3-SIDED (PENINSULA), VENTED DECORATIVE GAS APPLIANCE

OWNER’S OPERATION AND INSTALLATION MANUAL

MARBLEHEAD

NATURAL GAS MODELS GL36PN AND GL36PNE

PROPANE/LP GAS MODELS GL36PNP AND GL36PNEP

WARNING: If the information in these instructions is

not followed exactly, a fire or explosion may result

causing property damage, personal injury or death.

FOR YOUR SAFETY

— Do not store or use gasoline or any other flammable

vapors or liquids in the vicinity of this or any other

appliance.

— WHAT TO DO IF YOU SMELL GAS :

• Do not try to light any appliance.

• Do not touch any electrical switch;

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

— Installation and service must be performed by a quali-

fied installer, service agency or the gas supplier.

Save this manual for future reference.

For more information, visit www.desatech.com

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause injury or property damage. Refer to this manual for correct installation

and operational procedures. For assistance or additional information consult a qualified installer, service

agency or the gas supplier.

NOT FOR USE WITH SOLID FUEL

CHECK LOCAL CODES PRIOR TO INSTALLATION

SAVE THIS BOOK

This book is valuable. In addition to instructing you on

how to install and maintain your appliance, it also con

tains information that will enable you to obtain replacement parts or optional accessory items when needed.

Keep it with your other important papers.

This appliance is only for use with the type of gas indicated on the rating plate.

This appliance is not convertible for use with other

gases.

-

TABLE OF CONTENTS

Safety Information ............................................... 3

Dimensions .......................................................... 4

Introduction .......................................................... 5

Selecting Location ............................................... 5

Fireplace Installation ........................................... 6

Operating Fireplace ........................................... 13

Cleaning and Maintenance ................................ 15

www.desatech.com

Technical Service .............................................. 15

Specifications .................................................... 15

Wiring Diagrams ................................................ 16

Troubleshooting .................................................

Replacement Parts and Accessories .................

Limited 2-Year Warranty ......................

Back Cover

55175-F2

17

19

SAFETY INFORMATION

WARNING: This product

cont a i n s and/ o r genera t e s

chemicals known to the State

of California to cause cancer or

birth defects or other reproductive harm.

IMPORTANT: Read this owner’s

manual carefully and completely

before trying to assemble, operate or service this fireplace.

Improper use of this fireplace

can cause serious injury or death

from burns, fire, explosions,

electrical shock and carbon

monoxide poisoning.

DANGER: Carbon monoxide

poisoning may lead to death!

This fireplace is a vented product. This fireplace

will not produce any gas leakage into your home if

properly installed. This fireplace must be properly

installed by a qualified service person. If this unit is

not properly installed by a qualified service person,

gas leakage can occur.

Carbon Monoxide Poison ing: Early signs of

carbon monoxide poisoning resemble the flu, with

headaches, dizziness or nausea. If you have these

signs, the fireplace may not have been installed

properly. Get fresh air at once! Have fireplace

inspected and serviced by a qualified service

person. Some people are more affected by carbon

monoxide than others. These include pregnant

women, people with heart or lung disease or

anemia, those under the influence of alcohol and

those at high altitudes.

Propane/LP gas and natural gas are both odorless.

An odor-making agent is added to each of these

gases. The odor helps you detect a gas leak. How

ever, the odor added to these gases can fade. Gas

may be present even though no odor exists.

Make certain you read and understand all warnings.

Keep this manual for reference. It is your guide to

safe and proper operation of this fireplace.

WARNING: Any change to

this fireplace or its controls can

be dangerous.

1. This appliance is only for use with the type

of gas indicated on the rating plate. This ap

pliance is not convertible for use with other

gases.

2. For propane/LP fireplace, do not place propane/

LP supply tank(s) inside any structure. Locate

propane/LP supply tank(s) outdoors. To prevent

performance problems, do not use propane/LP

fuel tank of less than 100 lbs. capacity.

3. If you smell gas

• shut off gas supply

• do not try to light any appliance

• do not touch any electrical switch; do not

use any phone in your building

• immediately call your gas supplier from a

neighborʼs phone. Follow the gas supplier's

instructions

• if you cannot reach you gas supplier, call the

fire department.

4. Never install the fireplace

• in a recreational vehicle

• where curtains, furniture, clothing or other

flammable objects are less than 42" from

the front, top or sides of the fireplace

• in high traffic areas

• in windy or drafty areas

5. This fireplace reaches high temperatures. Keep

children and adults away from hot surfaces to

avoid burns or clothing ignition. Fireplace will

remain hot for a time after shutdown. Allow

surfaces to cool before touching.

6. Carefully supervise young children when they

are in the room with fireplace.

7. A hearth extension is not required with this

appliance. If one is installed, it is for aesthetic

purposes only and does not have to meet the

standard requirements.

8. Turn fireplace off and let cool before servicing

or repairing. Only a qualified service person

should install, service or repair this fireplace.

Have fireplace inspected annually by a quali

fied service person.

9. You must keep control compartments, burn

-

ers and circulating air passages clean. More

frequent cleaning may be needed due to ex

cessive lint and dust from carpeting, bedding

material, etc. Turn off the gas valve and pilot

light before cleaning fireplace.

10. Have venting system inspected annually by a

qualified service person. If needed, have vent

ing system cleaned or repaired. See

and Maintenance, page 15.

-

-

-

-

-

Cleaning

55175-F 3

www.desatech.com

SAFETY INFORMATION

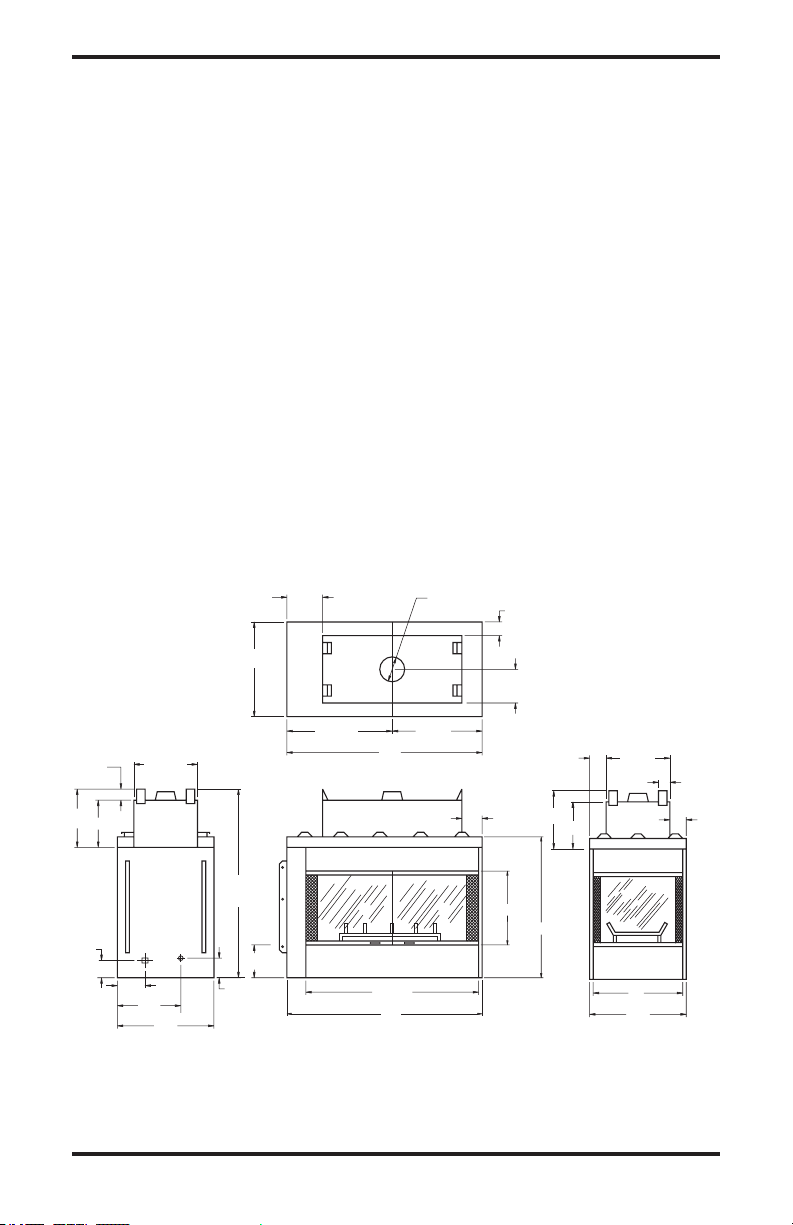

SIDE VIEW

FRONT VIEW

TOP VIEW

4

1

/2"

12"

2

1

/2"

24

"

40"

36 1/2"

8"

37 1/2"

3 1/4"

40"

9 1/2"

2 1/2"

24"

BACK VIEW

16"

12"

5 1/4"

5 1/2"

9"

13"

2 1/2"

20 1/2"

23

"

19 1/4"

19 3/8"

20 5/8"

6"

24"

19 1/4"

4"

6" O.D.

