Page 1

Deutz WP6C/WP4C Series Marine Diesel Engines

Operation and Maintenance Manual and

User Service Guide

13060345

Page 2

Deutz WP6C/WP4C Series Marine Diesel Engine Operation and Maintenance Manual

Deutz WP6C/WP4C Series Marine Diesel Engine User Service Guide

Important

In order to ensure your safety and give full play of high performance of diesel engine, please

carefully read this manual before operating the diesel engine and closely abide by the

operation and maintenance procedures specified in this manual.

In order to protect your lawful rights and interests, never dismantle the lead sealing for the

fuel amount from the fuel pump without permission.

The guarantee from the factory will be invalid for adjusting the fuel injection pump or

dismantling the lead sealing.

Because the fuel injection pump is sophisticated component, users are not allowed to

dismantle it. Failure to do so will cause the factory's guarantee invalid.

Because the rotor shaft of supercharger is sophisticated high-speed rotating part, users are not

allowed to dismantle it or let it be impacted. Failure to do so will cause the factory’s

guarantee invalid.

Because of the strict torque and turn angle requirements for the main bearing bolts and

connecting rod bolts of diesel engine, users are not allowed to loosen and dismantle them.

Failure to do so will cause the factory’s guarantee invalid.

At any time of starting the diesel engine, please check whether the coolant and oil is fully

filled.

As the connecting rod bolts are disposable, never reuse them.

Page 3

Deutz WP6C/WP4C Series Marine Diesel Engine Use and Maintenance Manual

Deutz WP6C/WP4C Series Marine Diesel Engine User Service Guide

Precautions

1. Before delivery of the engine, the delivery test is already and strictly done based on test

specifications. As the throttle openness is already limited by lead sealing, never randomly

dismantle the lead sealing to increase the throttle. Otherwise, our factory will not perform the

Three-guarantee. Users are hoped to pay attention to this.

2. The operator should carefully read this Operation and Maintenance Manual, be familiar with

the structure of this diesel engine and closely abide by the technical operation and

maintenance procedures specified in this manual.

3. Before using the new diesel engine, please perform the trial operation for 50h.

4. After the diesel engine is cold started, please slowly increase the rotating speed and never

idle for long time. After engine running with load, do not immediately stop it. It is necessary

to idle for 5-10 min at low speed.

5. After engine is stopped, if the ambient temperature is lower than 0 , yet the antifreeze ℃

additive is not applied, please completely drain the water in water tank and diesel engine.

6. The diesel engine is prohibited to work without air cleaner which could prevent unfiltered air

from entering the cylinders.

7. Please select the specified fuel and oil grades which will be filled into the diesel engine (it is

suggested to use Weichai Power special oil sold at all service stations of Weichai). Use the

special clean container. The fuel and oil should be filtered through the strainer before being

added. Precipitate the fuel for 72h or more.

8. The inspection of electrical system should be done by the personnel mastering the electrical

knowledge.

9. The valid duration of oil sealing for the diesel engine is one year. If the valid duration is

beyond one year, please take necessary supplement measures.

10. The power calibration and revision of diesel engine should be based on the

CB/T3254.1-1994.

Page 4

Deutz WP6C/WP4C Series Marine Diesel Engine Operation and Maintenance Manual

Deutz WP6C/WP4C Series Marine Diesel Engine User Service Guide

Preface

WP6/WP4 series marine diesel engines are manufactured by Weifang Weichai Deutz Diesel

Engine Co. Ltd - the joint venture of Weichai Power Co. Ltd and Deutz AG. This series diesel

engines are classified into supercharge type and supercharge and intercooled type based on the

aspiration methods. There are two kinds of cylinder types: 4-cylinder and 6-cylinder. These series

diesel engines are of four stroke, water cooling, in-line, DI combustion chamber and high speed

engines, featuring by compact structure, reliability operation, excellent power performance and

economy indexes, advanced emission indicators, quick start, easy operation and convenient

maintenance etc. These series diesel engines are the ideal propulsion power for small vessels used

for inland water transportation, fishery and high-speed ships.

This manual mainly covers the main technical parameters, performance indicators, structural

features and operation and maintenance precautions for WP6/WP4 series marine main and

auxiliary engines. Before using this engine, please closely follow all requirements specified in this

manual. This could ensure the operation reliability and prolong the useful life of diesel engine.

Before servicing, disassembling and installing the diesel engine, please carefully read the Deutz

WP6/WP4 Series Marine Diesel Engine Parts Catalogue to master the basic structures of all

systems of the diesel engine.

What this manual describes is the basic models of WP6/WP4 series marine diesel engines. As to

other model information which is not listed into basic model, users could consult according to the

contact phone, fax etc on the “User Feedback Card”. As the products continuously develop, the

structure will also change. Partial content in this manual may be slightly different from the actual

products. This manual will be subject to be revised without notice. Access the www.weichai.com

for updated product information and hope users timely pay close attention to all the issued

technical information. If you feel the content important, please timely contact with the technical

department or sale department of Weichai Power Co. Ltd to avoid unnecessary trouble during the

normal use and maintenance.

Welcome comments and suggestions for product improvement from users. Please send the “User

Feedback Card” annexed at the end of this manual to the Sales Company or Application

Engineering Department of Weichai Power Co. Ltd.

Mar.2010

Page 5

Deutz WP6C/WP4C Series Marine Diesel Engine Use and Maintenance Manual

Deutz WP6C/WP4C Series Marine Diesel Engine User Service Guide

Contents

I. Deutz WP6C/WP4C Series Marine Diesel Engine Use and Maintenance

Manual

WP6/WP4 series diesel engines model meaning ........................................................................... 1

WP6/WP4 series marine diesel engine structural features: ............................................................ 1

1 Main performance and technical parameters for WP6C/WP4C series marine diesel engines

.......................................................................................................................................................... 2

2 Fuel, oil and coolant used for diesel engines .............................................................................. 3

2.1 Oil ............................................................................................................................................... 3

2.2 Fuel ............................................................................................................................................. 3

2.3 Coolant ........................................................................................................................................ 4

3 Diesel engine installation and connection ................................................................................... 6

3.1 Diesel engine hoisting ................................................................................................................. 6

3.2 Diesel engine installation ............................................................................................................ 6

3.3 Installation of external connection systems for diesel engine ..................................................... 7

4 Operation and maintenance of diesel engine ............................................................................. 8

4.1 Preparations before operation ..................................................................................................... 8

4.2 Operation precautions ............................................................................................................... 10

4.3 Maintenance of diesel engine .................................................................................................... 11

5. Common fault analysis and troubleshooting .......................................................................... 13

II. User Service Guide (Warranty Card) ................................................................... 1

Weichai Power Product Warranty Card (for User) ............................................................................ 1

Maintenance Registration Form (Filled by Maintenance Personnel) ................................................ 2

Warranty Instructions ........................................................................................................................ 3

Regulations about Term of Three Guarantees Service for Weichai Power Marine or Power

Generating Diesel Engine ................................................................................................................. 5

Customer Satisfaction Questionnaire ................................................................................................ 6

