Page 1

DOP-B_M_EN_20100531

Page 2

Preface

Thank you very much for purchasing DELTA’s DOP-B Series Human Machine Interface

(hereinafter “HMI” ) products.

This manual will be helpful in the installation, operation and specifications of Delta HMI

product and HMI Screen Editor software program. Before using the product, please read this

user manual to ensure correct use.

You should thoroughly understand all safety precautions (DANGERS, WARNINGS and STOPS)

before proceeding with the installation, wiring and operation. If you do not understand please

contact your local Delta sales representative. Place this user manual in a safe location for

future reference.

Using This Manual

Contents of this manual

This manual is a user guide that provides the information on how to install

and operate Delta HMI products and Screen Editor software program.

Who should use this manual

This user manual is intended for the following users:

Those who are responsible for designing.

Those who are responsible for installing or wiring.

Those who are responsible for operating or programming.

Important precautions

Before using the product, please read this user manual thoroughly to ensure correct

use and store this manual in a safe and handy place for quick reference whenever

necessary. Besides, please observe the following precautions:

Install the product in a clean and dry location free from corrosive and

inflammable gases or liquids.

Ensure that HMI is correctly connected to a ground. The grounding method

must comply with the electrical standard of the country.

Do not modify or remove wiring when power is applied to HMI.

Before starting the operation, make sure the emergency stop equipment can

be energized and work at any time.

Do not touch the power supply during operation. Otherwise, it may cause

electric shock.

Revision May, 2010 i

Page 3

Preface

NOTE

The content of this manual may be revised without prior notice. Please consult our distributors or

download the most updated version at http://www.delta.com.tw/industrialautomation

.

ii Revision May, 2010

Page 4

Table of Contents

Chapter 1 Introduction............................................................................... 1-1

1.1 DOP-B Series Human Machine Interface (HMI).................................................... 1-1

1.2 Features............................................................................................................ 1-1

Chapter 2 Working with Hardware Devices ................................................. 2-1

2.1 Usage of SD Card and USB Disk ........................................................................ 2-1

Chapter 3 Creating and Editing Screens ..................................................... 3-1

3.1 Screen Editor Setup........................................................................................... 3-1

3.2 How to Start Screen Editor ................................................................................ 3-9

3.3 Internal Memory ............................................................................................... 3-17

3.3.1 Internal Register (Read / Write) : $ ............................................................. 3-17

3.3.2 Non-volatile Internal Register (Read / Write) : $M....................................... 3-17

3.3.3 Indirect Address Register (Read / Write) : *$ .............................................. 3-18

3.3.4 Recipe Number Register (Read / Write) : RCPNO ........................................ 3-18

3.3.5 Recipe Group Register (Read / Write) : RCPG.............................................. 3-19

3.3.6 Recipe Register (Read / Write) : RCP........................................................... 3-19

3.4 Control Block and Status Block.......................................................................... 3-24

3.4.1 Control Block............................................................................................. 3-25

3.4.2 Status Block............................................................................................... 3-36

3.5 Menu Bar and Toolbar (File) .............................................................................. 3-42

3.5.1 New........................................................................................................... 3-42

3.5.2 Open ......................................................................................................... 3-43

3.5.3 Close......................................................................................................... 3-44

3.5.4 Save .......................................................................................................... 3-44

Revision May, 2010 iii

Page 5

Table of Contents

3.5.5 Save as ...................................................................................................... 3-45

3.5.6 Make Ext. Memory Data............................................................................. 3-45

3.5.7 Open Ext. Memory Data............................................................................. 3-46

3.5.8 Password Protect ....................................................................................... 3-46

3.5.9 Print .......................................................................................................... 3-47

3.5.10 Print Preview............................................................................................ 3-47

3.5.11 Print Setup............................................................................................... 3-48

3.5.12 File Quick Access..................................................................................... 3-49

3.5.13 Exit.......................................................................................................... 3-49

3.6 Menu Bar and Toolbar (Edit).............................................................................. 3-50

3.6.1 Undo ......................................................................................................... 3-50

3.6.2 Redo.......................................................................................................... 3-50

3.6.3 Cut ............................................................................................................ 3-50

3.6.4 Copy.......................................................................................................... 3-51

3.6.5 Paste ......................................................................................................... 3-51

3.6.6 Delete........................................................................................................ 3-51

3.6.7 Select All ................................................................................................... 3-51

3.6.8 Find........................................................................................................... 3-51

3.6.9 Replace ..................................................................................................... 3-53

3.6.10 Station Replace ........................................................................................ 3-56

3.6.11 Group ...................................................................................................... 3-56

3.6.12 Ungroup .................................................................................................. 3-57

3.6.13 Order....................................................................................................... 3-57

3.6.14 Align........................................................................................................ 3-57

3.6.15 Make Same Size ....................................................................................... 3-58

iv Revision May, 2010

Page 6

Table of Contents

3.6.16 Text Process ............................................................................................ 3-58

3.6.17 Picture ..................................................................................................... 3-58

3.6.18 Duplicate ................................................................................................. 3-58

3.7 Menu Bar and Toolbar (View) ............................................................................ 3-61

3.7.1 Tools......................................................................................................... 3-61

3.7.2 Property Table ........................................................................................... 3-69

3.7.3 Record and Output Window ....................................................................... 3-70

3.7.4 Zoom In..................................................................................................... 3-71

3.7.5 Zoom Out .................................................................................................. 3-72

3.7.6 Actual Size ................................................................................................ 3-72

3.7.8 I/O Screen ................................................................................................. 3-73

3.7.9 Grid Setup ................................................................................................. 3-74

3.7.10 Cross Reference Table ............................................................................. 3-75

3.7.11 Element Part List...................................................................................... 3-75

3.7.12 Memory List............................................................................................. 3-76

3.8 Menu Bar and Toolbar (Element) ....................................................................... 3-81

3.8.1 Create an Element ..................................................................................... 3-81

3.8.2 Button Elements ........................................................................................ 3-92

3.8.2.1 Set / Reset / Maintained / Momentary Buttons ................................... 3-94

3.8.2.2 Multistate Button................................................................................ 3-100

3.8.2.3 Set Value Button................................................................................. 3-102

3.8.2.4 Set Constant Button ........................................................................... 3-104

3.8.2.5 Increment / Decrement ...................................................................... 3-106

3.8.2.6 Goto Screen / Previous Page............................................................... 3-108

Revision May, 2010 v

Page 7

Table of Contents

3.8.2.7 System DateTime/Password Table Setup/Enter Password/Contrast

Brightness/Low Security/System Menu/Report List/Screen Capture/Remove

Storage/Import&Export Recipe/Calibration/Language Changer......................... 3-111

