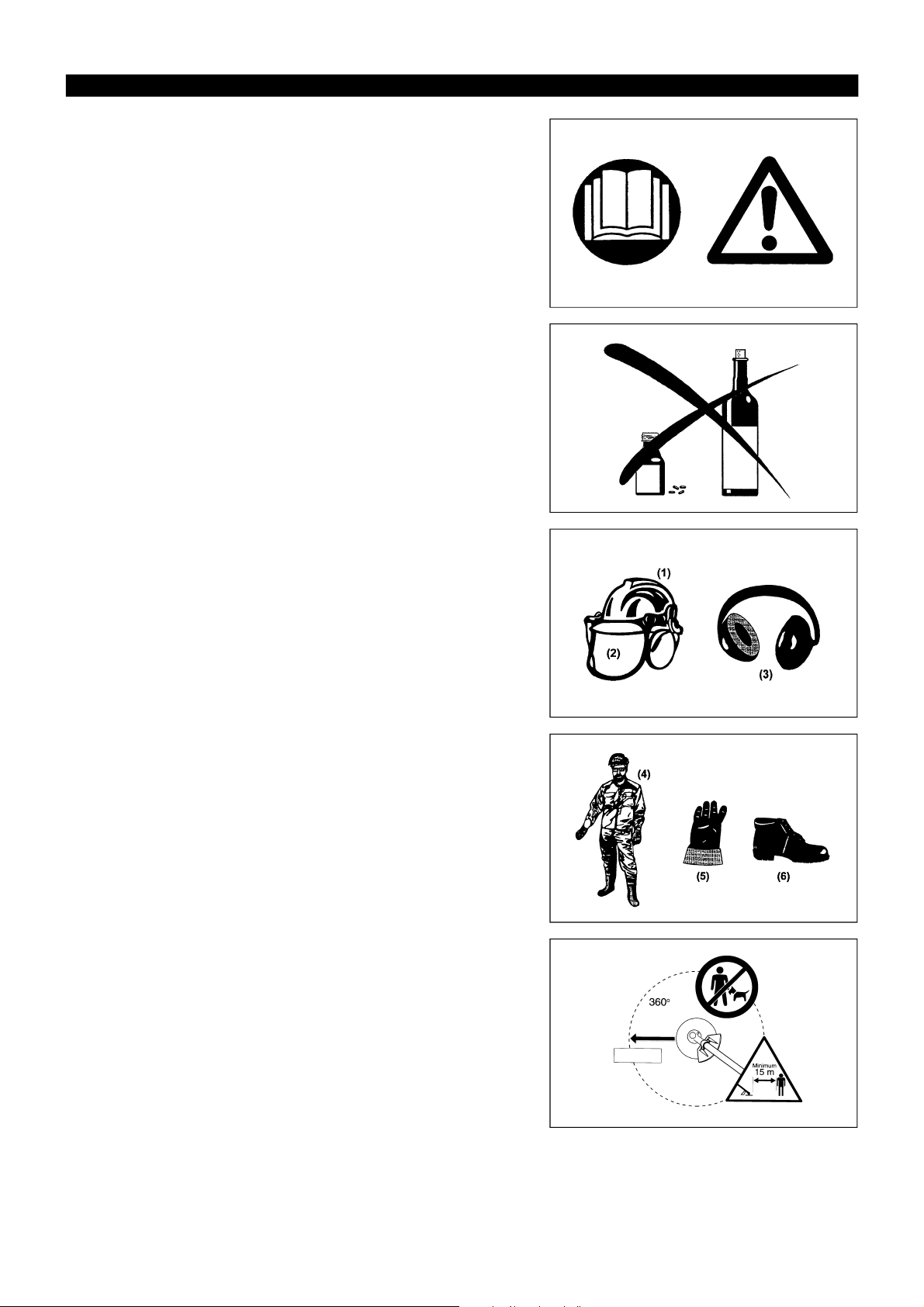

SAFETY INSTRUCTIONS

General Instructions

– To ensure correct operation, user has to read this instruction manual to make

himself familiar with the handling of the Brush Cutter/String trimmer. Users

insufficiently informed will risk danger to themselves as well as others due to

improper handling.

– It is recommended only to lend the Brush Cutter/String trimmer to people who

have proven to be experienced with Brush Cutter/String trimmers.

Always hand over the instruction manual.

– First users should ask the dealer for basic instructions to familiarize oneself

with the handling of an engine powered cutter.

– Children and young persons aged under 18 years must not be allowed to

operate the Brush Cutter/String trimmer. Persons over the age of 16 years

may however use the device for the purpose of being trained only whilst

under supervision of a qualified trainer.

– Use Brush Cutter/String trimmers with the utmost care and attention.

– Operate the Brush Cutter/String trimmer only if you are in good physical

condition. Perform all work calmly and carefully. The user has to accept

liability for others.

– Never use the Brush Cutter/String trimmer after consumption of alcohol or

drugs, or if feeling tired or ill.

Intended use of the machine

– The Brush Cutter/String trimmer is only intended for cutter grass, weeds,

Bushes, undergrowth it should not be used for any other purpose such as

Edging or hedge cutting as this may cause injury.

Personal protective equipment

– The clothing worn should be functional and appropriate, i.e. it should be tight-

fitting but not cause hindrance. Do not wear either jewelry or clothing which

could become entangled with bushes or shrubs.

– In order to avoid either head-, eye-, hand-or foot injuries as well as to protect

your hearing the following protective equipment and protective clothing must

be used during operation of the Brush Cutter/String trimmer.

– Always wear a helmet where there is a risk of falling objects. The protec-

tive helmet (1) is to be checked at regular intervals for damage and is to be

replaced at the latest after 5 years. Use only approved protective helmets.

– The visor (2) of the helmet (or alternatively goggles) protects the face from

flying debris and stones. During operation of the Brush Cutter/String trimmer

always wear goggles, or a visor to prevent eye injuries.

– Wear adequate noise protection equipment to avoid hearing impairment (ear

muffs (3), ear plugs etc.).

– The work overalls (4) protect against flying stones and debris.

We strongly recommend that the user wears work overalls.

– Special gloves (5) made of thick leather are part of the prescribed equipment

and must always be worn during operation of the Brush Cutter/String

trimmer.

– When using the Brush Cutter/String trimmer, always wear sturdy shoes (6)

with a non-slip sole. This protects against injuries and ensures a good

footing.

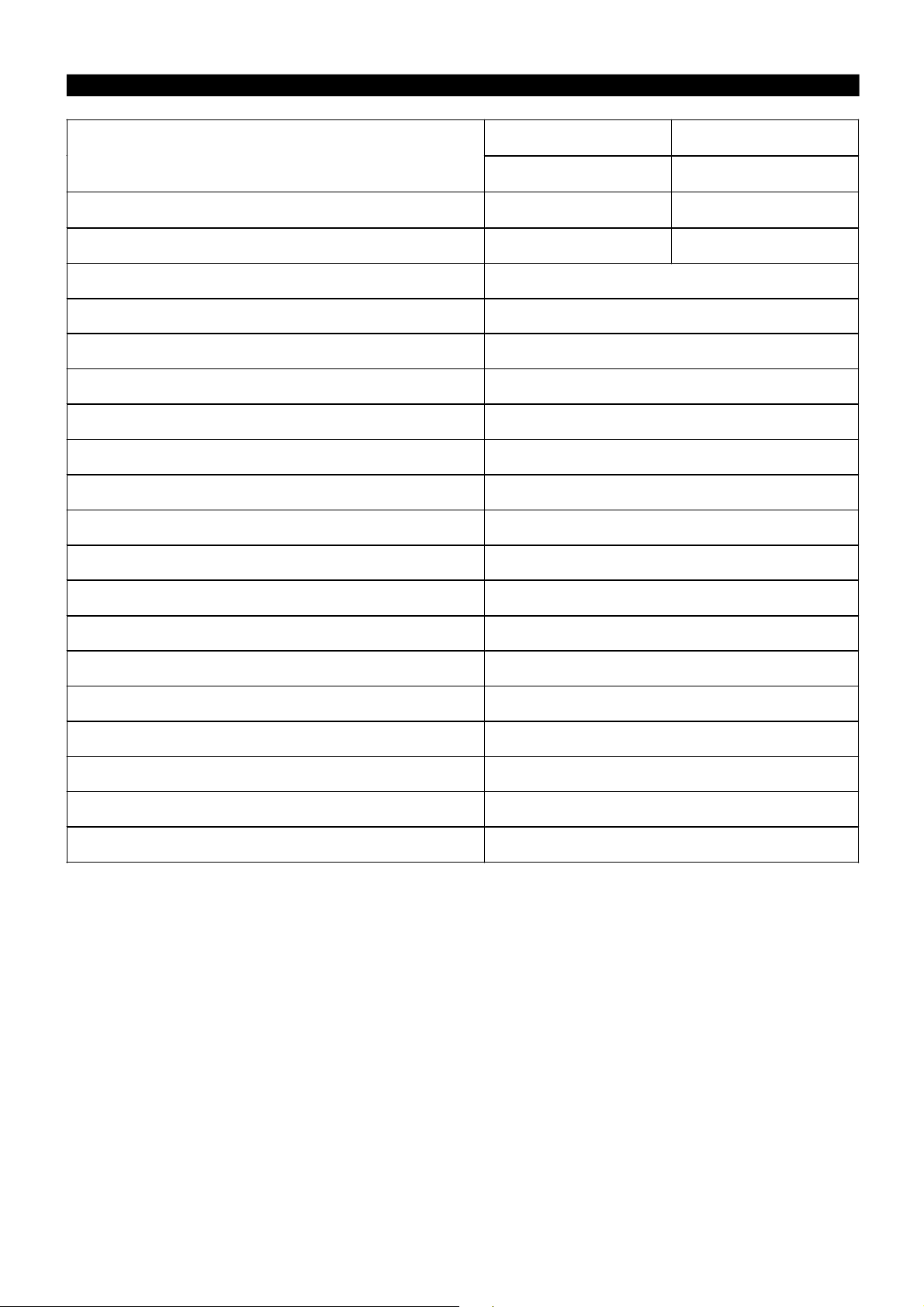

Starting up the brush cutter

– Please make sure that there are no children or other people within a working

range of 15 meters (49ft), also pay attention to any animals in the working

vicinity.

– Before use always check that the Brush Cutter/String trimmer is safe for

operation:

Check the security of the cutting tool, the control lever for easy action and

check for proper functioning of the control lever lock.

– Rotation of the cutting tool during idling speed is not allowed. Check with

your dealer for adjustment if in doubt. Check for clean and dry handles and

test the function of the start/stop switch.

Diagrammatic figure

15 Meter

2

Page 4

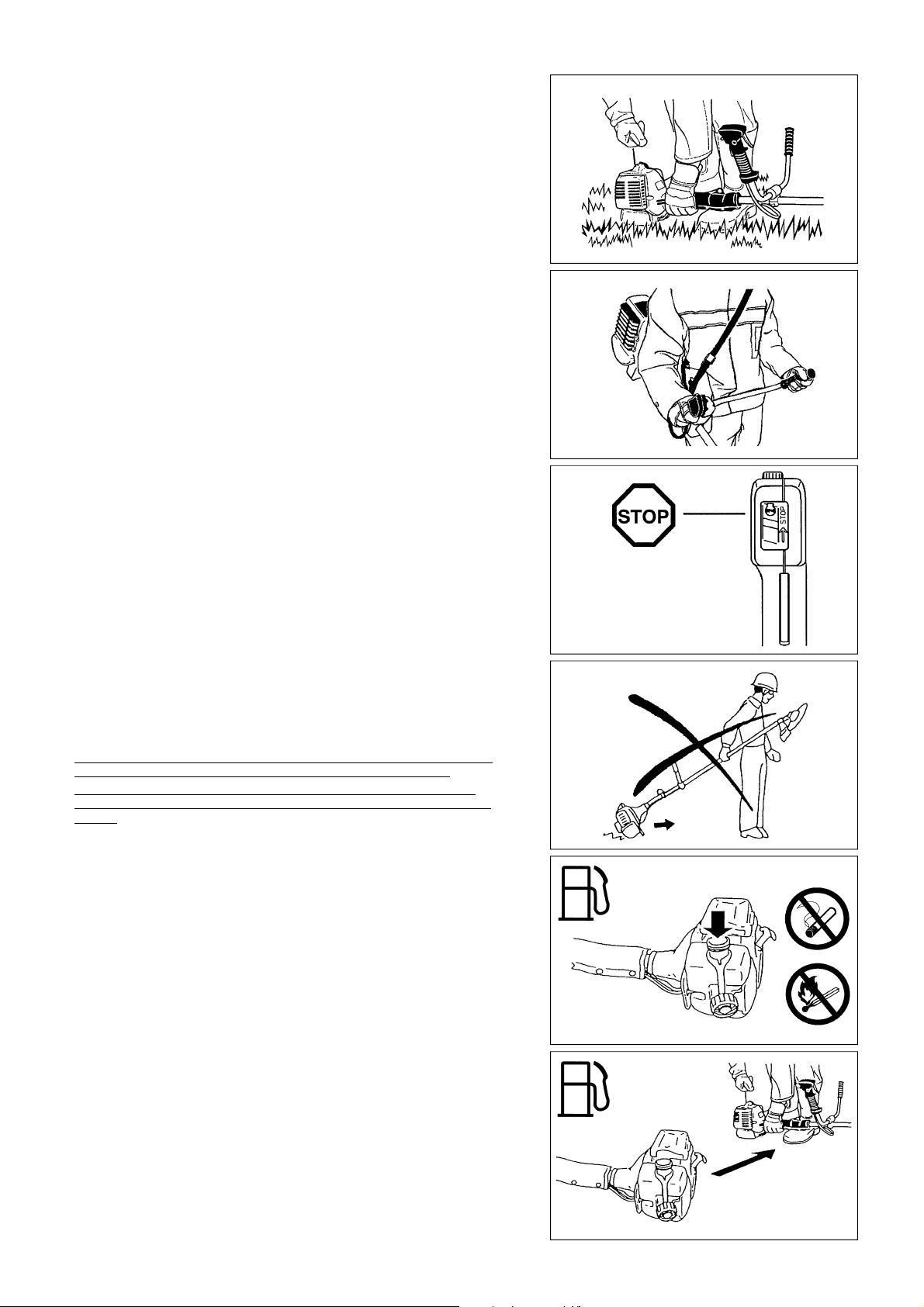

Start the Brush Cutter/String trimmer only in accordance with the instructions.

Do not use any other methods for starting the engine!

– Use the Brush Cutter/String trimmer and the tools only for such applications

as specified.

– Only start the Brush Cutter/String trimmer engine, after the entire assembly is

done. Operation of the device is only permitted after all the appropriate

accessories are attached!

– Before starting make sure that the cutting tool has no contact with hard

objects such as branches, stones etc. as the cutting tool will revolve when

starting.

– The engine is to be switched off immediately in case of any engine problems.

– Should the cutting tool hit stones or other hard objects, immediately switch off

the engine and inspect the cutting tool.

– Inspect the cutting tool at short regular intervals for damage (detection of

hairline cracks by means of tapping-noise test).

– Operate the Brush Cutter/String trimmer only with the shoulder strap

attached which is to be suitably adjusted before putting the Brush Cutter/

String trimmer into operation. It is essential to adjust the shoulder strap

according to the user’s size to prevent fatigue occurring during use. Never

hold the cutter with one hand during use.

– During operation always hold the Brush Cutter/String trimmer with both

hands.

Always ensure a safe footing.

– Operate the Brush Cutter/String trimmer in such a manner as to avoid

inhalation of the exhaust gases. Never run the engine in enclosed rooms

(risk of gas poisoning). Carbon monoxide is an odorless gas.

– Switch off the engine when resting and when leaving the Brush Cutter/

String trimmer unattended, and place it in a safe location to prevent danger to

others or damage to the machine.

– Never put the hot Brush Cutter/String trimmer onto dry grass or onto any

combustible materials.

– The cutting tool has to be equipped with it’s appropriate guard.

Never run the cutter without this guard!

– All protective installations and guards supplied with the machine must be

used during operation.

– Never operate the engine with faulty exhaust muffler.

– Shut off the engine during transport.

– During transport over long distances the tool protection included with the

equipment must always be used.

– Ensure safe position of the Brush Cutter/String trimmer during car transpor-

tation to avoid fuel leakage.

– When transporting the Brush Cutter/String trimmer, ensure that the fuel tank

is completely empty.

– When unloading the Brush Cutter/String trimmer from the truck, never drop

the Engine to the ground or this may severely damage the fuel tank.

– Except in case of emergency, never drop or cast the Brush Cutter/String

trimmer to the ground or this may severely damage the Brush Cutter/String

trimmer.

– Remember to lift the entire equipment from the ground when moving the

equipment. Dragging the fuel tank is highly dangerous and will cause

damage and leakage of fuel, possibly causing fire.

