DNP CX-120 Service Manual

KAS-T089

June 2005

DIRECT DYE SUBLIMATION PRINTER

SERVICE MANUAL

CX-120

DNP

SPECIFICATIONS

䡵 Specifications and appearance of this unit may be changed for the purpose of product improvement without

prior notice.

Item Description

Recording Mode Dye sublimation printing

Paper Feed Mode

Automatic feeding

Recording Density

300 dpi

Color 256 gradations per color

Printing Time Approx. 20 seconds (Single-sided printing in

standard mode for all of YMC, Resin K and

OP, encoding time excluded)

Interface USB2.0 Hi-Speed (USB-IF certified product)

Usage Temperature : 15°C – 30°C

Environment Humidity : 35% – 70%

(without condensation)

Storage Environment

Temperature : -15°C – 55°C

Humidity : 20% – 80%

Power Supply AC 100 – 120 V (tolerance ±10%)

AC 220 – 240 V (tolerance ±10%)

Power 1.8 A (100 V)

Consumption 0.9 A (200 V)

Mass 12kg and below (excluding MG/IC encoder)

15kg and below (including MG/IC encoder)

Dimension Approx. 299 (W) x 311 (D) x 308 (H)mm

Accessories Power Cord :

AC120V

(Dark gray: North America)

1

AC200V (Europe) 1

Instruction Manual : English CD 1

Startup Guide

: English 1

Cleaning Card 1

Protection Card 1

USB Cable (1.5 m) 1

Consumable Cleaning Card 10 pcs / set (CX-120CC1)

Items Cleaning Kit (CX210-CKIT1)

Cleaning Unit (CX-120CL1)

Thermal Head (CX-120HD1)

Ink Ribbon

YMCKO 750screen pages (CY-15C-75)

YMCKOK 600 screen pages (CY-16K-60)

Optional Items Card Cassette (CX-120HP1)

Hand Gloves

M Size (U105-M)

L Size (U105-L)

Laminator Unit (CL-500)

Item Description

䡵 IMPORTANT SAFETY PRECAUTIONS

䡵 Startup Guide

Notes for safe operation ...................................................... 5

Before use ........................................................................... 7

Printer Characteristics ................................................... 7

Checking Accessories ................................................... 7

Content of Attached CD-ROM ....................................... 7

Protection of Color Printing Part .................................... 7

Handling the Ink Ribbon and Card ................................ 7

Cautions for Handling................................................. 7

Storage Method ......................................................... 7

Storage and Handling of Card After Printing .............. 8

Purchase of Ink Ribbon and Card .............................. 8

Escape Clause .............................................................. 8

Part Names ......................................................................... 9

(Front / Right) ............................................................. 9

(Rear / Left) ................................................................ 9

(When Printer Door is Open) ..................................... 9

Setup ................................................................................. 10

Location for Installation................................................ 10

Setting Up the Printer .................................................. 10

Connecting the Laminator ........................................ 10

Connecting the Power Cord ..................................... 11

Mounting the Card Stacker ...................................... 11

Ejection of Card ....................................................... 11

Setting the Ink Ribbon .............................................. 12

Adjusting Card Thickness ........................................ 14

Setting the Card ....................................................... 14

When Using a Magnetic Card .................................. 16

When Using a Contact-type IC Card ........................ 16

Supply of Card ......................................................... 16

Connecting the USB Cable.......................................... 17

Connecting Multiple Printers ....................................... 17

Installation of Software ...................................................... 18

Connecting to the Host Computer ............................... 18

About software ......................................................... 18

Operation Environment ............................................ 18

Installation of USB Driver - WindowsXP ...................... 19

Installation of USB Driver - Windows2000................... 20

Installation of CX-120 Status Monitor .......................... 21

Checking Connection with the Host Computer ................. 22

How to read the Instruction Manual (Electronic Manual) .. 23

Content of the Instruction Manual (electronic manual) 23

Maintenance...................................................................... 24

Cleaning the Cleaning Roller ....................................... 24

Cleaning the Thermal Head......................................... 25

Cleaning the Fan Filter ................................................ 25

Cleaning the Card Transport Roller ............................. 26

Cleaning the Magnetic Head ....................................... 27

After Maintenance ....................................................... 27

Troubleshooting (Simplified Version) ................................. 28

Action for Error Code List ............................................ 28

Removing Jammed Card ............................................. 29

Feed Jam ................................................................. 29

When there are frequent feed jams.......................... 29

Jam inside the printer ............................................... 29

A. When card is at the right (near inverter) .............. 30

B. When card is at the left (near printing unit) .......... 31

CONTENTS

C. When card can barely be seen from

the encoding unit .................................................. 31

Jam Inside Laminator ............................................... 31

Procedures for Changing Thermal Head .......................... 32

Checking After Changing Thermal Head ..................... 35

Consumable/Optional Items .............................................. 36

Memo .......................................................................... 37~40

Software use permission contract .............................. P1~P4

䡵 INSTRUCTIONS

Operating the Printer ........................................................... 2

LED Display ................................................................... 2

Names of Various Sections on Control Panel ................ 2

Button Control ............................................................... 3

Initialization .................................................................... 4

Test print using the printer alone ................................... 4

Differences Between Printing Modes .................................. 4

How to Use the Status Monitor ........................................... 5

Screen Configuration ..................................................... 5

Monitoring Printer Status ............................................... 6

Ready Status Display ................................................. 7

Error Status Display ................................................... 7

Other Status Display .................................................. 7

Changing Printer Settings ................................................... 8

Checking the Media and Printing Status ............................. 9

Display When Ink is Unknown ........................................... 10

Checking Printer Configuration ......................................... 11

Resetting the [No. of Cards Issued] Item .......................... 12

Test Printing ...................................................................... 12

Upgrading Firmware.......................................................... 13

Software Upgrade ............................................................. 14

Software Licensing Agreement.................................... 14

Update of USB Driver - WindowsXP ........................... 14

Update of USB Driver - Windows2000 ........................ 15

Update of CX-120 Status Monitor ............................... 18

Uninstalling Software ........................................................ 19

Deletion of USB Driver - WindowsXP .......................... 19

Detetion of USB Driver - Windows2000 ...................... 20

Deletion of CX-120 Status Monitor .............................. 21

Troubleshooting (Detailed Version) ................................... 22

Internal Configuration .................................................. 22

List of Error Codes and Corresponding Actions .......... 23

When ink ribbon is torn ................................................ 25

Problems Related to Printing ....................................... 25

Problems related to Color Printing .............................. 26

Problems Related to Text Printing ............................... 27

Problems Related to Protective Layer (OP) ................. 28

Actions to Take When Printer Fails to Start Up ............ 28

Version Upgrade ............................................................... 29

Specifications .................................................................... 30

