Page 1

P/N 125166

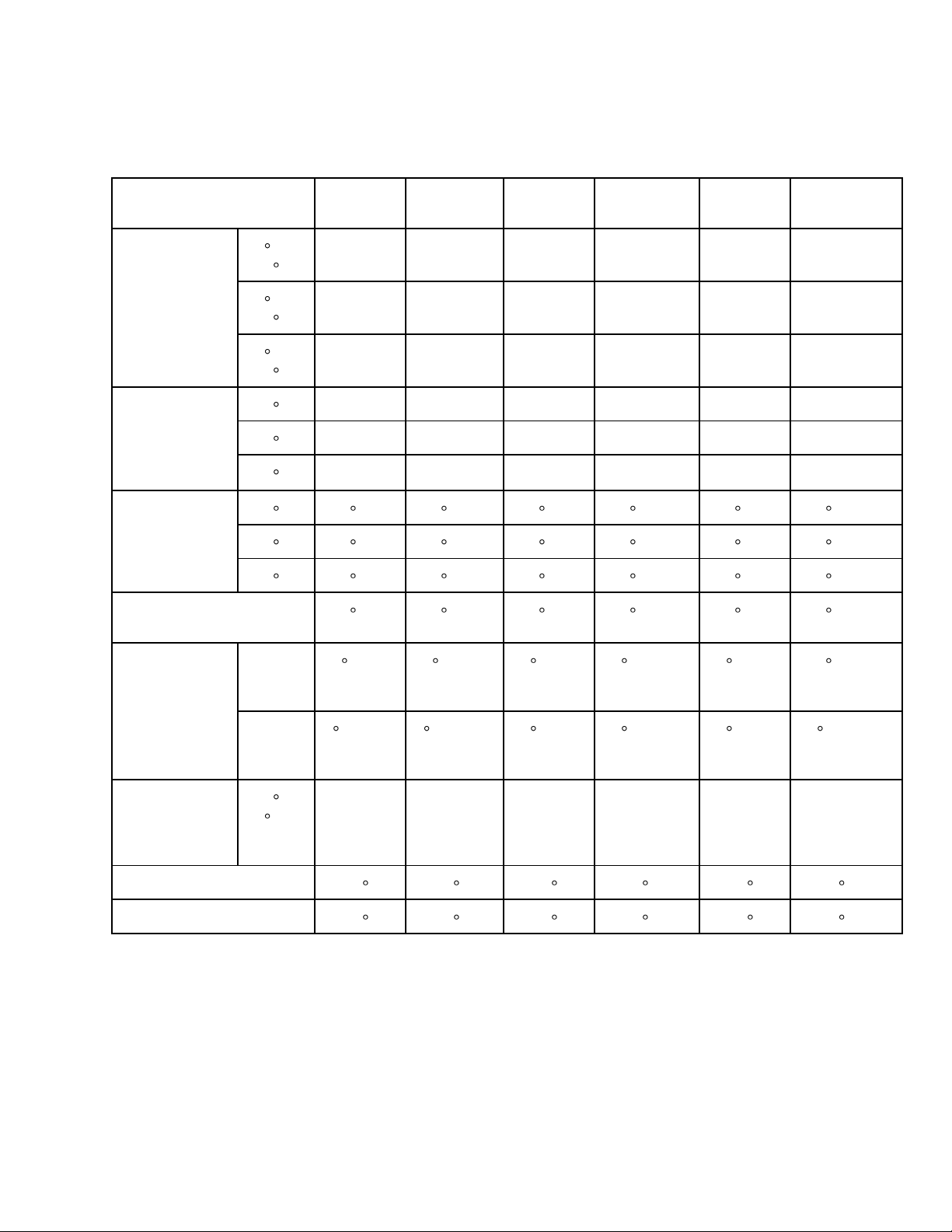

Model

Volts

Phase Hz

Heater Watts

Total

LCC 1-11

240 1 50/60

3,000

14.2

LCC 1-11N

240 1 50/60

3,000

14.2

LCC 1-54

240 1 50/60

6,000

26.7

LCC 1-54N

240 1 50/60

6,000

26.7

LCC 1-54NV

240 1 50/60

6,000

26.7

LCC 1-87

240 1 50/60

9,000

42.2

LCC 1-87N

240 1 50/60

9,000

42.2

LCC 1-87NV

240 1 50/60

9,000

42.2

REV. 11/07

C-159

LCC SERIES OVENS

INSTRUCTION MANUAL

Prepared by:

Despatch Industries

P.O. Box 1320

Minneapolis, MN 55420-1320

Customer Service 800-473-7373

Page 2

Notice

Users of this equipment must comply with operating procedures and training of

operation personnel as required by the Occupational Safety and Health Act (OSHA) of

1970, Section 6 and relevant safety standards, as well as other safety rules and

regulations of state and local governments. Refer to the relevant safety standards in

OSHA and National Fire Protection Association (NFPA), section 86 of 1990.

Caution

Setup and maintenance of the equipment should be performed by qualified personnel

who are experienced in handling all facets of this type of system. Improper setup and

operation of this equipment could cause an explosion that may result in equipment

damage, personal injury or possible death.

Thank you for choosing Despatch Industries. We appreciate

the opportunity to work with you and to meet your heat

processing needs. We believe that you have selected the

finest equipment available in the heat processing industry.

At Despatch, our service does not end after the purchase

and delivery of our equipment. For this reason we have

created the Service Products Division within Despatch. The

Service Products Division features our Response Center for

customer service. The Response Center will direct and

track your service call to ensure satisfaction.

Whenever you need service or replacement parts, contact

the Response Center at 1-800-473-7373: FAX 612-781-

5353.

Thank you for choosing Despatch.

Sincerely,

Despatch Industries

Page 3

Page 4

Page 5

i

PREFACE

NOTE:

Read the entire

INTRODUCTION and THEORY

OF OPERATION before

installing the oven.

WARNING:

Failure to heed warnings in this

instruction manual and on the

oven could result in personal

injury, property damage or

death.

This manual is your guide to the Despatch oven. It is organized to give you the

information you need quickly and easily.

The INTRODUCTION section provides an overview

of the Despatch oven.

The THEORY OF OPERATION section details the

function and operation of assemblies and subassemblies on the Despatch oven.

The INSTRUCTIONS section provides directions on unpacking, installing, operating

and maintaining the Despatch oven.

The APPENDIX section contains Special Instructions

for operating the control instrument, a Troubleshooting Table, and a list of Accessories.

An efficient way to learn about the oven would be to

read the manual while working with the corresponding

oven control system. This will give you practical

hands-on experience with information in the manual

and the oven.

Before operating the equipment, be sure you understand all of the technical information

contained in this manual. Information skipped, not understood or misunderstood could

create the possibility of operating the equipment in an unsafe manner. This can cause

damage to the oven or personnel or reduce the efficiency of the equipment.

Page 6

ii

Page 7

iii

TABLE OF CONTENTS

INTRODUCTION ............................................................................................................. 1

Special Features .................................................................................................. 1

SPECIFICATIONS .......................................................................................................... 2

Dimensions ........................................................................................................... 2

Capacities ............................................................................................................. 3

Power ................................................................................................................... 3

Temperature ......................................................................................................... 4

THEORY OF OPERATION ............................................................................................. 5

Construction ......................................................................................................... 6

Cooling ................................................................................................................. 6

Inert Atmosphere .................................................................................................. 6

HEPA Filters ......................................................................................................... 7

Definitions .................................................................................................. 7

Packaging and Shipping ............................................................................ 7

Handling ..................................................................................................... 8

HEPA Filter Validation Testing .................................................................. 8

D.O.P. Testing ................................................................................ 8

Class 100 Testing ........................................................................... 8

Validation Testing ........................................................................... 9

The Necessity of the Burn-off Process ...................................................... 9

Filter Unit Replacement ............................................................................ 9

CONTROL Instrument ........................................................................................ 10

HIGH LIMIT Instrument ...................................................................................... 10

Product High Limit Instrument ................................................................. 10

Oven High Limit Instrument ..................................................................... 11

INSTRUCTIONS ........................................................................................................... 12

Unpacking and Inspection .................................................................................. 12

Set-up ................................................................................................................. 13

HEPA Filter Installation ............................................................................ 15

HEPA Filter Burn-off ................................................................................ 16

OPERATING ................................................................................................................. 18

Loading the Oven ............................................................................................... 18

Pre-Startup Checklist .......................................................................................... 19

Startup ................................................................................................................ 19

Shut Down ............................................................................................... 22

Maintenance ....................................................................................................... 23

Checklist .................................................................................................. 23

Tests ................................................................................................................... 24

Nitrogen Supply Check ........................................................................... 24

Page 8

iv

Control Output Check .............................................................................. 24

Thermocouple Test .................................................................................. 25

Safety Controls ........................................................................................ 25

Replacement ...................................................................................................... 26

Parts ........................................................................................................ 26

CONTROL Instrument ............................................................................. 26

Fan Motor ................................................................................................ 27

Replacing HIGH LIMIT ............................................................................ 28

Thermocouple Break Protection .............................................................. 29

Replacing the Thermocouple ........................................................ 29

Heater Unit ............................................................................................... 30

APPENDIX .................................................................................................................... 31

Troubleshooting .................................................................................................. 31

Factory Installed Options .................................................................................... 33

Drawings ............................................................................................................. 34

Page 9

v

Page 10

1

INTRODUCTION

This section provides an overview of the Despatch LCC Series oven. The LCC offers

HEPA filtration for processes where minimization of contamination is essential. Fresh

air and nitrogen (noted with an N suffix) models are available.

Special Features

The removable HEPA (High Efficiency Particulate Air) filter is designed to provide a

constant flow of 99.97% clean air to the product. Other special features include:

Digital TEMP CONTROL and manual reset HIGH LIMIT to protect the chamber

workload as well as the oven itself.

Stainless steel interior with all interior seams continuously welded on the

insulation side to protect the work chamber from contamination and to permit

chamber washing without damaging insulation.