• Resting

• Transport

• Refuelling

• Maintenance

• Tool Replacement

Refuelling

– Shut off the engine during refuelling, keep away from open flames and do

not smoke.

– Avoid skin contact with mineral oil products. Do not inhale fuel vapor.

Always wear protective gloves during refuelling. Change and clean

protective clothing at regular intervals.

– Take care not to spill either fuel or oil in order to prevent soil contamination

(environmental protection). Clean the Brush Cutter/String trimmer immedi-

ately after fuel has been spilt.

– Avoid any fuel contact with your clothing. Change your clothing instantly if

fuel has been spilt on it (to prevent clothing catching fire).

– Inspect the fuel cap at regular intervals making sure that it can be securely

fastened and does not leak.

– Carefully tighten the fuel tank cap. Change location to start the engine (at

least 3 meters away from the place of refuelling).

– Never refuel in closed rooms. Fuel vapors accumulate at ground lever (risk of

explosions).

– Only transport and store fuel in approved containers. Make sure the fuel

stored is not accessible to children.

3

s

r

e

t

e

m

3

Page 5

Method of operation

– Only use the Brush cutter/String trimmer in good light and visibility. During

the winter season beware of slippery or wet areas, ice and snow (risk of

slipping). Always ensure a safe footing.

– Never cut above waist height.

– Never stand on a ladder and run the Brush cutter/String trimmer.

– Never climb up into trees to perform cutting operation with the Brush cutter/

Strin g trimmer.

– Never work on unstable surfaces.

– Remove sand, stones, nails etc. found within the working range.

Foreign particles may damage the cutting tool and can cause dangerous

kick-backs.

– Before commencing cutting, the cutting tool must have reached full working

speed.

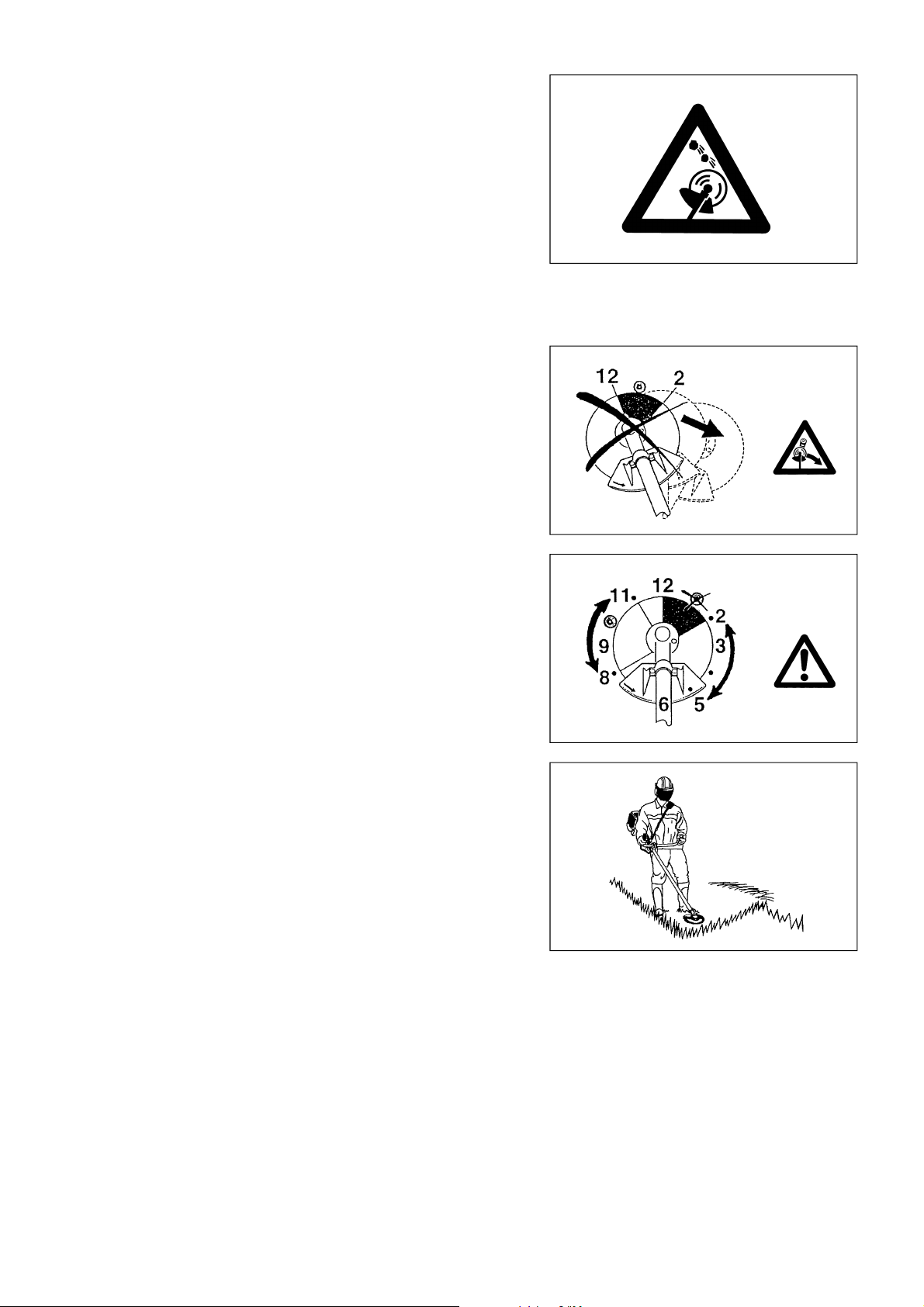

Kickback

– When operating the brush cutter, uncontrolled kickback may occur.

– This is particularly the case when attempting to cut within a blade segment

between 12 and 2 o’clock.

– Never apply the brush cutter within a segment between 12 and 2 o’clock.

– Never apply this segment of the brush cutter blade to solids, such as bushes

and trees, etc., having a diameter in excess of 3 cm or the brush cutter will be

deflected at great force with the risk of injuries.

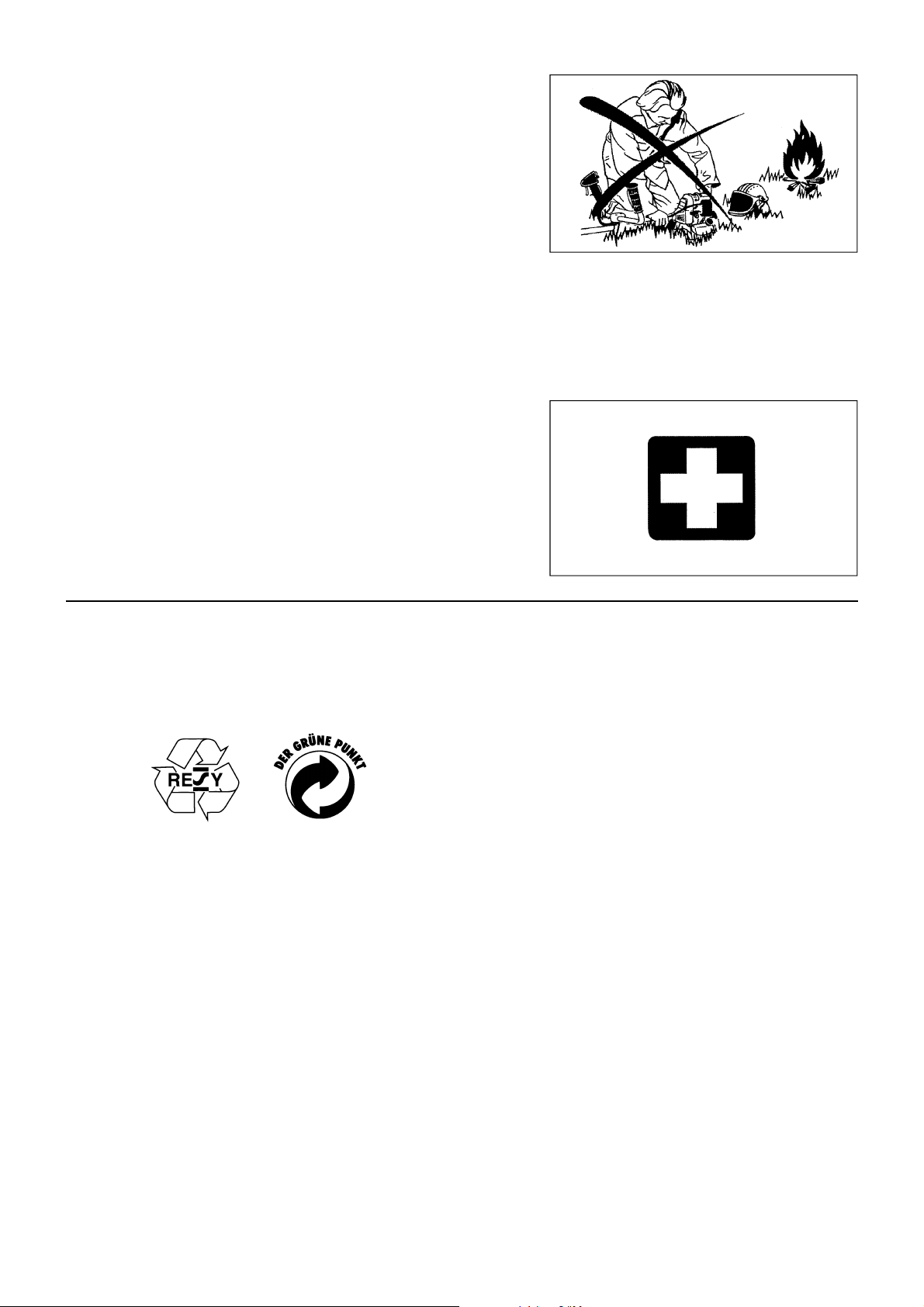

Kickback prevention

To avoid kickbacks, observe the following:

– Operation within a blade segment between 12 and 2 o’clock presents positive

hazards, especially when using metal cutting tools.

– Cutting operations within a blade segment between 11 and 12 o’clock, and

between 2 and 5 o’clock, must only be performed by trained and experienced

operators, and then only at their own risk.

Easy cutting with almost no kickback is possible within a blade segment

between 8 and 11 o’clock.

Cutting Tools

Employ only the correct cutting tool for the job in hand.

Caution:

Kickback

Diagrammatic

flgure

Diagrammatic

flgure

MS-250.4, MS-251.4 with cutter blade (Star Blade (4 teeth), Eddy Blade (8

teeth)), Nylon cutting head

For cutting thick materials, such as weed, high grass, bushes, shrubs,

underwood, thicket etc. (max. 2 cm dia. thickness). Perform this cutting work

by swinging the brush cutter evenly in half-circles from right to left (similar to

using a scythe).

Maintenance instructions

– The condition of the cutter, in particular of the cutting tool of the protective

devices and also of the shoulder strap must be checked before commencing

work. Particular attention is to be paid to the cutting blades which must be

correctly sharpened.

– Turn off the engine and remove spark plug connector when replacing or

sharpening cutting tools, and also when cleaning the cutter or cutting tool.

4

Page 6

Never straighten or weld damaged cutting tools.

– Operate the Brush cutter/Grass trimmer with as little noise and contamination

as possible. In particular check the correct setting of the carburetor.

– Clean the Brush cutter/Grass trimmer at regular intervals and check that all

screws and nuts are well tightened.

– Never service or store the Brush cutter/Grass trimmer in the vicinity of

naked flames.

– Always store the Brush cutter/Grass trimmer in locked rooms and with an

emptied fuel tank.

Observe the relevant accident prevention instructions issued by the relevant trade associations and by the insurance companies.

Do not perform any modifications on the Brush cutter/Grass trimmer as this will endanger your safety.

The performance of maintenance or repair work by the user is limited to those activities as described in the instruction manual. All other

work is to be done by an Authorized Service Agent. Use only genuine spare parts and accessories released and supplied by DOLMAR.

Use of non-approved accessories and tools means increased risk of accidents.

DOLMAR will not accept any liability for accidents or damage caused by the use of non-approved cutting tools and fixing devices of cutting

tools, or accessories.

First Aid

In case of accident make sure that a first-aid box is available in the vicinity of

the cutting operations. Immediately replace any item taken from the first aid

box.

When asking for help, please give the following information:

– Place of accident

– What happened

– Number of injured persons

– Kind of injuries

– Yo u r n a m e

Packaging

The DOLMAR Brush cutter/Grass trimmer will be delivered in two protective

cardboard boxes to prevent transport damage. Cardboard is a basic raw

material and is therefore consequently reusable or suitable for recycling

(waste paper recycling).

5

Page 7

TECHNICAL DATA MS-250.4, MS-251.4

Model

MS-251.4 MS-250.4

Loop handle U handle

Dimensions : length x width x height (without cutting blade) mm

Mass (without plastic guard and cutting blade) kg

Volume (fuel tank) L

Volume (oil tank) L

Engine displacement cc

Maximum engine performance HP

Engine speed at recommended max. spindle speed /min

Maximum spindle speed (corresponding) /min

Maximum fuel consumption kg/h

Maximum specific fuel consumption g/HPh

Idling speed /min

Clutch engagement speed /min

Carburetor type

1760x330x265 1760x600x405

5.2 5.4

0.5

0.08

24.5

0.885 at 7000 /min

8500

6500

0.33

304

3000

3750

WALBRO WYL

Ignition system type

Spark plug type

Electrode gap mm

Fuel

Engine Oil

Gear ratio

Solid state ignition

NGK CMR6A

0.7 - 0.8

Automobile gasoline

SAE 10W-30 oil of API Ciassification,

Class SF or higher (4-stroke engine for automobile)

