Denon DCD-1650SR Service Manual

SERVICE MANUAL

For Asia & China model

Hi-Fi Component

MODEL

DCD-1650SR

STEREO CD PLAYER

Some illustrations using in this service manual are slightly different from the actual set.

16-11, YUSHIMA 3-CHOME, BUNKYOU-KU, TOKYO 113-0034 JAPAN

Telephone: 03 (3837) 5321

X0140 NC 0204

DCD-1650SR

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

SPECIFICATIONS

AUDIO

No. of Channels: 2 channels

Frequency Response: 2~20,000 Hz

Dynamic Range: 100 dB

Signal-to-noise Ratio: 118 dB

Harmonic Distortion: 0.0018 % (1 kHz)

Separation: 110 dB (1 kHz)

Wow & Flutter: Below measurable limit:

(±0.001 % W.peak)

Output Voltage: FIXED 2.0 V

DISCS CD-DA (Compact Disc-Digital Audio) format

CD-R/RW Disc for Audio consumer use

GENERAL CHARACTERISTICS

Power Supply: 230 V/50 Hz

Power Consumption: 17 W

Dimensions: 434 (W) × 135 (H) × 340 (D) mm

Mass: 12.7 kg

REMOTE CONTROL UNIT RC-281

Remote Control System: Infrared pulse system

Power Supply: 3 V DC; two R6P (standard size AA)

dry cell batteries

External Dimensions: 68 (W) × 233 (H) × 20 (D) mm

Mass: 160 g (including batteries)

2

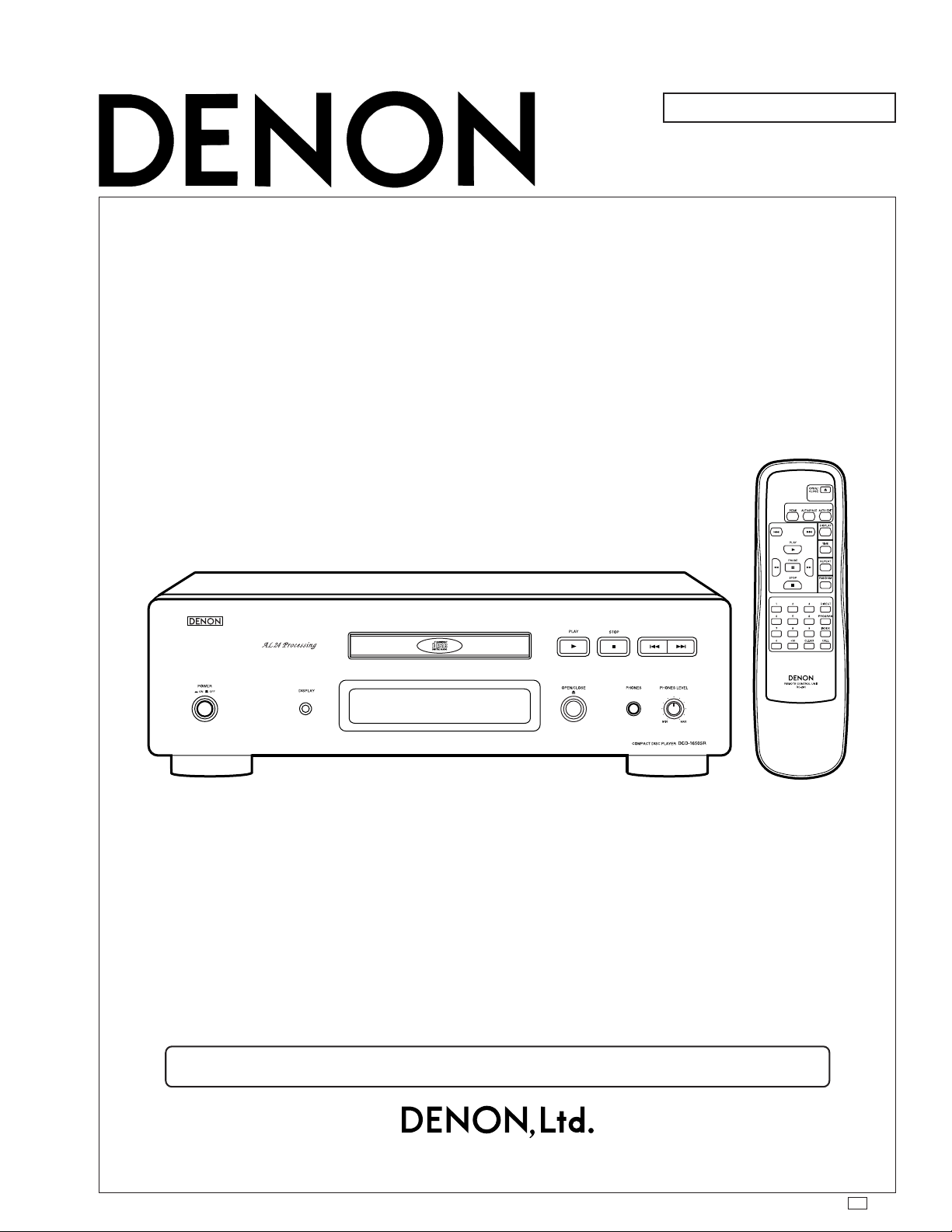

DISASSEMBLY

(To reassemble reverse disassembly)

1. Top Cover

1. Remove 2 screws from rear side and 4 screws from both sides,

then remove 5 upper screws.

2. Detach the Top Cover as shown in the arrow direction.

DCD-1650SR

Top Cover

2. Front Panel

1. Remove 3 upper screws, 2 below screws and 1P Contact.

2. Detach the Front Panel as shown in the figure.

Front Panel

3. Bottom Cover

1. Remove 12 screws from bottom side.

2. Detach the Bottom Cover as shown in the arrow direction.

Bottom Cover

3

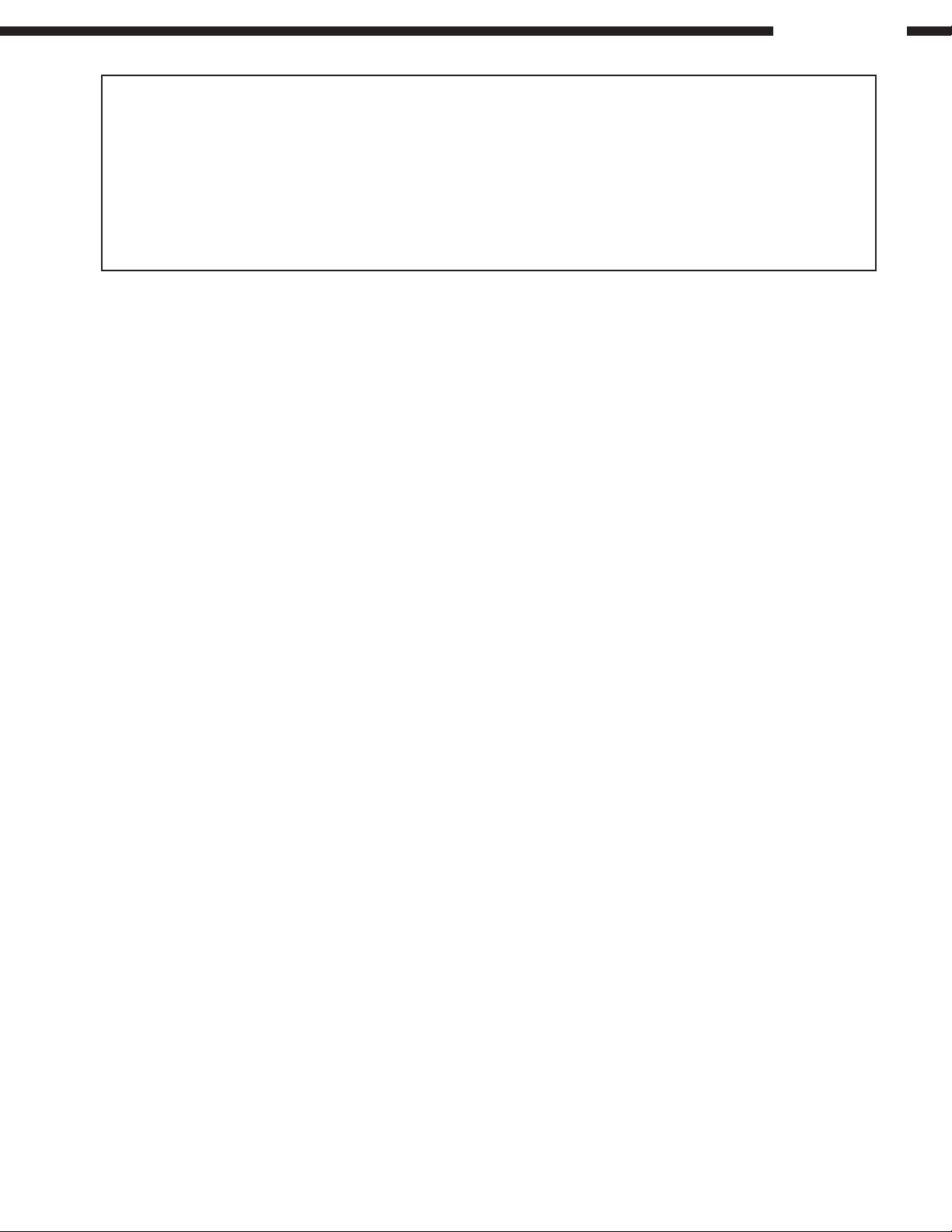

4. Mechanism Unit

1. Remove 4 screws fixing the Mechanism Cover and detach the Mechanism

Cover as shown in the arrow direction.

2. Remove 4 screws fixing the Mechanism Unit, then detach the Mechanism

Unit as shown in the figure.

Mechanism Unit

DCD-1650SR

Mechanism Cover

5. Clamper

1. Remove 4 screws fixing the Clamper.

2. Detach the Clamper as shown in the arrow direction.

Clamper

Caution Before Disassembling Power Trans. & Power P.W.B. Unit

Be sure to disconnect AC Inlet from the rear panel before disconnecting 3P connector cord of the Power Trans. from CN035

connector base on the Power P.W.B. Unit.

