Page 1

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 Printed in U.S.A. (JAN02-CD-1) Form No. 606564

DW151, DW159 Copyright © 2002

The following are trademarks for one or more DEWALT power tools: the yellow and black color scheme; the “D” shaped air intake grill; the array of

pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps on the surface of the tool.

606564/DW151 10/1/02 10:20 AM Page 2

Page 2

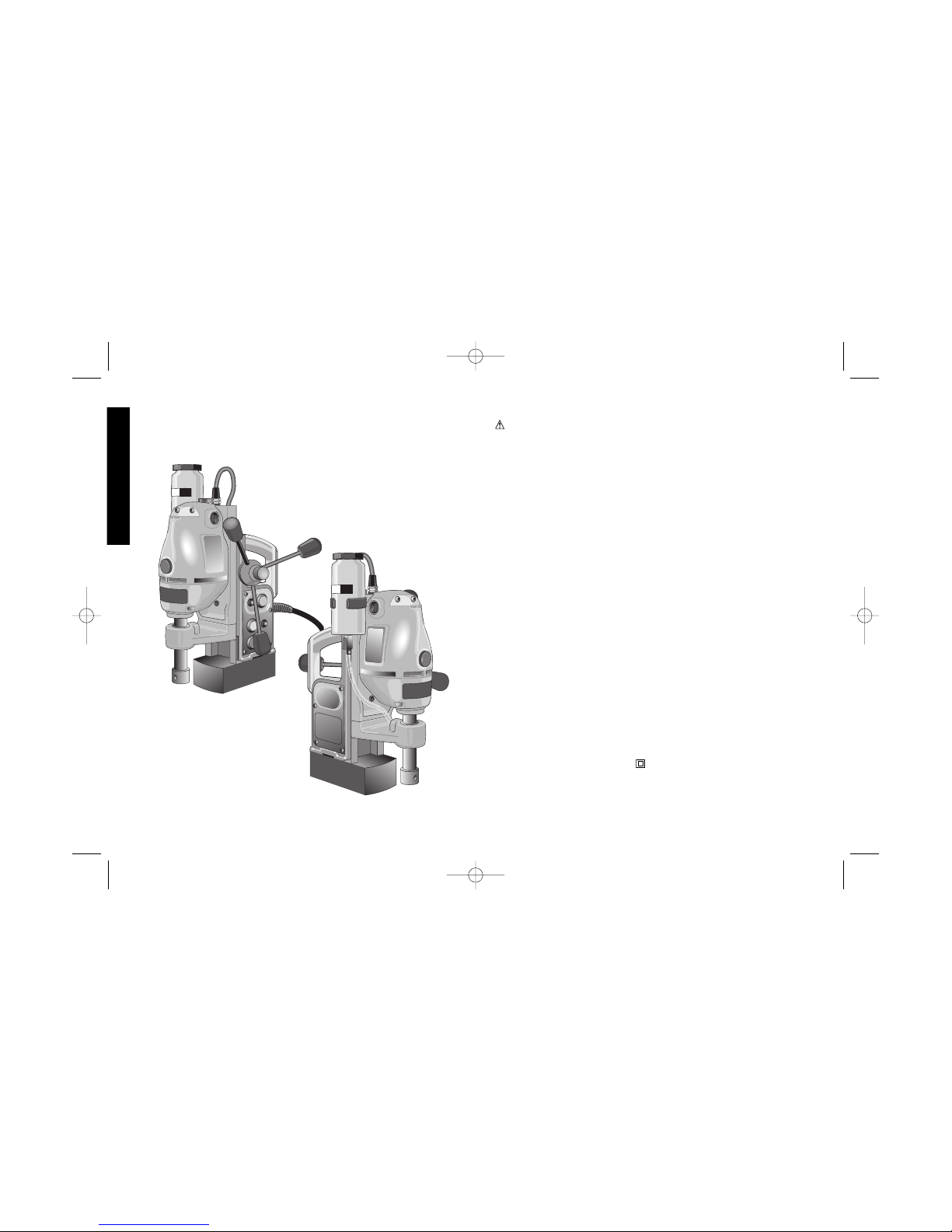

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW151, DW159

Heavy Duty Magnetic Drill Press

Perceuse magnétique à colonne de service intensif

Taladro de columna magnético para trabajo pesado

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

Questions? See us on the World Wide Web at www.dewalt.com

606564/DW151 10/1/02 10:20 AM Page 3

Page 3

General Safety Rules

WARNING! Read and understand all instructions. Failure to follow

all instructions listed below may result in electric shock, fire and/or

serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered benches and dark

areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in

the presence of flammable liquids, gases, or dust. Power tools

create sparks which may ignite the dust or fumes.

• Keep bystanders, children, and visitors away while operating a

power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

• Grounded tools must be plugged into an outlet properly installed

and grounded in accordance with all codes and ordinances.

Never remove the grounding prong or modify the plug in any way.

Do not use any adapter plugs. Check with a qualified electrician if

you are in doubt as to whether the outlet is properly grounded. If

the tools should electrically malfunction or break down, grounding

provides a low resistance path to carry electricity away from the user.

Applicable only to Class I (Grounded) tools.

• Double insulated tools are equipped with a polarized plug (one

blade is wider than the other.) This plug will fit in a polarized

outlet only one way. If the plug does not fit fully in the outlet,

reverse the plug. If it still does not fit, contact a qualified

electrician to install a polarized outlet. Do not change the plug in

any way. Double Insulation eliminates the need for the three wire

grounded power cord and grounded power supply system. Applicable

only to Class ll tools.

• Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of

electric shock if your body is grounded.

English

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS

OR ANY D

EWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

606564/DW151 10/1/02 10:20 AM Page 4

Page 4

• Don’t expose power tools to rain or wet conditions. Water entering

a power tool will increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the tools or

pull the plug from an outlet. Keep cord away from heat, oil, sharp

edges or moving parts. Replace damaged cords immediately.

Damaged cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor extension

cord marked “W-A” or “W.” These cords are rated for outdoor use

and reduce the risk of electric shock.

Recommended Minimum Wire Size for Extension Cords

Total Length of Cord

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Wire Gauge

18 AWG 18 AWG 16 AWG 16 AWG 14 AWG 14 AWG 12 AWG

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use tool while tired or under

the influence of drugs, alcohol, or medication. A moment of

inattention while operating power tools may result in serious personal

injury,

• Dress properly. Do not wear loose clothing or jewelry. Contain

long hair. Keep your hair, clothing, and gloves away from moving

parts. Loose clothes, jewelry, or long hair can be caught in moving

parts.

• Avoid accidental starting. Be sure switch is off before plugging in.

Carrying tools with your finger on the switch or plugging in tools that

have the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the tool on. A

wrench or a key that is left attached to a rotating part of the tool may

result in personal injury.

• Do not overreach. Keep proper footing and balance at all times.

Proper footing and balance enables better control of the tool in

unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask,

1

English

non-skid safety shoes, hard hat, or hearing protection must be used for

appropriate conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure and support the

workpiece to a stable platform. Holding the work by hand or against

your body is unstable and may lead to loss of control.

• Do not force tool. Use the correct tool for your application. The

correct tool will do the job better and safer at the rate for which it is

designed.

• Do not use tool if switch does not turn it on or off. Any tool that

cannot be controlled with the switch is dangerous and must be

repaired.

• Disconnect the plug from the power source before making any

adjustments, changing accessories, or storing the tool. Such

preventive safety measures reduce the risk of starting the tool

accidentally.

• Store idle tools out of reach of children and other untrained

persons. Tools are dangerous in the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools, with sharp cutting edges are less likely to

bind and are easier to control.

• Check for misalignment or binding of moving parts, breakage of

parts, and any other condition that may affect the tools operation.

If damaged, have the tool serviced before using. Many accidents

are caused by poorly maintained tools.

• Use only accessories that are recommended by the manufacturer

for your model. Accessories that may be suitable for one tool, may

become hazardous when used on another tool.

SERVICE

• Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by unqualified

personnel could result in a risk of injury.

• When servicing a tool, use only identical replacement parts.

Follow instructions in the Maintenance section of this manual.

Use of unauthorized parts or failure to follow Maintenance Instructions

606564/DW151 10/1/02 10:20 AM Page 1

Page 5

2

may create a risk of electric shock or injury.

Additional Safety Instructions

• Always use safety strap. Mounting can release. Electrical power

may fail or unit may accidentally disconnect.

• Always be sure that the drill press is plugged into the correct

voltage system. Place cord so that it cannot be pulled from the

receptacle accidentally. Check for correct line fuse.

• Before operating unit, make sure it is grounded correctly in

accordance with instructions under “Electrical Safety.”

• Always use the correct gauge extension cord .

• Care should be taken to place the base on a flat surface. Do

not set magnet on objects such as bolt heads, screws, rivets, or

steel chips, since space between magnet and working surface

weakens the magnetic pull.

• Always place the unit on a surface that is clear of shavings,

chips or surface dirt to allow for optimum magnetic hold.

CAUTION: Wear appropriate personal hearing protection during

use. Under some conditions and duration of use, noise from this

product may contribute to hearing loss.

CAUTION: DO NOT USE FEED HANDLE TO LIFT UNIT.

CAUTION: After switching power to the magnet off, the magnetic

base will continue to adhere to the surface for 5 seconds before

releasing. A light blow with the hand will release the base.

WARNING: Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, such as dust masks that are specially designed to filter

out microscopic particles.

• Avoid prolonged contact with sawdust from treated lumber. Do

not allow dust to get into your mouth, eyes or lay on the skin. Wear

protective clothing whenever possible.

