DNP DualCom Installation Manual

PROGRAMMING AND INSTALLATION GUIDE

DualCom™ Series Universal Alarm Communicator

Digital Monitoring Products, Inc.

© 2021

TABLE OF CONTENTS

About the Communicator ......................1

System Components ...............................1

Terminals.......................................................................1

Programming (PROG) Connection ....................2

Tamper...........................................................................2

Reset Button ...............................................................2

Load Button ................................................................2

Backlit Logo ................................................................3

ECP and DSC Passthru ............................................3

Installation ...............................................4

Select a Location .......................................................4

Mount the Communicator ......................................4

Wire the Communicator .........................................5

Connect the Antenna ..............................................5

Applications .............................................6

CID Dialer Connection .............................................6

Communication Failure (DualComNF only) ...6

Zones 1‑4 Input Connection ..................................6

Zone4 Bell Connection ..........................................7

ECP Passthru Connection ......................................9

DSC Passthru Connection ......................................11

Arming and Disarming ...........................12

Use the Virtual Keypad App .................................12

Use Outputs ................................................................12

Initialization .............................................18

Clear All Codes ..........................................................18

Clear All Schedules ...................................................18

Clear Events ................................................................18

Clear Zone Programming .......................................18

Clear Communication ..............................................18

Set to Factory Defaults ...........................................18

Communication .......................................19

Account Number .......................................................19

Transmission Delay ...................................................19

Communication Type ..............................................19

Backup Cell ..................................................................19

Test Time ......................................................................19

Net/Cell Test Days ....................................................19

Check‑In Minutes .......................................................19

Fail Time Minutes ......................................................19

Backup Check‑In Minutes ......................................19

Backup Fail Time Minutes ......................................19

Receiver1 Programming .........................................20

Receiver2 Programming ........................................21

Network Options .....................................22

Wi‑Fi Setup..................................................................22

WPS ................................................................................22

List ..................................................................................22

Activate the Cellular Module .................14

Dealer Admin Activation ........................................14

Tech APP Activation ................................................14

Remote Link Activation ..........................................14

Programming ...........................................15

Before You Begin ......................................................15

Getting Started ..........................................................15

Programming Menu ..................................................15

Reset Timeout ............................................................16

Special Keys ................................................................16

Letters and Special Characters............................17

Current Programming .............................................17

Manual ...........................................................................22

Test .................................................................................23

Wireless Security Type ............................................23

Wireless Network Key .............................................23

DHCP Mode Enabled ...............................................23

Local IP Address ........................................................23

Gateway Address ......................................................23

Subnet Mask ................................................................23

DNS Server ..................................................................23

Programming Port ....................................................23

Remote Options ......................................24

Remote Key .................................................................24

Remote Disarm ..........................................................24

App Key ........................................................................24

System Reports .......................................24

Opening/Closing Reports ......................................24

Zone Restoral Reports ............................................24

System Options .......................................25

Entry Delay 1 ...............................................................25

Exit Delay .....................................................................25

Cross Zone Time ........................................................25

Power Fail Delay ........................................................25

Swinger Bypass Trips ..............................................25

Reset Swinger Bypass .............................................25

Time Changes .............................................................26

Hours from GMT .......................................................26

Keypad Input ..............................................................26

CID Format ..................................................................26

Zone Number ..............................................................31

Stop ........................................................... 32

Set Lockout Code ...................................32

Stop ................................................................................32

Set Lockout Code .....................................................32

Z‑Wave Setup (DualComWZ Only) ................... 33

Add Z‑Wave Devices (ADD) .................................33

List Z‑Wave Devices (LIST) ...................................33

Rename Z‑Wave Devices .......................................33

Status of Z‑Wave Devices ......................................34

Remove Z‑Wave Devices (REMOVE) ................34

Favorites (FAV) ..........................................................34

Adding a Favorite .....................................................34

Add Devices to Favorites .......................................34

Output Options .......................................27

Cutoff Outputs ...........................................................27

Output Cutoff Time ..................................................27

Communication Failure Output ...........................27

Armed Output ............................................................27

Remote Arming Output ..........................................27

Heat Saver Temperature ........................................27

Cool Saver Temperature ........................................27

Area Information .....................................28

Area Number ..............................................................28

Area Name ...................................................................28

Automatic Arming ....................................................28

Automatic Disarming ...............................................28

Zone Information ....................................29

Zone Number ..............................................................29

Zone Name ..................................................................29

Zone Type ....................................................................29

Next Zone .....................................................................30

Alarm Action ...............................................................30

Disarmed Open ..........................................................30

Message To Transmit................................................30

Output Number .........................................................30

Output Action.............................................................31

Swinger Bypass .........................................................31

Cross Zone ...................................................................31

Change Device Settings in Favorites.................35

Edit Devices in Favorites ........................................35

Remove Devices from Favorites ..........................35

Transfer Controller (XFER) ....................................36

Optimize (OPT) ..........................................................36

Appendix ..................................................37

ECP Passthru .............................................................37

DSC Passthru ..............................................................37

False Alarm Reduction ............................................37

Diagnostics Function ...............................................38

Using the 984 Command Function ....................39

NET .................................................................................39

CELL ...............................................................................39

Using the Walk Test ..................................................39

Walk Test ......................................................................39

Trip Counter for Walk Test (STD) ........................39

Test End Warning ......................................................39

Failed Zones Display ................................................39

Cross Zoning ...............................................................40

Z‑Wave Information (DualComWZ only) ..............40

Arming/Disarming Ademco Vista Panels ........41

FCC NOTICE .............................................42

Industry Canada ......................................42

NFPA 72 ....................................................42

Receiver Routing .......................................................31

ABOUT THE COMMUNICATOR

The DualCom™ communicator provides a fully supervised alarm communication path and integrated primary and

secondary communication on one PCB. For commercial fire or residential fire installations, DualComNF modules

feature primary network communication, secondary cellular communication, and two sets of tip and ring terminals.

For non‑fire residential installations, DualComWZ modules feature built‑in primary Wi‑Fi communication, secondary

cellular communication, Z‑Wave integration, and one set of tip and ring terminals.

Use the DualCom communicator to take over panels. The communicator can be connected to a control panel’s dialer

output and used to capture Contact ID messages based on SIA DC‑05‑1999.09‑DCS.

The communicator also provides four input zones and two open‑collector outputs for connection to control panel

outputs and zones. Connect to the bell output of an existing control panel using zone4 on the communicator. The

communicator operates in a variety of applications: CID Dialer Connection, Zones1‑4 Input Connections, or Zone4

Bell Connection. See Applications.

DualComNF modules include a red enclosure and a Model 685‑R (Red) Backbox.

Features

• Can be powered from 12VDC or 24VDC

• Zone1‑4 terminals with 12V and 24V power input

• EASYconnect™

• 2sets of tip and ring terminals (DualComNF only)

• 1set of tip and ring terminals (DualComWZ only)

• Programming header for connecting to a programming keypad

• LED to indicate armed state

What is Included

• PCB with enclosure

• Model685‑R Backbox (DualComNF only)

• Hardware pack

• External antenna

SYSTEM COMPONENTS

Terminals

Power Connection Terminals

The communicator may be powered from the 12VDC or 24VDC auxiliary output of the control panel. Observe

polarity and use 18‑22 AWG wire to connect the

on the

terminal on the control panel auxiliary output.

control panel auxiliary output

. See Figure 1. Connect the communicator terminal G(ground) to the negative

Control Panel Standby Power

During a power outage, the communicator draws power from the control panel’s backup battery. The communicator

must be included in the standby battery calculations for the control panel.

