Page 1

Stackable LCC/LCD Oven Owner’s Manual PREFACE

ULTRAFLEX DRYING AND FIRING

FURNACE

MODELS 1000, 3615, 3630, 3640

C-204

VERSION 26

10/2008

STACKABLE LCC/LCD OVEN

OWNER’S MANUAL

C-195

PN 156452

VERSION 26

09/2010

Version 26 1

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 2

PREFACE Stackable LCC/LCD Oven Owner’s Manual

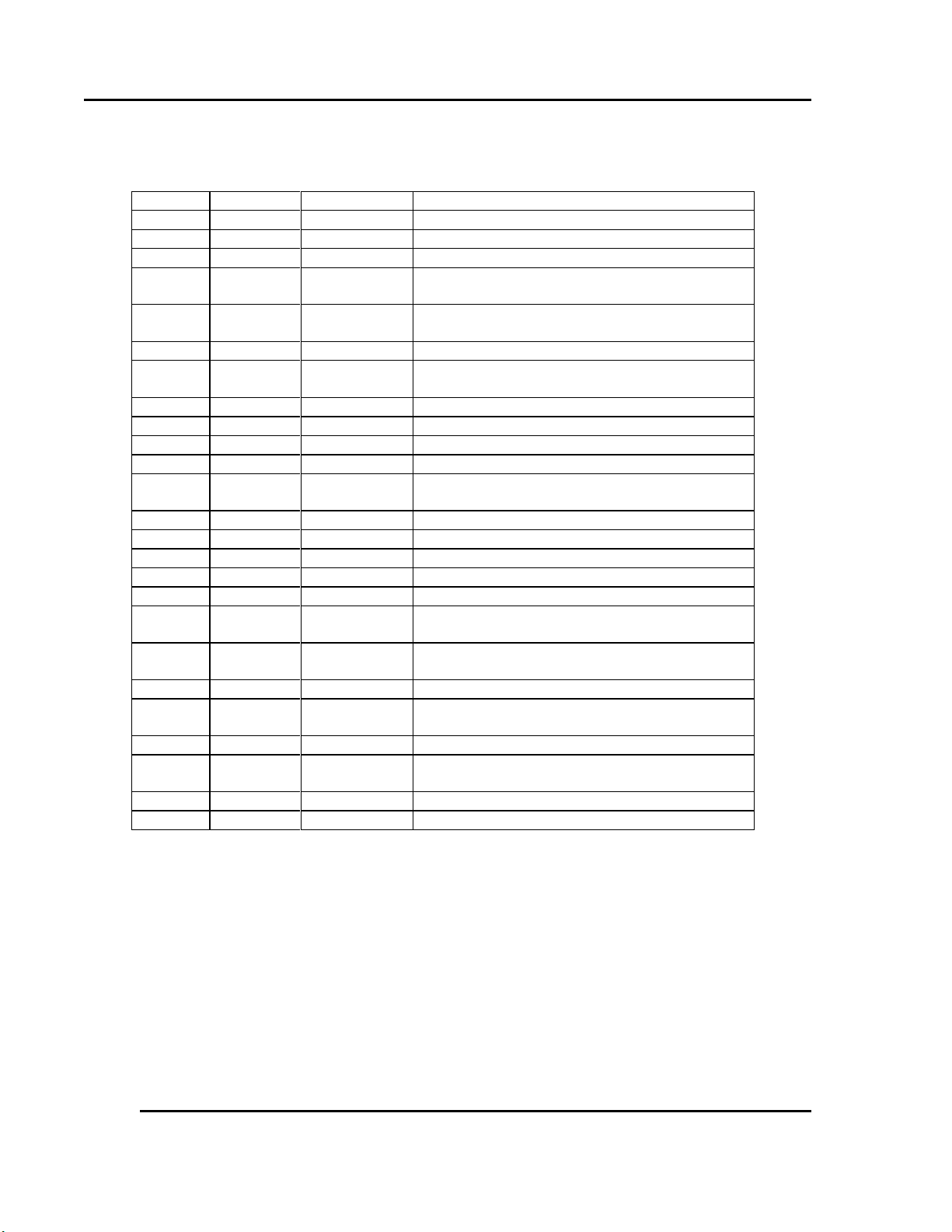

Revision

Date

Author

Description

B

6/01

Various corrections

C

11/01

Corrections, addition of schematic drawings

D

1/02

Corrections, update of schematic drawings

E

4/02

Update of schematic drawings, modified per

Rev C Protocol Plus software

F

7/02

Corrections to Protocol Plus software

description

G

9/02

Miscellaneous corrections

H

11/02

Modify operating procedure, update schematic

drawings

I

1/03

Update Despatch warranty pages

J

5/03

Update of schematic drawings

K

8/03

Update of schematic drawings

L

11/03

Update to Protocol Plus Version 4.0.

M

12/03

Add door lock manual override and Nitrogen

needle valve information

N

2/04

Update of schematic drawings

P

9/04

Update of schematic drawings

Q

11/04

Update of schematic drawings

R

3/05

Update of schematic drawings

S

6/05

Update Declaration of Conformity

T

12/05

Update Declaration of Conformity, add LLC

notes

U

8/06

Revised Protocol Plus numbers. Updated

Despatch address. Updated CE documents.

V

11/07

Updated warranty

W

12/07

Corrected Nitrogen Inlet connection from 3/8”

to 1/4” X 3/09

Updated Controller Section

Y

2/10

Updated Declaration of Conformity and

drawings

25

7/10

K. Livingston

Revise format

26

9/10

K. Livingston

Remove Protocol Plus to separate manual

2 Version 26

Revision History

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 3

Stackable LCC/LCD Oven Owner’s Manual PREFACE

Version 26 3

Table of Contents

1. About This Manual ................................................................................................. 6

1.1. Important User Information .......................................................................... 6

1.2. Manufacturer & Service ................................................................................ 7

1.3. Organization of this Manual ......................................................................... 7

1.4. Conventions .................................................................................................. 8

1.5. Specifications ................................................................................................ 9

1.5.1. Model Numbering and Naming Conventions ........................................... 9

1.5.2. Dimensions ................................................................................................ 9

1.5.3. Capacities ................................................................................................ 10

1.5.4. Power ....................................................................................................... 10

1.5.5. Temperature ............................................................................................ 11

2. Safety .................................................................................................................... 12

2.1. Safety Information ...................................................................................... 12

2.1.1. Lockout.................................................................................................... 12

2.1.1.1. Lockout Requirements ......................................................................... 12

2.1.1.2. Lockout Procedure ............................................................................... 12

2.1.2. Door and Panel ........................................................................................ 13

2.2. Maintenance ................................................................................................ 13

2.3. Electrical Power .......................................................................................... 13

2.4. Fire .............................................................................................................. 14

2.5. Equipment Lockout Requirements ............................................................. 14

2.5.1. Emergency Stop ...................................................................................... 14

3. Theory of Operation .............................................................................................. 15

3.1. The Stackable LCC/LCD Series Oven ....................................................... 15

3.2. The Protocol Plus Controller ...................................................................... 16

3.3. HEPA Filters ............................................................................................... 17

3.3.1. Definitions ............................................................................................... 17

3.3.2. Filter Packaging, Shipping and Handling ............................................... 17

3.3.3. HEPA Filter Validation Testing .............................................................. 18

3.3.3.1. D.O.P. Testing ..................................................................................... 18

3.3.3.2. Class 100 Testing................................................................................. 18

3.3.3.3. Validation Testing ............................................................................... 19

3.3.3.4. HEPA Filter Burn-off Process Not Necessary .................................... 19

3.3.4. HEPA Filter Unit Replacement ............................................................... 19

3.3.5. HEPA Filter: Magnehelic Pressure Gauge .............................................. 20

4. Assembly & Setup ................................................................................................ 21

4.1. Unpack & Inspect The LCC/LCD Oven ..................................................... 21

4.1.1. If Damaged During Shipping .................................................................. 22

4.2. Set-up The LCC/LCD Oven ....................................................................... 22

4.2.1. Select Oven Location .............................................................................. 22

4.2.1.1. Single Oven Placement Requirements ................................................ 22

4.2.1.2. Multiple Oven Placement Requirement .............................................. 22

4.2.2. Oven Utility Connections ........................................................................ 23

4.2.2.1. Nitrogen With Water-Cooled Models ................................................. 24

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

Copyright © 2010 by Despatch Industries.

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Page 4

PREFACE Stackable LCC/LCD Oven Owner’s Manual

4 Version 26

4.2.2.2. Air Atmosphere with Optional Water Cooling Model ........................ 25

4.2.3. Exhaust Connections ............................................................................... 27

4.2.4. Wiring & Power Connections ................................................................. 27

4.3. HEPA Filter Installation ............................................................................. 29

4.3.1. HEPA Filter Burn-Off ............................................................................. 33

4.3.1.1. HEPA Filter Burn-Off Process ............................................................ 33

4.3.1.2. Location of HEPA Filter Burn-Off Process ........................................ 33

4.3.1.3. Recommended HEPA Filter Burn-Off Process ................................... 34

4.4. MRC5000 Setup (Optional) ........................................................................ 35

5. Operation............................................................................................................... 37

5.1. Load Oven ................................................................................................... 37

5.2. Pre-Startup Checklist .................................................................................. 38

5.3. Operating Procedure ................................................................................... 39

5.3.1. Start Oven ................................................................................................ 39

5.3.2. Working with Protocol Plus Operating Modes ....................................... 39

5.3.3. Sequence of Operation for Ovens Equipped with Optional Beacon Light

39

5.3.4. Sequence of Operation for Ovens Equipped for Inert Atmosphere Oven41

5.3.5. Manual Unlock and Main Disconnect ..................................................... 43

5.3.5.1. Manual Unlock .................................................................................... 43

5.3.5.2. Main Disconnect Switch ...................................................................... 43

6. Maintenance .......................................................................................................... 44

6.1. Checklist ..................................................................................................... 44

6.2. Lubrication .................................................................................................. 44

6.3. HEPA Filter Replacement........................................................................... 44

7. Troubleshooting: Error Messages and Alarm ....................................................... 45

8. Appendices ............................................................................................................ 46

