Model 1600-N1P

Model 6400-N1P

NEMA 1 Control Panel

Operator’s Installation and Instruction Manual

The Woodlands, Texas 77387

Ph.281.367.4100 / Fax 281.298.2868

Sept 27, 2007 • Document #3352 • Revision 1.1

DETCON, Inc.

3200 Research Forest Dr.,

www.detcon.com

1600/6400-N1P

This page left intentionally blank

1600/6400-N1P- Instruction Manual ii

1600/6400-N1P

Table of Contents

1.0 Description................................................................................................................................................ 1

2.0 System Configuration.............................................................................................................................. 2

3.0 Installation................................................................................................................................................ 3

3.1 Installing the I/O Modules.................................................................................................................... 6

3.2 Connecting to the I/O Modules ............................................................................................................ 6

4.0 Start-Up.................................................................................................................................................... 9

4.1 Applying Power.................................................................................................................................... 9

4.2 Setting Device Identification on the I/O Modules................................................................................ 9

5.0 Operator Interface................................................................................................................................. 10

5.1 Using the Touch-screen Display ........................................................................................................ 10

5.2 Main Display...................................................................................................................................... 10

5.3 Program Menu Selections .................................................................................................................. 12

5.3.1 Select # Active Channels and Relays.............................................................................................................12

5.3.2 Modbus™ Addressing and Relay Type.........................................................................................................12

5.3.3 Select Gas Type and Range ...........................................................................................................................16

5.3.4 Set Active Alarm Levels................................................................................................................................16

5.3.5 View Alarm History.......................................................................................................................................17

5.3.6 View Tag Information....................................................................................................................................17

5.3.7 Edit Date and Time........................................................................................................................................18

5.3.8 4-20mA Output Setup....................................................................................................................................18

5.3.9 View Channel History....................................................................................................................................19

5.4 Touch Screen Utilities........................................................................................................................ 20

5.5 Dipswitch Settings.............................................................................................................................. 20

6.0 Password Protection.............................................................................................................................. 20

7.0 Secondary Modbus™ Port.................................................................................................................... 21

8.0 System Expansions................................................................................................................................. 25

9.0 Troubleshooting..................................................................................................................................... 25

10.0 Spare Parts............................................................................................................................................. 25

11.0 Specifications.......................................................................................................................................... 26

12.0 Warranty................................................................................................................................................ 27

13.0 1600/6400-N1P Configuration .............................................................................................................. 27

14.0 Appendix................................................................................................................................................. 29

14.1 RS-485 System Integration Wiring.................................................................................................... 29

14.2 Hexadecimal Table............................................................................................................................. 34

14.3 Drawings ............................................................................................................................................ 35

Table of Figures

Figure 1 Block Diagram....................................................................................................................................... 1

Figure 2 System Configurations........................................................................................................................... 2

Figure 3 Unit Mounting and Dimensional............................................................................................................ 3

Figure 4 No Comm. Fault Relay and Serial Communications PCB’s.................................................................. 4

Figure 5 Interconnect Wiring Diagram................................................................................................................ 5

Figure 6 I/O Module Installation .......................................................................................................................... 6

Figure 7 Model DA-4 and 4-20mA Gas Sensors ................................................................................................. 6

Figure 8 Modbus™ Gas Sensor Connections....................................................................................................... 7

Figure 9 Model RL-4 Relay Module.................................................................................................................... 7

