Page 1

EZ4600

Operators Manual

HELLO

Ft. Atkinson, Wisconsin USA

Panningen, The Netherlands

www.digi-star.com

D3716-US REV A April 14, 2008

Page 2

EZ4600

Table of Contents

FEED MANAGEMENT SOFTWARE.............................................................. 4

CAB CONTROL (WIRELESS)........................................................................ 5

BEFORE CHARGING BATTERY OR WELDING .......................................... 6

INDICATOR OVERVIEW................................................................................ 7

OPERATION................................................................................................... 9

TURN ON INDICATOR............................................................................... 9

DATA TRANSFER........................................................................................ 10

DATAKEY MODE...................................................................................... 10

RF DATALINK MODES ............................................................................ 10

INDICATOR DATA FORMATS ................................................................. 11

LOADING AND FEEDING............................................................................ 11

COMPLETE LOADS MODE......................................................................... 11

STARTING A RECIPE .............................................................................. 11

RESIZE RECIPE WEIGHT ....................................................................... 12

LOADING RECIPE.................................................................................... 13

UNLOADING TO PENS............................................................................ 14

RECIPE AND PEN LIST MODE................................................................... 15

STARTING A RECIPE .............................................................................. 15

LOADING RECIPE.................................................................................... 16

UNLOADING PENS.................................................................................. 16

ADVANCED COMMANDS ........................................................................... 17

UNLOAD PARTIAL PENS ........................................................................ 17

GO BACK TO SKIPPED INGREDIENT.................................................... 17

CHANGE FEEDING NUMBER ................................................................. 18

USE ARROW KEYS RECIPE OR PENS LIST......................................... 18

CLEAR INDICATOR MEMORY ................................................................ 19

RE-USE RECIPE AND PEN DATA .......................................................... 19

ADD A PEN TO PEN LIST........................................................................ 20

HOLD ........................................................................................................ 21

PRINTING..................................................................................................... 21

BACKLIGHT INTENSITY.......................................................................... 21

COMMONLY USED DIRECT ACCESS NUMBERS .................................... 22

PRE-ALARM ............................................................................................. 22

AUTO INGREDIENT / MANUAL PEN ADVANCE.................................... 22

AUTO ADVANCE...................................................................................... 23

TOLERANCE ............................................................................................ 23

PEN TOLERANCE.................................................................................... 23

DELAY TIME............................................................................................. 23

DRIVE RATIO ........................................................................................... 24

SCALE ID OR TRUCK ID ......................................................................... 24

RADIO NUMBER ...................................................................................... 25

RESIZE OPTION ...................................................................................... 25

CHANGE TIME ......................................................................................... 26

CHANGE DATE ........................................................................................ 26

2 D3716

Page 3

Operators Manual

DIRECT ACCESS NUMBERS LIST .............................................................27

MENU 1. BASIC FEATURES IN MOST INDICATORS ............................27

MENU 2. CLOCK, PRINTER, COMMUNICATIONS & ESTIMATED

WEIGHT FEATURES ................................................................................ 27

MENU 3. SCALE CALIBRATION SETTINGS........................................... 28

MENU 4. PRESET. BATCHING & ROTATION COUNTER FEATURES . 28

CALIBRATION........................................................................................... 29

TROUBLESHOOTING ..................................................................................30

INSTALLATION............................................................................................. 32

INDICATOR MOUNTING .......................................................................... 32

LOAD CELL DIRECTION.......................................................................... 32

CABLE CONNECTION.............................................................................. 33

CONNECT LOAD CELLS TO J-BOX........................................................ 34

CHANGE SETUP AND CALIBRATION NUMBERS ................................. 34

OPTIONAL EQUIPMENT.............................................................................. 35

ROTATION COUNTER SENSOR............................................................. 35

TRANSMITTER/RECEIVER...................................................................... 35

REMOTE INDICATORS............................................................................ 35

D3716 3

Page 4

EZ4600

FEED MANAGEMENT SOFTWARE

A full featured WindowsR based system that

offers powerful features that are easy to use.

Entry level system easily upgraded.

Based on features of TMR Tracker

Remote site monitoring software.

Works with email service to connect

Tracker to remote location

Front-end tool for beef feeding customers

to enter ingredient, recipe, corral and

wagon information.

For additional information go to www.digi-star.com

4 D3716

Page 5

Operators Manual

CAB CONTROL (WIRELESS)