8.1. HEPA Filter Pressure Reading Worksheet ................................................. 46

8.2. Standard Products Warranty ....................................................................... 47

8.3. EC Declaration of Conformity .................................................................... 48

8.4. Electrical Schematics .................................................................................. 48

Figures

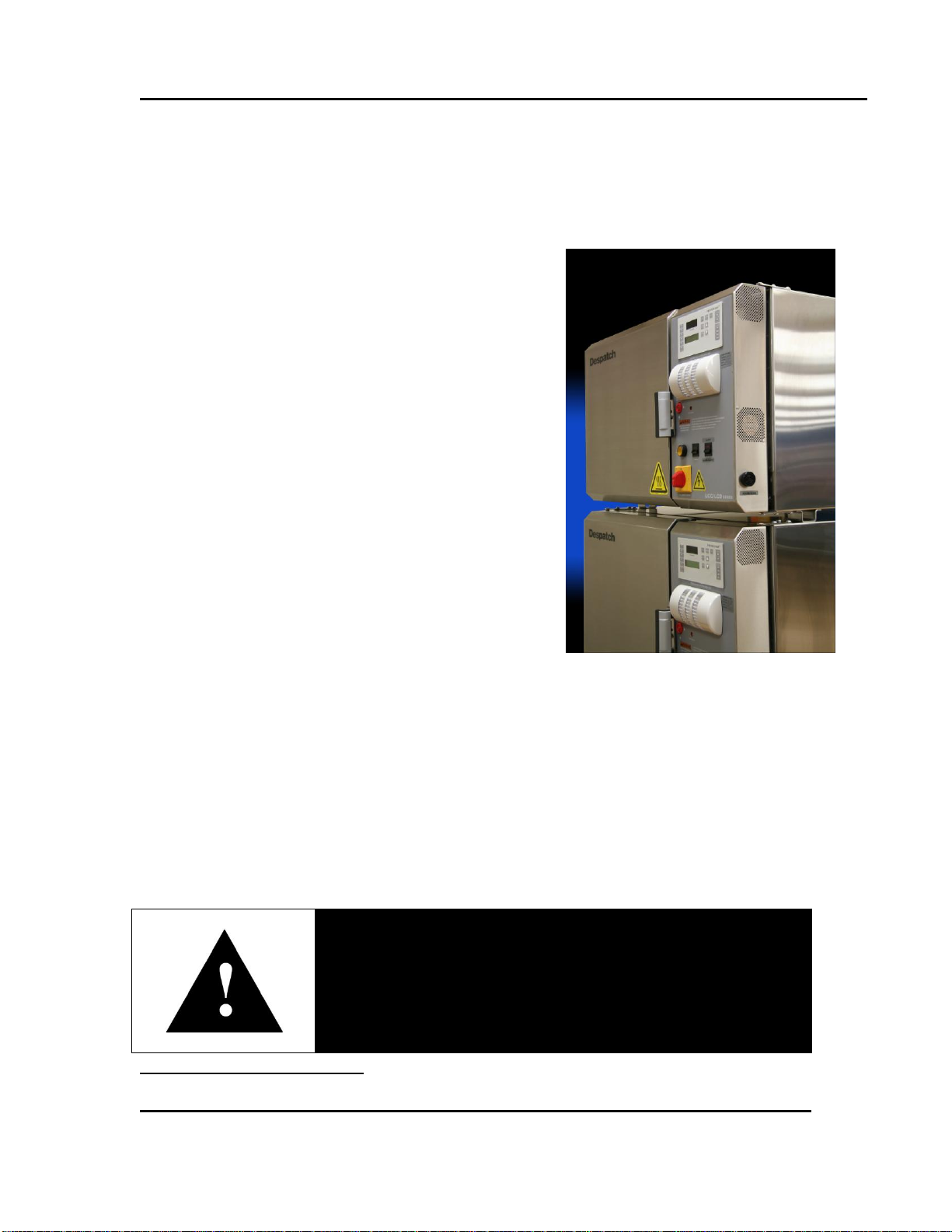

Figure 1. Stackable LCC/LCD Series Oven. .................................................................... 15

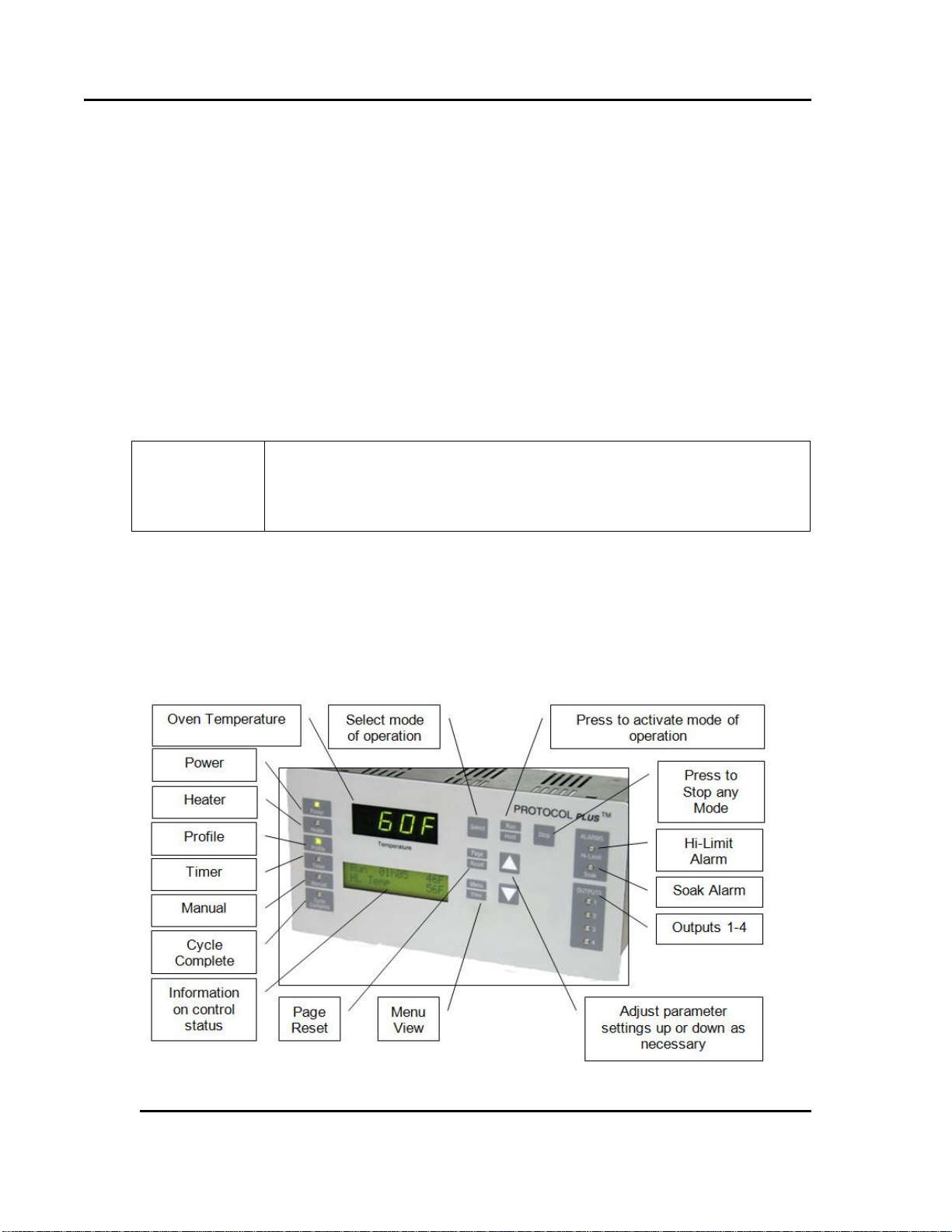

Figure 2. Protocol Plus Displays and Control Buttons. .................................................... 16

Figure 3. This Side Up graphic. ........................................................................................ 17

Figure 4. Magnehelic Pressure Gauge Measures Pressure in front of the HEPA filter. ... 20

Figure 5. Door Lock Manual Override Key (LCC/LCD/LLC/LLD). .............................. 21

Figure 6. LCC/LCD Connections Panel. .......................................................................... 24

Figure 7. Exhaust Port on the Left Side of the LCC/LCD Oven. ..................................... 27

Figure 8. Open the front panel for access. ........................................................................ 28

Figure 9. Conduit entrance at rear of oven and open front panel. .................................... 29

Figure 10. Example HEPA Filter (Silicone-free) and Close-Up. ..................................... 31

Figure 11. Remove inner casing to install HEPA filter. ................................................... 32

Copyright © 2010 by Despatch Industries.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Page 5

Stackable LCC/LCD Oven Owner’s Manual PREFACE

Version 26 5

Figure 12. Options for Starting Termikfil 2000 Filter. ..................................................... 34

Figure 13. Power the Oven. .............................................................................................. 39

Figure 14. Nitrogen Flowmeter......................................................................................... 41

Figure 15. Adjust Nitrogen Maintain Needle Valve. ........................................................ 42

Figure 16. Water and Nitrogen Piping Schematic. ........................................................... 42

Figure 17. LCC1-16-3 (Drawing 150008-01). .................................................................. 49

Figure 18. LCC1-16-3 (Drawing 150008-02). .................................................................. 49

Figure 19. LCC1-16-3 (Drawing 150008-03). .................................................................. 49

Figure 20. LCC1-16N-3 (Drawing 150047-01). ............................................................... 49

Figure 21. LCC1-16N-3 (Drawing 150047-02). ............................................................... 49

Figure 22. LCC1-16N-3 (Drawing 150047-03). ............................................................... 49

Figure 23. LCC1-51-3 (Drawing 150044-01). .................................................................. 49

Figure 24. LCC1-51-3 (Drawing 150044-02). .................................................................. 49

Figure 25. LCC1-51-3 (Drawing 150044-03). .................................................................. 49

Figure 26. LCC1-51N-3 (Drawing 159135-01). ............................................................... 49

Figure 27. LCC1-51N-3, Drawing 159135-02). ............................................................... 49

Figure 28. LCC1-51N-3 (Drawing 159135-03). ............................................................... 49

Figure 29. LCC1-51N-3 (Drawing 159135-04). ............................................................... 49

Figure 30. LCC1-51-3 (Drawing 159159-01). .................................................................. 49

Figure 31. LCC1-51-3 (Drawing 159159-02). .................................................................. 49

Figure 32. LCC1-51-3 (Drawing 159159-03). .................................................................. 49

Figure 33. LCC1-51N-3 (Drawing 163141-01). ............................................................... 49

Figure 34. LCC1-51N-3 (Drawing 163141-02). ............................................................... 49

Figure 35. LCC1-51N-3 (Drawing 163141-03). ............................................................... 49

Figure 36. LCC1-51N-3 (Drawing 163141-04). ............................................................... 49

Tables

Table 1. Model Number Key. ............................................................................................. 9

Table 2. HEPA Filter Pressure Reading Worksheet. ........................................................ 20

Table 3. Oven Utility Connections. .................................................................................. 23

Table 4. Exhaust Connection Requirements. .................................................................... 27

Table 5. MRC 5000 Settings. ............................................................................................ 36

Table 6. Desired Oxygen Concentration. .......................................................................... 41

Table 7. Error Messages and Next Steps. ......................................................................... 45

Copyright © 2010 by Despatch Industries.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Page 6

