Page 1

2006-03-10

http://w ww.delta.com.tw/industrialautoma tion/

5011641001-PCE1

DVP-PCC01

Program Transfer Module

1 Warning

Please set the RD/WR switch before operating the .

Do not disconnect PCC01 before Transmission ends; otherwise, it may cause data loss in the PCC01

Do not change the RD/WR switch during PCC01 operation.

2 Introduction

PCC01 can read or write PLC programs, devices (coils and registers) and passwords to all series of PLC via

COM. It provides rapidly and safely data transmission to PLC.

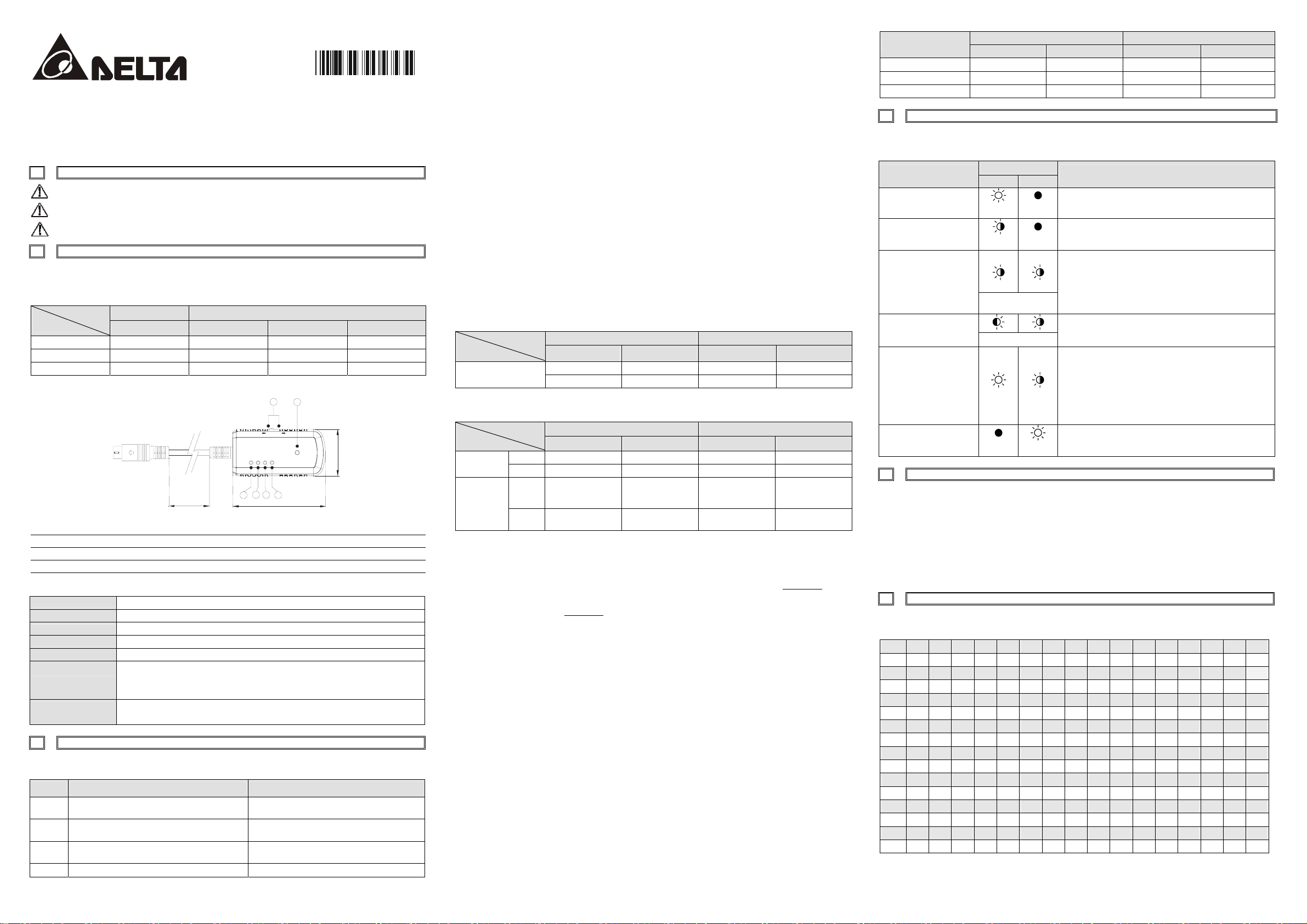

Applicable Models and Read/Write Device Types:

Device type

Models

DVP-ES/EX/EC/SS 4K D0~D599 M0~M1279 N/A

DVP-SA/SX/SC 8K D0~D4999 M0~M4095 1600

DVP-EH/SV 16K D0~D9999 M0~M4095 10000

Product Profile

1. Power LED 4. Error LED

2. Communication Indicator LED 5. Operation mode: read/write functional switch

3. Operation completed LED 6. PCC01 Data Erase button

Specification

Data Retention 10 years

Write Cycles At Least 10,000 times

Transmission speed 9600 /19200 bps (PB: 9600 bps only)

Storage

Operation

Noise Immunity

Vibration / Shock

Resistance

3 Operation and Function Description

3.1 Read/Write Operation Sequence:

Step

1 Set RD/WR switch to “RD” mode

Connect PCC01 to PLC COM1.Reading will start

2

after 5sec. waiting.