• The label on your tool may include the following symbols.

V....................volts

A....................amperes

Hz..................hertz

W ..................watts

min ................minutes

AC ................alternating current

DC ................direct current

n

o ..................no load speed

..................

Class II Construction

…/min ............revolutions or reciprocation per minute

..................earthing terminal

..................safety alert symbol

Motor

Your DEWALT tool is powered by a DEWALT-built motor. Be sure your

power supply agrees with the nameplate marking.

Volts 60 Hz or “AC only” means your tool must be operated only with

alternating current and never with direct current.

Voltage decrease of more than 10% will cause loss of power and

overheating. All D

EWALT tools are factory tested; if this tool does not

operate, check the power supply. If the motor does not operate when

the green button is pushed, check the voltage at the power supply.

Operation

The magnet in this unit is designed for use on 3/8"(10mm) thick

steel—with zero air gap. Air gap may be defined as the distance

English

606564/DW151 10/1/02 10:20 AM Page 2

Page 6

between the magnet core surface and the mounting plate. The two

surfaces will be kept apart by curvature, coats of paint, by surface

irregularities, bolt heads, etc. Holding power is reduced by rough or

uneven surfaces, insufficient thickness of steel or insufficient

mounting area for the magnet base. The

magnet rapidly loses its holding power when

this surface irregularity raises the air gap above

1/64"(.4mm). Keep this air gap to a minimum

and be sure to smooth the surface removing

any undue projections, chips or other items that

will not allow full metal to metal contact. If the

magnet fails to hold on a metal surface, it may

be due to this condition and a check can be

made with a feeler gauge or similar device in

order to determine if an air gap exists under the

magnet at the crucial points.

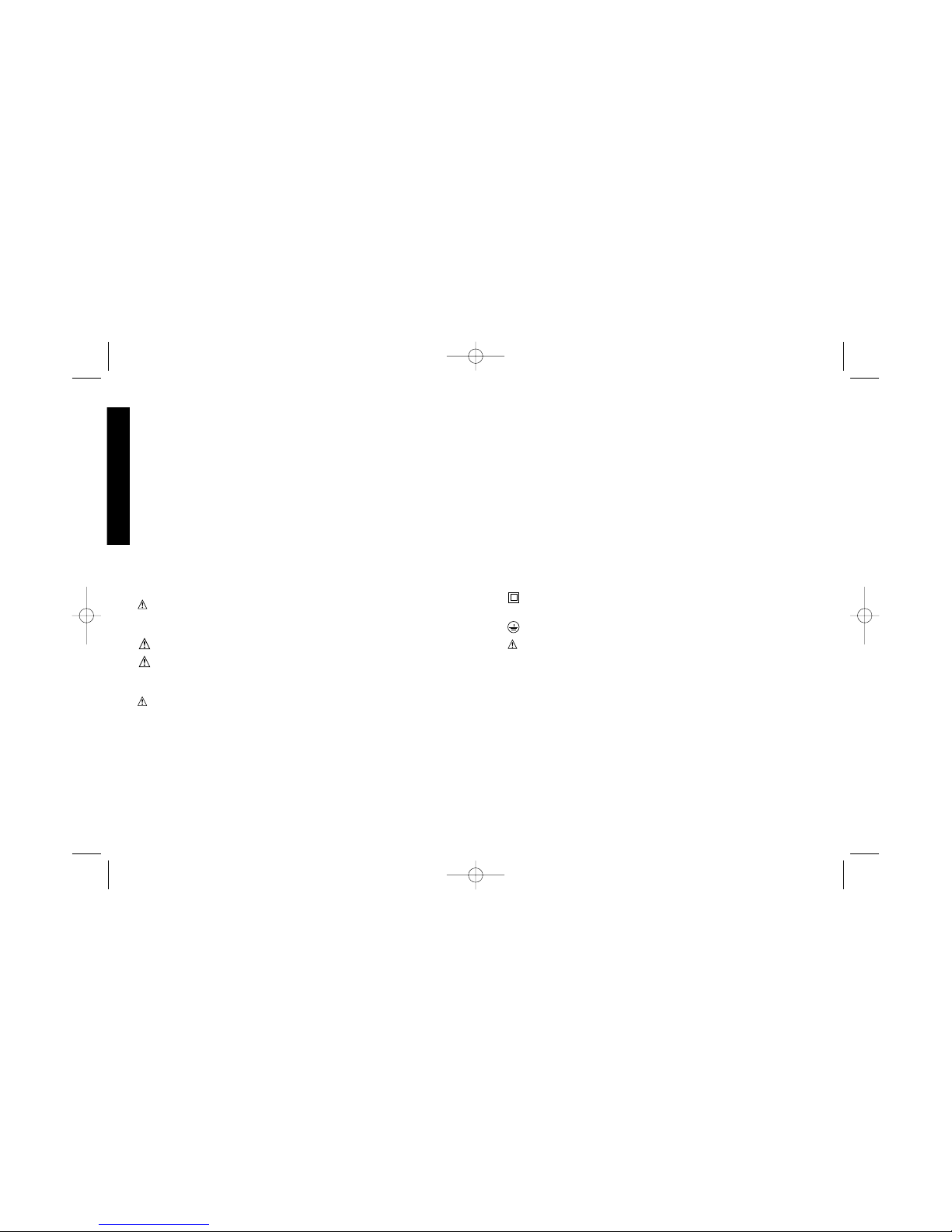

1. Place drill press on work surface so that drill

point or cutter pilot is directly over spot to be drilled. Push the red

button (A) to give power to the tool. Position the cutter directly over

the spot to be drilled and turn the magnet on by pressing the

yellow button (B). Turn power on to the motor by pressing the

green button (C). When drilling in an overhead or vertical position,

the safety strap (D) must be employed.

(Fitted in slot in base as shown)

NOTE: Replace strap if edges become frayed.

Inspect the strap before each use. New straps

are available at your retailer or D

EWALT service

center.

2. Gently apply pressure to feed handle until twist

drill or cutter has a full bite then apply steady

pressure until cut is complete.

3. Turn off motor and allow motor to run down

3

English

before turning magnet off.

4. Turn magnet off by pressing the yellow button. The magnet will

remain engaged for 5 seconds before releasing.

5. After each use, remove all chips from

magnet surface.

Operation with DEWALT

Annular Cutters

1. This unit was designed with user

convenience and safety in mind

2. User safety:

The switches are arranged to prevent

accidental motor start up before the magnet is energized.

The handles are arranged to allow for easy vertical and overhead

placement.

3. This unit comes equipped with a quick release feed handle (E). By

depressing a button, the feed handle can be

switched from the left to the right side of the unit.

The magnet is designed to adhere to 3/8”(10mm)

or greater thickness of flat steel or iron.

NOTE: DW151 can be adapted for use with twist

drill bits with addition of DW1561 Chuck Adapter.

4. Place proper pilot pin into desired cutter from the

top and insert cutter into the arbor. Line up cutter

flats with arbor set screws. Tighten both set

screws securely. (Make sure flats are properly

located under set screws so that they remain

recessed below surface of the shaft).

5. Fill reservoir with non oil-based cutting fluid. This

fluid is formulated to give the best performance

and life to the rotary cutters. Fluid will be released down pilot shaft

by gravity feed. Test by running cutter up and down against work

surface to start fluid flowing. Do not use liquid cutting fluids while

A

B

D

E

C

F

G

606564/DW151 10/1/02 10:20 AM Page 3

Page 7

drilling vertically or overhead. Dip cutter in cutting paste for these

applications..

NOTE: This unit features an on-board lubrication system. To use

the lubrication system, remove the hose (F) from the bottle by

depressing the black collar (G) into the bottle. Remove the hose

from the bottom of the petcock. Remove the bottle from the

bracket and fill with cutting fluid. Replace bottle in bracket and

replace hose. Turn the petcock counterclockwise to start the fluid.

Turn the petcock clockwise to close the valve when the cut is

finished. The bearings are lubricated by the on-board system.

WARNING: Do not pour cutting fluid into the bottle while

mounted in the bracket. Do not allow cutting fluid to enter the

drill motor. Electric shock may result.

6. Start motor by pressing the green button.

7. Bring cutter lightly to the surface to be cut allowing 25-30

revolutions, bringing up light chip so that cutter has established an

external groove. This will position you properly. Apply steady

pressure through the entire cut. It is more important to keep rpms

up than to apply excessive force, causing cutter to slow motor

down. This will attain better cutting action, better cutter life, and

cleaner holes.

8. Slug should be expelled on the down stroke. If not, it will be

expelled automatically when motor is returned to the extreme up

position.

CAUTION: Gloves should be worn when handling slugs to avoid

injury to the hand by hot surfaces or sharp edges.

Operation of Swivel Base (DW159)

1. Place unit on work surface sot that the point is near the center of

the hole to be drilled.

