Page 1

Landoll 5210

Grain Drill

Scale Kit

Instructions

And

Repair Parts

Ft. Atkinson, Wisconsin USA

Panningen, The Netherlands

www.digi-star.com

D3949-US-Rev A January 16, 2013

Page 2

Table Of Contents

TABLE OF CONTENTS

INTRODUCTION ..................................................................................................................................................................... 1

Charging Battery and Welding ............................................................................................................................................. 1

SCALE BRACKET AND LOAD CELL MOUNTING INSTALLATION ..................................................................................... 2

Single Hopper Overall View ................................................................................................................................................. 2

Dual Hoppers Overall View ................................................................................................................................................. 2

Outer Load Cell Assembly Instructions for Dual and Single Hoppers ............................................................................ 3

Middle Load Cell Support Assembly Instructions For Dual Hoppers .............................................................................. 4

Single Hopper Load Cell Assembly Installation .............................................................................................................. 4

Dual Hopper Load Cell Assembly Installation ................................................................................................................. 6

JUNCTION BOX MOUNTING ................................................................................................................................................. 7

Connect Load Cell and J-Box Cable ................................................................................................................................... 7

Installing Wires into Terminal Block ..................................................................................................................................... 7

INDICATOR MOUNTING ........................................................................................................................................................ 8

Power Connection: .............................................................................................................................................................. 8

Load Cell Connection: ......................................................................................................................................................... 8

TROUBLE SHOOTING ........................................................................................................................................................... 9

How to Check the Drill Scale After Installation .................................................................................................................... 9

REPAIR PARTS .................................................................................................................................................................... 10

408026 Kit – Landoll 5210 (2 PT) ...................................................................................................................................... 10

408025 Kit – Landoll 5210 (4 PT) Outer Load Cell Support .............................................................................................. 11

408025 Kit – Landoll 5210 (4 PT) Middle Load Cell Support ............................................................................................ 12

Indicator Swivel Mount....................................................................................................................................................... 13

LICENSE AGREEMENT ....................................................................................................................................................... 14

All rights reserved. Reproduction of any part of this manual in any form whatsoever without Digi-Star’s express written permission is forbidden. The contents of this manual are

subject to change without notice. All efforts have been made to assure the accuracy of the contents of this manual. However, should any errors be detected, Digi-Star would

greatly appreciate being informed of them. The above notwithstanding, Digi-Star can assume no responsibility for errors in this manual or their consequence.

© Copyright! 2012 Digi-Star, Fort Atkinson (U.S.A.).

Landoll 5210 Grain Drill Scale Kit D3949-US-Rev A

Page 3

Introduction

Disconnect

Scale Indicator

Optional

INTRODUCTION

Congratulations on the purchase of your new Digi-Star Grain Drill Scale System. This scale system is

specifically designed to weigh the seed hopper on a Grain Drill or other seeding hoppers. The scale kit can be

used to record and monitor seed weight going into or out of the seed hopper.

This scale system is covered by the following US patents: 6732667, 7059258 and 7273017. The single-use

license is included with this document (see page 14).

This

SAFETY ALERT SYMBOL

symbol, be alert to the possibility of

NEVER OPERATE WITHOUT ALL COVERS, SHIELDS AND GUARDS IN PLACE. KEEP

HANDS, FEET AND CLOTHING AWAY FROM MOVING PARTS. FAILURE TO HEED MAY RESULT IN

SERIOUS PERSONAL INJURY OR DEATH.

Some covers and guards have been removed for illustrative/photographic purposes only in this manual.

For information on ordering repair parts, refer to Parts Section in this book.

This supersedes all previous published instructions.

indicates important safety messages in the manual. When you see this

PERSONAL INJURY

and carefully read the message that follows.

Important!

