Page 1

For Europe model

SERVICE MANUAL

MODEL

HOME THEATER SYSTEM

HOME THEATER SYSTEM (DHT-500SD) consists of DVD SURROUND

RECEIVER (ADV-500SD) and SPEAKER SYSTEM (SYS-500SD).

DHT-500SD

注 意

Ver. 3

Please refer t o t he

MODIFICATION NOTICE.

For purposes of improvement, specifications and

●

design are subject to change without notice.

Please use this service manual with referring to

●

the operating instructions without fail.

Some illustrations using in this service manual are

●

slightly different from the actual set.

Denon Brand Company, D&M Holdings Inc.

サービスをおこなう前に、このサービスマニュアルを

必ずお読みください。本機は、火災、感電、けがなど

に対する安全性を確保するために、さまざまな配慮を

おこなっており、また法的には「電気用品安全法」に

もとづき、所定の許可を得て製造されております。

従ってサービスをおこなう際は、これらの安全性が維

持されるよう、このサービスマニュアルに記載されて

いる注意事項を必ずお守りください。

● 本機の仕様は性能改良のため、予告なく変更すること

● 補修用性能部品の保有期間は、製造打切後

●

● 本文中に使用しているイラストは、説明の都合上現物

TOKYO, JAPAN

があります。

8年です。

修理の際は、必ず取扱説明書を参照の上、作業を行って,

ください。

と多少異なる場合があります。

X0198V.03 DE/CDM 0607

Page 2

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power

cord is less than 460 kohms, the unit is defective.

LASER RADIATION

Do not stare into beam or view directly with optical instruments, class 3A laser product.

DHT-500SD

CAUTION

Please heed the points listed below during servicing and inspection.

◎ Heed the cautions!

Spots requiring particular attention when servicing, such as

the cabinet, parts, chassis, etc., have cautions indicated on

labels or seals. Be sure to heed these cautions and the cautions indicated in the handling instructions.

◎ Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching inter-

nal metal parts when the set is energized could cause

electric shock. Take care to avoid electric shock, by for example using an isolating transformer and gloves when

servicing while the set is energized, unplugging the power

cord when replacing parts, etc.

(2)There are high voltage parts inside. Handle with extra care

when the set is energized.

◎

Caution concerning disassembly and assembly!

Though great care is taken when manufacturing parts from

sheet metal, there may in some rare cases be burrs on the

edges of parts which could cause injury if fingers are moved

across them. Use gloves to protect your hands.

◎ Only use designated parts!

The set's parts have specific safety properties (fire resistance, voltage resistance, etc.). For replacement parts, be

sure to use parts which have the same properties. In particular, for the important safety parts that are marked ! on wiring

diagrams and parts lists, be sure to use the designated parts.

◎ Be sure to mount parts and arrange the

wires as they were originally!

For safety reasons, some parts use tape, tubes or other insulating materials, and some parts are mounted away from the

surface of printed circuit boards. Care is also taken with the

positions of the wires inside and clamps are used to keep

wires away from heating and high voltage parts, so be sure to

set everything back as it was originally.

◎ Inspect for safety after servicing!

Check that all screws, parts and wires removed or disconnected for servicing have been put back in their original positions, inspect that no parts around the area that has been

serviced have been negatively affected, conduct an insulation

check on the external metal connectors and between the

blades of the power plug, and otherwise check that safety is

ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect the

antenna, plugs, etc., and turn the power switch on. Using a

500V insulation resistance tester, check that the insulation resistance between the terminals of the power plug and the externally exposed metal parts (antenna terminal, headphones

terminal, microphone terminal, input terminal, etc.) is 1MΩ or

greater. If it is less, the set must be inspected and repaired.

CAUTION

Many of the electric and structural parts used in the set have

special safety properties. In most cases these properties are

difficult to distinguish by sight, and using replacement parts

with higher ratings (rated power and withstand voltage) does

not necessarily guarantee that safety performance will be preserved. Parts with safety properties are indicated as shown

below on the wiring diagrams and parts lists is this service

manual. Be sure to replace them with parts with the designated part number.

(1) Schematic diagrams ... Indicated by the ! mark.

(2) Parts lists ... Indicated by the ! mark.

Concerning important safety parts

Using parts other than the designated parts

could result in electric shock, fires or other

dangerous situations.

注 意

サービス、点検時にはつぎのことにご注意願います。

◎注意事項をお守りください!

サービスのとき特に注意を必要とする個所についてはキャ

ビネット、部品、シャーシなどにラベルや捺印で注意事項を

表示しています。これらの注意書きおよび取扱説明書などの

注意事項を必ずお守りください。

◎感電に注意!

(1) このセットは、交流電圧が印加されていますので通電時

に内部金属部に触れると感電することがあります。従っ

て通電サービス時には、絶縁トランスの使用や手袋の着

用、部品交換には、電源プラグを抜くなどして感電にご

注意ください。

(2) 内部には高電圧の部分がありますので、通電時の取扱に

は十分ご注意ください。

◎分解、組み立て作業時のご注意!

板金部品の端面の『バリ』は、部品製造時に充分管理をして

おりますが、板金端面は鋭利となっている箇所が有りますの

で、部品端面に触れたまま指を動かすとまれに怪我をする場

合がありますので十分注意して作業して下さい。手の保護の

ために手袋を着用してください。

◎指定部品の使用!

セットの部品は難燃性や耐電圧など安全上の特性を持った

ものとなっています。従って交換部品は、使用されていたも

のと同じ特性の部品を使用してください。特に配線図、部品

表に

!印で指定されている安全上重要な部品は必ず指定の

ものをご使用ください。

◎部品の取付けや配線の引きまわしは、

元どおりに!

安全上、テープやチューブなどの絶縁材料を使用したり、プ

リント基板から浮かして取付けた部品があります。また内部

配線は引きまわしやクランパーによって発熱部品や高圧部

品に接近しないように配慮されていますので、これらは必ず

元どおりにしてください。

◎サービス後は安全点検を!

サービスのために取り外したねじ、部品、配線などが元どお

りになっているか、またサービスした個所の周辺を劣化させ

てしまったところがないかなどを点検し、外部金属端子部

と、電源プラグの刃の間の絶縁チェックをおこなうなど、安

全性が確保されていることを確認してください。

(絶縁チェックの方法)

電源コンセントから電源プラグを抜き、アンテナやプラグな

どを外し、電源スイッチを入れます。500V 絶縁抵抗計を用

いて、電源プラグのそれぞれの端子と外部露出金属部[アン

テナ端子、ヘッドホン端子マイク端子、入力端子など]との

間で、絶縁抵抗値が1 MΩ 以上であること、この値以下の

ときはセットの点検修理が必要です。

注 意

本機に使用している多くの電気部品、および機構部品は安全

上、特別な特性を持っています。この特性はほとんどの場合、

外観では判別つきにくく、またもとの部品より高い定格(定

格電力、耐圧)を持ったものを使用しても安全性が維持され

るとは、限りません。安全上の特性を持った部品は、この

サービスマニュアルの配線図、部品表につぎのように表示し

ていますので必ず指定されている部品番号のものを使用願

います。

(1) 配線図…!マークで表示しています。

(2) 部品表…!マークで表示しています。

安全上重要な部品について

指定された部品と異なるものを使用した場合に

は、感電、火災などの危険を生じる恐れがあり

ます。

2

Page 3

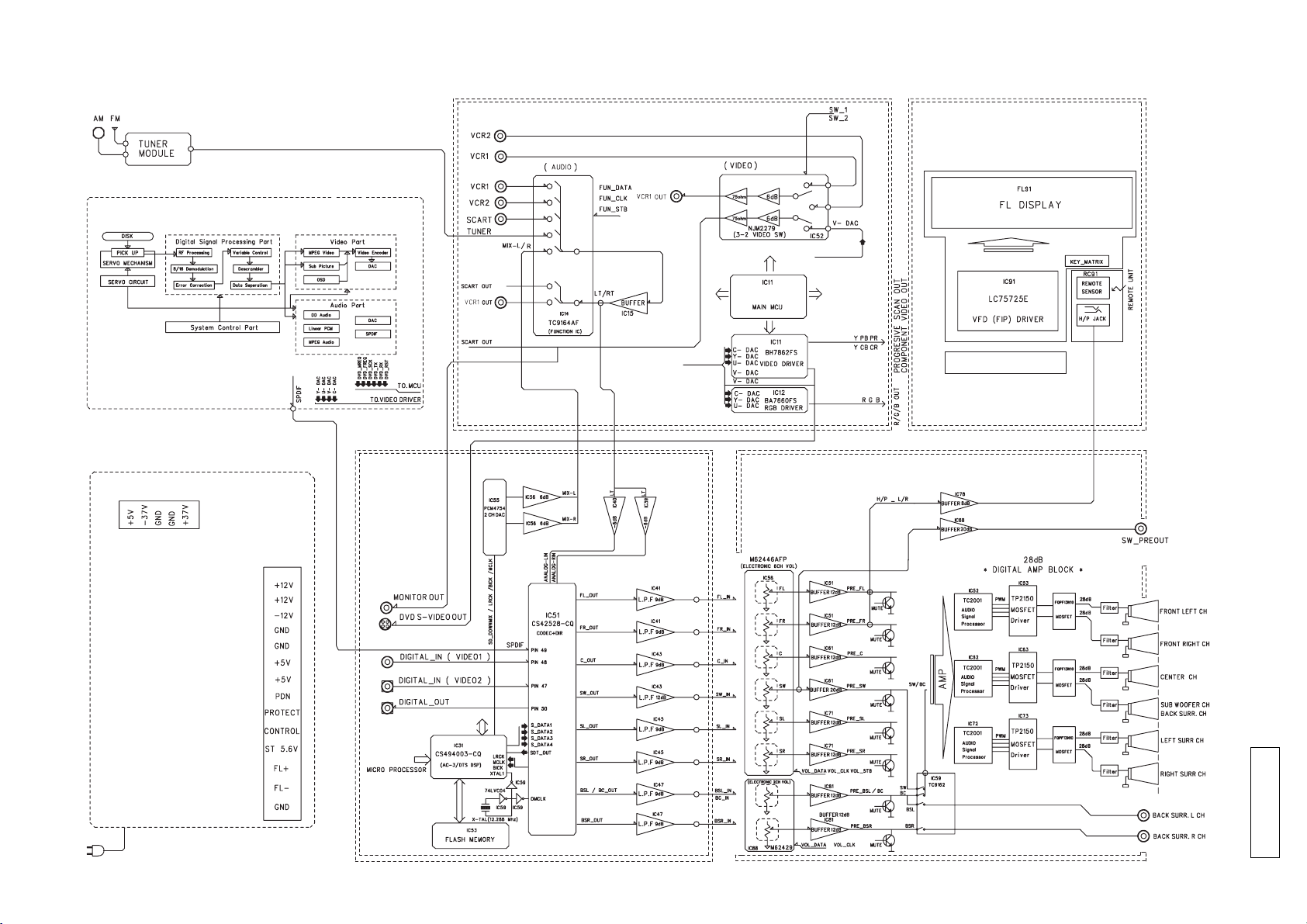

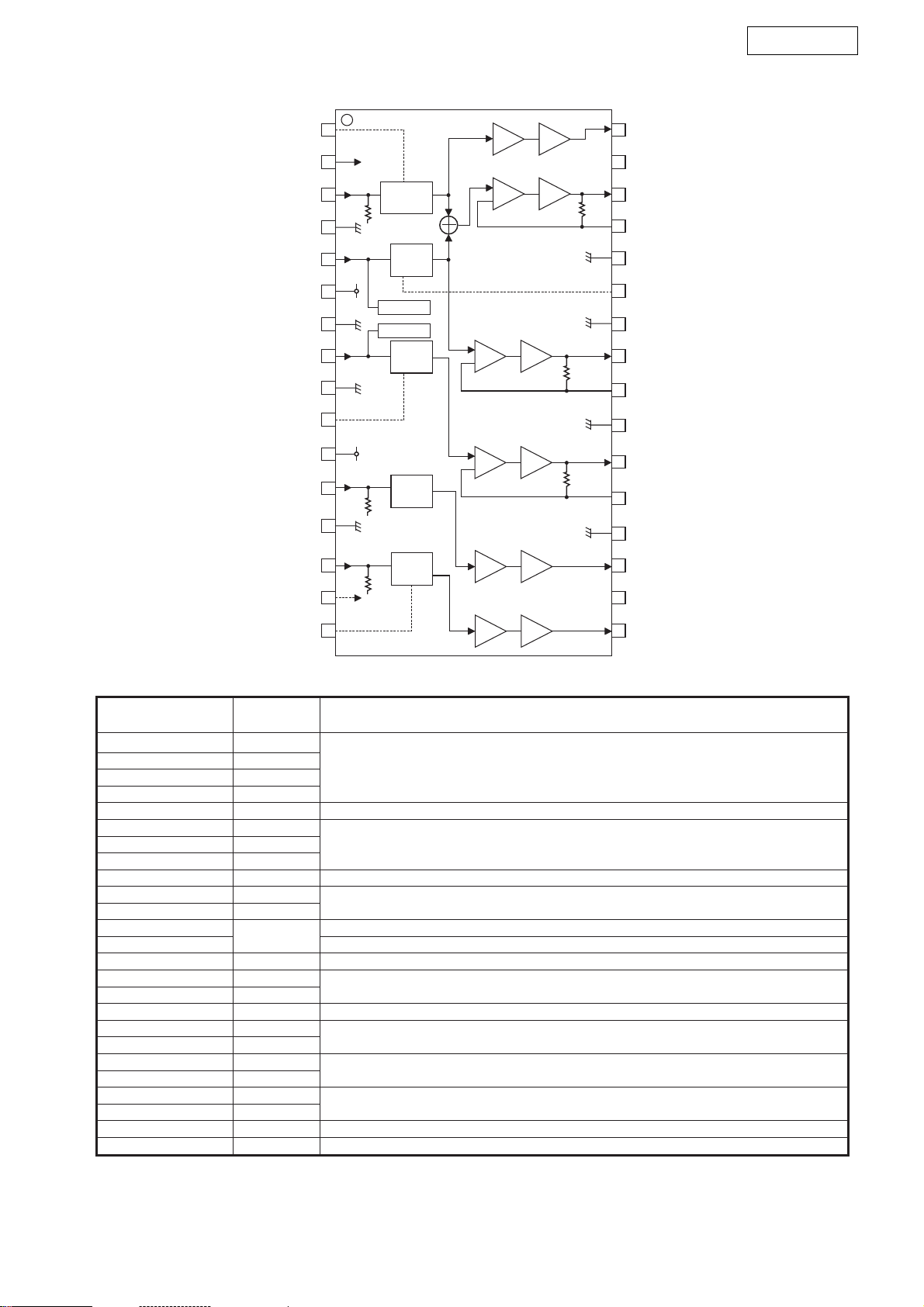

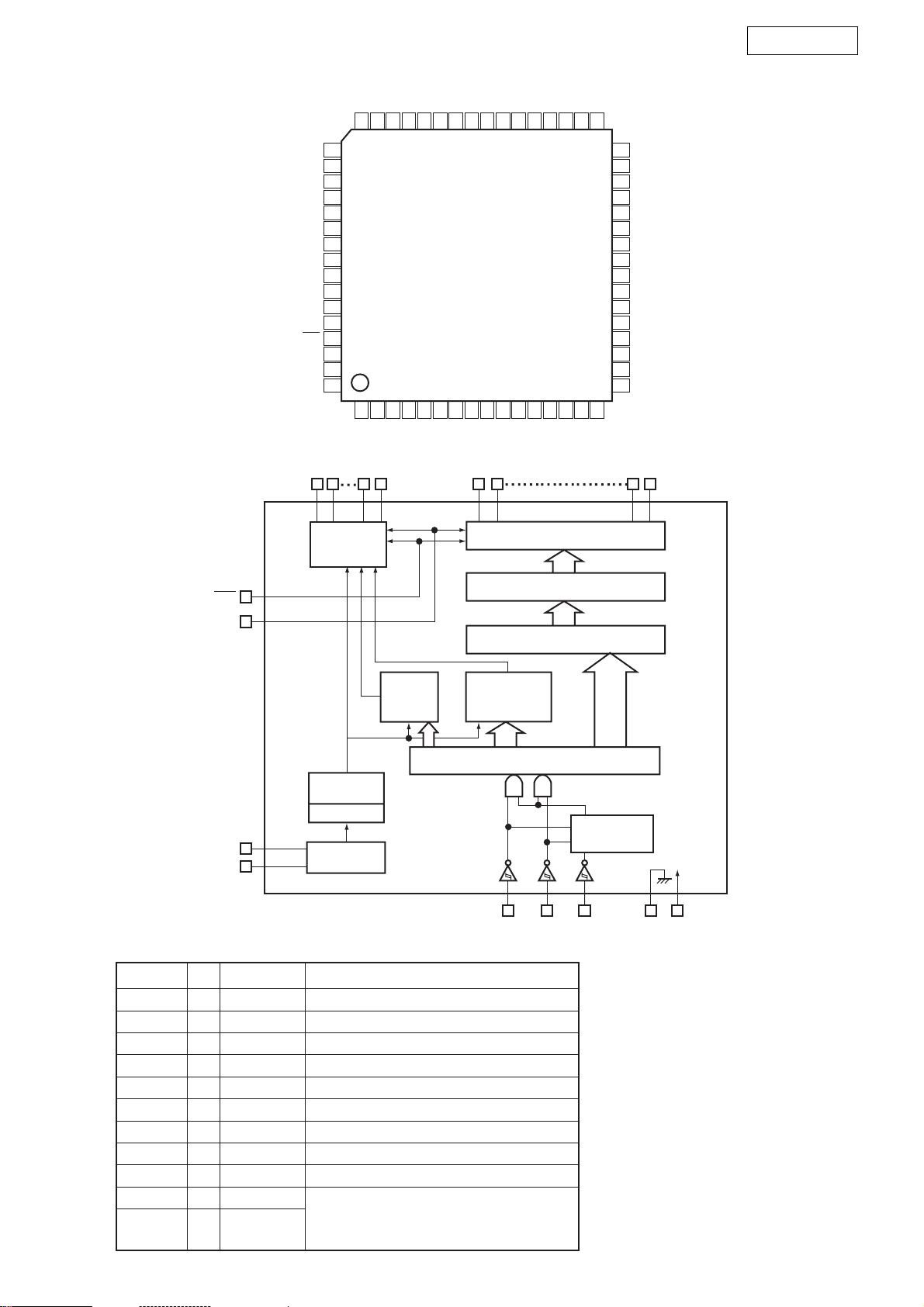

BLOCK DIAGRAM

MAIN P.W.B. UNIT ASS'Y

FRONT P.W.B. UNIT ASS'Y

VFD P.W.B.

