Diodes AP6503 User Manual

A

C

C

%

P6503

340kHz 23V 3A SYNCHRONOUS DC/DC BUCK CONVERTER

high

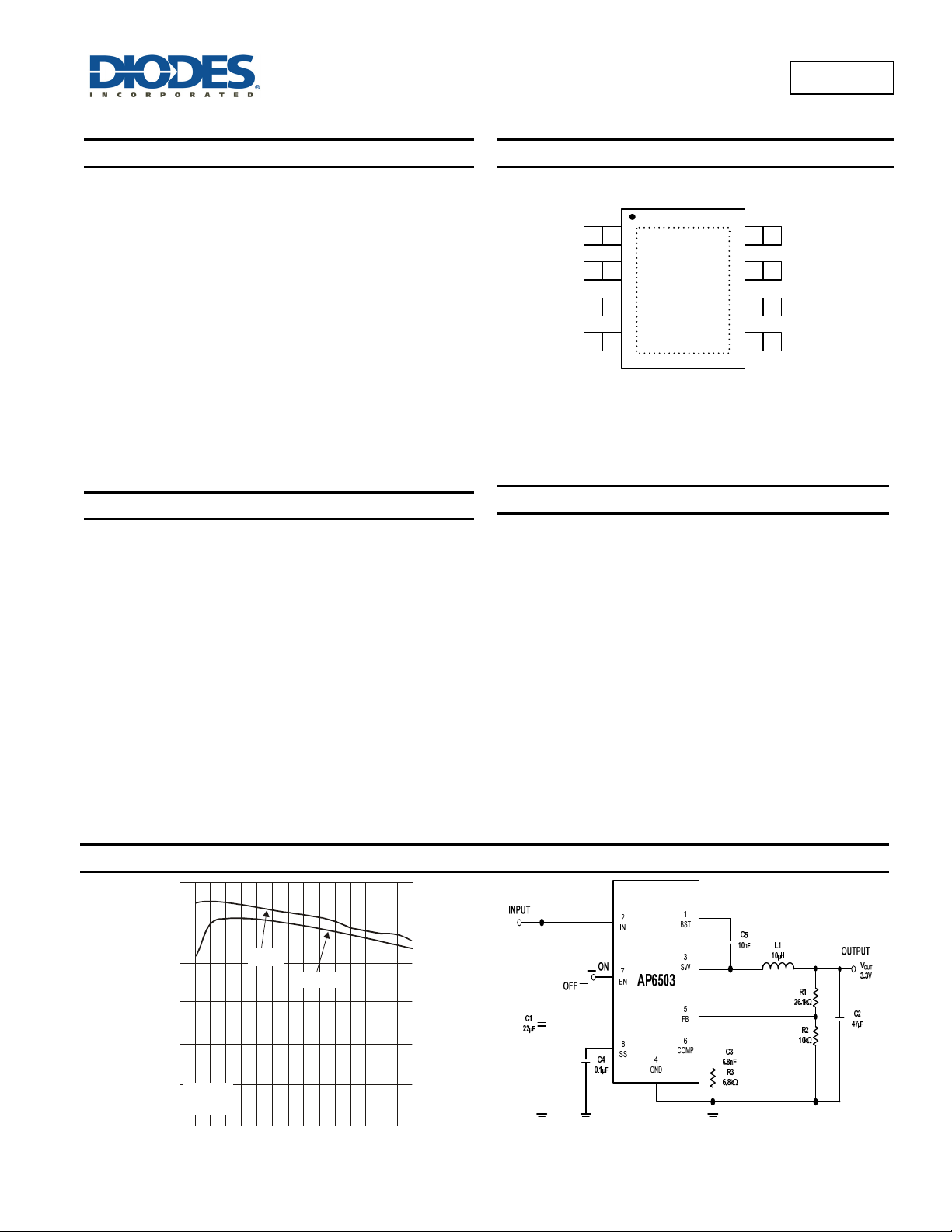

Pin Assignments

( Top View )

BS

SW

GND

1

2

IN

3

4

Applications

• Gaming Consoles

• Flat Screen TV sets and Monitors

• Set Top Boxes

• Distributed power systems

• Home Audio

• Consumer electronics

• Network Systems

• FPGA, DSP and ASIC Supplies

• Green Electronics

SO-8EP

8

SS

EN

7

COMP

6

5

FB

Description

The AP6503 is a 340kHz switching frequency external compensated

synchronous DC/DC buck converter. It has integrated low R

DSON

and low side MOSFETs.