3.8.3 Meter Elements.......................................................................................... 3-117

3.8.4 Bar Elements ............................................................................................. 3-120

3.8.4.1 Normal............................................................................................... 3-120

3.8.4.2 Differential......................................................................................... 3-122

3.8.5 Pipe Elements............................................................................................ 3-125

3.8.5.1 Pipe(1)/Pipe(2) ................................................................................... 3-125

3.8.5.2 Pipe(3)................................................................................................ 3-127

3.8.5.3 Pipe(4)................................................................................................ 3-128

3.8.5.4 Pipe(5)................................................................................................ 3-128

3.8.5.5 Pipe(6)/Pipe(7) ................................................................................... 3-129

3.8.6 Pie Elements.............................................................................................. 3-130

3.8.7 Indicator Elements..................................................................................... 3-133

3.8.7.1 Multistate Indicator ............................................................................ 3-133

3.8.7.2 Range Indicator .................................................................................. 3-134

3.8.7.3 Simple Indicator ................................................................................. 3-136

3.8.8 Data Display Elements ............................................................................... 3-137

3.8.8.1 Numeric Display................................................................................. 3-137

3.8.8.2 Character Display ............................................................................... 3-139

3.8.8.3 Date Display....................................................................................... 3-141

3.8.8.4 Time Display ...................................................................................... 3-142

3.8.8.5 Day-of-week Display ........................................................................... 3-142

3.8.8.6 Prestored Message ............................................................................. 3-143

vi Revision May, 2010

Page 8

Table of Contents

3.8.8.7 Moving Sign ....................................................................................... 3-143

3.8.9 Graph Display Elements............................................................................. 3-145

3.8.9.1 State Graphic...................................................................................... 3-145

3.8.9.2 Animated Graphic .............................................................................. 3-147

3.8.9.3 Dynamic Line ..................................................................................... 3-149

3.8.9.4 Dynamic Rectangle............................................................................. 3-150

3.8.9.5 Dynamic Ellipse.................................................................................. 3-152

3.8.9.6 Real Image ......................................................................................... 3-154

3.8.10 Input Elements......................................................................................... 3-157

3.8.10.1 Numeric Entry .................................................................................. 3-157

3.8.10.2 Character Entry ................................................................................ 3-161

3.8.10.3 Barcode Input ................................................................................... 3-164

3.8.11 Curve Elements........................................................................................ 3-168

3.8.11.1 Trend Graph ..................................................................................... 3-168

3.8.11.2 X-YChart........................................................................................... 3-171

3.8.11.3 X-Y Distribution ................................................................................ 3-175

3.8.12 Sampling Elements .................................................................................. 3-178

3.8.12.1 Historical Trend Graph ..................................................................... 3-178

3.8.12.2 Historical Data Table ........................................................................ 3-181

3.8.12.3 Historical Event Table....................................................................... 3-183

3.8.13 Alarm Elements ....................................................................................... 3-185

3.8.13.1 Alarm History Table.......................................................................... 3-185

3.8.13.2 Active Alarm List .............................................................................. 3-186

3.8.13.3 Alarm Frequency Table ..................................................................... 3-188

3.8.13.4 Alarm Moving Sign ........................................................................... 3-189

Revision May, 2010 vii

Page 9

Table of Contents

3.8.14 Keypad Elements ..................................................................................... 3-191

3.8.15 Drawing Elements.................................................................................... 3-194

3.8.15.1 Line .................................................................................................. 3-194

3.8.15.2 Rectangle ......................................................................................... 3-195

3.8.15.3 Circle ............................................................................................... 3-196

3.8.15.4 Polygon ............................................................................................ 3-198

3.8.15.5 Arc ................................................................................................... 3-199

3.8.15.6 Text ................................................................................................. 3-200

3.8.15.7 Scale ................................................................................................ 3-201

3.8.15.8 Table................................................................................................ 3-203

3.9 Menu Bar and Toolbar (Screen) ......................................................................... 3-205

3.9.1 New Screen................................................................................................ 3-205

3.9.2 Open Screen .............................................................................................. 3-205

3.9.3 Screen Management .................................................................................. 3-206

3.9.4 Cut Screen................................................................................................. 3-208

3.9.5 Copy Screen .............................................................................................. 3-209

3.9.6 Paste Screen .............................................................................................. 3-209

3.9.7 Delete Screen ............................................................................................ 3-209

3.9.8 Export ....................................................................................................... 3-209

3.9.9 Import ....................................................................................................... 3-209

3.9.10 Clear Import Data .................................................................................... 3-210

3.9.11 Screen Open Macro.................................................................................. 3-210

3.9.12 Screen Close Macro ................................................................................. 3-210

3.9.13 Screen Cycle Macro .................................................................................. 3-211

3.9.14 Auxiliary Key ........................................................................................... 3-211

viii Revision May, 2010

Page 10

Table of Contents

3.9.15 Screen Properties..................................................................................... 3-212

3.10 Menu Bar and Toolbar (Tools) ......................................................................... 3-216

3.10.1 Compile................................................................................................... 3-216

3.10.2 Download Screen & Recipe....................................................................... 3-218

3.10.3 Upload Screen & Recipe ........................................................................... 3-219

3.10.4 Download Screen ..................................................................................... 3-221

3.10.5 Upload Recipe.......................................................................................... 3-221

3.10.6 Download Recipe ..................................................................................... 3-222

3.10.7 On Line Simulation .................................................................................. 3-222

3.10.8 Off Line Simulation .................................................................................. 3-223

3.10.9 Upgrade Firmware ................................................................................... 3-223

3.10.10 Get Firmware Information ...................................................................... 3-225

3.11 Menu Bar and Toolbar (Options....................................................................... 3-226

3.11.1 Configuration .......................................................................................... 3-226

3.11.2 Alarm Setup............................................................................................. 3-237

3.11.3 History Buffer Setup................................................................................. 3-241

3.11.4 Password Setting ..................................................................................... 3-246

3.11.5 Tag Table ................................................................................................ 3-247

3.11.6 Print Typesetting ..................................................................................... 3-248

3.11.7 Recipe ..................................................................................................... 3-254

3.11.8 32 bits Recipe.......................................................................................... 3-258

3.11.9 Picture Bank............................................................................................. 3-262

3.11.10 Text Bank .............................................................................................. 3-265

3.11.11 Submacro .............................................................................................. 3-266

3.11.12 Initial Macro........................................................................................... 3-266

Revision May, 2010 ix

Page 11

Table of Contents

3.11.13 Background Macro ................................................................................. 3-266

3.11.14 Clock Macro........................................................................................... 3-266

3.11.15 Environment .......................................................................................... 3-267

3.12 Menu Bar and Toolbar (Window)...................................................................... 3-269

3.12.1 Close Window .......................................................................................... 3-269

3.12.2 Close All Windows ................................................................................... 3-269

3.12.3 Next Window ........................................................................................... 3-269

3.12.4 Previous Window...................................................................................... 3-269

3.12.5 Cascade................................................................................................... 3-270

3.12.6 Title Horizontal........................................................................................ 3-271

3.12.7 Title Vertical ............................................................................................ 3-272

3.12.8 Window Summary .................................................................................... 3-273

3.13 Menu Bar and Toolbar (Help)........................................................................... 3-274

3.13.1 Help ........................................................................................................ 3-274

3.14 Macro Function ............................................................................................... 3-275

3.14.1 Macro Type.............................................................................................. 3-275

3.14.1.1 On Macro ......................................................................................... 3-276

3.14.1.2 Off Macro ......................................................................................... 3-279

3.14.1.3 Before Execute Macro ....................................................................... 3-280

3.14.1.4 After Execute Macro ......................................................................... 3-281

3.14.1.5 Screen Open Macro .......................................................................... 3-282

3.14.1.6 Screen Close Macro .......................................................................... 3-282

3.14.1.7 Screen Cycle Macro .......................................................................... 3-283

3.14.1.8 Initial Macro ..................................................................................... 3-284

3.14.1.9 Background Macro............................................................................ 3-284

x Revision May, 2010

Page 12

Table of Contents

3.14.1.10 Clock Macro ................................................................................... 3-286

3.14.1.11 Sub-Macro ...................................................................................... 3-286

3.14.2 Macro Editing .......................................................................................... 3-289

3.14.2.1 Macro Editing Widow and Toolbar .................................................... 3-289

3.14.2.2 Macro Command Dialog Box ............................................................ 3-293

3.14.2.3 Keypad Entry .................................................................................... 3-299

3.14.3 Macro Operation...................................................................................... 3-300

3.14.3.1 Arithmetic Operation ........................................................................ 3-300

3.14.3.2 Logical Operation ............................................................................. 3-321

3.14.3.3 Data Transfer ................................................................................... 3-328

3.14.3.4 Data Conversion............................................................................... 3-333

3.14.3.5 Comparison...................................................................................... 3-343

3.14.3.6 Flow Control..................................................................................... 3-348

3.14.3.7 Bit Setting......................................................................................... 3-351

3.14.3.8 Communication................................................................................ 3-354

3.14.3.9 Drawing ........................................................................................... 3-365

3.14.3.10 Others ............................................................................................ 3-369

3.14.4 Macro Error Messages.............................................................................. 3-376

Chapter 4 Example ....................................................................................4-1