2. Push the red button to turn power on.

3. Push the yellow button to activate magnet.

4

English

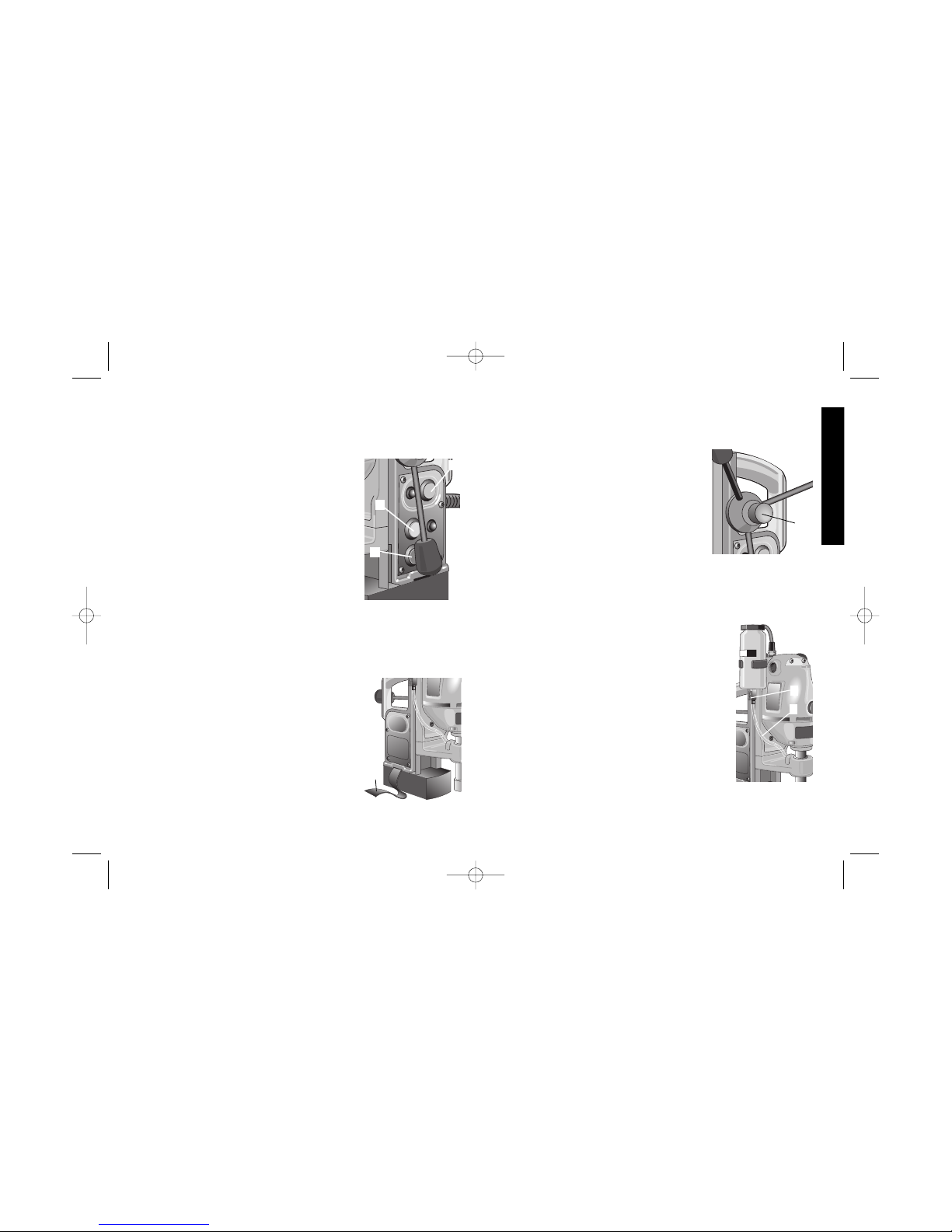

4. Turn lever (H) counterclockwise to loosen the

swivel base.

5. Move the drill and rotate about the magnet

until the pilot pin is directly above the center

of the hole to be drilled.

6. Turn lever clockwise to tighten the swivel.

Operation of the Forward/Reverse

Feature (DW159)

The forward/reverse switch is a collar (I) on the top of the drill unit of

the DW159 only.

Control

Apply sufficient pressure to achieve a smooth, progressive cut. Do

not force unit. If magnet starts to lift from work plate, decrease

pressure slightly and it will reclamp. Drill point pressure may exceed

holding power under one or more of the following conditions:

1. Excessive air gap—1/64"(.4mm) or more.

2. Thin metal (under 3/8"(10mm) depending upon position and

condition of metal surface.)

3. Metal with low magnetic properties.

4. Uneven or rough surface.

H

I

606564/DW151 10/1/02 10:20 AM Page 4

Page 8

5

English

5. Low line voltage.

How To Drill

For accuracy drill a small lead hole before using the final size drill.

Large diameter drills will “walk” off center until drill reaches full

diameter at which point the outside diameter acts as a pilot in the

hole being drilled. This is not peculiar to magnetic drill presses, but

is general machine shop knowledge on any large hole drilling.

Brushes

Carbon brushes should be regularly inspected for wear. When the

cap is unscrewed, the spring and brush assembly may be withdrawn

from the tool.

Keep brushes clean and sliding freely in their guides. Carbon

brushes have varying symbols stamped into them, and if the brush

is worn down to the line closest to the spring, they must be replaced.

New brush assemblies are available at service centers.

Adjustments

This unit is designed with a lubricated gib and is adjusted at the factory.

The gib may by lubricated periodically with grease to ensure smooth

operation. The gib should be tight enough to retain the motor in the

upward (retracted) position. Should this need adjustment, tighten 5

self-locking set screws on the side of the drill press body.

Accessories

Recommended accessories for use with your tool are available at

extra cost from your distributor or your local service center.

CAUTION: The use of any non-recommended accessory may be

hazardous.

If you need assistance in locating any accessory, call us at:

1-800-4-D

EWALT or contact DEWALT Industrial Tool Co., 701 East

Joppa Road, Baltimore, MD 21286

1. DW1561 Chuck Adapter for DW151.

2. Mandrels and hole saws up to 2"(51mm) diameter.

3. Rotary cutters and pilots 7/16"(11mm) thru 2"(51mm) diameter.

4. Twist drill bits 1/4" (6mm) to 13/16" (21mm)

5. Taps 1/4" (6mm) to 13/16" (21mm)(DW159 only)

6. Reamers, Light Gauge 1/4" (6mm) to 5/8"(16mm)

Reamers, Heavy Gauge1/4" (6mm) to 1/2"(13mm)

Important

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by authorized service centers or other qualified service

organizations, always using identical replacement parts.

Full Warranty

D

EWALT heavy duty industrial tools are warranted for one year from

date of purchase. We will repair, without charge, any defects due to

faulty materials or workmanship. For warranty repair information, call

1-800-4-D

EWALT. This warranty does not apply to accessories or

damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may have

other rights which vary in certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your

D

EWALT heavy duty industrial tool, simply return it to the participating

seller within 30 days for a full refund. Please return the complete

unit, transportation prepaid. Proof of purchase may be required.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-DEWALT for a free

replacement.

606564/DW151 10/1/02 10:20 AM Page 5

Page 9

6

Français

SI VOUS AVEZ DES QUESTIONS OU VOUS VOULEZ NOUS FAIRE

PART DE VOS COMMENTAIRES CONCERNANT CET OUTIL OU

TOUT AUTRE OUTIL DEWALT, COMPOSEZ SANS FRAIS LE :

1 800 433-9258.

Règles de sécurité – Généralités

AVERTISSEMENT! Lire et comprendre toutes les directives, car le

non-respect des directives suivantes peut entraîner un choc

électrique, un incendie ou des blessures graves.

CONSERVER CES DIRECTIVES

ZONE DE TRAVAIL

· Garder la zone de travail propre et bien éclairée; les établis

encombrés et les endroits sombres sont propices aux accidents.

· Ne pas utiliser les outils électriques dans une atmosphère

explosive, comme à proximité de liquides, de gaz ou de

poussières inflammables; le moteur peut créer des étincelles et

enflammer les vapeurs ou les poussières environnantes.

· Tenir les enfants, les visiteurs ou toute autre personne

éloignés lorsqu’on utilise un outil électrique; les distractions

peuvent faire perdre la maîtrise de ce dernier.

MESURES DE SÉCURITÉ - ÉLECTRICITÉ

· Les outils mis à la terre doivent être branchés dans une prise

bien installée et mise à la terre conformément à tous les codes

et règlements en vigueur. Ne jamais retirer la broche de terre ni

modifier la fiche. Ne pas utiliser d'adaptateur. Vérifier auprès d'un

électricien qualifié en cas de doute quant à la mise à la terre de la

prise. En cas de défaillance électrique ou de bris de l'outil, la mise

à la terre procure un chemin de faible résistance au courant qui

autrement traverserait l'utilisateur. Cette protection ne s’applique

qu’aux outils de classe I (mis à la terre).

· Les outils à double isolation sont munis d’une fiche polarisée

POUR TOUT RENSEIGNEMENT SUPPLÉMENTAIRE SUR CET

OUTIL OU TOUT AUTRE OUTIL DEWALT, COMPOSER SANS

FRAIS LE NUMÉRO:

1 800 4-DEWALT (1 800 433-9258)

606564/DW151 10/1/02 10:20 AM Page 6

Page 10

7

Français

(c’est-à-dire que l’une des lames est plus large que l’autre),

laquelle ne peut être raccordée qu’à une prise polarisée et ce,

dans un seul sens; on doit l’inverser si on est incapable de

l’enfoncer complètement. Si la fiche ne s’adapte toujours pas,

on doit demander à un électricien qualifié d’installer la prise

appropriée. On ne doit jamais modifier la fiche. La double isolation

élimine le besoin d’installer un cordon d’alimentation trifilaire et un

système d’alimentation électrique pourvus d’une mise à la terre;

seuls les outils de classe II (à double isolation) sont munis d’une

telle protection.

· Éviter tout contact entre le corps et les éléments mis à la terre,

comme les tuyaux, les radiateurs, les cuisinières et les

réfrigérateurs, afin de réduire les risques de choc électrique.

· Ne pas utiliser l’outil électrique dans des endroits mouillés, ni

l’exposer à la pluie; l’infiltration d’eau à l’intérieur de l’outil

augmente les risques de choc électrique.

