Page 1

Scale System

Troubleshooting Guide

for

Digi-Star Scales with

EZ 150, EZ 210 and EZ 320

Indicators

F3214B December 1997

Page 2

Table Of Contents

Symptoms

Troubleshooting Guide

Digi-Star Indicators ........................ 1

Introduction .............................. 2

Indicator Flashes “±RANGE” .............. 3

Indicator Will Not Come On ................ 4

Indicator Will Not Weigh .................. 6

Indicator Unstable (Drifts) ................. 6

System Inaccurate ....................... 7

Indicator Will Not Balance (zero) ........... 9

Testing the Indicator Using Simulator ......... 9

Inspect Junction Box Wiring ................ 10

Test the Junction Box ..................... 10

Testing the Load Cells .................... 11

Load Cell Resistance Chart ................ 12

Page 3

EZ Indicators

EZ 150

EZ 210

EZ 320

Page 4

Introduction

There are many scale applications, each using a variety of load cells and indicators.

Platform (large decks and animal)

Mobile Grain Cart (3 or 4 point)

Stationary Mixer

Bulk Feed Tanks (poultry, veal)

Others

This guide includes troubleshooting flowcharts and step by step procedures for

troubleshooting problems commonly found with most Digi-Star scale systems.

Required Tools

Multimeter [AC/DC Volts and Resistance]

Simulator (sold by Digi-Star)

Small Screwdriver (straight blade)