4.1 How to Create a 16bits Recipe Data .................................................................. 4-1

4.2 How to Create a 32bits Recipe Data .................................................................. 4-6

4.3 How to Use Windows Excel CSV File .................................................................. 4-12

4.4 How to Use Multi-Language Function ................................................................ 4-14

4.5 How to Use Flash Transfer Function.................................................................. 4-20

4.6 How to Use Real Image Element........................................................................ 4-28

Revision May, 2010 xi

Page 13

Table of Contents

4.7 How to Create a Curve Element......................................................................... 4-33

Chapter 5 System Menu ............................................................................. 5-1

5.1 System Menu Introduction ................................................................................ 5-1

5.2 System Setting Menu ........................................................................................ 5-5

5.3 Up/Download Menu .......................................................................................... 5-18

5.4 System Info Menu ............................................................................................. 5-21

5.5 HMI Doctor Menu.............................................................................................. 5-22

Appendix A List of Functions Added..........................................................A-1

A.1 New Macro Commands ..................................................................................... A-1

A.2 Print Typesetting - Custom Print ....................................................................... A-6

A.3 New Button Elements ........................................................................................ A-7

A.4 New Input Element............................................................................................ A-10

A.5 New Curve Element........................................................................................... A-12

A.6 Show Disk Access Error Message ...................................................................... A-14

A.7 Additional Internal Parameters.......................................................................... A-15

A.8 Invisible Address .............................................................................................. A-17

A.9 Auto Reboot After Firmware Upgrading ............................................................ A-18

A.10 USBCommMode (Data Transfer via USB Disk)................................................... A-19

Appendix B New Upload/Download Function............................................. B-1

B.1 Upload and Download DVP Series PLC Programs ............................................... B-1

Appendix C Multi-Link Connection............................................................. C-1

xii Revision May, 2010

Page 14

Table of Contents

About this Manual…

User Information

Be sure to store this manual in a safe place.

Due to constantly growing product range, technical improvement and alteration or changed

texts, figures and diagrams, we reserve the right of this manual contained information change

without prior notice.

Coping or reproducing any part of this manual, without written consent of Delta Electronics

Inc. is prohibited.

Technical Support and Service

Welcome to contact us or visit our web site (http://www.delta.com.tw/industrialautomation/)

if you need any technical support, service and information, or, if you have any question in

using the product. We are looking forward to serve you needs and willing to offer our best

support and service to you. Reach us by the following ways.

ASIA

DELTA ELECTRONICS, INC.

TAOYUAN Plant/

31-1, SHIEN PAN ROAD, KUEI SAN

INDUSTRIAL ZONE TAOYUAN 333, TAIWAN

TEL: 886-3-362-6301

FAX: 886-3-362-7267

NORTH/SOUTH AMERICA

DELTA PRODUCTS CORPORATION

Sales Office/

JAPAN

DELTA ELECTRONICS (JAPAN) INC.

Sales Office/

DELTA SHIBADAIMON BLDG.

2-1-14 SHIBADAIMON, MINATO-KU,

TOKYO, 105-0012, JAPAN

TEL: 81-3-5733-1111

FAX: 81-3-5733-1211

EUROPE

DELTRONICS (NETHERLANDS) B.V.

Sales Office/

P.O. BOX 12173

5101 DAVIS DRIVE,

RESEARCH TRIANGLE PARK, NC 27709,

U.S.A.

TEL: 1-919-767-3813

DE WITBOGT 15, 5652 AG EINDHOVEN,

THE NETHERLANDS

TEL: 31-40-259-2860

FAX: 31-40-259-2851

FAX: 1-919-767-3969

Revision May, 2010 xiii

Page 15

Table of Contents

This page intentionally left blank.

xiv Revision May, 2010

Page 16

Chapter 1 Introduction

1.1 DOP-B Series Human Machine Interface (HMI)

DOP-B series HMI is manufactured by adopting easy-to-use software and high-speed hardware

to provide a powerful and stable programmable interface. Screen Editor software program is a

user-friendly program editor of DOP-B series HMI for Windows. Please refer to the following

section for an introduction to its features and functions.

1.2 Features

External Controller Serial Drivers Support

DOP-B series HMIs support more than twenty brands of external controllers, including

Delta, Omron, Siemens, Mitsubishi, etc. All of the newly supported communication

protocol information could be found on our website

(http://www.delta.com.tw/industrialautomation/

requirements. (All other trademarks in this manual are property of their respective

companies.)

) for upgrade to meet the users’

Windows® Fonts Support

Screen Editor software program also provides all fonts used by Windows®.

Quick Execution and Communication Macro

Screen Editor software program is able to handle complicated calculations by executing

macros. In addition, the users can create a communication protocol by using

communication macro command and connect to the specific system or the controller via

the COM port.

Rapid USB Upload/Download

Not only RS-232, the users also can use Screen Editor to upload and download screen data

and programs via USB interface. Screen Editor software program shortens the upload /

download time by using USB interface.

Recipes

Screen Editor software program provides a useful recipe editor that is similar to Microsoft

Excel for the users to edit recipe easily and input multiple recipes simultaneously. When

the users need to download multiple recipes simultaneously, the recipe function can swap

Revision May, 2010 1-1

Page 17

Chapter 1 Introduction

internal memory of HMI. After the users finish editing the recipes, the users can download

the recipes individually.

Direct Communication with Three External Controllers

DOP-B series HMI is capable of connecting to three different or the same controllers

directly via three communication ports.

Support Multiple Controllers Connections

One DOP-B series HMI is able to connect to multiple controllers in serial through RS-485

interface of COM2 and COM3 ports.

(NOTE 1)

.

Simulation Function

(NOTE 2)

Screen Editor software program provides simulation feature which allows the users to

develop and debug software on a PC connected to DOP-B series HMI before downloading it

to DOP-B series HMI.

Off-line Simulation: When the editing and compile operation is completed, the users can

use off-line simulation function to simulate HMI operation and check if it is correct on a

stand-alone a PC directly without connecting to the controller.

On-line Simulation: When the editing and compile operation is completed, the users can

use on-line simulation function to simulate HMI operation and check if it is correct on a

stand-alone PC directly with connecting to the controller.

USB Host Port (USB Host) Equipped

DOP-B series HMI has a built-in USB Host interface for the connection to USB disk, card

reader and printer with a USB socket. The users can save data, copy programs, print the

screen immediately and increase the data storage space.

Print Function

DOP-B series HMI supports the printers which have COM port or USB interface.

Multiple Security Protection

DOP-B series HMI provides passwords to protect the designer’s intellectual property rights

and also for the users to set the user priority for important elements. Only the users

whose priority is higher than the element can use the element.

Multi-language Support

Up to 16 languages can be selected and used without installing a multilingual operating

system. A multi-language environment is very important and enables the users to work

more efficiently.

1-2 Revision May, 2010

Page 18

Chapter 1 Introduction

NOTE

1) The controller should provide RS-485 interface.

2) Off-line/On-line simulation functions are only provided for some parts of the controllers. Also,

the execution time of on-line simulation only can continue 30 minutes. After the simulation

time has finished, HMI will return to the main screen of Screen Editor V2.0 software program

from simulation window automatically.

3) When executing simulation function, the resolution of PC screen should be set to 24bit and

higher, otherwise the simulation function may not work normally.

Revision May, 2010 1-3

Page 19

Chapter 1 Introduction

This page intentionally left blank

1-4 Revision May, 2010

Page 20

Chapter 2 Working with Hardware Devices

2.1 Usage of SD Card and USB Disk

SD Card

SD card (supports SDHC) can be used to save and transmit data. The supporting file

format is FAT32. Before using a SD card, reformatting (FAT32) via HMI is needed. Only SD

card that formatted by HMI can be used on both HMI and Windows® OS system. (Even it

can be read/written in some format, but faults may occur due to different format among

Win95/98/2000/XP versions)

USB Disk

USB disk can be used to save data. It also can be used to copy data from HMI and its

format is FAT32 as well. When using USB disk to save data, we recommend that the

storage capacity should be less than 2GB and the users should enter system screen first

and then remove the USB disk. Follow this process can ensure that the data is saved

completely in USB disk.

There are two kinds of methods for removing the USB disk:

1. Press SYS button for 3 seconds to enter intro the system setting screen. Then, the

users could choose the function to remove the USB disk.

