Denon DVD-9000, DVD-A1 Service Manual

SERVICE MANUAL

For U.S.A., Canada,

Europe, China, Asia,

Taiwan & Korea models

Digital Player

MODEL

DVD-9000 (U.S.A., Canada Model)

DVD-A1 (Others)

DVD AUDIO/VIDEO PLAYER

DVD-9000

DVD-A1

Some illustrations using in this service manual are slightly different from the actual set.

16-11, YUSHIMA 3-CHOME, BUNKYOU-KU, TOKYO 113-0034 JAPAN

Telephone: 03 (3837) 5321

X0136 NC 0207

DVD-9000/DVD-A1

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

SPECIFICATIONS

Signal System: NTSC/PAL

Applicable Discs: (1) DVD/Audio/Video discs

S-Video Output: Y output level : 1 Vp-p (75 Ω/ohms)

Video Output: Output level : 1 Vp-p (75 Ω/ohms)

Component Output: Y output level : 1 Vp-p (75 Ω/ohms)

RGB Output: Output level : 0.7 Vp-p (75 Ω/ohms) (For Europe model)

Audio Output: Output level : 2 Vrms

Audio Output Properties: (1) Frequency response

Digital Audio Output: Optical digital output : Optical connector, 1 set

Digital Audio Input: Optical digital input : Optical connector, 1 set

Power Supply: AC 120 V, 60 Hz (For U.S.A. & Canada model)

Power Consumption: 42 W

Maximum External dimensions:

Mass: 18.5 kg

Remote Control Unit: RC-552

Type: Infrared pulse

Power Supply: DC 3 V, 2 "AA" /R06 batteries

* Design and specifications are subject to change without notice in the course of product improvement.

1-layer 12 cm single-sided discs, 2-layer 12 cm single-sided discs,

2-layer 12 cm double-sided discs (1 layer per side)

1-layer 8 cm single-sided discs, 2-layer 8 cm single-sided discs,

2-layer 8 cm double-sided discs (1 layer per side)

(2) Compact discs (CD-DA, Video CD)

12 cm discs, 8 cm discs

C output level : 0.286 Vp-p (For U.S.A. & Canada models)

0.3 Vp-p (For Europe & Asia models)

Output connectors : S connectors, 2 sets

AV 1 connector, 1 set (For Europe model)

Output connector : Pin-plug jacks, 2 sets

AV 1 connector, 1 set (For Europe model)

B/CB output level : 0.648 Vp-p (75 Ω/ohms) (For U.S.A. & Canada models)

P

0.7 Vp-p (75 Ω/ohms) (For Europe, Asia models)

PR/CR output level : 0.648 Vp-p (75 Ω/ohms) (For U.S.A. & Canada models)

0.7 Vp-p (75 Ω/ohms) (For Europe, Asia models)

Output connector : Pin jack, 1 set

Output connector : AV 1 connector, 1 set (For Europe model)

2 channel (FL, FR) output connector: Pin jacks, 2 sets

Multi channel (C, SW, SL, SR) output connector: Pin jak, 1 set

: AV 1 connector, 1 set (For Europe model)

1

DVDs (linear PCM) : 2 Hz to 22 kHz (48 kHz sampling)

: 2 Hz to 44 kHz (96 kHz sampling)

: 2 Hz to 88 kHz (192 kHz sampling)

2

CDs : 2 Hz to 20 kHz

(2) S/N ratio

1

DVDs : 118 dB

2

CDs : 118 dB

(3) Total harmonic distortion

1

DVDs : 0.0015 %

2

CDs : 0.0018 %

(4) Dynamic range

1

DVDs : 108 dB

2

CDs : 100 dB

Coaxial digital output : Pin jack, 1 set

DENON LINK output : DENON LINK connector, 1 set

Coaxial digital input : Pin jack, 1 set

AC 230 V, 50 Hz (For Europe & Asia models)

AC 220 V, 50 Hz (For China model)

434 (W) × 136 (H) × 411 (D) mm (including protruding parts)

2

DVD-9000/DVD-A1

2

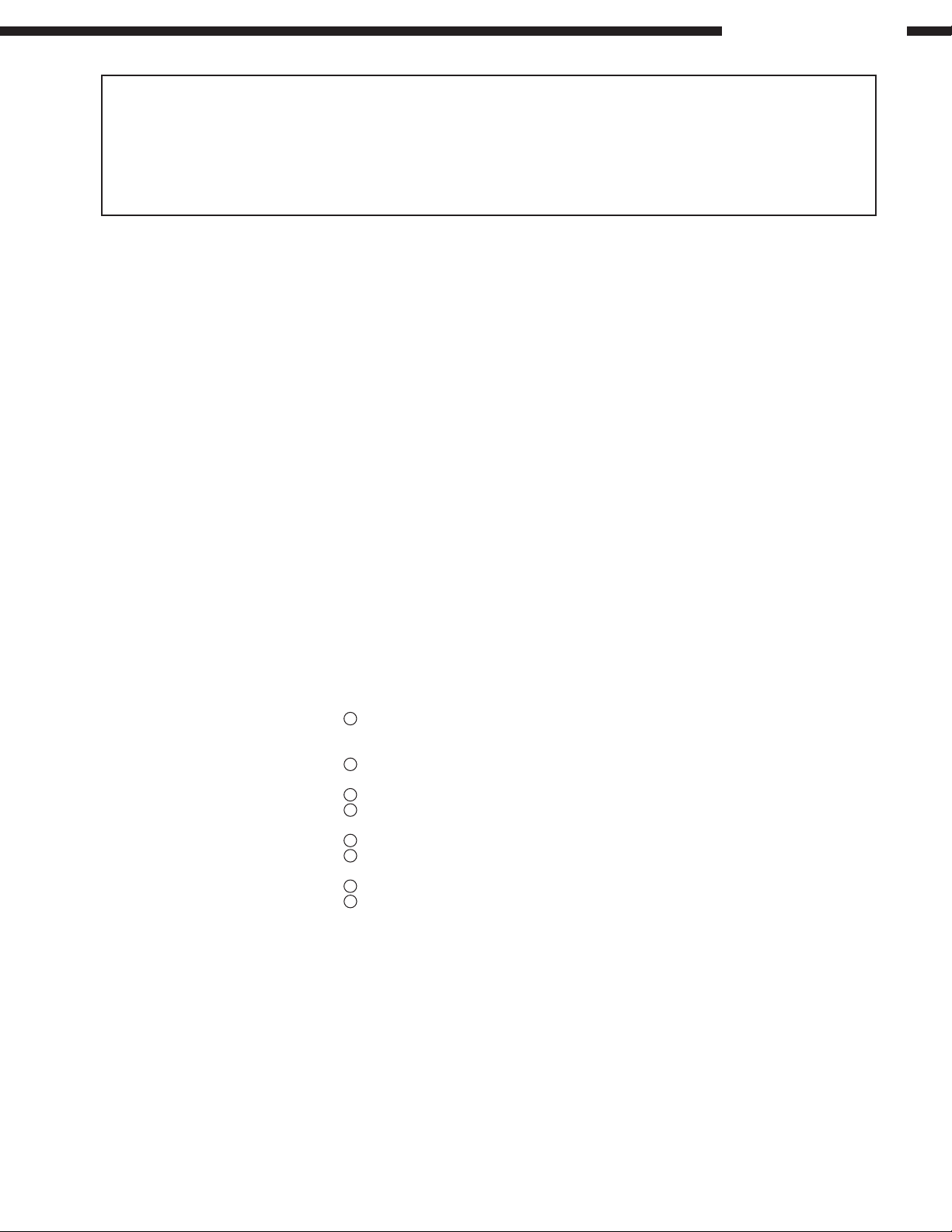

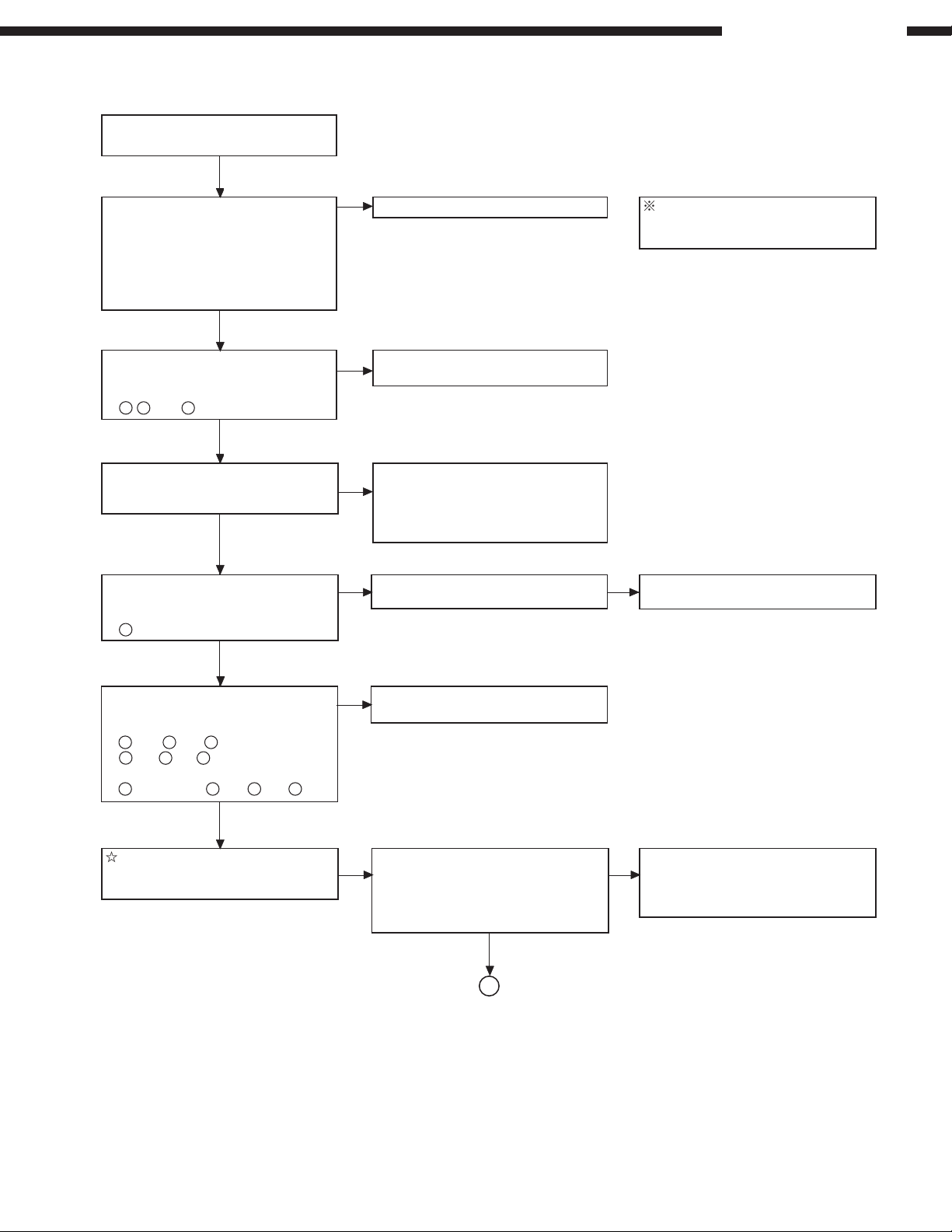

Iop Measurement (Judging for Traverse Unit Replacement)

As to deciding whether optical pickup is defect or not (for replacing traverse unit), follow the steps below.

1. Judging Step

(1) Disc play abnormal

Problems such as disc no read, unsteady playback, etc.

(2) Laser drive current (Iop) check

Check Iop according to the measuring method described in step 2 below.

If the checked value is 1.5 times or more than the initial Iop indicated

on the rear of mechanism unit, the traverse unit should be replaced.

(3) Replacing traverse unit

Referring to “How to Replace Traverse Unit”, replace the traverse unit.

No mechanism adjustment is required as the whole unit is replaced with

a new one.

DVD mA

CD mA

2. Iop Measuring Method

DVD laser drive current measuring points

1

4

Laser current initial value on the rear of mechanism

Nearby C532

29 39

1

48

37

717

6

1

40

814

7

1

1732

16

40

11

12

24

25 36

18

28

14

15

61

80

1

28

8

1

60

1

45

41

40

21

20

2140

1

20

76

100

1

1

115

1

20 21

5175

50

26

25

CD laser drive current measuring points

[CD] IOP silk point

GU-3389 P.W.B. (foil side)

(1) DVD laser drive current measurement

• Playback the title-1/chapter-1 of DVDT-S01 or commercially available DVD disc.

• Connect an oscilloscope to the test point above and measure the voltage.

• DVD laser drive current is calculated by:

Iop = Measured Voltage Value / 39 (Resistance Value)

(2) CD laser drive current measurement

• Playback the track-1 of TCD-784 or commercially available CD disc.

• Connect an oscilloscope to the test point above and measure the voltage.

• CD laser drive current is calculated by:

Iop = Measured Voltage Value / 39 (Resistance Value)

3

DVD-9000/DVD-A1

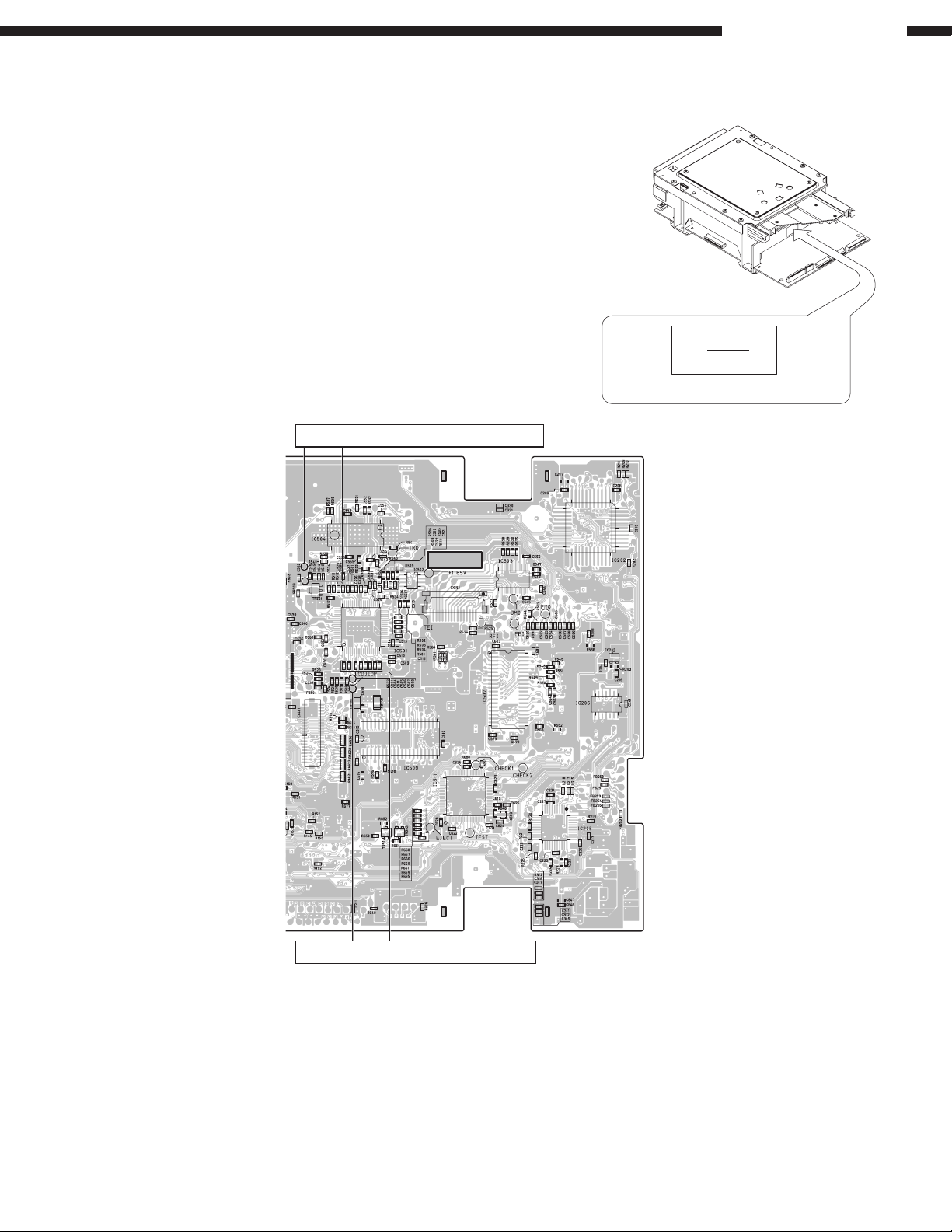

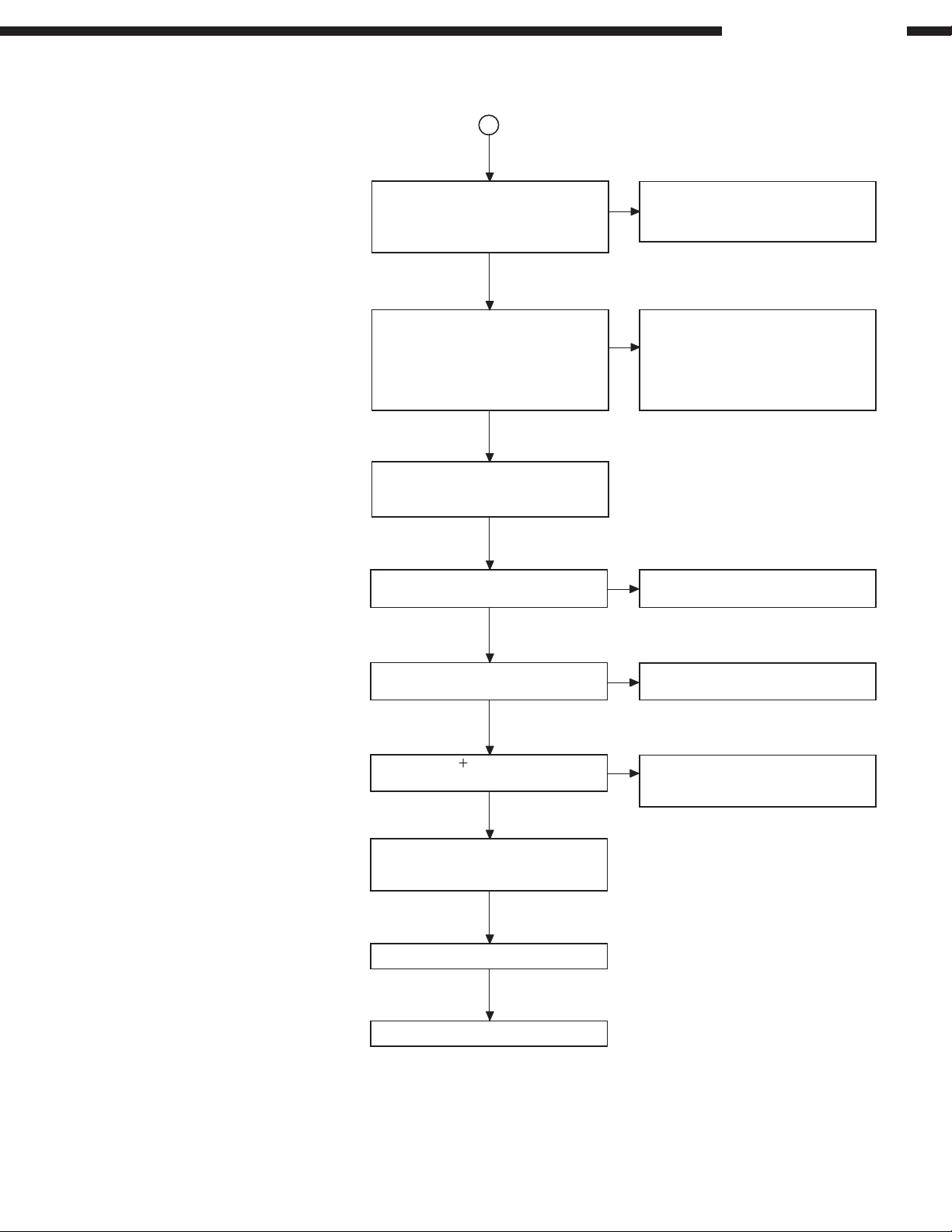

DIAGNOSTICS OF OPTICAL PICKUP AND REPLACING TRAVERSE UNIT

1. Note for Handling the Laser Pick-up

The protection for the damage of laser diode.

If you want to change the optical device unit from any other units, you must keep the following.

(1) It should be done at the desk already took measures the static electricity in care of removing the OPU's

(Optical device unit) connector cable.

(2) Workers should be put on the "Earth Band".

(3) It shold be done to add the solder to the short land to prevent the broken Laser diode before removing the

24P FFC cable.

(4) Don't touch OPU's connector parts carelessly.

2. Optical Pick-up Diagnostics and Replacement

When repairing, carry out failure diagnostics by following the procedure described below.

If the present value of the laser drive current is 50% up to initial value, it is the point of the pickup replacement.

In case of the pickup replacement, replace the Traverse Unit with no adjustment.

The initial value is indicated on the label on back side of Mecha.

NO DISC indicated, Playback not smooth, etc.

Laser drive current check

HF signal check

Present value: 50% up to initial value

Traverse Unit replacement (refer to page 8)

Laser drive current check after replacement.

If the present value is less than 80mA, write on

the new label by hand, put on the new label over

the old label.

If the present value exceeds 80mA,

replace the Traverse Unit with a new one.

Cause: Damaged electrostatically when replaced.

4

DVD-9000/DVD-A1

DISASSEMBLY

( Follow the procedure below in reverse order when reassembling )

* Caution: Each edge inside of the metal parts may be "sharp edge", so be careful not to be injured when handling them.

