Despatch LEB1-69, LEB2-18 User Manual

C-189 P.N. 146231 REVISION I 8/2007

LEB SERIES OVENS

INSTRUCTION MANUAL

MODEL |

VOLTS |

HEATER WATTS |

AMPS |

HZ |

PHASE |

|

|

|

|

|

|

LEB1-23* |

120 |

1,200 |

10.4 |

50/60 |

1 |

|

|

|

|

|

|

LEB1-23 |

240 |

1,200 |

5.2 |

50/60 |

1 |

LEB1-69* |

120 |

2,400 |

20.4 |

50/60 |

1 |

LEB1-69 |

240 |

2,400 |

10.2 |

50/60 |

1 |

LEB2-18 |

240 |

3,600 |

15.2 |

50/60 |

1 |

* A 240V conversion kit is available.

Prepared by:

Despatch Industries

8860 207th St. West

Lakeville, MN 55044

Customer Service 800-473-7373

NOTICE

Users of this equipment must comply with operating procedures and training of operation personnel as required by the Occupational Safety and Health Act (OSHA) of 1970, Section 6 and relevant safety standards, as well as other safety rules and regulations of state and local governments. Refer to the relevant safety standards in OSHA and National Fire Protection Association (NFPA), section 86 of 1990.

CAUTION

Setup and maintenance of the equipment should be performed by qualified personnel who are experienced in handling all facets of this type of system. Improper setup and operation of this equipment could cause an explosion that may result in equipment damage, personal injury or possible death.

Dear Customer,

Thank you for choosing Despatch Industries. We appreciate the opportunity to work with you and to meet your heat processing needs. We believe that you have selected the finest equipment available in the heat processing industry.

At Despatch, our service does not end after the purchase and delivery of our equipment. For this reason we have created the Service Products Division within Despatch. The Service Products Division features our Response Center for customer service. The Response Center will direct and track your service call to ensure satisfaction.

Whenever you need service or replacement parts, contact the Response Center at 1-

800-473-7373: FAX 612-781-5353.

Thank you for choosing Despatch.

Sincerely,

Despatch

Despatch Industries

Advantage Service Assurance Program (ASAP)

CONTACT: DESPATCH SERVICE AGREEMENTS SPECIALIST at 800-473-7373 or 952-469-8230 or e-mail: service@despatch.com

Despatch continues to deliver exceptional products backed by a strong sense of responsibility and drive for long term customer satisfaction. Your partnership with Despatch can offer even higher value through your subscription to one of Despatch’s Advantage Service Assurance Program(ASAP).

Warranty

Despatch’s exclusive, comprehensive service programs start with the 1 year parts only warranty which is described on the other side of this document. This warranty can be expanded immediately to meet your most stringent service needs. Despatch Service Products Group will be able to answer your service questions and provide a quotation for the immediate expansion of your product warranty. Call 800-473-7373 or 952-469-8230; or e-mail service@despatch.com.

Immediate Service Response

The key to an effective service program is response. Wherever your location, Despatch is only a phone call away. Our U.S. and Canadian customers can reach Despatch at 1-800-473-7373. Worldwide customers can call 1-952-469-8230 or FAX 1-952-469-8193. Our Customer Service Technicians have over 150 years combined experience and access to detailed design and manufacturing documentation specific to your Despatch unit(s). This exacting level of service is a benefit only Despatch can provide and means that you can expect speedy, accurate and the most cost effective response.

Field Service Network

A worldwide network of factory trained Service Professionals is available to support your Despatch equipment. From routine repair to certified instrument calibration, the Despatch service network is positioned to respond to your needs. As a manufacturer of custom equipment, our service programs are customized to meet your specific needs regarding:

1.Service scope

2.Response time

3.Preventive maintenance frequency and content

4.Payment method

Sustained Service Support

At Despatch, long term customer satisfaction means more than just responding quickly and effectively to our customers’ service needs. It means offering comprehensive customer support well beyond the scope and duration of our initial warranty. Despatch offers two basic service packages which are customized to each individual customer’s need. These service packages are titled Full Service and Preventive Maintenance Plus+ service agreement products. Each is unique in the industry and offer the following benefits:

1.Priority response for minimum production interruption

2.Preventive maintenance for longer product life

3.Discounts on parts and services

4.Various payment plans to ease budgeting and recording expenses

5.Reduce purchase ordering costs

i

PREFACE

This manual is your guide to the Despatch oven. It is organized to give you the information you need quickly and easily.

