Page 1

DEWALT Industrial Tool Company, P.O. Box 158, 626 Hanover Pike, Hampstead, MD 21074 Printed in U.S.A. (APR97-CD-1) Form No. 383945

DW100-220 Copyright © 1997

383945/DW100-220 5/3/02 1:15 PM Page 2

Page 2

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW100-220

3/8" V .S.R. Drill

Perceuse de 10 mm (3/8 po) à régulateur de vitesse et inverseur de marche

Taladro V.V.R. de 10 mm (3/8")

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

383945/DW100-220 5/3/02 1:15 PM Page 3

Page 3

Important Safety Instructions

WARNING: When using electric tools, basic safety precautions

should always be followed to reduce risk of fire, electric shock, and

personal injury, including the following:

READ ALL INSTRUCTIONS

Double Insulation

Double insulated tools are constructed throughout with two separate

layers of electrical insulation or one double thickness of insulation

between you and the tool’s electrical system. Tools built with this

insulation system are not intended to be grounded. As a result, your

tool is equipped with a two prong plug which permits you to use

extension cords without concern for maintaining a ground

connection.

NOTE: Double insulation does not take the place of normal safety

precautions when operating this tool. The insulation system is for

added protection against injury resulting from a possible electrical

insulation failure within the tool.

CAUTION: WHEN SERVICING USE ONLY IDENTICAL

REPLACEMENT PARTS. Repair or replace damaged cords.

Safety Instructions For All Tools

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite

injuries.

• CONSIDER WORK AREA ENVIRONMENT. Don’t expose power

tools to rain. Don’t use power tools in damp or wet locations. Keep

work area well lit. Do not use tool in presence of flammable liquids

or gases.

• GUARD AGAINST ELECTRIC SHOCK. Prevent body contact

with grounded surfaces. For example; pipes, radiators, ranges, and

refrigerator enclosures.

English

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS

OR ANY D

EWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

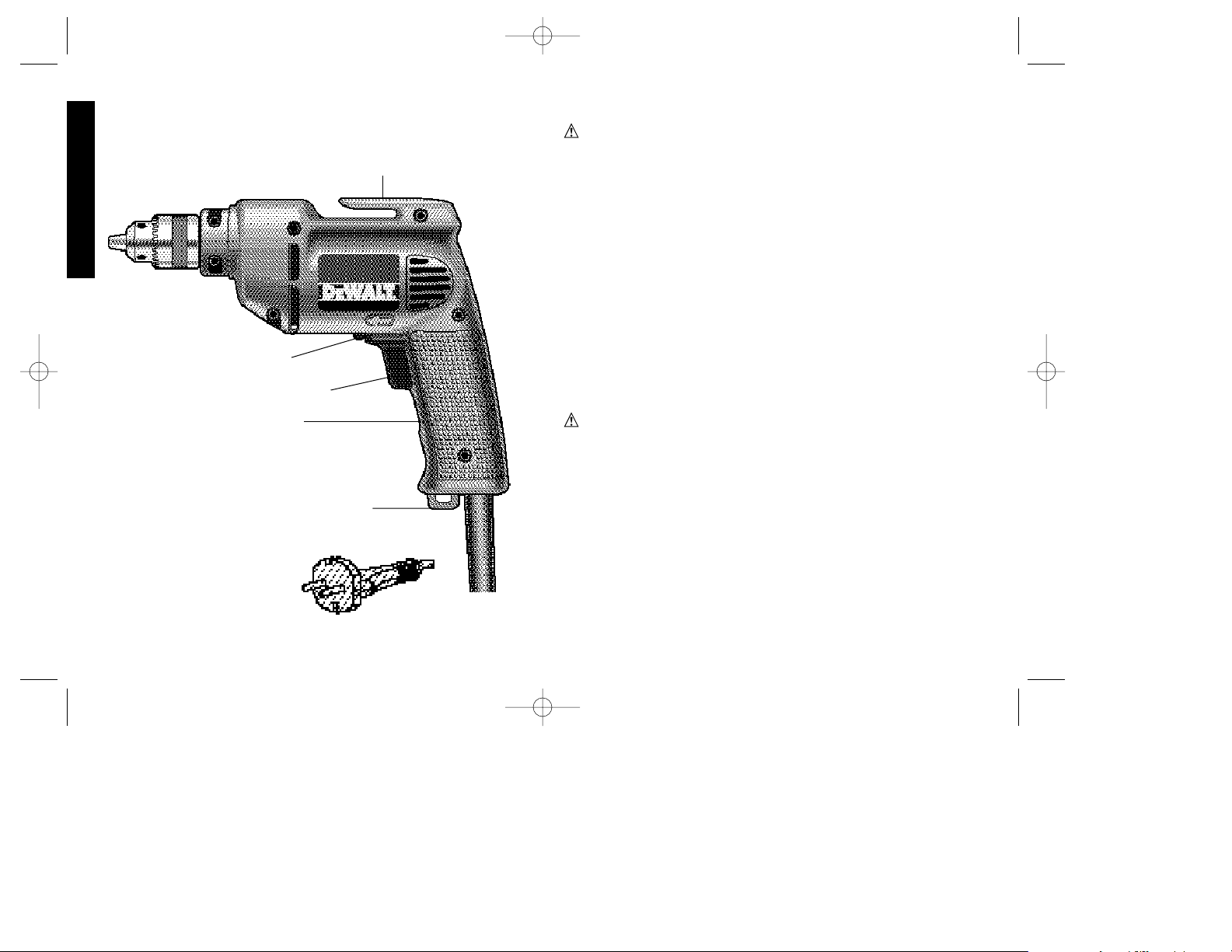

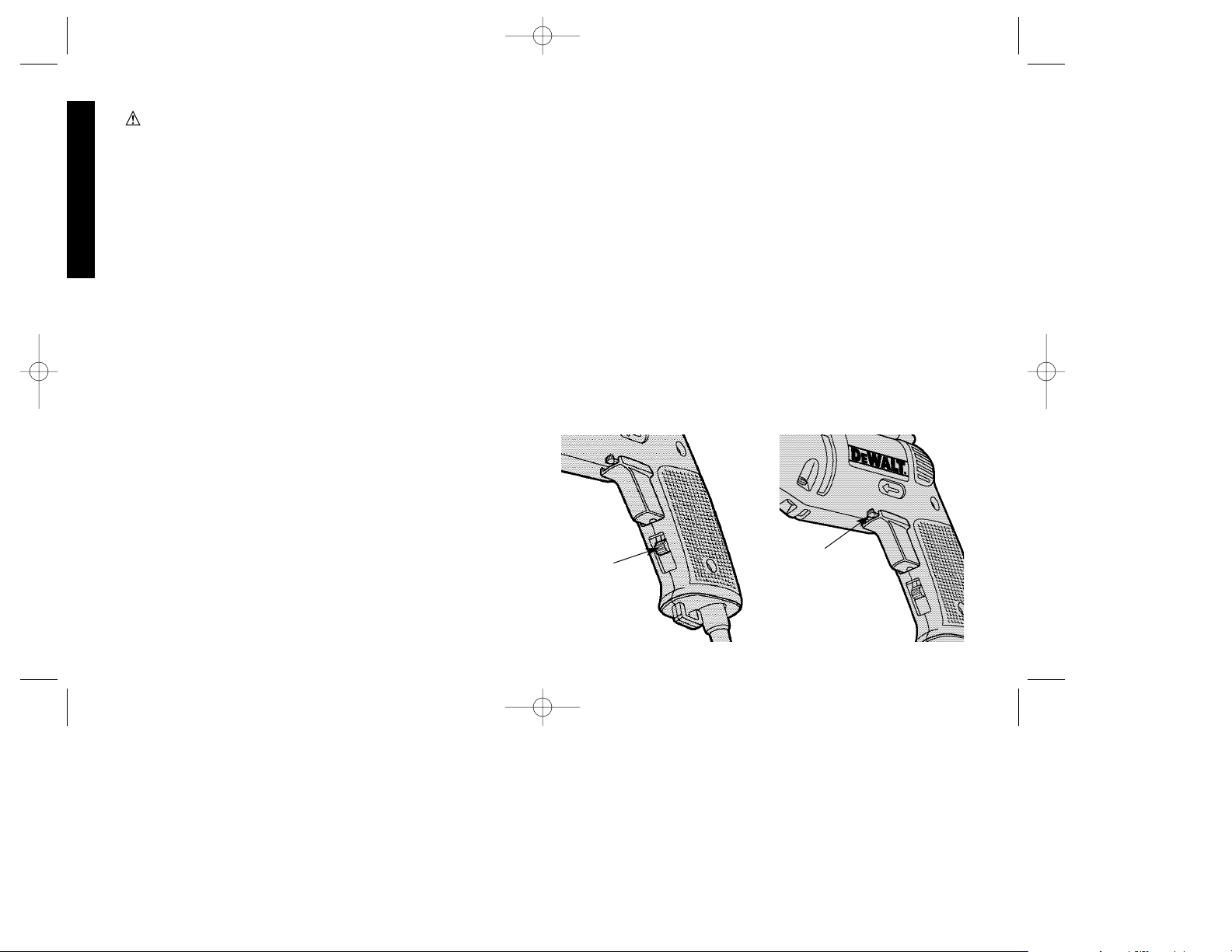

REVERSING LEVER

TRIGGER SWITCH

LOCKING BUTTON

BELT CLIP

LANYARD RING

220 VOLT PLUG

383945/DW100-220 5/3/02 1:15 PM Page 4

Page 4

• KEEP CHILDREN AWAY. Do not let visitors contact tool or

extension cord. All visitors should be kept away from work area.