Features

• Wireless remote with full key control of indicator on mixer

• Mount remote in easy view of loading

• Improves loading accuracy

Functions

• Communicates with multiple mixers

• Easily call-up recipes without leaving loader

Specification

• Internally mounted 2.4 GHz radios

• Up to 1000 foot range

• 24 channels

• 12 or 24 volt DC system

For additional information go to www.digi-star.com

D3716 5

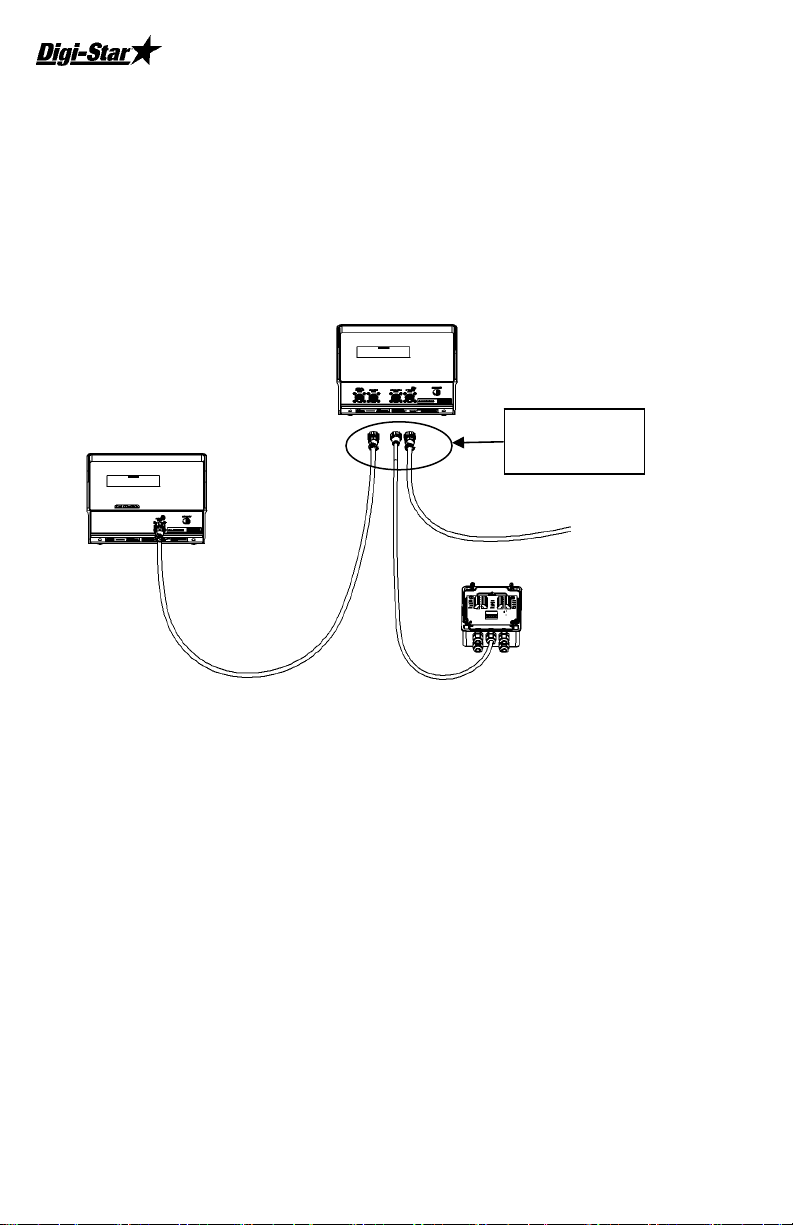

Page 6

EZ4600

BEFORE CHARGING BATTERY OR

WELDING

Important Precaution

Disconnect all indicator leads before charging battery or welding.

Damage may occur to indicator and load cells.