14/19

6

Page 8

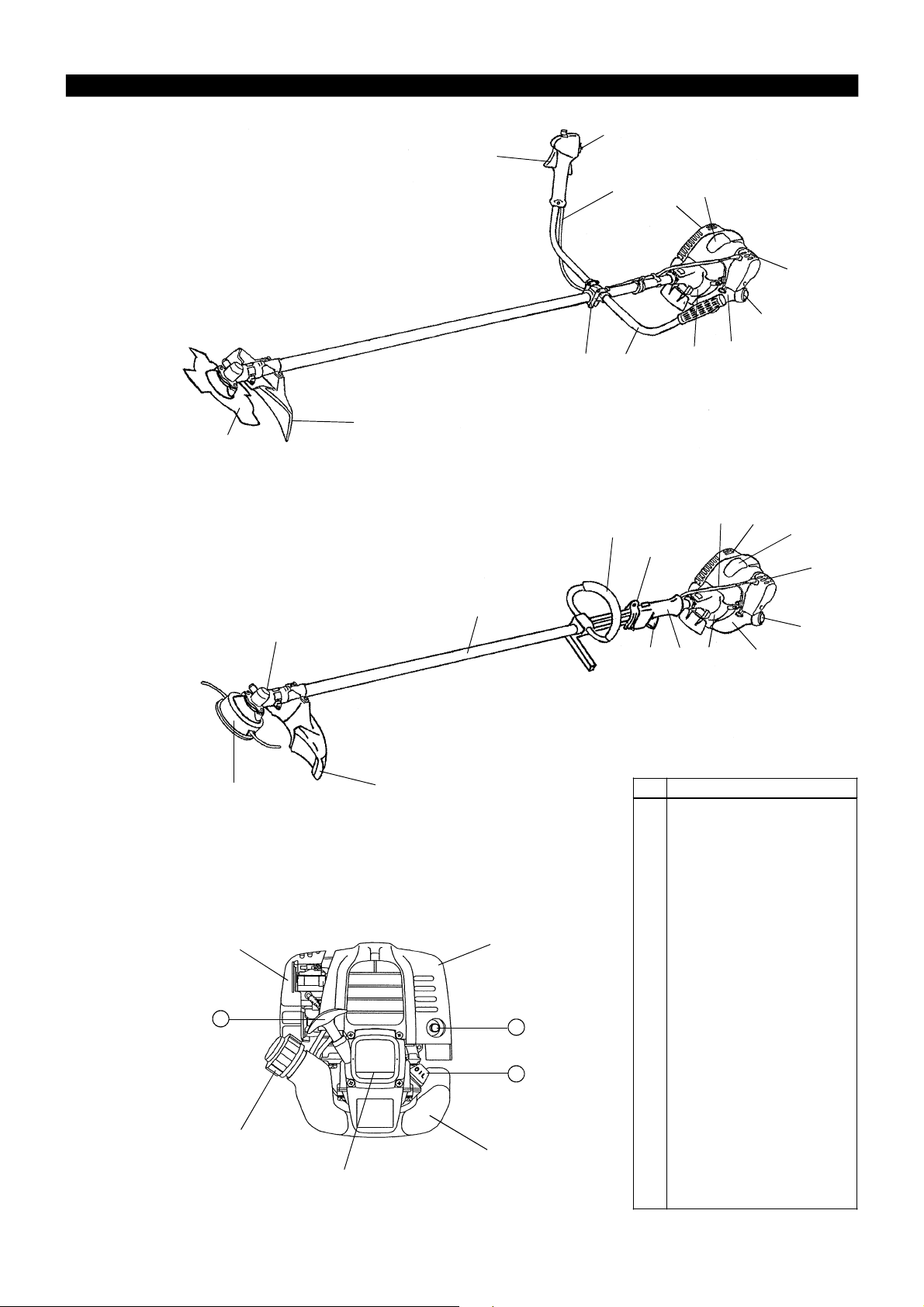

DESIGNATION OF PARTS

④

⑪

MS-250.4

Brush Cutter

⑰

MS-251.4

String trimmer

⑮

⑭

⑬

⑯

⑩

⑫

⑩

⑨

⑨

⑪

⑥

⑧

④

⑦

⑤

⑦

⑫

①

⑥

①

③

⑳

⑤

③

⑳

21

⑱

③

⑳

②

⑭

⑥

①

24

25

GB DESIGNATION OF PARTS

1 Fuel Tank

2 Rewind Starter

3 Air Cleaner

4 I-O Switch (on/off)

5 Spark Plug

6 Exhaust Muffler

7 Clutch Case

8 Rear Grip

9 Hanger

10 Handle

11 Control Lever

12 Control Cable

13 Shaft

14 Protector

15 Gear Case/Head Case

16 Handle Holder

17 Cutter Blade

18 Nylon Cutting Head

20 Fuel Filler Cap

21 Starter Knob

24 Exhaust Pipe

25 Oil Gauge

7

Page 9

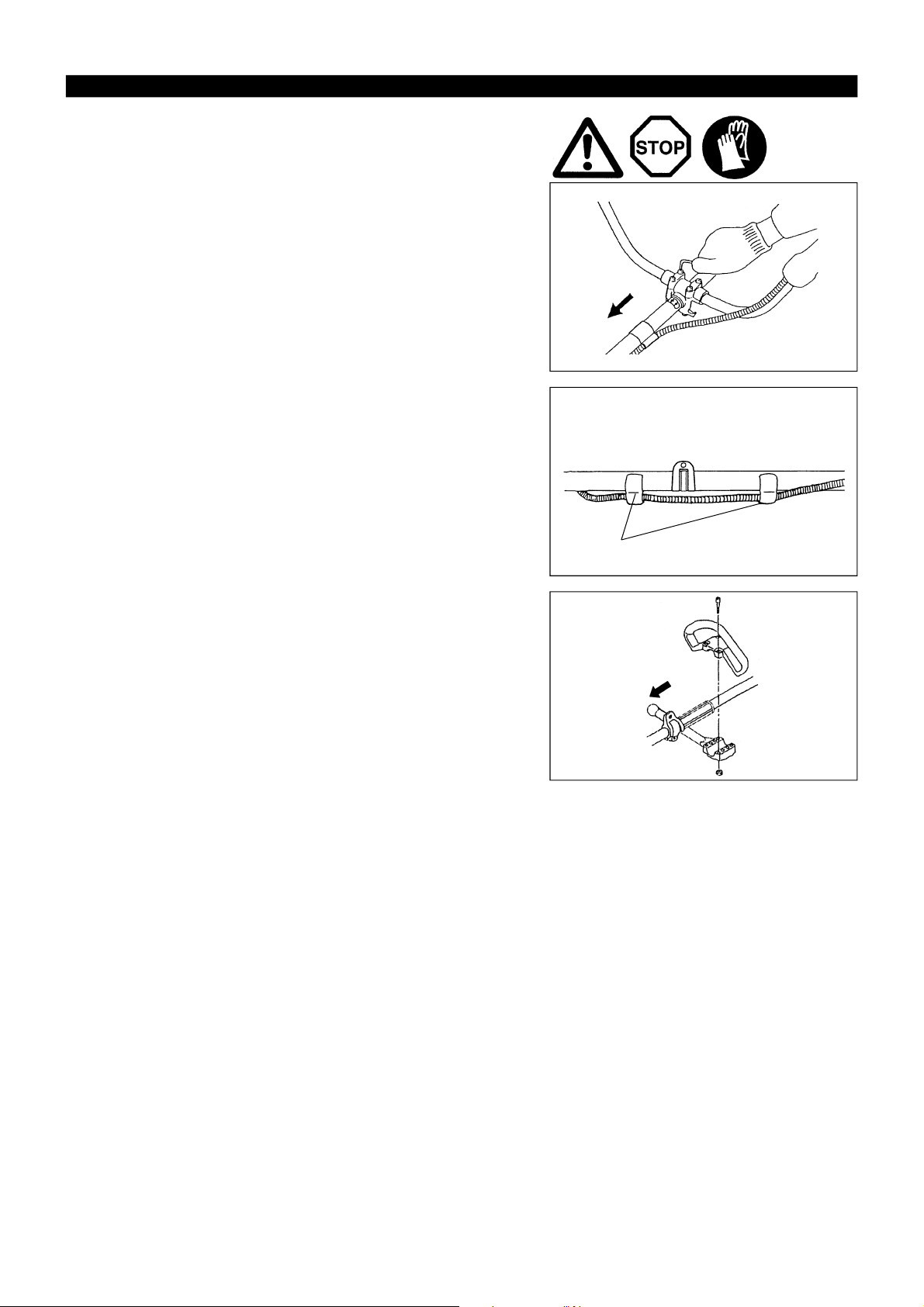

MOUNTING OF HANDLE

CAUTION: Before doing any work on the brush cutter, always stop the engine

and pull the spark plug connector off the spark plug.

Always wear protective gloves!

CAUTION: Start the brush cutter only after having assembled it completely.

For machines with U Handle models

– Insert the handle bar into the handle holder, making sure that the boss in the

handle holder fits into the hole in the handle.

– After the handle bar is in place, tighten the four bolts (M5 x 25).

NOTE: Be sue the bolts are tight, but do not overtighten.

– Fit the control cable (together with the earth cord) to the handle with two clips

(3).

– Avoid any tendency of the control cable to loop at the handle bar.

e

n

i

g

n

e

o

t

(3)

For machines with Loop Handle

– Fix a barrier to the left side of the machine together with the handle for

operator’s protection.

– Do not adjust position of the loop handle too close to the control grip. Keep

not less than 250mm distance between the handle and the grip.

(a distance collar is provided for this purpose.)

to engine

8

Page 10

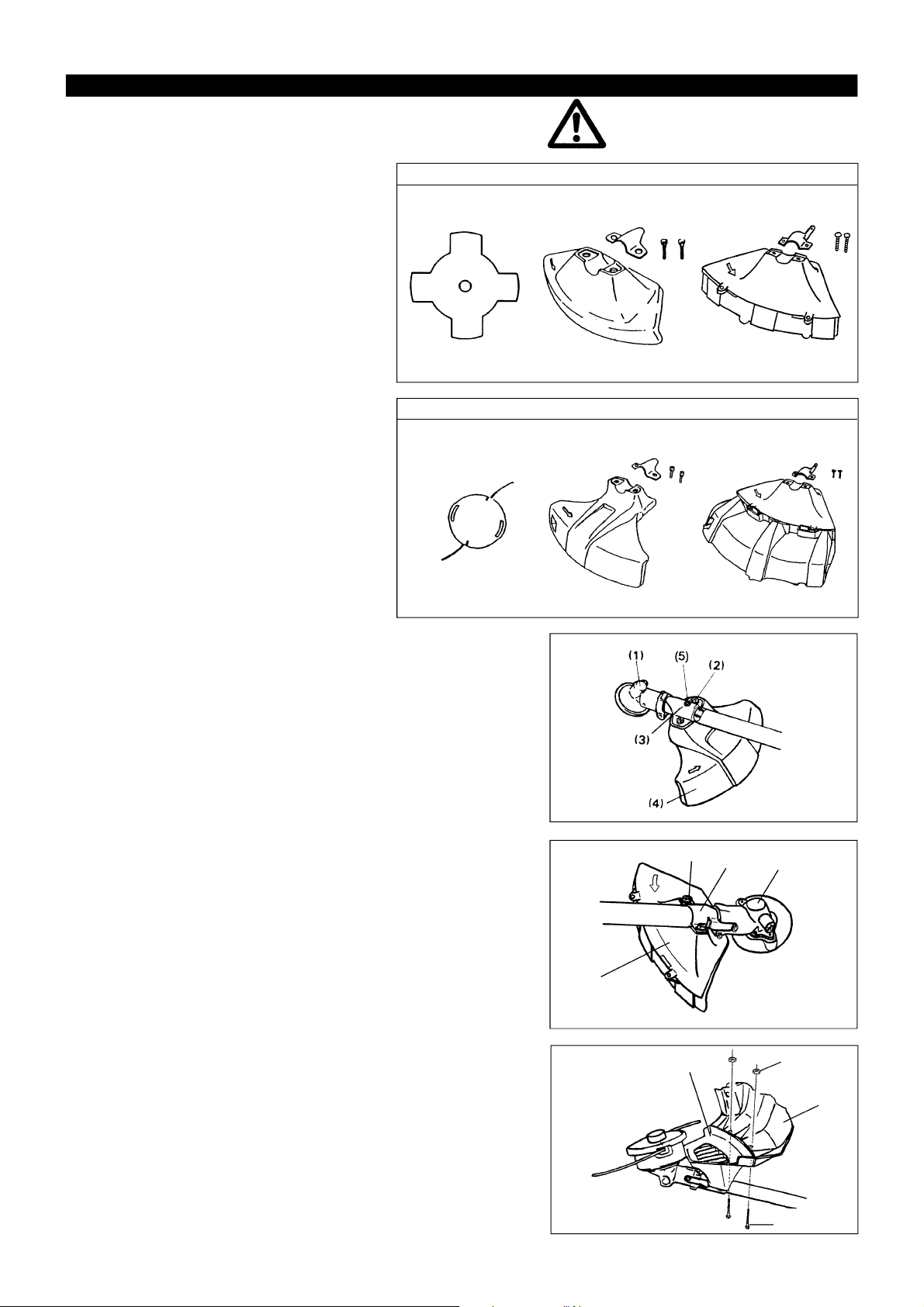

MOUNTING OF PROTECTOR

To meet the applicable safety provisions, only the tool/

protector combinations as indicated in the table must

be used.

Be sure to use genuine DOLMAR cutter blades

or nylon cutting head.

– The cutter blade must be well polished, free of

cracks or breakage. If the cutter blade hits against a

stone during operation, stop the engine and check

the blade immediately.

– Polish or replace the cutter blade every three hours

of operation.

– If the nylon cutting head hits against a stone during

operation, stop the engine and check the nylon

cutting head immediately.

Star Blade

MS-250.4

Protector for metal blades

Protector for metal blades

(Use of protector for metal

blade/cord cutter)

CAUTION : The appropriate protector must always be

installed, for your own safety and in order

to comply with accident-prevention

regulations.

Operation of the equipment without the

guard being in place is not permitted.

Nylon cutting head

For MS-250.4

– The outside diameter of the cutter blade must be

230mm (9-1/16"). Never use any blades surpassing

230mm (9-1/16") in outside diameter.

For MS-250.4, MS-251.4

– Install the clamp (3) on the shaft so that the projection of the clamp (3) is

inserted into the opening between the gear case (1) and the shaft.

Secure the protector (4) with the installation bolts M6 x 30 (2) and screw

M5 x 8 (5).

MS-251.4

Protector for cord cutter

Protector for cord cutter

(Use of protector for metal

blade/cord cutter)

Use of protector for metal blade / cord cutter.

– In use of the metal blade, fasten the protector (4) to the clamp (3) with two

bolts M6 x 30 (2).

NOTE : Tighten the right and left bolts evenly so that the gap between the

clamp (3) and the protector (4) will be constant.

Otherwise, the protector sometimes may not function as specified.

– In use of the cord cutter, insert the protector (2) into the protector (1), and

fasten them with two screw (4) and two nuts (3).

9

(4)

(2)

(1)

(3)

(1)

(3)

(2)

(4)

Page 11

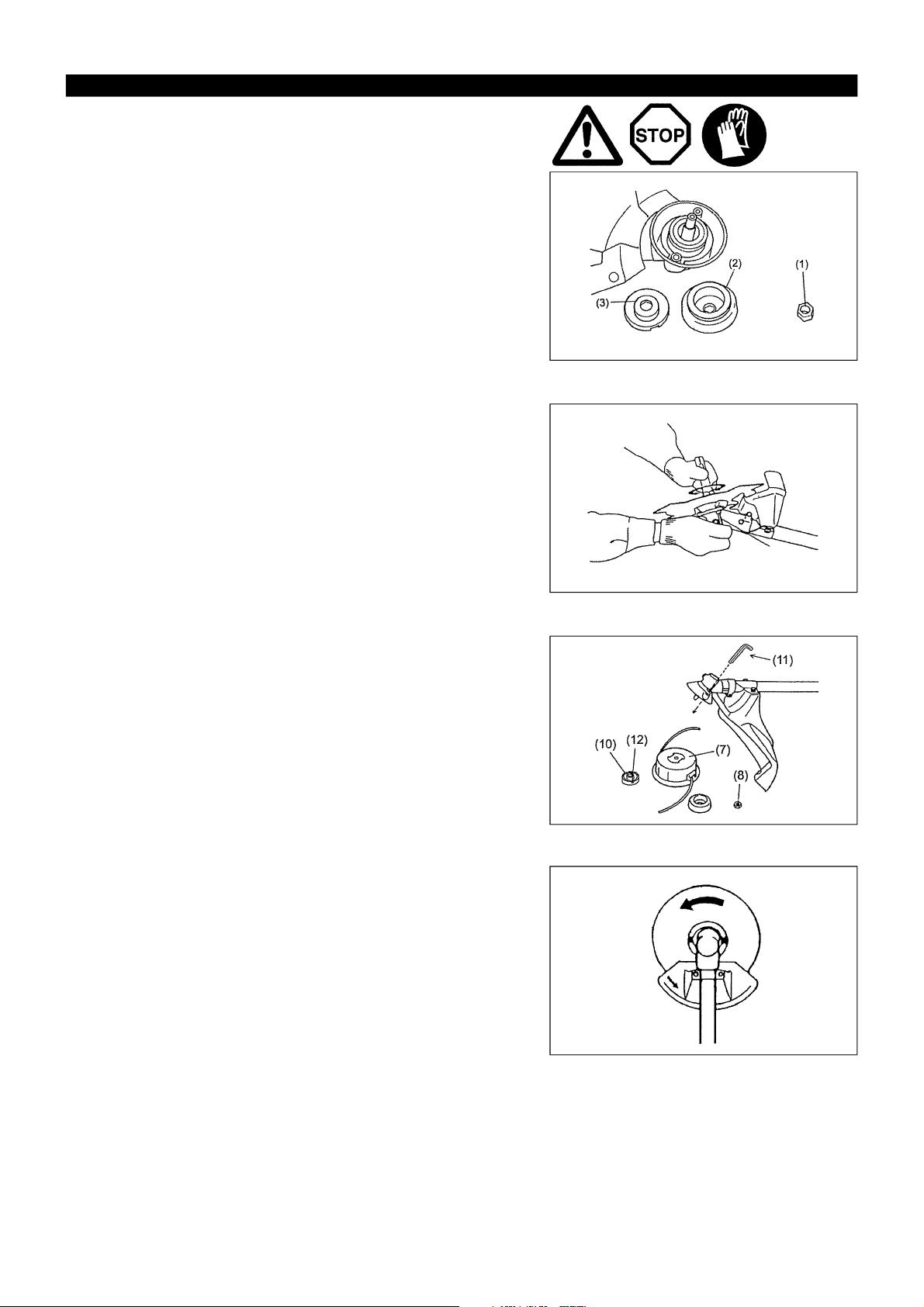

MOUNTING OF CUTTER BLADE OR NYLON CUTTER HEAD

Turn the machine upside down, and you can replace the cutter blade easily.

For MS-250.4, MS-251.4

– Insert the hex wrench through the hole in the gear case and rotate the

receiver washer (3) until it is locked with the hex wrench.

– Loosen the nut (1) (left-hand thread) with the socket wrench and remove the

nut (1), and clamp washer (2).

For MS-250.4 with the hex wrench still in place.

– Mount the cutter blade onto the shaft so that the guide of the receiver washer

(3) fits in the arbor hole in the cutter blade. Install the clamp washer (2) and

secure the cutter blade with the nut (1).

[Tightening torque: 13 - 23 N-m]

NOTE: Always wear gloves when handling the cutter blade.

NOTE: The cutter blade-fastening nut (with spring washer) is a consumable

part. If there appears any wear or deformation on the spring washer,

replace the nut.

Hex wrench

Mounting of nylon cutting head

For MS-251.4

– To install the nylon cutting head (7), remove the tightening nut (8).

