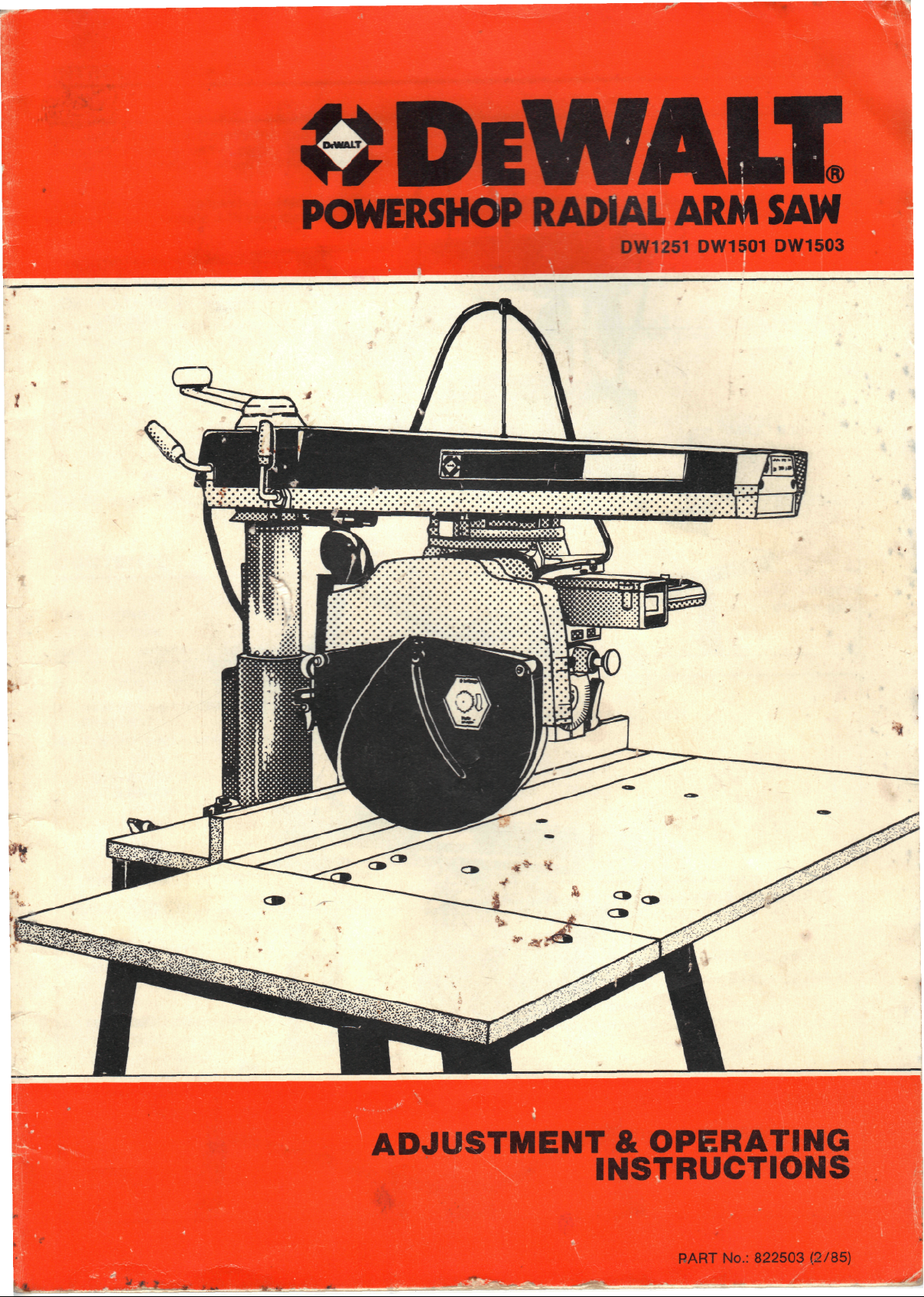

Page 1

POWERSHOP

RADIAL

W1251

ARM

DW1501 DW1503

SAW

ADJUSTMENT

&

OPERATING

INSTRUCTIONS

PART

No.:

822503

(2/85)

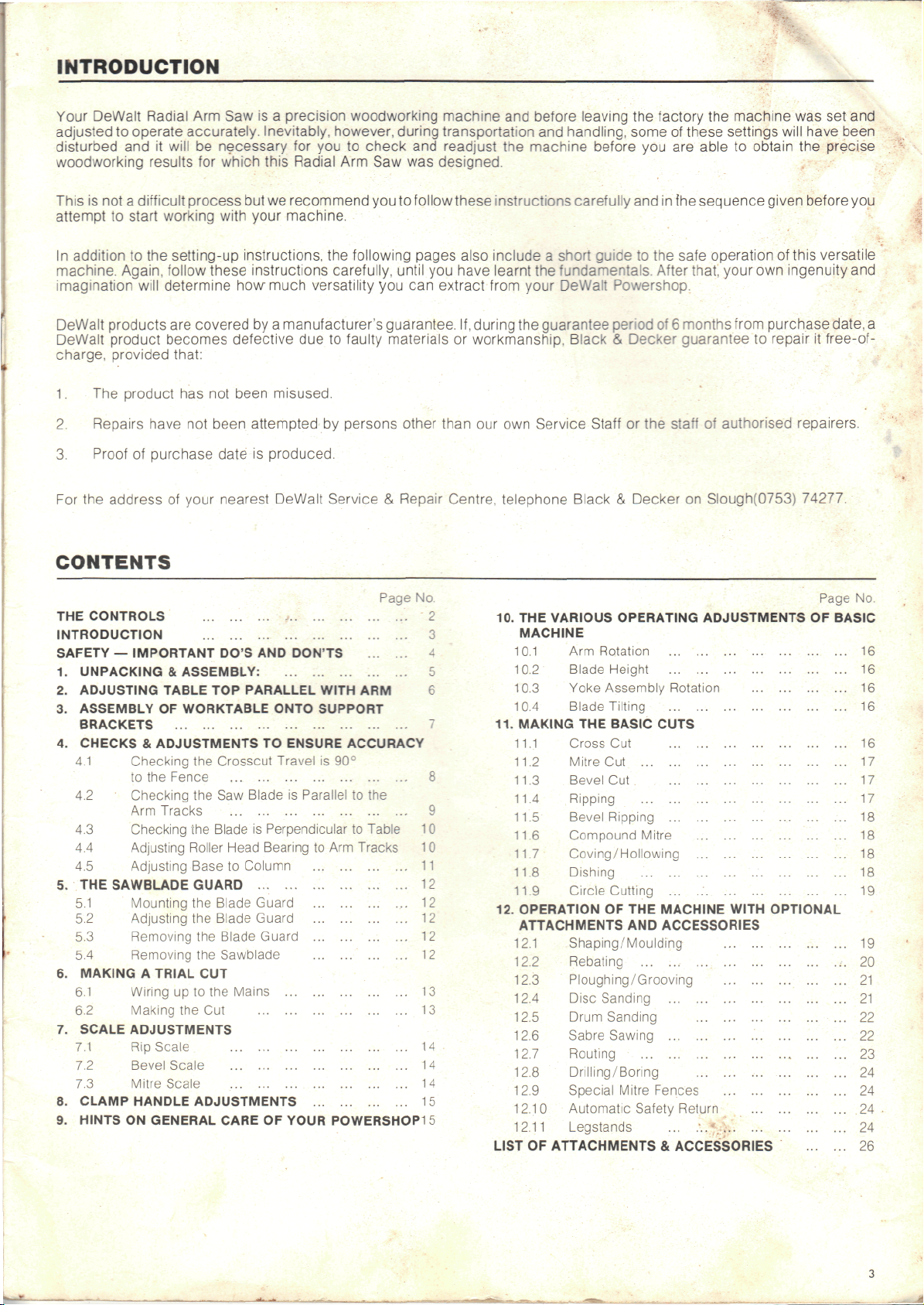

Page 2

THE

CONTROLS

1.

MITRE SCALE

18.

MITRE CLAMP

19.

MIRE

17.

YOKE

16.

TABLE CLAMP

15.

FENCE

LATCH

—i

2.

ARM

END-CAP

3. ARM

4.

RIP-LOCATING

SLIDE

BAR

5.

WORKTABLE

8.

ROLLER

YOKE

14.

BEVEL

13.

BEVEL

12.

BEVEL

HEAD/

ASSEMBLY

LATCH

SCALE

CLAMP

-

-

6.

ELEVATING

HANDLE

7.

RIPLOCK

10.

YOKE CLAMP

9.

COLUMN

11.