ABOUT THIS MANUAL Stackable LCC/LCD Oven Owner’s Manual

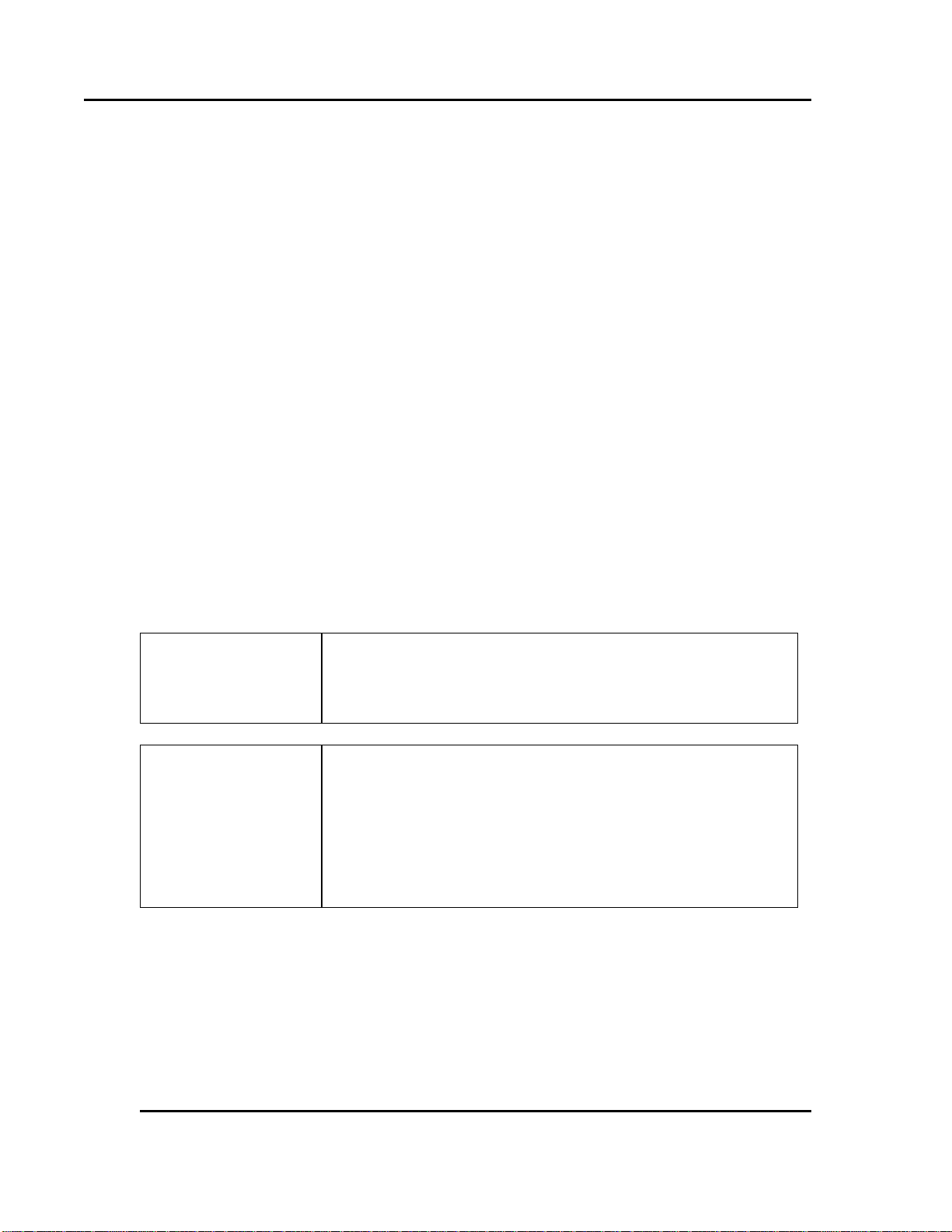

Values displayed on screens are examples only. Though

those values may be typical, contact Despatch Industries for

the final value.

Users of this equipment must comply with operating

procedures and training of operation personnel as required

by the Occupational Safety and Health Act (OSHA) of 1970,

Section 6 and relevant safety standards, as well as other

safety rules and regulations of state and local governments.

Refer to the relevant safety standards in OSHA and National

Fire Protection Association (NFPA), section 86 of 1990.

6 Version 26

1. About This Manual

1.1. Important User Information

Copyright © 2010 by Despatch Industries.

All rights reserved. No part of the contents of this manual may be reproduced, copied, or

transmitted in any form or by any means including graphic, electronic, or mechanical

methods or photocopying, recording, or information storage and retrieval systems without

the written permission of the publisher, unless it is for the purchaser's personal use.

Printed and bound in the United States of America.

The information in this manual is subject to change without notice and does not represent

a commitment on the part of Despatch Industries. Despatch Industries does not assume

any responsibility for any errors that may appear in this manual.

In no event will Despatch Industries be liable for technical or editorial omissions made

herein, nor for direct, indirect, special, incidental, or consequential damages resulting

from the use or defect of this manual.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 7

Stackable LCC/LCD Oven Owner’s Manual ABOUT THIS MANUAL

Danger!

Only fully-trained and qualified personnel should setup and

maintain this equipment. Improper setup and operation of this

equipment could cause an explosion that may result in

equipment damage, personal injury or possible death.

Global Headquarters

Contact

Service & Technical

Support

Despatch Industries

8860 207th Street

Lakeville, MN 55044

USA

International/Main: 1-952-469-5424

US toll free: 1-888-337-7282

Fax: 1-952-469-4513

info@despatch.com

www.despatch.com

Service: 1-952-469-8230

US toll free: 1-800-473-7373

Service @despatch.com

Version 26 7

The information in this document is not intended to cover all possible conditions and

situations that might occur. The end user must exercise caution and common sense when

installing or maintaining Despatch Industries products. If any questions or problems

arise, call Despatch Industries at 1-888-DESPATCH or 1-952-469-5424.

1.2. Manufacturer & Service

The Stackable LCC/LCD Oven is manufactured by Despatch Industries.

Despatch has specialized in thermal processing for over 100 years. Technical expertise

gained over those years helps provide innovative solutions to critical applications in

vertical markets and cutting edge technology worldwide. Despatch products are backed

by a drive for long-term customer satisfaction and a strong sense of responsibility. The

worldwide network of factory-trained Service Professionals is available to support your

Despatch equipment. From full service preventive maintenance to routine repair and

certified calibration and uniformity, the Despatch service network is positioned to

respond to your business needs. Our service programs are customized to meet your

specific needs using our Advantage Service Assurance Program (ASAP). For more

information on ASAP, visit www.despatch.com.

1.3. Organization of this Manual

This owner’s manual contains the most comprehensive set of information for the

Despatch Stackable LCC ovens, including installation instructions, theory of operation,

operating instructions, among other things.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 8

ABOUT THIS MANUAL Stackable LCC/LCD Oven Owner’s Manual

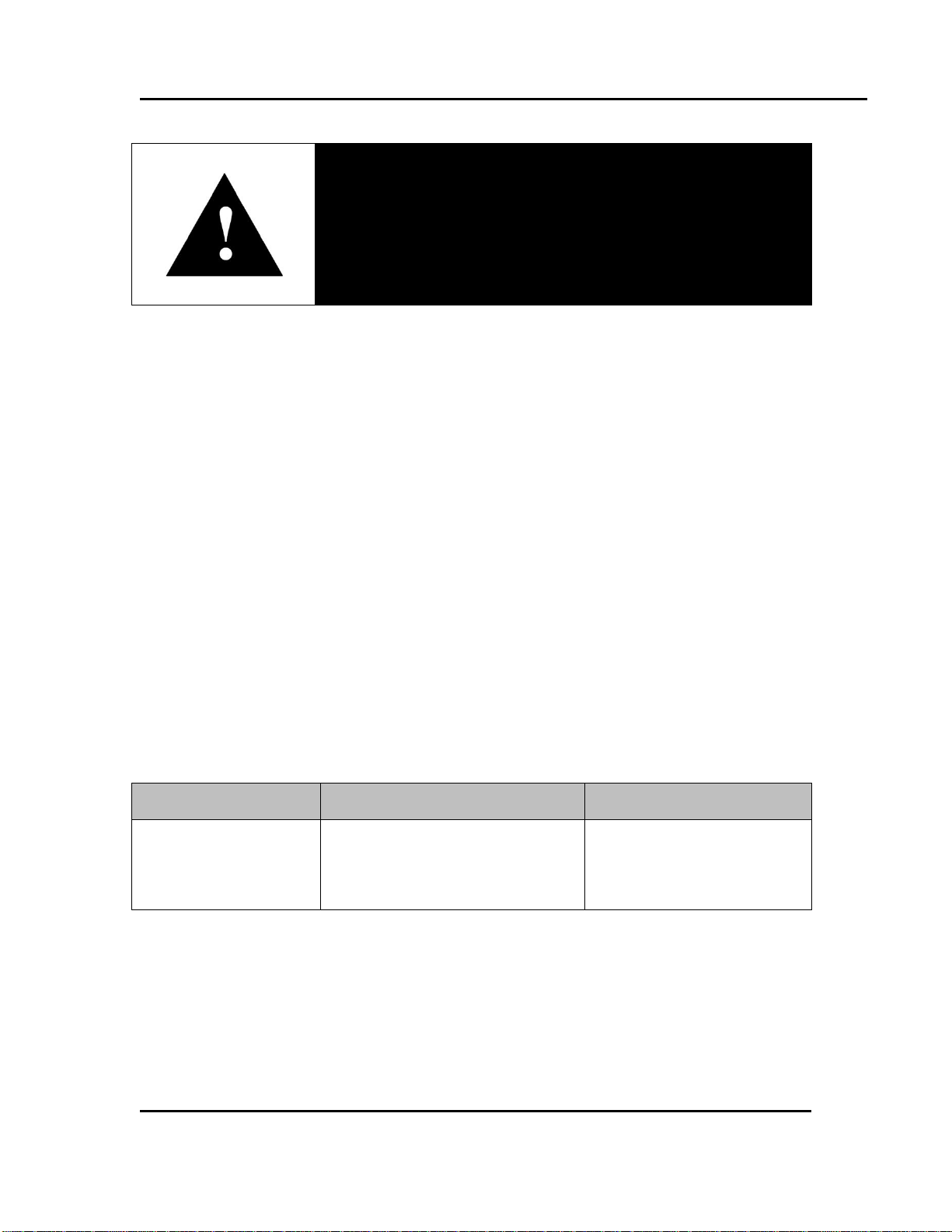

Danger!

Failure to heed warnings in this instruction manual and on the

oven could result in personal injury, property damage or death.

This icon signifies important information.

This icon signifies information that describes an unsafe condition

that may result in death, serious injury, or damage to the

equipment.

Danger!

A condition that may result in death, serious injury, or damage to

equipment.

Warning!

A condition that may result in serious injury or damage to

equipment.

Caution!

A condition that may result in damage to equipment or product.

LOG OUT

Reversed-out, Bold, 10pt Arial typeface indicates a specific key or

button on screen to click.

