Page 1

ELECTRIC FIREPLACE

OWNER’S OPERATION AND INSTALLATION MANUAL

MODELS E32L, E32LB, E32LH, E32LBH,

E36L, E36LB, E36LH AND E36LBH

PLEASE READ THIS MANUAL BEFORE INSTALLING

AND USING APPLIANCE.

WARNING: If the information in this manual is not followed exactly, an electrical shock or re may result causing property damage, personal injury or loss of life.

FOR YOUR SAFETY

— Do not store or use gasoline or other ammable va-

pors and liquids in the vicinity of this or any other

appliance.

— Installation and service must be performed by a quali-

ed service agency.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

For more information, visit www.desatech.com

Page 2

TABLE OF CONTENTS

Safety .................................................................. 2

Product Specication ........................................... 3

Installation ........................................................... 3

Features and Operation....................................... 7

Accessory Installation .......................................... 8

Troubleshooting ................................................. 14

Wiring Diagram .................................................. 15

SAFETY

WARNING: Electrical wiring

must comply with local building codes and other applicable

regulations to reduce the risk of

re, electrical shock and injury

to persons.

WARNING: Do not use this

replace if any part of it has

been under water. Immediately

call a qualied service technician to inspect the replace and

replace any part of the electrical

system.

CAUTION: Extreme caution

is necessary when any heater is

used by or near children or invalids and whenever the heater is

left operating and unattended.

1. Read all instructions before using this

replace.

2. This replace is hot when in use. To avoid

burns, do not let bare skin touch hot surfaces. If provided, use handles when accessing replace controls. Keep combustible materials, such as furniture, pillows,

bedding, papers, clothes, and curtains at

least 3 feet from front of replace.

3. Extreme caution is necessary when any

heater is used by or near children or invalids and whenever heater is left operating

and unattended.

4. Always place main power switch in OFF

position when not in use.

5. Do not operate replace if any part has

been damaged or is malfunctioning.

Maintenance ...................................................... 16

Technical Service............................................... 23

Replacement Parts ............................................ 23

Parts .................................................................. 24

Accessories ....................................................... 27

Warranty .............................................. Back Cover

6. Any repairs to this replace should be

done by a qualied service person.

7. Do not use outdoors.

8. This replace is approved for installation

in bedrooms.

9. Under no circumstances should this

replace be modied. Parts having to be

removed for servicing must be replaced

prior to operating this replace.

10. This replace is not intended for use in

bathrooms, laundry areas and similar

locations where it would be subject to

excessive moisture.

11. This replace may not be installed outdoors or in an unenclosed space where

exposed to the elements.

12. To disconnect this replace, turn off at

circuit breaker or fuse panel.

13. Th is appliance , must be elec trically

grounded in accordance with local codes

and the National Electric Code, ANSI/

NFPA No. 70 or in Canada with CSA

C22.1 Canadian Electrical code.

14. Do not insert or allow foreign objects to

enter any ventilation or exhaust openings.

This may cause an electrical shock, re

or damage to replace.

15. To prevent a possible re do not block air

intakes or exhaust.

16. This firepl ace has hot and arcin g or

sparking parts inside. Do not use in areas

where gasoline, paint or ammable liquids

are used or stored. This replace should

not be used to dry clothing or for hanging

decorations.

17. Use this replace only as described. Any

other use not recommended by the manufacturer may cause re, electric shock or

injury to persons.

18. SAVE THESE INSTRUCTIONS.

www.desatech.com

111076-01F2

Page 3

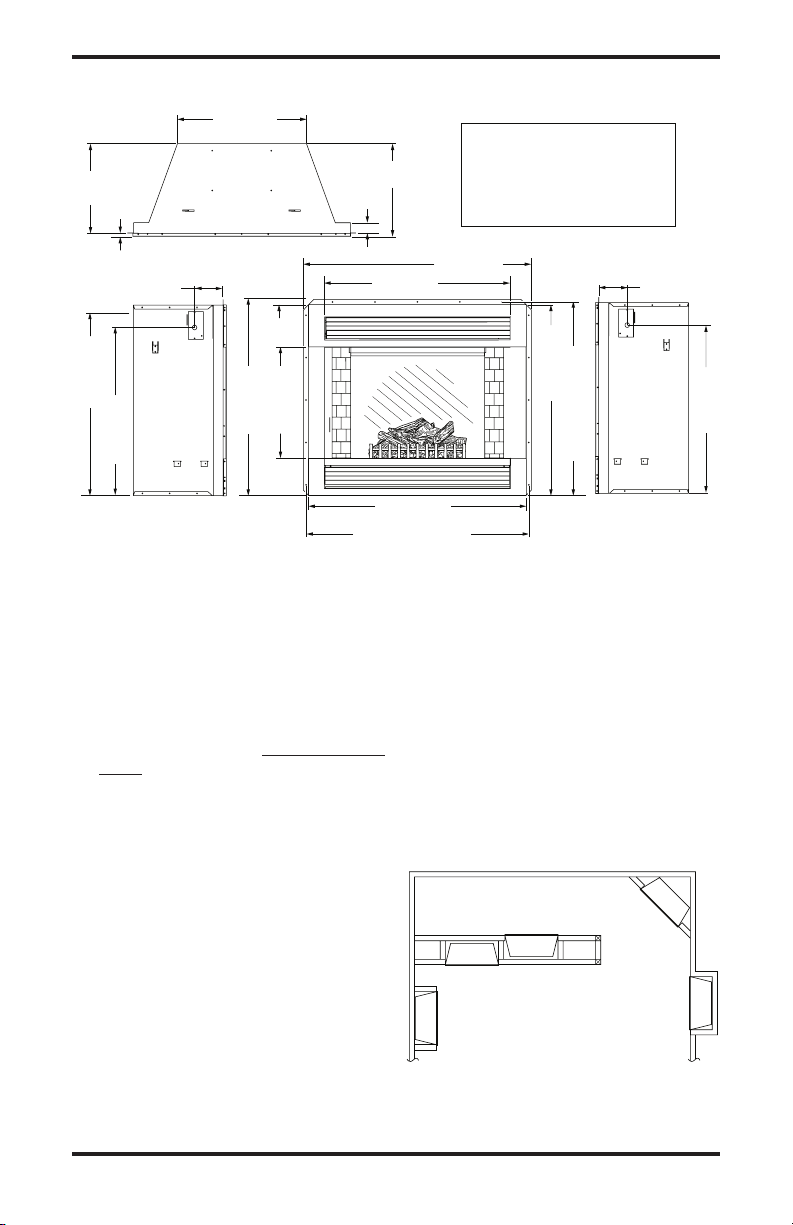

E32 = 155/8"

E36 = 17"

E32 = 161/4"

E36 = 175/8"

E32 = 221/4"

E36 = 241/4"

E32 = 293/8"

E36 = 35"

E32 = 7"

E36 = 8"

E32 = 61/2"

E36 = 51/4"

E32 = 18

3

/

8

"

E36 = 21"

E32 = 33

3

/

8

"

E36 = 37"

E32 = 363/8"

E36 = 43"

E32 = 353/8"

E36 = 42"

E32 = 345/8"

E36 = 411/4"

E32 = 32

5

/

8

"

E36 = 36

1

/

4

"

E32 = 28

3

/

8

"

E36 = 31

3

/

4

"

E32 = 32

7

/

8

"

E36 = 36

1

/

2

"

17/8"

5/8"

TOP

FRONT

LEFT SIDE RIGHT SIDE

E32 = 32

1

/

8

"

E36 = 36

1

/

8

"

E32 = 28

3

/

8

"

E36 = 31

3

/

4

"

To Nail

Location

To Nail

Location

E32 = 8"

E36 = 51/4"

ELECTRICAL SPECIFICATIONS

Voltage: 120 VAC, 60 Hz

Total Amps: 12.5 Amps

Total Watts: 1500 Watts

Heater Rating: 1100 Watts

Max. Bulb Rating: 100 Watts

Use only on 15 amp circuit

Internal Wall

Installation

Full Projection

Installation

Flush

Installation

Corner

Installation

PRODUCT SPECIFICATION

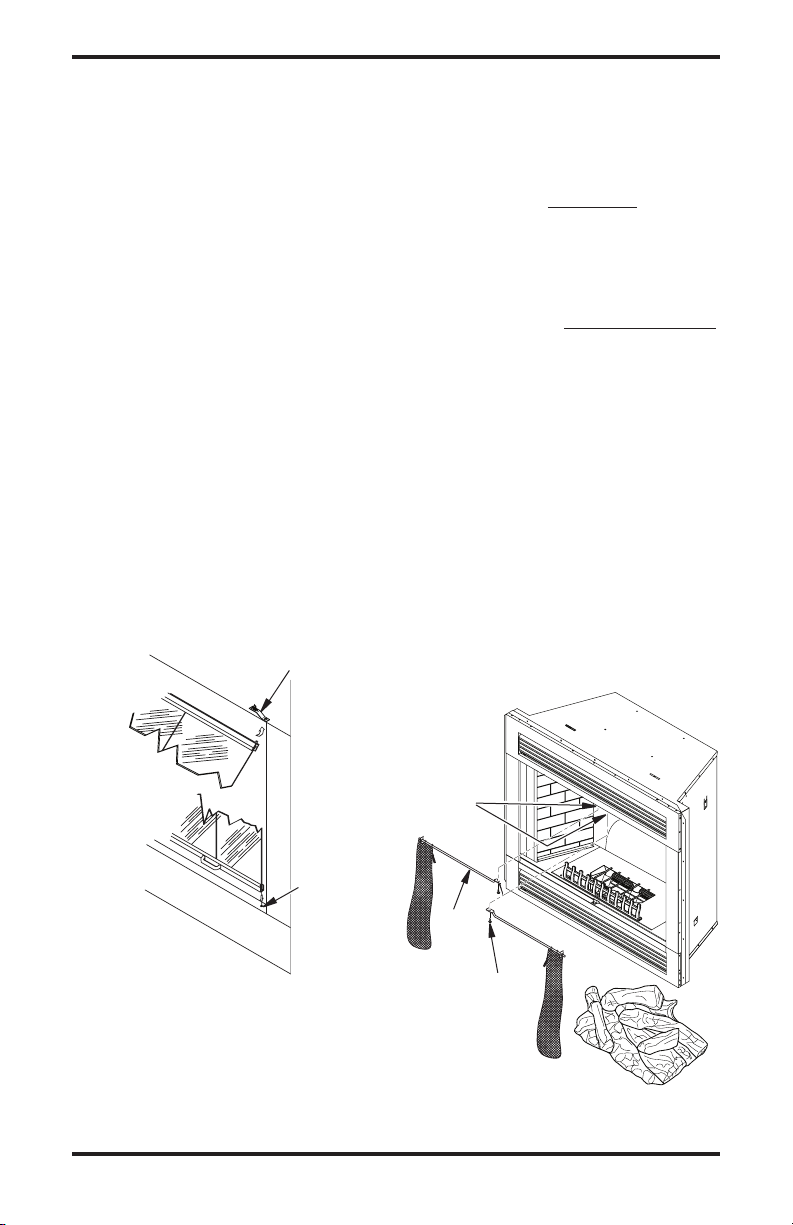

Figure 1 - Unit Dimensions

INSTALLATION

LOCATING FIREPLACE

Plan where to locate and frame replace.