2. Create a “Remove storage” button on the screen first. After settings and compile

operation is completed, pressing this button is able to remove the USB disk. For more

information on “Remove storage” button, please refer to section 3.8.2.7 in Chapter 3.

Please use the above two methods to remove the USB disk to ensure that the data is saved

completely in USB disk.

Revision May, 2010 2-1

Page 21

Chapter 2 Working with Hardware Devices

This page intentionally left blank.

2-2 Revision May, 2010

Page 22

Chapter 3 Creating and Editing Screens

In this chapter, it will introduce general functions of Screen Editor software program with

Windows. The user can use it to design what he wants. Detail information for each function

will be discussed in following chapters.

3.1 Screen Editor Setup

Recommended System Requirements

CPU: Intel® Pentium 4.1 or greater

Memory: 1GB RAM or greater

Hard Disk: 400MB and above free hard disk space

Monitor Display: 1024 × 768 resolution higher full-color display recommended

Printer: Printer compatible with Windows® 2000 / Windows® XP

Operation System: Windows® 2000 / Windows® XP / Windows® Vista / Windows® 7

Software installation

The user can download the Screen Editor software program via the link below:

http://www.delta.com.tw/product/em/download/downlo

d=3

To start the Delta HMI Screen Editor software program setup, please refer to the following

steps:

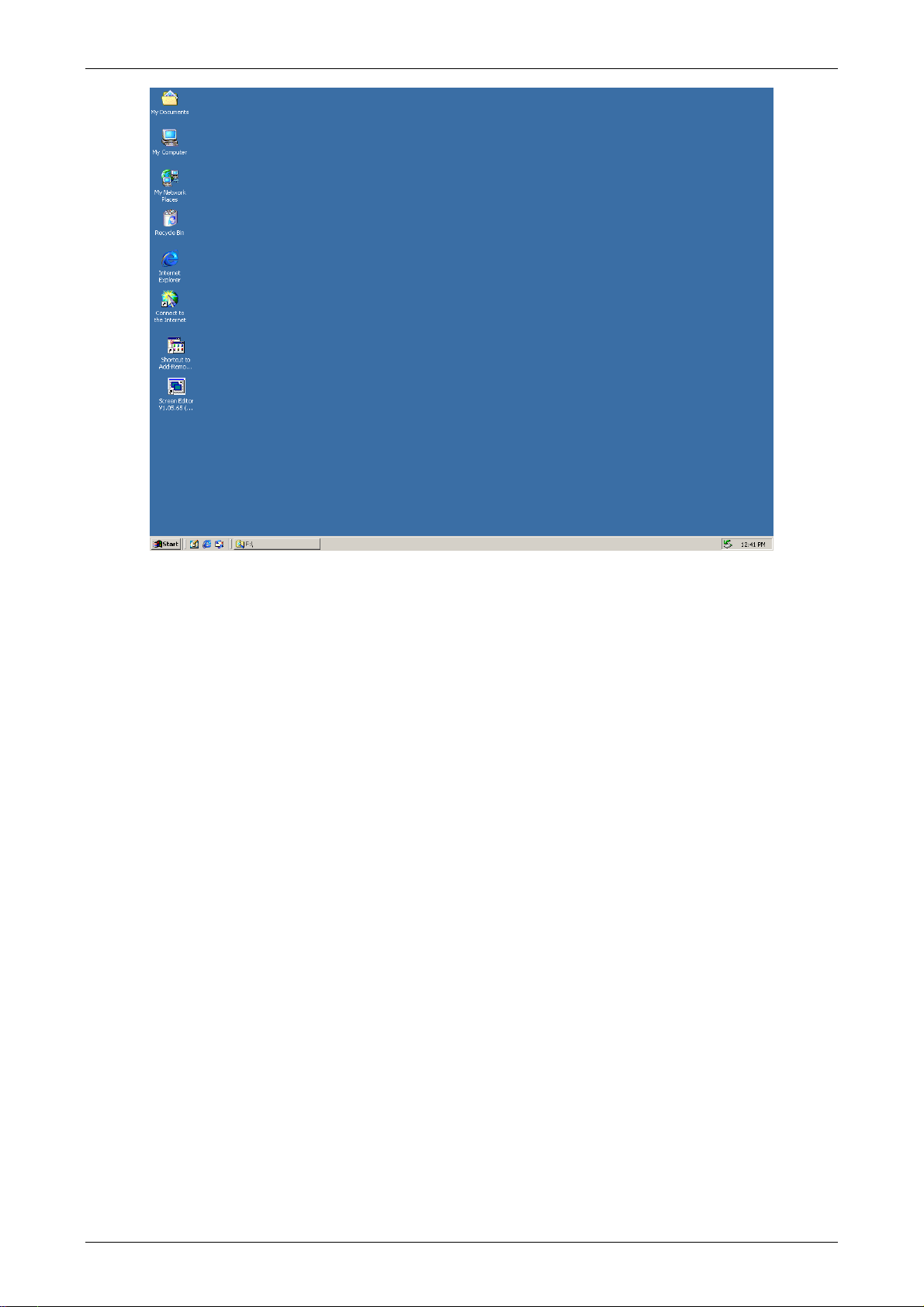

Step 1: Please start-up your computer to Win2000/WinXP system (Fig. 3-1-1).

ad_main.asp?act=3&pid=3&cid=2&tpi

Revision May, 2010 3-1

Page 23

Chapter 3 Creating and Editing Screens

Fig. 3-1-1 Open Microsoft Windows

Step 2: Execute setup.exe from Windows taskbar by clicking “Start” > “Run”. After pressing

OK, system will setup automatically and you will get the following dialog box to select

the desired display language (Fig. 3-1-2).

Fig. 3-1-2 Select Language

3-2 Revision May, 2010

Page 24

Chapter 3 Creating and Editing Screens

After pressing OK, system will setup automatically and you will get the following

dialog box to choose destination location (Fig. 3-1-3).

Fig. 3-1-3 Directory for installing Screen Editor software program

To select the default directory C:\Program Files\Delta Industrial Automation\Screen

Editor 2.00.XX\, click Next> for the next step. Setup will install in the directory

indicated in the Destination Directory box at the bottom of the dialog box.

To select a directory other than the default directory, click Browse. A list of available

directories appears. Highlight the desired directory for Screen Editor and click OK,

then Next> for the next step. If necessary, click < Back button to take you back

through Setup dialog boxes one by one.

Please remember the location of the destination directory. If the destination directory

is missing or changed, the user cannot upgrade the software successfully.

Step 3: After pressing Next, system will ask you to select the installation software, i.e. Screen

Editor (Fig. 3-1-4).

Revision May, 2010 3-3

Page 25

Chapter 3 Creating and Editing Screens

Fig. 3-1-4 Select Screen Editor software program

Step 4: Then click Install button to start Screen Editor Installation (Fig. 3-1-5, Fig. 3-1-6).

Fig. 3-1-5 Starting Screen Editor installation

3-4 Revision May, 2010

Page 26

Chapter 3 Creating and Editing Screens

Fig. 3-1-6 Finish installing Screen Editor

Step 5: After finish installing Screen Editor software program (Fig. 3-1-6), the system will ask

you to install HMI USB driver, please click Yes to install.

Fig. 3-1-7 Install HMI USB driver

Revision May, 2010 3-5

Page 27

Chapter 3 Creating and Editing Screens

Step 6: After installing HMI USB driver, click Close to complete the installation. After the

installation is completed, connect HMI and PC by communication cable via USB port.

Wait for few seconds and activate Screen Editor software program. Then choose Tools

> Get Firmware Information. At this time, if there is no error message and the

firmware information shows up successfully, it indicates that Screen Editor software

program has been installed and the user can use PC to communicate with HMI via USB

port without problem.

Software upgrade (ScrEdit-Path Setup)

When receiving the software upgrade technical announcement, the user can download the

upgrade software program, Patch_DOPB_yyyymmdd at Delta’s website. The upgrade software

program includes the firmware and the enhanced functions. Before installing the upgrade

software program, the user needs to confirm if the software destination directory is the

default setting, i.e. C:\Program Files\Delta Industrial Automation\Screen Editor 2.00.XX.