8 Version 26

1.4. Conventions

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 9

Stackable LCC/LCD Oven Owner’s Manual ABOUT THIS MANUAL

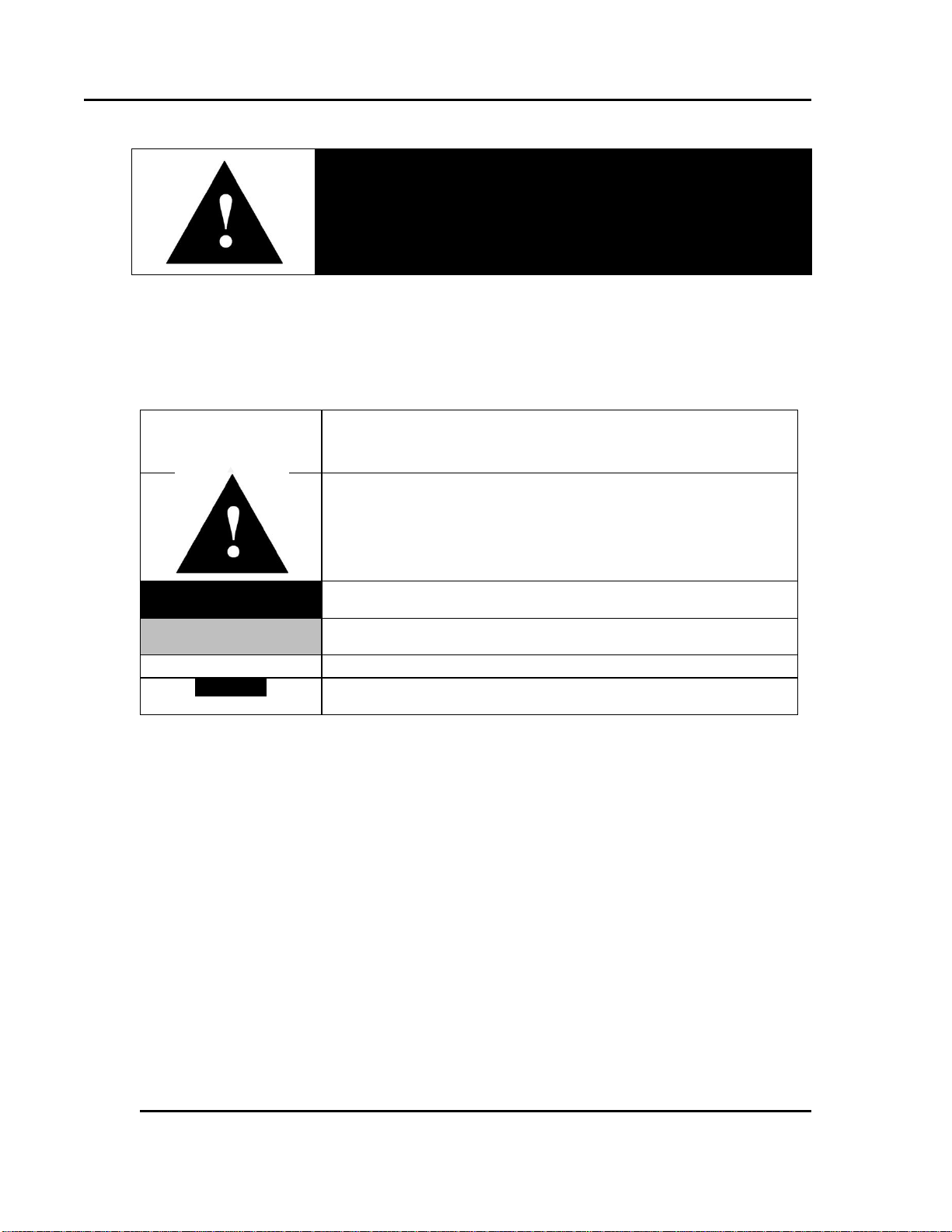

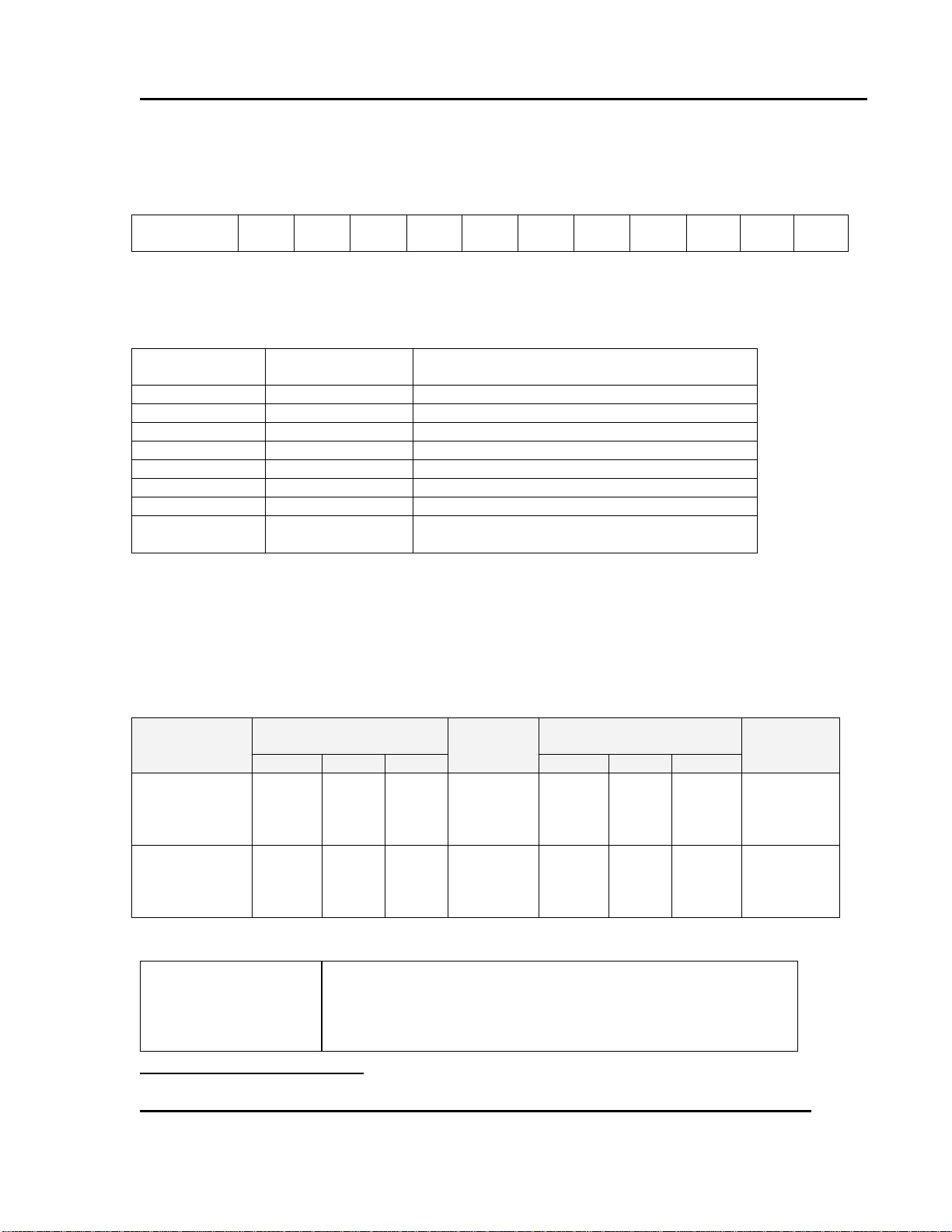

Model

Number

L 1 - - 3

Position in

Number

1 2 3 4 5 6 7 8

Position in

Model Number

Letter / Number

Letter Meaning

2

C

Model has a HEPA filter

2

L

Model does not have a HEPA filter

3

C

Model operates at 260°C

3

D

Model operates at 350°C

5 & 6

16

1.6 cubic foot model

5 & 6

51

5.1 cubic foot model

7 & 8

N

Model uses a nitrogen atmosphere

7 & 8

V

Model uses Viton* synthetic rubber (Siliconefree option)

Models

Chamber Size

inches (cm)

Capacity

ft3 (liters)

Overall Size

inches (cm)

Maximum

number of

Shelves

W D H W D

H

LCC1-16-3

LCD1-16-3

LCC1-16N-3

LCD1-16N-3

15

(38)

14

(36)

14

(36)

1.6

(45)

32.5

(83)

35.5

(90)

20.75

(53)

5

LCC1-51-3

LCD1-51-3

LCC1-51N-3

LCD1-51N-3

23

(58)

20

(51)

20

(51)

5.1

(144)

40.5

(103)

42.5

(108)

27

(69)

8

The LCC/LCD oven is not intended to process solvents or

other volatile or flammable materials. Oven exhaust is

intended for cooling purposes only.

Version 26 9

1.5. Specifications

1.5.1. Model Numbering and Naming Conventions

Table 1 lists the model numbers and follows these conventions:

Table 1. Model Number Key.

Example: LLD1-51NV-3

This 5.1 ft3 model does not have a HEPA filter, operates at 350°C, uses nitrogen

and is silicone-free.

1.5.2. Dimensions

*LLC & LLD models have same dimensions.

*

Trademark of E. I. Du Pont De Nemours & Company Corporation.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 10

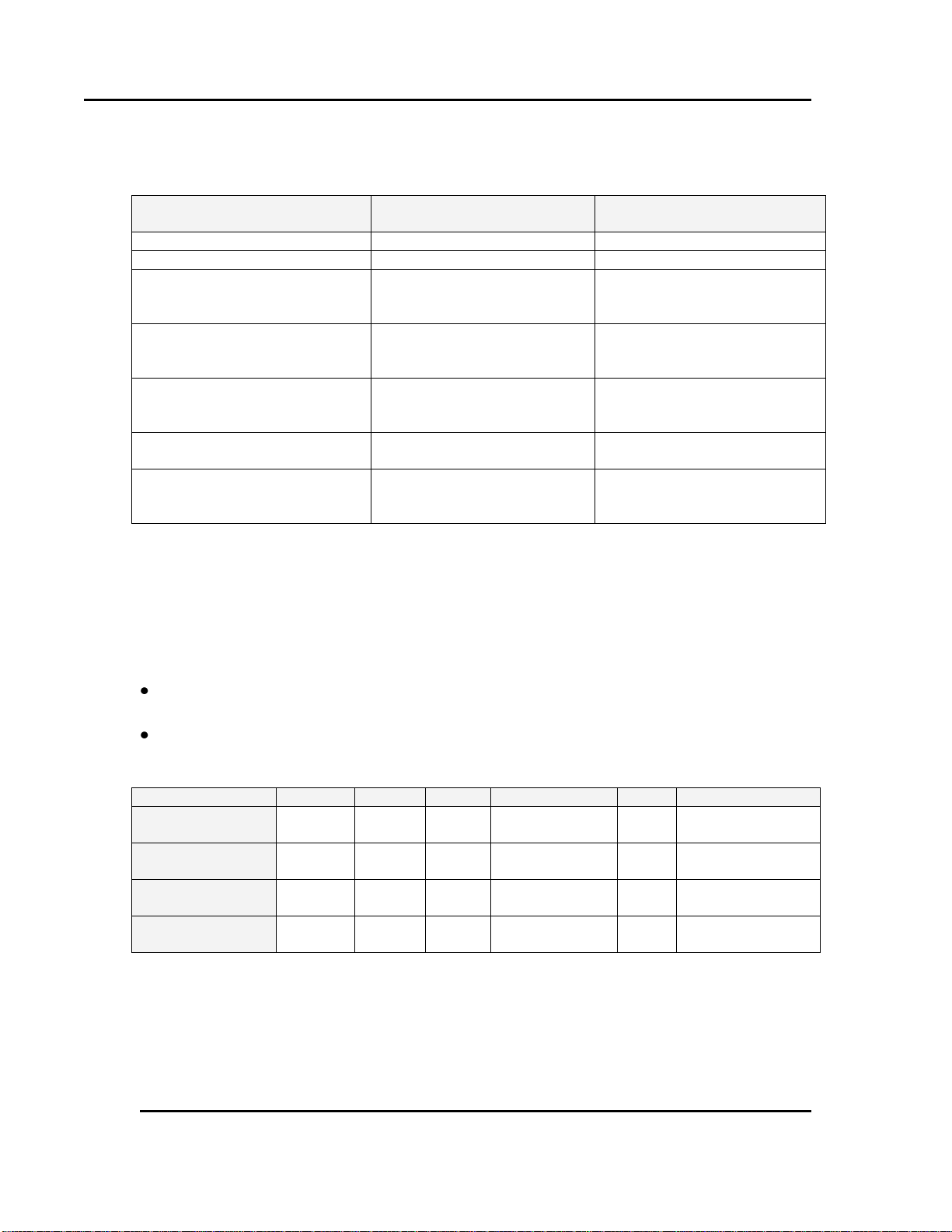

ABOUT THIS MANUAL Stackable LCC/LCD Oven Owner’s Manual

Model

LCC1-16-3 & LCD1-16-3

LCC1-16N-3 & LCD1-16N-3

LCC1-51-3 & LCD1-51-3

LCC1-51N-3 & LCD1-51N-3

Maximum Load (Lbs)

200

200

Maximum shelf load (Lbs)

50

25

Recirculating fan

(CFM)

240

435

(H.P.)

1/4

1/4

Net weight (Approximate)

(Lbs)

250

380

(KG)

114

172

Shipping weight (Approximate)

(Lbs)

350

525

(KG)

159

238

Exhaust capacity (forced

exhaust) (CFM)

35

73

Exhaust Outlet

(Inch)

1.88 x 2.88

1.88 x 2.88

(mm)

(48.0 x 73.4)

(48.0 x 73.4)

Model

Volts *

Amps

Hertz

Heater Phase

KW

Cord and Plug

LCC1-16-3

LCD1-16-3

240

14.8

50/60

1

3

None, hardwired

LCC1-16N-3

LCD1-16N-3

240

14.0

50/60

1

3

None, hardwired

LCC1-51-3

LCD1-51-3

240

27.7

50/60

1

6

None, hardwired

LCC1-51N-3

LCD1-51N-3

240

27.7

50/60

1

6

None, hardwired

10 Version 26

1.5.3. Capacities

1.5.4. Power

If the line voltage for your LCC/LCD Oven varies more than 10% from the oven voltage

rating, electrical components such as relays and temperature controls may operate

erratically.