16"

52 1/2"

Continued

11. Keep the area around your fireplace clear of

combustible materials, gasoline and other

flammable vapor and liquids. Do not run fireplace where these are used or stored. Do not

place items such as clothing or decorations on

or around fireplace.

12. Do not use this fireplace to cook food or burn

paper or other objects.

13. Do not use any solid fuels (wood, coal, paper,

cardboard, etc.) in this fireplace. Use only the

gas type indicated on fireplace nameplate.

14. This appliance, when installed, must be electri

cally grounded in accordance with local codes

or, in the absence of local codes, with the

National Electrical Code, ANSI/NFPA 70 or

the Canadian Electrical Code, CSA C22.1

15. Do not obstruct the flow of combustion and

ventilation air in any way. Provide adequate

clearances around air openings into the combus

tion chamber along with adequate accessibility

clearance for servicing and proper operation.

.

DIMENSIONS

16. Do not install fireplace directly on carpeting,

vinyl tile or any combustible material other

than wood. The fireplace must set on a metal

or wood panel extending the full width and

depth of the fireplace.

17. Do not use fireplace if any part has been ex

posed to or under water. Immediately call a

qualified service person to arrange for replace

ment of the unit.

18. Do not operate fireplace if any log is broken.

19. Do not use a blower insert, heat exchanger

insert or other accessory not approved for use

with this fireplace.

20. Prov id e adequate clearances arou nd air

openings.

-

-

-

www.desatech.com

55175-F4

INTRODUCTION

Models GL36PN/P and GL36PNE/P are decorative gas appliances that use a millivolt gas control

and piezo pilot or an electronic gas control valve

with an electronic ignition system respectively.

These systems require a 6", B-type venting system

for operation.

The 6" B-type vent is not supplied by DESA.

For installation guidelines, check your B-vent

instructions.

This appliance complies with ANSI Z21.50B-1990

and CAM/CGA-2.22-M89 as a Vented Gas Ap

pliance and is listed and tested by the Omni Test

Laboratories.

WARNING: Installation of

this appliance should be done by

a qualified service person well

trained in the installation of such

appliances. You will also need a

building permit from your local

WARNING: This gas appliance must not be connected to

a chimney flue servicing a solid

fuel burning appliance.

Models GL36PN and GL36PNE are smooth face

units for natural gas only. The GL36PNP and

GL36PNEP are smooth face units for propane/LP

gas only. To determine which type of gas your unit

is approved and tested for, check the rating plate on

the lift-out plate located inside the firebox under

the access panel.

BEFORE YOU BEGIN

Before beginning the installation of your appliance, read these instructions through completely.

This DESA appliance and its approved compo

nents are safe when installed according to this

installation manual and are operated as recommended by DESA. Unless you use DESA approved

components tested for this appliance, YOU MAY

CAUSE A FIRE HAZARD!

The DESA warranty will be voided by and DESA dis

claims any responsibility for the following actions :

A) Modification of the appliance or any of the

components manufactured by DESA unless

otherwise permitted by DESA.

B) Use of any component part not approved by

DESA in combination with this appliance.

C) Installation and/or operation in a manner other

than instructed in this manual.

D) The burning of anything other than the type of

gas approved for use in this gas appliance.

This appliance, when installed, must be electrically

grounded in accordance with local codes or, in the

absence of local codes, with the National Electri

cal Code, ANSI/NFPA 70-1987 and the CSA C22.1

Canadian Electrical Code for Canada.

The installation must conform with local codes

or, in the absence of local codes, with the current

National Fuel Gas Code, ANSI Z223.1/NFPA 54

or with the current CAN/CGA B149 Installation

Codes for Canada.

55175-F 5

www.desatech.com

Building and Safety Commissioner

before installing this appliance;

otherwise your insurance company may not cover this appliance.

NOTICE: This appliance is not

intended to be used as a primary

source of heat.

SELECTING LOCATION

To determine the safest and most efficient location

for your appliance, you must take into consider

ation the following guidelines:

1. The location must allow for proper clearances

(see Clearances, page 6). Note: This decora

-

tive appliance is not designed for outdoor

installation.

2. The location should be in a place where drafts,

air conditioning ducts, windows or doors will

not affect fireplace heat output.

-

3. A location that avoids the cutting of joists

or roof rafters will make installation easier.