Engine Mandatory Maintenance Card

Page 6

Page 7

Deutz WP6C/WP4C Series Marine Diesel Engine Use and Maintenance Manual

1

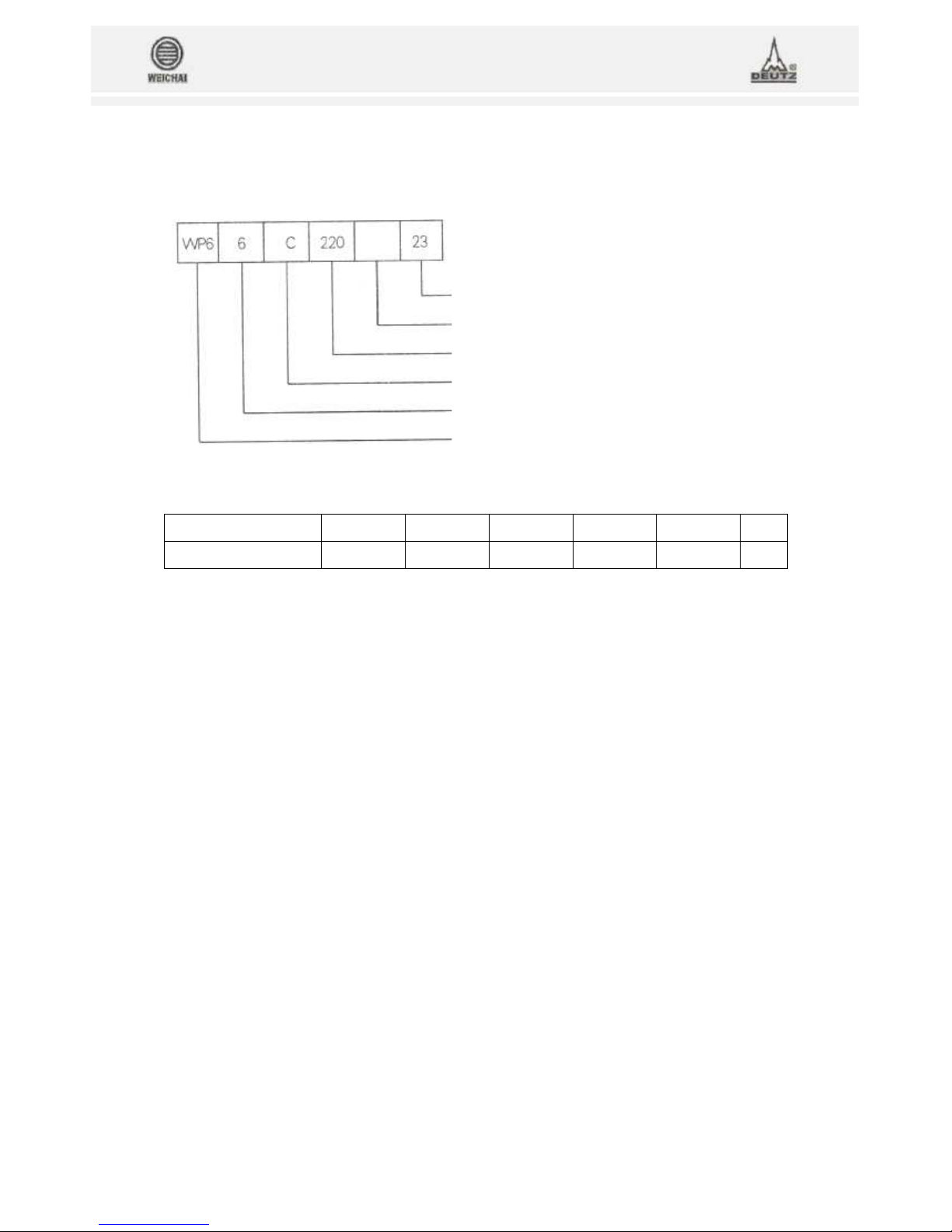

WP6/WP4 series diesel engines model meaning

The symbols of all models from the WP6/WP4 series diesel engines are shown as follows:

Table 1

Rotating speed 1500r/min 1800r/min 2100r/min 2300r/min 2500r/min

Rotating speed code 15 18 21 23 25

WP6/WP4 series marine diesel engine structural features:

One head for one cylinder, reliable operation and convenient disassembly.

With the high body rigid, preassembled camshaft sleeve should increase the engine reliability.

Compact engine layout, special and flat oil sump, convenient for matching with the ship.

Rotating speed code (see table 1)

Dash

Power code (expressed in HP)

Application feature symbol (C- marine main engine; CD

-

marine auxiliary engine)

