Page 1

SERVICE MANUAL

For Europe & U.K. model

Version 2

MODEL

STEREO CD RECEIVER

UD-M31

Some illustrations using in this service manual are slightly different from the actual set.

16-11, YUSHIMA 3-CHOME, BUNKYOU-KU, TOKYO 113-0034 JAPAN

Telephone: 03 (3837) 5321

X0164V.02 DE/CDM 0302

Page 2

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

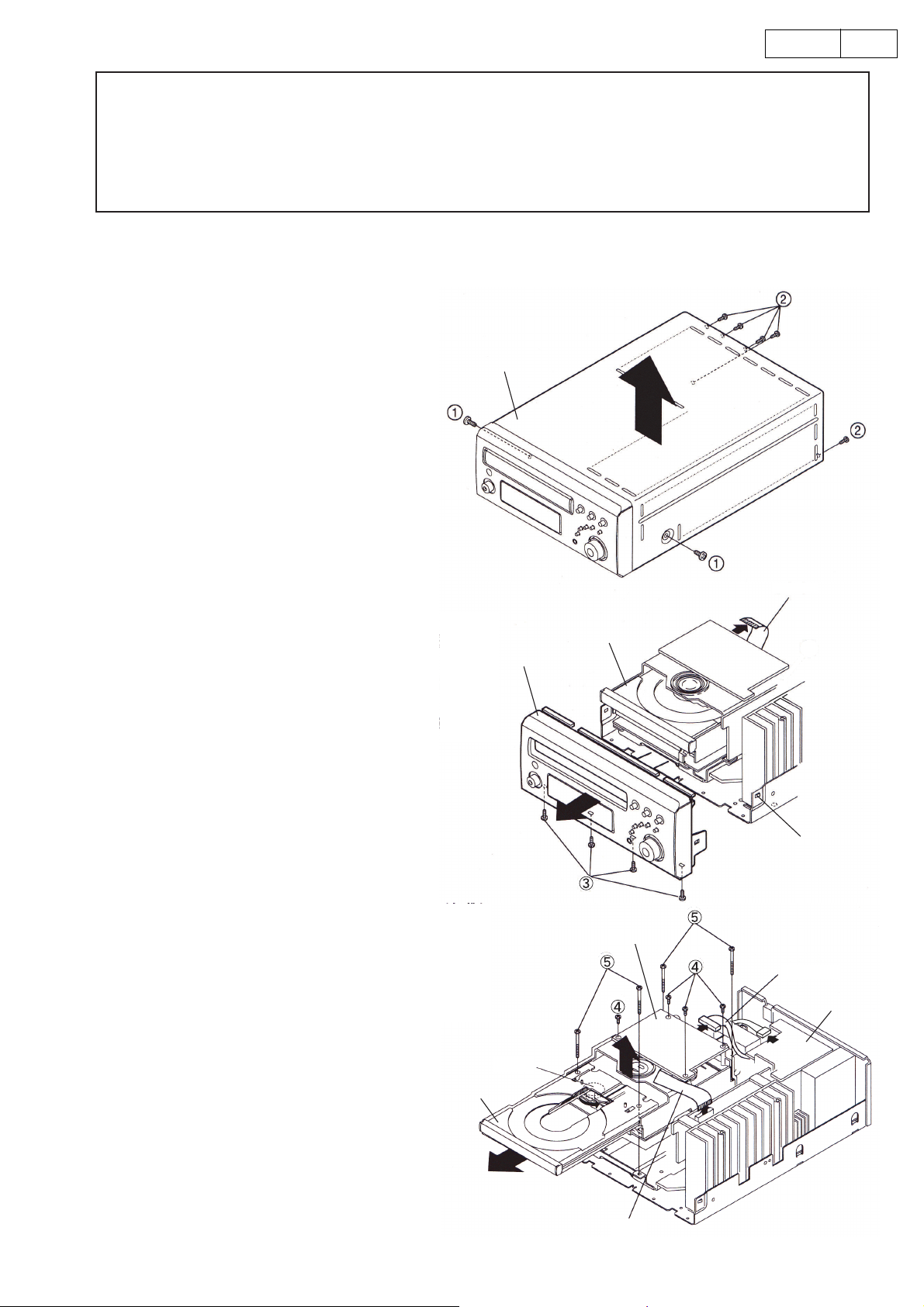

DISASSEMBLY

(Follow the procedure below in reverse order when reassembling)

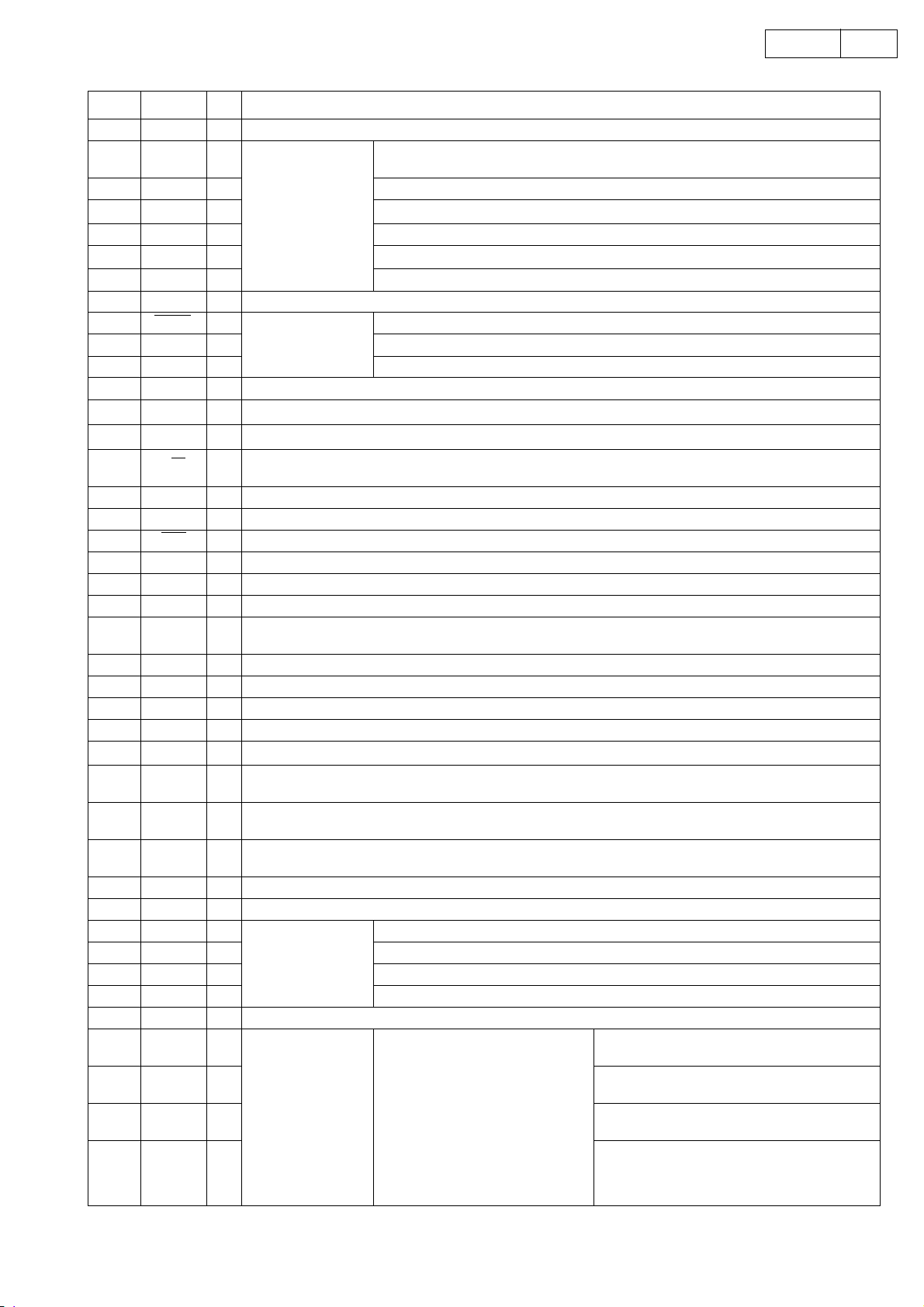

1. TOP COVER

(1) Remove 2screws ① on both sides.

(2) Remove 5screws ② on the rear.

(3) Detach the Top Cover to the arrow direction.

Top cover

2UD-M31

2. FRONT PANEL

(1) Disconnect FFC on thr rear of the CD

Mecha.

(2) Remove 4 lower screws ③

(3) Detach the Front Panel with releasing the

hooks on both sides.

3. CD MECHANISM UNIT

(1) Disconnect FFC coming from the top of the

CD Mecha.

(2) Unplug the connector on fhe rear of the

µcom PWB .

(3) Unplug the connector on the I/O PWB.

(4) Remove 4 screws ④ on the µcom PWB .

(5) Fully pull out the loader by turning the gear

under the loader of the CD Mecha.

(6) Remove 4 screws ⑤ to detach the CD

Mecha.

FFC

CD Mecha.

Front Panel

Hook

µcon P.W.B.

Connector

I/O P.W.B.

Gear

Loader

FFC

2

Page 3

3UD-M31

4. REAR PANEL

(1) Pull out the cord bush.

(2) Remove 12 screws ⑥

5. MAIN PWB

(1) Remove 4 screws ⑦ fixing the radiator the chas-

sis.

(2) Unplug 3 connectors on the AMP PWB.

(3) Detach the Main PWB together with the radiator .

(4) Remove 5 screws ⑧ .

(5) Detach the Power PWB.

Cord Bush

Connector

Power

P.W.B.

6. DISPLAY PWB

(1) Pull out the VR knob.

(2) Remove the spacer and the VR nut ⑨ .

(3) Remove 7 screws ⑩ .

Main P.W.B.

