Page 1

DW715-XE (230 VOLT)

305MM (12") COMPOUND MITER SAW

INSTRUCTION MANUAL

Questions? See us on the World Wide Web at www.dewalt.com

Page 2

1

TABLE OF CONTENTS

DOUBLE INSULATION ....................................................................................................................................2

SAFETY INSTRUCTIONS FOR ALL TOOLS ......................................................................................................2

ADDITIONAL SAFETY RULES ........................................................................................................................2

ELECTRICAL SAFETY ....................................................................................................................................3

ACCESSORIES ..............................................................................................................................................3

BLADE DESCRIPTIONS ..................................................................................................................................3

UNPACKING YOUR SAW................................................................................................................................4

SPECIFICATIONS............................................................................................................................................4

FAMILIARIZATION ..........................................................................................................................................4

BENCH MOUNTING........................................................................................................................................4

CHANGING OR INSTALLING A NEW BLADE ..................................................................................................5

TRANSPORTING THE SAW ............................................................................................................................6

ADJUSTMENTS..............................................................................................................................................6

MITER SCALE ADJUSTMENT ..................................................................................................................6

MITER POINTER ADJUSTMENT................................................................................................................6

BEVEL SQUARE TO TABLE ......................................................................................................................6

BEVEL POINTER ......................................................................................................................................6

BEVEL STOP ADJUSTMENT ....................................................................................................................6

FENCE ADJUSTMENT ..............................................................................................................................6

AUTOMATIC ELECTRIC BRAKE........................................................................................................................7

GUARD ACTUATION AND VISIBILITY ........................................................................................................7

MITER LOCK ADJUSTMENT ....................................................................................................................7

BRUSHES ......................................................................................................................................................7

CONTROLS....................................................................................................................................................7

OPERATION ..................................................................................................................................................7

SWITCH ..................................................................................................................................................7

CUTTING WITH YOUR SAW ....................................................................................................................7

CROSSCUTS ....................................................................................................................................................7

BEVEL CUTS ....................................................................................................................................................8

QUALITY OF CUT ..............................................................................................................................................8

BODY AND HAND POSITION ............................................................................................................................8

CLAMPING THE WORKPIECE ..................................................................................................................8

SUPPORT FOR LONG PIECES ..................................................................................................................8

CUTTING PICTURE FRAMES, SHADOW BOXES

AND OTHER FOUR-SIDED PROJECTS......................................................................................................9

CUTTING TRIM MOLDING AND OTHER FRAMES......................................................................................9

CUTTING COMPOUND MITERS ................................................................................................................9

VERNIER SCALE ..............................................................................................................................................9

CUTTING BASE MOLDING........................................................................................................................9

CUTTING CROWN MOLDING........................................................................................................................11

SPECIAL CUTS ............................................................................................................................................12

MAINTENANCE ............................................................................................................................................12

WARRANTY ................................................................................................................................................12

TABLE 1: COMPOUND MITER CUT ..............................................................................................................13

TROUBLESHOOTING GUIDE ........................................................................................................................14

Page 3

2

Important Safety Instructions

WARNING: When using electric tools, basic safety precautions should always be followed to reduce risk

of fire, electric shock, and personal injury, including the following:

READ ALL INSTRUCTIONS

Double Insulation

Double insulated tools are constructed throughout with two separate layers of electrical insulation or one double

thickness of insulation between you and the tool’s electrical system. Tools built with this insulation system are

not intended to be grounded.

NOTE: Double insulation does not take the place of normal safety precautions when operating this tool. The

insulation system is for added protection against injury resulting from a possible electrical insulation failure

within the tool.

CAUTION: WHEN SERVICING USE ONLY IDENTICAL REPLACEMENT PARTS. Repair or replace damaged cords.

Safety Instructions For All Tools

• KEEP GUARD IN PLACE and in working order.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that keys and adjusting

wrenches are removed from spindle before turning tool on.

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

• DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power tools in damp or wet locations, or expose

them to rain or snow. Keep work area well lighted.

• KEEP CHILDREN AWAY. All visitors should be kept at a safe distance from work area.

• MAKE WORKSHOP KID PROOF with padlocks, master switches, or by removing starter keys.

• DON’T FORCE TOOL. It will do the job better and be safer at the rate for which it was designed.

• USE RIGHT TOOL. Don’t force tool or attachment to do a job for which it was not designed.

• WEAR PROPER APPAREL. No loose clothing, gloves, neckties, rings, bracelets, or other jewelry to get

caught in moving parts. Non-slip footwear is recommended. Wear protective hair covering to contain long

hair. Air vents may cover moving parts and should also be avoided.

• ALWAYS WEAR SAFETY GLASSES. Also use face or dust mask if cutting operation is dusty. Everyday

eyeglasses have only impact resistant lenses, they are NOT safety glasses.

• SECURE WORK. Use clamps or vise when you cannot secure the workpiece on the table and against the

fence by hand or when your hand will be dangerously close to the blade [within 150mm (6")].

• DON’T OVERREACH. Keep proper footing and balance at all times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

• DISCONNECT TOOLS before servicing; when changing accessories such as blades, bits, cutters, etc.

• REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is in OFF position before plugging in.

• USE RECOMMENDED ACCESSORIES. Consult the instruction manual for recommended accessories. The

use of improper accessories may cause risk of injury to persons.

• NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if the cutting tool is unintentionally

contacted.

• CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly and perform its intended function—check for

alignment of moving parts, binding of moving par ts, breakage of parts, mounting and any other conditions

that may affect its operation. A guard or other part that is damaged should be properly repaired or replaced.

Do not use tool if switch does not turn it on and off.

• NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don’t leave tool until it comes to a

complete stop.

• DO NOT OPERATE ELECTRIC TOOLS NEAR FLAMMABLE LIQUIDS OR IN GASEOUS OR EXPLOSIVE

ATMOSPHERES. Motors in these tools may spark and ignite fumes.

• EXTENSION CORDS. Make sure your extension cord is in good condition. When using an extension cord, be

sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause a

drop in line voltage resulting in loss of power and overheating. The following table shows the correct size to

use depending on cord length and nameplate ampere rating. If in doubt, use the next heavier gage. The

smaller the gage number, the heavier the cord.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet (Meters)

230V 0-50 (0-15.2) 51-100 (15.2-30.5) 101-200 (30.5-61.0) 201-300 (61.0-91.5)

Ampere Rating

MoreNot more AWG/mm

Than Than

0 - 6 18 (0.8) 16 (1.3) 16 (1.3) 14 (2.1)

6 - 10 18 (0.8) 16 (1.3) 14 (2.1) 12 (3.3)

10 - 12 16 (1.3) 16 (1.3) 14 (2.1) 12 (3.3)

12 - 16 14 (2.1) 12 (3.3) Not Recommended

Additional Safety Rules For Miter Saws

CAUTION: FAILURE TO HEED THESE WARNINGS MAY RESULT IN PERSONAL INJURY AND SERIOUS DAM-

AGE TO THE SAW.

• DO - Protect electric supply line with at least a 15 ampere time-delay fuse or a circuit breaker.

• DO - Make certain the blade rotates in the correct direction and that the teeth at the bottom of the blade are

pointing to the rear of the miter saw.

• DO - Be sure all clamp handles are tight before starting any operation.

• DO - Be sure all blade and clamp washers are clean and recessed sides of collars are against blade. Tighten

arbor screw securely.

• DO - Keep saw blade sharp.

• DO - Keep motor air slots free of chips and dirt.

• DO - Use blade guards at all times.

• DO - Keep hands out of path of saw blade.

• DO - Shut off power, disconnect cord from power source and wait for saw blade to stop before servicing

or adjusting tool.

• DO - Support long work with an outboard tool rest.

• DON’T - Attempt to operate on anything but designated voltage.

• DON’T - Operate unless all clamp handles are tight.

• DON’T - Use blades larger or smaller than those which are recommended.

• DON’T - Wedge anything against fan to hold motor shaft.

• DON’T - Force cutting action. (Stalling or partial stalling of motor can cause major damage. Allow motor

to reach full speed before cutting.)