· Ne pas utiliser le cordon de manière abusive; on ne doit pas

transporter l’outil en le tenant par le cordon, ou utiliser ce

dernier pour le débrancher. On doit tenir le cordon éloigné des

sources de chaleur, de l’huile, des bords tranchants ou des pièces

mobiles. Remplacer immédiatement les cordons endommagés, car

ces derniers augmentent les risques de choc électrique.

· Lorsqu’on utilise un outil électrique à l’extérieur, on ne doit utiliser

que des rallonges conçues pour cet usage, comme celles de type

W-A ou W, afin de réduire les risques de choc électrique.

Calibre minimal des cordons de rallonge

Longueur totale du cordon

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7,6 m 15,2 m 22,9 m 30,5 m 38,1 m 45,7 m 53,3 m

Intensité

18 AWG 18 AWG 16 AWG 16 AWG 14 AWG 14 AWG 12 AWG

10- 12 16 16 14 12

12- 16 14 12 Non recommandé

SÉCURITÉ PERSONNELLE

· Rester vigilant en tout temps et faire preuve de jugement

lorsqu’on utilise un outil électrique; ne pas utiliser l’outil lorsqu’on

est fatigué ou sous l’influence de drogues, d’alcool ou de

médicaments, car un moment d’inattention peut entraîner des

blessures graves.

· Porter des vêtements appropriés; ne pas porter de vêtements

amples ni de bijoux. Couvrir ou attacher les cheveux longs. Garder les

cheveux, les vêtements, les bijoux et les gants éloignés des pièces

mobiles, car ceux-ci peuvent s’y coincer.

· Éviter les démarrages accidentels; s’assurer que l’interrupteur soit

en position d’arrêt avant de brancher l’outil. Ne pas transporter l’outil

en laissant le doigt sur l’interrupteur ni le brancher lorsque l’interrupteur

est en position de marche, car cela pourrait causer un accident.

· Retirer les clés de réglage avant de démarrer l’outil; une clé laissée

sur une pièce rotative peut entraîner des blessures.

· Ne pas trop étendre les bras; les pieds doivent rester ancrés

fermement au sol afin de maintenir son équilibre en tout temps et de

mieux maîtriser l’outil dans des situations imprévues.

· Utiliser le matériel de sécurité approprié; toujours porter des

lunettes de protection. Porter un masque anti-poussières, des

chaussures antidérapantes, un casque de sécurité ou des protecteurs

auditifs lorsque la situation le requiert.

UTILISATION ET ENTRETIEN DE L’OUTIL

· Fixer et soutenir la pièce sur une plate-forme stable au moyen

d’une butée fixe ou de tout autre dispositif semblable; la pièce est

instable lorsqu’on la retient manuellement ou qu’on l’appuie contre le

corps, ce qui peut faire perdre la maîtrise de l’outil.

· Ne pas forcer l’outil ni l’utiliser pour des travaux autres que ceux

pour lesquels il a été conçu. Pour obtenir de meilleurs résultats et

prévenir les risques de blessure, laisser l’outil couper à la vitesse pour

laquelle il a été conçu.

· Ne pas utiliser l’outil lorsque l’interrupteur marche-arrêt ne

fonctionne pas; tout outil qui ne peut être commandé au moyen de

606564/DW151 10/1/02 10:20 AM Page 7

Page 11

8

Français

l’interrupteur est dangereux et doit être réparé.

· Débrancher l’outil avant d’effectuer un réglage, de changer les

accessoires ou de ranger l’outil; ces mesures de sécurité

préventives réduisent les risques de démarrage accidentel.

· Lorsqu’on n’utilise pas l’outil, le ranger hors de la portée des

enfants ou des personnes non qualifiées; les outils sont dangereux

entre les mains de personnes inexpérimentées.

· Bien entretenir l’outil et s’assurer qu’il soit toujours bien propre

et aiguisé; les outils bien entretenus et dont les bords sont bien

tranchants sont moins susceptibles de rester coincés et sont plus

faciles à maîtriser.

· Vérifier les pièces mobiles afin de s’assurer qu’elles soient bien

alignées et qu’elles ne restent pas coincées; vérifier également les

pièces afin de s’assurer qu’il n’y ait ni bris ni aucune autre condition

susceptible de nuire au bon fonctionnement de l’outil; faire réparer

l’outil si ce dernier est endommagé avant de s’en servir à nouveau, car

les accidents sont souvent causés par des outils mal entretenus.

· N’utiliser que les accessoires recommandés par le fabricant pour

le modèle en question; un accessoire destiné à un outil particulier

peut devenir dangereux lorsqu’il est utilisé avec un autre.

ENTRETIEN

· L’outil doit être entretenu par le personnel qualifié seulement;

toute maintenance effectuée par une personne non qualifiée peut

entraîner des risques de blessure.

· Lors de l’entretien, n’utiliser que des pièces de rechange

identiques et suivre les directives de la section «Entretien» du

présent manuel afin de prévenir les risques de choc électrique ou de

blessure.

Consignes de sécurité additionnelles

· Toujours utiliser la courroie de sécurité, car la base pourrait se

dégager. L’alimentation électrique risque d’être coupée si l’outil est

débranché accidentellement.

· Toujours s’assurer que la perceuse à colonne est enfichée dans

une prise ayant la tension appropriée. Placer le cordon de manière

à éviter de le débrancher accidentellement; s’assurer que le fusible du

circuit convient à l’outil.

· Avant de faire fonctionner l’outil, s’assurer qu’il est bien mis à la

terre, conformément à la section « Directives de mise à la terre » du

présent guide.

· Toujours utiliser une rallonge de calibre approprié.

· S’assurer de placer la base de l’outil sur une surface plane; ne pas

déposer l’aimant sur des objets tels que les têtes de boulons, les vis,

les rivets ou les copeaux d’acier puisque l’espace entre l’aimant et la

surface de travail affaiblit sa capacité d’adhérence.

· Toujours placer l’outil sur une surface exempte de particules, de

copeaux et de poussière afin d’optimiser sa capacité d’adhérence.

AVERTISSEMENT! Porter des lunettes de sécurité ou autre dispositif

de protection oculaire car le martelage peut faire projeter des

particules et entraîner des dommages irréversibles aux yeux.

MISE EN GARDE : NE PAS SOULEVER L’OUTIL AU MOYEN DE LA

POIGNÉE D’ALIMENTATION.

MISE EN GARDE : la base magnétique adhère à la surface pendant

5 secondes une fois que l’aimant est mis hors tension; frapper légèrement

la base avec la main afin de détacher l’aimant.

AVERTISSEMENT : certains outils électriques, tels que les sableuses,

les scies, les meules, les perceuses ou certains autres outils de

construction, peuvent produire de la poussière contenant des produits

chimiques susceptibles d’entraîner le cancer, des malformations

congénitales ou pouvant être nocifs pour le système reproductif. Parmi

ces produits chimiques, on retrouve :

· le plomb dans les peintures à base de plomb,

· a silice cristalline dans les briques et le ciment et autres produits

de maçonnerie,

· l’arsenic et le chrome dans le bois de sciage ayant subi un traitement

chimique (comme l’arséniate de cuivre et de chrome).

Le risque associé à de telles expositions varie selon la fréquence avec

laquelle on effectue ces travaux. Pour réduire l’exposition à de tels

produits, il faut travailler dans un endroit bien aéré et utiliser le matériel

606564/DW151 10/1/02 10:20 AM Page 8

Page 12

9

Français

de sécurité approprié, tel un masque anti-poussières spécialement

conçu pour filtrer les particules microscopiques.

• Éviter tout contact prolongé avec la poussière soulevée par cet

outil ou autres outils électriques. Porter des vêtements de

protection et nettoyer les parties exposées du corps avec de l'eau

savonneuse. S'assurer de bien se protéger afin d'éviter d'absorber par

la bouche, les yeux ou la peau des produits chimiques nocifs.

Moteur

Cet outil est entraîné par un moteur DEWALT. On doit s’assurer que

l’intensité nominale du cordon d’alimentation correspond à celle

indiquée sur la plaque signalétique; sur cette dernière, la mention «

60 Hz » ou « c. a. seulement » signifie que l’outil ne doit être branché

que dans une prise de courant alternatif de 60 Hz, et non pas dans une

prise de courant continu. Une chute de tension de plus de 10 %

pourrait entraîner une perte de puissance et une surchauffe de plus

de 10 %. Tous les outils D

EWALT sont soumis à des essais en usine;

si cet outil ne fonctionne pas, vérifier la source d’alimentation

électrique. Si le moteur ne fonctionne pas lorsqu’on appuie sur le

bouton vert, vérifier la tension de la source d’alimentation.

Fonctionnement

Cet outil est doté d’un aimant destiné à être utilisé sur une surface en

acier de 10 mm (3/8 po) d’épaisseur dépourvue

d’une couche d’air. Le terme « couche d’air »

décrit la distance entre la surface de l’âme d’un

aimant et la plaque d’assemblage. Les deux

surfaces doivent être tenues séparées au moyen

d’une courbure, d’une couche de peinture, d’une

déformation verticale, d’une tête de boulon et

ainsi de suite. La capacité d’adhérence de

l’aimant est réduite par les surfaces

rugueuses ou inégales ou par l’épaisseur

insuffisante de l’acier ou de la surface sur laquelle la base magnétique

est assemblée. L’aimant perd rapidement sa capacité d’adhérence

lorsque la déformation verticale augmente la

couche d’air au-dessus de 0,4 mm (1/64 po). On

doit donc réduire autant que possible la couche

d’air et rendre la surface lisse en enlevant les

projections, les copeaux ou autres éléments

susceptibles d’empêcher le contact entre les

métaux. Si l’aimant n’adhère pas à la surface

métallique, vérifier si le contact se fait au moyen

d’une jauge d’épaisseur ou d’un dispositif

semblable afin de déterminer s’il existe une

couche d’air aux endroits critiques situés sous

l’aimant.