#2 Phillips Screwdriver

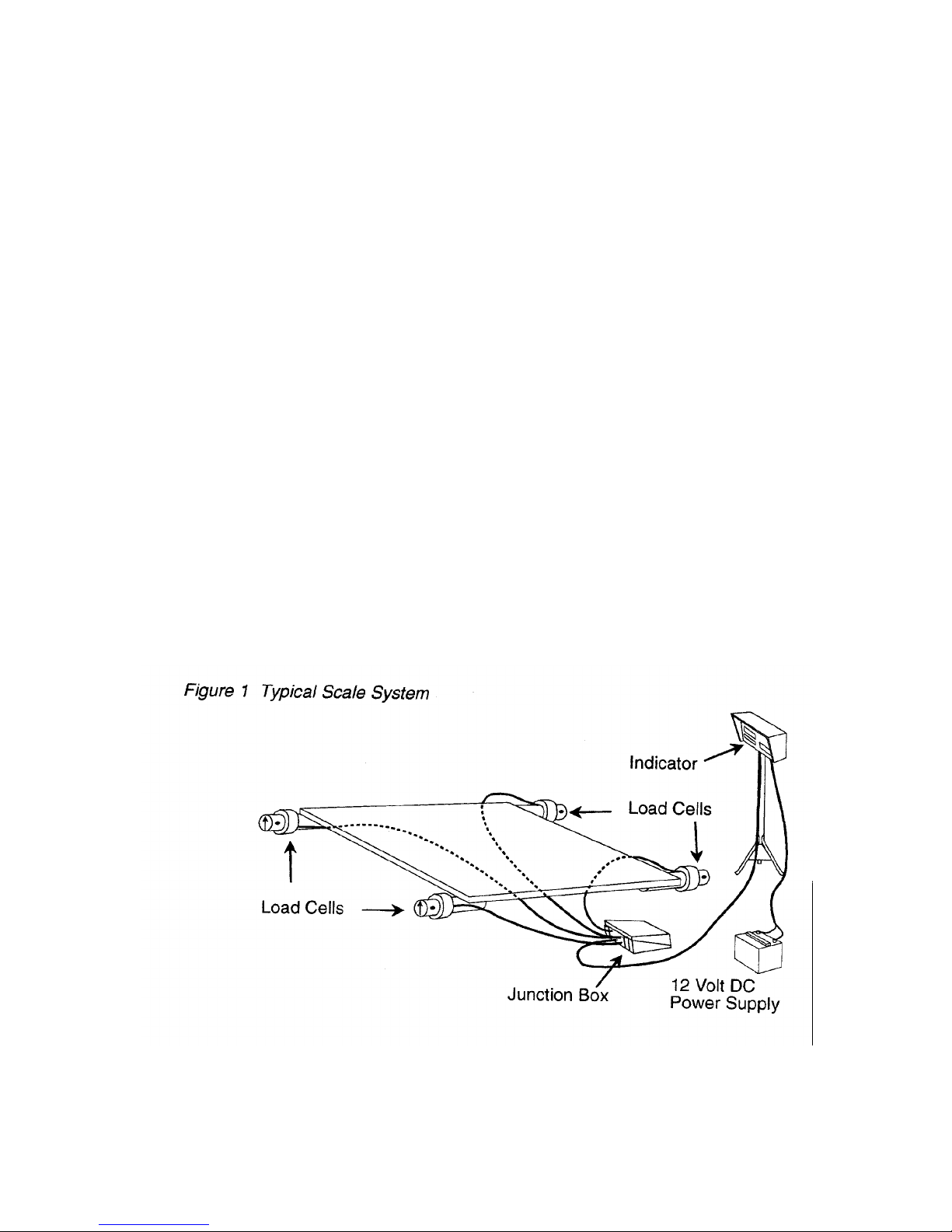

Digi-Star Scales

The basic elements of the Digi-Star scale system are:

Indicator

Load Cells (3 to 8 cells per system)

Junction Box

Power Supply (Battery or AC/DC Converter)

Page 5

Indicator Flashes “±RANGE”

Indicator Flashing

"+

Remove Junction Box

Cable from Indicator

RANGE"

(J902)

Indicator is Defective

Return Indicator to Factory

No Yes

Does Indicator

Stop Flashing

"+

RANGE"

Replace or Repair

Junction Box

Continue

Test Load Cells

(see pages 11-12)

EZ Series Indicator

1. With the power “ON” disconnect the junction box from indicator.

Check Junction Box

(see page 10)

No

Is Junction

Box Good?

Yes

2. If indicator continues to flash ”±RANGE” replace the indicator.

3. If indicator stops flashing ”±RANGE” and stabilizes at a weight, reconnect the junction

box and inspect the junction box wiring (see page 10).

4. If all connections in the junction box appear good and the display continues to flash

”±RANGE”, disconnect all load cell wires from junction box.

5. If the display continues to flash ”±RANGE” and the indicator checked out OK the junction

box is defective. Replace the junction box and continue to test load cells to assure that

they have not been damaged (see page 11).

6. If the display stops flashing and stabilizes at a weight, the junction box is OK. Test Load

Cells (see page 11).

Page 6

Replace Battery

Fuse

Indicator will not come on

Indicator Will Not

Check for Bad Power Cord,

Bad Connection or Bad Ground

New Cord w/Green Stripe

Red Wire = POS+

Black Wire = Neg-

Come On

Replace

Check for Bad

AC/DC Converter

(see note)

Good

Check 110

VAC Outlet

BadGood

Check AC Circuit

Breaker, etc.

with Known

Good Battery

Bad

Check Fuse

Replace AC/DC

Bad

Battery

in Supply

Converter

Check 12V

Voltage at

Source

Good

NOTE: A battery may check good with a meter but still

may not be strong enough to power the system.

Indicator Will Not Come On

Two conditions cause the indicator not to come on. They are:

No Power to Indicator (12 Volts DC)

Bad Indicator

Page 7

No Power to Indicator

Check AC Power Source (if applicable)

Check outlet with a multimeter or plug in another device to the outlet to make sure there

is 110 volts present to the power supply.

Check for DC Power to Indicator

Measure the DC output of the power supply (or battery on mobile units) using a

multimeter. The indicator requires between 10.5 and 14.5 volts DC.

Make sure battery or power supply terminals are tight. Remove the power supply cover

and tighten terminals if necessary.

Check the fuse on the power supply (fuse may be on rear or inside power supply).

Make sure the RED wire is connected to the positive terminal and the BLACK wire

connected to the negative terminal of the DC power cable.

Remove the power connector from the indicator and use multimeter to measure

between PIN 1 (POS) and PIN 2 (NEG). The meter should read between 10.5 and 14.5

volts DC.

Mobile Applications

A bad vehicle ground or a weak battery can cause problems even if voltages check OK.

Connect the indicator to a known good power source (your service vehicle battery is a

good choice). If the indicator works OK, check into the vehicle battery and ground

connections or replace the battery.