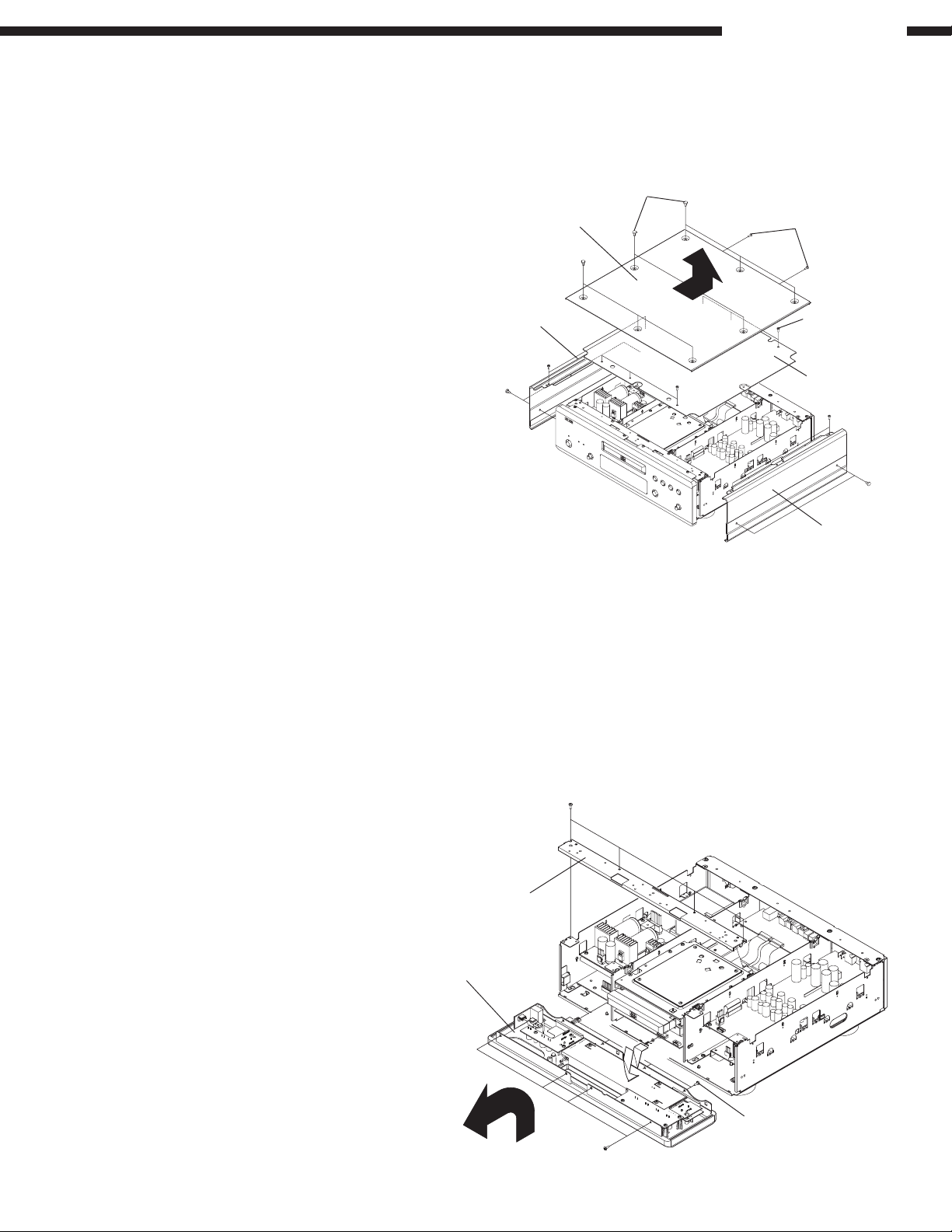

1. Top/Side Cover

(1) Top Cover

Remove 8 pcs of 4mm S-tight screw (a) and 2 pcs of

3mm B-tight screw (b), then detach the Top Cover to the

arrow direction.

(2) Inner Top Cover

Remove 6 pcs of 3mm B-tight screw (c) and detach the

Inner Top Cover upward.

(3) Side Cover

Remove 4 pcs of 4mm special screw (d) and 4 pcs of

3mm B-tight screw (e) on both sides, then detach the

Side Cover upward. The Side Cover is commonly used

either left and right.

Screwing torque : 1.6Nm for (a) and (d)

Screwing torque : 1.1Nm (unless otherwise specified)

Top Cover

(a)

Side Cover

(e)

(d)

(a)

(c)

(b)

(c)

Inner Top Cover

(e)

(d)

2. Front Panel Ass'y/Front Angle

(1) Front Panel Ass'y

Remove 8 pcs of 3mm B-tight screw (d’), 4 pcs on the

top and bottom each, and pull out the Front Panel Ass'y

to the arrow direction.

[A]: Disconnect VH wire from [CY025] on the Power SW

P.W.B.

[B]: Disconnect PH wire from [CX041] on the Digital

Power P.W.B.

[C]: Disconnect FFC wire from [CX171] on the Main

P.W.B.

Detach the Front Panel Ass'y.

(2) Front Angle

Remove 4 pcs of 3mm B-tight screw (e’), and take out

the Front Angle upward.

Screwing torque : 1.1Nm (unless otherwise specified)

Front Panel Ass’y

Side Cover

(e’)

Front Angle

[A]

[B]

[C]

(d’)

(d’)

5

DVD-9000/DVD-A1

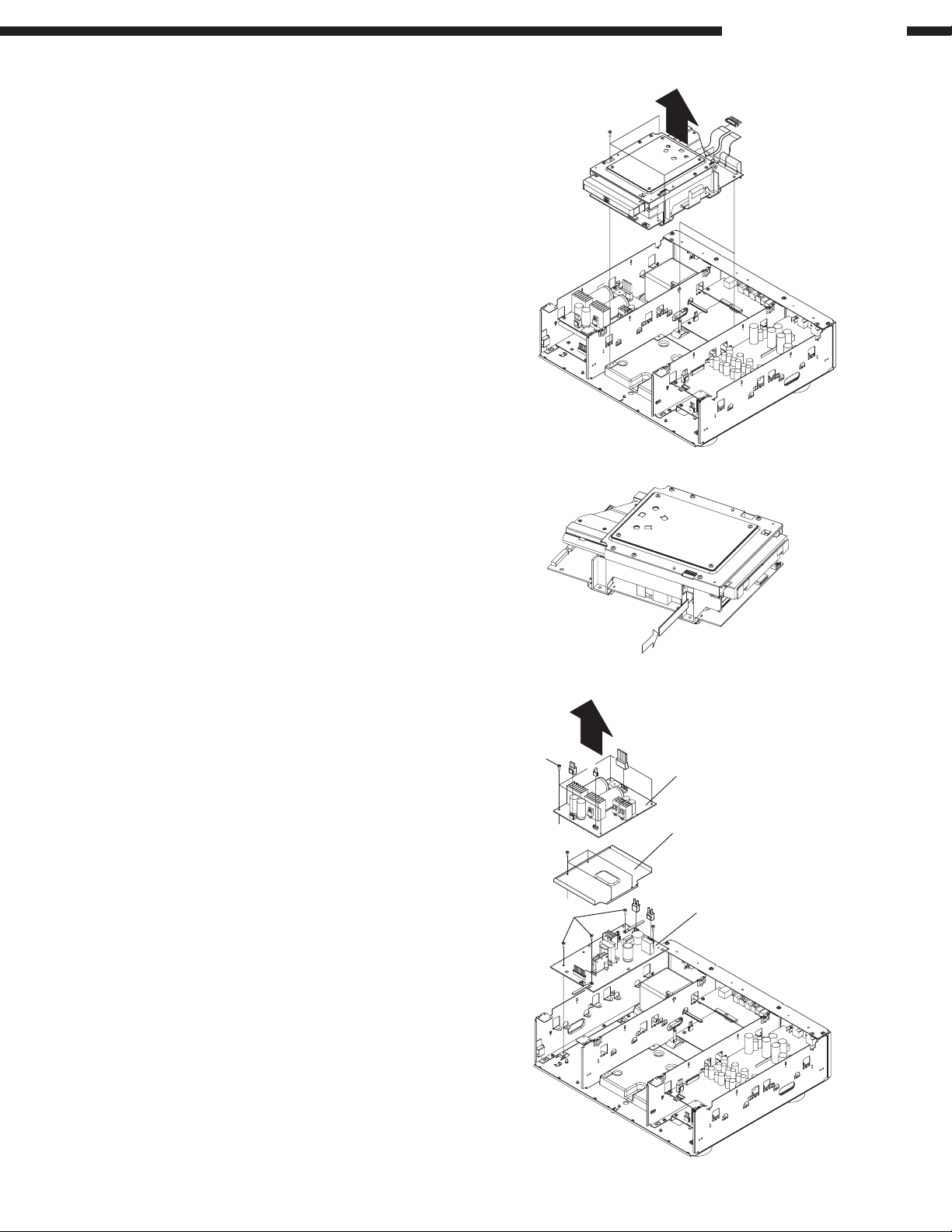

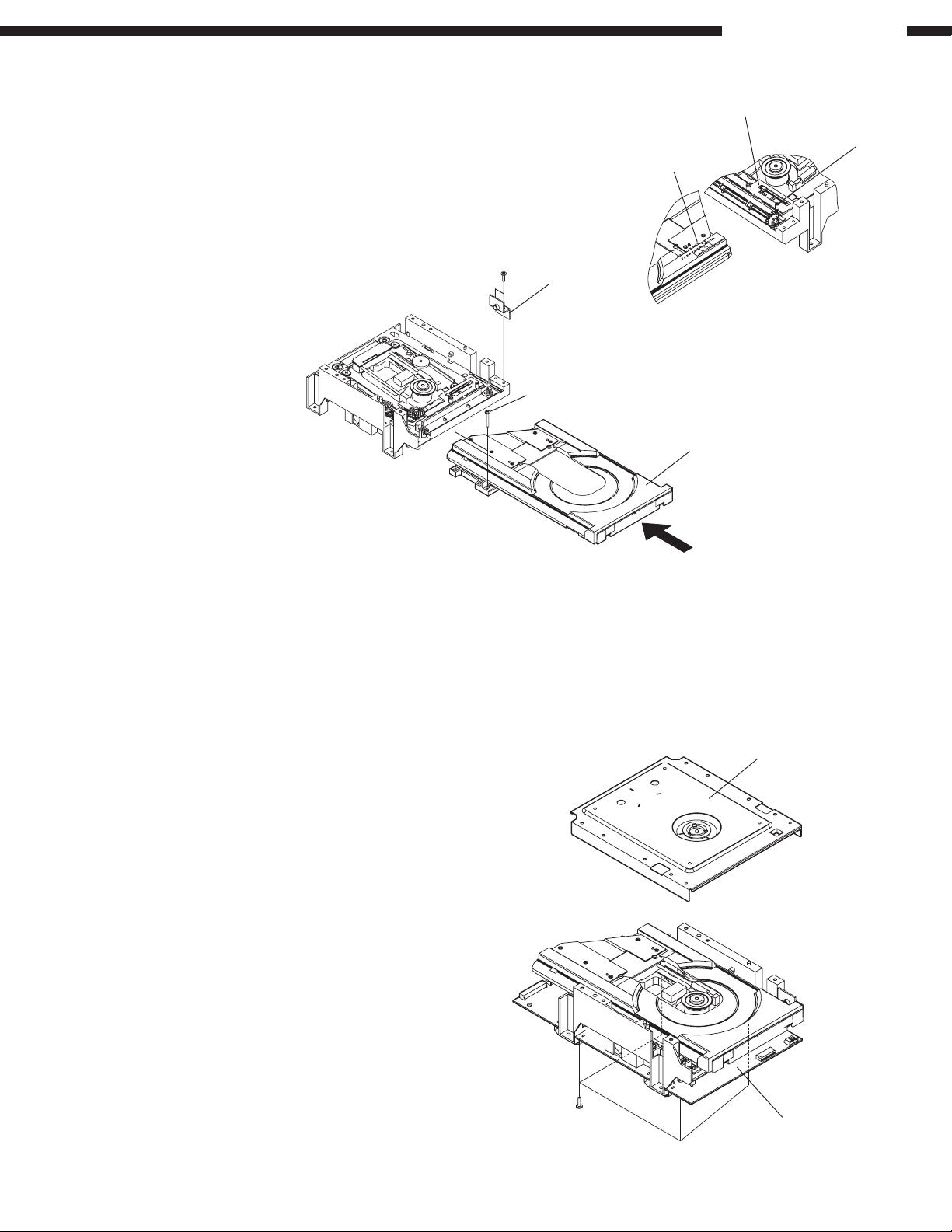

3. DVD Mecha. Ass'y

(1) DVD Mecha. Ass'y

Remove 4 pcs of 3mm machine screw (f).

[D]: Disconnect PH wire from [CX141] on the Main P.W.B.

[E]: Disconnect FFC wire from [CY212] on the Interface

P.W.B.

[F]: Disconnect FFC wire from [CY211] on the Interface

P.W.B.

[G]: Disconnect FFC wire from [CY131] on the Video

P.W.B.

[H]: Disconnect FFC wire from [CY272] on the Video

P.W.B.

Release 2 pcs of P.W.B. support (g) on the Main P.W.B.

Detach the DVD Mecha. Ass'y to the arrow direction.

Screwing torque : 0.8Nm (unless otherwise specified)

(2) In Case of Ejecting the Tray Manually

When the Tray cannot be ejected by pressing the [OPEN/

CLOSE] button due to electrical malfunction etc., push

the slider shown figure right with a ruler or driver through

the rectangular hole until the Tray moves a little.

(The Traverse Unit lowers and Tray moves forward.)

Pull out the Tray by hand.

[D]

(f)

[E]

[F]

[G]

[H]

(g)

4. Digital Power P.W.B./Analog Power P.W.B.

(1) Analog Power P.W.B.

Remove 4 pcs of 3mm B-tight screw (h).

[I]: Disconnect VH wire of the Power Trans. from

[CX061].

[J]: Disconnect VH wire to the 2ch Audio P.W.B. from

[CY032].

[K]: Disconnect PH wire to the Video P.W.B. from

[CX033].

Take out the Analog Power P.W.B.

(2) Shield Plate

Remove 4 pcs of 3mm B-tight screw (i).

Pull out the Shield Plate upward.

(3) Digital Power P.W.B.

Remove 4 pcs of 3mm B-tight screw (j).

Note: 2 pcs are used for fixing with cord holders.

[L]: Disconnect VH wire of the AC Inlet from [CX024].

[M]:Disconnect VH wire of the Power Trans. from

[CX026].

Take out the Digital Power P.W.B.

Screwing torque : 0.9Nm (unless otherwise specified)

(h)

[K]

[I]

Analog Power P.W.B.

Shield Plate

[L]

Digital Power P.W.B.

[M]

(j)

[J]

(l)

(j)

6

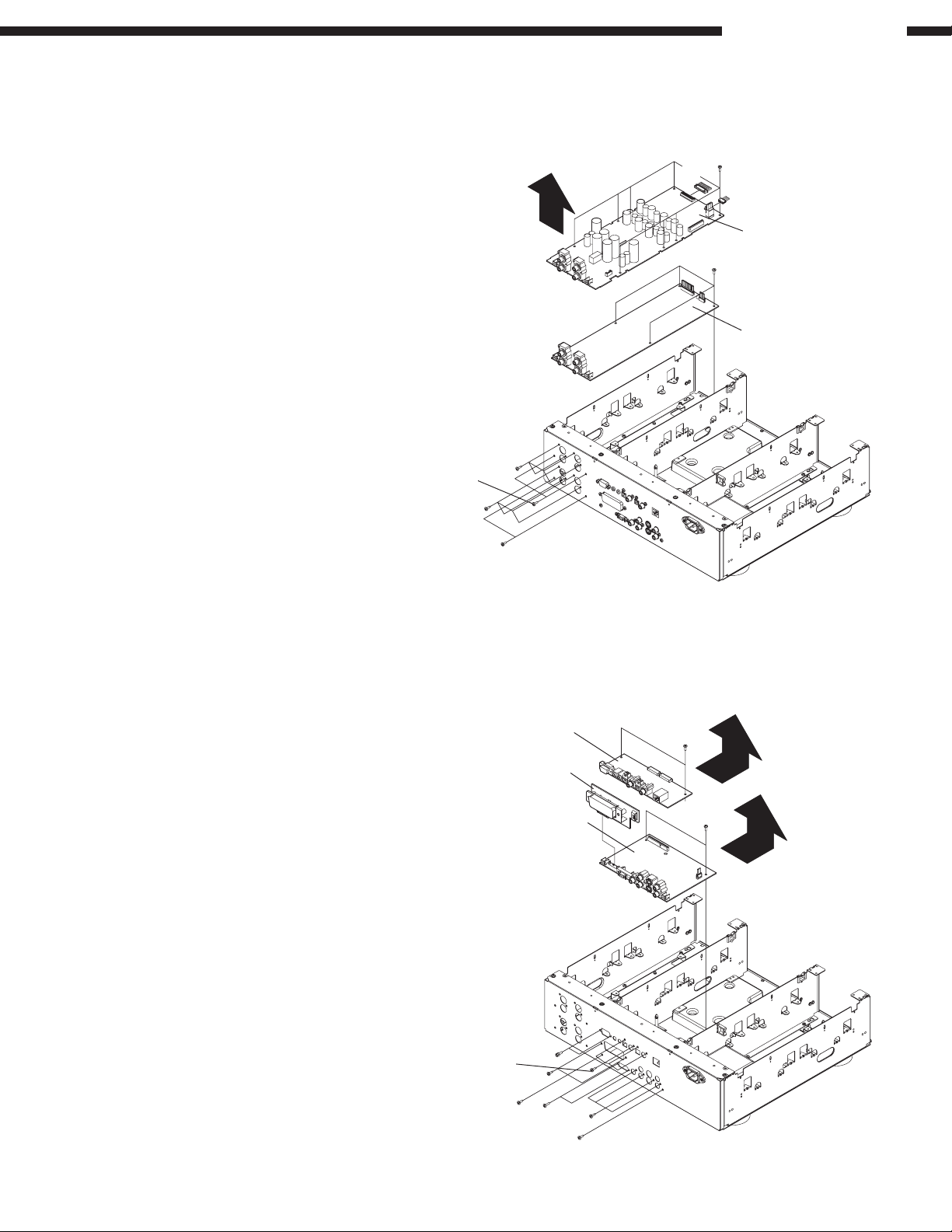

5. 2ch Audio P.W.B./5.1ch Audio P.W.B.

(1) 2ch Audio P.W.B.

Remove 4 pcs of 3mm B-tight screw (k), 2 pcs of 3mm

screw (l) on the Rear Panel, and 8 pcs of 3mm B-tight

screw (m) on the top.

[N]: Disconnect PH wire of the 5.1ch Audio P.W.B. from

[CX131].

[O]:Disconnect EH wire of the 5.1ch Audio P.W.B. from

[CX042].

Take out the 2ch Audio P.W.B.

(2) 5.1ch Audio P.W.B.

Remove 4 pcs of 3mm B-tight screw (n), 2 pcs of 3mm

screw (o) on the Rear Panel, and 4 pcs of 3mm B-tight

screw (p) on the top.

Take out the 5.1ch Audio P.W.B.

Screwing torque: 0.6Nm for (k), (l), (n), and (o)

Screwing torque: 0.9Nm for (m) and (p)

DVD-9000/DVD-A1

(m)

[N]

[O]

2ch Audio P.W.B.

(p)

5.1ch Audio P.W.B.

(k)

(l)

(n)

(o)

6. Interface P.W.B./Video P.W.B./Scart P.W.B.

(1) Interface P.W.B.

Remove 2 M3 nuts (q) and 4 screws (r) on the Rear

Panel. And remove 2 screws (s) on the top.

Detach the Interface P.W.B. in the arrow direction.

(2) Video P.W.B.

Remove 2 screws (t), (u), and 4 screws (v) on the Rear

Panel. And remove 2 screws (w) on the top.

Detach the Video P.W.B. in the arrow direction.

(3) Scart P.W.B. (Europe model only)

Detach the Scart P.W.B. from the Video P.W.B.

Screwing torque : 0.6Nm for (q), (r), (t), (u), and (v)

Screwing torque : 0.9Nm for (s) and (w)

Interface P.W.B.

Scart P.W.B.

(Europe

model only)

Video P.W.B.

