Page 1

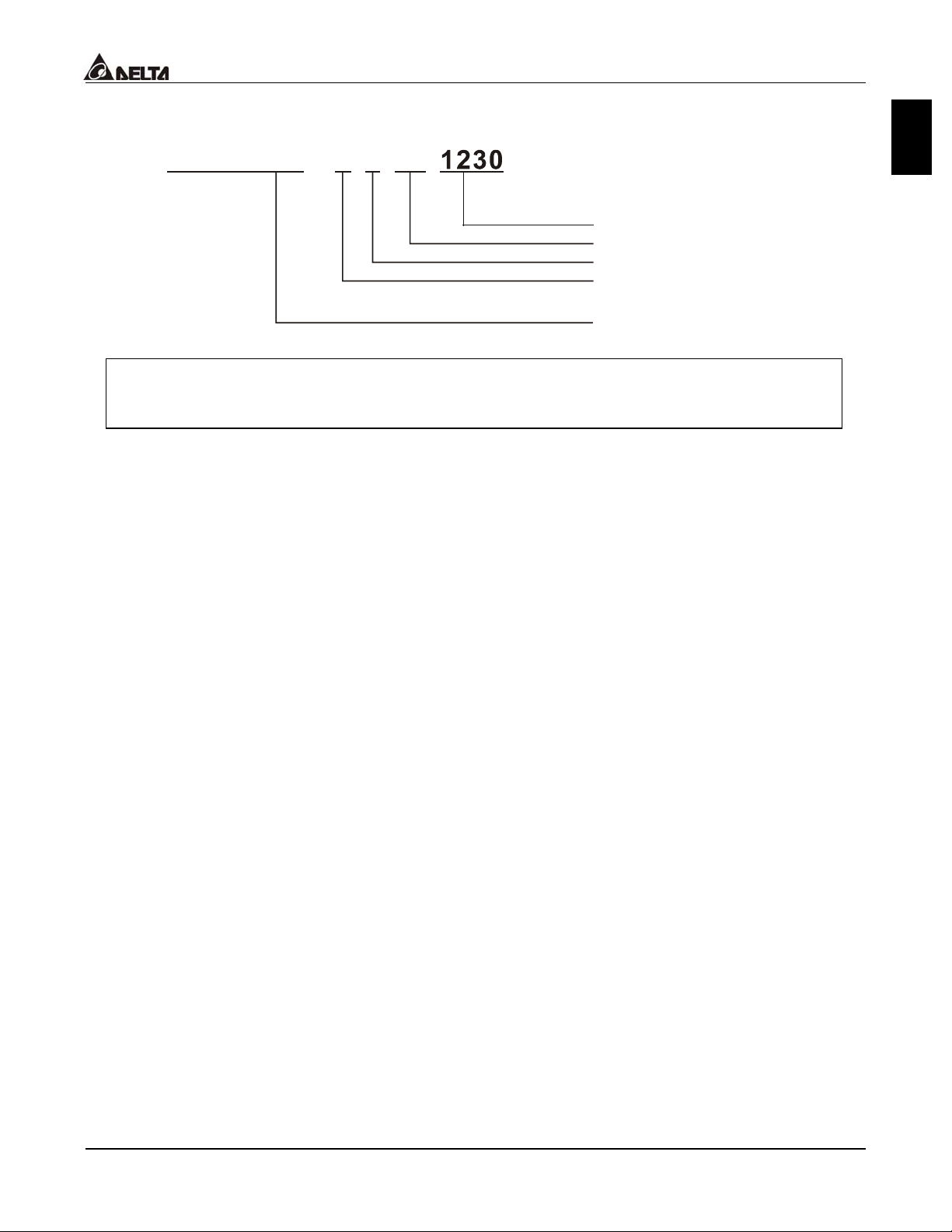

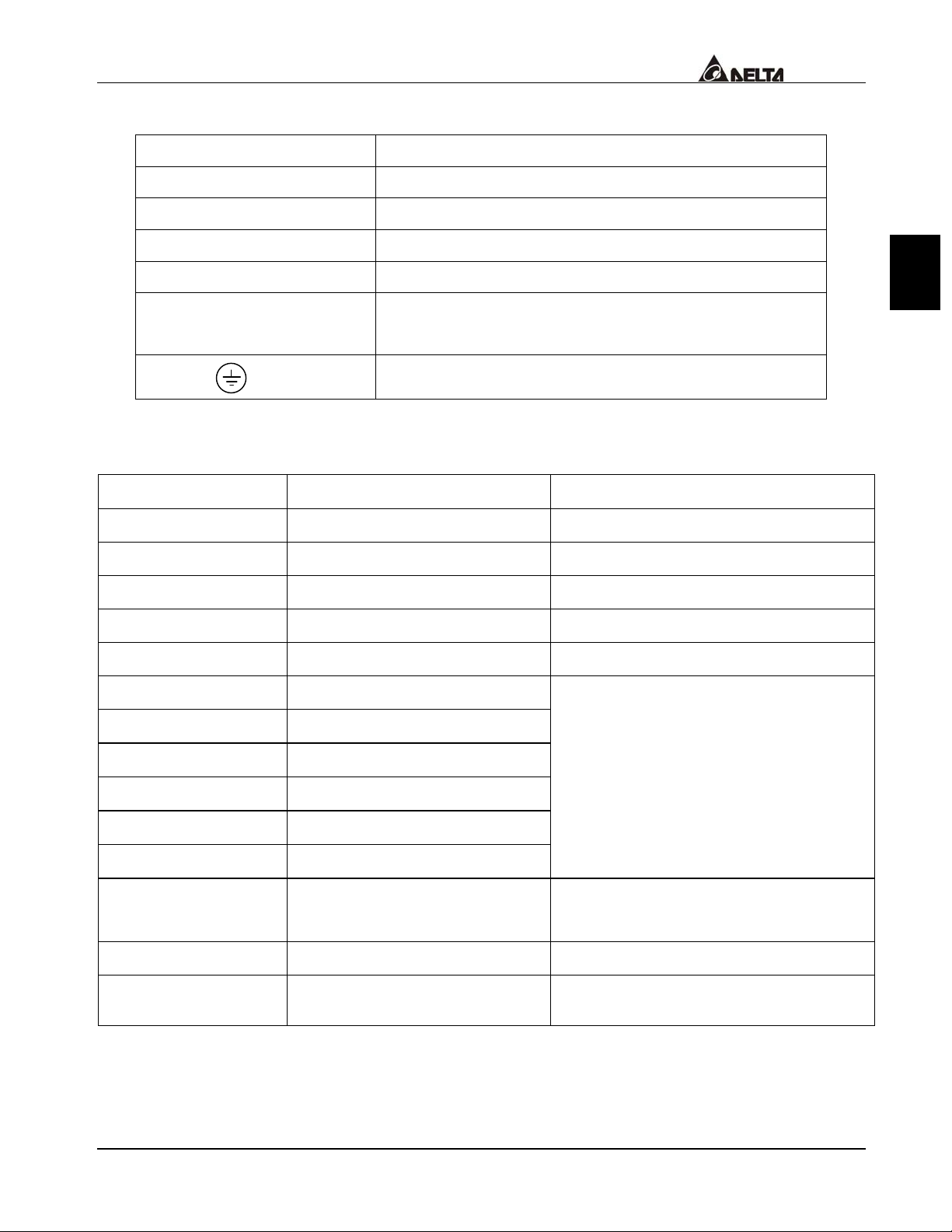

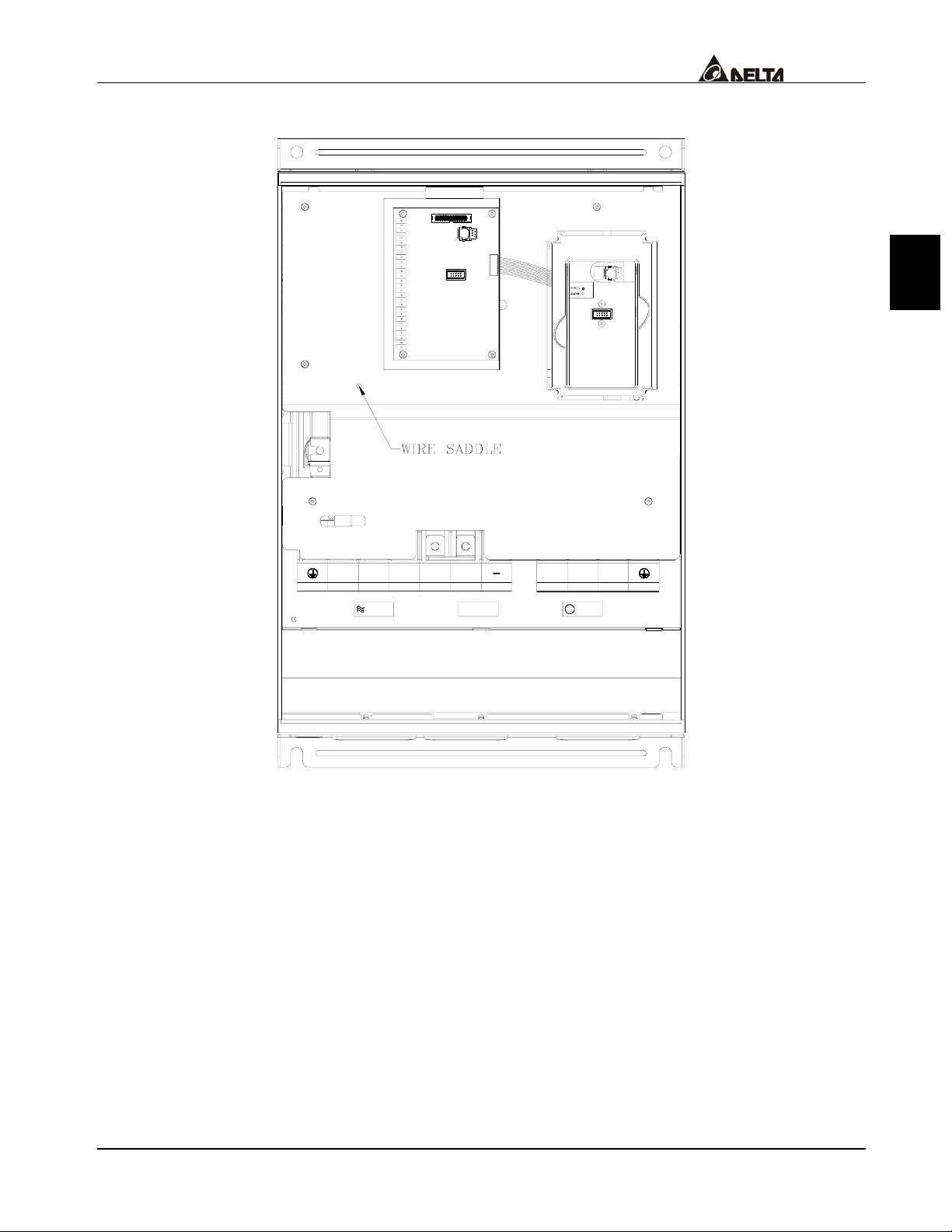

230V Series

370.75 KW

1.0 50HP

460V Series

70.75 5KW

1.0 100HP

Page 2

Page 3

Page 4

VFD-B Series

Preface

Thank you for choosing DELTA’s high-performance VFD-B Series. VFD-B Series are

manufactured by adopting high-quality components, material and incorporating the latest

microprocessor technology available.

Getting Started

This manual will be helpful in the installation, parameter setting, troubleshooting, and daily

maintenance of the AC motor drives. To guarantee safe operation of the equipment, read

the following safety guidelines before connecting power to the AC drives. Keep this

operating manual handy and distribute to all users for reference.

!

WARNING

!

Always read this manual thoroughly before using VFD-B series AC Motor Drives.

!

DANGER!

not connect or disconnect wires and connectors while power is applied to the

circuit. Maintenance must be performed by qualified technicians.

!

CAUTION! There are highly sensitive MOS components on the printed circuit boards.

These components are especially sensitive to static electricity. To avoid damage to

these components, do not touch these components or the circuit boards with metal

objects or your bare hands.

!

DANGER! A charge may still remain in the DC-link capacitor with hazardous voltages

even if the power has been turned off. To avoid personal injury, please ensure that

power has turned off before operating AC drive and wait ten minutes for capacitors to

discharge to safe voltage levels.

!

CAUTION! Ground the VFD-B using the ground terminal. The grounding method

must comply with the laws of the country where the AC drive is to be installed. Refer to

Basic Wiring Diagram.

!

DANGER! The AC drive may be destroyed beyond repair if incorrect cables are

connected to the input/output terminals. Never connect the AC drive output terminals

U/T1, V/T2, and W/T3 directly to the AC main circuit power supply.

!

CAUTION! The final enclosures of the AC drive must comply with EN50178. (Live

parts shall be arranged in enclosures or located behind barriers that meet at least the

requirements of the Protective Type IP20. The top surface of the enclosures or barrier

that is easily accessible shall meet at least the requirements of the Protective Type

IP40). (VFD-B series corresponds with this regulation.)

AC input power must be disconnected before any maintenance. Do

CAUTION! Heat sink may heat up over 70oC (158oF), during the operation. Do not

touch the heat sink.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 5

Page 6

VFD-B Series

TABLE OF CONTENTS

CHAPTER 1 RECEIVING AND INSPECTIONS

1.1 Nameplate Information ....................................................................... 1 - 1

1.2 Model Explanation .............................................................................. 1 - 1

1.3 Serial Number Explanation................................................................. 1 - 2

CHAPTER 2 STORAGE AND INSTALLATION

2.1 Storage ............................................................................................... 2 - 1

2.2 Installation .......................................................................................... 2 - 2

CHAPTER 3 WIRING

3.1 Basic Wiring Diagram ......................................................................... 3 - 2

3.2 External Wiring ................................................................................... 3 - 6

3.3 Terminal Explanation .......................................................................... 3 - 7

3.4 Control Terminal Explanation..............................................................3 - 7

3.5 Main Circuit Wiring ............................................................................3 - 9

3.6 Wiring Notes ....................................................................................... 3-16

3.7 Motor Operation Precautions.............................................................. 3-17

CHAPTER 4 DIGITAL KEYPAD OPERATION

4.1 Description of the Digital Keypad VFD-PU01 ..................................... 4 - 2

4.2 Operation steps of the Digital Keypad VFD-PU01.............................. 4 - 4

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 7

VFD-B Series

CHAPTER 5 DESCRIPTION OF PARAMETER SETTINGS

Group 0: User Parameters .......................................................................5 - 1

Group 1: Basic Parameters ...................................................................... 5 - 5

Group 2: Operating Method Parameters .................................................. 5- 11

Group 3: Output Function Parameters .....................................................5-17

Group 4: Input Function Parameters ........................................................ 5-22

Group 5:Multi-step Speed and PLC (Process Logic Control) Parameter . 5-32

Group 6: Protection Parameters...............................................................5-38

Group 7: Motor Parameters...................................................................... 5-44

Group 8: Special Parameters ...................................................................5-47

Group 9: Communication Parameters ...................................................... 5-54

Group 10: PID Control Parameters ..........................................................5-69

Group 11: Fan and Pump Control Parameters ......................................... 5-74

CHAPTER 6 MAINTENANCE AND INSPECTIONS

6.1 Periodic Inspection ............................................................................. 6 - 1

6.2 Periodic Maintenance ......................................................................... 6 - 1

CHAPTER 7 TROUBLESHOOTING AND FAULT INFORMATION........... 7 - 1

CHAPTER 8 SUMMARY OF PARAMETER SETTINGS ............................ 8 - 1

APPENDIX A SPECIFICATIONS ............................................................... A - 1

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 8

VFD-B Series

APPENDIX B ACCESSORIES

B.1 Non-fused Circuit Breaker and Fuse Specification Chart................... B - 1

B.2 Braking Resistors & Braking Units ..................................................... B - 3

B.3 AMD-EMI Filter Cross Reference ....................................................... B - 7

B.4 PG Cards ...........................................................................................B-16

B.5 Remote Controller RC-01................................................................... B-22

B.6 Remote Panel Adapter ....................................................................... B-23

B.7 Zero Phase Reactor ........................................................................... B-24

APPENDIX C DIMENSIONS....................................................................... C - 1

APPENDIX D EC DECELERATION OF CONFORMITY............................. D - 1

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 9

Page 10

VFD-B Series

A

A

CHAPTER 1 RECEIVING AND INSPECTION

This VFD-B AC drive has gone through rigorous quality control tests at the factory before

shipment. After receiving the AC drive, please check for the following:

Receiving

Check to make sure that the package includes an AC drive, the User Manual, dust

covers and rubber bushings.

Inspect the unit to insure it was not damaged during shipment.

Make sure that the part number indicated on the nameplate corresponds with the part

number of your order.