Main Specifications ..................................................... 30

External Dimension ..................................................... 30

䡵 SERVISE MANUAL

MODEL NAME .................................................................... 1

1. DETAILED SPECIFICATIONS .................................. 1

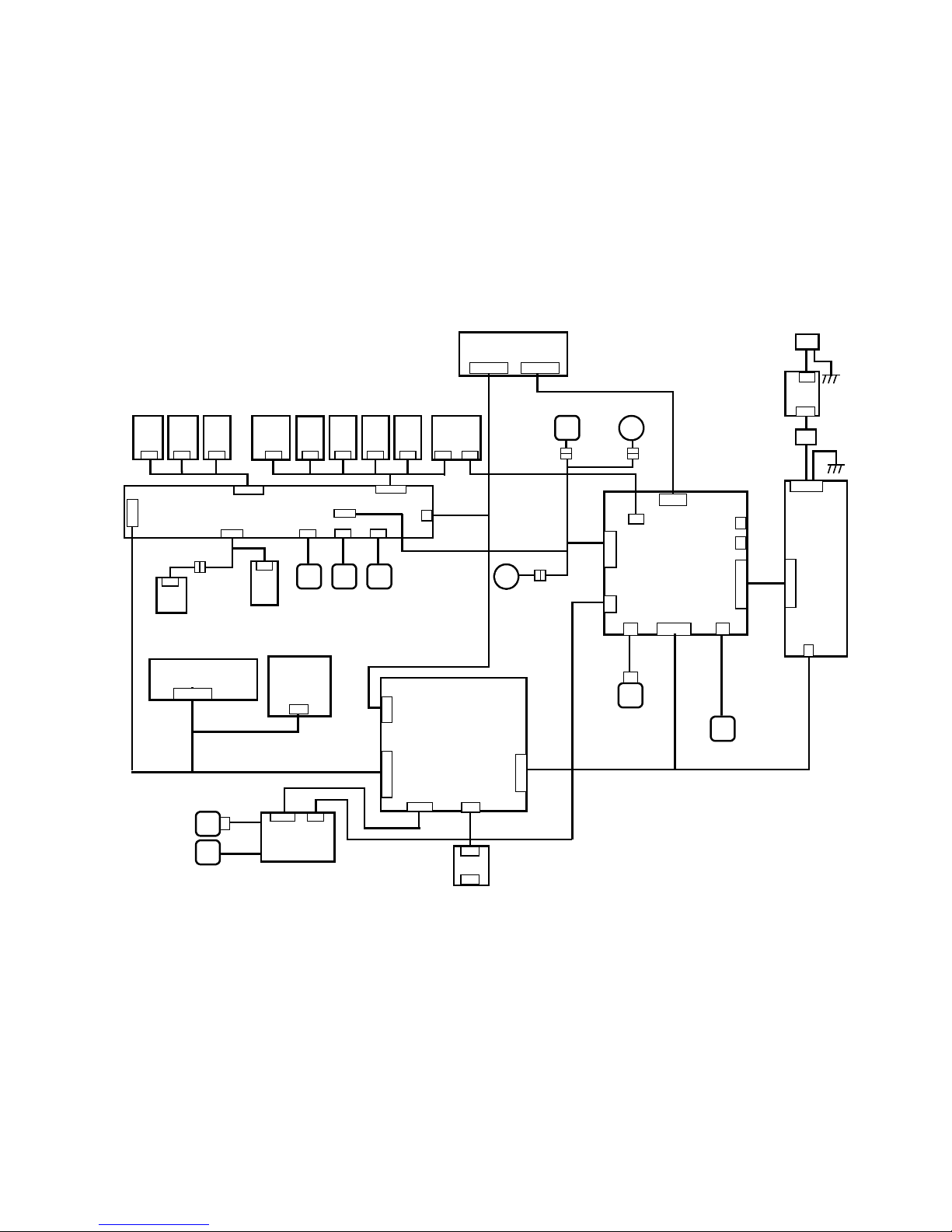

BLOCK DIAGRAM .............................................................. 2

1. BLOCK DIAGRAM OF ENTIRE UNIT ...................... 2

2. CONNECTION DIAGRAM ........................................ 3

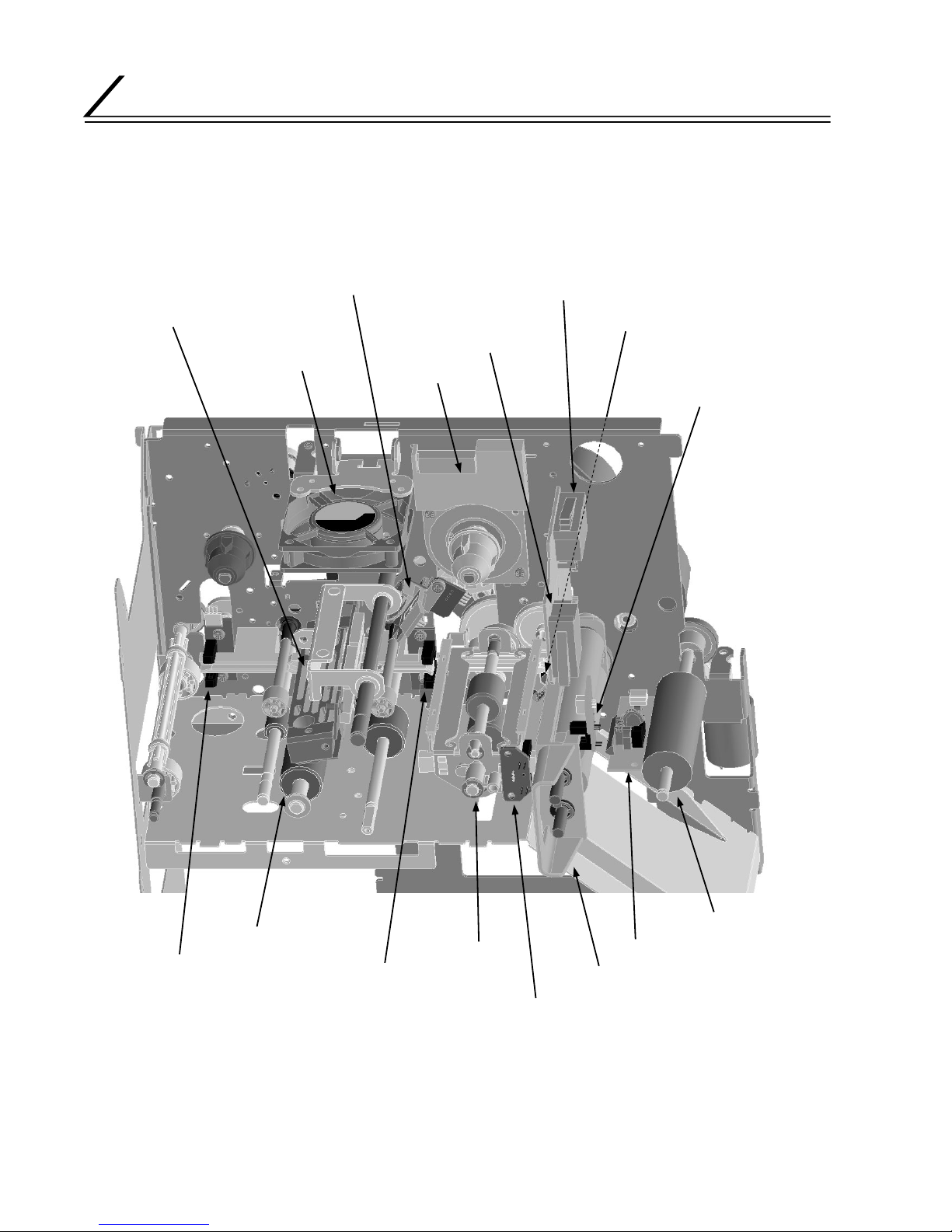

LAYOUT OF KEY PARTS .................................................... 4

1. FRONT: HEAD, FEED ROLLER, TURNOVER UNIT

AND SENSORS ........................................................ 4

2. REAR: MOTOR, FAN AND SENSORS....................... 5

3. BOARDS AND POWER SOURCES ......................... 6

4. MG / IC UNIT ............................................................ 7

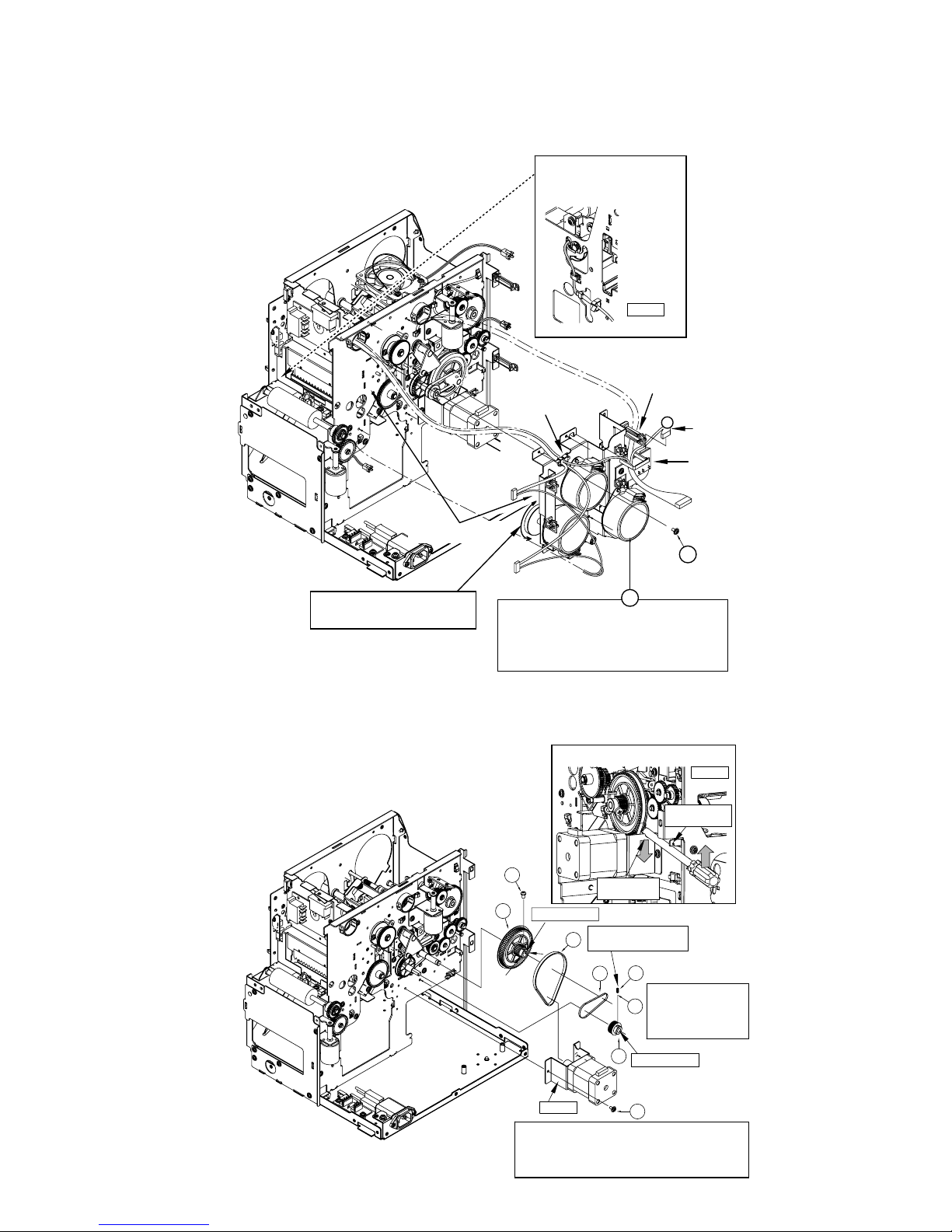

DISMANTLING KEY PARTS ............................................... 8

1. LAYOUT DIAGRAM DURING MAINTENANCE ........ 8

2. DISMANTLING EXTERNAL PARTS AND

REFERENCE WIRING DIAGRAM ............................ 8

2.1 Dismantling the Top Cover ................................. 8

2.2 Dismantling the Front Panel ............................... 8

2.3 Reference Wiring Diagram ................................. 9

3. DISMANTLING THE MG / IC UNIT ........................ 10

4. SEPARATING THE CHASSIS AND MECHANICAL

UNIT AND DISMANTLING BOARDS ..................... 10

4.1 Dismantling the Chassis, Mechanical Unit and

Rear Panel ....................................................... 10

4.2 Dismantling Boards and Power Supply Units ... 11

4.2.1 Dismantling the DAD Board .................. 11

4.2.2 Dismantling the Drive Board .................. 11

4.2.3 Dismantling the Main Board .................. 12

4.2.4 Dismantling the Power Circuit Board ..... 12

5. DISMANTLING THE MOTOR ASSEMBLY ............. 13

5.1 Dismantling the Turn Motor Assembly .............. 13

5.2 Dismantling the Stepping Motor Assembly ...... 13

5.3 Dismantling the DC Motor ................................ 14

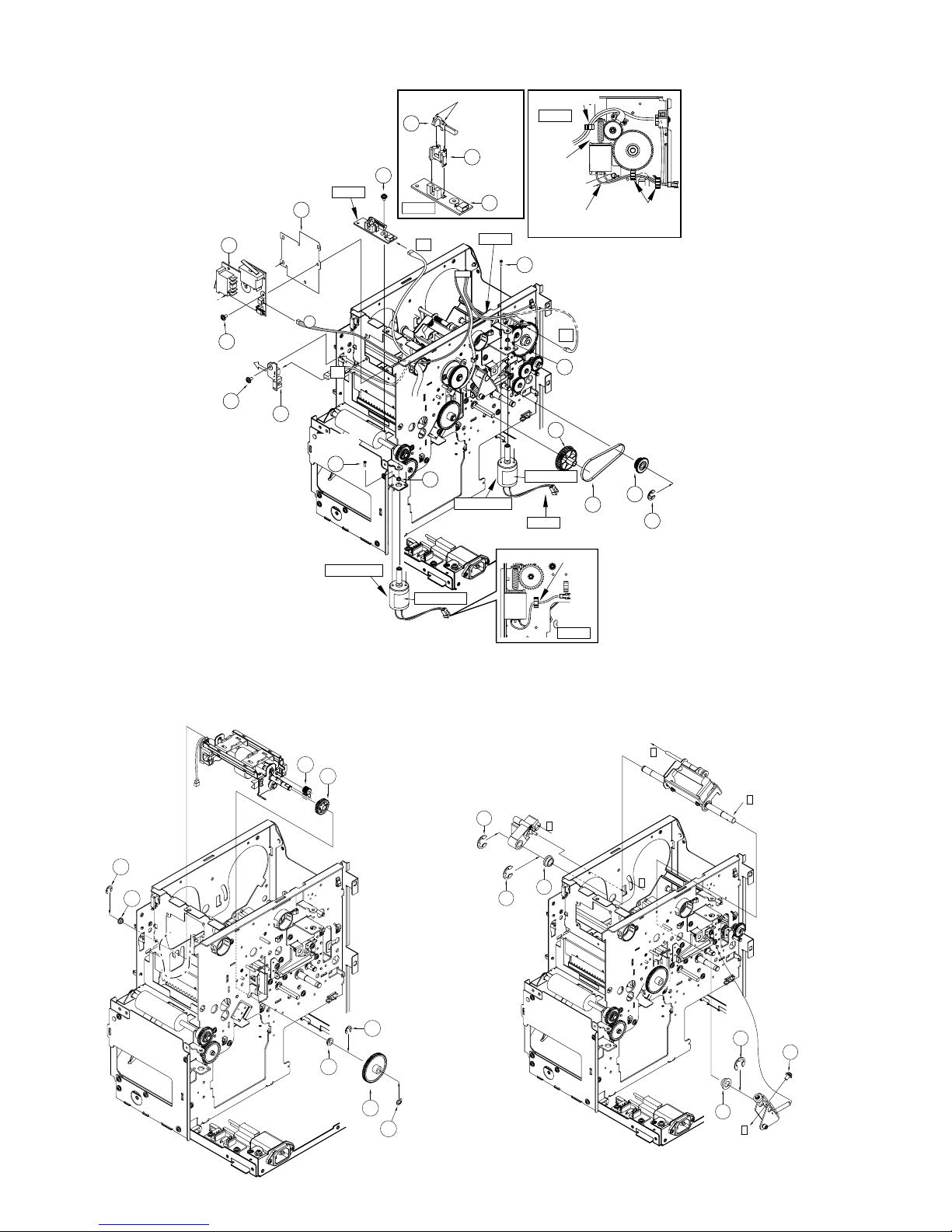

6. DISMANTLING THE TURNOVER UNIT ................. 14

7. DISMANTLING THE HEAD PRESS ASSEMBLY ... 14

MECHANICAL OPERATIONS .......................................... 15

1. INITIALIZE OPERATION ........................................ 15

2. FEED OPERATION ................................................. 15

3. PRINT OPERATION ............................................... 17

4. MG OPERATION .................................................... 19

5. IC OPERATION ....................................................... 19

TROUBLESHOOTING ...................................................... 20

1. ERROR CODE LIST AND CORRESPONDING

SERVICING PROCEDURES .................................. 20