Total displacement L

Weichai Power

Page 8

Deutz WP6C/WP4C Series Marine Diesel Engine Use and Maintenance Manual

2

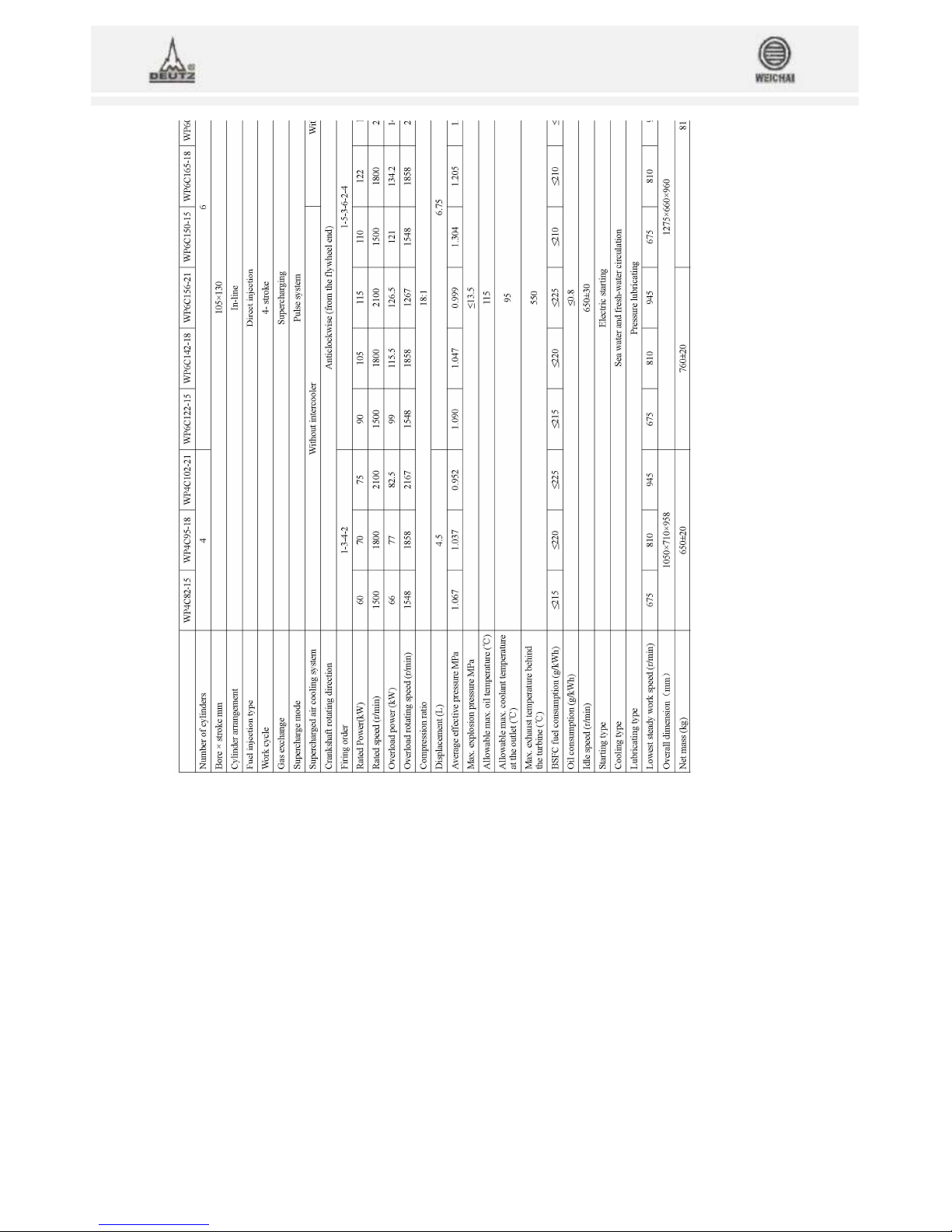

Tab

le 1

1 Main

performa

nce and

technical

parameter

s for

WP6C/W

P4C series

marine

diesel

engines

Page 9

Deutz WP6C/WP4C Series Marine Diesel Engine Use and Maintenance Manual

3

2 Fuel, oil and coolant used for diesel engines

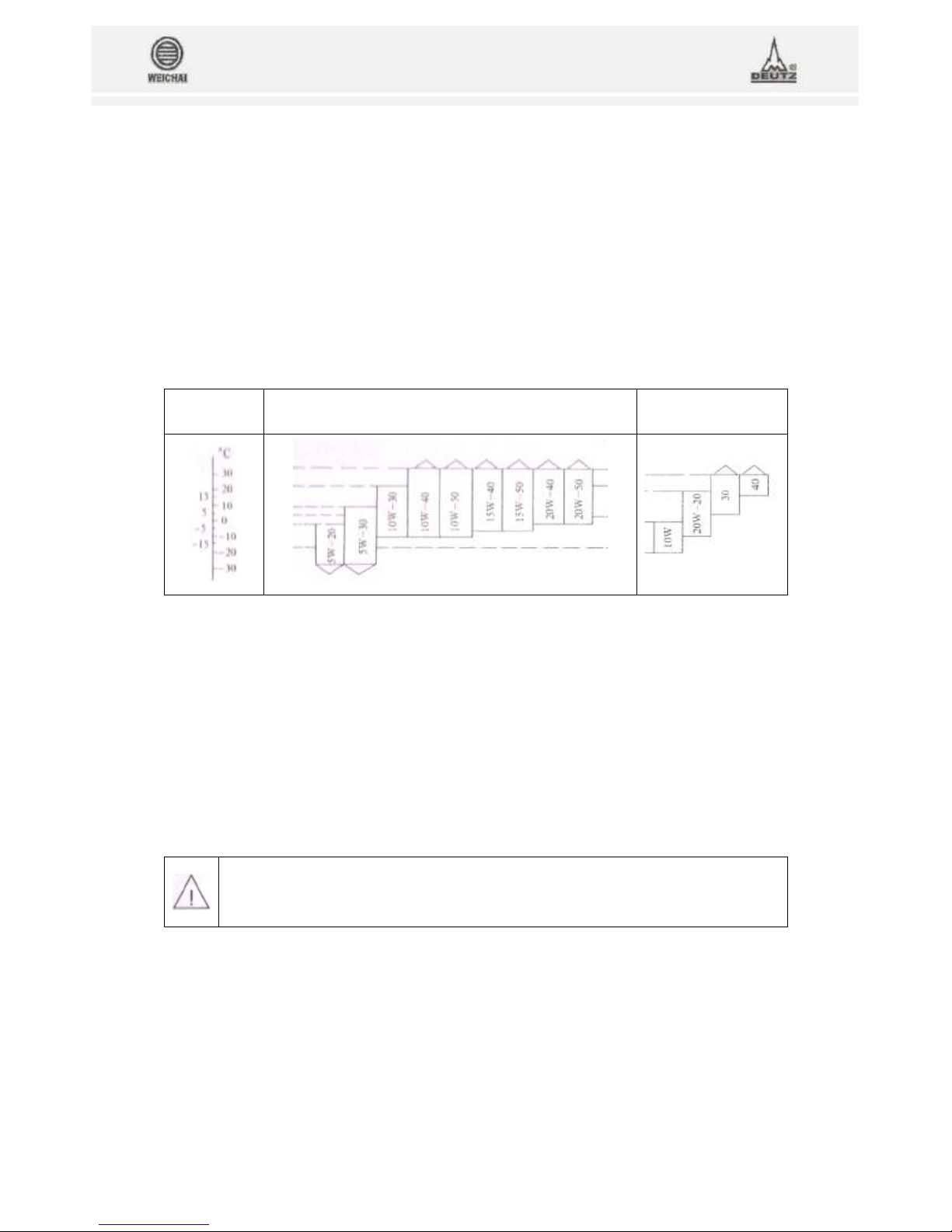

2.1 Oil

Quality grade: Oil should be classed according to its quality and features. Generally apply the

API or GB for classification.

Oil allowable to be used: CD grade or better

Viscosity

Oil viscosity greatly depends on the temperature. Please refer to the fig.2-1 (ambient

temperature ) to select proper oil.℃ The ambient temperature should not exceed the temperature

limit for long time to keep the wear within the lowest limit.

Ambient

temperature.

Multi-grade oil Single-grade oil

Fig.2-1 Selection of oil grade

Suggestion:

1. Use the multi-grade oil to avoid changing oil as the season changes. Therefore the fuel

consumption rate can be decreased.

2. If the ambient temperature is -15℃ or more, use the CF-4 grade 15W/40 oil. If the ambient

temperature is -15℃ or less, use the 5W/20 oil.

It is recommended to use the Weichai Power special (Shell) 15W-40 oil, which is mixed by the

imported quality basic oil and selected additive. This oil is sold at all service stations of Weichai at

the unified national sale price.

Caution:

1. Do not check the lubricant level during engine running.

2. It is not allowed to mix the different grades of oil.

2.2 Fuel

This diesel engine uses the light diesel as the fuel;

Quality grade

Sulfur content in the fuel of specified grade should not be higher than 0.5%.

Apply the following grades of diesel fuel based on the ambient temperature.

Page 10

Deutz WP6C/WP4C Series Marine Diesel Engine Use and Maintenance Manual

4

If the ambient temperature is higher than 5℃, it is recommended to use the 0# diesel (GB 252-94)

At low temperature, the diesel fuel may precipitate the waxy material which causing poor

flowability of diesel fuel. In such case, the fuel system will be clogged, causing failures of diesel

engine. Therefore when the ambient temperature is less than 0 , please use the winter diesel℃ fuel.

According to the GB252 diesel fuel standard, if the ambient temperature is -5 or more, please ℃

choose the -10# diesel fuel. If the ambient temperature is -14 or more, ℃ please choose the -20#

diesel fuel. If the ambient temperature is -29 or more, please choose the ℃ -35# diesel fuel. If the

ambient temperature is -44 or more, please choose the ℃ -50# diesel fuel.

2.3 Coolant

The coolant of diesel engine should be soft water added by the anticorrosive agent and

long-lasting antifreeze.

Long-lasting antifreeze

Long-lasting antifreeze is of resistance to corrosion and freeze. Please refer to antifreeze related

manual for the proportion of long-lasting antifreeze. See the table 2-1 for the domestic long-lasting

antifreeze.

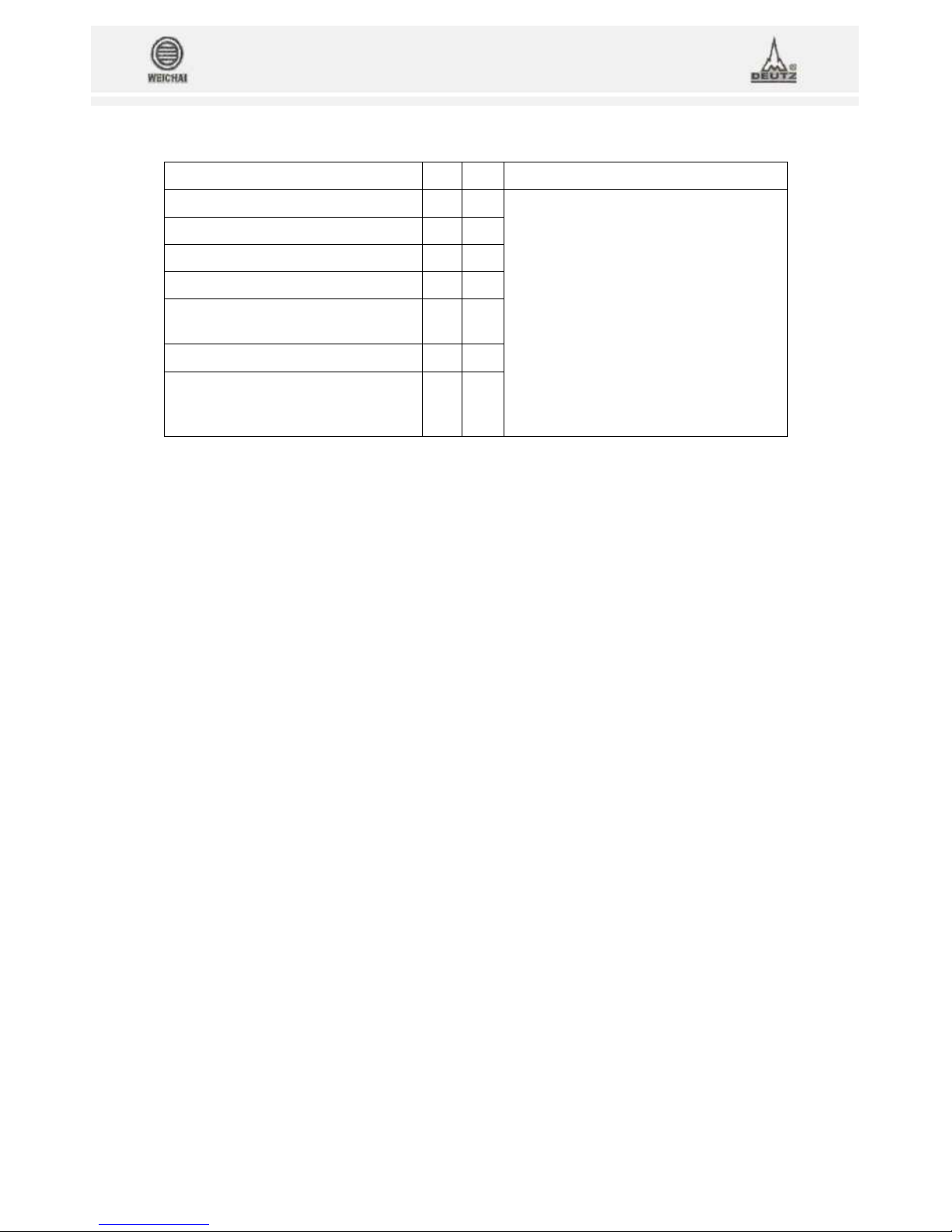

Table 2-1 Domestic long-lasting antifreeze

Grade

Items

JFL-318 JFL-336 JFL-345

Glycol content % 33 50 56

Specific gravity (15.6 )℃ 1.05 1.074 1.082

Boiling point ℃ 104.5±1 108.5±1 110.0±1

Freezing point ℃ -18±1 -36±1 -45±1

Proper min. temperature ℃ -10 -26 -35

Caution

1. Periodically check the antifreeze concentration if temperature is below 0 .The ℃

℃℃

℃

concentration of antifreeze should be inspected every 1000h yet at least once for

each quarter. The antifreeze should be changed every two years to avoid

corrosion.

2. As to the regions where the temperature is always higher than 0℃℃℃℃, use the

water anti-rust and anti-scale treated as the coolant. Never use the untreated

water as the coolant.

Anti-corrosive agent

If the ambient temperature is higher than 5℃ (in summer or autumn or regions with higher

temperature), the anti-corrosive agent should be added into the coolant (NL emulsified anti-rust

agent or LQS comprehensive protective agent). Please refer to related manual for the proportion of

anti-corrosion agent and soft water.

Coolant

For the composition of coolant, see the table 2-2.