Silicon door seals, shaft seals and gasketing (Viton Fluorocarbon on NV

models).

Door seals and interior chamber walls are removable for cleaning.

Heater with a five year warranty.

Cooling coil to provide rapid cooldown and low temperature operation (nitrogen

models only).

Scratch-resistant SilverClay® baked enamel exteriors and a stainless steel

interior for easy cleaning.

Silicon-free construction on NV models.

Nitrogen operation (N and NV models only)

Page 11

2

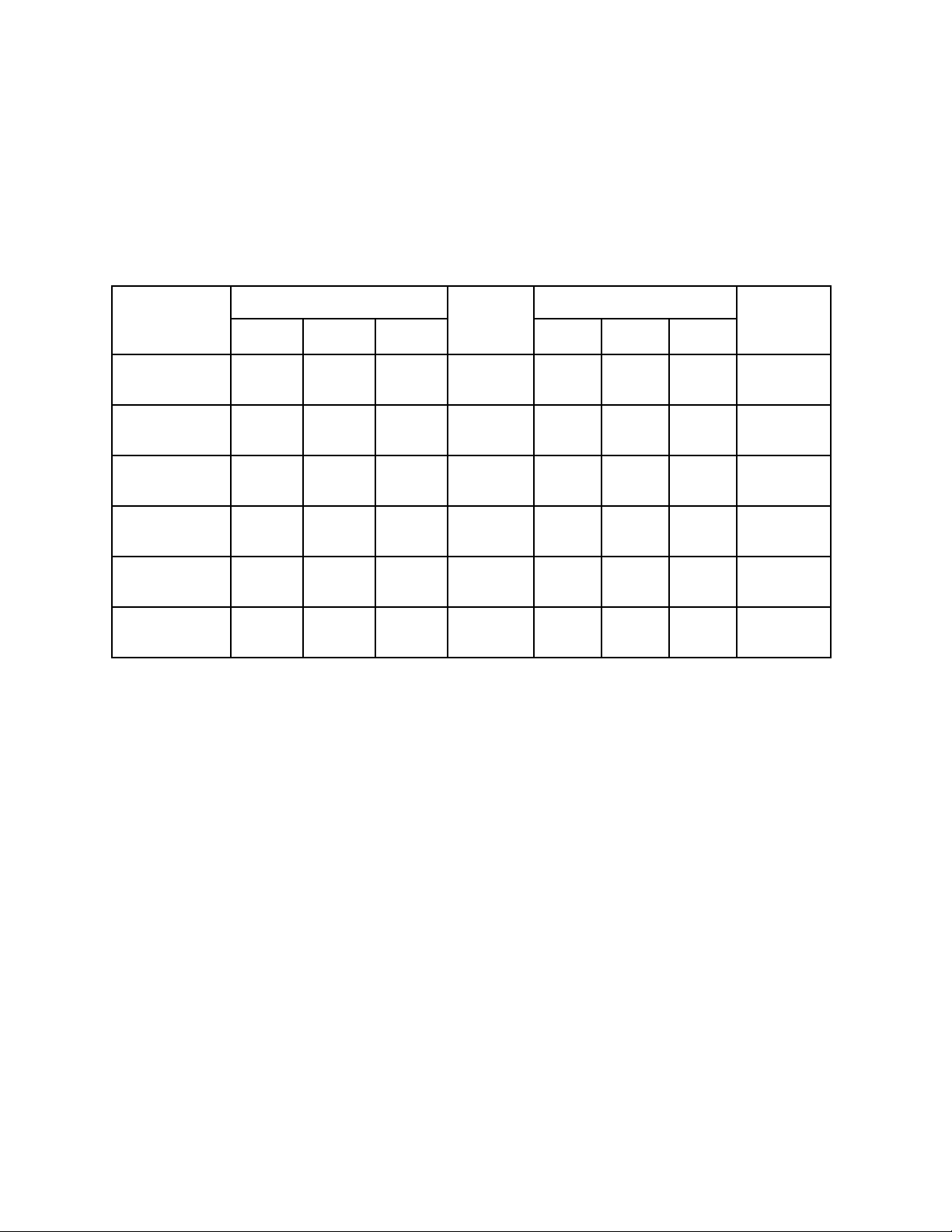

SPECIFICATIONS

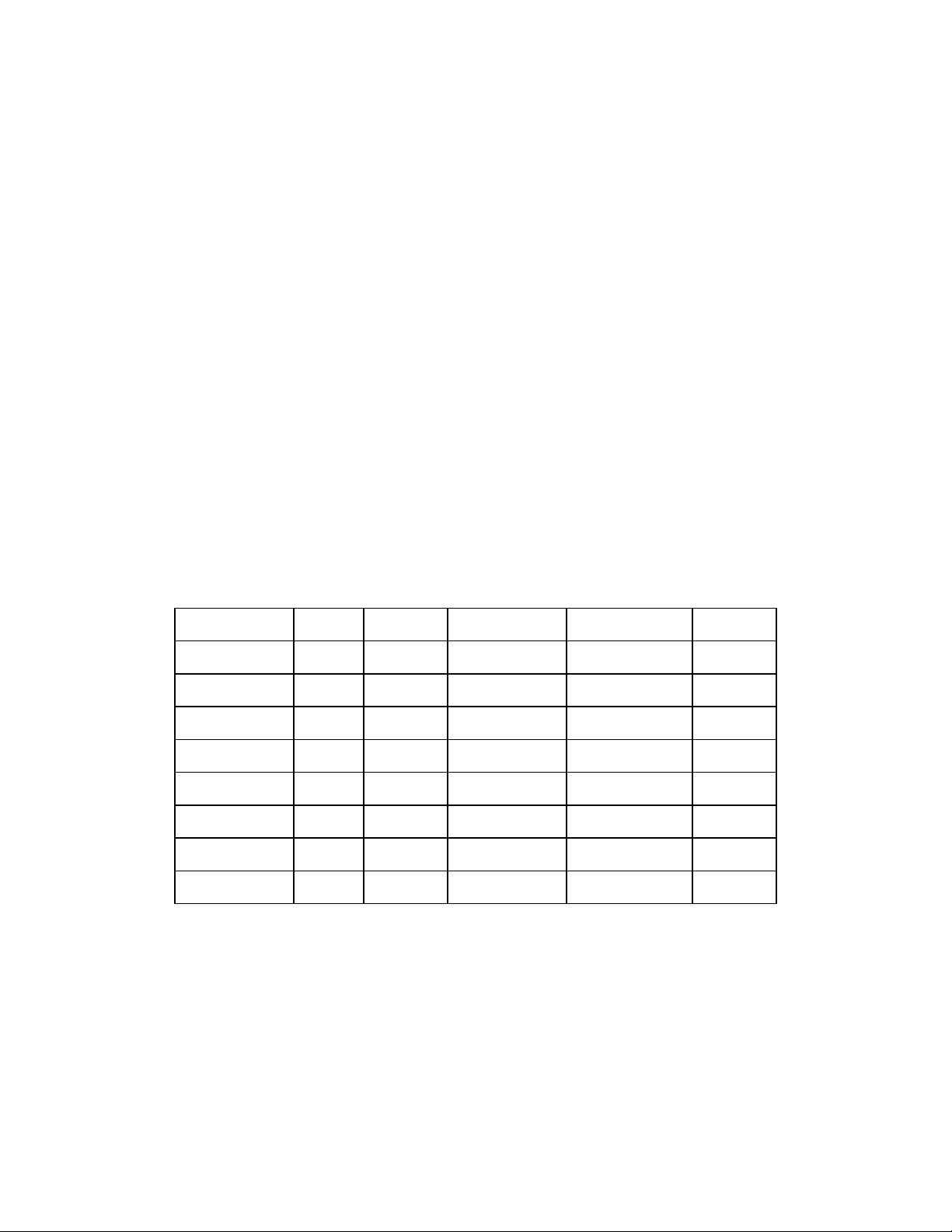

Model

Chamber Size, inches (cm)

Capacity,

ft3 (liters)

Overall Size, inches (cm)

Maximum

Number of

Shelves

W D H W D

H

LCC 1-11

10

(25)

14

(35)

14

(35)

1.1

(31)

25

(64)

21

(53)

32

(81)

5

LCC 1-11N

10

(25)

14

(35)

14

(35)

1.1

(31)

26

(66)

21

(53)

32

(81)

5

LCC 1-54

18

(46)

20

(51)

26

(66)

5.4

(153)

34

(153)

29

(74)

43

(109)

11 LCC 1-54N,

LCC 1-54NV

18

(46)

20

(51)

26

(66)

5.4

(153)

34

(153)

29

(74)

43

(109)

11 LCC 1-87

22

(56)

20

(51)

34

(86)

8.7

(248)

39

(99)

29

(74)

52

(132)

14 LCC 1-87N,

LCC 1-87NV

22

(56)

20

(51)

34

(86)

8.7

(248)

39

(99)

29

(74)

52

(132)