MAINTENANCE ................................................................ 21

1. CLEANING.............................................................. 21

2. GREASING ............................................................. 21

3. LIST OF REPLACEABLE PARTS ........................... 21

ITEMS FOR ADJUSTMENT ............................................. 22

1. POWER SUPPLY VOLTAGE ADJUSTMENT .......... 22

MG / IC ENCODING UNIT ................................................ 23

1. MG/ IC ENCODER SPECIFICATIONS ................... 23

1.1 Magnetic Encoding Unit Specifications ............ 23

1.2 General Equipment Specifications ................... 23

2. BLOCK DIAGRAM .................................................. 24

2.1 MG / IC Unit Block Diagram ............................. 24

2.2 Connection Diagram ........................................ 25

3. REPLACING THE MG / IC ENCODING UNIT ........ 26

3.1 Repair Services................................................ 26

3.2 Replacement Procedure .................................. 26

3.3 DIP Switch ........................................................ 28

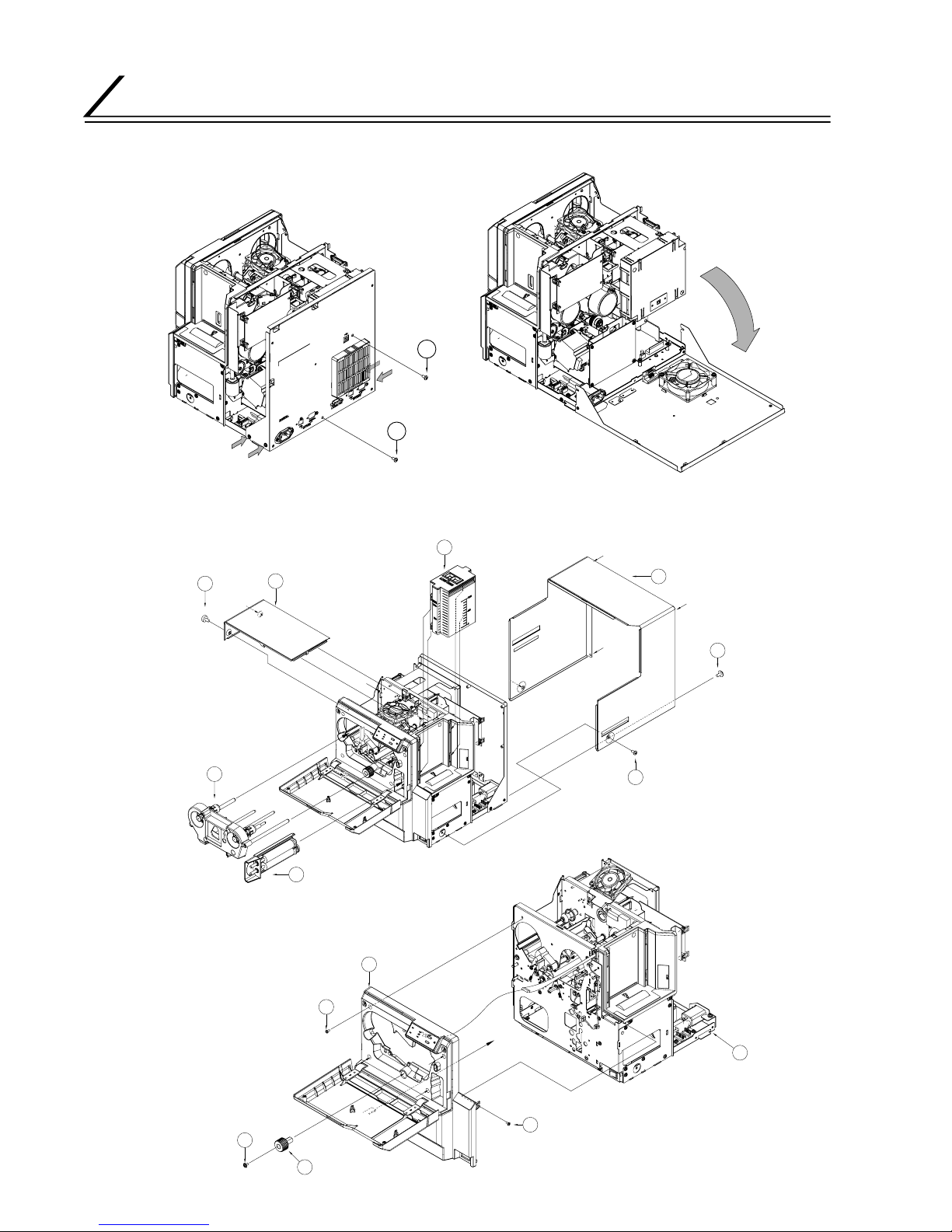

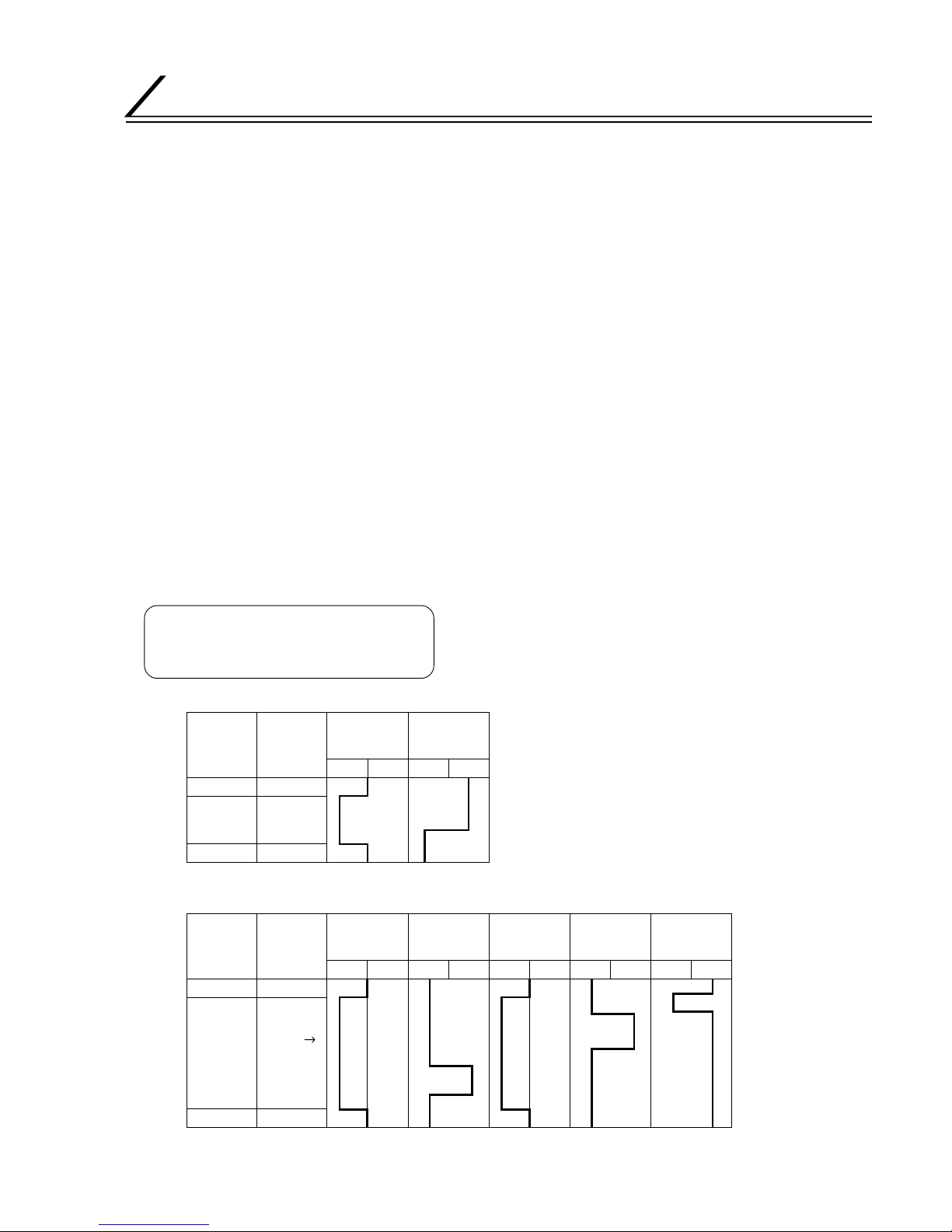

ASSEMBLY DIAGRAM AND PARTS LIST ........................ 29

1. CAUTIONS ............................................................. 29

2. ASSEMBLY DIAGRAM AND PARTS LIST .............. 30

Exploded Head Press Assembly Diagram .............. 30

Exploded Frame Assembly Diagram ....................... 31

Exploded Frame (Center Frame) Assembly

Diagram .................................................................. 32

Exploded Bottom Assembly Diagram ..................... 33

Exploded Turnover Unit Assembly Diagram ............ 34

Exploded Turn Motor Assembly Diagram ................ 35

Exploded Mechanical Assembly (Bottom) Diagram ... 36

Exploded Mechanical Assembly (Feed 1)

Diagram .................................................................. 37

Exploded Mechanical Assembly (Feed 2)

Diagram .................................................................. 38

Exploded Mechanical Assembly (Turn Unit)

Diagram .................................................................. 39

Exploded Mechanical Assembly (Press) Diagram.... 40

Exploded Mechanical Assembly (Wind) Diagram..... 41

Exploded Mechanical Assembly (Motor) Diagram.... 42

Exploded Mechanical Assembly (Fan) Diagram ..... 43

Exploded Mechanical Assembly (Turn Motor)

Diagram .................................................................. 44

Exploded PWB Assembly (DAD) Diagram .............. 45

Exploded PWB Assembly (Drive) Diagram ............. 46

Exploded PWB Assembly (RF-ID) Diagram............ 47

Exploded PWB Assembly (Power) Diagram ........... 48

Exploded PWB Assembly (Main) Diagram ............. 49

Exploded Hopper Base Assembly Diagram ............ 50

Exploded Front Panel Assembly Diagram............... 51

Exploded Final Assembly (MG/IC) Diagram ........... 52