Radiator

VR knob

3

Page 4

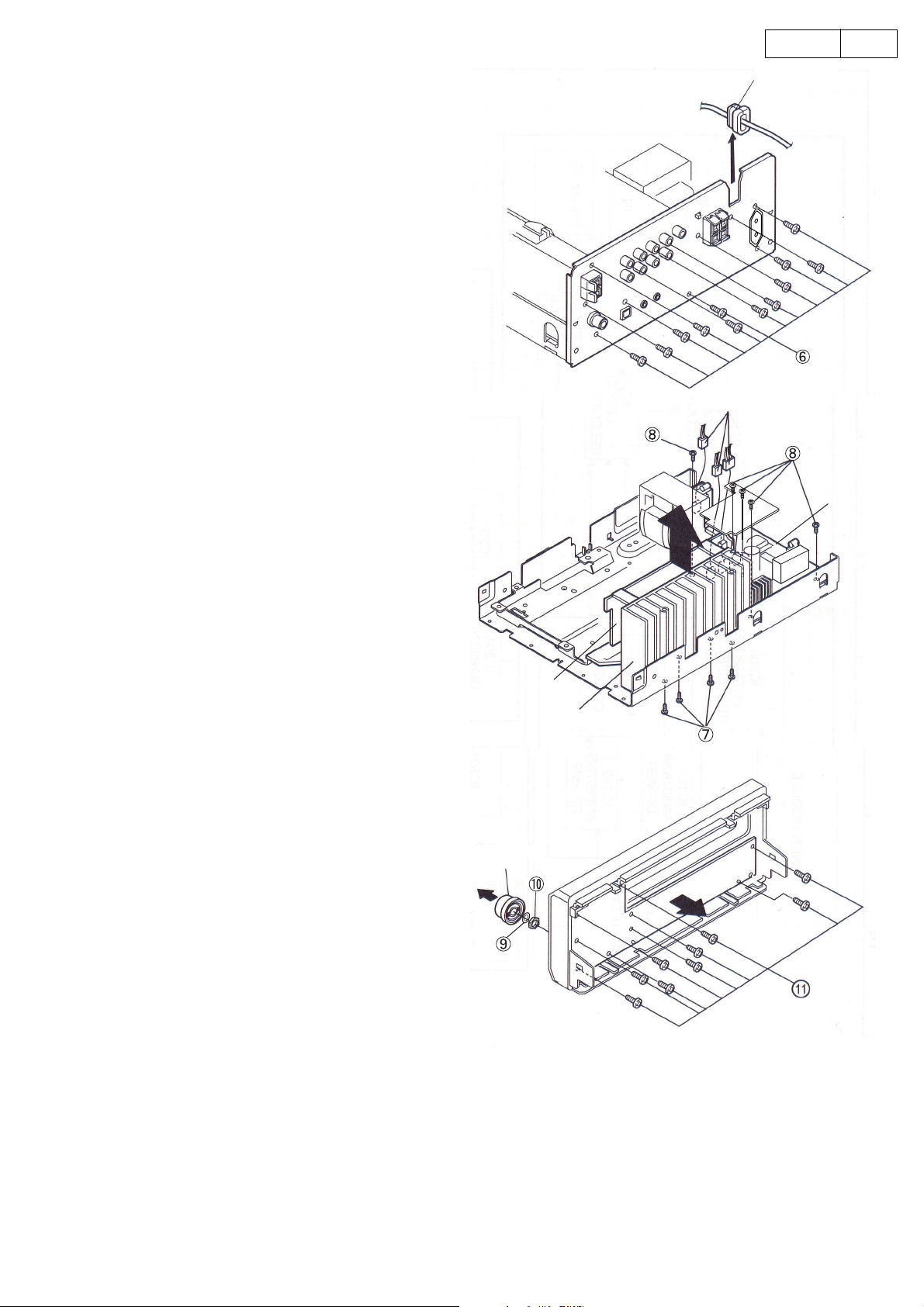

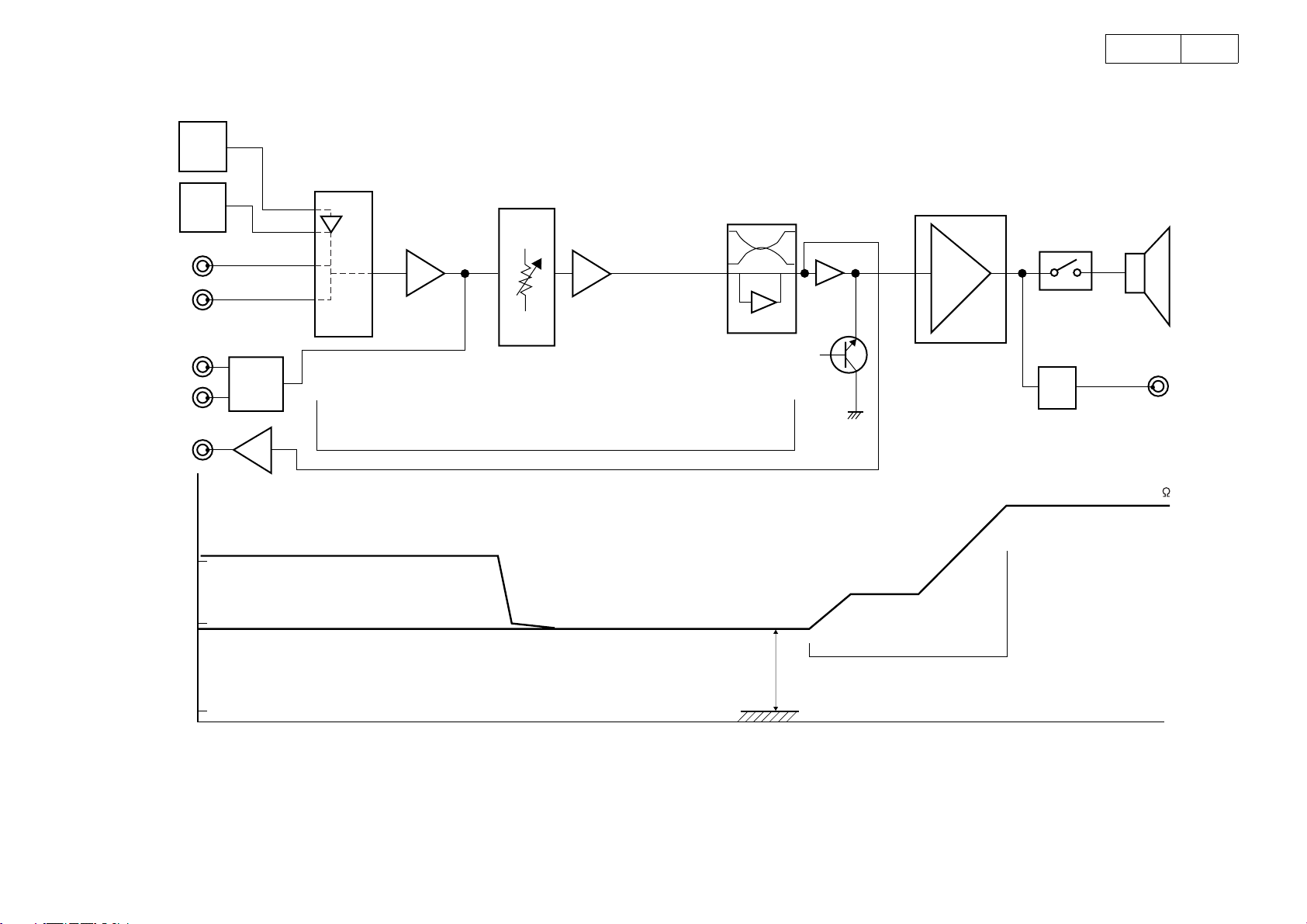

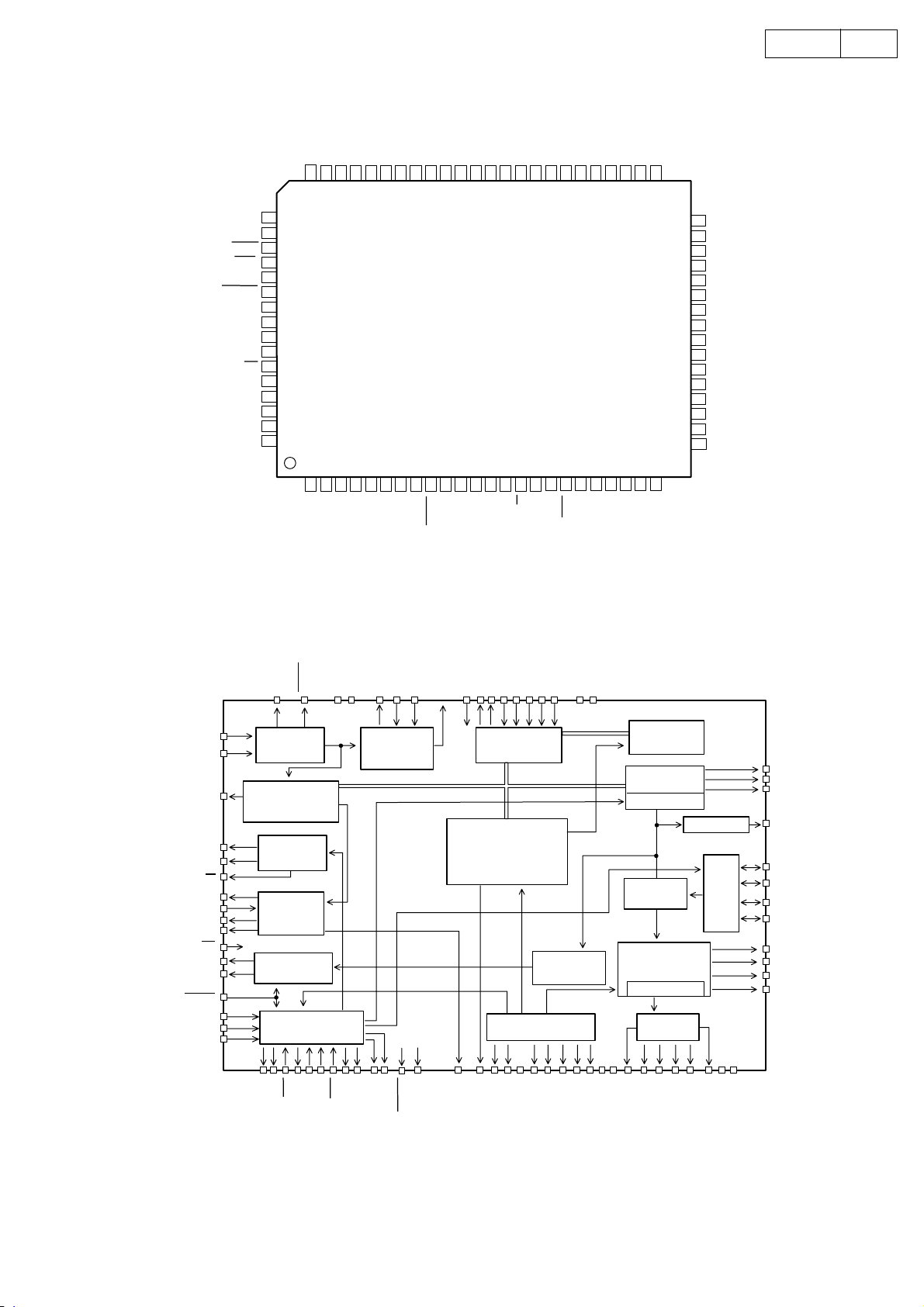

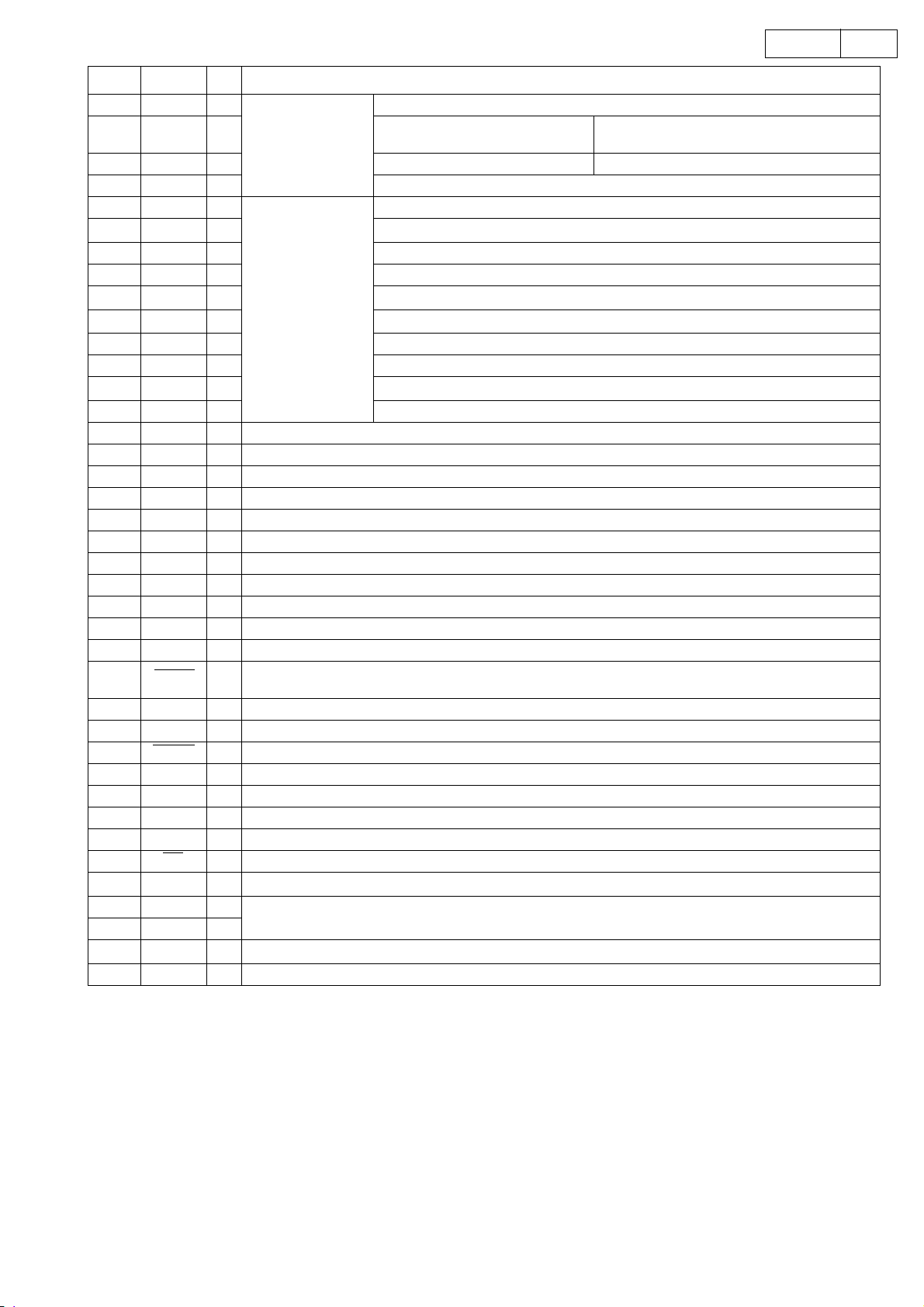

BLOCK DIAGRAM

TUNER MODULE

CD

MECHA

CD11FTA3N

FL401

FL TUBE

IC801

LA6559

DRIVER

IC802

LA9241

RF AMP

LC75725E

FL DRIVER

IC401

IC803

LC78625E

CD DSP

IC805

BA6287F

IC303

LC72720NM

RDS(E2/EK only)

IC804

BA4510F

IC202

93LC66

IC201

UPD784216

MICON

IC301

BU4066BCF

REC OUT SEL

IC302

LC75432M

SELECTOR & VR & EQ

IC304

BA15218F

IC305

BA15218F

REC out

IN

REC out

IN

Pre out

UD-M31

4

IC402

RPM6938

TACT SW & VR ENCORDER

IC203

BA05ST

DENON

BUS

TR601∼603

IC602

NJM

7805FA

P.DOWM

IC603

NJM

7812FA

IC604

NJM

7806FA

TR607

4

IC205

M51957

IC501

STK402-050

POWER AMP

IC605

NJM7805F

POWER

TRANS

RL601

SP

RELAY

Protection

TR501∼

SUB

TRANS

RL602

POWER

RELAY

SP

OUT

AC IN

Page 5

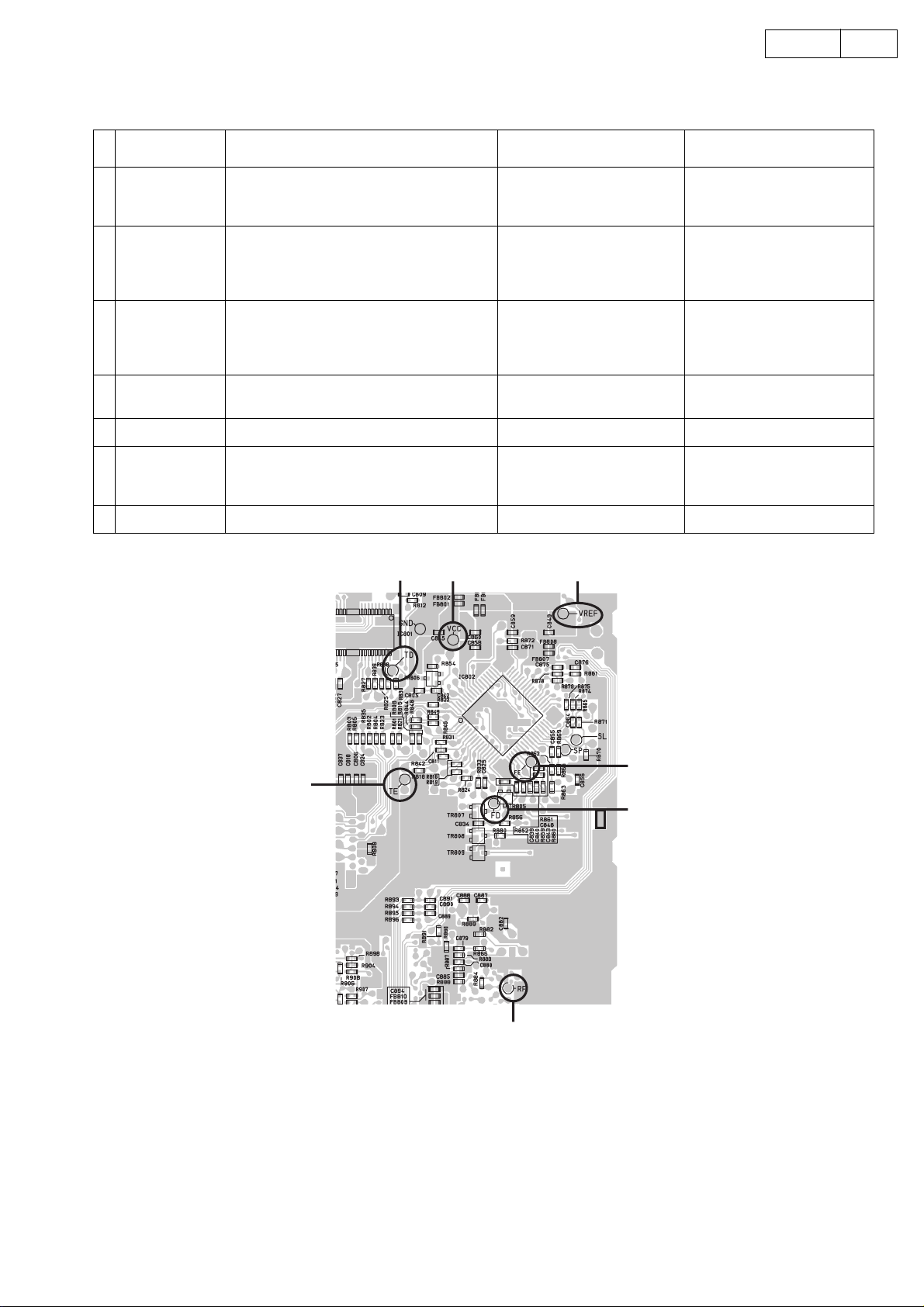

LEVEL DIAGRAM

0dB=0.55V

CD

UNIT

UD-M31

5

LINE 1

LINE 2

LINE 1

REC

LINE 2

REC

PRE OUT

-10dB

TU

UNIT

ANALOG

SWITCH 4066

(dBV)

+16dB

0dB play back CD=1.1V

0dB

LINE:1kHZ,150mV

EQ:FLAT

SDB:OFF

FUNCTION SWITCH

+4dB

+0.83dB

MASTER VOLUME

BUFFER BUFFER

LC75342M

MUTE

-16.4dB

(+6dB)

TOTAL 36dB

POWER AMPTONE/SDB

RELAY SP

ATT

(+30dB)

HP

15W/6

9.49V

-104dB

87.6dB

5

Page 6

CD TEST MODE

Setting of the test mode and explanation of each button

ITEM OPERATION FUNCTION DISPLAY

6UD-M31

1 Start the mode

2 Disc load

Focus and Track-

3

ing check mode

4 Move pick up

5 Stop move Push the STOP button Stop the movement 1.Display "01"

6 All Servo on Push the SKIP button All servo on, and auto adjust

7 Clear this mode Unplug the AC cord

Plug the AC cord to the wall outlet while pushing the POWER button and the Function button

1.Push the OPEN/CLOSE button and the

LOADER open

2.Place the disc and push the OPEN/CLOSE

button again

1.Push the PLAY button

2.Push the PLAY button again

3.Push the PLAY button again

1.Push the SKIP forward button or the SKIP

reverse button while stopping

TD

VCC VREF

1.This service mode starts

2.Pick up moves to the 10mm

position.

1.Load the CD disc

2.The pick up moves to the

10mm position

1.The laser ON

2.forcus servo on,the disc turns

3.Tracking servo and Slide

servo on

The pick up move forward or

reverse

1.Display "01"

2.The PLAY and the PAUSE

mark lit

1.Display "01"

2.The PLAY and the PAUSE

mark lit

1.Display "02 L on"

2.Display"03 Fon"

3.Display "04 t on"

1.Display "5 O PU"

1.Display "06 Adj."

1.after auto adjust,d

display "01"

FE

TE

FD

1U-3507

CD UNIT

RF

* Laser light of the pickup is always emitted regardless of DISC loading in the test mode.

You may lose your eyesight if you look into the laser directly.

So be careful enough when operating in the test mode.