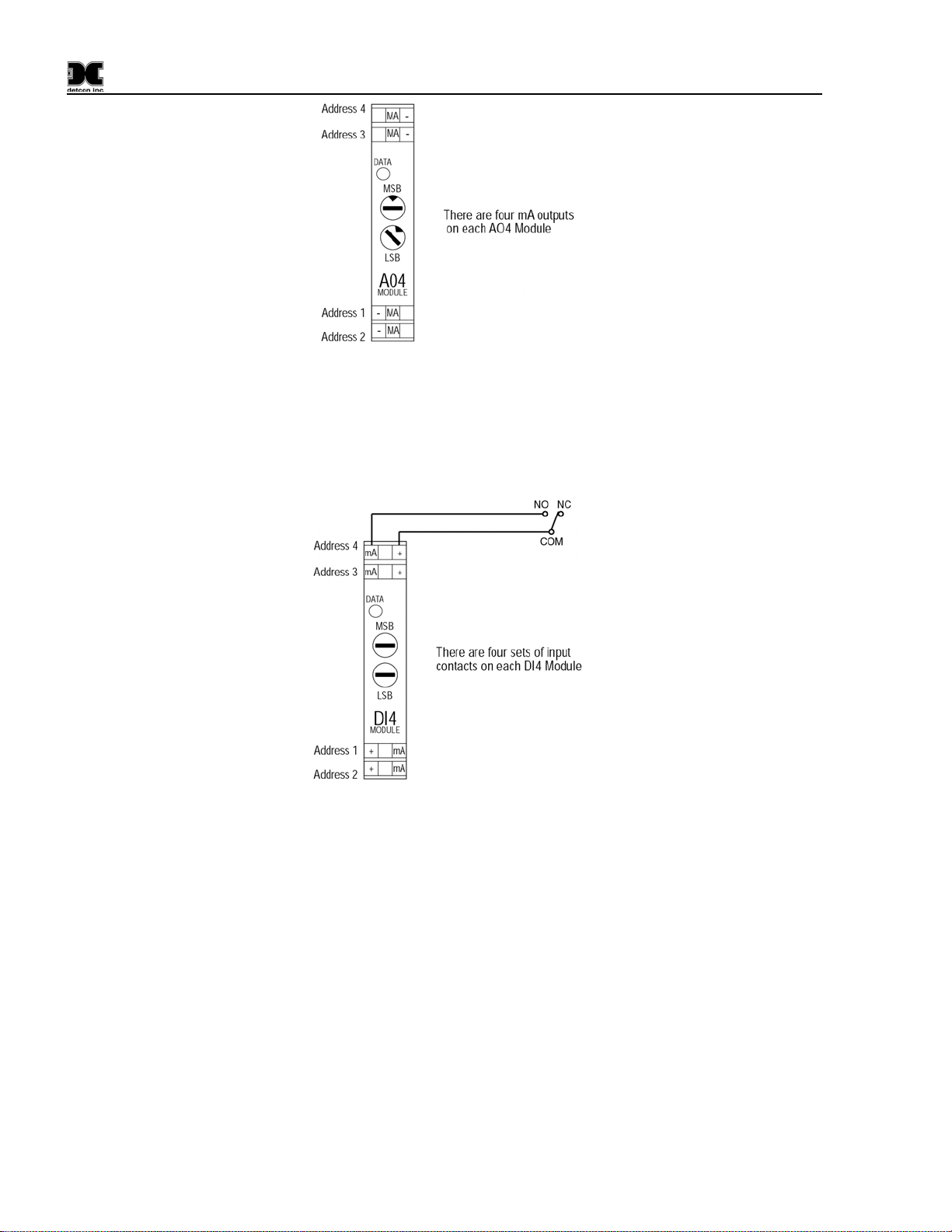

Figure 10 Model AO-4 Module............................................................................................................................ 8

1600/6400-N1P- Instruction Manual iii

1600/6400-N1P

Figure 11 Model DI-4 Module............................................................................................................................. 8

Figure 12 Power In............................................................................................................................................... 9

Figure 13 Setting Device Addresses................................................................................................................... 10

Figure 14 Main Display...................................................................................................................................... 11

Figure 15 Program Menu ................................................................................................................................... 12

Figure 16 Set # Active Channels and Relays ..................................................................................................... 12

Figure 17 Addressing DA Modules.................................................................................................................... 13

Figure 18 Addressing Gas Channels .................................................................................................................. 13

Figure 19 Addressing Relay Modules................................................................................................................ 15

Figure 20 Addressing & Set-up of Relay Outputs.............................................................................................. 15

Figure 21 Select Gas Type ................................................................................................................................. 16

Figure 22 Set Alarm Level................................................................................................................................. 16

Figure 23 View Alarm History........................................................................................................................... 17