14

Dimensions

Page 12

3

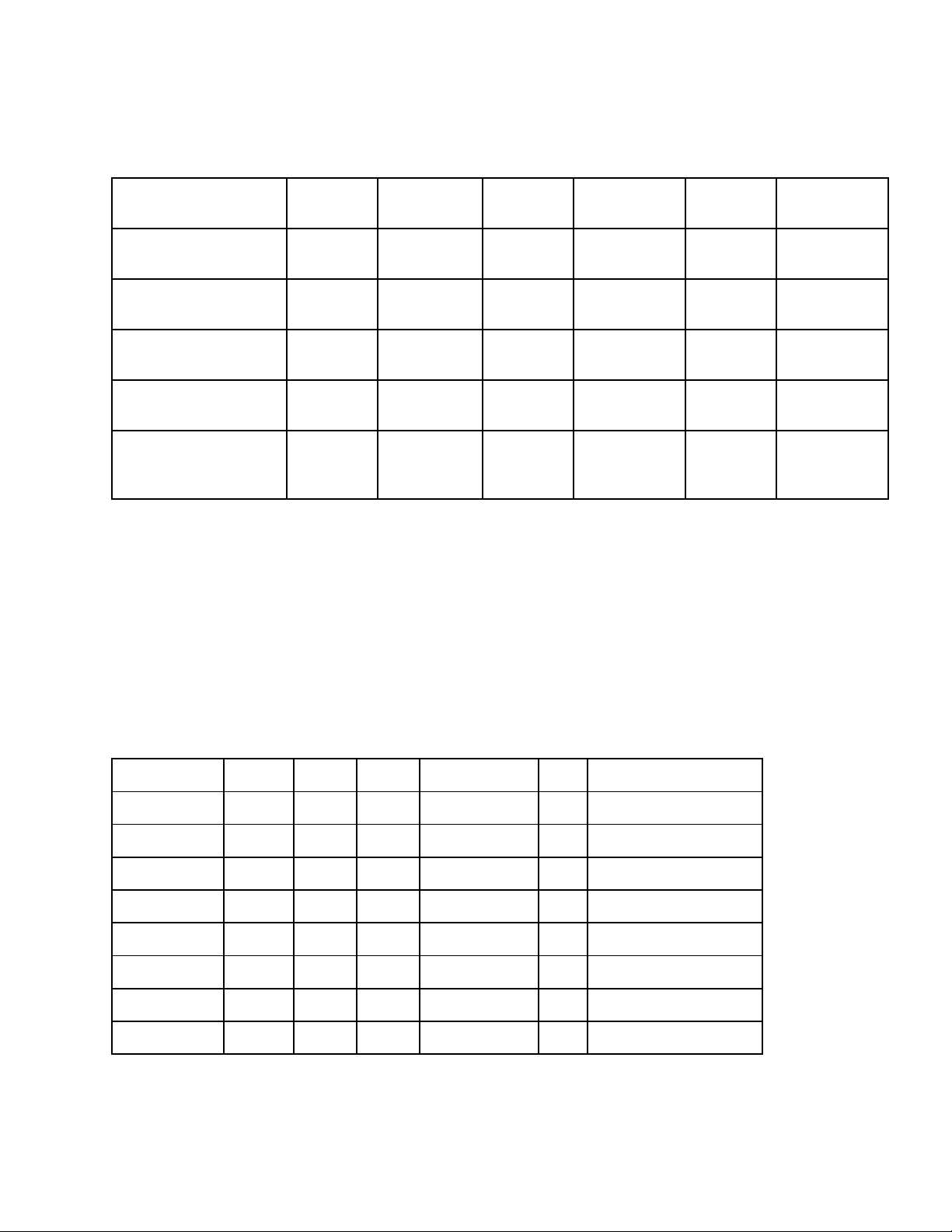

Capacities

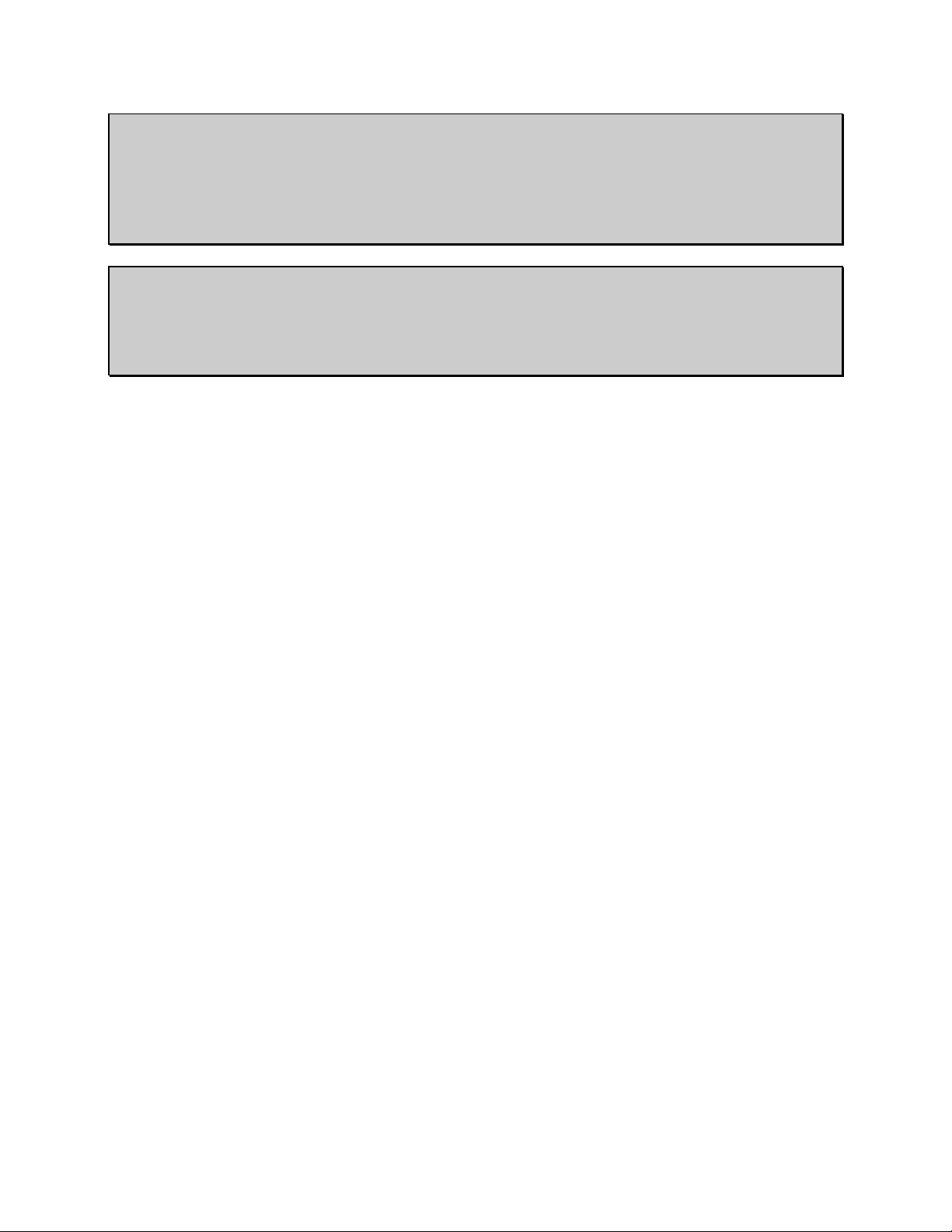

Model

LCC 1-11

LCC 1-11N

LCC 1-54

LCC 1-54N,

LCC 1-54NV

LCC 1-87

LCC 1-87N,

LCC 1-87NV

Maximum

Load

Lbs

25 25 150 150 200 200 Maximum

Shelf Load

Lbs

10 10 25 25 25 25 Recirculating

Fan

CFM

H.P.

265

1/4

265

1/4

400

1/4

400

1/4

990

3/4

990

3/4

Approximate

Net Weight

Lbs.

KG

285

129

285

129

380

172

380

172

500

227

500

227

Shipping

Weight

(approximate)

Lbs.

KG

400

181

400

181

615

279

615

279

750

341

750

341

Model

Volts *

Amps

Hertz

Heater Phase

KW Cord and Plug

LCC 1-11

240 14.2

50/60

1 3

None, Hardwired

LCC 1-11N

240 14.2

50/60

1 3

None, Hardwired

LCC 1-54

240 26.7

50/60

1 6

None, Hardwired

LCC 1-54N

240 26.7

50/60

1 6

None, Hardwired

LCC 1-54NV

240 26.7

50/60

1 6

None, Hardwired

LCC 1-87

240 42.2

50/60

1 9

None, Hardwired

LCC 1-87N

240 42.2

50/60

1 9

None, Hardwired

LCC 1-87NV

240 42.2

50/60

1 9

None, Hardwired

Power

Line voltages may vary in some geographical locations. If your line voltage is much

lower than the oven voltage rating, warm up time will be longer and motors may

overload or run hot. If your line voltage is higher than name plate rating, the motor may

run hot and draw excessive amps. If the line voltage varies more than 10% from the

oven voltage rating, some electrical components such as relays, temperature controls,

etc. may operate erratically.

* Oven designed for 240 volts (see nameplate on oven) will operate satisfactorily on a minimum of 208 volts, but with a 25%

reduction in heater power. If your power characteristics are lower, contact Despatch Industries.

