Page 1

Stock Weigh 10000

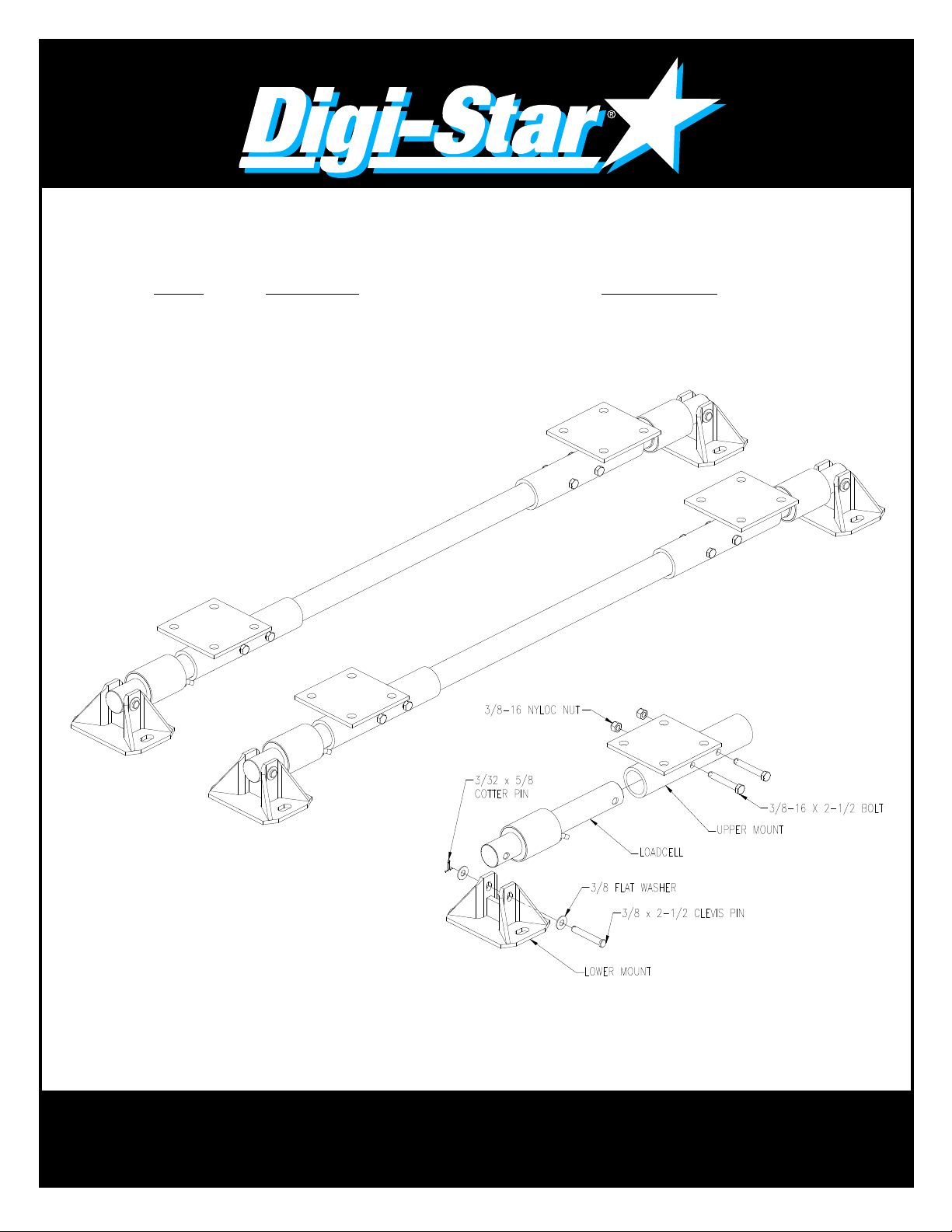

Part # Description Qty. Required

403666 Rail Assembly – 39” SW10K 2

403831 Rail Assembly – 43” SW10K 2

790 W Rockwell Avenue, Fort Atkinson, WI 53538

Phone: (800) 225-7695 Fax: (920) 563-9721

www.digi-star.com

sales@digi-star.com

techsupport@digi-star.com

Page 2

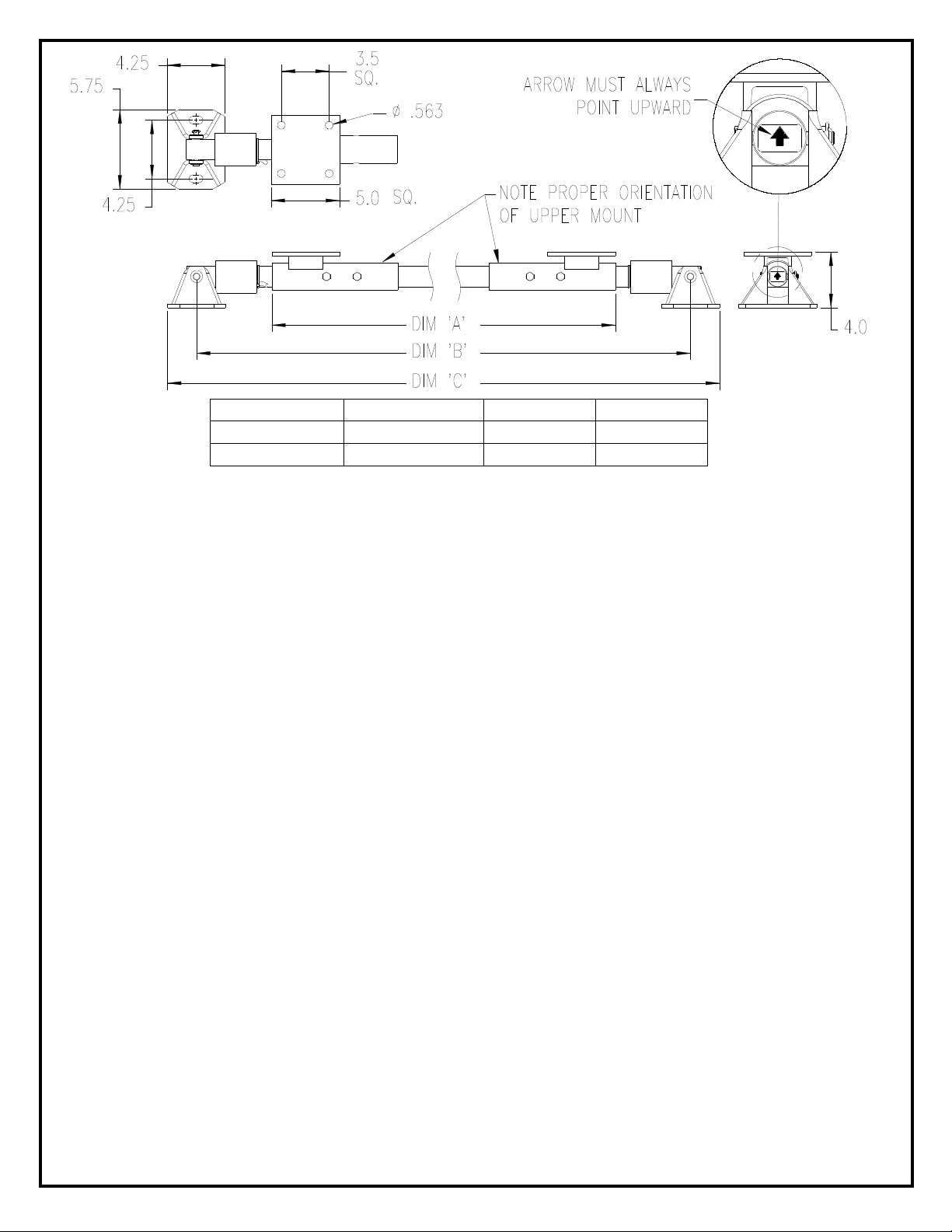

Part Number Dim ‘A’ Dim ‘B’ Dim ‘C’

403666 39.0 50.0 54.25

403831 43.063 54.063 58.313

Installation:

The scale must be installed on a flat, level, and well-drained surface. Concrete is preferred. Shim under the scale

as required. Usually flatness within ±1/8” is required.

The scale is approximately 4” high. Ramps or a shallow pit may be required to facilitate animal access if used as

an animal scale. If a pit is used, adequate drainage is a MUST.

Assemble loadcells and components as shown. The scale will NOT function properly if the upper mounts are not

installed correctly. Note “Bending Direction” decal on end of loadcell for proper installation (arrow should always

point UPWARD).

Position assembled unit as desired on the mounting pad. Mark all holes to be drilled using the parts as a

template. An angle iron bracket may be welded to the chute to provide mounting surfaces for the top mounts.

Mounting hardware is not provided. Grease all hardware with a weather resistant grease to make subsequent

disassembly easier.

The chute should be restrained with a horizontal chain or other flexible means if the scale system is not bolted to

concrete. The scale will not weigh accurately if the restraining method prevents weight from being transferred to

the scale.

Extension tube may be cut down to provide a custom scale width. Simply re-drill the mounting cross-hole after

cutting down the pipe on one end.

Wires and cables must be stowed and secured safely to prevent damage. Secure all cables up off ground and

away from animals with nylon ties or other fasteners.

If mounts are to be welded in place, loadcells must be disconnected from the indicator. Also, the ground should

be located so as to prevent the loadcell from being in the current path.

Maintenance:

There are no moving parts and no lubrication required. The only maintenance required is periodic cleaning of the

mounts and the area below the scale to assure free and unencumbered operation of the scale. Stand over each

of the 4 corners to troubleshoot for problems. Corners should weigh the same within ±2 display counts. Scale

system accuracy is ±1% maximum error.

D3658

Loading...

Loading...