1. Mettre la perceuse à colonne sur la surface de travail de manière à

orienter la pointe ou la goupille de retenue directement au-dessus

de la zone à percer. Mettre l’outil sous tension en appuyant sur le

bouton rouge (A), puis placer la pointe de coupe directement audessus de la zone à percer. Mettre l’aimant en marche en enfonçant

le bouton jaune (B). Mettre le moteur sous tension en appuyant sur

le bouton vert (C). On doit utiliser la courroie de sécurité (D)

lorsqu’on perce un trou en position verticale ou au plafond (la

courroie est fixée dans la fente située dans la base de l’outil, tel

qu’illustré).

REMARQUE : remplacer la courroie si les bords deviennent effilochés.

Inspecter la courroie avant chaque utilisation. On peut se procurer de

nouvelles courroies chez un détaillant local ou à un centre de service

D

EWALT.

2. Exercer une légère pression sur la poignée d’alimentation jusqu’à ce

que la mèche hélicoïdale ou la pointe de coupe morde dans la

pièce, puis appliquer une pression constante jusqu’à ce que la

coupe soit terminée.

3. Arrêter le moteur et attendre qu’il décélère avant de mettre l’aimant

D

A

B

C

606564/DW151 10/1/02 10:20 AM Page 9

Page 13

10

Français

hors tension.

4. Mettre l’aimant hors tension en appuyant sur le bouton jaune

(l’aimant continuera d’adhérer

à la surface pendant 5 secondes avant de se détacher).

5. Après chaque utilisation, retirer tous les copeaux qui se sont

accumulés sur la surface magnétique.

Fonctionnement des

perceuses avec une

pointe de coupe annulaire

D

EWALT

1. Cet outil pratique est conçu pour être

utilisé en toute sécurité.

2. Sécurité de l’utilisateur :

Les interrupteurs sont disposés de manière

à empêcher le démarrage accidentel du

moteur avant la mise sous tension de l’aimant.

Les poignées sont disposées de manière à permettre à l’utilisateur de

travailler facilement en position verticale ou au plafond.

3. L’outil est muni d’une poignée d’alimentation à dégagement rapide

(E). On peut déplacer la poignée du côté gauche au côté droit de

l’outil en appuyant tout simplement sur un bouton.

L’aimant est destiné à être utilisé sur une surface plane en acier ou de

fer de 10 mm (3/ 8 po) d’épaisseur.

REMARQUE : on peut adapter le modèle DW151 afin de pouvoir

l’utiliser avec des mèches hélicoîdales munies d’un porte-mandrin

modèle DW1561.

4. Installer la goupille de retenue appropriée dans la pointe de coupe

sélectionnée, à partir du haut, puis introduire la pointe dans la tige.

Aligner les surfaces planes de la pointe de coupe avec les vis de

retenue de la tige. Bien serrer les deux vis de retenue, en s’assurant

que les surfaces planes sont bien placées sous les vis de manière

à ce qu’elles soient en retrait sous la surface de l’arbre.

5. Remplir le réservoir de fluide de coupe à base

d’huile. Ce fluide est formulé en vue d’optimiser

le rendement et la durée de vie des pointes de

coupe rotatives. Le fluide est alimenté par gravité

dans l’arbre pilote. Vérifier le fonctionnement de

l’outil en le déplaçant verticalement contre la

surface de travail afin de faire écouler le fluide.

Lorsqu’on réalise une coupe en position verticale

ou au plafond, tremper la pointe dans une pâte

D

EWALT.

REMARQUE : cet outil est doté d’un système de

lubrification intégré. Pour utiliser ce système, retirer le

boyau (F) de la bouteille en enfonçant le collier noir

(G) dans celle-ci. Enlever le boyau situé au fond du

robinet de purge, puis dégager la bouteille de sa ferrure et la remplir de

fluide de coupe. Remettre la bouteille dans la ferrure et replacer le

boyau. Tourner le robinet de purge vers la gauche pour faire circuler le

fluide, puis vers la droite pour fermer le robinet une fois la coupe

terminée. Les roulements sont lubrifiés au moyen de ce système.

AVERTISSEMENT : ne verser aucun fluide dans la bouteille

lorsque celle-ci est installée dans la ferrure, ni ne laisser aucun fluide

pénétrer à l’intérieur du moteur de l’outil afin d’éviter les risques de

choc électrique.

Appliquer fréquemment une grande quantité d’huile sur les roulements

afin de les maintenir graissés en tout temps.

6. Démarrer le moteur en appuyant sur le bouton vert.

7. Déplacer lentement la pointe de coupe vers la zone à couper, en

laissant tourner l’outil de 25 à 30 révolutions. L’outil projettera de fins

copeaux lorsque la pointe pratique une rainure externe. Une fois la

position de l’outil bien établie, exercer une pression constante

jusqu’à ce que la coupe soit terminée. Il est plus important de

maintenir une vitesse de rotation élevée plutôt que d’exercer une

trop forte pression, ce qui a pour effet de ralentir le moteur. Cette

façon de procéder aide à améliorer la coupe, à prolonger la durée

E

F

G

606564/DW151 10/1/02 10:20 AM Page 10

Page 14

11

Français

de vie de la pointe et à produire des orifices plus précis.

8. Les copeaux de métal doivent être expulsés lorsqu’on abaisse l’outil;

sinon, ils seront automatiquement expulsés lorsqu’on soulève

complètement le moteur.

MISE EN GARDE : on doit porter des gants lorsqu’on manipule les

copeaux afin d’éviter de subir des blessures aux mains lorsqu’elles

entrent en contact avec les surfaces chaudes ou les bords tranchants.

Fonctionnement de la base pivotante

(DW159)

1. Placer l’appareil sur la surface de travail de manière à orienter la

pointe près du centre du trou à percer.

2. Enfoncer le bouton rouge afin de mettre l’appareil en marche.

3. Appuyer sur le bouton jaune pour actionner l’aimant.

4. Tourner le levier (H) vers la gauche pour desserrer la base

pivotante.

5. Déplacer la perceuse et tourner l’aimant de manière à placer la

goupille de retenue directement au-dessus du centre du trou à

percer.

6. Tourner le levier vers la droite pour resserrer la base pivotante.

Fonctionnement de l’interrupteur de

marche avant ou marche arrière (DW159)

Le collier (I) situé au-dessus de la perceuse (modèle DW159

seulement) sert d’interrupteur de marche avant ou marche arrière.

Commandes

Appliquer suffisamment de pression pour assurer un perçage précis;

ne pas forcer l’outil. Si l’aimant semble vouloir se détacher de la

surface de travail, diminuer légèrement la pression afin de bien l’y

adhérer. La pression exercée peut dépasser la capacité d’adhérence

en présence de l’une ou de plusieurs des conditions suivantes :

1. une couche d’air excessive (de 0,4 mm ou 1/ 64 po ou plus);

2. une tôle mince (d’une épaisseur inférieure à 10 mm ou 3/ 8 po (selon

la position et la condition de la surface métallique);

3. une pièce en métal ayant de faibles propriétés magnétiques;

4. une surface inégale ou rugueuse;

5. une faible tension électrique.

Perçage

Afin de réaliser une coupe précise, percer un avant-trou avant d’utiliser

la mèche voulue. Les mèches de grand diamètre ont tendance à

s’éloigner du centre avant d’atteindre le plein diamètre de l’orifice; le

diamètre de ce trou devient alors le « pilote » lorsqu’on effectue le

perçage. Cette situation n’est pas limitée aux perceuses magnétiques

à colonne; en effet, cela arrive fréquemment dans les ateliers

d’usinage lorsque les ouvriers percent de grands trous.

Balais

Inspecter régulièrement les balais de charbon afin de s’assurer qu’il n’y

a aucun signe d’usure. Lorsque le capuchon est dévissé, on peut

retirer l’ensemble ressort/balai de l’outil.

Maintenir les balais propres afin qu’ils puissent glisser librement dans

leurs guides. Divers symboles apparaissent sur les balais; on doit

remplacer ces derniers lorsque l’usure atteint la ligne la plus près du

ressort. De nouveaux balais sont offerts aux centres de service

H

I

606564/DW151 10/1/02 10:20 AM Page 11

Page 15

12

Français

autorisés.

Réglages

Cet outil est doté d’une cale lubrifiée en permanence et réglée en

usine. La cale peut être lubrifiée périodiquement au moyen de graisse

afin d’assurer qu’elle fonctionne correctement, et doit être

suffisamment serrée pour retenir le moteur en position verticale

(escamotée). Pour effectuer un réglage, serrer les cinq vis de retenue

à verrouillage automatique fixées sur la partie latérale du corps de

l’outil.

Accessoires

Les accessoires recommandés pour cet outil sont vendus séparément

chez tous les distributeurs ou dans tous les centres de service

autorisés.

MISE EN GARDE : l’utilisation d’accessoires autres que ceux qui

sont recommandés pourrait présenter un danger.

