Page 1

Page 2

Preface

Thank you very much for purchasing DELTA’s DOP-A Series, DOP-AE Series and DOP-AS series Human

Machine Interface (hereinafter “HMI” ) products.

This manual will be helpful in the installation, operation and specifications of Delta HMI product and HMI

Screen Editor software program (hereinafter “ScrEdit” ). Before using the product, please read this user

manual to ensure correct use.

You should thoroughly understand all safety precautions (DANGERS, WARNINGS and STOPS) before

proceeding with the installation, wiring and operation. If you do not understand please contact your local

Delta sales representative. Place this user manual in a safe location for future reference.

Using This Manual

Contents of this manual

z This manual is a user guide that provides the information on how to install and operate

Delta HMI products and ScrEdit.

Who should use this manual

This user manual is intended for the following users:

z Those who are responsible for designing.

z Those who are responsible for installing or wiring.

z Those who are responsible for operating or programming.

Important precautions

Before using the product, please read this user manual thoroughly to ensure correct use and store

this manual in a safe and handy place for quick reference whenever necessary. Besides, please

observe the following precautions:

z Install the product in a clean and dry location free from corrosive and inflammable gases

or liquids.

z Ensure that HMI is correctly connected to a ground. The grounding method must comply

with the electrical standard of the country.

z Do not modify or remove wiring when power is applied to HMI.

z Before starting the operation, make sure the emergency stop equipment can be energized

and work at any time.

z Do not touch the power supply during operation. Otherwise, it may cause electric shock.

Revision Apr. 30th, 2007, 2007PDD23000002 i

Page 3

Preface|ScrEdit Software User Manual

This page intentionally left blank.

ii

Revision Apr. 30th, 2007, 2007PDD23000002

Page 4

Table of Contents

Preface........................................................................................................................................... i

Chapter 1 Introduction........................................................................................................... 1-1

1.1 DOP Series Human Machine Interface ...................................................................................... 1-1

1.2 Features ..................................................................................................................................... 1-1

1.3 Ordering Information................................................................................................................... 1-3

1.4 Caution ....................................................................................................................................... 1-4

Chapter 2 Creating and Editing Screens............................................................................... 2-1

2.1 ScrEdit (Screen Editor) Setup .................................................................................................... 2-1

2.2 How to Start ScrEdit ................................................................................................................... 2-5

2.3 Menu Bar and Toolbar (File) ...................................................................................................... 2-12

2.4 Menu Bar and Toolbar (Edit) ...................................................................................................... 2-23

2.5 Menu Bar and Toolbar (View) .................................................................................................... 2-31

2.6 Menu Bar and Toolbar (Element)............................................................................................... 2-43

2.7 Menu Bar and Toolbar (Screen)................................................................................................. 2-52

2.8 Menu Bar and Toolbar (Tools) ................................................................................................... 2-63

2.9 Menu Bar and Toolbar (Options)................................................................................................ 2-91

2.10 Menu Bar and Toolbar (Window) ............................................................................................... 2-122

2.11 Menu Bar and Toolbar (Help)..................................................................................................... 2-126

Chapter 3 Element Function ................................................................................................. 3-1

3.1 How to Choose Element............................................................................................................. 3-1

3.2 Button Element........................................................................................................................... 3-3

3.3 Meter Element ............................................................................................................................ 3-19

3.4 Bar Element................................................................................................................................ 3-21

Revision Apr. 30th, 2007, 2007PDD23000002

Page 5

Table of Contents|ScrEdit Software User Manual

3.5 Pipe Element .............................................................................................................................. 3-24

3.6 Pie Element ................................................................................................................................ 3-27

3.7 Indicator...................................................................................................................................... 3-29

3.8 Data Display ............................................................................................................................... 3-32

3.9 Graph Display............................................................................................................................. 3-38

3.10 Input Element ............................................................................................................................. 3-46

3.11 Curve Element............................................................................................................................ 3-52

3.12 Sampling Element ......................................................................................................................3-60

3.13 Alarm Element ............................................................................................................................ 3-68

3.14 Graphic Element......................................................................................................................... 3-73

3.15 Keypad Element ......................................................................................................................... 3-81

Chapter 4 Macro Function..................................................................................................... 4-1

4.1 Macro Type................................................................................................................................. 4-2

4.2 Macro Editing.............................................................................................................................. 4-7

4.3 Macro Operation......................................................................................................................... 4-14

4.4 Error Messages .......................................................................................................................... 4-42

Chapter 5 Control Block and Status Block ............................................................................ 5-1

5.1 Control Block .............................................................................................................................. 5-2

5.2 Status Block................................................................................................................................ 5-9

Chapter 6 Internal Memory ................................................................................................... 6-1

Chapter 7 Example Explanation............................................................................................ 7-1

Appendix A Specifications and Installation .............................................................................. A-1

A.1 Specifications ............................................................................................................................. A-1

A.2 Dimensions and Profile .............................................................................................................. A-5

A.3 Installation .................................................................................................................................. A-10

Revision Apr. 30th, 2007, 2007PDD23000002

Page 6

Table of Contents|ScrEdit Software User Manual

Appendix B USB Flash Drive Function .................................................................................... B-1

Appendix C Main Menu Operation of HMI System .................................................................. C-1

Revision Apr. 30th, 2007, 2007PDD23000002

Page 7

Table of Contents|ScrEdit Software User Manual

About this Manual…

User Information

Be sure to store this manual in a safe place.

Due to constantly growing product range, technical improvement and alteration or changed texts, figures and

diagrams, we reserve the right of this manual contained information change without prior notice.

Coping or reproducing any part of this manual, without written consent of Delta Electronics Inc. is prohibited.

Technical Support and Service

Welcome to contact us or visit our web site (http://www.delta.com.tw/industrialautomation/) if you need any

technical support, service and information, or, if you have any question in using the product. We are looking

forward to serve you needs and willing to offer our best support and service to you. Reach us by the

following ways.

ASIA

DELTA ELECTRONICS, INC.

TAOYUAN Plant/

31-1, SHIEN PAN ROAD, KUEI SAN

INDUSTRIAL ZONE TAOYUAN 333, TAIWAN

TEL: 886-3-362-6301

FAX: 886-3-362-7267

NORTH/SOUTH AMERICA

DELTA PRODUCTS CORPORATION

Sales Office/

P.O. BOX 12173

5101 DAVIS DRIVE,

RESEARCH TRIANGLE PARK, NC 27709, U.S.A.

JAPAN

DELTA ELECTRONICS (JAPAN) INC.

Sales Office/

DELTA SHIBADAIMON BLDG.

2-1-14 SHIBADAIMON, MINATO-KU,

TOKYO, 105-0012, JAPAN

TEL: 81-3-5733-1111

FAX: 81-3-5733-1211

EUROPE

DELTRONICS (NETHERLANDS) B.V.

Sales Office/

DE WITBOGT 15, 5652 AG EINDHOVEN,

THE NETHERLANDS

TEL: 31-40-259-2860

TEL: 1-919-767-3813

FAX: 1-919-767-3969

FAX: 31-40-259-2851

Revision Apr. 30th, 2007, 2007PDD23000002

Page 8

Chapter 1 Introduction

1.1 DOP Series Human Machine Interface

DOP series HMI are manufactured by adopting high-speed hardware to provide you with a powerful

programmable interface. ScrEdit software is a user-friendly program editor of DOP-A, DOP-AE and DOP-AS

series HMI for Windows. Please refer to the following section for its features and function introduction.

1.2 Features

PLC Serial Drives Support

DOP series HMI’s support more than twenty brands of PLC’s, including Delta, Omron, Siemens,

Mitsubishi, etc. All of the newly supported PLC’s communication protocol information could be found on

our website (http://www.delta.com.tw/industrialautomation/) for upgrade to meet your requirements. (All

other trademarks in this manual are property of their respective companies.)

Windows® Fonts Support for ScrEdit Software

Except Simplified Chinese, traditional Chinese and English languages, ScrEdit software also provides

those fonts that Windows® uses.

Quick Execution and Communication Macro

It can handle complicated calculation by executing macro. The user can also write communication

protocol with communication macro command to connect specific system via COM port.

Rapid USB Upload/Download

It will shorten upload/download time by using USB Ver1.1.

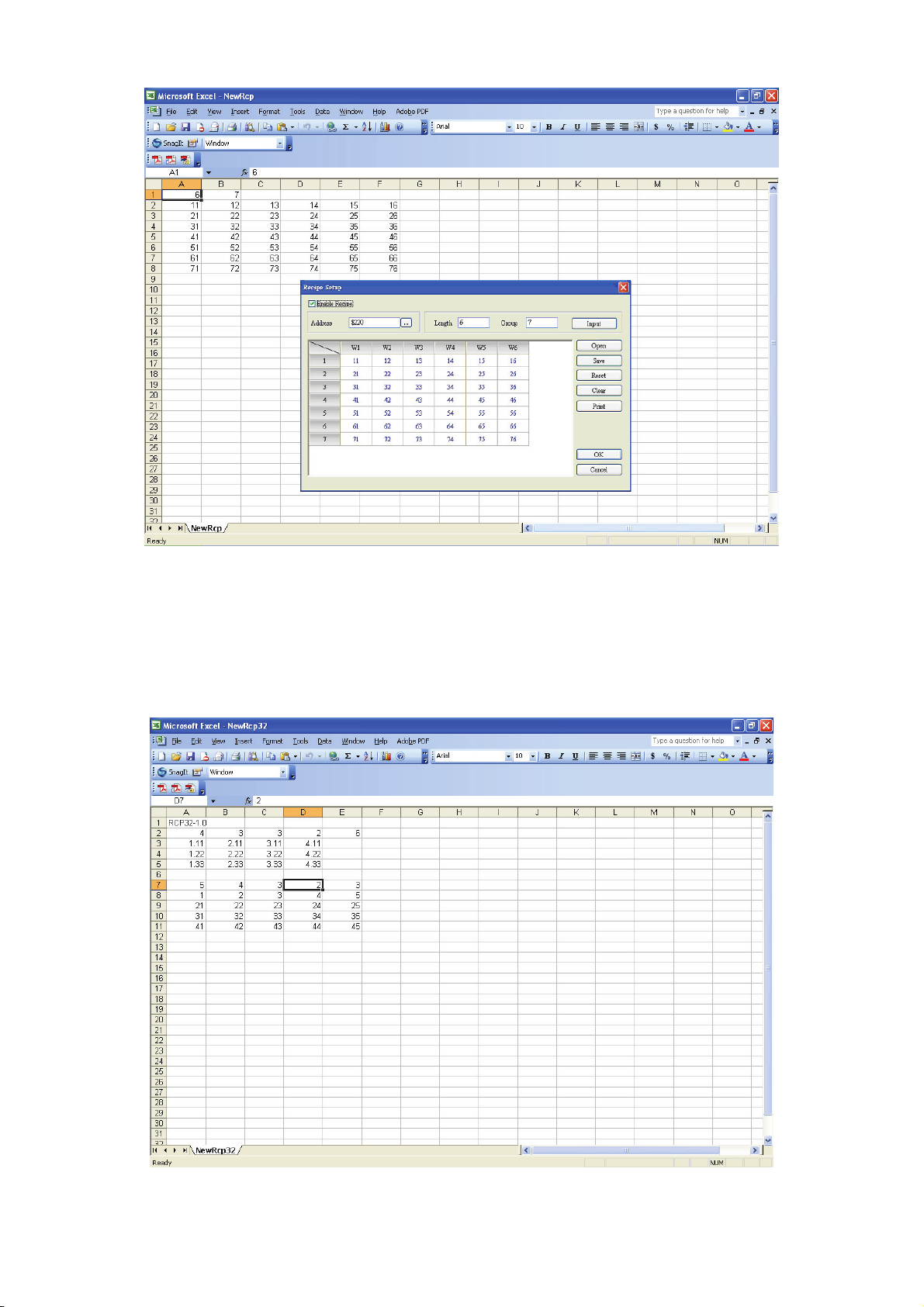

Recipes

It provides useful recipe editor that is similar to Microsoft excel for user to edit recipe easily and input

multiple recipes simultaneously (size limit is 64K). When downloading multiple recipes at the same time,

it can exchange by internal memory of HMI. If data has finished editing when downloading, you can

download recipe individually.

Direct Communication with Two or Three PLCs

DOP-A series HMI is able to connect to two different or the same controllers via two communication

ports. Up to three communication ports are provided in DOP-AE and DOP-AS series HMI for direction

connection to PLCs.

Revision Apr. 30th, 2007, 2007PDD23000002 1-1

Page 9

Chapter 1 Introduction|ScrEdit Software User Manual

Support Multiple PLC’s Connections

One DOP series HMI can connect to multiple controllers in serial through COM2 of RS-485 port

Simulation Function

HMI ScrEdit software provides simulation feature which allows the user to develop and debug software

on the PC connected to DOP series HMI before downloading it to DOP series HMI.

Off-line Simulation: When the editing and compile operation is completed, the user can use off-line

simulation function to simulate HMI operation and check if it is correct or not through the PC directly

without connecting to the controller.

On-line Simulation: When the editing and compile operation is completed, the user can use on-line

simulation function to simulate HMI operation and check if it is correct or not through the PC directly with

connecting to the controller.

(NOTE 2)

Using SM Card to Backup Data

SM card can also be used to backup data or transfer data to another HMI. After data transmission, the

data can be saved into the FLASH memory of HMI. History list and alarm message can be also saved in

SM card and the user can read these files by card reader for collecting data and printing.

(NOTE 1)

.

Multiple Security Protection

It provides passwords to protect designer’s intellectual property rights and also for the user to set the

user’s priority for important components. Only the user, whose priority is higher than the component, can

use the component.

USB Host Port (USB Host) Equipped

Parts of DOP series HMIs have a built-in USB Host interface for the connection to USB flash drive, card

reader and printer with USB socket. The user can save data, copy program and print the screen

immediately and increase the data storage space.

Multiple Security Protection

It provides passwords to protect designer’s intellectual property rights and also for user to set user

priority for important component.

Multi-Language Support

It is easy for the user to switch the desired language via HMI or the external controller. Furthermore,

Unicode editing is supported, and therefore it is convenient for the user to create and edit more quickly.

1-2 Revision Apr. 30th, 2007, 2007PDD23000002

Page 10

Chapter 1 Introduction|ScrEdit Software User Manual

NOTE

1) The controller should provide RS-485 interface.

2) Off-line/On-line simulation functions are only provided for some parts of the controllers. Also, the

execution time of on-line simulation only can continue 30 minutes. After the simulation time has

finished, HMI will return ScrEdit software main screen from simulation window automatically.

3) When executing simulation function, the resolution of PC screen should be set to 24bit and higher,

otherwise the simulation function may work abnormally.

1.3 Ordering Information

DOP – AE 10 TH T D – W

1 2 3 4 5 6 7

1. Product Name Delta Operation Panel

2. Series AS: USB Client, USB Host, COM Port x 3

A: USB Client, COM Port x 2

AE: USB Client, USB Host, COM Port x 3, Extension Port

3. Panel Size 38: 3.8 inches

57: 5.7 inches

75: 7.5 inches

80: 8 inches

94: 9.4 inches

10: 10.4 inches

4. Panel Color and Type BS: Blue/White 16 Grays STN

GS: Black/White 16 Grays FSTN

CS: 256 Colors STN

TC: 256 Colors TFT

TH: 65536 Colors TFT

5. Interface Type T: Touch Panel

6. Input Power D: DC +24V

7. Case Color None: Gray

W: White (currently be provided for AS38, A57 and AE57 models only)

Revision Apr. 30th, 2007, 2007PDD23000002 1-3

Page 11

Chapter 1 Introduction|ScrEdit Software User Manual

1.4 Caution

Operation Environment (temperature and humidity)

HMI should be operated in the following environment parameters to adjust screen brightness and

contrast to get the best image. If operating out of the range, LCD may be improperly displayed when

using for long time.

Ambient Operating Temperature: 0 ºC to 50 ºC (32 ºF to 122 ºF)

Relative Humidity: 10% ~ 90%, no condensation allowed

SM Card

SM card can be used to save and transmit data. Only SM card that formatted by HMI can be used on

both HMI and Windows® OS system. (Even it can be read/written in some format, but faults may occur

due to different format among Win95/98/2000/XP versions)

USB Flash Drive

USB flash drive can be used to save data. It also can be used to copy data from HMI and its format is

FAT32. When using USB flash drive to save data, we recommend the user should enter system screen

first and then remove the USB flash drive. Follow this process can ensure that the data is saved

completely in USB flash drive.

1-4 Revision Apr. 30th, 2007, 2007PDD23000002

Page 12

Chapter 2 Creating and Editing Screens

2.1 ScrEdit (Screen Editor) Setup

In this chapter, it will introduce general functions of Screen Editor with Windows. The user can use it to

design what he wants. Detail information for each function will be discussed in following chapters.

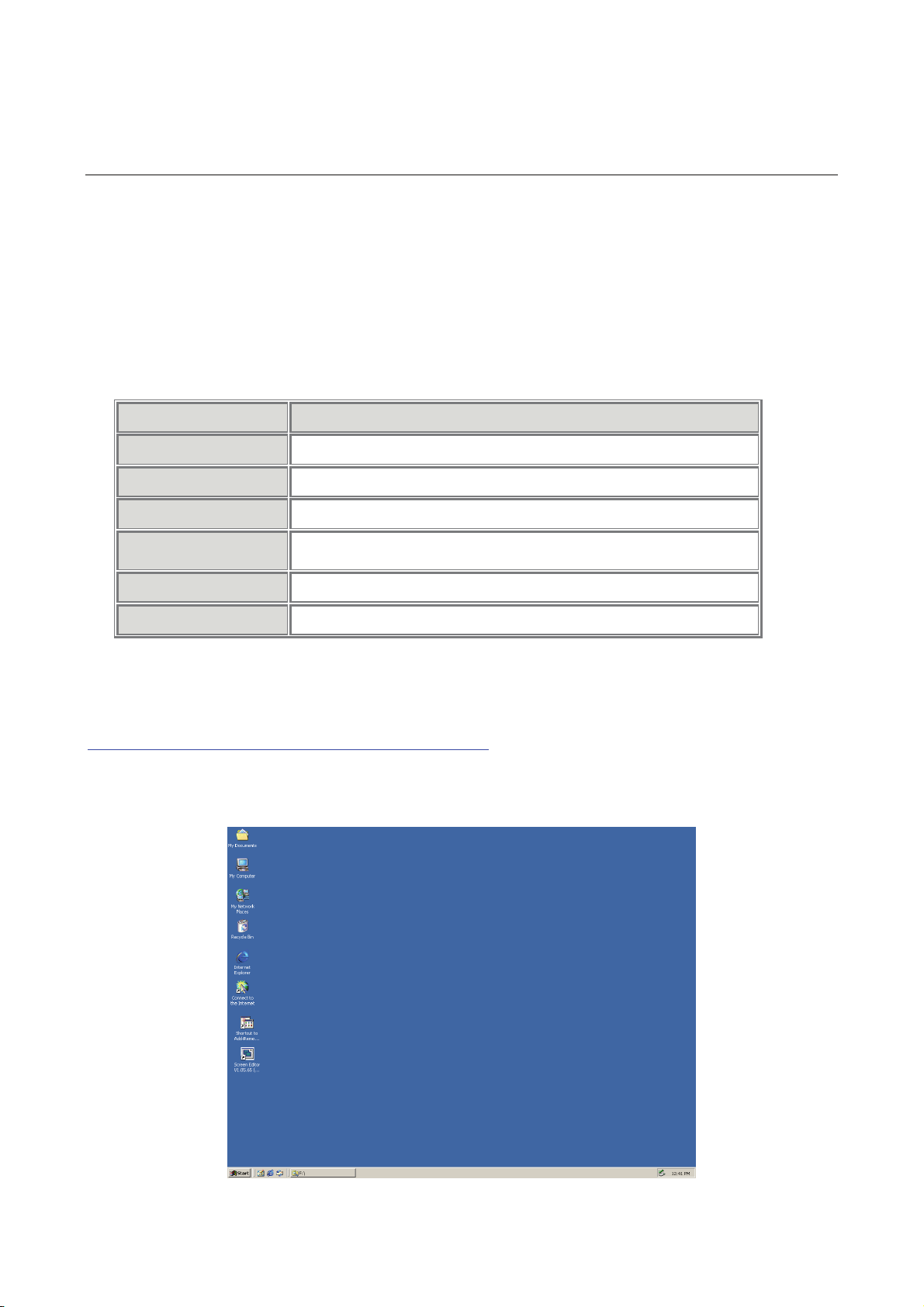

Minimum System Requirement

Below are the system requirements to comply with the operation environment of ScrEdit:

Item System Requirement

CPU Pentium III, 500MHz or greater is recommended

Memory 256MB and above is recommended

Hard Disk Capacity: 400MB and above

Monitor

Printer Printer compatible with Windows® 2000 & Windows® XP

Operation System Windows® 2000 & Windows® XP

Support resolution: 800 × 600 or higher full-color display.

Software installation

The user can download the Screen Editor, the program editor of Delta HMI product via the link below:

http://www.delta.com.tw/product/em/hmi/hmi_software.asp

To start the Delta HMI ScrEdit setup, please refer to the following steps:

1. Step 1: Please start-up your computer to Win2000/WinXP system (Fig. 2.1.1).

.

Fig. 2.1.1 Open Microsoft Windows

Revision Apr. 30th, 2007, 2007PDD23000002 2-1

Page 13

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

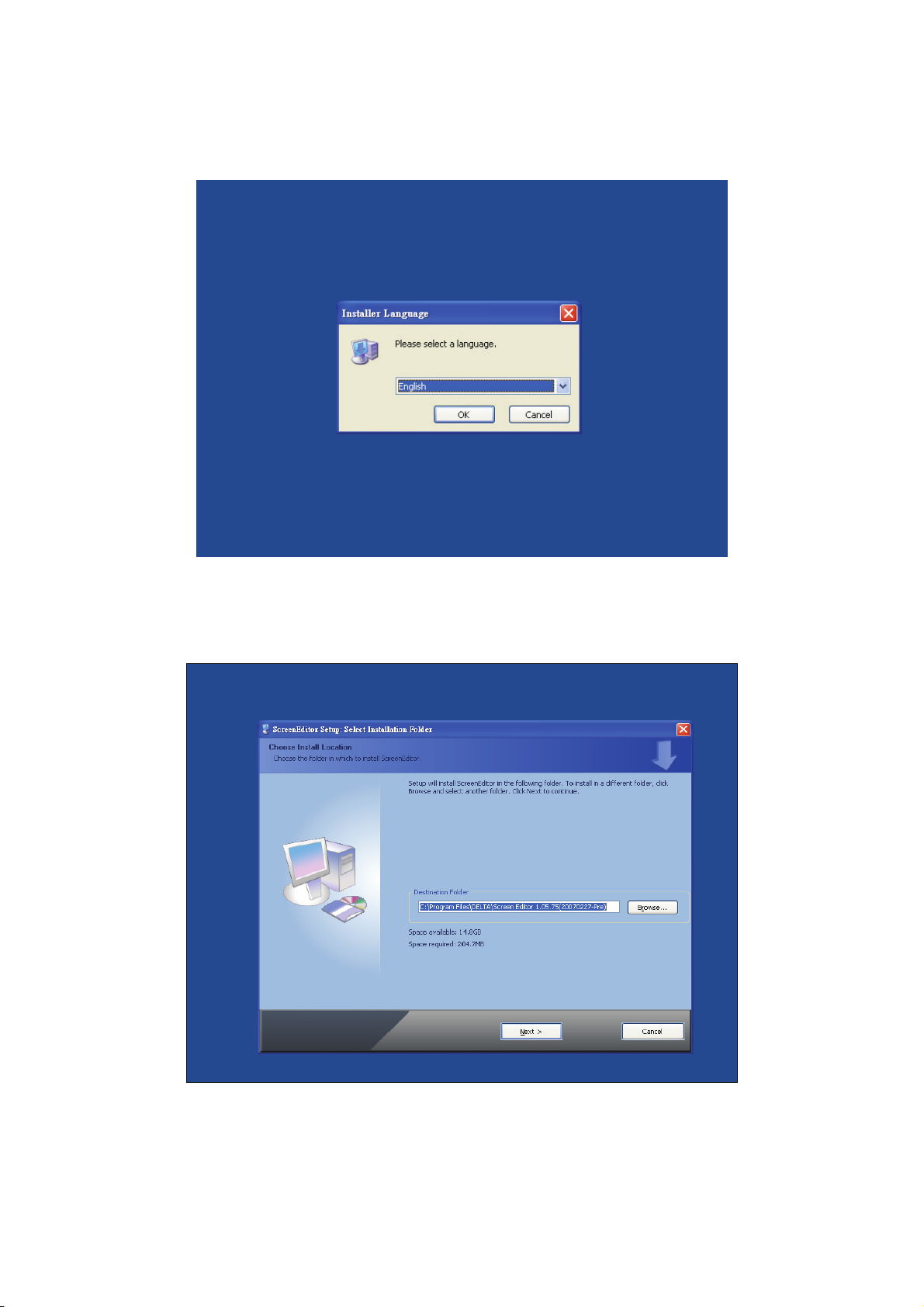

2. Step 2: Execute setup.exe from Windows taskbar by clicking “Start” > “Run”. 3. After pressing OK,

system will setup automatically and you will get the following dialog box to select the desired display

language (Fig. 2.1.2).

Fig. 2.1.2 Select Language

After pressing OK, system will setup automatically and you will get the following dialog box to choose

destination location (Fig. 2.1.3).

Fig. 2.1.3 Directory for installing ScrEdit

To select the default directory C: \Program File\Delta\Screen Editor 1.05.XX\, click Next> for the next

step. Setup will install in the directory indicated in the Destination Directory box at the bottom of the

dialog box.

2-2 Revision Apr. 30th, 2007, 2007PDD23000002

Page 14

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

To select a directory other than the default directory, click Browse. A list of available directories appears.

Highlight the desired directory for the Delta HMI ScrEdit and click OK, then Next> for the next step.

If necessary, click < Back button to take you back through Setup dialog boxes one by one.

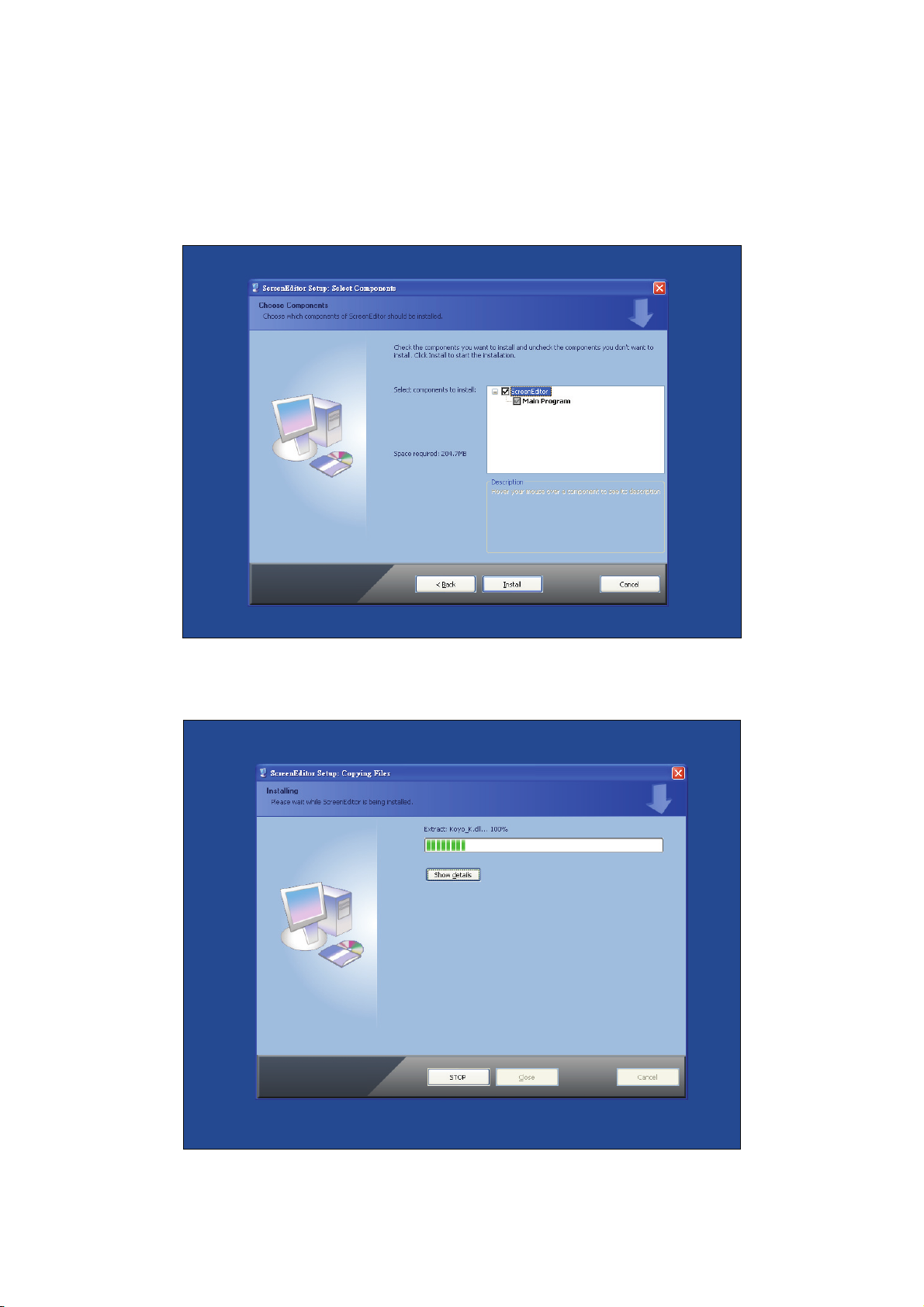

3. Step 3: After pressing Next, system will ask you to select the installation software, i.e. ScrEdit (Fig.

2.1.4).