MECHANISM(DVD LOADER:RL-874) P.W.B. UNIT ASS'Y

ST92F150CVT1

FROM DVD LOADER

3

TO AMP P.W.B. UNIT ASS'Y

TO CONNECTING P.W.B.

DSP P.W.B.

UNIT ASS'Y

AMP P.W.B. UNIT ASS'Y

CONNECTING P.W.B.

(TO VFD P.W.B. and Main P.W.B. UNIT ASS'Y)

HEAD PHONE P.W.B.

SMPS P.W.B. UNIT ASS'Y

DHT-500SD

Page 4

LEVEL DIAGRAM

DHT-500SD

4

Page 5

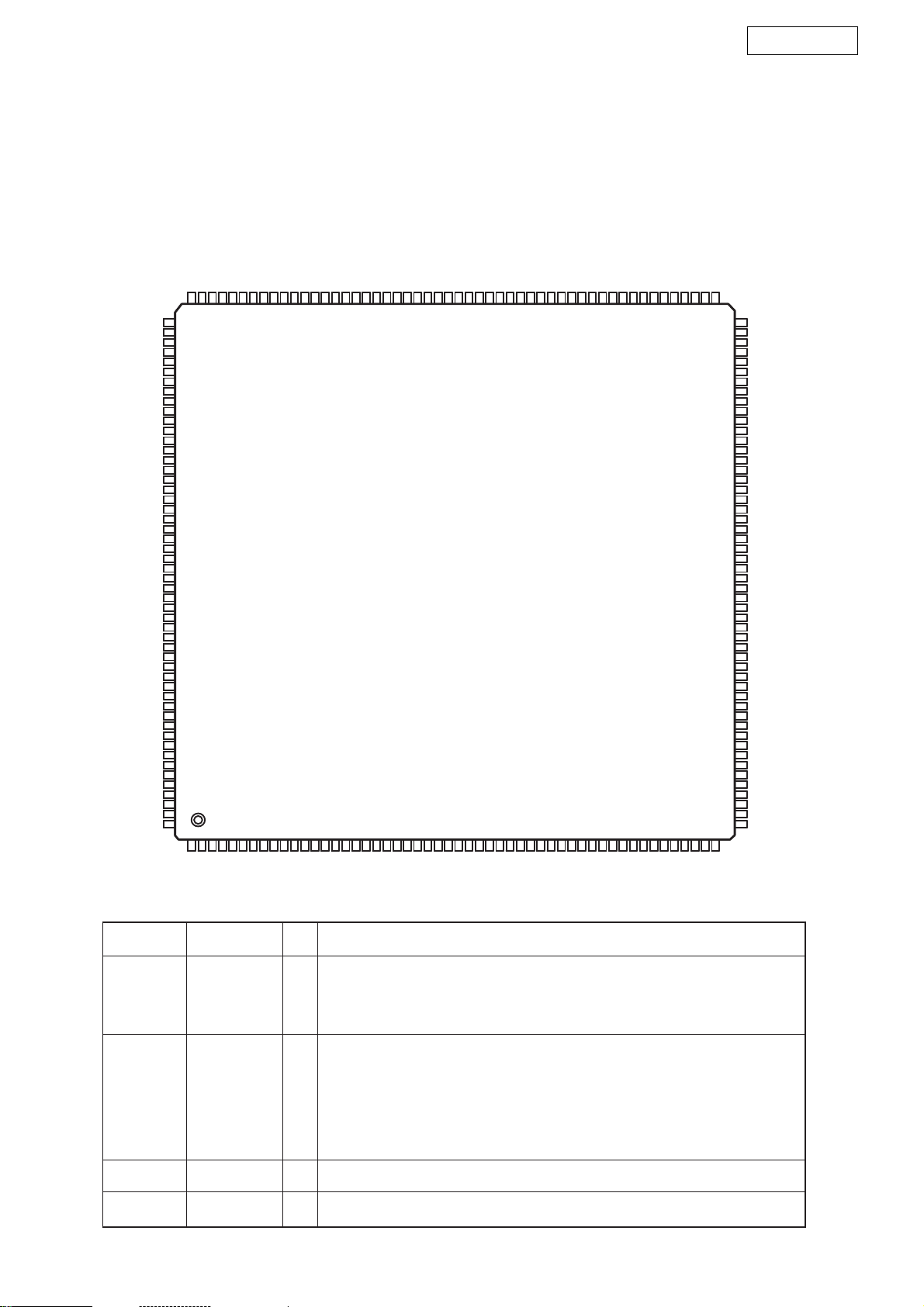

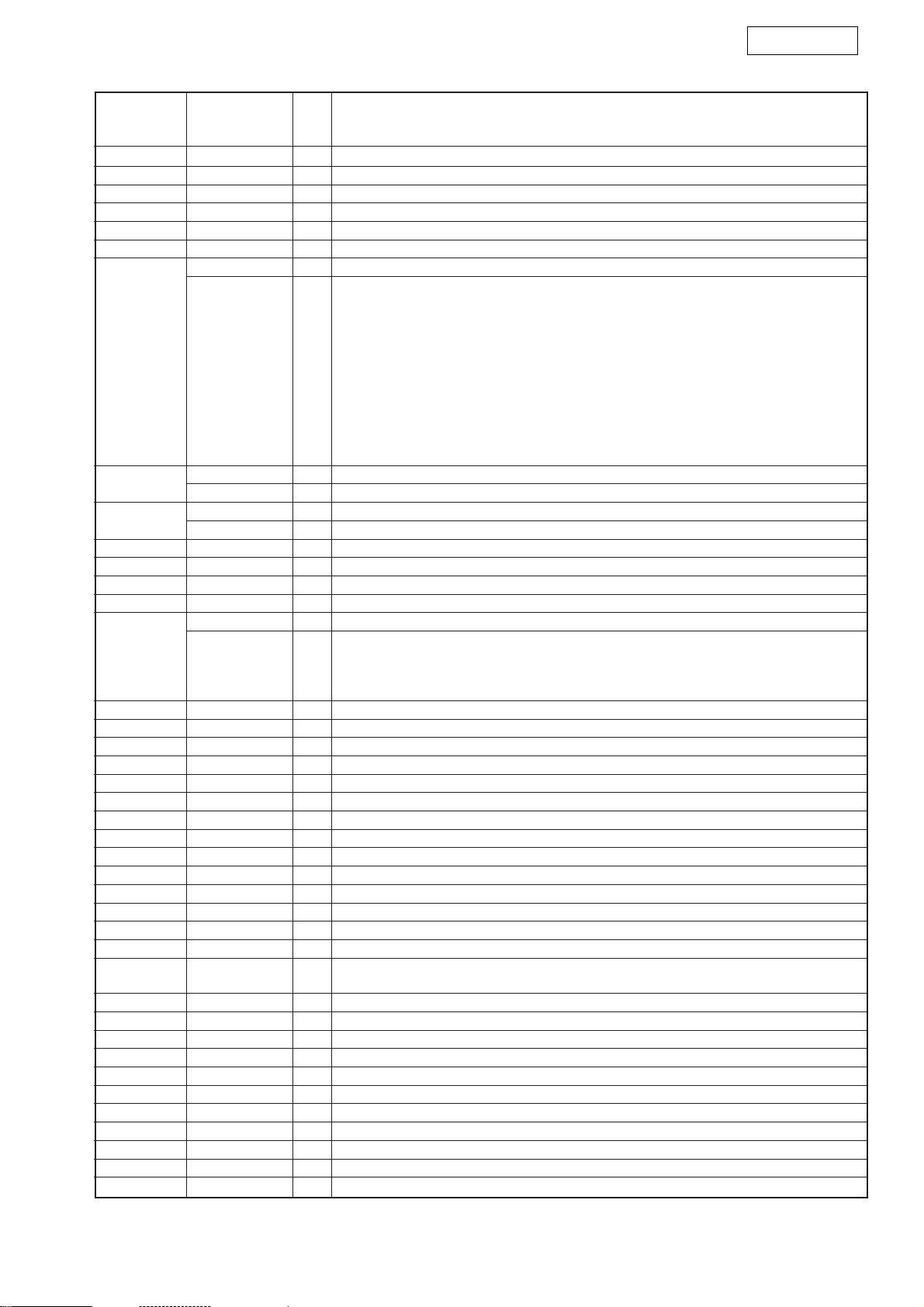

SEMICONDUCTORS / 半導体一覧表

Only major semiconductors are shown, general semiconductors etc. are omitted to list.

主な半導体を記載しています。汎用の半導体は記載を省略しています。

● IC's

Note: Abbreviation ahead of IC No. indicates the name of P.W.B., etc.

注 ): IC No. の前の記号は、基板の名称を表します。

AMP: AMP P.W.B. ME: MECHANISM P.W.B. FR: FRONT P.W.B. SM: SMPS P.W.B.

MA: MAIN P.W.B. DS: DSP P.W.B.

ES6128F (ME: U9)

VSS

HA1

HA0

HCS3FX#

HCS1FX#

HIOCS16#

HRD#

HWR#

VEE

VSS

HIORDY

HRST#

HIRQ

HRDQ#

HWRQ#

HD15

HD14

VCC

VSS

HD13

HD12

HD11

HD10

HD9

HD8

HD7

VEE

VSS

HD6

HD5

HD4

HD3

HD2

HD1

HD0

VCC

VSS

HSYNC#

VSS

HA1

HA0

HCS3FX#

HCS1FX#

HIOCS16#

HRD#

HWR#

VEE

156

155

154

153

152

151

150

149

VEE

VEE

VEE

VEE

AUX[0]

AUX[0]

AUX[1]

AUX[1]

AUX[2]

AUX[2]

VSS

VSS

VEE

VEE

AUX[3]

AUX[3]

AUX[4]

AUX[4]

AUX[5]

AUX[5]

AUX[6]

AUX[6]

AUX[7]

AUX[7]

LOE#

LOE#

VSS

VSS

VCC

VCC

LCS0#

LCS0#

LCS1#

LCS1#

LCS2#

LCS2#

LCS3#

LCS3#

VSS

VEE

VSS

LD10

LD10

LD11

LD11

VSS

VEE

LD12

LD12

LD13

LD13

LD14

LD14

LD15

LD15

LWRLL#

LWRLL#

LWRHL#

LWRHL#

VSS

VEE

CAMIN0

CAMIN0

CAMIN1

CAMIN1

VSS

156

155

154

153

123456789101112131415161718192021222324252627282930313233343536373839404142434445464748495051

123456789101112131415161718192021222324252627282930313233343536373839404142434445464748495051

LA4

LA5

LA6

LA4

LA5

LA6

VEE

VEE

HA2

HA2

VSS

LD0

LD0

LD1

LD1

LD2

LD2

LD3

LD3

LD4

LD4

VEE

VSS

LD5

LD5

LD6

LD6

LD7

LD7

LD8

LD8

LD9

LD9

VSS

VEE

VSS

VEE

LA0

LA0

LA1

LA1

LA2

LA2

LA3

LA3

VSS

157

157

158

158

159

159

160

160

161

161

162

162

163

163

164

164

165

165

166

166

167

167

168

168

169

169

170

170

171

171

172

172

173

173

174

174

175

175

176

176

177

177

178

178

179

179

180

180

181

181

182

182

183

183

184

184

185

185

186

186

187

187

188

188

189

189

190

190

191

191

192

192

193

193

194

194

195

195

196

196

197

197

198

198

199

199

200

200

201

201

202

202

203

203

204

204

205

205

206

206

207

207

208

208

148

152

151

150

149

148

LA7

LA8

LA9

LA7

LA8

LA9

VSS

VSS

VCC

VCC

ES6128 F Terminal Function

VSS

147

147

LA10

LA10

HIORDY

HRST#

146

145

146

145

LA11

LA12

LA11

LA12

HIRQ

144

144

LA13

LA13

HRDQ#

143

143

LA14

LA14

HWRQ#

HD15

142

141

142

141

LA15

LA16

LA15

LA16

HD14

140

140

VSS

VSS

VCC

139

139

VEE

VEE

VSS

138

138

LA17

LA17

HD13

137

137

LA18

LA18

HD12

136

136

LA19

LA19

HD11

135

135

LA20

LA20

HD10

134

134

LA21

LA21

HD9

133

133

RESET#

RESET#

HD8

132

132

TDMDX

TDMDX

HD7

131

131

VSS

VSS

VEE

130

130

VEE

VEE

VSS

129

129

TDMDR

TDMDR

HD6

128

128

TDMCLK

TDMCLK

HD5

127

127

TDMFS

TDMFS

HD4

126

126

TDMTSC#

TDMTSC#

HD3

125

125

TWS/SEL_PLL2

TWS/SEL_PLL2

HD2

124

124

TSD0/SEL_PLL0

TSD0/SEL_PLL0

HD1

123

123

VSS

VSS

HD0

122

122

VCC

VCC

VCC

121

121

TSD1/SEL_PLL1

TSD1/SEL_PLL1

VSS

120

120

TSD2

TSD2

VSYNC#

HSYNC#

VSYNC#

119

118

119

118

TSD3

TSD3

MCLK

MCLK

PCLKQSCN

PCLK2XSCN

YUV7

PCLKQSCN

PCLK2XSCN

YUV7

117

116

115

117

116

115

NC

NC

TBCK

TBCK

SPDIF/PLL3

SPDIF/PLL3

YUV6

YUV6

114

114

VSS

VSS

YUV5

YUV5

113

113

VCC

VCC

VSS

VSS

112

112

RSD

RSD

ADVEE

ADVEE

111

111

RWS

RWS

YUV4

YUV4

110

110

RBCK

RBCK

YUV3

YUV3

109

109

NC

NC

YUV2

YUV2

108

108

XIN

XIN

YUV1

YUV1

107

107

XOUT

XOUT

YUV0

YUV0

106

106

AVEE

AVEE

DCLK

DCLK

105

105

104

104

103

103

102

102

101

101

100

100

52

52

VSS

VSS

99

99

98

98

97

97

96

96

95

95

94

94

93

93

92

92

91

91

90

90

89

89

88

88

87

87

86

86

85

85

84

84

83

83

82

82

81

81

80

80

79

79

78

78

77

77

76

76

75

75

74

74

73

73

72

72

71

71

70

70

69

69

68

68

67

67

66

66

65

65

64

64

63

63

62

62

61

61

60

60

59

59

58

58

57

57

56

56

55

55

54

54

53

53

DHT-500SD

VEE

VEE

VSS

VSS

DSCK

DSCK

DQM

DQM

DCS0#

DCS0#

VEE

VEE

VSS

VSS

DCS1#

DCS1#

DB15

DB15

DB14

DB14

DB13

DB13

DB12

DB12

VEE

VEE

VSS

VSS

DB11

DB11

DB10

DB10

DB9

DB9

DB8

DB8

DB7

DB7

DB6

DB6

VSS

VSS

VCC

VCC

DB5

DB5

DB4

DB4

DB3

DB3

DB2

DB2

DB1

DB1

DB0

DB0

VSS

VSS

VEE

VEE

DMBS1

DMBS1

DMBS0

DMBS0

DRAS#

DRAS#

DWE#

DWE#

DSCK_EN

DSCK_EN

DCAS#

DCAS#

VEE

VEE

VSS

VSS

DMA11

DMA11

DMA10

DMA10

DMA9

DMA9

DMA8

DMA8

DMA7

DMA7

DMA6

DMA6

VSS

VSS

VEE

VEE

DMA5

DMA5

DMA4

DMA4

DMA3

DMA3

DMA2

DMA2

DMA1

DMA1

DMA0

DMA0

1, 18, 27, 59,

68, 75, 92, 99,

104, 130, 148, VEE I I/O power supply.