COLUMN

BASE

Page 3

INTRODUCTION

Your

DeWalt Radial

adjusted

disturbed

to

operate accurately.

and it

woodworking

This

is not a

attempt

In

addition

difficult

to

start working with your machine.

to the

machine. Again,

imagination will determine

Arm Saw is a

will

be

results

necessary

for

which this Radial

process

setting-up instructions,

follow

these instructions carefully, until

'

precision woodworking

Inevitably,

for you to

but we

recommend

how

much versatility

however, during transportation

check

Arm Saw was

you

the

following pages also include a short

you can

and

machine

readjust

and

before leaving

and

the

handling, some

machine before

designed.

to

follow these instructions carefully

guide

you

have learnt

the

fundamentals. After

extract from your DeWalt Powershop.

the

factory

of

you are

and

in

to the

the

machine

these settings

able

to

fhe

sequence given before

safe operation

that,

your

will

obtain

of

own

was set and

this versatile

ingenuity

have

the

been

precise

you

and

DeWalt products

DeWalt

product becomes defective

are

covered

charge, provided that:

1.

The

2.

Repairs

3.

Proof

For

the

product

have

of

purchase date

address

has not

not

of

your nearest DeWalt Service & Repair Centre, telephone Black & Decker

been misused.

been attempted

CONTENTS

THE

CONTROLS

INTRODUCTION

SAFETY — IMPORTANT DO'S

1.

UNPACKING & ASSEMBLY:

2.

ADJUSTING TABLE

3.

ASSEMBLY

BRACKETS

4.

CHECKS & ADJUSTMENTS

4.1

Checking

4.2

Checking

4.3

Checking

4.4

Adjusting

4.5

Adjusting Base

THE

5.

5.1

Mounting

5.2

Adjusting

5.3

Removing

5.4

Removing

6.

MAKING A TRIAL

6.1

Wiring

6.2

Making

7.

SCALE ADJUSTMENTS

7.1

Rtp

7.2

Bevel Scale

7.3

Mitre Scale

8.

CLAMP

9.

HINTS

OF

to

the

Arm

Tracks

SAWBLADE

Scale

HANDLE

ON

GENERAL CARE

TOP

WORKTABLE ONTO SUPPORT

the

Crosscut Travel

Fence

8

the Saw

9

the

Blade

Roller

Head Bearing

to

GUARD

the

Blade Guard

the

Blade Guard

the

Blade Guard

the

Sawblade

CUT

up to the

the Cut

Mains

ADJUSTMENTS

by a

manufacturer's guarantee.

due to

is

produced.

AND

DON'TS

PARALLEL WITH

TO

ENSURE ACCURACY

Blade

is

is

Perpendicular

Column

... 12

11

12

12

...

OF

YOUR POWERSHOP1

faulty materials

by

persons other than

.

.

ARM

C

is

90

Parallel

to Arm

to the

to

Table

Tracks

Page

No.

... 2

... 5

10

10

If,

during

the

or

workmanship. Black & Decker

our own

3

4

6

12

12

13

13

14

14

14

15

5

guarantee period

Service

10. THE

11

12.

LIST

VARIOUS OPERATING

MACHINE

101

Arm

10.2

Blade Height

10.3

Yoke Assembly Rotation

10.4

Blade

MAKING

11.1

CrossCut

11.2

Mitre

11.3

Bevel

11.4

Ripping

11.5

Bevel Ripping ...'

11.6

Compound Mitre

11.7

Coving/Hollowing

11.8

Dishing

11.9

Circle

OPERATION

ATTACHMENTS

12.1

12.2

12.3

12.4

12.5

12.6

12.7

12.8

12.9

12.10

12.11

OF

Shaping/Moulding

Rebating

Ploughing/Grooving

Disc Sanding

Drum Sanding

Sabre

Routing

Drilling/Boring

Special Mitre Fences

Automatic Safety Return

Legstands

ATTACHMENTS & ACCESSORIES

of 6

months from purchase date,

guarantee

Staff

or the

staff

of

on

ADJUSTMENTS

Rotation

Tilting

THE

Cut 17

Cut 17

OF THE

Sawing

16

BASIC

Cutting

CUTS

17

18

18

18

'

MACHINE

AND

ACCESSORIES

19

20

21

21

22

' 22

... ...

to

repair

it

authorised repairers.

Slough(0753) 74277.

OF

18

19

WITH

OPTIONAL

free-of-

Page

No.

BASIC

a

16

16

16

16

23

24

24

24

24

26

Page 4

SAFETY - IMPORTANT DO'S

For

your

own

safety

and

efficient

use of

your DeWalt Powershop. follow these instructions carefully.

AND

DON'TS

DO

Ensure

the

permanently wired

Be

the

Always disconnect your machine from

supply before changing

accessories.

4.

Ensure

clamping

'

the

5.

Always wear close-fitting clothing without

loose ends. Remove loose-fitting ornaments

and

closely

6.

Wear protective

7.

Make sure

collars

sides

that

the

mains

sure that

earth terminal

all

machine.

ties,

covered.

or

of the

machine

via a

the

guards

handles

and

ensure long hair

the

sides

flanges

collars

is

13

amp

in

earth wire

in the

are

are

eye

are

are

properly connected

fused plug (240v)

(415v).

is

firmly

plug.

any

attachments

correctly positioned

tightened before starting

is

secured

shields.

of the

blade

and

and the

that

the

clean

against

connected

the

blade.

or

the

power

or

and all

or

arbor

recessed

to

1.

to 2.

3.

DO

Never connect

other

than

Never switch

guards being properly mounted.

Never switch

handles

4.

Do not

5.

Do not

6.

Never

7.

Never

allow spectators (especially children)

within

the

working

leave

mains while unattended.

use

supplied

rip

anti-kickback

the

that stated

are

tightened.

vicinity

with

blades larger

as

standard equipment (250mm).

without

machine

on the

on the

of the

it.

the

machine plugged into

the

fingers correctly adjusted.

NOT

up to any

on the

machine without

machine

riving knife

motor rating plate.

unless

machine

in

while

diameter than that

and

voltage

the

all

clamping

the

correct

8.

Make sure

using both

9.

Before switching

sure that

position.

material

forward.

10.

Keep

11.

When ripping always

anti-kickback

12.

Keep

bearings

dry and

13.

Periodically

ensure accurate woodworking

the

recommended sequence

14.

Keep your

the

arbor

the

alien

on to

the

fence

The

blade should

until

you

pull-the

saw

blades sharp

fingers

the

bearing tracks

on the

free from grease.

roller head assembly clean

check

saw in a dry

nut is

securely tightened

key and

is in the

use the

in

the

spanner provided.

make a cut, make

correct

not

contact

saw

carriage

and

properly set.

riving knife

their

correct positions.

in the arm and the

machine's adjustments

place.

and

readjust

if

necessary.

the

and

and

to

in

Never feed

ripping - follow

the

arm.

9.

Never attempt

motor.

10.

Never wedge anything against

hold

the

11.

Never feed

it

will

12.

Do not

worktable.

in

motor shaft

the

cut it

comfortably.

lift

the

material from

the

instruction label

to oil or

material into

Powershop

grease

still.

the

wrong side when

the arm

the

motor

the

blade faster than

by its

on the top of

tracks

or

fan to

Page 5

1.

UNPACKING & ASSEMBLY

1.

Open

2.

Remove

easily

3.

Tip the

carton

4. You

carton single-handed

forward

floor.

5.

If you are

existing

If

you are

optional

now

(See

6.

Having identified

the top of the

supplied.

7.

By

machine

motor/yoke assembly

8.

Remove

(2)

9.

Take

carton

the

tracks

rip

slide

10.

Check that

tracks

forwards

will

required.

If

either

remove

procedure 9 again.

11.

Replace

the two

12.

Fix the

(Numbers

the top of the

all the

accessible components.

carton carefully until

is

resting

will

now be

until

it is

going

bench,

going

legstand,

and

secure

para.

12.11).

turning

and

left,

lock

release

the

so

that

the two

take

the cap

the

complete motor/yoke assembly

and

carefully insert

1 on the

inside

the

(7) is

strip

on the

the

is

smooth

along

and

of

these checks indicates incorrect mounting,

the

rollerhead from

the arm

alien screws.

cable support spring

in

brackets

carton.

loosely-packed table parts

on the

able

to

you

to

the

column with

elevating handle, raise

the

alien screws from

right)

arm.

released

lower right-hand side

movement

by

the

lock

end-cap

floor.

to

slide

and

then

resting with

mount

mount

we

the

arm.

the

will find

the

suggst

machine

elevating handle (6), secure

the

carton containing

can be

off.

the

of the

In

doing

and

lined

of the

pushing

Check

the

rollerhead

the arm

(2) and

refer

to

Controls Illustrations

the

column-end

the

machine

tilt

the

its

base frame

Powershop

it

easier

Powershop

you set up the

to it

before proceeding

cross-head screw

removed.

the arm

three bearings

roller head into

so

take care

up

rollerhead

it

backwards

also that

in

secure

on the

arm:

out of the

machine

on to an

to do

this now.

on to its

the arm of the

the

out of its

correctly

of the

and

the rip

position

tracks

it

and

other

of the

on the

legstand

it to

end-cap

(2 on

the

that

the

with

its

arm.

in the arm

lock

as

and

repeat

firmly

with

on

page

2).