Fig. 2.1.4 Select ScrEdit

4. Step 4: Then click Install button to start ScrEdit installation (Fig. 2.1.5).

Fig. 2.1.5 Starting ScrEdit installation

Revision Apr. 30th, 2007, 2007PDD23000002 2-3

Page 15

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

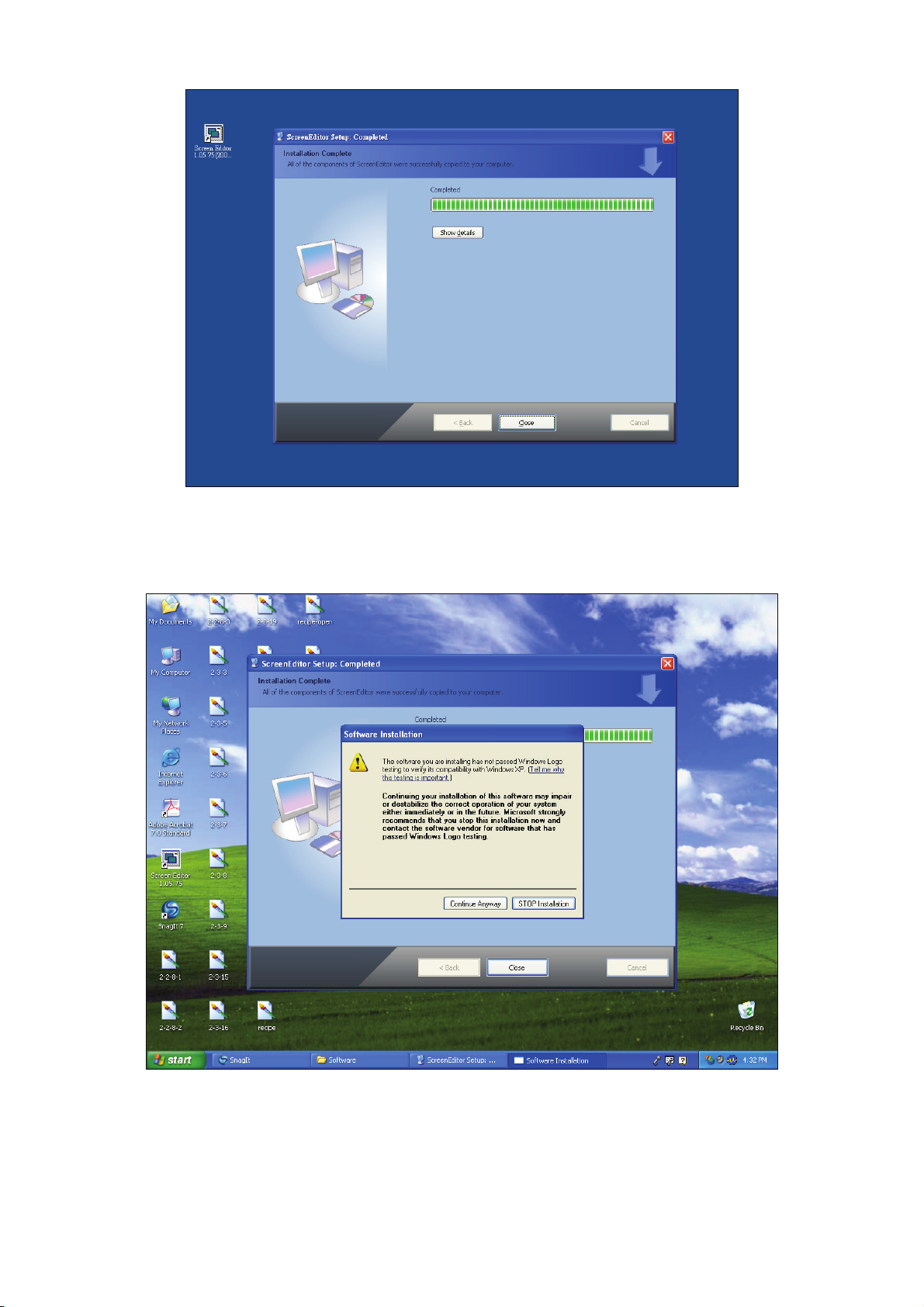

Fig. 2.1.6 Finish installing ScrEdit

5. Step 5: After finish installing ScrEdit (Fig. 2.1.6), system will ask you to install HMI USB driver, please

click Yes to install.

Fig. 2.1.7 Install HMI USB driver

6. Step 6: After installing HMI USB driver, click Close to complete the installation.

2-4 Revision Apr. 30th, 2007, 2007PDD23000002

Page 16

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

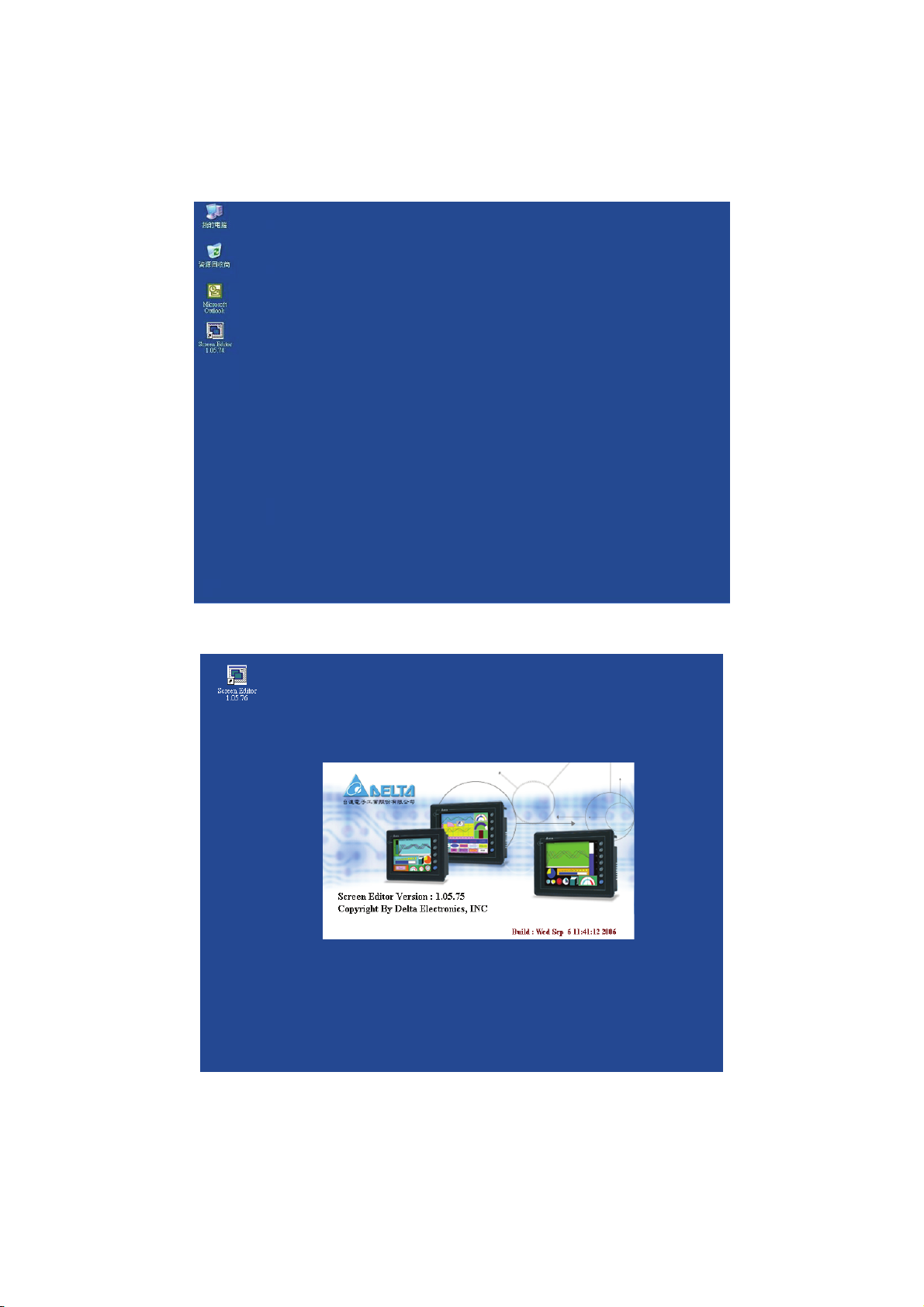

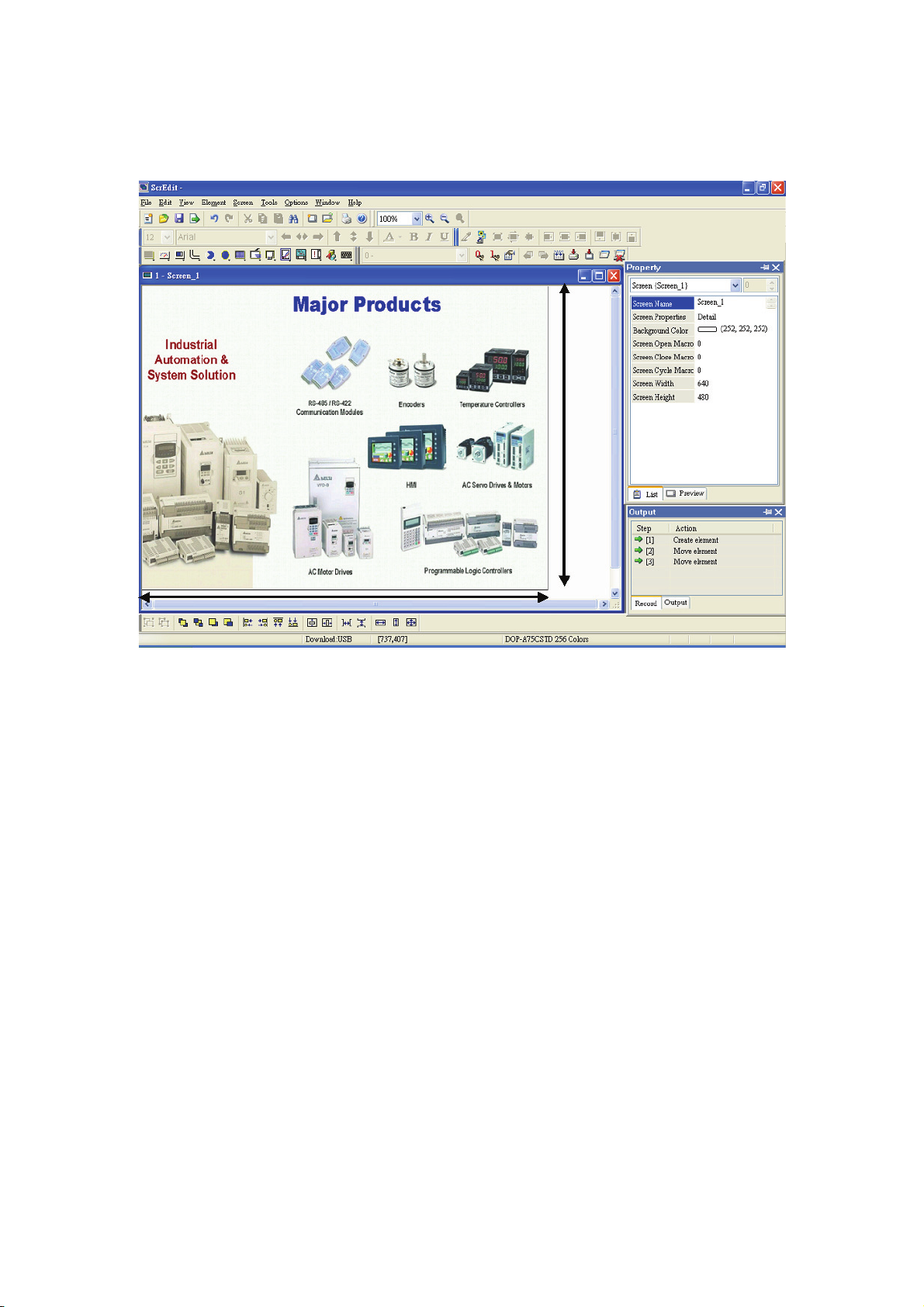

2.2 How to Start ScrEdit

1. After setup, you can start ScrEdit by clicking Screen Editor 1.05.XX shortcut on the desk (Refer to Fig.

2.2.1) or from Windows taskbar, click Start > Programs > Delta > Screen Editor 1.05.XX.

Fig. 2.2.1

Fig. 2.2.2 Start-up display

Revision Apr. 30th, 2007, 2007PDD23000002 2-5

Page 17

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

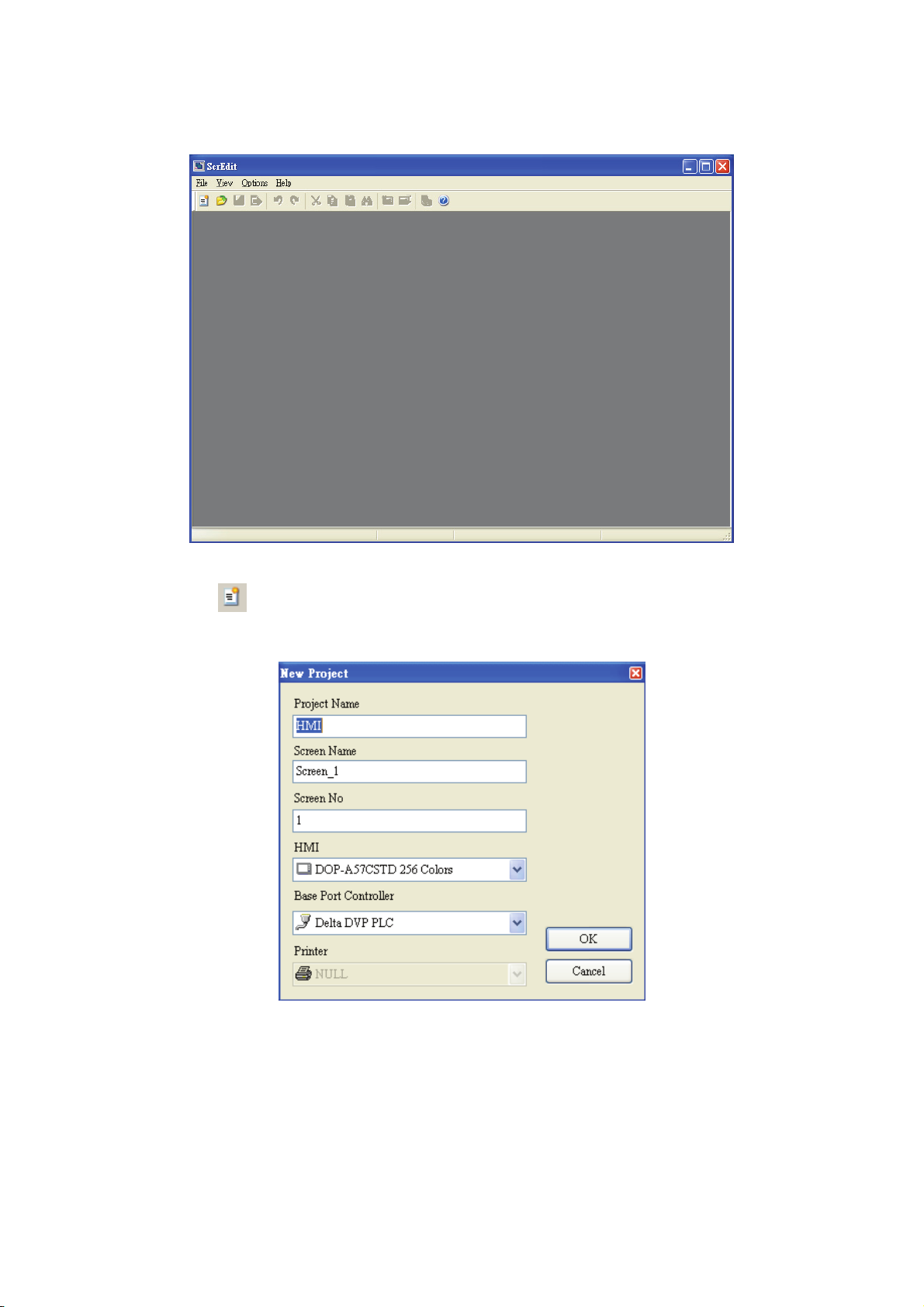

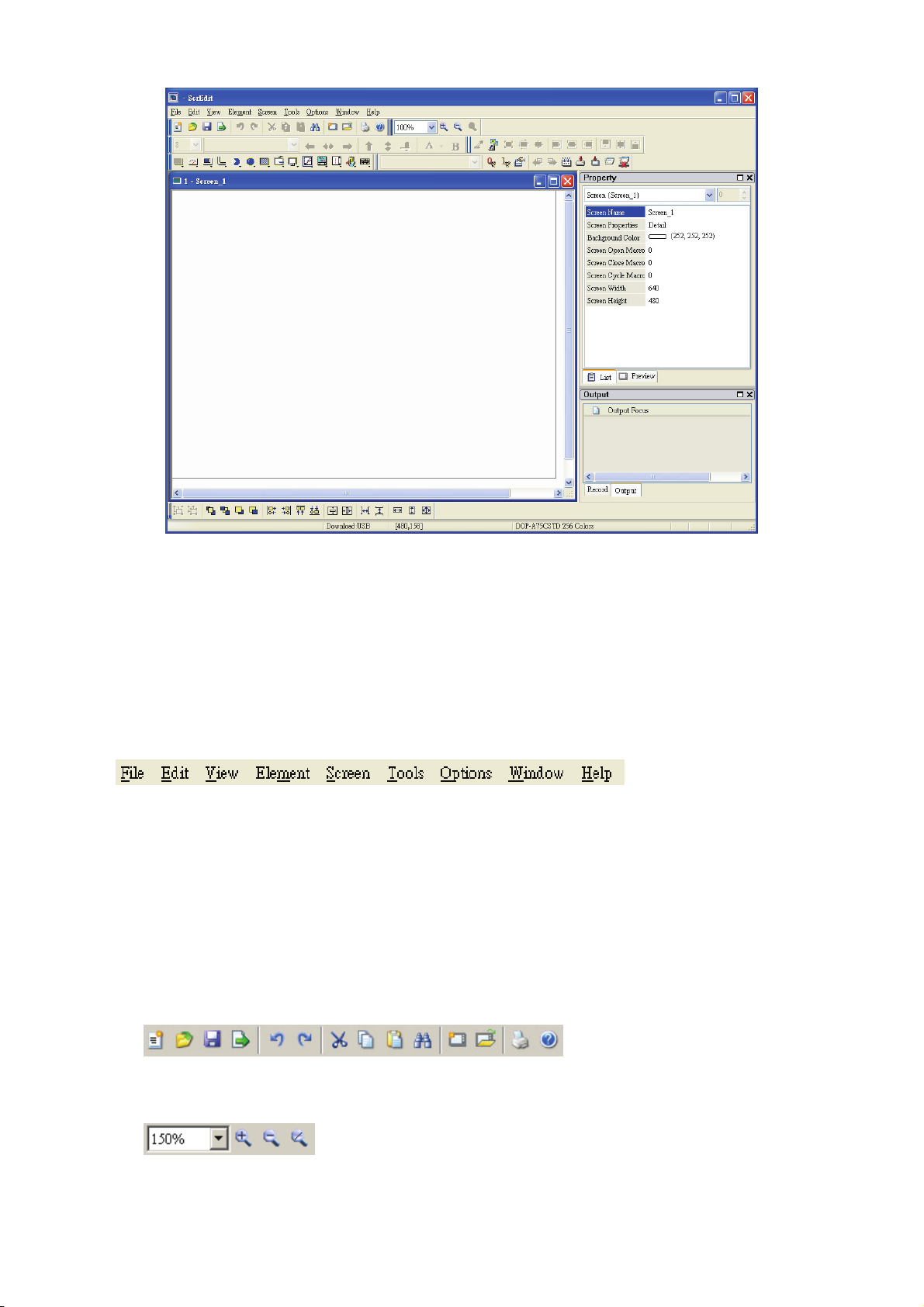

When ScrEdit is activated for the first time, the first window to show up is as follows. There are only File (F),

View(V), Option(O) and Help(H) on the toolbar.

2. After pressing

shown in the following. (Fig. 2.2.4)

or click File > New, it can create a new project and you will get a dialog box as

Fig. 2.2.3 Screen without editing file

Fig. 2.2.4 Creating a New project

3. Enter the Project Name, Screen Name, Screen No. and select connected HMI, controller or printer.

Then, click OK. It can create a new project in ScrEdit as shown in the following. (Fig. 2.2.5)

2-6 Revision Apr. 30th, 2007, 2007PDD23000002

Page 18

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Fig. 2.2.5 New project screen of ScrEdit

There are five parts in the following for ScrEdit editing window.

Menu Bar

There are nine functions for selection: File, Edit, View, Element, Screen, Tools, Options, Window, and

Help.

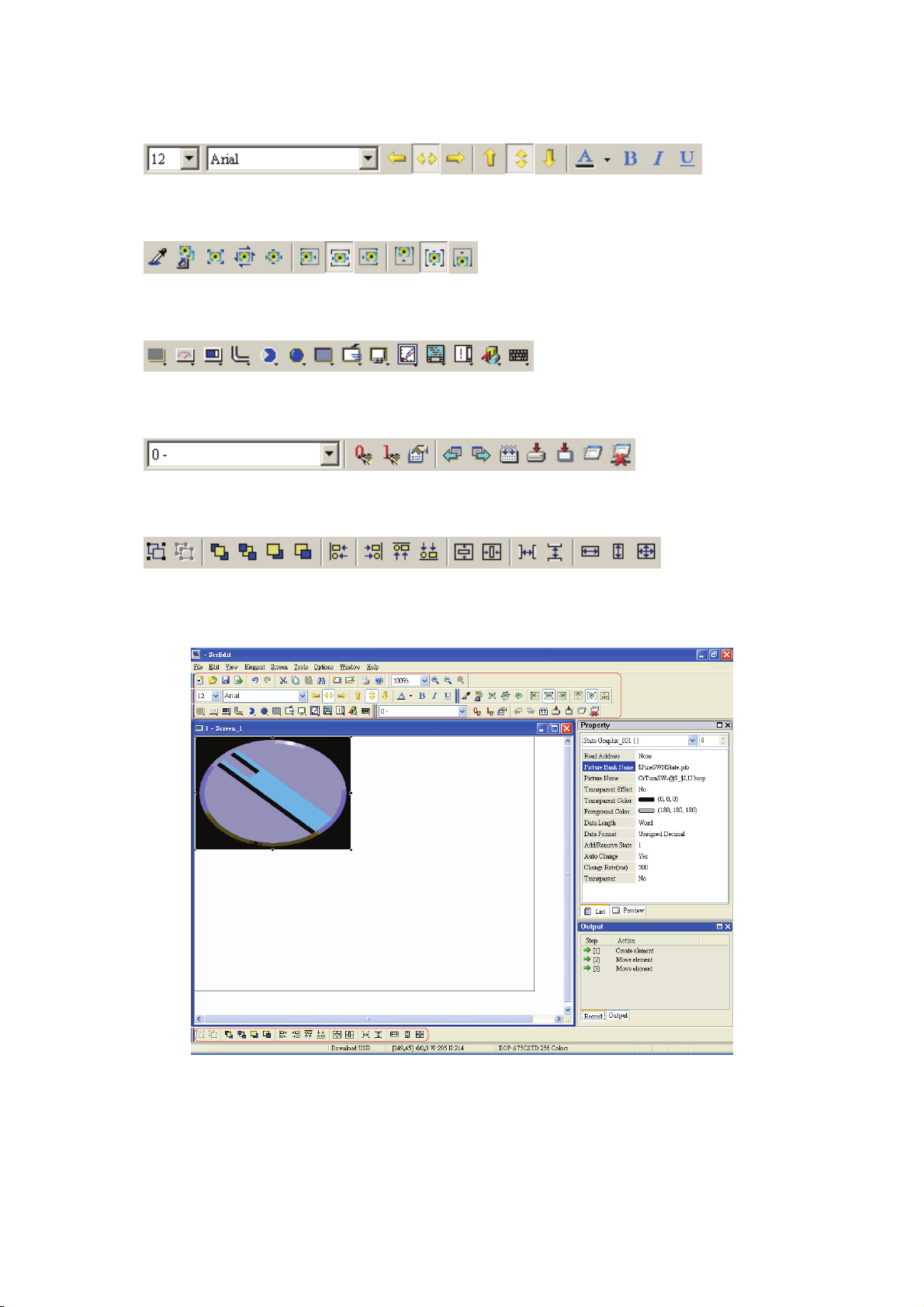

Toolbar

Toolbar (Fig. 2.2.6) is like those toolbar in Windows® program. It is easy to use for editing and the user

can arrange its position freely. For example, the user can move the Toolbar to the left side of the screen.

Also, the user can arrange the toolbar position by their usage. The followings are the available toolbar on

ScrEdit.