• DON’T - Cut ferrous metals (Those with any iron or steel content) or any masonry.

• DON’T - Use abrasive wheels. The excessive heat and abrasive particles generated by them will damage

the saw.

• DON’T - Allow anyone to stand behind saw.

• DON’T - Apply lubricants to the blade when it’s running.

• DON’T - Place either hand in the blade area when the saw is connected to the power source.

• DON’T - Use blades rated less than 4800 R.P.M.

• DO NOT - Cut small pieces without clamping. Keep hands 150mm (6") or more from blade.

• DON’T - Operate saw without guards in place.

• DON’T - Perform any operation freehand.

• DON’T - Reach around or behind saw blade.

• DON’T - Place hands closer than 150mm (6") from the saw blade.

• DO NOT - Reach underneath the saw unless it is turned off and unplugged. The saw blade is exposed on

the underside of the saw.

• DO NOT - Move either hand from saw or workpiece or raise arm until blade has stopped.

• DO NOT - Use lubricants or cleaners (particularly spray or aerosol) in the vicinity of the plastic guard. The

polycarbonate material used in the guard is subject to attack by certain chemicals.

• Never use without kerf plate, and replace when kerf plate is damaged because small chip accumulation under

saw may interfere with saw blade or may cause instability of workpiece when cutting.

CAUTION: Do not connect unit to electrical power source until complete instructions are read and understood.

CAUTION: Wear appropriate personal hearing protection during use. Under some conditions and duration

of use, noise from this product may contribute to hearing loss.

Page 4

3

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated timber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such

as those dust masks that are specially designed to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and other construction

activities. Wear protective clothing and wash exposed areas with soap and water. Allowing dust to get

into your mouth, eyes, or lay on the skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious and permanent

respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection appropriate for the dust

exposure. Direct particles away from face and body.

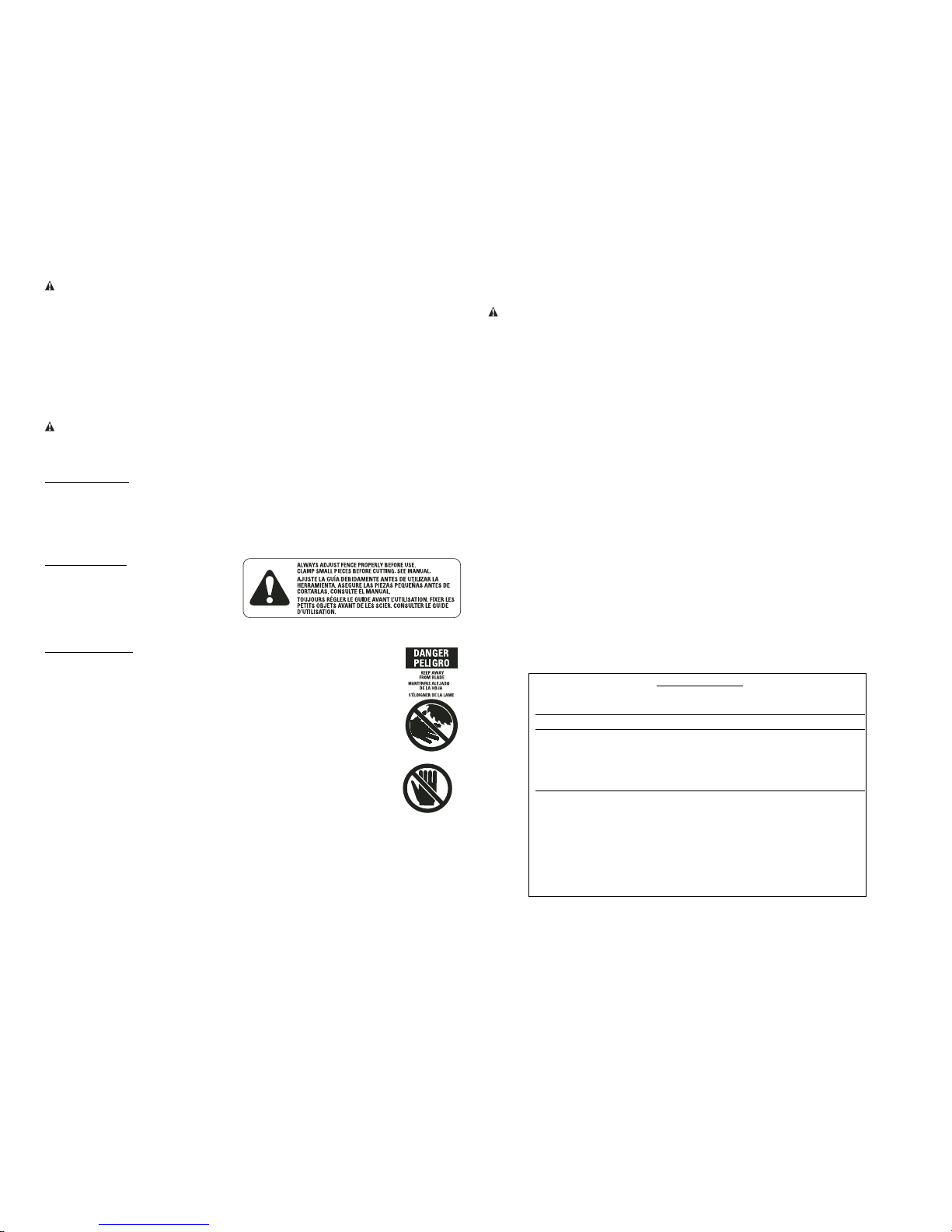

For your convenience and safety, the following warning labels are on your miter saw.

ON MOTOR HOUSING:

WARNING: FOR YOUR OWN SAFETY, READ INSTRUCTION MANUAL BEFORE OPERATING SAW.

WHEN SERVICING, USE ONLY IDENTICAL REPLACEMENT PARTS.

DO NOT EXPOSE TO RAIN OR USE IN DAMP LOCATIONS.

ALWAYS WEAR EYE PROTECTION.

ON MOVING FENCES:

ALWAYS ADJUST FENCE PROPERLY BEFORE USE.

Clamp small pieces before cutting. See manual.

ON GUARD: DANGER – KEEP AWAY FROM BLADE.

ON UPPER GUARD: PROPERLY SECURE BRACKET

WITH BOTH SCREWS BEFORE USE.

ON TABLE: (2 PLACES)

ALWAYS TIGHTEN ADJUSTMENT KNOBS BEFORE USE.

KEEP HANDS 150MM (6") FROM PATH OF SAW BLADE.

NEVER PERFORM ANY OPERATION FREEHAND.

NEVER CROSS ARMS IN FRONT OF BLADE.

THINK! YOU CAN PREVENT ACCIDENTS.

DO NOT OPERATE SAW WITHOUT GUARDS IN PLACE.

TURN OFF TOOL, KEEP SAW HEAD DOWN AND WAIT FOR SAW TO

STOP BEFORE MOVING HANDS, WORKPIECE OR CHANGING SETTINGS.

UNPLUG TOOL BEFORE CHANGING BLADE, MOVING OR SERVICING UNIT.

Electrical Safety

The electric motor has been designed for one voltage only. Always check that the power supply corresponds to

the voltage on the rating plate. 230 V AC means your tool will operate on alternating current. As little as 10%

lower voltage can cause loss of power and can result in overheating. All DEWALT tools are factory tested; if this

tool does not operate, check the power supply. Your DEWALT tool is double insulated, therefore no earth wire is

required.

• Young children and the infirm. This appliance is not intended for use by young children or infirm persons

without supervision. Young children should be supervised to ensure that they do not play with this appliance.

• Replacement of the supply cord. If the supply cord is damaged, it must be replaced by the manufacturer or

an authorised DEWALT Service Centre in order to avoid a hazard.

Accessories

Recommended accessories for use with your tool are available at extra cost from your local service center.

CAUTION: The use of any non-recommended accessory may be hazardous. Dado sets, molding cutters or

abrasive wheels should not be used on your miter saw.