DW1251

DW1

51 01

Insert

/3

Fix the end of the

end of

along

the top of the

point

on the

inserting

end-loop

The

cable

down

the

the

spring into small hole

right-hand side

screw provided through

of the

is

then routed along

back

arm.

spring

spring.

of the

to the

of the arm by

column.

half

way

mounting

the

the arm and

Page 6

7

2.

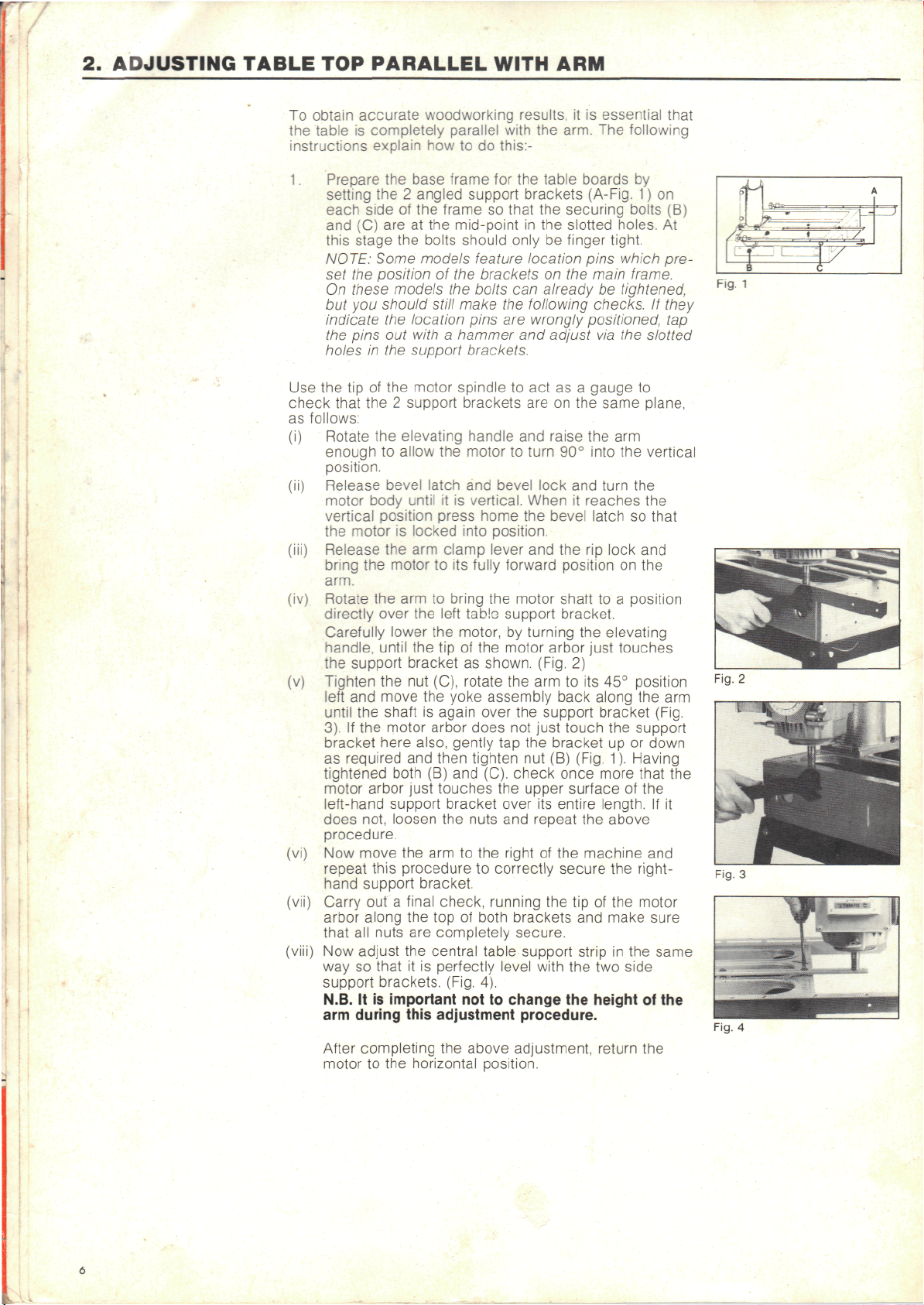

ADJUSTING TABLE

TOP

To

obtain accurate woodworking results,

the

table

instructions explain

1.

Prepare

PARALLEL WITH

is

completely parallel with

how to do

the

setting

each side

and (C) are at the

this

stage

NOTE: Some

set

the

On

these

but you

indicate

the

pins

holes

base frame

the 2

angled

of the

the

bolts should only

models

position

models

should

the

out

in the

still make

location

with a hammer

support brackets.

frame

mid-point

of the

the

this:-

for the

support

so

that

feature

brackets

bolts

can

the

pins

are

brackets

in the

location

and

ARM

it is

the

arm.

table boards

the

on the

already

following

wrongly

(A-Fig.

securing bolts

slotted holes.

be

finger

pins which

checks.

positioned:

adjust

essential that

The

following

by

1)

on

(B)

tight.

main frame.

be

via the

At

pre-

tightened,

If

they

tap

slotted

Fig.

1

Use the tip of the

check that

as

follows:

Rotate

(i)

enough

position.

Release bevel latch

motor

vertical position press home

the

motor

Release

bring

the

arm.

(iv)

Rotate

directly over

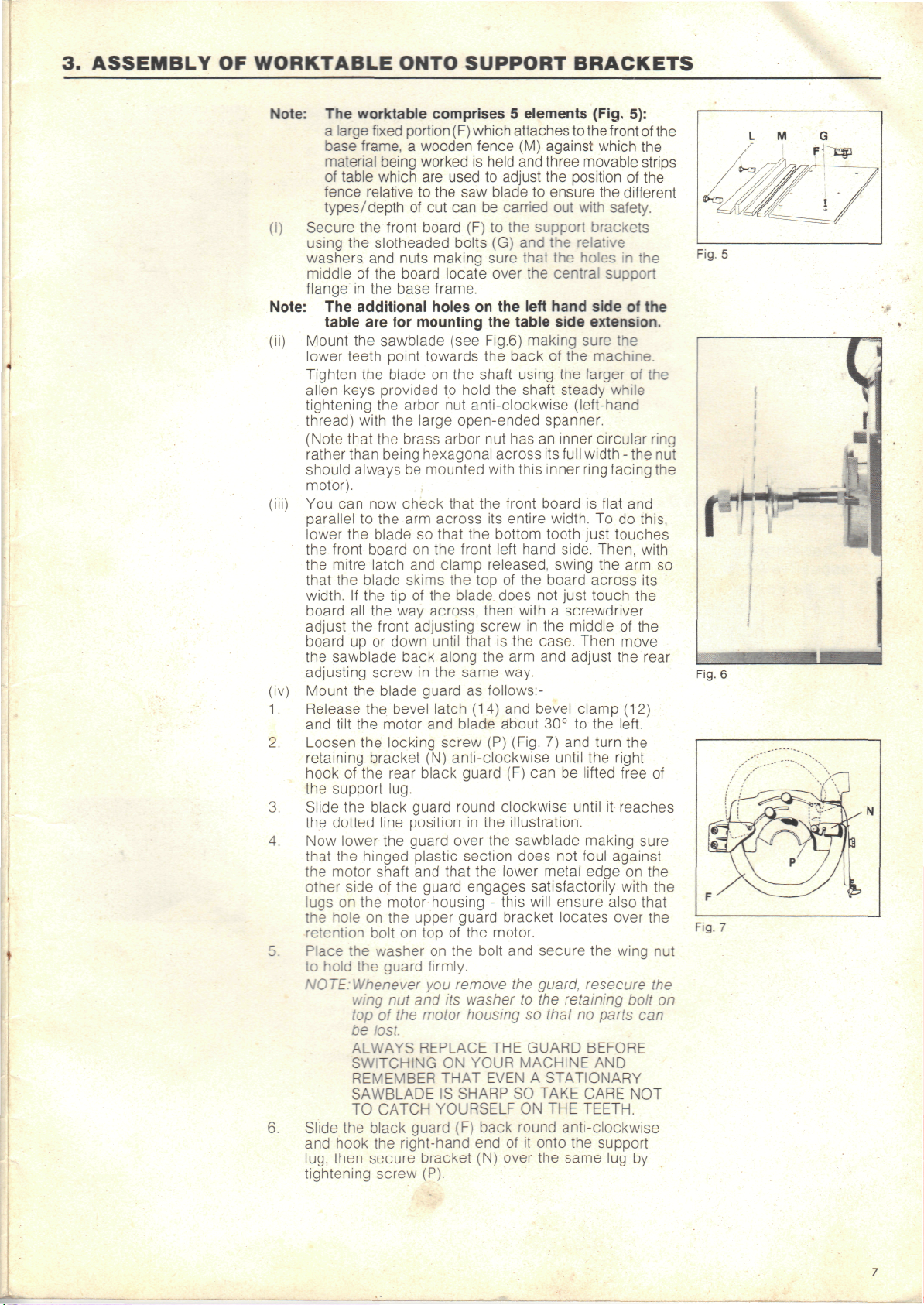

Carefully

handle,

the

support bracket

(v)

Tighten

left

and

until

the

3). If the

bracket here also, gently

as

required

tightened both

motor

left-hand support bracket over

does

not,

procedure.