Pour obtenir plus d’information sur les accessoires, communiquer avec

D

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD

21286, aux États- Unis ou composer le 1 800 433- 9258. Parmi ces

accessoires, on retrouve :

1. un porte-mandrin modèle DW1561 (pour le modèle DW151);

2. des mandrins (« mandrels ») et des scies à trous de 51 mm (2 po)

de diamètre ou moins;

3. des pointes de coupe rotatives et des pilotes de 11 mm (7/ 16 po) à

51 mm (2 po) de diamètre;

4. des mèches hélicoïdales de 6 mm (1/4 po) à 21 mm (13/16 po);

5. des tarauds de 6 mm (1/ 4 po) à 21 mm (13/ 16 po) de diamètre

(pour le modèle DW159 seulement);

6. des alésoirs de faible calibre de 6 mm (1/ 4 po) à 16 mm (5/ 8 po)

de diamètre et des alésoirs de fort calibre de 6 mm (1/ 4 po) à 13

mm (1/ 2 po) de diamètre.

Important

Pour assurer la SÉCURITÉ et la FIABILITÉ de cet outil, toutes les

opérations de réparation, d’entretien et de réglage doivent être

effectuées dans un centre de service autorisé ou par du personnel

qualifié (cela comprend l’inspection et le remplacement du balai); on ne

doit utiliser que des pièces de rechange identiques.

Garantie complète

DEWALT garantit les outils industriels de service intensif contre tout

défaut de matériel ou de fabrication pour une période d’un an à

compter de la date d’achat; le produit défectueux sera réparé sans

frais. Pour obtenir de plus amples renseignements sur les réparations

couvertes par la présente garantie, composer le 1 800 433-9258. Cette

garantie ne s’applique pas aux accessoires et ne vise pas les

dommages causés par des réparations effectuées par un tiers. Cette

garantie confère des droits légaux particuliers à l’acheteur, mais celuici pourrait aussi bénéficier d’autres droits variant d’un territoire à l’autre.

En plus de la présente garantie, la

GARANTIE SANS RISQUE DE 30 JOURS EN CAS DE NON-

SATISFACTION

s’applique également aux outils D

EWALT.

Si l’acheteur n’est pas entièrement satisfait du rendement de l’outil

industriel de service intensif D

E

WALT, celui-ci peut le retourner au

vendeur participant dans les 30 jours pour obtenir un remboursement

intégral. Retourner l’outil au complet en payant le transport à l’avance;

une preuve d’achat peut être requise.

REMPLACEMENT GRATUIT DE L'ÉTIQUETTE

Si vos étiquettes d'avertissement deviennent illisibles ou sont

manquantes, composez le 1-800-4-D

EWALT pour obtenir une étiquette

de remplacement gratuite.

606564/DW151 10/1/02 10:20 AM Page 12

Page 16

13

Español

SI TIENE CUALQUIER PREGUNTA O COMENTARIO ACERCA DE

ESTA O CUALQUIER OTRA HERRAMIENTA DEWALT, POR FAVOR

LLÁMENOS AL: 326-7100

SI TIENE PREGUNTAS O COMENTARIOS SOBRE ESTA U OTRA

HERRAMIENTA DEWALT, LLÁMENOS GRATIS AL:

1-800-4-DEWALT (1-800-433-9258)

Reglas generales de seguridad

¡ADVERTENCIA! Lea y entienda todo el instructivo. El no seguir

todas las instrucciones enumeradas a continuación puede resultar en

electrochoque, fuego y/o seria lesión personal.

GUARDE ESTAS INSTRUCCIONES

ÁREA DE TRABAJO

· Mantenga su área de trabajo limpio y bien iluminado. Bancos de

trabajo abarrotados de cosas y áreas oscuras son una invitación a los

accidentes.

· No opere herramientas eléctricas en atmósferas explosivas,

donde hay presencia de líquidos, gases, o polvos inflamables.

Las herramientas eléctricas crean chispas que podrían encender el

polvo o los gases.

· Mantenga a los transeúntes, niños, y visitantes alejados mientras

opera una herramienta eléctrica. Las distracciones podrían causar

la pérdida de control.

SEGURIDAD ELÉCTRICA

· Herramientas a tierra deberán conectarse a un tomacorriente Las

instalado correctamente y puesto a tierra de acuerdo con todos

los códigos y ordenanzas. Nunca debe quitar el clavijero de tierra o

modificar el enchufe de algún modo. No usar enchufes adaptadores.

Infórmese con un electricista competente si duda que el tomacorriente

esté adecuadamente puesto a tierra. Si las herramientas funcionan

mal eléctricamente, o fallan, la puesta a tierra provee una vía de

resistencia baja que aparta del usuario la electricidad extraída. Sólo

aplica a la Clase I herramientas (a tierra).

· Las herramientas con doble aislamiento están equipadas con un

enchufe polarizado (una clavija es más ancha que la otra.) Este

enchufe encajará en un tomacorriente polarizado de una sola

606564/DW151 10/1/02 10:20 AM Page 13

Page 17

14

Español

SEGURIDAD PERSONAL

· Manténgase alerta, observe lo que está haciendo y use sentido

común al usar una herramienta eléctrica. No la use cuando esté

cansado o bajo la influencia de drogas, alcohol, o medicinas. Un

instante de inatención mientras opera herramientas eléctricas puede

resultar en serias lesiones personales.

· Vístase adecuadamente. No use vestimenta suelta o joyas.

Mantenga el cabello largo sujeto. Mantenga su cabello, vestimenta

y guantes apartados de piezas en movimiento. La vestimenta suelta,

las joyas o el cabello largo podrían quedar atrapados en las partes en

movimiento.

· Evite un arranque accidental. Asegúrese de apagar la herramienta

antes de enchufarla. El cargar las herramientas con el dedo en el

interruptor o enchufar herramientas que tienen el interruptor activado

es una invitación a los accidentes.

· Quite las llaves de ajuste antes de activar la herramienta. Una llave

que se deja anexada a una parte giratoria de la herramienta puede

resultar en lesión personal.

· No se extralimite. Mantenga la pisada firme y el balance apropiado

todo el tiempo. El pie bien afincado y el balance apropiado permite un

mejor control de la herramienta en situaciones inesperadas.

· Utilice equipo de seguridad. Use siempre protección para los ojos.

Se deberá usar máscara contra el polvo, calzado protector antirresbalante, casco, o protector de oído en las condiciones que los

justifican.

USO Y CUIDADO DE HERRAMIENTAS

· Utilice tornillos de banco u otra forma práctica para sujetar y

apoyar la pieza de trabajo a una plataforma estable. Sujetar la

pieza manualmente o contra su cuerpo es inestable y puede llevar a

la pérdida de control.

· No fuerce la herramienta. Use la herramienta correcta para la

aplicación. La herramienta correcta hará una labor mejor y más

segura, con la energía nominal para la cual fue diseñada.

· No use la herramienta si el interruptor no prende y apaga. La

manera. Si el enchufe no encaja bien en el tomacorriente, invierta

el enchufe. Si todavía no encaja, contacte a un electricista

competente para que instale un tomacorriente polarizado. No

cambie el enchufe. El aislamiento doble elimina la necesidad de un

cable eléctrico a tierra de tres alambres y un sistema de alimentación

eléctrica puesto a tierra. Sólo aplica a la Clase II herramientas

(aislamiento doble).

· Evite que su cuerpo haga contacto con superficies a tierra tales

como tuberías, radiadores, cocinas, y refrigeradoras. Existe un

mayor riesgo de electrochoque.

· No exponga las herramientas eléctricas a la lluvia o condiciones

húmedas. La penetración de agua a una herramienta eléctrica

incrementará el riesgo de electrochoque

· No maltrate el cable. No lo use nunca para acarrear las herramientas

o halar el enchufe de un tomacorriente. Mantenga el cable alejado del

calor, aceite, bordes afilados o partes en movimiento. Reemplace

inmediatamente los cables dañados. Los cables dañados incrementan el riesgo de electrochoque.

· Al operar una herramienta eléctrica a la intemperie, use un cable

de extensión para exteriores marcado “W-A” o “W.” Estos cables

están hechos para uso exterior y reducen el riesgo de electrochoque.

Calibre mínimo para juegos de cables

Voltios Largo total del cable en pies

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Amperaje nominal

Más No más AWG

de de

0- 6 18 16 16 14

6 - 10 18 16 14 12

10- 12 16 16 14 12

12 - 16 14 12 No recomendado

606564/DW151 10/1/02 10:20 AM Page 14

Page 18

15

Español

herramienta que no se puede controlar con el interruptor es peligrosa

y debe ser reparada.

· Desconecte el enchufe de la toma de corriente antes de efectuar

cualquier ajuste, cambio de accesorios, o guardar la herramienta.

Estas medidas de seguridad preventivas reducen el riesgo a que la

herramienta arranque accidentalmente.

· Mantenga herramientas que no estén en uso fuera del alcance

de los niños y otras personas no entrenadas. Las herramientas

son peligrosas en manos de usuarios no entrenados.

· Las herramientas deben recibir un mantenimiento cuidadoso.

Mantenga las herramientas para corte afiladas y limpias. Las

herramientas bien cuidadas con bordes de corte afilados son menos

susceptibles a trabarse y más fáciles de controlar.

· Revise si hay desalineación o traba en las partes movibles, partes

rotas u otra condición que pueda afectar la operación de la

herramienta. De estar dañada, dar servicio a la misma antes de

utilizarla. Muchas veces la causa de accidentes se debe a

herramientas con poco mantenimiento.

· Use solamente los accesorios que el fabricante recomienda para

su modelo. Los accesorios adecuados para una herramienta, pueden

resultar peligrosos cuando se usa en otra.

SERVICIO

· El servicio a la herramienta debe ser realizado por personal de

reparación calificado únicamente. El servicio o mantenimiento

efectuado por personal no calificado puede entrañar un riesgo o lesión.