Page 11

Deutz WP6C/WP4C Series Marine Diesel Engine Use and Maintenance Manual

5

Table 2-2 Coolant composition

Water quality min max

PH 6.5 8.5

Only if the coolant meets the water-quality

composition, can it be mixed with the

antifreeze or anti-corrosion agent.

Chloride ion content mg/dm3 - 100

Carbonate content mg/dm3 - 100

Total negative ion content mg/dm3 - 150

Total hardness when using the

long-lasting antifreeze, mg/dm3

3 12

Carbonate hardness mg/dm3 3 Total hardness when using the

anti-corrosive agent (take note of the

instruction of supplier) mg/dm3

0 10

Note: Because inner galvanized tube is not suitable to use anti-corrosive agent, this tube is not

used as the coolant pipe.

Page 12

Deutz WP6C/WP4C Series Marine Diesel Engine Use and Maintenance Manual

6

3 Diesel engine installation and connection

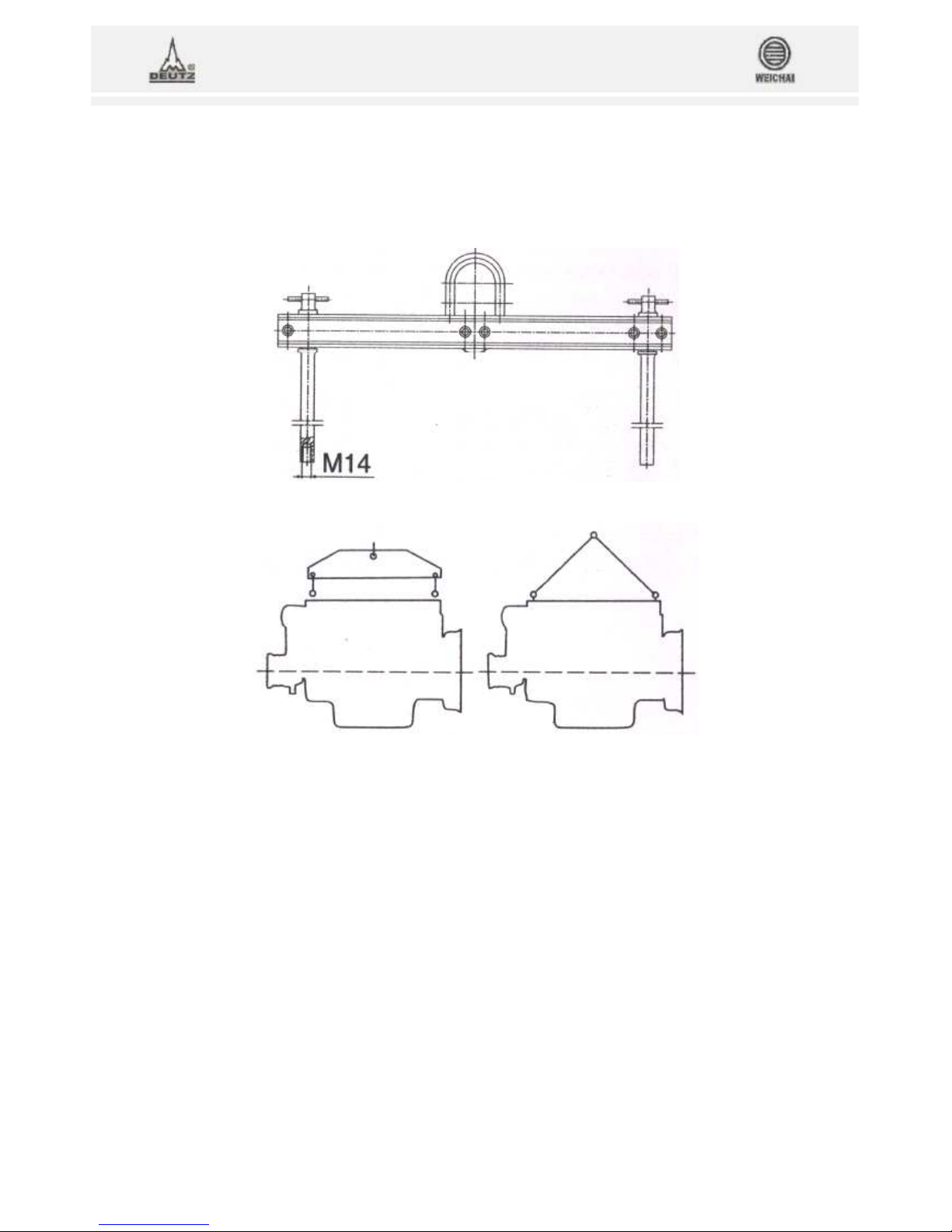

3.1 Diesel engine hoisting

Incorrect hoisting will cause damage to diesel engine.

Fig. A

Fig. B

2 special cylinder-head bolts have been installed on each diesel engine, which are used for hoisting

diesel engine. A M14 threaded rod is mounted on the six-square end face of the two bolts, which is

used to mount the special slings (see fig. A) and lifting eyes. When using the special slings, screw

the suspender with M14 threaded hole onto two cylinder head bolts, adjust the center of gravity

and then it is good for hoisting. If the engine is hoisted through the lifting eyes attaching to the

cylinder head bolts, the slings as shown in fig. B is recommended. When hoisting the engine, its

crankshaft should be at horizontal level and two slings should at parallel status. Do not use one

sling which will lift the engine in the way of triangle. If you use one sling, the sling, cylinder head

bolts and lifting eyes are not at the same line. Therefore, this could cause damage to the bolts and

even fracture during hoisting, leading to damage to diesel engine.

3.2 Diesel engine installation

Apply the elastic coupler and ensure the crankshaft center line is concentric to the axis of the input

shaft of gearing equipments (gearbox, transmission). There should be no additive axial force on

the crankshaft caused by installation.

Correct

Wrong

Page 13

Deutz WP6C/WP4C Series Marine Diesel Engine Use and Maintenance Manual

7

3.3 Installation of external connection systems for diesel engine

The exhaust pipeline of diesel engine should avoid excessive bends. Expansion joint should be

mounted around the middle of the pipeline. In addition, additive support should be mounted for

pipeline. The inner diameter of exhaust pipeline should not be less than 83mm and the exhaust

back pressure should not be less than 6kPa.

Rain cover should be mounted onto the outdoor outlet of exhaust pipe. In order to smoothly drain

the condensed water from the exhaust pipe, water drain valve should be installed at the lowest

place of the exhaust pipe.

Waterproof cap should be installed onto the outdoor inlet to prevent the rain water from entering

the intake system.

The capacity of fuel tank should satisfy that the diesel engine works for 8h at rated load. The fuel

tank should be positioned where the fuel filler is not lower than inlet of fuel delivery pump. The

inner diameter of fuel pipeline should not be less than 12mm.

Page 14

Deutz WP6C/WP4C Series Marine Diesel Engine Use and Maintenance Manual

8

4 Operation and maintenance of diesel engine

4.1 Preparations before operation

4.1.1 Unseal

When the diesel engine package is opened, first, the user should check the diesel engine and

accessories according to the factory packing list, check whether the diesel engine surface is

damaged, whether the connecting pieces are not loosened, etc., and then carries out the following

operations:

(1) Scrub the rustproof layer, the anticorrosive agent, etc. of the exposed parts.

(2) Drain the oil-sealed oil of the fuel filter and the fuel system parts (starting without draining

the oil-sealed oil of the fuel system is permitted, but only when the oil-sealed oil of the fuel

system is consumed and the normal diesel fuel is available, the loaded operation of engine is

permitted.)

(3) Check whether the water plug and the oil plug are plugged, whether the water temperature

and oil temperature sensors are complete, and make sure that all necessary parts are available.

Note: Do not start before the diesel engine is correctly installed and connected to the final

position. Ensure the ventilation and make sure that the exhaust gas is emitted to the

atmosphere when the diesel engine runs in enclosed environment.

4.1.2 Add the oil

(1) The oil should meet the specified requirements; otherwise, it may lead to insufficient oil

pressure, even wear and starting difficulty. The oil must be very clean. Weichai Power special

oil (Shell) CD/15W-40 is recommended (refer to 2.1).

(2) Tighten the oil drain plug.

(3) Open the oil filler cap (refer to figure 4-1) and add the oil through the filter screen.

(4). Place the diesel engine on the flat ground, and pull out the dipstick to check the oil level. Add

oil to the upper limit of the dipstick when necessary.

(5) Tighten the oil filler cap. Note: Check the oil level every time before starting the diesel

engine.

Figure 4-1 Engine oil filler

Page 15

Deutz WP6C/WP4C Series Marine Diesel Engine Use and Maintenance Manual

9

4.1.3 Add the fuel

(1) The diesel fuel should meet the related regulations (refer to 2.2).

(2) Pay attention to the cleanliness of the diesel fuel, and store the diesel fuel still for above 72h

before adding. Add the diesel fuel into the fuel tank through the internal filter screen.

Note: Check the diesel fuel level every time before starting the diesel engine.

