B

SERVICE MANUAL

MODEL

DCD-485/685

STEREO CD PLAYER

DCD-485

Hi-Fi Component

DCD-685

Some illustration using in this service manual is slightly from the actual set.

2

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

The following check should be performed for the continued prtection of the customer and service

technician.

LEAKAGE CURRENT CHECK

Before reterning the unit to the customer,make sure you make either (1) a

leakage current check or (2) a line to chassis resistance check. If the leakage current exceeds 0.5

miliamps, or if hte resistance from chassis to either side of the power cord is less than 460 kohms,

the unit is detective.

SPECIFICATIONS

SPECIFICATIONS

DCD-485

AUDIO

Number of Channels:

Freqency Responese:

Dynamic Range:

Signal to Noise ratio:

Harmonic distortion:

Separation:

Wow and Flutter:

Output Voltage:

DISCS

GENERAL CHARACTERISTICS

Power consumption: 11 W

Dimensions:

Mass: 3.4 kg

FUNCTIONS AND DISPLAY

Functions:

Others:

REMOTE CONTROL UNIT

Remote Control System:

Mass: 85 g including batteries

2 channels

2 to 20 kHz

98 dB

105 dB

0.003 % (1 kHz)

102 dB (1 kHz)

Below measurable limit:

( 0.001

0.2 to 2.0 V

Compact Disc format

AC 230 V, 50 Hz Power Supply:

434 (W) x 100 (H) x 285 (D) mm

Automatic searchi, programmed playback, repeat playback, manual search, auto space,

time mode, auto edit, dimmer, random playback, pitch control (DCD-685 only)

Track number, time, music calendar and engaged modesDisplay:

Headphones jack

RC-266

Infrared pulse system

3V DC; two R6P (standard size AA) dry cell batteriesPower Supply:

54.5 (W) x 140 (H) x 24.8 (D) mmExternal Dimensions:

% W. peak)

DCD-685

100 dB

110 dB

103 dB (1 kHz)

12 W

3.6 kg

✽ Specifications and design are subject to change without notice for purpose of improvement.

3

DISASSENBLY

Follow the procedure below in reverse order when reassembling

(Follow the procedure below in reverse order when reassembling)

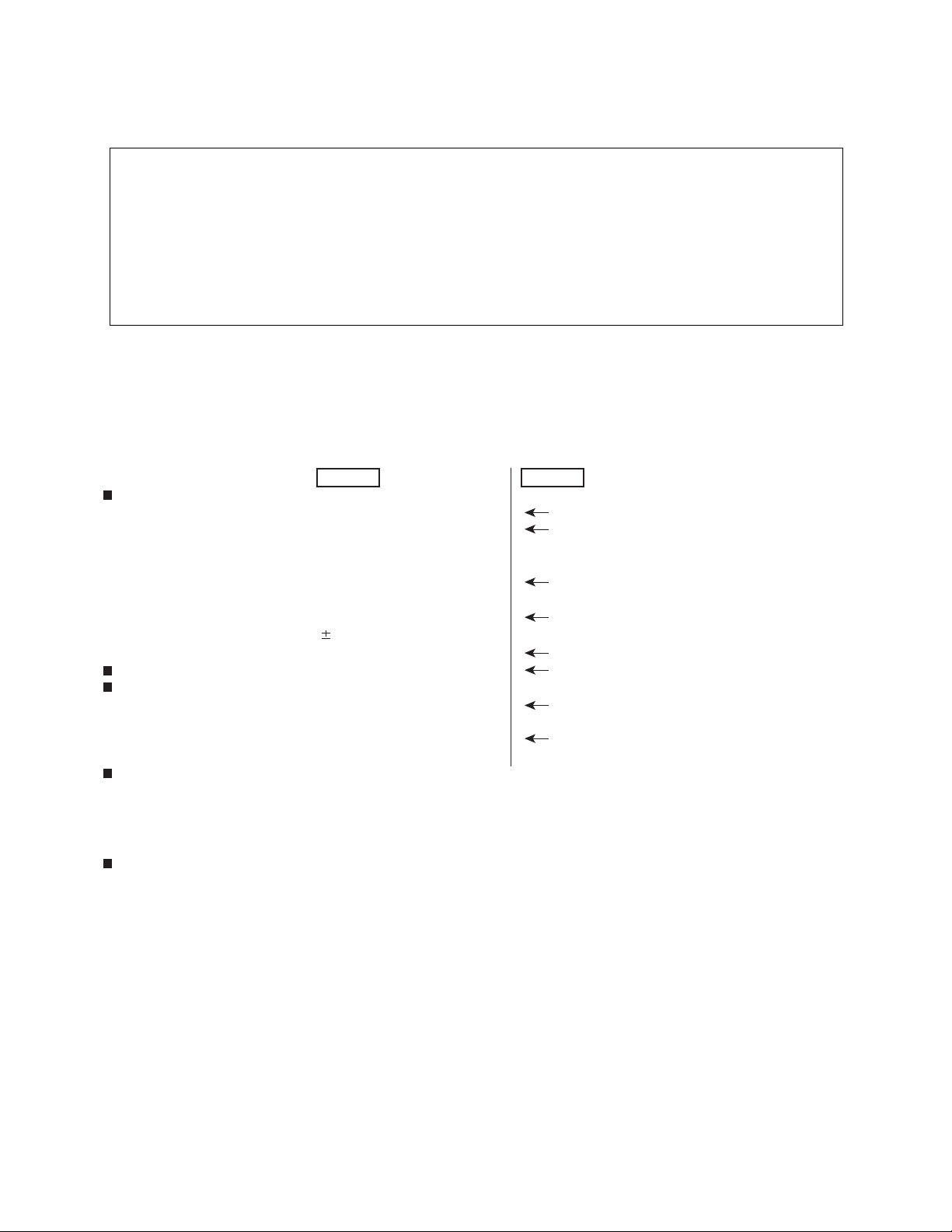

1. Top Cover

1. Remove 4 screws

2. Remove 2 screws

3. Detach the Top Cover as shown in the fig.

on both sides.

1

on the Rear Panel.

2

2. Front Panel

1. Remove 1 screw 3 on the Rear Panel and

1 screw

(only DCD-485)

2. Take off the Mecha Cover after removing

2 screws

Open the Tray by turning the Gear (a) clockwise,

then detach the Loader Panel.

3. Remove 3 screws

Front Panel.

4. Remove 2 screws

Panel and 1 screw

fixing Support Bracket (b).

4

.

5

on the bottom edge of the

6

, at L/R ends of the Front

7

fixing Phone P.W.B.

8

Support Bracket

3. CD Mecha. Unit

1. Remove 4 screws

2. Unplug Connectors (b), (c) and FFC from each

socket.

3. Release the FFC from the Clamper.

fixing the CD Mecha.

9

4. Main P.W.B.

1. Remove 5 screws 10, 5 screws

Panel and detach it.

2. Remove 3 screws

3. Unfasten 1 P.W.B. Holder to detach the Main

P.W.B.

4. Remove 1 screw

Power P.W.B.

5. Unfasten 1 P.W.B. Holder to detach the Power

P.W.B.

fixing the Main P.W.B.