An efficient way to learn about the oven would be to read the manual while working with the corresponding oven control system. This will give you practical hands-on experience with information in the manual and the oven.

Before operating the equipment, be sure you understand all of the technical information contained in this manual. Information skipped, not understood

or misunderstood could create the possibility of operating the equipment in an unsafe manner. This can cause damage to the oven or personnel or reduce the efficiency of the equipment.

ii

Revision B: drawings updated

Revision C: drawings updated

Revision D: updates to Specifications section; addition of stand assembly and stacking kit assembly instructions

Revision E: Corrections, additional drawings added, addition of options and features in APPENDIX

Revision F: Update Drawings, Product Warranty, and hi-limit information

Revision G: Update Drawing

Revision H: Parts lists corrections in DRAWING AND SPARE PARTS LISTS section.

Corrected Despatch address

Revision I: Update Product Warranty

iii

TABLE OF CONTENTS |

|

PREFACE ........................................................................................................................ |

i |

INTRODUCTION............................................................................................................. |

1 |

Special Features.......................................................................................................... |

1 |

SPECIFICATIONS .......................................................................................................... |

2 |

Dimensions.................................................................................................................. |

2 |

Power....................................................................................................................... |

3 |

Temperature............................................................................................................. |

4 |

Capacities ................................................................................................................ |

4 |

THEORY OF OPERATION ............................................................................................. |

5 |

CONTROL Instrument ................................................................................................. |

6 |

HI-LIMIT Instrument..................................................................................................... |

7 |

Product HI-LIMIT Instrument.................................................................................... |

8 |

Oven HI-LIMIT Instrument........................................................................................ |

8 |

Oven Theory................................................................................................................ |

9 |

INSTRUCTIONS ........................................................................................................... |

10 |

Unpacking and Inspection ......................................................................................... |

10 |

Setup ......................................................................................................................... |

11 |

Operating................................................................................................................... |

12 |

Loading the Oven................................................................................................... |

12 |

Pre-Startup Checklist ............................................................................................. |

13 |

Startup ................................................................................................................... |

14 |

Control Instructions.................................................................................................... |

16 |

Changing Setpoint.................................................................................................. |

16 |

Parameter Programming Mode.............................................................................. |

17 |

Set-Up Parameters ................................................................................................ |

19 |

Changing Display From °C To °F ..................... |

......................................................... 20 |

Oven Zone Calibration ........................................................................................... |

21 |

HI-LIMIT INSTRUCTIONS......................................................................................... |

22 |

Changing Setpoint ..................................................................................................... |

22 |

Parameter Setup Mode.............................................................................................. |

23 |

Setup Parameters .................................................................................................. |

24 |

Changing Display From °C To °F .............................................................................. |

26 |

Maintenance .............................................................................................................. |

27 |

Checklist ................................................................................................................ |

27 |

Tests ...................................................................................................................... |

28 |

Replacement.......................................................................................................... |

28 |

Control Instrument.................................................................................................. |

29 |

Replacement of Hi-limit Instrument ........................................................................ |

30 |

Heater Unit............................................................................................................. |

31 |

Troubleshooting......................................................................................................... |

32 |

DRAWINGS .................................................................................................................. |

35 |

LEB 1-23-1 (120 VAC) Parts.................................................................................. |

36 |

LEB 1-23-1 (120 VAC) Drawing ............................................................................. |

37 |

LEB 1-23-1 (240 VAC) Parts.................................................................................. |

38 |

LEB 1-23-1 (240 VAC) Drawing ............................................................................. |

39 |

iv |

|

LEB 1-69-1 (120 VAC) Parts.................................................................................. |

40 |

LEB 1-69-1 (120 VAC) Drawing ............................................................................. |

41 |

LEB 1-69-1 (240 VAC) Parts.................................................................................. |

42 |

LEB 1-69-1 (240 VAC) Drawing ............................................................................. |

43 |

LEB2-18-1 Parts..................................................................................................... |

44 |

LEB 2-18-1 Drawing .................................................................................................. |

45 |

Despatch Customer Service ...................................................................................... |

46 |

Procedures and Customer Responsibilities ........................................................... |

46 |

Attachment A - Sustained Service Support ............................................................ |