(s)

(w)

(r)

(t)

(u)

(q)

(v)

(t)

7

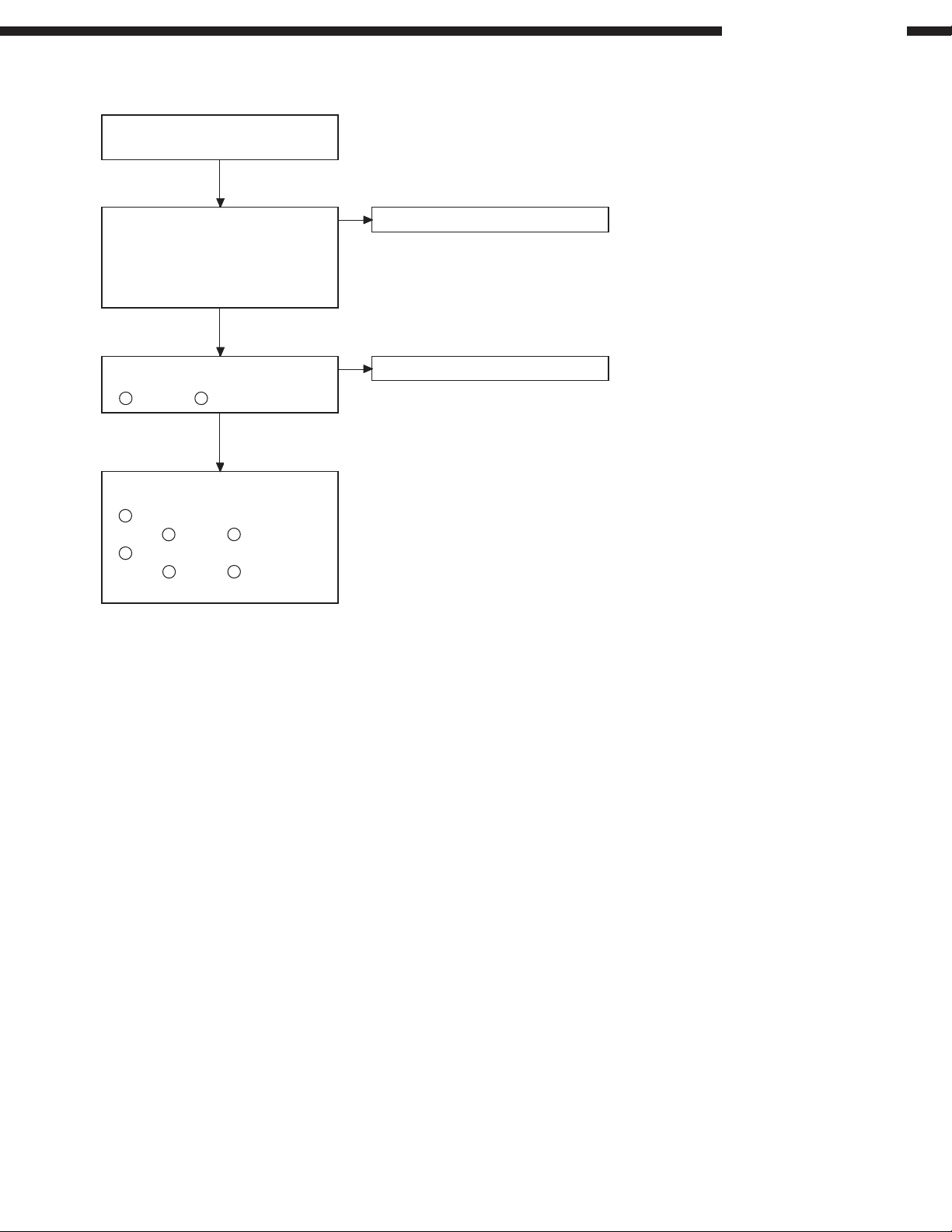

A

Solder to short-circuit (CD)

Solder to short-circuit (CD)

Short-circuit with solder (enlarged fig. A)

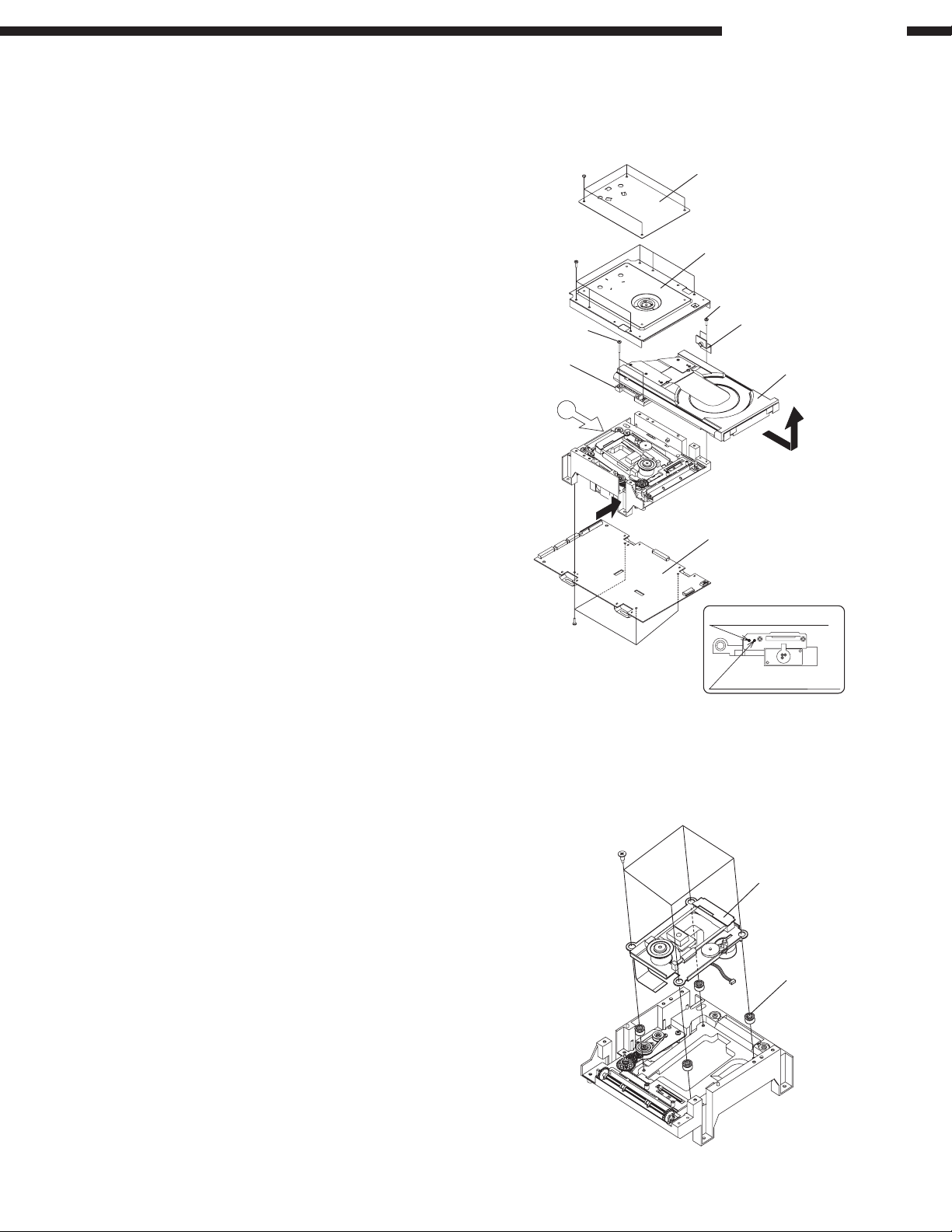

How to Replace Traverse Unit

1. Preparing for Replacement

(1) Removing Clamp Base Damper

Remove 4 pcs of 2.6mm machine screw (a), and detach

the Clamp Base Damper upward.

(2) Removing Clamp Base

Remove 6 pcs of 3mm P-tight screw (b), and detach the

Clamp Base upward.

(3) Ejecting Loader

Through the left rectangular hole of the Mechanism Unit,

push the slider with a ruler or driver until the Traverse

portion lowers and the Loader comes out a little.

(4) Removing Loader

• Remove 2 pcs of 3mm P-tight screw (c) on the Loader

Holder left.

• Remove 2 pcs of 3mm P-tight screw (d) on the Loader

Holder right, then pull up the Bearing Plate.

• Fully pull out the Loader forward, and lift up to take it

out.

(5) Shorting Pickup

To protect the Pickup from static electricity, short-circuit

2 positions as shown in figure.

(6) Removing Main P.W.B. Ass'y

Remove 4 pcs of 3mm P-tight screw (e), and detach the

Main P.W.B. Ass'y downward.

(b)

Holder

(c)

(a)

(3)

DVD-9000/DVD-A1

Clamp Base Damper

Clamp Base

(d)

Bearing Plate

Loader

(4)

Main P.W.B. Ass'y

(e)

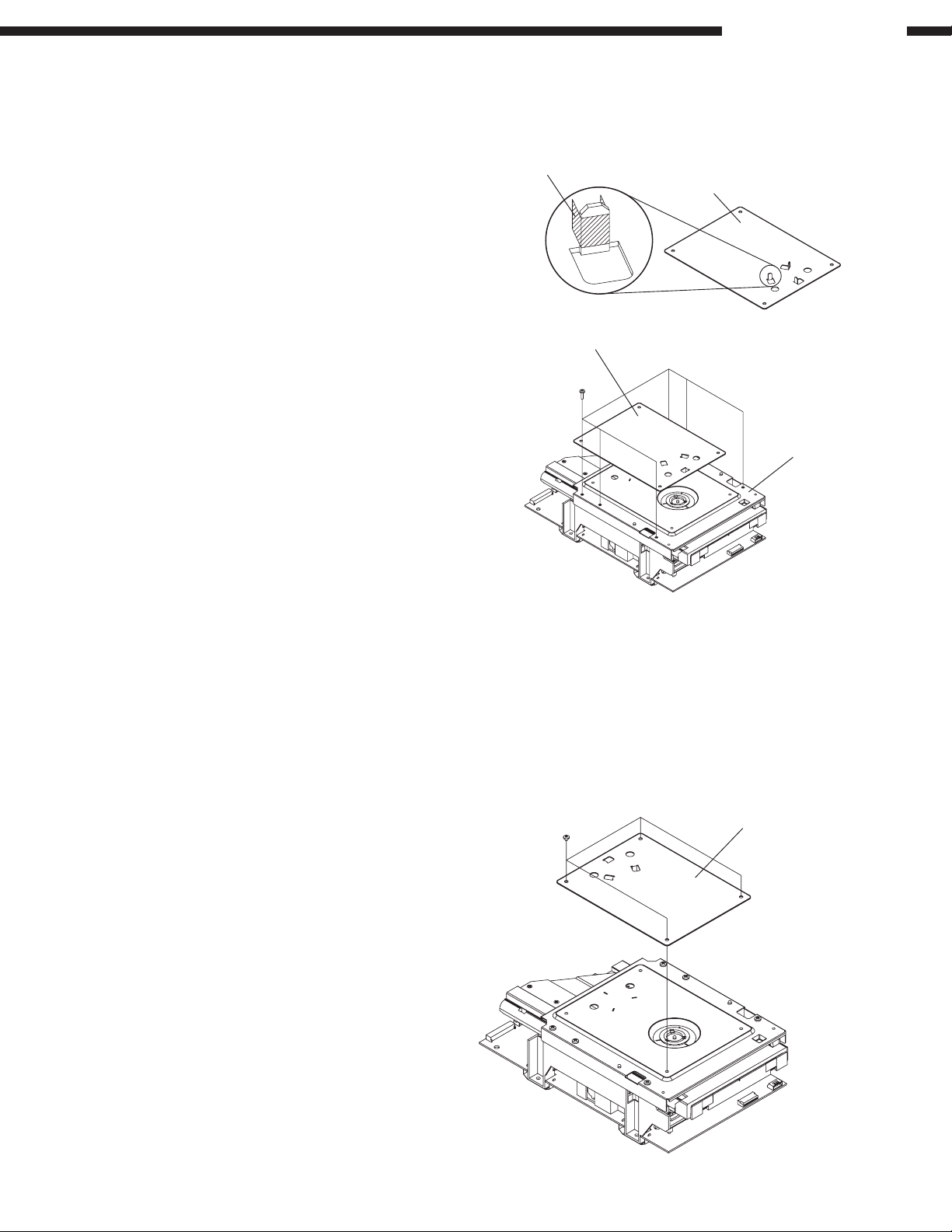

2. Replacing Traverse Unit

(1) Removing Wires

• CX241: 24P-FFC for Pickup

• CX151: 15P-FFC for Spindle

• CX031: 3P-PH wire for PU Slide

(2) Removing Traverse Unit

Remove 4 pcs of special screw (f) and dampers, then

take out the Traverse Unit upward.

(3) Mounting Traverse Unit

Mount the Traverse Unit following the reverse order.

(f)

Traverse Unit

Damper

8

3. Installing Loader

(1) Inserting Loader

Set and push the Loader to the arrow direction until it

stops. When installing the Loader, move the Plate Gear

to right beforehand so as that the boss of the Plate Gear

fits in the backside groove of the Loader. (See figure right)

(2) Fixing Loader

Fix the Loader with each 2 screws (c) and (d).

DVD-9000/DVD-A1

Plate Gear

Boss

Groove

(d)

Bearing Plate

(c)

Loader

4. Assembly (1)

(1) Assembling Main P.W.B. Ass'y

Fix the Main P.W.B. Ass'y with 6 pcs of 3mm P-tight

screw (e).

(2) Removing Pickup-short Solder

After connecting 24P-FFC of the Pickup with P.W.B.,

remove solder from 2 shorted positions.

(3) Temporary Positioning Clamp Base

To protect your eyes from laser light, put the Clamp Base

temporarily.

(4) Positioning up Traverse Unit

Connect the following wires of the Mechanism Unit, and

operate it.

• CX141: 14P-PH wire for power

• CX131: 13P-FFC wire from Display P.W.B.

Turn on the power to the unit, and press "OPEN/CLOSE"

button to close the Loader.

The Traverse Unit rises up. (display: 0h00m00s)

Pull out the Loader forward, and lift up to take it out.

Clamp Base

(e)

Main P.W.B. Ass'y

9

5. Assembly (2)

(1) Attaching Tape to Clamp Base Damper

Attach acetate cloth tape to 3 projections of the Clamp

Base Damper backside.

(2) Assembling Clamp Base

Set the Clamp Base Damper with positioning for clamper

by 3 projections.

Fix the Clamp Base with 6 pcs of 3mm P-tight screw (b).

DVD-9000/DVD-A1

Acetate Cloth Tape

Clamp Base Damper

Clamp Base Damper

(b)

Clamp Base

6. Assembly (3)

(1) Detaching Tape from Clamp Base Damper

Detach acetate cloth tape from 3 projections of the Clamp

Base Damper backside.

(2) Assembling Clamp Base Damper

Set the Clamp Base Damper to the Clamp Base contrary

to the direction set in step above.

Fix the Clamp Base Damper with 4 pcs of 3mm S-tight

screw (a).

(a)

Clamp Base Damper

10

DVD-9000/DVD-A1

Service Mode

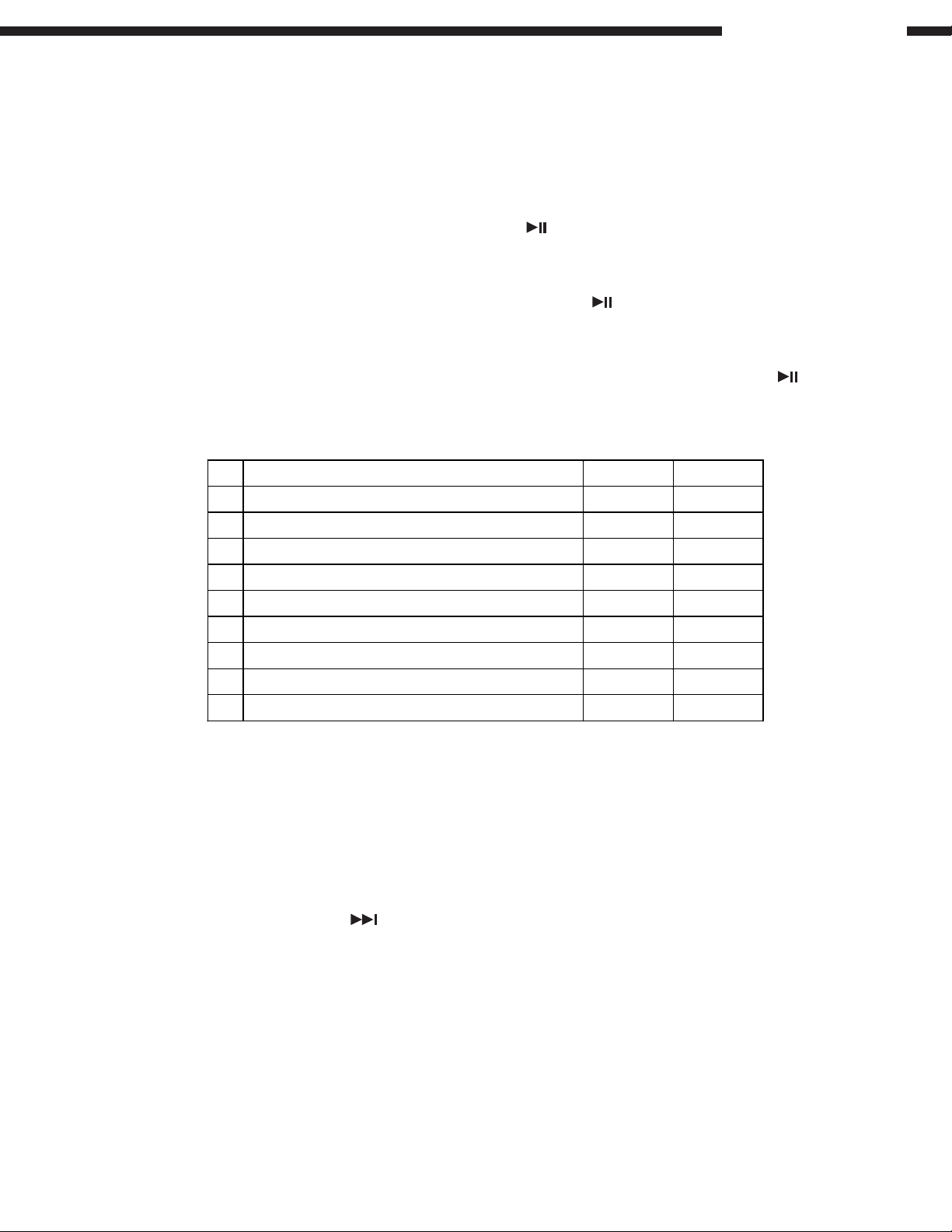

1. Aging Mode

(1) Preparation

(a) Equipment used: Any one of DVD Karaoke Disc (containing more than 10 titles), CD/Video CD (Ver1.0: None

playback control), or No-menu DVD. (Setting varies according to the disc used.)

(b) Unit setting: No spec other than the following procedure (Aging mode)

At the tray open status, press the "POWER" button to turn on the power while pressing the "PLAY" and

"OPEN/CLOSE" buttons for DVD operation simultaneously.

run mode.

(2) Procedure

(a) According the above, set to the aging mode.

(b) Set a DVD Karaoke disc to the tray and press the "PLAY" button once.

peration (after playback title-1 and title-10 of the disc, the tray open/close is made automatically, then playback the

title-1 again) starts. This aging operation continues automatically until it is stopped or it stops caused by an error.

(c) When using other than a DVD Karaoke disc, aging operation (after playback all titles of the disc, the tray open/close

is made automatically, then playback all titles again) starts by pressing the "PLAY" button once, and

the FL lights. The aging operation continues automatically until it is stopped or it stops caused by an error. In case

of some error in DVD, the tray opens and the following error messages are displayed on the FL.