If the line voltage is lower than the oven voltage rating, heat-up time may be

significantly longer and motors may overload or run hot

If the line voltage is higher than the nameplate rating, motors may run hot and draw

excessive amperage

*The LCC/LCD Oven is designed for 240 volts (see oven nameplate) will operate

satisfactorily on a minimum of 208 Volts, but will result in 25% reduced heater output. If

your power characteristic is lower, contact Despatch Industries.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 11

Stackable LCC/LCD Oven Owner’s Manual ABOUT THIS MANUAL

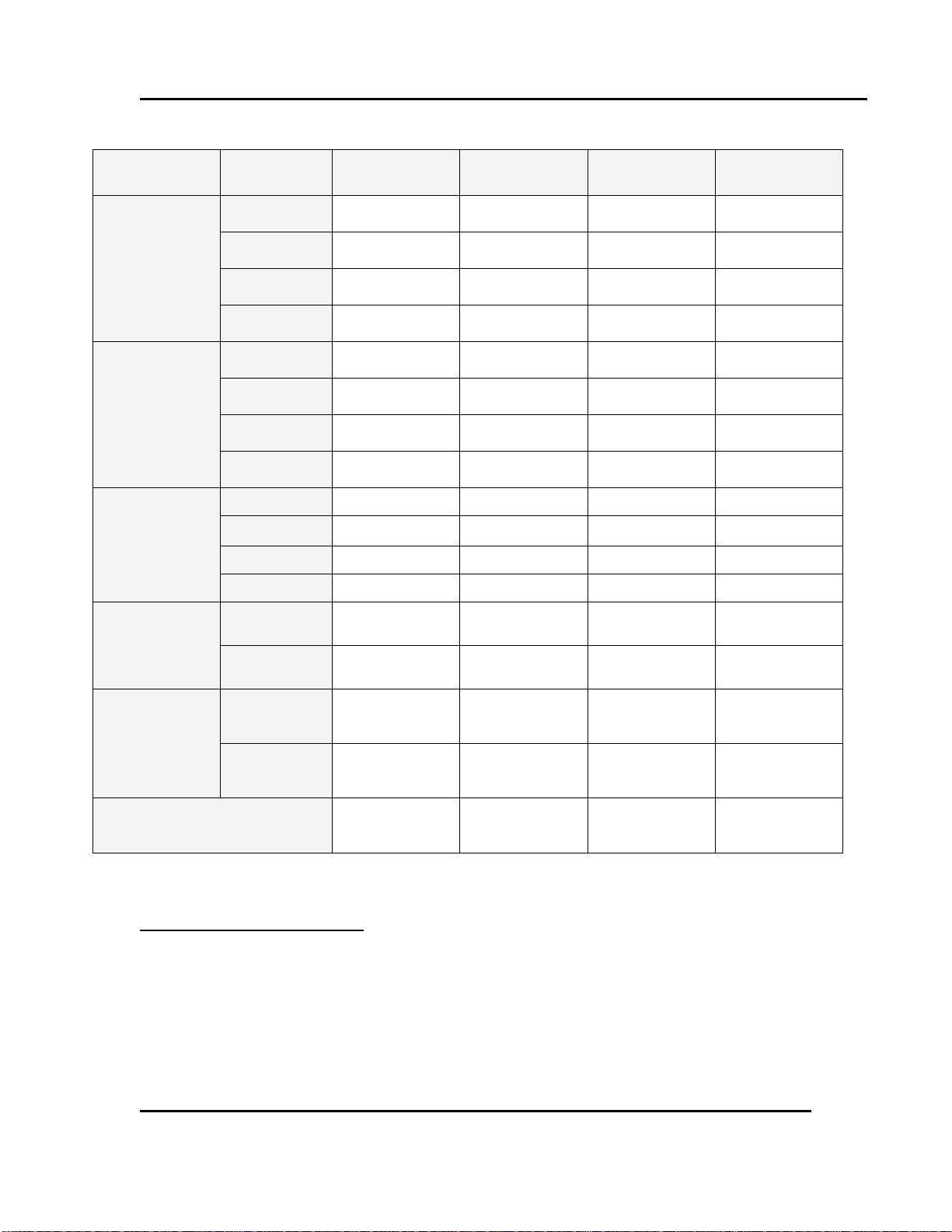

Model

LCC1-16-3

LCD1-16-3

LCC1-16N-3

LCD1-16N-3

LCC1-51-3

LCD1-51-3

LCC1-51N-3

LCD1-51N-3

Time to

Temperature

(approximate

minutes)

(no load)

40°C –

100°C

7 min.

7 min.

5 min.

5 min.

40°C –

200°C

30 min.

30 min.

27 min.

27 min.

40°C –

260°C

45 min.

45 min.

35 min.

35 min.

40°C –

350°C†

60 min.

60 min.

50 min.

50 min.

Cooling Time to

Temp

Minutes

(No Load)‡

100°C –

55°C

35 min.

30§ min.

40 min.

25§ min.

200°C –

55°C

65 min.

55§ min.

75 min.

40§ min.

260°C –

55°C

75 min.

60§ min.

85 min.

45§ min.

350°C –

55°C†

130 min.

80§ min.

115 min.

50§ min.

Temperature

Uniformity at**

100°C

±1°C

±1°C

±1°C

±1°C

200°C

±2°C

±2°C

±2°C

±2°C

260°C

±3°C

±3°C

±3°C

±3°C

350°C

±4°C

±4°C

±4°C

±4°C

Maximum

Operating

Temperature

LCC

260°C

260°C

260°C

260°C

LCD

350°C

350°C

350°C

350°C

Operating

Range w/20°C

Ambient

LCC

40°C-260°C

35°C-260°C††

45°C- 260°C

35°C-260°C††

LCD

40°C-350°C

40°C-350°C††

40°C-350°C

40°C-350°C††

Control Stability

+/- 0.5°C

+/- 0.5°C

+/- 0.5°C

+/- 0.5°C

Version 26 11

1.5.5. Temperature

†

For LCD & LLD only, LCC & LLC maximum temperature: 260°C.

‡

Minimum operating temperatures and cooling times are based on a 20°C ambient temperature measured at

the fresh air inlet.

§

Based on cooling water supplied at 2 GPM (7.6 LPM), 16°C for nitrogen atmosphere units.

**

Uniformity figures are based on a nine-point test conducted in an empty oven with thermocouples

connected at 3 inches (7.6 cm) from walls after the oven temperature has reached stabilization. Uniformity

can vary slightly depending on unit and operating conditions. Class 100 HEPA filtration will limit ramp

rates.

††

Requires water cooling be activated for minimum temp rating and operation below 85°C.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 12

SAFETY Stackable LCC/LCD Oven Owner’s Manual

Danger!

Electrical panels contain high voltage. Disconnect and lock out

the power supply before working inside any electrical panels.

Failure to lock out the power supply can result in death or injury.

12 Version 26

2. Safety

2.1. Safety Information

Do not work on the Stackable LCC/LCD Oven without reading and understanding this

section which contains important information and warnings. Ignoring these warnings can

result in death, serious injury or damage to the machine and product.

2.1.1. Lockout

Machine lockout places the Stackable LCC/LCD Oven into a zero energy state and

prevents accidental machine start up. Always follow the Lockout Procedure described in

this Section before cleaning, maintaining or repairing the Stackable LCC/LCD Oven. An

accidental start-up, while working on the Stackable LCC/LCD Oven, can result in serious

injury or death.

2.1.1.1. Lockout Requirements

1. Every power source that can energize any element of the Stackable LCC/LCD Oven

must be shut off at the closest possible power source. This includes air, water and

electricity, including the Disconnect Switch.

2. After energy sources are locked out, test to ensure circuits are de-energized.

2.1.1.2. Lockout Procedure

Personnel authorized to lockout equipment must have the necessary locks to perform the

lockout.

1. Physically disconnect all electrical power to the machine or lockout the appropriate

breaker or disconnects.

2. Close all valves and bleed off any pressure.

3. Test for power by attempting a start with the machine controls.

4. Identify the Lockout Condition with a tag on the electrical disconnect and pneumatic

shut off valve.

5. When work is complete, remove all tags and restore the machine to its working state.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 13

Stackable LCC/LCD Oven Owner’s Manual SAFETY

Danger!

Contact with energized electrical sources may result in serious

injury or death.

Danger!

Electrical panels contain high voltage. Disconnect and lock out

the power supply before working inside any electrical panels.

Failure to lock out the power supply can result in death or injury.

Version 26 13

2.1.2. Door and Panel

The door and rear panel on the Stackable LCC/LCD Oven protect against hazards. Power

is required to open the door and the oven heater is OFF when the door is open. Operation

without these safety devices in place creates hazards that the doors and covers are

intended to render safe for personnel.

The door requires a Manual Override Key for use when power is off. The door and panel

that require a tool to open are part of the safety system of the Stackable LCC/LCD Oven.

Do not open the door while the machine is running.

2.2. Maintenance

Only qualified and trained personnel should perform maintenance or repair.

2.3. Electrical Power

Only qualified and trained personnel should perform electrical maintenance or electrical

repair.

Before performing maintenance, disconnect all electrical power from the machine.

Use a padlock and lockout all disconnects feeding power to the machine.

Never clean, or repair the oven when in operation.

Unauthorized alterations or modifications to Stackable LCC/LCD Oven are strictly

forbidden. Never modify any electrical circuits. Unauthorized modifications can

impair the function and safety of the Stackable LCC/LCD Oven.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 14

SAFETY Stackable LCC/LCD Oven Owner’s Manual

Danger!

Always disconnect all power before extinguishing a fire.

Attempting to extinguish a fire in a machine connected to

electrical power can result in serious injury or death!

14 Version 26

2.4. Fire

Keep the Stackable LCC/LCD Oven clean and free of scrap materials, oil or solvents to

prevent the possibility of fire. In the event of fire, use a fire extinguisher as follows.

1. De-energize the machine immediately by turning OFF the DISCONNECT SWITCH.

2. Turn off the remote main disconnect (customer supplied disconnect).

3. Extinguish the fire.

2.5. Equipment Lockout Requirements

To prevent injury or equipment damage during inspection or repair, the Stackable

LCC/LCD Oven must be locked out.

2.5.1. Emergency Stop

When a risk of personal injury or damage to the Stackable LCC/LCD Oven exists, turn

OFF the DISCONNECT SWITCH on the front of the oven. This shuts off all electrical

power to the oven.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 15

Stackable LCC/LCD Oven Owner’s Manual THEORY OF OPERATION

Danger!

Use care when working with nitrogen. Nitrogen presents an

asphyxiation hazard. Handle nitrogen according the safe

handling procedures listed in the material safety data sheet.

Figure 1. Stackable LCC/LCD Series Oven.

Version 26 15

3. Theory of Operation

3.1. The Stackable LCC/LCD Series Oven

The Stackable LCC/LCD Series Oven (Figure 1)

offers HEPA (High Efficiency Particulate Air)

filtration for processes where minimized

contamination is essential. The removable HEPA filter

is designed to provide a constant flow of 99.97% clean

air to the product being heated. The HEPA filter with

silicone seal provides 99.99% filtration.

The oven operator interface is located on the hinged

control panel at the front of the oven (Figure 1). Power

components are located on the equipment panel,

behind the hinged control panel, for easy access

(Figure 8). Electrical components are either touchproof or are shielded with Lexan7 material to prevent

accidental exposure during maintenance and

troubleshooting.