The AP6503 enables continues load current of up to 3A with

efficiency as high as 95%.

The AP6503 features current mode control operation, which enables

fast transient response times and easy loop stabilization.

The AP6503 simplifies board layout and reduces space requirements

with its high level of integration and minimal need for external

components, making it ideal for distributed power architectures.

The AP6503 is available in a standard Green SO-8EP package with

exposed PAD for improved thermal performance and is RoHS

compliant.

Features

• VIN 4.7V to 23V

• 3A continuous Output Current, 4A Peak

• V

• 340kHz switching frequency

• Programmable Soft-Start

• Enable pin

• Protection

• Totally Lead-Free & Fully RoHS Compliant (Notes 1 & 2)

• Halogen and Antimony Free. “Green” Device (Note 3)

Notes: 1. No purposely added lead. Fully EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant.

2. See http://www.diodes.com for more information about Diodes Incorporated’s definitions of Halogen- and Antimony-free, "Green" and Lead-free.

3. Halogen- and Antimony-free "Green” products are defined as those which contain <900ppm bromine, <900ppm chlorine (<1500ppm total Br + Cl)

and <1000ppm antimony compounds

adjustable to 0.925 to 20V

OUT

OCP

Thermal Shutdown

.

Typical Applications Circuit

100

90

V = 5V

80

)

Y (

70

IEN

60

EFFI

50

V = 3.3V

OUT

L = 10µH

40

0123

AP6503

Document number: DS35077 Rev. 5 - 2

IN

V = 12V

IN

LOAD CURRENT (A)

Efficiency vs. Load Current

1 of 15

www.diodes.com

Figure 1 Typical Application Circuit

January 2013

© Diodes Incorporated

A

Pin Descriptions

Pin

Number

1 BS

2 IN

3 SW

4 GND Ground (Connect the exposed pad to Pin 4).

5 FB

6 COMP

7 EN

8 SS

EP EP EP exposed thermal pad connect to Pin 4 GND

Pin

Name

High-Side Gate Drive Boost Input. BS supplies the drive for the high-side N-Channel MOSFET switch.

Connect a 0.01µF or greater capacitor from SW to BS to power the high side switch.

Power Input. IN supplies the power to the IC, as well as the step-down converter switches. Drive IN with a

4.7V to 23V power source. Bypass IN to GND with a suitably large capacitor to eliminate noise on the input

to the IC. See Input Capacitor.

Power Switching Output. SW is the switching node that supplies power to the output. Connect the output LC

filter from SW to the output load. Note that a capacitor is required from SW to BS to power the high-side

switch.c

Feedback Input. FB senses the output voltage and regulates it. Drive FB with a resistive voltage divider

connected to it from the output voltage. The feedback threshold is 0.925V. See Setting the Output Voltage.

Compensation Node. COMP is used to compensate the regulation control loop. Connect a series RC

network from COMP to GND. In some cases, an additional capacitor from COMP to GND is required. See

Compensation Components.

Enable Input. EN is a digital input that turns the regulator on or off. Drive EN high to turn on the regulator;

low to turn it off. Attach to IN with a 100k pull up resistor for automatic startup.

Soft-Start Control Input. SS controls the soft-start period. Connect a capacitor from SS to GND to set the

soft-start period. A 0.1µF capacitor sets the soft-start period to 15ms. To disable the soft-start feature, leave

SS floating.