Now

move

repeat this

hand support bracket.

(vii)

Carry

arbor

along

that

all

Now

adjust

way

so

support

N.B.

It is

arm

during this adjustment

After

completing

motor

motor spindle

the 2

support brackets

the

elevating handle

to

allow

the

body

until

it is

is

locked into position.

the arm

motor

the arm to

lower

until

the nut

move

shaft

motor arbor does

arbor just touches

out a

nuts

that

brackets. (Fig.

important

to the

clamp

to its

bring

the

left

the

the tip of the

(C),

the

yoke assembly back along

is

again over

and

then tighten

(B) and

loosen

the

the arm to the

procedure

final check, running

the top of

are

completely secure.

the

central table support strip

it is

perfectly level with

the

horizontal position.

to act as a

are on the

and

motor

to

turn

and

bevel lock

vertical. When

fully

tablo

motor,

as

rotate

nuts

to

not to

above adjustment, return

the

lever

and the rip

forward position

the

motor

support bracket.

by

turning

motor arbor just touches

shown. (Fig.

the arm to its 45°

the

support bracket

not

just touch

tap the

nut (B)

(C).

check

the

upper surface

its

and

repeat

right

of the

correctly

both brackets

4).

the tip of the

change

procedure.

gauge

same plane,

raise

the arm

90°

into

and

turn

it

reaches

bevel latch

lock

shaft

to a

the

elevating

2)

(Fig.

once

the

machine

and

the two

the

height

the

up or

more that

above

the

make sure

in the

bracket

entire length.

secure

to

the

vertical

the

the

so

and

on the

position

position

the arm

support

down

1).

Having

of the

and

right motor

side

of the

the

that

(Fig.

the

If it

same

Fig.

Fig.

2

4

Page 7

3.

ASSEMBLY

OF

WORKTABLE

Note:

(i)

Secure

Note:

(ii)

Mount

(iii)

You can now

(iv)

Mount

1.

Release

2.

Loosen

3.

Slide

4.

Now

6.

Slide

ONTO

The

worktable comprises 5 elements (Fig.

a

large fixed

base

frame, a wooden fence

material being worked

of

table which

fence

types/depth

using

washers

middle

flange

The

lower

Tighten

alien keys provided

tightening

thread)

(Note

rather

should always

motor).

parallel

lower

the

the

that

width.

board

adjust

board

the

adjusting

and

retaining

hook

the

the

that

the

other

lugs

the

retention bolt

Place

to

NOTE:Whenever

and

lug,

tightening

the

the

of the

in the

additional holes

table

are for

the

teeth point towards

the

with

that

than being hexagonal across

to the arm

the

front

mitre latch

the

blade skims

If the tip of the

all the way

the

up or

sawblade back along

the

tilt

the

the

of the

support lug.

the

dotted line position

lower

the

hinged plastic section does

motor shaft

side

on the

hole

the

hold

the

wing

top of the

be

ALWAYS

SWITCHING

REMEMBER

SAWBLADE

TO

the

hook

then

portion

are

relative

front board

slotheaded bolts

and

nuts making sure that

board locate over

base frame.

sawblade (see

blade

the

the

the

blade

board

front adjusting screw

down until that

screw

blade guard

the

bevel latch

motor

locking screw

bracket

rear

black guard round clockwise until

the

of the

motor housing - this will ensure also that

on the

on top of the

washer

guard

nut and its

lost.

CATCH YOURSELF

black

the

right-hand

secure bracket

screw (P).

used

to the saw

of cut can be

mounting

on the

to

arbor

nut

large open-ended spanner.

brass arbor

be

mounted with this inner ring facing

check that

across

so

that

on the

and

clamp released, swing

the top of the

across, then with a screwdriver

in the

and

(N)

anti-clockwise until

black guard

guard over

and

that

guard engages satisfactorily with

upper guard bracket locates over

on the

firmly.

you

motor

REPLACE

ON

THAT EVEN A STATIONARY

IS

guard

SUPPORT

(F)

which attaches

(M)

is

held

and

to

adjust

blade

carried

(F) to the

(G) and the

on the

the

table side extension.

Fig.6)

the

back

shaft

hold

the

front

blade,

same way.

as

blade about

in

remove

washer

housing

SHARP

(F)

using

the

anti-clockwise (left-hand

(14)

the

YOUR MACHINE

end of it

shaft steady

nut has an

the

front board

its

entire

bottom tooth just touches

left

hand side. Then, with

does

is the

the arm and

follows:-

and

(P)

(Fig.

(F) can be

the

illustration.

the

sawblade making sure

lower metal edge

motor.

bolt

and

the

to the

so

THE

SO

ON THE

back round anti-clockwise

(N)

over

BRACKETS

to

the

against which

three movable strips

the

position

to

ensure

support

the

left

hand side

making sure

of the

its

width.

board across

not

in the

case. Then move

bevel clamp (12)

30° to the

7) and

secure

guard,

that

GUARD BEFORE

TAKE CARE

onto

the

the

out

with safety.

brackets

relative

the

holes

central support

machine.

the

larger

inner circular ring

full

width

is

To do

the arm so

just

touch

middle

adjust

turn

the

lifted

not

foul

the

resecure

retaining bolt

no

parts

AND

TEETH.

the

support

same

5):

front

of the

different

in the

of the

the

of the

while

- the nut

flat

and

of the

the

left.

the

right

free

it

reaches

against

on the

wing

NOT

lug by

of

the

this,

its

the

rear

of

the

the

nut

the

can

the

the

on

Fig.

Fig.

Fig.

f

5

-

i

«t

'

I

6

7

Page 8

(v)

Position

according

cut to be

Note: Never

the

rear table boards

to the

carried

worktable

having

lift

to

your

material

out.

Powershop

or you

repeat

thickness

risk twisting

the

support bracket

adjustment procedure.

and the

and the

by

gripping

it and

fence (Fig.

type

therefore

of

8)