Zones 1‑4

Terminals Z1 to Z3, G(ground), Z4+ and Z4‑ provide four zones to connect to individual relay outputs on the control

panel. Zone4 (Z4+ and Z4‑) can be connected to the control panel bell output. See Zone4 Bell Connection.

Open‑Collector Outputs

Terminals O1 and O2 can be programmed to indicate the activity of the zones or conditions occurring on the system.

Open‑Collector outputs do not provide a voltage but instead switch‑to‑ground the voltage from another source.

Maximum voltage is 30VDC at 50mA. The outputs can respond to any of the conditions listed below:

• Activation by zone condition: Steady, Pulse, Momentary, or Follow

• Communication

• Armed area annunciation

• Remote Arming Output

communicator terminal +12 to the +12 or +24V positive terminal

Dialer Connection

Directly connect the Telco phone line (tip and ring) from the control panel to the terminalR(Ring) and one into

terminalT(Tip). For more information, refer to “CID Dialer Connection”.

DualCom

Programming and Installation Guide Digital Monitoring Products

1

Programming (PROG) Connection

A 4‑pin programming header is provided to connect a keypad when using a DMP Model330 programming cable.

This provides a quick and easy connection for programming the communicator. For 24VDC applications using the

communicator, connect the keypad using a Model330‑24 4‑wire programming harness with an in‑line resistor. After

programming is complete, remove the keypad.

Caution: If connecting to a 24VDC control panel, do not connect a keypad using a Model330 harness.

Tamper

The tamper is pressed when the cover of the communicator is secured onto the enclosure. When the cover is

removed, the communicator sends a tamper trouble message to the central station.

Reset Button

The reset button is located on the upper right side of the circuit board and is used to reset the communicator. After

resetting the communicator, begin programming within 30minutes. If you wait longer than 30minutes, reset the

communicator again.

Note: After the panel is reset, cell suppression is disabled for 30 minutes.

Load Button

Firmware can be updated with the programming header. Firmware updates are available for download, free of charge,

on the DMP Dealer Direct website at DMP.com/Dealer_Direct.

Caution: Do not connect a Model401 to the communicator if using 24V power.

Performing a Firmware Update

To update the communicator with a new firmware version, complete the following steps at the protected premise:

399 Programming Cable

1. Connect a DMP 399 Cable from the programming header to the serial port of your PC operating RemoteLink

and containing the communicator RU file.

2. Start RemoteLink and create or open the account that matches the communicator to be updated.

3. Set the connection information type to direct with a baud rate of 38400 and choose the appropriate COM port.

4. Select Panel > Remote Update, then select the correct RU file for the communicator.

5. Press and hold the load button, then press and release the reset button.

6. Release the load button and select <Update> in Remote Link.

7. After the firmware update is completed, remove the 399 cable and press the reset button to resume normal

operation.

Model401 USB Flash Module

When loading the firmware RU file onto a USB drive, place the file in the root directory of the USB drive. The update

cannot be inside a folder. Format the USB drive as FAT32.

Place only one firmware file in the root directory. If more than one RU file exists on the USB drive, the communicator

will choose the RU file with the most recent date modified.

Caution: DualCom, CellCom, iCom, and XTL+ do not use the same RU files. Using the wrong RU file for the update

will cause the communicator to stop working until the correct RU file is used to flash the firmware.

1. Connect the USB flash drive to the Model401.

2. Press and hold the reset button on the communicator. You will continue to hold reset until step 6.

3. Connect the assembly to the communicator’s programming header.

4. Press and release the button on the Model401.

5. With your finger still on RESET, press and hold the load button. Continue to hold LOAD until step 8.

6. Release the reset button.

7. Press and release the button on the Model401.

8. When the green LED on the Model401 starts a slow flash, release the load button. The slow flash will last

5minutes, then the green LED will become steady, indicating the firmware version is updated.

Note: If the LED blinks rapidly, the update was unsuccessful. Press and release RESET. Begin again at step1

9. Press and hold RESET. Remove the Model401, then release RESET to resume normal operation.

In the event the Model401 USB Flash Module is inadvertently removed from the communicator before the update

finishes, repeat steps1‑9.

Digital Monitoring Products

2

DualCom

Programming and Installation Guide

Backlit Logo

The backlit logo indicates the power and armed status of the communicator. Depending on the operation, the LED

displays in red or green as listed in the Table 1. The LED indicates the armed state and status of the system primary

power.

COLOR AND ACTIVITY OPERATION

Green Steady Communicator Disarmed, Primary Power OK

No Light No Power

Red Steady Communicator Armed, Primary Power OK

Table 1: LED Status

ECP and DSC Passthru

Perform an ECP or DSC Passthru and communicate through the communicator over the host panel’s bus. This

also allows users to manage host panels through Virtual Keypad including arming, disarming, viewing zone status,

bypassing zones, view history, manage users, and more.

Note: Programming a DSC panel remotely requires a Model 330‑DSC Programming Harness (sold separately).