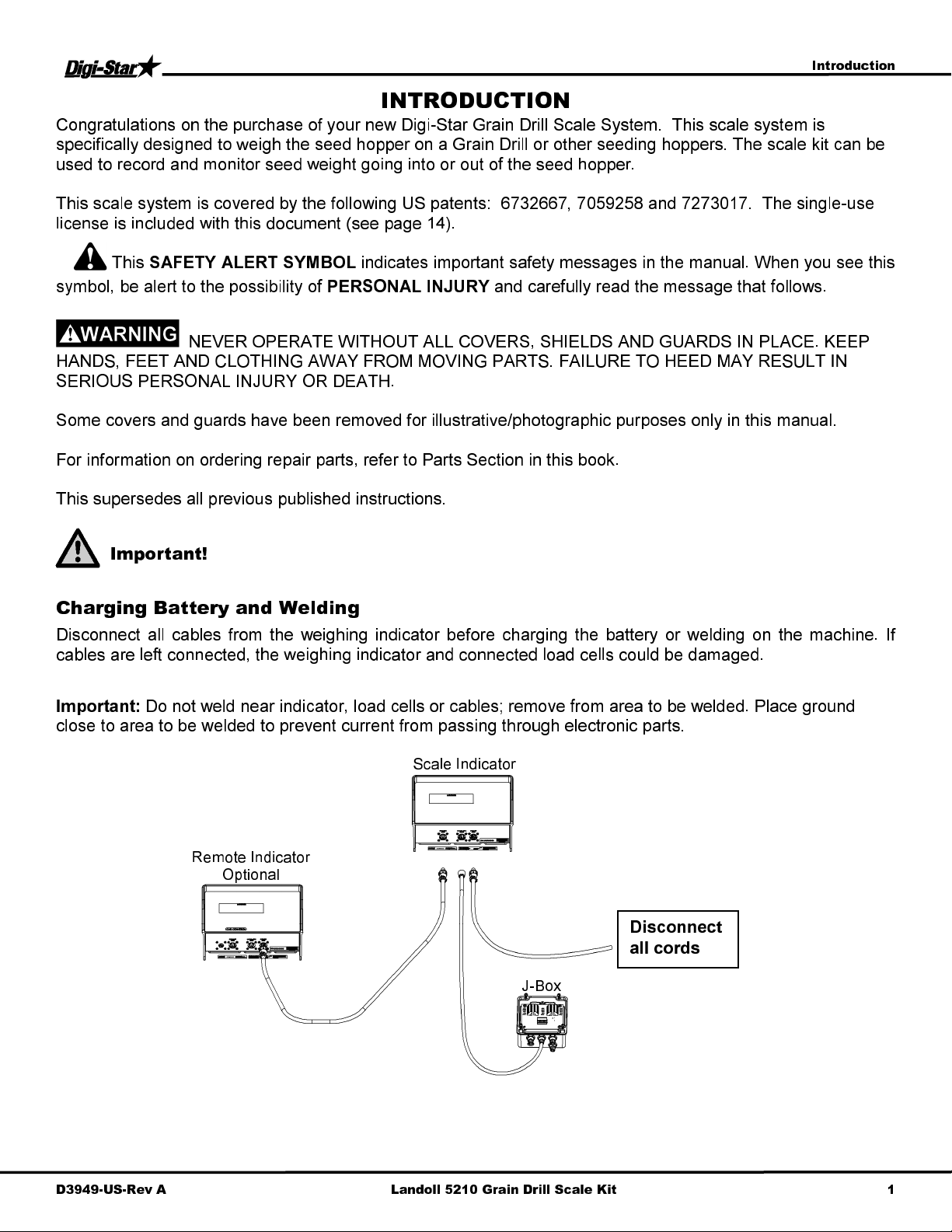

Charging Battery and Welding

Disconnect all cables from the weighing indicator before charging the battery or welding on the machine. If

cables are left connected, the weighing indicator and connected load cells could be damaged.

Important:

close to area to be welded to prevent current from passing through electronic parts.

Do not weld near indicator, load cells or cables; remove from area to be welded. Place ground