Before installation consider the following:

1. Fireplace location must allow for wall and

2. Fireplace screen should not be exposed

3. A 15 amp, 120 Volt, 60 Hz circuit with

Flush Installations are recommended where

living space is limited or at a premium. Since

space required to enclose replace would

be located beyond an outside wall, this installation would require additional planning

and construction. Check local codes for any

restrictions.

ceiling clearances (see Installation Clear-

ances, page 4).

to direct sunlight from windows or doors.

proper ground must be available. A dedicated circuit should be provided to avoid

circuit breaker trips or blown fuses.

Projected Installations can extend any distance into room. A projection may be ideal for

a new addition on an existing, nished wall.

Corner Installations make use of space

that may not normally be used and provides

a wider and more efcient viewing angle and

heat distribution.

Internal Wall Installations provide a discrete

option for room separation and can also be an

ideal addition to an existing wall.

Figure 2 - Possible Installation Locations

111076-01F 3

www.desatech.com

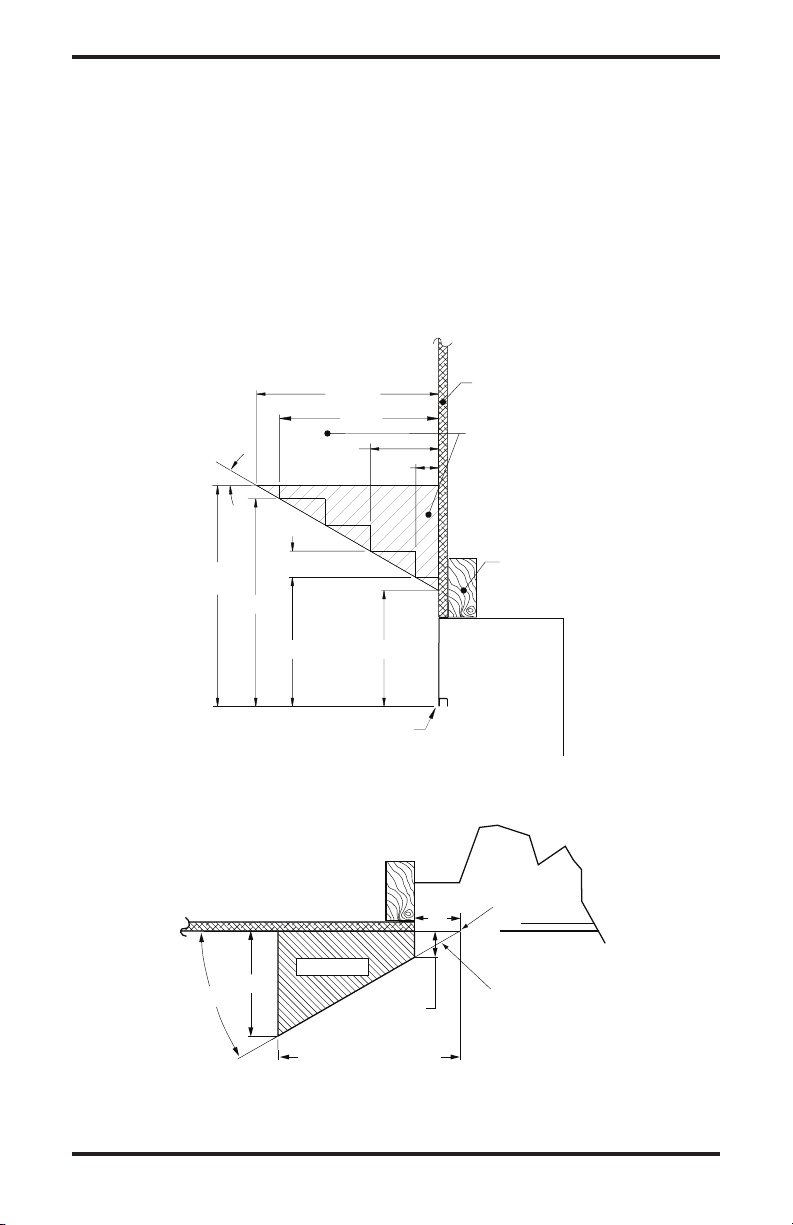

Page 4

Facing Material May

Be Noncombustible

Wall Treatments or

Combustible Wood

Combustible Wood

Mantels and Trims

May Extend Above

Profile Shown when

Maintained within

30° Parameter

Shown

Framed

Material

Top of Cabinet

Note: All Mantel Clearances

are Measured from Top of

Fireplace Opening

30°

16 5/8"

Ref.

9 5/8" Ref.

12" Ref.

13 3/4"

4 1/2"

1 1/2"

1 3/4"

10 1/2" Min.

10 1/2"

Top View of Fireplace

Safe Zone

5"

3"

30°

1 3/4" Max.

Minimum 10" from

Perpendicular Side Wall

Edge of Firebox

Opening

Combustible

MaterialMust

Not Overlap

Front Face

INSTALLATION

Continued

INSTALLATION CLEARANCES

Minimum clearances to combustible construction are:

• Top, Back and Sides of Recessed

Cabinet . . . . . . . . . . . . . . . . . . . . .0" Min.

• Drywall to Sides of Front Face . . .0" Min.

• Framing at Nailing Flanges . . . . . .0" Min.

• Ceiling to Opening . . . . . . . . . . . .36" Min.

Mantel Clearances

For mantel clearances see Figures 3 and 4.

• Floor . . . . . . . . . . . . . . . . . . . . . . .0" Min.

• Front . . . . . . . . . . . . . . . . . . . . . .36" Min.

• Perpendicular Side Wall . . . . . . .10" Min.

Figure 3 - Mantel Clearances

Figure 4 - Mantel Side Clearances

www.desatech.com

111076-01F4

Page 5

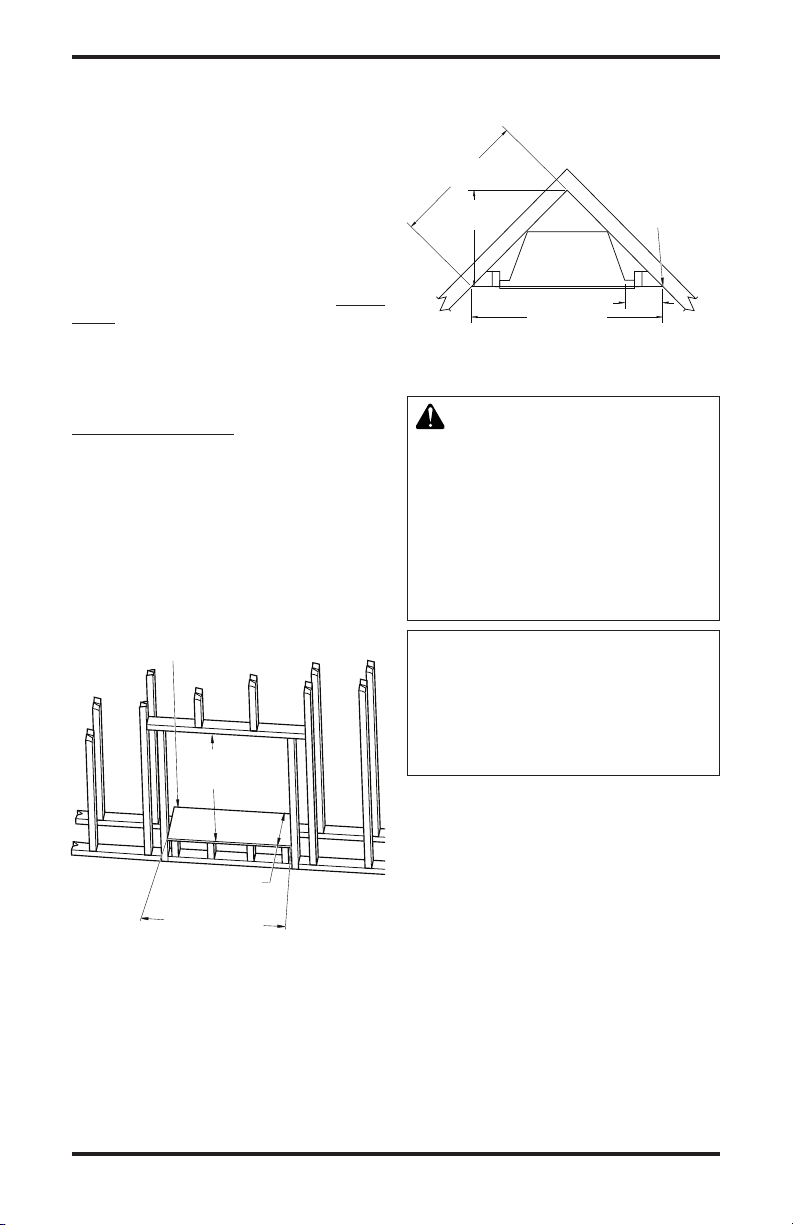

BUILT-IN INSTALLATION

VE32 = 34 5/8"

VE36 = 41 1/4"

VE32 = 15 7/8"

VE36 = 17 1/4"

VE32 = 32 5/8"

VE36 = 36 1/4"

Platform/Subflooring

VE32 = 37 5/8"

VE36 = 42 3/8"

VE32 = 26 5/8"

VE36 = 29 3/8"

VE32 = 52 3/4"

VE36 = 58 1/4"

11 5/8"

These Dimensions

Allow for 11 5/8" of

Clearance to Side

Wall of Fireplace

and 10' Clearance

to Perpendicular

Side Walls

Built-in installations require a framed enclosure constructed of 2" x 4" or heavier lumber

and sized in accordance with Figure 5. This

allows unit to slide into opening and be nailed

to stud at sides and top nailing anges. These

anges accept 5/8" drywall or plywood board

to nish unit ush to face. Optional trim accessories are available that will extend 1/2"

over rough edge of wall opening (see Acces-

sories, page 25).

