Page 1

http://www.delta.com.tw/industrialautoma tion/

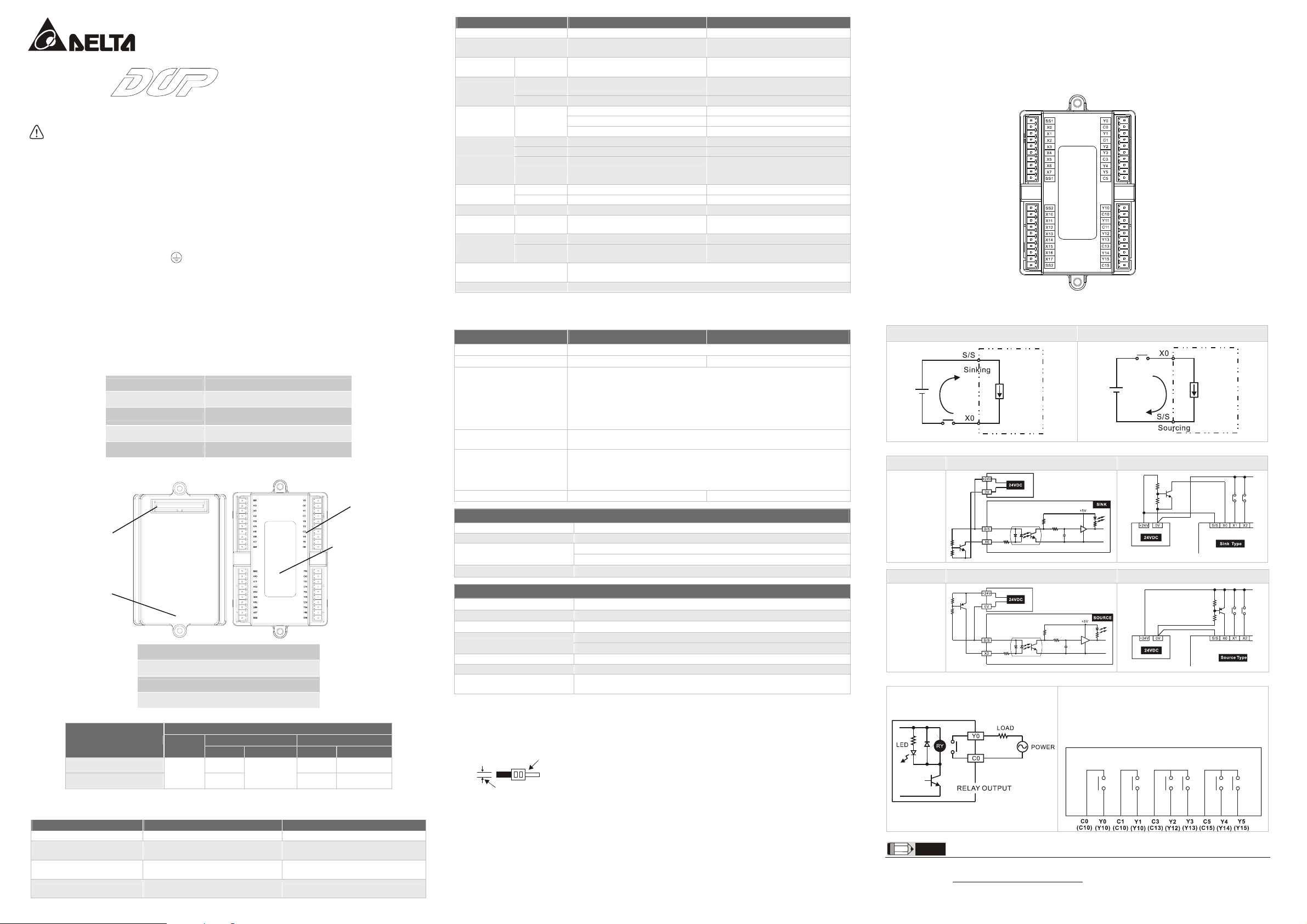

Extension Digital I/O Module

Instruction Sheet

Warning

3 Please read this instruction carefully before use.

3 DOP series Extension Digital I/O Module should be used with DOP-AE series HMI product. Ensure to

switch off the power before wiring.

