Page 1

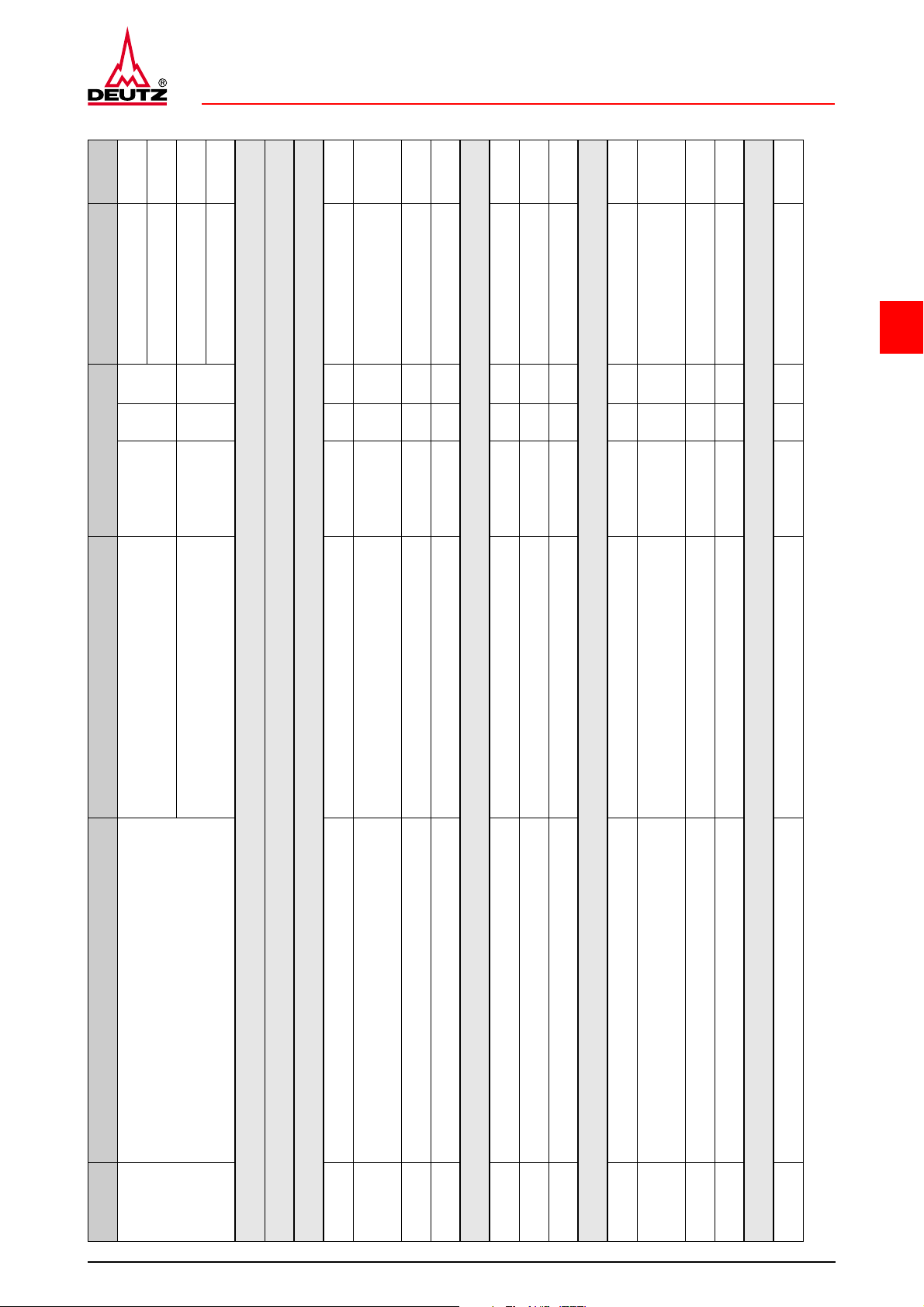

TCD 2015

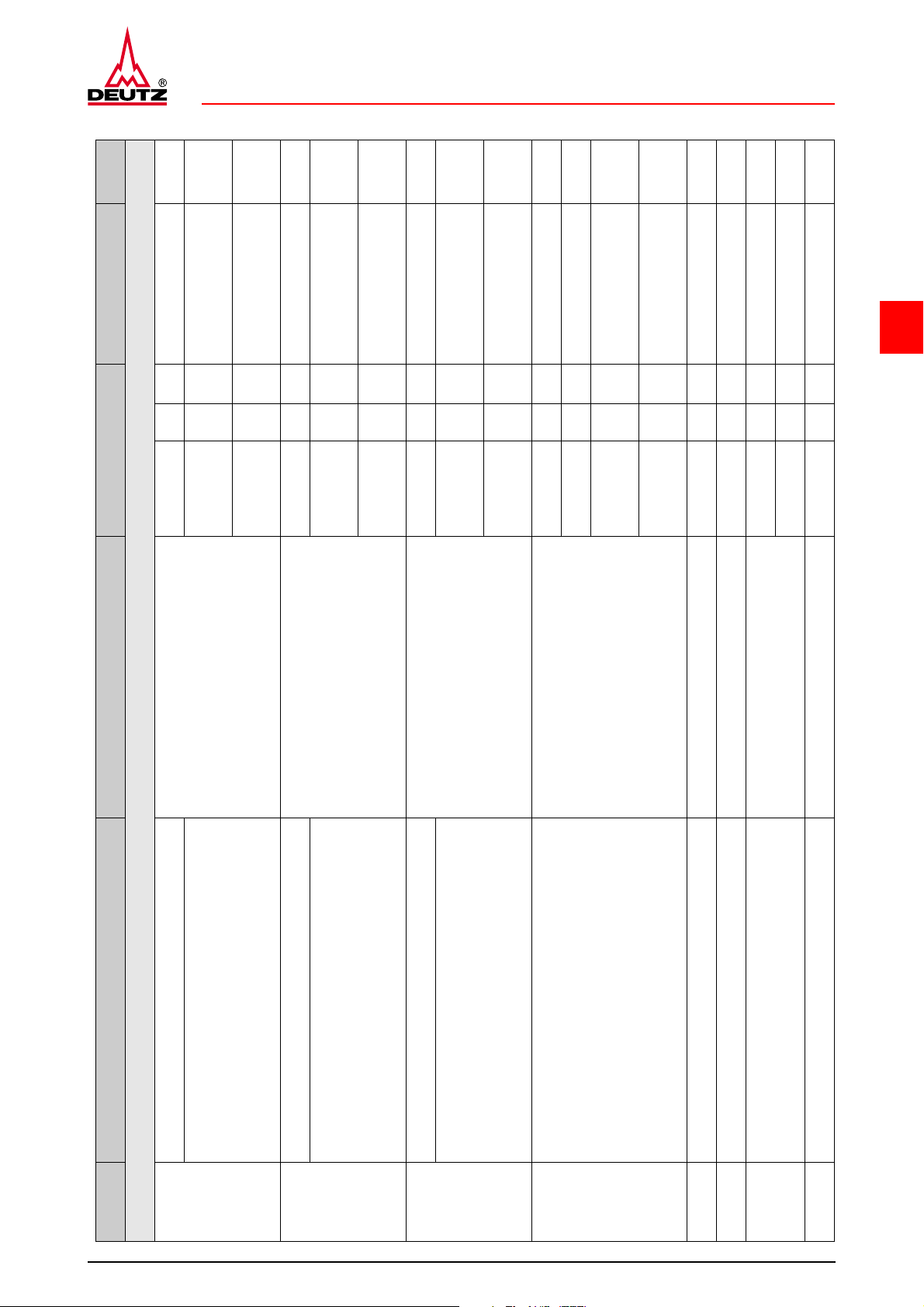

4 Technical data

4.1 Testing and setting data

Technical data

4

© 06/2006 8145-001

1/28

Page 2

Technical data

Testing and setting data

TCD 2015

4

© 06/2006 8145-001

2/28

Page 3

TCD 2015

Technical data

Testing and setting data

3

3

4

TCD 2015 V06 1200 mm

V06 1107 mm

TCD 2015

(Railway)

about all data

V08 1454 mm

TCD 2015

(Railway)