Remote Indicator

all cords

J-Box

D3949-US-Rev A Landoll 5210 Grain Drill Scale Kit 1

Page 4

Scale Bracket and Load Cell Mounting Installation

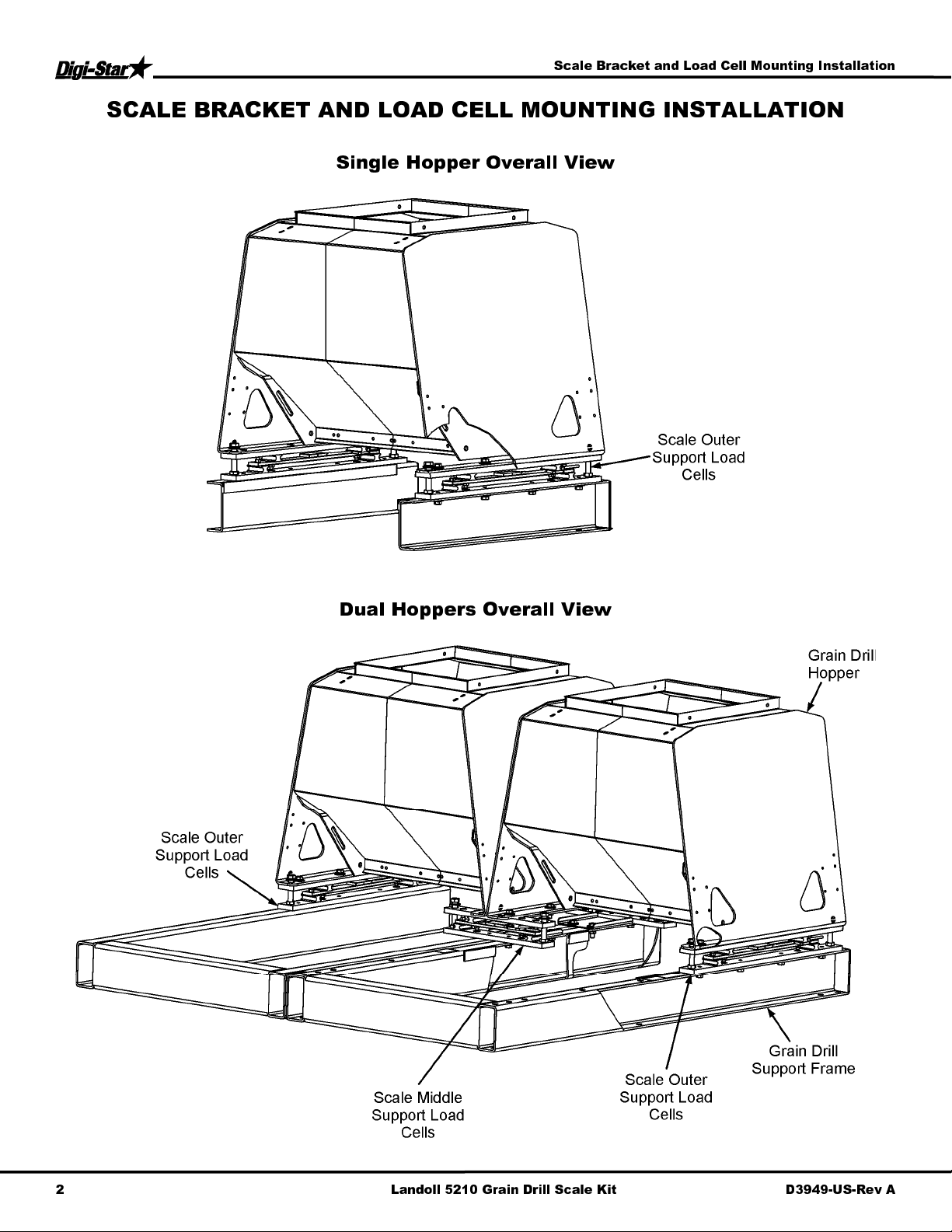

SCALE BRACKET AND LOAD CELL MOUNTING INSTALLATION

Single Hopper Overall View

Dual Hoppers Overall View

2 Landoll 5210 Grain Drill Scale Kit D3949-US-Rev A

Page 5

Scale Bracket and Load Cell Mounting Installation

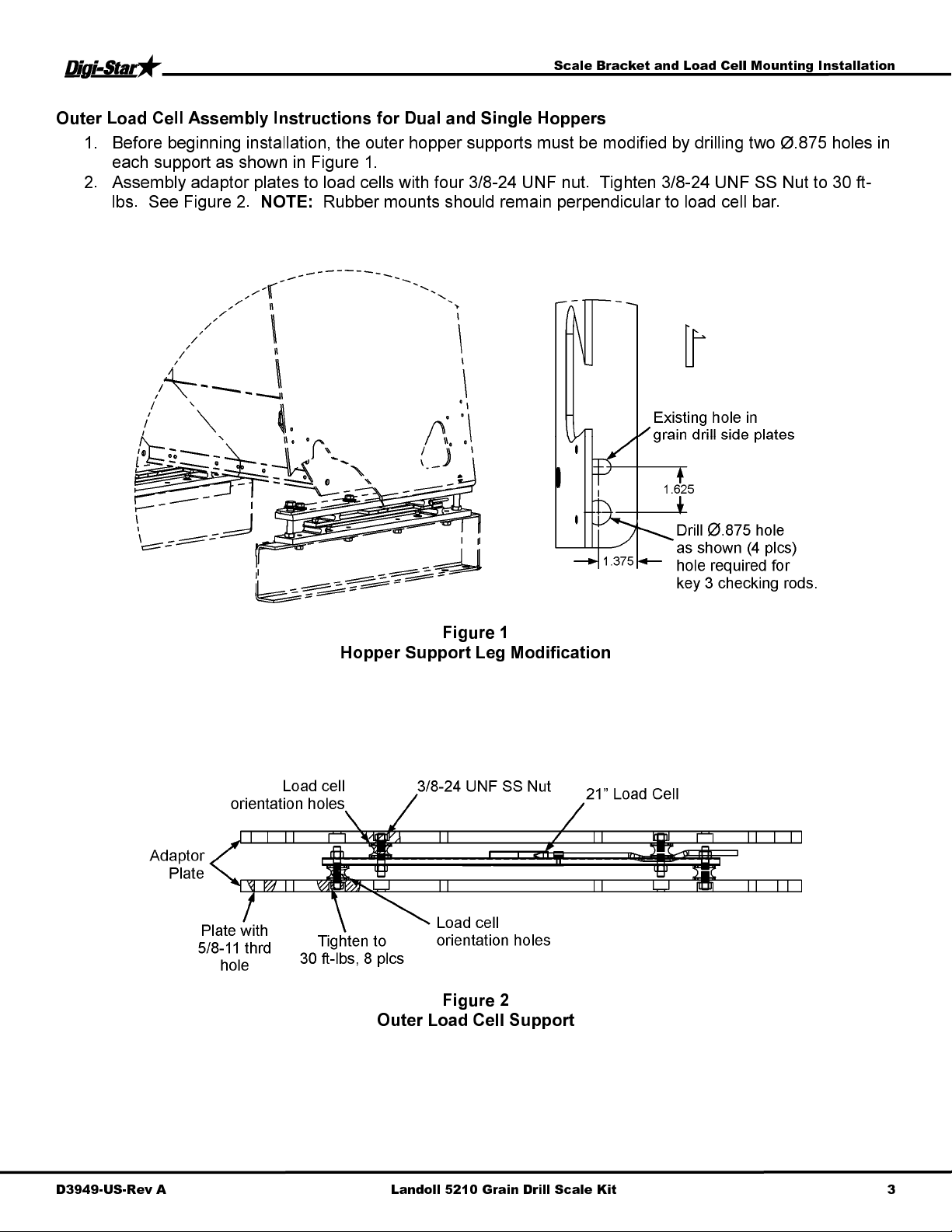

Outer Load Cell Assembly Instructions for Dual and Single Hoppers

1. Before beginning installation, the outer hopper supports must be modified by drilling two Ø.875 holes in

each support as shown in Figure 1.

2. Assembly adaptor plates to load cells with four 3/8-24 UNF nut. Tighten 3/8-24 UNF SS Nut to 30 ft-

lbs. See Figure 2.

NOTE:

Rubber mounts should remain perpendicular to load cell bar.

Figure 1

Hopper Support Leg Modification

Figure 2

Outer Load Cell Support

D3949-US-Rev A Landoll 5210 Grain Drill Scale Kit 3

Page 6

Scale Bracket and Load Cell Mounting Installation

Middle Load Cell Support Assembly Instructions For Dual Hoppers

Figure 3

1. Assemble 13" Load Cells to top and bottom middle load cell support weldment with (8) 3/8-24 UNF hex

nut. Tighten to 30 ft-lbs.

NOTE:

Rubber mounts should remain perpendicular to load cell bar.

Single Hopper Load Cell Assembly Installation

(See Figure 4)

1. On the right hopper side loosen the four 1/2" bolts that hold the seed hopper to the frame. Do not

remove hardware.

2. On the left side remove the 1/2" bolts that hold the seed hopper to the frame.

3. If possible, on the inner frame on the left side (that runs under the seed hopper) place a jack between

the frame and seed hopper. Lift the seed hopper up so that the load cell assembly can slide

underneath the hopper. It is recommended the hopper be supported by two methods when attaching

the load cells and brackets. In addition to lifting the hopper with a chain or nylon strap, the hopper

should be supported in the middle with a hydraulic jack or stands.