6

Page 7

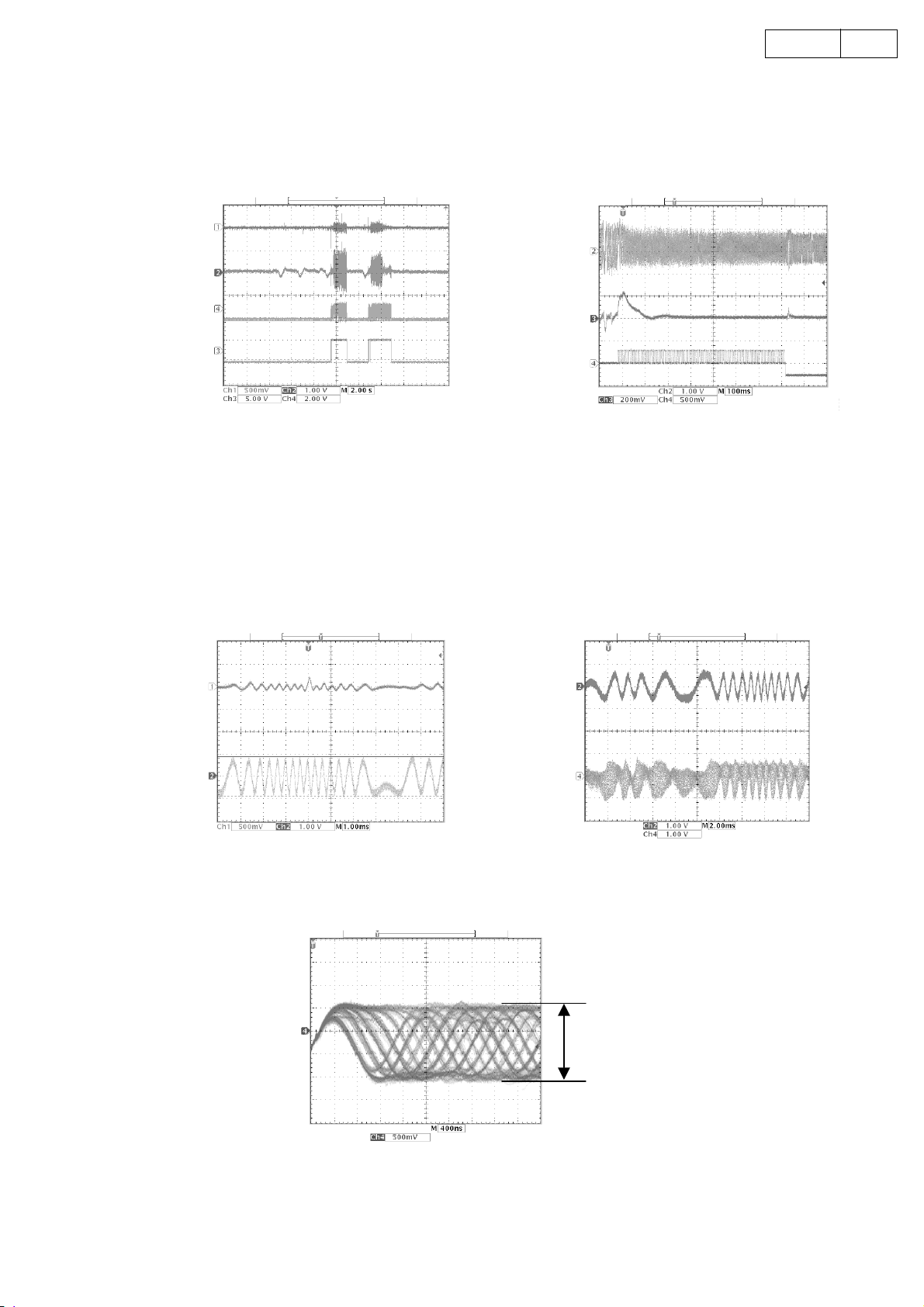

How to check the test mode

( 1 ) DISC discrimination, adjustment

* Insert DISC, and press the AUTO SEARCH REVERSE button.

* “06 Adj” is displayed, and discrimination of DISC size 8 cm/12 cm, discrimination of DISC reflectance (CD, CD-

R/CD-RW), adjustment of focus, tracking offset, and EF balance will be performed. (Adjusted values are not

displayed: Refer to Fig. 2, 3)

7UD-M31

FE

TE

RI

FE

TB

SLD

DRF

Fig. 2 DISC discrimination,

Fig. 3 Adjustment of EF balance

adjustment (Case of CD-RW)

* After completing the discrimination and adjustment, it becomes stop condition.

* Once discrimination of DISC has been carried out in the “06 Adj” mode, discrimination of size and reflectance is

no longer made, and only adjustment will be performed.

( 2 ) Checking of servo state

* Press the PLAY button after performing above (1) “DISC discrimination, adjustment”.

* “02 L on” is displayed, and the laser will start to light. (The pickup may vibrate with a rattling noise if DISC has

been loaded, but this is not abnormal.)

* Press the PLAY button again.

* “03 F on” is displayed. DISC starts turning, and focus servo will be actuated. (Refer to Fig. 4, 5)

FE

TE

TE

RF

Fig. 4 In “03 F on” Fig. 5 In “03 F on”

* Press the PLAY button again.

* “04 t on” is displayed. Tracking, CLV, and slide servo will be actuated.

* Monitor HF signal using the Test Point, HF point and VC point.

Check that the signal’s amplitude is 1.5V±0.3Vp-p. (Refer to Fig. 6)

RF

A (A=1.5±0.3Vp-p)

Fig. 6 In “04 t on”

7

Page 8

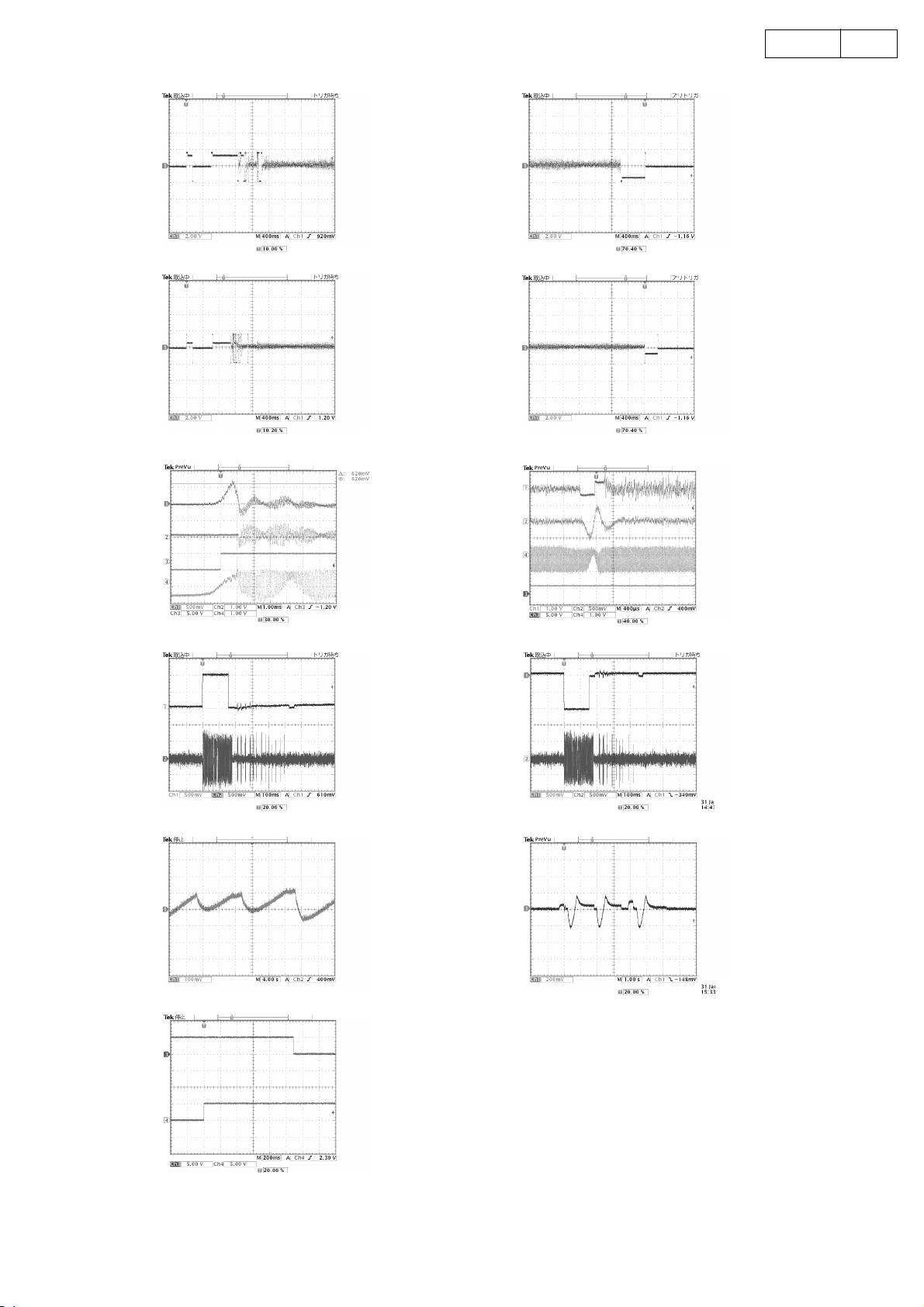

WAVE-FORMS OF EACH POINT

8UD-M31

SP

SP

FE

TE

DRF

RF

When 12 cm DISC

start

When 8 cm DISC

start

When focus

servo on

SP

SP

TD

TE

RF

DRF

When 12 cm DISC

stop

When 8 cm DISC

stop

During PAUSE

SL

TE

SL

OPEN

CLOSE

Track search

(when forward)

During PLAY

When the tray

OPEN

SL

TE

FD

Track search

(when reverse)

Focus search

(no DISC)

8

Page 9

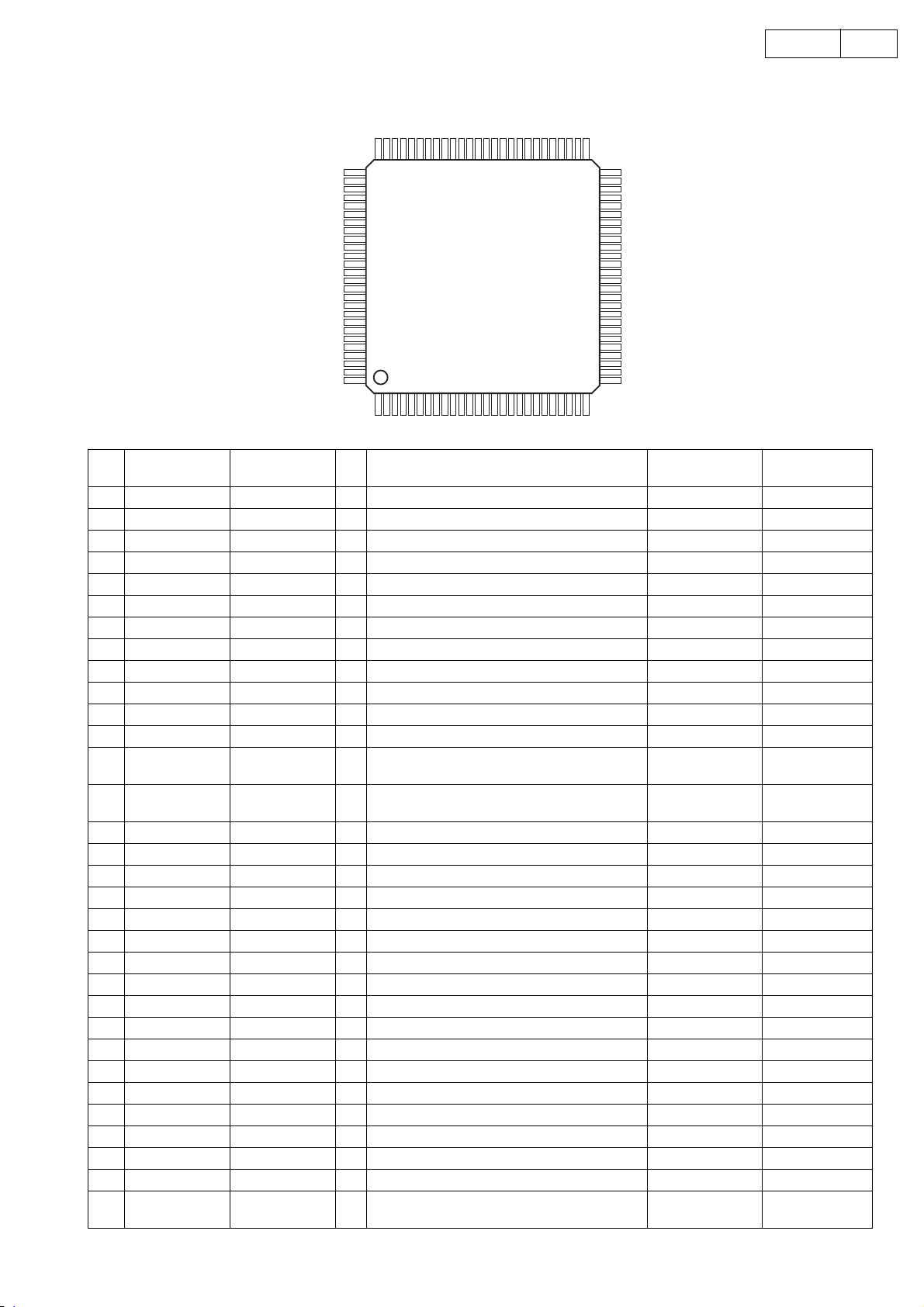

SEMICONDUCTOR

IC’s µPD784216AGC-8EU(IC201)

76

75

9UD-M31

51

50

100

1

26

25

µPD784216AGC-8EU Terminal Function

Pin

No.

1 P120/RTP0 ENC A I Rotary encoder INPUT A RECIEVER -

2 P121/RTP1 ENC B I Rotary encoder INPUT B RECIEVER -

3 P122/RTP2 V.MUTE O Volume mute output, mute;High RECIEVER H

4 P123/RTP3 POWER O Amp circuit power ON/OFF output, ON:High RECIEVER L

5 P124/RTP4 /R.MUTE O Speaker Relay ON/OFF output, ON:High RECIEVER L

6 P125/RTP5 NC O Not used :NC OTHER L

7 P126/RTP6 SEL.EEPROM O EEPROM chip enable output RECIEVER L

8 P127/RTP7 FLCE O Chip select output to FL tube controller OTHER L

9 VDD VDD - Positive power OTHER -

10 X2 X2 - X'tal connection for main clock oscillation OTHER -

11 X1 X1 I X'tal connection for main clock oscillation OTHER -

12 VSS VSS - GND potential OTHER -

13 XT2 XT2 - x'tal connection for main sub-clock oscillation,

14 XT1 XT1 I x'tal connection for main sub-clock oscillation,

15 /RESET /RESET I Micro-computer reset input OTHER -

16 P00/INTP0 REMOCON I Remote-control receive data input RECIEVER -

17 P01/INTP1 50/60 I 50/60Hz AC input RECIEVER -

18 P02/INTP2/NMI /DB RXD I DENON BUS Data input (interrupt input) RECIEVER -

19 P03/INTP3 PROTECT I Speaker Terminal DC voltage detect signal input RECIEVER -

20 P04/INTP4 SEL.EEPROM O EEPROM chip enable output RECIEVER L

21 P05/INTP5 WRQ I SUB CODE Q STAND BY CD L

22 P06/INTP6 /INT I NC, connect to grand OTHER -

23 AVDD AVDD - A/D converter analog power OTHER -

24 AVref0 Avref0 - A/D converter reference voltage input OTHER -

25 P10/ANI0 KEY1 I Unit operation button input1 RECIEVER -

26 P11/ANI1 KEY2 I Unit operation button input2 RECIEVER -

27 P12/ANI2 KEY3 I Not used :Connect to GND OTHER -

28 P13/ANI3 KEY4 I Not used :Connect to GND OTHER -

29 P14/ANI4 NC I Not used :Connect to GND OTHER -

30 P15/ANI5 DRF I REFLECTION OF DISC SIG. Input CD -

31 P16/ANI6 FSEQ I EFM SYNC SIG. INPUT CD -

32 P17/ANI7 DARXD I DATA BUS(for VOL,PLL,RDS IC, EEPROM)

Port Symbol I/O Function RECIEVER or CD

not used : :NC

not used :Connect to VSS orVCC

-

Data in

outputs of

standby&Defoult

9

Page 10

10UD-M31

Pin

No.