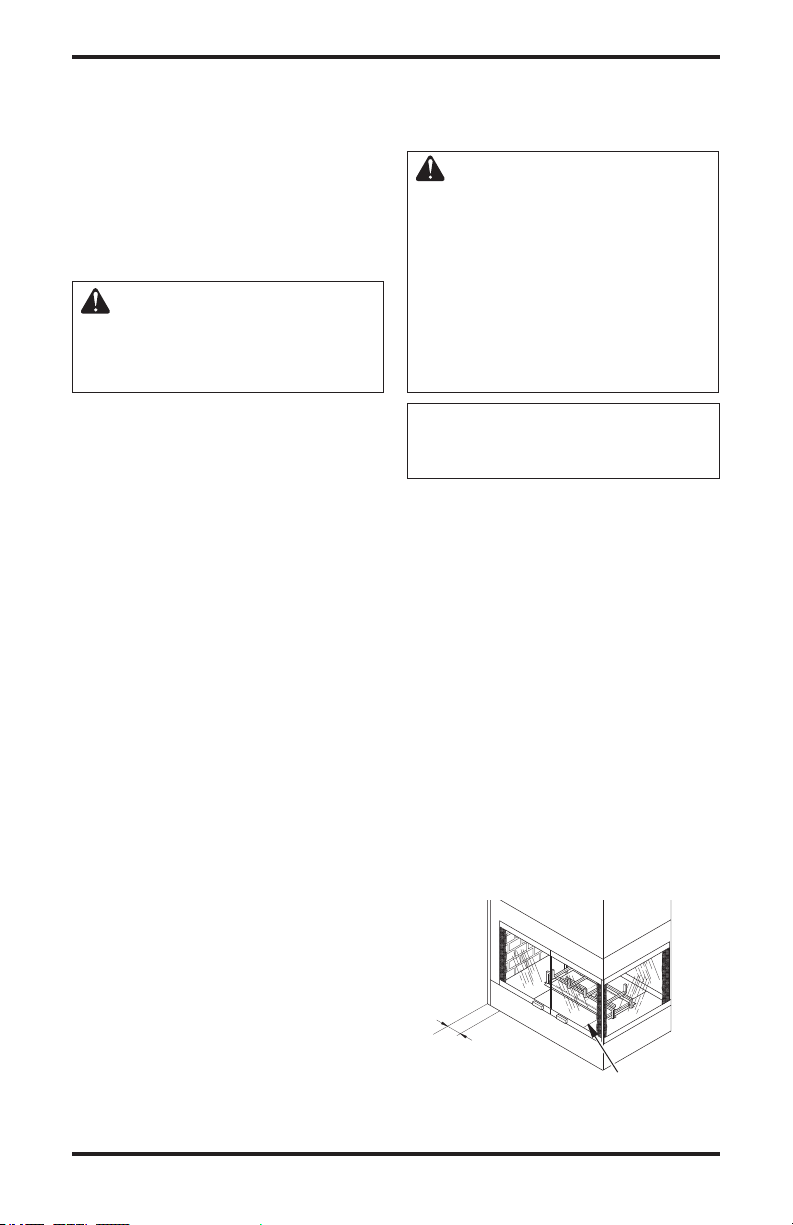

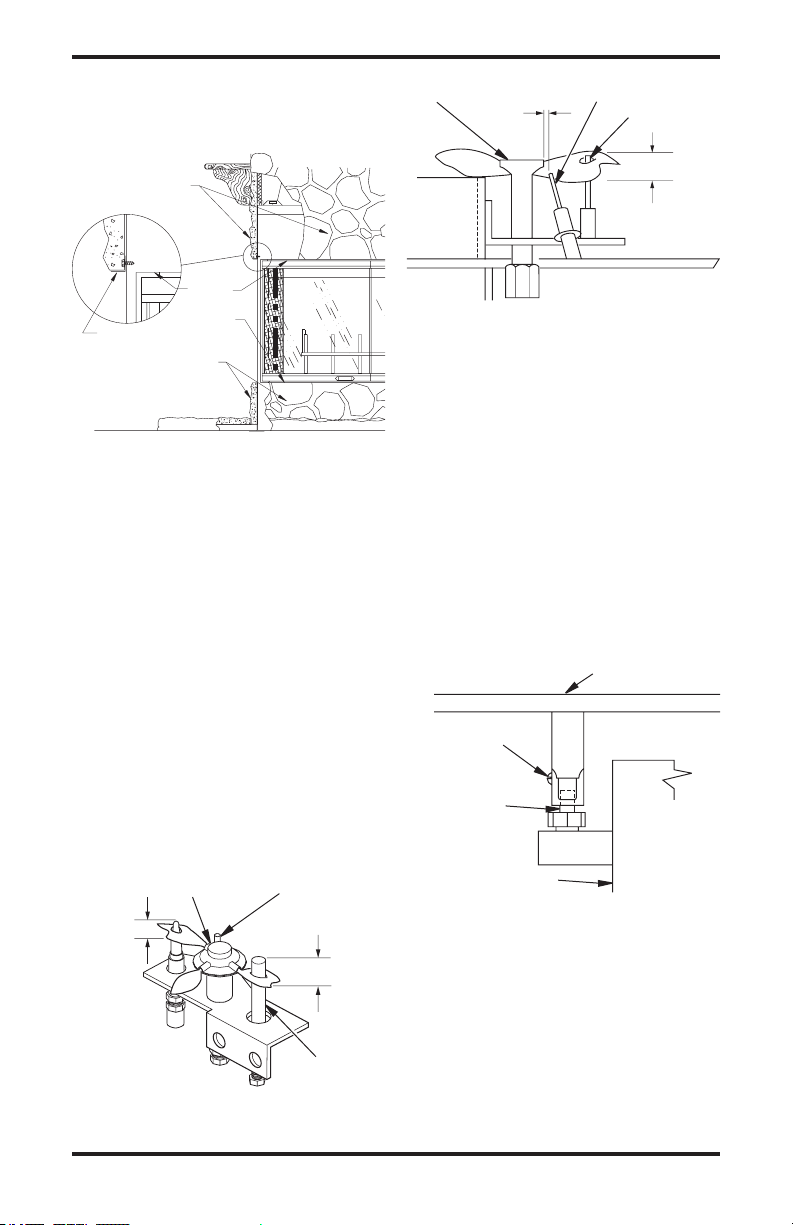

Figure 2 shows a typical three-sided fireplace

installation.

IMPORTANT: Side openings must be located at

least 3 feet from facing wall or combustible mate

rial. End opening must be located at least 1 foot

from facing wall or combustible material.

Existing

Side

Wall

-

4" From Opening to

Perpendicular Wall

Figure 2 - Typical Two-Sided Fireplace

Installation

Access

Control Panel

-

-

-

-

SELECTING LOCATION

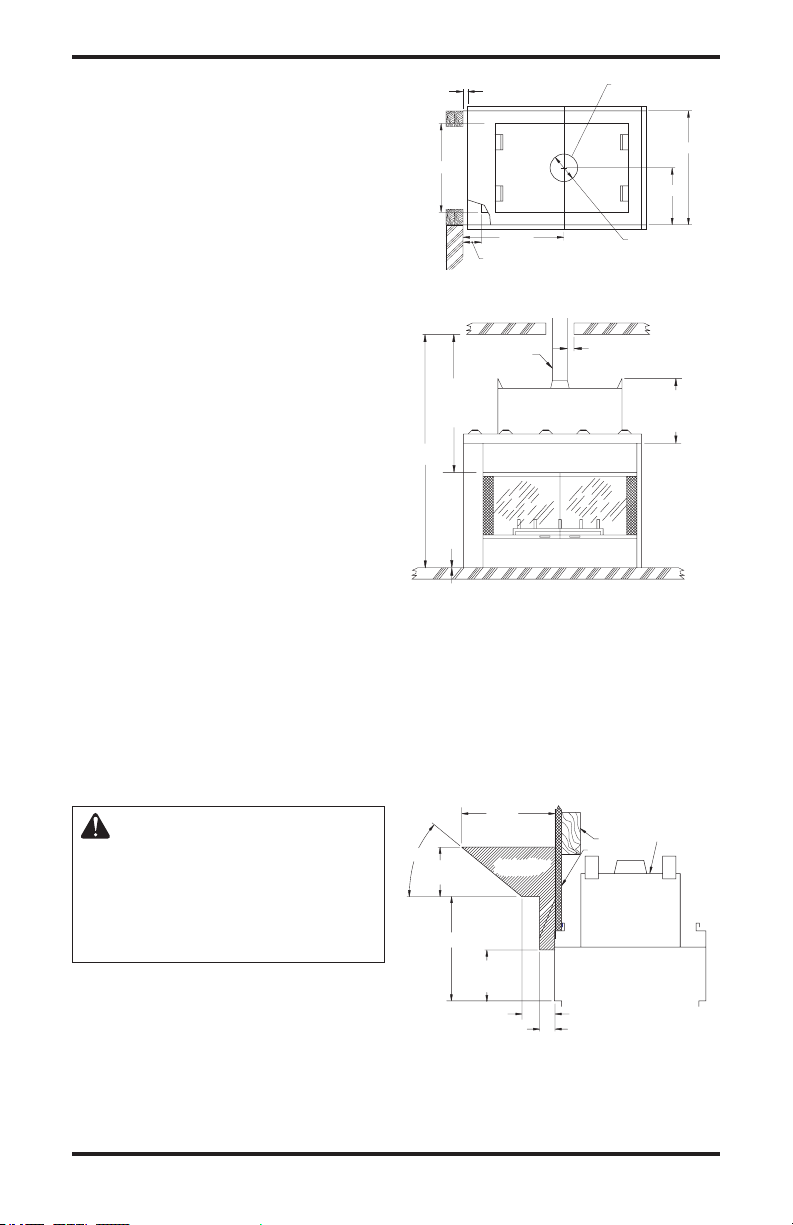

1" Minimum

Clearance to Combustibles

1" Minimum

Clearance from Pipes

to Combustibles

4" Min. from the Perpendicular

Side Wall to the Fireplace Opening (T

yp.)

6" O.D.

19"

11

3/8"

22 3/4"

21 5/8"

35" Min. to

Effective

Opening

to Ceiling

Doublewall

6" B-Vent

1" Min. Clearanc

e

from Pipes to Combustibles

Do Not Pack Space

Between Spacer with

Any Type of Insulation

0" to

Floor

63 7/8"

Minimum

Note: Mantel clearances apply

to both sides of the applliacne.

Header

Drywall

Fireplace To

p

12 1/4"

(Ref.)

6" (Ref.)

33°

12" Min.

7" Min.

to Effective

Opening

3" Nom.

1 1/2" Max.

Combustible

Materials

Continued

In selecting a location, the following precautions

must be observed:

1. Do not connect this appliance to a chimney

system used for a solid fuel burning fire

place.

2. Install in an area providing ventilation and

adequate combustion air.

3. Due to high temperatures, do not locate this

appliance in high traffic areas or near furniture

and draperies.

4. Never obstruct the front opening of the appli

ance or the flow of combustion and ventilation

air. Keep control compartments accessible.

5. DO NOT locate in the vicinity where gasoline

or other flammable liquids may be stored. The

appliance area must be kept clear and free

from these combustible materials.

FIREPLACE

INSTALLATION

CLEARANCES

Minimum clearances to combustibles are:

• Fireplace flanges to studs . . . . . . . . . . . . . .

• Fireplace back/sides . . . . . . . . . . . . . . . . . .

• Fireplace spacers to framing . . . . . . . . . . . .

• Openings to perpendicular wall

• End glass to facing wall

. . . . . . . . . 4"

. . . . . . . . . . . . . . 12"

• Side glass to facing wall . . . . . . . . . . . . . .

• Bottom of fireplace to floor or platform . . .

• “B” vent surfaces

. . . . . . . . . . . . . . . . . . . . 1"

• Top of fireplace opening to ceiling . . . . . .

See Figures 3 and 4.

0"

1"

0"

36"

0"

35"

-

Figure 3 - Clearances from Top View

-

Figure 4 - Clearances from Side View

MANTEL CLEARANCES

Woodwork, such as wood trims, mantels and other

combustible materials, should not be placed within

7" of the opening of this appliance (see Figure

5). Combustible material above the fireplace

projecting more than 1 1/2" from the applianceʼs

front face must not be less than 12" from the appliance opening.