The cooling fan is controlled on/off by an event relay

in the Protocol Plus Control. The cooling fan is used

for rapid cool-down at the end of the process cycle, or

to maintain low temperature setpoints during process

cycle. It may also be turned on at the start of a process cycle to assure that starting

temperature is less than 70°C.

The nitrogen models have stainless steel water coil which permits rapid cool down and

lower temperature operation. The nitrogen oven comes with an adjustable flowmeter a for

adjusting purge rate, and needle valve for setting maintain rate, separate solenoid valves

for purge and maintain operation and a pressure relief exhaust port. An exhaust fan which

powers on whenever the oven is running maintains consistent chamber pressure control

with varied exhaust stack conditions.

7

Trademark of SABIC Innovative Plastics.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 16

THEORY OF OPERATION Stackable LCC/LCD Oven Owner’s Manual

Stackable units are available in air or nitrogen atmosphere models.

Nitrogen atmosphere models are noted with an N suffix. Model

numbers beginning with “LL*1-*” do not use a HEPA filter.

Figure 2. Protocol Plus Displays and Control Buttons.

16 Version 26

The oven has a type 304-2B stainless steel interior and a type 304-#4 stainless steel

interior. All interior seams are continuously welded on the insulation side. This protects

the work chamber from contaminated air and permits chamber washing without

damaging the insulation. Interior ductwork may be easily removed for cleaning. Heater

frame, fan wheel and motor shaft are constructed of stainless steel.

Two electropolished stainless steel wire shelves are provided. The shelves are removable

and adjustable on two inch centers.

The LCC/LCD series design offers a stackable oven body. Multiple oven systems of two

or three oven stack options are available. When operating multiple ovens, network the

Despatch Protocol Plus controllers together with a Modbus communication option. Use

the optional Despatch Protocol Manager software to enable customer PC control of

multiple ovens.

3.2. The Protocol Plus Controller

The Protocol Plus controller has two displays. A dedicated LED upper display shows the

oven temperature (Figure 2). A two line LCD lower display provides information on

control status, high limit temperature and allows changes to be made to the control

settings. Review the Protocol Plus controller Owner’s Manual for more information.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 17

Stackable LCC/LCD Oven Owner’s Manual THEORY OF OPERATION

LCC oven chamber temperature transitions must not exceed

1.5°C/minute to maintain class 100 chamber conditions. For ramp

rates greater than 1.5°C/minute and up to 5°C/minute, the LCD model

will maintain class 100 chamber conditions.

Ship, handle, store and install HEPA filters with pleats positioned

vertically. Horizontally-positioned pleats risk breaking at the adhesive

line of the filter medium. Horizontally-positioned pleats also collect

entrapped material on “shelves.” The accumulated weight of the

entrapped material may cause sag and lead to early failure of the filter

unit.

THIS SIDE UP

Figure 3. This Side Up Graphic.

Version 26 17

3.3. HEPA Filters

The Stackable LCC/LCD Ovens use HEPA (High Efficiency Particulate Air) filters limit

particulate size in the work chamber to 0.3 microns or less.

3.3.1. Definitions

Binder: Organic substance used in filter construction to provide the media with

structural strength

Burn-Off: Process for eliminating the binder and D.O.P. contained in the filter from

the manufacturing and testing function.

D.O.P.: Dioctyl Phthalate - Aerosol particles of submicron size used in testing phase

to spot defects or measure filter efficiency.

HEPA: High Efficiency Particulate Air

3.3.2. Filter Packaging, Shipping and Handling

Packaging practice varies among the filter unit

manufacturers. Filter units are typically packaged in

cardboard cartons with varying approaches for

strengthening the container and making it impact-resistant.

Shipping cartons are typically marked with a vertical arrow

and "This Side Up" (Figure 3). A filter unit is placed in the

carton so the pleated folds are vertical (running from top to

bottom), versus side to side.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 18

THEORY OF OPERATION Stackable LCC/LCD Oven Owner’s Manual

Caution!

Despatch does not recommend D.O.P. filter testing.

18 Version 26

The filter is typically shipped in the original carton or package provide by the filter

manufacturer. This carton or package provides good storage and maximum protection

from dirt and moisture. Store and move HEPA filters upright in the shipping carton.

Minimize handling of the filter. During installation, remove the filter from the shipping

carton and install directly into the oven.

If an unpackaged HEPA filter unit must be placed with its face on the floor or other

surface, clear the surface entirely of every object or irregularity which might damage the

filter pack.

3.3.3. HEPA Filter Validation Testing

Despatch Industries guarantees the HEPA filters will meet specified efficiency ratings

when the following recommendations are followed:

The filter is properly installed

The filter is run at or below 200°C, at a constant temperature

The filter is run before burn-in

3.3.3.1. D.O.P. Testing

D.O.P. testing uses aerosol particles of submicron size to spot defects or measure filter

efficiency. Degenerative by-products of this test are distributed throughout the oven

chamber upon heat-up. Despatch does not recommend D.O.P. filter testing.

3.3.3.2. Class 100 Testing

Despatch guarantees a Class 100 environment within the oven. This classification is

based on measurement of the particulate level within the oven work chamber.

Class 100 testing may be performed before or after a proper filter burn-in procedure has

been performed. Despatch guarantees Class 100 condition measurements based on two

methods of test. The direct method employs an extraction-type particulate analyzer. The

indirect method involves particle settling over a specified period of time onto a clean

disk.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 19

Stackable LCC/LCD Oven Owner’s Manual THEORY OF OPERATION

Version 26 19

3.3.3.3. Validation Testing

Despatch recommends the following test sequence for pharmaceutical Class 100 ovens.

1. Proper installation of the HEPA filters (Section 3.3.2).

2. Ambient air challenge to determine integrity of oven chamber and filter

gaskets.

3. Proper filter burn-off procedure.

4. Class 100 testing inside the work chamber.

3.3.3.4. HEPA Filter Burn-off Process Not Necessary

HEPA filters contain a binder material which protects the filter media during production

and shipping. Smoke produced from burning this binder at elevated temperatures is

undesirable during normal oven operation. Burning off the binder will ensure a clean

process at elevated temperatures.

However, when the binder is burned out of the filter media, the filter becomes

very fragile: too fragile to withstand normal shipping and handling. For this reason,

Despatch does not perform the burn-off procedure. The burn-off process is not necessary

at temperatures under 200°C.

3.3.4. HEPA Filter Unit Replacement

Periodic replacement the HEPA filter unit due to:

Resistance, or pressure drop, across the filter unit. Maximum level of resistance in

inches (water gauge) will vary depending upon the operation of the filter and the

available fan capacity. Adequate fan capacity must be available.

Loss of efficiency (leakage), determined from air-sampling measurements made

downstream of the filter unit.

Visible damage or rupture of the filter media in a unit.

Change in process application.

Excessive build-up of lint or combustible particulate matter on the filter unit.

Water droplets in airstream through filter, free water (RH = 100%), will saturate filter

very quickly and may cause burnout or holes in burned off filter media.

High level of radiation in the vicinity of the filter unit.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

Copyright © 2010 by Despatch Industries.

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Page 20

THEORY OF OPERATION Stackable LCC/LCD Oven Owner’s Manual

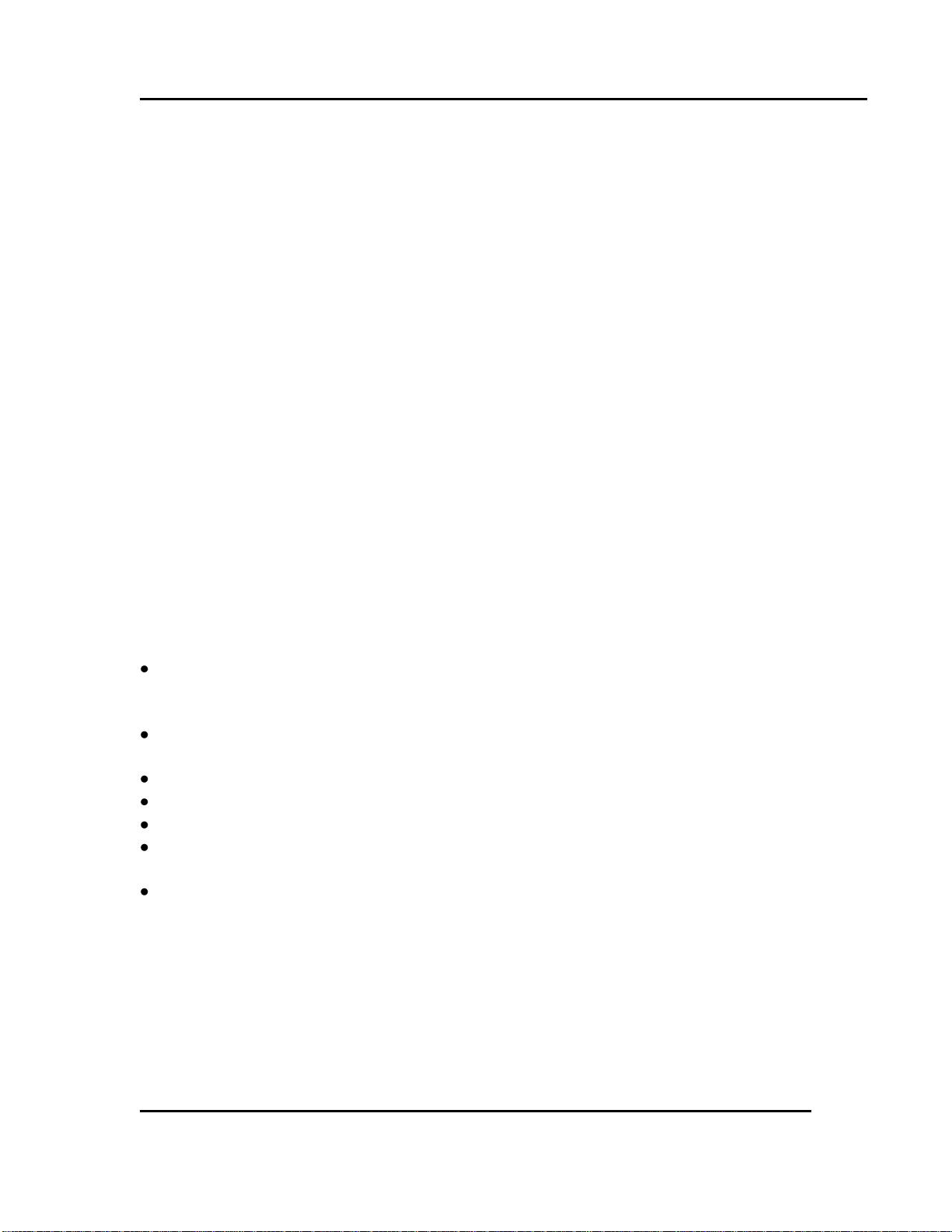

A B C D E

F

Date

Comments

Pressure

(inches of

water)8

Pressure with:

150 SCFH (LCC1-

16); 200 SCFH

(LCC1-51) nitrogen

purge9

Pressure with:

75 SCFH (LCC1-

16); 150 SCFH

(LCC1-51) nitrogen

maintain9

Oven

Temperature

Typical

Values

2-3”

1.5-2” above value

in Column C

0.5-1” above value

in Column C

60°C

Filter first

installed

Figure 4. Magnehelic Pressure

Gauge Measures Pressure in front of

the HEPA filter.

20 Version 26

3.3.5. HEPA Filter: Magnehelic Pressure Gauge

The LCC Series oven is equipped with a Magnehelic

pressure gauge which measures the pressure in front of the

HEPA filter (Figure 4). As the filter becomes dirty, pressure

increases. Despatch recommends changing the filter when

the pressure is 1” w.c. greater than when the filter was first

installed (Refer to section 4.3 for filter replacement).