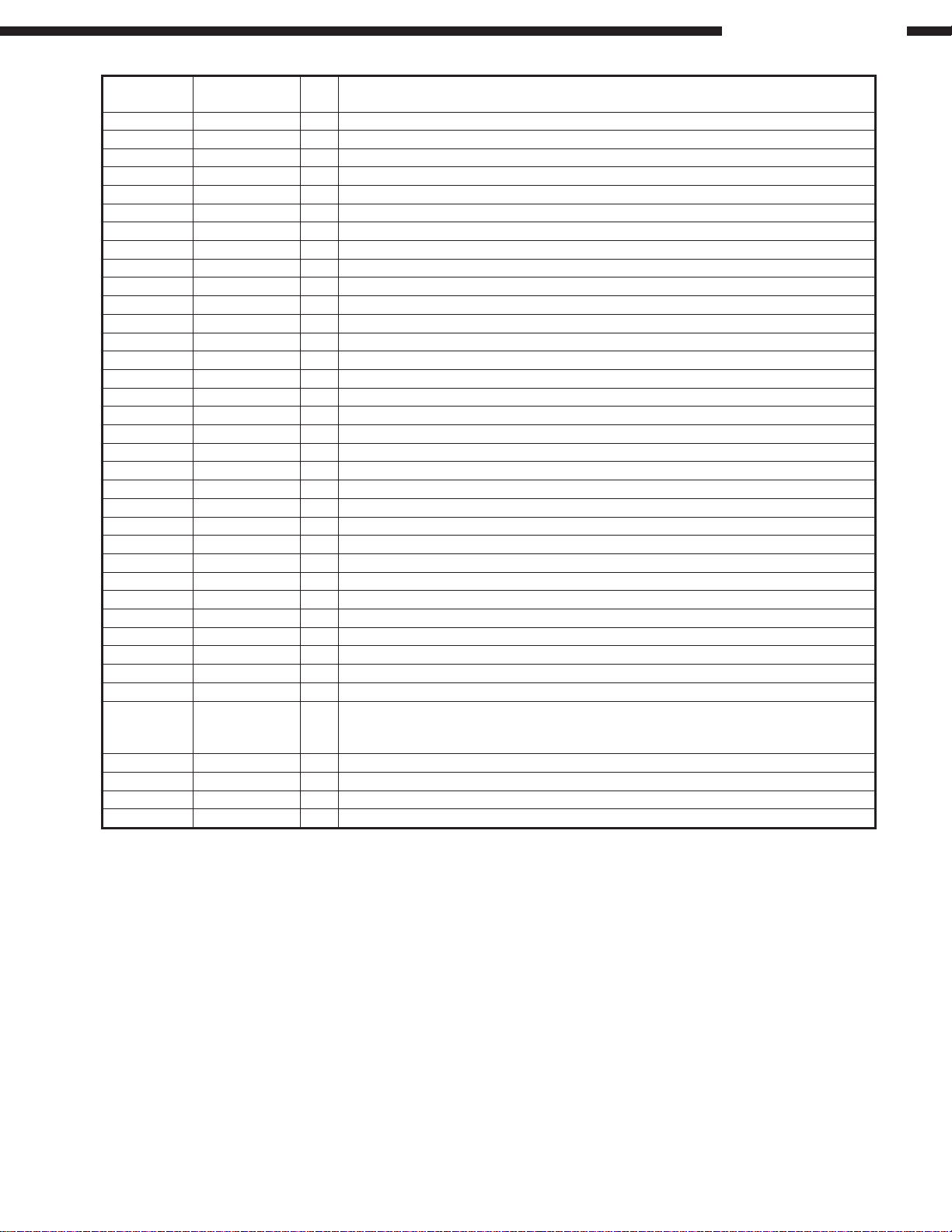

No. Error contents Error code FL display

1 During tray work, it doesn’t end within the time specified. 045300 ERROR 01

2 No spindle work during playback. 040990 ERROR 02

3 Out of focus during playback, search, or pause. 031100 ERROR 04

4 No data read when spin up. 031100 ERROR 04

5 No data read when playback. 031100 ERROR 04

6 Cannot read TOC within the time specified. 025700 ERROR 05

7 No sub-code read 025700 ERROR 05

8 No response from DVD drive more than 10 sec. 0B4000 ERROR 06

9 Error not specified (other than above). --- ERROR 07

mark on the FL lights, and the unit is set to the heat

mark on the FL blinks, and aging

mark on

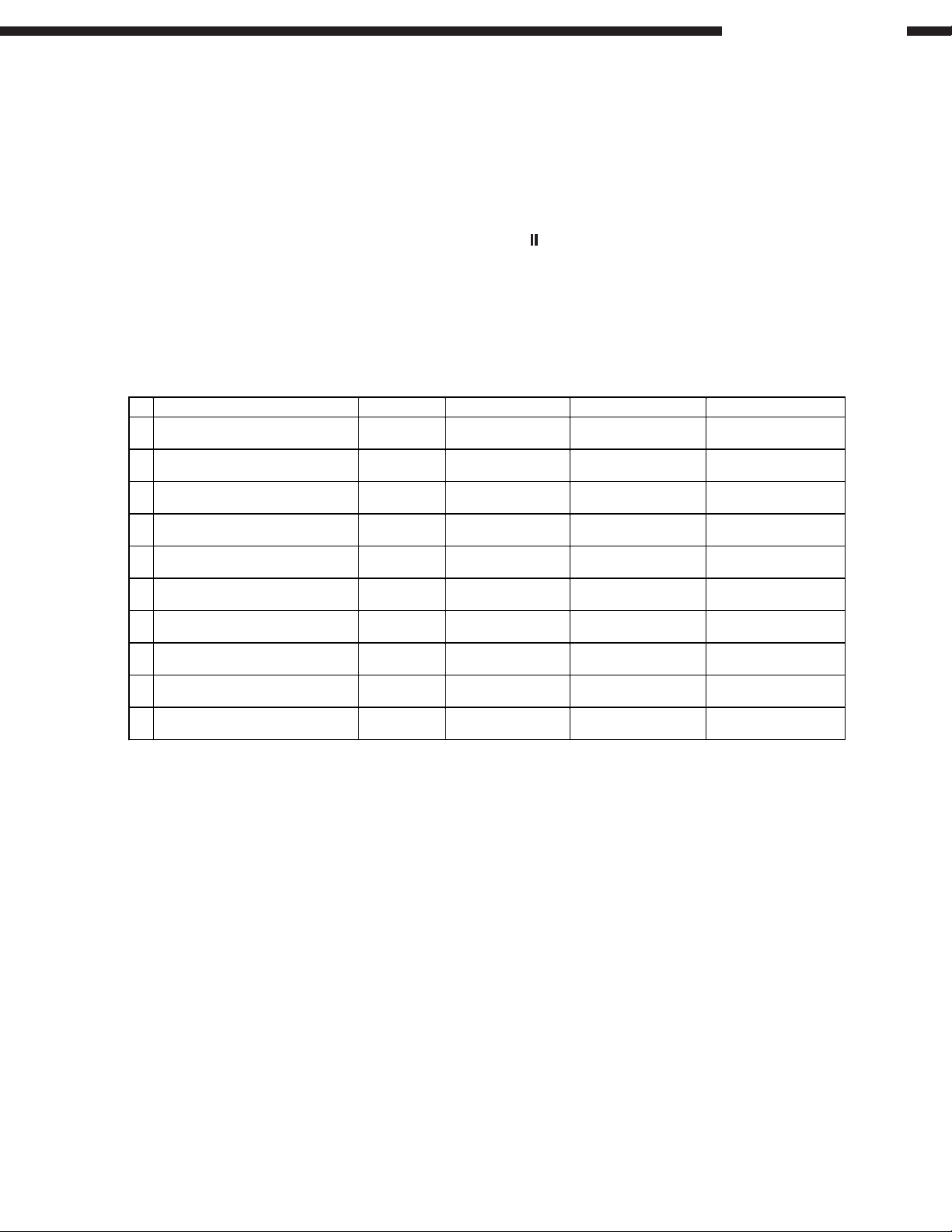

2. Initial Setting Mode

(1) Preparation

(a) Equipment used: None

(b) Unit setting: No spec other than the following procedure

(2) Procedure

(a) Initialize the DVD player when µcom, peripheral parts of µcom, or Main P.W.B. has been replaced in servicing.

(b) Carry out the following to restore factory setting mode. At the player stop condition, press 3 buttons for DVD peration

("PLAY", "OPEN/CLOSE", and "

("Initialized" appears and disappears on the TV screen.)

(c) All user setting will be lost and its factory setting will be restored when this initialization is made. Be sure to

memorize your setting for restoring again after the initialization.

SKIP") until "INITIALIZE" appears and disappears in the FL.

11

DVD-9000/DVD-A1

3. P.W.B. Check Mode

(1) Preparation

(a) Equipment used: None

(b) Unit setting: No spec other than the following procedure

(2) Procedure

(a) Press the "POWER" button to turn on the power while pressing the "PLAY" and "OPEN/CLOSE" buttons for DVD

operation simultaneously.

(b) FL all light/extinguish mode.

This mode is for detecting FL defects. Press "STILL/PAUSE (

segments, and press it once again to extinguish them.

(c) DVD µcom and main unit µcom firm check mode.

This mode is for displaying the status of each µcom employed.

• DVD µcom firm: Press the "MENU" button. Each time the "MENU" button is pressed, µcom firm is displayed one

after another.

Ex.: [DRV_6062, ESS_6070, PANEL 6061]

Set Serial No. (lower 5 digits) Bass Manager Drive Pcom ESS Pcom Panel Pcom

1V.28

2V.28

3V.28

Ver. 6062

(Display) 6062

Ver. 6062 Ver. 6077 Ver. 6061

Ver. 6100 Ver. 6101 Ver. 6091

)" on the remote control unit once to light all FL

Ver. 6070

(Display) 6070

Ver. 6061

(Display) 6061

10

4

5

6

7

8

9

12

TROUBLESHOOTING

1. No power

(FL tube doesn't light.)

Check connector insertion.

Switching power (GU-3391-2):

[CX024, CX025, CX026, CX041,

CX141]

Main PCB (GU-3389):

[CX031, CX051, CX131, CX141,

CX171, CX272]

DVD-9000/DVD-A1

No

Re-insert the connector. When replacing µcom, µcom

peripheral parts, or Main PCB,

perform initializing of DVD player.

Check switching power (GU-3391-2)

voltages.

[CX141]: 14P PH for Main PCB:

5

, +5V, "(3.3V)

(1) Check reset signal (3V) at 67pin of

IC601 on KEY/DISP PCB.

(2) Check 4.3MHz at 65pin of IC601.

Check switching power (GU-3391-2)

voltages.

[CX041]: 4P PH for Main PCB:

1

+3.6V

Check switching power (GU-3391-2)

voltages.

[CX141]: 14P PH for Main PCB:

1

+12V2-12V3+5V

9

3.3V +5V!+3.3V

[CX041]: 4P PH for KEY/DISP PCB:

1

ON/ST(3.6V)2-24V3-29V4-32V

Replace the switching power

No

unit (GU-3391-2).

(1) Check R681, R602 solderring.

No

(2) After checking X601 and IC601

soldering, change X601.

If still NG after changing, replace

IC601.

Check soldering of IC201 on Main PCB

No No

(GU-3389).

Replace the switching power unit

No

(GU-3391-2).

Check after replacing IC201 on Main

PCB (GU-3389).

Perform operation check after

changing Main PCB (GU-3389) with

a perfect one.

There is something wrong in Main PCB

No No

(GU-3389).

→ Check 27MHz output of IC101 (49)

pin/XIN, (105) pin/CLK, and (116) pin/

PCLK2X on Main PCB.

Check soldering of IC108, IC110 and

IC116 on Main PCB (GU-3389), then

change IC101 if it's NG. Change IC111 if

it's still NG.

A

Note: When switching power unit is repairable, refer to the waveforms and voltages shown in Schematic Diagram.

13

DVD-9000/DVD-A1

A

There is something wrong in Main PCB

(GU-3389).

→ Check 11MHz input of IC101 (39) pin/

MCLK.

There is something wrong in Main PCB

(GU-3389).

→ Check if CLOCK and DATA signals of

ICBUS are output on IC101 (160) pin/

AUX0, (161) pin/AUX1 when the power

is on.

Check soldering of IC101 (208 pins) on

Main PCB (GU-3389).

→ Perform re-soldering.

Caused by Main PCB (GU-3389).

→Check 20MHz output on IC703(10) pin.

Check IC109→IC113→IC112→IC111

No

(see Schematic Diagram) on Main PCB

(GU-3389).

Check soldering of IC106, IC703, IC706

and IC101 on Main PCB (GU-3389), and

No

change IC101 if it's NG. Change IC106,

then IC703 and IC706 if it's still NG.

Finally, change IC421 on Video PCB

(GU-3390-2) if still NG.

Check soldering of IC703 and X701, and

No

replace if NG.

Caused by Main PCB (GU-3389).

→Check 27MHz input on IC706 (32) pin.

Check RESET 5V output of IC511 (30)

pin on Main PCB.

Check Laser drive current/HF wave form.

Criterion: Iop is less than 1.5 times of its

initial value.

Replace Traverse Unit.

Write Iop after replacing the unit.

Check soldering of IC706, and replace

No

if NG.

Check soldering of R637 and IC101

No

(145) pin on Main PCB.

→ Perform re-soldering.

14

2. No power

(Both FL tube & LED don't light.)

DVD-9000/DVD-A1

Check connector insertion.

Switching power:

[CX024, CY025, CX026, CX141,

CX041]

Main PCB (GU-3389):

[CX141, CX171]

Check switching power voltages.

[CX141]: 14P PH for Main PCB:

+5V(NSW)"+3.3V(NSW)

Check Main PCB voltages.

[CX171]:

1

pin: +5V check

(CX141 →CX1711 break check)

pin: +3.3V check

(CX141"→CX1712 break check),

etc.

No

Re-insert the connector.

No

Replace the switching power unit.

15

DVD-9000/DVD-A1

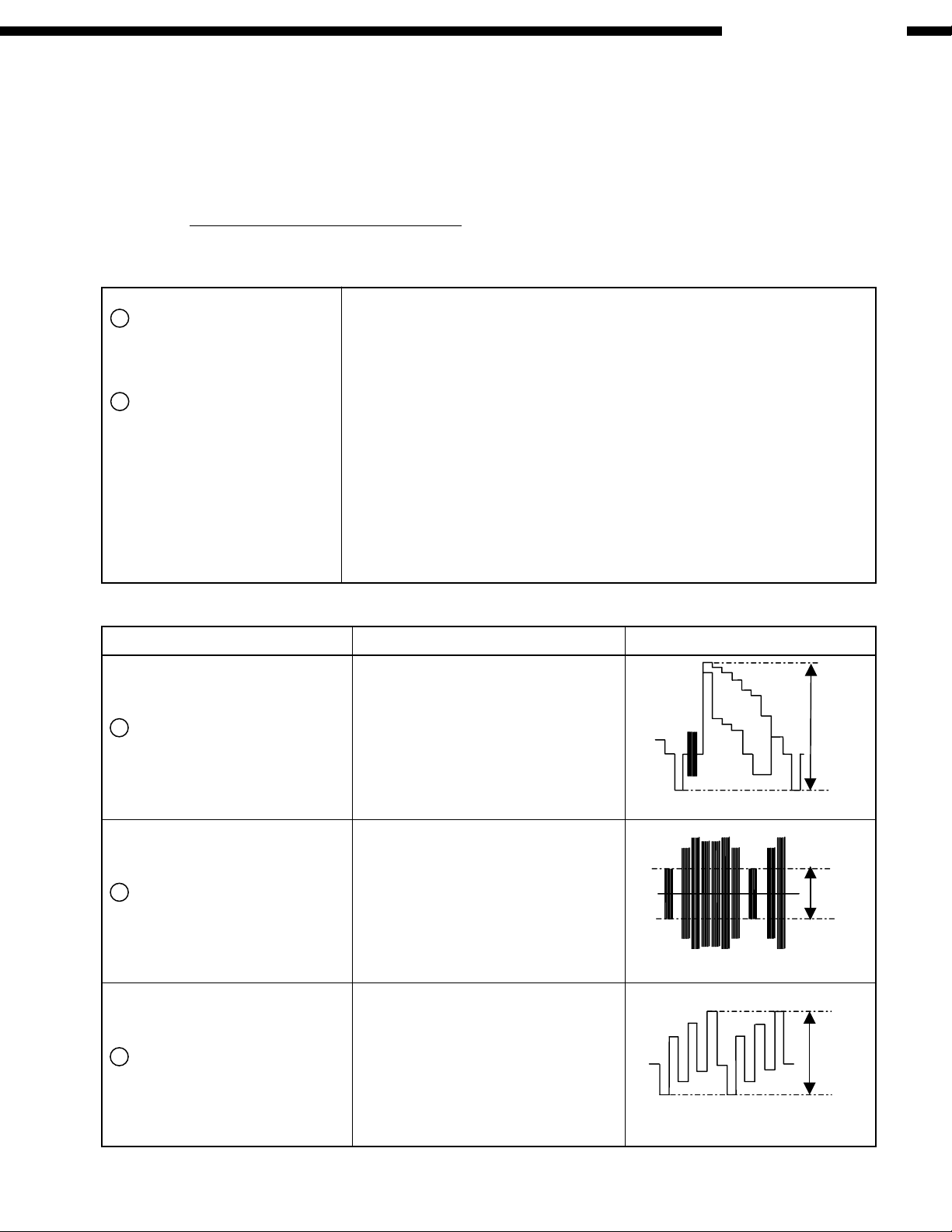

Electrical Adjustment for Video

SETTING

1. Connect the monitor TV to the video output 1 terminal.

2. Connect the Oscilloscope to the Y-signal and C-signal of S2 video output terminal and each terminate at 75 Ohms.

3. Connect the Oscilloscope to the PB -signal , CB -signal and Y- signal of Component video output terminal and

each terminate at 75 Ohms.

Use the 75 Ohms resistance must be 1%

4. DVD test disc : DVDT-S01

ADJUSTMENT

Setting the Oscilloscope as bellow.

1

PB / CB / PR / CR

(a) TIME / DIV : 2 µS

(b) VOLT / DIV : 100 mV

(use the probe : ×10)

2

Y / C

(a) TIME / DIV :2 µS

(b) VOLT / DIV :50 mV

(use the probe : ×10)

Power on. Power Supply

U.S.A.& Canada : 120 V

Asia : 230 V

China : 220 V

Europe : 230 V

1. Set the [SOURCE] selector knob : DVD.

2. Push [OPEN/CLOSE] button, then open the Disc Tray.

3. Set DVD test disc (DVDT-S01) on the Disc Tray, and then push [CLOSE]

button.

4. FL display appear "STOP", push [PLAY] button to playback DVD.

5. Set the Video output to INTERLACED by remote control unit. (Push the

[SETUP] button, set to the mode of VIDEO SETUP.)

6. Push the [DISPLAY] button of remote control unit and then appear the ONScreen Display (GUI) on the monitor TV.

7. Push the [12] button, select title 12 of DVD.

8. Push the [SELECT] button, playback title 12. (color bar 75%)

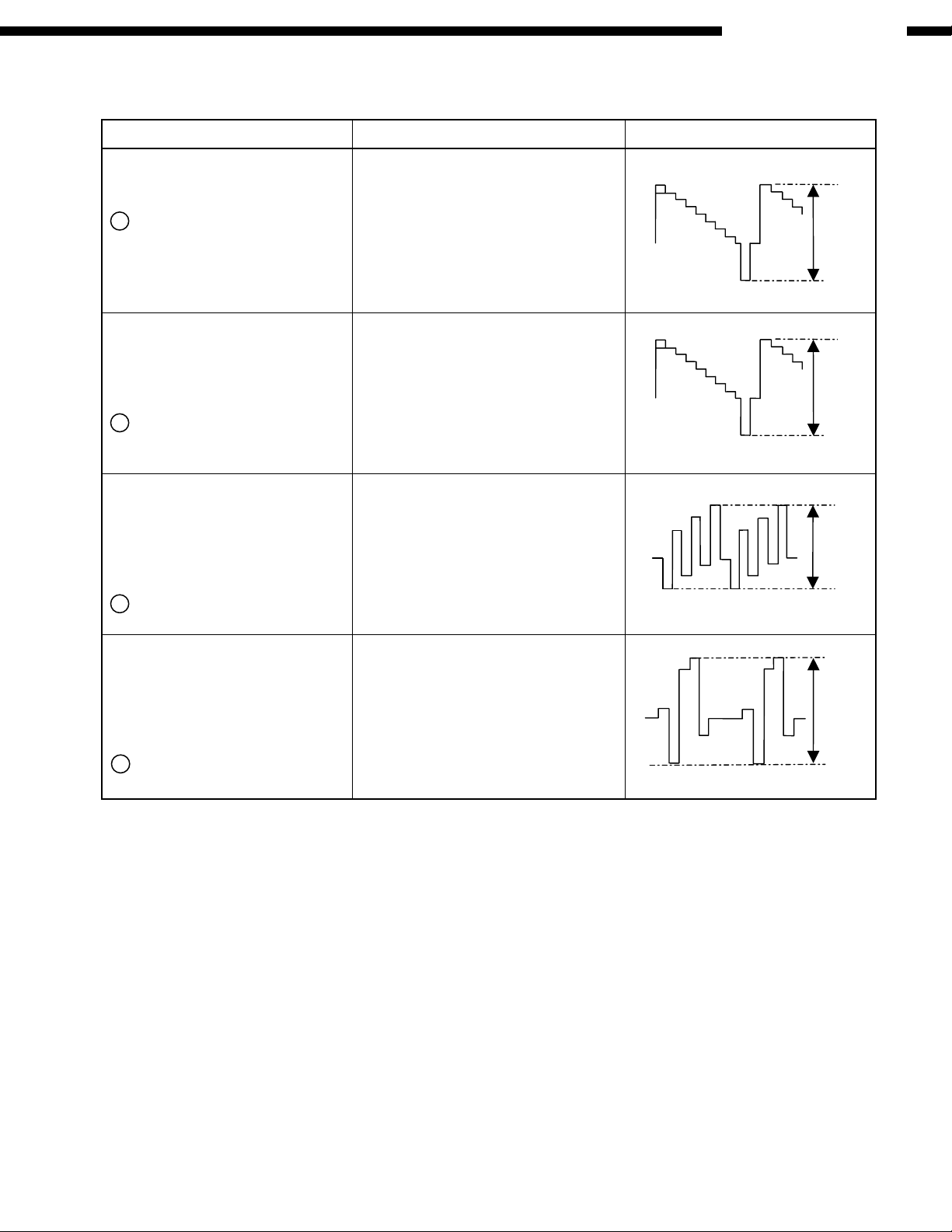

Adjustment Point & Adjustment Value Wave

Adjust the signal of S2 video out by

the wave of Oscilloscope.

1

Y-signal

Adjust the signal of S2 video out by

the wave of Oscilloscope.

2

C-signal

Adjust the signal of Component

video out.

1

CB-signal

Point : VR422

Adjustment Value : 1000 ±20 mV

Point : VR423

Adjustment Value :

286 ±5 mV

300 ±5 mV (For Europe & Asia models)

Point : VR421

Adjustment Value :

486 ±10 mV

525 ±10 mV

(For U.S.A & Canada models)

(For U.S.A & Canada models)

(For Europe & Asia models)

Y-signal of S2 video out

C-signal of S2 video out

P

B-signal

Y

C

B

P

16

DVD-9000/DVD-A1

Adjustment Point & Adjustment Value Wave

Adjust the signal of Component

video out

2

Y-signal

Set the Video output to

PROGRESSIVE by remote control

unit. (Push the [SETUP] button, set

to the mode of VIDEO SETUP.)

1

Y-signal

Set the Video output to

PROGRESSIVE by remote control

unit.

(Push the [SETUP] button, set to the

mode of VIDEO SETUP.)

Point: VR424

Adjustment Value: 1000 ±20mV

Point: VR710

Adjustment Value: 1000 ±20mV

Point: VR709

Adjustment Value:

486 ±10 mV

525 ±10 mV

(For U.S.A & Canada models)

(For Europe & Asia models)

Wave

Y-signal

Y

Y

B

P

2

PB-signal

Set the Video output to

PROGRESSIVE by remote control

unit.

(Push the [SETUP] button, set to the

mode of VIDEO SETUP.)