12

and 2 screw fixing the

on the Rear

11

4

5

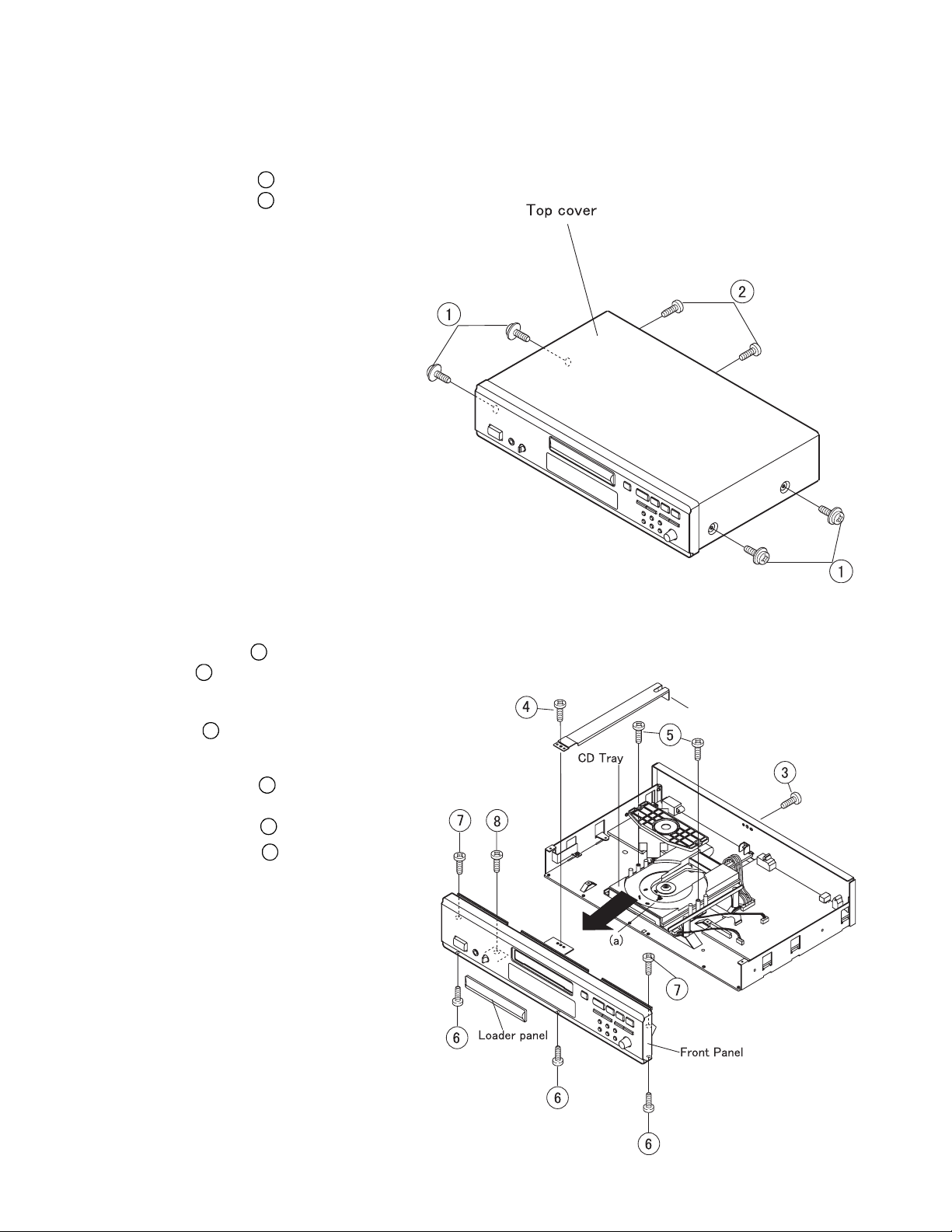

CD TEST MODE

z

Setting of the test mode

How to start the test mode: Turn on the power in the condition that CLOSE (Pin No. 3 )

and OPEN (Pin No. 4 ) of CX053 are being shorted. ( “01” is indicated on the DISPLAY)

To exit from the test mode, turn off the power.

(Refer to Fig. 1 “Test Point Layout”)

Fig. 1 “Test Point” Layout

* Laser light of the pickup is always emitted regardless of DISC loading in the test mode.

You may lose your eyesight if you look into the laser directly.

So be careful enough when operating in the test mode.

z

Used DISC: A-BEX TCD784

z

Explanation of each button

* Use only the buttons described below for operations while in the test mode,

and don’t push any other buttons.

Names of buttons Operation

OPEN / CLOSE * Loads or unloads DISC

PLAY * Emits laser light

* Repeats search operation (No DISC condition: While it’s

pressed)

* Actuates focus servo (In case of DISC loaded)

* Actuates tracking servo

STOP * Stops operation

PAUSE * Performs auto adjustment

MANUAL SEARCH

* Moves pickup

FORWARD / REVERSE

z

How to check the test mode

( 1 ) DISC discrimination, adjustment

* Insert DISC, and press the PAUSE button.

* “06 Adj” is displayed, and discrimination of DISC size 8 cm/12 cm, discrimination of

DISC reflectance (CD, CD-R/CD-RW), adjustment of focus, tracking offset,

and EF balance will be performed. (Adjusted values are not displayed:

FEO

TEO

HF

DRF

Fig. 2 DISC discrimination, adjustment Fig. 3

TEO

TB

SLD

Refer to Fig. 2, 3)

(Case of CD-RW) Adjustment of EF balance

* After completing the discrimination and adjustment, it becomes stop condition.

* Once discrimination of DISC has been carried out in the “06 Adj” mode, discrimination of

size and reflectance is no longer made, and only adjustment will be performed.

( 2 ) Checking of servo state

* Press the PLAY button after performing above (1) “DISC discrimination, adjustment”.

* “02 L on” is displayed, and the laser will start to light. (The pickup may vibrate with a rattling

noise if DISC has been loaded, but this is not abnormal.)

* Press the PLAY button again.

* “03 F on”is displayed. DISC starts turning,and focus servo will be actuated.

FEO

TEO

TEO

HF

(Refer to Fig. 4, 5)

6

¥¥¥

Fig. 4 In “03 F on”

¥¥¥ ¥¥¥¥¥¥¥¥¥

Fig.

5 In “03 F on”

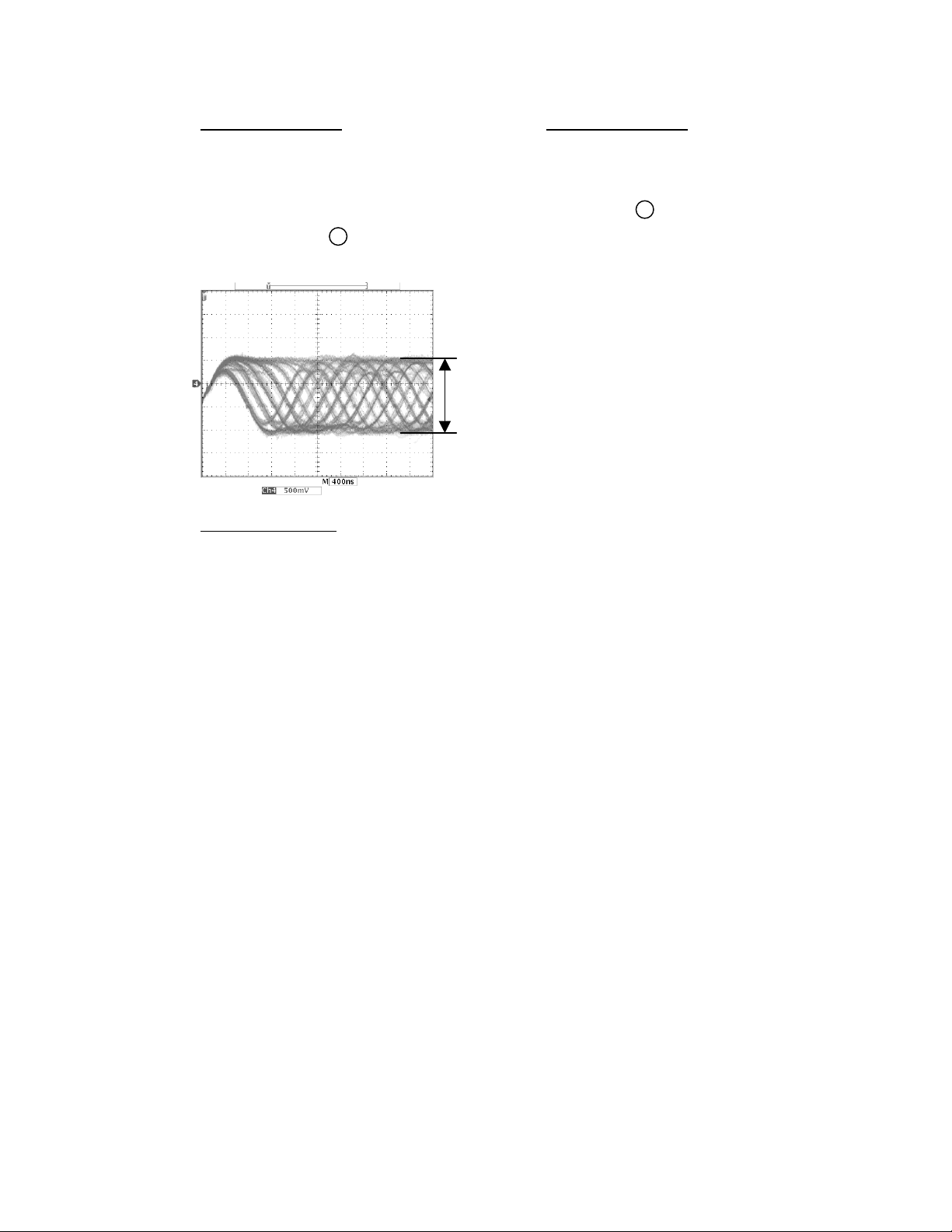

* Press the PLAY button again.

* “04 t on” is displayed. Tracking, CLV, and slide servo will be actuated.