CAUTION: Do not block

required air spaces with insulation or any other material. Do

not obstruct effective opening

of appliance with any type of

facing material.

www.desatech.com

Figure 5 - Mantel Clearances

55175-F6

FIREPLACE

52 3/4"

Min.

40

3

/

8

"

22

3

/

4

"

Nailing Flanges

1" Min. to Combustibles

Prepared Framing

Nails or Screws

52

3

/

4

"

Min.

22

3

/

4

"

*

INSTALLATION

Continued

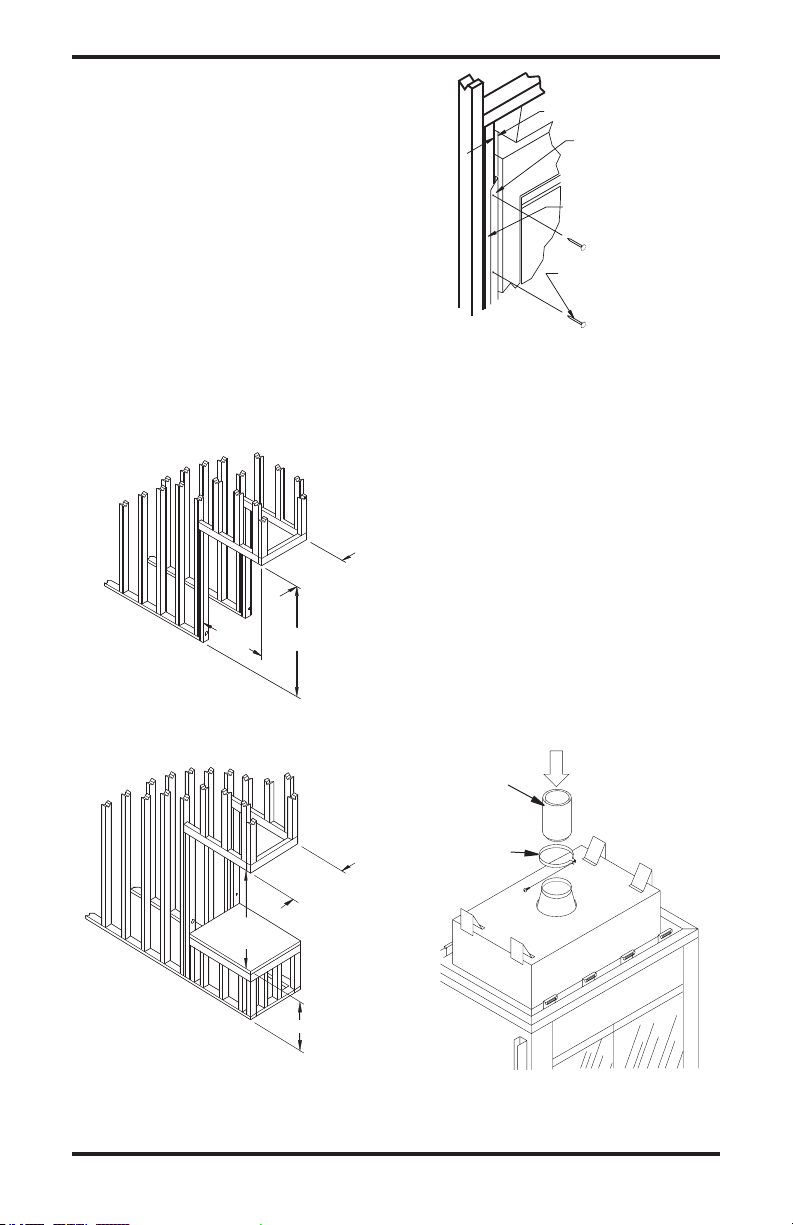

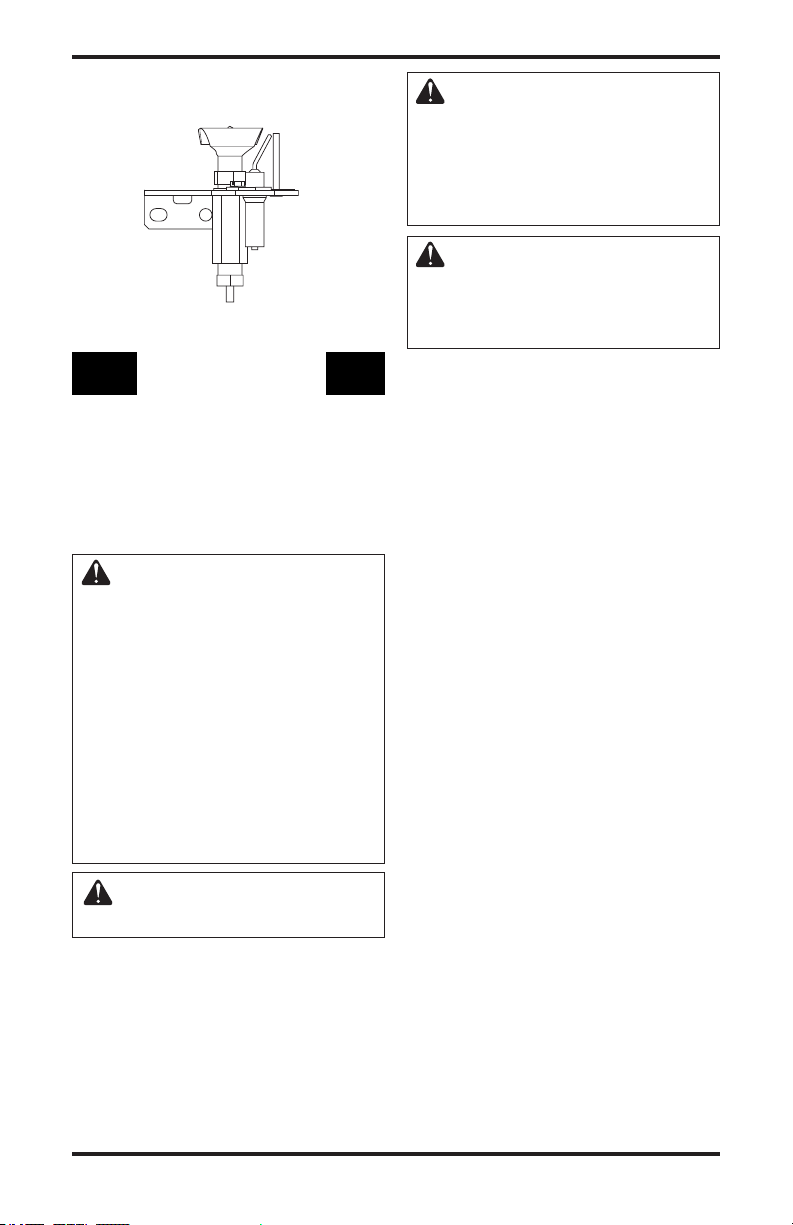

FRAMING

Construct framing using dimensions shown if Figures

6, 7 and 8. (Use the figure applicable to your applica

tion.) Figure 6 shows the framing dimensions prior

to having the appliance in place. If installing on a

platform, platform must be solid, flat and fully supported (see Figure 7). Once the unit has been fitted,

bring studs in against nailing flanges located on the

side of the appliance making sure a 1" clearance is

maintained as shown in Figure 8.

If the fireplace is to be installed directly on carpeting,

tile (other than ceramic) or any combustible mate

rial other than wood flooring the fireplace must be

installed upon a metal or wood panel extending the

full width and depth of the fireplace.

Figure 6 - Framing Dimensions Prior to

Placing Appliance

-

Figure 8 - Securing Appliance with

-

Nailing Flanges

VENT PIPE INSTALLATION

A 6", B-1 type gas vent pipe is a double-wall, venting system (not supplied) which must be installed

during rough framing of the appliance. Any B-1

type gas vent system may be used for proper venting as long as the vent system is installed per the

vent manufacturerʼs recommendations.

DESA supplies this appliance with a tapered starter

pipe for a snug fit. Slide B-1 type vent pipe over

this starter pipe until vent pipe is fully seated.

Secure this first section of B-vent pipe by strap

ping the connector around the vent pipe and then

tightening the strap with any 1/8" nut and bolt (see

Figure 9). Note: Visually inspect for proper vent

connection by looking inside top of appliance. If

connection does not appear to be correct, contact

your local service technician.