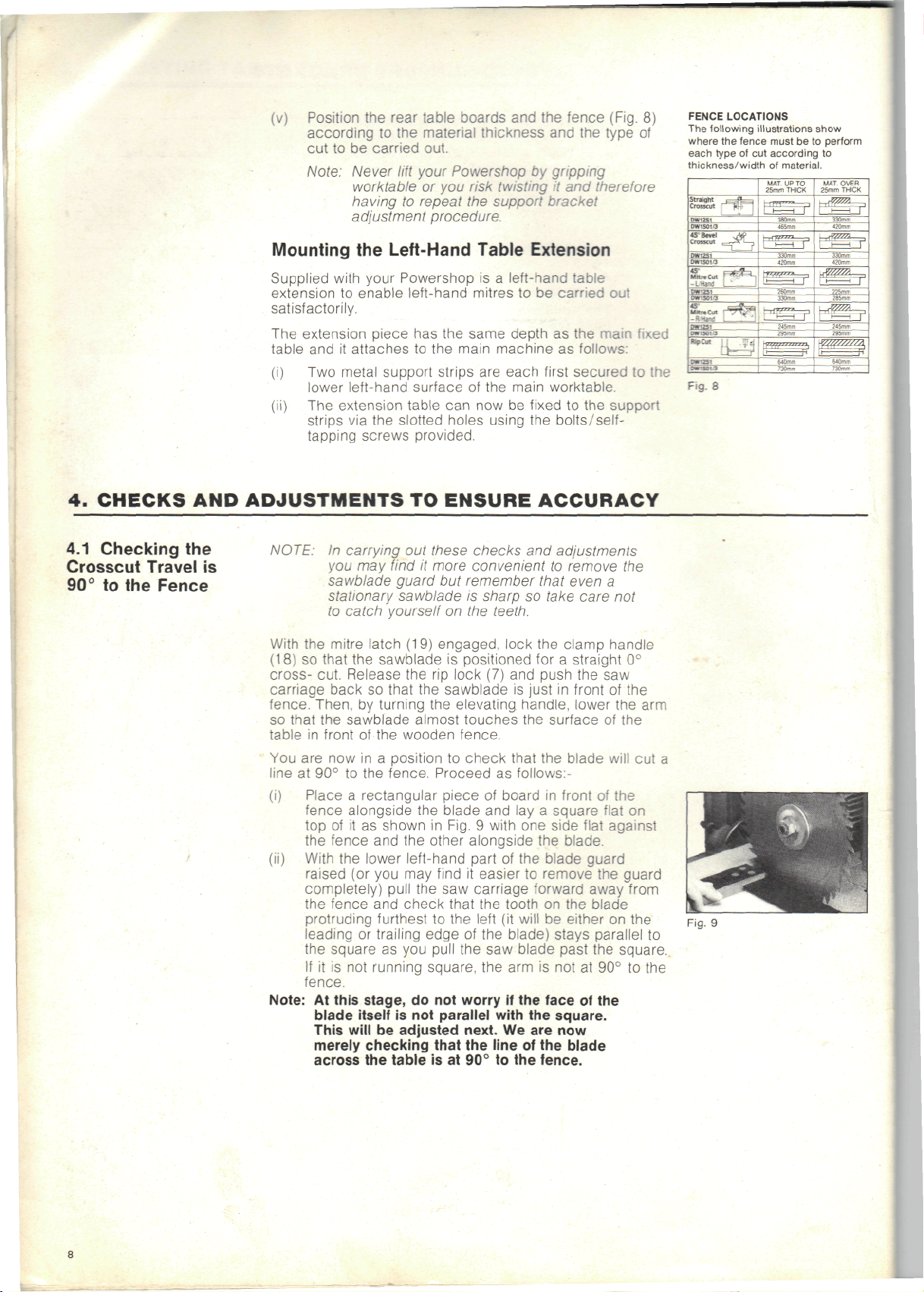

FENCE LOCATIONS

The

following

where

each

thickness/width

the

type

illustrations

fence

of cut

of

must

according

be to

material.

show

perform

to

4.

CHECKS

4.1

Checking

Crosscut

90° to the

AND

the

Travel

Fence

Mounting

Supplied with your Powershop

extension

satisfactorily.

The

extension

table

and it

(i)

Two

(ii)

The

ADJUSTMENTS

NOTE:

is

With

the

(18)

so

crosscarriage back

fence. Then,

so

that

table

in

You are now in a

line

at 90° to the

(i)

Place a rectangular piece

(ii)

With

Note:

At

the

Left-Hand

to

enable left-hand mitres

piece

attaches

has the

to the

main machine

metal support strips

lower

left-hand surface

extension table

strips

via the

slotted holes using

can now be

tapping screws provided.

TO

ENSURE ACCURACY

In

carrying

you may

sawblade guard

out

these

find

it

more convenient

but

stationary sawblade

to

catch

yourself

mitre latch

that

the

sawblade

cut. Release

so

that

by

turning

the

sawblade almost touches

front

of the

position

on the

(19)

engaged, lock

is

the rip

lock

the

sawblade

the

elevating handle, lower

wooden fence.

to

fence. Proceed

fence

alongside

top of it as

the

fence

the

lower left-hand part

raised

(or you may

completely) pull

the

fence

protruding furthest

leading

square

If

it is not

or

the

the

shown

and the

blade

in

Fig. 9 with

other alongside

find

the saw

and

check that

to the

trailing edge

as you

pull

the saw

running square,

fence.

this stage,

blade itself

This

will

do not

is not

be

parallel with

adjusted next.

worry

merely checking that

across

the

table

is at 90° to the

Table

same depth

are

of the

checks

remember that even

is

Extension

is a

left-hand

to be

as the

each

first

main worktable.

fixed

the

and

to

sharp

so

take care

table

carried

out

main

as

follows:

secured

to the

to the

support

bolts/self-

adjustments

remove

the

a

not

teeth.

the

clamp handle

positioned

(7) and

is

for a

push

just

straight

the saw

in

front

0°

of the

the arm

the

check that

as

follows:-

of

board

and lay a

one

of the

it

easier

to

surface

the

in

square

side

the

blade guard

remove

of the

blade will

front

of the

flat

flat

blade,

the

on

against

guard

carriage forward away from

the

tooth

left

(it

will

be

of the

blade) stays parallel

blade past

on the

blade

either

the

on the

square.

the arm is not at 90° to the

if the

face

the

of the

square.

We are now

the

line

of the

blade

fence.

fixed

cut a

to

Fig.

Fig.

8

9

Page 9

Fig.

10

To

Adjust

(i)

With

slacken

(ii)

Loosen

shown

(ill)

Release

the

arm

required, loosen

either

needs

the

right

If

the

move

left

and

flanges a little

latch

blade

overtighten

will

be too

(iv)

Once

retighten

Fig.

(v)

Adjust

registers

the

Crosscut

the

mitre latch engaged

the

mitre clamp.

the

lock nuts

in

Fig.

10.

the

mitre latch

needs

to

side

to go to the

of the arm and

opposite

to the

tighten

and

relative

satisfied

the

and

of the arm

is the

right, loosen

the

at a

clamp

and

to the

the

adjusting flanges

stiff

to

operate

that

lock nuts

10).

the

pointer

0° in

this

Travel

on

each

and

move

to

give

tighten

(Fig.

left,

loosen

tighten

case,

the

flange

time

the

on the

position.

on the

and

check

fence

with a square.

easily.

crosscut travel

on

each side

mitre scale

in the 0°

side

of the

depending

the

the

11)

and the arm

re-engage

the

true

adjusting

if the

front

the

adusting

the

flange

adjusting

right.

crosscut travel

or the

of the arm (as in

so

position.

arm.

on

which

90°

crosscut

flanges

of the arm

flange

on the

needs

flange

Adjust

the

mitre

Do not

mitre

is

accurate,

that

it

on the

the

latch

as

way

on

on

left.

to

of the

Fig.

11

4.2. Checking

Saw

Blade

to

the Arm

is

Tracks.

the

Parallel

This check

position,

run

"dog fashion" (Fig.

adjusted

set of the

would

being

To

Check

(i)

Place a square

To

Adjust

The

illustration

yoke

with yoke

to

the

(i)

Firstly,

(ii)

Then,

(iii)

Having adjusted

(iv)

Now

is to

the

blade

in

this way.

blade (distance across

also tend

cut.

with

the

crosscut

lock)

parallel

is

assembly.

yoke

movement

nut

locating slide

release

(J)

until

therefore

all

in

carriage

surface

clamp

is

the

carriage

the

If

the

accurate

sawblade just

position

check that

to the

necessary.

(Fig.

(17)

is

by the

grasp yoke

(H)

which increases

if the

the

(Fig.

13/13a)

the

blade

also parallel

nuts.

this

way,

forward.

of the

release

and

facing

the

the

slide

bar and the

backwards until

fence.

blade

fence,

parallel

ensure that,

runs true across

it

to

cause scorch marks

against

the

square.

13)

The

precise alignment

made

locking nuts (J).

left

or

bar (K) and

blade

yoke

clamp

and

is in

the

release

table

the rip

then rotate

fence

is

completely flat, across

this

will

in the

12).

If the

blade

will produce

the

fence

in

(lock

shows

possible

right,

is

Raise

confirm

rip

front

it in

left

in

still

fact parallel

blade parallel

the rip

by

locating

and

yoke clamp. Then push

cutting.

that position

hand face

If it is not

the

by

both hands

if

there

the

nylon

not

parallel

(10)

turn

yoke slightly

to the arm

lock

the saw

turning

the

yoke

lock

the

that

straight

the

a cut

the

of the

components

collar

is

friction between

and

the

slide

it

into

blade

the saw

90°

table

is

tips

on the

as in

of the

parallel,

of

and

movement tighten

block

loosen

to the

tracks. Then

to the arm

and

blade just above

elevating handle.

bar and the

90° so

that

is

cross-

and

incorrectly

wider than

of the

teeth).

timber

Fig. 9 and,

fence

with

blade

adjustment

of the

rollerhead

(I)

which

check

(L).

to the

square.

the

to

left

square

pull

the saw

that

position

resting against

its

face against

will

cut

does

not

the

It

in the 90°

the rip

is

(8)

is

fixed

it for

the rip

lock nuts

or

right

and

tighten

tracks

the

yoke

the

blade

with

the saw

perform

Fig.

Fig.

Fig.