1. Standard Toolbar

2. Zoom Toolbar

Revision Apr. 30th, 2007, 2007PDD23000002 2-7

Page 19

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

3. Text Format Toolbar

4. Bitmap Toolbar

5. Element Toolbar

6. Build Toolbar

7. Layout Toolbar

Fig. 2.2.6 ScrEdit Toolbar

2-8 Revision Apr. 30th, 2007, 2007PDD23000002

Page 20

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Fig. 2.2.7 Move ScrEdit toolbar to the left side of the screen

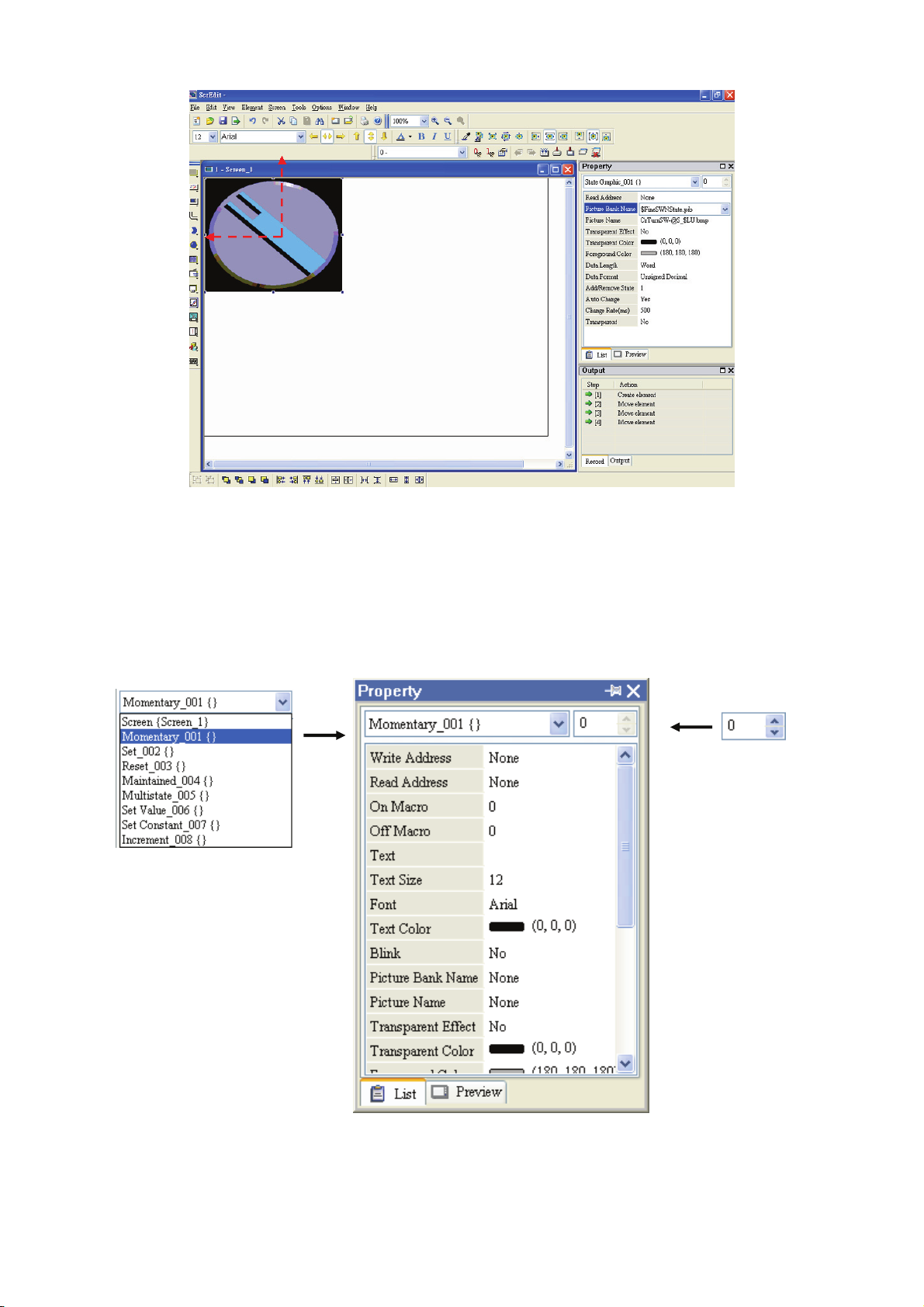

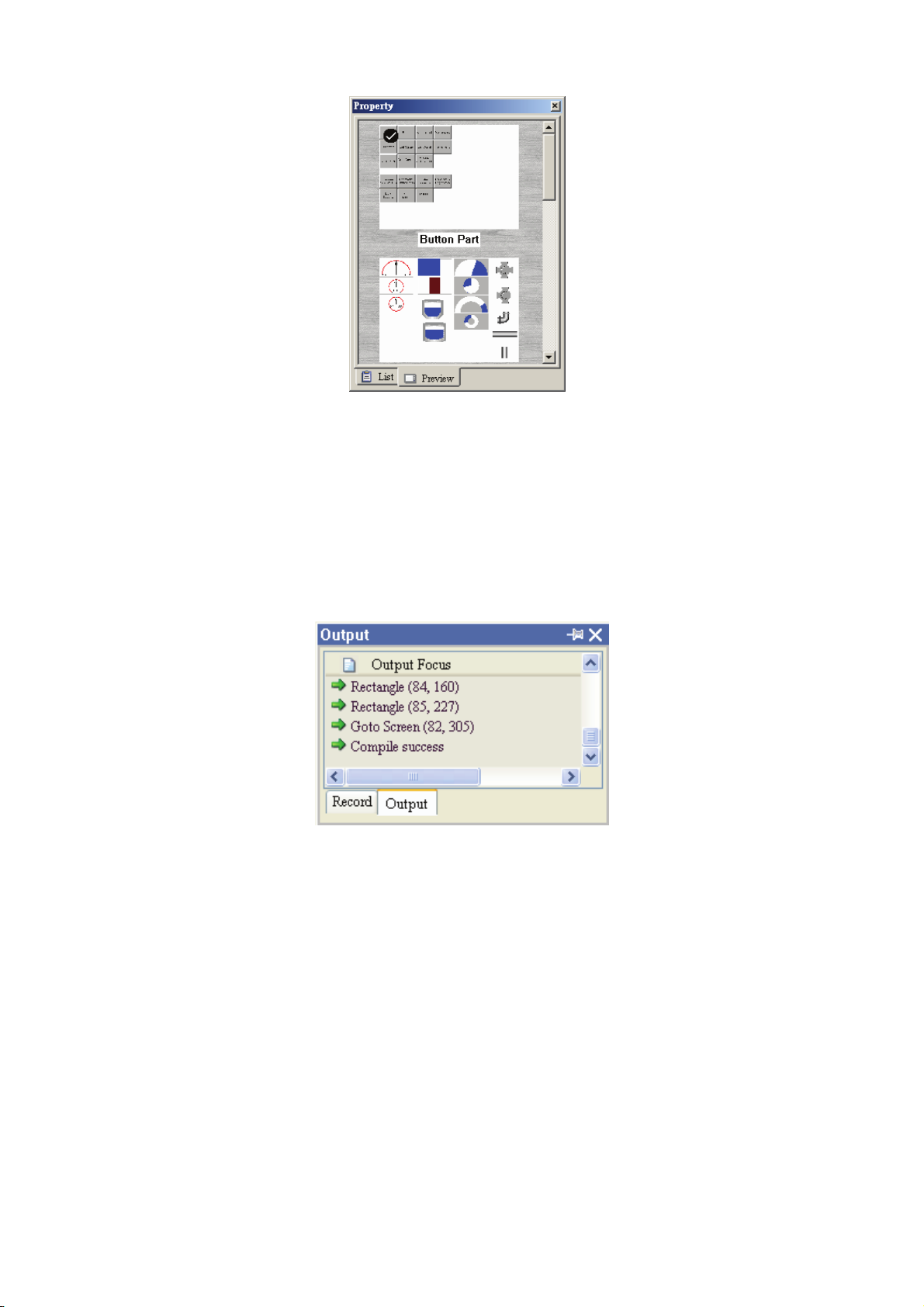

Property Table

It provides element property settings for each element (Fig. 2.2.8 & Fig. 2.2.9). Please refer to Chapter 3

for detailed description.

Element state selection

All elements on current

editing screen

Fig. 2.2.8 Property table

Revision Apr. 30th, 2007, 2007PDD23000002 2-9

Page 21

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Fig. 2.2.9 Editing screen preview

Output Window

All editing actions and output message when compile function is enabled will be shown here (Fig. 2.2.10).

When compiling, ScrEdit will detect the error of user program automatically. Once error occurs, the

correspondent message will display in output window. Click error message to get error element window.

Fig. 2.2.10 Output window

2-10 Revision Apr. 30th, 2007, 2007PDD23000002

Page 22

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Work Place

Following is an editing example display (Fig. 2.2.11).

Fig. 2.2.11 ScrEdit Work Place

Revision Apr. 30th, 2007, 2007PDD23000002 2-11

Page 23

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

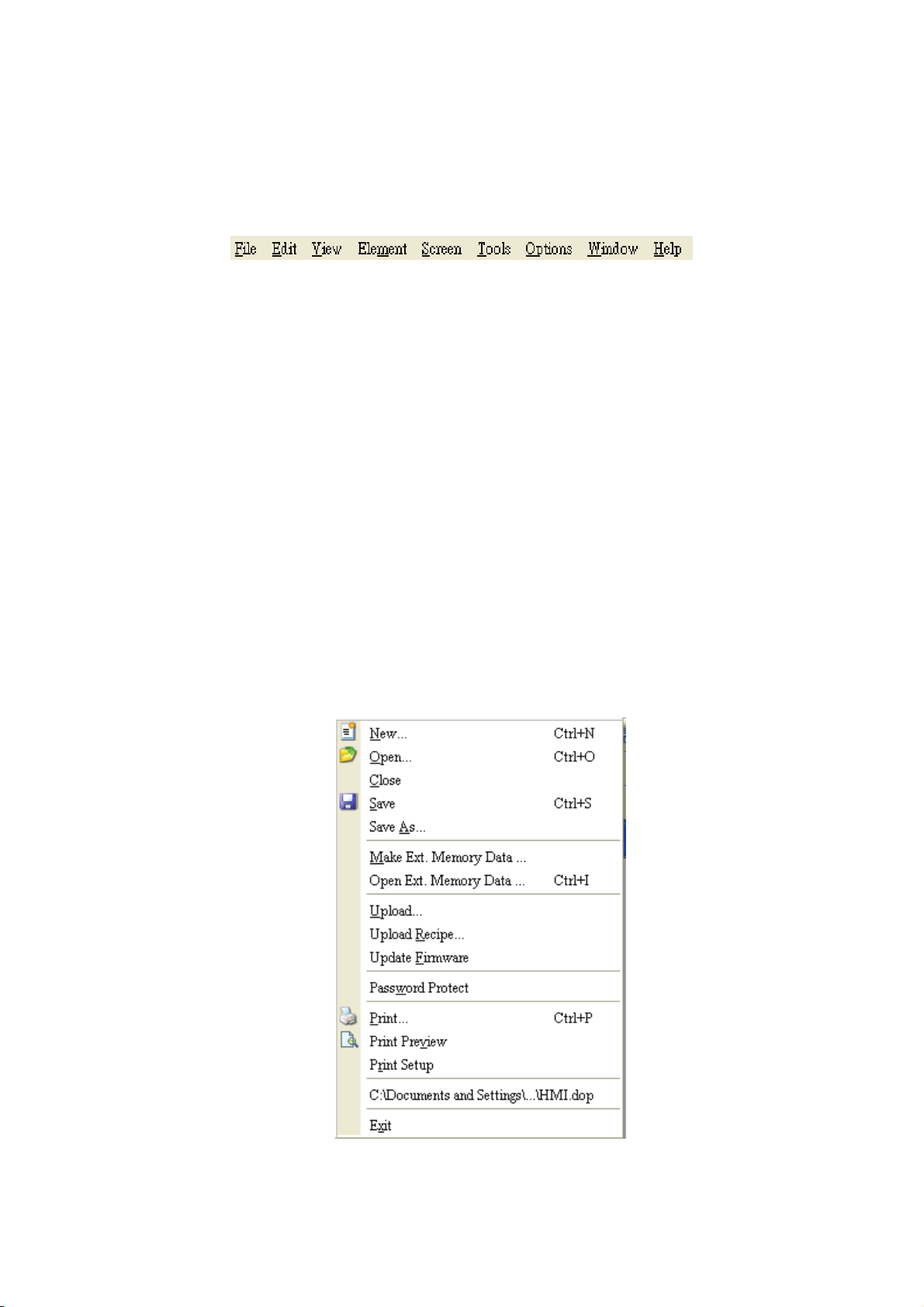

2.3 Menu Bar and Toolbar (File)

ScrEdit provides the convenient pull-down Menu and makes it easy for the user to create, edit and manage

includes elements, pictures, graphs, macro program, recipes and displays in DOP series HMI. The pull-down

menu options of Menu bar are described as follows:

File

The “File” menu performs many common functions.

1. Allows user to create new project, open old project, close file, save current file and save current file

to another file name, etc. options.

2. Make and Open external memory data (Ext. Memory Data).

3. Upload the editing display and data of DOP series HMI to PC and save to hard disk.

4. Update the firmware of DOP series HMI.

5. Password protection function.

6. Screen print, print preview and print setup functions.

7. By default, ScrEdit presents a list of the most recent used files on the File menu for quick access.

Just click the file name to open the file.

8. Exit command is to close all open editing files and offer to save those which have not been save

yet and finally exit the ScrEdit.

Fig. 2.3.1 File options

2-12 Revision Apr. 30th, 2007, 2007PDD23000002

Page 24

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

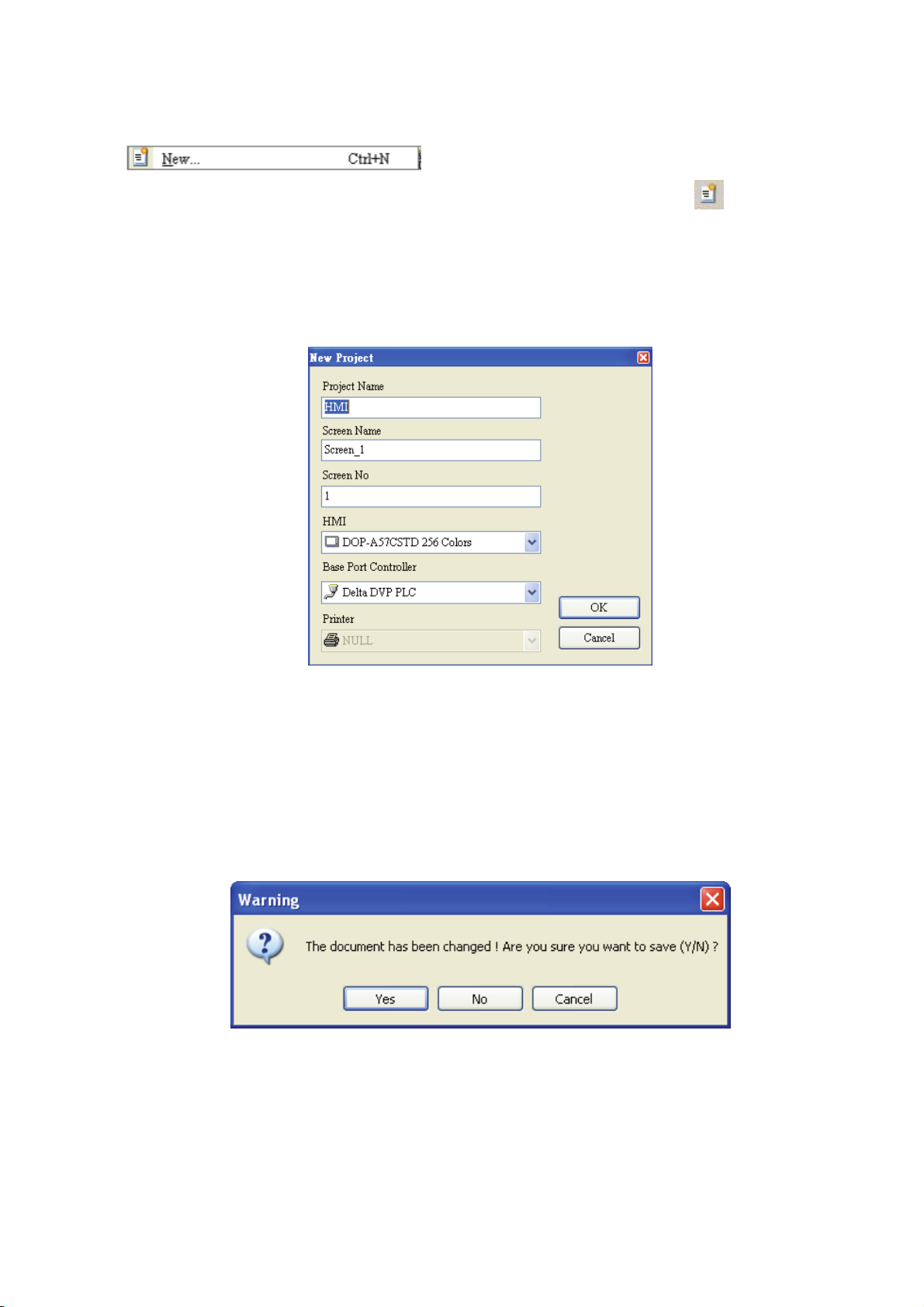

Create a New Project

Creates a new project by choosing File > New (Fig. 2.3.2) or clicking the New icon

(Fig. 2.3.3), or using keyboard shortcuts by pressing Ctrl + N.

1. If this is the first time use and there is no old project, the following dialog box (Fig. 2.3.2) will show

up for the user to input project name, screen name, screen number, HMI type and connecting

base port controller after creating a new project.

from toolbar

Fig. 2.3.2 New project dialog box

2. If other project files already exist and are open, the user will get the following dialog box to remind

the user of saving project (Fig. 2.3.3) before creating new project. Press Yes button to save the

existed file, press No button not to save the file and press Cancel button to cancel the save

operation. After the user press the Yes or No button, the new project dialog box will appear again

(Fig. 2.3.2).

Fig. 2.3.3 Saving dialog box

3. Input project name, screen name, select HMI model and connecting base port controller (Fig.

2.3.4), and then press OK button.

Revision Apr. 30th, 2007, 2007PDD23000002 2-13

Page 25

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Fig. 2.3.4 HMI model and base port controller options

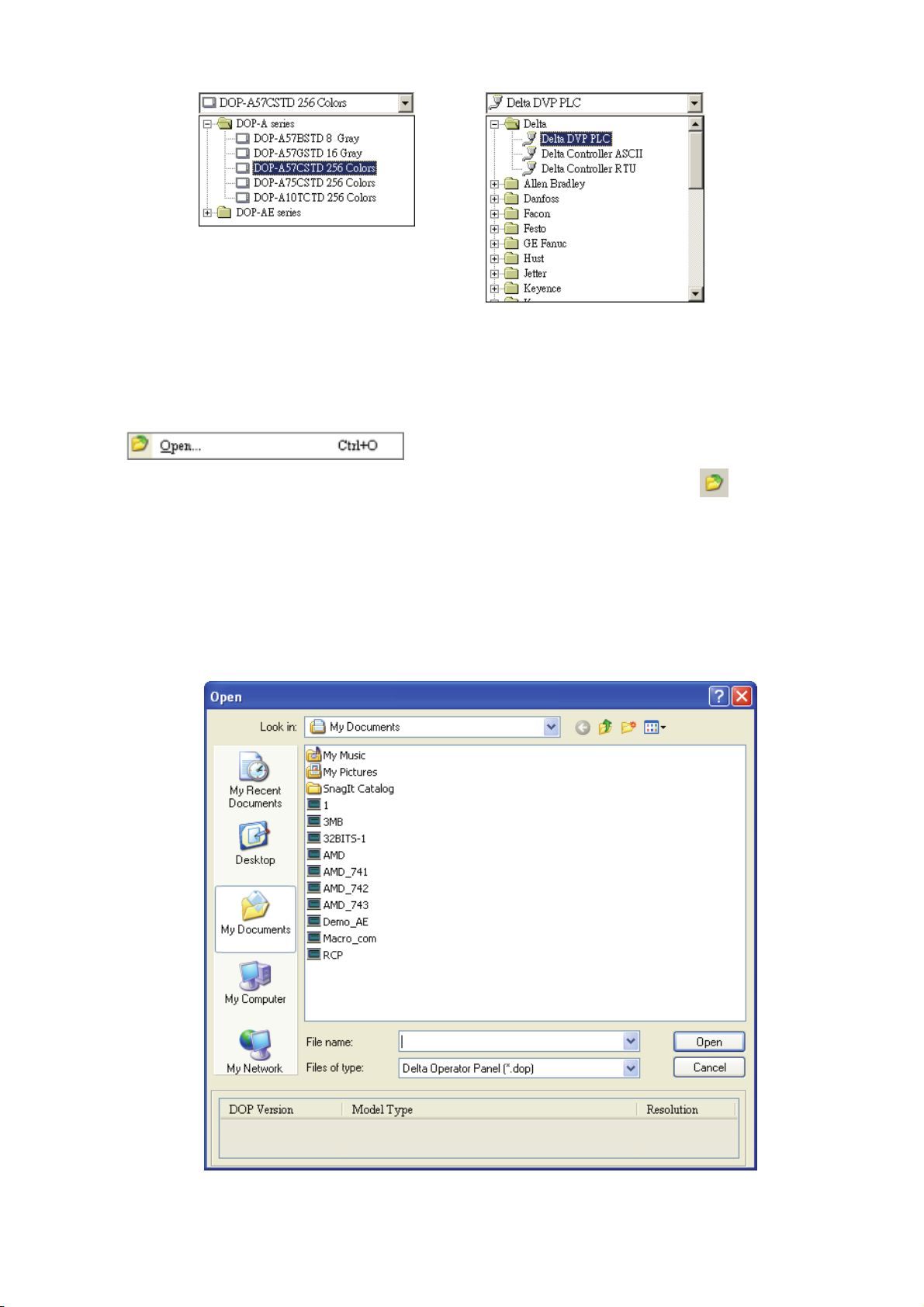

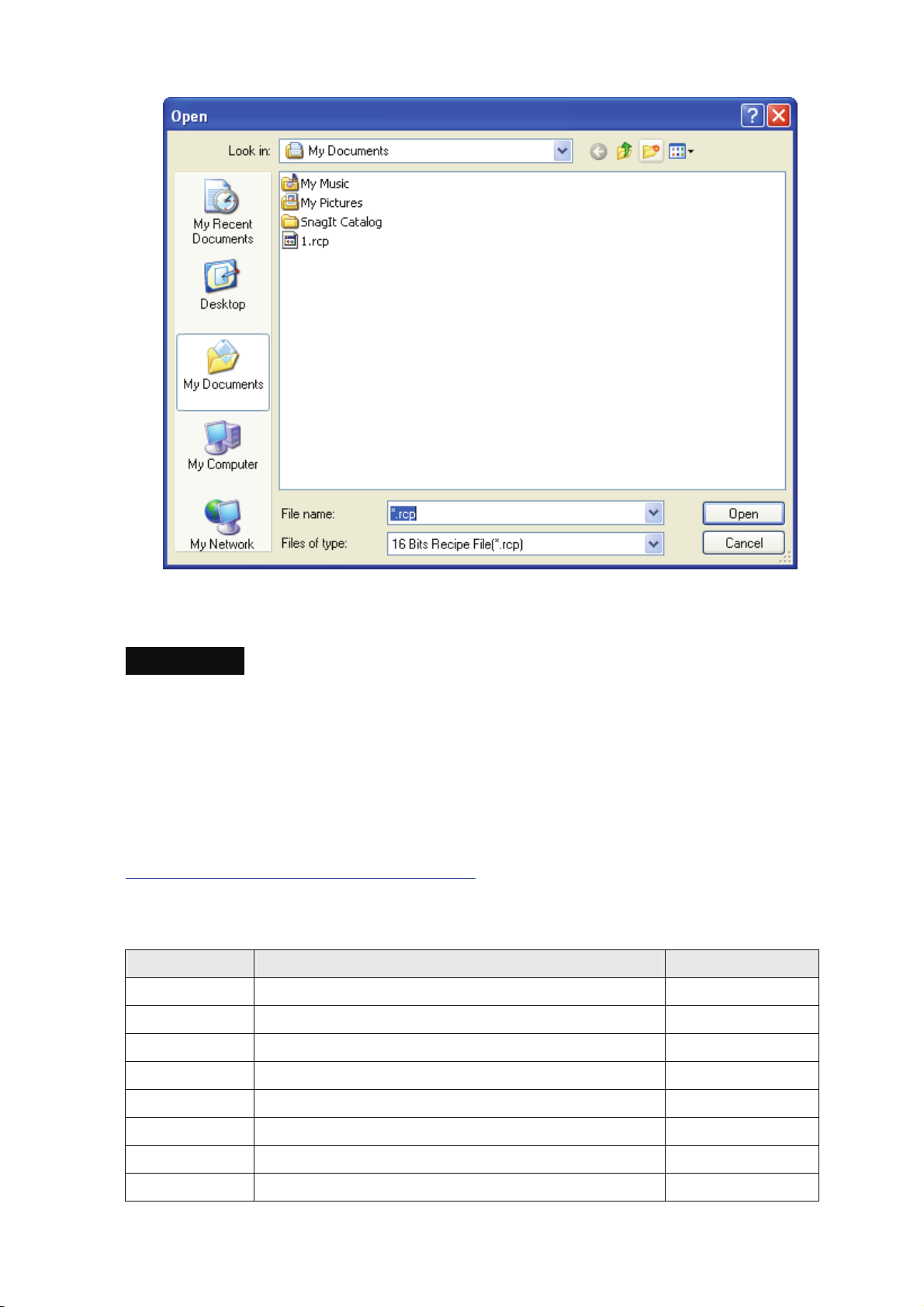

Open Old Project

Open current project by choosing File > Open (Fig. 2.3.7) or clicking the Open icon

or using keyboard shortcuts by pressing Ctrl + O.

1. If other project files exist before opening an old project, the user will get the Saving dialog box (Fig.

2.3.3) to remind the user of saving file and then get the following dialog box for opening existing

dop file (Fig. 2.3.5).

2. If save operation is complete or there is no old project files, the following dialog box for opening

existing dop file (Fig. 2.3.5) will show up directly.

from toolbar,

Fig. 2.3.5 Open an old project in ScrEdit

2-14 Revision Apr. 30th, 2007, 2007PDD23000002

Page 26

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

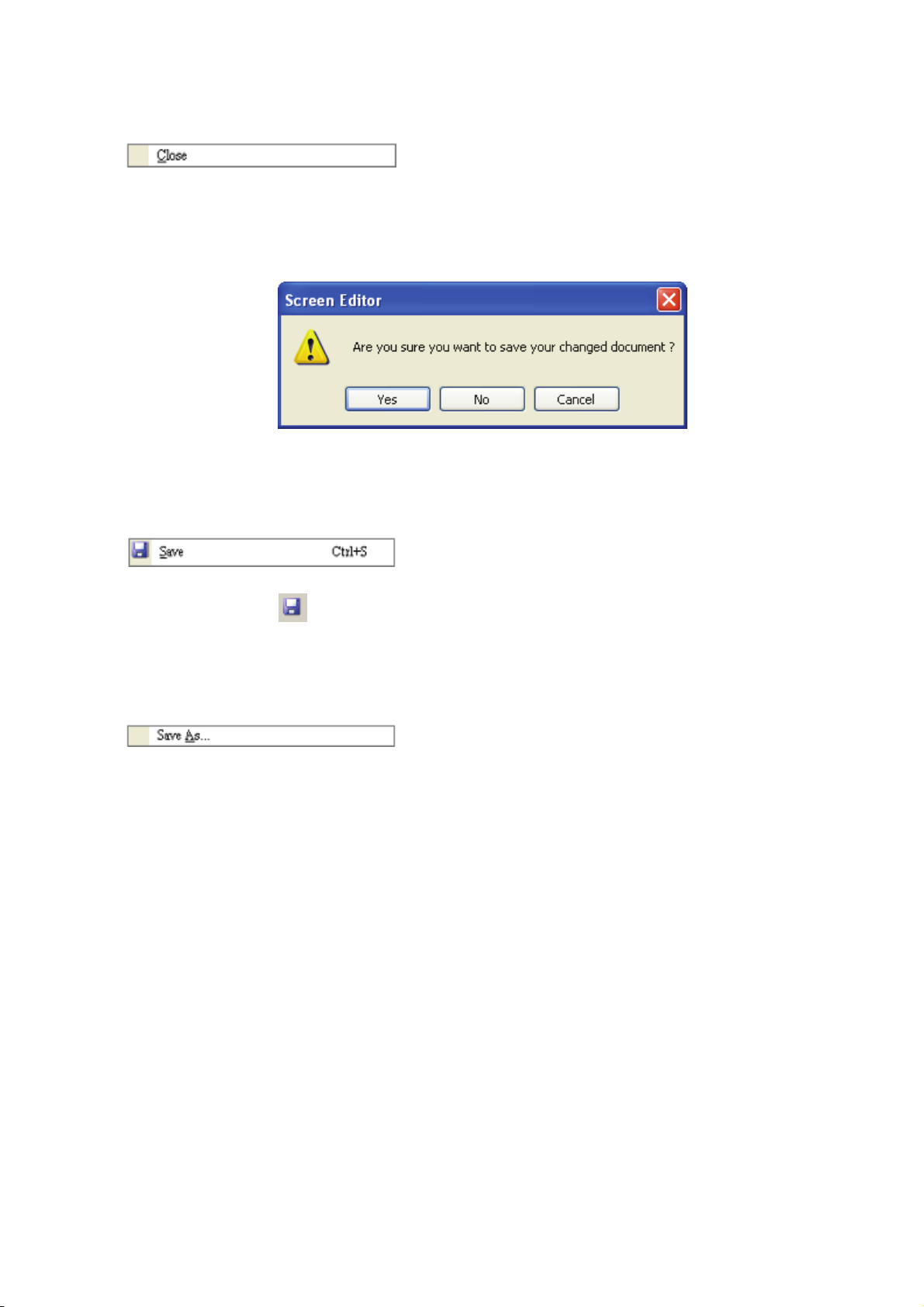

Close File

Closes project by clicking File > Close (Fig. 2.3.10).

1. If project didn’t get saved before issuing the command of closing project, the user will get saving

dialog box (Fig. 2.3.6) to remind the user of saving project.

Fig. 2.3.6 Saving dialog box

Save File

Save current project into hard disk with extension file “dop” by choosing File > Save (Fig. 2.3.12) or

clicking the Save icon

is a new file, the Save as dialog box will show up (Fig. 2.3.15). If the project is an old file, the Save

function will perform immediately and the Save as dialog box will not show up.

Save As

(Fig. 2.3.13), or using keyboard shortcuts by pressing Ctrl + S. If the project

Save current project to another file name by clicking File > Save As (Fig. 2.3.14). The user will get

Save as dialog box (Fig. 2.3.15) to input project name with extension file dop. This dialog also appears

automatically when the first time any project file is saved no matter whether Save As or Save command

is used.