B-1 Type

Vent (Not

Supplied)

Strap

(Fasten with

#6 Screw or

Bolt)

-

www.desatech.com

Figure 9 - Installing B-Vent Pipe

*As required by design as

long as ceiling clearance is

maintained

Figure 7 - Framing Dimensions Prior to

55175-F 7

Placing Appliance Using a Platform

FIREPLACE

O

F

P

I

L

O

T

O

N

F

T

O

I

P

L

7

TP

T

H

TP

TH

INSTALLATION

Continued

OPTIONAL OUTSIDE AIR KIT

(MODEL AK4)

The installation of an outside air kit should be

completed during the rough framing of the fireplace due to the nature of it's location. Outside

combustion air is accessed through a vented

crawl space.

CAUTION: Air inlet ducts

must not be terminated in an

attic space.

Avoid installing outside air eyebrow in areas where

inlet opening may be blocked by snow, bushes or

other obstacles (see Figure 10).

The maximum height for the air inlet termination

cannot exceed 3 feet below the B-vent termination

exhaust height.

Secure to Collars with Duct Tape or

Screws

CAUTION: Do not connect

this millivolt system wall switch

to a regular 120v power source!

Gas valve will be damaged beyond repair.

Wall Switch Installation

1. Remove the J-box cover plate from side of

applianceʼs outer surround.

2. Using the 18 ga. millivolt wire and wall switch

(both supplied), connect wiring per wiring

diagram (see Figure 11). For more detail, see

Wiring Diagrams

Note: If any of the original 10 feet supplied wire

must be replaced, use Thermostat Millivolt Wire

18 AWG Type CL2-105 C or equivalent only.

IMPORTANT: Do not hook up to standard 120

VAC household wiring.

on page 16.

To Thermopile

Wall Switch

(Supplied)

Air Inlet

Location

Must Allow

For Bushes

or Snow

Air Inlet

Eyebrow

Vented Crawl Space

(Check Local Codes

Before Installing in a

Vent Hood

Required for

Wall Installation

Vented Crawl Space)

Figure 10 - Outside Air Kit

MILLIVOLT MODELS (GL36PN/PNP)

The installation of a wall switch in this millivolt

control appliance allows you to activate the gas

control valve without the use of normal current.

Figure 11 - Wall Switch Installation

ELECTRONIC MODELS

(GL36PNE/PNEP)

This appliance must be properly wired to standard

120v household current through the DESA-pro

vided wall switch before its remote control unit

can be used to activate the automatic pilot ignition

(turn fireplace flames ON).

Wall Switch Installation

1. Remove the J-box cover plate from side of

applianceʼs outer surround.

2. Using the 18 ga. wires coming through strain

relief grommet on side of applianceʼs outer

wall to standard household 120 VAC current

through the wall switch provided, as shown in

Figure 12, page 9. For more detail, see Wiring

Diagrams, page 16.

Note: If any of the original 10 feet supplied wire

must be replaced, use 20 AWG electrical wire or

equivalent only.

www.desatech.com

Route Millivolt Wires

Back View

(Supplied) Through

Electrical Conduit Bushing

-

55175-F8

FIREPLACE

E

A

INSTALLATION

Continued

Strain Relief

Common

Ground Wire

Figure 12 - Wiring Through Outer Surround

GAS SUPPLY TESTING

Note: This section is intended as a guide for qualified technicians installing gas to this appliance.

Grommet

The gas control valve is secured to the burner pan

assembly underneath the front ledge. A 1/8" NPT

plugged tapping is provided on the gas control

valve for a test gauge connection immediately

upstream of the gas supply connection to the ap

pliance (see Figures 13 and 14).

Pilot Gas Line

Pilot

ON/OFF

Knob

Inlet

Pressure

Figure 13 - Millivolt Control Valve

Adjustment

Cap

Outlet

Pressure

Do Not Kink

To Pilot

Burner

To Main

Burner

To

Main

Burner

-

CAUTION: Do not connect

appliance before pressure testing gas piping. Damage to gas

valve may result and an unsafe

condition may be caused.

The appliance and its individual shut-off valve

must be disconnected from the gas supply piping

system during any pressure testing of that system at

test pressures in excess of 1/2 psig (3.5 kPa).

The appliance must be isolated from the gas sup

ply piping system by closing its individual manual

shut-off valve during any pressure testing of the

gas supply piping system at test pressures equal

to or less than 1/2 psig (3.5 kPa).

This unit has been tested for installation at high

altitude in accordance with Canadian test stan

dard CAN/CGA-2.17. Higher altitudes affect the

atmospheric pressure and heat valve of gaseous

fuels. When installing this unit at high altitudes,

the rated input will be lower than at sea level. The

lowered oxygen content in the air and the lowered

gas density require installation of a different size

orifice in order to achieve clean combustion of

the unit. Consult the unit data plate for the proper

high-altitude orifice size. Fill out the information

sticker attached to the unit when field converting.

See Specifications, page 15, when derating.

55175-F 9

www.desatech.com

From

Gas

Supply

Inlet

Pressure

Figure 14 - Electronic Control Valve

Outlet

Pressure

GAS LINE HOOK-UP

WARNING: Gas line hookup

should be done by your gas

-

supplier or a qualified service

person.

WARNING: Before you pro-

ceed, make sure your gas supply

-

is OFF.

A manual shutoff valve has been included in the

applianceʼs gas supply system. You may consider

installing an extra gas shutoff valve outside the ap

plianceʼs enclosure (check with local codes) where

it can be accessed more conveniently with a key

through a wall as shown in Figure 15, page 10.

A 30" long, 1/2" NPT SCHD 40 flexible gas line

(supplied) may be used between the incoming 1/2"

NPT black iron gas line and the fireplace regulator

(located inside the firebox, under the access plate).

The incoming gas line may be routed toward the

appliance from either the left or right hand side of

fireplace outer surround.

-

FIREPLACE

INSTALLATION

Continued

To install:

1. Remove gas line cover plate from applianceʼs

outer surround at the location to be used.

2. Remove insulation from inside the gas line

conduit sleeve.

3. Run gas line through sleeve.

4. Prepare incoming black iron gas line with

Teflon tape or pipe joint compound. (Check

local codes as to the use of Teflon tape.)

CAUTION: Compounds used

on threaded joints of gas piping

shall be resistant to the action

of Liquefied Petroleum (LP or

propane) and should be applied

lightly to ensure excess sealant

does not enter the gas line.

5. Connect incoming gas line to regulator. Secure

all joints tightly with wrench, but do not over

tighten. If a flexible gas line is used, take care

not to kink the connector.

6. Re-pack insulation in and around the conduit

sleeve and flexible gas line.

Key

Typical Exterior Wall Gas

Shutoff Installation

Figure 15 - Typical Exterior Wall Gas

Shut-Off Installation

Shutoff

Valve

Extension

LOG SET PLACEMENT

Carefully remove log set from packaging. Place

the two bottom logs over grate and align with pins.

Place three loose logs, or twigs, onto alignment

pins on two bottom logs (see Figure 16).

Bottom Logs

WARNING: All gas piping

and connections must be tested

for leaks after the installation is

completed.

After ensuring that the gas valve

is on, apply a commercial leak

detection solution to all connections and joints. If bubbles

appear, leaks can be detected

and corrected.

Do not use an open flame for leak

testing and do not operate any

appliance if a leak is detected.

www.desatech.com

Top Logs (Twigs)

Figure 16 - Log Placement

FIREPLACE FACING

Any non-combustible material may be used for

facing (glass, tile, brick, etc.) as long as the proper

clearances are adhered to and the fireplace openings are not blocked or obstructed in any way. See

Clearances, page 6, and Figure 17 on page 11.

Use only heat-resistant, noncombustible mortar

or adhesive when securing facing material to the

front of the fireplace.

55175-F10

FIREPLACE

Noncombustible

Facing Material

Do Not

Block

Effective

Opening

"L" Shaped

Metal Support

Noncombustible

Facing Material

3/8" to 1/2"

1/8" to 1/4"

3/8" to 1/2"

(10 mm - 13 mm)

1/8" (3 mm)

INSTALLATION

Continued

Pilot Burner

Pan

Burner

Ignitor

Flame

Sensor

Figure 17 - Fireplace Facing Material

MANTELS

Mantels, combustible or non-combustible, may

be constructed as long as proper clearances are

observed (see Figure 5, page 6 and Clearances,

page 6).

PILOT ASSEMBLY ADJUSTMENT

The pilot assembly is factory preset for the proper

flame height. Alteration to factory settings may

have occurred during shipping. If this is the case,

some minor readjustments may be necessary and

should be done by a qualified technician.

The pilot assembly is located behind the burner

next to the rear refractory piece at the right-hand

side. The thermopile (in millivolt models) or the

sensor (in electronic models) should be engulfed

with the pilot flame approximately 3/8" to 1/2" in

order for the regulator to receive proper signal (see

Figures 18 and 19).