4.1.4 Air bleeding of fuel system (Refer to figure 4-2)

(1) Unscrew the fuel screw 1 at the outlet of fuel delivery

pump for half a turn. Operate the hand pump 2 of the fuel

delivery pump 3 until the diesel fuel emits out and then

tighten the fuel screw.

(2) Unscrew the air bleed screw 4 on the fuel filter 5. Operate

the hand pump of the fuel delivery pump until the diesel

fuel emits out and then tighten the air bleed screw.

(3) Unscrew the air bleed screw 6 on the fuel injection pump

7. Operate the hand pump of the fuel delivery pump until

the diesel fuel emits out and then tighten the air bleed

screw.

(4) Continue to operate the hand pump, check the fuel line for leakage, and then tighten the hand

pump.

4.1.5 Add the coolant

The coolant is prepared from softened cleaning water and anticorrosion agent or antifreeze, strictly

conform to the regulations of additive manufacturer during preparation (refer to 2.3).

Add the coolant from the water filler of the radiator or the heat exchanger, and bleed the air from

the cooling circulation system.

Note: Frequent water adding and changing will generate scales in the system. Repair the

leakages of the cooling system as soon as possible. Add softened cleaning water as much as

possible and try to avoid frequent changing of coolant. The coolant drained from the water

tank can be reused after being filtered by fabric and fine screen.

Check the coolant level every time before starting the diesel engine.

4.1.6 Battery charging

Please refer to the battery instruction manual.

Note: The gases generated during charging are explosive. No smoking is allowed around the

battery, and the battery must be kept away from any naked flame and spark. There is strong

corrosive acid in the battery, please flush with a large amount of fresh water if the acid is

splashed into the eyes or on the skin.

Operation sequence for charging:

(1) Open the seal cover.

(2) Add the battery sulfuric acid from the filler to the marked position.

(3) Fasten the seal cap.

(4) Apply antirust grease on the battery electrodes.

(5) Connect the terminal and the electrodes, Connect the positive electrode firstly.

Figure 4-2 Air bleeding of fuel system

Page 16

Deutz WP6C/WP4C Series Marine Diesel Engine Use and Maintenance Manual

10

(6) It is not allowed to place any metal object on the battery.

(7) Check the sulfuric acid level every day after the use of battery. Add distilled water if needed.

4.2 Operation precautions

4.2.1 Operation precautions

Prior to starting the diesel engine, check the levels of oil, cooling water and fuel and the

connections of pipelines (refer to 4.1).Rotate the crankshaft for several turns and confirm that

there is no clamping or binding phenomenon.

When starting the diesel engine, if it is not started in 15s, wait for 2min and then restart it.

After starting the diesel engine, run it at idle speed for 2~3min and the oil pressure should be

higher than 120kPa, if not, stop it immediately for check; if the cooling water temperature is not

higher than 60 , do not run the diesel engine suddenly in high speed and with large load, because ℃

this will affect the wear resistance and the reliability of the engine.

Check the diesel engine for “three leakages” every time after operation.

If the diesel engine runs with load, prior to shutdown, decrease the load, lower the speed, and run

it at idle speed for 4-5min to avoid full-load shutdown;

Check the oil level of the diesel engine: carry out the check 5min later after shutdown.

Note: To avoid damaging the diesel engine, during operation, it is not allowed to remove the

cable connecting the diesel engine pressure regulator and the cable connecting the battery

anode. Different from the DC generator, it is not allowed to check the alternator voltage by

grounding temporarily.

4.2.2 Precautions for starting and operation in cold environment

(1) If long-acting antifreeze is not added in the cooling water of the diesel engine, during use in

cold days, the cooling water must be drained out after shutdown to avoid frosting the diesel

engine. Open the special drain valve (Refer to figure 4-3) at lower position of the cylinder

block of injection pump side, the cooling water in the diesel engine can be drained out.

Figure 4-3 Drain valve

(2) Before the cold seasons begin, check electrolyte level, viscosity and unit voltage of the

battery. If the engine is in an environment with very low temperature for a long time, take the

battery down and store it in a warm room.

Page 17

Deutz WP6C/WP4C Series Marine Diesel Engine Use and Maintenance Manual

11

4.3 Maintenance of diesel engine

Maintenance schedule of diesel engine

No repetitive operation is needed after maintenance according to the following time:

Operation item Running time h

Retighten the connecting bolts and the cylinder

head bolts

30

Check the belt and the tightness 30 125

Change the oil and replace the oil filter

element

30 125

Check the valve clearance 30 125

Repeat the maintenance operation according to the following time:

Operation item

Running time h

250 500 1000

Clean the air filter element 1) ×

Check and tighten the V-belt ×

Check the raw water pump impeller 2) ×

Check the zinc anode 2) ×

Change the oil and replace the oil filter element

×

Check the valve clearance ×

Replace the diesel filter element ×

Clean the crankcase ventilation device 3) ×

1). Replace earlier if there is more dust.

Clean the wet air filter at least in 200h’s operation.

2). Only for marine engines only.

3). Only for conditions when the crankcase ventilation device is not guided to air inlet

Maintenance instructions for standby state and emergency state

Seal the diesel engine up if it is not used for weeks (for example, in winter).

Time Maintenance requirements

Every month Trial run with load

6 months

After operating for 6 months, if the operation time does not reach 500h, carry

out all maintenance operations required in this period.

After12 months

After operating for 12 months, if the operation time does not reach 1000h,

carry out all maintenance operations required in this period.

Page 18

Deutz WP6C/WP4C Series Marine Diesel Engine Use and Maintenance Manual

12

Overhaul

The operation reliability of the diesel engine will be affected by wear and corrosion. To avoid

abnormal operation of the diesel engine, we recommend that complete overhaul be carried out

according to the following table. Carry out the first overhaul after 2000h’s or 2 years’ (in the case

of not reaching to 2000h) operation of the diesel engine.

Items Operation time

Check the nozzle 2000

Check the compression pressure 2000

Check the bearing clearance of water pump 5000

Check the supercharger 5000

Check the fuel injection pump 5000

Check the cylinder head 5000

Check the cylinder liner 5000

Clean the water cavity of the water cooling

exhaust pipe and check the corrosion

10000

Check the connecting rod and the main bearing

10000

Check the piston 10000

Check the crankshaft 10000

Check the camshaft 10000

Check the secondary balance mechanism 10000

Check the transmission gear 10000

Overhaul the fuel injection pump thoroughly 10000

Replace the oil pump 10000

Replace the water pump 10000

Replace the crankshaft oil seal 10000

Replace the shock absorber 10000

The above checks and repairs require professional skills and should be carried out by

professionals.

Page 19

Deutz WP6C/WP4C Series Marine Diesel Engine Use and Maintenance Manual

13

5. Common fault analysis and troubleshooting

5.1 The diesel engine cannot start

S/N

Cause Troubleshooting

1 Use

(1) Air starter: The air pressure

in the starting air bottle is

insufficient or is not in

optimal starting position.

Always keep the pressure in the air bottle above

2MPa; prior to starting, barring the engine and make

one of the cylinders at an angle about 15° behind the

top dead center.

(2) Electric starter: The battery is

low in capacity.

Check the specific gravity of battery electrolyte

(which should be 1.28-1.30) and keep the battery

warm in winter or cold regions or use the insulation

(low-temperature) battery.

(3) The service handle is not in

the service position.

Tighten the service handle to the service position.

(4) The diesel engine is loaded. Unloading

(5) The oil viscosity is high and

the liquidity is poor.

Select the oil according to ambient temperature or heat

the oil.

(6) There is air in the fuel

system.

Bleed the air in the system.

(7) There is water in the diesel

fuel.

Check the fuel tank; unscrew the plug at the lower part

of the diesel filter, and discharge the water.

(8) The bleed screw of the fuel

injector is not tightened, and

there is no fuel injection.

Tighten it clockwise.

(9) The selected diesel fuel is

improper.

Select according to regions and seasons.

2 Fuel system

(1) There is leakage from the

fuel pipe joint.

Check and tighten the joint.

(2) The fuel pipe is blocked. Check and clean or blow free the fuel pipe.

(3) The diesel filter is blocked. Remove, clean or replace the filter element.

(4) The spray of the fuel injector

is not good.

Adjust and repair the fuel injector. Replace the needle

valve coupled parts when necessary.

(5) The fuel supply advance

angle is incorrect.

Adjust as required.

(6) The fuel injection pump or

the fuel injector is damaged.

Overhaul or replace

3 Others

(1) There is leakage from the

inlet/exhaust valve.

Overhaul and readjust the valve clearance.

Page 20

Deutz WP6C/WP4C Series Marine Diesel Engine Use and Maintenance Manual

14

S/N

Cause Troubleshooting

(2) There is air leakage from the

cylinder.

Check the cylinder head gaskets and tighten the

cylinder head nuts.

(3) The valve spring is broken. Replace it.

(4) There is gas leakage from the

piston rings.

Replace the piston ring.

(5) The piston is stuck in the

cylinder.

Remove and repair.