Scale Indicator

Remote Indicator

Optional

Disconnect

all cords

J-Box

6 D3716

Page 7

Operators Manual

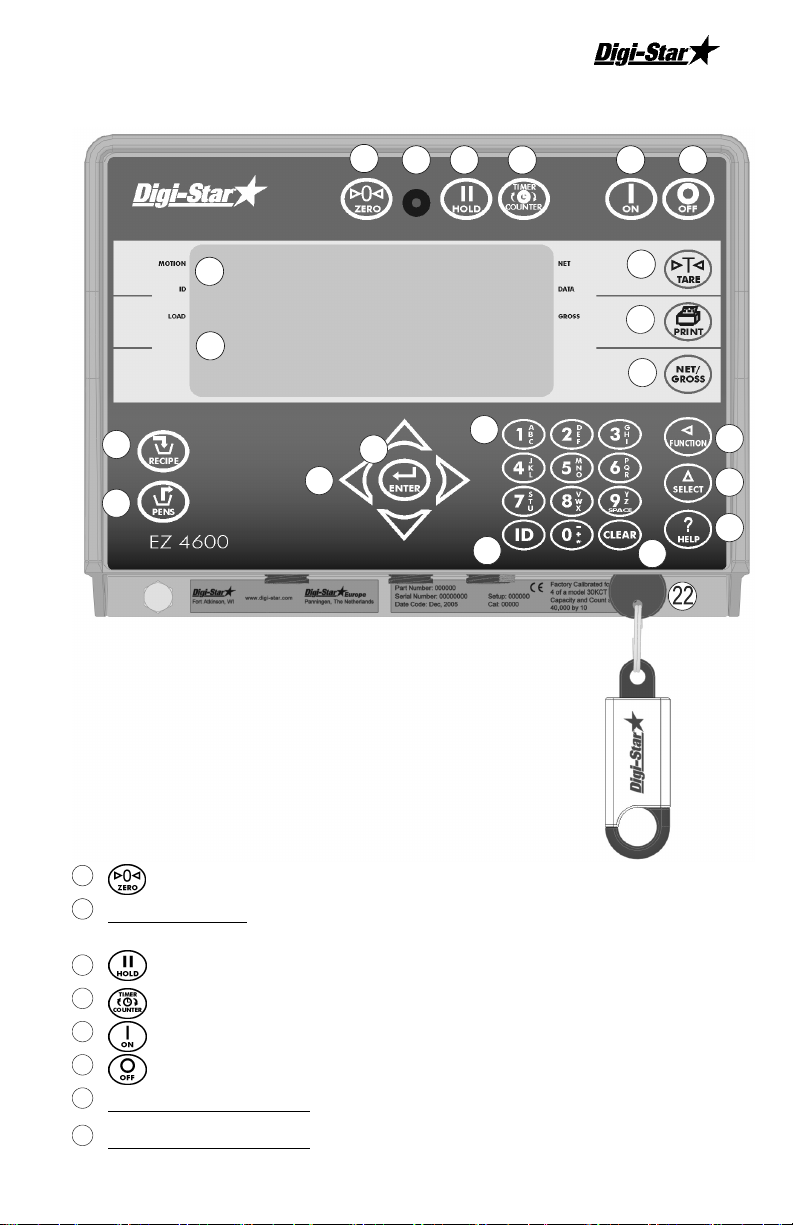

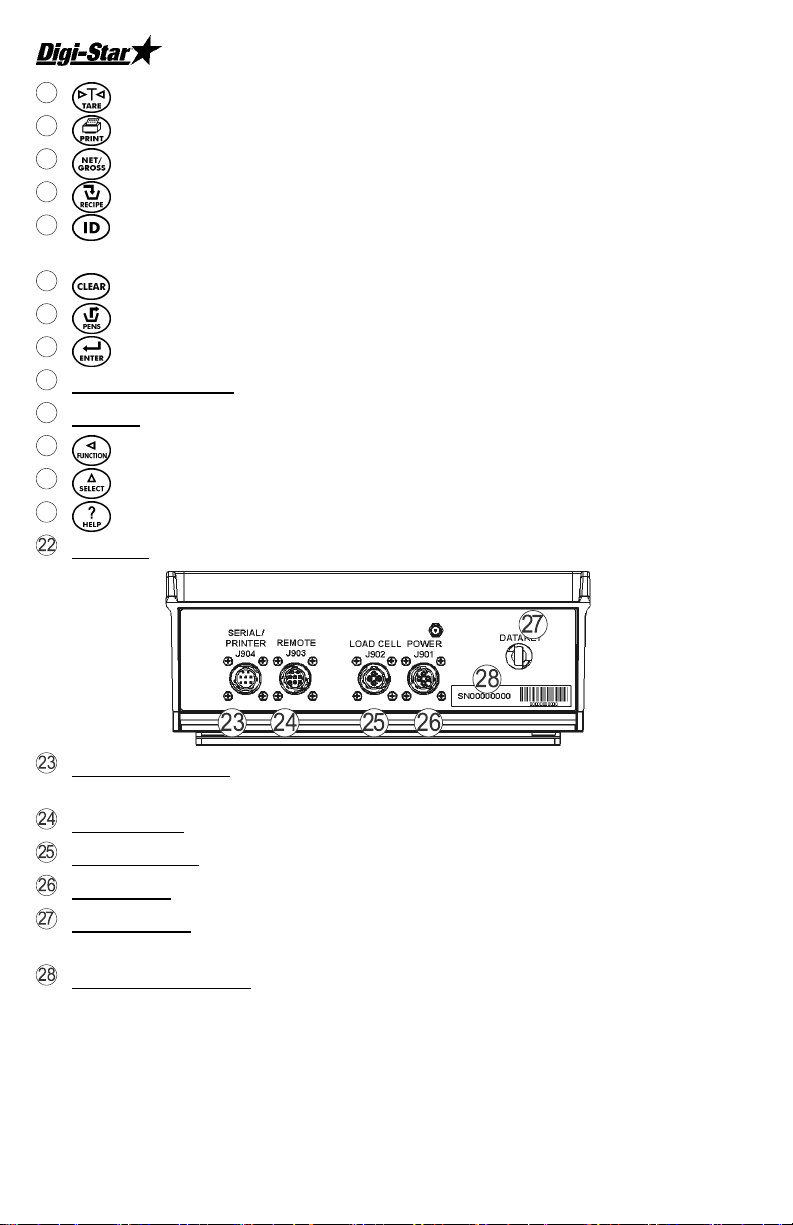

INDICATOR OVERVIEW

7

8

12

17

15

Note: See page 32-34 for

installation instructions

1

16

3

2

4

5 6

9

10

11

18

13

14

19

20

21

1

-press and hold for 3 seconds to zero balance indicator.

2

Pre-Alarm Light – Flashes and alarm sounds when weight is within

preset limit. See page 22

3

– holds displayed weight when moving machine.

4

– not used.

5

– - turns indicator on, press quickly 2 times to run self test.

6

- turns indicator off.

7

Upper Display Window – Displays current actions.

8

Lower Display Window – Lists 3 lines (i.e. ingredients, recipes, pens).

D3716 7

Page 8

EZ4600

9

- temporary zero (Net Mode).

10

- records to memory or prints displayed weight.

11

- toggles between Net and Gross weights.

12

- selects recipes in memory.

13

- enter user number and feeding number. Any number can be used

for user until number assigned by management software.

14

–Clear (backspace).

15

– press in List Mode to begin pen unloading. See page 16

16

– accepts change or proceeds to next item.

17

Directional Arrows - moves through list of information.

18

Keypad – inputs numbers or letters as required.

19

– performs the task displayed by select.

20

– displays additional tasks.

21

– press for additional information.

DataKey – Used for data transfer between computer and indicator.

Serial/Printer Port – optional, to communicate with computer and other

digital input/output devices.

Remote Port – optional, for remote display.

Load Cell Port– for J-Box cord.

Power Port – for power cord.

DataKey Port– for DataKey insertion. Turn DataKey to upload/download

data.

Serial Number Plate – Serial Number of indicator.