• STORE IDLE TOOLS. When not in use, tools should be stored in

dry, and high or locked-up place — out of reach of children.

• DON’T FORCE TOOL. It will do the job better and safer at the

rate for which it was intended.

• USE RIGHT TOOL. Don’t force small tool or attachment to do the

job of a heavy-duty tool. Don’t use tool for purpose not intended.

• DRESS PROPERLY. Do not wear loose clothing or jewelry. They

can be caught in moving parts. Rubber gloves and non-skid

footwear are recommended when working outdoors. Wear

protective hair covering to contain long hair.

• USE SAFETY GLASSES. Also use face or dust mask if operation

is dusty.

• DON’T ABUSE CORD. Never carry tool by cord or yank it to

disconnect from receptacle. Keep cord from heat, oil, and sharp

edges.

• SECURE WORK. Use clamps or a vise to hold work. It’s safer than

using your hand and it frees both hands to operate tool.

• DON’T OVERREACH. Keep proper footing and balance at all

times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for

better and safer performance. Follow instructions for lubricating

and changing accessories. Inspect tool cords periodically and if

damaged, have repaired by authorized service facility. Inspect

extension cords periodically and replace if damaged. Keep

handles dry, clean, and free from oil and grease.

• DISCONNECT OR LOCK OFF TOOLS when not in use, before

servicing, and when changing accessories, such as blades, bits,

cutters.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of

checking to see that keys and adjusting wrenches are removed

from tool before turning it on.

• AVOID UNINTENTIONAL STARTING. Don’t carry tool with finger

on switch. Be sure switch is off when plugging in.

• EXTENSION CORDS. Make sure your extension cord is in good

condition. When using an extension cord, be sure to use one

heavy enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in loss

of power and overheating. The following table shows the correct

size to use depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gage. The smaller the gage

number, the heavier the cord.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0-6 18161614

6 - 10 18 16 14 12

10-1216161412

12 - 16 14 12 Not Recommended

• OUTDOOR USE EXTENSION CORDS. When tool is used

outdoors, use only extension cords intended for use outdoors and

so marked.

• STAY ALERT. Watch what you are doing. Use common sense.

Do not operate tool when you are tired.

• CHECK DAMAGED PARTS. Before further use of the tool, a

guard or other part that is damaged should be carefully checked

to determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced by an authorized service

center unless otherwise indicated elsewhere in this instruction

manual. Have defective switches replaced by authorized service

1

English

383945/DW100-220 5/3/02 1:15 PM Page 1

Page 5

2

center. Do not use tool if switch does not turn it on and off.

• CAUTION: When drilling or driving into walls, floors or wherever

live electrical wires may be encountered, DO NOT TOUCH ANY

METAL PARTS OF THE TOOL! Hold the tool only by insulated

grasping surfaces to prevent electric shock if you drill or drive into a

live wire.

SAVE THESE INSTRUCTIONS

Motor Brushes

DEWALT uses an advanced brush system which automatically stops

the drill when the brushes wear out. This prevents serious damage to

the motor.

Switches

To start drill, depress trigger switch; to stop drill, release trigger. To

lock trigger in “ON” position for continuous operation, depress trigger

and push up locking button “A” Figure 1, then gently release trigger.

To release locking mechanism, depress trigger fully, then release it.

Before using the tool (each time) be sure that the locking button

release mechanism is working freely.

Do not lock the switch “ON” when drilling by hand so that you can

instantly release the trigger switch if the bit binds in the hole.

The locking button is for use only when the drill is mounted in a drill

press stand or otherwise held stationary.

Be sure to release the locking button before disconnecting the plug from the

power supply. Failure to do so will cause the tool to start immediately the

next time it is plugged in. Damage or injury could result.

THE VARIABLE SPEED TRIGGER SWITCHpermits speed control –

the farther the trigger is depressed, the higher the speed of the drill.

NOTE: Use lower speeds for starting holes without a center punch,

drilling in metal or plastics, driving screws or drilling ceramics. Higher

speeds are better for drilling wood and composition boards, and for

using abrasive and polishing accessories.

THE REVERSING LEVER is used for withdrawing bits from tight

holes and removing screws. It is located above the trigger switch

(Fig. 2). To reverse the motor, release the trigger switch FIRST and

then push the lever to the right. After any reversing operations, return

lever to forward position.

Operation

DRILLING

1. Always unplug the drill when attaching or changing bits or

accessories.

2. Use sharp drill bits only. For WOOD, use twist drill bits, spade bits,

power auger bits, or hole saws. For METAL, use high speed steel

twist drill bits or hole saws. For MASONRY, such as brick, cement,

cinder block, etc., use carbide-tipped bits.

3. Be sure the material to be drilled is anchored or clamped firmly. If

drilling thin material, use a wood “back-up” block to prevent

damage to the material.

English

FIG. 1

A

FIG. 2

REVERSING

LEVER

(Shown in Forward

Position)

383945/DW100-220 5/3/02 1:15 PM Page 2

Page 6

4. Always apply pressure in a straight line with the bit. Use enough

pressure to keep drill biting, but do not push hard enough to stall

the motor or deflect the bit.

5. Hold tool firmly to control the twisting action of the drill.

6. IF DRILL STALLS, it is usually because it is being overloaded or

improperly used. RELEASE TRIGGER IMMEDIATELY, remove

drill bit from work, and determine cause of stalling. DO NOT

CLICK TRIGGER OFF AND ON IN AN ATTEMPT TO START A

STALLED DRILL — THIS CAN DAMAGE THE DRILL.

7. To minimize stalling or breaking through the material, reduce

pressure on drill and ease the bit through the last fractional part

of the hole.

8. Keep the motor running when pulling the bit back out of a drilled

hole. This will help prevent jamming.

9. With variable speed drills there is no need to center punch the

point to be drilled. Use a slow speed to start the hole and

accelerate by squeezing the trigger harder when the hole is deep

enough to drill without the bit skipping out.

Drilling in Metal

Use a cutting lubricant when drilling metals. The exceptions are cast

iron and brass which should be drilled dry. The cutting lubricants

that work best are sulfurized cutting oil or lard oil; bacon-grease will

also serve the purpose.

Drilling in Wood

Holes in wood can be made with the same twist drills used for metal.

These bits may overheat unless pulled out frequently to clear chips

from the flutes. For larger holes, use power drill wood bits. Work that

is apt to splinter should be backed up with a block of wood.

Drilling in Masonry

Use carbide tipped masonry bits at low speeds. Keep even force on

the drill but not so much that you crack the brittle materials. A

smooth, even flow of dust indicates the proper drilling rate.