Figure 24 View Tag Information........................................................................................................................ 18

Figure 25 Set Time and Date.............................................................................................................................. 18

Figure 26 Set-up 4-20mA Outputs..................................................................................................................... 19

Figure 27 View Channel History........................................................................................................................ 19

Figure 28 Screen Utilities...................................................................................................................................20

Figure 29 Non-Protected vs. protected............................................................................................................... 21

Figure 30 Dip-switches ...................................................................................................................................... 21

Figure 31 RTU Addressing ................................................................................................................................ 22

Figure 32 RS-485 Bus with 4 transceiver chips................................................................................................. 29

Figure 33 Correct and incorrect wiring schemes................................................................................................ 30

Figure 34 Unbalanced Data Bus......................................................................................................................... 31

Figure 35 Data Bus using two repeaters............................................................................................................. 31

Figure 36 Daisy Chain wiring diagram.............................................................................................................. 32

Figure 37 Unbalanced Data Bus......................................................................................................................... 32

Figure 38 Four repeater Data Bus ...................................................................................................................... 33

Figure 39 Wire length vs. data speed ................................................................................................................. 33

Figure 40 Unit Dimensional............................................................................................................................... 35

Figure 41 Component Layout............................................................................................................................. 36

Figure 42 Interconnect Wiring........................................................................................................................... 37

1600/6400-N1P- Instruction Manual iv

1600/6400-N1P

1.0 Description

The Detcon Models 1600-N1P and 6400-N1P is a “user-configurable” multi-channel alarm controller

platforms. The 1600 is configurable for up to 16 channels. The 6400 is configurable for up to 64 channels.

They can receive analog inputs consisting of either 4-20mA or contact closure, and can alternatively poll serial

sensors via RS-485 Modbus™ RTU.

The 1600-N1P and 6400-N1P controllers use a modular design approach that allows the user to customize the

selection of stand-alone input and output modules. I/O modules are available in four channel sets for 4-20mA

inputs, contact closure input, relay outputs, and 4-20mA outputs. Detcon’s I/O Modules are din-rail mounted

and stackable allowing for seamless system expansion. These addressable I/O modules can be located

remotely near the gas sensors to simplify wiring.

The status of sensor inputs are displayed on a backlit graphic display that utilizes a touch-screen user interface.

Typical sensor status includes channel number, tag name, gas type, concentration, and alarm/fault status. Each

input channel can be assigned up to three alarm levels and fault. A standard RS-485 or optional RS 232 serial

output is provided for communication with PLC’s, PC’s, monitoring devices, and remote screens.

The controller can be powered by 110/220VAC, 11.5-30VDC, or both. The enclosure is rated for NEMA 4

locations. Remote mounted gas sensors (purchased separately) can include serial or 4-20mA input devices

such as; toxic gas, combustible gas, or oxygen deficiency sensors or contact closure inputs such as liquid level,

temperature, pressure, heat, smoke, pull station, etc. Additional features include: one-touch Alarm Inhibit,

Alarm Reset, and Alarm Silence (Acknowledge) functions. An Alarm Reset Switch is also mounted on the

outside of the enclosure on the left side. The Model 1600/6400-N1P controllers have onboard data logging to

record all alarm, fault, maintenance, and trend history.

The Model 1600/6400-N1P controller provides for a unique combination of user programming flexibility and

customizable expansion capability, in a low-cost and simple-to-operate package.

RS-485/RS-232

to Master Control

System, DCS, PC, etc.

The 1600 will only handle a

maximum of 16 channels.

Model 6400-N1P

Multi-Channel Gas Detection Control System

Alarm 1

Alarm 2

Alarm 3

Fault

Power Input

Sensor 1

Sensor 2

Sensor 3

Sensor . . .