33 AVSS AVSS - A/D,D/A converter GND position OTHER -

34 P130/ANO0 LINE1 O LINE OUT Control signal output1 OTHER L

35 P131/ANO1 LINE2 O LINE OUT Control signal output2 OTHER L

36 AVref1 Avref1 - D/A converter reference voltage input OTHER -

37 P70/RxD2/SI2 SQOUT I Sub Q code data input CD L

38 P71/TxD2/SO2 COIN O CD-DSP serial communication data output CD L

39 P72/ASCK2/

40 P20/RxD1/SI1 NC I Pull up RECIEVER -

41 P21/TxD1/SO1 FLDT O DATA BUS for FL driver, Data output RECIEVER L

42 P22/ACSK1/

43 P23/PCL NC I Pull up RECIEVER -

44 P24/BUZ /RDSRST O RDS IC reset output RECIEVER -

45 P25/SI0/SDA0 DB RXD I DATA BUS for DENON BUS Data input RECIEVER -

46 P26/SO0 DB TXD O DATA BUS for DEON BUS Data output RECIEVER L

47 P27/SCK0/SCL0 DB CLK O DENON BUS Clock output RECIEVER L

48 P80/A0 /SD I FM/AM Tuning signal input, Tuned:Low RECIEVER -

49 P81/AÇP /ST INC I FM stereo demodulation detect input, Ste-

50 P82/A2 /TMUTE O Tuner mute output, mute:Low RECIEVER L

51 P83/A3 AUTO/MONO O FM AUTO/MONO switching, MONO:High RECIEVER L

52 P84/A4 USA I Initial setting input RECIEVER -

53 P85/A5 EURO I Initial setting input RECIEVER -

54 P86/A6 FREQ I Initial setting input RECIEVER -

55 P87/A7 RDS I Initial setting input RECIEVER -

56 P40/AD0 SL+ O SLIDE kick Forward CD L

57 P41/AD1 SL- O SLIDE kick Reverse CD L

58 P42/AD2 CD/!RW O CD, CD-RW gain switching CD L

59 P43/AD3 SERACH O SEARCH control CD L

60 P44/AD4 NC O OPEN CD L

61 P45/AD5 NC O OPEN CD L

62 P46/AD6 LED POWER G O POWER/STANDBY Green LED out-

63 P47/AD7 LED POWER R O POWER/STANDBY Red LED output,Light:High

64 P50/A8 NC I Pull up CD -

65 P51/A9 NC I Pull up CD -

66 P52/A10 CLSW I LOADER CLOSE SW input CD -

67 P53/A11 OPSW I LOADER OPEN SW input CD -

68 P54/A12 NC I Pull up CD -

69 P55/A13 NC I Pull up CD -

70 P56/A14 NC I Pull up CD -

71 P57/A15 O Not used :NC OTHER L

72 VSS VSS - GND potential OTHER -

73 P60/A16 BLK O FLD ON/OFF control port, L= black out FLD

74 P61/A17 DATXD O DATA BUS(for VOL,PLL,RDS IC, EEPROM)

75 P62/A18 DACLK O DATA BUS(for VOL,PLL,RDS IC, EEPROM)

76 P63/A19 DACE O DATA BUS(for VOL,PLL,RDS IC) Chip enable

77 P64/RD DRP_RST O CD-DSP reset output, output, reset:High CD L

78 P65/WR O Not used :NC OTHER L

79 P66/WAIT PWBCHK I Start PWB check mode OTHER -

Port Symbol I/O Function RECIEVER or CD

CQCK O CD-DSP serial communication clock output CD L

SCK2

FLCLK O DATA BUS for FL driver, Clock output RECIEVER L

SCK1

RECIEVER -

reo:Low

put,Light:High

RECIEVER L

Data output

RECIEVER L

Clock output

RECIEVER L

output

outputs of

standby&Defoult

10

Page 11

11UD-M31

Pin

No.

80 P67/ASTB O Not used :NC OTHER L

81 VDD VDD - Positive power OTHER -

82 P100/TI5/TO5 OPEN O CD mecha. Open CD L

83 P101/TI6/TO6 CLOSE O CD mecha. Close CD L

84 P102/TI7/TO7 O NC OTHER L

85 P103/TI8/TO8 O NC OTHER L

86 P30/TO0 RWC O CD-DSP serial communication read / write CD L

87 P31/TO1 O Not used :NC OTHER L

88 P32/TO2 DRV_MUTE O DRIVER MUTE CD L

89 P33/TI1 O Not used :NC, CD L

90 P34/TI2 CDPOWER O CD power control signal output CD L

91 P35/TI00 O Not used :NC, OTHER L

92 P36/TI02 O Not used :NC OTHER L

93 P37 HPSW I HEADPHONE Insertswitch detective signal input

94 TEST/VPP TEST I not used :Connect to GND OTHER -

95 P90 O Not used :NC, OTHER L

96 P91 OPSW I Pickup inner-most detect input, inner most:Low

97 P92 O Not used :NC OTHER L

98 P93 O Not used :NC OTHER L

99 P94 O Not used :NC OTHER L

100 P95 O Not used :NC OTHER L

Port Symbol I/O Function RECIEVER or CD

-

at on

outputs of

standby&Defoult

11

Page 12

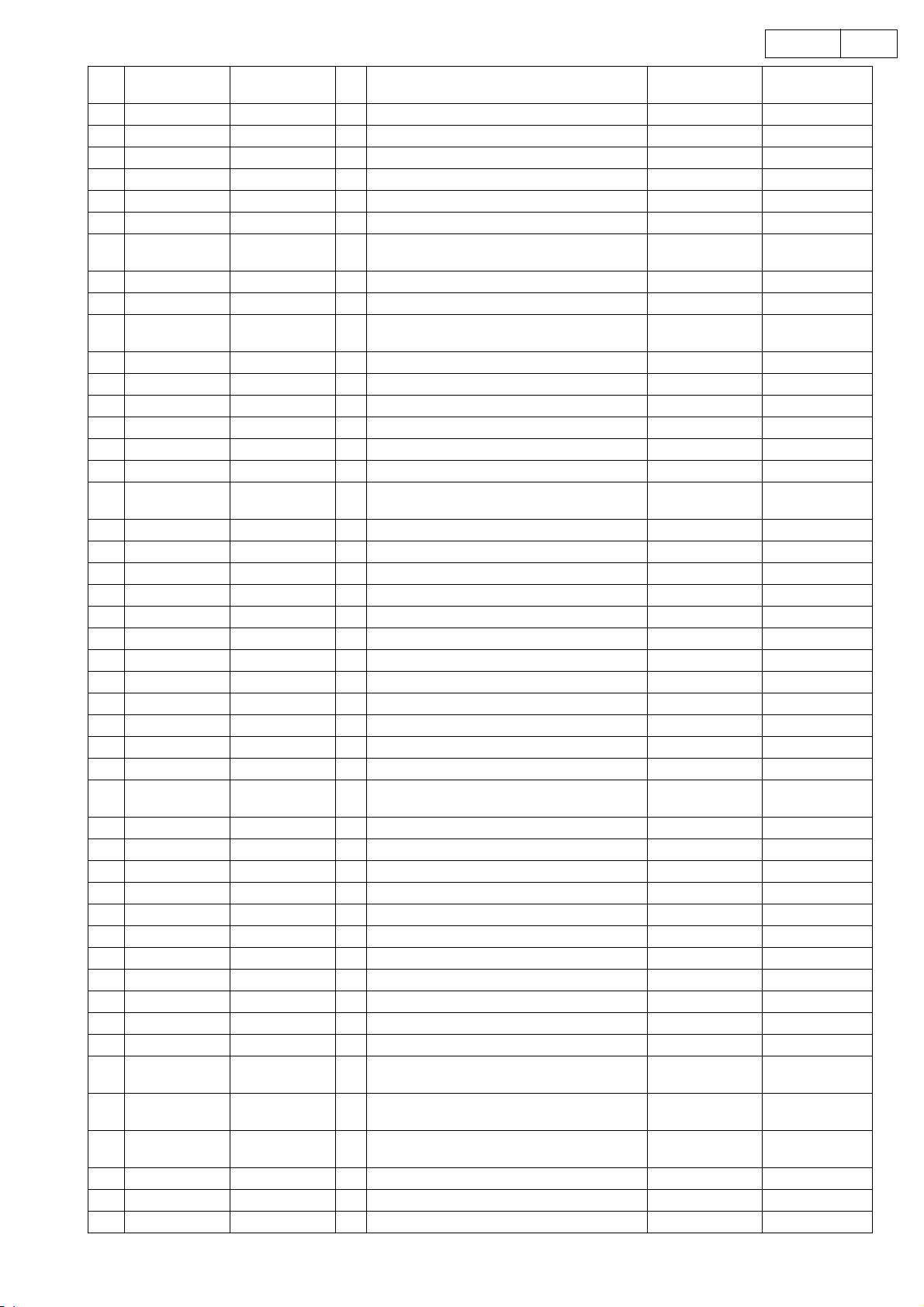

LC78625E(IC803)

RWC

WRQ

626364

FSX

SBCK

SFSYPWEFLG

59

58

6061

SBSY

57

56

DOUT

55

MUTER

RVDDRCHP

53

54

RCHN

RVSSLVSSLCHN

50

5152

49

LCHP

48

47

LVDDMUTEL

C2F

45

44

46

12UD-M31

ROMXA

CK2

LRSY

ASLRCK/P3

43

4142

SQOUT

CO IN

CQCK

RES

TST11

LASER

16M

4.2M

CONT

TEST5

CS

XV

XIN

XOUT

XV

TEST1

65

66

67

68

69

70

71

72

73

74

75

76

SS

77

78

79

DD

80

1

23

DEFI

4567

TAI

PDO

FR

ISET

VVSS

VVDD

8

9

VSS

10

EFMO

EFMO

11

EFMIN

12 13

TEST2

17 18 19 20

15 16

14

V/P

FST

FOCS

FZD

CLV-

CLV+

HFL

21

TES

22

PCK

FSEQ

23 24

TOFF

TGL

40

ASDEPC/P2

39

ASDFIN/P1

38

ASDACK/P0

37

TST10

36

DACKO

35

DFOLO

34

DFORO

33

LRCKO

32

EMPH

31

TEST4

30

DEMO

29

JP-

28

JP+

27

V

DD

26

TEST3

25

THLD

DEFI

EFMIN

FSEQ

CLV+

CLV-

V/P

PW

SBCK

SBSY

SFSY

CS

WRQ

SQOUT

CQCK

CO IN

RWC

DEMO

EFMO

EFMO

Slice Level

Control

Synchronization

detection

EFM Demodulation

CLV

Digital servo

Subcode

separation

Q CRC

Microprocessor

Interface

Servo

commander

FST

HFL

FZD

TOFF

FOCS

TES

DD

RES

VVSSVV

JP+

PDO

ISET

VCO

oscillator

Clock control

JP-

TGL

THLD

PCK

FR

detection and correction

CONT

LASER

EMPH

TST11

TST10

TAI

2k

TEST1

´

RAM

TEST2

8-bit

TEST3

C1 and C2 error

Flag processing

Crystal oscillator system

Timing generator

SS

16M

XV

4.2M

EFLG

TEST5

TEST4

Level meter

Peak meter

XIN

FSX

XOUT

DD

XV

DD

VSSV

CK2

RAM address

generator

Interpolation

and mute

Bilingual function (1)

Digital

attenuator

8´ oversampling

digital filters

Bilingual function (2)

One-bit D/A

converter

SS

DD

RV

RV

RCHP

MUTER

Digital output

LCHN

RCHN

LCHP

interface

ports/Anti-shock

General-purpose

SS

DD

LV

LV

MUTEL

LRSY

C2F

ROMXA

DOUT

ASDACK/P0

ASDFIN/P1

ASDEPC/P2

ASLRCK/P3

DACKO

DFOLO

DFORO

LRCKO

12

Page 13

LC78625E Terminal Function

Pin No. Symbol I/O Function

1 DEFI I Defect detection signal (DEF) input (This pin must be connected to 0 V if unused.)

2TAII

3 PDO O External VCO control phase comparator output

4

VV

SS

PLL pins

5 ISET AI PDO output current adjustment resistor connection

6

VV

DD

7 FR AI VCO frequency range adjustment

8 VSS Digital system ground. (This pin must be connected to 0 V.)

9EFMOO

10 EFMO O EFM signal output

Slice level control

11 EFMIN I EFM signal input

12 TEST2 I Test input. A pull-down resistor is built in. This pin must be connected to 0 V in normal operation.

+

13

14

CLV

CLV

15 V/P O

O Spindle servo control output. Acceleration when CLV+ is high, deceleration when CLV- is high.

-

O Three-value output is also possible when specified by microprocessor command.

Rough servo/phase control automatic switching monitor output. Outputs a high level during rough servo and a low

level during phase control.

16 FOCS O Focus servo on/off output. Focus servo is on when the output is low.

17 FST O Focus start pulse output. This is an open-drain output.

18 FZD I Focus error zero cross signal input. (This pin must be connected to 0 V if unused.)

19 HFL I Track detection signal input. This is a Schmitt input.

20 TES I Tracking error signal input. This is a Schmitt input

21 PCK O EFM data playback clock monitor. Outputs 4.3218 MHz when the phase is locked.

22 FSEQ O

Synchronization signal detection output. Outputs a high level when the synchronization signal detected from the

EFM signal and the internally generated synchronization signal agree.

23 TOFF O Tracking off output

24 TGL O Tracking gain switching output. Increase the gain when low.

25 THLD O Tracking hold output

26 TEST3 I Test input. A pull-down resistor is built in. (This pin must be connected to 0 V.)

27

28

29

V

JP

JP

DD

+

-

30 DEMO I

Digital system power supply.

Track jump output. A high level output from JP+ indicates acceleration during an outward jump or deceleration dur-

O

ing an inward jump.

A high level output from JP- indicates acceleration during an inward jump or deceleration during an outward

O

jump.Three-value output is also possible when specified by microprocessor command.

Sound output function input used for end product adjustment manufacturing steps. A pull-down resistor is built in.

(This pin must be connected to 0 V.)

31 TEST4 I Test input. A pull-down resistor is built in. (This pin must be connected to 0 V.)

32 EMPH O De-emphasis monitor pin. A high level indicates playback of a de-emphasis disk.

33 LRCKO O

34 DFORO O Right channel data output

35 DFOLO O Left channel data output

Digital filter outputs

36 DACKO O Bit clock output

37 TST10 O Test output. Leave open. (Normally outputs a low level.)

38

39

40

ASDACK

/P0

ASDFIN/

P1

ASDEPC

/P2

When antishock

I/O

mode is not

used,these pins are

I/O Left and right channel data input

used as general purpose I/O ports (P0 to

P3). They must either

I/O

be set to input mode

and connected to 0 V,

41

ASLRCK/

P3

or set to output mode

I/O L/R clock input

and left open, if

unused.

Test input. A pull-down resistor is built in. (This pin must be connected to 0 V in normal

operation.)

Internal VCO ground. (This pin must be connected to 0 V.) PLL pins

Internal VCO power supply.

EFM signal inverted output

Word clock output

Bit clock input

The antishock inputs in antishock

mode.

Sets the built-in de-emphasis filter on or off.(High:

on, low: off)

13UD-M31

13

Page 14

Pin No. Symbol I/O Function

42 LRSY O

43 CK2 O Bit clock output(after reset)

44 ROMXA O Interpolation data output(after reset) ROM data output (during ROMXA mode)

ROMXA application

output signals

L/R clock output

Inverted polarity clock output(during CK2CON

mode)

45 C2F O C2 flag output

46 MUTEL O

47

LV

DD

Left channel mute output

Left channel power supply

48 LCHP O Left channel P output

49 LCHN O Left channel N output

50

51

LV

RV

SS

SS

One-bit D/A converter

signals

Left channel ground. Must be connected to 0 V.

Right channel ground. Must be connected to 0 V.