TCD 2015 V06 1200 mm

V06 1125 mm

TCD 2015

(Railway)

about all data

V08 1120 mm

TCD 2015

(Railway)

TCD 2015 V06 1300 mm

V06 835 mm

TCD 2015

(Railway)

about all data

V08 837 mm

TCD 2015

(Railway)

TCD 2015 V06 approx. 1020-1200 kg

TCD 2015 V08 1244 kg

V06 920 kg

TCD 2015

(Railway)

V08 1160 kg

TCD 2015

(Railway)

TCD 2015 V06 11906 cm

TCD 2015 V08 15874 cm

Length of engine

ID no. Name Information Series Value Unit

General engine data

© 06/2006 8145-001

Length of engine with connection housing

P00 01

Width of engine

Width of engine with connection housing

P00 02

Height of engine

3/28

Height of engine with connection housing

P00 03

P00 04 Engine weight according to DIN 70020-A without operating media

P00 20 Combustion process TCD 2015 Direct injection -

P00 10 Working principle TCD 2015 4 stroke -

P00 30 Total volume

P00 31 Bore TCD 2015 132 mm

Page 4

Technical data

+0

0

+0

0

+0

0

+0

0

+0

0

+0

0

+0

0

Testing and setting data

TCD 2015

kPa

(bar)

-

.

.

.

.

.

.

.

0

0

0

0

0

0

0

4

A1-B4-A4-B1-B3-A3-

16.5:1 -

TCD 2015 17.5:1 -

TCD 2015

(Railway)

3200-3400

(32-34)