Sensor 62

Sensor 63

Sensor 64

Figure 1 Block Diagram

1600/6400-N1P- Instruction Manual Rev. 1.1 Page 1 of 38

1600/6400-N1P

2.0 System Configuration

Hardware Configurations

The Model 1600/6400-N1P is a “user configurable” alarm controller platform. The basic 1600/6400-N1P

Controller includes the NEMA 1 panel enclosure with Controller Module (including display), Power Supply,

AC and DC breakers, AC and DC over-voltage protection modules, and an RS-485 Isolated Repeater. NOTE:

The I/O modules are factory installed unless specifically instructed otherwise. A maximum of two I/O

modules will fit on the standard N1P enclosure. I/O Modules are purchased separately.

The available Detcon I/O modules include:

Model DA-4 – Four channel analog 4-20mA input module

Model RL-4 – Four channel relay output module

Model AO-4 – Four channel analog 4-20mA output module

Model DI-4 – Four channel contact input module

Detcon I/O modules are individually addressable and operate on 11.5-30 VDC. Each module communicates

with the controller via the RS-485 Modbus™ RTU protocol. Up to eight I/O modules can be mounted in the

main NEMA 4X enclosure; other modules should be mounted in separate enclosures. In many cases,

customers find it more convenient to mount the Model RL4 relay modules in the 1600/6400-N1P enclosure,

with the Model DA4 input modules mounted remotely, in a separate enclosure, near the gas sensors. This

simplifies the wiring between the gas sensors and the Controller. The following figure shows the typical

configurations of the 1600/6400-N1P controllers.

Figure 2 System Configurations

Programming Configuration

The 1600/6400 controllers are normally configured at Detcon based on application specific information

provided by the customer on the Configuration Form (See Section

quantity and type of I/O modules have been purchased to support the customer’s configuration requirements.

On the Configuration Form, the customer should supply all site-specific information pertaining to:

1600/6400-N1P- Instruction Manual Rev. 1.1 Page 2 of 38

13.0). It must be verified that the correct

1600/6400-N1P

1) Number of gas channels

2) Range, units and gas type for each channel

3) Alarm level(s) for each gas channel

4) Tag Name for each channel

5) Assignment and set-up information for each relay contact

NOTE: The set-up configuration is fully field-programmable and can easily be executed by the user in the

field by following the instructions within this Operators Manual. Modifications to the set-up configuration are

expected to take place at the customers site due to requirement changes and/or system expansions.

3.0 Installation

Securely mount the Model 1600/6400-N1P enclosure in a suitable panel opening. The recommended opening

cut-size is 9”W X 7.25”H and the required depth is 14”.

0.375"

10.5"

9.75"

0.218"

Slot Detail

R0.109"

Model 6400-N1P

Multi-Channel Gas Detection Control System

PLUGTRUBPLUGTRUB

5A

2A

I

3.5"

8"

I

O

O

C

NC

NO

RS-485 VDC

RESET

Ground

24VDC

VAC (L1)

Data Data

B&B

B

A

+

Figure 3 Unit Mounting and Dimensional

Connect 110/220VAC input wiring to the terminals labeled “ACV (L1)”, “Neutral (L2)”, and “Ground” (See

Figure 5). The Power Supply is capable of handling AC inputs from 100-240VAC 50-60Hz without

degradation.

If applicable, connect 24 VDC to the terminals labeled “24VDC” and “DC Comm”, in

Figure 5. This input

can be used for primary power or back-up power in the event of AC power failure.

Where applicable, connect the RS-485 wiring from remotely located I/O devices to the terminals located on

the Back Panel. These terminals are labeled RS-485 “A” (+), “B” (–), and “Shld” (shield) for primary RS-485

communication (

Figure 5). RS-485 wiring should consist of a two conductor, shielded twisted pair (Belden

cable P/N 9841 is recommended). Also available are two output terminal blocks to provide 24VDC to external

RS-485 devices. This power should be used only to power remotely located I/O modules and/or sensors, and

should not exceed a total of 3-3.5Amps accumulative for all I/O modules and sensors attached to the

controller. (I.E. if there are two modules mounted on the enclosure that have an accumulative current draw of

0.5Amps, the sensors qnd/or I/O modules connected to the output 24VDC should not exceed 3.0Amps.) Refer

to each module and sensor manual for maximum expected current draw from each.