– Insert the socket-head wrench (11) through the hole in the gear case and

tum the support washer until it will be locked with its notch (12) (or the shaft

will be locked).

– Then screw the nylon cutting head onto the shaft by turning it counter-

clockwise.

– Remove the socket-head wrench.

– Make sure that the blade is the left way up.

Rotation

10

Page 12

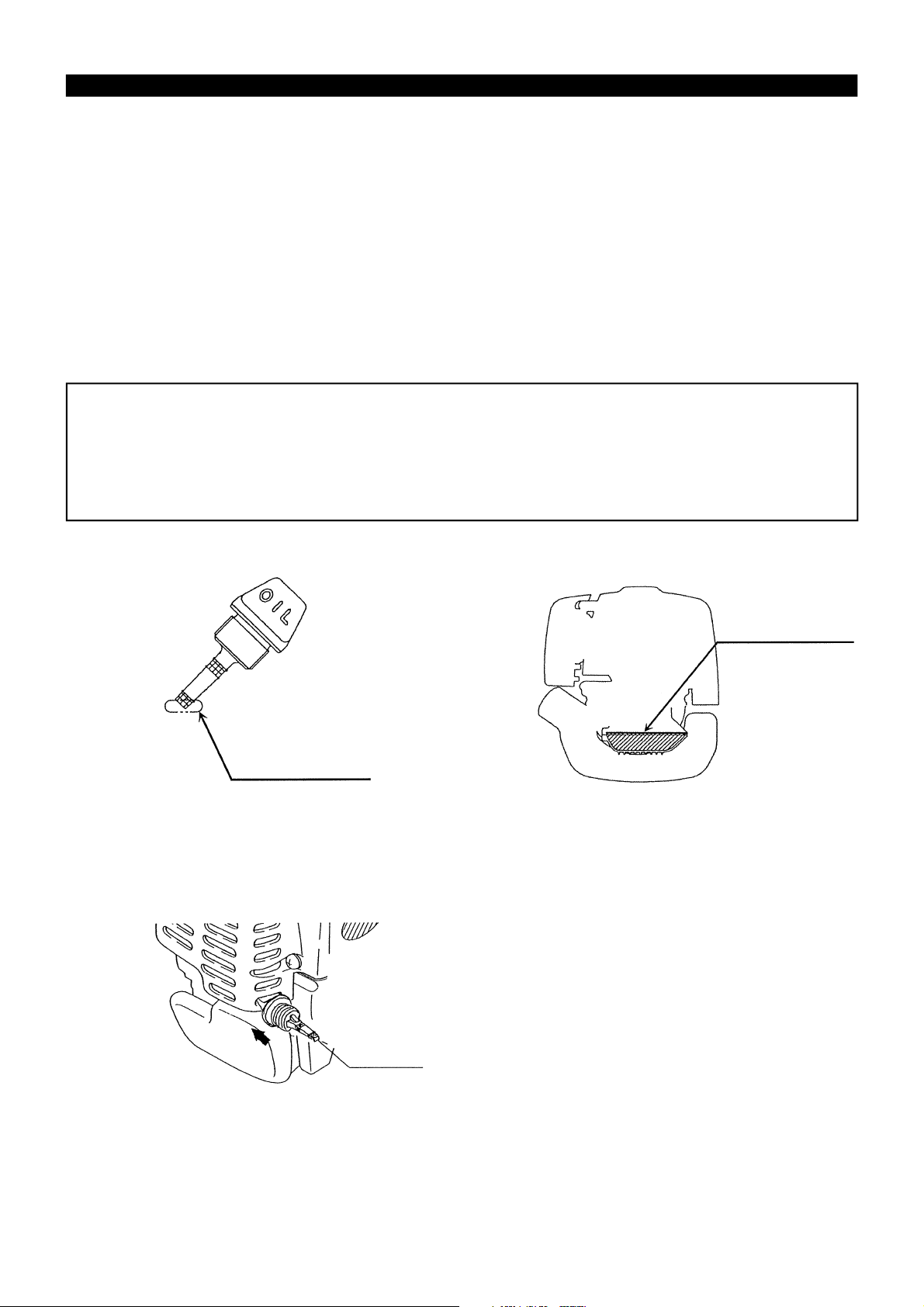

BEFORE START OF OPERATION

Inspection and Refill of Engine Oil

– Perform the following procedure, with the engine cooled down.

– While keeping the engine level, remove the oil gauge, and confirm that the oil is filled within the upper and lower limit marks.

When the oil is in short in such a way that the oil gauge touches the oil only by its tip, in particular with the oil gauge remaining inserted in the

crankcase without screwing-in (Fig. 1), refill new oil near the port (Fig. 2).

– For reference, the oil refill time is about 10h (10 times or 10 tanks of oil refill).

– If the oil changes in color or mixes with dirt, replace it with new one. (For the interval and method of replacement, refer to P 17)

Recommended oil: SAE 10W-30 oil of API Classification, Class SF or higher (4-stroke engine for automobile)

Oil volume: Approx. 0.08L

Note: If the engine is not kept upright, oil may go into around the engine, and may be refilled excessively.

If the oil is filled above the limit, the oil may be contaminated or may catch fire with white.

Point 1 in Replacement of Oil “Oil Gauge”

– Remove dust or dirt near the oil refill port, and detach the oil gauge.

– Keep the detached oil gauge free of sand or dust. Otherwise, any sand or dust adhering to the oil gauge may cause irregular oil

circulation or wear on the engine parts, which will result in troubles.

– As an example to keep the oil gauge clean, it is recommended to insert the oil gauge on its knob side into the engine cover, as shown

in Fig.3.

If oil adheres around

this tip, refill new oil.

Fig.1

Upper limit

(Edge of oil refill port)

Fig.2

Oil gauge

Fig.3

11

Page 13

(1) Keep the engine level, and detach the oil gauge.

(2) Fill oil up to the edge of the oil refill port. (Refer to Fig.2 of the preceding

page).

Feed oil with the lubricant refill container.

(3) Securely tighten the oil gauge. Insufficient tightening may cause oil

leakage.

Point 2 in Replacement of Oil: “If oil spills out”

– If oil spills out between the fuel tank and engine main unit, the oil is sucked into through the cooling air intake port, which will

contaminate the engine. Be sure to wipe out spilt oil before start of operation.

REFUELING

Handling of Fuel

It is necessary to handle fuel with utmost care. Fuel may contain substances similar to solvents. Refueling must be performed in a sufficiently

ventilated room or in the open air. Never inhale fuel vapor, and keep fuel away from you. If you touch fuel repeatedly or for a long time, the

skin becomes dry, which may cause skin disease or allergy. If fuel enters into the eye, clean the eye with fresh water. If your eye remains

still irritated, consult your doctor.

Storage Period of Fuel

Fuel should be used up within a period of 4 weeks, even if it is kept in a special container in a well-ventilated shade.

If a special container is not used or if the container is not covered, fuel may deteriorate in one day.

STORAGE OF MACHINE AND REFILL TANK

−Keep the machine and tank at a cool place free from direct sunshine.

−Never keep the fuel in the cabin or trunk.

Fuel

The engine is a four-stroke engine. Be sure to use an automobile gasoline (regular gasoline or premium gasoline).

Points for Fuel

– Never use a gasoline mixture which contains engine oil. Otherwise, it will cause excessive carbon accumulation or mechanical troubles.

– Use of deteriorated oil will cause irregular startup.

Refueling

WARNING: INFLAMMABLES STRICTLY PROHIBITED

Gasoline used: Automobile gasoline (unleaded gasoline)

– Loosen the tank cap a little so that there will be no difference in atmospheric

pressure.

– Detach the tank cap, and refuel, discharging air by tilting the fuel tank so that

the refuel port will be oriented upward. (Never refill fuel full to the oil refill

port.)

– Wipe well the periphery of the tank cap to prevent foreign matter from

entering into the fuel tank.

– After refueling, securely tighten the tank cap.

●

If there is any flaw or damage on the tank cap, replace it.

●

The tank cap is consumable, and therefore should be renewed every two to

three years.

12

Fuel tank cap

Fuel upper limit

Fuel tank

Page 14

CORRECT HANDLING OF MACHINE

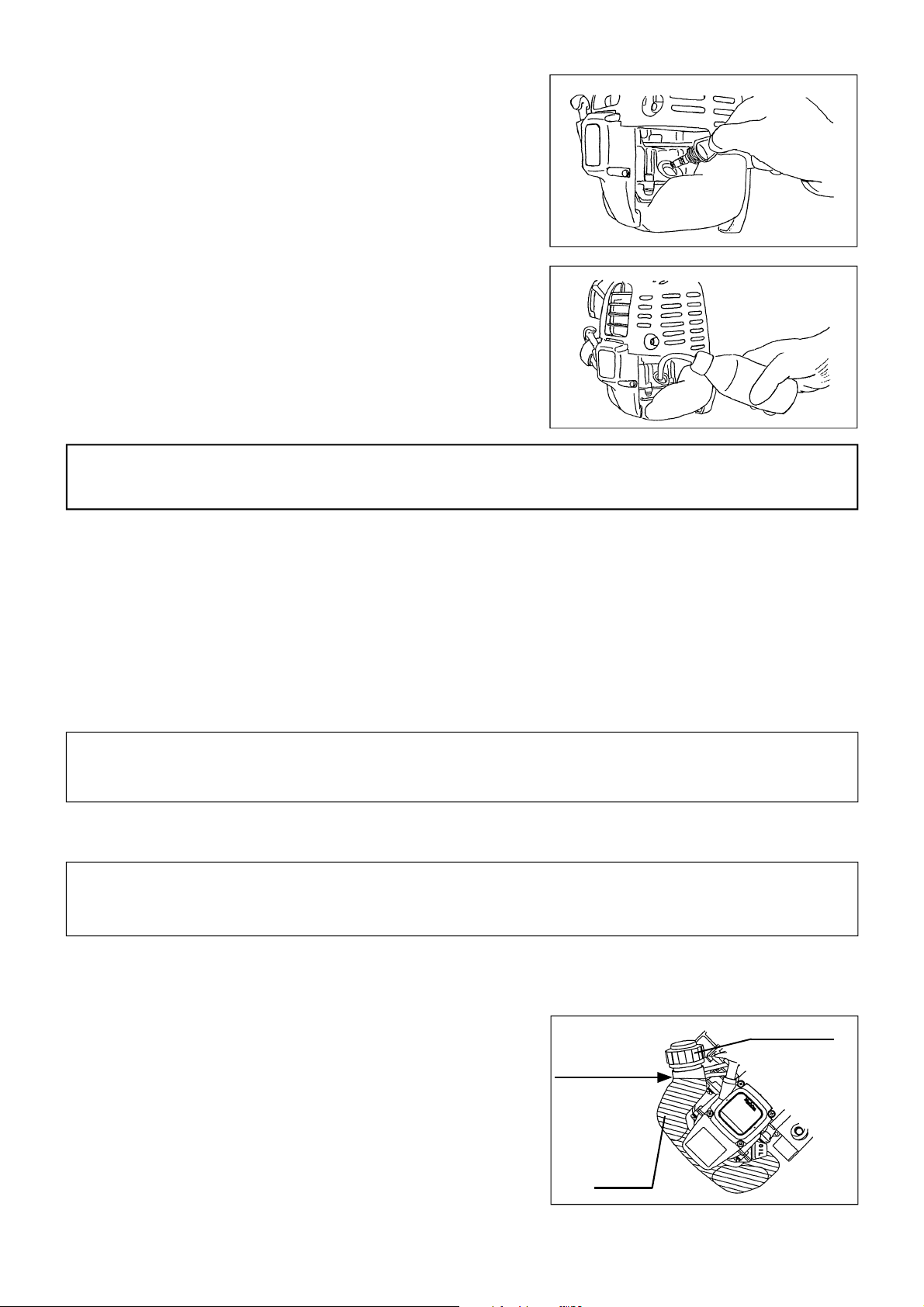

Attachment of shoulder strap

– Adjust the strap length so that the cutter blade will be kept parallel with the

ground.

Detachment

For MS-251.4

– In an emergency, push the notches (1) at both sides, and you can detach

the machine from you.

Be extremely careful to maintain control of the machine at this time. Do not

allow the machine to be deflected toward you or anyone in the work vicinity.

WARNING: Failure to maintain complete control of the machine at all could

result in serious bodily injury or DEATH.

For MS-250.4

– In case of emergency, remove the emergency detachment lever (2) by

pulling strongly with a finger. The machine sill detach from body.

Be extremely careful to maintain control of the machine at this time. Do not

allow the machine to be deflected toward you or anyone in the work

vicinity.

WARNING: Failure to maintain complete control of the machine at all could

result in serious bodily injury or DEATH.

Hanger

(2)

Hanger

POINTS IN OPERATION AND HOW TO STOP

Observe the applicable accident prevention regulations!

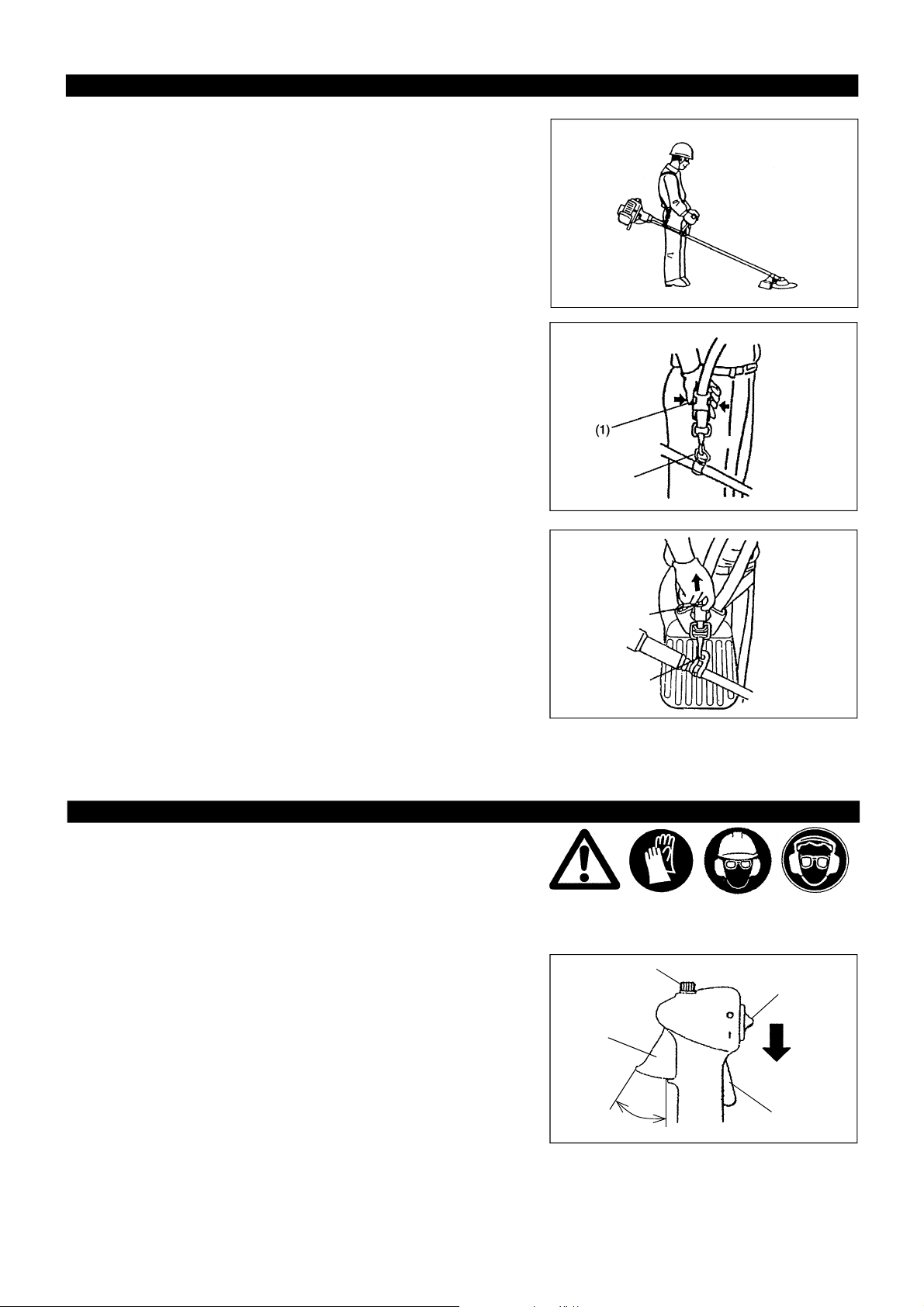

STARTING

Move at least 3m away from the place of refuelling. Place the brush cutter on a clean piece of ground taking care that the cutting tool does

not come into contact with the ground or any other objects.

A:Cold start

1) Set this machine on a flat space.