Page 13

4

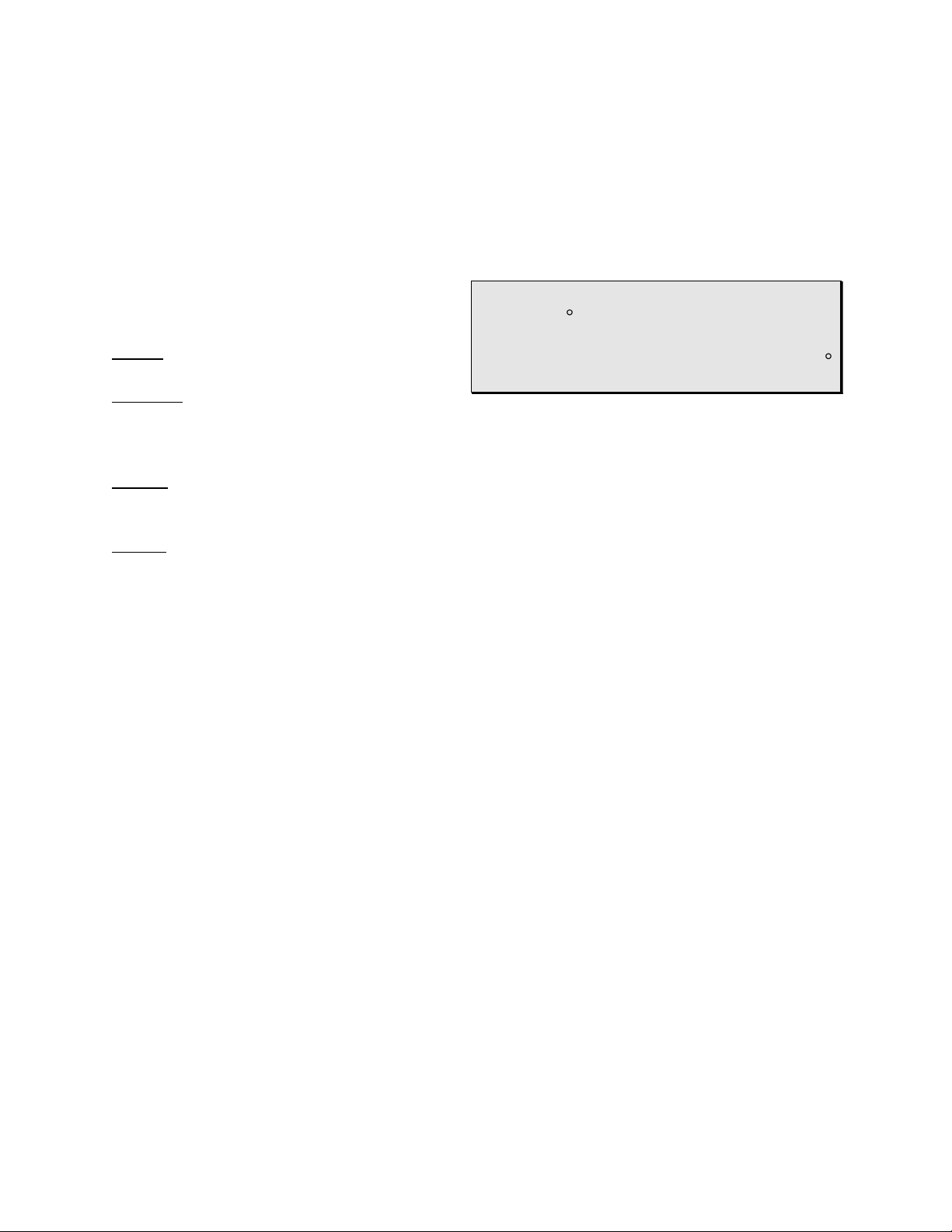

Temperature

Model

LCC 1-11

LCC 1-11N

LCC 1-54

LCC 1-54N,

LCC 1-54V

LCC 1-87

LCC 1-87N,

LCC 1-87NV

Time to

Temperature

(approximate

minutes)

25 C 100 C

4 4 5 5 4 4

25 C 200 C

13 13 14 14 12 12

25 C 260 C

20 20 23 23 18 18

Recovery Time

Door Open 1

Minute

(approximate

minutes)

125 C

0.5 0.5 1 1 1 1

200 C

1 1 2 2 2

2

260 C

2.5 2.5 3 3 3 3

Temperature

Uniformity at

(maximum)

125 C

± 1 C

± 1 C

± 2 C

± 2 C

± 1 C

± 1 C

200 C

± 2 C

± 2 C

± 2 C

± 2 C

± 2 C

± 2 C

260 C

± 3 C

± 3 C

± 3 C

± 3 C

± 3 C

± 3 C

Maximum Operating

Temperature

260 C

260 C

260 C

260 C

260 C

260 C

Minimum

Operating

Temperature

Above Ambient

(approximate)

Without

Water

Cooling

48 C

53 C

34 C

85 C

54 C

116 C

With

Water

Cooling

9 C 9 C 18 C

18 C

35 C

40 C

Cooling Time

Empty Oven

(approximate

minutes)

200 C 50 C

63 64 48 58 54 78

Control Stability

± 0.3 C

± 0.3 C

± 0.3 C

± 0.3 C

± 0.3 C

± 0.3 C

Repeatability

± 0.5 C

± 0.5 C

± 0.5 C

± 0.5 C

± 0.5 C

± 0.5 C

Page 14

5

THEORY OF OPERATION

The THEORY OF OPERATION section details the function and operation of the

Despatch LCC Series Ovens.

The LCC series oven is a class 100 clean room oven with HEPA (High Efficiency

Particulate Air) filtration. This oven is ideal for processes where minimization of

contamination is essential.

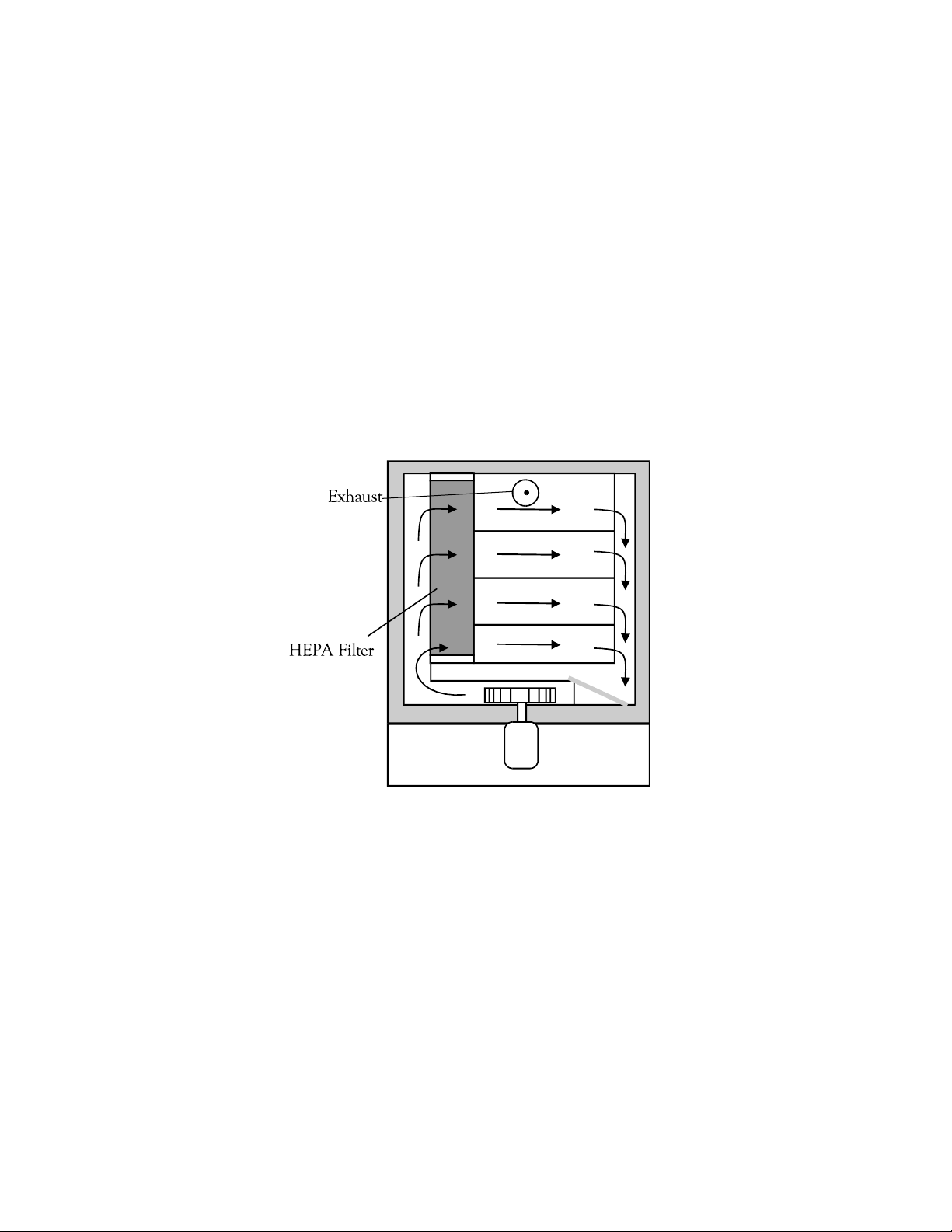

Forced convected airflow, provides rapid uniform distribution of heat. An absolute

HEPA (High Efficiency Particulate Air) filter is mounted in a stainless steel frame in the

supply plenum. These filters are 99.97% effective in filtering 0.3 micron particles.

Page 15

6

Construction

The LCC series oven has a type 304-2B stainless steel interior. All interior seams are

continuously welded on the insulation side. This protects the work chamber from

contaminated air and permits chamber washing without damaging the insulation.

Interior chamber walls and silicon door gaskets (Viton Fluorocarbon on NV models) can

be easily removed for cleaning. Heater frame, fan wheel and motor shaft are

constructed of stainless steel.

Exteriors are steel finished in SilverClay enamel, baked to a 2H hardness for chip and

scratch resistance. All controls are mounted on the front of the oven for easy operation

and readability. Two electropolished stainless steel wire shelves are provided. The

shelves are removable and adjustable on two inch centers.

Cooling

Air models have an adjustable fresh air damper which allows cooling of the oven.

Nitrogen models have a stainless steel water coil. When used in conjunction with the

optional flowmeter the cooling coil permits rapid cooldown and low temperature

operation.

Inert Atmosphere

An inert atmosphere option offers the advantages of both a clean room oven and inert

atmosphere oven. The nitrogen portion for the LCC series oven includes a manual

three way valve and two flowmeters, connected by piping to the inlet connection on the

lower back panel marked nitrogen supply.

Page 16

7

HEPA Filters

NOTE:

Chamber temperature transitions must not

exceed 1.5 C/minute in order to maintain

class 100 chamber conditions. Optional

filter is available for transition rates up to 5

C/minute. Consult the factory.

Absolute HEPA (High Efficiency Particulate Air) filters are used to limit particulate size

in the work chamber to 0.3 microns or less. The gentle entrance and exit air velocity to

and from the HEPA filter results in high efficiency and long life for the HEPA filters.

Definitions

HEPA - High Efficiency Particulate Air

Burn-Off - A process for getting rid of the

binder and D.O.P. contained in the filter

from the manufacturing and testing function.

D.O.P. - Dioctyl Phthalate - Aerosol particles of submicron size used in the testing

phase to spot defects or measure filter efficiency.

Binder - An organic substance that is used in the construction of the filter that gives

some structural strength to the media.