1600/6400-N1P- Instruction Manual Rev. 1.1 Page 3 of 38

1600/6400-N1P

WARNING: Do not attach more devices to the controller power supply than the power supply has the

capacity for, as damage may occur to the controller and the warranty will be void. Modules and

sensors attached to the unit that exceed this power rating should be powered by an external power

supply capable of handling the extended load.

The secondary serial RS-485 port from the controller can be connected to a PLC, PC/HMI, DCS, or other

Modbus™ master polling serial communications device, refer to Section

7.0 Secondary Modbus™ Port.

Optionally, (the RS-485 output is standard, but can be replaced with the optional RS-232) connect the RS-232

output wiring to the D-sub connector located on the optional RS-232 Serial Communications PCB. (Refer to

Figure 4.) Use standard RS-232 cable and D-Sub connector. This serial output may be connected to a PC or

external serial printer.

J3

SBA

RS-485

RS-485

PCB

Secondary

Port

A

B

S

RS-485

Input Port

RS-232

Output Port

J2

(Optional) RS-232

Serial Communications

PCB

500-003053-001

No Comm

Fault Relay PCB

500-005081-000

Relay

CNONC

J1

Relay Contact connections

are brought out to the

Terminal Block via J1

Primary

Port

S

B

Input Output

A

J3 J7

Serial Communications

500-003054-000

Figure 4 No Comm. Fault Relay and Serial Communications PCB’s

The No Communications Fault Relay is connected to a set of Terminal Blocks on the din-Rail (

Figure 5 and

Figure 4.) The Terminal Blocks are labeled “NO COMM” “C”, “NO” and “NC”. The No Comm. Fault Relay

PCB, mounted on the back of the controller PCB, will de-energize the on board relay in the event there is a

‘No Communication Fault’ condition with any activated device. A ‘No Communication Fault’ condition will

‘short’ the common and normally closed contacts and create an open between the normally open and common

relay contacts of the on-board relay. This is required for fail-safe operation. There is a two-minute delay

before any active device will trigger a no communication condition.

The unit includes connections for a Remote Alarm Reset Switch. A set of Terminal Blocks is supplied for the

connection of a Remote Alarm Reset Switch that can be mounted anywhere outside the unit. The Remote

Alarm Reset incorporates a set of normally closed contacts that cause the unit to reset the Alarms when contact

is broken. To install a Remote Reset Switch the jumper between terminal blocks 8 and 9 (labeled “Remote

Reset”) must be removed and the switch wired to these terminals. Connect only a normally closed switch to

these terminal blocks. If more than one switch is to be connected, the switches must be connected in series.

NOTE: The Remote Alarm Reset switch should be a ‘Normally Closed’ Switch and should be wired as

such. Failure to wire the switch correctly will cause the Enclosure Alarm Reset and all subsequently

connected Remote Alarm Reset Switches to be non operational.

1600/6400-N1P- Instruction Manual Rev. 1.1 Page 4 of 38

1600/6400-N1P

MADE IN CHINA

V ADJ

+V -V L N+V -V

H

GROUND

Green 18AWG

Black 18AWG

White 18AWG

Red 16AWG

Black 16AWG

D1 D2

Red 16AWG

Red 16AWG

Red 18AWG

Black 18AWG

Black 16AWG

Black 18AWG

Red 16AWG

Red 18AWG

+VDC

-VDC

RTN

-VDC

RTN

-VDC

Note1:

Wiring shown for clarity only.

Correct connections shown

above.

RTN connected to +24VDC.

-VDC connected to -24VDC.

( For more information contact

Enrique Marrero)

Note 2:

Jumper must be removed

if a Remote Alarm Reset

Switch is installed.

TB1

Green 18AWG

White 18AWG

Green 18AWG

PLUGTRUB PLUGTRUB

-VDC RTN

Connections shown

for clarity only.

L0A

D

F7905

15DCF6

corcom

15 AMP 80 V

LIN

E

Connections shown

for clarity only.