157, 159, 164,

183, 193, 201

8, 17, 26, 34,

43, 52, 60, 67,

76, 84, 91, 98,

103, 112, 120, VSS I Ground.

129, 138, 147,

156, 163, 171,

177, 184, 192,

200, 208

23:19, 16:10,

7:2, 207:204

9, 35, 44, 83,

121, 139, 172

LA[21:0] O Device address output.

VCC I Core power supply.

FunctionI/OPin No. Pin Name

5

Page 6

DHT-500SD

Pin No. Pin Name

24 RESET# I Reset input, active low.

25 TDMDX O TDMtransmit data.

28 TDMDR I TDM receive data.

29 TDMCLK I TDM clock input.

30 TDMFS I TDM frame sync.

31 TDMTSC# O TDMoutput enable.

TWS O Audio transmit frame sync.

SEL_PLL2 I System and DSCK output clock frequency selection is made at the rising edge of RESET#.

The matrix below lists the available clock frequencies and their respective PLL bit settings.

SEL_PLL2 SEL_PLL1 SEL_PLL0 ClockType

0 0 0 VCO off.

001DCLK

32 0 1 0 Bypass mode

0 1 1 DCLK x 2

1 0 0 DCLK x 4.5

1 0 1 DCLK x 3

1 1 0 DCLK x 3.5z

1 1 1 DCLK x 4

33

36

37 TSD[2] O Audio transmit serial data output 2.

38 TSD[3] O Audio transmit serial data output 3.

39 MCLK I/O Audio master clock for audio DAC.

40 TBCK O Audio transmit bit clock.

41 SEL_PLL3 Clock Source

42,48 NC No connect pins. Leave open.

45 RSD I Audio receive serial data.

46 RWS I Audio receive frame sync.

47 RBCK I Audio receive bit clock.

49 XIN I Crystal input.

50 XOUT O Crystal output.

51 AVEE I Analog power for PLL.

66:61, 58:53 DMA[11:0] O DRAM address bus [11:0]

69 DCAS# O DRAM column address strobe,

70 DSCK_EN O DRAM clock enable.

71 DWE# O DRAM write enable.

72 DRAS# O DRAM row address strobe.

73 DMBS0 O SDRAM bank select 0.

74 DMBS1 O SDRAM bank select 1.

96:93, 90:85,

82:77

97, 100 DCS[1:0]# O SDRAM chip select [1:0]

101 DQM O Data input/output mask.

102 DSCK O Output clock to SDRAM.

105 DCLK I 27 MHz clock input to PLL.

106 UDAC O Video UDAC output.

107 VREF I Internal voltage to video DAC.

108 CDAC O Video CDAC output.

109 COMP I Compensation input.

110 RSET I DAC current adjustment resistor input.

111 ADVEE I Analogpower for video DAC.

113 YDAC O Video YDAC output.

TSD0 O Audio transmit serial data port 0.

SEL_PLL0 I Refer to the description and matrix for SEL_PLL2 pin 32.

TSD1 O Audio transmit serial data port 1.

SEL_PLL1 I Refer to the description and matrix for SEL_PLL2 pin 32.

SPDIF O S/PDIF output.

SEL_PLL3 I Clock source select.

0 Crystal oscillator

1 DCLK input

DB[15:0] I/O DRAM data bus [15:0]

FunctionI/O

6

Page 7

DHT-500SD

Pin No. Pin Name

114 VDAC O Video VDAC output.

115 YUV7 O YUV7 pixel output data.

116 PCLK2XSCN I/O 27 MHz video output pixel clock.

117 PCLKQSCN O 13.5 MHz video output pixel clock.

118 VSYNC# I/O Vertical sync, active low.

119 HSYNC# I/O Horizontal sync, active low.

127:122 HD[5:0] I/O Host data I/O [5:0].

128 HD[6] I/O Host data I/O [6].

131 HD[7] I/O Host data I/O [7].

132 HD[8] I/O Host data bus 8.

133 HD[9] I/O Host data bus line 9.

134 HD[10] I/O Host data bus line 10.

135 HD[11] I/O Host data bus line 11.

136 HD[12] I/O Host data bus line 12.

137 HD[13] I/O Host data bus line 13.

140 HD[14] I/O Host data bus line 14.

141 HD[15] I/O Host data bus line 15.

142 HWRQ# O Host write request.

143 HRRQ# O Host read request.

144 HIRQ I/O Host interrupt.

145 HRST# O Host reset.

146 HIORDY I HostI/O ready.

149 HWR# I/O Host write.

150 HRD# O Host read.

151 HIOCS16# I Device16-bit data transfer.

152 HCS1FX# O Host select 1.

153 HCS3FX# O Host select 3.

158, 155:154 HA[2:0] I/O Host address bus.

160 AUX[0] O I

162 AUX[2] I/O Auxiliary ports 2.

165 AUX[3] I/O Auxiliary ports 3.

169:166 AUX[7:3] I/O Auxiliary ports 7:3.

170 LOE# O Device output enable.

176:173 LCS[3:0]# O Chip select [3:0].

197:194,

191:185, LD[15:0] I/O EPROM device data bus.

182:178

198 LWRLL# O Device low-byte write enable.

199 LWRHL# O Device high-byte write enable.

202 CAMIN0 I CameraYUV 0.

203 CAMIN1 I CameraYUV 1.

161 AUX[1]OI

2

C DATA.

2

CCLK.

FunctionI/O

7

Page 8

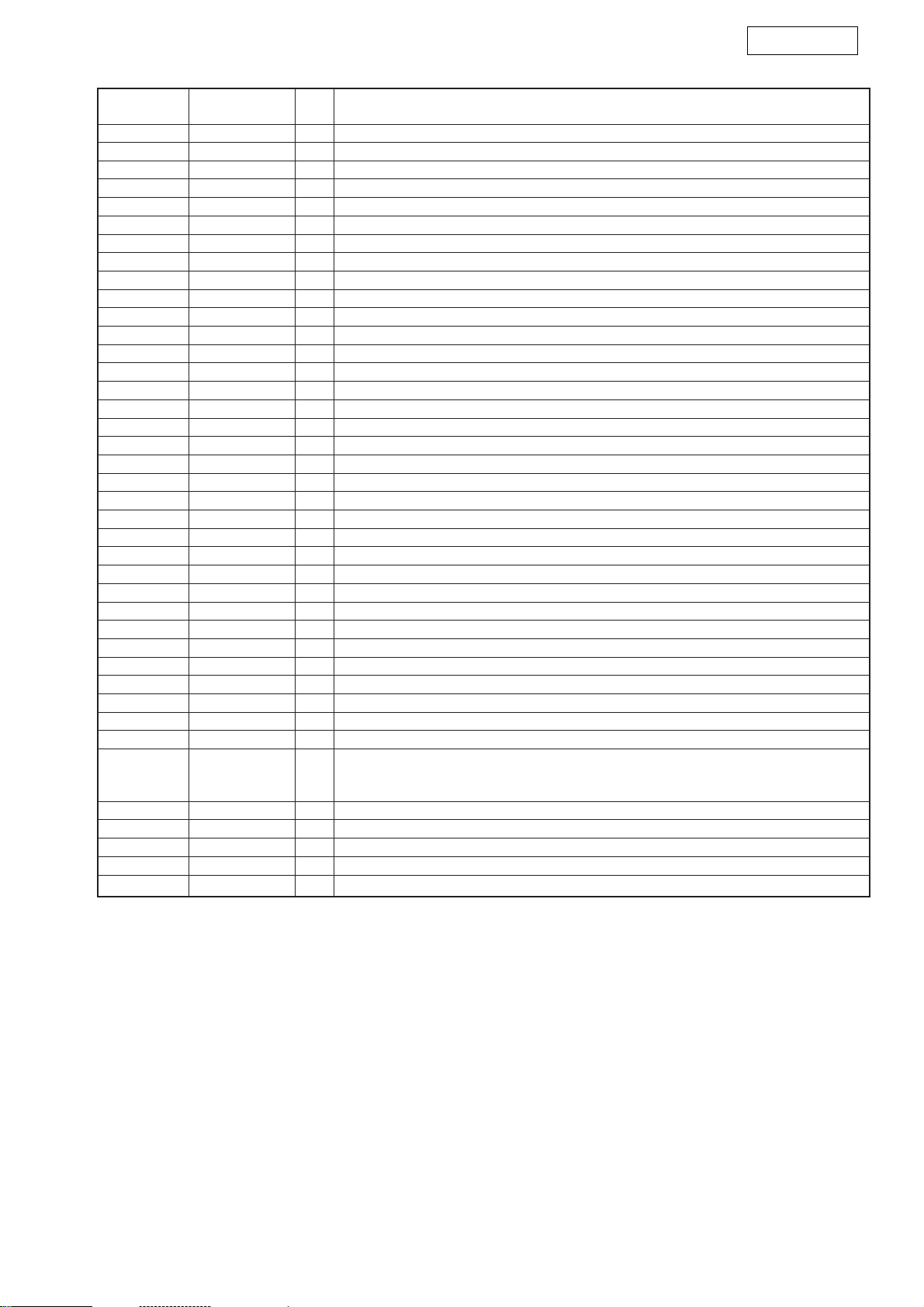

M5705 (ME: U1)

AVSS-DS

XSRFIN

XSIPIN

AVDD5-D S

XSDSSLV

XSRSLINT

XSAWRC

XSRFGC

XSEFGC

XSFOCUS

XSTRACK

XSSLEG

AVDD5-D A

XSMOTOR

AVSS-DA

XSRFRPLP

XSTELP

XSVREF2

XSRFRP

XSTEXI

AVSS-AD

XSTEI

XSFEI

XSAEI

AVDD5-A D

XSSBAD

XSDFCT

XSCSJ

XSCLK

XSDATA

XSLDC

XSFGIN

XSSPDON

XSFLAG(3)

XSFLAG(2)

XSFLAG(1)

XSFLAG(0)

XMP1_7

XMP1_6

XMP1_4

XSAWRCVCO

XSVREFO

XSPDOFTR2

XSVR_PLL

XSFTROPI

XSFDO

AVSS_PL

XSPLLFTR2

AVDD5_PL

XSFDIREF

XSPDIREF

GND

XTSLRF

XTPLCK

VDD

XRA(3)

XRA(2)

XRA(1)

XRA(0)

XRA(4)

XRA(5)

XRA(6)

GND

XRA(7)

XRA(10)

XRA(11)

VDD

XRA(8)

XRA(9)

XROEJ

VDD

176

175

174

173

172

171

170

169

168

167

166

165

164

163

162

161

160

159

158

157

156

155

154

153

152

151

150

149

148

147

1

2

3

4

5

6

VDD

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

GND

28

29

30

31

32

33

34

35

36

37

38

39

40

41

GND

42

NC

43

44

45464748495051525354555657585960616263646566676869707172737475767778798081828384858687

VDD

VDD

GND

XOSC1

XOSC2

XMP1_3

XMFSCSJ

XMP1_2

XGPIO(2)

XMP1_1

XMRSTJ

XGPO(1)

XGPO(0)

XCRSTJ

XMPSENJ

XMALE

XMP1_0

XMD(0)

XMD(1)

XMD(2)

XMD(3)

XMD(4)

XMD(5)

XMD(6)

XMD(7)

146

XMCSJ

XMRDJ

XMWRJ

XMA(11)

XMA(10)

XMINT1J

4M DRAM

M5705

XRCASJ

XRRASJ

145

144

VDD

XMA(9)

XRSDCLK

XRWEJ

143

142

XMA(8)

XMA(7)

XRD(7)

141

XMA(6)

XRD(8)

140

XMA(5)

XRD(6)

139

XMA(4)

GND

138

XMA(3)

XRD(9)

137

XMA(2)

XRD(5)

136

XMA(1)

XRD(10)

XRD(4)

135

134

XMA(0)

XMA(12)

XRD(11)

133

132

131

130

129

128

127

126

125

124

123

122

121

120

119

118

117

116

115

114

113

112

111

110

109

108

107

106

105

104

103

102

101

100

88

GND

99

98

97

96

95

94

93

92

91

90

89

XRD(3)

XRD(12)

GND

XRD(2)

XRD(13)

XRD(1)

XRD(14)

XRD(0)

XRD(15)

XHD(7)

XHD(8)

XHD(6)

XHD(9)

XHD(5)

XHD(10)

XHD(4)

XHD(11)

VDD

XHD(3)

XHD(12)

XHD(2)

XHD(13)

GND

XHD(1)

XHD(14)

XHD(0)

XHD(15)

XHDRQ

XHIOWJ

XHIORJ

XHIORDY

XHDACKJ

XHINT

XHCS16J

XHA(1)

XHPDIAGJ

XHA(0)

XHA(2)

XHCS1J

XHCS3J

XHDASPJ

XMA(15)

XMA(14)

XMA(13)

DHT-500SD

ATAPI

M

Motor

Driver

Data

Separator

Digital

Servo

DVD-DSP

CD-DSP

RAM

Arbiter

Targe t

Search

&

MPEG

I/F

C3 ECC

EDC

MCU

ROM

M5705 Terminal Function

Pin Name

Type

2 XSRFIN I/A Analog RF signal input after passing through the equalizer

3 XSIPIN I/A Inverting input pin of data slicer

5 XSDSSLV O/A Slice level output pin

6 XSRSLINT I/A Reference current setting pin for analog data slicer

8 XSAWRC O/A Output for enlarge VCO range. Analog output from DAC buffer

9 XSRFGC O/A RFgain control output

10 XSEFGC O/A E,F gain control output

11 XSFOCUS O/A Output voltage level for focusing buffer IC

12 XSTRACK O/A Output voltage level for tracking buffer IC

13 XSSLEG O/A Output voltage level for sledge buffer IC

15 XSMOTOR O/A Output voltage level for spindle motor buffer IC

17 XSRFRPLP I/A High bandwidth low pass filter input for RFRP

18 XSTELP I/A High bandwidth low pass filter input forTE

19 XSVREF2 I/A 2.1V reference voltage input

20 XSRFRP I/A RF ripple/envelope signal input

21 XSTEXI I/A Tracking zero crossing input signal

23 XSTEI I/A Tracking error input signal

24 XSFEI I/A Focus error input signal

25 XSCEI I/A

1. Center error input signal

2. Photo Interrupt input

DescriptionPin No.

PC

MPEG

DEC.