IMPORTANT: If installing a perimeter trim kit,

you must install shoulder screws before inserting replace into opening. See instructions

included with trim kit. If installing a mantel,

you must follow clearance instructions (see

Installation Clearances, page 4).

A hearth extension is suggested for a more

pleasing appearance. The replace may be

raised on a wood or non-combustible platform

supporting its entire width and depth and

extending in front of the replace as long as

louvers are not obstructed.

Note: When installing replace in cold climates against a non-insulated exterior wall,

wall must be fully insulated in accordance with

local building code.

Figure 5 - Framing Dimensions

INSTALLATION

Continued

Figure 6 - Corner Dimensions

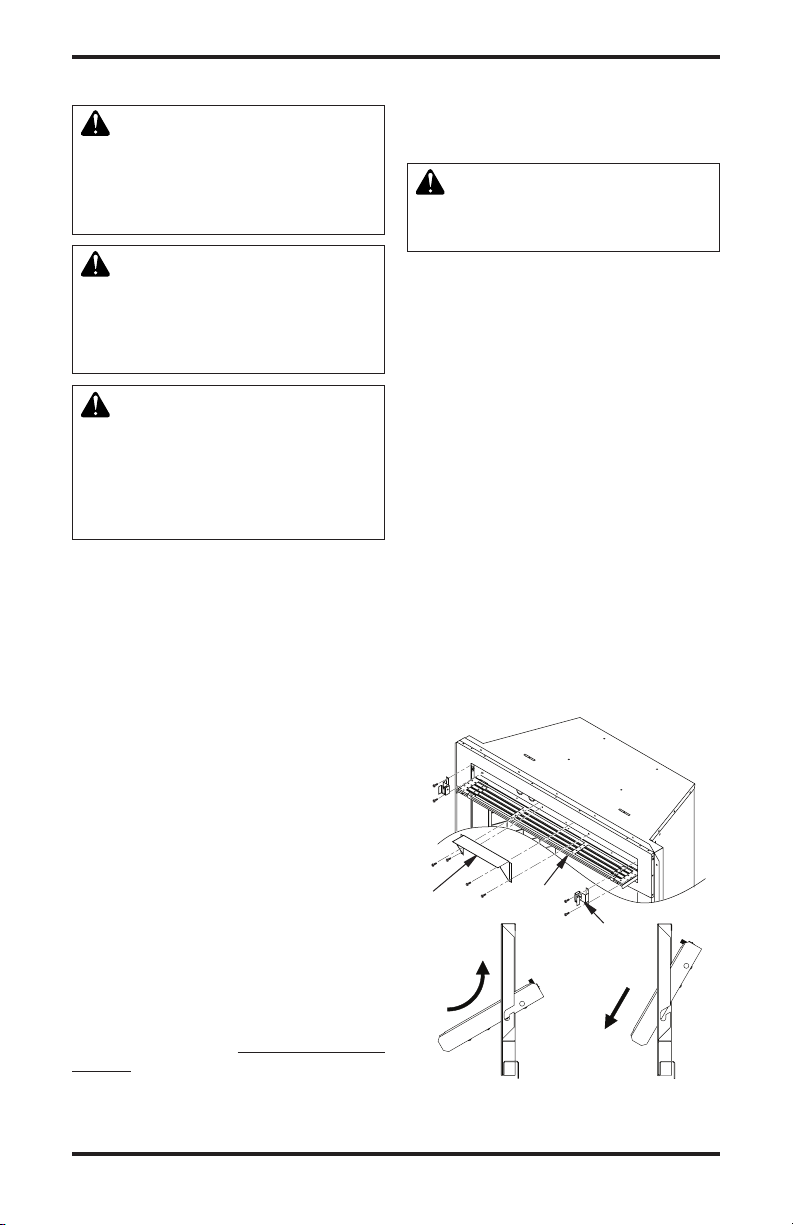

ELECTRICAL INSTALLATION

WARNING: Any electrical re-

wiring of this appliance must be

done by a qualied electrician.

This wiring must be done in ac-

cordance with local codes and/or

in the U.S.A. with the current, Na-

tional Electrical Code ANSI/NFPA

No 70 and in Canada with CSA

C22.1 Canadian Electric code.

This replace should be connected to a dedicated 15 Amp,

circuit as other appliances may

cause the circuit breaker to trip

or fuse to blow when replace

is in operation.

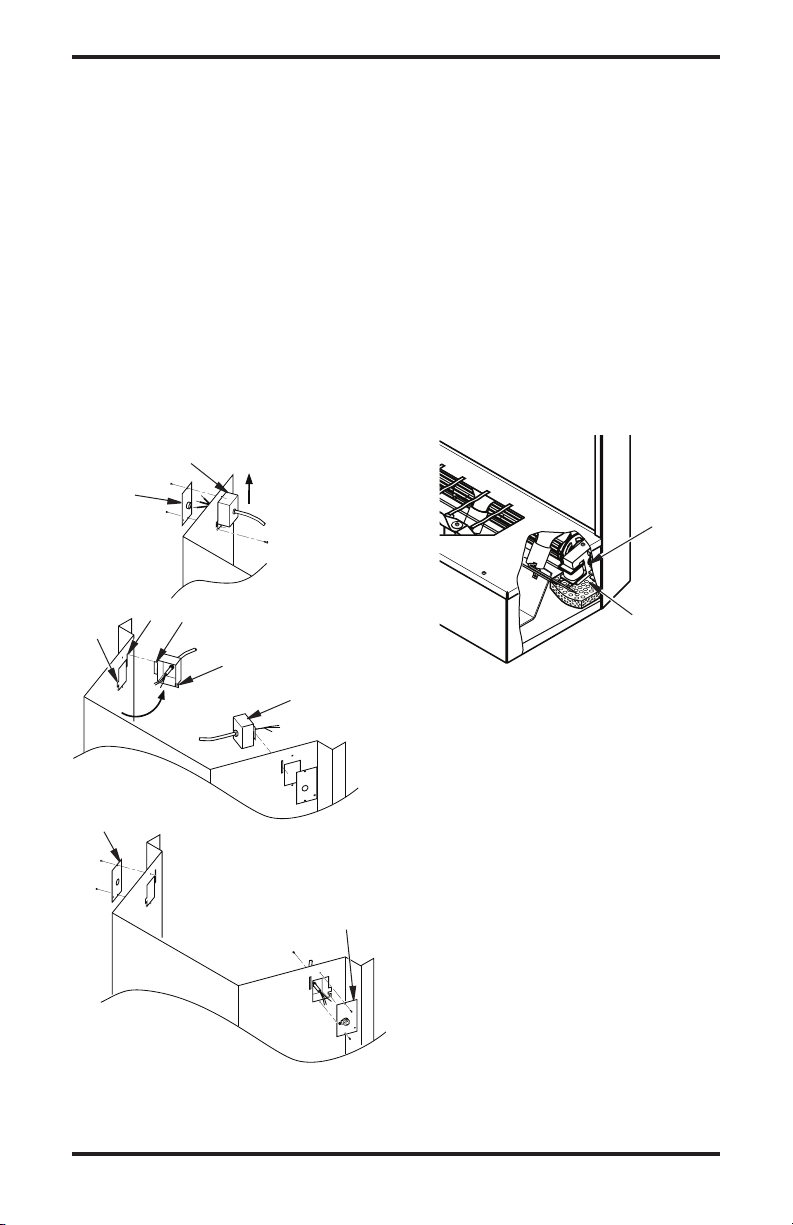

A junction box with universal strain adaptor is

provided to hard wire unit to a 15 amp, 120

Volt 60 Hz grounded circuit. If necessary,

junction box may be relocated to route supply to left side.

1. Remove 2 screws and outer cover on right

side (see Figure 7, page 6).

2. Remove inner screw securing junction

box.

3. Slide junction box up until mounting tab

is lined up to notch in outer cabinet.

4. Swing box out and slip retaining ange

out through slot in outer cabinet.

5. Remove 2 screws and outer cover on left

side and reattach on right side of outer

cabinet.

111076-01F 5

www.desatech.com

Page 6

INSTALLATION

Continued

6. Swing junction box with harness to left

side while pulling sufcient length of harness out through control panel cover to

reach mounting location on left side.

7. Reinsert retaining ange through slot and

swing screw mounting tab back through

notch as before.

8. Slide junction box down until mounting

holes line up and replace inner retaining

cover.

9. Pull end of 3 wire Romex supply line

through universal strain relief bushing in

remaining cover.

10. Strip back outer Romex to about 4” and

connect black, white and green wires accordingly using approved connectors.

Junction Box

Screws

and

Outer

Cover

11. Tuck tailing wires into junction box and

replace cover using 2 remaining screws.

12. Tighten down strain adjustment on universal bushing until Romex sheathing is

secured.

IMPORTANT: Inspect components and wiring for damage before connecting power to

unit. If any components are found damaged,

contact an authorized dealer for original DESA

Heating Products replacement part(s) or call

DESA Heating Products at 1-866-872-6040

for referral.

IMPORTANT: Prior to operation remove foam

shipping brace located under motor mount

(see Figure 8).