Revision Apr. 30th, 2007, 2007PDD23000002 2-15

Page 27

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

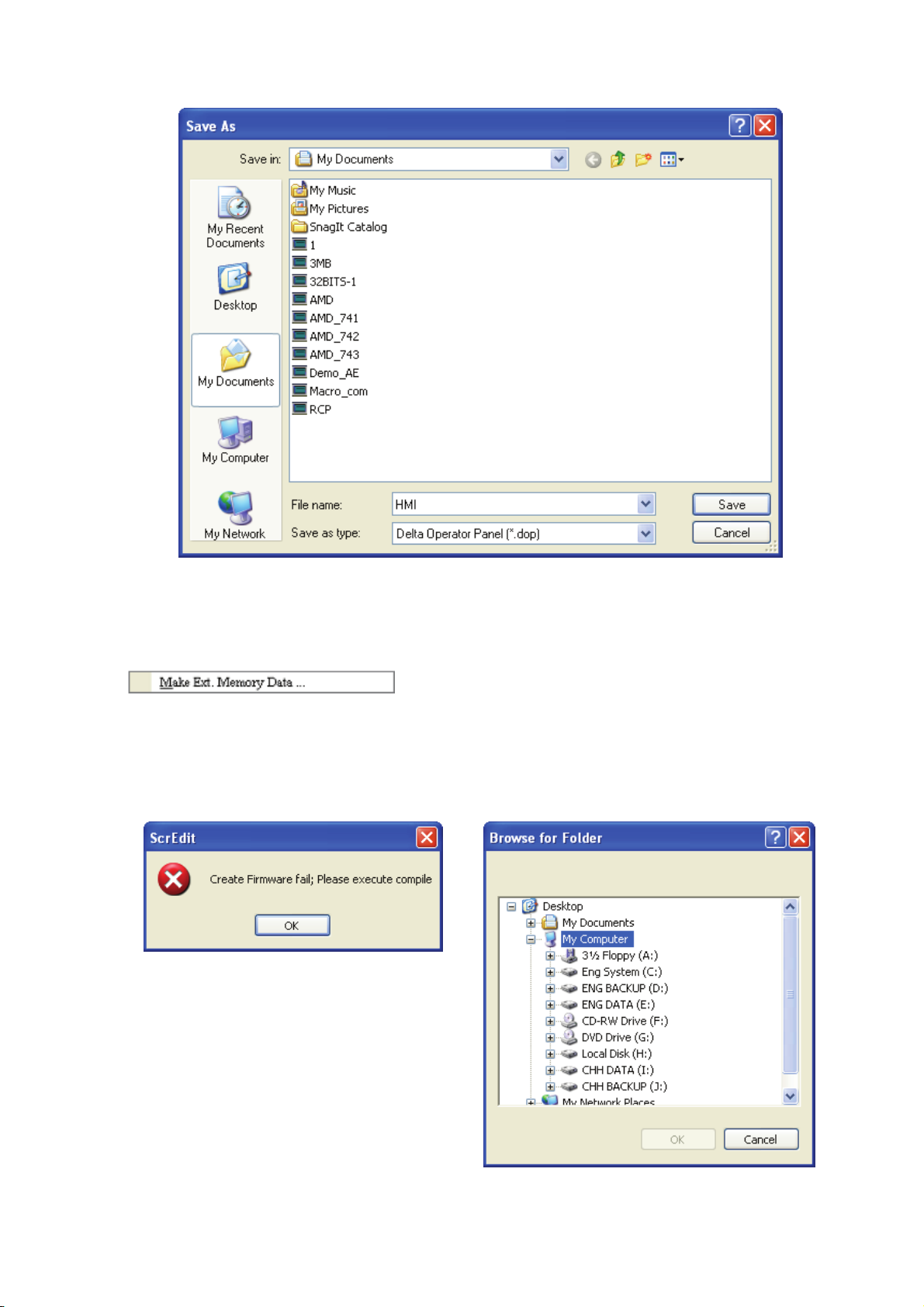

Fig. 2.3.7 Save as dialog box (Dialog box that let user input project name to save as.)

Make Ext. Memory Data

Before using this command, ensure to compile the editing screen data. If not execute the compilation

first, the ScrEdit cannot make screen data and an error message dialog box will show up (Fig. 2.3.8).

Please execute the compilation first and then clicking File > Make Ext. Memory Data to copy the

compiled HMI program into SM card (Fig. 2.3.9) or a USB flash drive. If the SM card or USB flash drive

with compiled HMI program stored inside is inserted into HMI, HMI will startup by reading the data of

SM card or USB flash drive directly.

Fig. 2.3.8 Error message dialog box when

making Ext. Memory Data

Fig. 2.3.9 Make Ext. Memory Data Dialog Box

2-16 Revision Apr. 30th, 2007, 2007PDD23000002

Page 28

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

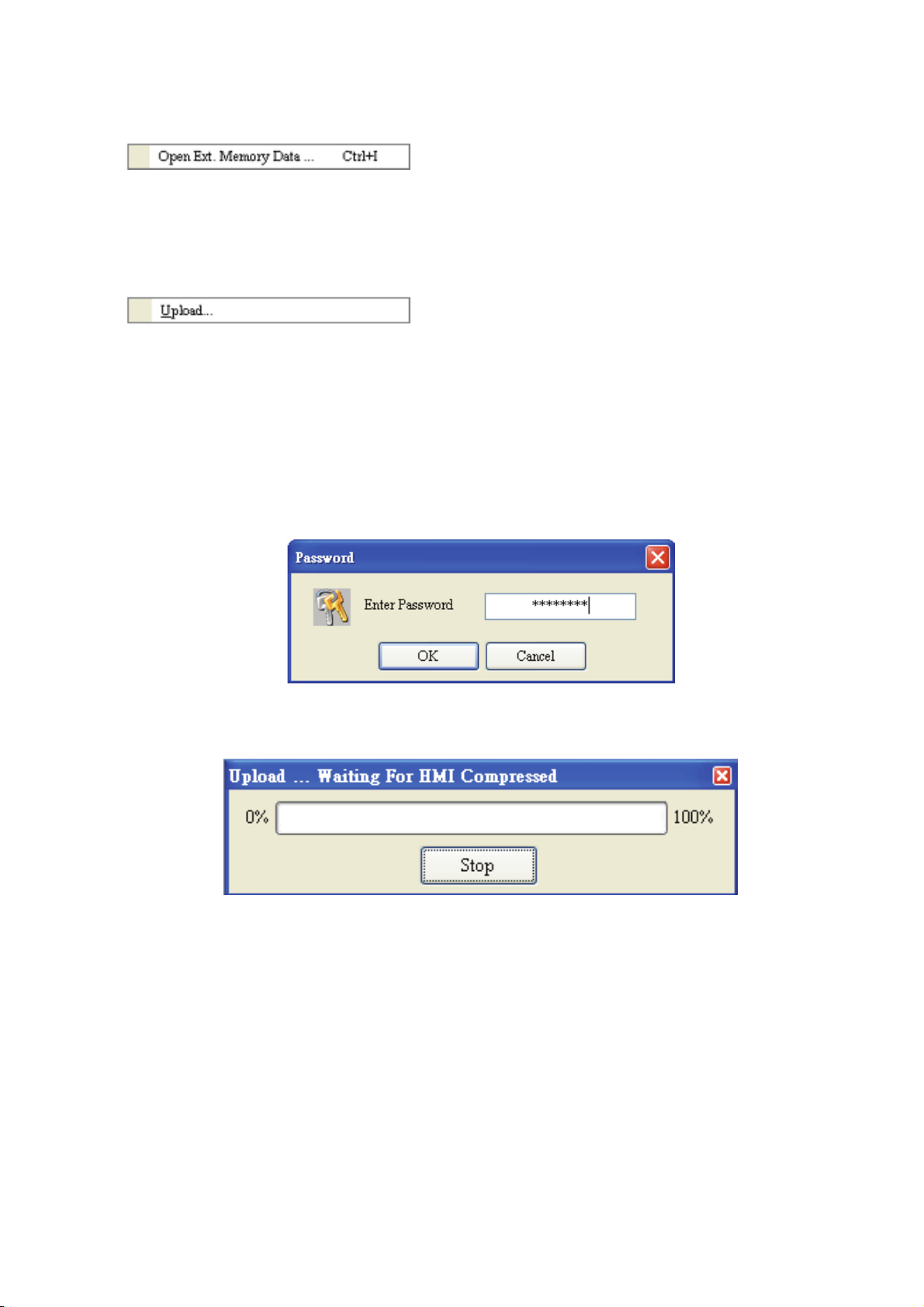

Open Ext. Memory Data

In HMI, the user can move the screen data saved in the flash memory into SM card through folder

manager. Then, perform Open Ext. Memory Data function and the user will get the user will get Fig.

2.3.9 dialog box. At this time, the user can open the screen data and edit the HMI screen data directly.

Upload

After clicking File > Upload, the password dialog box will show up first (Fig. 2.3.10), the user needs to

input password (the password is the highest priority saved in HMI, which is set by clicking Options >

Configuration > Standard > Security). When entering the correct password, the user can get save as

dialog box (Fig. 2.3.7). After inputting project file name, the uploading will start (Fig. 2.3.11). The user

can get the progress with progress box and stop uploading by clicking Stop button. When progress

goes to 100%, it indicates that the uploading is complete. The user can press Stop button to exit the

dialog box. The file that is uploaded from HMI can be restored to original editing file for user to edit.

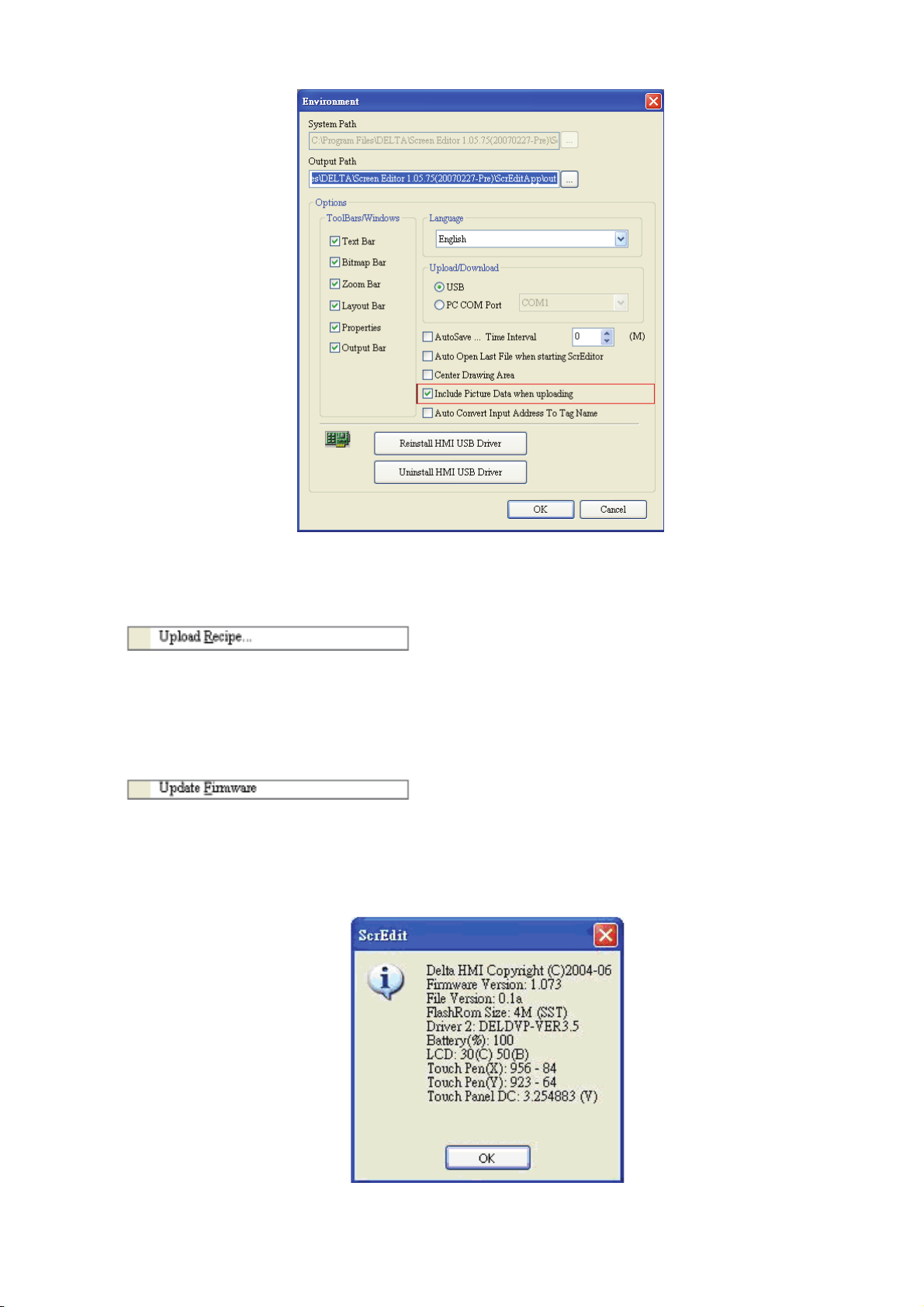

This option is to avoid losing the original editing file. If the user wants to upload data with pictures also,

just select the “Include Picture Data when uploading” in Environment dialog box by clicking Options >

Environment.

Screen Data and Recipe

Fig. 2.3.10 Enter password dialog box

Fig. 2.3.11 Uploading screen

Revision Apr. 30th, 2007, 2007PDD23000002 2-17

Page 29

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Fig. 2.3.12 Environment dialog box

Upload Recipe

This function is similar to upload function but it can only upload recipe. Before uploading, it also needs

to enter password (the password is the highest priority saved in HMI, which is set by clicking Options >

Configuration > Standard > Security).

Update Firmware

This option is for upgrading HMI firmware or adding function for HMI (Fig. 2.3.13). Keeping HMI

firmware version to be the most updated version can optimize HMI operation. Ensure that the software

version of ScrEdit matches the firmware version. The user can get the firmware information by clicking

Tools > Get Firmware Information. Regarding the software version of ScrEdit, the user can find it by

clicking Help > About ScrEdit (Fig. 2.3.14).

Fig. 2.3.13 Choosing Update Firmware command from menu bar

2-18 Revision Apr. 30th, 2007, 2007PDD23000002

Page 30

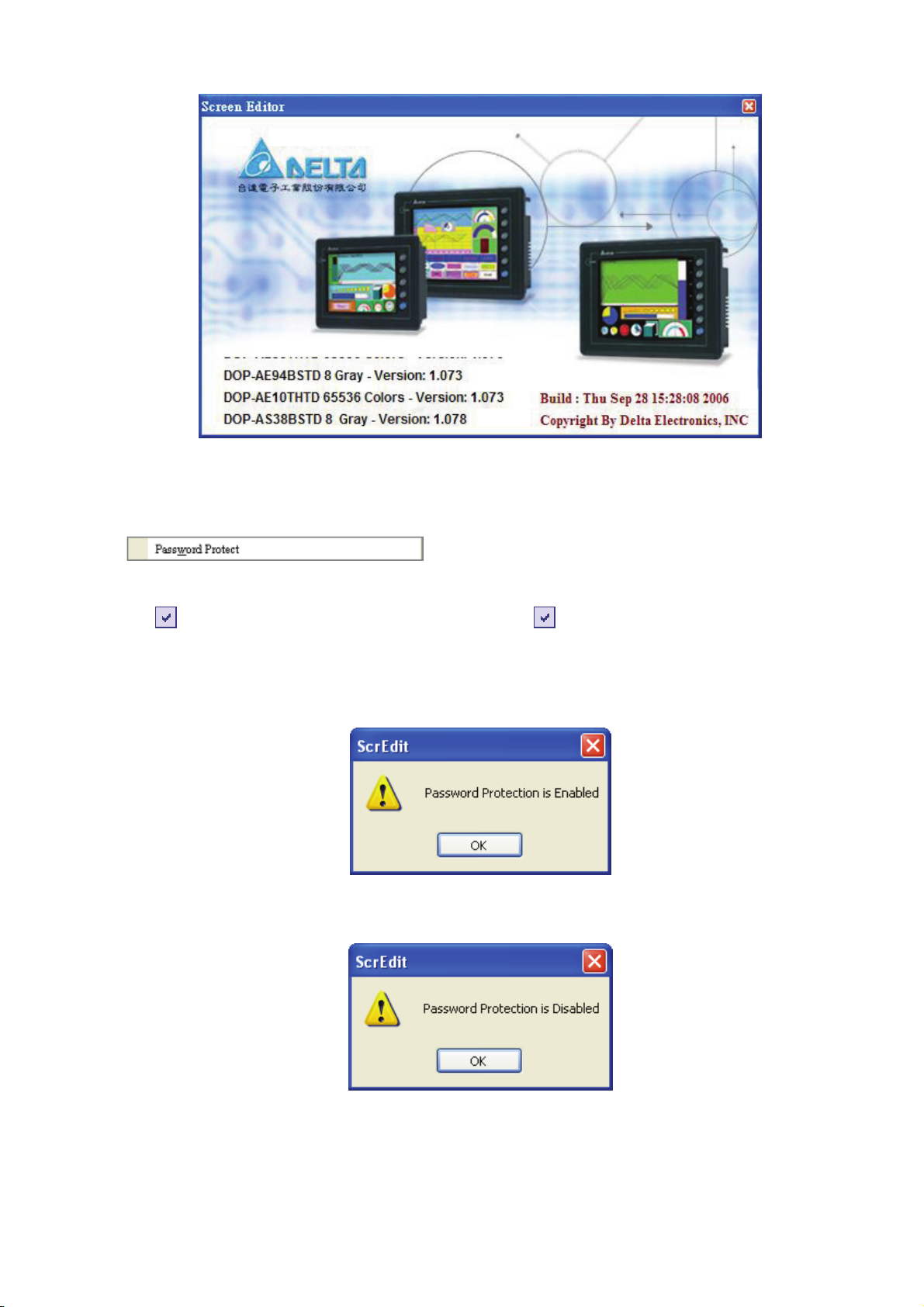

Password Protect

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Fig. 2.3.14 About ScrEdit

The user can enable and disable password protect function (Fig. 2.3.15 & Fig. 2.3.16) by clicking File >

Password protect. Once password protect function is enabled, the user will get Fig. 2.3.15 dialog box

and

Protect” command from File menu, it indicates that this dop file is password protected and the user will

need to input password before opening dop file. The password is set by clicking Options >

Configuration > Standard > Security) (Fig. 2.3.17). If the password protect function is disabled, the

Fig. 2.3.16 dialog box will show up.

symbol before “Password Protect” command. If the symbol shows before “Password

Fig. 2.3.15 Password protect function is enabled

Fig. 2.3.16 Password protect function is disabled

Revision Apr. 30th, 2007, 2007PDD23000002 2-19

Page 31

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Fig. 2.3.17 Password settings - Security

Print

Print current screen by choosing File > Print, or clicking the Print icon

using keyboard shortcuts by pressing Ctrl + P.

Print Preview

Select this function by clicking File > Print Preview. Using this function can preview the full page after

printing (Fig. 2.3.18).

from toolbar (Fig. 2.3.28), or

Fig. 2.3.18 Print Preview screen

2-20 Revision Apr. 30th, 2007, 2007PDD23000002

Page 32

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

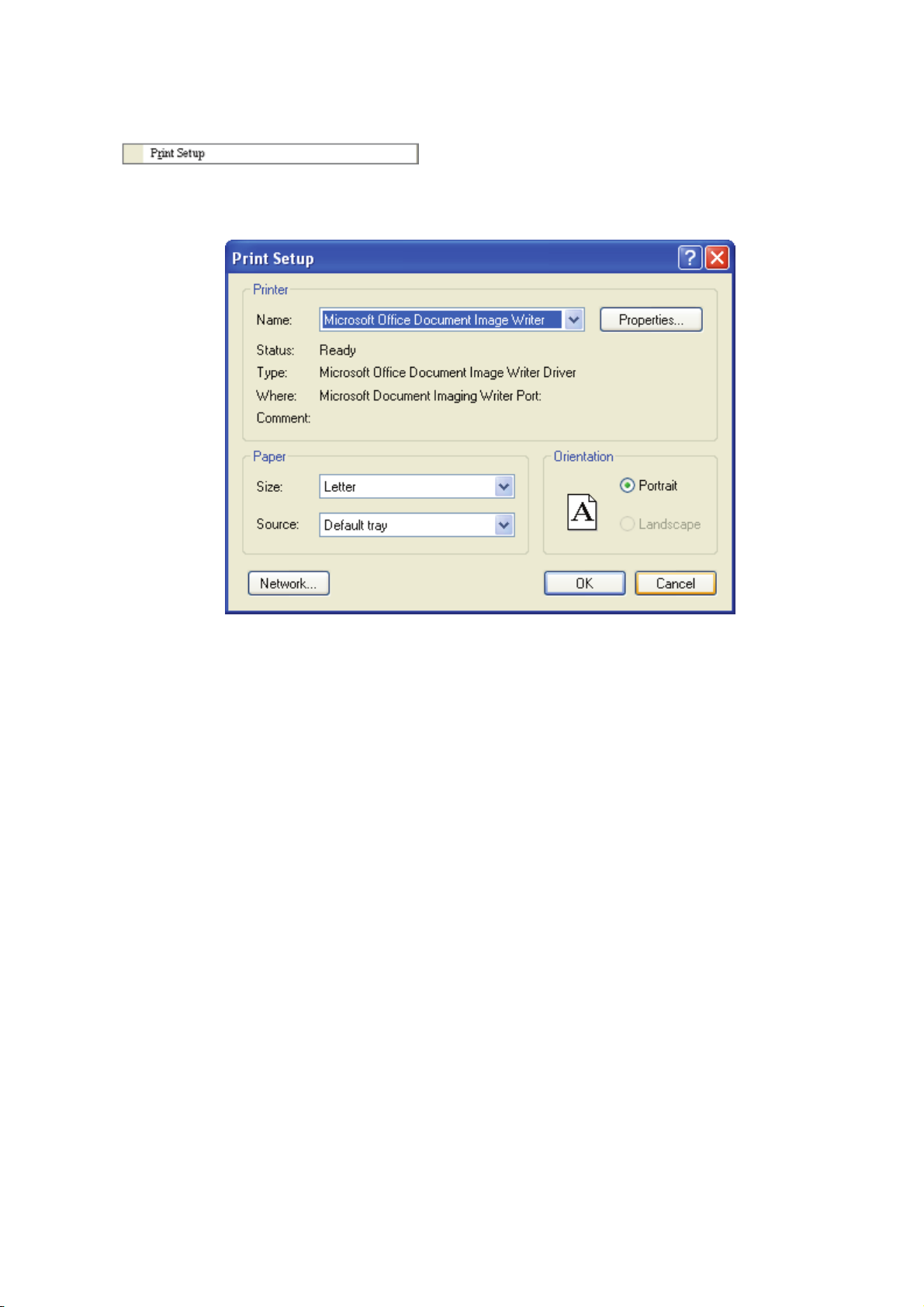

Print Setup

Printer and paper settings. Select this function by clicking File > Print Setup. Using this function can set

the property of printer, print paper and print direction, etc. several functions (Fig. 2.3.19).

Fig. 2.3.19 Print Setup dialog box

File Quick Access

By default, ScrEdit presents a list of the four most recent used files on the File menu for quick

access (Fig. 2.3.20). Just click the file name to open the file. This function is similar to the Open

command and the user can refer to the description of Open command on the page 2-14. If the

saving path is too long, the too long path will display as “….”. The user still can see the complete

dop file name.

Revision Apr. 30th, 2007, 2007PDD23000002 2-21

Page 33

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Fig. 2.3.20 Most recent used files

Exit

Exit function is to close all open editing files and offer to save those that have not been save yet and

finally exit the ScrEdit. Select this function by clicking File > Exit. If the file has been changed or not

saved yet, the saving dialog box (Fig. 2.3.6) will show up to remind the user of saving project. If the

user press Cancel button at this time, the exit command is cancelled. Either pressing Yes button to

save the file, or pressing No button not to save the file can exit the ScrEdit. After the user press the

Yes button, the Save As dialog box will appear (Fig. 2.3.7) for saving the file.

2-22 Revision Apr. 30th, 2007, 2007PDD23000002

Page 34

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

2.4 Menu Bar and Toolbar (Edit)

Edit

Adopt pull-down menu similar to Microsoft Office style and provide user-friendly Edit pull-down menu (Fig.

2.4.1).

Fig. 2.4.1 Edit options

Undo

Undo the last action. Select this function by choosing Edit > Undo or clicking the Undo icon

toolbar, or use keyboard shortcuts by pressing Ctrl + Z. All actions are recorded in output window.

Redo

Redo the undo action. Select this function by choosing Edit > Redo or clicking the Redo icon from

toolbar, or use keyboard shortcuts by pressing Ctrl + Y. All actions are recorded in output window.

Cut

Deletes the selected element and save it in clipboard to paste to other place. Select this function by

from

choosing Edit > Cut from menu bar or clicking the Cut icon

shortcuts by pressing Ctrl + X.

Revision Apr. 30th, 2007, 2007PDD23000002 2-23

from toolbar, or use keyboard

Page 35

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

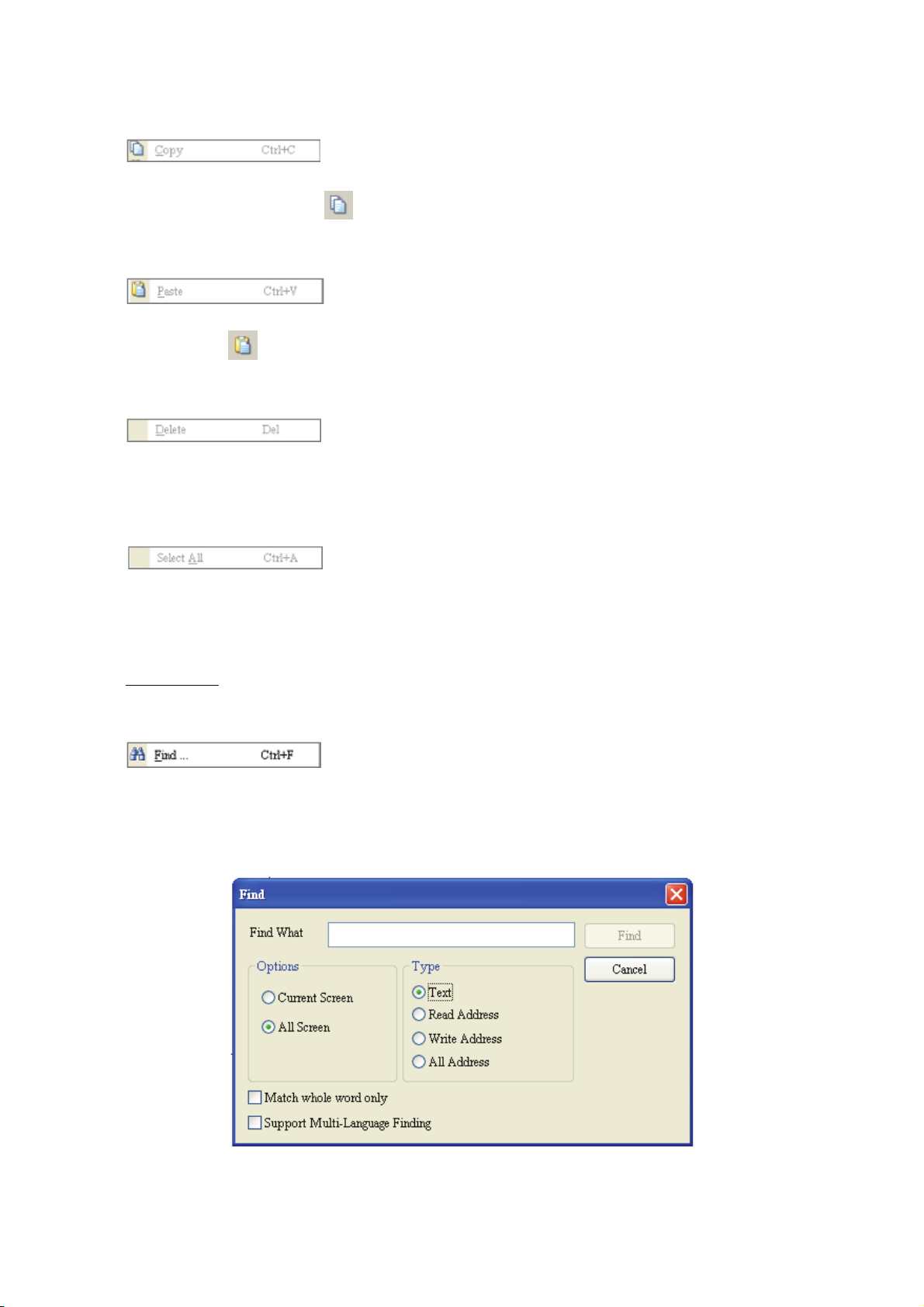

Copy

Copy the selected element to the clipboard. Select this function by choosing Edit > Copy from menu

bar or clicking the Copy icon

Paste

Paste element from clipboard. Select this function by choosing Edit > Paste from menu bar or clicking

the Paste icon

Delete

Delete selected element. Select this function by choosing Edit > Delete from menu bar or use

keyboard shortcuts by pressing Del.

Select All

It is used to select all elements. Select this function by choosing Edit > Select All from menu bar or

use keyboard shortcuts by pressing Ctrl + A. When selecting all, the last created element, i.e. the

picture on the top will be a square that is filled with blue color and the border is in white. The other

created elements will be in white color and the border is in black. This is to provide a reference for Align

and Make Same Size function. When there are two and more elements, one element should be the

base element

from toolbar, or use keyboard shortcuts by pressing Ctrl + V.

. The base element is used to align or resize.

from toolbar, or use keyboard shortcuts by pressing Ctrl + C.

Find

It is used to find the content matches the find criteria. Select this function by choosing Edit > Find from

menu bar or use keyboard shortcuts by pressing Ctrl + F. The user can find element text, read

address, write address or memory address in current screen, or all screens (Fig. 2.4.2). Once it finds,

the result of find content will be shown in the output window. Click some of the result of find content, it

will jump to its location in ScrEdit (Fig. 2.4.3).