* Monitor HF signal using the test terminals, HF of CX053 (Pin No. 1 ) and

VC of CX063 (Pin No. 5 : 2.5V ref. signal). Check that the signal’s amplitude

is 1.5Vâ0.3Vp-p. (Refer to Fig. 6)

HF

¥¥¥

A ( A = 1.5 ± 0.3 V

Fig. 6 In “04 t on”

P-P

)

7

8

p

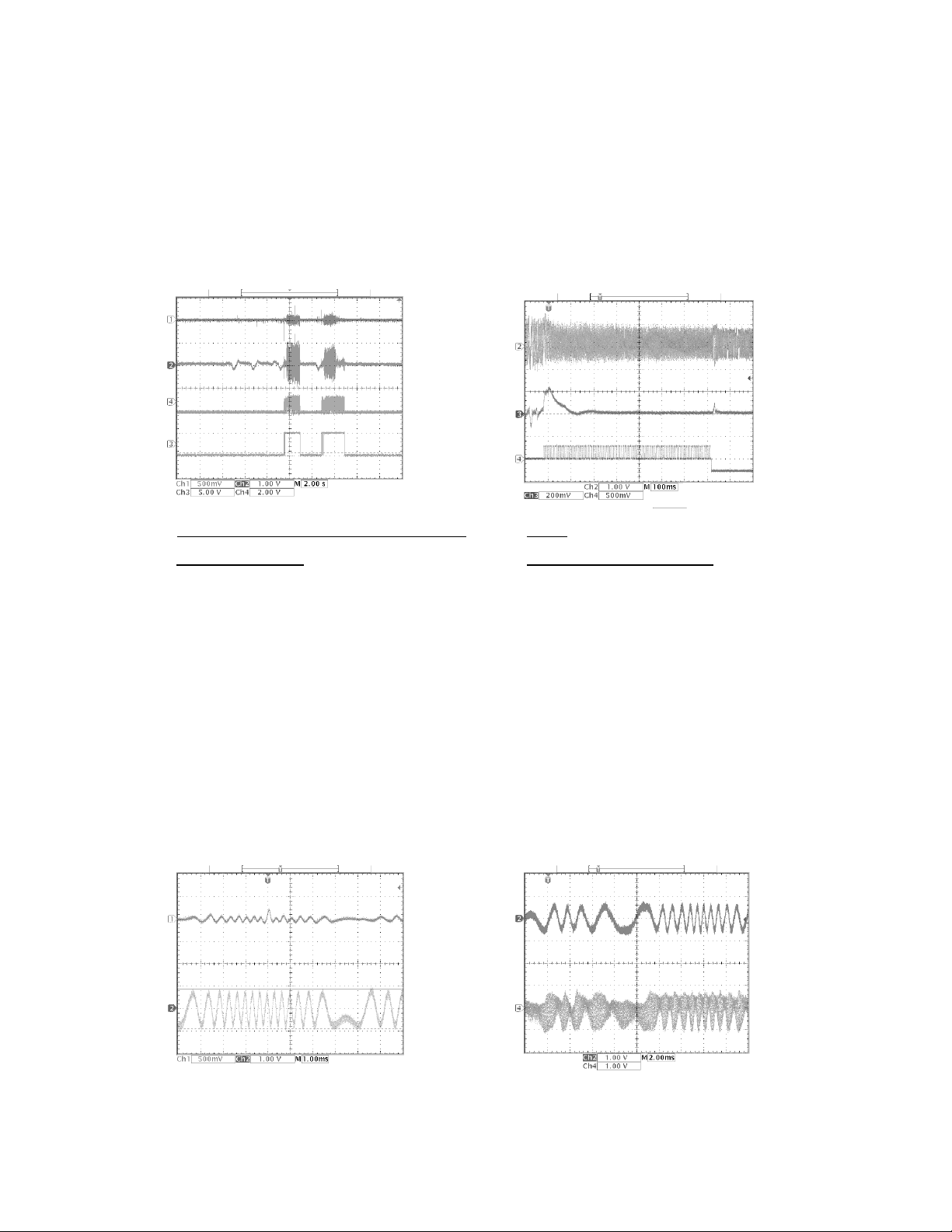

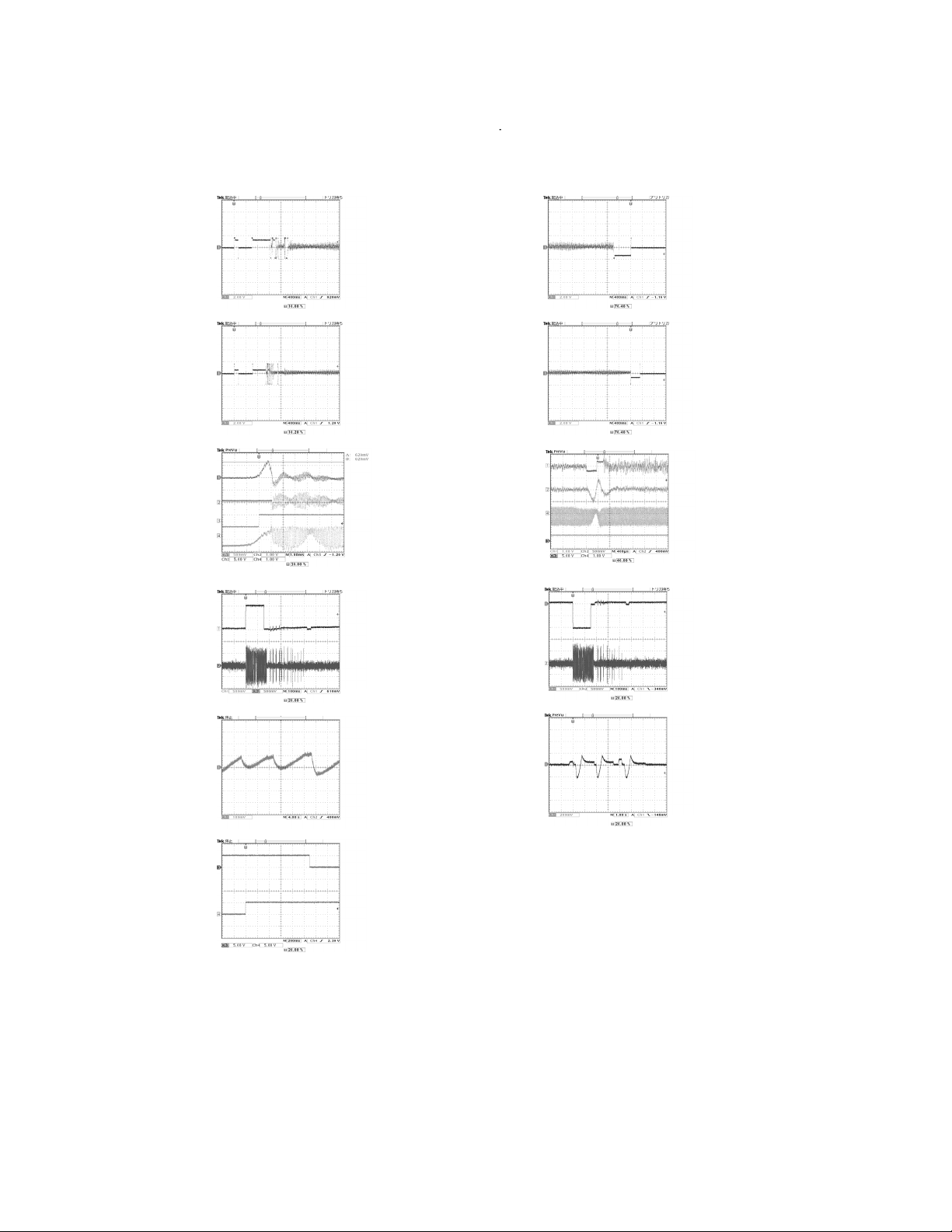

Wave-forms of each point

SPD

SPD

FEO

TEO

DRF

HF

SLD

TEO

When 12 cm DISC

start

When 8 cm DISC

start

When focus servo

on

Track search

(when forward)

SPD

SPD

TD

TEO

HF

DRF

SLD

TEO

When 12 cm DISC

stop

When 8 cm DISC

stop

During PAUSE

Track search

(when reverse)

SLD

OPEN

CLOSE

During PLAY

When the tray

OPEN

FD

Focus search

(no DISC)