Please ensure that the destination directory is the default setting or the user could not

perform the upgrade successfully.

[Installation methods of Patch_DOPB_yyyymmdd]

Step 1: Click Patch_DOPB_yyyymmdd direcly under Windows and the system will start the

installation (Fig. 3-1-8). The user can click Install button to upgrade your Screen Editor.

Step 2: During installation, the user can click Show details button to see the detailed items

(Fig. 3-1-9).

Fig. 3-1-8 Install Patch_DOPB_yyyymmdd

3-6 Revision May, 2010

Page 28

Chapter 3 Creating and Editing Screens

Fig. 3-1-9 Starting installation

Fig. 3-1-10 Show details

Fig. 3-1-11 Finish upgrading

Revision May, 2010 3-7

Page 29

Chapter 3 Creating and Editing Screens

Fig. 3-1-12 Finish installation

Step 3: After upgrading is finished, click Close to complete the installation.

3-8 Revision May, 2010

Page 30

Chapter 3 Creating and Editing Screens

3.2 How to Start Screen Editor

1. After setup, you can start Screen Editor software program by clicking Screen Editor

2.00.XX shortcut on the desk (Fig. 3-2-1) or from Windows taskbar, click Start >

Programs > Delta Industrial Automation > HMI > Screen Editor 2.00.XX.

Fig. 3-2-1

Fig. 3-2-2 Start-up display

Revision May, 2010 3-9

Page 31

Chapter 3 Creating and Editing Screens

When Screen Editor software program is activated for the first time, the first window to show

up is as follows. There are only File, View, Tools, Options and Help on the toolbar.

Fig. 3-2-3 Screen without editing file

2. After pressing

or click File > New, it can create a new project and you will get a dialog

box as shown in the following (Fig. 3-2-4).

Fig. 3-2-4 Creating a New project

3-10 Revision May, 2010

Page 32

Chapter 3 Creating and Editing Screens

3. Enter the project name, screen name, screen No. and select connected HMI, controller or

printer. Then, click OK. It can create a new project in Screen Editor software program as

shown in the following (Fig. 3-2-5).

Fig. 3-2-5 New project screen of Screen Editor

There are five parts in the following for editing window of Screen Editor software program.

Menu Bar

There are nine functions for selection: File, Edit, View, Element, Screen, Tools, Options,

Window, and Help.

Toolbar

Toolbar (Fig. 3-2-6) is like those toolbar in Windows® program. It is easy to use for editing

and the user can arrange its position freely. For example, the user can move the Toolbar

to the left side of the screen. Also, the user can arrange the toolbar position by their

usage. The followings are the available toolbar on Screen Editor software program.

1. Standard Toolbar

2. Zoom Toolbar

Revision May, 2010 3-11

Page 33

Chapter 3 Creating and Editing Screens

3. Text Toolbar

4. Bitmap Toolbar

5. Element Toolbar

6. Layout Toolbar

7. Drawing Toolbar

Fig. 3-2-6 Toolbar of Screen Editor

3-12 Revision May, 2010

Page 34

Chapter 3 Creating and Editing Screens

Position of toolbar

can be moved.

Fig. 3-

2-7 Element Toolbar has been moved

Element Tool Window

The Element Tool window provides various kinds of element icons for selection (Fig. 3-2-8).

The user can use the mouse to select the desired element icon and drag it onto the work

place to create a new element. In addition, the user can save the element in the Element

Bank for editing the element next time (Fig. 3-2-9).

Revision May, 2010 3-13

Fig. 3-2-8 Fig. 3-2-9

Page 35

Chapter 3 Creating and Editing Screens

Property Table

The Property Table displays the element property settings for each element (Fig. 3-2-10 &

Fig. 3-2-11).

Element state selection

All elements on the current

editing screen

Fig. 3-2-10 Property Table and Editing Screen Preview

3-14 Revision May, 2010

Page 36

Chapter 3 Creating and Editing Screens

Record and Output Window

The Record and Output Window displays all the editing actions and output message when

compile function is enabled (Fig. 3-2-11). When HMI program is compiled, the system will

detect the program automatically. Once error occurs, the error messages will be displayed

in Output Window. To get to the error element window, click on the error message.

Fig. 3-2-11 Record and Output window

Work Place

Following is an editing example display (Fig. 3-2-12).

Editing Area

Fig. 3-2-12 Work Place of Screen Editor

Revision May, 2010 3-15

Page 37

Chapter 3 Creating and Editing Screens

Status Bar

Following is the status bar of Screen Editor (Fig. 3-2-13).

Function

Download

rface

Inte

Mous

Fi

g. 3-

2-13 Status Bar of Screen Editor

e is moving

Element Coordinate

and S

ze

i

Connect

HMI Model

ing

CAP LOCK

LOCK

NUM

SCROLL LOCK

3-16

Revision May, 2010

Page 38

Chapter 3 Creating and Editing Screens

3.3 Internal Memory

There are six kinds of registers for selection. They are internal register $, Non-volatile Internal

Register $M, Indirect Address Register *$, Recipe Number Register RCPNO, Recipe Group

Register RCPG and Recipe Register RCP (Fig. 3-3-1). For more details on settings, please refer to

the following descriptions.

Fig. 3-3-1 HMI Internal Memory

3.3.1 Internal Register (Read / Write) : $

Word Access : $n ( n : 0-65535 )

Bit Access : $n.b( n : 0-65535, b : 0-15 )

Delta DOP-B series HMI provides 65536 16-bit internal registers ($0.0 - $65535.15).

Note: The setting values of this register are not retained when power is off.

Non-volatile Internal Register (R/W): $M

Word access: $Mn (n: 0~1023)

Bit access: $Mn.b (n: 0~1023, b: 0~15)

Delta DOP series HMI provides 1024 16-bit non-volatile internal registers ($M0 ~ $M1023).

3.3.2 Non-volatile Internal Register (Read / Write) : $M

Word Access : $Mn ( n : 0-1023 )

Bit Access : $Mn.b( n : 0-1023, b : 0-15 )

Delta DOP-B series HMI provides 1024 16-bit non-volatile internal registers($M0.0 -

$M1023.15). As the setting values of this register are retained when power is off, the user

can use this register to store the important data or records.

Revision May, 2010 3-17

Page 39

Chapter 3 Creating and Editing Screens

3.3.3 Indirect Address Register (Read / Write) : *$

Word Access:*$n( n : 0-65535 )

Indirect address register is an area where an address is stored. The user must get the

address from *$n and then get the values stored in this address.

For example: if $7 = 20; $20 = 39; then *$7 = 39.

The general formula:if $n = m; $m = x, then *$n = x (m : 0-65535)。

The value of m must not be more than 65535.

Note: The setting values of this register are not retained when power is off.

3.3.4 Recipe Number Register (Read / Write) : RCPNO

This register is used to specify the recipe data number (Fig. 3-3-2). When upload/download

the data to HMI or the external controller, HMI or the external controller uses the settings of

recipe number register to read/write the data of recipe. If RCPNO is set to 1, it indicates it is

defined as 1

st

number of recipe data. If RCPNO is set to 4, it indicates it is defined as 4th

number of recipe data. In addition, when editing the recipe data, the user can set the size of

each number of recipe data. For more details, please refer to the descriptions of Recipe

Register RCP.

Note: The setting values of this register are not retained when power is off.

1st Number, RCPNO = 1

4th Group, RCPNO = 4

Fig. 3-

3-2 Recipe Editing Screen

3-18 Revision May, 2010

Page 40

Chapter 3 Creating and Editing Screens

3.3.5 Recipe Group Register (Read / Write) : RCPG

This register is used to specify the 32-bit recipe group (Fig. 3-3-3). It is different than RCPNO.

The difference is that when using RCPG, not only the recipe number, the recipe group also

must be set. When the user wants to upload/download the recipe data of 1

st

number of 1st

group, RCPG must be set to 1 and RCPNO must be set to 1. If HMI or the external controller

needs to read/write the recipe data of 4

th

number of 3rd group, RCPG must be set to 3 and

RCPNO must be set to 4. The recipe group number is determined when editing the recipe

table. For more details, please refer to the descriptions of Recipe Register RCP.