Pilot Burner

Ignitor

Figure 19 - Correct Pilot Flame Pattern

- Electronic Assembly

BURNER FLAME ADJUSTMENT

The air shutter, located at the base of the main

burner tube, has been factory preset to the proper

air to bas ratio which results in a long, blue, cleaner

burning flame (see Figure 20).

If readjustment is necessary, loosen the air shut

ter screw and rotate air shutter until proper flame

setting is achieved, retighten air shutter screw. See

Figure 20 for air shutter location.

Closing the air shutter reduces the air-to-gas mix,

resulting in a longer, yellow flame which produces

excessive carbon monoxide (CO) and could also

cause sooting.

Burner Pan

Air Shutter

Screw

Orifice

Gas Valve

Figure 20 - Air Shutter Adjustment

-

Figure 18 - Correct Pilot Flame Pattern

Thermopile

- Millivolt Assembly

55175-F 11

www.desatech.com

FIREPLACE

INSTALLATION

Continued

OPTIONAL GLASS DOOR

Glass doors are optional with this gas appliance (see

Replacement Parts and Accessories, page 19).

Installing Glass Door

1. Be sure top spring clip hole is aligned with

hole in fireplace frame (see Figure 21). Fit

glass door top pin into aligned holes.

2. Swing inner end of bottom clip out away from

fireplace frame. Fit door bottom pin into clip.

Push clip into frame until bottom door pin

slips into hole in frame.

3. Check door alignment. If doors do not align

with each other, use top spring clip to align.

a. Use Phillips screwdriver to loosen screw

that holds top spring clip in place.

b. Push spring clip left or right in its align

ment slot until door is at proper angle

(aligned with opposing door). Moving

spring clip to the LEFT (your left as you

face the fireplace) moves glass doorʼs top,

inner corner UP; moving spring clip to

the RIGHT moves glass doorʼs top, inner

corner DOWN.

c. When door alignment is satisfactory, use

Phillips screwdriver to retighten spring

clip screw.

WARNING: When fireplace

is in operation, both sets of

cabinet doors on each side of the

fireplace must be either FULLY

OPEN or FULLY CLOSED. If not,

a fire hazard may be created.

Only doors certified with this appliance may be

used. When operating doors, do not slam or abuse

them. Always keep area below bottom edge of

doors clear of obstacles or debris. Do not operate

this appliance if glass doors are broken or dam

aged. See Figure 22.

Top Slot

Under Frame

Adjustment

Clip

Adjustment

Screw

Long Pivot Pin

Bottom Pin

Bottom Slot

Adjustment Clip

Figure 21 - Installing Glass Doors

-

Glass Doors Must be Fully Open

(as Shown) or Fully Closed when

Appliance is in Operation

Figure 22 - Glass Doors Shown Fully

Open

-

www.desatech.com

55175-F12

OPERATING FIREPLACE

MILLIVOLT MODELS

FOR YOUR SAFETY

READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly,

a fire or explosion may result

causing property damage, personal injury or loss of life.

A. This appliance has a pilot which must be

lighted by hand. When lighting the pilot,

follow these instructions exactly.

B. BEFORE LIGHTING smell all around the

appliance area for gas. Be sure to smell next

to the floor because some gas is heavier than

air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not

use any phone in your building.

• Immediately call your gas supplier

from a neighborʼs phone. Follow the

gas supplierʼs instructions.

• If you cannot reach your gas supplier,

call the fire department.

C. Use only your hand to push in or turn the

gas control knob. Never use tools. If the

knob will not push in or turn by hand, donʼt

try to repair it, call a qualified service tech

nician or gas supplier. Force or attempted

repair may result in a fire or explosion.

D. Do not use this appliance if any part has

been und er w ater. Immedi ately call a

qualified service technician to inspect the

appliance and to replace any part of the

control system and any gas control which

has been under water.

LIGHTING

INSTRUCTIONS

1. STOP ! Rea d the safe ty in for mat io n,

column 1.

2. Turn wall switch to the OFF position.

3. Turn off all electric power to the appliance.

4. Open control access panel.

5. Push in gas control knob and turn clock

wise

Figure 23).

you maintain the gas control knob in the

full OFF position during lengthy periods

of seasonal non usage.

6. Wait five (5) minutes to clear out any gas.

Then smell for gas, including near the floor.

If you smell gas, STOP! Follow “B” in the

safety information above. If you donʼt smell

gas, go to the next step.

7. Turn control knob counterclockwise

to the PILOT position.

8. Push in control knob all the way and hold

in. Immediately light the pilot by pressing

the red ignitor button until a flame ap

pears. Continue to hold the control knob

in for about (1) minute after the pilot is lit.

Release knob and it will pop back up. Pilot

should remain lit. If it goes out, repeat steps

5 through 8.

• If knob does not pop up when released,

stop and immediately call your service

technician or gas supplier.

• If the pilot will not stay lit after sev

eral tries, turn the gas control knob to

-

“OFF” and call your service technician

or gas supplier.

9. Turn gas control knob counterclockwise

“ON” only if the control knob is popped out.

10. Replace control access panel.

11. Turn on all electric power to the appliance.

Gas Control Knob

to the OFF posi tion (see

Note: It is recommended that

to “ON”. Knob can be turned to

-

-

-

NOTICE: During initial operation

of new heater, burning logs will

give off a paper-burning smell.

Orange flame will also be pres

Position Indicator

-

Figure 23 - Millivolt Control Valve

ent. Open window to vent smell.

This will only last a few hours.

55175-F 13

www.desatech.com

OPERATING FIREPLACE

E

A

Continued

TO TURN OFF GAS

TO APPLIANCE

1. Turn off the wall switch.

2. Turn off all electric power to the appliance

if service is to be performed.

3. Remove control access panel.

4. Push in gas control knob and turn clockwise

to “OFF”. Do not force.

5. Replace control access panel.

Pilot

Burner

Ignitor

Figure 24 - Pilot

ELECTRONIC MODELS

FOR YOUR SAFETY

READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly,

a fire or explosion may result

causing property damage, per

sonal injury or loss of life.

A. This appliance has a pilot which must be

lighted by hand. When lighting the pilot,

follow these instructions exactly.

B. BEFORE LIGHTING smell all around the

appliance area for gas. Be sure to smell next

to the floor because some gas is heavier than

air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not

use any phone in your building.

• Immediately call your gas supplier

from a neighborʼs phone. Follow the

gas supplierʼs instructions.

• If you cannot reach your gas supplier,

call the fire department.

Thermopile

-

C. Use only your hand to push in or turn the

gas control knob. Never use tools. If the

knob will not push in or turn by hand, donʼt

try to repair it, call a qualified service technician or gas supplier. Force or attempted

repair may result in a fire or explosion.

D. Do not use this appliance if any part has

been und er w ater. Immedi ately call a

qualified service technician to inspect the

appliance and to replace any part of the

control system and any gas control which

has been under water.

LIGHTING

INSTRUCTIONS

NOTICE: During initial operation

of new heater, burning logs will

give off a paper-burning smell.

Orange flame will also be present. Open window to vent smell.

This will only last a few hours.

1. STOP ! Rea d the safe ty in for mat io n,

column 1.

2. Set the thermostat to lowest setting (if

applicable).

3. Turn off wall switch.

4. Open control access panel or louver.

5. Smell for gas, including near the floor. If you

smell gas, STOP! Follow “B” in the safety

information in column 1. If you donʼt smell

gas, go to the next step.

6. Turn the main burner wall switch to the ON

position for ignition. There will be a spark

at the electrode.

7. Replace control access panel or louver once

there is a flame at the burner.

8. If burner will not stay lit after several tries,

flip the wall switch to OFF and call your

service technician or gas supplier.

To

Main

Burner

From

Gas

Supply

Inlet

Pressure

Figure 25 - Electronic Control Valve

Outlet

Pressure

www.desatech.com

55175-F14

OPERATING FIREPLACE

Continued

Figure 26 - Pilot

TO TURN OFF GAS

TO APPLIANCE

1. Turn off all electric power to the appliance

if service is to be performed.

2. Remove control access panel.

3. Close the gas valve.

CLEANING AND

MAINTENANCE

WARNING: Installation and

repair should be done by a qualified service person. The appliance should be inspected before

each use and at least annually

by a qualified service person.

More frequent cleaning may be

required due to excessive lint

from carpeting, bedding material, pet hair, etc. It is imperative

that the control compartments,

burners and circulating air system be kept clean.

WARNING: The logs can be

hot. Handle only when cool.

55175-F 15

www.desatech.com

WARNING: Turn off gas and

electrical power before servicing

appliance. Any safety screen

or guard removed for servicing

must be replaced prior to operat

ing the appliance.