9

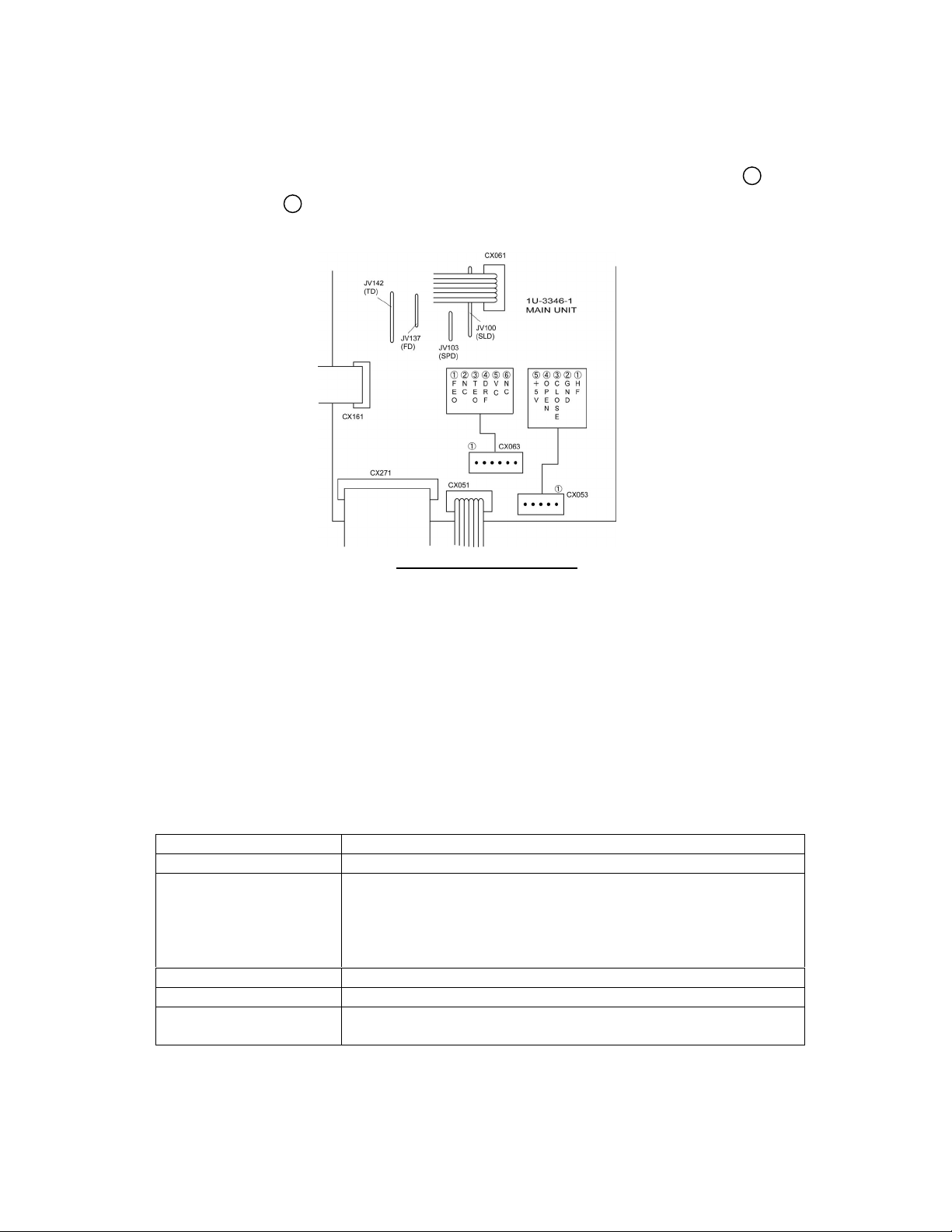

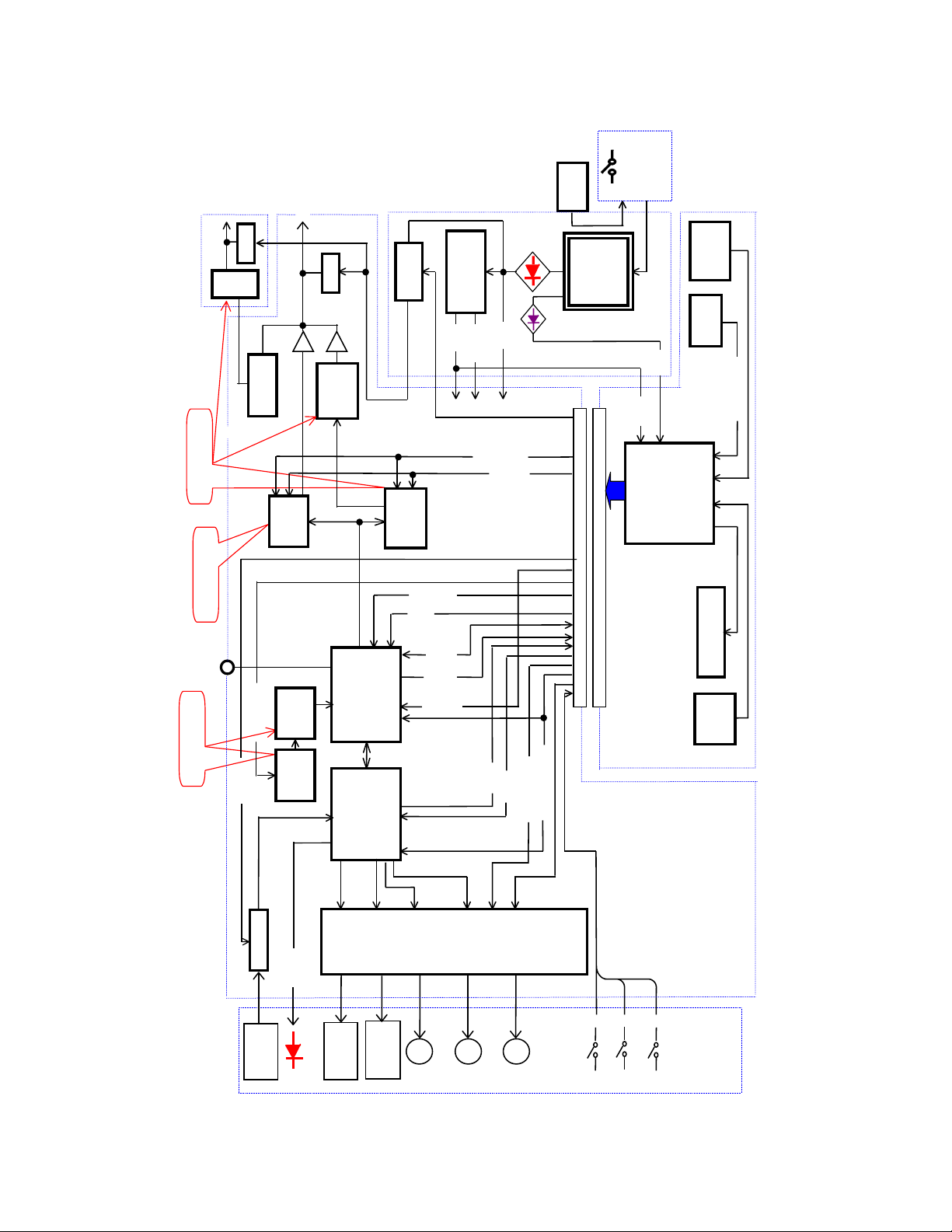

BLOCK DIAGRAM

MUTE

H/P UNIT

1U-3346-4

V

1U-3346-5

AC

INLET

POWER CONT.

±5V

IC501

M5290P

RESET

±8V

CONTROL

XRST2

MUTE

IC315

H/P AMP

DAC

PCM1702

IC602/603

MUTE

CONTROL

POWER SW

S616

ROTALY

PT501

TRANS.

POWER

POWER

1U-3346-2

-HB

DD

+V

ENCODER

UNIT

KEY

MATRIX

A/D INPUT

DCD-685 only

IC105

DF&DAC

PCM1735

DCD-485 only

OPT.OUT

DSP

VCO

IC108

TC9246F

CONTROL

DCD-685 only

PLL

IC107

CD/RW

BU2616F

LC78625E

ASP

LA9241M

D.FILTER

SM5841BS

IC102

IC101

2

IC703

MD

D.MUTE

CODE

SUB

FSEQ

XRST1

DRF

CX271

CY271

1U-3346-3

SL

DRV.MUTE

COTROL BUS

µ-COM

µPD78044F

DISPLAY

1U-3346-1

MAIN UNIT

IC201

VFD

REMOTE

FL601

IC702

SENSOR

RW SW

UP

PICK

LD ON

L.DIODE

FOCUS

FOCUS

COIL Drv.

COIL

SLIDE

COIL Drv.

TRACKING

M

COIL

TRACKIN

Mtr Drv.