3

PR-signal

Point: VR708

Adjustment Value:

486 ±10 mV

525 ±10 mV

(For U.S.A & Canada models)

(For Europe & Asia models)

B-signal

P

P

R-signal

R

P

17

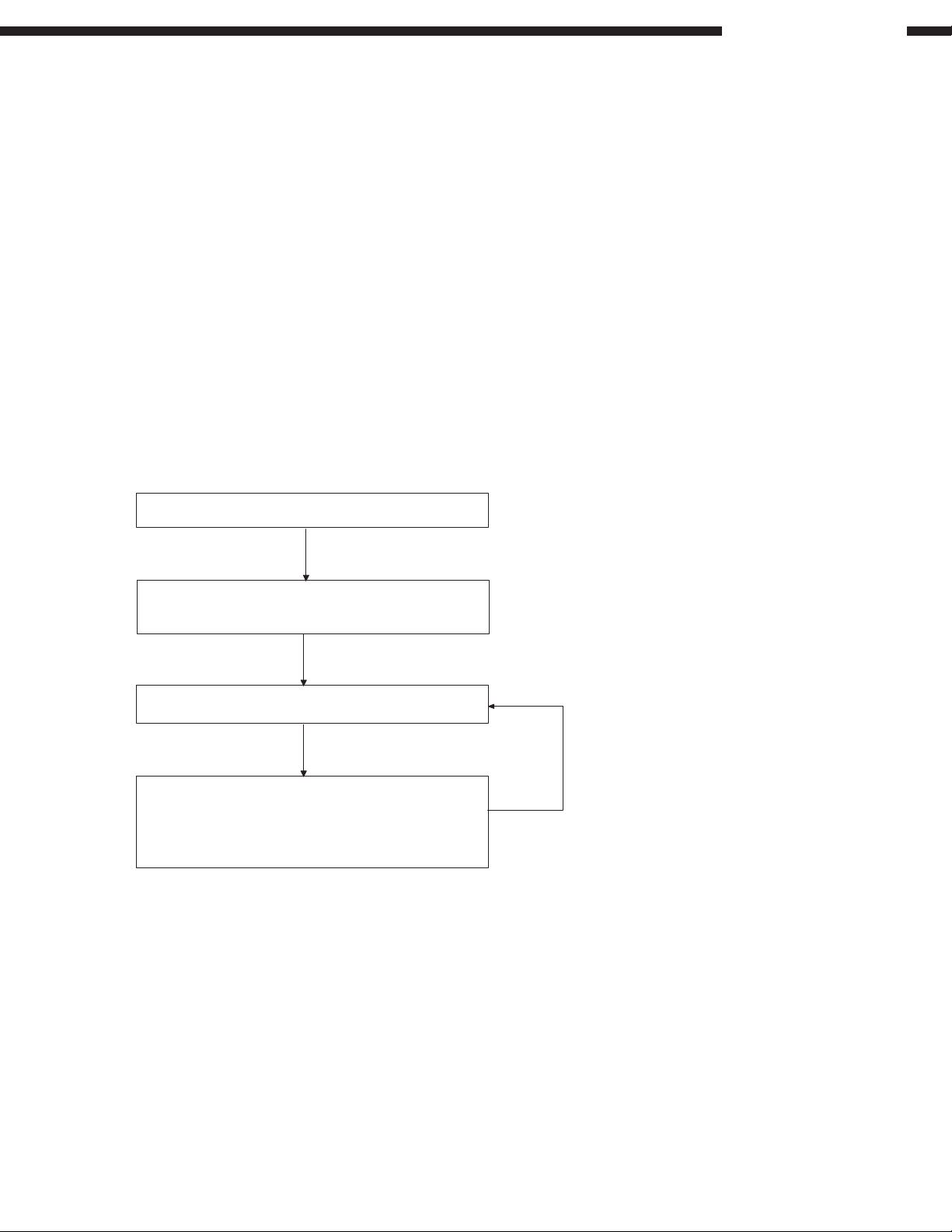

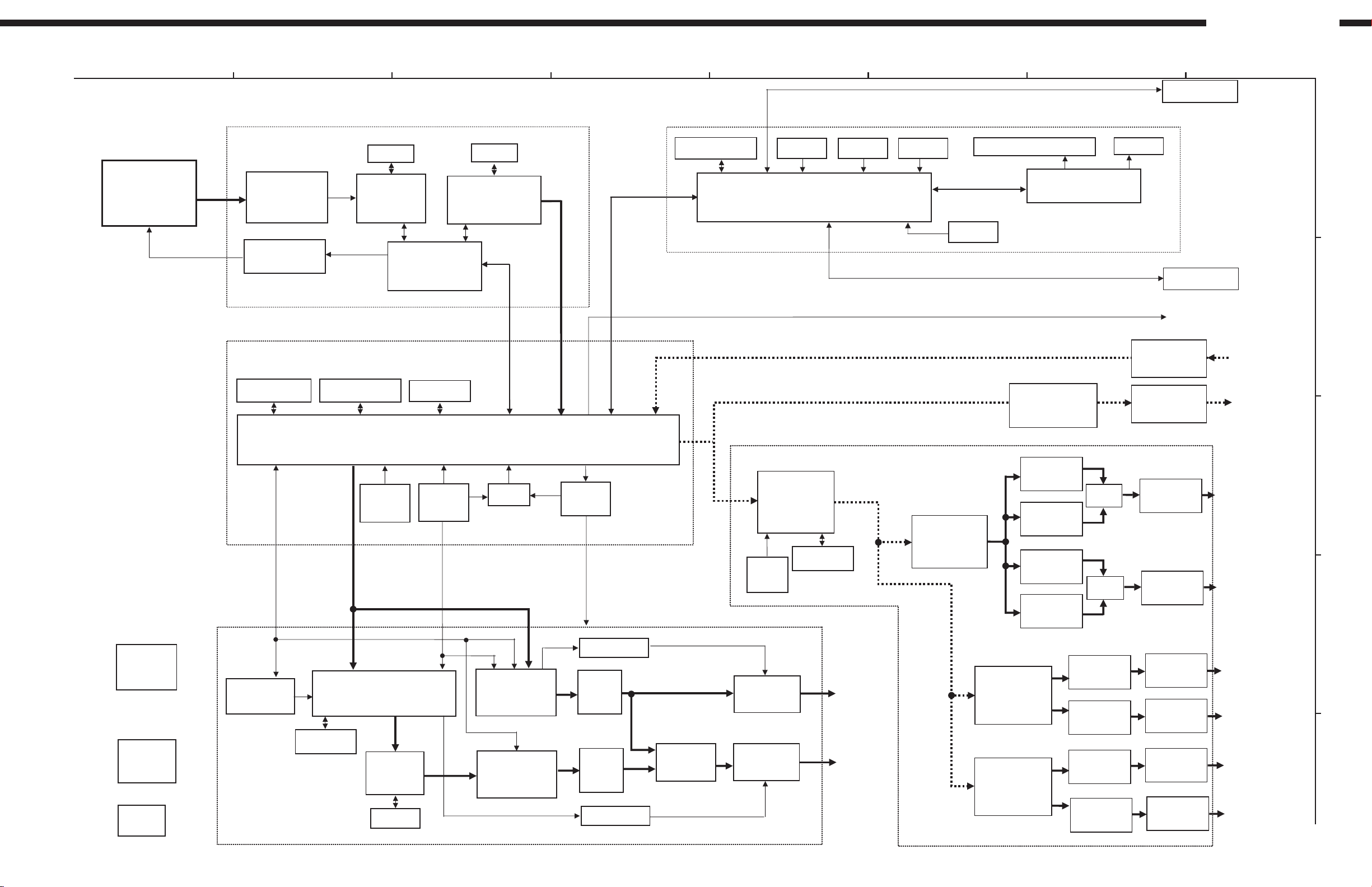

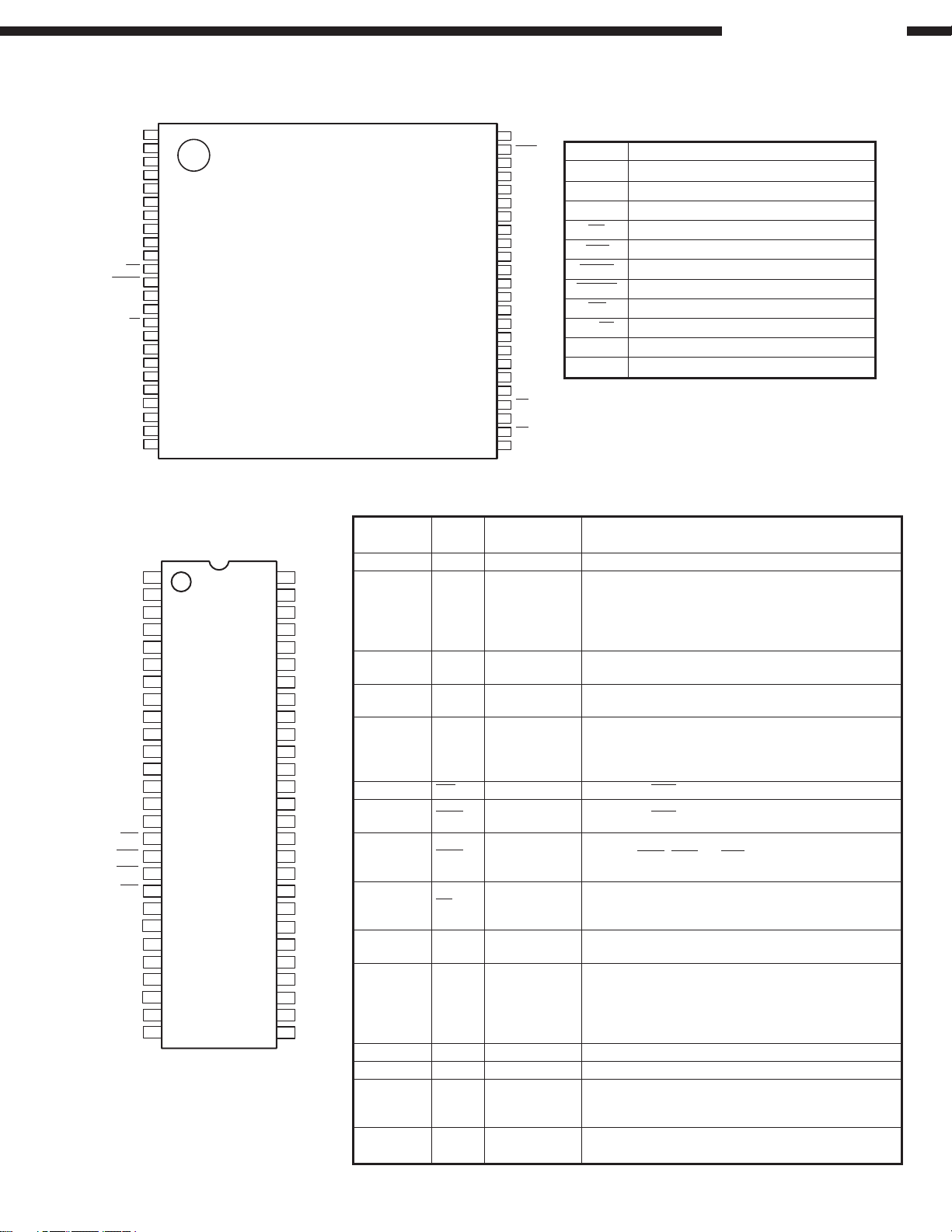

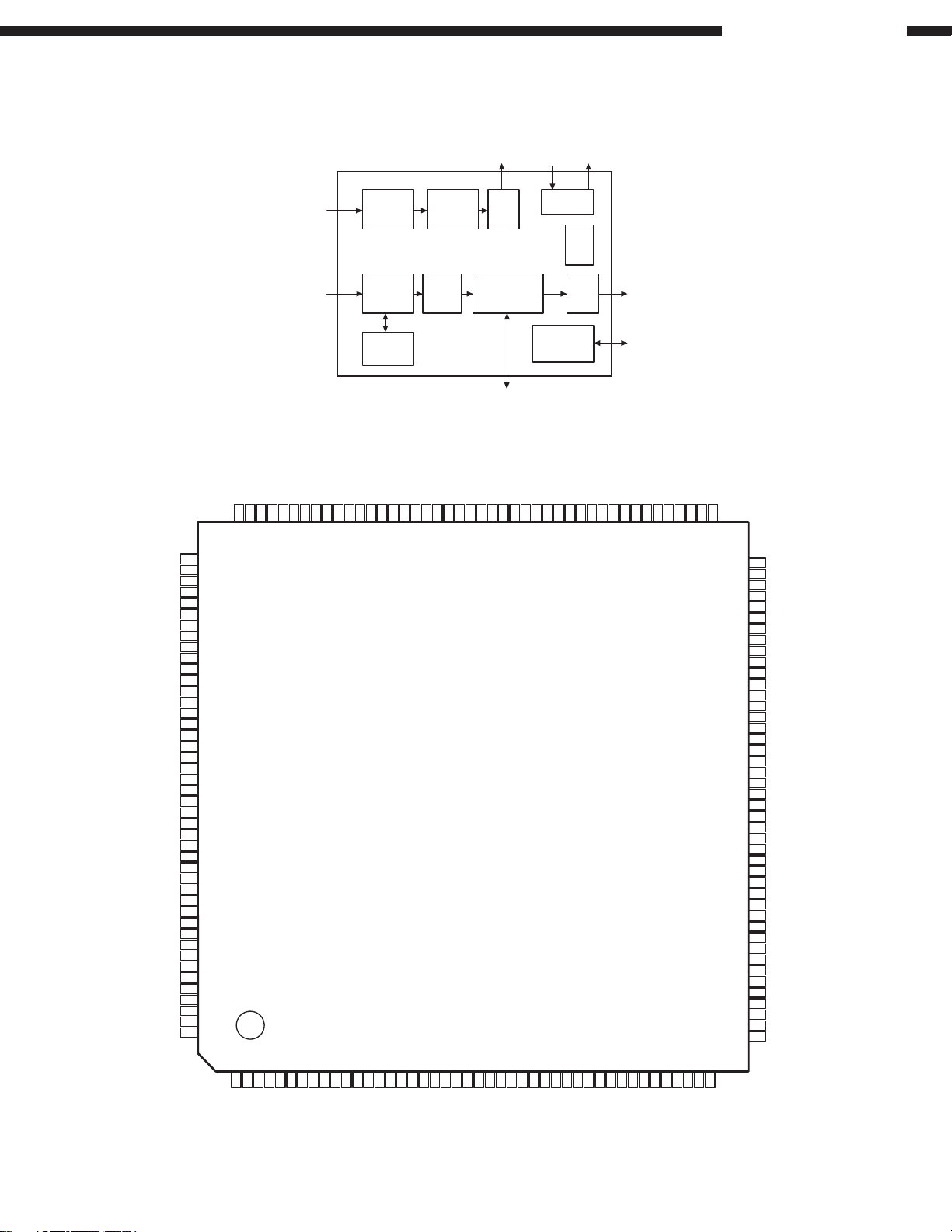

DVD DRIVE

MECHA UNIT

[FG-180]

FRONTEND

PROCESSOR

[TA1293F]

PROCESSOR

DISC SERVO

[TC9453F]

ACT/MOTOR

DRIVER

ATAPI INTERFACE

DVD DECODER

[TC9469BF]

DRIVE CONTROL

[TMP95CW64]

DVD PROCESSOR

[ES6038]

64M SDRAM 16M FLASH ROM

E2PROM

DIGITAL

POWER

UNIT

I/O

EXPAN

PLL

27MHz

OSC

DENON DIGITAL

PROCESSOR

[EPM3128A]

RESET

DIT

[AK4101]

MONO MULTI

MONO MULTI

ANALOG

POWER

UNIT

POWER

TRANS

DRAM

< FRONT END >

< BACK END >

DRAM

-COM

PANEL CONTROL

µ-COM

[MN102H460B]

FLASHROM

FLT

FL DRIVER

[ML9207]

KEY ROT SW.REM

LED

< PANEL CONTROL >

I/P µCOM

[PIC18LC242]

I/P CONVERTER

[SiI504]

VIDEO ENCODER

[ADV7304]

VIDEO ENCODER

[ADV7304]

64M SDRAM

VR &

FILTER

SELECTOR

< VIDEO BLOCK>

RS-232C

WIRED REM

VR &

FILTER

CLAMP &

DRIVER

CLAMP &

DRIVER

DIR

[LC89055]

ALPHA

PROCESSOR

[DXP7001]

FILTER&

AMP

DIFF

DAC

[PCM1704]

DAC

[PCM1704]

DAC

[PCM1704]

DAC

[PCM1704]

FILTER &

AMP

FILTER &

AMP

FILTER &

AMP

FILTER &

AMP

DIGITAL FILTER

[DF1704]

DAC

[PCM1704]

DAC

[PCM1704]

DAC

[PCM1704]

DAC

[PCM1704]

525I/625I

525P

SW

S L

C

S R

FILTER&

AMP

DIFF

F L

F R

< AUDIO BLOCK >

33MHz

OSC

FPGA

XC2530

PROM

BASS

MANAGEMENT.

DSP

[ADSPMEL322]

FLASH ROM

12MHz

OSC

SPDIF OUT

EXT. IN

DENON

LINK

DIGITAL FILTER

[DF1704]