Fig. 2.4.2 Find option

2-24 Revision Apr. 30th, 2007, 2007PDD23000002

Page 36

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

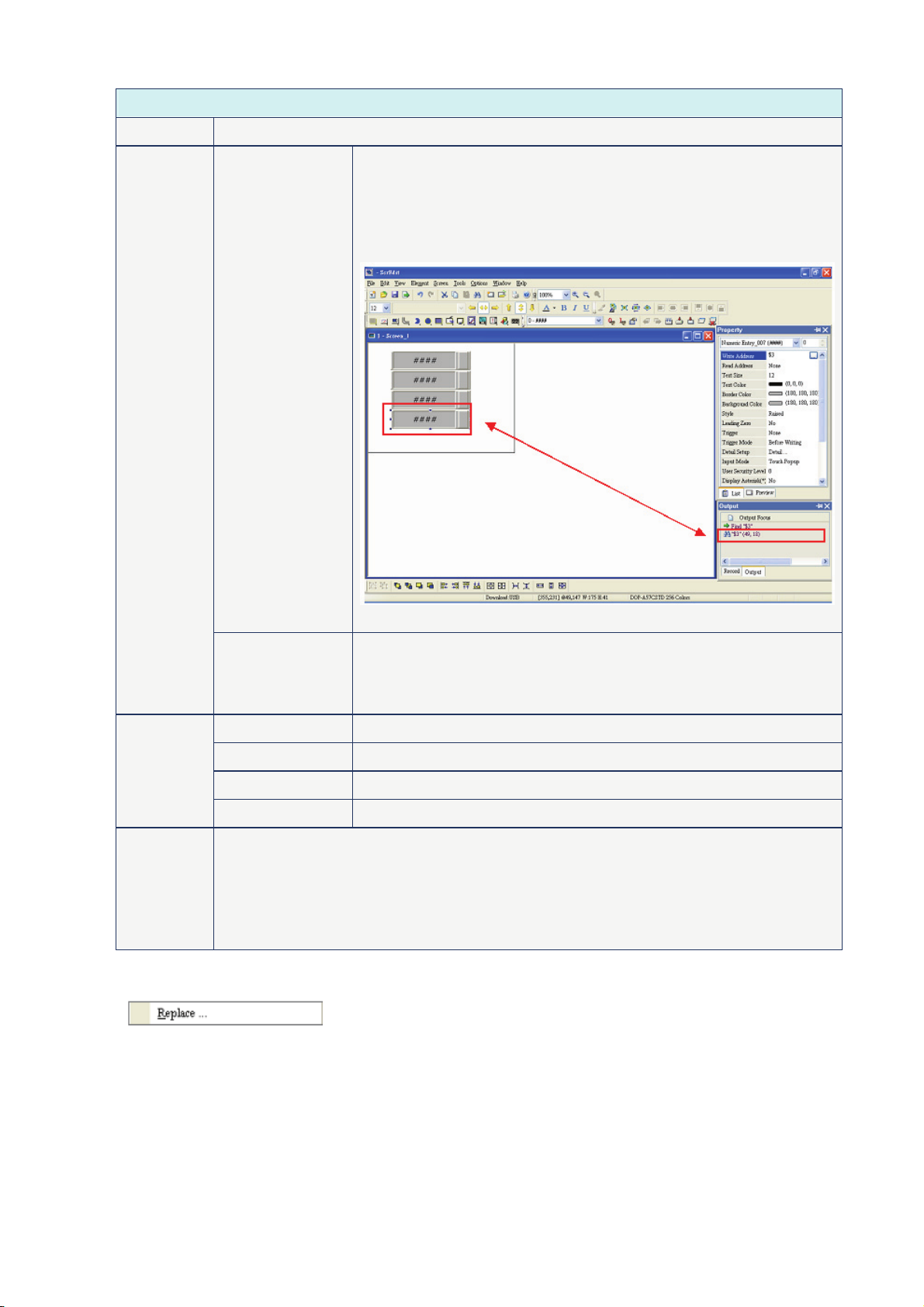

Find

Find What This field is where the user enters the word or phase that the user is looking for

Options

Current Screen This causes ScrEdit to navigate the current screen only and find the

matching word or phase that the user is looking for. The output

window will display all matching words or phases. When the user

double clicks the word or phase, ScrEdit will jump to that location of

the matching word or phase. Please refer to the example screen

below.

Fig. 2.4.3

All Screen This causes ScrEdit to navigate all screens and find the word or phase

that the user is looking for. The output window will display all matching

words or phases. When the user double clicks the word or phase,

ScrEdit will also jump to that location of the matching word or phase.

Type

Text This causes ScrEdit to find the text.

Read Address This causes ScrEdit to find the read address.

Write Address This causes ScrEdit to find the write address.

All Address This causes ScrEdit to find the read and write address.

Check Box If “Match whole word only” box is checked, only the exact word or phase that the user

types will be found. If “Match whole word only” box is not checked, all words that contain

the word or phase that the user types will be found.

If “Support Multi-Language Finding” box is checked, all multi language words that contain

the word or phase that the user types will be found. However, “Support Multi-Language

Finding” option can only be enabled when the find content type is text.

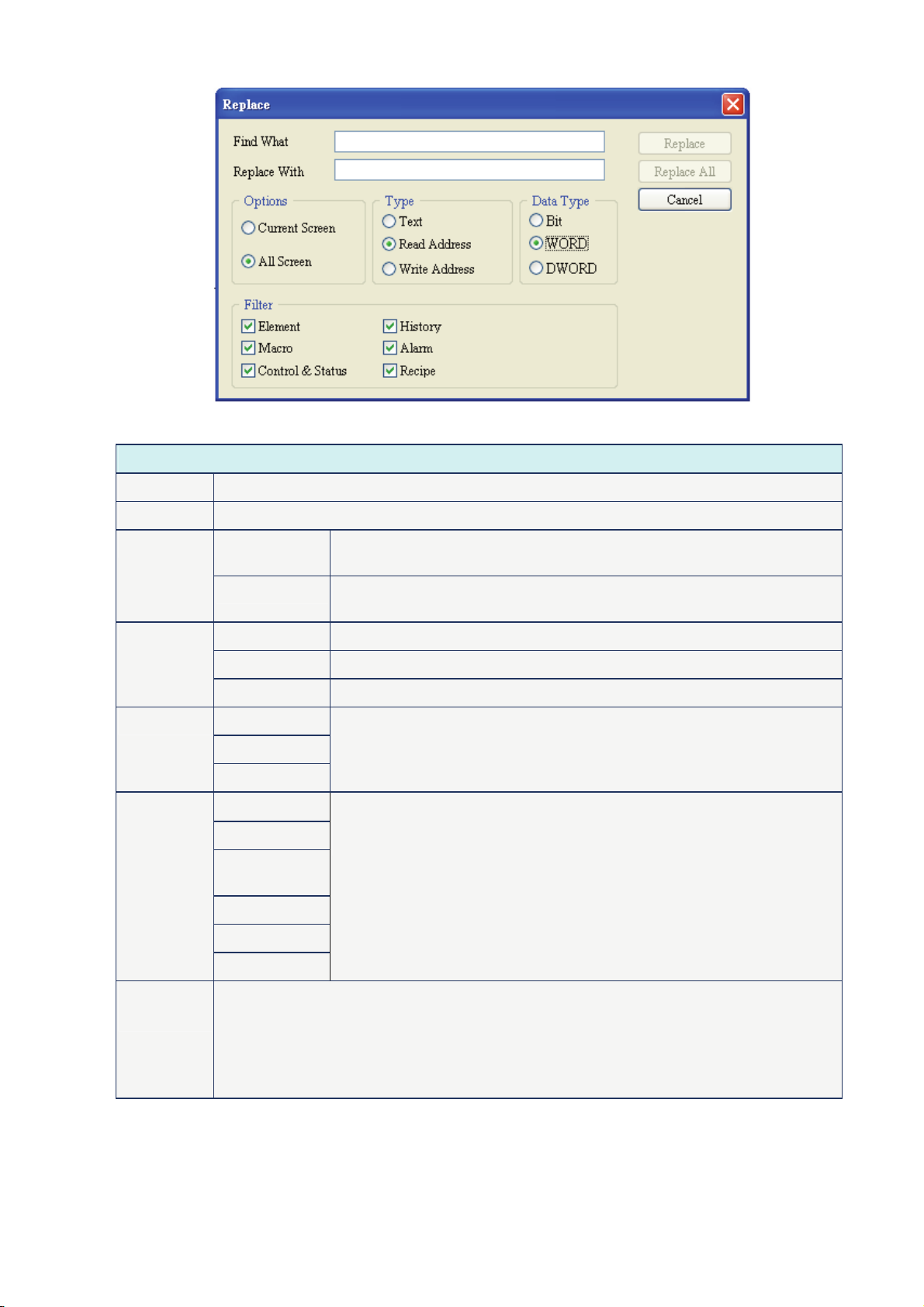

Replace

It is used to replace the content (Fig. 2.4.4). Using this command can replace text, read address and

write address in current screen or all screens. Its function is very similar to Find command expect that it

not only can find the word or phase that the user is looking for but also can replace it with a new entry.

The replace content type could be text, read and write address and the replace content data type could

be Bit, Word or Double Word. The function of replace content data type is enabled only when the

replace content type is either read or write address. Select this function by choosing Edit > Replace

from menu bar or use keyboard shortcuts by pressing Ctrl + R.

Revision Apr. 30th, 2007, 2007PDD23000002 2-25

Page 37

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Fig. 2.4.4 Replace option

Replace

Find What This field is where the user enters the word or phase that the user is looking for

Replace With This field is where the user enters the word or phase that the user wants to replace with

Options

Type

Data Type

Filter

Current Screen This causes ScrEdit to navigate the current screen only, find the matching

word or phase that the user is looking for and replace it.

All Screen This causes ScrEdit to navigate all screens and find the matching word or

phase that the user is looking for and replace it.

Text This causes ScrEdit to find and replace the text.

Read Address This causes ScrEdit to find and replace the read address.

Write Address This causes ScrEdit to find and replace the write address.

Bit

WORD

DWORD

Element

Macro

Control &

Status

History

Alarm

The function of replace content data type is enabled only when the

replace content type is either read or write address. The replace content

data type could be Bit, Word or Double Word.

This option is available when the replace content is read and write

address. There are six options for selection, Element, Macro, Control &

Status, History, Alarm and Recipe.

Recipe

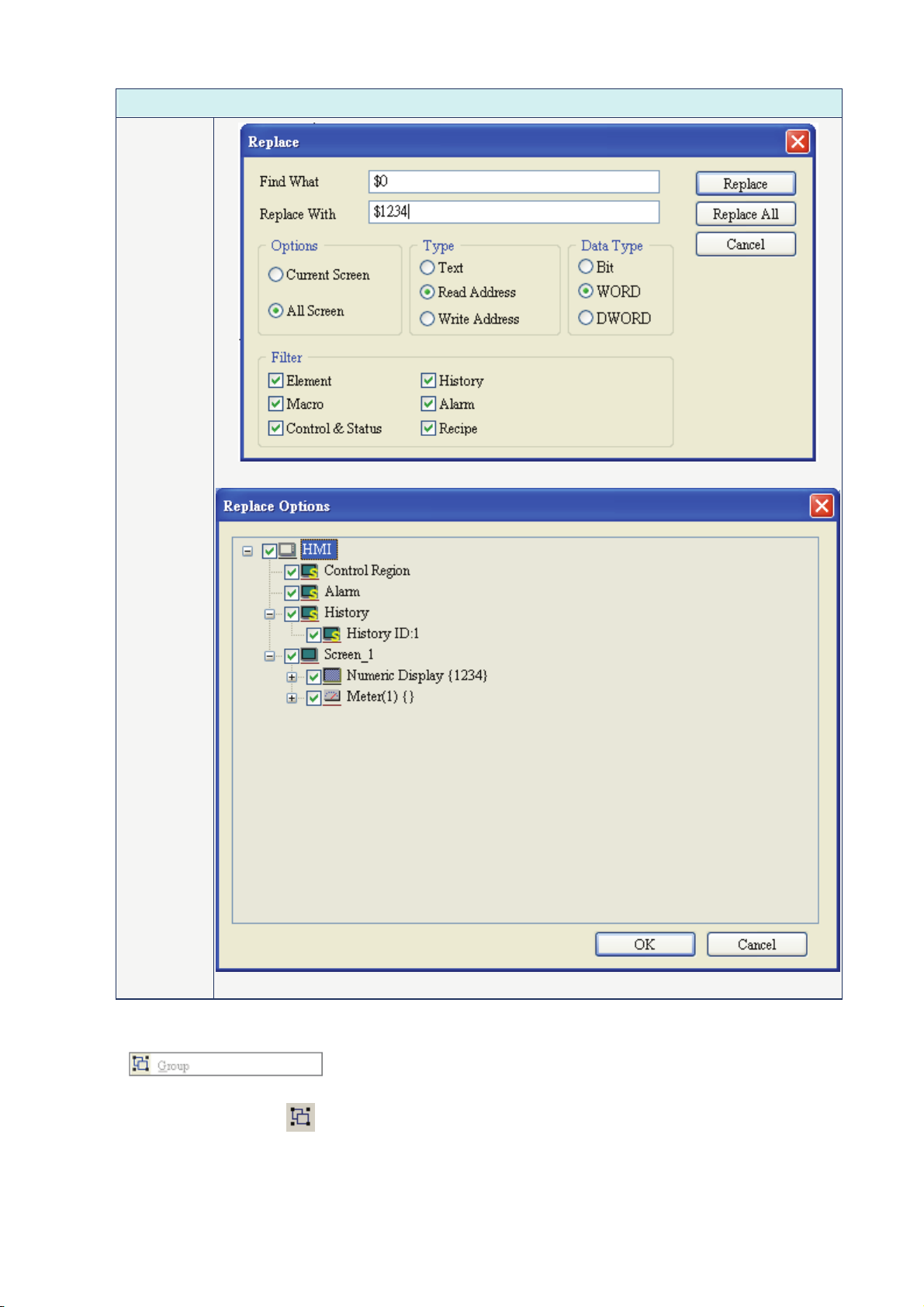

Replace

Replace All

2-26 Revision Apr. 30th, 2007, 2007PDD23000002

Replace button is used to replace the word or phase that the user types and find and

select the next one. For example, the user wants to replace the read address from $0 to

$1234, enter $0 in Find What field, enter $1234 in Replace With field and press Replace

button (Fig. 2.4.5). ScrEdit will find the matching address (Fig. 2.4.6) and the user can

select which the address of the element should be replaced. Replace All button is used to

replace all found matching words automatically.

Page 38

Replace

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Fig. 2.4.5

Fig. 2.4.6

Group

It is used to group elements in ScrEdit. Select this function by choosing Edit > Group from menu bar or

clicking the Group icon

as a single unit and move together but the element size cannot be changed.

Revision Apr. 30th, 2007, 2007PDD23000002 2-27

from toolbar. When two or more elements are grouped, it will be regarded

Page 39

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Ungroup

It is used to ungroup elements in ScrEdit. Select this function by choosing Edit > Ungroup from menu

bar or clicking the Group icon

Order

It is used to set and change the stacking order of the selected element. Select this function by

choosing Edit > Order from menu bar or clicking the Order icons

Bring to Front. Move the selected element to the front of all other elements.

Send to Bottom. Move the selected element behind all other elements.

Bring Forward. Move the selected element forward one position.

Send Backward. Move the selected element behind one position.

Align

It is used to align the element. The user can select this function by choosing Edit > Align from menu

bar or clicking the Align icons from toolbar.

The Align icons includes:

from toolbar.

from toolbar.

: Align Left; : Align Right; : Align Top; : Align Bottom;

: Center Vertically; : Center Horizontally;

: Across Space Evenly; : Down Space Evenly.

Align Left, Align Right, Align Top and Align Bottom commands are available when two or more

elements are selected. That is because the element only can be left, right, top and bottom aligned

relative to another element. Align Vertical Center and Align Horizontal Center commands are available

when one or more elements are selected. Across Space Evenly and Down Space Evenly are available

when three or more elements are selected.

After Align commands are used, the coordinates of the elements will changed to the coordinates of the

new position.

Center Vertically: Set the element to be the vertical position of the work place.

Center Horizontally: Set the element to be the horizontal position of the work place.

Across Space Evenly: Make all the elements align in a consistent width.

Down Space Evenly: Make all the elements align in a consistent height.

Make Same Size

It is used to make the element to be the same size. The user can select this function by choosing Edit

> Make Same Size from menu bar or clicking the Make Same Size icons from toolbar.

This function is available only when two or more elements are selected. The user has to select one

element first and treat it as standard, and use this command to make other two or more elements to be

the same size.

2-28 Revision Apr. 30th, 2007, 2007PDD23000002

Page 40

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

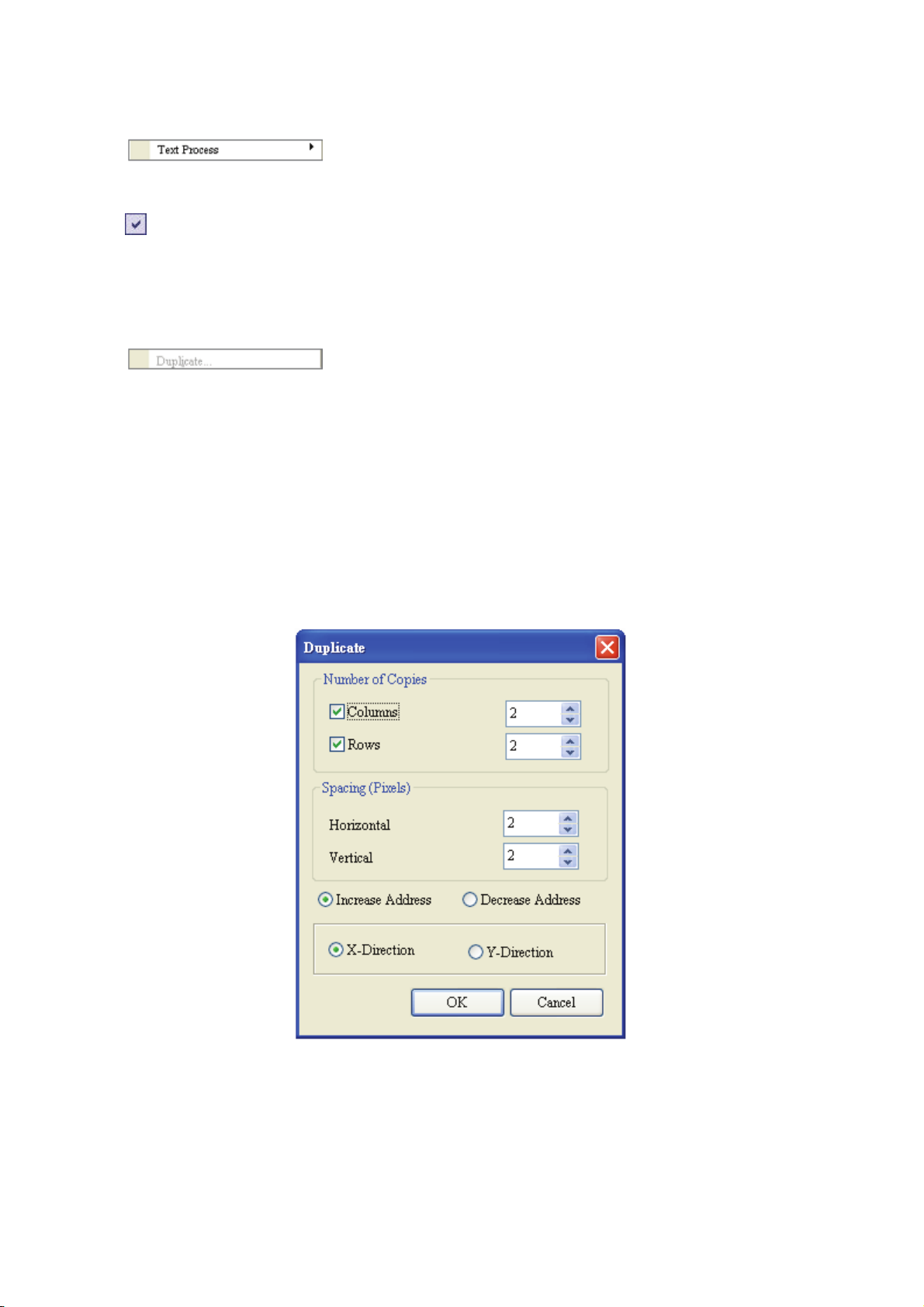

Text Process

It is used to set and change text direction and import text in ScrEdit. The user can select this function

by choosing Edit > Text Process from menu bar or clicking the Text Process icons from toolbar.

next to the Text Process command represents that this function is enabled. In the Import Text

dialog box, the user can decide if use Text Bank Edit Font or not. If the user checks the box next to

Text Bank Edit Font, the imported text will be display by adopting the fonts of Text Bank. For the

settings of Text Bank, please refer to Option > Text Bank.

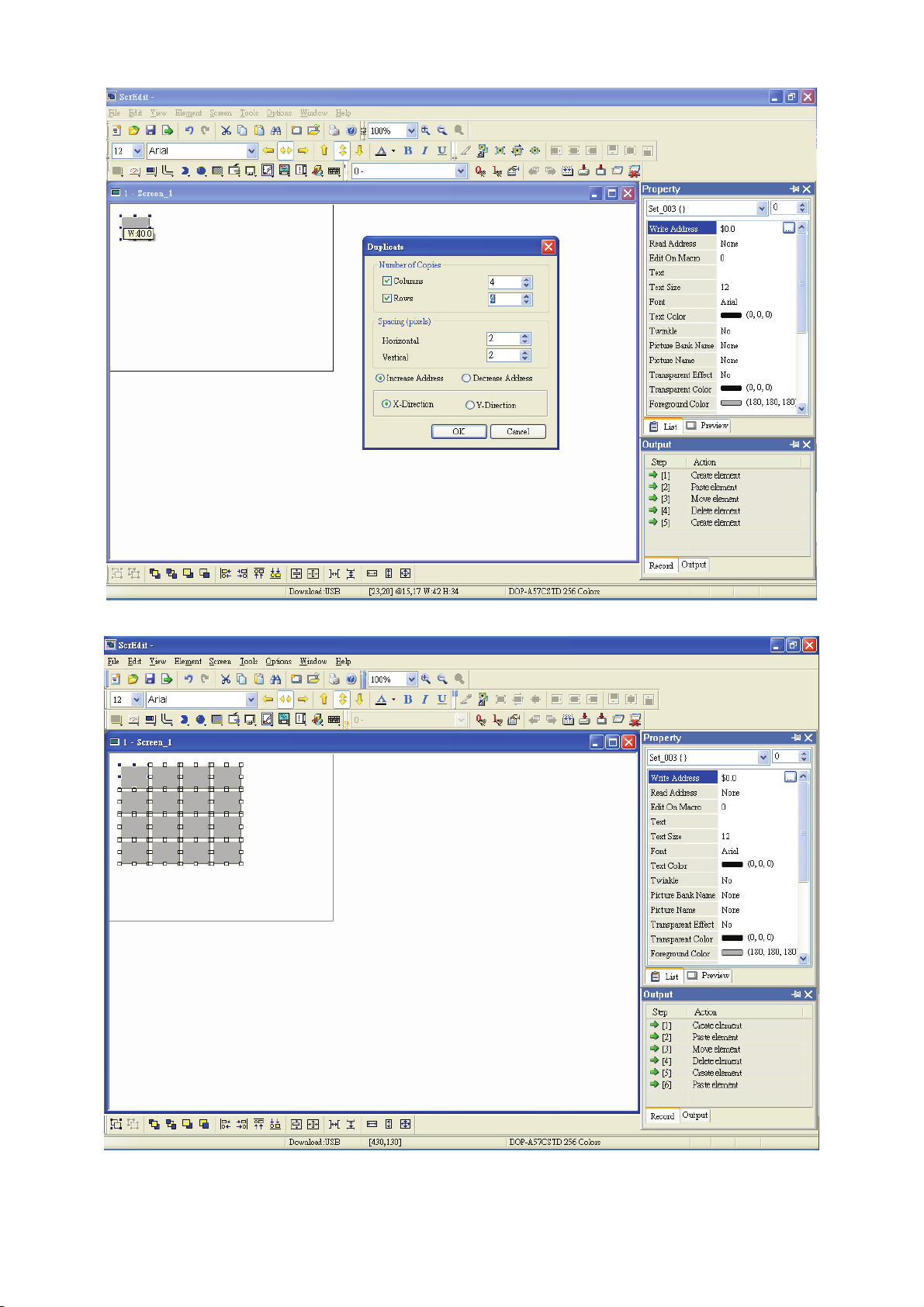

Duplicate

It allows the user to copy one or more elements horizontally and vertically at the same time. After

selecting this function by choosing Edit > Duplicate from menu bar, the Fig. 2.4.7 dialog box will show

up. The user can enter the number of columns and rows to get the total copy numbers. If the user only

wants to copy the number of Rows, please uncheck the box next to Columns. If the user only wants to

copy the number of Columns, please uncheck the box next to Rows.

Spacing (pixels): This option is used to set the spacing by horizontal or vertical direction between every

element. After this option is set, the duplicated elements will be placed in this spacing.

Increase / Decrease Address: This option is used to place the element that the user copies by

ascending or descending address. The unit of the address can be Word or Bit.

X-direction / Y-direction: This option is used to place the element that the user copies by horizontal (Xdirection) or vertical (Y-direction) direction.

Please refer to Fig 2-4-30 and Fig. 2-4-31 for example.

Fig. 2.4.7 Duplicate dialog box

Revision Apr. 30th, 2007, 2007PDD23000002 2-29

Page 41

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Fig. 2.4.8 Duplicate Example 1

Fig. 2.4.9 Duplicate Example 2

2-30 Revision Apr. 30th, 2007, 2007PDD23000002

Page 42

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

2.5 Menu Bar and Toolbar (View)

View

Toolbars

Docking windows

Fig. 2.5.1 View options

In View option, the user can decide how toolbars and docking windows display. Once the user clicks on it, it

will have icon

windows by themselves. If

display on the screen. The description of each toolbar is introduced in the following sections.

Standard Toolbar

in front of it and display on screen. The user can also arrange these toolbars and docking

not show in front of the toolbar, it indicates that the toolbar is hided and not

Table 2.5.1 Standard toolbar

Icon Function Description

New Create a new project

Open Open an old project

Save Save current edited project

Export Export an project to BMP format

Revision Apr. 30th, 2007, 2007PDD23000002 2-31

Undo Undo an action (some can’t be undo)

Redo Redo an action

Cut Cut selected elements

Copy Copy selected elements

Page 43

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Icon Function Description

Status Bar

Display current editing states.

Text Format Toolbar

Paste Paste the element the user copy or cut

Find Find specific text, write address or read address

New Screen Create a new screen

Open Screen Open an old screen

Print Print current project

Help Screen editor version

Fig. 2.5.2 Status bar

Table 2.5.2 Text toolbar

Icon Function Description

Font Size Display and change text size

Font Name Display and change text font

Align Left Align text to left

Center Horizontal

Align Right Align text to right

Align Top Align text to top

Center Vertical

Align Bottom Align text to bottom

Text Color Change text color

The space at the right/left sides of text will be the

same

The space at the top/bottom sides of text will be the

same

2-32 Revision Apr. 30th, 2007, 2007PDD23000002

Bold Text bold

Italic Text Italic

Underline Add line under text

Page 44

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Bitmap Toolbar

Table 2.5.3 Bitmap toolbar

Icon Function Description

Select Transparent

Picture Stretch 1: 1 Scale the picture relative to original picture size

Color

Chang Mode for

Process All State

Picture

Picture Stretch All Stretch the selected picture to the whole range of the element.