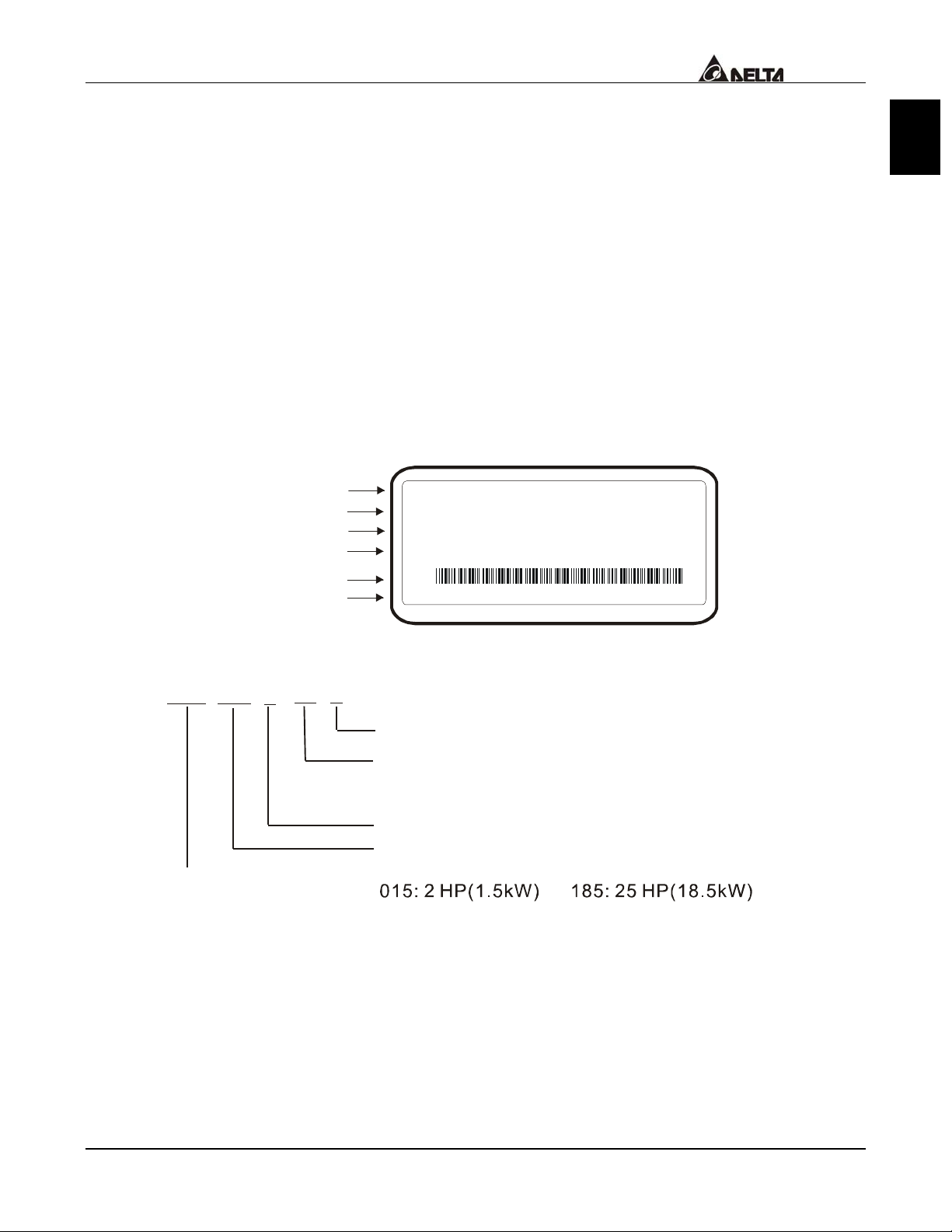

1.1 Nameplate Information: Example for 1HP/0.75kW 3-phase 230V AC drive

AC Drive Model

Input Spec.

Output Spec.

Output Frequency Range

MODE : VFD007B23A

INPUT : 3PH 200-240V 50/60Hz 6.0A

OUTPUT : 3PH 0-240V 5.0A 1.9kVA 1HP

Freq. Range : 0.1~400Hz

ENCLOSURE: TYPE 1

1

Enclosure type

Serial Number & Bar Code

1.2 Model Explanation:

VFD

007

Series Name

23

B

007B23A0T0220001

Version Type

Input Voltage

21:Single phase 230V

23:Three phase 230V

43:Three phase 460V

B Series

pplicable motor capacity

007: 1 HP(0.7kW) 150: 20HP(15kW)

022: 3 HP(2.2kW) 220: 30 HP(22kW)

037: 5 HP(3.7kW) 300: 40HP(30kW)

055: 7.5HP(5.5kW) 370: 50 HP(37kW)

075: 10 HP(7.5kW) 450: 60HP(45kW)

110: 15 HP(11kW) 550: 75HP(55kW)

750: 100HP(75kW)

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

1-1

Page 11

VFD-B Series

3

1.3 Series Number Explanation:

007B23A0

230V 3-phase 1HP(0.75kW)

If there is any nameplate information not corresponding to your purchase order or any

problem, please contact your distributor.

T

01

Production number

Production week

Production year 2003

Production factory

(Taoyuan)

Model

1

1-2

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 12

VFD-B Series

CHAPTER 2 STORAGE AND INSTALLATION

2.1 Storage

The AC drive should be kept in the shipping carton before installation. In order to retain the

warranty coverage, the AC drive should be stored properly when it is not to be used for an

extended period of time.

Ambient Conditions:

Operation

Air Temperature: -10oC to +40oC (14oF to 104oF) (UL & cUL);

+50oC (122oF) without dust cover.

Atmosphere pressure: 86 to 106 kPa

Installation Site Altitude: below 1000m

Vibration: Maximum 9.80 m/s2 (1G) at less than 20Hz

Maximum 5.88 m/s2 (0.6G) at 20Hz to 50Hz

2

Storage

Temperature: -20oC to +60oC (-4oF to 140oF)

Relative Humidity: Less than 90%, no condensation allowed

Atmosphere pressure: 86 to 106 kPa

Transportation

Temperature: -20oC to +60oC (-4oF to 140oF)

Relative Humidity: Less than 90%, no condensation allowed

Atmosphere pressure: 86 to 106 kPa

Vibration: Maximum 9.80 m/s2 (1G) at less than 20Hz, Maximum 5.88

2

(0.6G) at 20Hz to 50Hz

m/s

Pollution Degree 2: good for a factory type environment.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

2-1

Page 13

VFD-B Series

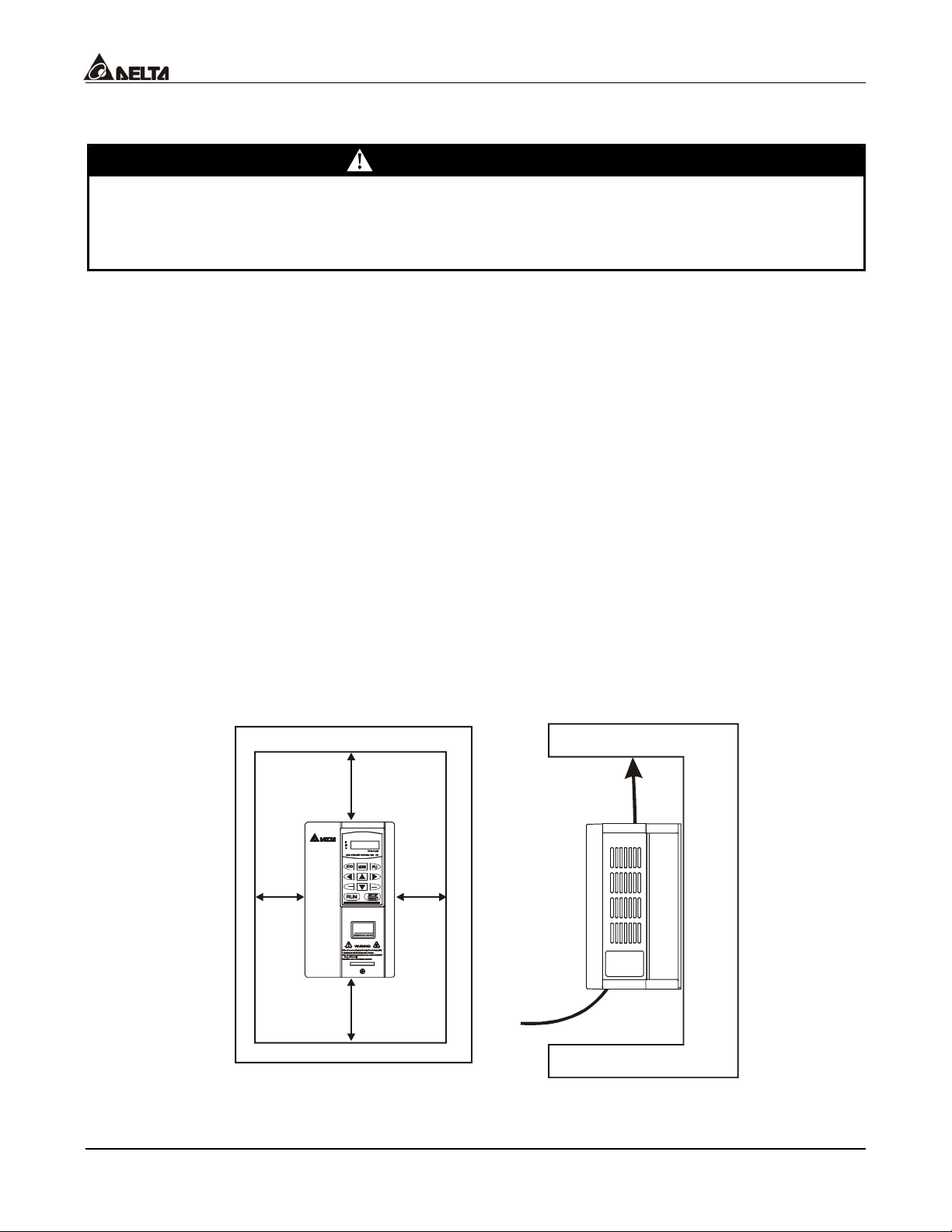

2.2 Installation

CAUTION

The control, power supply and motor leads must be laid separately. They must not be

fed through the same cable conduit / trunking.

High voltage insulation test equipment must not be used on cables connected to the

drive.

Improper installation of the AC drive will greatly reduce its life. Be sure to observe the

following precautions when selecting a mounting location.

Failure to observe these precautions may void the warranty!

Do not mount the AC drive near heat-radiating elements or in direct sunlight.

Do not install the AC drive in a place subjected to high temperature, high humidity,

excessive vibration, corrosive gases or liquids, or airborne dust or metallic particles.

Mount the AC drive vertically and do not restrict the air flow to the heat sink fins.

The AC drive generates heat. Allow sufficient space around the unit for heat dissipation.

120mm

Air Flow

50mm

FWD

PROG

REV

DATA

50mm

120mm

2-2

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 14

VFD-B Series

CHAPTER 3 WIRING

DANGER

Hazardous Voltage

Before accessing the AC drive:

Disconnect all power to the AC drive.

Wait five minutes for DC bus capacitors discharge.

Any electrical or mechanical modification to this equipment without prior written

consent of Delta Electronics, Inc. will void all warranties and may result in a safety

hazard in addition to voiding the UL listing.

Short Circuit Withstand:

The rated voltage must be equal to or less than 240V (460V model is 480Volts) and the

current must be equal to or less than 5000A RMS. (the model of 40HP or above is 10000A

3

RMS)

General Wiring Information

Applicable Codes

All VFD-B AC drives except 015B21A, 015B23A and 075B23B are Underwriters

Laboratories, Inc. (UL) and Canadian Underwriters Laboratories (cUL) listed, and therefore

comply with the requirements of the National Electrical Code (NEC) and the Canadian

Electrical Code (CEC).

Installation intended to meet the UL and cUL requirements must follow the instructions

provided in “Wiring Notes” as a minimum standard. Follow all local codes that exceed UL

and cUL requirements. Refer to the technical data label affixed to the AC drive and the

motor nameplate for electrical data.

The "Line Fuse Specification" in Appendix B, lists the recommended fuse part number for

each B-Series part number. These fuses (or equivalent) must be used on all installations

where compliance with U.L. standards is a required.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

3-1

Page 15

VFD-B Series

V

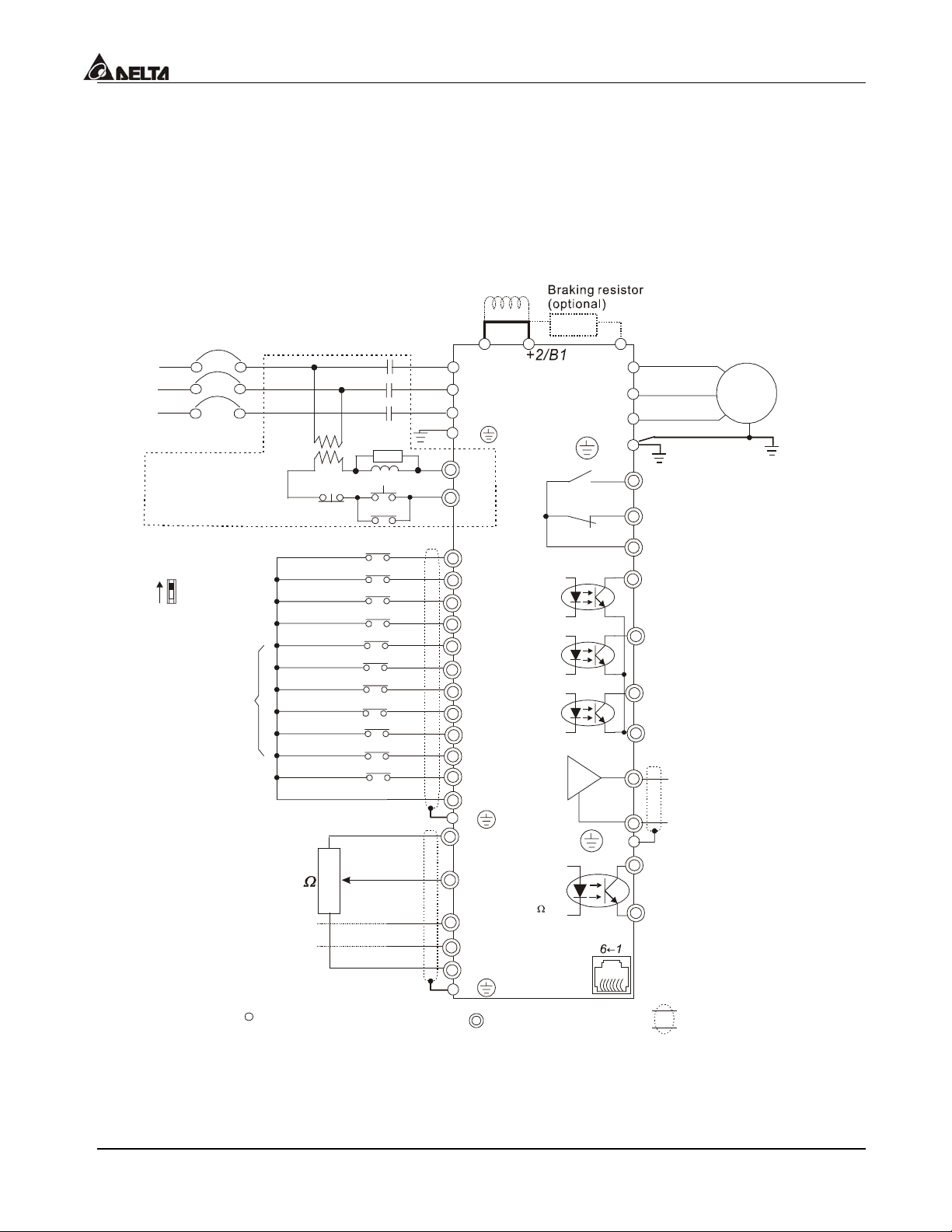

3.1 Basic Wiring Diagram

Users must connect wires according to the following circuit diagram shown below. Do not

plug a Modem or telephone line to the RS-485 communication port, permanent damage may

result. Terminals 1 & 2 are the power sources only for the optional copy keypad and should

not be used while using RS-485 communication.