52 RCHN O Right channel N output

53 RCHP O Right channel P output

54

RV

DD

Right channel power supply

55 MUTER O Right channel mute output

56 DOUT O Digital output

57 SBSY O Subcode block synchronization signal output

58 EFLG O C1, C2, single and double error correction monitor pin

59 PW O Subcode P, Q, R, S, T, U and W output

60 SFSY O Subcode frame synchronization signal output. This signal falls when the subcodes are in the standby state.

61 SBCK I Subcode readout clock input. This is a Schmitt input. (This pin must be connected to 0 V if unused.)

62 FSX O Output for the 7.35 kHz synchronization signal divided from the crystal oscillator

63 WRQ O Subcode Q output standby output

64 RWC I Read/write control input. This is a Schmitt input.

65 SQOUT O Subcode Q output

66 COIN I Command input from the control microprocessor

67 CQCK I

Input for the command input acquisition clock or the SQOUT pin subcode readout clock input. This is a Schmitt

input.

68 RES I Reset input. This pin must be set low briefly after power is first applied.

69 TST11 O Test output. Leave open. (Normally outputs a low level.)

70 LASER O Laser on/off output. Controlled by serial data commands from the control microprocessor.

71 16M O 16.9344 MHz output

72 4.2M O 4.2336 MHz output

73 CONT O Supplementary control output. Controlled by serial data commands from the control microprocessor.

74 TEST5 I Test input. A pull-down resistor is built in. (This pin must be connected to 0 V.)

75 CS I Chip select input. A pull-down resistor is built in. This pin must be connected to 0 V if unused.

76

XV

SS

77 XIN I

78 XOUT O

79

XV

DD

Crystal oscillator ground. Must be connected to 0 V.

Connections for a 16.9344 MHz crystal oscillator

Crystal oscillator power supply

80 TEST1 I Test input. A pull-down resistor is built in. (This pin must be connected to 0 V.)

14UD-M31

Note: All power-supply pins (VDD, VVDD, LVDD, RVDD, and XVDD) must be connected to the same potential.

14

Page 15

LC75725E(IC401)

S23

S22

S21

S20

S19

S18

S17

S16

S15

S14

S13

S12

S11

S10

S9

48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33

15UD-M31

S24

BLK

VFL

S8

S7

S6

S5

S4

S3

S2

S1

Vss

OSC0

OSC1

V

BLK

CE

CL

49

50

51

52

53

54

55

56

57

58

59

DD

60

61

62

63

64

DI

G11

DIGIT

DRIVER

1 2 3 4 5 6 7 8 9 10111213141516

G11

G10

G9

G8

G7

G6

G5

G4

G3

G2

G1

VFL

G10G2G1

S43

S42

SEGMENT DRIVER

MPX

LATCH

VFL

S43

S42

S41

32

S25

31

S26

S27

30

29

S28

28

S29

27

S30

26

S31

25

S32

24

S33

23

S34

22

S35

21

S36

20

S37

19

S38

18

S39

17

S40

S2

S1

GRID

CONTROL

DIMMER

TIMING

GENERATOR

SHIFT REGISTER

TIMING

GENERATOR

DIVIDER

OSCI

OSCO

CLOCK

GENERATOR

Terminal Function

Pin No. I/O Name Function

1,13 Power supply pin to driver block

2~12 Digit output pin

14~56 Segment output pin

57 power supply pin

58 OSCO Pin for oscillator

59 OSCI Pin for oscillator

60 V

61 BLK Display off input pin

62 CE Input for serial data transfer

63

64

O

O

-

O

I

-

I

I

I

I

FL

V

G1~G11

S1~S43

Vss

DD

CL

DI

Power supply pin to ligic block

CE : Chip enable

CL : Sync clock

DI : Transfer data

DI

CL

ADDRESS

DETECTOR

CE

VSS

DD

V

15

Page 16

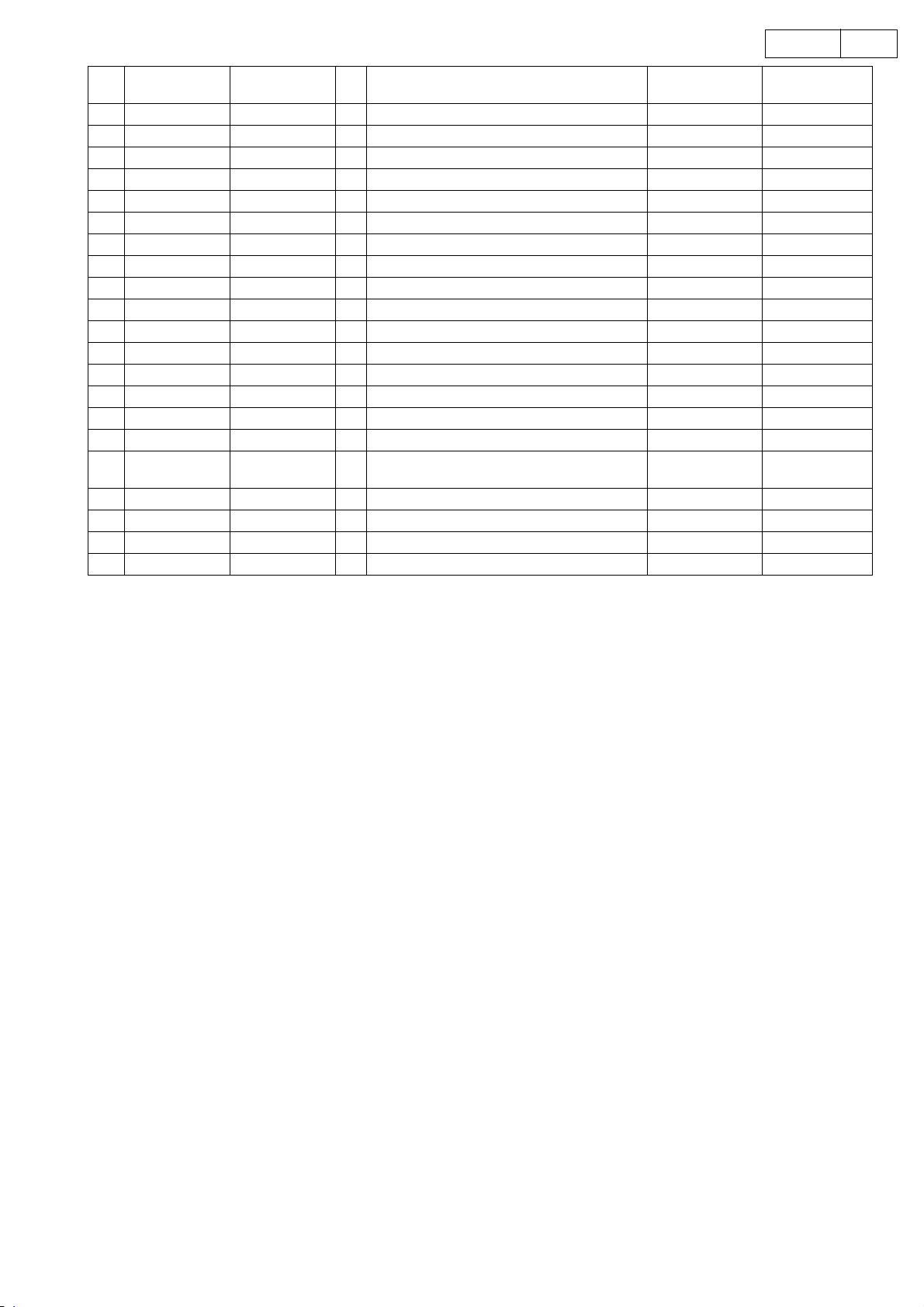

LA9241M(IC802)

VCC1

LDS

LDD

BH1

PH1

LF2

VR

REFI

VCC2

FSS

DRFCEDATCLCLK

646362616059585756555453525150

FIN2

1

FIN1

2

E

3

F

4

TB

5

-

TE

6

TE

7

TESI

8

SCI

9

TH

10

TA

11

-

TD

12

TD

13

JP

14

15

TO

16

FD

171819202122232425262728293031

FAFAFE

FD

-

-

FE

AGND

NC

SP

SPG

-

SP

SPD

LA9241M Terminal Function

SLD

SLEQ

16UD-M31

VCC1

LDS

LDD

BH1

DEF

49

1

48

NC

47

TBC

46

FSC

45

DGND

44

SLI

43

SLC

-

42

RFS

41

RFSM

+

40

CV

-

39

CV

38

SLOF

37

HFL

36

TES

35

TOFF

34

TGL

+

33

JP

32

-

-

+

JP

SL

SL

FIN2

FIN1

TESI

2

3

E

4

F

5

TB

6

TE

TE

7

8

9

SCI

10

TH

TA

11

-

TD

12

TD

13

JP

14

TO

15

FD

16

APC

I/V

T. SERVO & T.LOGIC

PH1

RF DET

VCA

VCABAL

TE

F.SERVO & F.LOGIC

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

FA

FD

FAFEFE

LF2VRREFI

REF

INTER FACE

-

AGND

-com

SPINDLE

SERVO

SP

NC

VCC2FSS

SP

SPG

DRFCEDATCLCLK

SLED SERVO

SPD

SLEQ

49505152535455565758596061626364

SLC

RF Amp

SLSLJP

SLD

DEF

NC

48

47

TBC

FSC

46

45

DGND

SLI

44

SLC

43

-

42

RFS

RFSM

41

+

CV

40

-

CV

39

SLOF

38

37

HFL

TES

36

TOFF

35

TGL

34

+

33

JP

-

+

Pin No. Symbol Contents

1FIN2

Pickup photodiode connection pin. Added to FIN1 pin to generate the RF signal, subtracted from FIN1 pin to generate

the FE signal.

2 FIN1 Pickup photodiode connection pin.

3 E Pickup photodiode connection pin. Subtracted from F pin to generate the TE signal.

4 F Pickup photodiode connection pin.

5 TB TE signal DC component input pin.

6

TE

-

Pin which connects the TE signal gain setting resistor between this pin and TE pin.

7 TE TE signal output pin.

8 TESI TES (Track Error Sense) comparator input pin. The TE signal is input through a bandpass filter.

9 SCI Shock detection input pin.

10 TH Tracking gain time constant setting pin.

11 TA TA amplifier output pin.

-

12

TD

Pin for configuring the tracking phase compensation constant between the TD and VR pins.

13 TD Tracking phase compensation setting pin.

14 JP Tracking jump signal (kick pulse) amplitude setting pin.

15 TO Tracking control signal output pin.

16 FD Focusing control signal output pin.

-

17

FD

Pin for configuring the focusing phase compensation constant between the FD and FA pins.

18 FA Pin for configuring the focusing phase compensation constant between the FD- and FA- pins.

19

FA

-

Pin for configuring the focusing phase compensation constant between the FA and FE pins.

20 FE FE signal output pin.

21

FE

-

Pin which connects the FE signal gain setting resistor between this pin and FE pin.

22 AGND Analog signal GND.

23 NC No connection

24 SP CV+ and CV- pins input signal single-end output.

25 SPG 12-cm spindle mode gain setting resistor connection pin.

-

26

SP

Spindle phase compensation constant connection pin, along with the SPD pin.

27 SPD Spindle control signal output pin.

28 SLEQ Sled phase compensation constant connection pin.

29 SLD Sled control signal output pin.

30

31

SL

SL

-

Input pin for sled movement signal from microprocessor.

+

Input pin for sled movement signal from microprocessor.

16

Page 17

Pin No. Symbol Contents

32

33

JP

JP

-

Input pin for tracking jump signal from DSP.

+

Input pin for tracking jump signal from DSP.

34 TGL Input pin for tracking gain control signal from DSP. Gain is low when TGL is high.

35 TOFF Input pin for tracking off control signal from DSP. Tracking servo is off when TOFF is high.

36 TES Output pin for TES signal to DSP.

37 HFL The High Frequency Level is used to determine whether the main beam is positioned over a bit or over the mirrored

38 SLOF Sled servo off control input pin

-

39

40

CV

CV

Input pin for CLV error signal from DSP.

+

Input pin for CLV error signal from DSP.

41 RFSM RF output pin.

42

RFS

-

RF gain setting and EFM signal 3T compensation constant setting pin, along with the RFSM pin.

43 SLC Slice Level Control is an output pin that controls the data slice level used by the DSP for the RF waveform.

44 SLI Input pin used by DSP for controlling the data slice level.

45 DGND Digital system GND pin.

46 FSC Focus search smoothing capacitor output pin.

47 TBC Tracking Balance Control; EF balance adjustment variable range setting pin

48 NC No connection

49 DEF Disc defect detection output pin.

50 CLK Reference clock input pin. 4.23 MHz signal from the DSP is input.

51 CL Microprocessor command clock input pin.

52 DAT Microprocessor command data input pin.

53 CE Microprocessor command chip enable input pin.

54 DRF RF level detection output (Detect RF).

55 FSS Focus Search Select; focus search mode (Å} search/+search vs. the reference voltage) switching pin

56

V

Servo system and digital system VCC pin.

CC

2

57 REFI By-pass capacitor connection pin for reference voltage.

58 VR Reference voltage output pin.

59 LF2 Disc defect detection time constant setting pin.

60 PH1 RF signal peak hold capacitor connection pin.

61 BH1 RF signal bottom hold capacitor connection pin.

62 LDD APC circuit output pin.

63 LDS APC circuit input pin.

1

64

V

RF system VCC pin.

CC

17UD-M31

17

Page 18

LA6559(IC801)

18UD-M31

REV

S-VCC

VCC2

VLO-

VLO+

VO4+

VO4-

VO3+

VO3-

VO2+

VO2-

VO1+

VO1-

VCC1

VIN1

VIN1-

VIN1+

VIN2

1

2

3

4

5

6

7

8

9

FR

FR

10

11

12

13

14

15

16

17

18

Signal System VCC

S

Power Supply

Power Supply

(LOADING)

(LOADING)

Power

Power

System

System

GND

Power Supply

(CH1 to CH4)

11k

11k

Input

Input

(For rd/Reverse/

(Forward/Reverse/

Break/OFF)

Control

Output

Output

Level

Shift

Level

Shift

Level

Shift

Level

Shift

ft

33k

Signal System GND

CH2 to CH4

Output

CH1 Output

ON/OFF

33k

Power System GND

3.3VREG

(External PNP)

33k

3.3VREG GND

3.3VREG

Power Supply

33k

T

Thermal

Sh

Shutdown

MUTE2

t

MUTE1

11k

11k

PNP Tr

Collector

PNP Tr

PNP Tr

)

11k

u

11k

Base

Base

36

FWD

35

S-GND

34

MUTE2

33

MUTE1

32

VIN4

31

VIN4-

30

VIN4+

29

VREF-IN

28

VCONT(LOADING)

FR

FR

27

REG-OUT

26

REG-IN

25

VIN3+

24

VIN3-

23

VIN3

22

GND-VREG

21

VCC-VREG

20

VIN2+

19

VIN2-

Pin

No.