DualCom

Programming and Installation Guide Digital Monitoring Products

3

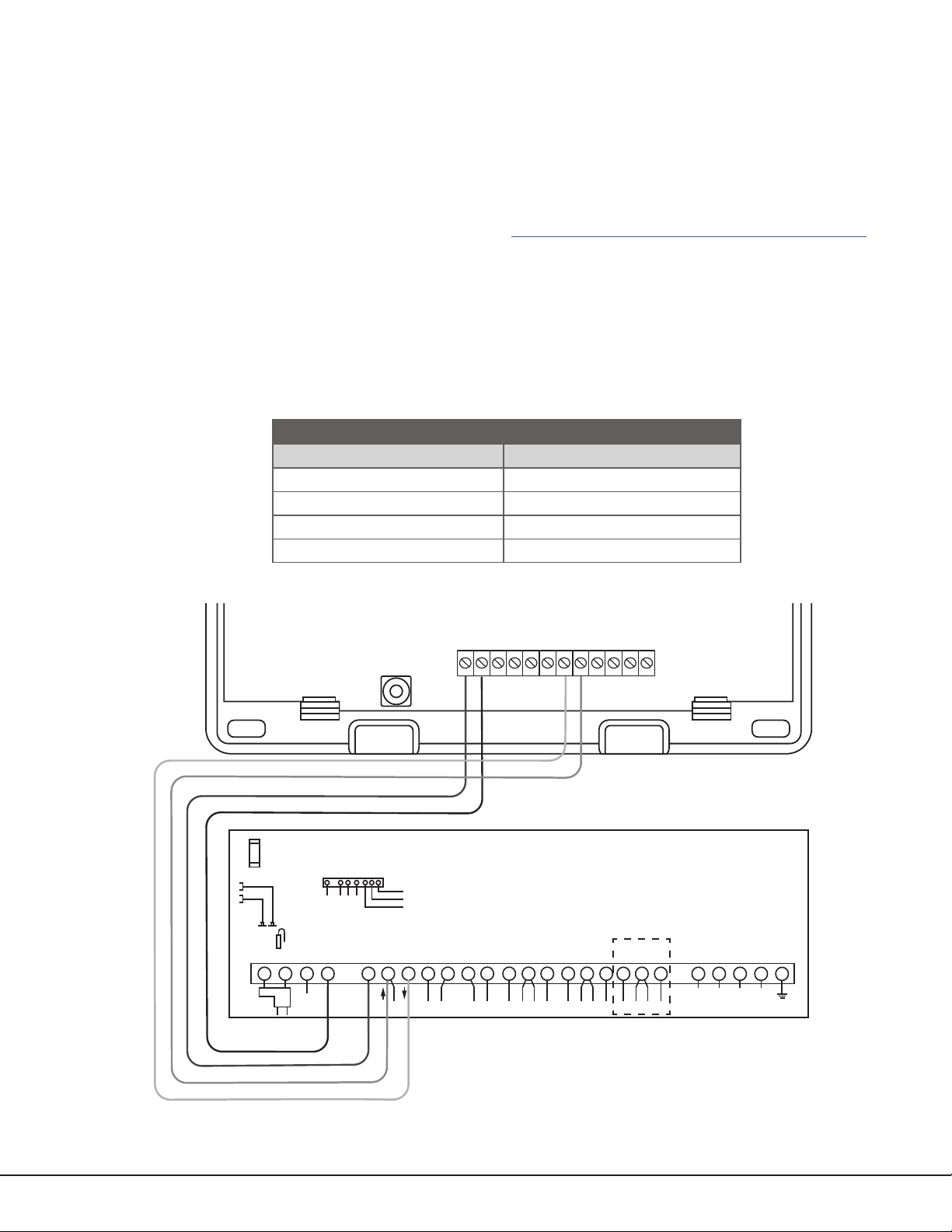

INSTALLATION

D

Select a Location

Install the communicator away from metal objects. Do not mount the communicator inside or on a control panel metal

enclosure. Mounting the communicator on or near metal surfaces impairs cellular performance.

Mount the Communicator

The communicator should be mounted to a wall using the included #6 screws in the mounting holes. See Figure 1.

Mount the communicator in a secure, dry place to protect the communicator from damage due to tampering or the

elements. It is not necessary to remove the PCB when installing the communicator.