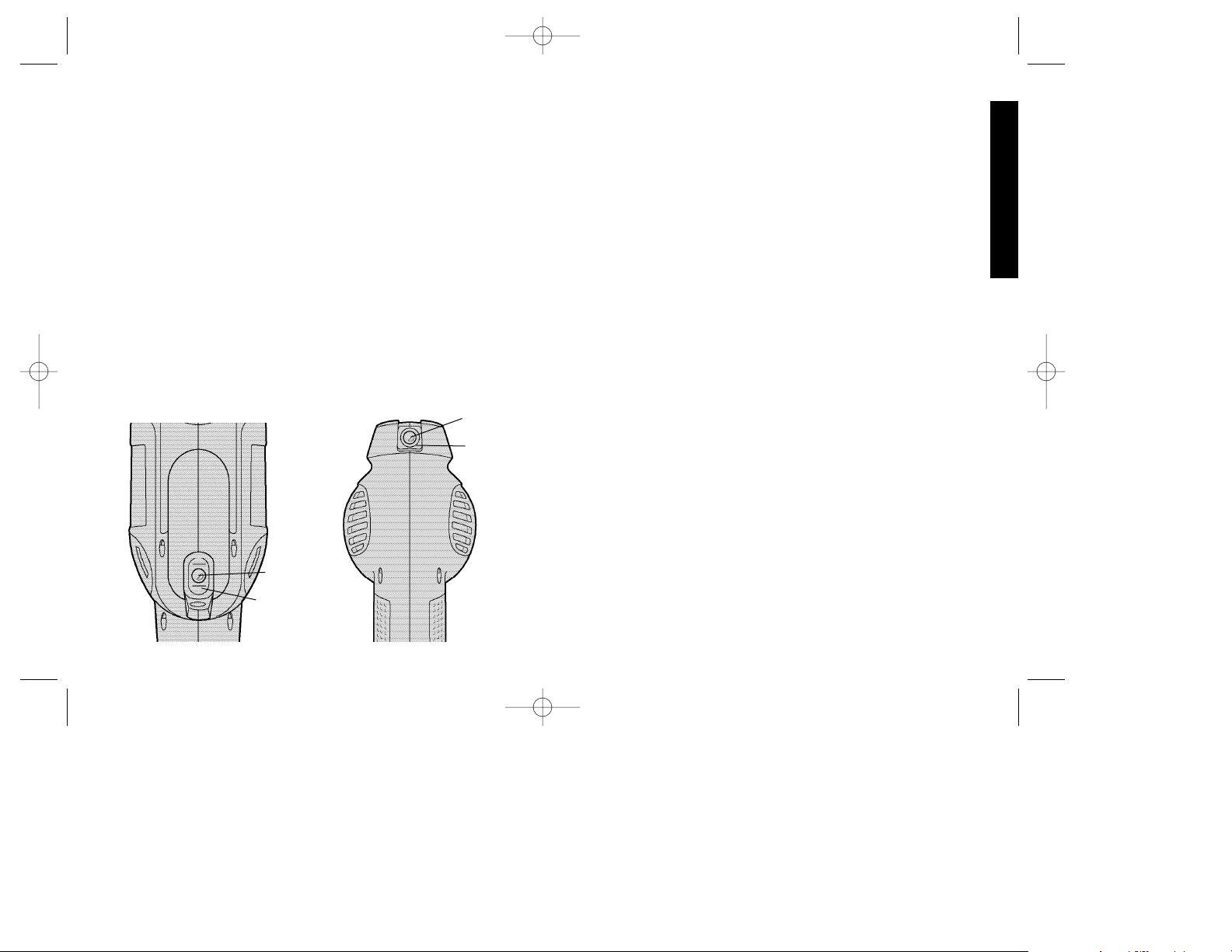

Bubble Level

Your drill is equipped with a bubble level that assists you in drilling

level holes.

For horizontal drilling, tilt the drill up or down as required so that the

bubble floats in the center of the parallel lines drawn on the glass.

When the bubble is centered between the lines, as shown in Figure

3A, the drill is level.

For vertical drilling, align the drill so that the bubble floats in the

center of the bull’s-eye, as shown in Figure 3B.

To assure accuracy, first place a level on your work piece and

position it so that it is level. Then, when the drill reads level, the two

will be aligned. (Any bubble level can only indicate level to the earth’s

surface.)

NOTE: The level is filled with mineral oil that may cause minor skin

irritation when contacted. If the level breaks and this fluid gets on

3

English

FIG. 3A

FIG. 3B

BUBBLE

BUBBLE

LEVEL

BUBBLE

BUBBLE

LEVEL

383945/DW100-220 5/3/02 1:15 PM Page 3

Page 7

4

your skin, rinse thoroughly with water. If any liquid gets in your eyes,

rinse thoroughly with water and call a physician immediately.

Chuck

Open chuck jaws by turning collar with fingers and insert shank of

bit about 3/4" into chuck. Tighten chuck collar by hand. Place chuck

key in each of the three holes, and tighten in clockwise direction. It’s

important to tighten chuck with all three holes. To release bit, turn

chuck counter clockwise in just one hole, then loosen the chuck by

hand.

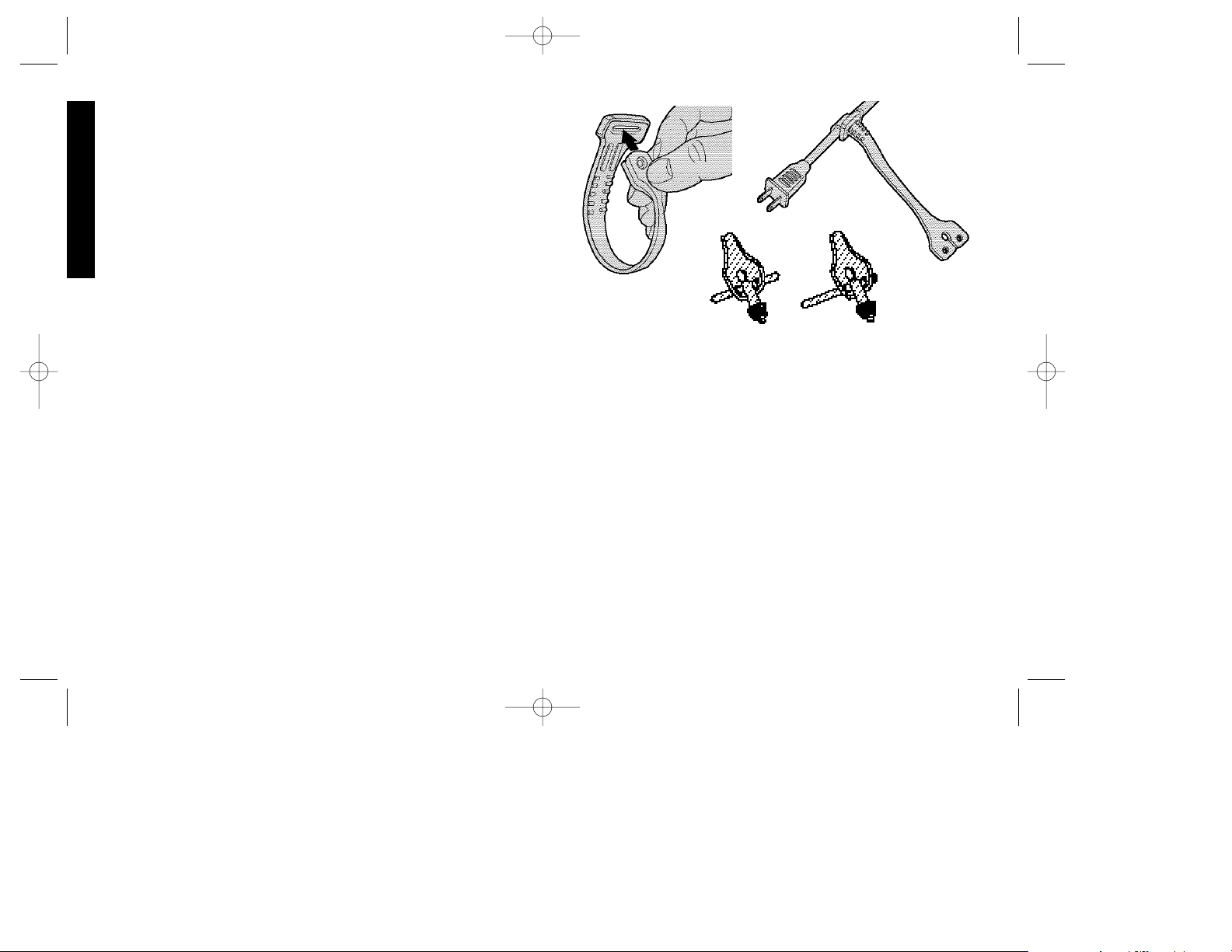

Chuck Key Holder

(May be installed already.)

1. Push double-hole end of holder through the slot in other end of

holder (Figure 4.)

2. Slip loop over electric plug and draw loop tight around cord

(Figure 5.)

3. Push ends of Chuck Key Handle through two holes in end of

holder (Figure 6.)

Chuck Removal

Place chuck key in any one of the three holes in the chuck, as shown

in Figure 7. Strike the key sharply in the counterclockwise direction

(when viewed from the front of the tool). This will loosen the chuck so

that it can be removed by hand.

Chuck Installation

Screw the chuck on by hand as far as it will go. Place the chuck key

in any of the three holes in the chuck and strike it sharply in the

clockwise direction (when viewed from the front of the tool) as shown

in Figure 8. (145-160 in. lbs. of torque is recommended.)

Lubrication

When the tool is taken apart for motor brush replacement a small

amount of grease should be added (or redistributed from that

remaining in housing) to the gears.

The ball bearings used in this tool are lubricated during manufacture

and require no lubrication.

Accessories

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center. If you

need assistance in locating any accessory for your tool, please

contact your local dealer or authorized service center.

If you need assistance in locating any accessory, please contact

D

EWALT Industrial Tool Company, P.O. Box 158, 626 Hanover Pike,

Hampstead, MD 21074 or call 1-800-433-9258.

English

FIG. 5

FIG. 4

FIG. 6

383945/DW100-220 5/3/02 1:15 PM Page 4

Page 8

CAUTION: The use of any other accessory not recommended

for use with this tool could be hazardous.