Note: The setting values of this register are not retained when power is off.

1st Number, RCPNO = 1

1st Group, RCPG = 1 3rd Group, RCPG = 3

Fig. 3-

3-3 Recipe Group Editing Screen

3.3.6 Recipe Register (Read / Write) : RCP

This register is used to save the recipe data that the user downloaded from HMI after exiting

Screen Editor software program. There are two kinds of recipe register, 16-bit recipe register

and 32-bit recipe register.

16-bit Recipe Register

The size of this register is 16bit (1 Word). If the data storage area is an external memory, i.e.

a USB disk or SM card is connected, the data space of 16-bit recipe register is 4MB words. If

the data storage area is an internal memory, the data space of 16-bit recipe register is 64K

words.

Revision May, 2010 3-19

Page 41

Chapter 3 Creating and Editing Screens

Assume that the data size is L and the recipe number is N, and the actual recipe data space is

equal to L x N words, i.e. L x N recipe registers are occupied. Delta DOP-B series has a recipe

buffer area (Table 3-3-2) which stores the selected recipe data by the user. The size of this

buffer area is the same as the data size of the selected recipe. It also means that L recipe

registers are occupied in recipe buffer area. Therefore, there will be L x (N+1) registers

occupied in one recipe table. Use the following method to access data that set with recipe.

Word Access: RCPn ( n : 0-L*(N+1)-1 )

Note: -1 indicates that the number of RCP starts from 0.

RCPNO = 1

RCP0

36

RCP2

36

RCP4

12

RCP1

42

RCP3

42

RCP5

33

Recipe Buffer

Area

1st Number of Recipe

Data

RCP6

27

RCP7

51

Table 3-3-1 Recipe Table Table 3-3-2 Layout of Recipe Registers

Example 1:

Table 3-3-1 is an example of how to access data. The size L is set to 2 and the number N is

set to 3 with the recipe data. Thus the layout of the recipe data will be shown as Table 3-3-2,

i.e. RCP0~RCP7 are occupied. When RCPNO is set to 1 and the recipe buffer area will show the

st

1

number of recipe data. If RCPNO is change to 3, the recipe buffer area will show 3rd

number of recipe data shown as in Table 3-3-4.

RCPNO = 3

RCP0

27

RCP2

36

RCP4

12

RCP1

51

RCP3

42

RCP5

33

Recipe Buffer

Area

RCP6

27

T

abl

e 3-3-3 Recipe Table Table 3-3-4 Layout of Recipe Registers

RCP7

51

3rd Number

Data

of Recipe

3-20 Revision May, 2010

Page 42

Chapter 3 Creating and Editing Screens

e

Example 2:

In Table 3-3-5, the size L is set to 3 and the number N is set to 2 with the recipe data. Thus

the layout of the recipe data will be shown as Table 3-3-6, i.e. RCP0~RCP8 are occupied.

When RCPNO is set to 2 and the recipe buffer area will show the 2

nd

number of recipe data.

RCPNO = 2

RCP0

12

RCP3

36

RCP1

33

RCP4

42

RCP2

76

RCP5

1

Recipe Buffer

Ar

a

RCP6

12

RCP7

33

RCP8

76

2nd Number of

Recipe Data

Table 3-3-5 Recipe Table Table 3-3-6 Layout of Recipe Registers

32-bit Recipe Register

The size of this register is 32bit (2 Words or Double Word, DW). If the data storage area is an

external memory, i.e. a USB disk or SM card is connected, the data space of 32-bit recipe

register is 50MB words. If the data storage area is an internal memory, the data space of

32-bit recipe register depends on the specification of HMI flash memory. The user can refer

to the specifications shown on DOP-B series catalogue. Please note that not only recipe data,

there are also other screen data stored in flash memory. It indicates the total memory size of

the recipe data space must be less than the space of the flash memory. For more details,

please refer to HMI Memory dialog by clicking View > Memory List (Fig. 3-3-4).

Fig. 3-

Revision May, 2010 3-21

3-4 HMI Memory

Page 43

Chapter 3 Creating and Editing Screens

p

Assume that the data size is L and the recipe number is N, and the actual recipe data space is

equal to L x N DW words, i.e. L x N recipe registers are occupied. Delta DOP-B series has a

recipe buffer area (Table 3-3-8) which stores the selected recipe data by the user. The size of

this buffer area is the same as the data size of the selected recipe. It also means that L recipe

registers are occupied in recipe buffer area. Therefore, there will be L x (N+1) registers

occupied in one recipe table. Use the following method to access data that set with recipe.

Double Word Access: RCPn ( n : 0-L*(N+1)-1 )

Note: -1 indicates that the number of RCP starts from 0.

Table 3-3-7 Recipe Table Table 3-3-8 Layout of Recipe Registers

Recipe Buffer

ea

Ar

1st Number of

e Data

Reci

RCPNO = 1

RCP0

1

RCP3

1

RCP6

4

RCP9

7

RCP12

10

RCP1

2

RCP4

2

RCP7

5

RCP10

8

RCP13

11

RCP2

3

RCP5

3

RCP8

6

RCP11

9

RCP14

12

Example 1:

Table 3-3-7 is an example of how to access data which is built in the first group (RCPG=1).

The size L is set to 3 and the number N is set to 4 with the recipe data. Thus the layout of the

recipe data will be shown as Table 3-3-8, i.e. RCP0~RCP14 are occupied. When RCPNO is set

to 1 and the recipe buffer area will show the 1

3, the recipe buffer area will show 3

rd

number of recipe data shown as in Table 3-3-10.

st

number of recipe data. If RCPNO is change to

Recipe Buffer

Area

RCPNO = 3

3rd Number of

Recipe Data

Table 3-3-9 Recipe Table Table 3-3-10 Layout of Recipe Registers

RCP0

7

RCP3

1

RCP6

4

RCP9

7

RCP12

10

RCP1

8

RCP4

2

RCP7

5

RCP10

8

RCP13

11

RCP2

9

RCP5

3

RCP8

6

RCP11

9

RCP14

12

3-22 Revision May, 2010

Page 44

Chapter 3 Creating and Editing Screens

Example 2:

In Table 3-3-11, suppose that it is built in the first group (RCPG=1). The size L is set to 2 and

the number N is set to 3 with the recipe data. Thus the layout of the recipe data will be shown

as Table 3-3-12, i.e. RCP0~RCP7 are occupied. When RCPNO is set to 3 and the recipe buffer

area will show the 3

rd

number of recipe data.

RCPNO = 3

RCP0

14

RCP2

10

RCP4

12

RCP6

14

RCP1

15

RCP3

11

RCP5

13

RCP7

15

Ta

ble 3-3-11 Recipe Table Table 3-3-12 Layout of Recipe Registers

Recipe Buffe

Ar

r

ea

3rd Number of

Recipe Data

Revision May, 2010 3-23

Page 45

Chapter 3 Creating and Editing Screens

3.4 Control Block and Status Block

For two-way communication between Delta DOP series HMI and all other brands of PLCs, the

address of the control block and status block must be defined. These settings are located in the

Configuration dialog box (Fig. 3-4-2) by clicking Options > Configuration (Fig. 3-4-1). For

more details on settings, please refer to the following descriptions.

Fig. 3-4-1 Clicking Configuration Command

Fig. 3-4-2 Configuration Dialog Box

3-24 Revision May, 2010

Page 46

Chapter 3 Creating and Editing Screens

Note: Checking of Auto reset flags will reset the control block flags (Bits) automatically after

the desired procedure has been executed. If this box is not checked, the system will ask the

user to reset the flags.