(6) There is gathered water in

the cylinder.

Remove the cylinder head, drain the water, and find

out the cause.

(7) The timing of air distribution

plate of the air starter is

wrong.

Remove and reinstall.

5.2 The diesel engine cannot output specified power

S/N

Cause Troubleshooting

1 Use

(1) The speed is low. Adjust to the rated speed.

(2) The elevation or ambient temperature of

operation regions is too high.

Correct according to the

environmental conditions, refer to

annex “Power correction table”.

2 Fuel system

(1) The fuel injector is faulted (the injection hole

is clogged, the spray is not good, the fuel

injection pressure is insufficient, or the height

of the injection nozzle stretching out of the

cylinder head is incorrect).

Adjust or overhaul the fuel injector as

required.

(2) The fuel supply of the fuel injection pump is

uneven or one or two sub-pumps are

inoperative.

Adjust the fuel capacity or overhaul

the fuel injection pump.

(3) The fuel injection pump is worn, the fuel

supply is insufficient.

Unscrew the limit screw of the fuel

pump control rack, increase the fuel

capacity or replace a new plunger and

barrel assembly.

(4) The diesel fuel filter is clogged, the fuel

pressure of the fuel delivery pump is

insufficient, the check valve of the fuel

delivery pump is broken or worn, or the

spring is broken.

Check and clean or adjust and replace

(5) The diesel fuel selected is improper.

Select the specified grade according

to regions and seasons (ambient

temperature).

(6) The fuel supply advance angle is incorrect. Check and adjust

3 Air distribution system

Page 21

Deutz WP6C/WP4C Series Marine Diesel Engine Use and Maintenance Manual

15

S/N

Cause Troubleshooting

(1) The air filter, the supercharger compressor or

the intercooler is unclean.

Remove and clean.

(2) The external exhaust pipe does not meet the

requirements or the exhaust back pressure is

too high.

Design and install the external

exhaust pipe as required.

(3) There is leakage from the inlet/exhaust valve. Check and grind repair.

(4) The inlet/exhaust timing is incorrect. Check and adjust.

(5) There is air leakage from the air inlet valve or

the start valve on the air starter cylinder head.

Remove and grind repair.

4 Others

(1) The compression pressure is insufficient (the

compression ratio is incorrect or the piston

rings are excessively worn)

Check, adjust or replace the piston

rings.

(2) The piston and the cylinder liner are scuffed

or other worn parts are faulted.

Remove the cylinder head, check the

internal surface of the cylinder liner

or other worn parts, and repair or

replace timely.

(3) The diesel engine is not sufficiently cooled

and is too hot.

Check the belt tightness and all parts

of the cooling system, or remove the

water scales.

(4) The bearings are not well lubricated or are too

hot.

Overhaul the lubrication system or

clean it.

5.3 Exhaust smoke

S/N

Cause Troubleshooting

1 Off-white smoke

(1) The diesel engine is too cold. Adjust to rated speed.

(2) There is water leakage in the cylinder.

Remove the exhaust pipe or the

cylinder head and check

(3) Incomplete combustion.

Check the fuel injector or the

compression pressure in the

cylinder.

2 Taupe smoke

(1) The diesel engine load is too high. Lower the load

(2) There is too much fuel pumped out from some

sub-pump.

Adjust according the method

described in chapter 4.

(3) The fuel injector is faulted (if the fuel drops

from the fuel nozzle, the exhaust will smoke

intermittently).

Check the fuel injector or repair or

replace the injection nozzle.

(4) The fuel supply advance angle is insufficient

(there is black smoke or flame in the exhaust).

Adjust the fuel supply advance

angle as required.

3 Sky-blue smoke

Page 22

Deutz WP6C/WP4C Series Marine Diesel Engine Use and Maintenance Manual

16

S/N

Cause Troubleshooting

(1) In the case of cold state, the engine oil enters

the combustion chamber.

Rise the inlet water temperature.

(2) The running time of the new engine is not long. Increase the running-in time.

(3) The piston rings are worn. Overhaul

5.4 Abnormal noise or vibration during diesel engine running

S/N

Cause Troubleshooting

1

Premature fuel injection or uneven fuel delivery

causes the clear, rhythmic and metallic knocking

noise, especially at start or low speed.

Adjust the fuel supply advance

angle or adjust the uniformity of

fuel amount.

2

The clearances of the intake valves or exhaust valves

are excessive, making rhythmic and slight knocking

noise.

Adjust valve clearance

3

Increase load before diesel engine is preheated. The

clearance between the piston and cylinder liner is

excessive, making knocking noise.

Unloading for idle warning of

diesel engine.

4

The wear of piston, piston rings and cylinder liner are

excessive, making knocking noise.

Replace the related parts

5

The wear between each journal and bearing bush of

crankshaft is excessive, making knocking noise along

the overall length of diesel engine.

Repair or replace it

6

Compression ratio is too high, causing rough

operation and large vibration.

The compression ratio should be

adjusted to specification.

7

The clearances of the intake valves or exhaust valves

are small, or the exhaust or intake timing is not

correct, causing that the valve impacts the top of

piston.

Adjust valve clearance or timing

8

Individual cylinder does not work and diesel engine

vibration is aggravated.

Check the fuel system and solve

the failure.

9

The valve is fractured (the valve lock clip is damaged,

valve drops or the piston fractures, causing sudden or

strong knocking noise)

Immediately stop the engine for

inspection.

10

Air leaks from the cylinder head gasket, making

howling.

Check the cylinder head nuts for

tightness or replace the cylinder

head gasket.

11

Wear of each gear is excessive, making knocking

noise.

Check and then replace it

12

The fixing bolts attaching to diesel engine is loose or

damaged, aggravating vibration.

Tighten or replace the bolts

13

Diesel engine is not coaxial to the connected work

device, aggravating the vibration.

Check and adjust it

14

Uneven foundation causes the deformation of

common base plate.

Check and adjust it

Page 23

Deutz WP6C/WP4C Series Marine Diesel Engine Use and Maintenance Manual

17

5.5 Unstable diesel engine operation

S/N

Cause Troubleshooting

1

The clearance increases due to inflexible

movement of

governor flyweight movement or wear factors.

Check for the existence of stuck

phenomenon. Repair or replace

accordingly.

2

The buffering clamp spring of the speed governor loses

its elasticity or is fractured and results in control rack

vibration and unstable speed.

Check or replace

3

The diesel engine speed is too low and the engine runs

at the intermediate speed. The land engine

double-speed governor fails to operate automatically.

Accelerate to the rated speed.

4 The diesel engine load changes frequently.

Check the condition of load

output.

5

Some of cylinder ignites interruptedly. Therefore, these

cylinders explode fiercely due to excessive

accumulated fuel and this leads to cylinder knocking.

Check the fuel system.

6

Injection volume and injection time for injection

pumps are different.

Check and adjust

7 There is air in the fuel system. Check and carry out air bleeding

8 There is moisture in the fuel system.

Check the fuel and carry out

water drainage.

9 There is left and right movement of timing gear. Check all gears for fastening.

5.6 Water pump does not pump water or water supply is insufficient

S/N

Cause Troubleshooting

1

There is air in the water pump or water

absorption pipe.

Fill some water to bleed air from it.

2

The water pipe is clogged or frozen (in

cold season).

Remove clogging or fill the cooling system

with hot water or fill with antifreeze in

advance.

3

The water pump sealing device or sealing

gasket is damaged and there is air

leakage.

Overhaul or replace.

4 The water pump belt is too loose. Check and adjust.

5

There is excessive water scale in the

diesel engine water pump.

Remove water scale.

6

The water pump suction height is

excessive.

Install the water pump according to relevant

specifications.

Page 24

Deutz WP6C/WP4C Series Marine Diesel Engine Use and Maintenance Manual

18

5.7 Oil pressure is too low

S/N

Cause Troubleshooting

1

The lubrication oil is in poor quality (the specific

phenomenon is the oil pressure drops gradually with

diesel engine running).

Select proper lubrication oil

according to relevant

specifications.

2

The diesel engine is overheated and the oil gets

thinner.

Troubleshoot according to items

in Section 5.8 of this chapter.

3 The oil filter is clogged. Clean

4

There are loose pipe joints and oil leakage in the oil

line or there is air in the pipeline.

Check and tighten.

5 There is diesel fuel mixed in the oil. Change and find out the cause.

6

The spring for the pressure adjusting valve of the oil

pump gets fractured.

Replace

7

Oil pressure in the oil sump is too low or the oil pump

suction height is excessive.

Add some oil or reinstall the oil

pump and oil tank.

8

The clearance between the connecting rod bearing and

the main bearing is too large.

Check and replace

5.8 Diesel engine is overheated

S/N

Cause Troubleshooting

1 There is no sufficient coolant.

Troubleshoot according to items in Section 5.6 of

this chapter.

2

The water inlet temperature is too

high.

Reduce the water inlet temperature.