8

Page 9

DHT-500SD

Pin Name

27 XSSBAD I/A Sub-beam addition signal input

166 XSPDIREF I/A

167 XSFDIREF I/A

169 XSPLLFTR2 I/A Data PLL loop filter pin#2

171 XSFDO O/A Output node of frequency detector charge pump circuit

172 XSFTROPI I/A Input node of loop filter OP circuit

173 XSVR_PLL I/A PLL reference voltage input

174 XSPDOFTR2 I/A Phase detector filter pin#1

175 XSVREFO O/A Reference voltage output

176 XSAWRCVCO I/A Auto Wide Range Control of VCO input pin. For enlarge VCO range in CAV mode

29 XSDFCT I Detect detection signal input

30 XSCSJ O Chip select signal for accessing control registers

31 XSCLK O Clock output for accessing control registers

32 XSDATA I/O Registers data input/output pin

33 XSLDC O Laser diode on/off control output for both CD/DVD

34 XSFGIN I Motor Hall sensor input

35 XSSPDON O Spindle motor on output

36, 37, 38, 39 XSFLAG[3:0] O These pins are used to monitor some status of servo control block

48, 51, 52 XGPIO[2:0] I/O

40 XMP1_7 I/O Internal microcontroller programmable I/O port 1.7.

41 XMP1_6 I/O Internal microcontroller programmable I/O port 1.6.

43 XMP1_5 I/O This pin is now changed to be NC.

44 XMP1_4 I/O Internal microcontroller programmable I/O port 1.4.

45 XMP1_3 I/O Internal microcontroller programmable I/O port 1.3.

47 XMP1_2 I/O Internal microcontroller programmable I/O port 1.2.

49 XMP1_1 I/O Internal microcontroller programmable I/O port 1.1.

57 XMP1_0 I/O

46 XMFSCSJ I/O Output chip select connected to external flash ROM chip enable pin

54 XMPSENJ I/O Output program store enable connected to external ROM PSENJ pin.

56 XMALE I/O This signal is used as address latch signal in address/data mux mode

70 XMCSJ I/O

71 XMRDJ I/O

72 XMWRJ I/O This signal is used as the Wire Strobe signal

73 XMINT1J I/O

74, 75, 77, 78,

79, 80, 81, 82,

83, 84, 85, 86,

87, 89, 90, 91

62, 63, 64, 65,

66, 67, 68, 69 bus for the 8-bit processor mode.

163 XTPLCK I/O PLCK test pin

164 XTSLRF I/O SLRF test pin

59 XOSC1 I Crystal input/System clock. The input frequency from outside crystal or oscillator is 33.8688MHz

60 XOSC2 O Crystal output

53 XCRSTJ I

94 XHCS1J I This pin is used to select the command block task file registers

93 XHCS3J I This pin is used to select the control block task file registers

103 XHIORJ I Asserted by the host during a host I/O read operation

104 XHIOWJ I Asserted by the host during a host I/O write operation

105 XHDRQ O

101 XHDACKJ I

99 XHCS16J O

50 XHRSTJ I Host Reset. The reset of ATA bus

100 XHINT O

XMA[15:0] I/O These pins are used as address bus

XMD[7:0] I/O

Type

Phase detector reference current generator. Connect a resistor between this pin and

ground to set reference current

Frequency detector reference current generator. Connect a resistor between this pin and

ground to set reference current

1. These pins are used as general purpose I/O bus

2. When use internal microcontroller, XGPIO[2] can be used as programmable I/O port 3.6.

Internal microcontroller programmable I/O port 1.0.

This pin is default used as the A16 (microcontroller address line 16)

1. This signal must be asserted for all microcontroller accesses to the register of this chip

2. When use internal microcontroller, this signal can be used as programmable I/O port 3.1

1. This signal is used as the Read Strobe signal

2. When use internal microcontroller, this signal can be used as programmable I/O port 3.0

1. This signal is an interrupt line to the microcontroller

2. When use internal microcontroller, this signal can be used as programmable I/O port 3.7

These pins are used as data bus for the 16-bit processor mode, or the address/data mux

Chip Reset. As asserted low input generates a component reset that stops all operations within

the chip and deasserts all output signals. All input/output signals are set to input.

1.

DMA request. This pin is configured as the DMA request signal, and is used during DMA transfer

between the host and the controller. This pin is tri-stated when DMA transfers are not enabled.

2.

MPEG acknowledge. This pin is used as the ACKJ signal when MPEG interface mode is selected.

1. DMA acknowledge. This pin is configured as DACKJ, and is used as the DMA acknowledge

signal during DMA data transfers.

2. MPEG request. This pin is used as the REQ signal when MPEG interface mode is selected

1. 16-bit data select. This signal indicates that a 16-bit data transfer is active on the host data

bus. This pin is open-drain tri-state output.

2. MPEG clock. This pin is used as the CLOCK signal when MPEG interface mode is selected.

1. Host interface request. This tri-state pin is the host interrupt request, and is asserted to

indicate to the host that the controller needs attention.

2. MPEG begin. This pin is used as the BEGIN signal when MPEG interface mode is selected

DescriptionPin No.

9

Page 10

DHT-500SD

Pin Name

97 XHPDIAGJ I/O This pin is used as the Passed Diagnostics signal, and may be an input or an open-drain output

92 XHDASPJ I/O

102 XHIORDY I/O

95, 96, 98 XHA[2:0] I

106, 107, 108, 2.

109, 111, 112, 3. VCD I/F. Bit3-0 are used as VCD I/F signal when VCD function is enabled. The relationship of

113, 114, 116, bit3-0 and VCD I/F is as follow

117, 118, 119, HD0—CD-DATA

120, 121, 122, HD1—CD-LRCK

123 HD2—CD-BCK

143 XRSDCLK O This signal is the clock output for SDRAM

147 XROEJ O

142 XRWEJ O This signal is asserted low when a buffer memory write operation is active

144 XRRASJ O

145 XRCASJ O

148, 149, 151,

152, 153, 155,

156, 157, 158,

159, 160, 161

124, 125, 126,

127, 128, 129,

131, 132, 134,

135, 136, 137,

138, 139, 140,

141

4 AVDD5_DS Analog Power +5V for Data Slicer part

14 AVDD5_DA Analog Power +5V for DAC part

26 AVDD5_AD Analog Power +5V for ADC part

168 AVDD5_PL Analog Power +5V for Data PLL part

7, 55, 58, 76,

115, 146,

150, 162

1 AVSS_DS Analog Ground for Data Slicer part

16 AVSS_DA Analog Ground for DAC part

22 AVSS_AD Analog Ground for ADC part

170 AVSS_PL Analog Ground for Data PLL part

28, 42, 61,

88, 110, 130,

138, 154, 165

XHD[15.0] I/O

XRA[11:0] O 1: Normal operation

XRD[15:0] I/O These signals are the 8-bit parallel data lines to/from the buffer memory.

VDD Power +3.3V for digital core logic and pad

GND Digital Ground core logic and pad.

Type

This pin is used as the Drive Active/Slave Present signal, and is an input or an open-drain

output. This pin is used for Master/Slave drive communication and/or for driving an LED

1. I/O channel ready. This signal is driven low to extend host transfer cycles when the controller

is not ready to respond. This pin will be tri-stated when a read or write is not in progress.

2. MPEG error. This pin is used as the ERROR signal when MPEG interface mode is selected

Host address lines. The host address lines A[2:0] are used to access the various host control,

status, and data registers

1. Host data bus. This bus is used to transfer data and status between the host and the controller.

MPEG data bus 7-8. The HD[7:0] are used as the DATA [7:0] when MPEG interface mode is selected.

HD3—CD-C2PO

This signal is used as the memory output enable for external DRAM buffers. After RSTJ is

asserted, this signal will be low

This signal is used as Row address output to external DRAM buffer. After RSTJ is asserted, this

signal will be high

This signal is used as column address output to external DRAM. After RSTJ is asserted, this

signal will be high

1. RAM address lines. These are bits11-0 for addressing the buffer memory.

2. Hardware setting. The bits6-0 are used as hardware setting for some functions.

RA[9] : FLASH size is 64K/128K

1: FLASH size is 64K

0: FLASH size is 128K

RA[8] : External CPU is 8032/H8

1: 8032

0: H8

RA[7] : Microcontroller programmable I/O port 1 pin control

1: By internal microcontroller

0: By registers to decide input/output

RA[6] : System test pin output

0: System test pin output

RA[5] : For testing purpose, don’t need to set

RA[4] : IDE master/slave

1: Slave

0: Master

RA[3] : For testing purpose, don’t need to set

RA[2] : For testing purpose, don’t need to set

RA[1-0] : MCU Mode selection

11: Normal Mode (inter nal uP, internal address latch)

10: Outside uP Mode (ICE Mode)

01: Test mode for internal uP testing

00: Internal uP mode with external address latch

DescriptionPin No.

10

Page 11

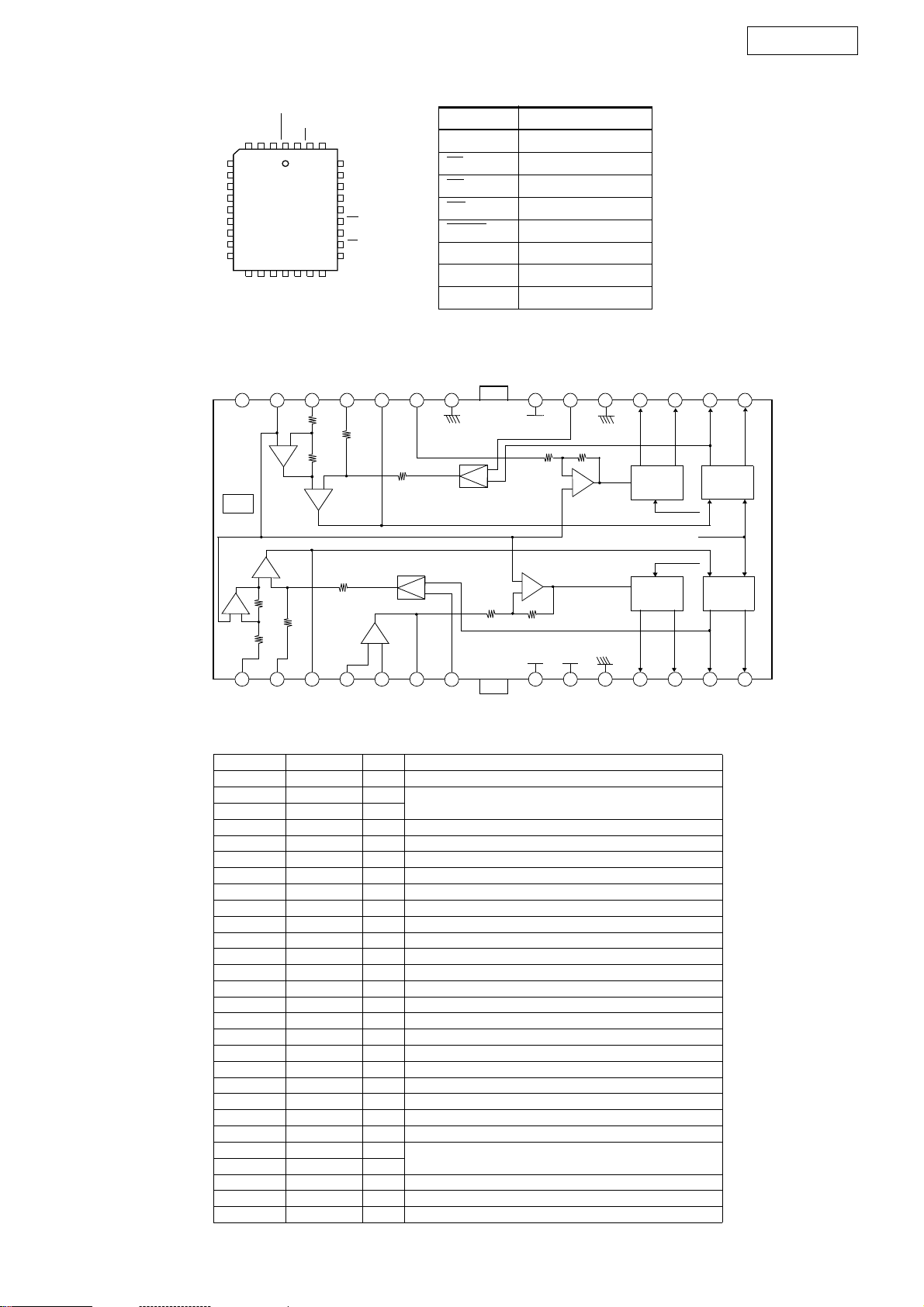

SP3721A (ME: U2)

CDRF

CDRDDC

DHT-500SD

HOLD1

VNA

FNN

FNP

DIP

DIN

RX

BYP

SIGO

VPA

AIP

AIN

ATON

ATOP

49505152535455565758596061626364

DVDRFP

DVDRFN

PD1

PD2

CP

CN

A2

B2

C2

D2

1

2

3

4

5

6

7

8

9

10

11

D

12

C

13

B

14

A

15

F

16

E

NC

VCI2

CDTE

TOP VIEW

VNB

DVDLD

DVDPD

CDLD

CDPD

VC

LDON#

VCI

VPB

VIIRR

VIP

32313029282726252423222120191817

VIB

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

FDCHG#

SDEN

SDATA

SCLK

LCP

LCN

CE

FE

TE

MEI

MEV

TPH

DFT

PI

MIN

MEVO

MLPF

SP3721A Terminal Function

Pin Name

Type

1, 2 DVDREP, DVDREN I RF Signal Inputs.Differential RF signal attenuator input pins

63 CDRF I RF Signal Inputs.Single-ended RF signal attenuator input pin

59, 60 AIP, AIN I AGC Amplifier Inputs.Differential AGC amplifier input pins

53, 54 DIP, DIN I

Analog inputs for RF Single Buffer.Differential analog inputs to the RF single-ended output buffer

and full wave rectifier

Low Impedance Enable.A TTL compatible input pin that activates the FDCHG switches. A low

32 FDCHG# I

level activates the switches and the falling edge of the internal FDCHG triggers the fast decay for

the MIRR bottom hold circuit. (open high)

49 HOLD1 I

Hold Control. A TLL compatible control pin which, when pulled high, disables the RF AGC charge

pump and holds the RF AGC amplifier gain at its present value.(open high)

11~14 D, C, B, A I Photo Detector Interface Inputs. Inputs from the main beam Photo detector matrix outputs

5~8 A2, B2, C2, D2 I

Photo Detector Interface Inputs.AC coupled inputs for the DPD from the main beam Photo

detector matrix outputs

15~16 F, E I CD tracking Error Inputs. Inputs from the CD photo detector error outputs.

3~4 PD1, PD2 I CD Photo detector Interface Inputs. Inputs from the CD photo detector error outputs

40 MEI I Mirror Envelope Inputs.The SIGO envelope input pin

35 MIN I

RF signal Input for Mirror. AC coupled inputs for the mirror detection circuit from the pull-in signal

output. (PI)

21 DVDPD I APC Input. DVD APC input pin from the monitor photo diode

23 CDPD I APC Input. CD APC input pin from the monitor photo diode

25 LDON# I APC Output On/Off.APC output control pin. A low level activates the LD output. (open high)

61, 62 ATON/ATOP O DifferentialAttenuator Output. Attenuator outputs

51, 52 FNN, FNP O Differential Normal Output. Filter normal outputs

57 SIGO O Single Ended Normal Output. Single-ended RF output

64 CDRFDC O CD RF Signal Output. Single ended CD RF summing output

42 FE O FocusingError Signal Output. Focus error output reference to VCI

41 TE O Tracking Error Signal Output. Tracking error output reference to VCI

DescriptionPin No.

11

Page 12

DHT-500SD

Pin Name

43 CE O Center Error Signal Output. Center error output reference to VCI

34 NEVO O SIGO Bottom Envelope Output. Bottom envelope for mirror detection

37 DFT O

29 MIRR O Mirror Detect Output. Mirror Detect comparator output. Pseudo CMOS output

36 PI O

22 DVDLD O APC output. DVD APC output pin to control the laser power

24 CDLD O APC output. CD APC output pin to control the laser power

56 BYP I/O The RF AGC integration capacitor CBYP, is connected between BYP and VPA

9 CP I/O

10 CN I/O

45 LCP — Center Error LPF pin. An external capacitance is connected between this pin and the LCN pin

44 LCN — Center Error LPF pin. An external capacitance is connected between this pin and the LCP pin

30 MP — MIRR signal Peak hold pin. An external capacitance is connected to between this pin and VPB

31 MB — MIRR signal Bottom hold pin. An external capacitance is connected to between this pin and VPB

39 MEV — Sigo Bottom Envelope pin. An external capacitance is connected to between this pin and VPB

17 CDTE — CD Tracking. E-F Opamp output for feedback

38 TPH — PI Top Hold pin. An external capacitance is connected to between this pin and VPB

26 VC —

27 VCI — Reference Voltage input. DC bias voltage input for the servo input reference

18 VCI2 — Reference Voltage input. DC bias voltage input for the servo input reference

55 RX —

33 MLPF — MIRR signal LPF pin. An external capacitance is connected between this pin and VPB

19 NC — No Connect

48 SDEN I

47 SDATA I/O

46 SCLK I

58 VPA Power. Power supply pin for the RF block and serial port

28 VPB Power. Power supply pin for the servo block

50 VNA Ground. Ground pin for the RF block and serial port

20 VNB Ground. Ground pin for the servo bolck

Type

Defect Output. Pseudo CMOS output. When a defect is detected, the DFT output goes high. Also

the servo AGC output can be monitored at this pin, when CAR bits 7-4 are ‘0011’

Pull-in Signal Output. The summing signal output of A, B, C, D or PD1, PD2 for mirror detection.