Exploded Final Assembly (Front) Diagram ............. 53

Exploded Final Assembly (Rear 1) Diagram ........... 54

Exploded Final Assembly (Rear 2) Diagram ........... 55

Exploded Final Assembly (Top Cover) Diagram ..... 56

Exploded Annex Assembly (Attachments)

Diagram .................................................................. 57

Exploded Annex Assembly (Packaging) Diagram ... 58

Exploded Packing Assembly Diagram .................... 59

3.

MG / IC UNIT ASSEMBLY DIAGRAM AND PARTS LIST ...

60

Exploded MG Unit Assembly Diagram.................... 60

SAFETY PRECAUTION

Important Safety Precautions

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes of the

countries in which they are to be sold. However, in order to maintain such compliance, it is equally important to implement the following precautions

when a set is being serviced.

Fig.1

1. Locations requiring special caution are denoted by labels and inscriptions on the cabinet, chassis and certain parts of the product.

When performing service, be sure to read and comply with these

and other cautionary notices appearing in the operation and service manuals.

2. Parts identified by the ! symbol and shaded ( ) parts are

critical for safety.

Replace only with specified part numbers.

Note: Parts in this category also include those specified to com-

ply with X-ray emission standards for products using

cathode ray tubes and those specified for compliance

with various regulations regarding spurious radiation

emission.

3. Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

4. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

5. Use specified insulating materials for hazardous live parts. Note

especially:

1) Insulation Tape 3) Spacers 5) Barrier

2) PVC tubing 4) Insulation sheets for transistors

6. When replacing AC primary side components (transformers, power

cords, noise blocking capacitors, etc.) wrap ends of wires securely

about the terminals before soldering.

Power cord

Fig.2

10. Also check areas surrounding repaired locations.

11. Products using cathode ray tubes (CRTs)

In regard to such products, the cathode ray tubes themselves, the

high voltage circuits, and related circuits are specified for compliance with recognized codes pertaining to X-ray emission.

Consequently, when servicing these products, replace the cathode ray tubes and other parts with only the specified parts. Under

no circumstances attempt to modify these circuits.

Unauthorized modification can increase the high voltage value and

cause X-ray emission from the cathode ray tube.

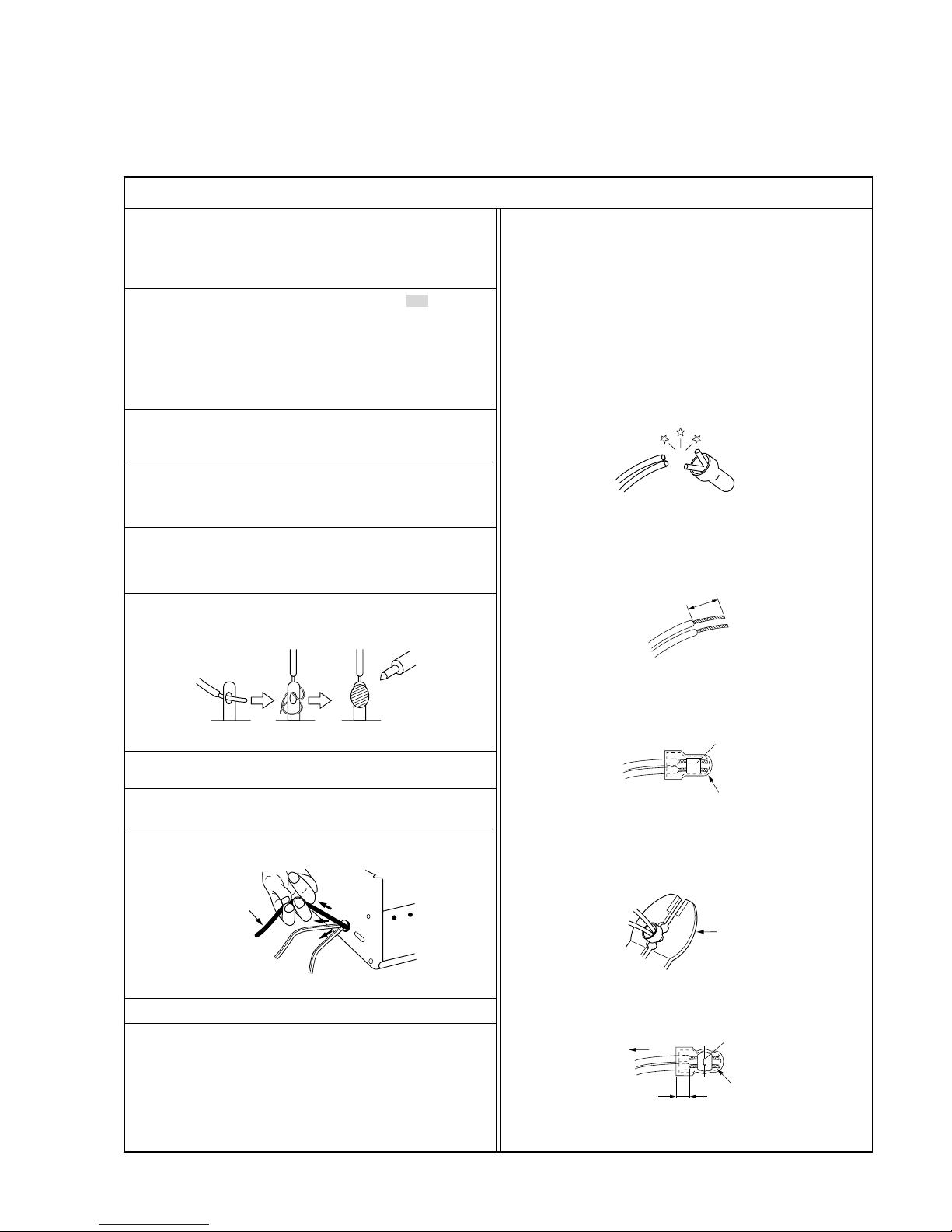

12. Crimp type wire connector

In such cases as when replacing the power transformer in sets

where the connections between the power cord and power transformer primary lead wires are performed using crimp type connectors, if replacing the connectors is unavoidable, in order to prevent

safety hazards, perform carefully and precisely according to the

following steps.