If a tractor power cord is used, make sure that it’s RED wire is connected to the RED

wire of the indicator power cord and it’s BLACK wire is connected to the WHITE wire

of the indicator power cord.

Bad Indicator

If the above power checks are OK, replace the indicator.

Indicator Will Not Weigh

If the indicator flashes “LOW BAT” along the bottom of the display, turn to “Indicator Will Not

Balance” (page 9).

1. Test indicator using simulator. (See page 9)

2. Inspect the junction box wiring. (See page 10)

3. Remove load cells and test junction box. (See page 10)

4. Test the load cells. (See Page 11)

Page 8

Indicator Unstable (Drifts)

Slow Drift

Variations of 50 lbs with 1" DB cells and up to 350 lbs on 2 ” DB and larger cells are normal

for most scale systems with daily temperature changes. Temperature compensated cells

minimize temperature drift but do not eliminate drifting entirely. Balance indicator before

use to prevent drift from causing inaccurate weight readings, except for feed bins where

you want to save inventory data. For feed bins, scale must be empty before balancing it.

Zero Track

EZ Series indicators with “Zero Track” turned on will hold the indicator on zero. “Zero

Track” is designed to compensate for slow changing variations on an empty scale (i.e.:

snowfall or temperature drift). “Zero Track” is not functional while weight is applied, or in

“NET” mode.

1. If rapid or intermittent changes in the display occurs, test the indicator by disconnecting

the junction box from the indicator and short pins 2 and 3 on the load cell jack.

• If the symptoms persist, replace the indicator.

2. Inspect the junction box wiring. (See page 10)

NOTE: Moisture inside the junction box can cause unstable or drifting readings.

3. Test the junction box. (See page 10)

4. Test the Load Cells. (See page 11)

Mobile Units

Uneven terrain causes weight shifts. Always seek smooth flat terrain to make weight

readings. Wheel alignment (toe-in/toe-out) can cause weight shift when unit moves (even

on smooth flat terrain).

Page 9

System Inaccurate

Inaccurate systems are usually caused by:

Indicator with wrong set-up. (An indicator that was set up for another scale

application.)

Debris under/around mounts or structure.

Mounts, platform or cart not shimmed or supported properly to provide equal load

to each load cell.

Defective load cell.

Load cell up-side down. (new installations)

First, determine if the inaccuracy is caused by the indicator or something else. To do

this, stand in the middle of the scale and note your weight (tough for mobile systems).

Stand or hang at each load cell and note each reading. If the readings are all within 1

display count, the indicator is causing the problem.

If you find that one or more of the readings are more than 2 display counts different

from the others, then continue to one of the other possibilities in this section.

Indicator with Wrong Set-Up or Miscalibrated:

Verify that the indicator has the proper set-up. Compare the system configuration (size,

type and number of load cells) to the decal on the bottom of the indicator.

Inaccurate calibration: If the indicator needs re-calibration, it is best to contact your

dealer first. See scale operation manual for calibration instructions.

Debris Under/Around Mounts or Structure:

Readings will be less than actual if debris is lodged under or around the mounts and

platform.

Insure that the mounts, load cells and weighing structure are free of ice and debris.

Inspect around the edges of platform for any gravel or product that may have fallen

through the cracks around the deck.

On Weighmasters you can often clear the object without raising the deck. Use a piece

of stiff wire (like welding rod) and a needle nose pliers to dislodge debris.

Page 10

System Inaccurate (continued)

Mounts, Platform or Cart Not Shimmed or Supported Properly to

Provide Equal Load at Each Load Cell:

On MOBILE applications, side pressure on a wheel or tongue can cause inaccurate

readings. Make sure wheels are on a level surface and there is no draw bar pull on

tongue.

On PLATFORM applications, use a large screwdriver or pry bar to pry up on the corners

of the deck. If one of the corners has noticeably less resistance, the deck may require

shimming or adjustment of the leveling screws (if present).

On FEED BIN applications, rock the bin back and forth, and check the mounts for any

movement or play. Insure that each mount has equal pressure and is secured to the slab.

Defective Load Cell:

If you suspect that you have a defective load cell, test them using the procedure on page

11.

Load Cell Up-Side Down:

If one load cell is mounted up-side down, the corner with the upside-down cell would read

negative. Visually check load cells for proper orientation (see below). The load cell should

deflect the same direction as the black arrow on the end of the cell.