Original Picture Resize the selected picture to the actual picture size

Picture Align Left Align the selected picture to left

Picture Center

Horizontal

Picture Align Right Align the selected element to right

Picture Align Top Align the selected element to top

Picture Center

Vertical

Remove the color of the picture and determine the transparent color

of the picture

If this function is enabled, not only the current picture with current

state but also all pictures with all states will be stretched, resized or

aligned

The space at the right/left sides of the selected picture will be the

same

The space at the top/bottom sides of the selected element will be

the same

Picture Align Bottom Align the selected element to bottom

Element Toolbar

Table 2.5.4 Element toolbar

Icon Function Drop-down Menu

Button

Revision Apr. 30th, 2007, 2007PDD23000002 2-33

Page 45

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Icon Function Drop-down Menu

Meter

Bar

Pipe

Pie

Indicator

Display

Movement

Input

Curve

History

2-34 Revision Apr. 30th, 2007, 2007PDD23000002

Page 46

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Icon Function Drop-down Menu

Alarm

Graphic

Keypad

Build / Layout Toolbar

Build Toolbar

Icon Function Description

Table. 2.5.5 Build toolbar

Current Element State Text on selected element

View State OFF/1 Switch and view current state OFF/1

View State ON/1 Switch and view current state ON/1

Display All Read/Write

Address

Previous windows Select previous windows

Next windows Select the next windows

Display all read/write addresses of all

elements

Download Screen and

Revision Apr. 30th, 2007, 2007PDD23000002 2-35

Compile Compile current element

Recipe

Download Screen Download screen data

On-line Simulation

Off-line Simulation

Download screen data and recipe

Test editing file at PC side and it needs to

connect to the controller

Test editing file at PC side and it doesn’t

need to connect to the controller

Page 47

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Layout Toolbar

Table. 2.5.6 Layout toolbar

Icon Function Description

Group Group the selected elements

Ungroup Ungroup the selected elements

Bring to Front

Send to Bottom

Bring Forward

Send Backward Move the selected element behind one position

Align Left Align the selected elements to left

Align Right Align the selected elements to right

Align Top Align the selected elements to top

Align Bottom Align the selected elements to bottom

Center Vertically

Move the selected element to the front of all

other elements

Move the selected element behind all other

elements

Move the selected element forward one

position

Set the element to be the vertical position of

the work place

Set the element to be the horizontal position of

the work place

Make all the elements align in a consistent

width

Make all the elements align in a consistent

height

Make the selected elements to be the same

width

Make the selected elements to be the same

height

Make the selected elements to be the same

size

Zoom Toolbar

Center Horizontally

Across Space Evenly

Down Space Evenly

Make Same Width

Make Same Height

Make Same Size

Table. 2.5.7 Zoom toolbar

Icon Function Description

Display Level

Lets the user set a zoom level, including 25%, 50%, 75%, 100%, 150%,

200% and 300%

2-36 Revision Apr. 30th, 2007, 2007PDD23000002

Zoom In

Lets the user change the magnification level, including 150%, 200%

and 300%.

Page 48

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Icon Function Description

Property Table

Element property table. Please refer to Chapter 3 for detailed description.

Zoom Out

1:1 Lets the user change element size to actual size (100%).

Lets the user reduce the magnification level, including 25%, 50% and

75%.

Fig. 2.5.3 Property table

Output Window

All editing processes during compile operation will be shown here for user’s reference. It can let the

user know the result of the compile operation and it is also convenient for tracing error address when

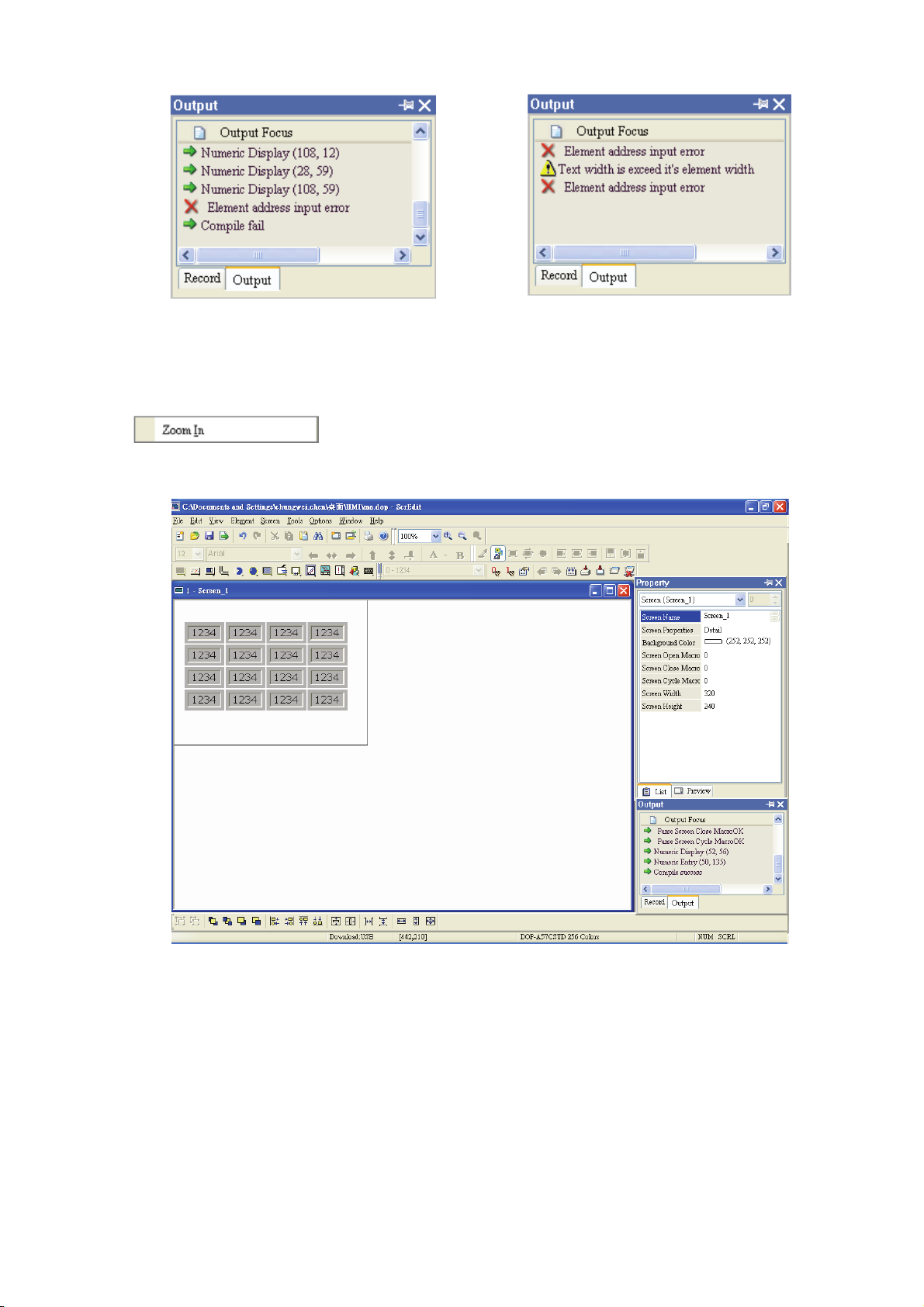

creating and editing screen (See Fig. 2.5.4, Fig. 2.5.5, Fig. 2.5.6 and Fig. 2.5.7).

Fig. 2.5.4 Output window

Fig. 2.5.5 Output window during compile operation

Revision Apr. 30th, 2007, 2007PDD23000002 2-37

Page 49

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Fig. 2.5.6 Output result of compile operation

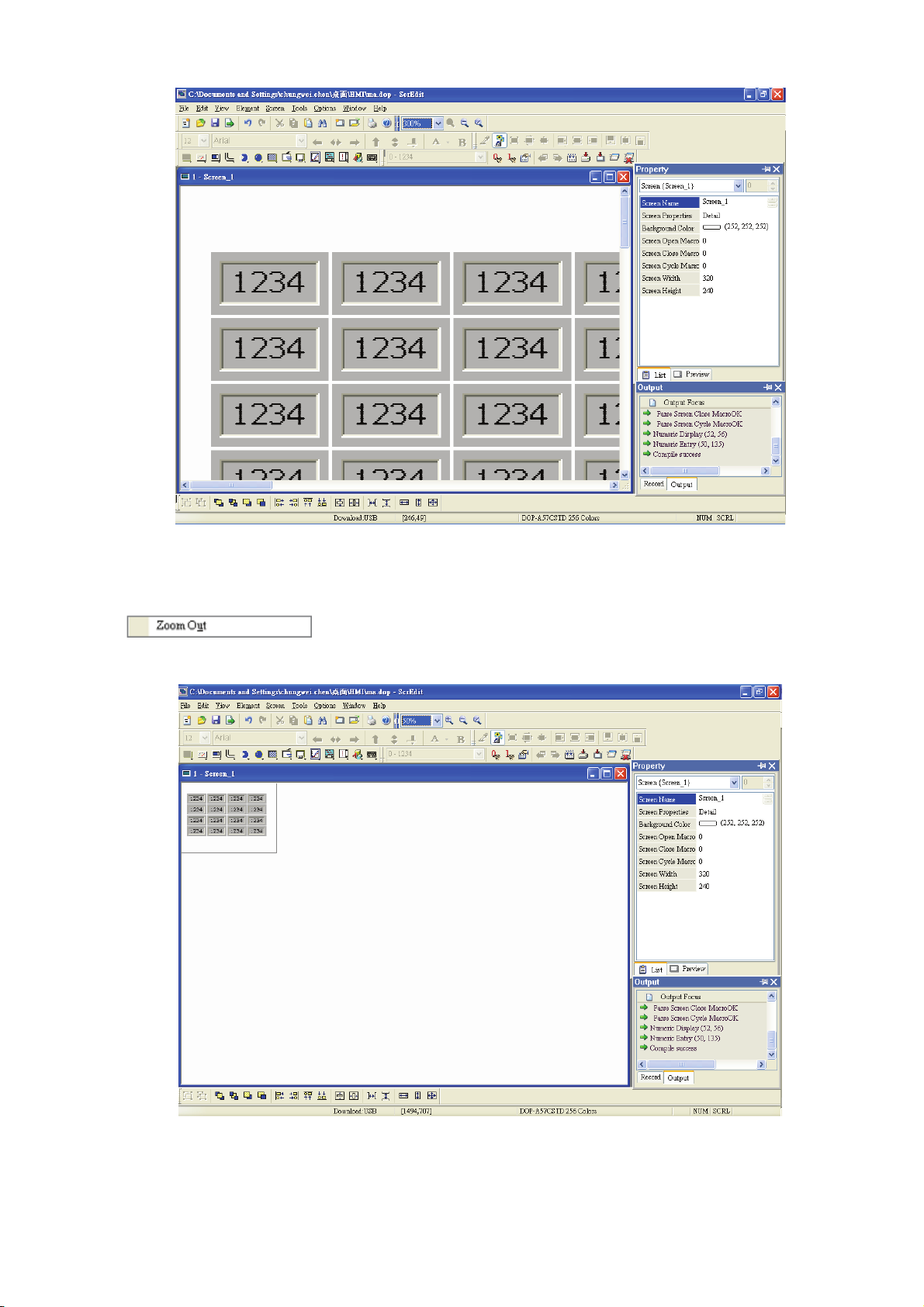

Zoom In

Zoom in to get a close look at the elements on ScrEdit work place. (Refer to Fig. 2.5.8, Fig. 2.5.9)

Fig. 2.5.7 Error output

Fig. 2.5.8 Zoom level = 100% (Before Choosing Zoom In command)

2-38 Revision Apr. 30th, 2007, 2007PDD23000002

Page 50

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Fig. 2.5.9 Zoom level = 300% (After Choosing Zoom In command)

Zoom Out

Zoom out to see more look of the elements on ScrEdit work place. (Refer to Fig. 2.5.10)

Fig. 2.5.10 Zoom level = 50% (After Choosing Zoom Out command)

Revision Apr. 30th, 2007, 2007PDD23000002 2-39

Page 51

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

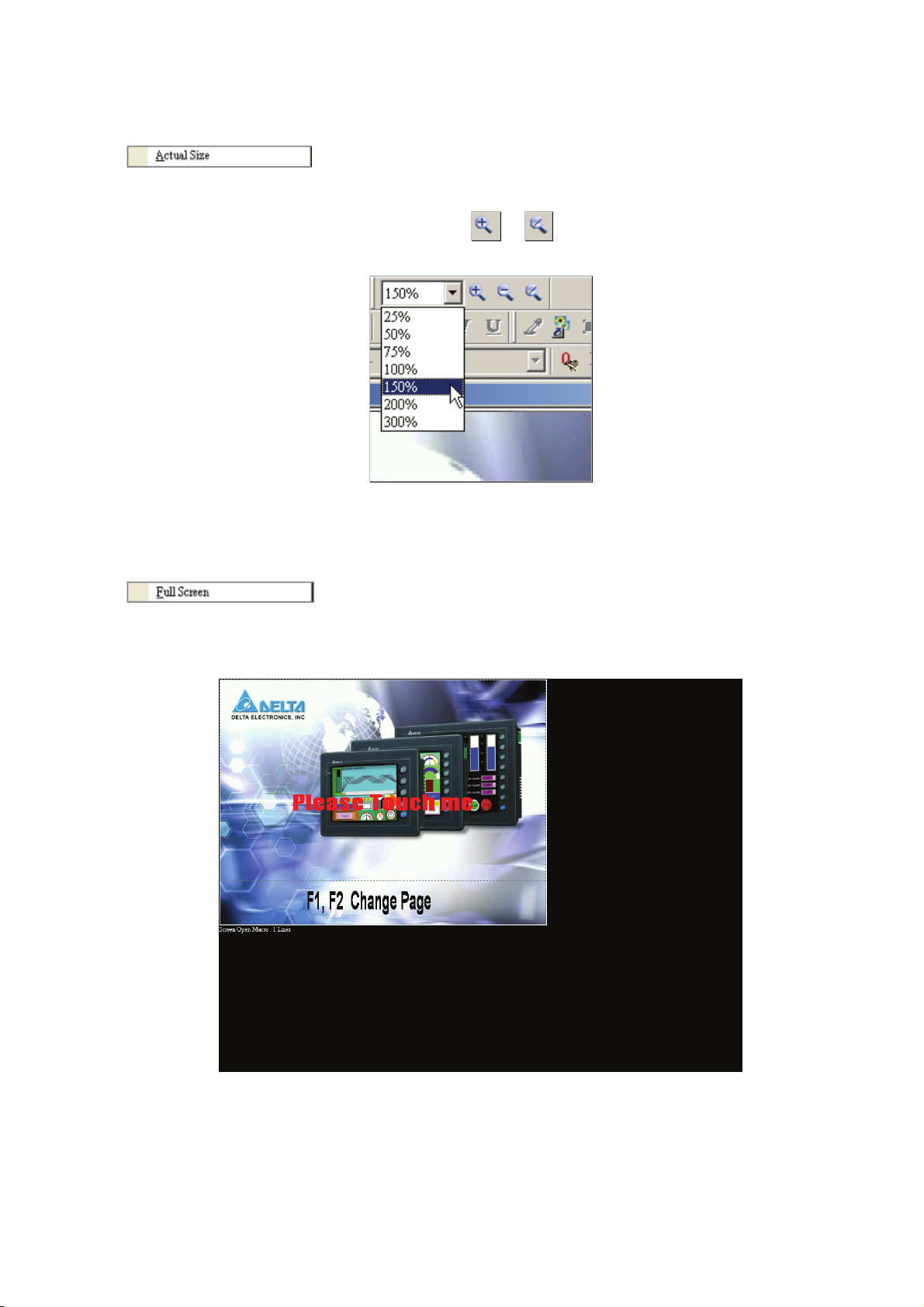

Actual Size

Return to actual size (100%). This size is relative to the screen size of HMI.

The user can also zoom in or out by clicking icon or or selecting the Zoom level directly (Fig.

2.5.11).

Fig. 2.5.11 Zoom level

Full Screen

As Fig. 2.5.12. Full screen provides maximum view to edit in ScrEdit. Full screen view will hide all

toolbars and docking windows other than the ScrEdit work place itself. Fig. 2.5.12 full screen also

shows the reference macro command.

Fig. 2.5.12 Full Screen (Pressing Esc key or left-click the mouse can exit Full screen)

2-40 Revision Apr. 30th, 2007, 2007PDD23000002

Page 52

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

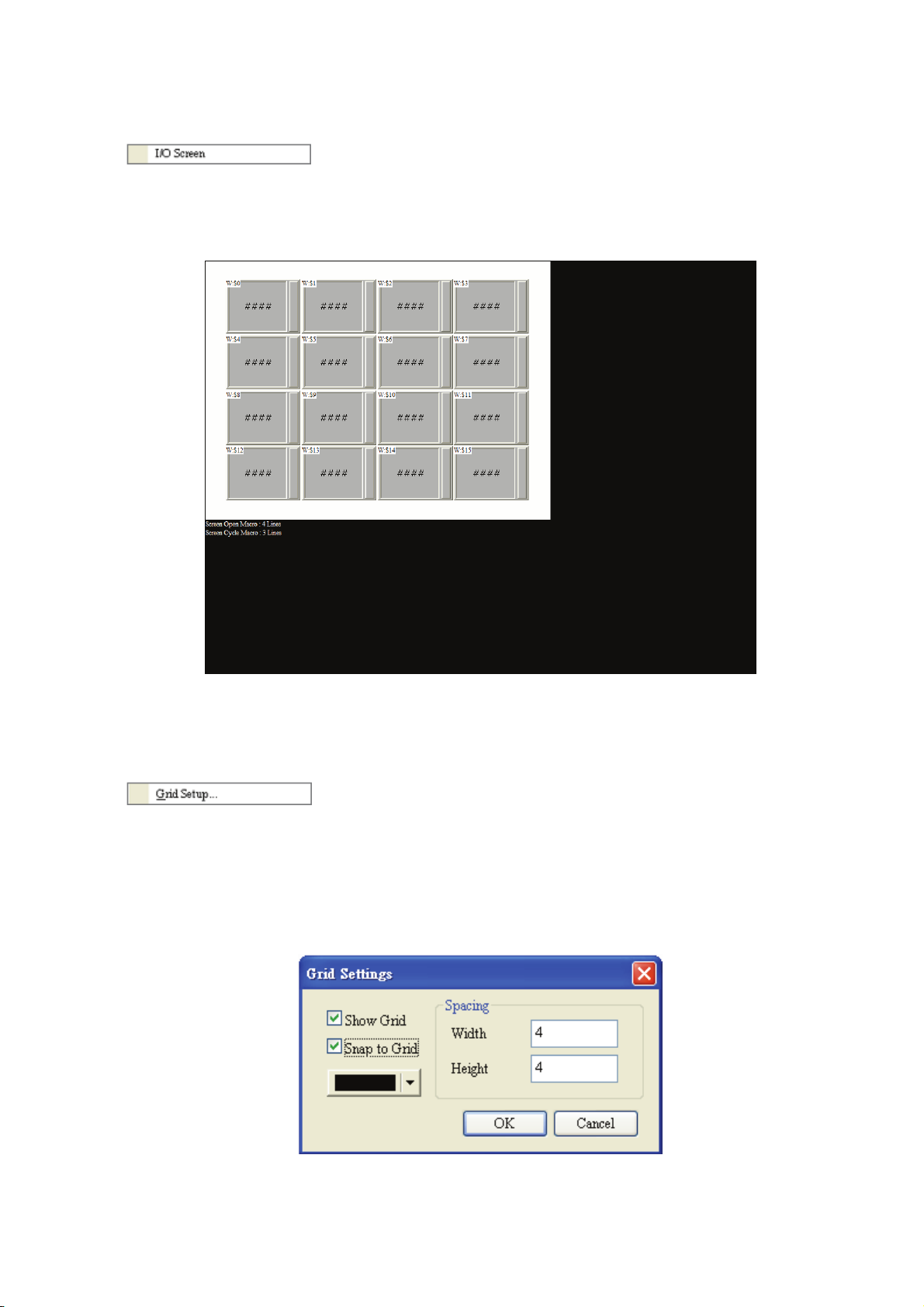

I/O Screen

As Fig. 2.5.13. I/O screen also provides maximum view to edit in ScrEdit just like Full screen. But the

difference is that I/O Screen will show the read and write addresses of the element and also shows the

set macro commands.

Fig. 2.5.13 I/O Screen (Pressing Esc key or left-click the mouse can exit Full screen)

Grid Setup

Grid Setup is a function that can help the user to align and position the element more easily and

precisely. The distance (spacing) between the grid dots can be set by the user freely (Fig. 2.5.14 and

Fig. 2.5.15).

Show Grid: Show the grid dots on the screen.

Snap to Grid: Make the elements snap to grid so that the elements can jump between grid lines when

the user moves them.

Fig. 2.5.14 Gird Settings dialog box

Revision Apr. 30th, 2007, 2007PDD23000002 2-41

Page 53

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Fig. 2.5.15 Show Gird screen

2-42 Revision Apr. 30th, 2007, 2007PDD23000002

Page 54

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

2.6 Menu Bar and Toolbar (Element)

Element

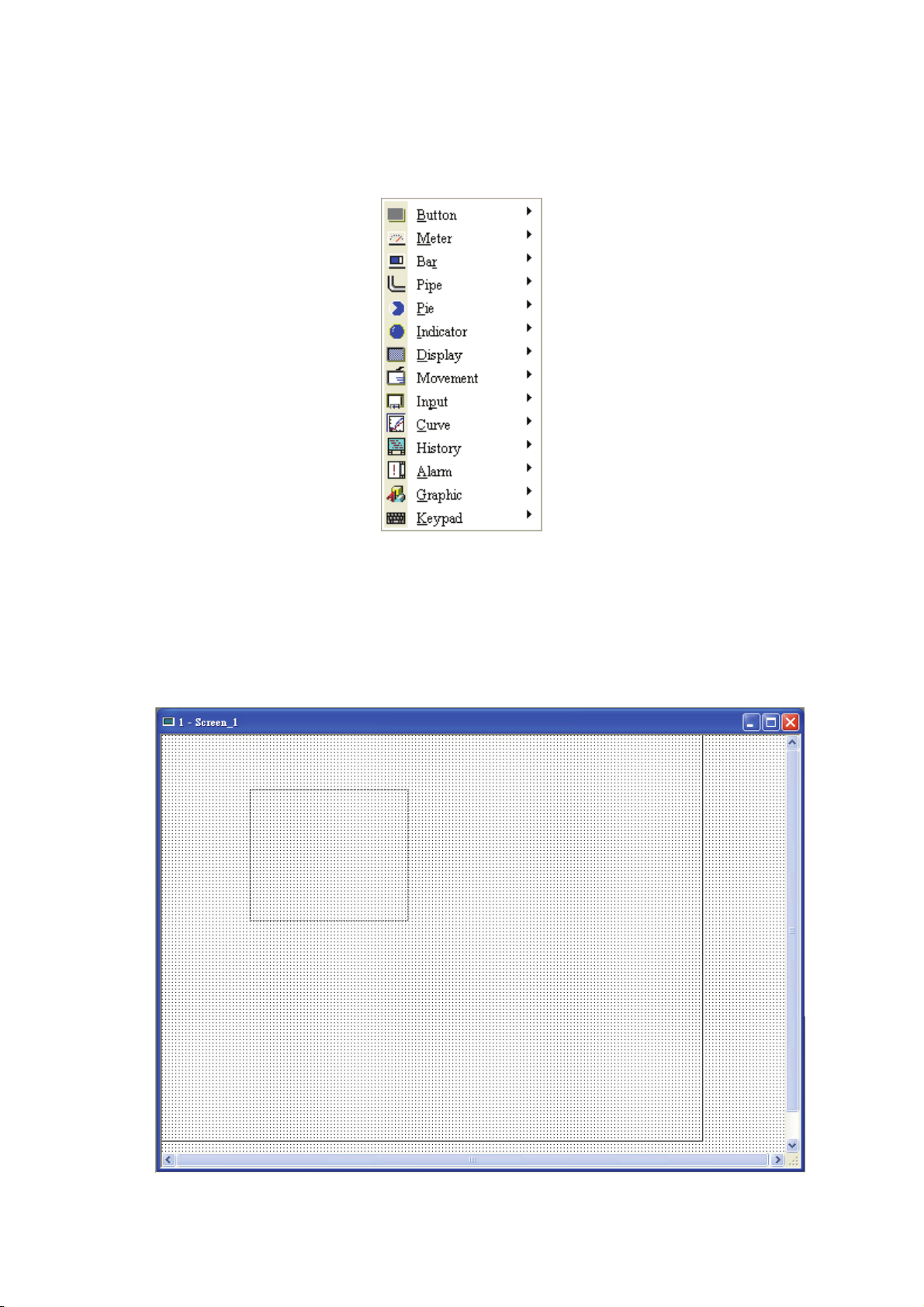

Fig. 2.6.1 Element options

Screen editor provides 14 types of elements and there are many styles for each type. These 14 types

include Button, Meter, Bar, Pipe, Pie, Indicator, Display (data display), Movement (graph display), input,

curve, history (sampling), alarm, graphic and, keypad, etc. The user can select a desired element from the

pull-down menu and drag the size needed on ScrEdit work place (as Fig. 2.6.2 and Fig. 2.6.3).

Fig. 2.6.2 Drag mouse to determine the element size

Revision Apr. 30th, 2007, 2007PDD23000002 2-43

Page 55

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Fig. 2.6.3 Element display (Create an element)

The user can also right-click the mouse to select the desired element. For the property of each element,

please refer to Chapter 3 for detailed description.

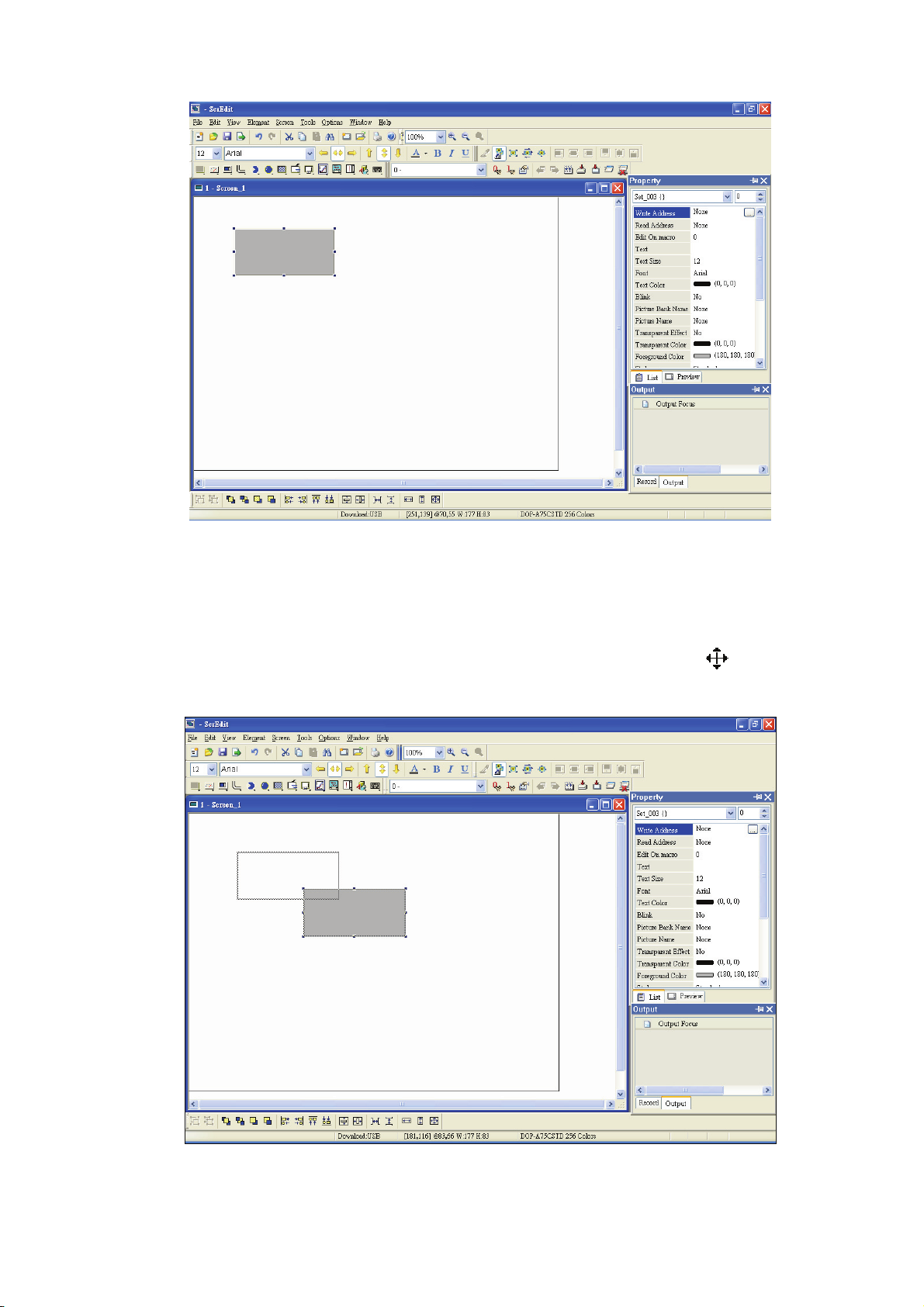

Create an Element

The user can select an element by right-clicking the mouse in work place. Place your mouse pointer in

work place and right-click the mouse to get pull-down menu. Then, the user can select the desired

element and determine the element size by left-clicking the mouse. Later set the property of the

element (Fig. 2.6.4, Fig. 2.6.5, Fig. 2.6.6 and Fig. 2.6.7).

Fig. 2.6.4 Right-click the mouse to select the element

2-44 Revision Apr. 30th, 2007, 2007PDD23000002

Page 56

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Fig. 2.6.5 Select an element by choosing Element command from menu bar

Fig. 2.6.6 Drag with left mouse button (Left-click the mouse, hold it to drag and release it to finish)

Revision Apr. 30th, 2007, 2007PDD23000002 2-45

Page 57

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Fig. 2.6.7 Release left mouse button to create an element

Move an Element

The user can use the mouse to move an element. Mouse operation is the same as working in

Windows® operating system. When the mouse cursor changes to a four-arrow icon

left-click the mouse and move the element freely (Fig. 2.6.8).