12

13

133

Page 10

4.3

Checking

Blade

to

Fig.

is

Table

14

the

Perpendicular

If

by any

the

and

blade parallel

For

accurate woodworking,

sawblade cuts a precise

chance

fence then return

repeat

the

the

above adjustment procedure (making

to arm

90°

blade

does

it to the 0°

tracks).

it is

vertical

not lie

cross-cut position

also necessary that

line

flat against

when

intended

the

to

do so.

To

Check

With

the arm in the

latches/Clamp handles engaged, place a steel square with

one

edge

and the

(make sure

blade

then completely flat against

also

To

(i)

Remove bevel pointer disc

(iv)

(v)

Replace

on the

other edge against

the

and

rests against

not at

right angles (90°)

Adjust

screws

Tilt

the

Firmly

NOTE:It

(B) in

Loosen

the

motor

square.

retighten

screw

you do so, be

before replacing

cross-cut position

worktable parallel

square passes between

Fig.

the two

left

may be

(M)

the

bevel pointer disc.

the

left

the

inner face).

the

square,

to the

15

outside

or

right

the

alien

necessary

slightly before

(A) by

and

re-engage

alien

until

screw(s)

to

sure

to

the

bevel pointer disc.

secure

and all

to the

fence (Fig.

face

of the

the

If the

it

follows

worktable.

removing

the

screws

the

blade

L.

loosen

the

motor

it

sawblade

teeth

blade

bevel

(Fig.

16).

is

the

centre

will

again

14)

of the

is not

that

the two

latch.

flat

against

alien

tilt.

firmly

it is

If

Fig.

Fig.

15

16

4.4

Adjusting

Roller

Head

to Arm

10

Bearings

Tracks.

In

most cases

necessary

Radial

However,

the

adjustment

tracks

The

(Fig.

shafts

to

Arm

Saw.

in

time

which

roller head

17).

Two of

(Q) and the

(R).

If

there

is

arm

proceed

(i)

Pull

(ii) Remove

lateral movement between

tracks, (and

as

follows:

the

tracks

and

assembly

With

the rip

with

an

18).

Having slackened this screw, also loosen

13mm

lock

Then

release

the

access hole

rotate

the

sufficiently

that

all 3

moved backwards

find

it

difficult

you

may

so

that

tracks.

Once satisfied that

retighten

alien screw

NOTE:

The top and

bearings

over

their

should move freely

the

above adjustments will

enable accurate

it is

possible that play might develop

of the

will

yoke assembly forward

the rip

alien

bearings rotate

find

you can see the 3

the

should

roller

cause inaccuracy.

is

suspended

these

are

third

you

will

lock

it in

scale

by

withdrawing

scale pointer removed,

key to the

nut (J)

the rip

in the

eccentric bearing

in

contact with

to

feel when

it

easier

13mm

and

replace

be in

entire length

sawing

head

bearings

by

three special bearings

mounted

is

mounted

be

able

to

position with

pointer

the two

locking

immediately beneath

lock

and

underside

(R)

the arm

as the

and

forwards along

the

if you

remove

bearings rotating

the

lock

nut and

the

ripscale pointer.

bottom edges

contact

and the

but

without side-play.

be all

that

with

your

DeWalt

to the arm

on

straight bearing

on an

eccentric shaft

the

bearings

feel

it, if

to the end of the arm

the rip

on the

right

Phillips screws.

you

screw

as

with

an

alien

of the

slightly until

track

yoke assembly

adjustment

the Arm

adjustment

then

the

of all

with

the arm

roller

head assembly

and the

there

is)

lock.

of the

have access

shown. (Fig.

the

it.

(Fig. 19).

key via

yoke (Fig.

it is

to

ensure

the

arm.

is

correct,

end-cap

in the

is

correct,

horizontal

three

tracks

are

in

yoke

20)

is

If you

Fig.

Fig.

Fig.

Fig.

17

18

19

20

Page 11

Note:

From

time

build-up

of

bearings - especially

accuracy

and

necessary

follows:

(i)

Remove

(ii)

The

the

the arm

yoke assembly will

arm.

With a clean,

their

entire length

(Fig.

21).

With a vacuum cleaner

on the 3

can be

(v)

Remount

replace

screws

bearings

used

the

the arm end

are

to

time,

you may

dust

in the arm

after

ease

clear

of

this

to

end-cap.

dry

cloth wipe

to

remove

and

of the

if

necessary

yoke assembly

cap, making sure

tightly

secured.

find

that

tracks

or on the

ripping.

operation,

dust.

then

the arm

all

cloth,

it

This

can be

come

out at the end of

tracks

dust

and

clean

yoke assembly.

to

remove

compacted

in the arm

there

To

maintain

will

grease

off all

White

tracks

all

is a

be

done

along

dust

spirit

dust.

and

retaining

as

4.5

Adjusting Base

to

Column

CAUTION: Never attempt

these bearings

to

lubricate

or the arm

cause premature wear

The

following adjustment

will

also normally

unnecessary unless your Powershop

frequently

If.

after,

cut

position

side,

arm

following adjustment

(i)

Loosen

(ii)

Turn

from site

the

mitre latch

and the

or

up-and-down,

caused

by the

the

alien

screws

rear)

and

an

alien key.

the

down.

If

adjust

by

the

correct

to

site.

is

engaged

mitre clamp

movement

column moving

is

necessary:

lock nuts

on the

(U in

left

then slacken

elevating handle

base

is

seen

to be

unscrewing

fit has

the two

been achieved. Avoid binding

in the 0°

is

secured, there

at the

in its

Fig.

of the

the

inner brass screws with

to

move

slack around

nuts W (Fig. 22a) until

overtightening.

If

the

base

is too

unscrewing nuts

tight around

(X) and

the

tightening nuts

correct fit.

(iii)

Retighten

back

them

CAUTION:

of the

in

position.

After

again

to

the

the

brass screws against

column

carrying

the

and set the

out

this adjustment, check

straight cross-cut travel

fence

- and

adjust

the

tracks,

and

inaccuracy.

surface

as

of

this

be

has

been moved

straight cross-

is

front

end of the

base,

22) on the 2

still

the

brass

base (looking from

the

column

the

up and

column,

column, adjust

(W) for

the key on the

lock nuts

to

hold

is at 90°

if

necessary.

can

the

by

by

Fig.

22

Fig.

22a

Page 12

5. THE

5.1

Mounting

SAWBLADE

Blade Guard

the

GUARD

See

instruction

3.

(iv)

5.2

Adjusting

Blade Guard

the

— For Rip

(i)

Loosen

(ii)

Loosen

Important:

—

For

Neither

needed

adjusted

Cuts:

knife bracket

(C)

machine's worktable.

from

loosening

within

lower

bottom

timber (i.e. when

(L)

the

blade).

into

should

the 2

is

approximately

the

the

the

the

of the

are

positioned

wood before

Once

contact

be at the

It is

kickback fingers

they

throw

Note that

kickback fingers onto

be

be

It

is

correct position when

timber

Cross-Cutting:

the

riving knife

for

cross -cuts,

up out of the

knobs

(B)

blade must

the

screws

bracket

knob

bracket

bracket just

the

with

essential

prevent

the

loosened

angled

also important

binding

(H)

down until

10mm

(G) and

slots).

(Q) on the

(D)

the

tips

at

about 1/8"

you

start

anti-kickback fingers

the

surface

angle indicated.

for

the

timber back towards

the

alien

to

for

bevel-ripping.

nor the

so

way.

(Fig.

23) and

the tip of the

(%")

The

distance

be

between

sliding

back

until

the

central spring

touches

of all

anti-kickback

below

to

feed

of the

safe rip-cutting that

are

correctly positioned

tendency

screw mounting

allow

on the

make sure that they

its

the

to use the

ripping

blade.

anti-kickback fingers

slide

from

the

of the

1-3mm.

the

knife

of the

guard

the

surface

the

the

timber

have

timber,

of the

support bracket

kickback fingers

blade

the

riving knife

to

the

riving

riving

surface

riving

(adjust

left

on the

fingers

surface

into

come

they

the

to

operator.

the

prevent

are

both

knife

of

the

knife

by

or

right

and

of the

of

the

anti-

•

anti-

can

to

in its

the

are

";

5.3

Removing

Blade

5.4

Guard

Removing

Sawblade

12

the

the

Follow

the

mounting procedure

The

arbor

turn

(i)

Fit the

(ii)

Fit the

(iii)

Holding

(iv)

(iv)

Hold

nut has a

it

clockwise

large alien

the

motorshaft

(Note

that

rather

should always

motor).

as

near

large

nut

will loosen.

Remove

noting

you

If

the nut is

following method:

Lock

rip

lock.