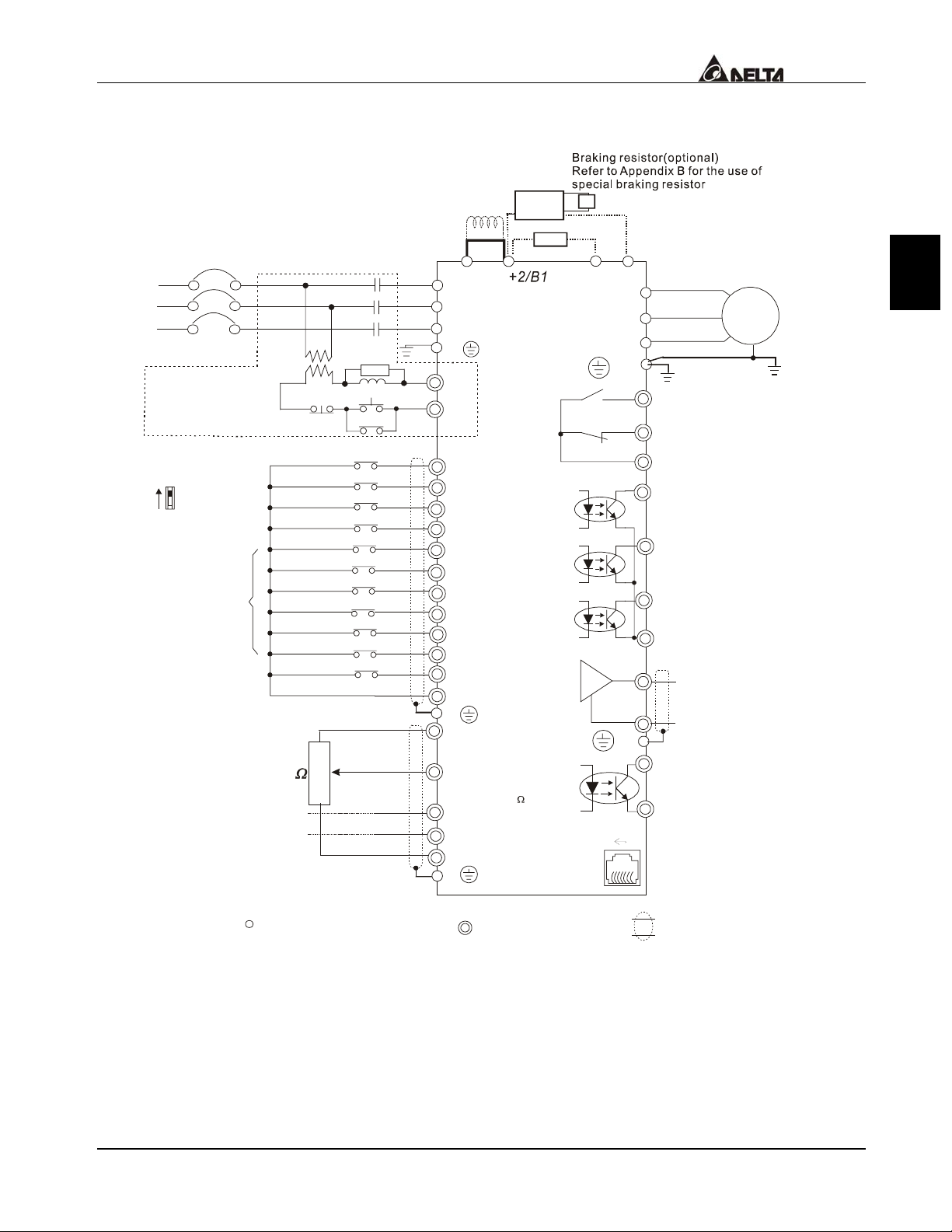

Figure 1 for models of VFD-B Series

FD007B21A/23A/43A, VFD015B21A/21B/23A/23B/43A

SA

ON

DC choke

(optional)

MC

MC

Jumper

+1

R(L1)

S(L2)

T(L3)

E

RB

RC

+24V

FWD

REV

JOG

EF

MI1

MI2

MI3

MI4

MI5

MI6

TRG

DCM

E

+10V

Power supply

+10V 20mA

AVI

Master Frequency

0 to 10V 47K

ACI

AUI

ACM

E

MO1

MO2

MO3

B2

U(T1)

V(T2)

W(T3)

E

RA

RB

RC

MCM

AFM

ACM

E

DFM

DCM

Motor

IM

3~

Please refer to “Control

Terminal Explanation”.

Factory default:

indicates during operation

48V50mA

Factory default:

Freq. Setting Indication

48V50mA

Factory default:

Low-voltage Indication

48V50mA

Multi-function

Photocoulper Output

Analog Multi-function Output

Te rm in al

Factory default: Analog freq.

/ current meter

Analog Signal common

Digital Frequency Output

Te rm in al

Factory default: 1:1

Duty=50%

Digital Signal Common

RS-485

Serial interface

1: EV 2: GND

5:NC

4: SG+

6: for communication

0~10VDC/2mA

3: SG-

VFD022B23B/43B

Fuse/NFB(None Fuse Breaker)

R(L1)

S(L2)

T(L3)

Recommended Circuit

when power supply

is turned OFF by a

fault output

Factory Default:

SINK Mode

Sink

Sw1

Source

Please refer to Figure 4

for wiring of SINK

mode and SOURCE

mode.

Factory

default

* Don't apply the mains voltage directly

to above terminals.

OFF

FWD/STOP

REV/STOP

JOG

E.F.

Multi-step 1

Multi-step 2

Multi-step 3

Multi-step 4

RESET

Accel/Decel prohibit

Counter

Digital Signal Common

3

5K

2

1

4~20mA

-10~+10V

Analog Signal Common

Main circuit (power) terminals

Control circuit terminals

Shielded leads & Cable

3-2

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 16

AFMA

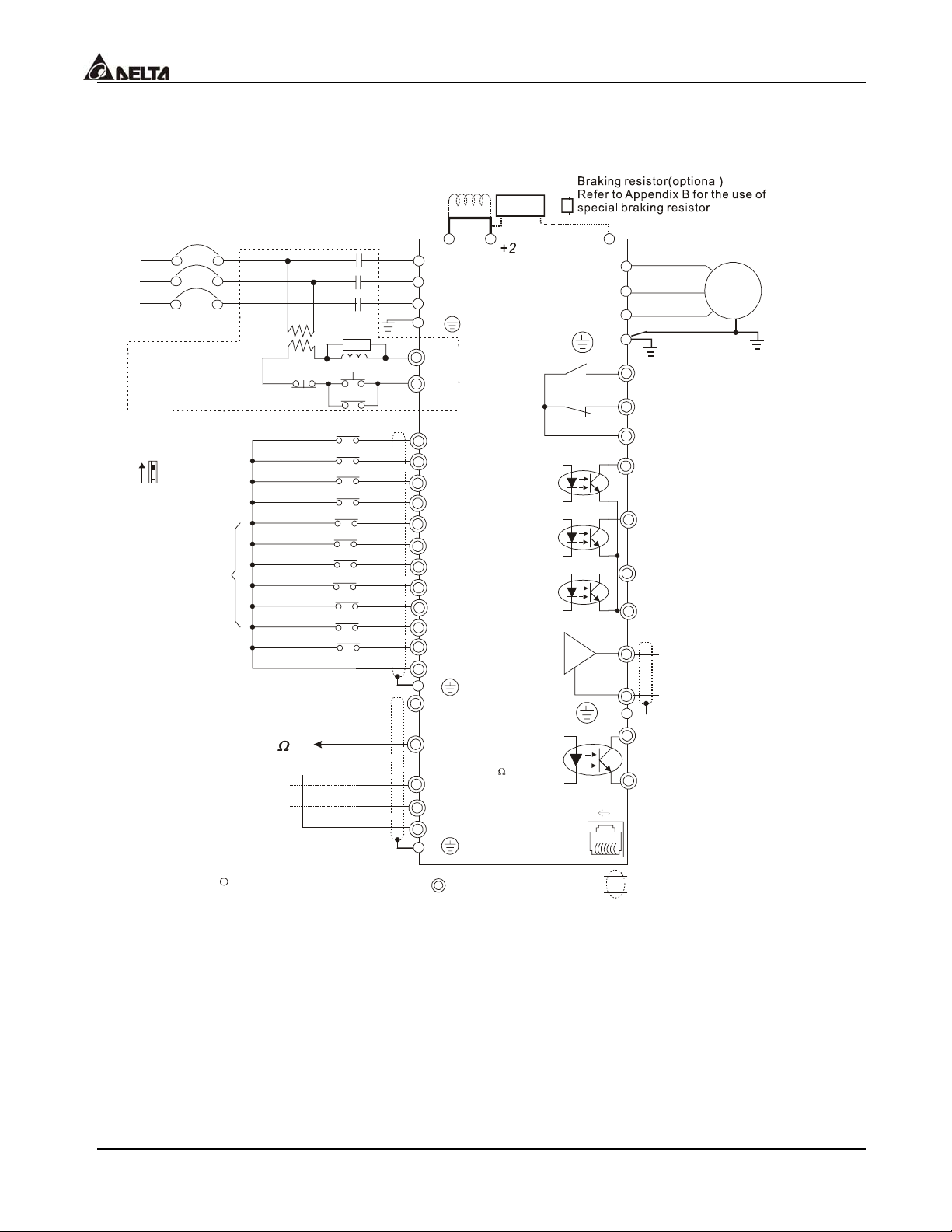

Figure 2 for models of VFD-B Series 3-15 HP

VFD022B21A, VFD037B23A/43A, VFD055B23A/43A, VFD075B23A/43A, VFD110B23A/43A

* Three phase input power may apply to single phase drives.

* For the single phase application, the AC input line can

be connected to any two of the three input terminals R,S,T

DC chock

(optional)

Fuse/NFB(None Fuse Breaker)

Jumper

R(L1)

S(L2)

T(L3)

2

4~20mA

SA

ON

MC

MC

Recommended Circuit

when power supply

is turned OFF by a

fault output

Factory Default:

SINK Mode

Sink

Sw1

Source

Please refer to Figure 4

for wiring of SINK

mode and SOURCE

mode.

Factory

default

* Don't apply the mains voltage directly

to above terminals.

OFF

FWD/STOP

REV/STOP

JOG

E.F.

Multi-step 1

Multi-step 2

Multi-step 3

Multi-step 4

RESET

Accel/Decel prohibit

Counter

Digital Signal Common

3

5K

1

-10~+10V

Analog Signal Common

VFDB

+1

R(L1)

S(L2)

T(L3)

E

RB

RC

+24V

FWD

REV

JOG

EF

MI1

MI2

MI3

MI4

MI5

MI6

TRG

DCM

E

+10V

Power supply

+10V 20mA

AVI

Master Frequency

0 to 10V 47 K

ACI

AUI

ACM

E

BR

MO2

MO3

BR

B2

W(T3)

MO1

-(minus sign)

U(T1)

V(T2)

E

RA

RB

RC

MCM

CM

E

DFM

DCM

RS-485

6 1

Serial interface

1: EV 2: GND

4: SG+

6: for communication

Please refer to “Control

Terminal Explanation”.

Factory default:

indicates during operation

48V50mA

Factory default:

Freq. Setting Indication

48V50mA

Factory default:

Low-voltage Indication

48V50mA

Multi-function

Photocoulper Output

Analog Multi-function Output

Te rm in al

Factory default: Analog freq.

/ current meter

Analog Signal common

Digital Frequency Output

Term in al

Factory default: 1:1

Duty=50%

Digital Signal Common

5:NC

Motor

IM

3~

3: SG-

VFD-B Series

3

0~10VDC/2mA

Main circuit (power) terminals

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Control circuit terminals

3-3

Shielded leads & Cable

Page 17

VFD-B Series

Figure 3 for models of VFD-B Series 20 HP and above

VFD150B23A/43A, VFD220B23A/43A, VFD300B23A/43A,

VFD185B23A/43A,

VFD370B23A/43A, VFD450B43A, VFD550B43A, VFD750B43A

DC chock

Fuse/NFB(None Fuse Breaker)

R(L1)

S(L2)

T(L3)

Recommended Circuit

when power supply

is turned OFF by a

fault output

Factory Default:

SINK Mode

Sink

Sw1

Source

Please refer to Figure 4

for wiring of SINK

mode and SOURCE

mode.

Factory

default

* Don't apply the mains voltage directly

to above terminals.

SA

MC

OFF

FWD/STOP

REV/STOP

JOG

E.F.

Multi-step 1

Multi-step 2

Multi-step 3

Multi-step 4

RESET

Accel/Decel prohibit

Counter

Digital Signal Common

3

5K

1

ON

2

4~20mA

-10~+10V

Analog Signal Common

(optional)

Jumper

R(L1)

S(L2)

T(L3)

E

RB

RC

MC

+24V

FWD

REV

JOG

EF

MI1

MI2

MI3

MI4

MI5

MI6

TRG

DCM

E

+10V

Power supply

+10V 20mA

AVI

Master Frequency

0 to 10V 47K

ACI

AUI

ACM

E

+1

+1

VFDB

-(minus sign)

U(T1)

V(T2)

W(T3)

E

RA

RB

RC

MO1

MO2

MO3

MCM

AFM

ACM

DFM

DCM

6

Please refer to “Control

Terminal Explanation”.

Factory default:

indicates during operation

48V50mA

Factory default:

Freq. Setting Indication

48V50mA

Factory default:

Low-voltage Indication

48V50mA

Multi-function

Photocoulper Output

Analog Multi-function Output

Te rm in al

Factory default: Analog freq.