3 Please install this DOP series Extension Digital I/O Module in an enclosure free of airborne dust,

humidity, electric shock and vibration. The enclosure should prevent non-maintenance staff from

operating the device (e.g. key or specific tools are required for opening the enclosure) in case danger

and damage on the device may occur.

3 DO NOT connect input AC power supply to any of the I/O terminals; otherwise serious damage may

occur. Check all the wiring again before switching on the power.

3 DO NOT touch any internal circuit in 1 minute after the power is switched off. Do NOT touch any

terminal when the power is switched on.

3 Make sure the ground terminal

interference.

3 DO NOT place any heavy objects on the connection port of DOP series Extension Digital I/O Module.

Doing so may damage the product.

is correctly grounded in order to prevent electromagnetic

X Introduction

1.1 Model Explanation

DOP - EXIO 14 R AE

(1) (2) (3) (4)

(1) Product Name DOP: Delta Operation Panel

(2) Series EXIO: Extension Digital I/O

(3) Input / Output Point

(4) Output Contact Type R: Relay

(5) Applicable HMI Series AE: DOP-AE Series HMI

14: 8 input points / 6 output points

28: 16 input points / 12 output points

(5)

1.2 Product Outline

3

1

2

4

1. Connection Port

2. Direct Mounting Hole

3. Input / Output Terminals

1.3 Model Name

Model Name

DOP-EXIO14RAE 8 6 Relay

DOP-EXIO28RAE

4. Nameplate

Power

5VDC,

supplied

by HMI

Input / Output

Input Unit Output Unit

Point Type Point Type

16

DC Type

Sink or

Source

12 Relay

Y Function Specifications

Item Specifications Remark

Control Method Stored program, cyclic scan system -

I/O Processing Method Batch I/O (refresh)

Execution Speed

Program Language

Basic command (average approx. 30

us)

Commands + Ladder Diagram +

SFC

Immediate refresh command available

only with I/O of the MPU

Application command (30 ~ hundreds

us)

Step commands included

Item Specifications Remark

Program Capacity 999 Steps Built-in EEPROM

Commands

Step Relay

(Latched)

Auxiliary

Relay

Timer Digital

Counter

Data Register

Pointer P 64 Points P0 ~ P63

Index

Register

Constant

Self Diagnosis / Protection

Monitor / Debug Program execution time display, bit / word, device settings

*1: M1000, M1001, M1002, M1003, M1020, M10 21, M1022, M1067, M10068, and M1161 are the special auxiliary relays (special M).

General

Step Point

General 1280 Points

Latched 256 Points M512 ~ M767

General 112 Points C0 ~ C111

Latched 16 Points C112 ~ C127

32bit 13 Points

General 408 Points D0 ~ D407

Latched 192 Points D408 ~ D599

E / F 2 E, F

Decimal K 16bit: -32768 ~ +32767 32bit: -2147483648 ~ +2147483647

Hexadecim

al H

Basic commands: 32 (including the

STL commands)

128 Points S10 ~ S127

64 Points T0~T63 (100 ms time base)

63 Points T64~T126 (10 ms time base)

1 Points T127 (1 ms time base)

16bit: 0000 ~ FFFF 32bit: 00000000 ~ FFFFFFFF

I/O check, system execution timeout check, invalid command check, program

check and password settings

Application commands: 59

M0 ~ M511, M768 ~ M999, 744 points;

M1000 ~ M1279, 280 points*1

C235,C236,C237,C238,C241,C242,

C244,C246,C247,C249,C251,C252,

C254 (all of them are latched type)

Z Electrical Specifications

Item / Model Name DOP-EXIO14RAE DOP-EXIO28RAE

Power Supply Voltage

Power Consumption 0.25W 0.5W

Noise Immunity

Ambient Temperature /

Humidity

Vibration / Shock

Weight Approx. 95.5g Approx. 116g

Input Type DC (SINK or SOURCE)