Fit

the

Position a striking block

with

clockwise until

block

CAUTION:

HAND

AND

MEANS

the

than being hexagonal across

large open-ended spanner onto

parallel

the

spanner clockwise with

the

the

order

remount

the

roller

large spanner

the

spanner

some

force, turning

and the nut

TAKE CARE

ON THE

NEVER

OF

(3.(iv))

left-hand thread,

to

remove

to

brass

be

alien

blade

the

difficult

head

the end of the

EXPOSED TEETH

TRY TO JAM THE

HOLDING

it

from

key

supplied into

hold

the

shaft steady.

arbor

nut has an

mounted with this inner ring facing

to the

alien

key

firmly with

and all

of

assembly

blade.

on the

loosens.

to

loosen

in

position

to the

of

the

NOT TO

THE

flanges

nut, while

in

reverse order.

so it is

the

motor

the

its

key as

arbor

wood

blade/motor shaft anti-

SHAFT STATIONARY

possible.

one

hand,

the

other hand

on the

and

positioning

in

this way,

on the arm

nut

as

shown

at the

spanner strikes

CATCH

OF THE

MOTOR

necessary

shaft.

front

inner

circular

full width

the

arbor

turn

motor shaft

use the

with

only.

in

same time,

YOUR

BLADE

FAN AS A

to

end of

ring

- the nut

the

nut

the

and the

for

when

the

Fig.

24.

the

Rotate

spanner

anti-clockwise

Fig.

24

Page 13

6.

MAKING A TRIAL

6.1

Wiring

up to the

Mains

CUT

Having

now

Note:

completed

time

to

If,

when

saw

carriage

would

pieces

arm

tracks

assembly.

tracks

the

above adjustment

make a straight cross-cut

you

were

setting

travel

was not as

expect,

of

that

probably

polystyrene

or to the 3

packing

bearings

With a clean,

and the

bearings

Single-Phase 240v Models

Connect a standard

to

the

cable attached

illustration. Make sure that

outer sheath

the

plug.

Plug

in and

of the

switch

13

amp

to the

rubber-covered

machine

the

cable

cable securely before fixing

on at the

mains socket.

in a

up

your

smooth

means there

stuck

dry

cloth

to

eliminate

as

clamp

procedure,

piece

machine,

as you

either

on the

wipe

yoke

both

this.

earthed

shown

is

holding

in the

the cap to

it is

of

timber.

the

are

to the

the

. ;-•

plug

the

6.2

Making

the Cut

Three-Phase

415v

Models

Three-phase machines should

mains

by a

suitably qualified electrician.

(i)

With

(ii)

Release

the

handle

straight

so

that

mitre

so

that

0°

cross- cut.

the rip

the

sawblade

lock

the

sawblade

lock

engaged,

and

is

correct position depending

(See

Fig. 25).

(iii)

Now,

(iv)

Gripping

by

turning

so

that

the

the

table. Place

of

the

of

the

sawblade almost touches

fence.

the

switch handle, press

push- button switch

the

elevating handle, lower

the

piece

same hand.

(v)

Once

the

sawblade

has

(after a short speed build-up

rotate

the

cut a

elevating handle

shallow groove

or

table.

(vi)

Now

pull

cuts a vertical slot

the

piece

to

the

(vii)

Now

switch

side

of the

With

a set

timber

further adjustment

the saw

of

column.

square check that

is a

timber,

off the

switch.

true

90° in

blade

in the

and

machine

each plane.

is

necessary

appropriate instruction.

Note:

The

3

very

useful

(1)

It

"locks

to

be

maintained — useful when ripping (obviously)

but

also advantageous

(2)

There

removing power from

control

switch

on

your

feautures:

on" so

that thumb pressure does

for

is

motor overload protection built into

the

overheating.

(3)

It has a

of

actuated before

"no-volt release"

power

the

switch

the

has to be

motor

be

wired directly into

lock

the arm

is

positioned

push

behind

on the

the saw

the

carriage back

fence

material thickness

the

of

timber against

the

with

reached

of 2 or 3

to

allow

kerf

in the

slowly towards

wooden fence

then

push

by

the cut in

right-hand side

the

thumb

maximum speed

seconds)

the

blade

surface

you so

and

the

carriage

pressing

your piece

If it is

and

refer

Powershop

incorporates

left-hand operators.

motor

in the

event

so

that

if

there

deliberately

will

run.

clamp

for a

in its

the arm

surface

the

of the

to

of the

that

through

the

left-hand

not, then

back

to the

not

need

it

of it

is a

removal

re-

the

of

front

just

it

back

of

FENCE

LOCATIONS

The

following

where

the

45

Mitre

45

Mitre

-R Hi

LHai

type

ut

25

fence must

of cut

each

thickness/width

Fig.

illustrations

be to

according

of

material.

show

perform

to

V--

25*Tv-

: .

THICK

~

13

Page 14

7.

SCALE

ADJUSTMENTS

7.1 Rip

Scale

The rip

When

column, that

material must

When

operator,

material

The

adjustable

1.

2.

3.

4.

5.

Note:

scale

is

located

the

motor

is

positioned with

is

called

be fed

the

motor

that

is

must

be fed

pointer

Place a board

the

Position

towards

assembly along

forward

Loosen

move

lines

scale. Tighten

Now

rip" position without moving

The

position

position

for

indicating

as

follows:

fence

in its

the

the

edge

the two

the

pointer until

up

with

remove

"in-rip" pointer should

on the

of the

the

fence when "in-ripping".

It is

generally good practice

cut

with a tape rather than relying solely

scale, although

complete

differing

first

widths (i.e. +5mm

cutting

the

through

is

positioned with

called

the

from

the

of

known

"rip" position (See Fig. 25).

motor

in its

front

of the

the arm

of the

material.

screws

the

known width

the two

the

board

upper

blade here indicates

the

confidence

width).

on the

scale

right side

the

"in-rip"

left

ripping width

machine)

on the

the

screws.

and

scale

position

the

blade from right

"out-rip" position

width

"out-rip" position

until

when

the

to

right.

(say

and

the

blade just

pointer assembly

edge

of the

of the

place

the

the

yoke assembly.

now

line

(adjust

to

can be

making

or

-7mm relative

of the

radial arm.

blade facing

and

your

blade facing

and the

on the

about

board

up

if

necessary).

the

check

used with

scale

24cm)

(blade

move

the

touches

"out-rip"

on the

motor

in its

with

the

ideal

location

the

on the

several

width

the

to

left.

the

is

against

yoke

and

pointer

lower

"in-

zero

The

of

cuts

at

to the

the

7.2

7.3

Bevel

Mitre

Scale

Scale

The

bevel scale

beneath

for a vertical cut,

scale.

disc,

then retighten

The

the

can be

been correctly positioned

cross-cut.

right.

provide accurate

the

To

adjust, loosen

and

move

mitre scale

elevating

adjusted

The

mitre latch engages with machined locations

is

located

switch handle. When

the

pointer

the

disc

the

screws.

is

located

handle.

The

On top of the arm is a

to

align with

scale

is

then marked

45°—0°—45°

on the

the

until

on the top of the arm

and

front

of the

the

blade

should

screws retaining

the

the

be at

pointer points

'0'when

clamped

for a

0°-50°

positioning.

zero

motor'

is

positioned

on the

the

pointer

to

'0'

and

beneath

pointer

the arm has

to

straight

left

and

which

to

14

Page 15

8.

CLAMP HANDLE ADJUSTMENTS

(i)

The

(ii)

(iii)

(a)

(b)

(c)

(d)

Having removed

(e)

Mitre

Clamp

adjusted

the

the

the nut on the

surrounding

half a turn

when

elevating

The

same

to do so

The

involved.

If

you

movement

adjust

Remove

Remove

tracks.

While

downwards with a screwdriver

so

turn

large

underneath moves

lever,

within

the

NOTE:

arm, take

the arm

Replace

if its

elvating handle.

clamp handle

it is

Bevel

way as in (i)

adjustment

find

as

levering

that

the

screwdriver

check that

the

yoke assembly

While

secure position means

other

casting.

and

pull

again

handle.

Clamp

with

the

that

the

to

satisfactorily

follows:

the arm

the

complete yoke assembly

the

it

will

pass over

central bolt

movement

the

the

opportunity

tracks with a clean

the arm

handle

and

retightened

motor

of the

end-cap.

so

the

the

yoke assembly

end-cap.

(18)

may

need

it

In

such a case,

push

it

end

You can

the

clamp handle back

handle (12)

above

yoke clamp

Yoke Clamp

spring steel locking flange

in the top of the

that

on one

small screwdriver used

clamp does lock satisfactorily

arc

to the

into

protrudes from

then tighten

it

does

may be

but you may

in its

vertical position.

has

clamp

(as

the lug on the

the

locking flange

segment past

available

armtracks.

is

to

clean

dry

cloth.

hinders

simply

the

casting

not

obstruct

adjusted

find

is a

little

insufficient

the

yoke securely,

from

shown

yoke casting,

yoke with

and

then return

removed

the

bearings

to be

slacken

so

its

up the nut

out so

it

easier

more

the arm

in

Fig.

the

lug.

as a

from

use of

that

that

the

in

the.