Reference to VCI

Differential Phase tracking LPF pin. An external capacitance is connected between this pin and

the CN pin

Differential Phase tracking LPF pin. An external capacitance is connected between this pin and

the CP pin

Reference Voltage output. This pin provides the internal DC bias reference voltage (+2.5V lix).

Output Impedance is less than 50ohms

Reference Resistor Input. An external 8.2kohm, 1% resistor is connected from this pin to ground

to establish a precise PTAT (proportional to absolute temperature) reference current for the filter

Serial Data Enable. Serial Enable CMOS input. A high level input enable the serial port (Not to be

left open)

Serial Data. Serial data bi-directional CMOS pin. NRZ programming data for the internal registers

is applied to this input ( Not to be left open)

Serial Clock. Serial Clock CMOS input. The clock applied to this pin is synchronized with the data

applied to SDATA (Not to be left open)

DescriptionPin No.

12

Page 13

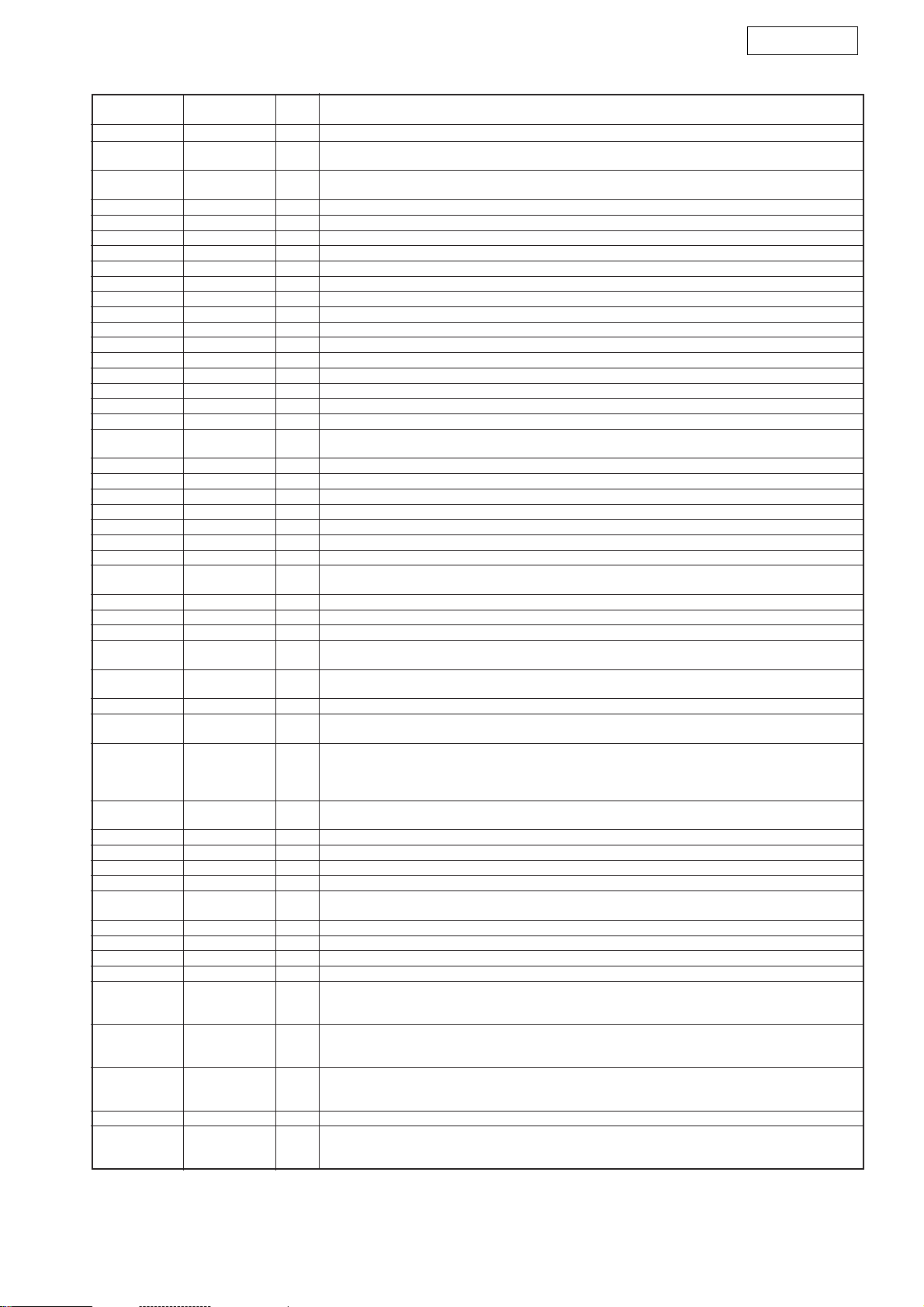

HY57V651620BTC-75 (ME: U11)

DHT-500SD

DD

V

DQ0

V

DDQ

DQ1

DQ2

SSQ

V

DQ3

DQ4

DDQ

V

DQ5

DQ6

V

SSQ

DQ7

DD

V

LDQM

/W E

/CAS

/RAS

/CS

BA0

BA1

A10/ A P

A0

A1

A2

A3

V

DD

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

SS

V

DQ15

V

SSQ

DQ14

DQ13

DDQ

V

DQ12

DQ11

SSQ

V

DQ10

DQ9

V

DDQ

DQ 8

SS

V

NC

UDQM

CLK

CKE

NC

A11

A9

A8

A7

A6

A5

A4

V

SS

PIN DESCRIPTION

PIN PIN NAME DESCRIPTION

CLK Clock

CKE Clock Enable

CS

BA0,BA1 Bank Address

A0 ~ A11 Address

RAS

, CAS,WE

LDQM, UDQM Data Input/Output Mask Controls output buffers in read mode and masks input data in write mode

DQ0 ~ DQ15 Data Input/Output Multiplexed data input / output pin

V

DD/VSS Power Supply/Ground Power supply for internal circuits and input buffers

V

DDQ/VSSQ Data Output Power/Ground Power supply for output buffers

NC No Connection No connection

Chip Select Enables or disables all inputs except CLK, CKE and DQM

Row Address Strobe,

Column Address Strobe,

Write Enable

The system clock input. All other inputs are registered to the SDRAM on the

rising edge of CLK

Controls internal clock signal and when deactivated, the SDRAM will be one

of the states among power down, suspend or self refresh

Selects bank to be activated during RAS

Selects bank to be read/written during CAS

Row Address : RA0 ~ RA11, Column Address : CA0 ~ CA7

Auto-precharge flag : A10

RAS

, CAS and WE define the operation

Refer function truth table for details

activity

activity

13

Page 14

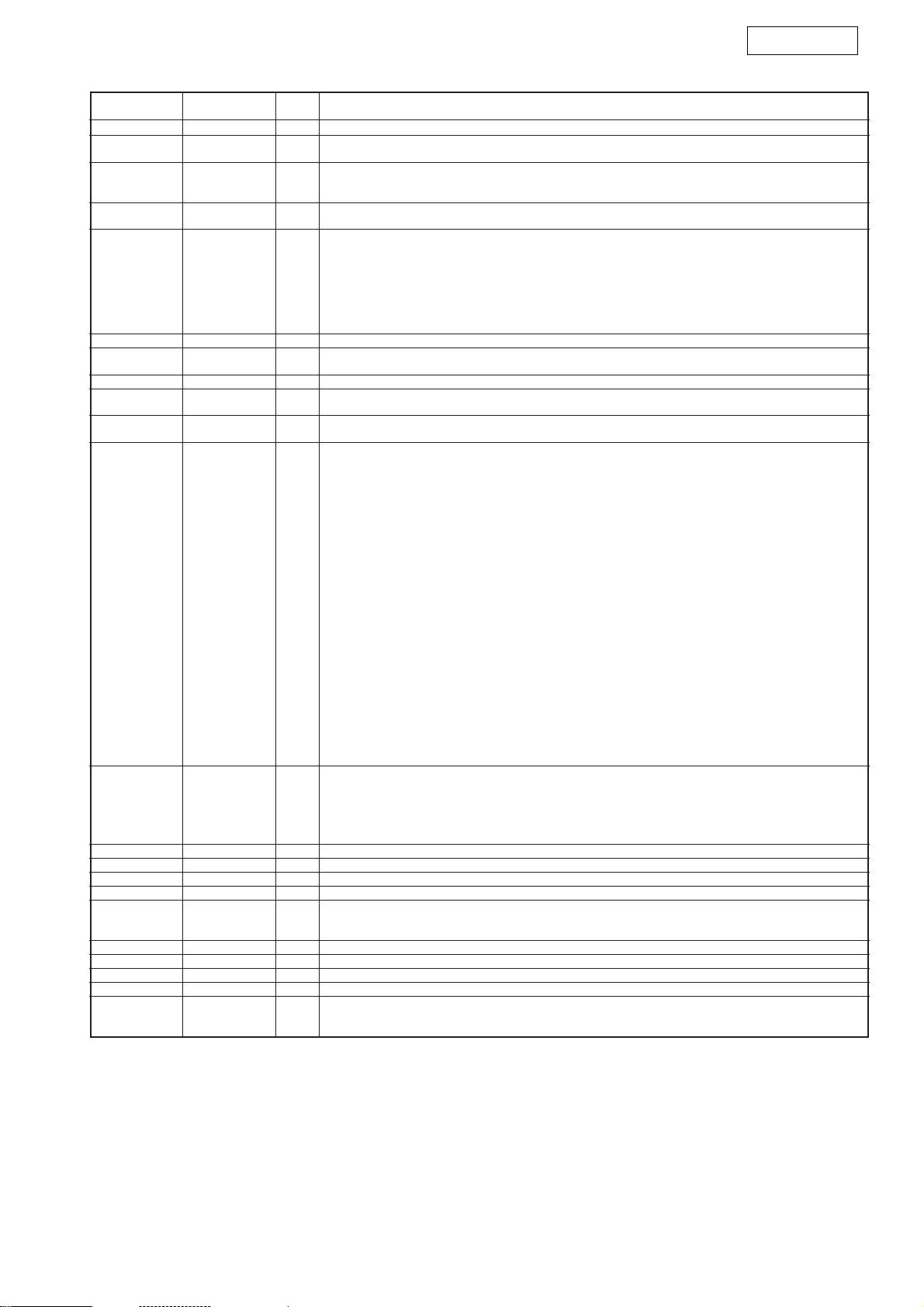

T431616A-8S(ME:U5)

DHT-500SD

DD

V

DQ0

DQ1

SSQ

V

DQ2

DQ3

DDQ

V

DQ4

DQ5

V

SSQ

DQ6

DQ7

DDQ

V

LDQM

WE

CAS

RAS

CS

BA

A10/ AP

A0

A1

A2

A3

V

DD

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

SS

V

DQ15

DQ14

V

SSQ

DQ13

DQ12

DDQ

V

DQ11

DQ10

SSQ

V

DQ9

DQ8

V

DDQ

N.C / RFU

UDQM

CL K

CK E

N.C

A9

A8

A7

A6

A5

A4

V

SS

PIN DESCRIPTION

PIN PIN NAME DESCRIPTION

CLK System Clock

CS

CKE Clock Enable

A0 ~ A10/AP

BA Bank Select Address

RAS

CAS

WE

L(U)DQM Data Input/Output Mask

DQ0 ~ DQ15

DD/VSS Power Supply/Ground

V

VDDQ/VSSQ

N.C/RFU

Chip Select

Address

Row Address Strobe

Column Address Strobe

Write Enable

Data Input/Output

Data Output Power/Ground

No Connection/Reserved

for Future Use

Active on the positive going edge to sample all input.

Disables or enables device operation by masking or enabling all input

except CLK,CKE and L(U)DQM

Masks system clock to freeze operation from the next clock cycle.

CKE should be enabled at least one cycle prior to new command.

Disable input buffers for power down in standby.

Row/column aaddresses are multiplexed on the same pins.

Row address : RA0 ~ RA10,column address : CA0 ~ CA7

Selects bank to activated during row address latch time.

Select bank for read/write during column address latch time.

Latches row addresses on the positive going edge of the CLK

with RAS low.

Enables row access & precharge.

Latches column addresses on the positive going edge of the CLK

with CAS low.

Enables column access.

Enables write operation and row precharge.

Latches data in starting from CAS, WE active.

Makes data output Hi-Z, t

Blocks data input when L(U)DQM active.

Data inputs/outputs are multiplexed on the same pins.

Powe and ground for the input buffers and the core logic.

Isolated power supply and ground for the output buffers to provide

improved noise immunity.

This pin is recommended to be left No Connection on the device.

SHZ after the clock and masks the output.

14

Page 15

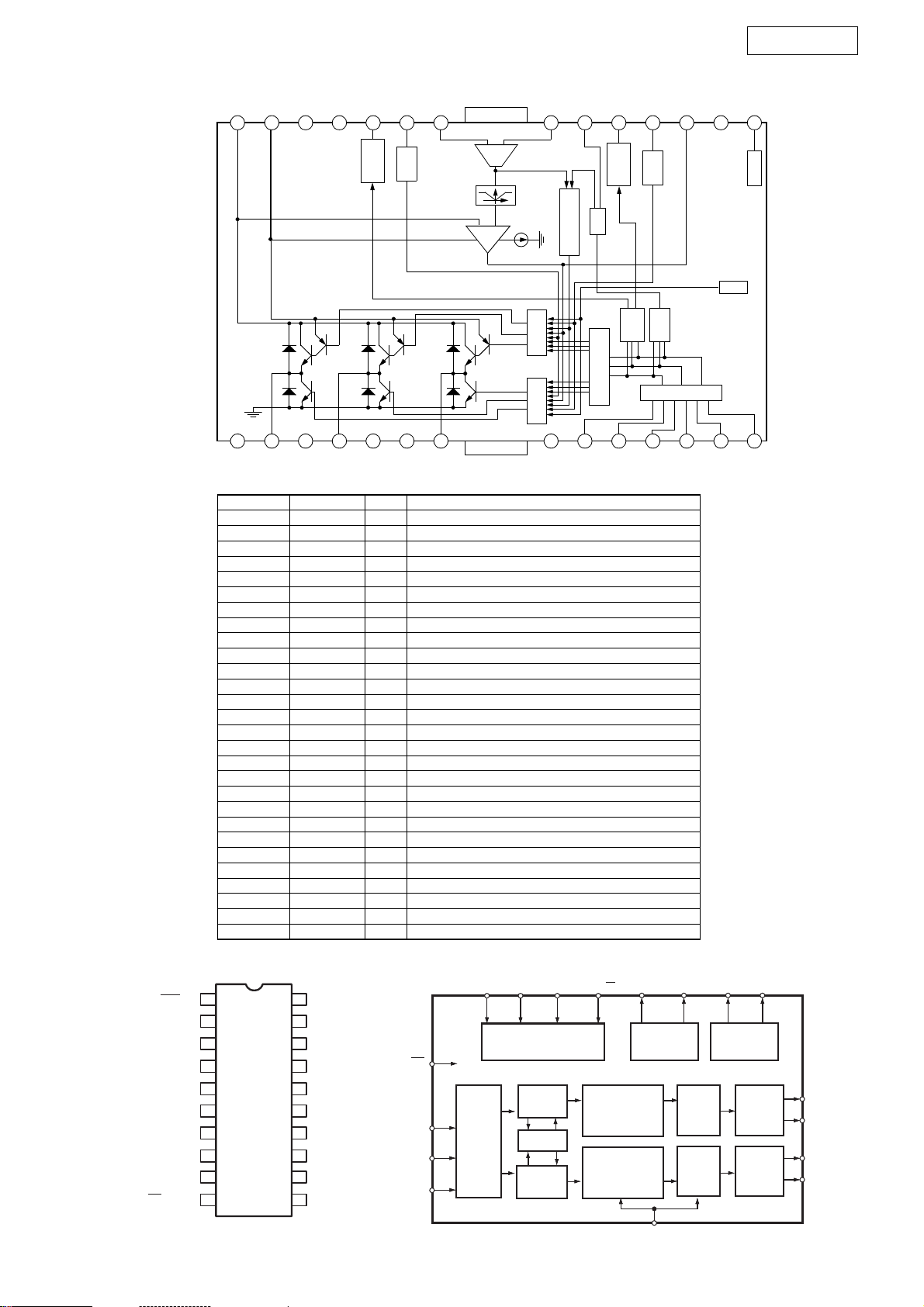

MX29LV800ABTC-70 (ME: U10)