Throttle control dial

Throttle lever (6)

Low speed

I-O switch (1)

OPERATION

Lock-off lever

High speed

13

Page 15

For machine with U Handle or Loop Handle

1) Set the I-O switch (1) to OPERATION.

2) Choke lever

Close the choke lever.

Choke opening:

– Full closing in cold or when the engine is cold.

– Full or half opening in restart just after stop of operation.

3) Primer pump

Continue to push the primer pump until fuel enters into the primer pump. (In

general, fuel enters into the primer pump by 7 to 10 pushes.)

If the primer pump is pushed excessively, an excess of gasoline returns to

the fuel tank.

CLOSE

Carburetor

Primer Pump

4) Recoil starter

– Pull the start knob gently until it is hard to pull (compression point).

Then, return the start knob, and pull it strongly.

– Never pull the rope to the full. Once the start knob is pulled, never

release your hand immediately. Hold the start knob until it returns to its

original point.

5) Choke lever

When the engine starts, open the choke lever.

– Open the choke lever progressively while checking the engine

operation. Be sure to open the choke lever to the full in the end.

– In cold or when the engine is cooled down, never open the choke lever

suddenly. Otherwise, the engine may stop.

6) Warm-up operation

Continue warm-up operation for 2 to 3 minutes.

OPEN

Note: – If the starter handle is pulled repeatedly when the choke lever remains at “START” position, the engine will not start easily due to

excessive fuel intake.

– In case of excessive fuel intake, remove the spark plug and pull the starter handle slowly to remove excess fuel. Also, dry the

electrode section of the spark plug.

Caution during operation:

If the throttle lever is opened fully in a no-load operation, the engine rotation is increased to 10,000/min or more. Never operate the engine at

a higher speed than required and at an approximate speed of 6,000 - 8,500/min.

14

Page 16

B: Startup after warm-up operation

1) Push the primer pump repeatedly.

2) Keep the throttle lever at the idling position.

3) Pull the recoil starter strongly.

4) If it is difficult to start the engine, open the throttle by about 1/3.

Pay attention to the cutter blade which may rotate.

Attention in Operation

When the engine is operated upside down, white smoke may come out from the muffler.

STOPPING

1) Release the throttle lever (6) fully, and when the engine rpm has lowered,

set the I-O switch to STOP the engine will now stop.

2) Be aware that the cutting head may not stop immediately and allow it to

slow down fully.

Throttle lever (6)

ADJUSTMENT OF LOW-SPEED ROTATION (IDLING)

When it is necessary to adjust the low-speed rotation (idling), perform it by the carburetor adjusting screw.

CHECKUP OF LOW-SPEED ROTATION

– Set the low-speed rotation to 3000/min.

If it is necessary to change the rotation speed, regulate the adjusting screw

(illustrated on the left), with Phillips screwdriver.

– Turn the adjusting screw to the right, and the engine rotation will increase.

Turn the adjusting screw to the left, and the engine rotation will drop.

– The carburetor is generally adjusted before shipment. If it is necessary to

readjust it, please contact Authorized Service Agent.

Adjusting screw

Carburetor

STOP

I-O switch (1)

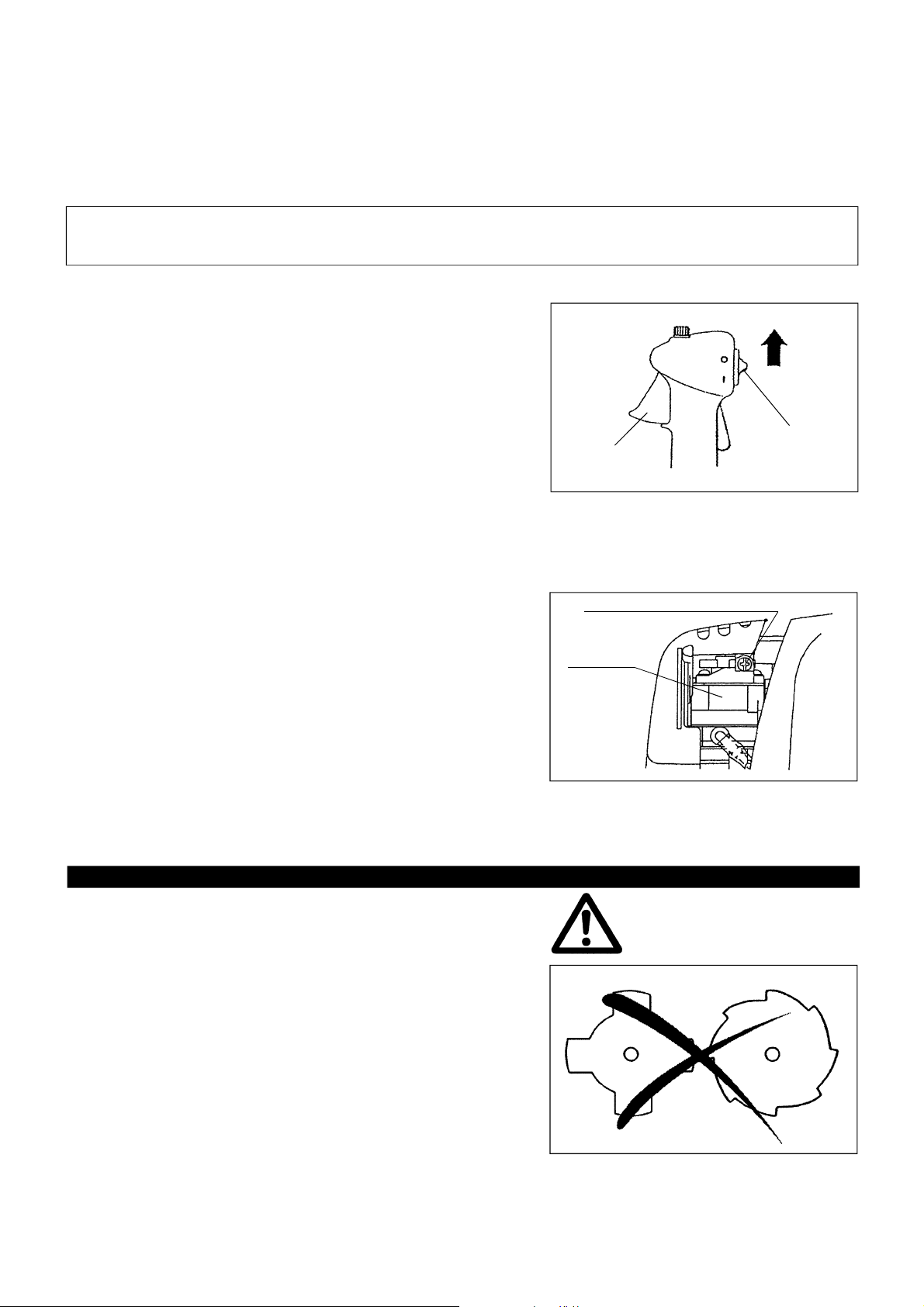

RESHARPENING THE CUTTING TOOL

CAUTION : The cutting tools mentioned below must only be resharpened by

– cutter blade (star blade (4 teeth), eddy blade (8 teeth))

An expert resharpening and balancing service is provided by Authorized

Service Agents.

NOTE : To increase the service life of the cutter blade (star blade, eddy blade)

an authorized facility. Manual resharpening will result in imbalances of the cutting tool causing vibrations and damage to the

equipment.

it may be turned over once, until both cutting edges have become

blunt.

15

Page 17

NYLON CUTTING HEAD

The nylon cutting head is a dual string trimmer head capable of both automatic

and bump & feed mechanisms.

The nylon cutting head will automatically feed out the proper length of nylon

cord by the changes in centrifugal force caused by increasing or decreasing

rpms. However, to cut soft grass more efficiently, bump the nylon cutting

head against the ground to feed out extra cord as indicated under operation

section.

Operation

– Increase the nylon cutting head speed to approx. 6,000/min.

Low speed (under 4,800/min) is not suitable, the nylon cord will not feed out

properly at low speed.

– The most effective cutting area is shown by the shaded area.

If the nylon cord does not feed out automatically proceed as follows:

1. Release the throttle lever to run the engine idle and then squeeze the

throttle lever fully. Repeat this procedure until the nylon cord feeds out to

the proper length.

2. If the nylon cord is too short to feed out automatically with the above

procedure, bump the knob of the nylon cutting head against the ground to

feed out the nylon cord.

3. If the nylon cord does not feed out with procedure 2, rewind/replace the

nylon cord by following the procedures described under “Replacing the

nylon cord”.

Replacing the nylon cord

– First, stop the engine.

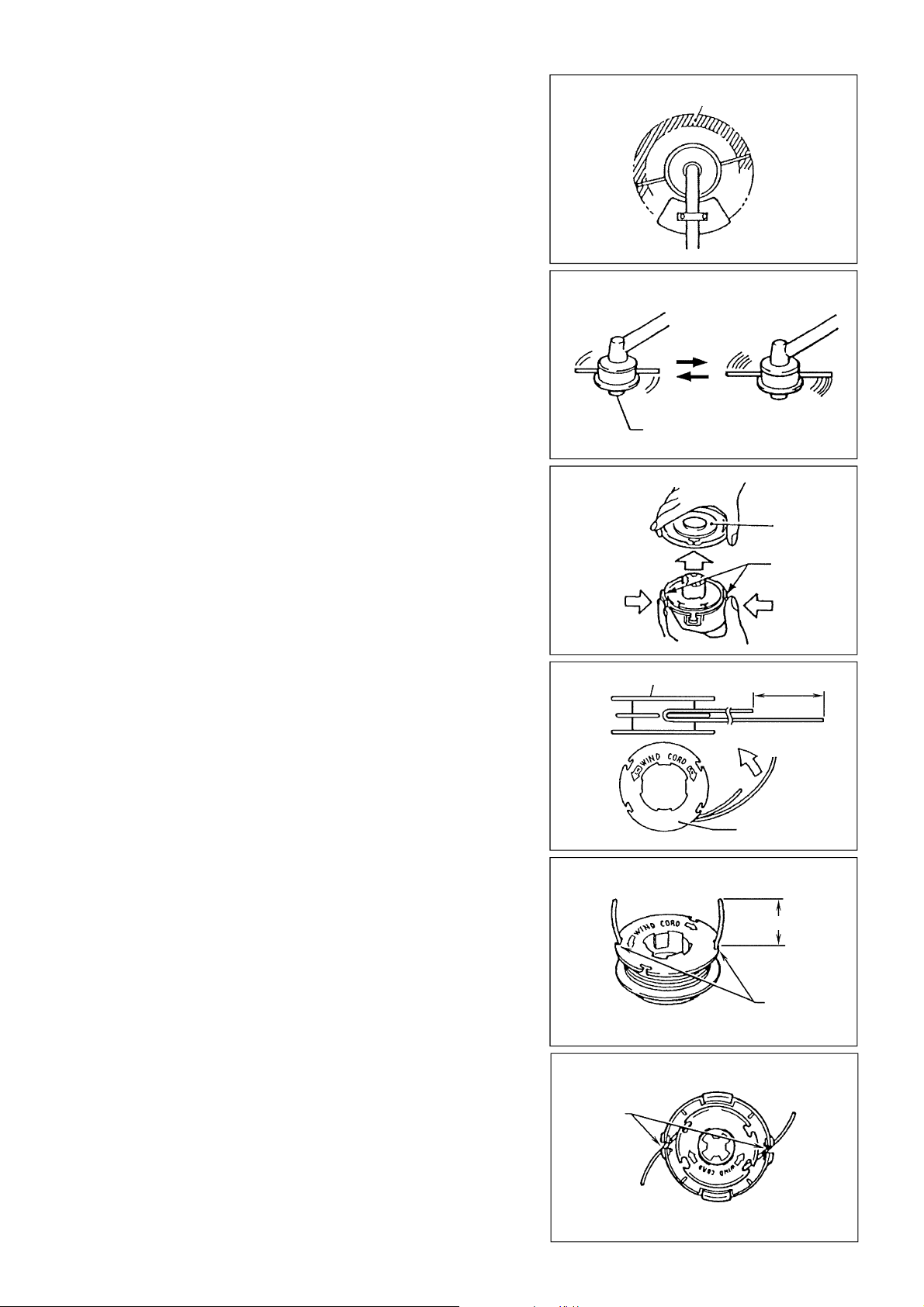

– Press on the housing latches inward to lift off the cover, then remove the

spool.

Most effective cutting area

Idle speed

Knob

Full speed

Cover

Latches

– Hook the center of new nylon cord into the notch in the center of the spool,

with one end of the cord extending about 80mm (3-1/8") more than the other.

Then wind both ends firmly around the spool in the direction of the head

rotation (left-hand direction indicated by LH and right-hand direction by RH

on the side of the spool).

– Wind all but about 100mm (3-15/16") of the cords, leaving the ends tempo-

rarily hooked through a notch on the side of the spool.

Press

Spool

Press

80mm(3-1/8”)

For left hand rotation

Spool

100mm(3-15/16”)

Notches

– Mount the spool in the housing so that the grooves and protrusions on the

spool match up with those in the housing. Keep the side with letters on the

spool visible on the top. Now, unhook the ends of the cord from their

temporary position and feed the cords through the eyelets to come out of the

housing.

16

Eyelets

Page 18

– Align the protrusion on the underside of the cover with the slots of the

eyelets.

Then push cover firmly onto the housing to secure it.

SERVICING INSTRUCTIONS

Cover

Protrusion

Slot of eyelet

CAUTION : Before doing any work on the Brush cutter/String trimmer, always stop the engine and pull the plug cap off the spark plug (see

To ensure a long service life and to avoid any damage to the equipment, the following servicing operations should be performed at regular

intervals.

“checking the spark plug”).

Always wear protective gloves!

Daily checkup and maintenance

– Before operation, check the machine for loose screws or missing parts. Pay particular attention to the tightness of the cutter blade or

nylon cutting head.

– Before operation, always check for clogging of the cooling air passage and the cylinder fins.

Clean them if necessary.

– Perform the following work daily after use:

• Clean the Brush cutter/String trimmer externally and inspect for damage.

• Clean the air filter. When working under extremely dusty conditions, clean the filter the severall times a day.

• Check the blade or the nylon cutting head for damage and make sure it is firmly mounted.

• Check that there is sufficient difference between idling and engagement speed to ensure that the cutting tool is at a standstill while the

engine is idling (if necessary reduce idling speed).

If under idling conditions the tool should still continue to run, consult your nearest Authorized Service Agent.

– Check the functioning of the I-O switch, the lock-off lever, the control lever, and the look button.

REPLACEMENT OF ENGINE OIL

Deteriorated engine oil will shorten the life of the sliding and rotating parts to a great extent. Be sure to check the period and quantity of

replacement.

ATTENTION : In general, the engine main unit and engine oil still remain hot just after the engine is stopped. In replacement of oil,

Note: If the oil filled above the limit, it may be contaminated or may catch fire with white smoke.

Interval of replacement : Initially, every 20 operating hours, and subsequently every 50 operating hours

Recommended oil : SAE10W-30 oil of API Classification SF Class or higher (4-stroke engine oil for automobile)

confirm that the engine main unit and engine oil are sufficiently cooled down. Otherwise, there may remain a risk of

scald.

In replacement, perform the following procedure.

1) Confirm that the tank cap is tightened securely.

2) Detach the oil gauge.

Keep the oil gauge free from dust or dirt.