26)

a

the

and

Fig.

26

9.

HINTS

ON

GENERAL CARE

1.

Keep

2.

When

3.

Keep

4.

From time

5.

Never attempt

6.

When carrying your Powershop resist

OF

the

machine

build-up

machine could

sure

before

amount

be

dry

particulary

clean

may

remove

tracks.

remove

If

you

be

cap

bearings

premature

to

frame instead.

twisting

your

of

dust

in the

be

changing

that

the

securing.

the

worktable clear

of

cut

could cause inaccuracy.

cloth

to

the arm

find

it

the

White

compacted dust.

remove

sure

to

securely.

or the arm

lift

it by

it and

machine.

or

blade

dust between

to

time wipe

eliminate dust build-up which

after

a lot of rip

tracks

easier

yoke assembly completely from

spirit

the

tighten

to

lubricate

wear

and

gripping

If you

therefore

YOUR POWERSHOP

clean

for

efficient operation.

immediate vicinity

hazardous

remounting

and

and the 3

to

detach

can be

yoke assembly, when replacing

the

retaining screws

tracks,

inaccuracy.

the

worktable — grip

lift

and

lead

to

the

sawblade, make

adjacent flanges

of

sawdust. Just a small

the

fence

and the

the arm

it by the

reducing

tracks with a clean,

cutting

the arm end cap and

used

the

as

or

sanding.

yoke bearings,

if

necessary

in the arm end

surface

this

of

can

cause

the

worktable

the

accuracy

the

A

of the

inaccuracy.

are

clean

material

can

ensue

To

you

the

to

these

temptation

base

you

risk

of

to

it

15

Page 16

10.

The

numbers

10.1

Arm

10.2

Blade

THE

VARIOUS

in

bracki

Rotation

Height

OPERATING

refer

to

those

in the

''Controls"

The

radial

arm

Release

(19).

Then swing

angle. Then lock

The

calibrated mitre scale

handle

and

'0'

straight cross-cut position.

The

mitre latch

0° and 45°

clamp handle also

other,

position.

The

Radial Arm,

raised

or

top

of the

moves

the

rotates

the

mitre clamp handle (18)

indicates

(15)

positions

lowered

column. Each complete rotation

blade

ADJUSTMENTS

illustrations

to

right

or

left

for

the arm (2)

the

clamp

the

angle

is

only used

but

adopt

to

secure

and

hence also

by

turning

up or

down

right

handle(18).

(1)

is

the arm in

the

by

and the

or

left

just below

of the arm

to

locate

the

habit

the Saw

elevating

about 3mm.

OF

BASIC

on

page

mitre cuts.

mitre latch

to the

required

the

elevating

relative

the arm in the

of

using

this,

as

blade,

handle

of the

2

to the

the

well

as any

can be

(6)

handle

MACHINE

mitre

10.3 Yoke

Rotation

10.4

Blade

11.

MAKING

11.1

Cross

(Fig.

27)

Assembly

Tilting

THE

Cut

Changing from cross-cut

seconds.

Release

then

automatically

always secure

Turn

the

Tilt

clamp released,

popular

BASIC

(iii)

(v)

the rip

swing

the

table. Release bevel clamp (12)

the

motor

0°. 45° and 90°

slide

the

at the

elevating handle

to the

bar (4) and the

yoke

to

four

the

yoke clamp also

desired

the

latch will automatically locate

CUTS

Set

the

radial

registered

elevating

tighten

Turn

the

position

the

thickness

To

cut

right through

necessary

table top.

on

the

motor before

table surface

when lowering continues. Switch

Place

material

the

fence, keeping your thumb

from

the

Switch

fence

and

will

find that

assembly forward - rather

speed

of

tend

to

After

completing

return

the

fence.

arm at

as 0° on the

handle.

the arm

behind

path

on

jam.

clamp handle.

elevating handle

the

of the

to cut a

If

such a groove

so

on

the

motor

and

across

you do not

travel

in the cut

sawblade

to the rip

right

or

90°

to

angle

angle positions.

right angles

Lock

the

fence

material being

the

shallow groove

the

that

it

will

worktable

sawblade will take.

draw

the

material

the

cut, switch

to its

position takes

yoke clamp (10)

left.

The

positions,

to

raise

the

sawblade

and

on the

mitre

lower

is not

cut

into

and

and

the

sawblade

to

to

will need

to the

latch

correct

to be

already

off the

hold

make

pull

off and

mitre scale beneath

to

in its

material

blade actually

need

you

otherwise

rest position

only

well

scale.

in the

the

into

it is

also

slightly

against

well

cut.

limit

will

the

and

to

above

(1'

With

and

for

25)

in the

switch

the

away

the

You

the

yoke locks

but

remember

maximise accuracy.

bevel

latch

bevel

fence.

in

position

the

blade

position

cut

(See Fig.

sawn

or

kerf

there,

touches

the

table

motor.

firmly

fingers

through

the

the

motor

to

the

blade

carefully

behind

Fig.

27

16

Page 17

11.2

(Fig.

11.3

(Fig.

Mitre

28)

Bevel

30)

Cut

Cut

Release

Swing

mitre scale.

The

the

mitre

intermediate angles, lock

clamp handle only.

The

the

Proceed

crosscutting. Remember that

slightly

material

different

When cutting a left-hand mitre (Fig. 29),

(v)

probably require a different

needed when cutting

angle.

moveable table strips into position behind

hand table extension.

Set

Rotate

above

Release

Tilt

bevel scale.

The

0°,

handle

required,

motor rigidly

Place

thickness

Then, with

carefully

it

just cuts into

be

the arm

the arm to the

mitre

latch

0°

straight cross-cut position

positions, together with

fence should

thickness

to

into

and

slot

You

arm as for 0°

the

elevating handle

the

surface

the

the

motor

bevel latch enables

45° and 90°

as a

the

the

fence

of

the

lower

drawn through

clamp

required angle shown

should

of the

make

the

table surface

each

cut in the

will also need

bevel

in the

secondary lock.

bevel

in

position.

material (See Fig. 25).

sawblade still behind

the

the

be

be

placed

material (See Fig. 25).

the cut in the

mitre angle

fence.

the

cross cut.

of the

clamp

yoke

positions,

clamp

in

position depending

blade

table surface.

the

fence

handle

used

the

the arm in

in

you

to cut

fence position from that

corresponding right-hand

to

slide

to

table.

handle

to the

you to

but use the

If any

on its own

with

the

and

and the

to

position

same

cut

raise

and the

required

accurately locate

into

mitre

latch.

on the

locate

and at the 45°

clamp

will need

will require

the

motor running until

The

the arm at

handle.

position

way as for

right through

fence

the

other angle

will hold

on the

the

blade

the

with

depending

to cut

you

will

and

the

blade well

bevel latch.

angle

bevel clamp

fence,

can

material.

At

arm

your

a

left-

on the

the

is

the

then

on

Fig.

Fig.

Fig.

28

29

30

11.4 Ripping

(Fig.

31)

Set

the arm as for

Pull

the

yoke assembly

Release

clamp.

Revolve

wide

narrower

accordingly (Note: Photo actually shows machine

bevel-ripping).

Make sure

(v)

appropriate

once

Position

desired width

right

position

Now,

section 5.2. Then turn

dust

Then, following

(viii)

arm, switch

firmly

quickly

When

IX

machine

the rip

the

panels (Fig.

cuts (Fig. 32), positioning

the

yoke slot

again

to

the

side

of the

with

adjust

is not

thrown into your face.

against

into

the

you

have finished

by

cross cut.

out to the end of the

locating slide

motor

90° to the

31)

or 90° to the

slide

bar

lock

yoke assembly along

of rip

the rip

the

on the

the

pressing

and the

the

cut. using

arm,

and

lock.

sawblade guard

the

the

instruction label

machine and, with

fence,

revolving

the

bar and the

right

locates positively

yoke

clamp

in

position.

the rip

lock

the

dust ejection spout

feed

it

evenly

saw

blade.

the

cut, switch

main switch again.

for

left

the

is

the arm for the

scale

yoke assembly

as

described

on the top of the

arm.

yoke

out- ripping

for

in-ripping

fence

in the

tightened

on the

in

so

the

material

and not too

off the

on

in

that

Fig.

Fig.

31

32

17

Page 18

IMPORTANT:

1. Use a

2.

Before switching

3.

After

notched "push-stick" (Fig.

and see

wood through

down

keeping

from

ripping,

anti-kickback

positioned

completed,

has

the

clean,

11.

drawing

at the

your

the

blade.