TCD 2015 V06 A1-B3-A3-B2-A2-B1 -

B2-A2

TCD 2015 V08

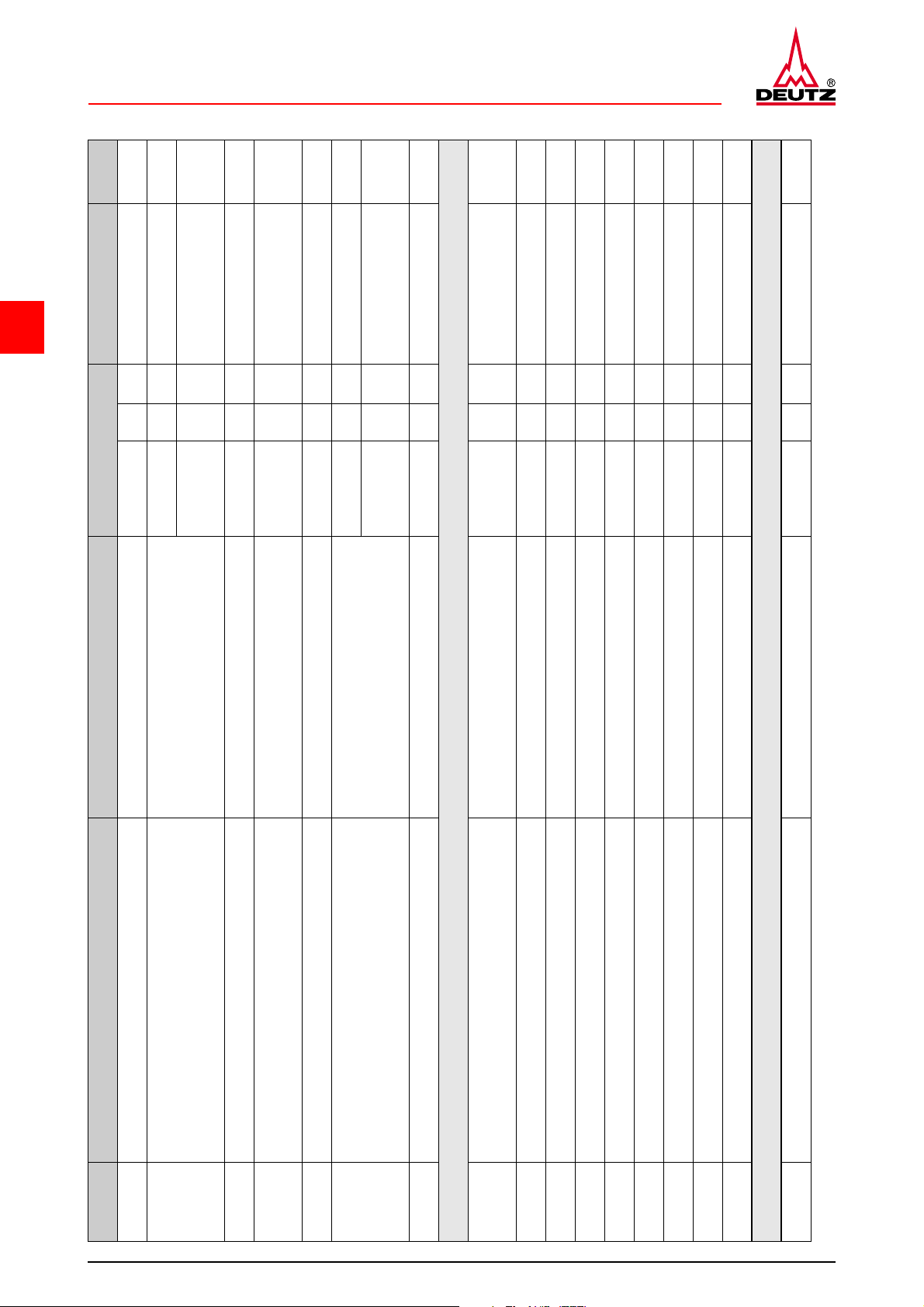

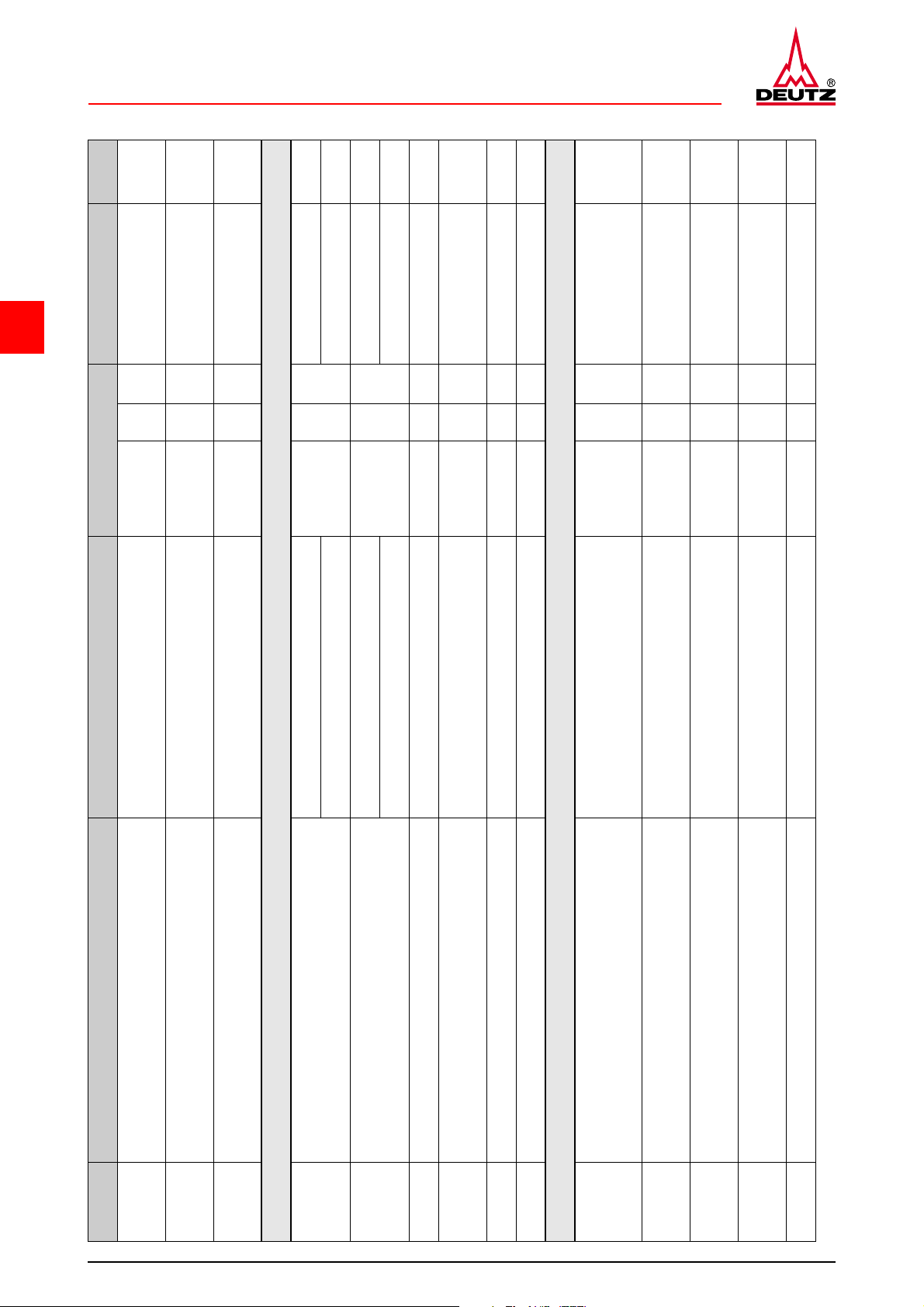

TCD 2015 47.500 mm

ID no. Name Information Series Value Unit

P00 32 Stroke TCD 2015 145 mm

P00 40 Compression ratio

Standard

fit H6

P00 51 Compression pressure TCD 2015

P00 70 Spark gap TCD 2015 V06 120 °

P00 50 Direction of rotation looking onto the flywheel TCD 2015 counter-clockwise -

P00 71 Ignition sequence

P00 81 Cylinder and side view TCD 2015 T00 81 -

Cylinder head

P01 01 Valve seat insert, bore (inlet)

P01 02 Valve seat insert, bore (outlet) Standard TCD 2015 44.500 mm

P01 03 Valve seat insert, bore (inlet) 1. oversize level TCD 2015 47.800 mm

P01 04 Valve seat insert, bore (outlet) 1. oversize level TCD 2015 44.300 mm

P01 05 Valve guide, bore in cylinder head Standard TCD 2015 15.000 mm

P01 06 Valve guide, bore in cylinder head 1. oversize level TCD 2015 15.100 mm

P01 07 Valve guide, bore in cylinder head 2. oversize level TCD 2015 15.200 mm

P01 08 Cylinder head, height Standard TCD 2015 120 mm

P01 09 Cylinder head, height Undersize TCD 2015 119.70 mm

Valve guide

P01 11 Valve guide, external diameter Standard TCD 2015 15.0 mm

© 06/2006 8145-001

4/28

Page 5

TCD 2015

+0

0

+0

0

+0

07

6

+0

07

6

+0

07

6

+0

07

6

+0

00

0

+0

00

0

+0.

2

+0.

2

+0.

2

+0.

2

.

.

0

0

Technical data

Testing and setting data

.

.

.

+0.0

.

+0.0

+0.0

+0.0

.

.

-0.0

-0.0

-0.

-0.

-0.

-0.

4

TCD 2015 2.5 mm

Standard

(from the center of the valve head to the

cylinder head sealing surface)

TCD 2015 1.20 - 1.60 mm

Wear limit

(from the center of the valve head to the

cylinder head sealing surface)

P01 37 Valve head diameter (inlet) Standard TCD 2015 46.0 mm

P01 22 Valve seat insert, outside diameter (outlet) Standard TCD 2015 44.0 mm

P01 23 Valve seat insert, outside diameter (inlet) 1. oversize level TCD 2015 47.800 mm

P01 12 Valve guide, external diameter 1. oversize level TCD 2015 15.1 mm

P01 13 Valve guide, external diameter 2. oversize level TCD 2015 15.2 mm

P01 14 Valve guide, inside diameter (inlet) Standard TCD 2015 8.030 mm

P01 15 Valve guide, inside diameter (outlet) Standard TCD 2015 8.030 mm

Valve seat insert

ID no. Name Information Series Value Unit

© 06/2006 8145-001

P01 21 Valve seat insert, outside diameter (inlet) Standard TCD 2015 47.5 mm

P01 24 Valve seat insert, outside diameter (outlet) 1. oversize level TCD 2015 44.300 mm

Valve

P01 31 Valve shaft diameter (inlet) Standard TCD 2015 7.97 mm

5/28

P01 32 Valve shaft diameter (outlet) Standard TCD 2015 7.96 mm

P01 33 Valve shaft clearance (inlet) Wear limit TCD 2015 0.12 mm

P01 34 Valve shaft clearance (outlet) Wear limit TCD 2015 0.14 mm

P01 35 Valve edge thickness, valve head (inlet) Standard TCD 2015 1.9 mm

P01 36 Valve edge thickness, valve head (outlet) Standard TCD 2015 1.5 mm

P01 38 Valve head diameter (outlet) Standard TCD 2015 42.0 mm

Valve seat

P01 45 Valve stand back dimension (inlet)

Page 6

Technical data

+1

+0.

+1

+0.

+0

02

+0

02

0

04

6

Testing and setting data

mm

4

58.7

0

90 °

0.25 mm

0

108 °

0.30 mm

TCD 2015

.

.

0

.

0

-

-0.0

TCD 2015 2.4 mm

Standard

(from the center of the valve head to the

cylinder head sealing surface)

TCD 2015 1.25 - 1.65 mm

Wear limit

(from the center of the valve head to the

cylinder head sealing surface)

TCD 2015

TCD 2015

with cold engine

with rotation angle disc

with feeler gauge

TCD 2015

with cold engine

with rotation angle disc

with feeler gauge

TCD 2015 T01 63 -

Valve overlap according to adjustment

schematic

Valve spring wire diameter 4.25

Valve spring length untensioned, normal

ID no. Name Information Series Value Unit

© 06/2006 8145-001

P01 46 Valve stand back dimension (outlet)

Valve spring

P01 51

Valve clearance

P01 61 Valve clearance (inlet)

6/28

P01 62 Valve clearance (outlet)

P01 63 Valve clearance setting

Rocker arm/bracket

P01 72 Rocker arm, bore, diameter (outlet) TCD 2015 28 mm

P01 73 Rocker arm, bore, diameter (inlet) TCD 2015 28 mm

P01 74 Rocker arm shaft (diameter) TCD 2015 28 mm

P01 75 Axial clearance of the toggle levers Axial bearing clearance with cold engine TCD 2015 0.2 - 0.4 mm

Page 7

10 Rz

0

01

3

+60+0

06

+0

06

+0

06

0

01

3

TCD 2015

20 [Rmax]

16 Rz

20 [Rmax]

Technical data

Testing and setting data

.

.

.

-

-0.0

.

.