8 D3716

Page 9

Operators Manual

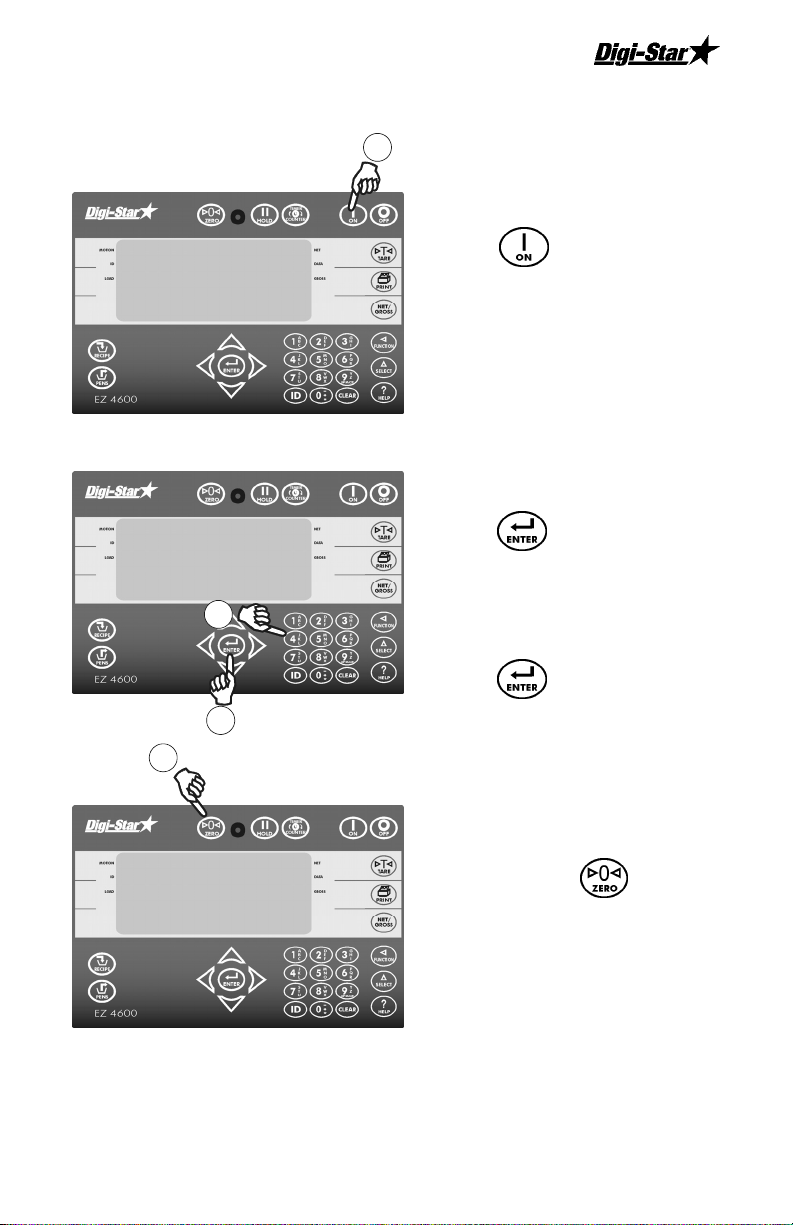

O

OPERATION

Turn on indicator

HELL

Digi-star

Feed delivery system

1

1. Press .

1. Enter ID Number if required.

ENTER user id

ENTER ID NUMBER ON KEYPAD

PRESS ID KEY TO USE SCALE

1

10:41A 2JL07

PRESS RECIPE TO LOAD

2. Press .

1

2

0

1. Enter Feeding Number (only req’d

st

time in loads mode).

1

2. Press .

1. Press and hold for 3 seconds

to zero balance indicator.

D3716 9

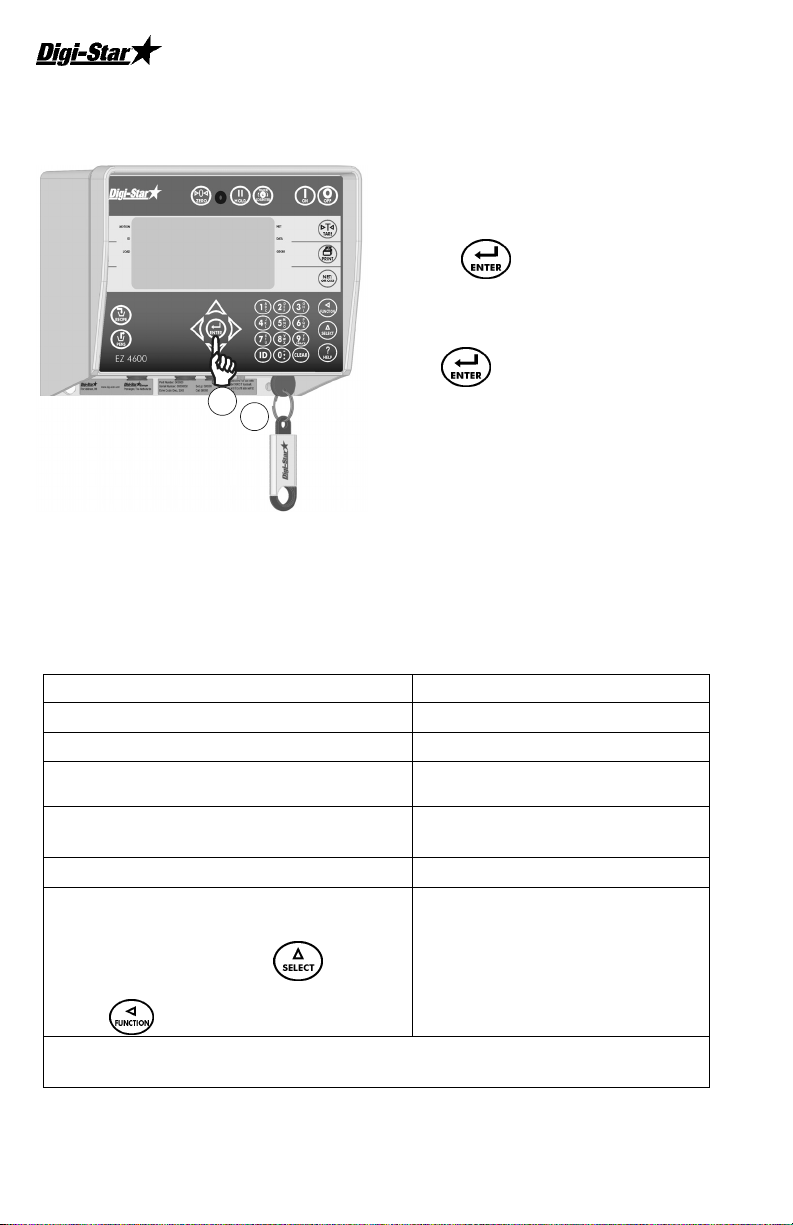

Page 10

EZ4600

DATA TRANSFER

DataKey Mode

2

1

RF DataLink Modes

Operation Message

DataLink connects with indicator

DataLink sends data to indicator

Indicator receives data

Data compete, indicator sends data to

DataLink

Data sending

To send data to PC if operator does

not complete all feeding at end of

feeding schedule. Press until

display shows message (right column),

press to select

The indicator marks uncompleted data as completed and sends feeding

data to DataLink.