BLOCK DIAGRAM

1 5678

DVD-9000/DVD-A1

32

4

A

B

C

D

E

18

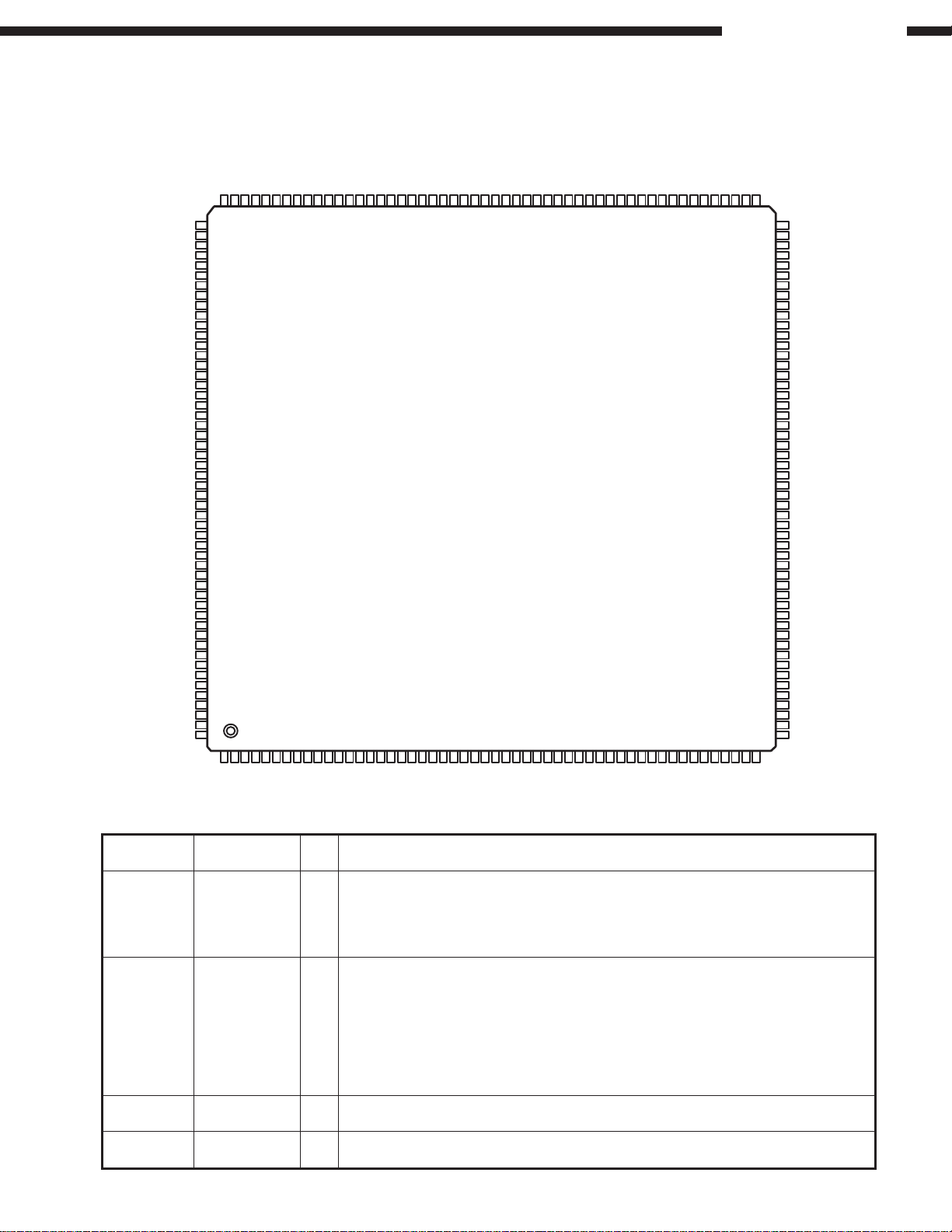

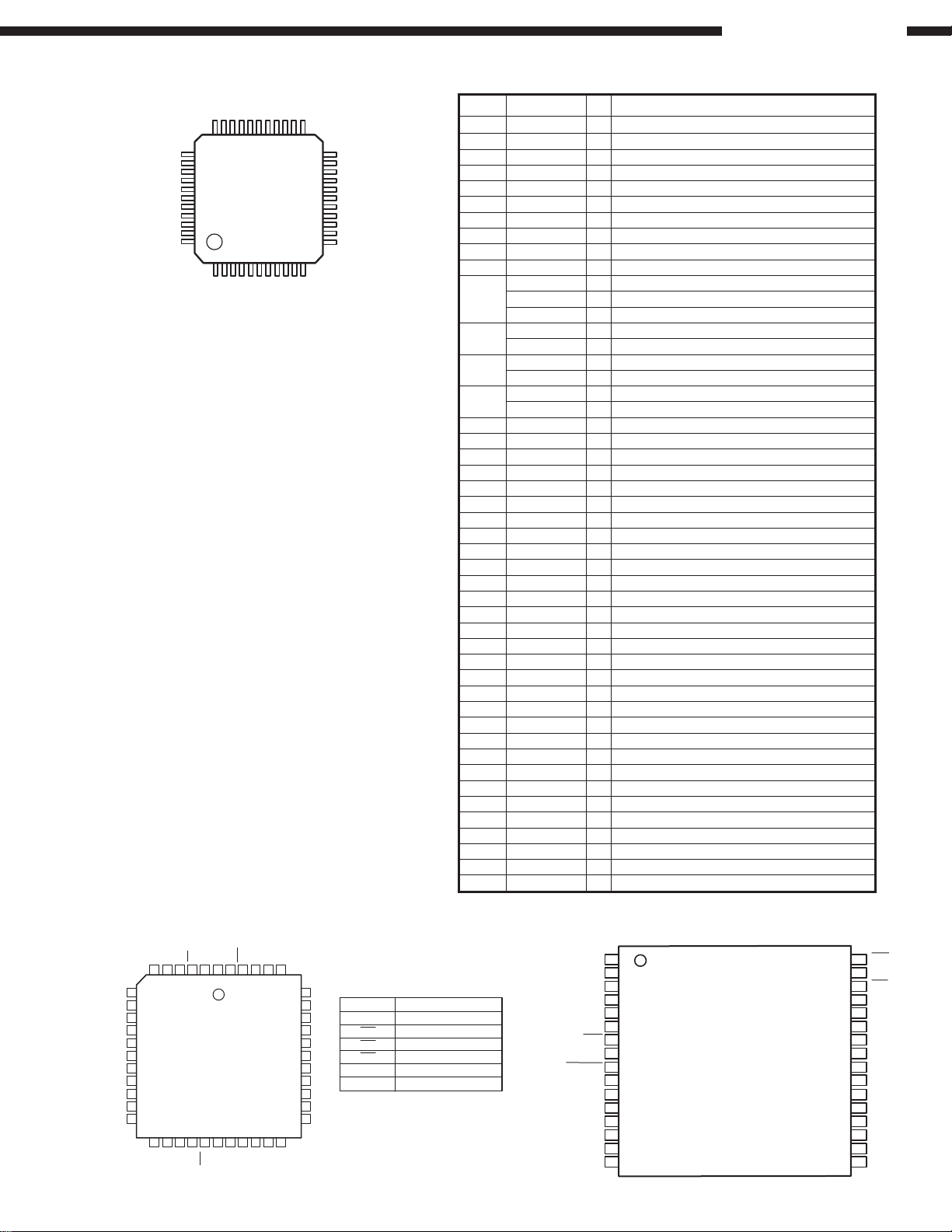

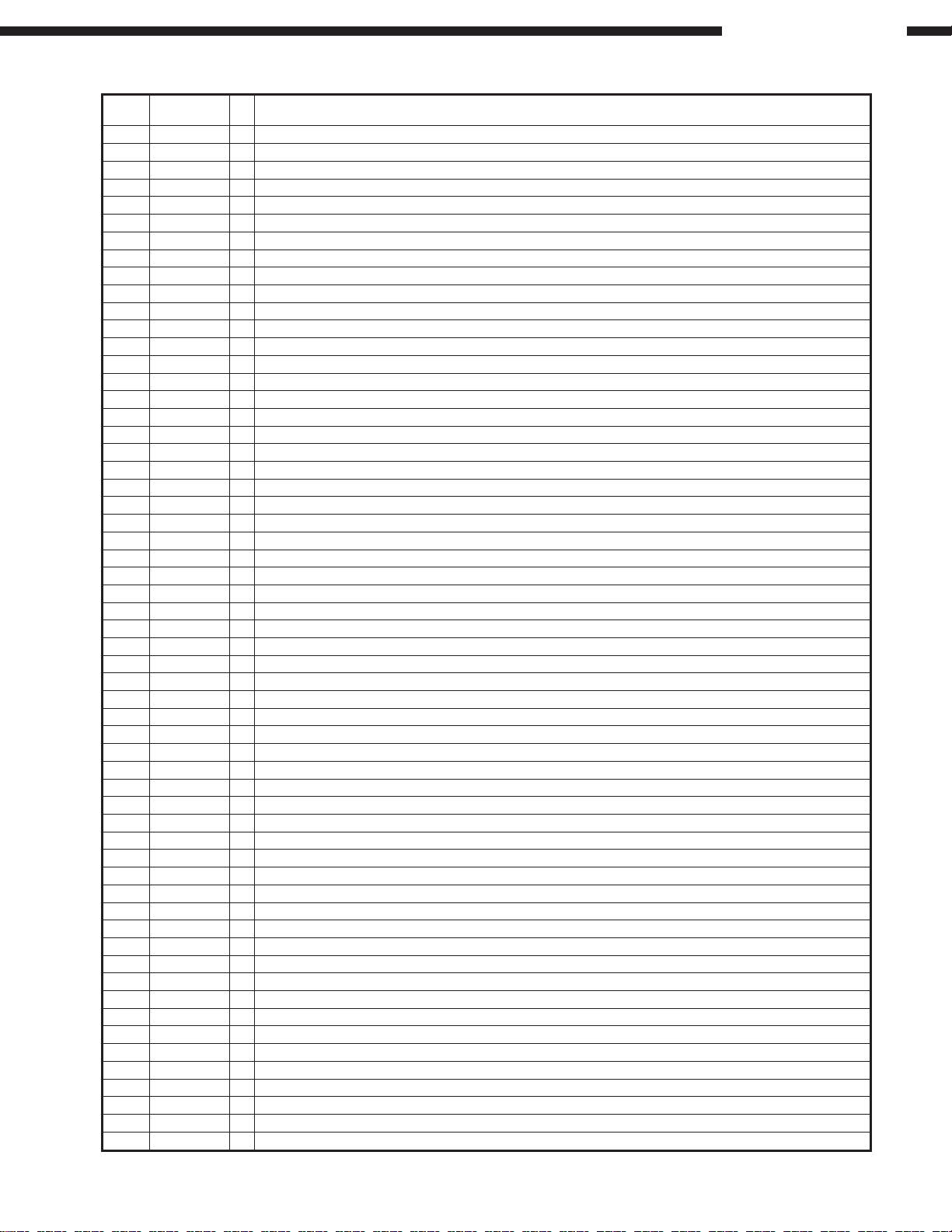

SEMICONDUCTORS

IC’s

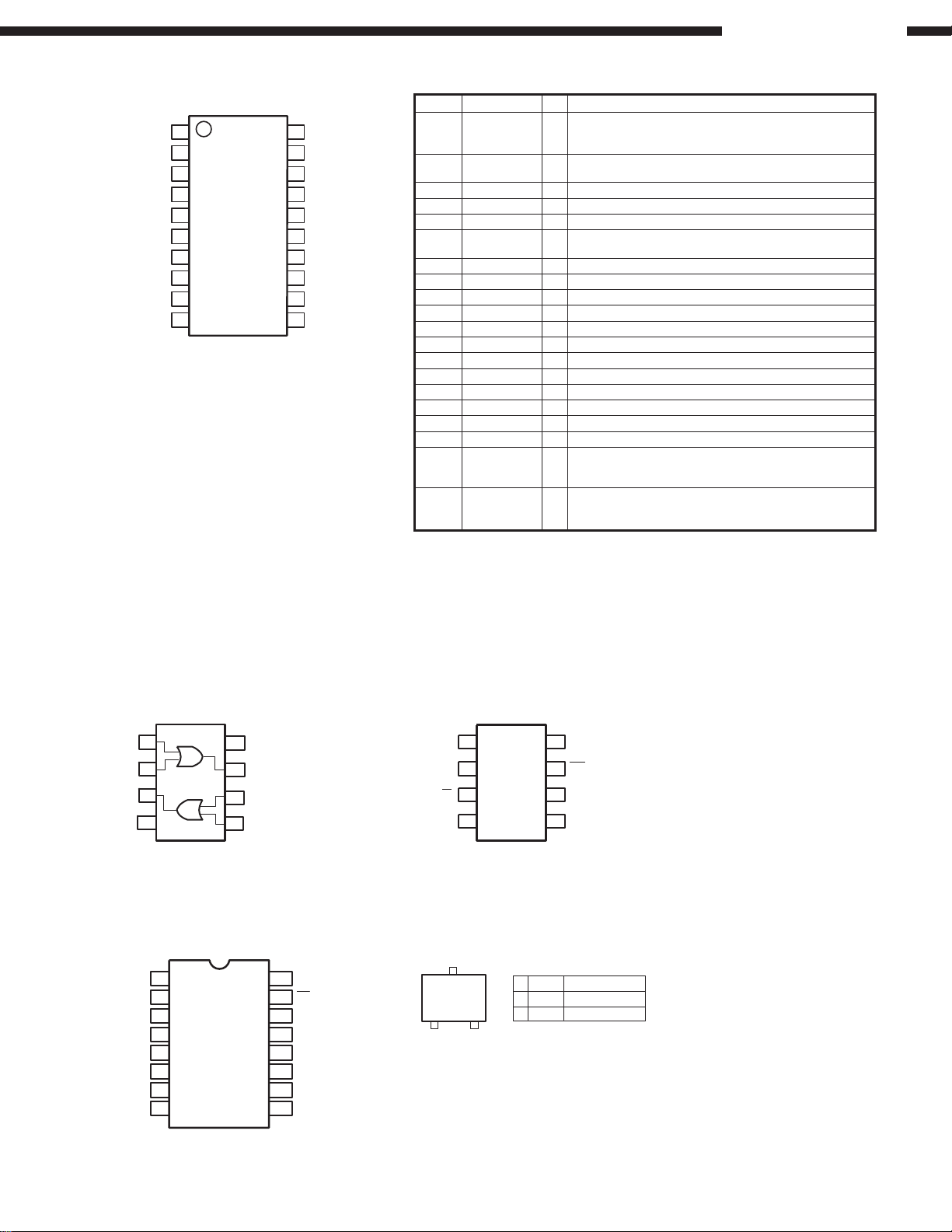

ES6038 (IC101)

VSS

HA1

HA0

HCS3FX#

HCS1FX#

HIOCS16#

HRD#

156

155

154

153

152

151

VEE

VEE

AUX[0]

AUX[1]

AUX[2]

VSS

VEE

AUX[3]

AUX[4]

AUX[5]

AUX[6]

AUX[7]

LOE#

VSS

VCC

LCS0#

LCS1#

LCS2#

LCS3#

VSS

VEE

VSS

LD10

LD11

VSS

VEE

LD12

LD13

LD14

LD15

LWRLL#

LWRHL#

VSS

VEE

CAMIN0

CAMIN1

VSS

157

HA2

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

LD0

178

LD1

179

LD2

180

LD3

181

LD4

182

183

184

LD5

185

LD6

186

LD7

187

LD8

188

LD9

189

190

191

192

193

194

195

196

197

198

199

200

201

202

203

LA0

204

LA1

205

LA2

206

LA3

207

208

123456789101112131415161718192021222324252627282930313233343536373839404142434445464748495051

150

HWR#

149

VEE

148

VSS

147

HIORDY

HRST#

146

145

HIRQ

144

HRDQ#

143

HWRQ#

HD15

142

141

HD14

140

VCC

139

VSS

138

HD13

137

HD12

136

HD11

135

HD10

134

HD9

133

HD8

132

HD7

131

VEE

130

VSS

129

HD6

128

HD5

127

HD4

126

HD3

125

HD2

124

HD1

123

HD0

122

VCC

121

VSS

120

HSYNC#

VSYNC#

119

118

PCLKQSCN

PCLK2XSCN

117

116

YUV7

115

YUV6

114

YUV5

113

DVD-9000/DVD-A1

VSS

AVEE

YUV4

YUV3

YUV2

YUV1

YUV0

DCLK

112

111

110

109

108

107

106

105

104

VEE

103

VSS

102

DSCK

101

DQM

100

DCS0#

99

VEE

98

VSS

97

DCS1#

96

DB15

95

DB14

94

DB13

93

DB12

92

VEE

91

VSS

90

DB11

89

DB10

88

DB9

87

DB8

86

DB7

85

DB6

84

VSS

83

VCC

82

DB5

81

DB4

80

DB3

79

DB2

78

DB1

77

DB0

76

VSS

75

VEE

74

DMBS1

73

DMBS0

72

DRAS#

71

DWE#

70

DSCK_EN

69

DCAS#

68

VEE

67

VSS

66

DMA11

65

DMA10

64

DMA9

63

DMA8

62

DMA7

61

DMA6

60

VSS

59

VEE

58

DMA5

57

DMA4

56

DMA3

55

DMA2

54

DMA1

53

DMA0

52

LA4

LA5

LA6

LA7

LA8

VEE

LA9

VSS

VCC

LA10

LA11

LA12

VSS

LA13

VEE

LA14

LA15

LA16

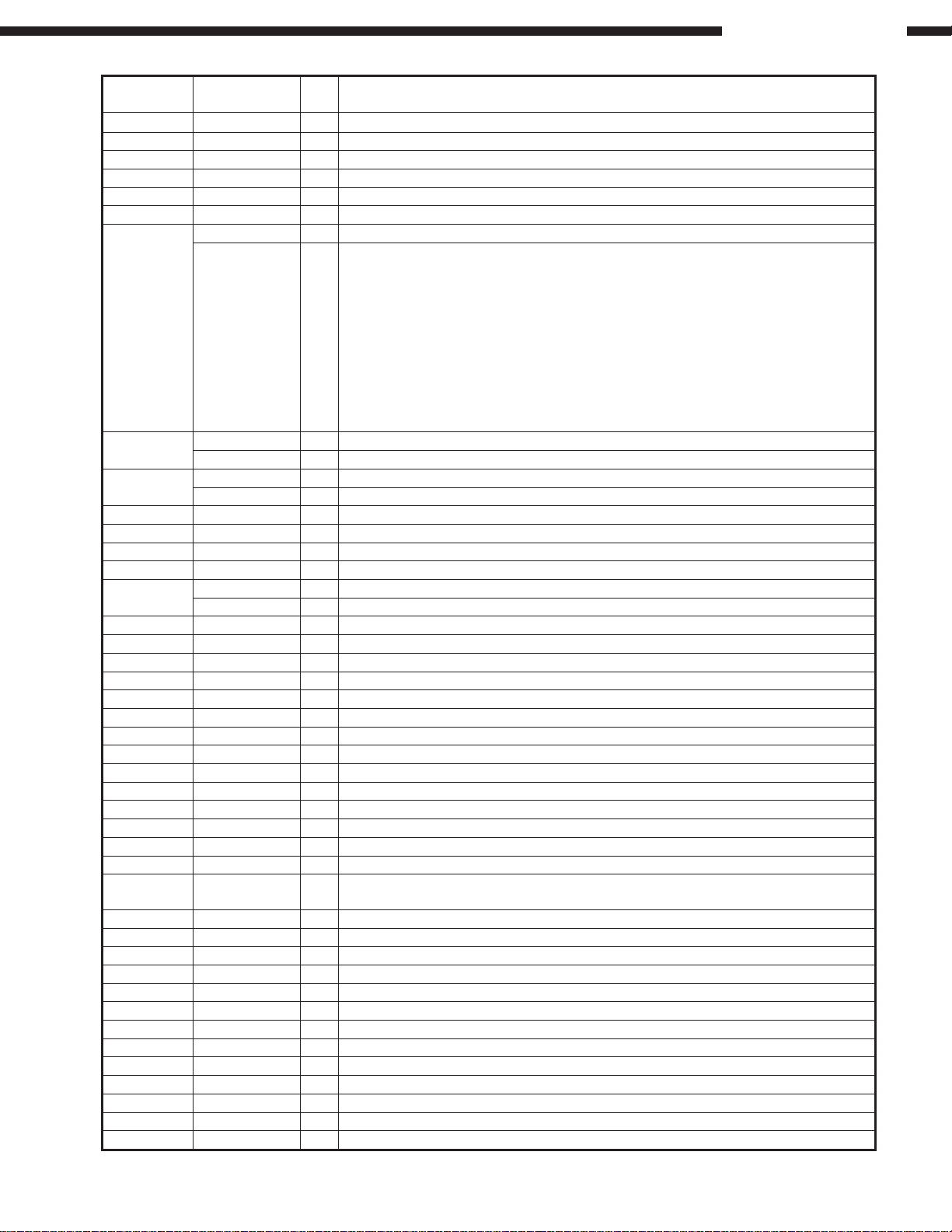

ES6038 Terminal Function

1, 18, 27, 59,

68, 75, 92, 99,

104, 130, 148, VEE I I/O power supply.

157, 159, 164,

183, 193, 201

8, 17, 26, 34,

43, 52, 60, 67,

76, 84, 91, 98,

103, 112, 120, VSS I Ground.

129, 138, 147,

156, 163, 171,

177, 184, 192,

200, 208

23:19, 16:10,

7:2, 207:204

9, 35, 44, 83,

121, 139, 172

LA[21:0] O Device address output.

VCC I Core power supply.

VSS

LA17

LA18

LA19

LA20

VEE

LA21

TDMDX

TDMDR

RESET#

TDMCLK

VSS

VCC

TDMFS

TDMTSC#

TWS/SEL_PLL2

TSD2

TSD0/SEL_PLL0

TSD1/SEL_PLL1

NC

TSD3

VSS

TBCK

MCLK

SPDIF/PLL3

VCC

RSD

RWS

RBCK

NC

XIN

VSS

AVEE

XOUT

FunctionI/OPin No. Pin Name

19

DVD-9000/DVD-A1

Pin No. Pin Name

24 RESET# I Reset input, active low.

25 TDMDX O TDM transmit data.

28 TDMDR I TDM receive data.

29 TDMCLK I TDM clock input.

30 TDMFS I TDM frame sync.

31 TDMTSC# O TDM output enable.

TWS O Audio transmit frame sync.

SEL_PLL2 I System and DSCK output clock frequency selection is made at the rising edge of RESET#.

The matrix below lists the available clock frequencies and their respective PLL bit settings.

SEL_PLL2 SEL_PLL1 SEL_PLL0 Clock Type

0 0 0 VCO off.

0 0 1 DCLK

32 0 1 0 Bypass mode

0 1 1 DCLK x 2

1 0 0 DCLK x 4.5

1 0 1 DCLK x 3

1 1 0 DCLK x 3.5z

1 1 1 DCLK x 4

33

36

37 TSD[2] O Audio transmit serial data output 2.

38 TSD[3] O Audio transmit serial data output 3.

39 MCLK I/O Audio master clock for audio DAC.

40 TBCK O Audio transmit bit clock.

41

42,48 NC I No connect pins. Leave open.

45 RSD I Audio receive serial data.

46 RWS I Audio receive frame sync.

47 RBCK I Audio receive bit clock.

49 XIN I Crystal input.

50 XOUT O Crystal output.

51 AVEE I Analog power for PLL.

66:61, 58:53 DMA[11:0] O DRAM address bus [11:0]

69 DCAS# O DRAM column address strobe,

70 DSCK_EN O DRAM clock enable.

71 DWE# O DRAM write enable.

72 DRAS# O DRAM row address strobe.

73 DMBS0 O SDRAM bank select 0.

74 DMBS1 O SDRAM bank select 1.

96:93, 90:85,

82:77

97, 100 DCS[1:0]# O SDRAM chip select [1:0]

101 DQM O Data input/output mask.

102 DSCK O Output clock to SDRAM.

105 DCLK I 27 MHz clock input to SDRAM.

106 YUV0 O YUV0 pixel output data.

107 YUV1 O YUV1 pixel output data.

108 YUV2 O YUV2 pixel output data.

109 YUV3 O YUV3 pixel output data.

110 YUV4 O YUV4 pixel output data.

111 ADVEE I Analog power for video DAC.

113 YUV5 O YUV5 pixel output data.

114 YUV6 O YUV6 pixel output data.

115 YUV7 O YUV7 pixel output data.

TSD0 O Audio transmit serial data port 0.

SEL_PLL0 I Refer to the description and matrix for SEL_PLL2 pin 32.

TSD1 O Audio transmit serial data port 1.

SEL_PLL1 I Refer to the description and matrix for SEL_PLL2 pin 32.

SPDIF O S/PDIF output.

SEL_PLL3 I Clock source select.

DB[15:0] I/O DRAM data bus [15:0]

FunctionI/O

20

DVD-9000/DVD-A1

Pin No. Pin Name

116 PCLK2XSCN I/O 27 MHz video output pixel clock.

117 PCLKQSCN O 13.5 MHz video output pixel clock.

118 VSYNC# I/O Vertical sync, active low.

119 HSYNC# I/O Horizontal sync, active low.

127:122 HD[5:0] I/O Host data I/O [5:0].

128 HD[6] I/O Host data I/O [6].

131 HD[7] I/O Host data I/O [7].

132 HD[8] I/O Host data bus 8.

133 HD[9] I/O Host data bus line 9.

134 HD[10] I/O Host data bus line 10.

135 HD[11] I/O Host data bus line 11.

136 HD[12] I/O Host data bus line 12.

137 HD[13] I/O Host data bus line 13.

140 HD[14] I/O Host data bus line 14.

141 HD[15] I/O Host data bus line 15.

142 HWRQ# O Host write request.

143 HRRQ# O Host read request.

144 HIRQ I/O Host interrupt.

145 HRST# O Host reset.

146 HIORDY I Host I/O ready.

149 HWR# I/O Host write.

150 HRD# O Host read.

151 HIOCS16# I Device16-bit data transfer.

152 HCS1FX# O Host select 1.

153 HCS3FX# O Host select 3.

158, 155:154 HA[2:0] I/O Host address bus.