-

-0.0

4

Surface for cylinder head gasket TCD 2015

Surface for cylinder head cover TCD 2015

TCD 2015 0.25 each mm

Undersize stage

3 stages

TCD 2015 0.25 each mm

Undersize stage

3 stages

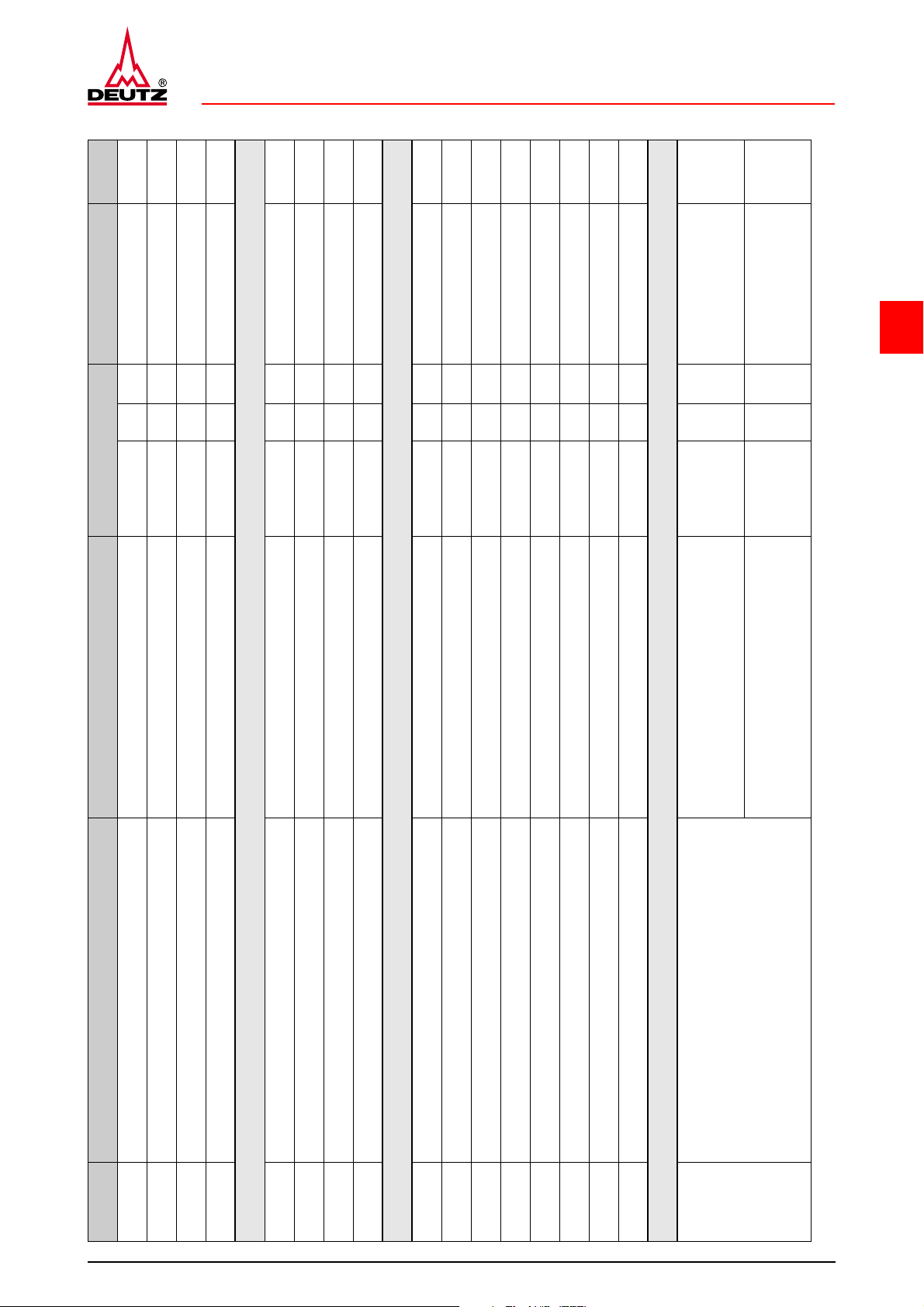

P02 06 Main journal, unroundness Wear limit TCD 2015 0.010 mm

ID no. Name Information Series Value Unit

© 06/2006 8145-001

P01 93 Roughness

Main running gear

Crankshaft

Main journal

P02 03 Main journal, diameter Standard TCD 2015 108 mm

P02 04 Main journal, diameter

P02 07 Main journal, hardness Standard TCD 2015 50 HRC

7/28

Fit journal

P02 11 Fit bearing, width Standard TCD 2015 38 mm

P02 12 Fit bearing, width Oversize stage TCD 2015 38.25 mm

P02 13 Fit bearing, width Limit value for oversize stage TCD 2015 38.50 mm

Lifting journal

P02 22 Lifting journal, diameter TCD 2015 91 mm

P02 23 Lifting journal, diameter

P02 25 Lifting journal, unroundness Wear limit TCD 2015 0.010 mm

P02 26 Radial run-out, crankshaft maximum permissible deviation TCD 2015 0.15 mm

Main bearing

P02 34 Axial clearance of crankshaft permissible TCD 2015 0.205 - 0.392 mm

Page 8

Technical data

+0

05

+0

05

+0

05

+0

0

+0

05

+0

03

0

Testing and setting data

TCD 2015

.

.

.

.

0

4

TCD 2015 3.36 mm

TCD 2015 3.485 mm

max. 0.06 mm

TCD 2015 3.610 mm

TCD 2015

max. 0.10 mm

TCD 2015

TCD 2015 0.04 - 0.063 mm

.

0

TCD 2015 91.048 mm

TCD 2015 0.25 each mm

.

-0.0

TCD 2015 95 mm

TCD 2015 0.060 - 0.136 mm

ID no. Name Information Series Value Unit

Standard

(upper and lower half)

1. oversize stage=0.125 mm

(upper and lower half)

P02 35 Thrust ring half, thickness

P02 36 Thrust ring half, thickness

2. oversize stage=0.125 mm

(upper and lower half)

P02 37 Thrust ring half, thickness

Permissible deviation (a)

at a distance of (x) 100 mm

Permissible deviation (A) to (B)

at a distance of (x) 100 mm

Connecting rod

P02 41 Parallelism of the connecting rod

P02 42 Taper on periphery of the connecting rod

P02 43 Small end bush, inside diameter installed, unmachined TCD 2015 52.040 mm

Small end bush clearance between piston pin

P02 45

and small end bush

P02 46 Assembly temperature of the small end bush cooled in coolant to TCD 2015 approx. -40 °C

after separation and re-assembly of rod

Undersize stage

installed

identification (n) / top

lining spattered

Big end bearing

P02 47 Assembly temperature of the connecting rod heated up in hot-air oven to TCD 2015 max. 220 °C

P02 52 Big end bearing shells, inside diameter

3 stages

P02 54 Big end bearing

and cover

Theoretical clearance between the big end bea-

ring / lifting journal

P02 55 Big end bearing, bore in connecting rod

P02 56

P02 57 Big end bearing clearance Wear limit TCD 2015 0.17 mm

© 06/2006 8145-001

8/28

Page 9

TCD 2015

+0

00

0

+0

00

0

+0

0

1

+0

0

0

Technical data

Testing and setting data

.

-0.0

TCD 2015 132 mm

.

-0.0

TCD 2015 132 mm

.

-0.0

TCD 2015 132 mm

.

+0.0

0.35 - 0.45 mm

TCD 2015

0.9 mm

1.1 - 1.3 mm

1.4 mm

TCD 2015

4

ID no. Name Information Series Value Unit

Piston pin

P02 61 Piston pin, diameter TCD 2015 51.992 - 52.000 mm

P02 62 Piston pin clearance Wear limit TCD 2015 0.09 mm

Measuring point 1

Piston

at height 22.5 mm

(Identification of the installation position

on the piston head)

Measuring point 2

at height 87.5 mm

P02 71 Piston, diameter

P02 72 Piston, diameter

(Identification of the installation position

on the piston head)

Measuring point 3

at height 122.7 mm

(Identification of the installation position

on the piston head)

P02 73 Piston, diameter

P02 75 Piston projection 1.4 = 1 hole (cylinder head gasket) TCD 2015 -0.05 to 0.10 mm

P02 76 Piston projection 1.6 = 2 holes (cylinder head gasket) TCD 2015 0.10 to 0.30 mm

P02 77 Piston projection 1.8 = 3 holes (cylinder head gasket) TCD 2015 0.30 to 0.51 mm

P02 78 Piston pin, bore TCD 2015 52 mm

Piston rings

Wear limit

(identification TOP in direction of piston

Standard

head)

P02 84 Closed gap, piston ring 1

Wear limit

(identification TOP in direction of piston

Standard

head)

P02 85 Closed gap, piston ring 2

© 06/2006 8145-001

9/28

Page 10

Technical data

+0

03

+0

03

+0

05

+0

0

+0

03

+0

2

+0

2

+0.

5

+0.

5

+0

0

+0

0

Testing and setting data

-

.

.

.

.

0

0

0

0

.

4

0.4 - 0.7 mm

1.2 mm

Measure with trape-

zoidal groove wear

gauge

69.990 mm

TCD 2015

0

.

.

-0.2

-0.2

-0.

-0.

0.5 mm

3 mm

.

-0.0

.