Fuel tank cap

Oil gauge

17

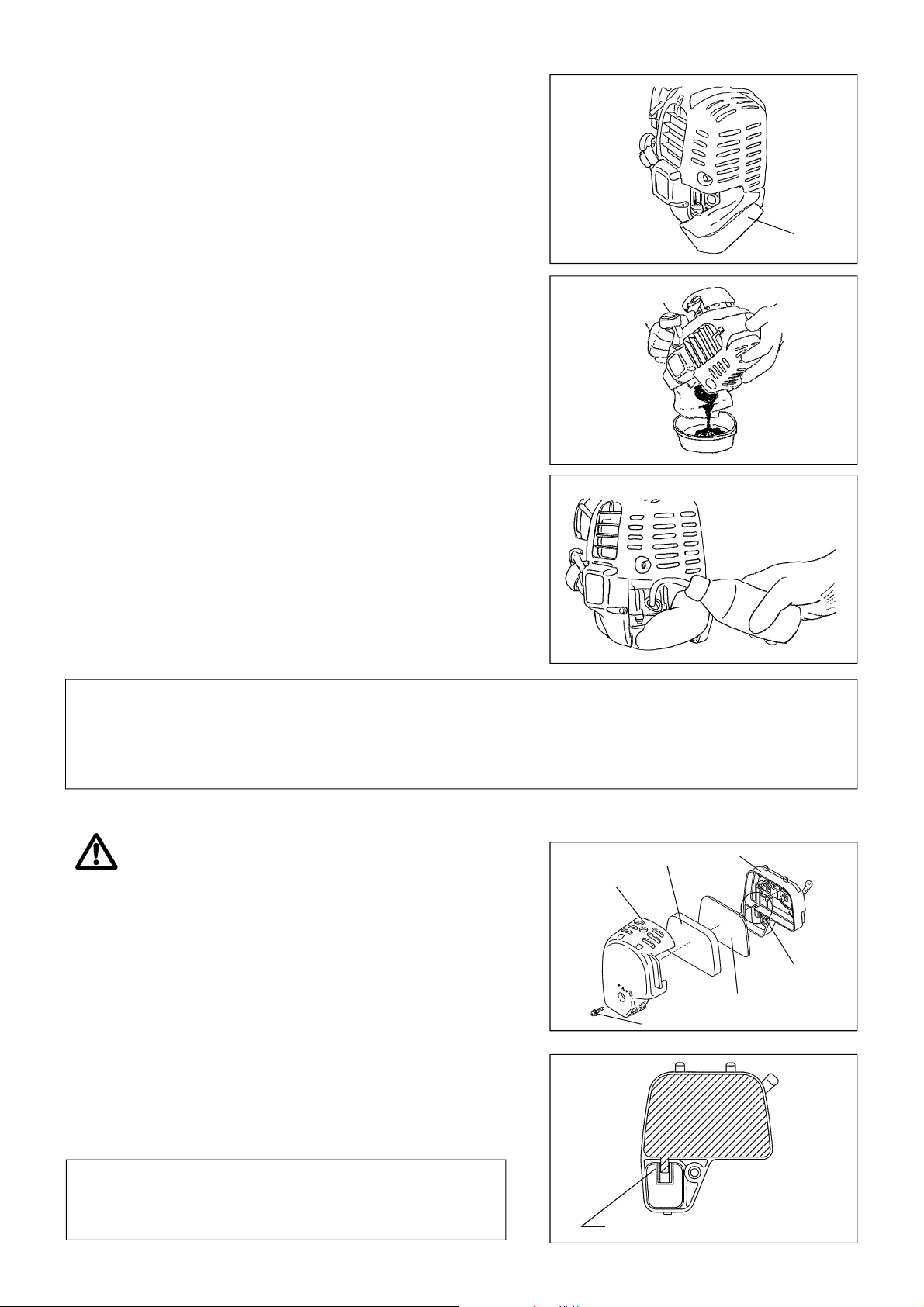

Page 19

3) Place waste or paper near the oil refill port.

4) Detach the oil gauge, and drain oil, tilting the main unit toward the oil refill

port.

Drain oil in a container.

5) Keep the engine level, and feed new oil up to the edge of the oil refill port.

In refill, use a lubricant refill container.

6) After refill, securely tighten the oil gauge. Insufficient tightening of the oil

gauge will lead to oil leakage.

Waste or paper

POINTS ON OIL

– Never discard replaced engine oil in garbage, earth or sewage ditch. Disposal of oil is regulated by law. In disposal, always follow

the relevant laws and regulations. For any points remaining unknown, contact Authorized Service Agent.

– Oil will deteriorate even when it is kept unused. Perform inspection and replacement at regular intervals (replace with new oil

every 6 months).

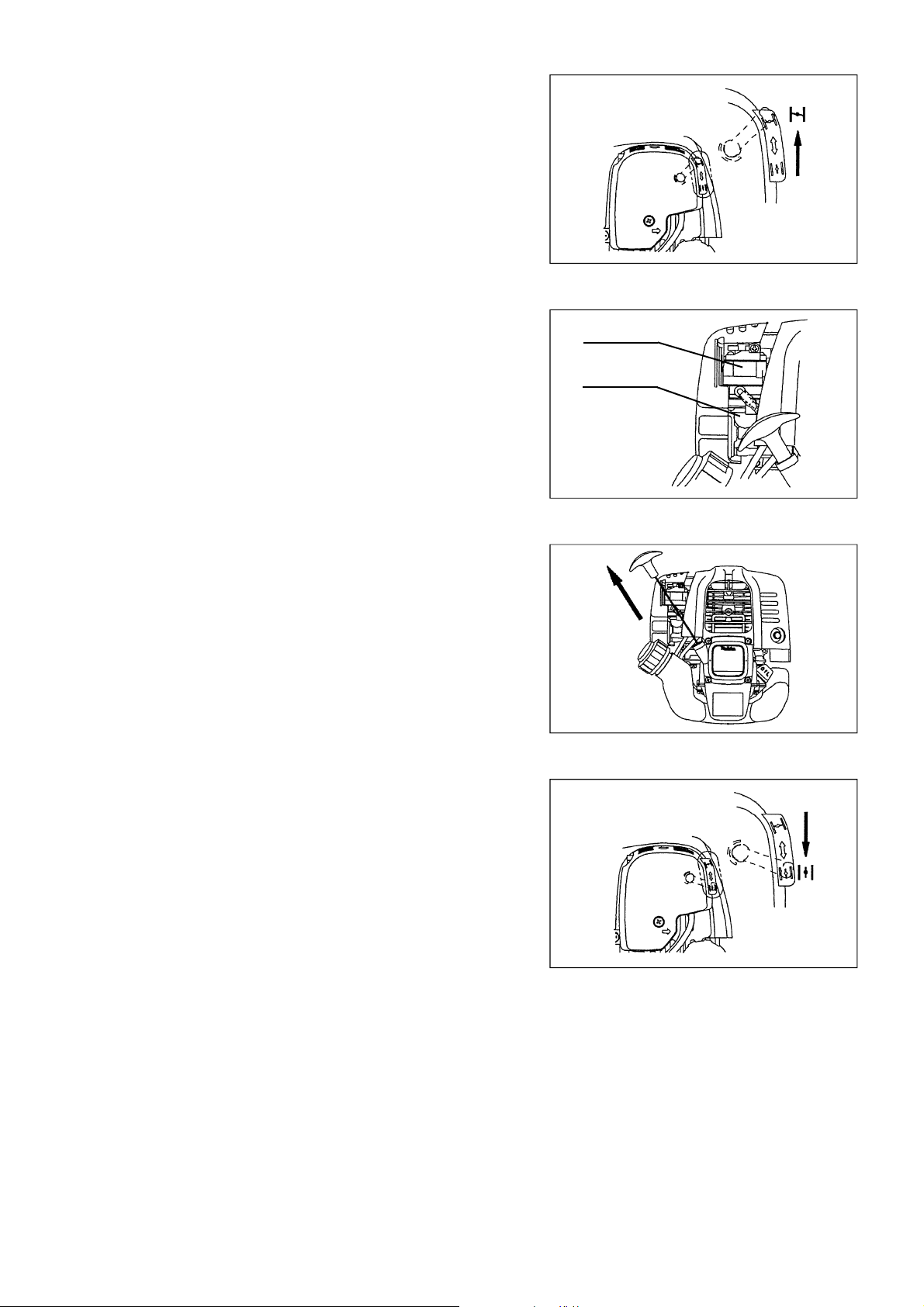

CLEANING OF AIR CLEANER

DANGER: INFLAM MABLES STRICTLY PROHIBITED

Interval of Cleaning and Inspection: Daily (every 10 operating hours)

– Turn the choke lever to the full close side, and keep the carburetor off from

dust or dirt.

– Remove the air cleaner cover-fixing bolts.

– Pull the cover lower side and detach the air cleaner cover.

– If oil adheres to the element (sponge), squeeze it firmly.

– For heavy contamination:

1) Remove the element (sponge), immerse it in warm water or in water-diluted

neutral detergent, and dry it completely.

2) Clean the element (felt) with gasoline, and dry it completely.

– Before attaching the element, be sure to dry it completely. Insufficient drying

of the element may lead to difficult startup.

– Wipe out with waste cloth, oil adhering around the air cleaner cover and plate

breather.

– Immediately after cleaning is finished, attach the cleaner cover and tighten it

with fixing bolts. (In remounting, first place the upper claw, and then the lower

claw.)

Element (sponge)

Air cleaner cover

Fixing bolt

Plate

Breather Part

Element (felt)

Points in Handling Air Cleaner Element

– Clean the element several times a day, if excessive dust adheres to it.

– If operation continues with the element remaining not cleared of oil, oil in

the air cleaner may fall outside, resulting in oil contamination.

18

Pick this part and remove the element (felt).

Page 20

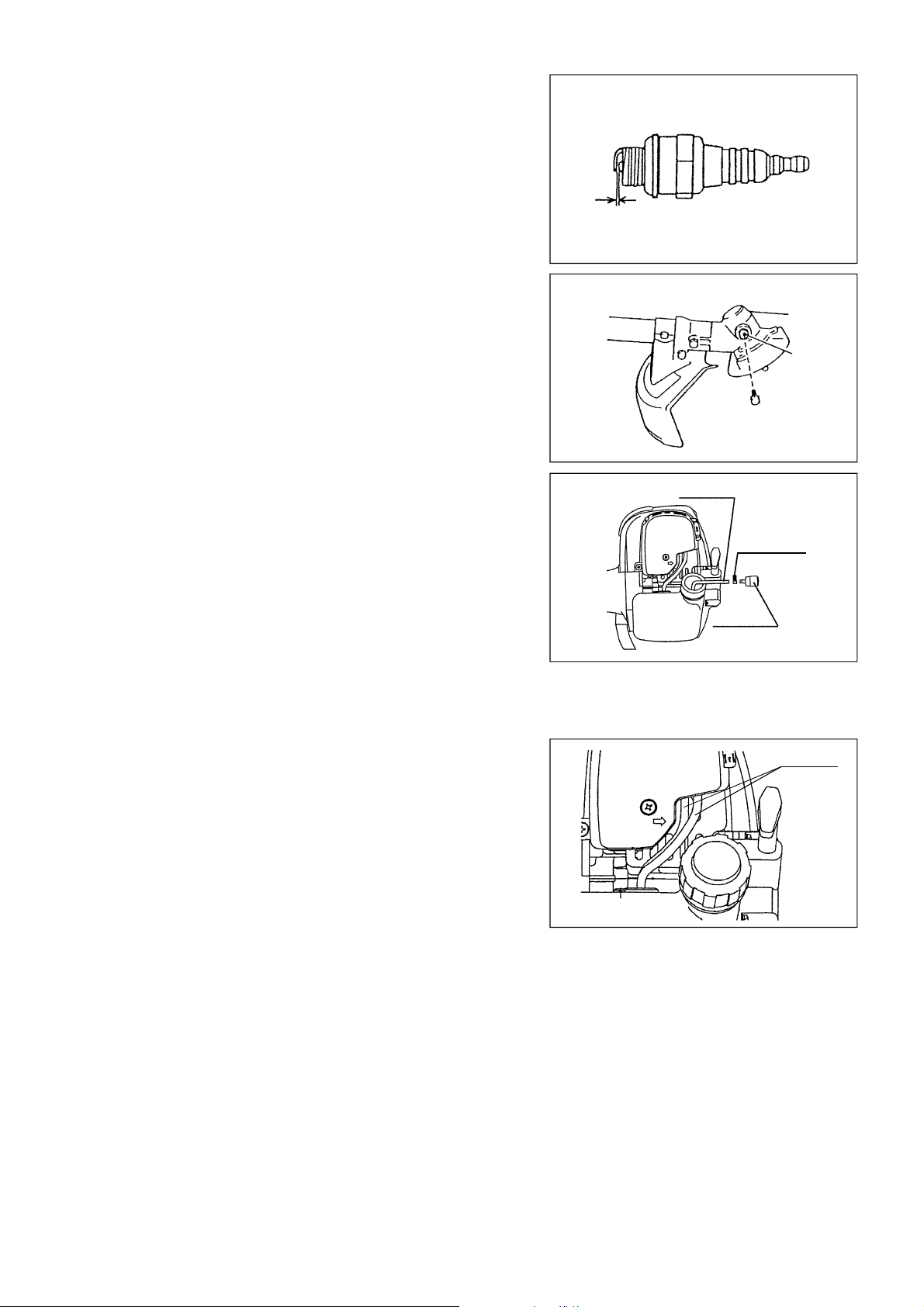

CHECKING THE SPARK PLUG

– Only use the supplied universal wrench to remove or to install the spark

plug.

– The gap between the two electrodes of the spark plug should be 0.7-0.8mm

(0.028”-0.032”). If the gap is too wide or too narrow, adjust it. If the spark

plug is clogged with carton or fouled, clean it thoroubhly or replace it.

CAUTION : Never touch the spark plug connector while the engine is running

(danger of high voltage electric shock).

SUPPLY OF GREASE TO GEAR CASE

– Supply grease (Shell Alvania 2 or equivalent) to the gear case through the

grease hole every 30 hours. (Genuine DOLMAR grease may be purchased

from your DOLMAR dealer.)

CLEANING OF FUEL FILTER

WARNING: INFLAMMABLES STRICTLY PROHIBITED

Interval of Cleaning and Inspection: Monthly (every 50 operating hours)

Suction head in the fuel tank

– The fuel filler (1) of the suction head is used to filler the fuel required by the

carburetor.

– A periodical visual inspection of the fuel filter is to be conducted. For that

purpose open the tank cap, use a wire hook and pull out the suction head

through the tank opening. Filters found to have hardened, been polluted or

clogged up are to be replaced.

– Insufficient fuel supply can result in the admissible maximum speed being

exceeded. It is therefore important to replace the fuel filter at least quarterly

to ensure satisfactory fuel supply to the carburetor.

0.7mm-0.8mm

(0.028”-0.032”)

Fuel pipe

House clamp

Fuel

filter(1)

Gear case

Grease hole

REPLACEMENT OF FUEL PIPE

Fuel pipe

CAUTION: INFLAMMABLES STRICTLY PROHIBITED

Interval of Cleaning and Inspection: Daily (every 10 operating hours)

Replacement: Annually (every 200 operating hours)

Replace the fuel pipe every year, regardless of operating frequency. Fuel

leakage may lead to fire.

If any leakage is detected during inspection, replace the oil pipe immediately.

INSPECTION OF BOLTS, NUTS AND SCREWS

– Retighten loose bolts, nuts, etc.

– Check for fuel and oil leakage.

– Replace damaged parts with new ones for safety operation.

CLEANING OF PARTS

– Keep the engine always clean.

– Keep the cylinder fins free of dust or dirt. Dust or dirt adhering to the fins will

cause seizure.

REPLACEMENT OF GASKETS AND PACKINGS

In reassembling after the engine is dismounted, be sure to replace the gaskets and packings with new ones.

Any maintenance of adjustment work that is not included and described in this manual is only to be performed by Authorized Service Agents.

19

Page 21

STORAGE

WARNING: When draining the fuel, be sure to stop the engine and confirm that the engine cools

down.

Just after stopping the engine, it may still hot with possibility of burns, inflammability and fire.

ATTENTION: When the machine is kept out of operation for a long time, drain up all fuel from the

fuel tank and carburetor, and keep it at a dry and clean place.

– Drain up fuel from the fuel tank and carburetor according to the following

procedure:

1) Remove the fuel tank cap, and drain fuel completely.

If there is any foreign matter remaining in the fuel tank, remove it

completely.

2) Pull out the fuel filter from the refill port using a wire.

3) Push the primer pump until fuel is drained from there, and drain fuel

coming into the fuel tank.

4) Reset the filter to the fuel tank, and securely tighten the fuel tank cap.

5) Then, continue to operate the engine until it stops.

– Remove the spark plug, and drip several drops of engine oil through the

spark plug hole.

– Gently pull the starter handle so that engine oil will spread over the engine,

and attach the spark plug.

– Attach the cover to the cutter blade.

– During storage, keep the rod horizontal or keep the machine upright with the

blade edge oriented upward. (In this case, pay full attention to prevent the

machine from falling.)

Never store the machine with the cutter blade edge oriented downward.

Lubricating oil may spill out.

– Keep the drained fuel in a special container in a well-ventilated shade.

Drain fuel

Humidity

Attention after long-time storage

– Before startup after long-time shutdown, be sure to replace oil (refer to P 17). Oil will deteriorate while the machine is kept out of

operation.

Fault location

Fault System Observation Cause

Engine not starting or with

difficulty

No ignition spark

Fuel supply Fuel tank filled

Compression

Mechanical fault Starter not engaging Broken starter spring, broken parts inside of the engine

Warm start problems

Engine starts but dies Fuel supply Tank filled Incorrect idling adjustment, carburetor contaminated

Ignition system Ignition spark O.K.

No compression when

pulled over

Tank filled ignition spark

existing

Fault in fuel supply or compression system, mechanical

defect

STOP-switch operated, wiring fault or short circuit, spark

plug or connector defective, ignition module faulty

Incorrect choke position, carburetor defective, fuel supply

line bent or blocked, fuel dirty.