Motor

Mount

Slot

Retaining

Notch

Screws and

Outer Cover

from Other Side

Figure 7 - Relocating Junction Box to

Flange

Mounting

Tab

Junction Box

Cover with

Universal

Strain Relief

Left

www.desatech.com

Foam

Shipping

Brace

Figure 8 - Removing Shipping Brace

111076-01F6

Page 7

INSTALLATION

Continued

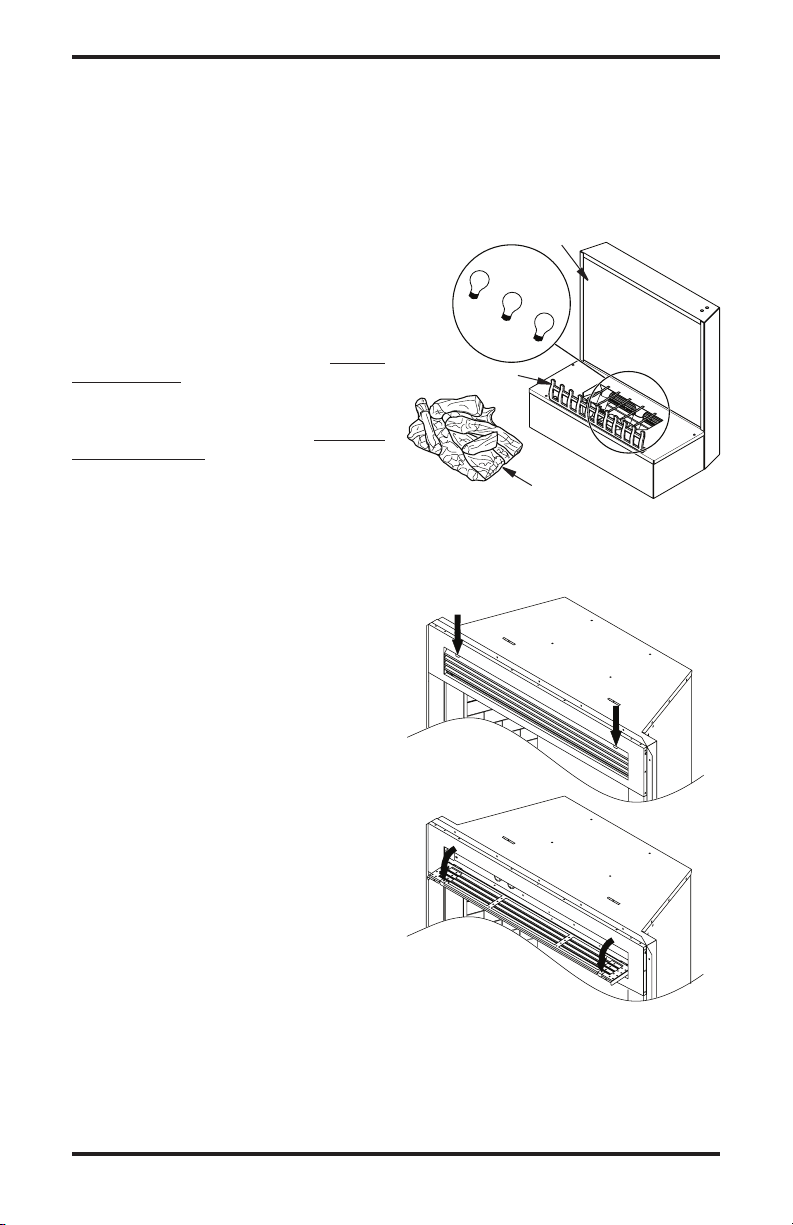

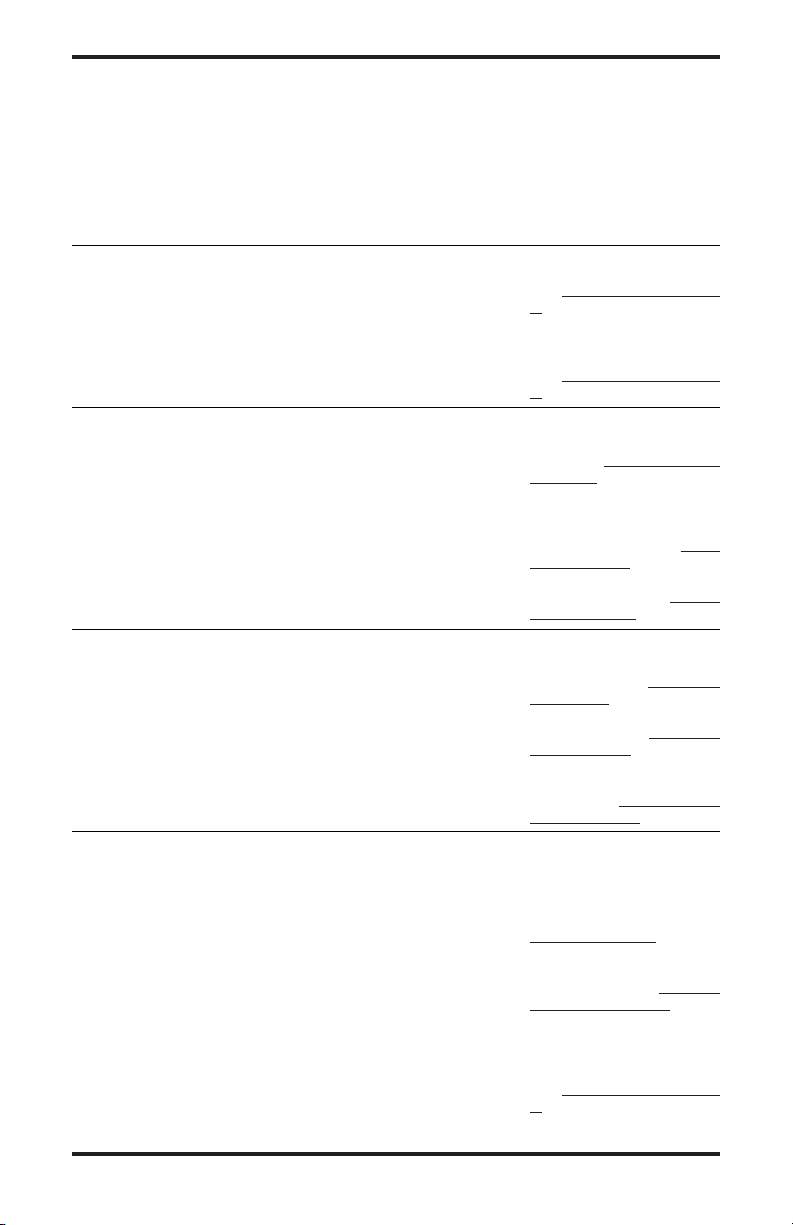

LAMPS AND LAVA ROCK

Before operating replace, lamp bulbs must

be inspected and lava rock may be added if

desired.

1. Lift log bed off hearth base to gain access

to lamp xtures (log bed is attached with

contact magnets).

2. Turn on power to light circuit and check

that all bulbs are operating. Bulb placement front left to right are red, yellow and

orange (see Figure 9).

Note: If bulbs need replacing, see Replacing Light Bulbs, page 16. Be careful not to

tear or damage reective strips. If they have

come loose, ends can be easily reattached or

replaced at support brackets. See Replacing

Reective Ribbons, page 21.

FEATURES AND OPERATION

This electronic fir eplace series features

a random ame effect, and a realistic log

bed with glistening embers that can be adjusted for ame speed and light intensity.

E36/32LH models have a circulating heater,

rated at 1100 Watts. Models E36/32LB and

E36/32LBH include a hand detailed, textured,

red-brick lining.

Access controls by pulling two handle tabs

of upper louver until panel releases from

magnetic catches and swings down to open

position (see Figure 10).

Figure 11, page 8, shows control layout for

heater equipped models with main power

switch to ame controls and heater power

switch (when equipped) to heating unit. This

allows independent and efcient operation of

both features.

Once main power is turned on, ame speed

and brightness may be turned on and adjusted

independently.

3. Center log bed over opening between

viewing panel screen and grate.

4. Cover remaining hearth area with 1/4" of

lava rock (provided), if desired.

Viewing Panel

Screen

Red

Yellow

Orange

Grate

Log Bed

Figure 9 - Bulb Placement

Figure 10 - Accessing Controls

111076-01F 7

www.desatech.com

Page 8

LOWLOW

MAIN

POWER

HI- OFF

FLAME SPEED

HI- OFF

FLAME BRIGHTNESS

HEATER

ON/OFF

Switch

FEATURES AND OPERATION

Continued

Flame Speed

Heater Switch

Flame Brightness

Figure 11 - Control Panel

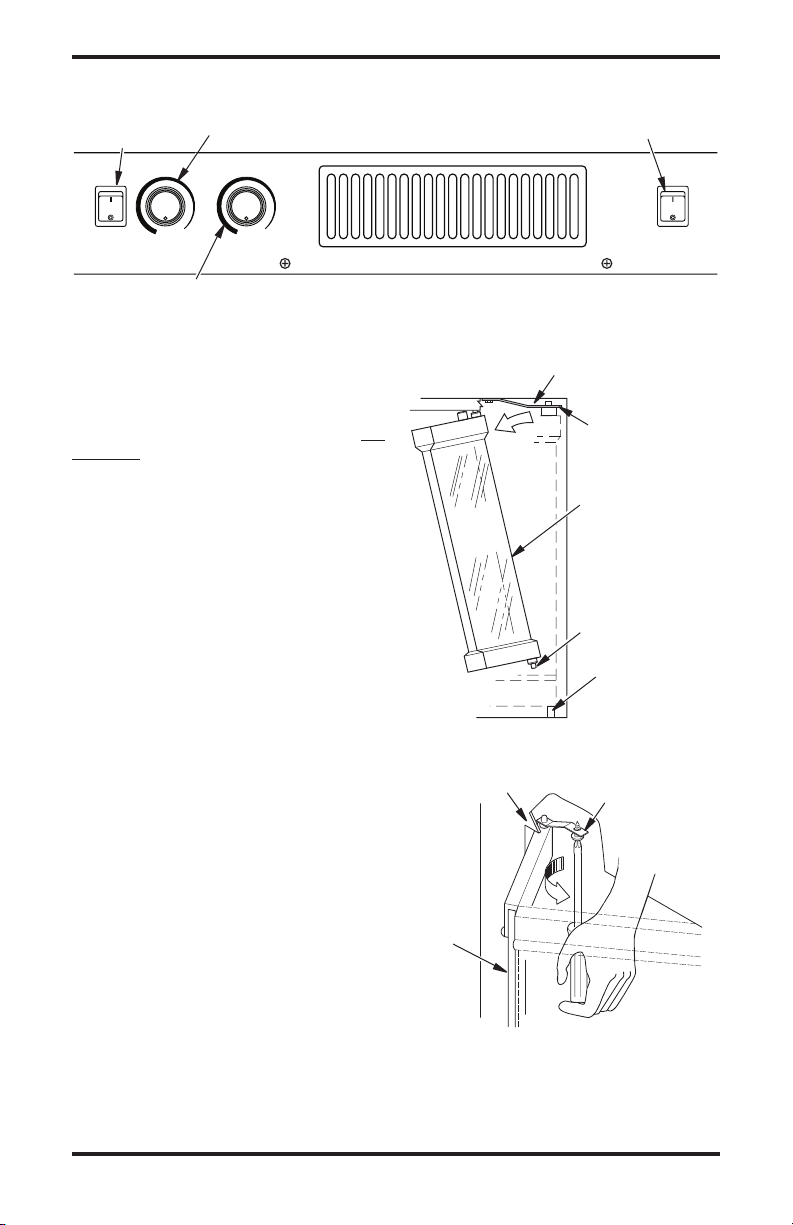

ACCESSORY INSTALLATION

OPTIONAL GLASS DOORS

Models E36L and E32L will accept bifold glass

doors that are fully operable or a xed panel

door that limits access to replace, (see Ac-

cessories, page 25).