If you need any assistance in locating any accessory, please contact: DEWALT Industrial Tool Co., 20 Fletcher

Road, Mooroolbark, VIC 3138 Australia, call 1800 654 155 or 21 Hugo Johnston Drive, Penrose, Auckland, New

Zealand, call 09 5797600.

Optional Accessories

The following accessories, designed for your saw, may be helpful. In some cases, other locally obtained work

supports, length stops, clamps, etc., may be more appropriate. Use care in selecting and using accessories.

Laser Guide System: DW7187

Laser is available at extra cost from DEWALT Service Centers and your home improvement retailer.

Instructions for installation are included with the accessory. Read and follow all directions for safe

installation and use.

Extension, Work Support: DW7080 (page 4)

Used to support long overhanging workpieces, the work suppor t is user assembled. Your saw table is

designed to accept two work supports; one on each side.

Adjustable Length Stop: DW7051 (page 4)

Requires the use of one work support (see drawing). It is used to make repetitive cuts of the same length

from 0 to 1067mm (0 to 42").

Clamp: DW7082 (similar model included)

Used for firmly clamping workpiece to the saw table for precision cutting.

Dust Bag: DW7053 (Included with some models)

Equipped with a zipper for easy emptying, the dust bag will capture the majority of the sawdust produced

(not shown).

NOTE: Deflector on dust spout channels debris to ground. Spout has a provision to attach a vacuum hose to

collect sawdust. Lift dust spout to connect hose.

Crown Molding Fence: DW7084 (Not available in Australia or New Zealand)

Used for precision cutting of crown molding.

SAW BLADES: ALWAYS USE 305mm (12") SAW BLADES WITH 25.4mm (1") ARBOR HOLES. SPEED RATING

MUST BE AT LEAST 4800 RPM. Never use a smaller diameter blade. It will not be guarded properly.

* Currently not available in Australia or New Zealand

BLADE DESCRIPTIONS

TOOTH

APPLICATION MODEL # TEETH GRIND

Construction Saw Blades (thin kerf with anti-stick rim)

General Purpose DW3123 32 ATB

Fine Crosscuts DW3126 60 ATB

Fine Crosscuts DW3128 80 ATB

Woodworking Saw Blades (provide smooth, clean cuts)

Fine crosscuts DW7648 60 ATB

*Fine crosscuts DW7649 80 ATB

*Ultra-fine crosscuts DW7650 96 ATB

*Laminates DW7661 80 TCG

*Solid surface

and plastics DW7668 80 Mod TCG

*Non-ferrous metals DW7666 80 TCG

Page 5

4

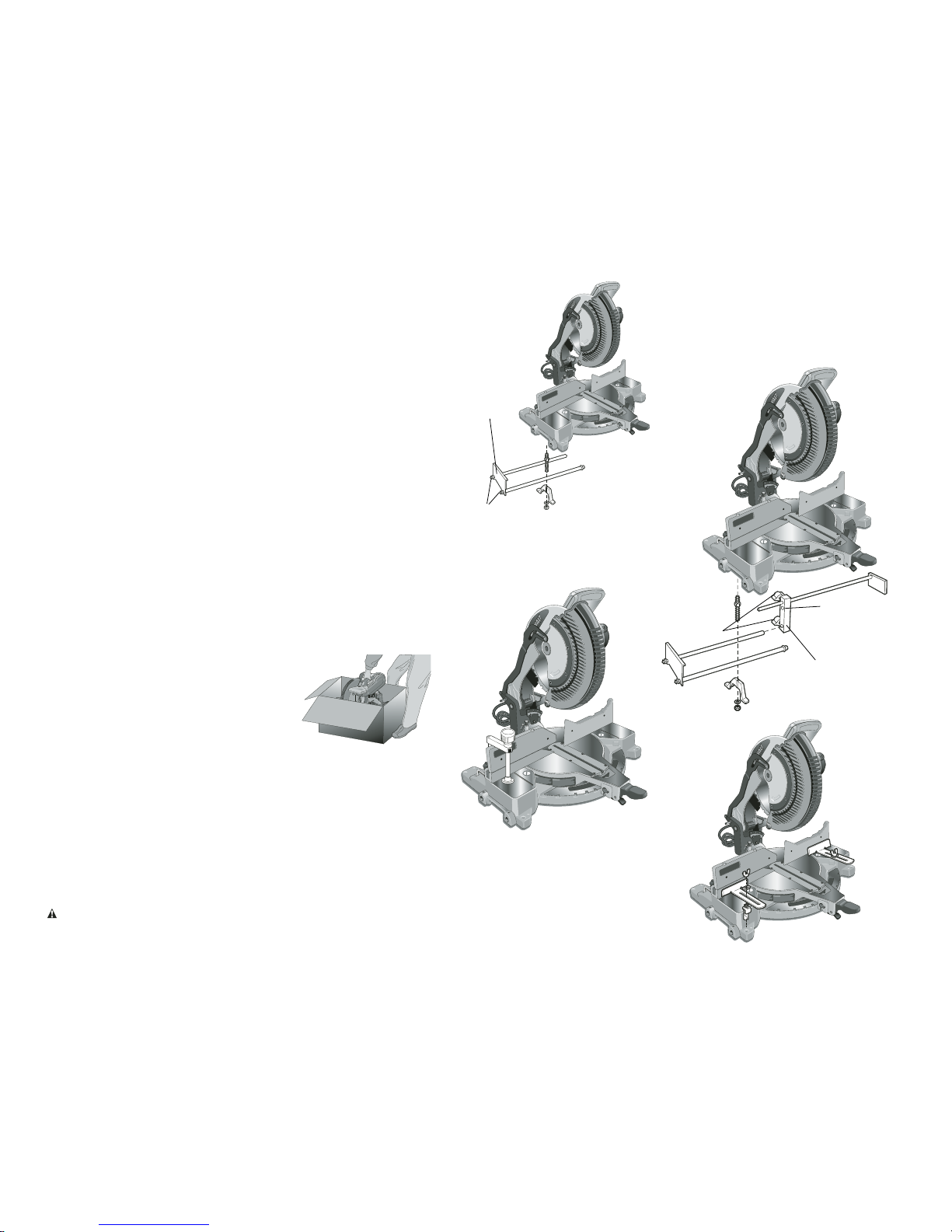

Unpacking Your Saw

Check the contents of your miter saw carton to make sure that you have received all par ts. In

addition to this instruction manual, the carton should contain:

1. One No. DW715 miter saw.

2. One DEWALT 305mm (12") dia. saw blade

3. One blade wrench in wrench pocket shown in Figure 2.

4. One DW7053 dustbag (some models).

DW7051

KNOBS

BRACKET

TOP HOLE

(USE FOR DW716)

LOCKNUTS

END

PLATE

DW7080

DW7082

DW7084

Specifications

CAPACITY OF CUT

50˚ miter left and right

48˚ bevel left, 3˚ bevel right

0˚ miter

Max. Height 89mm (3.5") Result Width 165mm (6.5")

Max. Width 196mm (7.7") Result Height 66mm (2.6")

45˚ miter

Max. Height 89mm (3.5") Result Width 120mm (4.7")

Max. Width 140mm (5.5") Result Height 66mm (2.6")

45˚ bevel - Left

Max. Height 58mm (2.3") Result Width 170mm (6.7")

Max. Width 196mm (7.7") Result Height 41mm (1.6")

DRIVE

230 Volt Motor

1375 Watts in Cut Helical Gears

4000 RPM Roller Bearings

Automatic Electric Brake Carbide Blade

Familiarization

Your miter saw is fully assembled in the carton. Open the box and

lift the saw out by the convenient carrying handle, as shown in

Figure 1.

Place the saw on a smooth, flat surface such as a workbench or

strong table.

Examine Figure 2 to become familiar with the saw and its various

parts. The section on adjustments will refer to these terms and you

must know what and where the parts are.