· Al dar servicio a la herramienta, use sólo piezas de repuesto

idénticas. Siga las instrucciones contenidas en la sección

Mantenimiento de este manual. El uso de repuestos no autorizados o

el no cumplir con las instrucciones de Mantenimiento puede crear el

riesgo de electrochoque o lesión.

Instrucciones adicionales de seguridad

• Utilice siempre la banda de seguridad. El montaje puede soltarse.

La corriente eléctrica puede fallar o la unidad puede desconectarse

accidentalmente.

• Asegúrese siempre que el taladro de columna esté conectado a

un sistema con el voltaje adecuado. Coloque el cable de manera

que no pueda desconectarse de la toma de corriente por accidente.

Verifique que la líneas tenga el fusible adecuado.

• Antes de operar la unidad, asegúrese que esté aterrizada

correctamente según las instrucciones bajo “Seguridad eléctrica”.

• Utilice siempre cables de extensión con el calibre adecuado.

• Tenga cuidado de colocar la base en una superficie plana. No

coloque el magneto sobre objetos tales como tornillos, remaches,

pernos, rebabas, etc., ya que el espacio entre el magneto y la

superficie de trabajo debilita la atracción magnética.

• Siempre coloque la unidad sobre una superficie libre de rebabas,

astillas o suciedad para lograr el óptimo agarre magnético.

PRECAUCIÓN: Utilice la protección auditiva adecuada durante el

uso de esta unidad. Bajo ciertas condiciones y duración de3 uso, el

ruido producido por este producto puede contribuir a la pérdida

auditiva.

PRECAUCIÓN: NO UTILICE EL MANGO DE ALIMENTACIÓN PARA

LEVANTAR LA UNIDAD

PRECAUCIÓN: Después de cortar la corriente al magneto, la base

magnética continuará adherida a la superficie de trabajo durante 5

segundos antes de soltarse. Un golpe ligero con la mano liberará la

base.

ADVERTENCIA: El polvo originado por lijar, aserrar, esmerilar,

taladrar y otras actividades constructivas contiene productos químicos

que se sabe causan cáncer, defectos congénitos u otros daños

reproductivos. Algunos ejemplos de estos químicos son:

• plomo de pinturas con base de plomo.

• sílice cristalino de ladrillos y cemento y otros productos de

mampostería, y

• arsénico y cromo de madera tratada químicamente (CCA).

Su riesgo de exposición variará de acuerdo a la frecuencia con

que efectúe este tipo de trabajos. Para reducir su exposición a

estos químicos: trabaje en un área bien ventilada, y trabaje con

606564/DW151 10/1/02 10:20 AM Page 15

Page 19

16

Español

condiciones; usted puede verificar que no haya

colchón de aire debajo del magneto en los puntos

cruciales con un calibrador de laminillas u otro

dispositivo similar.

1. Coloque el taladro de columna sobre la

superficie de manera que la punta o el piloto

de el cortador quede directamente sobre el

punto en que se perforará. Encienda la unidad

oprimiendo el botón rojo (A). Coloque el

cortador directamente sobre el punto a

perforar y encienda el magneto, oprimiendo el

botón amarillo (B). Encienda el motor

oprimiendo el botón verde (C). Cuando

perfore sobre su cabeza o en posición

vertical, debe usar siempre la banda de

seguridad (D). (Colocada en la ranura de la

base, como se ilustra.)

NOTA: reemplace la banda si las orillas se

ven raídas. Inspeccione la banda antes de

cada uso. Hay bandas nuevas a su

disposición con el distribuidor o en el centro

de servicio de su localidad.

2. Aplique un poco de presión en el volante de

alimentación hasta que la broca o el cortador penetren y después

aplique presión uniforme hasta completar el corte.

3. Apague el motor y permita que se detenga antes de desconectar

el magneto.

4. Apague el magneto oprimiendo el botón amarillo. El magneto

permanecerá activado durante 5 segundos y emitirá un sonido

antes de soltarse.

5. Después de cada uso, quite todas las rebabas de la superficie del

magneto.

equipo de seguridad aprobado, tal como máscaras contra polvo

diseñadas específicamente para filtrar partículas microscópicas.

• Evite el contacto prolongado con polvos originados por lijar,

aserrar, esmerilar, taladrar y otras actividades constructivas. Vista

ropas protectoras y lave las áreas expuestas con agua y jabón.

Permitir que el polvo se introduzca en su boca, ojos, o dejarlo sobre la

piel promueve la absorción de químicos dañinos.

Motor

Su herramienta DEWALT funciona con un motor DEWALT. Asegúrese

que la alimentación concuerde con las indicaciones de la placa de

identificación.

Volts 60 Hz o “AC only” significa que su herramienta debe operarse

solamente con corriente alterna y nunca con corriente directa.

Disminuciones en el voltaje de 10% o mayores causarán pérdida de

potencia y sobre calentamiento. Todas las herramientas D

EWALT se

prueban en la fábrica; si esta herramienta no funciona, revise la

alimentación de corriente. Si el motor no funciona al oprimir el botón

verde, revise el voltaje en la toma de corriente.

Operación

El magneto de esta unidad está diseñado para usarse en acero de 10

mm (3/8”) de espesor–sin colchón de aire. El colchón de aire puede

definirse como la distancia entre la superficie del magneto y la placa

de montaje. Las dos superficies pueden quedar separadas debido a

curvaturas, capas de pintura, irregularidades en la superficie, cabezas

de tornillos, etc. La fuerza de sujeción se reduce en superficies

rugosas o desniveladas, debido a espesor insuficiente del acero o área

de montaje insuficiente para la base del magneto. El magneto pierde

rápidamente su fuerza de sujeción cuando estas irregularidades

incrementan el colchón de aire a más de 0.4 mm (1/64”). Conserve al

mínimo este colchón de aire y asegúrese de alisar la superficie

eliminando cualquier proyección indebida, rebabas o cualquier otra

cosa que no permita el contacto completo de metal con metal. Si el

magneto falla para sujetarse a una superficie, puede deberse a estas

A

B

D

C

606564/DW151 10/1/02 10:20 AM Page 16

Page 20

17

Español

Operación con cortadores anulares

D

EWALT

1. Esta unidad se diseñó teniendo en mente la comodidad y la

seguridad del operador.

2. Seguridad del operador:

Los interruptores se han dispuesto para evitar que el operador

encienda el motor accidentalmente antes

de energizar el magneto.

Los mangos están dispuestos para permitir

su fácil colocación en posiciones vertical y

por arriba de la cabeza.

3. Esta unidad viene equipada con un volante

de alimentación de liberación rápida (E).

Con el simple movimiento de oprimir un

botón, se puede cambiar del lado izquierdo

al lado derecho de la unidad.

El magneto está diseñado para adherirse a placas de acero o hierro

con espesor de 10 mm (3/8”) o mayor.

NOTA: El modelo DW151 puede adaptarse para emplear brocas

helicoidales con la adición del adaptador de

broquero DW1561.

4. Coloque el perno piloto apropiado en el cortador

que desee a partir de la punta e inserte el

cortador en el eje. Haga coincidir los planos del

cortador con los prisioneros. Apriete con firmeza

ambos prisioneros. (Asegúrese que ambos

planos estén correctamente colocados bajo los

prisioneros de manera que queden ocultos bajo

la superficie del eje.)

5. Llene el depósito con fluido de corte con base no

oleosa. Este fluido está formulado para

proporcionar el mejor rendimiento y la mayor

duración a los cortadores. El fluido será liberado

hacia el piloto por gravedad. Haga pruebas haciendo que el

cortador suba y baje contra la superficie de trabajo para que el

fluido comience a circular. No utilice fluido de corte cuando corte en

posición vertical o por arriba de la cabeza, sumerja el cortador en

pasta de corte para estas aplicaciones.

NOTA: Esta unidad cuenta con un sistema lubricación a bordo.

Para usar el sistema de lubricación, retire la manguera (F) de la

botella oprimiendo el collarín negro (G) en la botella. Retire la

manguera del fondo del grifo. Retire la botella del soporte y llene

con fluido de corte. Coloque de nuevo la botella en el soporte y

coloque la manguera de nuevo. Gire la llave en sentido opuesto a

las manecillas del reloj para que circule el fluido. Gire la llave en el

sentido de las manecillas del reloj para cerrar la válvula cuando hay

terminado el corte. Los baleros son lubricados por el sistema a

bordo.

ADVERTENCIA: No vacíe fluido de corte en la botella mientras esté

montada en el soporte. No permita que el fluido de corte entre al motor

del taladro. Puede resultar en choque eléctrico.

6. Encienda el motor oprimiendo el botón verde.

7. Lleve el cortador lentamente hacia la superficie a cortar y deje que

gire 25 a 30 revoluciones, produciendo rebabas ligeras al cortar un

canal externo. Esto le permitirá la posición adecuada. Aplique

presión uniforme durante todo el corte. Es más importante

conservar las revoluciones que aplicar fuerza en exceso,

ocasionando que la velocidad del motor baje. Así obtendrá una

mejor acción de corte, mayor durabilidad en sus cortadores y

orificios más limpios.

8. El metal deberá salir en el golpe hacia abajo. Si no, saldrá

automáticamente cuando el motor regrese a la posición extrema

arriba.

PRECAUCIÓN: deben utilizarse guantes para el manejo de las

piezas de corte para evitar lesiones a las manos por superficies

calientes o bordes afilados.