Packaging and Shipping

Packaging practice varies among the filter unit manufacturers. Normally units are

packaged in cardboard cartons with various approaches for internal strengthening and

impact-resistance of the container. The shipping carton normally is marked with a

vertical arrow and "This Side Up". A filter unit is placed in the carton so that the pleated

folds are vertical (running from top to bottom - not side to side).

Filters should be shipped, handled and stored with the pleats in the vertical position. If

shipped with the pleats in the horizontal position, the filter medium may break at the

adhesive line. If handled or stored with the pleats in the horizontal position the pleats

may sag.

Moreover, the filter unit should be installed with the pleats in the vertical position. When

installed in the horizontal position the pleats form shelves for the collection of entrapped

material. The accumulated weight of this material causes sagging and leads to an early

failure of the unit.

Page 17

8

Handling

The filter is shipped in the original carton or package that the filter manufacturer uses.

This will give good storage and maximum protection from dirt and moisture.

HEPA filters should be stored and moved in the shipping carton with in the upright

position. Handling should be kept to a minimum. During installation the filter should be

removed from the shipping carton and installed directly into the oven.

If for any reason an unpackaged filter unit must be placed with its face on the floor or

other surface, the surface must be cleared of every object or irregularity which might

damage the filter pack.

HEPA Filter Validation Testing

This section describes the Despatch position and recommendations for HEPA filter

testing and oven validation procedures. Despatch guarantees that the filters will meet

specified efficiency ratings when the filter is:

properly installed

run at or below 200 C, at a constant temperature

run before burn-in

D.O.P. Testing

In D.O.P. testing aerosol particles of submicron size are used to spot defects or

measure filter efficiency. Degenerative by-products of this test are distributed

throughout the oven chamber upon heat-up. Therefore Despatch does not recommend

D.O.P. filter testing.

Class 100 Testing

Despatch guarantees the environment within the oven to be Class 100. This

classification is based upon measurement of the particulate level within the oven work

chamber.

Class 100 testing may be performed before or after a proper filter burn-in procedure

has been performed. Despatch will guarantee Class 100 conditions measurements

based on two methods of test. The direct method of test employs an extraction type

particulate analyzer. The indirect method involves particle settling over a specified

Page 18

9

period of time onto a clean disk.

Validation Testing

Based on the issues discussed in this section, Despatch recommends the following test

sequence for pharmaceutical Class 100 ovens.

1. Proper installation of the HEPA filters.

2. Cold D.O.P. challenge to determine integrity of oven chamber and filter gaskets.

3. Proper filter burn-off procedure.

4. Class 100 testing inside the work chamber.

The Necessity of the Burn-off Process

HEPA filters contain a binder material which protects the filter media during production

and shipping. This smoke is typically not desirable during normal operation of the oven.

Burning off the binder will ensure a clean process at elevated temperatures.

When the binder is burned out of the filter media, the filter becomes very fragile, too

fragile to withstand normal shipping and handling. For this reason, Despatch does not

perform the burn-off procedure.

Filter Unit Replacement

Replacement of the filter unit will be necessary for various reasons.

Resistance, or pressure drop, across the filter unit. Maximum level of resistance

in inches (water gauge) will vary depending upon the operation of the filter and

the available fan capacity. Adequate fan capacity must be available.

Loss of efficiency (leakage), determined from air-sampling measurements made

downstream of the filter unit.

Visible damage or rupture of the filter media in a unit.

Change in process application.

Excessive build-up of lint or combustible particulate matter on the filter unit.

Page 19

10

Water droplets in airstream through filter, free water (RH = 100%), will saturate

NOTE:

Despatch Industries cannot be responsible

for either the process, the process

temperature used, or for the quality of the

product being processed. It is the

responsibility of the purchaser and operator

to see that the product undergoing

processing in a Despatch oven is

adequately protected from damage.

Carefully following the instructions in this

manual will assist the purchaser and

operator in fulfilling that responsibility.

filter very quickly and may cause burnout or holes in burned off filter media.

High level of radiation in the vicinity of the filter unit.

CONTROL Instrument

The CONTROL instrument operates the heating element in response to the entered

temperature setpoint. It provides digital indication of the setpoint and actual oven

temperature. Please refer to the operator’s manual for the CONTROL instrument

provided with the oven, for detailed operating instructions.

HIGH LIMIT Instrument

The purpose of the HIGH LIMIT instrument is to protect the product and/or the oven

from excessively high temperatures. If the setting on the HIGH LIMIT is exceeded, the

heating process will discontinue.

The HIGH LIMIT instrument must be set to a temperature slightly higher than the

CONTROL instrument setpoint or to a temperature that should not be exceeded in the

process. The instrument must be manually reset by pushing the red button.

Product High Limit

Instrument

If the product being processed has a

critical high temperature limit, the HIGH

LIMIT instrument should be used as a

product high limit instrument. The HIGH

LIMIT instrument should be set to a

temperature somewhat below the

temperature at which the product could be

damaged. Use the CONTROL instrument

or a pyrometer to determine the product

setting. If the destructive temperature of

the product is already known, this could be

used as a point below which the product

HIGH LIMIT is set.

Page 20

11

Oven High Limit Instrument

If the product does not have a critical high temperature limit, the HIGH LIMIT can be

used as an oven HIGH LIMIT instrument. An oven HIGH LIMIT instrument protects

oven equipment.

Since the HIGH LIMIT instrument does not show the temperature, it can be properly set

only after oven is in operation. Until then, the HIGH LIMIT should be set at maximum

position so all preliminary testing and adjusting can be done.

Never operate the oven at a temperature in excess of the maximum operating

temperature of 260 C (500 F).

Page 21

12

INSTRUCTIONS

The INSTRUCTIONS section provides directions on unpacking, installation, operation

and maintenance of the Despatch LCC Series Ovens.

Unpacking and Inspection

Remove all packing materials and thoroughly inspect the oven for damage of any kind

that could have occurred during shipment.

See whether the carton and plastic cover sheet inside carton are still in good

condition.

Look at all outside surfaces and corners of the oven for scratches and dents.

Check the oven controls and indicators for normal movement, bent shafts,

cracks, chips or missing parts such as knobs and lenses.

Check the door and latch for smooth operation.

Check the filter carton for damage.

If there is damage that could have happened during shipment follow these instructions:

1. Contact the shipper immediately and file a written damage claim.

2. Contact Despatch Industries to report your findings and to order replacement

parts for those that were damaged or missing.

3. Please send a copy of your filed damage claims to Despatch.

4. Check to make sure you have received all the required materials. Your shipment

should include:

One (1) Despatch oven,

One (1) Filter,

One (1) oven instruction manual,

One (1) control instrument instruction manual,

One (1) high limit instrument manual,

One (1) Warranty card,

Two (2) Shelves

One (1) Package containing four rubber pads

If any of these items are missing from the packaged contents, contact Despatch

Page 22

13

Industries to have the appropriate materials forwarded to you. Any optional

WARNING:

DO NOT use oven in wet,

corrosive, or explosive

atmosphere.

WARNING:

DO NOT use with other than inert gases

(nitrogen model only).

CAUTION:

The design and piping of the drain system

should preclude the possibility of operator

injury from high temperature or pressure

buildup. Piping must be able to withstand

short periods of up to 450 temperatures.

Drain lines should be insulated or warning

labels installed for the distance that a

hazard exists.

accessories ordered will be shipped separately.

5. Complete the warranty card and mail it to Despatch within 15 days after receipt

of the equipment.

Set-up

1. Remove adhesive backing sheet from the rubber pads.

2. Attach rubber pads to the bottom corners of the oven.

3. Place oven on a bench top or an optional

cabinet base. The oven must have a minimum

of two (2) inches clearance in the rear to

provide proper ventilation. The oven may be

placed next to another cabinet, or next to

another oven, with three-quarters (¾) of an inch clearance (the doors are still

open).

4. Make sure oven is level and plumb; this will assure proper heat distribution and

operation of all mechanical components.

5. (Nitrogen models only) Connect the

nitrogen supply line (from your

plant nitrogen system) to the inlet

marked nitrogen supply on the oven

rear panel. The nitrogen supply to the oven must not exceed 40 PSI.

6. (Nitrogen models only) Install water

connection for cooling coils.

a. Pipe the coil with a

three-way water supply/drain

valve on the inlet (bottom

fitting) and a vacuum breaker

valve at the high point of the

drain line. This will keep

water moving through the

cooling coil, minimizing

steam generation. The water

supply to the oven must not exceed 100 PSI.

b. Mount the optional cooling water flowmeter (included in cooling kit part

number 090020.)

Page 23

14

WARNING: never allow

drain to be plugged as a

hot oven will generate a

small amount of steam

when the water is first

turned on. Steam

burns.

WARNING:

All grounding and safety

equipment must be in

compliance with

applicable codes,

ordinances and accepted

safe practices.

The brass needle valve on the face of the

water flowmeter can be used for adjusting the

water flow or shutting off the water flow.

i. Run tubing from flowmeter to water valve.

ii. Connect a clean water supply to the flowmeter marked inlet.

iii. Adjust the water flow. Cooldown times and steam generation are

dependent on cooling water flow rate. Recommended flow rate is

50 gallons per hour.

c. The pipe on the rear of the oven marked WATER DRAIN should be piped

to a vacuum breaker and then to an open drain.

Page 24

15

7. Identify correct power source indicated on the specification plate. Power

NOTE: Repairing the damaged

filter unit, particularly the medium,

should not be attempted by the

user. Any unit so repaired must be

retested to assure that hidden

damage does not exist which will

reduce filtering efficiency. Repair

and retest is uneconomical for

most users.

requirements are also listed on the cover of this manual.

8. Hardwire oven directly to a disconnect switch and wire the disconnect switch

directly to the electric supply. Refer to the electrical schematic in the back of this

manual and the power requirements table in the Specifications section.

HEPA Filter Installation

Craftsmen responsible for installing the filter should use caution. The filter is delicate

and must not be damaged during installation. Any filter unit dropped, whether or not in

the carton, should be examined for damage. Equally important, the filter unit must be

installed so that unfiltered air will not leak past the unit.