Mtr. Drv.

SPINDLE

LOADING

M

SLIDE

M

SPINDLE

IC104

LA6995

Mtr. Drv.

LOADING

OPEN-SW

INMOST-SW

CD MECHA

CLOSE-SW

KSL-2130CCM

10

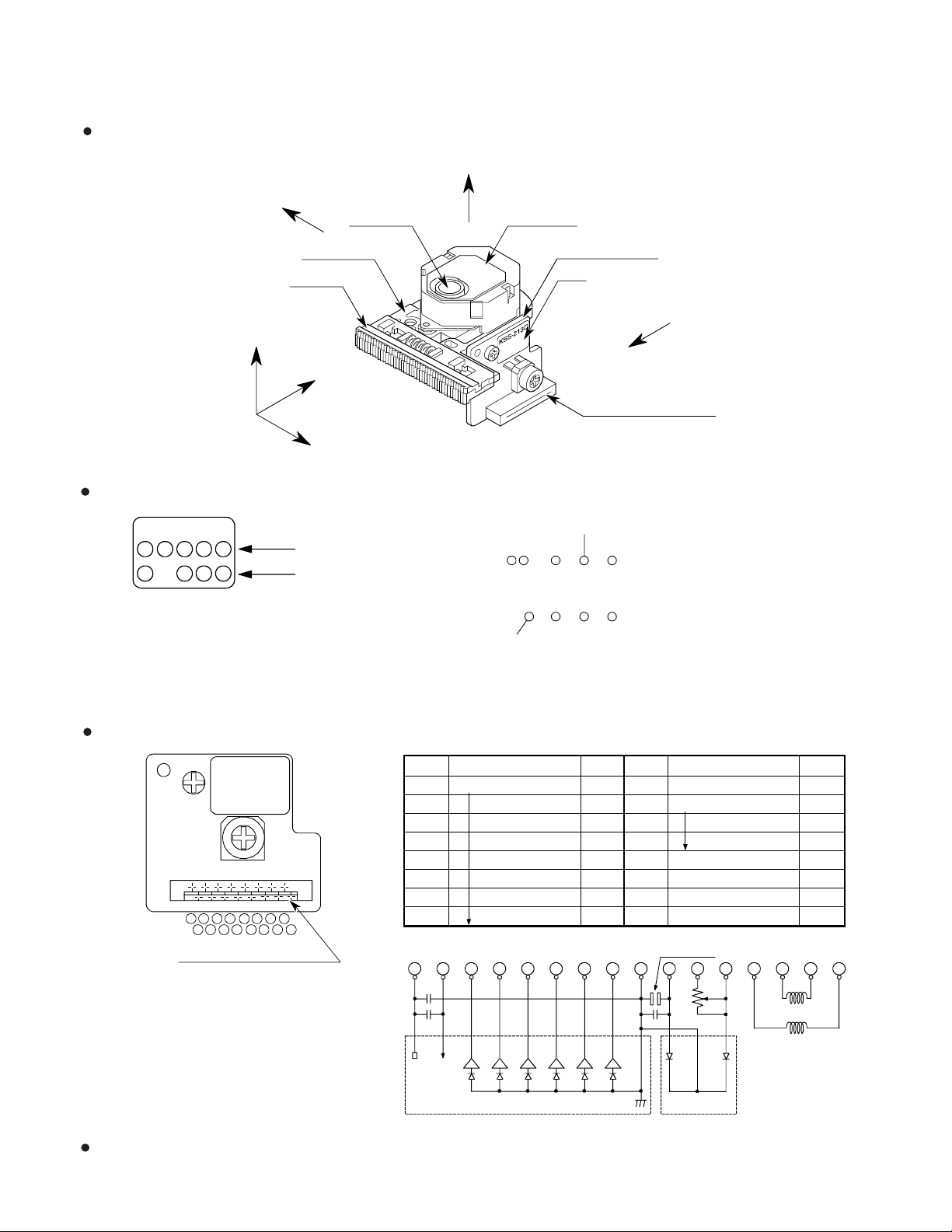

NOTE FOR HANDLING OF LASER PICK-UP

Description of the Components

+Z-axis direction

Label

+X-axis direction

KSS-213C

Z-axis

OP Slide base

Slide rack

Y-axis

(Tangental direction)

X-axis

(Radial direction)

Lot No.

lop

Object Lens

Actuator cover

PAL-2 Flexible board

Label

+Y-axis direction

Flexible flat cable connector

year

(last figure)

day month quality control No.

Lot No.

Oct. Nov. and Dec. are ex pressed by alphabetical letters

of X, Y and Z.

lop No.

10 1 10

LD drive currentquality control

The expressed unit is by mA, with omission of the

decimal point as for example, 56.5mA will be expressed as 565, but the head of English letter means

the control in the manufacturning plant.

-1

Pin Connector

KSS-213C

Pin No. Description

1 PD IC Vc IN

2 Vcc IN

3 E OUT

4 D OUT

5 A OUT

6 B OUT

7 C OUT

1 3 5 7 9 11 13 15

2 4 6 8 10 12 14 16

8 F OUT

Flexible flat cable connector

+2.5V +5V

CAUTION: The soldered connecting portion must be bridged when removing CX161.

IN/OUT

Pin No. Description

10 LD LD IN

11 VR IN

12 PD OUT

13 FCS (+) IN

14 TRK (+) IN

15 TRK (−)IN

16 FCS (−)IN

987654321

LD

IN/OUT

9 GND IN

PDIC

SHORT LAND

10

11

LDPDIC

13

12

14

15

TRACKING

FOCUSING

16

Caution for Handling the Laser Pick-up

The laser pick-up KSS-213C is assembled and precisely

adjusted using a sophisticated manufacturing process in our

plant. Do not disassemble or attempt to readjust it. Please

observe the following instructions carefully in handling the

pick-up.

1. Handle with Care

(1) Storage

Do not store the pick-up in dusty, high-temperatured or

high-humidity environments.

(2) Please take care for preventing from shock by falling

down or careless handling.

2. Laser Diode (LD)

(1) Protect your eyes

The laser beam may damage the human eye, since the

intensity of the focused spot may reach 7×10

2

W/cm

even if the intensity at the objective lens is 400µW

maximum. As the light beam spreads after focused

through the objective lens, it does not effect you in the

place as far as more than 30 cms. However, do not look

at the laser light beam either through the objective lens

directly nor another lens or a mirror.

(2) Poison of As

Since the LD chip contains As (Arsenic), as GaAs +

GaAlAs, as known as the poison, although the poison is

relatively weak, in comparing with others, e.g. As

etc., and the amount is small, avoid putting the

AsCl

3

chip in acid or an alkali solution, heating it over 200 °C

or putting it into your mouth.

(3) Avoid surge current or electrostatic discharge

The LD may be damaged or deteriorated by its own

strong light if a large current is supplied to it, even if only

a short pulse.

Make sure that there is no surge current in the LD driving

circuit by switches or else. Be careful to handle pick-up

as it may be damaged in a moment by human

electrostatic discharge. The pins of the LD are shortcircuited by solder for protection during shipment.

For safety handling of an LD, grounding the human body,

measuring equipments and jig is strongly recommended.

And still it is further desirable to make use of mat on the

platform and floor for handling the LD.

To open the short-circuit, remove the soldering quickly

with a soldering iron whose metal part is grounded.

The temperature of the soldering iron should be less than

320°C (30W).

2O3

4. Metal Bearing

As the metal bearing of Cu-compound sintered alloy is

impregnated with FROIL946P, never fail to supply the

bushing with the same lubricant at the time of replacing the

pick-up.

5. Handling

Please handle the laser pick-up with holding the slide base.

(resin molded part).

When either a part of human body or some other things may

happen to touch directly with the circuit part of P.W.Board, it

may cause deterioration, take careful attention in handling

this base.

6. Deterioration

As KSS-213C comprises built-in RF Amp and APC circuit,

resists stronger against external electrostatic damages than

3

the former typed pickup. However, there is possibility of

pickup deterioration in the following cases.

(1) Low HF level, or with great numbers of jitters.

(2) Tracking offset (EF Balance) is out of order (Refer to

“Confirmation Method of Adjustment”for confirmation (1)

and (2)).

,

3. Actuator

(1) The performance of the actuator may be affected if

magnetic material is located nearby, since the actuator

has a strong magnetic circuit. Do not permit dust to enter

through the clearance of the cover.

(2) Cleaning the lens

It may change the specifications by attaching dust or

ash on the objective lens. Clean the lens with a cleaning

paper dampened with, not pressing lens with so much

strength by the cleaning paper.