-VDC RTN

Black 18AWG

Red 16AWG

Black 16AWG

6

2

1

Note1

Black 18AWG

3

2A

I

O

J4 J3

+ -

VDC IN

White 18AWG

Purple 18AWG

RV1

Yellow 18AWG

Bllue 18AWG

Orange 18AWG

Red 18AWG

Orange 18AWG

Bllue 18AWG

Yellow 18AWG

4

5A

I

O

Gray 18AWG

Gray 18AWG

White 18AWG

Purple 18AWG

765

9

8

CBA

1211101413

GHJ

RS-232

RS-485

S

Primary

B

Secondary

A

J7 J3

Serial Communications PCB

6400 Controller PCB

No Comm

Fault Relay PCB

CNONC

J1

Gray 18AWG

Gray 18AWG

DEF

Detcon

www.detcon.com

Data Data

Black 18AWG

Black 18AWG

Red 16AWG

Black 16AWG

Red 18AWG

A

B

S

S1

S2

J2

Purple 18AWG

White 18AWG

Black 18AWG

Red 18AWG

SBA-+

Customer

Supplied

Purple 18AWG

White 18AWG

Red 18AWG

White 18AWG

Modules

Purple 18AWG

N

Gnd

L1

12345612345

NC

A

RS-485 VDC

RESET

+

C

NO

B

MLK

-

Customer Connections

Legend:

VAC (L1)

- VDC

Neutral (L2)

Ground

Customer Supplied Power

+VDC

Pre-Wired

Customer Wired

Figure 5 Interconnect Wiring Diagram

1600/6400-N1P- Instruction Manual Rev. 1.1 Page 5 of 38

1600/6400-N1P

3.1 Installing the I/O Modules

Normally, the I/O modules will be factory installed on the main NEMA 1 rack and ready for wiring to external

devices (sensors and alarm enunciators). If they are not installed, follow the procedure below.

I/O modules are mounted to industry-standard 37.5 x 7.5 mm din-rail. Install the first I/O module on the din

rail and slide it all the way to the right side stop. When installing additional I/O modules, make sure there is

about 0.5 inch clearance spacing on either side of the module and snap onto the din rail (the 0.5” spacing is to

allow for connector clearance). Once the I/O module is snapped onto the din-rail, slide it to the right and

assure that it firmly plugs into the next module. Repeat as necessary for the balance of the modules. The

Controller Enclosure has room for a maximum of two (2) I/O modules. Additional modules should be

mounted in a separate enclosure.

I/O Connector

Detcon P/N 306-189320-300

+

S

B

A

RL4 Relay Module

RL4 Relay Module

RL4 Relay Module

RL4 Relay Module

DA4 4-20 mA Module

DA4 4-20 mA Module

DA4 4-20 mA Module

DA4 4-20 mA Module

RS-485 Cable

Use Belden PN 9841

RS-485 and power Cable

Use Belden PN 1502P

Figure 6 I/O Module Installation

For addressable I/O modules or Modbus™ sensors that are being located remotely from the Model 1600/6400N1P controller use Belden 1502P cable for serial and power connections. For serial only connections use

Belden 9841 cable. Interconnect them using the din-rail terminal blocks shown in

Figure 5.

3.2 Connecting to the I/O Modules

4-20mA Gas Sensors

Connect 4-20mA type gas sensors to the Model DA4 4-20mA input modules. There are four 4-20mA inputs

in each Model DA4 module.

Figure 7 Model DA-4 and 4-20mA Gas Sensors

1600/6400-N1P- Instruction Manual Rev. 1.1 Page 6 of 38

1600/6400-N1P

RS-485 Modbus Gas Sensors

Connect the five wires from the Modbus™ gas sensors (Detcon Model 600 and Model 700 Series types) to the

din rail mounted terminals labeled RS-485 “A”, “B”, and “Shld” and VDC “+” and “-”. Note: the controller

power supply is only capable of handling 3-3.5Amps accumulative. If the external sensors plus the controllers

internal modules exceeds this rating, only three wires (RS-485 “A”, “B”, and “Shld”) should be used and a

remote DC power source should be utilized to provide DC power for the remote mounted gas sensors.