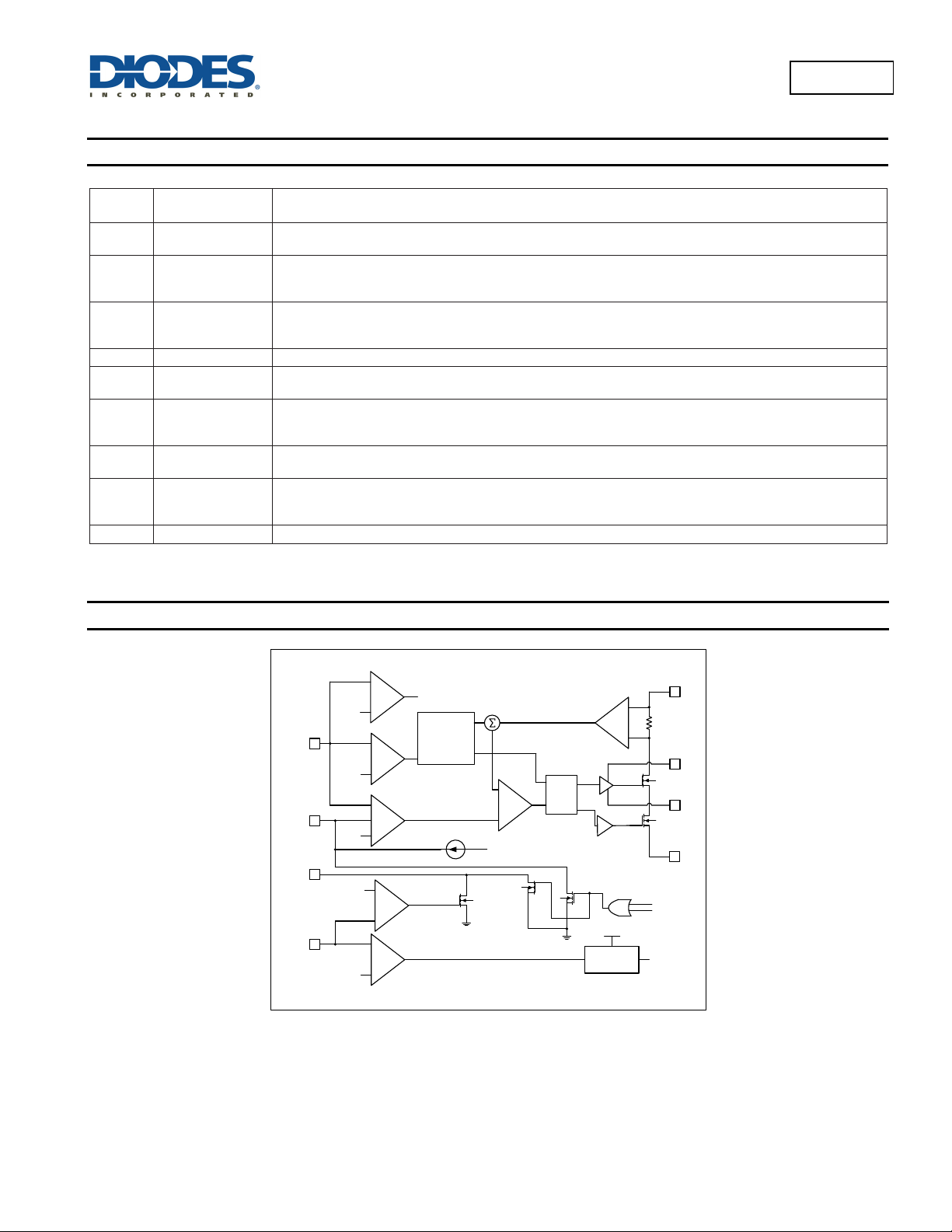

Functional Block Diagram

P6503

Function

COMP

+

-

1.1V

0.3 V

0.923 V

0.9V

+

-

-

+

+

2.5V

+

-

5

FB

SS

8

6

EN

7

+

-

ERROR

AMPLIFIER

LOCKOUT

COMPARATOR

COMPARATOR

OVP

OSCILLATOR

100/340 KHz

EN OK

SHUTDOWN

RAMP

E

CLK

+

-

6uA

CURRENT

SENSE

AMPLIFIER

Logic

CURRENT

COMPARATOR

IN

INTERNAL

REGULATORS

+

-

IN < 4.10V

disable

100m

100m

5V

IN

2

BS

1

SW

3

GND

4

Figure 2 Functional Block Diagram

AP6503

Document number: DS35077 Rev. 5 - 2

2 of 15

www.diodes.com

January 2013

© Diodes Incorporated

A

P6503

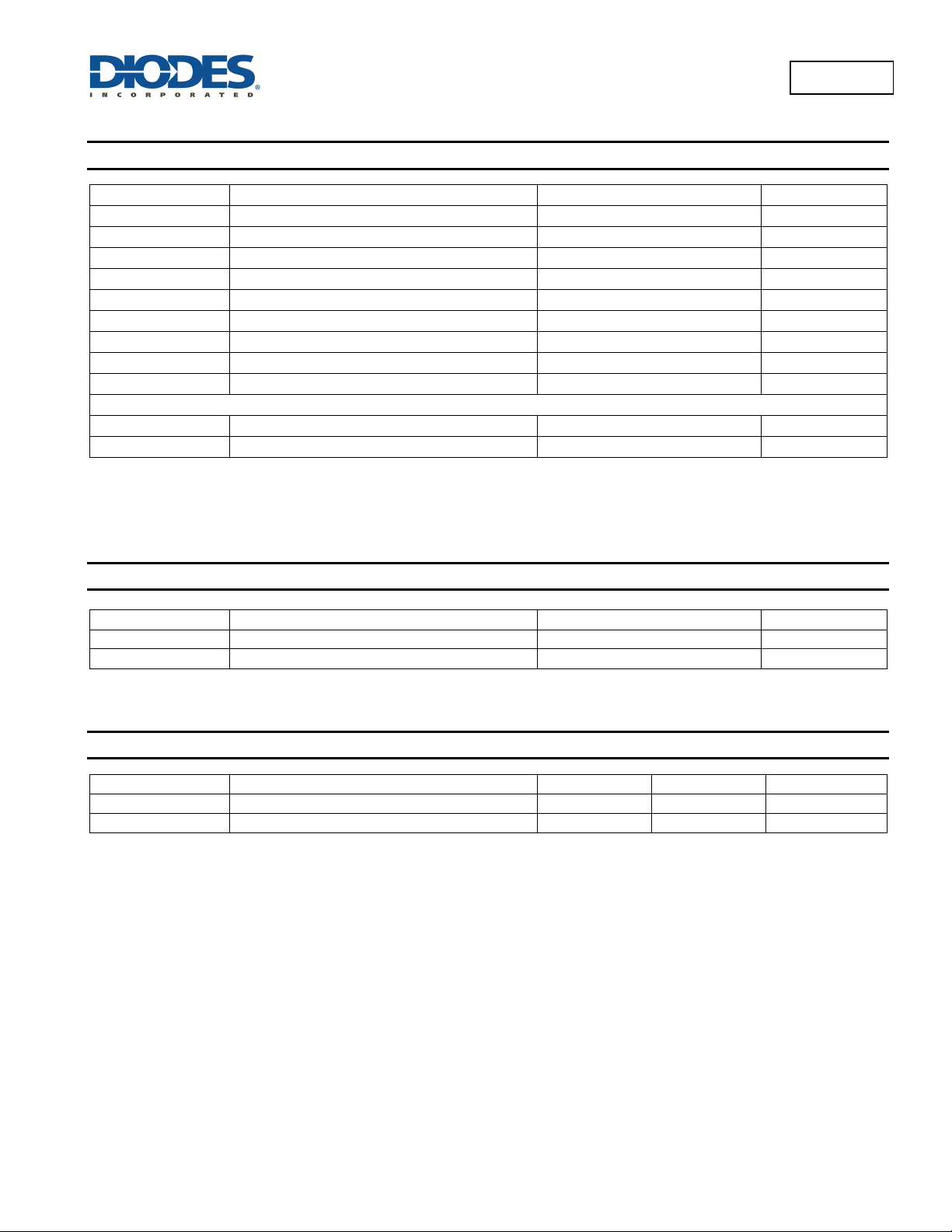

Absolute Maximum Ratings (Note 4) (@T

Symbol Parameter Rating Unit

VIN

VSW

VBS

VFB

VEN

V

COMP

TST

TJ

TL

ESD Susceptibility (Note 5)

HBM Human Body Model 3 kV

MM Machine Model 250 V

Notes: 4. Stresses greater than the 'Absolute Maximum Ratings' specified above, may cause permanent damage to the device. These are stress ratings only;

functional operation of the device at these or any other conditions exceeding those indicated in this specification is not implied. Device reliability may

be affected by exposure to absolute maximum rating conditions for extended periods of time.

5. Semiconductor devices are ESD sensitive and may be damaged by exposure to ESD events. Suitable ESD precautions should be taken when

handling and transporting these devices.