Press down lightly on the operating handle and pull out the lock

down pin, as shown in Figure 2. Gently release the downward pressure and hold the arm allowing it to

rise to its full height. Use the lock down pin when carrying the saw from one place to another. Always use

the carrying handle to transport the saw or the hand indentations shown in Figure 2.

Bench Mounting

Holes are provided in all four feet to facilitate bench mounting, as shown in Figure 2. (Two different sized

holes are provided to accommodate different sizes of screws. Use either hole, it is not necessary to use

both.) Always mount your saw firmly to a stable surface to prevent movement. To enhance the tool’s

portability, it can be mounted to a piece of 12.7mm (1/2") or thicker plywood which can then be clamped

to your work support or moved to other job sites and reclamped.

NOTE: If you elect to mount your saw to a piece of plywood, make sure that the mounting screws don’t

protrude from the bottom of the wood. The plywood must sit flush on the work support. When clamping

the saw to any work surface, clamp only on the clamping bosses where the mounting screw holes are

located. Clamping at any other point will surely interfere with the proper operation of the saw.

CAUTION: To prevent binding and inaccuracy, be sure the mounting surface is not warped or otherwise

uneven. If the saw rocks on the surface place a thin piece of material under one saw foot until the saw sits

firmly on the mounting surface.

FIG. 1

Page 6

5

FIG. 2

GUARD

MITER

LOCK LEVER

MITER

SCALE

BENCH MOUNTING HOLES

LOCK DOWN PIN

OPERATING HANDLE

BENCH MOUNTING HOLES

BEVEL SCALE

TRIGGER SWITCH

OPERATING HANDLE

LEFT SIDE

FENCE

FENCE LOCK KNOB

MOTOR HOUSING

0˚/45˚ BEVEL

OVERRIDE LEVERS

DUST SPOUT

MOTOR END CAP

LOCK DOWN PIN

BEVEL STOP

33.85˚ PAWL

CARRY HANDLE

BLADE

WRENCH

0˚

BEVEL STOP

ADJUSTMENT SCREW

BEVEL LOCK

KNOB

HAND

INDENTATIONS

IMPORTANT SAFETY INSTRUCTIONS

Changing or Installing a New Saw Blade (Fig. 3)

CAUTION:

• Never depress the spindle lock button while the blade is under power

or coasting.

• Do not cut ferrous metal (containing iron or steel) or masonry or

fiber cement product with this miter saw.

A

B

D

FIG. 3

Removing the Blade

1. Unplug the saw.

2. Raise the arm to the upper position and raise the lower guard (A) as

far as possible.

3. Loosen, but do not remove guard bracket screw (B) until the bracket

can be raised far enough to access the blade screw. Lower guard

will remain raised due to the position of the guard bracket screw.

Page 7

6

4. Depress the spindle lock button (C) while carefully rotating the saw

blade by hand until the lock engages.

5. Keeping the button depressed, use the other hand and the wrench

provided (D) to loosen the blade screw. (Turn clockwise, left-hand

threads)

6. Remove the blade screw (E), outer clamp washer (F), and blade (G).

The 1" (25.4mm) blade adapter (H), if used, and the inner clamp

washer (I), may be left on the spindle.

NOTE: For blades with a blade hole of 15.88mm (5/8"), the 25.4mm (1")

blade adapter is not used.

Installing a Blade

1. Unplug the saw.

2. With the arm raised, the lower guard held open and the pivot plate

raised, place the blade on the spindle, onto the blade adapter [if using

a blade with a 25.4mm (1") diameter blade hole] and against the

inner clamp washer with the teeth at the bottom of the blade pointing

toward the back of the saw.

3. Assemble the outer clamp washer onto the spindle.

4. Install the blade screw and, engaging the spindle lock, tighten the

screw firmly with wrench provided. (Turn counterclockwise, lefthand threads)

E

F

G

I

H

FIG. 3B

C

FIG. 3A

the miter latch locks it at the 0 miter position. Do not lock miter lock lever

(J). If the saw blade is not exactly perpendicular to the fence, loosen the

three screws that hold the miter scale to the base and move the scale left

or right until the blade is perpendicular to the fence, as measured with

the square. Retighten the three screws. Pay no attention to the reading of

the miter pointer at this time.

MITER POINTER ADJUSTMENT (FIG. 5, 6)

To unlock, lift the miter lock lever (J) up and squeeze the miter latch (K)

to move the miter arm to the zero position. With the miter lock lever

unlocked allow the miter latch to snap into place as you rotate the miter

arm to zero. Observe the pointer and miter scale through the viewing

opening shown in Figure 6. If the pointer does not indicate exactly zero,

loosen the screw holding the pointer in place, reposition the pointer and

tighten the screw.

BEVEL SQUARE TO TABLE (FIG. 2, 7)

To align the blade square to the rotary table, lock the arm in the down

position. Place a square against the blade taking care to not have the

square on top of a tooth. Loosen the bevel lock knob (L) and ensure the

arm is firmly against the 0˚ bevel stop. Move the 0˚ bevel stop adjusting

screw as necessary so that the blade is at zero degrees bevel to the

table. Ensure the bevel override levers (N) are pushed inward to obtain

an accurate adjustment.

BEVEL POINTER (FIG. 7)

If the bevel pointer (M) does not indicate zero, loosen the screw that

holds it in place and move the pointer as necessary. Do not remove the

steel plate in front of the bevel pointer. This plate prevents wood resin

from accumulating on the bevel scale during use.

ADJUSTING THE BEVEL STOP TO 45˚ LEFT (FIG. 8)

NOTE: Adjust the 45˚ bevel angle only after performing the 0˚ bevel

angle and pointer adjustment. Ensure the 45˚ bevel override levers (N)

are pushed inward to obtain an accurate adjustment.

To adjust the left 45˚ bevel stop, first loosen the bevel lock knob (L) and

tilt the head to the left. If the pointer does not indicate exactly 45˚, turn

the left bevel stop screw until the pointer reads 45˚.

ADJUSTING THE BEVEL STOP TO 33.85˚ (FIG. 8)

NOTE: Adjust the 33.85˚ bevel angle only after performing the 0˚ bevel

angle and pointer adjustment.

To set the 33.85˚ bevel angle, flip out the stop pawl (P). Loosen the

bevel lock knob (L) and tilt the head to the left. If the pointer does not

indicate exactly 33.85˚, turn the screw contacting the pawl until the

pointer reads 33.85˚.

FENCE ADJUSTMENT

Turn Off and Unplug the Miter Saw

In order that the saw can bevel to a full 48 degrees left or right, the

fences can be adjusted to provide clearance. To adjust a fence, loosen

the plastic knob (Figure 8, R), and slide the fence outward. Make a dry

run with the saw turned off and check for clearance. Adjust the fence

to be as close to the blade as practical to provide maximum workpiece

support, without interfering with arm up and down movement. Tighten

knob securely. When the bevel operations are complete, don’t forget to

relocate the fence.

NOTE: The guide groove of the fences can become clogged with

sawdust. If you notice that it is becoming clogged, use a stick or low

pressure air to clear the guide groove.

WARNING: Always use eye protection. All users and bystanders must

wear eye protection that conforms to ANSI Z87.1. (CAN/CSA Z94.3)

NOTE: When using blades with a 15.88mm (5/8") diameter blade hole,

the blade adapter will not be used and should be stored in a safe place

for future use.

5. Return the guard bracket to its original position and firmly tighten the

guard bracket screw to hold bracket in place.

WARNING:

• The guard bracket must be returned to its

original position and the screw tightened

before activating the saw.

• Failure to do so may allow the guard

to contact the spinning saw blade resulting

in damage to the saw and severe personal

injury.

Transporting the Saw

TURN OFF AND UNPLUG THE MITER SAW BEFORE ATTEMPTING TO

MOVE IT OR MAKE ANY ADJUSTMENTS WHAT SO EVER!

In order to conveniently carry the miter saw from place to place, a

carrying handle has been included on the top of the saw arm and

hand indentations in the base, as shown in Figures 2, 4.

Adjustments

PERFORM ALL ADJUSTMENTS WITH THE MITER SAW UNPLUGGED.