3 The oil pressure is too low.

Troubleshoot according to items in Section 5.7 of

this chapter

4 The diesel engine is overloaded. Reduce its load and find out the cause.

5 Fuel injection is too late. Check and adjust.

6

There is air leakage at the piston

ring.

Check and replace

7 The bearing fit is too tight. Check and properly grind.

8 The ambient temperature is too high.

Implement power correction and reduce the load

effect.

Page 25

Deutz WP6C/WP4C Series Marine Diesel Engine User Service Guide

1

II. User Service Guide (Warranty Card)

Weichai Power Product Warranty Card (for User)

Item Content Item Content

Model

Customer Name

Order Number

Post Code

Serial Number

Address

Date of Purchase

Office Tel.

Distributor

Home Tel.

Dear customer,

Welcome to use Weichai products and thank you to select Weichai products!

For proper usage and maintenance of your diesel engine, please read the Operation and

Maintenance Manual of Diesel Engine carefully and keep strict compliance with relevant

specifications in operations. In the case of diesel engine faults, please contact with Weichai

Maintenance Service Center or Weichai Power Co., Ltd. Customer Service Center as soon as

possible. We will provide you with timely and effective maintenance service.

“Maintenance Registration Form” should be filled by the Maintenance Service Center during

maintenance and customers should keep this form properly.

Weichai Power Co., Ltd.

Address: 26 Minsheng Dong Street, Kuiwen District, Weifang, Shandong

Post Code: 261001

Website: http://www.weichai.com

Main Engine Sales Tel.: 0536-8232488/ 8233371

Spare Parts Sales Tel.: 0536-2297313/ 2297319

Service Hotline:

400 Free Service Hotline: 400-6183066

800 Free Service Hotline: 800-8603066

Customer Service Center Hotline: 0536-8235369 (Fax)

Customer Service Center Complaint Phone: 0536-2297322

24-Hour Service Hotline

Page 26

Deutz WP6C/WP4C Series Marine Diesel Engine User Service Guide

2

Maintenance Registration Form (Filled by Maintenance Personnel)

Item Content Item Content

Model Customer Name

Order Number Post Code

Serial Number Address

Date of Purchase

Office Tel.

Distributor Home Tel.

Name of

Maintenance

Service Center

Date

Warranty

Item

Replaced

Spare Part

Quantity

Signature of

Maintenance

Man

Signature of

Customer

Page 27

Deutz WP6C/WP4C Series Marine Diesel Engine User Service Guide

3

Warranty Instructions

1. Service Commitment:

Our company provides maintenance service within the service area of maintenance service units.

Once an user message arrives and corresponding service demand is confirmed, maintenance men

from the maintenance service center would arrive the service site within 3 hours for local urban

areas, 24 hours for general areas and 48 hours for remote areas (when force majeure is excluded).

2. Further Hints:

Diesel engine operators should carefully read this Operation and Maintenance Manual and be

familiar with structure of the diesel engine, strictly follow technical operations and

maintenance regulations specified in the manual and pay attention to cautions and warning

signs.

This diesel engine has passed factory test according to relevant test specifications. A lead seal

limit has been applied to the throttle and it is prohibited to remove the lead seal at will for a

larger throttle opening. Otherwise, Weichai Power would be exempted from the liability of

warranty.

Bolts of the diesel engine possess various strict tightening torque requirements and times of

usage so that users are not allowed to loose main bearing bolts or connecting rod bolts at will.

For detailed requirements, please refer to the Operation and Maintenance Manual.

In the case of a new engine, customers should implement 50h trial run for the engine.

After cold start of the diesel engine, please increase the engine speed slowly. Neither let the

engine run at a high speed suddenly nor let it idle for a long time.

After stopping, if the ambient temperature is lower than 0 and antifreeze additive is not ℃

used, you should completely drain water from the water tank and the diesel engine.

The diesel engine is prohibited to operate without an air filter. To prevent unfiltered air from

getting into air cylinders, you should clean the air filter element more frequently or shorten

its replacement interval in the case of severe operation environment so as to avoid faults like

premature wears of the diesel engine.

When filling the diesel engine with fuel and oil, it is necessary to select that with specified

grade and adopt special clean containers. During filling, they should be filtered by the filter

screen. Moreover, fuel should be precipitated by more than 72 hours.

3. “Three Guarantees” Service Principles and Rules:

(1) Three Guarantees Service Principles

For product damages due to their manufacturing and assembling in the case of normal use

and proper maintenance, these Weichai engines or products equipped with Weichai engines

are included in “Three guarantees” scope during the “Three guarantees” period.

The diesel engine and parts should be repaired firstly of all. If it is confirmed that they are not

repairable, replace them with corresponding parts: If it meets the conditions for the whole

engine replacement specified by Weichai Power Co., Ltd. , the replacement should be submit

to the person in charge for approval.

Page 28

Deutz WP6C/WP4C Series Marine Diesel Engine User Service Guide

4

(2) Three Guarantee Period

For end engine products manufactured by Weichai, their Three guarantees service and

warranty period starts from the actual date of sales and Weichai sales invoices and warranty

cards or sales invoices from distributors can be taken as the evidence (The Three guarantee

period for marine main engine starts from the actual testing and adjusting date of the engine).

For that of matching engines for the other products, the agreement between two parties

prevails; If there are specific specifications for the engine three guarantees issued by the main

engine manufacturer, these specifications prevail.The attached warranty card is regarded as

the evidence for the executive standard. If there is no specific standard for the three

guarantees service of the engine or detailed contents are unknown, Weichai standards prevail.

Three guarantees service and the start date would depend on the actual sales date of the

matching products and relevant sales invoice and warranty card are taken as the evidence.

For original quality problems in spare parts purchased from Weichai, the three guarantee

period for assembly parts is 3 months, for basic parts, it is 1 year. In the case of wear parts,

rubber parts, piston rings, oil seals, bearing bushes, bolts, fuel injector couplings etc are not

included in the scope of three guarantees after their installation. If there are quality problems

of basic parts in the three guarantee period, the three guarantees service will be billed

according to work hours after the site confirmation from the dispatched man in the center

service and preservation of effective photographs. For three guarantee period of spare parts,

the sales invoice date of center warehouse or special service center prevails. Assembling

quality problems are not included in the scope of Weichai’s three guarantees but it should be

the assembling entity which undertakes the three guarantees.

4. Regulations about Non-“Three Guarantee” Items:

Diesel engine faults due to improper usage, maintenance and matching; Damages occur

during loading and unloading of transport after purchasing; Operating conditions exceed the

scope specified in the product manual; improper matching and overspeed and overload

application etc; Running-in and maintenance which are not implemented according to

product manual; Application of oil/fuel, antifreeze and filters etc which are in poor quality

and do not comply with relevant specifications.

Faults due to modification, adjustment and disassembling of parts which are not allowed to

be modified, adjusted and disassembled.

Oil, antifreeze, filtering elements, hoses, belts and fuel injector couplings etc which are

applied to normal use, consumption and maintenance.

Absence of three guarantees evidences like warranty card and relevant invoice etc and the

user fails to prove the purchased product is still in the valid three guarantee period. The

product specification and model on the evidence or invoice do not comply with those

included in the three guarantees or such specification and model have been altered.

The user fails to remain the original status after fault occurrence but implements

troubleshooting at will and it is impossible to implement technical appraisals for the detection

of fault causes.

Faults caused by misoperation.

Damages result from force majeure like wars and natural disasters etc.

Diesel engine damages due to traffic accidents.

Page 29

Deutz WP6C/WP4C Series Marine Diesel Engine User Service Guide

5

Regulations about Term of Three Guarantees Service for Weichai

Power Marine or Power Generating Diesel Engine

S/N

Product Model

Term of Three

Guarantees

Remarks

I. Complete diesel engine

The date of actual

sales prevails and

the sales invoice,

warranty card or

time counter are

take as evidences;

1

Marine diesel engine, diesel engine for generating set and

diesel engine for other power equipments

1 year

II. Diesel engine components

1

Basic

parts

Engine body, crankshaft, engine seat and

connecting rod

2 years (with

original faults in

manufacturing like

air blisters etc)

2

Important

parts

Cylinder head, flywheel, flywheel housing,

timing gear chamber, connecting rod bolt, piston,

piston ring, piston pin, connecting rod bearing

shell, main bearing shell, camshaft bearing bush,

camshaft, cylinder liner, valve, valve spring,

valve seat, valve guide pipe, valve cover, tappet,

push rod, rocker arm and shaft, various gears and

gear shafts, tension pulley, ring gear, oil pump,

intake and exhaust manifold, oil sump, front and

rear brackets, belt pulley and flange, water tank,

high-pressure fuel pump, fuel injector body, fuel

pump holder, coupling, air compressor, various

cover plates and base plates, water pump, oil

radiator, fan bracket, silicone oil clutch, pressure

limiting valve, shock absorber, crankshaft balance

mechanism, rear oil seal and seat, various metal

oil pipes, water pipes and pipe joints, steering

pump, thermostat, oil-gas separator, cylinder

gasket, ECU, common-rail pipe, high-pressure

fuel pipe, air filter body, diesel fuel filter body, oil

filter body, muffler, distribution plate, starting

valve, intercooler, heat exchanger, air bottle,

thrust washer, suction filter, dipstick pipe fitting,

cooling oil nozzle etc.