Cylinder bottom gasket defective, crankshaft seals

damaged, cylinder or piston rings defective or improper

sealing of spark plug

Carburetor contaminated, have it cleaned

Insufficient performance

Several systems

may simultaneously

be affected

Engine idling poor

20

Fuel tank vent defective, fuel supply line interrupted,

cable or STOP-switch faulty

Air filter contaminated, carburetor contaminated, muffler

clogged, exhaust duct in the cylinder clogged

Page 22

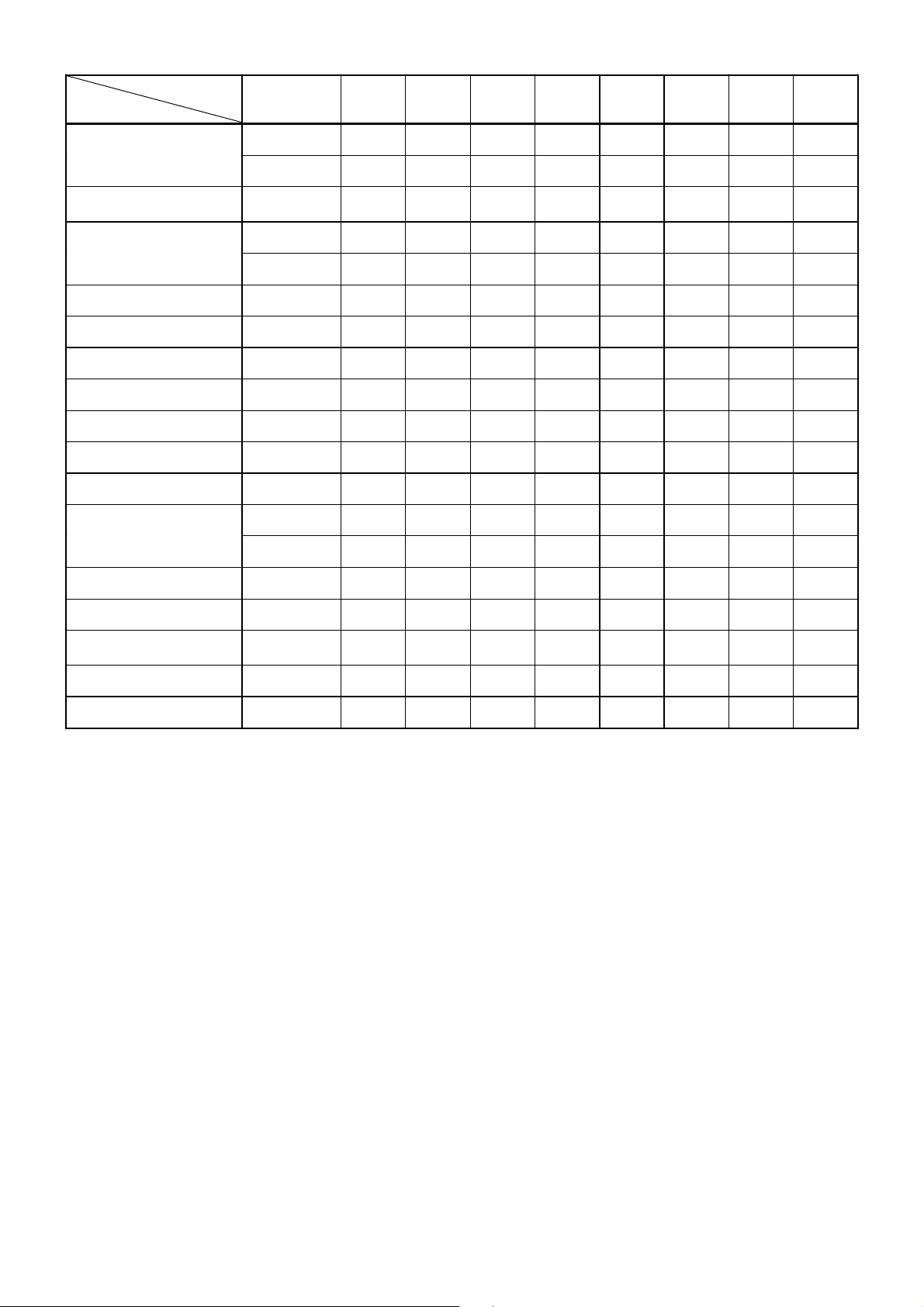

Operating time

Item

Engine oil

Tightening parts

(bolt, nut)

Before

operation

After

lubrication

Daily

(10h)

30h 50h 200h

Shutdown

/rest

Corres-po

nding P

Inspect/clean ○ 11

*1

Replace ○

17

Inspect ○ 19

Fuel tank

Drain fuel ○

*3

20

Throttle lever Check function ○ 13

Stop switch Check function ○ 13

Cutting blade Inspect ○ ○ 9

Low-speed rotation Inspect/adjust ○ 15

Air cleaner Clean ○ 18

Ignition plug Inspect ○ 19

Cooling air duct Clean/inspect ○ 19

Inspect ○ 19

Clean/inspect ○ ―

Fuel pipe

Replace ◎

Gear-case grease Refill

19

○

*2

―

Fuel filter Clean/replace ○ 19

Clearance between air intake

valve and air discharge valve

Adjust ◎

*2

―

Engine overhaul ◎*2 ―

Carburetor Drain fuel ○

*3

20

*1 Perform initial replacement after 20h operation.

*2 For the 200 operating hour inspection, request Authorized Service Agent or a machine shop.

*3 After emptying the fuel tank, continue to run the engine and drain fuel in the carburetor.

21

Page 23

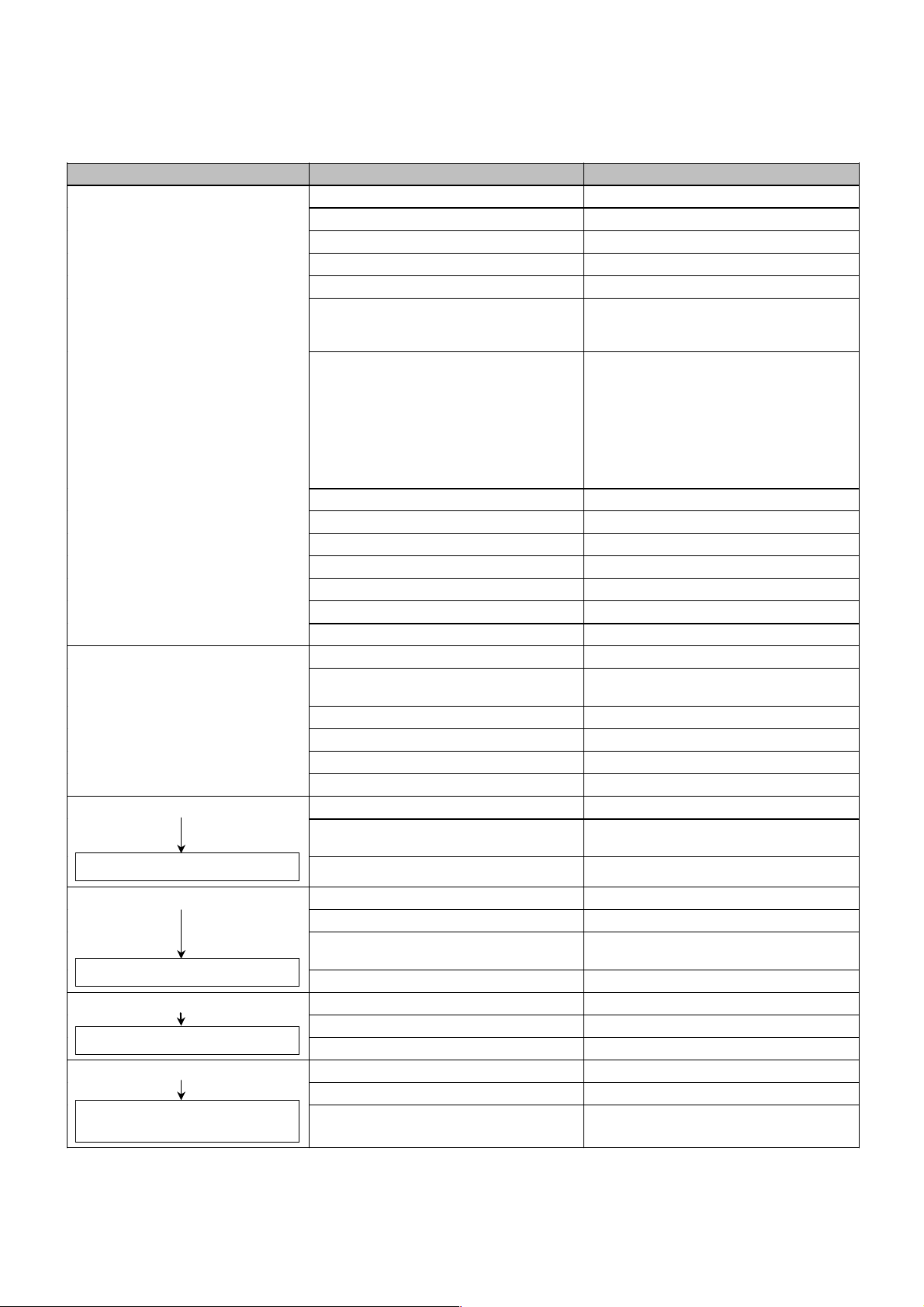

TROUBLESHOOTING

Before making a request for repairs, check a trouble for yourself. If any abnormality is found, control your machine according to the

description of this manual. Never tamper or dismount any part contrary to the description. For repairs, contact Authorized Service Agent or

local dealership.

State of abnormality Probable cause (malfunction) Remedy

Failure to operate primer pump Push 7 to 10 times.

Low pulling speed of starter rope Pull strongly.

Lack of fuel Feed fuel.

Clogged fuel filter Clean

Broken fuel tube Straighten fuel tube

Engine does not start

Engine stops soon

Engine speed does not increase

Cutter blade does not rotate

Stop engine immediately㩷

Deteriorated fuel

Excessive suction of fuel

Detached plug cap Attach securely

Contaminated spark plug Clean

Abnormal clearance of spark plug Adjust clearance

Other abnormality of spark plug Replace

Abnormal carburetor Make request for inspection and maintenance.

Starter rope cannot be pulled Make request for inspection and maintenance

Abnormal drive system Make request for inspection and maintenance

Insufficient warm-up Perform warm-up operation

Choke lever is set to “CLOSE” although engine

is warmed up

Clogged fuel filter Clean

Contaminated or clogged air cleaner Clean

Abnormal carburetor Make request for inspection and maintenance

Abnormal drive system Make request for inspection and maintenance

Loosened cutter blade-tightening nut Tighten securely

Twigs caught by cutter blade or

dispersion-preventing cover

Abnormal drive system Make request for inspection and maintenance.

Deteriorated fuel makes starting more difficult.

Replace with new one. (Recommended

replacement: 1 month)

Set throttle lever from medium speed to high

speed, and pull starter handle until engine

starts. Once engine starts, cutter blade

starts rotating. Pay full attention to cutter

blade.

If engine will not start still, remove spark plug,

make electrode dry, and reassemble them as

they originally are. Then, start as specified.

Set to “OPEN”

Remove foreign matter

Main unit vibrates abnormally.

Stop engine immediately㩷

Cutter blade does not stop immediately.

Stop engine immediately㩷

Engine does not stop.

Run engine at idling, and set choke

lever to CLOSE.

When the engine does not start after warm-up operation:

If there is no abnormality found for the check items, open the throttle by about 1/3 and start the engine.

㩷

Broken, bent or worn cutter blade Replace cutter blade

Loosened cutter blade-tightening nut Tighten securely

Shifted convex part of cutter blade and cutter

blade support fitting

Abnormal drive system Make request for inspection and maintenance

High idling rotation Adjust

Detached throttle wire Attach securely

Abnormal drive system Make request for inspection and maintenance

Detached connector Attach securely

Abnormal electric system Make request for inspection and maintenance.

Attach securely

22

Page 24

EMISSION COMPLIANCE PERIOD

For handheld engines : The Emissions Compliance Period referred to on the

Emissions Compliance label indicates the number of operating hours for which

the engine has been shown to meet Federal emission requirements.

Category C=50 hours, B=125 hours, and A=300 hours.

Air Index and durability period information

The Air Index Information hang-tag for this engine is provided in accordance

with the California emission regulations.

The graphical representation of the Air Index on the hang-tag shows the

emissions performance of this engine, and can be used to compare the

emissions performance with other available engines.

The lower the Air Index, the less pollution.

Note: Remove the hang-tag before operating the engine.

The Emissions Durability Period referred to on the hang-tag indicates the

number of operating hours for which the engine has been shown to meet the

California emission requirements.

Descriptive term Applicable to Emissions Durability Period

Moderate 50hours (0-80 cc, inclusive)

Intermediate 125hours (0-80 cc, inclusive)

Extended 300hours (0-80 cc, inclusive)

23

Page 25

CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The California Air Resources Board and Makita U.S.A., Inc. are pleased to explain the emission control system warranty

on your 2000 and later Small Off-Road engine (herein “engine”). In California, the engine must be designed, built and

equipped to meet the State's stringent anti-smog standards Makita U.S.A., Inc. must warrant the emission control system

on your engine for the periods of time described below, provided there has been no abuse, neglect or improper

maintenance of your engine. Your emission control system includes parts such as the carburetor and the ignition system.

Also included may be hoses, connectors and other emission-related assemblies. Where a warrantable condition exists,

Makita U.S.A., Inc. will repair your engine at no cost to you including diagnosis, parts and labor.

MANUFACTURER'S WARRANTY COVERAGE:

The 2000 and later engines are warranted for two (2) years. If any emission-related part on your engine is

defective, the part will be repaired or replaced by Makita U.S.A., Inc.

OWNER'S WARRANTY RESPONSIBILITIES:

- As the engine owner, you are responsible for the performance of the required maintenance listed in your Owner's

Manual. Makita U.S.A., Inc. recommends that you retain all receipts covering maintenance on your engine, but

Makita U.S.A., Inc. cannot deny warranty solely for the lack of receipts or for your failure to ensure the

performance of all scheduled maintenance.

- As the engine owner, your should however be aware that Makita U.S.A., Inc. may deny you warranty coverage if

your engine or a part has failed due to abuse, neglect, improper maintenance or unapproved modifications.

- You are responsible for presenting your engine manufactured by Makita U.S.A., Inc. to a dealer, distributor or

warranty station authorized by Makita Factory Service Center which is the U.S. importer and/or OEM of the

Small Off-Road/engine as soon as a problem exists. The warranty repairs should be completed in a reasonable

amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and responsibilities, you should contact Makita Factory

Service Center nearest you.

Makita Factory Service Center

Address Phone NO.

14930 Northam Street

La Mirada, CA 90638-5753

41850 Christy Street

Fremont, CA 94538-5107

1421N. Clovis Ave., Ste. 112

Fresno, CA 93727

4554 Roseville Rd., Ste E

North Highlands, CA 95660

392 S. Arrowhead Ave., #A-1

San Bernardino, CA 92408

7674 Clairemont Mesa Blvd.

San Diego, CA 92111

333 Littlefield Ave.

S.San Francisco, CA 64080

1714 E McFadden Ave., Unit M

Santa Ana, CA 92705

16735 Saticoy St., Ste. 105

Van Nuys, CA 91406

(714) 522-8088

(510) 657-9881

(209) 252-5166

(916) 331-6211

(909) 885-1289

(619) 278-4471

(415) 875-1002

(714) 667-5066

(818) 782-2440

24

Page 26

LIMITED WARRANTY on Emission Control Systems

- California Only -

Makita U.S.A., Inc., a distributor of Small Off-Road Engine in the U.S. warrant to the owner of the 2000 and later engine

that the engine (1) has been designed, built and equipped so as to conform at the time of manufacture with the applicable

regulations of the California Air Resources Board, and (2) is free from defects in materials and workmanship which cause

it to fail to conform with those regulations as may be applicable in the terms and conditions stated below;

A. WARANTY COMMENCEMENT DATE

The warranty period begins on the date the engine is delivered to a first retail purchaser.

B. LENGTH OF COVERAGE

Makita U.S.A., Inc. warrants to a first retail purchaser and each subsequent purchaser that the engine is free from

defects in materials and workmanship which cause the failure of a warranted emission-related part for a period of two

(2) years after the date of delivery to the first retail purchaser.

C. WHAT IS COVERED:

1. REPAIR OR REPLACEMENT PARTS

Repairs and replacement of any warranted part will be performed at no charge to you by an authorized dealer,

distributor or a warranty station. You may contact Makita Factory Service Center which is the U.S. importer/OEM

of the Small Off-Road /engine manufactured by Makita U.S.A., Inc. to get the nearest appropriate location where your

warranty repairs are performed.

2. WARRANTY PERIOD

This warranty continues for a period of two (2) years and shall apply only to the repair, replacement or adjustment of

the component parts which are not scheduled for replacement as required maintenance. Further component parts or

which are scheduled only for regular inspection to the effect of "repair or replace as necessary" shall be warranted for

the warranty period. Any warranted part which is scheduled for replacement as required maintenance shall be

warranted for the period of time up to the first scheduled replacement point for that part.