NOTE: Your miter saw is fully and accurately adjusted at the factory at

the time of manufacture. If readjustment due to shipping and handling or

any other reason is required, follow the steps below to adjust your saw.

Once made, these adjustments should remain accurate. Take a little time

now to follow these directions carefully to maintain the accuracy of

which your saw is capable.

MITER SCALE ADJUSTMENT (FIG. 5)

Place a square against the saw’s fence and blade. (Do not touch the tips

of the blade teeth with the square. To do so will cause an inaccurate

measurement.) Unlock miter lock lever (J) and swing the miter arm until

FIG. 4

Page 8

7

AUTOMATIC ELECTRIC BRAKE

Your saw is equipped with an automatic electric blade brake which stops

the saw blade within 5 seconds of trigger release. This is not adjustable.

On occasion, there may be a delay after trigger release to brake

engagement. On rare occasions, the brake may not engage at all

and the blade will coast to a stop.

If a delay or “skipping” occurs, turn the saw on and off 4 or 5 times. If

the condition persists, have the tool serviced by an authorized DEWALT

service center.

Always be sure the blade has stopped before removing it from the kerf.

The brake is not a substitute for guards or for ensuring your own safety

by giving the saw your complete attention.

GUARD ACTUATION AND VISIBILITY

The blade guard on your saw has been designed to automatically raise

when the arm is brought down and to lower over the blade when the

arm is raised.

The guard can be raised by hand when installing or removing saw

blades or for inspection of the saw. NEVER RAISE THE BLADE GUARD

MANUALLY UNLESS THE SAW IS TURNED OFF.

NOTE: Certain special cuts of large material will require that you manually

raise the guard. See page 12.

The front section of the guard is louvered for visibility while cutting.

Although the louvers dramatically reduce flying debris, they are openings

in the guard and safety glasses should be worn at all times when viewing through the louvers.

MITER LOCK ADJUSTMENT (FIG. 10)

The miter lock rod should be adjusted if the table of the saw can be

moved when the miter lock handle is locked down. To adjust, put the

miter lock handle in the up position. Using a 3/32 hex wrench, loosen the

set screw (W) on the pivot pin. Using a slotted screwdriver, adjust the

lock rod in 1/8 clockwise turn increments to increase the lock force. To

ensure the miter lock is functioning properly, re-lock miter lock handle to

a non-detent miter angle. Tighten set screw.

Brushes

DISCONNECT PLUG FROM POWER SUPPLY

Inspect carbon brushes regularly by unplugging tool, removing the motor

end cap (Fig. 2), lift the brush spring and withdraw the brush assembly.

Keep brushes clean and sliding freely in their guides. Always replace a

used brush in the same orientation in the holder as it was prior to its

removal. Carbon brushes have varying symbols stamped into their sides,

and if the brush is worn down to approximately 12.7mm (1/2”), the

spring will no longer exert pressure and they must be replaced. Use only

identical DEWALT brushes. Use of the correct grade of brush is essential

for proper operation of electric brake. New brush assemblies are available

at DEWALT service centers. The tool should be allowed to “run in” (run at

no load) for 10 minutes before use to seat new brushes. The electric

brake may be erratic in operation until the brushes are properly seated

(worn in). Always replace the brush inspection cap after inspection or

servicing the brushes.

While “running in” DO NOT TIE, TAPE, OR OTHERWISE LOCK THE

TRIGGER SWITCH ON. HOLD BY HAND ONLY.

Controls

Your compound miter saw has several main controls, which will be

discussed briefly here. For more information on these controls, see

the respective sections later in the manual.

MITER CONTROL (FIG. 5)

The miter lock/adjustment lever and trigger allows you to miter your saw

50˚ left and right. To miter the saw, unlock miter lock lever (J) by pulling

upward, squeeze the detent trigger (K) and set the miter angle desired on

the miter scale. Lock miter lock handle by pressing downward. Override

the detent trigger by rotating knob (Fig. 9, V).

TRIGGER SWITCH (FIG. 2)

The trigger switch turns your saw on and off. A hole is provided in the

trigger for insertion of a padlock to secure the saw.

BEVEL LOCK (FIG. 8)

The bevel lock knob (L) allows you to bevel the saw 48˚ left or right. To

loosen the handle and adjust the bevel setting, turn the handle counterclockwise, the saw head bevels easily to the left. To tighten, turn the handle clockwise. Bevel degree markings are on the bottom front of the saw

arm (Fig. 7, M).

0˚/45˚ BEVEL STOP OVERRIDES (FIG. 8)

The bevel stop overrides (N) are held secure with their attachment screw

to prevent inadvertent movement. Use the bit on the blade wrench to

loosen the attachment screw. This allows the slides, to be pulled outward

and the saw head to pivot past the 0˚/45˚ mark. Be sure to retighten the

attachment screw when finished.

33.85˚ BEVEL STOPS (FIG. 8)

The pawl (P) is used to stop the saw head bevel setting at 33.85˚. This

setting is used primarily for cutting crown moldings laid flat on the table.

HEAD DOWNLOCK PIN (FIG. 8)

To lock the saw head in the down position, push the head down, push the

pin (U) in and release the saw head. This will hold the saw head safely

down for moving the saw from place to place. To release, press the saw

head down and pull the pin out.

Operation

Plug the saw into any household 60 Hz power source. Refer to the nameplate for voltage. Be sure the cord will not interfere with your work.

SWITCH

To turn the saw on, depress the trigger switch. To turn the tool off,

release the switch. Allow the blade to spin up to full operating rpm before

making the cut. Release the trigger switch and allow the brake to stop the

blade before raising the saw head. There is no provision for locking the

switch on, but a hole is provided in the trigger for insertion of a padlock

to lock the saw off.

CUTTING WITH YOUR SAW

NOTE: Although this saw will cut wood and many non-ferrous materials,

we will limit our discussion to the cutting of wood only. The same guidelines apply to the other materials. DO NOT CUT FERROUS (IRON AND

STEEL) MATERIALS OR MASONRY WITH THIS SAW. Do not use any

abrasive blades.

CROSSCUTS

Cutting of multiple pieces is not recommended but can be done safely by

ensuring that each piece is held firmly against the table and fence. A

crosscut is made by cutting wood across the grain at any angle. A

straight crosscut is made with the miter arm at the zero degree position.

Set the miter arm at zero, hold the wood on the table and firmly against

the fence. Turn on the saw by squeezing the trigger.

When the saw comes up to speed (about 1 second) lower the arm

smoothly and slowly to cut through the wood. Let the blade come to a

full stop before raising arm.

FIG. 5

FIG. 6

MITER

SCALE

POINTER

J

K

M

FIG. 7

POINTER

ADJUSTMENT

SCREW

L

Page 9

8

Miter crosscuts are made with the miter arm at some angle other than

zero. This angle is often 45 degrees for making corners, but can be set

anywhere from zero to 50 degrees left or right. After selecting the desired

miter angle, be sure to lock miter lock lever. Make the cut as described

above.

BEVEL CUTS

A bevel cut is a crosscut made with the saw blade at a bevel to the

wood. In order to set the bevel, loosen the bevel clamp knob and move

the saw to the left as desired. (It is necessary to move the fence to allow

clearance). Once the desired bevel angle has been set, tighten the bevel

clamp knob firmly.

Bevel angles can be set from 48 degrees right to 48 degrees left and can

be cut with the miter arm set between zero and 50 degrees right or left.

At some extreme angles, the right or left side fence might have to be

removed. To remove the left or right fence, unscrew the knobs several

turns and slide the fence out.

QUALITY OF CUT

The smoothness of any cut depends on a number of variables. Things like

material being cut, blade type, blade sharpness and rate of cut all contribute to

the quality of the cut.

When smoothest cuts are desired for molding and other precision work,

a sharp (60 tooth carbide) blade and a slower, even cutting rate will

produce the desired results.

Ensure that material does not creep while cutting, clamp it securely in

place. Always let the blade come to a full stop before raising arm.