/ current meter

E

1

Analog Signal common

Digital Frequency Output

Te rm in al

Factory default: 1:1

Duty=50%

Digital Signal Common

RS-485

Serial interface

1: EV 2: GND

5:NC

4: SG+

6: for communication

Motor

IM

3~

3: SG-

0~10VDC/2mA

Main circuit (power) terminals

Control circuit terminals

3-4

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Shielded leads & Cable

Page 18

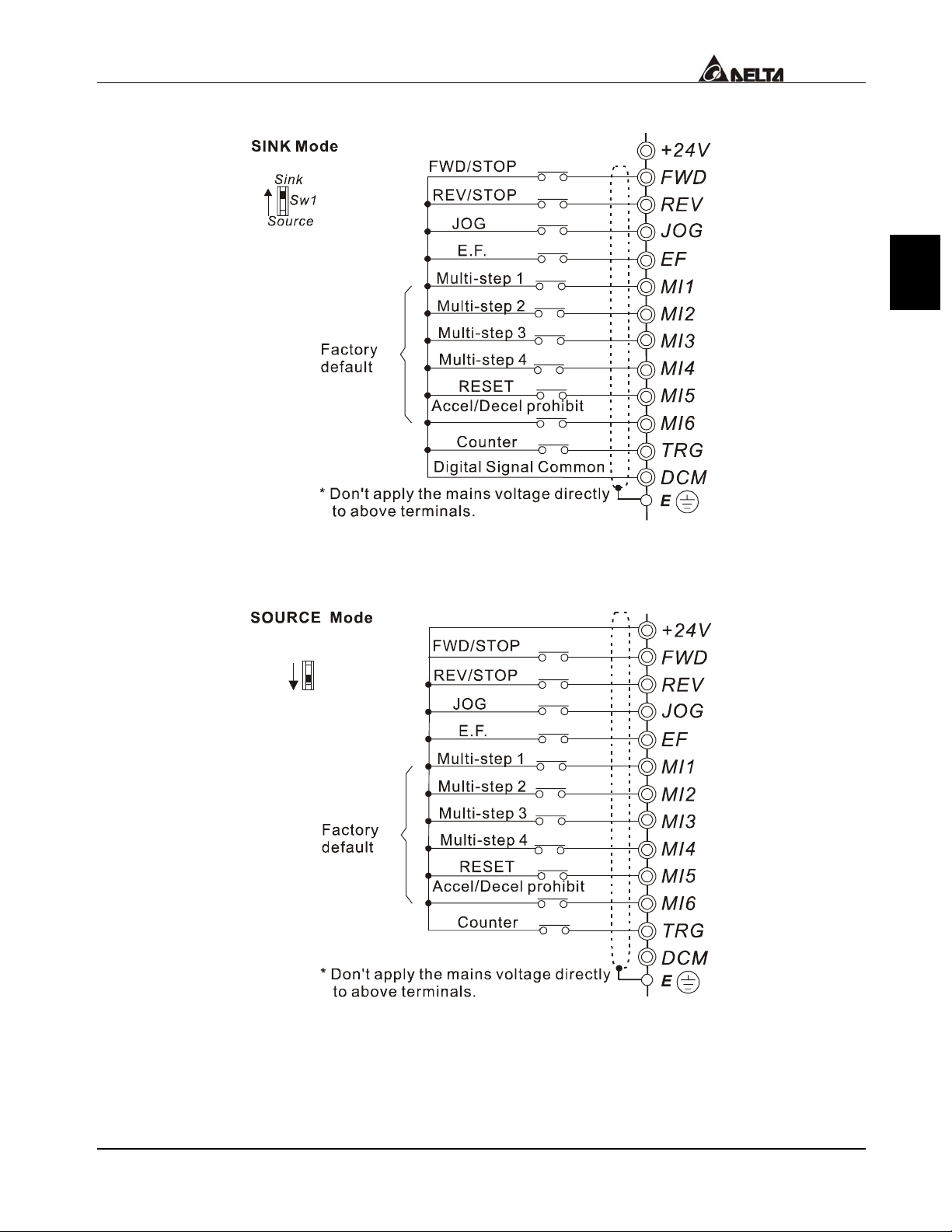

Figure 4 Wiring for SINK mode and SOURCE mode

VFD-B Series

3

Sink

Sw1

Source

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

3-5

Page 19

VFD-B Series

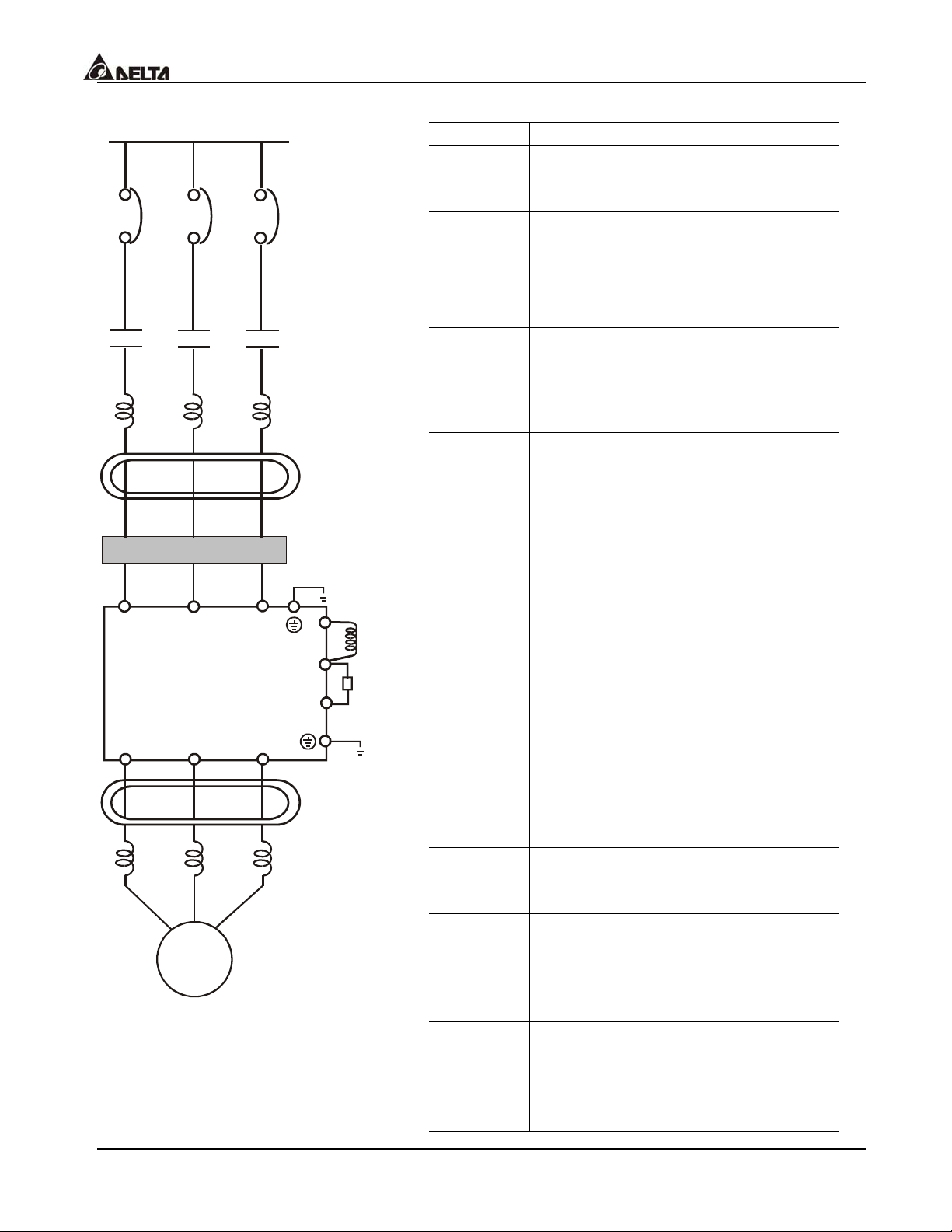

3.2 External Wiring

Power Supply

FUSE/NFB

Magnetic

contactor

Items Explanations

Power

supply

Please follow the specific power

supply requirement shown in

APPENDIX-A.

There may be inrush current during

Fuse/NFB

power up. Please check the chart of

APPENDIX B and select the correct

(Optional)

fuse with rated current. NFB is

optional.

EMI Filter

R/L1 S/L2

U/T1 V/T2

T/L3

W/T3

Input AC

Line Reactor

Zero-phase

Reactor

+1

+2/B1

B2

Zero-phase

Reactor

Output AC

Line Reactor

DC

Choke

Braking

Resistor

Magnetic

contactor

(Optional)

Input AC

Line

Reactor

(Optional)

Zero-phase

Reactor

(Ferrite

Core

Common

Choke)

(Optional)

EMI filter

(Optional)

Please do not use a Magnetic

contactor as the I/O switch of the AC

drive, this will reduce the operating

life cycle of the AC drive.

In order to improve the input power

factor, reduces harmonics and

protection from AC line

disturbances. (Surge, switching

spike, power flick, etc.) AC line

reactor should be installed when the

power supply capacity is 500kVA or

more and exceeds 6 times of the

inverter capacity, or the wiring

distance within 10m.

Zero phase reactors are used to

reduce radio noise specify when the

audio equipments installed near the

inverter. Good effective for noise

reduction on both the input and

output sides. Attenuation quality is

good in a wide range from AM band

to 10Mhz. Appendix B for specifies

zero phase reactors. (RF220X00A)

To reduce the electromagnetic

interference. Please refer to

Appendix B for detail.

Motor

Braking

Resistor

(Optional)

Output AC

Line

Reactor

(Optional)

3-6

Used to reduce stopping time of the

motor. Please refer to the chart on

Appendix B for specific Braking

Resistors.

Motor surge voltage amplitudes

depending on the motor cable

length. For long motor cable

application, it is necessary installed

on the inverter output side.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 20

VFD-B Series

3.3 Terminal Explanations

Terminal Symbol Explanation of Terminal Function

R/L1, S/L2, T/L3 AC line input terminals

U/T1, V/T2, W/T3 AC drive output terminals motor connections

+1,+2 Connections for DC Link Reactor (optional)

+2/B1~B2 Connections for Braking Resistor (optional)

+2 ~ -(minus sign)

Connections for External Braking Unit (VFDB series)

+2/B1~ -(minus sign)

Earth Ground

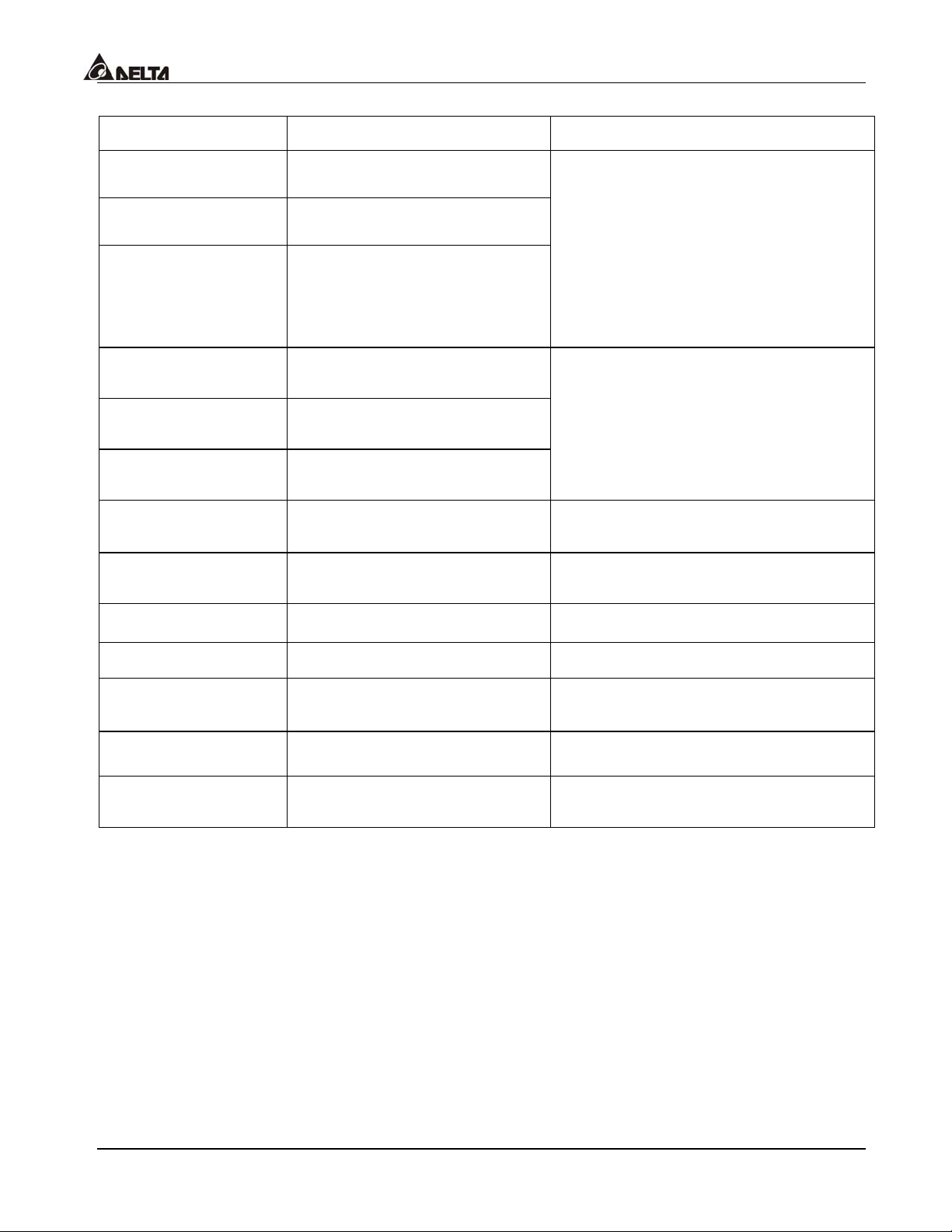

3.4 Control Terminals Explanations

Terminal Symbols Terminal Functions Factory Settings

FWD Forward-Stop command

3

REV Reverse-Stop command

JOG Jog command

EF External fault

TRG External counter input

MI1

MI2

MI3

MI4

MI5

MI6

Multi-function Input 1

Multi-function Input 2

Multi-function Input 3

Multi-function Input 4

Multi-function Input 5

Multi-function Input 6

Digital Frequency Meter

Refer to Pr.04-04 to Pr.04-09

Multi-function Input Terminals

Factory setting 1:1

DFM

(Maximum 48VDC, 50mA)

(+24V, 20mA), used for source mode.

Used as common for digital inputs

and used for sink mode.

+24V

DCM

(Open Collector Output)

DC Voltage Source

Digital Signal Common

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

3-7

Page 21

VFD-B Series

Terminal Symbols Terminal Functions Factory Settings

RA

RB

RC

MO1

MO2

MO3

MCM

+10V

Multi-function Relay output

(N.O.) a

Multi-function Relay output

(N.C.) b

Multi-function Relay common

Multi-function output 1

(Photocoupler)

Multi-function output 2

(Photocoupler)

Multi-function output 3

(Photocoupler)

Multi-function output common

Potentiometer output power

source

Resistor Load

5A(N.O.)/3A(N.C.) 240VAC

5A(N.O.)/3A(N.C.) 24VDC

Inductive Load

1.5A(N.O.)/0.5A(N.C.) 240VAC

1.5A(N.O.)/0.5A(N.C.) 24VDC

Refer to Pr.03-01 to Pr.03-03

Maximum 48VDC, 50mA

Refer to Pr.03-01 to Pr.03-03

Maximum 48VDC, 50mA

+10V 20mA

AVI Analog voltage Input

ACI Analog current Input

AUI

AFM

Auxiliary analog voltage input -10 to +10V

Analog output meter 0 to 10V, 2mA

Analog control signal

ACM

(common)

* Control signal wiring size: 18 AWG (0.75 mm2).

0 to +10V

4 to 20mA

3-8

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 22

3.5 Main Circuit Wiring

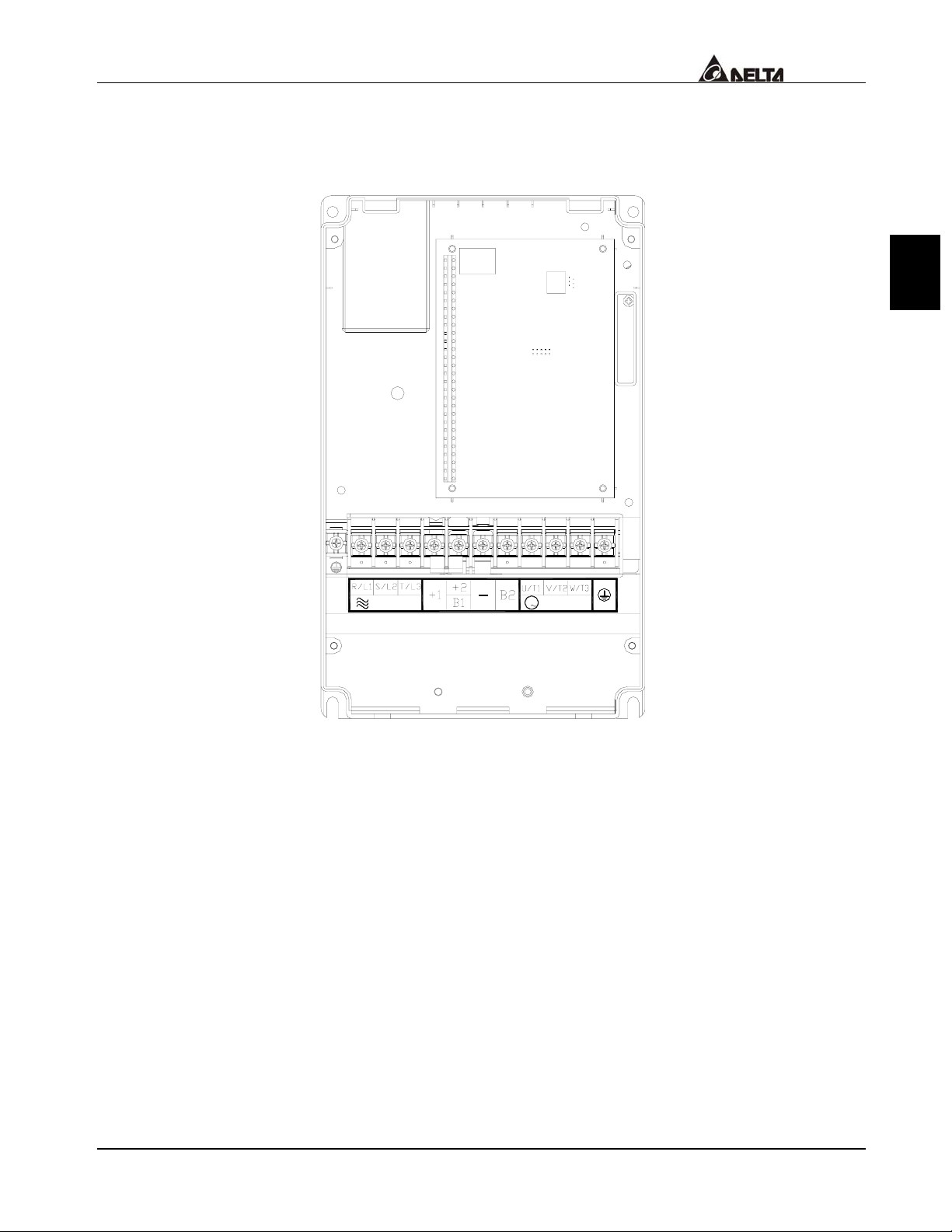

1HP to 3HP (VFD007B23A, VFD007B43A, VFD007B21A, VFD015B21A,

VFD015B23A, VFD015B43A, VFD015B21B, VFD015B23B,

VFD-B Series

VFD022B23B, VFD022B43B)

3

S

R

T

/

/

/

L3

L2

L1

+2

/

+1 B2

B1

V

U

/

W

/

/

T1

T3

T2

Control Terminal

Torque: 4Kgf-cm (3 in-lbf)

Wire: 12-24 AWG

Power Terminal

Torque: 18 kgf-cm (15.6 in-lbf)