3.4.1 Control Block

The control block is the way a PLC is used to control the HMI. Through the settings set in the

registers, the controller which is connected to HMI can know HMI internal operation, i.e.

screen switch, backlight on and off, current priority, curve sampling data and clear flag, etc.

information and the user can also get the current system status of HMI. The register is a

continuous data block and its length is from 0 to 8 words (Fig. 3-4-2). When using control

block features, the actual length of control block is determined by the used control block

features. For example, when Screen Switch feature (Screen Number Designation Register) is

used, the control block must be set to a length of 1 or more. At this time, only Screen Number

Designation Register can be used. One more example, when using History Buffer features

(Sampling History Buffer Register), the control block must be set to a length of 4 or more. At

this time, only Sampling History Buffer Register can be used. In addition, when using the

function of Multi-language Setting Value Bit (System Control Flag Register), it is best that the

length of the control block be set to 8 words. At this time, all the register in control block can

be used. When the control block is set to a length of zero, the control block is disabled.

The function and explanation of each WORD is listed as Table 3-4-1 below. In the following

table, in the following example 1 we assume that the user uses a Delta PLC, so the available

starting addresses in control block are Dn ~ Dn+7 (D0 ~ D7). In the following example 2, we

assume that the user uses HMI internal register $, so the available starting address in control

block is$n ~ $n+7 ($15 ~ $22). The user can choose if the control block designations are

stored in PLC or HMI.

Word

Number

Register Number

Example 1

(PLC register)

Address Example Address Example

Example 2

(HMI register)

1 Screen Number Designation Register (SNIR) Dn D0 $n $15

2 Control Flag Register (CFR) Dn+1 D1 $n+1 $16

3 Curve Control Register (CUCR) Dn+2 D2 $n+2 $17

4 Sampling History Buffer Register (HBSR) Dn+3 D3 $n+3 $18

5 Clearing History Buffer Register (HBCR) Dn+4 D4 $n+4 $19

6 Recipe Control Register (RECR) Dn+5 D5 $n+5 $20

7 Recipe Number Designation Register (RBIR) Dn+6 D6 $n+6 $21

8 System Control Flag Register Dn+7 D7 $n+7 $22

Table 3-4-1 Control Block Designations

Revision May, 2010 3-25

Page 47

Chapter 3 Creating and Editing Screens

Screen Number Designation Register (SNIR)

To use this register, write a value of the screen number that the user desires to have

displayed into this register; then HMI will change to that screen. For example (refer to

Table 3-4-1), if set D0 or $15.0 to 1, HMI will change to the 1st screen. If set D0 or $15.0 to

7, HMI will change to 7th screen.

Control Flag Register (CFR)

Bit

0 0000 0000 0000 000x Enable / Disable Communication

1 0000 0000 0000 00x0 Enable / Disable Backlight

2 0000 0000 0000 0x00 Enable / Disable Buzzer

3 0000 0000 0000 x000 Clear Alarm Buffer

4 0000 0000 000x 0000 Clear Alarm Counter

5 0000 0000 00x0 0000 Update USB Data

6-7 0000 0000 xx00 0000 Reserved

8 0000 000x 0000 0000 Set User Security Level (Level 1)

9 0000 00x0 0000 0000 Set User Security Level (Level 2)

10 0000 0x00 0000 0000 Set User Security Level (Level 4)

11-15 xxxx x000 0000 0000 Reserved

Binary Display of Relative

Function

Position (x)

Enable / Disable Communication

Bit 0 controls the HMI communication. When bit 0 is turned ON, HMI communication is

disabled. When bit 0 is turned OFF, HMI communication is enabled. By checking

Communication Interrupt check box (Fig. 3-4-3) under the Communication tab of

the Configuration dialog box when communication between one certain PLC is lost

this bit will be turned ON and disable the communication automatically and the

communication fault message will not display (this will not affect the communications

between other PLCs). Then, the user can clear it to enable the communication again. If

this check box is not checked, this flag is disabled (To disable and enable the

communication manually, the user can use OPENCOM/CLOSECOM macro commands.

For more details on macro commands, please refer to section 3.14)

For example (refer to Table 3-4-1 and Fig. 3-4-4), if the PLC which is connected via

COM2 port has communication error and communication retry time has reached three

times, HMI will disable the communication between that PCL automatically (but will

not disable the communication between other PLCs) and will not show communication

errors. At this time, if D1 or $16.0 is set to 0, i.e. the communication flag is turned

OFF, the communication will be enabled again and HMI will communicate with that

PLC again. If the communication is lost for three times, this flag will be ON again.

When D1=0, it indicates that Bit 0 of D1 is 0 (0000 0000 0000 0000).

3-26 Revision May, 2010

Page 48

Chapter 3 Creating and Editing Screens

Communication retry times

is 3 times

Fig. 3-4-3 Communication tab Fig. 3-4-4 PLC Connections

Enable / Disable Backlight

Bit 1 controls the backlight of HMI. When bit 1 is turned ON, the HMI backlight turns

OFF. When bit 1 is turned OFF, the HMI backlight turns ON. For example (refer to Table

3-4-1), if D1 is set to 2 or $16.1 is set to 1, this flag is enabled and the HMI backlight

turns OFF. When D1 = 2, it indicates that Bit 1 of D1 is 1(0000 0000 0000 0010).

Enable / Disable Buzzer

Bit 2 controls the buzzer of HMI. When bit 2 is turned ON, the HMI buzzer turns OFF.

When bit 2 is turned OFF, the HMI buzzer turns ON. For example (refer to Table 3-4-1),

if D1 is set to 4 or $16.2 is set to 1, the HMI buzzer turns ON. At this time, if an alarm

occurs, it will sound. When D1 = 4, it indicates that Bit 2 of D1 is 1 (0000 0000 0000

0100).

Clear Alarm Buffer

Bit 3 clears the alarm buffer. When an alarm history table is used, setting this bit is

able to clear all data inside of that table. When bit 3 is turned ON, the alarm buffer is

cleared. To clear the alarm buffer again, this flag must be turned OFF and then ON

again. For example (refer to Table 3-4-1), if D1 is set to 8 or $16.3 is set to 1, this flag

is turned ON and the alarm buffer will be cleared. When D1 = 8, it indicates that Bit 3

of D1 is 1 (0000 0000 0000 1000).

Clear Alarm Counter

Bit 4 clears the alarm counter. When an alarm frequency table is used, setting this bit

is able to clear the values for the alarms. When bit 4 is turned ON, the alarm counter is

cleared. To clear the alarm counter again, this flag must be turned OFF and then ON

again. For example (refer to Table 3-4-1), if D1 is set to 16 or $16.4 is set to 1, this flag

is turned ON and the alarm counter will be cleared. When D1 = 16, it indicates that Bit

4 of D1 is 1 (0000 0000 0001 0000).

Revision May, 2010 3-27

Page 49

Chapter 3 Creating and Editing Screens

Update USB Data

Bit 5 updates the USB data. When this flag is used, the user can update the stored data

in alarm buffer area into the USB disk. If one of alarm buffer, history buffer or recipe

function is activated and the non-volatile memory area is set to USB disk, when this

flag is enable, HMI will backup and update the data that is stored in buffer area into

USB disk in real-time. Please note that all the data will be stored in the buffer area first.

Before reaching the limit of the buffer memory (the memory capacity of buffer area is

64KB and it can be user-defined as well in Configuration dialog box), the system will

not backup and update the data into USB disk. The purpose is not to frequently

overwrite the USB disk and avoid the damage to USB disk. Therefore, if the amount of

data is less than the memory capacity, to avoid the data may be lost, the user can

enable this flag and update the data into USB disk.

For example (refer to Table 3-4-1), if D1 is set to 32 or $16.5 is set to 1, this flag is

turned ON and the function of update USB data will be enabled. When D1 = 32, it

indicates that Bit 5 of D1 is 1 (0000 0000 0010 0000).

Set User Security Level

Bits 8 to 10 set the user security level. The HMI security level settings are divided into two

parts: one is level 0 (lowest) to level 7 and the other is highest level. Bits 8 to 10 controls

the level 0 (lowest) to level 7 but cannot control the highest level. When Bit 8 is turned ON,

the user security level is 1. When Bit 9 is turned ON, the user security level is 2. When Bit

10 is turned ON, the user security level is 4. For more details on settings, please refer to

the following descriptions.