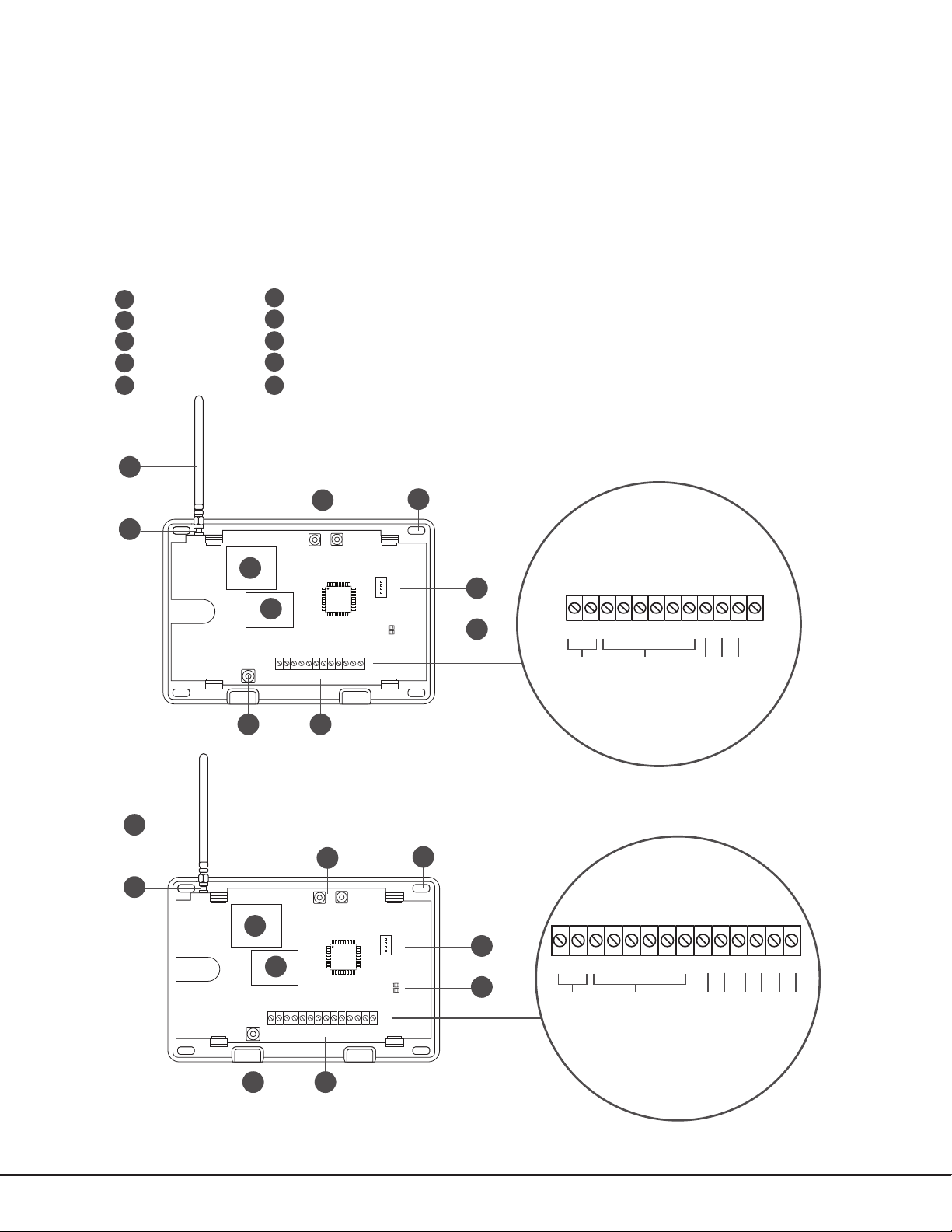

Mounting Holes

A

Cellular Antenna

B

SMA Connector

C

Cell Modem

D

Ethernet

E

B

C

D

Tamper

F

Terminal Block

G

Programming Connection

H

Power and Armed LEDs

I

Load and Reset Buttons

J

J

RESETLOAD

E

+Z4-

+DC- Z1 Z2 Z3

T

O1 O2

G

GF

DualCom

A

BR

PROG

R

H

I

+DC- Z1 Z2 Z3

DC Power

+Z4-

G

Zones 1 - 4

O1 O2

Output 1

T R

Tip 1

Ring 1

Output 2

B

C

Digital Monitoring Products

4

D

E

+DC- Z1 Z2 Z3 G T1 R1 T2+Z4- R2O1 O2

DualComNF

J

RESETLOAD

A

BR

PROG

H

+DC- Z1 Z2 Z3 G T1 R1 T2+Z4- R2O1 O2

I

DC Power

Zones 1 - 4

Output 1

Output 2

Tip 1

Tip 2

Ring 1

Ring 2

GF

Figure 1: System Components

DualCom

Programming and Installation Guide

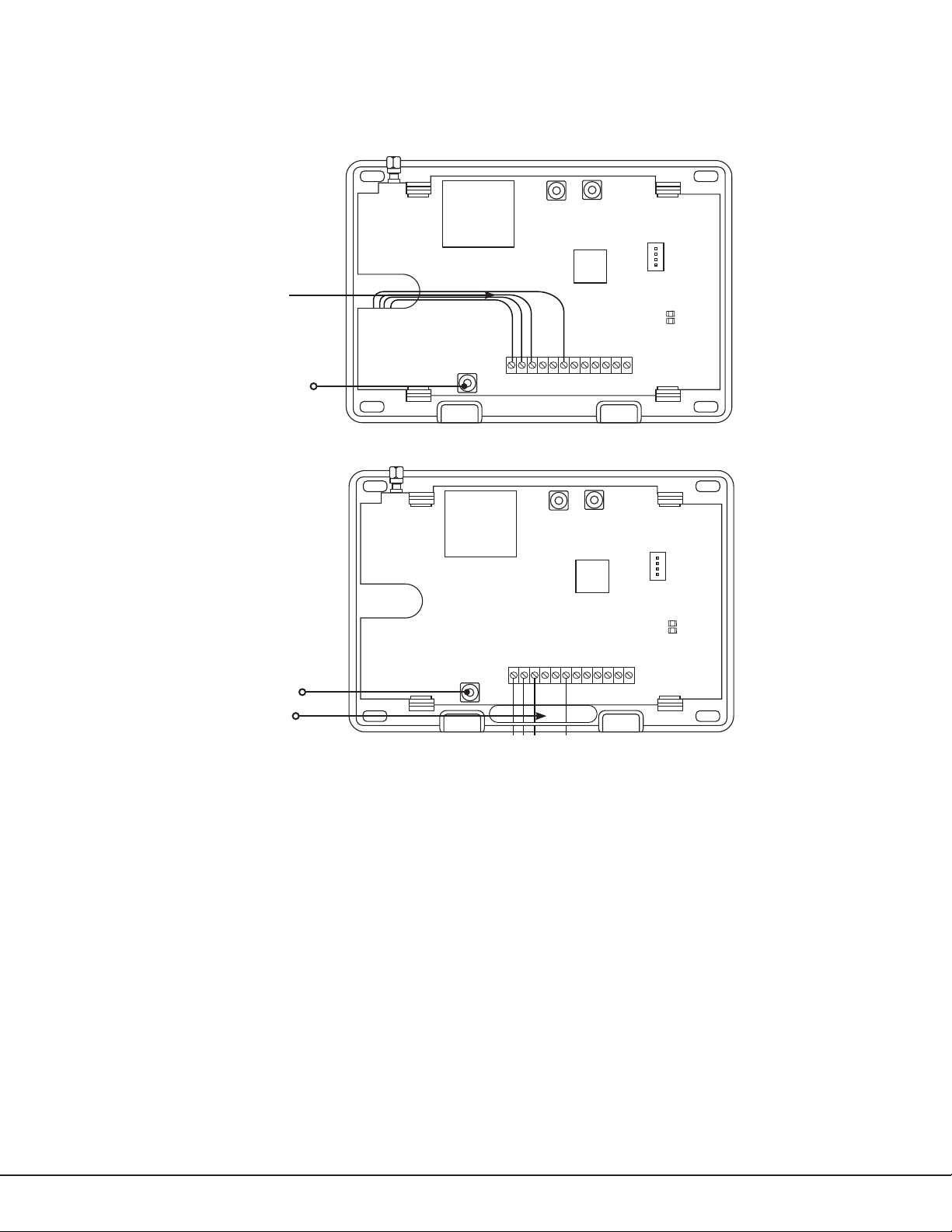

Wire the Communicator

Wiring

When connecting component wires, route all wires so they will not interfere with the tamper switch. See Figure 2 and

Figure 3 for wire routing options.

RESETLOAD

BR

PROG

+Z4-

Tamper

+DC- Z1 Z2 Z3

G

Figure 2: Wire Routing Option One

T

R

O1 O2

RESETLOAD

BR

PROG

+Z4-

Tamper

+DC- Z1 Z2 Z3

G

O1 O2

T

R

Wiring

Figure 3: Wire Routing Option Two

Connect the Antenna

Place the antenna onto the SMA connector. Refer back to Figure 1. Twist the antenna until it is securely tightened.

Replace the housing cover on the mounted base. Be sure to not damage any PCB components when removing or

replacing the housing cover.