Wire Gauge: 10-18 AWG stranded wire, 12-18 AWG solid wire

Wire Type: Copper only, 75°C

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

3-9

Page 23

VFD-B Series

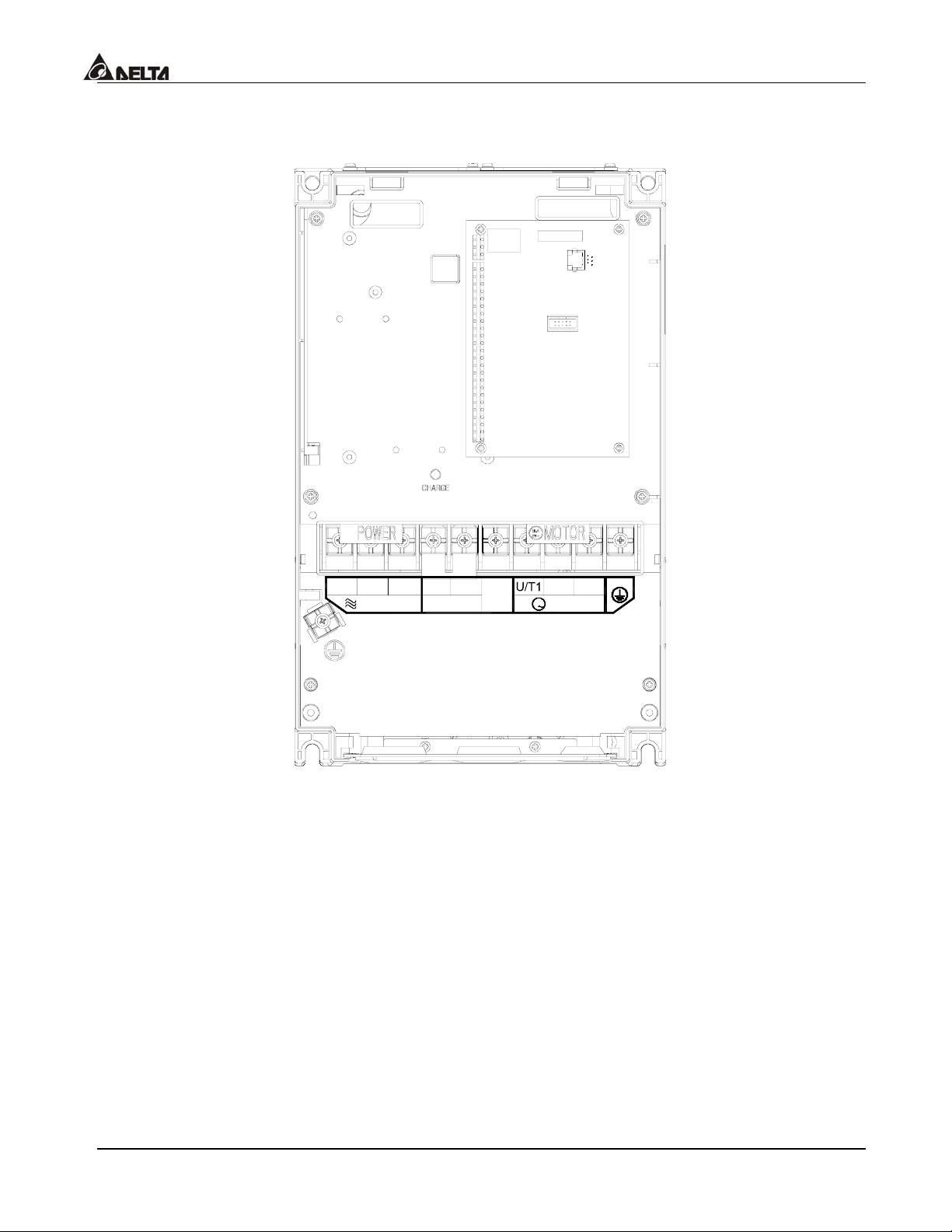

3HP to 5HP (VFD022B21A, VFD037B23A, VFD037B43A)

+2

+1

R/L1 S/L2 T/L3

Control Terminal

Torque: 4Kgf-cm (3 in-lbf)

Wire: 12-24 AWG

Power Terminal

]Torque: 18 kgf-cm (15.6 in-lbf)

Wire Gauge: 10-18 AWG

Wire Type: Stranded copper only, 75°C

-

B

B

1

U/T1 V/T2 W/T3

2

Screw Torque :

Wire Gauge :

18Kgf-cm

18~10AWG

3-10

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 24

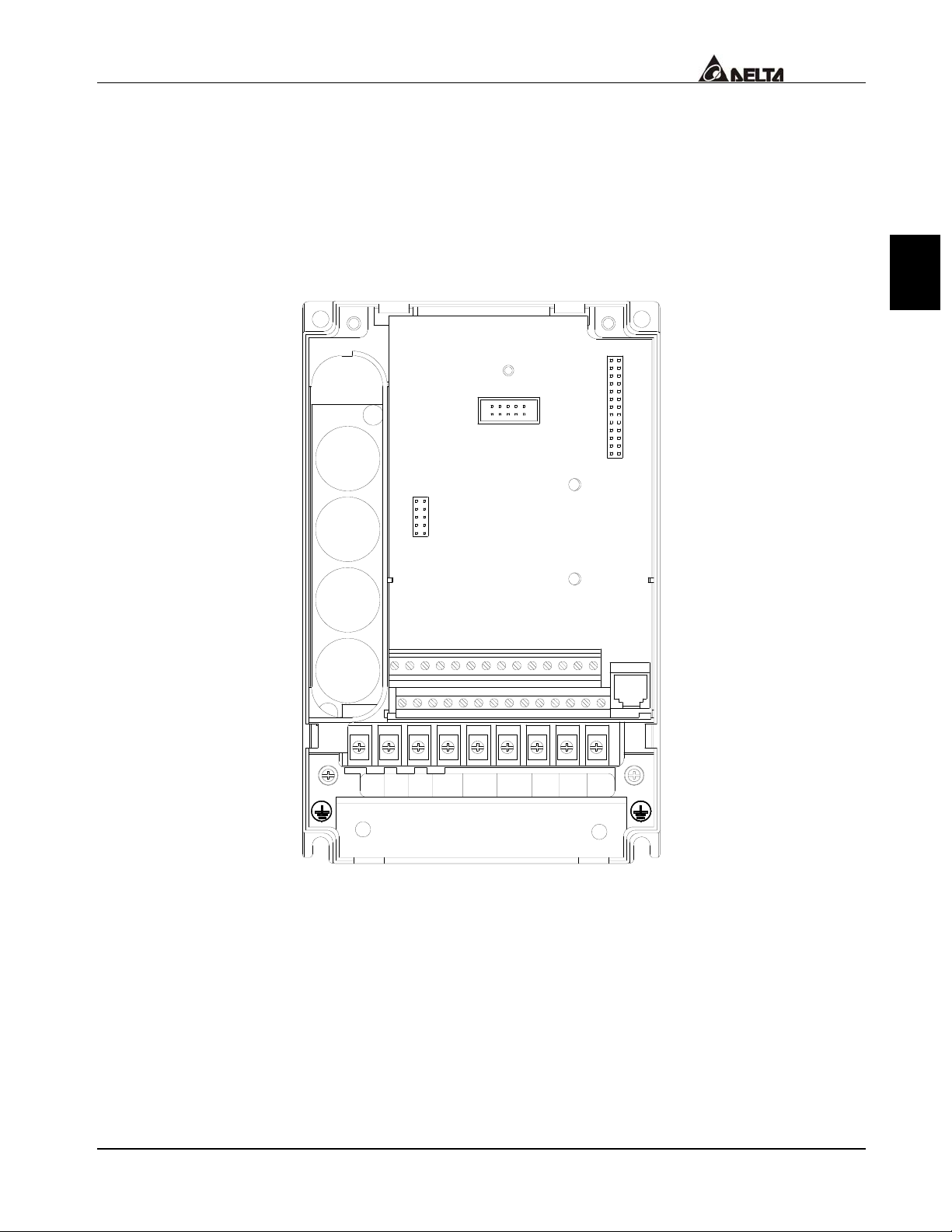

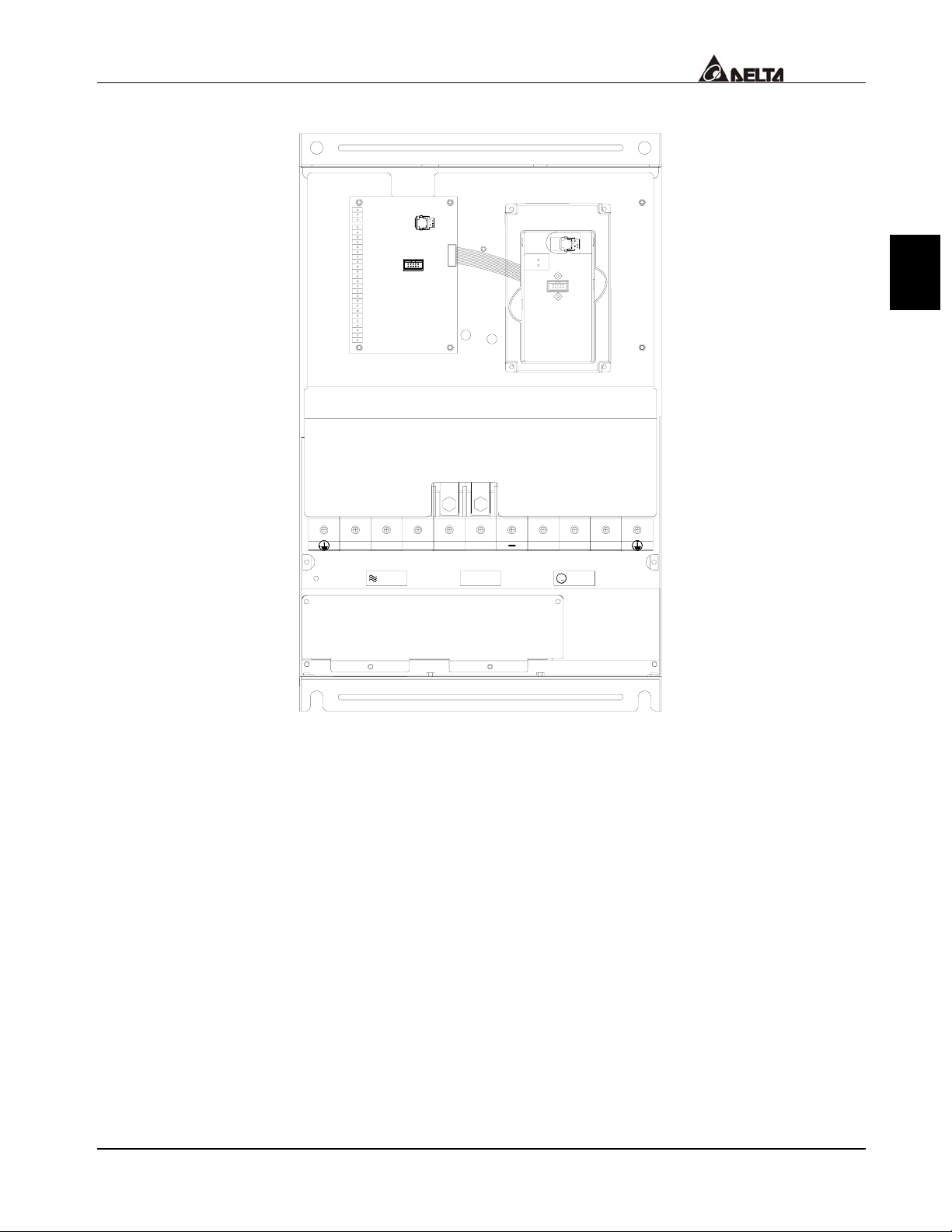

7.5 HP to 15 HP (VFD055B23A, VFD055B43A, VFD075B23A, VFD075B43A,

VFD110B23A, VFD110B43A)

VFD-B Series

3

POWER

IM

MOTOR3

Control Terminal

Torque: 4Kgf-cm (3 in-lbf)

Wire: 12-24 AWG

Power Terminal

Torque: 30Kgf-cm (26 in-lbf)

Wire: 8-12 AWG

Wire Type: Stranded Copper only, 75°C

NOTE: If wiring of the terminal utilizes the wire with a 6AWG-diameter, it is thus necessary

to use the Recognized Ring Terminal to conduct a proper wiring.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