-0.0

TCD 2015

Wear limit

Standard

(identification TOP in direction of piston

TCD 2015 75.000 mm

head)

TCD 2015

TCD 2015

First assembly

TCD 2015

Repairs 3.5 mm

Repairs 7 mm

First assembly

Installation depth of the crankshaft sealing ring

Installation depth of the crankshaft sealing ring

Bore diameter for camshaft bearing liner in the

crankcase

P02 89 Axial clearance, 3rd piston ring Wear limit TCD 2015 0.15 mm

ID no. Name Information Series Value Unit

© 06/2006 8145-001

P02 86 Closed gap, piston ring 3

P02 87 Axial clearance, 1st piston ring Wear limit TCD 2015

P02 88 Axial clearance, 2nd piston ring Wear limit TCD 2015 0.25 mm

Crankcase

Camshaft bearing

P03 11

10/28

P03 12 Camshaft bearing liner, outside diameter TCD 2015 75.090 mm

Camshaft bearing liner, inside diameter

Camshaft bearing liner, wall thickness 2.0493 mm

P03 14 Camshaft bearing liner, inside diameter Wear limit TCD 2015 70.100 mm

P03 23 Tappet bores, diameter TCD 2015 25.000 mm

P03 13

P03 24 Tappet bores, diameter Wear limit TCD 2015 25.050 mm

(rear cover)

P03 25

(genset support)

P03 26

Cylinder liners

P03 31 Cylinder bore Standard TCD 2015 132 mm

P03 35 Fitting depth for cylinder liner TCD 2015 9.87 mm

Page 11

TCD 2015

0

+0

0

0

06

7

+0.

Technical data

Testing and setting data

-0.0

.

-0.0

.

-

-0.0

TCD 2015 0.3 mm

TCD 2015 5.000 mm

TCD 2015 0.2 - 0.45 mm

TCD 2015 0.04 - 0.3 mm

TCD 2015 1.0 mm

TCD 2015 0.3 - 0.9 mm

TCD 2015 0.04 - 0.3 mm

4

Tooth edge clearance between gear wheel of the

camshaft for injection pumps and camshaft gear

Clearance between speed governor (cr ankshaft)

Thickness of the gasket for axial clearance set-

ting

Overhang of the parallel pin on the camshaft gear

wheel

Axial clearance of the camshaft for injection

pumps

Tooth edge clearance of the idler gear - idler gear

to camshaft gear wheel

P03 37 Thickness of shim Standard TCD 2015 1.0 mm

P03 36 Collar height of cylinder liner TCD 2015 9.02 mm

ID no. Name Information Series Value Unit

© 06/2006 8145-001

P03 39 Overhang of cylinder liner TCD 2015 0.09 mm

Control system

Camshaft

P04 31 Camshaft bearing pin diameter Standard TCD 2015 70 mm

P04 35 Axial clearance of the camshaft TCD 2015 0.25 - 0.75 mm

P04 37

P04 39

P04 43

11/28

P04 44

Speed governing system

and flywheel

Clearance between speed governor (camshaft)

and camshaft gear wheel

P05 91

P05 92

Fuel system

P07 19 Plunger lift of the camshaft for injection pumps see name plate TCD 2015 4.00 mm

wheel

P07 20

Injection valve

P07 52 Nozzle opening pressure of the fuel injector TCD 2015 280 - 288 bar

Page 12

Technical data

+5

0

+5

0

+5

0

0

3

Testing and setting data

mmfor 3.50 bar 32

TCD 2015

4

35

TCD 2015

TCD 2015 79 °C

500 N

-5

550 N

TCD 2015

-5

350 N

-5

300 N

TCD 2015

-

ID no. Name Information Series Value Unit

P07 91 Installation dimensions of the fuel shut-off valve dimension X TCD 2015 approx. 25 mm

for 3.00 bar

Lubricating oil system

P07 92 Installation angle of the fuel pipe dimension X TCD 2015 approx. 30 °

Lube oil pressure

for 4.00 bar 29.1

Basic setting of the pressurestat when using new

parts

P08 63

Coloured marking black

venting notch top

Cooling system

P09 11 Thermostat, start opening (A-bank)

P09 12 Thermostat, start opening (B-bank) Venting notch top TCD 2015 87 °C

P09 13 Thermostat, stroke distance TCD 2015 at least 8 mm

with V-belt tension measuring device

8115

with V-belt tension measuring device

8115

Check after 15 minutes running under

Tension of the single V-belt (first assembly, gene-

rator, 120 Ampere)

Tension of the single V-belt (first assembly, gene-

rator, 55 Ampere)

Tension of the single V-belt (generator, 120 Am-

Other components

P12 11

load

pere)

P12 21

Check after 15 minutes running under

load

dimension X TCD 2015 60 mm

Tension of the single V-belt (generator, 55 Ampe-

re)