160 AUX[1:0] I/O Auxiliary ports 1:0.

162 AUX[2] I/O Auxiliary ports 2.

165 AUX[3] I/O Auxiliary ports 3.

169:166 AUX[7:3] I/O Auxiliary ports 7:3.

170 LOE# O Device output enable.

176:173 LCS[3:0] O Chip select [3:0].

197:194,

191:185, LD[15:0] I/O EPROM device data bus.

182:178

198 LWRLL# O Device low-byte write enable.

199 LWRHL# O Device high-byte write enable.

202 CAMIN0 I Camera YUV 0.

203 CAMIN1 I Camera YUV 1.

FunctionI/O

21

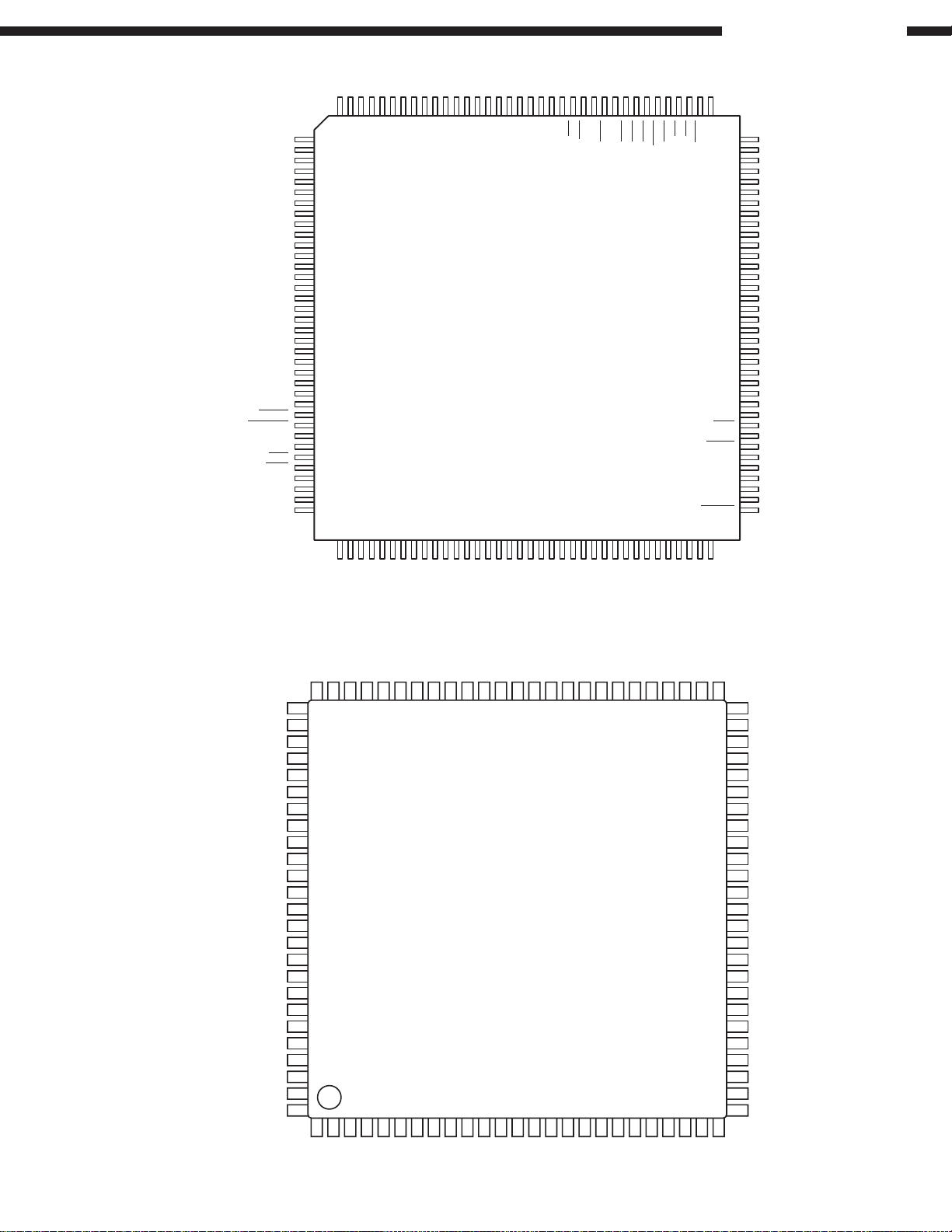

MX29LV160BTC-90 (IC102)

DVD-9000/DVD-A1

1

A15

2

A14

3

A13

4

A12

5

A11

6

A10

7

A9

A8

8

A19

9

NC

10

11

WE

RESET

12

NC

13

14

NC

RY/BY

15

A18

16

17

A17

A7

18

19

A6

20

A5

21

A4

22

A3

23

A2

24

A1

W986416DH (IC103)

1

V

CC

2

DQ0

3

VCCQ

4

DQ1

5

DQ2

6

SS

Q

V

7

DQ3

DQ4

8

V

CC

Q

9

DQ5

10

11

DQ6

Q

V

SS

12

DQ7

13

14

CC

V

LDQM

15

16

WE

CAS

17

18

RAS

19

CS

20

BS0

21

BS1

A10/AP

22

A0

23

24

A1

25

A2

26

A3

27

Vcc

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

A16

BYTE

GND

Q15/A-1

Q7

Q14

Q6

Q13

Q5

Q12

Q4

V

Q11

Q3

Q10

Q2

Q9

Q1

Q8

Q0

OE

GND

CE

A0

Pin Description

A0~A19 Address Input

Q0~Q14 Data Input/Output

Q15/A-1 Q15 (Word mode)/LSB addr (Byte mode)

CC

BYTE Word/Byte Selection input

RESET Hardware Reset Pin/Sector Protect Unlock

RY/BY Ready/Busy Output

Pin NameSymbol

CE Chip Enable Input

WE Write Enable Input

OE Output Enable Input

VCC Power Supply Pin (2.7V~3.6V)

GND Ground Pin

W986416DH Terminal Function

Pin No.

1, 14, 27 VCC Power (+3.3V) Power for input buffers and logic circuit inside DRAM.

54

V

SS

53

DQ15

52

VssQ

51

DQ14

50

DQ13

49

CC

V

48

DQ12

DQ11

47

V

SS

46

DQ10

45

44

DQ9

V

CC

43

DQ8

42

41

SS

V

NC

40

UDQM

39

38

CLK

CKE

37

36

NC

35

A11

34

A9

33

A8

32

A7

31

A6

30

A5

29

A4

28

Vss

2, 4, 5, 7, 8,

10, 11, 13, DQ0 Data

42, 44, 45, -DQ15 Input/Output Multiplexed pins for data output and input.

47, 48, 50,

51, 53

Q

3, 9, 43, 49 VCCQ

6, 12, 46, 52 VSSQ

Q

15, 39 UDQM Input/Output when DQM is sampled high in read cycle. In write cycle,

Q

16 WE Write Enable Referred to RAS.

17 CAS

18 RAS Strobe the clock RAS, CAS and WE define the operation to

19 CS Chip Select When command decoder is disabled, new command

20, 21

22, 23~26,

29~35 A10 is sampled during precharge command to

28, 41, 54 VSS Ground Ground for input buffers and logic circuit inside DRAM.

36, 40 NC No Connection No Connection

37 CKE Clock Enable When CKE is low. Power Down mode, Suspend mode,

38 CLK Clock Inputs

Pin

Name

DescriptionFunction

Power (+3.3V) Separated power from VCC, to improve

for I/O buffer DQ noise immunity.

Ground for Separated ground from VSS, to improve

I/O buffer DQ noise immunity.

The output buffer is placed at HI-Z (with latency of 2)

LDQM mask sampling DQM high will block the write operation with

zero latency.

Column Address

Strobe

Referred to RAS.

Row Address Command input. When sampled at the rising edge of

be executed.

Disable or enable the command decoder.

is ignored and previous operation continues.

BS0,

BS1 or bank to read/write during address latch time.

Bank Select

Select bank to activate during row address latch time,

Multiplexed pins for row and column address.

A0-A11 Address

Row address: A0-A11. Column address: A0-A7.

determine if all banks are to be precharged or bank

selected by BS0, BS1.

CKE controls the clock activation and deactivation.

or Self Refresh mode is entered.

System clock used to sample inputs on the rising

edge of clock.

22

DVD-9000/DVD-A1

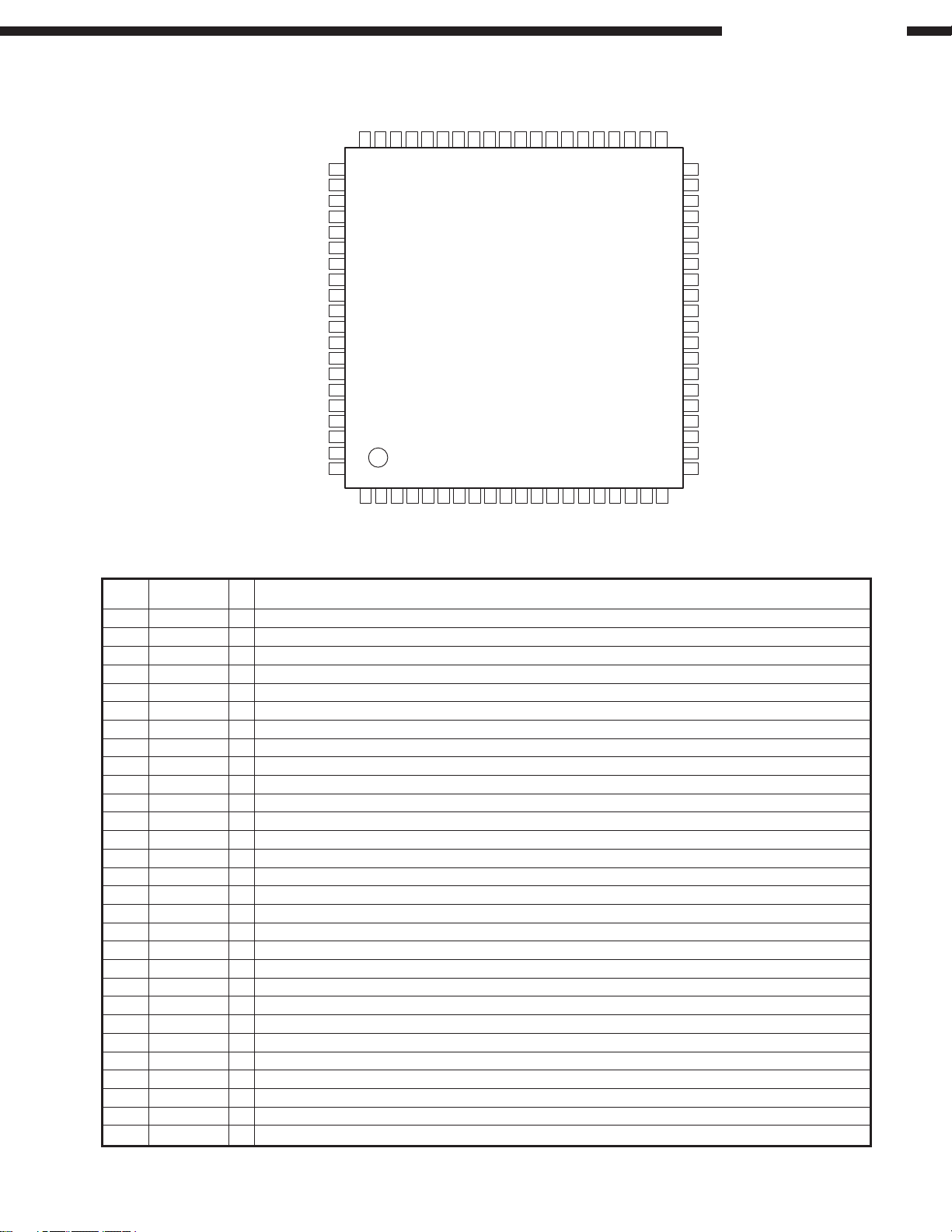

SM8701BM (IC109)

P/S

V

GND

XTO

XTI

GNDP

V

DD

DD

V

MO

1

2

DD

3

4

5

6

7

P

8

3

9

10

MLEN/R2

20

19

18

17

16

15

14

13

12

11

MCK/R1

MDT/R0

RSTN

SO3

DD

O

V

GNDO

SO2

SO4

SO1

MON

SM8701BM Terminal Function

Pin No.

Pin Name Function

1 MLEN/R2 Ip

2 P/S Ip

3VDD 5V supply (Digital block)

4 GND Ground (Digital block)

5 XTO O Reference signal crystal oscillator element connection

6 XTI I

7 GNDP Ground (PLL block)

8VDDP 5V supply (PLL block)

9VDD3 3.3V supply (output buffer)

10 MO O 27 MHz fixed-frequency output

11 MON O 27 MHz fixed-frequency output (inverted)

12 SO1 O 33.8688 MHz fixed-frequency output

13 SO4 O 768fs output

14 SO2 O 256fs output

15 GNDO Ground (output buffer)

16 VDDO 3.3V supply (output buffer)

17 SO3 O 384fs output

18 RSTN Ip2LOW-level reset input

19 MDT/R0 Ip1In serial mode: control data input signal

20 MCK/R1 Ip1In serial mode: clock signal

Note: 1. Schmitt trigger input with pull-down resistor

2. Schmitt trigger input with pull-up resistor

I/O

Control signal input.

1

In serial mode: latch enable signal

In parallel mode: sampling rate select signal

Mode select signal.

1

LOW: serial mode, HIGH: parallel mode

Reference signal crystal oscillator element connection

or external clock input

Control signal input.

In parallel mode: sampling frequency select signal

Control signal input.

In parallel mode: sampling frequency select signal

TC7W32F (IC107)

1A

1

1B

2

2Y

3

GND

4

TC74VHC157AF

SELECT

1A

1B

1Y

2A

2B

2Y

GND

1

2

3

4

TOP

VIEW

5

6

7

8

Vcc

8

1Y

7

2B

6

2A

5

(IC113)

16

15

14

13

12

11

10

TC7WH157FU (IC112, 503)

1

A

2

B

3

Y

4

GND

MN1382-S

(IC203)

2

Vcc

ST

4A

4B

4Y

3A

3B

3Y

9

TOP

VIEW

1

3

8

Vcc

7

ST

6

SELECT

5

Y

1 OUT Reset Out

2 VDD Power

3 Vss GND

23

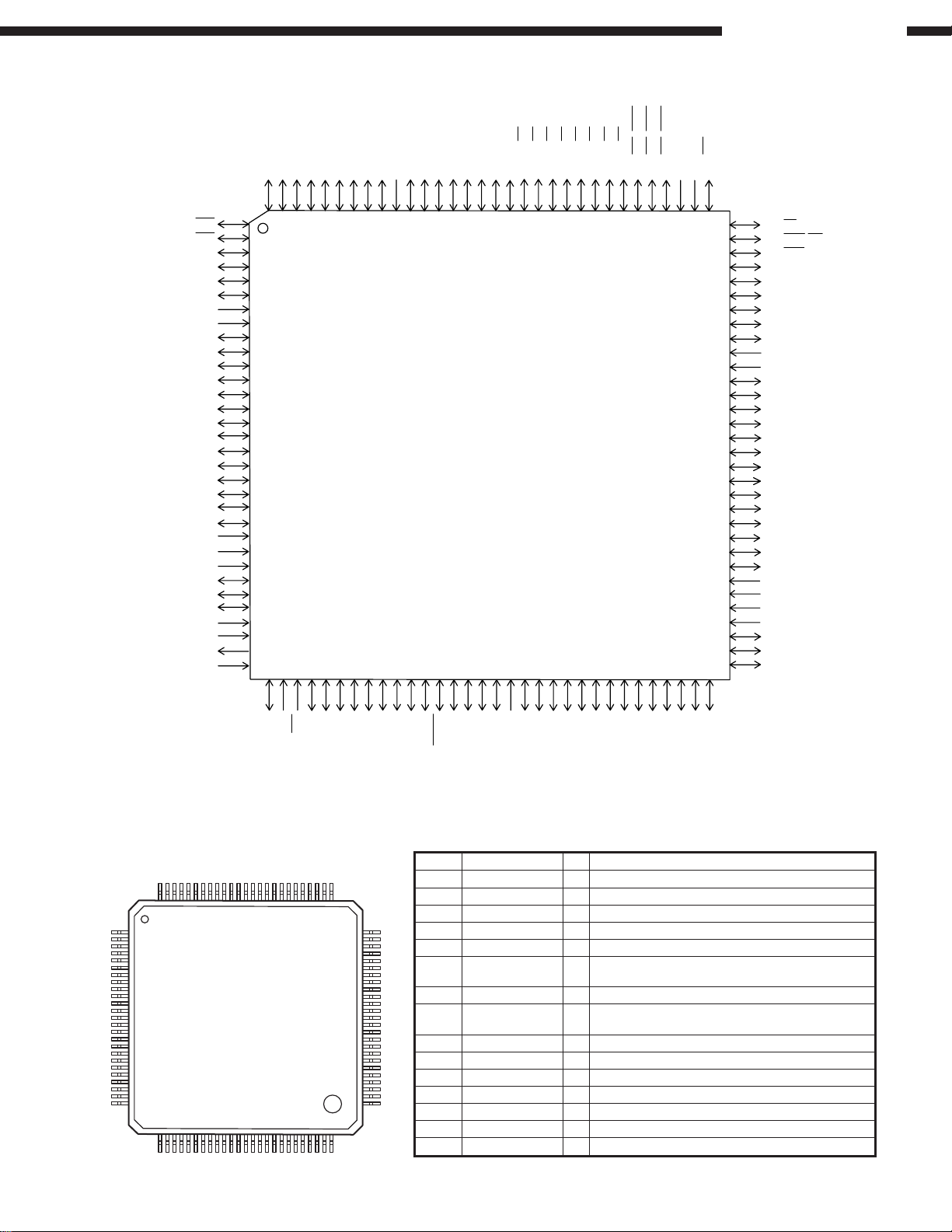

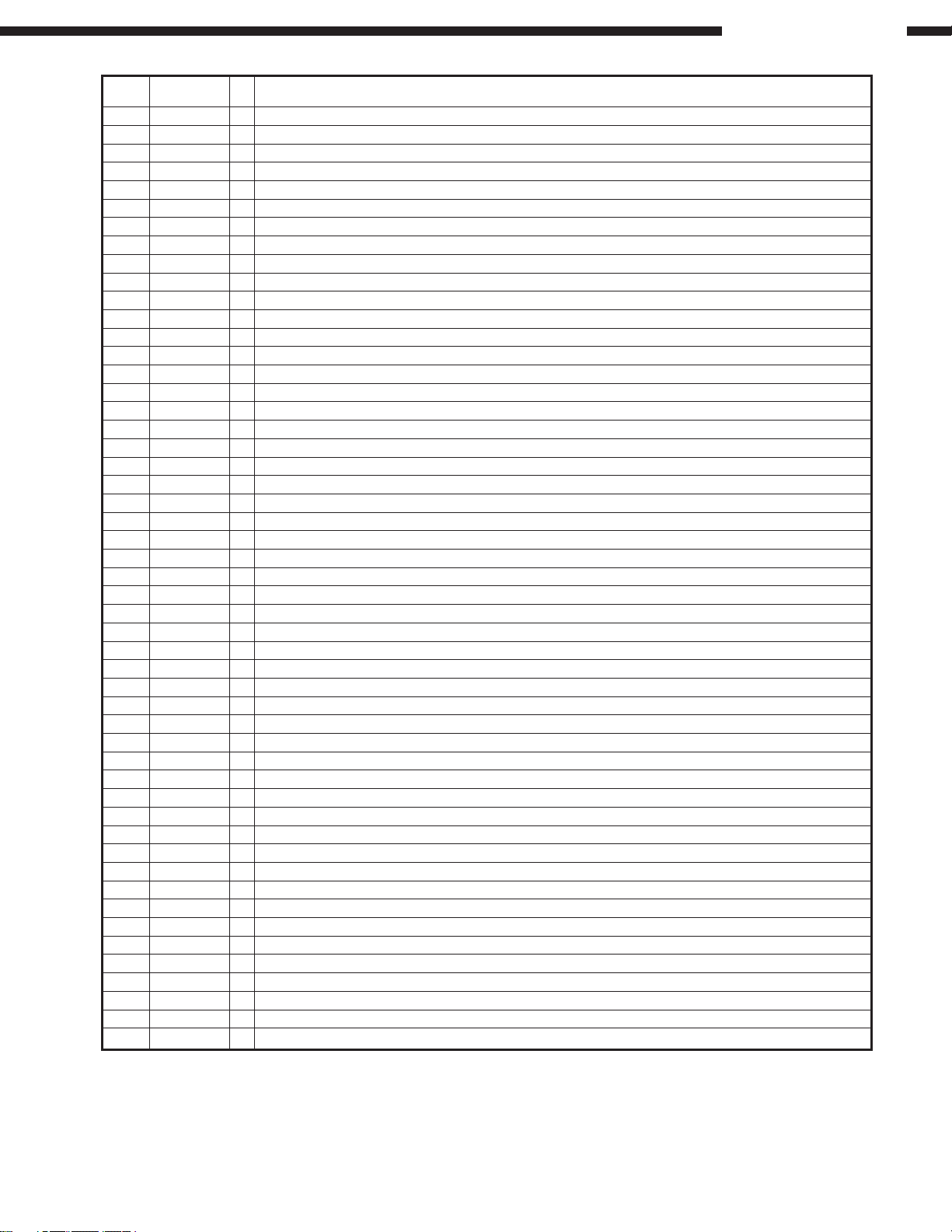

MN102H460B (IC201)