For safety in use, the following accessories should be used only in

sizes up to the maximums shown in the table below.

MAXIMUM RECOMMENDED CAPACITIES

DRILL CAPACITY 3/8"

R.P.M. 0-2500

BITS, METAL DRILLING 3/8"

WOOD, FLAT BORING 1"

BITS, MASONRY DRILLING 1/2"

HOLE SAWS 1-1/8"

ACCESSORY MUST BE RATED FOR USE AT SPEED EQUAL TO

OR HIGHER THAN NAMEPLATE R.P.M. OF TOOL WITH WHICH IT

IS BEING USED.

WIRE WHEEL BRUSHES ....................4" Diameter Maximum

WIRE CUP BRUSHES ..........................3" Diameter Maximum

BUFFING WHEELS ..............................3" Diameter Maximum

RUBBER BACKING PADS....................4-5/8" Diameter Maximum

Important

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by authorized service centers or other qualified service

organizations, always using identical replacement parts.

Full Warranty

DEWALT heavy duty industrial tools are warranted for one year from

date of purchase. We will repair, without charge, any defects due to

faulty materials or workmanship. For warranty repair information,

call 1-800-4-D

EWAL T. This warranty does not apply to accessories or

damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may

have other rights which vary in certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your

D

EWAL Theavy duty industrial tool, simply return it to the participating

seller within 30 days for a full refund. Please return the complete unit,

transportation prepaid. Proof of purchase may be required.

5

English

FIG. 7 FIG. 8

383945/DW100-220 5/3/02 1:15 PM Page 5

Page 9

6

Français

POUR TOUT RENSEIGNEMENT SUPPLÉMENTAIRE SUR CET

OUTIL OU TOUT AUTRE OUTIL D

EWALT, COMPOSER SANS

FRAIS LE NUMÉRO:

1 800 4-DEWALT (1 800 433-9258)

Importantes mesures de sécurité

AVERTISSEMENT : Afin de réduire les risques d’incendie, de

secousses électriques ou de blessures lorsqu’on utilise des outils

électriques, il faut toujours respecter les mesures de sécurité

suivantes.

LIRE TOUTES LES DIRECTIVES.

Double isolation

Les outils à double isolation comportent deux couches distinctes

d’isolant électrique ou une double épaisseur d’isolant qui protègent

l’utilisateur contre les risques de blessures provenant du système

électrique de l’outil. Ce système de double isolation élimine le besoin

de mettre les outils à la terre. En effet, l’outil est muni d’une fiche à

deux broches, ce qui permet d’utiliser une rallonge ordinaire sans

avoir à se soucier d’assurer la mise à la terre.

NOTE : La double isolation ne dispense pas des mesures de sécurité

normales lors de l’utilisation de l’outil. Elle vise à procurer une

protection supplémentaire contre les blessures que peut entraîner

une défectuosité de l’isolant électrique à l’intérieur de l’outil.

MISE EN GARDE : LORS DE L’ENTRETIEN, N’UTILISER QUE

DES PIÈCES DE RECHANGE IDENTIQUES. Réparer ou

remplacer les cordons endommagés.

Mesures de sécurité pour tous les outils

• BIEN DÉGAGER LA SURFACE DE TRAVAIL. Des surfaces et

des établis encombrés peuvent être la cause de blessures.

• TENIR COMPTE DU MILIEU DE TRAVAIL. Protéger les outils

électriques de la pluie. Ne pas s’en servir dans des endroits

humides ou mouillés. Bien éclairer la surface de travail. Ne pas se

servir de l’outil en présence de liquides ou de vapeurs

inflammables.

• SE PROTÉGER CONTRE LES SECOUSSES ÉLECTRIQUES.

INVERSEUR DE MARCHE

INTERRUPTEUR À

DÉTENTE

BOUTON DE

VERROUILLAGE

PINCE POUR LA CEINTURE

CROCHET DE

SUSPENSION

FICHE DE 220 VOLTS

383945/DW100-220 5/3/02 1:15 PM Page 6

Page 10

Éviter tout contact avec des objets mis à la terre, comme des

tuyaux, radiateurs, cuisinières, réfrigérateurs et autres objets du

genre.

• ÉLOIGNER LES ENFANTS. Tous les visiteurs doivent être tenus

à l’écart de l’aire de travail et il faut les empêcher de toucher à

l’outil ou au cordon de rallonge.

• RANGER LES OUTILS INUTILISÉS. Il faut ranger les outils dans

un endroit sec, situé en hauteur ou fermé à clé, hors de la portée

des enfants.

• NE JAMAIS FORCER L’OUTIL. Afin d’obtenir un rendement sûr

et efficace, utiliser l’outil à son rendement nominal.

• UTILISER L’OUTIL APPROPRIÉ. Ne jamais exiger d’un petit outil

ou d’un accessoire le rendement d’un outil de fabrication plus

robuste. Se servir de l’outil selon l’usage prévu.

• PORTER DES VÊTEMENTS APPROPRIÉS. Éviter de porter des

vêtements amples et des bijoux qui peuvent être happés par les

pièces en mouvement. Porter des gants de caoutchouc et des

chaussures à semelle antidérapante pour travailler à l’extérieur.

Protéger la chevelure si elle est longue.

• PORTER DES LUNETTES DE SÉCURITÉ. Porter également un

masque respiratoire si le travail de coupe produit de la poussière.

• NE PAS MANIPULER LE CORDON DE FAÇON ABUSIVE. Ne

pas transporter l’outil par le cordon ni tirer sur ce dernier pour le

débrancher de la prise. Éloigner le cordon des sources de chaleur,

des flaques d’huile et des arêtes tranchantes.

• ASSUJETTIR LA PIÈCE. Immobiliser la pièce à l’aide de brides

ou d’un étau. On peut alors se servir des deux mains pour faire

fonctionner l’outil, ce qui est plus sûr.

• NE PAS DÉPASSER SA PORTÉE. Toujours demeurer dans une

position stable et garder son équilibre.

• PRENDRE SOIN DES OUTILS. Conserver les outils propres pour

qu’ils donnent un rendement supérieur et sûr. Suivre les directives

concernant la lubrification et le remplacement des accessoires.

Inspecter régulièrement le cordon de l’outil et le faire réparer au

besoin à un atelier d’entretien autorisé. Inspecter régulièrement les

cordons de rallonge et les remplacer lorsqu’ils sont endommagés.

S’assurer que les poignées sont toujours propres, sèches et libres

de toute tache d’huile ou de graisse.

• DÉBRANCHER OU VERROUILLER EN POSITION HORS

TENSION LES OUTILS NON UTILISÉS. Respecter cette mesure

lorsqu’on ne se sert pas de l’outil, ou qu’on doit le réparer ou en

changer un accessoire (comme une lame, un foret ou un couteau).

• ENLEVER LES CLÉS DE RÉGLAGE. Prendre l’habitude de

vérifier si les clés de réglage ont été retirées avant de faire

démarrer l’outil.

• ÉVITER LES DÉMARRAGES ACCIDENTELS. Ne pas laisser le

doigt sur l’interrupteur lorsqu’on transporte l’outil. S’assurer que

l’interrupteur est à la position hors circuit lorsqu’on branche l’outil.

• CORDONS DE RALLONGE. S’assurer que le cordon de rallonge

est en bon état. Lorsqu’on se sert d’un cordon de rallonge,

s’assurer qu’il est de calibre approprié pour la tension nécessaire

au fonctionnement de l’outil. L’utilisation d’un cordon de calibre

inférieur occasionne une baisse de tension entraînant une perte de

puissance et la surchauffe. Le tableau suivant indique le calibre

approprié selon la longueur du cordon et les mentions de la plaque

signalétique de l’outil. En cas de doute, utiliser un cordon de calibre

supérieur. Le chiffre indiquant le calibre est inversement

proportionnel au calibre du cordon.

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V 0-25 26-50 51-100 101-150

240 V 0-50 51-100 101-200 201-300

Intensité (A)

Au Au Calibre moyen de fil (AWG)

moins plus

0-6 18161614

6 - 10 18 16 14 12

10-1216161412

12 - 16 14 12 Non recommandé

7

Français

383945/DW100-220 5/3/02 1:15 PM Page 7

Page 11

8

• CORDONS DE RALLONGE PRÉVUS POUR L’EXTÉRIEUR.

Lorsque l’outil est utilisé à l’extérieur, ne se servir que d’un cordon

de rallonge conçu pour l’extérieur et portant la mention appropriée.

• DEMEURER VIGILANT. Travailler avec vigilance et faire preuve

de bon sens. Ne pas se servir de l’outil lorsqu’on est fatigué.

• VÉRIFIER LES PIÈCES ENDOMMAGÉES. Avant de continuer à

utiliser l’outil, il faut vérifier si le protecteur ou toute autre pièce

endommagée remplit bien la fonction pour laquelle il a été prévu.