WARNING: Failure to keep

the primary air opening(s) of

the burner(s) clean may result in

sooting and property damage.

Keep control compartment, logs, burner and area

surrounding logs clean by vacuuming or brushing

at least twice a year. Take care not to alter the set

tings on the pilot assembly.

Do not use abrasive liquids or cleaners for cleaning

glass doors and trims. Any household glass cleaner

should suffice. Do not clean doors when hot. Allow

appliance to cool before cleaning.

TECHNICAL SERVICE

You may have further questions about installation,

operation or troubleshooting. If so, contact DESAʼs

Technical Service Department at 1-866-672-6040.

When calling please have your model and serial

numbers of your heater ready.

You can also visit DESAʼs Technical Services web

site at www.desatech.com.

SPECIFICATIONS

GL36PN, GL36PNE

• Maximum Input Rating at Altitudes: 2,000 ft.

- 42,000 Btu/hr., 2,000 ft. to 4,000 ft. - 37,800

Btu/hr.

• Manifold Pressure: 3.5 W.C. (.87 kPa)

• Supply Pressure (in. of water): Minimum* - 4.5"

(1.12 kPa), Maximum - 11.0" (2.74 kPa)

• Orifice Size at Altitudes: 2,000 ft. - #30, 2,000 ft.

to 4,000 ft. - #31

* For the purpose of input adjustment

GL36PNP, GL36PNEP

• Maximum Input Rating at Altitudes: 2,000 ft.

- 42,000 Btu/hr., 2,000 ft. to 4,000 ft. - 37,800

Btu/hr.

• Manifold Pressure: 11.0 W.C. (2.74 kPa)

• Supply Pressure (in. of water): Minimum* -

12.0" (2.89 kPa), Maximum - 13.0" (3.23 kPa)

• Orifice Size at Altitudes: 2,000 ft. - #49, 2,000 ft.

to 4,000 ft. - #51

* For the purpose of input adjustment

-

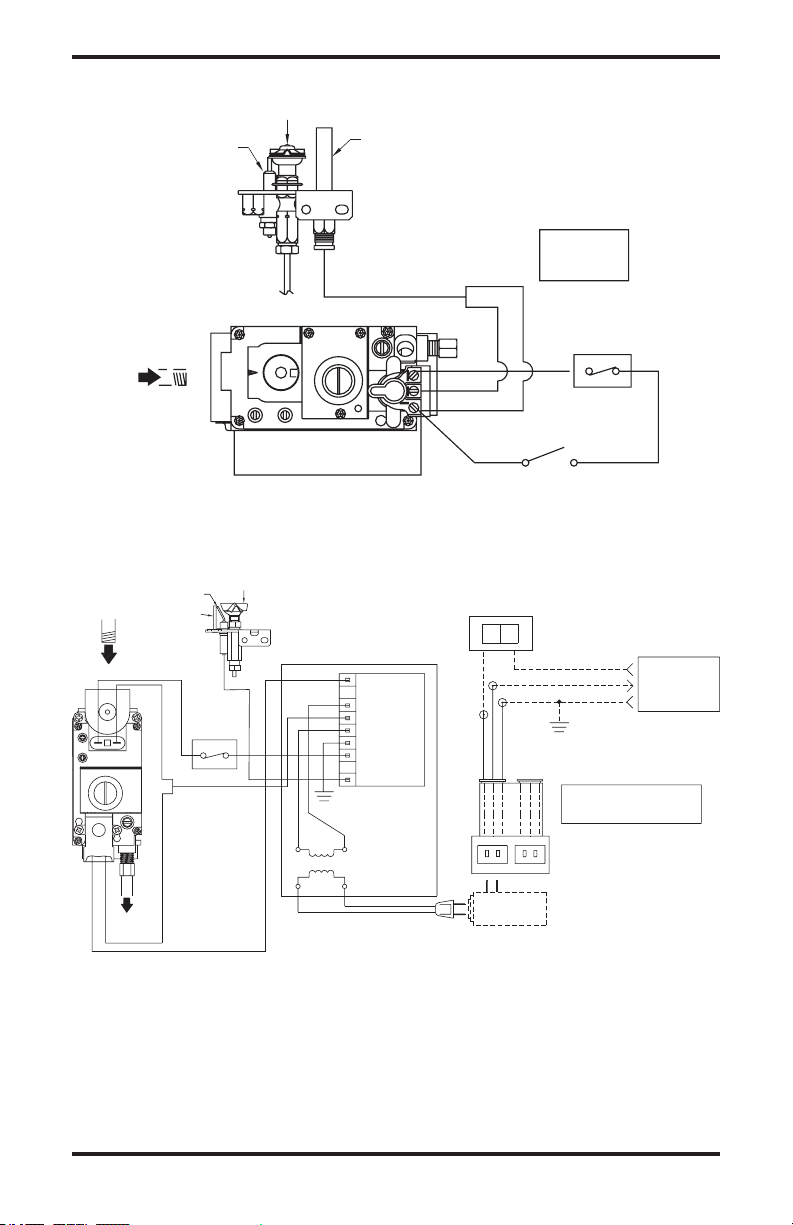

-

DO NOT

CONNECT

N.C.SW

HEAT LIMIT SWITCH

TH/TP

TP

TH

WA

LL SWITCH

(SUPPLIED)

TO 120V

THERMOPILE

PILOT

IGNITOR

O

F

F

P

I

L

O

T

O

N

PILOT SAFETY WIRE

MAIN GAS

INCOMING

SUPPLY

STEP DOWN

TRANSFORMER

EV2

SUPPLY

INCOMING

MAIN GAS

EV1

TO

GAS LINE

BURNER

24V AC

N.C.SW

HEAT LIMIT

SWITCH

120V AC

120V AC

INCOMING

OR BREAKER)

(FUSE BOX

OFF

ON

(SUPPLIED)

WALL SWITCH

GREEN

BLACK

WHITE

120v, 60Hz, 0.7A

ELECTRICAL RATING:

BLACK

WHITE

GREEN

OPTIONAL

REMOTE

CONTROL

SENSOR

PILOT

IGNITOR

PV

GND

PV/MV

TR

MV

TH

IG

N

WIRING DIAGRAMS

MILLIVOLT WIRING DIAGRAM

ELECTRONIC WIRING DIAGRAM

www.desatech.com

55175-F16

TROUBLESHOOTING

MILLIVOLT SYSTEM

Note: Before troubleshooting the system, make sure the gas shutoff valve is ON.

The two most common causes of a malfunctioning gas appliance are:

1. Loose wiring connections

2. Construction debris clogging the pilot and/or gas control valve filter

OBSERVED PROBLEM

Pilot will not light

Pilot will not stay lit

POSSIBLE CAUSE

1. No gas supply or shutof f

valve is OFF

2. Air in gas line

3. Construct ion debris clogging pilot orifice

4. Low gas pressure

5. Control valve knob is not on

the PILOT position

6. Kinked pilot line

7. Bad valve

1. Loose wiring on thermopile

to control valve.

2. No millivolt current is being

sent back to regulator

3. If valve knob and wall switch

are in the ON position, prob

able defective control valve

REMEDY

1. Check to see if you have gas

supply

2. Hold regulator control valve

in the PILOT position for 2 to

3 minutes to purge air. If you

smell gas stop and wait for a

few minutes before trying to

light the fireplace

3. Remove debris and dirt, inspec t and clean any oth er

possible obstructions

4. Contact your gas supplier

5. Ref e r to sect ion on pi l ot

lighting

6. Have a qualified technician

replace pilot line

7. Replace control valve (see

Replacement Parts and Accessories, page 19)

1. Check wiring connections.

Refer to wiring diagrams on

page 15

2. Have a qualified technician

check millivolts

3. Have a qualified technician

replace valve (see Replace

-

ment Parts and Accessories

page 19)

-

,

No gas to burner, although wall

switch and valve are set to the

ON position

Frequent pilot outage

Pilot goes out when wall switch

is ON

55175-F 17

1. Wall switch wires defective

2. Thermopil e or sensor not

generating sufficient voltage

1. P ilot f lame ma y be too

low, causing safety pilot to

“drop out”

1. Millivolt output on thermo

pile too high

www.desatech.com

1. Check electrical connections

and wires for continuity

2. See Pilot wil l not stay lit

above

1. Clean and adjust pilot flame

for maximum flame impinge

ment on thermopile

1. Have a qualified technician

replace thermopile

,

-

TROUBLESHOOTING

ELECTRONIC IGNITION SYSTEM

Note: Before troubleshooting the system, make sure the gas shutoff valve is ON.