NC

WE

NC

NC

1

2

3

4

5

6

7

A9

8

A8

9

10

11

12

13

14

15

16

17

18

A7

19

A6

20

A5

21

A4

22

A3

23

A2

24

A1

A15

A14

A13

A12

A11

A10

A19

RESET

RY/BY

A18

A17

BLOCK DIAGRAM

DHT-500SD

48

A16

47

BYTE

46

GND

45

Q15/A-1

44

Q7

43

Q14

42

Q6

41

Q13

40

Q5

39

Q12

38

Q4

37

VCC

36

Q11

35

Q3

34

Q10

33

Q2

32

Q9

31

Q1

30

Q8

29

Q0

28

OE

27

GND

26

CE

25

A0

CE

OE

WE

RESET

A0-A19

CONTROL

INPUT

LOGIC

ADDRESS

LATCH

AND

BUFFER

PROGRAM/ERASE

HIGH VOLTAGE

X-DECODER

FLASH

ARRAY

Y-DECODER

Y-PASS GATE

SENSE

AMPLIFIER

ARRAY

SOURCE

PGM

DATA

HV

HV

WRITE

S TAT E

MACHINE

(WSM)

STATE

REGISTER

COMMAND

DA TA

DECODER

COMMAND

DATA LATCH

Q0-Q15/A-1

PROGRAM

DATA L AT C H

I/O BUFFER

15

Page 16

BH7862FS (MAIN:IC11)

DHT-500SD

01CTRAP

02MUTE1 MUTE1

CIN

03

04GND

05YIN

06VCC

07GND

08PYIN

09GND

10PYTRAP

11VCC

12PbIN

13GND

14PrIN

15MUTE2

1.5-6M

20k

CLAMP

CLAMP

20k

20k

MUTE2

BPF

LPF

12M

LPF

LPF

LPF

6M

6M

6M

6dB

6dB

6dB

6dB

6dB

75ohm

75ohm

75ohm

75ohm

75ohm

TEST

32

31

30

29

28

27

22

21

20

19

18

COUT

TEST

MIXOUT

MIXFB

GND

YTRAP

GND26

YOUT25

YFB24

GND23

PYOUT

PYFB

GND

PbOUT

N.C.

16PrTRAP

6dB

75ohm

BH7862FS Terminal Function

Pin No.

Port

1 CTRAP

10 PYTRAP

16 PrTRAP

Pin for LC resonation

27 YTRAP

2 MUTE1 Mute control pin, L: C, MIX,Y simultaneous mute

3CIN

12 PbIN Signal input pin, chroma signal & color-difference signal

14 PrIN

4, 7, 9, 13, 20, 23, 26, 28

GND GND pin

5 YIN Signal input pin, luminance signal

8 PYIN

6

11 Powersupply for PY, Pb, Pr

VCC

Powersupply for C, MIX,Y

15 MUTE2 Mute control pin, L: PY,Pb, Pr simultaneous mute

17 PrOUT

19 PbOUT

Signal output pin, color-difference signal

18 N.C.

21 PYFB

22 PYOUT

24 YFB

25 YOUT

29 MIXFB

30 MIXOUT

Signal output pin, luminance signal (progressive)

Signal output pin, luminance signal (interlace)

Signal output pin,Y/C MIX signal

31 TEST TEST pin

32 COUT Signal output pin, chroma signal

Description

17

PrOUT

16

Page 17

AT49F001N-70JC(ME:U3)

I

4

3

1

0

7

G

*

P

A12

A15

A16

432

5

A7

6

A6

7

A5

8

A4

9

A3

10

A2

11

A1

12

A0

13

/O0

14151617181920

ND

I/O1

I/O2

*Note: This pin is a DC on the AT49F001N(T).

FAN8024BDTF(ME:U6)

RESET

VCCWENC

1

323130

I/O3

I/O4

I/O5

29

28

27

26

25

24

23

22

21

I/O6

DHT-500SD

Pin Configurations

Pin Name Function

A0 - A16 Addresses

A1

A1

A8

A9

A1

OE

A1

CE

I/O

CE

OE

Chip Enable

Output Enable

WE Write Enable

RESET

RESET

I/O0 - I/O7 Data Inputs/Outputs

NC No Connect

DC Don’t Connect

STBY

REF

IN4

CAP4.1

CAP4.2

7

5

.

-

IN2.2

IN3

K

X

2

67

OUT2

28 27 26 25 24 23 22 21 20 19 18 17 16 15

+

S

T

D

-

+

K

0

-

2

+

K

0

1

12345

IN1

K

0

1

K

5

.

-

+

K

5

.

7

CAP1.1

7

K

0

2

-

7

.

K

5

+

IN2.1

CAP1.2

VCCGND

X

FB1

GND

2

0

1

GND

K

PVCC2

V

P

C

C

2

1

0

K

+

-

5

2

K

V

P

V

C

C

89

VCC

FB4

PGND2

DO3−DO3+

5

1

K

-

+

1

C

C

VCC1

10 11

PGND1

Loading

Driver

Sled

Driver

−

DO2

DO4−DO4+

Actuator

Driver

V

P

C

C

1

V

P

2

C

C

V

C

C

Actuator

Driver

12

13 14

−

DO1+

DO1

DO2+

Pin Definitions

Pin Number Pin Name I/O Pin Function Description

1 IN1 I CH1 input

2 CAP1.1 - Connection with capacitor

3 CAP1.2 - for CH1

4 IN2.1 I OP-AMP CH2 input(+)

5 IN2.2 I OP-AMP CH2 input(-)

6 OUT2 O OP-AMP CH2 output

7 FB1 I Feedback for CH1

8 V C C - Signal Vcc

9 PVCC1 - Power Supply 1

10 PGND1 - Power Ground 1

11 DO2

−

O Drive2 Output (-)

12 DO2+ O Drive2 Output (+)

13 DO1

−

O Drive1 Output (-)

14 DO1+ O Drive1 Output (+)

15 DO4+ O Drive4 Output (+)

16 DO4

−

O Drive4 Output (-)

17 DO3+ O Drive3 Output (+)

18 DO3

−

O Drive3 Output (-)

19 PGND2 - Power Ground 2

20 FB4 - Feedback for CH4

21 PVCC2 - Power Supply 2

22 VCCGND - Vcc ground

23 IN3 I CH3 input

24 CAP4.2 - Connection with capacitor

25 CAP4.1 - for CH4

26 IN4 I CH4 input

27 RE F I Bias voltage input

28 S T BY I Stand-by input

17

Page 18

FAN8423D3TF(ME:U7)

CS1

28 27 26 25 24 23 22 21 20 19 18 17 16 15

1234567

NC

Pin Definitions

Pine Number Pin Name I/O Pin Function Description

1 NC - No connection

2 A3 O Output (A3)

3 NC - No connection

4 A2 O Output (A2)

5 NC - No connection

6 NC - No connection

7 A1 O Output (A1)

8 GND - Ground

9 H1+ I Hall signal (H1+)

10 H1- I Hall signal (H1-)

11 H2+ I Hall signal (H2+)

12 H2- I Hall signal (H2-)

13 H3+ I Hall signal (H3+)

14 H3- I Hall signal (H3-)

15 VH I Hall bias

16 NC - No connection

17 PC1 - Phase compensation capacitor

18 SB I Short brake

19 FG3X O FG waveform (3X)

20 DIR O Rotational direction output

21 ECR I Output current control reference

22 EC I Output current control voltage

23 S/S I Power save (Start/Stop switch)

24 FG1X O FG waveform (1X)

25 VCC - Supply voltage (Signal)

26 NC - No connection

27 VM - Supply voltage (Motor)

28 CS1 - Output current detection

DHT-500SD

GND

VM

NC

VCC

FG1X

FG1X

Generator

A3

A2

NC

NC

S/S

Stop

Start

NC

EC

Current Sense

Amp

A1

-

+

Output

Current Limit

GND

Absolute

Values

Upper

Lower

ECR

DIR

FG3X

SB

PC1

Short

Brake

FG3X

Generator

tion

Logic

Reverse Rota-

tor

tion

Direc-

Distribu-

Distribu-

8

91011121314

GND

Detec-

Selector

Commutation

H1+

Hall Amp

H1-

H2-

H2+

NC

TSD

H3+

VH

Hall

H3-

CS4392(ME:U16)

RST

VL

SDATA

SCLK

LRCK

MCLK

M3

(SCL/CCLK) M2

(SDA/CDIN) M1

(AD0/CS) M0

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

AMUTEC

AOUTA-

AOUTA+

VA

AGND

AOUTB+

AOUTB-

BMUTEC

CMOUT

FILT+

RST

SCLK

LRCK

SDATA

M1

(SDA/CDIN) (SCL/CCLK) (AD0/CS)

SERIAL

PORT

M2 M0

M3

MODE SELECT

( CONTROL PORT)

VOLUME

CONTROL

MIXER

VOLUME

CONTROL

INTERPOLATION

FILTER

INTERPOLATION

FILTER

18

AMUTEC BMUTEC CMOUT FILT+

EXTERNAL

MUTE CONTROL

MCLK

△

DAC

△

DAC

Σ

Σ

REFERENCE

ANALOG

FILTER

ANALOG

FILTER

AOUTA+

AOUTA-

AOUTB+

AOUTB-

Page 19

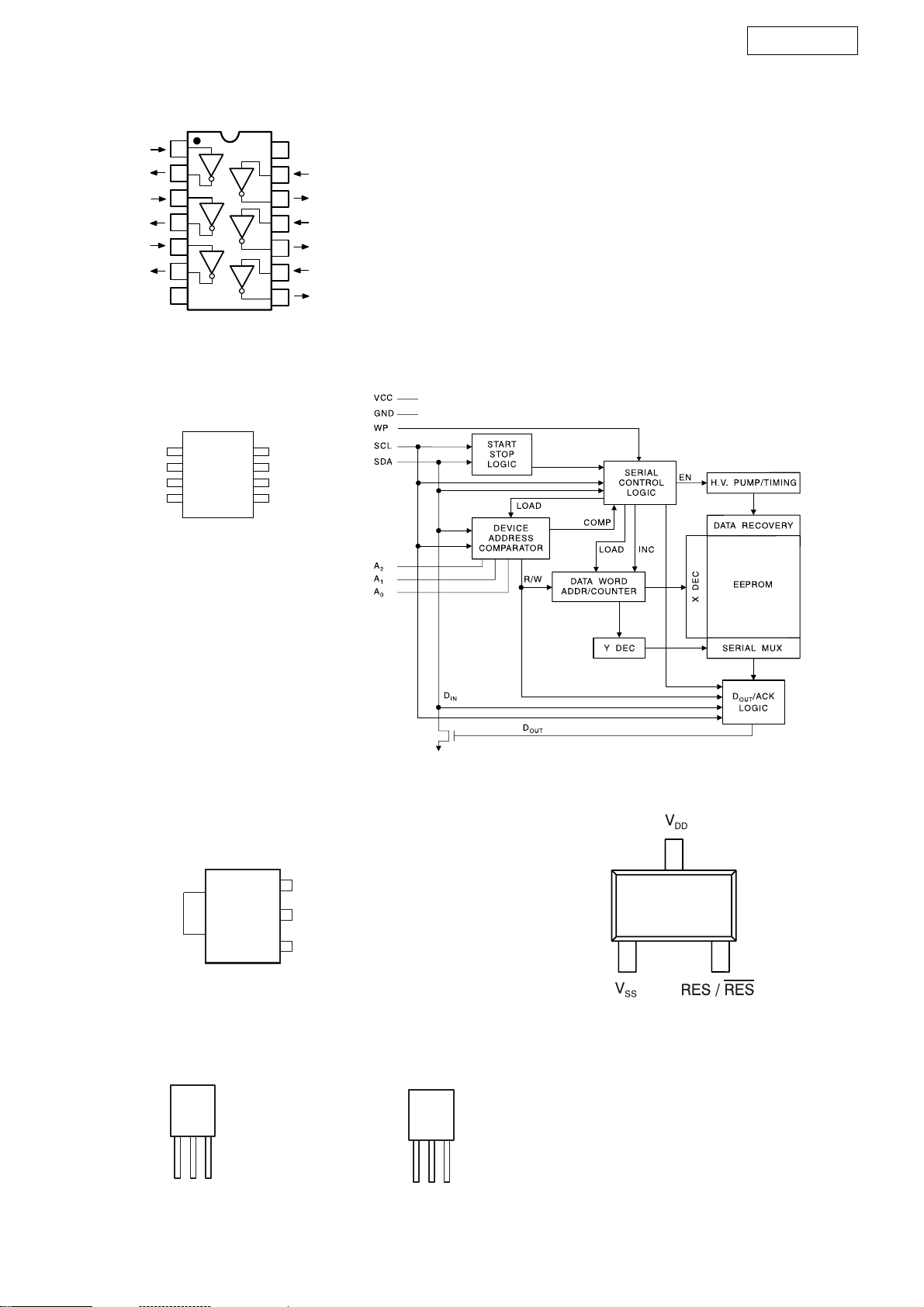

SN74HCU04PWR (ME: U8)

Block Diagram

1

1A

1Y

2A

2Y

3A

3Y

GND

2

3

4

5

6

7

14

13

12

11

10

9

8

AT24C02N(ME: U13)

DHT-500SD

Vcc

6A

6Y

5A

5Y

4A

4Y

A0

A1

A2

GND

1

2

3

4

VCC

8

WP

7

SCL

6

SDA

5

NPC1117ST20T3(ME: Q4)

LM117S-3V3 (DS:IC33)

LM117S-2V5 (DS:IC32)

3

V6309M(ME: Q5)

IN

V

OUT

2

1

KA78L08AZ (SM: IC93)

FRONT

VIEW

GND

Input

Output

OUT

ADJ/GND

KA79L08AZ (MA: IC17)

FRONT

VIEW

GND

Input

Output

19

Page 20

LC75725E(FR:IC91)