It is the same with

the term of the

complete diesel

engine three

guarantees.

3

Common

parts

Front oil seal and other oil seals, supercharger,

intake manifold gasket, exhaust manifold gasket,

supercharger gasket, valve cover gasket, rubber

hose, fuel injector return pipe, fuel delivery

pump, dipstick, fan, waterproof and oil-proof

rubber gaskets, bowl plug.

6 months or 750

hours

Electrical

parts

Starter, generator, instrument, various sensors,

electronic speed controller, throttle pedal, harness,

solenoid valve and flame preheater.

6 months or 750

hours

4

Wear

parts

Belt, fan shroud, fuel spray nozzle, plunger

coupled parts, other gaskets, various braided hose,

clamps, time counter.

1 month

Remarks: 1. If the time counter of marine or power generating engine is damaged, you can calculate the three

guarantee period on the basis of 15h/day;

2. The start date of warranty period should begin from the testing and adjusting date for the new

engine. However, the time interval between the testing and adjusting date and date of purchase

should not exceed 1 year.

Page 30

Deutz WP6C/WP4C Series Marine Diesel Engine User Service Guide

6

No

te:

Ple

ase

tic

k

wit

h

“√”

in

cor

res

po

ndi

ng

col

um

ns.

Custom

er

Satisfac

tion

Questio

nnaire

Page 31

Deutz WP6C/WP4C Series Marine Diesel Engine User Service Guide

7

Page 32

Deutz WP6C/WP4C Series Marine Diesel Engine User Service Guide

8

Page 33

1

Engine Mandatory Maintenance Card

License Plate

Number

Manufacturer

The first copy Counterfoil

Customer Name Engine Number

Detailed Address

Date of Mandatory Maintenance

Mileage of Mandatory

Maintenance

Purchase Entity Date of Purchase

Identifier:

Service Station Official Seal:

Customer Signature:

Valid Documentation:

Customer Tel.:

Label of Weichai Power Special

Oil:

Prompt: This Mandatory Maintenance Card is in triple and all of them should be signed by the customer and it

would be invalid in the case of any missed out item.

Weichai Power Service Hotline: 400-6183066 800-8603066

After the completion of mandatory maintenance, this card and the Customer Satisfaction Questionnaire in

this manual will be returned to the administrative area office by the service station.

Engine Mandatory Maintenance Card

License Plate

Number

Manufacturer

The first copy Counterfoil

Customer Name Engine Number

Detailed Address

Date of Mandatory Maintenance

Mileage of Mandatory

Maintenance

Purchase Entity Date of Purchase

Identifier:

Service Station Official Seal:

Customer Signature:

Valid Documentation:

Customer Tel.:

Label of Weichai Power Special

Oil:

Prompt: This Mandatory Maintenance Card is in triple and all of them should be signed by the customer and it

would be invalid in the case of any missed out item.

Weichai Power Service Hotline: 400-6183066 800-8603066

After the completion of mandatory maintenance, this card and the Customer Satisfaction Questionnaire

in this manual will be returned to the administrative area office by the service station.

Engine Mandatory Maintenance Card

License Plate

Number

Manufacturer

The first copy Counterfoil

Customer Name Engine Number

Detailed Address

Date of Mandatory Maintenance

Mileage of Mandatory

Maintenance

Purchase Entity Date of Purchase

Identifier:

Service Station Official Seal:

Customer Signature:

Valid Documentation:

Customer Tel.:

Label of Weichai Power Special

Oil:

Prompt: This Mandatory Maintenance Card is in triple and all of them should be signed by the customer and it

would be invalid in the case of any missed out item.

Weichai Power Service Hotline: 400-6183066 800-8603066

After the completion of mandatory maintenance, this card and the Customer Satisfaction Questionnaire

in this manual will be returned to the administrative area office by the service station.

Page 34

2

Engine Mandatory Maintenance Card

License Plate

Number

Manufacturer

The second copy For Weichai

Customer Name Engine Number

Detailed Address

Date of Mandatory Maintenance

Mileage of Mandatory

Maintenance

Purchase Entity Date of Purchase

Identifier:

Service Station Official Seal:

Customer Signature:

Valid Documentation:

Customer Tel.:

Label of Weichai Power Special

Oil:

Prompt: This Mandatory Maintenance Card is in triple and all of them should be signed by the customer and it

would be invalid in the case of any missed out item.

Weichai Power Service Hotline: 400-6183066 800-8603066

After the completion of mandatory maintenance, this card and the Customer Satisfaction Questionnaire

in this manual will be returned to the administrative area office by the service station.

Engine Mandatory Maintenance Card

License Plate

Number

Manufacturer

The second copy For Weichai

Customer Name Engine Number

Detailed Address

Date of Mandatory Maintenance

Mileage of Mandatory

Maintenance

Purchase Entity Date of Purchase

Identifier:

Service Station Official Seal:

Customer Signature:

Valid Documentation:

Customer Tel.:

Label of Weichai Power Special

Oil:

Prompt: This Mandatory Maintenance Card is in triple and all of them should be signed by the customer and it

would be invalid in the case of any missed out item.

Weichai Power Service Hotline: 400-6183066 800-8603066

After the completion of mandatory maintenance, this card and the Customer Satisfaction Questionnaire

in this manual will be returned to the administrative area office by the service station.

Engine Mandatory Maintenance Card

License Plate

Number

Manufacturer

The second copy For Weichai

Customer Name Engine Number

Detailed Address

Date of Mandatory Maintenance

Mileage of Mandatory

Maintenance

Purchase Entity Date of Purchase

Identifier:

Service Station Official Seal:

Customer Signature:

Valid Documentation:

Customer Tel.:

Label of Weichai Power Special

Oil:

Prompt: This Mandatory Maintenance Card is in triple and all of them should be signed by the customer and it

would be invalid in the case of any missed out item.

Weichai Power Service Hotline: 400-6183066 800-8603066

After the completion of mandatory maintenance, this card and the Customer Satisfaction Questionnaire

in this manual will be returned to the administrative area office by the service station.

Page 35

3

Engine Mandatory Maintenance Card

License Plate

Number

Manufacturer

The third copy For service station

Customer Name Engine Number

Detailed Address

Date of Mandatory Maintenance

Mileage of Mandatory

Maintenance

Purchase Entity Date of Purchase

Identifier:

Service Station Official Seal:

Customer Signature:

Valid Documentation:

Customer Tel.:

Label of Weichai Power Special

Oil:

Prompt: This Mandatory Maintenance Card is in triple and all of them should be signed by the customer and it

would be invalid in the case of any missed out item.

Weichai Power Service Hotline: 400-6183066 800-8603066

After the completion of mandatory maintenance, this card and the Customer Satisfaction Questionnaire

in this manual will be returned to the administrative area office by the service station.

Engine Mandatory Maintenance Card

License Plate

Number

Manufacturer

The third copy For service station

Customer Name Engine Number

Detailed Address

Date of Mandatory Maintenance

Mileage of Mandatory

Maintenance

Purchase Entity Date of Purchase

Identifier:

Service Station Official Seal:

Customer Signature:

Valid Documentation:

Customer Tel.:

Label of Weichai Power Special

Oil:

Prompt: This Mandatory Maintenance Card is in triple and all of them should be signed by the customer and it

would be invalid in the case of any missed out item.

Weichai Power Service Hotline: 400-6183066 800-8603066

After the completion of mandatory maintenance, this card and theCustomer Satisfaction Questionnaire in

this manual will be returned to the administrative area office by the service station.

Engine Mandatory Maintenance Card

License Plate

Number

Manufacturer

The third copy For service station

Customer Name Engine Number

Detailed Address

Date of Mandatory Maintenance

Mileage of Mandatory

Maintenance

Purchase Entity Date of Purchase

Identifier:

Service Station Official Seal:

Customer Signature:

Valid Documentation:

Customer Tel.:

Label of Weichai Power Special

Oil:

Prompt: This Mandatory Maintenance Card is in triple and all of them should be signed by the customer and it

would be invalid in the case of any missed out item.

Weichai Power Service Hotline: 400-6183066 800-8603066

After the completion of mandatory maintenance, this card and the Customer Satisfaction Questionnaire

in this manual will be returned to the administrative area office by the service station.

Page 36

Page 37

WEIFANG WEICHAI DEUTZ DIESEL ENGINE CO.,LTD.

Address: 121, Beigong Street, Weifang, Shandong

Tel: +86-0536-8679536

Fax: +86-0536-8679526

Post Code: 261009

Part Number: 13060345

Design Version Number: ppbsj sjzl 201040

Amended in March, 2009

This material is provided as reference only. In the case of any

product parameter changes, the actual product prevails without

any further notice.

Loading...

Loading...