1. Remove the filter from the carton.

a. Place the carton on the floor. The floor must be clear of nuts, bolts, and

similar protrusions which would damage the face of the unit. Do not drop

or jar the carton.

b. Tilt the carton on one corner. Be

sure to handle the carton at

opposing corners.

c. Remove the sealing tape and fold

the flaps of the carton back.

d. Gently upend the filter to place the

exposed end of the filter on the

floor. Do not jar the filter.

e. Pull the carton from the filter unit. Do not pull the filter from the carton.

2. Inspect the filter. Use a strong lamp to examine the exposed areas of both faces

to assure that no breaks, cracks, or pinholes are evident. A flashlight, can be

used in a darkened room.

Look for visible defects with the light projected along the full length of

each channel created by the separators. Translucent spots may not

necessarily indicate holes or cracks but may simply be variations in

thickness of the filter medium.

Check that the adhesive seal around the filter unit faces are complete and

unbroken.

Page 25

16

Check the corner joints of the frame for adhesive sealing and tightness.

NOTE: If it is necessary to move the

equipment after the burn-off process,

considerable care should be used.

The binder which gives strength to new

filters is now burned-off and the media

is very fragile. Rough handling of

either the filter alone or the equipment

with the filter installed is not

recommended as it may tear the

media and lose its efficiency rating.

Check that the gaskets are cemented firmly to the filter frame and that the

gasket pieces are butted or mated at the joints.

3. Remove the old HEPA filter.

a. Unscrew the four (4) brass nuts on the left side of the work chamber.

b. Remove the perforated duct exposing the filter.

c. Remove and discard the old HEPA filter.

4. Install the filter with the gasket centered around the hole in the side wall of the

oven. Be sure to install the filter with pleats and separators running from top to

bottom.

5. Install and tighten the perforated duct. Be sure to compress the gasket evenly

and equally at all points with the filter frame completely covering the opening.

HEPA Filter Burn-off

The burn-off process will take place in any

piece of equipment where a new HEPA filter

is used at temperatures above 150 C /

300 F. There will be smoke, possibly a

pungent odor, and a light residue on interior

surfaces. This is the result of oxidation of

the binder and the evaporation/

decomposition of any D.O.P.. Most of the

binder will leave the filter after running at a

temperature of 260 C/500 F for eight (8) to 48 (forty-eight) hours. After eight hours

6.7% of the total media weight is lost, 11.2% after 24 hours and 16.0% after 48 hours.

Check the oven for particles or the exhaust for smoke and odor to determine that the

process is finished.

Significant advantage in paper strength and shedding characteristics is obtained for

some filters if some of the binder is left on the media (burn-off done below 220 C/428 F

and lower.) Lower burn-off temperature are more advantageous. However, the

burn-off should be done at or above the maximum process temperature. If the binder

is burned off in the range from 150 C/300 F to 220 C/428 F, it is wise to remember that

additional binder will be given off if the oven is ever heated above this temperature.

Select a location for this process where the smoke and odor generated will be

ventilated with the least amount of interruption and inconvenience. Ideally this will be in

Page 26

17

the final location for the oven. However, it may be a receiving dock, some well

ventilated space or even outside if the weather is acceptable. If this location is a very

clean area, then special attention must be given to an exhaust hook-up that will capture

the smoke and odor.

The following procedure is recommended:

1. Locate the equipment exhaust opening where chamber air is being expelled.

If the oven filter is burned off in a clean area, be sure to handle the equipment

exhaust appropriately. If the equipment is large and the exhaust stack is a

permanent service connection, it should be connected before the burn-off

process is run. If the equipment is small with no permanent exhaust duct

required, arrange a temporary connection out of the clean area that will handle

the maximum temperature of the equipment. Direct the smoke and odor outside,

or to a highly ventilated area.

2. Filters for 260 C/500 F and below: Set the temperature control at the maximum

process temperature.

Filters for above 260 C/500 F: To maximize the life of the filter, set the control to

ramp the oven temperature at 1 C (1.8 F) per minute or slower. Program a 3

hour soak at 75 C/167 F, and a 3.5 hour soak at 105 C/220 F during the first

heating ramp. The limited ramp rate and soaks will cure the ceramic adhesive in

these filters for maximum strength.

3. Start the fan after making the electrical power connections.

4. Energize the equipment heater.

Use enough fresh air or purge nitrogen to remove the smoke, while still being

able to achieve and maintain the necessary temperature. The completion of the

burn-off period should be based on the particle level in the oven or smoke-free

exhaust and minimal odor level.

The filter hold-down nuts should be checked after burn-off and tightened again if

necessary. For best oven particle control, this step should be repeated on a regular

basis.

Page 27

18

OPERATING

Users and operators of this oven must comply with operating procedures and training of

operating personnel as required by the Occupational Safety and Health Act (OSHA) of

1970, Section 5 and relevant safety standards, and other safety rules and regulations of

state and local governments. Refer to the relevant safety standards in OSHA and

National Fire Protection Association (NFPA), Section 86 of 1990.

Loading the Oven

Despatch Industries cannot be responsible for either the process or process

temperature used, or for the quality of the product being processed. It is the

responsibility of the purchaser and operator to see that the product undergoing

processing in a Despatch oven is adequately protected from damage.

Carefully following the instructions in this manual will help the purchaser and operator in

fulfilling that responsibility.

When loading the oven avoid spills of anything onto the heater elements or onto the

floor of the oven. Do not place the load on the oven floor plate. This may cause the

load to heat unevenly and the weight may cause shorting out of the heater elements.

Use the shelves provided.

The two shelves are designed to be pulled out about half way without tipping. The

support capacity of the shelves is listed in the Capacities Table in the Specifications

section in this manual. Do not overload the shelves.

Distribute the workload evenly so that airflow is not restricted. Do not overfill your oven.

The workload should not take up more than two-thirds of any dimension of the inside

cavity.

Page 28

19

Pre-Startup Checklist

WARNINGS:

Do not use any flammable solvent or other

flammable material in this oven. Do not

process closed containers of any substance

or liquid in this oven because they may

explode under heat.

WARNING:

DO NOT touch cooling coil drain

piping during chamber operation

- steam can be generated in the

cooling coil and STEAM BURNS.

Know the system. Read this manual carefully. Make use of its instructions and

explanations. The know how of safe, continuous, satisfactory, trouble-free

operation depends primarily on the degree of your understanding of the system

and of your willingness to keep all parts in proper operating condition.

Check line voltage. This must correspond to nameplate requirements of motors

and controls. A wrong voltage can result in serious damage. Refer to the

section on power connections in the INTRODUCTION of this manual.

Check fresh air & exhaust dampers (Non-atmosphere models only). Do not be

careless about restrictions in and around the fresh air and exhaust openings and

stacks. Under no condition, permit them to become so filled with dirt that they

reduce airflow.

Startup

For fastest oven heat-up time, close the

vent (fresh air models). After desired

temperature is reached, vent may be

adjusted as needed.

1. Start fan.

a. Open oven door.

b. Press POWER toggle switch to the ON

position. You will hear the recirculating

fan start.

c. Shut oven door.

d. Check that the amber LED on the CONTROL panel is on.

2. Enter setpoint on the CONTROL instrument.

3. Set HIGH LIMIT instrument to a temperature 10 C - 15 C higher than the

setpoint or to a temperature that should not be exceeded in the process. It will

be necessary to reset the HIGH LIMIT instrument whenever it has tripped. To

reset, allow the oven to cool slightly or increase the HIGH LIMIT setpoint above

the actual temperature. Press the RESET button.

Page 29

20

4. For the inert atmosphere ovens,

NOTE: When operating the oven without

the optional water cooling, the minimum

operating temperature is approximately

78 C (nitrogen models) and

approximately 20 C (non-nitrogen

models) over the ambient room

temperature. This is the result of the

heat generated by the recirculating fan.

NOTE: This graph is an approximate measure.

Actual conditions will vary. The grade of the inlet

gas used will also affect performance.

adjust flow rate.

a. Determine the desired

oxygen level.

b. Use the following chart to

determine the time to

achieve the desired oxygen

level.

Page 30

21

c. Turn the nitrogen valve

WARNING: Never operate the oven at a

temperature in excess of the maximum

operating temperature which is 260 C

(500 F).

WARNING: Never operate the oven at a

temperature in excess of the maximum

operating temperature which is 260 C

(500 F).

switch to the PURGE

position for the time to

achieve oxygen level as

determined in step 2b.

d. When the purge is complete, turn the nitrogen valve switch to the

MAINTAIN position.

e. Determine the MAINTAIN flowmeter value to maintain the oxygen

stabilization level.

f. Adjust the MAINTAIN flowmeter to the value determined in step 2e.

5. Press the heater toggle switch to the ON position. The white light will come on,

indicating a heat on condition. Heater indicator light should come on. When the

desired temperature is reached, the control instrument will proportion power to

the heater as needed and the heater indicator light will flash on and off.

6. To cool down the oven, set the control to a lower temperature. If necessary, turn

on water supply to the cooling coil or the valve on the face of the optional cooling

water flowmeter. On fresh air models, you may open the fresh air damper by

adjusting the damper control knob.

The water cooling coil should be used when cooling a load in a relatively short

period of time. The water is controlled by the optional cooling water flowmeter

and can be adjusted or shut off by the brass needle valve on its face.

Page 31

22

7. After heating cycle is complete, turn the heater toggle switch to the OFF position.

Do not turn the power off until the oven chamber temperature is below 100 C

(212 F).

Shut Down

1. Push the heater switch to OFF after the heating cycle is complete.

2. Do not turn the power off until the oven temperature is below 150 C (302 F). If

the oven is turned off before it is properly cooled, the fan shaft and motor

bearings may become overheated, shortening the life of the motor.

3. Turn the nitrogen control valve to OFF (nitrogen models).

4. Turn off the water supply to the cooling coil or the valve on the face of the

optional cooling water flowmeter (nitrogen models).