Vérifier l’alignement et les attaches des pièces mobiles, le degré

d’usure des pièces et leur montage, ainsi que tout autre facteur

susceptible de nuire au bon fonctionnement de l’outil. Faire réparer

ou remplacer tout protecteur ou toute autre pièce endommagée

dans un centre de service autorisé, sauf si le présent guide fait

mention d’un avis contraire. Confier le remplacement de tout

interrupteur défectueux à un centre de service autorisé. Ne jamais

se servir d’un outil dont l’interrupteur est défectueux.

• MISE EN GARDE : Lorsqu’on perce ou qu’on visse dans les

murs, les planchers ou tout autre endroit où peuvent se trouver des

fils sous tension, NE PAS TOUCHER AUX COMPOSANTS

MÉTALLIQUES DE L’OUTIL. Ne le saisir que par ses surfaces en

plastique afin de se protéger des secousses électriques si on entre

en contact avec un fil sous tension.

CONSERVER CES MESURES.

Balais du moteur

Les outils DEWALT sont dotés d’un système perfectionné de

vérification des balais qui arrête automatiquement l’outil lorsque les

balais sont usés afin d’empêcher d’endommager le moteur.

Interrupteurs

Pour mettre la perceuse en marche, enfoncer l’interrupteur à détente;

pour la mettre hors circuit, relâcher l’interrupteur à détente. Lorsqu’on

veut verrouiller l’outil en mode de fonctionnement continu, il suffit

d’enfoncer l’interrupteur à détente et le bouton de verrouillage (A),

illustrés à la figure 1, puis de relâcher lentement l’interrupteur. Pour

libérer le mécanisme de verrouillage, appuyer à fond sur

l’interrupteur à détente et le relâcher. Toujours s’assurer que le

bouton de verrouillage fonctionne bien avant d’utiliser l’outil (chaque

fois).

Ne pas verrouiller l’interrupteur en mode de fonctionnement continu

lorsqu’on perce à la main de façon à pouvoir relâcher immédiatement

la détente si le foret se coince dans le trou.

Utiliser le bouton de verrouillage seulement lorsque la perceuse est

immobilisée dans une presse ou autrement.

Veiller à ce que le bouton de verrouillage soit dégagé avant de

débrancher l’outil, sinon ce dernier se remettra immédiatement en

marche la prochaine qu’on s’en servira et cela présente des risques

de dommages et de blessures.

LE RÉGULATEUR DE VITESSE permet de contrôler la vitesse de

l’outil. Plus on enfonce l’interrupteur à détente, plus l’outil fonctionne

rapidement. NOTE : Se servir de la basse vitesse pour amorcer des

trous sans poinçon ainsi que pour percer les métaux, les plastiques

et la céramique, ainsi que pour enfoncer des vis. La vitesse élevée

convient mieux au perçage du bois et des panneaux d’agglomérés,

ainsi qu’à l’utilisation d’accessoires pour le ponçage et le polissage.

L’INVERSEUR DE MARCHE sert à sortir les vis ou les forets

bloqués. Il se trouve au-dessus de l’interrupteur à détente, comme

le montre la figure 2. Pour actionner la marche arrière, il faut

D’ABORD relâcher l’interrupteur à détente, puis faire glisser

l’inverseur de marche vers la droite. Après les travaux en marche

arrière, toujours remettre l’inverseur à la marche avant.

Français

383945/DW100-220 5/3/02 1:15 PM Page 8

Page 12

Fonctionnement

PERÇAGE

1. Toujours débrancher l’outil lorsqu’on en change les forets ou les

accessoires.

2. N’utiliser que des forets bien affûtés. Pour le BOIS : forets

hélicoïdaux, à langue d’aspic, de tarière ou des emporte-pièce;

pour le MÉTAL : forets hélicoïdaux en acier de coupe rapide ou

des emporte-pièce; pour la MAÇONNERIE (brique, ciment et

béton, etc.) : forets au carbure.

3. Veiller à ce que la pièce à percer soit solidement retenue ou fixée

en place. Afin d’éviter les avaries aux matériaux minces, les

adosser à un bloc de bois épais.

4. T oujours exercer la pression en ligne directe avec le foret. N’user

que de la force qu’il faut pour que le foret continue de percer;

éviter de trop forcer, ce qui pourrait faire caler le moteur ou

dévier le foret.

5. Saisir fermement la perceuse afin de contrer l’effet de torsion de

l’outil en marche.

6. LA PERCEUSE S’ÉTOUFFE habituellement lorsqu’elle est

surchargée ou utilisée de façon inappropriée. RELÂCHER

IMMÉDIATEMENT L’INTERRUPTEUR À DÉTENTE, retirer le

foret du matériau et déterminer la cause du blocage. ÉVITER DE

METTRE EN MARCHE ET HORS CIRCUIT L’OUTIL À L’AIDE

DE L’INTERRUPTEUR À DÉTENTE DANS LE BUT DE FAIRE

DÉMARRER LA PERCEUSE BLOQUÉE, CELA POURRAIT

L’ENDOMMAGER.

7. Afin de minimiser l’étouffement du moteur ou le défoncement de

la pièce, réduire la pression et faire avancer plus doucement le

foret vers la fin de sa course.

8. Laisser le moteur en marche lorsqu’on retire le foret d’un trou afin

d’éviter qu’il se coince.

9. Il n’est pas nécessaire de pratiquer un creux de guidage avec les

perceuses à régulateur de vitesse. Utiliser plutôt la basse vitesse

pour commencer le trou, puis accélérer en enfonçant plus

profondément l’interrupteur à détente lorsque le foret est

suffisamment inséré dans la pièce.

Perçage dans le métal

Utiliser de l’huile de coupe pour percer dans les métaux, sauf la fonte

et le laiton qui se percent à sec. L’huile de coupe la plus efficace est

l’huile sulfurisée ou l’huile de lard; la graisse de bacon est parfois

suffisante.

Perçage dans le bois

Les forets hélicoïdaux à métal peuvent servir à percer le bois, mais

il faut les retirer souvent du trou pour chasser les copeaux et

rognures des goujures afin d’éviter qu’ils ne surchauffent. Pour

percer de gros trous, utiliser les forets à bois d’une perceuse

électrique. Adosser les matériaux friables à un bloc de bois

quelconque.

9

Français

FIG. 1

A

FIG. 2

INVERSEUR DE

MARCHE

(illustré en marche

avant)

383945/DW100-220 5/3/02 1:15 PM Page 9

Page 13

10

Perçage dans la maçonnerie

Utiliser des forets à maçonnerie à basse vitesse. Exercer une

pression constante, sans forcer afin d’éviter de casser les matériaux

friables. Une production uniforme de poussière à débit moyen

indique un perçage convenable.

Niveau à bulle d’air

La perceuse est munie d’un niveau à bulle pour s’assurer que les

trous percés sont de niveau avec les plans horizontal ou vertical.

Dans le cas des trous percés à l’horizontale, placer la perceuse de

sorte que la bulle se trouve entre les repères (comme le montre la

figure 3A). À ce moment-là, la perceuse est de niveau avec le plan

horizontal.

Pour percer des trous à la verticale, il suffit de placer la perceuse

pour que la bulle flotte au centre du verre indicateur, comme l’illustre

la figure 3B.

Pour obtenir une plus grande précision, mettre un niveau sur la pièce

à percer et placer cette dernière de niveau. Puis, aligner la perceuse,

qui est de niveau, sur la pièce. (Tous les niveaux n’indiquent que le

niveau par rapport au champ de gravitation de la terre.)

NOTE : Le niveau contient de l’huile minérale qui peut causer une

légère irritation au contact de la peau. Si le niveau se brise et que

l’huile entre en contact avec la peau, bien la rincer avec de l’eau. Si

le liquide entre en contact avec les yeux, les rincer à fond avec de

l’eau, puis téléphoner immédiatement à un médecin.

Mandrin

Ouvrir les mâchoires du mandrin en tournant le collet à la main et y

insérer environ 19 mm (3/4 po) de l’arbre du foret. Resserrer la

bague du mandrin à la main. Placer la clé du mandrin dans chacun

des trois trous et serrer dans le sens horaire. Il est essentiel de bien

serrer les trois trous du mandrin. Pour dégager le foret, il suffit de

Français

FIG. 3A

FIG. 3B

BULLE

NIVEAU

À BULLE

BULLE

NIVEAU

À BULLE

FIG. 5

FIG. 4

FIG. 6

383945/DW100-220 5/3/02 1:15 PM Page 10

Page 14

faire tourner la clé du mandrin dans le sens antihoraire dans l’un

des trous, puis de desserrer le mandrin à la main.

Porte-clé du mandrin

(Peut être déjà installé.)

1. Insérer l’extrémité à deux trous du porte-clé dans la fente qui se

trouve à l’autre extrémité du porte-clé (fig. 4).