Installing Bifold Glass Doors

Follow these steps to install left and right

operable panels:

1. With handle down, completely fold panel

on its hinges.

2. With handle facing center of rebox opening insert lower pivot pin on door panel

into hole in bottom outer edge of rebox

opening (see Figure 12).

3. Keep folded door tilted and slide upper two

pins into guide track below upper facial

edge of rebox opening.

4. Tilt glass assembly fully vertical until outer

pivot pin snaps into mounting hole in upper spring clip.

5. Once top and bottom pins are secured,

unfold door into closed position.

6. Repeat steps 1 through 5 for opposite

door assembly.

7. To adjust doors, slide partially open.

Using a Phillips screwdriver, loosen holddown screws on spring clips (see Figure

13).

8. Close both doors until evenly joined at

middle and note gap as measured to outer

edges of front face.

9. Reopen each door one at a time and

retighten the hold-down screw while preserving noted gap at each edge.

10. Repeat process until both doors are evenly joined, spaced and working freely.

Spring Clip

Depress Spring

Clip to Release

Pivot Pin

Fold Bifold Door

After Releasing

Spring Clip to

Slide Door Out of

Upper Track

Remove Pivot Pin

From Bottom Face

While Sliding Door

Out of Upper Track

Pivot Pin

Figure 12 - Installing/Removing Glass

Doors

Side Front

Face

Spring Clip

Partially

Opened

Door

Figure 13 - Adjust Glass Door

www.desatech.com

111076-01F8

Page 9

ACCESSORY INSTALLATION

Continued

Removing Bifold Glass Doors

Bifold doors may be removed for replacing

or cleaning.

1. Partially open each door and press up on

upper spring clip with a screw driver until

outer top pivot pin is free of the clip.

2. Fully fold frame assembly and slide upper

edge towards center of rebox opening

until the guide pins are free of the frame

rail (see Figure 12, page 8).

Installing Series Fixed Glass Doors

1. Hold glass door rmly at both handles and

insert top pins into clips located below upper facial edge of rebox opening. Make

sure top pins snap securely into holes on

spring clips (see Figure 14).

2. Push up on glass against tension of spring

clips. Swing lower door into face until lower

pins clear bottom rail and set into locating

holes on each end (see Figure 14).

Note: If pins do not align into spring clips,

slightly loosen retaining screws on each clip

(see Figure 13, page 8). Reinsert panel into

each spring clip and align panel into lower

locating holes. Remove panel, nish tighten

screws and reinsert panel.

Spring Clip

OPTIONAL BRICK LINERS

Installing or Removing Brick Liner Kits

Brick liner kits are availab le for Models

E36/32(L)(H) (see Accessories, page 25).

These brick panels may be installed anytime

after replace installation is complete.

Follow these steps to install left and right

brick panels:

1. Remove glass doors (if equipped). Follow

instructions under Optional Glass Doors,

page 8.

2. Remove each retaining screw holding

screen rods and pull entire screen and rod

assembly out of locating hole on inside top

edge of rebox (see Figure 15).

3. Remove log bed from hearth pan and

place in a safe area. Log bed is attached

with contact magnets only.

4. Remove two screws holding each refractory bracket to rebox. Pull up and lift out

of positioning slot at bottom of hearth pan

(see Figure 16, page 10).

Note: E36L and E36LH models require

removal of additional hearth brackets and

face panels which are held in place by 2

screws on hearth pan and one screw at top

retainer bracket (see Figure 16, page 10).

Mounting

Holes

Locating

Hole

Figure 14 - Installing Fixed Glass Doors

111076-01F 9

www.desatech.com

Screen

Rod

Retaining

Screw

Figure 15 - Removing Screen/Rod

Assembly

Page 10

ACCESSORY INSTALLATION

Continued

5. Insert brick panel, beveled edge first,

through rebox opening. Tilt and angle top

edge into brick retainer until beveled edge

contacts imager and panel is at against

rebox (see Figure 17).

6. Align hearth pan bracket over holes near

lower edge of brick panel and secure with

2 pan screws provided.

7. Replace refractory bracket using 2 screws

removed in step 4, page 9.

8. Repeat steps 5 through 7 for opposite

panel assembly.

9. Replace each screen assembly by positioning screen rod into locating holes

under top edge of rebox and securing

with 2 Phillips screws removed in step 2,

page 9.

Note: Rods may have to be angled into

locating holes at the top of each screen

pocket. Once inserted, pull free end of rod

forward until it lines up over farthest mounting hole respectively so rods overlap.

10. Replace log bed over hearth opening

and center between grate and viewing

screen.

11. Replace glass doors if removed. See

Optional Glass Doors, page 8.

Face Panel

(Models E36L

and E36LH

Only)

Refractory

Bracket

Figure 16 - Removing Refractory Bracket

Hearth Pan Bracket

(Models E36L and

E36LH Only)

and Hearth Pan Bracket

Refractory

Bracket

Hearth Pan

Bracket

Figure 17 - Installing Brick Panels and

Brackets

Refractory

Retainer

Bracket

OPTIONAL HEATER ACCESSORY

WARNING: Disconnect

power before attempting any

maintenance or cleaning to re-

duce the risk of re, electrical

shock or personal injury.

Blower/heater kit model BHKE is available

for models E36/32L and E36/32LB. Either

of 2 types of blower/heater assemblies can

be installed.

1. Open upper control door (see Figure 10,

on page 7) and remove 2 Phillips screws

below heater grill on control panel (see

Figure 18, page 11).

2. Remove 2 Phillips screws holding control

cover to control panel inside rebox (see

Figure 14, page 9).

3. Slide control cover to the right and swing

out locking tabs from notched openings

on top (see Figure 18, page 11).

4. Let control cover hang down off harnesses. Be careful not to damage any

wiring. If necessary, unscrew harness

strap at blower mount to gain slack.

5. Remove 2 hex screws at rear of blower

mount (see Figure 18, page 11).

www.desatech.com

111076-01F10

Page 11

ACCESSORY INSTALLATION

Continued

6. Slide blower mount towards rear of rebox

until locking tabs line up with notched

openings and lower mount down and

away (see Figure 18).

7. Remove blower/heater assembly with 4

screws from packaging. Blower is prewired for convenience.

8. Align blower assembly over hole pattern on

blower mount and attach with 4 pan head

screws provided (see Figures 19 and 20).

9. With discharge pointing towards you, guide

assembled blower mount into replace

and center rear mounting anges between

standoff brackets at rear of the replace.

10. Lift blower mount up and position 4 locking

tabs through notched openings in rebox

top. Slide assembly forward until locked

into position.

11. Remove control panel knockout plug located in heater switch position by pressing

locking tabs and pushing plug out through

front of panel (see Figure 21).

12. Firmly insert red power switch into open

mount location with “ON” (I) indicator

positioned on top.

Notches for Control Cover

Blower Mount

Notch (1 of 4)

Heater/

Blower

Assembly

Harness

Strap

Mounting

Screws

Figure 19 - Mounting Heater/Blower

Heater/

Blower

Assembly

Blower

Mount

Mounting

Screws

Blower

Mount

Control

Panel

Screws

Figure 18 - Disassembling Blower Mount

111076-01F 11

Control

Cover

Screws

Blower

Mount

Figure 20 - Mounting Alternate Heater/

Blower

Knockout Plug

Remove to

Install Power

Switch

Power

Switch

Hex

Screws

Control

Cover

Figure 21 - Installing Heater Power Switch

www.desatech.com

Page 12

ACCESSORY INSTALLATION

BLK

BLK

TERMINAL

WHT

BLK

GRN

BLK

D C

CONNECTION

SUPPLY

RED

RED

N 1

4 L

5 L

HEATER

COIL

AB

HEATER

POWER

MOTOR

WHT

CUTOUT

WHT

WHT

WIRES TO HEATER CIRCUIT

WHT - ALTERNATE

BLK

HARNESS 4" BLK

Continued

13. Connect white heater wire to neutral connection marked 'B' or 'A' on terminal block.

See partial wiring diagram, Figure 22.

14. Connect black heater wire to terminal

marked 'N-1' on heater power switch (see

Figure 23, page 13).

Note: On alternate style heaters white and

black wires are connected common to

terminal 'N-1' (see Figure 24, page 13).

15. Connect red hea te r wire to terminal

marked 'L-4' on heater power switch (see

Figure 23 or 24, page 13.

16. Connect one end of black jumper lead,

provi ded in kit, to power connectio n

marked 'D' on terminal block and other

end to switch terminal marked 'L-5' (see

Figure 25, page 13).

17. Replace 2 hex screws on rear anges of

blower mount removed in step 5, page 10.

18. Remount harness strap to blower mount,

if removed.

19. Make sure all wires are clear of heater

discharge area, line up mounting holes on

front blower mount to holes in control panels

and replace the 2 black pan head screws.

20. Raise control cover up and position 2

locking tabs through notched openings in

rebox top, then slide to left until locked

into position (see Figure 18, page 11).