Supply Voltage -0.3 to +26 V

Switch Node Voltage

Bootstrap Voltage

Feedback Voltage -0.3V to +6 V

Enable/UVLO Voltage -0.3V to +6 V

Comp Voltage -0.3V to +6 V

Storage Temperature -65 to +150 °C

Junction Temperature +150 °C

Lead Temperature +260 °C

= +25°C, unless otherwise specified.)

A

-1.0 to V

V

-0.3 to VSW +6

SW

IN

+0.3

V

V

Thermal Resistance (Note 6)

Symbol Parameter Rating Unit

JA

JC

Note: 6. Test condition for SO-8EP: Measured on approximately 1” square of 1 oz copper

Recommended Operating Conditions (Note 7) (@T

Symbol Parameter Min Max Unit

VIN

TA

Note: 7. The device function is not guaranteed outside of the recommended operating conditions.

Operating Ambient Temperature Range -40 +85 °C

Junction to Ambient 74 °C/W

Junction to Case 16 °C/W

= +25°C, unless otherwise specified.)

A

Supply Voltage 4.7 23 V

AP6503

Document number: DS35077 Rev. 5 - 2

3 of 15

www.diodes.com

January 2013

© Diodes Incorporated

A

t

t

g

P6503

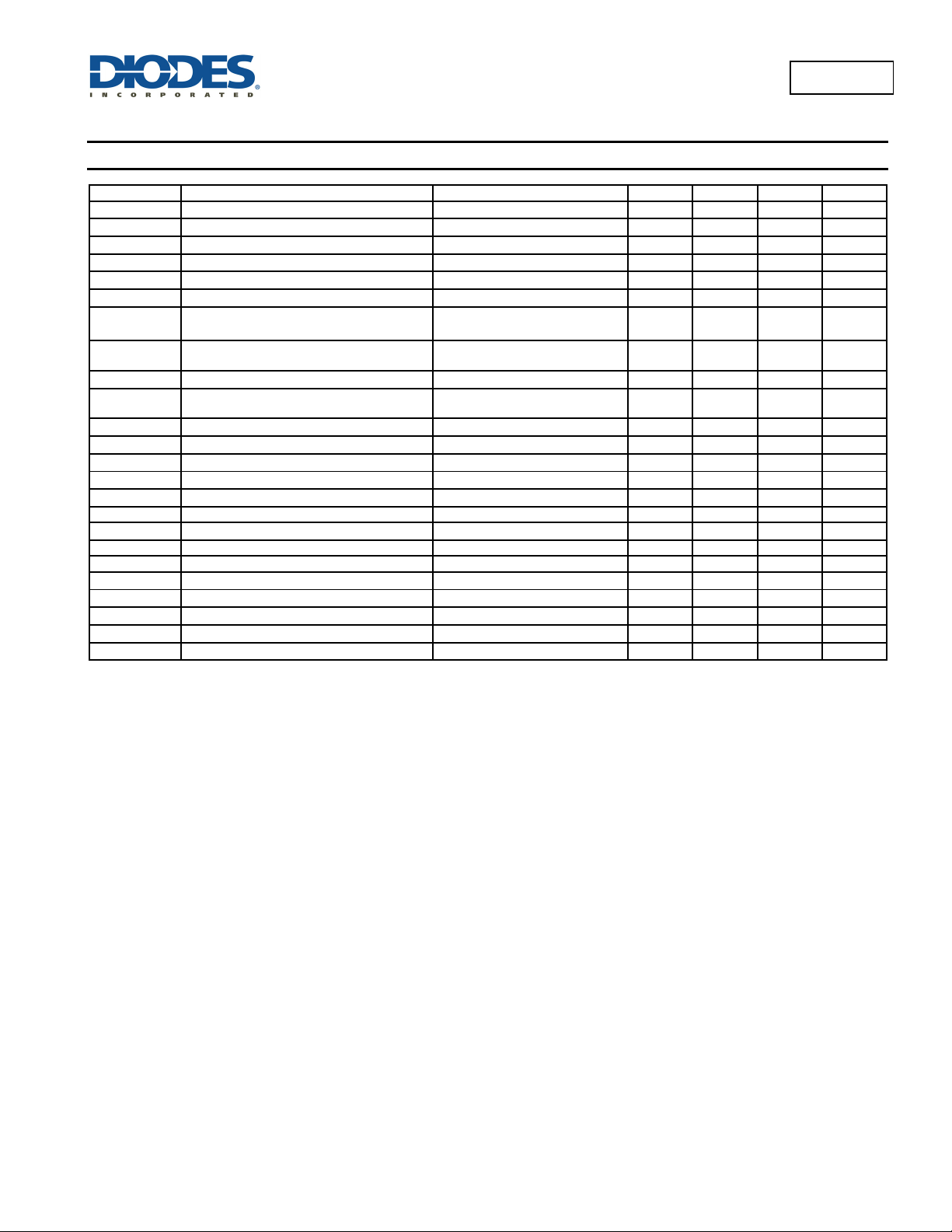

Electrical Characteristics (V