IMPORTANT:

The lifting chains, bucket attachments, loader/skid steer or winch must be capable of lifting and

controlling 1000 lbs.

4. Install the outer load cell and bracket assembly with 1/2 x 1.0 bolt, lock washer and flat washer between

the seed hopper and support frame. Keep the hardware loose. It may be necessary to loosen or

remove the meter drive chain.

5. Go to the right hopper side and repeat steps 2-4.

6. The seed hopper is now supported by the two outer load cells. Install the outer 5/8" x 4.0" check bolts

flat washer and 5/8" jam nut. Thread the 5/8" bolt into the lower bracket threaded hole until the check

bolts bottoms out on the main hopper support frame. Then secure with the 5/8" jam nut. The 5/8"

check rod should be centered in the top plate 7/8" diameter clearance hole. If not, loosen the (8) 1/2" x

1.0 bolts and adjust and align the top and bottom plates and retighten 1/2" x 1.0" bolts.

4 Landoll 5210 Grain Drill Scale Kit D3949-US-Rev A

Page 7

Scale Bracket and Load Cell Mounting Installation

Figure 4

Single Hopper Load Cell Assembly Installation

D3949-US-Rev A Landoll 5210 Grain Drill Scale Kit 5

Page 8

Scale Bracket and Load Cell Mounting Installation

Figure 5

Dual Hopper Load Cell Assembly Installation

1. Loosen all of the right, left and middle hopper 1/2 bolts that hold the seed hopper to the frame. Do not

remove.

2. Remove the middle hopper hardware that holds the hopper to the main frame and if possible, on the

inner frame on the right and left side (that runs under the seed bin) place a jack between the frame and

seed hopper to support the middle of both hoppers. Lift the seed hopper up so that the middle load cell

assembly can slide underneath the middle. It is recommended the hopper be supported by two

methods when attaching the load cells and brackets. In addition to lifting the hopper with a chain or

nylon strap, the hopper should be supported in the middle with a hydraulic jack or stands.

IMPORTANT:

The lifting chains, bucket attachments, loader/skid steer or winch must be capable of

lifting and controlling 1000 lbs.

3. Slide the middle load cell assembly with the support weldments between the two hopper middle

mounting flanges. Secure with mounting hardware listed in Figure 5. Keep the hardware loose. It may

be necessary to loosen or remove the meter drive chain.

4. Install the outer load cell supports and follow steps listed on page 4, steps 1 - 6.

5. After all the 4 load cells are installed Install the outer 5/8" x 4.0 check bolts flat washer and 5/8 jam nut

(qty-8 on all load cell assemblies. Thread the 5/8 bolt into the lower bracket threaded hole until the

check bolts bottoms out on the main hopper support frame. Then secure with the 5/8 jam nut. The 5/8

check rods should be centered in the top plate 7/8" diameter clearance hole. If not loosen the eight 1/2

x 1.0 bolts and adjust and align the top and bottom plates and retighten 1/2 x 1.0 bolts.

6 Landoll 5210 Grain Drill Scale Kit D3949-US-Rev A

Page 9

Junction Box Mounting

JUNCTION BOX MOUNTING

The junction box is water resistant, not water-proof. It should be mounted to avoid submersion during wet

weather and to avoid physical abuse. The junction box can be mounted on the front or rear of the drill,

planter or seeder. All load cell cables must reach the J-Box. Install by removing the double sided tape

backing and apply to thoroughly cleaned surface.

Connect Load Cell and J-Box Cable

1. Route front and rear load cell cables to J-box

location. Make sure they are not bound or

pinched. Cable tie (customer provided) load cell

cables in place.

2. Insert load cell and J-box cables through each of

the water-tight strain-reliefs.

3. Remove each terminal block from the J-box.

4. Connect wires of the same color to the same

terminal block. See instructions below.

5. Install terminal block into the J-box as shown

(location not important).

6. Tighten nuts on the water-tight strain-reliefs.

7. Assure that gasket is properly installed in the

cover.

8. Attach cover using 4 screws (provided).

Installing Wires into Terminal Block

1. Open levers 90º to locked position.

2. Insert individual wires into terminal.

3. Close lever.

4. Tug wire to assure solid connection.

Note: Wire strip length is 7/16” (11mm).