3. DIAGNOSIS

You shall not be charged for diagnostic labor, which leads to the determination that a warranted part is defective, if the

diagnostic work is performed at an authorized dealer, distributor or warranty station.

4. CONSEQUENTIAL DAMAGES

If a warranted part failed causing damages to other engine components, consult a warranty station.

D. WHAT IS NOT COVERED

1. This limited warranty does not cover any part which malfunctions, fails or is damaged due to failure to follow

the maintenance and operating instructions set forth in the 2000 and later Owner's Manual including:

(1) improper or inadequate maintenance of any warranted parts

(2) improper installation, adjustment or repair of the engine or of any warranted part unless performed by an

authorized dealer

(3) failure to follow recommendations on fuel use contained in the 2000 and later Owner's Manual

(4) repairs performed outside of the authorized warranty service facility

(5) use of parts, which are not authorized by Makita U.S.A., Inc..

2. Add-on or modified parts

This warranty does not cover any part which malfunctions, fails or is damaged due to alterations by changing, adding

to or removing parts from the engine.

3. Expenses incurred by processing warranty claims

Makita Factory Service Center, any authorized dealer, distributors and warranty station shall not be liable for any

loss of use of the engine, for any alternative usage, for any damage to goods, loss of time or inconvenience.

E. HOW TO FILE A CLAIM

All repairs qualifying under this Limited Warranty must be performed by a dealer who sold you the engine or

distributors or warranty stations authorized by Makita Factory Service Center. In the event that any emission-related

part is found to be defective during the warranty period, you shall notify Makita Factory Service Center and you will

be given the appropriate warranty service facilities where the warranty repair is performed.

25

Page 27

F. WHERE TO GET WARRANTY SERVICE

It is recommended that warranty service be performed by the authorized dealer, who sold you the engine, although

warranty service will be performed by any authorized dealers, distributors and warranty stations anywhere in the

United States. When warranty repair is needed, the engine must be brought to an authorized dealer, distributorship or

warranty station's place of business during normal business hours. In all cases, a reasonable time, not to exceed 30

days, must be allowed for the warranty repair to be completed after the engine is received by the authorized dealer,

distributor or service station.

G. MAINTENANCE, REPLACEMENT AND REPAIR OF EMISSION-RELATED PARTS

Only warranted engine replacement parts approved by Makita U.S.A., Inc. should be used in the performance of any

warranty maintenance or repairs on emission-related parts. If other than authorized parts are used for maintenance,

replacement or repair of components affecting emission control, you should assure yourself that such parts are

warranted by their manufacturer to be equivalent to authorized parts in performance and durability. Makita U.S.A.,

Inc., however, assumes no liability under this warranty with respect to parts other than authorized parts. The use of

non-authorized replacement parts does not invalidate the warranty on other components unless the non-authorized

parts cause damage to warranted parts.

H. PARTS COVERED UNDER THE CALIFORNIA EMISSION WARRANTY

1) Fuel Metering system

(i) Carburetor and internal parts

(ii) Air cleaner plate ( including choke system)

(iii) Air cleaner cover

(iv) Air cleaner element

(v) Fuel Filter

2) Ignition System

(i) Spark plug

(ii) Flywheel magneto

(iii) Ignition coil

3) Miscellaneous Item Used in Above Systems

(i) Hoses and sealing gaskets, bolts, connectors, and assemblies.

I. MAINTENANCE STATEMENTS

It is your responsibility to have all scheduled inspection and maintenance service performed at the times recommended

in the 2000 and later Owner's Manual and to retain proof that inspection and maintenance service are performed at the

times when recommended. Makita U.S.A., Inc. will not deny a warranty claim solely because you have no record of

maintenance; however, Makita U.S.A., Inc. may deny a warranty claim if your failure to perform required maintenance

resulted in the failure of warranted part. The proof, which you maintain, should be given to each subsequent owner

of the engine. You are responsible for performing the scheduled maintenance described below based on the

procedures specified in the 2000 and later Owner's Manual. The scheduled maintenance below is based on the

normal engine-operating schedule.

1) Clean engine and check bolts and nuts. Retighten if necessary. :Every 8 hours (daily)

2) Check and refill engine oil (4stroke) :Every 8 hours (refill daily up to upper limit)

3) Change engine oil (4stroke) :Initial 20 hours and every 50 hours afterward

Check clogging of cooling air passage and cylinder fins.

4)

Remove and clean if necessary.

5) Clean air cleaner. :Every 8 hours (daily)

6) Check spark plug. Clean and adjust if necessary. :Every 8 hours (daily)

7) Check muffler exhaust outlet (or port). Clean if necessary. :Every 50 hours (monthly)

8) Check fuel filter. If clogged, replace with new one. :Every 50 hours (monthly)

9) Adjust valve clearance, if applicable (4stroke). :Every 200 hours (yearly)

10) Replace fuel lines. :Every 200 hours (yearly)

11) Overhaul engine. :Every 200 hours (yearly)

12) Replace packings and gaskets and gaskets with new ones. :Every reassembling

PROCEDURE INTERVAL

:Every 8 hours (daily)

26

Page 28

REPAIR AND REPLACEMENT OF EMISSION-RELATED PARTS

It is recommended that only engine replacement parts which have been authorized and

approved by Makita U.S.A., Inc. should be used in the performance of any warranty

maintenance or repairs of emission-related parts. These replacement parts will be

provided at no charge if the part is still under warranty.

HOW TO FILE A WARRANTY CLAIM

AND WHERE TO GET WARRANTY SERVICES

Contact the nearest Makita Factory Service Center Manager to determine the appropriate

location where the required warranty services are to be performed. A list of the Factory

Service Center locations and phone numbers are provided below for your convenience.

14930 Northam Street

La Mirada, CA 90638-5753

(714) 522-8088

1421N. Clovis Ave., Ste. 112

Fresno, CA 93727

(209) 252-5166

392 S. Arrowhead Ave., #A-1

San Bernardino, CA 92408

(909)885-1289

333 Littlefield Ave.

S. San Francisco, CA 94080

T. (415)875-1002

16735 Saticoy St., Ste. 105

Van Nuys, CA 91406

(818) 782-2440

41850 Christy Street

Fremont, CA 94538-5107

(510) 657-9881

4554 Roseville Rd., Ste E

North Highlands, CA 95660

(916)331-6211

7674 Clairemont Mesa Blvd.

San Diego, CA 92111

(619) 278-4471

1714 E McFadden Ave., Unit M

Santa Ana, CA 92705

(714) 667-5066

27

Page 29

FEDERAL EMISSION COMPONENT DEFECT WARRANTY

EMISSION COMPONENT DEFECT WARRANTY COVERAGE - This emission warranty is

applicable in all States, except the State of California

Makita U.S.A., Inc., La Mirada, California, (herein "MAKITA") warrant to the initial retail

purchaser and each subsequent owner, that this utility equipment engine (herein "engine" )

was designed, built, and equipped to conform at the time of initial sale to all applicable

regulations of the U.S. Environmental Protection Agency (EPA), and that the engine is free

of defects in materials and workmanship which would cause this engine to fail to conform

with EPA regulations during its warranty period.

For the components listed under PARTS COVERED, Makita Factory Service Center or

service center authorized by Makita will, at no cost to you, make the necessary diagnosis,

repair, or replacement necessary to ensure that the engine complies with applicable U.S.

EPA regulations.

EMISSION COMPONENT DEFECT WARRANTY PERIOD

The warranty period for this engine begins on the date of sale to the initial purchaser and

continues for a period of 2 years.

PARTS COVERED

Listed below are the parts covered by the Emission Component Defect Warranty. Some of

the parts listed below may require scheduled maintenance and are warranted up to the first

scheduled replacement point for that part.

1) Fuel Metering System

(i) Carburetor and internal parts

(ii) Fuel filter, if applicable

(iii) Throttle stopper, if applicable

(iv) Choke System, if applicable

2) Air Induction System

(i) Air cleaner plate

(ii) Air cleaner case

(iii) Air cleaner element

3) Ignition System

(i) Spark plug

(ii) Flywheel Magneto

(iii) Ignition Coil

4) Miscellaneous Items Used in Above Systems

(i) Fuel hoses. clamps and sealing gaskets

28

Page 30

OBTAINING WARRANTY SERVICE

To obtain warranty service, take your engine to the nearest MAKITA Factory Service

Center or Service Center authorized by MAKITA. Bring your sales receipts indicating date

of purchase for this engine. The dealer or service center authorized by MAKITA will perform

the necessary repairs or adjustments within a reasonable amount of time and furnish you

with a copy of the repair order. All parts and accessories replaced under this warranty

become the property of MAKITA.

WHAT IS NOT COVERED

* Conditions resulting from tampering, misuse, improper adjustment (unless they were

made by the dealer or service center authorized by MAKITA during a warranty repair),

alteration, accident, failure to use the recommended fuel and oil, or not performing

required maintenance services.

* The replacement parts used for required maintenance services.

* Consequential damages such as loss of time, inconvenience, loss of use of the engine of

equipment, etc.

* Diagnosis and inspection charges that do not result in warranty-eligible service being

performed.

* Any non-authorized replacement part, or malfunction of authorized parts due to use of

non-authorized parts.

OWNER'S WARRANTY RESPONSIBILITIES

As the engine owner, you are responsible for the performance of the required

maintenance listed in your owner's manual, MAKITA recommends that you retain all

receipts covering maintenance on your engine, but MAKITA can not deny warranty solely

for the lack of receipts or for your failure to ensure the performance of all scheduled

maintenance.

As the engine owner, you should however be aware that the MAKITA may deny your

warranty coverage if your engine or a part has failed due to abuse, neglect, improper

maintenance or unapproved modifications.

You are responsible for presenting your engine to the nearest MAKITA Factory Service

Center or service center authorized by MAKITA when a problem exists.

If you have any questions regarding your warranty rights and responsibilities, you should

contact the Makita Warranty Service Department at 1-800-4-MAKITA for the information.

29

Page 31

THINGS YOU SHOULD KNOW ABOUT THE EMISSION CONTROLL SYSTEM

WARRANTY

MAINTENANCE AND REPAIRS

You are responsible for the proper use and maintenance of the engine. You should

keep all receipts and maintenance records covering the performance of regular

maintenance in the event questions arise. These receipts and maintenance records

should be transferred to each subsequent owner of the engine. MAKITA reserves the

rights to deny warranty coverage if the engine has not been properly maintained.

Warranty claims will not be denied, however, solely because of the lack of required

maintenance or failure to keep maintenance records.

MAINTENANCE, REPLACEMENT OR REPAIR OF EMISSION CONTROL DEVICES

AND SYSTEMS MAY BE PERFORMED BY ANY REPAIR ESTABLISHMENT OR

INDIVIDUAL; HOWEVER, WARRANTY REPAIRS MUST BE PERFORMED BY

MAKITA FACTORY SERVICE CENTER OR SERVICE CENTER AUTHORIZED BY

Makita. THE USE OF PARTS THAT ARE NOT EQUIVALENT IN PERFORMANCE

AND DURABILITY TO AUTHORIZED PARTS MAY IMPAIR THE EFFECTIVENESS

OF THE EMISSION CONTROL SYSTEM AND MAY HAVE A BEARING ON THE

OUTCOME OF WARRANTY CLAIM.

If other than the parts authorized by MAKITA are used for maintenance replacements or

for the repair of components affecting emission control, you should assure yourself that

such parts are warranted by their manufacturer to be equivalent to the parts authorized by

MAKITA in their performance and durability.

HOW TO MAKE A CLAIM

All repairs qualifying under this limited warranty must be performed by Makita Factory

Service Center or service center authorized by MAKITA. In the event that any

emission-related part is found to be defective during the warranty period, you shall notify

Makita Warranty Service Department at 1-800-4-MAKITA and you will be given the

appropriate warranty service facilities where the warranty repair can be performed.

30

Page 32

Nous vous remercions d'avoir fait l'acquisition de la débroussailleuse /

taille-bordures DOLMAR. Nous sommes heureux de pouvoir vous

conseiller la débroussailleuse / taille-bordures DOLMAR qui représente le

résultat d'un long programme de développement et de plusieurs années de

recherche et d'expérience.

Veuillez lire cette brochure qui fait référence en détail aux différents points

témoignant de l'efficacité exceptionnelle de votre débroussaileuse

DOLMAR.

SYMBOLES

Vous rencontrerez les symboles suivants en parcourant le manuel d'instructions.

Lire le manuel d'instructions

Etre particuliérement soigneux et

attentif

Interdit

Table des matières Page

Symboles................................................................... 31

Consignes de sécurité................................................32

Caractéristiques techniques....................................... 36

Nomenclature des pièces...........................................37

Montage de la poignée...............................................38

Montage du dispositif de protection............................39

Montage de la lame de coupe ou de la tête

de coupe à fil .............................................................40

Avant mise en marche ...............................................41

Manipulation correct de la machine............................43

Consignes de mise en marche et arrêt de la machine 43

Réaffûtage de l'outil de coupe.................................... 45

Instructions relatives aux réparations.........................47

Remisage...................................................................50

Porter des protections visuelles et

auditives (pour la taille bordures

d’herbe)

Porter un casque de protection, des

protections visuelles et auditives (pour

la débroussailleuse uniquement)

Ne pas utiliser de lames métalliques

(Pour la taille bordures uniquement)

Maintenir ses distances

Risque de projections d'objets

Interdit de fumer

Pas de flame nue

Porter des gants de protection

Rejet

Maintenir toute personne et tout

animal domestique à l'écart de la zone

de travail

Vitesse maximale carburant et d’huile

Carburant (Essence)

Démarrage manuel de la machine

Arrêt d'urgence

Premier secours

Recyclage

On/Démarrage

Off/Arrêt

31

Page 33

CONSIGNES DE SÉCURITÉ

Instructions générales

– Pour utiliser la machine correctement, I’utilisateur doit lire ce manuel

d’instructions afin de se familiariser avec la manipulation de la

débroussailleuse / taille-bordures. Les utilisateurs disposant d’informations

insuffisantes risquent de mettre leur propre vie comme celle de tiers en

danger en manipulant la machine de façon incorrecte.

– Il est conseillé de prêter la débroussailleuse / taille-bordures uniquement à

des personnes ayant fait leurs preuves dans la manipulation de

débroussailleuse / taille-bordures.

Toujours leur remettre le manuel d’instructions.

– Les premiers utilisateurs devraient demander au concessionnaire de leur

dispenser les instructions de base afin de se familiariser à la manipulation de

débroussailleuse / taille-bordures thermique.

– Les enfants et les jeunes gens de moins de 18 ans ne sont pas autorisés à

utiliser la débroussailleuse / taille-bordures. Cependant, les jeunes gens

âgés de plus de 16 ans peuvent utiliser la machine pour s'entraîner, mais

uniquement sous la surveillance d'un formateur qualifié.

– Utiliser les débroussailleuse / taille-bordures avec le plus de soin et

d'attention possibles.

– Utilisez la débroussailleuse / taille-bordures uniquement si vous être en

bonne condition physique.

Procédez aux travaux avec calme et attention. L’utilisateur est responsible

vis à vis des autres personnes.

– Ne jamais utiliser la débroussailleuse / taille-bordures après absorption

d'alcool ou de médicaments ou si l'on se sent fatigué ou souffrant.

Utilisation spéciale de la machine

– La débroussailleuse / taille-bordures est seulement pour couper l’herbes,

broussailles et en sous-bois. Ne jamais employer la machine pour les

usages comprenant tailles de bordure et de haies que pouvaient causer des

blessures.

Équipement personnel de protection

– Les habits doivent être fonctionnels et adaptés, c'est-à-dire qu'ils doivent être

serrés sans toutefois entraver les mouvements. Ne pas porter de bijoux ou

d'habits qui pourraient s'accrocher dans les buissons ou les broussailles.

– Porter l'équipement et les habits de protection lors de l'utilisation de la

débroussailleuse / taille-bordures afin d'éviter les blessures au niveau de la

tête, des yeux, des mains ou des pieds.

– Toujours porter un casque dans les endroits o'les chutes d'objets sont

possibles. Vérifier à intervalles réguliers si le casque de protection (1) n'est

pas endommagé et le remplacer au plus tard aprés 5 ans. Utiliser

uniquement des casques de protection réglementaires.

– La visière (2) du casque (ou les lunettes) protège le visage des débris et des

pierres projetées. Toujours porter des lunettes ou une visière pour éviter les

blessures au niveau des yeux lors de l'utilisation de la débroussailleuse /

taille-bordures.

– Porter un équipement de protection contre le bruit approprié pour éviter une

détérioration de l'ouïe (serre-tête (3), protège-tympans etc.).

– La combinaison de travail (4) protège contre les projections de débris et de