Symbol Parameter Test Conditions Min Typ Max Unit

IIN

IIN

R

DS(ON)1

R

DS(ON)2

I

Limi

I

Limi

High-Side Switch Leakage Current

AVEA

GEA Error Amplifier Transconductance

GCS

FSW

FFB

D

MAX

TON

VFB

Feedback Overvoltage Threshold 1.1 V

V

EN_Risin

EN Lockout Threshold Voltage 2.2 2.5 2.7 V

EN Lockout Hysteresis 220 mV

INUV

INUV

HYS

Soft-Start Current

Soft-Start Period

TSD

Note: 8. Guaranteed by design

Shutdown Supply Current

Supply Current (Quiescent)

High-Side Switch On-Resistance (Note 8) 100 m

Low-Side Switch On-Resistance (Note 8) 100 m

HS Current Limit Minimum duty cycle 5.5 A

LS Current Limit From Drain to Source 0.9 A

Error Amplifier Voltage Gain

(Note 8)

COMP to Current Sense

Transconductance

Oscillator Frequency

Fold-back Frequency

Maximum Duty Cycle

Minimum On Time 130 ns

Feedback Voltage

EN Rising Threshold 0.7 0.8 0.9 V

V

Vth

Under Voltage Threshold Rising

IN

VIN Under Voltage Threshold Hysteresis

Thermal Shutdown (Note 8) 160 °C

= 12V, TA = +25°C, unless otherwise specified.)