Screw-in height of the flame glow plug in connec-

ting line

P13 66

© 06/2006 8145-001

12/28

Page 13

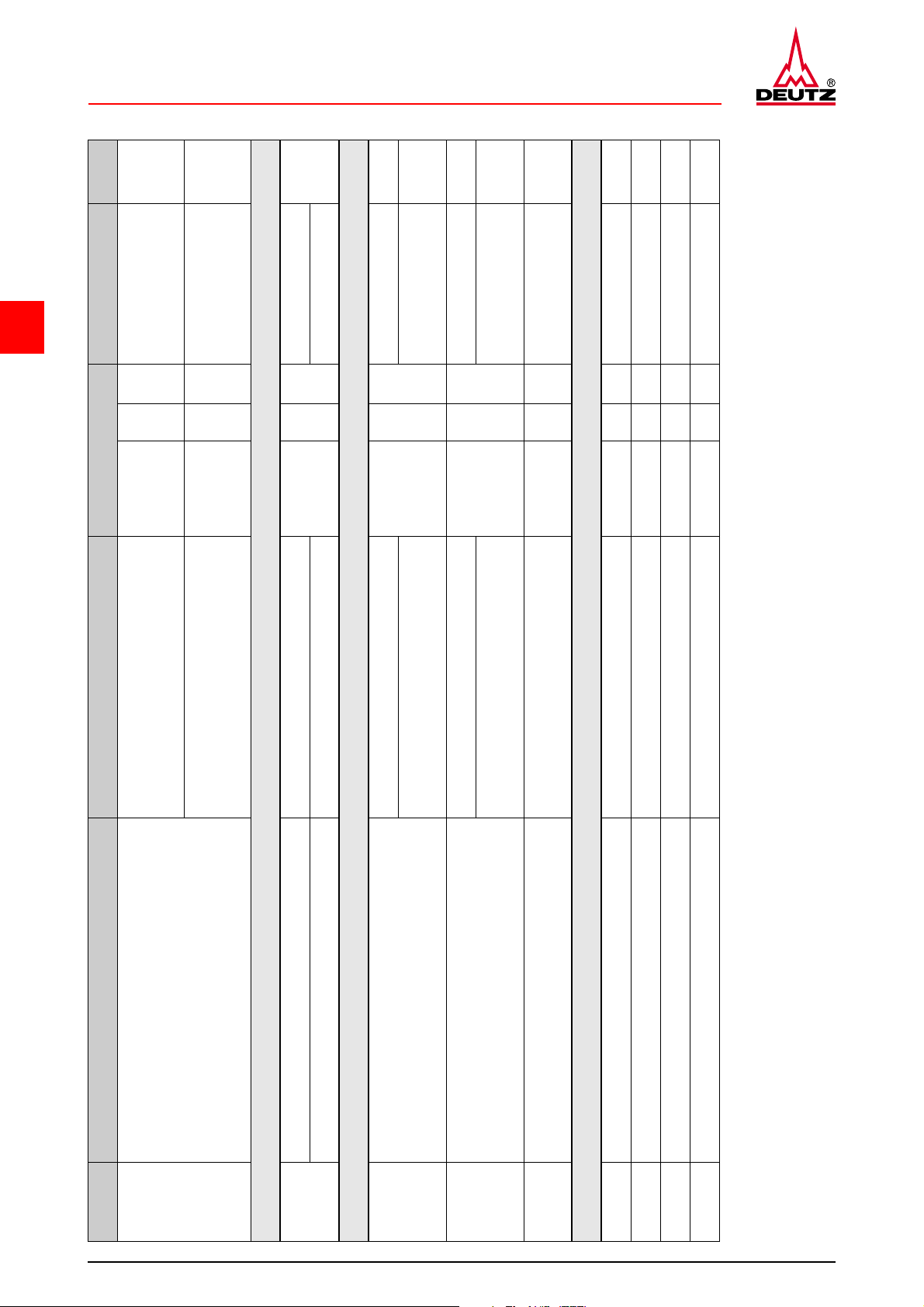

TCD 2015 Testing and setting data

© 45418-0

© 45885-0

© 00000-0

T00 81

Cylinder and side view

engine TCD 2015 V06

A1

Technical data

A3

A2

B3

B2

B1

4

T00 81

Cylinder and side view

engine TCD 2015 V08

T01 63

Setting valve clearance

engine TCD 2015 V06

Ignition sequence: A1-B3-A3-B2-A2-B1

A1

A4

A3

A2

B4

B3

B2

B1

Valve overlap on cylinder

Setting on

cylinder

A1 B2

B3 A2

A3 B1

B2 A1

A2 B3

B1 A3

© 06/2006 8145-001

13/28

Page 14

Technical data

© 00000-0

© 40971-0

© 00000-0

T01 63

Setting valve clearance

engine TCD 2015 V08

Ignition sequence: A1-B4-A4-B1-B3-A3-B2- A2

TCD 2015Testing and setting data

Valve overlap on cylinder

Setting on

cylinder

A1 B3

B4 A3

A4 B2

4

B1 A2

B3 A1

A3 B4

B2 A4

A2 B1

T13 054

Connection plan of the injection pumps

engine TCD 2015 V06

Item Component Cylinder assignment

1Y15.1 A1

2Y15.5 A2

3Y15.3 A3

4Y15.6 B1

1

2

3

5Y15.4 B2

6Y15.2 B3

T13 054

Connection plan of the injection pumps

engine TCD 2015 V08

Item Component Cylinder assignment

Y15.1 A1

Y15.8 A2

Y15.6 A3

Y15.3 A4

Y15.4 B1

Y15.7 B2

Y15.5 B3

Y15.2 B4

4

5

6

© 08/2008 8145-002

14/28

Page 15

TCD 2015

4.2 Tightening specifications

Technical data

4

© 06/2006 8145-001

15/28

Page 16

Technical data

Tightening specifications

TCD 2015

4

© 06/2006 8145-001

16/28

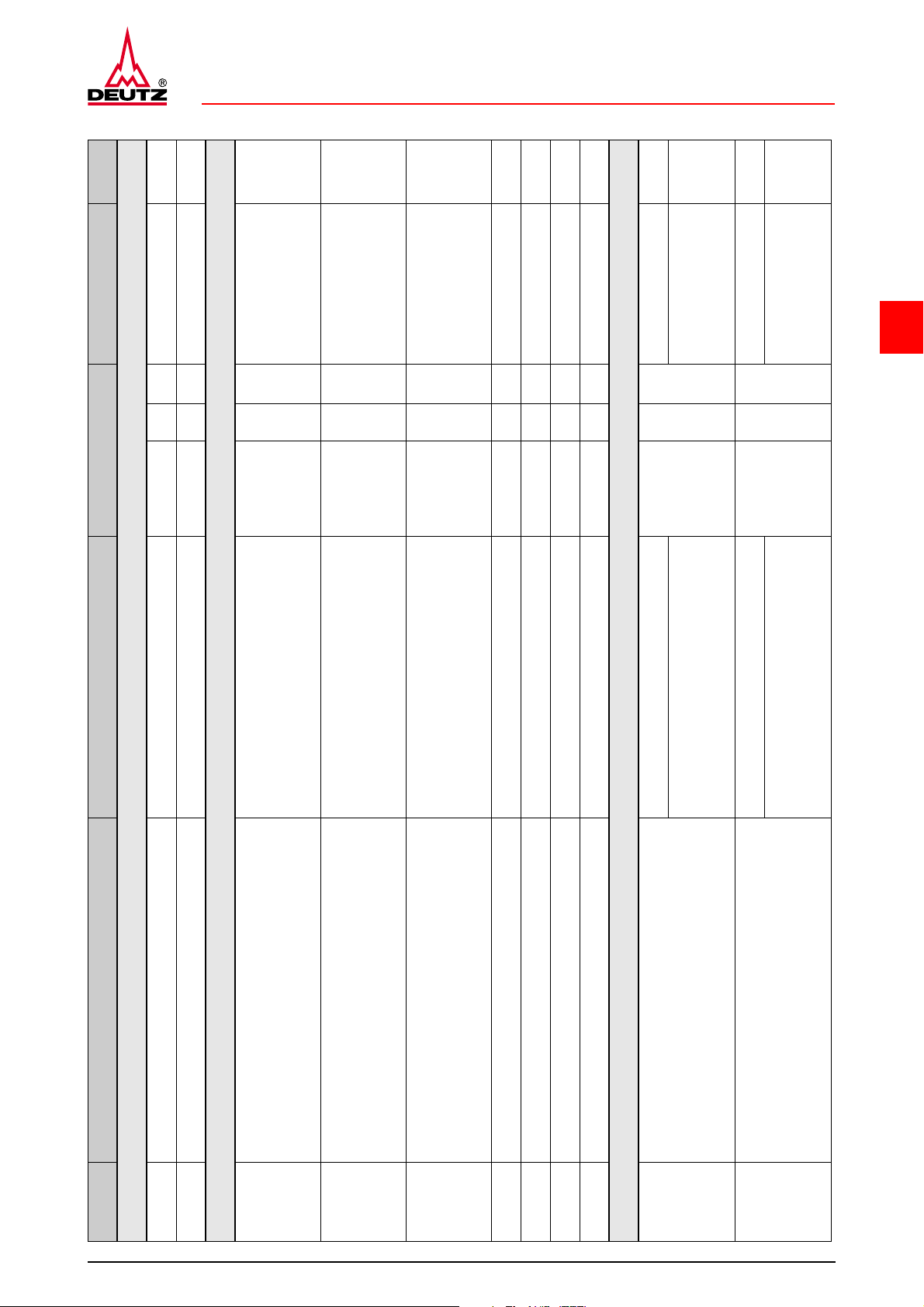

Page 17

Post-

clamping

value

Pre-clam-

ping value

TCD 2015

+120°

+120°

+60°

Technical data

Tightening specifications

+60°

+60°

+30°

+60°

+60°

+120°

4

TCD 2015 106 Nm

Mounting feet/engine moun-

ting on crankcase, elastic

TCD 2015 30 Nm +45°

Mounting feet/engine moun-

ting on crankcase, rigid

oil lightly

elastic TCD 2015 106 Nm

TCD 2015 30 Nm +45°

rigid

oil lightly

TCD 2015 50 Nm

Screw can be used a

max. 3 times, otherwise re-

new every time they are loo-

sened.

Oil lightly

TCD 2015 22 Nm

oil lightly

hexagonal socket

TCD 2015 50 Nm

Screws can be used a

max. 3 times, otherwise re-

new every time they are loo-

sened.

Screws with

washers

Oil lightly

ID no. Name Screw type Notes / Remarks Series

© 06/2006 8145-001

A00 001 Clamping bracket on crankcase

A00 002 Clamping bracket on adapter for assembly block TCD 2015 90 Nm

A00 003 Mounting feet/engine mounting on crankcase

A01 001 Cylinder head on crankcase

17/28

A01 002 Rocker arm bracket on cylinder head TCD 2015 61 Nm

A01 003 Lock nut valve clearance setting screw TCD 2015 20 Nm

A01 004 Cylinder head cover on cylinder head oil lightly TCD 2015 22 Nm

A01 005 Cylinder head cover on cylinder head hood M8x30

A02 001 Counterweight on crankshaft oil lightly TCD 2015 50 Nm

A02 010 Main bearing cover, vertical screws

Page 18

Technical data

Tightening specifications

+60°

Post-

clamping

value

+30°

+30°

+60°

TCD 2015

Pre-clam-

ping value

24 Nm

120 Nm

30 Nm

30 Nm

20 Nm

4

TCD 2015

TCD 2015 80 Nm

Screws can be used a

max. 3 times, otherwise re-

new every time they are loo-

sened.

TCD 2015 50 - 60 Nm

Renew screws every time

they are loosened.