4

DCD-1650SR

NOTE IN HANDLING FOR LASER PICK-UP

1. Protection of the LD

Short a part of the LD circuit by soldering. After connection to a circuit, remove the short solder.

2. Precautions when handling the CD mechanism

Handle the laser pick-up so that it is not exposed to dust.

Do not leave the laser pick-up bare. Be sure to cover it.

If dust adheres on lens of the pick-up, blow it off with a blower brush.

Do not shock the laser pick-up.

Do not watch the light of the laser pick-up.

3. Cautions on assembling and adjustment

Be sure that to the bench, jig, head of soldering (with ceramic) iron and measuring instruments are well grounded.

Workers who handle the laser pick-up must be grounded.

The finished mechanism (prior to anchoring in the set) should be protected against static electricity and dust.

The mechanism must be stored so that damaging outside forces are not received.

When carrying the finished mechanism, hold it by the chassis body.

For proper operation, storage and operating environment should not contain corrosive gases. For example H

NO2, CL2 etc. In addition storage environment should not have materials that emit corrosive gases especially from

silicic, cyanic, formailn and phenol group. In the mechanism or the set, existence of corrosive gases may cause no

rotation in motor.

2S, SO2

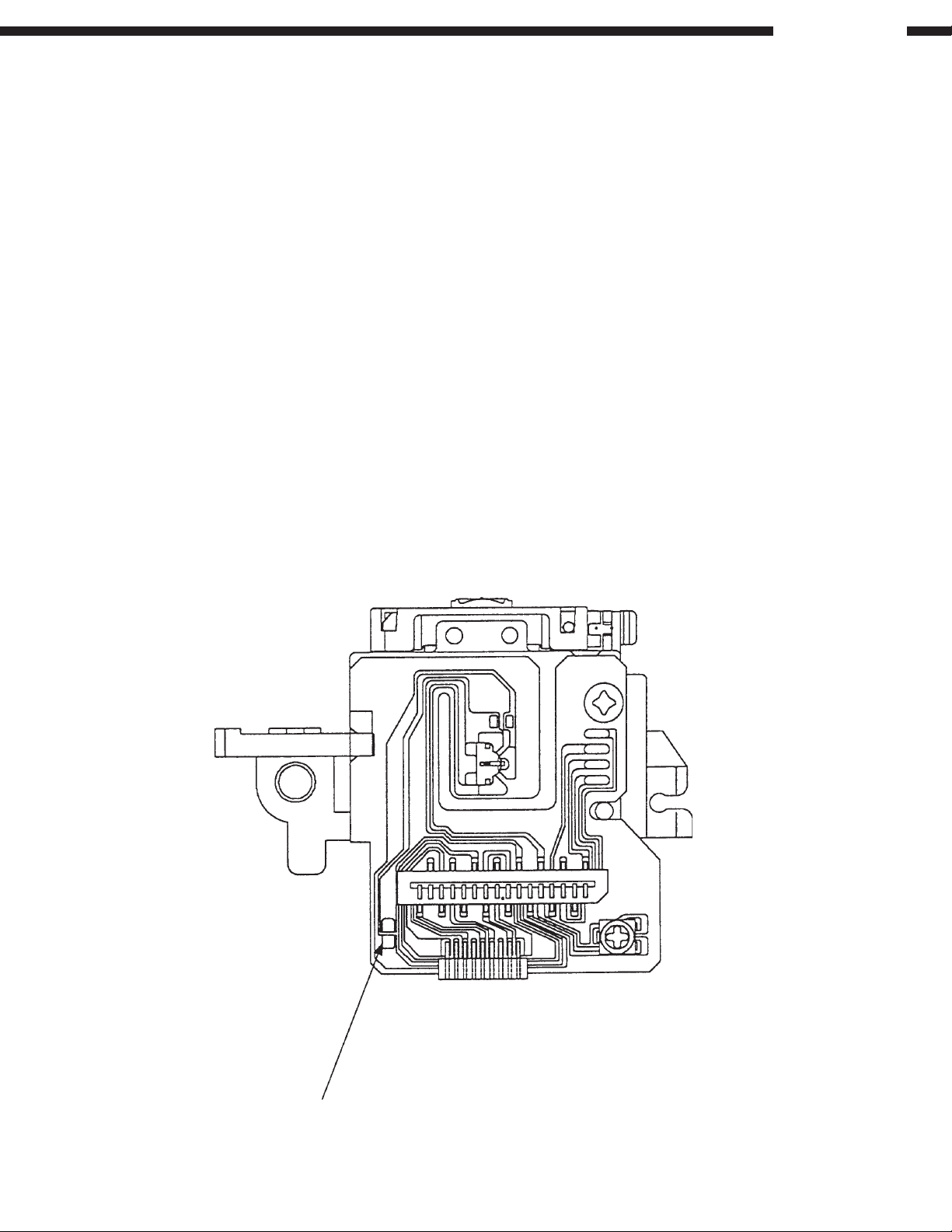

4. Location to shorting PAD

SF-P101NXR

Protective soldering place for laser diode.

(Remove before APC circuit power on, while conneting the connector)

5

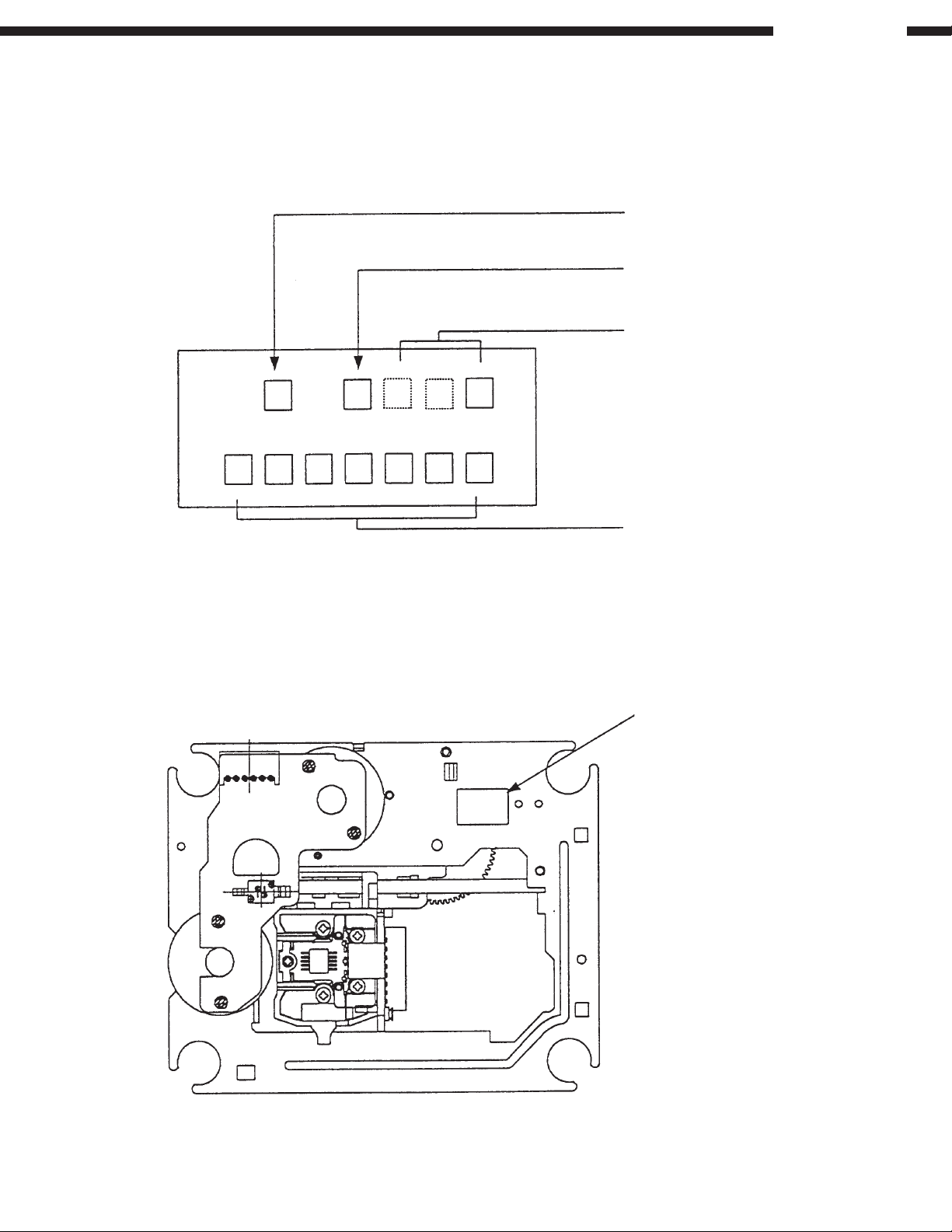

5. Serial number formation

Serial number label

DCD-1650SR

Factory number

CD mechanism ass’y number

Production process line number

(1, 2, or 3 digits)