DualCom

Programming and Installation Guide Digital Monitoring Products

5

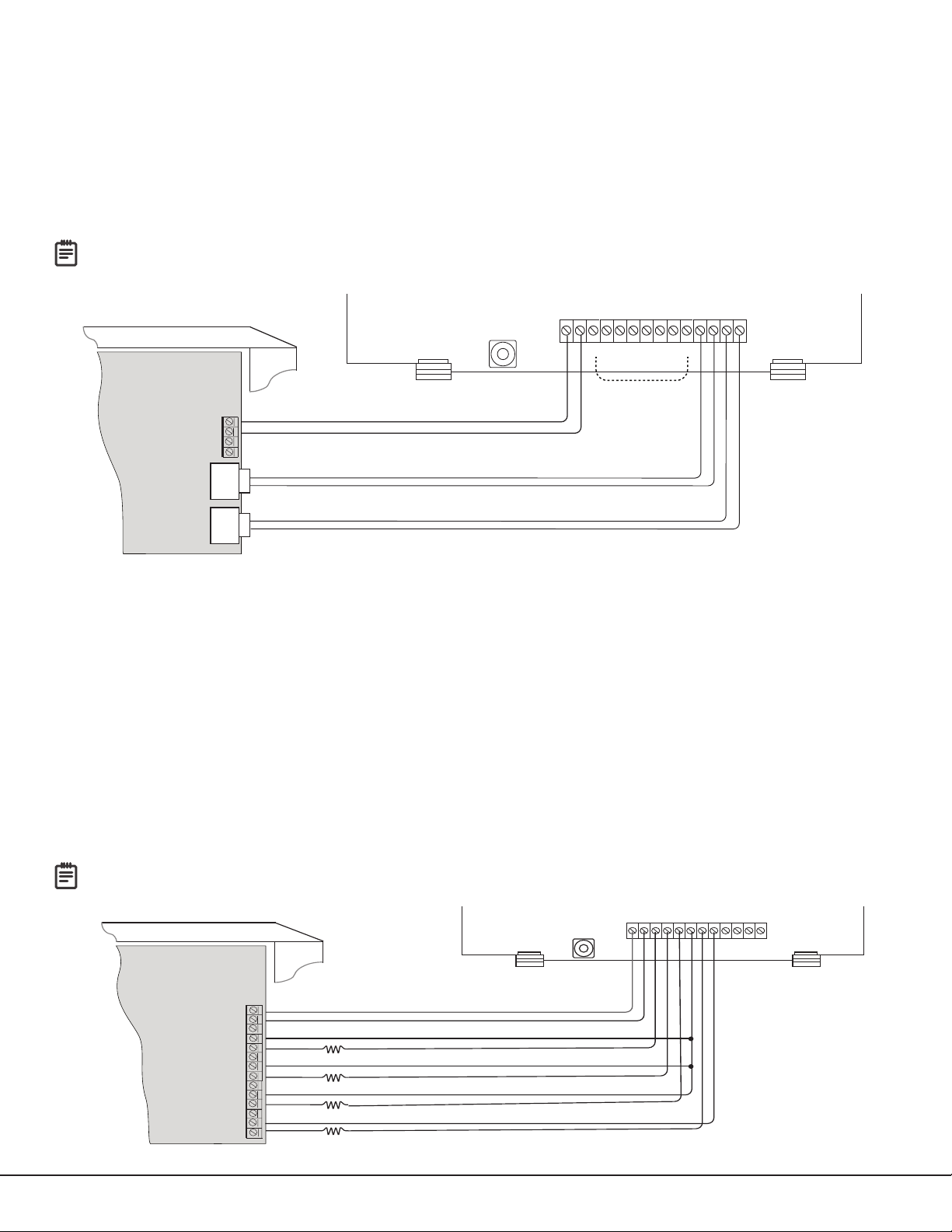

APPLICATIONS

+DC- Z1 Z2 Z3

G

T

R

+Z4-

O1 O2

Use 18-22 AWG for

Power Supply connection

Z3 +

Z4 +

Z4 -

GND

Aux. Output

+

-

Ground

Control Panel

The panel or separate power

supply must be 12/24 Volt

Regulated and Power Limited.

Z1 +

+

–

Z2 +

Normally Open

Common

Normally Closed

Normally Open

Common

Normally Closed

Normally Open

Common

Normally Closed

Normally Open

Common

Normally Closed

1k ohm

1k ohm

1k ohm

1k ohm

Figure 5: Wiring Diagram for Burglary Zones 1‑4

The communicator can be used in a variety of applications.

CID Dialer Connection

Directly connect one or both tip and ring terminals from the control panel to the communicator. See Figure 4. This

connection captures Contact ID messages from any fire panel that are based on the SIA communication standard

DC‑05‑1999.09‑DCS. Messages are then formatted into a Serial 3 message and sent to an SCS‑1R Receiver or SCS‑VR

Receiver.

Note: CID Dialer Connection cannot be used when using Zone 4 Bell Connection. Do not connect telephone

company wires to the communicator. Remove any connected telephone company wires from the control panel.

Use 18-22 AWG

for Power Supply

Control Panel

The panel or separate power

supply must be listed for fire,

regulated, and power limited.

12/24 VDC Aux. Output

Ground

BELL +

BELL -

Telephone

Jack

Connector

Telephone

Jack

Connector

connection

+

-

If FACP only has one phone line, connect to T2, R2

Wiring to FACP shall be connected within 20 ft in the same room and routed in conduit.

+DC- Z1 Z2 Z3 G T1 R1 T2+Z4- R2O1 O2

+

–

No Connection

(Zone Inputs Not

Evaluated By UL)

Tip 2

Ring 2

Ring 1

Tip 1

Figure 4: Wiring Diagram for Tip and Ring Connection

Communication Failure (DualComNF only)

The phone line voltage on the second tip and ring will drop when the DualComNF is in a communication failure state.

This triggers the host panel to annunciate a communication failure. When communication is restored, voltage is

restored on the second tip and ring terminal and the host panel sees a restoral on the phone line.

Zones 1‑4 Input Connection

Connect each control panel relay output to a zone on the communicator. For programming purposes, the zone

numbers are 1‑4. The following are examples of how you might use this application for a burglary or fire alarm.

Burglary

Use a normally closed output on a burglary control panel to indicate a burglary alarm. The communicator zone should

be programmed with a zone name and burglary zone type. When the output on the control panel turns on and trips

the communicator zone, a message is sent to an SCS‑1R or SCS‑VR receiver at the central station. The zone name

programming can be used to describe which control panel zone indicated a burglary. See Figure 5.

Note: Zone4 can only be used as a standard input zone when not programmed as zone type Auxiliary2 (A2). See

Zone4 Bell Connection.

Digital Monitoring Products

6

DualCom

Programming and Installation Guide

Zone4 Bell Connection

Table 2: Message Breakdown

Zone4 (Z4+ and Z4‑) can be connected to the control panel bell output. This zone detects an alarm condition on the

control panel by monitoring the voltage and cadence timing of the bell output. The communicator evaluates the first

3.5seconds of bell cadence timing to detect the type of alarm sent. See Figure 6.