Level

Level 0 Bit 8, Bit 9, Bit 10 0000 0000 0000 0000

Level 1 Bit 8 Bit 9, Bit 10 0000 0001 0000 0000

Level 2 Bit 9 Bit 8, Bit 10 0000 0010 0000 0000

Level 3 Bit 8, Bit 9 Bit 10 0000 0011 0000 0000

Level 4 Bit 10 Bit 8, Bit 9 0000 0100 0000 0000

Flag Control

Binary Display

ON OFF

Level 5 Bit 8, Bit 10 Bit 9 0000 0101 0000 0000

Level 6 Bit 9, Bit 10 Bit 8 0000 0110 0000 0000

Level 7 Bit 8, Bit 9, Bit 10 0000 0111 0000 0000

For example (refer to Table 3-4-1), if D1 is set to 1280 or $16.8 and $16.10 is set to 1,

this flag is enabled and the user security level is 5. When D1 = 1280, it indicates that

Bit 8 and Bit 10 of D1 are both 11(0000 0101 0000 0000).

3-28 Revision May, 2010

Page 50

Chapter 3 Creating and Editing Screens

Curve Control Register (CUCR)

Bit

Function

Position (x)

0 0000 0000 0000 000x Curve Sampling Flag 1

1 0000 0000 0000 00x0 Curve Sampling Flag 2

2 0000 0000 0000 0x00 Curve Sampling Flag 3

3 0000 0000 0000 x000 Curve Sampling Flag 4

4-7 0000 0000 xxxx 0000 Reserved

8 0000 000x 0000 0000 Curve Clear Flag 1

9 0000 00x0 0000 0000 Curve Clear Flag 2

10 0000 0x00 0000 0000 Curve Clear Flag 3

11 0000 x000 0000 0000 Curve Clear Flag 4

12-15 xxxx 0000 0000 0000 Reserved

Curve Sampling Flag

Bits 0 to 3 (flags 1 to 4) control the curve (Trend Graph, X-Y Chart, X-Y distribution or

Curve Input) sampling. When this flag is turned ON, HMI will read continuous data

from the set PLC address to sample once, changes the data to the graph and shows it

Binary Display of Relative

on HMI screen (For more details on the settings of curve element, please refer to

section 3.8.10). To control the curve sampling flag again, this flag must be turned OFF

and then ON again.

Each curve element has to be assigned to a sampling flag where the sample flag is

setup in the detail property of the element. To enable the curve element, set the

corresponding bit in this register. For example (refer to Table 3-4-1 and Fig. 3-4-5), if

D2 or $17.0 is set to 1, the curves of figure 1 and 2 will be activated and show on the

screen and the curves of figure 3 and 4 will not. When D2=1, it indicates that Bit 0 of

D2 is 0 (0000 0000 0000 0001).

Revision May, 2010 3-29

Page 51

Chapter 3 Creating and Editing Screens

Fig. 3-4-5 Curve Elements on HMI Screen

Curve Clear Flag

Bits 8 to 11 (flags 1 to 4) clear the curve (Trend Graph, X-Y Chart, X-Y distribution or

Curve Input) when this flag is turned ON (For more details on the settings of curve

element, please refer to section 3.8.10). To control the curve clear flag again, this flag

must be turned OFF and then ON again.

For example (refer to Table 3-4-1 and Fig. 3-4-5), if D2 is set to 512 or $17.9 is set to

1, the curves of figure 3 will be cleared and the curves of figure 1, 2 and 4 will not.

When D2=512, it indicates that Bit 9 of D2 is 1(0000 0010 0000 0000).

Sampling History Buffer Register (HBSR)

Delta DOP-B series has 12 Bits that control the sampling address of history buffer (refer to

Fig. 3-4-6 and the following table). Not only Timer, the history buffer can be controlled by

a PLC if the Trigger Source in the History Buffer setup is set to a PLC from Timer. For more

details on History Buffer setup, please refer to section 3.11.3.

Corresponding

Buffer Area

Buffer Area 1 0 0000 0000 0000 000x Sampling History Buffer 1

Buffer Area 2 1 0000 0000 0000 00x0 Sampling History Buffer 2

Buffer Area 3 2 0000 0000 0000 0x00 Sampling History Buffer 3

3-30 Revision May, 2010

Bit

Binary Display of Relative

Corresponding Flag

Function

Position (x)

Page 52

Chapter 3 Creating and Editing Screens

Corresponding

Corresponding Flag

Binary Display of Relative

Buffer Area

Bit

Function

Position (x)

Buffer Area 4 3 0000 0000 0000 x000 Sampling History Buffer 4

Buffer Area 5 4 0000 0000 000x 0000 Sampling History Buffer 5

Buffer Area 6 5 0000 0000 00x0 0000 Sampling History Buffer 6

Buffer Area 7 6 0000 0000 0x00 0000 Sampling History Buffer 7

Buffer Area 8 7 0000 0000 x000 0000 Sampling History Buffer 8

Buffer Area 9 8 0000 000x 0000 0000 Sampling History Buffer 9

Buffer Area 10 9 0000 00x0 0000 0000 Sampling History Buffer 10

Buffer Area 11 10 0000 0x00 0000 0000 Sampling History Buffer 11

Buffer Area 12 11 0000 x000 0000 0000 Sampling History Buffer 12

12-15 xxxx 0000 0000 0000 Reserved

Sampling History Buffer Flag

Bits 0 to 11 control the sampling history buffer operation of HMI by the PLC. When this

flag is turned ON, HMI performs sampling one time. To control the sampling history

buffer flag again, this flag must be turned OFF and then ON again.

Fig. 3-4-6 History Setup

Revision May, 2010 3-31

Page 53

Chapter 3 Creating and Editing Screens

Clearing History Buffer Register (HBCR)

The history buffer when controlled by a PLC can also be cleared by the PLC.

Corresponding

Buffer Area

Buffer Area 1 0 0000 0000 0000 000x Clearing History Buffer Flag 1

Buffer Area 2 1 0000 0000 0000 00x0 Clearing History Buffer Flag 2

Buffer Area 3 2 0000 0000 0000 0x00 Clearing History Buffer Flag 3

Buffer Area 4 3 0000 0000 0000 x000 Clearing History Buffer Flag 4

Buffer Area 5 4 0000 0000 000x 0000 Clearing History Buffer Flag 5

Buffer Area 6 5 0000 0000 00x0 0000 Clearing History Buffer Flag 6

Buffer Area 7 6 0000 0000 0x00 0000 Clearing History Buffer Flag 7

Buffer Area 8 7 0000 0000 x000 0000 Clearing History Buffer Flag 8

Buffer Area 9 8 0000 000x 0000 0000 Clearing History Buffer Flag 9

Buffer Area 10 9 0000 00x0 0000 0000 Clearing History Buffer Flag 10

Buffer Area 11 10 0000 0x00 0000 0000 Clearing History Buffer Flag 11

Buffer Area 12 11 0000 x000 0000 0000 Clearing History Buffer Flag 12

12-15 xxxx 0000 0000 0000 Reserved

Bit

Binary Display of Relative

Position (x)

Corresponding Flag

Function

Clearing History Buffer Flag

Bits 0 to 11 clear the history buffer. When this flag is turned ON, HMI clears the history

buffer one time. To control the clearing history buffer flag again, this flag must be

turned OFF and then ON again.

Recipe Control Register (RECR)

Bit

0 0000 0000 0000 000x Change Recipe Number Flag

1 0000 0000 0000 00x0

2 0000 0000 0000 0x00

3 0000 0000 0000 x000 Change Recipe Group Number Flag

4-7 0000 0000 xxxx 0000 Reserved

8-15 xxxx xxxx 0000 0000 Designate Recipe Group Number

Binary Display of Relative

Function

Position (x)

Read Recipe Flag (PLC → HMI):

Read recipe data from PLC and store it in HMI

Write Recipe Flag (PLC ← HMI)

Write recipe data from HMI into PLC

Change Recipe Number Flag

To change recipe number, the user can use Recipe Number Register RCPNO directly or

use this flag. To specify the recipe number, write the recipe number into the Recipe

Number Designation Register (RBIR) and then turn ON this flag (Bit 0). After the above

3-32 Revision May, 2010

Page 54

Chapter 3 Creating and Editing Screens

settings, the RCPNP can change to the designated recipe number automatically. To