, the user can

Fig. 2.6.8 Move an Element

2-46 Revision Apr. 30th, 2007, 2007PDD23000002

Page 58

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Modify Element Width

The user can also use the mouse to modify the width of an element. When the mouse cursor changes

to a two-arrow icon

, the user can left-click the mouse and modify the element width (Fig. 2.6.9).

Fig. 2.6.9 Modify Element Width

Modify Element Height

The user can also use the mouse to modify the height of an element. When the mouse cursor changes

to a two-arrow icon

, the user can left-click the mouse and modify the element height (Fig. 2.6.10).

Fig. 2.6.10 Modify Element Height

Revision Apr. 30th, 2007, 2007PDD23000002 2-47

Page 59

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Modify Element Width and Height Simultaneously

The user can also use the mouse to modify the width and height of an element simultaneously. When

the mouse cursor changes to a two-arrow icon

the element width and height at the same time (Fig. 2.6.11).

Fig. 2.6.11 Modify Element Width and Height Simultaneously

or , the user can left-click the mouse and modify

Input Characters

The user can input a string of characters that Windows® operating system accepts in the property

table. When the mouse cursor changes to an icon

Windows® operating system accepts where the cursor

, the user can start to input any characters that

blinks (Fig. 2.6.12).

Fig. 2.6.12 Input Characters

2-48 Revision Apr. 30th, 2007, 2007PDD23000002

Page 60

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Right-click the Mouse

The user can find that different menu will pop up when right-clicking the mouse (Fig. 2.6.13, Fig. 2.6.14

and Fig. 2.6.15).

Fig. 2.6.13 Right-click the mouse on Toolbar - Toolbars window

Fig. 2.6.14 Right-click the mouse in Work Place - Element Selection

Revision Apr. 30th, 2007, 2007PDD23000002 2-49

Page 61

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Fig. 2.6.15 Right-click the mouse on the element - Editing options (Layout Toolbar)

Cross Reference Table

When creating and editing various kinds of elements, what usually happens is that the repeat use of the

same address. In order to avoid this situation, ScrEdit provides the cross reference table function for

the user’s convenience and quick reference. The user can view the read and write addresses of the

selected element and see their relationship or connection with the addresses of other elements, macro

commands or system control area. The user can see how to choose Cross Reference Table

command from menu bar. Fig. 2.6.16 is one simple example to introduce the usage of this function.

The first row of the cross reference table displays the referred element the user selected and the other

rows below the first row displays the elements which have the same write address. The user can

double-click the row and ScrEdit will switch to the corresponding screen of the referred address

automatically. In Fig.2.6.16, ScrEdit switches to the corresponding screen of the referred address

automatically and select the reference element.

Fig. 2.6.16 Cross Reference Table dialog box

2-50 Revision Apr. 30th, 2007, 2007PDD23000002

Page 62

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Element Part List

When Element Part List function is enabled, ScrEdit will sort out and classify all the elements on the

current screen. The user can click the tab to switch to the classification that the user wants to view. The

related addresses and corresponding properties will be listed in each classification (Name, Describe,

Write / Read address, Trigger address, Trigger type, Interlock and Level) in each tab (Fig. 2.6.17). The

user can double-click the column to let ScrEdit select the element automatically and allow the user to

edit the detailed property of the selected element in property table.

Fig. 2.6.17 Element Part List dialog box

Revision Apr. 30th, 2007, 2007PDD23000002 2-51

Page 63

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

2.7 Menu Bar and Toolbar (Screen)

Screen

In Screen options, ScrEdit provides some screen editing functions (Fig. 2.7.1). Please refer to the following

sections for more detailed introduction.

Fig. 2.7.1 Screen options

If the user presses the close box, it will hide the current screen without exiting. In Windows, it will exit the

current screen by clicking close box and remind the user to save before exiting. However, in ScrEdit

environment, the current screen will not be deleted and it will not remind the user to save. The function of

clicking the close box only hides the current screen.

New Screen

Create a new screen. The user can choose Screen > New Screen or click the New Screen icon

or use keyboard shortcuts by pressing Shift + N to open a new editing screen. The new screen can be

named and numbered by the user. The setting dialog box is shown as Fig. 2.7.2.

,

Fig. 2.7.2 New Screen dialog box

2-52 Revision Apr. 30th, 2007, 2007PDD23000002

Page 64

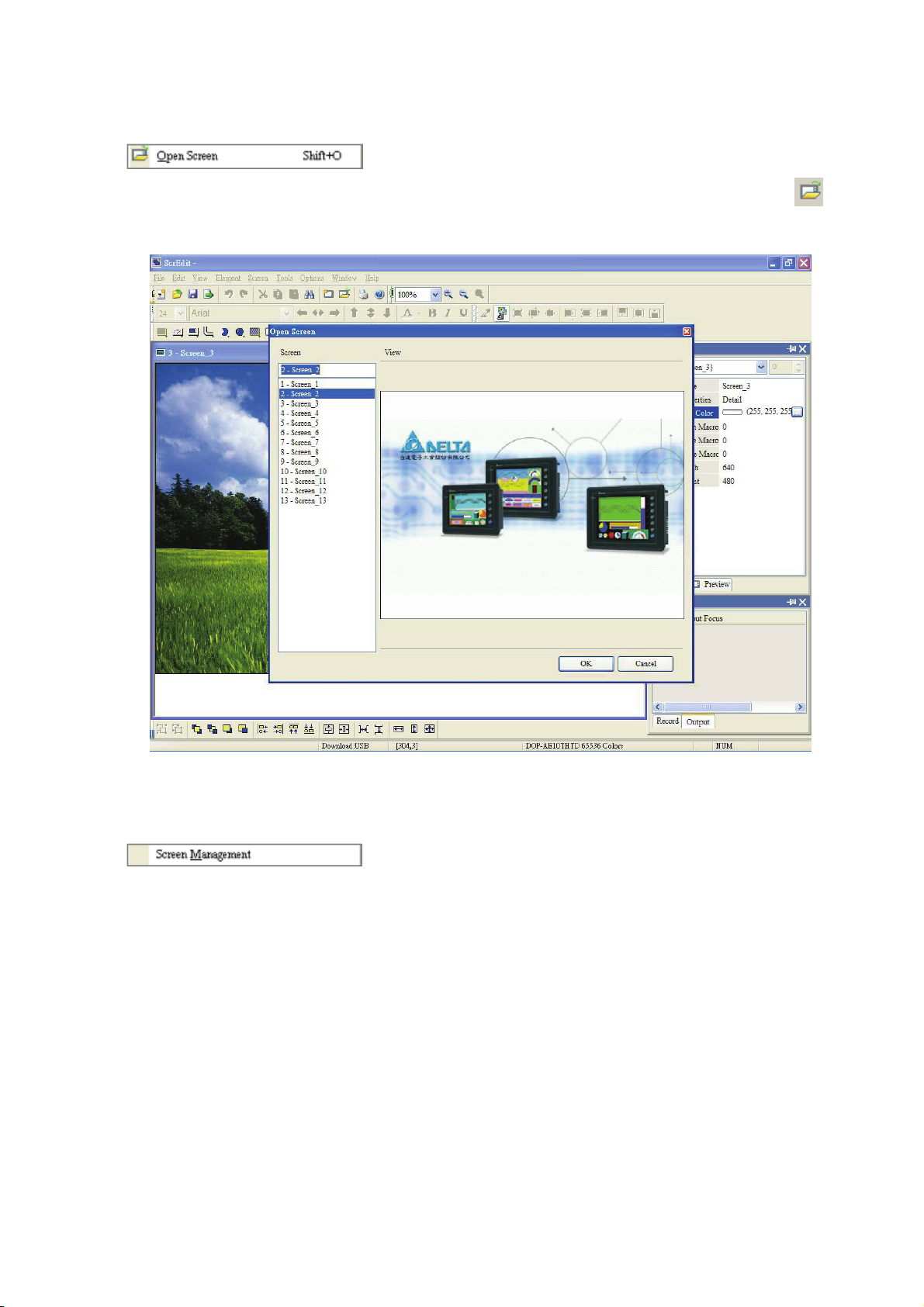

Open Screen

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Open an old screen. The user can choose Screen > Open Screen or click the Open Screen icon

or use keyboard shortcuts by pressing Shift + O. When choosing open screen, the user can preview

each screen in Open Screen dialog box (Fig. 2.7.3).

,

Fig. 2.7.3 Open Screen dialog box

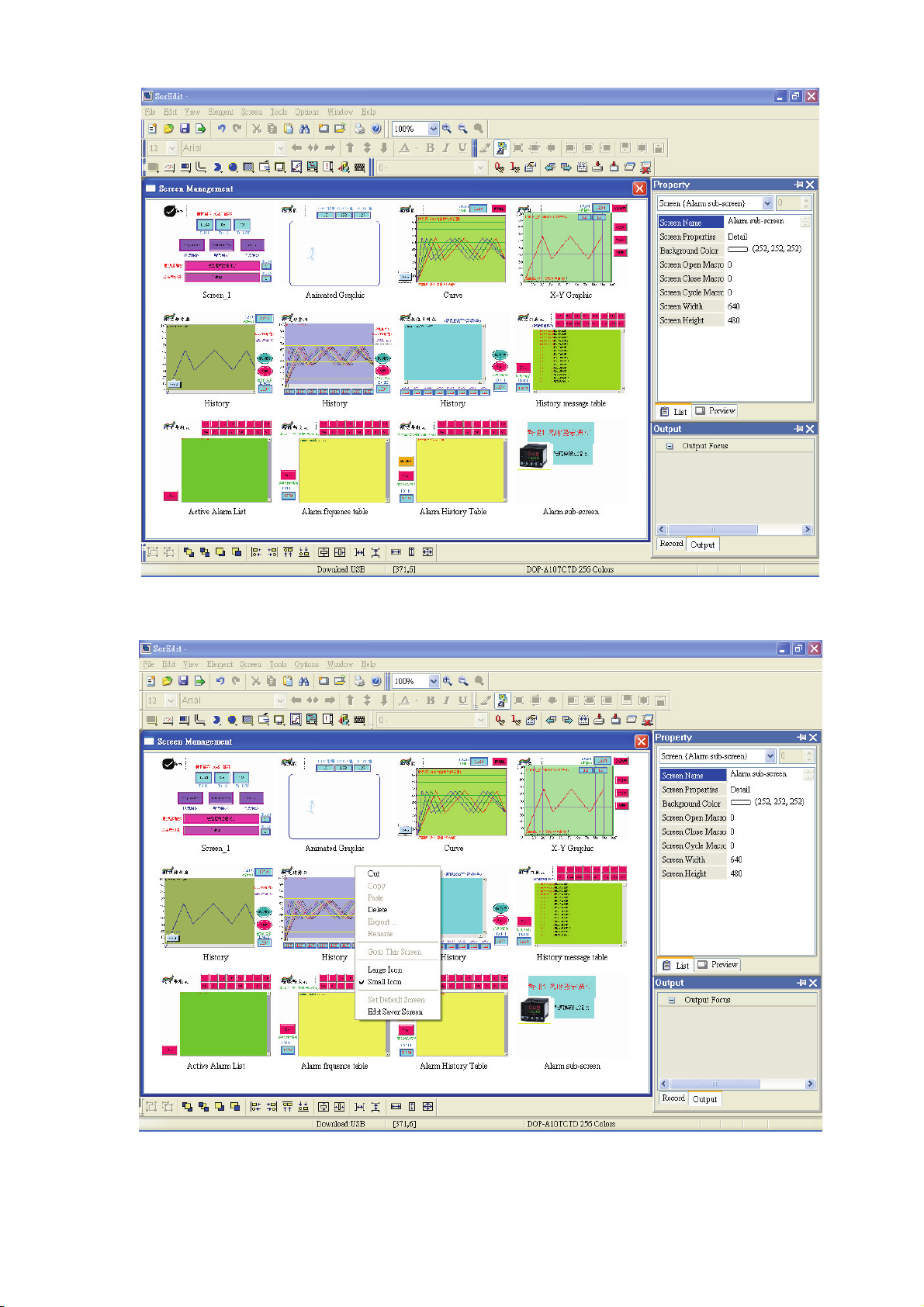

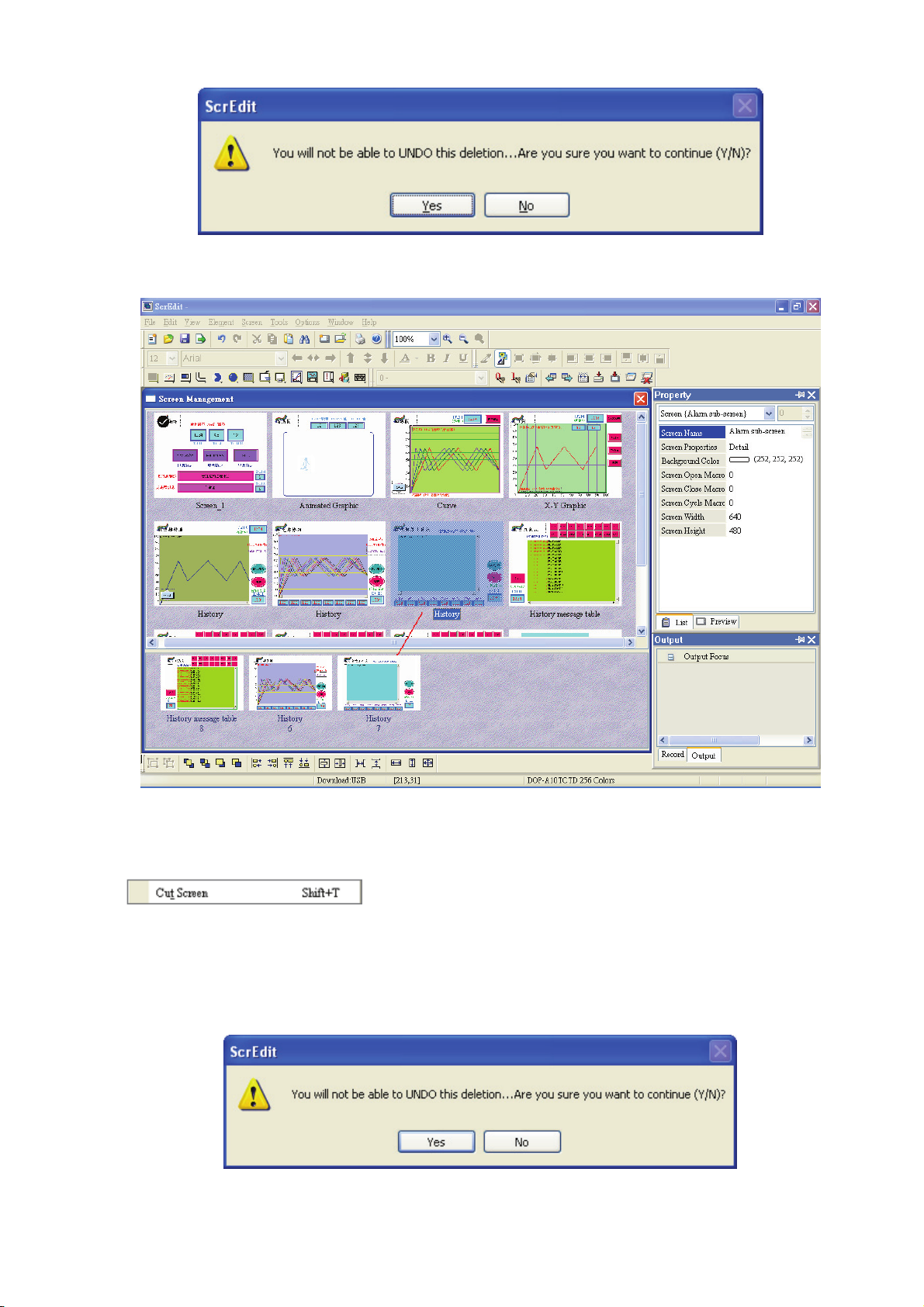

Screen Management

When Screen Management function is enabled (Fig. 2.7.4), the user can duplicate, paste and cut the

screen using the mouse, just like the function of Windows Explorer in Windows® operating system. In

Screen Management dialog box, the user can right click the mouse to manage all of the screens (Fig.

2.7.5). Please note that the user cannot undo the action of cut screen. It is the same as delete screen

that screen will be lost but it can be pasted to get the same screen (Fig. 2.7.6). Besides, right-click the

mouse to select the Edit Save Screen function, and then the user can drag the mouse to determine

the screen saver display (Fig. 2.7.7). For the setting of screen saver, please click Options >

Configuration > Other.

Revision Apr. 30th, 2007, 2007PDD23000002 2-53

Page 65

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Fig. 2.7.4 Screen Management dialog box

Fig. 2.7.5 Right-click the mouse

2-54 Revision Apr. 30th, 2007, 2007PDD23000002

Page 66

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Fig. 2.7.6 Warning message after screen is cut

Fig. 2.7.7 Drag the mouse to determine the screen saver display

Cut Screen

Cut whole screen to clipboard, just like the Microsoft Office Clipboard function. The difference is that

Microsoft Office Clipboard allows the user to cut text and graphic items and the Cut Screen function

only allows the user to cut a whole screen. The user can execute this function by choosing Screen >

Cut Screen, or use keyboard shortcuts by pressing Shift + T.

Please note that the user cannot undo the action of cut screen. It is the same as delete screen

that screen will be lost but it can be pasted to get the same screen (Fig.2.7.8).

Fig. 2.7.8 Cut Screen message

Revision Apr. 30th, 2007, 2007PDD23000002 2-55

Page 67

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Copy Screen

Copy whole screen. The user can execute this function by clicking Screen > Copy Screen or use

keyboard shortcuts by pressing Shift + C.

Paste Screen

The user can paste a screen by clicking Screen > Paste Screen or use keyboard shortcuts by pressing

Shift + P. All screen setting will be the same as original screen after pasting but the screen number will

be given automatically by ScrEdit.

Delete Screen

Delete the current editing screen or element. The user can delete a screen by clicking Screen > Delete

Screen or use keyboard shortcuts by pressing Shift + D.

Please note that after executing Delete Screen, the user cannot undo the action of delete screen

(Fig.2.7.9).

Fig. 2.7.9 Delete Screen Message

Export

Export an project to BMP format. The user can execute this function by clicking Screen > Export or

clicking the Export icon

Import

Import a picture to be the background of the editing screen. Please note that this background of the

editing screen is different than the base screen. The nature of an imported picture differs greatly from

that of the base screen. The imported picture cannot exist in ScrEdit as an element. However, the base

screen can be regarded as an element and then exist in the editing screen after a compile operation is

completed (The definition and usage of the base screen will be introduced more in the section of

“Screen Properties”). The file types of available imported picture can be BMP, JPG and GIF, etc. The

user can execute this function by clicking Screen > Import or use keyboard shortcuts by pressing Shift

+ I.

, or use keyboard shortcuts by pressing Shift + E.

2-56 Revision Apr. 30th, 2007, 2007PDD23000002

Page 68

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

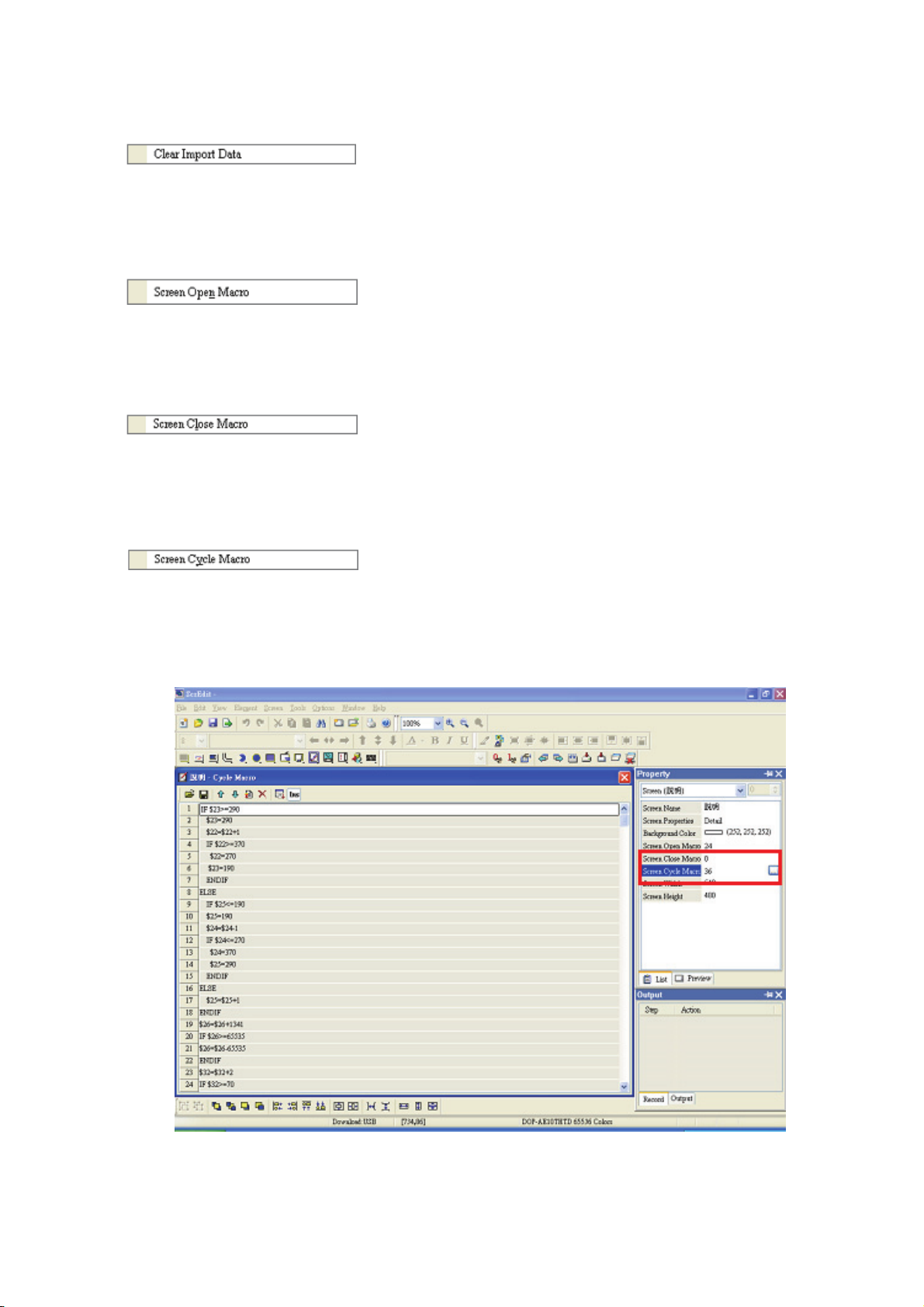

Clear Import Data

The user can free more disk space by clearing the imported data that the user does not want to use.

Execute this function by clicking Screen > Clear Import Data.

Screen Open Macro

When Screen Open Macro function is selected, the Macro will be executed automatically once

opening screen occurs. (Please refer to Chapter 4 for the usage and editing method of Macro.)

Screen Close Macro

When Screen Close Macro function is selected, the Macro will be executed automatically once the

screen is closed. (Please refer to Chapter 4 for the usage and editing method of Macro.)

Screen Cycle Macro

When Screen Cycle Macro function is selected, the Macro will be executed continuously once the

screen is displayed. (Macro will be executed continuously by the cycle time setting) (Please refer to

Chapter 4 for the usage and editing method of Macro.)

The user also can click the Screen Open Macro, Screen Close Macro and Screen Cycle Macro options

from the Property Table to enter intro Screen Open Marco editing environment (Fig. 2.3.10).

Fig. 2.7.10 Screen Open Marco editing environment

Revision Apr. 30th, 2007, 2007PDD23000002 2-57

Page 69

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Auxiliary Key

DOP series HMI allows the user to determine the function of auxiliary keys in each screen. The user

can execute this function by clicking Screen > Auxiliary Key. Auxiliary key set up for each screen can

be completed by pressing the auxiliary keys on HMI panel (Fig. 2.7.11) or on the screen (Fig. 2.7.12).

Fig. 2.7.11 Auxiliary Keys on HMI panel

Fig. 2.7.12 Auxiliary Key setting on the screen

2-58 Revision Apr. 30th, 2007, 2007PDD23000002

Page 70

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

In Table 2.7.1, the user can see how many user-defined auxiliary keys are available for each model.

Table 2.7.1 Available user-defined auxiliary keys

DOP-A/AE/AS Series Model Name Available User-defined Auxiliary Keys

DOP-AS38BSTD 4

DOP-A (E) 57BSTD 4

DOP-A (E) 57GSTD 4

DOP-A (E) 57CSTD 4

DOP-A75CSTD 6

DOP-AE80THTD 6

DOP-AE94BSTD 11

DOP-A10TCTD 7

DOP-AE10THTD 7

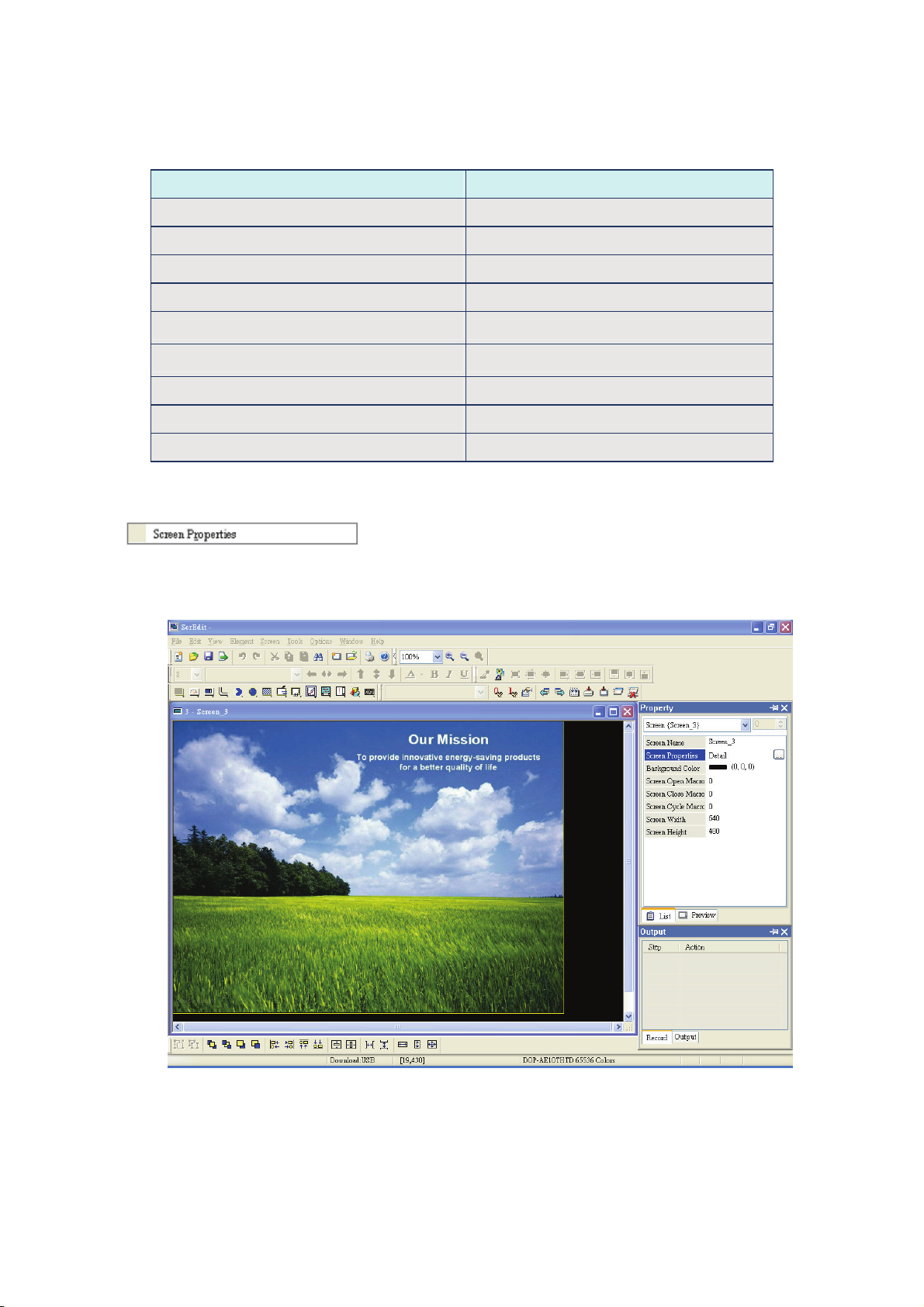

Screen Properties

The user can decide the properties of the current editing screen by clicking Screen > Screen

Properties or choosing Screen Properties from docking windows to set the current screen (Fig.

2.7.13). For the setting of Screen Properties, please refer to Fig. 2.7.14 and Table 2.7.2.