TCD 2015 21 Nm

Insert with locking agent

DEUTZ DW 59

TCD 2015 28 Nm

Gasket steel beading

Observe tightening order

TCD 2015

(Railway)

TCD 2015

oil lightly TCD 2015 120 Nm

(Railway)

TCD 2015

(Railway)

TCD 2015

(Railway)

(Railway)

Breather pipe (holder) on cable harness rail TCD 2015 20 Nm

Pipe (crankcase breather) on cable harn e ss ra il

A03 010 Rear cover on crankcase

ID no. Name Screw type Notes / Remarks Series

© 06/2006 8145-001

A02 011 Main bearing cover, horizontal screws

A02 020 Big end bearing cover on connecting rod

A03 020 Genset support on crankcase M10 TCD 2015 55 Nm

A03 030 Lubricating oil pan on crankcase

18/28

A03 031 Oil drain plug on lubricating oil pan

A03 034 Half-flange on connecting flange M8x30-10.9

A03 035 Connecting flange on lubricating oil pan M10x20-10.9

A03 051 Valve housing (pressurestat) on crankcase oil lightly TCD 2015 50 Nm 210 Nm

A03 060 Crankcase breather Pipe clamp TCD 2015 8 Nm

A03 064 Breather pipe on intake elbow/oil separator Hose clip TCD 2015 6.5 Nm

A03 069

Page 19

Post-

clamping

value

TCD 2015

+30°

+30°

+60°

+60°

+60°

+60°

+60°

+60°

Technical data

Tightening specifications

+90°

Pre-clam-

ping value

TCD 2015

6.5 Nm

(Railway)

TCD 2015 30 Nm

Insert with locking agent

TCD 2015 30 Nm

Insert with locking agent

DEUTZ DW 59

TCD 2015 21 Nm

Insert with locking agent

DEUTZ DW 59

DEUTZ DW 59

TCD 2015 30 Nm

Insert with locking agent

DEUTZ DW 59

TCD 2015 30 Nm

DEUTZ DW 59

oil lightly TCD 2015 50 Nm +150°

Insert with locking agent

TCD 2015 22 Nm

Insert with locking agent

DEUTZ DW 72

Fastening screw for diverter

4

TCD 2015 8.5 Nm

stopper

Central screw for camshaft gear wheel on cams-

haft

A03 080 Connection housing on lubricating oil pan TCD 2015 70 Nm

ID no. Name Screw type Notes / Remarks Series

© 06/2006 8145-001

A03 070 Pipe (cr ankc as e breather ) Hose clip

A03 081 Connection housing to crankcase M12x1.5x35

A03 082 Connection housing to crankcase M12x1.5x90

A03 085 Cover on connection housing M8x16

A03 088 Connection housing to crankcase M12x190

A03 089 Connection housing to crankcase M12x175

19/28

A04 001

A04 002 Stop cover (camshaft) on crankcase

A04 004 Gear wheel on camshaft for injection pumps TCD 2015 30 Nm +30°

A04 003 Camshaft gear wheel on idler gear oil lightly TCD 2015 30 Nm

A04 005 Plug of injection pump camshaft on crankcase

A04 011 Fastening screw for idler gear on genset support TCD 2015 80 Nm

A04 012 Screw plug for bolt idler gear oil lightly TCD 2015 79 Nm

A04 015 Pad thrust bearing on crankcase oil lightly TCD 2015 30 Nm

A04 013 Screw for bolt idler gear M12x100 oil lightly TCD 2015 70 Nm

Page 20

Technical data

Tightening specifications

Post-

clamping

value

TCD 2015

Pre-clam-

ping value

21 Nm

35 Nm

10 Nm 35 Nm

5 Nm

4

TCD 2015

TCD 2015 21 Nm

TCD 2015

(Railway)

TCD 2015 20 Nm

Insert with locking agent

TCD 2015 8 Nm

DEUTZ DW 72

TCD 2015 60 Nm

Insert with fitting compound

TCD 2015 22 Nm

DEUTZ S1

Insert with fitting compound

DEUTZ S1

Insert with fitting compound

TCD 2015 18 Nm

DEUTZ S1

TCD 2015 35 Nm

TCD 2015

TCD 2015

(Railway)

Insert with fitting compound

DEUTZ S1

(Railway)

Insert with fitting compound

DEUTZ S1

TCD 2015 5 Nm

Hose clip

housing position of the hose

clip top

screw head rear

(Railway)

ID no. Name Screw type Notes / Remarks Series

M8x35

M8x45

Speed governor on connection housing (cranks-

haft)

A04 020 Gear case cover on crankcase

A04 022 Cover (stop cover) on crankcase

A05 012 Speed governor on cover (camshaft) TCD 2015 8 Nm

A05 011

A06 001 Exhaust pipe at cylinder head

A06 002 Exhaust pipe on exhaust manifold

A06 003 Exhaust pipe on exhaust line Nut

Nut

Exhaust manifold to connection housing TCD 2015 28 Nm

Exhaust manifold to exhaust line

A06 010

A06 020 Exhaust turbocharger to exhaust manifold

A06 021 Intake elbow to exhaust turbocharger

A06 024 Tubing connection to turbocharger Hose clip

© 06/2006 8145-001

20/28

Page 21

Post-

clamping

value

TCD 2015

Technical data

Tightening specifications

Pre-clam-

ping value

TCD 2015 60 Nm

TCD 2015 20 Nm

20 Nm

TCD 2015

(Railway)

20 Nm

TCD 2015

(Railway)

20 Nm

TCD 2015

TCD 2015 20 Nm

20 Nm

TCD 2015

(Railway)

TCD 2015 70 Nm

without leak oil

Insert with fitting compound

TCD 2015 40 - 50 Nm

DEUTZ S1

4

ID no. Name Screw type Notes / Remarks Series

M10 x 85

Charge air pipe to cylinder head TCD 2015 20 Nm

A06 030

Charge air pipe to air intake pipe

M10 x 65

Nut

A06 033 Connection pipe to air intake pipe

Joint plate on connecting pipe TCD 2015 57 Nm

Holder on exhaust manifold

A06 034

Nut

A06 038 Screw plug on charge air pipe TCD 2015 34 Nm

Stud 4.5 Nm

A06 046 Connecting elbow to charge air pipe

Nozzle cap

A06 056 Connecting pipe to holder

A06 058 Retaining plate on genset support TCD 2015 20 Nm

A07 001 Fuel injector on cylinder head Union screw

nut

A07 002 Injection nozzle on fuel injector

A07 003 Injection line on fuel injector/injection pump Union nut TCD 2015 25 Nm

A07 006 Pipe clamp for injection pipe M6x12 TCD 2015 10 Nm

A07 009 Injection pump housing on crankcase oil lightly TCD 2015 60 Nm

A07 012 Injection pump on injection pump housing oil lightly TCD 2015 60 Nm

© 06/2006 8145-001

21/28

Page 22

Technical data

Tightening specifications

Post-

clamping

value

TCD 2015

Pre-clam-

ping value

25 Nm

8.5 Nm

50 Nm

7.5 Nm

42 Nm

39 Nm

4

TCD 2015

TCD 2015 25 Nm

TCD 2015

(Railway)

TCD 2015 42 Nm

TCD 2015

(Railway)

TCD 2015

TCD 2015 8.5 Nm

Pipe clamp/holder

oil thread and head contact

surface.

(Railway)

(Railway)

TCD 2015 42 Nm

TCD 2015

(Railway)

TCD 2015 39 Nm

TCD 2015

(Railway)

ID no. Name Screw type Notes / Remarks Series

Bearing housing (fuel supply pump) to genset

support

A07 015 Fuel pipe to injection pump housing

A07 018 Fuel pipe to fuel shut-off valve (flame flow plugs) Union nut TCD 2015 20 Nm

A07 023 Temperature transmitter on connector TCD 2015 22 Nm

A07 024

Fuel pipe fastening

A07 034 Fuel line on fuel supply pump Hollow screw TCD 2015 max.35 Nm

Union nut

Connector (fuel pressure holding valve) to fuel

A07 066

pipe

A07 067 Overflow valve on connector

A07 068 Screw-in nipple on fuel shut-off valve TCD 2015 18 Nm

Fuel pipe fastening Pipe clamp

A07 044

A07 057 Adapter (flame glow plug) on charge air pipe M45x1.5 SW50

A07 059 Flame glow plug to connecting pipe Lock nut TCD 2015 25 Nm

A07 058 Ground cable on lock nut (flame glow plug)

© 06/2006 8145-001

22/28

Page 23

Post-

clamping

value

TCD 2015

Technical data

Tightening specifications

Pre-clam-

ping value

TCD 2015

42 Nm

(Railway)

Pipe clamp TCD 2015 20 Nm

TCD 2015 40.5 Nm

Oil thread and head contact

TCD 2015 21 Nm

Oil thread and head contact

surface.

surface.