Manufacturing number

Serial number label

6

CD TEST MODE

g

g

y

y

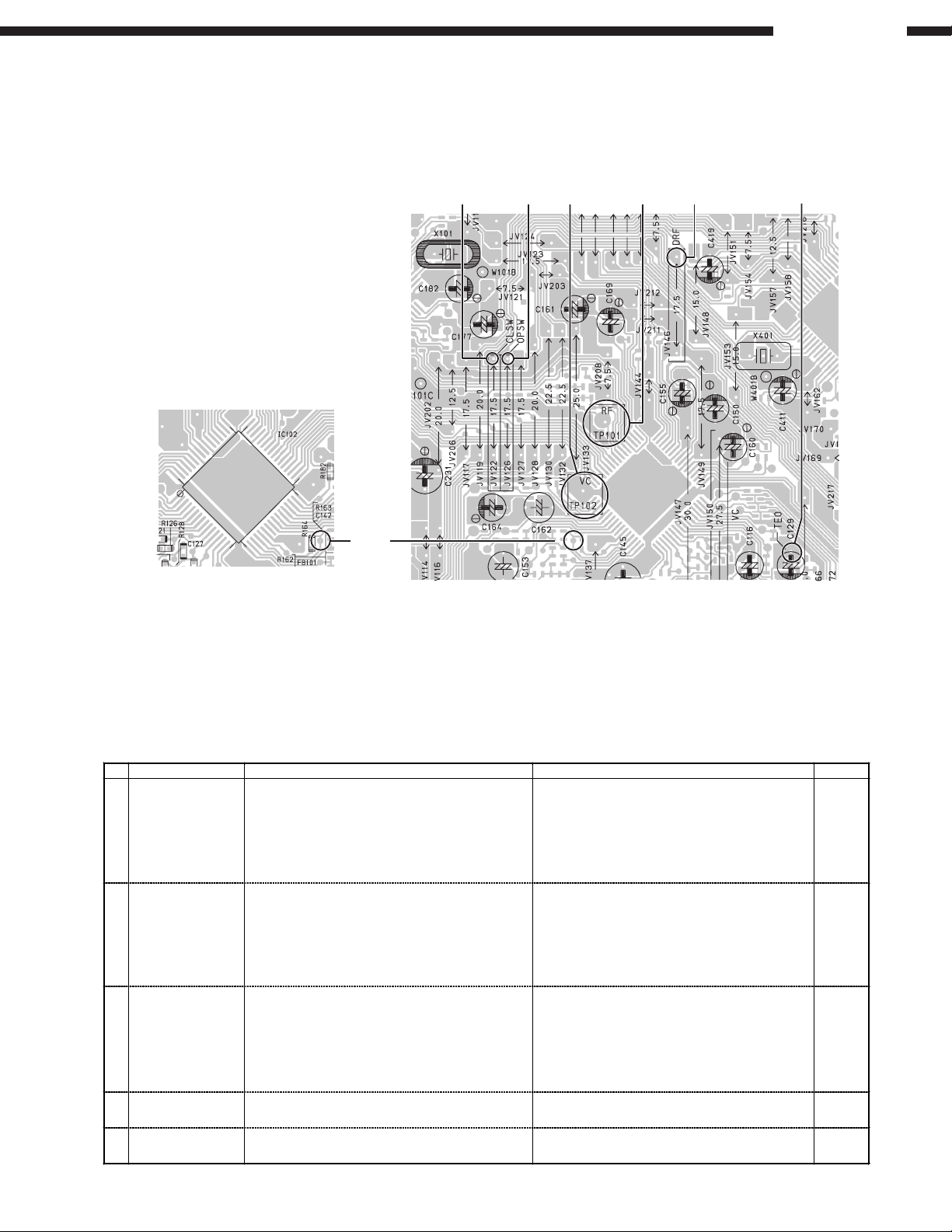

Setting of the test mode

How to start the test mode: Turn on the power in the condition that CLSW (Test Point)

and OPSW (Test Point ) are being shorted. ( “01” is indicated on the DISPLAY)

To exit from the test mode, turn off the power. (Refer to Fig. 1 “Test Point Layout”)

CLSW OPSW RFVC DRF TEO

DCD-1650SR

FEO

(Foil Side)

Fig. 1 “Test Point” Layout

* Laser light of the pickup is always emitted regardless of DISC loading in the test mode.

You may lose your eyesight if you look into the laser directly.

So be careful enough when operating in the test mode.

Used DISC: A-BEX TCD784

Explanation of each button

* Use only the buttons described below for operations while in the test mode, and don’t push any other buttons.

No Name of button Function Display Note

Simultaneous

1

turn-on of Mecha.

OPEN and CLOSE

SW

Pressing

2

OPEN/CLOSE button

Pressin

3

4

5

PLAY button Focus/Tracking check mode

Pressing MANUAL

SEARCH REV or

FWD button

Pressing

PAUSE button

Mode activation

1. This mode starts.

2. Slide moves to the initial setting position

(10mm from inner circle).

3. To cancel this mode, turn off the power and on a

4. Other key input used other than this mode is not

guaranteed. (it may become abnormal operation).

Disc loading mode

1. Loader opens by OPEN/CLOSE input.

2. Disc chucking is made when closing the loader

with OPEN/CLOSE key after setting a disc.

3. Slide moves to the initial setting position

(10mm from inner circle).

4. It stops at the status 3.

1. Laser turns on when PLAY is pushed once

(servo stop status).

2. It performs Focus search when PLAY is pushed

Again, and Focus servo is turned on (disc rotation,

Tracking off). If no disc, it stops after retry. It repeats

Focus search if the button is kept depressed.

3. Tracking servo/Slide servo turns on when PLAY is

pushed once more, and CLV is locked.

Pickup move mode

Pickup moves to REV or FWD direction when the

button is pushed at stop status.

Auto adjust mode

It performs auto adjust mode. 1. “06” is indicated on the TRACK No. display, and

1. To show now in this mode, “01” is indicated on the

TRACK No. display.

ain.

1. “01” is indicated continuously.

1. “02” is indicated on the TRACK No. displa

on the TIME display.

2. “03” is indicated on the TRACK No. display, and

“F on” on the TIME display.

3. “04” is indicated on the TRACK No. displa

on the TIME display.

1. “05” is indicated on the TRACK No. display, and

“O PU” on the TIME display.

“A dJ” on the TIME display.

, and “L on”

, and “t on”

Mute on

7

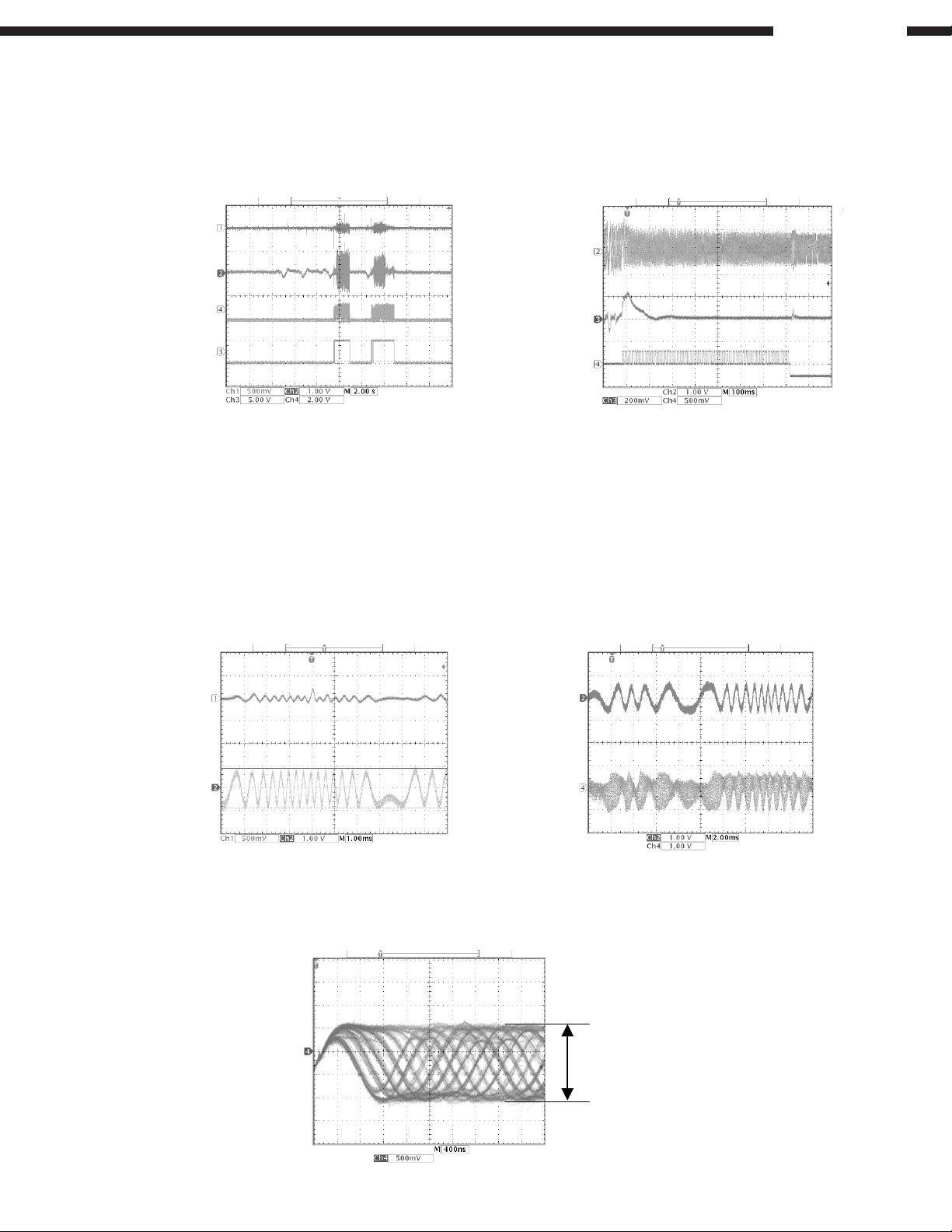

How to check the test mode

( 1 ) DISC discrimination, adjustment

* Insert DISC, and press the PAUSE button on the Remote Control Unit.

* “06 Adj” is displayed, and discrimination of DISC size 8 cm/12 cm, discrimination of DISC reflectance (CD, CD-

R/CD-RW), adjustment of focus, tracking offset, and EF balance will be performed. (Adjusted values are not

displayed: Refer to Fig. 2, 3)

DCD-1650SR

FEO

TEO

RF

FEO

TB

SLD

DRF

Fig. 2 DISC discrimination,

Fig. 3 Adjustment of EF balance

adjustment (Case of CD-RW)

* After completing the discrimination and adjustment, it becomes stop condition.

* Once discrimination of DISC has been carried out in the “06 Adj” mode, discrimination of size and reflectance is

no longer made, and only adjustment will be performed.