NOTE: Each load cell is manufactured so that the cable comes off of the same side of the

cell (see diagram). Decals are also placed on the same side of each load cell.

Page 11

Indicator Will Not Balance (Zero)

Observe the display and watch for the “Zero” indicator to appear for two seconds after

performing a balance to verify that the indicator has balanced.

Low Battery

Indicator will not balance if you have a low battery (less than 10.5 volts loaded).

- The “LO BAT” indicator should appear in the bottom of your display.

- Check the ground connections on a mobile unit if voltage reads above 10.5 Volts

and “LO BAT” is indicated on display.

Battery OK

1. Test the indicator using the simulator. (See page 9)

2. Inspect the junction box wiring. (See page 11)

3. Remove load cells and test junction box. (See page 10)

4. Test Load Cells. (See page 11)

Stability Feature is On (Motion Detection)

EZ Series indicators will not allow you to balance if the stability feature is turned ON and

the display is unstable.

NOTE: On EZ Series indicators, a “ ” will appear under the word “Motion” to indicate an

unstable condition.

Testing the Indicator Using Simulator

1. With the power “ON” disconnect the junction box from indicator.

2. Set simulator on middle position (zero) and connect to indicator.

3. Balance the indicator.

4. Switch the simulator to either .2 or .4.

5. Verify that the indicator displays the calibration number for you setup. (See calibration

sticker on rear of indicator.)

6. If the indicator does not register any weight using the simulator, replace the indicator.

Page 12

Inspect Junction Box Wiring

1. Connect the junction box to the indicator.

2. Open the junction box cover and check wiring for the following:

• Wires connected to proper connection point, by color code.

• Terminal blocks are clamped onto metal lead, not insulation.

• Connections are tight.

3. Check for water or condensation in the junction box. If damp, dry the entire box and

printed circuit board thoroughly with a hair dryer.

NOTE: No hazardous voltages are present in the junction box.

Test the Junction Box

NOTE: Test the indicator using a simulator and inspect the junction box wiring (pages 9

& 10) before testing the junction box.

1. Disconnect all load cell wires from junction box.

2. If the failure mode does not change and the indicator checked out OK earlier (page 10),

the junction box is defective. Be sure to test load cells using an ohm meter (see page

11) to assure that they have not been damaged.

3. If the display stops flashing and stabilizes at a weight, the junction box is OK.

Testing the Load Cells

Using Working Indicator & Junction Box

1. Disconnect all load cells from the junction box.

2. Connect one load cell to any junction box terminal. Be sure connections are tight and

connected to proper locations by color code.

3. Observe a positive weight change after each load cell is connected. Record the

reading of each load cell.

Load cell is bad if it causes:

• indicator to flash “±RANGE”

• indicator to display a negative weight (check for upside down load cell)

• indicator to become unstable

Page 13

4. Stand over or hang on each load cell and observe increase in weight reading on the

indicator (displayed weight will not be correct).

5. Disconnect load cell and repeats steps 3 through 6 for each load cell.

6. After all load cells are checked, compare the readings. If one cell is substantially

different than the others, it is bad.

NOTE: Be sure to check each load cell to insure there are not two bad cells.

Using a Multimeter

If an operational indicator or junction box is not available, load cells can be tested using a

multimeter.

NOTE: This method is not fool-proof. A load cell may pass this test and still have a

problem. For best results, test load cells using a working indicator.

1. Identify the load cell type and use the chart on page 12 to determine the resistance

values between the wires on the load cell.

2. Using an ohm meter, measure the resistance between leads on the load cell.

3. Replace the load cell if it measures more than 15% above or below the value listed in

the chart on page 12.

NOTE: Bad load cells will typically show no reading or double the correct value.

Load Cell Resistance Chart

Load Cell

Wire Color

Red & Black 350 395 350 700

White & Green 350 350 350 700

Red & Green 262 297 262 525

Green & Black 262 307 262 525

Black & White 262 307 262 525

White & Red 262 297 262 525

Shield to any other Infinite (open) Infinite (open) Infinite (open) Infinite (open)

wire

Non Temp Temp. Comp CT CT & CTH

(White & Black) (Blue) (Black) (Blue & Tan)

Loading...

Loading...