IN

VEN = 0V

VEN = 2.0V, VFB = 1.0V

= 0V, VSW = 0V,

V

EN

=12V

V

SW

800 V/V

I

= ±10µA

C

2.8 A/V

V

= 0.75V

FB

V

= 0V

FB

VFB = 800mV

TA = -40°C to +85°C

3.80 4.05 4.40 V

250 mV

V

= 0V

SS

C

= 0.1µF

SS

0.3 3.0 µA

0.6 1.5 mA

0 10 A

1000 µA/V

300 340 380 kHz

0.30

fSW

90 %

900 925 950 mV

6 A

15 ms

AP6503

Document number: DS35077 Rev. 5 - 2

4 of 15

www.diodes.com

January 2013

© Diodes Incorporated

A

C

O

G

P6503

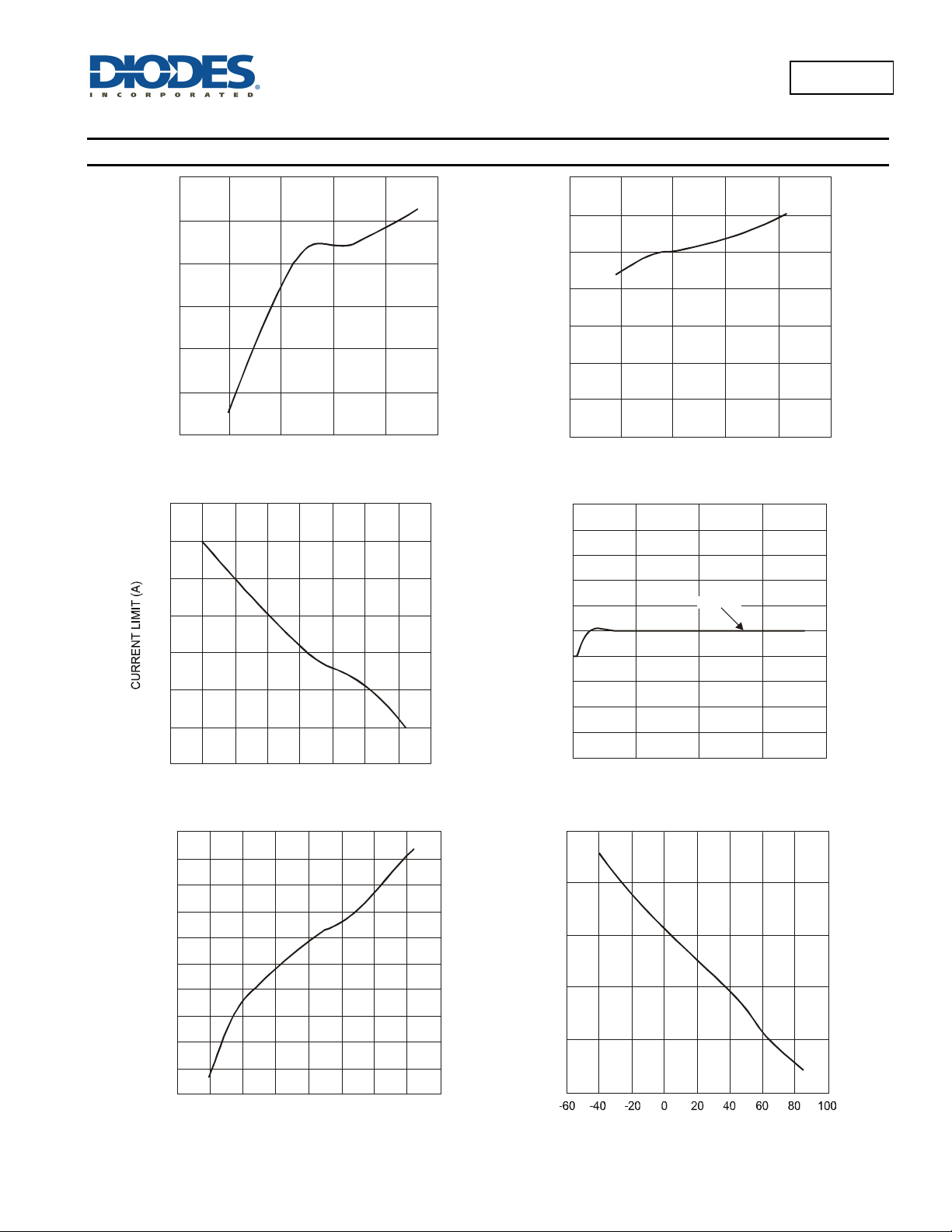

Typical Performance Graphs (V

0.6

0.58

0.56

0.54

0.52

0.5

QUIESCENT SUPPLY CURRENT (mA)

0.48

0 5 10 15 20 25

INPUT VOLTAGE (V)

Quiescent Supply Current vs. Input Voltage

6.2

6

5.8

5.6

5.4

= 12V, V

IN

= 3.3V, TA = +25°C, unless otherwise noted)

OUT

0.074

0.064

0.054

0.044

0.034

0.024

0.014

SHUTDOWN SUPPLY CURRENT (µA)

0.004

0 5 10 15 20 25

3.33

3.329

3.328

3.327

3.326

3.325

3.324

Shutdown Supply Current vs. Input Voltage

INPUT VOLTAGE (V)

V = 12V

IN

5.2

5

4.8

-60 -40 -20 0 20 40 60 80 100

TEMPERATURE (C)

Current Limit vs. Temperature

0.92

0.918

0.916

0.914

E (V)

0.912

LTA

0.91

K V

0.908

0.906

FEEDBA

0.904

0.902

0.9

-60 -40 -20 0 20 40 60 80 100

TEMPERATURE (°C)

Feedback Voltage vs. Temperature

3.323

OUTPUT VOLTAGE (V)

3.322

3.321

3.32

4.75 9.75 14.75 19.75 24.75

INPUT VOLTAGE (V)

Line Regulation

375

370

365

360

355

OSCILLATOR FREQUENCY (Khz)

350

TEMPERATURE (°C)

Oscillator Frequency vs. Temperature

AP6503

Document number: DS35077 Rev. 5 - 2

5 of 15

www.diodes.com

January 2013

© Diodes Incorporated

Loading...

Loading...