11

12

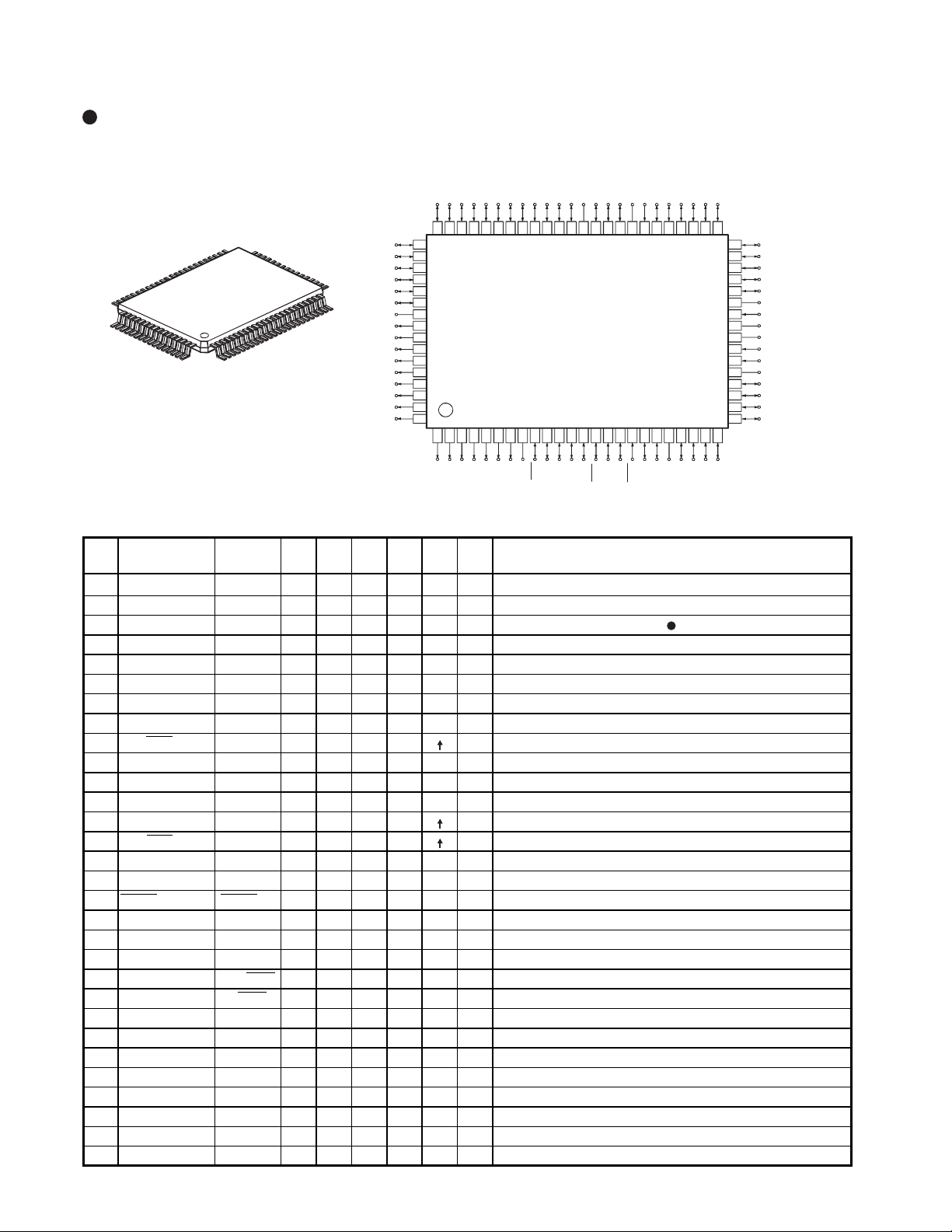

SEMICONDUCTORS

IC's

µPD78044FGF-188-3B9 (IC601)

P114/FIP22

P115/FIP23

P116/FIP24

P117/FIP25

P120/FIP26

P121/FIP27

P122/FIP28

P123/FIP29

P124/FIP30

P125/FIP31

P126/FIP32

P127/FIP33

VDDP70

P71

P72

IC (Vpp)

POO/INTPO/T10

PO1/INTP1

PO2/INTP2

P03/INTP3/C10

P31/TO0

P31/TO1

P32/TO2

25

24

P113/FIP21

P112/FIP20

P111/FIP19

P110/FIP18

P107/FIP17

P106/FIP16

LOAD

V

P105/FIP15

P104/FIP14

P103/FIP13

P102/FIP12

P101/FIP11

P100/FIP10

P197/FIP9

P196/FIP8

P195/FIP7

41

40

64

65

1

80

µPD78044FGF-188-3B9 Terminal Function

Pin

No.

Terminal Port I/O Typ Rst Ini Act Ext

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49 48 47 46 45 44 43 42 41

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

123456789

P94/FIP6

P93/FIP5

P92/FIP4

PD78044FGF-188-3B9

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

DD

P90/FIP2

P81/FIP1

V

P80/FIP0

P27/SCK0

P26/SO0/SB1

P91/FIP3

P23/STB

P24/BUSY

P25/SIO/SBO

P21/SO1

P22/SCK1

REST

P20/SI1

P74

P73

AVss

Function

P17/AN17

P16/AN16

P15/AN15

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

P14/AN14

P33/TI1

P34/TI1

P35/PCL

P36/BUZ

P37

X2

X1

Vss

XT2

P04/XT1

AV

RES

AV

DD

P10/AN10

P11/AN11

P12/AN12

P13/AN13

1 P94/FIP6 NC O C Hz −−−Not used (Open)

2 P93/FIP5 6G O C Hz L H P. D VFD grid 6G (EMPHASIS, PLAY, PAUSE,REPEAT)

3 P92/FIP4 5G O C Hz L H P. D VFD grid 5G (11~20, A-B, PROG, )

4 P91/FIP3 4G O C Hz L H P. D VFD grid 4G (1~10)

5 P90/FIP2 3G O C Hz L H P. D VFD grid 3G (Seconds Digit, S, SINGLE)

6 P81/FIP1 2G O C Hz L H P. D VFD grid 2G (Minutes Digit, M, TOTAL)

7 P80/FIP0 1G O C Hz L H P. D VFD grid 1G (Track No., A.SPACE)

8VDD VDD −−−−−−Positive power (Connect to +5V)

9 P27/SCK0 MCK O B Hz H P. UP SM5841/PCM1735/BU2616 mode control clock output

10 P26/S00/SB1 MDT O B Hz −−P. UP SM5841/PCM1735/BU2616 mode control data output

11 P25/SI0/SB0 NC I B Hz −−P. DG Not used (Connect to GND)

12 P24/BUSY NC I B Hz −−P. DG Not used (Connect to GND)

13 P23/STB MLE O B Hz − P. UP SM5841/PCM1735 mode control latch output

14 P22/SCK1 CQCK O B Hz − − DSP, ASP Command clock & SUBQ readout clock output

15 P21/SO1 COIN O B Hz −−−DSP, ASP Command data output

16 P20/SI1 SUBQ I B Hz −−−DSP sub-code Q data input

17 RESET RESET I −−−L − Reset signal input

18 P74 NC I B Hz −−P. DG Not used (Connect to GND)

19 P73 XTAL O B Hz H L P. UP TC9246XTAL MODE change Lo:ON (Pitch 0),Hi:OFF(Variable pitch)

20 AVss AVss −−−−−−GND for A/D converter

21 P17/ANI7 DSP XRST O B Hz L L P. DG DSP reset signal output

22 P16/ANI6 DF XRST O B Hz L L P. DG Digital filter reset signal output

23 P15/ANI5 JOG B I B Hz −−P. UP Rotaly encoder JOG B input

24 P14/ANI4 JOG A I B Hz −−P. UP Rotaly encoder JOG A input

25 P13/ANI3 AD3 I B Hz − A P. UP Key data input 3 (A/D)

26 P12/ANI2 AD2 I B Hz − A P. UP Key data input 2 (A/D)

27 P11/ANI1 AD1 I B Hz − A P. UP Key data input 1 (A/D)

28 P10/ANI0 AD0 I B Hz − A P. UP Key data input 0 (A/D)

29 AVDD AV DD −−−−−−A/D converter analog power (Connect to +5V)

30 AVREF AVREF I −−−−−A/D converter Ref. V input (Connect to +5V)

Pin

No.