Note: After sending, uncompleted data erased.

To upload data:

1. Insert DataKey turn clockwise.

2. Press .

Note: If indicator displays

uncompleted data in memory,

press to overwrite

uncompleted data.

Remove DataKey when transfer

complete.

To download data:

Insert DataKey, turn clockwise,

indicator automatically sends data to

DataKey. Remove DataKey.

←PC→

DL←IN

ALL FEED LINES RECIVED -PRESS

RECIPE KEY TO CONTINUE

←PC→

DL→OUT

EZ→PC

10 D3716

Page 11

Operators Manual

k

-

Indicator Data Formats

Complete Loads Mode: Each load built by PC software. It assigns pens to a

recipe and builds exact load for pens.

Recipe and Pen List Mode: PC software sends recipe data and pen data in

two different fields. Operator selects recipe to build and pen deliveries.

LOADING AND FEEDING

COMPLETE LOADS MODE

Starting A Recipe

1

0

10:41A 2JL07

PRESS RECIPE TO LOAD

1

3

Milk- 6

Fresh- 5

Mil

1

Feeding 1

1. Press .

1. Indicator scrolls feeding number,

first recipe and pen number.

Recipes listed below.

2. Press

desired recipe.

and to find

3. Desired recipe in upper display

line, press .

2

D3716 11

Page 12

EZ4600

Resize Recipe Weight

23000

Enter number of animals

To feed pen 6

Animal 230 preset 20643

1

Indicator gives option to resize pen

load weight.

1. Enter a new weight or keep original

weight.

2. Press .

2

Note: Press to resize by

number of

Note: Press to accept pen

values without resizing.

Note: If indicator warns resized

amount is over capacity, press

to override.

head in pen.

12 D3716

Page 13

Operators Manual

f

Loading Recipe

2

Alfal

Fd- 1 ctr- 000 ing alfa

2n-0-rec milk pre-2760

6 o use advance to log

1

3

Displayed when in load or unload mode.

Line 1:

feeding number: FD-2

number of rotations during pen delivery: CTR-000 (RC option only)

pen name: PEN-1

Line 2:

zone number: ZN-1

name of recipe: REC-PREFRE

call weight of pen: PRE-1200

Line 3:

gross weight: G-10000

Instruction data: USE ADVNCE TO LOG

1. First ingredient weight flashes in

upper display, load ingredient.

2. Weight approaches zero, alarm will

flash and sound.

3. a. Manual Advance: Weight

reached, press to accept.

Press again to start next

ingredient.

or

3. b. Auto Advance: When preset

weight reached, indicator

advances to next ingredient.

D3716 13

Page 14

EZ4600

s

Unloading to Pens

Start deliverie

Pen 6 pre- 20640

1

Note: Do not press .

Note:

If different pen needed press

or to find desired pen.

Press for pen delivery.

Ingredients loaded, indicator displays

first pen to unload.

1. Manually advancing, press

st

for 1

pen. When weight reached

press to accept. Press

again to start next pen.

or

1. b. Auto Advance: When preset

weight reached, indicator

advances to next pen.

Last pen complete, indicator

displays: “Recipe Complete”