If small fibers of wood still split out at the rear of the workpiece, stick

a piece of masking tape on the wood where the cut will be made. Saw

through the tape and carefully remove tape when finished.

For varied cutting applications, refer to the list of recommended saw

blades for your saw and select the one that best fits your needs (page 3).

BODY AND HAND POSITION (FIG. 11)

Proper positioning of your body and hands when operating the miter saw

will make cutting easier, more accurate and safer. Never place hands near

cutting area. Place hands no closer than 150mm (6") from the blade.

Hold the workpiece tightly to the table and the fence when cutting. Keep

hands in position until the trigger has been released and the blade has

completely stopped. ALWAYS MAKE DRY RUNS (UNPOWERED) BEFORE

FINISH CUTS SO THAT YOU CAN CHECK THE PATH OF THE BLADE. DO

NOT CROSS HANDS, AS SHOWN IN Figure 11A.

Keep both feet firmly on the floor and maintain proper balance. As you

move the miter arm left and right, follow it and stand slightly to the side

of the saw blade. Sight through the guard louvers when following a

pencil line.

CLAMPING THE WORKPIECE

TURN OFF AND UNPLUG SAW

If you cannot secure the workpiece on the table and against the fence by

hand, (irregular shape, etc.) or your hand would be less than 150mm (6")

from the blade, a clamp or other fixture must be used.

For best results use the DW7082 clamp made for use with your saw. It

is available for purchase at your local retailer or DEWALT service center.

Other aids such as spring clamps, bar clamps or C-clamps may be

appropriate for certain sizes and shapes of material. Use care in selecting

and placing these clamps. Take time to make a dry run before making the

cut. The left or right fence will slide from side to side to aid in clamping.

TO INSTALL CLAMP

1. Insert it into the hole behind the fence. The clamp should be facing

toward the back of the miter saw. The groove on the clamp rod

should be fully inserted into the base. Ensure this groove is fully

inserted into the base of the miter saw.

If the groove is visible, the clamp will not be secure.

2. Rotate the clamp 180 degrees toward the front of the miter saw.

3. Loosen the knob to adjust the clamp up or down, then use the fine

adjust knob to firmly clamp the workpiece.

NOTE: Place the clamp on the opposite side of the base when beveling.

ALWAYS MAKE DRY RUNS (UNPOWERED) BEFORE FINISH CUTS TO

CHECK THE PATH OF THE BLADE. ENSURE THE CLAMP DOES NOT

INTERFERE WITH THE ACTION OF THE SAW OR GUARDS.

WARNING: A workpiece that is clamped, balanced and secure before a

cut may become unbalanced after a cut is completed. An unbalanced load

may tip the saw or anything the saw is attached to, such as a table or workbench. When making a cut that may become unbalanced, properly support

the workpiece and ensure the saw is firmly bolted to a stable surface.

WARNING: The clamp foot must remain clamped above the base of the

saw whenever the clamp is used. Always clamp the workpiece to the base

of the saw–not to any other part of the work area. Ensure the clamp foot is

not clamped on the edge of the base of the saw.

SUPPORT FOR LONG PIECES

Turn Off and Unplug Saw

ALWAYS SUPPORT LONG PIECES.

Never use another person as a substitute for a table extension; as addi-

tional support for a workpiece that is longer or wider than the basic miter

saw table or to help feed, support or pull the workpiece.

For best results, use the DW7080 extension work support to extend the

table width of your saw. Available from your dealer at extra cost. Support

long workpieces using any convenient means such as sawhorses or similar devices to keep the ends from dropping.

FIG. 8

FIG. 9

L

V

R

P

U

O

N

FIG. 10

W

Page 10

9

CUTTING PICTURE FRAMES, SHADOW BOXES AND OTHER

FOUR-SIDED PROJECTS

To best understand how to make the items listed here, we suggest that

you try a few simple projects using scrap wood until you develop a

“FEEL” for your saw.

Your saw is the perfect tool for mitering corners like the one shown in

Figure 13. Sketch A in Figure 12 shows a joint made by using the bevel

adjustment to bevel the edges of the two boards at 45 degrees each to

produce a 90 degree corner. For this joint the miter arm was locked in the

zero position and the bevel adjustment was locked at 45 degrees. The

wood was positioned with the broad flat side against the table and the

narrow edge against the fence. The cut could also be made by mitering

right and left with the broad surface against the fence.

CUTTING TRIM MOLDING AND OTHER FRAMES

Sketch B in Figure 12 shows a joint made by setting the miter arm at

45 degrees to miter the two boards to form a 90 degree corner. To make

this type of joint, set the bevel adjustment to zero and the miter arm to

45 degrees. Once again, position the wood with the broad flat side on the

table and the narrow edge against the fence.

The two sketches in Figure 12 are for four-side objects only.

As the number of sides changes, so do the miter and bevel angles. The

chart below gives the proper angles for a variety of shapes.

(The chart assumes that all sides are of equal length.) For a shape that is

not shown in the chart, use the following formula. 180 degrees divided

by the number of sides equals the miter (if the material is cut vertically)

or bevel angle (if the material is cut laying flat).

- EXAMPLES -

NO. SIDES ANGLE MITER OR BEVEL

4 45°

5 36°

6 30°

7 25.7°

8 22.5°

9 20°

10 18°

CUTTING COMPOUND MITERS

A compound miter is a cut made using a miter angle and a bevel angle at

the same time. This is the type of cut used to make frames or boxes with

slanting sides like the one shown in Figure 14.

NOTE: If the cutting angle varies from cut to cut, check that the bevel

clamp knob and the miter lock knob are securely tightened. These knobs

must be tightened after making any changes in bevel or miter.

The chart shown on page 13 will assist you in selecting the proper bevel

and miter settings for common compound miter cuts. To use the chart,

select the desired angle “A” (Figure 14) of your project and locate that

angle on the appropriate arc in the chart. From that point follow the chart

straight down to find the correct bevel angle and straight across to find

the correct miter angle.

Set your saw to the prescribed angles and make a few trial cuts. Practice

fitting the cut pieces together until you develop a feel for this procedure

and feel comfortable with it.

Example: To make a four-sided box with 26° exterior angles (Angle A,

Figure 14), use the upper right arc. Find 26° on the arc scale. Follow

the horizontal intersecting line to either side to get miter angle setting on

saw (42°). Likewise, follow the vertical intersecting line to the top or bottom

to get the bevel angle setting on the saw (18°). Always try cuts on a few

scrap pieces of wood to verify settings on saw.

VERNIER SCALE

Your saw is equipped with a vernier scale for added precision. The vernier

scale allows you to accurately set miter angles to the nearest 1/4 degree.

To use the vernier scale follow the steps listed below.

(As an example, let’s assume that the angle you want to miter is

24-1/4 degree right).

1. Turn off miter saw.

2. Set the miter angle to the nearest whole degree desired by aligning

the center mark in the vernier scale, shown in Figure V1, with the

whole degree number etched in the miter scale. Examine Figure V2

closely; the setting shown is 24 degrees right miter.

3. To set the additional 1/4 degree, squeeze the miter arm lock and

carefully move the arm to the RIGHT until the 1/4 degree vernier

mark aligns with the CLOSEST degree mark on the miter scale. In our

example, the closest degree mark on the miter scale happens to be

25 degrees. Figure V2 shows a setting of 24-1/4 degrees right miter.

For settings that require partial degrees (1/4, 1/2, 3/4 degrees) align the

desired vernier mark with the CLOSEST degree mark on the miter scale,

as described below (The plastic vernier plate is inscribed with marks for

1/4, 1/2, 3/4 and 1 degrees. Only the 1/2 degree and the 1 degree are

numerically labeled.)

WHEN MITERING TO THE RIGHT

To increase the miter angle when mitering to the right, move the arm to

align the appropriate vernier mark with the closest mark on the miter

scale to the right. To decrease the miter angle when mitering to the right,

move the arm to align the appropriate vernier mark with the closest mark

on the miter scale to the left.