47 |

APPENDIX: OPTIONAL FEATURES ............................................................................ |

48 |

Protocol Plus Control Option ..................................................................................... |

48 |

Timer Option.............................................................................................................. |

48 |

Timer Operation ..................................................................................................... |

49 |

Timer Configuration................................................................................................ |

49 |

Stand Assembly Instructions ..................................................................................... |

50 |

Stacking Kit Assembly Instructions ............................................................................ |

51 |

Timer Option with Audible and Visual Alarm.............................................................. |

52 |

High Limit Alarm Option............................................................................................. |

52 |

Recorder Option ........................................................................................................ |

52 |

v

INTRODUCTION

The INTRODUCTION section provides an overview of the Despatch LEB Series Ovens.

The LEB Series Ovens have the most effective heat distribution and the fastest processing time of any lab ovens their size. Air is discharged from the floor plate of the oven and distributed through the chamber.

Special Features

∙The sturdy construction and high grade insulation of the Despatch LEB Series ovens contribute to excellent high temperature performance. Other special features include:

∙Proportional digital CONTROL instrument to control temperature fluctuations.

∙Manual reset HI-LIMIT instrument to protect the chamber workload as well as the oven itself.

∙Unique Despatch design with a system of perforated stainless steel walls for the ultimate in temperature performance.

∙Welded double wall construction and fiberglass insulation to reduce heat loss.

Silicone rubber gaskets further minimize heat leakage.

∙Rapid response heater with a five year warranty.

∙Scratch-resistant baked enamel exterior and stainless steel interior for easy cleaning.

∙Space-saving, stackable design.

1

SPECIFICATIONS

Dimensions

Model |

Chamber Size |

Capacity |

Overall Size |

Shelves |

Maximum |

Chamber |

||||

|

inches (cm) |

feet3 |

inches (cm) |

Provided on |

Number of Shelf |

Doors |

||||

|

W |

D |

H |

(liters) |

W |

D |

H |

Shelf Centers |

Positions |

|

LEB1-23 |

18 |

18 |

12 |

2.3 |

24 |

23 |

26 |

2 on 2" |

5 |

1 |

|

(46) |

(46) |

(30) |

(65) |

(61) |

(58) |

(66) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LEB1-69 |

30 |

18 |

22 |

6.9 |

34 |

23 |

36 |

2 on 2" |

10 |

2 |

|

(76) |

(46) |

(56) |

(195) |

(86) |

(58) |

(91) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LEB2-18 |

37 |

24 |

35 |

18 |

43 |

29 |

51 |

2 on 2" |

16 |

2 |

|

(94) |

(61) |

(89) |

(510) |

(102) |

(74) |

(130) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2

Power

Line voltages may vary in some geographical locations. If your line voltage is much lower than the oven voltage rating, warm up time will be longer and motors may overload or run hot. If your line voltage is higher than nameplate rating, the motor may run hot and draw excessive amps.

If the line voltage varies more than 10% from the oven voltage rating, some electrical components such as relays, temperature controls, etc. may operate erratically.

Model |

Volts |

Amps |

Hertz |

Phase |

Heater (KW) |

Cord and Plug |

LEB1-23 |

120 |

10.4 |

50/60 |

1 |

1.2 |

Included, 15 Amp |

|

240* |

5.2 |

|

|

|

|

|

|

|

|

|

|

|

LEB1-69 |

120 |

20.4 |

50/60 |

1 |

2.4 |

None, Hardwired |

|

240* |

10.2 |

|

|

|

|

|

|

|

|

|

|

|

LEB2-18 |

240 |

15.2 |

50/60 |

1 |

3.6 |

None, Hardwired |

|

|

|

|

|

|

|

The LEB1-69 and LEB2-18 must be hardwired to the electric supply using 10AWG or larger wires suitable for at least 75°C (167° F).

Ovens designed for 240 volts (see name plate on oven) will operate satisfactorily on a minimum of 208 volts, but with a 25% reduction in heater power. If your power characteristics are lower, contact Despatch Industries.

* Order 240V conversion kit for 240V, on LEB1-23 and LEB1-69.