3 After reading data from PLC, “OK” LED will light

4 Disconnect PCC01 when read process is done. Disconnect PCC01 when write process is done.

Program area PLC device area

Program (Steps) D register M device File register

-25℃~70℃ (Temperature), 5~95% (Humidity)

0℃~55℃ (Temperature), 50~95% (Humidity), Pollution degree 2

ESD: ±4KV Air Discharge

EFT: Power Line: 2KV

RS: 0.15MHz~80MHz, 10V/m

Surge : ±1KV

International Standard: IEC1131-2, IEC 68-2-6(TEST Fc)

IEC1131-2 & IEC 68-2-27 (TEST Ea)

(PLC→PCC01) RD (Read) (PLC←PCC01) WR (Write)

300

Unit: mm

Instruction Sheet

56

WR RD

33

DVP-PCC01

66.3

ERASE

ERR

POWEROKCOM

234

1

Set RD/WR switch to “WR” mode and confirm PLC

is STOP status

Set RD/WR switch to “WR” mode and place the

PLC RUN/STOP switch in the STOP position.

Connect PCC01 to PLC COM1.Writing will start

after 5 sec.

3.2 Password Function

The PCC01 transfer module can obtain a password from the source PLC along with the program. When the

program is transferred from the ACPGMXFER to the destination PLC it will compare the password and if the

password in the PLC matches or no password was previously set the transfer will complete. This will require

future ACPGMXFER transfers to a password protected PLC to have the same password as the PLC, Also if a

password is set via the transfer module any WPLSOFT users will be required to enter the password before any

program changes can be made.

The password is entered into registers D1086 and D1087 and set on by enabling M1086. These addresses

serve only as an entry point for the password at the source PLC. When the file is ‘Wrote’ to the destination PLC

the unit will be password protected and registers D1086 and D1087 will not be populated with the password. If

M1086 is not set on the passwords will be ignored.

The password is set in the source PLC by using the Batch Monitoring feature of the PLC software or hand held

programmer to enter the password into registers D1086 and D1087. Enter the value in Hexadecimal format, a

password of 1234 would be entered as follows. H3132 into register D1086 followed by H3334 into register

D1087. Refer to the table in section 6 for cross reference of valid ASCII characters. Next set M1086 on to make

this password active.

Connect the transfer module to the source PLC with the switch set to read. This will upload the program and the

password of 1234. The destination PLC will have to be in the stop mode, next connect the transfer module to

the destination PLC with the switch set to the “write” position. The transfer module will download the program

and set the password to 1234.

The password key has four digits. Each digit is 8bits number and form with ASCII in D1086 and D1087.

Example as follows:

D1086 D1087 Password Key

Password setting

ASCII code (HEX)

3.3 The conditions when PCC01 will read/write to an PLC:(w/ PW: with password; w/o PW: without password)

PCC01

PLC Status

RUN

STOP

3.4 PCC01 force PLC in RUN/STOP status

PCC01 provide Run/Stop function in DVP-ES/EX/EC series MPUs. When PCC01 ERR and OK LEDs are blinking

simultaneously in WR mode and PLC is in RUN status, user can press the ERASE button within 30 seconds

PLC in STOP After that, disconnect PCC01 from the PLC and then connect to PLC again. Once data write-in is

completed, push ERASE within 30 seconds

3.5 PCC01 Data Erase function:

Once PCC01 connects to PLC, please press and hold the ERASE button within 5 secs. Continue to hold the button

until the OK LED turns on. Release the button and the ACPGMXFER module can now be removed.

3.6 Data Duplication Function

Besides program transfer, the PCC01 can also read/write register and coil data to/from the PLC. The PCC01

will monitor coil M1085 to see if it should read/write the data. When M1085 is OFF, the PCC01 will read or

write the data depending on the operation selected. If M1085 is ON he PCC01 will not read or write the data.

Data Duplication steps:

1.) Set M1085 On/Off in PLC

2.) Select PCC01 RD/WR switch in reading or writing mode.

3.) Connect PCC01 to PLC COM1 communication port

4.) After operation is completed, “OK” LED will turn on.

5.) Disconnect PCC01 from the PLC.