2. Faire glisser la boucle sur la fiche du cordon et bien serrer la

boucle autour du cordon (fig. 5).

3. Passer les extrémités de la clé du mandrin dans les deux trous

du porte-clé (fig. 6).

Retrait du mandrin

Placer la clé du mandrin dans l’un des trois trous du mandrin de la

façon illustrée à la figure 7. Frapper la clé dans le sens antihoraire

(lorsqu’on se place à l’avant de l’outil). On desserre ainsi le mandrin

de façon à pouvoir le retirer à la main.

Installation du mandrin

Visser à fond le mandrin à la main. Placer la clé du mandrin dans l’un

des trois trous du mandrin et la frapper dans le sens horaire

(lorsqu’on se place à l’avant de l’outil), comme le montre la figure 8.

(Il est recommandé d’exercer un couple variant entre 145 et 160 lbpo.)

Lubrification

Il est conseillé d’ajouter une quantité minimale de graisse aux

engrenages lorsqu’on remplace les balais (ou de redistribuer la

graisse qui reste dans le boîtier).

Les roulements à billes de cet outil ont été lubrifiés en usine et il n’est

pas nécessaire de les lubrifier de nouveau.

Accessoires

On peut se procurer séparément les accessoires recommandés pour

l’outil chez les détaillants ou au centre de service de la région. Pour

trouver un accessoire, prière de communiquer avec les détaillants ou

le personnel du centre de service de la région.

Pour trouver un accessoire, prière de communiquer avec D

EWALT

Industrial Tool Company, 626 Hanover Pike, P.O. Box 158,

Hampstead, MD 21074, É.-U., ou composer sans frais le

1 (800) 433-9258).

MISE EN GARDE : L’utilisation de tout accessoire non

recommandé peut être dangereuse.

Par mesure de sécurité, n’utiliser que les accessoires suivants et

uniquement ceux ne dépassant pas les dimensions maximales

recommandées.

11

Français

FIG. 7

FIG. 8

383945/DW100-220 5/3/02 1:15 PM Page 11

Page 15

12

CAPACITÉS MAXIMALES RECOMMANDÉES

CAPACITÉ DE LA PERCEUSE 3/8 po

RÉGIME (trs/min) De 0 à 2 500

FORETS À MÉTAUX 3/8 po

FORETS À BOIS 1 po

FORETS À MAÇONNERIE 1/2 po

EMPORTE-PIÈCE 1 1/8 po

LA VITESSE NOMINALE DES ACCESSOIRES DOIT ÊTRE ÉGALE

OU SUPÉRIEURE AU RÉGIME DE L'OUTIL (INDIQUÉ SUR LA

PLAQUE SIGNALÉTIQUE DE CE DERNIER) AVEC LEQUEL ILS

SONT UTILISÉS.

MEULES MÉTALLIQUES......................4 po max. de diamètre

MEULES-BOISSEAUX

MÉTALLIQUES......................................3 po max. de diamètre

COIFFES À POLIR................................3 po max. de diamètre

DISQUE D'APPUI EN

CAOUTCHOUC....................................4 5/8 po max. de diamètre

Important

Pour assurer la SÉCURITÉ D’EMPLOI et la FIABILITÉ de l’outil, n’en

confier la réparation, l’entretien et les rajustements (y compris

l’inspection des balais) qu’à un centre de service ou à un atelier

d’entretien autorisé n’utilisant que des pièces de rechange

identiques.

Garantie complète

Les outils industriels de service intensif DEWALT sont garantis

pendant un an à partir de la date d’achat. Toute pièce d’un outil

D

EWALT qui s’avérait défectueuse en raison d’un vice de matière ou

de fabrication sera réparée sans frais. Pour obtenir de plus amples

renseignements sur les réparations couvertes para garantie,

composer le 1 (800)4-D

EWALT. Il suffit de retourner l’outil complet à

un centre de service D

EWALT. La présente garantie ne couvre pas

les accessoires ni les avaries dues aux réparations tentées ou

effectuées par des tiers. Les modalités de la présente garantie

donnet des droits légaux spécifiques. L'utilisateur peut également

se prévaloir d'autres droits selon l'état ou la province qu'il habite.

En outre, la garantie suivante couvre les outils D

EWALT .

GARANTIE DE SATISFACTION DE 30 JOURS OU ARGENT

REMIS

Si, pour quelque raison que ce soit, l’outil ne donne pas entière

satisfaction, il suffit de le retourner où il a été acheté dans les 30 jours

suivant la date d’achat afin d’obtenir un remboursement intégral.

Prière de retourner l'outil complet port payé. Une preuve d'achat peut

être requise.

Français

383945/DW100-220 5/3/02 1:15 PM Page 12

Page 16

Instrucciones importantes de seguridad

ADVERTENCIA: Es indispensable sujetarse a las precauciones

básicas de seguridad, con la finalidad de reducir el peligro de

incendio, choque eléctrico y lesiones personales, en todas las

ocasiones en que se utilicen herramientas eléctricas. Entre estas

precauciones se incluyen la siguientes:

LEA TODAS LAS INSTRUCCIONES

Doble aislamiento

Las herramientas DOBLEMENTE aisladas se han elaborado de

manera integral con dos capas separadas de aislamiento eléctrico o

una capa doble de aislamiento entre usted y el sistema eléctrico

que contienen. Las herramientas construidas con este sistema de

aislamiento no requieren conectarse a tierra. Como resultado su

herramienta está equipada con una clavija de dos patas que le

permite emplear cordones de extensión sin preocuparse por tener

una conexión a tierra.

NOTA: El doble aislamiento no substituye a las precauciones

normales de seguridad cuando se opera esta herramienta. La

finalidad de este sistema de aislamiento es ofrecer a usted

protección añadida contra lesiones resultantes de fallas en el

aislamiento eléctrico interno de la herramienta.

PRECAUCION: UTILICE SOLAMENTE REFACCIONES

ORIGINALES CUANDO HAGA SERVICIO a cualquier herramienta.

Repare o reemplace los cordones eléctricos dañados.

Instrucciones de seguridad para todas

las herramientas

• CONSERVE LIMPIA LA ZONA DE TRABAJO. Las superficies y

los bancos con objetos acumulados en desorden propician los

accidentes.

13

Español

PALANCA DE REVERSA

GATILLO INTERRUPTOR

BOTON DE ENCENDIDO

PERMANENTE

PINZA PARA EL CINTURON

ARILLO PARA

COLGAR

CLAVIJA PARA 220

VOLTS

383945/DW100-220 5/3/02 1:15 PM Page 13

Page 17

14

• OTORGUE PRIORIDAD A LA ZONA DE TRABAJO. No deje las

herramientas eléctricas expuestas a la lluvia. No las utilice en

lugares inundados o mojados. Conserve bien iluminada la zona de

trabajo. No utilice la herramienta en presencia de líquidos o gases

inflamables.

• PROTEJASE CONTRA EL CHOQUE ELECTRICO. Evite el

contacto corporal con superficies aterrizadas, por ejemplo,

tuberías, radiadores, antenas y gabinetes de refrigeración.

• CONSERVE APARTADOS A LOS NIÑOS. No permita que los

visitantes toquen las herramientas o los cables de extensión.

Todos los visitantes deben estar alejados de la zona de trabajo.

• GUARDE LAS HERRAMIENTAS QUE NO EMPLEE. Las

herramientas que no se utilizan deben guardarse en un lugar seco

y elevado o bajo llave — fuera del alcance de los niños.

• NO FUERCE LA HERRAMIENTA.Esta cumplirá su función mejor

y con más seguridad a la velocidad y la presión para las que se

diseñó.

• EMPLEE LA HERRAMIENTA ADECUADA. No fuerce a una

herramienta pequeña o a sus dispositivos de montaje en un

trabajo de tipo pesado. No emplee la herramienta en una tarea

para la que no se diseñó.

• VISTASE DE LA MANERA ADECUADA.No use ropas o artículos

de joyería flojos, pues podrían quedar atrapados por las partes

móviles de las herramientas. Se recomienda el empleo de guantes

de caucho y calzado antiderrapante cuando se trabaje al aire libre.

Cúbrase bien la cabeza para sujetarse el cabello si lo tiene largo.

• COLOQUESE ANTEOJOS DE SEGURIDAD. Póngase también

una mascarilla contra el polvo si lo produce la operación que va a

efectuar.

• TENGA CUIDADO CON EL CORDON ELECTRICO. Nunca

levante la herramienta tomándola por el cordón, ni tire de éste para

desconectarlo del enchufe. Apártelo del calor y los objetos

calientes, las substancias grasosas y los bordes cortantes.

• ASEGURE LOS OBJETOS SOBRE LOS QUE TRABAJE. Utilice

prensas o tornillos de banco para sujetar los objetos sobre los

que va a trabajar. Esto ofrece mayor seguridad que sujetar los

objetos con la mano, y además deja libres ambas manos para

operar la herramienta.