S23

S22

S21

S20

S19

S18

S17

S16

S15

S14

S13

S12

S11

S10

S9

48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33

DHT-500SD

S24

BLK

VFL

S8

S7

S6

S5

S4

S3

S2

S1

Vss

OSC0

OSC1

V

BLK

CE

CL

49

50

51

52

53

54

55

56

57

58

59

DD

60

61

62

63

64

DI

G11

DRIVER

DIGIT

1 2 3 4 5 6 7 8 9 10111213141516

G11

G10

G9

G8

G7

G6

G5

G4

G3

G2

G1

VFL

G10G2G1

S43

S42

SEGMENT DRIVER

MPX

LATCH

VFL

S43

S42

S41

32

S25

31

S26

S27

30

29

S28

28

S29

27

S30

26

S31

25

S32

24

S33

23

S34

22

S35

21

S36

20

S37

19

S38

18

S39

17

S40

S2

S1

GRID

CONTROL

DIMMER

TIMING

GENERATOR

SHIFT REGISTER

TIMING

GENERATOR

DIVIDER

OSCI

OSCO

CLOCK

GENERATOR

Terminal Function

Pin No. I/O Name Function

O

O

-

O

I

-

I

I

I

I

FL

V

G1~G11

S1~S43

Vss

DD

CL

DI

Power supply pin to ligic block

CE : Chip enable

CL : Sync clock

DI : Transfer data

1,13 Power supply pin to driver block

2~12 Digit output pin

14~56 Segment output pin

57 power supply pin

58 OSCO Pin for oscillator

59 OSCI Pin for oscillator

60 V

61 BLK Display off input pin

62 CE Input for serial data transfer

63

64

DI

CL

ADDRESS

DETECTOR

CE

VSS

DD

V

20

Page 21

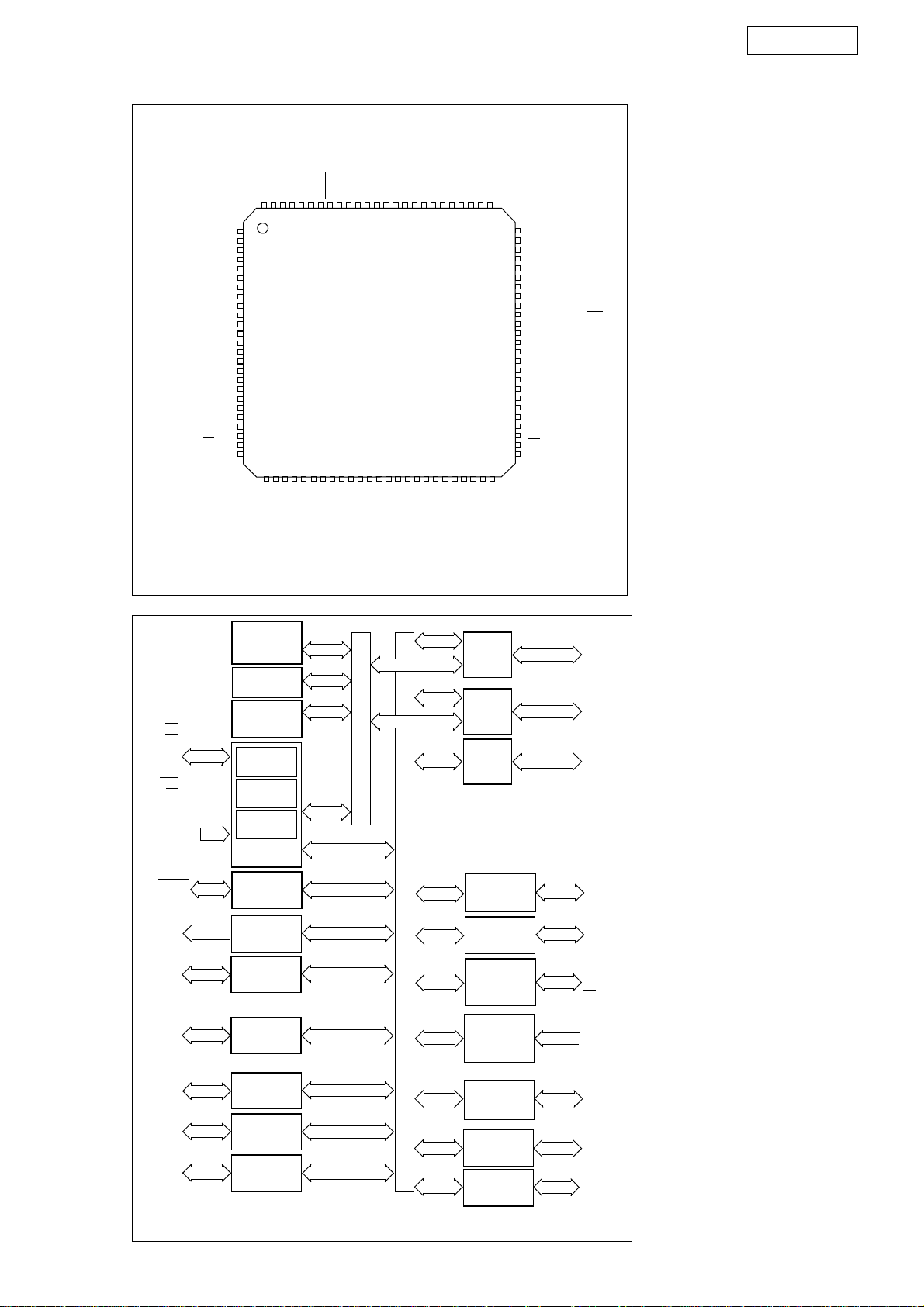

ST92F150CVT1(MAIN:IC11)

Pin Configuration (Top-view TQFP100)

P9.5/A19

100 99 98 97 96 95 94 9392 91 90 89 8887 86 8584 83 82 81 8079 78 7776

1

A20/P9.6

2

A21/P9.7

V

V

/P3.4

3

4

5

6

7

8

9

10

11

12

13

14

SS

15

DD

16

17

18

19

20

21

22

23

24

25

26

27 28 29 30 3132 33 3435 36 37 38 3940 41 4243 44 45 46 4748 49 50

MOSI/P3.6

TX0/WAIT

RX0/WKUP6/WDOUT/P5.1

/WKUP5/P5.0

SIN/WKUP2/P5.2

WDIN/SOUT/P5.3

TXCLK/CLKOUT/P5.4

RXCLK/WKUP7/P5.5

DCD/WKUP8/P5.6

WKUP9/RTS/P5.7

ICAPA1/P4.0

CLOCK2/P4.1

OCMPA1/P4.2

ICAPB1/OCMPB1/P4.3

EXTCLK1/WKUP4/P4.4

EXTRG/STOUT/P4.5

SDA/P4.6

WKUP1/SCL/P4.7

ICAPB0/P3.1

ICAPA0/OCMPA0/P3.2

OCMPB0/P3.3

EXTCLK0/SS

MISO/P3.5

*V

must be kept low in standard operating mode.

TEST

DHT-500SD

SS

P9.4/A18

P9.2/A16

P9.3/A17

P9.0/RDI

P9.1/TDO

RW

REG

V

TINPA0/P2.0

SCK/WKUP0/P3.7

DD

HW0SW1

P7.7/AIN15/7/WKUP13

RESET

OSCOUT

P7.6/AIN14/WKUP12

OSCIN

P7.5/AIN13/WKUP11

V

V

ST92F150CVT1

(MAIN:IC11)

SS

DD

V

V

REG

V

TINPB0/P2.1

TINPB1/P2.5

TINPA1/P2.4

TOUTA0/P2.2

TOUTB0/P2.3

TOUTB1/P2.7

TOUTA1/P2.6

P7.4/AIN12/WKUP3

P7.1/AIN9

P7.3/AIN11

P7.0/AIN8/CK_AF

P7.2/AIN10

TEST

*V

A8/P1.0

P8.7/AIN7

AVSSAVDDP8.6/AIN6

P8.5/AIN5

75

P8.4/AIN4

74

P8.3/AIN3

73

P8.2/AIN2

72

P8.1/AIN1/WKUP15

71

P8.0/AIN0/WKUP14

70

NC

69

P6.5/WKUP10/INTCLK

68

P6.4/NMI

67

P6.3/INT3/INT5

66

P6.2/INT2/INT4/DS2

65

P6.1/INT6/RW

64

P6.0/INT0/INT1/CLOCK2/8

63

P0.7/A7/D7

62

V

DD

61

V

SS

P0.6/A6/D6

60

P0.5/A5/D5

59

P0.4/A4/D4

58

P0.3/A3/D3

57

P0.2/A2/D2

56

P0.1/A1/D1

55

P0.0/A0/D0

54

AS

53

DS

52

P1.7/A15

51

NC

A9/P1.1

WKUP6

A10/P1.2

A11/P1.3

A12/P1.4

A13/P1.5

A14/P1.6

Architectural Block Diagram

FLASH

128/64 Kbytes

3TM

E

1Kbyte

RAM

AS

DS

RW

WAIT

NMI

DS2

RW*

INT[5:0]

INT6*

WKUP[13:0]

WKUP[15:14]*

OSCIN

OSCOUT

RESET

CLOCK2/8

INTCLK

CK_AF

STOUT

ICAPA0

OCMPA0

ICAPB0

OCMPB0

EXTCLK0

ICAPA1

OCMPA1

ICAPB1

OCMPB1

EXTCLK1

TINPA0

TOUTA0

TINPB0

TOUTB0

TINPA1

TOUTA1

TINPB1

TOUTB1

V

REG

2/4 Kbytes

256 bytes

Register File

8/16 bits

CPU

Interrupt

Management

ST9 CORE

RCCU

ST. TIMER

EF TIMER 0 *

EF TIMER 1 *

MF TIMER 0

MF TIMER 1

VOLTAGE

REGULATOR

MEMORY BUS

REGISTER BUS

* Not available on 64-pin version.

The alternate functions (Italic characters) are mapped on Port 0, Port 1, Port2, Port3, Port4, Port5, Port6, Port7,

Port8* and Port9*.

Ext. MEM.

ADDRESS

DATA

Port0

Ext. MEM.

ADDRESS

Ports

1,9*

Fully

Prog.

I/Os

I2CBUS

WATCHDOG

SPI

ADC

SCI M

SCI A*

CAN_0

A[7:0]

D[7:0]

A[10:8]

A[21:11]*

P0[7:0]

P1[7:3]*

P1[2:0]

P2[7:0]

P3[7:4]

P3[3:1]*

P4[7:4]

P4[3:0]*

P5[7:0]

P6[5:2,0]

P6.1*

P7[7:0]

P8[7:0]*

P9[7:0]*

SDA

SCL

WDOUT

HW0SW1

MISO

MOSI

SCK

SS

AV

DD

AV

SS

AIN[15:8]

AIN[7:0]*

EXTRG

TXCLK

RXCLK

SIN

DCD

SOUT

CLKOUT

RTS

RDI

TDO

RX0

TX0

21

Page 22

NJM2279(MAIN:IC13)

BA7660F(MAIN:IC12)

MUTE

DHT-500SD

1

16

CC

V

INA

GND

INB

GND

N.C.

INC

2

3

4

5

6

7

6dB

75ǡ6dB

75ǡ6dB

75ǡ

15

14

13

12

11

10

OUTA1

OUTA2

OUTB1

OUTB2

N.C.

OUTC1

MUTE (1pin)

GND

OUTC2

8

9

H3c

LNORMA

h

MUTE

L

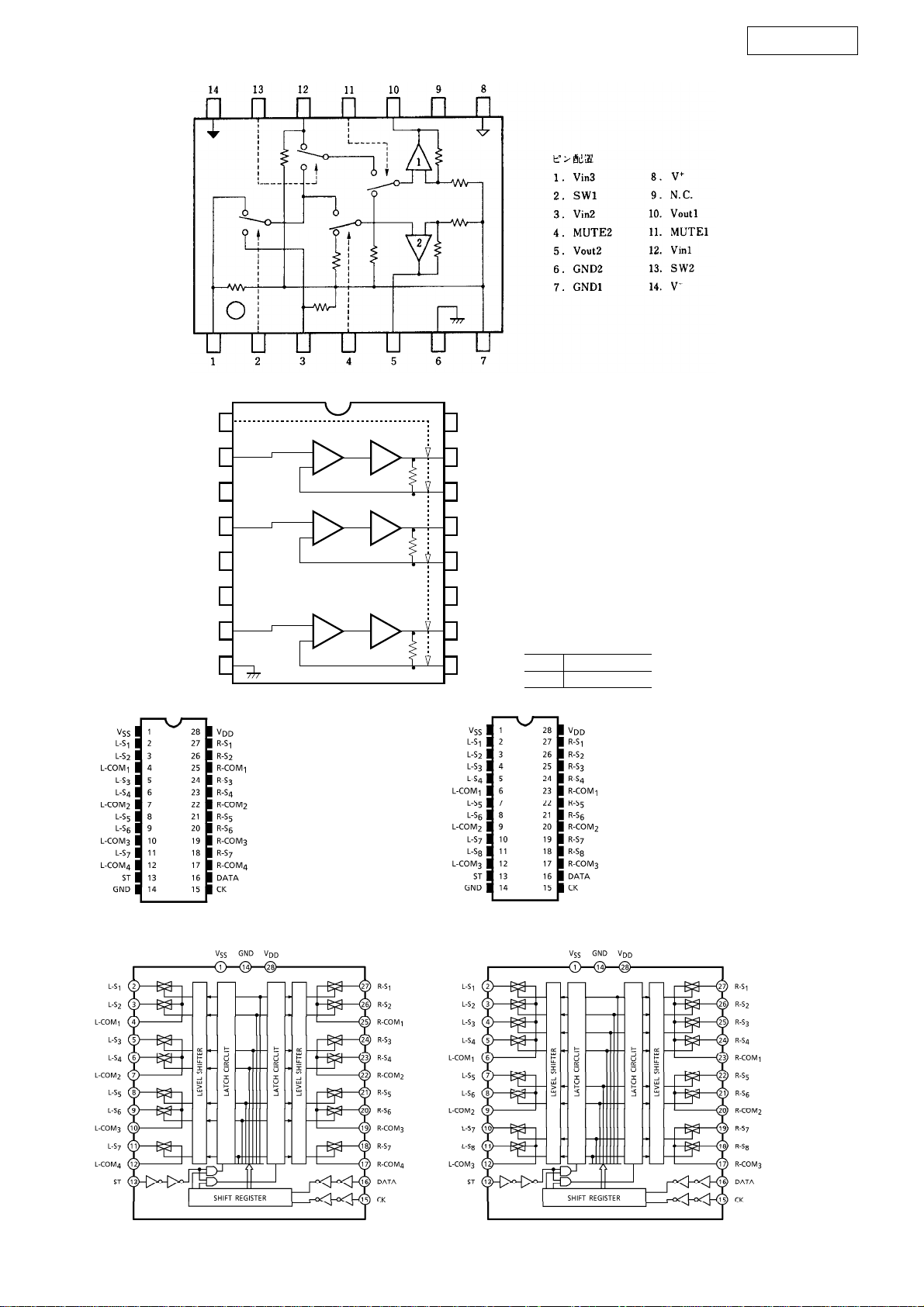

TC9162AN/AF(AMP:IC59) TC9164AN/AF(MAIN:IC14)

22

Page 23

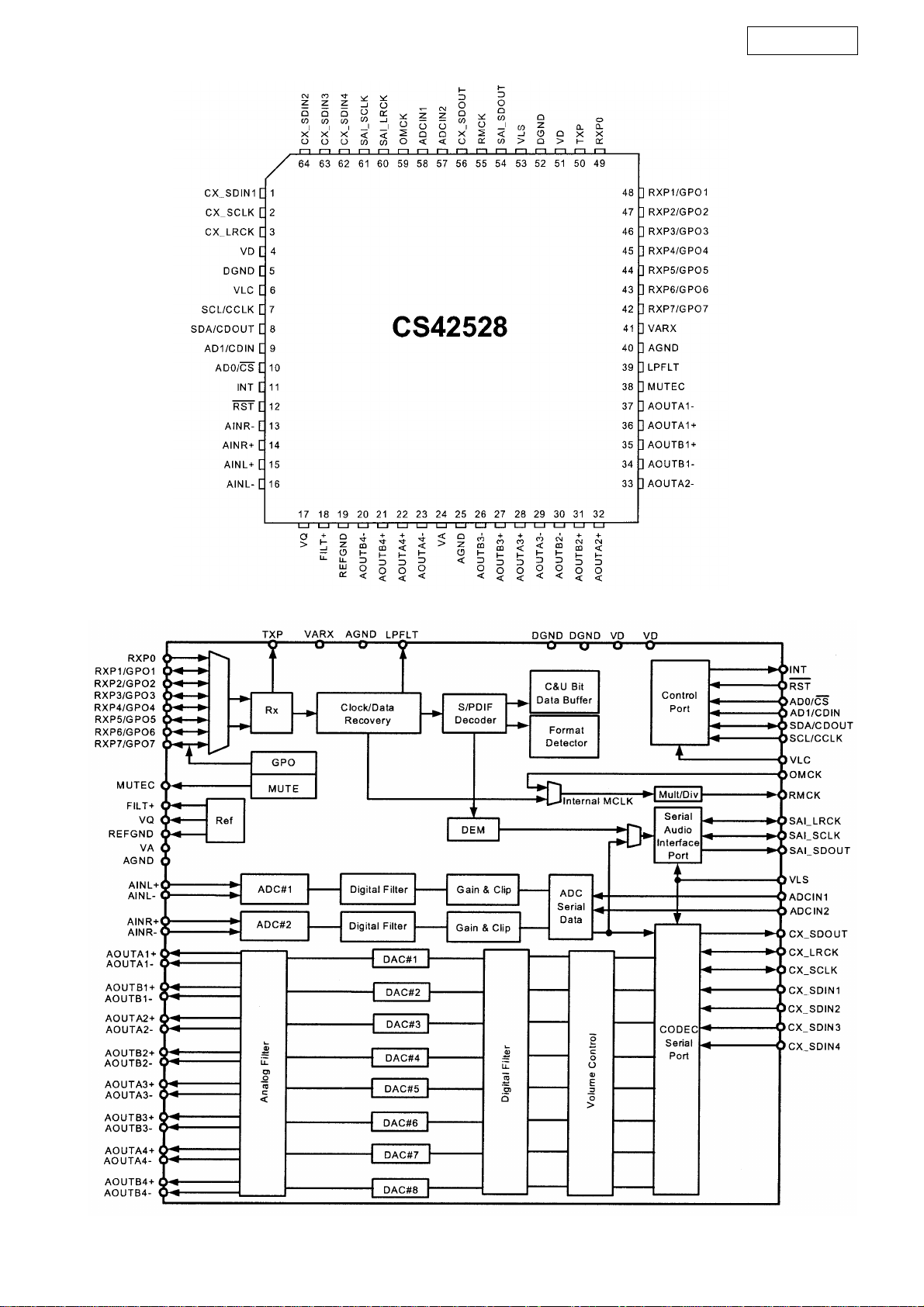

CS42528(DSP:IC51)