Strain

Relief

406232 J-Box Lever Nut 4Pt (Planter)

141837 Cable - 30Ft J-Box

406074 Cable - 45Ft J-Box

403335 Cable - Power 17Ft 2-Wire

406073 Cable - Power 36Ft 2-Wire

406072 Cable - Power 6Ft 2-Wire

824316 Cable - 15Ft-J-Box

145096 Cable - 70Ft-J-Box

406276 Cable – Power 65Ft 2-Wire

D3949-US-Rev A Landoll 5210 Grain Drill Scale Kit 7

Page 10

Indicator Mounting

Wire color

Wire Function

INDICATOR MOUNTING

S

INDICATOR MOUNTING

The scale indicator can be mounted in the tractor cab or on the drill with swivel mounting pack (406081). Two

cables must be connected to the indicator bottom panel, J-Box and power cables. Refer to Indicator Manual

D3831-US for details of indicator mounting options and connection of power cord.

U-BOLT MOUNTING TRACTOR CAB MOUNTING

1. Bolt the readout in the cab with the bracket, or mount the bracket in the front of the lift cylinder.

2. Install power cord to a 12-volt negative ground battery.

3. Route J-box cable to indicator and install to indicator bottom panel.

4. Program indicator with the following set-up and calibration number (see Indicator manual).

4-pt (4 Load Cells) Dual Hopper set-up #114008 calibration #1532

2-pt (2 Load Cells) Single Hopper set-up #114004 calibration #778

Power Connection:

The power cable should be connected directly to a vehicle battery or regulated power supply. The scale end of

the power cable is attached to the J901 connector located on the bottom panel of the indicator.

Connect the RED wire from the power cable to +12 VDC and the BLACK wire to GROUND. The indicator is

fused internally at 4 amps.

Power Cable Connections:

Red

Black

Battery (+12 VDC)

GROUND

Load Cell Connection:

The indicator is designed to operate with strain gage load cells. The indicator will normally be supplied with a

“J-BOX” cable going between the scale and the load cell junction box.

Load Cell Wire Digi-Star Function

1 RED +EX

2 GREEN -SIG

3 WHITE +SIG

4 BLACK -EX

5 CLEAR SHIELD

8 Landoll 5210 Grain Drill Scale Kit D3949-US-Rev A

Page 11

Trouble Shooting

TROUBLE SHOOTING

How to Check the Drill Scale After Installation

For the first test, lift the drill all the way up, to a level area. Put 200-250 pounds of weight on the right side,

then compare it to the left. Both sides should be within four to six pounds of each other.

•

If the weight is not within the four to six pound range, the drive chain might be too tight or the clutch is

binding. Loosen the chain and check the weight again.

•

If loosening the chain does not fix the problem, you must remove the clutch arm, and then check the

weight on both sides.

The second test is to lift the drill to a level area and zero the scale. Lift the drill up and down two to three times,

checking to see if the scale zeros out. Each time the scale is in the up position, it should be within four to six

pounds. If not, remove the clutch arm and repeat the test. If this solves the weigh problem, the clutch is

binding or it needs lubrication.

If further assistance is necessary, please call Digi-Star, LLC at 920-563-9700.

NOTE

NOTE

: The clutch arm needs to be on the back of the clutch to work properly.

: The clutch arm needs to be on the back of the clutch to work properly.