21. Tuck any excess slack in harnesses into

control cover. Swing cover down to line

up mounting holes on control panel and

replace 2 Phillips screws removed in

step 2, page 10.

22. Restore power to unit and check operation

of the heater.

IMPORTANT: Be sure to inspect components

and wiring for damage before connecting

power to unit. If any components are found

damaged, contact an authorized dealer for

original DESA Heating Products replacement

parts(s) or call DESA Heating Products at

1-866-872-6040 for referral.

Figure 22 - Heater Circuit Diagrams

www.desatech.com

111076-01F12

Page 13

Terminal Block

ACCESSORY INSTALLATION

Continued

Terminal Block

White (A-B)

Rocker

Switch

Red (L-4)

Figure 23 - Connecting Heater Wires

White (A-B)

Rocker

Switch

Red (L-4)

Figure 24 - Connecting Alternate Heater Wires

Black (N-1)

Heater/Blower

White (N-1)

Heater/Blower

Terminal (D)

Switch

Terminal (L-5)

Figure 25 - Connecting Jumper Lead

111076-01F 13

www.desatech.com

Jumper

Lead

Page 14

TROUBLESHOOTING

Note: Before troubleshooting system, make sure power to circuit from breaker or fuse panel

is turned ON.

The three most common causes of a malfunctioning electric replace are:

1. Tripped circuit breaker or blown fuse.

2. Loose or burned out light bulb.

3. Obstructed or clogged fan blower.

OBSERVED PROBLEM

No operation or indicator light

at power/heater switch

Poor ame motion; ame pattern is sporadic or uneven in

viewing area

Dull ame appearance or inactive ember bed effect

No heat or intermittent heat

output. (If equipped with a

heater)

POSSIBLE CAUSE

1. No power to replace

2. Defective switch lamp

3. Defective wiring

1. Tangled or loo se flame

pennants

2. Obstructed or clogged fan

blower

3. Damaged or dislodged fan

blower wheel

1. Burned out or loose light

bulb

2. Broken lamp xture

3. Loose or missing reective

ribbons

1. Obstructed heater blower

2. Burned out heat element

or blower fan

3. Defective heater switch or

wiring

REMEDY

1.

Check circuit breaker or fuse

2. Replace defective switch.

See Servicing Control Pan-

el, page 17

3. Check connections from

main power harnesses to

terminals on control panel.

See Servicing Control Pan-

el, page 17

1. Inspect ame pennants. Untangle or replace if necessary. See Servicing Flame

Pennants, page 19

2. Check fan blower for debris. Vacuum areas around

blower wheel and remove

any obstructions. See Main-

taining Motors, page 16

3. Remove and inspect fan

blower housing See Servic-

ing Fan Blower, page 19

1. Inspect light bulbs; tighten

or replace light bulbs as

necessary. See Replacing

Light Bulbs, page 16

2. Remove and replace broken

lamp xture. See Replacing

Lamp Fixtures, page 20

3. Inspect reective ribbons.

Reattach or replace as necessary. See Replacing Re-

ective Ribbons, page 20

1.

Clear heater fan of debris

or blockage; vacuum area

around blower intake and

remov e any obstructi ons

in the discharge area. See

Maintaining Motors, page 16

2. Remove and replace blower

heater assembly. To access

and remove see Optional

Heater Access or y, page

10

3. Inspect wiring connections

from switch to blower. Replace switch if defective.

See Servicing Control Pan-

el, page 17

www.desatech.com

111076-01F14

Page 15

YELLOW LAMP

WHT

HARNESS 4" BLK

HEATER

POWER

FRONT HARNESS TO LAMP CIRCUIT

RED LAMP

SPLICE CONNECTION

MALE CONNECTION

FEMALE CONNECTION

GRN

BLK

WHT

BLK

SUPPLY

ORANGE LAMP

FAN MOTOR

FLAME PROJECTOR - ELECTRICAL DIAGRAM

WHT

BLK

CONTROL PANEL - ELECTRICAL DIAGRAM

BLK

HARNESS 24"

WHT

BLK

GRN

GRN

WHT

FLAME

CONTROL

TERMINAL

CD AB

BLK

5 L

4 L

N 1

BLK

GRN

BLK

FAN

CONTROL

CD B

TERMINAL

HARNESS 4" BLK

REAR HARNESS TO

MOTOR CIRCUIT

BLK

BLK

BLK

A

WHT

5 L

BLACK

BLK

4 L

N 1

MAIN

HEATER ASSEMBLY - ELECTRICAL DIAGRAM

HEATER

COIL

RED

RED

BLK

BLK

MOTOR

CUTOUT

WHT

CAUTION: USE SUPPLY WIRES SUITABLE FOR 105°C OR EQUIVALENT

CAUTION: DISCONNECT FIREPLACE FROM THE ELECTRICAL SUPPLY

BEFORE REMOVING THIS COVER

POWER

CONNECTION

HARNESS

4" WHT

BLK

WHT

BLK

WHT

WHT - ALTERNATE

CIRCUIT

WIRING DIAGRAM

111076-01F 15

Figure 26 - Wiring Diagram

www.desatech.com

Page 16

MAINTENANCE

WARNING: Disconnect

power before attempting any

maintenance or cleaning to re-

duce the risk of re, electrical

shock or personal injury.

6. If all bulbs are working properly, replace

log bed over center opening between rear

screen and front grate.

CAUTION: Make sure power

is turned off at supply prior to

disassembling this unit.

WARNING: Any electrical

repairs or rewiring of this unit

should be carried out by a licensed electrician in accordance

with national and local codes.

WARNING: Do not exceed

60 watts per bulb when replacing bulbs. Use of higher-rated

bulbs may result in a re, caus-

ing property damage, personal

injury, or loss of life.

REPLACING LIGHT BULBS

There are (3) colored lamps rated at 120V,

60 Watts, for use in a medium sized socket.

These bulbs are located under the log bed

and can be replaced as follows:

1. If you are unsure which bulb needs replacement, defective bulbs may be visually

located as any of 3 bulbs colored - Red,

Yellow and Orange starting from the left

(see Figure 9, page 7). Defective bulbs can

be replaced individually or for convenience

you may want to replace all bulbs at the

same time; even if only one is defective.

2. Disconnect power to unit at main breaker

or fuse panel.

3. Lift log bed off hearth base to gain access

to lamp xtures. Log bed is attached with

contact magnets only.

4. Remove each defective bulb from its

socket and replace with appropriate color

and size bulb.

Note: Be careful not to tear or damage reective ribbons. If they have come loose, they

can be easily reattached or replaced at the

support brackets. See Replacing Reective

Ribbons, page 21.

5. Return power to circuit and turn main power

switch and lamp power on to check operation of bulbs before replacing log set.

MAINTAINING MOTORS

Motors used on fan and heater assembly

are perm an ently lub ri cated and do not

require lubrication. Annual cleaning and/or

vacuuming around heater and fan unit is

recommended.

REMOVING/REPLACING CONTROL

DOOR

Upper control door may be removed for service or replacement when necessary:

1. Open upper control door (see Figure 10,

page 7).

2. Remove 4 Phillips screws from deector

shield. Angle deector shield out of opening (see Figure 27).

3. Remove 4 Phillips screws from magnet

assemblies.

4. Lift up on inner control door and push

in each end until pivot pins are free of

notches located on each side of access

opening (see Figure 27).

Deector

Shield

Push

Door Up

and

Back

Figure 27 - Removing/Replacing Control

Control

Door

Magnet

Assembly

Angle

Door and

Slide

Out of

Housing.

Door

www.desatech.com

111076-01F16

Page 17

MAINTENANCE

LOWLOW

MAIN

POWER

FLAME SPEED FLAME BRIGHTNESS

HEATER

Continued

5. Rotate control door up into control compartment and slide on end into side of

compartment.

6. Tilt out one end rst then pull remaining

door assembly through opening.

7. Replace door, by starting with door upside

down, pins up and facing unit. Follow step

5 in reverse until pins are rmly set back

in notches and door will close.

8. Replace discharge deector and magnet

assemblies.

SERVICING CONTROL PANEL

Control panel can be serviced from inside

unit by removing rear control cover on inside

of rebox. Follow steps 2 through 4 under

Optional Heater Accessory, page 10.

9. Angle control panel out through opening

(see Figure 30).

10. Follow these instructions in reverse order

to reassemble control panel assembly.

Note: Be certain that all wires, harnesses and

bushings are returned to their normal position

and free of damage before reconnecting supply power to the replace.

CAUTION: Note location of

all wires prior to disconnecting.

Be sure to reconnect wires to

their proper locations. If you

are unsure about proper wire

locations, follow wiring diagram

Figure 26, on page 15.

Bushings

If control assembly needs complete replacement, proceed to remove entire control assembly as follows:

1. Remove glass doors (if equipped). Follow

instructions under Optional Glass Doors,

page 8.

2. Remove each retaining screw holding

screen rods and pull entire screen and

rod assembly out from locating hole on

inside top edge of replace (see Figure

Power

Harnesses

Figure 28 - Detaching Power Harnesses

Panel Screws

Control

Cover

18, page 11).

3. Remove log bed from hearth pan and

place in a safe area. Log bed is attached

with contact magnets only. This step is

included to keep logs from being damaged

during panel replacement.

4. Remove 2 Phillips screws holding control

Figure 29 - Panel Screws Location

cover to control panel inside rebox (see

Figure 18, page 11).

5. Slide control cover right and swing out

locking tabs from notched openings on

top. See detail Figure 18, page 11.

6. Pop out bushings on control cover and slip

power harnesses free from control cover

(see Figure 28).

7. Remove magnet assemblies, deector

shield and control door. See Removing/

Replacing Control Door, page 16.

8. Remove 4 screws from control panel (see

Figure 29). Tilt entire control assembly

forward to clear lower ange at upper

Control

Panel

door rail and slide assembly down through

space between front face and firebox

mount (see detail Figure 30).

111076-01F 17

www.desatech.com

Figure 30 - Removing Control Panel

Page 18

MAINTENANCE

Continued

ACCESSING IMAGING UNIT

Imaging unit can be accessed from inside

replace for servicing as follows:

1. Remove glass doors (if equipped). See

Optional Glass Doors, on page 8.