5. Push the POWER switch to OFF.

Page 32

23

Maintenance

Do not attempt any service on this oven before opening the main power disconnect

switch.

Checklist

Keep equipment clean. Gradual dirt accumulation retards air flow. A dirty oven

can result in unsatisfactory operation such as unbalanced temperature in the

work chamber, reduced heating capacity, reduced production, overheated

components, etc. Keep the walls, floor and ceiling of the oven work chamber

free of dirt and dust. Floating dust or accumulated dirt may produce

unsatisfactory work results. Keep all equipment accessible. Do not permit other

materials to be stored or piled against it.

Protect controls against excessive heat. This is particularly true of controls,

motors or other equipment containing electronic components. Temperatures

greater than 51.5 C (125 F) should be avoided.

Establish maintenance & checkup schedules. Do this promptly and follow the

schedules faithfully. Careful operation and maintenance will be more than paid

for in continuous, safe and economical operation.

Maintain equipment in good repair. Make repairs immediately. Delays may be

costly in added expense for labor and materials and in prolonged shut down.

Practice safety. Make it a prime policy to know what you are doing before you

do it. Make CAUTION, PATIENCE, and GOOD JUDGEMENT the safety

watchwords for the operation of your oven.

Lubrication, Fan motor bearings are permanently lubricated. All door latches,

hinges, door operating mechanisms, bearing or wear surfaces should be

lubricated to ensure easy operation.

Page 33

24

Tests

WARNING:

High voltage is present on terminals,

voltage checks should be made only by

qualified electrical maintenance personnel:

e.g. electrician or technician. Failure to

heed this warning can result in serious

bodily injury, property damage, or death.

Tests should be performed carefully and regularly. The safety of personnel as well as

the condition of equipment may depend upon the proper operation of any one of these

controls at any time.

Nitrogen Supply Check

This test is necessary in nitrogen models only.

1. Turn the inert atmosphere valve on

the control panel to the OFF

position.

2. Screw the adjusting knob on the

flowmeters clockwise all the way to

the OFF position. The adjusting

knobs must be off on both the

PURGE and MAINTAIN flowmeters.

3. Open the tank valve on the nitrogen supply and set the pressure regulator to

about 40 psi.

4. Check the nitrogen plumbing for leaks using a soapy water solution. As nitrogen

gas is odorless, all leaks should be stopped to prevent the possibility of

suffocation in a small work area in which a nitrogen leak might displace much of

the oxygen in the atmosphere.

Control Output Check

1. On a cool oven (< 100 C or 212 F), adjust CONTROL setpoint to 20 F (11 C)

higher than current actual chamber temperature.

2. Set HEATER switch to ON.

3. When the CONTROL output indicator light is on, the HEATER indicator should

also be on.

4. When the CONTROL output indicator light turns off, the HEATER indicator light

should also turn off. If the HEATER light remains on, the SSR may be shorted.

You can also verify the CONTROL output by measuring across the output (+ and

-) terminals with a voltage meter. The output should measure >4 VDC when on,

Page 34

25

and < 1 VDC when off.

5. Reconnect line power to the control.

6. Replace the SSR if shorted or replace the CONTROL instrument if the output

does not measure properly.

Thermocouple Test

1. Place a jumper or short the thermocouple terminals on the control. The display

should read ambient temperature and be very stable.

2. Replace the CONTROL if the unit is not stable.

Safety Controls

Make these tests carefully and do them regularly. The safety of personnel as well as

the equipment may depend upon the proper operation of any one of these controls at

any time.

Temperature Control (every 40 hours) - The heater indicator light should flash every 1

to 2 seconds when the control is operating at a steady set point temperature.

HIGH LIMIT (every 40 hours) - With the oven operating at a given temperature,

gradually lower the high limit setpoint to the setpoint operating temperature. Verify that

the HIGH LIMIT trips (heater indicator will turn off and remain off). Return the HIGH

LIMIT to its original setting and press the high limit reset button.

Page 35

26

Replacement

WARNING:

Shut down nitrogen supply and

disconnect main power switch

or power cord before

attempting any repairs or

adjustments.

Parts

To return parts contact Despatch Industries to obtain an MRA (material return

authorization) number. This number must be attached to the returned part for our

identification. If required, a new part will be sent and invoiced to you. When the return

part is received, credit will be given, if in warranty.

When ordering parts or service, be sure to specify the model, serial number and part

number. This will expedite the process of obtaining your replacement part.

CONTROL Instrument

(Tools needed: one quarter (¼) inch socket set)

1. Disconnect power.

2. Remove screws from the face of the control panel and slide it forward.

3. Remove wires from the old control, noting which numbered wires connect to

which terminals.

4. Replace old control with new control.

5. Reattach wires to the new CONTROL instrument. Make sure that the wires are

connected correctly. Refer to the wiring diagram in the appendix of this manual.

6. Replace control panel.

Page 36

27

Fan Motor

(Tools needed: Screwdriver, Allen wrench, crescent wrench)

1. Disconnect power.

2. Remove filter cover and filter from left side.

3. Remove floor plate.

a. Remove screws from the floor plate.

b. Lift floor plate out of the oven.

4. Remove the screws from the heater frame then tip up and to the right.

5. Loosen set screws on fan wheel inside fan housing.

6. Remove the screws from the face of the control panel and slide it forward to

uncover motor.

7. Tip oven on its back.

8. Remove outside floor.

9. Unbolt the four bolts holding the motor to the motor mount.

10. Remove motor. After fan wheel has run at temperature for a while it will stick to

the shaft. Some force may be required to separate the two. Suggest holding the

fan wheel against the insulated wall while using a mallet and center punch to

loosen the shaft from the fan.

11. Disconnect motor leads from terminal block.

12. Hold new motor in place while you remount fan wheel to motor shaft. Reattach

motor to motor mount.

13. Attach motor lead wires to terminal block (see wiring diagram).

14. Replace oven control panel and bottom, then tip oven upright again.

15. Adjust fan wheel for 3/16 inch clearance between wheel and inlet ring.

Page 37

28

16. Tighten set screws making sure set screws hit the flats machined into the motor

shaft.

17. Bolt heater back in place.

18. Replace interior floor.

19. Replace filter and filter cover.

20. Reconnect power.

Replacing HIGH LIMIT

(Tools needed: Screwdriver, one quarter (¼) inch socket set)

1. Disconnect power.

2. Remove screws from face of control panel and slide it forward.

3. Remove wires from HIGH LIMIT noting which numbered wires connect to which

terminals. Refer to wiring diagram in this manual.

4. Replace old HIGH LIMIT with new HIGH LIMIT.

5. Reattach wires to the new HIGH LIMIT. Make sure the wires are connected

correctly.

6. Replace control panel.

Page 38

29

Thermocouple Break Protection

If the thermocouple breaks, the control instrument will shut off power to the heater,

preventing excessive temperature in the chamber.

Replacing the Thermocouple

(Tools needed: Small screwdriver and small crescent wrench)

The controller thermocouple is type J (iron/constantan) and is replaceable using the

following procedure:

1. Disconnect power and remove screws from the face of the control panel and

slide it forward.

2. Locate thermocouple along the left side of the control chamber.

3. Loosen the nut on the fitting holding the thermocouple in place.

4. Pull thermocouple out of brass fitting.

5. Feed new thermocouple through the nut and ferrule and place back into the

fitting.

6. Re-tighten the fitting nut.

7. Remove old thermocouple from terminals on the CONTROL and HIGH LIMIT

instruments.

8. Attach new thermocouple leads to the proper terminals of the CONTROL and

HIGH LIMIT instruments.

9. Replace oven control panel.

Page 39

30

Heater Unit

(Tools needed: Crescent wrench, screwdriver, one quarter (¼) inch socket set)

1. Disconnect power.

2. Remove filter cover and filter from left side.

3. Remove floor plate.

a. Remove screws from the floor plate.

b. Lift floor plate out of the oven.

4. Disconnect heater leads from heater element with wrench. Note which wires go

on which terminals.