Fig. 2.7.13 Choosing Screen Properties from docking windows

Revision Apr. 30th, 2007, 2007PDD23000002 2-59

Page 71

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

A

Fig. 2.7.14 Screen Properties dialog box

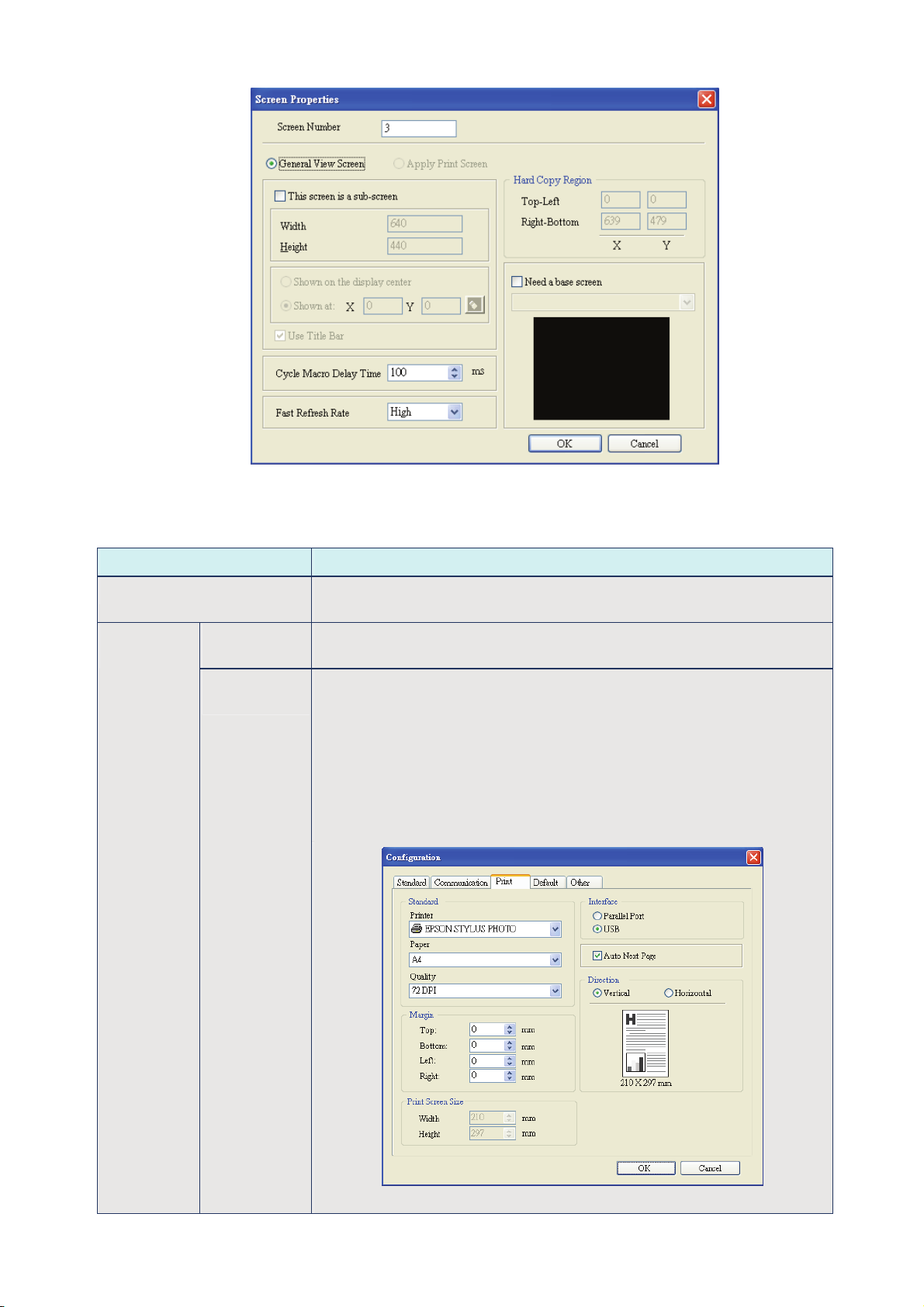

Table 2.7.2 Screen Properties setting

Function Description

Screen Number The screen number range is within 1~65535 and the number cannot be

repeated.

Screen

pplication

General View

Screen

Apply Print

Screen

Regarded as general view screen. The element created by the user can be

downloaded to HMI after compile operation and display on HMI screen.

1. Regarded as print screen. The printer can print the element created by

the user after a compile operation. This option is only available in DOP

series HMI which supports printer function.

2. When Apply Print Screen function is selected, the editing range will be

scaled to the actual paper size of the printer. The user can only print

the elements within the range of the paper size. This option is usually

used for print typesetting.

The user can find a printer setting by clicking Option > Configuration >

Print shown as Fig. 2.7.15 below.

Fig. 2.7.15 Print tab in Configuration option

2-60 Revision Apr. 30th, 2007, 2007PDD23000002

Page 72

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Function Description

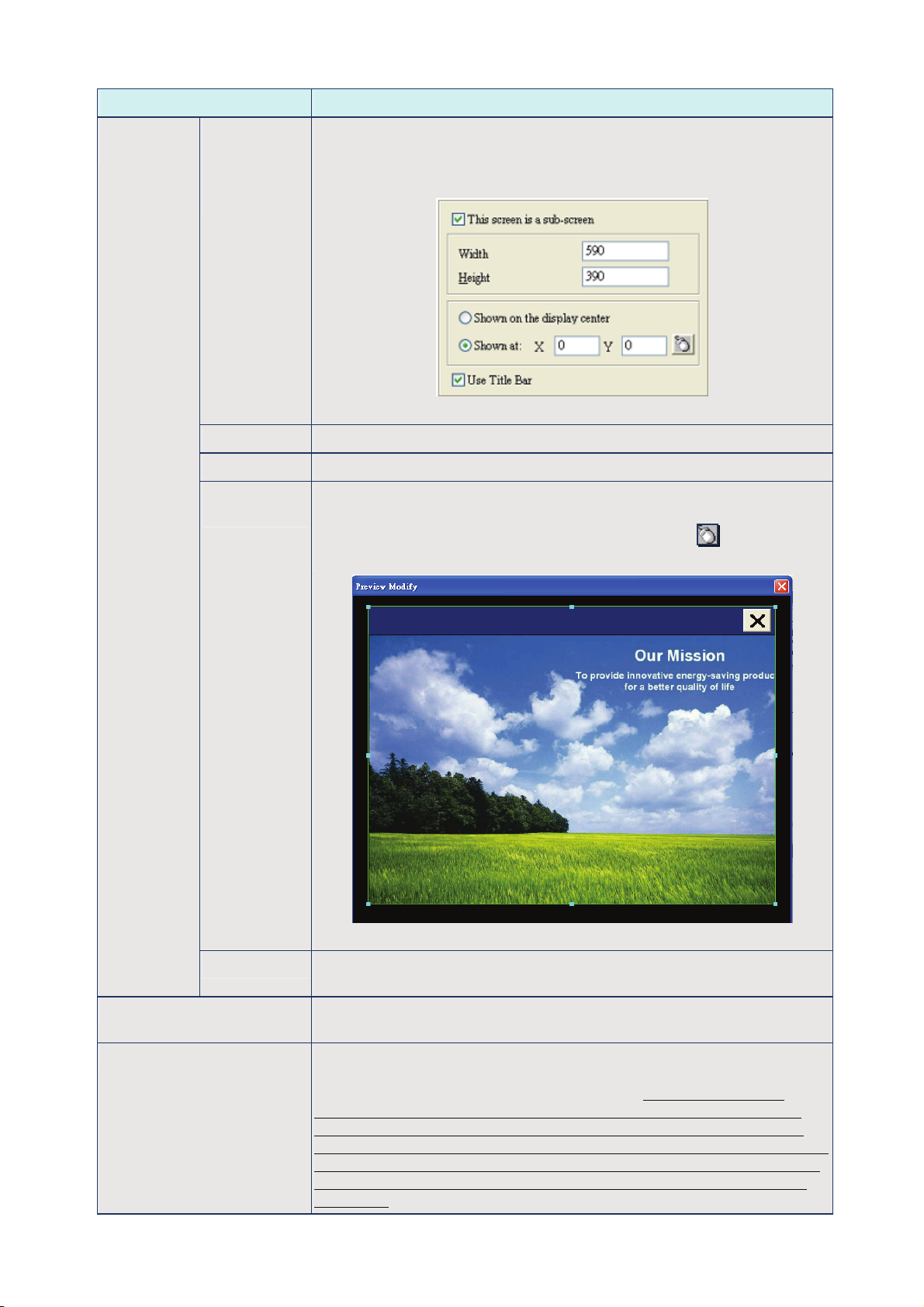

Sub-screen

Setting

Check the

check box next

to “This screen

is a sub-

The check box next to “This screen is a sub-screen” can be checked only

when General View Screen option is selected. Therefore, before setting

sub-screen function, please ensure General View Screen option is

selected.

screen”

Fig. 2.7.16 Sub-screen setting

Width It is used to set the width of sub-screen and the unit is Pixel.

Height It is used to set the height of sub-screen and the unit is Pixel.

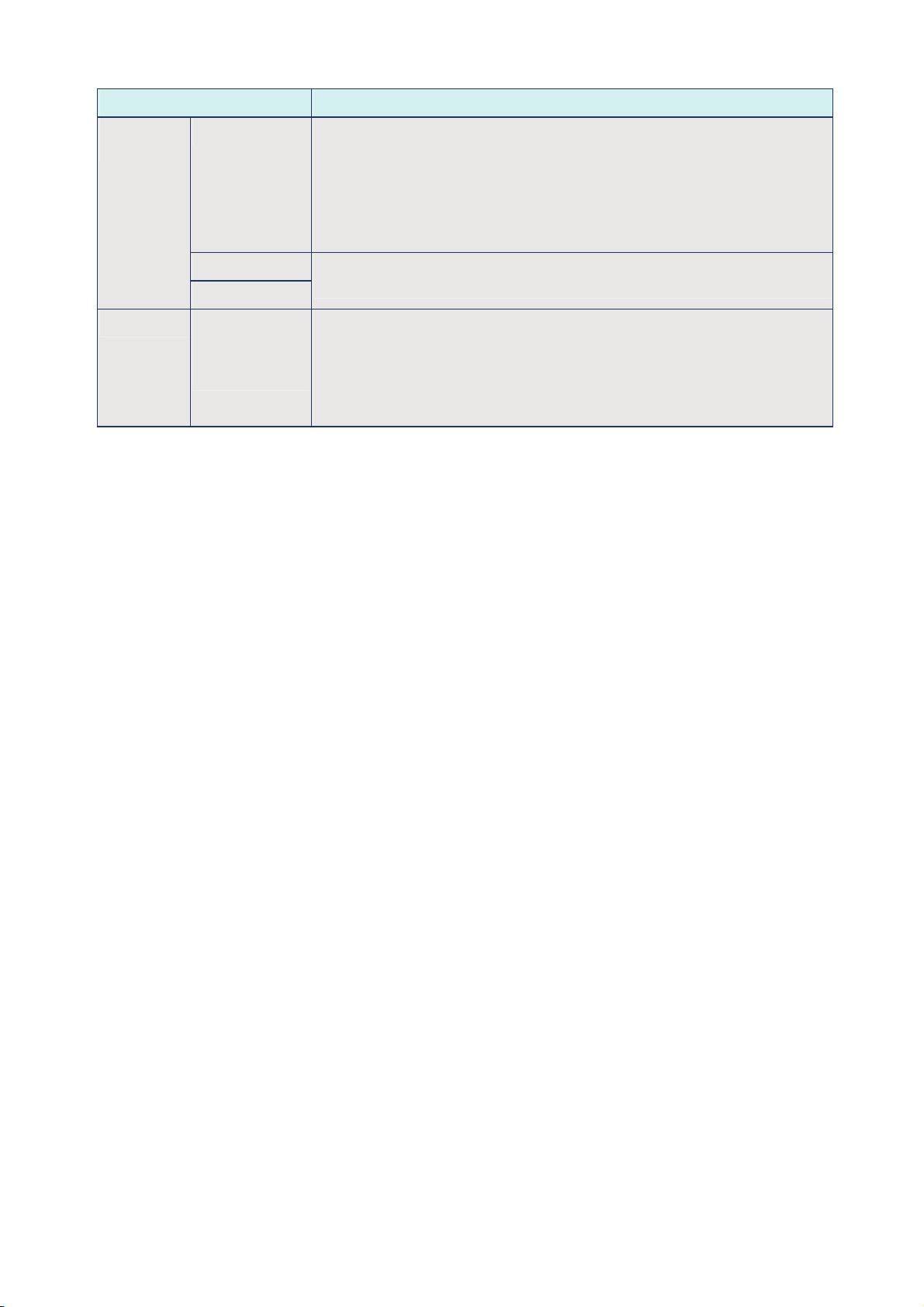

Sub-screen

Position

The user can decide if the sub-screen is shown on the center position of

HMI display or specify the display position freely. Only input the coordinate

value directly (X and Y axis) or press the mouse button to drag the

sub-screen to the position the user decided (Fig. 2.7.17).

Fig. 2.7.17 Sub-screen position

Title Bar When the check box next to “Use Title Bar” is checked, the title bar will be

shown when opening sub-screen.

Cycle Macro Delay Time It is used to set Cycle Macro Delay Time when this screen is executed

every time. The range of the cycle macro delay time is within 100ms ~ 5s.

Fast Refresh Rate There are three levels of the Fast Refresh Rate and they are High, Medium

and Low. The purpose of this function is used to make some elements be

displayed immediately when switching screens. Please note that this

function is designed to provide fast value refresh speed for the element

which performs communication frequently. Therefore, it only allows four

elements that can be renewed immediately in each screen. If the user uses

this function on too many elements, it may affect the normal speed of HMI

operation. So, we recommend the user not to activate this function if not

necessary.

Revision Apr. 30th, 2007, 2007PDD23000002 2-61

Page 73

Chapter 2 Creating and Editing Screens|ScrEdit Software User Manual

Function Description

Hard Copy

Region

Base Screen Check the check

Setting The user can find this function only in DOP series HMI which supports

Top-Left

Right-Bottom

box next to

“Need a base

screen”

printer function. If the user wants to enable this function, setting the printer

in advance is necessary. Please go to Option > Configuration > Print

(Fig. 2.7.15) and select the printer first. When this function is enabled, if

one report list button is created and its assigned output device is a printer,

once the user presses the report list button, HMI will refer to the setting in

Hard Copy Region option and execute the screen-printing.

It is used to set the region of HMI printing area (also called Hard Copy

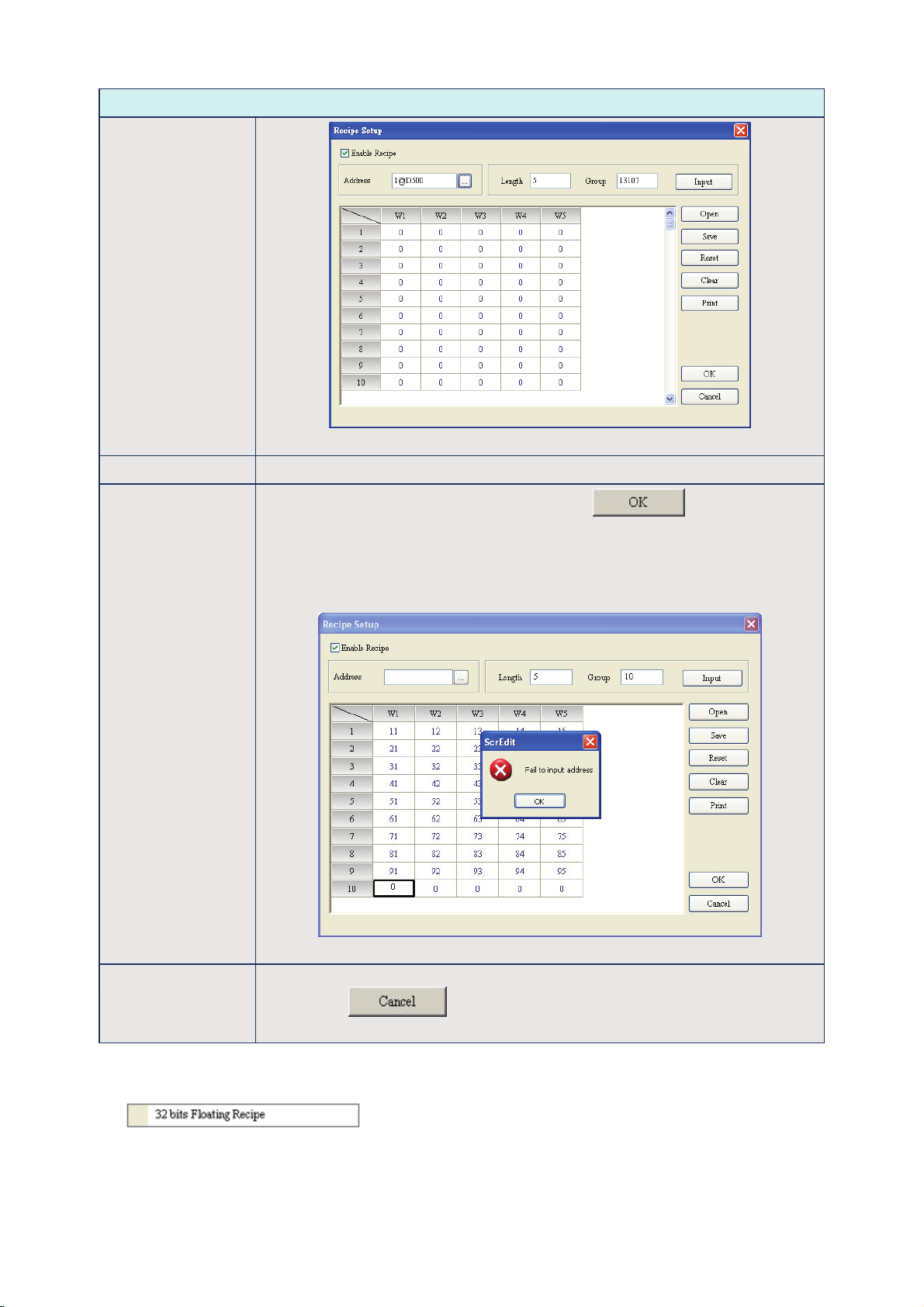

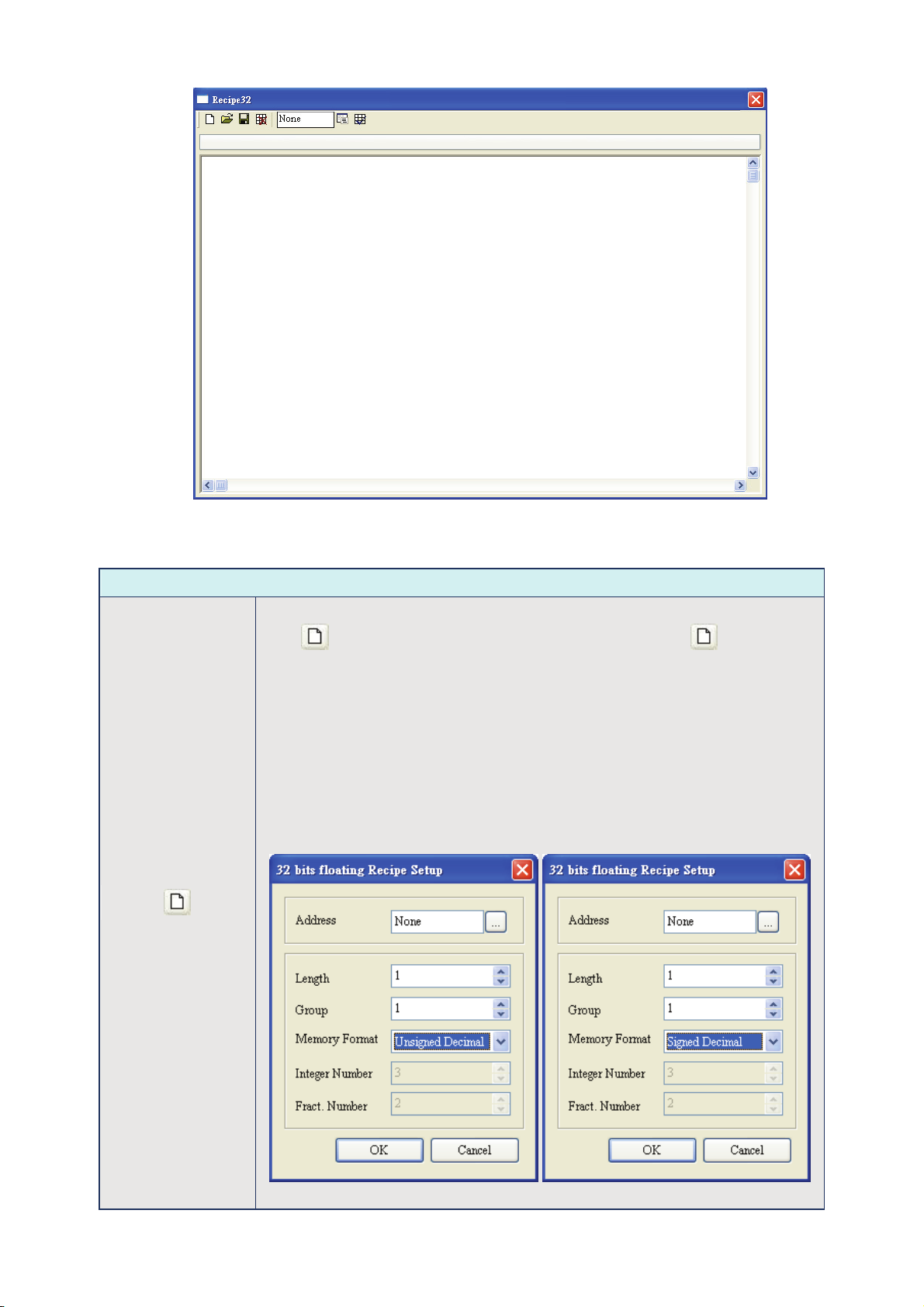

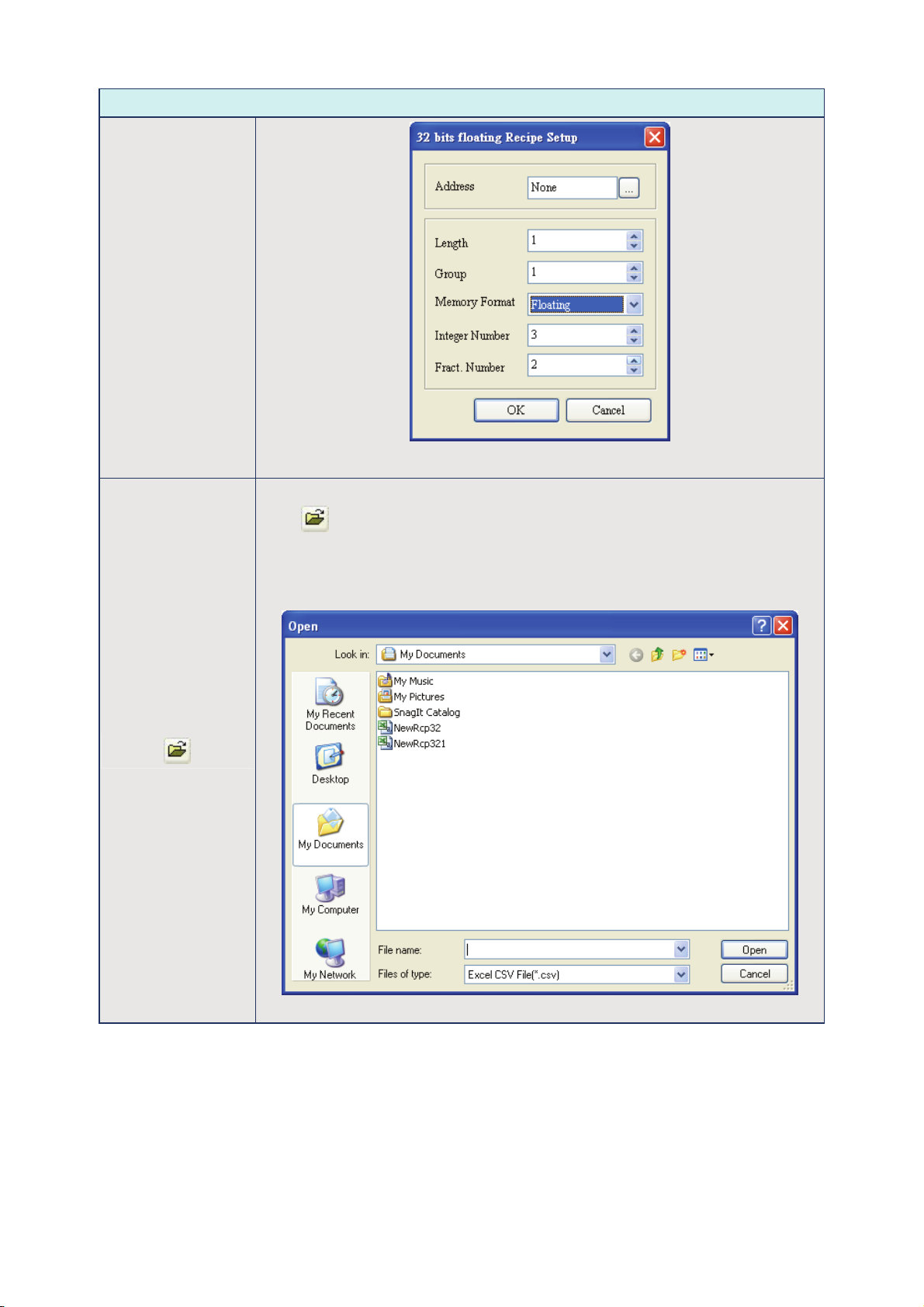

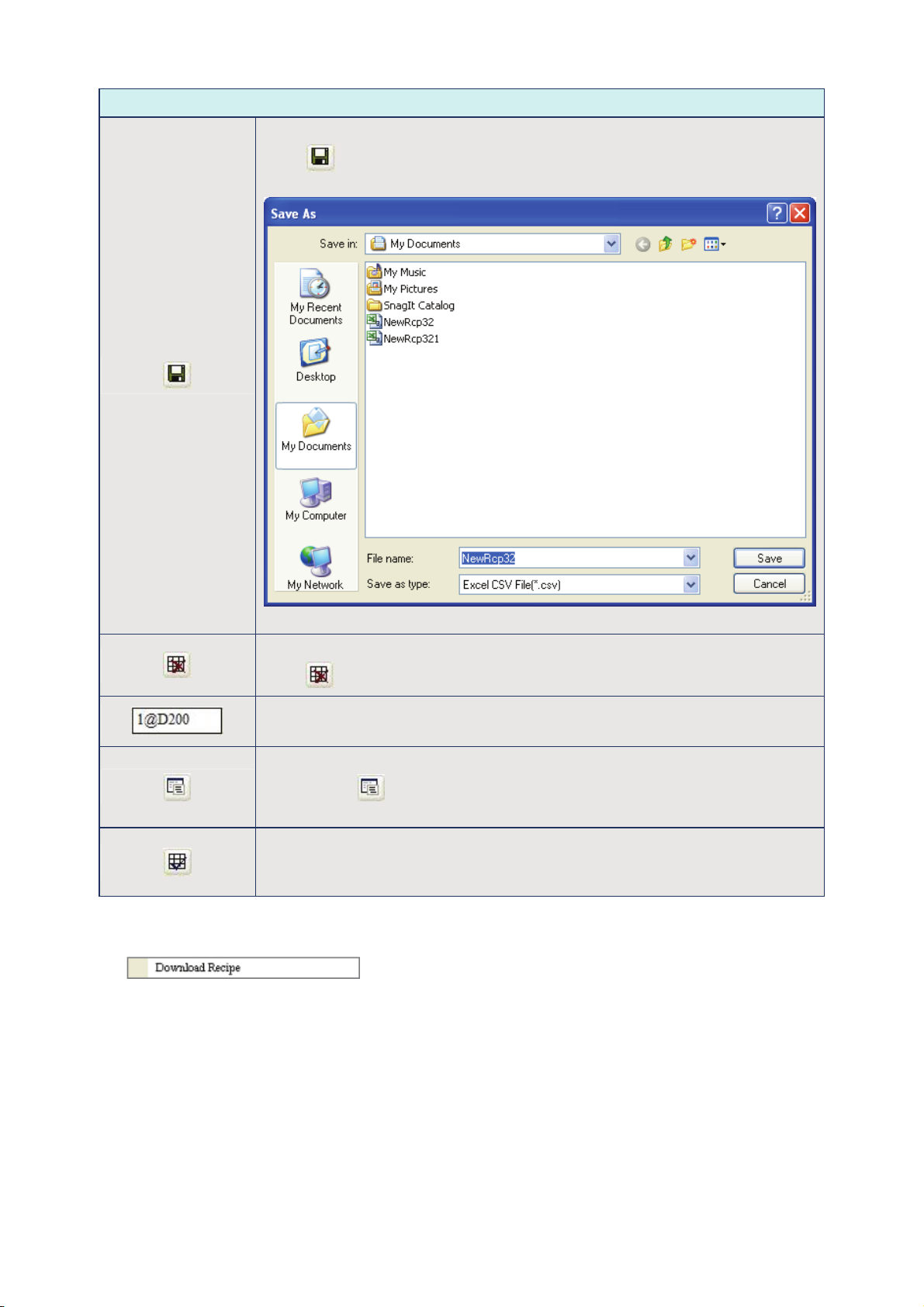

Region) and the unit is Pixel.