Name

1 REV

2 S-Vcc

Function

5CH output change terminal, logic input of

loading block

signal system power supply

(BTL-AMP:CH1~4)

3 Vcc2 Power supply for loading block

4 VLO- Loading output (-)

5 VL0+ Loading output (+)

6 VO4+ Output terminal (+) for channel 4

7 VO4- Output terminal ( ) for channel 4

8 VO3+ Output terminal (+) for channel 3

9 VO3- Output terminal (- ) for channel 3

10 VO2+ Output terminal (+) for channel 2

11 VO2- Output terminal (- ) for channel 2

12 VO1+ Output terminal (+) for channel 1

13 VO1- Output terminal (- ) for channel 1

14 Vcc1 CH1 `CH4(BTL-AMP) output stage power supply

15 VIN1 Input terminal for channel 1

16 VIN1- OP-AMP input AMP-A input terminal (- )

)

17 VIN1+ OP-AMP input AMP-A input terminal (+)

18 VIN2 Input terminal for channel 2, input AMP output

19 VIN2- Input terminal (- ) for channel 2

20 VIN2+ Input terminal (+) for channel 2

21 Vcc-VREG 3.3VREG power supply

22 GND-VREG 3.3VREG GND

23 VIN3 Input terminal for channel 3, input AMP output

24 VIN3- Input terminal (- ) for channel 3

25 VIN3+ Input terminal (+) for channel 3

26 REG-IN PNP transistor base connected

27 REG-OUT

3.3V power output to which the PNP transistor

collector connected

28 VCONT Loading output voltage set terminal

29 VREF-IN Reference voltage applied terminal

30 VIN4+ Input terminal (+) for channel 4

31 VIN4- Input terminal (- ) for channel 4

32 VIN4 Input terminal for channel 4, input AMP output

33 MUTE1 Output ON/OFF for channel 1 (BTL AMP)

34 MUTE2 Output ON/OFF for channel 2 to 4 (BTL AMP)

35 S-GND Signal system GND

36 FWD

Output change terminal (FWD) for loading

output (VLO+,-), logic input of loading block

18

Page 19

LC75342M(IC302)

19UD-M31

DI

CE

VSS

TEST

LOUT

LBASS2

LBASS1

LTRE

LIN

LSELO

L4

L3

L2

L1

NC

NC

Vref

DD

V

27

28

29

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

ROUT

30

CL

29

VDD

28

VREF

27

NC

26

ROUT

25

RBASS2

24

RBASS1

23

RTRE

22

RIN

21

RSELO

20

R4

19

R3

18

R2

17

R1

16

NC

RBASS2 RBASS1

RTRE RIN RSELO

212223242526

+

+

+

19

R420

R3

30

CL

1

DI

2

CE

3

Vss

TEST

4

LC72720NM(IC303)

Vref

1

MPXIN

2

Vdda

3

Vssa

4

FLOUT

5

CIN

6

T1

7

T2

XOUT

8

9

10

11

12

T3 (RDCL)

T4 (RDDA)

T5 (RSFT)

+

RVref

-

CCB

INTERFACE

+

-

+

-

LVref

+

-

567

SYR

24

CE

23

DI

22

CL

21

DO

20

RDS-ID

19

SYNC

18

T7 (CORREC/ARI-ID/BEO)

17

T6 (ERROR/57K/BE1)

16

Vssd

15

Vddd

14

XIN

13

LBASS2

Vdda

Vssa

MPXIN

T3 T7

DO

CL

DI

CE

T1

T2

LBASS1

REFERENCE

VOLTAGE

ANTIALIASING

FILTER

CCB

TEST

CONTROL

CIRCUIT

LOGIC

CIRCUIT

CONTROL

CIRCUIT

+

-

LTRELOUT

VREF

57kHz

BPF

(SCF)

(24 BLOCK DATA)

MEMORY CONTROL

R2

18

+

+

-

RAM

9

LIN

FLOUT

SMOOTHING

FILTER

10

LSELO

CIN

VREF

ERROR CORRECTION

(SOFT DECISION)

CLK(4.332MHz)

OSC/DIVIDER

PLL

(57kHz)

CLOCK

RECOVERY

(1167.5Hz)

DATA

DECODER

SYNC/EC CONTROLLER

SYNC

DETECT-1

8

SYNC

DETECT-2

17

16

15

14

13

12

11

R1

NC

NC

L1

L2

L3

L4

Vddd

Vssd

RDS-ID

SYNC

SYR

19

XIN XOUT

Page 20

20UD-M31

STK402-050(IC501)

FRONT VIEW

1

BA6287F(IC805)

8

4

R1

C1

1

TR1 TR2

2

R3

R4

15

TR3

D1

R2

SUB

13

5

TR4

TR7

R6

TR5

TR8

TR6

R5

R7

7610

12

TR9

TR11

R8

C2

TR14

TR12

TR13

R9

R11

R12

R10

TR10

11

R13

TR15

TR16

R14

9

14 15

93LC66(IC202)

1

CS

2

SK

3

DI

4

DO

M51957BFP(IC205)

TOP VIEW

NC

NC

GND

1

IN

2

3

4

8

7

6

5

8

Vcc

7

WP

6

ORG

5

GND

NC

V

CC

OUT

Delay Cap.

DI

CS

SK

(2K/4K)

ORG

INSTRUCTION

REGISTER

INSTRUCTION

DECODE

CONTROL

AND

CLOCK

GENERATION

DATA

REGISTER

ADDRESS

REGISTER

Vcc RANGE

DETECTOR

WRITE ENABLE

DUMMY BIT

R/W AMPS

DECODER

HIGH VOLTAGE

GENERATOR

DO

MEMORY ARRAY

256/512 X 8

OR

64/128/256 X 16

20

Page 21

21UD-M31

FL DISPLAY HNA-11SS47T (FL401)

GRID ASSIGNMENT

11G

9G

PIN CONNECTION

col

Dp

10G

8G

7G 6G

f

g

r

e

1G

5G 4G 3G 2G

a

h

j

b

k

m

n

c

p

d

[11G~2G]

PIN NO.

CONNECTION

NOTE 1) Fin ---- Filament pin

45444342414039383

F2F2NPNP1G2G3G4G5

2) nG ---- Grid pin

3) Pn ---

-

4) NP ---- No pin

5) NC ---- No connection

Anode pin

3

3

3

3

3

3

3

2

2

2

2

2

2

2

2

2

2

1

1

1

1

1

1

1

1

1

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

7

1

1

P

P

P

P

P

P

P

P

P

P

P

6

7

8

9

0

1

N

2

2

2

2

2

2

1

G

G

G

G

G

G

G

C

5

4

3

2

1

1

0

9

8

P

1

1

1

1

7

5

6

4

4

P

P

P

P

1

1

1

1

3

2

1

0

1

3

2

1

0

9

8

7

6

54321

P

P

P

9

8

7

P

P

P

P

5

4

P2P1NPNPF1F

3

1

6

21

Page 22

PRINTED WIRING BOARD

1U-3498 MAIN UNIT Ass'y COMPONENT SIDE

Parts List

UD-M31

22

22

Page 23

1U-3498 MAIN UNIT Ass'y FOIL SIDE

Parts List

UD-M31

23

23

Page 24

1U-3507 CD UNIT ASS'Y

Parts List

UD-M31

24

COMPONENT SIDE

C923

R927

FOIL SIDE

24

Page 25

NOTE FOR PARTS LIST

l Part indicated with the mark "" are not always in stock and possibly to take a long period of time for supplying, or in

some case supplying of part may be refused.

l When ordering of part, clearly indicate "1" and "I" (i) to avoid mis-supplying.

l Ordering part without stating its part number can not be supplied.

l Part indicated with the mark " " is not illustrated in the exploded view.

l Not including Carbon Film ±5%, 1/4W Type in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

WARNING:

Parts marked with this symbol

Use ONLY replacement parts recommended by the manufacturer.

have critical characteristics.

25UD-M31

ll

Resistors

l

ll

Ex.: RN 14K 2E 182 G FR

Type Shape Power Resist- Allowable Others

and per- ance error

formance

t

RD : Carbon 2B : 1/8W F : ±1% P : Pulse-resistant type

RC : Composition 2E : 1/4W G : ±2% NL : Low noise type

RS : Metal oxide film 2H : 1/2W J : ±5% NB : Non-burning type

RW : Winding 3A : 1W K : ±10% FR : Fuse-resistor

RN : Metal film 3D : 2W M : ±20% F : Lead wire forming

RK : Metal mixture 3F : 3W

Resistance

1 8 2 ⇒ 1800 ohm = 1.8 kohm

s

s

• Units: ohm

1 R 2 ⇒ 1.2 ohm

s

s

• Units: ohm

t

3H : 5W

Indicates number of zeros after effective number.

2-digit effective number.

1-digit effective number.

2-digit effective number, decimal point indicated by R.

t

t

ll

Capacitors

l

ll

Ex.: CE 04W 1H 2R2 M BP

Type Shape Dielectric Capacity Allowable Others

and per- strength error

formance

t

CE : Aluminum foil 0J : 6.3V F : ±1% HS : High stability type

electrolytic

CA : Aluminum solid 1A : 10V G : ±2% BP : Non-polar type

electrolytic

CS : Tantalum electrolytic 1C : 16V J : ±5% HR: Ripple-resistant type

CQ : Film 1E : 25V K : ±10% DL : For change and discharge

CK : Ceramic 1V : 35V M : ±20% HF : For assuring high

CC : Ceramic 1H : 50V Z : +80% U : UL part

CP : Oil 2A :100V –20% C : CSA part

CM : Mica 2B : 125V P : +100% W : UL-CSA type

CF : Metallized 2C : 160V –0% F : Lead wire forming

CH : Metallized 2D : 200V C : ±0.25pF

Capacity (electrolyte only)

2 2 2 ⇒ 2200µF

s

s

• Units: µF.

2 R 2 ⇒ 2.2µF

s

s

• Units: µF.

Capacity (except electrolyte)

2 2 2 ⇒ 2200pF=0.0022µF

s

s

(More than 2) Indicates number of zeros after effective number.

• Units: pF.

2 2 1 ⇒ 220pF

s

s

(0 or 1) Indicates number of zeros after effective number.

• Units: pF.

• When the dielectric strength is indicated in AC, "AC" is included after the dieelectric

strength value.

t

2E : 250V D : ±0.5pF

2H : 500V = : Others

2J : 630V

Indicates number of zeros after effective number.

2-digit effective number.

1-digit effective number.

2-digit effective number, decimal point indicated by R.

2-digit effective number.

2-digit effective number.

t

t

requency

25

Page 26

PARTS LIST OF P.W.B. UNIT ASS'Y

1U-3498 MAIN UNIT ASS'Y

Ref. No. Part No. Part Name Remarks Q’ty New

SEMICONDUCTORS GROUP

IC201 262 3180 208 UPD784216AGC-203-8EU

IC202 262 2986 005 93LC66

IC203 263 1093 002 BA05ST

IC205 263 0454 901 M51957BFP(TP1)

IC301 262 1875 900 BU4066BCF-T1

IC302 262 3181 906 LC75342M *

IC303 262 2547 907 LC72720NM

IC304,305 263 0615 902 BA15218F-DXE2

IC401 262 3182 002 LC75725E *

IC402 499 0301 006 RPM6938-V4

IC501 265 0109 003 STK402-050

IC601 269 0170 005 TOTX178

IC602 263 0809 006 NJM7805FA(S)

IC603 263 0801 004 NJM7812FA(S)

IC604 263 0793 002 NJM7806FA(S)

IC605 263 0809 006 NJM7805FA(S)

IC606,607 268 0073 905 ICP-N15T

26UD-M31

TR209 269 0185 906 DTA115TKAT146

TR211 269 0083 901 DTA114EKT96

TR301 269 0066 902 DTC323TKT96

TR303,304 269 0054 901 DTC144EKT96

TR305 269 0083 901 DTA114EKT96

TR306 269 0066 902 DTC323TKT96

TR307 269 0082 902 DTC114EKT96

TR308 269 0066 902 DTC323TKT96

TR309 273 0426 907 2SC2412KLNT146

TR310 269 0083 901 DTA114EKT96

TR311,312 269 0066 902 DTC323TKT96

TR313 269 0082 902 DTC114EKT96

TR315 269 0066 902 DTC323TKT96

TR317 273 0384 900 2SC2412KT96(S)

TR401,402 269 0082 902 DTC114EKT96

TR501 271 0309 905 2SA1037AKT146S

TR502-504 273 0426 907 2SC2412KLNT146

TR601 271 0309 905 2SA1037AKT146S

TR602,603 273 0426 907 2SC2412KLNT146

TR604 269 0160 905 DTC143ZSATP

TR605 272 0025 907 2SB562(C)TF

TR606,607 273 0426 907 2SC2412KLNT146

TR611 269 0091 906 DTC143TKT96

TR612 269 0083 901 DTA114EKT96

TR613 269 0082 902 DTC114EKT96

D301-303 276 0375 905 1N4148T77 (TAPE)

D305,306 276 0375 905 1N4148T77 (TAPE)

D601 276 0375 905 1N4148T77 (TAPE)

D602,603 276 0772 003 1N4004

D604-606 276 0375 905 1N4148T77 (TAPE)

D607-610 276 0772 003 1N4004

D611 276 0741 005 D3SBA60

D612,613 276 0772 003 1N4004

26

Page 27

1U-3498 MAIN UNIT ASS'Y

Ref. No. Part No. Part Name Remarks Q’ty New

D614 276 0375 905 1N4148T77 (TAPE)

D615,616 276 0772 003 1N4004

D617-619 276 0375 905 1N4148T77 (TAPE)

D621,622 276 0375 905 1N4148T77 (TAPE)

D623-626 276 0772 003 1N4004

ZD601,602 276 0760 963 MTZJ6.2B T77

ZD603 276 0760 950 MTZJ5.6B T77

ZD604 276 0762 932 MTZJ33B T77

LD401 393 9618 007 SLR-9336DS-91

RESISTORS GROUP

R205 247 2011 942 RM73B--473JT

R207 247 2011 942 RM73B--473JT

R209-214 247 2009 909 RM73B--472JT (1608)

R216 247 2009 909 RM73B--472JT (1608)

R219 247 2009 909 RM73B--472JT (1608)

R221 247 2009 909 RM73B--472JT (1608)

R222 247 2007 943 RM73B--102JT

R224 247 2010 927 RM73B--153JT

R225 247 2011 900 RM73B--333JT

R226-228 247 2009 983 RM73B--103JT

R231 244 2055 941 RS14B3A331JNBST(S)

R234,235 247 2009 983 RM73B--103JT

R236 247 2007 943 RM73B--102JT

R237 247 2009 909 RM73B--472JT (1608)

R238 244 2055 941 RS14B3A331JNBST(S)

R239 247 2007 943 RM73B--102JT

R241-244 247 2018 903 RM73B--0R0KT

R245 247 2007 943 RM73B--102JT

R247 247 2009 909 RM73B--472JT (1608)

R250 247 2008 913 RM73B--202JT

R253,254 247 2011 942 RM73B--473JT

R255,256 247 2008 913 RM73B--202JT

R257 247 2006 960 RM73B--471JT

R258 247 2009 983 RM73B--103JT

R301,302 247 2013 982 RM73B--474JT

R303,304 247 2006 960 RM73B--471JT

R305,306 247 2013 982 RM73B--474JT

R307,308 247 2006 960 RM73B--471JT

R309,310 247 2013 982 RM73B--474JT

R311,312 247 2006 960 RM73B--471JT

R313,314 247 2013 982 RM73B--474JT

R315-317 247 2006 960 RM73B--471JT

R319,320 247 2012 925 RM73B--104JT

R321,322 247 2008 913 RM73B--202JT

R323-326 247 2009 983 RM73B--103JT

R327-329 247 2007 943 RM73B--102JT

R331 247 2010 969 RM73B--223JT

R332 247 2007 943 RM73B--102JT

R333,334 247 2010 969 RM73B--223JT

R335,336 247 2008 971 RM73B--362JT

R337 247 2009 954 RM73B--752JT

R338 247 2009 909 RM73B--472JT (1608)

R339,340 247 2012 925 RM73B--104JT

R341,342 247 2011 942 RM73B--473JT

R343,344 247 2008 913 RM73B--202JT

27UD-M31

27

Page 28

1U-3498 MAIN UNIT ASS'Y

Ref. No. Part No. Part Name Remarks Q’ty New

R345 247 2006 960 RM73B--471JT

R347,348 247 2007 943 RM73B--102JT

R349,350 247 2012 925 RM73B--104JT

R351,352 247 2007 969 RM73B--122JT

R353,354 247 2009 909 RM73B--472JT (1608)

R355,356 247 2011 942 RM73B--473JT

R357,358 247 2009 967 RM73B--822JT

R359,360 247 2007 985 RM73B--152JT

R361,362 247 2011 942 RM73B--473JT

R363-365 247 2009 909 RM73B--472JT (1608)

R368 247 2008 913 RM73B--202JT

R369 247 2009 909 RM73B--472JT (1608)

R371,372 247 2011 942 RM73B--473JT

R374 247 2009 983 RM73B--103JT

R376 247 2011 900 RM73B--333JT

R401 247 2006 944 RM73B--391JT

R402 247 2007 901 RM73B--681JT

R403 247 2006 915 RM73B--271JT

R404 247 2006 944 RM73B--391JT

R405 247 2005 961 RM73B--181JT

R406 247 2006 915 RM73B--271JT

R407 247 2005 945 RM73B--151JT

R408 247 2005 961 RM73B--181JT

R409 247 2005 987 RM73B--221JT

R410 247 2006 960 RM73B--471JT

R411 247 2005 945 RM73B--151JT

R414 247 2009 925 RM73B--562JT

R415 247 2009 909 RM73B--472JT (1608)