3.5 sec

On

Steady

O

On

Pulse

O

On

Temporal 3

O

On

Temporal 4

O

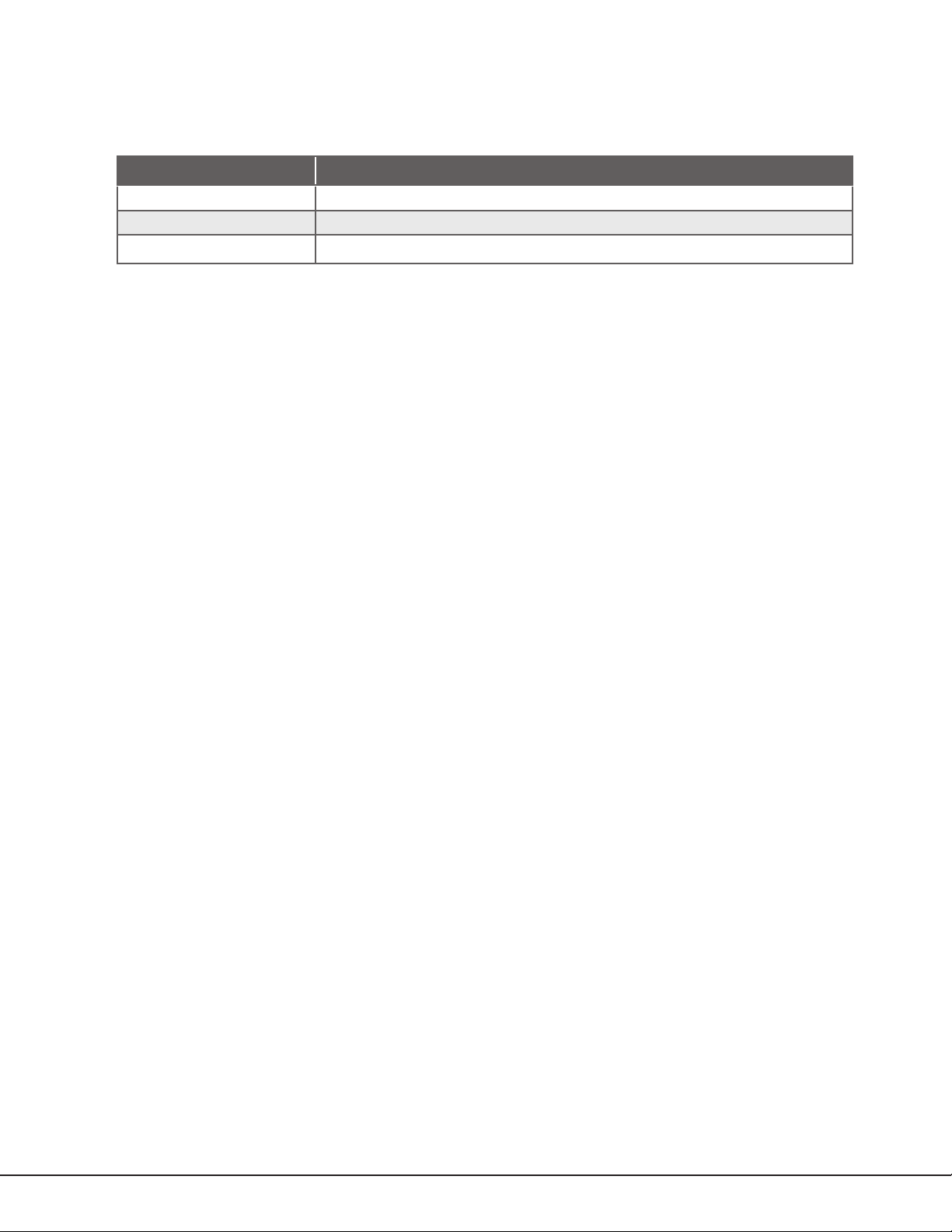

To enable alarm detection operation, Zone4 Bell Connection must be programmed as Zone Type (A2) in Zone

Information programming. See Table 2 for bell cadence type, zone number, and type of message sent to the receiver.

The communicator generates zones5 and6 using the zone name of zone4 to send to the central station. Zones5

and6 cannot be preprogrammed in Zone Information. CID Dialer Connection cannot be used when using Zone4 Bell

Connection.

1.0 sec 1.0 sec 1.0 sec 1.0 sec 1.0 sec

.5 sec .5 sec .5 sec 1.5 sec .5 sec.5 sec .5 sec .5 sec

Each .1 sec On

5.0 sec

Each .1 sec O

Figure 6: Zone 4 Bell Cadence Information

Each .1 sec On

Each .1 sec O

BELL CADENCE ZONE NUMBER TYPE OF MESSAGE

Steady Zone4 Burglary

Pulse or Temporal3 Zone5 Fire

Temporal4 Zone6 Emergency or Carbon Monoxide

DualCom

Programming and Installation Guide Digital Monitoring Products

7

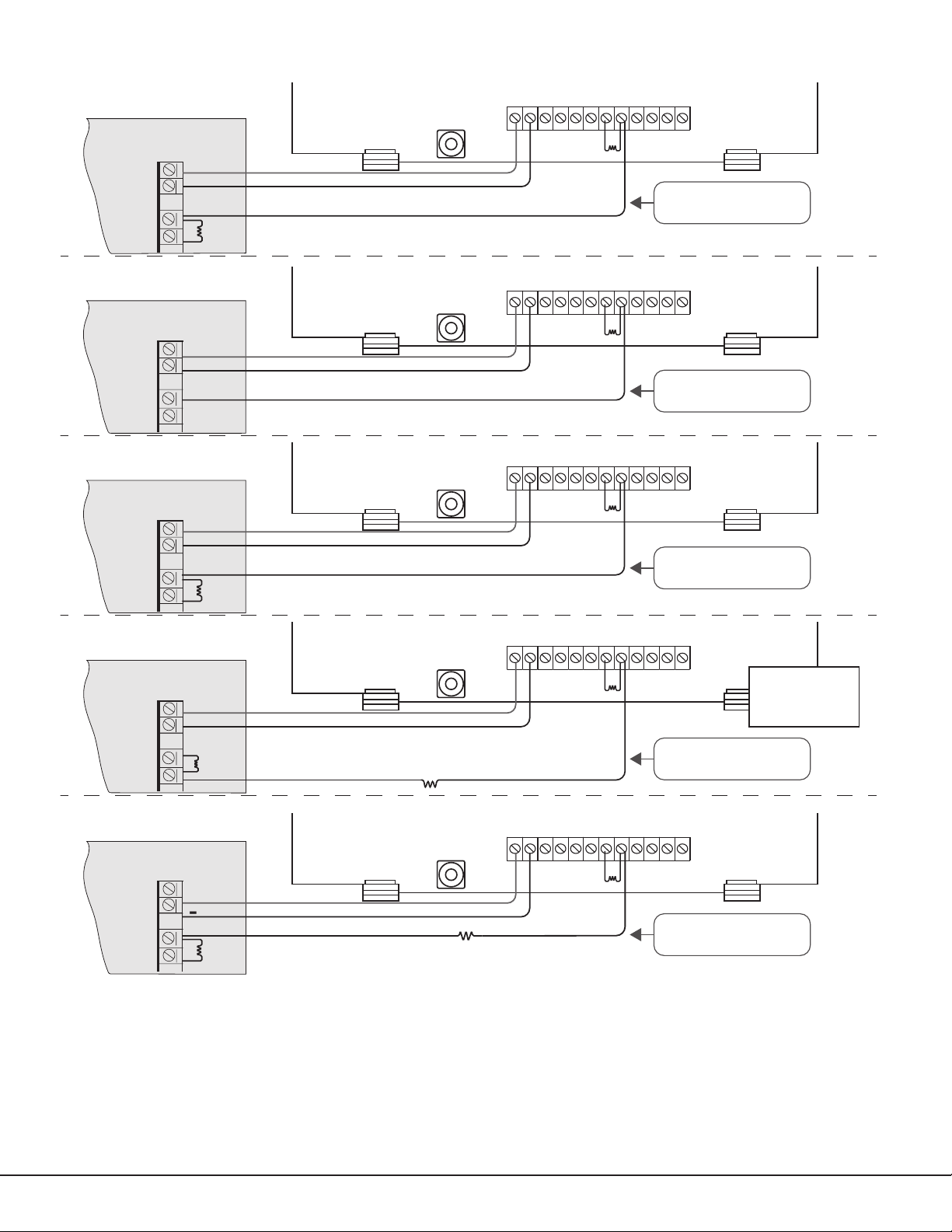

DMP Panel

12 VDC Aux. Output

+

Use 18-22 AWG

for Power Supply

connection

+DC- Z1 Z2 Z3

+

–

+Z4-

G

1k Ω

O1 O2

Z4 -

T

R

-

1k Ω (for Supervision)

ADEMCO Panel

12 VDC Aux. Output

+

-

12 VDC BELL +

BELL -

NAPCO Panel

12VDC Aux. Output

+

-

12 VDC BELL +

BELL -

2.2k

Ω

(for Supervision)