( 2 ) Checking of servo state

* Press the PLAY button after performing above (1) “DISC discrimination, adjustment”.

* “02 L on” is displayed, and the laser will start to light. (The pickup may vibrate with a rattling noise if DISC has

been loaded, but this is not abnormal.)

* Press the PLAY button again.

* “03 F on” is displayed. DISC starts turning, and focus servo will be actuated. (Refer to Fig. 4, 5)

FEO

TEO

TEO

RF

Fig. 4 In “03 F on” Fig. 5 In “03 F on”

* Press the PLAY button again.

* “04 t on” is displayed. Tracking, CLV, and slide servo will be actuated.

* Monitor RF signal using the Test Point, RF point and VC point.

Check that the signal’s amplitude is 1.5V±0.3Vp-p. (Refer to Fig. 6)

RF

A (A=1.5r0.3Vp-p)

Fig. 6 In “04 t on”

8

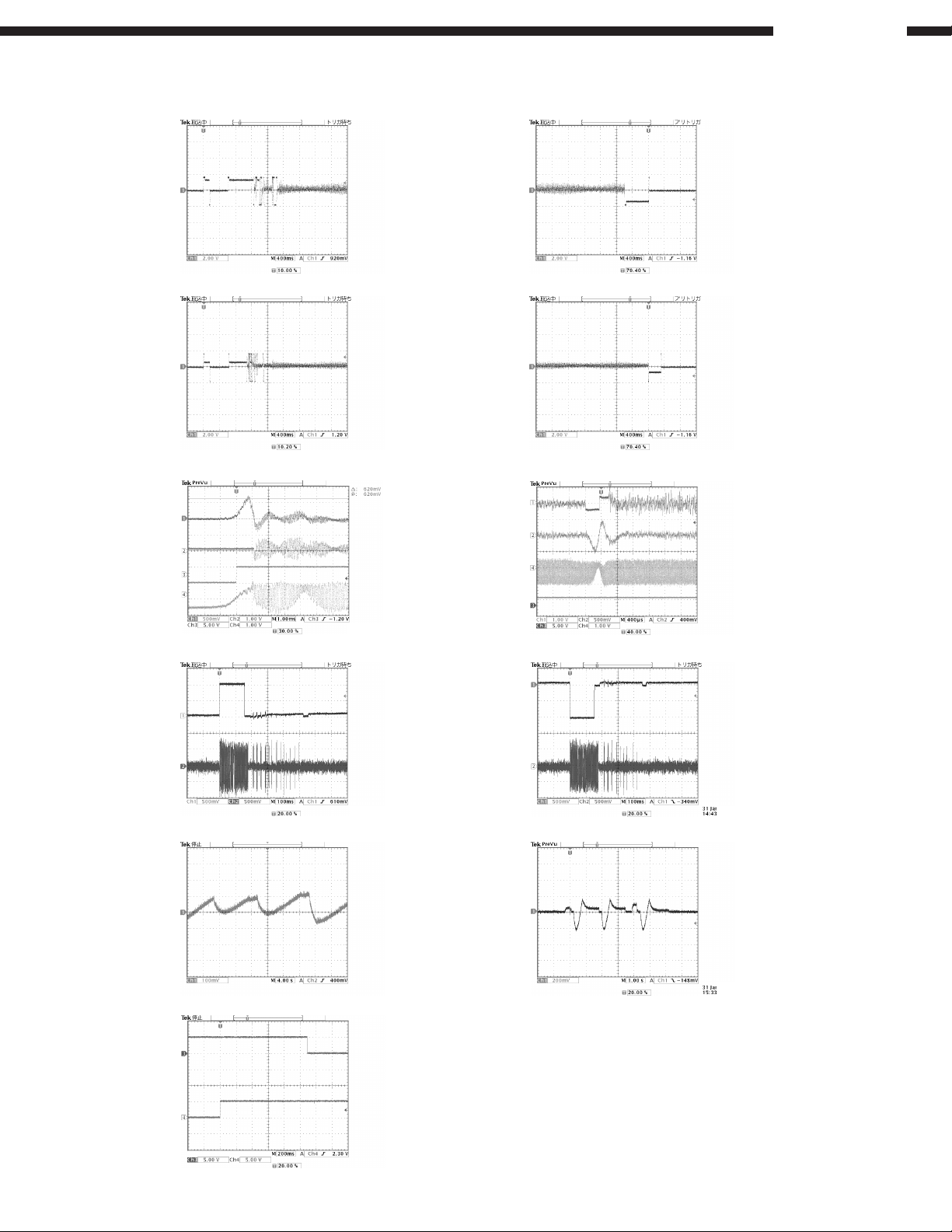

WAVE-FORMS OF EACH POINT

DCD-1650SR

SPD

SPD

FEO

TEO

DRF

RF

When 12 cm DISC

start

When 8 cm DISC

start

When focus

servo on

SPD

SPD

TD

TEO

RF

DRF

When 12 cm DISC

stop

When 8 cm DISC

stop

During PAUSE

SLD

TEO

SLD

OPEN

CLOSE

Track search

(when forward)

During PLAY

When the tray

OPEN

SLD

TEO

FD

Track search

(when reverse)

Focus search

(no DISC)