• CONSERVE EL EQUILIBRIO. Conserve en todo momento bien

apoyados los pies, lo mismo que el equilibrio.

• CUIDE SUS HERRAMIENTAS. Conserve sus herramientas

afiladas y limpias para que funcionen mejor y con mayor

seguridad. Siga las instrucciones para lubricación y cambio de

accesorios de su unidad. Revise periódicamente el cordón

eléctrico y hágalo reparar o reemplazar por un centro de servicio si

está dañado. Cambie los cordones de extensión si están dañados.

Conserve las empuñaduras secas, limpias y libres de aceite y

grasa.

• DESCONECTE Y APAGUE LAS HERRAMIENTAS cuando no las

use, antes de darles servicio y cuando cambie accesorios, tales

como discos, brocas y otros dispositivos de corte.

• RETIRE LAS LLAVES DE AJUSTE Y DE TUERCAS. Adquiera

el hábito de asegurarse que se han retirado las llaves de ajuste

de las herramientas antes de accionarlas.

• EVITE QUE LA HERRAMIENTA SE ACCIONE

ACCIDENTALMENTE.Nunca sostenga una herramienta que está

conectada con el dedo en el interruptor. Asegúrese que el

interruptor está en posición de “apagado” antes de conectar la

unidad.

• CORDONES DE EXTENSION. Asegúrese que su cordón de

extensión esté en buenas condiciones. Cuando utilice un cordón

de extensión, asegúrese que tenga el calibre suficiente para

soportar la corriente necesaria para su herramienta. Un cordón

eléctrico con calibre insuficiente causará una caída en el voltaje de

la línea, resultando en pérdida de potencia y sobrecalentamiento.

La tabla siguiente ilustra el calibre correcto que debe utilizarse de

conformidad con la longitud del cordón y el amperaje descrito por

la placa de identificación. Si tiene alguna duda, utilice el cable con

Español

383945/DW100-220 5/3/02 1:15 PM Page 14

Page 18

el calibre siguiente (mayor). Mientras más chico sea el número,

mayor será su calibre.

Calibre mínimo para cordones de extensión

Volts Longitud total del cordón en metros

120V 0-7,6 7,6-15,2 15,2-30,4 30,4-45,7

240V 0-15,2 15,2-30,4 30,4-60,9 60,9-91,4

AMPERAJE

MásNo más Calibre del cordón AWG

de de

0- 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16- 14 12 No recomendado

• CORDONES DE EXTENSION PARA INTEMPERIE. Cuando

opere su herramienta a la intemperie, utilice únicamente cordones

de extensión diseñados y marcados para este fin.

• NO SE DISTRAIGA. Concéntrese en lo que está haciendo.

Recurra al sentido común. No opere ninguna herramienta si está

fatigado.

• VERIFIQUE LAS PARTES DAÑADAS. Antes de seguir

empleando cualquier herramienta, es indispensable verificar con

mucho cuidado que las guardas u otras partes dañadas puedan

operar de la manera adecuada para cumplir con su función.

Verifique la alineación de las partes móviles, la firmeza con que

deben encontrarse sujetas a sus montaduras, las partes rotas, las

propias montaduras y cualesquiera otros detalles que pudieran

afectar la operación de la herramienta. Las guardas y otras partes

que se encuentren dañadas deberán cambiarse o repararse en un

centro de servicio autorizado, a menos que se diga otra cosa en

el manual del usuario. Haga que se cambien los interruptores

dañados en un centro de servicio autorizado. No emplee ninguna

herramienta que tenga estropeado o inutilizado el interruptor.

PRECAUCION: Cuando taladre o atornille en muros, pisos o

dondequiera que pueda encontrar cables eléctricos vivos, ¡NO

TOQUE NINGUNA PARTE METALICA DE LA HERRAMIENTA!

Sujete la herramienta únicamente por las superficies aislantes

(empuñaduras) para evitar el choque eléctrico si hace contacto

con un cable eléctrico vivo.

CONSERVE ESTAS INSTRUCCIONES

Carbones del motor

DEWALT utiliza un avanzado sistema de carbones que detiene

automáticamente el motor del taladro cuando se desgastan estas

piezas. Esto impide que el motor se dañe seriamente.

Interruptores

Oprima el interruptor de gatillo para accionar el taladro; suéltelo para

detenerlo. Para dejar fijo el interruptor en la posición de encendido a

fin de que opere de manera continua, oprímalo y presione el botón

de encendido permanente “A” (fig. 1), y suelte a continuación el

gatillo interruptor con suavidad. Para liberar el mecanismo de

trabado, oprima el gatillo hasta el fondo y suéltelo. Antes de utilizar

la herramienta (cada vez) asegúrese que el mecanismo del seguro

funciona libremente.

No asegure el interruptor en la posición de encendido permanente

cuando taladre a mano, de manera que pueda soltarlo si la broca se

atasca en el barreno.

El botón de encendido permanente se debe utilizar solamente

cuando el taladro se encuentra montado en una prensa o en un

banco.

Asegúrese de liberar el botón de encendido permanente antes de

desconectar la clavija de la toma de corriente. No hacerlo propiciará

que el taladro se encienda en el momento de volver a conectarlo,

con el peligro consecuente de daños o lesiones.

EL INTERRUPTOR DE GATILLO DE VELOCIDAD VARIABLE

permite controlar la velocidad. Cuanto más a fondo se oprima el

gatillo, mas elevada será la velocidad del taladro.

15

Español

383945/DW100-220 5/3/02 1:15 PM Page 15

Page 19

16

NOTA: Utilice velocidades bajas para perforar sin haber marcado el

“punto” de centro, taladrar en metal o plásticos, atornillar y perforar

cerámica. Las altas velocidades son mejores para barrenar madera

y aglomerados de ésta, y cuando se van a utilizar los accesorios

abrasivos y de pulido.

LA PALANCA DE REVERSA se utiliza para sacar las brocas

atascadas en barrenos muy apretados y para destornillar. Se

encuentra situada por arriba del interruptor de gatillo (fig. 2). Para

activar el motor en reversa, suelte PRIMERO el gatillo y, a

continuación, mueva la palanca hacia la derecha. Después de haber

efectuado una operación en reversa, devuelva la palanca hacia la

posición de marcha hacia adelante.

Operación

PARA TALADRAR

1. Desconecte siempre el taladro antes de poner o cambiar brocas

o accesorios.

2. Utilice exclusivamente brocas afiladas. Para taladrar MADERA

emplee brocas helicoidales, brocas de horquilla o brocas sierra.

Para taladrar METAL use brocas helicoidales de alta velocidad o

brocas sierra. Para taladrar MAMPOSTERIA, ladrillo, cemento,

etc., utilice brocas con punta de carburo de tungsteno.

3. Asegúrese de que el material que va a taladrar este firmemente

anclado o afianzado. Si perfora material delgado, aplique al

mismo un respaldo de madera para evitar dañarlo.

4. Aplique presión a la broca en línea recta. Haga suficiente presión

para que la broca siga perforando, pero no tanta para que el

motor se atasque o la broca se desvíe.

5. Sujete la herramienta firmemente para controlar la acción de

torsión de la broca.

6. SI EL TALADRO SE TRABA, esto se deberá posiblemente a que

está sobrecargado o que se está utilizando en forma indebida.

SUELTE EL GATILLO DE INMEDIATO, retire la broca del

barreno y determine la causa del atascamiento. NO APRIETE

EL GATILLO PARA HACER PRUEBAS DE ENCENDIDO Y

APAGADO, PUES PODRIA DAÑARLO.

7. Para reducir el peligro de que se atasque el taladro, reduzca la

presión y deje ir suavemente la broca hacia el final del barreno.

8. Conserve el motor trabajando al retirar la broca del interior del

barreno. De esta manera evitará que se atasque.

9. Con los taladros de velocidad variable no hay necesidad de poner

un “punto” de centrado para iniciar los barrenos. Utilice velocidad

baja para iniciar la perforación, y acelere oprimiendo el gatillo

cuando el barreno tenga suficiente profundidad.

Taladrado en metal

Utilice un lubricante para corte cuando perfore metales, excepto en

los casos de hierro colado o latón en los que se deberá taladrar en

seco. Los lubricantes más adecuados para corte son los de aceite

sulfúrico y la manteca de cerdo.

Español

FIG. 1

A

FIG. 2

PALANCA DE

REVERSA (mostrada

en posición de marcha

hacia adelante)

383945/DW100-220 5/3/02 1:15 PM Page 16

Page 20

Taladrado en madera

Los barrenos en madera pueden hacerse con las mismas brocas

que se utilizan para metal. Para evitar que las brocas se

sobrecalienten, deben sacarse frecuentemente del barreno para

quitar las virutas acumuladas en las estrías. Para hacer

perforaciones más grandes, emplee brocas de poder para madera.