1) Connector part number : E03830-001

2) Required tool : Connector crimping tool of the proper type which

will not damage insulated parts.

3) Replacement procedure

(1) Remove the old connector by cutting the wires at a point

close to the connector.

Important : Do not reuse a connector (discard it).

Fig.7

cut close to connector

Fig.3

(2) Strip about 15 mm of the insulation from the ends of the

wires. If the wires are stranded, twist the strands to avoid

frayed conductors.

15 mm

Fig.4

(3) Align the lengths of the wires to be connected. Insert the

wires fully into the connector.

Connector

Metal sleeve

Fig.5

(4) As shown in Fig.6, use the crimping tool to crimp the metal

sleeve at the center position. Be sure to crimp fully to the

complete closure of the tool.

I

•

Precautions during Servicing

7. Observe that wires do not contact heat producing parts (heatsinks,

oxide metal film resistors, fusible resistors, etc.)

8. Check that replaced wires do not contact sharp edged or pointed

parts.

9. When a power cord has been replaced, check that 10-15 kg of

force in any direction will not loosen it.

1.25

2.0

5.5

Crimping tool

Fig.6

(5) Check the four points noted in Fig.7.

Not easily pulled free

Crimped at approx. center

of metal sleeve

Conductors extended

Wire insulation recessed

more than 4 mm

S40888-01

SAFETY PRECAUTION

•

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires have been returned

to original positions, Afterwards, perform the following tests and confirm the specified values in order to verify compliance with safety

standards.

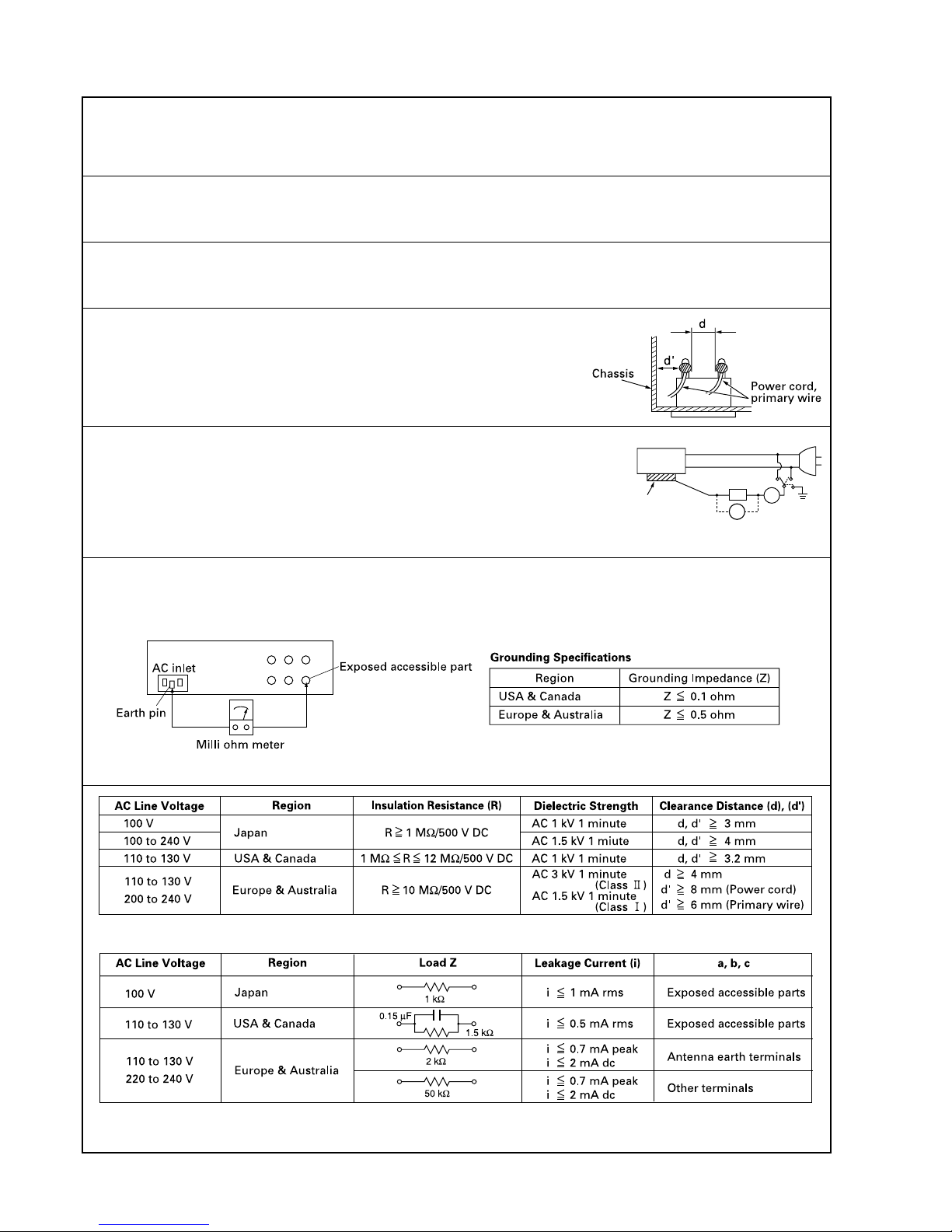

1. Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and externally exposed parts of the set (RF terminals, antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

2. Dielectric strength test

Confirm specified dielectric strength or greater between power cord plug prongs and exposed accessible parts of the set (RF terminals, antenna terminals, video and audio input and output terminals,

microphone jacks, earphone jacks, etc.). See table 1 below.

3. Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d’) between soldered terminals, and between terminals and surrounding metallic parts. See table 1

below.

4. Leakage current test

Confirm specified or lower leakage current between earth ground/power cord plug prongs and

externally exposed accessible parts (RF terminals, antenna terminals, video and audio input and

output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between earth ground/power cord plug prongs and externally exposed accessible

parts. Use an AC voltmeter to measure across both terminals of load Z. See figure 9 and following

table 2.

5. Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between earth pin in AC inlet and externally exposed accessible parts (Video in, Video out,

Audio in, Audio out or Fixing screw etc.).

Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and exposed accessible parts. See figure 10 and grounding specifications.

Fig. 10

Fig. 9

Fig. 8

Tab le 1 Specifications for each region

Tab le 2 Leakage current specifications for each region

Note: These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

II

S40888-01

ab

c

V

A

Externally

exposed

accessible part

Z

BLOCK DIAGRAM

1

Alphabets and numerals after the model name are used to distinguish the different regions of use and specifications.

ID Label: CX-120*-#-DN

1. DETAILED SPECIFICATIONS

*1 : * Portion — Region of use

U ........... North America (100 – 120 V)

E ........... Europe (220 – 240 V)

*2 : # Portion — Internal Option

Nil .......... No option (Standard model)