Since pressure can be affected by many factors involved in

the installation, it is important to record the pressure of a new

filter as a baseline. Recorded pressure readings allow for new

readings to be periodically checked against this baseline. Use

Table 2 for recording this information (See Section 8.1 for a

blank worksheet).

For a nitrogen atmosphere oven, pressure readings also give an indication of the integrity

of the seals. If the pressure recorded in Columns D or E decrease over time, inspect the

oven seals.

Table 2. HEPA Filter Pressure Reading Worksheet.

8

With Purge and Maintain valves off for a nitrogen atmosphere oven. Cooling fan off for an air

atmosphere oven.

9

For a nitrogen atmosphere oven only.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 21

Stackable LCC/LCD Oven Owner’s Manual ASSEMBLY & SETUP

Warning!

The LCC door requires a Manual Override Key for use when

power is OFF. The door and panel that require a tool to open are

part of the safety system of the Stackable LCC/LCD Oven. Do

not attempt to permanently mount the Manual Override Key.

Do not remove torx screw from door release mechanism. Manual

Override Key cannot be permanently mounted.

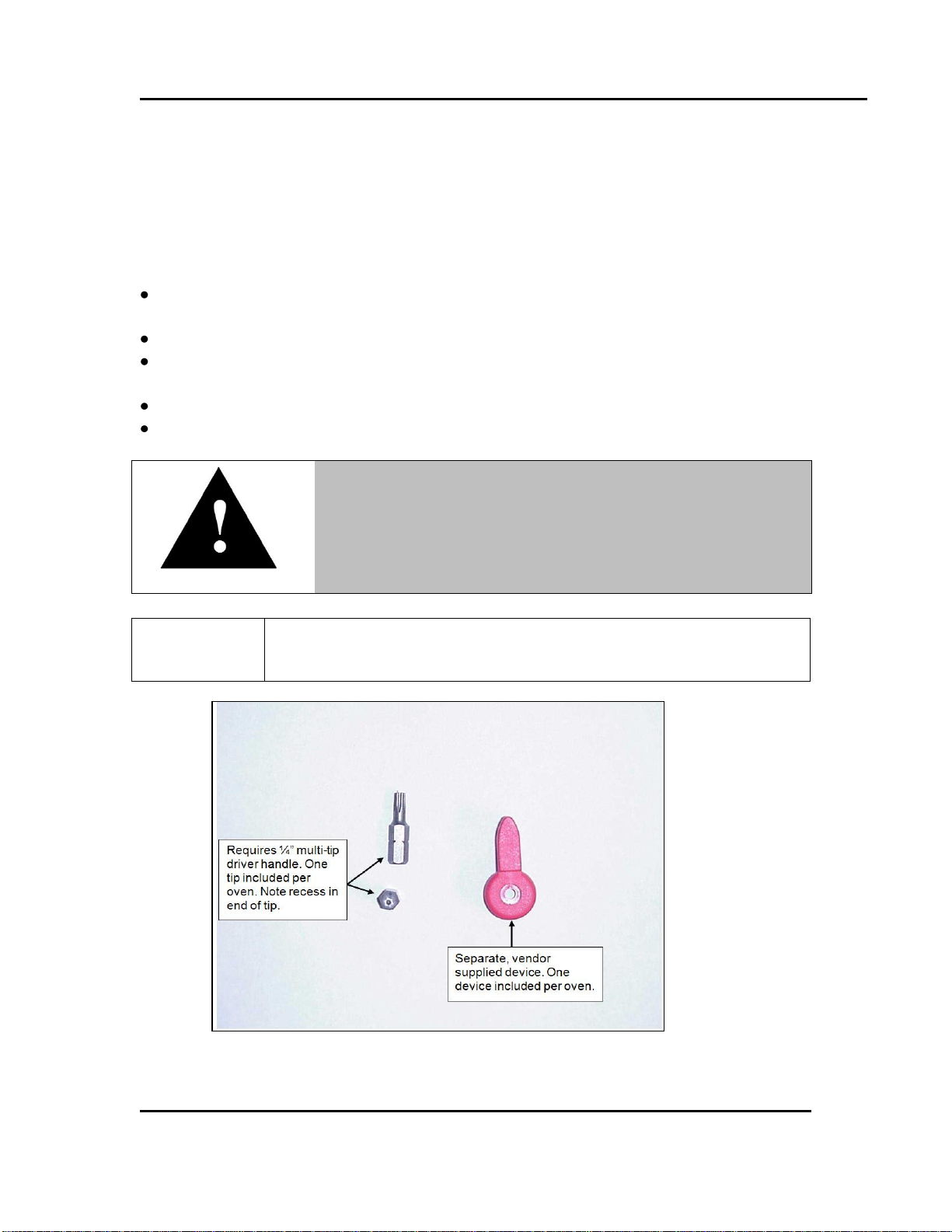

Figure 5. Door Lock Manual Override Key (LCC/LCD/LLC/LLD).

Version 26 21

4. Assembly & Setup

Assembly and Setup provides directions for unpacking and installing your LCC/LCD.

4.1. Unpack & Inspect The LCC/LCD Oven

Remove all packing materials and thoroughly inspect the oven for any damage that might

have occurred during shipment.

Note whether the carton and plastic cover sheet inside carton are still in good

condition

Observe all outside surfaces and corners of the oven for scratches and dents

Check oven controls and indicators for normal movement, bent shafts, cracks, chips

or missing parts such as knobs and lenses

Check the door and latch for smooth operation (Figure 5)

Check the filter carton for damage

Copyright © 2010 by Despatch Industries.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Page 22

ASSEMBLY & SETUP Stackable LCC/LCD Oven Owner’s Manual

Warning!

Do not use the oven in wet, corrosive or explosive atmospheres

unless this oven is specifically designed for a special

atmosphere.

22 Version 26

4.1.1. If Damaged During Shipping

If damage occurred during shipping:

1. Contact the shipper immediately and file a written damage claim.

2. Contact Despatch Industries (1-800-473-7373 or 1-952-469-8230 or

service@despatch.com) to report your findings and to order replacement parts for

those damaged or missing. Send a copy of your filed damage claims to Despatch

industries (Despatch Industries, 8860 207th Street, Lakeville, MN 555044, USA).

3. Check the packing list to ensure you received all the specified components of the

oven system. If any items are missing, contact Despatch Industries to have missing

products forwarded to you.

4. Complete the warranty card and mail it to Despatch within 15 days after receipt of the

equipment.

4.2. Set-up The LCC/LCD Oven

4.2.1. Select Oven Location

4.2.1.1. Single Oven Placement Requirements

Bench top (or other framework) capable of holding at least 250 Lbs (113.4 Kgs).

A minimum of three (3) inches (7.6 cm) available in the rear of the oven for proper

ventilation.

Leave room at the oven sides and rear for maintenance.

Oven exhaust opening is at the rear of the left side of the oven. Allow at least two (2)

inches (5.1 cm) clearance here as well. The oven may be placed next to another

cabinet on its right, or next to another oven, with three-quarters of an inch (19 mm)

clearance (measure with door open).

Plumb and level the oven to assure proper heat distribution and operation of all

mechanical components.

4.2.1.2. Multiple Oven Placement Requirement

Stack up to three ovens vertically, with or without the optional framework (base)

supplied by Despatch.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 23

Stackable LCC/LCD Oven Owner’s Manual ASSEMBLY & SETUP

For the LCC1-51 oven model, only two ovens may be stacked

vertically.

Connection

(Figure 6)

LCC/LCD Air Atmosphere with

optional Water-Cooled Models

LCC/LCD Nitrogen Atmosphere

Models with standard water-cooling

NITROGEN

INLET

Clean Dry Air Inlet (70-80 psi

(4.83-5.52 bar))

Purge water from coil prior to

heating oven

¼” NPT female brass

connections provided

Nitrogen Inlet (70-80 psi (4.83-5.52

bar))

Purge nitrogen, clean dry air and

water from coil prior to heating the

oven

1/4” NPT female brass connections

provided.

WATER

OUTLET

During cooling cycle, water flows through the water coil and out this

connection

3/8” NPT female brass connections provided

Piping must be rated for up to 250 °F (121°C)

WATER

DRAIN

At the end of a cooling cycle, Nitrogen or Clean Dry Air is purged through

the water coil. Water and pressurized nitrogen/air exit this connection for 30

seconds. Must be connected to gravity style drain (no backpressure).

3/8” NPT female brass connections are provided.

Piping must be rated for up to 250 F (121 C)

WATER

INLET

Water Inlet for cooling

3/8” NPT female brass

connections provided

Requires 2 GPM flow at 61 °F

(16°C) to meet published cooling

rates.

Maximum Pressure 100 PSI

(6.89 Bar)

Water Inlet for cooling

3/8” NPT female brass connections

provided

Requires 3 GPM flow at 61 °F

(16°C) to meet published cooling

rates.

Maximum Pressure 100 PSI (6.89

Bar)

Version 26 23

Supporting surface must be capable of holding three ovens (750 Lbs or 340.2 Kg) or

the weight of two LCC1-51 oven models.

Use the holes in the rear oven feet to bolt the ovens together by removing the hole

plugs in the top of the mating oven beneath.

4.2.2. Oven Utility Connections

Utility connections vary slightly on different LCC/LCD models. Table 3 lists the

connection purposes and parameters. Refer to Figure 6 for visual reference.

Table 3. Oven Utility Connections.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 24

ASSEMBLY & SETUP Stackable LCC/LCD Oven Owner’s Manual

Nitrogen inlet

Water inlet

Flow-meter valve

Water outlet

Water drain

Water pressure supplied to the oven must not exceed 100 psi

(6.89 bar). Despatch recommends installing a regulator to

prevent surging.

Nitrogen pressure supplied should be greater the 70 psi (4.83

bar) but not more than 80 psi (5.52 bar).

Figure 6. LCC/LCD Connections Panel.

24 Version 26

4.2.2.1. Nitrogen With Water-Cooled Models

1. Connect nitrogen supply line to NITROGEN INLET at the connections panel (Figure 6).

2. Install water connection for cooling coils to WATER INLET (Figure 6). Verify the

valve on the flowmeter is turned OFF, that is, fully clockwise.

3. Check for leaks by slowly opening the valve on the flowmeter and allowing any air to

bleed out.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 25

Stackable LCC/LCD Oven Owner’s Manual ASSEMBLY & SETUP

Caution!

Failure to allow air to bleed from the flowmeter may damage the

flowmeter. Bleed air from the flowmeter after every instance of

shutting off the water supply.

WATER DRAIN must be left open-to-atmosphere. Make closedloop connections using WATER OUTLET (Figure 6).

Warning!

Never allow WATER DRAIN to be plugged. A hot oven generates

a small amount of steam when the water is first turned on.

Steam can burn skin.

Caution!

Design the drain system to prevent operator injury from high

temperature or pressure buildup. Piping must withstand short

periods of up to 500 °F (260°C) temperatures (662 °F (350°C) for

LCD ovens). Insulate drain lines or install warning labels stating

the potential high temperature or pressure hazard.

Clean Dry Air pressure supplied should be at 100 psi (6.9 bar).

Version 26 25

4. Adjust the flowmeter to the recommended 3 gpm (11.4 lpm).

5. Complete the drain connection on oven side by connecting WATER OUTLET to the

closed loop system (Figure 6).

4.2.2.2. Air Atmosphere with Optional Water Cooling Model

1. Connect Clean Dry Air (CDA) line to DRY AIR 100 PSI at the connections panel

(Figure 6).