Use 18-22 AWG

for Power Supply

connection

Use 18-22 AWG

for Power Supply

connection

+DC- Z1 Z2 Z3

+

–

+DC- Z1 Z2 Z3

+

–

Voltages above 1.4 VDC

are considered Alarm

+Z4-

G

1k Ω

O1 O2

Z4 -

T

R

Voltages above 1.4 VDC

are considered Alarm

+Z4-

G

1k Ω

O1 O2

Z4 -

T

R

Voltages above 1.4 VDC

are considered Alarm

DSC Panel

12/24 VDC Aux. Output

12/24 VDC BELL +

BELL -

24 VDC Panel

12/24 VDC Aux. Output

24 VDC BELL +

BELL -

Use 18-22 AWG

for Power Supply

connection

+

-

1k

Ω

(for Supervision)

Use 18-22 AWG

for Power Supply

connection

+

-

4.7k Ω (for Supervision if required)

+DC- Z1 Z2 Z3

+

–

10k Ω

+DC- Z1 Z2 Z3

+

–

1k Ω

Figure 7: Zone 4 Bell Connection

+Z4-

G

1k Ω

O1 O2

Z4 -

T

R

Program Zone 4

DO - Alarm

AO - Alarm

Voltages above 0.7 VDC

are considered Alarm

+Z4-

G

1k Ω

O1 O2

Z4 -

T

R

Voltages above 1.4 VDC

are considered Alarm

Digital Monitoring Products

8

DualCom

Programming and Installation Guide

ECP Passthru Connection

PROG

B

R

RESETLOAD

+DC- Z1 Z2 Z3

G

T

R

+Z4-

O1 O2

DualCom

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

20

21 22 23 24

25

+ +–

HI

HI

HI

LO

LO

LO

LO

HI

HI

LO

LO

HI

HI

LO

LO

HI

TIP

(BROWN)

RING

(GRAY)

TIP

(GREEN)

RING

(RED)

+

-

BLACK

RED

SYNC

COM

DATA

(USE SA4120XM-1

CABLE)

1 2 3 4 5 6 7 8

OUT 17

+12 AUX

GND

OUT 18

VISTA 20P ONLY

VISTA-20P

From DC+

From DC–

From Z4+

From Z4-

To Data In (6)

To Data Out (7)

To Negative (4)

To Positive (5)

RED

BLACK

GREEN

YELLOW

RED

BLACK

GREEN

YELLOW

RED

BLACK

GREEN

YELLOW

The communicator can be connected to the ECP Bus of a compatible VISTA panel. Refer to “VISTA Panel

Compatibility” for VISTA compatibility details. See Table 3 and Figure 8 for wiring details.

Configuration

To configure the communicator for ECP Passthru, set KEYPAD INPUT to ECP, program VISTA keypad device

address20, then use the ECP SETUP feature in the Diagnostics (DIAG) menu. For details, refer to “Keypad Input” and

“ECP Setup”.

For more information about configuring ECP Passthru, refer to COM Series How‑To Guide: ECP Passthru (LT‑2209).

Program Vista Keypad Device Address 20

1. Power down and then power up the Honeywell panel.

2. Within 1 minute of powering up the Honeywell panel, simultaneously press and hold the # and * buttons on the

keypad.

3. The keypad displays INSTALLER CODE. Enter the installer code (default is 4112), followed by 800.

4. Enter *193, then enter 1 0.

5. To save and exit programming, enter *99.

COMMUNICATOR TO ECP WIRING

Communicator Terminal VISTA Terminal

+DC Keypad Power

‑DC Keypad GND

Z4+ Data Out

Z4‑ Data In

Table 3: ECP Terminal Connections

DualCom

Programming and Installation Guide Digital Monitoring Products

Figure 8: ECP Passthru Wiring

9

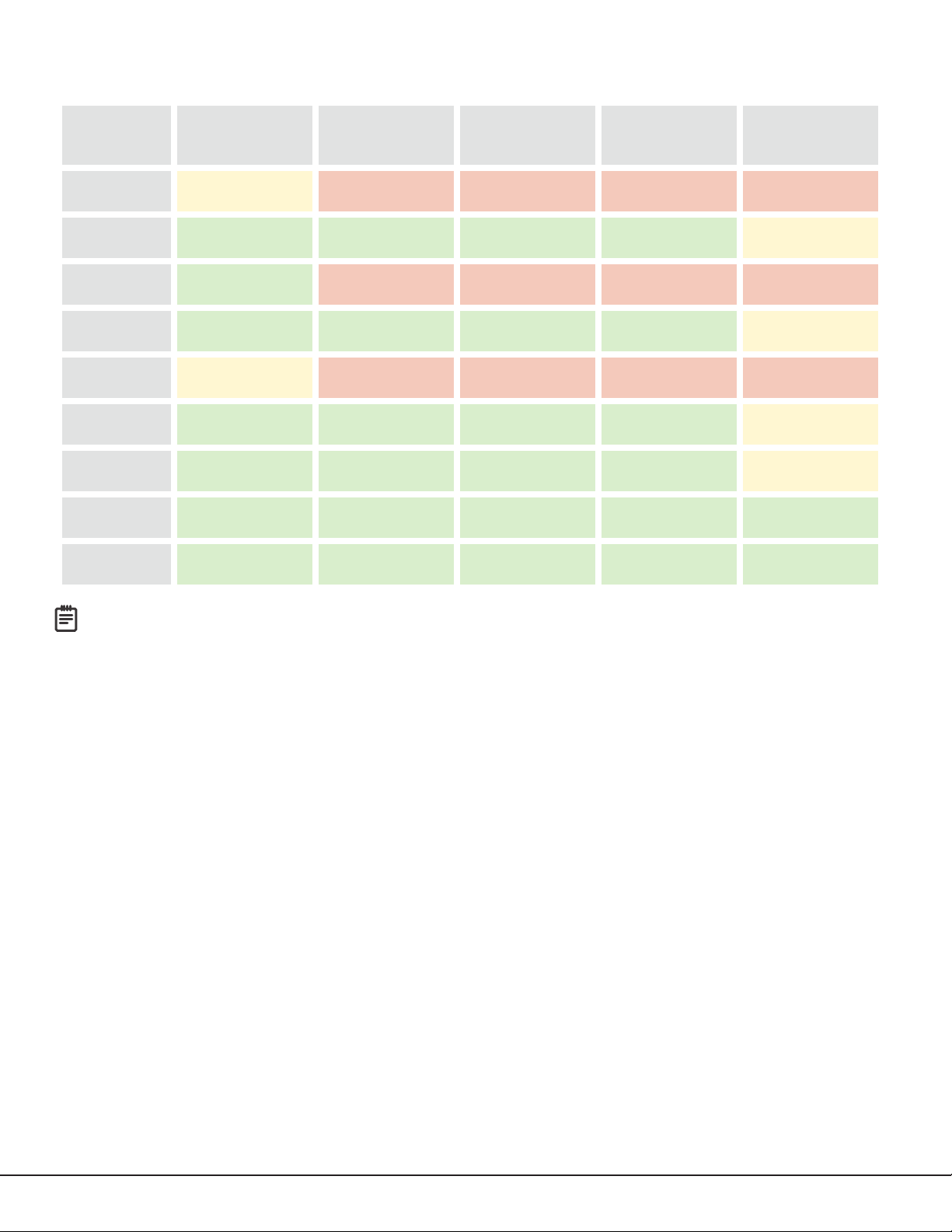

VISTA Panel Compatibility

Remote

Arming/

Disarming

Remote

Zone Status

Compatible with

Compass

Panel Type ECP

Remote

User Management

VISTA‑10SE Rev 15 or higher No No No No

VISTA‑10P Yes Ye s Yes Yes

Firmware version

2.0 or higher

VISTA‑15 Yes No No No No

VISTA‑15P Yes Yes Ye s Yes

Firmware version

5.2 or higher

VISTA‑20SE Rev 12 or higher No No No No

VISTA‑20P Yes Yes Ye s Yes

VISTA‑20PI Ye s Yes Ye s Yes

Firmware version

5.2 or higer

Firmware version

5.0 or higher

VISTA‑21iP Ye s Yes Ye s Yes Yes

VISTA‑21iPLTE Yes Ye s Yes Ye s Yes

Note: Panels must be programed in the Stay/Away mode for Remote Arming/Disarming (No Partitions).