A ........... Equipped with JIS magnetic encoder / IC contact

B ........... Equipped with ISO magnetic encoder / IC contact

MODEL NAME

BLOCK DIAGRAM

2

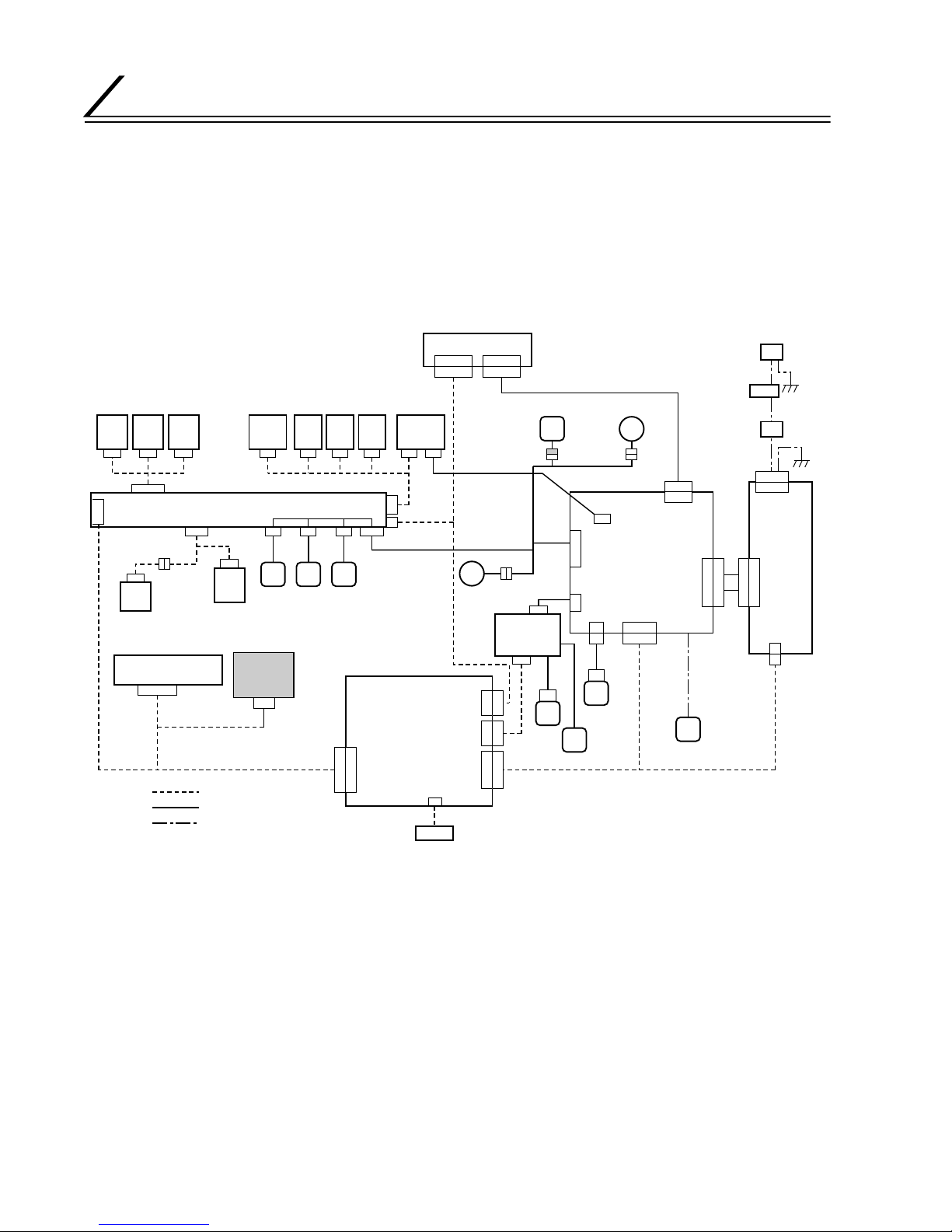

BLOCK DIAGRAM

1. BLOCK DIAGRAM OF ENTIRE UNIT

No Card

PCBCLPCB

Tu rn

PCB

Conn PCB

Print

PCB

DAD PCB

Main PCB

T pos

PCB

FG

PCB

Head

CAMP CB

Tu rn

over

motor

Hopper Motor

Tu rn

over

feed

motor

Head

motor

Inter Lock

PCB

Ink

PCB

Front PCB

MG PCB

MG

Motor

Soleoid

Rear FAN

Card feed

Motor

Head

PCB

Head

FAN

Ink motor

Inlet

BLEED

PCB

Powe r

Switch

RFID

Module

Exit

PCB

Drive PCB PSU

DC5V

DC24V

AC100-240V Primary

BLOCK DIAGRAM

3

2. CONNECTION DIAGRAM

Main PWB

Drive PWB

PSU

Head PWB

Inlet

Power

Switch

Conn PWB

Front PWB

RFID

Module

DADPWB

Inter LocK

PWB

Rear FAN

Head FAN Ink motor

Turn

over

motor

Head

motor

Turn

over

feed

motor

Hopper Motor

No Card

PWB

FG

PWB

Card feed

Motor

Head

CAMPWB

CL

PWB

Turn

PWB

Ink2

PWB

Tpos

PWB

Print

PWB

Exit

PWB

BLEED

PWB

MG PWB

MG

Motor

Solenoid

CN71

CN77 CN79 CN78

CN72

CN70

CN73

CN74CN76

CN7

CN4

CN8 CN5

CN6

CN35

CN23 CN21 CN32

CN33

CN36

CN37

CN24

CN2

CN3

CN1

CN30

CN34

CN100

CN101

CN53 CN52

CN97

CN98

CN96

J2

CN82 CN99 CN87 CN95 CN84 CN85 CN90 CN94 CN93

CN92

CN83

KW

S0735

CN88

Ink1

PWB

KWS0723

KWS0724

KWS0725

KWS0726

KWS0727

KWR18418

KWS0728

KWS0729

KWR15208

KWS0730

KWR15205

KWS0731

KWS0732

KW

R15209

KWS0733

KWS0734

KWS0736

KWR16003

KWS0737

J1 J3

LAYOUT OF KEY PARTS

4

1.

FRONT: HEAD, FEED ROLLER, TURNOVER UNIT AND SENSORS

LAYOUT OF KEY PARTS

Ink Ribbon Position Sensor

Interlock Switch (Head Exchange Door)

Head Cooling Fan

Tu rnover Unit Origin Sensor

Interlock (Printer Door)

Thermal Head and Press Mechanism

RF-ID Unit

Cleaning Roller Detection Sensor

Card Supply Roller

Platen Roller

Card Printing Position Sensor

Card Detection Sensor

Card Discharge Sensor

Tu rnover Unit

Cleaning Roller Unit

Card Sensor in Turnover Unit

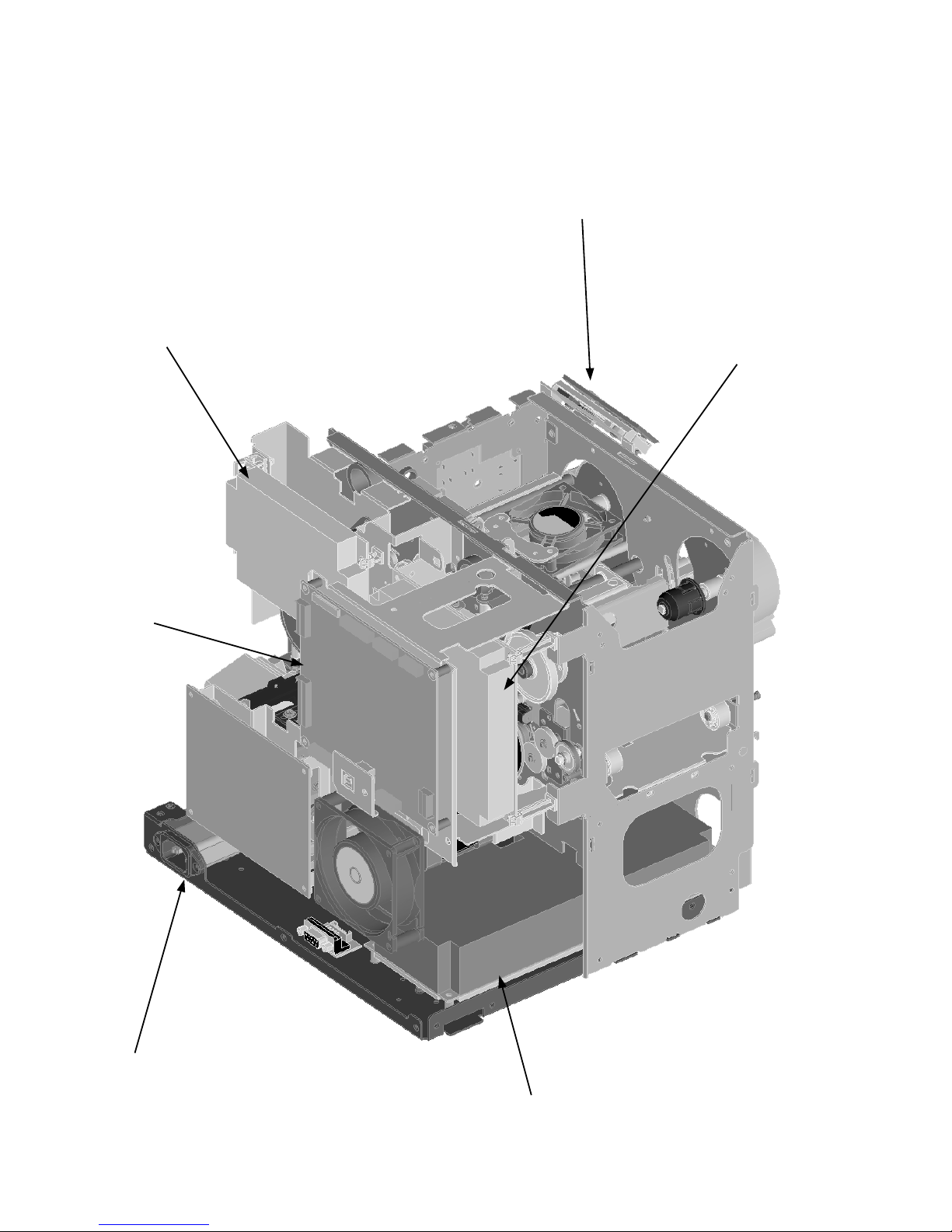

LAYOUT OF KEY PARTS

5

2. REAR: MOTOR, FAN AND SENSORS

Card Feed Motor in Turnover Unit

Head Press Cam Position Detection Sensor

Card Turnover Motor Ink Ribbon FG Sensor

Head Press Cam Motor

Ink Ribbon

Winding Motor

Card Feed Motor

Rear Fan

Card Supply Motor

MG / IC Unit (Optional)