3-11

Page 25

VFD-B Series

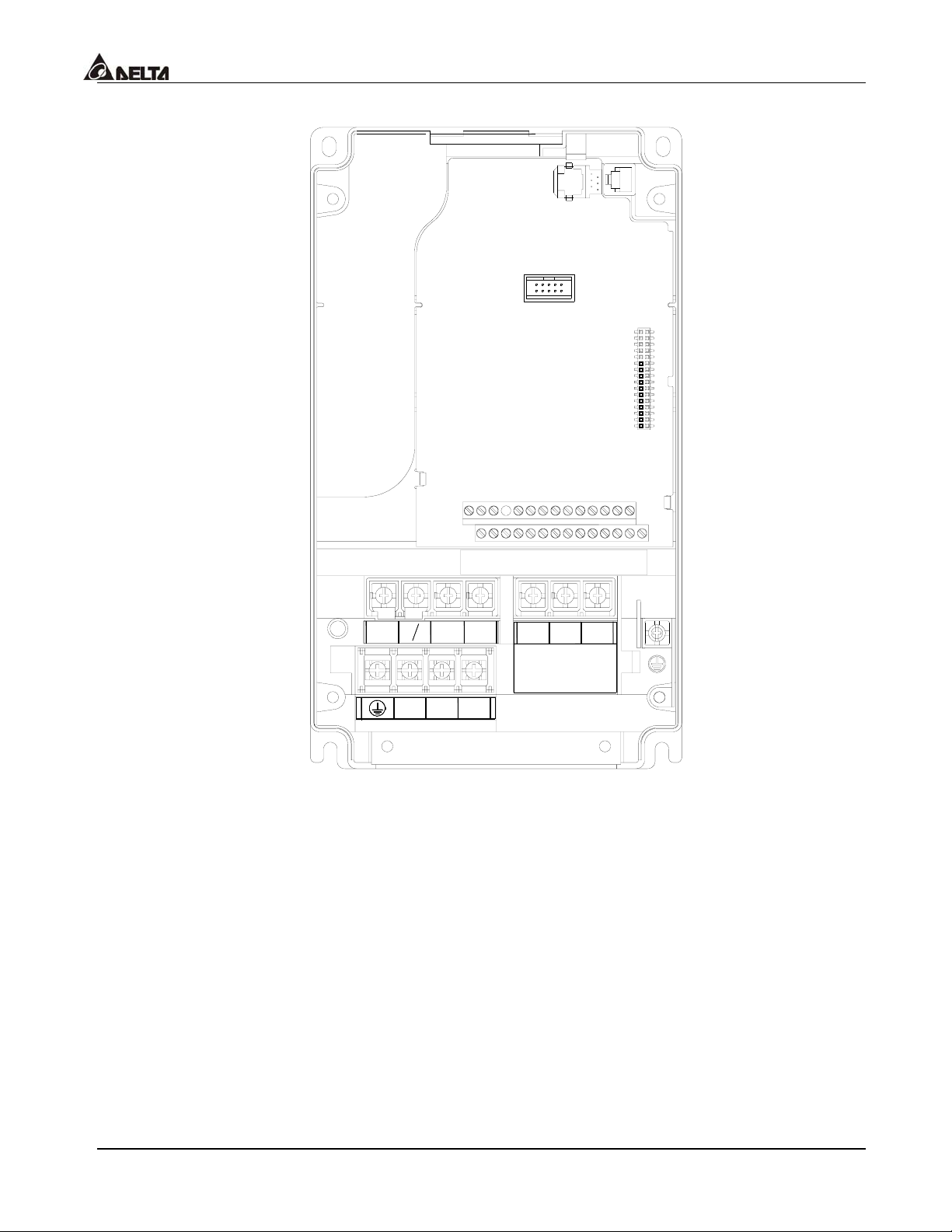

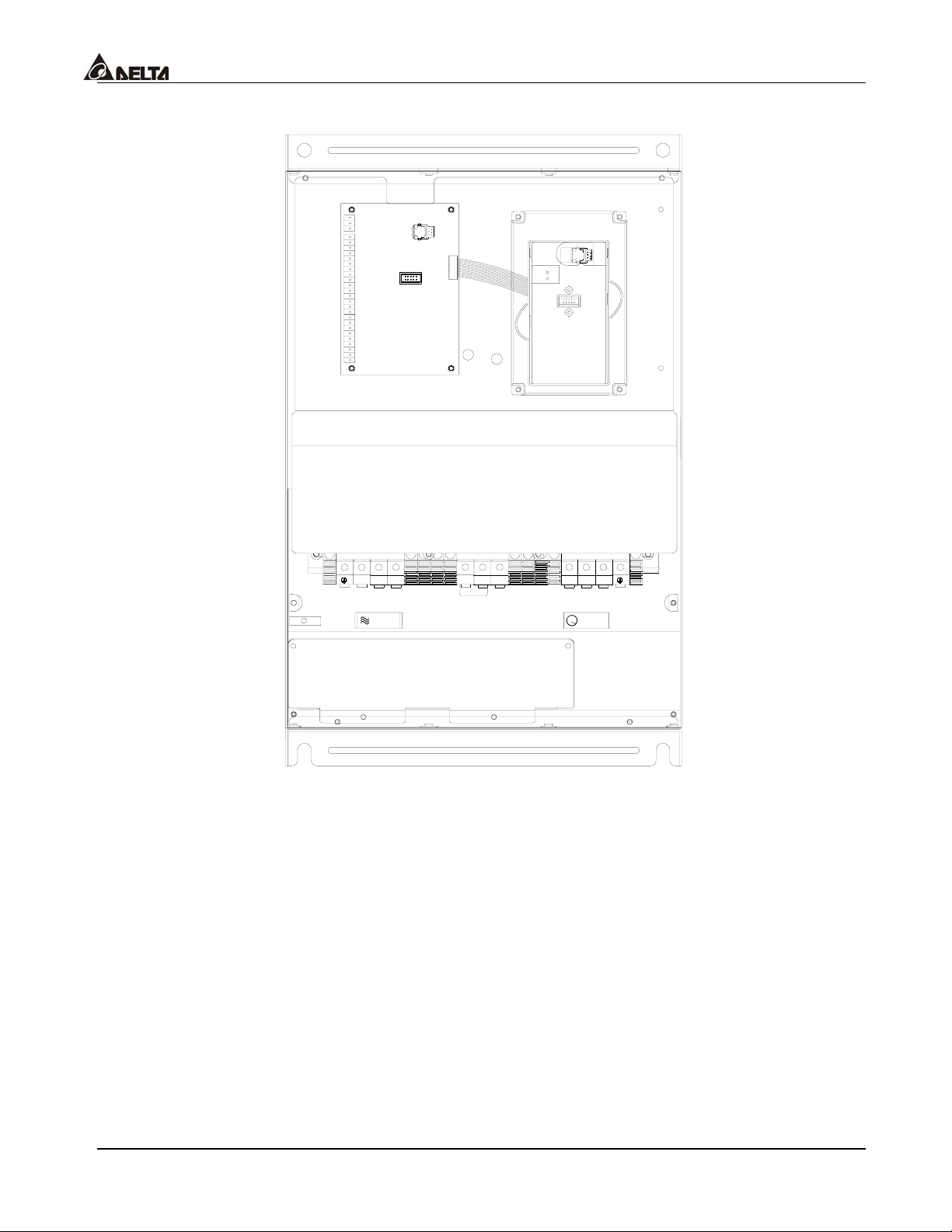

20 HP to 30 HP (VFD150B23A, VFD150B43A, VFD185B23A, VFD185B43A,

VFD220B23A, VFD220B43A)

R/L1

S/L2

POWER

T/L3

+1-+2

+ DC DC

- ( ) ( )

IM

3

W/T3V/T2

MOTOR

Control Terminal

Torque: 4Kgf-cm (3 in-lbf)

Wire: 12-24 AWG

Power Terminal

Torque: 30Kgf-cm (26 in-lbf)

Wire: 2-8 AWG

Wire Type: Stranded Copper only, 75°C

NOTE: If wiring of the terminal utilizes the wire with a 1AWG-diameter, it is thus necessary

to use the Recognized Ring Terminal to conduct a proper wiring.

3-12

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 26

40 HP to 50 HP 230V (VFD300B23A, VFD370B23A)

VFD-B Series

POWER

CHARGE

Screw Torque:

200kgf-cm

(173in-lbf)

POWER

ALARM

3

W/T3S/L2R/L1 T/L3 +2+1 U/T1 V/T2

IM

MOTOR

3

Control Terminal

Torque: 4Kgf-cm (3 in-lbf)

Wire: 12-24 AWG

Power Terminal

Torque: 200kgf-cm (173 in-lbf)

Wire Gauge: 2/0 - 3/0 AWG

Wire Type: Stranded copper only, 75°C

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

3-13

Page 27

VFD-B Series

40 HP to 60 HP 460V (VFD300B43A, VFD370B43A, VFD450B43A)

POWER

ALARM

CHARGE

R/L1

S/L2 T/L3 U/T1 V/T2 2/T3

POWER

Control Terminal

Torque: 4Kgf-cm (3 in-lbf)

Wire: 12-24 AWG

Power Terminal

Torque: 58.7kgf-cm (50.9 in-lbf) max.

Wire Gauge: 2-4AWG

Wire Type: Stranded copper only, 75°C

+1

-

+2

IM

MOTOR

3

3-14

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 28

75-100 HP 460V (VFD550B43A, VFD750B43A)

VFD-B Series

3

T/L3S/L2R/L1

POWER

Control Terminal

Torque: 4Kgf-cm (3 in-lbf)

Wire: 12-24 AWG

Power Terminal

Torque: 200 kgf-cm (173 in-lbf)

Wire Gauge: 2/0-3/0 AWG

Wire Type: Stranded copper only, 75°C

+1

+2

Scre w Torqu e:

200kgf-cm

(173in-lbf)

IM

3

V/T2U/T1

MOTOR

W/T3

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

3-15

Page 29

VFD-B Series

3.6 Wiring Notes:

PLEASE READ PRIOR TO INSTALLATION.

1. There are corresponding ring terminals which will be included with each unit (20-30HP),

and please use the proper crimping tool by KST INC. P/N: KST-HDC38A for securing

the conductor.

2.

CAUTION:

Do not connect the AC power to the U/T1, V/T2, W/T3 terminals, as it

will damage the AC drive.

3.

WARNING:

Ensure all screws are tightened to the proper torque rating.

4. During installation, follow all local electrical, construction, and safety codes for the

country the drive is to be installed in.

5. Ensure that the appropriate protective devices (circuit breaker or fuses) are connected

between the power supply and AC drive.

6. Make sure that the leads are connected correctly and the AC drive is properly grounded.

(Ground resistance should not exceed 0.1Ω.)

7. Use ground leads that comply with AWG/MCM standards and keep them as short as

possible.

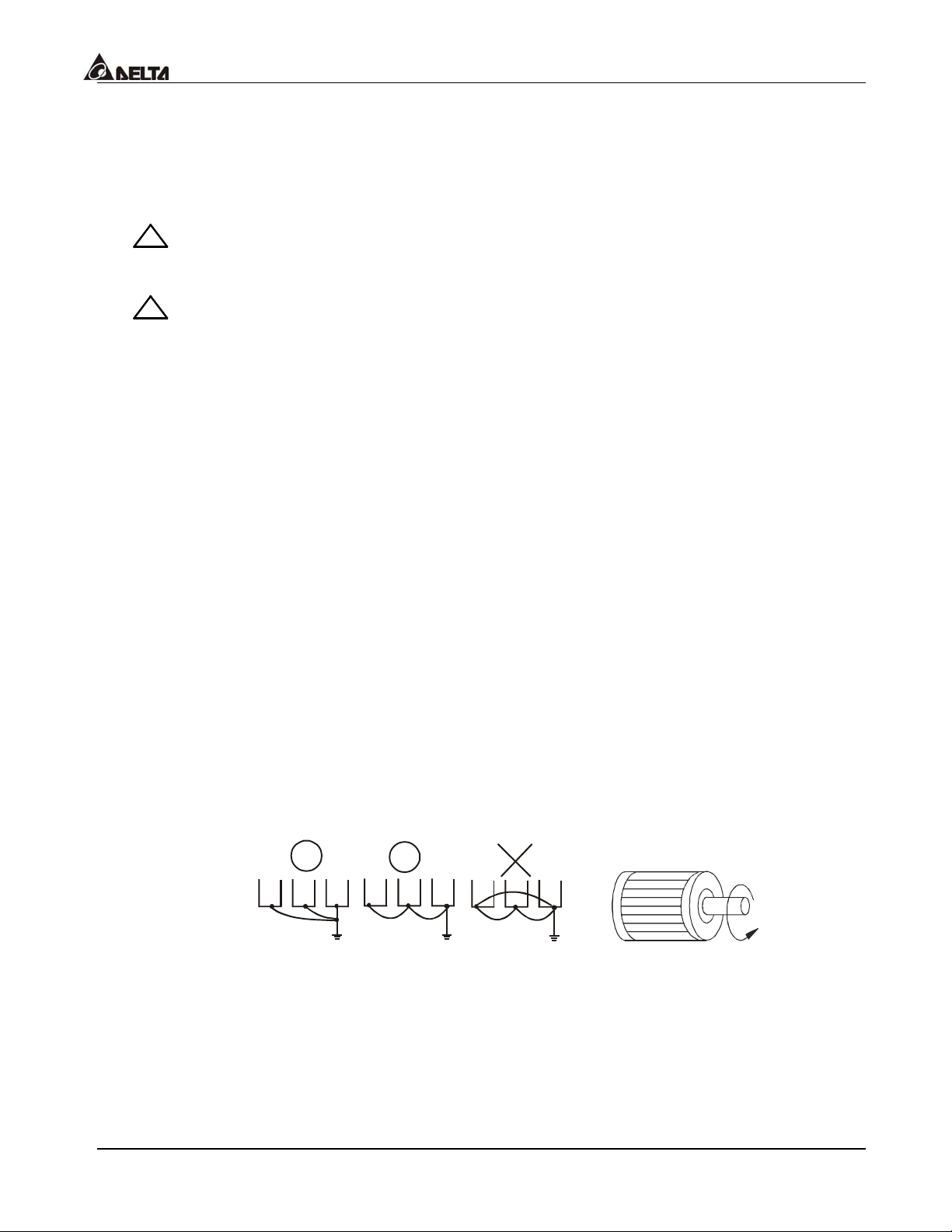

8. Multiple VFD-B units can be installed in one location. All the units should be grounded

directly to a common ground terminal. The VFD-B ground terminals may also be

connected in parallel, as shown in the figure below.

loops.

Ensure there are no ground

Forward

running

9. When the AC drive output terminals U/T1, V/T2, and W/T3 are connected to the motor

terminals U/T1, V/T2, and W/T3, respectively, the motor will rotate counterclockwise (as

viewed from the shaft ends of the motor) when a forward operation command is received.

To reverse the direction of motor rotation, switch over any of the two motor leads.

3-16

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 30

VFD-B Series

10. Make sure that the power source is capable of supplying the correct voltage and

required current to the AC drive.

11. Do not attach or remove wiring when power is applied to the AC drive.

12. Do not monitor the signals on the circuit board while the AC drive is in operation.

13. For the single-phase rated AC drives, the AC power can be connected to any two of the

three input terminals R/L1, S/L2, T/L3.

with single-phase motors.

Note: This drive is not intended for the use

14. Route the power and control wires separately, or at 90°angle to each other.

15. If a filter is required for reducing EMI (Electro Magnetic Interference), install it as close

as possible to AC drive. EMI can also be reduced by lowering the Carrier Frequency.

16. If the AC drive is installed in the place where a load reactor is needed, install the filter

close to U/T1, V/T2, W/T3, side of AC drive. Do not use a Capacitor or L-C Filter

(Inductance-Capacitance) or R-C Filter (Resistance-Capacitance), unless approved by

Delta.

17. When using a GFCI (Ground Fault Circuit Interrupt), select current sensor with sensitivity

3

of 200mA, and not less than 0.1-second detection to avoid nuisance tripping.

3.7 Motor Operation Precautions

1. When using the AC drive to operate a standard 3-phase induction motor, notice that the

energy loss is greater than for an inverter duty motor.

2. Avoid running a standard induction motor at low speed. Under these conditions, the

motor temperature may rise above the motor rating due to limited airflow produced by

the motor’s fan.

3. When the standard motor operates at low speed, the output load must be decreased.

4. If 100% output torque is desired at low speed, it may be necessary to use a special

“inverter-duty” rated motor.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

3-17

Page 31

Page 32

VFD-B Series

CHAPTER 4 DIGITAL KEYPAD OPERATION

This chapter describes the various controls and indicators found on the digital keypad/display

PU01. The information in this chapter should be read and understood before performing the

start–up procedures described in the chapter of parameter settings.

ª Description of the Keypad

ª Description of Display

ª Keypad Operation Modes & Programming Steps

VFD-PU01 Dimensions: mm (inch)

73.0 [2.87]

JOG

RUN

MODE

PROG

DATA

STOP

110.0 [4.33]

19.0 [0.75]

77.0 [3.03]

44.0 [1.73]

?

4

0

.

0

M4* 0.7(2X)

[

1

.

5

8

]

4

97.0 [3.82]

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

6.5 [0.26]

4-1

Page 33

VFD-B Series

4.1 Description of the Digital Keypad VFD-PU01

JOG

By pressing JOG key.

Initiates jog operation.

moves cursor to the left

UP and DOWN Key

Sets the parameter

number and changes the

numerical data, such as

Master Frequency.

Left key

F

H

U

JOG

RUN

VFD-PU01

STOP

RESET

LED Display

Display frequency, current, voltage

and error, etc.

Part Number

Status Display

Display the driver's current status

MODE

C

hanges between different

display mode.

STOP/RESET

RUN key

Display Message Descriptions

Display the AC drive Master Frequency.

Display the actual operation frequency present at terminals

U/T1, V/T2, and W/T3.

User defined unit, where (U = F x Pr.00-05)

4-2

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 34

VFD-B Series

Display Message Descriptions

Display the output current present at terminals U/T1, V/T2, and

W/T3.

Display the AC drive forward run status.

The AC drive reverse run status.

The counter value (C).

Display the specified parameter setting.

Display the actual value stored within the specified parameter.

External Fault.

Display “End” for approximately 1 second if input has been

accepted. After a parameter value has been set, the new

value is automatically stored in memory. To modify an entry,

use the

or keys.

4

Display “Err”, if the input is invalid.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

4-3

Page 35

VFD-B Series

4.2 Operation steps of the Digital Keypad VFD-PU01

Selecting mode

START

F

H

U

MODE

Note

Setting parameters

F

H

U

In the selection mode, press

:

H

F

U

MODE

F

H

U

MODE

to set the parameters.

F

H

U

MODE

move to previous display

F

H

U

F

H

U

F

H

U

MODEMODE

GO START

F

H

U

Success to set parameter.

F

H

U

Input data error

NOTE

:

To shift data

START

F

H

U

To modify data

START

F

H

U

Setting direction

MODE

F

H

U

F

H

U

F

H

U

F

H

U

to return the selecting mode.In the parameter setting mode, you can press

F

H

U

F

H

U

F

H

U

or

F

H

U

F

H

U

or

4-4

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 36

VFD-B Series

CHAPTER 5 DESCRIPTION OF PARAMETER SETTINGS

Group 0: User Parameters a: This parameter can be set during operation.

00 - 00

00 - 01

Identity Code of AC Drive Factory setting: ##

Factory Setting

Rated Current Display of the AC drive Factory setting: #.#

Settings None Unit: 0.1 A

This parameter displays the rated current of the AC drive. It is based on Pr.00-00, and is

read-only.

Users can use the following table to check if the rated current of the AC drive is

corresponds to the identity code.

230V Series

KW 0.75 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22 30 37

HP 1.0 2.0 3.0 5.0 7.5 10 15 20 25 30 40 50

Pr.00-00 04 06 08 10 12 14 16 18 20 22 24 26

Rated

current (A)

5.0 7.0 11 17 25 33 49 65 75 90 120 146

Max.

Carried

15KHz 15 KHz 9 KHz

Freq.

5

460V Series

KW 0.75 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22 30 37 45 55 75

HP 1.0 2.0 3.0 5.0 7.5 10 15 20 25 30 40 50 60 75 100

Pr.00-00 05 07 09 11 13 15 17 19 21 23 25 27 29 31 33

Rated

Current (A)

2.7 4.2 5.5 8.5 13 18 24 32 38 45 60 73 91 110 150

Max.

Carried

15 KHz 15 KHz 9 KHz 6 KHz

Freq.

00 - 02

Parameter Reset Factory Setting: 00

Settings 08 Keypad Lock

10 All parameters are reset to factory settings

This setting allows the user to return all parameters to the factory default settings except

the fault records (Pr.06-08 ~ Pr06-11).

If this parameter is set to 08, the operation function of VFD-PU01 keypad is disabled. At

this time, you should set Pr.00-02 to 00 to disable parameter lock function.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

5-1

Page 37

VFD-B Series

00 - 03

Start-up Display Page Selection

a

Factory Setting: 00

Settings 00 Display the Master Frequency (F)

01 Display the actual operation frequency (H)

02 Display the content of user-defined unit (U)

03 Multifunction display, [default setting: output current (A)]

04 FWD/REV command

This setting determines the display mode after power is applied to the drive.