NOTE: A 120Ω end of line resistor should be installed on the last gas sensor in the serial loop to enhance

communications reliability.

Figure 8 Modbus™ Gas Sensor Connections

Relay Output Contact Modules

There are four Form ‘C’ 5 Amp relay contacts in each Model RL4 module. These can be used to fire

annunciating devices or as signal inputs to other control devices. Connect to the relay contacts of the Model

RL4 module as shown Figure 9. Note that the Amp rating of the relay contact should not be exceeded.

Figure 9 Model RL-4 Relay Module

4-20mA Output Modules

There are four 4-20mA outputs in each Model AO-4 module. These can be used as signal inputs to other

control devices. Connect to the AO-4 modules as shown in

1600/6400-N1P- Instruction Manual Rev. 1.1 Page 7 of 38

Figure 10:

1600/6400-N1P

Figure 10 Model AO-4 Module

Contact Input Modules

There are four addressable contact inputs in each DI-4 Module. The Module is powered by 24VDC, and the

voltage is used to produce a 4mA level when the contacts are open and a 20mA level when the contacts are

closed.

Figure 11 Model DI-4 Module

General Wiring Notes:

When I/O Modules are located at a remote distance from the controller, an end of line terminating resistor

is required to enhance communications reliability. Identify the last I/O Module in the loop, and open the

module casing using the clip release points. Locate and install the jumper on JP6. This adds a 120Ω

resistor to the end of the line. If applicable, add a 120Ω resistor to the last Modbus™ gas sensor.

Follow generally accepted guidelines for RS-485 serial networks. Do not wire I/O Modules and/or

Modbus™ gas sensors in long-distance ‘T-Tap’ configurations. Stay with direct serial configurations. See

Section

14.0 Appendix for serial communications configuration guidelines.

Use Detcon Recommended cabling whenever possible.

• Belden P/N 1502P cable is recommended for a single cable providing serial communications and

power.

• Belden 9841 cable is recommended for a single cable providing serial communications only.

Ground the cable shielding at the Model 1600/6400-N1P Controller only. Other points of grounding may

cause a ground loop, and induce unwanted noise on the RS-485 line, which in turn may disrupt

communications.

1600/6400-N1P- Instruction Manual Rev. 1.1 Page 8 of 38

1600/6400-N1P

4.0 Start-Up

4.1 Applying Power

Before applying power, make sure that all I/O Modules are correctly installed and that all wiring connections

between I/O modules and external devices are made correctly.

NOTE: Applying power with devices hooked up incorrectly may cause damage.

Turn the applicable AC Breaker and DC Breaker switches to the ON positions. Verify that the main touchscreen LCD comes up displaying gas readings on the display. After 5 seconds, verify that all the I/O modules

are being polled by observing a sequence of blinking LED’s on the I/O Modules representing successful serial

communication. Enter and exit the “Program Menu” to bring the Main Display quickly up to date after power

boot-up.

Figure 12 Power In

NOTE: The polling of the input devices takes place more frequently than the communications to the relay

output devices. The sequence of polling communication will follow the order of the I/O device switch

addresses.

4.2 Setting Device Identification on the I/O Modules

NOTE: If your Model 1600/6400 controller has been configured at Detcon, you may elect to skip to the

Operator Interface (Section

For a unit that has not been properly configured, the I/O modules must be serially addressed to establish

correct communications. Typically, the I/O modules will be identified from 01 to FF starting from the module

on the right hand side of the stack. The I/O module’s identification is established by setting the two rotary

switches to the correspondingly correct position. The top rotary switch sets the most significant bit (MSB).

The bottom rotary switch sets the least significant bit (LSB). For an address of 01, set the top switch to 0 and

the bottom switch to 1. See

NOTE: All addresses must be unique. There can be no duplication of addresses or failure to

communicate will occur.

NOTE: Not all I/O modules communicate on every polling pass. Input modules are polled more often

than output modules.

5.0) for further review of system operation.

14.2 Hexadecimal Table for Decimal to Hexadecimal conversion.

1600/6400-N1P- Instruction Manual Rev. 1.1 Page 9 of 38

Loading...

Loading...