3.7 Estimation of Read/Write Operating Timing

w/o PW Able to read Password verify error Unable to write Unable to write

w/ PW Unable to read Unable to read Unable to write Unable to write

w/o PW Able to read Password verify error Able to write

w/ PW Unable to read Unable to read Password verify error

High byte Low byte High byte Low byte

Byte 1 Byte 2 Byte 3 Byte 4

1 (0x31=H31) 2 (0x32=H32) 3 (0x33=H33) 4 (0x34=H34)

Read Write

w/o PW w/ PW w/o PW w/ PW

Able to write and

write password to

PLC

Able to write after

verification

to force

while PCC01’s OK LED is ON to switch PLC status from STOP to RUN.

Model

DVP-ES/EX/SS 35 sec. 45 sec. 30 sec. 35 sec.

DVP-SA/SX/SC 1 min. 10 sec. 1 min. 15 sec. 1 min. 5 sec. 1 min. 10 sec.

DVP-EH/SV 2 min. 50 sec. 3 min. 1 min. 10 sec. 1 min. 20 sec.

M1085=OFF M1085=ON

Read Write Read Write

4 Error Indication

PCC01 will show an error or warning status with the ERR and OK LEDs.

Below is the summary:

Error Message

PCC01 Internal memory

error

Incompatible model

Operation error – unable

to write

Operation error – unable

to read

Password verify error

ERASE completed

5 Troubleshooting

If ERR LED is always ON or blinking. Please refer to section 4.

Disconnecting the PCC01 or powering down the PLC when the operation in progress will cause unexpected

results:

PCC01 in “RD” mode:

PCC01 data will be invalid. Please reboot the PLC again or re-connect PCC01 to PLC.

PCC01 in “WR” mode:

PLC program will be invalid. Please reboot PLC again or re-connect the PCC01 to PLC.

6 Appendix: ASCII Table

The password composed of 4 bytes. Each byte is an ASCII character of ‘0’~’9’, ‘A’~’Z’. ‘a’ ~’z’. The password is case

sensitive. Below is ASCII table.

HEX 0 1 2 3 4 5 6 7 8 9 A B C D E F

⌧ ⌧ ⌧ ⌧ ⌧ ⌧ ⌧ ⌧ ⌧ ⌧ ⌧ ⌧ ⌧ ⌧ ⌧ ⌧

ASCII

HEX 10 11 12 13 14 15 16 17 18 19 1A 1B 1C 1D 1E 1F

⌧ ⌧ ⌧ ⌧ ⌧ ⌧ ⌧ ⌧ ⌧ ⌧ ⌧ ⌧ ⌧ ⌧ ⌧ ⌧

ASCII

HEX 20 21 22 23 24 25 26 27 28 29 2A 2B 2C 2D 2E 2F

ASCII SP ! " # $ % & ' ( ) * + , - . /

HEX 30 31 32 33 34 35 36 37 38 39 3A 3B 3C 3D 3E 3F

ASCII 0 1 2 3 4 5 6 7 8 9 : ; < = > ?

HEX 40 41 42 43 44 45 46 47 48 49 4A 4B 4C 4D 4E 4F

ASCII @ A B C D E F G H I J K L M N O

HEX 50 51 52 53 54 55 56 57 58 59 5A 5B 5C 5D 5E 5F

ASCII P Q R S T U V W X Y Z

HEX 60 61 62 63 64 65 66 67 68 69 6A 6B 6C 6D 6E 6F

ASCII ` a b C d e f g h i j k l M n o

HEX 70 71 72 73 74 75 76 77 78 79 7A 7B 7C 7D 7E 7F

ASCII p q r s t u v w x y z { | } ~

Note: ‘⌧’:Denotes invalid ASCII character, do not use.

Indicator

ERR OK

On Off

Blinking Off

Synchronous blinking

Cross blinking

On Blinking

Off On

Recommend

PCC01 hardware may be damaged, please replace it.

Make sure PCC01 model record is compatible with PLC

model.

PCC01 doesn’t contain a valid program for “WR” mode.

PCC01 in “WR” mode, and PLC is in RUN mode. Please

place PLC in STOP mode.

Communication protocol error! Please confirm the PLC is in

STOP mode and reboot the PLC.

Check PLC program syntax.

PLC protect with password.

Communication protocol error! Please confirm PLC in STOP

mode and remove/apply power to.

PCC01 is in “RD” mode, and is protected by password.

Please push erase button when PCC01 connect to the PLC.

For more detailed operation of erasure, please reference to

section 3.4.

PCC01 is in “WR” mode, and PLC is protected by password.

Please disable the password in PLC, or set the same PLC’s

password in the PCC01. For more detailed operation , please

reference to section 3.2.

Please refer to section 3.5.

⌧ ⌧ ⌧ ⌧ ⌧

⌧

Loading...

Loading...