R416-419 247 2018 903 RM73B--0R0KT

R501,502 247 2007 943 RM73B--102JT

R503,504 247 2011 968 RM73B--563JT

R507,508 244 2051 987 RS14B3A4R7JNBST(S)

! R509,510 241 2313 901 RD14B2E101GFRST

R513,514 244 2051 987 RS14B3A4R7JNBST(S)

R515-517 247 2010 969 RM73B--223JT

R520 247 2009 938 RM73B--622JT

R521 247 2010 927 RM73B--153JT

R601 247 2009 983 RM73B--103JT

R602 247 2010 969 RM73B--223JT

R603 247 2009 983 RM73B--103JT

R604 247 2010 969 RM73B--223JT

R605 247 2009 983 RM73B--103JT

R606,607 247 2010 969 RM73B--223JT

R608 247 2008 926 RM73B--222JT

R609 247 2010 969 RM73B--223JT

R610 247 2007 943 RM73B--102JT

R611 247 2010 969 RM73B--223JT

R612 247 2011 942 RM73B--473JT

R613 247 2005 987 RM73B--221JT

R614-616 247 2005 903 RM73B--101JT

R617 247 2008 968 RM73B--332JT

R618 244 2050 933 RS14B3A181JNBST(S)

R619,620 247 2009 983 RM73B--103JT

R621 247 2008 968 RM73B--332JT

R622 247 2009 983 RM73B--103JT

R624 247 2011 942 RM73B--473JT

R625 244 2051 945 RS14B3A010JNBST(S)

R626 247 2009 909 RM73B--472JT (1608)

R627 247 2011 942 RM73B--473JT

R628 247 2007 943 RM73B--102JT

28UD-M31

28

Page 29

1U-3498 MAIN UNIT ASS'Y

Ref. No. Part No. Part Name Remarks Q’ty New

R921-923 247 2009 983 RM73B--103JT

CAPACITORS GROUP

C201 254 4538 900 CE04W1C100MT SMG/RE3

C202,203 257 0511 904 CK73F1H103ZT

C204 254 4524 943 CE04W1H010MT SMG/RE3

C208 257 0512 903 CK73F1E104ZT

C209 254 4524 956 CE04W1H2R2MT SMG/RE3

C210 254 4538 939 CE04W1C470MT SMG/RE3

C211 257 0512 903 CK73F1E104ZT

C212 257 0501 901 CK73B1H103KT (1608)

C216 257 0512 903 CK73F1E104ZT

C218,219 257 0506 951 CC73CH1H101JT

C220 257 0512 903 CK73F1E104ZT

C301,302 257 0508 917 CC73CH1H471JT

C303,304 254 4524 972 CE04W1H4R7MT SMG/RE3

C305,306 257 0508 917 CC73CH1H471JT

C307,308 254 4524 972 CE04W1H4R7MT SMG/RE3

C309,310 257 0508 917 CC73CH1H471JT

C311,312 254 4524 972 CE04W1H4R7MT SMG/RE3

C313,314 257 0508 917 CC73CH1H471JT

C315,316 254 4524 972 CE04W1H4R7MT SMG/RE3

C317 257 0509 929 CK73B1H102KT

C319,320 254 4524 972 CE04W1H4R7MT SMG/RE3

C321-323 257 0511 904 CK73F1H103ZT

C324 254 4524 901 CE04W1H0R1MT SMG/RE3

C325-330 254 4524 972 CE04W1H4R7MT SMG/RE3

C331-334 256 1058 971 CF93A1H104JT (JL)

C335 257 0509 929 CK73B1H102KT

C337,338 257 0510 905 CK73B1H272KT

C339 254 4538 913 CE04W1C220MT SMG/RE3

C340 257 0501 901 CK73B1H103KT (1608)

C341-343 254 4538 900 CE04W1C100MT SMG/RE3

C344 254 4536 915 CE04W1A470MT SMG/RE3

C345,346 257 0511 904 CK73F1H103ZT

C347 254 4538 900 CE04W1C100MT SMG/RE3

C348 254 4524 972 CE04W1H4R7MT SMG/RE3

C349,350 257 0504 908 CC73CH1H220JT

C351 257 0507 976 CC73CH1H331JT

C352 257 0508 933 CC73CH1H561JT

C353,354 254 4524 972 CE04W1H4R7MT SMG/RE3

C355,356 254 4524 972 CE04W1H4R7MT SMG/RE3 NICHICHEMI

C357-359 254 4538 939 CE04W1C470MT SMG/RE3

C360 254 4524 901 CE04W1H0R1MT SMG/RE3

C361,362 254 4538 900 CE04W1C100MT SMG/RE3

C363,364 254 4524 972 CE04W1H4R7MT SMG/RE3

C365 254 4538 939 CE04W1C470MT SMG/RE3

C366 254 4538 900 CE04W1C100MT SMG/RE3

C367 254 4524 901 CE04W1H0R1MT SMG/RE3

C368 257 0511 904 CK73F1H103ZT

C404 254 4192 922 CE04W1A470MT (SRA)

C405 257 0511 904 CK73F1H103ZT

C406 254 4192 922 CE04W1A470MT (SRA)

C407 257 0504 908 CC73CH1H220JT

C408 257 0511 904 CK73F1H103ZT

C409,410 257 0509 929 CK73B1H102KT

C411 253 1180 921 CK45B1H102KT(DD-3)

C501,502 254 3056 920 CE04D1H2R2MBPT (SME)

C503,504 254 4525 900 CE04W1H330MT SMG/RE3

29UD-M31

29

Page 30

1U-3498 MAIN UNIT ASS'Y

Ref. No. Part No. Part Name Remarks Q’ty New

C505,506 257 0508 917 CC73CH1H471JT

C509,510 254 4525 735 CE04W1H221MC SMG/RE3

C511,512 256 1058 971 CF93A1H104JT (JL)

C513,514 254 4524 985 CE04W1H100MT SMG/RE3

C515,516 257 0502 955 CC73CH1H3R0CT

C517 254 4536 944 CE04W1A331MT SMG/RE3

C518,519 257 0507 934 CC73CH1H221JT

C599 254 3056 917 CE04D1H010MBPT (SME)

C601 257 0509 929 CK73B1H102KT

C602 254 4536 915 CE04W1A470MT SMG/RE3

C603 257 0511 904 CK73F1H103ZT

C604 257 0509 929 CK73B1H102KT

C605 257 0511 904 CK73F1H103ZT

C606 254 4538 900 CE04W1C100MT SMG/RE3

C607 257 0511 904 CK73F1H103ZT

C608 254 4524 943 CE04W1H010MT SMG/RE3

C609 254 4538 900 CE04W1C100MT SMG/RE3

C610 257 0511 904 CK73F1H103ZT

C611 254 4524 943 CE04W1H010MT SMG/RE3

C612 254 4523 724 CE04W1V472MC SMG/RE3

C613 257 0511 904 CK73F1H103ZT

C614 253 8026 703 CK45E2EAC472MC

C615 257 0511 904 CK73F1H103ZT

C616 254 4541 939 CE04W1E470MT SMG/RE3

C617,618 254 4523 724 CE04W1V472MC SMG/RE3

C619,620 257 0511 904 CK73F1H103ZT

C621 254 4538 900 CE04W1C100MT SMG/RE3

C622 257 0511 904 CK73F1H103ZT

C623 254 4524 943 CE04W1H010MT SMG/RE3

C624,625 257 0511 904 CK73F1H103ZT

C626 254 4524 985 CE04W1H100MT SMG/RE3

C627 254 4396 906 CE04W1J101MT(SMG)

C628 257 0511 904 CK73F1H103ZT

C629 257 0501 901 CK73B1H103KT (1608)

C630 254 4538 900 CE04W1C100MT SMG/RE3

C631 257 0511 904 CK73F1H103ZT

C632 254 4524 943 CE04W1H010MT SMG/RE3

C633 254 4403 721 CE04W1E222MC (SMG)

C634,635 257 0511 904 CK73F1H103ZT

C640 257 0511 904 CK73F1H103ZT

C641 257 0512 903 CK73F1E104ZT

C655,656 254 4525 900 CE04W1H330MT SMG/RE3

C657 254 4537 707 CE04W1A102MC SMG/RE3

C701,702 257 0509 929 CK73B1H102KT

C703,704 255 1265 936 CQ93M1H103JT(B)

OTHER PARTS GROUP

30UD-M31

AS601,602 417 0476 049 RADIATOR

CX31 205 0653 036 3P VH CON.BASE

CX32 205 0581 056 2P VH CONNECTOR BASE

CX33 205 0581 001 2P VH CONNECTOR BASE

CX34 205 0355 033 3P KR CON BASE(L)

CX37 205 0355 033 3P KR CON BASE(L)

CX38 205 0323 036 3P CONNE.BASE(BLK)

CX41 205 0355 046 4P KR CON BASE(L)

CX42 205 0343 045 4P CONN.BASE(KR-PH)

CX43 205 0355 046 4P KR CON BASE(L)

CX51 205 0449 059 5P VH CONNECTOR BASE

CX52 205 0190 052 5P NH CONNECTOR BASE

30

Page 31

1U-3498 MAIN UNIT ASS'Y

Ref. No. Part No. Part Name Remarks Q’ty New

CX72 205 0535 086 7P CONN.BASE

CX81 205 0355 088 8P KR CON BASE(L)

CX121 205 0375 026 12P CONN.BASE(KR-PH)

CX143 205 0708 033 14P CONN.SOCKET

CX151 205 0480 050 15P KR CON BASE(L)

CX153 205 0767 058 15P CON BASE *

CX171 205 1006 080 17P FFC BASE(P=1)

CX181 205 1050 052 18P FFC BASE(SIDE) *

CX251 205 1050 010 25P FFC BASE (9603F)

CY38 205 0406 034 3P CON BASE(KR-PH)

CY41 203 6590 016 4P PH-SAN CONN CORD *

CY42 203 6592 001 4P PH-SAN CON CORD *

CY51 203 8535 011 5P VH-SAN CON CORD *

CY72 205 0536 085 7P CONN.SOCKET

CY81 204 2933 010 8P PH-SAN CON CORD *

CY121 205 0480 021 12P KR CON BASE(L)

CY143 205 0707 034 14P CONN.BASE

CY151 204 6753 005 15P PH-SAN CON CORD *

CY152 205 0736 076 15P FFC CON.BASE

CY153 205 0766 059 15P CON SOCKET *

CY171 205 1006 080 17P FFC BASE(P=1)

CY181 205 1050 052 18P FFC BASE(SIDE) *

31UD-M31

! F601 206 1074 073 FUSE (0.5A)

! F602 206 1075 043 FUSE(2.5A)

FF601,602 202 0040 909 FUSE CLIP (TAPE)

FH601,602 202 0040 909 FUSE CLIP (TAPE)

FL401 393 8068 001 FL TUBE(HNA-11SS47T)

JK301,302 204 8635 024 4P PIN JACK (C-GND)

JK303 204 8642 004 1P P1N JACK BK

JK401 204 8636 007 MINI JACK (ST.SW)

JK408 205 1261 003 SP TERMINAL(R) *

JK601,602 204 8637 006 MINI JACK (STEREO)

! JK604 203 3961 004 1P AC OUTLET(E2)

L501,502 235 0104 010 INDUCTOR(3UH) *

RL601 214 0206 005 RELAY(PCI212DM)

RL602 214 0224 003 RELAY(0JT-SS-109LM) *

RL603 214 0203 008 RELAY(NA12W-K)

SW402,403 212 0467 000 TACT SW(H=5)

SW405-407 212 0467 000 TACT SW(H=5)

SW409-412 212 0467 000 TACT SW(H=5)

SW413 212 0461 006 ROTARY ENCODER(V)

! T601 233 6383 004 POWER TRANS(SUB/E2)

W705 203 0322 057 1P CONTACT ASS'Y

W717 203 0541 058 1P SIN CORD ASS'Y

W719 001 0026 045 WIRE CORD

X201 399 0532 902 CST12.5MTW-TF01

X301 399 0178 007 X-TAL(4.332MHZ)

125 9002 007 UL TUBE (L=10) 2

31

Page 32

1U-3498 MAIN UNIT ASS'Y

Ref. No. Part No. Part Name Remarks Q’ty New

415 0908 003 SHIELD PLATE 1 *

449 0172 007 SENSOR HOLDER 1

461 1110 000 FL SPACER(D-SIDE) 2

471 3304 015 3X8 CBS-Z 2

32UD-M31

32

Page 33

1U-3507 CD PWB UNIT ASS'Y

Ref. No. Part No. Part Name Remarks New

SEMICONDUCTORS GROUP

IC801 263 1091 907 LA6559

IC802 263 1090 005 LA9241M

IC803 262 2903 004 LC78625E

IC804 263 0934 900 BA4510F-E2

IC805 263 0994 908 BA6287F-E2

TR801-804 269 0054 901 DTC144EKT96

TR805 269 0085 909 DTC144TKT96

TR806 271 0309 905 2SA1037AKT146S

TR807 269 0085 909 DTC144TKT96

TR810 272 0025 907 2SB562(C)TF

TR811 269 0082 902 DTC114EKT96

RESISTORS GROUP

R801 247 2011 900 RM73B--333JT

R802-805 247 2010 927 RM73B--153JT

R806 247 2011 900 RM73B--333JT

R807 247 2004 920 RM73B--470JT

R808 247 2018 903 RM73B--0R0KT

R809 247 2004 920 RM73B--470JT

R810 247 2012 925 RM73B--104JT

R811,812 247 2004 920 RM73B--470JT

R813 247 2010 969 RM73B--223JT

R814 247 2010 972 RM73B--243JT

R815 247 2009 925 RM73B--562JT

R816 247 2008 926 RM73B--222JT

R817 247 2004 920 RM73B--470JT

R818 247 2011 984 RM73B--683JT

R819 247 2010 914 RM73B--133JT

R820 247 2010 956 RM73B--203JT

R821 247 2009 925 RM73B--562JT

R822 247 2009 983 RM73B--103JT

R823 247 2007 943 RM73B--102JT

R824,825 247 2010 927 RM73B--153JT

R826 247 2010 972 RM73B--243JT

R827-829 247 2010 969 RM73B--223JT

R830 247 2018 903 RM73B--0R0KT

R831 247 2013 908 RM73B--224JT

R832 247 2010 956 RM73B--203JT

R833 247 2010 927 RM73B--153JT

R834 247 2006 999 RM73B--621JT

R835 247 2007 943 RM73B--102JT

R836 247 2011 900 RM73B--333JT

R837 247 2010 969 RM73B--223JT

R838 247 2018 903 RM73B--0R0KT

R839 247 2011 955 RM73B--513JT

R840 247 2012 983 RM73B--184JT

R841 247 2011 900 RM73B--333JT

R842 247 2010 943 RM73B--183JT

R843 247 2008 926 RM73B--222JT

R844 247 2010 985 RM73B--273JT

R845 247 2010 998 RM73B--303JT

R846 247 2010 985 RM73B--273JT

R847 247 2011 942 RM73B--473JT

R848,849 247 2009 983 RM73B--103JT

R850 247 2018 903 RM73B--0R0KT

R851 247 2011 971 RM73B--623JT

33UD-M31

33

Page 34

1U-3507 CD PWB UNIT ASS'Y

Ref. No. Part No. Part Name Remarks New

R852 247 2010 985 RM73B--273JT

R853 247 2010 972 RM73B--243JT

R854 247 2002 964 RM73B--100JT

R855 247 2004 991 RM73B--910JT

R856 247 2011 942 RM73B--473JT

R857 247 2004 991 RM73B--910JT

R858 247 2010 943 RM73B--183JT

R859 247 2011 900 RM73B--333JT

R860 247 2008 926 RM73B--222JT

R861 247 2010 985 RM73B--273JT

R862 247 2010 998 RM73B--303JT

R863 247 2006 931 RM73B--361JT

R864,865 247 2018 903 RM73B--0R0KT

R866 247 2011 913 RM73B--363JT

R867 247 2012 954 RM73B--134JT

R868 247 2011 984 RM73B--683JT

R869 247 2008 926 RM73B--222JT

R870 247 2010 901 RM73B--123JT

R871 247 2008 968 RM73B--332JT

R872 247 2009 909 RM73B--472JT (1608)