WHEN MITERING TO THE LEFT

To increase the miter angle when mitering to the left, move the arm to

align the appropriate vernier mark with the closest mark on the miter

scale to the left. To decrease the miter angle when mitering to the left,

move the arm to align the appropriate vernier mark with the closest mark

on the miter scale to the right.

CUTTING BASE MOLDING

ALWAYS MAKE A DRY RUN WITHOUT POWER BEFORE MAKING ANY

CUTS.

Straight 90 degree cuts:

Position the wood against the fence and hold it in place as shown in

Figure 15. Turn on the saw, allow the blade to reach full speed and

lower the arm smoothly through the cut.

CUTTING BASE MOLDING UP TO 25.4mm (1") THICK BY UP TO 91mm

(3-5/8") WIDE VERTICALLY AGAINST THE FENCE

• Position molding as shown in Figure 15

• All cuts made with the back of the molding against the fence and

bottom of the molding against the base

INSIDE CORNER:

Left side

1. Miter left 45°

2. Save left side of cut

Right side

1. Miter Right 45°

2. Save right side of cut

IMPROPER CUT

PROPER CUT

FIG. 11

FIG. 11A

Page 11

FIG. 15

FIG. 17

A

L

W

A

Y

S

A

D

J

U

S

T

F

E

N

C

E

P

R

O

P

E

R

L

Y

B

E

F

O

R

E

U

S

E

FIG. 16

10

OUTSIDE CORNER:

Left side

1. Miter right at 45°

2. Save left side of cut

Right side

1. Miter left at 45°

2. Save right side of cut

Material up to 91mm (3-5/8") can be cut as described above. For boards

[up to 173mm (6-3/4")] several minor concessions must be made:

When cutting a board between 91mm (3-5/8") and 173mm (6-3/4"),

the roller on the tip of the guard will hang up on the workpiece. If this

occurs, simply place your right thumb on the upper side of the guard

and roll the guard up just enough to clear the workpiece, as shown

in Figure 17. Once you have cleared the workpiece, you can release

the guard and it will continue to open as the cut progresses.

When mitering to the right side of a base molding 91mm (3-5/8")

standing vertically against the fence as in Figure 16, the saw can only

cut through the board up to 25.4mm (1") from the end of the board.

Trying to cut more than an inch will cause the saw’s gear case to

interfere with the workpiece. If you want to cut base molding between

91mm (3-5/8") and 173mm (6-3/4") vertically follow the directions

on this page.

CUTTING BASE MOLDING UP TO 25.4mm (1") THICK BY

91 x 173mm (3-5/8"– 6-3/4") WIDE 25.4mm (1") VERTICALLY

AGAINST THE FENCE

• Position molding as shown in Figure 15

• All cuts made with the back of the molding against the fence

INSIDE CORNER:

Left side

1. Position molding with bottom of molding against

the base of the saw

2. Miter left 45°

3. Save left side of cut

Right side

1. Position molding with top of the molding resting on

the base of the saw

2. Miter left 45°

3. Save left side of cut

OUTSIDE CORNER:

Left side

1. Position molding with bottom of molding against

the base of the saw

2. Miter right 45°

3. Save left side of cut

NOTE: If the cut must be made somewhere other than 1" from the end of

the molding: cut off the molding at 90° approx. 1" (25.4mm) longer than

your final length then make the miter cut as described above.

Right side

1. Position molding with bottom of the molding

against the base of the saw

2. Miter left 45°

3. Save the right side of cut

FIG. 12

FIG. 13

FIG. 14

A

B

ANGLE “A”

FIG. V1

FIG. V2

MITER

ANGLE

CENTER MARK ON VERNIER SCALE ALIGNS WITH

DESIRED WHOLE ANGLE ON MITER SCALE

(24° RIGHT MITER)

1/4° VERNIER MARK ALIGNS WITH CLOSET WHOLE

DEGREE MARK ON MITER SCALE

(24-1/4° RIGHT MITER)

KERF

PLATE

Page 12

11

CUTTING BASE MOLDING UP TO 45mm (1.8") THICK BY UP TO

195.6mm (7–11/16") WIDE LAYING FLAT AND USING THE

BEVEL FEATURE

• All cuts made with the saw set at 45° bevel and 0 miter.

• All cuts made with back of molding laying flat on the saw as shown

in Figures 17 and 18.

INSIDE CORNER:

Left side

1. Position molding with top of molding against the fence

2. Save left side of cut

Right side

1. Position molding with bottom of the molding against the fence

2. Save left side of cut

OUTSIDE CORNER:

Left side

1. Position molding with bottom of the molding against the fence

2. Save right side of cut

Right side

1. Position molding with top of molding against the fence

2. Save right side of cut

CUTTING CROWN MOLDING

Your miter saw is better suited to the task of cutting crown molding than

any tool made. In order to fit properly, crown molding must be compound mitered with extreme accuracy.

The two flat surfaces on a given piece of crown molding are at angles

that, when added together, equal exactly 90 degrees. Most, but not all,

crown molding has a top rear angle (the section that fits flat against the

ceiling) of 52 degrees and a bottom rear angle (the part that fits flat

against the wall) of 38 degrees.

Your miter saw has special pre-set miter latch points at 31.62 degrees left

and right for cutting crown molding at the proper angle and bevel stop pawl

at 33.85˚ left. There is also a mark on the bevel scale at 33.85 degrees.

The chart below gives the proper settings for cutting crown molding.

(The numbers for the miter and bevel settings are very precise and are

not easy to accurately set on your saw.) Since most rooms do not have

angles of precisely 90 degrees, you will have to fine tune your settings

anyway.

PRETESTING WITH SCRAP MATERIAL IS

EXTREMELY IMPORTANT!

INSTRUCTIONS FOR CUTTING CROWN MOLDING

LAYING FLAT AND USING THE COMPOUND FEATURES

1. Molding laying with broad back surface down flat on saw table

(Figure 19).

2. The settings below are for All Standard (U.S.) crown molding with

52° and 38° angles.

BEVEL SETTING TYPE OF CUT

LEFT SIDE, INSIDE CORNER:

33.85° 1. Top of molding against fence

2. Miter table set right 31.62°

3. Save left end of cut

RIGHT SIDE, INSIDE CORNER:

33.85° 1. Bottom of molding against fence

2. Miter table set left 31.62°

3. Save left end of cut

LEFT SIDE, OUTSIDE CORNER:

33.85° 1. Bottom of molding against fence

2. Miter table set left 31.62°

3. Save right end of cut

RIGHT SIDE, OUTSIDE CORNER:

33.85° 1. Top of molding against fence

2. Miter table set right 31.62°

3. Save right end of cut

When setting bevel and miter angles for all compound miters, remember

that:

The angles presented for crown moldings are very precise and

difficult to set exactly. Since they can easily shift slightly and

very few rooms have exactly square corners, all settings should

be tested on scrap molding.

PRETESTING WITH SCRAP MATERIAL

IS EXTREMELY IMPORTANT!

ALTERNATIVE METHOD FOR CUTTING CROWN MOLDING

Place the molding on the table at an angle between the fence and the saw

table, as shown in Figure 19A. Use of the crown molding fence accessory (DW7084) is highly recommended because of its degree of accuracy

and convenience. The crown molding fence accessory is available for

purchase from your local dealer.

The advantage to cutting crown molding using this method is that no bevel

cut is required. Minute changes in the miter angle can be made without

affecting the bevel angle. This way, when corners other than 90 degrees

are encountered, the saw can be quickly and easily adjusted for them. Use

the crown molding fence accessory to maintain the angle at which the

molding will be on the wall.

INSTRUCTIONS FOR CUTTING CROWN MOLDING ANGLED BETWEEN

THE FENCE AND BASE OF THE SAW FOR ALL CUTS:

1. Angle the molding so the bottom of the molding (part which goes

against the wall when installed) is against the fence and the top

of the molding is resting on the base of the saw, as shown in

Figure 19A.

2. The angled “flats” on the back of the molding must rest squarely on

the fence and base of the saw.