3

Temperature

Model |

|

|

LEB |

|

|

|

1-23 |

1-69 |

2-18 |

Time to Temperature |

25°C - 100°C |

12 |

10 |

12 |

(approximate minutes |

25°C - 150°C |

20 |

18 |

20 |

with no load) |

25°C - 204°C |

35 |

30 |

36 |

Recovery Time |

100°C |

2 |

2.4 |

2.2 |

Door Open 1 Min. (approximate 150°C |

4 |

4 |

4 |

|

minutes with no load) |

204°C |

6 |

7 |

7 |

Operating Range w/20°C Ambient |

|

30°C - 204°C |

|

|

Capacities

Model |

Standard Shelf |

Reinforced Shelf |

Max Load |

Stacked Max |

|

Capacity |

Capacity |

Capacity |

Load Capacity |

LEB1-23 |

50 lbs. (23 kg.) |

n/a |

200 lbs. (91 kg.) |

400 lbs. (182 kg.) |

LEB1-69* |

50 lbs. (23 kg.) |

200 lbs. (91 kg.) |

400 lbs. (182 kg.) |

400 lbs. (182 kg.) |

LEB2-18* |

50 lbs. (23 kg.) |

200 lbs. (91 kg.) |

600 lbs. (273 kg.) |

n/a |

NOTE that the shelves supplied with the LEB1-69 and 2-18 are reinforced. The standard shelf is optional for these ovens.

4

THEORY OF OPERATION

The Despatch LEB Series Ovens have the most economical approach when productivity and ease of operation are the deciding factors. These ovens are especially useful for testing, preheating, sterilizing, drying, aging and curing as well as other production applications. Gravity convected airflow with precision digital control to deliver fast processing. The overall result is efficient productivity under strenuous conditions. The LEB Series Ovens are precise and practical.

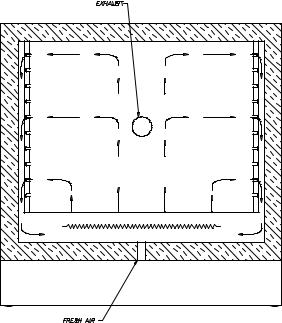

The unique Despatch design moves gravity convected heat through stainless steel ducts on each side. The chamber can be densely loaded without interfering with the process. Air temperature near the sensing element in the chamber is within 1°C of the process temperature appearing on the digital display. For your convenience the fresh air intake is fixed. The exhaust rate is regulated by a damper on the back of the unit.

Gravity Convected Airflow in the Despatch LEB Oven

5

CONTROL Instrument

The oven is equipped with a microprocessor based digital control instrument. The

Despatch CONTROL instrument has been configured as a proportional controller and set to its optimum operating values. Initially, the CONTROL will allow the heater to operate at full power. However; as the actual oven temperature reaches the setpoint, the Proportional Control will cycle the heater on and off, minimizing process temperature fluctuations.

|

CONTROL Instrument |

CONTROL Instrument Features |

|

|

|

Features |

Description |

Main (PV) Display |

Displays the actual oven temperature or displays the setpoint |

|

when the set key is pressed. Displays parameter code and |

|

value. |

Key |

Switches between PV and SP displays. Enters the data changed |

|

by the or keys. Switches through parameter displays. |

|

|

Down Key |

Decreases a setpoint or setup parameter. |

|

|

Up Key |

Increases a setpoint or setup parameter. |

|

|

LED SP Indicator |

Lights when the setpoint value is displayed. |

|

|

LED OUT Indicator |

Lights when the control is calling for heat. |

|

|

LED AL1 –2 Indicator |

N/A |

|

6 |

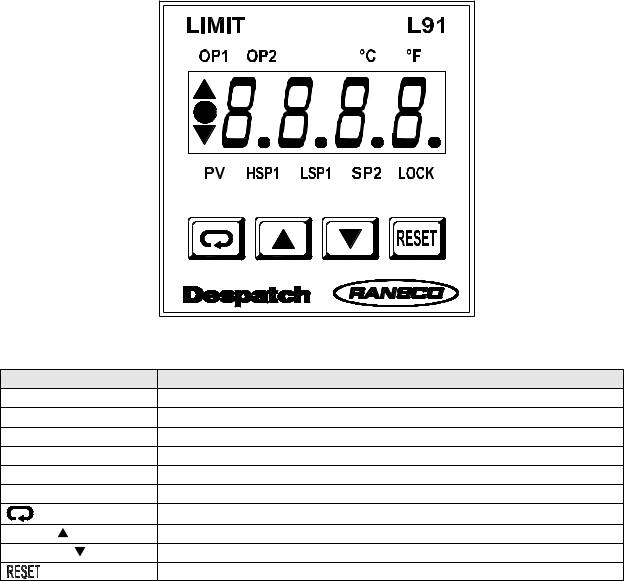

HI-LIMIT Instrument

The oven is equipped with a HI-LIMIT instrument. The purpose of the HI-LIMIT instrument is to provide a protective measure for the product and/or the oven itself. If the setting on the HI-LIMIT is exceeded, the heating process will discontinue, thus protecting the product and/or the oven.