LAYOUT OF KEY PARTS

6

3. BOARDS AND POWER SOURCES

Front Board

DAD Board

Drive Board

Main Board

AC Inlet

Power Supply Unit

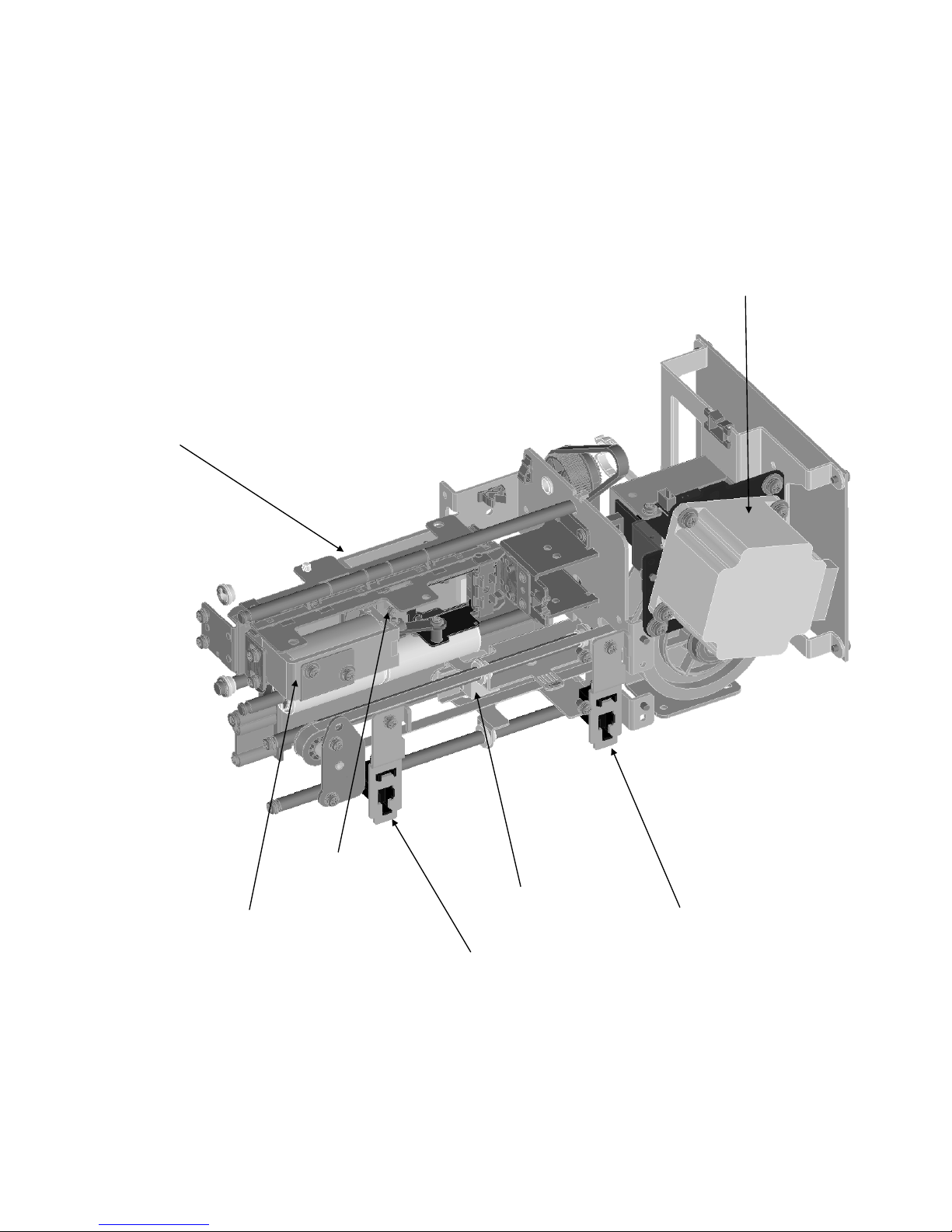

LAYOUT OF KEY PARTS

7

4. MG / IC UNIT

MG Head Carriage Motor

IC Contact

(ISO MG Type)

IC Contact

(JIS MG Type)

MG Head Assembly

IC Contact Pressure Solenoid (JIS MG Type)

MG Head Origin Sensor (For ISO)

MG Head Origin Sensor (For JIS)

8

DISMANTLING KEY PARTS

13

8

4

1

(TFA0022)

13

KJJ46271-003x4

14

KJJ46271-003

QYSPSPH3006N

QYSDSP3006N

x 2

8

QYSDSP4008N

Loosen the screws

8

Loosen the screws

1. LAYOUT DIAGRAM DURING MAINTENANC

DISMANTLING KEY PARTS

The rear panel can be opened for maintenance by removing the following screws.

2.

DISMANTLING EXTERNAL PARTS AND REFERENCE WIRING DIAGRAM

2.1 Dismantling the Top Cover

2.2 Dismantling the Front Panel

12

KJJ46697-001x2

QYSDSP4008Nx2

13

5

1

3

13

6

QYSDSP

4008N x4

2

9

DISMANTLING KEY PARTS

2.3 Reference Wiring Diagram

10

DISMANTLING KEY PARTS

3. DISMANTLING THE MG / IC UNIT

4. SEPARATING THE CHASSIS AND MECHANICAL UNIT AND DISMANTLING BOARDS

4.1 Dismantling the Chassis, Mechanical Unit and Rear Panel

QYSPSPH

3006Nx2

9

QYSPSPH3006N x2

QYSPSPH3006N

Figure 1

Figure 1

Figure 1

MG/IC

To J3

CN8

9

9

G.No.004

3

G.No.003

2

G.No.002

1

(MAIN)

Hang belt on the gear.

Front Screw Fitting

Front Screw Fitting

Front Screw Fitting

Clamp

MAIN

To CN8

J3

(MG/IC)

Gr

Be careful not

to catch the

wires when

assembling.

16

KJJ46271-003x2

3

16

KJJ46271

-003x2

16

KJJ46271

-003x2

CN5

KJJ46271-003x3

7

CN32

8

KJJ46271-003x4

7

QYSDSP4008N

8

QYSDSP4008N

11

DISMANTLING KEY PARTS

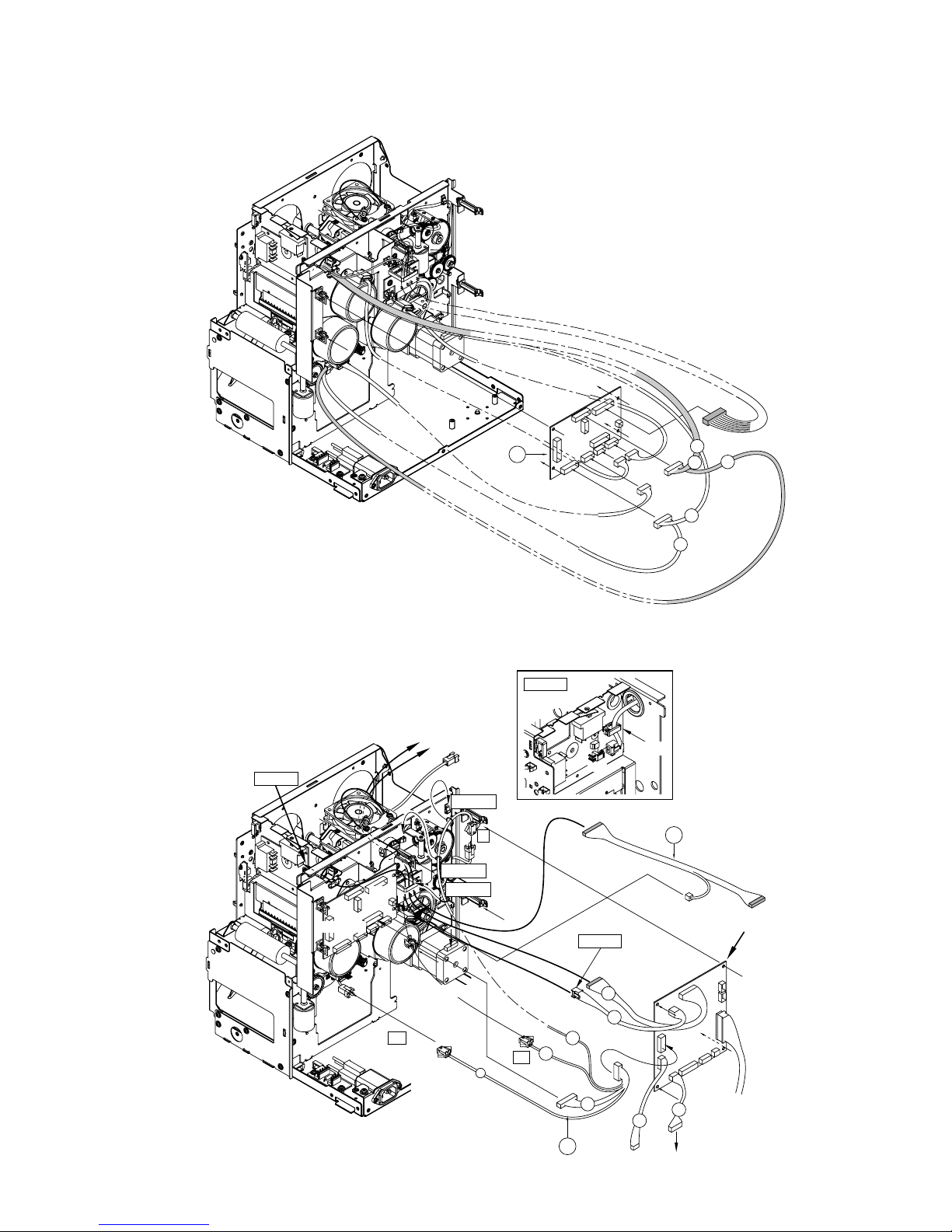

4.2 Dismantling Boards and Power Supply Units

4.2.1 Dismantling the DAD Board

4.2.2 Dismantling the Drive Board

3

(TPS239-1)