14 D3716

Page 15

Operators Manual

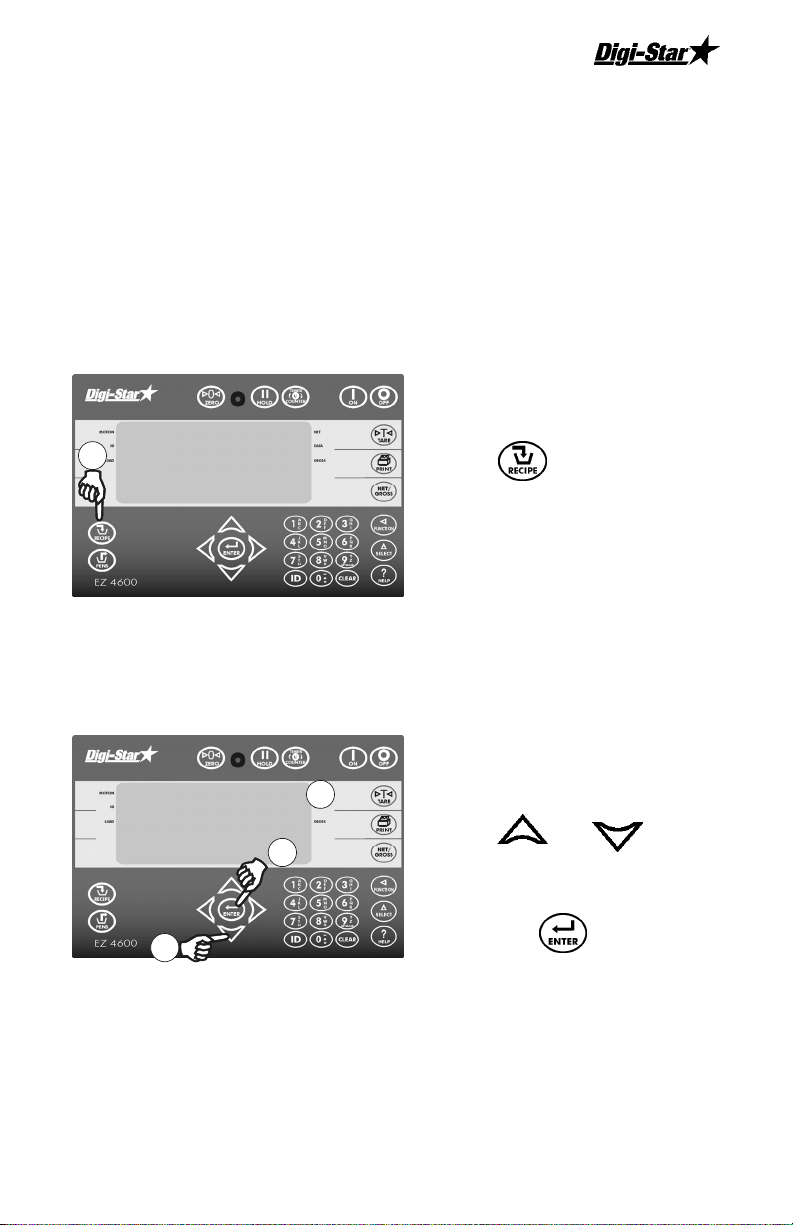

RECIPE AND PEN LIST MODE

Starting a Recipe

1. Press : .

2

Recipe - ri

R1 - 25000 TOt 5000

R2 – 20000 tot – 18000

R3 – 20000 tot - 10000

1

3

4

25000

Enter amount to be loaded

25000 tot - 50000

6

5

2. Display reads:

Example:

Line 1:

Line 2: R1 - 25000 TOT- 50000

Line 3: R2 - 20000 TOT-18000

Line 4: R3 - 20000 TOT- 10000

3

3. Press

recipe, to start.

Indicator will display: RESIZE, then the

resize weight.

4. Display reads:

Example:

Line 1: 25000

Line 2: Enter load amount

Line 3: (No Data)

Line 4: R1 - 25000 TOT- 50000

5. Enter the amount to build in this

load.

6. Press ..

Recipe R1

and to select

D3716 15

Page 16

EZ4600

Loading Recipe

2

Alfalf

3

Unloading Pens

4

Pen 1

5

3

1. First ingredient and weight flash in

upper display. Begin loading

ingredient.

2. Weight reached, alarm will flash

1

and sound.

3. a. Manual Advance: Weight

reached, press .

Press to start next

ingredient.

or

3. b. Auto Advance: When preset

weight reached, indicator

advances to next ingredient.

1. When ingredient loading complete,

display reads “Recipe Complete”.

Press . Indicator displays

unloading pens.

2. Press or to select

desired pen.

6

1

16 D3716

2

3. Press .

4. Pen and weight displayed, begin

unloading to pen.

5. a. Manual Advance: Weight

reached, press to accept.

Press again to start next

pen.

or

5. b. Auto Advance: When preset

weight reached, indicator

advances to next pen.

6. When unloading is complete

press to start next recipe.

Page 17

Operators Manual

ADVANCED COMMANDS

Unload Partial Pens

1

Go Back To Skipped

Ingredient

1. Press to advance to next

pen without finishing current pen.

Note: If pen tolerance is set and

feeding stopped before preset weight

reached, alarm sounds, indicator

displays:

Pen Underfed – Press Print

To remove pen from list-

Press on to keep pen

See page 23 for Pen Tolerance setup.

1. Press or to move

back.

2. Press .

2

1

D3716 17

Note: Ingredient weight changed

more than 4 display counts cannot

restart that ingredient.

Example: If minimum display change

is 10 lbs/kgs, more than 40 lbs/kgs,

cannot restart that ingredient.

Page 18

EZ4600

Change Feeding Number

4

2

5

3

1

Use Arrow Keys Recipe or

Pens List

Press advance

Ing-cluhay pre- 2850

Ing-cornsi pre- 9690

Ing-311pel pre- 3140

1

1

1. Press .

2. Enter user number.

3. Press .

4. Enter feeding number (1-9).

5. Press .

1. Press or to move list

three lines at a time.

18 D3716

Page 19

Operators Manual

r

e

Clear Indicator Memory

4

3

On=Clea

Digi-star

Feed delivery system

Re-Use Recipe and Pen

Data

3

1. Press .

2. Press and hold .

1

3. Press continue holding

indicator reads:

On=Clear Clear=Reuse Net=exit.

Release .

4. Press to erase feeding

memory.

2

3

1. Indicator .

1

2. Press and hold .

3. Press continue holding

Clear=reus

Digi-star

Feed delivery system

indicator scrolls:

On=Clear Clear=Reuse Net=exit.

Release .

Note: When re-using data stored in indicator, it takes recipe and pen

information and removes completed weights loaded or unloaded and marks

them undone. It will not accumulate data day to day. Download data to

DataKey before re-using recipe and pen data stored.

Note: For continuous re-use, set D.A.N. 466 to on. See page 29.

D3716 19

3

4

2

4. Press again to re-use recipe

and pen data.

Page 20

EZ4600

Add a Pen to Pen List

calf

1. Enter pen name or number.

10:29a 08aug07

Press recipe to load

2

Recipe calf

Calf select recipe

Clsups

drycow

2

1

Enter amount to be

unloaded

2

3

3000

2. Press .

3. Press .

1

1. Press or to find

desired recipe.

2. Press .

1. Enter amount to unload to pen.

2. Press .

1. Enter number of animals / pen.

2. Press .

1

Enter zone 0-9

2

20 D3716

1

1. If zones are active display reads:

“Enter Zone 0-9”

2. Press .

Page 21

Operators Manual

6

Hold

Hold mode prevents displayed

weight from changing while moving.