R873 247 2013 924 RM73B--274JT

R874,875 247 2012 996 RM73B--204JT

R876 247 2011 955 RM73B--513JT

R877 247 2010 969 RM73B--223JT

R878 247 2009 983 RM73B--103JT

R879 247 2011 926 RM73B--393JT

R881 247 2009 983 RM73B--103JT

R882 247 2018 903 RM73B--0R0KT

R883 247 2015 906 RM73B--155KT

R884 247 2006 902 RM73B--331JT (1608)

R885 247 2011 900 RM73B--333JT

R886 247 2007 901 RM73B--681JT

R887 247 2011 900 RM73B--333JT

R888 247 2007 969 RM73B--122JT

R890 247 2018 903 RM73B--0R0KT

R891 247 2003 947 RM73B--220JT

R893 247 2008 913 RM73B--202JT

R894,895 247 2018 903 RM73B--0R0KT

R896 247 2003 947 RM73B--220JT

R897-900 247 2009 967 RM73B--822JT

R901 247 2004 920 RM73B--470JT

R903-906 247 2009 938 RM73B--622JT

R907-910 247 2010 914 RM73B--133JT

R911,912 247 2008 913 RM73B--202JT

R913,914 247 2011 942 RM73B--473JT

R915,916 247 2007 943 RM73B--102JT

R918 247 2018 903 RM73B--0R0KT

R921 247 2018 903 RM73B--0R0KT

R923 244 2052 928 RS14B3A470JNBST(S)

R923 247 2009 983 RM73B--103JT

R926 247 2009 983 RM73B--103JT

CAPACITORS GROUP

34UD-M31

C801 257 0512 903 CK73F1E104ZT

C804-809 257 0512 903 CK73F1E104ZT

C810 254 4537 707 CE04W1A102MC SMG/RE3

C811 257 0516 925 CK73B1E333KT

C812 257 0507 976 CC73CH1H331JT

C813,814 257 0512 903 CK73F1E104ZT

C815 254 4192 935 CE04W1A101MT (SRA)

34

Page 35

1U-3507 CD PWB UNIT ASS'Y

Ref. No. Part No. Part Name Remarks New

C816 254 4196 928 CE04W1HR33MT (SRA)

C817 257 0501 927 CK73B1H153KT

C818 257 0501 901 CK73B1H103KT (1608)

C819 257 0517 908 CK73B1C473KT

C820 257 0516 954 CK73B1E104KT

C821 257 0506 993 CC73CH1H151JT

C822 254 4192 935 CE04W1A101MT (SRA)

C823 257 0517 908 CK73B1C473KT

C824 257 0501 901 CK73B1H103KT (1608)

C825,826 257 0517 908 CK73B1C473KT

C827 257 0512 903 CK73F1E104ZT

C829 254 4193 947 CE04W1C101MT (SRA)

C831,832 257 0512 903 CK73F1E104ZT

C833-835 257 0501 901 CK73B1H103KT (1608)

C837 257 0501 901 CK73B1H103KT (1608)

C838 257 0509 929 CK73B1H102KT

C840 257 0512 903 CK73F1E104ZT

C841 254 4193 934 CE04W1C470MT (SRA)

C842 257 0509 929 CK73B1H102KT

C843 257 0512 903 CK73F1E104ZT

C844 257 0507 934 CC73CH1H221JT

C845 257 0509 929 CK73B1H102KT

C846 254 4192 948 CE04W1A221MT(SRA)

C847 257 0514 901 CK73F1C334ZT

C848 257 0501 901 CK73B1H103KT (1608)

C849 257 0512 903 CK73F1E104ZT

C850 257 0517 908 CK73B1C473KT

C851 254 4538 942 CE04W1C101MT SMG/RE3

C852 257 0501 901 CK73B1H103KT (1608)

C853 254 3056 917 CE04D1H010MBPT (SME)

C854 257 0510 918 CK73B1H332KT

C855 257 0506 951 CC73CH1H101JT

C857 254 4538 900 CE04W1C100MT SMG/RE3

C858-860 257 0512 903 CK73F1E104ZT

C861 254 4193 947 CE04W1C101MT (SRA)

C862 254 4192 935 CE04W1A101MT (SRA)

C863 254 3056 917 CE04D1H010MBPT (SME)

C864 257 0510 918 CK73B1H332KT

C865 254 4538 939 CE04W1C470MT SMG/RE3

C867-869 257 0506 951 CC73CH1H101JT

C870 254 4524 972 CE04W1H4R7MT SMG/RE3

C872 257 0516 954 CK73B1E104KT

C873 257 0509 929 CK73B1H102KT

C874 257 0502 955 CC73CH1H3R0CT

C876 257 0503 941 CC73CH1H120JT

C877 257 0501 901 CK73B1H103KT (1608)

C878 254 4524 972 CE04W1H4R7MT SMG/RE3

C879 257 0517 908 CK73B1C473KT

C880 257 0516 954 CK73B1E104KT

C881 257 0506 951 CC73CH1H101JT

C882 257 0512 903 CK73F1E104ZT

C883,884 254 4536 928 CE04W1A101MT SMG/RE3

C885,886 257 0512 903 CK73F1E104ZT

C887,888 257 0503 967 CC73CH1H150JT

C889,890 257 0506 951 CC73CH1H101JT

C891 257 0512 903 CK73F1E104ZT

C893 257 0511 917 CK73F1H223ZT

C894 257 0512 903 CK73F1E104ZT

C895,896 257 0507 992 CC73CH1H391JT

C897,898 257 0507 950 CC73CH1H271JT

35UD-M31

35

Page 36

1U-3507 CD PWB UNIT ASS'Y

Ref. No. Part No. Part Name Remarks New

C899 257 0512 903 CK73F1E104ZT

C901,902 257 0507 950 CC73CH1H271JT

C903,904 254 4541 913 CE04W1E220MT SMG/RE3

C905,906 257 0509 929 CK73B1H102KT

C908 254 4536 915 CE04W1A470MT SMG/RE3

C909 254 4538 942 CE04W1C101MT SMG/RE3

C910 257 0512 903 CK73F1E104ZT

C912 257 0501 901 CK73B1H103KT (1608)

C913 254 4194 917 CE04W1E100MT (SRA)

C915 254 4538 900 CE04W1C100MT SMG/RE3

C918 257 0511 904 CK73F1H103ZT

C923 254 4536 931 CE04W1A221MT SMG/RE3

OTHER PARTS GROUP

CX52 205 0355 059 5P KR CON BASE(L)

CX61 205 0355 062 6P KR CON BASE(L)

CX162 205 0892 033 16P FFC BASE (P=1)

CX251 205 1050 010 25P FFC BASE (9603F)

36UD-M31

CY34 205 0355 033 3P KR CON BASE(L)

FB801-810 235 0130 903 CHIP EMIFIL(11A121)

W801 203 0301 052 1P CONTACT ASS

X801 399 0165 007 X'TAL (16.9344) REVER

Countermeasure for E2 model 1~5000, EK model 1~70000.

1U-3529 MT P.W.B. UNIT ASS’Y

Ref. No. Part No. Part Name Remarks New

IC101 262 3175 909 74VHC00MTCX

IC102 262 3176 908 74VHC74MTCX

D101,102 276 0375 905 1N4148T77 (TAPE)

TR101 269 0083 901 DTA114EKT96

C101 257 0512 903 CK73F1E104ZT

R102 247 2011 942 RM37B--473JT

R103 247 2009 983 RM37B--103JT

CX082 205 0343 087 8P CON.BASE (KR-PH)

CX082 204 2835 011 8P PH CONN CORD

222 3529 007 P.W.BOARD

36

Page 37

EXPLODED VIEW

UD-M31

37

Parts List

110

22

11

101

19

107

101

31

1-8

103

108

18

103

103

1-6

33

103

109

23

1-1

44

27

105

102

112

34

1-2

104

102

43

112

1-7

1-9

1-5

20

17

25

46

WARNING:

Parts marked with this symbol have critical

characteristics.

Use ONLY replacement parts recommended by the

manufacturer.

24

103

103

101

103

101

26

40

104

30

9

110

8

4

2

3

5

7

106

36

10

111

29

41

104

45

104

37

38

6

1-4

14

15

101

13

101

42

109

103

47

27

21

1-3

28

14

15

101

105

28

16

37

Page 38

PARTS LIST OF EXPLODED VIEW

Note: The symbols in the column “Remarks” indicate the following destinations.

E2: Europe model EK: U.K. model

Ref. No Part No Part Name Remarks Q'ty NEW

1 1U-3498 MAIN PWB UNIT 1

1-1 POWER UNIT

1-2 AMP1 UNIT

1-3 AMP2 UNIT

1-4 DISPLAY UNIT

1-5 SPEAKER UNIT

1-7 I/O UNIT

1-8 U-CON UNIT

1-9 JUNCTION UNIT

1-6 1U-3507 CD PWB UNIT 1

2 144 2820 106 FRONT PANEL 1 *

3 146 2300 208 INNER PANEL 1 *

4 143 1161 106 WINDOW 1 *

5 113 1947 109 KNOB (L) 3P 1 *

6 113 1948 001 KNOB(S)3P 1 *

7 113 1949 000 KNOB(S)2P 1 *

8 143 1086 003 REMOCON FILTER 1

9 113 1955 007 POWER KNOB ASS'Y 1 *

10 112 0856 104 VOLUME KNOB ASS'Y 1 *

11 146 2298 006 LOADER PANEL(UD) 1 *

13 411 1940 411 MAIN CHASSIS 1 *

14 104 0317 008 FOOT 4

15 461 1066 002 FELT 4

16 417 0596 013 HEAT SINK 1 *

17 415 0908 003 SHIELD PLATE 1 *

18 412 4621 002 MECHA HOLDER 1

19 337 0100 006 CD MECHA(CD11FTA3N) 1

20 105 1425 206 REAR PLATE (UD) 1 *

21 412 4622 001 PCB SUPPORT(A) 1

22 102 0633 139 TOP COVER 1 *

! 23 233 6441 001 POWER TRANS(E2) 1 *

! 24 206 2089 106 AC CORD W/CON.E2 For E2 1

! 206 2128 009 AC CORD W/CON EK For EK

25 445 0056 008 CORD BUSH 1

26 216 0108 002 TUNER PACK (TFCE1E5) 1

27 443 9015 002 P.W. SPACER 3

28 412 2814 002 CARD SPACER (L=8) 2

29 393 8068 001 FL TUBE(HNA-11SS47T) 1

30 449 0172 007 SENSOR HOLDER 1

31 415 0844 002 PVC SHEET 1

33 414 0982 000 PARTITION SHEET 1 *

35 415 0906 102 SAFETY COVER 1 *

36 441 1976 004 SPACER 1 *

37 412 4839 001 EARTH PLATE(H/P) 1

38 441 1977 003 WASHER 1 *

40 131 0156 106 DENON BADGE 1

42 412 5014 100 TRANS BRACKET 1 *

43 412 5012 005 PCB SUPPORT BRACKET 1 *

44 445 0048 016 CORD HOLDER (L50) 2

45 009 0241 028 16P FFC CABLE CX162 1 *

46 009 0207 020 15P FFC(1.25) CY152 1 *

47 415 0911 003 SAFTY SHEET 1

143 1085 004 LENS 1

415 0585 015 UL TUBE(16) BK L=30 1

445 8004 007 WIRE CLAMPER 5

513 3673 008 LASER PICK LABEL 1

513 3857 002 E2 LASER CAUTION (E) 1

513 3632 007 CAUTION LABEL 1

38UD-M31

38

Page 39

Ref. No Part No Part Name Remarks Q'ty NEW

513 3901 000 LASER CAUTION LABEL 1

203 4804 034 3P PH-PH SHIELD WIRE CX34 1

203 8533 000 5P PH-PH CON.CORD CX52 1

204 0567 006 6P PH-PH CON.CORD CX61 1

009 0241 015 17P FFC CABLE CX171 1 *

009 0207 017 18P FFC(1.25) CX181 1 *

009 0027 048 25P FFC CORD CX251 1

204 6347 000 12P PH-PH CON. CORD CY121 1 *

001 0144 037 VINYL WIRE W720 1

SCREWS

101 473 7015 005 3X6 CBTS(S)-B 17

102 473 7002 005 3X6 CBTS(S)-Z 10

103 473 7500 044 3X8 CBTS (P)-B 28

105 473 7501 014 3X14 CBTS (P)-Z 4

107 473 7005 057 3X25 CBTS (S)-Z 2

108 473 8079 024 SPECIAL SCREW 2

109 473 7004 016 4X6 CBTS (S)-Z 8

110 477 0263 018 3P.SWELLING SCREW 2

112 477 0096 010 PUSH RIVET 3

39UD-M31

39

Page 40

EXPLODED VIEW OF CD MECHANISM UNIT (CD11FTA3N)

3

40UD-M31

4

20

12

3

8

16

7

6

2

17

16

11

1

10

9

13

PARTS LIST OF CD MECHANISM UNIT

Ref. No. Part No. Part Name Remarks

1 964 0009 006 Frame chassis 1

2 964 0009 103 Magnet plate 1

3 964 0009 200 Rubber cushion 2

4 964 0009 307 Rubber cushion 2

5 964 0009 404 Magnet holder 1

6 964 0009 501 Drive gear 1

7 964 0009 608 Slide gear 1

8 964 0009 705 Pulley gear 1

9 964 0009 802 Square belt 1

10 964 0009 909 Magnet 1

Q'ty

15

18

14

19

Ref. No. Part No. Part Name Remarks

11 964 0010 008 Mecha lifter 1

12 964 0010 105 Loading table 1

13 964 0010 901 Loading motor 1

14 964 0010 202 5P Plug 1

15 964 0010 309 Push switch 2-1 2

16 964 0010 406 Cushion 9

17 964 0010 503 Cushion 2

18 964 0010 600 Motor P.W.B. 2

19 964 0010 707

20 964 0011 007 Mecha DA11T3CN 1

5

Screw 3 8 SCR S-TPG BIN

Q'ty

1

40

Page 41

PACKING VIEW

210

209

201 207~

41UD-M31

212

208

211

PACKING LIST OF PACKING & ACCESSORIES

Note: The symbols in the column “Remarks” indicate the following destinations.

E2:Europe model EK: U.K. model

Ref. No. Part No. Part Name Remarks Q’ty NEW

201 505 0038 030 POLY COVER 1

202 511 3982 007 INST MANUAL 1 *

203 515 0921 102 S.S.LIST(EX) 1

204 - BATTERY (UM-4) ASS 1

205 399 0855 003 REMOCON (RC-933) 1

206 231 0922 009 LOOP ANTENNA 1

207 395 0026 005 FM ANT. WIRE 1

208 - CONT.CARD(L) 1

209 501 2231 105 CARTON CASE 1 *

210 503 1451 005 CUSHION(L) 1 *

211 503 1452 004 CUSHION(R) 1 *

212 502 1074 007 CUSHION BOARD (A) For EK 1 *

213 517 1471 000 E2 POS LABEL For E2 1 *

517 1472 009 EK POS LABEL For EK 2 *

214 513 1642 002 NO. SHEET 1

215 505 0358 008 POLY COVER For EK 1

41

Page 42

WIRING

AC CORD

TRANS

POWER

CX032

1U-3498-8

SP UNIT

CX042

CX033

CX031

CX052

1U-3498-1 POWER UNIT

CY042

CY051

CX153

CY081

TUNER

PAC K

CY152

CX121

1U-3498-3

I/O UNIT

UD-M31

CX038

42

CX034

CX251

CY034

1U-3507 CD PWB UNIT

CX162

CX251

CX052

CX081

CD MECHA

1U-3498-2

µCON UNIT

CX181

CY153

1U-3498-7

JUNCTION UNIT

CY151

CX041 CY181

CX072

CX072

CX081 CX151

CX051

1U-3498-4 DISPLAY UNIT

CX171

CY171 CY041

CY121

CY038

CX143

1U-3498-5 AMP 1 UNIT

CY143

1U-3498-6 AMP 2 UNIT

42

Page 43

NOTE FOR SCHEMATIC DIAGRAM

WARNING:

Parts marked with this symbol have criticalcharacteristics.