P45,A21

P44,A20

P43,A19

P42,A18

P41,A17

P40,A16

P37,A15

P36,A14

PC4,TM12O,TM8I,TM21IA

VDD(VPP)

P35,A13

P34,A12

P33,A11

P32,A10

P31,A9

PD7,RTP7

PD6,RTP6

P30,A8

P27,A7, KI7,TMI17B

P26,A6, KI6

P25,A5, KI5

P24,A4, KI4

P23,A3, KI3

P22,A2, KI2

P21,A1, KI1

P20,A0, KI0

P56, CS3, UCAS,BIBT2

P55, CAS, LCAS,BIBT1

P54, RAS, RFSH

VSS

VDD

P53, CS2,ALE

DVD-9000/DVD-A1

P46,A22, CS0

P47,A23, CS1

P00,AD0,D0

P01,AD1,D1

P02,AD2,D2

P03,AD3,D3

VDD

VSS

P04,AD4,D4

P05,AD5,D5

P06,AD6,D6

P07,AD7,D7

P10,AD8,D8

P11,AD9,D9

P12,AD10,D10

PD0,RTP0

PD1,RTP1

P13,AD11,D11

P14,AD12,D12

P15,AD13,D13

P16,AD14,D14

P17,AD15,D15

MODE0

MODE1

MODE2

PC3,TM10O,TM7I,TM21IR

PC2,TM8O,TM6I

PC1,TM6O,TM11I

VDD

OSCI

OSCO

VSS

128 126 124 122 120 118 116 114

127 125 123 121 119 117 115 113

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33 35 37 39 41 43 45 47

34 36 38 40 42 44 46 48

TOP VIEW

112 110 108 106 104 102 100 98

111 109 107 105 103 101 99 97

49 51 53 55 57 59 61 63

50 52 54 56 58 60 62 64

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

P52, RE

P51, WEH,WE

P50, WEL

PC7,NBRACK

PC6,NBREQ

P97,AN15,TM20IB

P96,AN14,TM15O,TM19IB

P95,AN13,TM13O,TM2I

P94,AN12,TM11O,TM4I

AVDD

VREFH

P93,AN11

P92,AN10

P91,AN9

P90,AN8

PD5,RTP5

PD4,RTP4

P87,AN7

P86,AN6

P85,AN5

P84,AN4

P83,AN3

P82,AN2

P81,AN1

P80,AN0

VREFL

AVSS

VSS

VDD

PB5,SBT3,SCL3

PB4,SBO3,SDA3

PB3,SBI3

EPM3128A (IC204)

100

1

25

26

RST

PC5,NMI

PC0,TM4O,TM10I

P57,/DUMX,BOSC

P60,IRQ0

P76,TM19IOA

P61,IRQ1,TM3I

76

75

51

50

VDD

P62,IRQ2,TM16IA

P63,IRQ3,TM16IB

P64,IRQ4,TM17IA

P65,IRQ5,TM18IA

P66,IRQ6

PD2,RTP2

P70,TM16OA

P67,IRQ7, EXTDK

P71,TM16OB,WDOUT

PD3,RTP3

P77,TM20IOA

EPM3128A Terminal Function

Pin No.

24, 25 BITLENG[2:1] O Input data bit length detect pulse for DATA IN1

Pin Name Function

46 DATA IN1 I PCM audio data input 1

47 DATA IN2 I PCM audio data input 2

48 DATA IN3 I PCM audio data input 3

45 WCK IN I PCM audio data word clock input

90 BCK IN I PCM audio data bit clock input (64fs rate)

23 HI_FS I

89 PRES I Reset signal, negative logic

87 MCLK I

10 TEST I Test signal

70 DATA OUT1 O PCM audio data output 1

69 DATA OUT2 O PCM audio data output 2

68 DATA OUT3 O PCM audio data output 3

77 WCK OUT O PCM audio data word clock output

79 BCK OUT O PCM audio data bit clock output

P72,TM17OA

P74,TM18OA

P73,TM17OB,STOP

P75,TM18IOB,TM21ID

I/O

PA0,SBI0

PA3,SBI1

PA2,SBT0

PA1,SBO0

PA5,SBT1,SCL1

PA4,SBO1,SDA1

PB0,SBI2,TM16IC

PB2,SBT2,TM18IC

PB1,SBO2,TM17IC

H: when input data sampling frequency is

196kHz, 176.4kHz

Master clock input

(128fs equiv.: fs=192kHz, MCLK=24.576MHz)

24

DVD-9000/DVD-A1

D

AK4101VQ (IC205)

33 23

34

44

111

22

12

AK4101VQ Terminal Function

Pin No.

Pin Name Function

1 PDN I Power down and reset pin

2 MCLK I Master clock input pin

3 SDTI1 I Audio serial data input 1 pin

4 SDTI2 I Audio serial data input 2 pin

5 SDTI3 I Audio serial data input 3 pin

6 SDTI4 I Audio serial data input 4 pin

7 VDD Power pin, 4.75V ~ 5.25V

8 VSS Ground pin

9 BICK I/O Audio serial data clock in/out pin

10 LRCK I/O In/out channel clock pin

FS0 I Sampling frequency select 0 pin (sync. mode)

11 CSN I Host I/F chip select pin (async. mode)

AKMODE I AK4112A mode pin (audio rooting mode)

FS1 I Sampling frequency select 1 pin (sync. mode)

12

CDTI I Host I/F data input pin (async. mode)

FS2 I Sampling frequency select 2 pin (sync. mode)

13

CCLK I Host I/F bit clock input pin (async. mode)

FS3 I Sampling frequency select 3 pin (sync. mode)

14

CDTO O Host I/F data output pin (async. mode)

15 C1 I CH1 status bit input pin

16 C2 I CH2 status bit input pin

17 C3 I CH3 status bit input pin

18 C4 I CH4 status bit input pin

19 ANS I Async./Sync. mode select pin

20 BLS I/O Block start in/out pin

21 CKS0 I Clock mode select 0 pin

22 VSS Ground pin

23 CKS1 I Clock mode select 1 pin

24 TXN4 O CH4 differential inver ted output pin

25 TXP4 O CH4 differential non-inverted output pin

26 TXN3 O CH3 differential inver ted output pin

27 TXP3 O CH3 differential non-inverted output pin

28 VDD Power pin, 4.75V ~ 5.25V

29 VSS Ground pin

30 TXN2 O CH2 differential inver ted output pin

31 TXP2 O CH2 differential non-inverted output pin

32 TXN1 O CH1 differential inver ted output pin

33 TXP1 O CH1 differential non-inverted output pin

34 DIF0 I Audio serial I/F select 0 pin

35 VDD Power pin, 4.75V ~ 5.25V

36 DIF1 I Audio serial I/F select 1 pin

37 DIF2 I Audio serial I/F select 2 pin

38 U1 I CH1 user data bit input pin

39 U2 I CH2 user data bit input pin

40 U3 I CH3 user data bit input pin

41 U4 I CH4 user data bit input pin

42 V12 I CH1&2 validity bit input pin

43 V34 I CH3&4 validity bit input pin

44 TRANS I Audio rooting mode pin (sync. mode)

I/O

AT49LV1025-70JC (IC202)

I/O 13

I/O 14

I/O 15CENCNCVCCWENC

I/O12

I/O11

I/O10

I/O9

I/O8

GND

NC

I/O7

I/O6

I/O5

I/O4

65432

7

8

9

10

11

12

13

14

15

16

17

181920212223242526

I/O3

I/O2

1

4443424140

TOP VIEW

A0

NC

OE

I/O1

I/O 0

A1

A2A3A4

A15

27

A14

28

AT49LV002-70TC (IC210)

1

A11

2

A9

3

Terminal Function

A13

39

A12

38

37

36

35

34

33

32

31

30

29

Pin Name

A11

A0-A15

A10

A9

GND

NC

I/O0-I/O15 Data Inputs/Outputs

A8

A7

A6

A5

CE

OE

WE

NC

Address Inputs

Chip Enable

Output Enable

Write Enable

No Connection

Function

A8

A13

A14

A17

WE

V

RESET

A16

A15

A12

A7

A6

A5

A4

4

5

6

7

8

CC

9

10

11

12

13

14

15

16

32

OE

31

A10

30

CE

29

I/O7

28

I/O6

27

I/O5

26

I/O4

25

I/O3

24

GN

23

I/O2

22

I/O1

21

I/O0

20

A0

19

A1

18

A2

17

A3

25

DVD-9000/DVD-A1

ADSPMEL322 (IC207)

D14

D15

HAD0

HAD1

GND

HAD2

HAD3

HAD4

HAD5

HAD6

HAD7

HAD8

V

DDEXT

HAD9

HAD10

GND

HAD11

HAD12

V

DDINT

HAD13

HAD14

HAD15

HA16

HACK_P

V

DDEXT

HACK

HCMS

HCIOMS

GND

HALE

HRD

HWR

GND

PF0

PF1

PF2

144

143

142

141

140

139

138

137

136

135

134

133

132

131

130

129

128

127

126

125

124

123

122

121

120

119

118

117

116

DDEXT

V

D12

D11

D9D8D7D6D5

D10

GND

XTAL

D13

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

GND

DDEXT

V

CLKIN

CLKOUT

TOP VIEW

D4

D3D2D1

DDINT

V

D0

RD

WR

ACK

MS3

DDEXT

V

MS2

MS1

3738394041424344454647484950515253545556575859606162636465666768697071

115

MS0

114

113

BMS

IOMS

112

111

110

BR

BG

BGH

V

V

OPMODE

V

TRST

RESET

109

A21

A20

A19

A18

GND

A17

A16

A15

A14

DDEXT

A13

A12

A11

A10

A9

GND

A8

A7

A6

DDEXT

A5

A4

A3

A2

A1

A0

DDINT

EMU

GND

TCK

GND

TMS

TDI

TDO

72

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

XC2S30-5VQ100C (IC711)

VCCO

NC(TDO)

GND

NC(TDI)

YOUT<6>

YOUT<5>

YOUT<4>

YOUT<3>

YOUT<2>

VCCINT

YOUT<1>

YOUT<0>

NC

GND

VCCO

CLOCK

VCCINT

BYPASS

VCCINT

GRAYBITS<0>

GRAYBITS<1>

YDATA<9>

YDATA<8>

NC(TCK)

VCCO

PF3

PF4

PF5

PF6

PF7

DT2

DDEXT

TMR0

TMR1

V

CCLKNCDIN

75747372717069686766656463626160595857565554535251

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

1234567

GND

TMS

YDATA<7>

YOUT<7>

YOUT<8>

YDATA<6>

YDATA<5>

YOUT<9>

COUT<0>

YDATA<4>

YDATA<3>

DR2

TFS2

TMR2

COUT<1>

8

RFS2

TCLK2

RCLK2

COUT<2>

COUT<3>

COUT<4>

9

101112131415161718192021222324

GND

YDATA<2>

YDATA<1>

YDATA<0>

TXD

RXD

GND

VCCO

GND

GND

VCCO

NC

DT0

TCLK0

DELAYHSYNC

VCCINT

VCCINT

CDATA<9>

DDINT

TFS0

V

LAYVSYNC

CDATA<8>

DT1

DR0

DDEXT

RFS0

V

TCLK1

RCLK0

DELAYBLANKNCCOUT<5>

CDATA<7>

CDATA<6>

CDATA<5>

COUT<6>

CDATA<4>

TFS1

COUT<7>

CDATA<3>

DR1

RCLK1

COUT<8>

CDATA<2>

RFS1

BMODE0

BMODE1

COUT<9>

INIT-

M1

GND

BYPASS

NC

VCCO

50

49

DONE

48

GND

47

NC

46

NC

45

NC

44

NC

43

NC

42

VCCINT

41

RESET

40

BLANK

39

NC

38

GND

37

VCCO

36

NC

35

VCCINT

34

VSYNC

33

VCCINT

32

HSYNC

31

CDATA<0>

30

CDATA<1>

29

NC

28

NC

27

M2

26

VCCO

25

M0

26

TA1293F (IC501)

LDO1

MDI1

EQF

EQB

RFDC

GND2

EQDNCVcc2

60595857565554535251504948474645444342

VccO

PSC

FEB

TEB

DPDB

VccR

RFO

RPP

RPB

RPO

DVD-9000/DVD-A1

RPZ

41

61

P1TN

62

P1TP

P1FN

63

P1FP

64

LDP1

65

GNDR

66

P1DI

67

P1CI

68

P1BI

69

P1AI

70

LDP2

71

P2AI

72

P2BI

73

P2CI

74

P2DI

75

GNDS

76

P2FP

77

P2FN

78

P2TP

79

P2TN

80

123456789

NC

NC

VrA

MDI2

LDO2

GNDP

TA1293F Terminal Function

Pin Name FunctionPin No. I/O

1 GNDP GND pin

2 LDO2 O Drive pin

3 MDI2 I Monitor pin

4 NC Used connecting with VrA

5 NC Used connecting with VrA

6 VrA O Analog VREF

7 Vrfi Filter capacity for reference

8 VrD O Digital VREF, outputs 1/2 of Vdd

9 Vdd I Power pin, connect Vdd of servo IC

10 DPAC DPD AC coupling capacity 1

11 DPBD DPD AC coupling capacity 2

12 DPD1 DPD integral capacity 1

13 DPD2 DPD integral capacity 2

14 SCB I Control line (bit clock)

15 SCL I Control line (latch signal)

16 SCD I Control line (serial data)

17 VRCK I Ref. clock input

18 NC Used connecting with GND

19 NC Used connecting with GND

20 VCKF Capacity for adjusting time constant

21 VccP Power pin

22 NC Used in open

23 NC Used in open

24 NC Used in open

25 NC Used connecting with GND

26 RFSW I RFO control pin, outputs signal after EQ at L

27 VccS Power pin

28 NC Used in open

29 NC Used connecting with VrA

1011121314151617181920

Vrfi

VrD

Vdd

DPAC

DPBD

DPD1

DPD2

SCB

SCL

SCD

NC

VRCK

NC

VCKF

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

DFTN

NC

NC

NC

NC

NC

FEO

TEO

NC

LVL

NC

NC

NC

VccS

RFSW

NC

NC

NC

NC

VccP

27

DVD-9000/DVD-A1

Pin No.

Pin Name Function

30 NC Used connecting with VrA

31 LVL O Servo addition output

32 NC Used in open

33 TEO O TE output

34 FEO O TE output

35 NC Used connecting with VrA

36 NC Used connecting with VrA

37 NC Used connecting with VrA

38 NC Used connecting with VrA

39 NC Used connecting with VrA

40 DFTN I DPD defect, L: DPD out = Mute

41 RPZ O RF ripple center output

42 RPO O RF ripple output

43 RPB O Bottom of RF ripple

44 RPP O Peak of RF ripple

45 RFO O Equivalent RF output

46 VccR Power pin (RF)

47 DPDB I Pit depth adjustment

48 TEB I TE balance

49 FEB I FE balance

50 PSC I VRCK divide on/off, H: divide off

51 VccO Power pin

52 Vcc2 Power pin

53 NC Connect with VrD, or GND via C

54 EQD I Group delay correction

55 GND2 GND pin

56 RFDC DC feedback capacity

57 EQB I Boost adjustment

58 EQF I Frequency adjustment

59 MDI1 I Monitor input

60 LDO1 O Drive output

61 P1TN I TE(-) input (DVD)

62 P1TP I TE(+) input (DVD)

63 P1FN I FE(-) input (DVD)

64 P1FP I FE(+) input (DVD)

65 LDP1 I APC polarity 1, positive when connected to Vcc

66 GNDR GND pin

67 P1DI I D input (DVD)

68 P1CI I C input (DVD)

69 P1BI I B input (DVD)

70 P1AI I A input (DVD)

71 LDP2 I APC polarity 2, positive when connected to Vcc

72 P2AI I A input (CD)

73 P2BI I B input (CD)

74 P2CI I C input (CD)

75 P2DI I D input (CD)

76 GNDS GND pin

77 P2FP I FE(+) input (CD)

78 P2FN I FE(-) input (CD)

79 P2TP I TE(+) input (CD)

80 P2TN I TE(-) input (CD)

I/O

28

TC9453F (IC505)

to Driver

Digital

IN

Analog

Out

DVD-9000/DVD-A1

LPFN

LPFO

PVREF

VCOREF

VCOF

PVDD

SLCO1

TESM9

TEST2

RFCD

RFDVD

AVDD

RFCT

RFZ1

TEZ1

AWIN

AVSS

FE1

TE1

RFSB

RFRP

AVSS

TESM10

EXTAD

VREF

FOO

TRO

AVDD

AWCTL

FMO

DMO

TEBC

FEBC

DPDC

EQBC

ANMON

/DFCT

VRCK

VSS3

SCD

SCL

SCB

FGIN

NC

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

PDON2

132

PDOP2

131

from

RF-Amp.

(servo signal)

from

RF-Amp.

(RF signal)

PDON1

PDOP1

PESP

PVSS

130

129

128

127

PESV

126

PPW

125

CFC2

CFC1

124

123

VSS3

122

TESM8

121

ADC

RF Signal

Process

PLL

TESM7

TESM6

120

119

TESM5

118

PLCK

117

116

Digital

Servo

Sync

VDD3NCNC

115

114

DSP

BD15

113

BD14

112

BD13

111

Output

1Mbit

DRAM

VSS5

110

I/F

ECC

BD12

109

BD11

108

BD10

107

BD9

106

VSS3

105

1bit DAC

for CD-DA

Clock

PLL

Output

MPU I/F

BD8

BD7

BD6

104

103

102

I/F

Data Out

MPU

BD5

BD4

BD3

BD2

BD1

BD0

VDD5

9998979695949392919089

101

100

/BWU

/BWL

/BCAS

/BRAS

/BOE

VDD3

BA8

88

BA7

87

BA6

86

BA5

85

BA4

84

VSS5

83

BA3

82

BA2

81

BA1

80

BA0

79

VDD3

78

TESM4

77

DIGI

76

TESM3

75

VDD5

74

PDCK

73

/PDRQ

72

/PSYC

71

PD8

70

PD7

69

PD6

68

PD5

67

VSS3

66

PD4

65

PD3

64

PD2

63

PD1

62

VSS5

61

PD0

60

VDD3

59

VMCK

58

SMCK

57

NC

56

NC

55

VDD5

54

MD7

53

MD6

52

MD5

51

MD4

50

MD3

49

MD2

48

MD1

47

MD0

46

45

/MINT

123456789

NC

NC

LO

RO

DVR

DVSS

DVDD

DVSS

101112131415161718192021222324252627282930313233343536373839404142

XI

XO

XVSS

XVDD

VSS3

VDD3

TESM0

TESM1

TESM2

VSS3

VPFC

MON0

MON1

MON2

MON3

MON4

MON5

VLPF1

VLPF0

TEST0

MON6

NC

NC

VSS3

FLGA

VDD3

MON7

MON8

MON9

FLGB

TEST1

43

44

/MA

/RST

/MCE

/MRD

/MWR

29

TC9453F Terminal Function

DVD-9000/DVD-A1

Pin No.

Pin Name Function

1NC

2NC

3DVSS GND for DAC

4 RO O R-ch output signal, Analog output pin

5DVDD Power for DAC

6 DVR O Amp ref. signal output, Analog input pin

7 LO O L-ch output signal, Analog output pin

8DVSS GND for DAC

9XVSS GND for oscillator

10 XI I X’tal osc. input, Analog input pin

11 XO O X’tal osc. output, Analog output pin

12 XVDD Power for oscillator

13 TESM0 Test pin, Connect to GND

14 TESM1 Test pin, Open

15 TESM2 Test pin, Connect to VDD3

16 VDD3 3.3V digital power

17 VSS3 3.3V digital GND

18 VPFC O Clock PLL block phase/freq. comparator out, Analog output pin

19 TEST0 I Test mode pin, Connect to VDD3

20 VLPFI I VCO block filter input for clock PLL, Analog input pin

21 VLPFO O VCO block filter output for clock PLL, Analog output pin

22 VSS3 3.3V digital GND

23 MON0 O Test monitor

24 MON1 O Test monitor

25 MON2 O Test monitor

26 MON3 O Test monitor

27 MON4 O Test monitor

28 MON5 O Test monitor

29 MON6 O Test monitor

30 MON7 O Test monitor

31 MON8 O Test monitor

32 MON9 O Test monitor

33 VDD3 3.3V digital power

34 NC

35 NC

36 TEST1 I Test mode pin, Connect to VDD3

37 FLGA I/O Universal I/O or flag monitor

38 FLGB I/O Universal I/O or flag monitor

39 VSS3 3.3V digital GND

40 /RST I Reset pin, Pull-up resister built-in

41 /MA I µcom address enable signal, Fail-safe pin

42 /MRD I µcom data read signal, Fail-safe pin

43 /MWR I µcom data write signal, Fail-safe pin

44 /MCE I µcom chip enable signal, Fail-safe pin

45 /MINT O µcom interrupt signal, Open drain pin

46 MD0 O µcom data bus

47 MD1 O µcom data bus

48 MD2 O µcom data bus

49 MD3 O µcom data bus

50 MD4 O µcom data bus

51 MD5 O µcom data bus

52 MD6 O µcom data bus

53 MD7 O µcom data bus

54 VDD5 Power for 5V

55 NC

56 NC

57 SMCK O 22M block clock output

58 VMCK O Data output block (signal processing system) clock output

I/O

30