22 Nm

TCD 2015

(Railway)

TCD 2015 22 Nm

22 Nm

TCD 2015

(Railway)

TCD 2015 22 Nm

22 Nm

TCD 2015

(Railway)

4

TCD 2015 39 Nm

ID no. Name Screw type Notes / Remarks Series

Fuel shut-off valve (flame glow plug) on crankca-

se (thermostat housing)

A07 093

A07 069 Screw-in nipple on overflow valve M16x1.5

A08 002 Adapter on oil filter nozzle (genset support TCD 2015 50 Nm

A08 011 Plug on oil pump

A08 010 Oil pressure pump on genset support

A08 013 Lubricating oil pipe to genset support Hollow screw TCD 2015 18 Nm

A08 014 Lubricating oil pipe to fuel supply pump Union nut TCD 2015 20 Nm

M8x16 TCD 2015 22 Nm

M8x20

A08 015 Oil suction intake pipe on oil pump

M8x25

Holder oil suction pipe on retaining plate (main

bearing cover)

A08 016

M8x16

Holder on oil suction pipe

A08 038 Screw-in nipple (guide tube) on lubricating oil pan TCD 2015 45 Nm

A08 035 Guide tube on screw-in nipple (lubricating oil pan Union nut TCD 2015 30 Nm

Union nut

M14 x 1.5

A08 040 Lubricating oil pipe on exhaust turbocharger

© 06/2006 8145-001

23/28

Page 24

Technical data

Tightening specifications

Post-

clamping

value

TCD 2015

+30°

+60°

+60°

Pre-clam-

ping value

20 Nm

20 Nm

20 Nm

20 Nm

4

TCD 2015 20 Nm

TCD 2015

(Railway)

TCD 2015

(Railway)

TCD 2015 20 Nm

TCD 2015 28 Nm

TCD 2015

Holder of pipe clamp (fuel

pipe)

TCD 2015 50 Nm

Renew screws after every

loosening.

Oil lightly

oil lightly TCD 2015 30 Nm +120°

Oil pressure pipe on gear case cover Pipe clamps TCD 2015 8.5 Nm

Oil pressure pipe on genset support Pipe clamp

ID no. Name Screw type Notes / Remarks Series

© 06/2006 8145-001

A08 044 Oil return pipe to turbocharger/crankcase

A08 045

A08 050 Oil cooler housing cover on genset support TCD 2015 20 Nm

A08 051 Oil cooler on genset support TCD 2015 20 Nm

Holder (lubricating oil pipe) on genset support/

gear case cover

Relief valve of piston cooling nozzle on crankca-

se

A08 071 Screw plug on valve housing (pressurestat) Hexagon socket head TCD 2015 180 Nm

A08 079

A08 081

24/28

A08 091 Oil pressure pick-up on oil cooler housing M14 x 1.5 TCD 2015 20 Nm

Thermostat housing on crankcase

Holder on thermostat housing

A09 001

A09 002 Outlet branch on thermostat housing TCD 2015 20 Nm

A09 010 Coolant pump on genset support oil lightly TCD 2015 21 Nm

A09 011 Inlet adapter on coolant pump oil lightly TCD 2015 20 Nm

A09 031 Temperature transmitter on thermostat housing TCD 2015 22 nm

A12 001 Flywheel on crankshaft M16x70

Flanged hub (torsional vibration damper) on

A12 030

crankshaft

Page 25

Post-

clamping

value

Pre-clam-

ping value

TCD 2015

20 Nm

TCD 2015

(Railway)

TCD 2015 39 Nm

Technical data

Tightening specifications

45 Nm

TCD 2015

(Railway)

TCD 2015 13 Nm

18 Nm

TCD 2015

(Railway)

TCD 2015 39 Nm

TCD 2015 40 Nm

8.5 Nm

4

TCD 2015

oil lightly TCD 2015 30 Nm

M10x55 oil lightly TCD 2015 30 Nm +60°

M10x110 oil lightly TCD 2015 30 Nm +120°

M10x210 oil lightly TCD 2015 30 Nm +180°

M8x16-8.8 TCD 2015 18 Nm

Pipe union with ring piece,

pipe 6 mm

Hollow screw

M10x1

Breather pipe on oil cooler

cover

Fule pipe on fuel pressure

Hollow screw

M14x1.5

holding valve

V-belt pulley/torsional vibration damper on flan-

ged hub

Bearing housing (hydraulic pump drive) on crank-

case

Flange housing on bearing housing (hydraulic

pump drive)

Flange housing on bearing housing (hydraulic

pump drive)

ID no. Name Screw type Notes / Remarks Series

© 06/2006 8145-001

A12 031

A12 057

A12 058

A12 059

Holder on gear case cover

Heat shield on holder (gear case cover) M8x16-10.9 TCD 2015 20 Nm

A12 071

A12 080 Fuel pipe on flame glow plug Union nut TCD 2015 20 Nm

25/28

A12 082 Oil pressure pipe Union nut

Fuel hose to connector (overflow valve/fuel shut-

off valve)

A12 090

A12 092 Hollow screw pipe union with ring piece

A12 093 Hollow screw pipe union M16x1.5

Pipe clamps, fuel pipe to connecting pipe M6

Fuel hose to air intake pipe Pipe clamp 8.5 Nm

Clip (cable) on holder (central plug) M8 18 Nm

A12 095

Page 26

Technical data

Tightening specifications

+60°

Post-

clamping

value

+60°

TCD 2015

Pre-clam-

ping value

30 Nm

45 Nm

5 Nm

5 Nm

4

TCD 2015 1.0 Nm

TCD 2015

TCD 2015

(Railway)

TCD 2015

(Railway)

TCD 2015 70 Nm

TCD 2015 hand tight 42 Nm

TCD 2015 max. 5 Nm

TCD 2015

(Railway)

TCD 2015 9 Nm

(Railway)

ID no. Name Screw type Notes / Remarks Series

Screw-in nipple (lubricating oil pipe) on exhaust

turbocharger

A12 096 Breather pipe on holder Pipe clamp

A12 098

A13 001 Starter on crankcase Nut TCD 2015 30 Nm

M12x22

M12x28

A13 006 Heat shield (starter) on crankcase

A13 012 Generator on plate (console) TCD 2015 hand tight 20 Nm

Screw

A13 015 Generator on console TCD 2015 hand tight 20 Nm

lock nut

A13 017 Lock nut (V-belt) on generator holder

A13 018 Generator holder on genset support TCD 2015 42 Nm

A13 035 Cable to flame glow plug Nut M5

A13 037 Cable to pre-heating relay Nut M4 TCD 2015 2 Nm

Pressure sensor/temperature transmitter on con-

necting pipe

A13 038 Cable to pre-heating relay Nut M6 TCD 2015 7.5 Nm

A13 046

A13 054 Cable to injection pump

© 06/2006 8145-001

26/28

Page 27

Post-

clamping

value

TCD 2015

Technical data

Tightening specifications

Pre-clam-

ping value

20 Nm

TCD 2015 18 NmM8TCD 2015

(Railway)

8 Nm

TCD 2015

(Railway)

70 Nm

TCD 2015

(Railway)

4

ID no. Name Screw type Notes / Remarks Series

M8 x 20

M8 x 16

A13 090 Cable harness holder to connecting pipe

M6x12

M6 TCD 2015 7.5 Nm

A13 094 Cable harness rail on holder

M6x16

A13 098 Holder (cable harness) on connection housing

© 06/2006 8145-001

27/28

Page 28

Technical data

Tightening specifications

TCD 2015

4

© 06/2006 8145-001

28/28

Loading...

Loading...