HOLD

1

Feed 1- ctr 000 Pen

2n-0-rec-milk pre

20640

2

PRINTING

Backlight Intensity

1. Press .

2. Press indicator normal.

If weight added in hold mode,

press to cancel hold.

1. Reference technical manual D3648

at www.digi-star.com.

1. Press until dimmer is

displayed.

2. Press . to reduce backlight

2

1

D3716 21

intensity by 60%.

Press again for full

intensity.

Page 22

EZ4600

COMMONLY USED DIRECT ACCESS

NUMBERS

Pre-Alarm

Select weight or percentage method,

enter value to activate early warning

indicator reaching preset.

11:38a 08aug07

Press recipe to load

Press pens to deliver

4

1

Auto Ingredient / Manual

Pen Advance

Ingredients automatically advance

pens manually advance.

11:38a 08aug07

Press recipe to load

Press pens to deliver

1

4

401

461

3

1

2

3

1. Enter 401 and press .

2. Press again to change

between WEIGHT and PERCENT.

3. Press .

4. Enter Pre-Alarm value.

Press .

1. Enter 461 and press .

2. Press , choose on/off.

3. Press .

22 D3716

2

1

Page 23

Operators Manual

Auto Advance

Allows hands free operation of programmed recipes. When auto advance

feature activated, indicator automatically advances to next ingredient once

tolerance, and delay time requirements met.

Tolerance

11:38a 08aug07

Press recipe to load

Press pens to deliver

2

442

1

1. Enter 442 and press .

Press again to choose

desired percentage. Percentage

settings:

OFF, 0.5, 1 - 5, 7, or 10.

1

2. Press .

Pen Tolerance

Available in List Mode Only.

4

2

462

1

3

1

Delay Time

Changes time indicator waits before

automatically advancing to next

ingredient.

2

443

11:38a 08aug07

Press recipe to load

Press pens to deliver

1

1

1. Enter 462 and press .

Press again to choose weight

or percent.

2. Press , screen will display

“pentol”.

3. Enter weight or percentage

desired.

4. Press .

1. Enter 443 and press .

Press again to select delay

time (In seconds: Manual, 1, 2, 3,

5, 7, 10, 20, 30, or 60).

2. Press .

Note: Set to Manual prevents

automatic advance.

D3716 23

Page 24

EZ4600

Drive Ratio

Drive ratio is number of turns seen

by sensor divided by number of

mixing rotations.

2

422

11:38a 08aug07

Press recipe to load

Press pens to deliver

1

1

Scale ID or Truck ID

Each indicator has scale ID.

108

11:38a 08aug07

Press recipe to load

Press pens to deliver

3

1

1

1. Enter 422 and press to enter

drive ratio value.

2. Press .

1. Enter 108 and press .

2. Press to erase old ID, enter

new ID.

3. Press .

Note: TMR Tracker or Diet

Manager, software ID must match.

2

24 D3716

Page 25

Operators Manual

Radio Number

3

231

11:38a 08aug07

Press recipe to load

Press pens to deliver

2

1

1

2

Resize Option

Make weight change to pen unload

weight or recipe load size.

448

11:38a 08aug07

Press recipe to load

Press pens to deliver

2

1

1

1. Enter 231 and press .

2. Press to erase number,

enter new number.

3. Press .

Note: Do not use same number for

two different indicators.

1. Enter 448 and press ,

press again choose on/off.

2. Press .

D3716 25

Page 26

EZ4600

Change Time

11:36:53

11:38a 08aug07

Press recipe to load

Press pens to deliver

3

2

Change Date

080807

11:38a 08aug07

Press recipe to load

Press pens to deliver

2

4

1

1

3

1

1. Enter 202 and press .

2. Press to move cursor.

3. Press sets time.

4. Press .

1. Enter 204 and press .

2. Press to move cursor. Format

ddmmyy, set date.

3. Press .

1

26 D3716

Page 27

Operators Manual

DIRECT ACCESS NUMBERS LIST

Enter D.A.N. press displays setting name, allows value change.

Press to save setting.

SETTING/

DISPLAY

D.A.N

NO.

OPTIONS

(BOLD=DEFAULT)

DESCRIPTION

MENU 1. BASIC FEATURES IN MOST INDICATORS

LANGUAGE

{langag}

TR HOLD

{ tr hld}

SCALE ID SETUP

{scalid}

English(

(

French (

Dutch(

101

107

108 NEW EZ

Italian (

Portuguese (

Spanish (

Danish (

(

(

ON/OFF

ENGLSH)

NEDERL)

FRANCS)

DEUTSH)

ITAL)

ESPAN)

DANSK)

MAGYAR)

VESTA)

Select language to be displayed

PORT)

Display gross weight if TR key is

held for 3 seconds.

Identity of scale location (truck id

or Mixer number).

MENU 2. CLOCK, PRINTER, COMMUNICATIONS &

ESTIMATED WEIGHT FEATURES

TIME FORMAT

{time f}

1 TIME

{time)

DATE FORMAT

{date f}

DATE

{date}

SCALE NUMBER

SCL NO

201

202 XX:XX:XX

203

204 Enter XXXXXX

231

24 HR

AM/PM

1-mm-dd

2-mm/dd/yy

3-mm/dd/yyyy

4-dd-mm

5-dd/mm/yy

6-dd/mm/yyyy

7-ddmoyy

8-ddmoyyyy.

Select time format -AM/PM or 24

hour

Select key changes time,

function key chooses hh:mm:ss.

Select date format

Select key changes date function key chooses mm/dd/yy .

Select scale number for cab

control communication

.

D3716 27

Page 28

EZ4600

SETTING/

DISPLAY

REMOTE

DISPLAY RMDISP

D.A.N

NO.