Vista 32, 40, 50, 128, 250 are not compatable with ECP Virtual Keypad.

Digital Monitoring Products

10

DualCom

Programming and Installation Guide

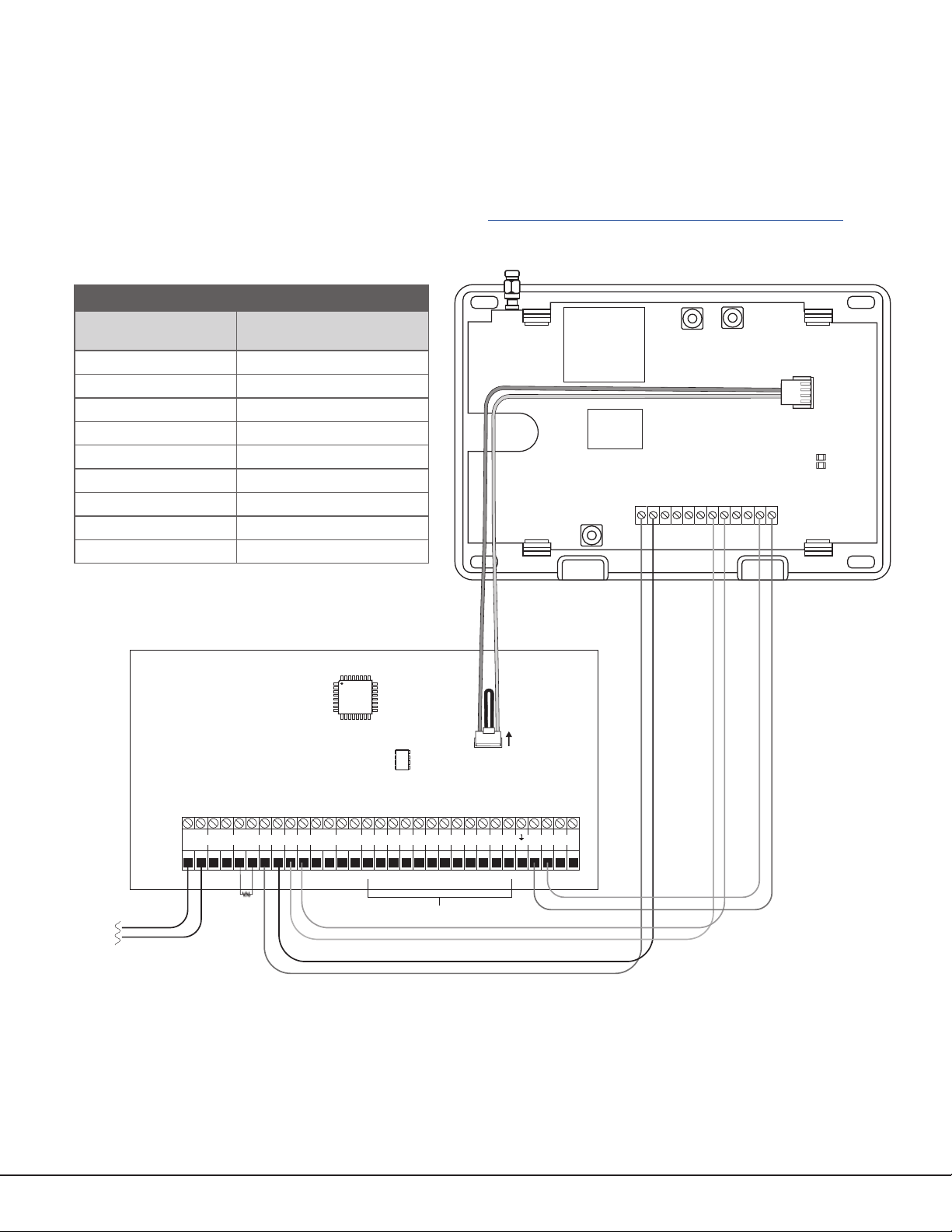

DSC Passthru Connection

RESETLOAD

+DC- Z1

Z2 Z3

G

T

R

+Z4-

O1 O2

+DC- Z1

Z2 Z3

G

T

R

+Z4-

O1 O2

DualCom

ETHERNET

DSC PC1864

AC AC +AUX- +BELL- RED BLKYEL GRN 1 PGM 2 3 PGM 4 Z1 COM Z2 Z3 Z4 Z5 Z6 Z7 Z8

EGND RING TIP

R-1 T-1COM COM COM

AC +AUX-

+BELL- REDBLK YEL GRN 1 PGM 2 3 PGM 4 Z1 COM Z2 Z3 Z4 Z5 Z6 Z7 Z8

EGND

A

RINGBTIPCR-1DT-1

COM COM COM

1k Ω

EOL

5.6k Ω EOL

To AC

Power

From DC +

From DC -

From Z4 +

From Z4 -

From T

To RED

To BLK

To YEL

To TIP

To RING

To GRN

From R

Remote

Programming

Connection

(Model 330-DSC)

RED

BLACK

BLACK

BLACK

YELLOW

GREEN

GREEN

RED

PROG

PC LINK

1

CON 4

YELLOW

GREEN

YELLOW

GREEN

TAB

UP

BR

The communicator can be connected to the DSC Bus of a DSC PowerSeries Model PC1616, PC1832, or PC1864. Refer

to Table 4 and Figure 9 for wiring details.

Configuration

To configure the communicator for DSC Passthru, set KEYPAD INPUT to DSC and use the DSC SETUP feature in the

Diagnostics (DIAG) menu. For details, refer to “Keypad Input” and “DSC Setup”.

For more about configuring DSC Passthru systems, refer to COM Series How‑To Guide: DSC Passthru (LT‑2208).

COMMUNICATOR TO DSC WIRING

Communicator

Terminal

DC+ RED

DC‑ BLK

Z4+ YEL

Z4‑ GRN

T or T1 TIP

R or R1 RING

N/A Bell+ to Bell‑ (1k Ω EOL)

N/A Zones 1 ‑ 8 (5.6k Ω EOL)

PROG PC Link (COM) Tab Up

Table 4: DSC Terminal Connections

DSC Terminal

Figure 9: DSC Passthru Wiring

DualCom

Programming and Installation Guide Digital Monitoring Products

11

Loading...

Loading...