5. Unscrew screws holding the frame to the oven body.

6. Remove heater and discard.

7. Screw down new heater frame.

8. Attach heater leads to appropriate terminals.

9. Replace interior floor and screws.

10. Replace filter and filter cover.

11. Reconnect power.

Page 40

31

APPENDIX

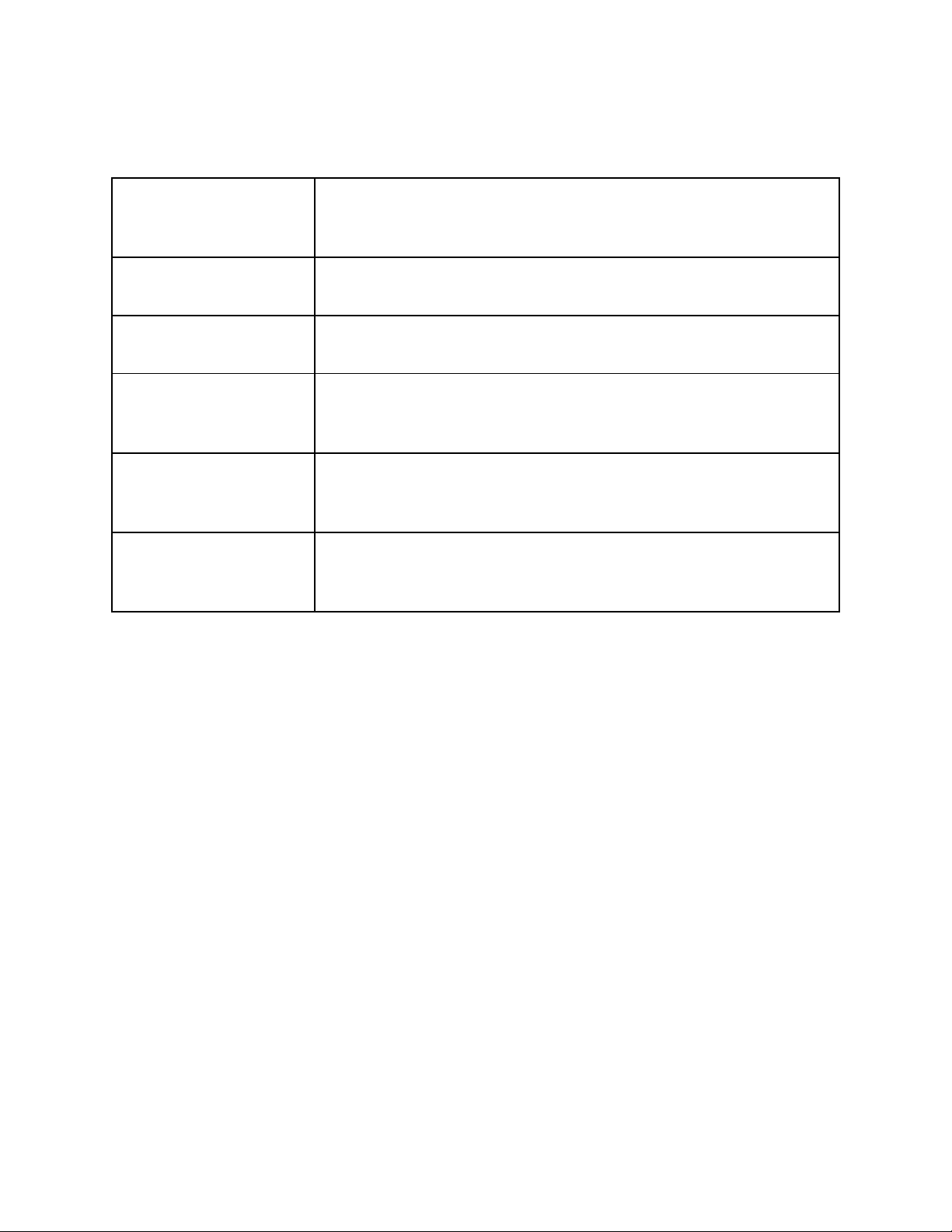

Difficulty

Probable Cause

Suggested Remedy

Failure to heat

No power

Check power source and/or oven and wall fuses.

Burned out heating

element

Replace element (see warranty statement).

CONTROL instrument

malfunction

See troubleshooting information in CONTROL

instrument manual.

Loose wire connections

Disconnect power and check connections behind

control panel.

Slow heat up

Improperly loaded

Reduce load or redistribute load in chamber

Low line voltage

Supply sufficient power and proper connections.

Check to see if circuit is overloaded.

Heating elements

Replace burned out element(s) (see warranty

statement)

240 volt oven is connected

to a 208 volt line.

Consult with factory.

Fan motor failure

Replace fan motor.

Water flow in optional

cooling coil.

Shut water off.

Filter clogged

Replace filter (see section on HEPA filter

Frequent heater

process. element

burn out

Harmful fumes generated

by load

Increase vent opening or discontinue

Overheating oven

Do not operate over 260+ C (500+ F)

Excessive dust build up in

filter

Replace filter (see section on HEPA filter)

Erratic or inaccurate

temperature

CONTROL instrument

malfunction

See troubleshooting information in CONTROL

instrument manual.

Inaccurate

temperatures

CONTROL miscalibration

See troubleshooting information in CONTROL

instrument manual.

Excess surface

Troubleshooting

Equipment operating for long periods may have occasional problems. Below are

possible problems and suggested solutions. If you have a problem not listed and do

not know what to do, contact Despatch Industries at our toll-free Help Line

(800-473-7373).

Page 41

32

Difficulty

Probable Cause

Suggested Remedy

temperature around

door

Door seal deterioration

Replace door seal.

Improper airflow

Fan motor failure

Replace fan motor.

Unbalanced fan heel

Replace fan heel.

Filter clogged

Replace filter.

Excessive vibration

Dirty fan wheel

Clean fan.

Unbalanced fan wheel

Replace fan.

Oven will not control

at setpoint

HIGH LIMIT instrument

set too low

Set the HIGH LIMIT instrument higher.

HIGH LIMIT is out of

calibration

Recalibrate the HIGH LIMIT

Solid state relay

malfunction

Replace solid state relay.

Control instrument

malfunction

See troubleshooting information in CONTROL

instrument manual.

Air friction of recirculation

fan

The minimum operating temperature is around

65 C above ambient room temperature. Use

optional water cooling coil.

Heater does not shut

off until the

temperature reaches

the high limit setting

Solid state relay shorted

Replace solid state relay.

Excessive O2 levels

Door seal deterioration

Replace door seal.

Pressure relief valve

leaking

Replace valve

Fan shaft seal leaking

Replace shaft seal (remove fan motor first)

Page 42

33

Factory Installed Options

Access Ports

Circular openings welded into top or rear of chamber.

Standard sizes available include 1, 2, 3 and 4 inches in

diameter and come complete with a threaded cap.

Door Switch

A switch activated by the chamber door which will disable the

heater, or the heater and recirculation fan.

High limit/end of cycle

alarm

Alarm horn and red light which will indicate a HIGH LIMIT

condition or the end of a process cycle.

Auto nitrogen

Solenoid valves actuate the purge and maintain flows of

nitrogen. Valves are controlled by event outputs on the

control instrument, or by a switch on the control panel.

Auto H20

Solenoid valves actuate the cooling water flow. Valves are

controlled by event output on the control instrument, or by a

switch on the control panel. Includes flow meter.

Door lock

Pneumatic cylinder locks closed chamber door. Cylinder is

actuated by solenoid valve which is controlled by event

output on the control instrument. Requires an air supply.

Page 43

34

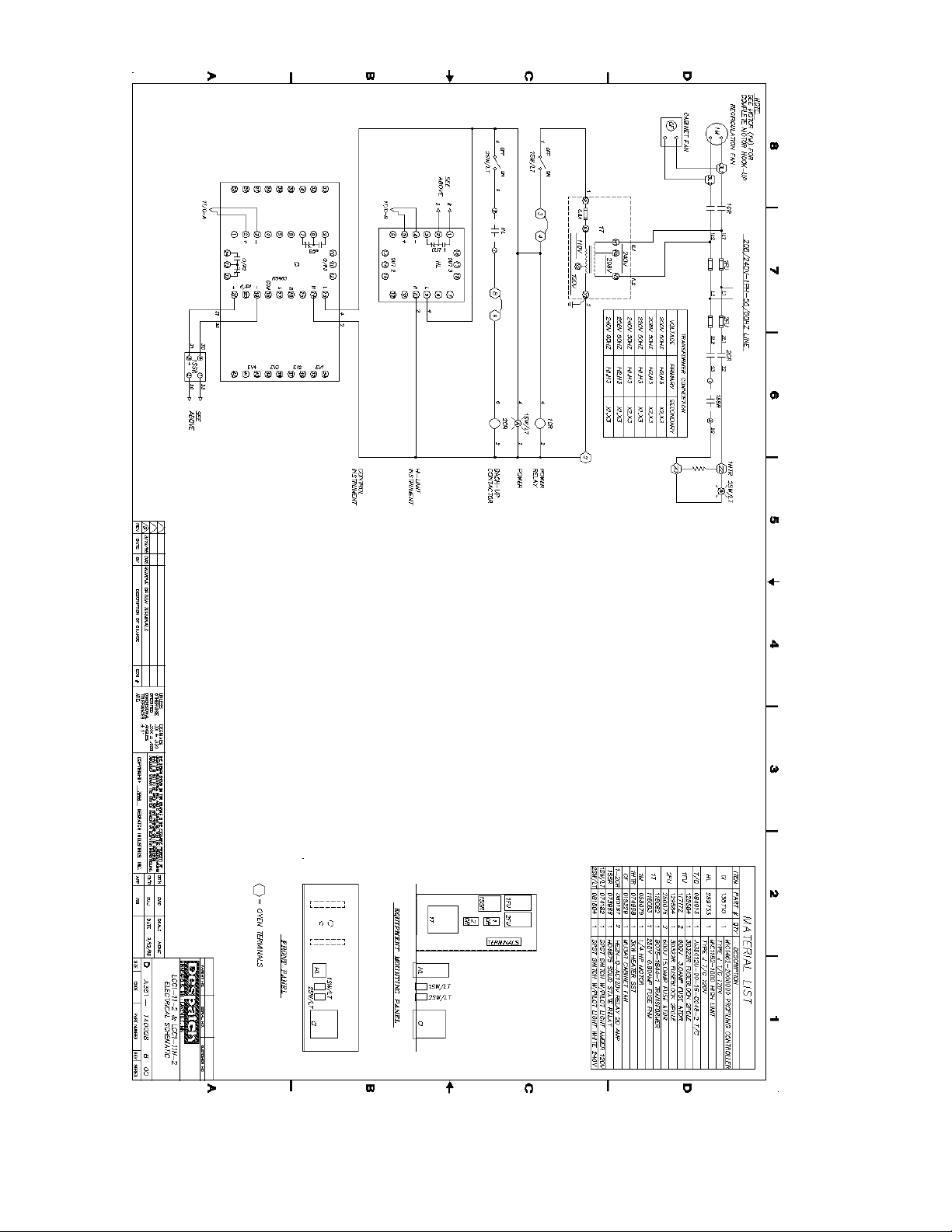

Drawings

The drawings on the next pages are the electrical schematics for the following ovens:

LCC 1 - 11 - 2 & LCC 1 - 11N – 2

Digitronic Controller DA351-080928J00

MIC1462 Controller DA351-140028B00

LCC 1 - 54 - 2 & LCC 1 - 54N - 2 & LCC 1 - 54NV – 2

Digitronic Controller CA351-054552T00

MIC1462 Controller DA351-140029B00

LCC 1 - 87 - 2 & LCC 1 - 87N - 2 & LCC 1 - 87NV – 2

Digitronic Controller CA368-081389I00

MIC1462 Controller DA351-140030B00

Page 44

35

Page 45

36

Page 46

37

Page 47

38

Page 48

39

Page 49

40

Loading...

Loading...