D3949-US-Rev A Landoll 5210 Grain Drill Scale Kit 9

Page 12

Repair Parts

REPAIR PARTS

408026 Kit – Landoll 5210 (2 PT)

KEY QTY. PART NO. DESCRIPTION

1 2 407949 PLATE-BOTTOM LANDOLL 5210

2 2 407950 PLATE-TOP LANDOLL 5210

3 4 408401 SCR - 5/8 X 4.0 HHCS ZP GRD 5

4 16 405228 SCR - 1/2-13 X 1.0 HHCS ZP GRD 5

5 16 405855 WASH-1/2 LOCK ZP

6 4 405252 WASH-5/8 FLAT NARROW ZP

7 16 405053 WASH-1/2 FLAT WIDE ZP

8 4 408402 NUT - 5/8-11 JAM NUT

9 8 146764 NUT - 3/8-24 UNF SS

10 2 408024 CELL-SW 21"-16' W/O CONN/EM

10 Landoll 5210 Grain Drill Scale Kit D3949-US-Rev A

Page 13

Repair Parts

408025 Kit – Landoll 5210 (4 PT)

Outer Load Cell Support

KEY QTY. PART NO. DESCRIPTION

1 2 407949 PLATE-BOTTOM LANDOLL 5210

2 2 407950 PLATE-TOP LANDOLL 5210

3 8 408401 SCR -5/8-11 X 4.0 HHCS ZP GRD 5

4 24 405228 SCR - 1/2-13 X 1.0 HHCS ZP GRD 5

5 24 405855 WASH-1/2 LOCK ZP

6 8 405252 WASH-5/8 FLAT NARROW ZP

7 32 405053 WASH-1/2 FLAT WIDE ZP

8 8 408402 NUT - 5/8-11 JAM HEX ZP

9 16 146764 NUT - 3/8-24 UNF SS

10 2 408024 CELL-SW 21"-16' W/O CONN/EM

D3949-US-Rev A Landoll 5210 Grain Drill Scale Kit 11

Page 14

Repair Parts

408025 Kit – Landoll 5210 (4 PT)

Middle Load Cell Support

KEY QTY. PART NO. DESCRIPTION

1 1 408019 WELD-MIDDLE TOP SUPPT LANDOLL

2 2 408023 WELD-MIDDLE BOTTOM LANDOLL

3 8 408401 SCR - 5/8-11 X 4.0 HHCS ZP GRD 5

4 8 406459 SCR -1/2-13 X 1.5 HHCS ZP GRD 5

5 24 405228 SCR - 1/2-13 X 1.0 HHCS ZP GRD 5

6 8 405252 WASH-5/8 FLAT NARROW ZP

7 24 405855 WASH-1/2 LOCK ZP

8 32 405053 WASH-1/2 FLAT WIDE ZP

9 8 408402 NUT - 5/8-11 JAM HEX ZP

10 8 406085 NUT-1/2-13 SER FLANGE ZP

11 16 146764 NUT - 3/8-24 UNF SS

12 2 408027 CELL-SW 13"-12' W/O CONN/EM

12 Landoll 5210 Grain Drill Scale Kit D3949-US-Rev A

Page 15

Repair Parts

PART

PART

Indicator Swivel Mount

406629

406385

KEY QTY.

NO. DESCRIPTION KEY QTY.

1 1 403180 Assembly – 1” Ram Mount 1 1 404230

NO. DESCRIPTION

Ram Suction Cup with

Twist Lock

2 1 403179 Mount Base - 1" Ball U-Bolt 2 2 403180 Assembly – 1” Ram Mount

3 4 403779

Scr - #10 x 5/8 PHSTS 48-

2 Blk ZP

3 2 403779

Scr - #10 x 5/8 PHSTS 48-2

Blk ZP

D3949-US-Rev A Landoll 5210 Grain Drill Scale Kit 13

Page 16

License Agreement

as otherwise provided by separate documentation

Use or sale of the Licensed Product o

r of Purchased Product shall bind Customer to all terms and

LICENSE AGREEMENT

IMPORTANT NOTICE: Acceptance and use of the enclosed electronic scale products (hereinafter referred to as “Purchased

Product”) constitutes your agreement to the following terms and conditions. Please carefully read the following terms and

conditions before using or reselling the Purchased Product.

1. Limited License. Digi-Star, LLC, a Wisconsin limited liability company

(“Owner”) is the owner of the following U.S. Patents related to grain

drills: 6,732,667, 7,059,258, 7,273,017, 7,357,087, 7,448,335, 7,523,710

and any other patents which result from continuation applications thereof

(“Patents”). Owner hereby grants to the customer (“Customer”) a non-

exclusive, non-transferable, revocable, limited license to use the

technology described in the Patents to use the Purchased Product to

assemble a seed planter product covered by the Patents (“Licensed

Product”), and to sell and offer for sale one (1) unit of the Licensed

Product in accordance with the terms and conditions set forth herein.

Alternatively, Customer may resell the Purchased Product to another

entity for the purpose of that entity assembling one (1) unit of a Licensed

Product under a permitted sublicense from the Customer with the same

terms as this Agreement. If Customer would like to assemble, use, sell or

offer for sale more than one (1) Licensed Product, or resell more than

one (1) Purchased Product, Customer understands and agrees that it must

purchase another Purchased Product from Owner or acquire a separate

license by requesting and purchasing another unit of the same SKU

number that resulted in this purchase.