INSIDE CORNER:

Left side

1. Miter right at 45°

2. Save the right side of cut

Right side

1. Miter left at 45°

2. Save left side of cut

OUTSIDE CORNER:

Left side

1. Miter left at 45°

2. Save right side of cut

Right side

1. Miter right at 45°

2. Save left side of cut

FIG. 19

FENCE

TABLE

CROWN MOLDING FLAT ON TABLE AND

AGAINST FENCE

CROWN MOLDING BETWEEN FENCE AND TABLE

TABLE

FENCE

BOTTOM SIDE OF

MOLDING

TOP SIDE

OF MOLDING

FIG. 19A

DW 7084 CROWN

MOLDING FENCE

FIG. 18

Page 13

FIG. 21

FIG. 21A

RIGHT

WRONG

12

Special Cuts

NEVER MAKE ANY CUT UNLESS THE MATERIAL IS SECURED ON THE

TABLE AND AGAINST THE FENCE.

ALUMINUM CUTTING

ALWAYS USE THE APPROPRIATE SAW BLADE MADE ESPECIALLY FOR

CUTTING ALUMINUM. Certain workpieces, due to their size, shape or

surface finish, may require the use of a clamp or fixture to prevent

movement during the cut. Position the material so that you will be cutting

the thinnest cross section, as shown in Figure 20. Figure 20A illustrates

the wrong way to cut these extrusions. Use a stick wax cutting lubricant

when cutting aluminum. Apply the stick wax directly to the saw blade

before cutting. Never apply stick wax to a moving blade.

The wax, available at most hardware stores and industrial mill supply

houses, provides proper lubrication and keeps chips from adhering to the

blade.

Be sure to properly secure workpiece. Refer to page 3 for correct saw

blade.

FIG. 20

BLADE

FENCE

RIGHT

FIG. 20A

BLADE

FENCE

WRONG

Normal wear parts are not covered in this service. Carbon brushes worn

more then 50% will be replaced.

NOTE: Three Year Warranty is not applicable to items deemed as consumables. Radial arm saws are covered by a one (1) year warranty only.

DEWALT Reserves the right to review its warranty policy |prior to launch

of any new business

development products.

30 DAY NO SATISFACTION GUARANTEE

If you are dissatisfied with any DEWALT power tool, laser or nailer, for any

reason, simply return it to

the point of purchase with your sales receipt within 30 days for a replacement unit or a full refund.

FREE WARNING LABEL REPLACEMENT: If your warning labels become

illegible or are missing, call (AUS) 1800 654 155 or (NZ) 09 526 2556

for a free replacement.

BOWED MATERIAL

When cutting bowed material always position it as shown in Figure 21

and never like that shown in Figure 21A. Positioning the material incorrectly will cause it to pinch the blade near the completion of the cut.

CUTTING PLASTIC PIPE OR OTHER ROUND MATERIAL

Plastic pipe can be easily cut with your saw. It should be cut just like

wood and CLAMPED OR HELD FIRMLY TO THE FENCE TO KEEP IT

FROM ROLLING. This is extremely important when making angle cuts.

CUTTING LARGE MATERIAL

Occasionally you will encounter a piece of wood a little too large to fit

beneath the blade guard. If this occurs, simply place your right thumb on

the upper side of the guard and roll the guard up just enough to clear the

workpiece, as shown in Figure 16. Avoid doing this as much as possible,

but if need be, the saw will operate properly and make the bigger cut.

NEVER TIE, TAPE, OR OTHERWISE HOLD THE GUARD OPEN WHEN

OPERATING THIS SAW.

Maintenance

1. All bearings are sealed. They are lubricated for life and need no

further maintenance.

2. Periodically clean all dust and wood chips from around AND UNDER

the base and the rotary table. Even though slots are provided to allow

debris to pass through, some dust will accumulate.

3. The brushes are designed to give you several years of use. If they

ever need replacement follow the instructions on page 7 or return the

tool to the nearest service center for repair. Service center locations

are packed with your tool.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustments should be performed by a D

EWALT factory service center, a

DEWALT authorized service center or other qualified service personnel.

Always use identical replacement parts.

Guarantee

Applicable to hand held Power Tools, Lasers and Nailers.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or

workmanship for three years from the date of purchase. Please return the

complete unit, transportation prepaid, to any DEWALT Service Centre, or

any authorised service station.

For warranty repair information, call (AUS) 1800 654 155 or (NZ) 09 526

2556.

This warranty does not apply to

• Accessories

• Damage caused where repairs have been made or attempted by

others.

• Damage due to misuse, neglect, wear and tear, alteration or

modification.

This warranty gives you specific legal rights and you may have other rights

under the provisions of the Consumer Guarantee Act 1993 (New Zealand

only), Trade Practices Act 1974 and State Legislation (Australia only).

In addition to the warranty, D

EWALT tools are covered by our:

FREE ONE YEAR SERVICE CONTRACT

D

EWALT will also maintain the tool for free at any time during the first

year of purchase. This includes labour, parts and lubrication required to

restore the product to sound mechanical and/or electrical condition.

Page 14

13

10

10

10

20

20

20

30

30

30

40

40

40

50

50

50

60

60

60

70

70

70

80

80

80

TABLE 1 COMPOUND MITER CUT (Position wood with broad flat side on the table and the narrow edge against the fence.)

SET THIS MITER ANGLE ON SAW

SQUARE BOX

6-SIDED BOX

SET THIS BEVEL ANGLE ON SAW

8-SIDED BOX

Page 15

14

Troubleshooting Guide

BE SURE TO FOLLOW SAFETY RULES AND INSTRUCTIONS

TROUBLE! SAW WILL NOT START

WHAT’S WRONG? WHAT TO DO…

1. Saw not plugged in 1. Plug in saw.

2. Fuse blown or circuit breaker tripped 2. Replace fuse or reset circuit breaker

3. Cord damaged 3. Have cord replaced by authorized service center

4. Brushes worn out 4. Have brushes replaced by authorized service center or replace them

yourself as instructed on page 7.

TROUBLE! SAW MAKES UNSATISFACTORY CUTS

WHAT’S WRONG? WHAT TO DO…

1. Dull blade 1. Replace blade. See pages 5, 6.

2. Blade mounted backwards 2. Turn blade around. See page 6.

3. Gum or pitch on blade 3. Remove blade and clean with turpentine and coarse steel wool or

household oven cleaner.

4. Incorrect blade for work being done 4. Change the blade type. See page 3.

TROUBLE! BLADE DOES NOT COME UP TO SPEED

WHAT’S WRONG? WHAT TO DO…

1. Extension cord too light or too long 1. Replace with adequate size cord. See page 2.

2. Low house voltage 2. Contact your electric company.

TROUBLE! MACHINE VIBRATES EXCESSIVELY

WHAT’S WRONG? WHAT TO DO…

1. Saw not mounted securely to stand or work bench 1. Tighten all mounting hardware. See page 4.

2. Stand or bench on uneven floor 2. Reposition on flat level surface. See page 4.

3. Damaged saw blade 3. Replace blade. See pages 5, 6.

TROUBLE! DOES NOT MAKE ACCURATE MITER CUTS

WHAT’S WRONG? WHAT TO DO…

1. Miter scale not adjusted correctly 1. Check and adjust. See page 6.

2. Miter pointer not adjusted correctly 2. Check and adjust. See page 6.

3. Workpiece is not perpendicular to table 3. Check and adjust fence. See page 6.

4. Workpiece moving 4. Clamp workpiece to fence or glue 120 grit sandpaper

to fence with rubber cement.

TROUBLE! MATERIAL PINCHES BLADE

WHAT’S WRONG? WHAT TO DO…

1. Cutting bowed material 1. Position bowed material as shown on page 12.

Page 16

DEWALT Industrial Tool Co.,

701 East Joppa Road, Baltimore, MD 21286 • 20 Fletcher Road, Mooroolbark, VIC 3138 Australia

(JUL05) Form No. 633365-00 DW715-XE Copyright © 2005 DEWALT

The following are trademarks for one or more DEWALT power tools: the yellow and black color scheme; the “D” shaped air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped

humps on the surface of the tool.

Loading...

Loading...