2. Install water connection for cooling coils to WATER INLET (Figure 6). Verify the

valve on the flowmeter is turned OFF, that is, fully clockwise.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 26

ASSEMBLY & SETUP Stackable LCC/LCD Oven Owner’s Manual

Water pressure supplied to the oven must not exceed 100 psi

(6.9 bar). Despatch recommends installing a regulator to prevent

surging.

Caution!

Failure to allow air to bleed from the flowmeter may damage the

flowmeter. Bleed air from the flowmeter after every instance of

shutting off the water supply.

WATER DRAIN must be left open-to-atmosphere. Make closedloop connections using WATER OUTLET (Figure 6).

Warning!

Never allow WATER DRAIN to be plugged. A hot oven generates

a small amount of steam when the water is first turned on.

Steam can burn skin.

Caution!

Design the drain system to prevent operator injury from high

temperature or pressure buildup. Piping must withstand short

periods of up to 500 °F (260°C) temperatures (LCD ovens: 662 °F

(350°C). Insulate drain lines or install warning labels stating the

potential high temperature or pressure hazard.

26 Version 26

3. Check for leaks by slowly opening the valve on the flowmeter and allowing any air to

bleed out.

4. Adjust the flowmeter to the recommended 3 gpm (11.4 lpm).

5. Complete the drain connection on oven side by connecting WATER OUTLET to the

closed loop system (Figure 6).

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 27

Stackable LCC/LCD Oven Owner’s Manual ASSEMBLY & SETUP

LCC/LCD1-16 Models

LCC/LCD1-51Models

Size

1.88” x 2.88” (4.8 cm x 7.3 cm)

Flow

35 cfm (991.5 lpm)

73 CFM (2067 lpm)

Temperature

LCC and LLC series:

500 °F (260°C)

LCC and LLC series:

500 °F (260°C)

LCD and LLD series:

662 °F (350°C)

LCD and LLD series:

662 °F (350°C)

The oven must be hardwired directly to the disconnect switch on

the equipment panel (Figure 9).

Danger!

All grounding and safety equipment must be in compliance with

applicable codes, ordinances and accepted safe practices.

Figure 7. Exhaust Port on the Left Side of the LCC/LCD Oven.

Version 26 27

4.2.3. Exhaust Connections

The LCC/LCD Exhaust port is located on the left side of the oven (Figure 7). Table 4 lists

the requirements for the exhaust stack for the LCC/LCD Oven.

Table 4. Exhaust Connection Requirements.

4.2.4. Wiring & Power Connections

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 28

ASSEMBLY & SETUP Stackable LCC/LCD Oven Owner’s Manual

Figure 8. Open the front panel for access.

28 Version 26

Run line voltage power through the conduit from rear of oven to front (Figure 9).

Consult electrical drawings included with the oven for details.

Access the conduit and Disconnect Switch by opening the front panel (Figure 8).

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 29

Stackable LCC/LCD Oven Owner’s Manual ASSEMBLY & SETUP

Not all ovens use a HEPA filter. This section applies only to

ovens are equipped with a HEPA filter. Model numbers

beginning with “LC” have a HEPA filter. For a complete

explanation of model numbers, refer to Section 1.5.1.

Warning!

Make certain power is disconnected from the oven before

removing or replacing the HEPA filter. Observe all applicable

safety procedures.

Caution!

The HEPA filter is fragile and care must be taken to avoid

damage during installation. If a filter unit is dropped, whether in

the carton or not, examine it carefully for damage.

Conduit on rear of oven

Connect line voltage

power to Disconnect

Switch labeled LINE

CONNECTION.

Line voltage power

emerges from conduit on

front of oven here.

Route line voltage power

through conduit

Figure 9. Conduit entrance at rear of oven and open front panel.

Version 26 29

Connect the line voltage power to the disconnect switch labeled LINE CONNECTION

(Figure 9).

4.3. HEPA Filter Installation

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 30

ASSEMBLY & SETUP Stackable LCC/LCD Oven Owner’s Manual

Caution!

The HEPA filter must be installed so that unfiltered air cannot

leak past the unit. The HEPA gasket (white triangular gasket) is

generally in the downstream position and in contact with the

oven-sealing surface

In general, defer to installation instructions provided by the filter

manufacturer.

Termikfil 2000 Filter Installation Notes:

If a spacer is required for the gasket, place the spacer on the

opposite side to the HEPA gasket

If the Termikfil 2000 filter is mounted in a slide, do not rub

the filter on its gaskets

Any clamping device used must allow necessary and

sufficient pressure on the gaskets provide an airtight fit.

NOTE: Over tightening may damage the Termikfil 2000 filter.

Clamping recommendation: Clamp the Termikfil 2000 filter to

a residual HEPA gasket thickness of 4 mm (1/6 inch)

Refer to installation instructions provided by the filter

manufacturer for more specific installation notes.

Sweep floor clear of nuts, bolts and other protrusions which

may damage the unit.

Do not drop or jar the filter carton.

30 Version 26

1. Remove filter from carton

a. Place carton on floor.

b. Tilt the carton on one corner. Handle the carton at opposing corners.

c. Remove sealing tape and fold back flaps of carton.

d. Gently upend the filter to place the exposed end of the filter on the floor. Do

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

not jar the filter.

e. Pull the carton from the filter unit. Be careful to not pull the filter from the

carton.

Copyright © 2010 by Despatch Industries.

Page 31

Stackable LCC/LCD Oven Owner’s Manual ASSEMBLY & SETUP

Opened pleats in the filter media are normal and result from the

tempering process.

Figure 10. Example HEPA Filter (Silicone-free) and Close-Up.

Version 26 31

2. Inspect the filter.

a. Visually inspect the two gaskets to ensure they have not been damaged during

handling.

b. Use a strong lamp to examine the exposed areas of both faces for evidence of

breaks, cracks, or pinholes (Figure 10). If a strong lamp is unavailable, use a

flashlight in a darkened room.

c. Look for visible defects with the light projected along the full length of each

channel created by the separators. Translucent spots may not necessarily

indicate holes or cracks but may simply be variations in thickness of the filter

medium.

d. Check that the adhesive seal around the filter unit faces are complete and

unbroken.

e. Check frame corner joints for adhesive sealing and tightness.

f. Check that gaskets are cemented firmly to the filter frame and that gasket

pieces are undamaged and butted or mated at the joints.

3. Pull shelves from the oven and set aside (Figure 11).

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 32

ASSEMBLY & SETUP Stackable LCC/LCD Oven Owner’s Manual

Danger!

Make certain power is disconnected from the oven before

removing or replacing the HEPA filter.

Remove shelves before installing HEPA FILTERS

Loosen threes screws to remove the entire inner

casing assembly as a single unit.

Loosen ¼ turn using

5/16 inch nut driver.

Figure 11. Remove inner casing to install HEPA filter.

32 Version 26

4. Loosen the two screws at the upper and lower corners of the right rear of the chamber

(Figure 11).

a. Pull out the shelf support/duct as a single unit and set it aside.

5. Note the position of the threaded rods behind the duct assembly on the right side. The

HEPA filter will be fitted over these rods.

6. Remove the brass nuts and washers from the rods that are temporarily locking the

rods to the oven wall.

a. Reuse these nuts to hold the filter in place.

7. This step for the LCC1-16-3 only:

a. Remove filter frame to be reinstalled after filter.

b. Remove the HEPA filter (shipped separately) from its container.

c. NOTE: The seal side goes toward the wall of the oven.

i. Place the filter inside the chamber and install filter mounting frame

over rods.

ii. Push filter tight to rear wall with mounting frame.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 33

Stackable LCC/LCD Oven Owner’s Manual ASSEMBLY & SETUP

While the Termikfil 2000 filter has undergone tempering

treatment at the factory, smells and/or fumes may be released

during the first use at temperature.

Version 26 33

8. This step for the LCC1-51-3 only:

a. Remove the HEPA filter (shipped separately) from its container.

b. NOTE: The seal side goes toward the wall of the oven.

i. Place the filter inside the chamber and install filter mounting angles

(shipped separately) over rods.

ii. Push filter tight to rear wall with mounting angles.

9. Reinstall the washers and brass nuts to tighten the filter frame down.

a. Tighten the four nuts alternately for even tightness (Correct installation torque

is 28 +/- 3 in-lbs. Be careful not to over tighten.

b. Correct installation torque is 28 +/- 3 in-lbs.

c. Be sure to compress the gasket evenly and equally at all points with the filter

frame completely covering the opening.

10. Reinstall the inner casing assembly using the three screws removed earlier (Step 4).

11. Reinstall the oven shelf.

4.3.1. HEPA Filter Burn-Off

4.3.1.1. HEPA Filter Burn-Off Process

The burn-off process takes place in any equipment where a new HEPA filter is used at

temperatures above 180°C / 356°F. Expect smoke, possibly a pungent odor and a light

residue on interior surfaces. This results from oxidation of the binder. Most of the binder

will leave the filter after running at a temperature of 260°C/500°F for 48 hours. Check

the oven for particles or the exhaust for smoke and odor to determine that the process is

finished.

4.3.1.2. Location of HEPA Filter Burn-Off Process

Select a location for the burn-off process where generated smoke and odor will be

ventilated with the least amount of interruption and inconvenience. Ideally this will be in

the final location for the oven. However, it may be a receiving dock, some well ventilated

space or even outside if the weather is acceptable. If this location is a very clean area, pay

special attention to an exhaust hook-up that fully captures the smoke and odor produced.

The post-Burn-off cleaning (that is, oven wipe down) may also generate dust. So take

care if in a clean room.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 34

ASSEMBLY & SETUP Stackable LCC/LCD Oven Owner’s Manual

LCC oven chamber temperature transitions must not exceed

1.5°C/minute to maintain class 100 chamber conditions. For ramp

rates greater than 1.5°C/minute and up to 5°C/minute, the LCD model

will maintain class 100 chamber conditions.

24 hours

24 hours

Process

Temperature

Option 1

Option 2

48 hours

48 hours

Temperature Ramp 1.7°C/min up

to 5°C/Min

Temperature

Ramp 1.7°C/

min

Figure 12. Options for Starting Termikfil 2000 Filter.

34 Version 26

4.3.1.3. Recommended HEPA Filter Burn-Off Process

1. Locate the equipment exhaust opening where chamber air is being expelled.

a. If the oven filter is burned off in a clean area, be sure to handle the equipment

exhaust appropriately.

b. If the equipment is large and the exhaust stack is a permanent service connection,

connect the equipment and exhaust stack before the burn-off process.

c. If the equipment is small with no permanent exhaust duct required, arrange a

temporary connection out of the clean area that will handle the maximum

temperature of the equipment. Direct the smoke and odor outside, or to a highly

ventilated area.

2. Set the temperature control at the maximum process temperature.

a. Silicone: Ramp at 1.25°C/min to 260°C and soak for 48 hours.

b. Media Pack: Ramp at 1.25°C/min to 260°C and soak for 48 hours.

c. Termikfil (Figure 12):

i. Option 1: Ramp at 1.7°C/min (or up to 5°C/min) to 350°C and soak for 48

hours.

ii. Option 2: Ramp to process temperature and soak for three consecutive three-

hour segments over 48 hours.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 35

Stackable LCC/LCD Oven Owner’s Manual ASSEMBLY & SETUP

If the equipment must be moved after the burn-off process, use

considerable care.

The binder which strengthened new filters is now burned-off

and the media is very fragile.

Rough handling of either the filter alone or the equipment

with the filter installed is not recommended as it may tear the

media and lead to reduced filter efficiency.

Removal of the filter after heating can also result in damage

to the frame seal, and is only recommended when replacing

the filter.

Refer to instructions provided recorder manufacturer for more

specific installation notes.

Version 26 35