El material que podría astillarse debe protegerse con un respaldo

de madera.

Taladrado en mampostería

Utilice brocas con punta de carburo de tungsteno a bajas

velocidades. Conserve uniforme la presión sobre el taladro, pero no

al grado que se despostillen los materiales. La salida continua de

volutas de polvo indica que se esta aplicando la velocidad apropiada.

Nivel de burbuja

Su taladro viene equipado con un nivel de burbuja, de utilidad para

perforar barrenos a nivel.

Para el taladrado horizontal mueva su unidad hacia arriba o hacia

abajo para que la burbuja, al flotar, vaya desplazándose hacia las

líneas paralelas grabadas en el vidrio. El taladro estará nivelado

una vez centrada la burbuja entre las líneas, como se ilustra en la

figura 3A.

Para el taladrado vertical, se debe alinear el taladro de manera que

la burbuja flote en el centro del ojo de buey, como se ilustra en la

figura 3B.

Para garantizar la precisión, coloque primero un nivel sobre la pieza

en la que esté trabajando y nivélela; a continuación, cuando el

taladro se encuentre nivelado, lo estarán entre si éste y la pieza de

trabajo. (Los dispositivos de burbuja pueden indicar sólo el nivel de

la superficie de la tierra).

NOTA: el nivel contiene aceite mineral, sustancia que podría

producir irritaciones menores de la piel al entrar en contacto con ella.

Si el nivel se rompiera y se derramara su contenido sobre su piel,

lávesela con agua en abundancia. Si le cayera en los ojos, láveselos

con agua en abundancia y llame de inmediato al médico.

Portabrocas

Abra las mordazas del portabrocas girando el collarín con los dedos

e inserte el vástago de la broca aproximadamente 19 mm dentro del

portabrocas. Apriete el collarín del portabrocas a mano. Coloque la

llave del portabrocas en cada uno de los tres orificios, y apriete en

el sentido de las manecillas del reloj. Es muy importante apretar el

portabrocas desde los tres orificios. Para sacar una broca, gire el

portabrocas en sentido contrario a las manecillas del reloj, desde uno

de los orificios, y después continúe a mano.

Porta llave

(Puede estar ya instalado.)

1. Empuje el extremo del porta llave que tiene dos orificios a través

de la ranura que se encuentra en el otro extremo (figura 4.)

17

Español

FIG. 3A

FIG. 3B

BURBUJA

NIVEL DE

BURBUJA

BURBUJA

NIVEL DE

BURBUJA

383945/DW100-220 5/3/02 1:15 PM Page 17

Page 21

18

2. Deslice el aro que se formó sobre la clavija y apriételo alrededor

del cable (figura 5).

3. Pase los extremos del asa de la llave a través de los dos orificios

del extremo del porta llave (figura 6.)

Remoción del portabrocas

Coloque la llave del portabrocas en uno de los tres orificios de éste,

como se observa en la figura 7. Aplique un golpe seco a la llave en

el sentido de las manecillas del reloj (visto desde el frente de la

herramienta). Esto aflojará el portabrocas para poder destornillarlo

a mano.

Instalación del portabrocas

Atornille el portabrocas a mano tanto como sea posible. Coloque la

llave en cualquiera de los tres orificios del portabrocas y aplíquele un

golpe seco en sentido contrario a las manecillas del reloj (viendo la

herramienta desde el frente) como se observa en la figura 8. (Se

recomienda aplicar un torque de 145 a 160 in. lbs.)

Lubricación

Cuando se lleve la herramienta a que le cambien los carbones, debe

añadírsele una pequeña cantidad de grasa (o debe redistribuirse de

la que queda en la carcaza) a los engranes.

Los baleros empleados en esta herramienta se lubricaron durante el

proceso de manufactura y no requieren lubricación.

Accesorios

Dispone usted de los accesorios para su herramienta por un cargo

adicional con su distribuidor local autorizado. Si necesita ayuda para

encontrar cualquier accesorio, por favor comuníquese al 326-7100.

Español

FIG. 5

FIG. 4

FIG. 6

FIG. 7 FIG. 8

383945/DW100-220 5/3/02 1:15 PM Page 18

Page 22

PRECAUCION: El empleo de cualquier otro accesorio no

recomendado para utilizarse con esta herramienta puede ser

peligroso.

Por seguridad en el uso, los siguientes accesorios deberán utilizarse

solamente en tamaños iguales o menores señalados en la tabla a

continuación.

CAPACIDADES MAXIMAS RECOMENDADAS

CAPACIDAD DEL TALADRO 9,5 mm (3/8”)

R.P.M. 0-2500

BROCAS PARA METAL 9,5 mm (3/8”)

BROCAS PARA MADERA 25,4 mm (1”)

BROCAS PARA MAMPOSTERIA 12,7 mm (1/2”)

BROCAS SIERRA 28,5 mm (1-1/8”)

EL ACCESORIO DEBE ESTAR CLASIFICADO PARA UTILIZARSE

A UNA VELOCIDAD IGUAL O MAYOR QUE LAS R.P.M.

SEÑALADAS EN LA PLACA DE IDENTIFICACION DE LA

HERRAMIENTA QUE SE ESTE EMPLEANDO.

CEPILLOS DE ALAMBRE........Diámetro máximo 101,6 mm (4")

CEPILLOS DE COPA ..............Diámetro máximo 76,2 mm (3")

BONETES PARA PULIR..........Diámetro máximo 76,2 mm (3")

RESPALDOS DE GOMA..........Diámetro máximo 117,4 mm (4-5/8")

Importante

Para garantizar la SEGURIDAD y la CONFIABILIDAD, deberán

hacerse reparaciones, mantenimiento y ajustes de esta herramienta

en los centros de servicio para herramientas industriales de D

EWALT .

u otras organizaciones calificadas. Estas organizaciones prestan

servicio a las herramientas D

EWALTy emplean siempre refacciones

legítimas D

EWALT.

PARA REPARACION Y SERVICIO DE SUS HERRAMIENTAS

ELECTRICAS FAVOR DE DIRIGIRSE AL CENTRO DE SERVICIO MAS

CERCANO

CULIACAN

Av . Nicolas Bravo #1063 Sur (91 671) 242 10

GAUDALAJARA

Av . La Paz #1779 (91 3) 826 69 78.

MEXICO

Eje Lázaro Cárdenas No. 18 Local D, Col. Obrera 588-9377

MERIDA

Calle 63 #459-A (91 99) 23 54 90

MONTERREY

Av . Francisco I. Madero Pte. 1820-A (91 83) 72 11 25

PUEBLA

17 Norte #205 (91 22) 46 37 14

QUERETARO

Av . Madero 139 Pte. (91 42) 14 16 60

SAN LOUIS POTOSI

Pedro Moreno #100 Centro (91 48) 14 25 67

TORREON

Blvd. Independencia, 96 pte. (91 17) 16 52 65

VERACRUZ

Prolongación Diaz Miron #4280 (91 29) 21 70 16

VILLAHERMOSA

Constitucion 516-A (91 93) 12 53 17

PARA OTRAS LOCALIDADES LLAME AL: 326 7100

19

Español

383945/DW100-220 5/3/02 1:15 PM Page 19

Page 23

20

Garantía Completa

Las herramientas industriales DEWalt están garantizadas durante un año a

partir de la fecha de compra. Repararemos, sin cargos, cualquier falla debida

a material o mano de obra defectuosos. Por favor regrese la unidad completa,

con el transporte pagado, a cualquier Centro de Servicio para Herramientas

Industriales de D

EWalt o a las estaciones de servicio autorizado enlistadas

bajo "Herramientas Eléctricas" en la Sección Amarilla. Esta garantía no se

aplica a los accesorios ni a daños causados por reparaciones efectuadas

por terceras personas. Esta garantía le otorga derechos legales específicos,

y usted puede tener otros derechos que pueden variar de estado a estado.

En adición a la garantía, las herramientas DEWALT están amparadas por

nuestra:

GARANTÍA DE SATISFACCIÓN SIN RIESGO POR 30 DÍAS

Si usted no se encuentra completamente satisfecho con el desempeño de

su herramienta industrial DEWalt, sencillamente devuélvala a los vendedores

participantes durante los primeros 30 días después de la fecha de compra

para que le efectúen un reembolso completo. Por favor regrese la unidad

completa, con el transporte pagado. Se puede requerir prueba de compra

Español

Epecificaciones (DW100-220)

Tensión de alimentación 220/240 V CA

Potencia nominal: 644/662 W

Frecuencia de operación:50/60 Hz

Consumo de corriente: 3,5/3,6 A

IMPORTADO: DEWALT S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS.

05120 MÉXICO, D.F

TEL. 326-7100

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

383945/DW100-220 5/3/02 1:15 PM Page 20

Loading...

Loading...