2. Acceptance of Terms and Conditions. Customer warrants that it has the

authority to enter into this binding agreement. If Customer does not

accept the terms and conditions, Customer shall not use the Purchased

Product. Customer understands and agrees that if it uses the Purchased

Product as permitted herein, it will be deemed to have accepted these

terms and conditions and they shall become a binding agreement.

3. Limitations on Use. Customer agrees that it will use the Licensed

Product only as expressly authorized in this Agreement, and that any use

not expressly authorized in this Agreement is prohibited. Customer

agrees that it will not: (i) loan, rent, lease, assign, sublicense, distribute or

otherwise transfer its rights under this Agreement to a third party, other

than to resell the Purchased Product to another entity for the purpose of

that entity assembling one unit of a Licensed Product; (ii) copy or

reproduce the Licensed Product; or (iii) grant any sublicenses other than

to an end user of the Licensed Product, or to another entity for the

purpose of that entity assembling one unit of a Licensed Product.

Customer agrees to use reasonable efforts to prevent any unauthorized

use or copying of the Licensed Product and will notify Owner

immediately upon learning of any such unauthorized use or copying.

Customer’s obligations under this section shall survive any termination

of this Agreement or the license granted hereunder. Any unauthorized

use of the Licensed Product will result in, among other things, the

immediate termination of this license.

4. Ownership of Proprietary Rights. Customer acknowledges that the

Licensed Product is covered intellectual and/or proprietary rights, and

that all such intellectual and proprietary rights are owned by Owner.

Customer hereby acknowledges that it has no rights in the

foregoing except as expressly granted herein.

5. NO WARRANTY. Customer agrees to fully test and evaluate the

Purchased Product and Customer acknowledges and agrees that

Owner will not assume any product liability or any other liability

for the Purchased Product or the Licensed Product. The

Purchased Product is furnished to Customer “AS IS.”

Except

OWNER MAKES NO WARRANTIES, EITHER

EXPRESS OR IMPLIED, WITH RESPECT TO THE

PURCHASED PRODUCT. Customer agrees that Owner

shall have no liability resulting from Customer’s use of

the Purchased Product for any indirect damages including

consequential, incidental or special damages for loss of

profit, good will or otherwise. Customer shall indemnify

and hold Owner harmless from any and all losses,

expenses, damages, costs or expenses of any kind,

including but not limited to reasonable attorneys’ fees,

incurred by Owner resulting from Customer’s use of the

Purchased Product. NO ORAL OR WRITTEN

STATEMENTS MADE BY OWNER OR ITS

EMPLOYEES INCLUDING BUT NOT LIMITED TO

STATEMENTS REGARDING CAPACITY,

SUITABILITY FOR USE, OR PERFORMANCE OF

THE PURCHASED PRODUCT SHALL BE DEEMED A

WARRANTY OR REPRESENTATION BY OWNER

FOR ANY PURPOSE NOR GIVE RISE TO ANY

LIABILITY OR OBLIGATION OF OWNER.

6. Remedies for Violations. Owner reserves the right to seek

all remedies available at law and in equity for violations

of this Agreement, including but not limited to the right to

recover the Licensed Product.

7. Fees. In consideration for the rights granted under this

Agreement, Customer has paid a license fee that was

included in the amount invoiced to the Customer for the

sale of the Purchased Product.

8. Entire Agreement. Except as expressly stated herein to the

contrary, this Agreement constitutes the entire agreement

between the parties regarding the subject matter hereof,

and no verbal or written prior statements or

representations of any sort made by any party shall be

effective or valid for any purpose whatsoever. This

Agreement may be amended only upon the mutual

consent of all parties in writing.

9. Severability. If any provision of this Agreement shall be

held to be invalid, illegal or unenforceable, the validity,

legality and enforceability of the remaining provisions

shall not in any way be affected or impaired thereby. The

failure of any party to enforce any provision of this

Agreement shall not be considered a waiver thereof, nor

shall such failure prevent the future enforcement of any

such provision.

10. Governing Law. This Agreement and the relationship

between the parties shall be governed in all respects by the

laws of the State of Wisconsin and the United States of

America. The parties consent to the jurisdiction and venue

of the Wisconsin and United States courts located in

Wisconsin for resolution of any dispute under to this

Agreement.

,

conditions herein without the necessity of signatures on this Agreement.

14 Landoll 5210 Grain Drill Scale Kit D3949-US-Rev A

Loading...

Loading...