The two most common causes of a malfunctioning gas appliance are:

1. Loose wiring connections

2. Construction debris clogging the pilot and/or gas control valve filter

OBSERVED PROBLEM

Pilot will not light

Pilot will not stay lit

No gas to burner, although wall

switch and valve are set to the

ON position

POSSIBLE CAUSE

1. No gas supply or shutof f

valve is OFF

2. Construct ion debris clog

ging pilot orifice

3. Low gas pressure

4. Control valve knob is not on

the PILOT position

5. Kinked pilot line

6. Bad valve

1. Loose wiring on thermopile

to regulator valve. No mil

livolt current is being sent

back to regulator

2. If valve knob and wall switch

are in the ON position, probable defective control valve

1. Wall switch wires defective

2. Thermocouple generator or

sensor not generating suf

ficient voltage

REMEDY

1. Check to see if you have gas

supply

-

2. Remove debris and dirt, in

spec t and clean any oth er

possible obstructions

3. Contact your gas supplier

4. Ref e r to sect ion on pi l ot

lighting

5. Have a qualified technician

replace pilot line

6. Replace control valve (see

Replacement Parts and Acces

sories, page 19)

1. Check wiring connections.

Refer to wiring diagrams on

page 16

2. Have a qualified technician

replace valve (see Replace

ment Parts and Accessories,

page 19)

1. Check electrical connections

and wires for continuity

2. See Pilot wil l not stay lit,

-

above

-

-

-

Frequent pilot outage

Pilot goes out when wall switch

is ON

1. P ilot f lame ma y be too

low, causing safety pilot to

“drop out”

1. Output on flame sensor too

high

www.desatech.com

1. Clean and adjust pilot flame

for maximum flame impinge

ment on thermopile

1. Replace flame sensor

55175-F18

-

REPLACEMENT PARTS AND ACCESSORIES

Purchase these fireplace replacement parts and

accessories from your local dealer. If they can not

supply these parts, call DESA at 1-866-672-6040

for referral information. You can also write to the

address listed on the back page of this manual.

Before ordering, please have your applianceʼs

model name or number and part number of the

item(s) you are ordering ready. The model name or

number for your particular appliance may be found

on the rating label located inside the appliance.

MILLIVOLT VALVE

Natural Gas - 14512

Propane/LP Gas - 14513

ELECTRONIC VALVE

Natural Gas - 14569

Propane/LP Gas - 14570

MILLIVOLT PILOT ASSEMBLY

Natural Gas - 112784-01

Propane/LP Gas - 112784-02

ELECTRONIC PILOT ASSEMBLY

Natural Gas - 108866-01

Propane/LP Gas - 108866-02

TRANSFORMER - 14129

For use with all models.

PIEZO IGNITER - 14261

For use with all models.

ORIFICE

Natural Gas - 23105

Propane/LP Gas - 23106

For use with all models.

WALL SWITCH KIT - 22180

Wall Switch - 14112

Cover Plate - 14113

For use with all models.

IGNITION CONTROL - 110286-01

For use with all models.

GAS VALVE CONVERSION KIT

Millivolt Propane/LP Gas - PC-GL36

Millivolt Natural Gas - NC-GL36

Electronic Propane/LP Gas - PC-GL36E

Electronic Natural Gas - NC-GL36E

BRUSHED BRASS CABINET STYLE

DOOR KIT - DBBGL36PN

Right Panel Assy - 22367

Left Panel Assy - 22368

End Panel Assy - 22369

For use with all models.

BURNER ASSEMBLY - 23439

For use with all models.

REMOTE CONTROL KIT - 01026

For Millivolt Units Only - Batteries required for

receiver and transmitter.

REMOTE CONTROL KIT - 00825

For Millivolt Units Only - No batteries required

for receiver or transmitter.

REMOTE CONTROL KIT - 11710

For use with all models.

VENT HOOD - AK4

For use with all models.

REFRACTORY

Side Refractory - 23519

Bottom Refractory - 23516

Face - 112139-01

For use with all models.

GRATE ASSEMBLY - 11159

For use with all models.

LOG SET ASSEMBLY - 25793

Bottom Rear Log - 25795

Bottom Front Log - 25794

Top Left Log - 25797

Top Center Log - 25672

Top Right Log - 25796

For use with all models.

"B-1 TYPE" VENT PIPE

For use with all models. Any B-1 type, 6" diameter, gas vent pipe may be purchased from your

local vent manufacturer.

55175-F 19

www.desatech.com

LIMITED 2-YEAR WARRANTY

55175

DESA warrants this gas appliance to be free from the defects in material or workmanship at the time of manufacture.

REMEDY AND EXCLUSIONS

The coverage of this warranty is limited to all components of the gas appliance manufactured by DESA, with the

exception of glass and refractory. The glass is warranted for 90 days. There will be no cost for replacement of glass

within 90 days of installation, provided that breakage is due to heat from the appliance. We do not warranty breakage

occurring during installation or transportation.

If the decorative gas appliance covered by this warranty is found to be defective within one year from the date of installation,

DESA will, at its option, replace or repair defective components of the decorative gas appliance manufactured by DESA

at no charge or will pay for reasonable costs incurred in replacing or repairing such components. These charges should be

pre-approved by DESA before any work is done. During the second year of the warranty, DESA shall supply replacement

parts, if readily available, at the current minimum wholesale price. DESA will not be responsible for any other expense.

REFRACTORY WARRANTY

FIRST YEAR: DESA warrants the refractory (except the hairline cracks less than 1/16” in width) one year from the

date of manufacture to be free from defect in material and workmanship. If the original owner of a DESA fireplace

believes that any of the refractory parts have failed during the above one year period, the current owner should notify

the nearest (DESA) distributor or dealer. DESA will pay for the refractory replacement and reasonable labor charges.

DESA will be responsible for the freight charges.

SECOND YEAR: DESA will supply the refractory replacement parts at the current list price that is in effect at time

of the replacement. DESA will assume no responsibility for any labor and freight charges incurred.

This warranty covers only parts and labor as provided above. In no case shall DESA be responsible for materials,

components or construction which are not manufactured or supplied by DESA. DESA will not be responsible for any

labor charges to remove such materials, components or construction. All replacement parts will be shipped. F.O.B.,

Santa Ana, to purchasersʼ address or the nearest DESA distributor.

QUALIFICATIONS TO THE WARRANTY

The decorative gas appliance warranty outlined above is further subject to the following qualifications:

1. The gas appliance must be installed as per the DESA installation instructions and local building codes. The use of

components manufactured by others with this DESA gas appliance (except for the Type B venting system as outlined

in the installation instructions, if applicable) could create serious safety hazards may result in denial of certification

by recognized national safety agencies and could be in violation of local building codes. This warranty does not

cover any damages occurring from the use of my components not manufactured or supplied by DESA.

2. The DESA appliance must be subjected to normal use. The decorative gas appliances are designed to burn either

natural or propane/LP gas only. Burning conventional fireplace fuels such as wood, coal or any other solid fuel will

cause damage to the decorative gas appliance, will produce excessive temperatures and will result in a fire hazard.

LIMITATION OF LIABILITY

It is expressly understood that DESAʼs sole obligation and purchaserʼs exclusive remedy under this warranty, expressed

or implied, or in contract, tort or otherwise, shall be limited to replacement or repair as specified above. In no event shall

DESA be responsible for any incidental or consequential damages caused by defects in its products, whether such dam

age occurs or is discovered before or after replacement or repair and whether or not such damage is caused by DESAʼs

negligence. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you. The duration of any implied warranty with respect to this DESA decorative

gas appliance is limited to the duration of the foregoing warranty.

INVESTIGATION OF CLAIMS AGAINST WARRANTY

DESA reserves the right to investigate any and all claims against this warranty and to decide upon method of settlement. DESA is not responsible for work done without written consent. DESA shall in no event be responsible for any

warranty work done without first obtaining DESAʼs written consent.

HOW TO REGISTER A CLAIM

A (DESA) dealer or distributor should be contacted directly by the owner for any service, including service under

these warranties. The repair and replacement of any defective part covered by these warranties is the responsibility

of the nearest (DESA) dealer or distributor.

OTHER

This warranty gives you specific rights and you may also have other rights which vary from state to state,. These

warranties are given in lieu of any other expressed warranties. DESA does not authorize any person or representative

to make representations to the contrary in connection with the sale of a decorative gas appliance.

-

NOT A UPC

2701 Industrial Drive

P.O. Box 90004

Bowling Green, KY 42102-9004

www.desatech.com

55175

Rev. F

09/05

Loading...

Loading...