Set the HI-LIMIT instrument to a temperature 10°C - 14°C higher than the CONTROL instrument setpoint or a temperature that should not be exceeded in the process. If the setting on the HI-LIMIT instrument is exceeded the heater will shut down. The HI-LIMIT instrument must be manually reset by pushing the RESET button on the HI-LIMIT instrument.

|

HI-LIMIT Instrument |

Features |

Description |

OP1 |

Output 1 status value. (OP2 normally not used for LBB Ovens). |

°C/°F |

Degree indicator. |

PV |

Process value. |

HSP1 |

High limit setpoint 1. (LSP1 normally not used for LBB Ovens). |

SP2 |

Setpoint 2 for output 2 (normally not used for LBB Ovens). |

LOCK |

Lock status indicator. |

|

Scroll Key, used for advancing available displays. |

Up Key |

Increases a setpoint or mode parameter. |

Down Key |

Decreases a setpoint or mode parameter. |

|

Reset the high limit, return to normal display. |

7

Product HI-LIMIT Instrument

If the product being processed has a critical high temperature limit, the HI-LIMIT instrument should be used as a product HI-LIMIT instrument. The HI-LIMIT instrument should be set to a temperature somewhat below the temperature at which the product could be damaged.

Oven HI-LIMIT Instrument

If the product does not have a critical high temperature limit, the HI-LIMIT can be used as an oven HI-LIMIT instrument. An oven HI-LIMIT instrument protects oven equipment. The HI-LIMIT should be set at 204°C

8

Oven Theory

The oven has an efficient gravity convected airflow to 204°C (400°F). A gravity convected oven relies on gravity to move air through the chamber. The process of moving air by relying on gravity is a slow responding process. Thus, the overall chamber temperature takes a finite amount of time (roughly a few minutes) to soak in at the desired operating temperature. The time that it takes the unit to soak in at setpoint is related to such parameters as chamber area, load mass, and exhaust rate. The unique Despatch design and CONTROL action compensates for this fact.

The oven uses an indicating microprocessor based digital control that displays the actual chamber temperature at the sensing point. Despatch strategically locates the CONTROL's temperature sensor to optimize the control action for the entire chamber for various load conditions. The CONTROL display will fluctuate a few degrees around the setpoint, but the overall chamber temperature will remain very stable. The underlying reason for this is that the display is showing temperature fluctuations at the temperature sensor location, not the overall chamber temperature. The strategic location of the sensor compensates for delays in gravity convection and enhances the performance and temperature control of the oven. The oven has been engineered to have an overall result of quality productivity while still maintaining an economical approach and ease of use.

9

INSTRUCTIONS

The INSTRUCTIONS section provides directions on unpacking, installation, operation and maintenance of the Despatch LEB Series Ovens.

Unpacking and Inspection

Remove all packing materials and thoroughly inspect the oven for damage of any kind that could have occurred during shipment.

∙See whether the carton and plastic cover sheet inside carton are still in good condition.

∙Look at all outside surfaces and corners of the oven for scratches and dents.

∙Check the oven controls and indicators for normal movement, bent shafts, cracks, chips or missing parts such as knobs and lenses.

∙Check the door and latch for smooth operation.

If there is damage, and it could have happened during shipment follow these instructions.

1.Contact the shipper immediately and file a written damage claim.

2.Contact Despatch Industries to report your findings and to order

replacement parts for those that were damaged or missing.

3. Please send a copy of your filed damage claims to Despatch.

Next, check to make sure you have received all the required materials. Your shipment should include:

∙One (1) Despatch oven,

∙One (1) Instruction manual,

∙One (1) Warranty card,

∙Two (2) Shelves

∙One (1) Damper assembly

If any of these items are missing from the packaged contents, contact Despatch Industries to have the appropriate materials forwarded to you.

10

Loading...

Loading...