2. Remove screens, grate, hearth pan brackets and brick liners. See Figure 31 and

instructions under Optional Brick Liners,

page 9.

3. Remove 4 Phillips screws holding hearth

pan to replace and 2 screws located at

lower frame rail (see Figure 32).

4. Lift rear ends of hearth pan up until front

edge clears lower frame rail then slide

up on end and angle out of replace

opening.

5. Remove 4 Phillips screws holding face

extensions at top refractory clips (see

Figure 32).

6. Remove viewing screen from cabinet

face. Viewing screen is attached by magnets (see Figure 33).

Note: Do not scratch viewing screen. Place

on a nonabrasive surface away from work

area. When replacing viewing screen painted

side must face inside of cabinet with pattern

facing up.

Hearth Pan

Bracket

Brick Liner

7. Remove 4 Phillips screws on base cover

and lift cover off cabinet base. See Figure

34, page 19.

Note: Only E32 series models have face

extensions that require removal to access

imaging unit. Model E36 series has inner face

panels that also require removal to access

imaging unit.

Refractory Clip

Hearth Pan

Face Extensions

Figure 32 - Removing Hearth Pan and

Face Extensions (Extensions for E32

Series Only)

Grate

Refractory

Brackets

Hearth Pan

Bracket

Figure 31 - Accessing Imaging Unit

Brick

Liner

Figure 33 - Removing Viewing Screen

www.desatech.com

Viewing Screen

111076-01F18

Page 19

MAINTENANCE

Continued

Base

Cover

Figure 34 - Removing Base Cover

SERVICING FAN BLOWER

To remove fan blower:

1. Follow instructions under Accessing Imag-

ing Unit, page 18.

2. Remove 3 light bulbs from lamp xtures

(see Replacing Light Bulbs, page 16).

3. Disconnect two 1/4" blade connectors at

from posts on motor unit.

4. Remove 4 hex nuts and washers located

on blower mounts at base of cabinet (see

Figure 35).

5. Lift entire fan assembly off of mounts and

tilt out of unit.

6. Remove screws with washers and hex

nuts from fan housing.

7. Mount new fan to blower mount in reverse

order.

8. Slide blower assembly with spacers over

mounting lugs and replace washer and

nut at each lug. Do not over tighten.

9. Attach blade connectors to posts on motor

mount.

Note: Wire connectors for fan motor are

non-polarized and may be connected to

either terminal for proper operation.

SERVICING FLAME PENNANTS

If ame pennants should become tangled or

detached reattach or replace.

1. Locate affected ame pennant. Slip hem

at base of ame pennant over proper

hanger bracket position. See Figure 36,

page 20, for proper location.

2. Pull ame cord up to proper hook location,

use a slip knot to adjust cord length and

attach cord to hook.

3. Tie another knot over slip knot and trim

away excess cord.

Hex Nut

Washer

Spacer

Screw

Fan Assembly

Posts for Blade

Connectors

Figure 35 - Removing Fan Assembly (Shown without Firebox for Clarity)

111076-01F 19

Washer

Hex

Nut

www.desatech.com

Blower

Mount

(1 of 4)

Page 20

MAINTENANCE

Continued

Note: Flame pennant should not be twisted

or tangled and should hang slightly loose to

allow free movement. If cord is too short or

pennant is torn you must obtain a replacement

ame assembly (see Replacement Parts, on

page 23).

4. After connecting and adjusting flame

cords, soak each knot with a drop of white

wood glue or clear nail polish to prevent

unraveling.

8"

Flame

Pennant

"

2

/

1

7"

3

Flame

Spacer

"

2

/

1

1

Flame Cord

Hook

Figure 36 - Locating Flame Pennants

REPLACING LAMP FIXTURES

Lamp xtures may be replaced as follows:

1. Turn off all power to replace at circuit

breaker or fuse.

2. Locate any of 3 defective lamp xtures

and trace wiring to crimp connectors in

harness and disconnect.

3. Remove 2 crimp connectors in harness

and disconnect white and black wires on

defective xture. See Wiring Diagram, Fig-

ure 26 on page 15, for proper locations.

4. Remove 2 Phillips screws at base of defective xture (see Figure 37, page 21).

www.desatech.com

5. Remove old xture and mount new xture

with 2 Phillips screws removed prior.

6. Twist bare ends of white and black wires

to corresponding wires in main harness

and secure them with 2 crimp connectors

provided.

Note: There should be no exposed bare

wire at any connection. Wiring should be

secured with wire ties, as short as possible,

and kept away from fan blades. If additional

parts are required, see Replacement Parts,

on page 23.

111076-01F20

Page 21

MAINTENANCE

Continued

7. Replace each light bulb with proper color,

(see Replacing Light Bulbs, page 16).

8. Restore power and check lamp circuit

operation before reassembling imaging

unit.

9. Reassem bl e imager. See A cc essing

Imaging Unit, page 18.

Make sure power is turned off

at supply prior to disassembling

this unit.

Screws and

Washers

Upper

Hanger

Bracket

Hanger

Screws

IMPORTANT: Be sure to inspect components and wiring for damage before connecting power to unit. If any components

are found damaged, contact an authorized

dealer for original DESA Heating Products

replacement part(s) or call DESA Heating

Products at 1-866-872-6040 for referral.

REPLACING REFLECTIVE RIBBONS

If reective ribbons become damaged or loose

they may be replaced as follows:

1. Turn off all power to replace at circuit

breaker or fuse.

2. Locate defective ribbon; there are 3 strips

mounted on rear cabinet and 3 mounted

in base (see Figure 37).

Reective Ribbon

Bottom Hanger

Bracket

Screws

Lamp

Fixture

Crimp

Connectors

Reective

Ribbon

Base

Cover

Figure 37 - Replacing Fixtures (Shown without FIrebox for Clarity)

111076-01F 21

www.desatech.com

Ribbon Support

Bracket

Cellophane

Tape

Page 22

MAINTENANCE

Continued

3. If upper back cabinet ribbons need replacing, remove 4 Phillips screws holding

corresponding bottom and top hanger

brackets (see Figure 37, page 21).

4. Remove any loose or damaged ribbon

material.

5. Cut an 18” strip of reective ribbon and

position top end about an inch above top

bracket position (see Figure 37, page 21).

Note: Ribbon material should be ap-

plied with reective side up, should not

be twisted or tangled, and should hang

slightly loose to allow free movement.

If additional parts are required, see Re-

placement Parts, page 23.

6. Replace top hanger bracket using 2 Phillips screws removed in step 2 and tighten

until reective ribbon is held in place.

7. Replace bottom hanger bracket using 2

remaining Phillips screws to secure lower

end of reective ribbon.

8. If replacing reective ribbons located in

base, remove screws and washers at

damaged ends of ribbon.

9. Cut a 9" long strip of ribbon and apply across

each ribbon support bracket with shiny side

facing up (see Figure 37, page 21).

10. Secure ribbon to brackets by replacing

each washer at end of the ribbon and rethreading screws through the ribbon into

each hole located on support brackets.

11. If replacing top reective ribbons on base

cover, cut a 3" section of ribbon and split

down the middle. With shiny side up, attach

with cellophane tape into rear edge of base

cover opening (see Figure 37, page 21).

12. Readjust ame pennants (if removed). See

Servicing Flame Pennants, page 19.

13. Reassemble i ma ger. See Acc es si ng

Imaging Unit, page 18.

14. Center log bed over opening between

viewing panel screen and grate.

15. Cover remaining hearth area with 1/4" of

lava rock (provided), if desired.

CLEANING VIEWING SCREEN

Clean viewing screen with an alcohol based,

nonabrasive, residue free cleaner (premoistened hand wipes are ideal). Do not use glass

cleaners with ammonium, abrasive scrubs or

degreaser solvents of any kind.

ACCESSING IMAGING UNIT FOR

REPLACEMENT

The imaging unit can be removed from inside

the rebox for servicing or replacement:

1. Follow steps under Accessing Imaging

Unit, on page 18.

2. Remove 4 hex screws on lower louver

panel and detach louver assembly from

front face (see Figure 38).

3. Rotate top edge of lower frame rail inward

and lift upward until locking tabs detach

from front face (see Figure 38).

4. Slide entire imaging unit forward and lift

out through front opening (see Figure 39,

page 23).

Note: An additional 3 feet of harness is tucked

behind imager to permit removal without dis-

connecting any control wiring.

Lower

Frame

Rail

Lower Panel

Figure 38 - Removing Lower Louver

www.desatech.com

Lower Frame

Rail

Locking Tab

Panel and Frame Rail

111076-01F22

Page 23

MAINTENANCE

Continued

Note: If full replacement of imager is necessary, wiring harnesses must be disconnected

and new harnesses reconnected at control

panel. For proper connection, follow wiring

diagram shown in Figure 26, page 15.

TECHNICAL SERVICE

You may have further questions about installation, operation or troubleshooting. If so,

contact DESA Heating Products’ Technical

Servi ce Department at 1-866-672 -6040.

When calling, please have your model and

serial numbers of your rebox ready.

REPLACEMENT PARTS

Note: Use only original replacement parts.

This will protect your warranty coverage for

parts replaced under warranty.

PARTS UNDER WARRANTY

Contact authorized dealers of this product. If

they can’t supply original replacement part(s),

call DESA Heating Products’ Technical Service Department at 1-866-672-6040.

When calling DESA Heating Products, have

ready

• your name

• your address

• model and serial numbers of your rebox

• how rebox was malfunctioning

• type of gas used (propane/LP or natural

gas)

• purchase date

Usually, we will ask you to return the part to

the factory.

Imaging

Unit

Figure 39 - Removing Imaging Unit

You can also visit DESA Heating Products’

technical services web site at

www.desatech.com.

PARTS NOT UNDER WARRANTY

Contact authorized dealers of this product. If

they can’t supply original replacement part(s),

call DESA Heating Products at 1-866-672-6040

for referral information.

When calling DESA Heating Products, have

ready

• model number of your rebox

• the replacement part number

Note: The rebox identication label (including

model number, serial number, clearances,

etc.) is located on the right front edge of the

rebox.