234

OPTIONS

(BOLD=DEFAULT)

DESCRIPTION

Select type of remote display

MENU 3. SCALE CALIBRATION SETTINGS

DISPLAY UNIT

{lb-kg}

MIMIC TYREL

{tc1300}

303

321

LB/KG

OFF/ON

Display pounds -lb or kilograms kg

If ON -records preset weights like

a TYREL TCX-1300 indicator.

Indicator Tracks gross weight

while batching.

MENU 4. PRESET. BATCHING & ROTATION

COUNTER FEATURES

Select weight or percentage

method, then enter a value to

activate an early warning that

indicator is reaching the preset.

ALARM BUZZER -allows user to

turn off alarm horn.

Select time or mixer revolutions

to decrement mix timer/counter.

Enter the number of input pulses

that equal 1 mixer revolution.

Select batch 1-amount/animal

2-percent/load

3- amount/load

Select tolerance weight

percentage to accept ingredient.

Select seconds to delay before

advancing to next ingredient.

If ON -operator must enter user

ID to use indicator.

If ON -operator can change

recipe size.

If ON -prevents auto-advancing if

preset exceeds tolerance

Select feed zone for recipe

deliveries.

If ON -displays all incomplete

recipes or enable if indicator is

stationary mixer/batch when

using Datalink.

PRE ALARM

{p mthd} & {p-alm} ..

BUZZER

{buzzer)

TIMER/

COUNTER

{tmrctr)

DRIVE RATIO

{dratio}

ENTRY METHOD

E MTHD

TOLERANCE

{toler)

INGR. ADVANCE

DELAY

{delay)

FORCE USER ID

{userid}

RESIZE RECIPE

{resize}

TOLER OVER

LOCK

{overlk}

FEED ZONE

{fdzone}

UNDONE

RECIPES

{undn 1}

401

404

421

422

441

442

443

446

448

453

454

455

WEIGHT

PERCNT

1-4, ON/OFF

REV

TIME

0001.00

1,2,3

OFF,.5,1-5,7,10

MANUAL, 1-

3,5,7, 10,20,30,60

ON/OFF

ON/OFF

ON/OFF

ALL, 1-9

ON/OFF

28 D3716

Page 29

Operators Manual

SETTING/

DISPLAY

AUTO START

PENS

{autpen)

MANUAL PEN

ADVANCE

{manpen)

PEN TOL

{t mthd} & {pentol}

PEN WEIGHT

{pen wt}

DOUBLE KEY

PRESS PREV

{dbkey}.

RECIPE REMAIN

ACTIVE

(RE-USE)

SETUP NUMBER

SETUP

CALIBRATION

NUMBER

CAL

D.A.N

NO.

458

461

462

OPTIONS

(BOLD=DEFAULT)

ON/OFF

ON/OFF

WEIGHT

PERCNT

LOAD

463

GROSS

NET

465

466

ON/OFF

ON/OFF

CALIBRATION

871

872

DESCRIPTION

If ON -starts pens list after recipe

is loaded in list mode format.

If ON -overrides automatic

advance for pens.

Select weight or percentage

method, then enter pen

tolerance.

Select method for displaying pen

Weight -net, load, or gross.

Select method ignores double

pressing of keys when advancing

ingr. While loading mixer.

Select ON to reuse recipes.

Quick entry method selects

weigh method 1-4lbs, 5-8 kg,

gain 1-9, display counts 1-9 and

capacity *1000

Weight displayed at 0.4mV/V for

these load cells

D3716 29

Page 30

EZ4600

TROUBLESHOOTING

30 D3716

Page 31

Operators Manual

D3716 31

Page 32

EZ4600

INSTALLATION

Indicator Mounting

Rail Mounting

Included

Rail Mount (Standard), Wing Mount w/ hardware, RAM Mount Kit w/

hardware kit.

Load Cell Direction

Wing Mount

Optional

RAM Mount

Optional

Observe direction of arrow on load cell when installing load cell.

32 D3716

Page 33

Operators Manual

Cable Connection

See Figure 1

Remote Indicator

(Optional)

Indicator Connection Diagram

J-Box

Connection

Scale

Indicator

Power Cord

Pin To 12VDC Power Supply

1 Red +Terminal

2 Black -Terminal

3 Orange Alarm Out

4 Blue

Remote Input

See

Figure 2.

J-Box

DataKey Insertion

Digital Input/

Output Connection

Remote Indicator

Connection

Power Cord

Connection

Figure 1. Bottom Panel Cable Connections

D3716 33

Page 34

EZ4600

Connect Load Cells To J-Box

Connect load cell

wires to terminal

blocks.

Wire Color Key

Color Description

1 White Signal +

2 Green Signal 3 Red Excitation +

4 Black Excitation 5 Shield Shield

Tighten nuts

J-Box Cable

Load cell cable

Figure 2. J-Box Connections

Connect to Indicator

bottom panel.

See Figure 1

Change Setup and Calibration Numbers

1. Enter 871 and press .

2

146040

3

1

1

34 D3716

2. Indicator shows

show a 6 digit number. Enter new

number.

3. Press .

Follow same procedure changes

calibration number except use 872.

SETUP briefly then

Page 35

Operators Manual

OPTIONAL EQUIPMENT

Rotation Counter Sensor

Transmitter/Receiver

Remote Indicators

Use with EZ3600 or EZ4600

indicators equipped with rotation

counter port. Sensor allows

operator to program indicator to

count auger or PTO rotations for

accurate mix.

Transmitter (shown) with factory

installed receiver in indicator. Use to

zero indicator from remote location.

Operating range about 90 feet.

RD440 small remote display with 1”

high numbers

RD2400V backlit remote display

with 1.7” high numbers

RD4000 LED remote display with 4”

high numbers

D3716 35

Loading...

Loading...