00 - 04

Content of Multi Function Display

a

Factory Setting: 00

Settings 00 Display the output current (A)

01 Display the counter value (C)

02 Display the content of PLC time (1.tt)

03 Display the DC BUS voltage (U)

04 Display the output voltage (E)

05 Display the power factor angle (n.)

06 Display the output power (P), unit: kW

07 Display actual motor speed (enable during vector control or Pulse

Generator feedback control) (HU)

08 Display the estimative value of the ration of torque (t)

09 Display PG numbers/10ms (G)

10 Display analog feedback signal value (b) (%)

11 Display AVI (U1.) (%)

12 Display ACI (U2.) (%)

13 Display AUI (U3.) (%)

This parameter determines the content for Multi function Display. User also can view

other information by pressing the “LEFT” key on the VFD-PU01 when the display page is

at Multi function Display.

The 100% of settings 11-13 is +10V or 20mA.

00 - 05

User Defined Coefficient K

a

Factory Setting: 1.00

Settings 0.01 to d 160.00 Unit: 0.01

The coefficient K determines the multiplying factor for the user-defined unit.

The display value is calculated as follows:

U (user-defined unit) = Frequency Command x K (Pr.00-05)

H (actual output) = (actual output frequency) x K (Pr.00-05)

5-2

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 38

VFD-B Series

The display window is only capable of showing five digits, yet you could use Pr.00-05 to

create larger numbers. The display windows use decimal points to signify numbers up

to seven digits as illustrated below:

Display Number Represented

99999 The absence of a decimal point indicates a five-digit integer.

9999.9

A signal decimal point between the middle and the right-most numbers is a true

decimal point. For example, the number 1234.5 would be displayed as “1234.5”.

A single decimal point after the right-most number is not a true decimal point;

99999.

instead it indicates that a zero follows the right-most number. For example, the

number 123450~123459 would be displayed as “12345.”

Two decimal points (one between the middle and the right-most numbers, and one

after the right-most number) are not true decimal points; instead they indicate that

9999.9.

two zeros follow the right-most number. For example, the number

3456700~3456799 would be displayed as “3456.7.”.

00 - 06

Software Version Factory Setting: ###

Settings None

The software version is read-only.

00 - 07

Password Decode Factory Setting: 00

Display 00-02 (times of wrong password)

5

Settings 1 to 65535 Unit: 1

Function of this parameter is to decode the password that is to be input into Pr.00-08.

Input the correct password here so as to revise the parameters; the trials are limit to 3

times only. If the entered passwords are wrong consecutively, a blinking “codE” will

show up to caution the users to restart the AC drive in order to key in the correct

password again.

00 - 08

Password Input Factory Setting: 00

Settings 1 to 65535 Unit: 1

To cancel the parameter lock, setting the parameter as 0. To lock all parameters, setting

a value other than 0 in the parameter as a password. To change the one of the

parameter settings of this AC drive, one must enter the correct password in Pr.00-07 to

activate this function. Be sure to keep the password in mind for later use.

Display states:

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

5-3

Page 39

VFD-B Series

00: no password 01: password has been set

Password Decode Flow Chart

00-08

Displays 0 when

password entered

correctly.

Correct Password

END

00-08

Displays 0 when

password entered

correctly.

00-07

Incorrect Password

END

00-07

3 chances to enter the correct

password.

1st time displays "1" if

password is incorrect.

2nd time displays "2", if

password is incorrect.

3rd time displays "codE

(blinking)

If the password was entered

incorrectly after three tries,

the keypad will be locked.

Turn the power OFF/ON to

re-enter the password.

00 - 09

Control methods Factory Setting: 00

Settings 00 V/F control

01 V/F + PG Control

02 Vector Control

03 Vector + PG Control

This parameter determines the control methods of the AC drive.

00 - 10

Reserved

5-4

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 40

Group 1: Basic Parameters

VFD-B Series

01 - 00

Maximum Output Frequency (Fmax) Factory Setting: 60.00

Settings 50.00 to 400.00 Hz Unit: 0.01Hz

This parameter determines the AC drive’s Maximum Output Frequency. All the AC drive

analog inputs (0 to +10V, 4 to 20mA, -10V to +10V) are scaled to correspond to the output

frequency range.

01 - 01

Maximum Voltage Frequency (Fbase) Factory Setting: 60.00

Settings 0.10 to 400.00Hz Unit: 0.01Hz

This value should be set according to rated frequency of the motor as indicated on the

motor nameplate. Maximum Voltage Frequency determines the volts per hertz ratio. For

example, if the drive is rated for 460 VAC output and the Maximum Voltage Frequency is

set to 60Hz, the drive will maintain a constant ratio of 7.66 V/Hz (460V/60Hz=7.66V/Hz).

This parameter value must be equal to or greater than the Mid-Point Frequency

(Pr.01-03).

01 - 02

Maximum Output Voltage (Vmax) Unit: 0.1

Settings 230V series 0.1 to 255.0V Factory Setting: 220.0

5

460V series 0.1 to 510.0V Factory Setting: 440.0

This parameter determines the Maximum Output Voltage of the AC drive. The Maximum

Output Voltage setting must be smaller than or equal to the rated voltage of the motor as

indicated on the motor nameplate. This parameter value must be equal to or greater than

the Mid-Point Voltage (Pr.01-04).

01 - 03

Mid-Point Frequency (Fmid) Factory Setting: 0.50

Settings 0.10 to 400.00Hz Unit: 0.01Hz

This parameter sets the Mid-Point Frequency of the V/F curve. With this setting, the V/F

ratio between Minimum Frequency and Mid-Point frequency can be determined. This

parameter must be equal to or greater than Minimum Output Frequency (Pr.01-05) and

equal to or less than Maximum Voltage Frequency (Pr.01-01).

01 - 04

Mid-Point Voltage (Vmid) Unit: 0.1

Settings 230V series 0.1 to 255.0V Factory setting: 1. 7V

460V series 0.1 to 510.0V Factory setting: 3.4V

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

5-5

Page 41

VFD-B Series

This parameter sets the Mid-Point Voltage of any V/F curve. With this setting, the V/F

ratio between Minimum Frequency and Mid-Point Frequency can be determined. This

parameter must be equal to or greater than Minimum Output Voltage (Pr.01-06) and

equal to or less than Maximum Output Voltage (Pr.01-02). However, this parameter is

ineffective when Pr.11-00 is set to 1 to 4.

01 - 05

Minimum Output Frequency (Fmin) Factory Setting: 0.50

Settings 0.10 to 400.00Hz Unit: 0.01Hz

This parameter sets the Minimum Output Frequency of the AC drive. This parameter

must be equal to or less than Mid-Point Frequency (Pr.01-03).

The settings of 01-03, 01-04, 01-06 are invalid in Vector Control mode.

01 - 06

Minimum Output Voltage (Vmin) Unit: 0.1

Settings 230V series 0.1 to 255.0V Factory setting: 1. 7V

460V series 0.1 to 510.0V Factory setting: 3.4V

This parameter sets the Minimum Output Voltage of the AC drive. This parameter must

be equal to or less than Mid-Point Voltage (Pr.01-04).

The settings of Pr.01-01 to Pr.01-06 have to meet the agreement that Pr.01-02 ≥

Pr.01-04 ≥ Pr.01-06 and Pr.01-01 ≥ Pr.01-03 ≥ Pr.01-05.

01 - 07

Upper Bound of Output Frequency Factory Setting: 100

Settings 1 to 120% Unit: 1%

This parameter must be equal to or greater than the Lower Bound of Output Frequency

(Pr.01-08). The Maximum Output Frequency (Pr.01-00) is regarded as 100%.

Upper Bound of Output Frequency value = (Pr.01-00 x Pr.01-07)/100

01-07

Upper Bound

Output Frequency

01-01

01-00

Maximum

Output

Frequency

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Vol tag e

01-02

Maximum

Output

Vol tag e

01-04

Mid-point

Vol tag e

01-06

Minimum

Output

Vol tag e

Minimum

Output

Freq.

01-08

Lower Bound

Output Frequency

01-05

01-03

Mid-point

Freq.

Output Frequency

setting limit

Maximum Voltage

Frequency

(Base Frequency)

V/F Curve

5-6

Page 42

VFD-B Series

01 - 08

Lower Bound of Output Frequency Factory Setting: 00

Settings 00 to 100% Unit: 1%

The Upper/Lower Bound is to prevent operation error and machine damage.

If the Upper Bound of Output Frequency is 50Hz and the Maximum Output Frequency is

60Hz, the Maximum Output Frequency will be limited to 50Hz.

If the Lower Bound of Output Frequency is 10Hz, and the Minimum Output Frequency

(Pr.01-05) is set at 1.0Hz, then any Command Frequency between 1.0-10Hz will

generate a 10Hz output from the drive.

This parameter must be equal to or less than the Upper Bound of Output Frequency

(Pr.01-07).

The Lower Bound of Output Frequency value = (Pr.01-00 x Pr.01-08) /100

01 - 09

01 - 10

01 - 11

Acceleration Time 1 (Taccel 1) a Factory Setting: 10.0

Deceleration Time 1 (Tdecel 1) a Factory Setting: 10.0

Acceleration Time 2 (Taccel 2) a Factory Setting: 10.0

5

01 - 12

01 - 18

01 - 19

01 - 20

01 - 21

Deceleration Time 2 (Tdecel 2) a Factory Setting: 10.0

Acceleration Time 3 (Taccel 3)

Deceleration Time 3 (Tdecel 3)

Acceleration Time 4 (Taccel 4)

Deceleration Time 4 (Tdecel 4)

a

a

a

a

Factory Setting: 10.0

Factory Setting: 10.0

Factory Setting: 10.0

Factory Setting: 10.0

Settings 0.01 to 3600.0 sec Unit: 0.1/0.01sec

♦ Factory setting 60sec is for the models of 30 HP and above.

Unit can be set by Pr.01-23.

The Acceleration Time is used to determine the time required for the AC drive to ramp

from 0 Hz to its Maximum Output Frequency (Pr.01-00). The rate is linear unless

S-Curve is “Enabled.”

The Deceleration Time is used to determine the time required for the AC drive to

decelerate from the Maximum Output Frequency (Pr.01-00) down to 0 Hz. The rate is

linear unless S-Curve is “Enabled.”

The Acceleration/Deceleration Time 1, 2, 3, 4 is switched according to the Multi-Function

Input Terminals Setting. See Pr.04-04 to Pr.04-09 for more details.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

5-7

Page 43

VFD-B Series

A

In the diagram shown below, the Acceleration/Deceleration Time of the AC drive is time

between 0 Hz to Maximum Output Frequency (Pr.01-00). Suppose the Maximum Output

Frequency is 60 Hz, Minimum Output Frequency (Pr.01-05) is 1.0 Hz, and

Acceleration/Deceleration Time is 10 seconds. The actual time for the AC drive to

accelerate from start-up to 60 Hz is 9.83 seconds and the deceleration time is also 9.83

seconds. ((60-1) x 10/60=9.83secs).

Frequency

01-00

Max.

Output

Freq.

Setting

running

Freq.

Time

a

Factory Setting: 1.0

01 - 13

Jog Acceleration Time

Accel

Time

01-09 01-11

01-18 01-20

ccel/Decel Time Definition

Decel

Time

01-10 01-12

01-19 01-21

Settings 0.1 to 3600.0 sec Unit: 0.1sec

01 - 22

Jog Deceleration Time

a

Factory Setting: 1.0

Settings 0.1 to 3600.0 sec Unit: 0.1sec

01 - 14

Jog Frequency

a

Factory Setting: 6.00

Settings 0.10 to 400.00Hz Unit: 0.01Hz

When the Jog command is “ON”, the AC drive will accelerate from Minimum Output

Frequency (Pr.01-05) to Jog Frequency (Pr.01-14). When the Jog command is “OFF”,

the AC drive will decelerate from Jog Frequency to zero. The Accel/Decel time is decided

by the Jog Accel/Decel time (Pr.01-13, Pr01-22).

During operation, the AC drive cannot perform Jog command. And during Jog operation,

other operation commands cannot be accepted, except command of FORWARD,

REVERSE and STOP keys on the digital keypad.

5-8

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 44

Frequency

01-14

JOG

Freq.

01 - 15

JOG

Accel

Time

01-13

Auto-Acceleration / Deceleration

JOG

Decel

Time

01-13

a

Settings 00 Linear acceleration / deceleration

01 Auto acceleration, linear Deceleration.

Time

Factory Setting: 00

VFD-B Series

5

02 Linear acceleration, auto Deceleration.

03 Auto acceleration / deceleration

04 Auto acceleration / deceleration (refer to Accel/Decel Time

setting)

If this parameter is set to 03, the AC drive will accel/decel in the fastest and smoothest

means possible by automatically adjusting the time of accel/decel.

If this parameter is set to 04, the real accel/decel time will be equal to or more than

parameter Pr.01-09 ~Pr.01-12 and Pr.01-18 to Pr.01-21.

01 - 16

01 - 17

Acceleration S-Curve Factory Setting: 00

Deceleration S-Curve Factory Setting: 00

Settings 00 to 07

This parameter is used to ensure a smooth acceleration and deceleration. The S-curve

is enabled when sets at 01-07. Setting 1 offers the quickest S-curve and 07 offers the

longest and smoothest S-curve. The AC drive will not follow Accel/Decel Time in

Pr.01-09 to Pr.01-12. To Disable the S-curve, set Pr.01-16 and Pr.01-17 to 00.

NOTE: From the diagram shown below, the original setting Accel/Decel Time will be for

reference when the function of the S-curve is enabled. The actual Accel/Decel Time will be

determined based on the S-curve selected (01 to 07).

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

5-9

Page 45

VFD-B Series

A

Freq.

ccel/Decel characteristics

(1), (2) Disabling S curve

(3), (4) Enabling S curve

01 - 23

Unit for Accel/Decel Time

Settings 00 Unit: 1 sec

01 Unit: 0.1 sec

02 Unit: 0.01 sec

a

Factory Setting: 00

This parameter can be used to set the unit of Accel/Decel Time and the setting range of

Accel/Decel Time is also changed at the same time.

5-10

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 46

Group 2: Operation Method Parameters

VFD-B Series

02 - 00

Source of First Frequency Command

a

Factory Setting: 00

Settings 00 Master Frequency determined by the digital keypad or external

UP/DOWN keys of the Multi Function Inputs.

01 Master Frequency determined by analog signal DC 0V to +10V

(external terminal AVI)

02 Master Frequency determined by analog signal DC 4mA to

20mA (external terminal ACI).

03 Master Frequency determined by analog signal DC -10V to +10V

(external terminal AUI).

04 Master Frequency determined by RS-485 serial communication.

(RJ-11).

05 Master Frequency determined by RS-485 serial communication.

(RJ-11). It won’t memorize the frequency.

06 Combined usage of the master and auxiliary frequency

command Pr. 02-10, 02-11,02-12

02 - 13

Source of Second Frequency Command

a

Factory Setting: 00

Settings 00 Master Frequency determined by the digital keypad or external

UP/DOWN keys of the Multi Function Inputs.

5

01 Master Frequency determined by analog signal DC 0V to +10V

(external terminal AVI)

02 Master Frequency determined by analog signal DC 4mA to

20mA (external terminal ACI).

03 Master Frequency determined by analog signal DC -10V to +10V

(external terminal AUI).

04 Master Frequency determined by RS-485 serial communication.

(RJ-11).

05 Master Frequency determined by RS-485 serial communication.

(RJ-11). It won’t memorize the frequency.

06 Combined usage of the master and auxiliary frequency

command Pr. 02-10, 02-11,02-12

These parameters set the Frequency Command Source of the AC drive.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

5-11

Page 47

VFD-B Series

02 - 01

Source of First Operation Command

a

Factory Setting: 00

Settings 00 Controlled by the digital keypad

01 Controlled by the external terminals, keypad STOP enabled.

02 Controlled by the external terminals, keypad STOP disabled.

03 Controlled by the RS-485 communication interface, keypad

STOP enabled.

04 Controlled by the RS-485 communication interface, keypad

STOP disabled.

02 - 14

Source of Second Operation Command

a

Factory Setting: 00

Settings 00 Controlled by the digital keypad

01 Controlled by the external terminals, keypad STOP enabled.

02 Controlled by the external terminals, keypad STOP disabled.

03 Controlled by the RS-485 communication interface, keypad

STOP enabled.

04 Controlled by the RS-485 communication interface, keypad

STOP disabled.

When the AC drive is controlled by external terminal, please refer to Pr.02-05 for

detailed explanations.

The first /second frequency/operation command is enable/disable by Multi Function

Input Terminals. Please refer to the setting of Pr.04-04 ~ 04-09.