9

0

SEMICONDUCTORS

IC’s

µµ

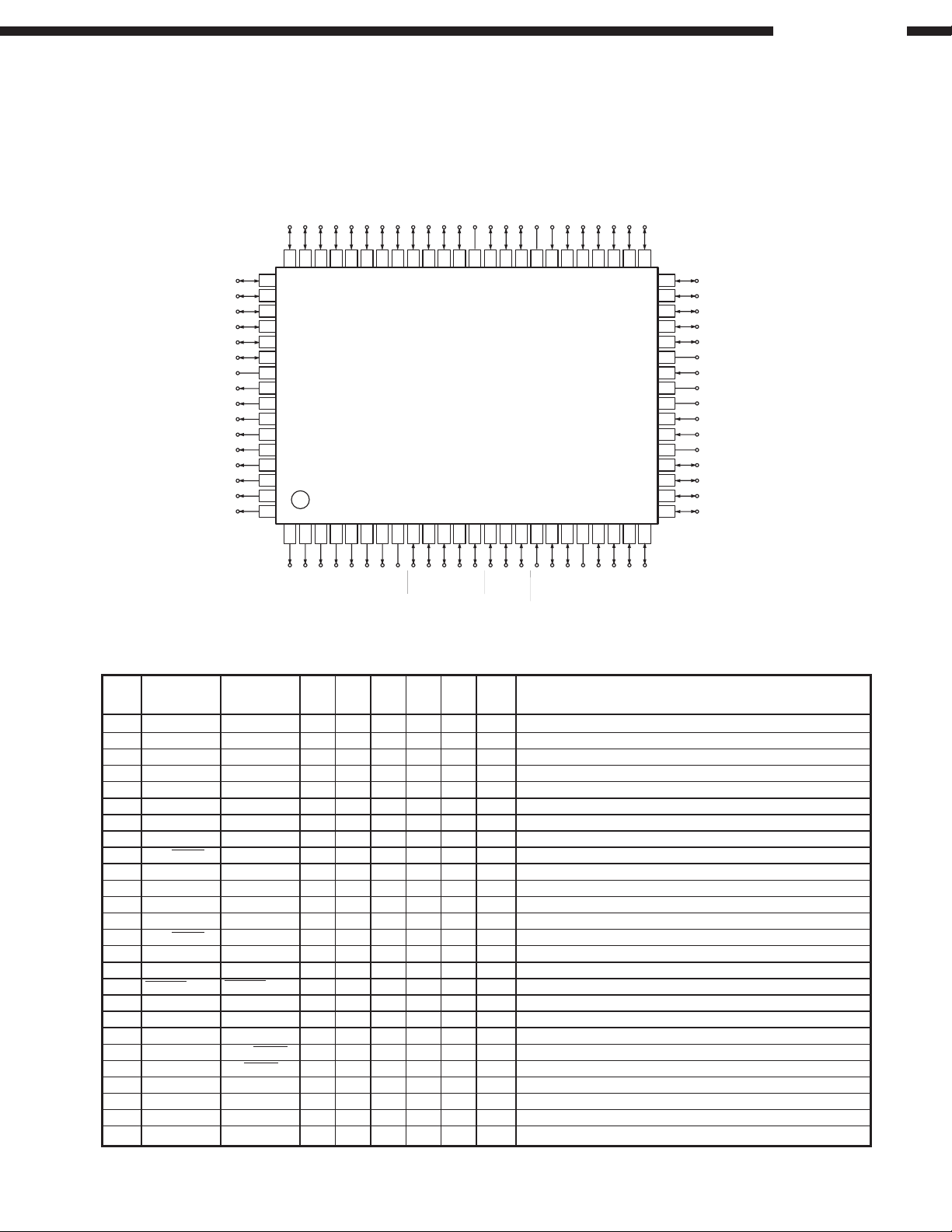

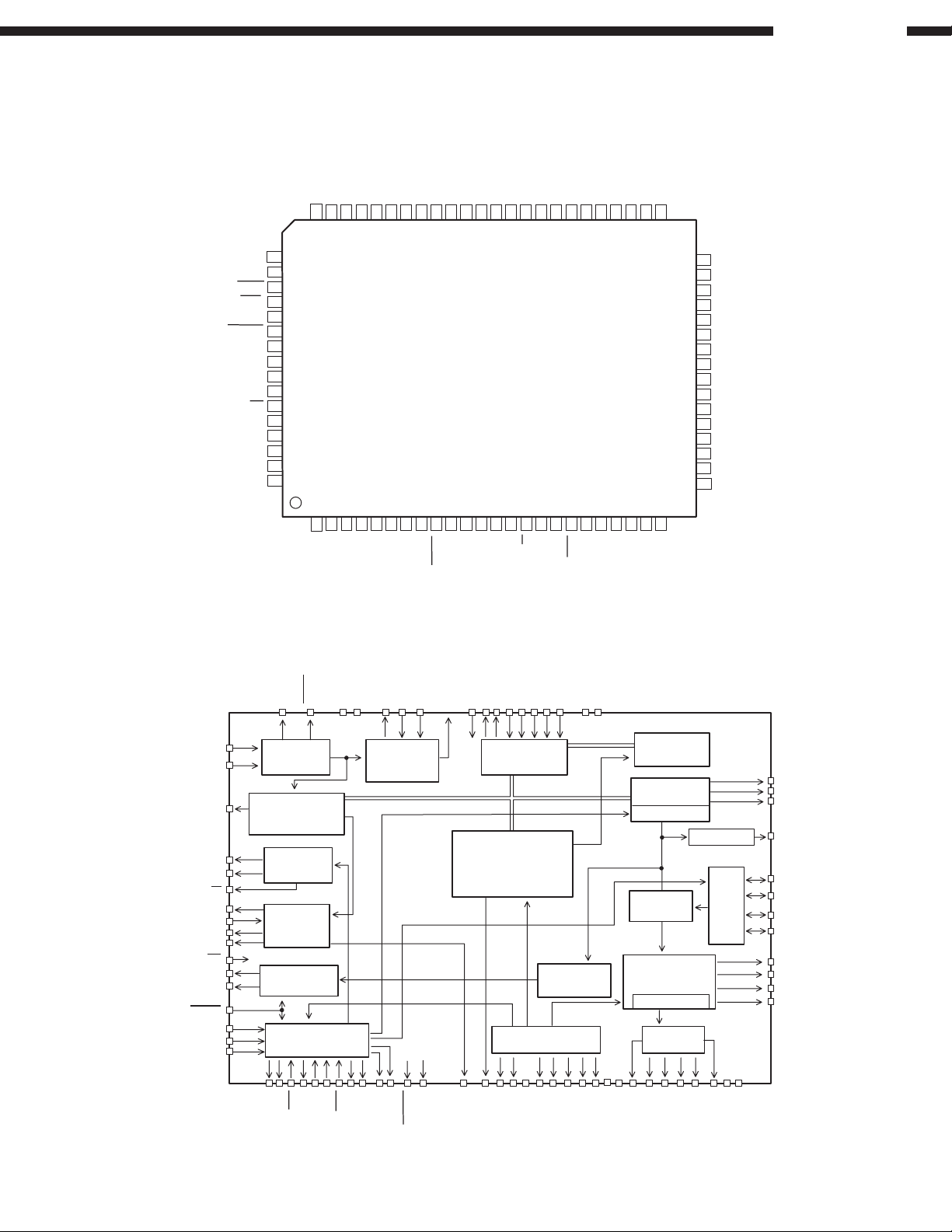

µPD78044*** (IC402)

µµ

P114/FIP22

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49 48 47 46 45 44 43 42 41

P113/FIP21

P112/FIP20

P111/FIP19

P110/FIP18

P107/FIP17

P106/FIP16

V

LOAD

P105/FIP15

P104/FIP14

P103/FIP13

P102/FIP12

P101/FIP11

P100/FIP10

P97/FIP9

P96/FIP8

P95/FIP7

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

123456789

DCD-1650SR

P115/FIP23

P116/FIP24

P117/FIP25

P120/FIP26

P121/FIP27

P122/FIP28

P123/FIP29

P124/FIP30

P125/FIP31

P126/FIP32

P127/FIP33

VDDP70

P71

P72

IC (Vpp)

PO0/INTP0/T1

PO1/INTP1

PO2/INTP2

P03/INTP3/C10

P30/TO0

P31/TO1

P32/TO2

40

P33/TI1

39

P34/TI1

38

P35/PCL

37

P36/BUZ

36

P37

35

X2

34

X1

33

Top View

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Vss

32

XT2

31

P04/XT1

30

AV

29

28

27

26

25

REF

AV

DD

P10/ANI0

P11/ANI1

P12/ANI2

P13/ANI3

DD

P94/FIP6

P93/FIP5

µµ

µPD78044*** Terminal Function

µµ

Pin

Pin Name FunctionI/OPort Typ Rst Ini Act Ext

No.

P92/FIP4

P91/FIP3

P90/FIP2

P81/FIP1

V

P80/FIP0

P27/SCK0

26/SO0/SB1

P24/BUSY

P25/SI0/SBO

P23/STB

P22/SCK1

P20/SI1

P21/SO1

P74

P73

AVss

RESET

P17/ANI7

P16/ANI6

P15/ANI5

P14/ANI4

1 P94/FIP6 4G O C HZ L H P.D VFD grid 4G

2 P93/FIP5 5G O C HZ L H P.D VFD grid 5G

3 P92/FIP4 6G O C HZ L H P.D VFD grid 6G

4 P91/FIP3 7G O C HZ L H P.D VFD grid 7G

5 P90/FIP2 8G O C HZ L H P.D VFD grid 8G

6 P81/FIP1 9G O C HZ L H P.D VFD grid 9G

7 P80/FIP0 10G O C HZ L H P.D VFD grid 10G

8VDD VDD Positive power (connect to +5V)

9 P27/SCK0 MCK O B HZ H ↑ P.UP DXP6001AF mode control clock

10

P26/SO0/SB1

MDT O B HZ P.UP DXP6001AF mode control data

11 P25/SI0/SB0 NC I B HZ P.DG Not used (connect to GND)

12 P24/BUSY NC I B HZ P.DG Not used (connect to GND)

13 P23/STB MLE O B HZ ↑P.UP DXP6001AF mode control latch

14 P22/SCK1 CQCK O B HZ H ↑DSP, ASP command clock and SUBQ taking clock output

15 P21/SO1 COIN O B HZ DSP, ASP command data output

16 P20/SI1 SUBQ I B HZ DSP sub-code Q data input

17 RESET RESET I L Reset signal input

18 P74 NC I B HZ P.DG Not used (connect to GND)

19 P73 NC I B HZ P.DG Not used (connect to GND)

20 AVSS AVSS GND for A/D converter

21 P17/ANI7 DSP XRST O B HZ L L P.DG DSP reset signal output

22 P16/ANI6 DF XRST O B HZ L L P.DG Digital filter reset signal output

23 P15/ANI5 NC I B HZ P.DG Not used (connect to GND)

24 P14/ANI4 NC I B HZ P.DG Not used (connect to GND)

25 P13/ANI3 AD3 I B HZ A P.UP Key data input 3 (A/D)

26 P12/ANI2 AD2 I B HZ A P.UP Key data input 2 (A/D)

10

DCD-1650SR

Pin

Pin Name FunctionI/OPort Typ Rst Ini Act

No.

27 P11/ANI1 AD1 I B HZ A P.UP Key data input 1 (A/D)

28 P10/ANI0 AD0 I B HZ A P.UP Key data input 0 (A/D)

29 AVDD AVDD Analog power for A/D converter (connect to +5V)

30 AVREF AVREF I Ref. V input for A/D converter (connect to +5V)

31 P04/XT1 NC I A P.DG Not used (connect to GND)

32 XT2 NC Not used (open)

33 VSS GND GND

34 X1 X1 I A

35 X2 X2

36 P37 NC O B HZ L Not used (open)

37 P36/BUZ NC O B HZ L Not used (open)

38 P35/PCL RWC O B HZ L L DSP read/write control output

39 P34/TI2 SL+ O B HZ L H ASP sled forward signal output

40 P33/TI1 SL- O B HZ L H ASP sled forward signal output

41 P32/TO2 NC I B HZ P.DG Not used (connect to GND)

42 P31/TO1 CD/RW O B HZ H L P.DG CD-RW gain switching output

43 P30/TO0 SEARCH O B HZ L H P.DG Servo control output while search

44

P03/INTP3/CI0

45 P02/INTP2 WRQ I B HZ L H DSP SUBQ output standby input

46 P01/INTP1 DRF I B HZ L H ASP DEFECT RF level detect output

47

P00/INTP0/TI0

48 IC IC Connect to GND

49 P72 FSEQ I B HZ L H DSP sync. signal detect input

50 P71 A.MUTE O B HZ H H P.UP Analog mute output, L: OFF, H: ON

51 P70 DRV.MUTE O B HZ H P.UP Motor drive mute control output, H: Output ON

52 VDD VDD Positive power (connect to +5V)

53 P127/FIP33 OPSW I C HZ L P.UP Loader open position detect switch input

54 P126/FIP32 CLSW I C HZ L P.UP Loader close position detect switch input

55 P125/FIP31 INSW I C HZ L P.UP Pickup inner circle position detect switch input

56 P124/FIP30 OPEN O C HZ L H P.DG Loader open drive (BA15218) signal output

57 P123/FIP29 CLOSE O C HZ L H P.DG Loader close drive (BA15218) signal output

58 P122/FIP28 NC O C HZ Not used (open)

59 P121/FIP27 NC O C HZ Not used (open)

60 P120/FIP26 NC O C HZ Not used (open)

61 P117/FIP25 NC O C HZ Not used (open)

62 P116/FIP24 NC O C HZ Not used (open)

63 P115/FIP23 NC O C HZ Not used (open)

64 P114/FIP22 NC O C HZ Not used (open)

65 P113/FIP21 S1 O C HZ L H P.D VFD segment S1

66 P112/FIP20 S2 O C HZ L H P.D VFD segment S2

67 P111/FIP19 S3 O C HZ L H P.D VFD segment S3

68 P110/FIP18 S4 O C HZ L H P.D VFD segment S4

69 P107/FIP17 S5 O C HZ L H P.D VFD segment S5

70 P106/FIP16 S6 O C HZ L H P.D VFD segment S6

71 VLOAD -HB I C Power for FLT (-HB)

72 P105/FIP15 S7 O C HZ L H P.D VFD segment S7

73 P104/FIP14 S8 O C HZ L H P.D VFD segment S8

74 P103/FIP13 S9 O C HZ L H P.D VFD segment S9

75 P102/FIP12 S10 O C HZ L H P.D VFD segment S10

76 P101/FIP11 S11 O C HZ L H P.D VFD segment S11

77 P100/FIP10 S12 O C HZ L H P.D VFD segment S12

78 P97/FIP9 1G O C HZ L H P.D VFD grid 1G

79 P96/FIP8 2G O C HZ L H P.D VFD grid 2G

80 P95/FIP7 3G O C HZ L H P.D VFD grid 3G

REMOCON I B HZ ↑P.UP Remote control input

NC I A HZ P.DG Not used (connect to GND)