DAD PWB

CN72

CN71

CN78

CN77

CN79

8p

6p

7p

5p

Br

CN73

10p

R

Or

Br

R

Clamp

Clamp

To CN74

of DAD PWB

CN74

DAD PWB

Connect to CN93 of

the Interlock PWB

KWS0728-001

5

DRIVE PWB SA

Clamp

Clamp

Figure 2

Figure 2

Figure 2

HF

CN76

IN

HO

KWS0733-001

8

INTERLOCK PWB

Card Feed Motor

CN93

CN24

Card Feed Motor

CN76

BL

Wh

GR

R

Y

OR

R

BR

To CN93

12

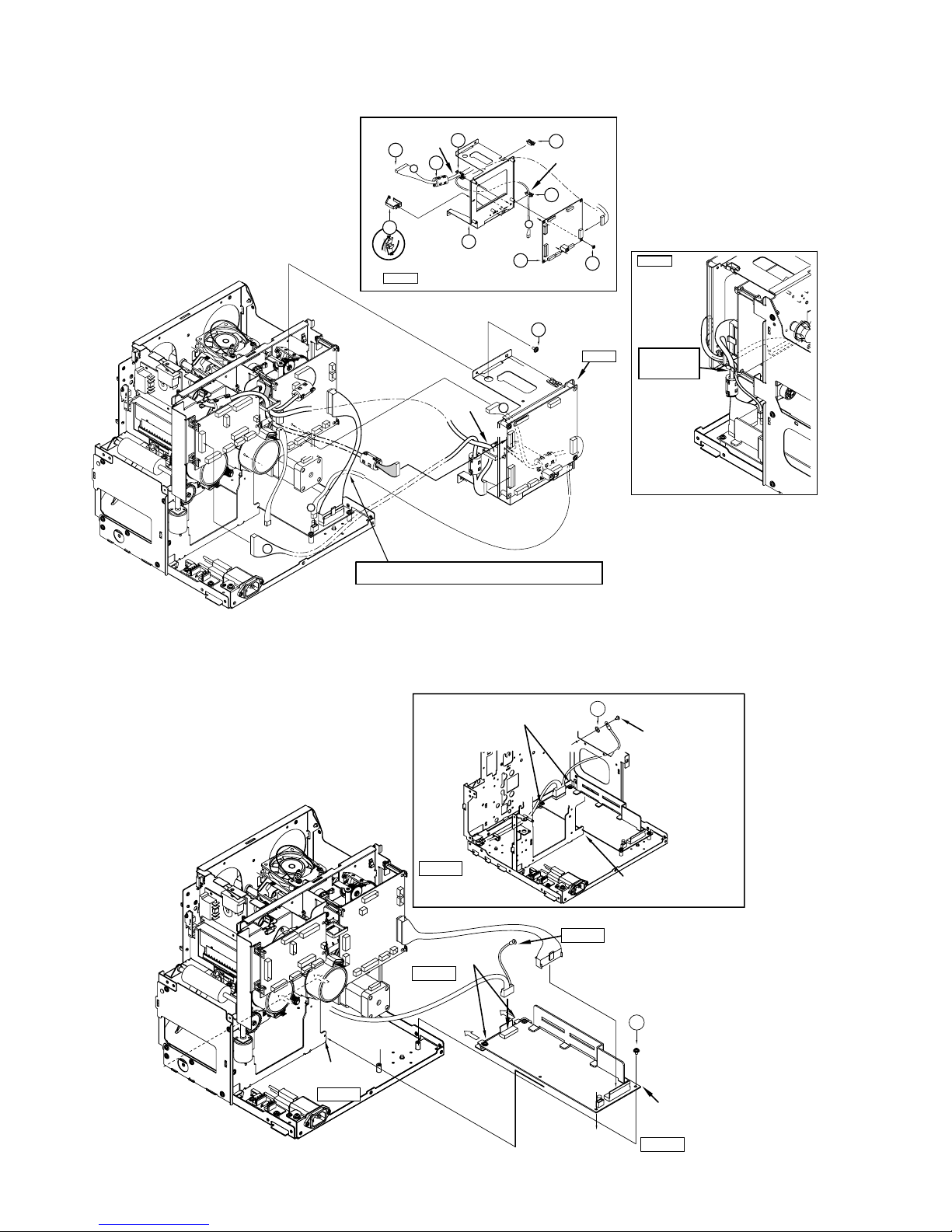

DISMANTLING KEY PARTS

4.2.3 Dismantling the Main Board

4.2.4 Dismantling the Power Circuit Board

Insert power

supply wiring

into the clamp

Wiring at

PWB BKT’s End

14

12

3

13

12

9

QYSPSPH

3006N x3

MAIN PWB

(TPS237-1)

Figure 2

Figure 1

2

KWS0729-001

CN6

PWB BKT SA

1

Clamp

Clamp

R

7

OR

CN7

OR

OR

KJJ46271-003x4

CN7

CN4

CN21

CN21

PWB BKT SA

Clamp

Insert red wire by guiding it from the rear of CN2

(Adjust accordingly such that the red wire does not protrude from behind)

CN2

R

CN70

10

CN70

Figure 2

7

QYSPSPH

3006N x2

Insert into the slit

at the bottom

POWER SUPPLY SA

Installing the

Power Source and Wiring

Clamp the power

circuit board

10

QYWBS326505N

Installing the

Power Source and Wiring

Remove screws on

the frame to fasten

the FG wires together.

Clamp the power

circuit board

Insert into the slit at the bottom

Figure 2

Figure 2

Figure 2

Figure 2

Figure 2

13

DISMANTLING KEY PARTS

5. DISMANTLING THE MOTOR ASSEMBLY

5.1 Dismantling the Turn Motor Assembly

5.2 Dismantling the Stepping Motor Assembly

1

5

KJJ46271

-003 x5

(TSS0233)

Clamp

Insert the

connector

Lead the wire from underneath

the card edge holder

[Before Installation]

• Check wiring (See Figure 1)

• Adjust position of wire of the turnover unit (See Figure 2)

• Check cam position (See Figure 3)

[During Installation]

• Ensure that wires are not trapped in the shaft

• Ensure that wires are not caught

Before installing the turn motor unit,

turn the turnover unit and ensure that

the wire is located on the left as

shown in the diagram.

Figure 2

Clamp the wire that is

guided through the bush

R

Be careful not to

catch the wires

Upon installing the turn motor assembly,

check by turning the jog dial to ensure

that the turnover unit rotates.

4

5

6

7

19

KJJ46271-003 x2

21

QYYASPW4006F

22

Lock the screws upon

fastening.

Perform secondary

tightening on the screws

(torque: 1.96 - 2.35 N.m)

23

QYSPSP

4008N x3

(126)

Shaft and Face 1

Shaft and Face 1

Fasten screws on the flat

surface of the shaft

STEPPING MOTOR SA

[Procedures for Fastening Screws on the Stepping Motor]

1) Tighten the screws temporarily to the main unit, and

tighten using a driver as shown in Figure 3.

2) After tension is properly adjusted, tighten the screws fully.

Hang the driver

on the notch

Use BKT as the

point of support

Figure 3

Figure 1

Tightening the Belt

14

DISMANTLING KEY PARTS

6.

DISMANTLING THE TURNOVER UNIT

7. DISMANTLING THE HEAD

PRESS ASSEMBLY

CL SENSOR

(KEP4103-Q)

CN99

CN82

20

6

20

KJJ46271-003

NC

CL

P

KJJ46271-003

Labeled Face

Labeled Face

Clamp

21

QYSPSPL

3004N x2

21

QYSPSPL

3004N x2

FG

CX-120-M04

3

3

9

20

INTERLOCK PWB

CN94

(KEP4103-N)

12

13

14

19

(184)

QYREE4000X

Figure 2

Figure 2

NC SENSOR PWB

(KEP4103-D)

6

7

8

Insert both ends firmly

Insert

6

KJJ46271-003x2

CX-120-M04

Clamp

Clamp

Ensure that the wire is not

in contact with the spring

Ensure that the

wire is not in

contact with

the gear

Figure 4

Figure 4

Figure 4

Figure 5

13

18

QYREE

5000X

QYREE

5000X

13

11

12

x2

18

15

17

QYREE4000X

20

28

20

A

A

28

B

B

QYREE7000X

QYREE7000X

QYREE

7000X

28

B

18

QYSPSPH4008N

5.3 Dismantling the DC Motor

15

MECHANICAL OPERATIONS

Operations of the card printer mechanism can be divided into 5 types, namely initialize operation, feed operation,

print operation, MG operation and IC operation. Commands from the host are made up using a combination of

these operations. For example, the actual print command is realized via the serial execution of a feed operation

from the hopper to the print position and a print operation. As an illustration, please refer to the sequence diagram

for each item, which describes operations required for duplex printing (paper feed, print, turnover and discharge).

1. INITIALIZE OPERATION

Upon turning on the power, perform the following steps to initialize the mechanism.

1) Initialize MG head position

2) Raise the thermal head

3) Load the ink ribbon to the ready position (when head is lowered or when using a new ink ribbon)

4) Check for any cards remaining in the card feed unit and discharge accordingly (NG Exit)

5) Check for any cards remaining in the MG unit and discharge accordingly (NG Exit)

2. FEED OPERATION

The feed operation is used to transfer a card to a specific position, and it is possible to add an optional turnover

operation. The feed unit is divided into 2 blocks, made up by a card feed motor inside the turnover unit and another

card feed motor. Feeding in the MG unit is performed using the card feed motor inside the turnover unit.

Card discharge from the print position and Card feed operation to a print position are illustrated in a sequence

diagram. In the sequence diagram, the direction of motor operation from right to left (top to bottom in the case of the

MG unit) when viewed from the front is indicated as FWD.

Feed Destinations

There are 6 feed destinations as indicated below.

MECHANICAL OPERATIONS

1

Stop

Inside Hopper

3

Stop

Print Position

2

Feeding

to Print

Position

Hopper

Print

Position

Operation Card

Position

Card Feed

Motor

Print Position

Sensor for

Card

FWD REV

Passed Blocked

Card Feed → Print Position

Card Feed

Motor in

Turnover Unit

Card Sensor

in Turnover

Unit

FWD REV

Passed Blocked

Card Supply

Motor

FWD REV

1

Stop

Print Position

3

Stop No Card

2

Discharging

Print Position

→

Discharge

Operation

Card

Position

Card Feed

Motor

Card Discharge

Sensor

FWD REV

Passed Blocked

Discharging from the Print Position

Print Position Non-contact IC Position

MG Position Card Exit

IC Position NG Card Exit

Loading...

Loading...