02 - 02

Stop Method Factory Setting: 00

Settings 00 STOP: ramp to stop; E.F. (External Fault) : coast to stop

01 STOP: coast to stop; E.F. : coast to stop

02 STOP: ramp to stop; E.F. : ramp to stop

03 STOP: coast to stop; E.F. : ramp to stop

The parameter determines how the motor is stopped when the AC drive receives a valid

stop command or External Fault.

1. Ramp: the AC drive decelerates to Minimum Output Frequency (Pr.01-05) according to

the deceleration time and then stops.

2. Coast: the AC drive stops output instantly upon command, and the motor free runs until it

comes to a complete stop.

3. The motor stop method is usually determined by the characteristics of the motor load

and the frequency of stop

5-12

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 48

VFD-B Series

(1) It is recommended to use “ramp to stop” for the personnel’s safety or to prevent the

materials from being wasted applications that the motor has to stop after the drive is

stopped. As for the deceleration time, it has to be set according to the field tuning.

(2) If the motor free run is okay or the loading inertia is great, it is recommended to set it

as “coast to stop”.

For example: blowers, punching machines, and pumps.

Hz

Hz

Motor

Speed

Operation

command

02 - 03

Freq.

Freq.

Motor

Speed

Time

RUN

Sto ps according

to deceleration

time

RUN

Free running

to stop

PWM Carrier Frequency Selections Unit: 1

HP Setting range Factory setting

1-5HP 01-15KHz 15

7.5-25HP 01-15KHz 09

30-60HP 01-09KHz 06

75-100HP 01-06KHz 06

5

Time

This parameter determines the PWM carrier frequency of AC drive.

Carrier Frequency Acoustic Noise

1kHz

15KHz

Significant

Minimal

Electromagnetic Noise,

Leakage Current

Minimal

Significant

Heat Dissipation

Minimal

Significant

From the table, we see that the PWM carrier frequency has a significant influence on the

electromagnetic noise, heat dissipation of the AC drive, and the acoustic noise to the

motor.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

5-13

Page 49

VFD-B Series

V

V

V

02 - 04

Settings 00 Enable Forward/Reverse operation

01 Disable Reverse operation

02 Disabled Forward operation

The parameter determines the direction that AC drive can operate.

02 - 05

Settings 00 FWD/STOP, REV/STOP

01 FWD/REV, RUN/STOP

02 3-wire Operation

There are three different types of control modes:

Motor Direction Control Factory Setting: 00

2-wire/ 3-wire Operation Control Modes Factory Setting: 00

External Terminal

FWD:("OPEN":STOP)

("CLOSE":FWD)

REV:("OPEN": STOP)

("CLOSE": REV)

00

2-wire

02-05

FWD /STOP

REV / STOP

FWD/STOP

REV/STOP

01

2-wire

02

3-wire

FWD/ REV

RUN / STOP

RUN/STOP

FWD/STOP

STOP RUN

RUN/FWD

DCM

FWD:("OPEN":STOP)

("CLOSE":RUN)

REV:("OPEN": F

("CLOSE": REV)

DCM

FWD:("CLOSE":RUN)

EF: ("OPEN":STOP)

REV:("OPEN": F

("CLOSE": REV)

DCM

WD)

WD)

FD-B

FD-B

FD-B

02- 06

Settings 00 Disable

01 Enable

Line Start Lockout Factory Setting: 00

5-14

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 50

VFD-B Series

When enabled, the AC drive will not start when powered up with run commands applied.

To start in Line Start Lockout mode, the AC drive must see the run command go from stop

to run after power up. When Line Start Lockout is disable (also known as Auto-Start), the

drive will start when powered-up with run commands applied.

The Line Start Lockout feature does not guarantee the motor will never start under this

condition. It is possible the motor may be set in motion by a malfunctioning switch.

02- 07

Loss of ACI Signal (4-20mA) Factory Setting: 00

Settings 00 Decelerate to 0Hz.

01 Stop immediately and display “EF”.

02 Continue operation by the last frequency command.

This parameter determintes the process when ACI is lost.

02 - 08

Up/Down Key Mode

a

Factory Setting: 00

Settings 00 Based on Accel/Decel Time

01 Constant speed

02 - 09

The Acce/Decel Speed of the UP/DOWN Key with

Constant Speed

a

Factory Setting: 0.01

Settings 0.01~1.00 Hz/msec

These parameters determine increasment/decreasment method of frequency command

when the Multi-Function Input parameters Pr.04-04~Pr.04-09 are set to 11 (Up command)

or 12 (Down command).

Pr.02-08=0: It will increase/decrease frequency command by the setting of accel/decel

5

speed.

Pr.02-08=1: It will accel/decel frequency command by Pr.02-09.

02 - 10

Source of the Master Frequency Command (FCHA)

Settings 00 Digital keypad

01 0 to +10V from AVI

02 4 to 20mA from ACI

03 -10 to +10Vdc from AUI

04 RS-485 communication interface

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

5-15

a

Factory Setting: 00

Page 51

VFD-B Series

02 - 11

Source of the Auxiliary Frequency Command (FCHB)

a

Factory Setting: 00

Settings 00 Digital keypad

01 0 to +10V from AVI

02 4 to 20mA from ACI

03 -10 to +10Vdc from AUI

04 RS-485 communication interface

02 - 12

Combination of the Master and Auxiliary Frequency

Command

a

Factory Setting: 00

Settings 00 Master frequency + Auxiliary frequency

01 Master frequency - Auxiliary frequency

These three parameters (Pr.02-10~02-12) are enabled when Pr.02-00 or Pr.02-13 is set to

06. If they are enabled, the frequency command will be determined by these parameters.

02 - 15

Keyboard Frequency Command

a

Factory Setting: 60.00

Settings 0.00 ~ 400.00Hz Unit: 0.01

This parameter can be used to set frequency command or read keypad frequency

command.

5-16

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 52

Group 3: Output Function Parameters

VFD-B Series

03 - 00

03 - 01

03 - 02

03 - 03

Multi-function Output Terminal

(Relay contact point RA, RB, RC)

Multi-function Output Terminal MO1 Factory Setting: 01

Multi-function Output Terminal MO2 Factory Setting: 02

Multi-function Output Terminal MO3 Factory Setting: 20

Factory Setting: 08

Settings 00 to 28

Function Table List:

Setting Functions Descriptions

00 No function

The terminal will be activated when there is

01 AC Drive Operational

an output from the drive or RUN command is

“ON”.

02 Master Frequency Attained

The output will be activated when the AC

drive attains the Output Frequency Setting.

The output will be activated when Command

03 Zero speed

Frequency is lower than the Minimum Output

Frequency.

The output will be activated as long as

04 Over-Torque detection

over-torque is detected. (Refer to Pr.06-03 ~

Pr.06-05)

The output will be activated when the output

05 Baseblock (B.B.) Indication

of the AC drive is shut off by external

baseblock.

06 Low-Voltage Indication

07 Operation Mode Indication

The output will be activated when low voltage

is detected.

The output will be activated when operation

command is controlled by external terminal.

The output will be activated when faults occur

08 Fault Indication

(oc, ov, oH, oL, oL1, EF, cF3, HPF, ocA, ocd,

ocn, GFF).

09 Desired Frequency Attained 1

10 PLC Program Running

11 PLC Program Step Completed

The output will be activated when the desired

frequency (Pr.03-04) is attained.

The Output will be activated when PLC

Program is running.

The Output will be activated for 0.5 sec when

each multi-step speed is attained.

5

12 PLC Program Completed

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

The output will be activated for 0.5 sec when

the PLC program cycle has completed

5-17

Page 53

VFD-B Series

Setting Functions Descriptions

13 PLC Operation Paused

14 Terminal Count Value Attained

15 Preliminary Count Value Attained

16

17

Auxiliary Motor 1, 2 and 3

18

19 Heatsink overheat warning (OH1)

20 AC drive ready

21 Emergency Stop Indication

22 Desired Frequency Attained 2

23 Soft Braking Signal

24

25

26

27

28

Zero Speed Output Signal

Low-current Detection

Operation Indication (H>=Fmin)

Feedback Signal Error

User-defined low-voltage Detection

The output will be activated when PLC

operation is paused.

The output will be activated when the counter

reaches Terminal Count Value.

The output will be activated when the counter

reaches Preliminary Count Value.

For the fan & pump control applications, one

can use the Multi-function Output Terminals to

define the auxiliary motor 1-3. Refer to CH

5-11 (PID Controls) and CH 5-12 (Fan and

Pump Control).

When heatsink overheats, it will signal to

prevent OH turn off the drive. > 85 oC (185oF)

o

ON, < 85

C (185 oF) OFF.

The output will be activated when the drive is

on and no abnormality detected.

The contact will be activated once the

drive’s emergency stop function is activated.

The output will be activated when the desired

frequency (Pr.03-10) is attained.

This function is used in conjunction with a

VFDB Braking Unit. The output will be

activated when the drive needs help braking

the load. A smooth deceleration is achieved

using this function.

The output is always active unless there is an

output frequency present at terminals U/T1,

V/T2, and W/T3.

The output will be activated once the drive’s

current is too low. (Refer to Pr.06-12, 06-13)

The output will be activated when there is

output voltage from U, V, W.

The output will be activated once the

feedback signal is abnormal. (Refer to

Pr.10-08, Pr.10-16)

The output will be activated once the DC Bus

voltage is too low. (Refer to Pr.06-16,

Pr.06-17)

03 - 04

Desired Frequency Attained 1 Factory Setting: 0.00

Settings 0.00 to 400.00 Hz Unit: 0.01Hz

5-18

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 54

VFD-B Series

03 - 10

Desired Frequency Attained 2

Factory Setting: 0.00

Settings 0.00 to 400.00 Hz Unit: 0.01

If a Multi-function output terminal is set to function as Desired Frequency Attained 1

(Pr.03-00 to Pr.03-03 = 09), then the output will be activated when the programmed

frequency is attained.

Freq.

Max. Output

Freq.

Desired Freq. 1

03-04

Max. Freq.

Attained

Indication

03-00 to 03-03

Desired Freq.

Attained 1

Indication

03-00 to 03-03

Detection range

+

2Hz

-

OFF

OFF

ON

ON

Detection range

+

4Hz

-

Detection

range

-2Hz

Time

OFF

OFF

5

Desired Freq. Attained 1 & Max. Freq. Attained

03 - 05

Analog Output Signal (AFM)

Factory Setting: 00

Settings 00 Analog Frequency Meter (from 0 to the Maximum Output

Frequency)

01 Analog Current Meter (from 0 to 250% of the rated AC drive

current)

02 Output voltage (from 0 to Pr.01-02)

03 Output frequency command (from 0 to the Maximum Frequency)

04 Output motor speed (from 0 to the Maximum Frequency)

05

Load power factor (cosθ = 90

o

to cosθ = 0o )

This parameter determines the meaning of the 0~+10VDC output from AFM and ACM.

03 - 06

Analog Output Gain

a

Factory Setting: 100

Settings 01 to 200% Unit: 1%

This parameter sets the voltage range of the analog output signal.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

5-19

Page 55

VFD-B Series

When Pr.03-05 is set to 0, the analog output voltage is directly proportional to the output

frequency of the AC drive. With Pr.03-06 set to 100%, the Maximum Output Frequency

(Pr.01-00) of the AC drive corresponds to +10VDC on the AFM output.

Similarly, if Pr.03-05 is set to 1, the analog output voltage is directly proportional to the

output current of the AC drive. With Pr.03-06 set to 100%, then 2.5 times the rated current

corresponds to +10VDC on the AFM output.

Note: Any type of voltmeter can be used. If the meter reads full scale at a voltage less than 10

volts, the parameter 03-06 should be set using the following formula:

Pr. 03-06 = ((meter full scale voltage)/10) x 100%

For Example: When using the meter with full scale of 5 volts, adjust Pr.03-06 to 50%. If

Pr.03-05 is set to 0, then 5Vdc will correspond to Maximum Output Frequency.

03 - 07

Digital Output Multiplying Factor

a

Factory Setting: 01

Settings 01 to 20 times Unit: 1

This parameter determines the multiplying factor for the AC drives digital output frequency

at the digital output terminals (DFM-DCM). The number of output pulses per second is

equal to the AC drive output frequency multiplied by Pr.03-07. (Pulse per second = actual

output frequency x Pr.03-07)

03 - 08

Terminal Count Value

a

Factory Setting: 00

Settings 00 to 65500 Unit: 1

The parameter determines the value of the internal counter. The internal counter can be

triggered by the external terminal TRG. Upon completion of counting, the specified output

terminal will be activated. (Pr.03-00, to Pr.03-03 set to 14).

When the display shows c5555, the drive has counted 5,555 times. If display shows

c5555., it means that real counter value is between 55,550 to 55,559.

03 - 09

Preliminary Count Value

a

Factory Setting: 00

Settings 00 to 65500 Unit: 1

When the counter value is counted up from “1” to the set value of this parameter, the

corresponding multi-function output terminal will be activated, when set to 15 (Preliminary

Count Value Setting). The corresponding multi-function output terminal will be deactivated

upon completion of Terminal Count Value Attained.

5-20

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 56

The timing diagram:

VFD-B Series

Display

(Pr.00-04=01)

TRG

Counter Trigger

Preliminary Count Value

(Pr. 03-00~Pr. 03-03=15)

Terminal Count Value

(Pr. 03-00~Pr. 03-03=14)

Ex:03-08=5,03-09=3

The width of trigger signal

should not be less than

2ms(<250 Hz)

2msec

2msec

03 - 11

EF Active when Preliminary Count Value Attained Factory Setting: 00

Settings 00 No function.

01 Preliminary count value attained, EF active.

If this parameter is set to 01, When the desired value of counter is attained, the AC drive

treat it as a fault, the drive will stop and show the “cEF” message on the display.

03 - 12

Fan Control Factory Setting: 00

5

Settings 00 Always fan on

01 Power off 1 minute later, fan off

02 Run and fan on, stop and fan off

03 Preliminary temperature attained, Fan start to run

This parameter determines the operation mode of cooling fan.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

5-21

Page 57

VFD-B Series

Group 4: Input Function Parameters

04 - 00

AVI Analog Input Bias

a Factory Setting: 0.00

Settings 0.00 to 200.00% Unit: 0.01%

04 - 01

AVI Bias Polarity

Factory Setting: 00

Settings 00 Positive Bias

01 Negative Bias

04 - 02

AVI Input Gain

a Factory Setting: 100

Settings 1 to 200% Unit: 1%

04 - 03

AVI Negative Bias, Reverse Motion Enabled

Factory Setting: 00

Settings 00 Forward motion only

01 Forward and reverse motion enabled. Forward motion with

positive bias. Reverse motion with negative bias.

02 Forward and reverse motion enabled. Forward and Reverse

motion with positive or negative bias. Select direction via the

keypad or external terminals.

04 - 11

ACI Analog Input Bias

a Factory Setting: 0.00

Settings 0.00 to 200.00% Unit: 0.01%

04 - 12

ACI Bias Polarity

Factory Setting: 00

Settings 00 Positive Bias

01 Negative Bias

04 - 13

ACI Input Gain

a Factory Setting: 100

Settings 01 to 200% Unit: 1%

04 - 14

ACI Negative Bias, Reverse Motion Enable

Factory Setting: 00

Settings 00 No ACI Negative bias command

01 Negative bias, REV motion enabled

02 Negative bias, REV motion disabled

04 - 15

AUI Analog Input Bias

a Factory Setting: 0.00

Settings 0.00 to 200.00% Unit: 0.01%

04 - 16

AUI Bias Polarity

Factory Setting: 00

Settings 00 Positive Bias

01 Negative Bias

5-22

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 58

VFD-B Series

A

A

A

A

A

04 - 17

AUI Input Gain

a Factory Setting: 100

Settings 01 to 200% Unit: 1%

04 - 18

No AUI Negative bias command

Factory Setting: 00

Settings 00 No ACI Negative bias command

01 Negative bias, REV motion enabled

02 Negative bias, REV motion disabled

Pr.04-00 ~ 04-03, Pr.04-11 ~ 04-18 are used when the source of frequency command is

the analog signal. Refer to the following examples.

Example 1:

Max.

60Hz

30Hz

0Hz

Pr.01-00

0V

4m

5V

12m

Factory Settings

Pr.01-00=60Hz--Max. output Freq.

Pr.04-11=0%--bias adjustment

Pr.04-12 =0-- bias polarity

Pr.04-13=100% -- pot. freq. gain

Pr.04-14=0 -- REV disable in negative bias

10V

20m

Output

Freq.

Example 2:

In this example with the potentiometer set to 0V the Output Frequency is 10 Hz. The mid-point

of the potentiometer becomes 40 Hz. Once the Maximum Output Frequency is reached any

further increase of the potentiometer will not increase output frequency. (If you want to use the

range of 60Hz, please refer to the example 3.) The value of external input voltage/current