Ext

Main system clock input

Type A: Standard input port Note) P.D: Pull-down to VDISP

B: Standard in/output port P.DG: Pull-down to GND

C: Hi-voltage proof in/output port

D: P-ch open drain hi-voltage

11

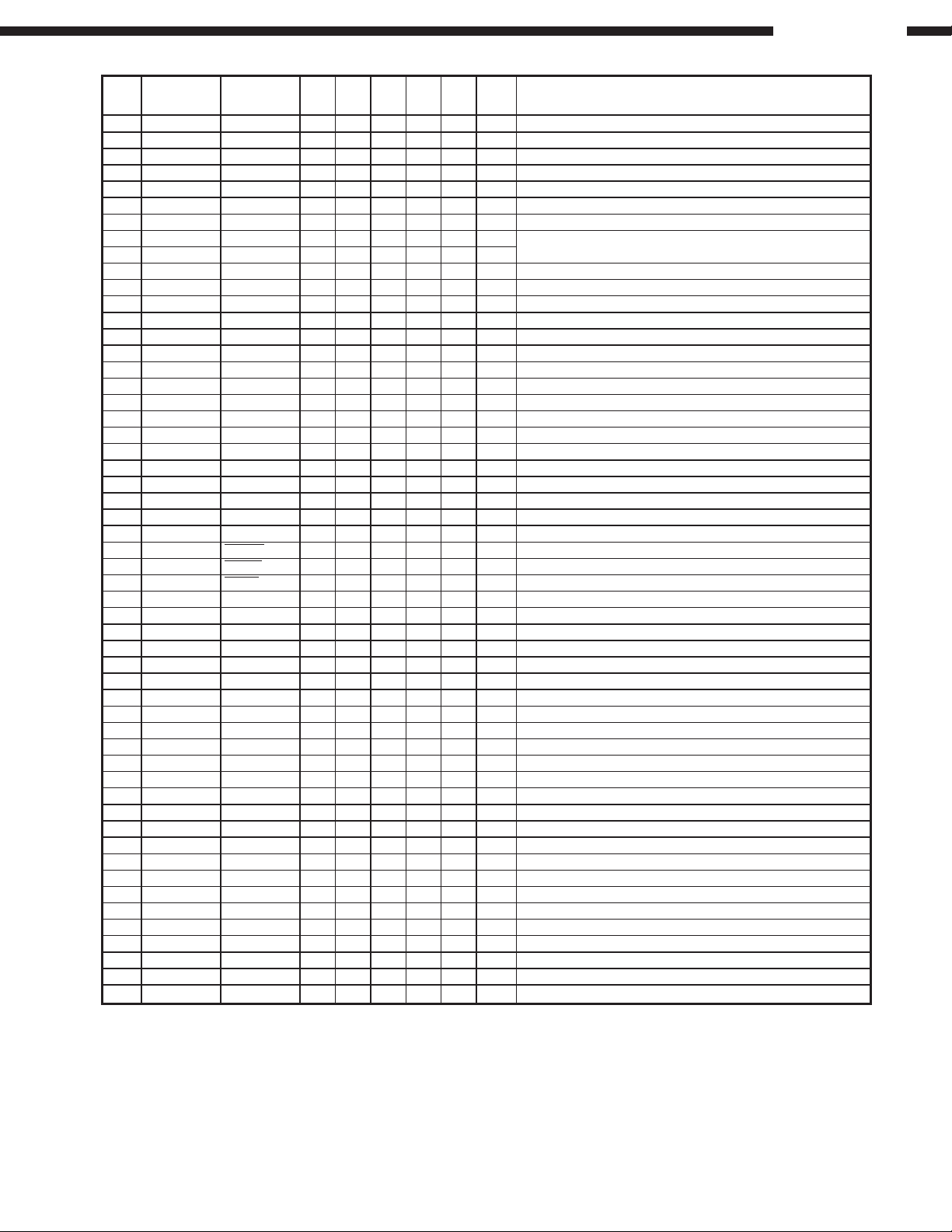

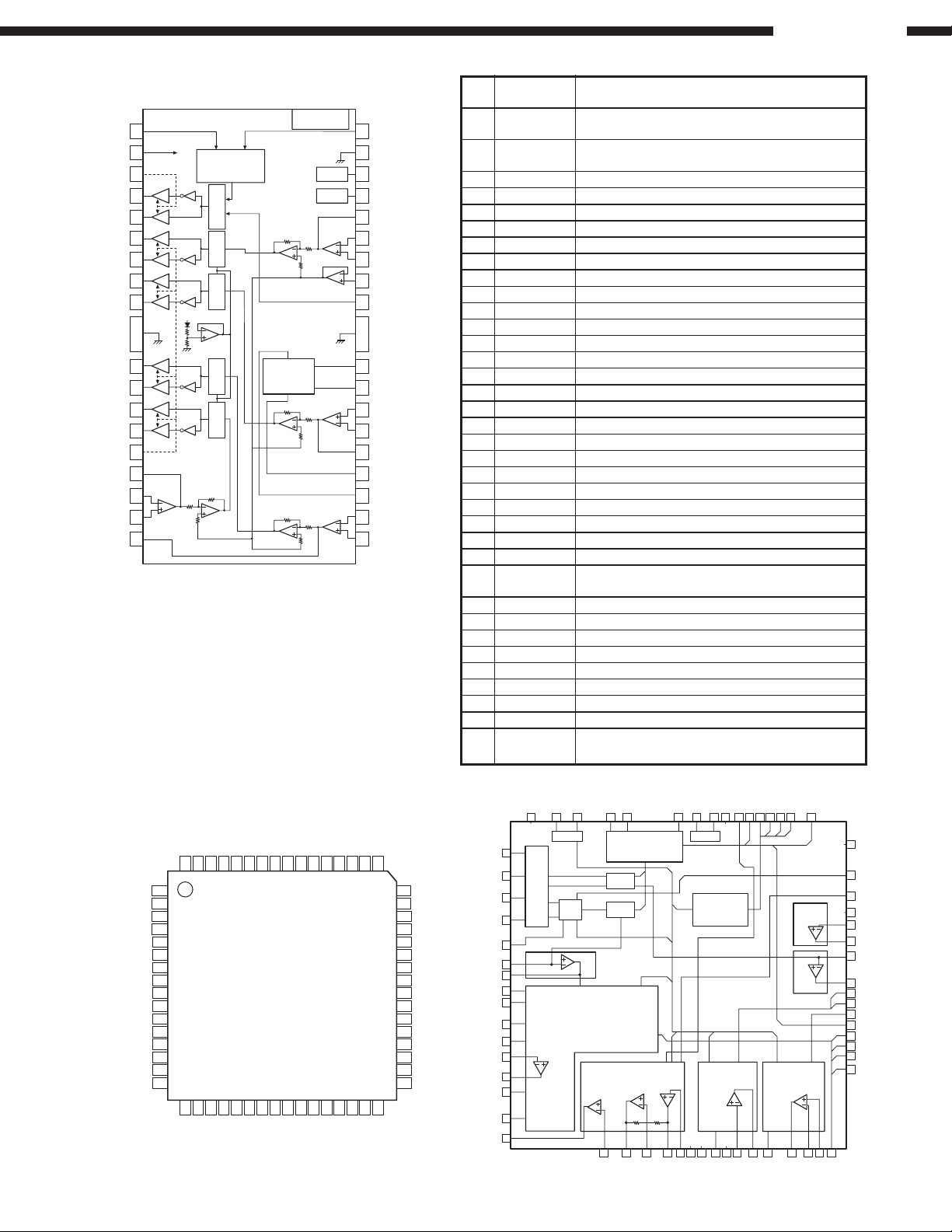

DXP6001AF (IC201)

4

33

DCD-1650SR

23

34

4

1

DXP6001AF Terminal Function

Pin

Pin Name I/O Descrption

No.

1 MDT Ip Microcomputer Interface Data

2 MCK Ip Microcomputer Interface Clock

3 MLEN Ip Microcomputer Interface Latch Enable

4 RSTN Ip Reset Terminal

5 DLRCK Ip Audio Serial Input Data L/R Clock

6 VSS Ground Terminal

7 DBCK Ip Audio Serial Input Bit Clock

8 DDT Ip Audio Serial Input Data

9 TEST2N Ip

10 TEST3N Ip

11 TEST4N Ip

12 DFBCK Ip Lambda-processor Input Bit Clock

13 DFWCK Ip Lambda-processor Input Word Clock

14 DOL Ip Lambda-processor Input Data L-channel

15 DOR Ip Lambda-processor Input Data R-channel

16 LMOD Ip Lambda-processor Operation Mode Set

17 OMOD1 Ip Output Mode Setting Terminal 1

18 OMOD2 Ip

19 INVIN Ip

20 BCKO O Lambda-processor Output Bit Clock

21 WCKO O Lambda-processor Output Word Clock

22 WCKO2 O

Test Setting Terminal 2 (Alpha-processor 1

Output shifts 12-bit.)

Test Setting Terminal 3 (Alpha-processor 2

Output stops.)

Test Setting Terminal 4 (Lambda-processor

Output stops.)

Output Mode Setting Terminal 2

OMOD1

LH

OMOD2

L

H

18bit

Alternate

20bit

Parallel

24bit

Alternate

24bit

Parallel

Lambda-processor Input Reversed

Polarity Terminal

Lambda-processor Output Word Clock 2

(for Canceling OFFSET on 1DAC

22

12

11

Pin

Pin Name I/O Descrption

No.