111076-01F 23

www.desatech.com

Page 24

PARTS

1

2

3

3

4

5

6

7

8

8

9

10

10

11

11

12

12

13

14

14

15

15

16

17

17

17

18

1920

20

21

22

23

24

25

26

27

27

28

28

29

31

30

30

32

32

33

34

34

35

36

37

MODELS E32L, E32LB, E32LH, E32LBH, E36L, E36LB, E36LH AND E36LBH

www.desatech.com

111076-01F24

Page 25

This list contains replaceable parts used in your replace. When ordering parts, follow the

PARTS

instructions listed under Replacement Parts on page 23 of this manual.

KEY

NO. PART NO. DESCRIPTION QTY.

1 111065-02 Louver Assembly (Bottom) • • • • 1

111062-04 Louver Assembly (Bottom) • • • • 1

2 111065-01 Louver Assembly )Top) • • • • 1

111065-03 Louver Assembly )Top) • • • • 1

3 110870-01 Refractory Bracket • • • • • • • • 2

4

5 112078-01 Hearth Pan • • • • 1

112078-02 Hearth Pan • • • • 1

6 112076-01 Lower Face Rail • • • • 1

112076-02 Lower Face Rail • • • • 1

7 20088 Door Stop • • • • • • • • 1

8 112138-01 Hearth Pan Bracket • • • • 2

112138-02 Hearth Pan Bracket • • • • 2

9 112288-02 Imager, Fireplace Insert (Except for bulbs, parts

10 112137-01 Refractory Panel, 36" • • 2

113662-01 Refractory Panel, 32" • • 2

11 120160-01 Hearth Panel • • • • 2

12 112414-01 Extension Face • • • • 2

112414-02 Extension Face • • • • 2

13 119084-01 Refractory Standoff Panel • • • • 2

14 110445-01 Hearth Bracket • • • • • • • • 4

15 110973-01 Junction Box Cover • • • • • • • • 2

16 14123 Universal Strain Relief Bushing • • • • • • • • 1

17 112075-01 Refractory Retainer Bracket • • • • 2

112075-02 Refractory Retainer Bracket • • • • 2

18 119089-01 Panel Valance • • • • • • • • 1

19 110974-01 Junction Box • • • • • • • • 1

20 M11143-01 Strain Relief Bushing • • • • • • • • 1

21 ** Firebox Outer Wrap • • • • • • • • 1

22 111064-01 Heater Standoff Bracket • • • • • • • • 1

23 110439-01 Heater Mount • • • • 1

110439-02 Heater Mount • • • • 1

24 111060-01 Heater Assembly • • • • 1

25 107941-02 Top/Bottom Fireplace • • • • 2

107941-03 Top/Bottom Fireplace • • • • 2

26 112302-01 Control Panel Assembly • • 1

112302-02 Control Panel Assembly • • 1

112302-04 Control Panel Assembly • • 1

112302-05 Control Panel Assembly • • 1

27 112783-01 Magnet Bracket • • • • • • • • 2

28 17223 Magnet Catch • • • • • • • • 2

29 112099-01 Heat Deector Shield • • • • • • • • 1

30 11439 Electrical Bushing 7/8" • • • • • • • • 2

31 112305-01 Control Cover • • • • • • • • 1

32 11418 Push-On nut • • • • • • • • 2

33 106691-01 Screen Rod, 36" • • • • 2

108701-01 Screen Rod, 32" • • • • 2

34 12105 Screen Assembly, 36" • • • • 2

108440-01 Screen Assembly, 32" • • • • 2

35 112748-01 Log Ember Bed Assembly • • • • • • • • 1

36 112735-01 Grate • • • • • • • • 1

37 112743-01 Viewing Panel Screen, 36" • • • • 1

117755-01 Viewing Panel Screen, 32" • • • • 1

11198 Screw #8 x 3.8 Hex • • • • • • • • 4

11166 Screw, #10 x 1/2 Phillips Black Oxide • • • • • • • • 12

11164 Screw, #10 x 1/2 Phillips Black Oxide • • • • • • • • 30

11105 Screw, #10 x 1/2 Hex Zinc • • • • • • • • 36

11102 Screw, #8 x 3/8 Phillips Zinc • • • • • • • • 5

25487 Lava Rock • • • • • • • • 1

114266-01 M4 - 8mm Phillips Pan Screw • • • • • • • • 40

** Not a eld replaceable part.

111076-01F 25

Face Weldment • • • • • • • • 1

**

not individually available for eld replacement.)

PARTS AVAILABLE - NOT SHOWN

www.desatech.com

E36L

E32L

• • • • • • • • 1

E36LB

E32LB

E32LH

E36LH

E36LBH

E32LBH

Page 26

PARTS

1

2

5

3

4

10

6

7

8

8/9

11

12

14

14

14

13

13

CONTROL PANEL FOR MODELS E32L, E32LB, E32LH, E32LBH, E36L,

E36LB, E36LH AND E36LBH

This list contains replaceable parts used in your replace. When ordering parts, follow the

instructions listed under Replacement Parts on page 23 of this manual.

KEY

NO. PART NO. DESCRIPTION QTY.

E32/36L(B)(H)

E32/36L(B)

1 111066-03 Control Panel Decal • 1

111066-01 Control Panel Decal • 1

2 111067-02 Control Circuit Harness • • 1

3 111059-01 4" Black Wire Harness • • 1

4 111059-02 4" White Wire Harness • • 1

5 111059-03 4" Green Wire Harness • • 1

6 111058-01 Flame Control • • 2

7 110799-01 Panel Control • • 1

8 108394-01 ON/OFF Switch • 1

108394-01 ON/OFF Switch • 2

9 113042-01 Hole Plug • 1

10 103651-01 Lock Nut • • 2

11 103650-01 Control Knob • • 2

12 103646-01 Power Wire Harness • • 1

13 099125-13 Terminal Block • • 2

14 11102 #8 - 32 x 3/8" Phillips Screw • • 5

PARTS AVAILABLE - NOT SHOWN

114275-01 4" Wire Tie • • 14

111066-01 Control Panel Decal • 1

111066-03 Control Panel Decal • 1

112469-01 Lamp Bulb (Red) • • 1

112469-02 Lamp Bulb (Yellow) • • 1

112469-03 Lamp Bulb (Orange) • • 1

** Not a eld replaceable part.

www.desatech.com

111076-01F26

Page 27

ACCESSORIES

Purchase these rebox accessories from your

local dealer. If they can not supply these accessories, call DESA Heating Products’ Sales

Department at 1-866-672-6040 for information. You can also write to the address listed

on the back page of this manual.

PERIMETER TRIM KITS

PT32 - 32" Black

PT32B - 32" Brushed Brass

PT32PB - 32" Polished Brass

PT32P - 32" Platinum

PT36 - 36" Black

PT36B - 36" Brushed Brass

PT36PB - 36" Polished Brass

PT36P - 36" Platinum

BIFOLD GLASS DOOR KITS

BD32 - 32" Black

BD32B - 32" Brushed Brass

BD32PB 32" Polished Brass

BD32P 32" Platinum

BD36 - 36" Black

BD36B - 36" Brushed Brass

BD36PB - 36" Polished Brass

BD36P - 36" Platinum

FIXED GLASS DOOR KITS

FD32 - 32" Black

FD32B - 32" Brushed Brass

FD32PB - 32" Polished Brass

FD32P - 32" Platinum

FD36 - 36" Black

FD36B - 36" Brushed Brass

FD36PB - 36" Polished Brass

FD36P - 36" Platinum

TEXTURED BRICK REFRACTORY

LINER KITS

BL32E - 32" Red

BL32EW - 32" White

BL36E - 36" Red

BL36EW - 36" White

ELECTRIC BLOWER/HEATER KIT

BHKE - 1100 Watt Electric Heater Kit

111076-01F 27

www.desatech.com

Page 28

WARRANTY

111076 01

KEEP THIS WARRANTY

Model ___________________________________

Serial No. ________________________________

Date Purchased ___________________________

Always specify model and serial numbers when communicating with the factory.

The only warranty applicable is our standard written warranty. We make no other warranty, expressed or

implied.

LIMITED 1 YEAR WARRANTY

DESA Heating, LLC warrants this product to be free from defects for one (1) year from the date of rst

purchase, provided that the product has been properly installed, operated and maintained in accordance with all applicable instructions. To make a claim under this warranty the Bill of Sale or cancelled

check must be presented.

This warranty is extended only to the original retail purchaser. This warranty covers the cost of part(s)

required to restore this heater to proper operating condition and an allowance for labor when provided by

a DESA Heating, LLC Authorized Service Center. Warranty part(s) MUST be obtained through authorized

dealers of this product and/or DESA Heating, LLC who will provide original factory replacement parts.

Failure to use original factory replacement parts voids this warranty. The product MUST be installed by

a qualied installer in accordance with all local codes and instructions furnished with the unit.

This warranty does not apply to parts that are not in original condition because of normal wear and tear

or parts that fail or become damaged as a result of misuse, accidents, lack of proper maintenance or

defects caused by improper installation. Travel, diagnostic cost, labor, transportation and any and all

such other costs related to repairing a defective product will be the responsibility of the owner.

TO THE FULL EXTENT ALLOWED BY THE LAW OF THE JURISDICTION THAT GOVERNS THE

SALE

OF THE PRODUCT; THIS EXPRESS WARRANTY EXCLUDES ANY AND ALL OTHER EXPRESSED

WARRANTIES AND LIMITS THE DURATION OF ANY AND ALL IMPLIED WARRANTIES, INCLUDING

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE TO ONE (1)

YEAR FROM THE DATE OF FIRST PURCHASE; AND DESA HEATING, LLC’S LIABILITY IS HEREBY

LIMITED TO THE PURCHASE PRICE OF THE PRODUCT AND DESA HEATING, LLC SHALL NOT

BE LIABLE FOR ANY OTHER DAMAGES WHATSOEVER INCLUDING INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES.

Some states do not allow a limitation on how long an implied warranty lasts or an exclusion or limitation

of incidental or consequential damages, so the above limitation on implied warranties or exclusion or

limitation on damages may not apply to you.

This warranty gives you specic legal rights and you may also have other rights that vary from state

to state.

For information about this warranty write:

2701 Industrial Drive

P.O. Box 90004

Bowling Green, KY 42102-9004

www.desatech.com

1-866-672-6040

NOT A UPC

111076-01

Rev. F

05/07

Loading...

Loading...