31 P04/XT1 NC I A −−−P. DG Not used (Connect to GND)

32 XT2 NC −−−−−−Not used (Open)

33 Vss GND −−−−−−GND

34 X1 X1 I A −−−−Main system clock input

35 X2 X2 −−−−−−Main system clock input

36 P37 MCS O B Hz H L P. DG PCM1735 chip select output

37 P36/BUZ MCE O B Hz L L − BU2616 chip enableoutput

38 P35/PCL RW C O B Hz L L − DSP read / write control output

39 P34/TI2 SL+ O B Hz L H − ASP sled drive signal output

40 P33/TI1 SL- O B Hz L H − ASP sled drive signal output

41 P32/T02 NC I B Hz −−P. DG Not used (Connect to GND)

42 P31/T01 CD/RW O B Hz H L P. DG CD / RW Gain change output

43 P30/T00 SEARCH O B Hz L H P. DG Servo control output at search

44 P03/INTP3/CI0 REMOCON I B Hz − − Remote control signal input

45 P02/INTP2 WRQ I B Hz L H − DSP SUBQ output standby input

46 P01/INTP1 DRF I B Hz L H − ASP DEFECT RF level detect input

47 P00/INTP0/TI0 NC I A Hz −−P. UP Not used (Connect to GND)

48 IC IC −−−−−−Connect to GND

49 P72 FSEQ I B Hz L H − DSP sync signal detect input

50 P71 A.MUTE O B Hz H H P. UP Analog mute output OFF: Lo, ON: Hi

51 P70 DRV.MUTE O B Hz H − P. UP MOTOR DRIVER MUTE control output Hi:Output ON

52 VDD VDD −−−−−−Positive power (Connect to +5V)

53 P127/FIP33 OPSW I C Hz − L P. UP Loader open position detect switch input

54 P126/FIP32 CLSW I C Hz − L P. UP Loader close position detect switch input

55 P125/FIP31 INSW I C Hz − L P. UP Pickup inner position detect switch input

56 P124/FIP30 OPEN O C Hz L H P. DG Loader open drive LA6559 signal output

57 P123/FIP29 CLOSE O C Hz L H P. DG Loader close drive LA6559 signal output

58 P122/FIP28 MODEL I C Hz −−−Model distinction input Lo:455, Hi:555

59 P121/FIP27 NC I C Hz −−P. DG Not used (Open)

60 P120/FIP26 NC I C Hz −−P. DG Not used (Open)

61 P117/FIP25 P1 O C Hz L H P. D VFD segment P1 (1a, 1, 11, EMPHASIS)

62 P116/FIP24 P2 O C Hz L H P. D VFD segment P2 (1b, 2, 12, PLAY)

63 P115/FIP23 P3 O C Hz L H P. D VFD segment P3 (1c, 3, 13, PAUSE)

64 P114/FIP22 P4 O C Hz L H P. D VFD segment P4 (1d, 4, 14, REPEAT)

65 P113/FIP21 P5 O C Hz L H P. D VFD segment P5 (1e, 5, 15)

66 P112/FIP20 P6 O C Hz L H P. D VFD segment P6 (1f, 6, 16)

67 P111/FIP19 P7 O C Hz L H P. D VFD segment P7 (1g, 7, 17)

68 P110/FIP18 P8 O C Hz L H P. D VFD segment P8 (2a, 8, 18)

69 P107/FIP17 P9 O C Hz L H P. D VFD segment P9 (2b, 9, 19)

70 P106/FIP16 P10 O C Hz L H P. D VFD segment P10 (2c, 10, 20)

71 VLOAD -HB I C −−−−Power for FL display (-HB)

72 P105/FIP15 P11 O C Hz L H P. D VFD segment P11 (2d, A-B)

73 P104/FIP14 P12 O C Hz L H P. D VFD segment P12 (2e, PROG)

74 P103/FIP13 P13 O C Hz L H P. D VFD segment P13 (2f, )

75 P102/FIP12 P14 O C Hz L H P. D VFD segment P14 (2g)

76 P101/FIP11 P15 O C Hz L H P. D VFD segment P15 (A.SPACE, TOTAL, SINGLE)

77 P100/FIP10 P16 O C Hz L H P. D VFD segment P16 (M, S)

78 P97/FIP9 NC O C Hz −−−Open (Not used)

79 P96/FIP8 NC O C Hz −−−Open (Not used)

80 P95/FIP7 NC O C Hz −−−Open (Not used)

Type A: Standard input port Note) P.D: Pull−down to VDISP

Terminal Port I/O Typ Rst Ini Act Ext Function

B: Standard in/output port P.DG: Pull−down to GND

C: Hi−voltage proof in/output port

D: P−ch open drain hi−voltage proof

13

D

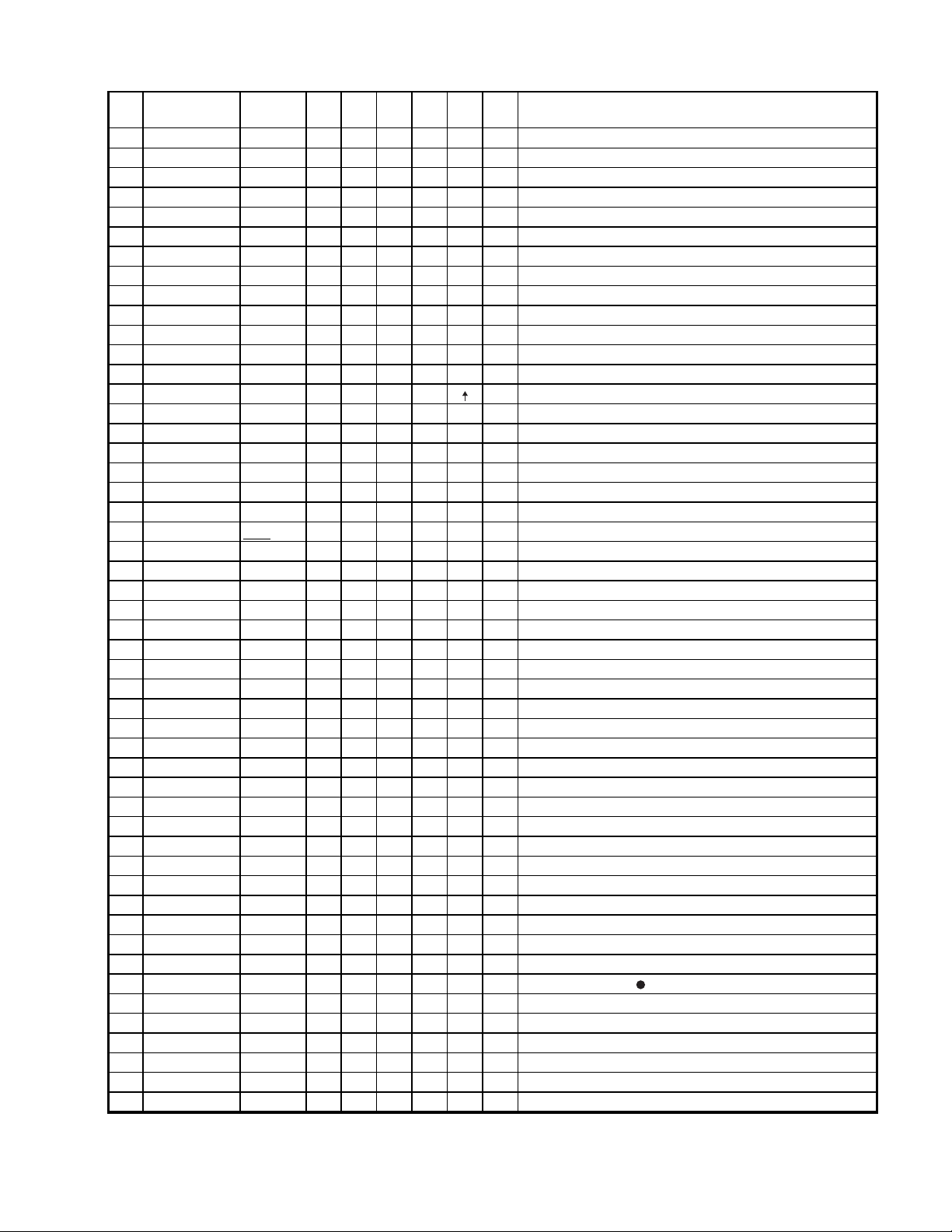

LA6559 (IC101)

1

REV

Signal System VCC

2

S-VCC

VCC2

VLO-

VLO+

VO4+

VO4-

VO3+

VO3-

VO2+

VO2-

VO1+

VO1-

VCC1

VIN1

VIN1-

VIN1+

VIN2

FR

3

4

5

6

7

8

9

Power

System

GND

FR

10

11

12

13

14

15

16

17

18

Power Supply

(LOADING)

Power Supply

(CH1 to CH4)

(Forward/Reverse/

Break/OFF)

Control

Shift

Shift

Shift

Shift

33k

11k

LA9241M (IC103)

Input

Output

Level

Level

Level

Level

Signal System GND

CH2 to CH4

Output

CH1 Output

ON/OFF

33k

Power System GND

3.3VREG

(External PNP)

33k

3.3VREG GND

3.3VREG

Power Supply

33k

Thermal

Shutdown

MUTE2

MUTE1

11k

PNP Tr

Collector

PNP Tr

11k

11k

Base

FWD

36

S-GND

35

MUTE2

34

33

MUTE1

32

VIN4

31

VIN4-

30

VIN4+

29

VREF-IN

28

VCONT(LOADING)

FR

FR

27

REG-OUT

26

REG-IN

25

VIN3+

24

VIN3-

23

VIN3

22

GND-VREG

21

VCC-VREG

20

VIN2+

19

VIN2-

Pin

No.