23P24L O/Lambda-processor Lch 24th bit Output *1, *2

24P23L O/Lambda-processor Lch 23rd bit Output *1, *2

25P22L O/Lambda-processor Lch 22nd bit Output *1, *2

26P21L O/Lambda-processor Lch 21st bit Output *1

27P20L O/Lambda-processor Lch 20th bit Output *1

28 VDD Power Supply Terminal

29 SO2L/P19L O

Lambda-processor Lch() Output /19

Output *1

30 SO1L O Lambda-processor Lch(+) Output

31 SO1R O Lambda-processor Rch(+) Output

32 SO2R/P19R O

Lambda-processor Rch() Output/19

Output *1

33P20R O/Lambda-processor Rch 20th bit Output *1

34P21R O/Lambda-processor Rch 21st bit Output *1, *2

35P22R O/Lambda-processor Rch 22nd bit Output *1, *2

36P23R O/Lambda-processor Rch 23rd bit Output *1, *2

37P24R O/Lambda-processor Rch 24th bit Output *1, *2

38 TEST1N Ip Test Terminal 1 (Alpha-processor 1 stops)

39 CKSLN Ip System Clock Select (384fs system /

256fs system)

40 CKDV1 Ip System Clock Divider Select Terminal 1

System Clock Divider Select Terminal 2

CKDV1

LH

41 CKDV2 Ip

CKDV2

192fs (CKSLN=H)

L

256fs (CKSLN=H)

192fs (CKSLN=H)

H

256fs (CKSLN=H)

42 XTI I X-TAL Oscillator Input Terminal

43 XTO O X-TAL Oscillator Output Terminal

44 CKO O Clock Output Terminal

th

th

768fs

384fs

bit

bit

(Ip = Input Terminal with pull-up)

*1: Outputted on OMOD1=L (18-bit Alternate Output or 20

*2: Internal Signal is outputted on OMOD1=H (24-bit Alternate Output or 24

-

bit Parallel Output)

-

bit Parallel Output) and one of TEST1N, TEST2N, TEST3N

or TEST4N is set to L.

12

Synchronization

detection

EFM Demodulation

Slice Level

Control

CLV

Digital servo

Subcode

separation

Q CRC

Microprocessor

Interface

VCO

oscillator

Clock control

2k

´

8-bit

RAM

RAM address

generator

C1 and C2 error

detection and correction

Flag processing

General-purpose

ports/Anti-shock

interface

8´ oversampling

digital filters

One-bit D/A

converter

Crystal oscillator system

Timing generator

DEFI

EFMIN

FSEQ

CLV+

CLV-

V/P

SFSY

CS

WRQ

SQOUT

CQCK

CO IN

RWC

FST

FOCS

FZD

TOFF

JP-

JP+

THLD

TGL

EMPH

EFLG

16M

4.2M

CK2

FSX

XV

SS

XOUT

XIN

XV

DD

RV

DD

MUTER

RCHP

RCHN

LCHN

LCHP

LV

SS

MUTEL

LRCKO

DFORO

DFOLO

DACKO

DOUT

ROMXA

C2F

LRSY

V

SSVDD

TEST3

TEST4

TEST5

TEST1

TEST2

TAI

PCK

FR

ISET

PDO

VV

SSVVDD

EFMO

TST11

PW

SBCK

SBSY

DEMO

EFMO

TST10

Level meter

Peak meter

Interpolation

and mute

Bilingual function (1)

Digital output

Bilingual function (2)

Digital

attenuator

ASDACK/P0

ASDFIN/P1

ASDEPC/P2

ASLRCK/P3

LV

DD

HFL

TES

Servo

commander

RES

LASER

CONT

RV

SS

SQOUT

CO IN

ASDEPC/P2

ASDFIN/P1

ASDACK/P0

TST10

DACKO

DFOLO

DFORO

LRCKO

1

23

4567

8

9

10

11

12 13

14

15 16

17 18 19 20

21

22

23 24

4142

43

44

45

46

47

48

49

50

5152

53

54

55

56

57

58

59

6061

626364

RWC

WRQ

FSX

SBCK

SFSYPWEFLG

SBSY

DOUT

MUTER

RVDDRCHP

RCHN

RVSSLVSSLCHN

LCHP

LVDDMUTEL

C2F

ROMXA

CK2

LRSY

ASLRCK/P3

EMPH

TEST4

DEMO

JP-

JP+

V

DD

TEST3

THLD

DEFI

TAI

PDO

VVSS

ISET

VVDD

FR

VSS

EFMO

EFMO

EFMIN

TEST2

CLV+

CLV-

V/P

FOCS

FST

FZD

HFL

TES

PCK

FSEQ

TOFF

TGL

CQCK

RES

TST11

LASER

16M

4.2M

CONT

TEST5

CS

XV

SS

XIN

XOUT

XV

DD

TEST1

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

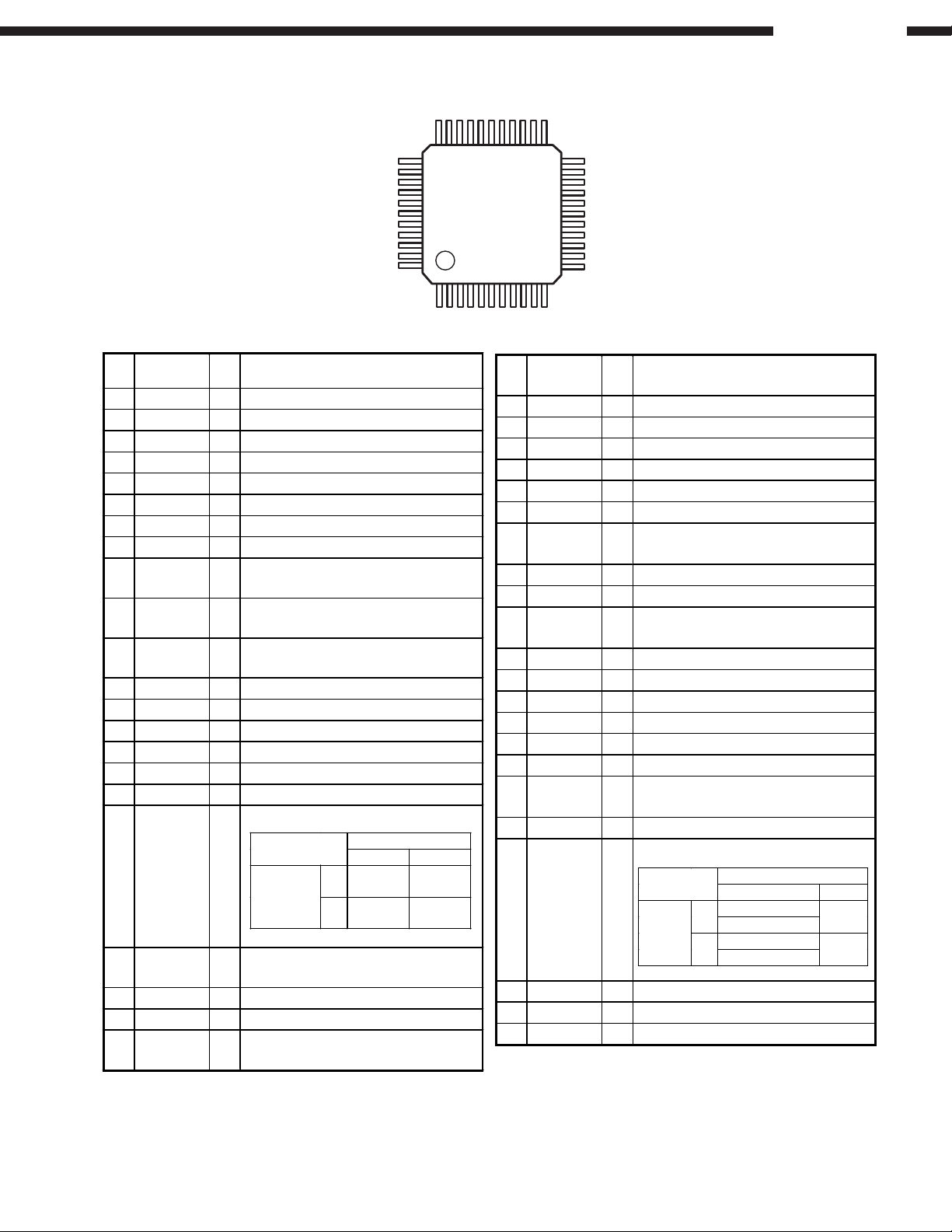

LC78625E (IC103)

DCD-1650SR

13

DCD-1650SR

)

S

2

D

LA6559 (IC101)

1

REV

Signal System VCC

2

-VCC

VCC2

VLO-

VLO+

VO4+

VO4-

VO3+

VO3-

VO2+

VO2-

VO1+

VO1-

VCC1

VIN1

VIN1-

VIN1+

VIN2

FR

3

4

5

6

7

8

9

Power

System

GND

FR

10

11

12

13

14

15

16

17

18

Power Supply

(LOADING)

(Forward/Reverse/

Power Supply

(CH1 to CH4)

11k

Input

Break/OFF)

Control

Output

Level

Shift

Level

Shift

Level

Shift

Level

Shift

33k

Signal System GND

CH2 to CH4

Output

CH1 Output

ON/OFF

33k

Power System GND

3.3VREG

(External PNP)

33k

3.3VREG GND

3.3VREG

Power Supply

33k

Thermal

Shutdown

MUTE2

MUTE1

11k

PNP Tr

Collector

11k

11k

PNP Tr

Base

FWD

36

S-GND

35

MUTE2

34

33

MUTE1

32

VIN4

31

VIN4-

30

VIN4+

29

VREF-IN

28

VCONT(LOADING

FR

FR

27

REG-OUT

26

REG-IN

25

VIN3+

24

VIN3-

23

VIN3

22

GND-VREG

21

VCC-VREG

20

VIN2+

19

VIN2-

Pin

No.