Input Voltage 24VDC (5mA)

Active Level

Response Time Approx. 10ms

Output Type Relay-R

Current Specifications 1.5A / 1 Point (5A/COM)

Voltage Specifications 250VAC, below 30VDC

Maximum Loading

Response Time Approx. 10 ms

Mechanical Life 2 × 107 times (without load)

Electrical Life

RS: Frequency: 80MHz ~ 1GHz, 1.4GHz ~ 2.0GHz, Test level 10V/m

CS: Frequency: 0.15MHz ~ 80MHz, Test level 10V (HMI power port & I/O line)

Operation: 0°C ~ 50°C (Temperature), 10 ~ 90% (Humidity),

Storage: -40°C ~ 85°C (Temperature), 10 ~ 90% (Humidity)

5Hz≦f<9Hz = Continuous: 1.75mm / Occasional: 3.5mm

9Hz≦f≦150Hz = Continuous: 0.5g / Occasional: 1.0g

Input Point Electric Specifications

Output Point Electric Specifications

5VDC, 1A (supplied by HMI)

ESD: Air discharge ±8KV

EFT: ±1.5KV (HMI power port)

±1KV (I/O line)

Surge: ±2KV (HMI power port)

IEC 61131-2 Compliant

X, Y, Z directions for 10 times

Off→On, above 16VDC

On→Off, below 14.4VDC

75VA (Inductive)

90 W (Resistive)

100,000 times (3A 250VAC/30VDC)

6,000 times (5A 250VAC/30VDC)

[ Installation & Wiring

4.1 Wiring

< 1.5mm

22-16AWG

1. Please use the 28-16 AWG (1.5mm

the multi-core wire (Stranded type) for the I/O wiring. The stripped length of

the wire should be 6-7mm, and the torque specification of the screw for the

terminal is 4.5lb-in. Please refer to the specifications of the terminal

in the figure on the left.

2. DO NOT place the I/O signal wires and power supply wire in the same

wiring duct.

2

) single-core bare wire (Solid type) or

shown

Wiring Note

1. Please avoid any conductive debris and tiny metal materials enter the Extension Digital I/O Module when

screwing and wiring.

2. Allow a minimum space of 50mm between the Extension Digital I/O Module and other control devices, and

keep the Extension Digital I/O Module away from the high-voltage lines or any power equipment.

4.3 Terminal Identification

4.4 Wiring

There are two types of DC inputs, SINK and SOURCE, and they are defined as follows:

Sink = (common port for current input S/S) Source = (common port for current output S/S)

Input Point Wiring (S/S shown in the wiring diagrams indicates SS1 or SS2 contact)

DC Signal IN Input point loop equivalent circuit Wiring loop

SINK mode

DC Signal IN Input point loop equivalent circuit Wiring loop

SOURCE mode

Output Point Wiring

Be careful with the connection of the common terminals

when wiring outputs. For example, when wiring

DOP-EXIO14RAE (DOP-EXIO28RAE), output terminal

Y0 (Y10) uses C0 (C10), Y1 (Y11) uses C1 (C11), Y2 ~

Y3 (Y12 ~ Y13) uses C3 (C13), Y4 ~ Y5 (Y14 ~ Y15)

uses C5 (C15), as shown below:

4.2 Caution

Environment

1. DO NOT install the Extension Digital I/O Module in a place subjected to corrosive or flammable gases,

liquids, or airborne dust or metallic particles.

2. DO NOT install the Extension Digital I/O Module in a location high temperature and high humidity (where

temperature and humidity will exceed specification).

3. DO NOT install the Extension Digital I/O Module in a location where vibration and shock will exceed

specification.

NOTE

1) The content of this instruction sheet may be revised without prior notice. Please consult our distributors or download the most

updated version at http://www.delta.com.tw/industrialautomation.

Loading...

Loading...