Name

1 REV

2 S-Vcc

Function

5CH output change terminal, logic input of

loading block

signal system power supply

(BTL-AMP:CH1~4)

3 Vcc2 Power supply for loading block

4VL0− Loading output (−)

5 VL0+ Loading output (+)

6 VO4+ Output terminal (+) for channel 4

7 VO4− Output terminal (−) for channel 4

8 VO3+ Output terminal (+) for channel 3

9 VO3− Output terminal (−) for channel 3

10 VO2+ Output terminal (+) for channel 2

11 VO2− Output terminal (−) for channel 2

12 VO1+ Output terminal (+) for channel 1

13 VO1− Output terminal (−) for channel 1

14 Vcc1 CH1•`CH4(BTL-AMP) output stage power supply

15 VIN1 Input terminal for channel 1

16 VIN1− OP-AMP input AMP-A input terminal (−)

17 VIN1+ OP-AMP input AMP-A input terminal (+)

18 VIN2 Input terminal for channel 2, input AMP output

19 VIN2− Input terminal (−) for channel 2

20 VIN2+ Input terminal (+) for channel 2

21 Vcc-VREG 3.3VREG power supply

22 GND-VREG 3.3VREG GND

23 VIN3 Input terminal for channel 3, input AMP output

24 VIN3− Input terminal (−) for channel 3

25 VIN3+ Input terminal (+) for channel 3

26 REG-IN PNP transistor base connected

27 REG-OUT

3.3V power output to which the PNP transistor

collector connected

28 VCONT Loading output voltage set terminal

29 VREF-IN Reference voltage applied terminal

30 VIN4+ Input terminal (+) for channel 4

31 VIN4- Input terminal (−) for channel 4

32 VIN4 Input terminal for channel 4, input AMP output

33 MUTE1 Output ON/OFF for channel 1 (BTL AMP)

34 MUTE2 Output ON/OFF for channel 2 to 4 (BTL AMP)

35 S-GND Signal system GND

36 FWD

Output change terminal (FWD) for loading

output (VLO+−), logic input of loading block

14

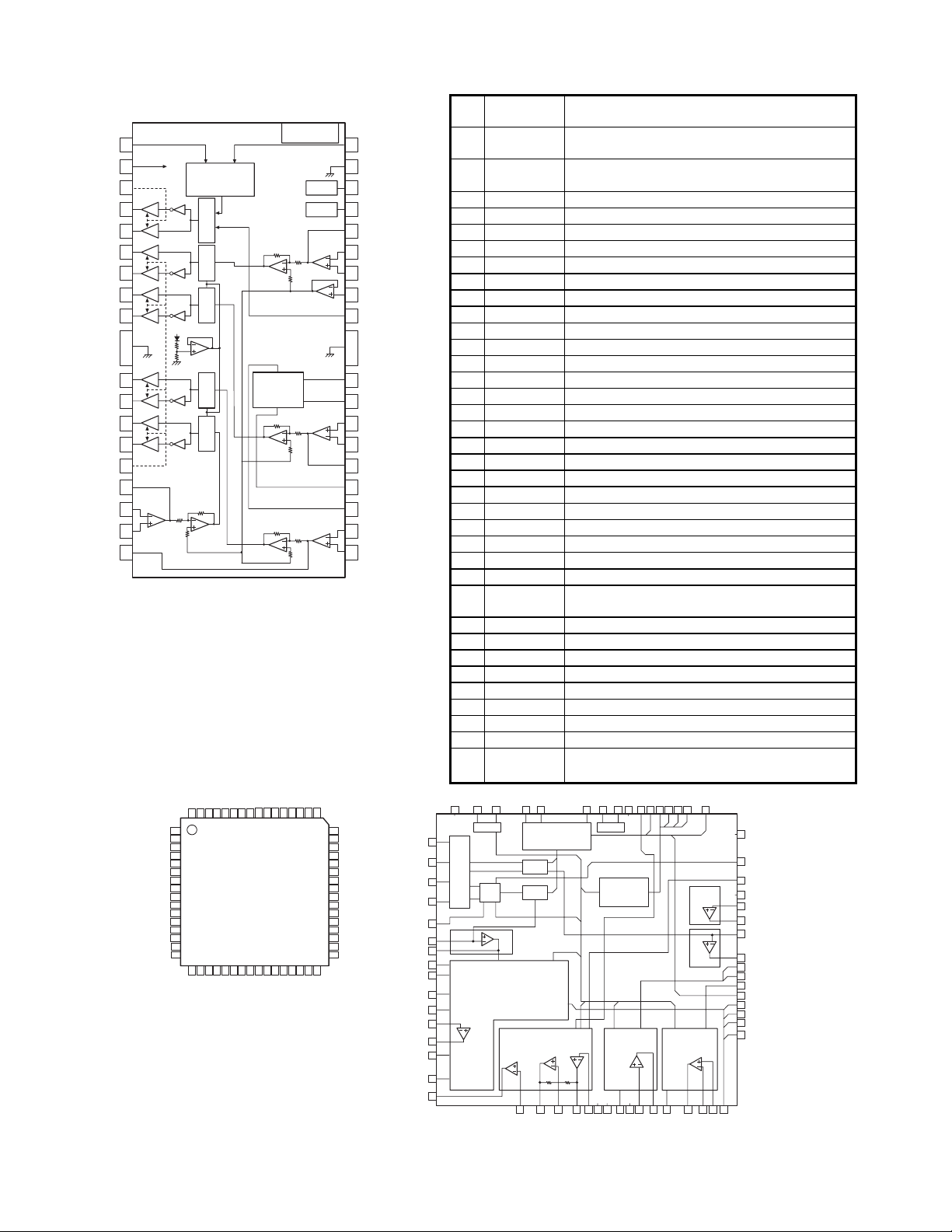

VCC1

LDS

LDD

BH1

646362616059585756555453525150

FIN2

1

FIN1

2

E

3

F

4

TB

5

-

TE

6

TE

7

TESI

8

SCI

9

TH

10

TA

11

-

TD

12

TD

13

JP

14

TO

15

FD

16

171819202122232425262728293031

-

FAFAFE

FD

VCC1

LDS

LDD

BH1

PH1

LF2VRREFI

VCC2

FSS

SPINDLE

SERVO

NC

-com

SP

SP

SPG

DRFCEDATCLCLK

SPD

PH1

LF2

VR

REFI

VCC2

FSS

DRFCEDATCLCLK

DEF

49

48

NC

47

TBC

46

FSC

45

DGND

44

SLI

43

SLC

-

42

RFS

41

RFSM

+

40

CV

-

39

CV

38

SLOF

37

HFL

36

TES

35

TOFF

34

TGL

+

33

JP

-

-

SP

NC

FE

SP

SPG

AGND

32

-

-

+

JP

SL

SL

SLD

SPD

SLEQ

FIN2

FIN1

TESI

1

2

3

E

4

F

5

TB

6

TE

TE

7

8

9

SCI

10

TH

TA

11

-

TD

12

TD

13

JP

14

TO

15

FD

16

APC

I/V

TE

T. SERVO & T.LOGIC

RF DET

VCA

VCABAL

F.SERVO & F.LOGIC

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

FAFAFE

FD

REF

INTER FACE

-

FE

GND

SLC

RF Amp

SLED SERVO

SLD

SLEQ

DEF

49505152535455565758596061626364

NC

48

47

TBC

FSC

46

45

DGN

SLI

44

SLC

43

-

42

RFS

RFSM

41

+

CV

40

-

CV

39

SLOF

38

37

HFL

TES

36

TOFF

35

TGL

34

+

JP

33

-

-

+

SL

JP

SL

Loading...

Loading...