DHT-500SD

23

Page 24

MX29LV400T/B(DSP:IC53)

48 TSOP (Standard Type) (12mm x 20mm)

NC

NC

WE

NC

NC

NC

1

2

3

4

5

6

7

A9

8

A8

9

10

11

12

13

14

15

16

17

18

A7

19

A6

20

A5

21

A4

22

A3

23

A2

24

A1

A15

A14

A13

A12

A11

A10

RSEET

RY/BY

A17

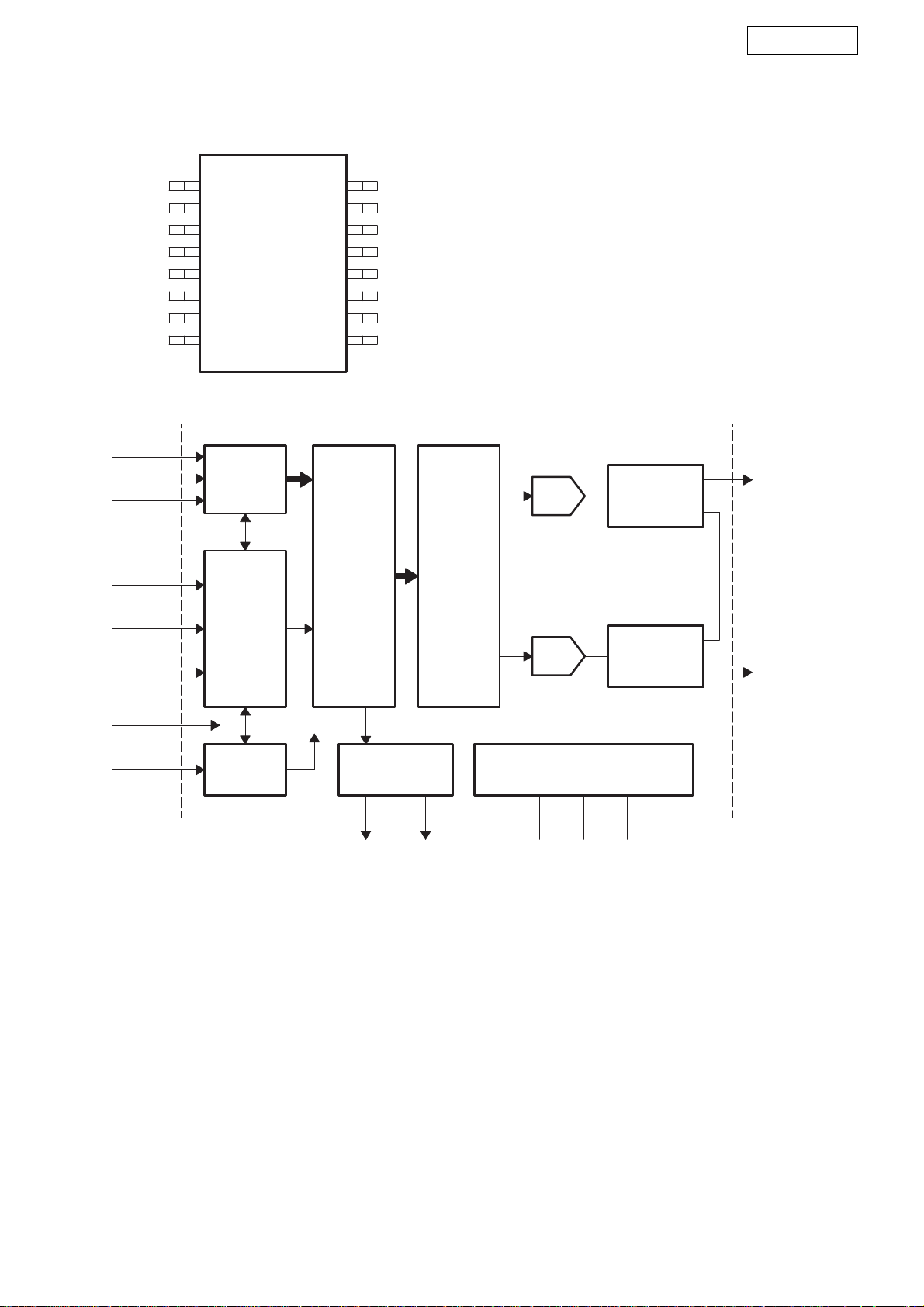

BLOCK DIAGRAM

MX29LV400T/B

DHT-500SD

48

A16

47

BYTE

46

GND

45

Q15/A-1

44

Q7

43

Q14

42

Q6

41

Q13

40

Q5

39

Q12

38

Q4

37

VCC

36

Q11

35

Q3

34

Q10

33

Q2

32

Q9

31

Q1

30

Q8

29

Q0

28

OE

27

GND

26

CE

25

A0

CE

OE

WE

RESET

A0-A17

CONTROL

INPUT

LOGIC

ADDRESS

LATCH

AND

BUFFER

PROGRAM/ERASE

HIGH VOLTAGE

X-DECODER

MX29LV400T/B

FLASH

ARRAY

Y-DECODER

Y-PASS GATE

SENSE

AMPLIFIER

ARRAY

SOURCE

PGM

DATA

HV

HV

WRITE

STATE

MACHINE

(WSM)

STATE

REGISTER

COMMAND

DA TA

DECODER

COMMAND

DATA LATCH

Q0-Q15/A-1

PROGRAM

DATA LATCH

I/O BUFFER

24

Page 25

PCM1754(DSP:IC55)

PIN ASSIGNMENTS

DHT-500SD

PCM1754

(TOP VIEW)

BCK

DATA

LRCK

DGND

V

V

OUT

V

OUT

NC

CC

L

R

1

2

3

4

5

6

7

8

FUNCTIONAL BLOCK DIAGRAM

BCK

LRCK

DATA

(FMT) ML

(MUTE) MC

(DEMP) MD

Audio

Serial

Port

Oversampling

Serial

Control

Port

16

15

14

13

12

11

10

9

4ı /8ı

Digital

Filter

and

Function

Control

SCK

FMT

MUTE

DEMP

TEST

ZEROA

V

COM

AGND

Enhanced

Multi-Level

Delta-Sigma

Modulator

DAC

DAC

Output Amp

and

Low-Pass Filter

Output Amp

and

Low-Pass Filter

V

OUT

V

COM

V

OUT

L

R

(TEST)

SCK

†

Open-DrainOutput for the PCM1755

( ): PCM1754

System

Clock

Manager

System Clock

Zero Detect

†

ZEROL/NA

†

(ZEROA)

ZEROR/ZEROA

Power Supply

CC

V

DGND

AGND

25

Page 26

TC2001(AMP:IC52,62,72)

DHT-500SD

24

23

22

21

20

19

18

16

15

28

27

26

25

17

INV2

OAOUT2

BBM0

BBM1

MUTE

INV1

OAOUT1

V5

AGND

VPPSENSE

OVRLDB

VNNSENSE

OCD1

REF

BIASCAP

FBKGND2

DCMP

FBKOUT2

VPWR

FBKGND1

FBKOUT1

HMUTE

Y1

Y1B

Y2B

Y2

NC

OCD2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

TC2001 Audio Signal Processor Pin Descriptions

Pin Function Description

1 BIASCAP Bandgap reference times two (typically 2.5VDC). Used to set the

common mode voltage for the input op amps. This pin is not capable of

driving external circuitry.

2, 6 FBKGND2,

FBKGND1

3 DCMP Internal mode selection. This pin must be grounded for proper device

4, 7 FBKOUT2,

FBKOUT1

5 VPWR Test pin. Must be left floating.

8 HMUTE Logic output. A logic high indicates both amplifiers are muted, due to the

9, 12 Y1, Y2 Non-inverted switching modulator outputs.

10, 11 Y1B, Y2B Inverted switching modulator outputs.

13 NC No connect

14 OCD2 Over Current Detect input.

15 REF Internal bandgap reference voltage; approximately 1.2 VDC.

16 OCD1 Over Current Detect input.

17 VNNSENSE Negative supply voltage sense input. This pin is used for both over and

18 OVRLDB A logic low output indicates the input signal has overloaded the amplifier.

19 VPPSENSE Positive supply voltage sense input. This pin is used for both over and

20 AGND Ground.

21 V5 5 Volt power supply input.

22, 27 OAOUT1, OAOUT2 Input stage output pins.

23, 28 IN1, IN2 Single-ended inputs. Inputs are a “virtual” ground of an inverting opamp

24 MUTE When set to logic high, both amplifiers are muted and in idle mode.

25, 26 BBM1, BBM0 Break-before-make timing control to prevent shoot-through in the output

Ground Kelvin feedback (Channels1&2)

operation.

Switching feedback (Channels 1 & 2)

mute pin state, or a “fault”.

under voltage sensing for the VNN supply.

under voltage sensing for the VPP supply.

with approximately 2.4VDC bias.

When low (grounded), both amplifiers are fully operational. If left floating,

the device stays in the mute mode. Ground if not used.

MOSFETs.

26

Page 27

TP2150B(AMP:IC53,63,73)

DHT-500SD

OCS2HP

OCS2HN

NC

HO2

OCS1HN

NC

OCS1HP

NC

HO1COM

HO1

VN10

LO1

LO1COM

LO2

VN10

VNN

HO2COM

NC

LO2COM

NC

OCS1LN

OCS1LP

NC

NC

VBOOT1

NC

SW-FB

SMPSO

NC

SLEEP

NC

NC

52

53

54

55

56

57

59

60

61

62

63

64

51 50 48 4749

1

NC

AGND

NC

NC

46

AGND

45 44 42 4143

98765432 191716 1815

V5

NC

OCD1

40 39 383736 35 34 33

14131110 12

Y2

NC

NC

CSS

OCD2

Y2B

NC

Y1B

Y1

NC

NC

32

31

30

29

27

2658

25

24

23

22

21

20

28

NC

OCS2LN

OCS2LP

NC

NC

VBOOT2

NC

NC

NC

NC

NC

NC

NC

TP2150B Pin Description

Pin Function Description

2,5 AGND Analog ground.

6 V5 5V power supply input.

7 OCD1 Over-current threshold output (Channel 1)

9 CSS Soft startup for VN10 controller, this pin should be tied to V5

10 OCD2 Over-current threshold output (Channel 2)

13,17 Y2, Y1 Non-inverted switching modulator inputs

14,16 Y2B, Y1B Inverted switching modulator inputs

27,57 VBOOT 2, VBOOT1 Bootstrapped voltage to supply drive to gate of high-side FET

(Channel2&1)

30,31 OCS2LP, OCS2LN Over Current Sense inputs, Channel 2 low-side

33,34 OCS2HP, OCS2HN Over Current Sense inputs, Channel 2 high-side

36,48 HO2, HO1 High side gate drive output (Channel 2 & 1)

37,47 HO2COM, HO1COM Kelvin connection to source of high-side transistor (Channel 2 & 1)

39,45 LO2COM, LO1COM Kelvin connection to source of low-side transistor (Channel 2 & 1)

40,44 LO2, LO1 Low side gate drive output (Channel 2 & 1)

41,43 VN10 “Floating” supply input for the FET drive circuitry. This voltage must be stable

and referenced to VNN.

42 VNN Negative supply voltage.

50,51 OCS1HN, OCS1HP Over Current Sense inputs, Channel 1 high-side

53,54 OCS1LN , OCS1LP Over Current Sense inputs, Channel 1 low-side

59 SW-FB Feedback for regulating switching power supply output for VN10

60 SMPSO Switching power supply output for VN10

62 SLEEP This pin is active high. Tie this pin to GND for normal operation. Tie this pin to

+5V to place the part in sleep mode.

1,3,4,8,

11,12,15,

18,19,20,

21,22,23,

24,25,26,

28,31,32,

35,38,46,

49,52,53,

56,58,61,

63,64

NC Not connected (bonded) internally. Please refer to the Application/Test circuit

for details on the how to connect these pins.

27

Page 28

M62429FP(AMP:IC88)

M62446AFP(AMP:IC58)

DHT-500SD

M4556AL(AMP:IC78)

28

Page 29

CS494003 (DS:IC31)

A

d

Adv

DHT-500SD

A4, GPIO28

AU D ATA1

AU D ATA0

CMPCLK, FSCLKN2

HDATA2, GPIO2

VSS3

VDD3

HDATA1, GPIO1

HDATA0, GPIO0

CMPREQ, FLRCLKN2

CMPDAT, FSDATAN2

FLRCLKN1

WR, DS, GPIO10

RD, R/W, GPIO11

PLLVSS

FILT2

FILT1

PLLVDD

XTALO

CLKIN, XTALI

CLKSEL

CS, GPIO9

A0, GPIO13

FSDATAN1

VDD4

VSS4

FSCLKN1, STCCLK2

SCS

SCDIN

VSS5

VDD5

A1, GPIO12

SCDOUT, SCDIO

HINBSY, GPIO8

SCCLK

UHS2, CS_OUT, GPIO17

RESET

110

115

120

125

130

135

140

144

UHS0, GPIO18

LRCLK0

1

SCLK0

AU D ATA2

AUDATA3, XMT958A

HDATA3, GPIO3

HDATA4, GPIO4

105

5

dvance

GPIO20

FA1, FSCDIN

UHS1, GPIO19

FAO, FSCCLK

INTREQ, ABOOT

AUDAT

VSS2

VDD2

100

FDAT7

GPIO21

MCLK

10

VDD6

SCLK1

HDATA5, GPIO5

, FDS

VSS6

FWR

FHS0,

HDATA6, GPIO6

HDATA7, GPIO7

95

W

FDAT6

FHS1, FRD, FR/

AUDATA5, GPIO29

AUDATA6, GPIO30

AUDATA7, XMT958B, GPIO31

15

FCS

FDBCK

FINTREQ

VSS1

FDAT5

VDD1

90

FDAT4

NC1

20

VDD7

NC2

VSS7

LRCLK1

FDAT3

NC4

NC3

LRCLKN, GPIO23

SCLKN, GPIO22

FDBDA

85

FDAT2

25

DBDA

DBCK

SDATAN0, GPIO24

FDAT1

SD_CAS

SDATAN1, GPIO25

SDATAN3, GPIO27

SDATAN2, GPIO26

80

30

TEST

FDAT0

, GPIO16

E

NV_OE, GPIO15

NV_W

SD_RAS

NV_CS, GPIO14

SD_ADDR0, EXTA0

SD_ADDR1 ,EXTA1

SD_ADDR2 ,EXTA2

SD_ADDR3 ,EXTA3

75

70

65

60

55

50

45

35

SD_DATA0, EXTD0

SD_DATA2, EXTD2

SD_DATA1, EXTD1

40

SD_WE

SD_ADDR10, EXTA10

SD_BA, EXTA19

VDDSD1

VSSSD1

SD_CS

SD_ADDR4, EXTA4

SD_ADDR5, EXTA5

SD_ADDR6, EXTA6

SD_CLK_EN

SD_ADDR7, EXTA7

SD_ADDR8, EXTA8

SD_CLK_IN

SD_ADDR9, EXTA9

SD_CLK_OUT

VDDSD2

VSSSD2

SD_DATA8, EXTA11

SD_DATA9, EXTA12

SD_DATA10, EXTA13

SD_DATA11, EXTA14

SD_DATA12, EXTA15

VDDSD3

VSSSD3

SD_DATA13, EXTA16

NC5

SD_DATA14, EXTA17

SD_DATA15, EXTA18

SD_DQM1

SD_DATA7, EXTD7

SD_DATA6, EXTD6

VDDSD4

VSSSD4

SD_DATA5, EXTD5

SD_DQM0

SD_DATA4, EXTD4

SD_DATA3, EXTD3

FHS2, FSCDIO, FSCDOUT

Compressed

Audio

Interface

Digital

Audio

Interface

DSP AB

PLL Clock

Manager

Frame

Shifter

Input

Buffer

RAM

Programmable

Multistandard

Audio Decoder

Parallel or Serial

Host Interface

Shared Memory

29

SAI 0

SAI 1

SAI 3

SAI 2