1 REV

2 S-Vcc

Name

5CH output change terminal, logic input of

loading block

signal system power supply

(BTL-AMP:CH1~4)

Function

3 Vcc2 Power supply for loading block

4 VL0− Loading output (−)

5 VL0+ Loading output (+)

6 VO4+ Output terminal (+) for channel 4

7 VO4− Output terminal (−) for channel 4

8 VO3+ Output terminal (+) for channel 3

9 VO3− Output terminal (−) for channel 3

10 VO2+ Output terminal (+) for channel 2

11 VO2− Output terminal (−) for channel 2

12 VO1+ Output terminal (+) for channel 1

13 VO1− Output terminal (−) for channel 1

14 Vcc1 CH1~CH4(BTL-AMP) output stage power supply

15 VIN1 Input terminal for channel 1

16 VIN1− OP-AMP input AMP-A input terminal (−)

17 VIN1+ OP-AMP input AMP-A input terminal (+)

18 VIN2 Input terminal for channel 2, input AMP output

19 VIN2− Input terminal (−) for channel 2

20 VIN2+ Input terminal (+) for channel 2

21 Vcc-VREG 3.3VREG power supply

22 GND-VREG 3.3VREG GND

23 VIN3 Input terminal for channel 3, input AMP output

24 VIN3− Input terminal (−) for channel 3

25 VIN3+ Input terminal (+) for channel 3

26 REG-IN PNP transistor base connected

27 REG-OUT

3.3V power output to which the PNP transistor

collector connected

28 VCONT Loading output voltage set terminal

29 VREF-IN Reference voltage applied terminal

30 VIN4+ Input terminal (+) for channel 4

31 VIN4− Input terminal (−) for channel 4

32 VIN4 Input terminal for channel 4, input AMP output

33 MUTE1 Output ON/OFF for channel 1 (BTL AMP)

34 MUTE2 Output ON/OFF for channel 2 to 4 (BTL AMP)

35 S-GND Signal system GND

36 FWD

Output change terminal (FWD) for loading

output (VLO+−), logic input of loading block

LA9241M (IC102)

VCC1

LDS

LDD

BH1

APC

I/V

T. SERVO & T.LOGIC

FIN2

FIN1

TE

TESI

SCI

TD

TO

FD

TB

TE

TH

TA

TD

JP

VCC1

LDS

LDD

BH1

PH1

LF2

VR

646362616059585756555453525150

1

2

E

3

F

4

5

6

7

8

9

10

11

12

13

14

15

16

171819202122232425262728293031

-

FD

-

FAFAFE

NC

FE

GND

REFI

SP

VCC

SPG

FSS

DRFCEDATCLCLK

-

SP

SPD

SLEQ

SLD

DEF

49

48

NC

47

TBC

46

FSC

45

DGND

44

SLI

43

SLC

32

-

-

+

JP

SL

SL

-

42

RFS

41

RFSM

+

40

CV

-

39

CV

38

SLOF

37

HFL

36

TES

35

TOFF

34

TGL

+

33

JP

FIN2

FIN1

TESI

1

2

3

E

4

F

5

TB

6

TE

TE

7

8

9

SCI

10

TH

TA

11

-

TD

12

TD

13

JP

14

TO

15

FD

16

PH1

RF DET

VCA

VCABAL

TE

F.SERVO & F.LOGIC

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

FA

FD

FAFEFE

LF2VRREFI

REF

INTER FACE

NC

AGND

VCC2FSS

m

-com

SPINDLE

SERVO

SP

SPG

DRFCEDATCLCLK

SP

SPD

SLC

RF Amp

SLED SERVO

SLD

SLEQ

DEF

49505152535455565758596061626364

-

+

SLSLJP

NC

48

47

TBC

FSC

46

45

DGN

SLI

44

SLC

43

-

42

RFS

RFSM

41

+

CV

40

-

CV

39

SLOF

38

37

HFL

TES

36

TOFF

35

TGL

34

+

33

JP

-

14

PCM1704U (IC601~604)

PCM1704U (IC601~604)

DATA

1

BCLK

2

NC

3

V

4

−

DD

DGND

5

+V

6

DD

WCLK

7

NC

8

9

20BIT

INVERT

10

20

−V

19

REF DC

18

NC

17

SERVO DC

16

AGND

15

AGND

14

I

OUT

13

NC

12

BPO DC

11

+V

DCD-1650SR

Pin

Symbol Function

CC

CC

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

DATA

BCLK

NC

-V

DD

DGND

+V

DD

WCLK

NC

20BIT

INVERT

+V

CC

BPO DC

NC

I

OUT

AGND

AGND

SERVO DC

NC

REF DC

-V

CC

Remarks:

(1) Not connected (Not used)

(2) Internal Pull -up

I/O

IN

Serial Audio Input

IN

Bit Clock Input for Serial Audio Data Input

NC (1)

Digital Power Supply -5V

Digital GND

Digital Power Supply +5V

Data Latch Accept Input

NC (1)

INPUT Data Language Select (2)

IN

INPUT Data Polarity Select (2)

IN

Analog Power Supply +5V

Bipotar Offset De-Coupling Capacitor

NC (1)

Audio Signal Analog Current Output

OUT

Analog GND

Analog GND

Servo Amp De-coupling Capacitor

NC (1)

Band Cap. Reference De-coupling Capacitor

Analog Power Supply -5V

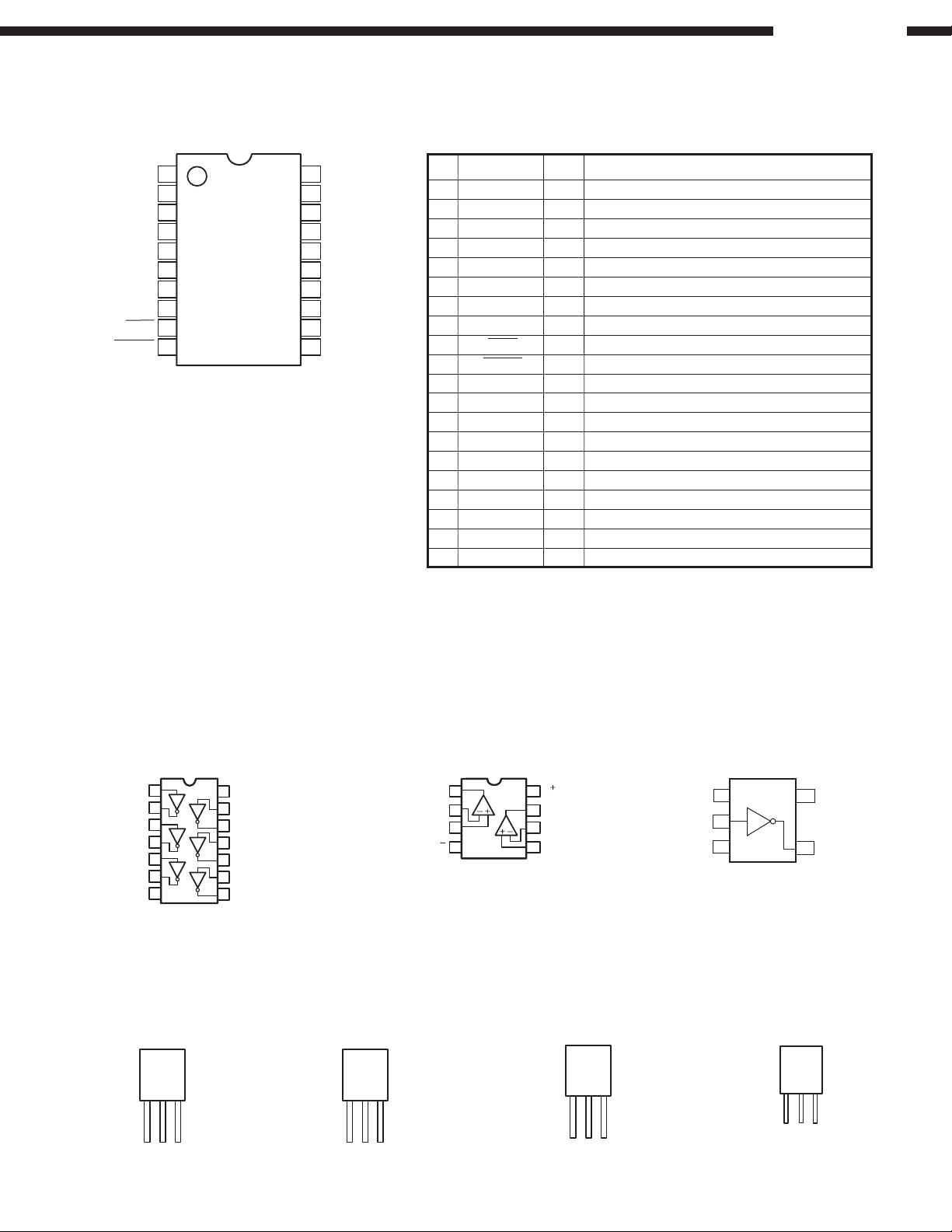

TC74HCU04AF (IC202)

GND

1

1A

2

1Y

3

2A

4

2Y

5

3A

6

3Y

7

Vcc

14

13

6A

6Y

12

11

5A

10

5Y

9

4A

8

4Y

NJM7805FA (IC804)

NJM7806FA (IC803)

NJM7812FA (IC801)

FRONT

VIEW

NJM4556AD (IC501, 502)

OP275GP (IC607~612)

BA15218 (IC104)

OPA2134PA (IC613, 614)

A OUTPUT

A I NPUT

A+INPUT

1

2

3

V

4

NJM7905FA (IC353, 354)

NJM79M12FA (IC802)

FRONT

VIEW

V

2

8

B OUTPUT

7

6

B I NPUT

B +INPUT

5

1

NJM78L05A (IC351, 352)

FRONT

VIEW

TC7SU04F (IC203)

NC

1

IN A

2

GND

3

PST600C (IC401)

FRONT

5

4

VIEW

Vcc

OUT Y

Input

GND

Output

GND

Input

Output

Output

GND

Input

DD

V

Out

GND

15

Loading...

Loading...