E

F

G

606564/DW151 10/1/02 10:20 AM Page 17

Page 21

18

Español

1. Colchón de aire excesivo—0.4 mm (1/64”) o más.

2. Metal delgado (espesor menor a 10 mm (3/8”), dependiendo de la

posición y la condición de la superficie del metal).

3. Metal con bajas propiedades magnéticas.

4. Superficie desnivelada o irregular.

5. Bajo voltaje en la línea.

Cómo taladrar

Para obtener mayor precisión, perfore un orificio pequeño antes de

utilizar la broca final. Las brocas con diámetros grandes “caminan”

hacia fuera del centro hasta alcanzar el diámetro completo en el punto

que el diámetro exterior actúa como piloto en el orificio que se perfora.

Esto no es una característica peculiar de los taladros de columna

magnéticos, sino que es parte del conocimiento general de taller en

perforaciones de grandes diámetros.

Carbones

Los carbones den inspeccionarse regularmente en busca de

desgaste. Cuando la tapa se desenrosque, el montaje de resorte y

carbón pueden retirarse de la herramienta.

Conserve los carbones limpios y deslizándose libremente en sus

guías. Los carbones tienen varios símbolos estampados en ellos, y si

el carbón se ha desgastado hasta la línea más cercana al resorte,

debe reemplazarse. En los centros de servicio hay montajes de

carbones nuevos a su disposición.

Ajustes

Esta unidad se ha diseñado con una cuña lubricada de manera

permanente y se ajusta en la fábrica. La cuña debe lubricarse

periódicamente con grasa para asegurar la suave operación. La cuña

debe estar lo suficientemente apretada para retener al motor en la

posición retraída (arriba). Si llegase a requerir ajustes, apriete los 5

prisioneros auto asegurables a un lado del cuerpo del taladro.

Operación de la base inclinable (DW159)

1. Coloque la unidad sobre la superficie de trabajo de manera que la

punta quede cerca del centro del orificio que se va a perforar.

2. Oprima el botón rojo para encender la corriente.

3. Oprima el botón amarillo para activar el magneto.

4. Gire la palanca (H) en sentido contrario a las manecillas del reloj

para aflojar la base inclinable.

5. Mueva el taladro y gire el magneto hasta que el perno piloto quede

directamente sobre el centro del orificio a perforar.

6. Gire la palanca en el sentido de las manecillas del reloj para

apretar la base inclinable.

Operación del dispositivo de marcha

hacia delante y reversa (DW159)

El interruptor de marcha hacia delante y reversa es un collarín (I) en

la superficie de la unidad del taladro DW159 únicamente.

Control

Aplique la presión suficiente para obtener un corte suave, progresivo.

No fuerce la unidad. Si el magneto se levanta de la placa de trabajo,

disminuya ligeramente la presión y se volverá a sujetar. La presión en

la punta de la broca puede exceder la fuerza de sujeción bajo una o

más de las siguientes condiciones:

H

I

606564/DW151 10/1/02 10:20 AM Page 18

Page 22

19

Español

Accesorios

Los accesorios recomendados para emplearse con su herramienta

se encuentran a su disposición con costo extra con su distribuidor o

centro de servicio locales.

PRECAUCIÓN: El uso de cualquier accesorio no recomendado

puede ser peligroso.

Si necesita ayuda para localizar algún accesorio, comuníquese por

favor al 1-800-4-DEWALT o a DEWALT Industrial Tool Co., 701 East

Joppa Road, Baltimore, MD 21286

1. Adaptador de broquero DW1561 para el taladro DW151

2. Mandriles y brocasierras con diámetro hasta 51 mm (2”).

3. Cortadores y pilotos desde 11 mm (7/16”) hasta 51 mm (2”) de

diámetro.

4. Brocas helicoidales 6 mm (1/4”) a 21 mm (13/16”) (DW151*)

5. Machuelos 6 mm (1/4”) a 21 mm (13/16”) (únicamente DW159)

6. Fresas, calibre ligero 6 mm (1/4”) a 16 mm (5/8”)

Fresas, calibre pesado 6 mm (1/4”) a 13 mm (1/2”)

Carbones

Los carbones deben inspeccionarse regularmente en busca de

desgaste. Para revisar los carbones, destornille las tapas de

inspección para sacar los montajes de carbones y resortes de la

herramienta.

Conserve los carbones limpios y deslizándose libremente en sus

guías. Los carbones tienen varios símbolos estampados, cuando se

han desgastado hasta la línea más cercana al resorte deben

cambiarse. Hay a su disposición montajes de carbones nuevos en los

centros de servicio. Consulte la última página de este manual.

Importante

Para garantizar la SEGURIDAD y la CONFIABILIDAD del producto, las

reparaciones, el mantenimiento y los ajustes (inclusive inspección y

cambio de carbones) deberán realizarse en centros de servicio

autorizados u otras organizaciones de servicio calificado, que utilicen

siempre refacciones idénticas.

Póliza de GarantÍía

IDENTIFICACIÓN DEL PRODUCTO:

Sello o firma del Distribuidor.

Nombre del producto: __________ Mod./Cat.: _____________

Marca: _____________________ Núm. de serie:__________

(Datos para ser llenados por el distribuidor)

Fecha de compra y/o entrega del producto: __________________

Nombre y domicilio del distribuidor donde se adquirió el producto:

_____________________________________________________

Este producto está garantizado por un año a partir de la fecha de

entrega, contra cualquier defecto en su funcionamiento, así como en

materiales y mano de obra empleados para su fabricación. Nuestra

garantía incluye la reparación o reposición del producto y/o

componentes sin cargo alguno para el cliente, incluyendo mano de

obra, así como los gastos de transportación razonablemente erogados

derivados del cumplimiento de este certificado.

Para hacer efectiva esta garantía deberá presentar su herramienta y

esta póliza sellada por el establecimiento comercial donde se adquirió

el producto, de no contar con ésta, bastará la factura de compra.

EXCEPCIONES.

Esta garantía no será válida en los siguientes casos:

• Cuando el producto se hubiese utilizado en condiciones distintas a

las normales;

• Cuando el producto no hubiese sido operado de acuerdo con el

instructivo de uso que se acompaña;

• Cuando el producto hubiese sido alterado o reparado por personas

distintas a las enlistadas al final de este certificado.

Anexo encontrará una relación de sucursales de servicio de fábrica,

centros de servicio autorizados y franquiciados en la República

606564/DW151 10/1/02 10:20 AM Page 19

Page 23

20

Mexicana, donde podrá hacer efectiva su garantía y adquirir partes,

refacciones y accesorios originales.

Garantía Completa

Las herramientas industriales DEWALT están garantizadas durante un

año a partir de la fecha de compra. Repararemos, sin cargos, cualquier

falla debida a material o mano de obra defectuosos. Por favor regrese

la unidad completa, con el transporte pagado, a cualquier Centro de

Servicio para Herramientas Industriales de D

EWALT o a las estaciones

de servicio autorizado enlistadas bajo "Herramientas Eléctricas" en la

Sección Amarilla. Esta garantía no se aplica a los accesorios ni a

daños causados por reparaciones efectuadas por terceras personas.

Esta garantía le otorga derechos legales específicos, y usted puede

tener otros derechos que pueden variar de estado a estado.

En adición a la garantía, las herramientas D

EWALT están amparadas

por nuestra:

GARANTÍA DE SATISFACCIÓN SIN RIESGO POR 30 DÍAS

Si usted no se encuentra completamente satisfecho con el desempeño

de su herramienta industrial DEWALT, sencillamente devuélvala a los

vendedores participantes durante los primeros 30 días después de la

fecha de compra para que le efectúen un reembolso completo. Por

favor regrese la unidad completa, con el transporte pagado. Se puede

requerir prueba de compra.

REEMPLAZO DE LAS ETIQUETAS DE ADVERTENCIA GRATUITO:

Si sus etiquetas de advertencia se tornan ilegibles o se pierden, llame

al 1-800-4-D

EWALT para que se las reemplacen sin cost.

Español

PARA REPARACION Y SERVICIO DE SUS HERRAMIENTAS

ELECTRICAS FAVOR DE DIRIGIRSE AL CENTRO DE SERVICIO MAS

CERCANO

CULIACAN

Av. Nicolas Bravo #1063 Sur (91 671) 242 10

GAUDALAJARA

Av. La Paz #1779 (91 3) 826 69 78.

MEXICO

Eje Lázaro Cárdenas No. 18 Local D, Col. Obrera 588-9377

MERIDA

Calle 63 #459-A (91 99) 23 54 90

MONTERREY

Av. Francisco I. Madero Pte. 1820-A (91 83) 72 11 25

PUEBLA

17 Norte #205 (91 22) 46 37 14

QUERETARO

Av. Madero 139 Pte. (91 42) 14 16 60

SAN LOUIS POTOSI

Pedro Moreno #100 Centro (91 48) 14 25 67

TORREON

Blvd. Independencia, 96 pte. (91 17) 16 52 65

VERACRUZ

Prolongación Diaz Miron #4280 (91 29) 21 70 16

VILLAHERMOSA

Constitucion 516-A (91 93) 12 53 17

PARA OTRAS LOCALIDADES LLAME AL: 326 7100

IMPORTADOR: DEWALT S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS.

05120 MÉXICO, D.F

TEL. 5-326-7100

Información Tecnica

DW151 DW159

Tensión de alimentación y 120 V ~ 120 V~

Consumo de corriente: 10 A 15 A

Frecuencia de Alimentación: 60 Hz 60 Hz

Potencia nominal: 1116 W 1728 W

Rotación sin carga: 375/min 375/min

606564/DW151 10/1/02 10:20 AM Page 20

Loading...

Loading...